Patents

Literature

65results about How to "Film stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

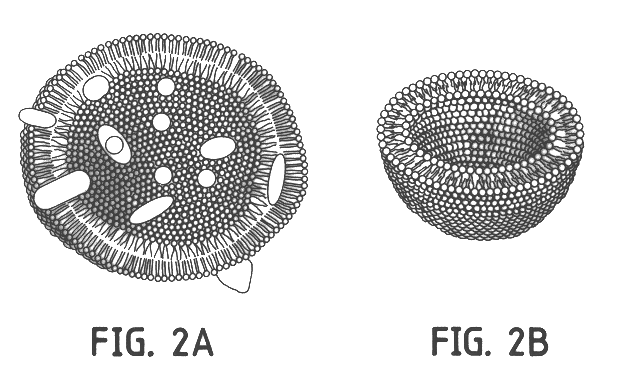

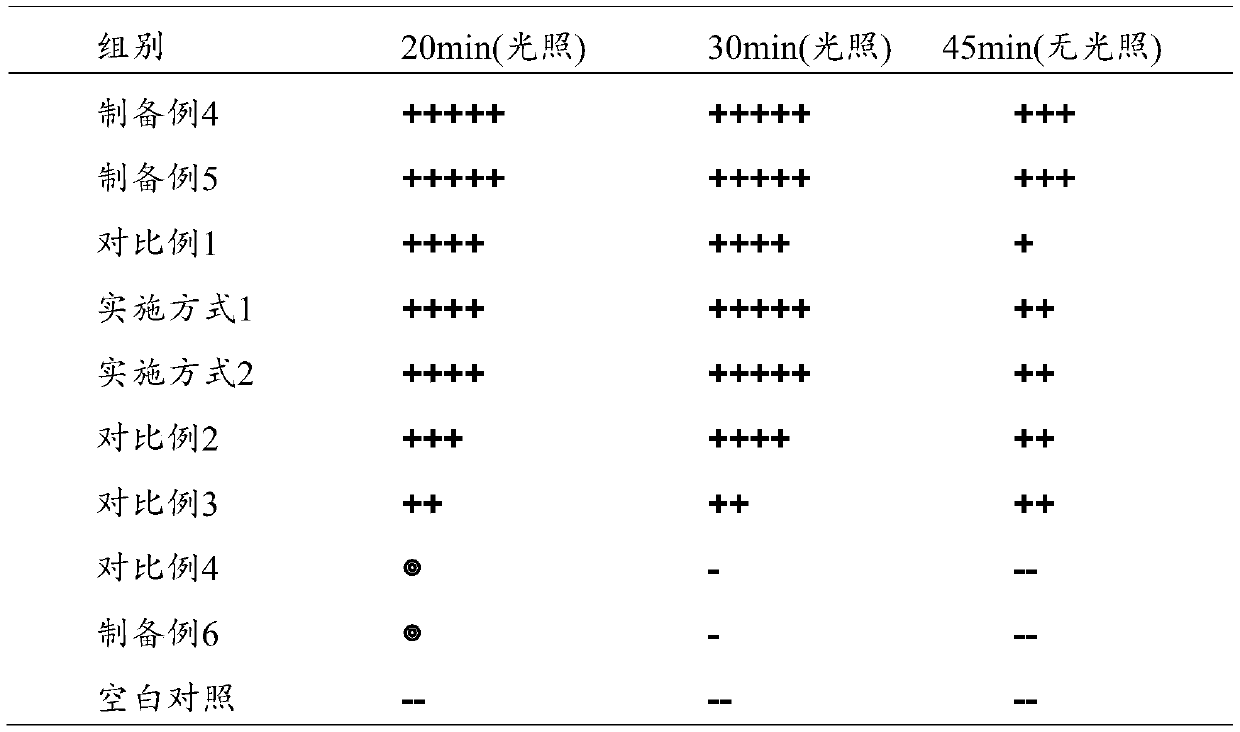

Direct colorimetric detection of biocatalysts

InactiveUS6468759B1Rapid optical signalFast response timeMaterial nanotechnologyColor measuring devicesAnalyteColor changes

The present invention relates to methods and compositions for the direct detection of membrane conformational changes through the detection of color changes in biopolymeric materials. In particular, the present invention allows for the direct colorimetric detection of membrane modifying reactions and analytes responsible for such modifications and for the screening of reaction inhibitors.

