Patents

Literature

81 results about "Modified technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

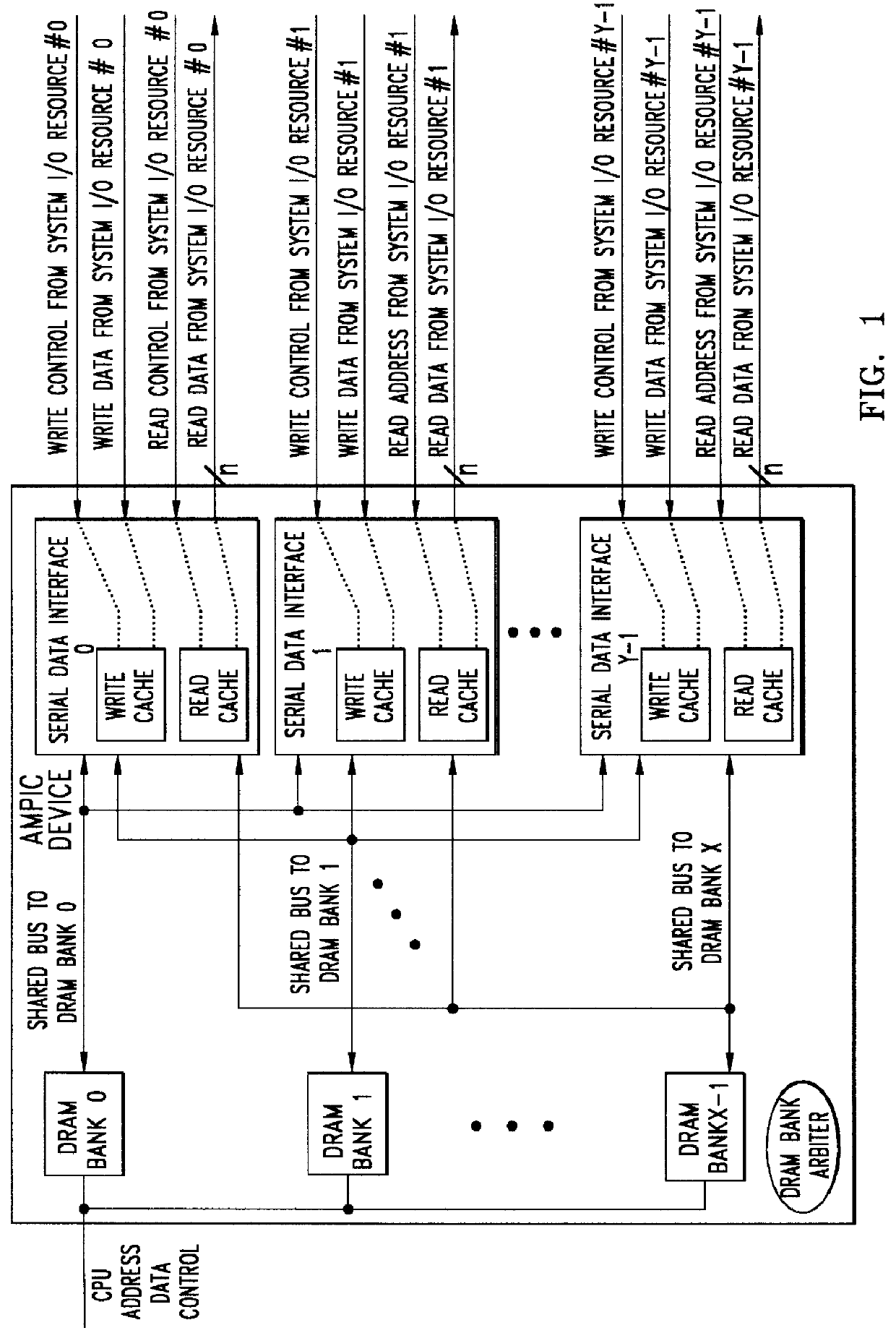

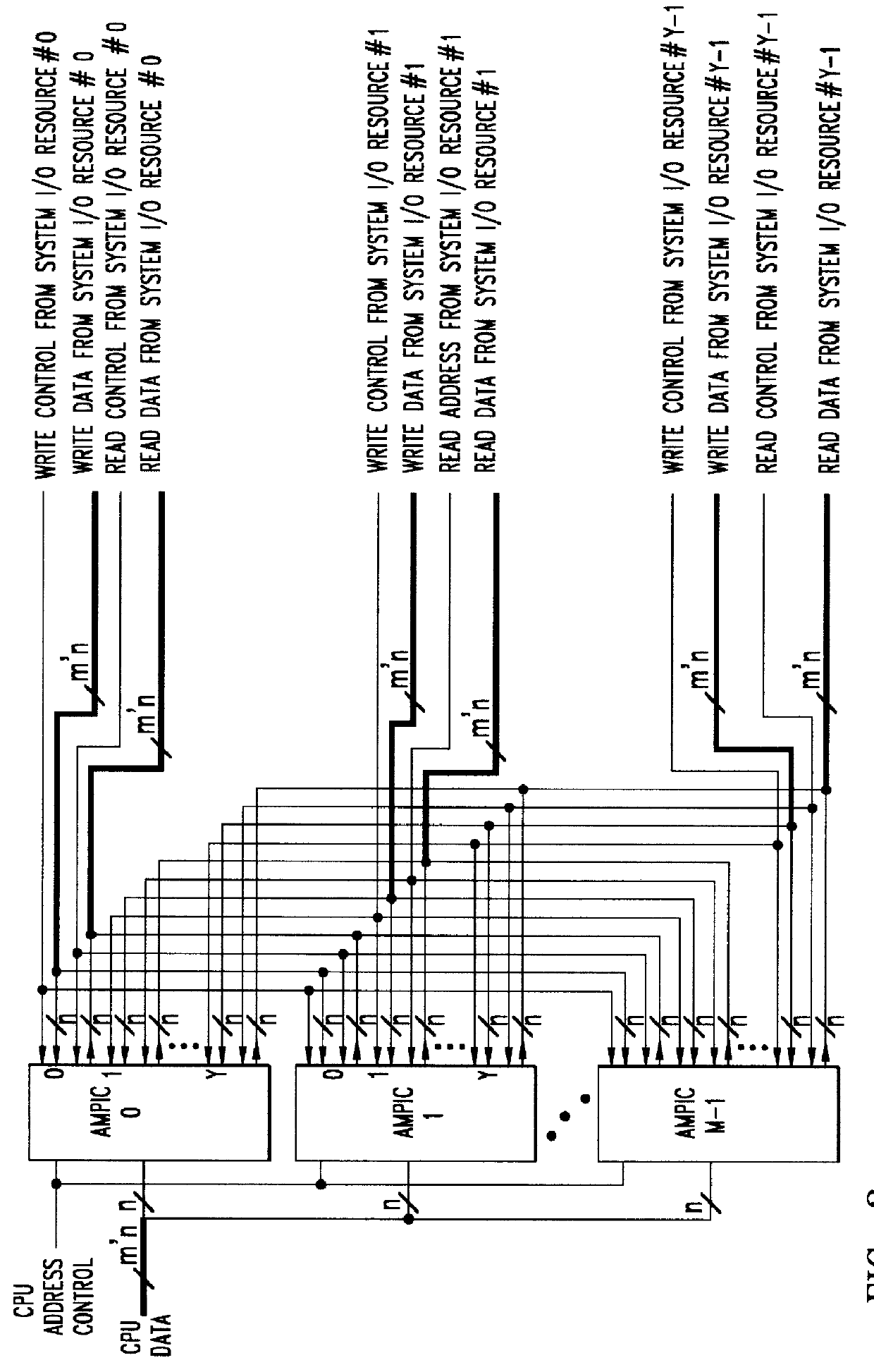

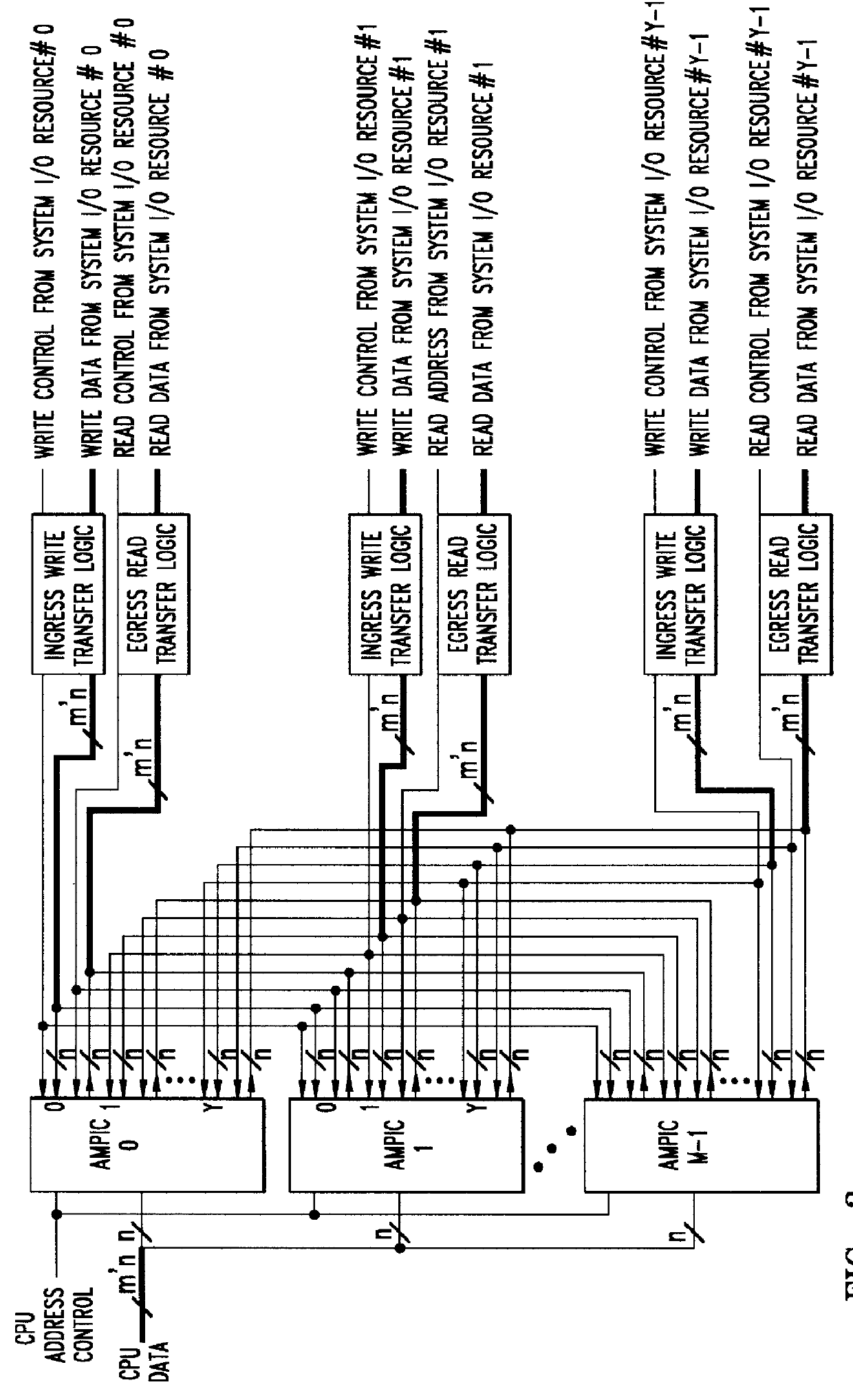

Method of and apparatus for validating data read out of a multi port internally cached dynamic random access memory (AMPIC DRAM)

InactiveUS6085290AEliminates race conditionMemory architecture accessing/allocationMemory adressing/allocation/relocationData validationStatic random-access memory

An apparatus for and method of enhancing the performance of a multi-port internal cached DRAM (AMPIC DRAM) by providing an internal method of data validation within the AMPIC memories themselves to guarantee that only valid requested data is returned from them, or properly marked invalid data. A modified technique for identifying bad data that has been read out of AMPIC memory devices in the system.

Owner:NEXABIT NETWORKS +1

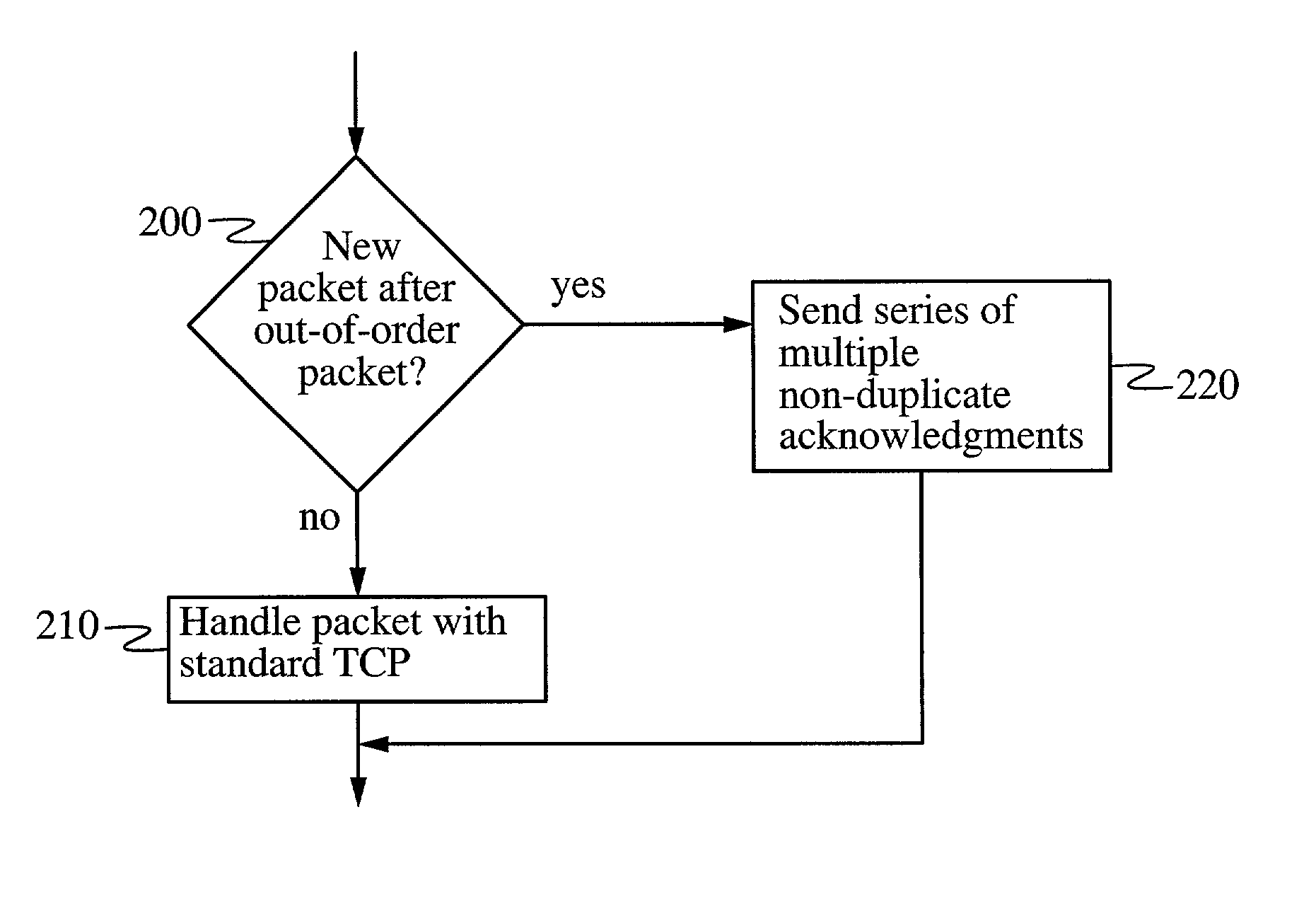

Data throughput over lossy communication links

InactiveUS7061856B2Promote recoveryError prevention/detection by using return channelFrequency-division multiplex detailsData connectionTelecommunications link

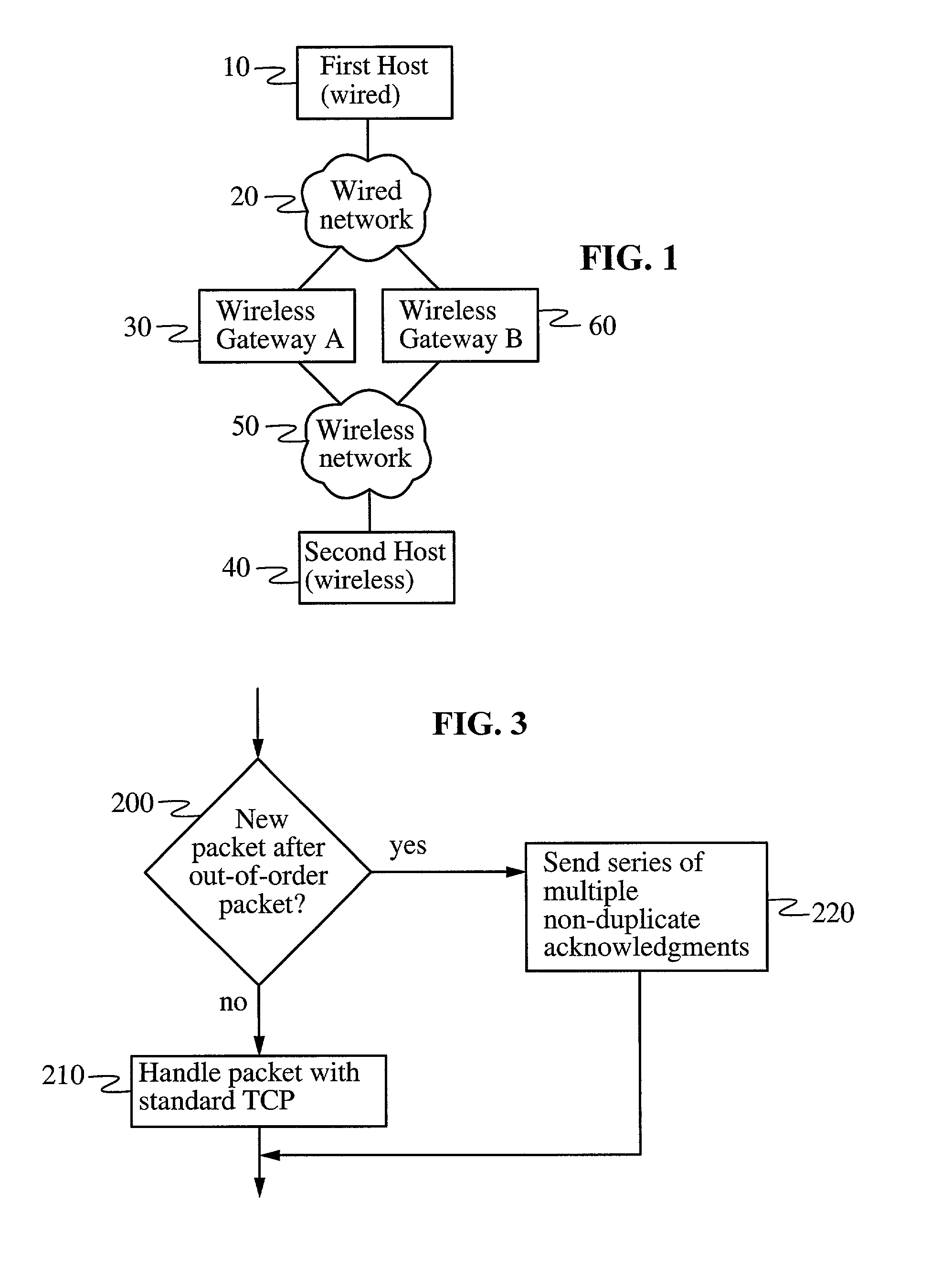

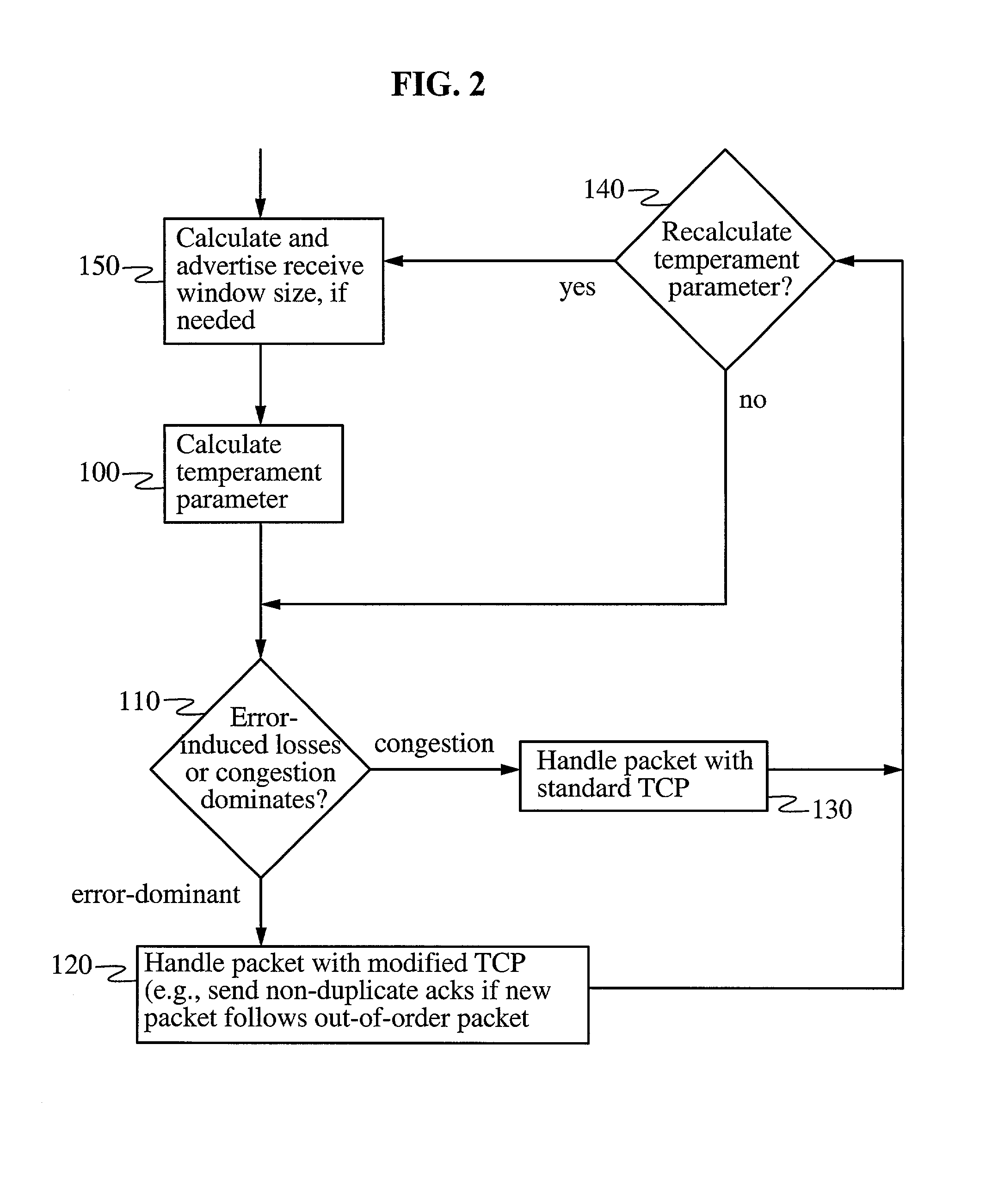

In a heterogeneous data network including both wired and wireless / lossy links, a transport protocol method implemented at the wireless host is fully compatible with existing wired networks and wireless gateways, and requires no modification to transport protocols at existing wired hosts. The wireless host calculates a temperament parameter [100] characterizing the error-proneness of the data connection and uses this parameter to determine whether error-induced losses or congestion-losses dominate the data connection [110]. If congestion-losses dominate the data connection, then the host uses a standard technique for acknowledging data packets [130]. If, on the other hand, error-induced losses dominate the connection, the host uses a modified technique for acknowledging data packets [120]. According to this modified technique, the wireless host sends a plurality of non-duplicate acknowledgements of a single packet whenever a packet is received after an out-of-order packet is received. By acknowledging distinct fragments of the packet, rather than identical (i.e., duplicate) acknowledgments of the packet, the acknowledgments have the effect of accelerating recovery of maximal window size at the wired host and increasing data throughput.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

