Epitaxial wafer of AlGaInP light emitting diode with sapphire underlay and preparation method thereof

A sapphire substrate and light-emitting diode technology, applied in the field of optoelectronics, can solve problems such as low luminous efficiency, achieve the effect of improving light output capability and reducing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

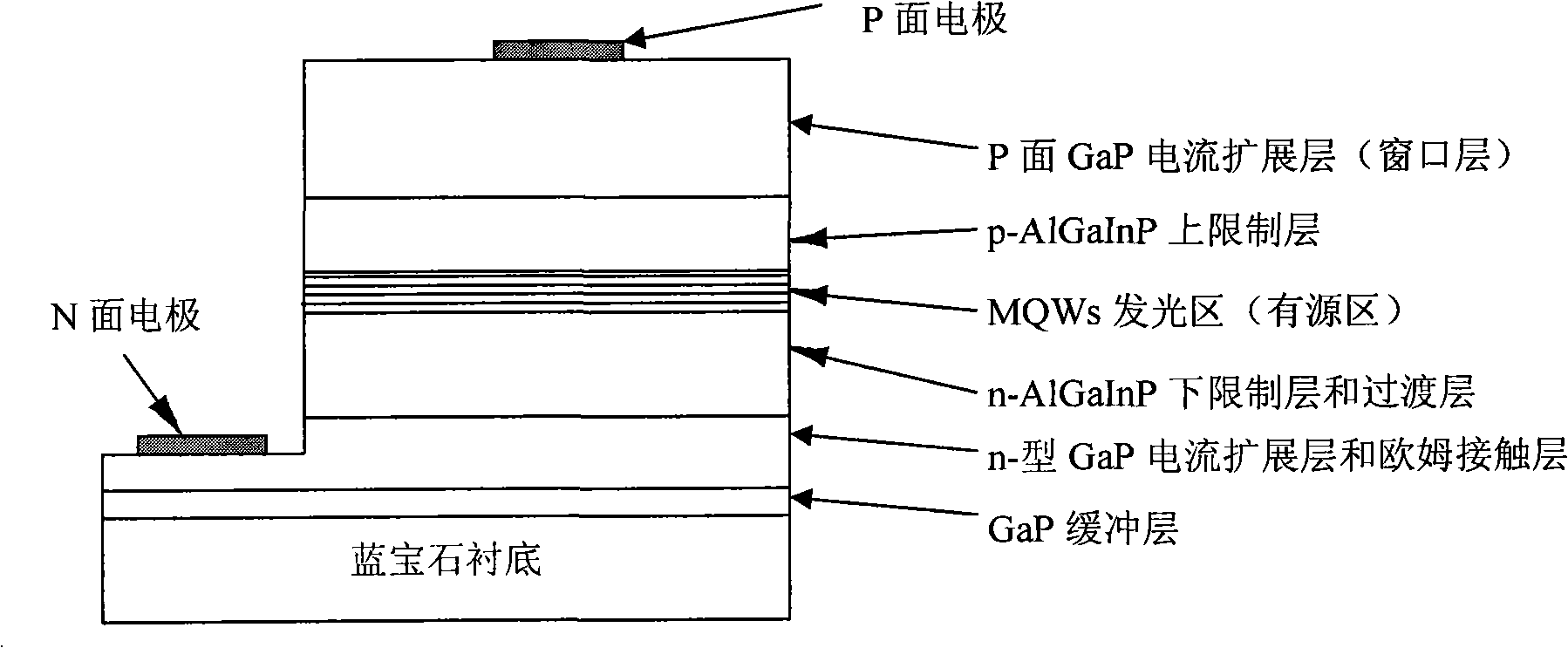

[0026] Such as figure 1 As shown, the AlGaInP light-emitting diode epitaxial wafer of the sapphire substrate of the present embodiment is a sapphire substrate, and its epitaxial structure is a GaP buffer layer (including two low-temperature GaP buffer layers and a high-temperature GaP buffer layer) on the sapphire substrate from bottom to top. layer combination), n-type GaP current spreading and ohmic contact layer, n-type AlGaInP transition and lower confinement layer, multiple quantum wells (MQWs) AlGaInP active region, p-type AlGaInP upper confinement layer and P-type current spreading layer. The P-face electrode (positive electrode) is made on the P-type current spreading layer by conventional die preparation technology, and the N-face electrode (negative electrode) is made on the n-type GaP current spreading and ohmic contact layer, so that the P-face electrode and the N-face electrode same above.

