Patents

Literature

272results about How to "Ingredient safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

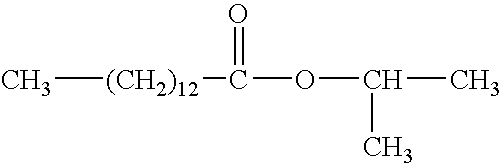

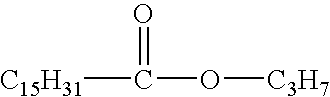

Pesticidal compositions containing isopropyl myristate and analogs of same as a synergist for plant essential oils

InactiveUS20070098750A1Safe and effective insecticideQuickly knockdownBiocideDead animal preservationCompound (substance)BULK ACTIVE INGREDIENT

Pesticidal compositions containing as a pesticidally acceptable carrier, at least one plant essential oil compound as a pesticidally active ingredient; and isopropyl myristate, isopropyl palmitate or analogs thereof, as a synergist, and methods for using same, are disclosed.

Owner:GIBRALTAR BUSINESS CAPITAL LLC

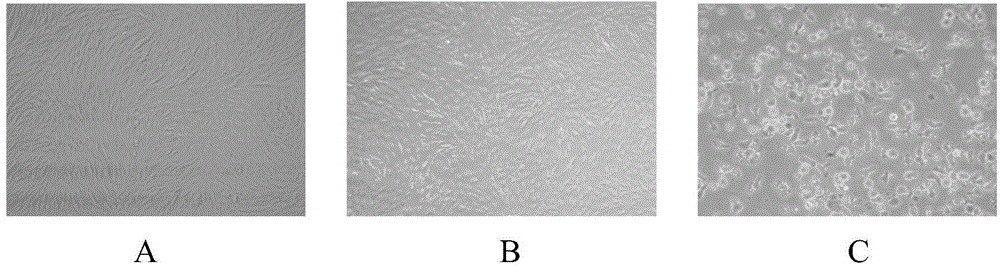

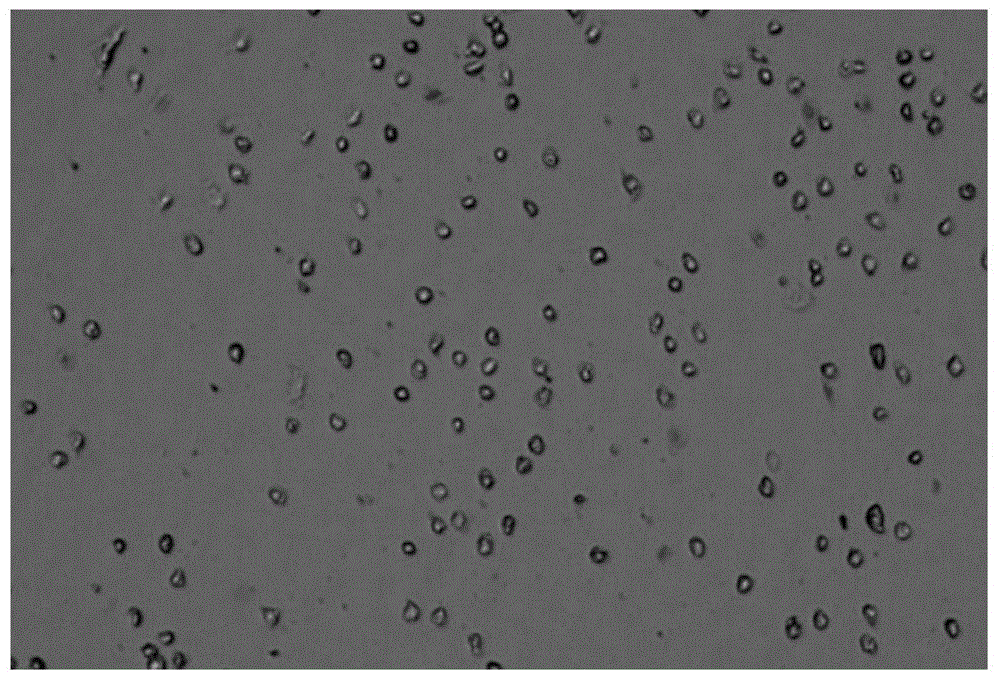

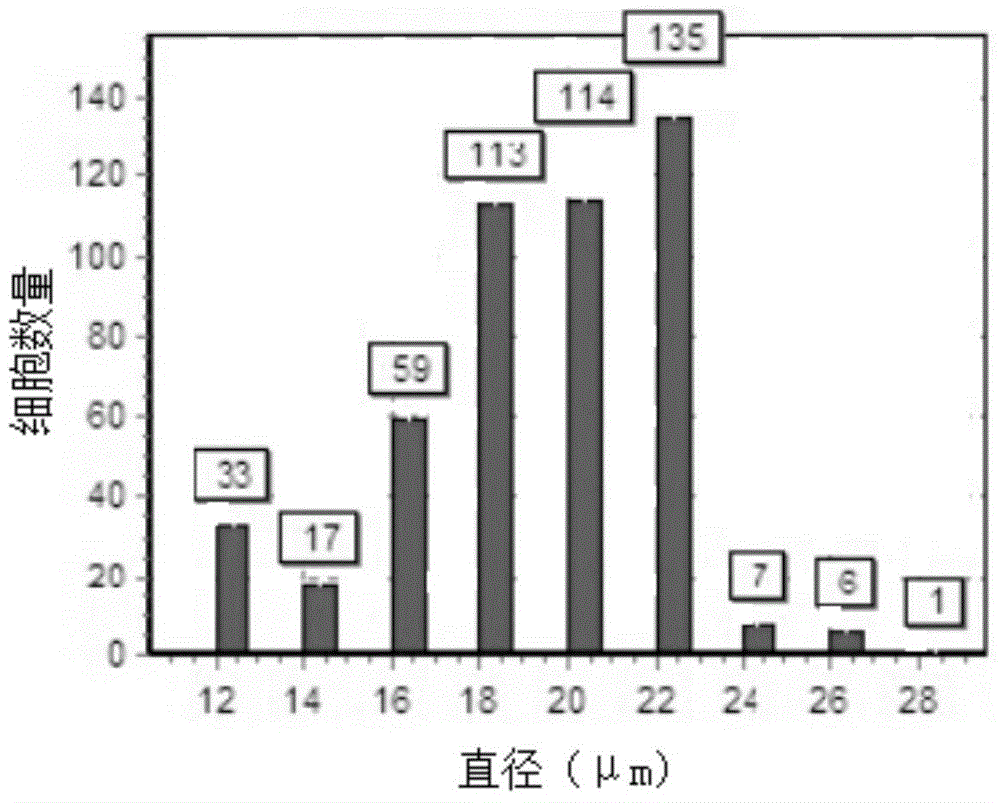

Cell preservation solution and preparation method and applications thereof

ActiveCN104542578AExcellent maintenance of biological characteristicsMaintain biological characteristicsDead animal preservationVitamin CAmino Acid Injection

The invention relates to the technical field of clinical medicines, and particularly relates to a cell preservation solution and a preparation method and applications thereof. The cell preservation solution comprises albumin, glucose, vitamin C and basic preservation liquid, wherein the basic preservation liquid is a mixture of compound electrolyte injection and compound amino acid injection. The cell preservation solution disclosed by the invention achieves a good maintaining effect on the viability and morphology of more than two kinds of seed cells, and can preserve the seed cells for a long time, and maintain the biological characteristics of the seed cells, thereby significantly improving the therapeutic effect of the seed cells.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

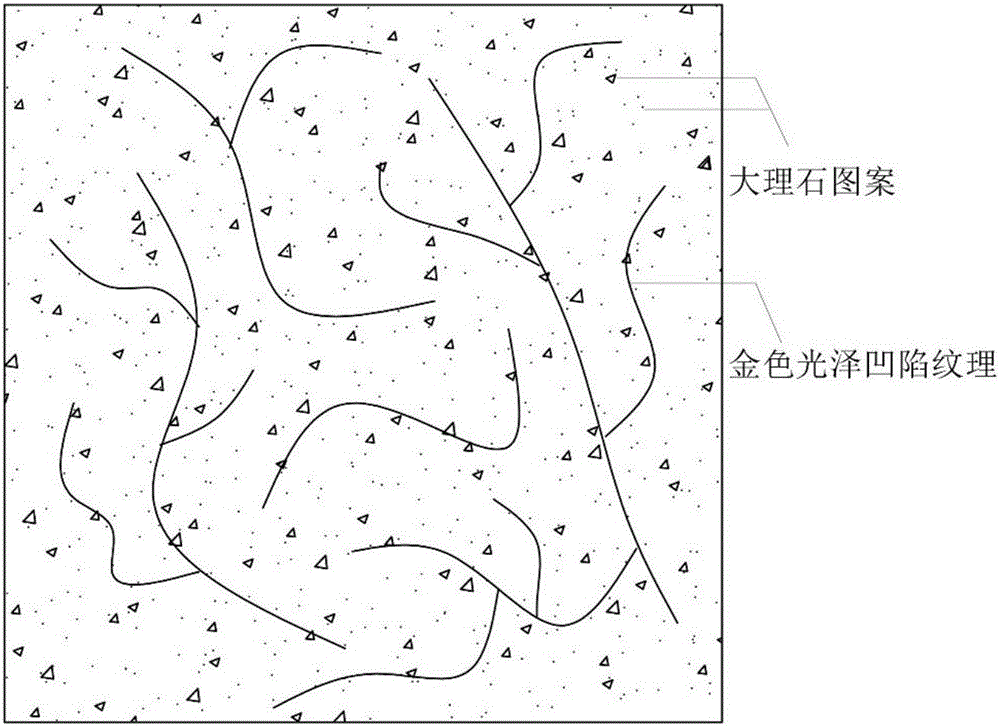

Preparation method for marble ceramic tile with metallic luster sunken textures

ActiveCN106518029ASimple compositionIngredient safetyCeramic shaping apparatusCeramic glazeCeramic tiles

The invention discloses a preparation method for a marble ceramic tile with metallic luster sunken textures. The method comprises the following steps: spraying a layer of ground coat on the surface of a ceramic bisque; printing the glaze slip with metallic luster after being sintered onto the ground coat; adopting an ink-jet printing technique for printing marble patterns on the positions except for the distribution position of the glaze slip with metallic luster after being sintered, and correspondingly forming marble pattern lines on the distribution position of the glaze slip; printing the ink-jet printing glaze with a sunken effect on the distribution position of the glaze slip with metallic luster after being sintered; spraying a layer of transparent glaze slip on the surface; putting the ceramic bisque coated with the transparent glaze slip into a kiln and sintering; and then softly polishing, thereby acquiring the marble ceramic tile with metallic luster sunken textures. According to the invention, safe and environment-friendly raw materials are adopted, and the ink-jet printing technique is smartly utilized to accurately align and prepare the marble ceramic tile with metallic luster sunken textures. The glaze slip with metallic luster after being sintered can further enhance the decorative effect of the marble ceramic tile.