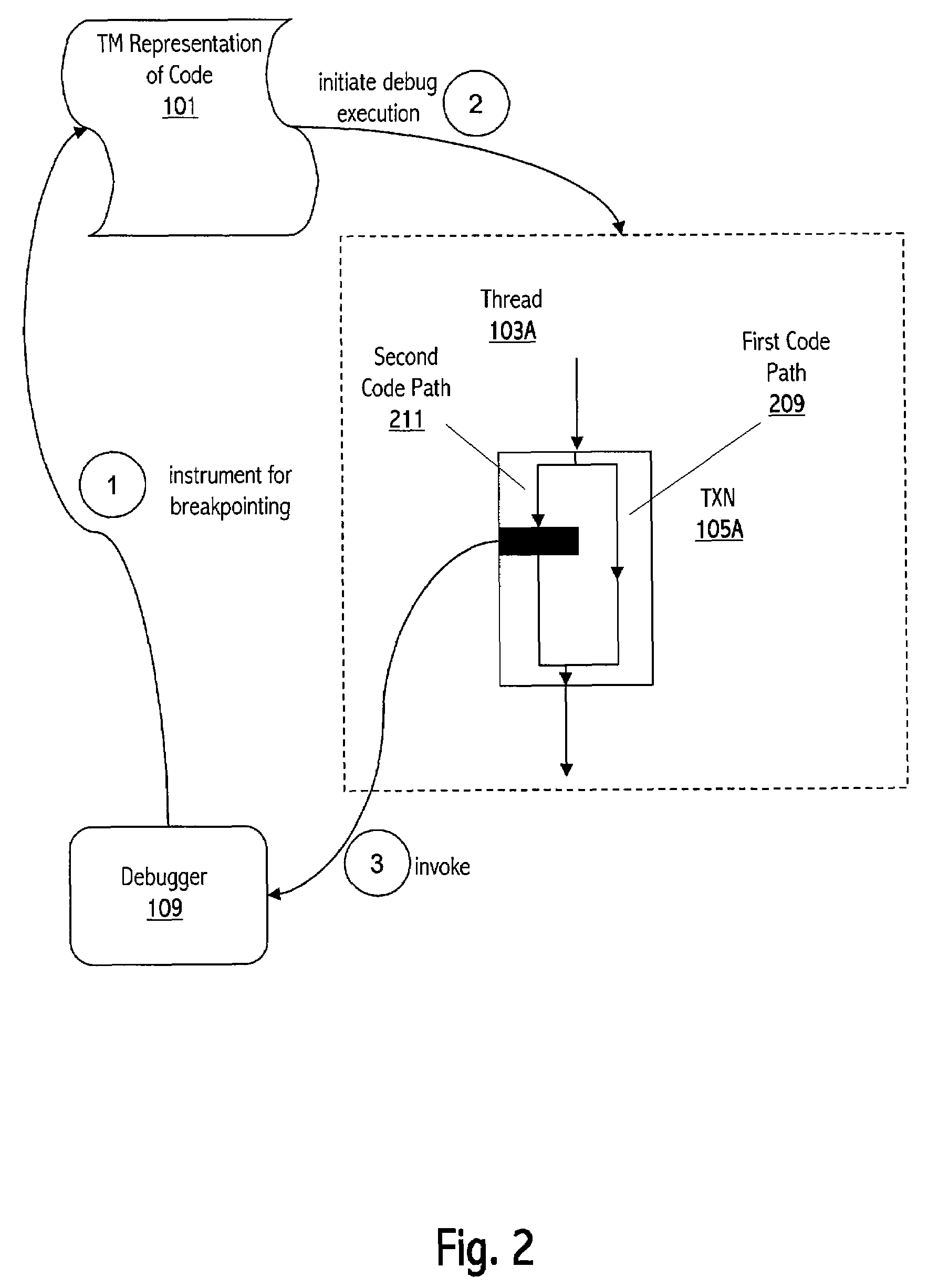

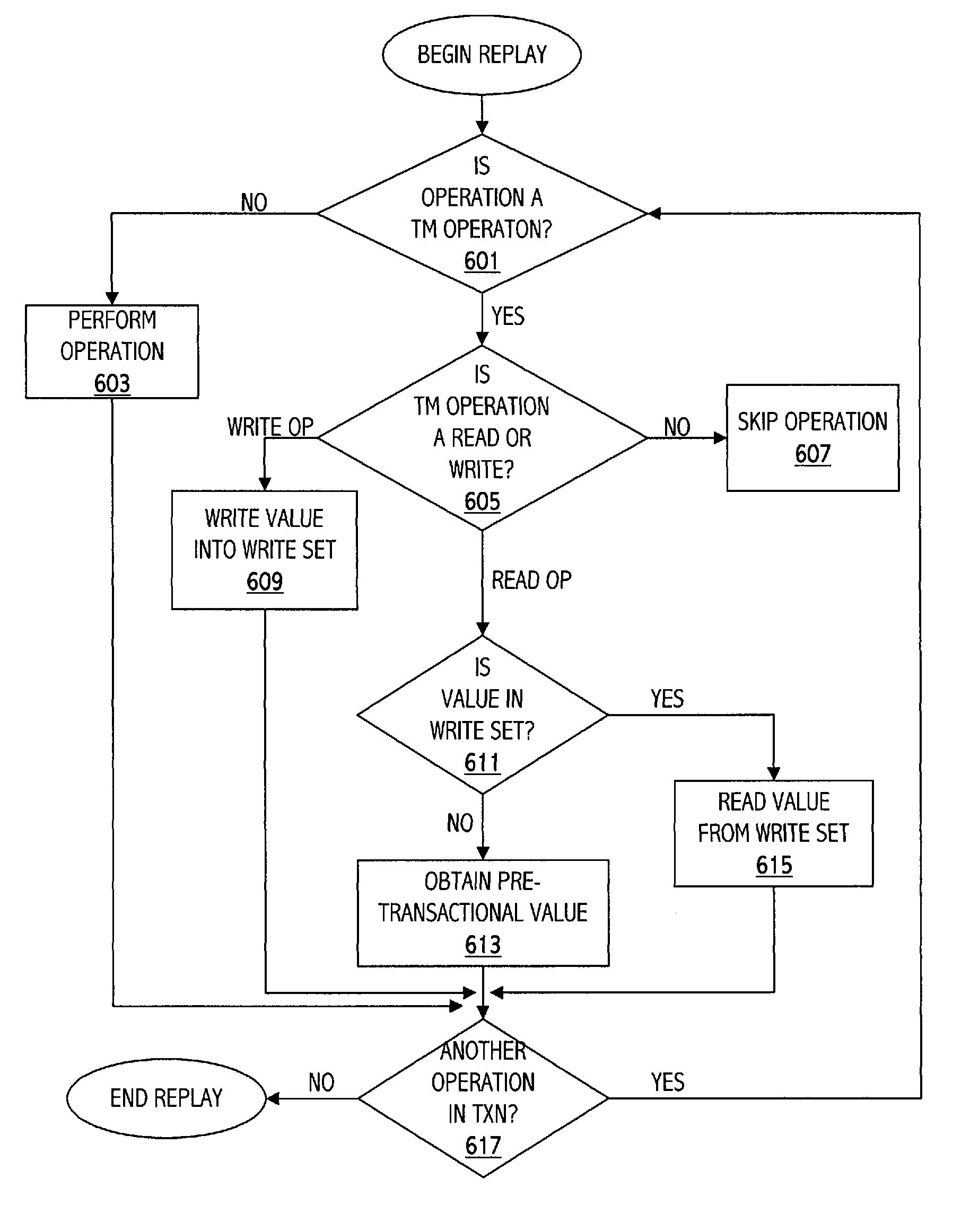

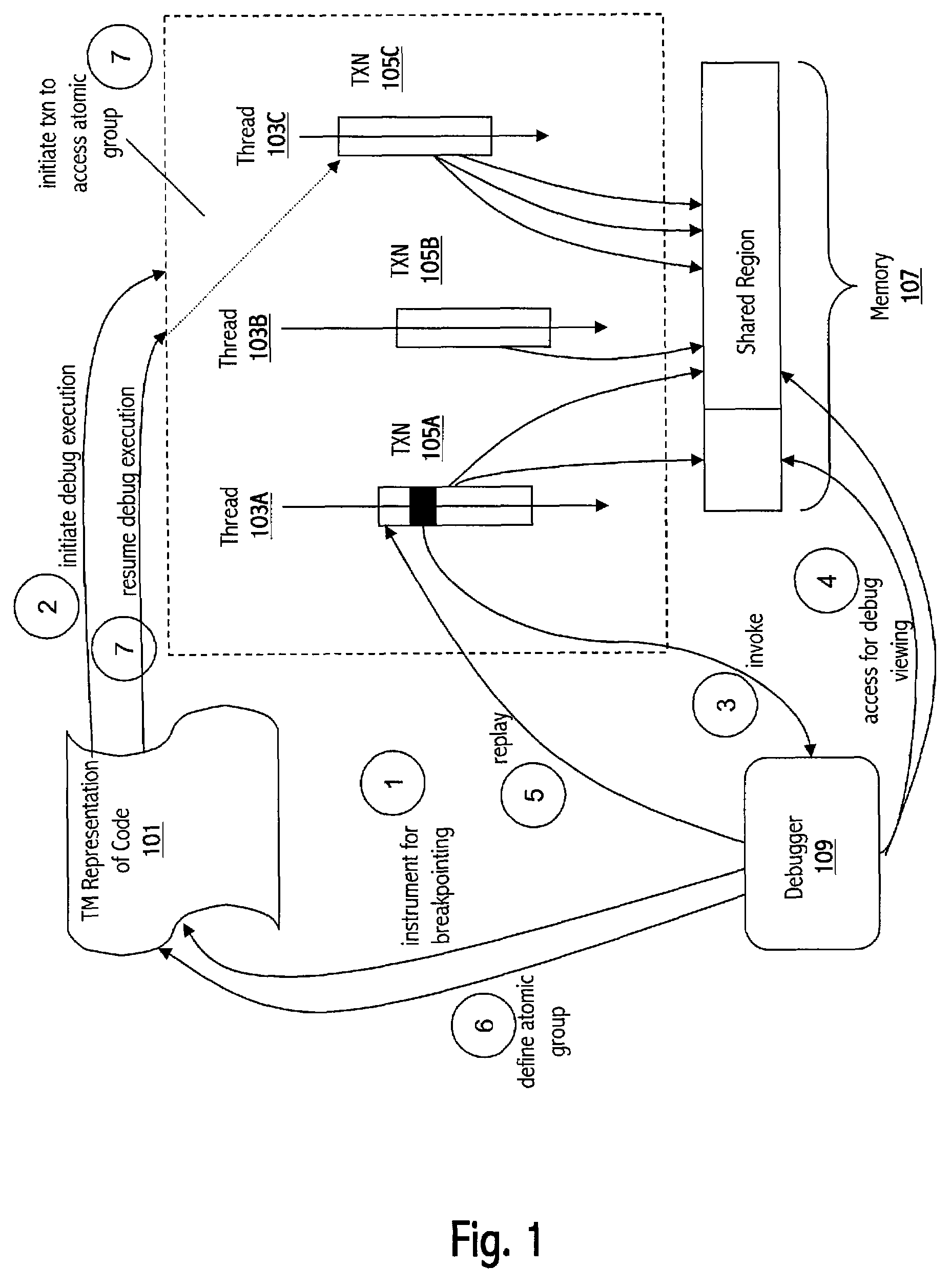

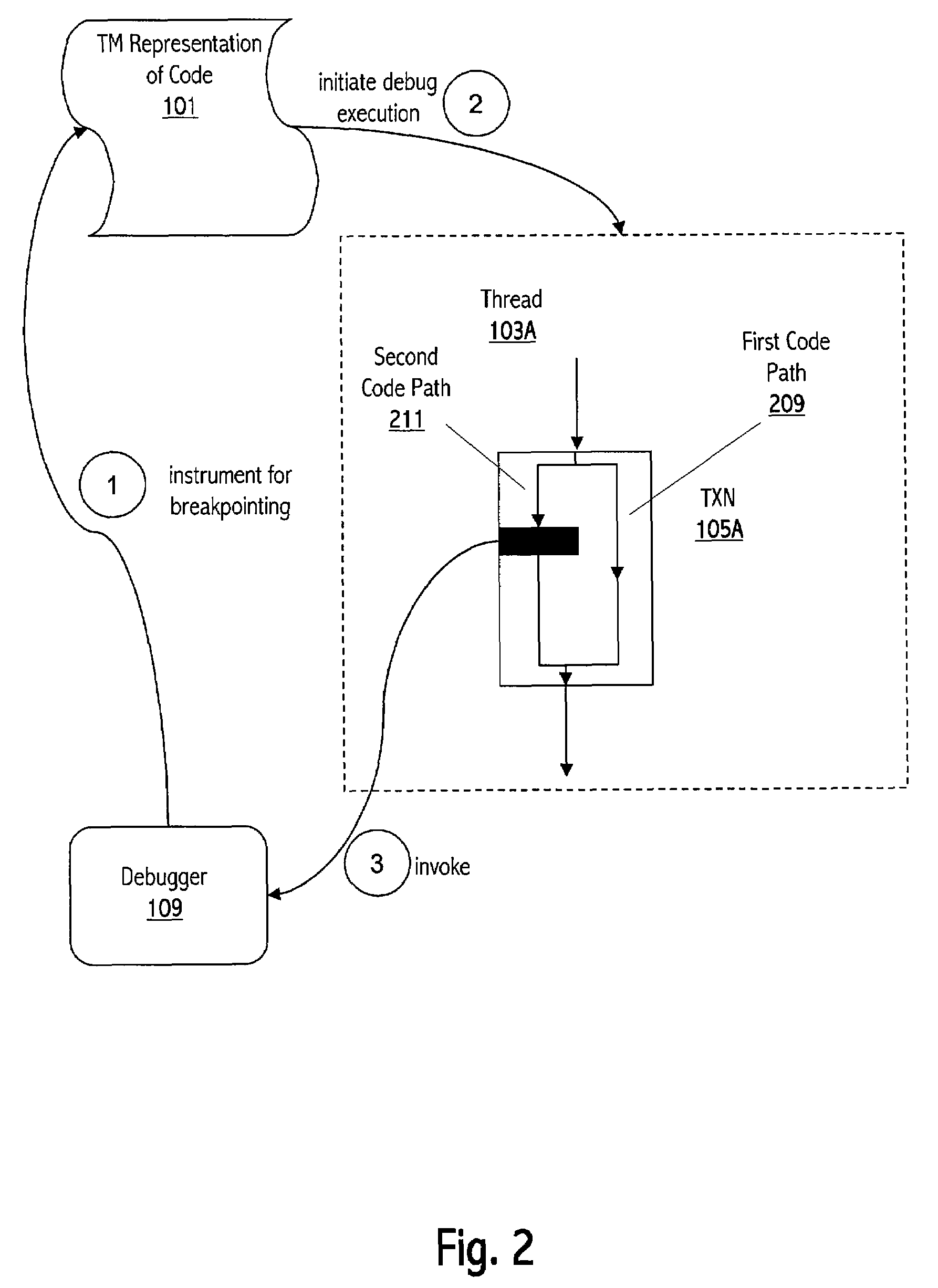

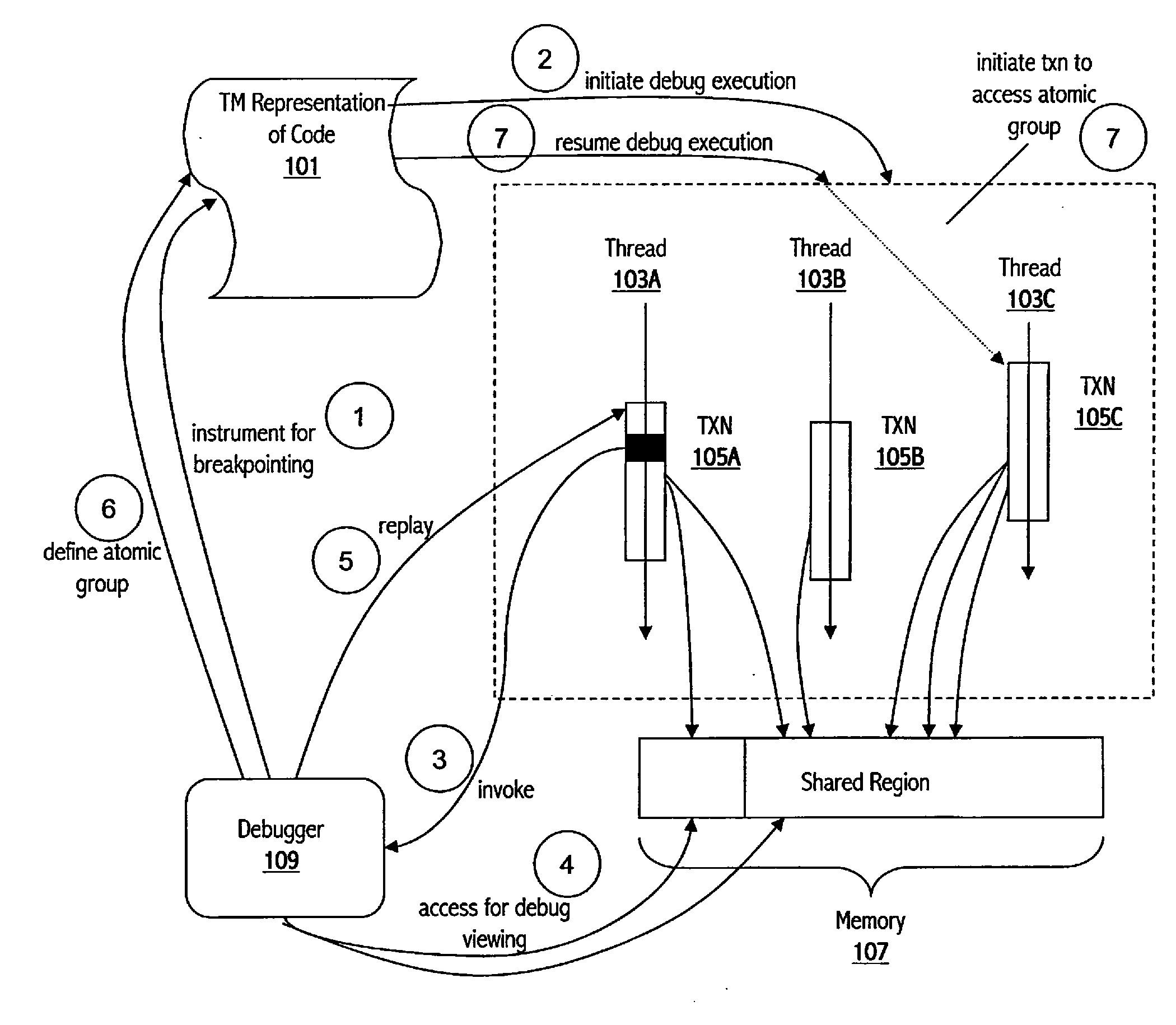

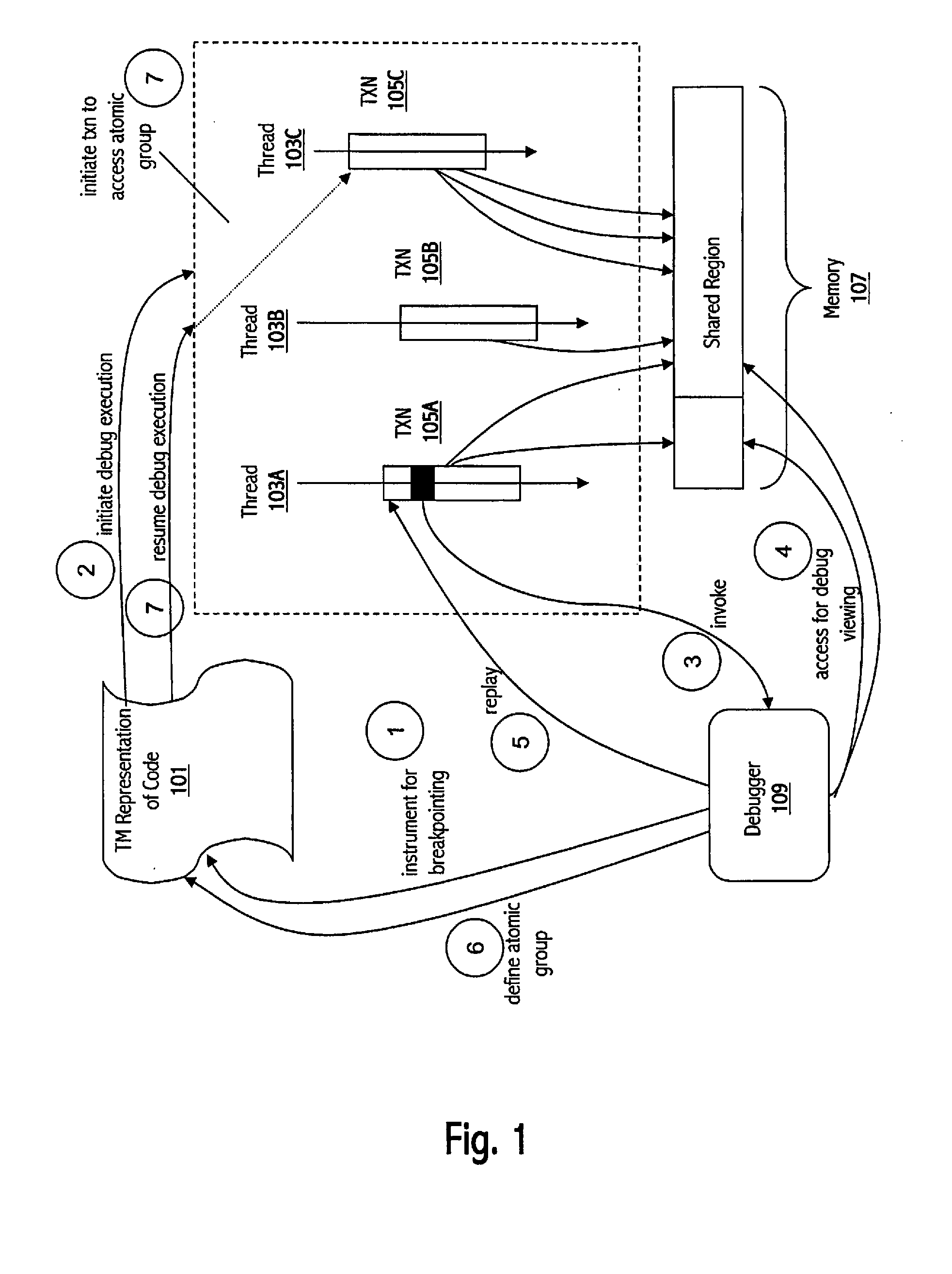

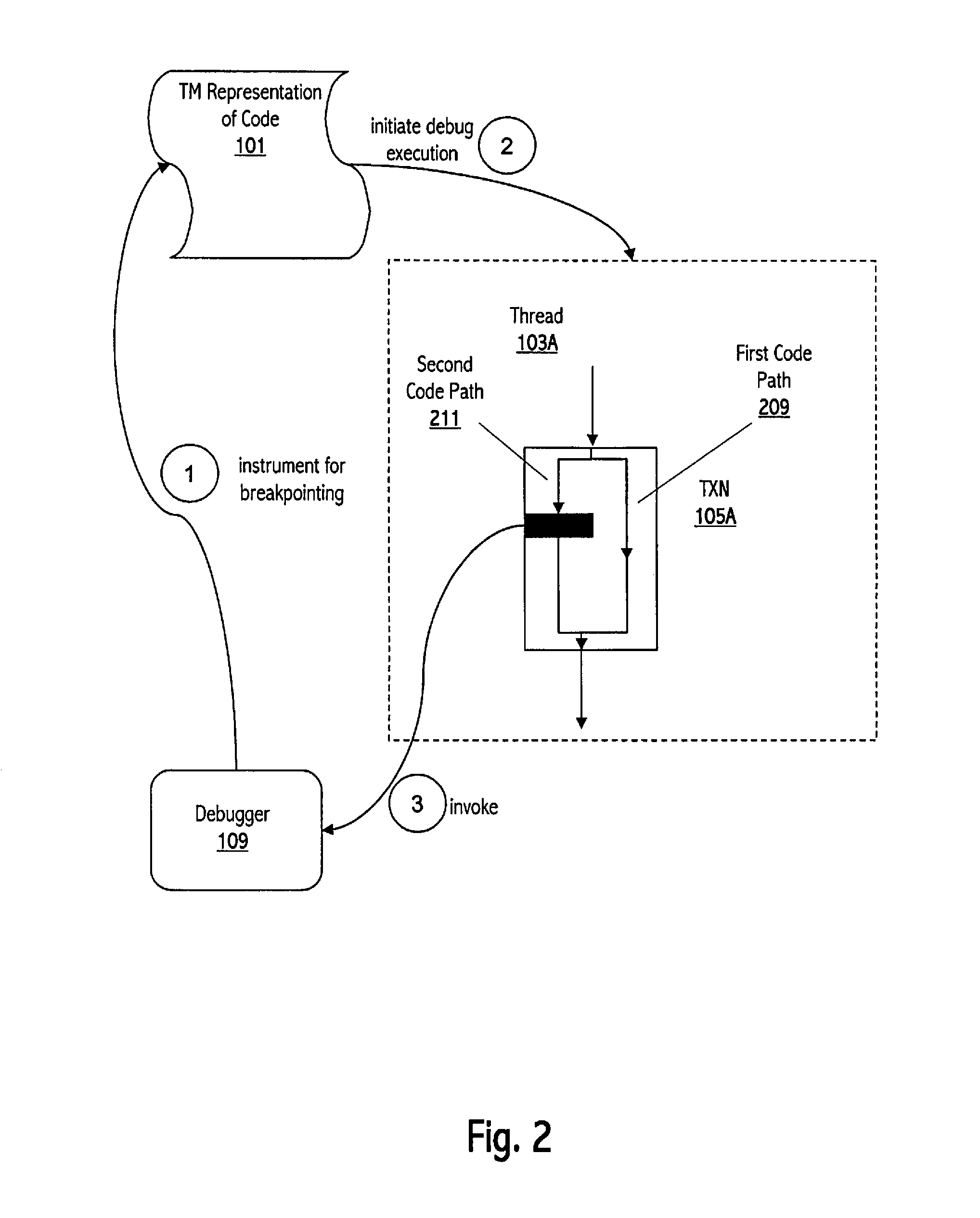

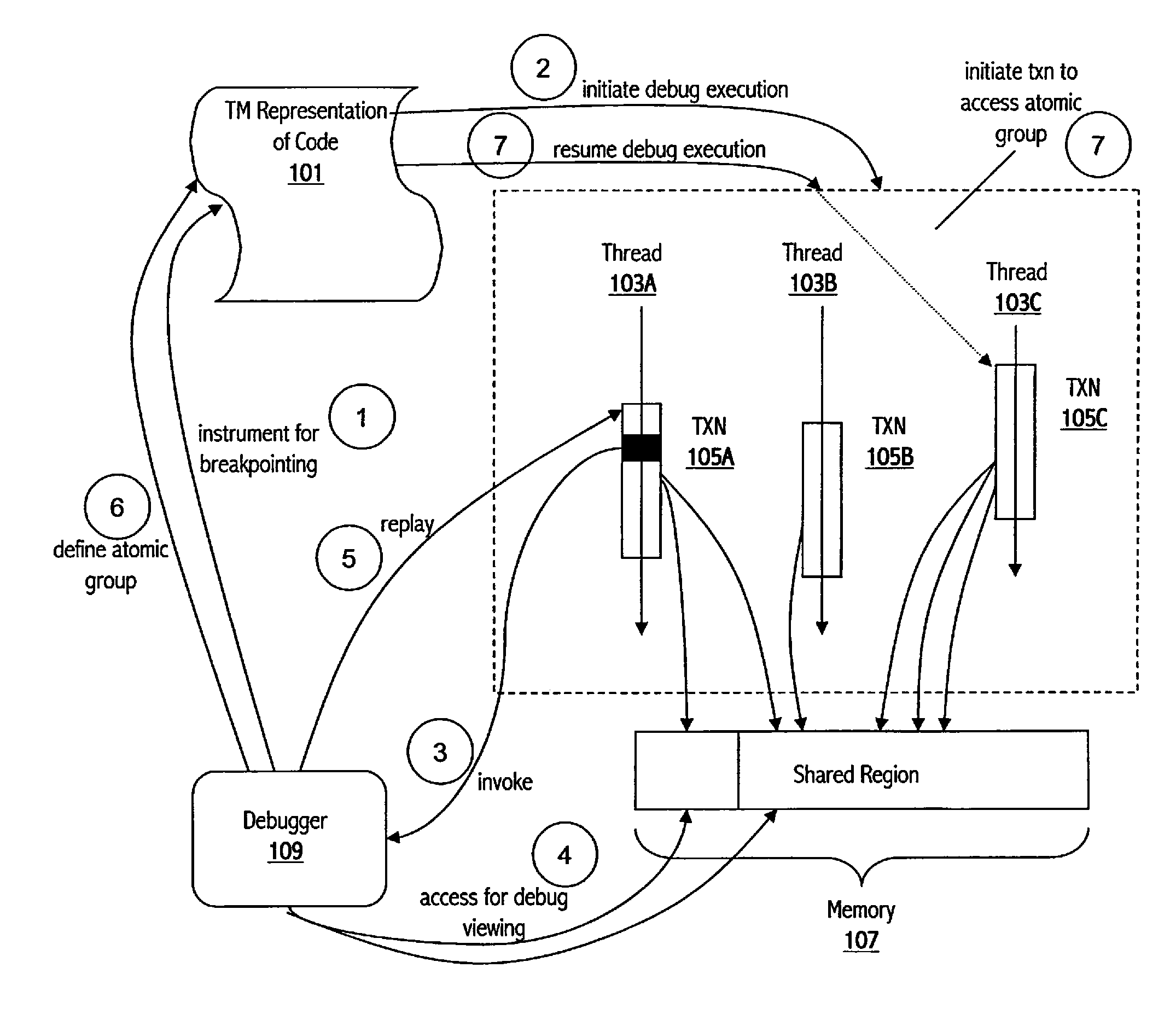

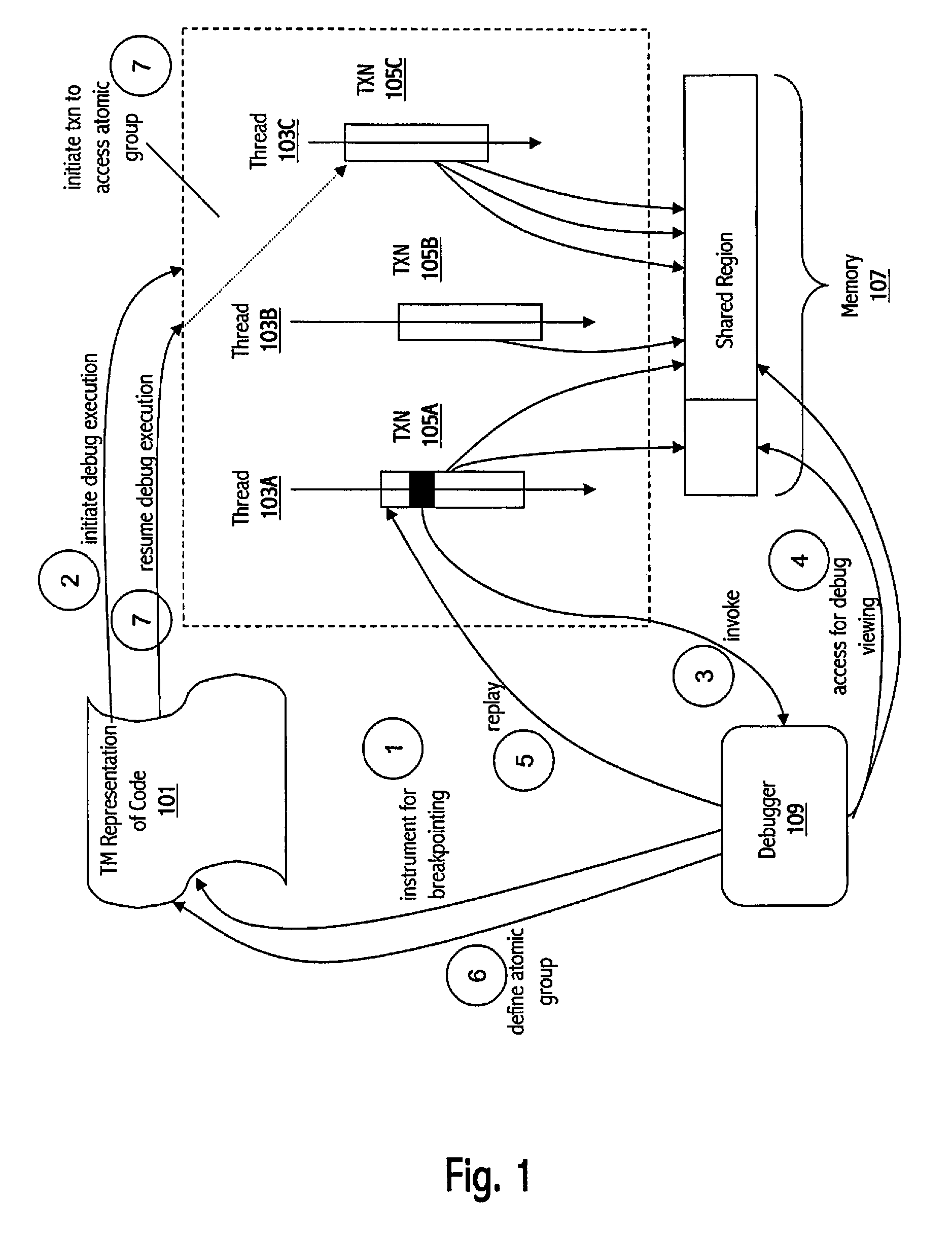

Replay debugging

ActiveUS20070288902A1Error detection/correctionSpecific program execution arrangementsParallel computingModified technique

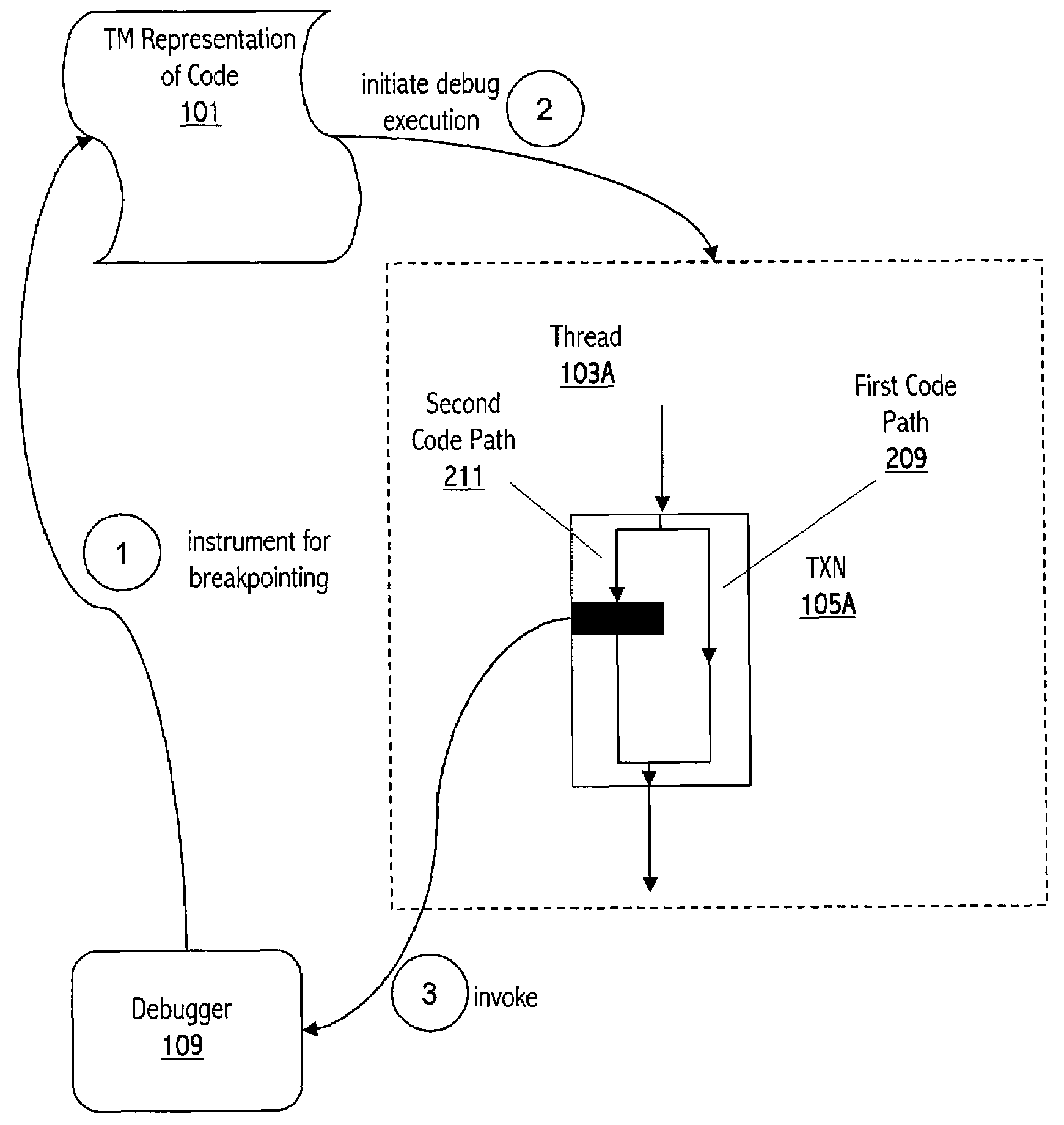

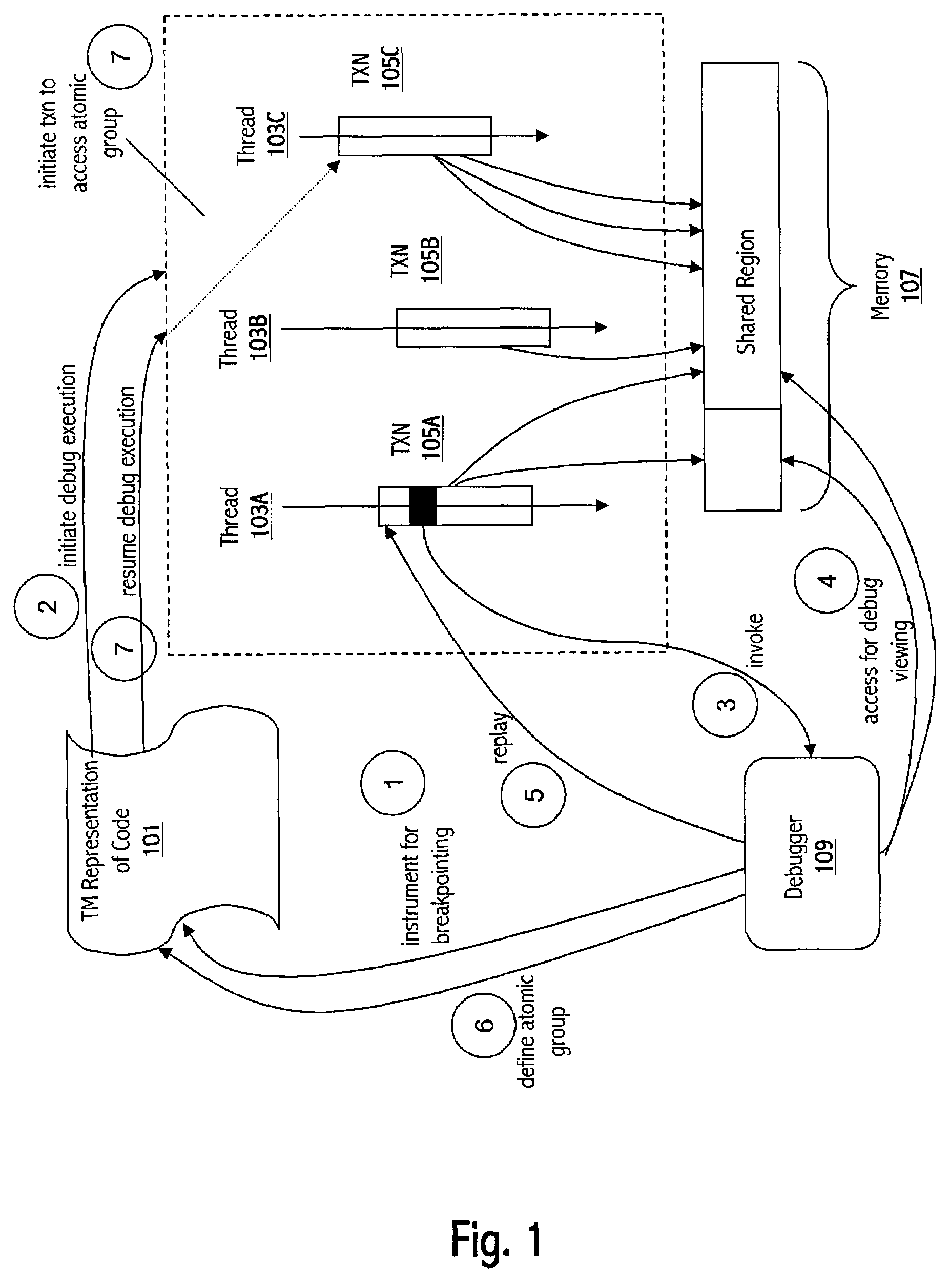

Transactional programming promises to substantially simplify the development and maintenance of correct, scalable, and efficient concurrent programs. Designs for supporting transactional programming using transactional memory implemented in hardware, software, and a mixture of the two have emerged recently. Unfortunately, conventional debugging programs are often inadequate when employed in relation to code that employs transactional memory and new or modified techniques are needed. We describe techniques whereby certain facilities of a transactional memory implementation can be leveraged to provide replay debugging. With replay debugging, the user can examine a partial or complete execution of an atomic block after it has happened—for example, right before the execution commits. Moreover, in some cases the user can modify the replayed execution, and decide to commit the new modified execution instead of the original replayed one.