Owner:RGT UNIV OF CALIFORNIA

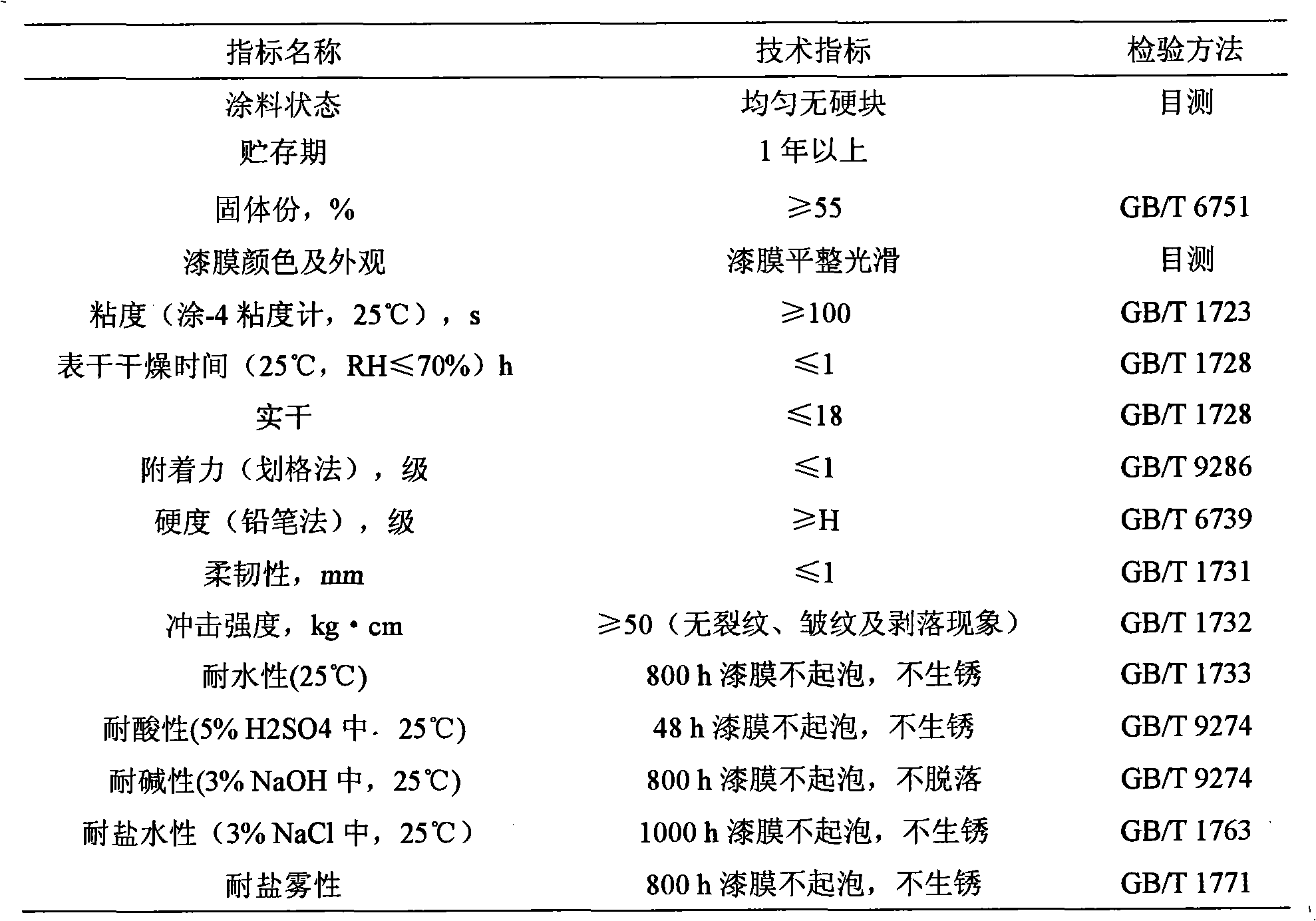

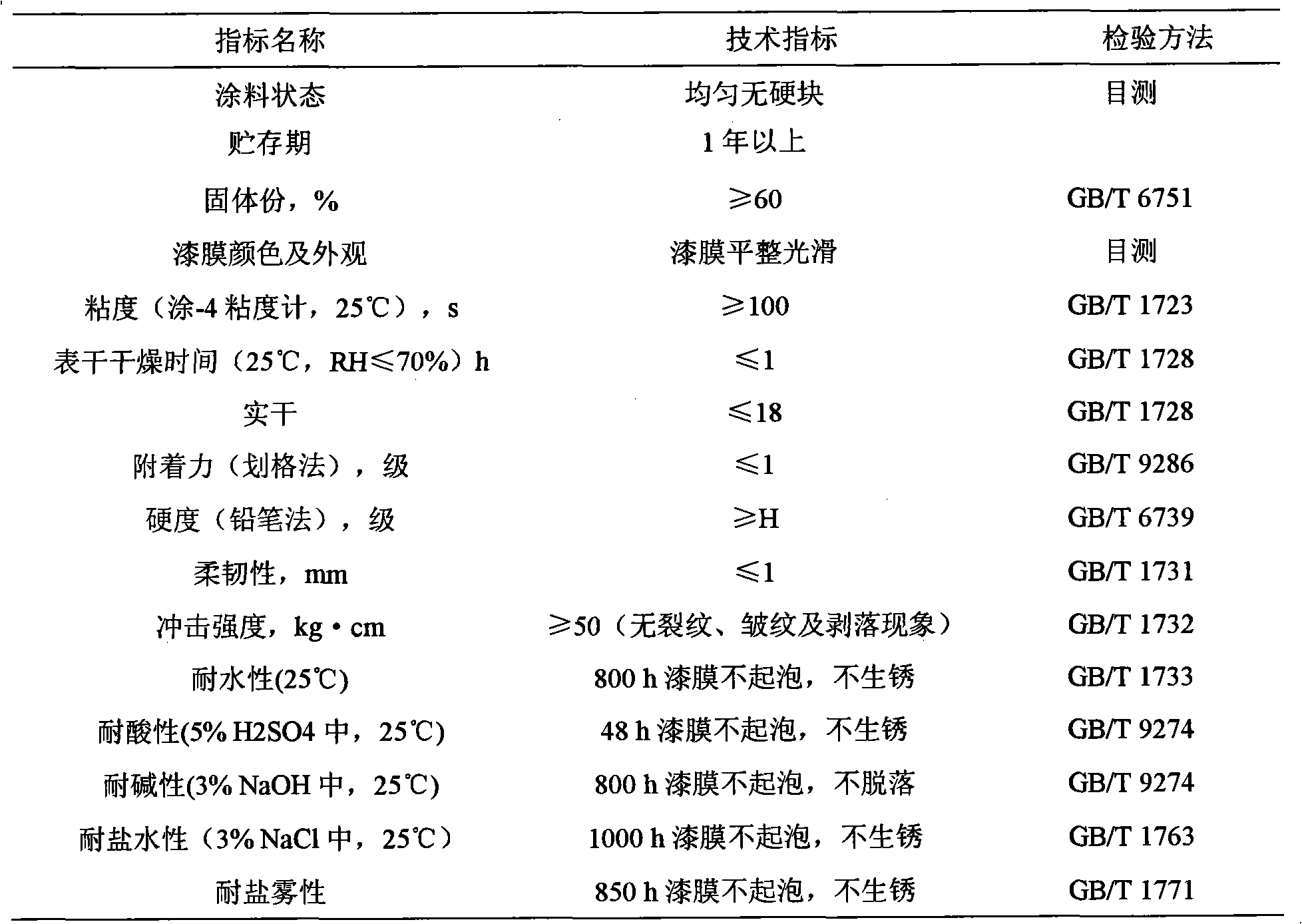

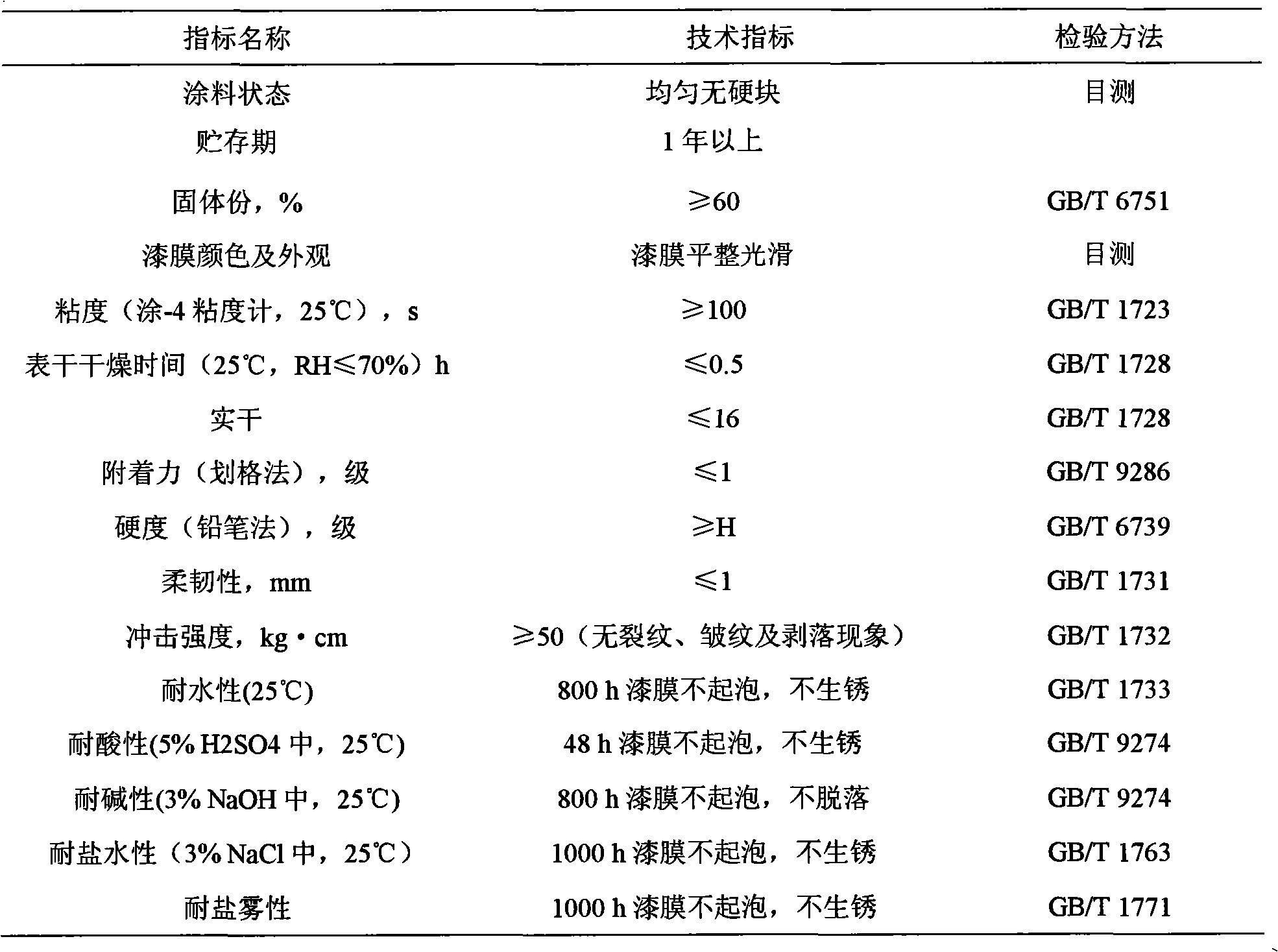

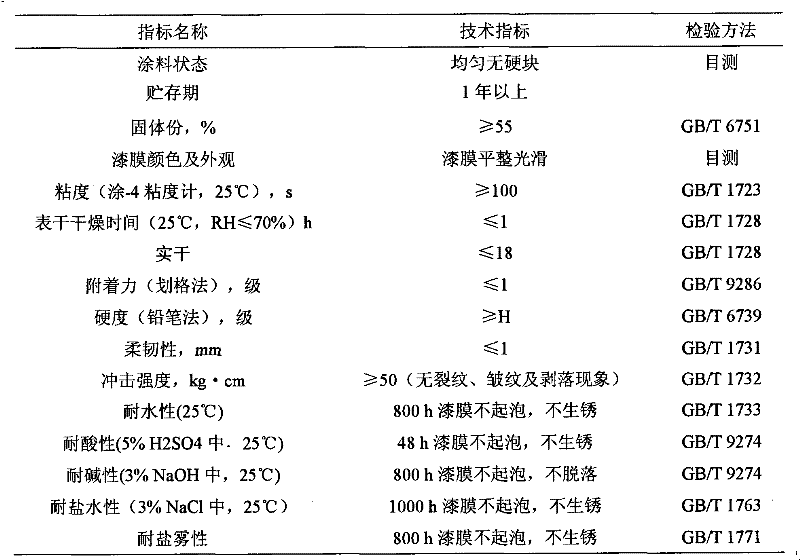

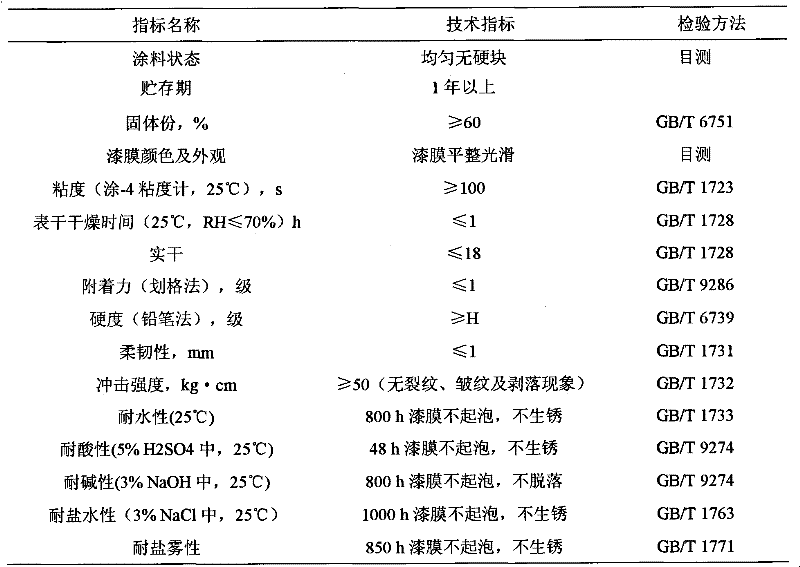

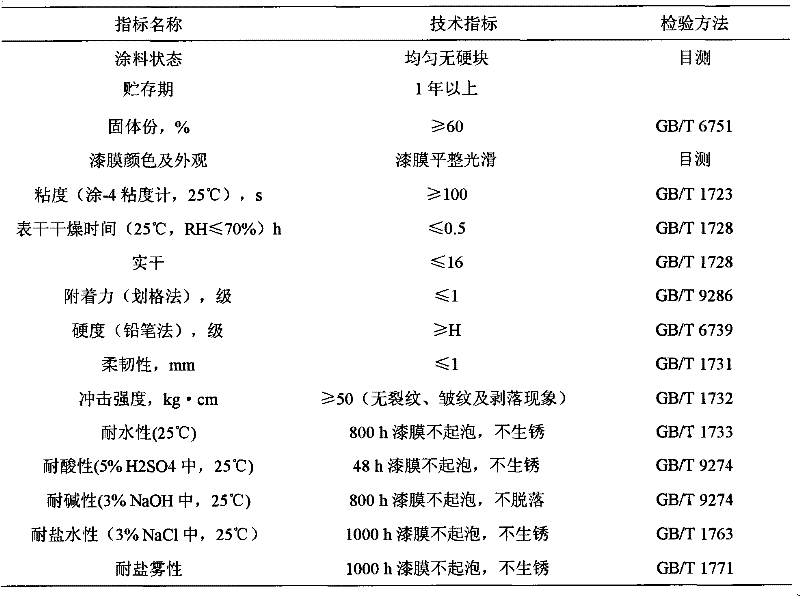

Water borne epoxy resin anticorrosive paint and preparation method thereof

InactiveCN101633814AGood value for moneyGood weather and humidity resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyHydrophilic monomer

The invention discloses a water borne epoxy resin anticorrosive paint and preparation method thereof and solves the contradiction between storage stability of water dispersion and water resistance and corrosion resistance of dispersion film in the prior art. The paint is prepared by mixing oxosilane modified water borne epoxy resin dispersion, iron oxide red, rustproofing pigment, talc powder, defoaming agent, flatting agent, flash rust proofing agent and deionized water in ratio, and the invention is characterized in that: hydrophilic monomer is introduced to epoxy resin molecular chain, so the paint has self-emulsifying characteristic; and oxosilane is applied to modifying of the water borne epoxy resin, so that the paint can be heated and self-solidified. The paint has good storage stability and good construction performance, film can be fast dried and has high rigidity after being dried, the film is bright and smooth, water proof, corrosion resistant, washing resistant, good in comprehensive performance and low in cost. The invention can meet the requirement of anticorrosive paint in the fields of storage tank, bridge and the like.

Owner:HUANGGANG NORMAL UNIV

High-temperature resistant aluminum powder paint

The invention discloses high-temperature resistant aluminum powder paint. Modified organic silicon resin, hydroxyl acrylic acid and acetate fiber are adopted as resin base materials; and aluminum powder, auxiliary agent and solvent are added. The aluminum powder paint has the better binding force with a metal substrate, can resist the high temperature of 400-450 DEG C for a long time, stably paints films, resists the chemical corrosion, and has excellent construction performance.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Environment-friendly fluorine/silicon-containing heavy anticorrosive epoxy resin paint and preparation method thereof

ActiveCN103450725AImprove amphiphobiaImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsWeather resistanceReactive diluent

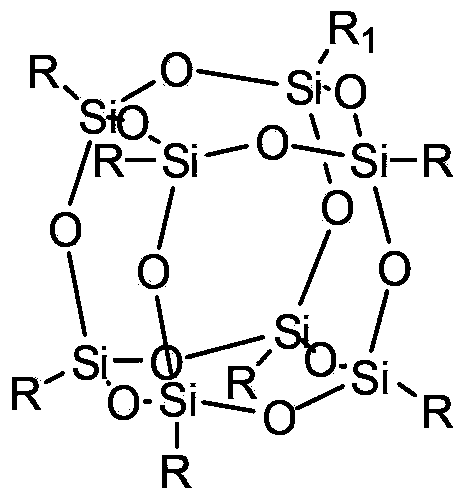

The invention relates to an anticorrosive paint and a preparation method thereof, particularly an environment-friendly fluorine / silicon-containing heavy anticorrosive epoxy resin paint and a preparation method thereof. The paint is composed of 30-70g of fluorine-containing epoxy resin, 10-40g of curing agent, 0.1-5g of POSS (polyhedral oligomeric silsesquioxane), 0.5-5g of silane coupling agent, 10-30g of reactive diluent, 0.5-3g of dispersant and 0.1-3g of photostabilizer. The paint provided by the invention has the advantages of high fluorine content, favorable adhesion to the substrate, simple construction technique, excellent corrosion resistance and excellent weather resistance, and is especially suitable for an anticorrosive coating under harsh conditions. The paint uses the reactive diluent capable of participating in curing reaction as the solvent instead of the organic volatile solvent component, and thus, has an environment-friendly function, thereby having great popularization and application value.

