Patents

Literature

158results about How to "Improve heat dissipation characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

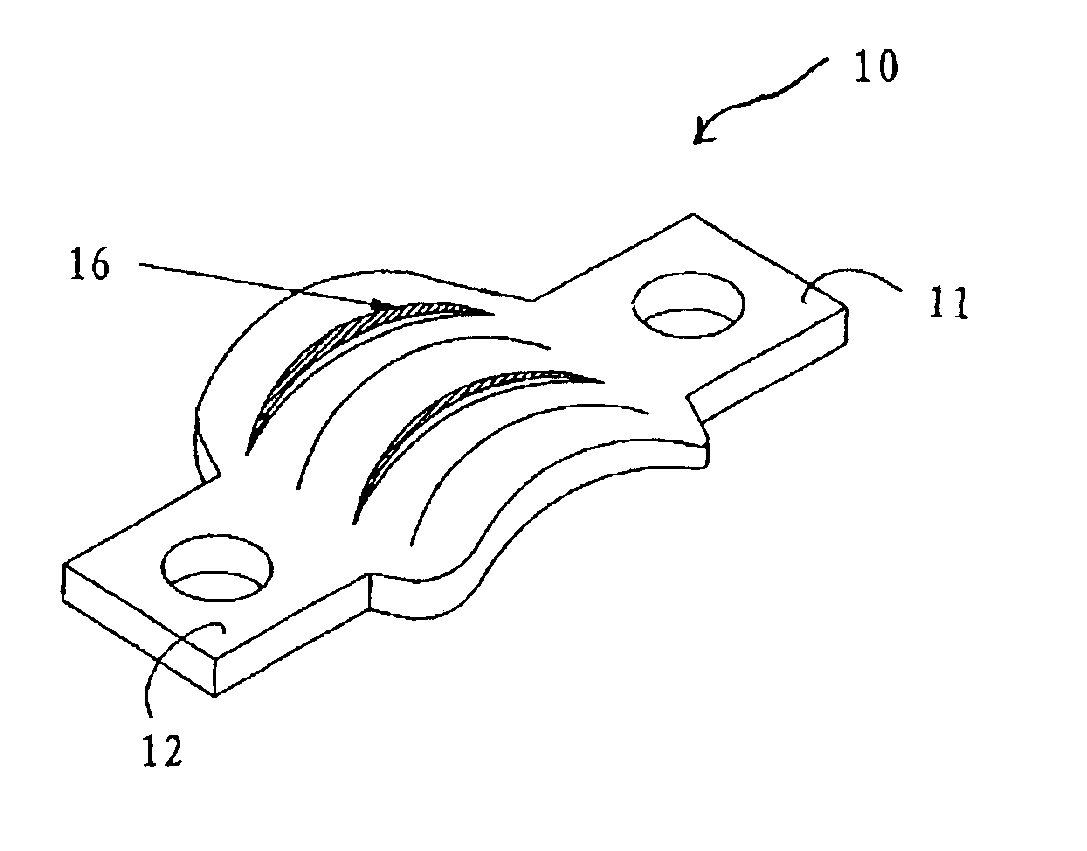

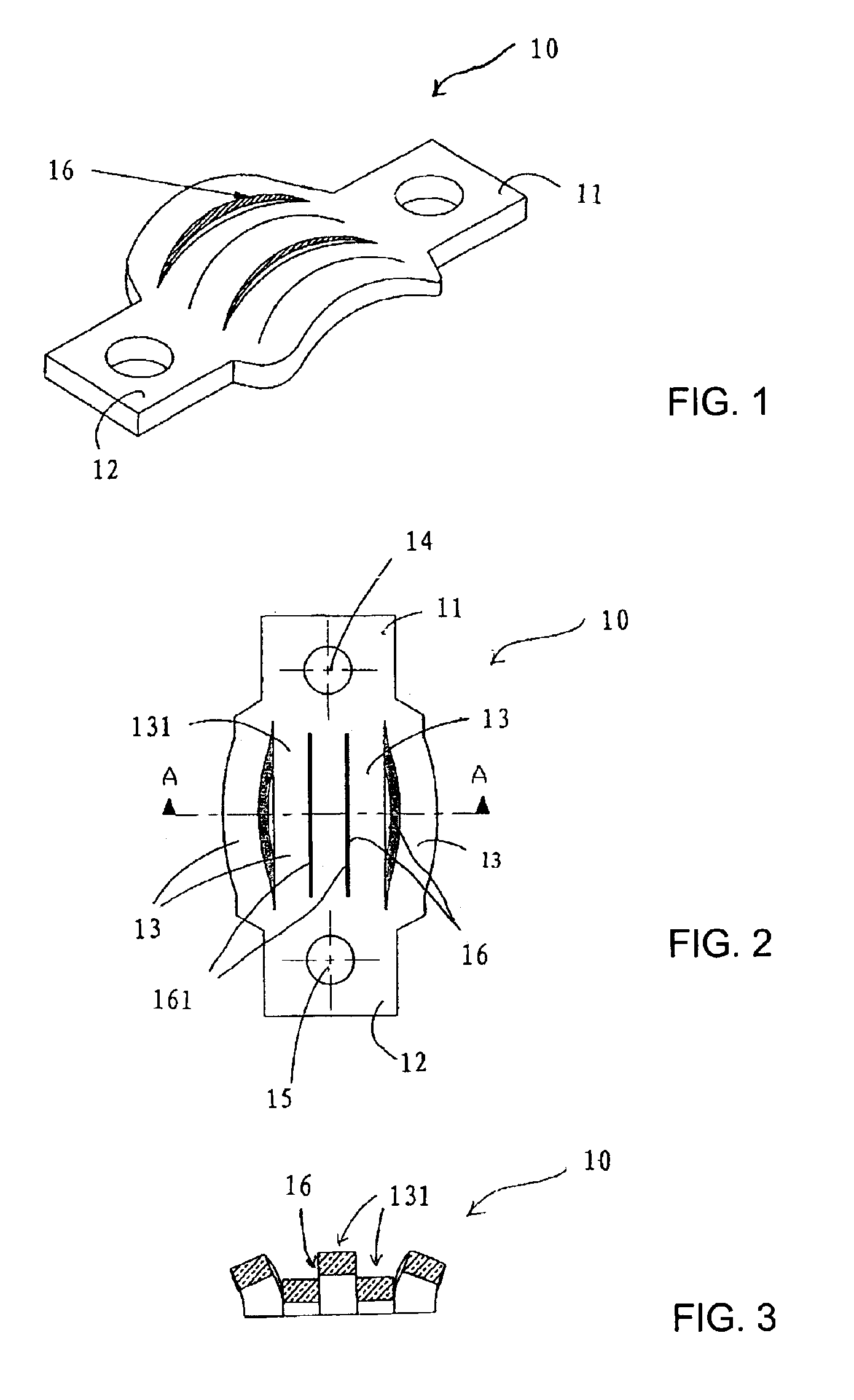

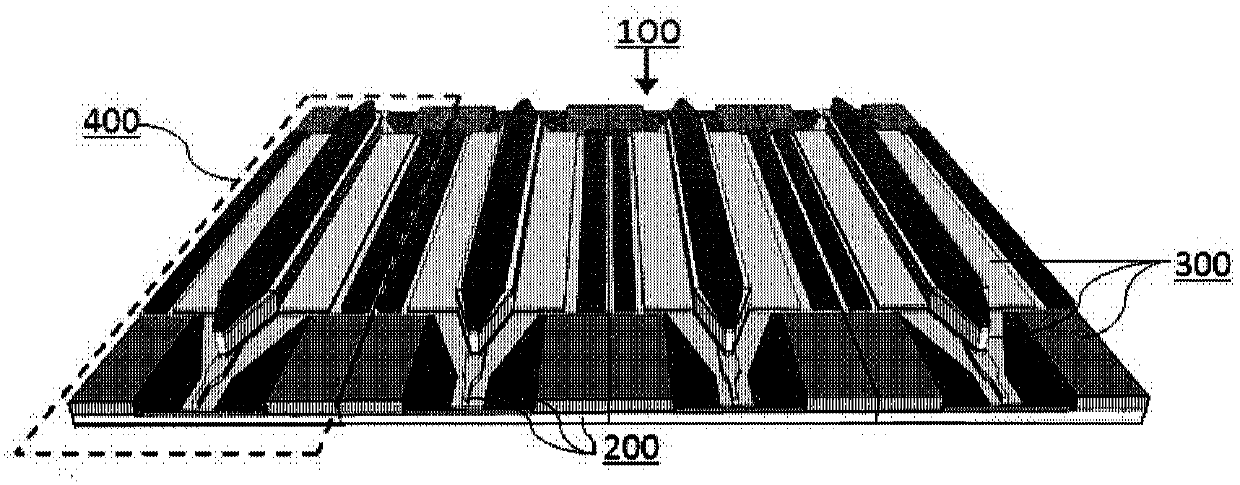

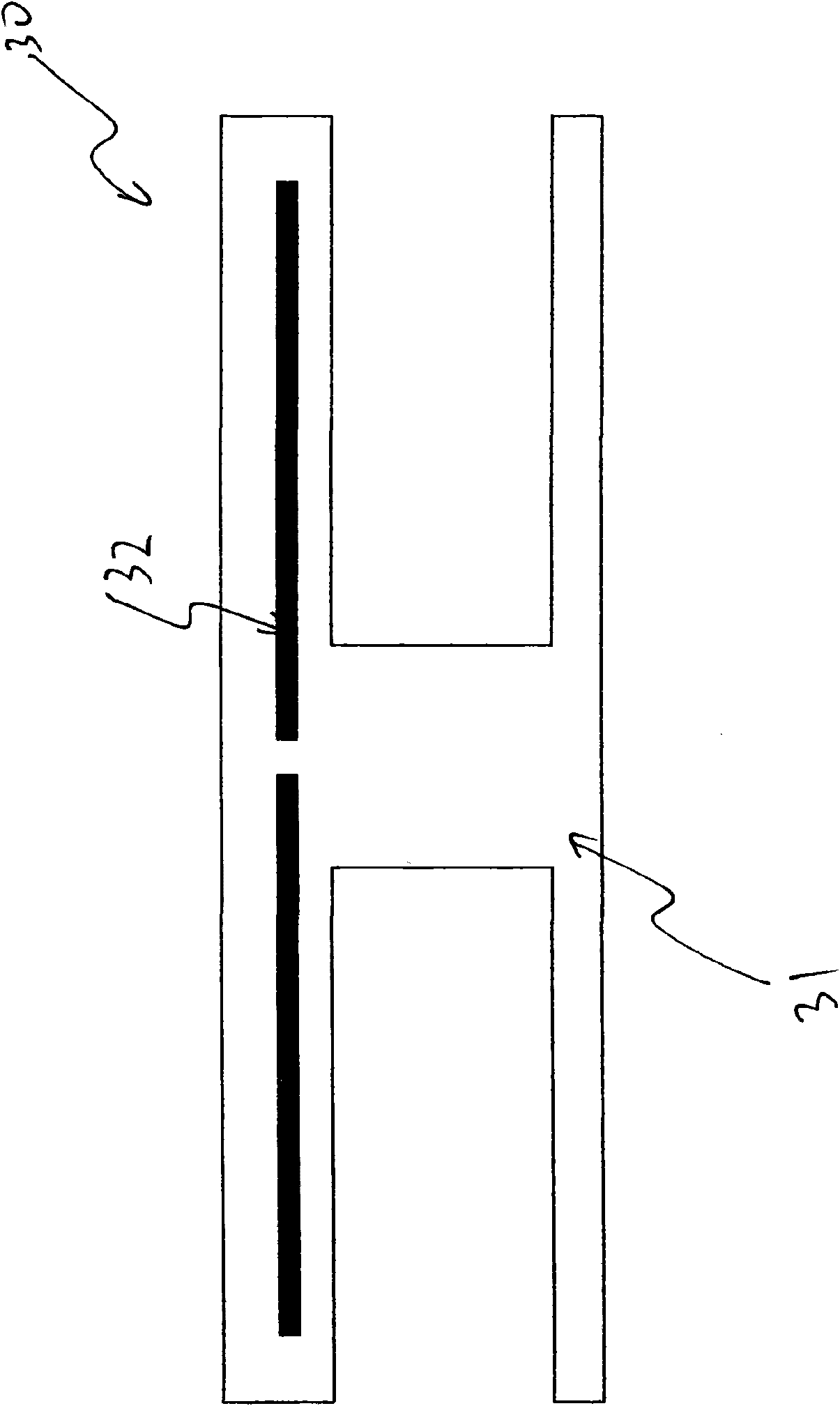

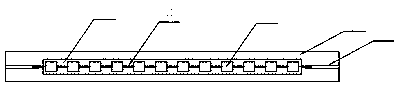

Combined electrical connector and radiator for high current applications

InactiveUS6929504B2Slow down buildingImprove heat dissipation characteristicsCoupling contact membersCell component detailsPower unitElectric vehicle

An electrical connector useful for both high-current and low-current applications including a first and a second conductive terminals, in which the terminals are interconnected by a plurality of substantially rigid and elongated conductive strips and apertures or gaps are disposed between at least some of the adjacent conductive strips. The connector provides enhanced heat dissipation characteristics and is particularly useful for high current applications such as for connecting batteries, accumulators, super-capacitors and the like storage power units for electric vehicle and other applications.

Owner:SYLVA INDS

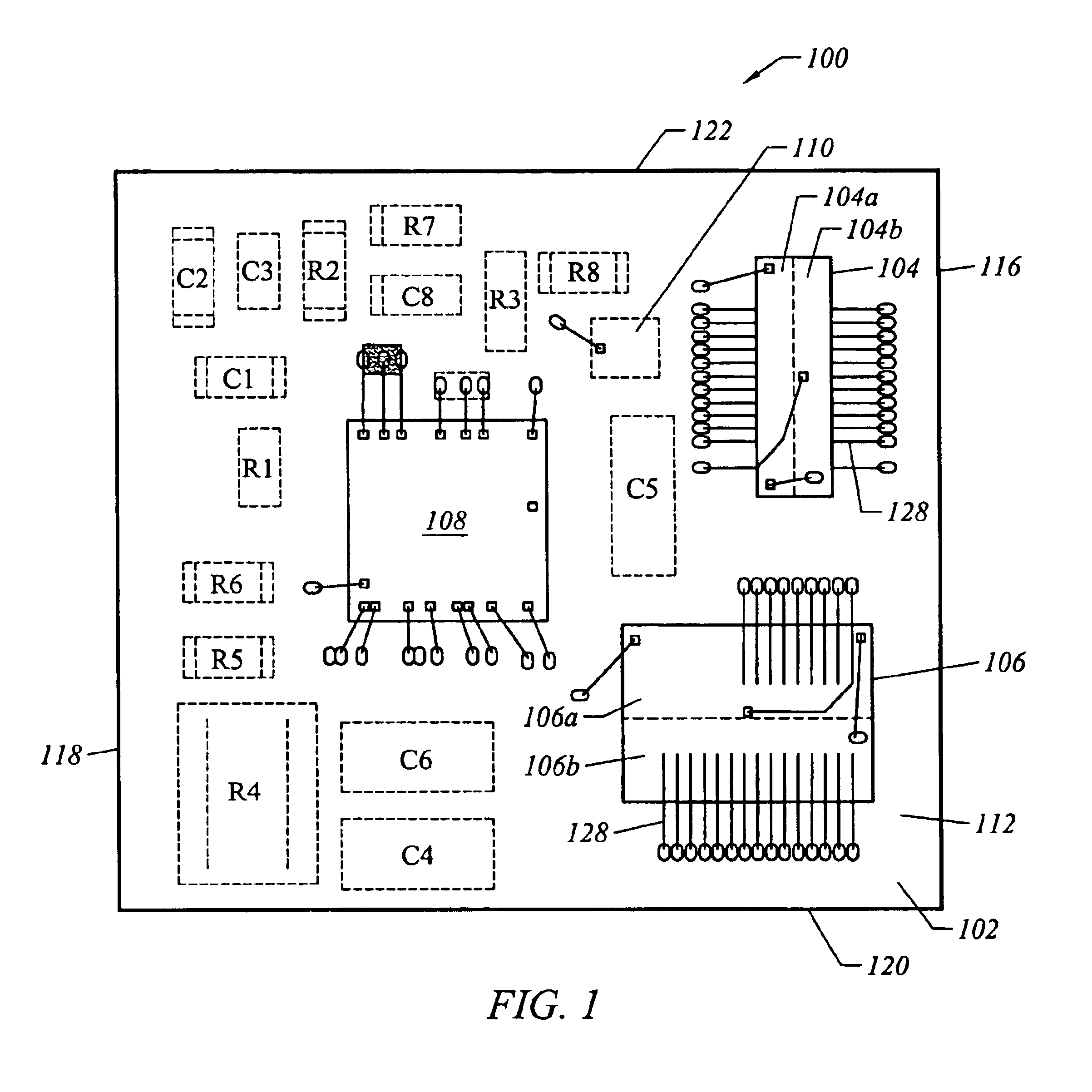

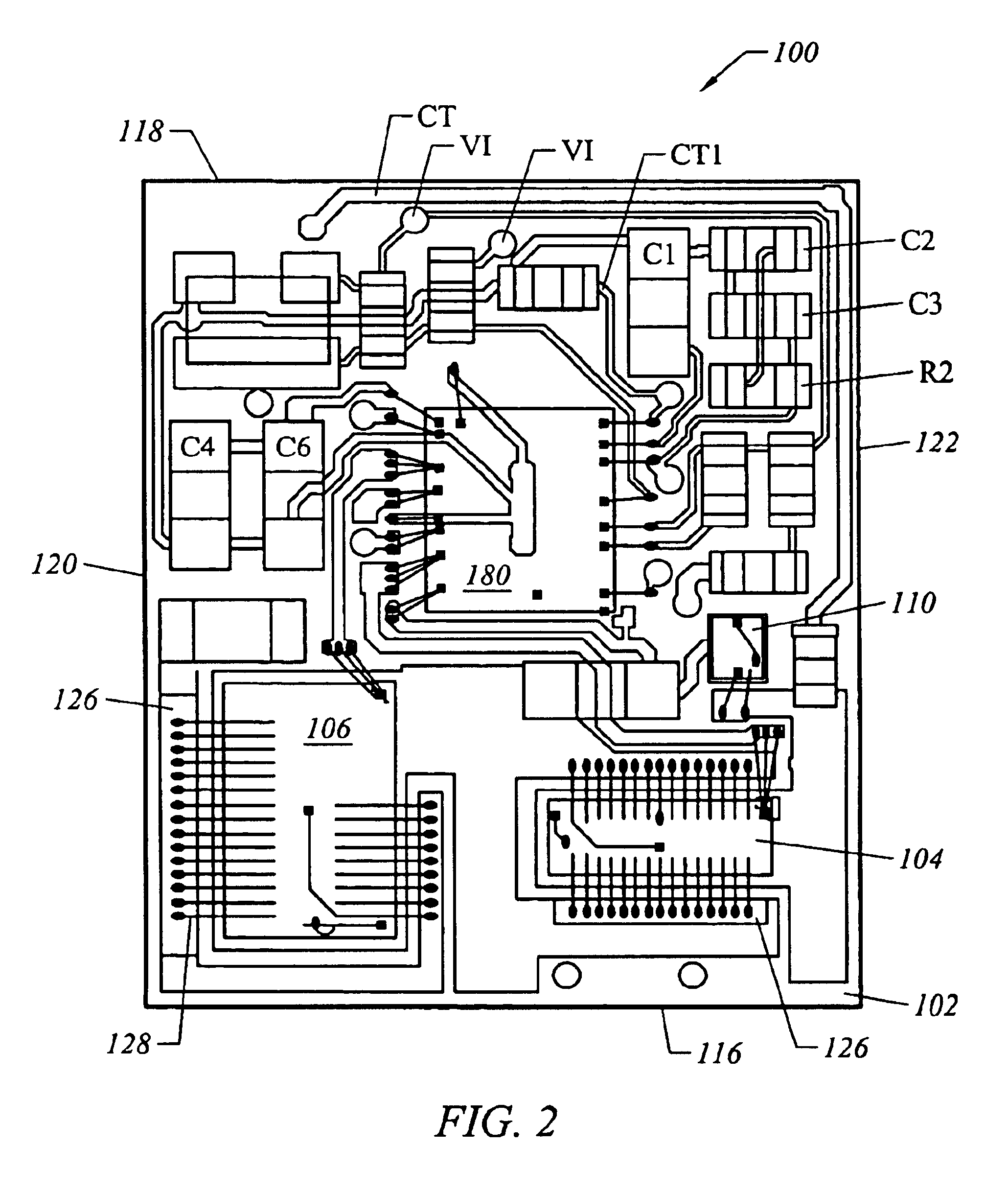

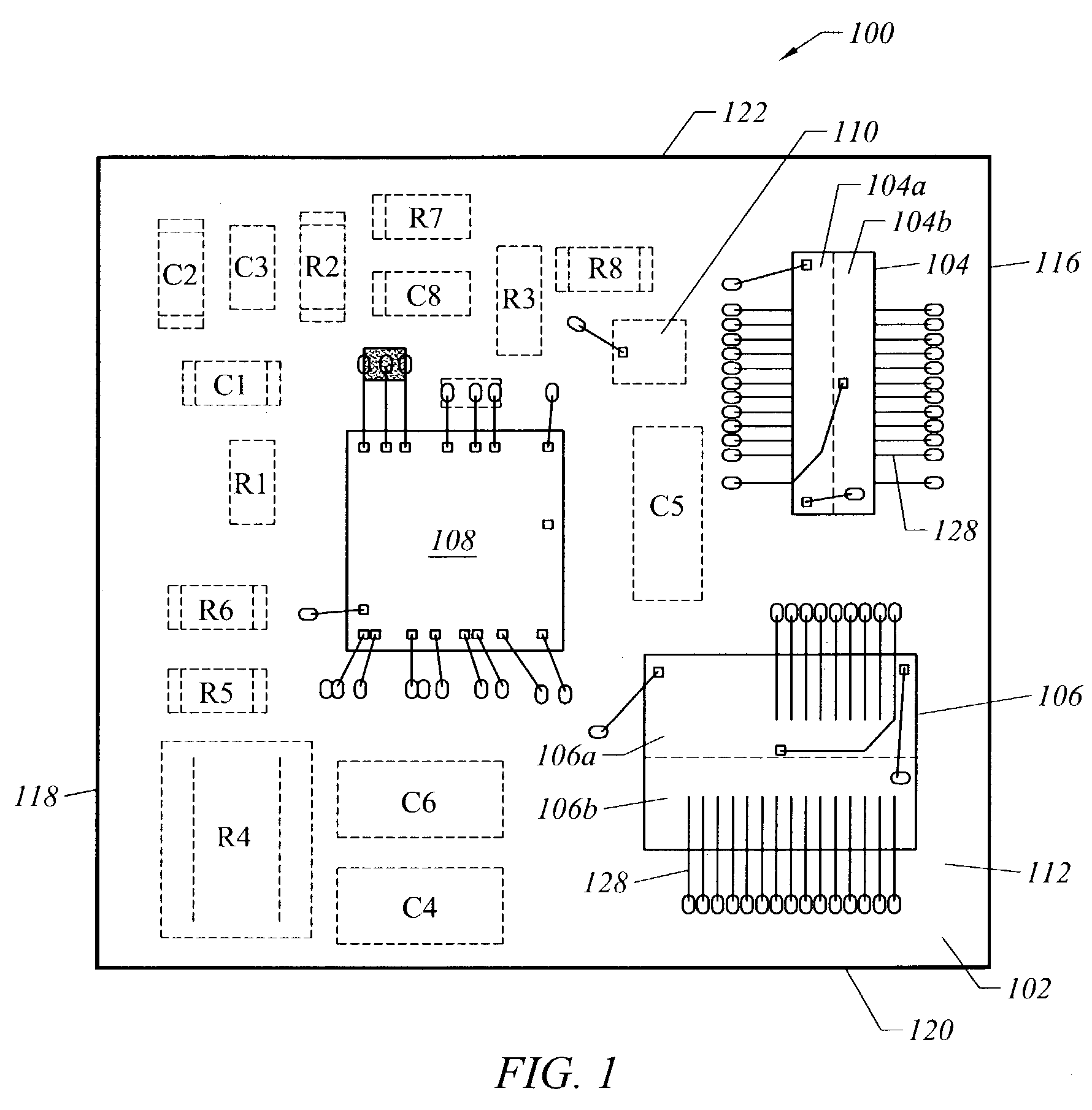

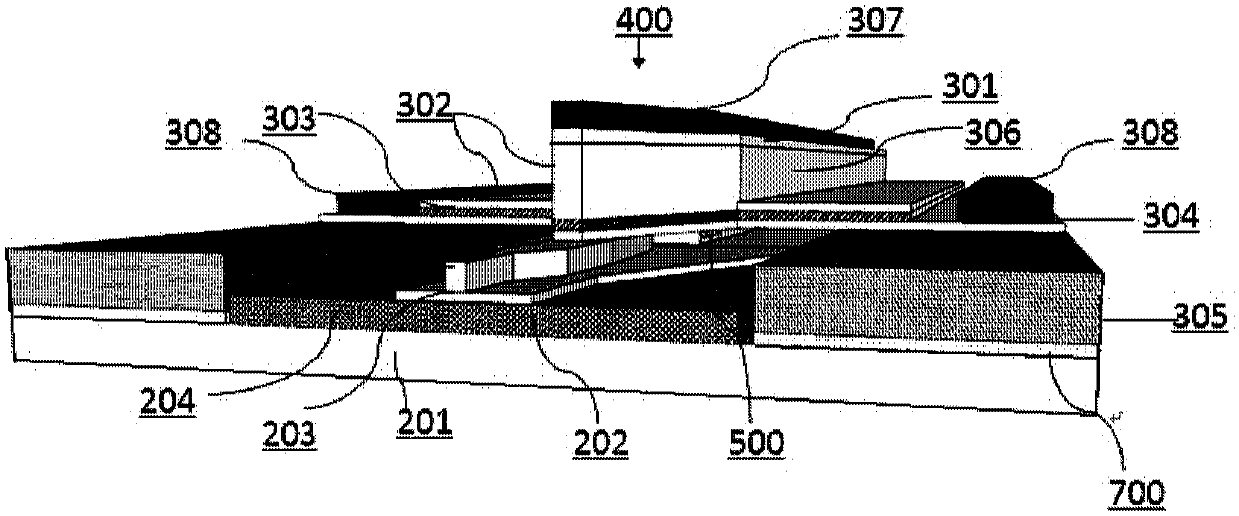

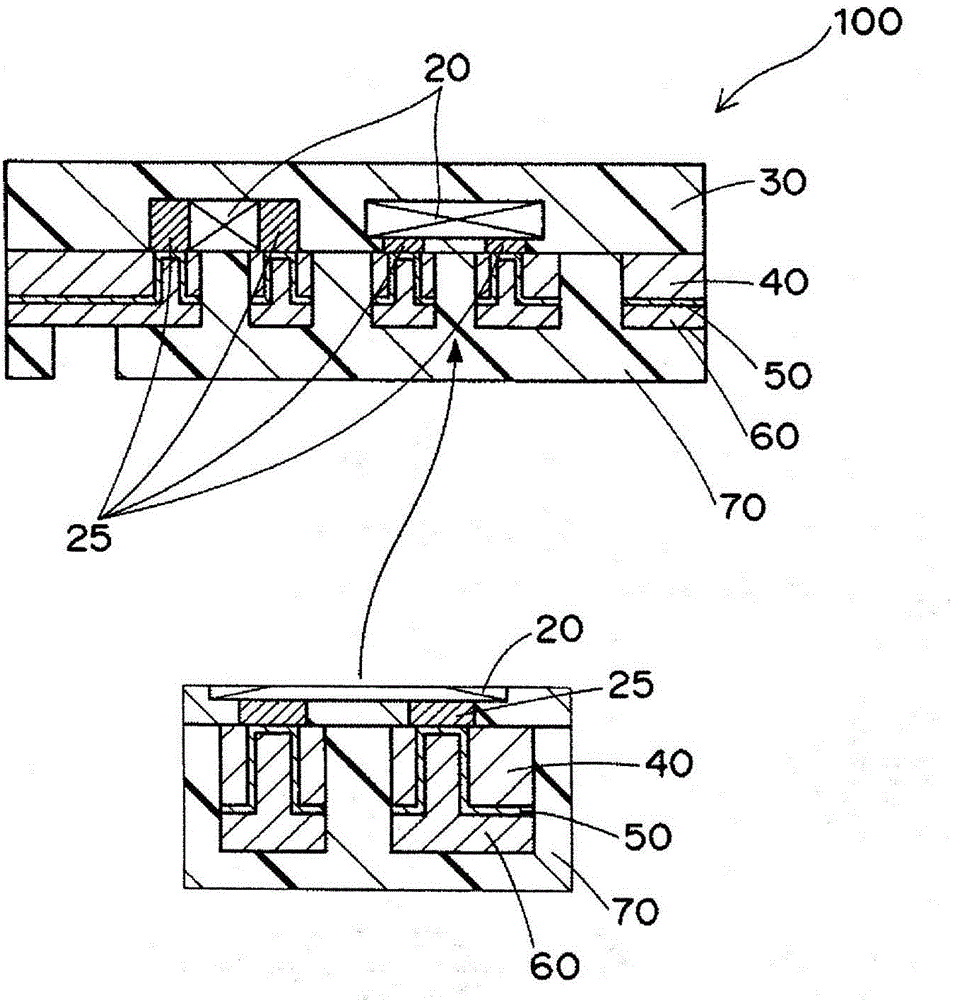

DC-DC converter implemented in a land grid array package

InactiveUS6940724B2Improve heat dissipation characteristicsHigh densityEfficient power electronics conversionSemiconductor/solid-state device detailsMOSFETSemiconductor chip

A semiconductor chip package that includes a DC—DC converter implemented with a land grid array (LGA) package for interconnection and surface mounting to a printed circuit board. The LGA package integrates all required active components of the DC—DC power converter, including a synchronous buck PWM controller, driver circuits, and MOSFET devices. In particular, the LGA package comprises a substrate having a top surface and a bottom surface, with a DC—DC converter provided on the substrate. The DC—DC converter including at least one power silicon die disposed on the top surface of the substrate. A plurality of electrically and thermally conductive pads are provided on the bottom surface of the substrate in electrical communication with the DC—DC converter through respective conductive vias. The plurality of pads include first pads having a first surface area and second pads having a second surface area, the second surface area being substantially larger than the first surface area. Heat generated by the DC—DC converter is conducted out of the LGA package through the plurality of pads.

Owner:PWER BRIDGE

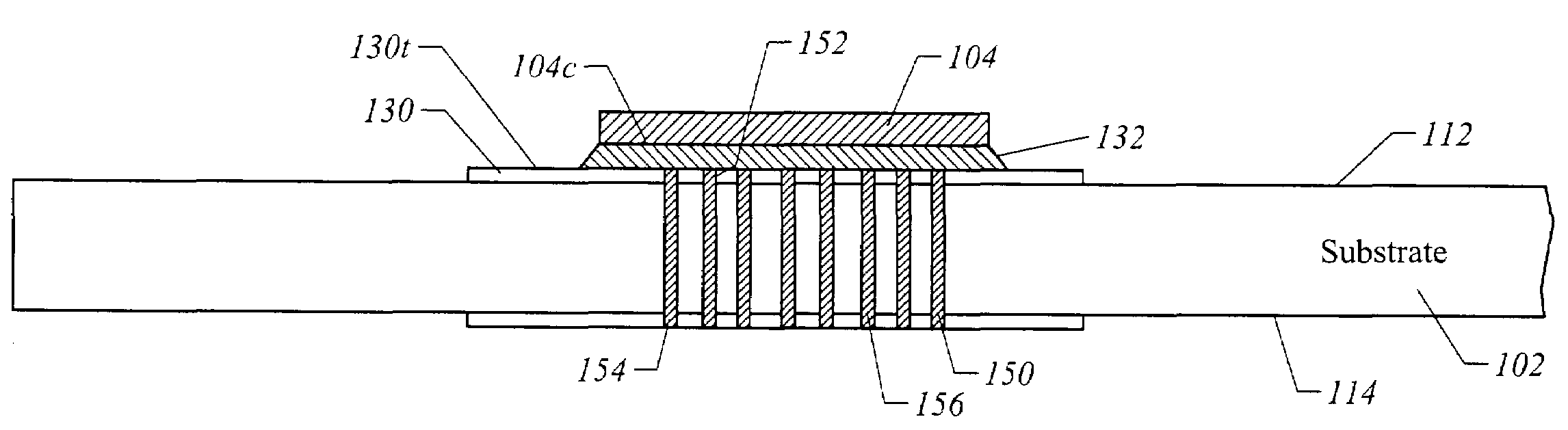

DC-DC converter implemented in a land grid array package

InactiveUS7026664B2Improve power densityImprove heat dissipation characteristicsTransistorThyristorElectricityDc dc converter

A semiconductor chip package that includes a DC—DC converter implemented with a land grid array for interconnection and surface mounting to a printed circuit board. The package includes a two layer substrate comprising a top surface and a bottom surface. At least one via array extends through the substrate. Each via in a via array includes a first end that is proximate to the top surface of the substrate and a second end that is proximate to the bottom surface of the substrate. At least one die attach pad is mounted on the top surface of the substrate and is electrically and thermally coupled to the via array. The DC—DC converter includes at least one power semiconductor die having a bottom surface that forms an electrode. The power semiconductor die is mounted on a die attach pad such that the bottom surface of the die is in electrical contact with the die attach pad. The bottom of the package forms a land grid array. The land grid array includes external pads that are separated into an interior region and a peripheral region. Each external pad located in the interior region of the land grid array is electrically and thermally coupled a via array.