Owner:广东协进陶瓷有限公司

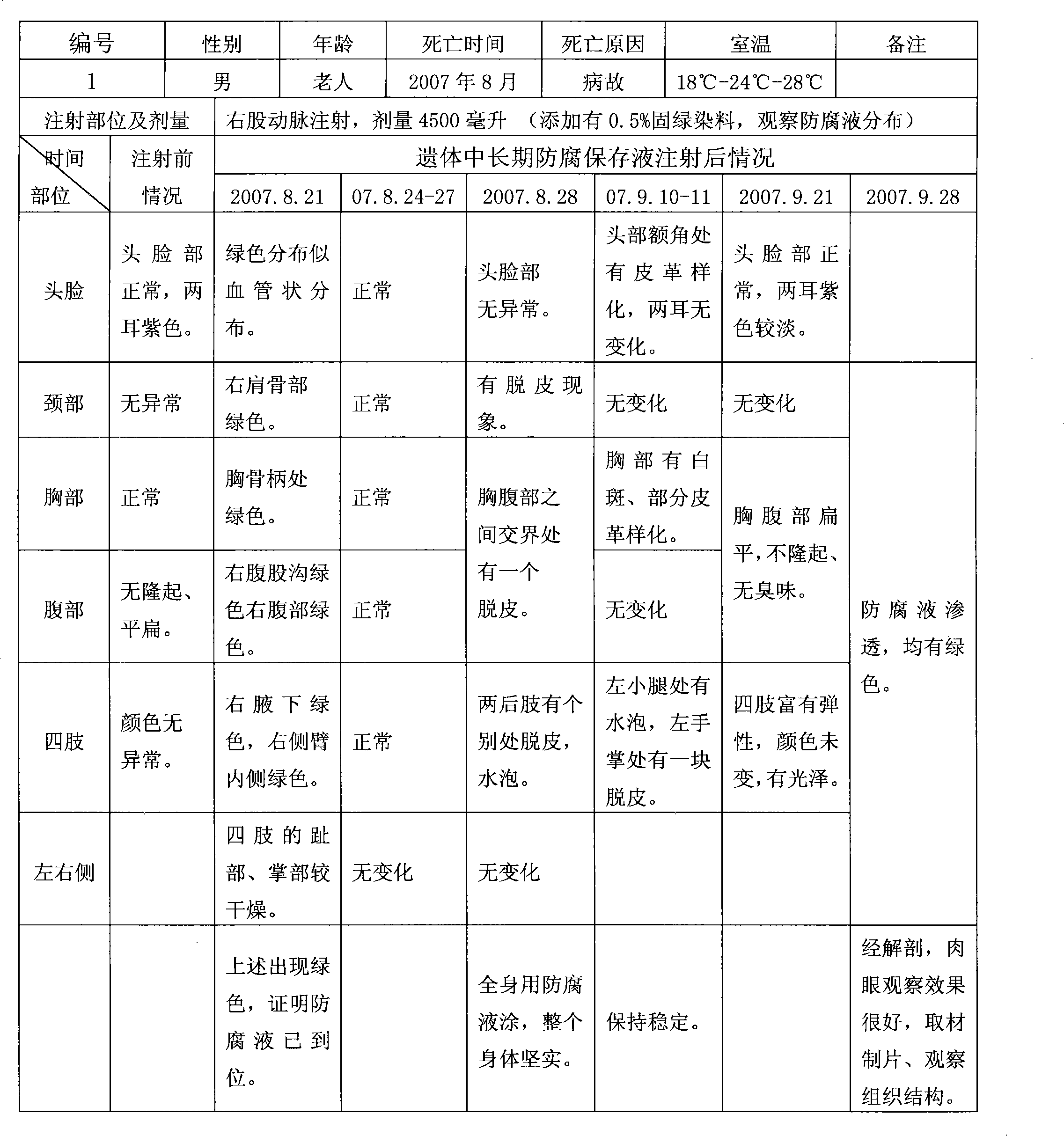

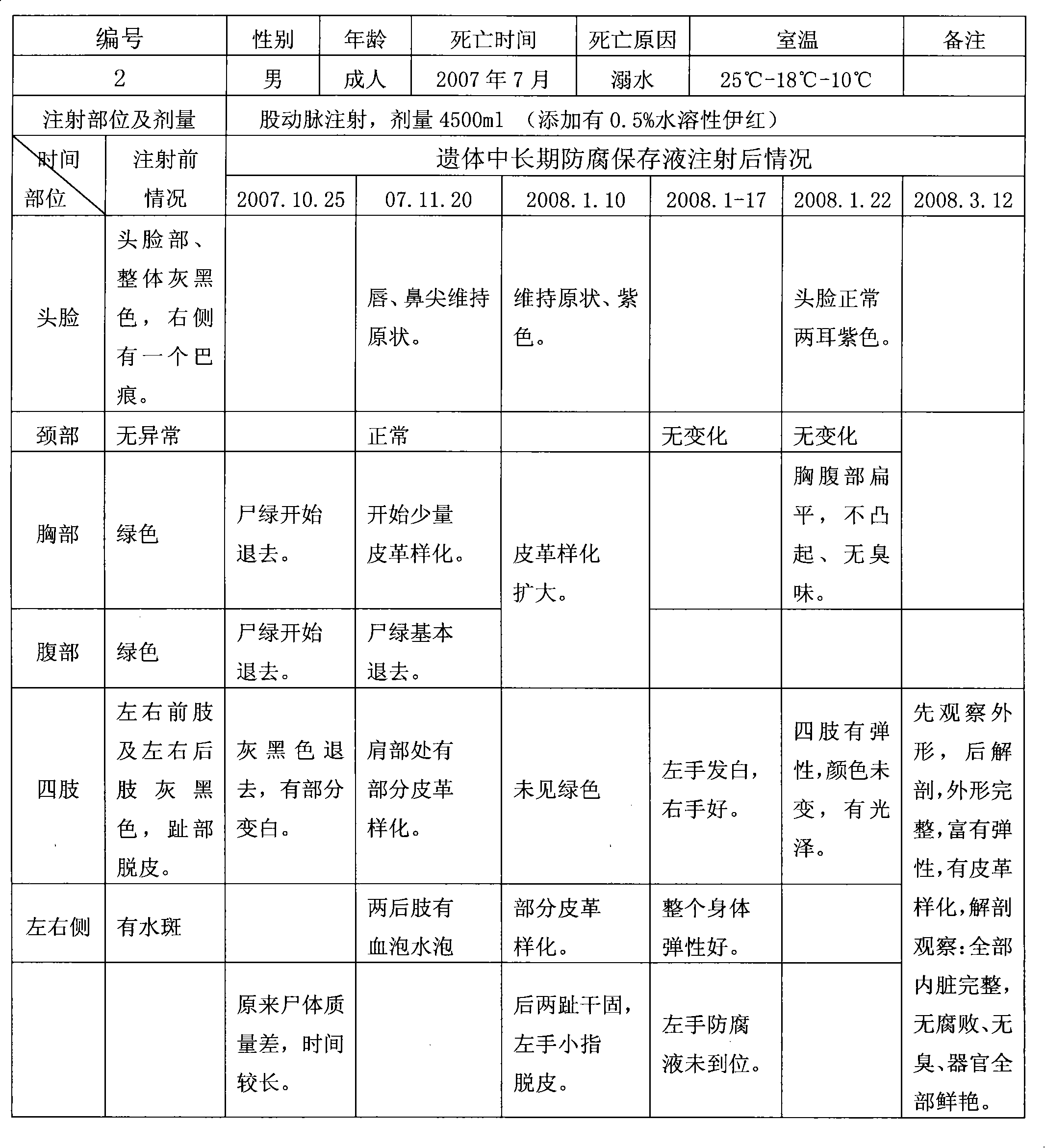

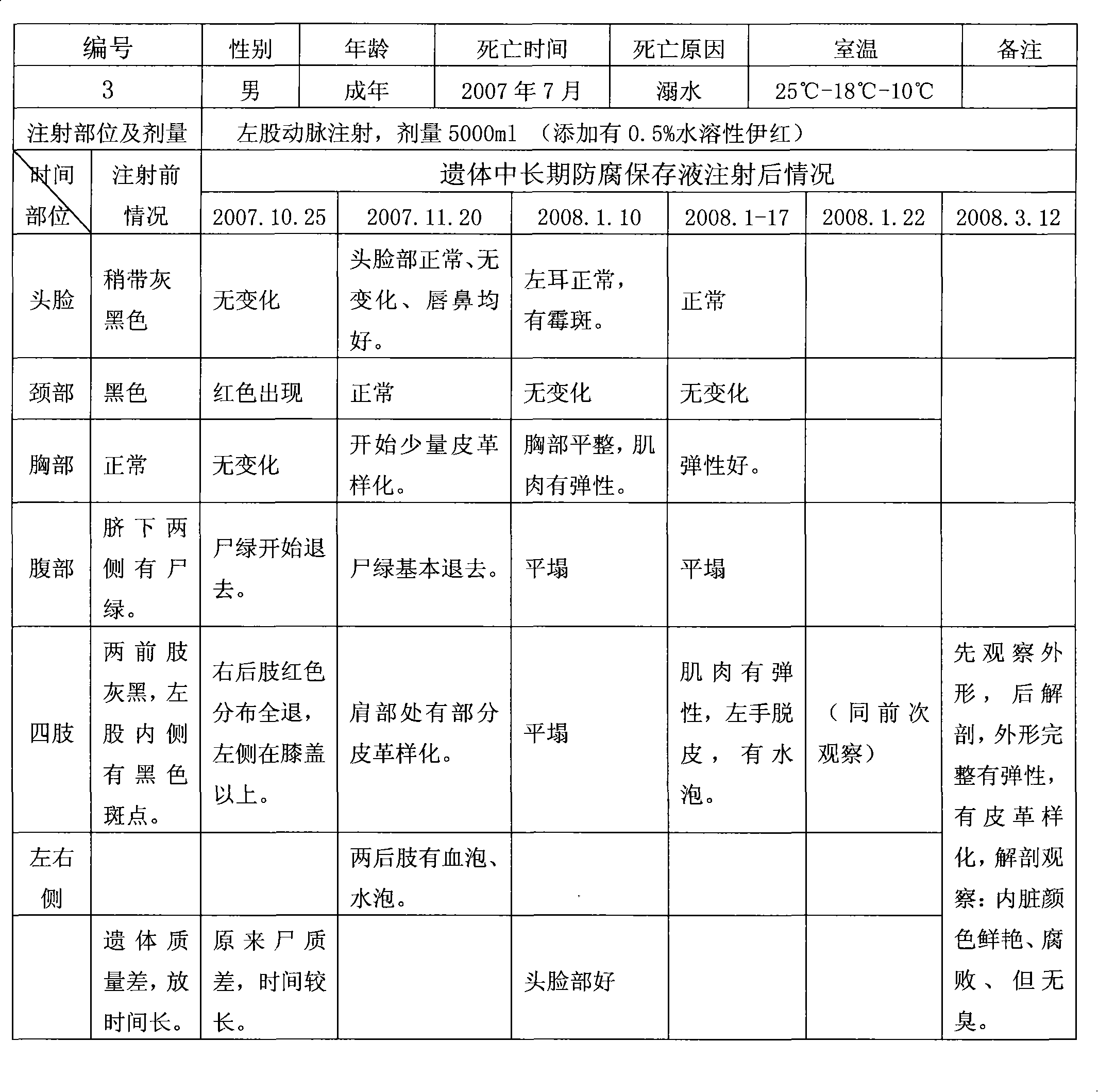

Long-term antiseptic preserving fluid of remains and application thereof

ActiveCN101601377AImprove disinfection effectReasonable formulaDead animal preservationPropanoic acidAdditive ingredient

The invention relates to a long-term antiseptic preserving fluid of remains, which comprises the following raw materials in percentage by weight: 15-40% of glycerine, 5-80% of alcohol, 1-20% of propionic acid, 0.5-25% of hexamine, 0.1-15% of 5chlorine-2-4methyl-4isothiazole-3ketone and the balance of water. The preserving fluid is applied to the remains of people and fish, amphibian and reptile and animal specimens gathered in the field and injected into the remains mainly through the axillary artery and / or the femoral artery of the remains, and the remains can be antiseptically preserved for 15-100 days under the conditions of a room temperature of 18-27 DEG C and a relative humidity of 45-60 percent. The invention has the advantages of reasonable formula, safe ingredient, accordance to environmental protection, no poison and harm to operators, no stimulation, no damages and blackening of tissues and organs by the antiseptic preservation of the remains, maintenance of a natural state of the remains, simple preparation method, convenient use and benefit to popularization.

Owner:上海市殡葬服务中心

Color protection preservation method of poached green leaf vegetable instant product

InactiveCN102919338AMaintain colorInhibit enzyme activityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingSucrosePotato starch

The invention discloses a color protection preservation method of a poached green leaf vegetable instant product, belonging to the field of fruit / vegetable food processing. The method mainly comprises the following steps of: performing pretreatment, blanching for enzyme deactivation and vacuum infiltration soaking with a color protection and crisp protection agent (sodium alginate, calcium chloride, potato starch and zinc gluconate) of the green leaf vegetable; and performing secondary color protection preservation soaking by use of the color protection preservation liquid consisting of table salt, edible glycerin, sodium carboxymethylcellulose and sucrose ester. The method reduces the color protection preservation cost, and improves the color of the poached green leaf vegetable product stored in normal-temperature condition. The nano ZnO antibacterial liquid (in which a sodium hexametaphosphate dispersion protector with concentration of 0.015% is added) is subjected to vacuum packing and low-frequency (915MHz) microwave uniform sterilization. The storage temperature is normal temperature. Through the invention, good color and fresh degree of the poached green leaf vegetable instant product are kept in the normal-temperature storage period.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

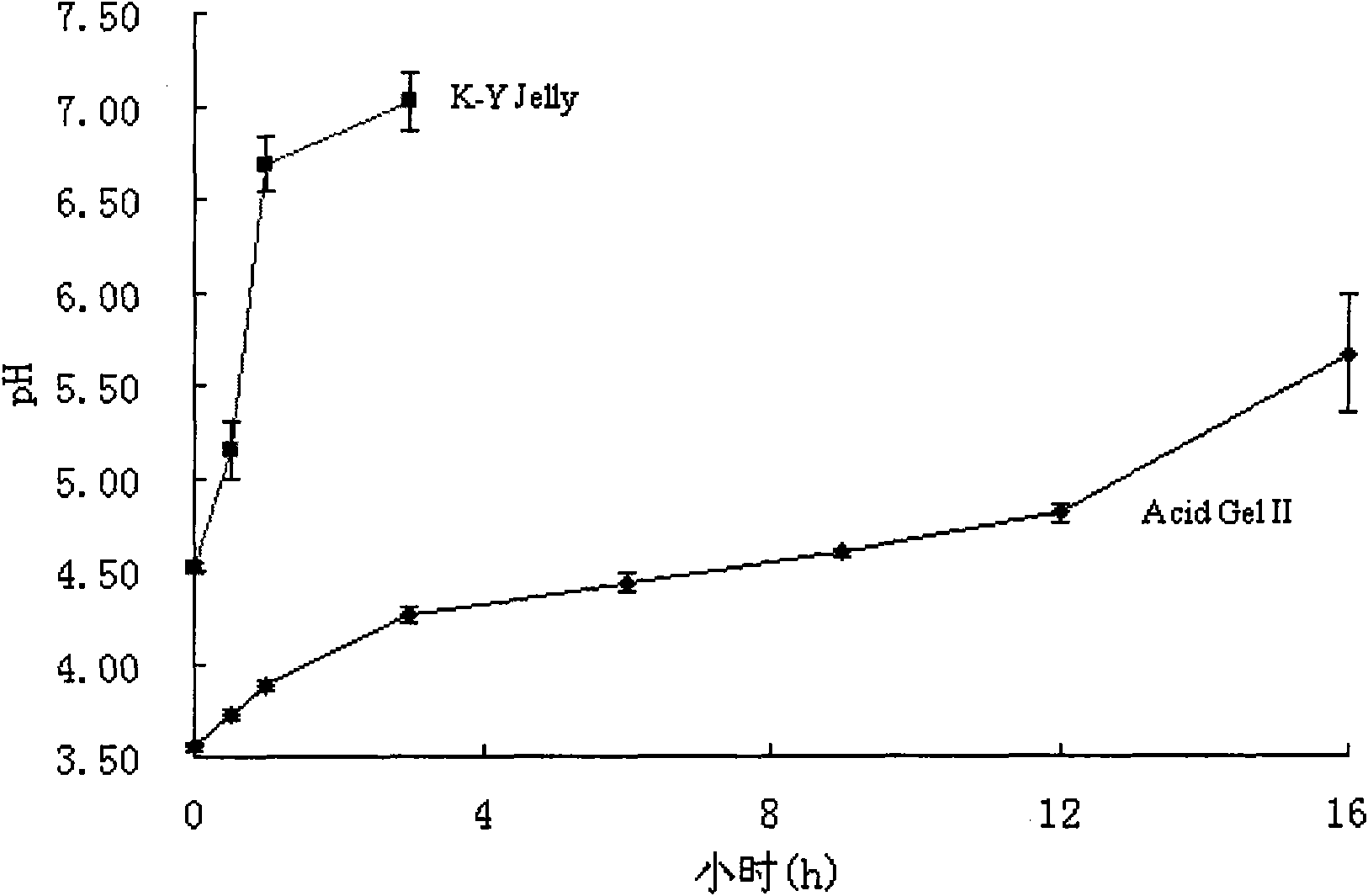

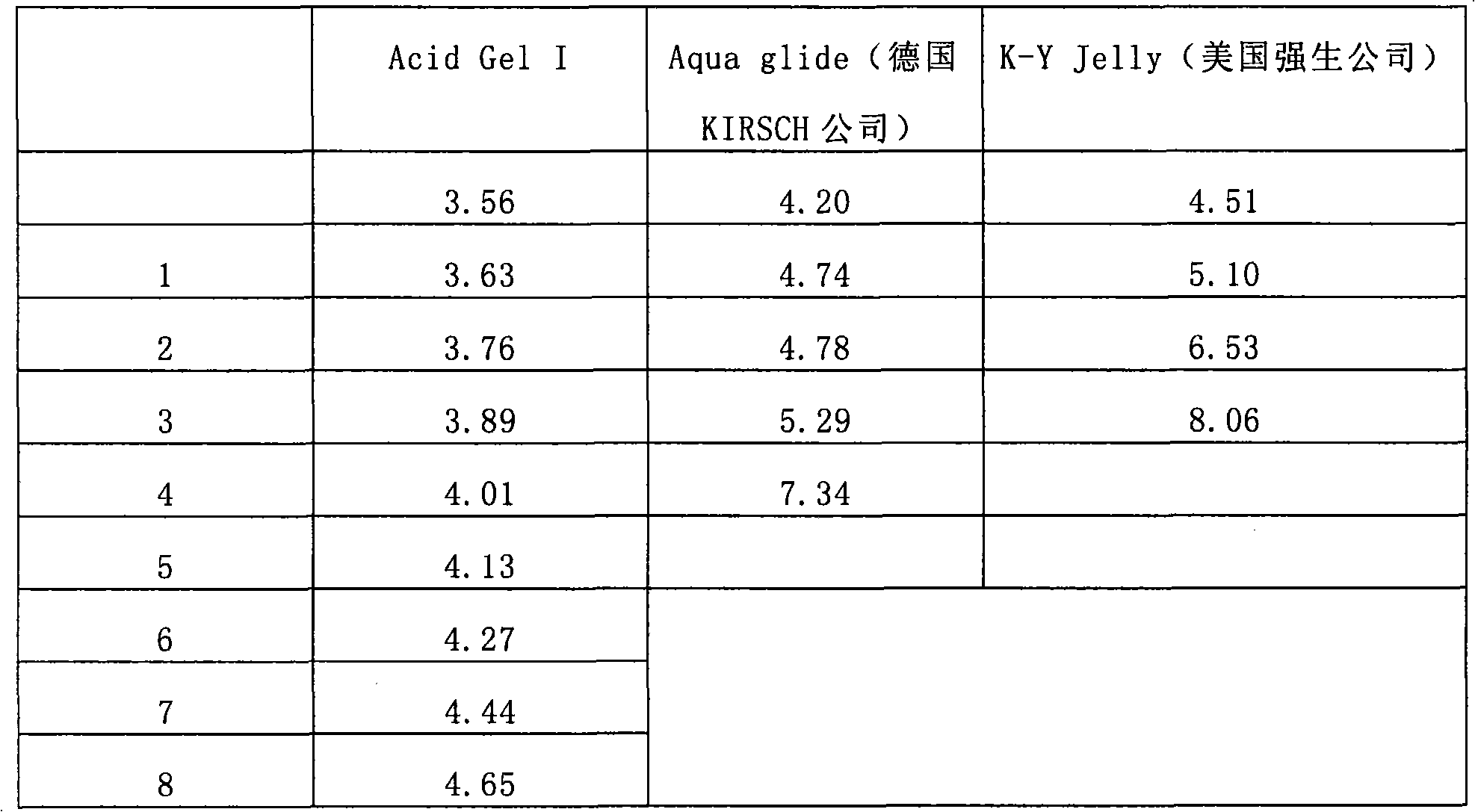

Acid vagina lubricant and preparation method and use thereof

InactiveCN101905041AImprove drynessThermoreversibleSurgerySodium carboxymethylcellulosePharmaceutical preservatives

