Environment-friendly fluorine/silicon-containing heavy anticorrosive epoxy resin paint and preparation method thereof

An epoxy resin coating, an environment-friendly technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of lack of adsorption force and easy shedding of coatings, and achieve good resistance to chloride ion penetration, not easy The effect of shedding and improving amphiphobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

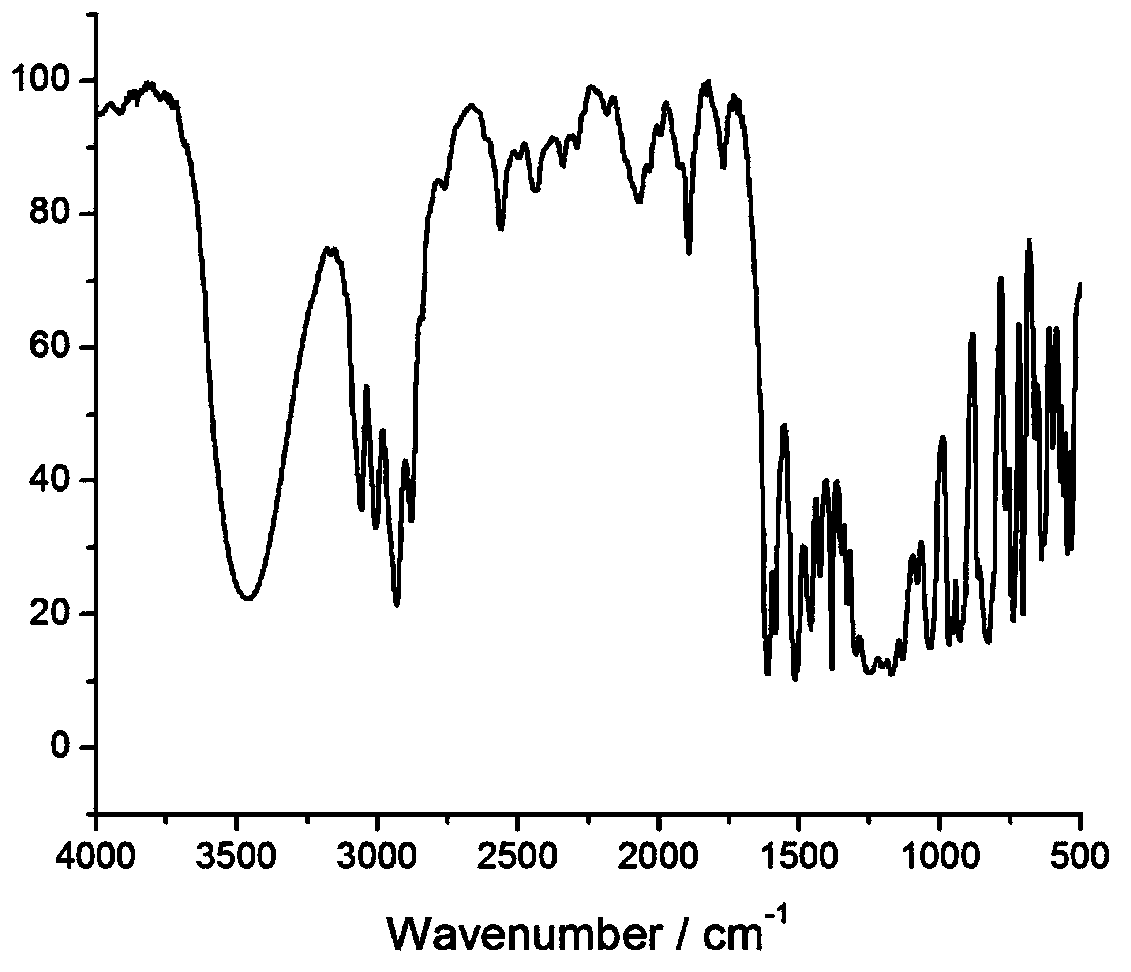

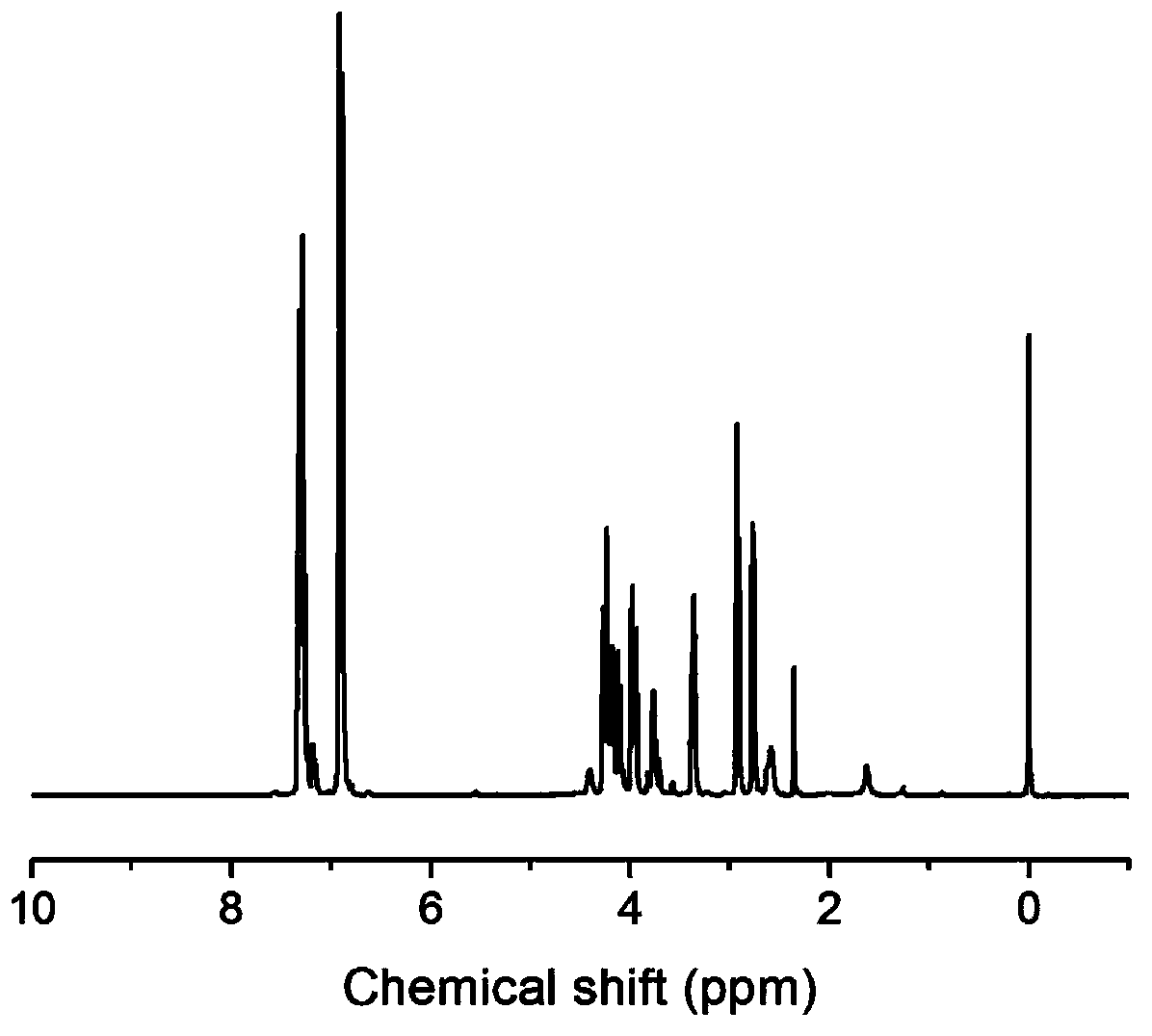

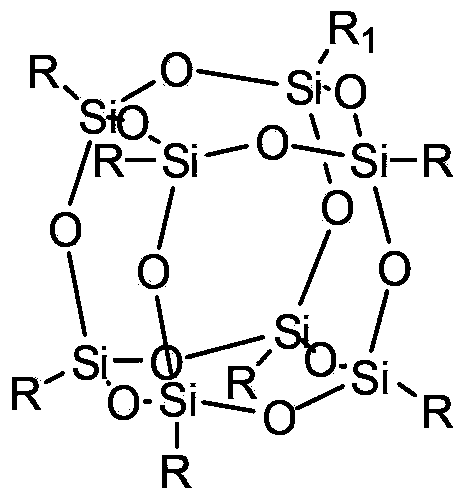

Method used

Image

Examples

Embodiment 1

[0031] Preparation of fluorine-containing epoxy resin:

[0032] (1) Add 35g of 1,1-bis(4-hydroxyphenyl)-1-(3-trifluoromethylphenyl)-2,2,2-trifluoroethane and 26g of epichlorohydrin with Stir the solution in a three-necked flask with a stirring rod and a temperature control device, and raise the temperature to 65°C.

[0033] (2) Take 7g of NaOH and 15ml of deionized water to make lye, add it to the reaction vessel within 1.5 hours, and keep the temperature at 65°C.

[0034] (3) After adding the lye dropwise, the reactant was refluxed at 70°C for 1.5 hours, and the system turned milky yellow.