Owner:BEL POWER SOLUTIONS INC

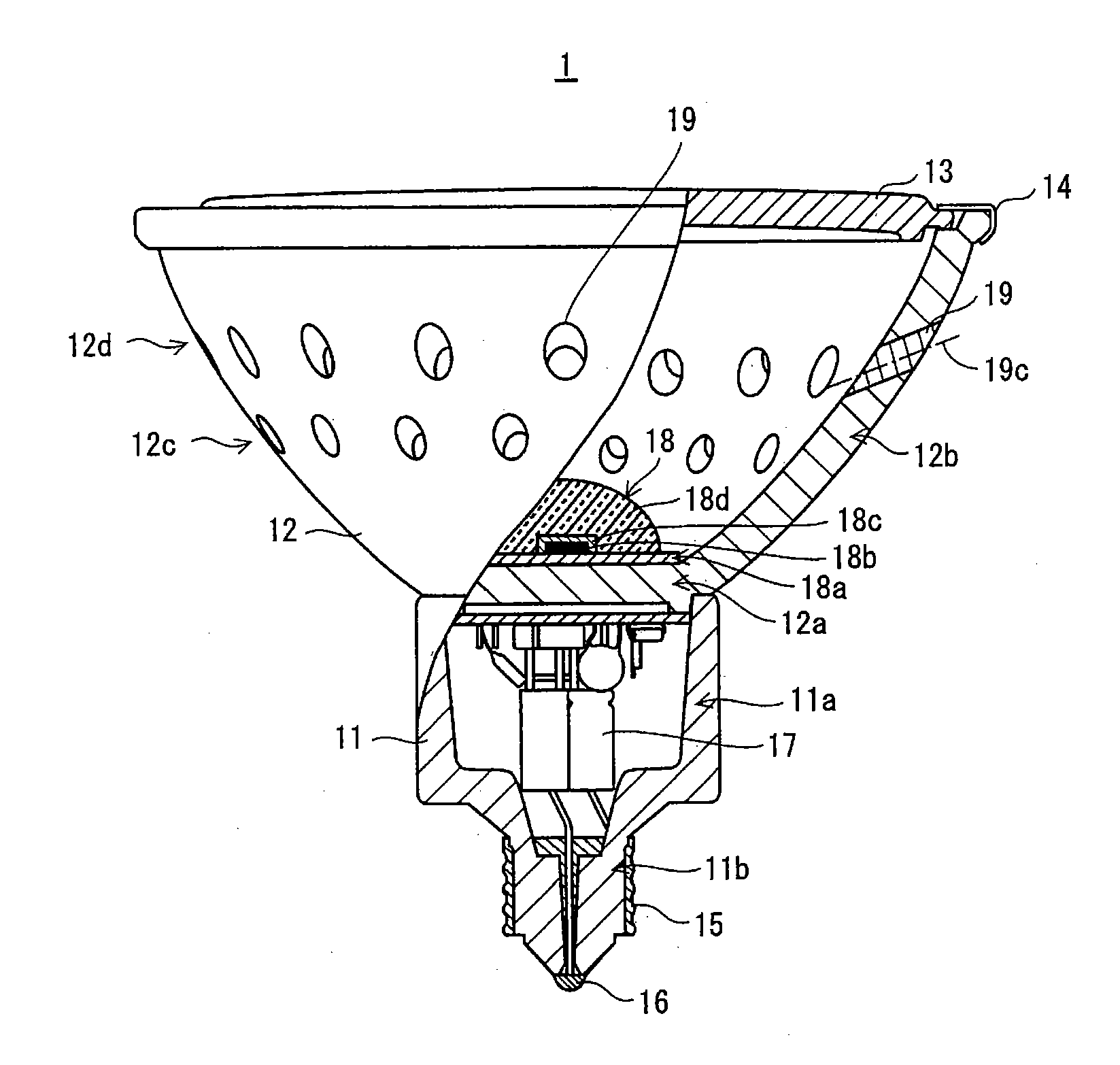

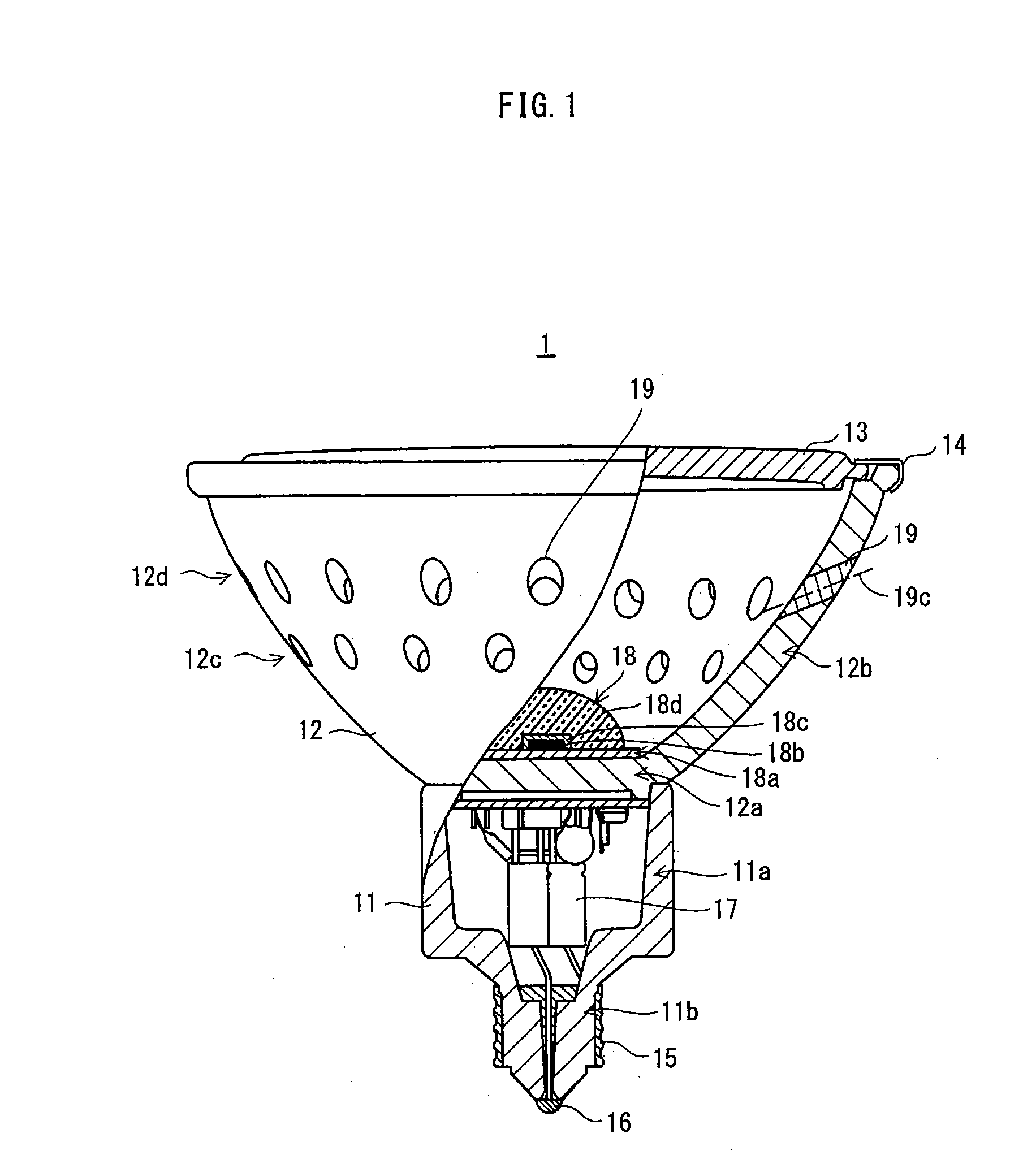

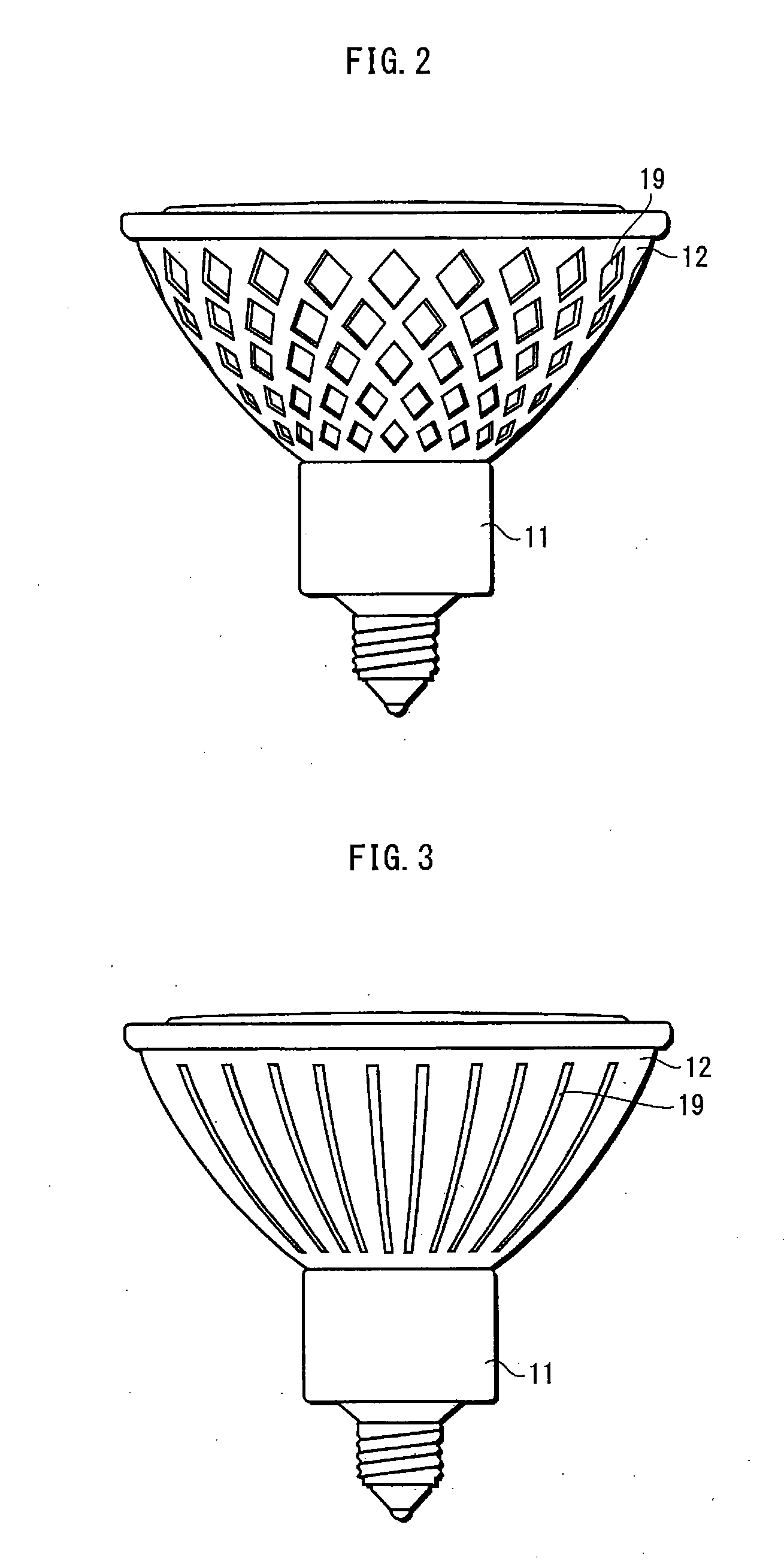

Illuminating apparatus

ActiveUS20110233593A1Low costImprove heat dissipation characteristicsPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

Provided is a lighting apparatus that is suitable as a substitute for a conventional halogen lamp when positively utilizing leaked light. The lighting apparatus comprises: a heat dissipator 12 that is in one of a bottomed cylindrical shape and a bowl shape, and that has a bottom portion, a circumferential wall portion, and an opening; and a light-emitting device 18b that is provided inside the heat dissipator 12 at the bottom portion and is operable to emit light, wherein the heat dissipator 12 has one or more windows 19 for leaking the emitted light outside the heat dissipator 12.

Owner:PANASONIC CORP

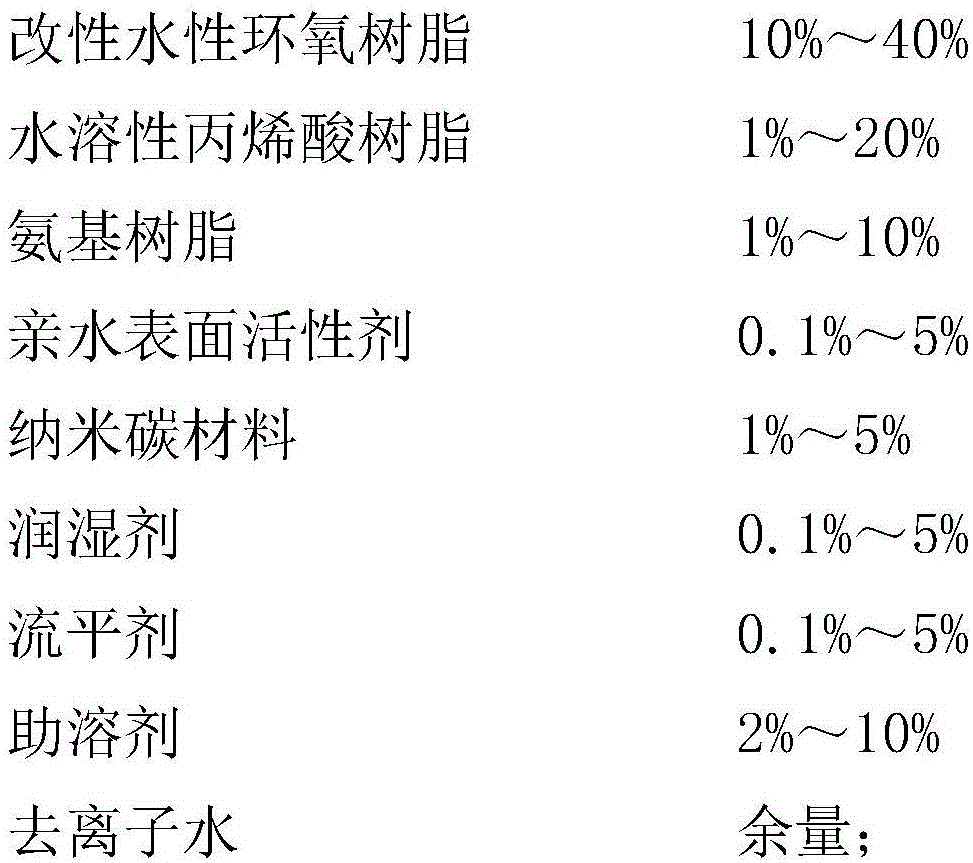

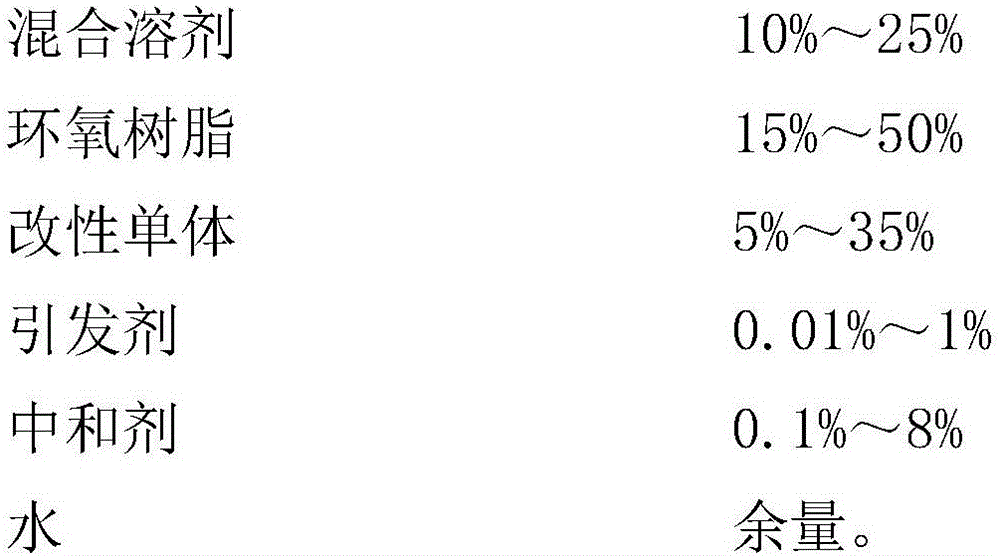

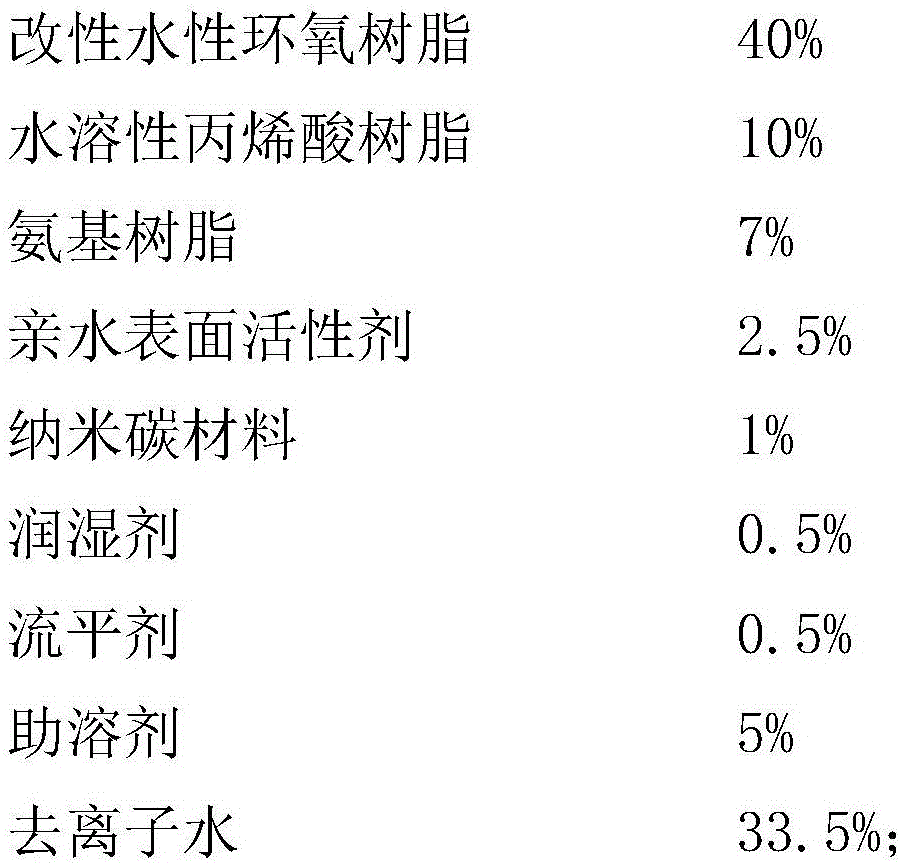

Heat dissipation hydrophilic coating and preparation method thereof

The invention relates to a heat dissipation hydrophilic coating and a preparation method thereof. The heat dissipation hydrophilic coating is prepared from, by weight, 10-40% of modified waterborne epoxy resin, 1-20% of water soluble acrylic resin, 1-10% of acrylic resin, 0.1-5% of hydrophilic surfactant, 1-5% of a carbon nanomaterial, 0.1-5% of a wetting agent, 0.1-5% of a flatting agent, 2-10% of cosolvent and the balance deionized water. Good compatible dispersion to the carbon nanomaterial is obtained through epoxy resin modification, a good film-forming property is obtained, the carbon nanomaterial can exert the characteristics of high thermal conductivity, high infrared radiance and the like, the hydrophilic coating can have the radiation and heat dissipation functions, heat dissipation and anti-corrosion performance of air conditioner aluminum foil, an aluminum foil heat exchanger and other equipment can be remarkably improved, the energy efficiency ratio is raised, and important business value is achieved.

Owner:芜湖海泰科新材料有限公司

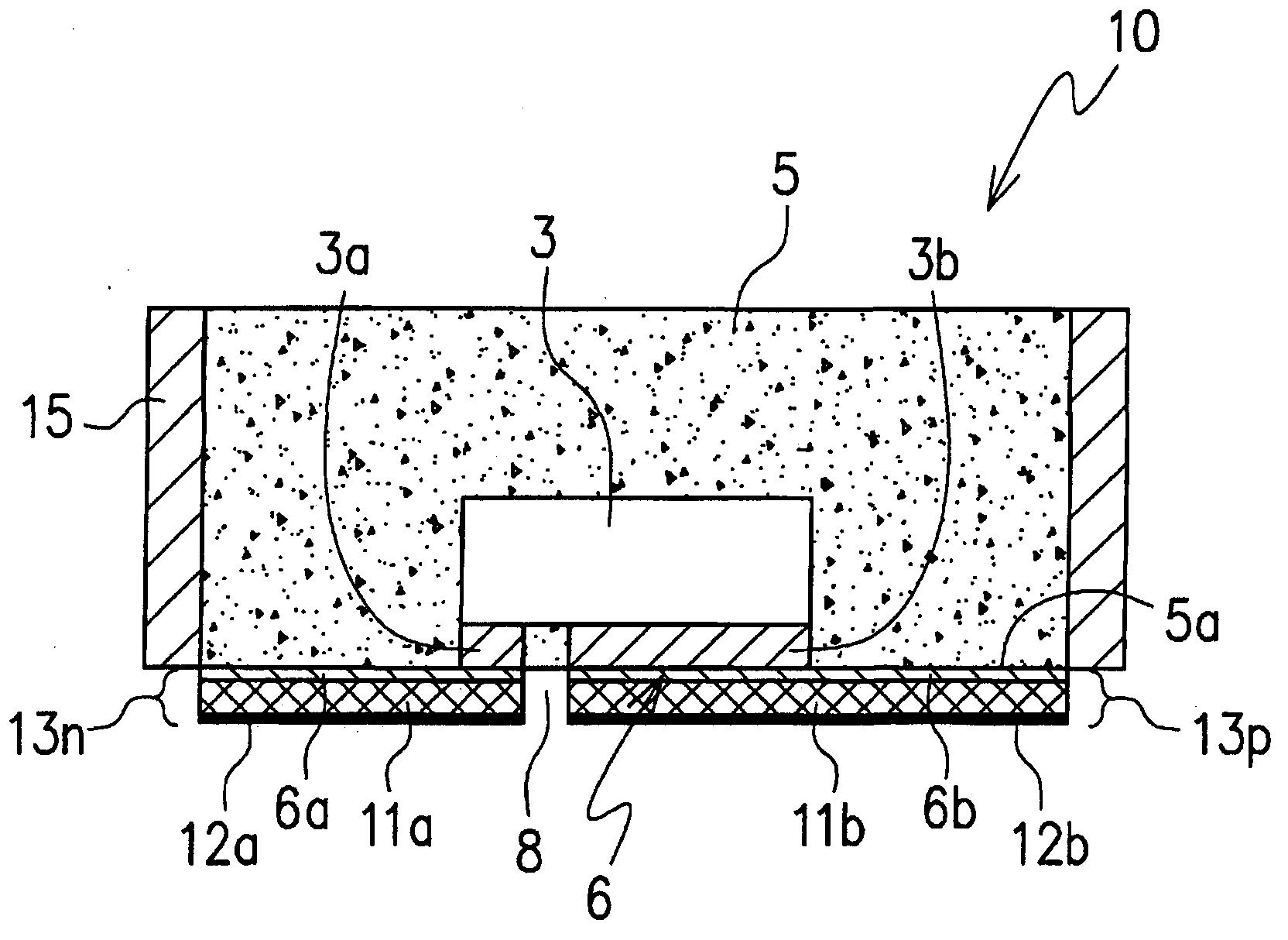

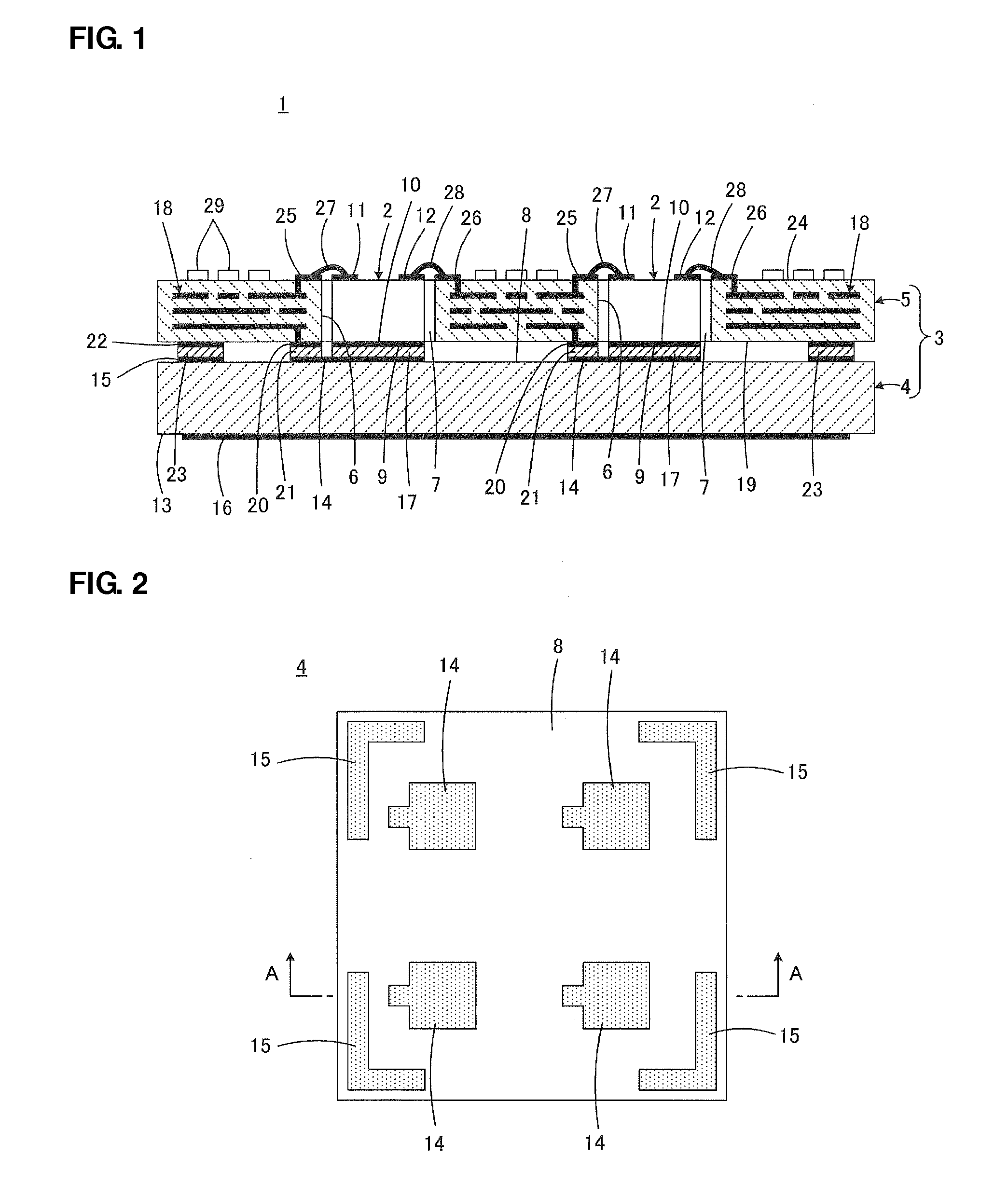

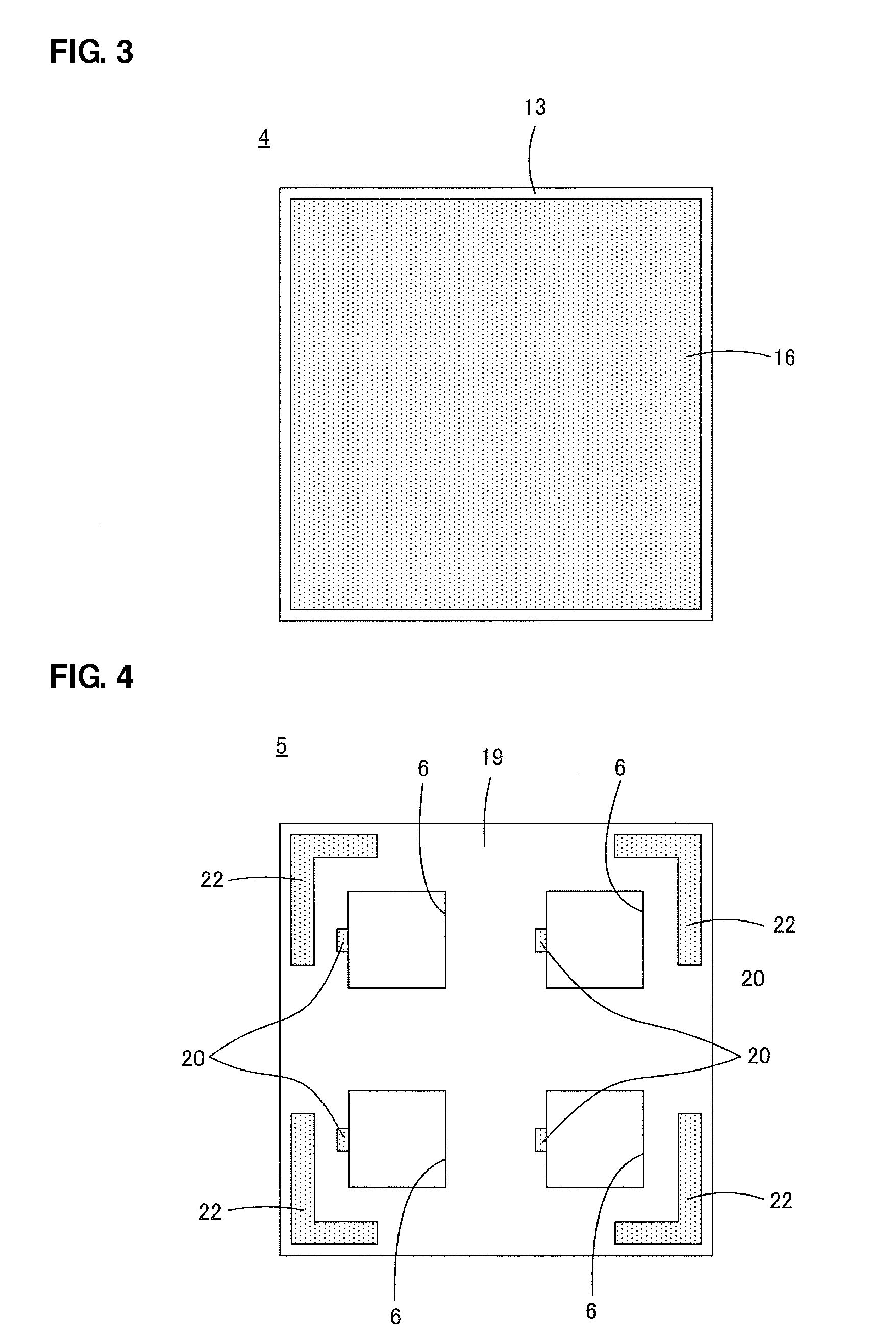

Method for producing light-emitting device and light emitting device

ActiveCN102884645AQuality improvementImprove heat dissipation characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceLight-emitting diode

In order to produce, via an extremely simple method, a thin light-emitting device that does not have a substrate in which a light-emitting element has been mounted, disclosed is a method for producing a light-emitting device, said method comprising: preparing a plurality of light-emitting elements each having a pair of element electrodes; arraying the plurality of light-emitting elements in a sealing member in a manner so that at least one surface of the pair of element electrodes provided to each light-emitting element is exposed; forming on the aforementioned sealing member a plurality of pairs of external connection electrodes, each pair connected to the pair of element electrodes provided to each light-emitting element; and dividing the aforementioned sealing member having a plurality of light-emitting elements, obtaining a plurality of light-emitting devices each provided with a light-emitting element having a pair of element electrodes, a sealing member that seals the light-emitting element in a state such that at least one surface of each of the pair of element electrodes is exposed, and a pair of external connection electrodes provided on the sealing member and electrically connected to the pair of element electrodes.

