Patents

Literature

264 results about "Material growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

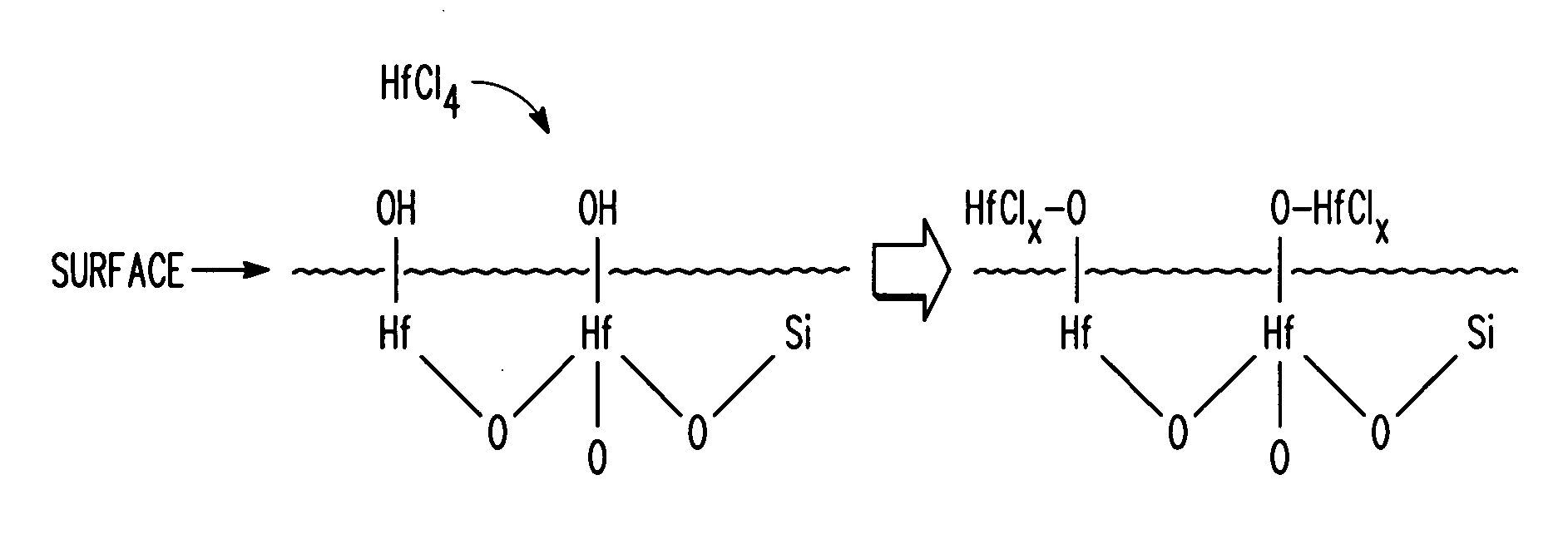

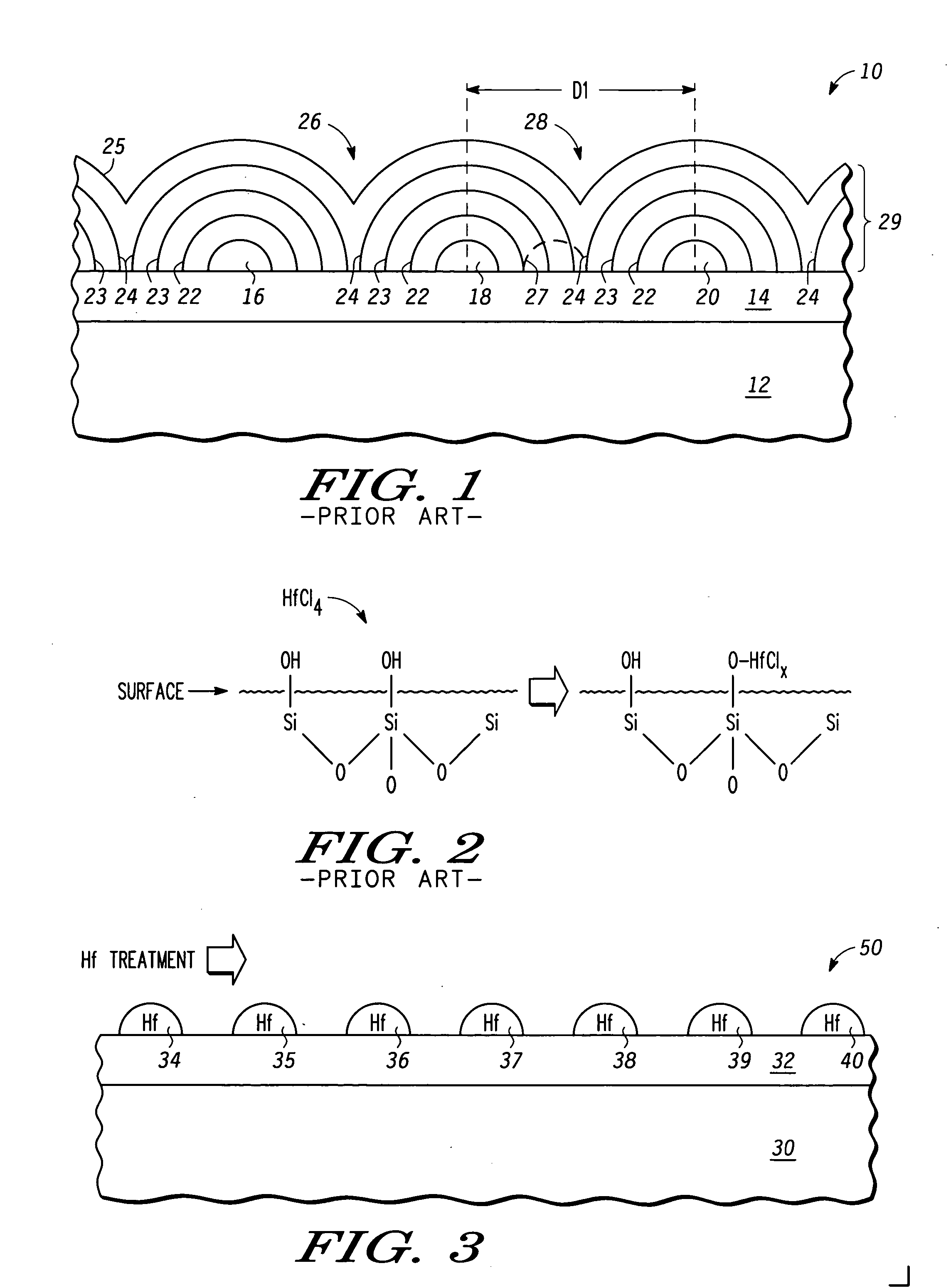

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS7132360B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMaterial growthPhysical chemistry

