Patents

Literature

58results about How to "Improve infrared radiation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building coating with heat insulation function and preparation method thereof

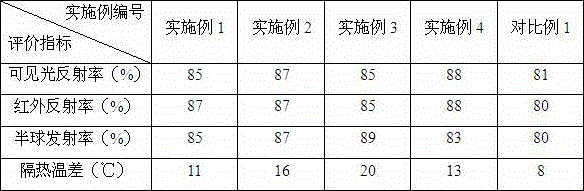

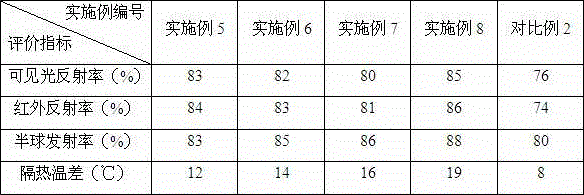

InactiveCN106118307AGood thermo-optic comprehensive performanceWith thermal insulation functionReflecting/signal paintsBuilding energyMetallurgy

The invention provides a building coating with a heat insulation function and a preparation method thereof. The building coating with the heat insulation function is divided into an internal wall coating and an external wall coating, wherein each of the internal wall coating and the external wall coating is composed of a basic carrier for film forming of the coating, a heat insulating material, a heat reflecting material, a heat radiating material, filler, an assistant and water. The preparation method comprises the following steps: preparation of heat insulating material slurry, preparation of function material slurry, grinding of slurry, and paint mixing. The film forming thickness of the building coating is 0.2-0.3mm, so that the building coating belongs to a thin building energy-saving coating; the internal and external wall building coatings have higher heat conducting resistance and lower convection heat transfer, so that the building coating has different heat radiating effects under different temperature environments in different seasons and has the heat insulation function; the building coating is high in safety and long in service life; and the preparation method is simple and is suitable for industrial production.

Owner:马承银

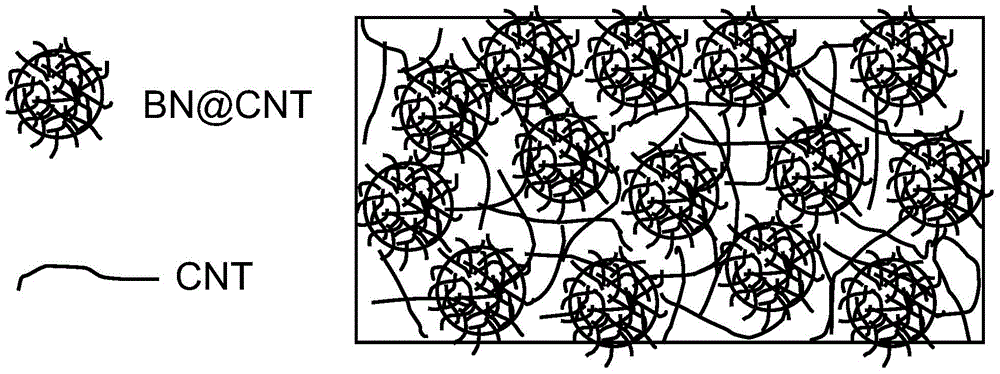

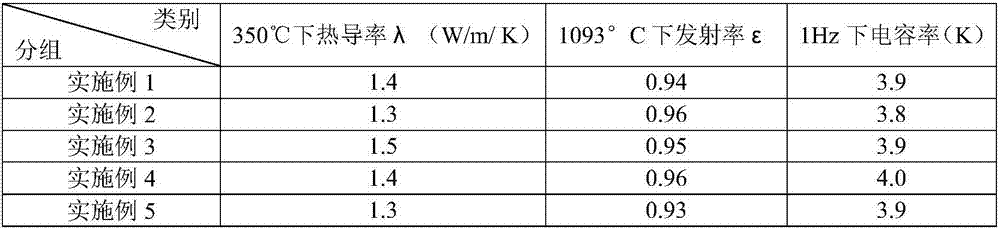

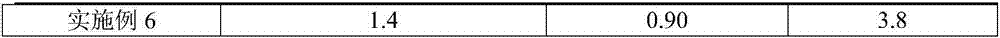

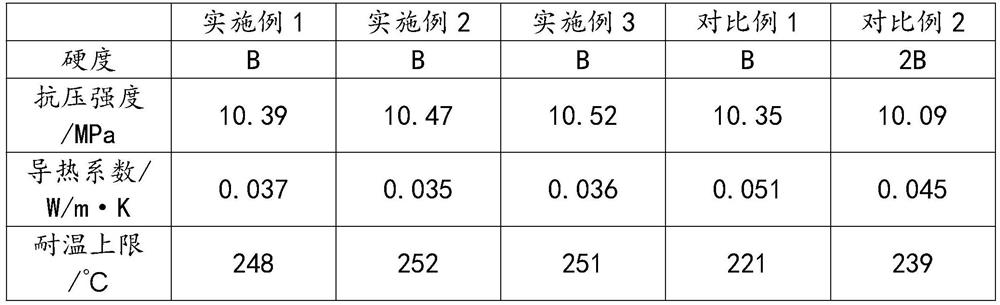

Aqueous heat dissipation coating and preparation method thereof

ActiveCN104804618AImprove cooling effectHigh thermal conductivityEpoxy resin coatingsBoron nitrideSlurry

The invention discloses an aqueous heat dissipation coating and a preparation method thereof. The aqueous heat dissipation coating comprises an aqueous dispersoid containing a base resin, nanometer carbon material-coated boron nitride composite powder and optional auxiliary materials. The composite powder comprises boron nitride and a boron nitride-coating nanometer carbon material. The preparation method comprises carrying out grinding dispersion on the aqueous dispersoid containing a base resin and the optional auxiliary materials to obtain dispersive slurry, at least adding slowly the composite powder into the dispersive slurry, carrying out high speed stirring and carrying out standing defoaming. The nanometer carbon material-coated boron nitride composite powder is used as a coating filler so that excellent thermal conductivity of the nanometer carbon material and boron nitride and conductive infrared radiation characteristics of the nanometer carbon material are fully utilized, interface thermal resistance of the nanometer carbon material and boron nitride is reduced, and the coating has the advantages of high thermal conductivity, high infrared radiation rate, construction convenience, safety, environmental friendliness and wide application prospect.