The invention discloses an acid vagina lubricant and a preparation method and use thereof. Based on the total weight of the lubricant, the acid vagina lubricant comprises the following components in percentage by weight: (a) 15 to 30 percent of substrate excipient, (b) 5 to 15 percent of viscous agent, (c) 20 to 40 percent of wetting agent and (d) 1 to 7 percent of acid buffer, wherein the substrate excipient is selected from polyoxyethylene polyoxypropylene polymer, carbomer, alginic acid or chitosan; the viscous agent is selected from xanthan gum, hydroxy propyl cellulose (HPC), hydroxypropyl methyl cellulose (HPMC) and sodium carboxymethylcellulose (CMC-Na); the wetting agent is selected from asparagus, glycerin, polysorbate, polyethylene glycol, propylene glycol or triacetin; and the acid buffer is selected from an acetic acid buffer pair, a boric acid buffer pair, a carbonic acid buffer pair, a phosphoric acid buffer pair or a citric acid buffer pair; and the acid vagina lubricant has the properties that: pH is between 3.0 and 4.5; and the lubricant is in liquid state at the temperature of less than or equal to 25 DEG C and in gel state at the temperature of more than or equal to 30 DEG C.

Owner:SHANGHAI INST OF PLANNED PARENTHOOD RES

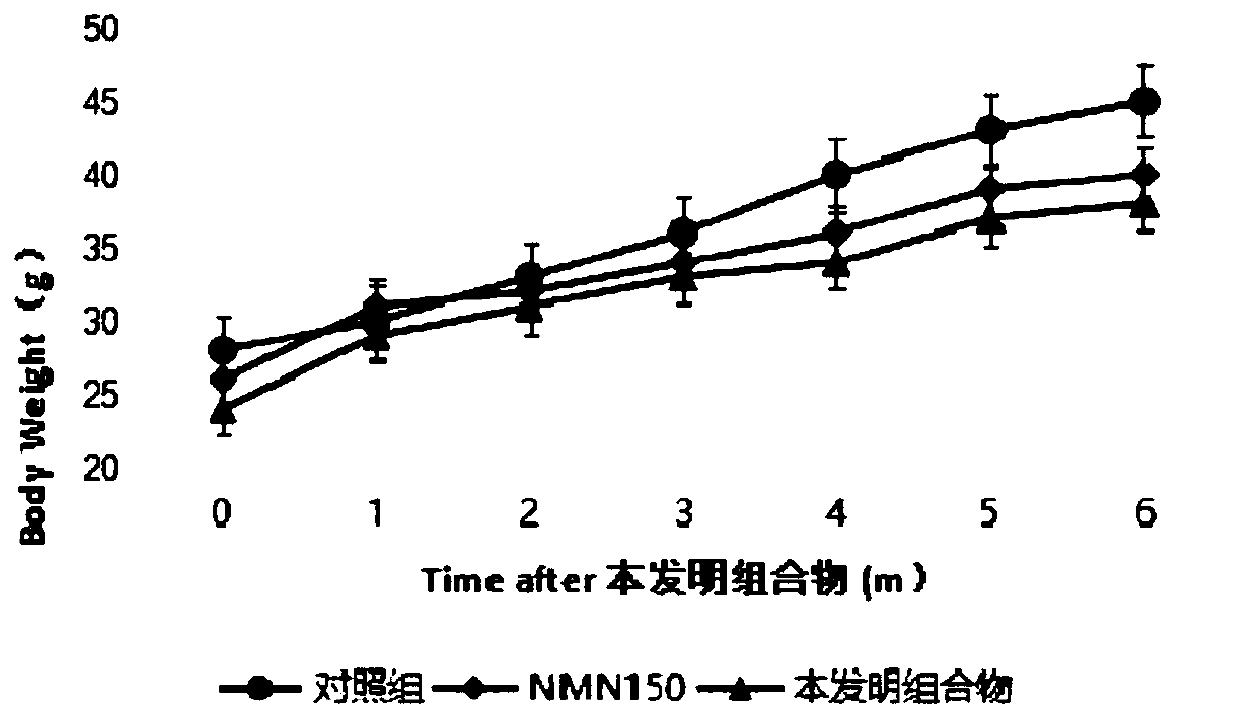

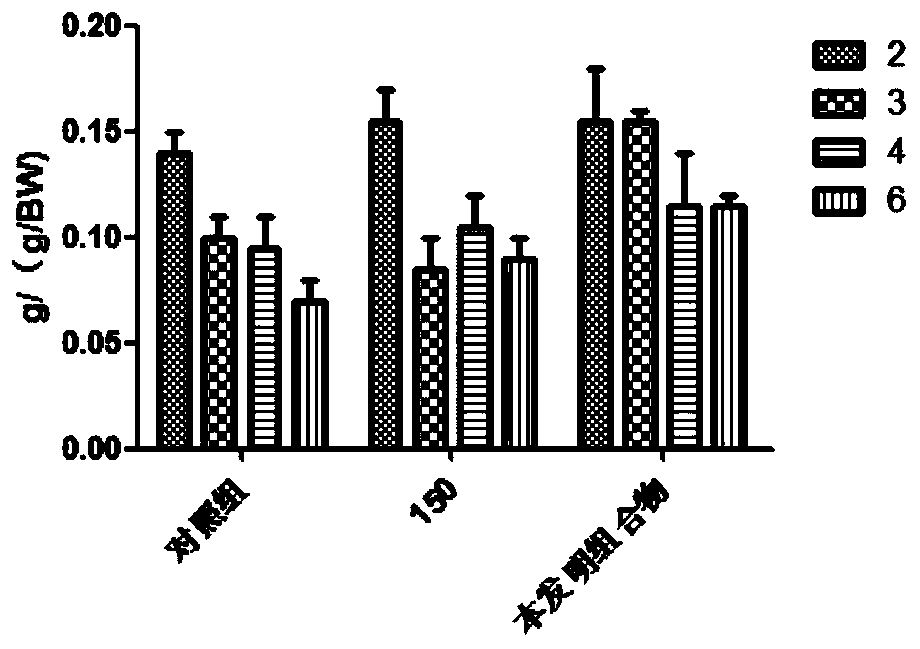

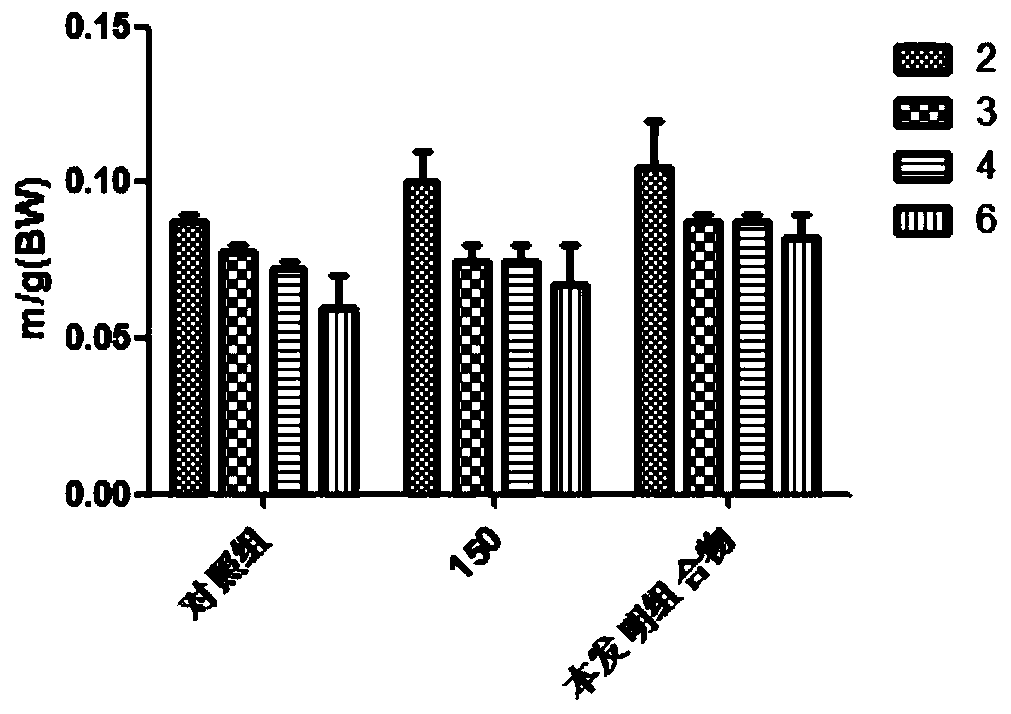

Application of nicotinamide mononucleotide containing composition to ageing resisting drugs/health-care products

InactiveCN110237118AActivate energy metabolismImproves oxidative stress responseOrganic active ingredientsAntinoxious agentsOxidative stressAgeing

The invention belongs to the fields of research and development of drugs and health-care products, particularly relates to an application of a nicotinamide mononucleotide containing composition to ageing resisting drugs / health-care products, provides a composition, further provides a preparation method of the composition, and further provides the composition or the application of the product prepared by the preparation method to ageing resisting drugs / health-care products. NMN can achieve the effects of activating organism energy metabolism and improving an organism oxidation stress reaction, and besides, through cooperation with synergism of other components, favorable effect of resisting ageing can be achieved; and the components in the composition are stable in structure. The prepared product is not liable to deteriorate or damage, and besides, the components are safe. The product basically has no poor reaction on human bodies. The composition solves the technical problems that in the prior art, the ageing resisting products do not have favorable ageing resisting effect, are free from damage to human bodies, and are stable in product quality.

Owner:HOBOOMLIFE BIO TECH SHENZHEN CO LTD

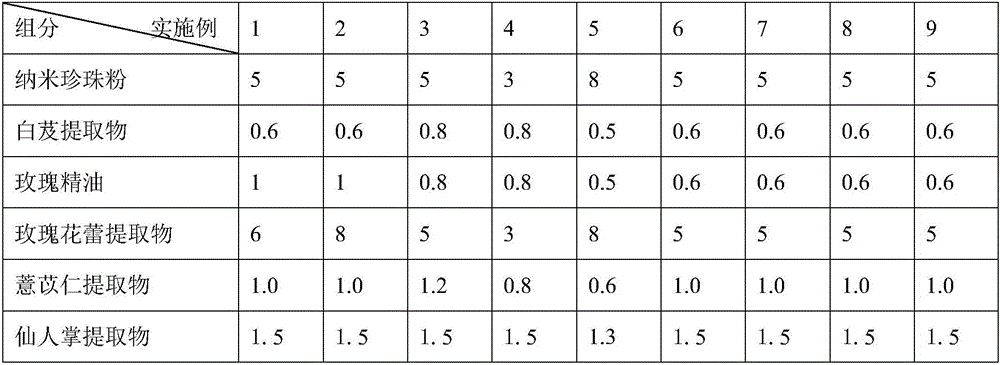

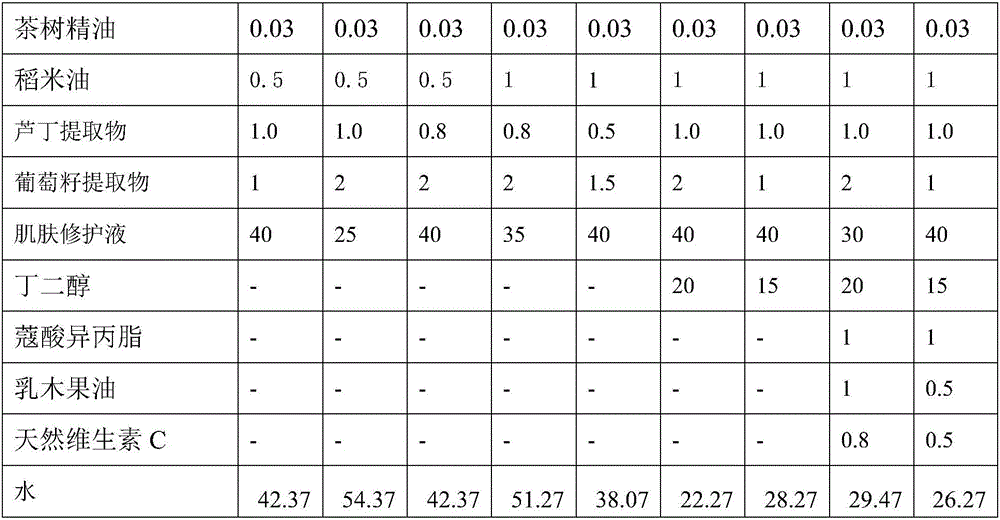

Acne-removing, oil control and skin beautifying cream

InactiveCN106176556AHas a health effectPromote repairCosmetic preparationsToilet preparationsSkin repairBud

The invention relates to acne-removing, oil control and skin beautifying cream and belongs to the technical field of cosmetics. The acne-removing, oil control and skin beautifying cream is prepared from, by weight, nano pearl powder 3-8%, bletilla extract 0.5-0.8%, rose essential oil 0.5-1%, rose bud extract 3-8%, coix seed extract 0.6-1.2%, cactus extract 1.3-1.5%, tea tree oil 0.01-0.03%, rice oil 0.5-1.0%, cactus extract 0.5-1.0%, grape seed extract 1-2%, skin repair liquid 25-40% and the balance water. The acne-removing, oil control and skin beautifying cream is prepared by compounding a variety of natural plant extracts and the skin repair liquid, can produce a remarkable acne-removing effect, can achieve swelling subsidence and promote skin inflammation subsidence, improve, fade and remove acne marks and meanwhile plays the effects of whitening skin and prevention and control of pigment plaques.