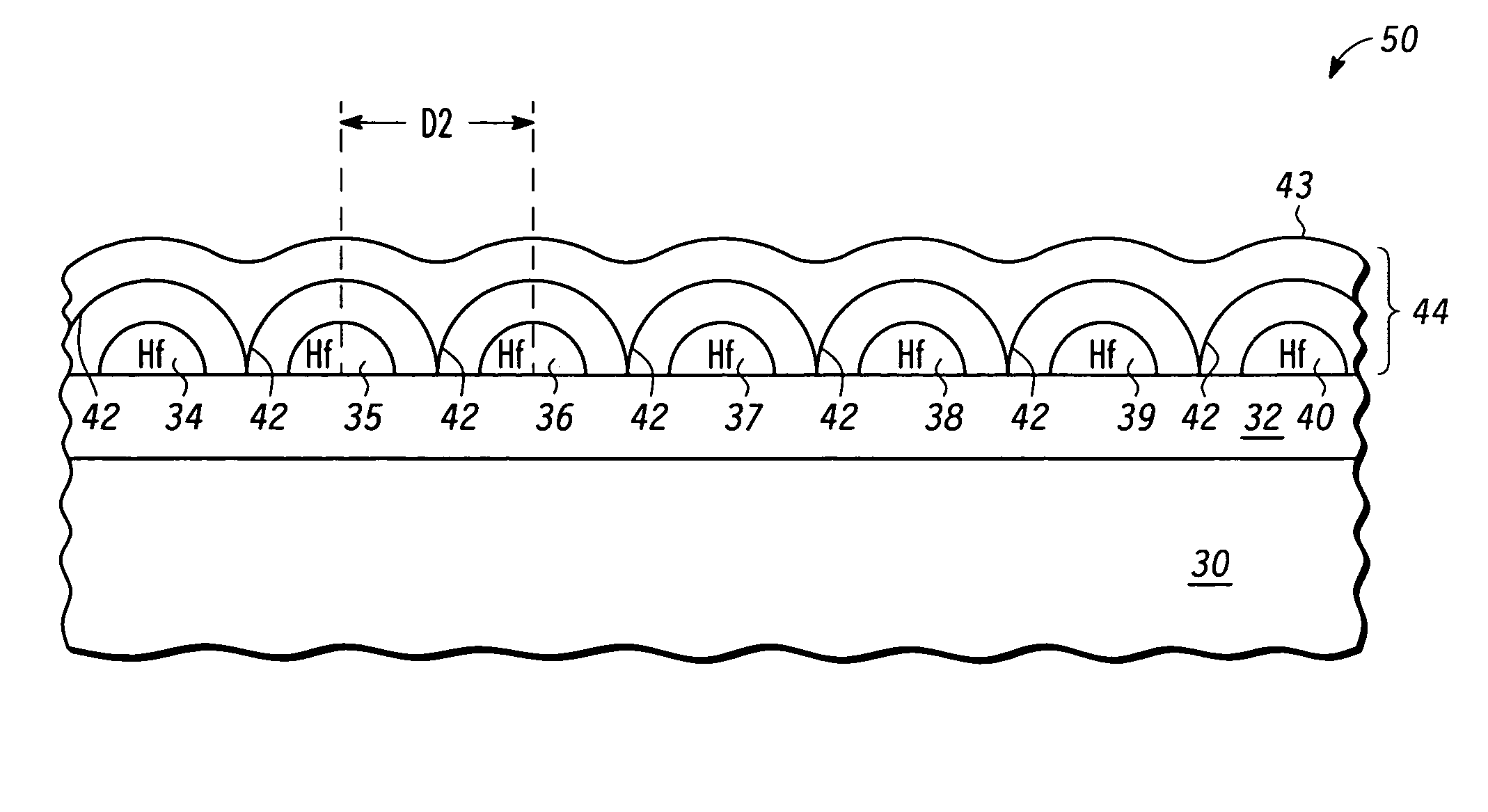

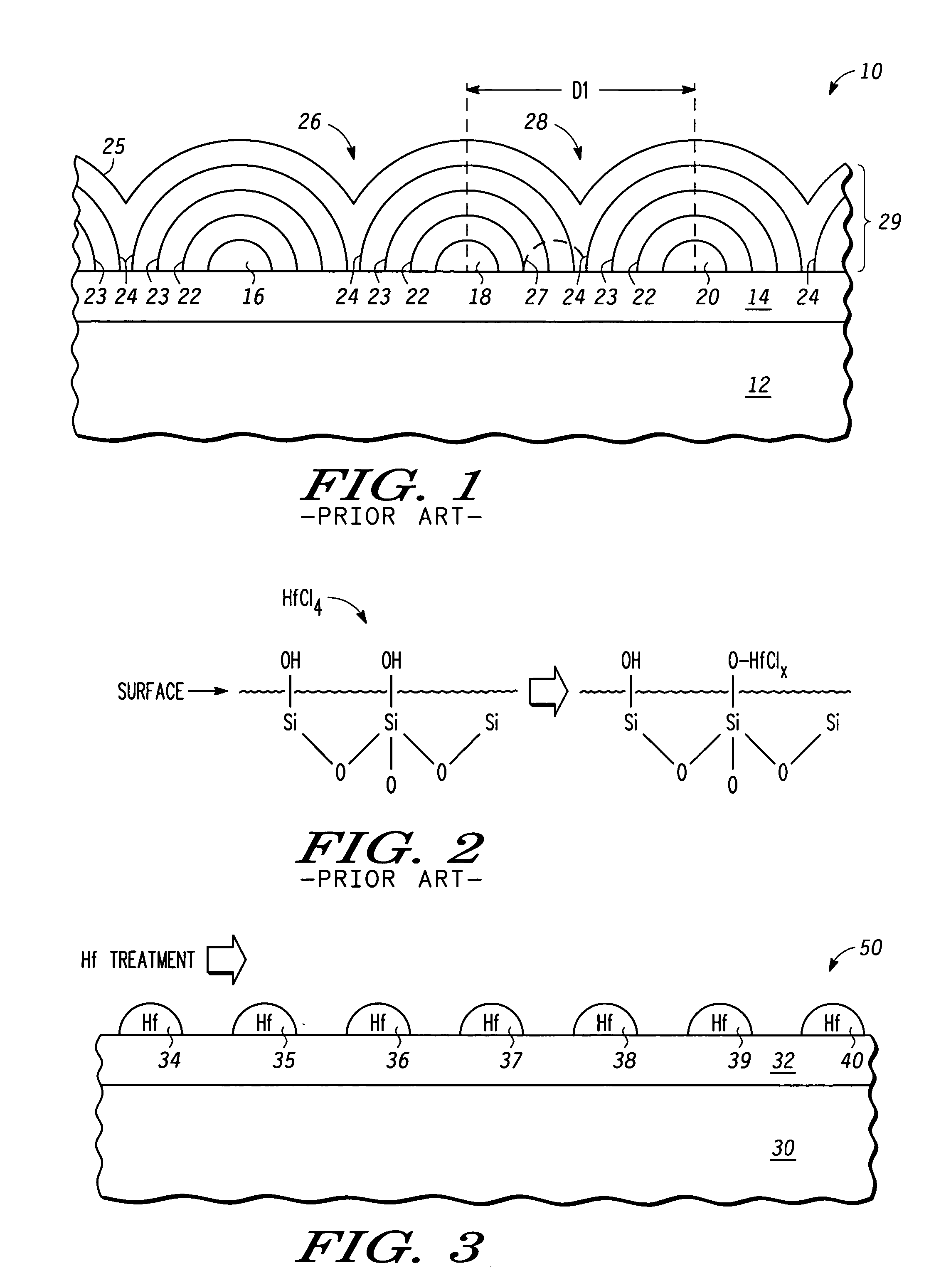

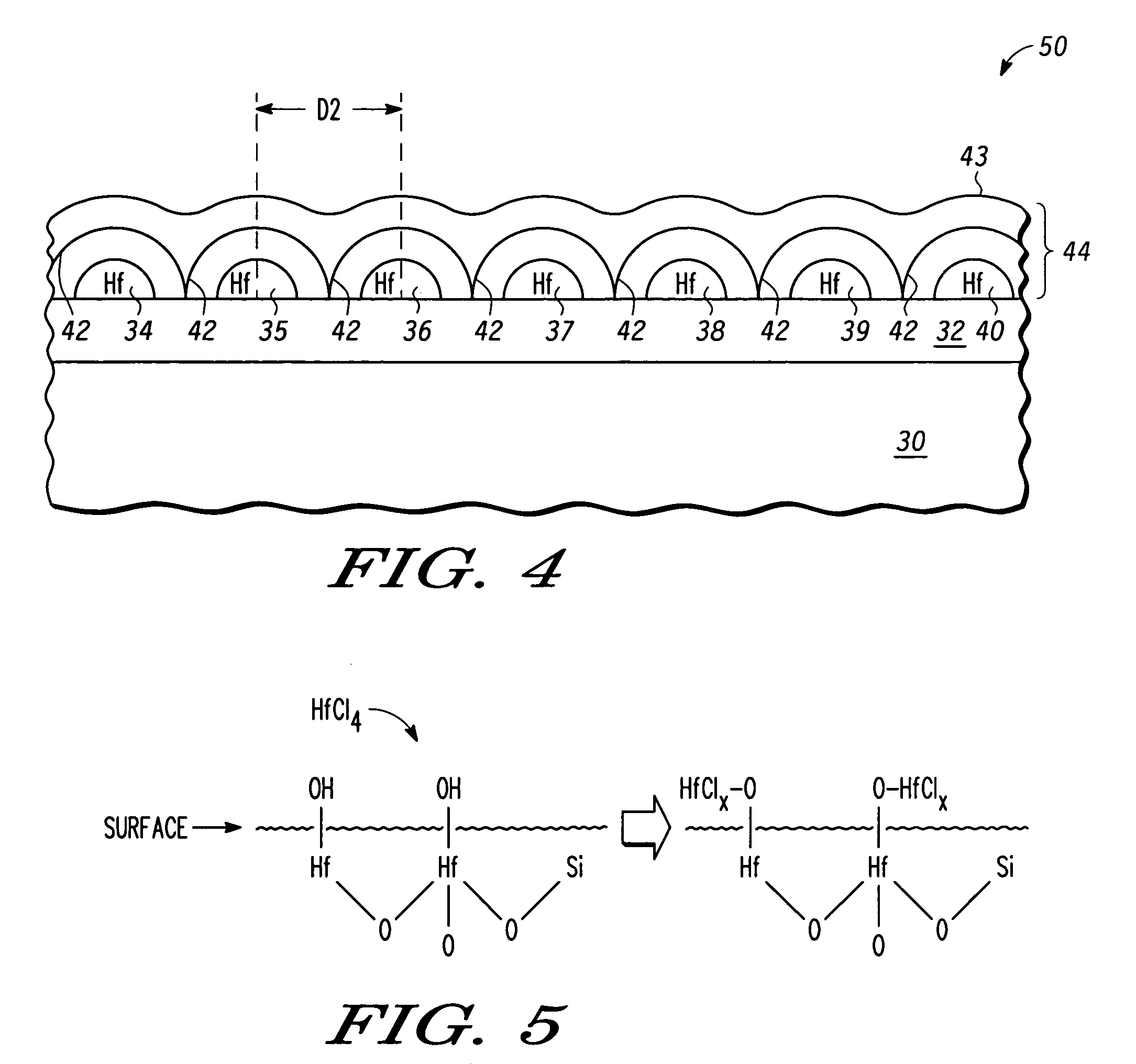

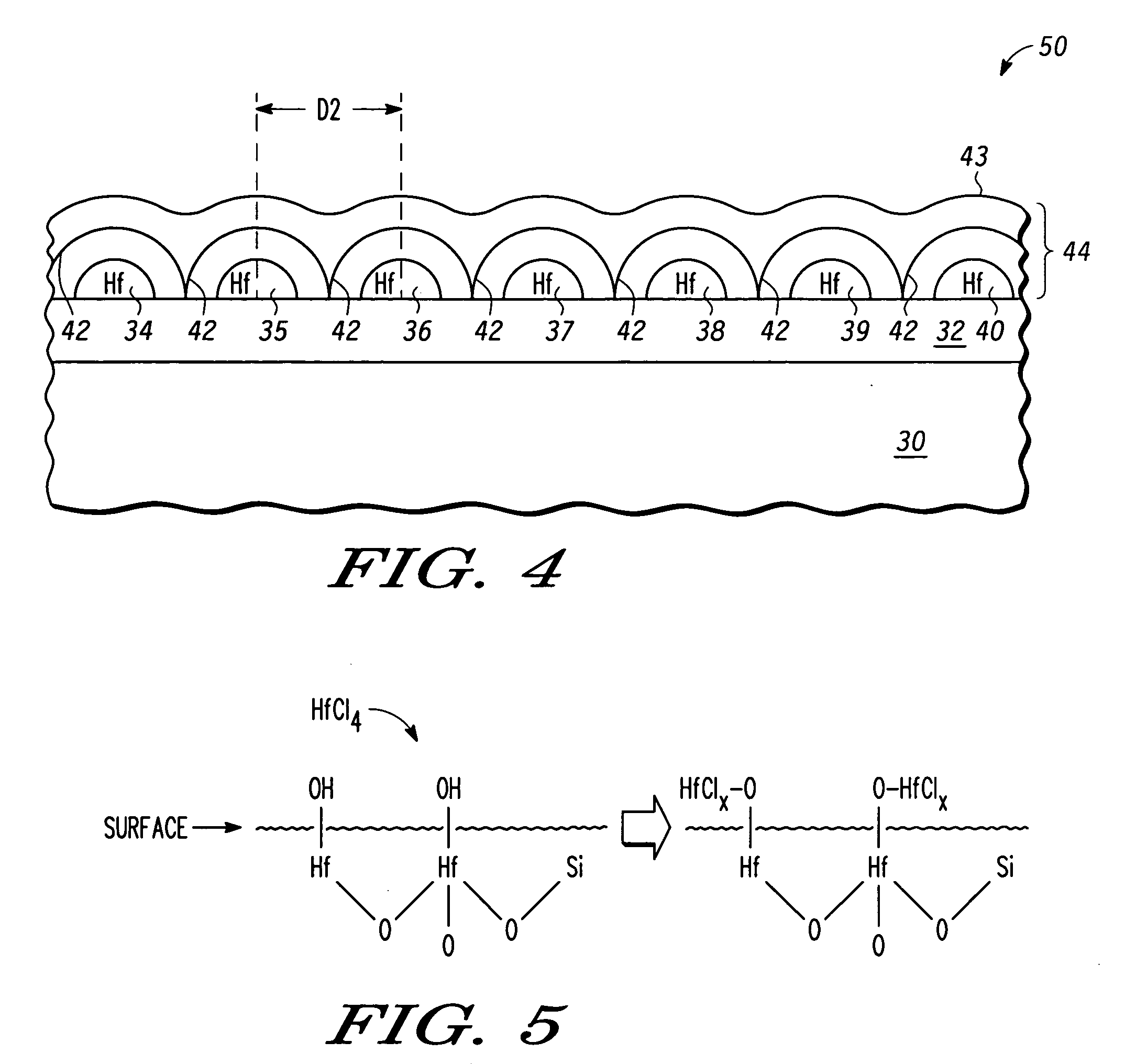

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

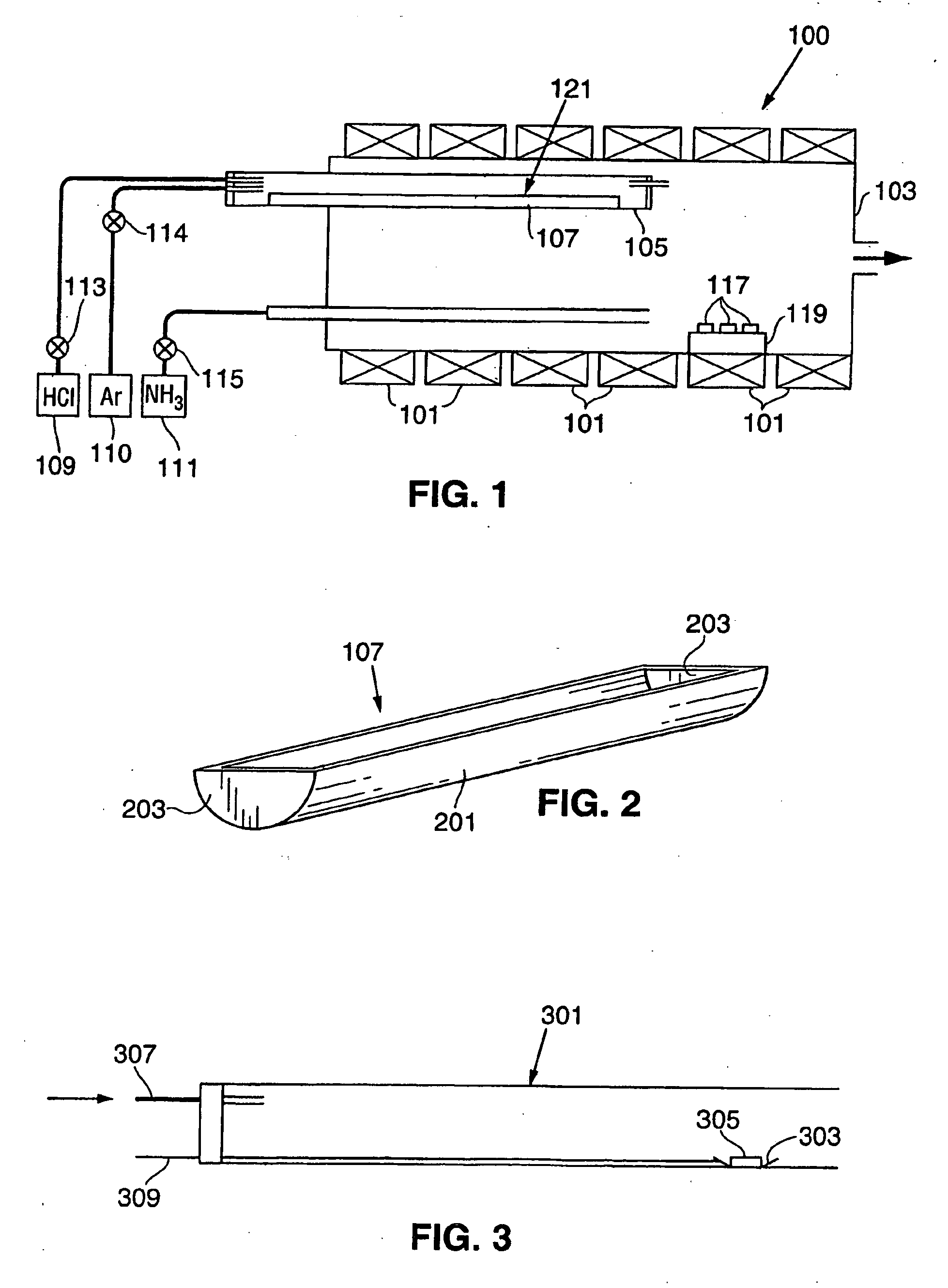

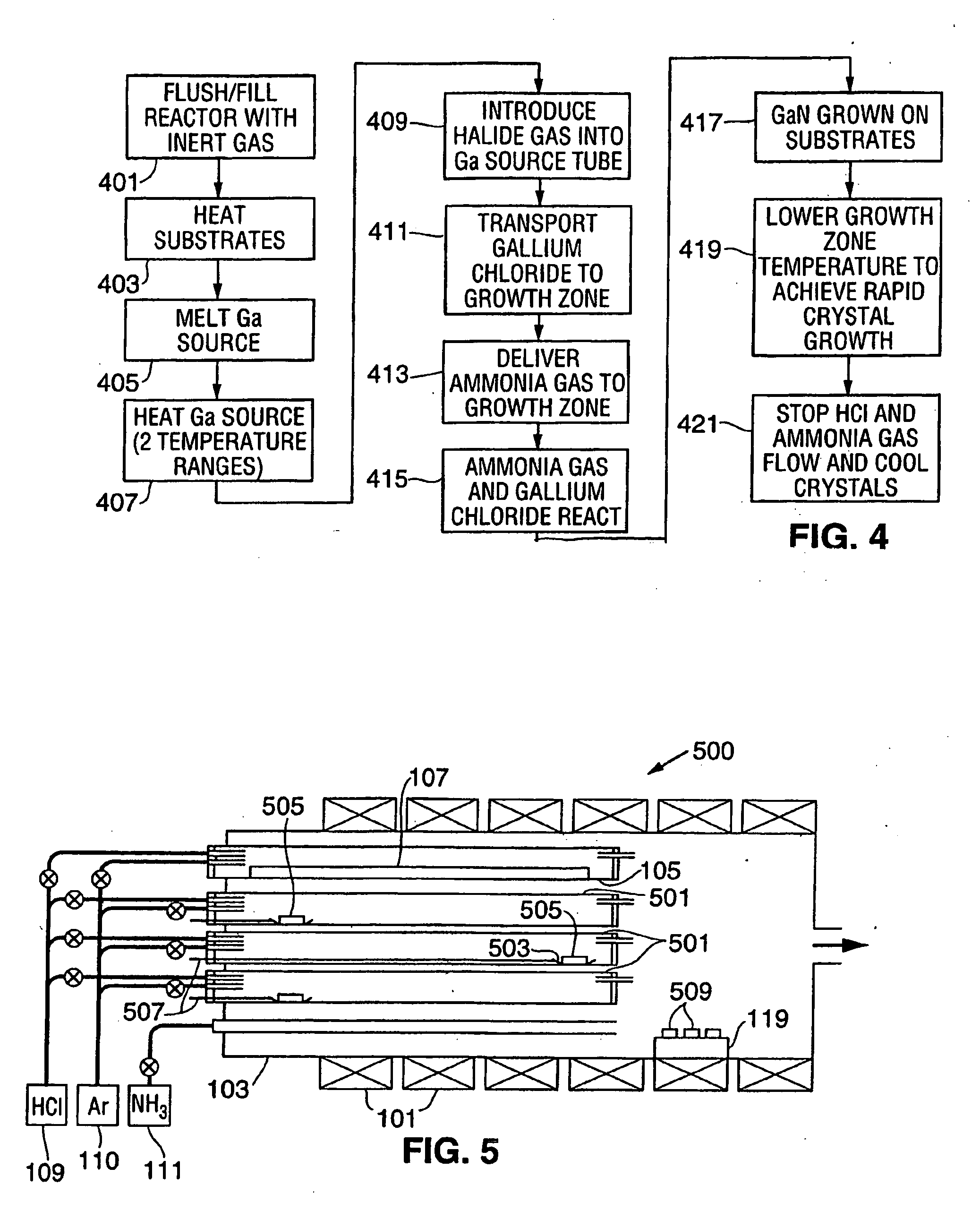

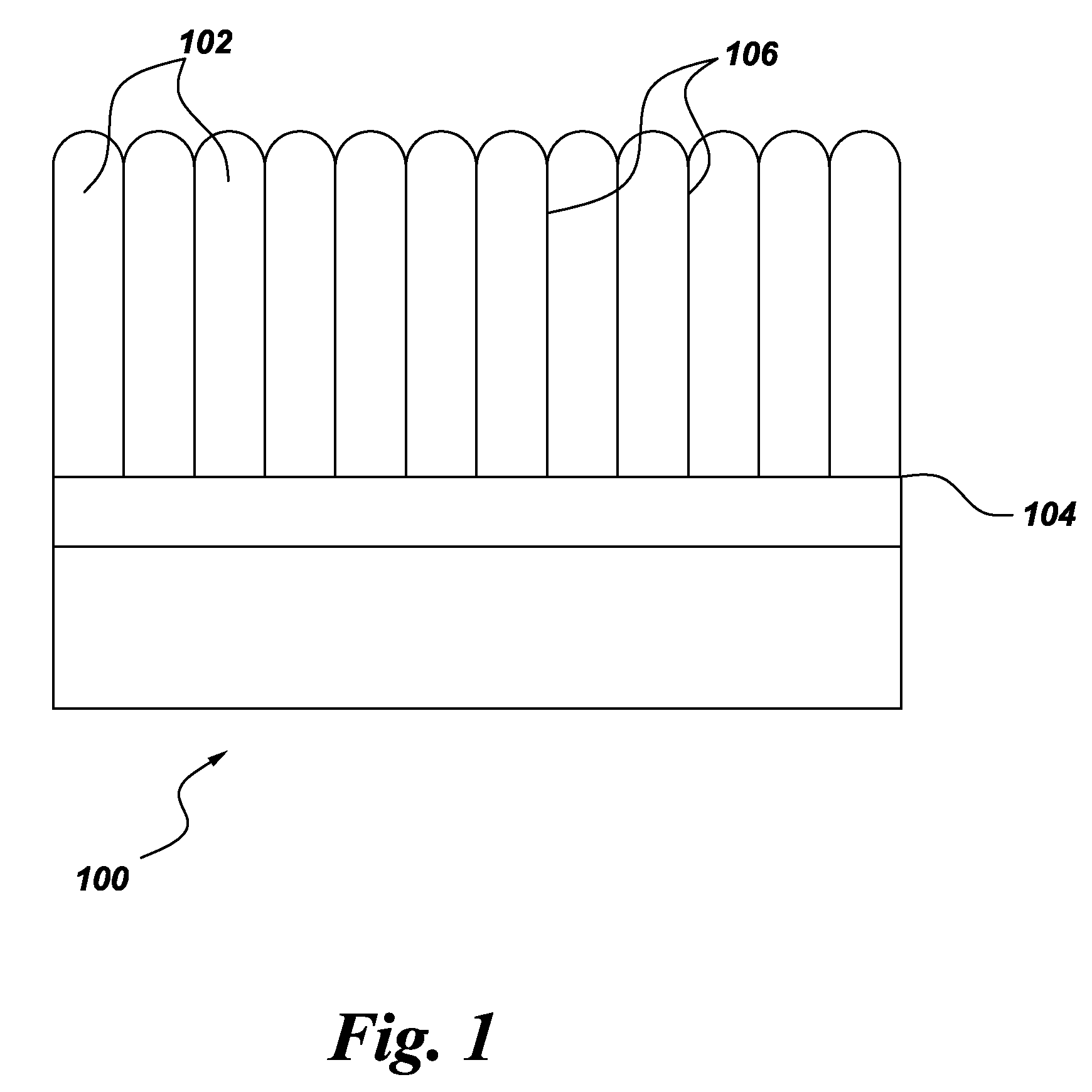

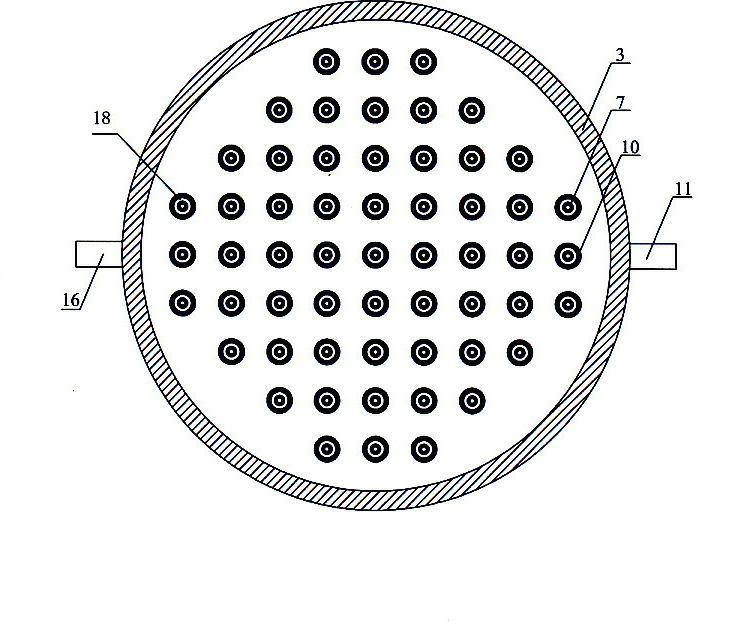

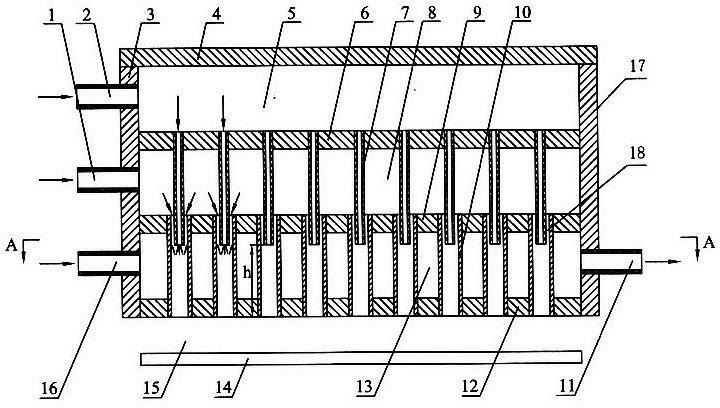

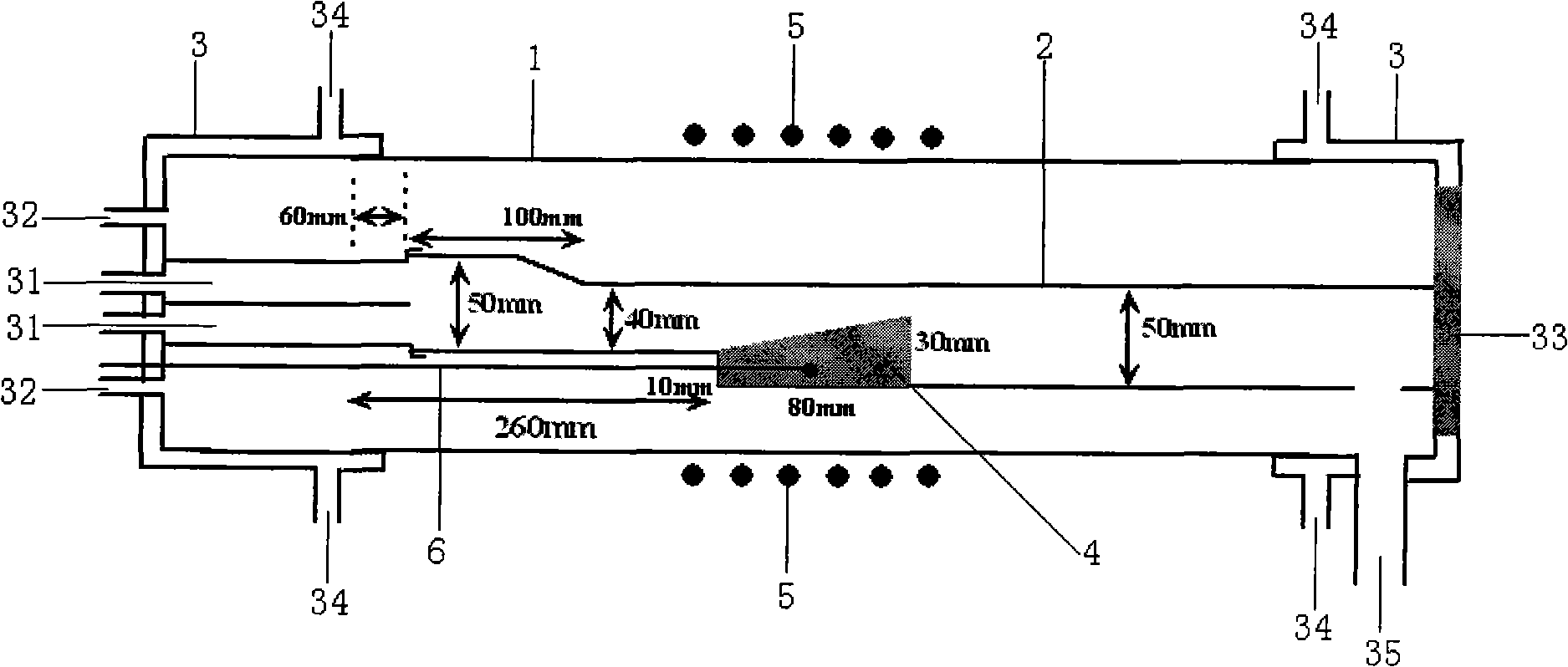

HVPE apparatus for simultaneously producing multiple wafers during a single epitaxial growth run

InactiveUS20060011135A1Polycrystalline material growthFrom chemically reactive gasesMaterial growthWafering

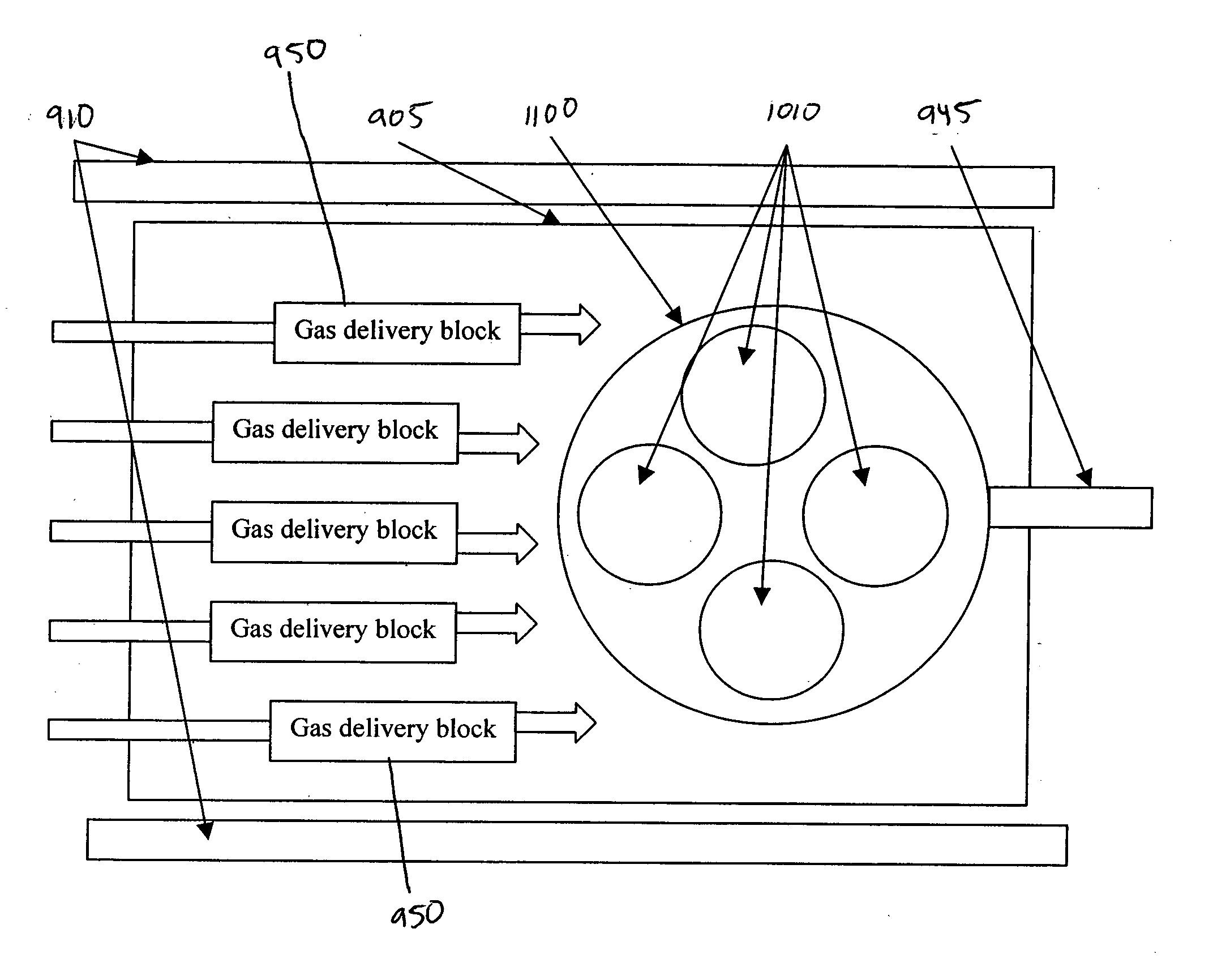

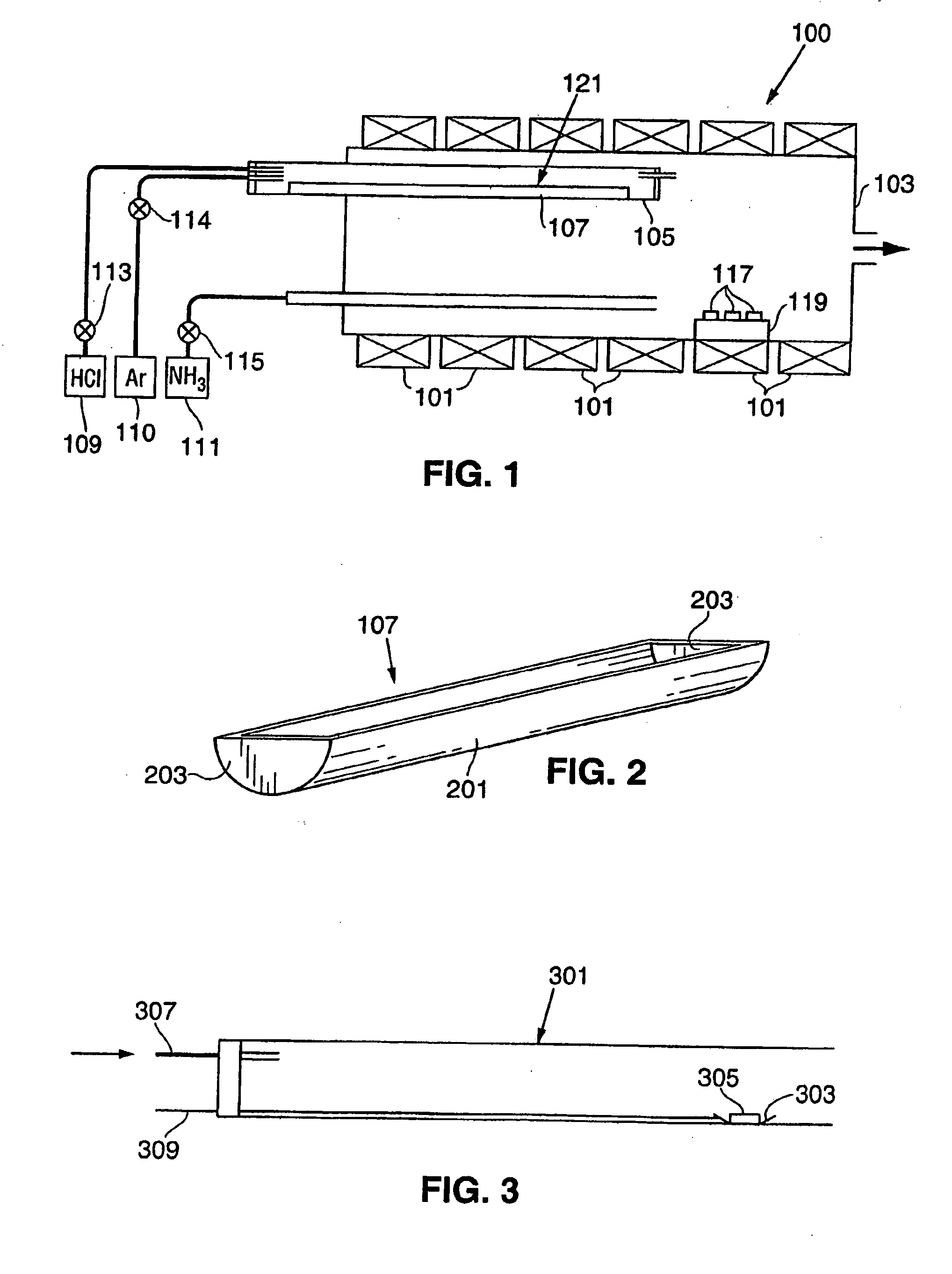

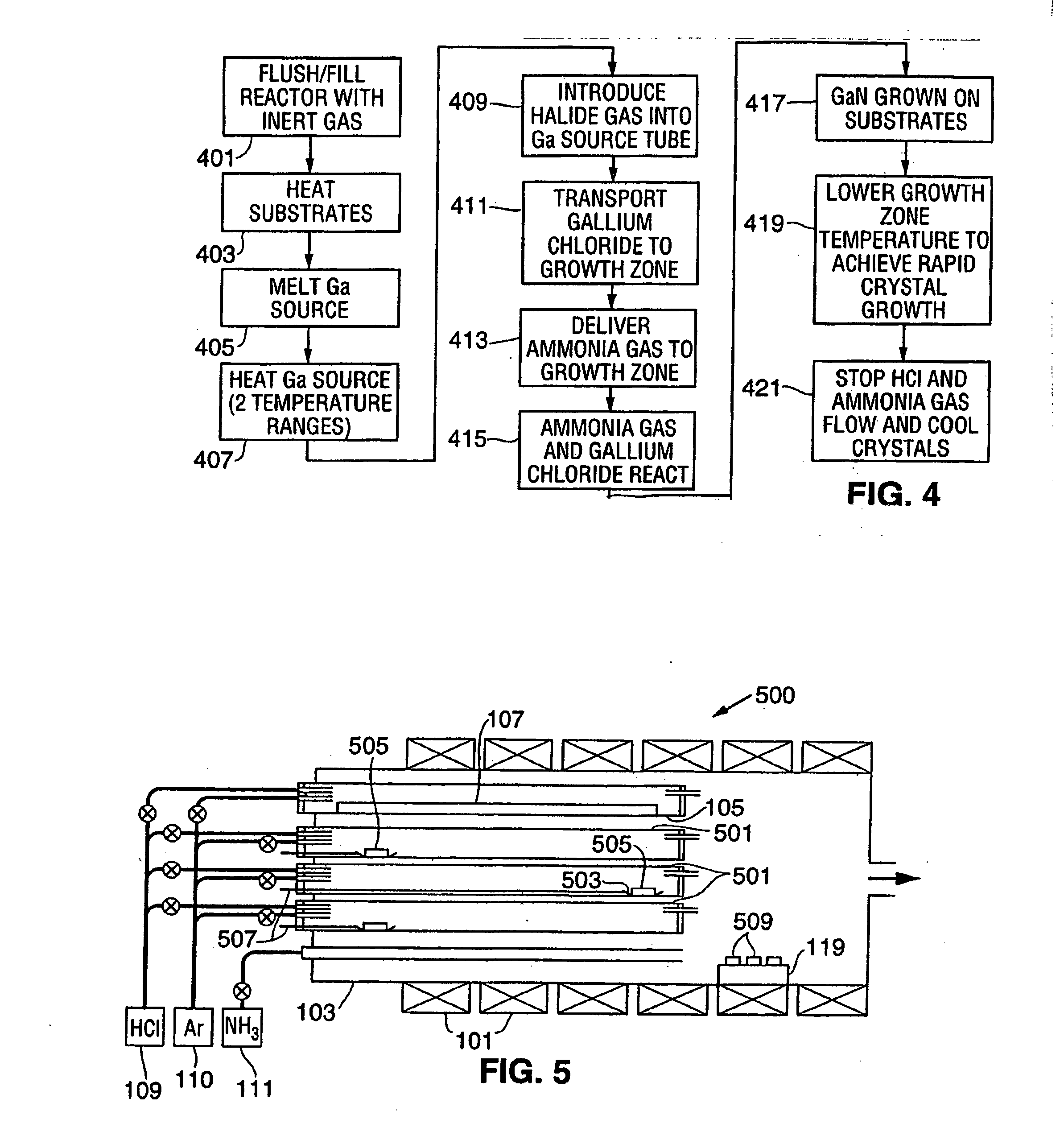

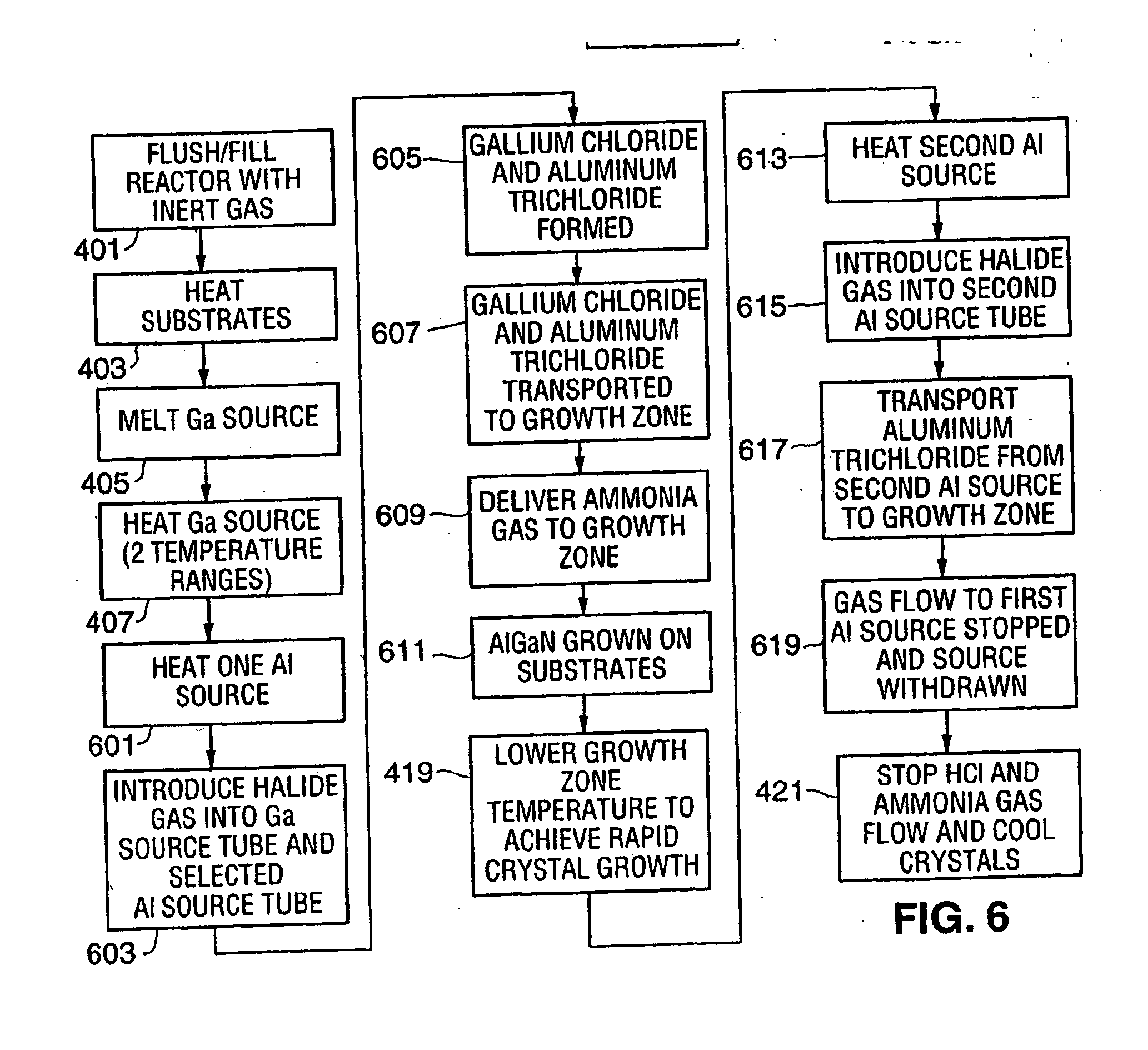

HVPE reactor for simultaneously fabricating multiple Group III nitride semiconductor structures during a single reactor run. The HVPE reactor includes a reactor chamber, a growth zone, a heating element and a gas supply system that can include a plurality of gas blocks. A substrate holder holds multiple substrates and can be a single or multi-level substrate holder. Gas flows from gas delivery blocks are independently controllable and are mixed to provide a substantially uniform gas environment within the growth zone. The substrate holder can be controlled, e.g., rotated and / or tilted, for uniform material growth. Multiple Group III nitride semiconductor structures can be grown on each substrate during a single fabrication run of the HVPE reactor. Growth on different substrates is substantially uniform and can be performed simultaneously on multiple larger area substrates, such as 3-12″ substrates.

Owner:FREIBERGER COMPOUND MATERIALS

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS20050277294A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare earthHafnium

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

Method for simultaneously producing multiple wafers during a single epitaxial growth run and semiconductor structure grown thereby

InactiveUS20070032046A1Added fabricationEasy to controlPolycrystalline material growthSemiconductor/solid-state device manufacturingMaterial growthWafering

HVPE method for simultaneously fabricating multiple Group III nitride semiconductor structures during a single reactor run. A HVPE reactor includes a reactor tube, a growth zone, a heating element and a plurality of gas blocks. A substrate holder is capable of holding multiple substrates and can be a single or multi-level substrate holder. The gas delivery blocks are independently controllable. Gas flows from the delivery blocks are mixed to provide a substantially uniform gas environment within the growth zone. The substrate holder can be controlled, e.g., rotated and / or tilted, for uniform material growth. Multiple Group III nitride semiconductor structures can be grown on each substrate during a single fabrication run of the HVPE reactor. Growth on different substrates is substantially uniform and can be performed on larger area substrates, such as 3-12″ substrates.