Owner:芜湖海泰科新材料有限公司

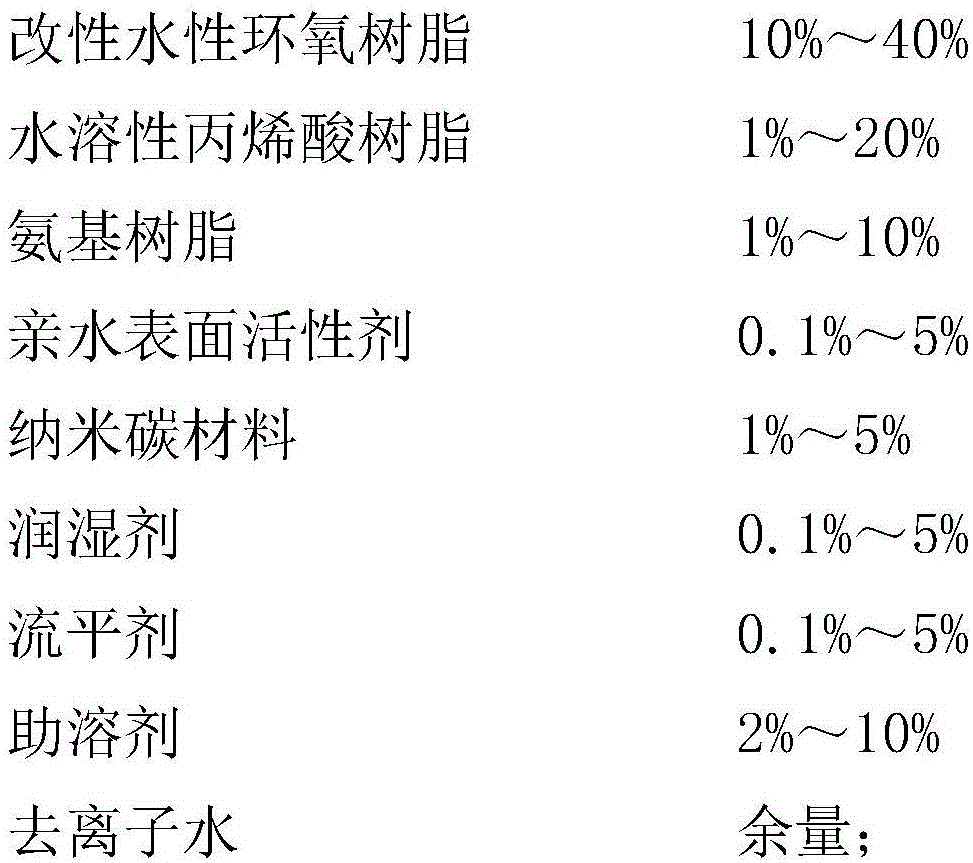

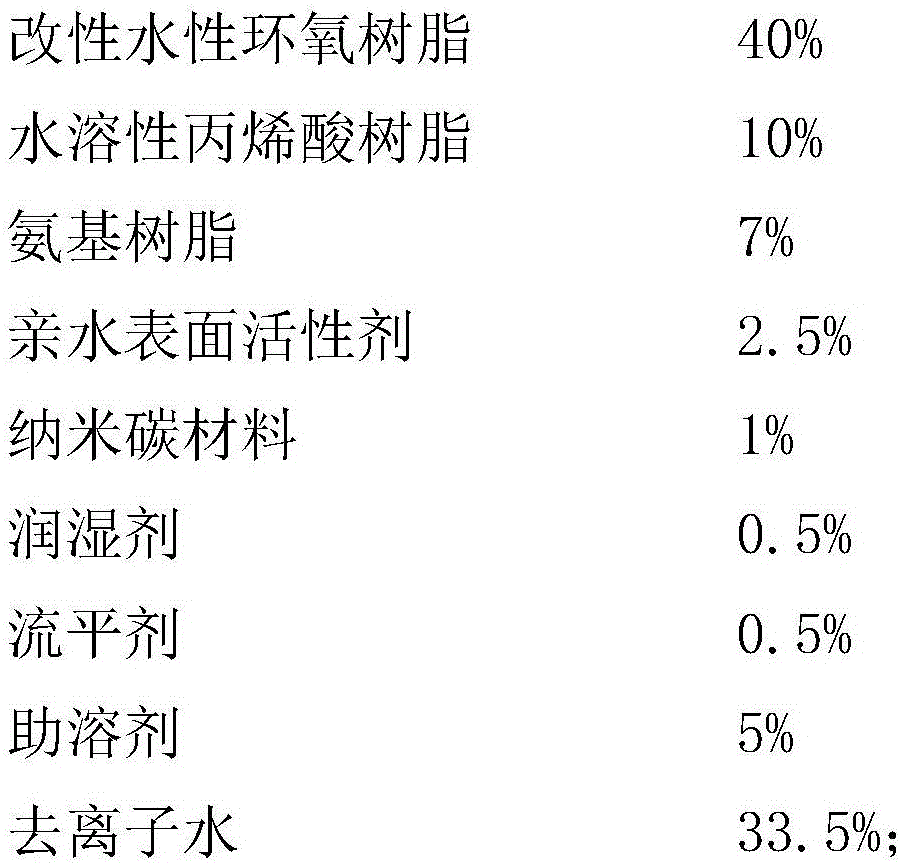

Heat dissipation hydrophilic coating and preparation method thereof

The invention relates to a heat dissipation hydrophilic coating and a preparation method thereof. The heat dissipation hydrophilic coating is prepared from, by weight, 10-40% of modified waterborne epoxy resin, 1-20% of water soluble acrylic resin, 1-10% of acrylic resin, 0.1-5% of hydrophilic surfactant, 1-5% of a carbon nanomaterial, 0.1-5% of a wetting agent, 0.1-5% of a flatting agent, 2-10% of cosolvent and the balance deionized water. Good compatible dispersion to the carbon nanomaterial is obtained through epoxy resin modification, a good film-forming property is obtained, the carbon nanomaterial can exert the characteristics of high thermal conductivity, high infrared radiance and the like, the hydrophilic coating can have the radiation and heat dissipation functions, heat dissipation and anti-corrosion performance of air conditioner aluminum foil, an aluminum foil heat exchanger and other equipment can be remarkably improved, the energy efficiency ratio is raised, and important business value is achieved.

Owner:芜湖海泰科新材料有限公司

High-temperature infrared radiant coating used for industrial furnace and preparation method thereof

The invention discloses a high-temperature infrared radiant coating used for an industrial furnace and a preparation method thereof. The high-temperature infrared radiant coating is mainly prepared from an infrared radiant base material, a high-temperature thermal expansivity regulator and a binder by direct ball-milling and mixing, wherein the infrared radiant base material has a stable spinel structure; the high-temperature thermal expansivity regulator is selected from micro silicon dioxide powder; the binder is one or two selected from the group consisting of high-temperature sol and micro oxide powder; and the infrared radiant base material is prepared by high-temperature sintering of transition metal oxides prepared by proportioning and mixing of MnO2, industrial grade chrome green, Co2O3, Ni2O3, CuO, Fe2O3, TiO2 and ZrO2. According to the invention, infrared radiance of the coating can be improved; stability of the infrared radiance of the coating can be guaranteed; meanwhile, the service life is enhanced; the process is simple and has no pollution to products in a furnace; and strong bonding strength and thermal shock resistance are achieved.

Owner:ZHEJIANG UNIV

Anticorrosive energy-saving coating based on infrared radiating body

The invention relates to an anticorrosion and energy saving paint based on infrared radiation body. The weight ratio of the invention is 15-25% randomly two or more oxide particles selected from zirconium dioxide, titanium dioxide, alumina, ferric oxide, ceria, manganese dioxide or calcium oxide,35-45% randomly two or more particles selected from carborundum, silicon nitride, kaolin or nm titanium dioxide, 35-45% one or two solution selected from silicate solution, PVA, or CMC. The invention has good heat endurance, and anticorrosion.

Owner:孙学明

High-temperature-resistant, infrared radiation preventing and energy-saving coating

ActiveCN106928832AReduce the rate of infrared radiationImprove infrared radiation rateFireproof paintsAlkali metal silicate coatingsUltrasound attenuationEmissivity

The invention discloses a high-temperature-resistant and energy-saving coating for preventing infrared emissivity attenuation. The coating is prepared from, by weight, 30-40 parts of high-temperature and high-radiation powder, 10-20 parts of quartz powder, 5-10 parts of super-high-temperature additive, 30-50 parts of bonding agent, 10-20 parts of solvent, 0.1-0.2 part of dispersant, 0.15-0.3 part of coupling agent and 0.05-0.15 part of defoaming agent. The invention aims to form a stable ternary structure inside the coating and hinder internal crystal development and growth when the coating is used at high temperature for a long time. On one hand, the infrared emissivity attenuation of the coating due to crystal growth can be reduced; on the other hand, the phenomena such as coating cracking and piece dropping produced by sintering and shrinkage can be prevented, the service life is prolonged, and the infrared emissivity attenuation is effectively prevented.

