Patents

Literature

73results about How to "Strong industrial operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

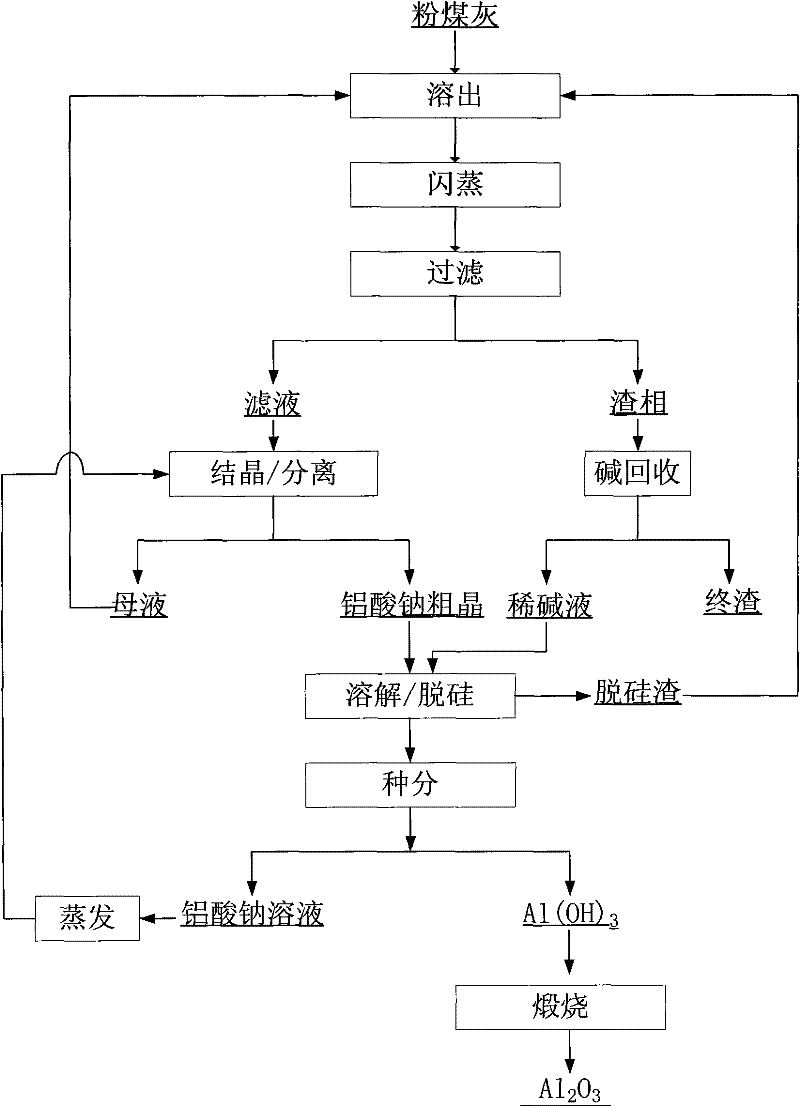

Method for extracting alumina from coal ash through wet process

ActiveCN102476820AObvious superiorityReduce energy consumptionSolid waste disposalAluminium oxides/hydroxidesSlagDecomposition

The invention provides a method for extracting alumina from coal ash through a wet process. The method comprises the following steps: 1, mixing the coal ash, calcium oxide and an alkaline solution, reacting, carrying out flash evaporation, and filtering to obtain an alkaline solution containing sodium aluminate and aluminum removed slag; 2, cooling and crystallizing the alkaline solution obtained in step 1 to obtain a coarse hydrated sodium aluminate crystal and a crystallization mother solution; 3, circulatingly applying the crystallization mother solution obtained in step 2 to a leaching reaction, dissolving the coarse hydrated sodium aluminate crystal with water or a diluted alkaline solution, carrying out silicon removal and seed decomposition to obtain aluminum hydroxide, and calcining aluminum hydroxide to obtain alumina; 4, evaporating the seed-decomposed mother solution, and mixing the evaporated seed-decomposed mother solution with the alkaline solution obtained in the step 1; and 5, carrying out hydrolysis sodium removal on the aluminum removed slag obtained in the step 1 in the diluted alkaline solution, filter-separating, and carrying out multistage countercurrent washing on the sodium removed slag. According to the method, the dissolving-out temperature and the dissolving-out pressure are low, the dissolving-out rate of alumina can reach above 90%, and the content of sodium oxide in the sodium removed slag is less than 1%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