Owner:CITIZEN ELECTRONICS CO LTD +1

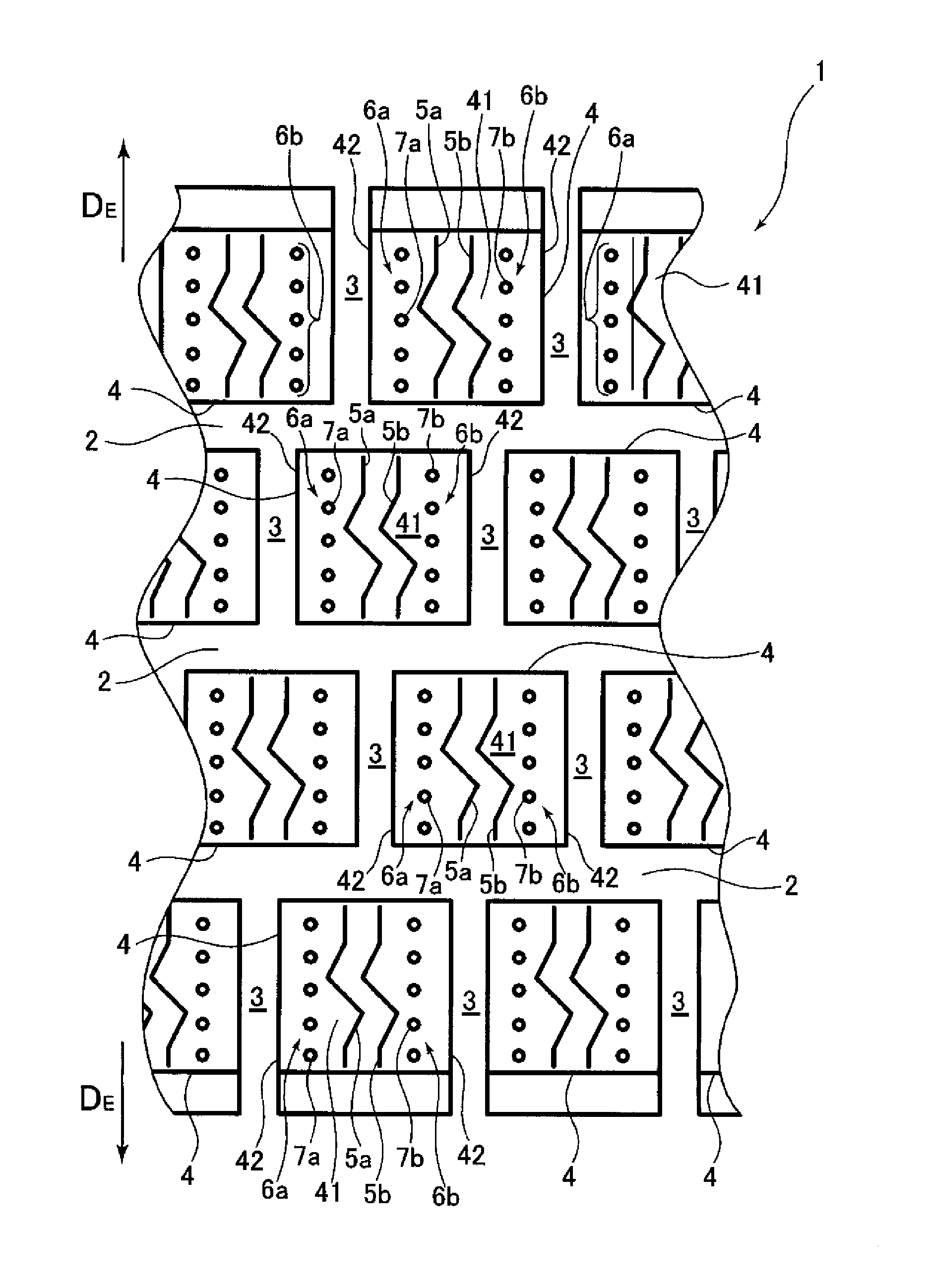

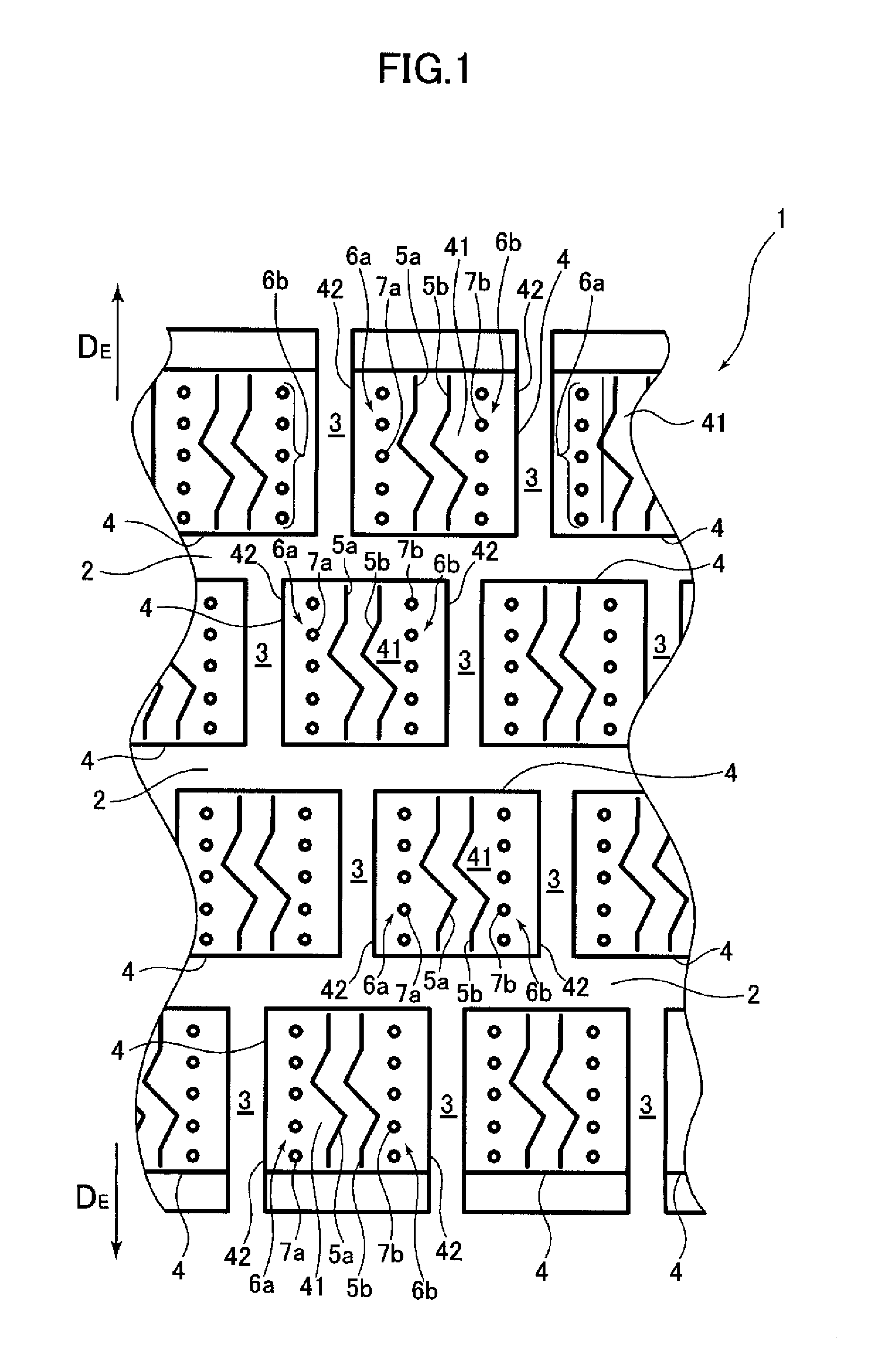

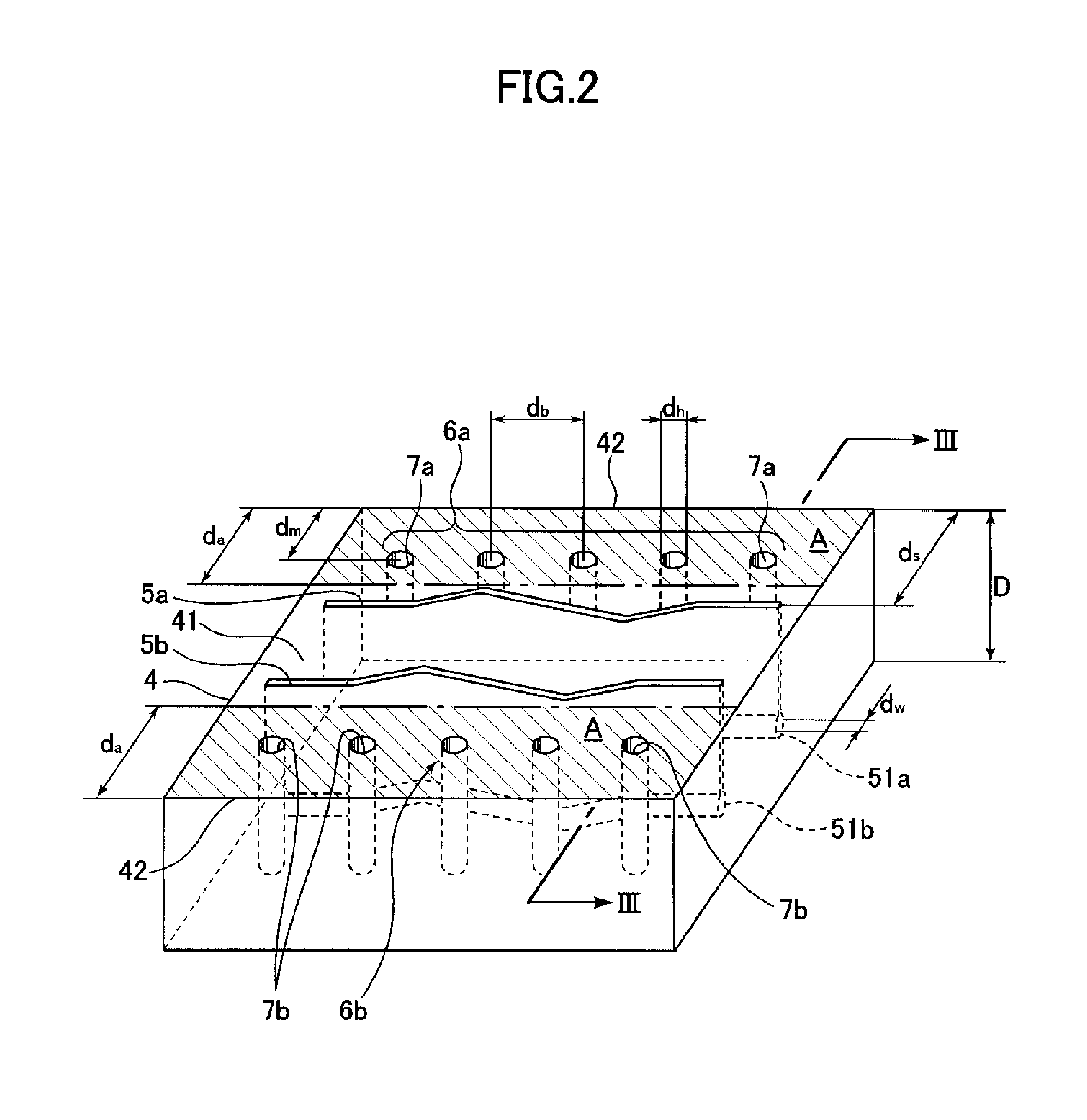

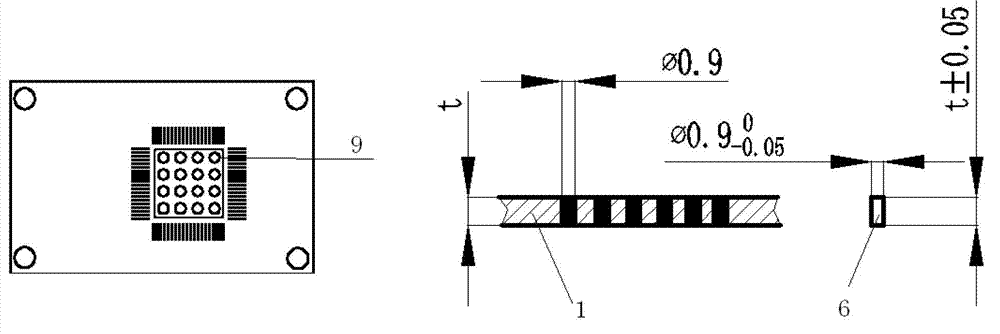

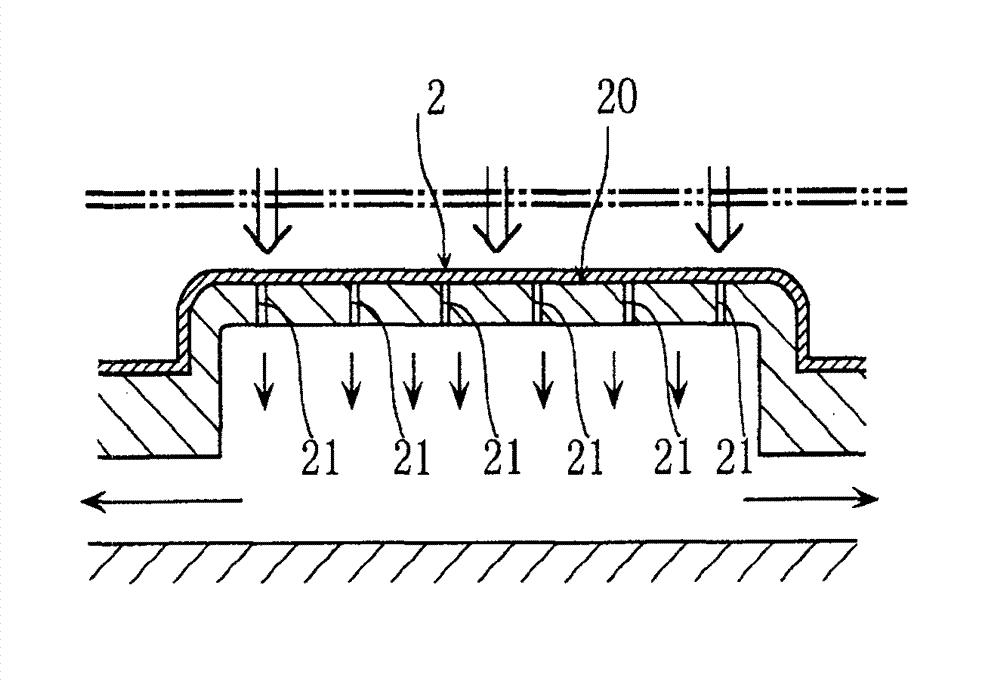

Tread for winter-use pneumatic tires

InactiveUS20130186533A1Increased durabilityHeat generationTyre tread bands/patternsNon-skid devicesGround contactTread

To provide a winter-use pneumatic tire with which the performance on ice can be enhanced and tread pattern durability can be enhanced. The tread for a winter-use pneumatic tire according to the present invention has blocks which are aligned in the circumferential direction and in which are formed respectively at least one thin incision which extends substantially parallel to a circumferential direction edge and which has a widened portion at its bottom, and at least one series of small holes comprising at least two small holes which open in a ground contacting surface of the block and extend in the inward radial direction of the tire, and the at least one series of small holes is formed in a neighboring region of the circumferential direction edge, and is formed in an intermediate portion between the circumferential direction edge and the at least one thin incision.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Manufacturing method of semiconductor device

InactiveUS20060177967A1Improve production yieldGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

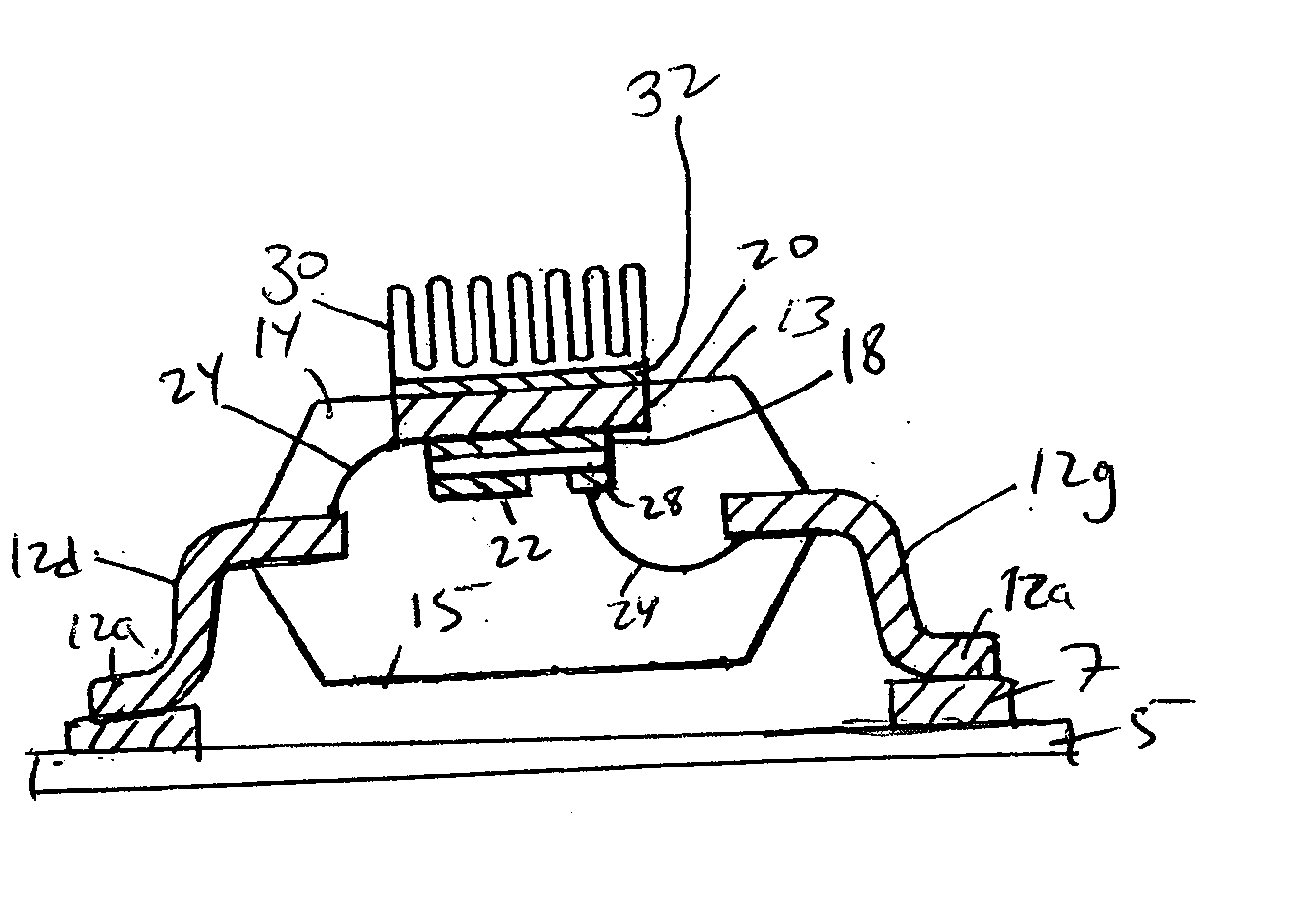

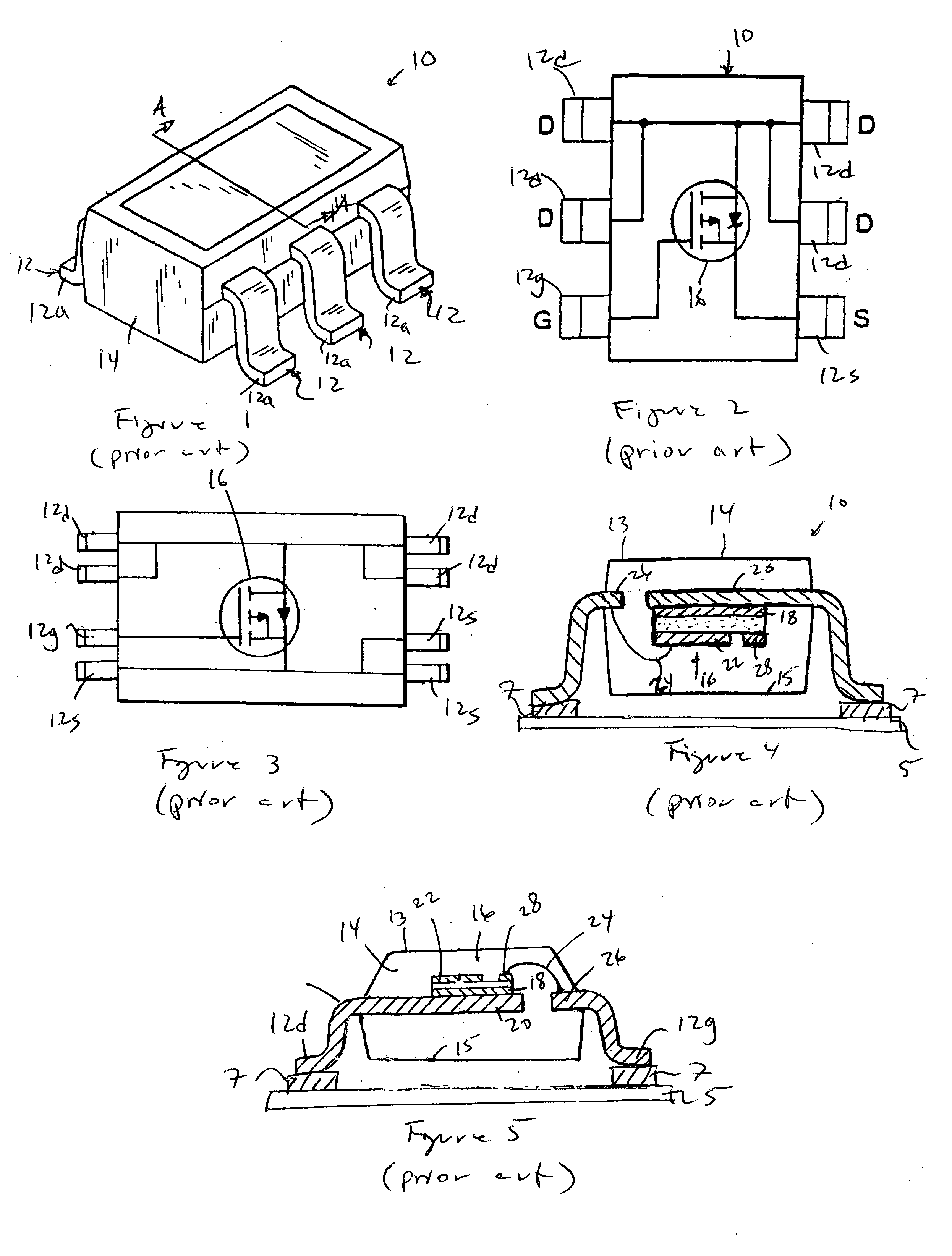

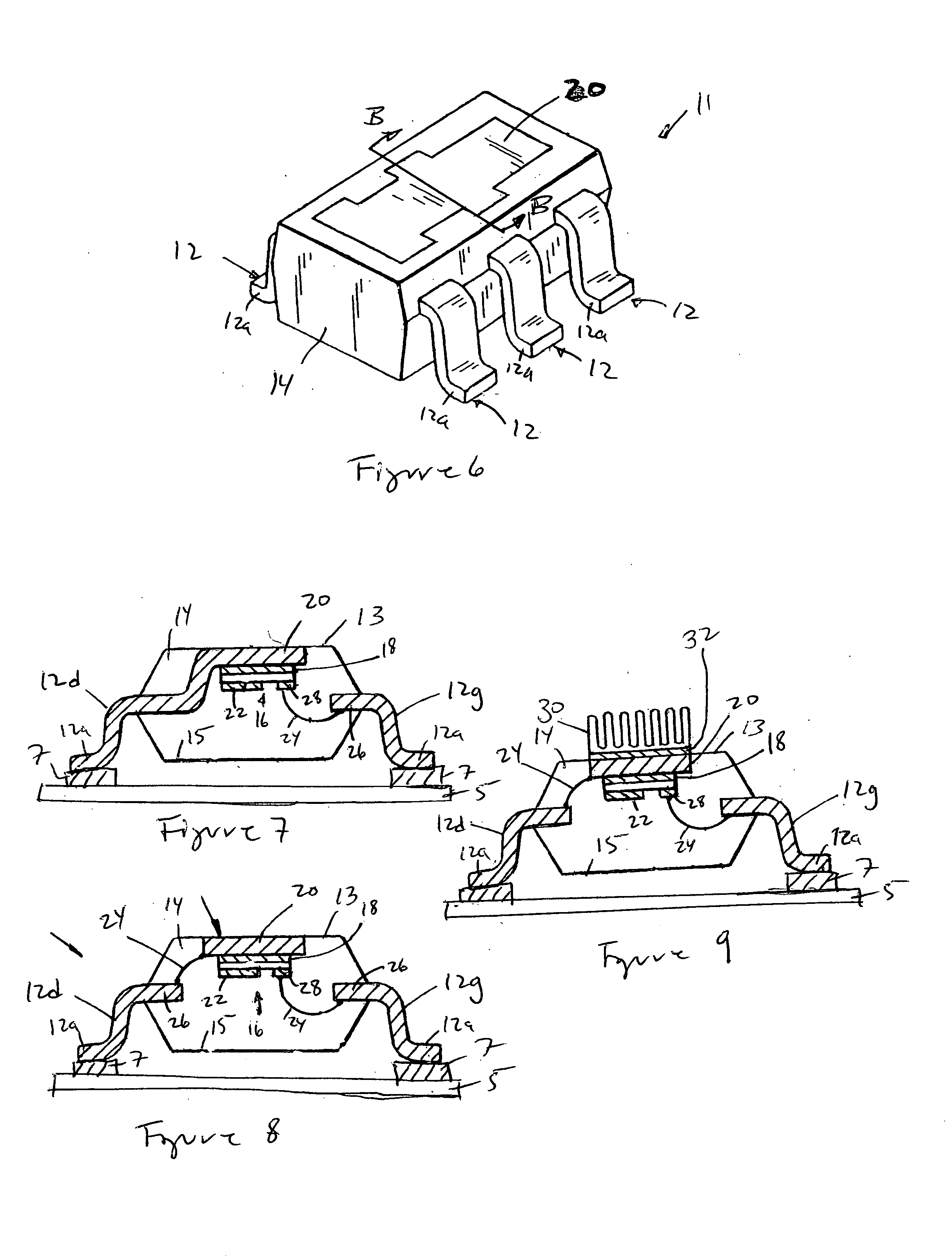

A semiconductor device in the form of a resin sealed semiconductor package is disclosed, wherein a gate terminal connected to a gate pad electrode formed on a surface of a semiconductor chip and a source terminal connected to a source pad electrode formed on the chip surface exposed to a back surface of a sealing resin portion, a first portion of a drain terminal connected to a back-surface drain electrode of the semiconductor chip is exposed to an upper surface of the sealing resin portion, and a second portion of the drain terminal formed integrally with the first portion of the drain terminal is exposed to the back surface of the sealing resin portion. When forming the sealing resin portion in such a semiconductor device, first the sealing resin portion is formed so as to also cover an upper surface of the first portion of the drain terminal and thereafter the upper surface side of the sealing resin portion is polished by liquid honing, thereby allowing the upper surface of the first portion of the drain terminal to be exposed on the upper surface of the sealing resin portion. Both heat dissipating property and production yield of the semiconductor device are improved.

Owner:RENESAS ELECTRONICS CORP

Topless semiconductor package

ActiveUS20050029634A1Improve heat dissipation characteristicsGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package which includes a die pad that is exposed through the top surface of its molded housing.

Owner:INFINEON TECH AMERICAS

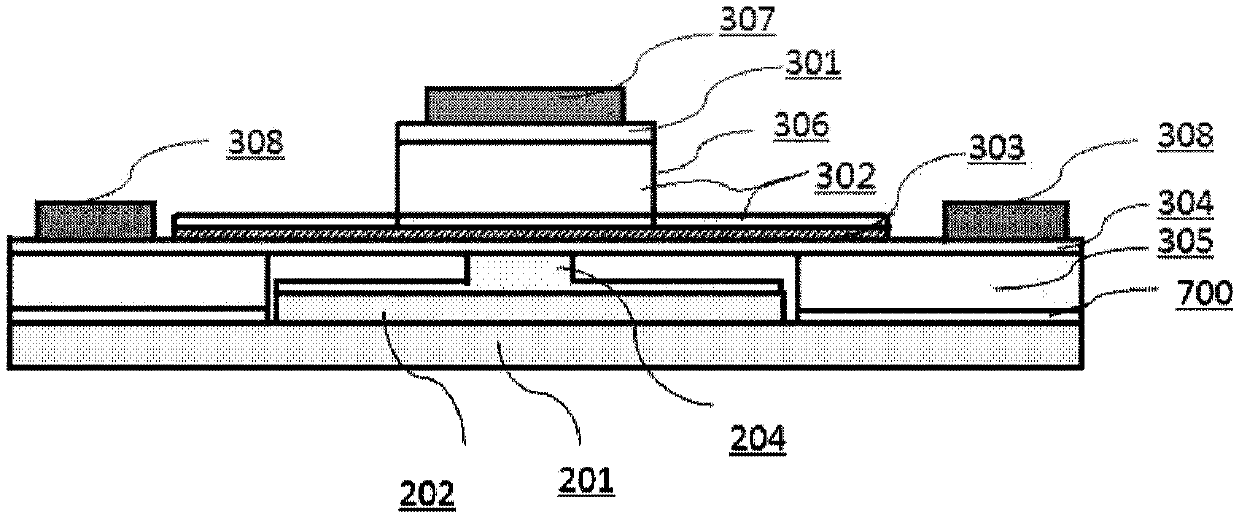

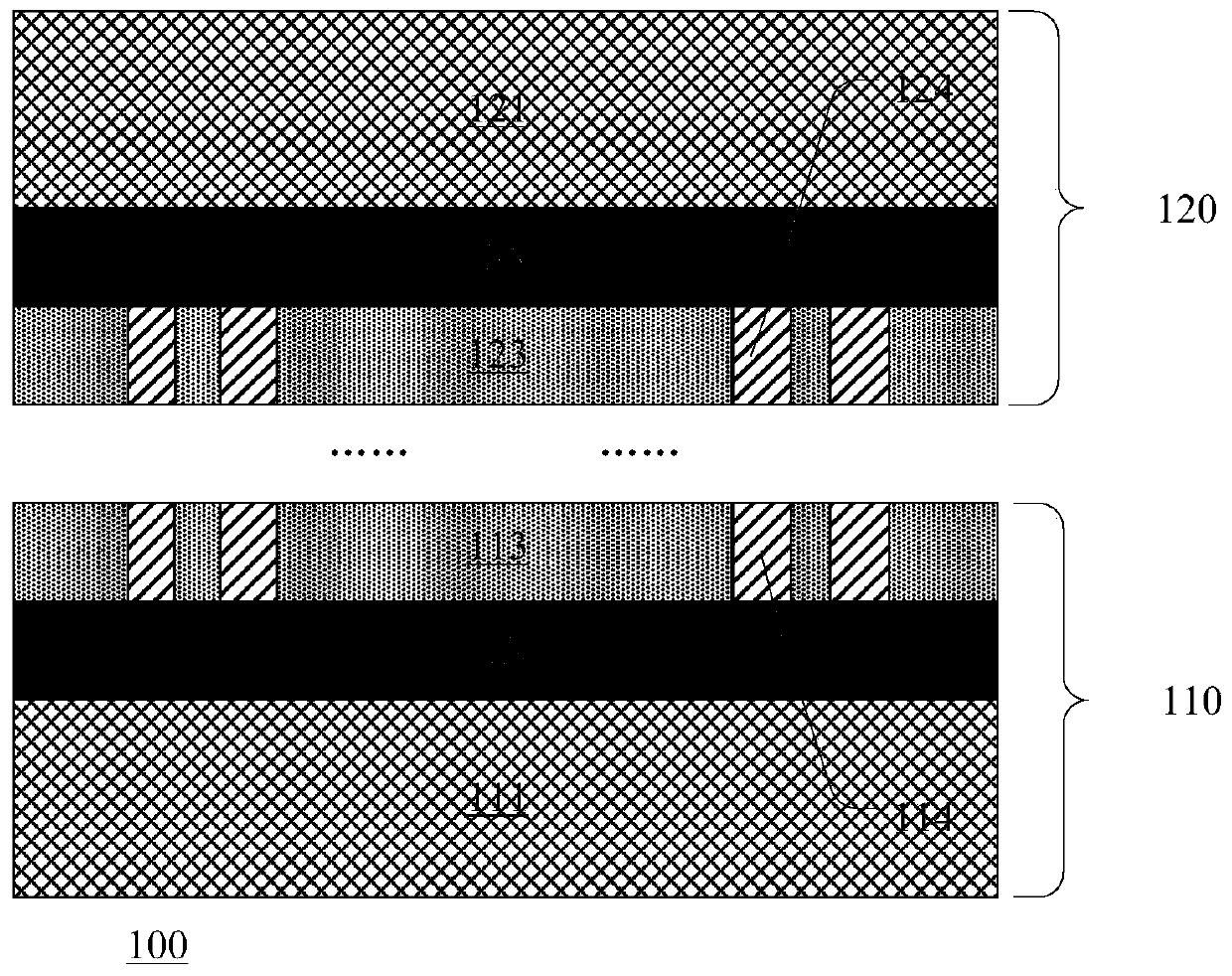

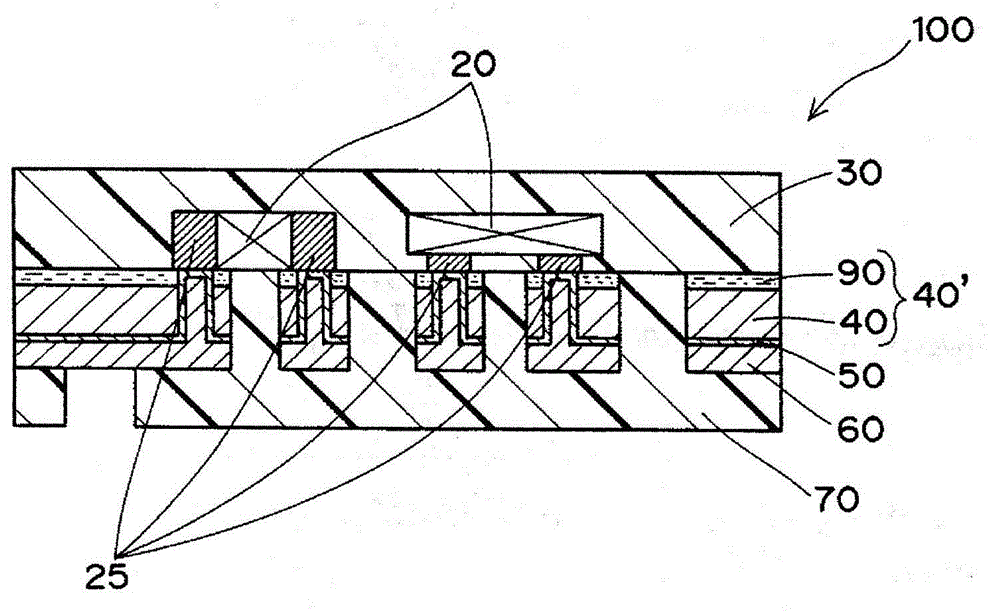

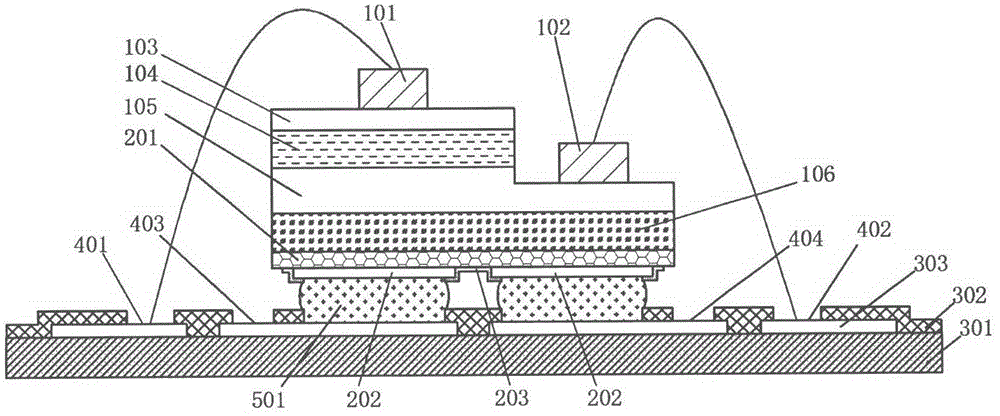

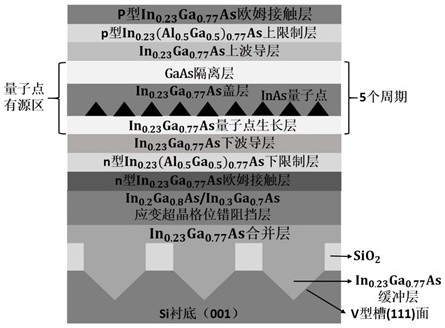

Silicon-based hybrid integrated laser array and preparation method thereof

ActiveCN109560462ASolve the problem of poor heat dissipation characteristicsImprove heat dissipation characteristicsOptical wave guidanceSemiconductor laser arrangementsLaser arrayOhmic contact