Owner:中国平煤神马控股集团有限公司 +1

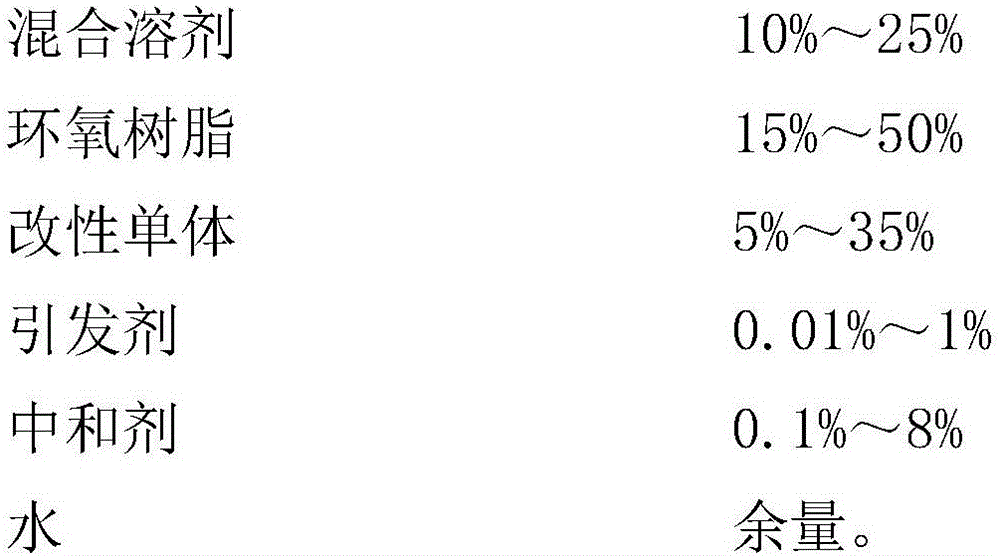

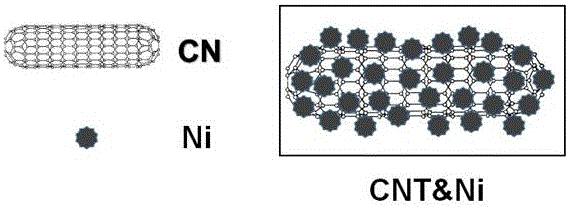

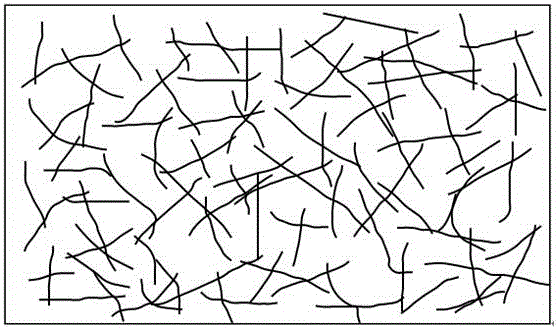

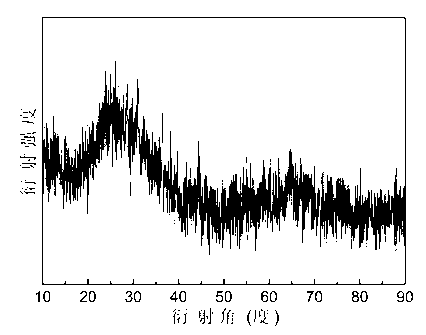

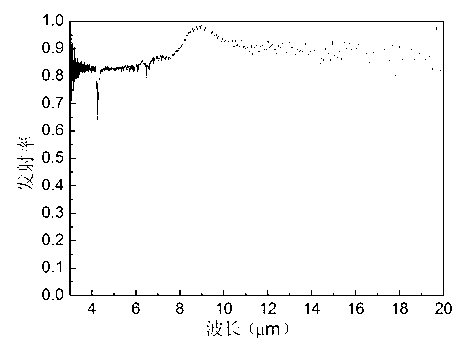

Water-based electrothermal coating and preparation method thereof

InactiveCN105778678AExcellent electric heating performanceImprove utilization efficiencyCoatingsWater basedLow voltage

The invention discloses a water-based electrothermal coating and a preparation method of the water-based electrothermal coating. The coating comprises a water-based dispersion containing a matrix resin, nickel coated carbon nanotube composite powder and auxiliary materials which can be selectively added, wherein the composite powder comprises a carbon nanotube and nickel coated on the carbon nanotube. The preparation method of the water-based electrothermal coating comprises the following steps: the surface of a carboxylated carbon nanotube is subjected to the adsorption of nickel ions, and the nickel ions are reduced to a nickel elementary substance to be served as a nucleation core, chemical nickel-plating is carried out to form the nickel coated carbon nanotube composite powder, and then the composite powder is mixed with the water-based dispersion containing the matrix resin and ground to obtain a composite dispersion paste, and the composite dispersion paste is further compounded with the other auxiliaries to prepare the electrothermal coating. According to the invention, the contact resistance of the original carbon nanotube network can be greatly reduced, so that the coating has the advantages of being low in resistance, high in electrothermal conversion efficiency and the like, is suitable for being used as various electrothermal coatings driven by low voltage, and further has convenience in construction, safety and environmental protection and wide application prospects.

Owner:江苏联科纳米科技有限公司

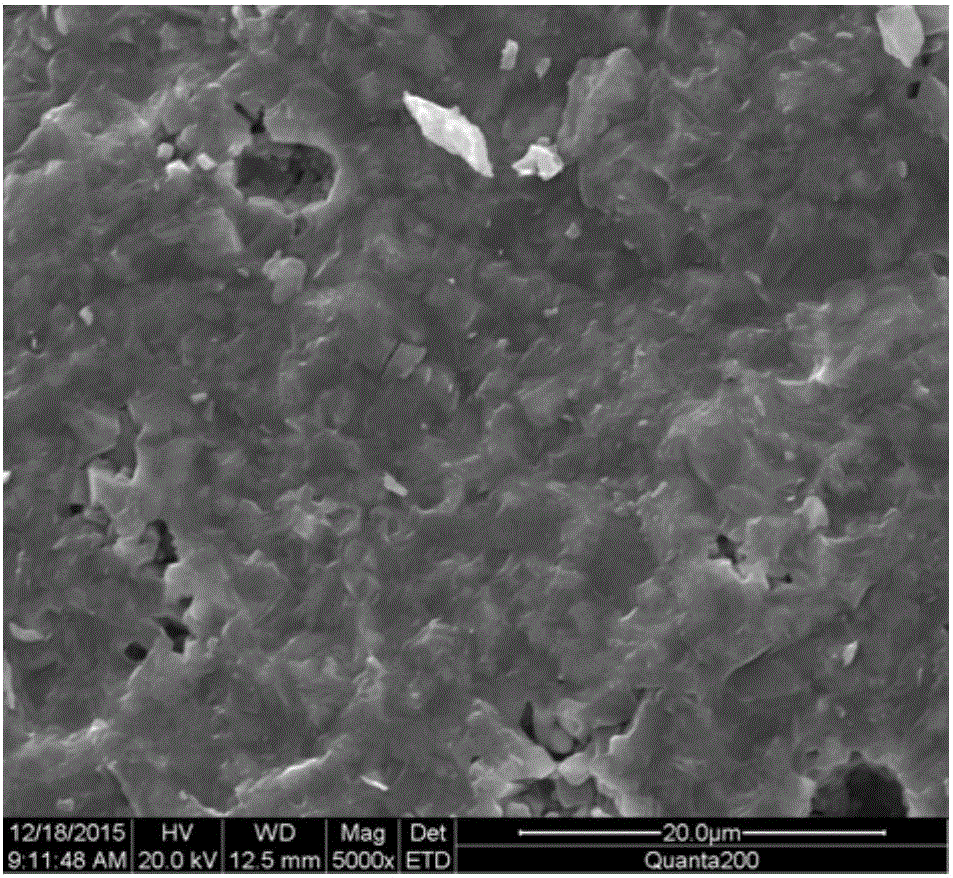

Method for preparing infrared radiation amorphous coating

The invention relates to a method for preparing an infrared radiation amorphous coating. The technical scheme is that 5wt.% to 20wt.% of ferric oxide fine powder, 5wt.% to 20wt.% of manganese oxide fine powder, 1wt.% to 3wt.% of copper oxide fine powder, 1wt.% to 3wt.% of cobalt oxide fine powder, 55wt.% to 80wt.% of cordierite fine powder, 1wt.% to 3wt.% of nickel oxide fine powder, 1wt.% to 3wt.% of titanium oxide fine powder and 1wt.% to 3wt.% of chromic oxide fine powder are uniformly mixed to form a mixture; the mixture is accommodated into a sagger to be placed into a microwave oven, the temperature rises to 1000 DEG C to 1250 DEG C, the thermal insulation is performed for 30minutes to 60 minutes, the mixture is smashed, and infrared radiation powder is obtained. Then, the infrared radiation powder performs plasma spraying for a roughened metallic matrix, the thickness of the infrared radiation amorphous coating is 100mm to 500 mm, and the infrared radiation amorphous coating is prepared. The method for preparing the infrared radiation amorphous coating has the characteristics of short cycle and low production cost, and the prepared infrared radiation amorphous coating has the advantages of high bonding strength, strong resistance to corrosion, good thermal shock resistance performance, long service life, high usage temperature and high infrared emittance.