Owner:XIAMEN UNIV

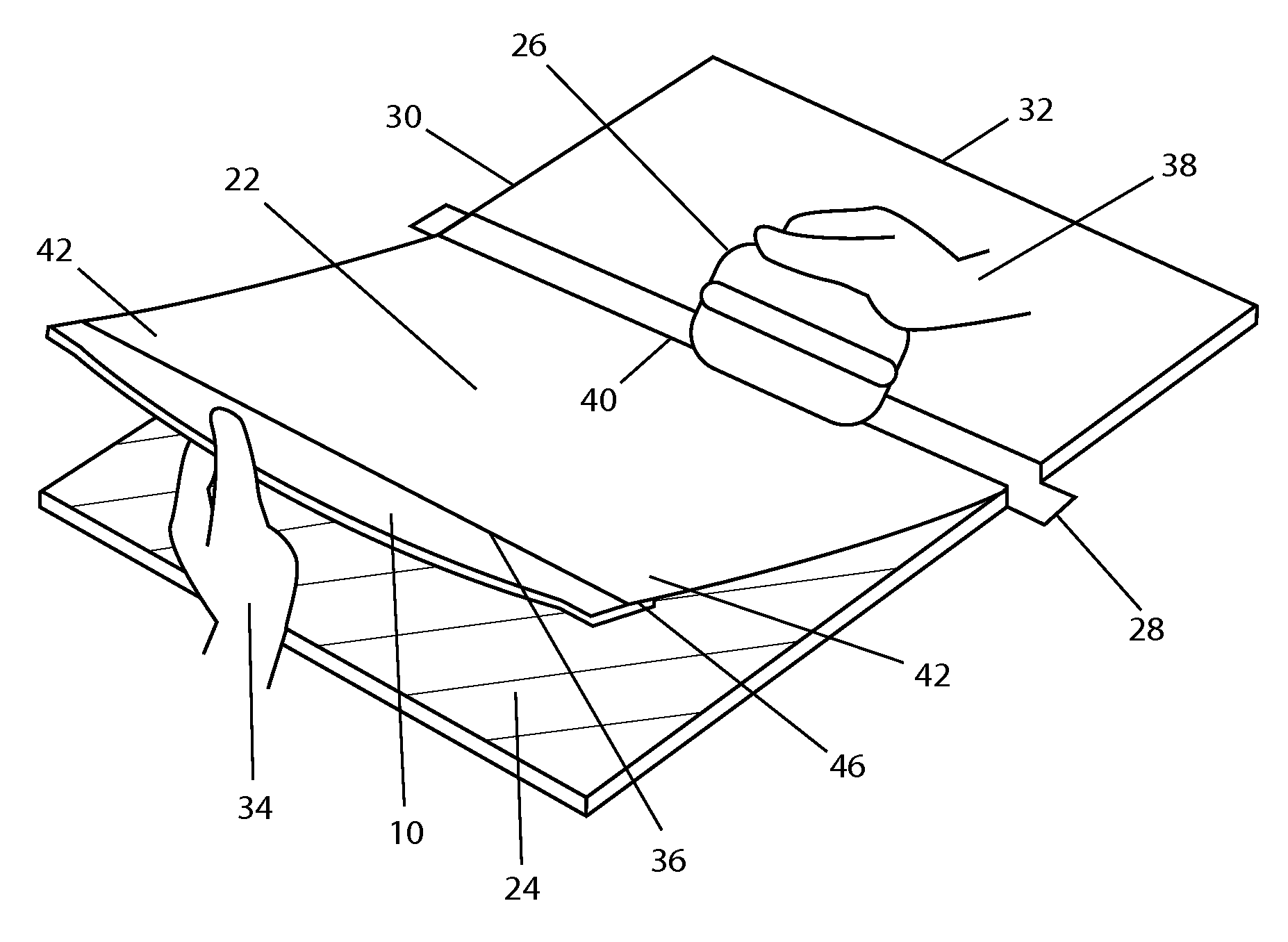

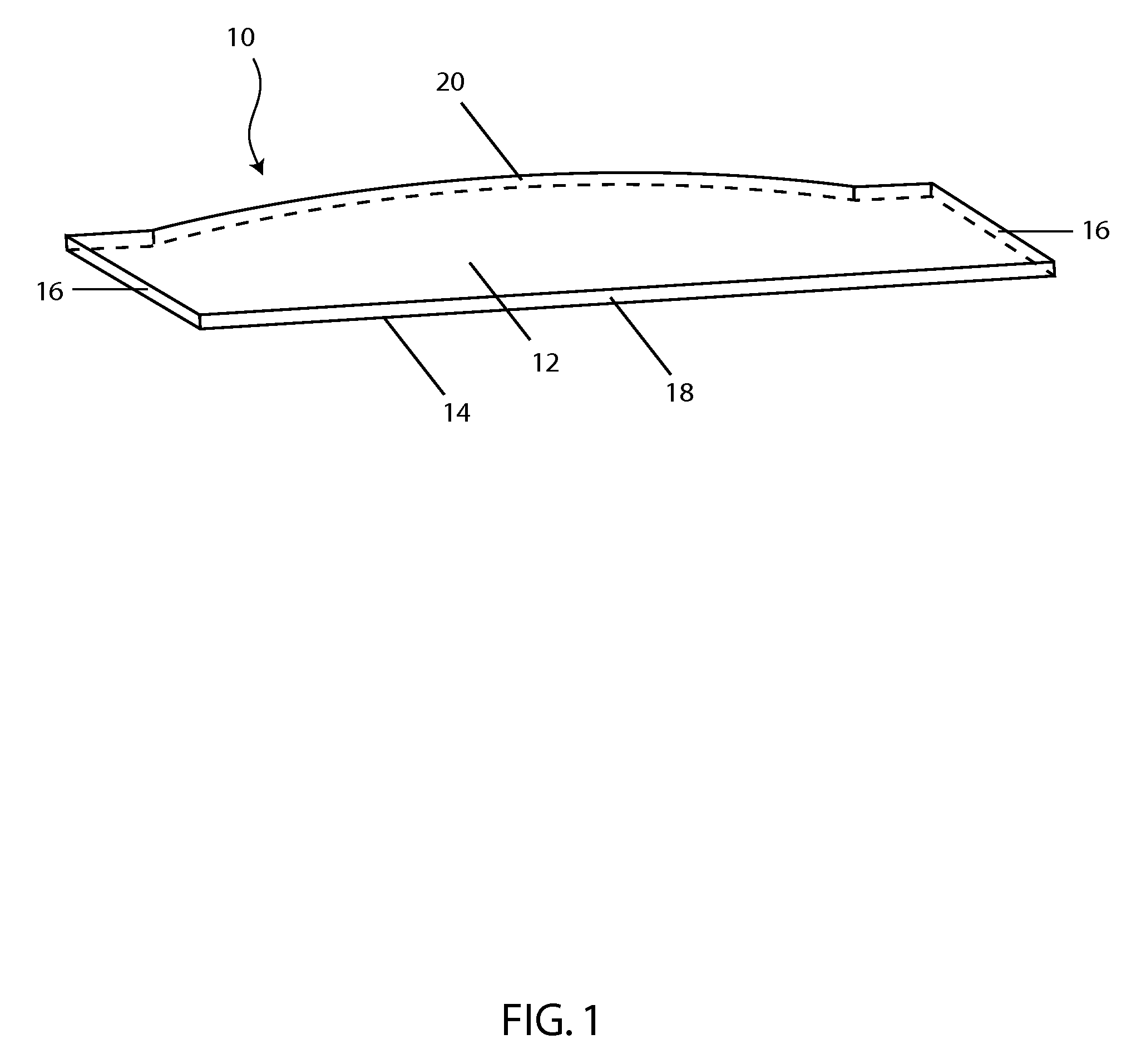

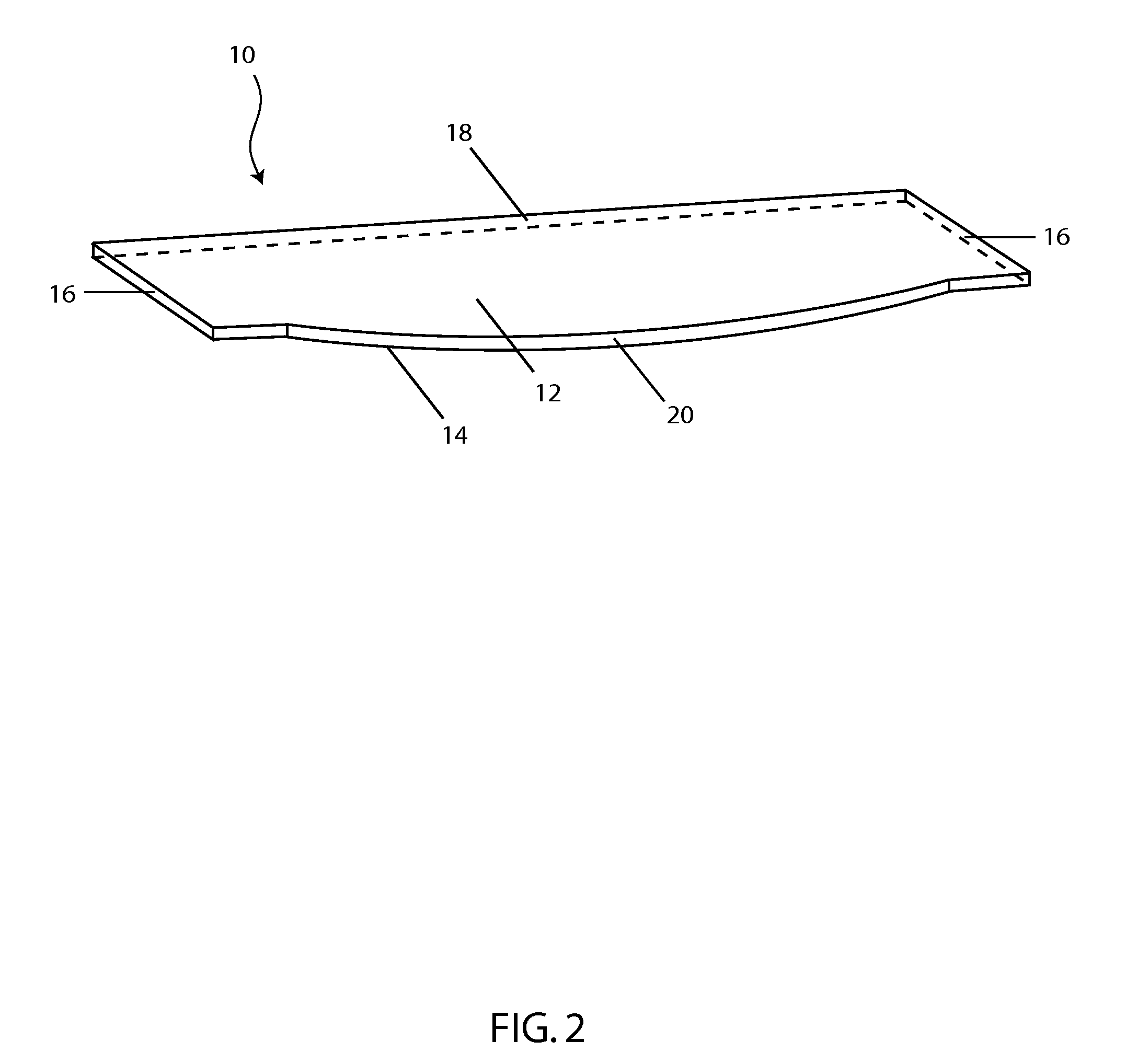

Handheld Accessory Tool and Method for the Application of Adhesive Films

InactiveUS20090308540A1Better gripping surfaceFine surfaceLaminationLamination apparatusGraphicsHand held

An accessory tool for the application of adhesive films to substrates. The tool is elongate and thin, and made of a lightweight semi-rigid to rigid material. The tool functions as a linear support for the free edge of the film piece during the application process. The tool improves the ability of a worker to hold a film piece taut at a level above the substrate. Use of the tool prevents premature adherence and reduces the formation of bubbles, wrinkles, and other defects commonly encountered during film application. The tool relies on the adhesive nature of the film piece itself in order to make a non-permanent connection between the two. The tool is useful for printing businesses that apply adhesive film pieces, such as graphics, to substrates daily. The invention also relates to an improved manual method for applying adhesive films to substrates.

Owner:PUCKETT JR LOWELL E +1

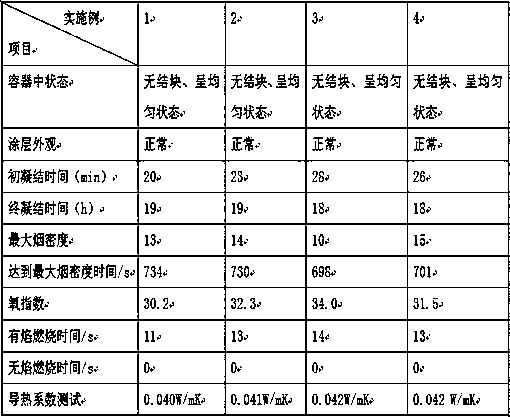

Inner wall heat-preservation flame-retardant diatom ooze and preparation method

InactiveCN107778929AHighlight substantive featuresSignificant progressFireproof paintsBuilding material handlingFiberEpoxy

The invention discloses inner wall heat-preservation flame-retardant diatom ooze and a preparation method. The diatom ooze comprises raw materials, namely kieselguhr, ramie fibers, epoxy resin, a composite coupling agent, vermiculite powder, barium sulfate, chlorinated paraffin, a pigment, a flame retardant, a defoaming agent, a thickening agent, a dispersant, a moistening agent and water. The diatom ooze disclosed by the invention has the advantages of good heat preservation effect, good flame retardancy, good adhesive property, no powder off, no cracking, high strength, a remarkable indoor air humidity adjustment effect, reduction of influence caused by wet air, and improvement of the comprehensive properties of the diatom ooze.

Owner:GUANGXI JISHUN ENERGY TECH

Oxygen-barrier material in particular for silage cover

InactiveUS20170129222A1Process stabilityPrevents potential interlayer delamination problemAgricultural articlesSynthetic resin layered productsPolymer sciencePolyolefin

A multilayer material, notably for silage cover, that comprises an oxygen-barrier core layer sandwiched between at least two polyolefin layers, each polyolefin layer being separated from the barrier core layer by an adhesive layer, characterized in that at least one of the adhesive layers contains LCB-mLLDPE.

Owner:SOC DEXTRUSION DU POLYETHYLENE A BARBIER & CIE

Electrostatically conductive oil-tolerant paint containing rich zinc and silicic acid

InactiveCN1390895AReduce manufacturing costFast dryingElectrically-conductive paintsAlcoholSilicic acid

An antistatic paint is prepared through mixing ethyl n-silicate with absolute alcohol, stirring, alcoholysis reaction, dropping hydrochloric acid diluted by purified water to make pH=2-3, laying aside, adding organic silanamine, stirring, adding zinc powder and stirring. Its advantages are high electrostatic conductivity and corrosion resistance, low cost, fast dry, and high firmness of film.

Owner:黄观明 +1

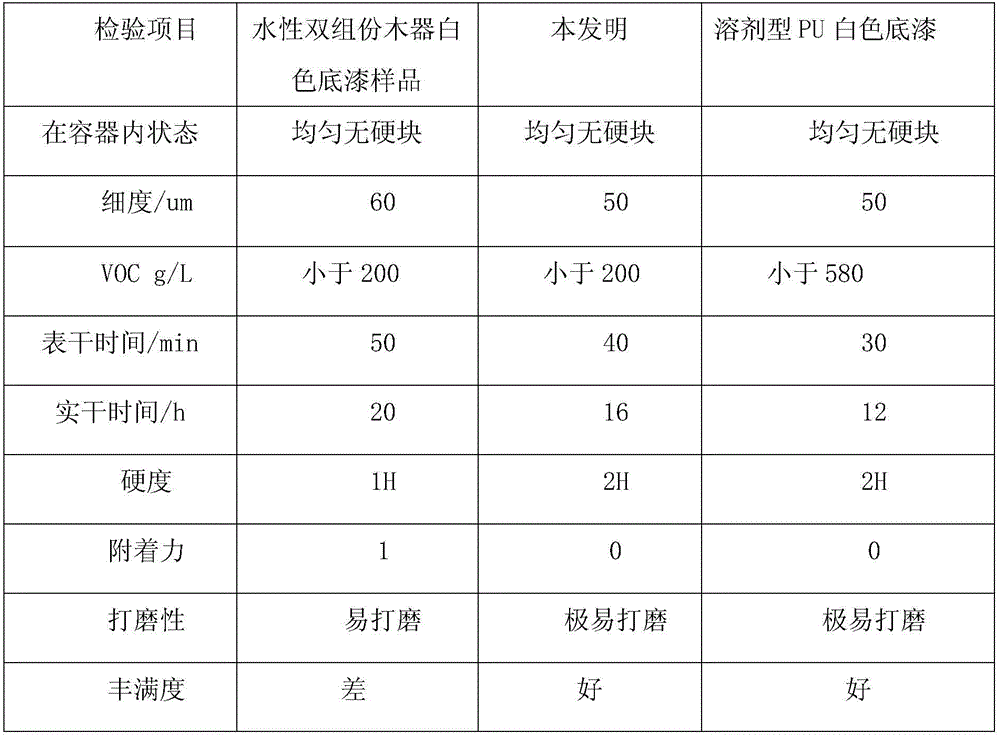

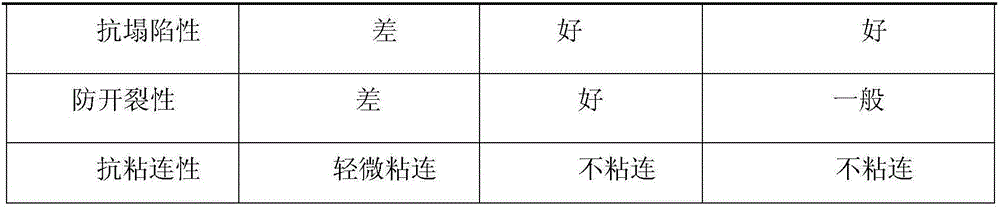

Water-thinned epoxy wood white primer and preparation method thereof

InactiveCN105754452AGood heat resistanceThe property of the coating film is stableEpoxy resin coatingsChemistryPolyamide

The invention discloses water-thinned epoxy wood white primer which is prepared from by main paint, a curing agent and a diluent.The main paint is prepared from, by mass, 40-55% of epoxy resin, 0.2-0.5% of a defoaming agent, 0.5-0.8% of a dispersion agent, 0.2-0.4% of a leveling agent, 1-2% of an anti-sedimentation agent, 15-20% of titanium dioxide, 10-20 parts of filler and 15-20% of a co-solvent.The curing agent is prepared from, by mass, 80% of polyamide and 20% of a modifying agent.Water is adopted as the diluent.The main paint and the curing agent exist in a solvent state, can be cured in the moist environment and have high cross-linking density.A formed coating film is relatively compact, high in hardness and good in stability.An emulsification agent is not adopted in the primer and the problem about water sensitivity of water-based paint is solved.The performance of the primer can be compared to solvent type PU white primer.Compared with PU paint, yellowing resistance can be greatly improved.The primer does not contain toxic matter and is safe and environmentally friendly.

Owner:CHENGDU YOUPIN CHEM CO LTD

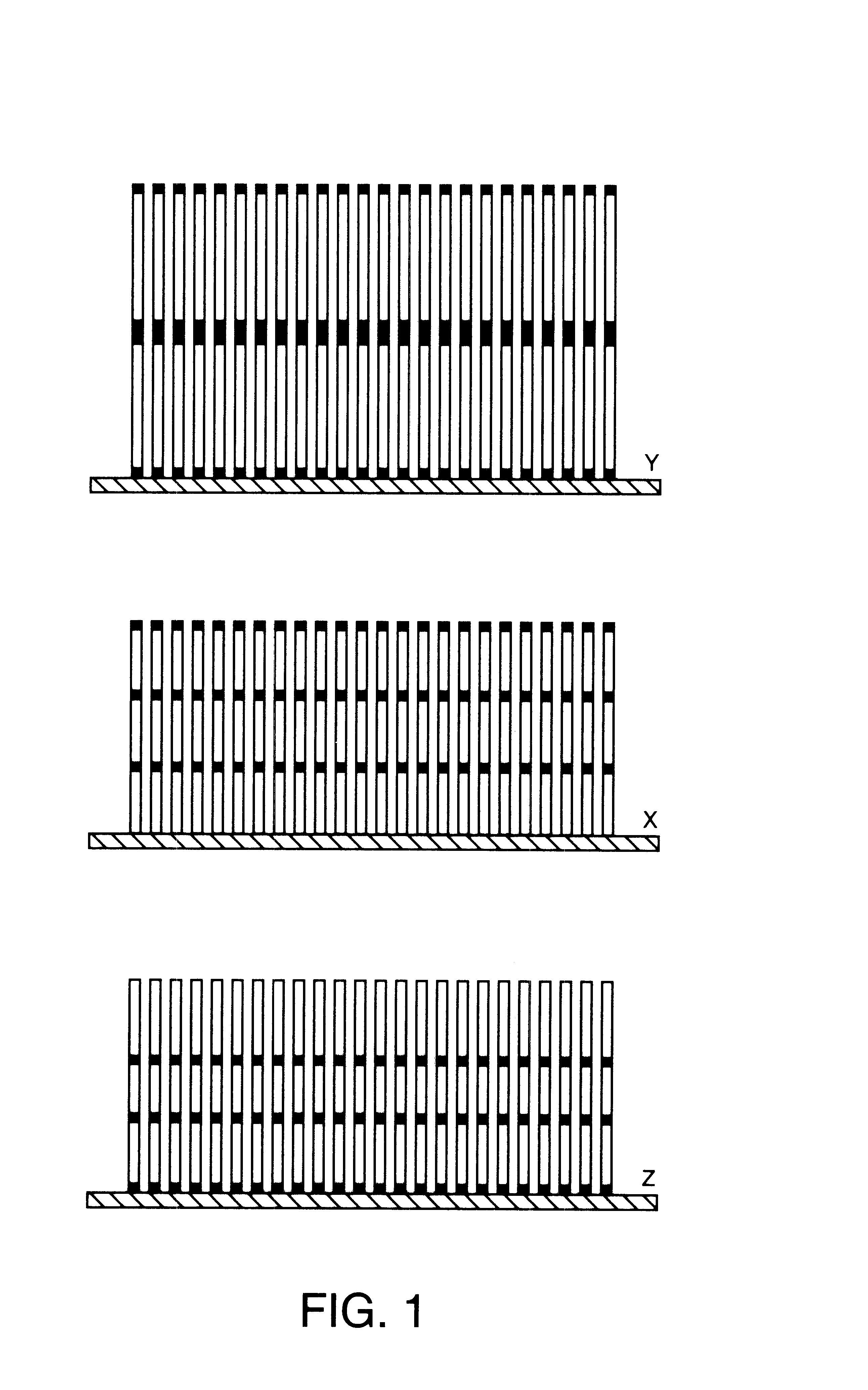

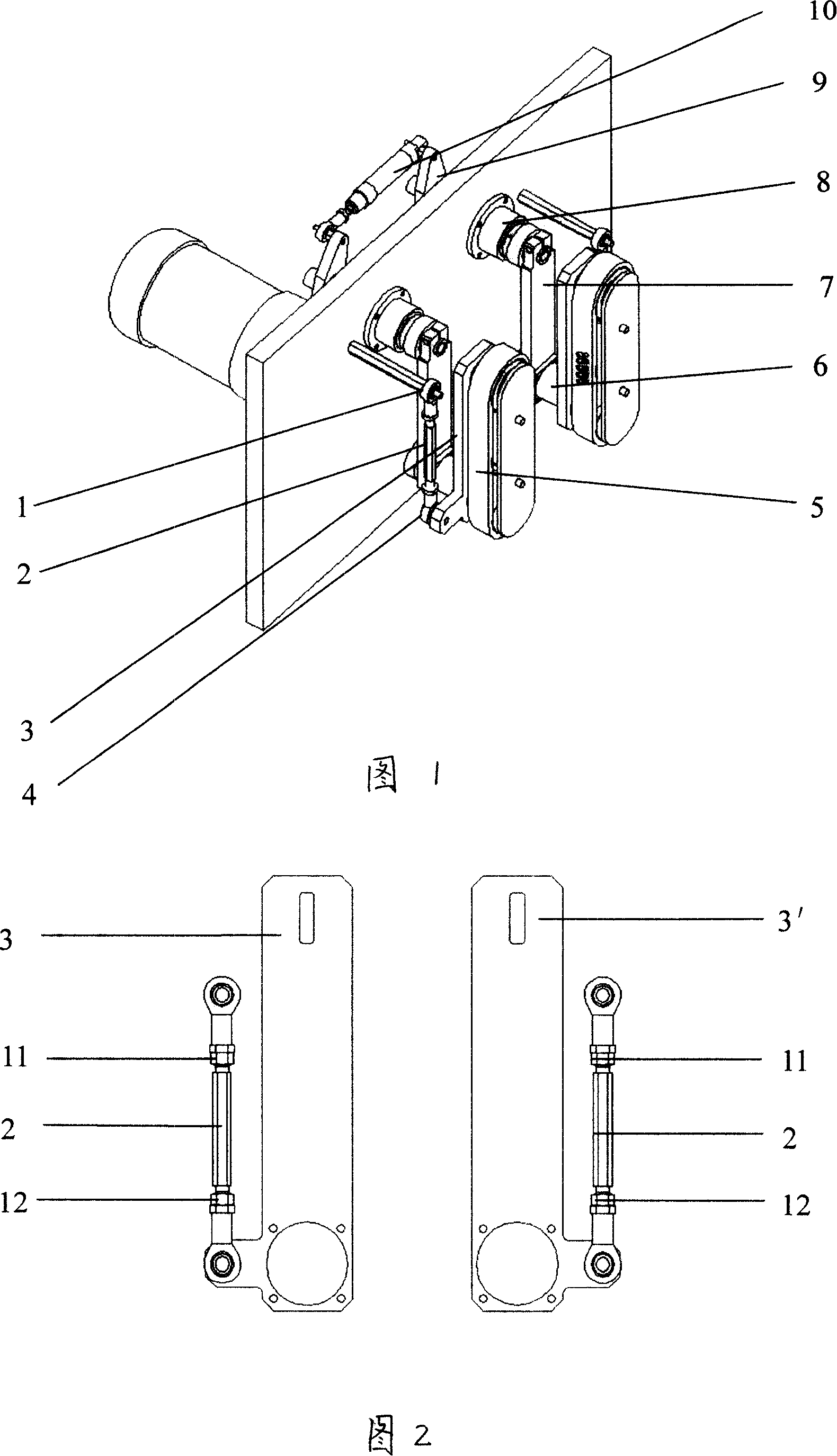

Parallelogram connecting-rod pressing-wheel film feeding mechanism of vertical quantitative filling packer