Owner:张进

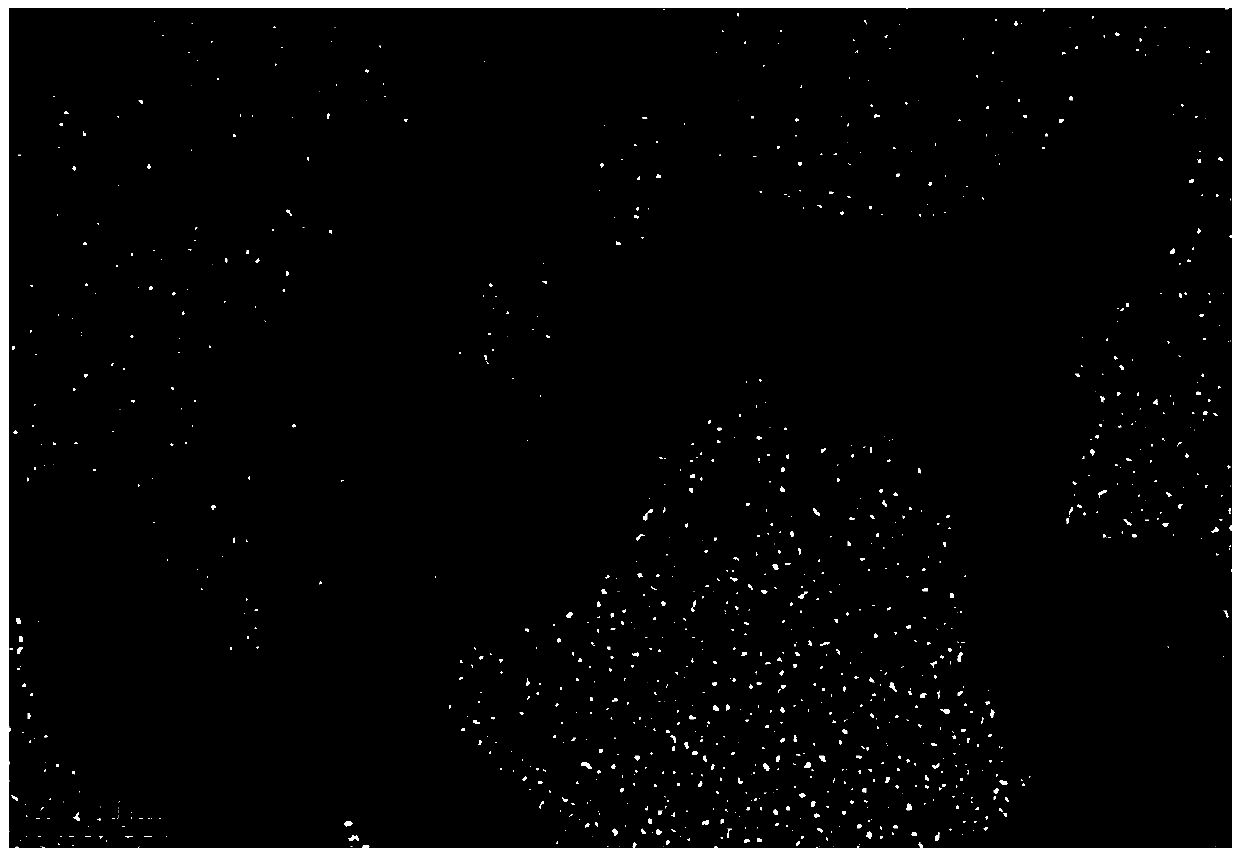

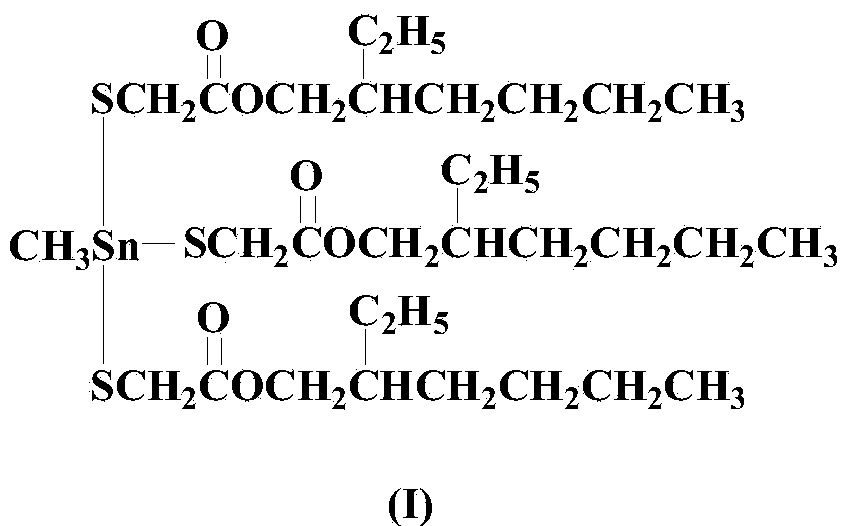

Chromium-free composite resin gel-type profile control agent for oil exploitation and preparation method and application thereof

ActiveCN105368423AExcellent oil recovery effectGood effectDrilling compositionCross-linkChromium free

The invention relates to a chromium-free composite resin gel-type profile control agent for oil exploitation. The profile control agent is prepared from a nano-silica modified cross-linked polymer, a stabilizing agent, a reinforcing agent, organic sulfonate, a density modifier, a surface active agent, an additive, a thickening agent, a wetting agent and water. According to the profile control agent, under the synergistic effect of unique modification of raw materials, suitable selection of components, unique steps and technological parameters of a preparation method and the like, the target product with the best effect is obtained; the target product has good mechanical performance, temperature resistance, mineralization resistance, alkali resistance and the like and has good application prospects and industrial potential in the energy exploitation field.

Owner:DONGYING FANGLI CHEM CO LTD

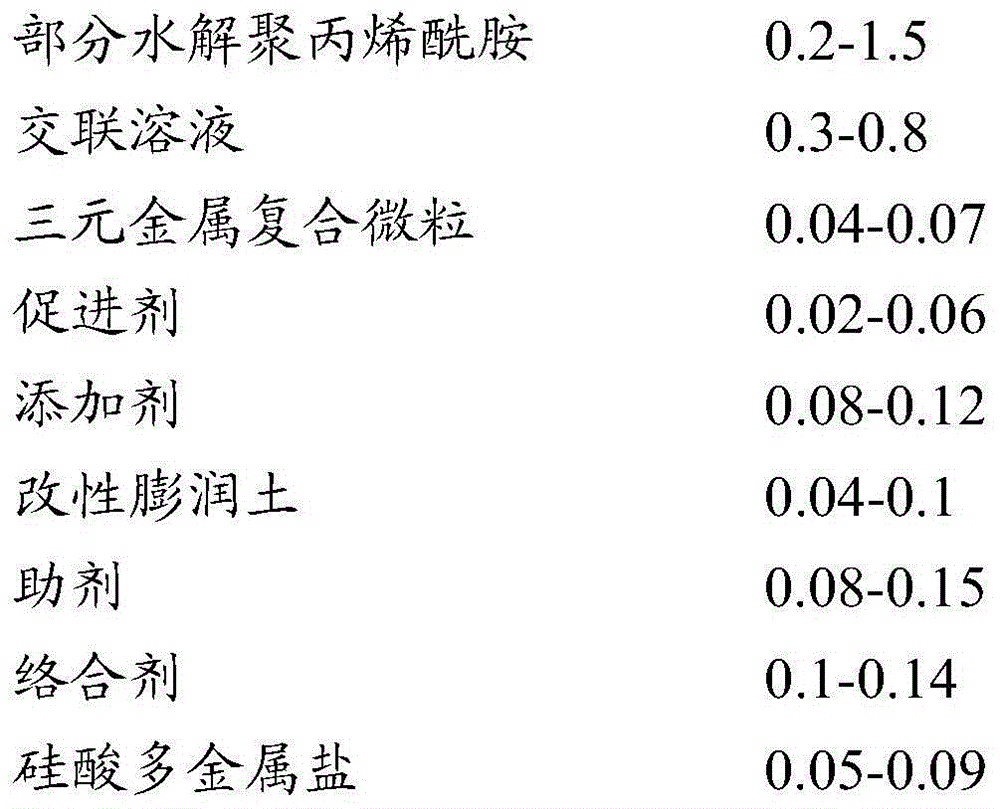

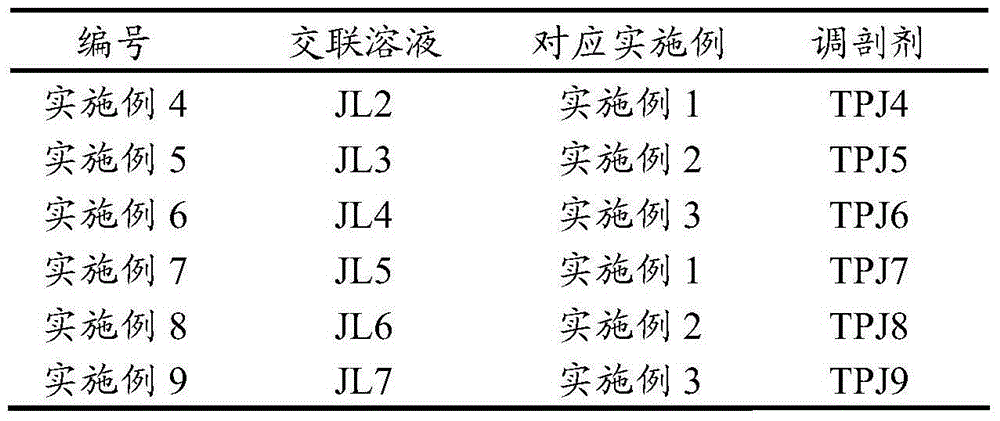

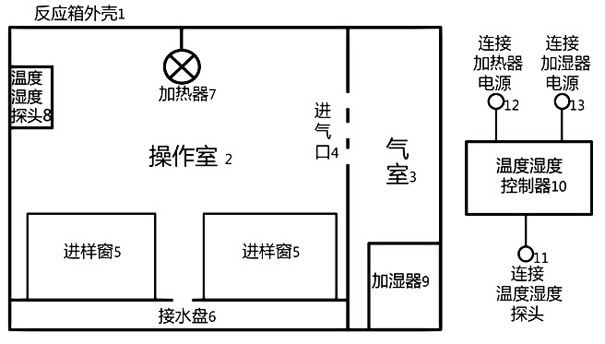

Environmental-friendly organic profile control agent and preparation method and use thereof

ActiveCN104927816AEnvironmentally friendly ingredientsGood effectDrilling compositionSodium BentoniteAccelerant

The invention relates to an environmental-friendly organic profile control agent. The environmental-friendly organic profile control agent comprises partially hydrolyzed polyacrylamide, a crosslinking solution, a ternary metal compound particles, an accelerant, additives, modified bentonite, auxiliaries, a complexing agent, polymetal silicate and water. The invention further provides a preparation method and use of the profile control agent. According to the profile control agent provided by the invention, the most excellent performances are obtained by proper selection of the components, a unique process of the preparation method and the like, so that the profile control agent has good application prospect and industrial potential in the field of petroleum industry.

Owner:DAQING TIANMAN PETROCHEM CO LTD

Preparation method of rare-earth magnesium nickel based hydrogen storage alloy

The invention discloses a preparation method of a rare-earth magnesium nickel based hydrogen storage alloy. The preparation method comprises the following steps: adopting a round or square graphite electrolytic cell, putting a carrying crucible at the bottom of the electrolytic cell, and presetting a certain amount of addition element metal blocks into the carrying crucible; taking fluoride molten salts including REF3-LiF-MgF2-BaF2 and the like as an electrolytic medium and a mixture of RE2O3 and MgO as a raw material, electrochemically precipitating out RE and Mg together at a cathode to obtain an RE-Mg alloy which sinks into the carrying crucible and alloyed with the metal blocks preset in the crucible so as to obtain the rare-earth magnesium nickel based hydrogen storage alloy. The preparation method can be used for effectively solving the problem of volatilization and oxidation of magnesium during smelting of the rare-earth magnesium nickel based hydrogen storage alloy, and is safe in production process, short in flow and low in cost. The rare-earth magnesium nickel based hydrogen storage alloy prepared by the method can be directly crushed mechanically or subjected to hydrogen crushing to obtain rare-earth magnesium nickel based hydrogen storage alloy powder, or can be used as a master alloy which is subjected to pouring or rapid quenching after a certain raw material is added, and then is crushed mechanically or subjected to hydrogen crushing to obtain the rare-earth magnesium nickel based hydrogen storage alloy powder.

Owner:GANNAN NORMAL UNIV

Method and device for preparing nano silver- and porous structure-containing medical high molecular material

InactiveCN102010514AHigh efficiency loadStable and not easy to fall offCatheterCoatingsEngineeringBiology

The invention relates to the technical field of medical appliance, in particular to a surface antibacterial treatment method and a device thereof for preparing a nano silver- and porous structure-containing medical high molecular material. The biggest problem of the implantation-type or insertion-type medical high molecular material in the clinical application is the infection which is caused by a biological film formed by the adherence of bacteria on the surface. A nano silver / polymer honeycomb structure-containing film can be processed and formed on the surface of the medical high molecular material through a water auxiliary method so as to realize the double antibacterial purposes of nano silver antibacterium and honeycomb structure antibacterial adsorption. The method has simple process, low requirement on equipment and strong universality, and is an economical, convenient and highly controlled antibacterial surface treatment method.

Owner:SOUTHEAST UNIV

Repair cream suitable for skin with eczemas

InactiveCN108245442AConvenient water supplyNutritional supplementsCosmetic preparationsToilet preparationsEczematous rashImmunocompetence

The invention provides repair cream suitable for skin with eczemas. The repair cream has the effects of deeply moistening the skin, reinforcing skin immune capacity, repairing damaged cutin, and preventing dependent dermatitis caused by hormone. The repair cream can effectively relieve the skin with eczemas; and compared with the commercially available cream, the repair cream has more excellent effects of moisturizing, preventing allergy and removing redness. The repair cream suitable for the skin with eczemas is prepared from the following components: 20-65% of a solvent, 6-34% of grease, 0.5-14% of an emulsifying agent, 12-36 parts of a humectant, 12-56% of a repair factor and 13-58% of anti-inflammatory and bacteriostatic components.