Owner:湖北赛格瑞新能源科技有限公司

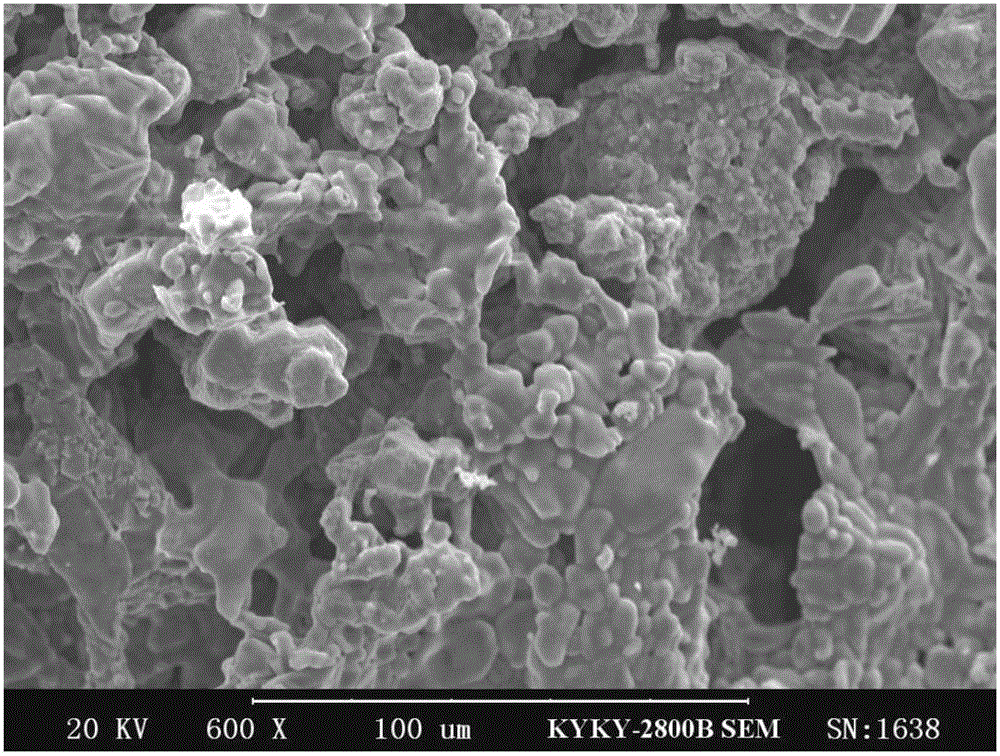

Preparation method of high-infrared-emittance heat dissipation coating

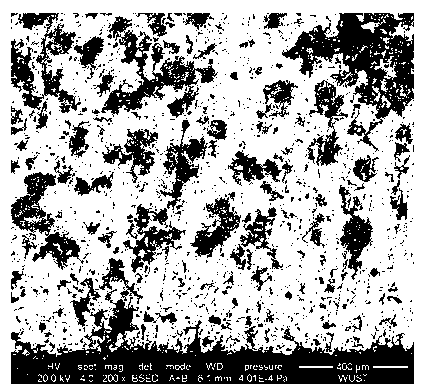

InactiveCN103173712AImprove infrared radiation rateHigh hardnessMolten spray coatingBonding strengthElectronic instrument

The invention relates to a preparation method of a high-infrared-emittance heat dissipation coating, which mainly solves the technical problem of short product service life due to poor heat dissipation and the technical problem of potential safety hazard due to temperature increase in the existing electronic device. The main component of the heat dissipation coating is Mn-Cr-Ti-Cu complex oxides, and the oxide powder can be subjected to plasma spray on a matrix surface to prepare the high-infrared-emittance coating. The coating powder is composed of one or more of the following oxides: 5-47% of MnO2, 37-70% of Cr2O3, 5-12% of CuO and 11-25% of TiO2. The prepared high-infrared-emittance heat dissipation coating material has the advantages of high infrared emittance, favorable heat dissipation and high bonding strength with the matrix, can effectively lower the temperature in electronic instruments and enhance the reliability of electronic equipment, and is applicable to the fields of electronic measuring instruments, computer room equipment, measurement and control systems, aircrafts, arms of precision and the like. The coating material also has the advantages of compact structure, light weight, high bonding property and high shock and vibration resistance; and the technique is practical and suitable for industrial production.

Owner:SHENYANG XINJIN POWDER ENG

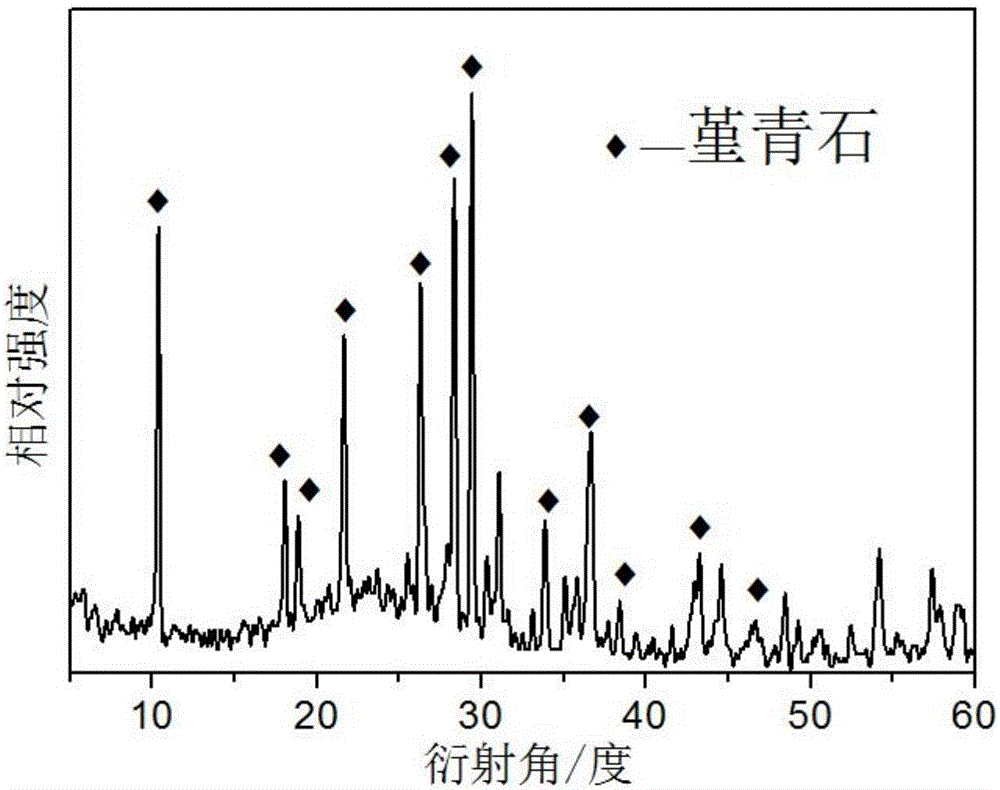

High-infrared-emitting-ability cordierite-spinel ceramic material and preparation method thereof

InactiveCN105198394AHigh infrared emissivityHigh emissivitySolid waste disposalSocial benefitsEmissivity

The invention discloses a high-infrared-emitting-ability cordierite-spinel ceramic material, and belongs to the technical field of preparation of ceramic materials. The high-infrared-emitting-ability cordierite-spinel ceramic material comprises the following raw materials in percentage by mass: 25-80% of pulverous coal, 10-25% of magnesia and 10-55% of alumina. The invention also discloses a preparation method of the material. Costs of the raw materials are greatly reduced, performance of products is excellent, and principal crystalline phases comprise a cordierite phase and a spinel phase. The high-infrared-emitting-ability cordierite-spinel ceramic material has the advantages of high radiance, small thermal expansion coefficient, good thermal shock resistance and the like, and is multifunctional. Sintering temperature is greatly reduced; when the minimum temperature is 1230 DEG C, the infrared ceramic material can be fired, temperature is easy to control, and infrared emitting ability of fired ceramics is quite high, and can be similar to that of a pure cordierite ceramic material. By the preparation method of the high-infrared-emitting-ability cordierite-spinel ceramic material, wastes can be reused and can be changed into things of value, and economic benefit and social benefit are excellent.

