Fluorinated graphite and preparation method thereof

A technology of fluorinated graphene and graphene, applied in the direction of single-layer graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as low fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

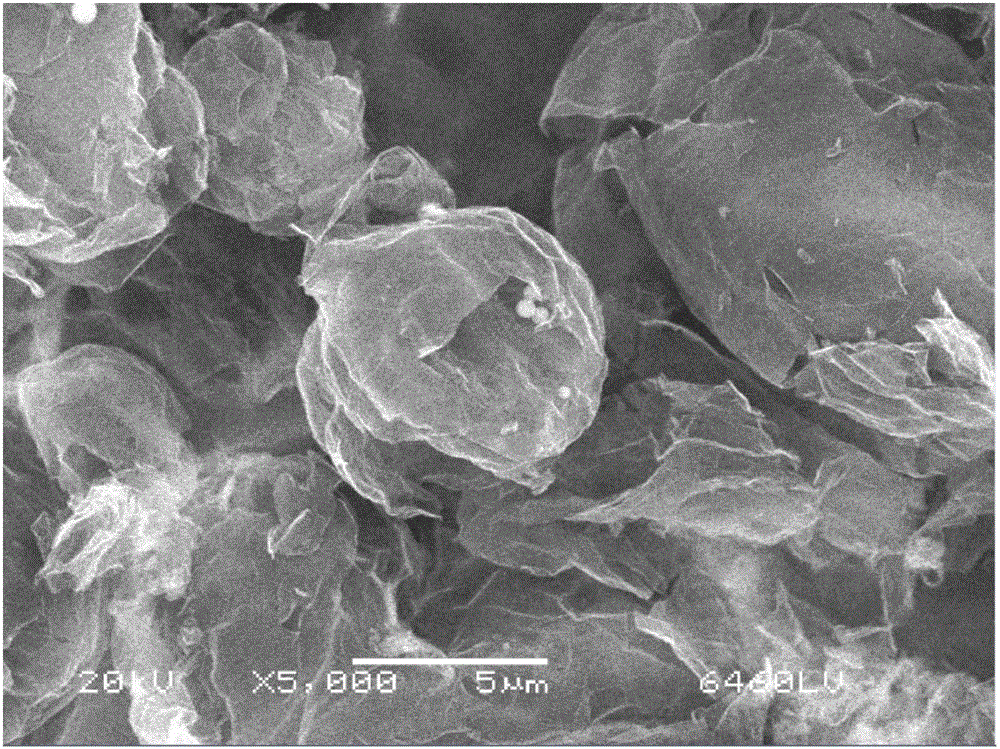

Image

Examples

preparation example Construction

[0025] The invention discloses a preparation method of fluorinated graphene, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0026] The embodiment of the present invention provides a kind of preparation method of fluorinated graphene, comprising:

[0027] S1), under the protection of an inert gas, fluorination reacti...

Embodiment 1

[0064] Weigh 1 g of graphene powder obtained by oxidation-reduction method and put it into a reactor. After replacing the reactor with nitrogen atmosphere, raise the temperature to 150°C, start to feed the fluorine-nitrogen mixed gas with the volume ratio of fluorine to the mixed gas at a volume ratio of 1:100, control the system pressure at 0.1Mpa, and control the gas flow rate at 0.1L / min, after 2 hours of fluorination, stop feeding fluorine-nitrogen mixed gas, change to nitrogen gas, and keep warm for 1 hour to complete the preliminary fluorination reaction, and obtain the crude product of preliminary fluorinated graphene fluoride powder. Next, the system is maintained at a temperature of 150°C, and the sulfur tetrafluoride gas diluted and protected by nitrogen is introduced. The volume ratio of sulfur tetrafluoride gas to the mixed gas is 20:100, and the system pressure is controlled at 0.1Mpa. Stop after 2 hours Sulfur tetrafluoride gas was introduced, replaced by nitrog...

Embodiment 2

[0066] Weigh 1 g of graphene powder obtained by oxidation-reduction method and put it into a reactor. After replacing the reactor with nitrogen atmosphere, raise the temperature to 550°C, start to feed the fluorine-nitrogen mixed gas whose volume ratio of fluorine to the mixed gas is 30:100, control the system pressure at 0.2Mpa, and control the gas flow rate at 20L / min After 20 hours of fluorination, stop feeding fluorine-nitrogen mixed gas, change to nitrogen gas, and keep warm for 1 hour to complete the preliminary fluorination reaction, and obtain the crude product of preliminary fluorinated graphene fluoride powder. Next, the temperature of the system was lowered to 400°C, and the phosphorus trifluoride gas diluted and protected by nitrogen gas was introduced. The volume ratio of phosphorus trifluoride gas to the mixed gas was 80:100, and the system pressure was controlled at 0.2Mpa. Stop after 10 hours Phosphorus trifluoride gas was introduced, replaced by nitrogen gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com