Preparation method for graphite negative electrode of lithium ion battery

A lithium-ion battery, graphite anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that the material capacity, efficiency or cycle performance cannot meet the requirements of use, expensive equipment, and high production costs, and achieve industrial operability. The effect of improving the strength, capacity and efficiency, and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 70g of water-based phenolic resin (Tianjin Resin Factory 216-4#), 1330g of deionized water, fully stir and dissolve in the dispersing equipment, the temperature of the water bath is 90°C, and the stirring speed is 80Hz.

[0037] Weigh 55.6g of aluminum nitrate and 7.8g of α-type aluminum oxide with a particle size of 0.5 micron and add it to the dispersion equipment, and fully disperse at a rotating speed of 900 rpm. Dry at 150°C for 24 hours.

[0038] Put the obtained powder through a 400-mesh sieve and roast in an argon furnace. The roasting system is: 5°C / min rises to 600°C for solidification for 6 hours, then rises to 850°C for carbonization at 5°C / min, and heats it for 10h. Cool in the furnace.

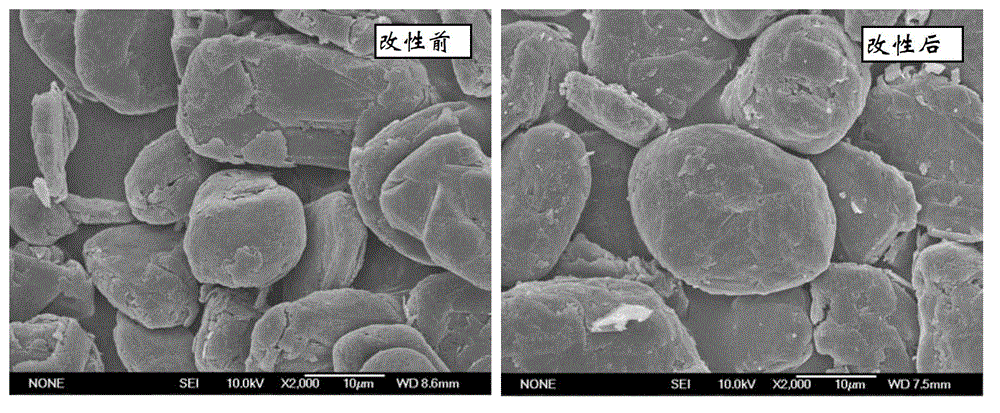

[0039] Through the analysis of electron microscope photos, it can be concluded that the surface of natural graphite is covered with a layer of pyrolytic carbon and aluminum oxide, and its microscopic morphology has not changed before and after modification. figure ...

Embodiment 2

[0042] Weigh 100g of water-based phenolic resin (Tianjin Resin Factory 216-4#), 1000g of deionized water, fully stir and dissolve in the dispersing equipment, the temperature of the water bath is 40°C, and the stirring speed is 70Hz.

[0043] Weigh 13.2g of α-type aluminum oxide with a particle size of 0.5 microns and add it to the dispersing equipment. The speed is 1200 rpm to fully disperse, add 1000g of artificial graphite with a particle size of 9 microns, stir fully, impregnate and evaporate to dryness, and dry at 80°C for 24 hours. Put the obtained powder through a 200-mesh sieve and roast in an argon furnace. The roasting system is: 5°C / min rises to 550°C for solidification for 6 hours, then rises to 1050°C for carbonization at 3°C / min, and heats it for 6h. Cool in the furnace.

[0044] According to the analysis of electron microscope photos, it can be concluded that the surface of graphite is coated with a layer of pyrolytic carbon and aluminum oxide, and its microscop...

Embodiment 3

[0046] Weigh 50g of water-based phenolic resin (Tianjin Resin Factory 216-2#), 250g of deionized water, fully stir and dissolve in the dispersing equipment, the temperature of the water bath is 70°C, and the stirring speed is 120Hz.

[0047] Weigh 14.8g of aluminum chloride and add it to the dispersing equipment, rotate at 200 rpm to fully disperse and dissolve, add 1000g of natural graphite with a particle size of 7 microns, stir fully, impregnate and evaporate to dryness, and dry at 200°C for 16h. Put the obtained powder through a 500-mesh sieve and roast in a nitrogen furnace. The roasting system is: 3°C / min rises to 400°C for solidification for 8 hours, then 3°C / min rises to 950°C for carbonization, heat preservation for 8h, and then Furnace cools.

[0048] According to the analysis of electron microscope photos, it can be concluded that the surface of graphite is coated with a layer of pyrolytic carbon and aluminum oxide, and its microscopic morphology has not changed befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com