Owner:ORACLE INT CORP

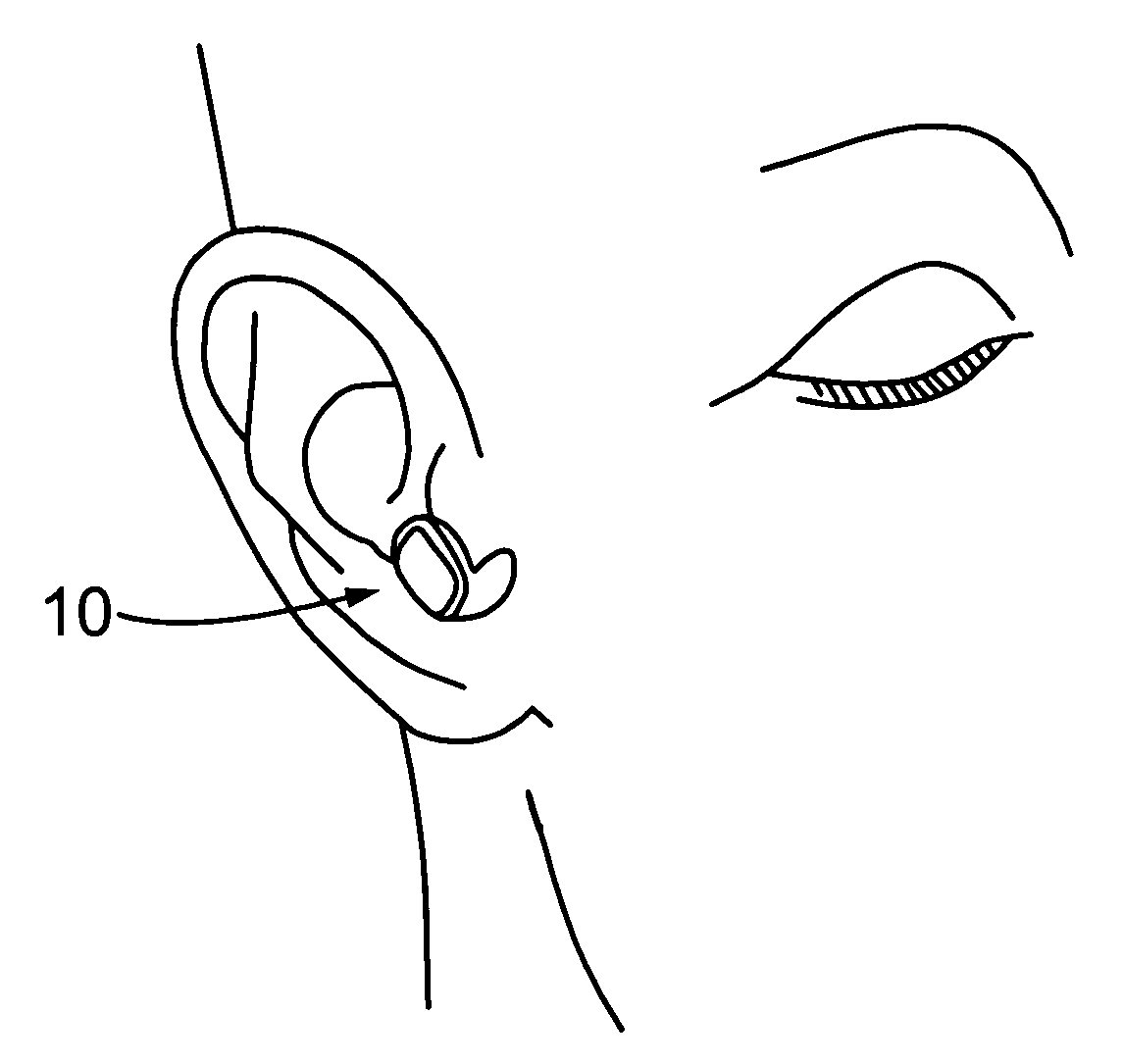

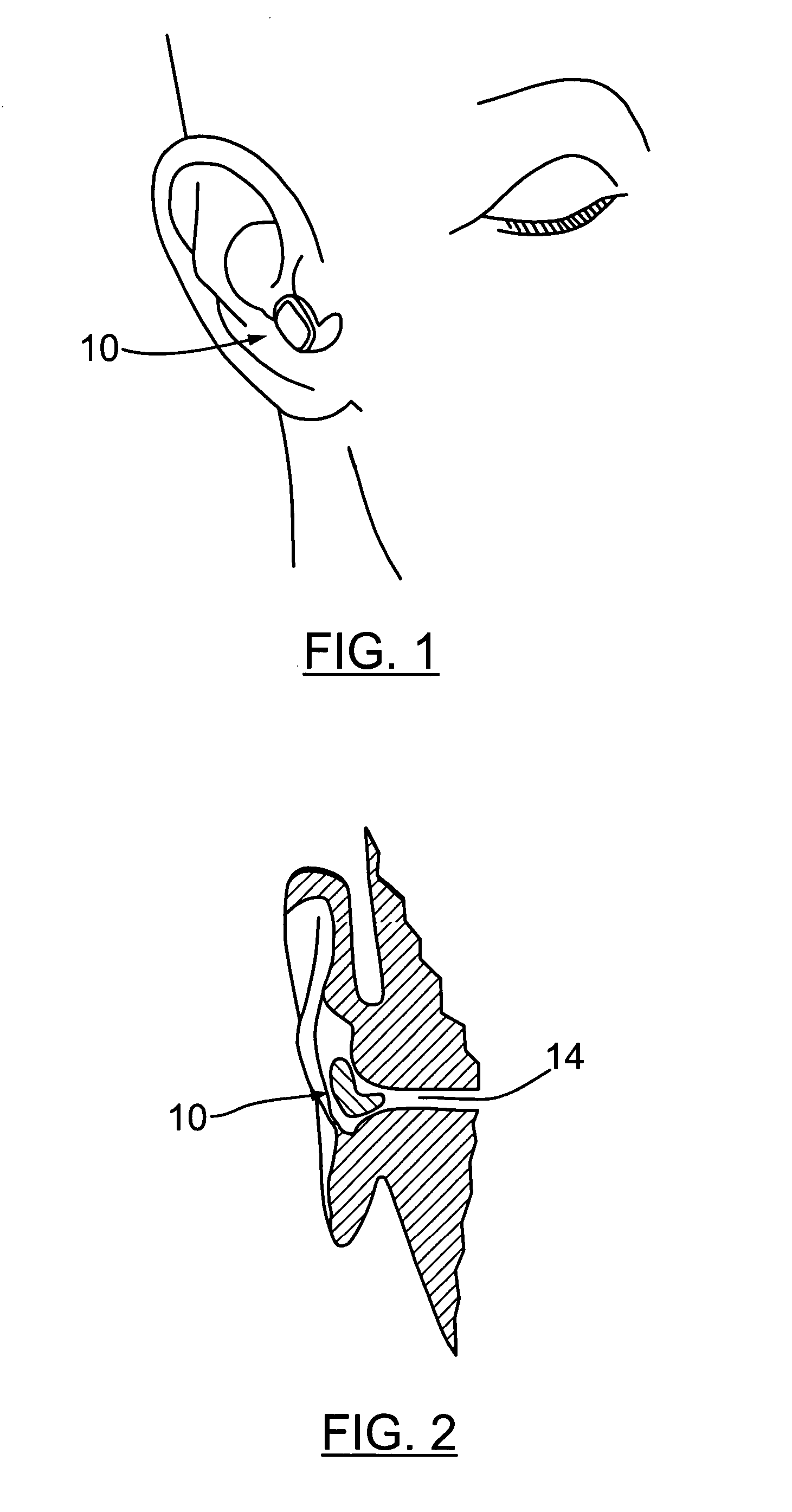

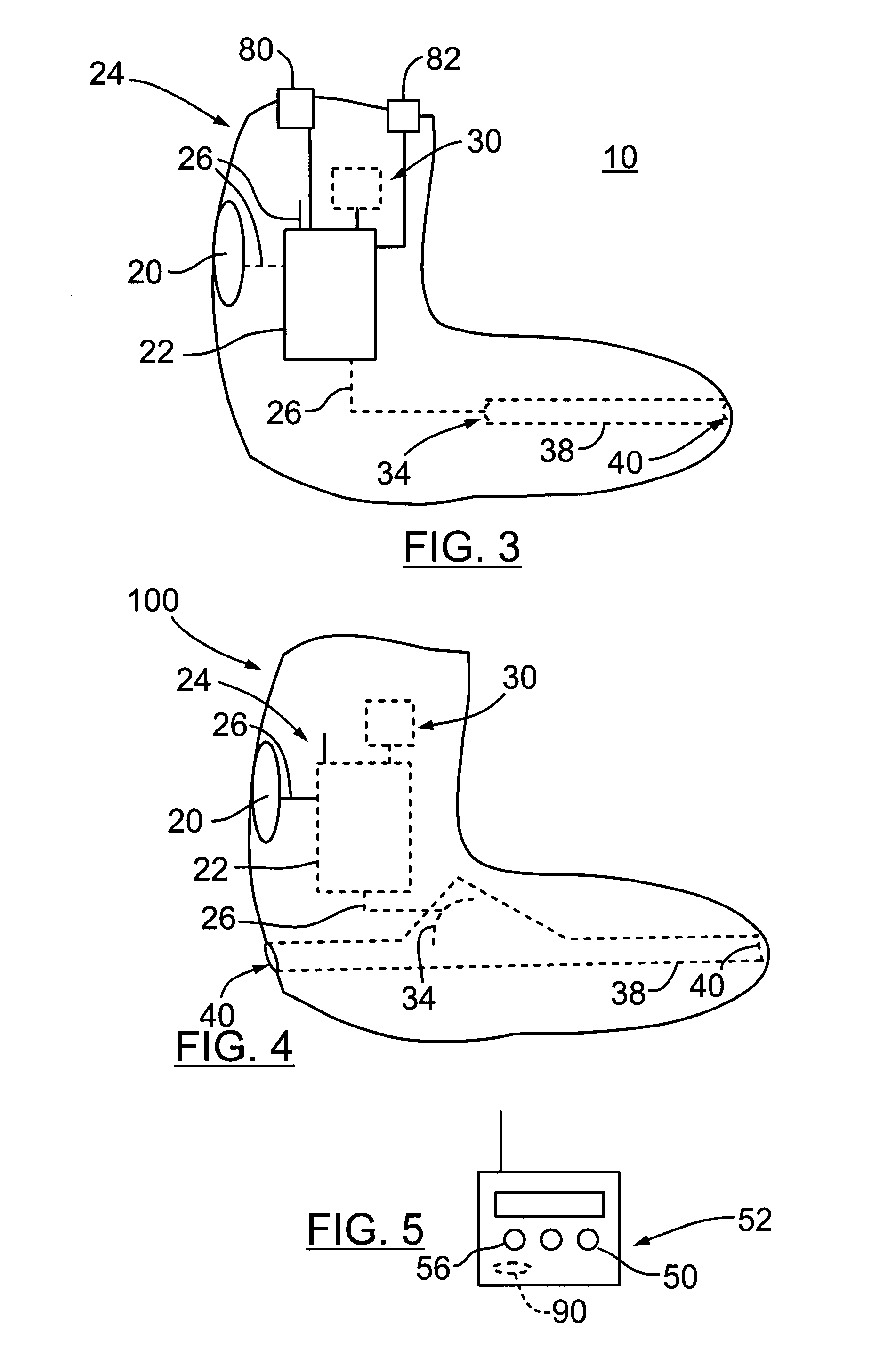

Training device and method to suppress sounds caused by sleep and breathing disorders

A training method and device to suppress sounds caused by sleep and breathing disorders, such as, snoring and sleep apnea. The system records the actual snoring of the subject, modifies it, by time delay and perhaps other sound modifying techniques, and broadcasts it to the subject by a speaker or earphone. This trains the person to attend to his / her own snoring, so that he / she might stop it by moving parts of his / her body or changing breathing patterns. The method and device may include the combination and / or integration of hearing aid functionality and means for detection of snoring sounds.