[0035] (4) Add 27ml of deionized water and 54ml of toluene, stir evenly, let stand to separate the liquid, remove the water layer, repeat several operations to remove the water layer to separate the organic phase, and distill off the solvent toluene and unreacted epoxy under reduced pressure Chloropropane, a light yellow viscous resin.

[0036] Preparation of fluorine-containing silicon ...

Embodiment 2

[0039] (1) Add 30g of 1,1-bis(4-hydroxyphenyl)-1-phenyl-2,2,2-trifluoroethane and 28g of epichlorohydrin into the three-port with stirring bar and temperature control device In the flask, the solution was stirred and the temperature was raised to 65°C.

[0040] (2) Take 6g NaOH and 17ml deionized water to make lye, add it into the reaction vessel within 1.5 hours, and keep the temperature at 65°C.

[0041] (3) After adding the lye dropwise, the reactant was refluxed at 70°C for 1.5 hours, and the system turned milky yellow.

[0042] (4) Add 27ml of deionized water and 54ml of toluene, stir evenly, let stand to separate the liquid, remove the water layer, repeat several operations to remove the water layer to separate the organic phase, and distill off the solvent toluene and unreacted epoxy under reduced pressure Chloropropane, a light yellow viscous resin.

[0043] Preparation of fluorosilicone heavy-duty epoxy resin coating:

[0044] 4,4'-methylene bis(2,6-diethylaniline)...

Embodiment 3

[0046] (1) Add 30g (3-trifluoromethylbenzene) hydroquinone and 32g epichlorohydrin into a three-necked flask equipped with a stirring rod and a temperature control device, stir the solution, and raise the temperature to 65°C.

[0047] (2) Take 8g of NaOH and 17ml of deionized water to make lye, add it to the reaction vessel within 1.5 hours, and keep the temperature at 65°C.

[0048] (3) After adding the lye dropwise, the reactant was refluxed at 70°C for 1.5 hours, and the system turned milky yellow.

[0049] (4) Add 27ml of deionized water and 54ml of toluene, stir evenly, let stand to separate the liquid, remove the water layer, repeat several operations to remove the water layer to separate the organic phase, and distill off the solvent toluene and unreacted epoxy under reduced pressure Chloropropane, a light yellow viscous resin.

[0050] Preparation of fluorosilicone heavy-duty epoxy resin coating:

[0051] 35g of 4,4'-methylenebis(2,6-diethylaniline), 2g of POSS, 1g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com