Owner:无锡简玺生物科技有限公司

Pure natural liquid handmade soap and preparation method thereof

InactiveCN106753916ASuitable for useFully saponifiedAntibacterial agentsAntipyreticHydrogenPotassium hydroxide

The invention belongs to the field of daily chemical articles, and discloses a pure natural liquid handmade soap. The pure natural liquid handmade soap is prepared by the following steps of mixing natural grease component, potassium hydroxide and pure water according to a certain ratio; performing saponification; after saponification is matured, sequentially adding a certain ratio of moisturizing component and easing component. The pure natural liquid handmade soap is prepared from the following raw materials in percentage by weight: 60 to 70% of the natural grease component, 4 to 4.5% of the potassium hydroxide and 30 to 36% of the pure water; 5 to 10% of the moisturizing component and 5 to 10% of the easing component are added into the soap liquid after the saponification is matured. The invention also discloses a preparation method of the pure natural liquid handmade soap. The pure natural liquid handmade soap prepared by the preparation method has the advantages that the components are natural, the property is mild, the pH (potential of hydrogen) is weak acid, the washing ability is strong, the health and environment-protection functions are realized, and the handmade soap is suitable for all kinds of skin, and is especially suitable for dry skin and sensitive skin.

Owner:刘彩英

Electrolytic eutectoid alloying method for rare-earth-magnesium-nickel-based hydrogen storage alloy

InactiveCN104131315AIngredient safetyComposition is stableElectrolysis componentsMagnesiumElectrochemistry

The invention belongs to the field of the preparation of rare-earth alloys and particularly relates to an electrolytic eutectoid alloying method for a rare-earth-magnesium-nickel-based hydrogen storage alloy. The electrolytic eutectoid alloying method for the rare-earth-magnesium-nickel-based hydrogen storage alloy, disclosed by the invention, comprises the steps: adopting a circular or square graphite electrolysis tank, and placing an undertake crucible at the bottom of the electrolysis tank; carrying out joint electrochemical precipitation on cathodes RE (Rare-Earth) and Mg (magnesium) in a manner of taking a metallic nickel (Ni) rod as a cathode, taking fluoride fused salts, such as REF3-LiF-MgF2-BaF2, as an electrolyte and taking a mixture of RE2O3 and MgO as a raw material, alloying with nickel which serves as a cathode, so as to obtain an RE-Mg-Ni alloy, and sinking into the undertake crucible, thereby obtaining the rare-earth-magnesium-nickel-based hydrogen storage alloy. The method has the beneficial effects that the problem that magnesium is subjected to volatilization and oxidation during the smelting of the rare-earth-magnesium-nickel-based hydrogen storage alloy is effectively solved, the rare-earth-magnesium-nickel-based hydrogen storage alloy is adjustable and controllable in ingredients and can be obtained stably, the electrolysis work is continuous, the production process is safe, the process flow is short, and the cost is low.

Owner:GANNAN NORMAL UNIV

Drug for preventing and treating alopecia

InactiveCN107158386AReduce permeabilityPromote growthInorganic phosphorous active ingredientsAlgae medical ingredientsVitamin CAndrogen

The invention provides a drug for preventing and treating alopecia and belongs to the technical field of drug preparation. The drug for preventing and treating alopecia contains the following effective constituent: compound of more than one of flavonoids compound for reducing capillary permeability, calcium and vitamin C. The compound provided by the invention can be used for achieving the purposes of effectively preventing and treating alopecia and promoting the hair growth, is safe, is wide in universality, is effective in treatment and is suitable for treatment of androgen alopecia.

Owner:段新方

Probiotic enteric capsule for treating intestinal flora disturbance and capsule body of probiotic enteric capsule

InactiveCN106727725AAvoid abuseAvoid drug resistanceDigestive systemUnknown materialsDiseaseBacteroides

The invention discloses a probiotic enteric capsule for treating intestinal flora disturbance and a capsule body of the probiotic enteric capsule. The probiotic enteric capsule comprises probiotic and auxiliary materials, wherein the auxiliary materials are stachyose, dietary fiber and fructose-oligosaccharide and the mass ratio is (70-85%):(6-10%):(5-11%):(3-10%); and the capsule body comprises sodium alginate, magnesium stearate, gelatin, pectin, glycerin and water. Compared with the prior art, the probiotic enteric capsule has the advantages that the natural probiotic contained in human intestinal tracts is completely adopted, so that the probiotic enteric capsule is safe and free of toxic or side effect, abuse of chemical drugs of antibiotic is avoided and the problem of drug resistance of intestinal harmful bacteria is effectively solved; and the diseases of diarrhea, acute enteritis, chronic enteritis, allergic reaction of food and the like can be effectively prevented and treated, so that the probiotic enteric capsule can be widely applied to the aspect of treatment and prevention of intestinal flora disturbance.

Owner:合肥赛为智慧医疗有限公司

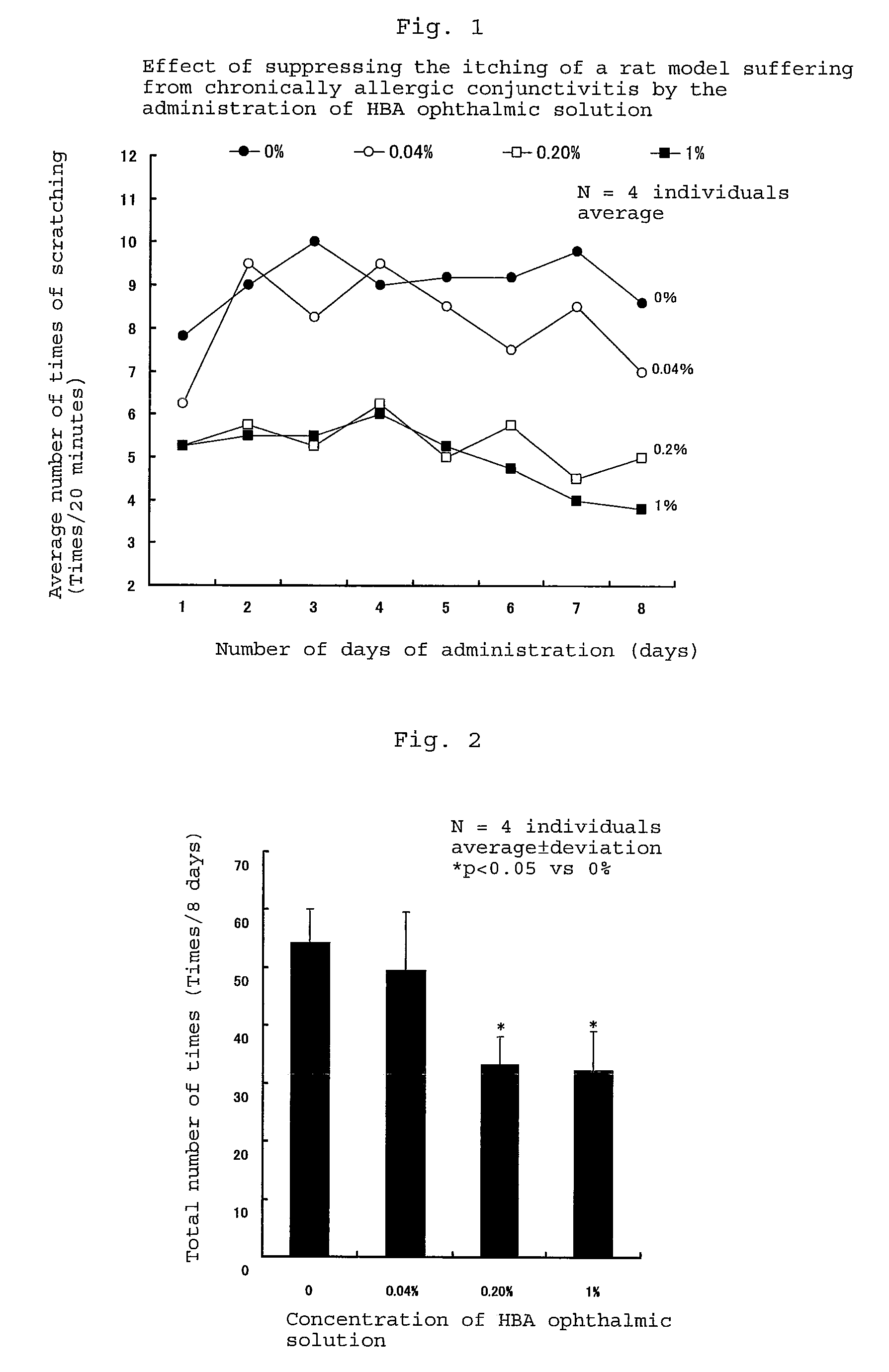

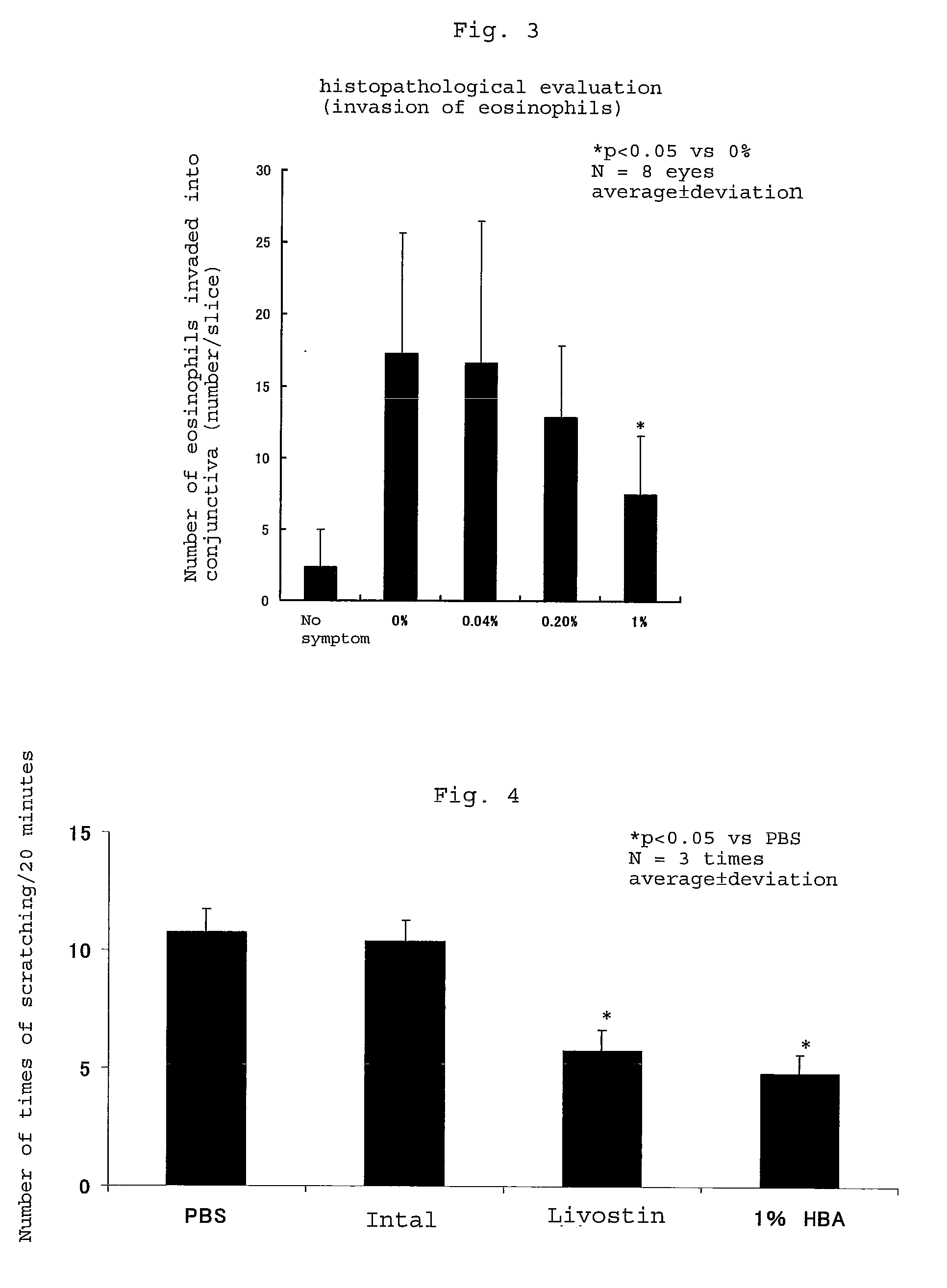

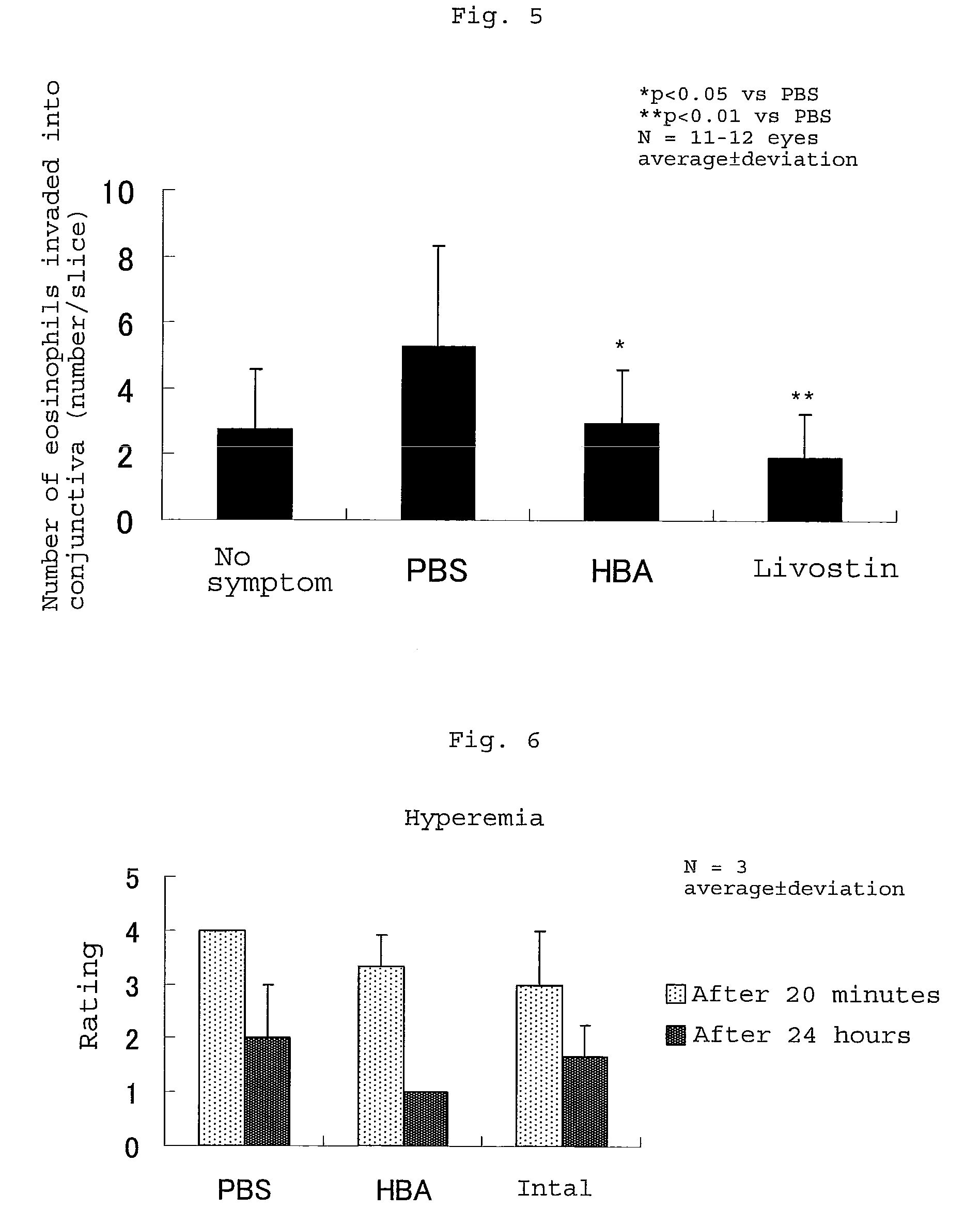

Antiallergenic composition

InactiveUS20100056631A1Safe antiallergenic compositionIngredient safetyCompounds screening/testingBiocideNuclear chemistry3-Hydroxybutyric Acid

An antiallergenic composition comprising 3-hydroxybutyric acid and / or a salt thereof. The antiallergenic composition is safe.

