Method for raising semiconductor laser yield

A technology of lasers and yield rate, applied in semiconductor lasers, lasers, laser components, etc., can solve problems such as increased production costs, laser damage, poor airtightness, etc., to save costs, avoid waste, improve reliability and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

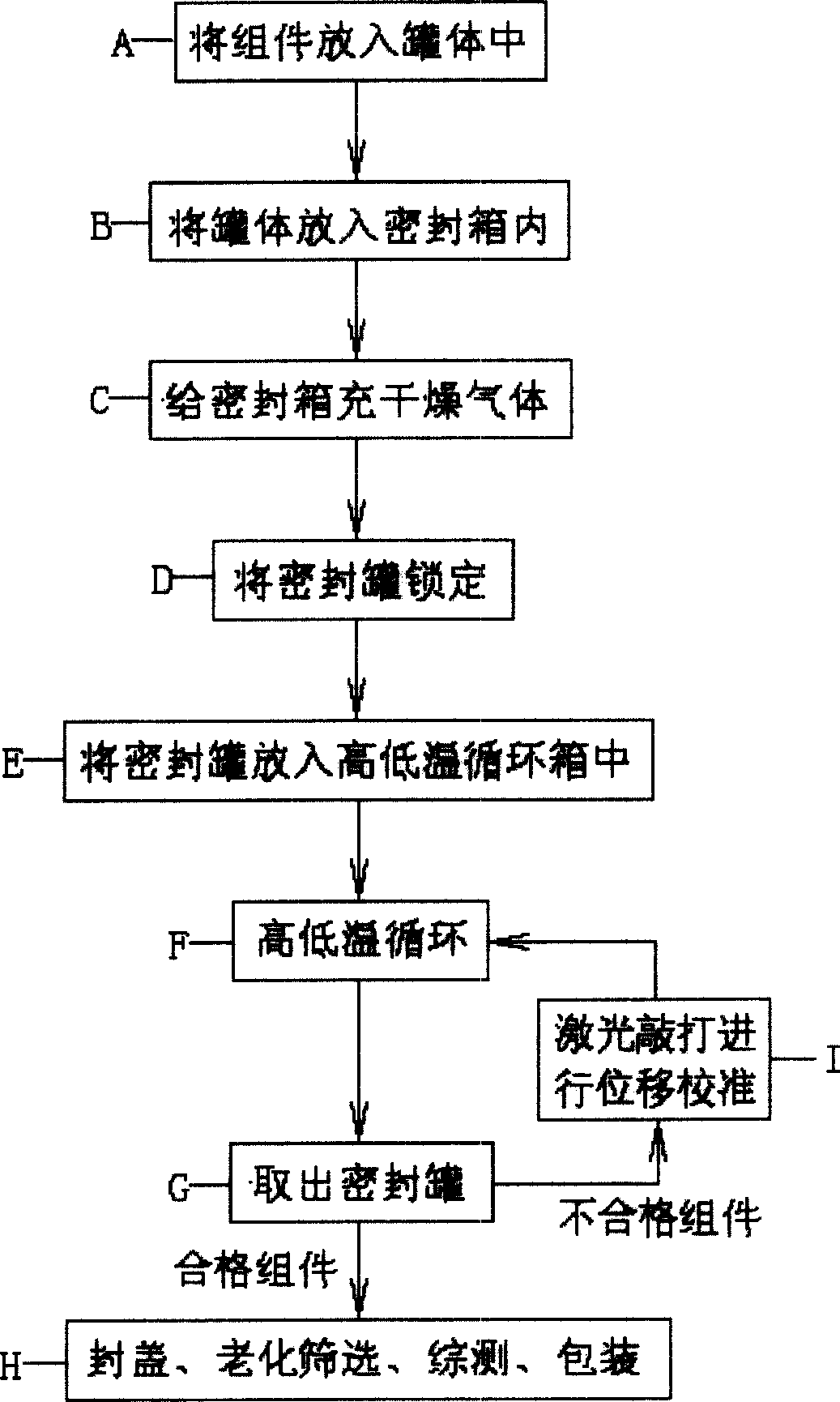

[0041] 1. The best state of the relevant steps

[0042] Step ③ Fill the sealed box with dry gas C for 30 minutes.

[0043] Step ④ lock the sealed tank D, the oxygen content in the sealed box is 20%, and the water vapor content is 5000ppm.

[0044] Step ⑥ high and low temperature cycle F, the set time of each cycle is 2 hours.