InactiveCN101200222AFilm StabilityEasy and feasible adjustment range controlWrapping material feeding apparatusWrappingWorking environmentElectric machinery

Disclosed is a film conveying and rolling mechanism with parallelogram connecting rod pressing wheel, which is used in vertical quantified filling packaging machine, comprising a towing belt, a bearing seat 1, a swing arm and a cylinder. The film rolling mechanism is driven by a motor and is separated into two shafts through synchronizing wheels which are fixed on a frame; swing rods are driven to rotate by the cylinder driving the swing arm, and the swing arm drives the swing rods to swing left and right, making the left and right synchronizing wheels fixing plate be close to the center; two symmetric parallelogram mechanisms are formed by the swing arm, the bearing seat, a pivot 1, a pivot 2 and a bearing seat 2; the connecting rod is fixed on a front panel by the pivot 1; the pivot 2 is connected with the synchronizing wheel fixing pate. The driving mechanism of the invention is driven by a motor which make the film drawing much more stable; the swing arm is driven by the cylinder to make the left and right synchronizing wheels fixing plate be close to the center; the transmission system is independent from the working environment through the bearing seat; the film drawing mechanism can adjust the relative position between the towing belt and a shaper. After adjustment, the shaper of different specifications can be adopted.

Owner:JOYEA CORP

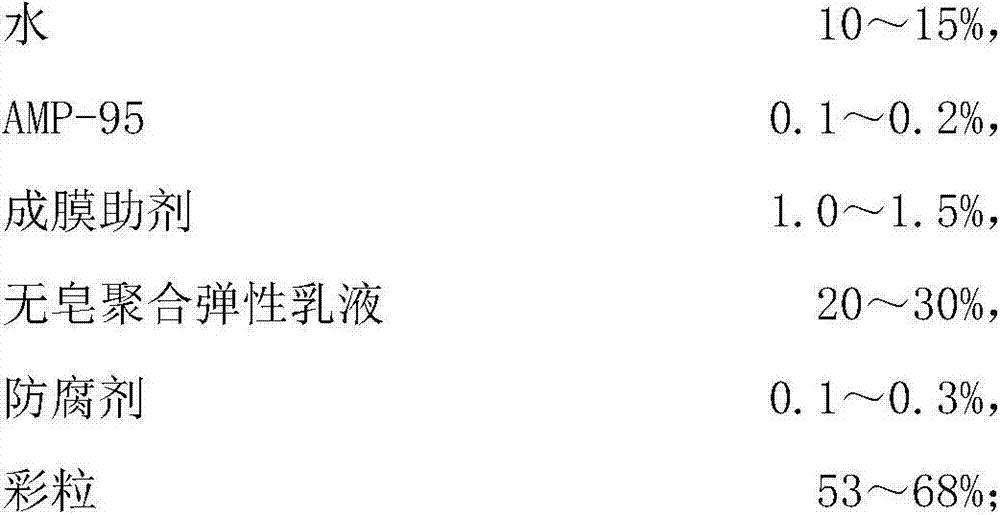

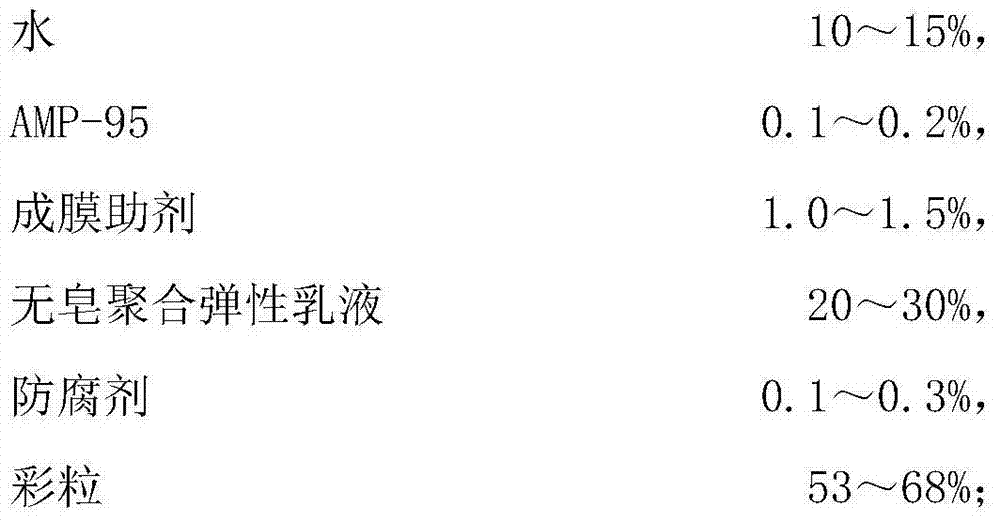

Smell-clearing waterborne colorful paint composition and preparation method thereof

The invention discloses a smell-clearing waterborne colorful paint composition and a preparation method thereof. The composition comprises the following components in percentage by weight: 10-15% of water, 0.1-0.2% of AMP-95, 1.0-1.5% of a film-forming additive, 20-30% of a soap-free polymerized elastic emulsion, 0.1-0.3% of a preservative and 53-68% of color particles. When the smell-clearing waterborne colorful paint composition is prepared, a colloidal solution and base paint are firstly prepared; color paste is added into the base paint to prepare color-mixing base paint, the color-mixing base paint is further added into the colloidal solution and dispersion and granulation are performed to prepare the color particles; and the water, the AMP-95, the film-forming additive, the soap-free polymerized elastic emulsion, the preservative and the color particles are uniformly mixed to prepare the smell-clearing waterborne colorful paint composition. The smell-clearing waterborne colorful paint composition disclosed by the invention mainly comprises a non-toxic and odorless finely classified filler, the emulsion and other additives, and the limit of harmful substances is in line with the requirements of GB 24408-2009 'Limit of harmful substances in exterior wall coatings for buildings'.

