Deformation-free thermal extrusion method for helix slow-wave component preparation

An extrusion method and a helix technique are applied in the field of preparation of slow wave components of a helical traveling wave tube to achieve the effect of improving heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

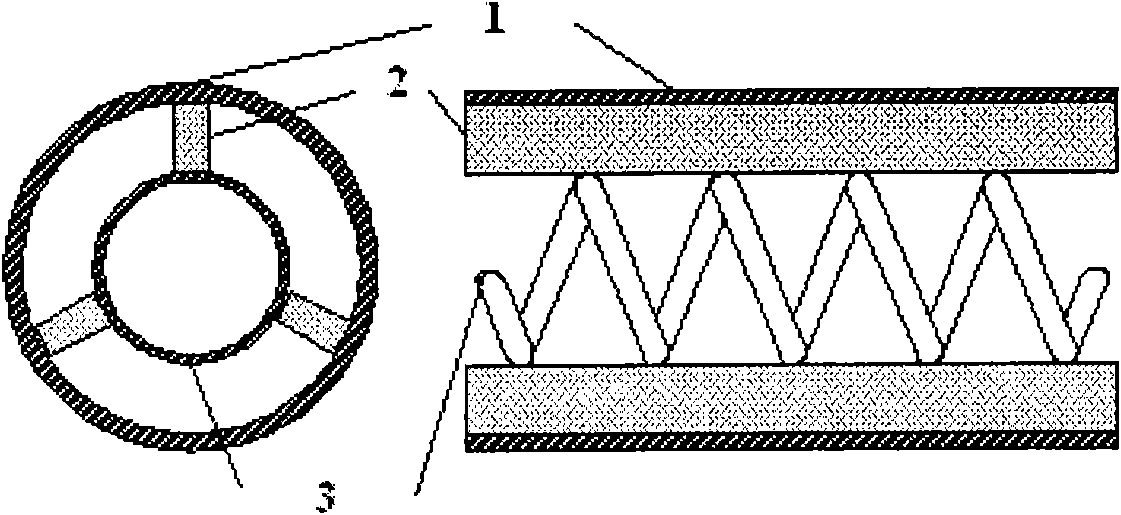

[0033] Such as figure 1 As shown, it is a structural schematic diagram of a helical slow-wave component with strong heat dissipation capacity composed of a tube shell 1, a helix 3 and a clamping rod 2 according to the present invention. 1 to form a slow wave component. The inner wall of the tube shell 1 is in close contact with the outer surface of the medium holding rod 2, and the inner surface of the medium holding rod 2 is in close contact with the outer surface of the helix 3, and the helix 3 is made of molybdenum helix or other metal helix. The medium holding rod 2 is made of aluminum oxide, beryllium oxide or boron nitride.

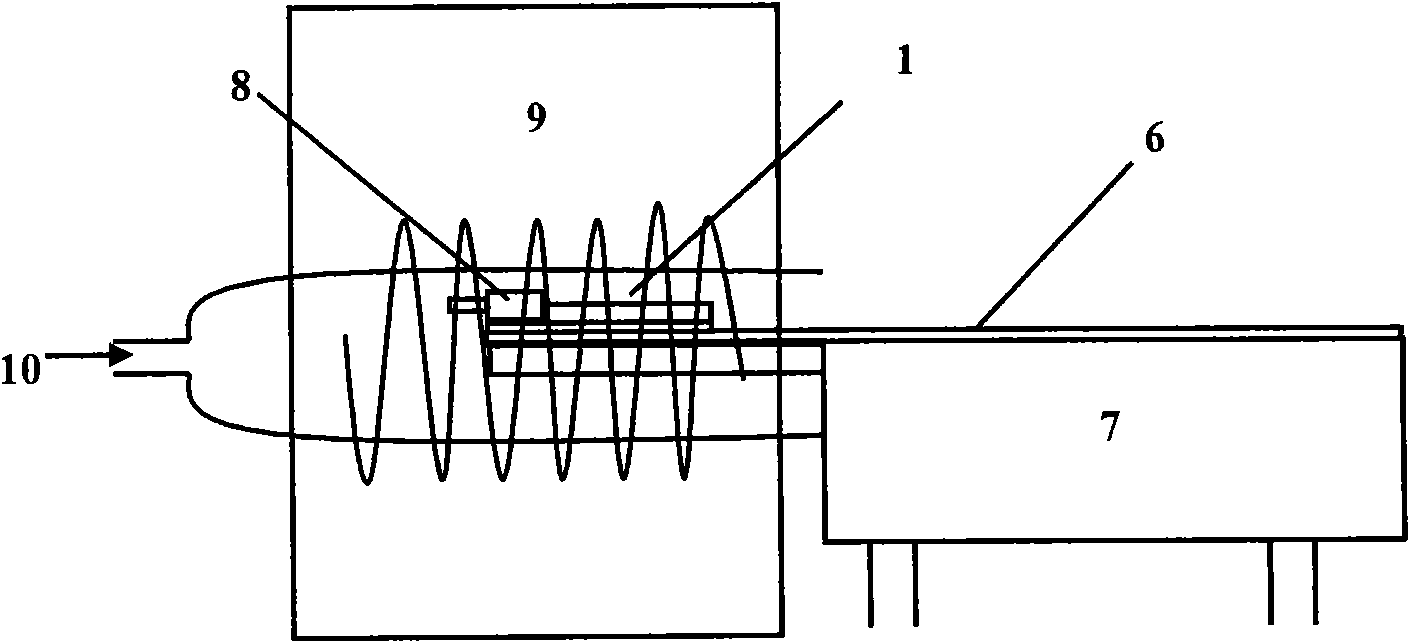

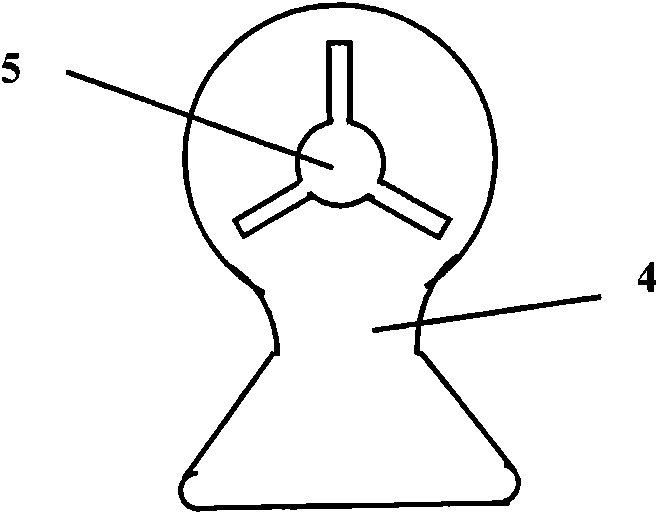

[0034] The non-deformation hot extrusion method prepared by the helical slow wave component of the present invention mainly utilizes such as figure 2 The assembly equipment and some other molds shown: the cross-section of the extrusion table 7 is as follows Figure 6 As shown, there is a dovetail groove track 6 on it, which is used to complete t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com