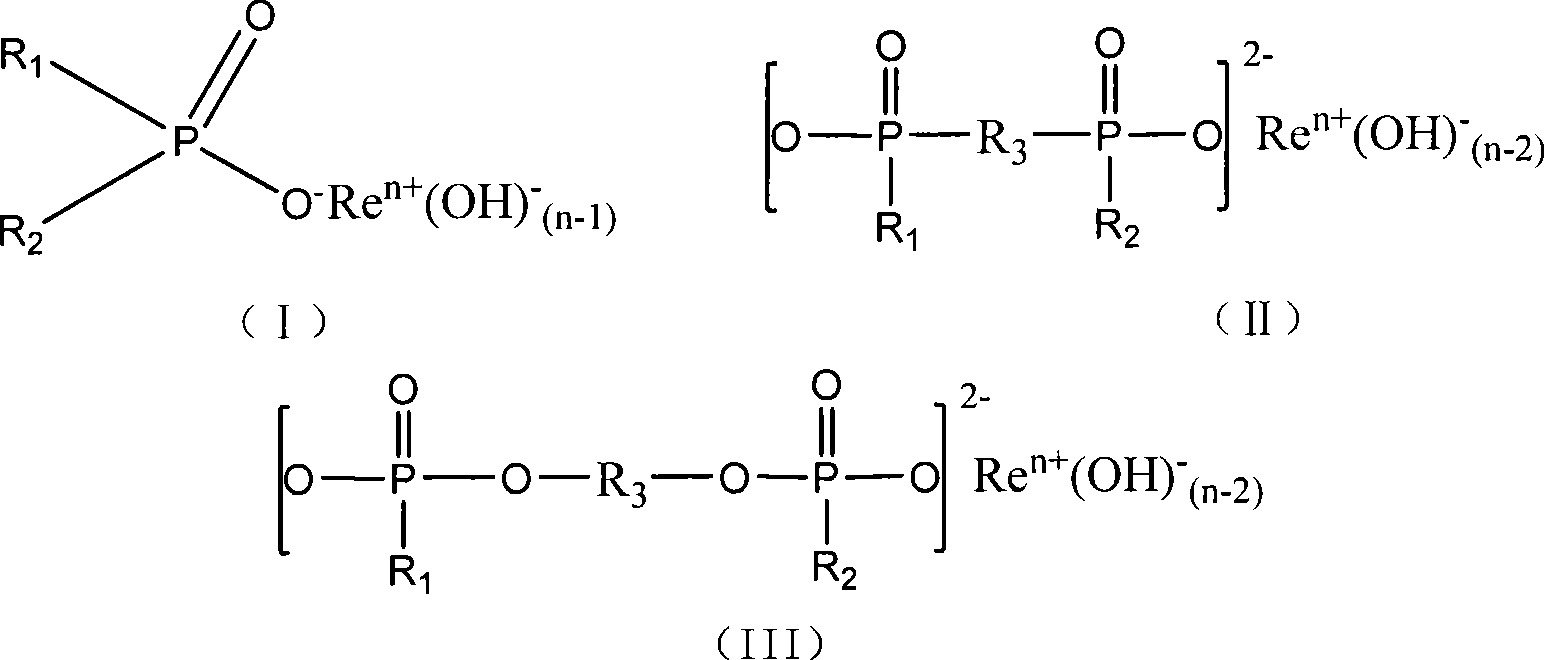

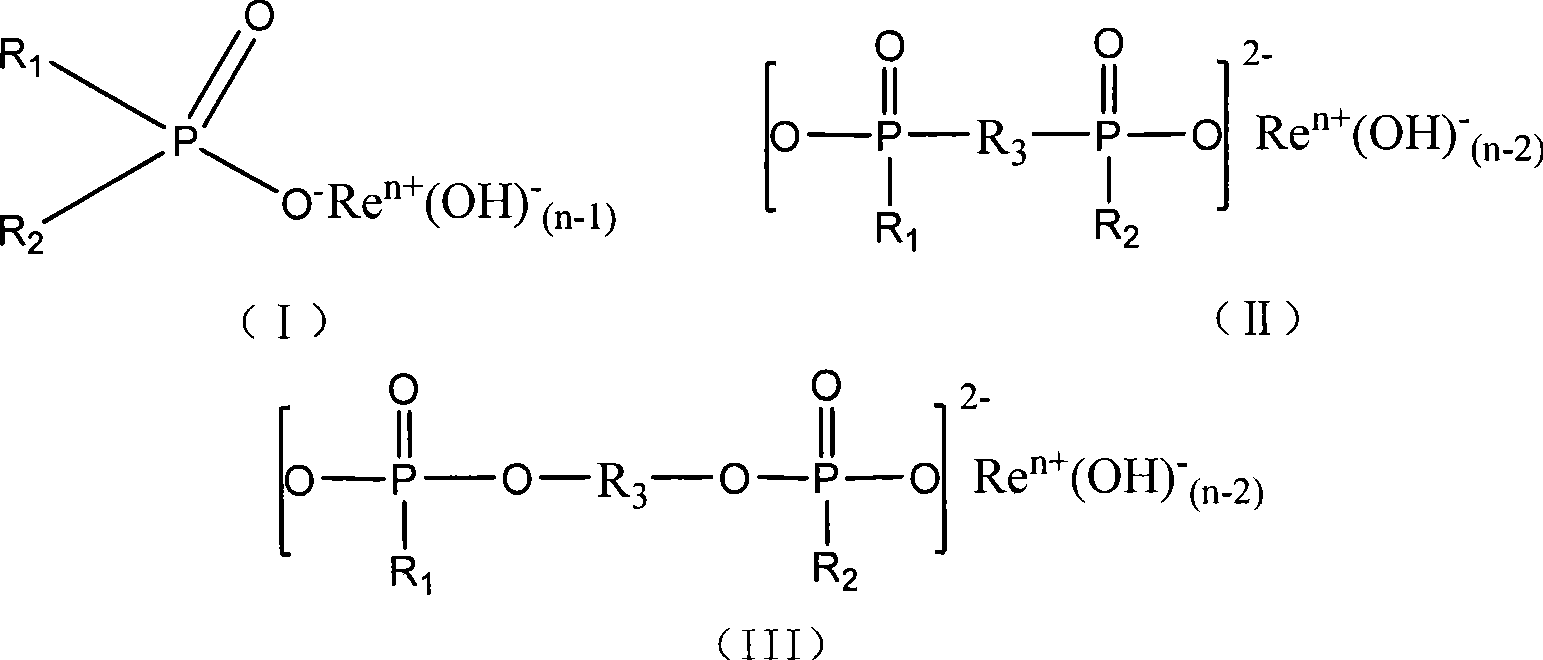

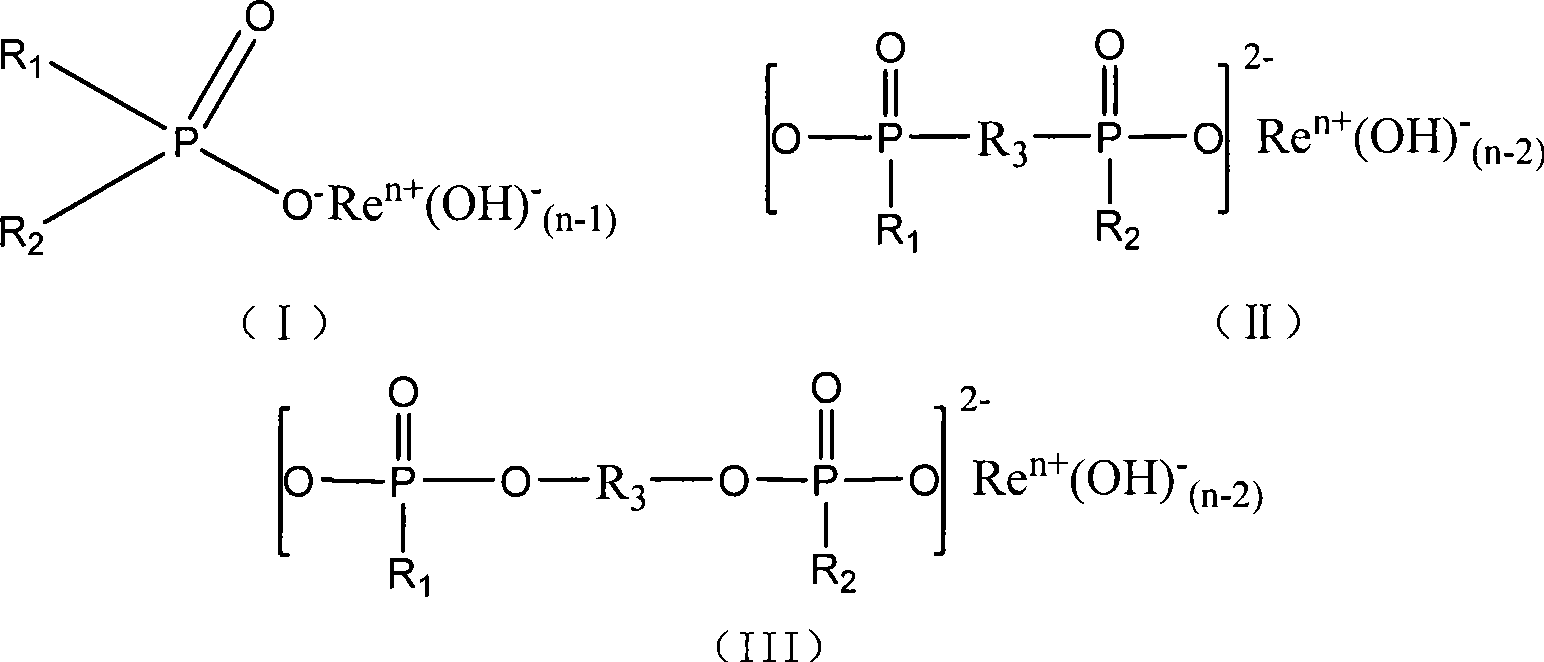

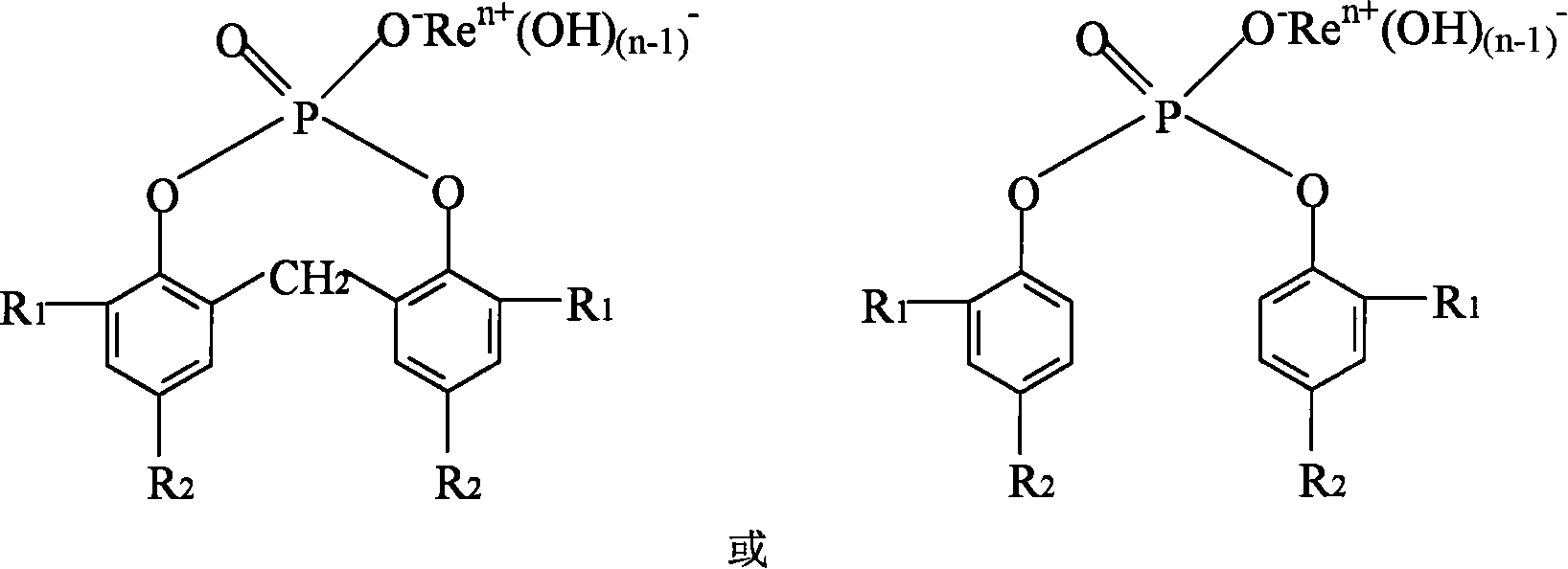

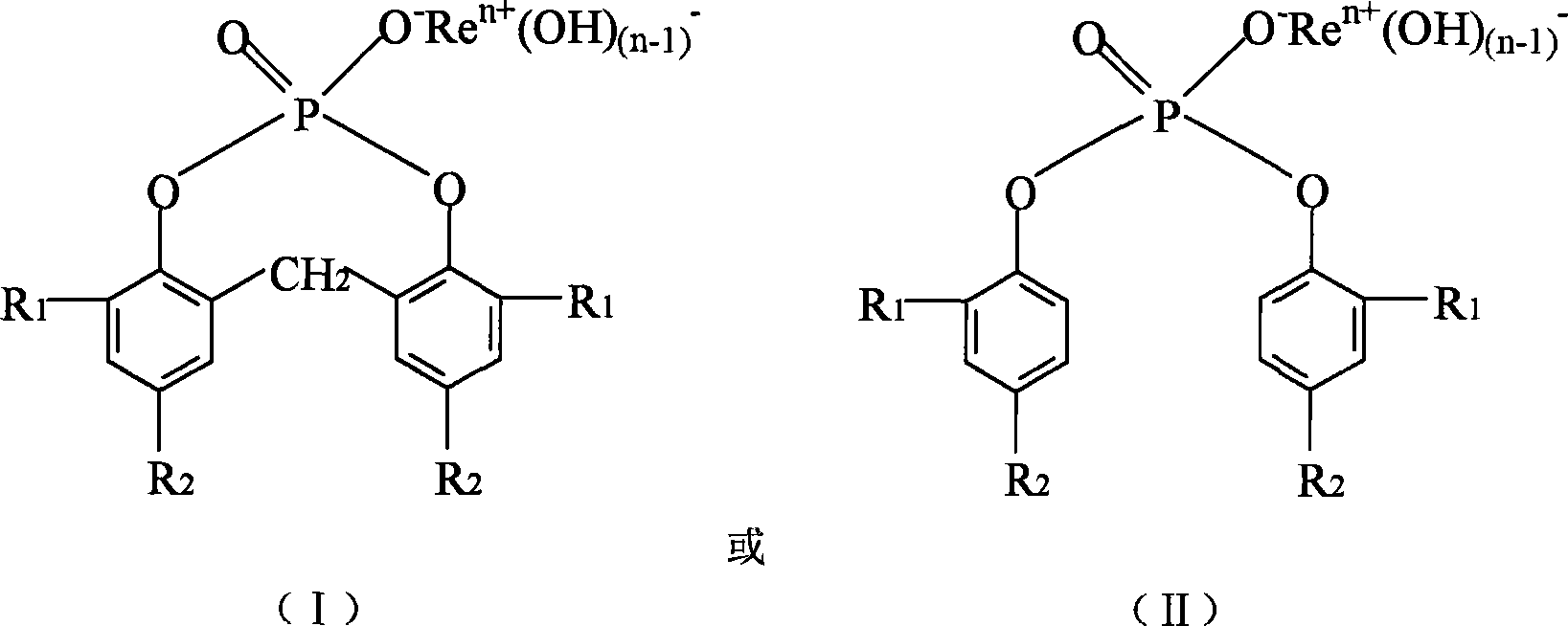

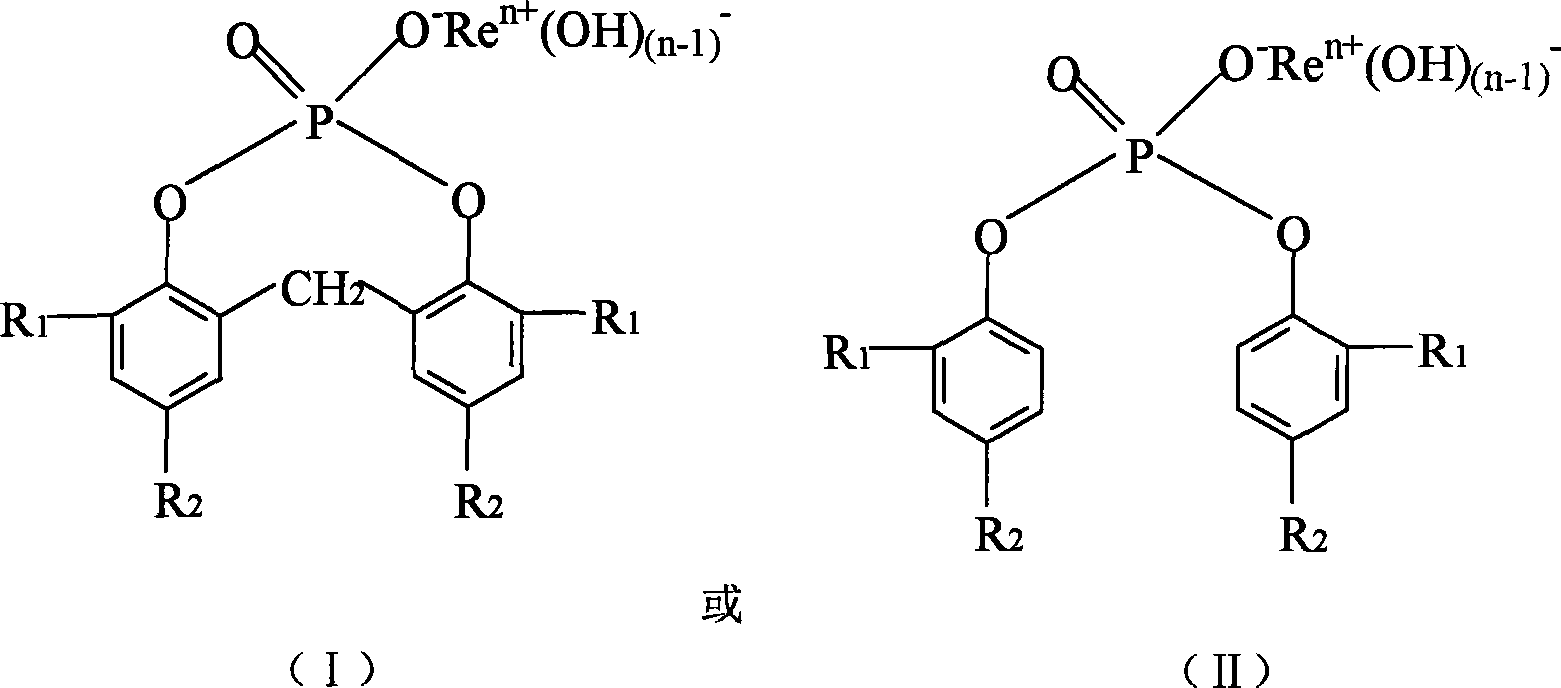

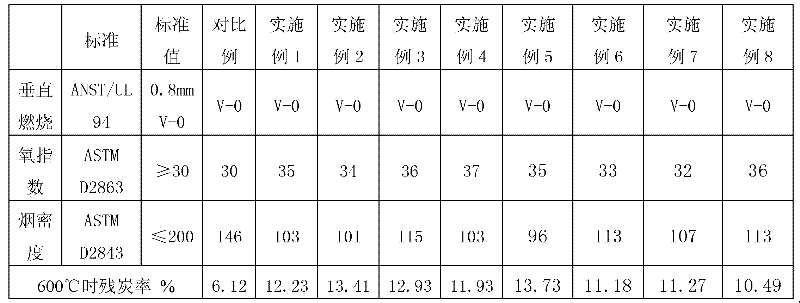

Rear earth organic phosphonate flame retardant, synthesizing method and use thereof

ActiveCN101475706AEffective structureStructure, and developed an efficient and feasible synthesis process for itGroup 5/15 element organic compoundsRare-earth elementOrganophosphorous compounds

The invention relates to organic phosphonic (phosphoric) acid rare-earth salt fire retardant and a synthetic method and application thereof, which belongs to the fields of fine chemical and macromolecular materials. The low-toxic, low-smoke, environment-friendly and efficient fire retardant is formed by combining with rare earth elements in organic phosphonic (phosphoric) acid structure. Compared with the organic phosphorous compound, the fire retardant has extremely high stability at normal temperature and plastic processing temperature; moreover, the use of rare earth elements ensures that the fire retardant and other components in macromolecular material are formed into a combination having better effects than Van Der Waals Force, hydrogen bond and the like; particularly, when mixed with other components of inflatable composite fire retardant, the fire retardant can obtain better synergic effects than currently used phosphinates such as aluminum phosphinate, zinc phosphinate and the like; moreover, the obtained macromolecular material can maintain better physical and mechanical properties.

Owner:广东华南精细化工研究院有限公司

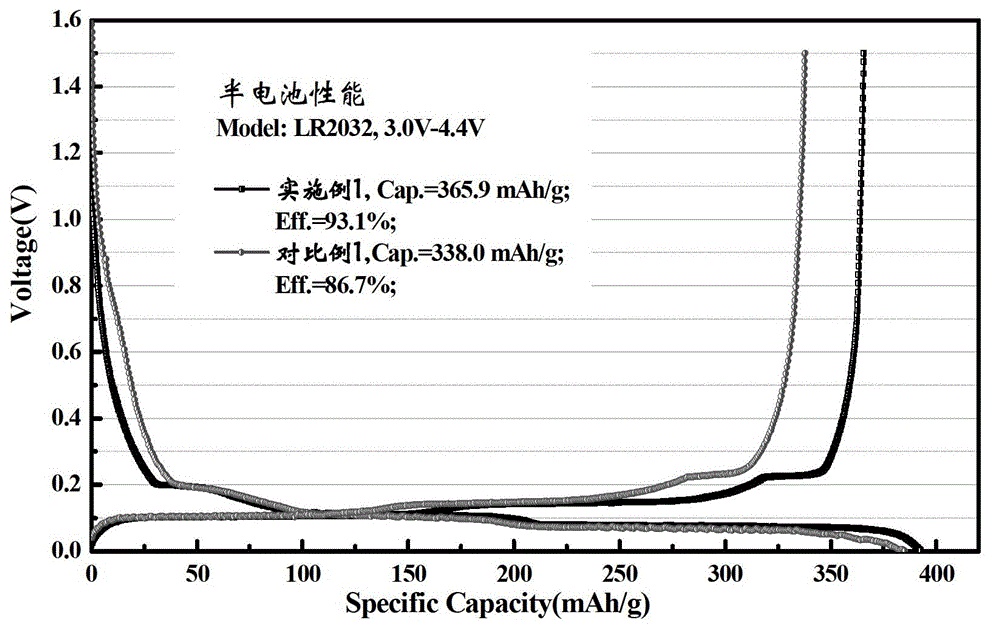

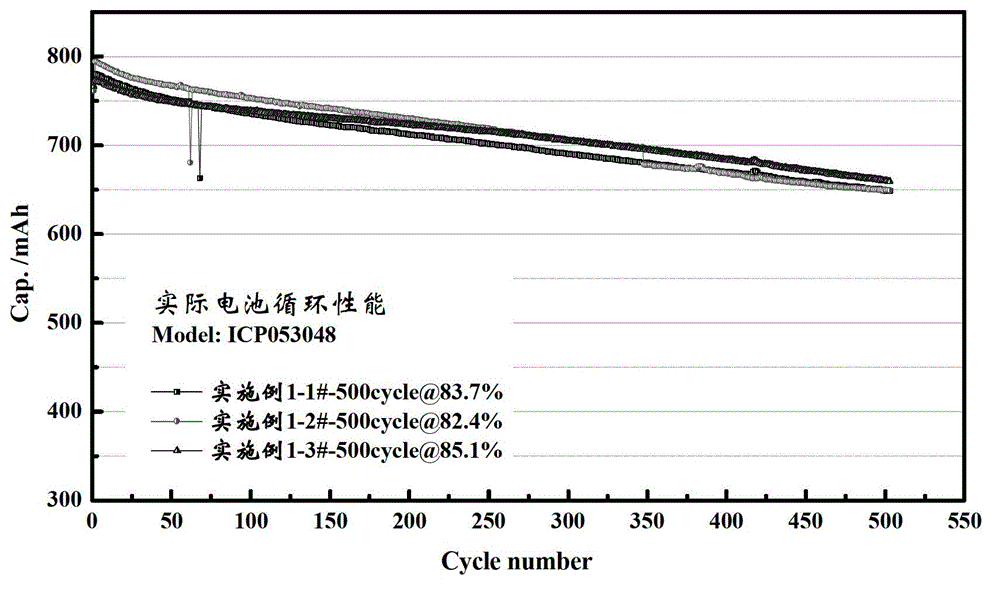

Preparation method for graphite negative electrode of lithium ion battery

InactiveCN102983307ALow cost of preparationStrong industrial operabilityCell electrodesWater solubleLithium electrode

The invention discloses a preparation method for a high-performance modified graphite negative electrode, and in particular discloses a preparation method for a graphite negative electrode of a lithium ion battery. The preparation method mainly comprises the following steps of: conducting procedures of liquid-phase even mixing, drying, roasting, screening and the like to water-soluble phenol-formaldehyde resin, an aluminum source and graphite negative electrode material to be modified to prepare a graphite negative electrode which is modified jointly by pyrolytic carbon and aluminum oxide, wherein the surfaces of the pyrolytic carbon are coated with phenolic resin. The modified graphite negative electrode material has the characteristics of being high in reversibility specific capacity, high in first-time charging and discharging efficiency, long in recycling life and good in safety property. The modified technique is simple to operate, low in cost, and obvious in modification effect.

Owner:TIANJIN B&M SCI & TECH

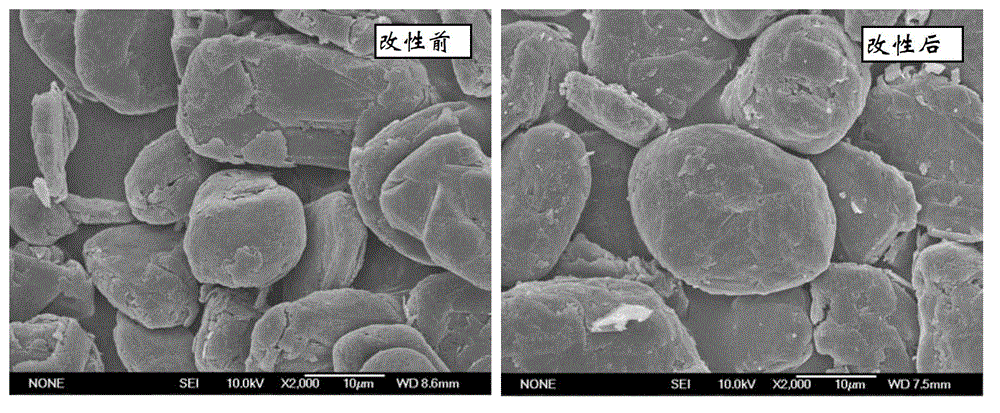

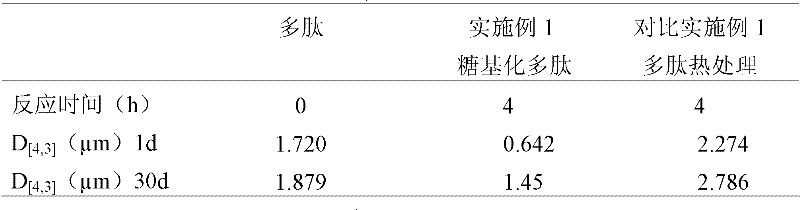

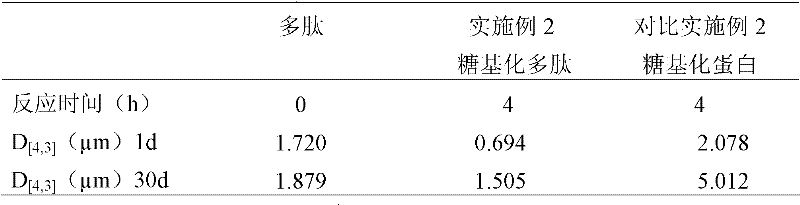

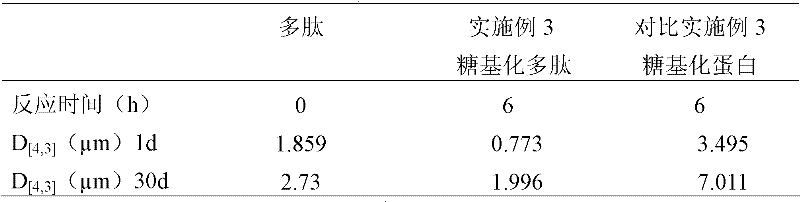

Method for rapidly preparing glycopeptides

InactiveCN102308904ASpeed up the processImprove efficiencyProtein foodstuffs working-upFood industrySucrose

The invention discloses a method for rapidly preparing glycopeptides. The method comprises the following steps: 1, carrying out enzymolysis on a protein to prepare polypeptide, deactivating an enzyme when the enzymolysis reaction is finished, centrifuging, taking a supernatant, and drying; 2, putting a dissolving reagent in a reaction apparatus, adding a buffer solution, and fully dissolving; 3, adding polysaccharides and polypeptides obtained in step 1 adding to a solution obtained in step 2, fully stirring for 2h, adding with 0.02%w / w NaN3 for anticorrosion, allowing to stand for a night at 5DEG C, stirring for 1-8h at 50-70DEG C, rapidly cooling to a temperature of below 25DEG C after a reaction is finished, and removing the dissolving reagent if the dissolving reagent is saccharosan 70 or polyethylene glycol 2000; and 4, centrifuging, taking a supernatant, and drying to obtain products of glycopeptides. The method has the advantages of convenient operation, short reaction time and high reaction efficiency, and the products glycopeptides obtained with the method which have superior functionality have wide application prospects in the food industry.