Owner:上海贝恒人居建设集团有限公司

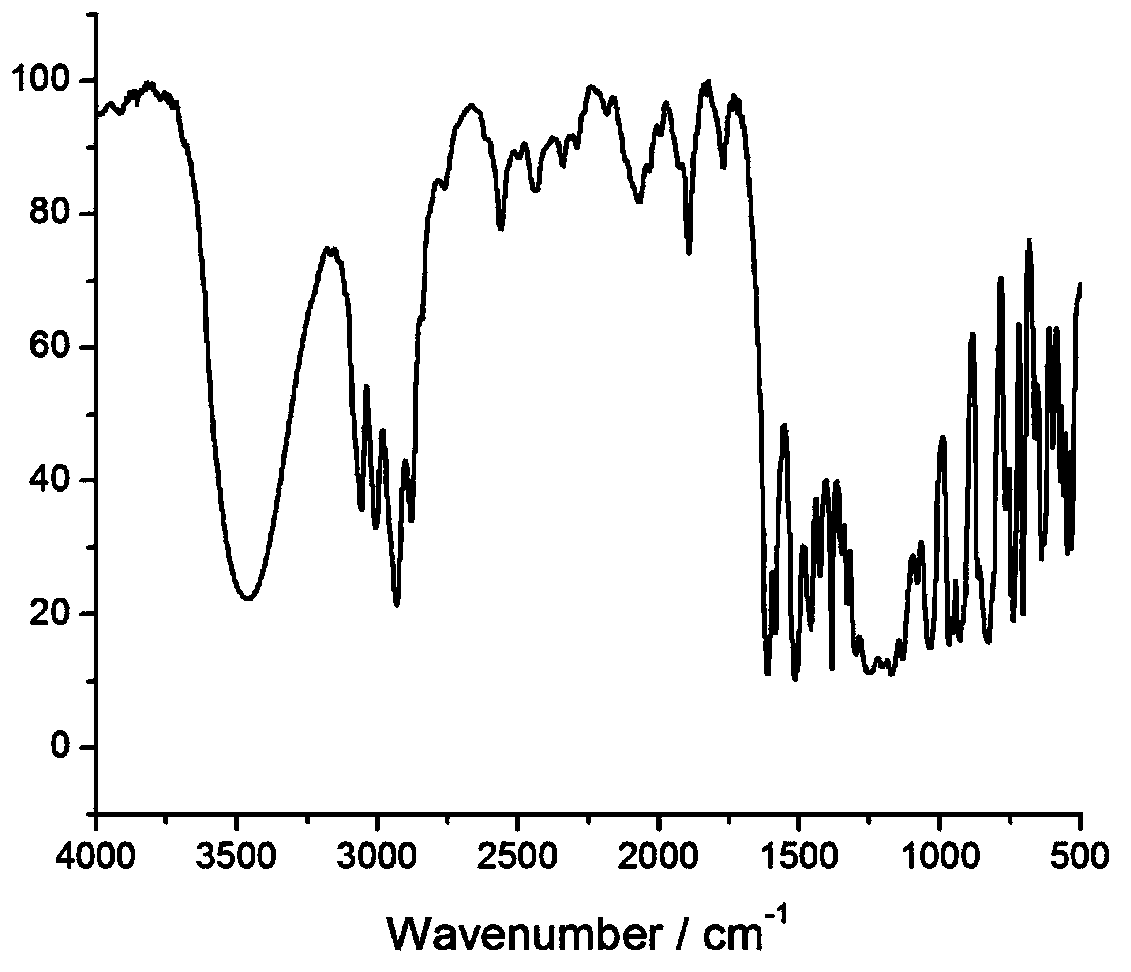

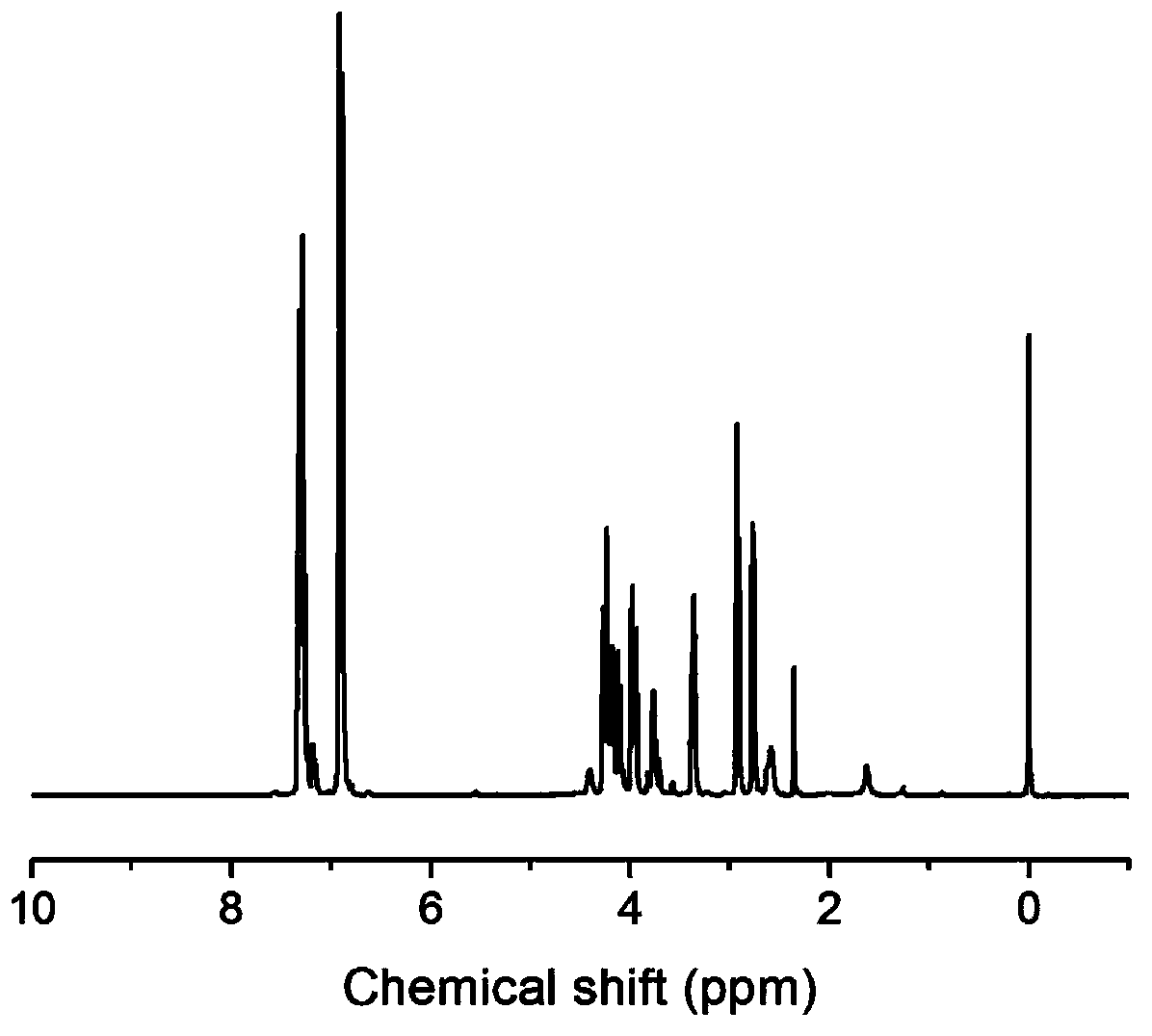

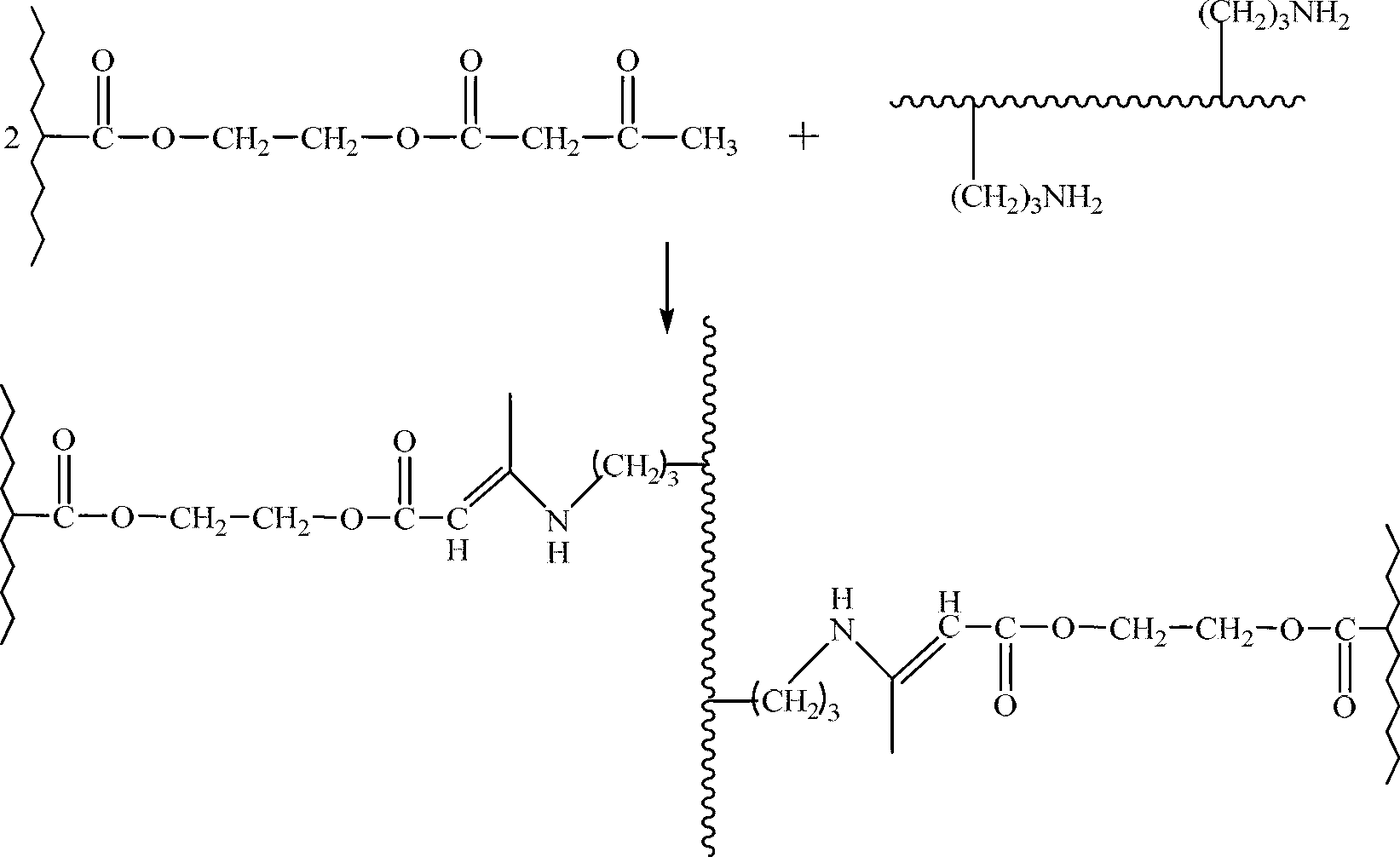

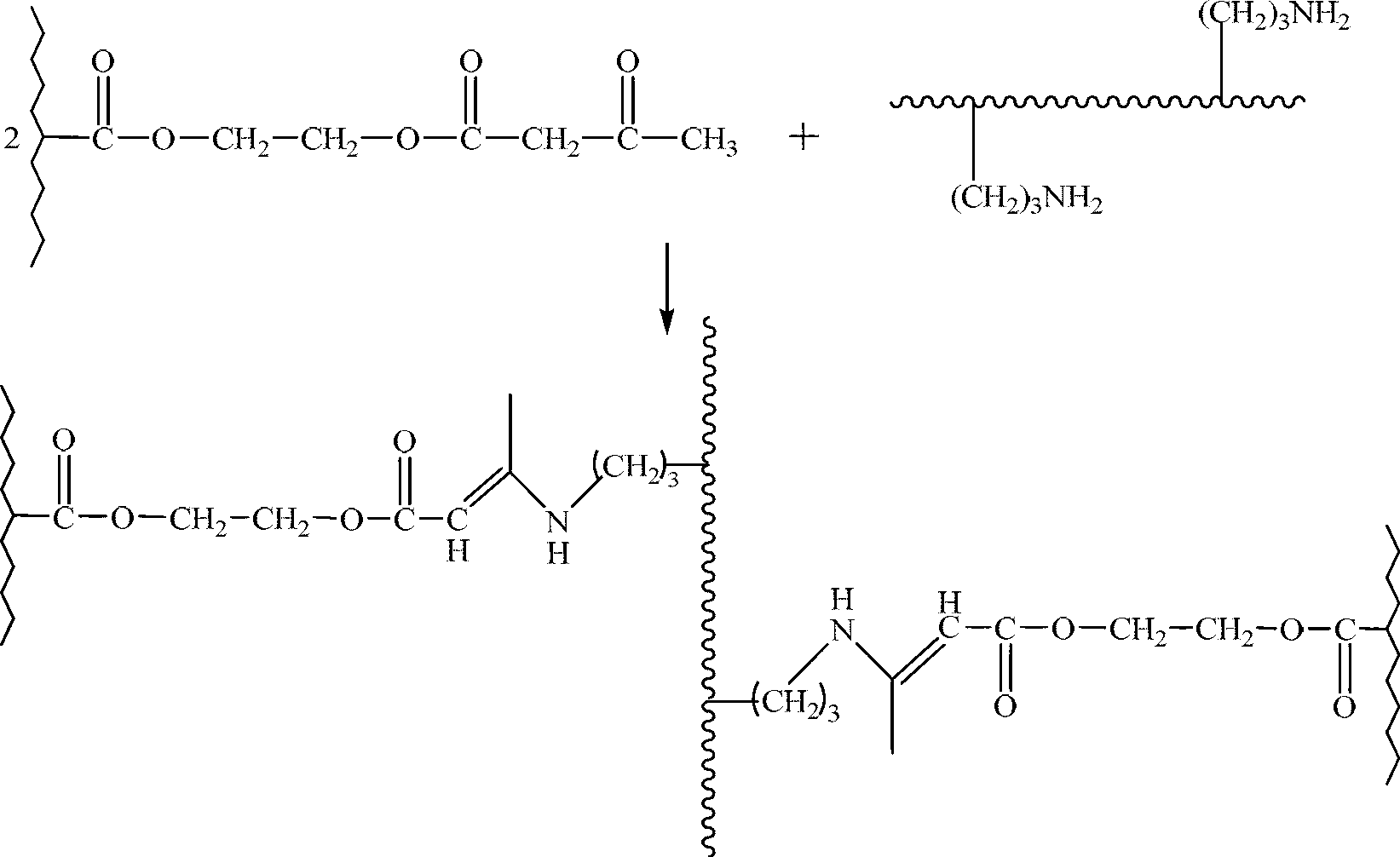

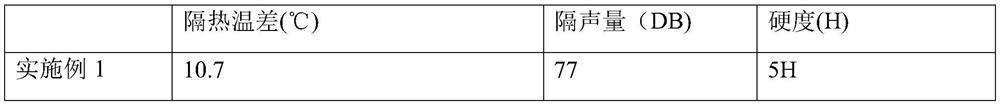

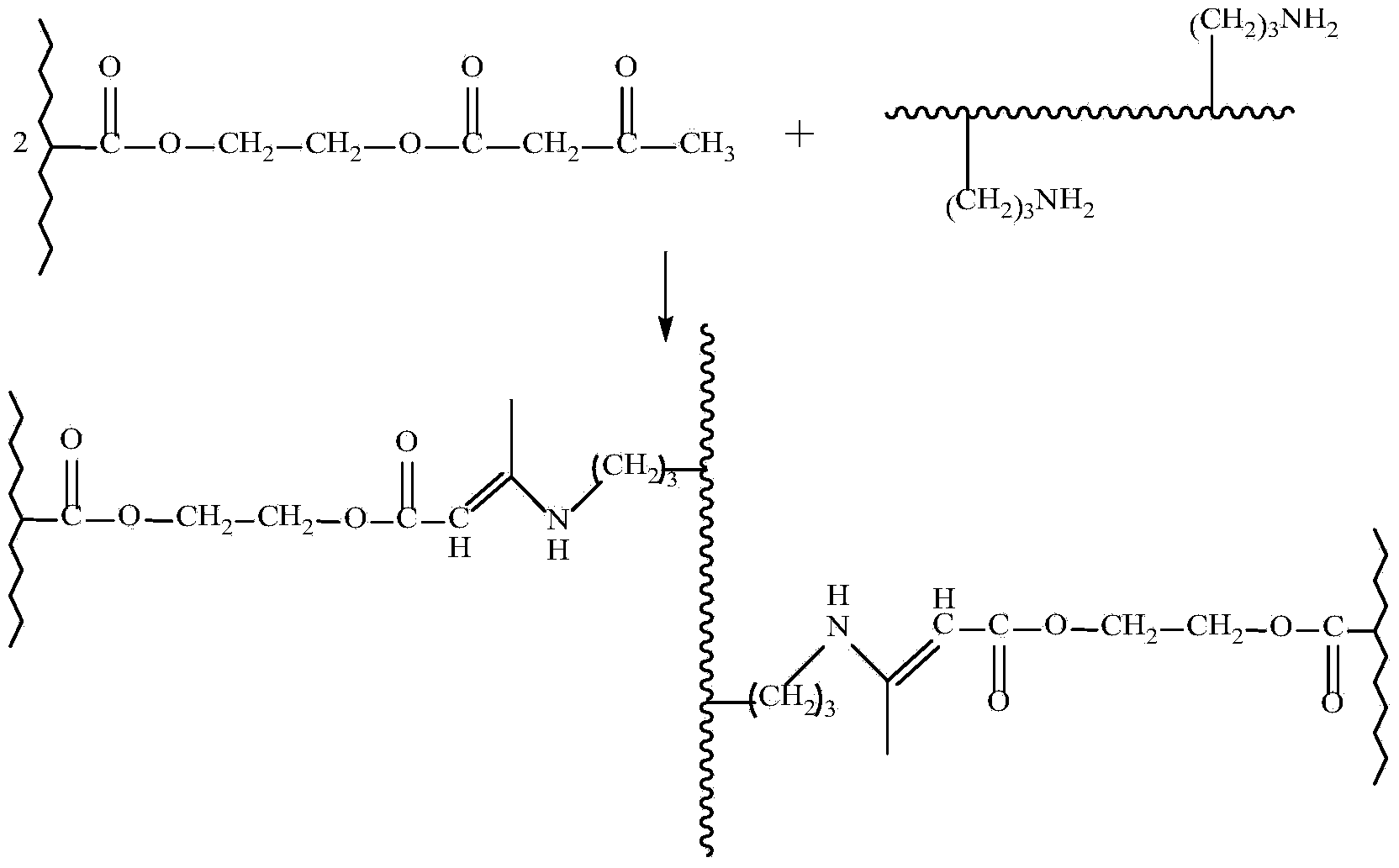

Method for preparing amino silicon oil modified acrylic resin leather finishing agent

InactiveCN103012804AHigh fullnessGood flexibilityCoatingsLeather surface finishingMethacrylateFunctional monomer

The invention discloses a method for preparing an amino silicon oil modified acrylic resin leather finishing agent. The method comprises the following steps of: firstly, introducing acetoacetic acid ethyl methacrylate (AAEM) serving as a functional monomer into an acrylic resin molecular chain to prepare self-crosslinking acrylic resin emulsion; and compounding the amino silicon oil emulsion and acrylic resin emulsion according to a certain proportion to prepare a room-temperature self-crosslinking acrylic resin leather finishing agent by using the amino silicon oil as a crosslinking agent. According to the invention, self-crosslinking is carried out on the leather finishing agent at the room temperature, and a amino silicon oil crosslinking acrylic resin net structure is formed after film formation; and due to introduction of the amino silicon oil, the flexibility and the smoothness of the film are increased and the hand feel of the film is improved. By the improvement method, the physical performance of leather coating can be obviously improved, the defect of hot stickiness and cold brittleness of the traditional acrylic resin is overcome, and the method has wide application prospect in the field of leather coating.

Owner:SHAANXI UNIV OF SCI & TECH

Electrostatically conductive oil-tolerant epoxy paint

InactiveCN1390903AReduce manufacturing costEasy constructionEpoxy resin coatingsElectrically-conductive paintsEpoxyAlcohol

An antistatic oil-resistant epoxy resin is prepared through mixing epoxy resin E42, meta-xylene phenolic rsin, organosilicon resin, dibutyl o-benzoate and ethyl n-silicate, adding Si-alloy powder, stirring, adding absolute alcohol or ethanediamine, and stirring. Its advantages are high electrostatic conductivity and oil resistance, low cost and firm film.

Owner:黄观明 +1

Antiviral emulsion composition, coating and preparation method thereof

ActiveCN111333862AReduce surface viral activityAvoid uneven loadAntifouling/underwater paintsPaints with biocidesPhosphonium saltPolyvinyl alcohol

The invention provides an antiviral water-based matrix emulsion composition and an antiviral coating containing the same. The emulsion composition is composed of an inorganic metal nanocomposite dispersion liquid with photocatalytic antiviral activity, a water-based high-molecular polymer emulsion containing a high-content quaternary phosphonium salt unit, and an optional polyvinyl alcohol auxiliary agent. The water-based matrix emulsion or the coating thereof can be used for surface coating treatment of textile articles, plastic products, glass products, leather, wooden products and other objects, so that the virus activity on the surfaces of the objects is reduced or inactivated in a short time, and the effects of inhibiting viruses and blocking propagation are achieved.

Owner:LONGHAI ZHENGUYUAN ADHESIVE CO LTD

Electrostatically conductive anticorrosion epoxyxylene phenolic paint

InactiveCN1390904AReduce manufacturing costFast dryingEpoxy resin coatingsElectrically-conductive paintsEpoxySilicate

An antistatic anticorrosion paint is prepared through mixing epoxy resin E42, meta-xylene phenolic resin, organosilicon resin, dibutyl o-benzoate and ethyl n-silicate, adding Ti powder, stirring, adding absolute alcohol or ethanediamine, and stirring. Its advantages are high electrostatic conductivity and corrosion resistance, low cost, fast dry and firm film.

Owner:黄观明 +1

Low-temperature curing epoxy resin and coating containing epoxy resin

ActiveCN108341926AAchieving Low Temperature CuringFast curingEpoxy resin coatingsEpoxyLow temperature curing

The invention provides low-temperature curing epoxy resin. The epoxy resin is epoxy resin of which an epoxy group is modified, and the modified group is a primary amine group or an isocyanate group. The invention also provides a coating containing the epoxy resin. According to the epoxy resin provided by the invention, a chemical modification method is used to convert all epoxy groups on a molecular chain of the epoxy resin into terminal amino-NH2 or isocyanate groups; and when the epoxy resin is applied, modified amino-containing epoxy resin and an isocyanate group-containing curing agent aremixed, or modified isocyanate group-containing epoxy resin and an amino-containing epoxy curing agent are mixed, rapid curing can be performed at the temperature of 0 DEG C or less, and a coating film is stable, and has high strength and wide application prospects.

Owner:西安天元化工有限责任公司

High-weather-resistance anti-rust oil

InactiveCN103484192AImprove aging resistanceImprove corrosion resistanceAdditivesPropanoic acidSarcosine

The invention discloses a high-weather-resistance anti-rust oil which is prepared from the following raw materials in parts by weight: 70-75 parts of 75SN base oil, 3-5 parts of calcium dinonylnaphthalene sulfonate, 2-3 parts of lanolin magnesium soap, 1-2 parts of citric acid, 1-2 parts of N-oleoylsarcosine octadecylamine salt, 2-3 parts of sulfurized fatty acid ester, 1-2 parts of 2-aminoethylheptadecenylimidazoline, 2-3 parts of film-forming assistant and 0.1-0.3 part of beta-(3,5-ditert-butyl-4-hydroxyphenyl)propionic acid n-octadecanol ester. The anti-rust oil disclosed by the invention has the advantages of high aging resistance, high corrosion resistance, stable coated film, favorable spreadability on the workpiece surface, favorable protective action on the metal workpiece, and high weather resistance; and the coated film can not be easily damaged under natural conditions.