Owner:SARINGER RES

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

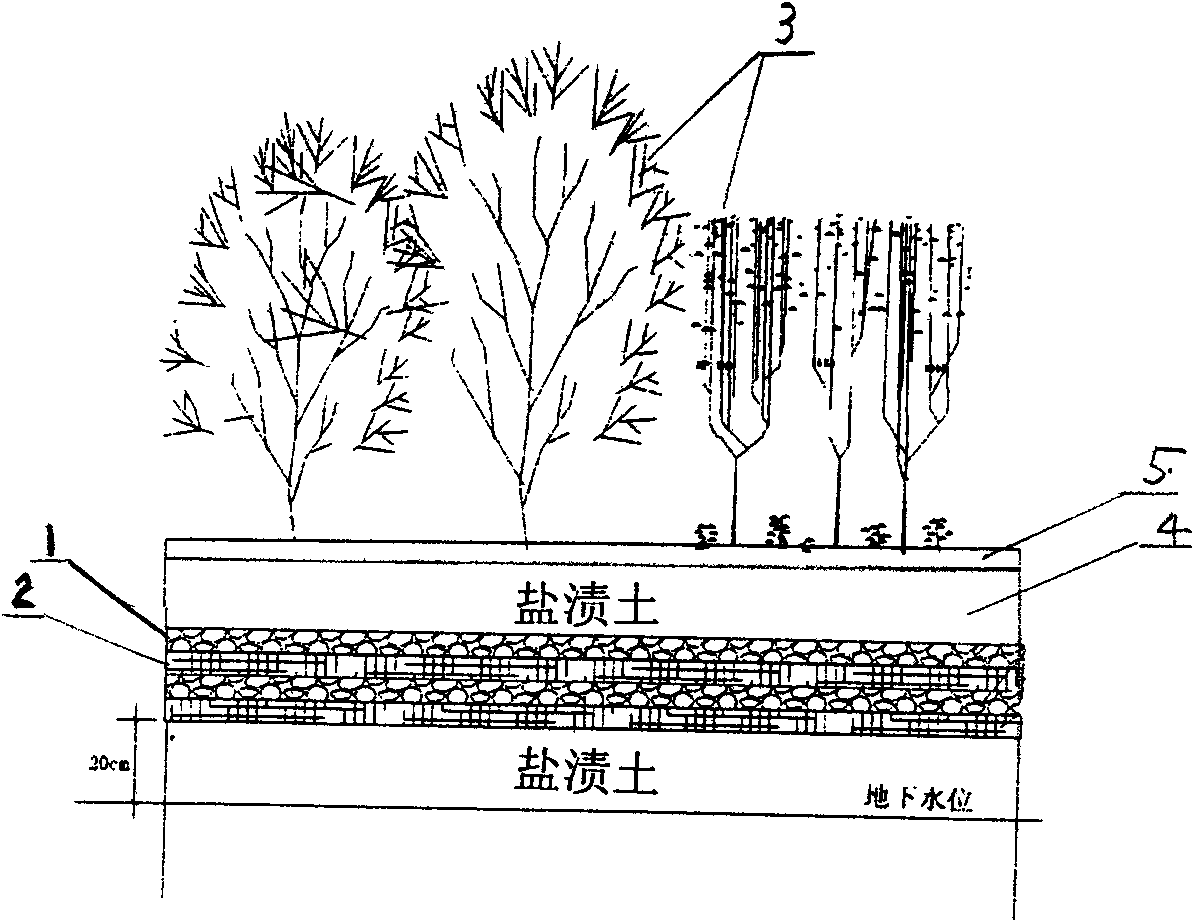

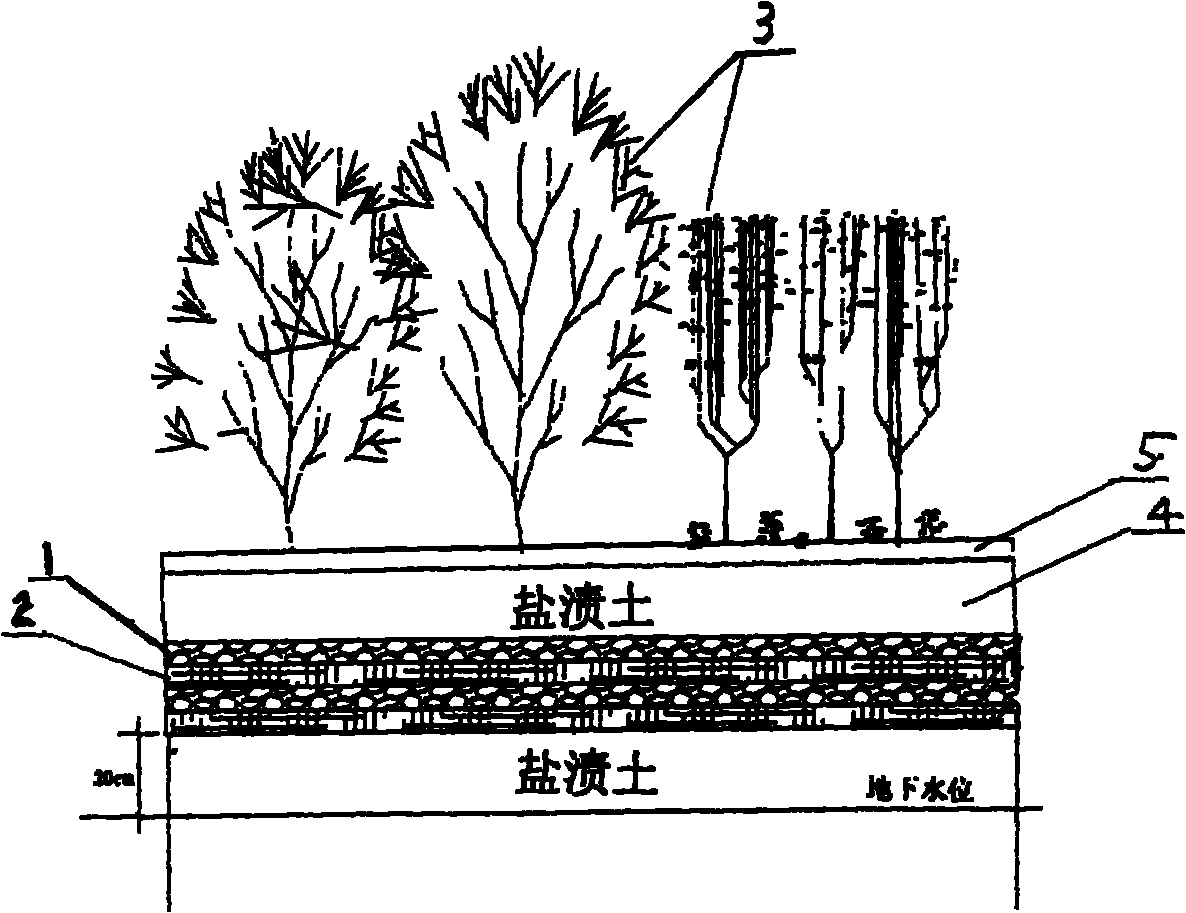

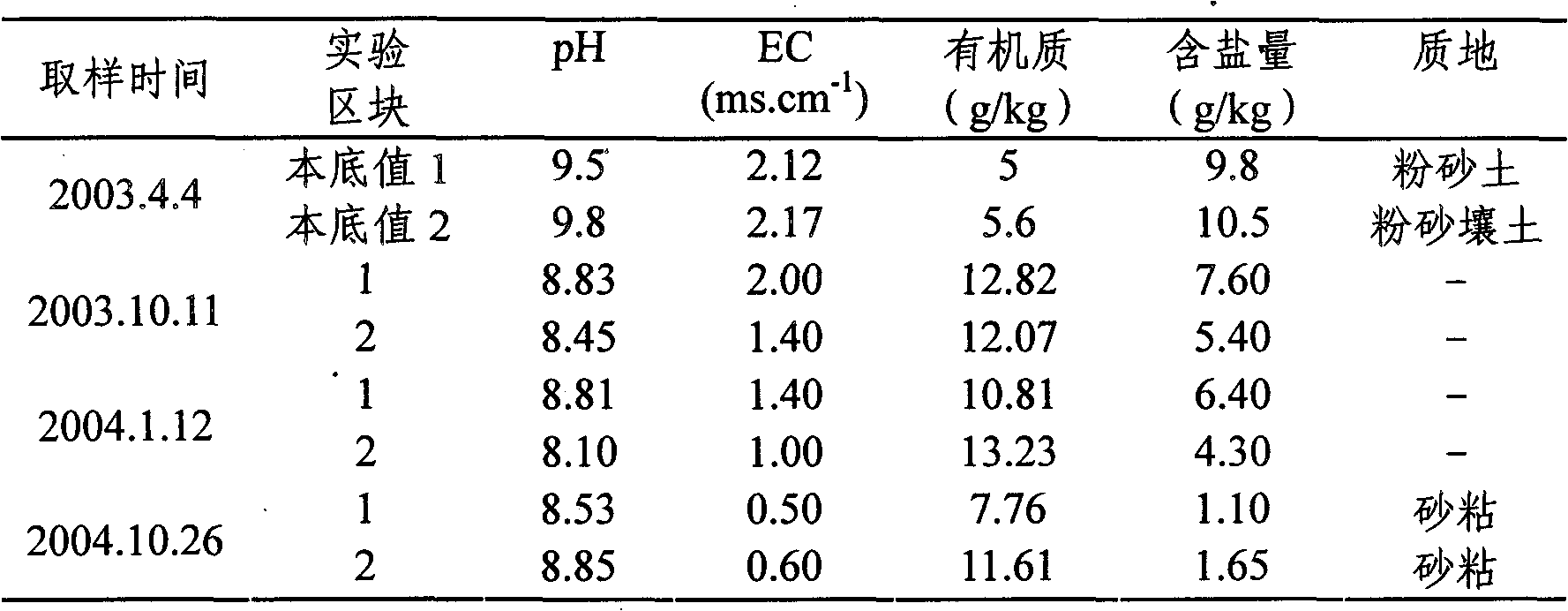

Method for improving coast salty soil by utilizing cotton straw

InactiveCN101849455AReduce salt contentIncrease organic matterHorticulture methodsSoil-working methodsCrushed stoneBiology

The invention relates to a method for improving coast salty soil by utilizing cotton straw, belonging to the soil improvement technical field. The invention is characterized in that: soil block to be improved is divided on coast salty soil; salty soil more than 20cm higher than ground water level is removed; cotton straws doped with straws are arranged in sequence, flatted and tied up into straw layers with the thickness of 10cm; the straw layers are spread and covered on the salty soil in the same direction and in parallel, broken stones with the grain diameter of 1-2cm are uniformly and additionally covered on the straw layer, the thickness thereof is 5cm, thus forming an isolating layer; so that two isolating layer are formed; and punning is carried out. Ambient salty soil is uniformly covered on the isolating layer; salt tolerant plants are planted in the saline soil; and straw with the thickness of 3cm is covered on the saline soil. By implementing the invention, soil salt content is obviously reduced; and soil organic matter is improved. Isolating effect is obvious, the cotton straw is isolated and also adds soil nutrient, thus being beneficial to plant growth. Operation is simple and convenient, cost is low, and the method can be popularized and applied in large scale; and the cotton straw is recycled.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

Replay debugging

ActiveUS7849446B2Error detection/correctionSpecific program execution arrangementsParallel computingModified technique

Transactional programming promises to substantially simplify the development and maintenance of correct, scalable, and efficient concurrent programs. Designs for supporting transactional programming using transactional memory implemented in hardware, software, and a mixture of the two have emerged recently. Unfortunately, conventional debugging programs are often inadequate when employed in relation to code that employs transactional memory and new or modified techniques are needed. We describe techniques whereby certain facilities of a transactional memory implementation can be leveraged to provide replay debugging. With replay debugging, the user can examine a partial or complete execution of an atomic block after it has happened—for example, right before the execution commits. Moreover, in some cases the user can modify the replayed execution, and decide to commit the new modified execution instead of the original replayed one.

Owner:ORACLE INT CORP

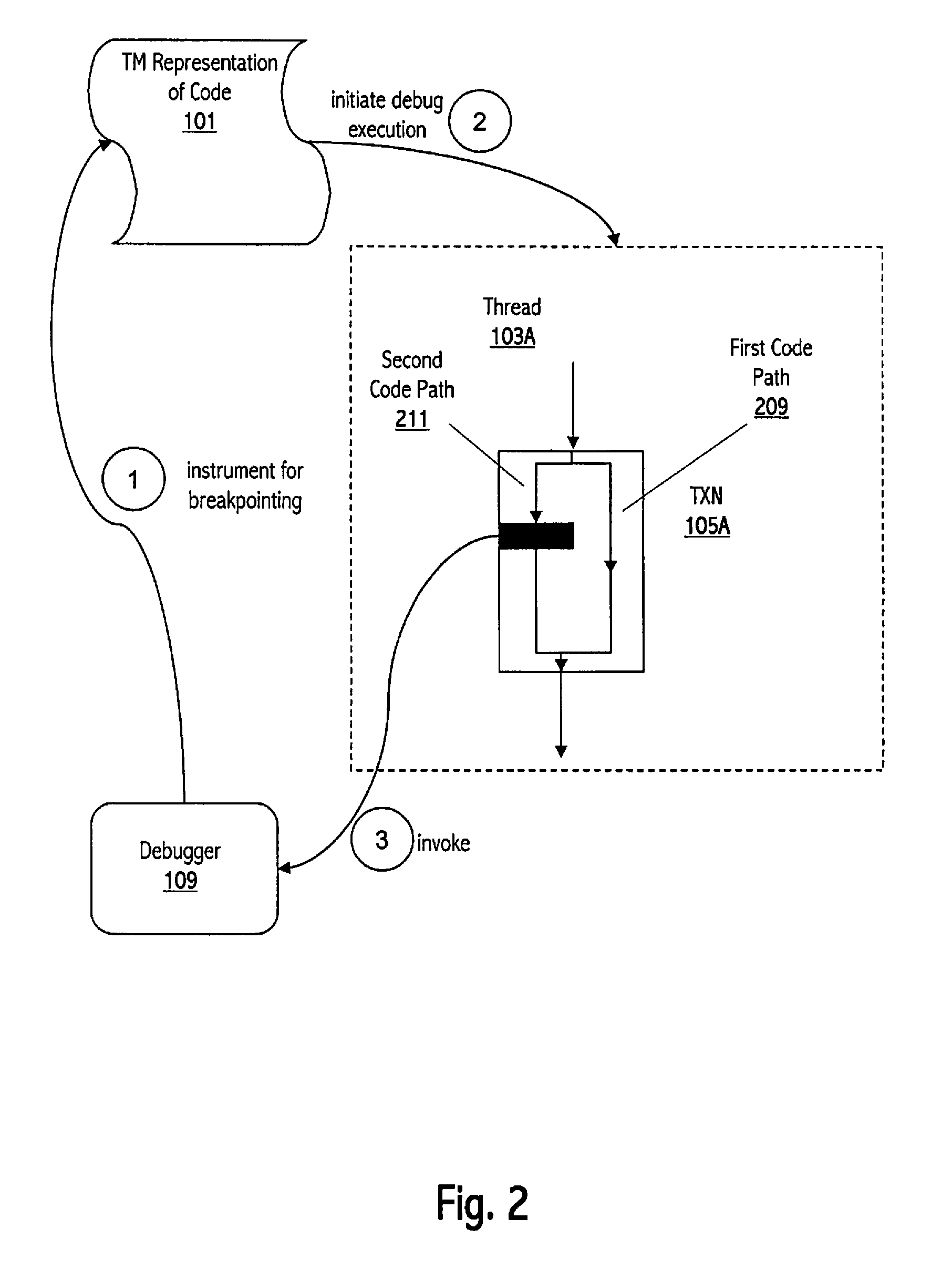

Delayed breakpoints

ActiveUS20080005193A1Minimizing side-effectsError detection/correctionDigital data processing detailsModified techniqueSoftware

Transactional programming promises to substantially simplify the development and maintenance of correct, scalable, and efficient concurrent programs. Designs for supporting transactional programming using transactional memory implemented in hardware, software, and a mixture of the two have emerged recently. Unfortunately, conventional debugging programs are often inadequate when employed in relation to code that employs transactional memory and new or modified techniques are needed. Implementations of delayed breakpoints are described that provide programmers with the benefits of breakpoints in transactional code, while minimizing the side-effects of breakpoints placed inside atomic block.

Owner:ORACLE INT CORP

Manufacturing method of novel environment-friendly kraft board paper

The invention discloses a manufacturing method of novel environment-friendly kraft board paper. According to the manufacturing method, starch in pulp is recycled, COD (chemical oxygen demand) of wastewater is reduced, retention and drainage agents, aluminum sulfate and macromolecular dry strength agents are added into a flowing system in order to solve the problems of short fibers and low pulp retention, the pulp retention and the strength of subsequent finished paper are improved, starch and small fibers are adsorbed on long fibers, high retention of the starch is achieved, a PH (potential of hydrogen) valve of the pulp is adjusted to neutral by the aluminum sulfate, anionic trash in the pulp is removed by the aid of aluminum ions, mutual combination between fibers is improved by the aidof the dry strength agents, combining capacity of the fibers is enhanced, the combining capacity of the fibers and the physical strength of the finished paper are improved by the aid of chemical fiber modified technique, sizing agents are added into the pulp, so that the strength of the finished paper is improved, high ash content is kept, the utilization rate of waste paper is increased, the strength of the finished paper is enhanced, and the manufacturing method is applicable to production lines of most kraft board paper and has a quite wide market prospect.

Owner:JIANGSU LEE & MAN PAPER MFG

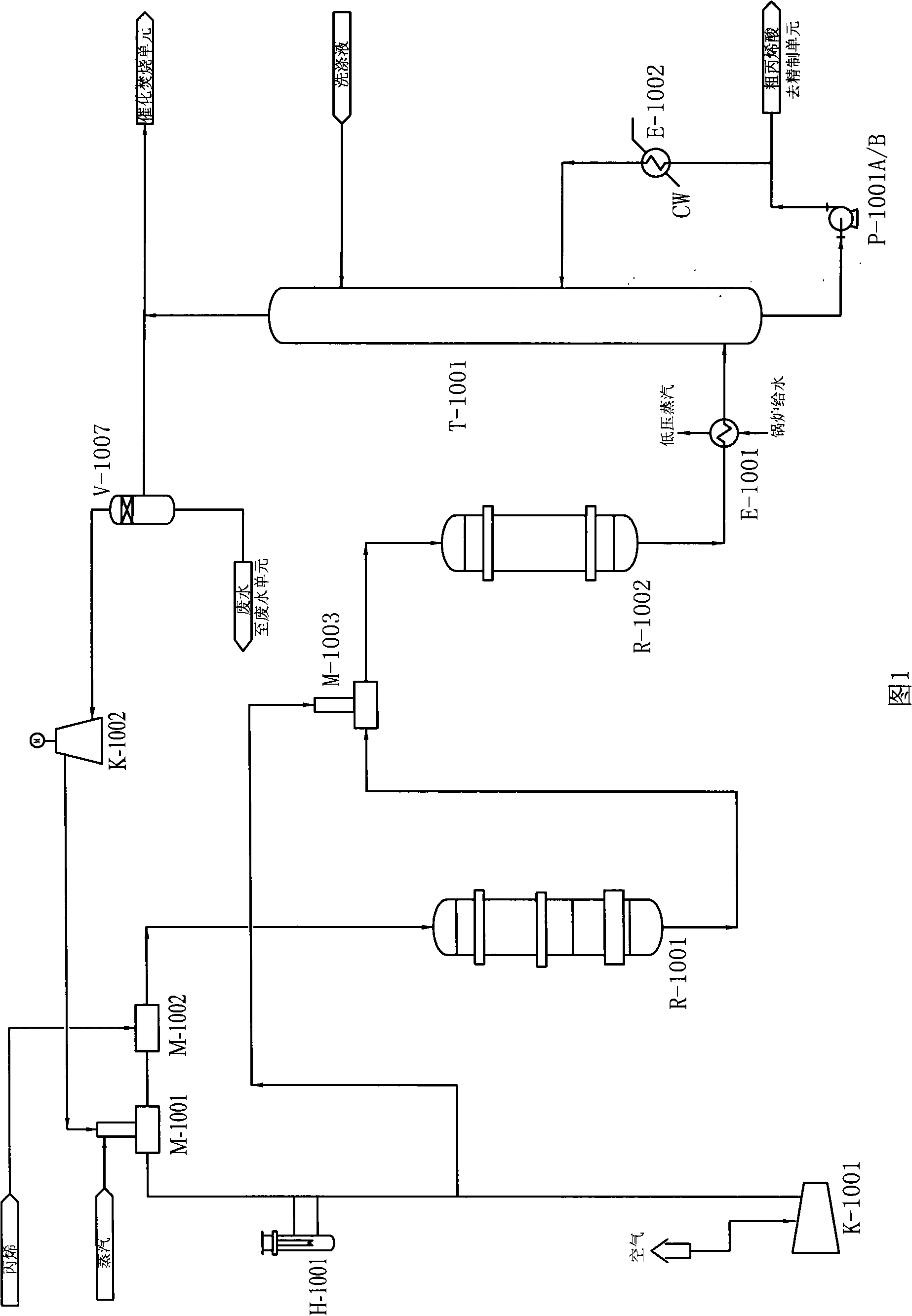

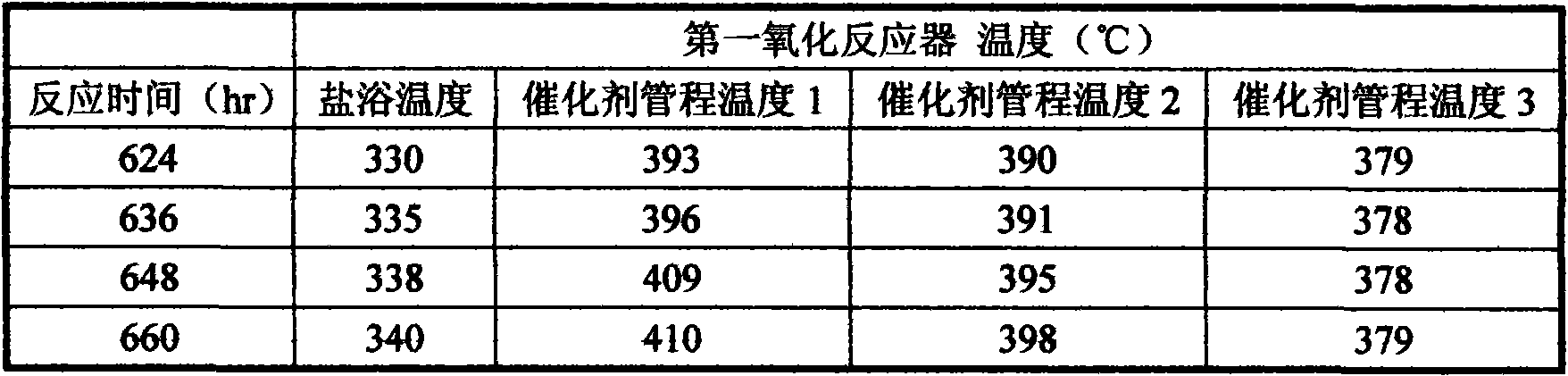

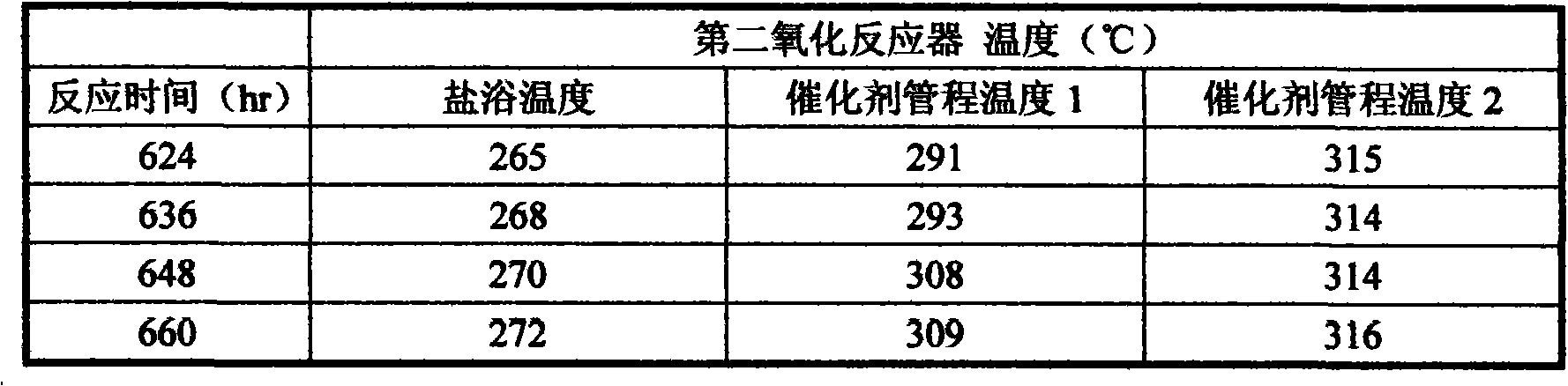

Modified technique for preparing acrylic acid by propylene two-step oxygenation method

ActiveCN101260032AImprove conversion rateHigh yieldOrganic compound preparationCarboxylic compound preparationHigh concentrationOperating point

The invention discloses an improved process of preparing acrylic acid through a propylene two-step method, which is characterized in that: the amount of propylene in raw material ratio is increased to ensure that the feed concentration of propylene is 8.0-9.88 percent (mol); washing liquid entering from the top of a washing tower is the mixture of desalted water and acrylic acid containing wastewater; the acrylic acid wastewater is the acid containing wastewater produced by an acrylic acid refining unit in an acrylic acid device; the quantity of wastewater accounts for 50-60 percent (wt) of the total amount of the washing liquid. The improvement has the advantages that: the adoption of high concentration propylene feed can raise the conversion rate of propylene as well as the yield coefficient of acrylic acid, regulate the operating point of oxidation reactant to be beyond the range of an explosion curve, ensure that the device operates in an optimal safe region, reduce the consumption of propylene raw material and raise the production capacity of the device; the adoption of the mixture of desalted water and acrylic acid containing wastewater reduces the dosage of desalted water, the treatment load of a wastewater unit of the device as well as the wastewater discharge amount of the device, and can recycle acrylic acid to the utmost extent, so as to decrease the production cost of the acrylic acid device.

Owner:中石油吉林化工工程有限公司

Persulphate combined heating and activation method for environmental restoration

InactiveCN108160693AExtended usage limitsUnaffected or reduced by seasonal changesContaminated soil reclamationActivation methodTreatment effect

A persulphate combined heating and activation method for environmental restoration comprises the steps that soil or a soil layer, containing organic pollutants, of a target restoration site is heatedto the temperature interval of 20-45 DEG C; under the condition of continuous heating and heat preservation, synergistic activation of hydrogen peroxide and chelating transition metal is implemented,the activation process is short in duration time but high in effect, the organic pollutants in the soil are promoted to be desorbed, and the degradation process of the organic pollutants is accelerated; and heating continues being conducted, and the continuous heat activation stage is started in a transition mode until the concentration of the target pollutants is decreased to be below a restoration target value. The restoration method adapts to environment restoration of soil and groundwater under cold regions / the low temperature environment, and is also an enhanced improved technology for semi volatile organic compound (SVOC) polluted soil which is difficult to restore through a general activation technology, the treatment effect can be effectively improved, thus engineer operation is not influenced by seasonal change, or the seasonal change influence is reduced, and the regional using range is expanded.

