Fluorine-containing carbonic ester solvent, its preparation method and electrolyte for lithium ion batteries

A lithium-ion battery and carbonate technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of low product yield and unfavorable industrial production, and achieve high yield, stable structure, and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

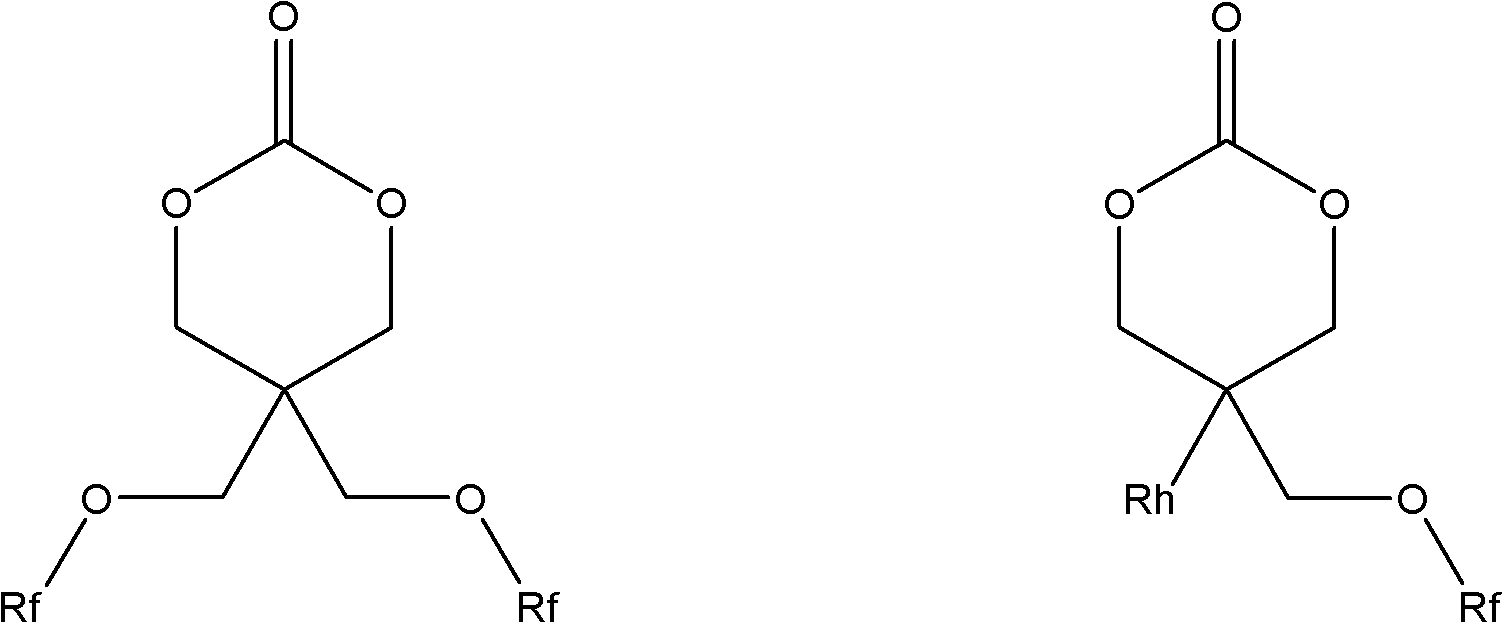

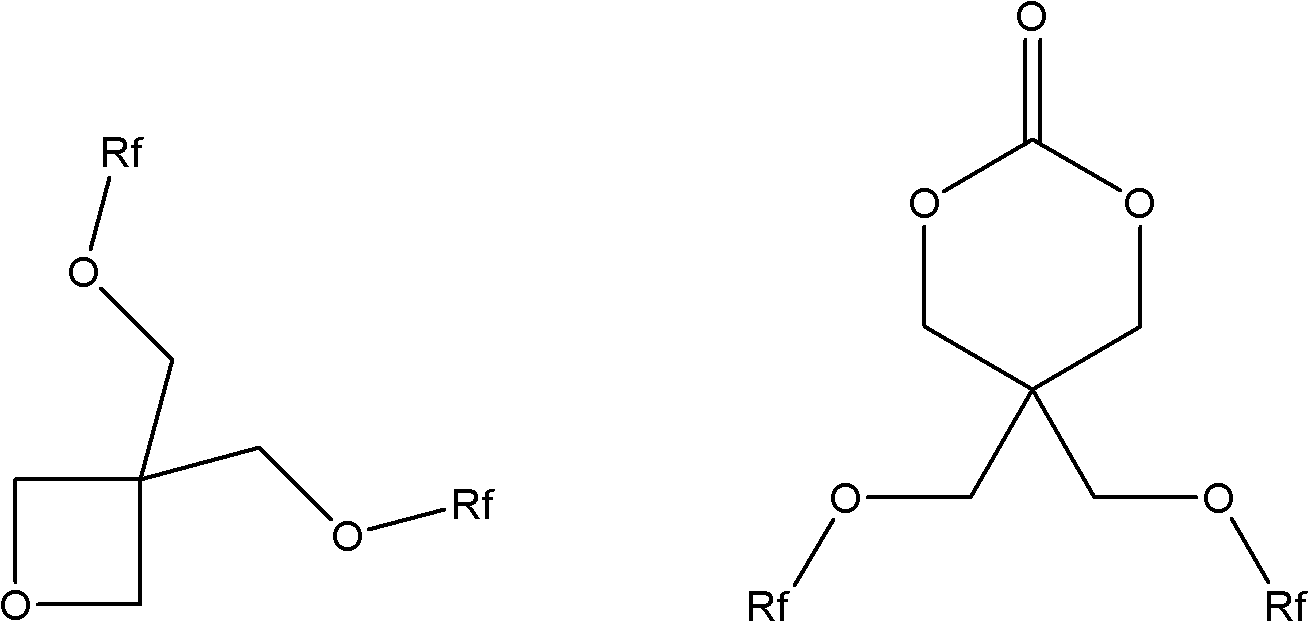

[0039] The present invention also provides a preparation method of a compound of formula I structure, comprising the following steps:

[0040] Compound shown in formula III and CO 2 React under the effect of catalyst, obtain the compound shown in formula I,

[0041]

[0042] Formula III Formula I

[0043] Wherein, Rf is a fluorocarbon group. The reaction process is as follows:

[0044]

[0045] In addition, the present invention also provides a preparation method of a compound of formula II, comprising the following steps:

[0046] With the compound shown in formula IV and CO 2 React under the effect of catalyst, obtain the compound shown in formula II,

[0047]

[0048] Formula IV Formula II

[0049] Wherein, Rh is H or a hydrocarbon chain group, and Rf is a fluorocarbon group. The reaction process is as follows:

[0050]

[0051] The present invention has no other restrictions on the raw materials of formula III and formula IV, commercially available prod...

