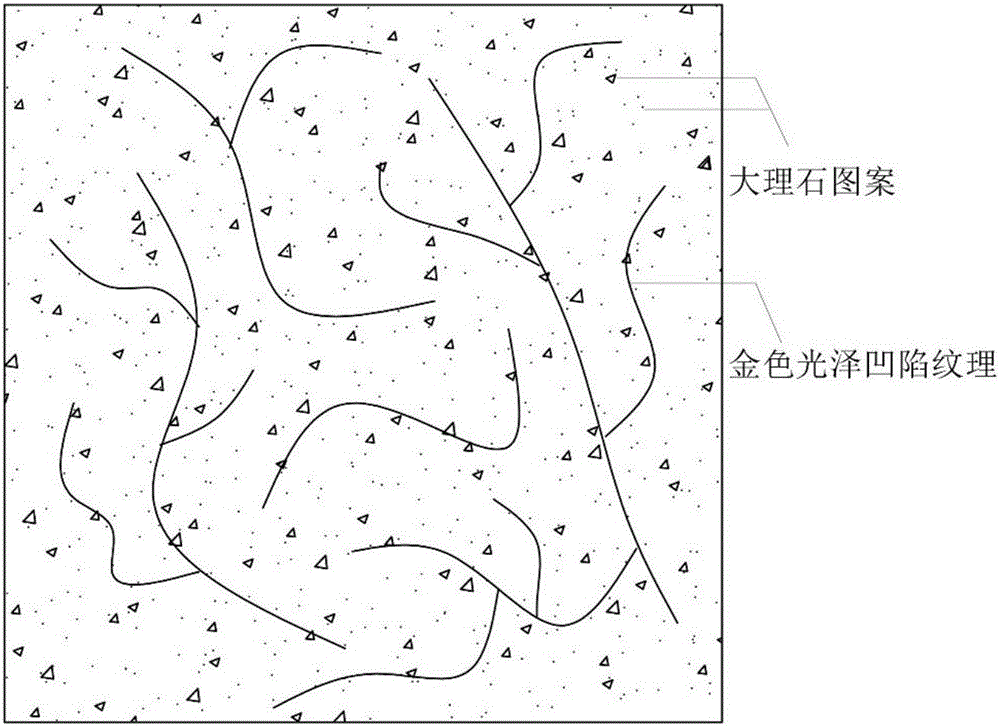

Preparation method for marble ceramic tile with metallic luster sunken textures

A metallic luster, marble technology, applied in the field of marble ceramic tiles and marble ceramic tiles with decorative functions, can solve the problems of air quality decline, environmental protection problems, dangers, etc., and achieve the effects of simple composition, convenient decorative patterns, and safe ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In terms of mass percentage (wt%), the ceramic green body is composed of: SiO 2 :65.5, Al 2 o 3 :15.7, Na 2 O: 2.5, K 2 O:2.9, MgO:1.2, CaO:1.2, TiO 2 :0.8, Fe 2 o 3 : 1.1, loss on ignition 9.1, prepare raw materials according to the general method in the field of building ceramics. The raw materials were mixed and wet ball milled for 6 hours to obtain ceramic slurry. The ceramic slurry is sprayed and granulated to obtain ceramic powder. The powder is molded under 40MPa pressure to obtain a ceramic green body. After the green body is dried, bisque firing is carried out at 1100° C. to obtain a ceramic green body.

[0032] In terms of parts by mass, the bottom glaze raw material formula uses 20 parts of ball clay, 25 parts of potassium feldspar, 13 parts of albite feldspar, 5 parts of quartz, 10 parts of calcined talc, 9 parts of zirconia, 18 parts of calcined kaolin, add water and 0.5 The grinding aid sodium hexametaphosphate was mixed for 8 hours by wet ball m...

Embodiment 2

[0040] Ceramic green body according to chemical composition (wt%) SiO 2 :64.8, Al 2 o 3 :18.7, Na 2 O: 1.8, K 2 O:2.7, MgO:0.8, CaO:1.3, TiO 2 :0.3, Fe 2 o 3 : 1.3, loss on ignition 8.3, prepare raw materials according to the general method in the field of building ceramics. The raw materials were mixed and wet ball milled for 8 hours to obtain ceramic slurry. The ceramic slurry is sprayed and granulated to obtain ceramic powder. The powder is molded under 45MPa pressure to obtain a ceramic green body. After the green body is dried, bisque firing is carried out at 1150° C. to obtain a ceramic green body.

[0041] The bottom glaze is made of 15 parts by mass of ball clay, 25 parts of potassium feldspar, 15 parts of albite, 2 parts of quartz, 13 parts of calcined talc, 8 parts of zirconia, 22 parts of calcined kaolin, adding water and a small amount of grinding aid hexadecimal The sodium phosphate was mixed by wet ball milling for 9 hours to obtain a glaze with a solid...

Embodiment 3

[0049] Ceramic green body according to chemical composition (wt%) SiO 2 :62.8, A l2 o 3 :19.7, Na 2 O: 2.6, K 2 O:1.8, MgO:1.2, CaO:1.2, TiO 2 :0.3, Fe 2 o 3 : 0.9, loss on ignition 9.5, prepare raw materials according to the general method in the field of building ceramics. The raw materials were mixed and wet ball milled for 8 hours to obtain ceramic slurry. The ceramic slurry is sprayed and granulated to obtain ceramic powder. The powder is molded under 42MPa pressure to obtain a ceramic green body. After the green body is dried, bisque firing is carried out at 1180° C. to obtain a ceramic green body.

[0050] The bottom glaze is made of 22 parts by mass of ball clay, 18 parts of potassium feldspar, 14 parts of albite, 6 parts of quartz, 12 parts of calcined talc, 8 parts of zirconia, 20 parts of calcined kaolin, adding water and a small amount of grinding aid hexadecimal The sodium phosphate was mixed by wet ball milling for 9 hours to obtain a glaze with a solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com