Owner:射阳县射阳港对虾养殖二公司

High-temperature-resisting infrared heat energy-saving coating and preparation method thereof

InactiveCN108250811AImprove adhesionHigh strengthFireproof paintsAlkali metal silicate coatingsHearthBinding force

The invention relates to high-temperature-resisting infrared heat energy-saving coating. The high-temperature-resisting infrared heat energy-saving coating is prepared from the following components inparts by weight: 50 to 60 parts of an adhesive, 3 to 5 parts of silicon carbide, 1 to 5 parts of titanium dioxide, 1 to 2 parts of manganese dioxide, 1 to 5 parts of copper oxide, 3 to 7 parts of graphite, 2 to 10 parts of zirconium oxide, 2 to 8 parts of aluminum oxide, 3 to 10 parts of kaolin, 10 to 20 parts of high-emissivity mullite, 0.5 to 1 part of a dense agent and 0.1 to 3 parts of a pH (Potential of Hydrogen) regulator. The coating provided by the invention can bear the temperature of 600 to 1500 DEG C and the whole infrared radiation coefficient in a wavelength range of 1 to 20mu mreaches 0.92 to 0.95; the high-temperature-resisting infrared heat energy-saving coating has excellent corrosion resistance, wearing resistance and thermal shock resistance. The binding force betweena coating layer and a matrix is strong; the coating layer can permeate the matrix to form a transition layer and the transition layer is denser. The high-temperature-resisting infrared heat energy-saving coating has strong infrared radiation, so that the temperature field intensity and uniformity in a hearth are improved and the combustion is more sufficient; the heat efficiency in the hearth is improved and the energy consumption is reduced.

Owner:北京志盛威华化工有限公司

Preparation method of tourmalinite fuel oil activator

ActiveCN103980964AStrong NMR propertiesImprove conductivityLiquid carbonaceous fuelsWater useCombustion

The invention discloses a preparation method of a tourmalinite fuel oil activator. The tourmalinite fuel oil activator comprises tourmalinite nano-powder as a main functional component. The preparation method comprises the following steps of compounding the tourmalinite nano-powder and spinel ferrite, mixing the compound and an additive according to a mass ratio of the tourmalinite nano-powder, the spinel ferrite to the additive of 87-93: 5-9: 2-4, carrying out sintering to obtain a solid mixture, and adding water and a surfactant into the mixture, wherein the amount of the used mixture is 1-5% the total amount of the solid-liquid mixture, a water use ratio is in a range of 5-98% and a surfactant use ratio is in a range of 2-30%. The tourmalinite fuel oil activator obtained by the preparation method can improve fuel oil quality, promote full combustion of fuel oil, improve combustion efficiency, save fuel oil, improve fuel oil atomization quality, and realize full combustion of fuel oil thereby reducing discharge of harmful gas so that energy saving and emission reduction are realized.

Owner:丘寿勇 +1

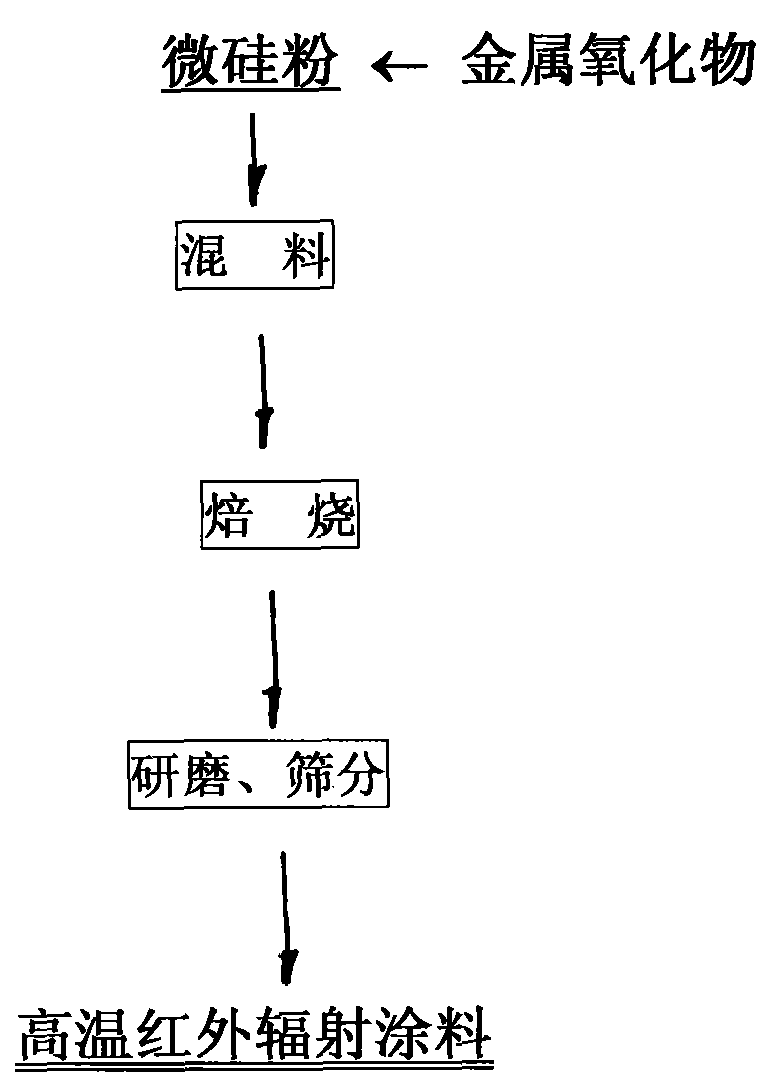

Silicon oxide series high-temperature infrared radiation coating and preparation method thereof

InactiveCN102031027ACheap and easy to getReduce energy consumptionCoatingsChemical industryInternational standard

The invention relates to a silicon oxide series high-temperature infrared radiation coating and a preparation method thereof. The infrared radiation coating for a high-temperature furnace lining comprises the following components in percentage by weight: 5 to 15 percent of Fe2O3, 10 to 20 percent of Al2O3, 5 to 10 percent of MgO, 5 to 10 percent of Cr2O3 and the balance of micro silicon powder. The preparation method is characterized in that the micro silicon powder is applied in the high-temperature infrared radiation coating. The preparation method comprises the following steps of: adding metal oxides such as Fe2O3, Al2O3, MgO, Cr2O3 and the like into the micro silicon powder, roasting the mixed components for 1 to 5 hours at the temperature of between 1,200 and 1,500 DEG C, and crushing and grinding, wherein the sieved powder of 80 meshes can be used for preparing an infrared coating raw material with high radiance at a high temperature. The silicon oxide series high-temperature infrared radiation coating can be applied to a high-temperature environment of more than 1,200 DEG C; the radiance of the coating exceeds 0.9; and the coating has good thermal shock resistance and good thermal matching performance with a furnace lining material, reaches international standard requirements, and can be applied in the industries of metallurgy, chemical industry, machinery, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