Owner:SOUTH CHINA UNIV OF TECH

Organic phosphate rare earth salt nucleater, synthesis method and application thereof

InactiveCN101054387AStrong industrial operabilityComply with the design requirements of the structureGroup 3/13 element organic compoundsRare-earth elementPhosphate

The present invention relates to nucleating agent of crystallized polymer and its synthesis process which comprise: dissolving substituted diaryl phosphoric acid containing substituted alkyl R1 and R2 in alcosol, adding the alkaline liquor step by step and stirring under heating condition, adding stepwisely rare-earth salt chloride aqueous solution, filtering, drying and crushing, obtaining final product. The present invention introduces light rare earth element in organic phosphate, mainly lanthanum, cerium, to form organic phosphate rare earth salt. The inventive product is nontoxic, safe and stable. The nucleating effect of the inventive product is invariable. The inventive product has relatively high crystal form conversion and nucleating agent which can be used in general plastic and engineered plastic.

Owner:广东华南精细化工研究院有限公司 +1

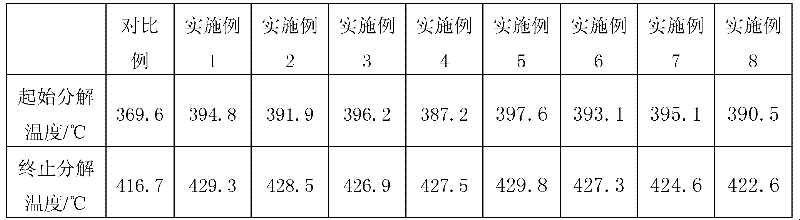

Phosphate rare earth salt with cagelike structure, synthesis method and application thereof

ActiveCN102351904AThe process is effective and feasibleStrong industrial operabilityGroup 5/15 element organic compoundsBulk chemical productionRare-earth elementChemistry

The invention discloses a phosphate rare earth salt with a cagelike structure, synthesis method and application thereof to preparation of fire retardant. According to the invention, stiff stable cagelike phosphate structure and a light rare-earth element with special electron distribution and corresponding electron cloud density are combined to fully play roles of good heat stability, high phosphorus content, high charcoal forming catalysis efficiency, increase of compatibility and inflaming retarding synergy by rare earth coordination linkage. The phosphate rare earth salt with cagelike structure can be applied to an expanding inflaming retarding system and is a fire retardant with structural innovativeness, safety, high efficiency, synergy and wide application prospects.

Owner:广东国望精细化学品有限公司

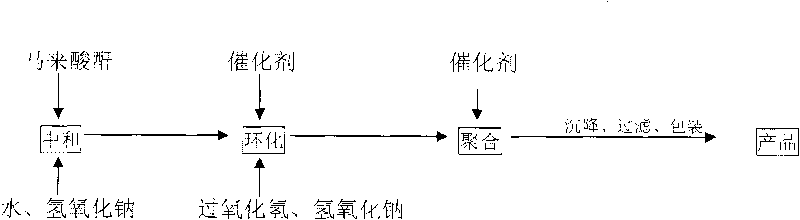

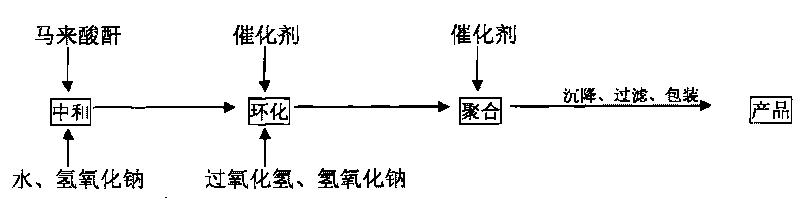

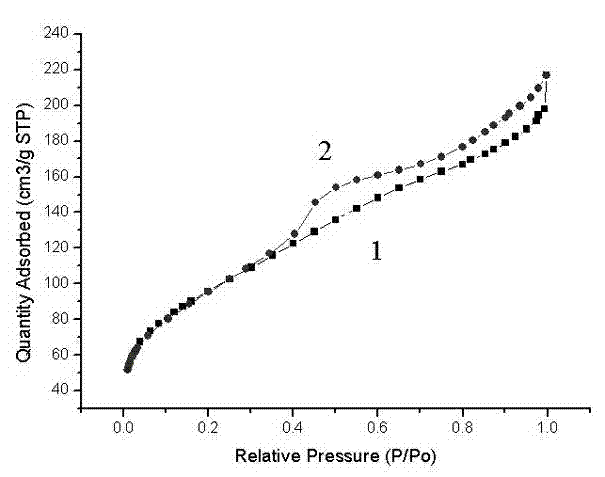

Synthesis method of high-concentration polyepoxysuccinic acid and salt thereof

InactiveCN101717498AIncrease concentrationImprove conversion rateHigh concentrationSynthesis methods

The invention discloses a synthesis method of high-concentration polyepoxysuccinic acid and salt thereof. The method comprises the following main processes: simultaneously adding maleic anhydride and sodium hydrate into water in a mode of feeding in batches; controlling the pH value of solution at 5-7 and the reaction temperature at 40-60 DEG C; adding sodium tngstate into a hydrolysis product as expoxidation catalyst at 50-60 DEG C; carrying out expoxidation reaction by adding hydrogen peroxide; adding sodium hydrate solution at the same time; controlling the pH value at 4-7; finishing the expoxidation reaction; stirring; raising the temperature to above 80 DEG C; adding initiator calcium oxide; and after polymerization, lowering the temperature and filtering to obtain the polyepoxysuccinic acid and salt solution thereof. In the preparation method, a one-pot synthesis is adopted, and therefore, the preparation method has the advantages of simple and unique technology, high product concentration, high raw material conversion rate, ideal molecular weight distribution and favorable industrial operability.

Owner:INNER MONGOLIA TIANCHEN SCI & TECH

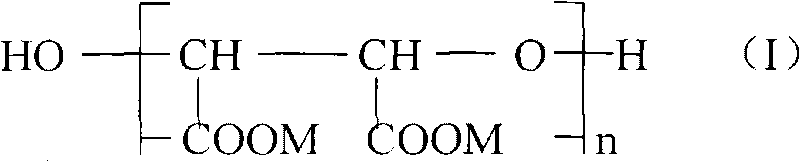

Preparation process of nickel-based supported catalyst and prepared catalyst

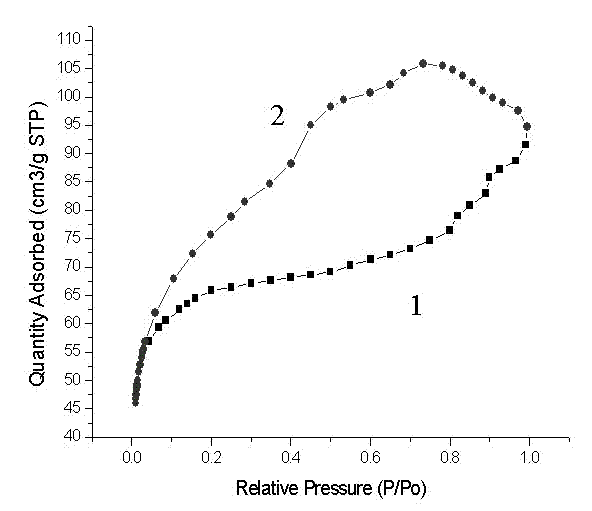

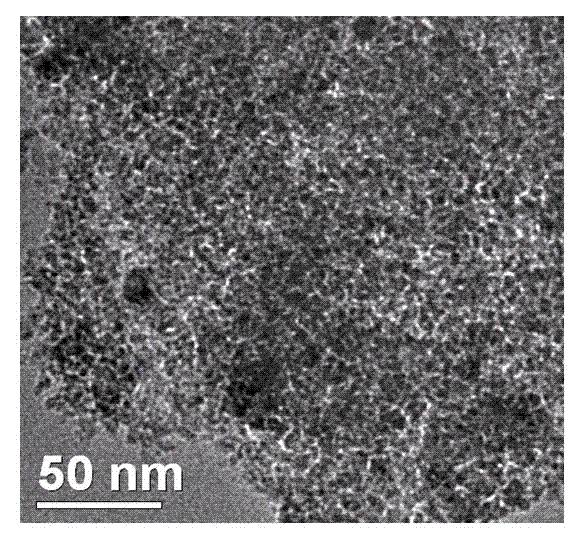

ActiveCN102527390AEnhance heat and mass transferPorous structure features are obviousCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOXALIC ACID DIHYDRATEPolyethylene glycol

The invention discloses a preparation process of a nickel-based supported catalyst in which one or more of silicon dioxide, titanium dioxide, alumina, zirconium dioxide and rare earth oxide are taken as carriers. The preparation process comprises the following steps of: preparing a precursor with a sol-gel method; drying the precursor; smashing the precursor into powder of 200-400 meshes; adding a bonding agent and a pore structure adjusting agent, and kneading; performing extrusion molding; baking; and pre-reducing, wherein the bonding agent is preferably commercial SB (Styrene-Butadiene) powder; and the adding amount of the bonding agent is 3-25 percent, preferably 8-15 percent of the total weight of a precursor oxide; the pore structure adjusting agent is preferably a mixture of polyethylene glycol and oxalic acid or citric acid in the molar ratio of 1:(0.8-0.1); and the adding amount of the pore structure adjusting agent is 0.1-25 percent, preferably 0.5-15 percent of the total weight of the precursor oxide. The invention further provides a nickel-based supported catalyst which is prepared with the process and has high mechanical strength and high catalytic performance. Due to the adoption of a solidification technology, the bottle neck problems of easiness in agglomerating, easiness in collapse of a pore structure, strip explosion, strip breakage and the like existing in precursor superfine powder prepared with a sol-gel method are solved.

Owner:CHINA PETROLEUM & CHEM CORP

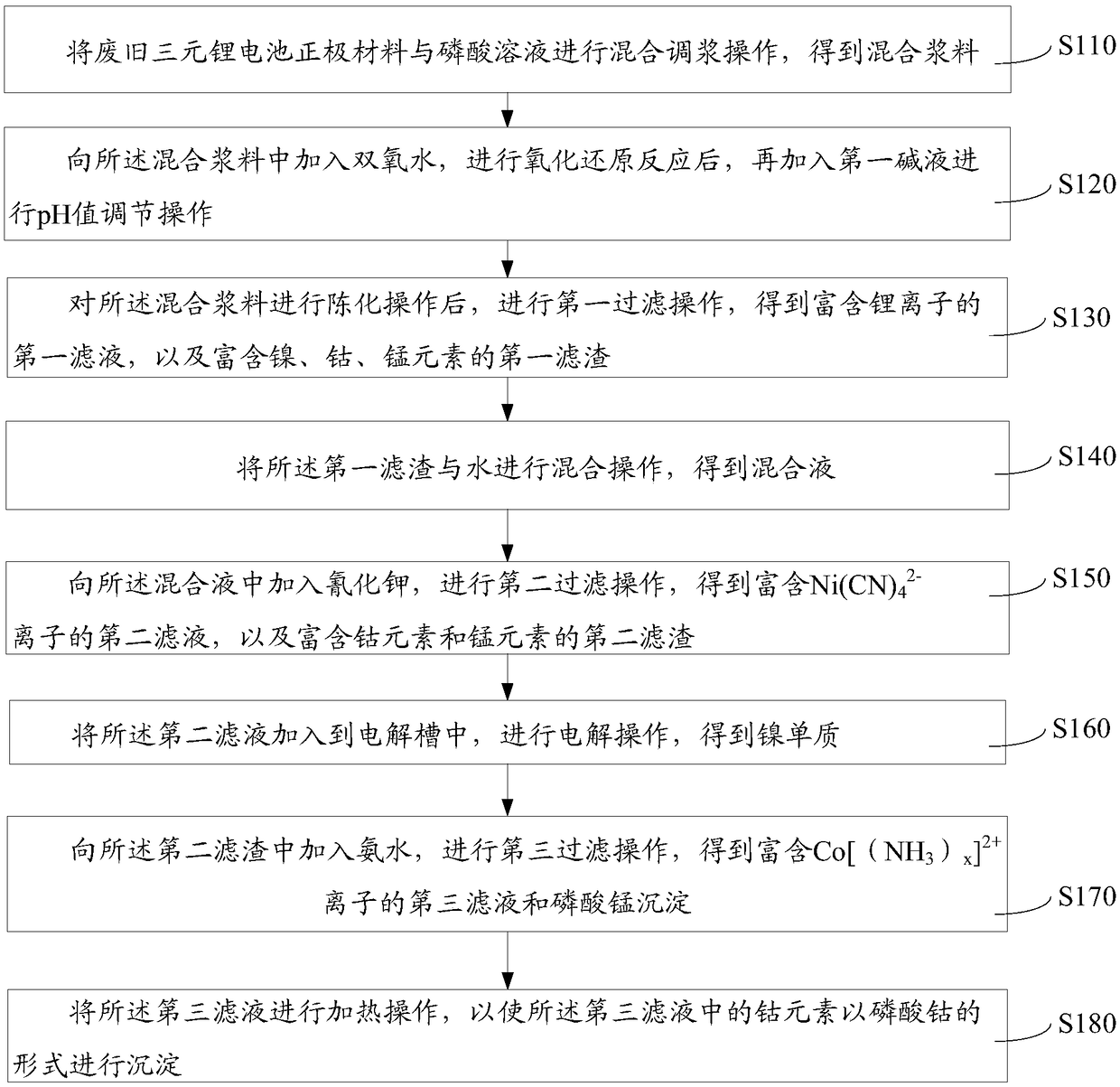

Selective extraction recycling method of waste ternary lithium battery

ActiveCN109473691AAchieve sustainable useReasonable and simple process designPhotography auxillary processesReclaiming serviceable partsRecovery methodElectrolysis

Disclosed is a selective extraction recycling method of a waste ternary lithium battery. The method includes the following steps: a waste ternary lithium battery anode material and a phosphoric acid solution are mixed to prepare a pulp, then hydrogen peroxide is added to carry out an oxidation-reduction reaction and regulate the pH value, a first filtrate rich in lithium ions is obtained after aging and filtering, water is added to dissolve a first filter residue, and then potassium cyanide is added to obtained a second filtrate rich in Ni(CN)4<2-> ions, the second filtrate is then subjected to electrolysis to obtain elemental nickel, ammonium hydroxide is added to a second filter residue subsequently, and a third filtrate rich in Co[(NH3)x]<2+> ions and manganese phosphate precipitation are obtained after filtering, and finally, a third filtrate is heated to obtain cobaltous phosphate. In this way, the selective extraction recycling method of a waste ternary lithium battery, which isprovided by the invention has better industrial operability through the design of a simpler and more rational overall process. In the meanwhile, a ternary element and elemental lithium that can be directly used in industry can be obtained pertinently.

Owner:EVE ENERGY CO LTD

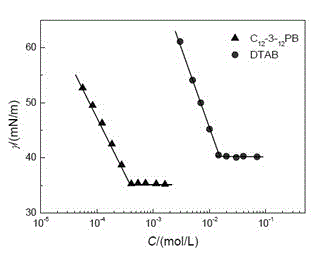

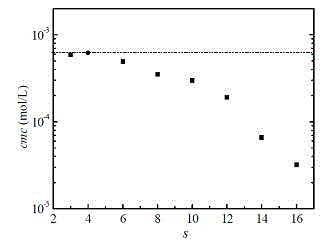

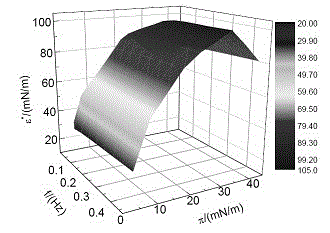

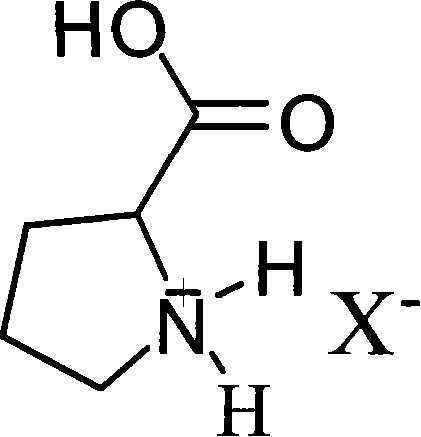

Gemini surface active agent using pyrrole ring as hydrophilic head group and preparation method of Gemini surface active agent using pyrrole ring as hydrophilic head group

InactiveCN102941035ASimple preparation processMild reaction conditionsOrganic chemistryTransportation and packagingChemical industryParaffin oils

The invention discloses a cation Gemini surface active agent using a pyrrole ring as a hydrophilic head group, and relates to a preparation method of the surface active agent. The preparation method comprises the specific steps of generating N-alkyl pyrrolidine by pyrrolidine and long-chain alkyl under the actions of N2 (nitrogen) protection and catalyst function, and carrying out reaction of the obtained N-alkyl pyrrolidine and dibromo-paraffin so as to obtain the cation Gemini surface active agent using the pyrrole ring as the hydrophilic head group. The Gemini surface active agent has good surface activity and viscoelasticity, the Gemini surface active agent can be singly used or compounded with other surface active agents due to the good property, and further the Gemini surface active agent is widely applied to the industrial practices, such as daily-use chemical industry, sterilizers, pesticide agents, petroleum production, and thick oil viscosity reduction.