The invention discloses a silicon-based hybrid integrated laser array and a preparation method thereof. The silicon-based hybrid integrated laser array comprises a plurality of distributed silicon-based hybrid integrated lasers in parallel integrated on an SOI substrate and an III-V semiconductor epitaxial layer. Each silicon-based hybrid integrated laser comprises: a silicon ridge waveguide; heatconducting layers located in special areas at two sides of the silicon ridge waveguide, wherein the special area is an area obtained after the SOI substrate removes a top silicon and a buried oxide layer; an intrinsic layer in a shape of a saddle and comprising a protrusion portion and a connection portion at two ends, wherein the protrusion portion at one end covers the upper portion of the heatconducting layers, the connection portion of the intrinsic layer is provided with an N-type waveguide layer, an active region and a P-type cover layer in order; an III-V waveguide formed by patterning the III-V semiconductor epitaxial layer and connected with the silicon ridge waveguide; a P-type ohmic contact layer; a P electrode; and an N electrode. The silicon-based hybrid integrated laser array is good in heat dissipation, simple and stable in preparation process, good in repeatability and low in manufacturing cost.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

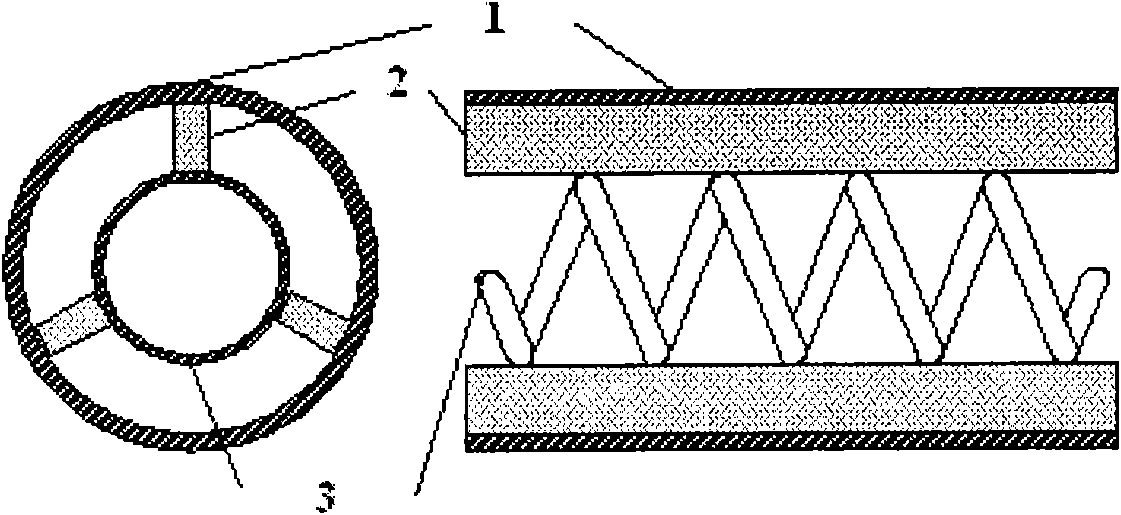

Deformation-free thermal extrusion method for helix slow-wave component preparation

InactiveCN101642865AInfluence of high frequency characteristicsWill not deformMetal working apparatusCold cathode manufactureMicrowaveRoom temperature

The invention discloses a deformation-free thermal extrusion method for helix slow-wave component preparation, which relates to the microwave device technology and is used for preparing a helix travelling wave tube component. The method comprises the following steps: placing and fixing a metal tube shell on an extrusion platform, feeding a helix and a medium clamping rod into an extrusion die, heating the tube shell firstly to increase the inside diameter of the tube shell, pushing the helix and the clamping rod of which positions are well fixed to the tube shell by using a push rod, then stopping heating, taking down the extrusion die, recovering the temperature of the whole component to the room temperature, and generating a great contraction force at the moment due to the contraction ofthe inside diameter of the tube shell to be applied to the helix and the clamping rod component to firmly extrude the both inside the tube shell so as to finish the preparation of the slow-wave component. Various dies required by the method can be prepared by machining of a linear cutting electro-discharge machine tool. The method not only can well improve the heat dissipation performance of theslow-wave component, but also can avoid the component structure deformation, dielectric performance reduction and high-frequency loss increment caused by the conventional assembly method.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

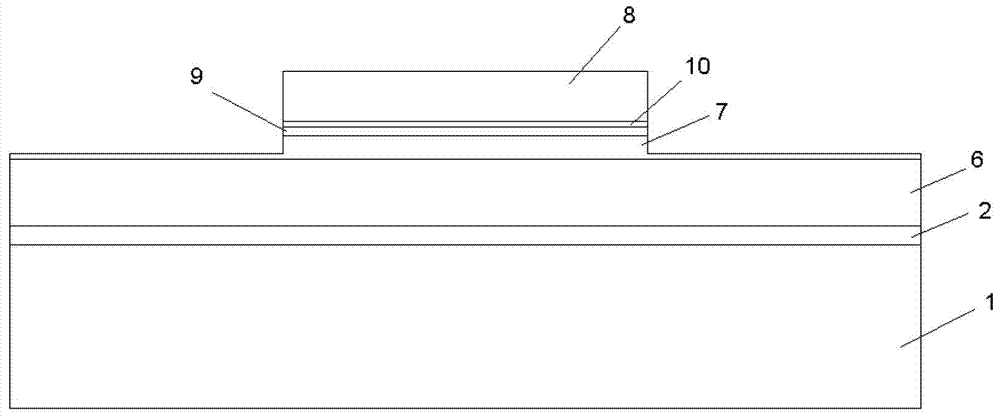

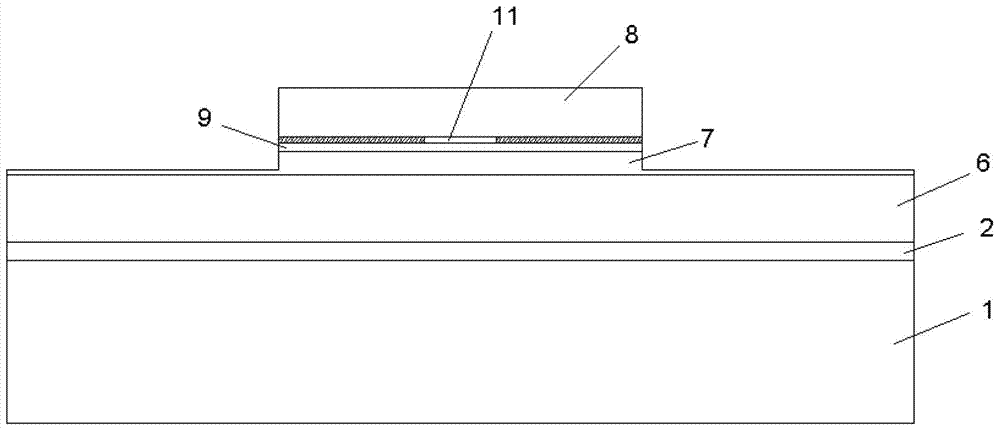

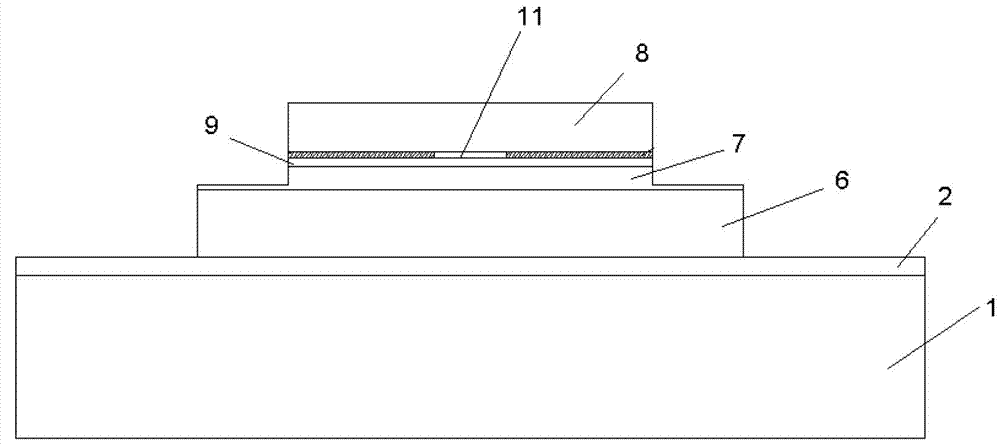

Semiconductor device

ActiveUS20140070394A1Thermal conductivityHeat dissipationSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical conductor

In a semiconductor device including a semiconductor element that produces heat and a substrate on which the semiconductor element is mounted, functions of the substrate are divided between a heat dissipating substrate and a wiring substrate. The heat dissipating substrate has a relatively high thermal conductivity, and includes principal surfaces defined by electric insulators, one of which is provided with an outer conductor located thereon. The wiring substrate is mounted on the upper principal surface of the heat dissipating substrate, has a thermal conductivity lower than that of the heat dissipating substrate, and includes a wiring conductor made mainly of silver or copper and located inside the wiring substrate, the wiring conductor being electrically connected to the outer conductor. The semiconductor element is mounted on the upper principal surface of the heat dissipating substrate and disposed in a through hole of the wiring substrate.

Owner:MURATA MFG CO LTD

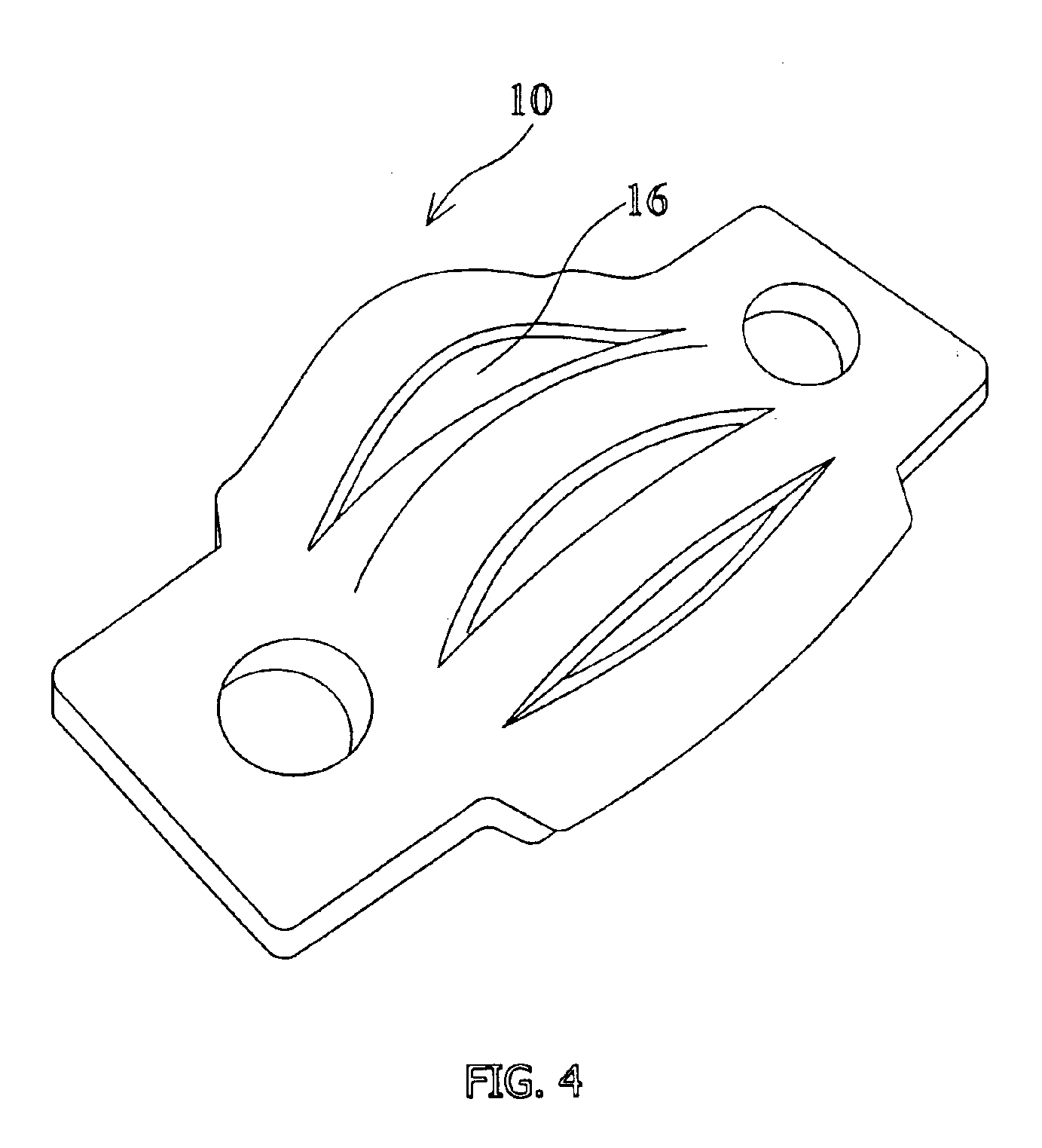

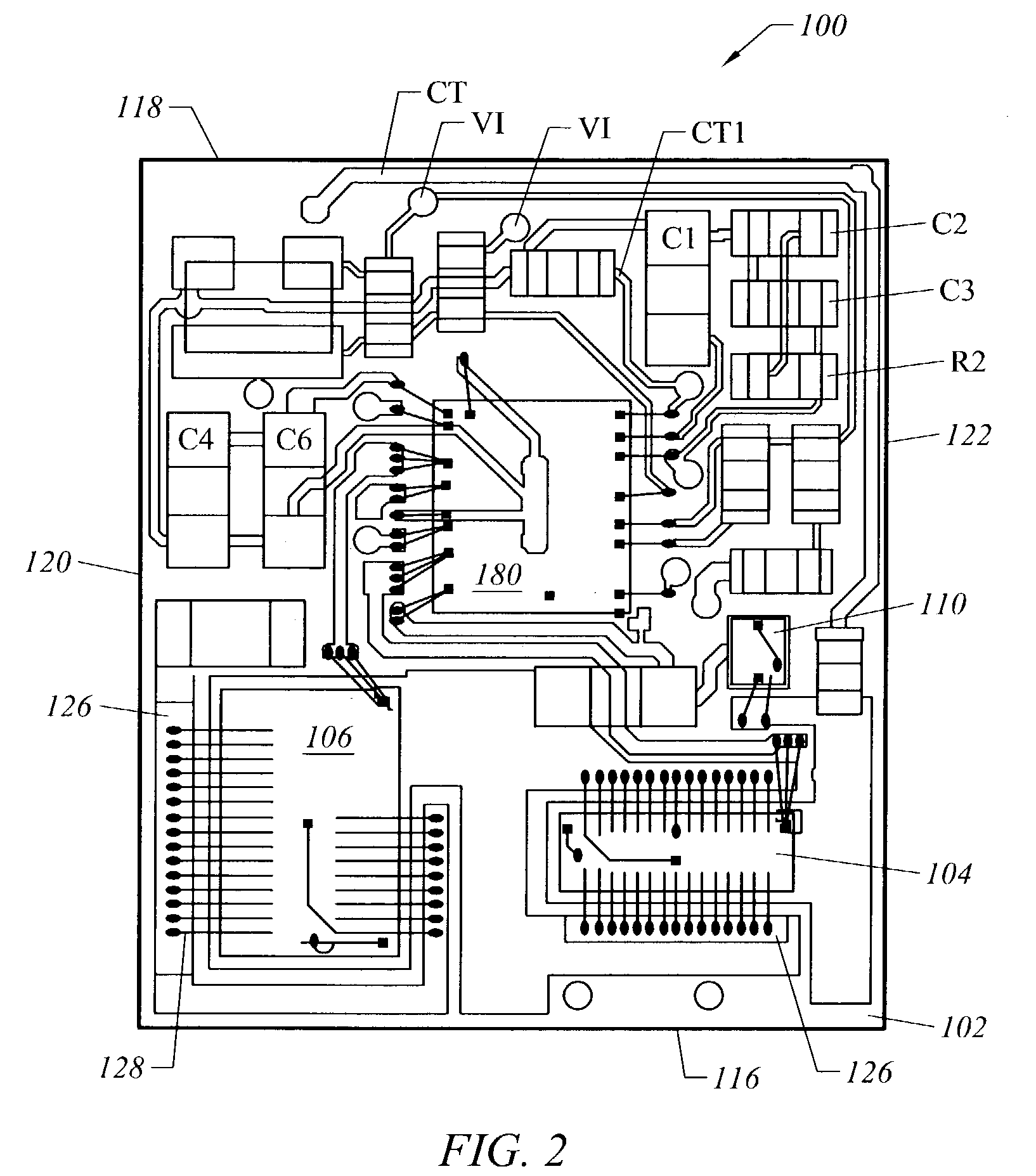

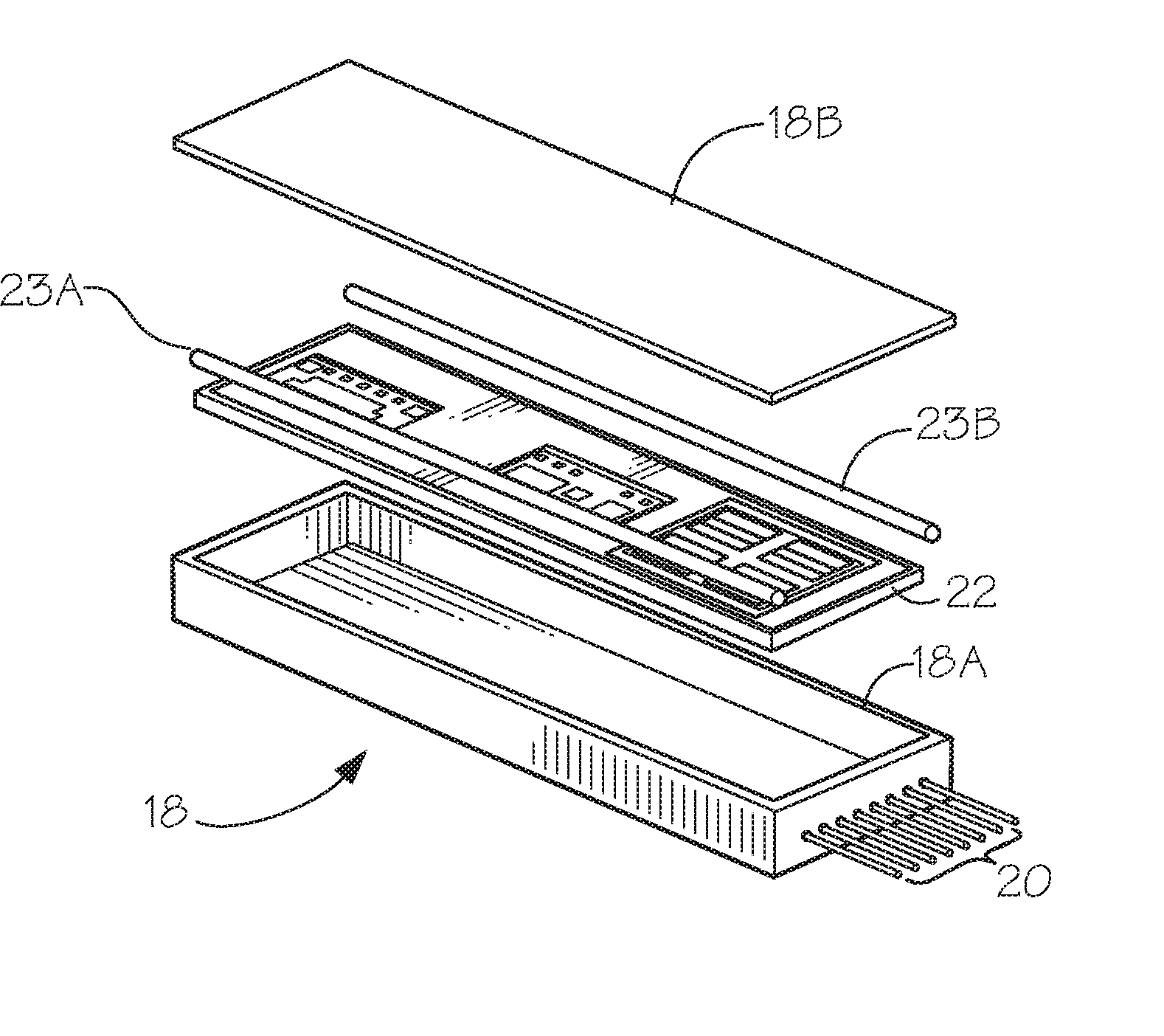

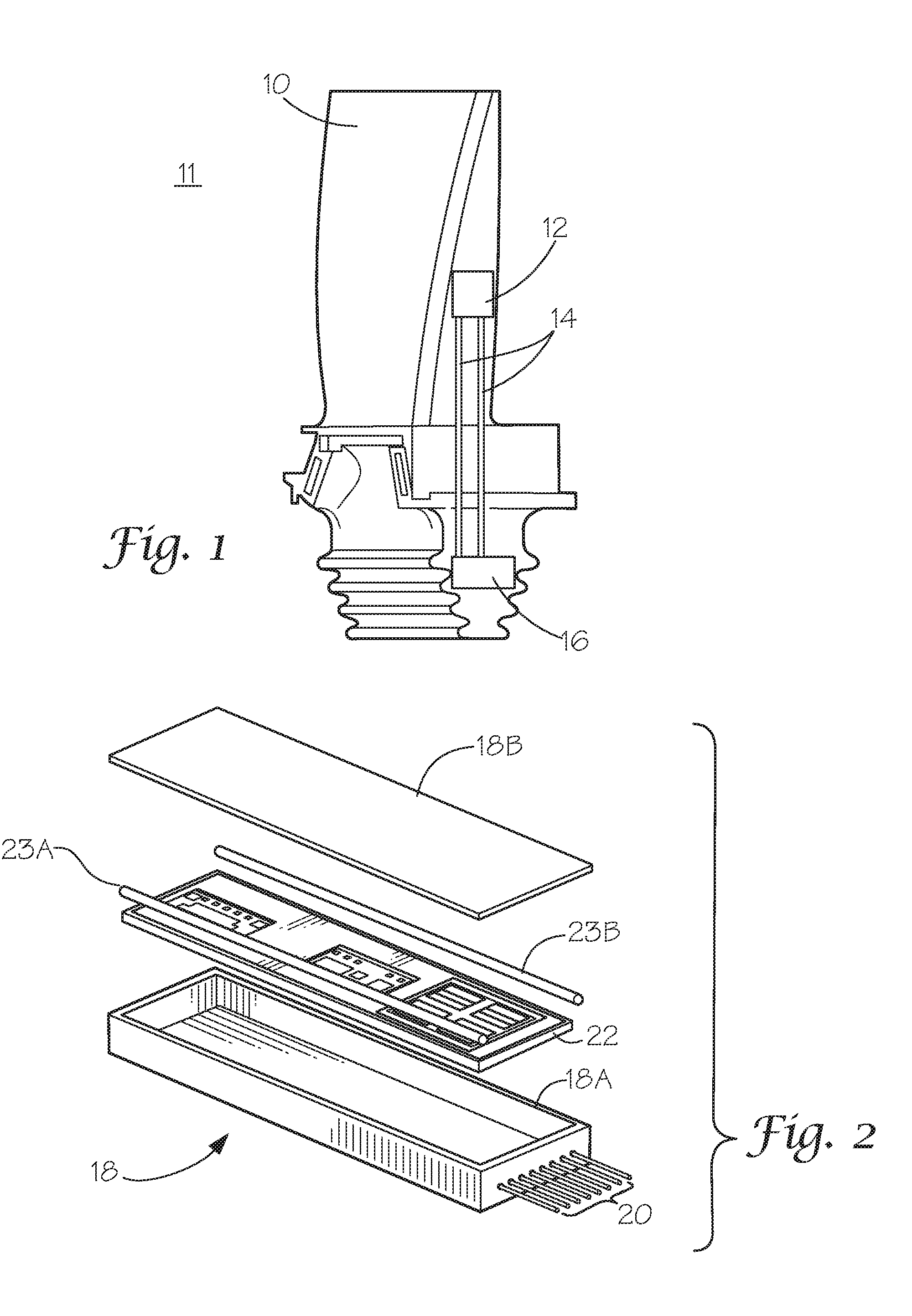

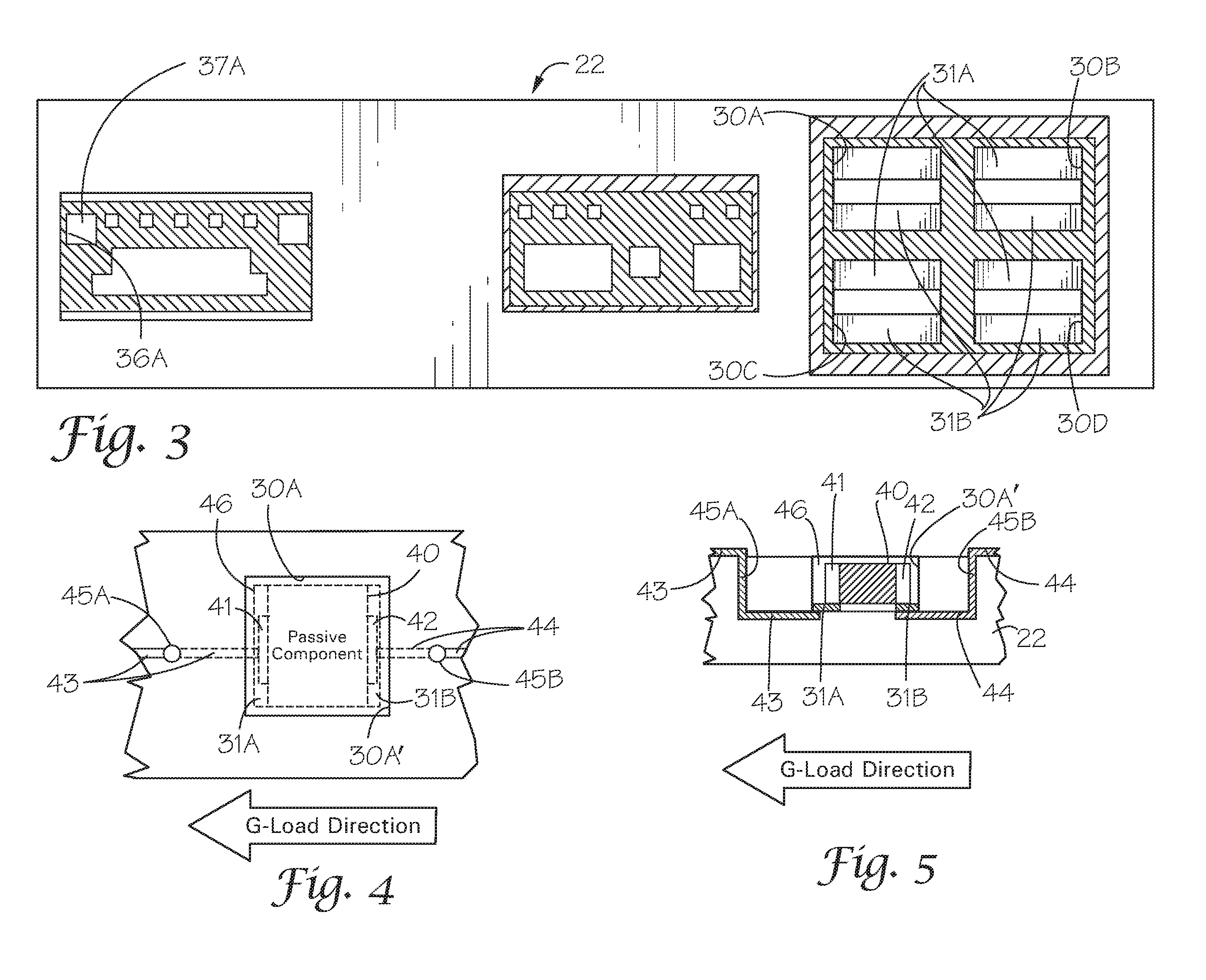

Printed Circuit Board for Harsh Environments

ActiveUS20100078202A1Improve heat dissipation characteristicsFinal product manufacturePrinted circuit aspectsContact padTitanium

A printed circuit board (PCB 22) capable of withstanding ultra high G forces and ultra high temperature as in a gas turbine (11). The PCB includes a substrate having a plurality of cavities (30A, 36A) formed therein for receiving components of a circuit, and conductors embedded in the PCB for electrically connecting the components together to complete the circuit. Each of the cavities has a wall (36A′) upstream of the G-forces which supports the respective component in direct contact in order to prevent the development of tensile loads in a bonding layer (37A). When the component is an integrated circuit (50), titanium conductors (63) are coupled between exposed ends of the embedded conductors and contact pads on the integrated circuit. A gold paste (51) may be inserted into interstitial gaps between the integrated circuit and the upstream wall.

Owner:SIEMENS ENERGY INC +1

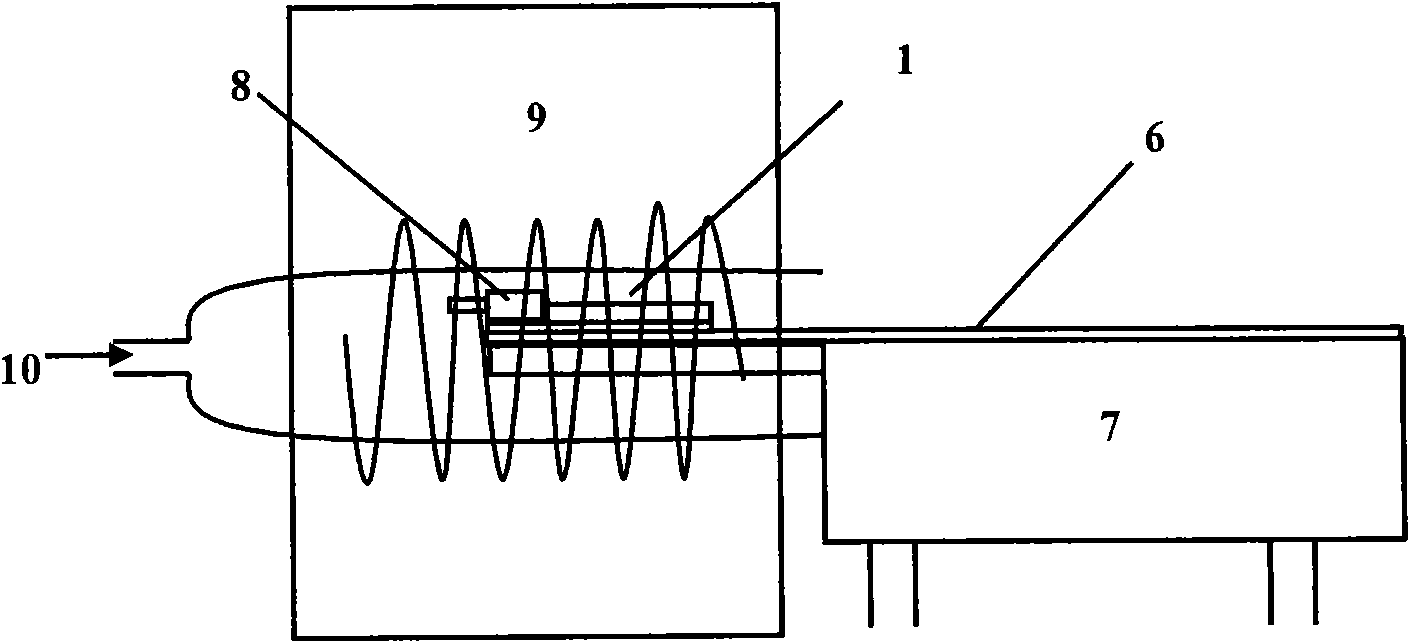

Integrated cooling system of high-power amplifier using waveguide space synthesis method

InactiveCN102315506AReduce volumeImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesSynthesis methodsEngineering

The invention relates to a novel cooling design for a space synthesis amplifier, which is characterized in that a heat pipe or a high-heat-conducting-factor material is implanted into the card of the amplifier to reduce the thermal impedance of the card; and at the same time, a cooling system for liquid refrigeration is directly implanted into the amplifier to improve the cooling capacity of the system. By using the novel cooling structure in the design of the high-power amplifier, the miniaturization of the system is realized, the internal temperature of the system can be effectively reduced and the service life of the system is improved.