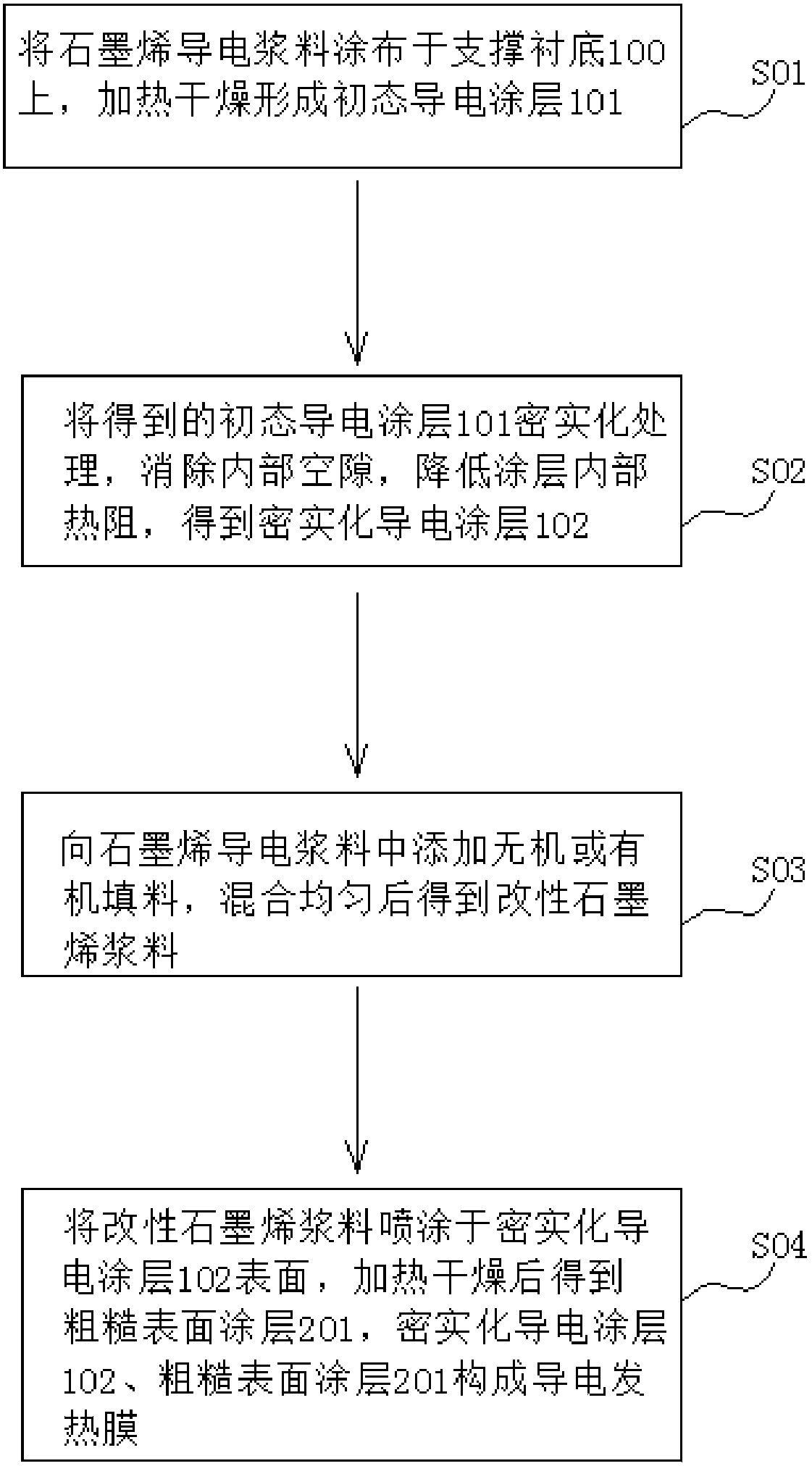

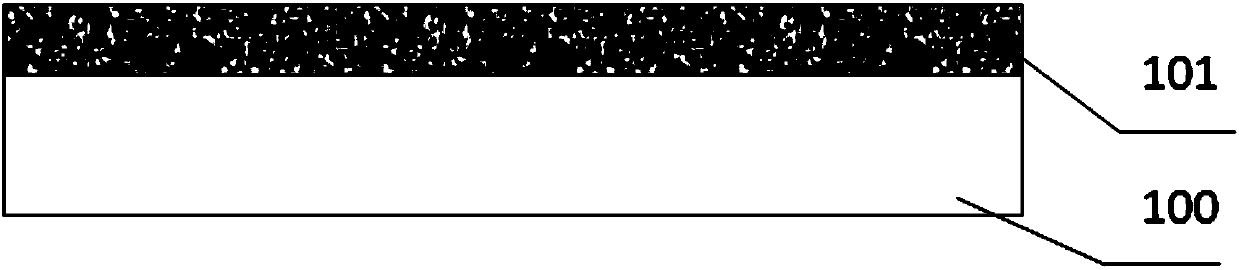

High infrared emitting electrothermal film based on graphene and preparation method of high infrared emitting electrothermal film

ActiveCN107787056AReduce transmission lossReduce internal porosityHeating element materialsFilm baseMaterials science

The invention provides a high infrared emitting electrothermal film based on graphene and a preparation method of the high infrared emitting electrothermal film. The preparation method comprises the following steps that S01, the surface of a supporting substrate is coated with graphene electroconduction slurry, an initial state conductive coating is formed through step-by-step heating and drying;S02, the obtained initial state conductive coating is densified, and the treated densified conductive coating is obtained; S03, inorganic or organic filler is added into the graphene electroconductionslurry obtained in the step S01, and modified graphene slurry is obtained after even mixing is carried out; S04, the surface of the densified conductive coating is coated with the modified graphene slurry, a rough surface coating is obtained after heating and drying are carried out, and the high infrared emitting electrothermal film is formed by the densified conductive coating and the rough surface coating. The electrothermal film is densified, internal holes are removed, the heat conductivity coefficient is increased, and the internal transmission losses of heat are reduced; by means of thesurface ultrathin rough coating, the infrared radiance rate is enhanced, and the radiative heat transfer proportion is increased.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

