Novel chip light source structure and preparation process thereof

A preparation process and light source technology, applied in the field of optoelectronics, can solve the problems of poor product index consistency, complex process, unfavorable environmental protection, etc., and achieve the effects of reducing production costs and cycle time, reducing environmental pollution, and improving light output capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

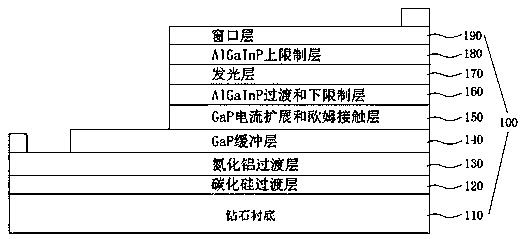

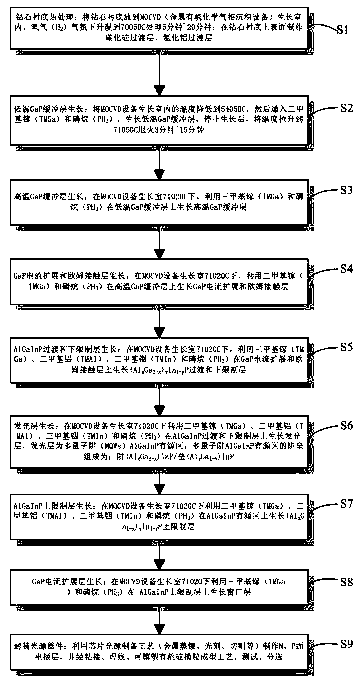

[0084] read on Figure 4 , the epitaxial structure includes from bottom to top a diamond substrate 110, a silicon carbide transition layer 120, an aluminum nitride transition layer 130, a low-temperature GaP buffer layer, a high-temperature GaP buffer layer, n-type GaP current spreading and ohmic contact layers 151, n Type AlGaInP transition and lower confinement layer 161, light emitting layer 170, p-type AlGaInP upper confinement layer 182, p-type window layer 192.

[0085] Further, the n-type AlGaInP transition and lower confinement layer 161 is provided with an N-face electrode layer 200, and the p-type window layer 192 is provided with a P-face electrode layer 300, so that the P-face electrode 300 and the N-face electrode 200 are simultaneously on the top.

[0086] In this specific embodiment, the diamond substrate 110 is made of a sapphire body rod, and the sapphire body is rod-shaped according to requirements, and the 2-inch or 4-inch rod is fixed, sliced, annealed, ch...

Embodiment 2

[0102] read on Figure 5 , the epitaxial structure 100 sequentially includes a diamond substrate 110, a silicon carbide transition layer 120, an aluminum nitride transition layer 130, a low-temperature GaP buffer layer, a high-temperature GaP buffer layer, a p-type GaP current extension and an ohmic contact layer 152 from bottom to top. , p-type AlGaInP transition and lower confinement layer 162, light emitting layer 170, n-type AlGaInP upper confinement layer 181, n-type window layer 191.

[0103] Further, the p-type AlGaInP transition and lower confinement layer 162 is provided with a P-face electrode layer 300, and the n-type window layer 191 is provided with an N-face electrode layer 200, so that the P-face electrode and the N-face electrode are on top .

[0104] In this specific embodiment, the diamond substrate 110 is made of a sapphire body rod, and the sapphire body is rod-shaped according to requirements, and the 2-inch or 4-inch rod is fixed, sliced, annealed, chamf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com