Owner:杨健

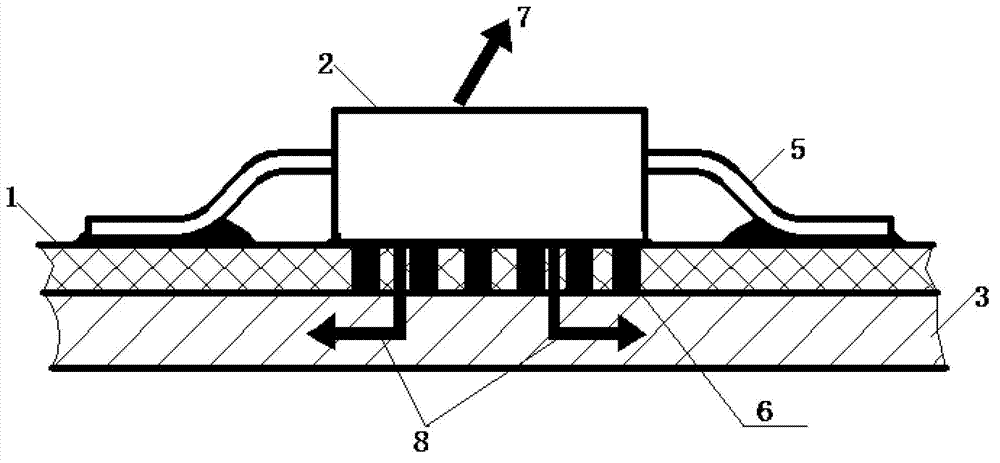

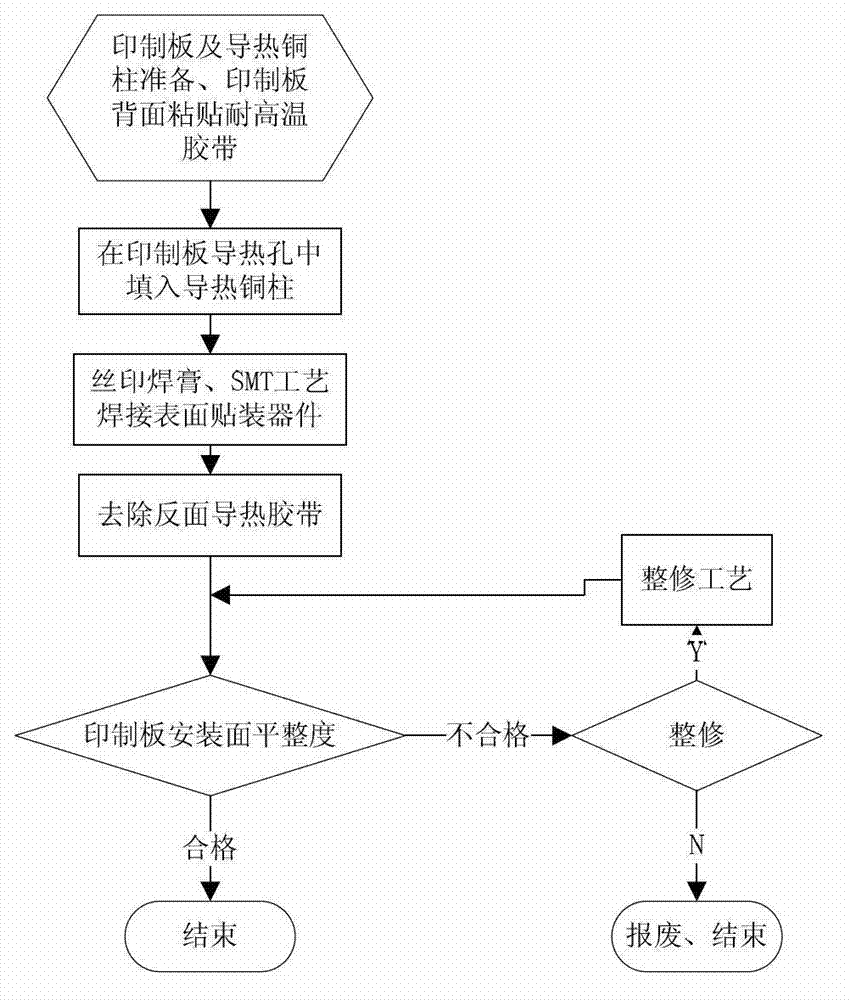

Method for improving thermal conduction capability of printed board of surface-mounted device

InactiveCN103179781AReduce the improvement effectSignificant improvementPrinted circuit assemblingPrinted circuit detailsSurface mountingWorking temperature

The invention provides a method for improving thermal conduction capability of a printed board of a surface-mounted device, and aims at providing an instructive and operable method for overcoming the defects that thermal conduction printed boards in the prior art are high in working temperature, poor in thermal reliability and the like due to poor thermal conduction capability, long thermal conduction route and large thermal conduction resistance. The technical scheme includes that the method includes: determining a layout of plated-through holes and thermal conductive copper pins according to ranges of power consumption parameters of a high-thermal-flux-density surface-mounted device; establishing a replicable and extendable thermal conducting route according to assembling relations among the surface-mounted device with a metal welding surface at the bottom, the printed board and a metal box; on reverse sides of thermal conductive through holes on the printed board and the surface-mounted device, sealing thermal conductive through holes with high temperature resistant adhesive tape; and respectively pressing the thermal conductive copper pins into correspondingly thermal conductive through holes and welding. By the method for improving the thermal conduction capability of the printed board of the surface-mounted device, the defect that the thermal conduction router of the high-thermal-flux-density surface-mounted device in low air pressure or vacuum is low in reliability is solved.

Owner:10TH RES INST OF CETC

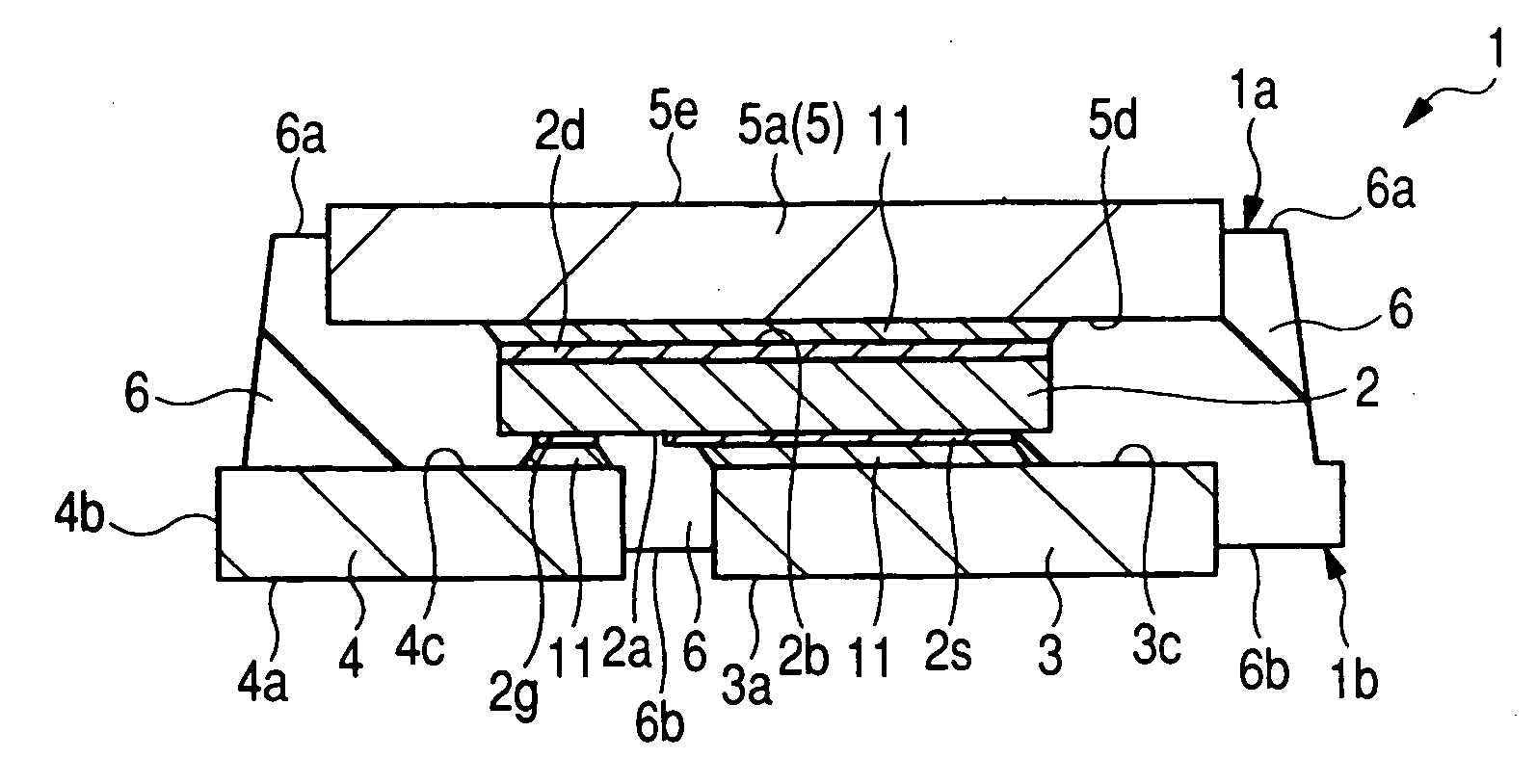

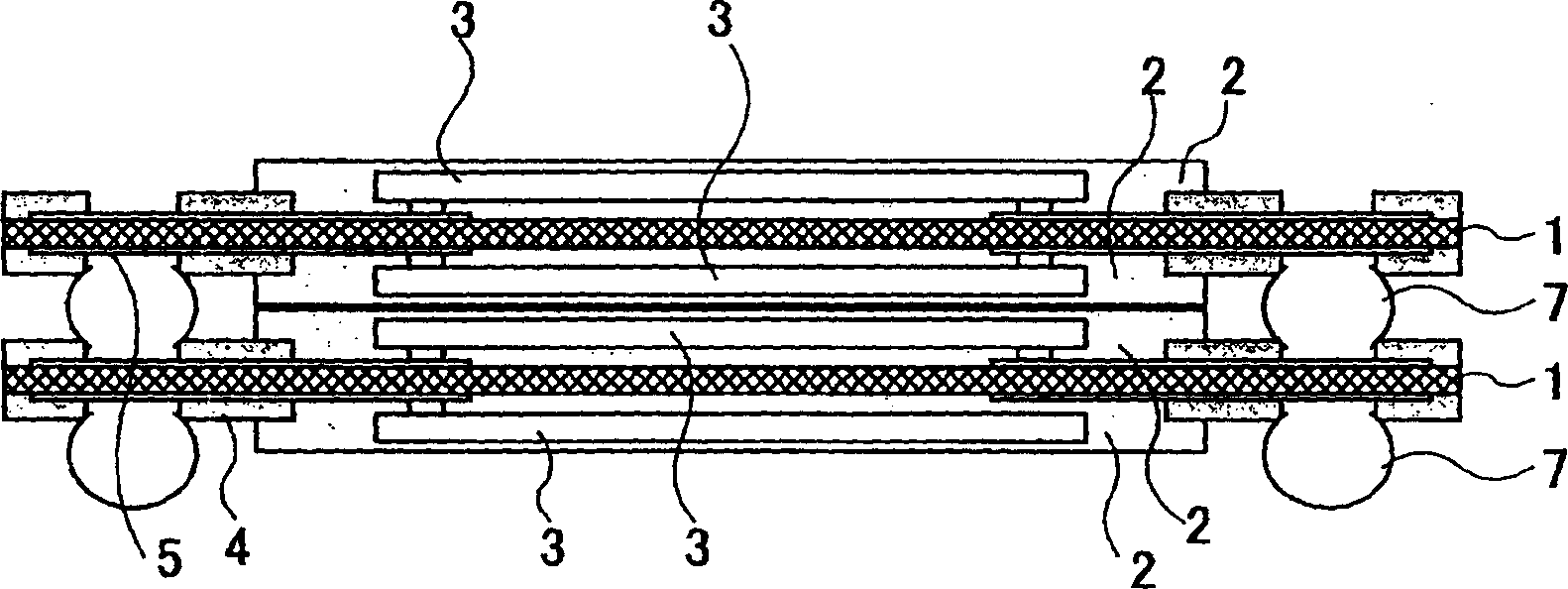

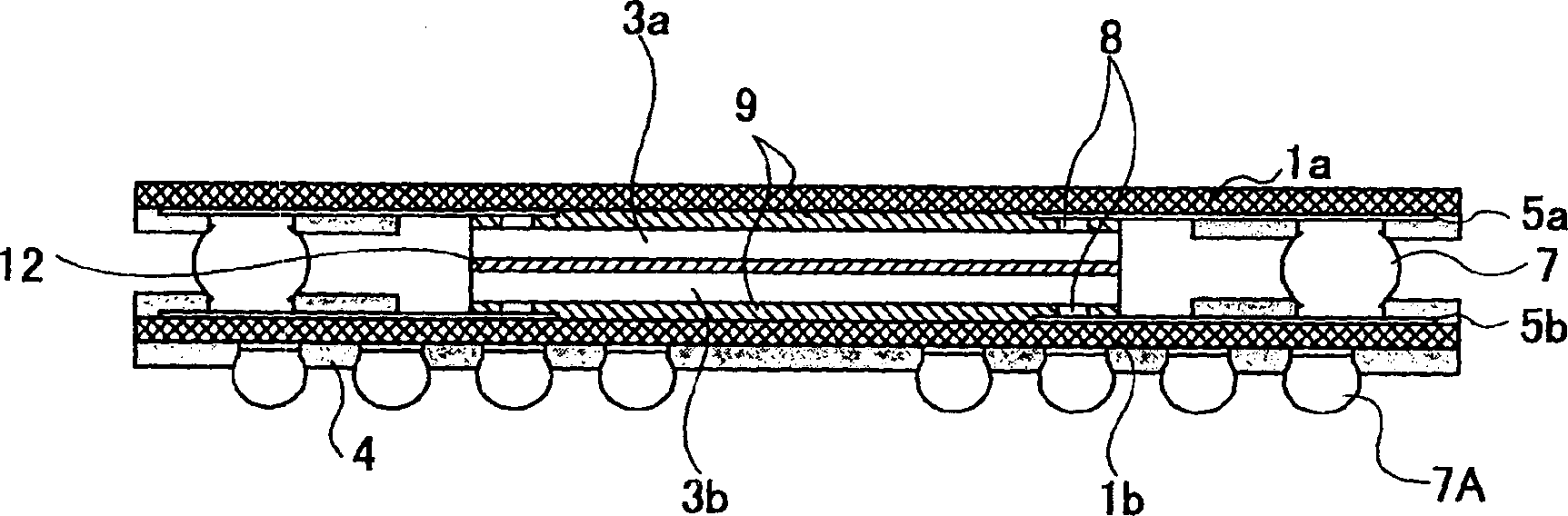

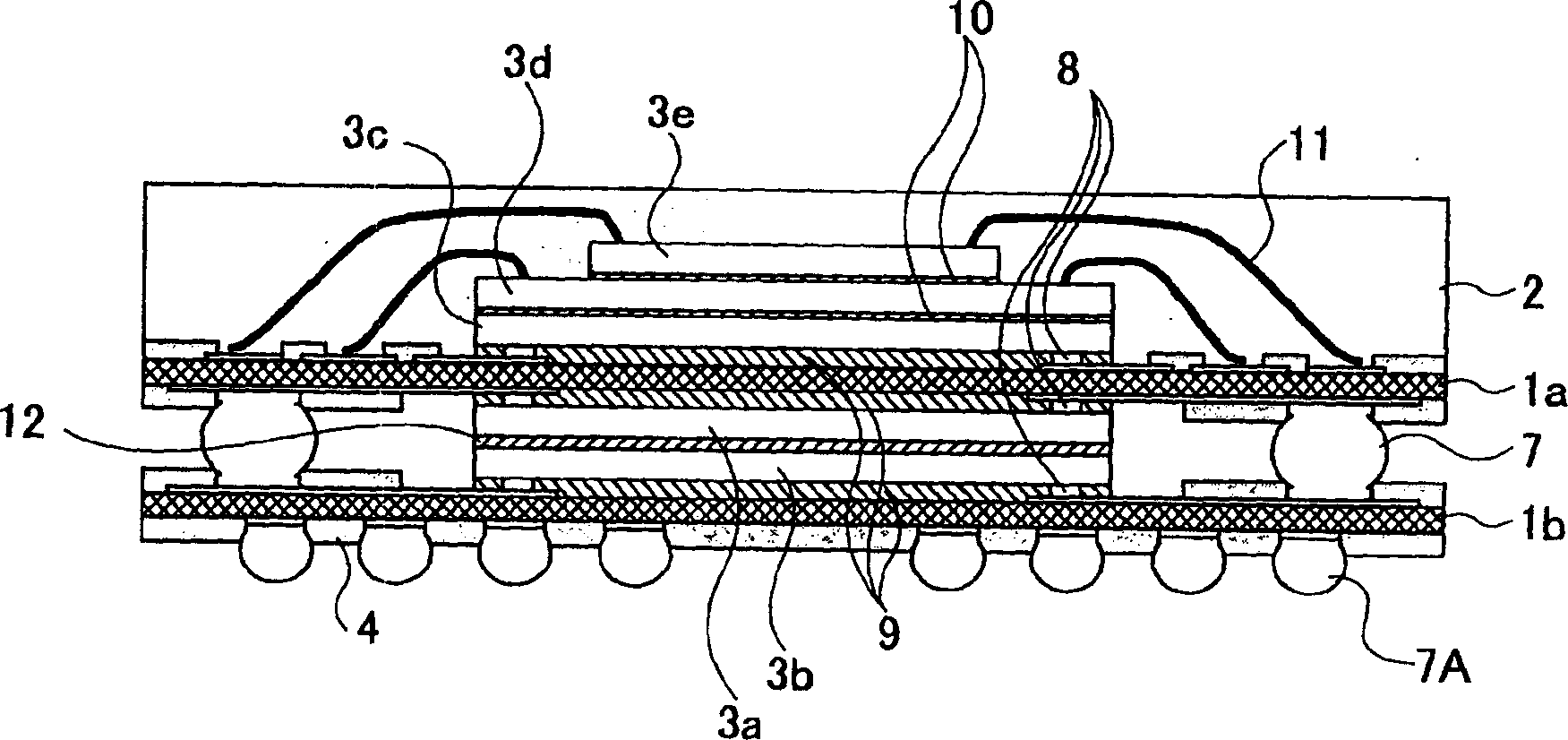

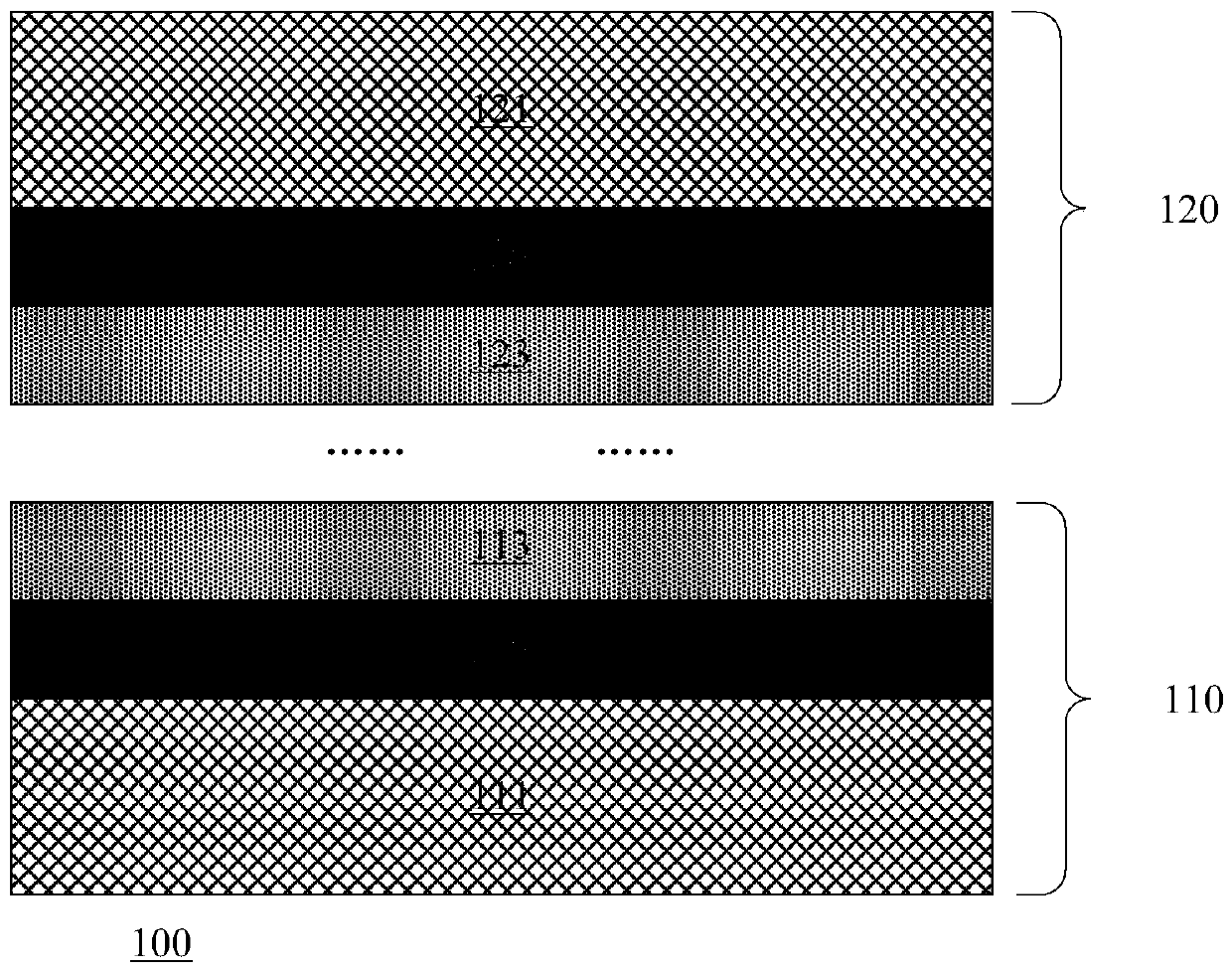

Semiconductor device and method for mfg. same

InactiveCN1452245AReduce overall heightImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A stacked type semiconductor device has a reduced overall height and reliability of improving the mechanical strength of the stacked structure. The semiconductor device also has improved heat dissipation characteristics. The first interposer has a surface on which the first electrode pads are formed, and the first semiconductor element is mounted such that the circuit forming surface is opposed to the first interposer. The second semiconductor element has a circuit forming surface and a back surface opposite to the circuit forming surface. The second interposer has a surface on which second electrode pads are formed, and the second semiconductor element is mounted such that the circuit forming surface is opposed to the second interposer. External connection terminals are provided on the surface of the second interposer opposite to the surface on which the second semiconductor element is mounted. The first and second inserts are electrically connected to each other by the conductive member therebetween. The back surface of the first semiconductor element and the back surface of the second semiconductor element are fixed to each other by an adhesive.