Owner:WUHAN UNIV

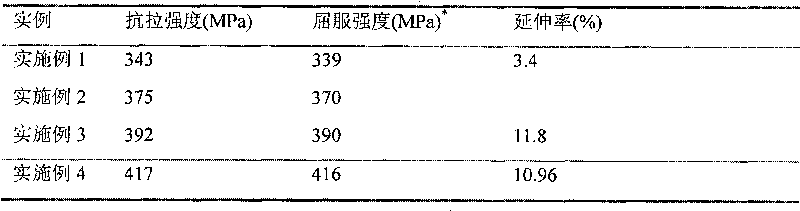

Thermal treatment method for lead-free aluminum alloy

The invention provides a thermal treatment method for lead-free aluminum alloy, and relates to a thermal treatment method for wrought aluminum alloy which contains Sn, Bi and does not contain Pb. The lead-free aluminum alloy uses bismuth, tin, copper, silicon and chromium as alloy elements, and uses aluminum as substrate. The method is characterized by comprising the following steps: (1) carrying out solution heat treatment on an alloy ingot in a thermal treatment furnace at a temperature of 535+ / -2 DEG C for 60 minutes; (2) carrying out water quenching on the alloy ingot which is subjected to the solution heat treatment at room temperature; (3) carrying out aging treatment on the alloy ingot which is subjected to water quenching at the temperature of 165+ / -2 DEG C for 10 hours; and (4) air cooling the alloy to room temperature after the reactant is discharged and cooled, and carrying out cold machining (cold-drawing) with cold machining deflection of between 0 an 4 percent. The method can greatly improve the mechanical performance of the wrought alloy, and further improve the alloy strength through cold machining.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

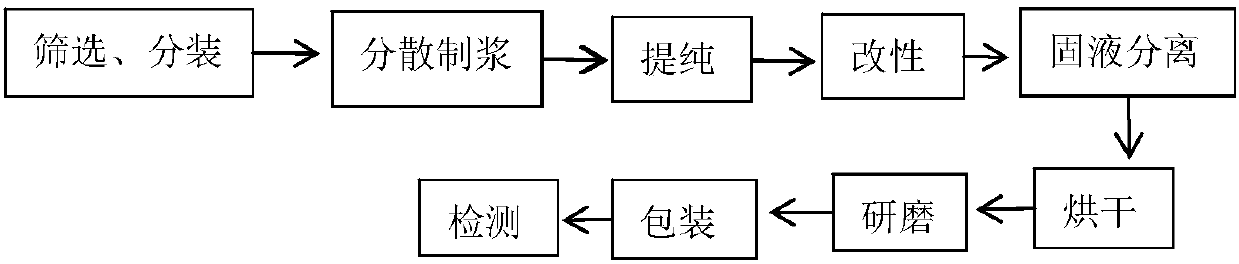

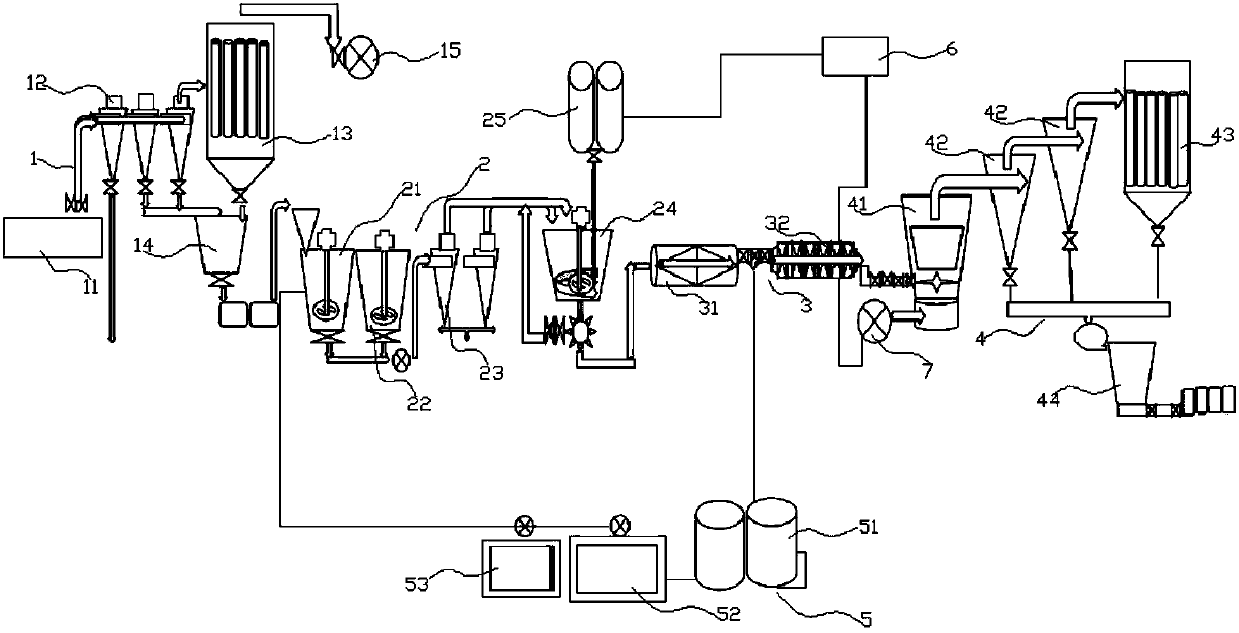

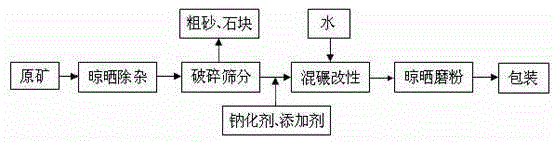

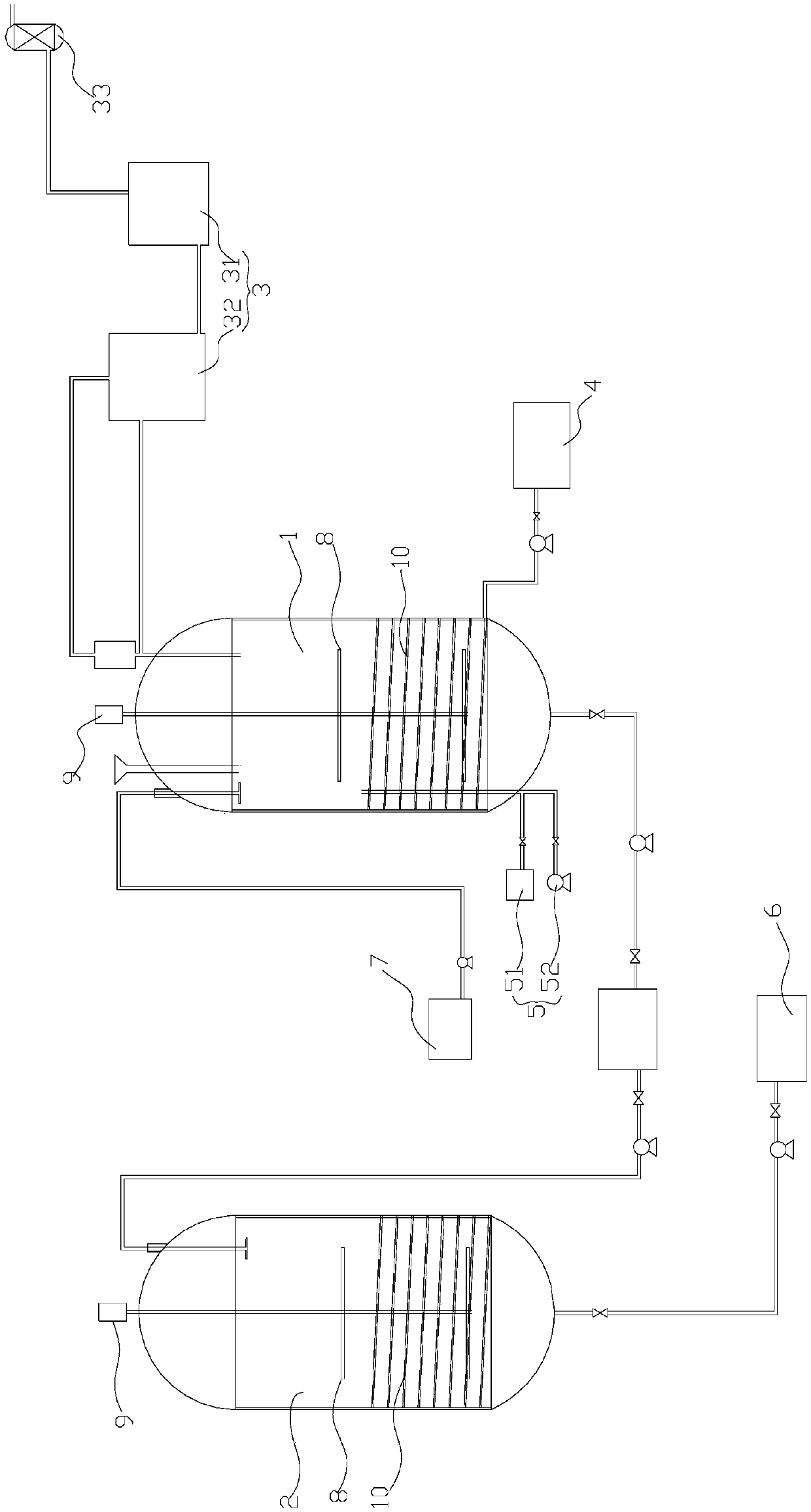

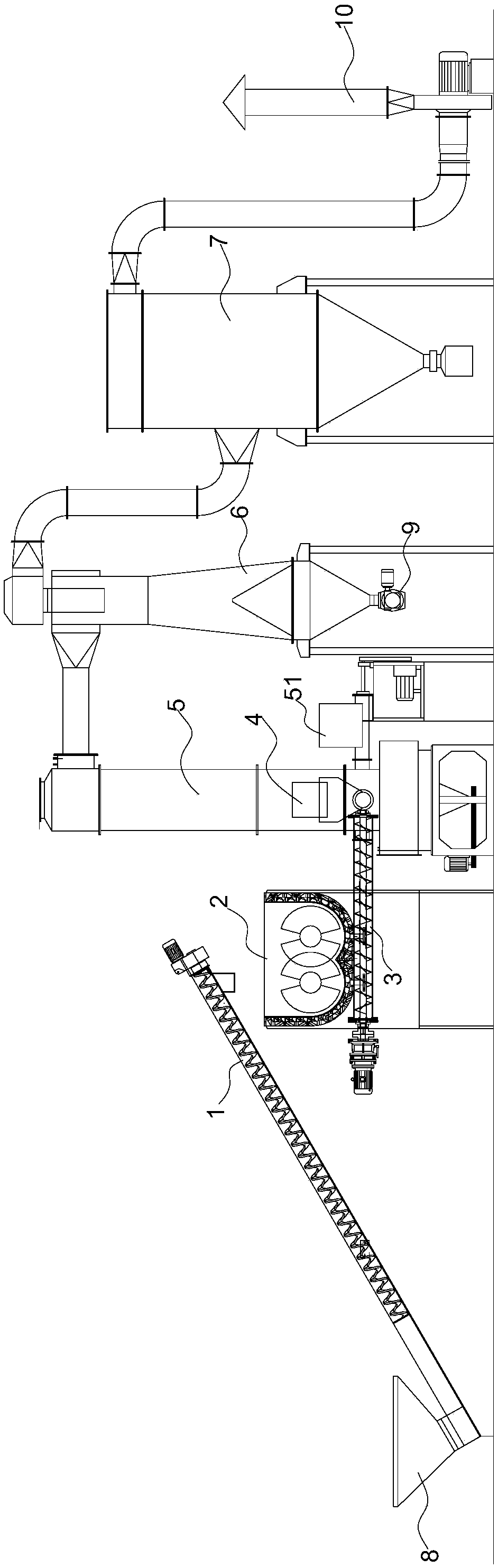

Production method of modified montmorillonite powder and system thereof

The invention discloses a production method of modified montmorillonite powder and a system thereof, and belongs to the technical field of modified montmorillonite powder. The production method disclosed by the invention sequentially comprises the steps of dispersion slurrying, sodium modification, standing for settlement, centrifuging, shear stirring, modification, solid-liquid separation, drying, grinding and packaging and the like; the modified montmorillonite powder with uniform form and stable performance is prepared; the technology is simple, and the energy consumption is reduced. The production system disclosed by the invention comprises a natural soil treatment device, a purifying and modifying device, a separating and drying device, a grinding and packaging device and a wastewatertreatment device, wherein the natural soil treatment device, the purifying and modifying device, the separating and drying device and the grinding and packaging device are communicated in turn; the wastewater treatment device is communicated with the separating and drying device and the purifying and modifying device through a pipeline respectively, so as to form a wastewater circulating loop. The production system has the advantages of compact and reasonable structure, strong industrial operability and good using effect.

Owner:联技精细材料(珠海)有限公司

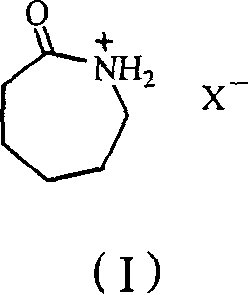

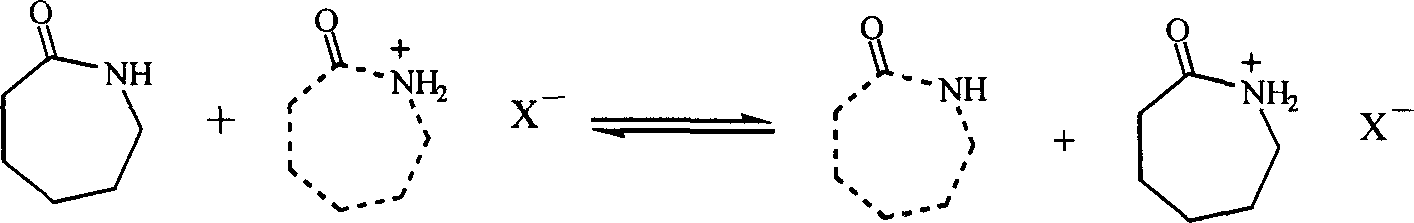

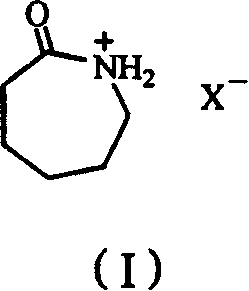

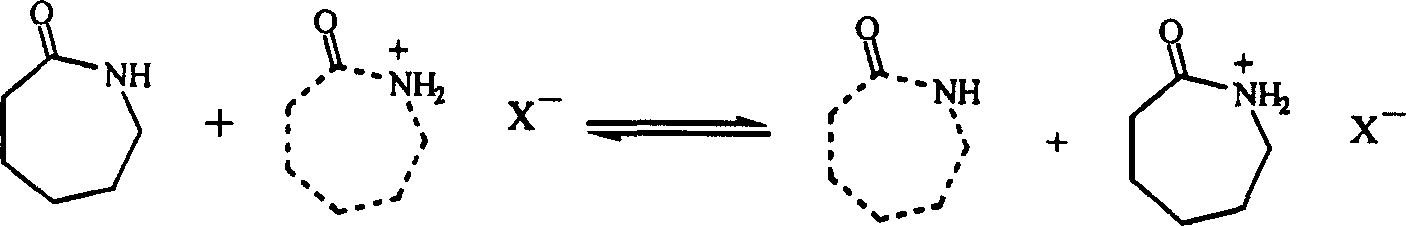

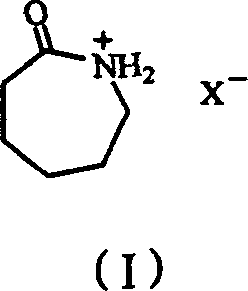

Process for preparing epsilon-hexanolactam by catalyzing cyclohexanone-oxime rearranging

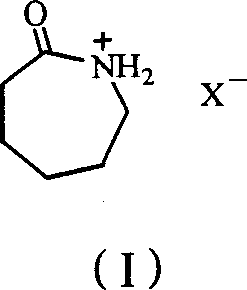

InactiveCN1781908ASimple reaction systemEasy to separateOrganic chemistryBeckmann rearrangementProtonation

The present invention relates to catalytic Beckmann rearrangement process of cyclohexanone-oxime by using the Bronsted acid ion liquid with N-protonated hexanolactam as cationic group serving as the catalyst and reaction medium to prepare epsilon-hexanolactam. The present invention produces epsilon-hexanolactam in mild reaction temperature, short reaction period, high conversion rate and high selectivity, and the acid ion liquid may be reused. The product is no longer combined with the acid ion liquid and needs no alkali neutralization, and the reaction system is simple, without environmental pollution, no corrosion on the apparatus, low cost of the acid ion liquid, and excellent industrial application foreground.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