Embodiment 1

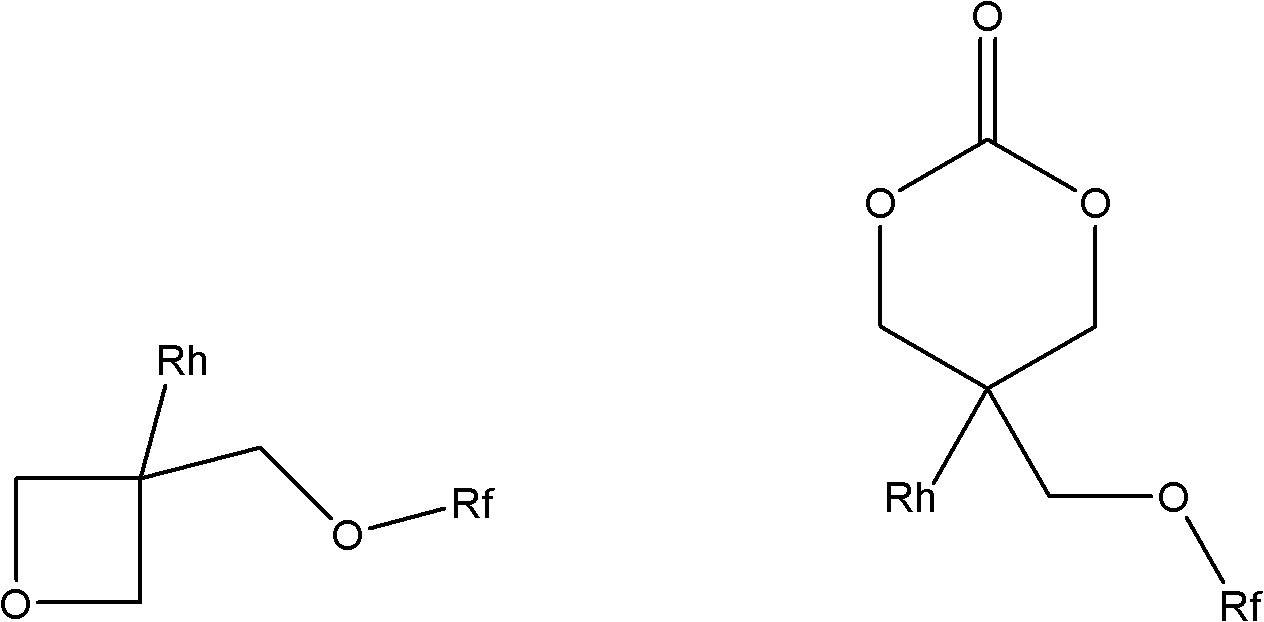

[0064] Synthesis of Compound of Formula VIII

[0065] Reference literature synthesis (Applied Surface Science 253(2006) 2304-2309)

[0066] 3-bromo-2,2-dibromomethylpropanol (32.5g, 100.0mmol), 10% NaOH aqueous solution (100.0g), phase transfer catalyst tetrabutylammonium bromide (TBAB, 0.79g, 2.46mmol ) and solvent CH 2 Cl 2 (150mL) was stirred at 30-35°C for 12 hours, the water phase was removed, the residual crude product was distilled under reduced pressure, and the fraction in the range of 92-95°C (4mmHg) was collected to obtain a colorless liquid, which was the target intermediate of formula VIIIa 17g, yield 70%.

[0067]

[0068] The above-mentioned reaction product (12.2g, 50mmol) is added in the 500ml three-necked bottle, then adds phase-transfer catalyst TABA solution (12%, 3g), KOH solution (45%, 6g) and tetrafluoropropanol (TFP) (14.5g , 110mmol), the mixture was stirred at 80-85°C for 24 hours, water (20mL) was added, the reaction system was cooled to room te...

Embodiment 2

[0076] The compound with the structure of formula IX was synthesized with reference to the literature (Applied Surface Science 253 (2006) 2304-2309).

[0077] 3-Bromo-2-bromomethylpropanol (23.2 g, 100.0 mmol), 10% aqueous NaOH (100.0 g), phase transfer catalyst tetrabutylammonium bromide (TBAB, 0.79 g, 2.46 mmol) and solvent CH 2 Cl 2 (150mL) was stirred at 30-35°C for 12 hours, the water phase was carefully removed, the residual crude product was distilled under reduced pressure, and the fractions in the range of 85-90°C (4mmHg) were collected to obtain a colorless liquid, which was the target intermediate of the formula IXa structure. Body 11.4g, yield 75%.

[0078]

[0079] Formula IXa

[0080] The above-mentioned reaction product (7.55g, 50mmol) was added in the 500ml three-necked bottle, then added phase transfer catalyst TABA solution (12%, 3g), KOH solution (45%, 6g) and tetrafluoropropanol (TFP) (7.3g , 55mmol), the mixture was stirred at 80-85°C for 24 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com