Owner:OPHTECS CORP

Hydrogel antipyretic patch and preparation process thereof

InactiveCN108125931AIngredient safetyFever fastHydroxy compound active ingredientsAntipyreticHydrophilic polymersMoisturizer

The invention belongs to the technical field of medicines, and particularly relates to a hydrogel antipyretic patch and a preparation process thereof. The hydrogel antipyretic patch provided by the invention is made by using NP-700 as a hydrophilic polymer and then being supplemented with a gel polymer, a gel rate control agent, a preservative, a moisturizer, a pH (potential of Hydrogen) control agent, a thickener and a cooling compound; the hydrogel antipyretic patch is safe in component and quick in antipyretic speed, has no pungent smell, has a light aroma, and is high in use comfort degree; nerol added into the hydrogel antipyretic patch can be closely combined with a high-molecular skeleton due to a unique molecular structure, and is used for dispersing the adsorptive power, to a water molecule, of a high molecule; at a certain temperature, the permeability of hydrogel is ameliorated; the vaporized water molecule can be quickly diffused; the effect of quickly lowering a temperature is achieved; in addition; the fresh smell of the nerol can be also used for promoting the use feeling of the antipyretic patch; the process for preparing the hydrogel antipyretic patch, which is provided by the invention, is simple; the cost is low; the making procedure is nontoxic and pollution-free.

Owner:NANJING FANKANG MEDICAL TECH

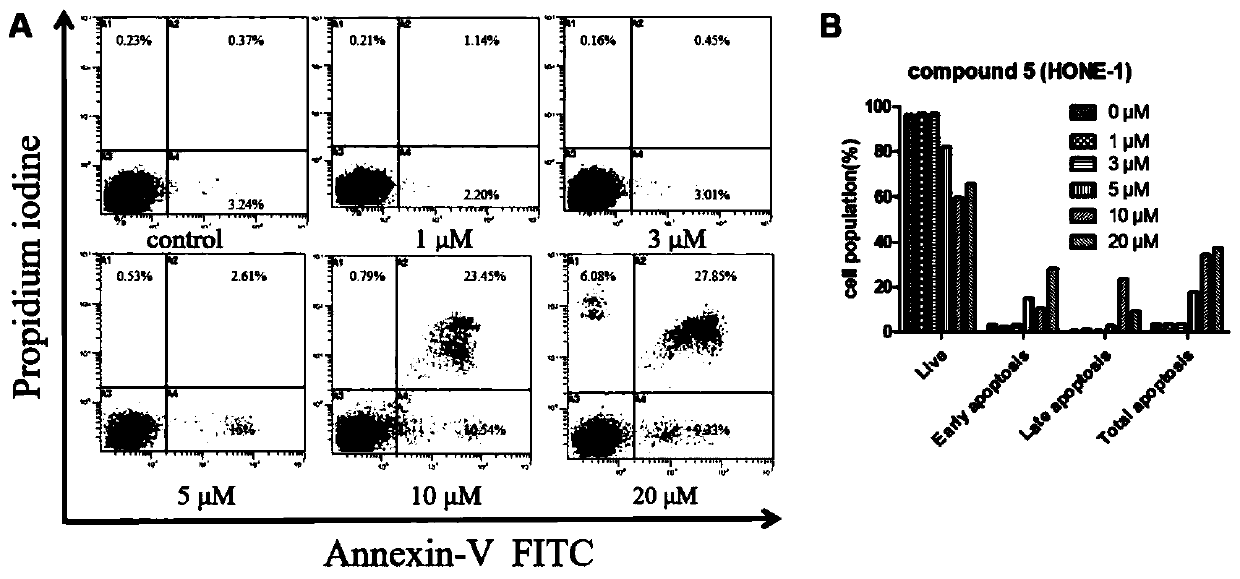

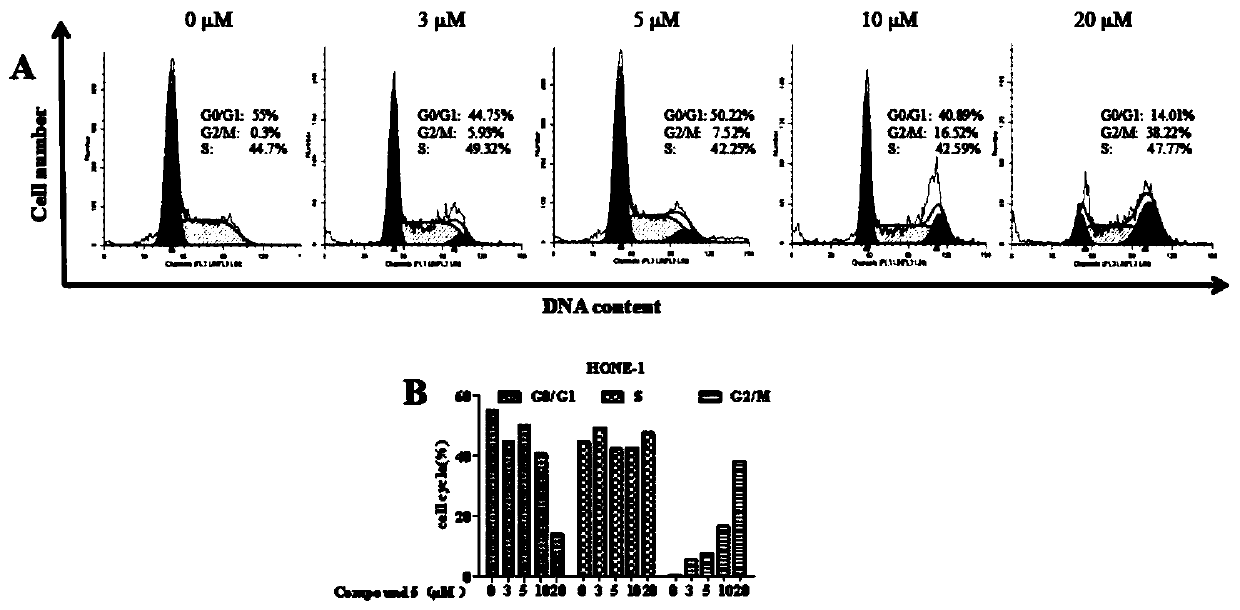

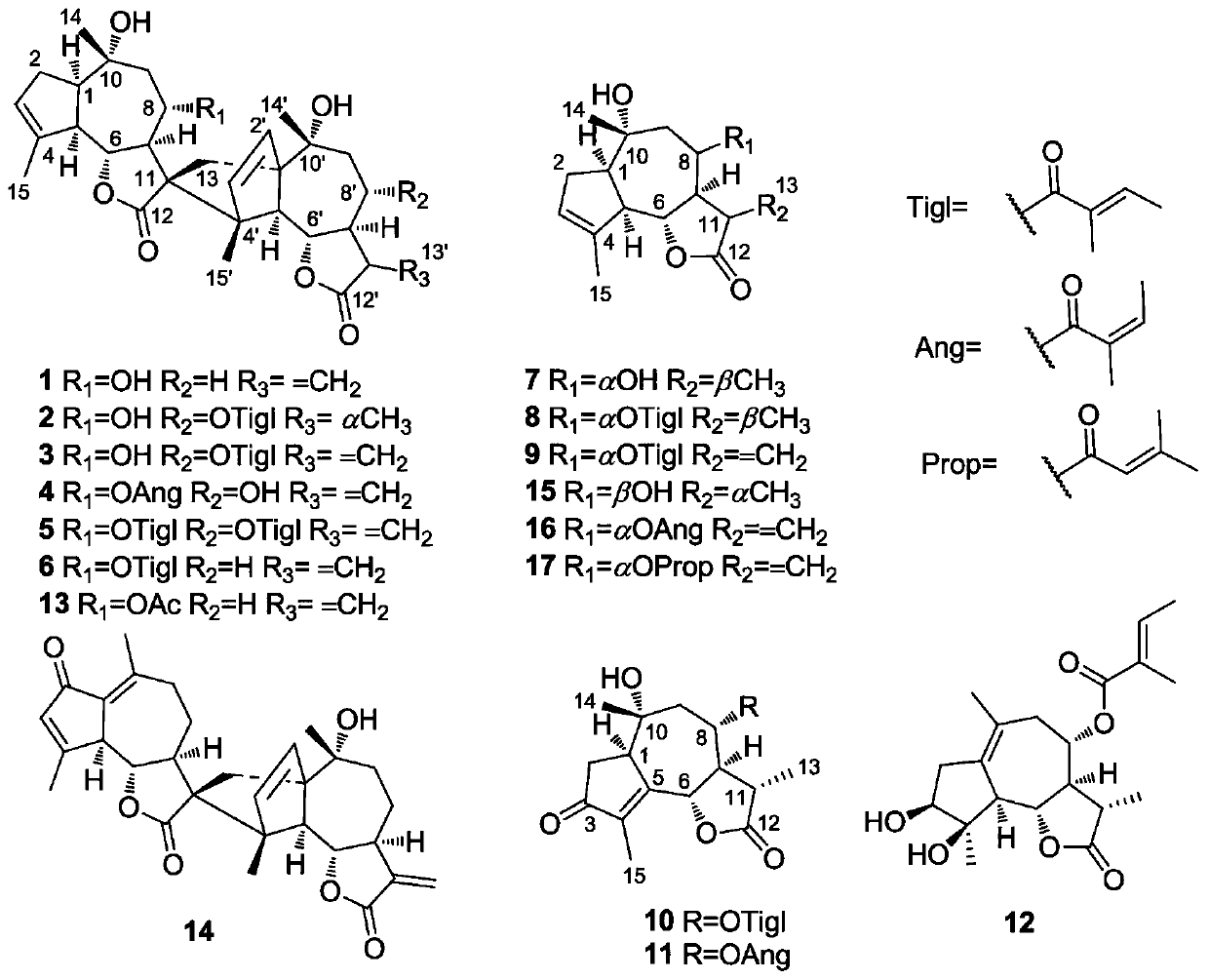

Flos chrysanthemi indici extract and preparation method thereof and application of flos chrysanthemi indici extract to preparation of drugs for treatment of nasopharyngeal carcinoma

ActiveCN110343116AGrowth inhibitionInduce apoptosisOrganic chemistry methodsAntineoplastic agentsMedicineApoptosis

The invention provides a flos chrysanthemi indici extract and new application of the flos chrysanthemi indici extract to preparation of drugs for prevention and treatment of nasopharyngeal carcinoma,and further provides a preparation method of the flos chrysanthemi indici extract. The provided flos chrysanthemi indici extract has the obvious effect on inhibiting the growth of nasopharyngeal carcinoma cells, the nasopharyngeal carcinoma cells HONE-1 can be blocked in the G2 / M period, and apoptosis of the nasopharyngeal carcinoma cells can be induced; and a compound provided by the flos chrysanthemi indici extract comes from plants, is safe and reliable, has the good effect of inhibiting nasopharyngeal carcinoma, and can be applied to preparation of the drugs for treatment of nasopharyngealcarcinoma.

Owner:SUN YAT SEN UNIV

Safe antirust anticorrosive metal cutting fluid

InactiveCN106190478AIngredient safetyImprove the lubrication effectLubricant compositionKeroseneFatty acid

The invention discloses a safe antirust anticorrosive metal cutting fluid, which is prepared from the following raw materials in parts by weight: 20 to 40 parts of castor oil, 5 to 15 parts of organic boric acid ester, 2 to 6 parts of fatty acid imidazoline boric acid monoester, 1 to 4 parts of sulfur-containing boric acid ester, 3 to 5 parts of glycerine polyoxyethylene ether, 1 to 6 parts of quaternary ammonium salt, 2 to 5 parts of sodium polyacrylate, 1 to 4 parts of kerosene, 1 to 4 parts of sodium molybdate, 2 to 8 parts of triethanolamine, 1 to 5 parts of compound boric acid ester antirust agent, 2 to 5 parts of extreme-pressure anti-wear additive, 3 to 9 parts of water and 4 to 6 parts of sodium benzoate. The metal cutting fluid provided by the invention is safe in components, is free from pollution, and has excellent antirust and anticorrosive performance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Liquid dressing and preparation method thereof

PendingCN110251720AIngredient safetyImprove the bactericidal effectBandagesPlasticizerBiomedical engineering

The invention belongs to the field of wound surface nursing, and particularly relates to a liquid dressing and a preparation method thereof. The liquid dressing comprises the following components in parts by weight: 5-12 parts of a film forming agent I, 0-8 parts of a film forming agent II, 50-90 parts of a volatile solvent and 1-10 parts of a plasticizer. The liquid dressing has the characteristics of safe components and comfortable skin feel, the preparation method of the liquid dressing is simple, the cost is low, and the liquid dressing is suitable for industrial application.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

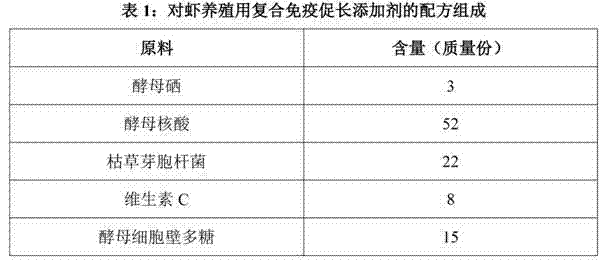

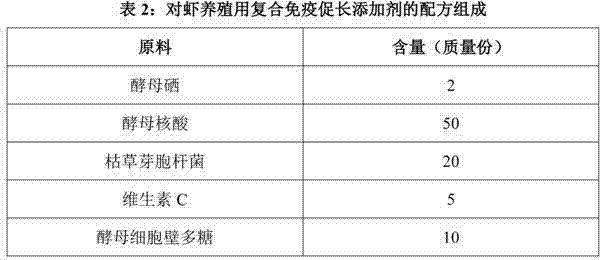

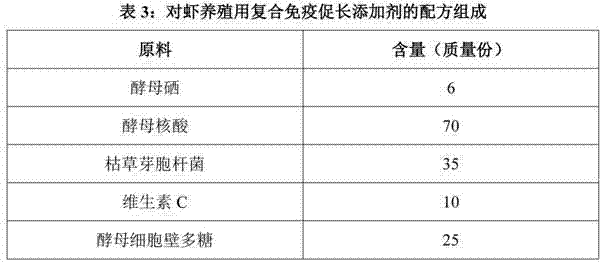

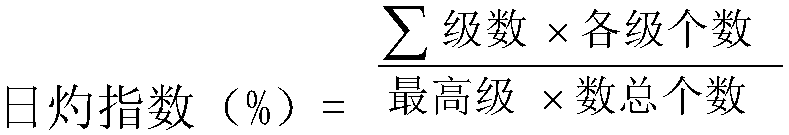

Compound immune promoter additive for breeding prawns

ActiveCN102396656AImprove the body's immunityIngredient safetyAnimal feeding stuffBiotechnologyMicroecosystem

The invention discloses a compound immune promoter additive for breeding prawns, which is prepared from the following raw materials in part by mass: 2 to 8 parts of selenium yeast, 50 to 75 parts of yeast nucleic acid, 20 to 35 parts of bacillus subtillis, 5 to 15 parts of vitamin C and 10 to 25 parts of yeast cell wall polysaccharides. The feed additive disclosed by the invention is used to be added into feed for prawns in an amount which is 0.1 to 0.3 percent; (2) the feed additive can increase the immunity and stress resistance in the body of prawns and has high resistant effect on diseases caused by taura syndrome virus (TSV), white spot syndrome virus (WSSV) and various bacteria; (3) the feed additive focuses on nutrition and immunity, avoids causing immune tolerance, and has obviouseffects on nutrient absorption, microecosystem in digestive tract, bacteria inhibition and the like of prawns; and (4) the raw material components used by the invention are safe and from stable sources and are cheap, the production process is mature, the operation is convenient, and the feed additive can be granulated directly and also can be mixed with feed to be fed to the prawns.