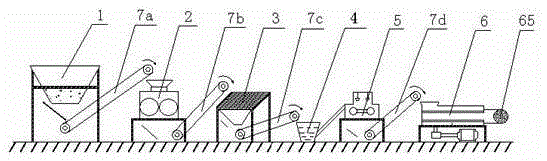

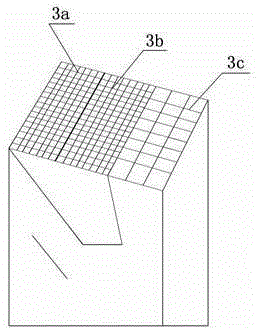

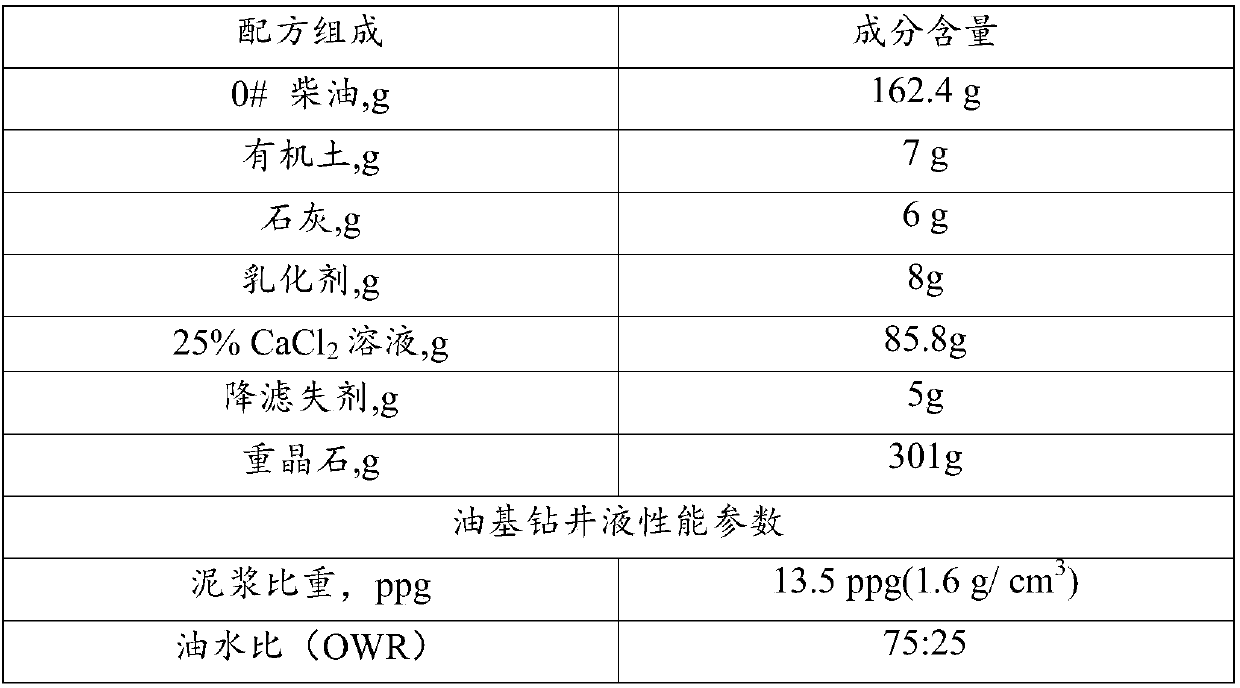

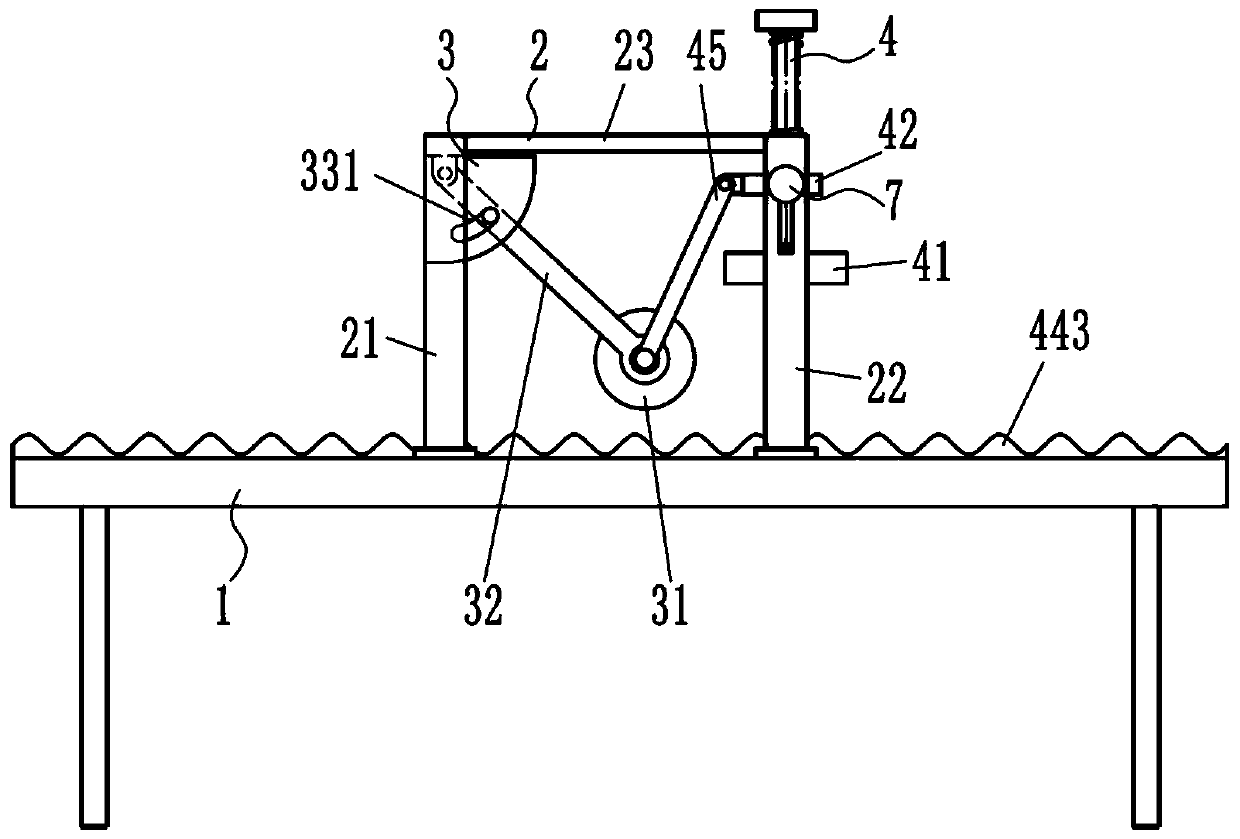

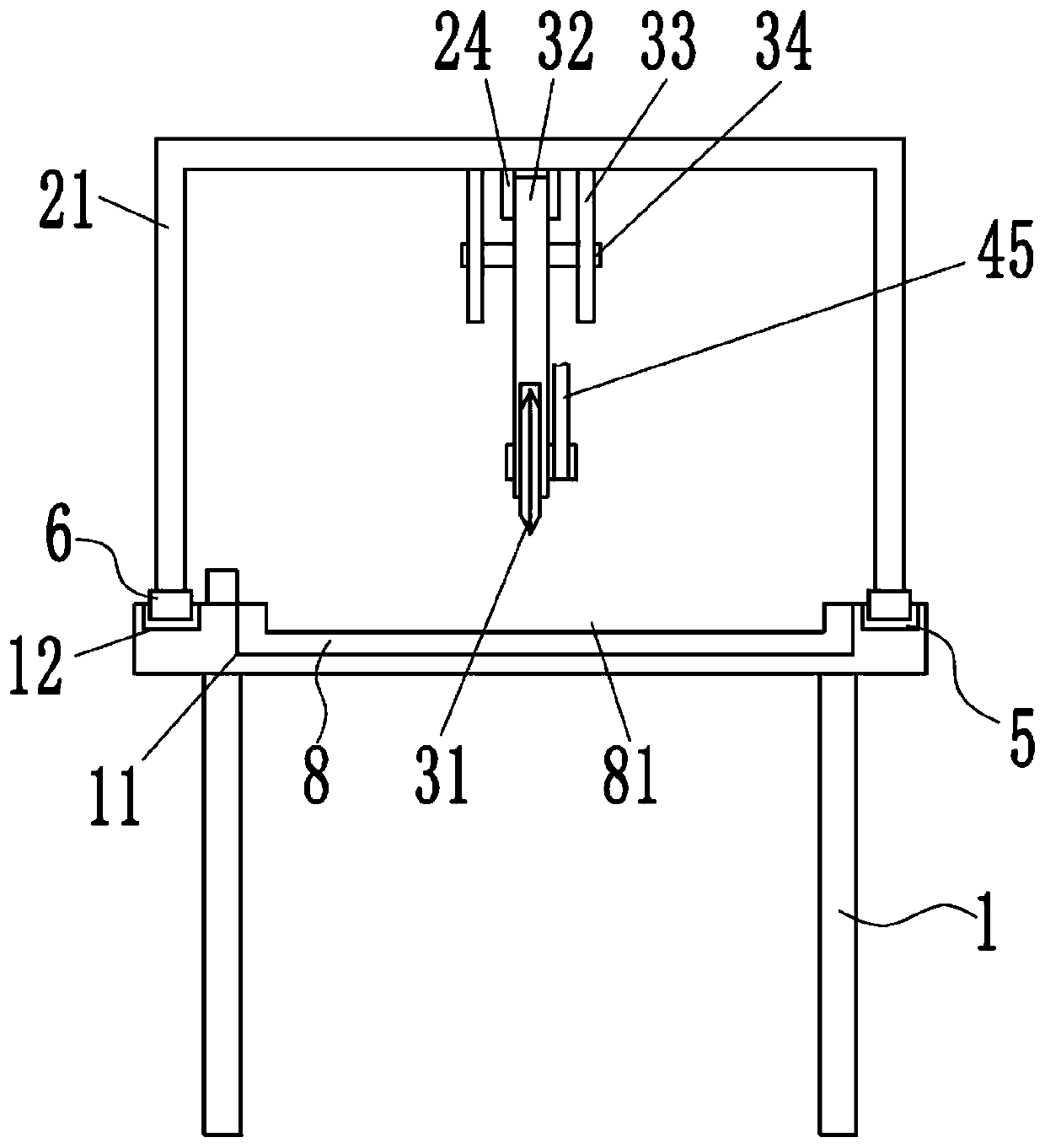

Preparation method of bentonite for drilling mud and device thereof

ActiveCN105366686AReduce usageGood modification effectDrilling compositionSilicon compoundsWell drillingVariable pitch propeller

The invention discloses a preparation method of bentonite for drilling mud and a device thereof. The preparation method comprises the following steps: crushing calcium bentonite raw ore and screening, conveying the crushed and screened calcium bentonite raw ore into a kolleroang to be fully mixed and ground together with a sodium modification agent, an auxiliary additive and water, carrying out extrusion modification by conveying the above mixture into a trans-variable-pitch screw extruder, extruding by masking to obtain a semi-finished product, airing, milling and packaging to obtain a bentonite finished product for drilling mud. According to the invention, trona is used as the sodium modifier, and the trans-variable-pitch screw extruder is adopted for modification. The materials are spirally pushed forward by two variable-pitch propellers, and extrusion force is gradually enhanced. Production problems such as material stacking and insufficient extrusion force are effectively solved. The modification effect is good, and product quality is stable. In addition, preparation cost is greatly reduced, and production cost can be saved by 60,000-70,000 yuan for each ton of the product.

Owner:中国非金属矿工业有限公司

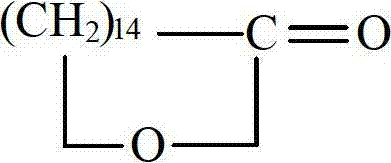

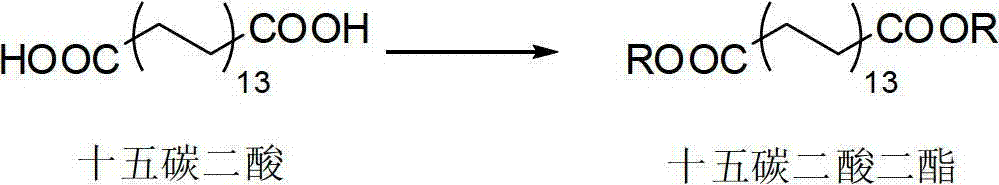

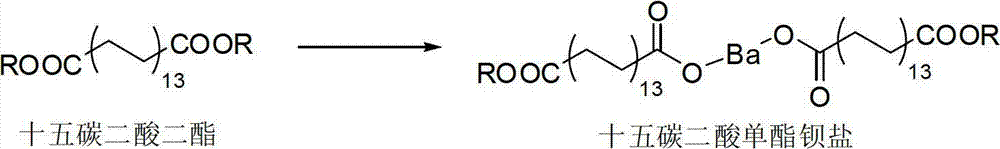

Synthesis method for pentadecanoicacid

The invention discloses a synthesis method for pentadecanoicacid. The pentadecanedioate is mixed with an organic dissolvent, and dimethylpentadecanedioate is obtained via reaction of adding a catalyst NaHSO4 and cyclohexane in a stirring condition; hydroxide is dissolved in the organic dissolvent and is dropped into the dimethylpentadecanedioate, and pentadecanedioate monoethanolamine is obtained after reaction; acid solution is used for treating the pentadecanedioate monoethanolamine to obtain pentadecanedioate monoester; the pentadecanedioate monoester is dissolved in the organic solution, adding sodium borohydride in batches to distill the organic dissolvent, and then acetic ether is utilized to extract 15-oxhydryl pentadecanoic acid; the mixture is dissolved in mixing solution of hydrobromic acid and glacial acetic acid to obtain 15-bromine pentadecanoic acid; the mixture is dissolved in organic dissolvent, carbonate and iodine are added, and the organic dissolvent is distilled to obtain a crude product of pentadecanoicacid; and the crude product of pentadecanoicacid is subjected to distillation at a reduced pressure, and fraction of 130-140 DEG C / 2mmHg is collected to obtain a product of pentadecanoicacid. The preparation method has simple process, low energy consumption, low cost, little pollution and easiness in realization of industrialization.