Owner:FREIBERGER COMPOUND MATERIALS

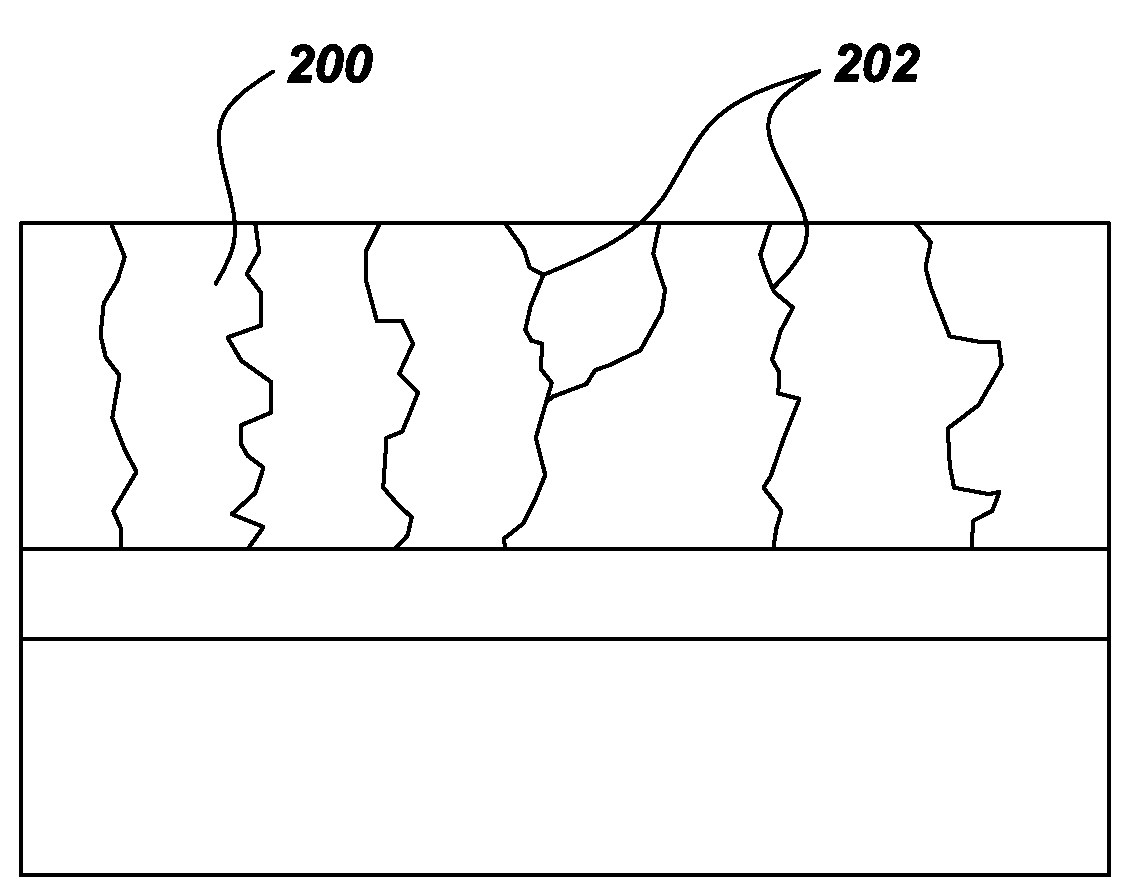

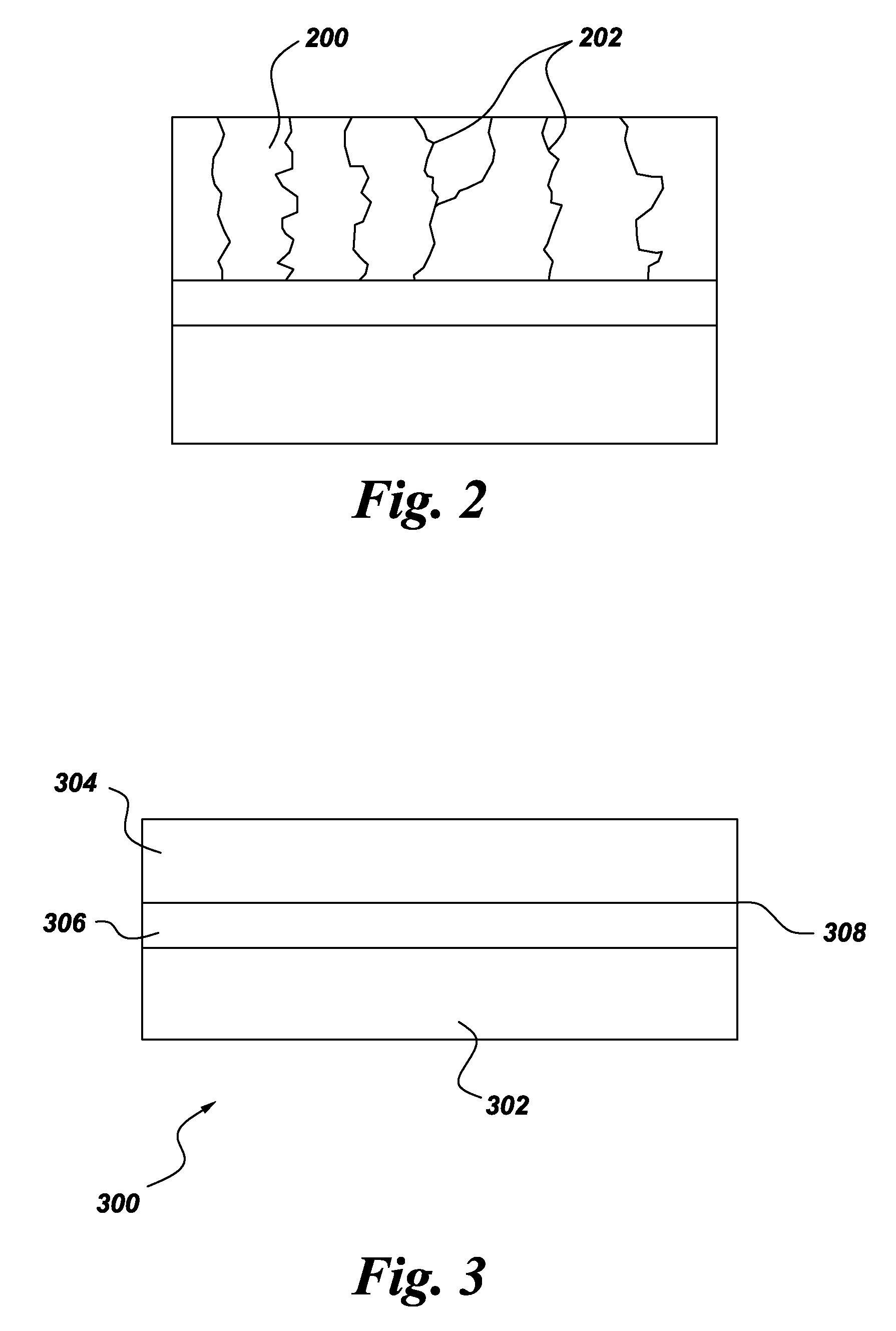

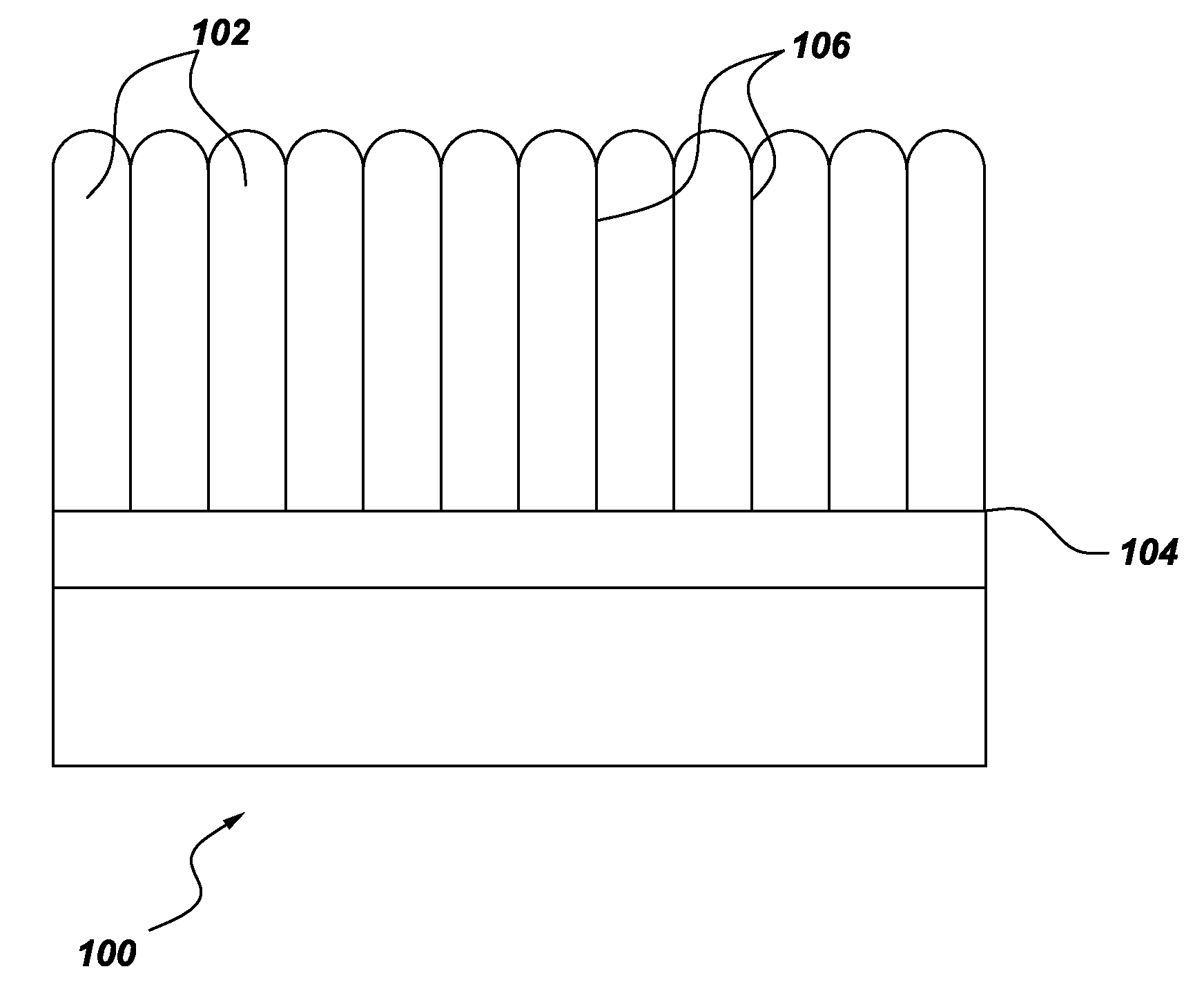

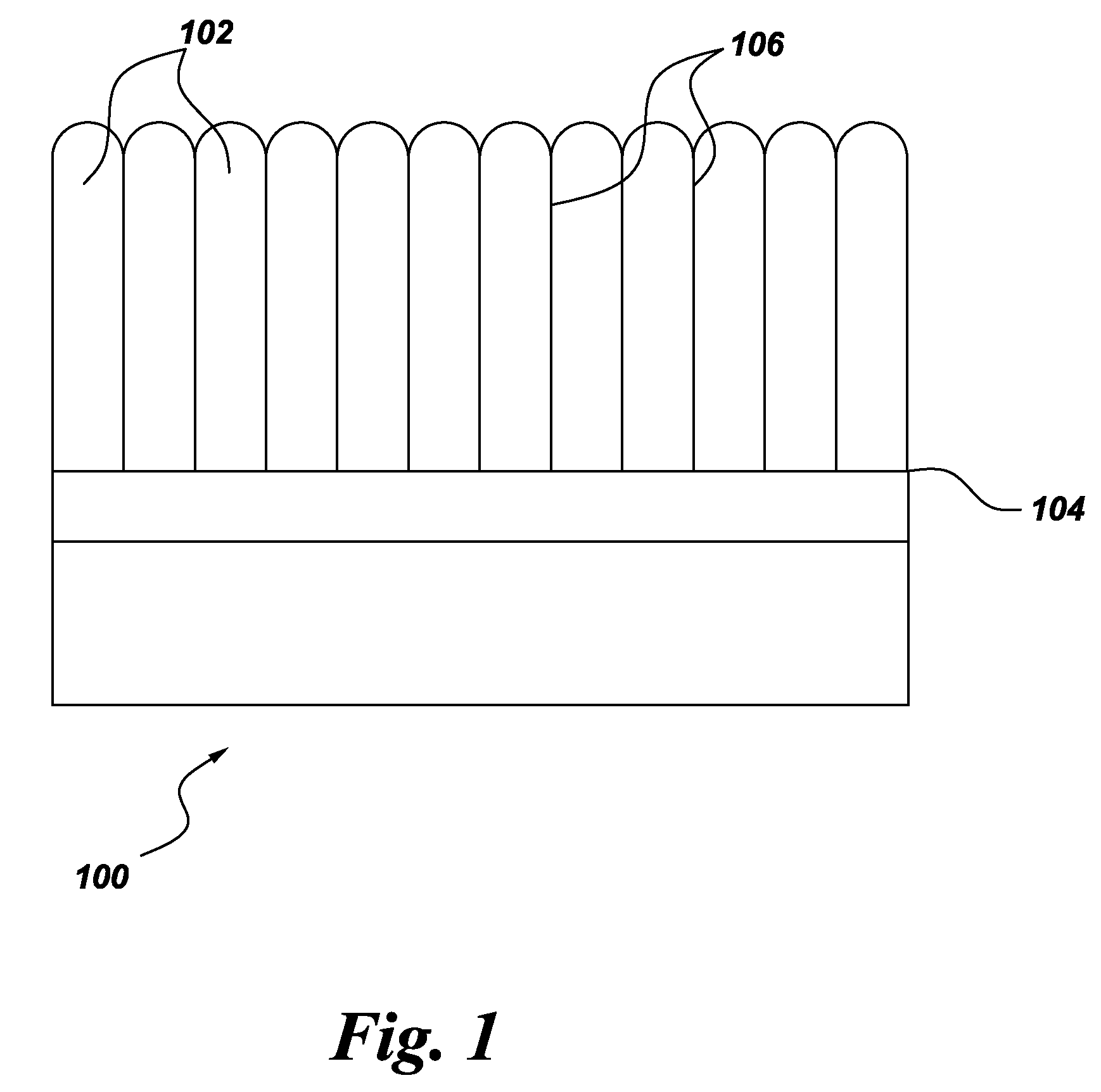

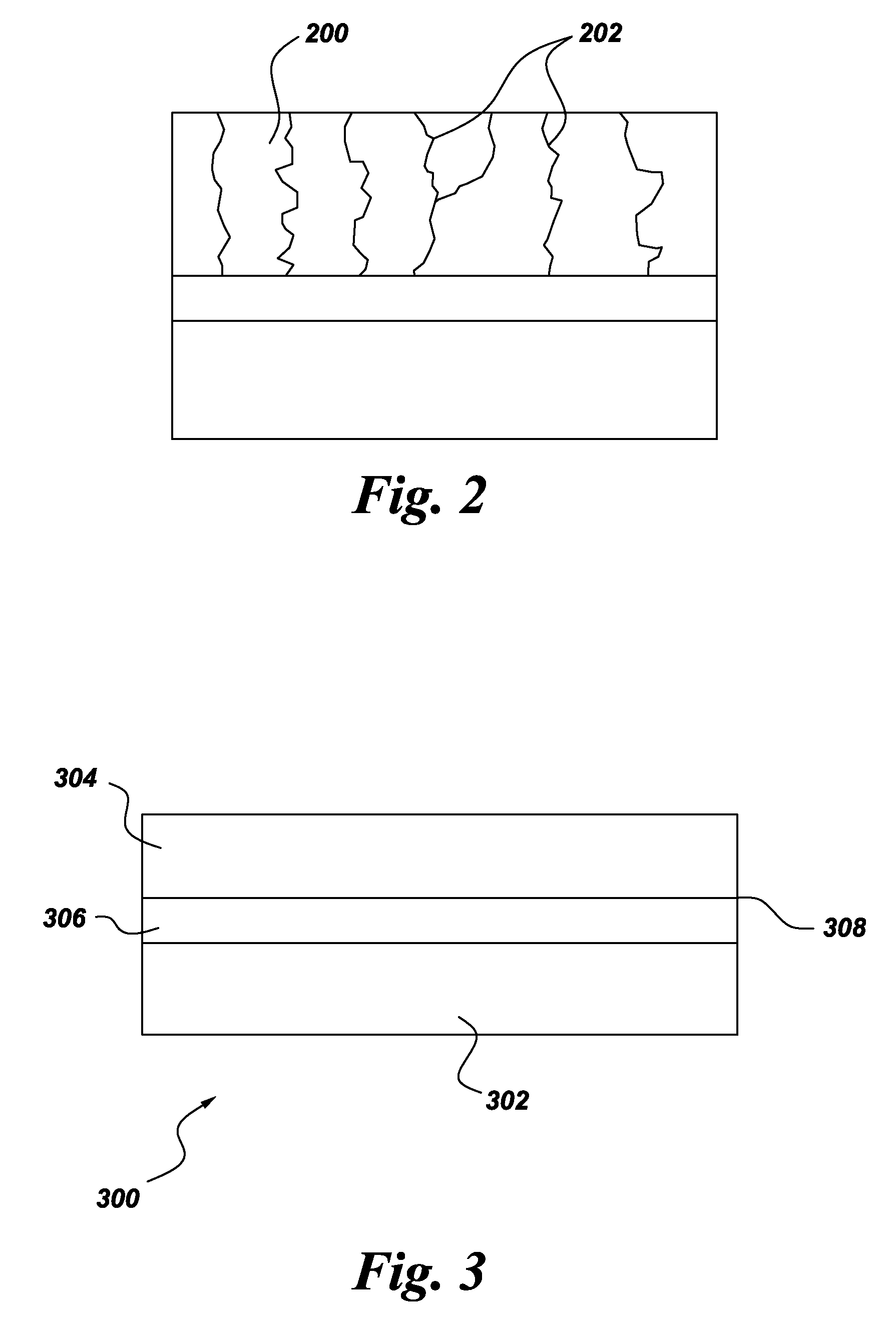

Protective coating with high adhesion and articles made therewith

Coatings and articles suitable for use in high temperature environments, for example, are presented. One embodiment is a coating that comprises a plurality of elongate material growth domains defined between domain boundaries. The domains have an intra-domain density of at least about 75% of theoretical density, have a substantially equiaxed grain morphology, and comprise a plurality of at least partially melted and solidified particles. Another embodiment is a coating that comprises a matrix comprising a substantially equiaxed grain morphology and a plurality of vertically oriented cracks disposed in the matrix. Further embodiments include articles comprising one or more of the coatings described above.

Owner:GENERAL ELECTRIC CO

Three-dimensional cultivation method for interplanting medicinal materials

In order to solve the problems that in the prior art, the three-dimensional cultivation mode of interplanting plants is imperfect, the land resources are not fully utilized, and the plant space distribution is unreasonable, the invention provides a three-dimensional cultivation method for interplanting medicinal materials, which perfects the three-dimensional cultivation technology for interplanting, enables plants to fully absorb nutrients, fully utilizes sunshine and land, and ensures that the space has hierarchy. Particularly, the three-dimensional cultivation method comprises the following technical steps: according to the sunshine and density requirements and the period of the medicinal materials growth, heliophilous and sciophilous, ligneous and herbaceous, and short-term and long-term plants are subjected to field management: three-dimensional cultivation for intercropping, strong seedling planting, watering and fertilizing, weeding and loosening the soil and the like. The medicinal materials comprise phellodendron Chinense schneid, salvia miltiorrhiza, rhizoma atractylodis macrocephalae, rhizoma paridis and herba leonuri. The three-dimensional cultivation method has the advantages of perfecting the three-dimensional cultivation method, achieving the three-dimensional cultivation hierarchy, ensuring the full utilization of land, improving the medicinal materials acre yield of the land, and increasing the economic benefits.

Owner:ANSHUN CITY XIXIU DISTRICT YULIN PLANTING & BREEDING FAMER SPECIALIZED COOP

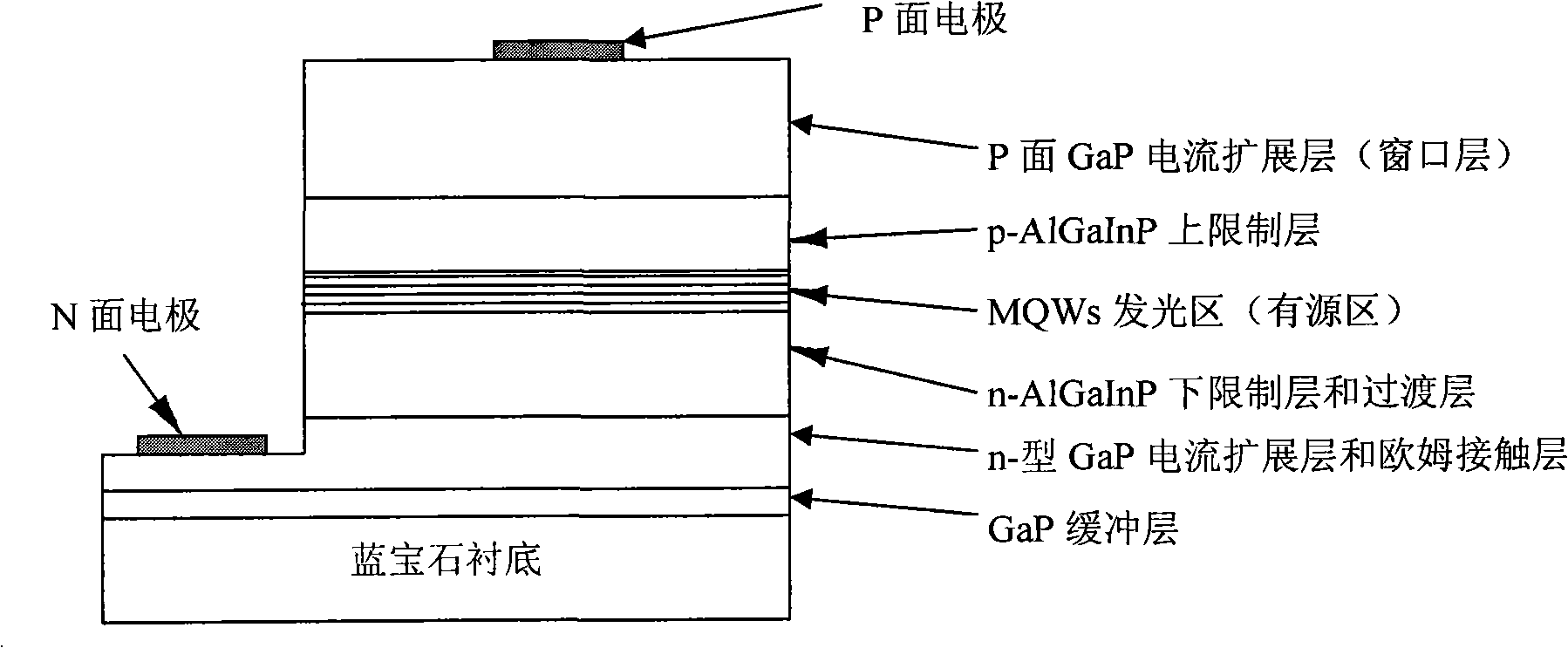

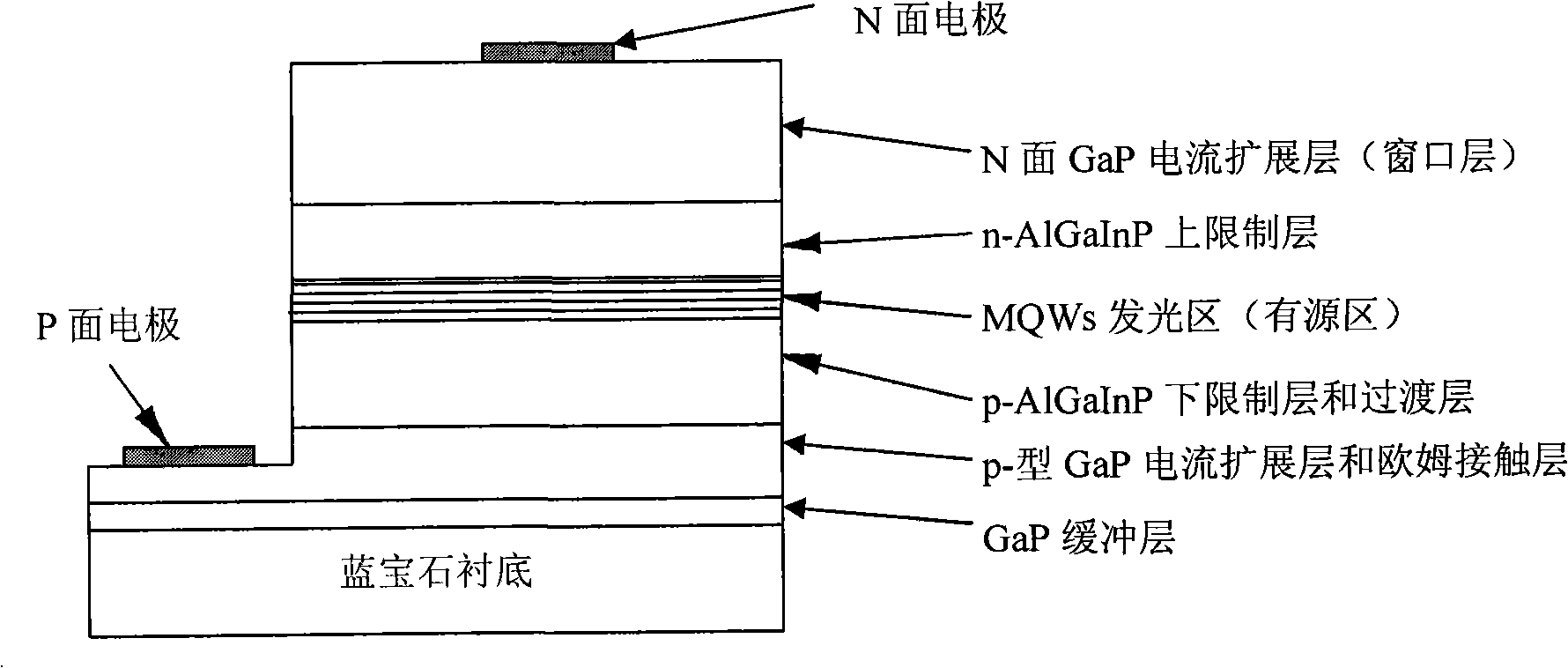

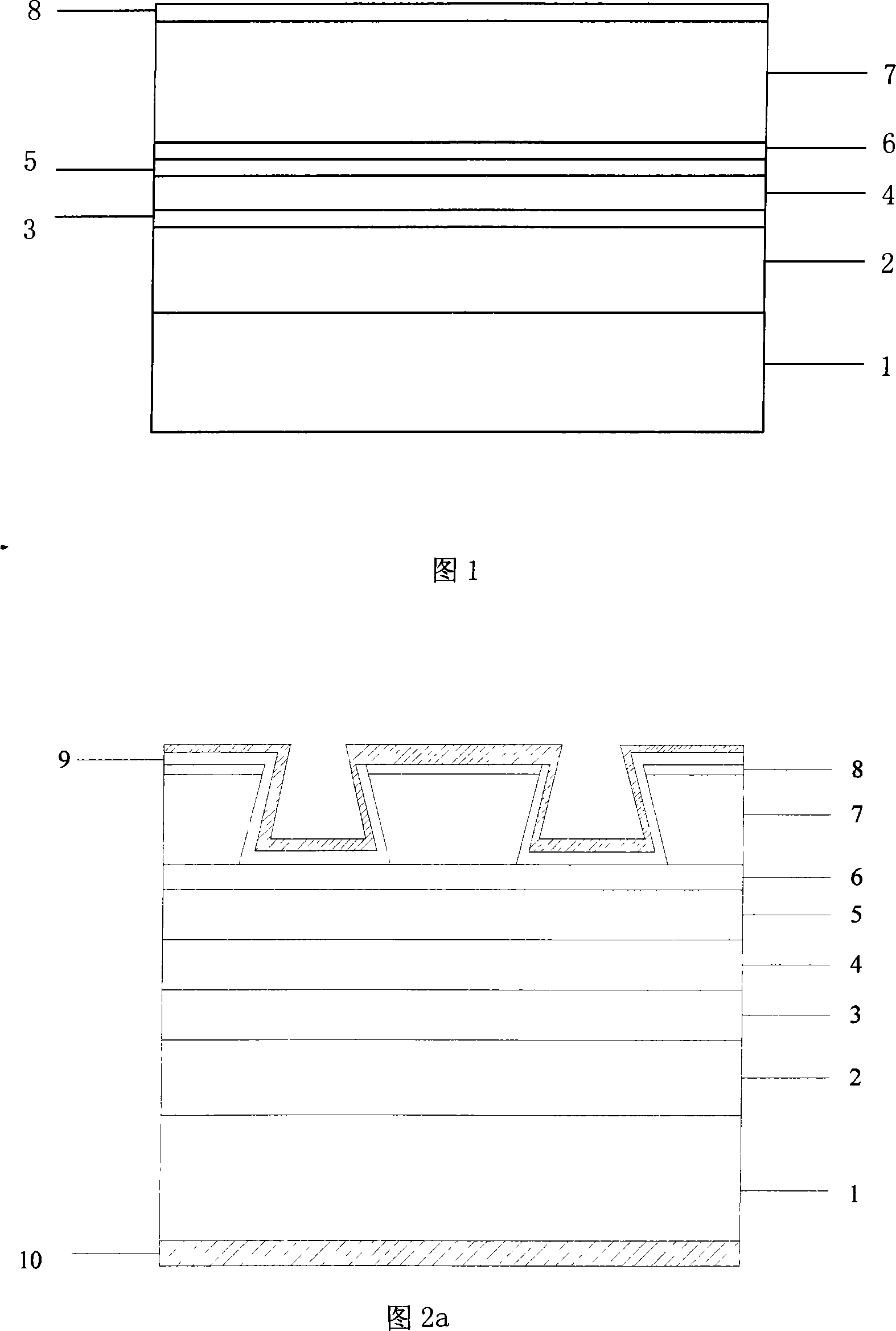

Epitaxial wafer of AlGaInP light emitting diode with sapphire underlay and preparation method thereof

InactiveCN101540359ANo light absorption problemInhibition of growth defectsSemiconductor devicesLattice mismatchLight-emitting diode

The invention provides an epitaxial wafer of an AlGaInP light emitting diode with a sapphire underlay and a preparation method thereof. An epitaxial structure of the light emitting diode sequentically comprises the sapphire underlay, a low-temperature GaP buffer layer, a high-temperature GaP buffer layer, a GaP current expansion and ohmic contact layer, an AlGaInP transition layer, a lower limiting layer, a multiple quantum well AlGaInP active area, an AlGaInP upper limiting layer and a GaP current expansion layer from bottom to top. The preparation method comprises the steps that each epitaxial layer grows on the sapphire underlay layer by layer sequentially. The epitaxial wafer uses the sapphire as the epitaxial growth underlay and uses gallium phosphide as the buffer layer. Because the sapphire and the gallium phosphide material are transparent to a wave band from yellow to red, the problem of light absorption of the underlay does not exist. The gallium phosphide buffer layer can inhibit the material growth defect caused by lattice mismatch and heat expansion coefficient mismatch between the sapphire underlay and the AlGaInP material so as to greatly improve the light output capability of the light emitting diode.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