Owner:BENGBU YINGLU PHOTOELECTRIC

Antirust high-temperature-resistant paint for aeronautical materials and preparation method of antirust high-temperature-resistant paint

InactiveCN106590422APrevent oxidationHigh strengthFireproof paintsAnti-corrosive paintsCyclohexanonePolystyrene

The invention discloses antirust high-temperature-resistant paint for aeronautical materials and a preparation method of the antirust high-temperature-resistant paint. The antirust high-temperature-resistant paint is prepared from coal tar pitch, zinc yellow, silver paste powder, paratoluensulfonyl chloride, zinc carbonate, titanium dioxide, polystyrene resin, zinc phosphate, glass powder, melamine, diphenyl ether resin, cyclohexanone, potassium dichromate and a drier. A product is in level 1 of adhesion, free of cracking and shedding at a high temperature, quick in drying and 30-70d in salt fog resistance and can be dried only by drying for 80-120min at 200 DEG C; pendulum hardness is 8-10, coating brightness, smoothness and great thermal strength and dielectric properties are realized, and fineness is 20-40micron; shedding is avoided at a high temperature of 1000-1400 DEG C, metal corrosion is avoided, and flexibility is 0.5-2.5mm; coating film firmness is achieved, steel materials are protected from oxidization and decarbonization, and the paint is resistant to water, acids, alkalis and low temperature and unchanged after being soaked in hydrochloric acid, sodium hydroxide and sodium chloride for 4-8 months.

Owner:江苏悠谷未来科技有限公司

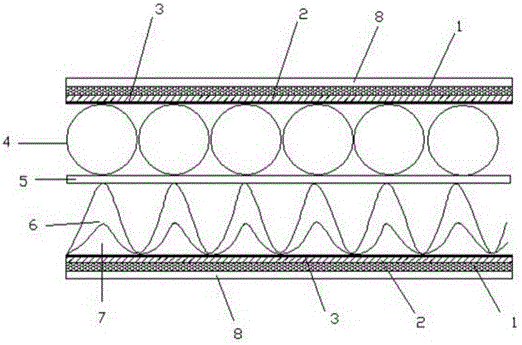

Environment-friendly fireproof corrugated board

InactiveCN105774066ALow costImprove buffering effectPaper/cardboard layered productsBoxesCardboardPulp and paper industry

The invention relates to an environment-friendly fireproof corrugated board.The environment-friendly fireproof corrugated board comprises two surface paper layers and a core paper layer arranged between the surface paper layers.The core paper layer mainly comprises an outer layer, an adhesion layer and an inner layer.Each surface paper layer comprises a waterproof layer and a buffer layer which are sequentially arranged in an attached mode, wherein a fireproof layer is attached to the surface of the waterproof layer made of kraft paper, and the buffer layer is a sponge layer pasted on the outer side of the surface paper layer.The outer layer is composed of round arrayed paperboards.The inner layer comprises a first U-shaped core paper interlayer and a second U-shaped core paper interlayer, transverse coordinate positions of crests and troughs of the first U-shaped core paper interlayer and the second U-shaped core paper interlayer are the same, and the crests of the first U-shaped core paper interlayer and the second U-shaped core paper interlayer make contact with each other.The adhesion layer is arranged between the outer layer and the inner layer.When the environment-friendly fireproof corrugated board is used for packaging fragile objects, the use amount of white foam can be reduced, so that pollution is reduced, and higher environmental friendliness is achieved; meanwhile, the fireproof and flame-retardant effect is achieved.

Owner:BAOYI NEW MATERIAL CO LTD

Water borne epoxy resin anticorrosive paint and preparation method thereof

InactiveCN101633814BGood value for moneyGood weather and humidity resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyHydrophilic monomer

The invention discloses a water borne epoxy resin anticorrosive paint and preparation method thereof and solves the contradiction between storage stability of water dispersion and water resistance and corrosion resistance of dispersion film in the prior art. The paint is prepared by mixing oxosilane modified water borne epoxy resin dispersion, iron oxide red, rustproofing pigment, talc powder, defoaming agent, flatting agent, flash rust proofing agent and deionized water in ratio, and the invention is characterized in that: hydrophilic monomer is introduced to epoxy resin molecular chain, so the paint has self-emulsifying characteristic; and oxosilane is applied to modifying of the water borne epoxy resin, so that the paint can be heated and self-solidified. The paint has good storage stability and good construction performance, film can be fast dried and has high rigidity after being dried, the film is bright and smooth, water proof, corrosion resistant, washing resistant, good in comprehensive performance and low in cost. The invention can meet the requirement of anticorrosive paint in the fields of storage tank, bridge and the like.

Owner:HUANGGANG NORMAL UNIV

Multifunctional heat-preservation diatom ooze for interior wall and preparation method thereof

InactiveCN107778930AHighlight substantive featuresSignificant progressFireproof paintsAnti-corrosive paintsEpoxyWeather resistance

The invention discloses multifunctional heat-preservation diatom ooze for an interior wall and a preparation method thereof. The multifunctional heat-preservation diatom ooze comprises diatomite, an inorganic expanded vitrified lightweight heat-insulation material, epoxy resin, a compound coupling agent, pearl powder, sepiolite, sericite powder, a de-foaming agent, a thickener, a dispersant, a wetting agent and water. The diatom ooze disclosed by the invention has excellent heat-preservation and heat-insulating properties and fireproof and anti-ageing properties, and also has the advantages ofno hollowness and cracking, high strength, corrosion resistance, chemical drug resistance, durability, weather resistance and toughness; the waterproof property, the scrubbing resistance and the likeof a coating film are improved and the strength of the coating film is improved; and the multifunctional heat-insulating diatom ooze has flame-retarding and heat-preservation effects.

Owner:GUANGXI JISHUN ENERGY TECH

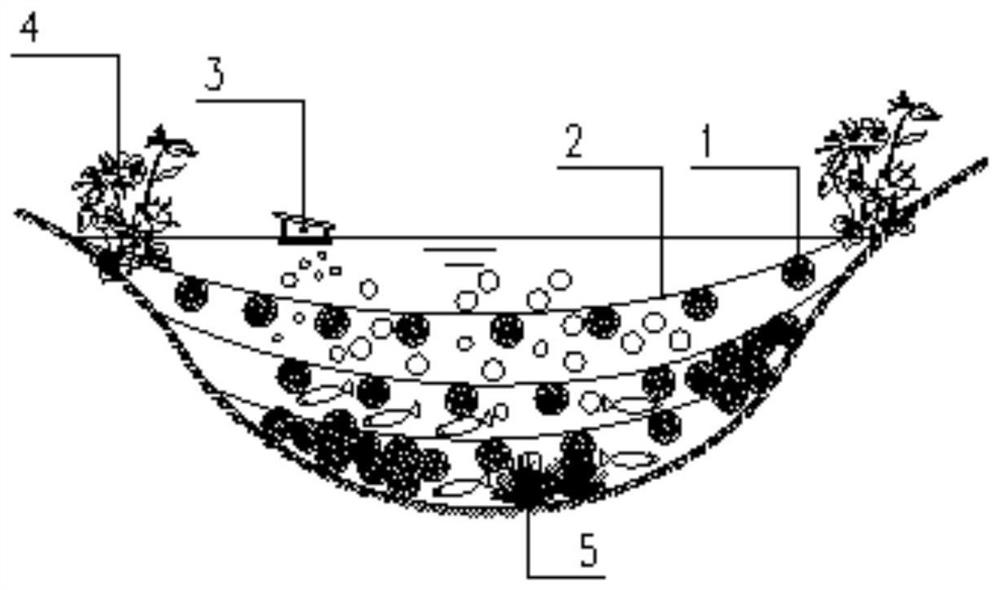

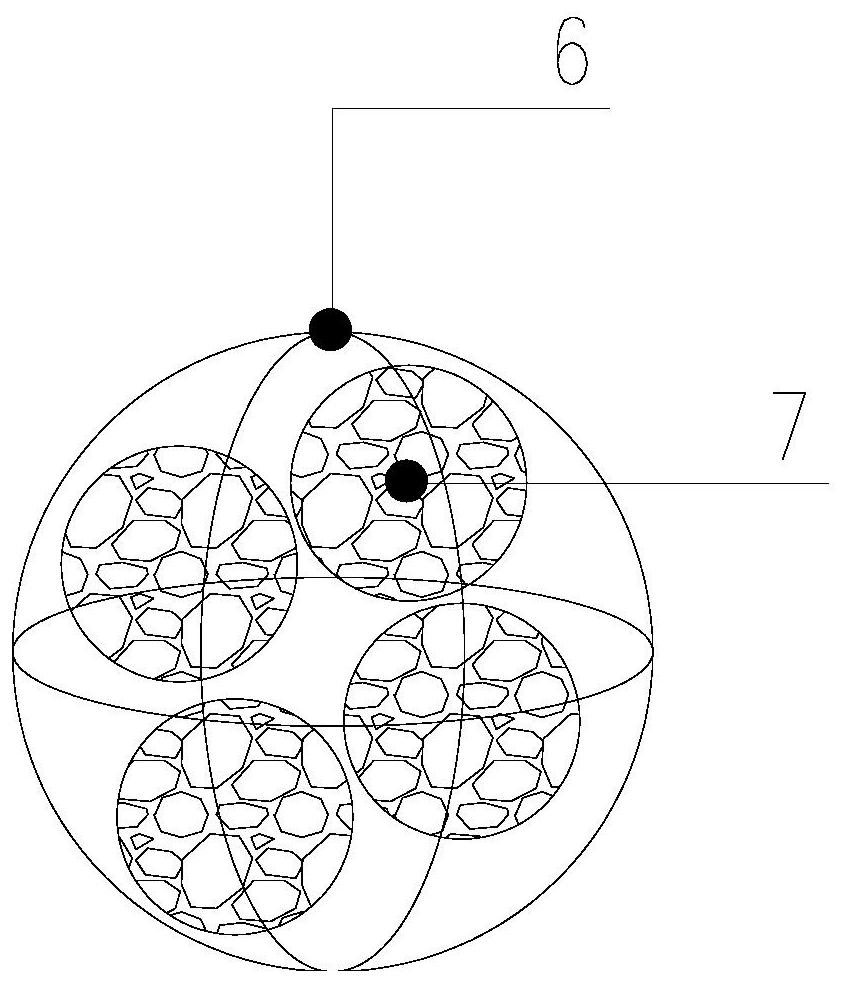

Method for purifying black and odorous water in riverway

InactiveCN112299564AChemically stableStable water purification efficiencyWater resource protectionWater aerationShrimpRiver routing

The invention discloses a method for purifying black and odorous water in a riverway. The method comprises the following steps: suspending a floating aeration device on a riverway section at a downstream position of the riverway by adopting a PVC rope; suspending a composite ecological filler on the PVC rope stretching across the riverway, wherein the composite ecological filler is formed by combining a suspended ball filler and light ceramsite; planting emergent aquatic plants and submerged plants at the position where the composite ecological filler is arranged according to different water depths; and piling fish reefs suitable for inhabitation of fishes, shrimps, shellfishes and crabs on the two sides of the part, located at the composite ecological filler, of the bottom of the riverwayfrom the composite ecological filler. The method has the following beneficial effects that the composite ecological filler is hung and transversely pulled on the section of the riverway through the PVC rope, and the emergent aquatic plants and the submerged plants are planted in the riverway to enhance water purification effect and improve the self-purification capacity of the riverway; an ecological system of the riverway is gradually restored through gradual improvement of a food chain; and the black and odorous water body of the riverway can be aerated and oxygenated, so the dissolved oxygen concentration of a water body is improved, and the habitat conditions of the water body are improved.