[0045] Step ⑦ Take out the sealed tank G, after completing 20 high and low temperature cycles as described in step ⑥, when the temperature in the circulation box is 25°C, take out the sealed tank 1 from the circulation box.

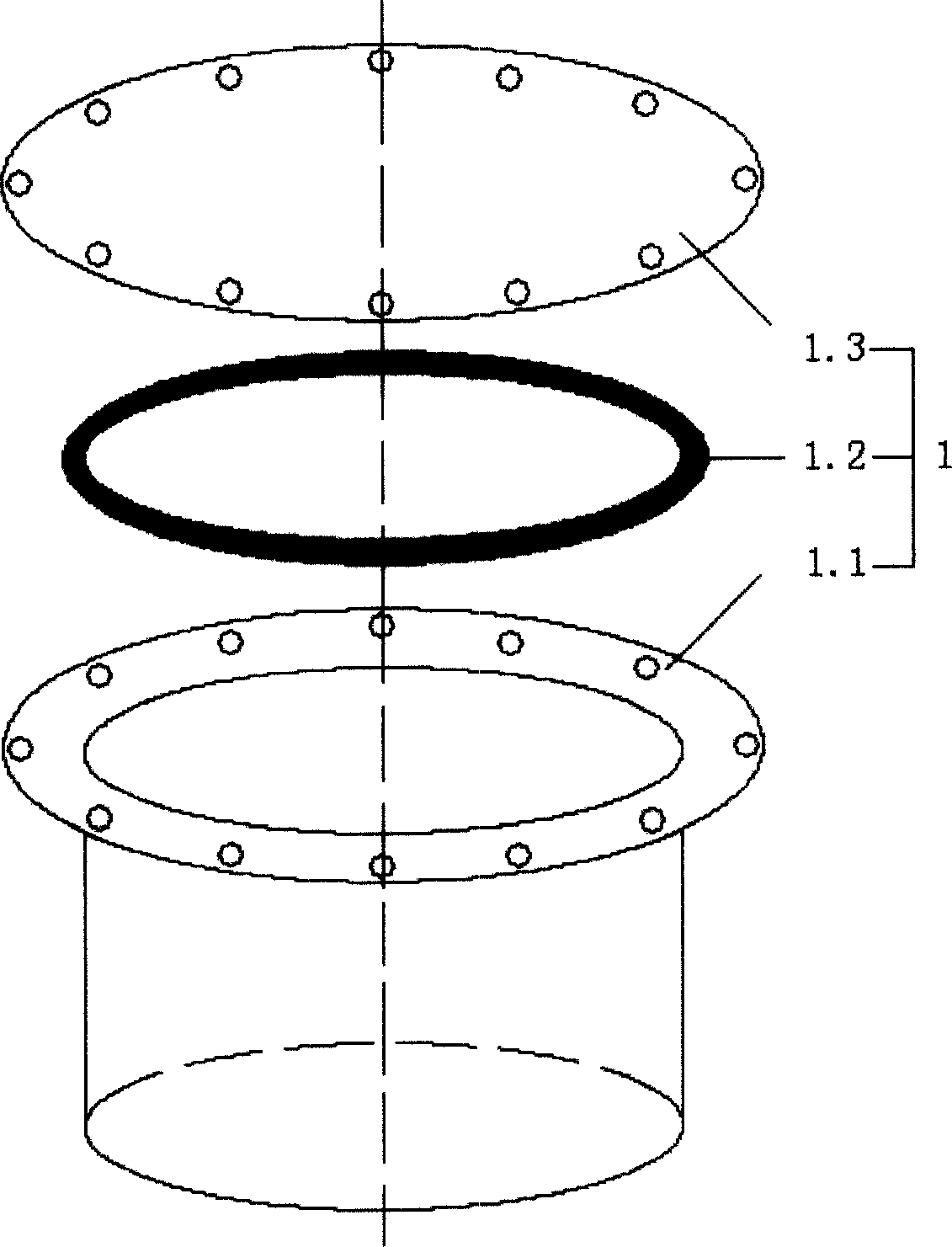

[0046] 2. The structure of the sealed tank 1

[0047] Such as figure 1 The sealed tank 1 is composed of a tank body 1.1, a tank cover 1.2 and a sealing ring 1.3; a sealing ring 1.3 is arranged between the tank body 1.1 and the tank cover 1.2, and is fixed by screws.

[0048] Described tank body 1.1, its structure is a kind of metal container that has edge, is evenly distributed with the small hole that is used for connecting on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com