Owner:北京宜为凯姆环境技术有限公司

Delayed breakpoints

ActiveUS7840947B2Minimizing side-effectsDigital data processing detailsError detection/correctionModified techniqueSoftware

Transactional programming promises to substantially simplify the development and maintenance of correct, scalable, and efficient concurrent programs. Designs for supporting transactional programming using transactional memory implemented in hardware, software, and a mixture of the two have emerged recently. Unfortunately, conventional debugging programs are often inadequate when employed in relation to code that employs transactional memory and new or modified techniques are needed. Implementations of delayed breakpoints are described that provide programmers with the benefits of breakpoints in transactional code, while minimizing the side-effects of breakpoints placed inside atomic block.

Owner:ORACLE INT CORP

Mildew resistant antimicrobial type low corrosion water-based scaling powder

InactiveCN101239428AInhibit growthDoes not cause corrosionWelding/cutting media/materialsSoldering mediaWater basedActive agent

The invention relates to soldering fluid technique, which is a modified technique based on prior art, specifically relates to a mildew resistant antibiotic low-corrosivity water-based soldering fluid, comprising components with following percentage by weight (): 1.0% of active agent, 1.0% of micro-enwrapping agent, 0.1% of surfactant, 0.01% of mildew resistant antibiotic agent, residue is solvent of de-ionized water, and the weight sum of each components are 100 The advantages of the invention are: the soldering fluid contains no volatile organic matter or halide, and can inhibit development of microorganisms such as bacteria and fungi and mildew; circuit and conveyor are not eroded during welding, no cleaning is needed after welded, and the soldering fluid is safe and environmentally-friendly; the soldering fluid can be coated on the PCB plate weld face by spraying, dipping or foaming mode to implement leadless welding of electronic products. The invented soldering fluid is practical and has great market potential.

Owner:PERFECTION SCI & TECH DONGGUAN

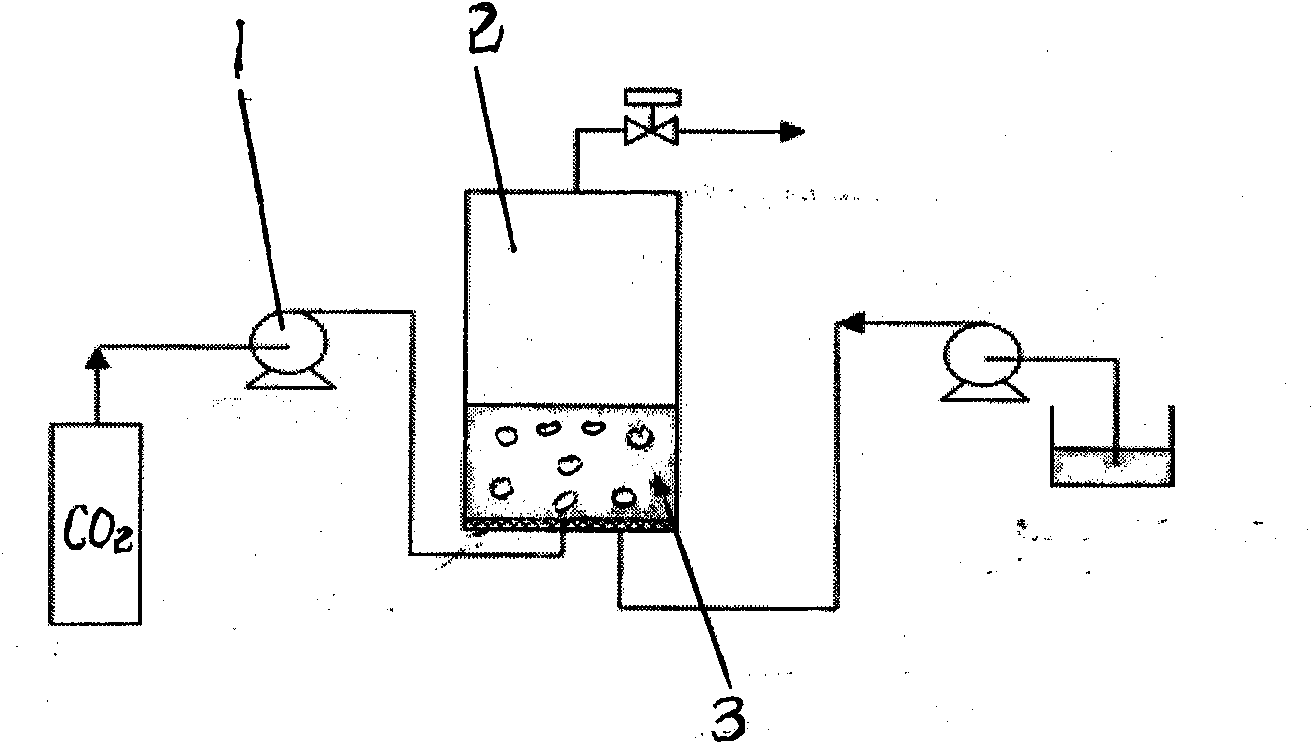

Supercritical fluid technology coating modifying technique of ammonium nitrate

The present invention relates to a supercritical fluid technology coating modifying technique of ammonium nitrate, and particularly to a supercritical fluid technology coating modifying technique of ammonium nitrate. The invention settles the problem of superfine ammonium nitrate coating existing in the prior art. The method is that the ammonium nitrate and the acetone are mixed and grinded so that the grain diameter of the ammonium nitrate is 2-10 mu m. The grinded ammonium nitrate and 10% of acetone nitrocellulose solution are prepared to a suspension and placed into a high-pressure deposition deposition kettle. Then the carbon diode is introduced as an antisolven for inter-dissolving with the acetone. The nitrocotton recrystallizes, separates out and precipitates on the surface of ammonium nitrate particle. Finally the particle with the grain diameter of 2-15 mu m is obtained. The extraction temperature of the high-pressure kettle is 30-32 DEG C. The constant-pressure extraction pressure is 9-11 Mpa. The product prepared by the technique of the invention has the advantages of no conglobation, no agglomeration, and remarkably reduced hygroscopicity.

Owner:NORTH BLASTING TECH

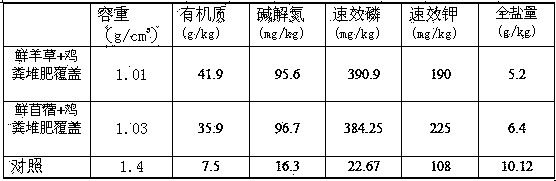

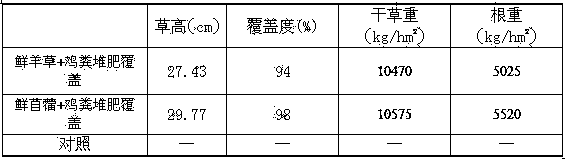

Rapid biological remediation method for alkali spots

InactiveCN103609222AImprove physical and chemical propertiesRebuild artificial vegetationSoil-working methodsDecompositionBioremediation

The invention provides a rapid biological remediation method for alkali spots. The rapid biological remediation method comprises the steps of utilizing rainy seasons with the high temperature, conducting direct composting and coverage on fresh grass and rural solid waste alkali spots, conducting ripping and burying with surface soil after thorough decomposition, and creating a germination layer. The saline-alkali tolerance forage grass variety is preferably planted in autumn so as to increase the vegetation coverage, and the yield of forage grass can be remarkably improved. The rapid biological remediation method is an improvement technology which is low in forming cost, easy to operate and obvious and rapid in improvement effect.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

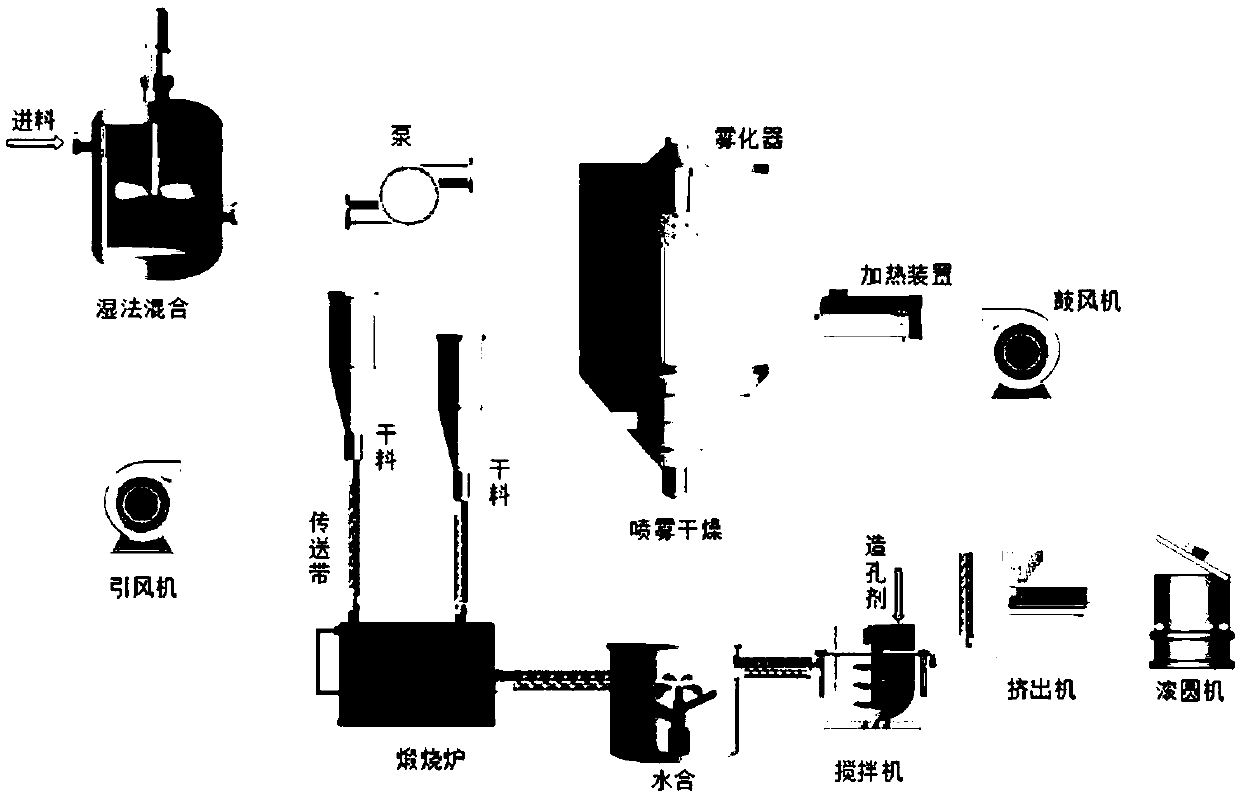

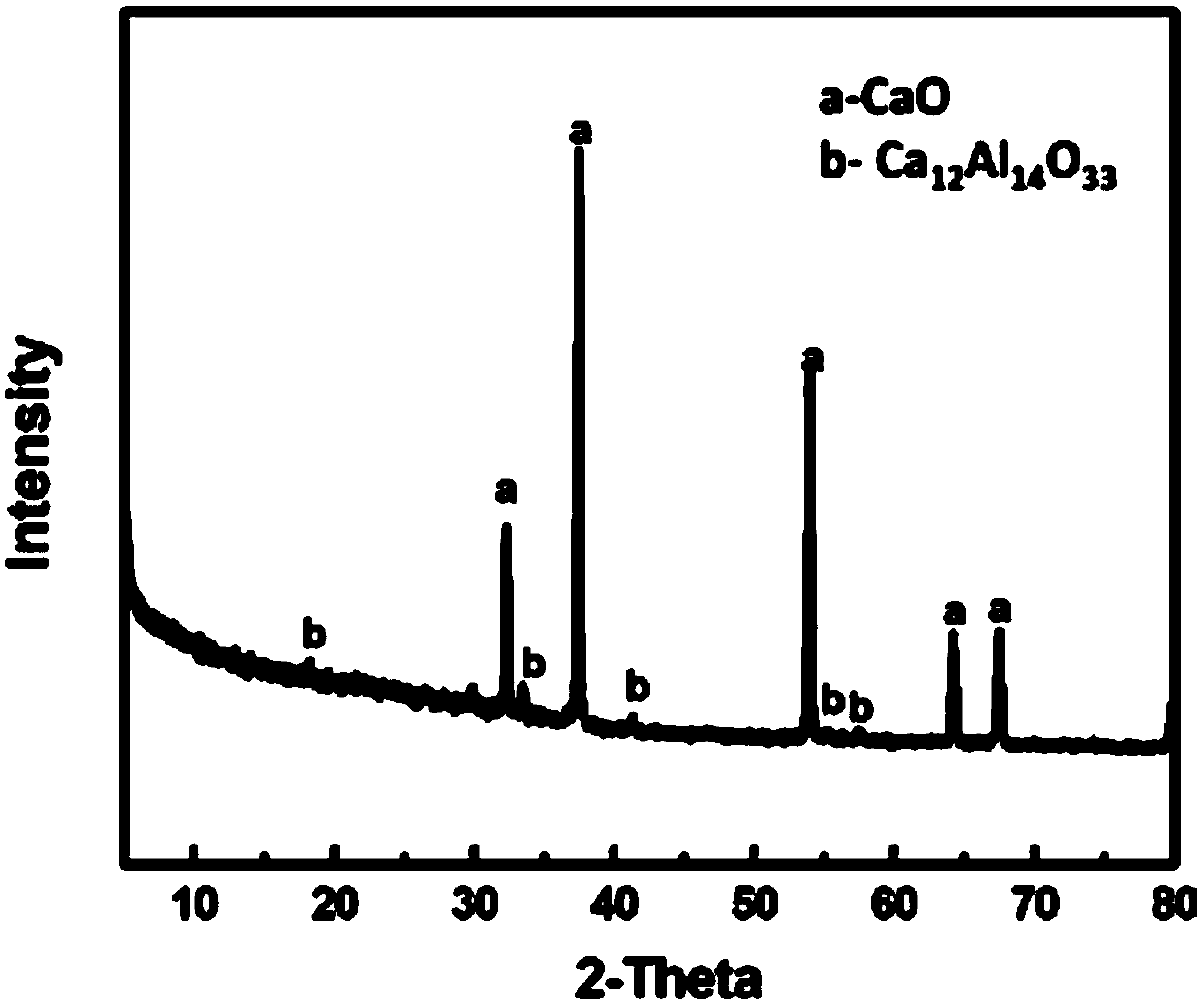

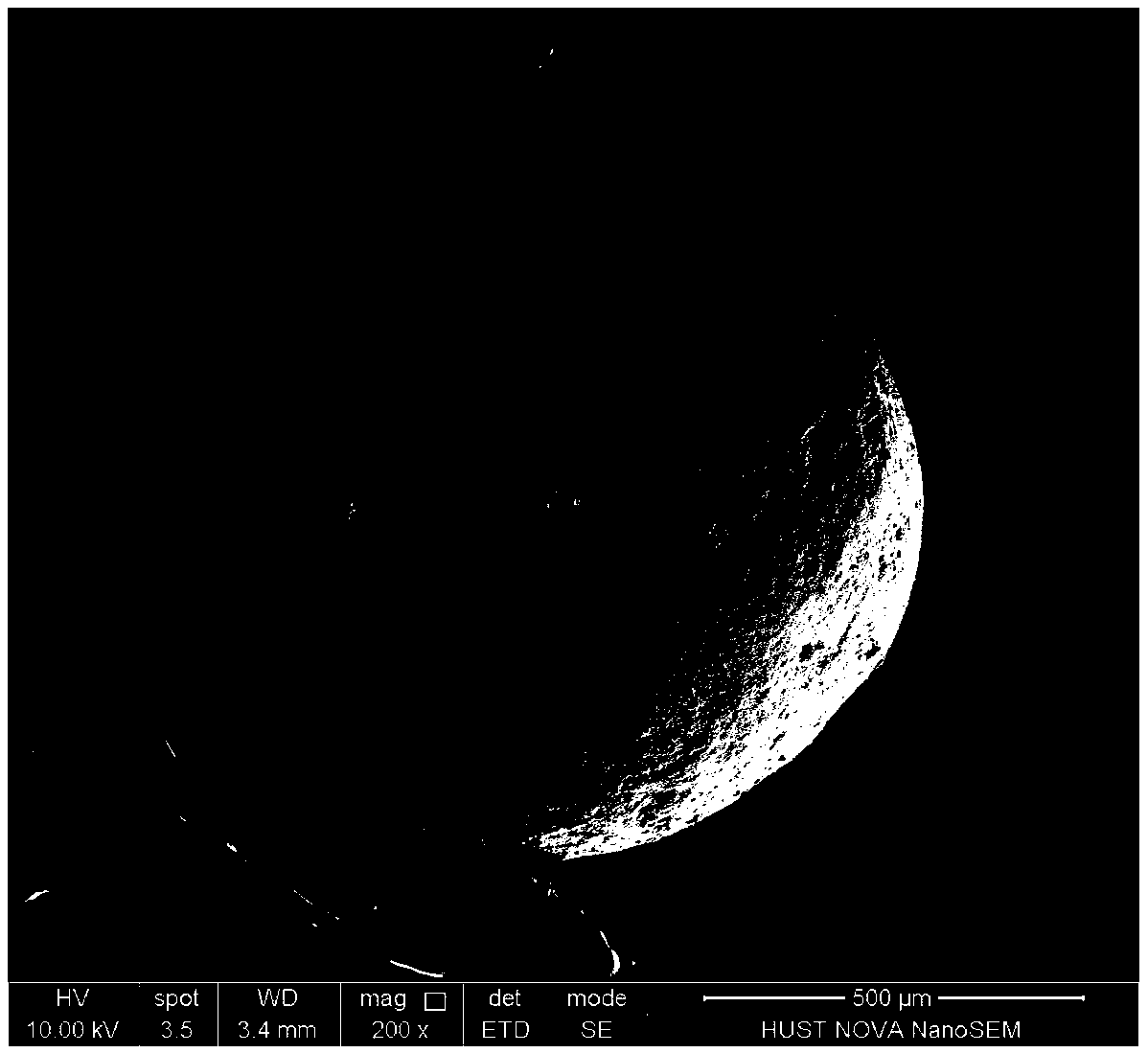

Preparation method of full-process industrialization globular calcium-based CO2 adsorbent

InactiveCN109621890AImprove cycle stabilityExtended service lifeGas treatmentOther chemical processesCalcium hydroxideFluidized bed

The invention belongs to the technical field of preparation and improvement of adsorbents and discloses a preparation method of a full-process industrialization globular calcium-based CO2 adsorbent. The method comprises the following steps that (a) the calcium-based adsorbent and inert carrier powder are selected and subjected to wet-method mixing, and an evenly-mixed solution is obtained and subjected to spraying drying to obtain the calcium-based adsorbent-inert carrier powder, namely precursor powder; (b) the precursor powder is calcined to obtain calcium oxide powder, the calcium oxide powder is hydrated to obtain a calcium hydroxide wet material, and after drying, calcium hydroxide powder is obtained; (c) the calcium hydroxide powder is extruded and rounded, and the required globularcalcium-based CO2 adsorbent is obtained. According to the method, the complete preparation process of the industrialization high-performance globular calcium-based CO2 adsorbent is designed, and the demands for industrial large-scale preparation and industrial circulation fluidized bed application are met at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

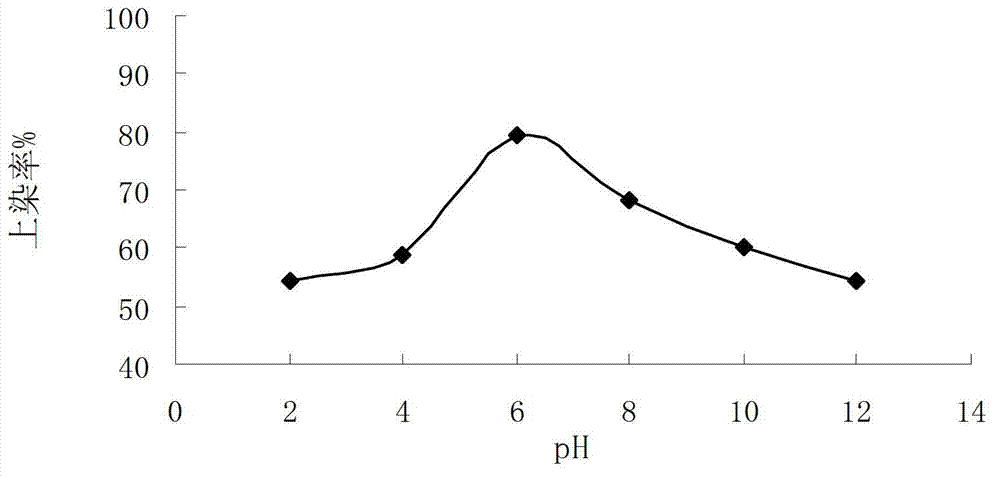

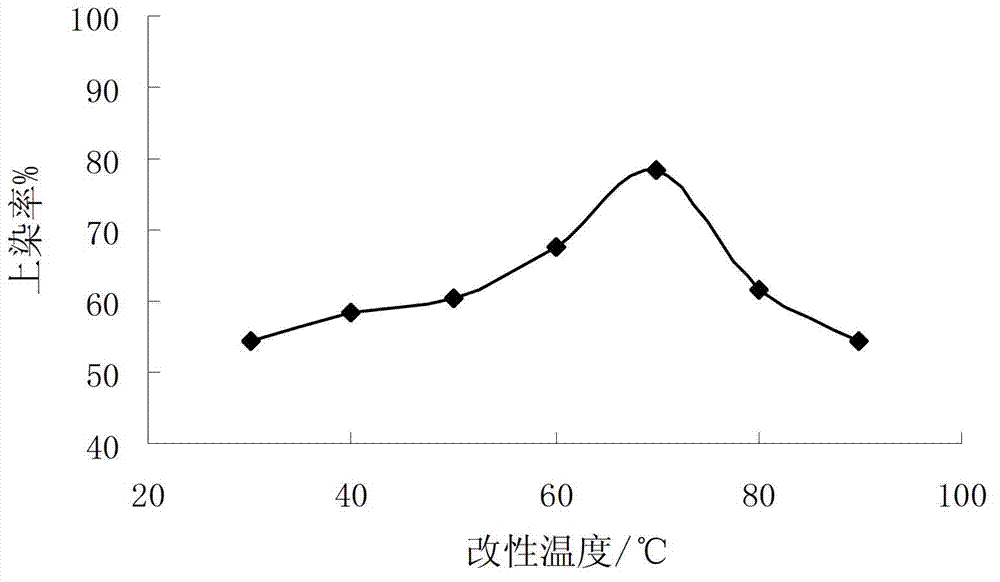

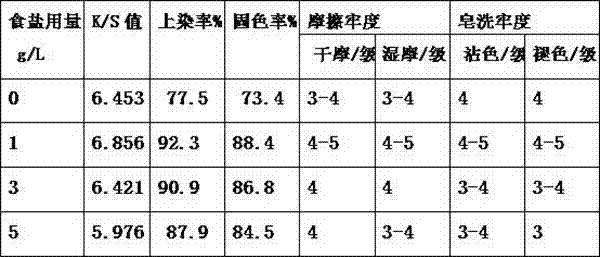

Tussah silk fiber or fabric cation modified finishing agent thereof and modified technique thereof

ActiveCN102965927AImprove adsorption capacityImprove dye uptakeAnimal fibresCooking & bakingFatty alcohol

The invention provides tussah silk fiber or a fabric cation modified finishing agent thereof and a modified technique thereof, wherein tussah silk fiber or the fabric cation modified finishing agent thereof is formed by mixing quaternary ammonium salt and a penetrant; the quaternary ammonium salt is at least one of solutions of dodecyl trimethyl ammonium chloride, myristyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride or octadearyl dimethyl ammonium chloride; the penetrant is a fatty alcohol-polyoxyethylene ether solution JFC in a nonionic surfactant; and the modified technique comprises the steps of: steeping degummed tussah silk or a fabric of the degummed tussah silk in the modified finishing agent for 20-30 minutes at the modified temperature of 65-75 DEG C, and then carrying out pre-drying and baking for 3 minutes, so as to obtain the modified tussah silk fiber or the fabric of the degummed tussah silk. The technical scheme provides an effective implementation scheme for high-performance and pollution-free dyeing of reactive dyes of the tussah silk fiber or the fabric of the degummed tussah silk.