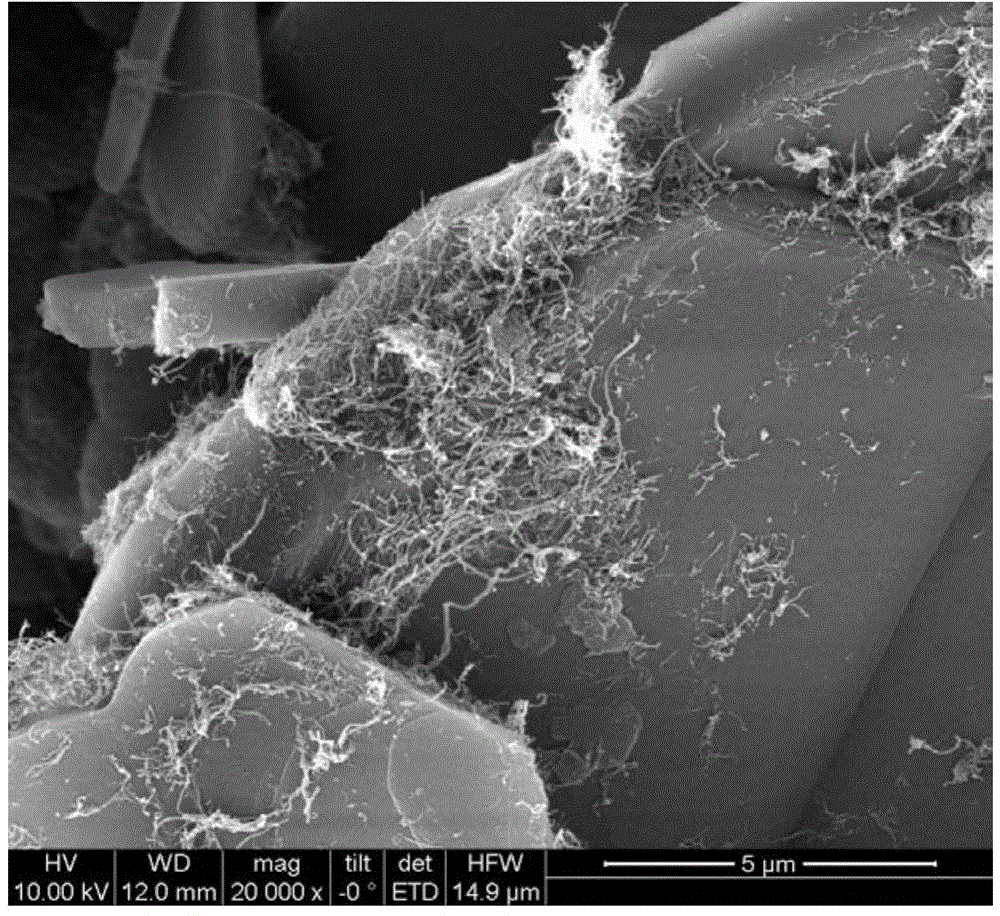

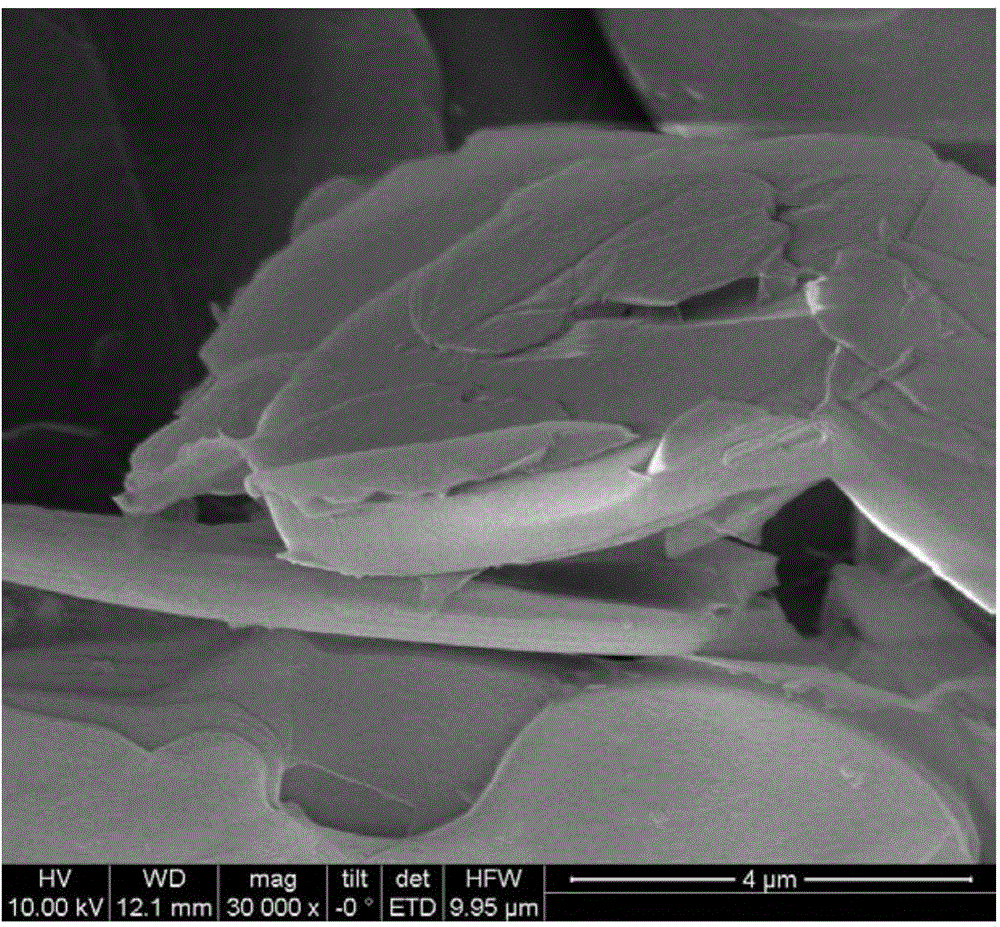

Nanometer carbon-coated boron nitride composite powder and its preparation method and use

ActiveCN104803369AImprove infrared radiation rateFacilitate constructionNitrogen compoundsElectrostatic adsorptionCarboxylation

The invention discloses nanometer carbon-coated boron nitride composite powder and its preparation method and use. The nanometer carbon-coated boron nitride composite powder comprises a nanometer carbon material and boron nitride. The nanometer carbon material is uniformly adsorbed and coats boron nitride surface so that a composite coated structure is formed. The preparation method comprises carrying out surface functionalization on the boron nitride powder by an amino coupling agent, carrying out oxidative carboxylation treatment on the nanometer carbon material, and carrying out electrostatic adsorption on the nanometer carbon material on the surface of boron nitride so that a desired product is obtained. The nanometer carbon-coated boron nitride composite powder utilizes boron nitride as a nanometer carbon material carrier, is conducive to nanometer carbon material addition and dispersion, has a high efficiency heat-conduction electric-conduction network, has excellent heat conduction performances of the nanometer carbon material and boron nitride and electric conduction and infrared radiation characteristics of the nanometer carbon material, and has an important application value in the field of composite materials and functional paint. The preparation method has a simple process route, is suitable for large-scale production and has an important industrialization prospect.

Owner:江苏联科纳米科技有限公司

Thermal insulation coating for building exterior walls and preparation method thereof

InactiveCN111826045AWeakening of hydrogen bondsWeaken agglomerationReflecting/signal paintsCarbide siliconThermal insulation

The invention discloses a thermal insulation coating for building exterior walls. The thermal insulation coating is prepared from the following raw materials in parts by weight: 50-60 parts of a silicone acrylic emulsion, 18-22 parts of modified aerogel, 7-9 parts of floating beads, 3-4 parts of reinforcing filler, 2-3 parts of mirabilite and 0.6-1 part of auxiliaries. The invention also disclosesa preparation method of the thermal insulation coating. According to the invention, the modified aerogel is added into the coating, the silicon dioxide aerogel can be uniformly dispersed in the coating after being modified, and the aerogel can greatly improve the microporosity in the coating and prolong the heat conduction path, so that the thermal insulation performance of the coating is improved; besides, materials (rutile titanium dioxide and silicon carbide) capable of reflecting radiant heat are introduced to block a propagation path of radiant heat conduction, and a phase change energystorage material (mirabilite) is used as an efficient storage substance of heat energy, so that the coating has excellent heat preservation and heat insulation performance by starting from three paths(conduction, radiation and convection) of heat transfer.

Owner:马鞍山市金韩防水保温工程股份有限公司

High-performance infrared radiation paint used for industrial furnace

ActiveCN107474723AIncreased impurity levelsIncrease concentrationFireproof paintsPolyamide coatingsDiiron TrioxideZirconia coating

The invention provides high-performance infrared radiation paint used for an industrial furnace. The paint comprises an infrared radiation agent, an infrared radiation modifying agent, a binding agent and a paint additive, wherein the infrared radiation agent comprises EN, SiO2, Mn2O3, SiC, Fe2O3 and CuO; the infrared radiation modifying agent is a zirconia coating of graphene. In the paint, a novel material of graphene and the cheaper materials of CuO, Fe2O3, SiC and the like are selected, so that the production cost can be effectively lowered; in addition, as the paint has a special structure of graphene, so that the impurity energy level and free carrier concentration in the basic materials can be remarkably increased, the using temperature of the paint is increased, and the radiation performance is remarkably improved.

Owner:浙江中智检测技术有限公司

Infrared radiation paint

InactiveCN101153125AImprove heat resistanceImprove impact performanceAlkali metal silicate coatingsHigh rateHeat resistance

Coating of infrared radiation is made of 20 percent of radiator, 40 percent of additive and 40 percent of bonding material. The radiator consists of solid soluble zirconia and titania; the additive consists of silicon carbide, kaolin or particles; the bonding material consists of silicate solution; the silicate solution is 97 percent to 98 percent of the total weight of the bonding material. The radiator, additive and boning material is mixed well and then the product can be made. The present invention has the advantages of the good heat-resistance and heat-resistant impact resistance, high rate of infrared radiation, good process, strong adhesive capability, corrosion resistance and low cost.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

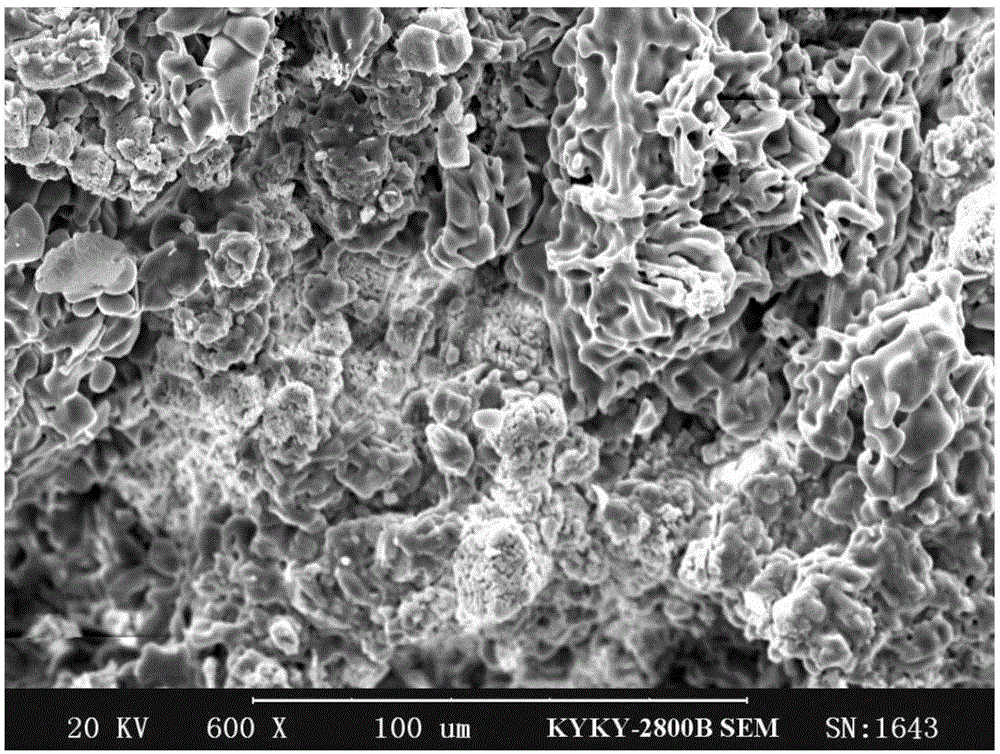

Preparation of mineral radiative powder and application thereof to building heat-insulating coating