Owner:FUJITSU LTD

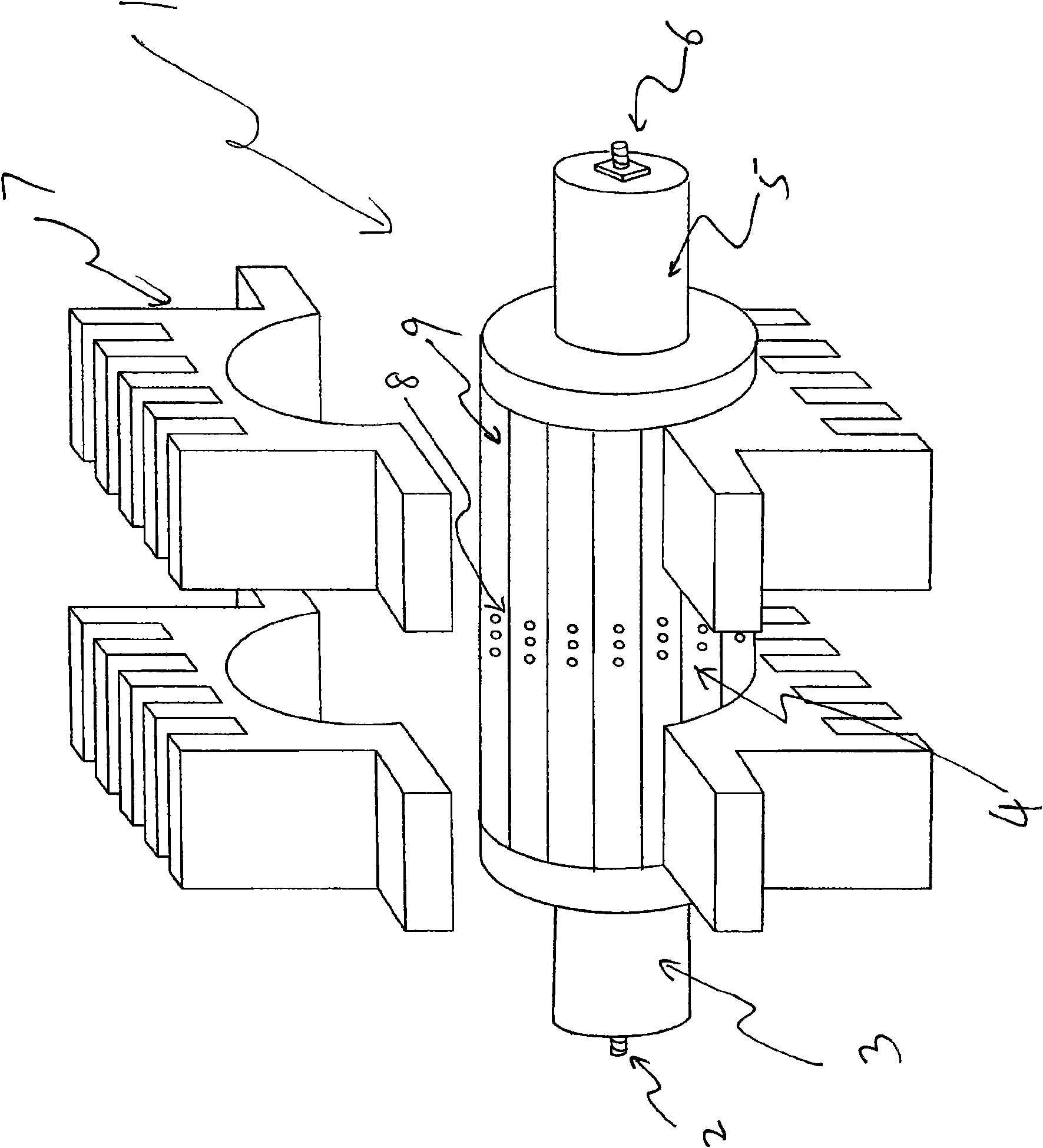

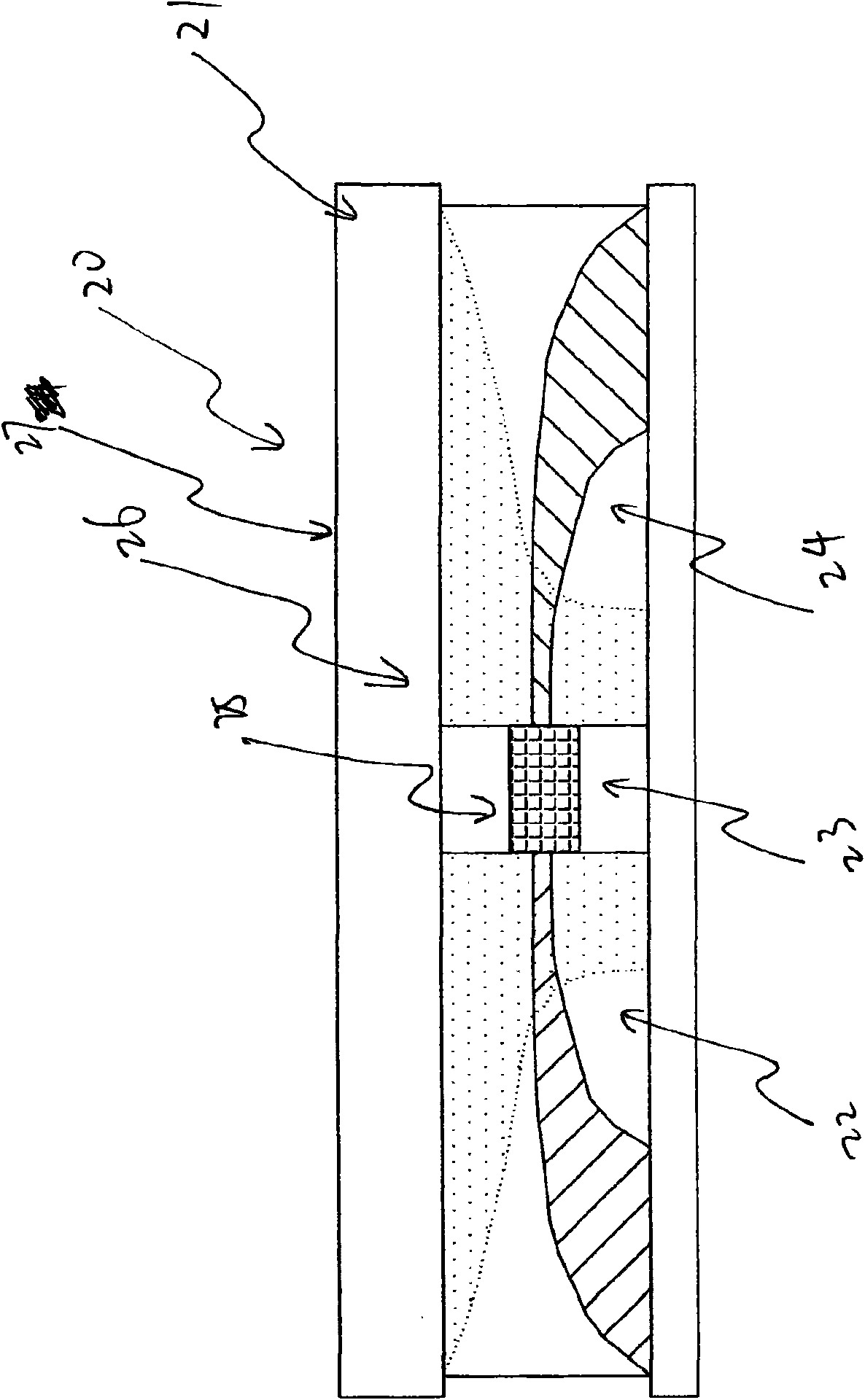

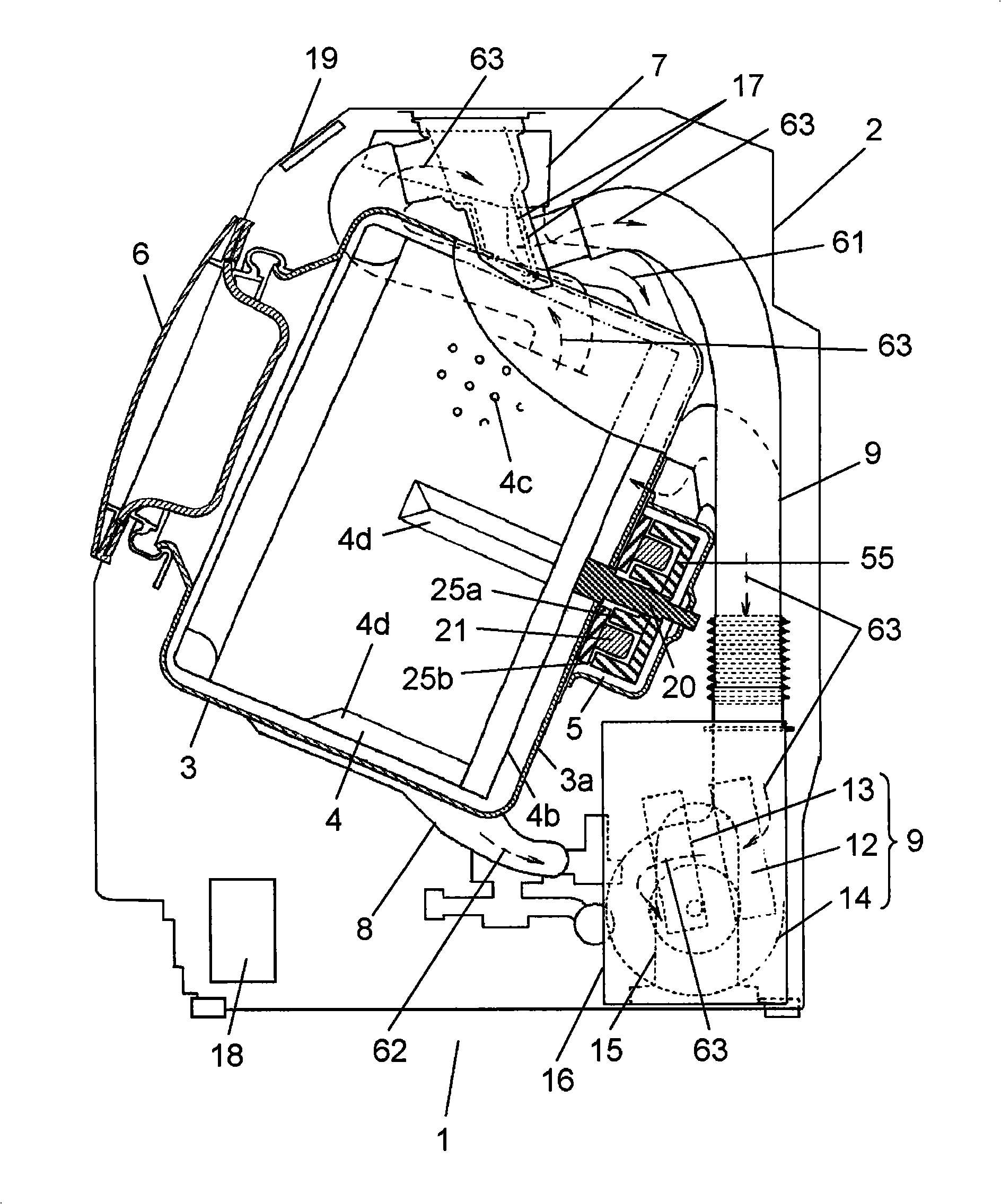

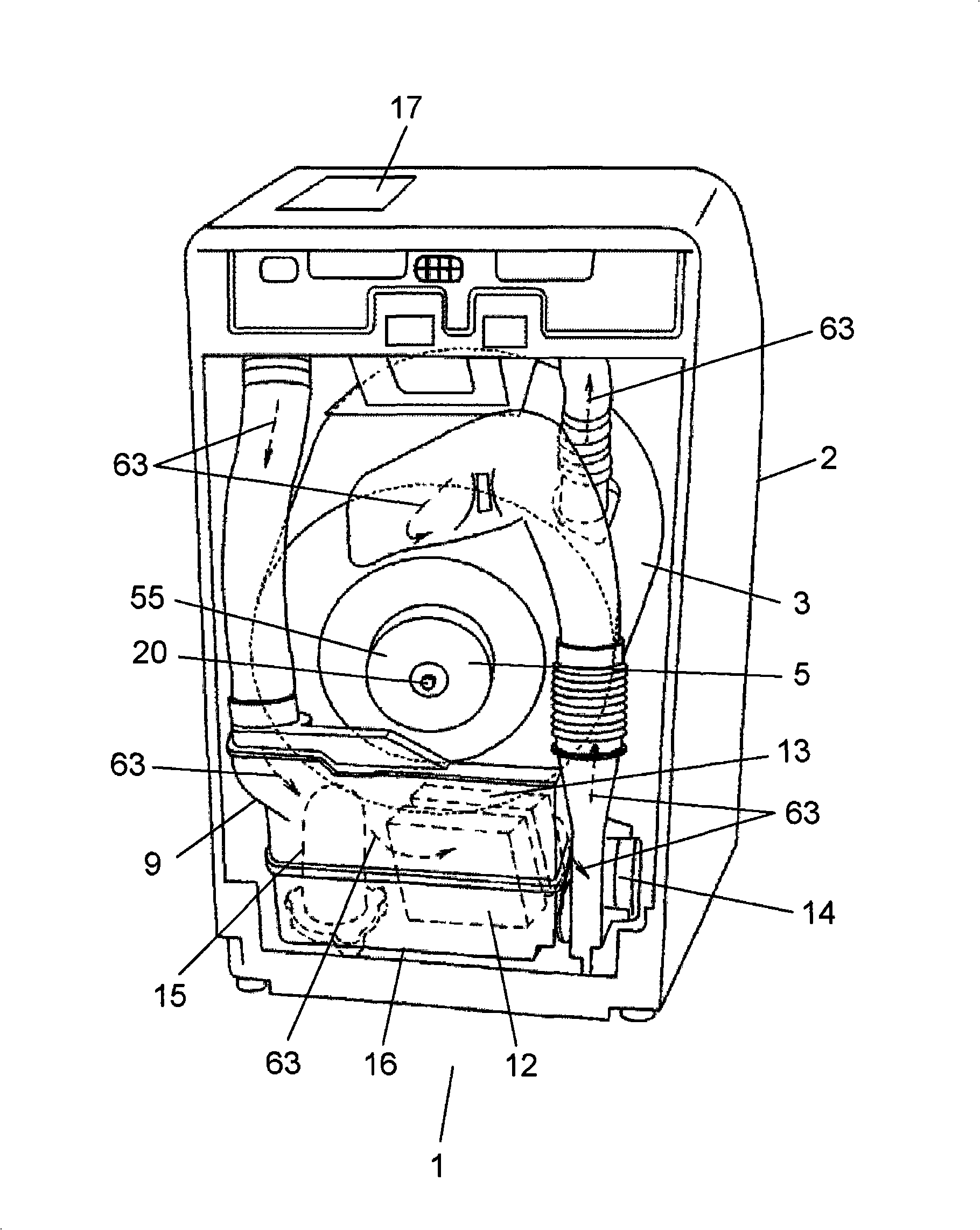

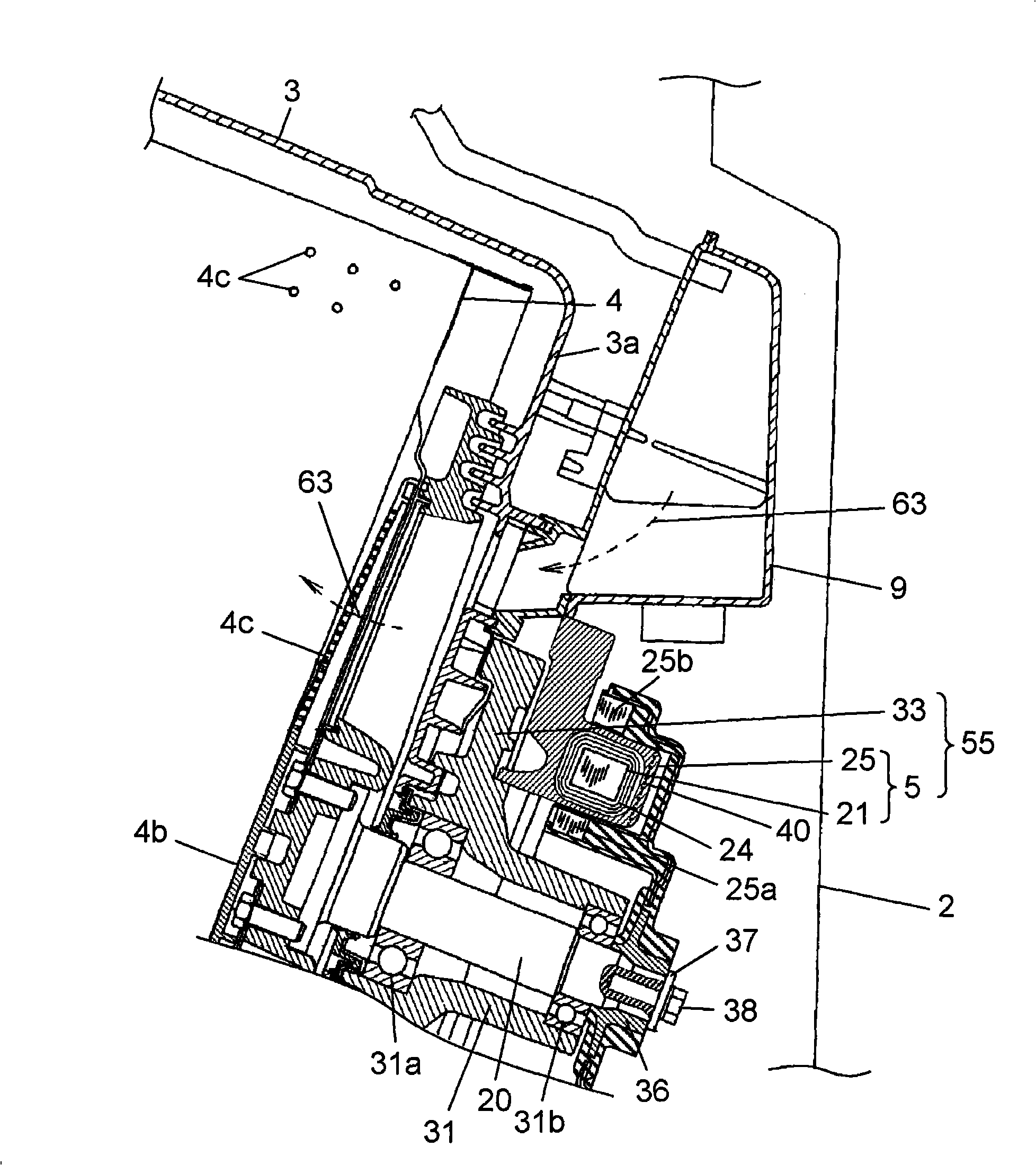

Electromotor

InactiveCN101267134AImprove heat dissipation characteristicsWindings insulation materialWindings insulation shape/form/constructionConductor CoilPhysics

The invention provides an electric motor. The electric motor (5) has rotor (25) and stator (21); the stator (21) has winding (24), stator resin mould (22) and concave-convex part (40); the stator resin mould (22) is formed by molding the winding (24) by the resin material; the concave-convex part (40) has recess (40a) and stator projection (40b) arranged on the end face (22a) of the stator resin mould (22); the recess (40a) is arranged on the end face (22a) extending from the winding (24) along the axial direction. Through the construction, the invention provides an electric motor (5) for improving the heat-radiating property radiating from the stator (21).

Owner:PANASONIC CORP

Method for manufacturing illuminant on transparent sapphire heat conductive plate

ActiveCN103236485ASimple processIncrease productivitySemiconductor devicesHeat conductingEngineering

The invention provides a method for manufacturing illuminant on a transparent sapphire heat conductive plate. The method includes two steps: manufacturing a first sapphire heat conducting light-transmitting plate for fixing chips, and manufacturing a second sapphire heat conducting light-transmitting plate which is closely attached with fluorescent powder film. The obtained illuminant on the sapphire heat conducting light-transmitting plates can be connected with an upper wiring plate and a lamp base in a grooved and clamped manner. The method is simple in technology and easy to operate, and heat generated by the chips can be transferred out by not mainly relying on heat radiation, but in a heat conducting manner via a base directly.

Owner:哈尔滨鎏霞光电技术有限公司

Semi-conductor surface emitting laser and production method and applications thereof

ActiveCN103208741ALower core layerHigh heat dissipation coefficientLaser detailsSemiconductor lasersBenzeneCapacitance

The invention relates to a semi-conductor surface emitting laser and a production method and applications thereof. An active layer utilizes a strain five quantum well; a lower DBR (Distributed Bragg Reflector) layer utilizes a binary N type AlAs / GaAs pair; an upper DBR layer utilizes a DBR of a general ternary N type Al0.92Ga0.08 As / Al0.12Ga0.88As; a plurality of pairs under the active layer utilize a same structure; the top utilizes a high thermal conductive ALN (Aluminium Nitride) layer; copper layers are arranged and covered on bilateral sides of the platform surface and above the platform; the size of an oxidation hole is 18 micron; and the capacitance of components are reduced through a BCB (p-bis benzene) layer. The production method of the semi-conductor surface emitting laser has the advantages of improving an integral heat dissipation level by improving processes, effectively solving the heat dissipation problem of a large power surface emitting laser, improving an stage of the power of the surface emitting laser, enabling the surface emitting laser to be improved in material character, improving the service life and working reliability of the surface emitting laser and achieving free space communication within 1-3 km.

Owner:WUHAN TELECOMM DEVICES

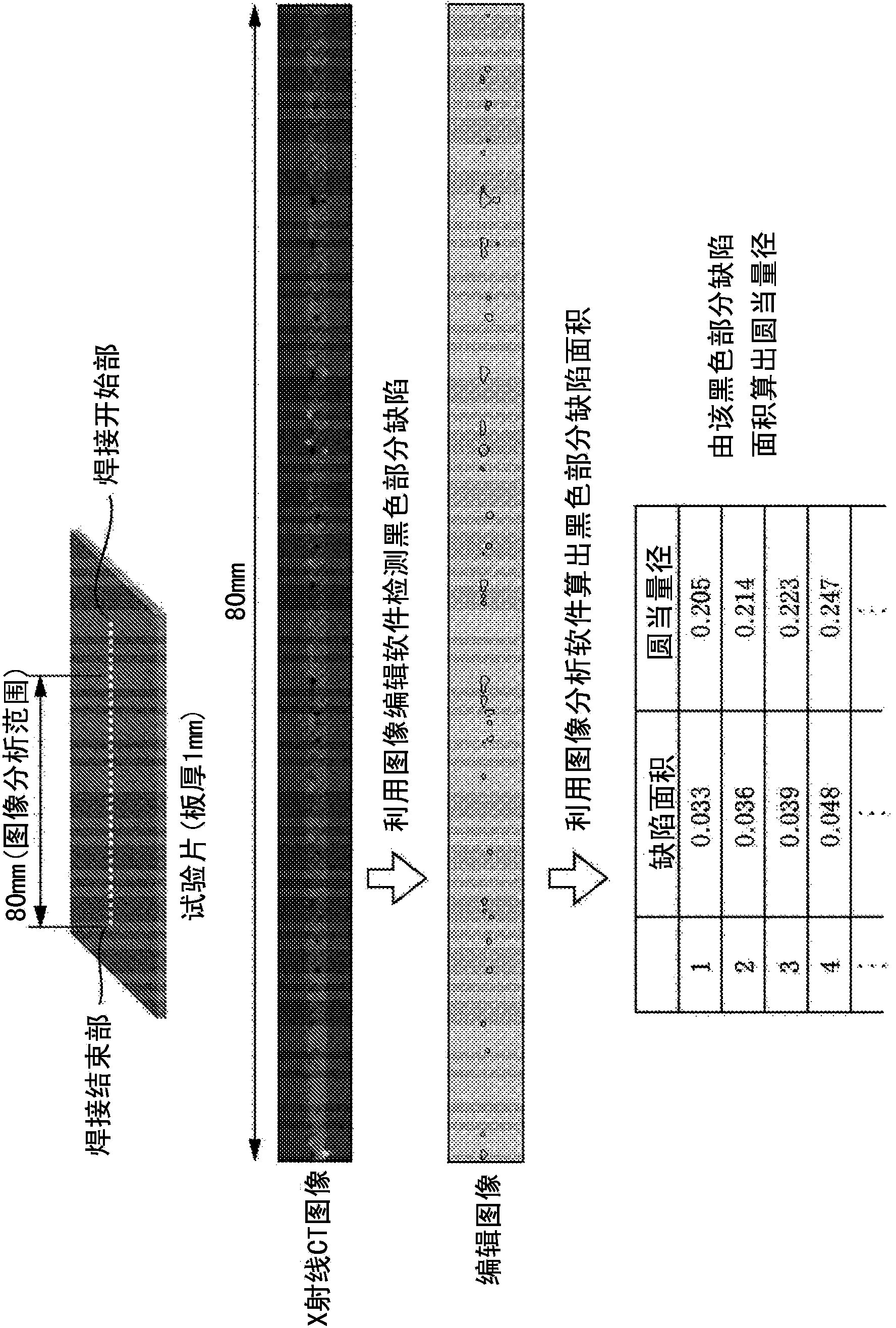

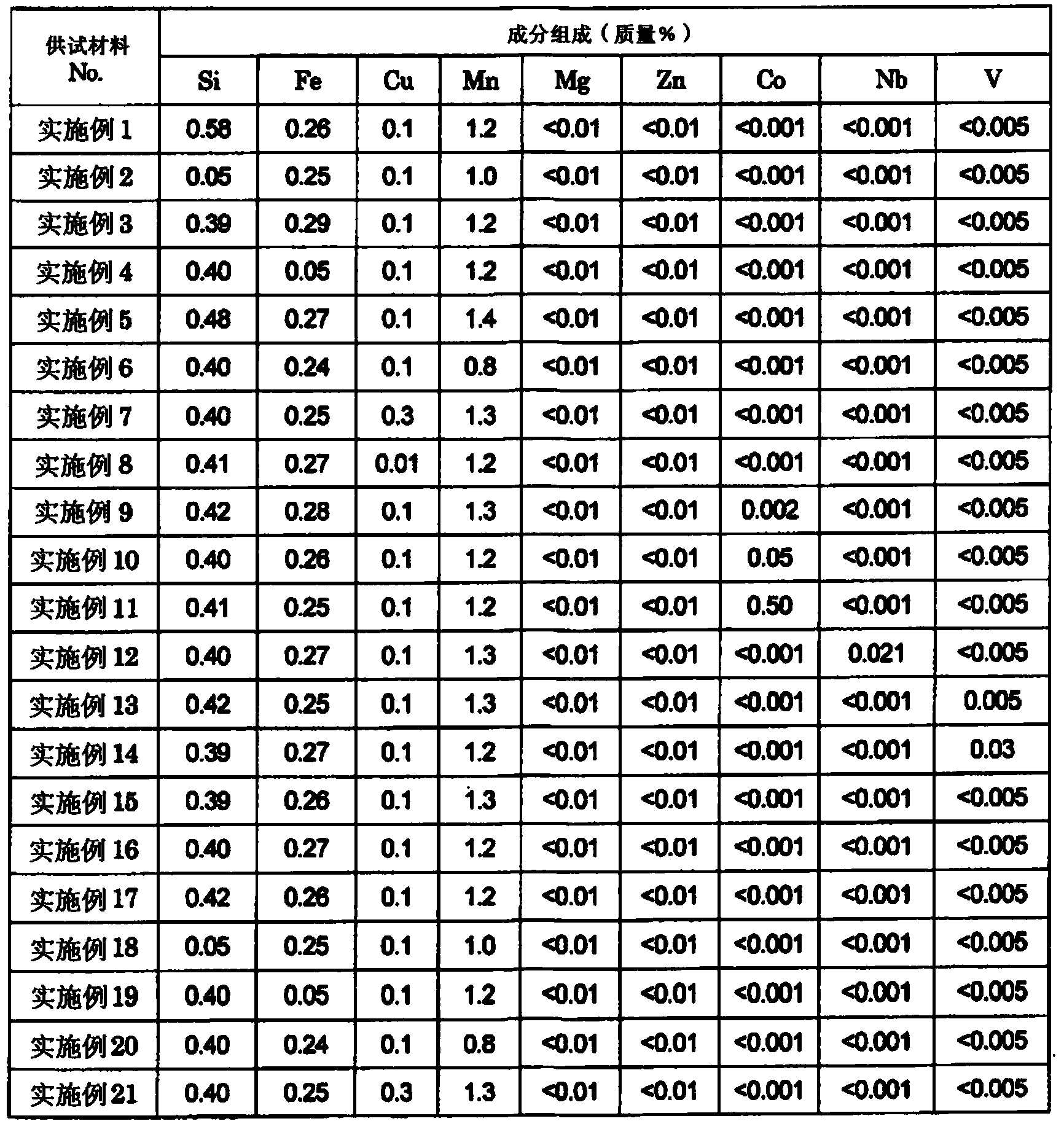

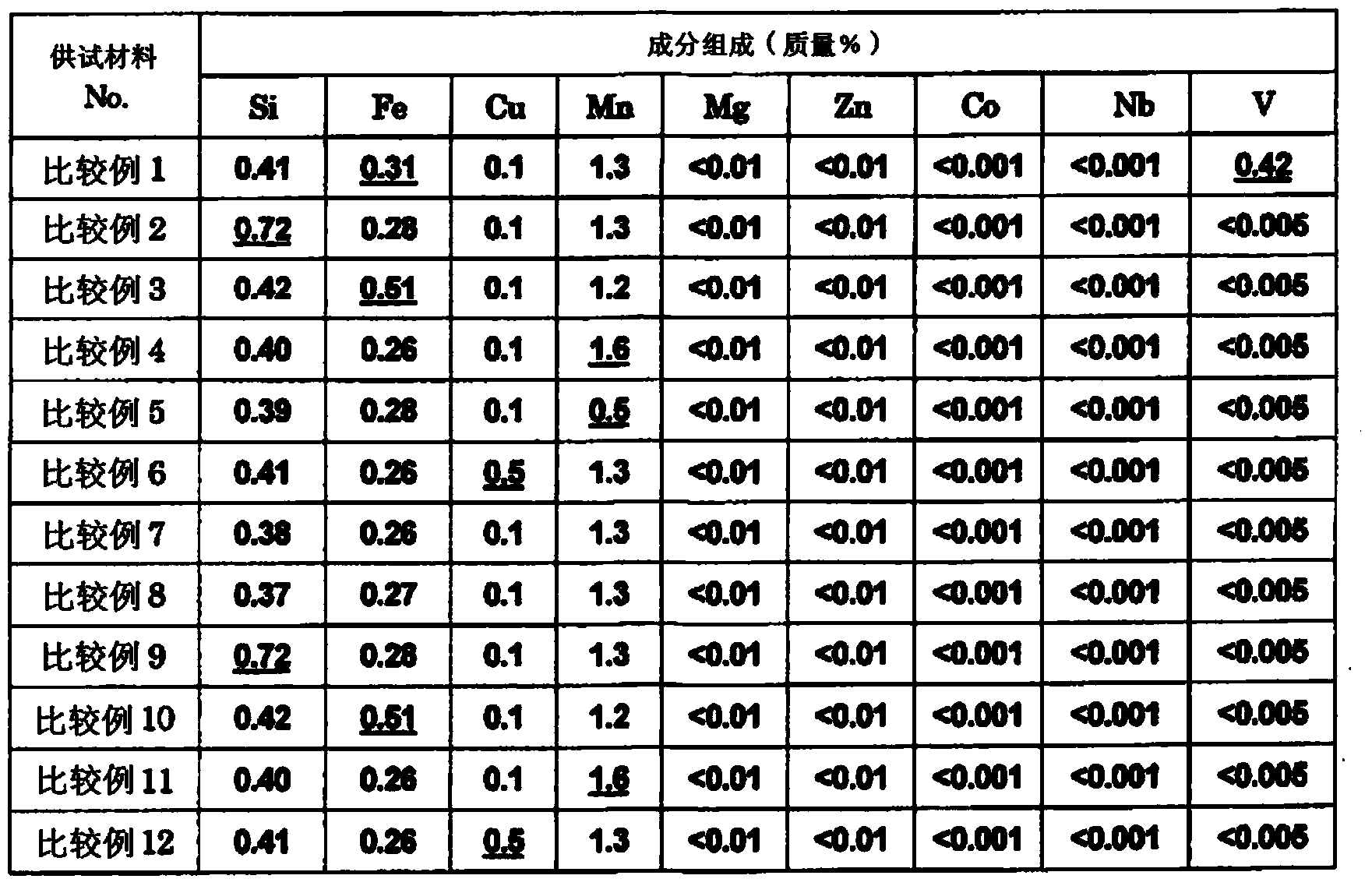

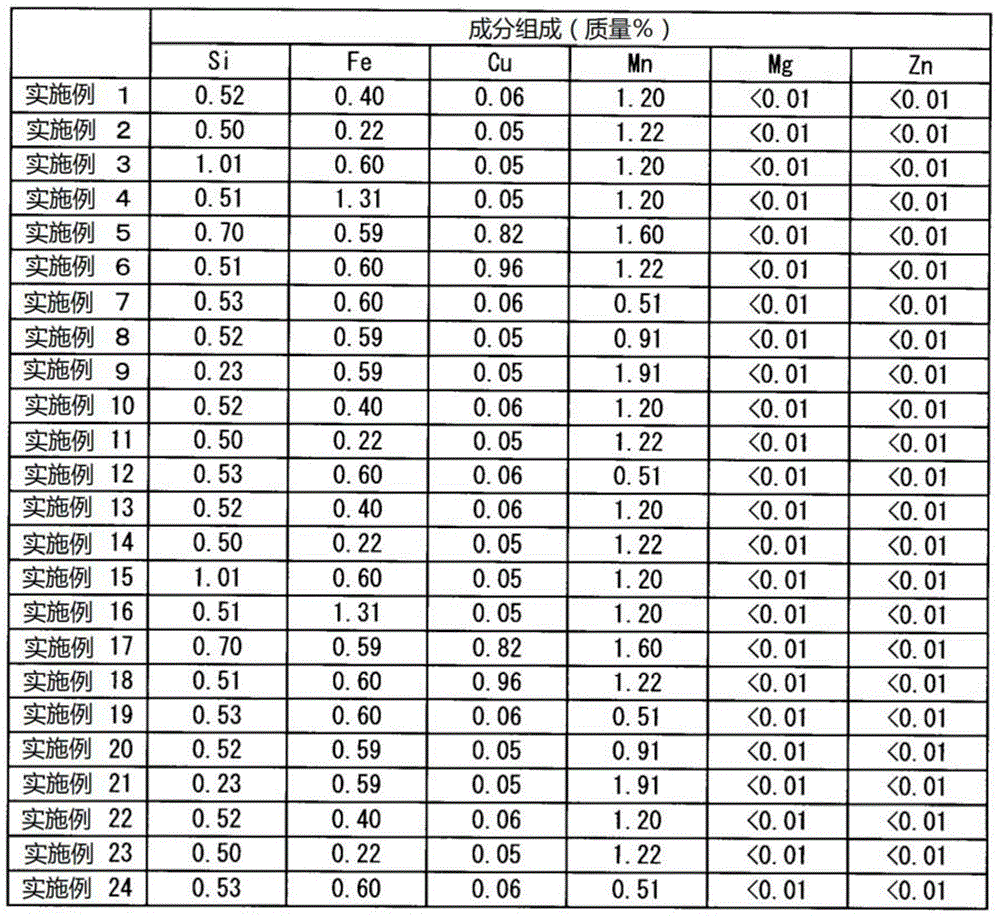

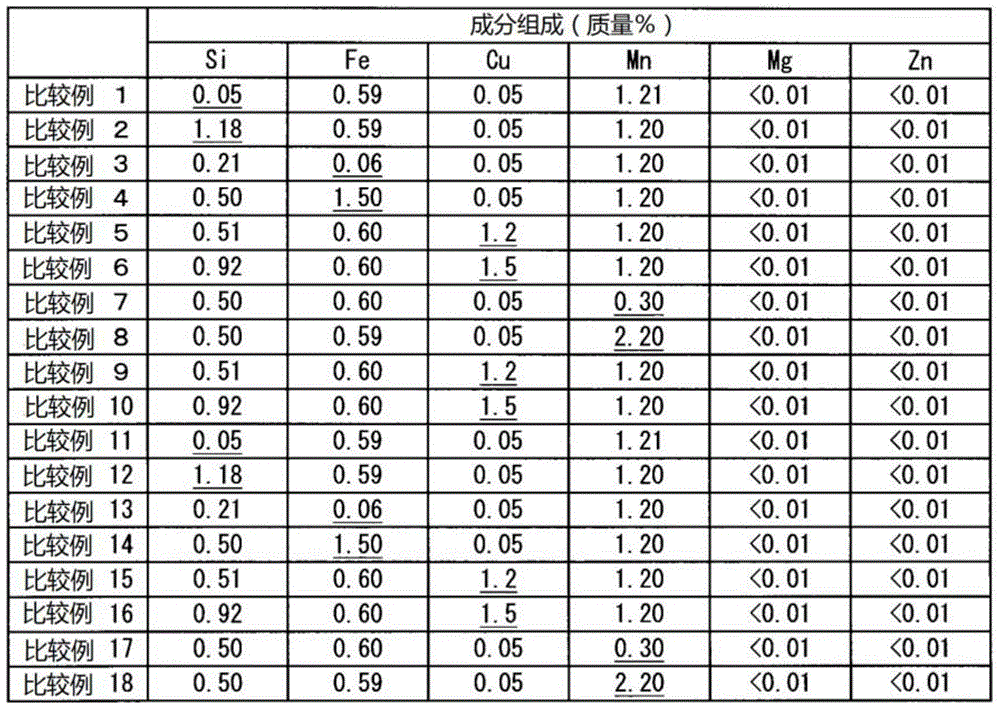

Aluminum alloy sheet for electric cell case, having excellent moldability, heat dissipation, and weldability

InactiveCN104204249AFast heat conductionGood formabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithiumImpurity

Provided is a 3000 series aluminum alloy sheet having heat-dissipating characteristics applicable to large lithium ion cell containers, and also having excellent moldability, shape-freezing properties, and laser weldability. The aluminum alloy sheet is a cold-rolled, annealed material having a component composition of, by mass, 0.05 to less than 0.3% Fe, 0.6 to 1.5% Mn, and 0.05 to 0.6% Si, with the balance being Al and impurities, the impurities being, by mass, less than 0.35% Cu and less than 0.05% Mg; and displaying an IACS electrical conductivity exceeding 45%, a 0.2% proof stress of 40 to less than 60 MPa, and an elongation value of 20% or more. Alternatively, the aluminum alloy sheet may be an as-cold-rolled material displaying an IACS electrical conductivity exceeding 45%, a 0.2% proof stress of 60 to less than 150 MPa, and an elongation value of 3% or more. To further increase the electrical conductivity, one or more of, by mass, 0.001 to 0.5% Co, 0.005 to 0.05% Nb, and 0.005 to 0.05% V may be included.