Owner:EASTERN LIAONING UNIV

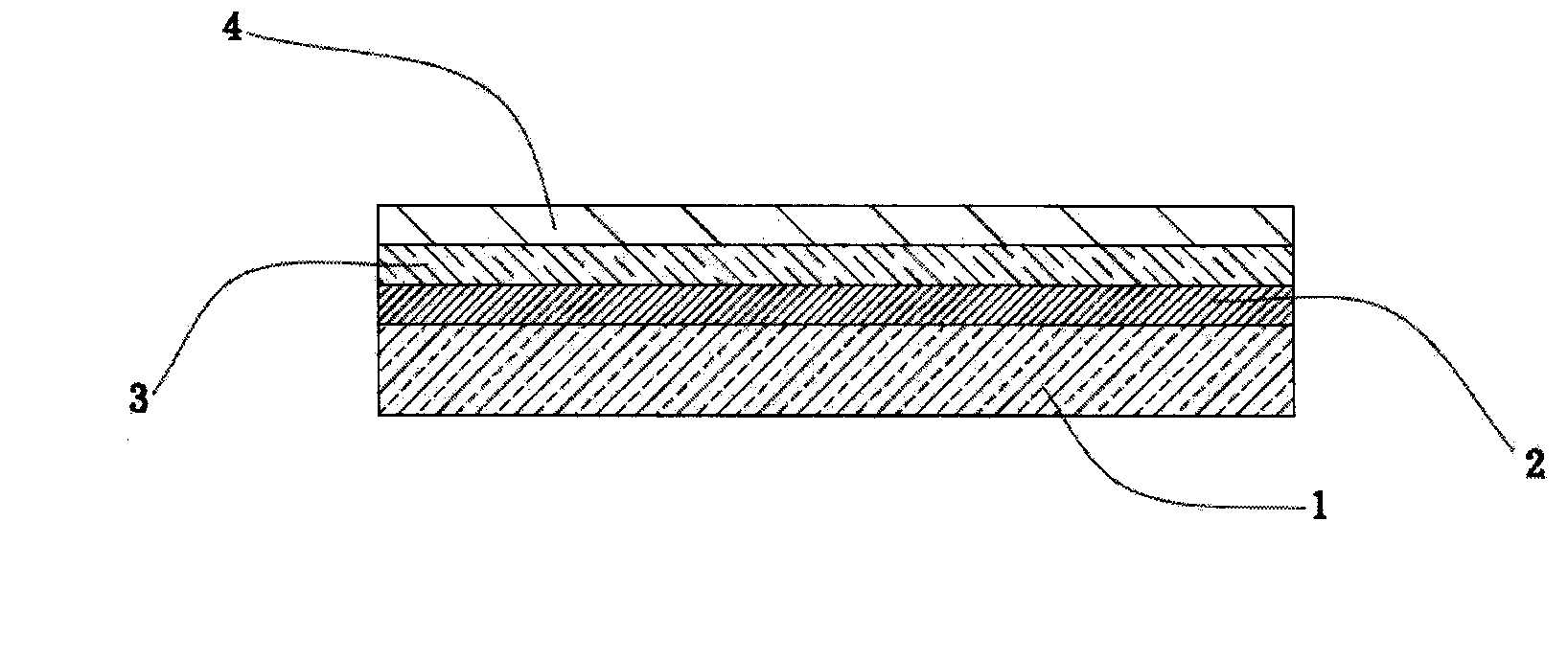

Bright white hot stamping foil as well as production method thereof

ActiveCN103847270AIncrease brightnessHot stamping effect is goodThermographyPolyamide coatingsPolyesterCross-link

The invention relates to the technical field of printing hot stamping, and particularly relates to a bright white hot stamping foil as well as a production method of the bright white hot stamping foil. The bright white hot stamping foil at least comprises a biaxial stretching polyester film base material which is sequentially coated with releasing agent resin, coloring extracts and a hot melt adhesive. According to the invention, before the coloring extracts are coated, the biaxial stretching polyester film base material is coated with highlight organic silicon resin, acrylic resin, methyl silicone resin, chopped fibers, dual-component epoxy resin, cross-linking agents, stabilizing agents, butanone and ethyl ester, is mixed, moistened and dispersed so as to prepare releasing agent resin; the coating technology is controlled reasonably, so that the prepared product has the characteristics of high brightness, good hot stamping effect, wide applicability, excellent surface scraping resistance and the like; meanwhile, the modified technique can be applied to production continuously and stably; the operation is simple and convenient; the production efficiency is improved.

Owner:ZHEJIANG HENGFENG PACKING

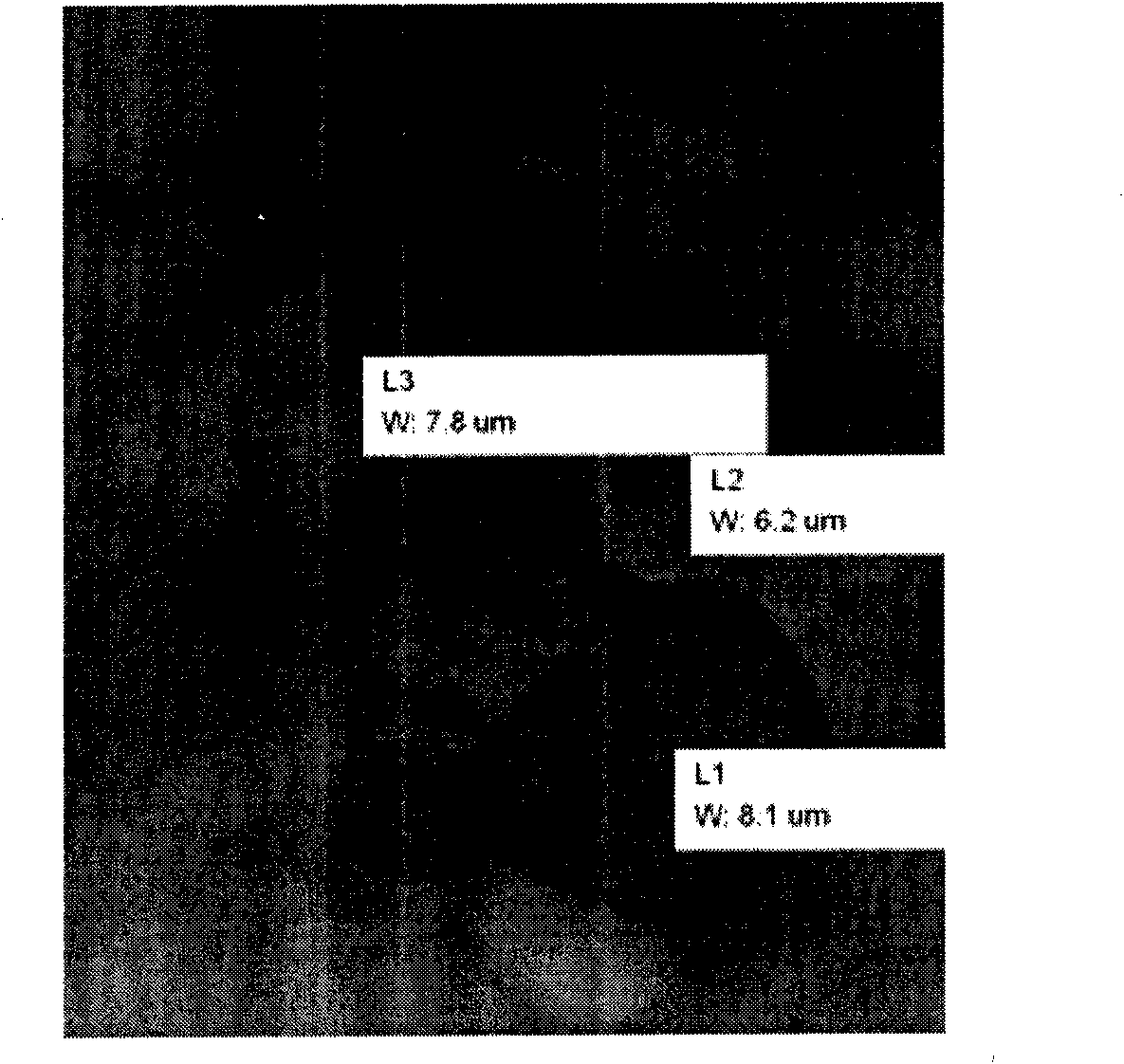

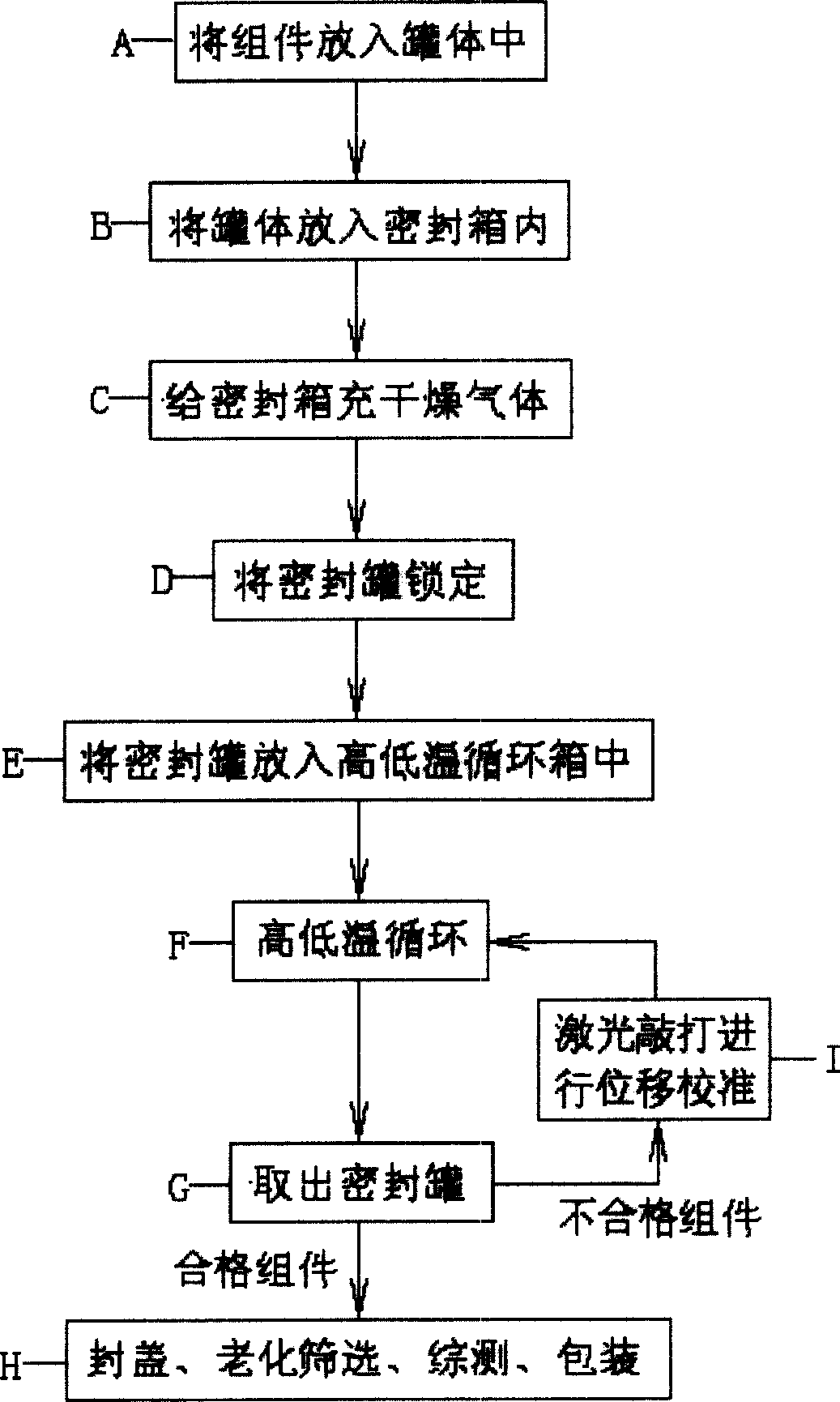

Method for raising semiconductor laser yield

ActiveCN1710762AImprove reliabilityImprove yieldLaser detailsSemiconductor lasersHeat conductingEngineering

The invention is related to modifying technique for packaging semiconductor laser. Other packaging steps finished and not closed over laser modules are put into airtight container with good heat-conducting property to carry out high and low temperature cycle. After residual stress is released fully, fine adjustment is carried out for coupling welded support in light power changed modules through laser beat etc. technique to make their light power get back to level before high and low temperature cycle. Then, steps including closing over, burn in screen, testing, packaging are carried out for the modules, which are through the said laser beat, passed high and low temperature cycle again and unchanged light power, so as to obtain high reliable semiconductor laser in high yield. The invention prevents wasting material and working hours, and saves cost.

Owner:WUHAN TELECOMM DEVICES

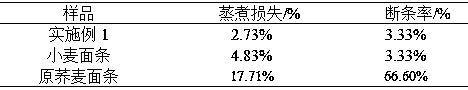

Processing method for improving quality of foods made of whole coarse cereal flour through extrusion modified coarse cereal powder

The invention relates to a processing method for improving quality of foods made of whole coarse cereal flour through extrusion modified coarse cereal powder, and belongs to the technical field of food processing. According to the processing method disclosed by the invention, coarse cereals rich in dietary fibers are used as raw materials, coarse cereal powder is modified under the extrusion condition of low screw speed, low extrusion temperature and high moisture content, and then the extrusion modified coarse cereal powder is added back to original coarse cereal powder, so that the quality and edibility characteristics of foods made of whole coarse cereal flour such as coarse cereal noodles and coarse cereal steamed buns can be obviously improved. According to the processing method disclosed by the invention, the processing performance of the coarse cereals can be improved through an extrusion modified technique, and besides, functional nutrient components of the coarse cereal powderare greatly reserved. The extrusion modified coarse cereal powder is added back to the original coarse cereal powder in proportion, foods wholly made of coarse cereal flour can be produced, additional addition of components of wheat flour, vital wheat gluten, hydrophilic colloid and the like is not needed, and the shortcoming that the coarse cereals do not contain structural protein, so that thedefect that when the coarse cereals are made into wheat flour foods, the wheat flour foods are difficult to shape can be overcome; and in addition, the wheat products are good in mouth feel and rich in dietary fibers and various functional nutrition components, and different consumer demands can be met.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Low odor nylon 6 composition

The invention introduces a low-smell nylon 6 composition, whose components comprises nylon 6 resin, compatilizer, filler, lubricant polysiloxane and additive. The invention is characterized in that the compatilizer of the composition is polyolefin and grafted copolymer of unsaturated acid and anhydride; the lubricant is super high molecular weight polysiloxane. The mixing amount (in part by weight) of the components respectively is: nylon 6 resin 40 to 97, the compatilizer 1 to 20, the filler 1 to 40, the lubricant 0.5 to 5, the other additives 0.3 to 2. The way to reduce the smell of the nylon 6 composition uses the modified technique with low cost to reduce the smell of the nylon 6 composition with simple operation, and meanwhile increases the performance of the nylon 6 composition.

Owner:CHONGQNG PRET NEW MATERIAL +2

Treatment method of continuous cropping soil

InactiveCN107360750AImprove buffering effectAlleviate salinizationContaminated soil reclamationOrganic fertilisersContinuous croppingPlant nodule

The invention relates to a treatment method of continuous cropping soil, and belongs to the technical field of soil improvement. Harmful bacteria in the continuous cropping soil are killed by high-temperature steam treatment, then struvite, mushroom spawn culture medium waste materials, sawdust, soybean root nodule and the like are used for fermentation, nutrients are activated in the growth process of soybean rhizobia, rhizobium fertilizer is prepared, and chemical elements of N and P accumulated in the soil are activated and balanced; then activated carbon in rice husks, silicon dioxide composite dolomite, fly ash and the like are used, so that the physical properties of the fertilizer are improved, the loss of fertilizer nutrients is reduced, the utilization rate of the fertilizer is improved, the buffering performance of the soil is enhanced, harmful elements in the soil are adsorbed, heavy metal pollution of the soil is treated, soil salinity and acidification are reduced, and soil continuous cropping obstacles are overcome.

Owner:胡果青

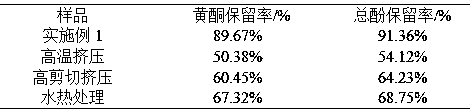

Preparation method of maleic anhydride grafted chlorinated polyvinyl chloride composite material

The invention relates to a modified technique of chlorinated polyvinyl chloride (CPVC) composite material, in particular to a preparation method for producing maleic anhydride grafted chlorinated polyvinyl chloride (MAH-g-CPVC) composite material by adopting a melting method to graft the maleic anhydride (MAH) onto a CPVC molecular link. The thermal decomposition temperature is 15 to 20 DEG C higher than that of ordinary CPVC resin, so that a melting processing temperature condition is satisfied, the Vicat softening temperature of the material can reach 125 to 135 DEG C, the maximal application temperature can reach 120 DEG C, and the long-term application temperature of the material is 105 DEG C. The defects that the melting temperature of the CPVC is close to or exceeds the thermal decomposition temperature, the overheating decomposition is likely to occur in the process for machining and forming a product, the machining difficulty is large, the fragileness of the product is large, and the impact resistance is poor can be overcome, so that the application prospect of the CPVC is wider.