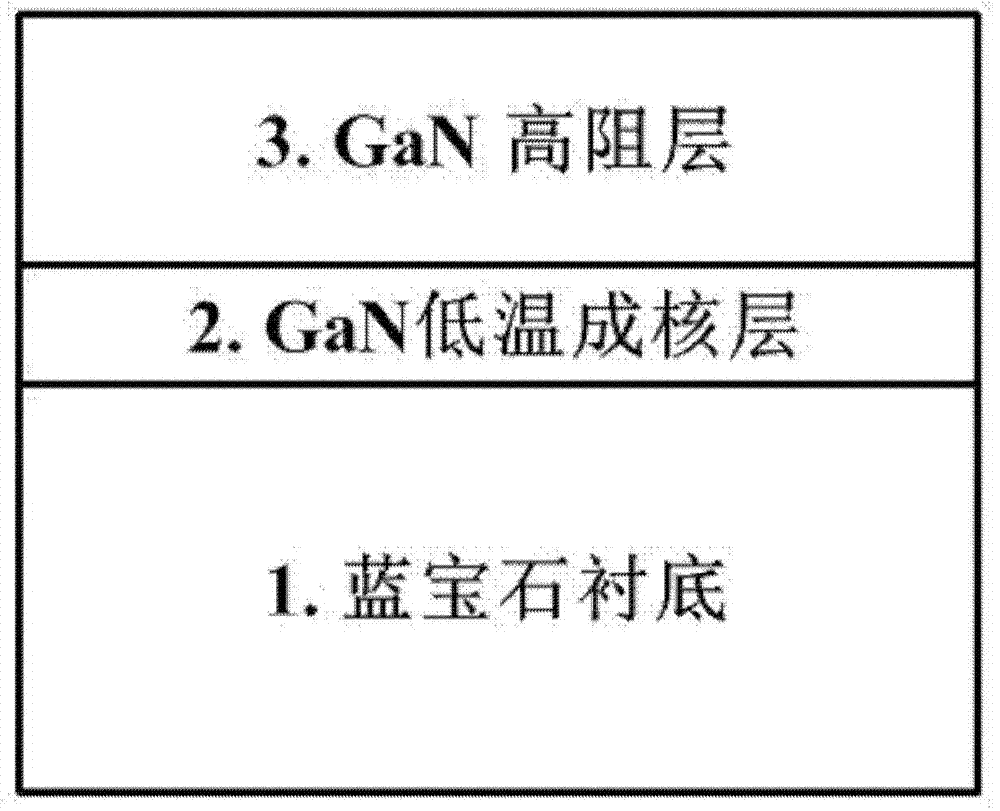

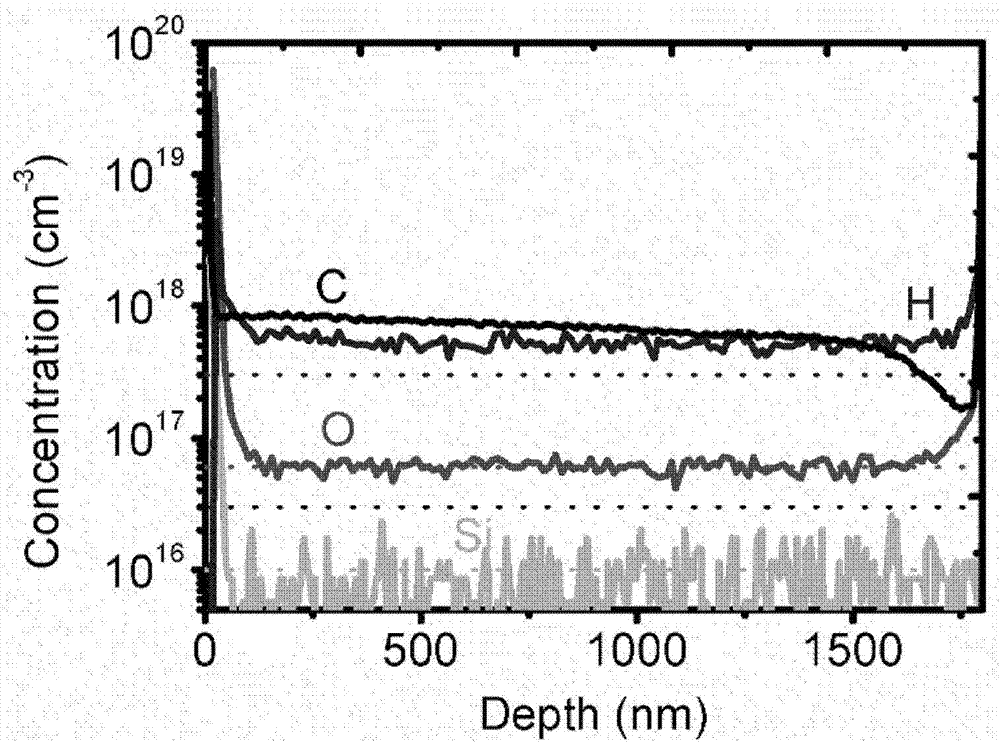

Method for manufacturing high-resistance GaN thin film

InactiveCN103578986AHigh resistivityQuality assuranceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceMaterial growth

The invention discloses a high-resistance GaN thin film and a method for manufacturing the high-resistance GaN thin film. The high-resistance GaN thin film comprises a substrate, a GaN low-temperature nucleating layer and a GaN high-resistance layer, wherein the GaN low-temperature nucleating layer is manufactured on the substrate, and the GaN high-resistance layer is manufactured on the GaN low-temperature nucleating layer. The high-resistance GaN thin film grows through MOCVD equipment, with trimethyl gallium and ammonia gas used as a gallium source and a nitrogen source, and with hydrogen used as carrier gas; the growth temperature of the GaN low-temperature nucleating layer is 550 DEG C, the pressure of a reaction chamber for the GaN low-temperature nucleating layer is 200 Torr, and the thickness of the GaN low-temperature nucleating layer ranges from 0.2 micrometer to 0.3 micrometer; the growth temperature of the GaN high-resistance layer is 1040 DEG C, the pressure of a reaction chamber for the GaN high-resistance layer is 50 Torr, and the thickness of the GaN high-resistance layer is 2 micrometers. According to the high-resistance GaN thin film, by controlling the pressure of the reaction chambers in the material growth process and controlling merging of carbon atoms in reaction precursors TMGa, carbon impurities are imported to acquire acceptor levels under the condition that a carbon source is not independently added, and background carrier concentration is compensated for.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

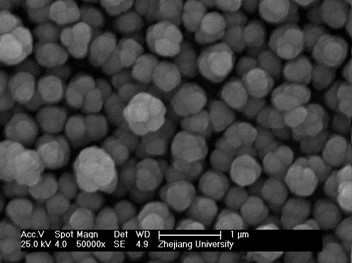

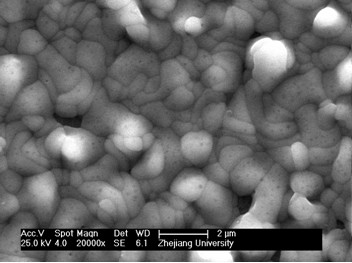

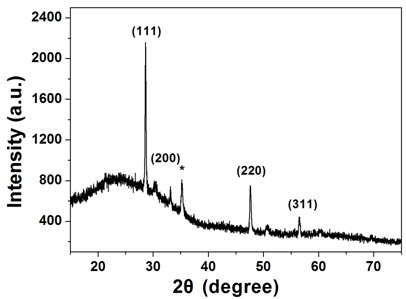

Method for preparing NaYF4:Yb,ER up-conversion fluorescent material by adopting electro-deposition

InactiveCN102140662ALow growth temperatureLow costElectrolytic inorganic material coatingLuminescent compositionsFluorescenceSodium ascorbate

The invention discloses a method for preparing a NaYF4:Yb,ER up-conversion fluorescent material by adopting electro-deposition, which comprises the following steps of: 1) cleaning indium tin oxide (ITO) conductive glass for 2 to 3 times by using acetone, cleaning the ITO conductive glass in an ultrasonic cleaner for 10 to 30 minutes by using deionized water, activating the ITO conductive glass in 10 percent salpeter solution for 10 to 30 seconds; and cleaning with deionized water for later use; 2) adding sodium ascorbate into coordination compound solution consisting of 0.003-0.3mol / L ethylene diamine tetraacetic acid and yttrium ions, ytterbium ions and erbium ions in a molar ratio of (75-94):(5-20):(1-5), adding solution of sodium fluoride, and regulating the pH value to be 5-7 to obtain the electrolyte for later use; and 3) taking the ITO conductive glass as a working electrode, a platinum electrode as a counter electrode, and a saturated calomel electrode as a reference electrode for electro-deposition, and annealing the prepared film. The method has the characteristics of simple equipment, low cost, high deposition rate, low material growth temperature, and capacity of being operated at normal temperature and normal pressure, and is expectedly used for industrial production.

Owner:ZHEJIANG UNIV

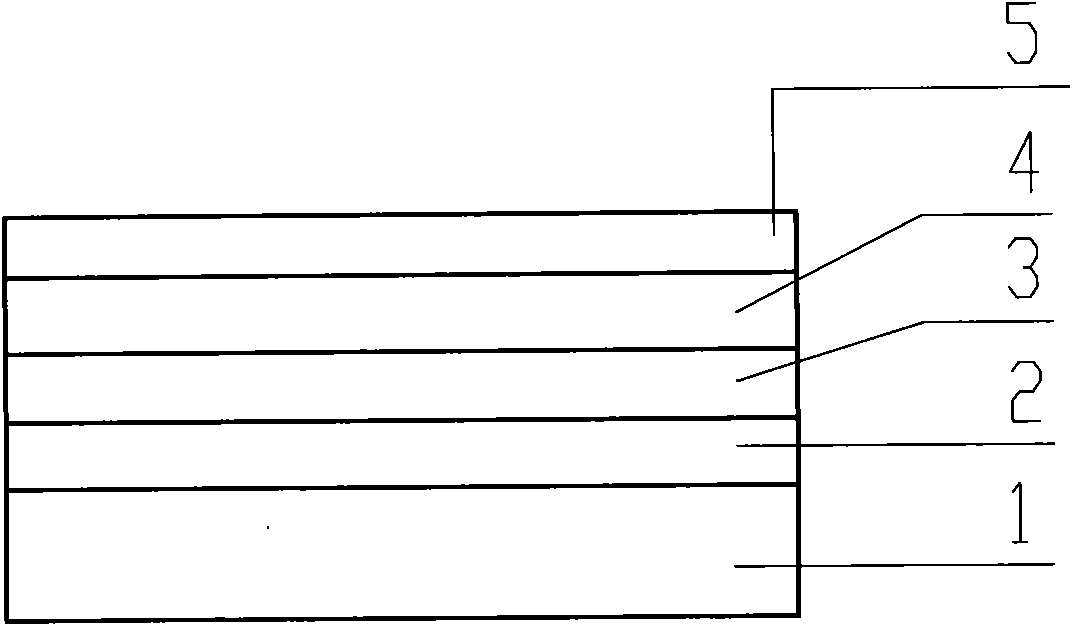

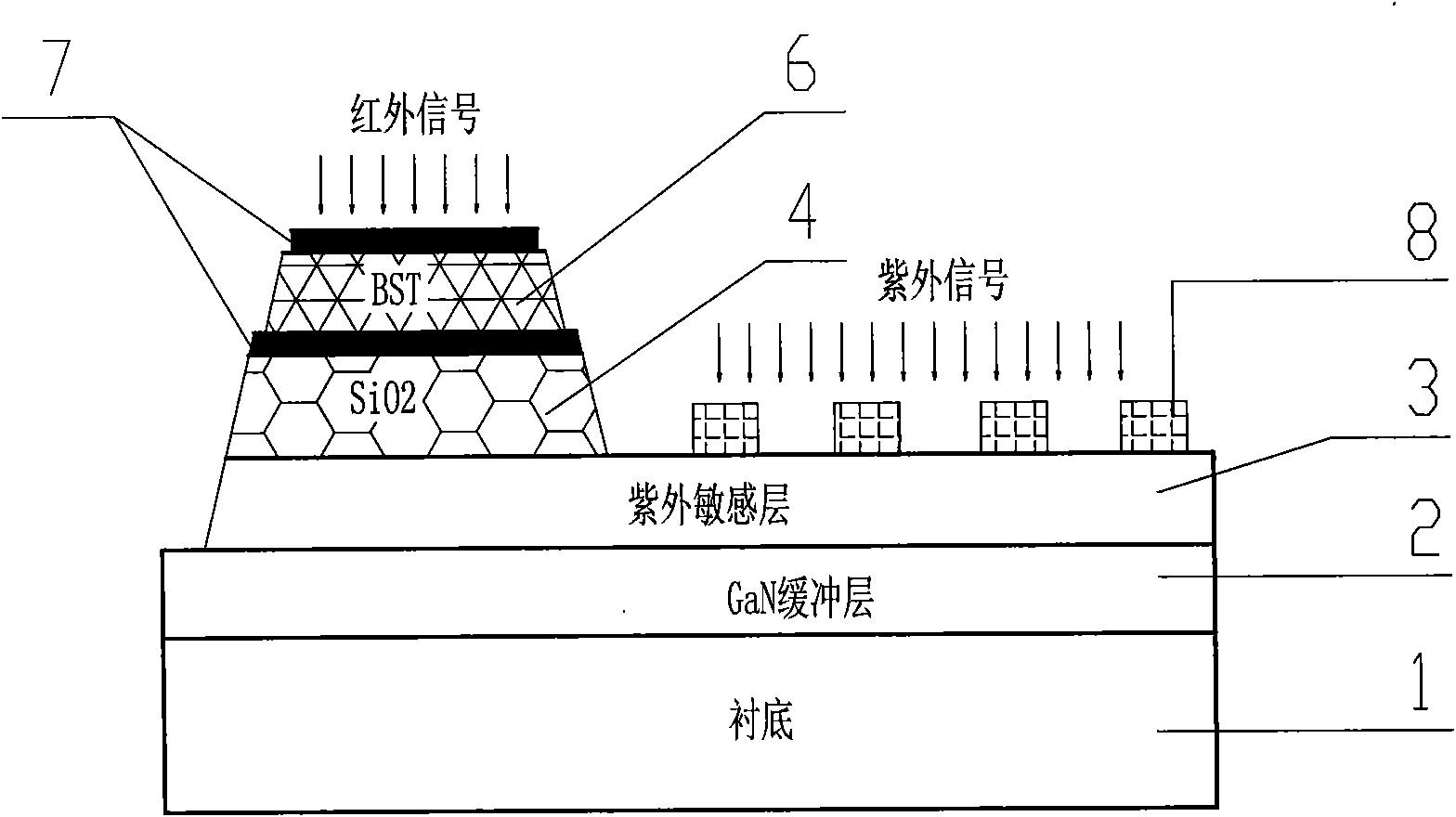

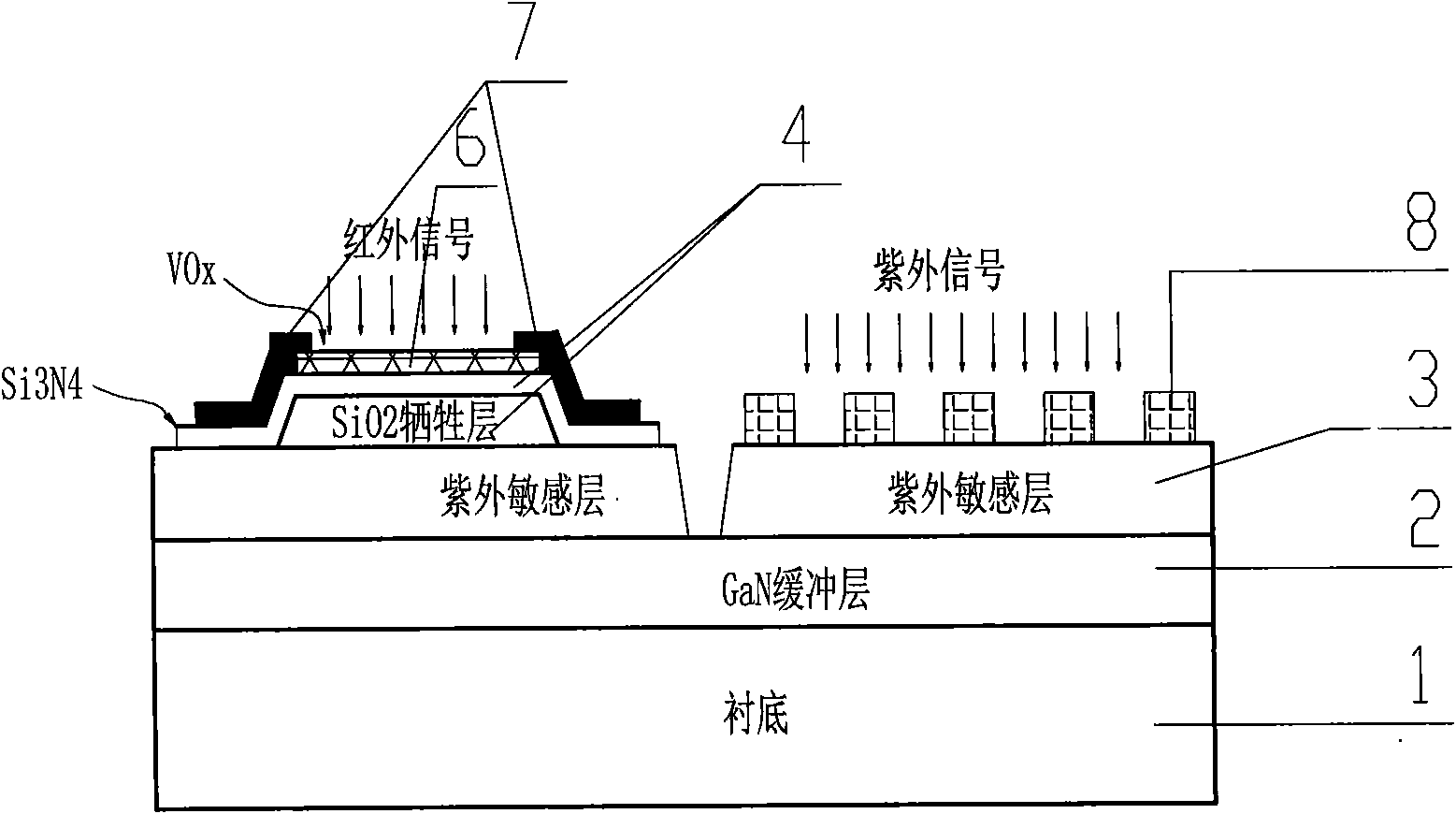

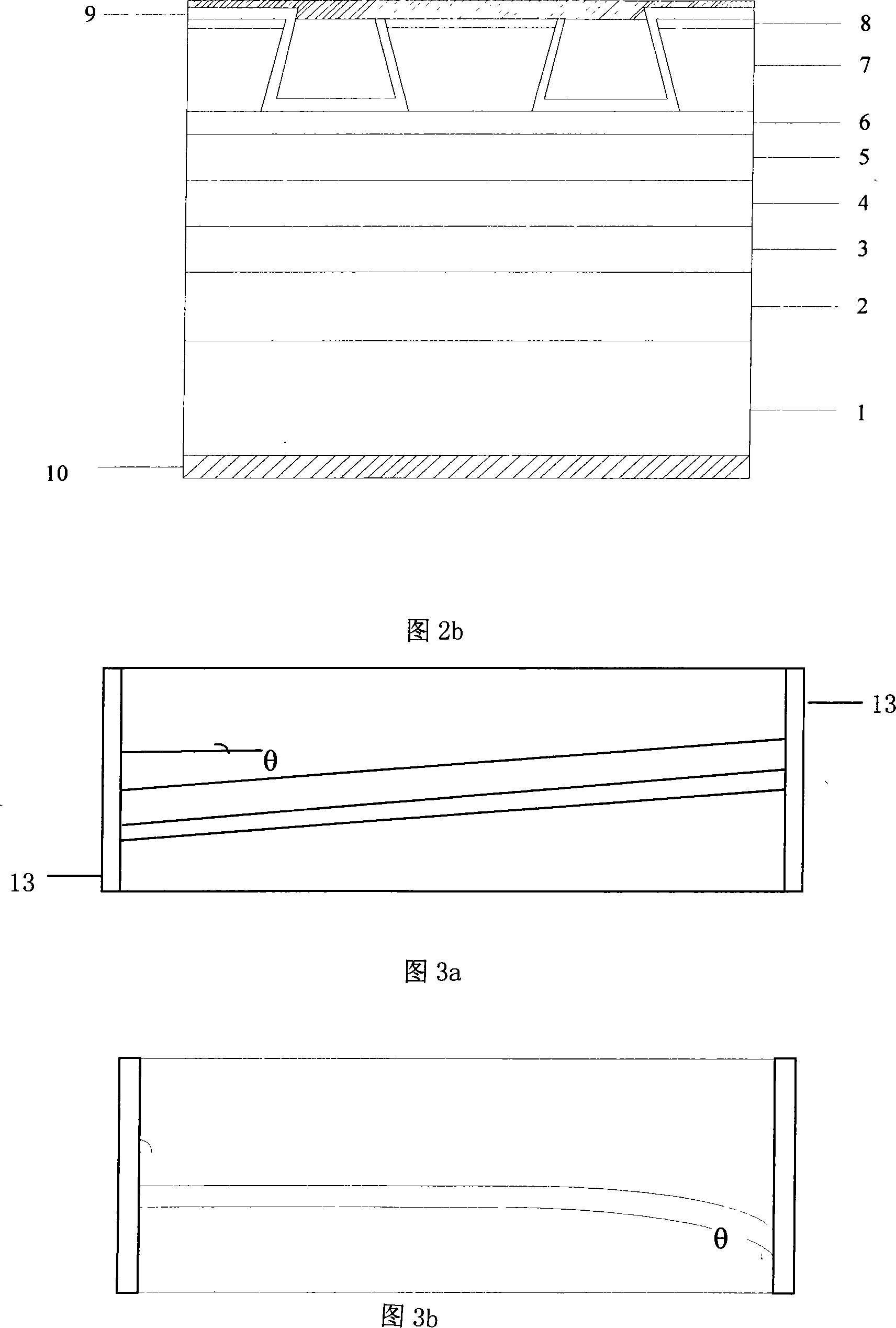

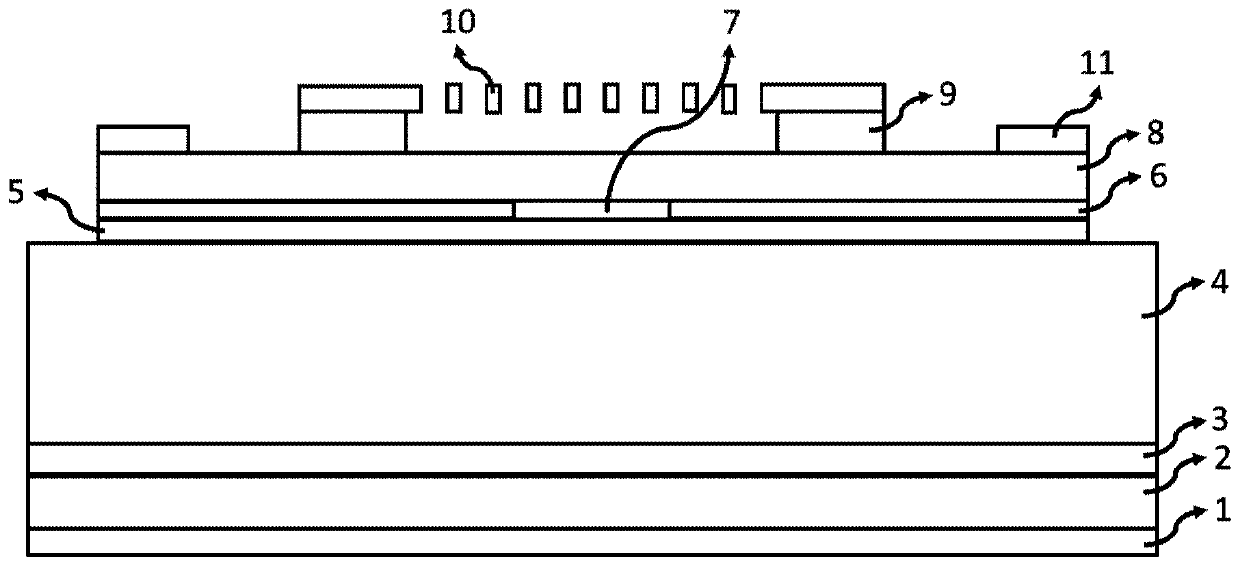

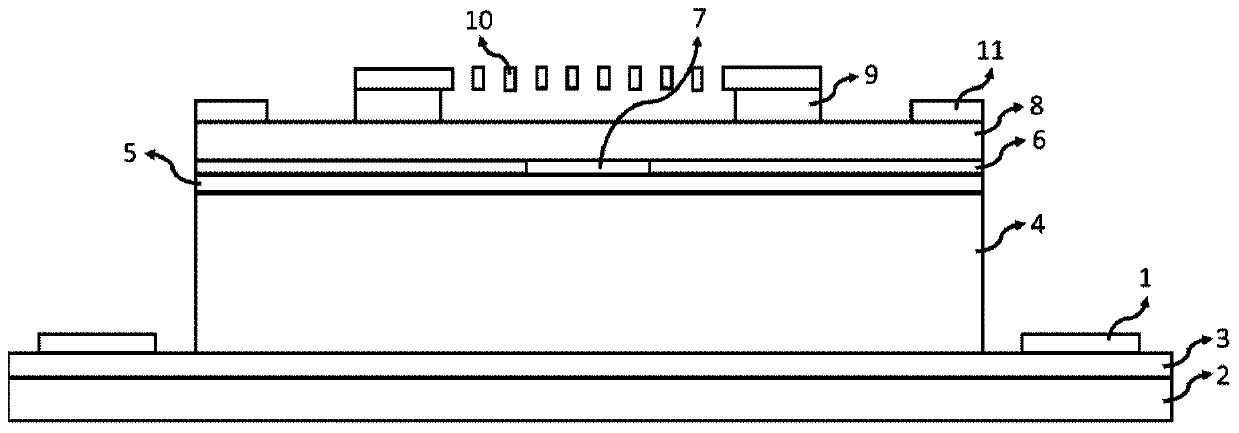

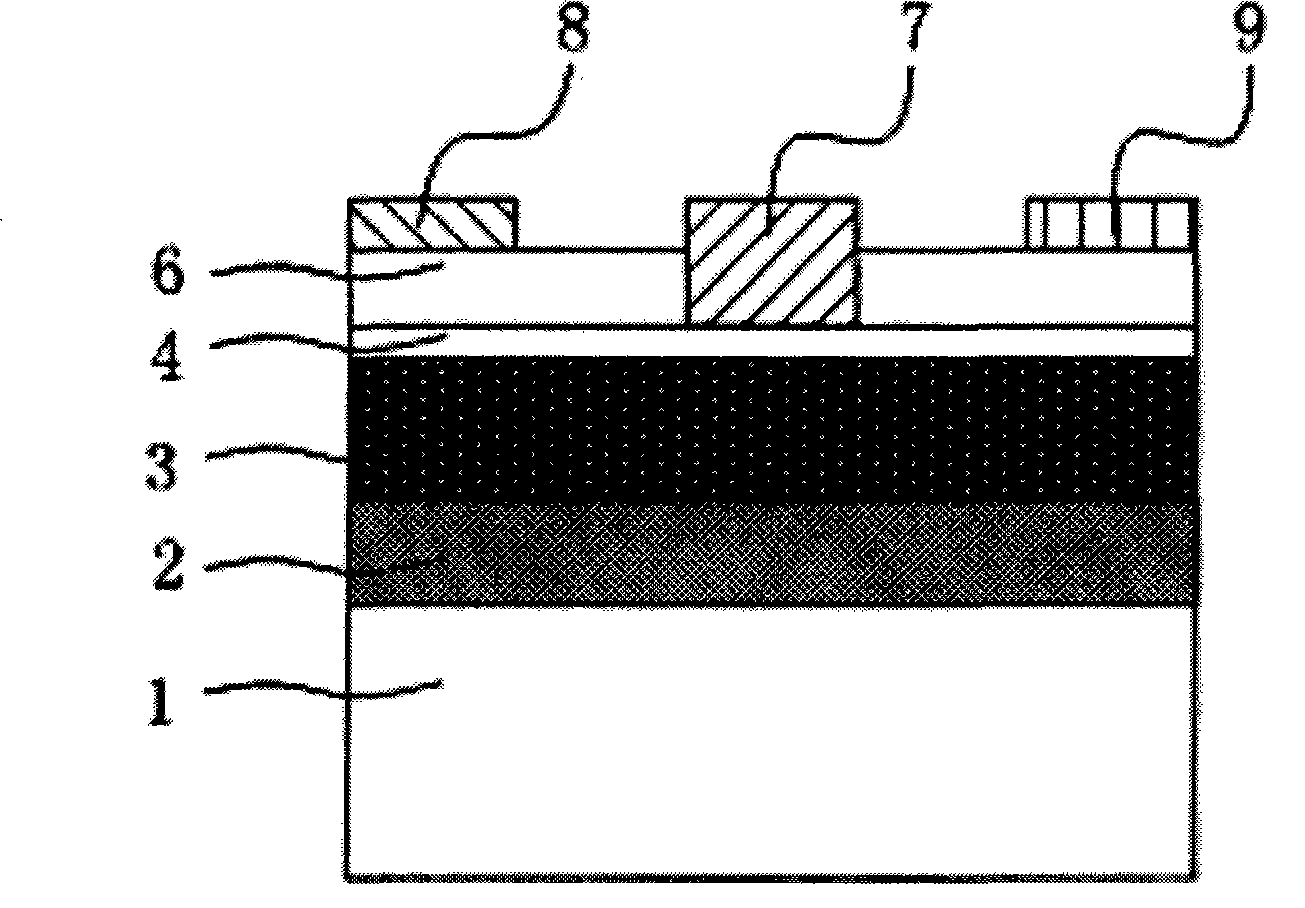

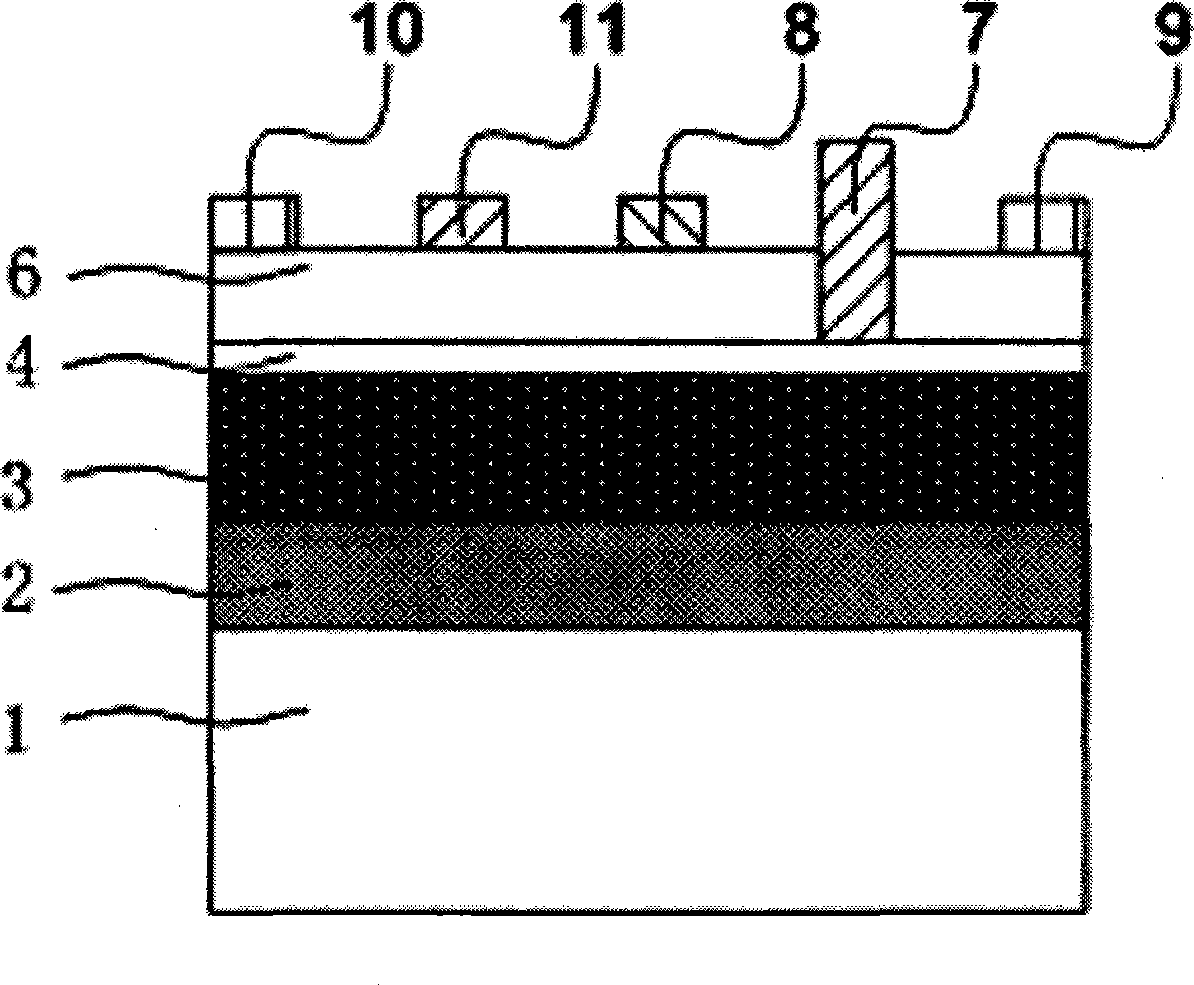

Monolithic integrated non-refrigerated infrared/ultraviolet double-color detector and manufacture method thereof