Owner:FUJIAN TIANFU BIOTECH DEV CO LTD

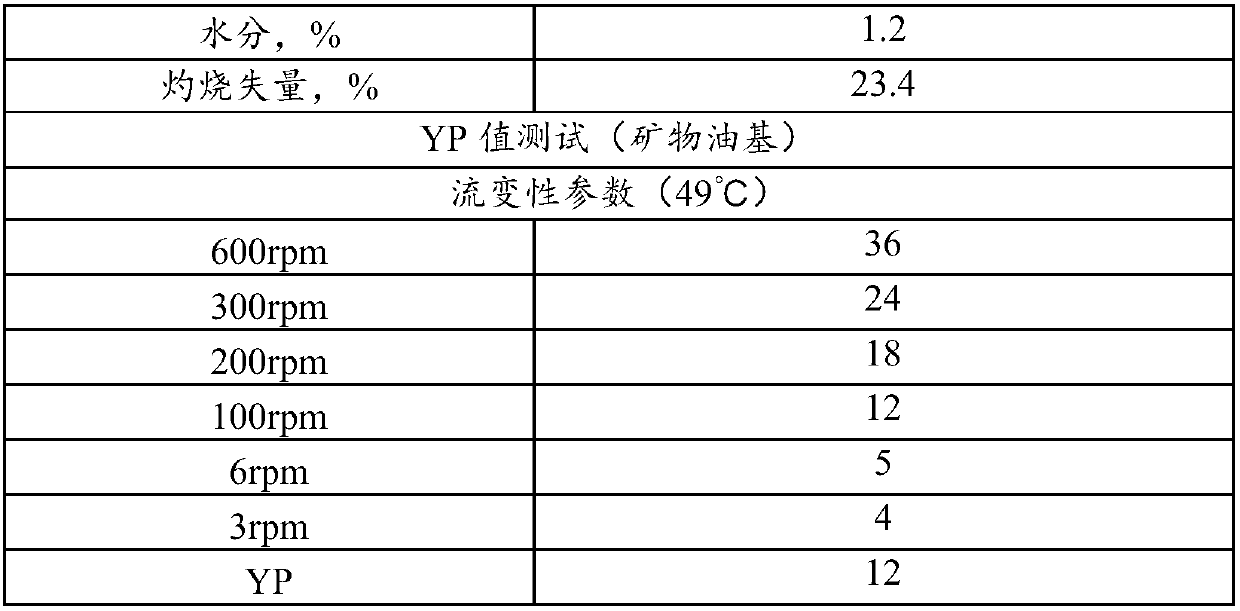

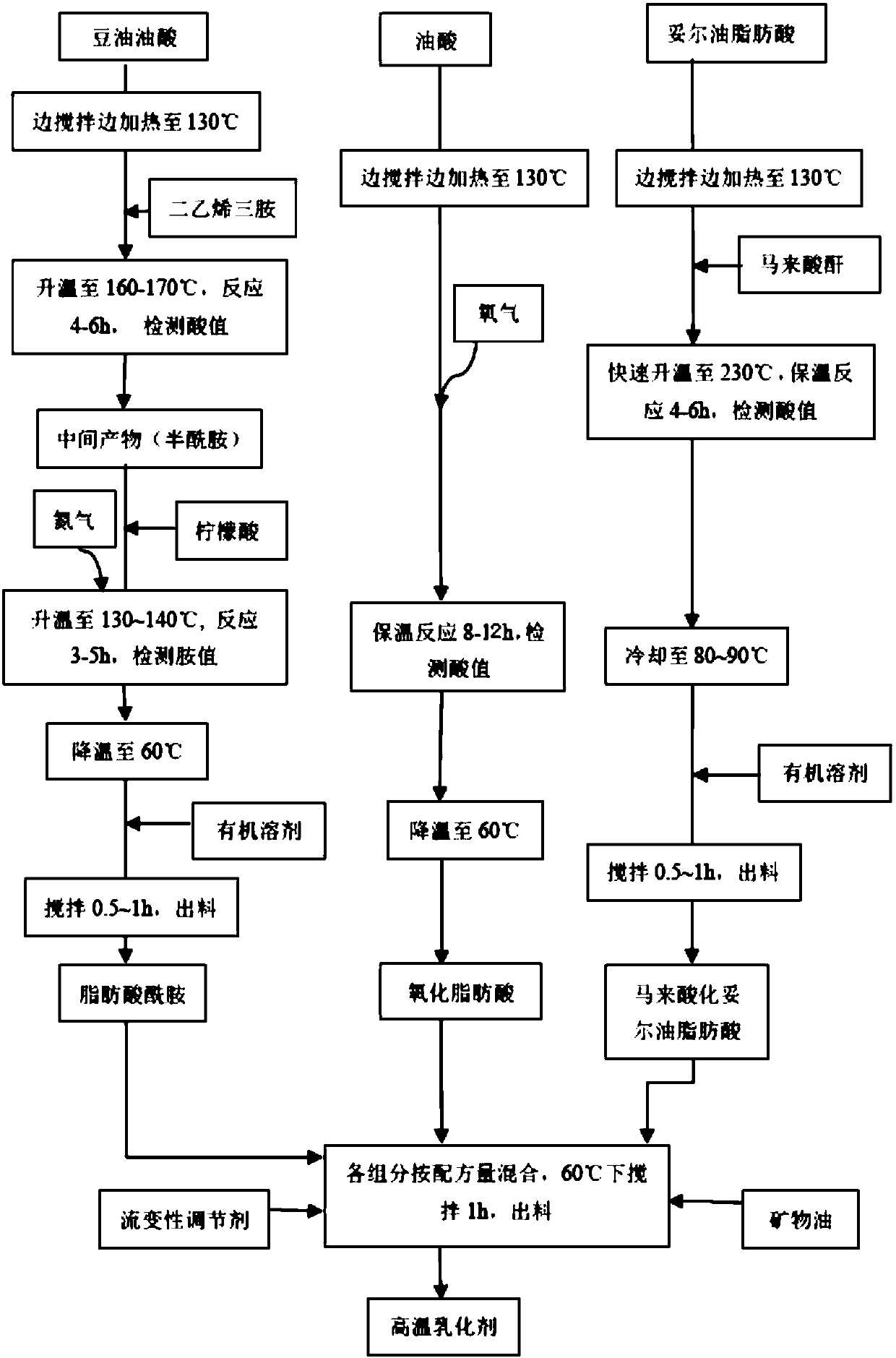

High-temperature emulsifier applied to oil-based drilling fluids and preparation method of high-temperature emulsifier

PendingCN107828391AReduce the number of additionsReduce the amount addedDrilling compositionPetroleum oilMineral oil

The invention discloses a high-temperature emulsifier applied to oil-based drilling fluids and a preparation method of the high-temperature emulsifier, and belongs to the technical field of petroleumdrilling fluids. The high-temperature emulsifier comprises, by mass, 10-45% of fatty acid amide, 30-60% of oxidized fatty acid, 10-30% of Malay acidized tall oil fatty acid, 5-20% of rheological property regulators and 10-30% of mineral oil. The total percentage of the raw materials is 100%. The preparation method includes mixing the fatty acid amide with the oxidized fatty acid, the Malay acidized tall oil fatty acid, the rheological property regulators and the mineral oil, stirring the raw materials at the temperature of 60 DEG C for 1-2 hours of reaction, and discharging the mixture to obtain the high-temperature emulsifier. The high-temperature emulsifier has the advantages of high temperature resistance, high demulsification voltage, low filter loss, capability of stabilizing a drilling fluid system, low adding amount, convenience and effectiveness in use, convenience in popularization and application, and the like. The preparation method has the advantages of simple procedure andstep, convenience in production and greatly reduced production cost.

Owner:联技精细材料(珠海)有限公司

Method for preparing polyvinyl chloride resin

The invention discloses a method for preparing polyvinyl chloride resin. The method is characterized by comprising the following steps: adding water, a vinyl chloride monomer, a composite dispersion system, a porosity adjusting agent, a chain transferring agent, a pH value buffer agent and an initiator into a polymerization kettle, performing a polymerization reaction kettle in the polymerization reaction kettle with a stirring device at the pressure of 1.00-1.20MPa, adding a reaction terminator, discharging out a residual vinyl chloride monomer, and collecting a target product from a reaction product, wherein the composite dispersion system is a mixture of polyvinyl alcohol and hydroxypropyl methyl cellulose which are subjected to partial alcoholysis. The polyvinyl chloride resin prepared by using the method disclosed by the invention is high in porosity, slight in fisheye, low in surface cover rate, tidy in granule morphology, concentrated in resin particle size distribution and easy in residual monomer desorption.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

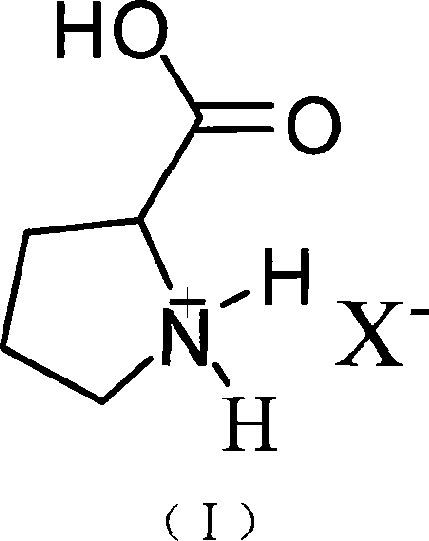

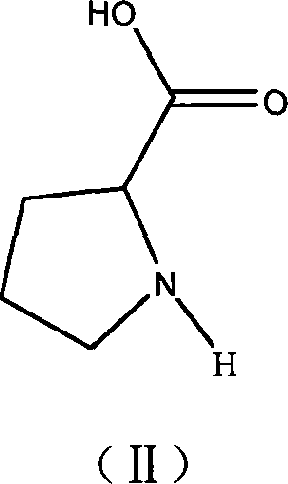

Bronsted acidic compound of containing L- proline radical, preparation method, and application

InactiveCN101050196AStrong acidLow raw material costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAcid catalyzedIonic liquid

This invention relates to a method for preparing L-proline-containing Bronsted acidic compound and its application. The L-proline-containing Bronsted acidic compound is prepared from L-proline and Bronsted acid by one-step neutralization in a mild condition. The L-proline-containing Bronsted acidic compound has strong acidity and high stability to water and air, thus can be used as ionic liquid, and can replace inorganic acid as both catalyst and reaction medium in acid catalytic reaction. The method has such advantages as simple reaction system, no pollution, saved resources, and is suitable for industrialization.

Owner:WUHAN UNIV

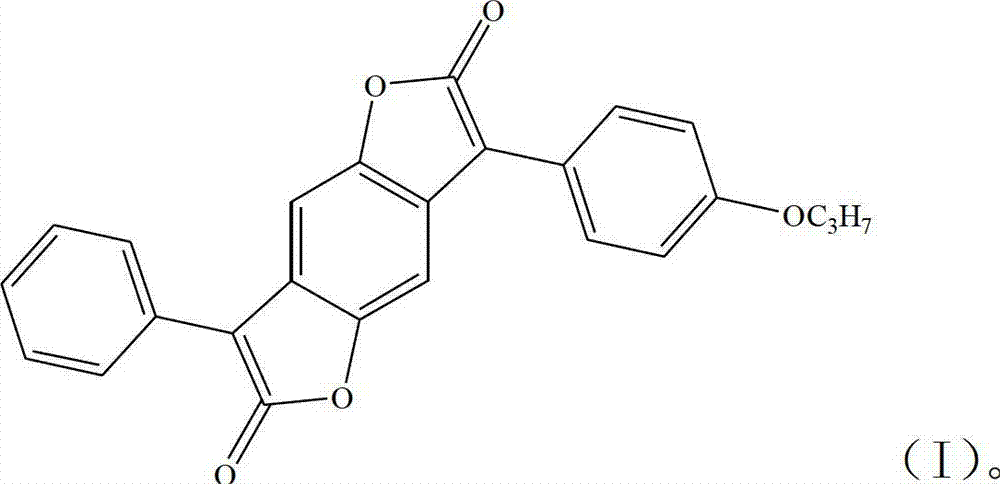

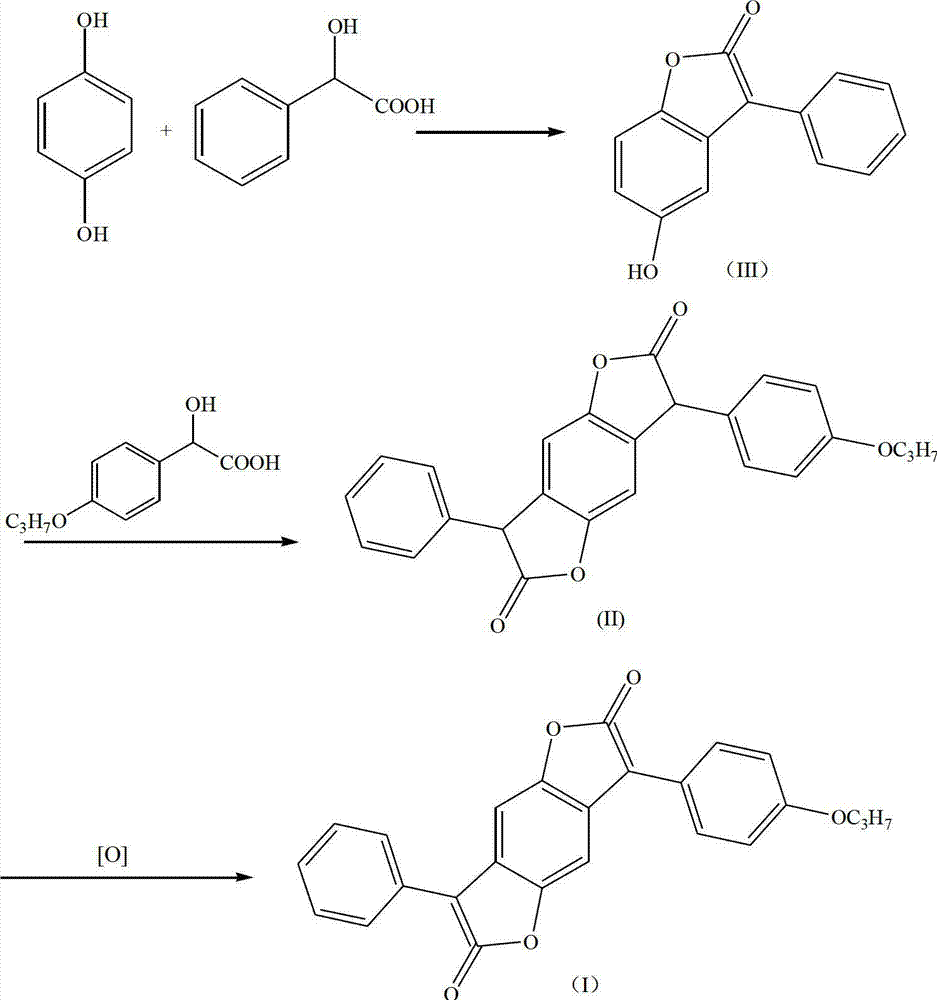

Preparation method for disperse red

InactiveCN102924961AEasy to makeStrong industrial operabilityAzo dyesPhosphoric acidHydroquinone Compound

The invention discloses a preparation method for disperse red, which comprises the following steps: hydroquinone is reacted with mandelic acid to obtain an intermediate compound (III); the compound (III) is further reacted with propoxy mandelic acid in presence of phosphoric acid to obtain an intermediate compound (II); and the intermediate compound (II) is oxidized by chloranil to obtain the target product. The process route disclosed by the invention is simple in preparation and strong in industrial operability; the yield of the compound (III) preparation step is over 91%; the yield of the compound (II) preparation step is over 71%; the yield in the preparation process of the target product compound (I) is over 98%; and the final product purity is high and is above 99.8%.

Owner:江苏德旺数码科技有限公司

Process for synthesizing high molecular weight polypeptide polymer

InactiveCN1793166AStrong acidNo adverse effectsPeptide preparation methodsOrganic solventHigh molecular mass

The invention relates to a compounding method for high molecular weight polypeptide polymer that uses aspartic acid or aspartic acid and glutamic acid as raw material. After grinding, taking condensation reaction in the reactor, high molecular weight polypeptide that the average molecular weight would be 1000-200000 would be gained. The invention has advanced technology, no harmful to the environment, wide application range, improves the yield of the agricultural product.

Owner:BOTAO BIO CHEM SCI & TETH JIUJIANG PETROCHEM +1

Process for preparing epsilon-hexanolactam by catalyzing cyclohexanone-oxime rearranging

InactiveCN1305855CSimple reaction systemEasy to separateOrganic chemistryBeckmann rearrangementProtonation

The present invention relates to catalytic Beckmann rearrangement process of cyclohexanone-oxime by using the Bronsted acid ion liquid with N-protonated hexanolactam as cationic group serving as the catalyst and reaction medium to prepare epsilon-hexanolactam. The present invention produces epsilon-hexanolactam in mild reaction temperature, short reaction period, high conversion rate and high selectivity, and the acid ion liquid may be reused. The product is no longer combined with the acid ion liquid and needs no alkali neutralization, and the reaction system is simple, without environmental pollution, no corrosion on the apparatus, low cost of the acid ion liquid, and excellent industrial application foreground.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

