Method for improving thermal conduction capability of printed board of surface-mounted device

A technology for surface mount devices and thermal conductivity, which is applied in the field of high heat flux density surface mount devices and electronic equipment, and can solve the problems of low thermal conductivity of thermally conductive printed boards, low heat dissipation reliability of thermal conduction paths, and high temperature of device casings. It is easy to accumulate design experience and knowledge, has reproducibility and scalability, and achieves the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

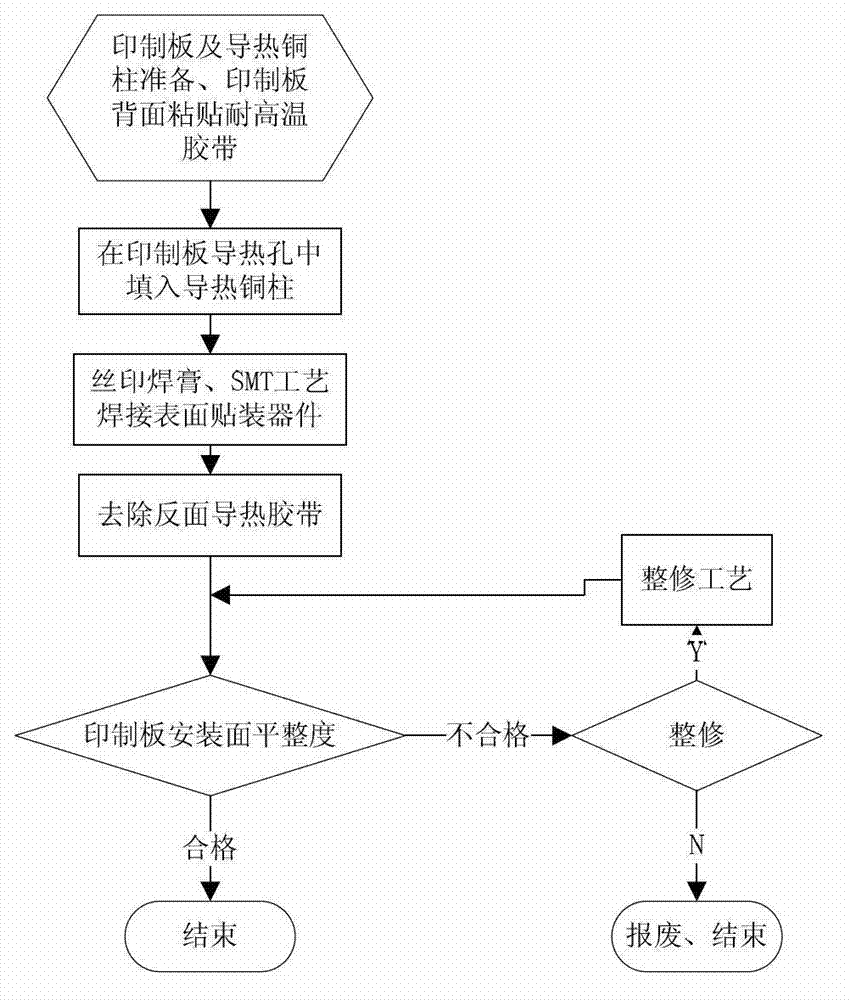

[0024] The specific implementation steps of the present invention will be further described in detail below in conjunction with the accompanying drawings.

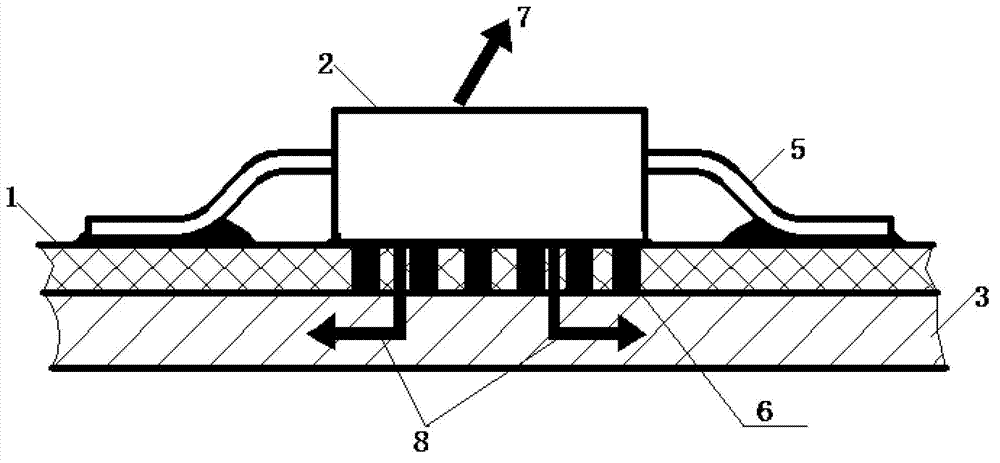

[0025] When using this method to design, the thermal conduction path should be optimized according to the assembly relationship of the device, printed board and metal box body, and the device is determined to be a surface soldered and mounted device, and its thermal conduction path is the same as figure 1 The same or a similar situation is shown for path 8 . This method can only be used when the heat dissipation characteristics of surface mount devices can be effectively improved by improving the thermal conductivity of the printed board.

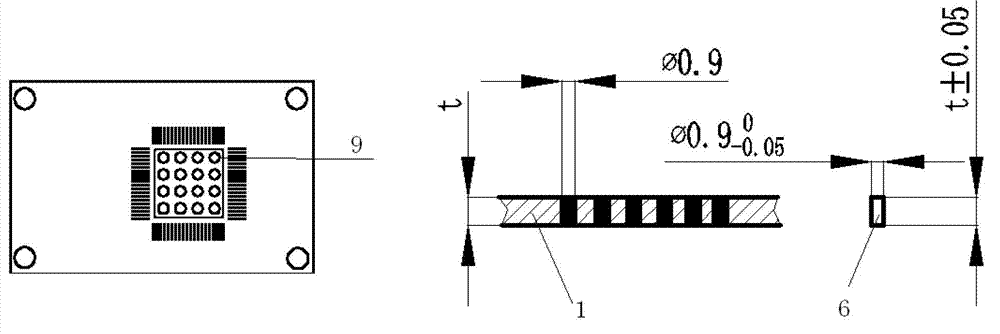

[0026] refer to Figure 1 ~ Figure 3 . figure 1 It shows that the high heat flux surface mount components 2 are mounted on the bottom with metal heat dissipation bosses, and the surface mount components that can be soldered to the grounding layer of the printed board 1 through the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com