ActiveCN101586985AReduce volumePrevent degradationTelevision system detailsImpedence networksFrequency spectrumResponse spectrum

The invention discloses a monolithic integrated non-refrigerated infrared / ultraviolet double-color detector and a manufacture method thereof, belonging to the field of photoelectric detectors. The detector comprises a substrate, an ultraviolet sensitive thin film structure and an infrared sensitive thin film structure thereof are integrated on the same substrate material; a cushion layer, an ultraviolet sensitive layer, an isolation layer and an infrared detecting structure are sequentially arranged on the substrate upwardly. In the invention, SiC, GaN series or AlxGa1-xN series of the broad-band gap high-temperature semiconductor ultraviolet sensitive thin film structure and ferro-electricity, vanadium oxide or amorphous silicon of the non-refrigerated infrared sensitive thin film structure grow on the same substrate, and a relative simple material growth method and processing process are adopted to realize the monolithic integration of the non-refrigerated infrared / ultraviolet double-color detector so as to develop the range of a response spectrum, and improve the detection and identification probability of a target; in the application, the invention has no requirement for low temperature, and reduces the volume of parts and the production cost.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Protective coating with high adhesion and articles made therewith

Coatings and articles suitable for use in high temperature environments, for example, are presented. One embodiment is a coating that comprises a plurality of elongate material growth domains defined between domain boundaries. The domains have an intra-domain density of at least about 75% of theoretical density, have a substantially equiaxed grain morphology, and comprise a plurality of at least partially melted and solidified particles. Another embodiment is a coating that comprises a matrix comprising a substantially equiaxed grain morphology and a plurality of vertically oriented cracks disposed in the matrix. Further embodiments include articles comprising one or more of the coatings described above.

Owner:GENERAL ELECTRIC CO

A stable torasemide injection and its preparation method

InactiveCN101007003AReduced dosing timeNo hemolyticPharmaceutical delivery mechanismPharmaceutical non-active ingredientsMaterial growthActivated carbon

There is provided an injection with torasemide as the main active ingredient in the invention, the preparing method of the injection is also included in the invention. The stability of the injection in the invention has been greatly improved. There is solubilizing agent and stabilizer in the preparation, the pH value is 9.0 or larger. The preparing method includes the following steps: adding 1-50% (by weight) of solubilizing agent to certain amount of injecting water; adding torasemide to the water, after it is completely dissolved, adding 0.1-5% part of stabilizer; adding water to requested amount and stirring uniformly; adding activated char to adsorb for 30min at high temperature; decarbonizing and filtering; adding medically used alkali to regulate the ph value to 9.0 or larger; aseptically filtering; after the assay is approved, packaging, degerming and stocking. The advantages of the invention include: high stability, short preparing time, low cost, no haemolyticus, blood vessel stimulus and allerfic response, low growing speed of relative substances.

Owner:YANGTZE RIVER PHARM GRP NANJING HAILING PHARM CO LTD +1

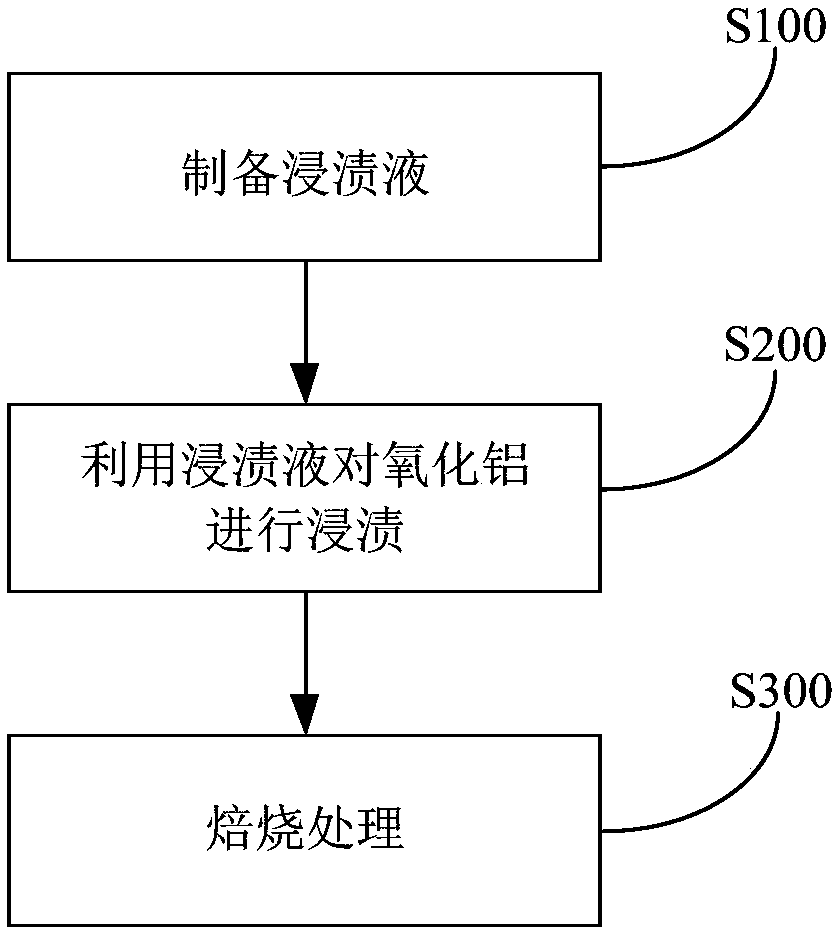

Method for preparing raw material for vapor-method aluminum nitride crystal growth

InactiveCN103643295AFulfil requirementsPolycrystalline material growthFrom condensed vaporsGas phaseSingle crystal

The invention discloses a method for preparing a raw material for vapor-method aluminum nitride crystal growth. The method comprises the specific steps of soaking a tungsten crucible and a crucible cover which are required to be used in aqua regia for 30-120 minutes, taking out the tungsten crucible and the crucible cover, cleanly flushing, and drying for later use; adding aluminum nitride powder into the tungsten crucible, and carrying out multi-layer compacting treatment; covering the tungsten crucible with the crucible cover, putting in a tungsten-mesh heating furnace, vacuumizing until the pressure is 1*10<-3>Pa, inflating with high-purity nitrogen gas until the pressure is 30kPa, heating to the temperature of 300 DEG C, keeping the temperature constant for 1 hour, heating to the temperature of 800 DEG C, and keeping the temperature constant for 1 hour; inflating the tungsten-mesh heating furnace with high-purity nitrogen gas until the pressure is 50kPa, heating to the temperature of 1800 DEG C, keeping the temperature constant for 5 hours, heating to the temperature of 2,050 DEG C, and keeping the temperature constant for 8 hours; cooling to room temperature, thereby obtaining an aluminum nitride sinter cake which serves as the raw material for vapor-method aluminum nitride crystal growth. According to the method, a compact sintered body is prepared from the aluminum nitride powder, so as to control vapor-phase reaction, thus the requirements of RVT (Physical Vapor Transport)-method aluminum nitride crystal material growth for raw materials are met.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

Substrate material for mercury cadmium telluride material growth by liquid phase epitaxy method and preparation thereof

InactiveCN101348941AImprove lattice qualityQuality improvementPolycrystalline material growthLiquid-phase epitaxial-layer growthMaterial growthProcess equipment

The invention relates to a substrate material used for the growth of a mercury cadmium telluride material by a liquid phase epitaxy method. On the basis of the prior substrate material, a layer of cadmium zinc telluride single-crystal film completely matched with the lattice constant of mercury cadmium telluride is grown. The substrate material of the invention has the advantages that an epitaxial film has high lattice quality, and compositions can be flexibly adjusted according to the lattice constants of short wave, medium wave and long wave mercury cadmium telluride materials; meanwhile, the cadmium zinc telluride film has even compositions; the method adopts mature process, and has the advantages of simpler process equipment, short process cycle and low cost; and the substrate material with large area, high quality and high composition evenness can be provided for an infrared focal plane detector.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

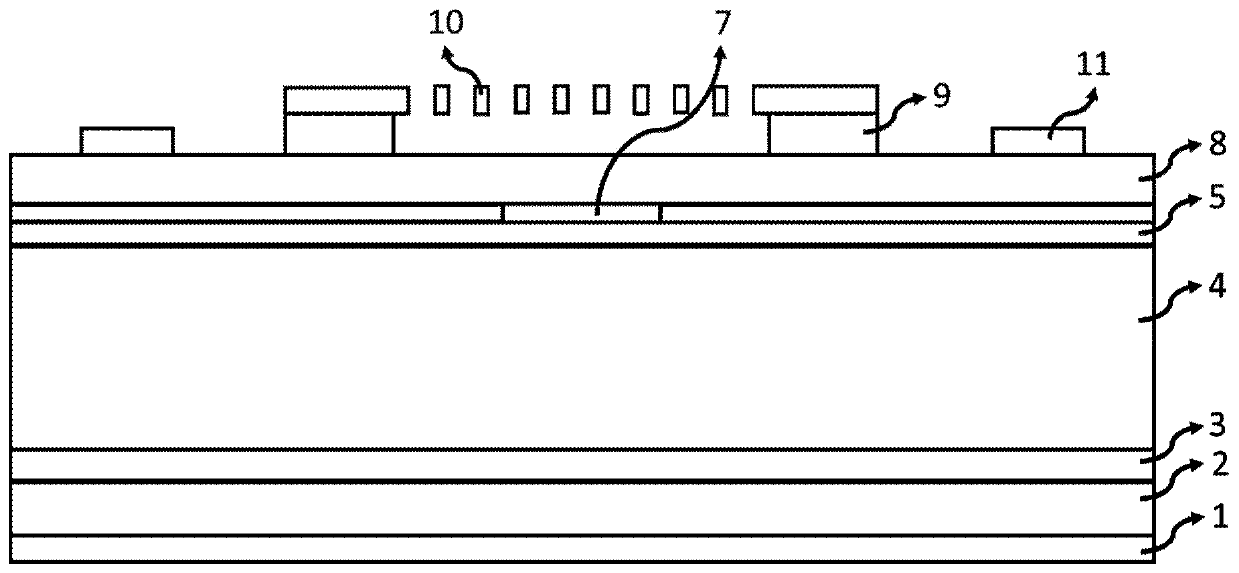

Super-radiation light emitting diode

InactiveCN101197407ASimple processImprove reliabilitySemiconductor devicesWaveguideLight-emitting diode

The invention discloses a super radiation luminescent diode, having a material growth part comprising a substrate, a lower cladding, a lower separate confinement layer, an active region, an upper separate confinement layer, an upper cladding, a optical confinement layer and an ohmic contact layer in sequence; a P-typed electrode layer is formed through an insulation medium layer above the ohmic contact layer and a N-typed electrode layer formed under the substrate; the active region positioned between the lower separate confinement layer and the upper separate confinement layer adopts body material structure, and the luminescent wavelength range of the active region is from 0.85 to 1.7um. The invention achieves low polarization design by combining the material active region design and waveguide structure, having the advantages of simple technique and high reliability. The invention can be applied to the wavelength range of 0.85 to 1.7um. The invention adopts ridge-waveguide structure to reduce the series resistance, increase injection efficiency, and thus improving device characteristics. The invention adopts tilted waveguide; after the waveguide is bent, the high anti-reflective film demand can be reduced by one to two orders of magnitude, and advantageous to realize super luminescent diode with low ripple coefficient.

Owner:GUANGXUN SCI & TECH WUHAN

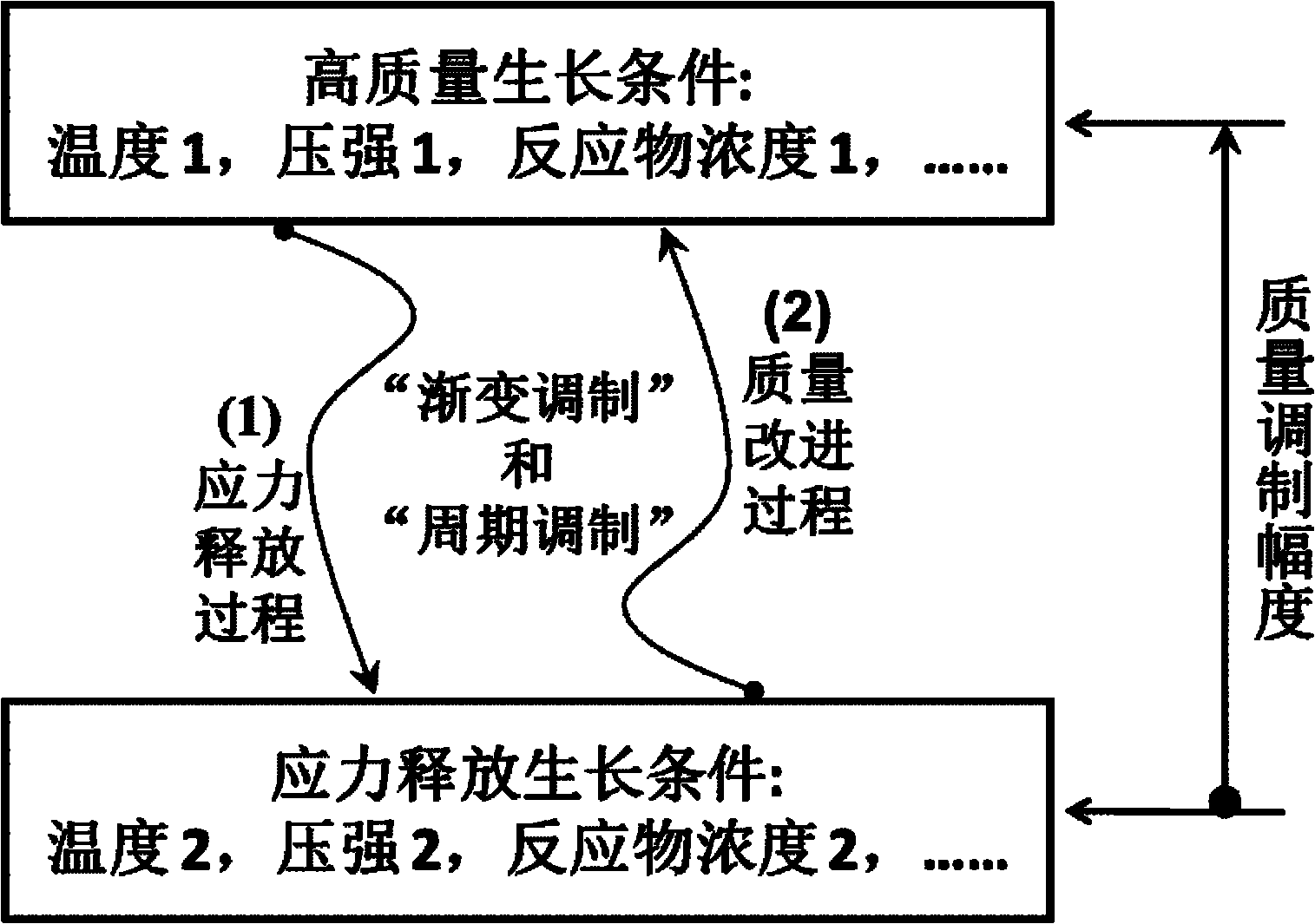

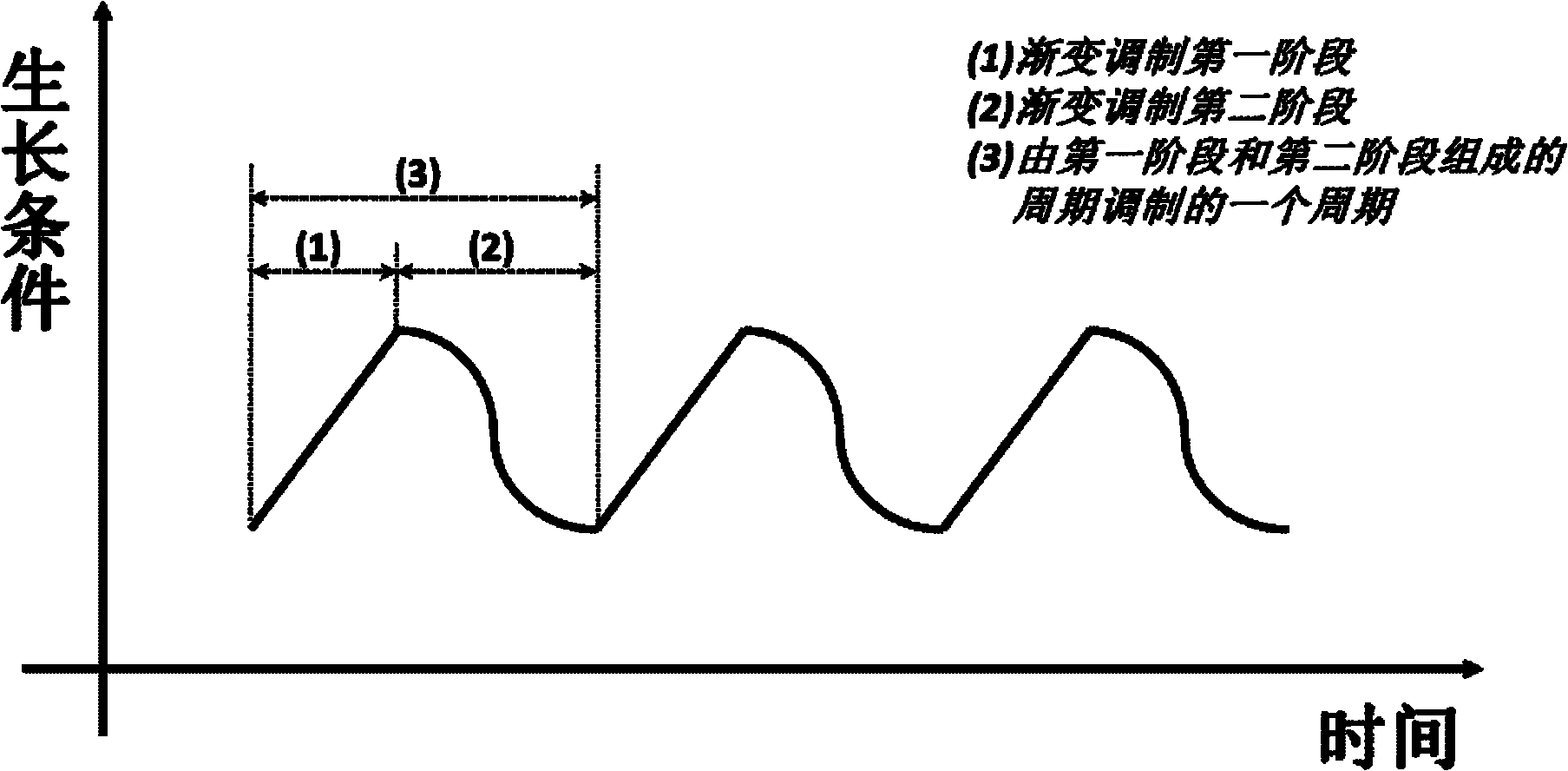

Heteroepitaxial growth method for high-quality monocrystalline thick-film material

ActiveCN101962803AQuality improvementEpitaxyFrom chemically reactive gasesMaterial growthEpitaxial material

The invention discloses a heteroepitaxial growth method for a high-quality monocrystalline thick-film material, which comprises the following steps of: pretreating a substrate; in the first stage, gradually modulating to effectively release stress, wherein process parameters are gradually changed to a stress release growth condition from a high quality growth condition; in the second stage, gradually modulating to improve the quality of an epitaxial material; continuously repeating the first stage and the second stage in a periodic modulation mode; stopping growth when the material is grown to reach the preset thickness; and taking the material growth effect as feedback, regulating a quality modulating amplitude parameter, and determining the growth condition of the material next time. The heteroepitaxial growth method solves two main problems of heteroepitaxial growth of the material, achieves the improvement of the quality of the material and the effective release of the stress, introduces a control parameter, namely the quality modulating amplitude, realizes the effective control of the quality and stress, and can well realize the heteroepitaxial growth of the high-quality monocrystalline thick-film material.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

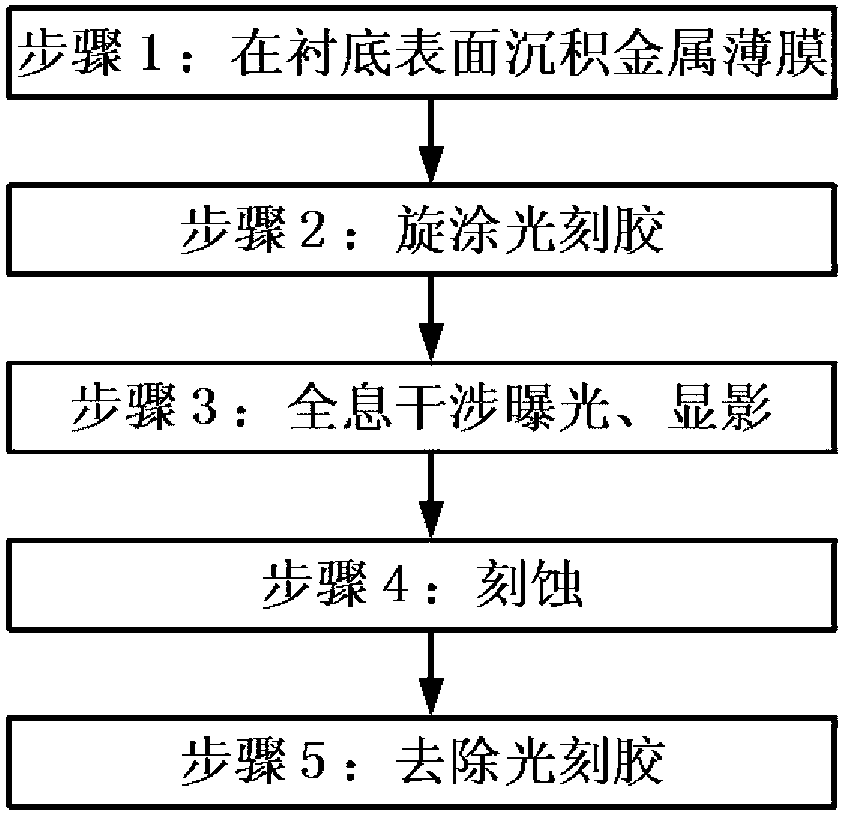

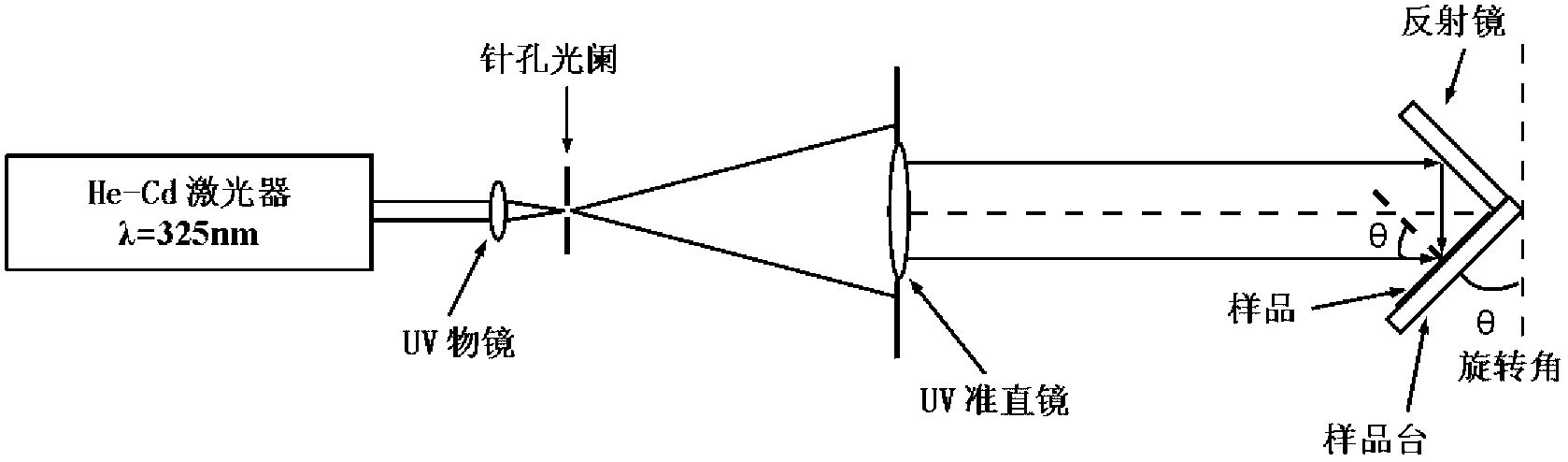

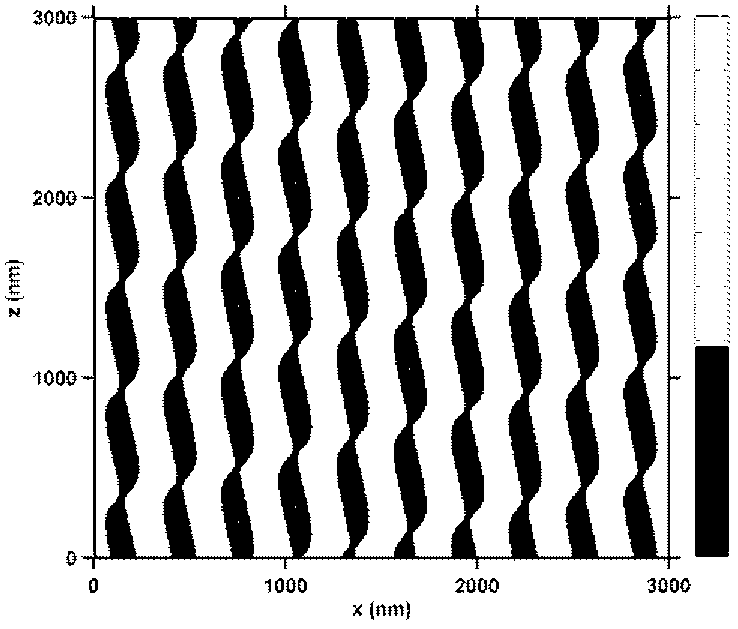

Preparation method of holographic grating provided with surface with periodically graded width

InactiveCN103226215AReduce manufacturing costEasy to operatePhotomechanical apparatusDiffraction gratingsMaterial growthGrating

A preparation method of a holographic grating provided with a surface with a periodically graded width. The preparation method comprises the following steps as follows: 1 depositing a thin-film material on the surface of a clean substrate by using a material growth technology, 2 spin-coating the thin-film material with a photoresist and conducting prebaking, 3 exposing and developing to obtain a graphical photoresist mask by using a holographic interference exposure technology so as to form a chip consisting of the substrate, the thin-film material and the graphical photoresist mask, 4 etching the surface of the chip, and 5 removing the residual photoresist to form the holographic grating provided with the surface with the periodically graded width, and accomplishing the preparation. The holographic grating with the periodically graded width prepared by the method has the advantages of large area, ordered and controllable structure, good repeatability, high stability, low manufacturing cost, simplicity in operation and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Asexual propagation seedling method of hybrid paper mulberry

InactiveCN108338071AQuality improvementStrong meristem abilityHorticulture methodsPlant tissue cultureMaterial growthBud

The invention discloses a tissue culture rapid propagation seedling method of hybrid paper mulberry, and belongs to the technical field of hybrid paper mulberry plantation. The tissue culture rapid propagation seedling method of hybrid paper mulberry comprises following steps: explant selection, induced culturing, subculturing, rooting culture, and transplanting. According to the tissue culture rapid propagation seedling method, current year stems with buds are selected as explants, the meristematic capacity is excellent, and differentiation propagation is more convenient to realize; LED illumination culture is capable of adjusting culture material growth process, increasing the environmental adaptability, realizing reasonable optimization on composition of induction medium, proliferationmedium, and rooting medium, and illumination conditions of different stages, increasing seedling tissue culture efficiency, and achieving relatively induction rate, reproduction rate, and rooting rate; the adventitious bud induction differentiation rate is 94% or higher; after subculture, average seedling height reaches 3.5cm, rooting rate reaches 100%, and transplanting survival rate reaches 68%or higher. The tissue culture rapid propagation seedling method is adopted for seedling of hybrid paper mulberry, the seedling efficiency is high, the propagation coefficient is large, seedling cost is reduced, and the obtained tissue culture seedlings are strong, and are high in quality.