Owner:北京远浪潮生态建设有限公司

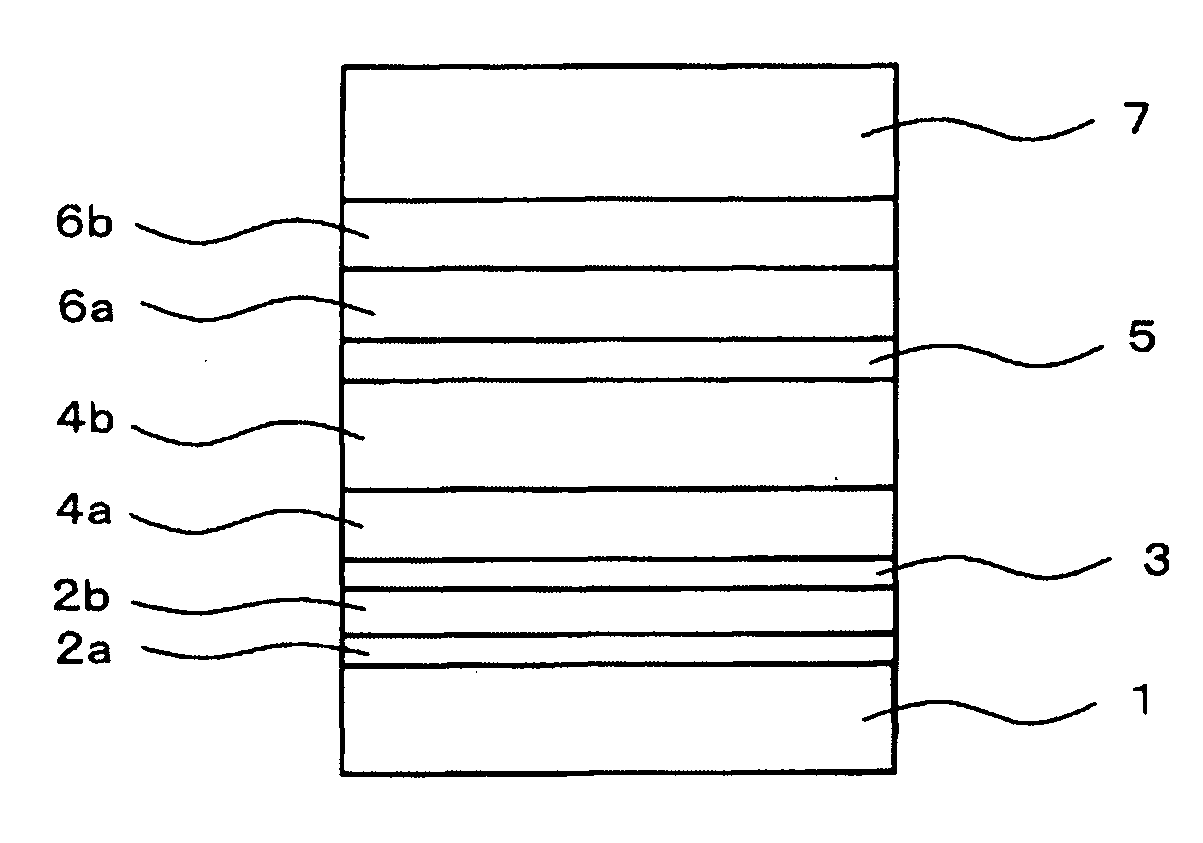

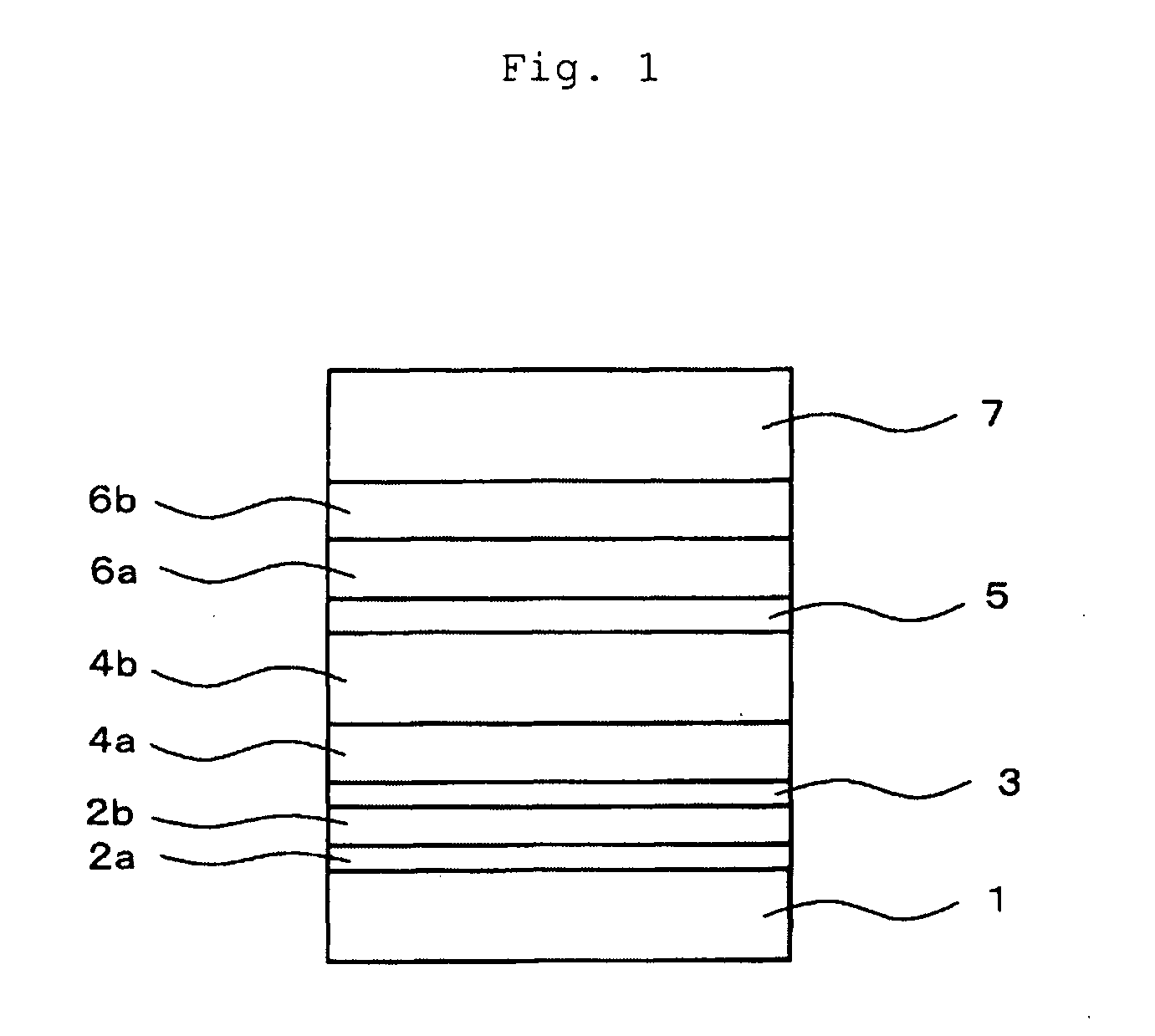

Electron transporting materials and organic light-emitting devices therewith

InactiveUS20090042061A1Improve heat resistanceImprove equipment efficiencyOrganic chemistryDischarge tube luminescnet screensHeat resistanceOrganic light emitting device

The present invention provides a novel electron transporting material having good heat resistance and being capable of forming devices with high thermal characteristics and an organic light-emitting device therewith. The phenanthroline derivative represented by the general formula below is used as the electron transporting material to form the organic light-emitting device:wherein the position of the substituent R6 or R7 depends on the position of the linkage between the phenanthrolinyl group and the fluorenyl group; X represents a single bond between the phenanthrolinyl group and the fluorenyl group; n0 and n1 each independently represent an integer of 0 to 2; and n2 and n3 each represent the number of the substituents and each independently represent an integer of 1 to 4.

Owner:YAMAGATA PROMOTIONAL ORG FOR INDAL TECH

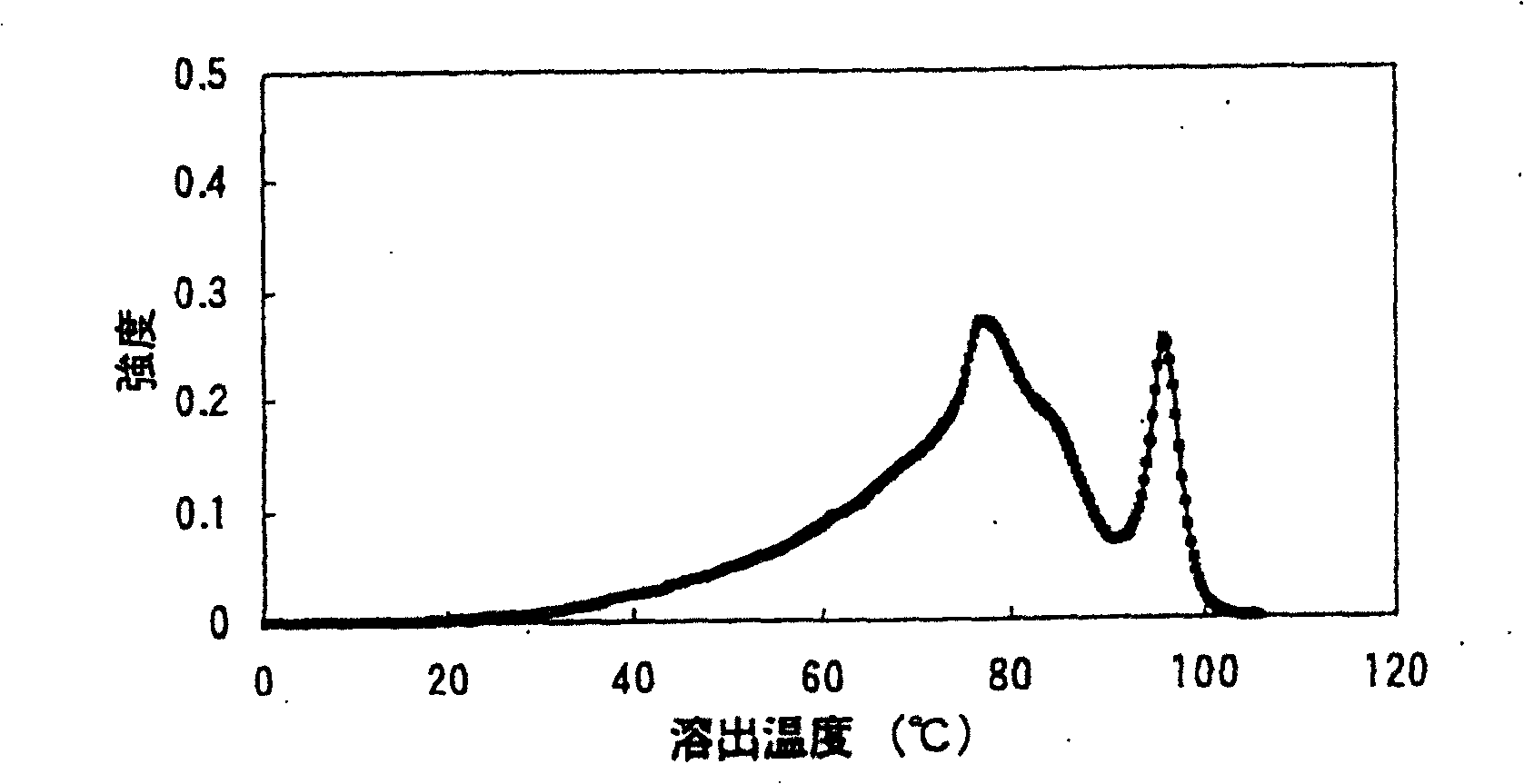

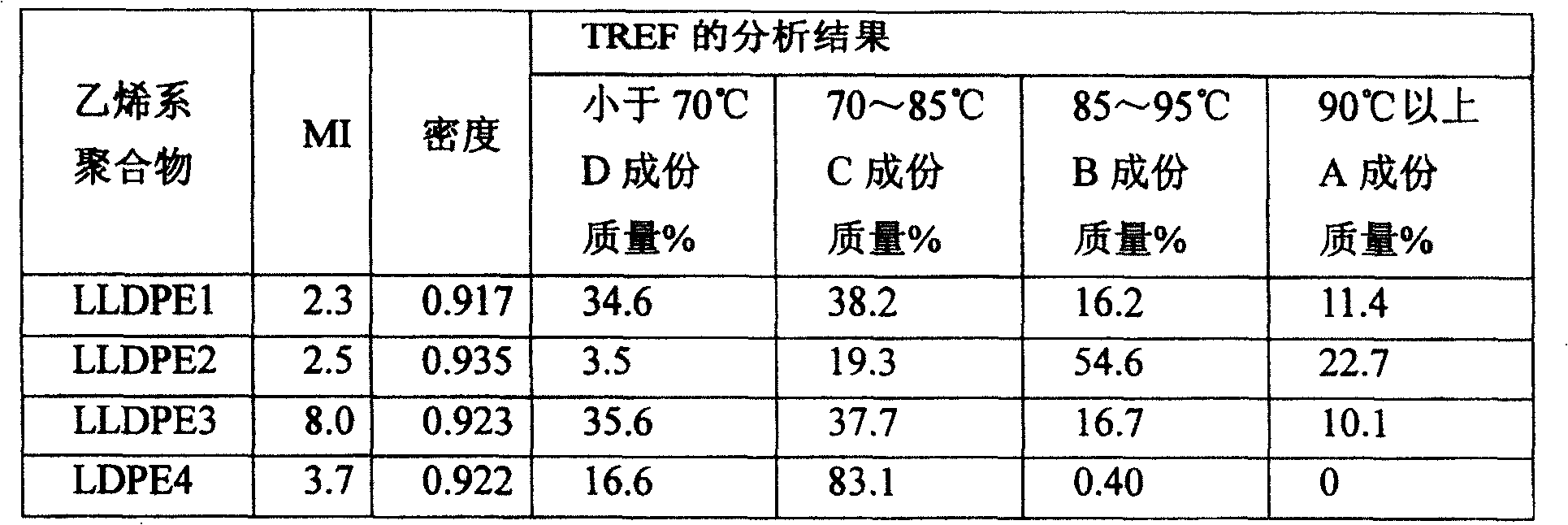

Ethylene series polymer composition for high-speed stretching making film and method for mfg. porous film

ActiveCN100436528CIncrease production capacityDoes not produce thick spotsLow-density polyethyleneFractionation

This ethylenic polymer composition for the high-speed drawn film-forming contains an ethylenic polymer in an amount of 35-60 mass% and an inorganic filler in an amount of 65-40 mass%, wherein the ethylenic polymer contains a branched-type low-density polyethylene in an amount of 3-20 mass% and is composed so that an elution component (component A) having an elution temperature of not less than 95[deg.]C and less than 120[deg.]C, an elution component (component B) having an elution temperature of not less than 85[deg.]C and less than 95[deg.]C, an elution component (component C) having an elution temperature of not less than 70[deg.]C and less than 85[deg.]C, and an elution component (component D) having an elution temperature of less than 70[deg.]C are contained in the olefinic polymer in amounts of 10-20 wt%, 20-40 wt%, 25-45 wt%, and 15-30 wt%, respectively, provided that the components A, B, C, and D are contained in an amount of 100 wt% in total, when the elution components having the specified temperature ranges are determined based on a curve relating the elution temperature to the amount of the elution component due to a continuous temperature-rising elution fractionation (TREF) method.

Owner:TOKUYAMA CORP

Furniture plate coating and production method

InactiveCN107916058AHighlight substantive featuresSignificant progressFireproof paintsAnti-corrosive paintsEpoxyFiber

The invention discloses furniture plate coating and a production method. The furniture plate coating is prepared from the following raw materials: polyurethane, epoxy resin, emulsion, linen fibers, acomposite coupling agent, water, dibutyl phthalate, ethylene glycol, a thickening agent, a wear-resistant agent, a levelling agent and a defoaming agent. The furniture plate coating disclosed by the invention is good in water-tolerant, oil-resistant, heat-resistant and ageing-resistant properties, covering power is improved, and durability and scrubbing property of a coating are improved. No pollution is produced, melt viscosity is low, a film is firm, leveling property is good, mechanical properties are good, reactivity, storage stability, corrosion resistance and chemical resistance are excellent, and color matching of the coating is good.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

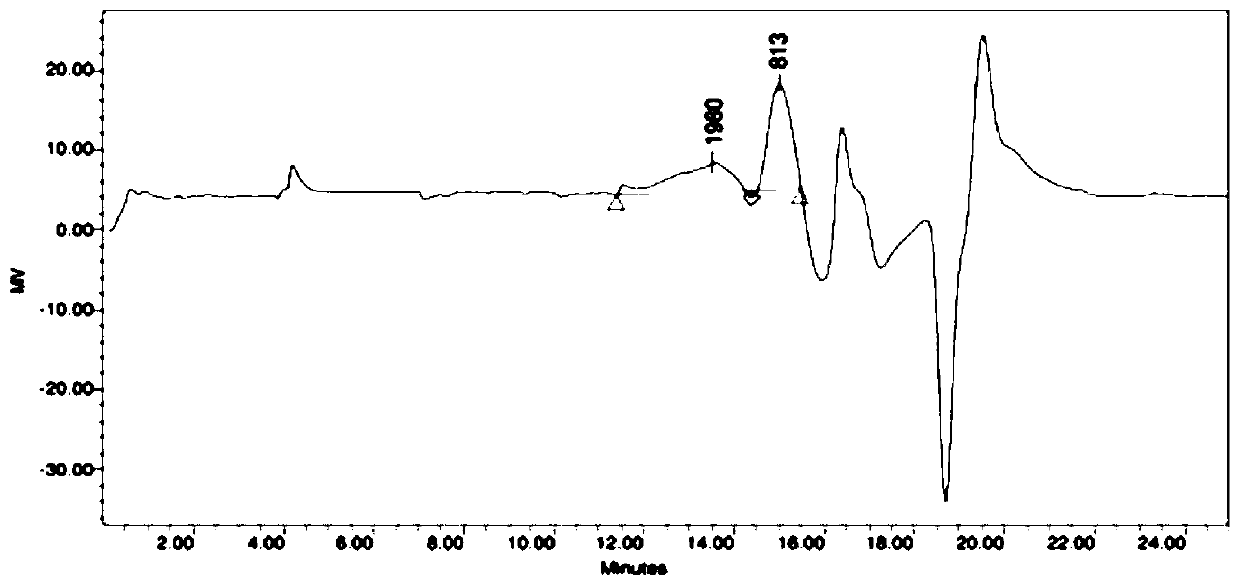

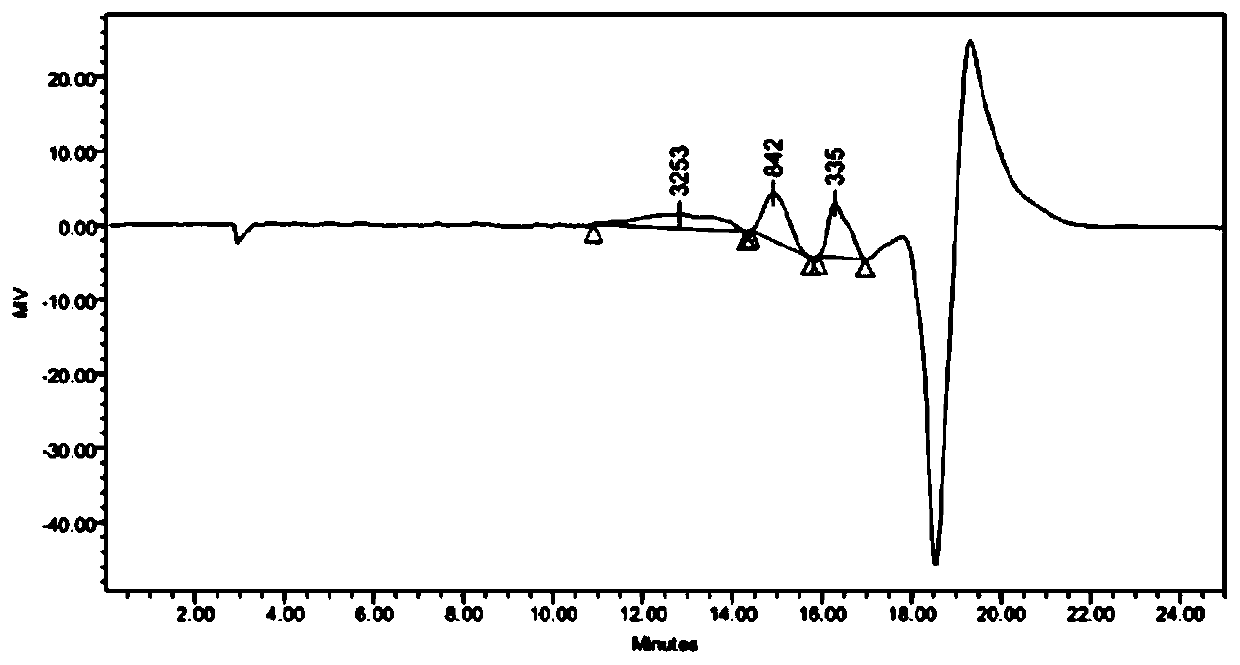

Water-soluble rosin resin and preparation method and application thereof

PendingCN111528277AImprove solubilityIngredient safetyFruits/vegetable preservation by coatingFood ingredient as coating agentPolymer sciencePreservative