[0027]The preparation method of the AlGaInP light-emitting diode epitaxi...

Embodiment 2

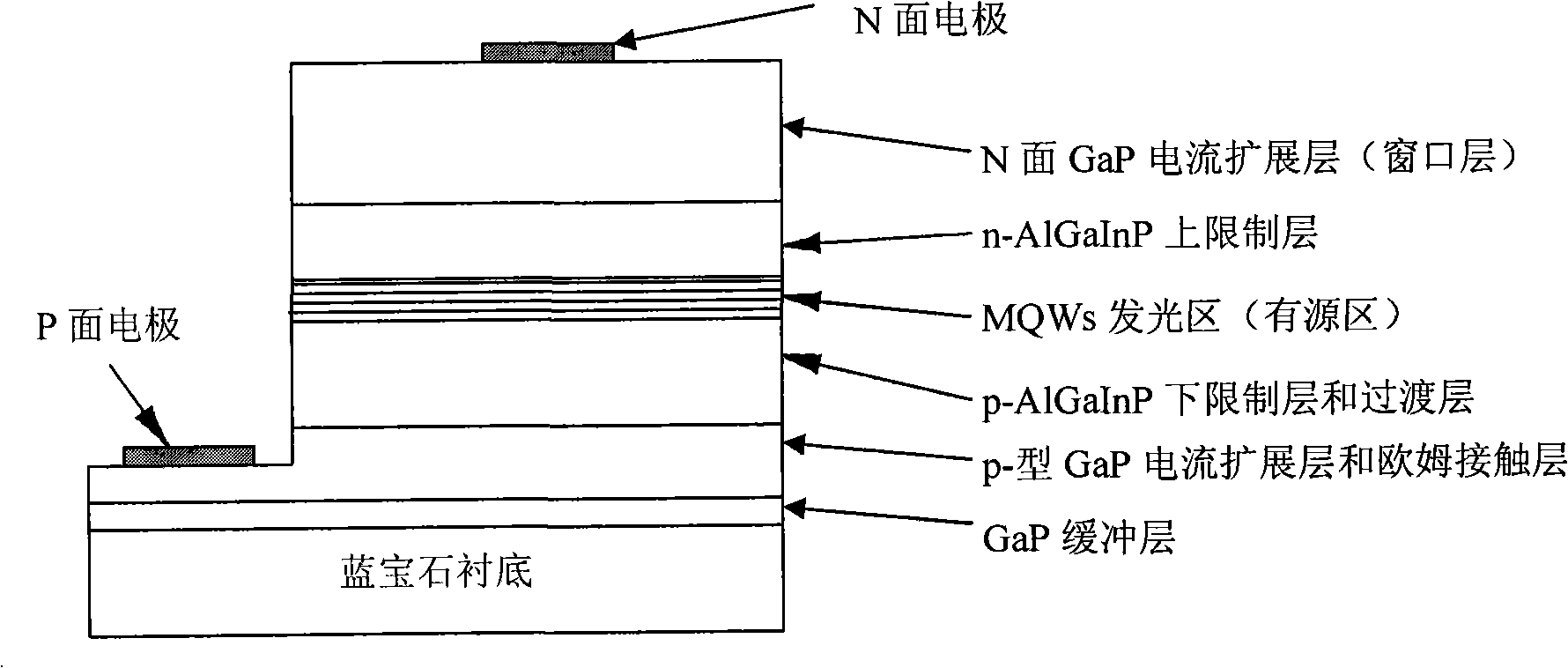

[0038] Such as figure 2 As shown, the epitaxial structure of the AlGaInP light-emitting diode epitaxial wafer on the sapphire substrate of this embodiment is a GaP buffer layer (including a combination of low-temperature GaP buffer layer and high-temperature GaP buffer layer) on the sapphire substrate from bottom to top, P-type GaP current expansion and ohmic contact layer, P-type AlGaInP transition and lower confinement layer, multiple quantum wells (MQWs) AlGaInP active region, n-type AlGaInP upper confinement layer, n-type GaP current expansion layer (window layer). The N-face electrode (negative electrode) is made on the n-type current spreading layer by conventional die preparation technology, and the P-face electrode (positive electrode) is made on the P-type GaP current spreading and ohmic contact layer, so that the P-face electrode and the N-face electrode same above.

[0039] The preparation method of the AlGaInP light-emitting diode epitaxial wafer of the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com