Owner:天长市金农农业发展有限公司

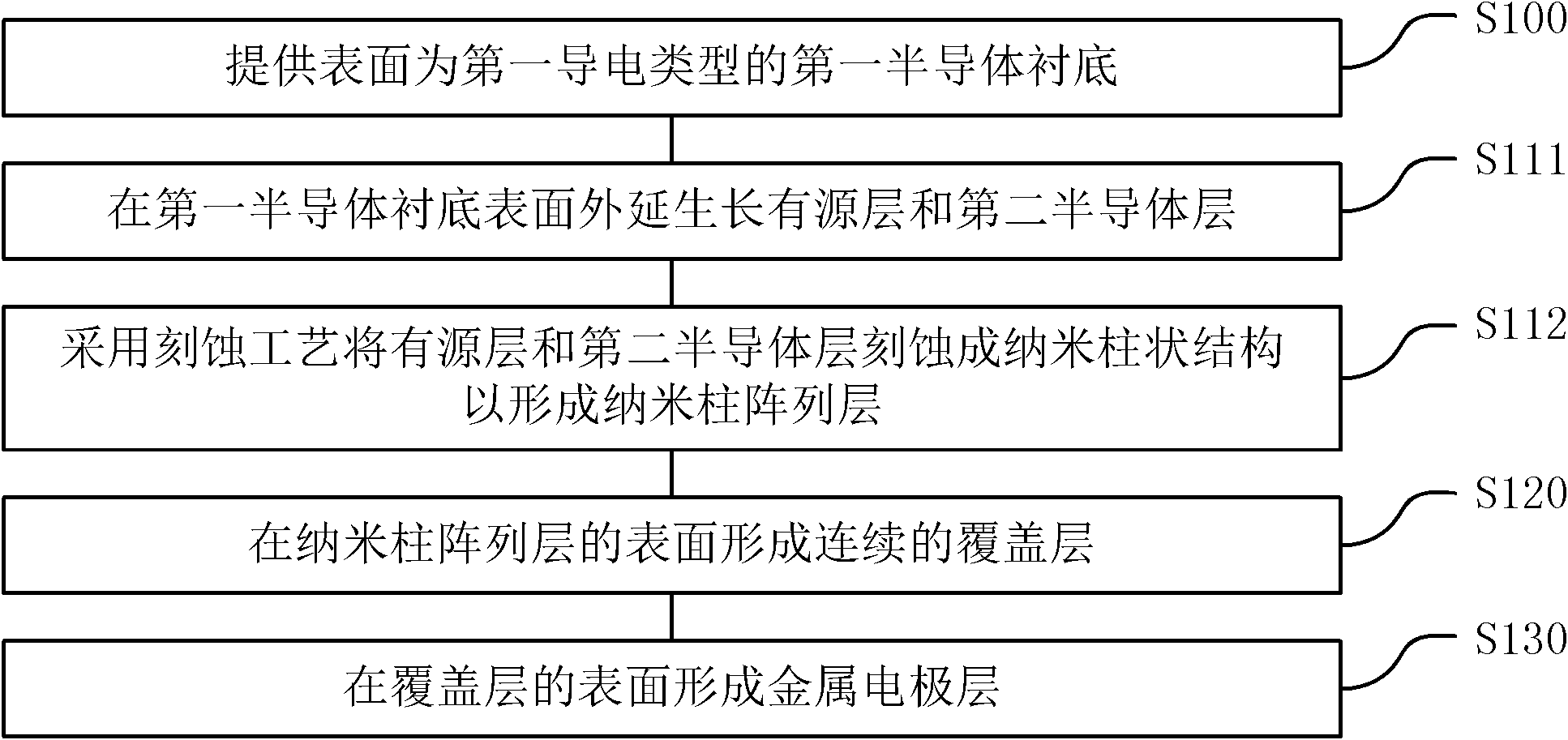

Light-emitting diode and preparation method thereof, and solar cell and preparation method thereof

InactiveCN102185043AImprove compound efficiencyLow efficiencyFinal product manufacturePhotovoltaic energy generationElectrical conductorLattice mismatch

The invention discloses a preparation method of a light-emitting diode. The method comprises the following steps of: providing a first semiconductor substrate having a first electric conduction type surface; forming a nanomcolumn array layer on the surface of the semiconductor substrate, wherein the nanomcolumn array layer comprises a second semiconductor layer having a second electric conduction type surface, and an active layer positioned below the second semiconductor layer and close to the first semiconductor substrate; forming a continuous graphene coating layer on the surface of the nanomcolumn array layer; and forming a metal electrode layer on the surface of the coating layer. The method has the advantages that: lattice mismatch of heterogenous junction material growth can be reduced; the composite efficiency of a charge carrier is improved; and the problems of low conversion efficiency and low stability of a multi-layer thin film and a horizontal structure caused by heating of a spreading resistor can be solved at the same time.

Owner:SUZHOU NANOWIN SCI & TECH +1

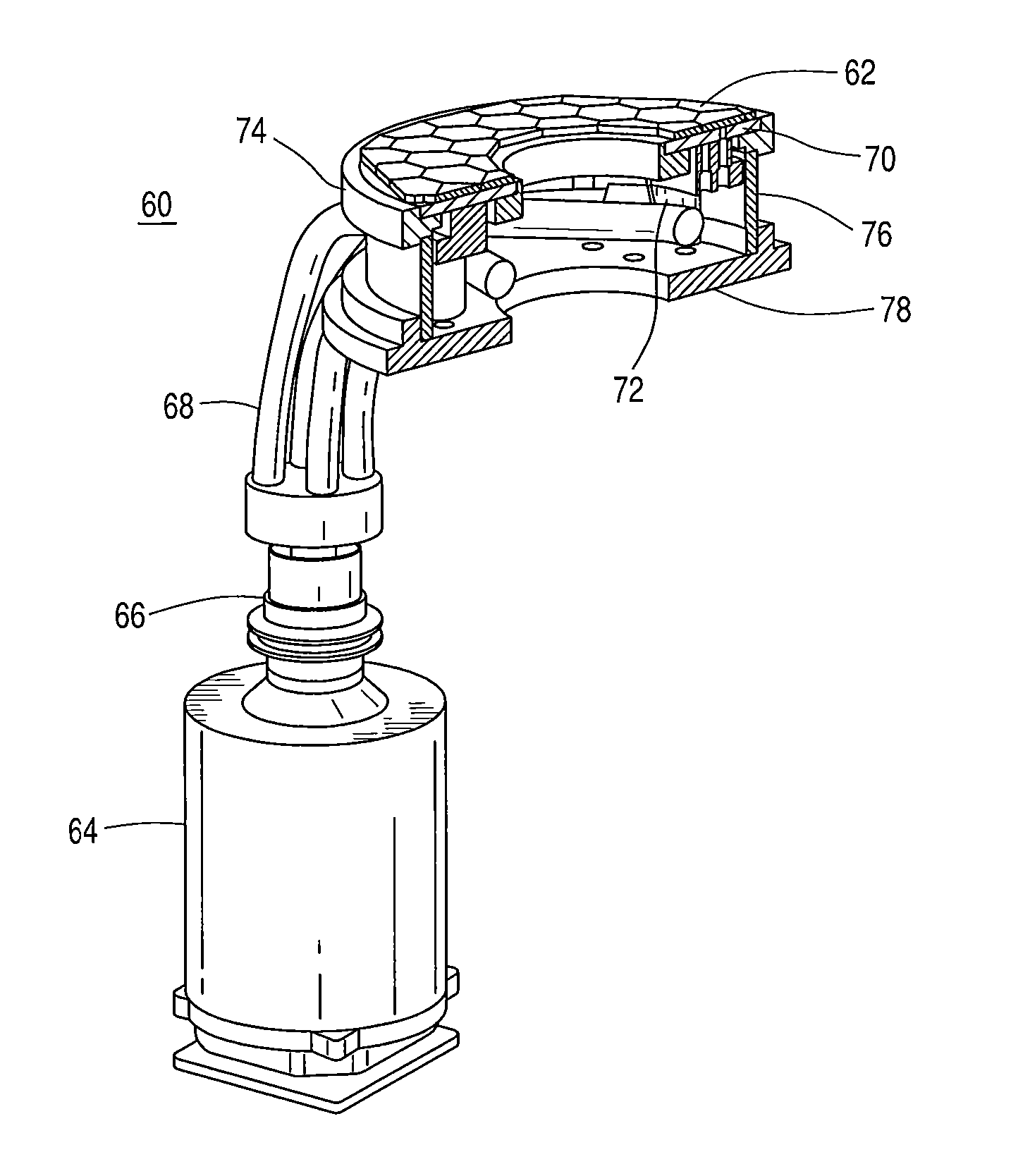

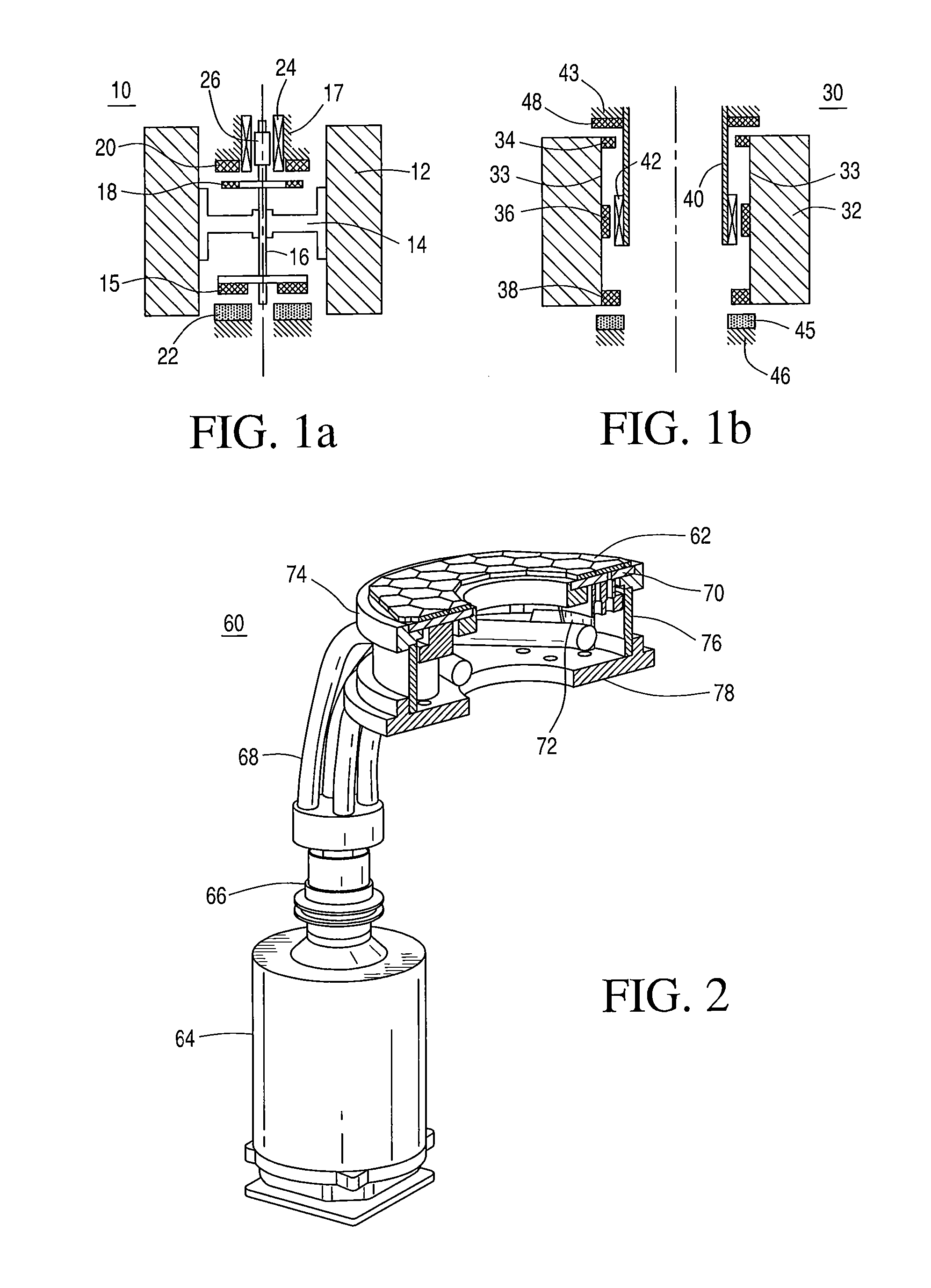

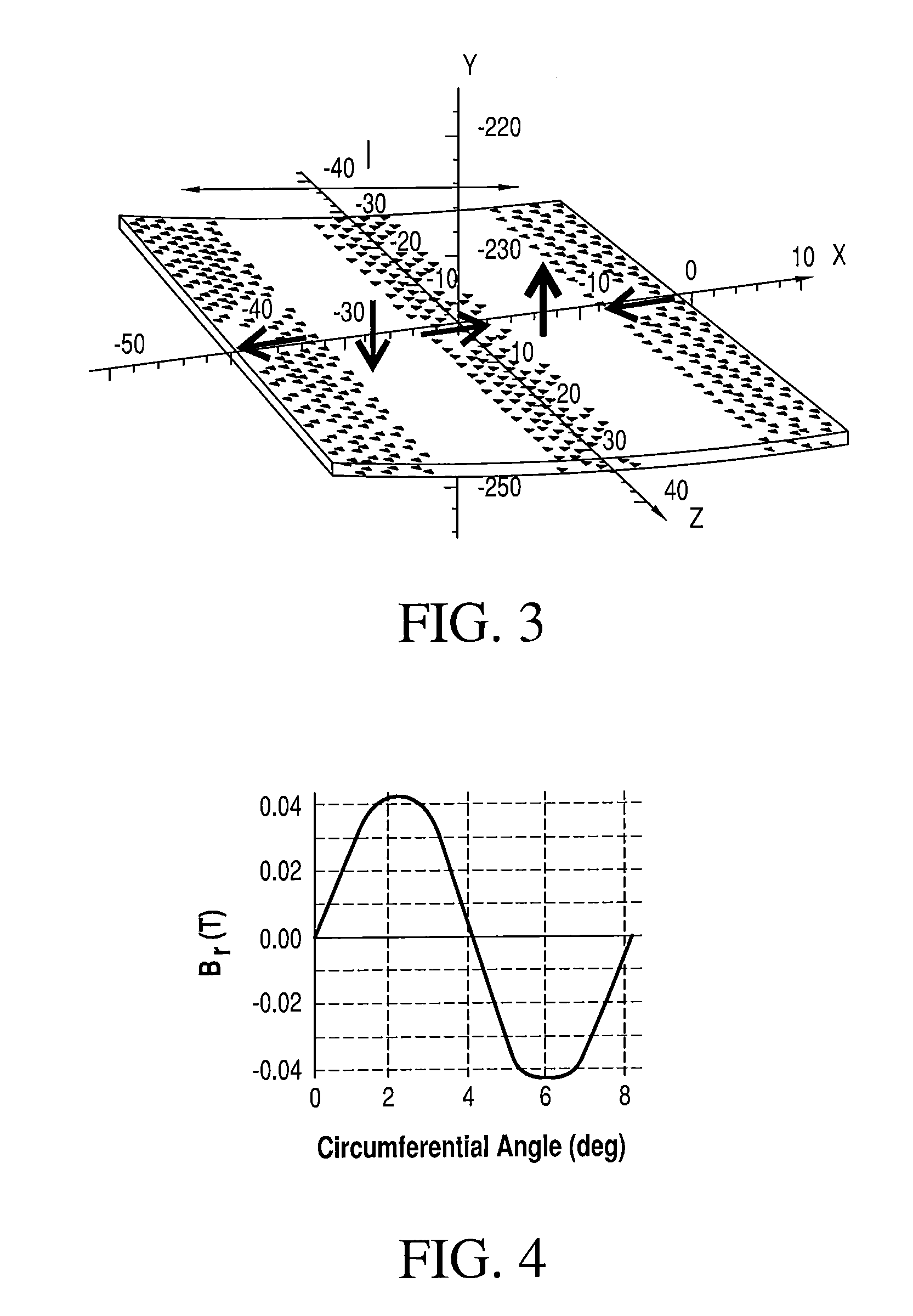

Open-core flywheel architecture

ActiveUS20130260999A1Eliminate the problemImprove performanceShaftsSuperconductor detailsMaterial growthHigh-temperature superconductivity

Apparatuses, systems and methods are described for a flywheel system incorporating a rotor made from a high-strength material in an open-core flywheel architecture with a high-temperature superconductive (HTS) bearing technology to achieve the desired high energy density in the flywheel energy storage devices, to obtain superior results and performance, and that eliminates the material growth-matching problem and obviates radial growth and bending mode issues that otherwise occur at various high frequencies and speeds.

Owner:THE BOEING CO

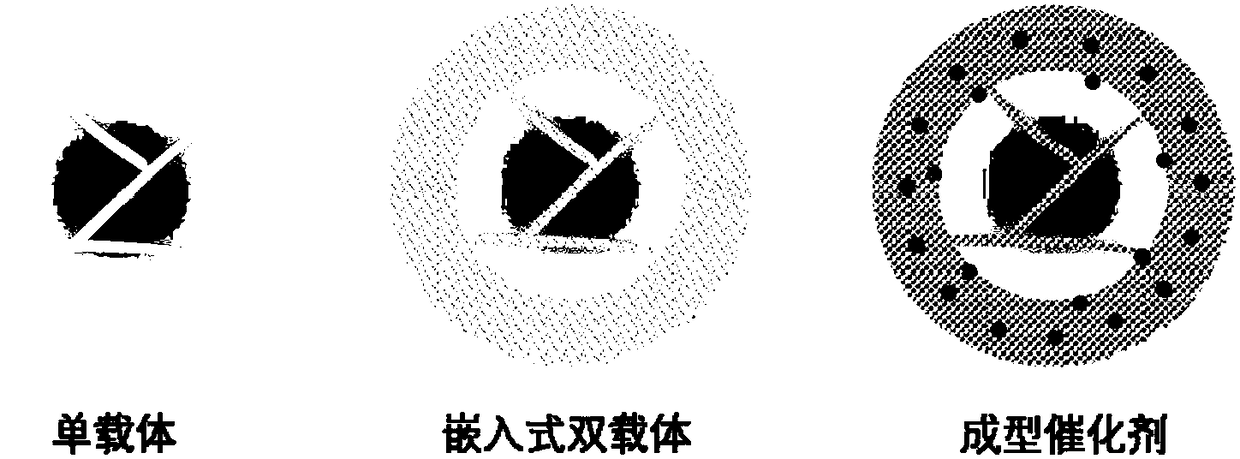

Double-carrier ozone catalyst and modular catalytic oxidation waste water treatment device

ActiveCN108479784AMultistage water/sewage treatmentWater/sewage treatment by degassingMaterial growthCatalytic oxidation

The invention discloses a double-carrier ozone catalyst and a modular catalytic oxidation waste water treatment device. The double-carrier ozone catalyst is prepared from a composite carrier, a firstcatalytic component and a second catalytic component, wherein the composite carrier is prepared from a carbon-based material and aluminum oxide, the first catalytic component comprises carbon-based material growth catalysis metal, and the second catalytic component is prepared from catalytic ozonation active metal. The composite carrier of the binary vector ozone catalyst comprises the carbon-based material and the aluminum oxide, has good surface activity of the carbon-based material and excellent mechanical performance of an aluminum oxide material, and thus is further conducive to giving play to the catalytic performance of the catalytic ozonation active metal, so that the stability and catalytic performance of the catalyst are improved on the whole.

Owner:TSINGHUA UNIV

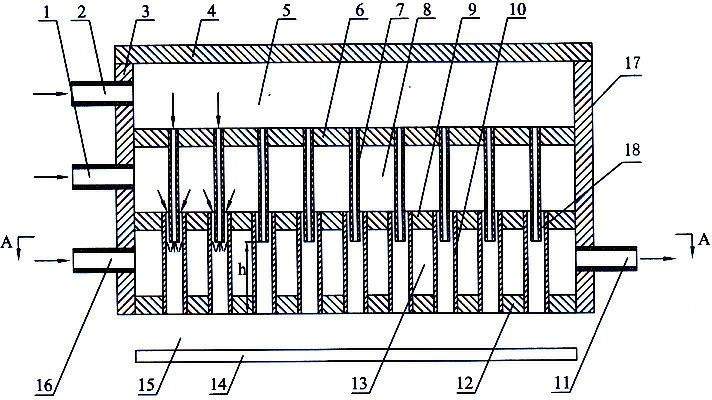

Double-layer gas inlet shower nozzle device of MOCVD (Metal Organic Chemical Vapor Deposition) equipment

InactiveCN102230166AImprove crystal qualityIncrease profitChemical vapor deposition coatingMaterial growthProcess engineering

The invention discloses a double-layer gas inlet shower nozzle device of MOCVD (Metal Organic Chemical Vapor Deposition) equipment, comprising a sealed outer shell in which an upper gas inlet chamber, a lower gas inlet chamber and a water cooling chamber are arranged. The double-layer gas inlet shower nozzle device of the MOCVD equipment is characterized in that a lower gas outlet pipe for realizing communication between the lower gas inlet chamber and a reaction chamber is mounted between the lower gas inlet chamber and the reaction chamber; an upper gas outlet pipe for communicating the upper gas inlet chamber with the lower gas outlet pipe is mounted between the upper gas inlet chamber and the lower gas outlet pipe; the external diameter of the upper gas outlet pipe is less than the internal diameter of the lower gas outlet pipe; and the lower end of the upper gas outlet pipe extends into the lower gas outlet pipe but cannot retract into the lower gas inlet chamber; and a clearance is formed between the upper gas outlet pipe and the lower gas outlet pipe. Two types of reaction gases are premixed in a space between an outlet of the upper gas outlet pipe and an outlet of the lower gas outlet pipe before entering the reaction chamber. The double-layer gas inlet shower nozzle device of the MOCVD equipment disclosed by the invention has the characteristic that different reaction gases are respectively fed into the reaction chamber so that the different reaction gases are sufficiently mixed with little pre-reaction before reaching a substrate; and the crystal quality and the raw material utilization rate during material growth can be improved.