The invention discloses water-soluble rosin resin and a preparation method and application thereof. The water-soluble rosin resin comprises the following raw materials in parts by weight: 80 to 100 parts of maleated rosin, 35 to 75 parts of PEG200, 10 to 50 parts of citric acid and 0.1 to 0.2 part of a catalyst. The preparation method of the water-soluble rosin resin comprises the following stepsof melting the maleated rosin, adding the PEG200 and the catalyst, and performing a reaction at 180-250 DEG C for 1-8 hours to obtain maleated rosin polyethylene glycol ester; and adding the citric acid into the maleated rosin polyethylene glycol ester, and performing a reaction at 150-180 DEG C for 1-6 hours to obtain the water-soluble rosin resin. Water and an alkali solution are added into thewater-soluble rosin resin, the pH value is adjusted to 7-8 to obtain a rosin-based fruit and vegetable preservative, and the surfaces of fruits and vegetables are coated with the obtained rosin-basedfruit and vegetable preservative. The water-soluble rosin resin disclosed by the invention is low in raw material preparation cost, easy to dissolve in the alkali solution, good in solubility, easy toclean and beneficial to guarantee of cleanness of the fruits and vegetables, and the water-soluble rosin resin disclosed by the invention is safe and reliable in component, belongs to the non-toxic grade, and is good in film-forming property and bright and durable in color and luster.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

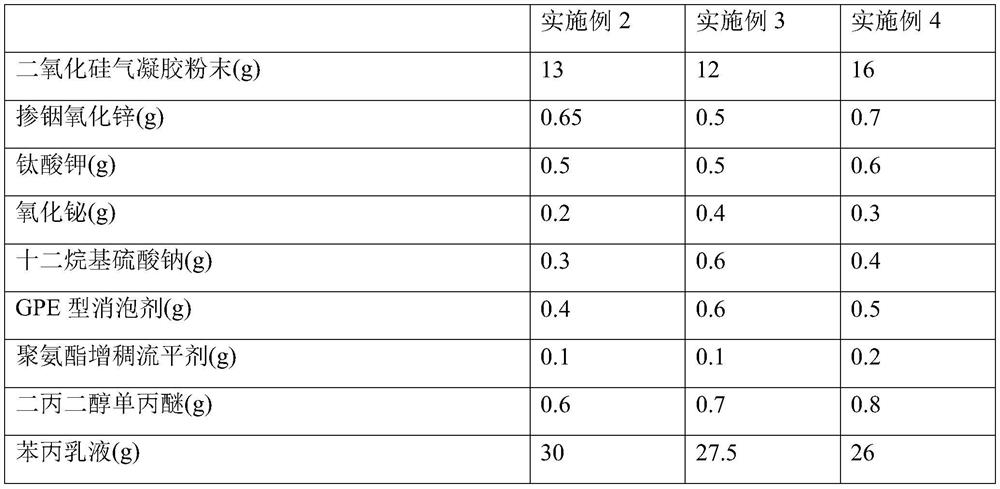

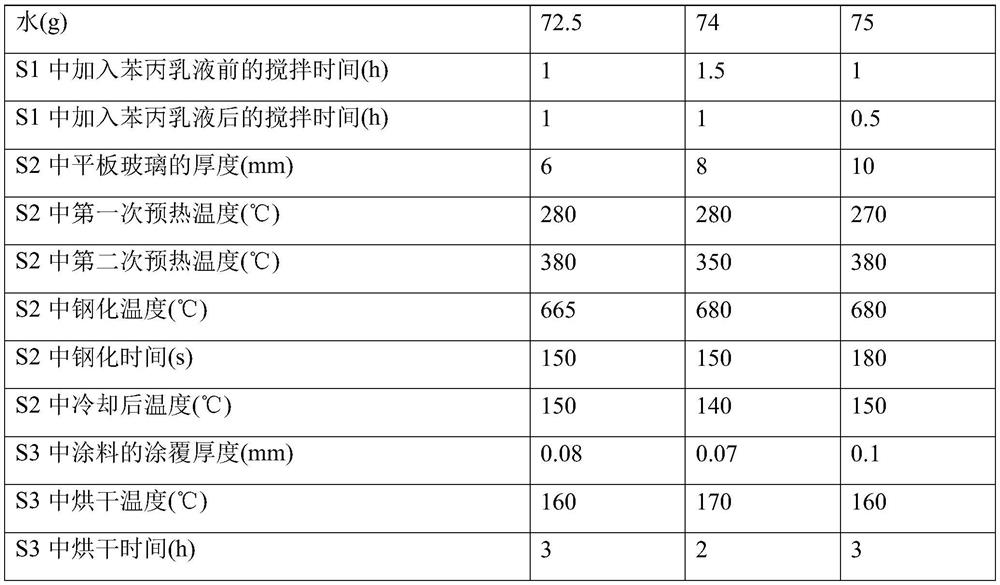

Preparation method of heat-insulating and noise-resisting tempered glass

ActiveCN111961370AImprove structural strengthGood heat insulationCoatingsSpecial surfacesFlat glassIndium

The invention discloses a preparation method of heat-insulating and noise-resisting tempered glass. The preparation method comprises the following steps: S1, dispersing and stirring silicon dioxide aerogel powder, indium-doped zinc oxide, potassium titanate, bismuth oxide, a dispersing agent, an antifoaming agent, a leveling agent, a coalescing agent and water, then adding styrene-acrylic emulsion, and continuing to stir, so as to obtain a heat-insulating and noise-resisting coating, S2, taking plate glass, preheating the plate glass at 270-280 DEG C, then further preheating the plate glass at350-380 DEG C, then toughening the plate glass at 650-680 DEG C for 150-180 seconds, and then cooling the plate glass to 140-150 DEG C to obtain toughened glass, S3, coating the surface of the tempered glass with the heat-insulating and noise-resisting coating, and drying at 160-170 DEG C for 2-3 hours to obtain heat-insulating and noise-resisting tempered glass. The preparation method disclosedby the invention has the advantages that the prepared tempered glass is heat-insulating, sound-insulating and relatively small in thickness.

Owner:广州利粤玻璃有限公司

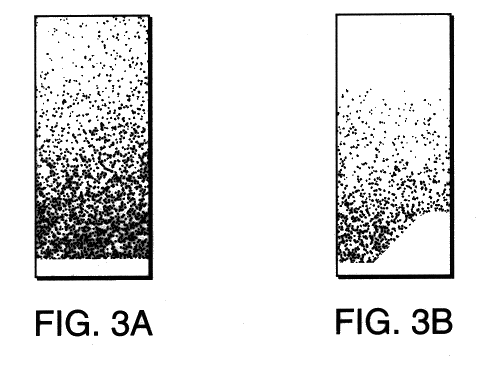

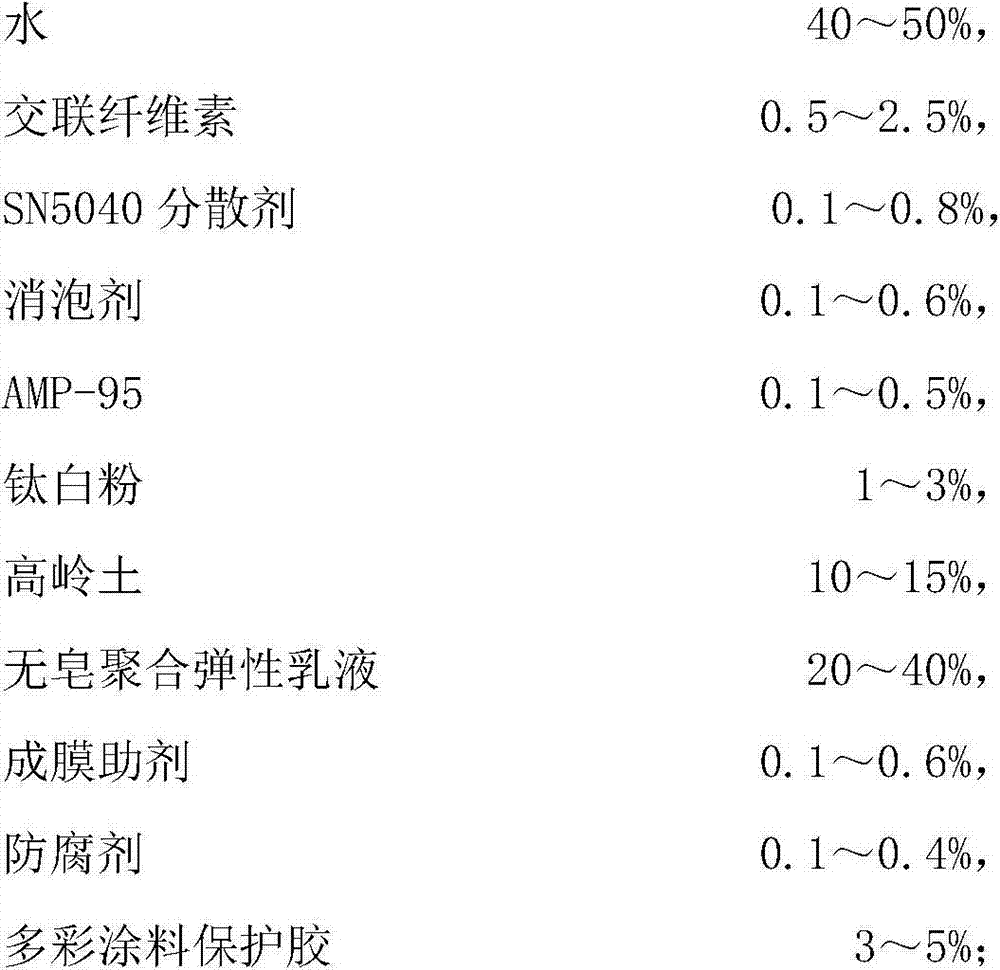

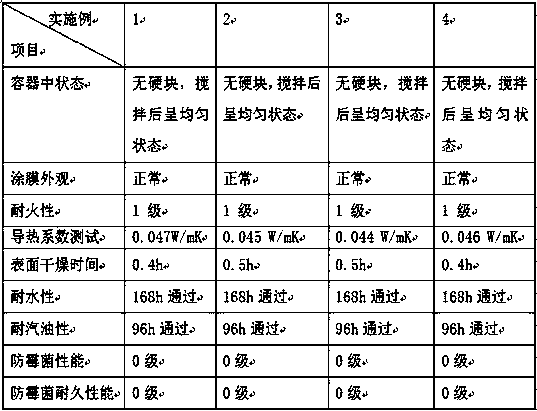

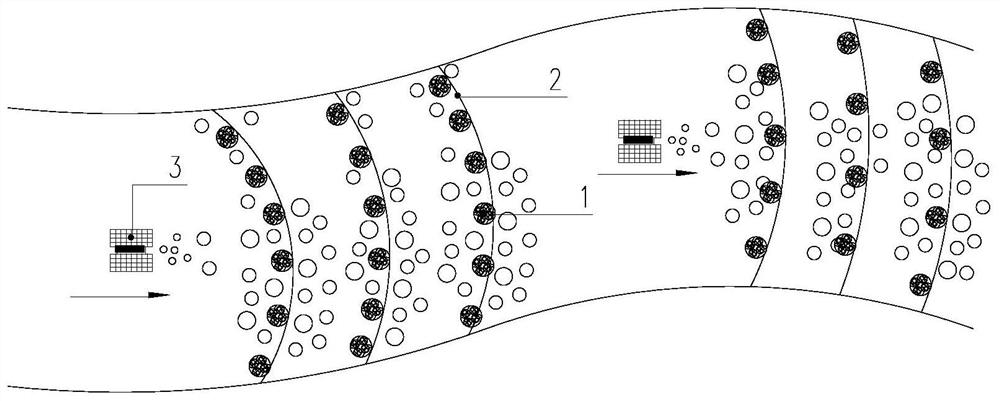

Water-based multicolor paint and preparation method thereof

InactiveCN111718628AFilm stabilizationImprove water resistanceMulticolor effect coatingsPolymer scienceOrganic chemistry

The invention discloses a water-based multicolor paint which comprises a protective glue, a base paint and a continuous phase, wherein the weight ratio of the protective glue to the base paint to thecontinuous phase is (5-15): (25-35): (7-13). The water-based multicolor paint prepared by the invention is placed for a long time after being oscillated, and colored particles are free from sedimentation or floating layer phenomenon, and are free from being bonded into clusters and bleeding phenomena. In addition, the water-based multicolor paint has the advantages of stable film, favorable waterresistance and favorable water whitening resistance, and thus, has very high practical application prospects.

Owner:厦门神石多彩节能科技有限公司

Method for preparing amino silicon oil modified acrylic resin leather finishing agent

InactiveCN103012804BHigh fullnessGood flexibilityCoatingsLeather surface finishingMethacrylateFunctional monomer

The invention discloses a method for preparing an amino silicon oil modified acrylic resin leather finishing agent. The method comprises the following steps of: firstly, introducing acetoacetic acid ethyl methacrylate (AAEM) serving as a functional monomer into an acrylic resin molecular chain to prepare self-crosslinking acrylic resin emulsion; and compounding the amino silicon oil emulsion and acrylic resin emulsion according to a certain proportion to prepare a room-temperature self-crosslinking acrylic resin leather finishing agent by using the amino silicon oil as a crosslinking agent. According to the invention, self-crosslinking is carried out on the leather finishing agent at the room temperature, and a amino silicon oil crosslinking acrylic resin net structure is formed after film formation; and due to introduction of the amino silicon oil, the flexibility and the smoothness of the film are increased and the hand feel of the film is improved. By the improvement method, the physical performance of leather coating can be obviously improved, the defect of hot stickiness and cold brittleness of the traditional acrylic resin is overcome, and the method has wide application prospect in the field of leather coating.

Owner:SHAANXI UNIV OF SCI & TECH

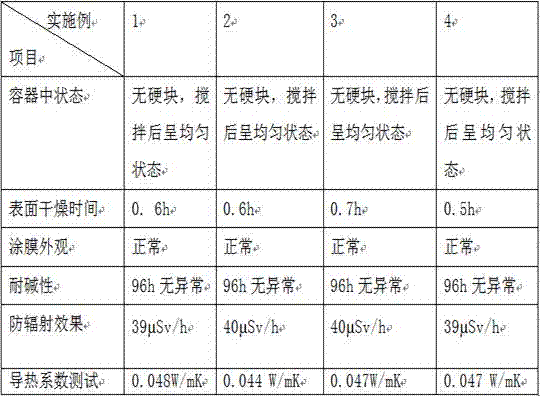

Interior-wall heat-preservation radiation-resistant diatom ooze and preparing method thereof

The invention relates to an interior-wall heat-preservation radiation-resistant diatom ooze and a preparing method thereof. The interior-wall heat-preservation radiation-resistant diatom ooze is prepared from diatomite, expanded perlite, epoxy resin, cobalt naphtenate, heavy calcium carbonate, a radiation-proof material, an antifoaming agent, a thickening agent, a dispersing agent, a wetting agentand water. By means of the interior-wall heat-preservation radiation-resistant diatom ooze, the content of indoor radiation substances is greatly lowered, and the harm to people is also greatly reduced; meanwhile, the interior-wall heat-preservation radiation-resistant diatom ooze is resistant to water, petrol, ageing and corrosion, simple in preparing technology, low in price, good in decorationeffect, excellent in thermal insulation effect, healthy, innoxious, green and environmentally friendly.

Owner:GUANGXI JISHUN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com