Owner:NIPPON LIGHT METAL CO LTD

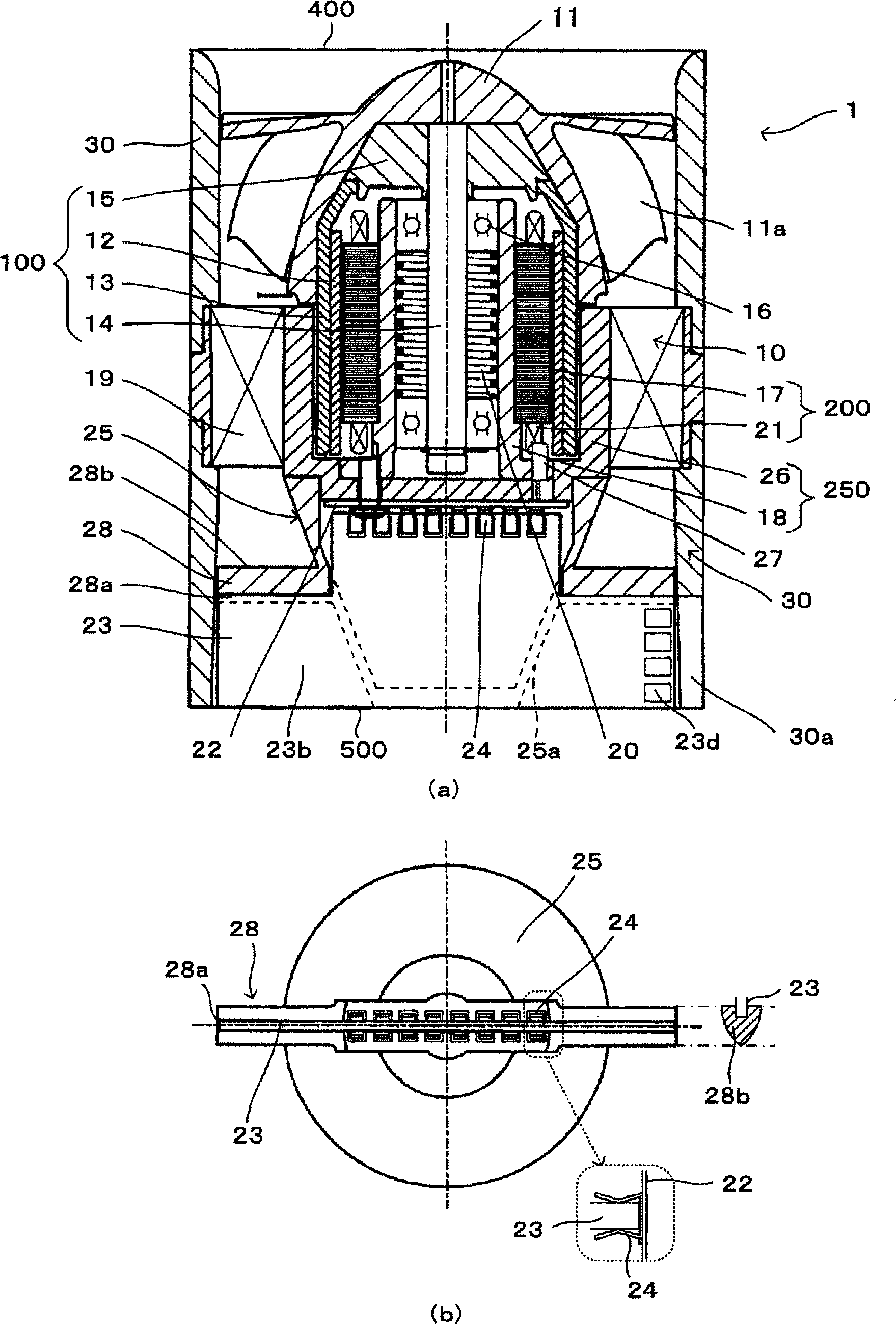

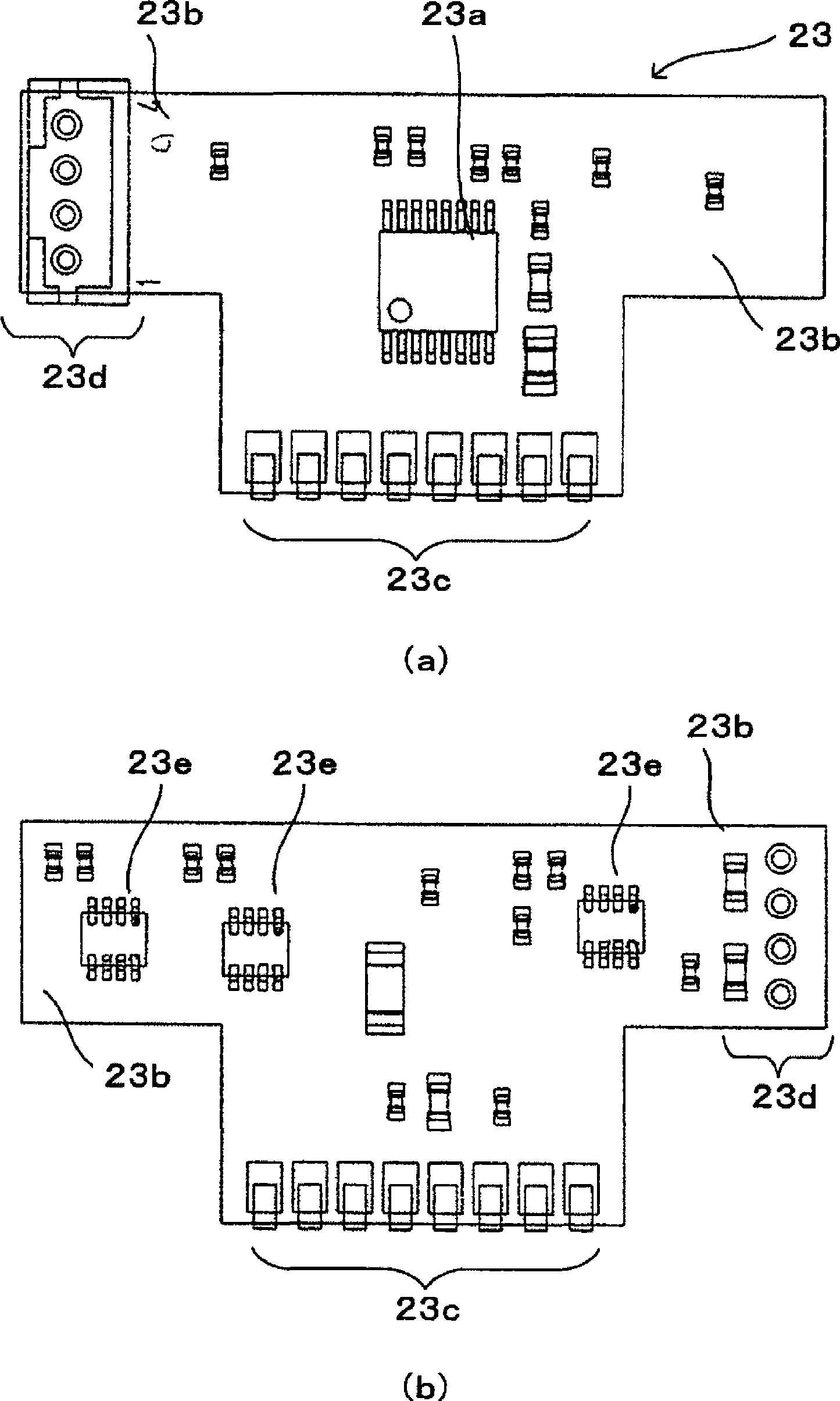

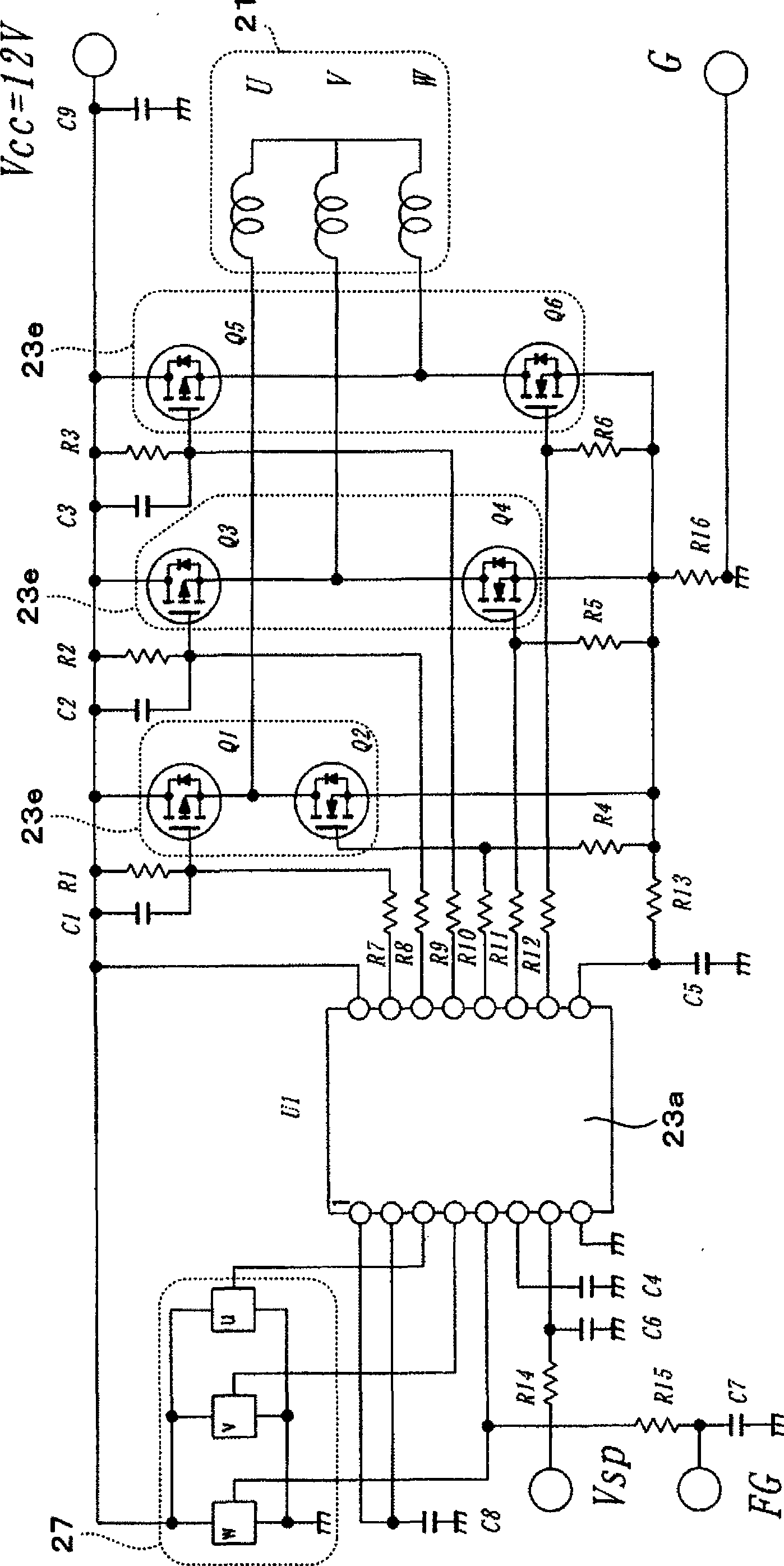

Fan motor

InactiveCN101523701AImprove heat dissipation characteristicsAssociation with control/drive circuitsPump componentsImpellerElectrical polarity

A fan motor having a stator supporting portion (26) for supporting a stator with a drive coil (21), a rotor rotatably supported by a rotating center shaft (rotating shaft (14)) provided at the stator supporting portion (26), a magnet (12) placed on the inner peripheral side of the rotor so as to face the drive coil, a fan (impeller portion (11)) provided on the outer peripheral side of the rotor, a control board (23) having a drive control IC (23a) performing polarity switching control of the drive coil, a hollow tubular frame having a suction opening and a discharge opening, and an installation member (guide blade (19)) for installing the stator supporting portion into the hollow portion of the frame. The control board (23) is placed in the frame so as to be substantially in parallel with the rotating center shaft.

Owner:SANKYO SEIKI MFG CO LTD +1

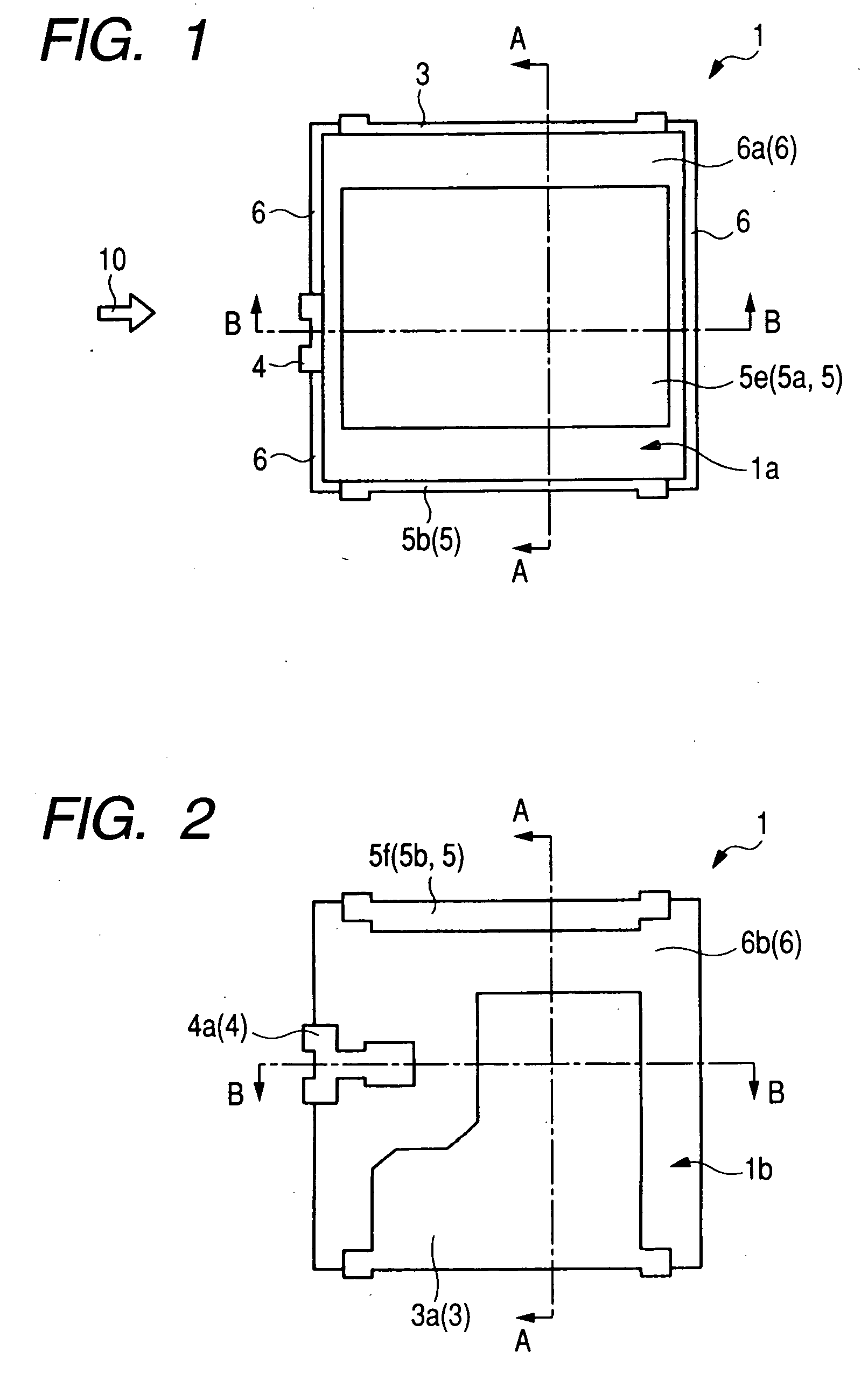

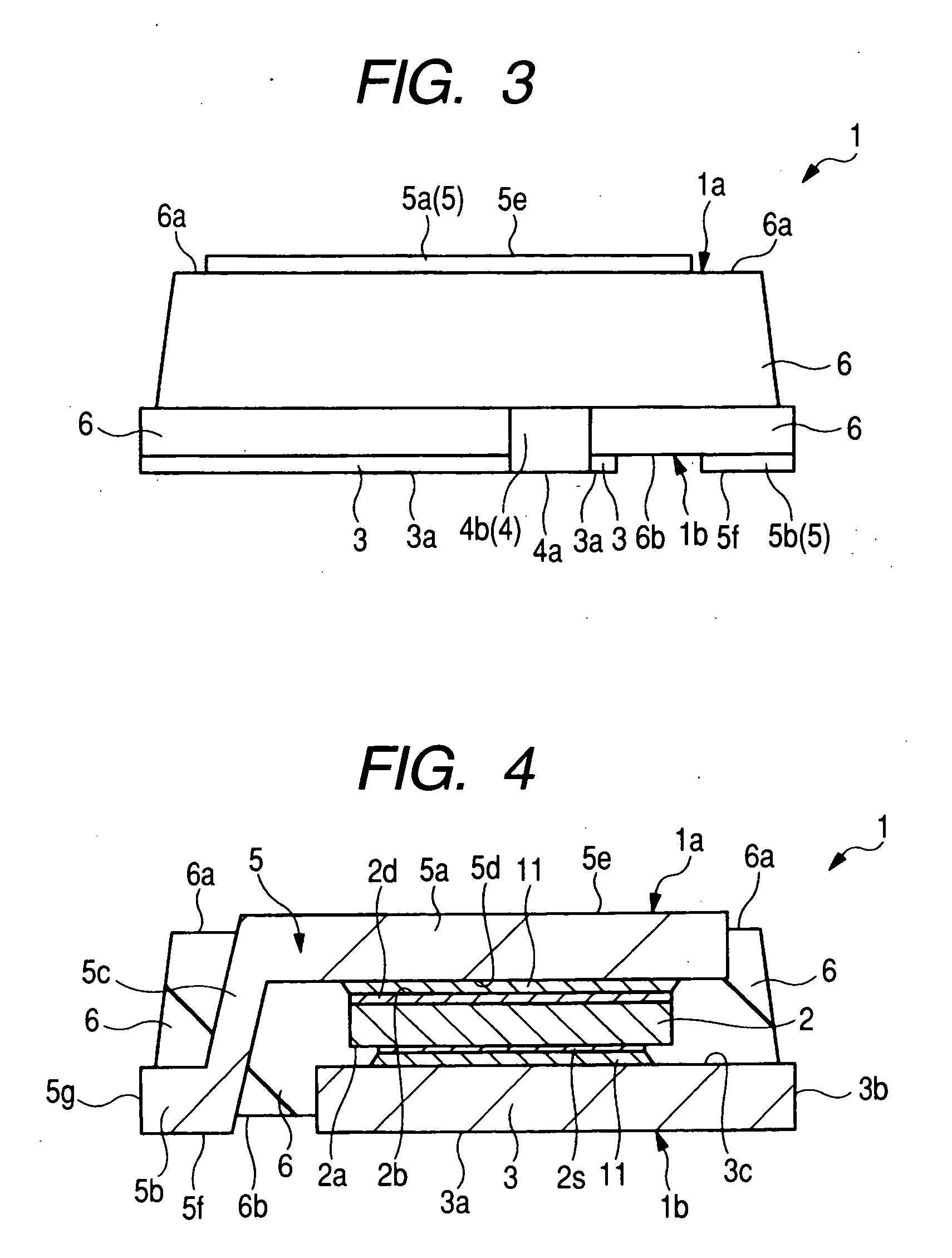

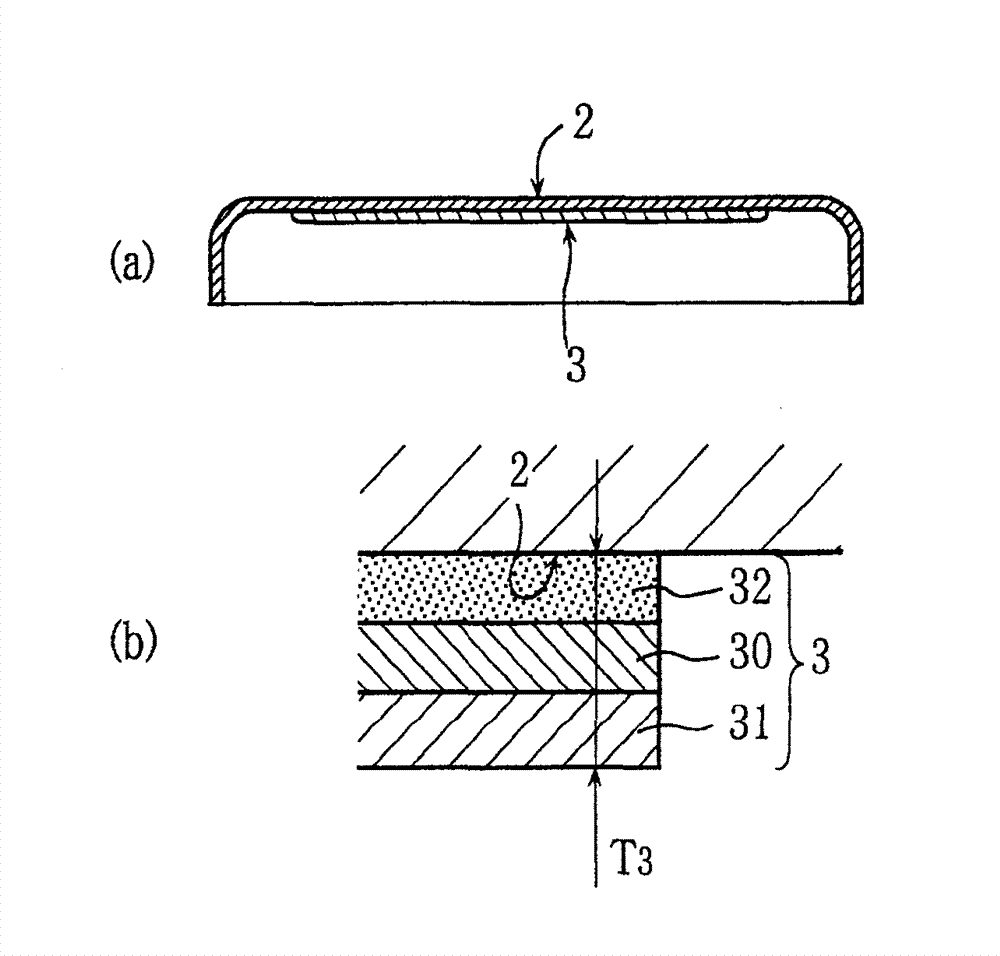

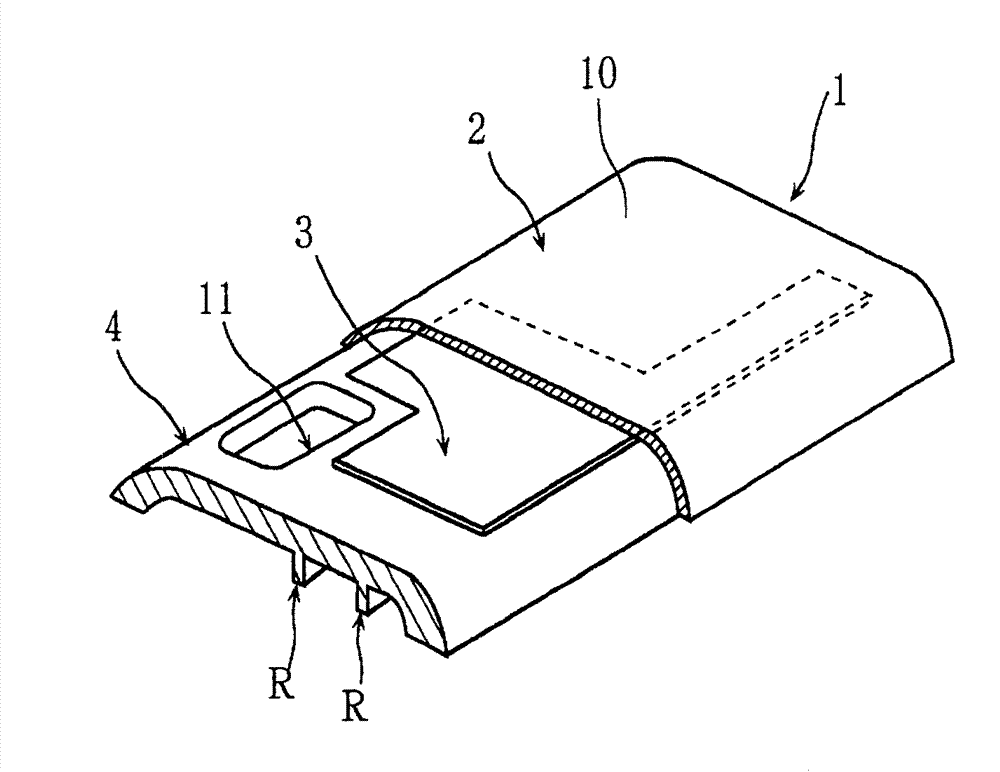

Portable electronic device and method for manufacturing housing of the electronic device

InactiveCN102740624AReliable integrationImprove cooling effectCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsElectronic componentBiomedical engineering

The invention provides a portable electronic device which can make heat generated by the internal electronic components diffused from the outer surface of the housing in an efficient way. The portable electronic device comprises a housing component (1). The housing component (1) comprises a thin-wall outer wall part (2) formed on the outer surface (10) of the housing; a heat conduction sheet body (3) laminated on a part of the thin-wall outer wall part (2) back and applied for transmitting heat from the heating part (6) of the internal electronic component (5) and performing heat radiation on the outer surface (10) of the housing; and an inner wall part (4) integrally laminated on the back faces of the heat conduction sheet body (3) and the thin-wall outer wall part (2) through the curing of fusing resins.

Owner:MITSUI BUSSAN PLASTICS TRADE

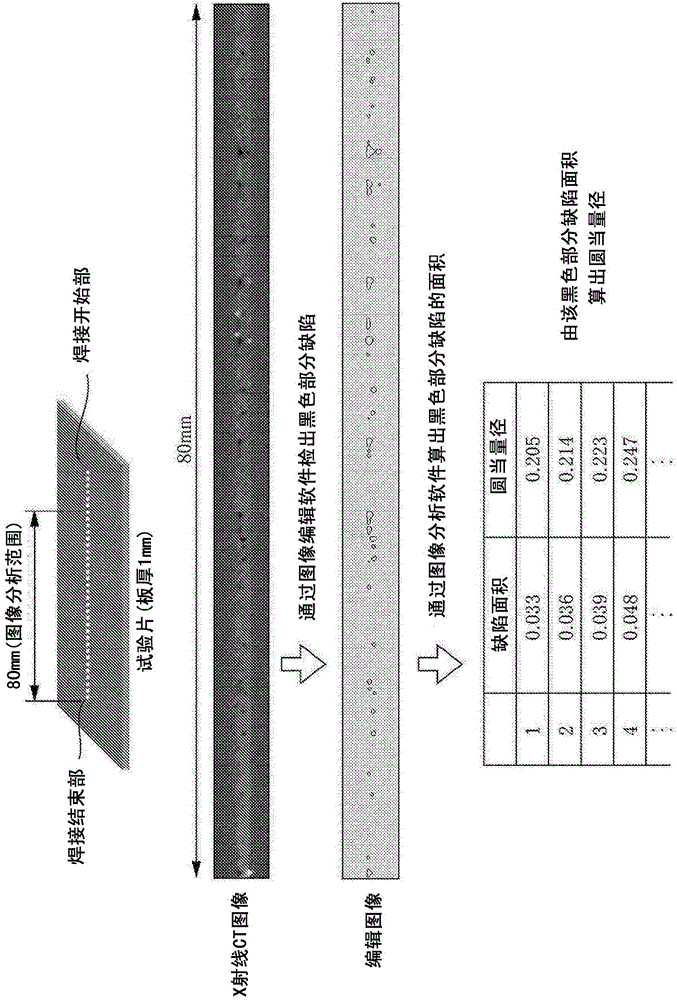

Battery-case aluminium alloy plate exhibiting excellent moulding properties, heat-dissipation properties, and welding properties

InactiveCN104838025AFast heat conductionGood formabilitySecondary cellsJackets/cases materialsLithium-ion batteryElectrical resistivity and conductivity

Provided is a 3000 series aluminium alloy plate which exhibits heat-dissipation characteristics applicable to large lithium ion battery containers, and which also exhibits excellent moulding properties, shape fixability, and laser welding properties. This aluminium alloy plate is a cold-rolled annealed material which has: a component composition including over 0.2 mass% but less than 1.4 mass% of Fe, 0.5-2.0 mass% of Mn, over 0.2 mass% but not more than 1.1 mass% of Si, 0.05-1.0 mass% of Cu, and less than 0.05 mass% of Mg, the remainder comprising Al and impurities; a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 30 MPa but less than 85 MPa; and an elongation value of at least 10%. Otherwise, this aluminium alloy plate is a cold-rolled material which has: a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 90 MPa but less than 180 MPa; and an elongation value of at least 3%.

Owner:NIPPON LIGHT METAL CO LTD

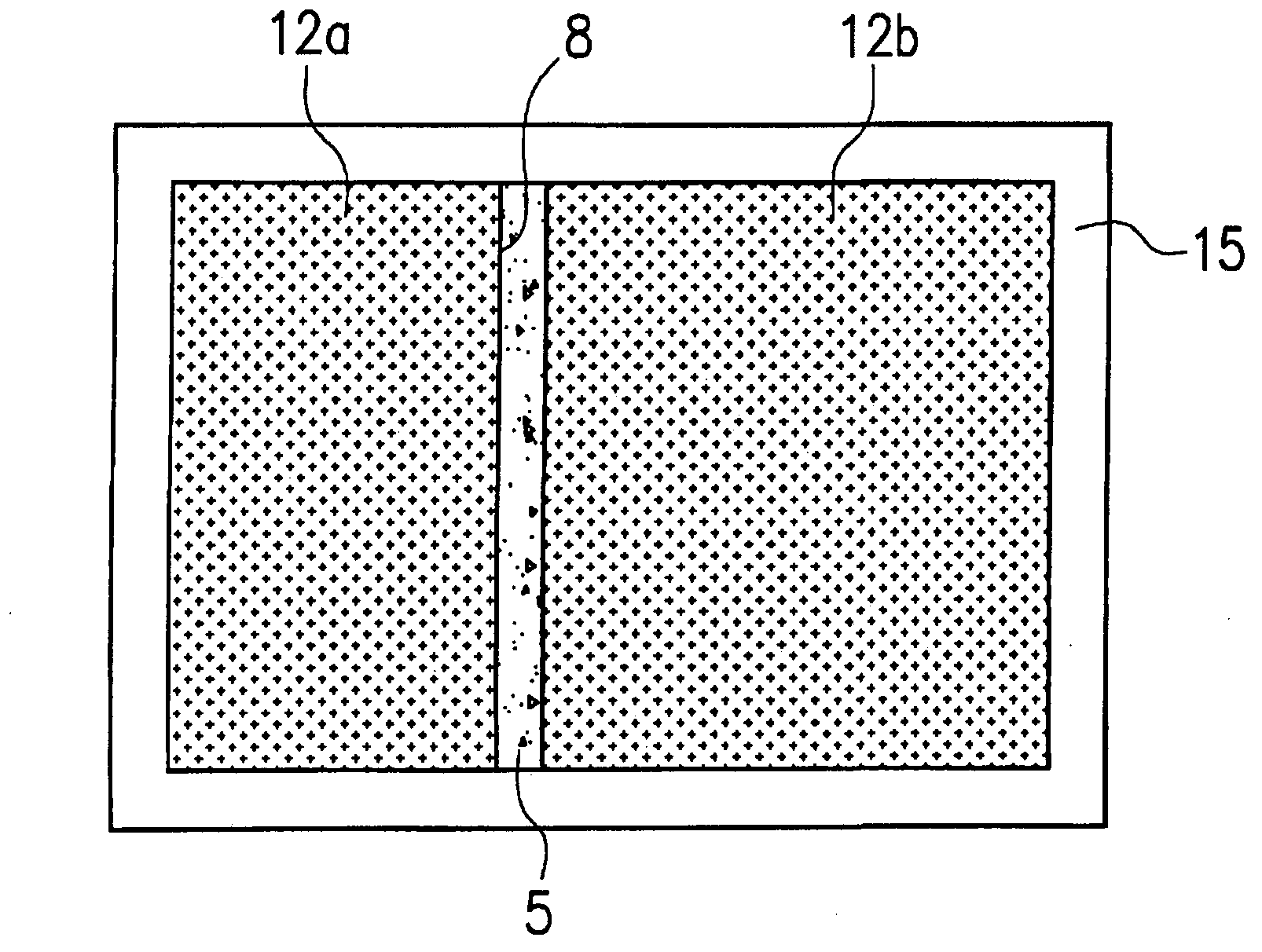

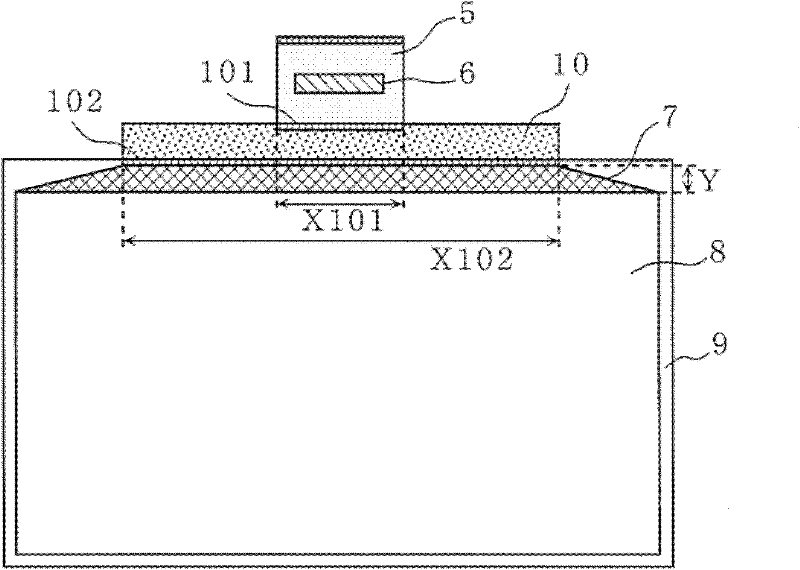

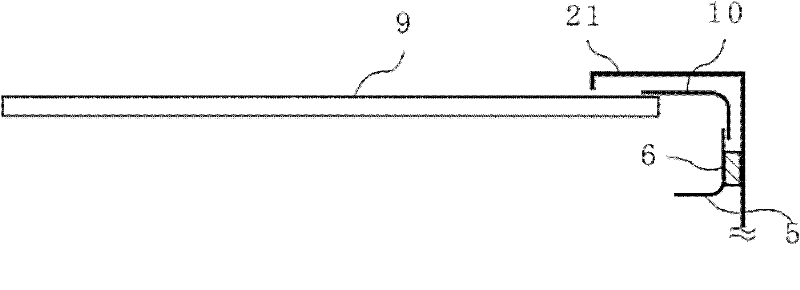

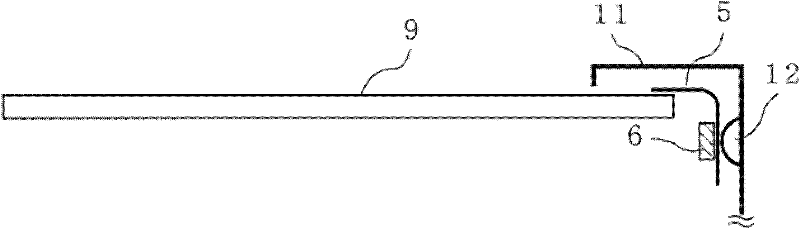

Display panel module and display device

InactiveCN102246218ALow costReduce in quantityPrinted circuit aspectsPrinted circuits structural associationsDisplay devicePrinted circuit board

Disclosed is a display panel module capable of increasing heat releasing performance of a driving circuit element and capable of reducing the number of display circuit elements without reducing the number of display panels produced from the display panel module. Specifically disclosed is a display panel module which comprises a film package (5), a display panel (9), and a flexible printed circuit board (10). The flexible printed circuit board (10) has a plurality of electrodes (301) connected to the film package (5), and a plurality of electrodes (302) that are disposed with a pitch larger than that of the electrodes (301) and that are connected to the display panel (9), and the flexible printed circuit board (10) that relays pixel data between the film package (5) and the display panel (9).