Owner:刘军林

Vertical cavity surface emitting laser and manufacturing method thereof

InactiveCN110429473AReduce difficultyPromote growthLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserMaterial growth

The present invention provides a vertical cavity surface emitting laser and a manufacturing method thereof. The vertical cavity surface emitting laser comprises a substrate, a buffer layer, a lower DBR, an active layer, a current limiting aperture, a current diffusion layer, an undoped suspension type HCG layer, an n side electrode and a p-side electrode. The material extension difficulty of the vertical cavity surface emitting laser is reduced, the universality of material growth is improved, the free carrier absorption is reduced, and the output efficiency of the device is improved; and thevertical cavity surface emitting laser has polarization selection and single mode output characteristics, and can be expanded to a tunable vertical cavity surface emitting laser. The vertical cavity surface emitting laser can be applied to the fields such as optical communication, optical interconnection, optical sensing, medical imaging and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

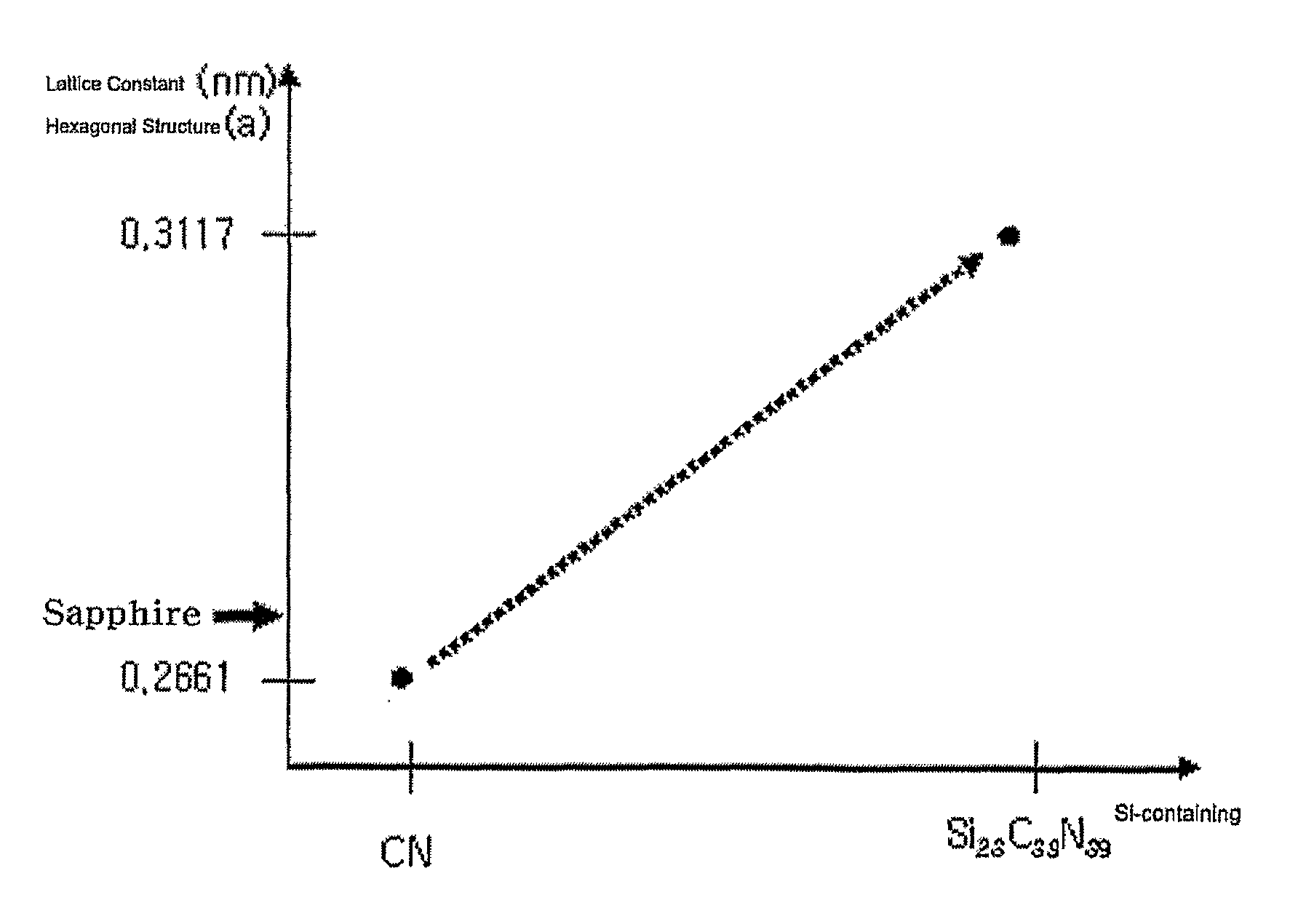

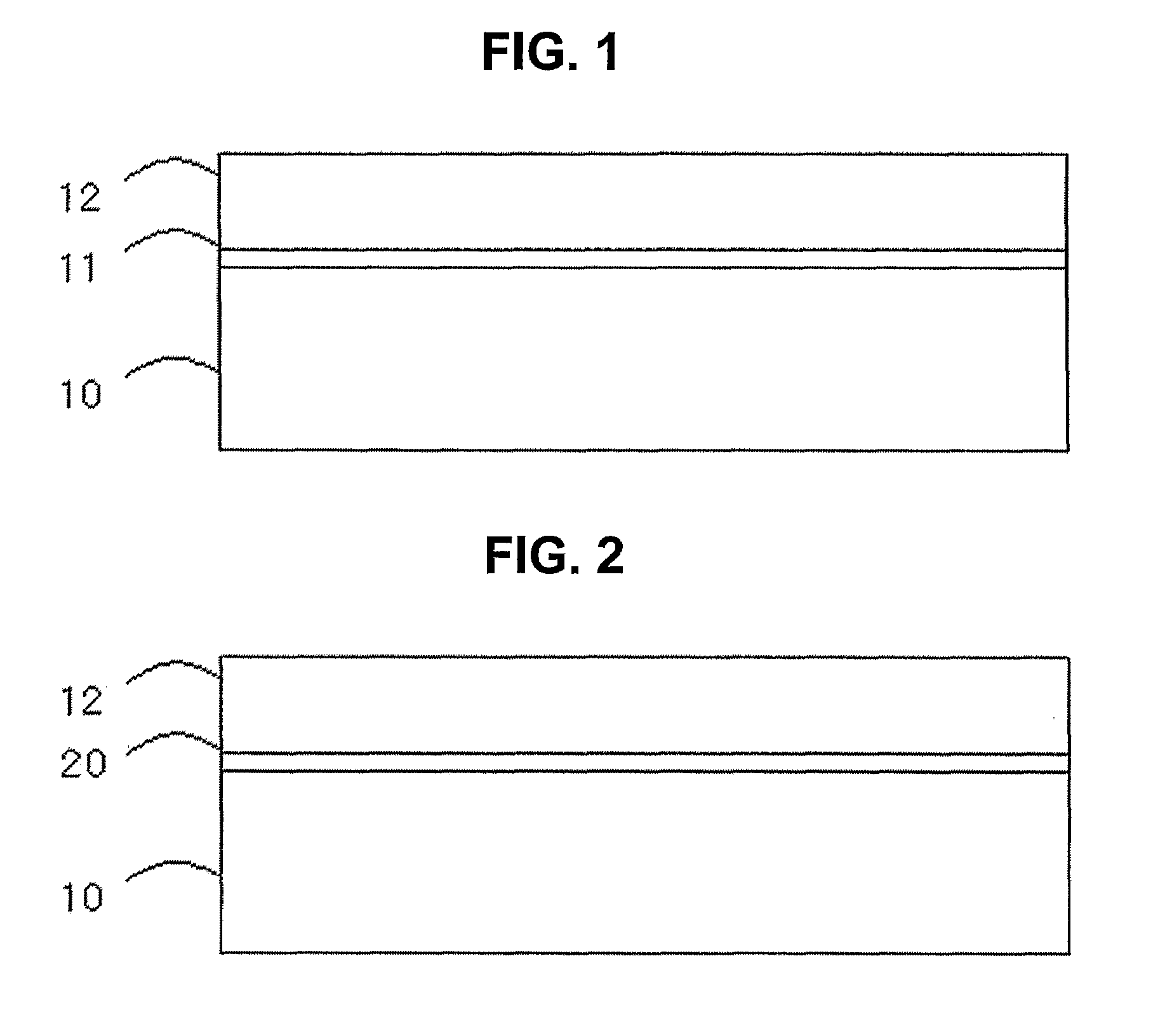

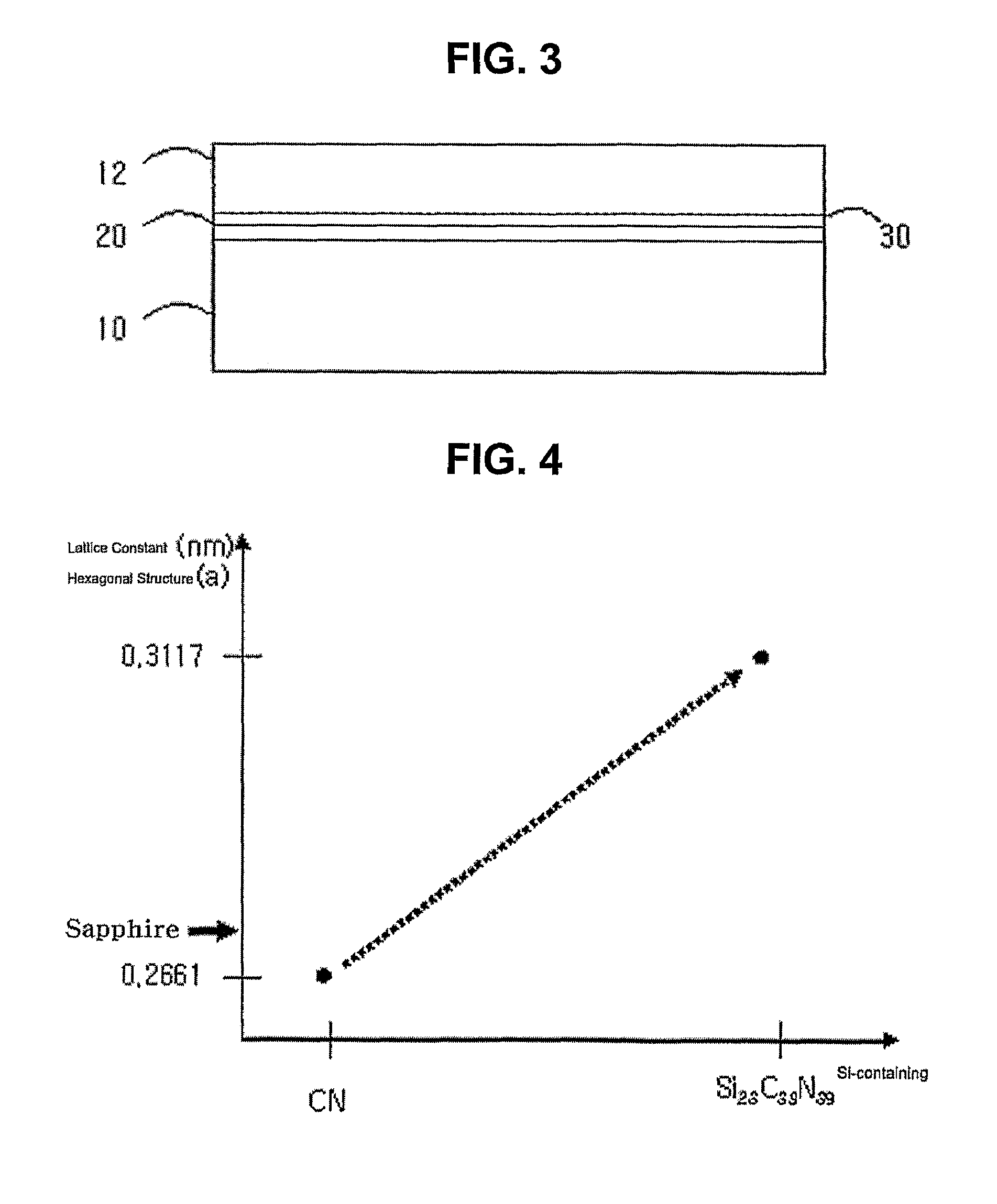

Method for material growth of GaN-based nitride layer

InactiveUS7393213B2Improve efficiencyMaintain good propertiesPolycrystalline material growthRotary current collectorMaterial growthNitride

Owner:EPIVALLEY

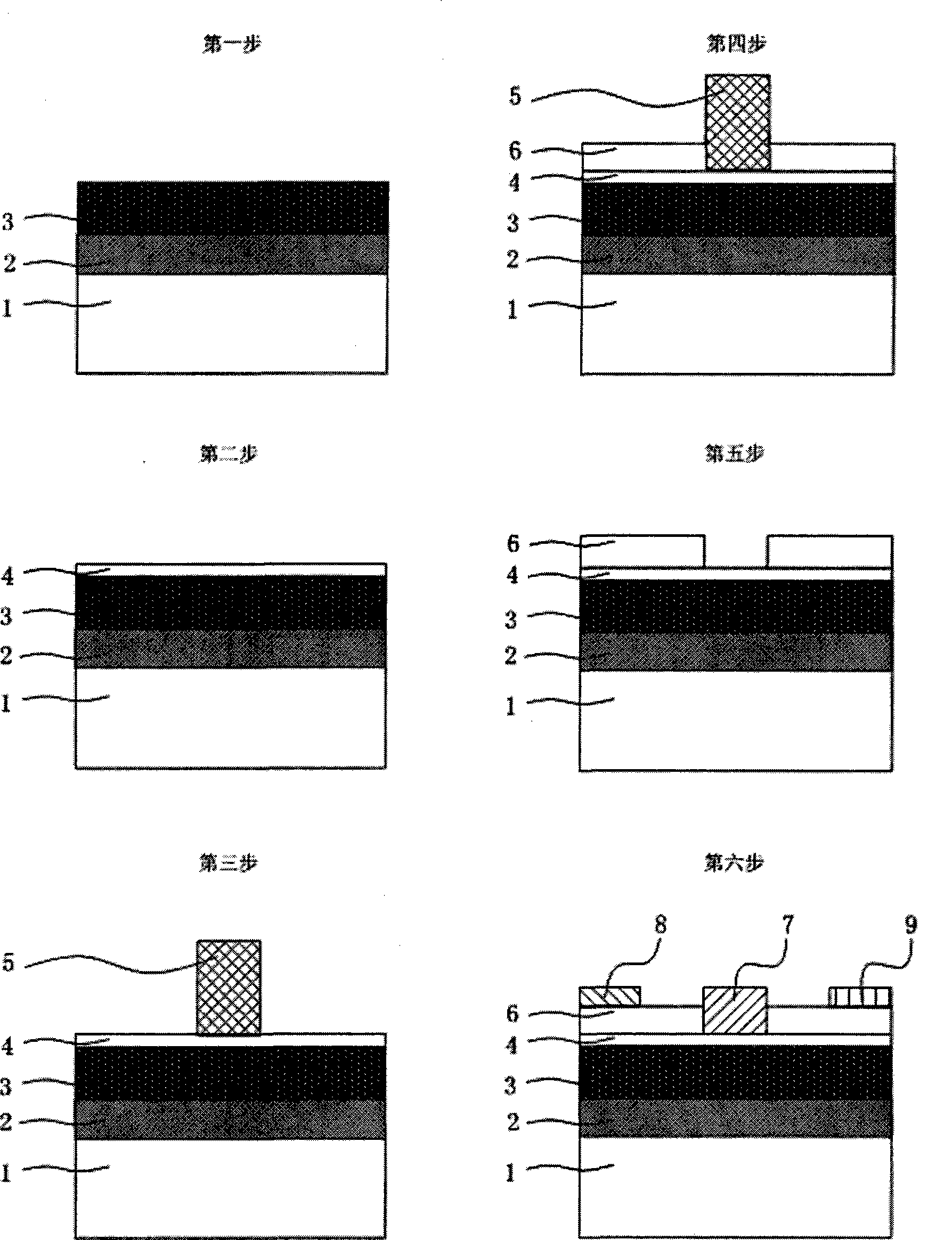

Enhanced AlGaN/GaN field effect tube and manufacturing method thereof

ActiveCN101477951AAvoid damageImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesMaterial growthField-effect transistor

The invention relates to a method for manufacturing an enhanced type AlGaN / GaN / field effect transistor, namely a method for manufacturing AlGaN / GaN HFET by adopting a secondary growth AlGaN layer. The method comprises the following steps: firstly, a buffer layer grows on a substrate firstly, and a GaN epitaxial layer grows on the buffer layer; secondly, a first AlGaN layer grows on the GaN epitaxial layer to accomplish the first material growth; thirdly, a SiO2 mask membrane is deposited on the first AlGaN layer, and the SiO2 mask membrane formed on a grid zone is reserved through the photoetching method; fourthly, a second AlGaN layer grows on the unmasked first AlGaN layer to accomplish the second material growth; fifthly, the SiO2 mask membrane is removed; sixthly, a source electrode and a drain electrode are formed on the second AlGaN layer, and then a grid electrode is formed on the grid zone. Moreover, the invention also discloses the enhanced type AlGaN / GaN / field effect transistor. The method has the advantages of simple process and good reliability, and can obtain higher threshold voltage and transconductance.

Owner:SUN YAT SEN UNIV

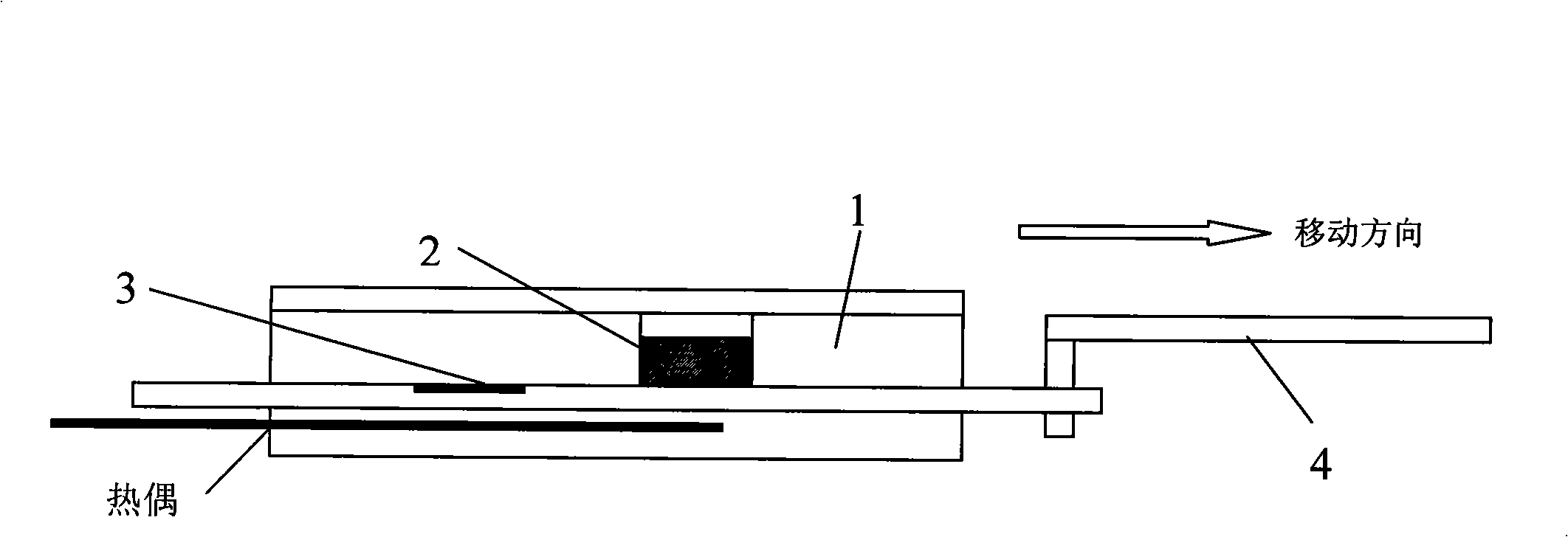

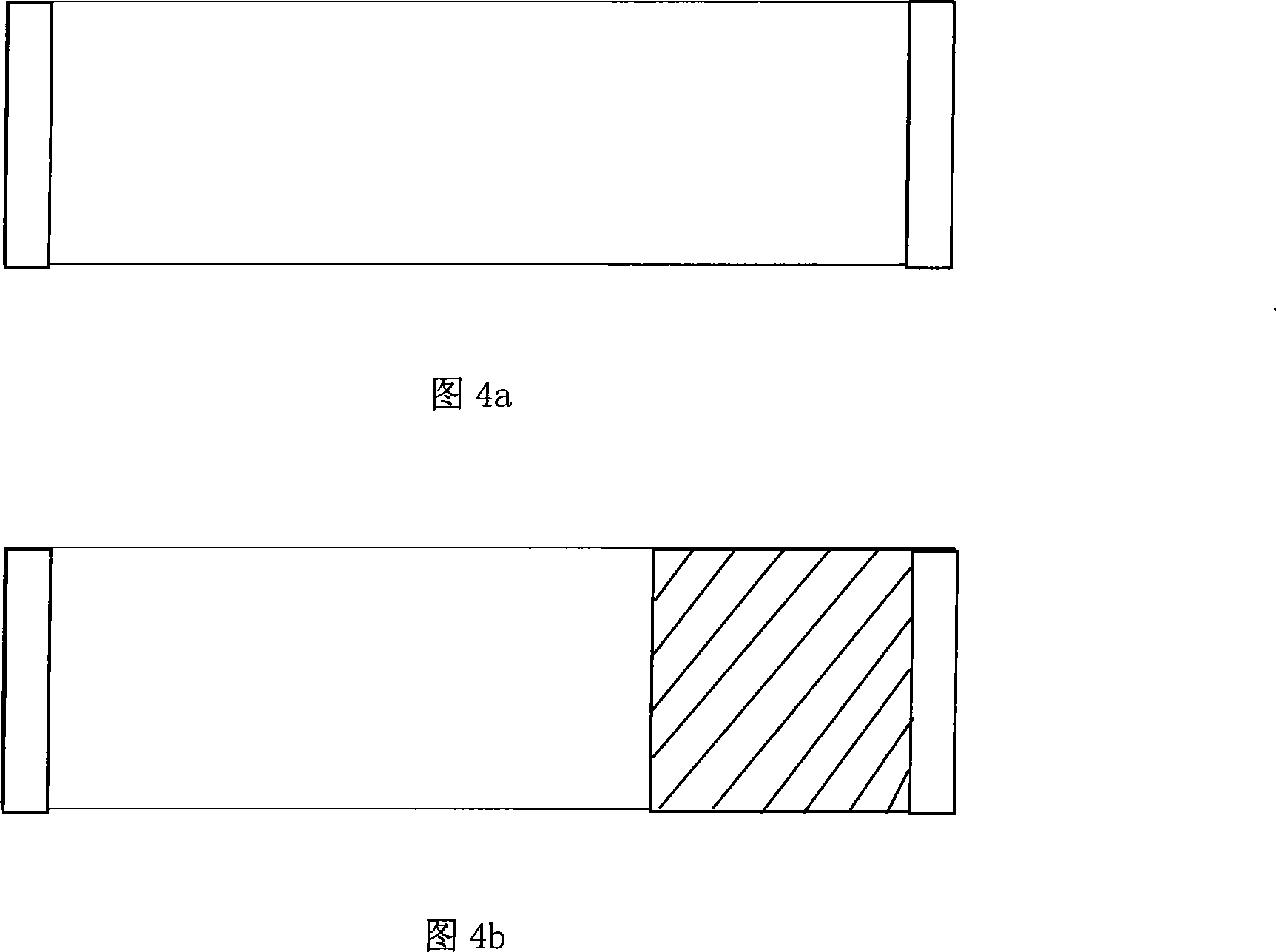

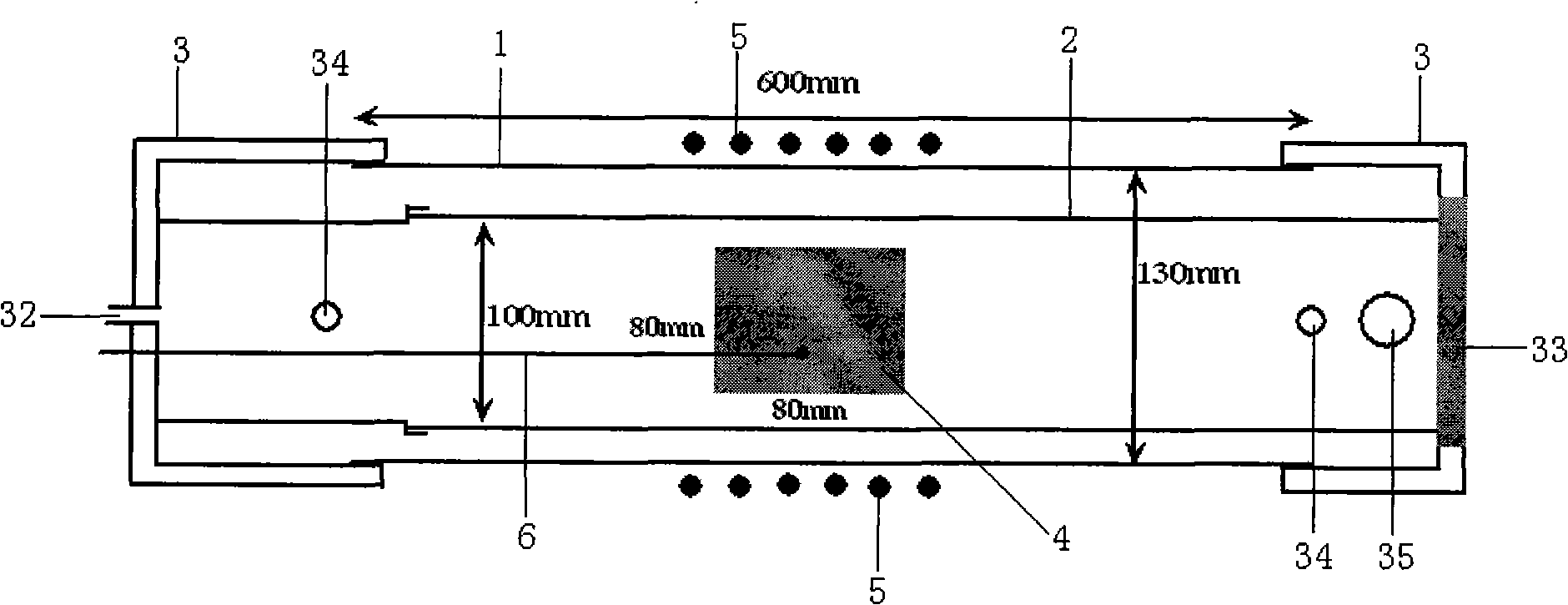

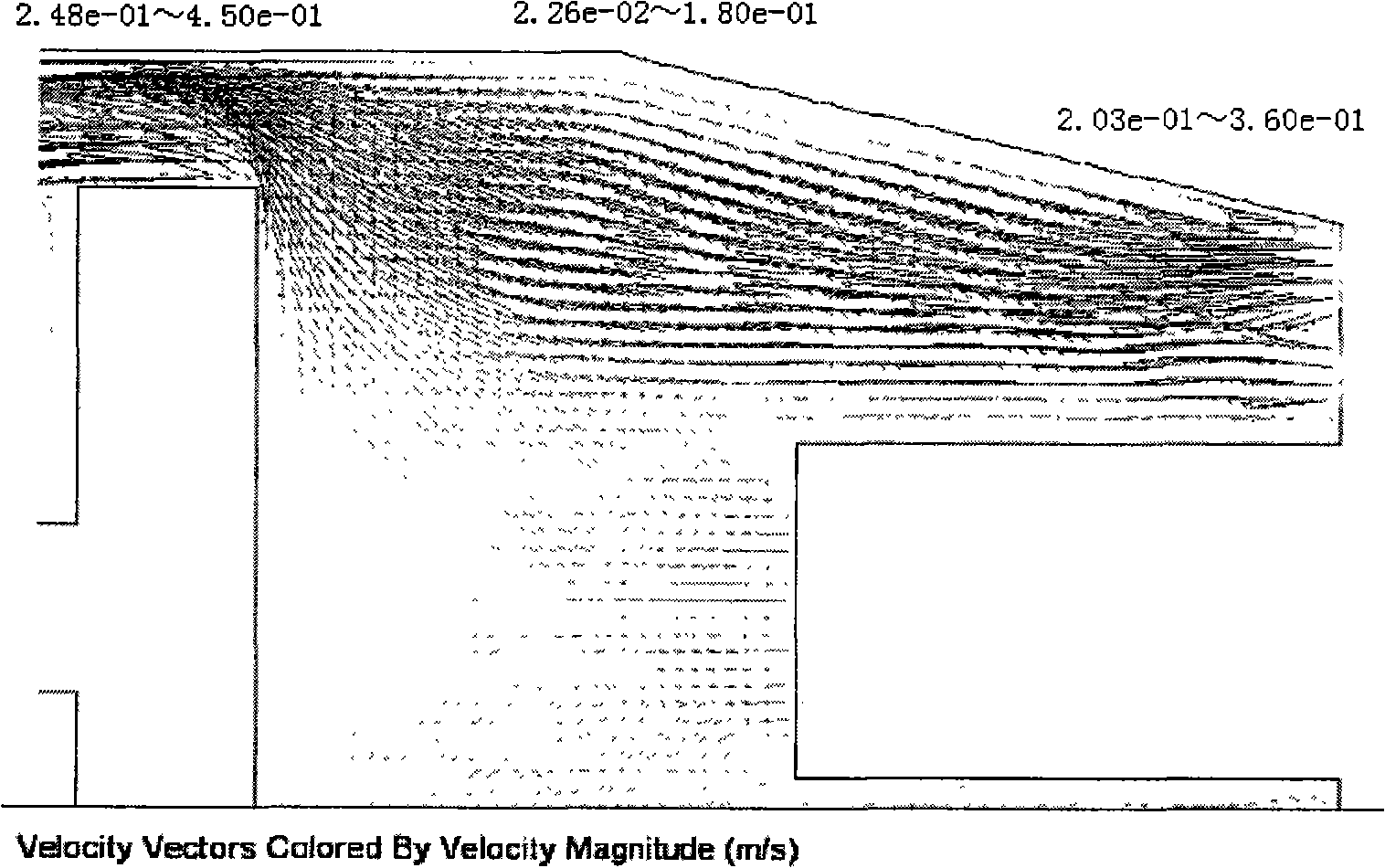

Double-layer airflow quartz fairing reaction chamber apparatus for MOCVD system

InactiveCN101298693ASimple designReduce design costPolycrystalline material growthFrom chemically reactive gasesMaterial growthSemiconductor materials

The invention discloses a reaction chamber device with double-layer airflow and a quartz false ogive that is used for a MOCVD system, comprises a horizontal quartz tube, metallic flanges that are arranged at two ends of the quartz tube and used for sealing the two ends of the quartz tube, the rectangle quartz false ogive and a substrate that are arranged inside the quartz tube, and an inclined plane lining that is placed on the substrate and arranged inside the quartz false ogive, and the arrangement of the quartz false ogive and the inclined plane of the substrate satisfies the ideal hydrokinetic model of the chemical gas phase reaction of the MOCVD. By utilizing the characteristics of simple design, good bearing pressure ability and convenient sealing and matching of the cylindrical quartz tube as well as the rectifying action of the reaction chamber with the rectangle false ogive, and combing with other MOCVD technical equipments, the invention forms the MOCVD system with the reaction chamber with the double-layer airflow and the quartz false ogive, which has simple structure, low production cost and even material growth; the quartz false ogive that has convenient disassembly and assembly is convenient for cleaning the reaction chamber, and the crystal growth pollution is reduced, thus obtaining crystal materials with high quality; the reaction chamber device with the double-layer airflow and the quartz false ogive can further be used for the CVD and MOCVD of the growth of other semiconductor materials such as Si, GaAs, InP and GaN, etc., as well as horizontal reaction systems of HVPE, etc.