Owner:HARBIN ZHONGDA PROFILE TECH

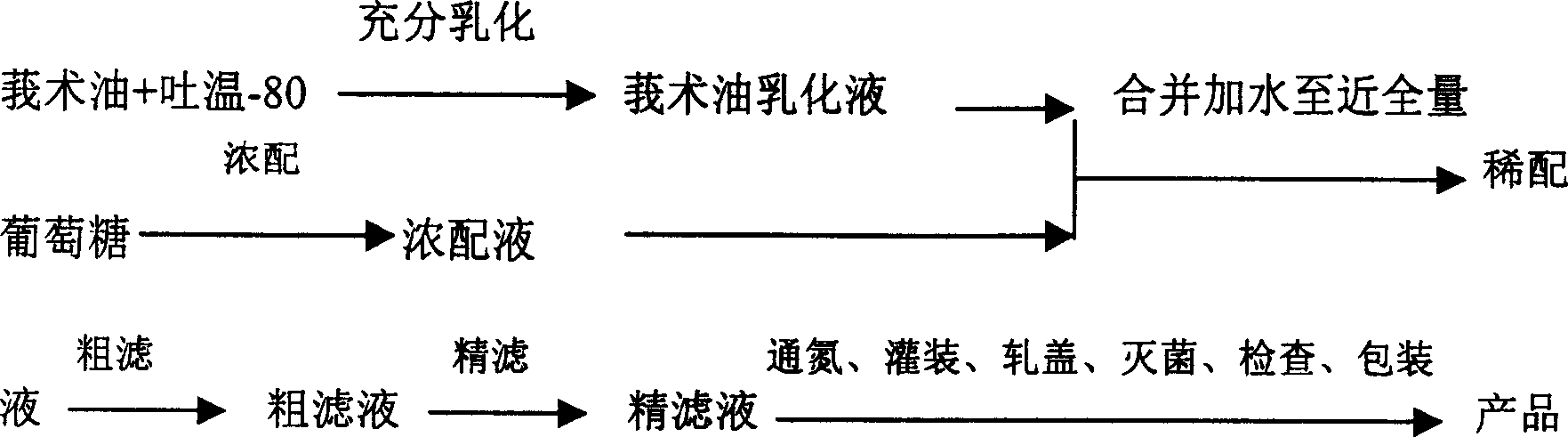

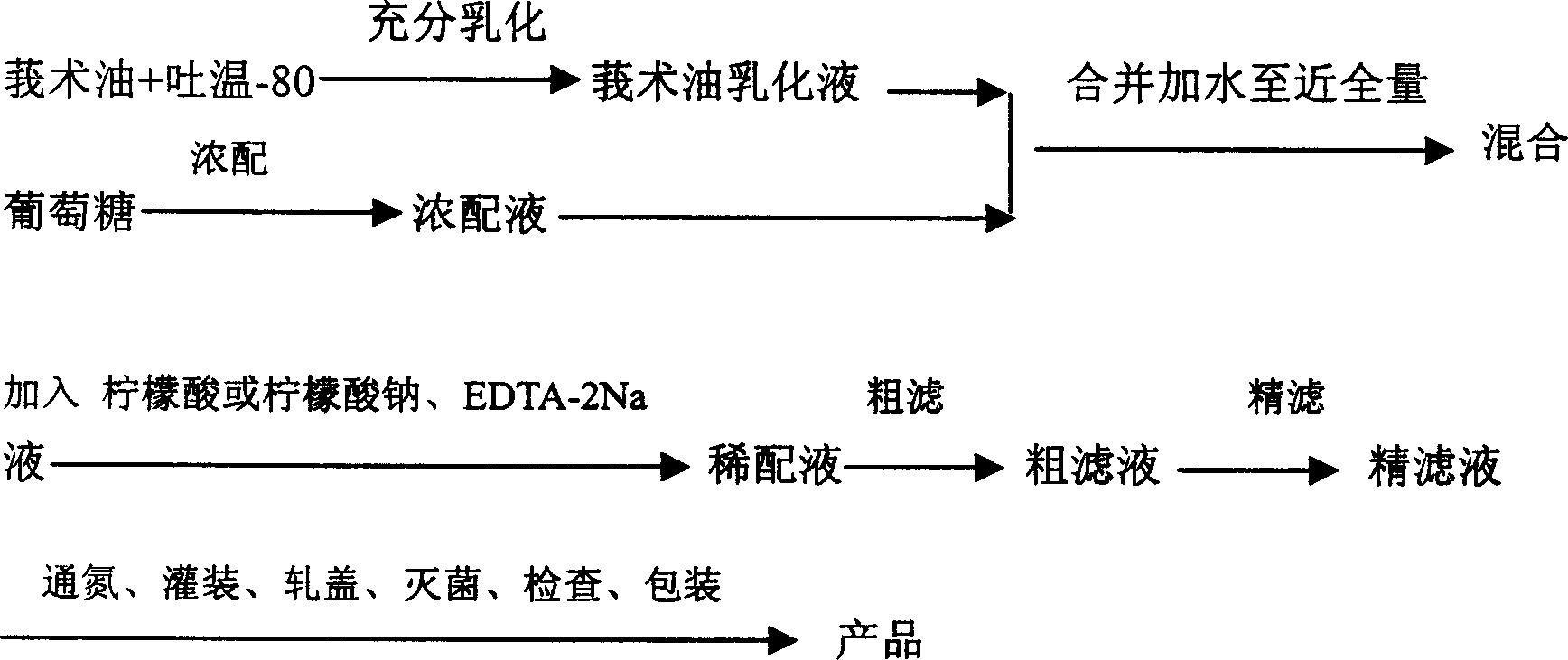

Modified technique for making zedoary turmeric oil and glucose injection

The invention relates to an improved process for preparing aromatic turmeric oil glucose injection which comprises, charging right amount of tween into aromatic turmeric oil, emulsifying sufficiently, preparing glucose solution, charging in right amount of activated charcoal, agitating, boiling a finite period of time, filtering, combining the two liquids, charing water for injection and sodium citrate or citric acid, dissolving with EDTA-2Na, adjusting pH to 3.5-5.0, and producing high capacity injection.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP

Improving method of saline-alkali land soil

InactiveCN109369298APrevent compactionBalanced fertilityCalcareous fertilisersAlkali orthophosphate fertiliserAlkali soilDrip irrigation

The invention discloses an improving method of saline-alkali land soil and relates to the technical field of saline-alkali land soil improving. According to the specific scheme, the improving method comprises the steps that conditioning fertilizer for improving the saline-alkali land soil is uniformly scattered on the surface of the soil, and turning burying is conducted; a plurality of mutually-parallel channels are excavated; and watering and film covering are conducted, film removing is conducted, watering is conducted for multiple times, and then dripping irrigation of wood vinegar is conducted. According to the improving method of the saline-alkali land soil, chemical improvement, biological improvement and physical improvement are organically combined, so that the optimal improvementeffect is achieved, and the problems that in chemical improvement, the soil is hardened, subsequent operation is affected consequently, in biological improvement, the cost is high, the consumed timeis long, and in physical improvement, resource waste is serious are also avoided; and through the improvement method provided by the invention, the soil is not hardened, soil fertility is balanced, the soil is suitable for crop growth, and the salinity and the pH value of the soil are decreased to the maximum extent on the basis of saving resources.

Owner:兴安盟隆华农业科技有限公司

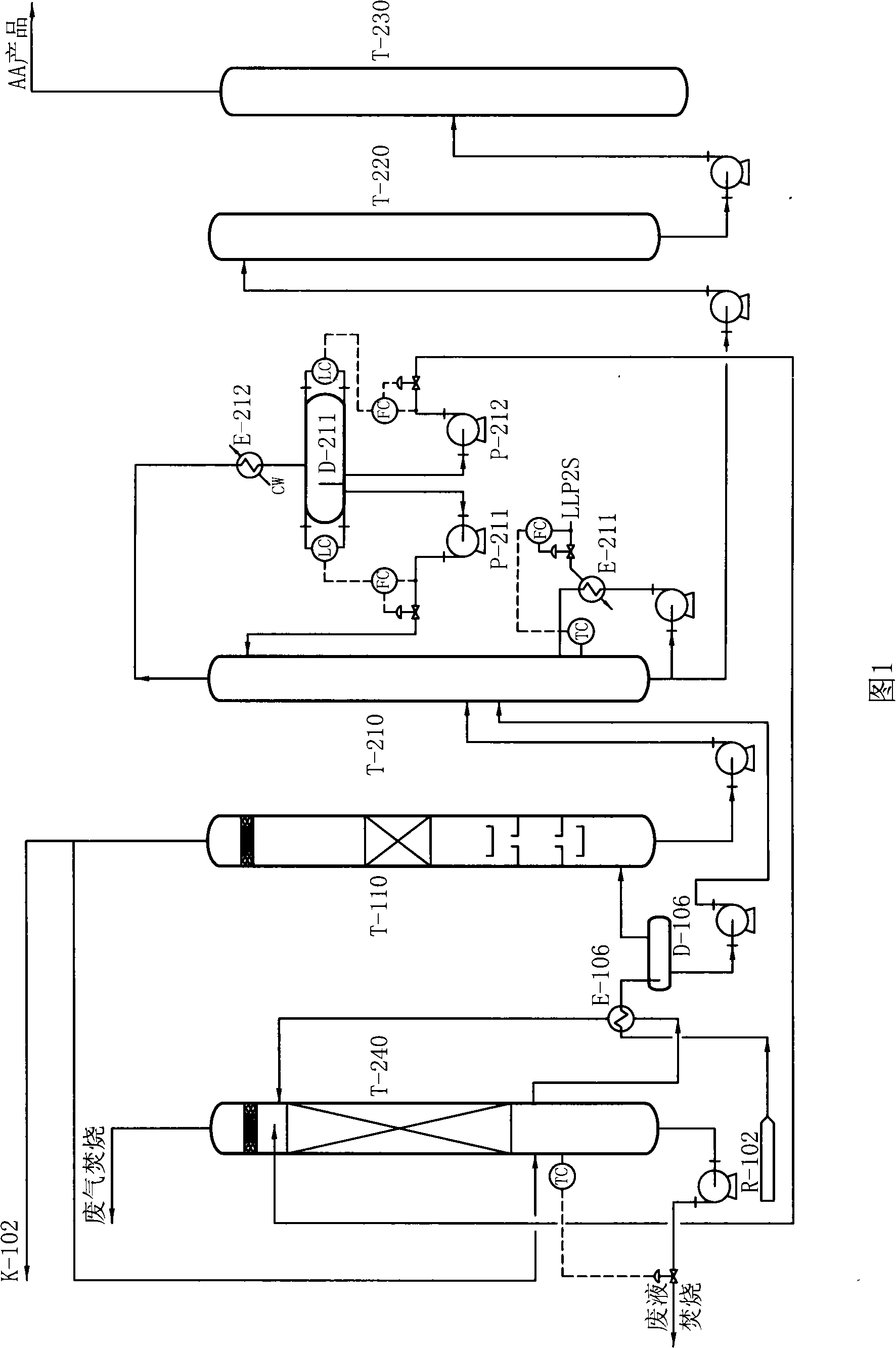

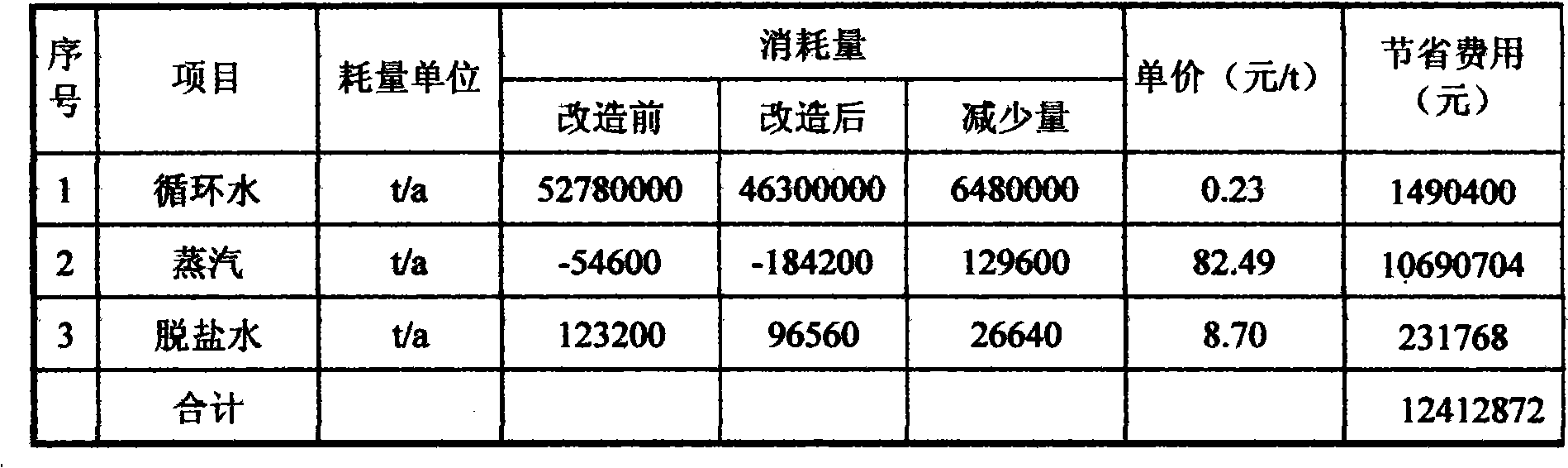

Modified technique for refined unit in acrylic acid production device

ActiveCN101260036ATemperature does not need to be strictly controlledLower feed temperatureChemical recyclingCarboxylic compound separation/purificationSocial benefitsAcetic acid

The invention discloses an improved process for a refining unit in an acrylic acid production device. Acrylic acid gas generated by a second acrylic acid reactor is cooled in a reactant cooler and is absorbed in an absorption tower; liquid on the lower part enters a light component fractionating tower; azeotropic distillation is carried out to water, acetic acid and acrylic acid; toluene is used as azeotrope former. The improved process is characterized in that: in the reactant cooler, circulating wastewater on the bottom of a stripping tower is adopted for cooling inside a shell side; the temperature of a tube side reactant outlet of the reactant cooler is 65-70 DEG C; a gas-liquid separation tank is provided additionally; an absorption tower bottom cooler is canceled; the overhead reflux ratio of the light component fractionating tower is 6.5-7.0; a wastewater stripping tower is provided. The improved process has the advantages that: for a 140, 000 ton / year acrylic acid device, 12, 000, 000 yuan of operation cost, 6, 400, 000 tons of circulating water, 120, 000 tons of steam and 26, 000 tons of desalted water can be saved each year; the improved process can reduce the discharge amount of acrylic acid waste gas and wastewater, is adapted to the industrial policy of China about saving energy and reducing emission, and has remarkable economic benefit as well as obvious social benefit.

Owner:中石油吉林化工工程有限公司

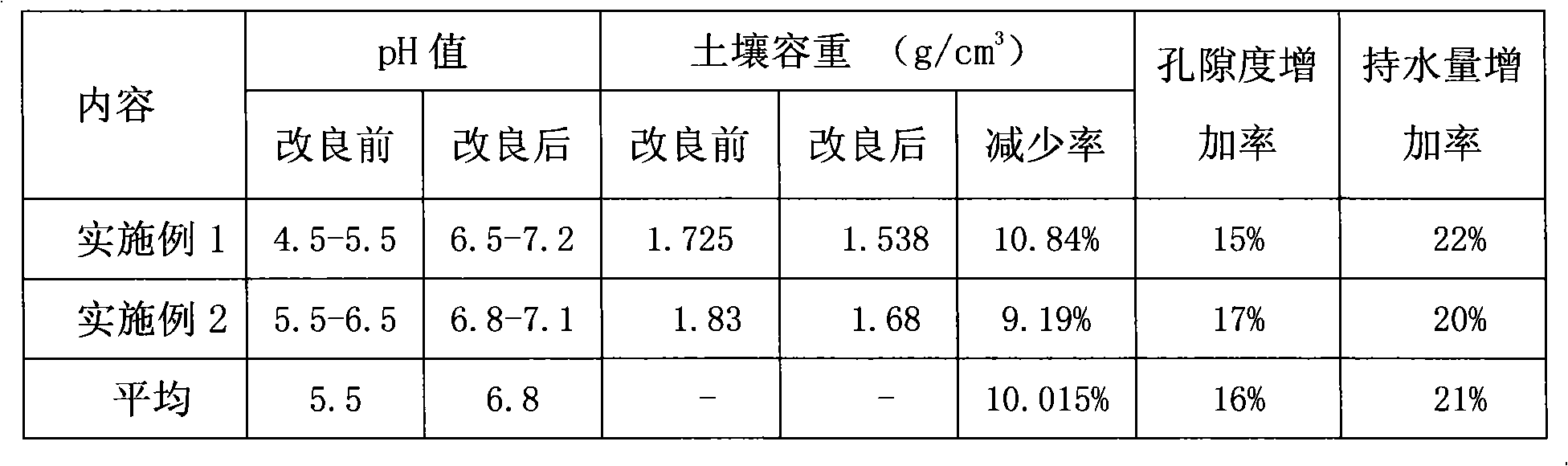

Method for improving acid soil using ground mass

InactiveCN101306428ARaise the pHSuitable for growth needsContaminated soil reclamationOrganic fertilisersGrowth plantSoil porosity

The invention discloses a method for improving the acid soil condition by using a matrix and belongs to the technology field of the soil improvement. The method is composed of seven steps including matrix preparation, pH value measurement, matrix amount confirmation, matrix applying time, soil humidity control, matrix applying operation and pre-plant soil preparation. The matrix is made from imperatoria and prepared by adopting the technological processes of drying, chopping, fermenting by using the Dadiwang viable bacteria stock solution, etc., wherein the imperatoria is suitable for being planted in the tropical area, and has rapid growth, high yield and sustainability, and the required matrix total amount of the soil improvement can be figured out by confirming the required matrix amount of neutralizing 1m<2> of the acid soil. The matrix is quantificationally mixed with the acid soil for more than two times. The method can effectively change the pH value and the physical behavior of the soil and can increase the soil fertility; the pH value of the soil can be directly increased from 4-6 to 6-8, so that the acidity and basicity of the soil is suitable for the plant growth; the soil bulk density is reduced by 10%, the soil porosity is increased by more than 15%, and the water holding capacity of the soil is increased by more than 20%.

Owner:RES INST OF TROPICAL ECO AGRI SCI YUNAN ACAD OF AGRI SCI

Low silver leadless solder and preparation

InactiveCN101239424ALow costAg content decreasedWelding/cutting media/materialsSoldering mediaCeriumOxidation resistant

The invention pertains to electronic solder technique field, and is a modified technique based on prior art, specifically relates to a low-silver leadless solder and preparing method thereof. The components and weight percent of the low-silver leadless solder are: 0.1-0.61f Ag, 0.45-0.79514612004f Cu, 1-51f Bi, 0.02-0.226154000f P, 0.02-0.09150547514f lanthanum-cerium mixed rare earth (RE), residue percent of Sn, and weight sum of each component is 100 In the precondition that the Ag content is decreased remarkably and the welding material cost is saved, the solder with a moderate fusion point, good antioxygenic property, excellent braze welding technique property and integrate mechanical property is obtaind. The invented braze welting material is provided with a stable property, a low cost and broad market application foreground.

Owner:PERFECTION SCI & TECH DONGGUAN

Novel degradable plastic bag material

InactiveCN106398069AProtect the safety of lifeFree from pollutionPollutionHydroxypropylmethyl cellulose

The invention provides a novel degradable plastic bag material which contains the following components in parts by weight: 50-60 parts of modified PAV, 20-30 parts of modified PVA resins, 30-40 parts of polyurethane, 20-30 parts of ethylene-vinyl acetate copolymer, 10-20 parts of styrene-ethylene / butane-styrene copolymer, 10-20 parts of sodium alginate, 10-20 parts of hydroxypropyl methyl cellulose, 30-40 parts of modified starch, 20-30 parts of aloe gel, 3-10 parts of plasticizer and 3-10 parts of stabilizer. According to the invention, the macromolecule blending and modifying technique is utilized and a specific film-forming technique is adopted for preparing the novel degradable plastic bag material; the products are nontoxic and can be naturally degraded; the fish living safety and the environment are protected; the traditional plastic bag is replaced by the novel degradable plastic bag material; the problems of failure to degrade as well as water and environment pollution can be solved.

Owner:ANHUI RUIYAN NEW MATERIAL TECH RES INST

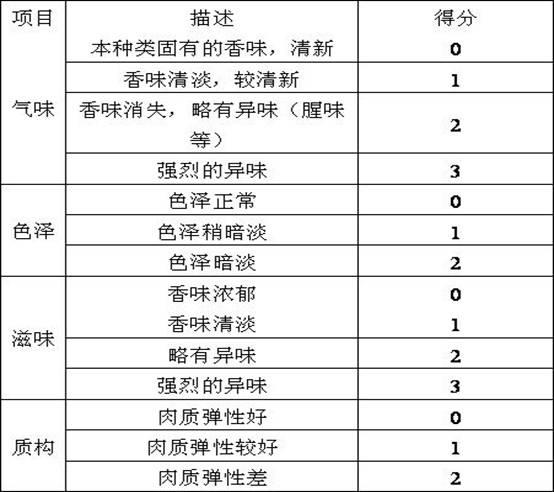

Quality improvement method of freshwater fish

InactiveCN102160569AMake sure it's intactAvoid destructionMeat/fish preservationFlavorModified technique

The invention discloses a quality improvement method of freshwater fish, comprising the steps of: 1) carrying out treatment of three removing on the freshwater fish, and carrying out vacuum packaging after rinsing cleanly; 2) putting the vacuum-packaged freshwater fish into an ultrahigh-voltage container; and 3) pressurizing to 50-600MPa, maintaining the pressure for 5-30 minutes, then releasing the pressure to normal pressure, and taking out the freshwater fish. For the fish meat treated by the quality improvement method, the shelf life is prolonged, the sensory indexes such as flavor, color, taste and tissues and the like after cooking are superior to those of the fish meat without treatment, the chewiness and the elasticity are improved, and the content of amino nitrogen is increased. In the quality improvement technology of the freshwater fish meat, the quality of the freshwater fish can be obviously improved, and the quality improvement technology is applicable to freshwater fish such as oxtail fish, silver carp fish and the like.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com