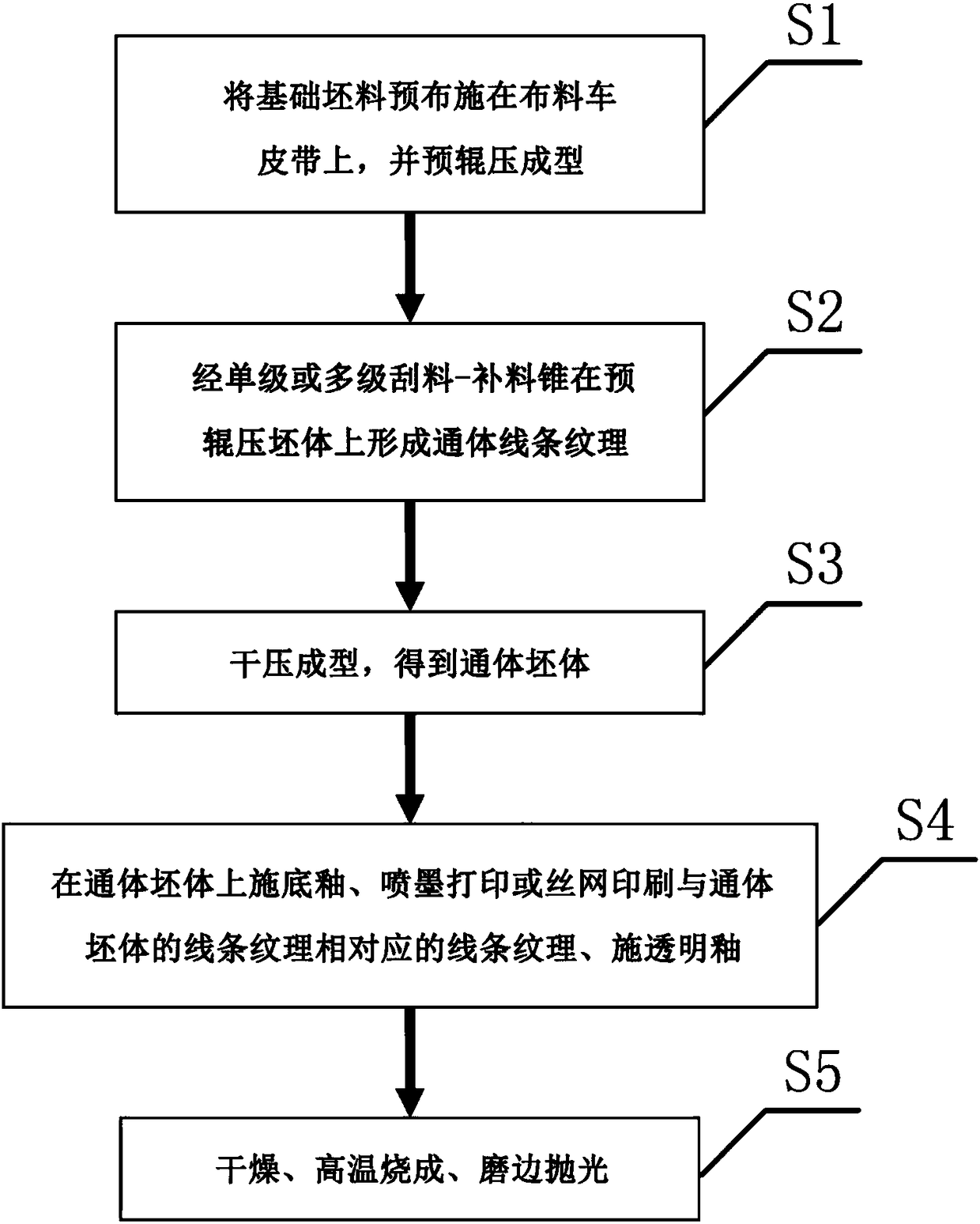

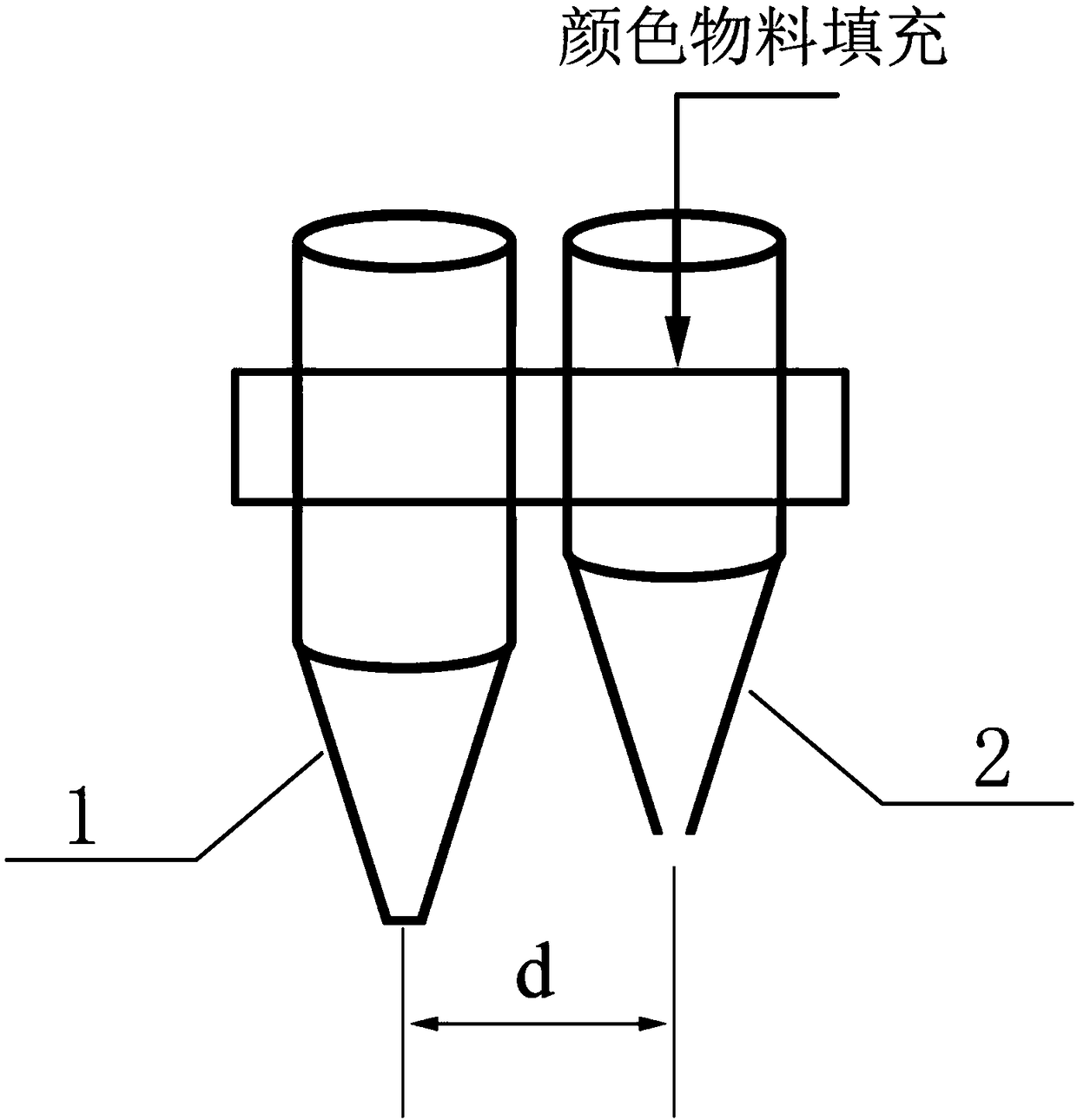

Full-body porcelain tile and preparing method thereof

InactiveCN108503346AImprove wear resistanceReal whole body effectShaping conveyorsScreen printingBrick

The invention discloses a full-body porcelain tile and a preparing method thereof. The preparing method includes the steps of evenly spreading a porcelain blank base material on a material spreading car belt, forming linear filling pits in a blank body according to the unclosed linear route through a material scrapping cone after pre-rolling forming, and instantaneously supplementing color-matchedporcelain powder through a material supplementing cone connected with the material scrapping cone. After a material scrapping and supplementing line is formed, the porcelain blank body with a coloredline texture on the full body is formed through dry-pressing forming. Ground glaze pouring, ink-jet printing or silk-screen printing for forming the line texture corresponding to the colored line texture on the full body and transparent glaze pouring are conducted on the porcelain blank body. The porcelain blank body is put in a kiln for high-temperature firing and edge grinding and polishing after being dried, so the porcelain tile with the full-body effect is obtained. The distribution of the textile lines of the surface of the prepared full-body porcelain tile is consistent with the distribution of the textile lines in the blank body, and the full-body porcelain tile has the real full-body effect and is good in pattern wear resistance, simple in process and low in cost.

Owner:佛山市高明贝斯特陶瓷有限公司 +3

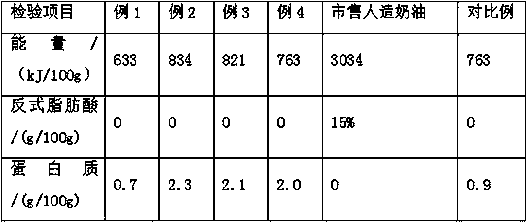

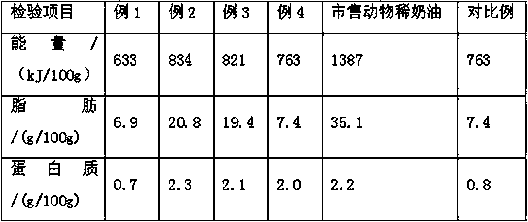

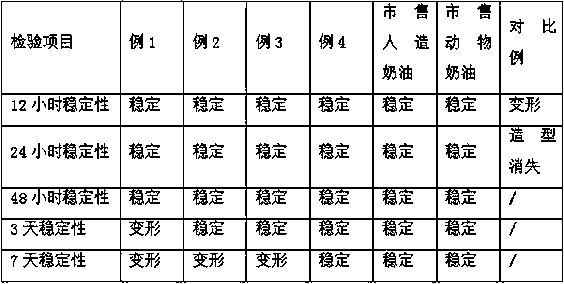

Coconut cream and preparation method thereof

InactiveCN108450563ASolve the real problemCreamy tasteEdible oils/fats ingredientsEdible oils/fats production/working-upHigh concentrationSucrose

The invention relates to coconut cream and a preparation method thereof, and belongs to the technical field of preparation of cream. The coconut cream comprises coconut syrup, water, modified starch and a polysaccharide macromolecular compound, wherein one or both of the modified starch and the polysaccharide macromolecular compound exist; the modified starch is one or several in any proportion ofhydroxypropyl distarch phosphate, acetylated distarch phosphate and crossbonded starch; and the polysaccharide macromolecular compound is one or several in any proportion of a mixture of agar polysaccharide and agar pectin, and a mixture of carrageenin, xanthan gum and guar gum. The coconut cream can be prepared by a simple method, and is particularly suitable for preparation in families. Finished products cannot bring high heat as animal cream, cannot contain high-concentration trans-fatty acids as plant cream, are free from cane sugar, soft and sweet in mouth feel, and far higher in stability than common coconut cream made in families.

Owner:成都甜椰食品有限公司

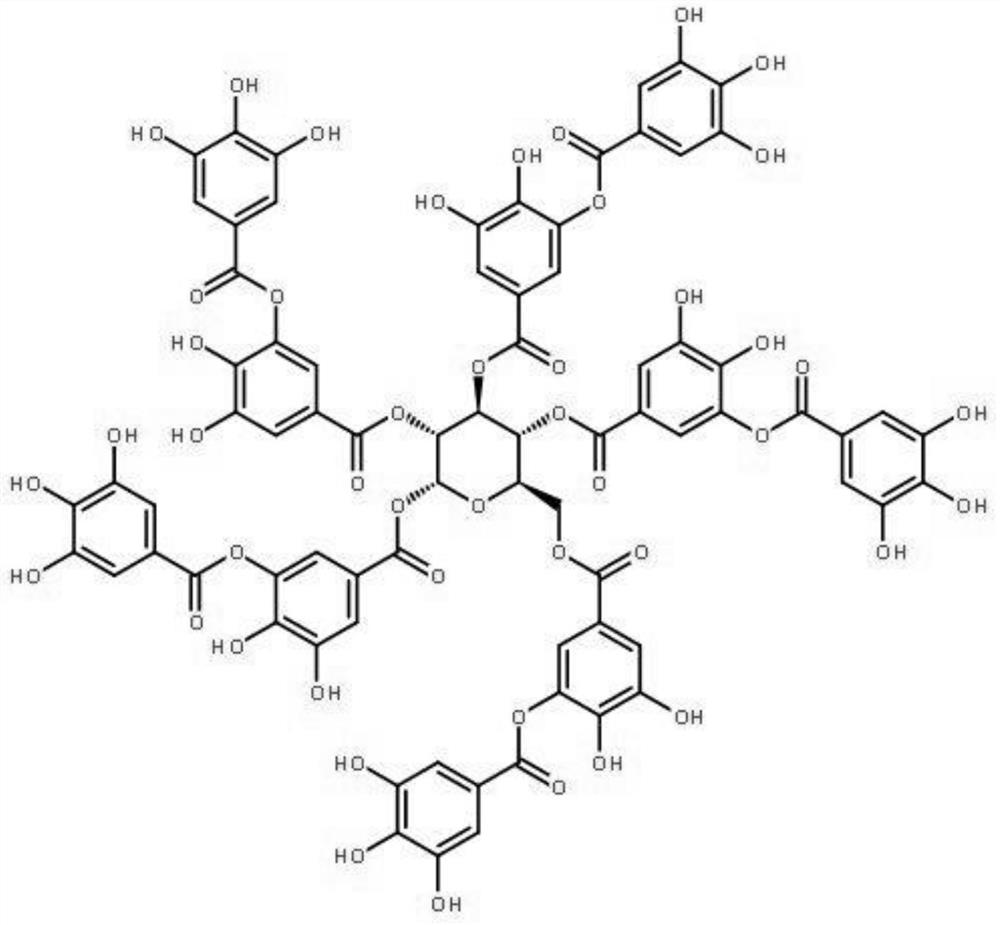

Anti-pollution composite reverse osmosis membrane and preparation method thereof

ActiveCN112870989ASimple processStrong industrial operabilitySemi-permeable membranesGeneral water supply conservationPolyvinyl alcoholReverse osmosis

The invention provides an anti-pollution composite reverse osmosis membrane and a preparation method thereof. The composite reverse osmosis membrane comprises a polyamide reverse osmosis membrane and an antifouling layer located on the surface of the polyamide reverse osmosis membrane, and the antifouling layer comprises tannic acid and polyvinyl alcohol. The method comprises the step of making the polyamide reverse osmosis membrane contact with a coating solution, wherein the coating solution is an aqueous solution containing tannic acid and polyvinyl alcohol. The surface of the polyamide reverse osmosis membrane is coated with the coating solution through a one-step method, the process is simple, and the industrialization operability is high. The anti-pollution composite reverse osmosis membrane disclosed by the invention is high in flux, good in selectivity, strong in anti-pollution property and long in service life, has a hydrophilic smooth surface in appearance, and is beneficial to later-stage assembly rolling of the membrane.

Owner:中化(宁波)润沃膜科技有限公司

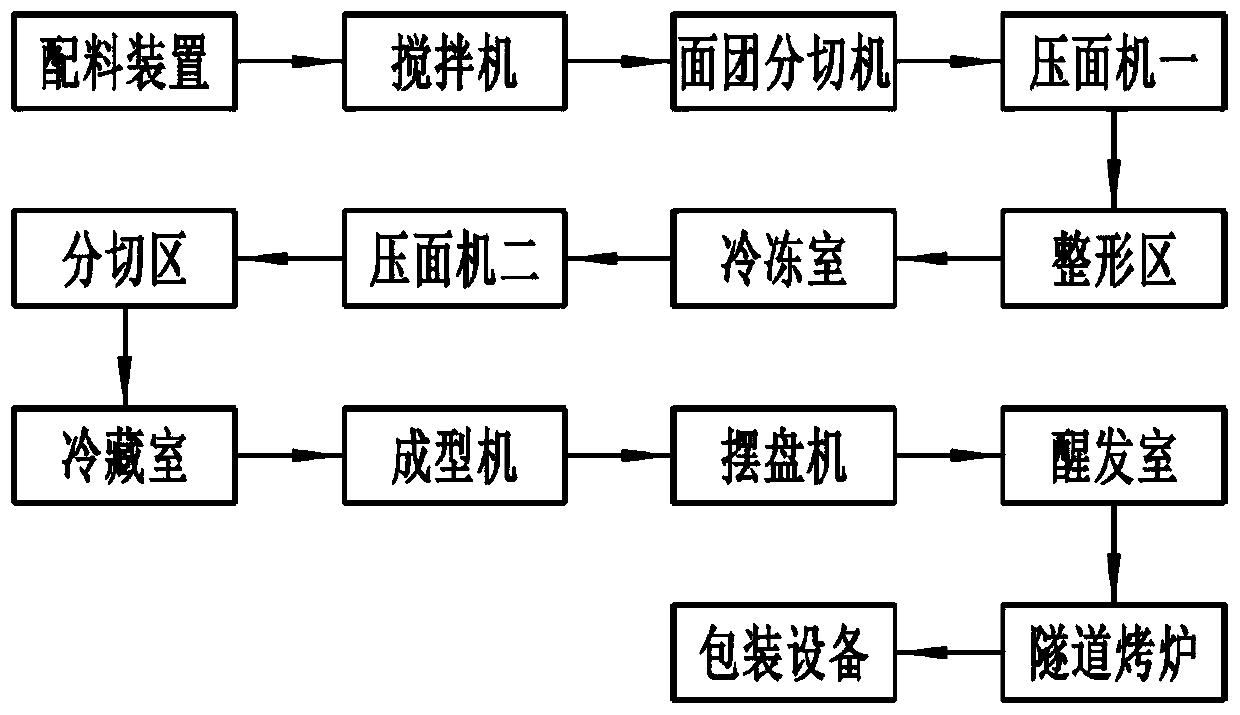

Pull-apart bread as well as production process and production line of pull-apart bread

ActiveCN111084213ALower water activityGreat commercial promotion advantagesDough treatmentPre-baking dough treatmentProcess engineeringFermentation

The invention discloses pull-apart bread as well as a production process and a production line of the pull-apart bread. The production process comprises the following steps: (1) preparing materials; (2) beating dough; (3), carrying out slicing and freezing; (4), making dough into short crust pastry; (5), shaping the short crust pastry; (6), carrying out fermentation; (7), performing baking, cooking and demoulding; and (8), performing packaging. According to the pull-apart bread as well as the production process and the production line of the pull-apart bread disclosed by the invention, the pull-apart bread prepared by adopting making the dough into the short crust pastry in multiple layers is softer, crisper and more fragrant; by adopting a cryogenic freezing technology, a puffy taste of the pull-apart bread is improved; and by adopting a long-term slow fermentation process, the taste and mouthfeel of the pull-apart bread obtained through precipitation is better, and baking is carriedout by adopting an intelligent tunnel stove, and thus, the lustre of the pull-apart bread is more even.