Owner:NANJING UNIV

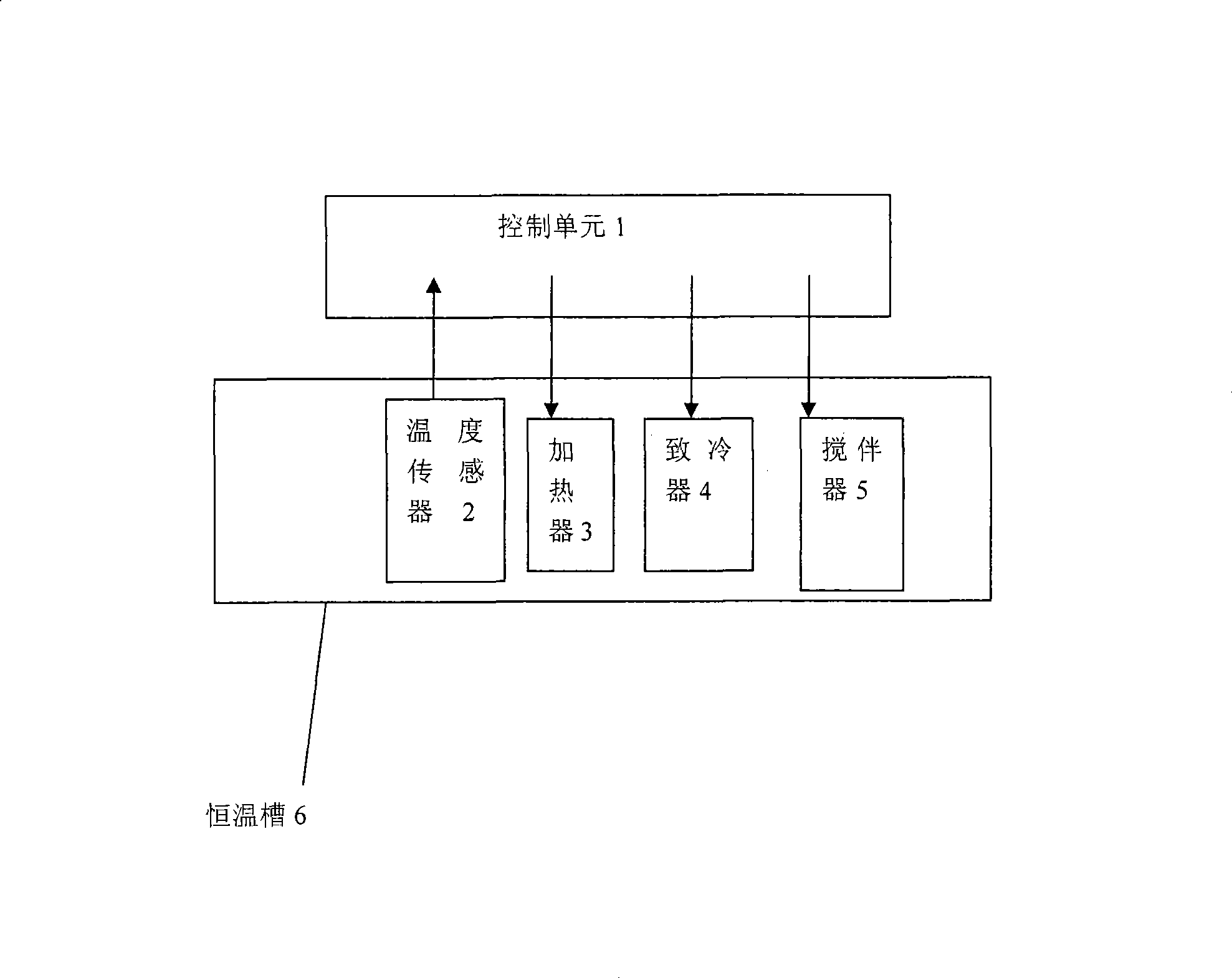

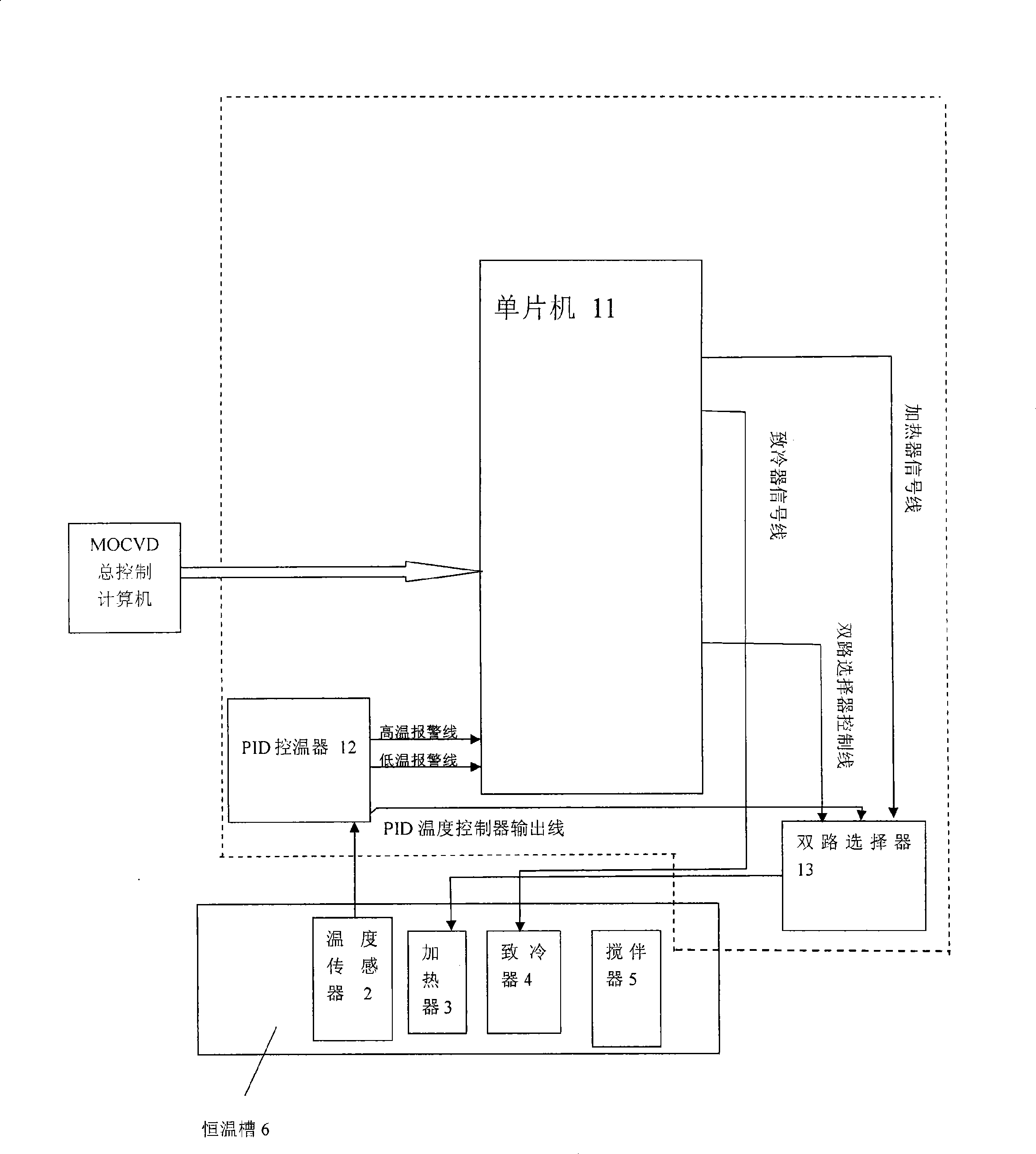

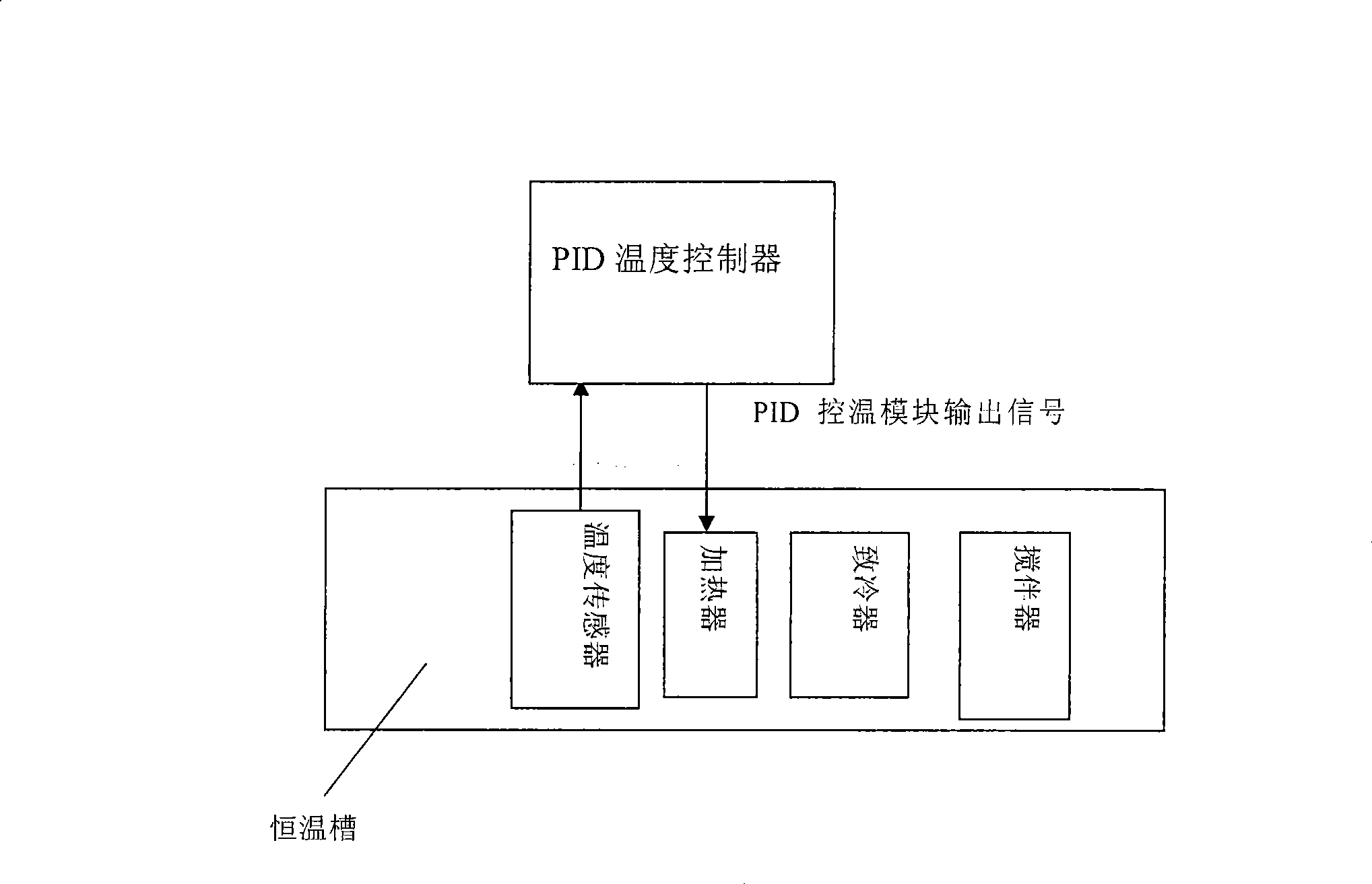

Thermostatic device and control method thereof

InactiveCN101380601AConstant storage temperatureMinimize consumptionHeating or cooling apparatusTemperatue controlTemperature controlMaterial growth

The invention relates to the technical field of semi-conductor material growth, and discloses a thermostatic device, which comprises a heater, a freezer, a stirrer, a temperature sensor and a control unit, wherein, the control unit comprises a PID temperature controller and a switching mode temperature controller; according to the temperature measured by the temperature sensor, the PID temperature controller controls the power of the heater by PID algorithm so as to adjust the temperature of the thermostatic device; and the switching temperature controller adjusts the temperature of the thermostatic device by opening or closing the heater or the freezer. The invention simultaneously discloses a method for controlling the thermostatic device. By adopting the device and the method, energy saving can be realized when meeting the temperature accuracy of the thermostatic device, in particular to a raw material storage thermostatic device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

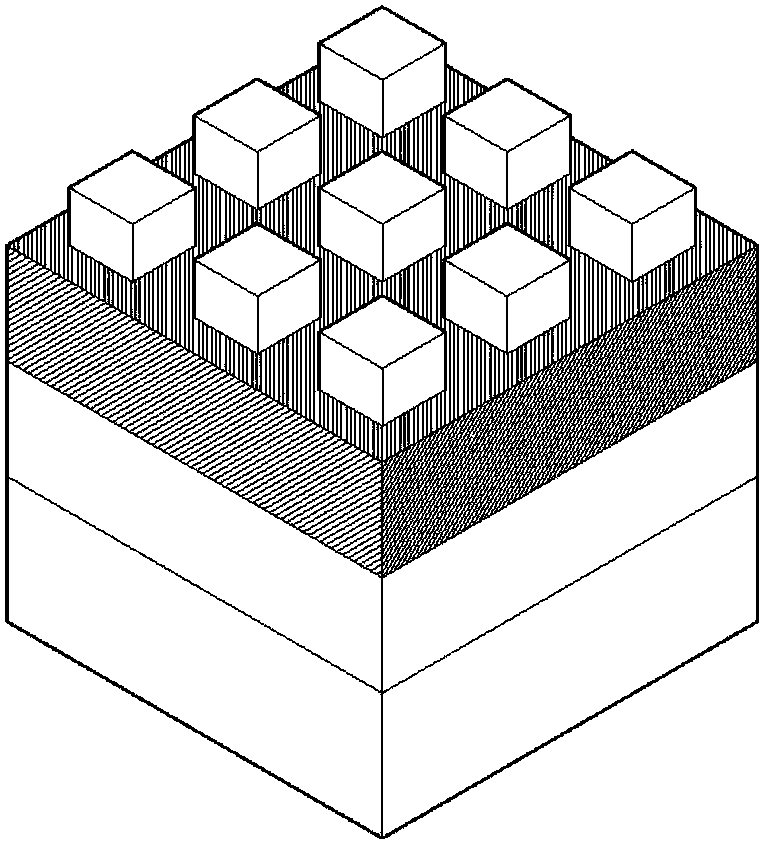

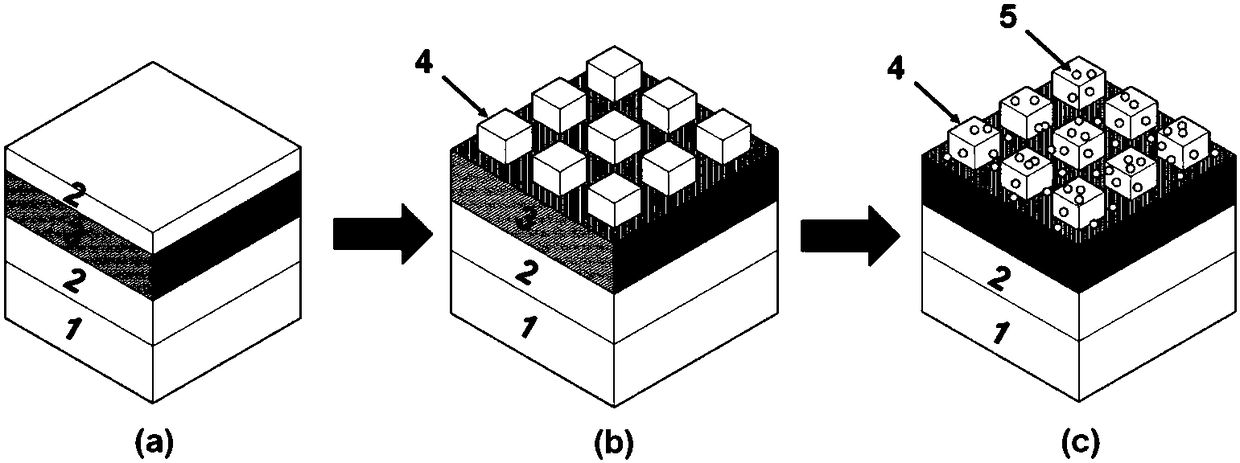

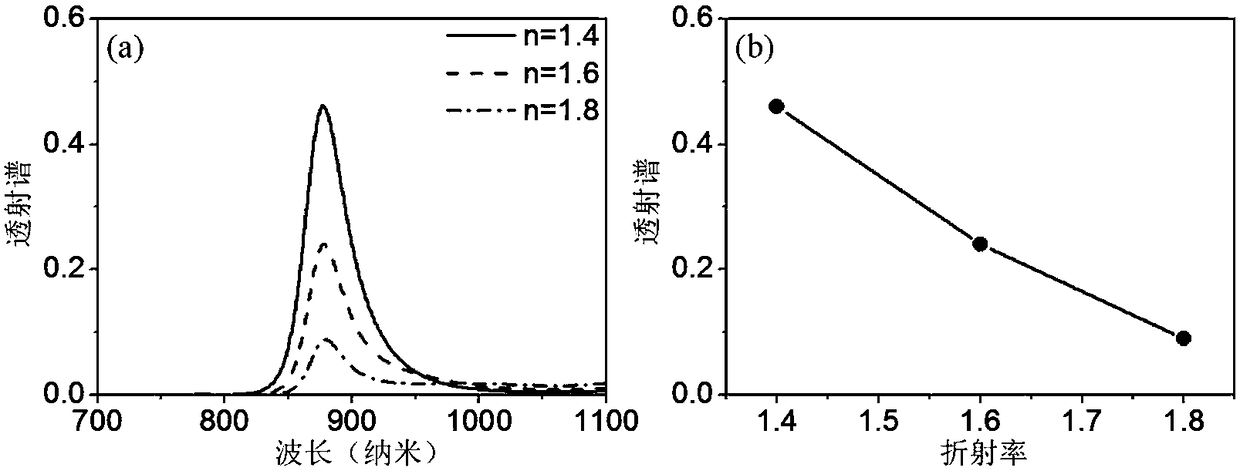

Photon metasurface biosensor

The invention provides a photon metasurface biosensor. A metal / dielectric / metal multilayer structure is grown on a glass substrate by a material growth process, wherein a metasurface is prepared on atop metal film layer by a dry or wet etching process; and at a particular wavelength, a very strong local surface plasmon resonance occurs between a metal nano-array and a dielectric layer. The transmittance at a center frequency of a transmission spectrum resonance peak is very sensitive to the change in a refractive index of a biological sample placed on a surface of the structure, so that biological samples having different refractive indexes can be detected by measuring a transmittance value at the center frequency of the transmission spectrum resonance peak. The photon metasurface biosensor provided by the invention has prominent advantages of small size, simple structure and easy realization, has a very broad application prospect in the field of biomedicine, and has important significance for development of biosensors.

Owner:DALIAN UNIV OF TECH

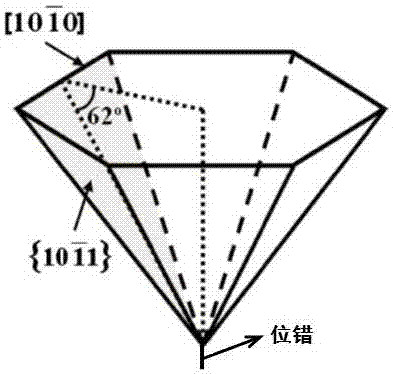

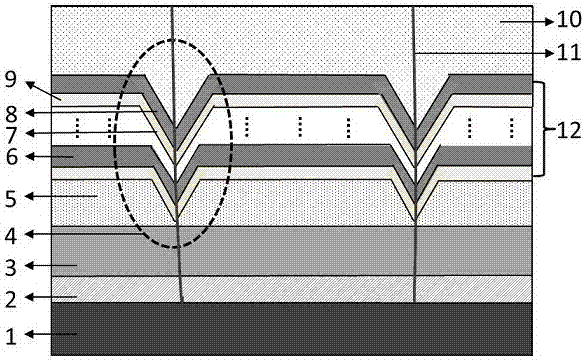

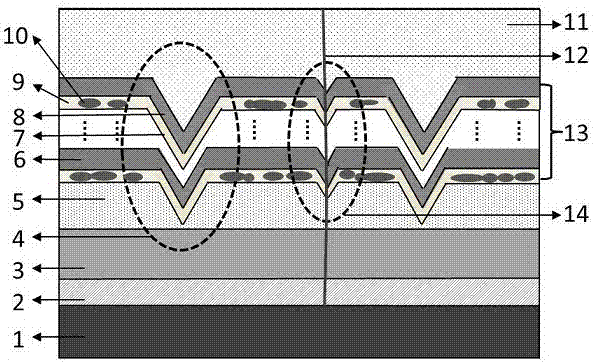

AlInGaN-based green and yellow light-emitting diode epitaxial structure

ActiveCN107068818AReduce the effect of dislocationsEnhanced hole injection functionSemiconductor devicesMaterial growthQuantum dot

The invention discloses an AlInGaN-based green and yellow light-emitting diode (LED) epitaxial structure, which comprise a substrate for material growth and an AlInGaN-based semiconductor lamination layer stacked up on the semiconductor, wherein the AlInGaN-based semiconductor lamination layer at least comprises an N-type layer, a P-type layer and AlInGaN multiple quantum wells arranged between the N-type layer and the P-type layer. The structure is characterized in that the multiple quantum wells are embedded by V-shaped pits in periodic arrangement in a growth plane, and such V-shaped pits are same in size; and the plane quantum wells have similar-quantum-dot structures, which become main light-emitting sources of the LED. The epitaxial structure has the following advantages: 1) the similar-quantum-dot structures in the multiple quantum wells reduces impact of dislocation; 2) the multiple quantum wells are embedded by the process V-shaped pits in periodic arrangement in the growth plane, thereby further enhancing the hole injection function of the V-shaped pits; and 3) optimization of enhancement of the hole injection function of the V-shaped pits can be realized, and luminous efficiency of the LED can be improved.

Owner:NANCHANG UNIV +1

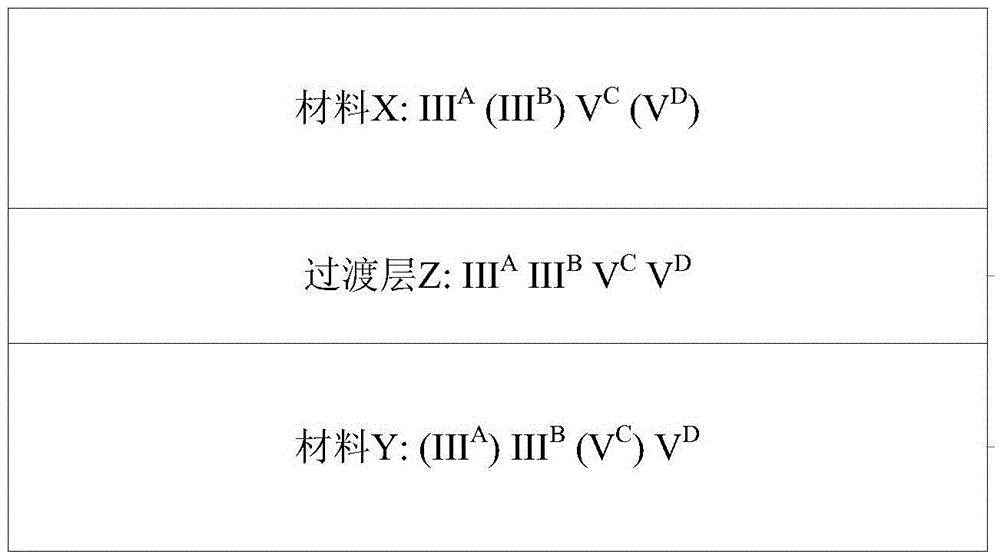

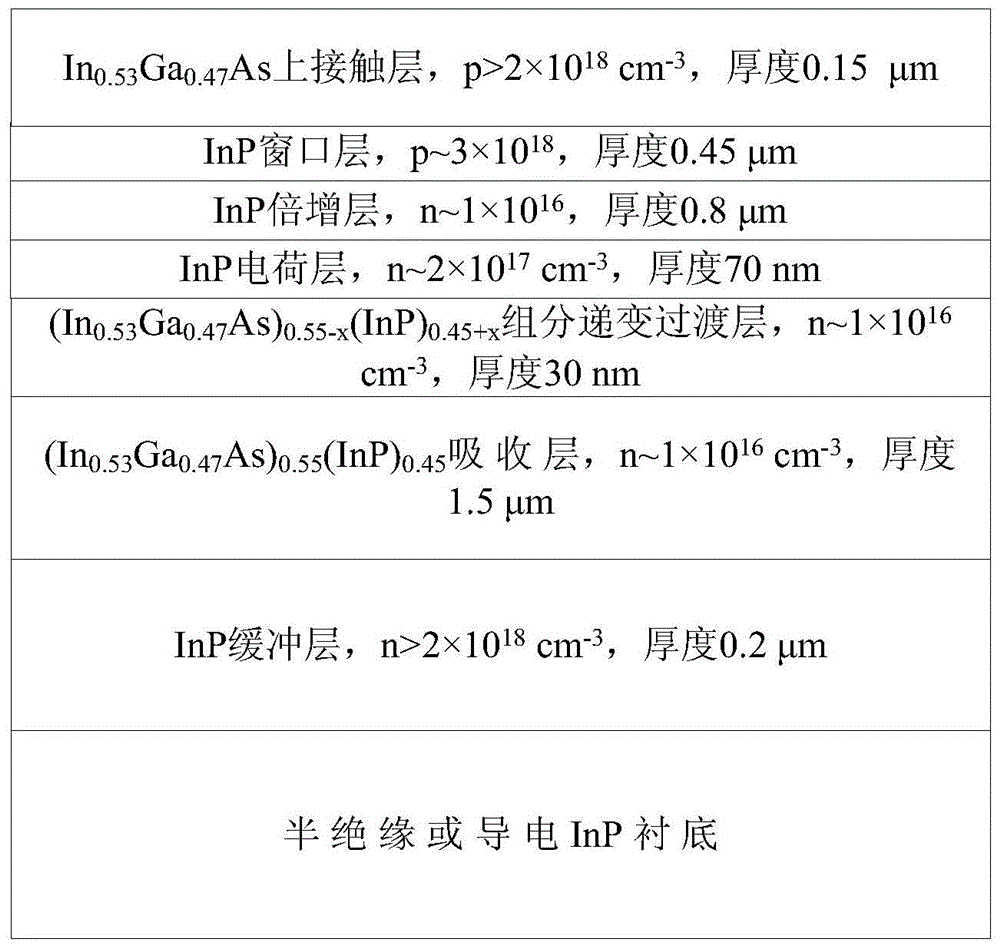

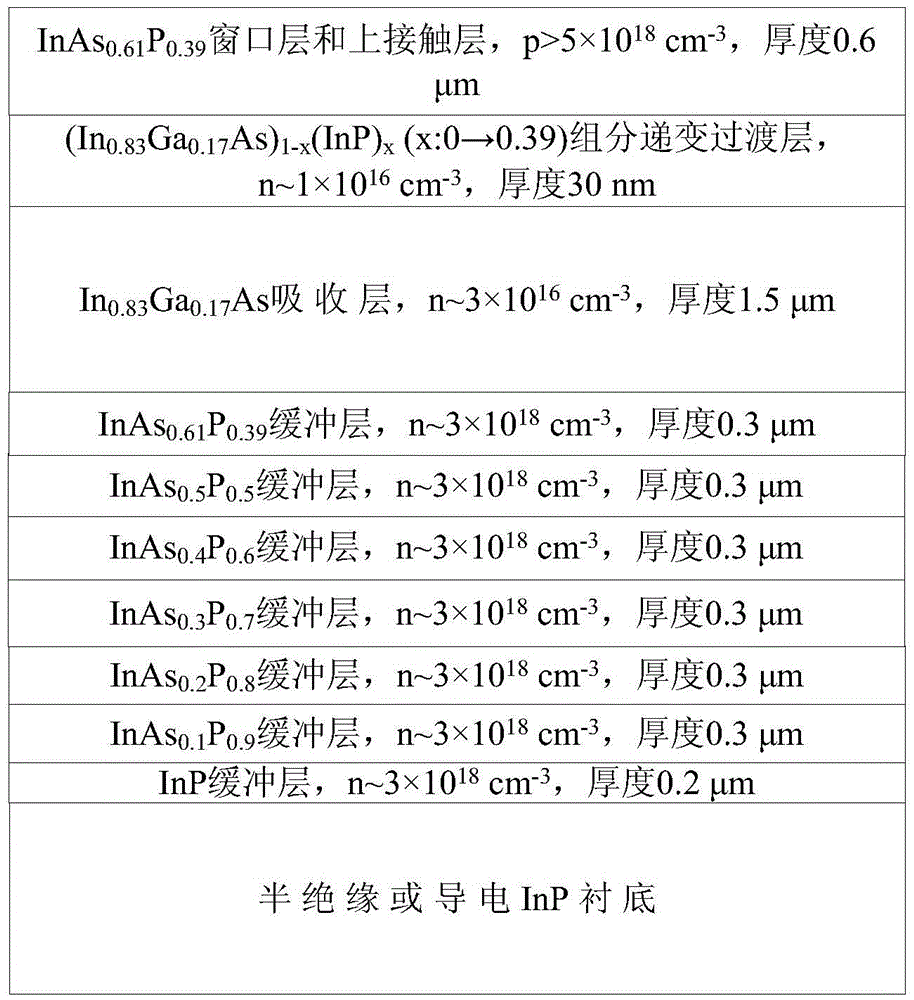

Gas source molecular beam epitaxy material growth method for component progressive transition layer

ActiveCN105609585AReduce blocking effectReduced transit timeFinal product manufactureSemiconductor/solid-state device manufacturingMaterial growthHeterojunction

The invention relates to a gas source molecular beam epitaxy material growth method for a component progressive transition layer, and the method comprises the steps: growing the component progressive transition layer with one-side or two-side materials of a heterojunction containing two or more types of group-V elements through employing a gas source molecular beam epitaxy growth method, employing two or more gas sources for growth, wherein a group-III beam source is solid, a beam flow is controlled through shutter switching, a group-V beam source is gaseous, and the group-V beam flow intensity or V-III ratio is adjusted through pressure or flow; and obtaining the component progressive transition layer. The component progressive transition layer obtained through the method can effectively alleviate negative effects, caused by energy band peak of a heterogeneous interface or crystal lattice and component abrupt changes in a heterojunction device, on the performance of a device, thereby facilitating the improvement of the performance of the device or the development of a novel device.

Owner:湖南汇思光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com