Owner:广东雅琪生物科技股份有限公司

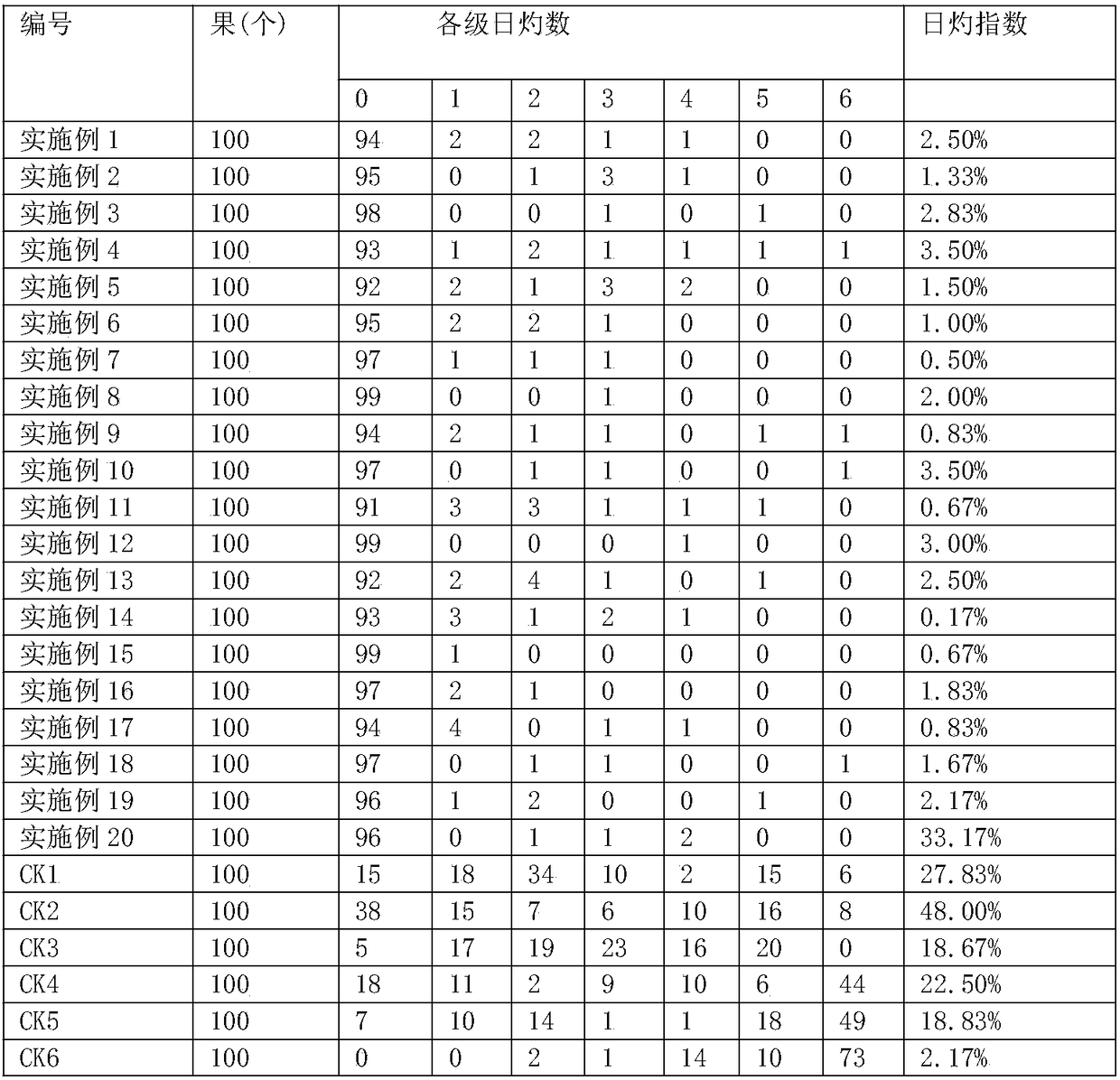

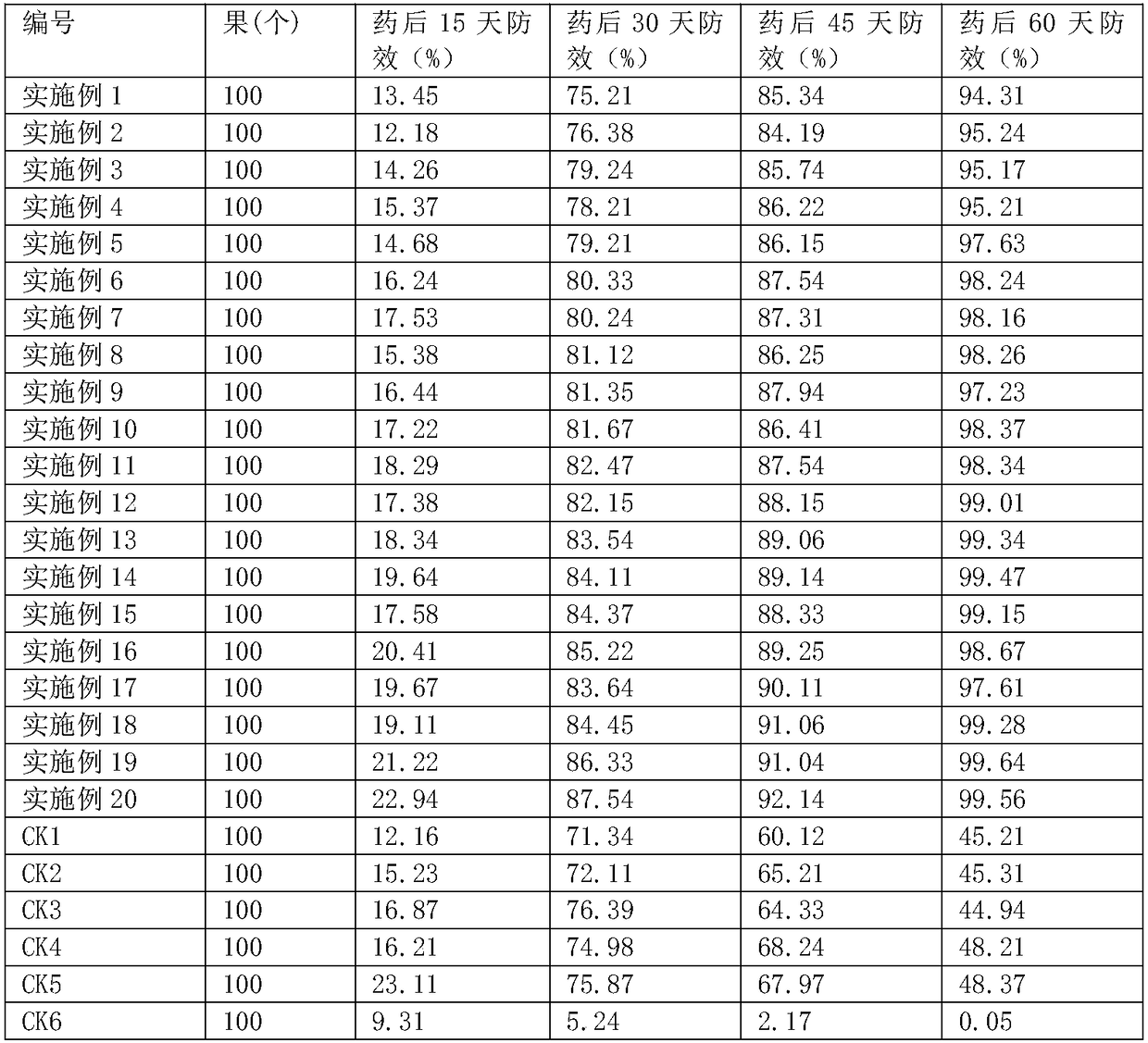

Fruit whitening agent composition and application thereof for preventing sunburn, holding water, preventing insects and preventing diseases

The invention discloses a fruit whitening agent composition and application thereof for preventing sunburn, holding water, preventing insects and preventing diseases. The whitening agent composition comprises the following content components: 0.01-10% of film forming agent, 0.01-40% of filler, 0.01-5% of white pigment, 0.1-2% of long carbon chain quaternary ammonium salt, 0.01-1% of suspension flow agent, and the balance water. The whitening agent composition is applied to orchard fruit whitening, sunscald and other pests and diseases are controlled through whitening, and the whitening agent composition is especially applied to sunscald and pest and disease control of honey murcott. The fruit whitening agent composition is environmentally friendly, has good food safety, stable quality, good rainwater scouring resistant effect and convenient use.

Owner:GAUNGXI TIANYUAN BIOCHEM

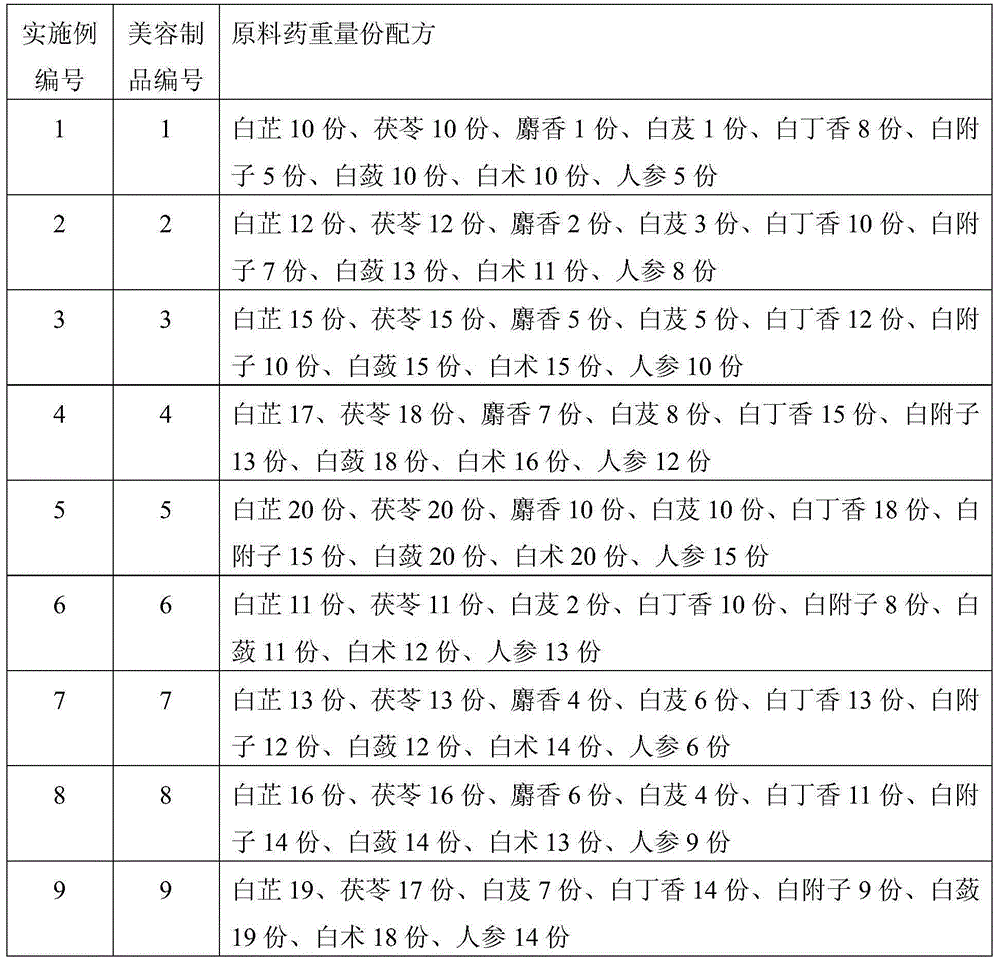

Feature-beautifying skin-care product and production method and application thereof

InactiveCN104984074AActive ingredientsComprehensive skin care effectCosmetic preparationsToilet preparationsWrinkle skinBletilla striata

The invention provides a feature-beautifying skin-care product and a production method and an application thereof, and belongs to the fields of traditional Chinese medicine compositions and health-care products. Effective components of the feature-beautifying skin-care product are prepared from the following pharmaceutical raw materials in parts by weight: 10-20 parts of radix angelicae, 10-20 parts of poria cocos, 1-10 parts of bletilla striata, 8-18 parts of syringa oblatavar alba, 5-15 parts of rhizoma typhonii, 10-20 parts of radix ampelopsis, 10-20 parts of white atractylodes rhizome, and 5-15 parts of ginseng. The feature-beautifying skin-care product is applicable to all kinds of people, especially patients with skin problems. The product has the efficacies of whitening skin, moisturizing skin, removing wrinkles, removing spot, dispelling cicatrix, expelling toxin of skin, resisting oxidation and aging, treating acne and the like.