Owner:PANASONIC CORP

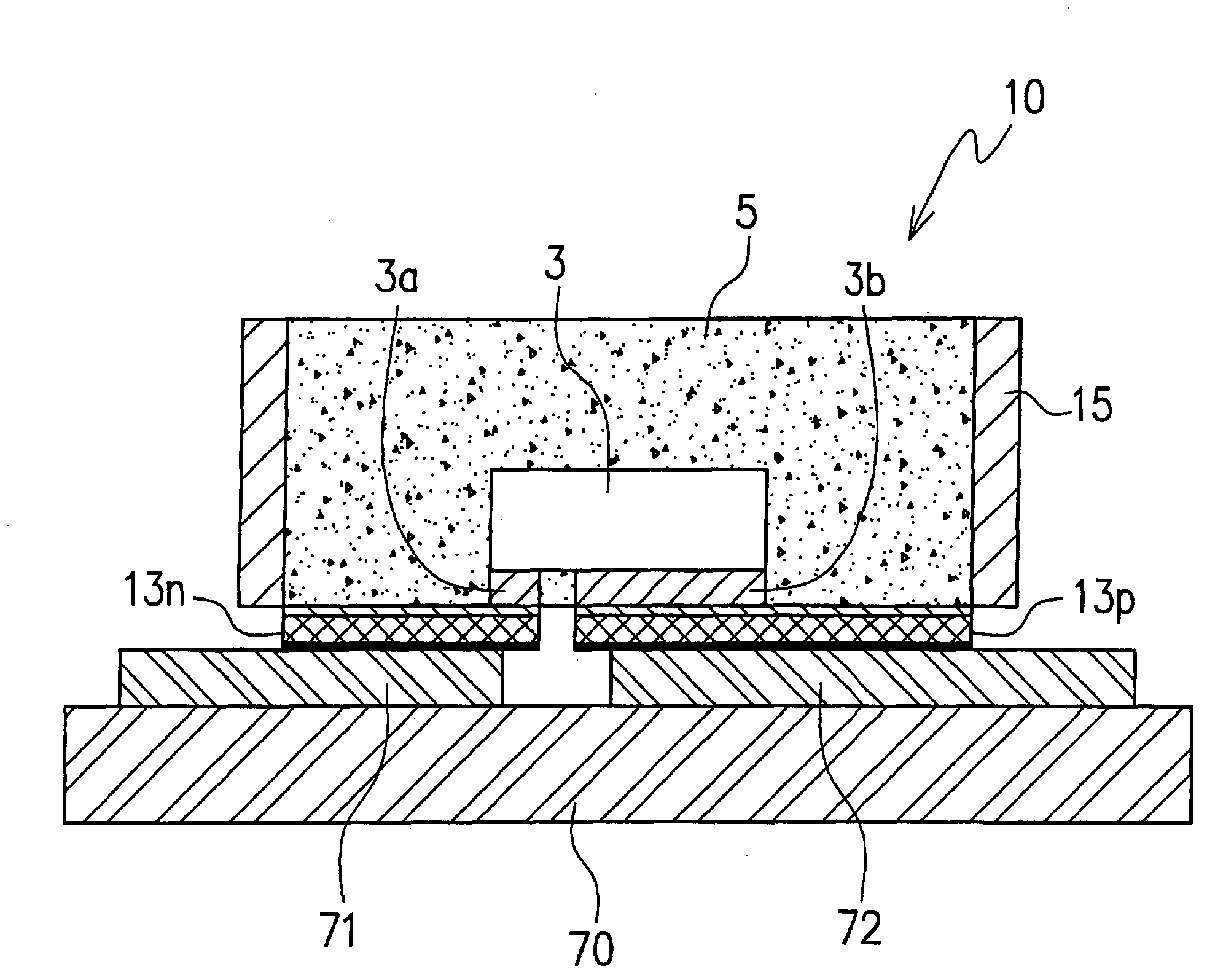

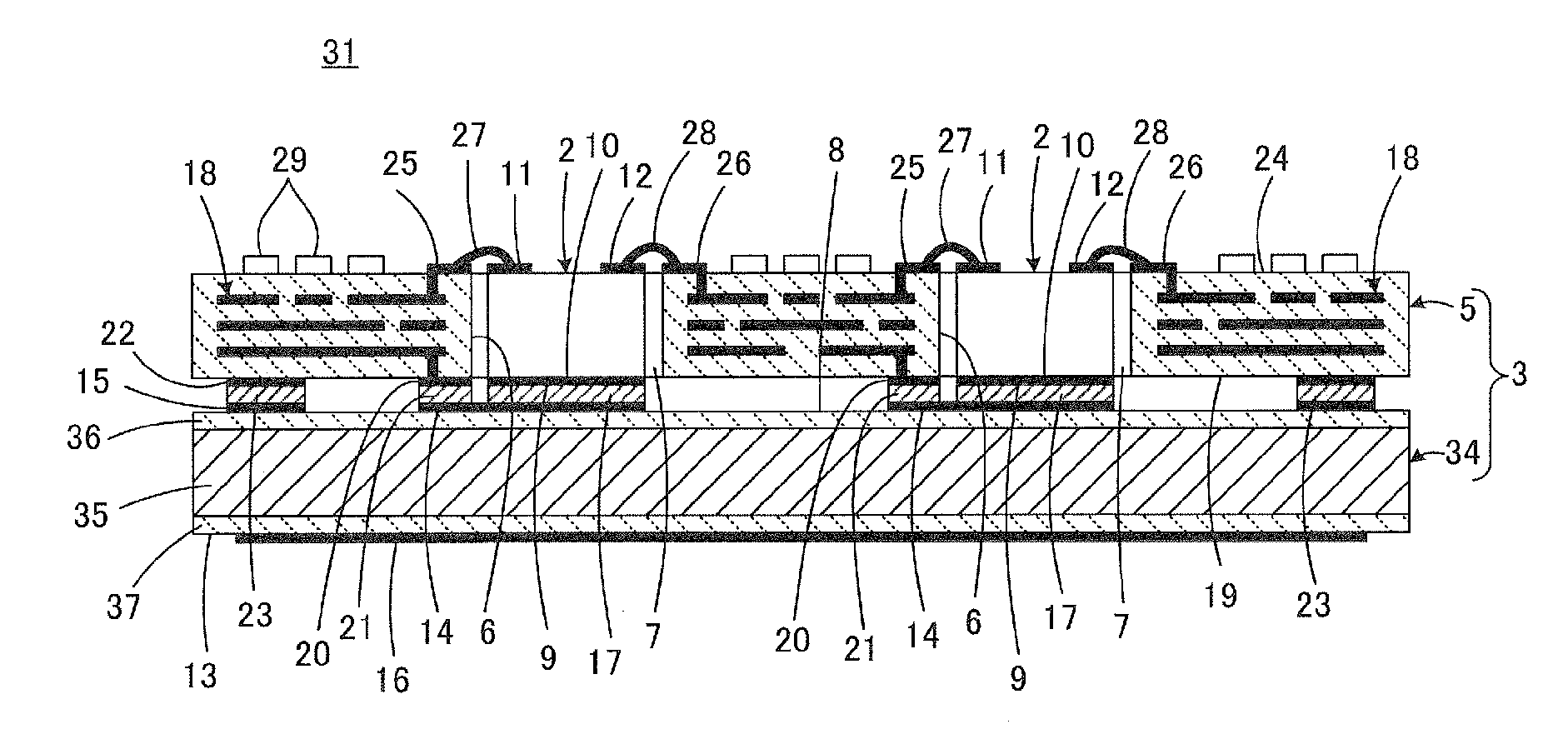

Semiconductor device and manufacturing method thereof

InactiveCN109935568AImprove heat dissipation characteristicsIncrease metal densitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

The invention discloses a semiconductor device and a manufacturing method thereof. A first bonding layer and a second bonding layer of the semiconductor device are in contact with each other to provide bonding between a first wafer and a second wafer. The contact surface of the first bonding layer and the second bonding layer is a bonding surface. A first conductive channel and a second conductivechannel are connected to each other to provide an electrical connection between the first wafer and the second wafer. The first wafer further comprises a first pseudo channel penetrating through thefirst bonding layer, and the second wafer further comprises a second pseudo channel penetrating through the second bonding layer, wherein the first pseudo channel and the second pseudo channel are incontact with each other to improve the mechanical connection bonding force between the first wafer and the second wafer. According to the semiconductor device, the pseudo channels connected with eachother are formed in the bonding layers of the first wafer and the second wafer to improve the pattern distribution of the bonding surfaces of the first wafer and the second wafer, so that the bondingstrength and reliability are improved.

Owner:YANGTZE MEMORY TECH CO LTD

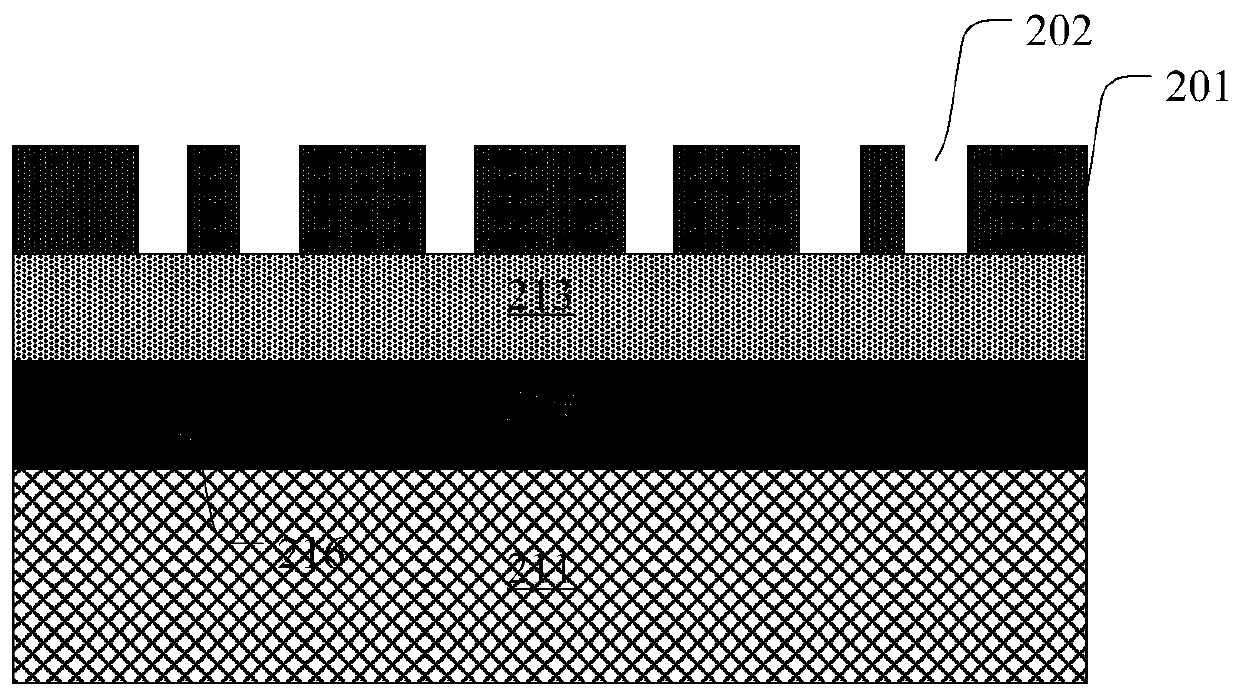

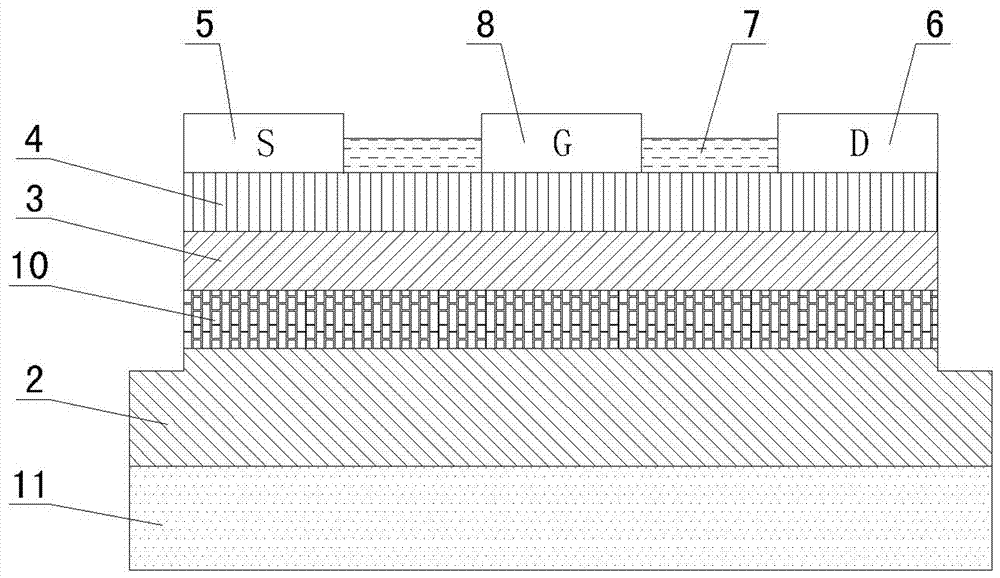

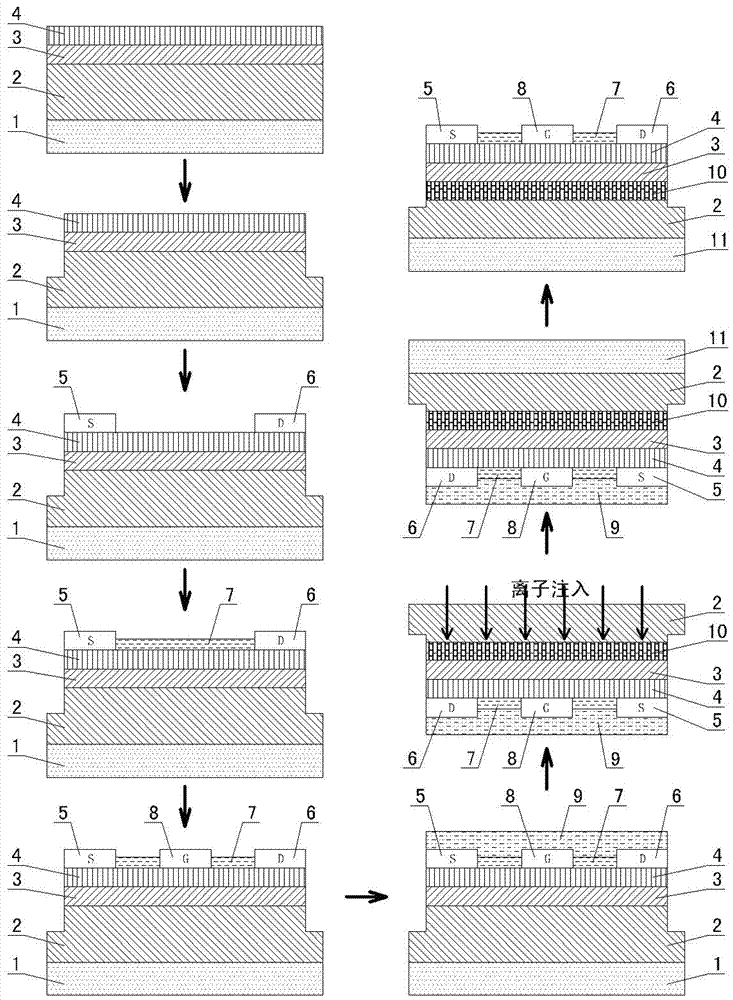

GaN power device based on ion implantation and manufacturing method thereof

PendingCN107170671ASuppress leakage currentImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactEngineering

The invention discloses a GaN power device based on ion implantation and a manufacturing method thereof. The GaN power device includes a GaN buffering layer, a GaN channel layer and an AiGaN barrier layer which are successively arranged from bottom to top. The A1GaN barrier layer is provided with an active electrode, a gate electrode and a drain electrode thereon, wherein the active electrode and the drain electrode are both ohmic contacts, the gate electrode is a Schottky contact, and all electrodes are covered with a passivation layer therebetween. The passivation layer is connected to the A1Gan barrier layer. The A1Gan barrier layer and the Gan channel layer are heterostructures and the interface between the A1Gan barrier layer and the Gan channel layer forms a 2D electron gas which acts as a transverse working conductive channel of the GaN power device due to polarization effects. An ion isolation region is formed by performing ion implantation on the bottom surface of the GaN buffering layer. The ion isolation region is disposed in the upper part of the GaN buffering layer and is connected to the GaN channel layer, and the GaN buffering layer is provided with an ion isolation region therein and then the bottom surface of the GaN buffering layer is bonded to a high heat conductive substrate. According to the invention, since an ion isolation region is formed by performing ion implantation, the GaN channel and the GaN buffering layer are isolated, such that current leakage is reduced and breakdown voltage is increased.

Owner:GUANGDONG INST OF SEMICON IND TECH

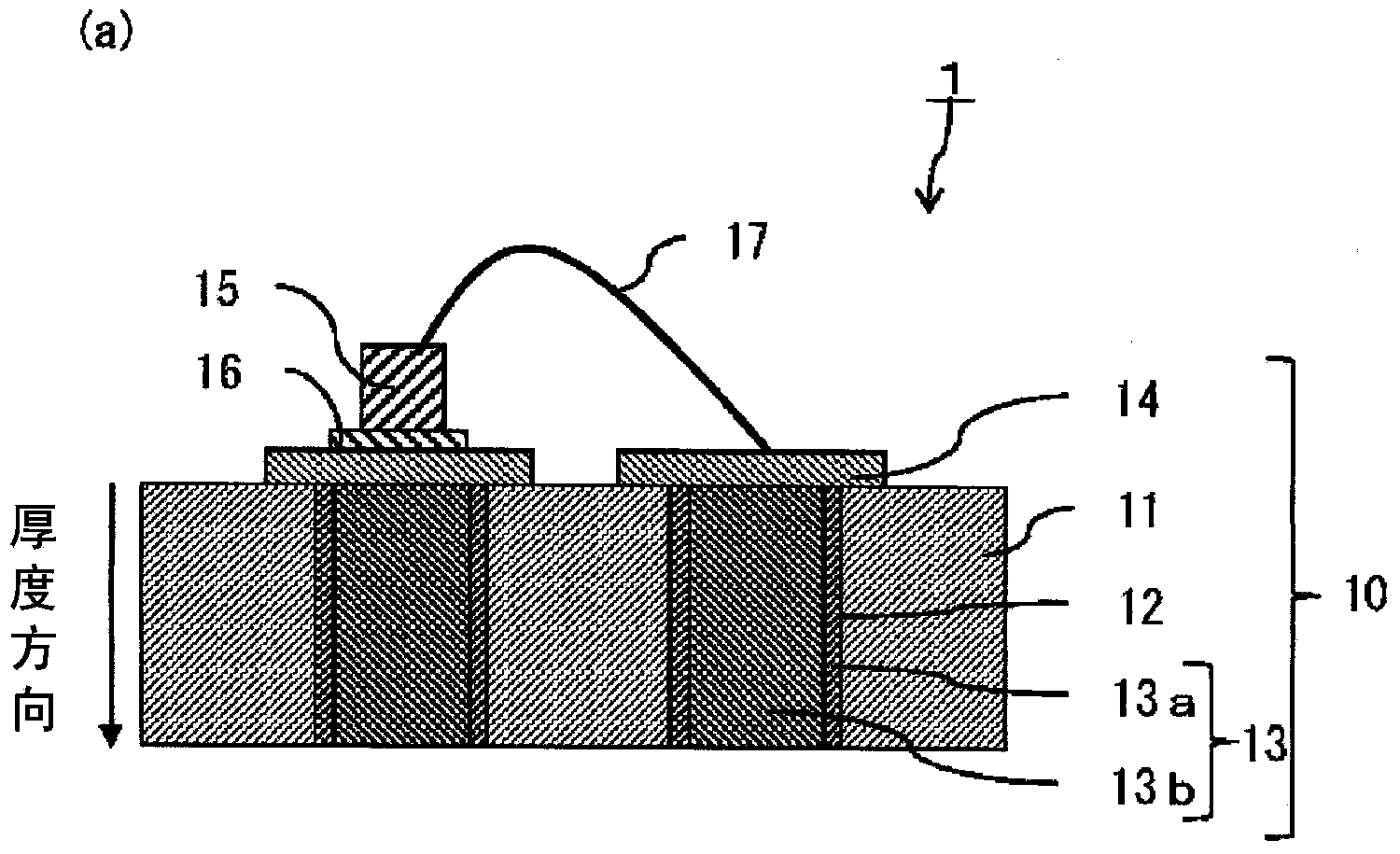

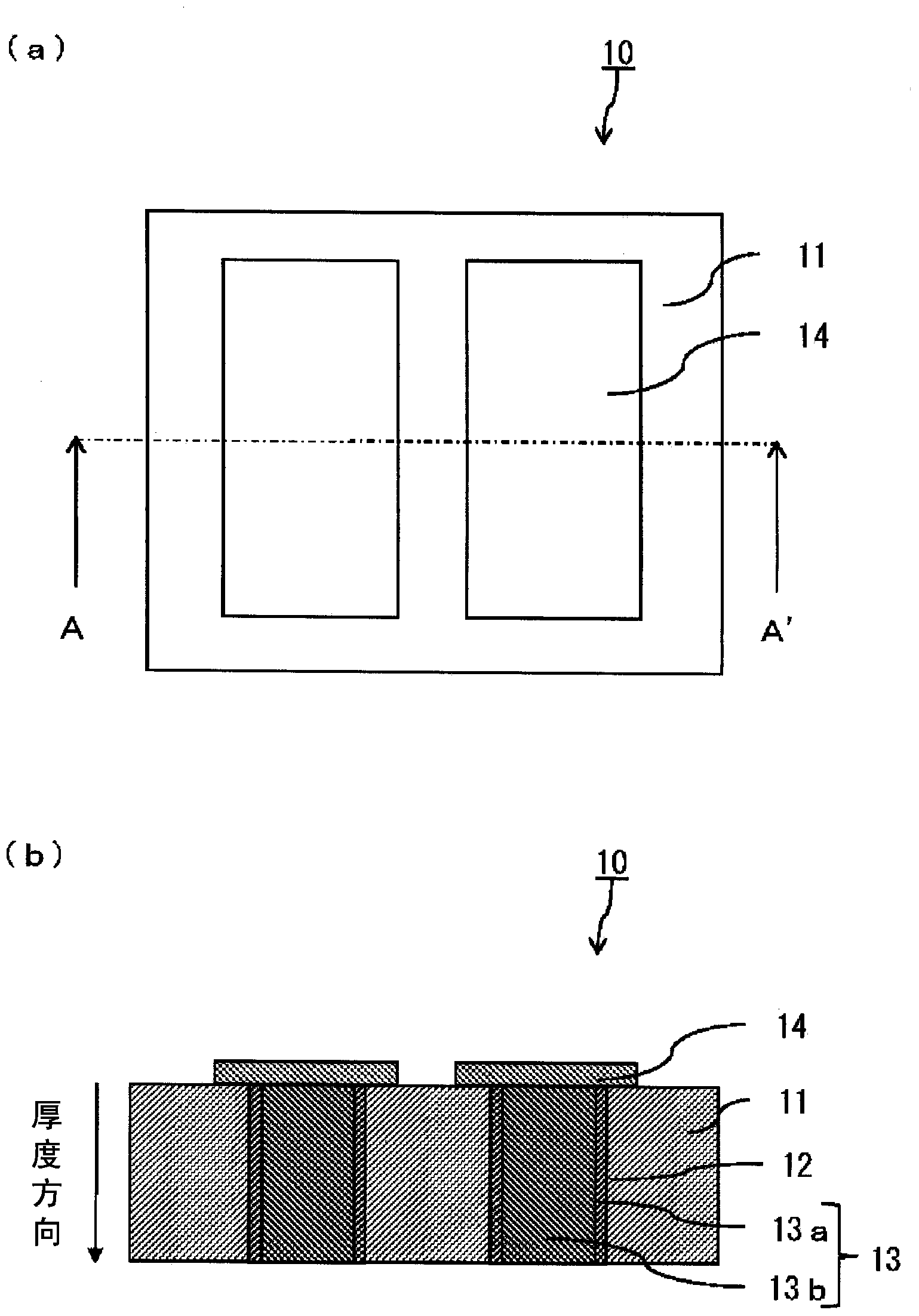

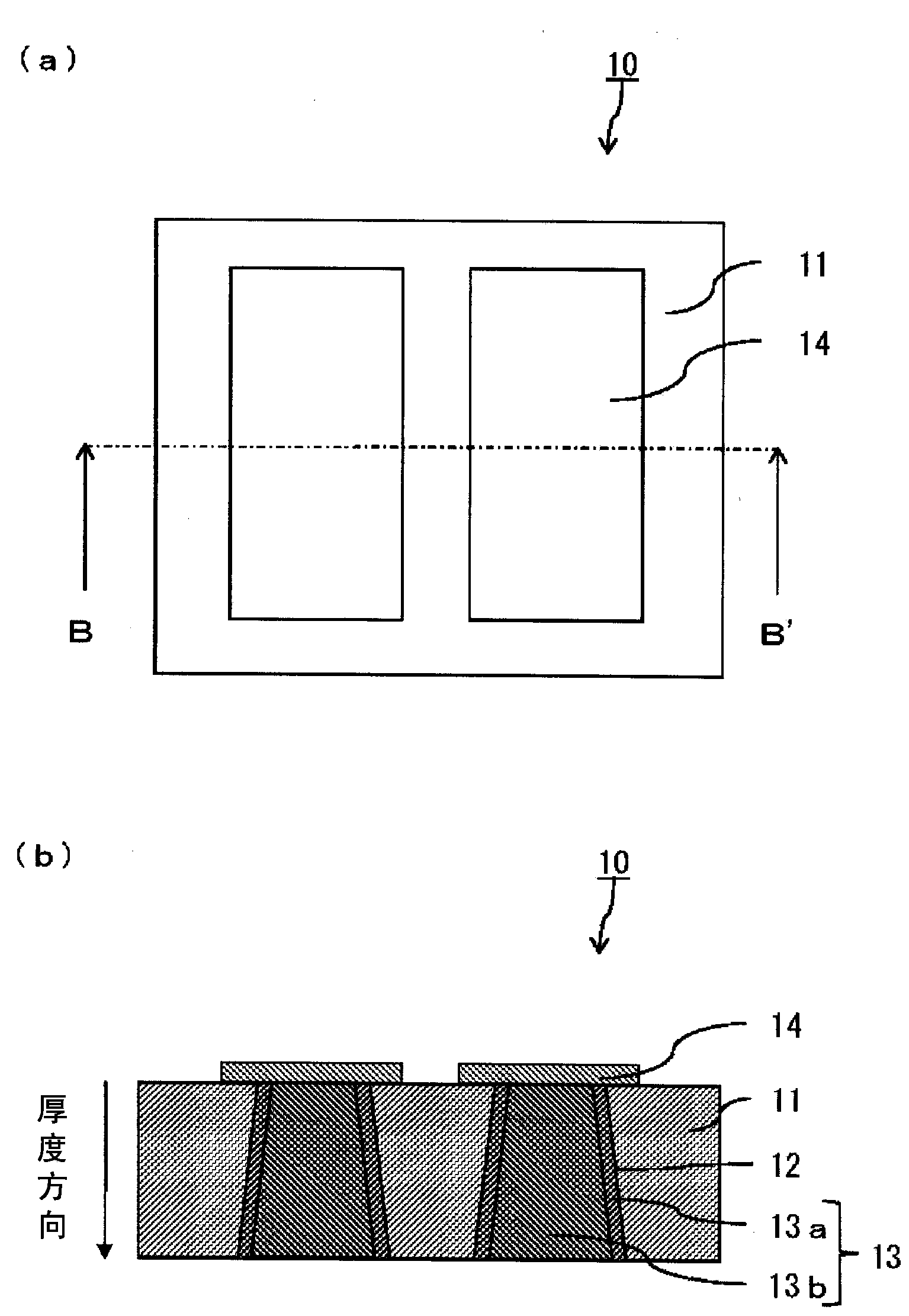

Circuit board and electronic device provided with same

InactiveCN103583087AReduce saggingImprove joint strengthSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorElectronic component

The invention provides a highly-reliable circuit board and an electronic device obtained by mounting electronic components on the circuit board, which have high bonding strength and excellent heat discharge properties, and can be used over a long period as a result of minimizing cavities in a metal wiring layer formed on a through conductor. A circuit board (10) is provided with a through conductor (13) comprising a metal in a through hole (12) that penetrates in the thickness direction of a ceramic sintered body (11), and a metal wiring layer (14) that covers and is connected to the surface of the through conductor (13) on at least one main surface side of the ceramic sintered body (11). The through conductor (13) comprises: a first area (13a) that is positioned on an inner wall side of the through hole (12), from one end to the other end of the through hole (12) in the thickness direction of the ceramic sintered body (11); and a second area (13b) that adjoins the first area (13a). The average crystal grain size in the second area (13b) is larger than the average crystal grain size in the first area (13a).

Owner:KYOCERA CORP

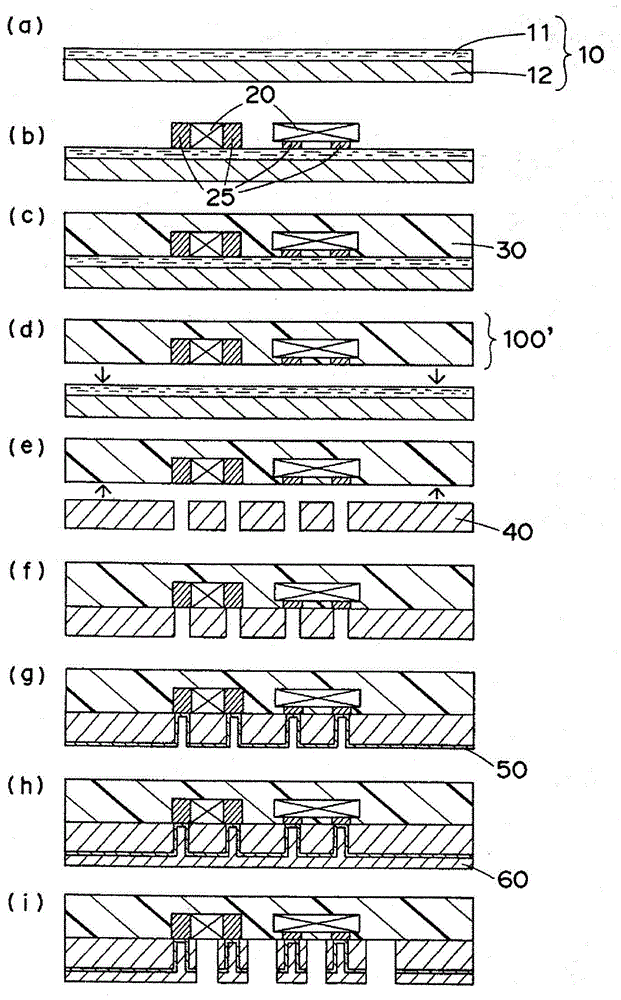

Electronic component package and method for producing same

InactiveCN104584208AImprove heat dissipation characteristicsImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesMetal foilElectronic component

This method for producing an electronic component package comprises: (i) a step wherein a package precursor, in which an electronic component is embedded in a sealing resin layer such that an electrode of the electronic component is exposed from the surface of the sealing resin layer, is formed; (ii) a step wherein a metal foil having a through hole is provided on the surface of the sealing resin layer such that the through hole is at a position where the through hole faces the electrode of the electronic component; and (iii) a step wherein a metal plating layer is formed on the metal foil. In step (iii), the metal plating layer is formed by performing a wet plating process after performing a dry plating process and the through hole of the metal foil is filled with the metal plating layer, so that the metal plating layer and the metal foil are integrated with each other.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

An LED device integrating graphene temperature sensing and a manufacturing method thereof

ActiveCN105023858AJunction Temperature MonitoringDoes not affect normal workSemiconductor/solid-state device testing/measurementSolid-state devicesJunction temperatureEngineering

The invention discloses an LED device integrating graphene temperature sensing and a manufacturing method thereof. A chip of the device includes an LED luminescent device and a temperature sensing device. The temperature sensing device is a grapheme device. The LED luminescent device and the temperature sensing device are in a back-to-back stacked structure. The LED luminescent device is in the upper position, and the temperature sensing device is in the lower position. The junction temperature of the LED luminescent device can be monitored by means of measuring changes of a graphene thin-film resistor in the temperature sensing device with temperature changes. The LED device integrating graphene temperature sensing of the invention can accurately and stably reflects the junction temperature of the LED device in real time, and can effectively raise the light extracting rate of the LED luminescent device and heat radiation of the whole device.

Owner:NANJING UNIV

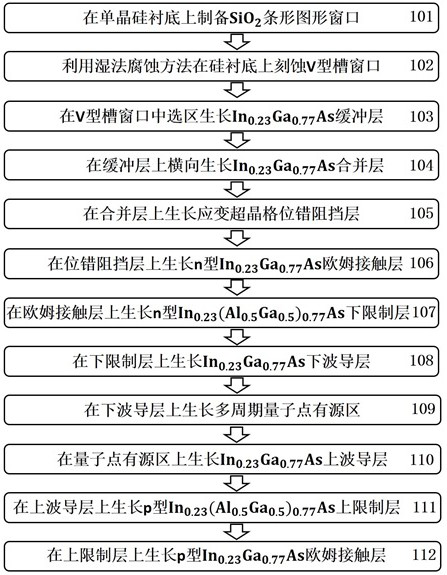

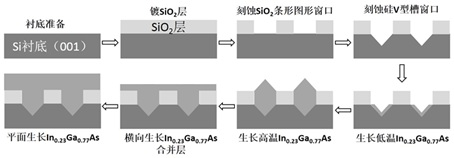

1.55-micron-wavelength silicon-based quantum dot laser epitaxial material and preparation method thereof

InactiveCN111628410AImprove heat dissipation characteristicsDoes not affect growth qualityLaser detailsLaser active region structureWaveguideMaterials science

The invention relates to the technical field of semiconductor lasers, in particular to a 1.55-micron-wavelength silicon-based quantum dot laser epitaxial material and a preparation method thereof. Themethod is characterized by comprising the following steps of: 101, preparing a strip-shaped pattern mask on a monocrystalline silicon substrate; 102, etching a window of the V-shaped groove; 103, selectively growing a buffer layer in the V-shaped groove window region; 104, transversely growing a merging layer; 105, growing a strain superlattice dislocation barrier layer; 106, growing an n-type ohmic contact layer; 107, growing an n-type lower limiting layer; 108, growing a lower waveguide layer; 109, growing a multi-layer quantum dot active region; 110, growing an upper waveguide layer; 111,growing a p-type upper limiting layer; and 112, growing a p-type ohmic contact layer to complete preparation. The growth quality of the laser epitaxial material is effectively improved, and the performance of the laser is improved.

Owner:JIANGSU HUAXING LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com