Owner:FUJIAN CHANGTING PANPAN FOOD CO LTD

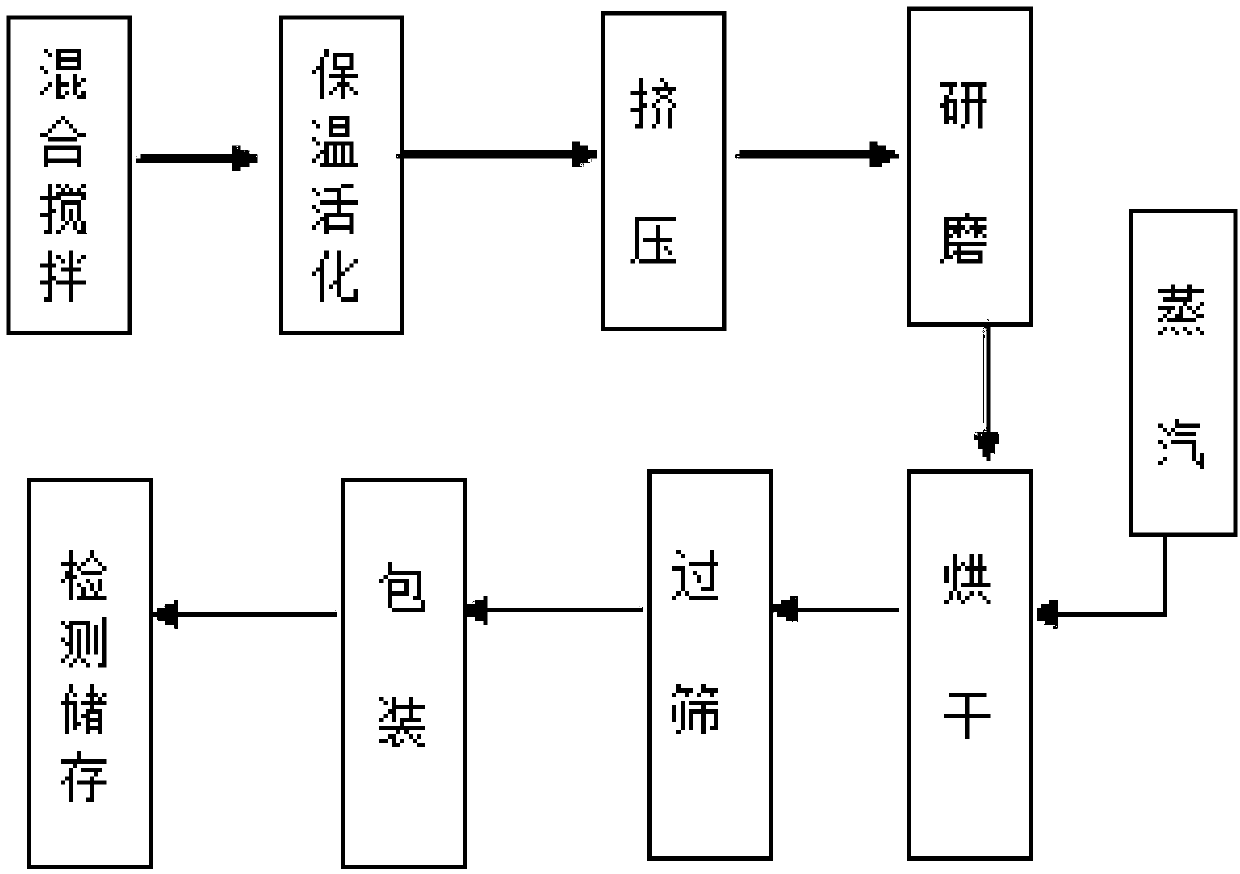

Feed additive using clay as carrier and preparation method thereof

PendingCN107821791AHigh adsorption rateImprove adsorption capacityFeeding-stuffAccessory food factorsParticulatesSorbent

The invention discloses a feed additive using clay as a carrier and preparation method thereof. Components of the feed additive include, by mass, 40%-90% of clay, 5%-50% of plant fatty acid ester, 1%-10% of sodium salt and 1%-10% of activator. The preparation method includes the steps of adding the clay and sodium salt solution to a mixer to evenly mix materials, adding the plant fatty acid esterand the activator to conduct organic activation, heat insulation, evenly mixing and then squeezing, grinding extruded particles to prepare solid powder, drying and sieving the materials to obtain thefeed additive. The feed additive has the advantages of effectively absorbing various mycotoxins such as aflatoxin, ochratoxin, fumonisin, and zeotolin mycotoxins in livestock and poultry and in contaminated feed, solving the problem that removing mycotoxins is simple and inefficient in current common clay mycotoxin adsorbent, having simple process and steps and convenient production, and greatly reducing production costs.

Owner:联技精细材料(珠海)有限公司

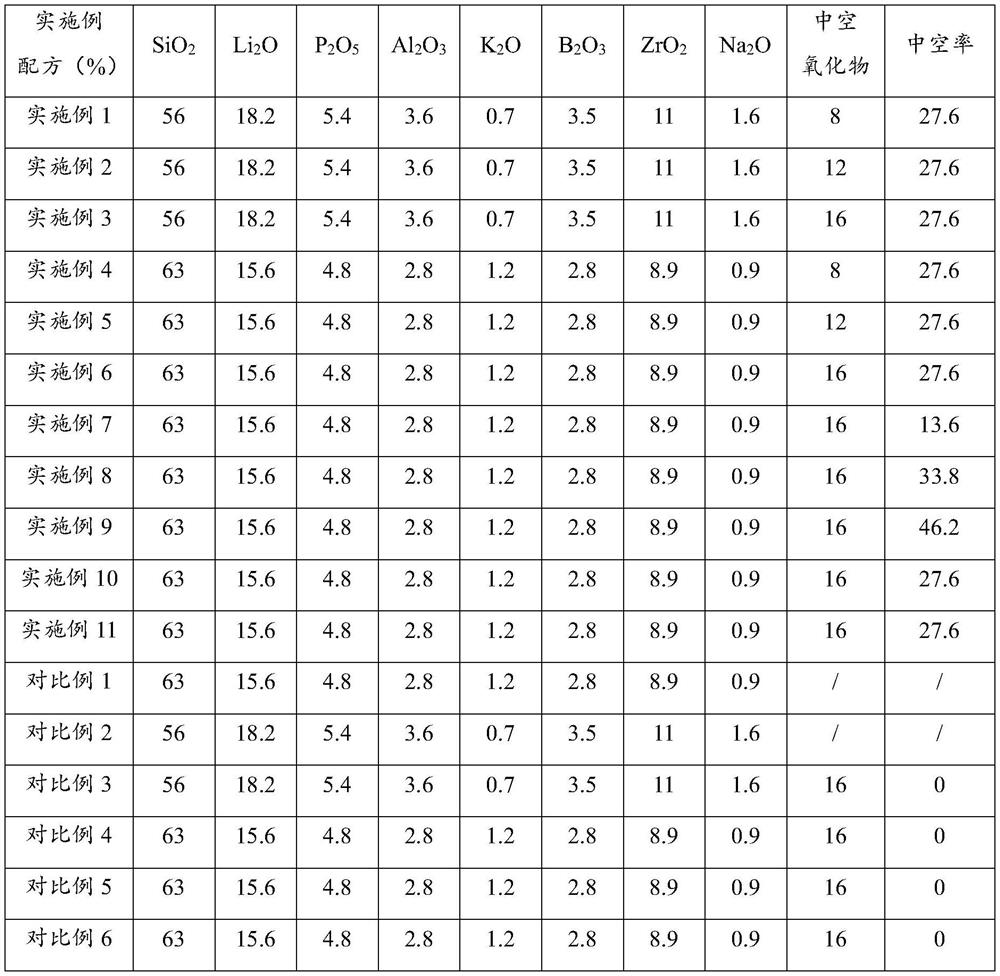

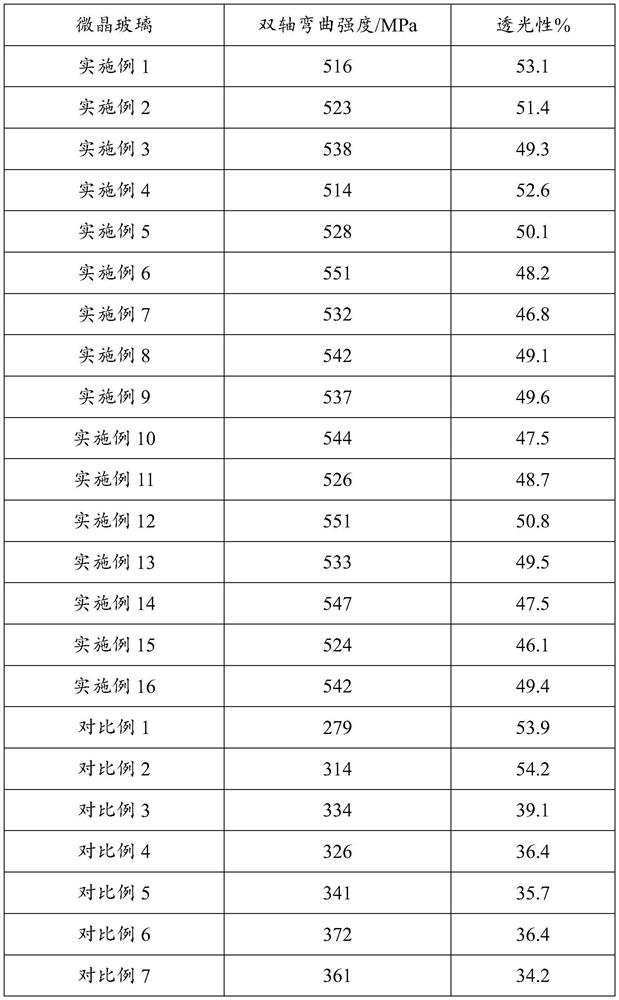

Glass ceramic composite material as well as preparation method and application thereof

PendingCN114380504AHigh strengthDoes not affect permeabilityImpression capsDentistry preparationsGlass compositesCrazing

The invention provides a glass ceramic composite material as well as a preparation method and application thereof, and relates to the technical field of glass materials. The glass ceramic composite material provided by the invention comprises the hollow oxide and the glass ceramic powder, and the hollow oxide forms natural pores to form a synergistic effect with crystals in the glass ceramic, so that crack propagation is prevented, and the strength is improved; meanwhile, the refractive index of the hollow oxide is adjusted by the hollow rate of the hollow oxide powder and is similar to the refractive index of microcrystalline glass, so that the permeability is not influenced while the strength is improved. The strength of the microcrystalline glass composite material provided by the invention is improved to 500 Mpa or above, and the microcrystalline glass composite material is good in permeability, has good processability and can be used for preparing false teeth.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

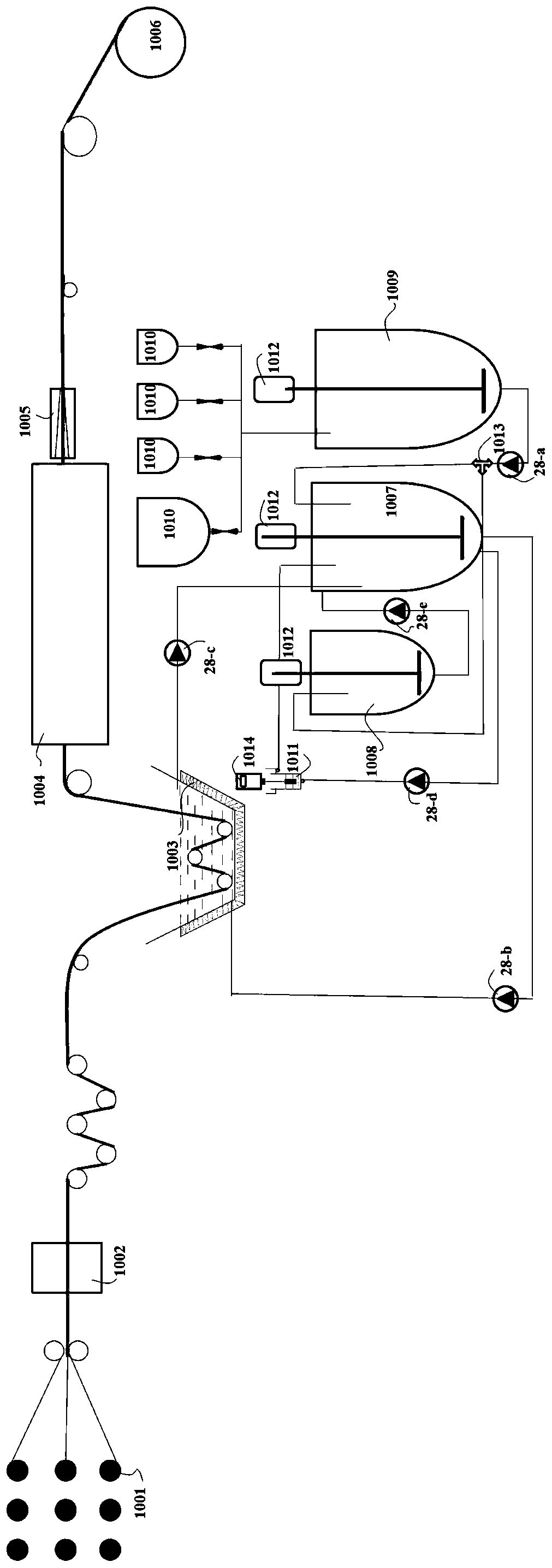

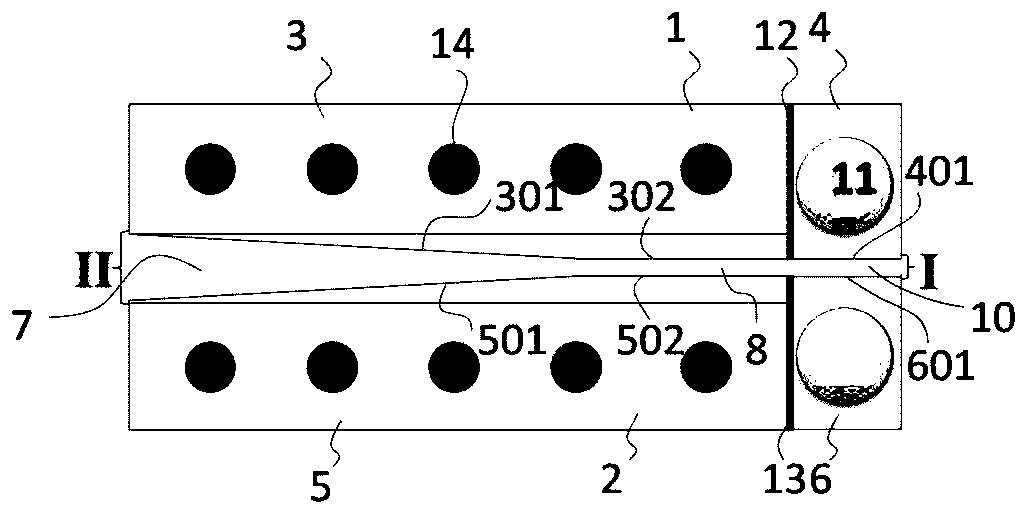

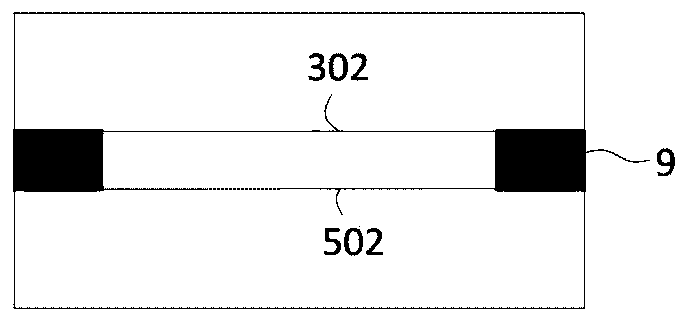

Production system for preparing thermoplastic prepreg through mud method

The invention discloses a production system for preparing thermoplastic prepreg through a mud method. The system comprises a sizing agent removal device, a gum dipping tank, a drying device, pultrusion mold and a winding device which are arranged in the fiber advancing direction. The gum dipping tank is connected with a slurry concentration adjusting device, the slurry concentration adjusting device comprises a buffer bucket, a high-concentration slurry storage tank, a slurry dispersion bucket and a raw material tank, a slurry outlet of the buffer bucket is connected with a slurry inlet of thegum dipping tank, a backflow pipe for conveying slurry in the gum dipping tank to the buffer bucket in a backflow manner is arranged between the buffer bucket and the gum dipping tank, the buffer bucket is connected with a sample detection pond through a slurry sample conveying pipeline, a viscometer is arranged in the sample detection pond, the high-concentration slurry storage tank is connectedwith the buffer bucket, the slurry dispersion bucket is connected with the buffer bucket and the high-concentration slurry storage tank, and is used for injecting slurry of the corresponding concentrations into the buffer bucket and the high-concentration slurry storage tank, and the raw material tank is connected with the slurry dispersion bucket. According to the production system for preparingthermoplastic prepreg through the mud method, the slurry concentration can be adjusted.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Method for Producing Nanometer Lithopone from Electrolytic Zinc Acid Leaching Residue

ActiveUS20150218338A1Ensure qualityImproves acidic soilPigmenting treatmentZinc sulfidesSulfate radicalsResource utilization

Disclosed is a method for producing nanometer lithopone from electrolytic zinc acid leaching residue. The method comprises specific steps of: leaching, purifying, carrying out a metathetical reaction, washing, smashing and the like. Through these steps, zinc is selectively leached out by an ammonia-ammonium sulfate process; and iron and arsenic are removed by ammonium persulfate, heavy metal elements such as nickel, copper, lead, cadmium and the like are removed by sulfurization method and zinc powder replacement method; and a metathetical reaction is carried out to obtain an nZnS—BaSO4 crystalline filter cake, the crystalline filter cake is dried and smashed to obtain a nanometer lithopone product. The zinc in the acid leaching residue can be recycled effectively by this method. The ammonia leaching method is used as the technical means of effectively treating the acid leaching residue, the obtained lithopone product is good in quality, and sulfate radicals needed in the production are provided by the acid leaching residue itself, so that the resource utilization of the acid leaching residue is implemented; and in addition, the production cost is low, and the operation is simple.

Owner:SICHUAN JUHONG TECH

Megastigmatrienone synthesis method

ActiveCN1803749BNo pollution in the processReduce pollutionOrganic compound preparationEssential-oils/perfumesSynthesis methodsOxygen

The related synthesis method for megastigmatrienone comprises: with a little catalyst, using peroxide to oxygenize the alpha-violet acetate into 3-oxo-alpha-violet acetate with high yield; taking acidolysis and purification to obtain the objective product. This invention has no pollution of heavy metal, needs mild reaction condition, and fit to industrialization.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com