Owner:吴进泉

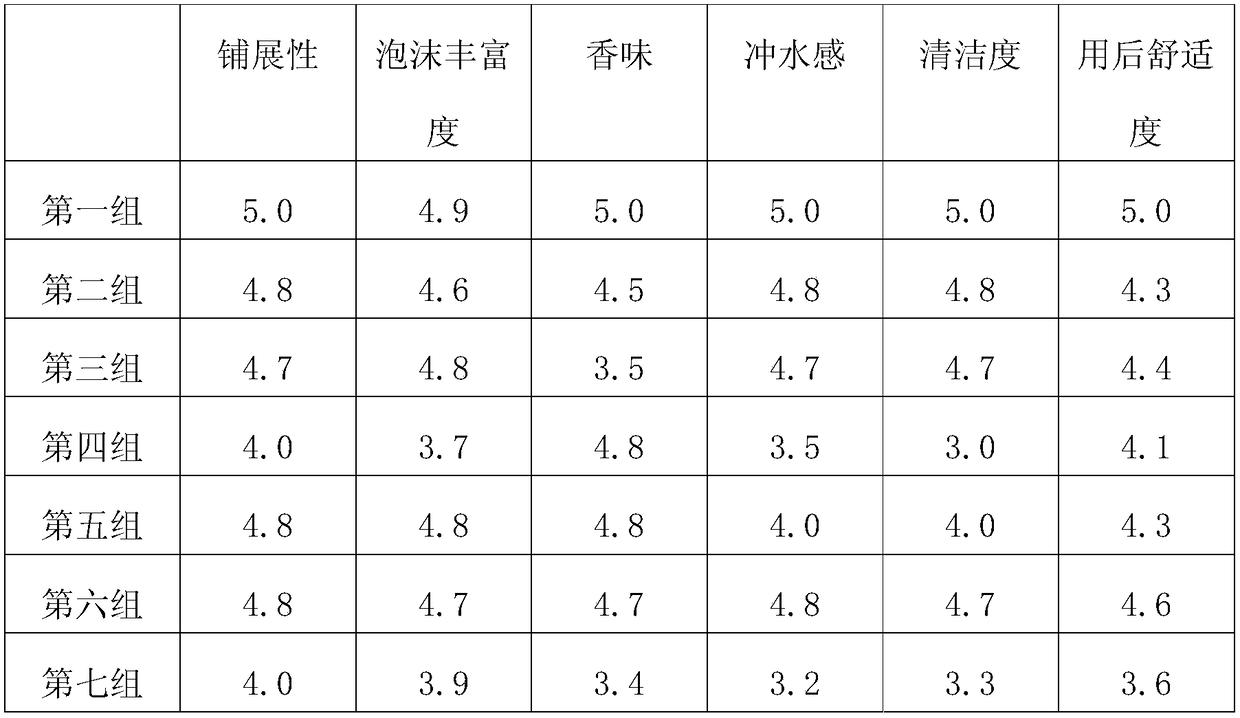

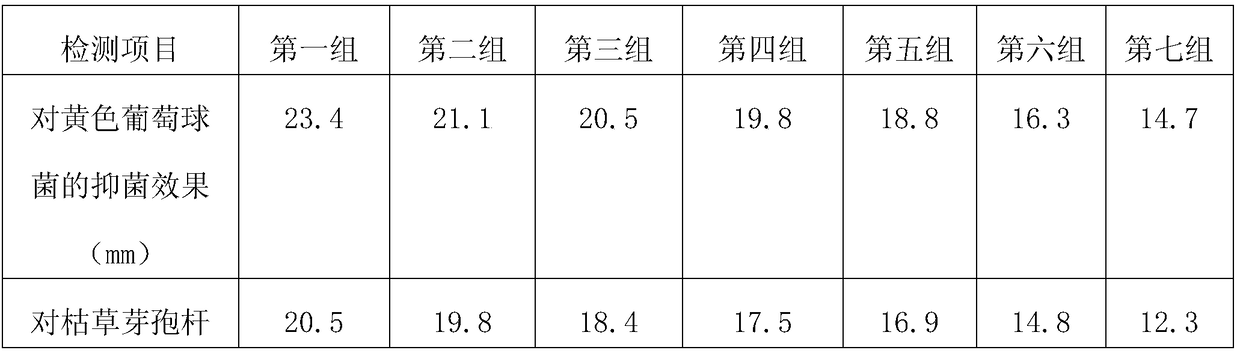

Tea saponin liquid soap and preparation method thereof

InactiveCN109125171AIngredient safetyEasy to processCosmetic preparationsToilet preparationsOsmanthusSodium lauroamphoacetate

The invention provides a tea saponin liquid soap and a preparation method thereof and relates to the technical field of daily articles. The tea saponin liquid soap is composed of raw materials including, by weight part, 10-20 parts of tea saponin, 3-8 parts of konjac glucomannan, 5-10 parts of osmanthus extract, 5-10 parts of wormwood extract, 2-4 parts of squalane, 3-8 parts of sodium lauroamphoacetate, 3-8 parts of alpha-sodium olefinsulfonate, 4-9 parts of total carbon aerogel, 4-9 parts of granular bamboo activated carbon, 1-3 parts of collagen, 4-9 parts of ledum essence and 6-12 parts ofdeionized water. The tea saponin liquid soap is safe in raw materials, simple in processing, free from pollutants, green and environmentally friendly and capable of meeting national ecological economic industrial policies; meanwhile, the tea saponin liquid soap is good in oil and dirt removing effects, excellent in foam characteristics, good in cleaning performance, free from washing residue andgood in moisturizing performance.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Preparation method of superfine hetian jade powder and application thereof

InactiveCN108295089AUniform particle sizeHigh porosityCosmetic preparationsHydroxy compound active ingredientsMaterials preparationMedicine

The invention relates to the field of material preparation, in particular to a preparation method and application of superfine hetian jade powder. The invention provides the preparation method of thesuperfine hetian jade powder; jade is made into jade powder by applying a superfine pulverizing technology, mercury and arsenic which are harmful to human bodies are removed at high temperature, and thus, the jade powder is applied to cosmetics and pharmaceutical preparations. The invention also provides the application of the superfine hetian jade powder in the pharmaceutical preparations; purplejade cream prepared by adding Chinese herbal medicines such as lithospermum root has the effects of eliminating illness, dehumidifying, expelling pus and decay, regenerating tissue, treating scaldingdue to hot water or fire, detoxifying, sterilizing, removing decay and moistening skin.

Owner:陈桂芳

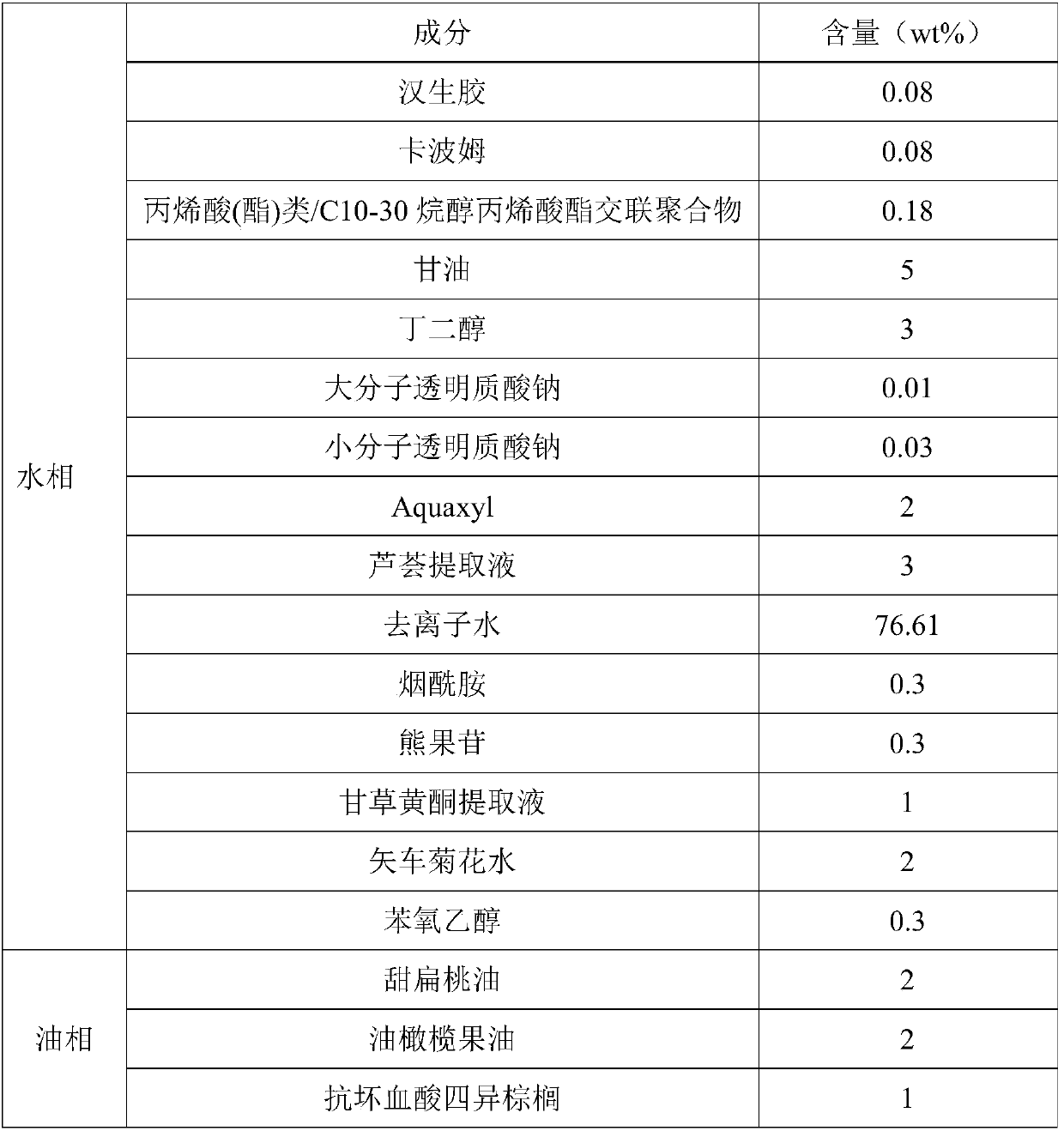

Whitening and moisture-retention gel containing suspension essential oil droplets used for sensitive skin and preparation method and application thereof

InactiveCN107595732AOvercome the problem of lack of moistureGood whitening effectCosmetic preparationsToilet preparationsWater solubleAntiseptic solutions

The invention discloses a whitening and moisture-retention gel containing suspension essential oil droplets used for sensitive skin and a preparation method and an application thereof. The gel is composed of a water-phase thickening agent, grease, essential oil, a humectant, a fat-soluble whitening agent, a water-soluble whitening agent, an antiseptic and deionized water, and optional essence, andthe suspension droplets are formed by grease, essential oil and the fat-soluble whitening agent. The whitening and moisture-retention gel has four effects of smoothing, moisture retention, nourishingand whitening; the whitening and moisture-retention gel has safe component and does not contain an emulsifier, greatly reduces the skin stimulation risk for population with sensitive skin while in use, and has the advantages of safety and low stimulation.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

Placenta preservation solution and preparation method thereof

InactiveCN108684653APrevents acidification or alkalinization of cellsImprove the survival rateDead animal preservationChemistryTrisodium citrate

The present invention relates to a composition for tissue preservation, and more particularly to a placenta preservation solution and a preparation method thereof. The placenta preservation solution comprises, in 1000 ml of an aqueous solution, 204 mg to 340 mg of potassium dihydrogen phosphate, 1.40 g to 1.50 g of disodium hydrogen phosphate, 7.6 g to 8.2 g of sodium chloride, 149 mg to 261 mg ofpotassium chloride, 100000U-1000000U of penicillin, 60mg-100mg of streptomycin, 12.5g of glucose, 5g of dextran-40, 7.35g of trisodium citrate and 352mg-528mg of vitamin C, and solution pH is 7.33-7.83. The placenta preservation solution is simple in components, stable and safe, has no toxic side effects, and has low cost. The placenta preservation solution is simple in preparation process and can be prepared in a large amount in a short time.

Owner:杭州联泽生物科技有限公司

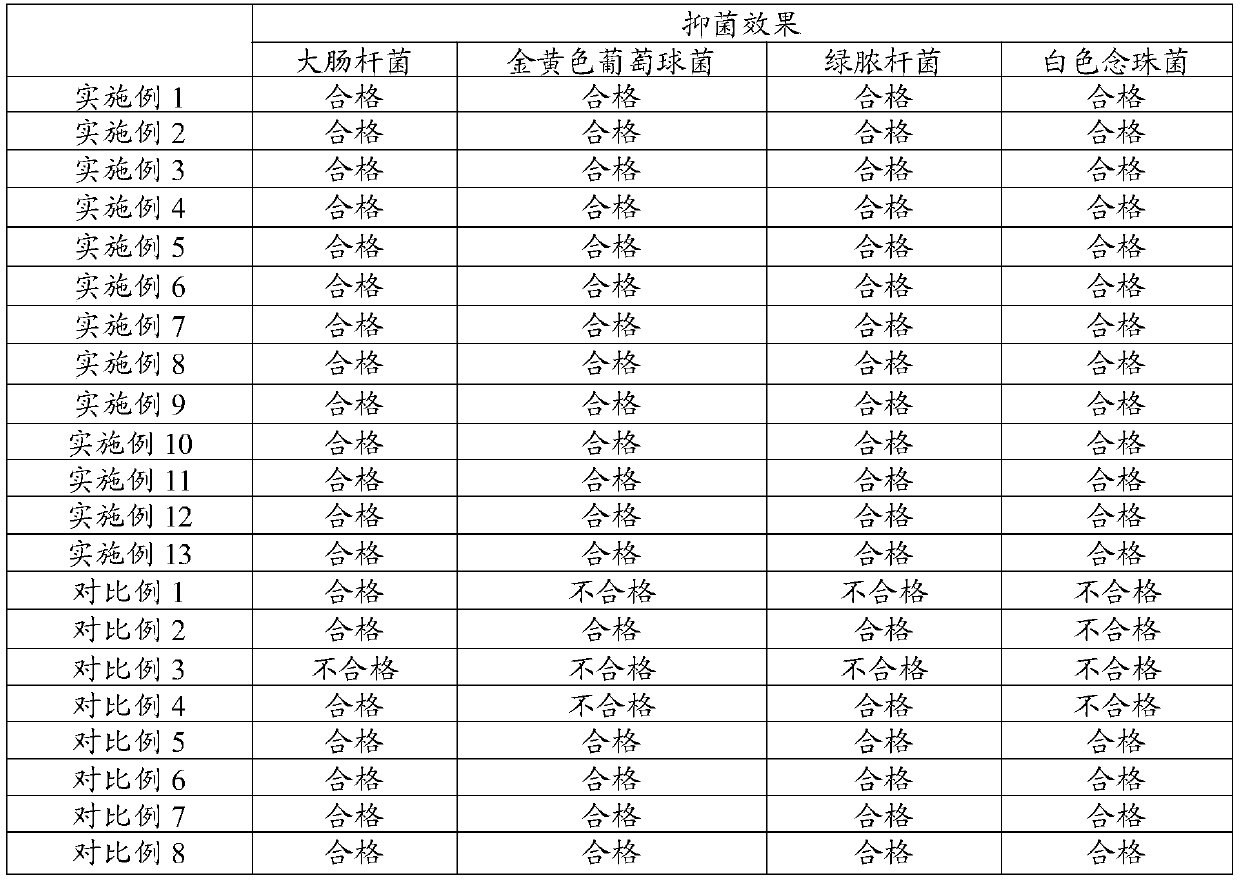

Contact lens care solution and preparation method

InactiveCN111518627AIngredient safetyGood antibacterial effectInorganic/elemental detergent compounding agentsOrganic active ingredientsOphthalmologyActive agent

The invention discloses a contact lens care solution. The contact lens care solution comprises ectoin or an eye science acceptable ectoin derivative, a surfactant, an antibacterial agent, a humectant,a buffer agent, an osmotic pressure regulator and a chelating agent. The invention further provides a preparation method of the contact lens care solution. According to the contact lens care solutionprovided by the invention, the moisturizing and lubricating performance of contact lenses can be improved, the wearing comfort is improved, a repairing effect is achieved, and the phenomena of redness, swelling, inflammation and the like caused by long-term wearing of the contact lenses can be eliminated.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com