The invention discloses preparation of mineral radiative powder and application thereof to a building heat-insulating coating. The mineral radiative powder is formed by mixing SiO2, Al2O3, MgO, Fe2O3, ZnO, Cr2O3, Co2O3, Ni2O3 and B2O3 proportionally, and performing three-stage calcination at 900 DEG C, 1,000 DEG C and 1,250 DEG C; the prepared products are mainly defective spinel phases, and the defective structures have a radiance of 0.94 within the wave band of 2.5-25 [mu]m. The filler provided by the invention is prepared through the three-stage calcination, and the calcinated products are of defective spinel structures; impurity ions cause lattice distortion, the symmetry of lattice vibration is reduced and the anharmonicity of polarized vibration is increased, which causes phonon combined radiation; the lattice distortion enhances radiance of infrared rays, so that the prepared coating has good radiative heat insulating performance.

Owner:SHANDONG UNIV OF SCI & TECH

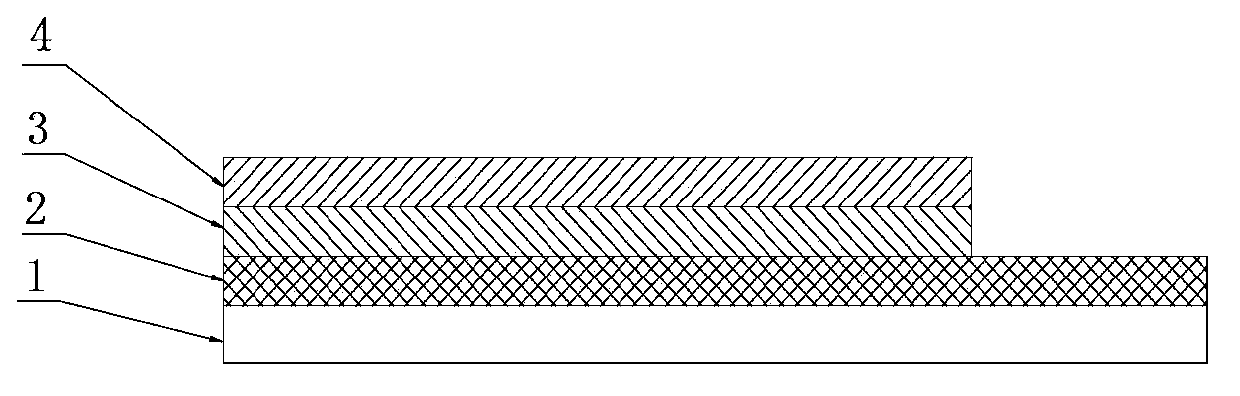

Selective absorbing coating

InactiveCN103388918AImprove infrared radiation rateReduce lossesSolar heat devicesMetal layered productsSurface layerGlass tube

The invention discloses a selective absorbing coating, which comprises a matrix, a metal layer, an absorption layer and a surface layer dielectric layer, wherein the metal layer, the absorption layer and the surface layer dielectric layer are successively arranged along the direction far away from the matrix; the metal layer is covered on the matrix; an area, which can be subjected to direct solar radiation, of the metal layer is at least covered by the absorption layer; and the absorption layer is at least covered by the surface layer dielectric layer. The selective absorbing coating is suitable for the inner glass tube of an all-glass vacuum solar collector tube, the outer wall of the inner tube of the all-glass vacuum solar collector tube, the metal fin of a glass-metal sealing heat tube and a high temperature resistant condensation tube or the metal plate core of a flat plate heat absorption plate. According to the selective absorbing coating disclosed by the invention, the infrared radiation rate of the absorption layer is far higher than that of the metal layer. On the premise of guaranteeing efficient absorption, the heat loss under the high temperature state is reduced to the greatest extent. When the temperature difference between the inside of a heat collector and the external environment is bigger, the effect on reducing the heat loss by the selective absorbing coating disclosed by the invention is more obvious.

Owner:北京天普太阳能工业有限公司

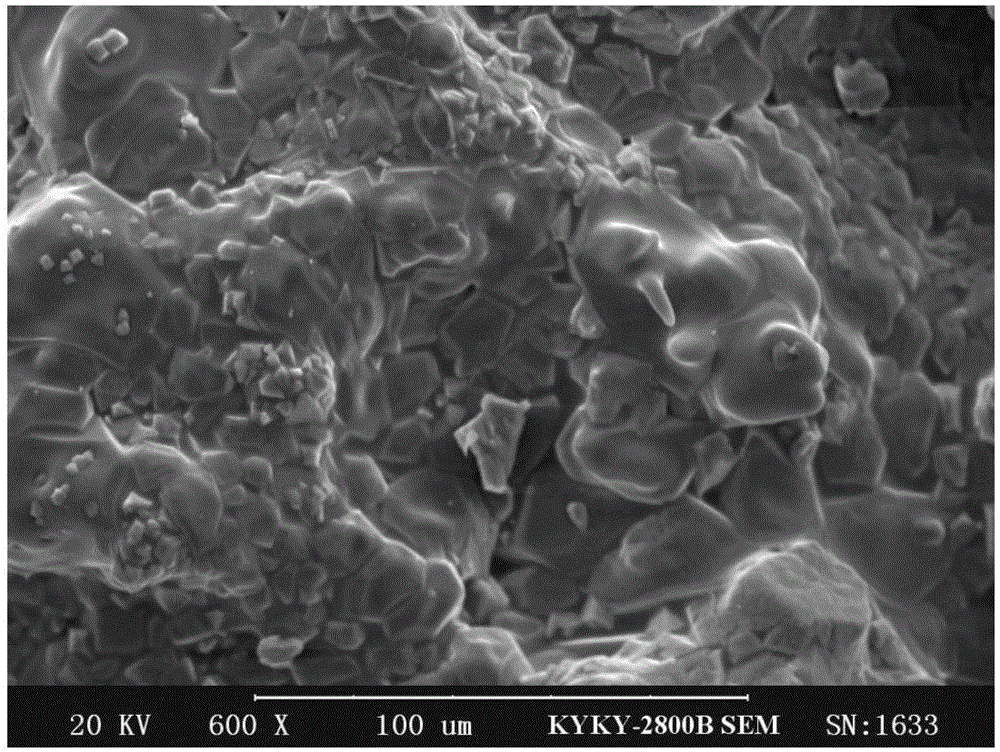

Preparation method of cordierite infrared radiation multiphase ceramic

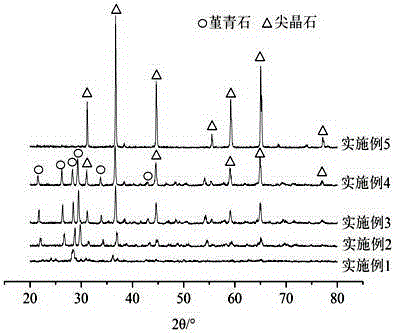

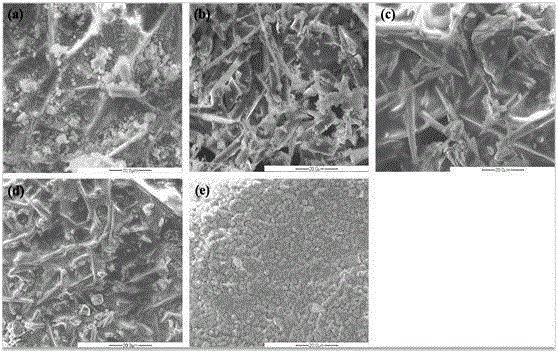

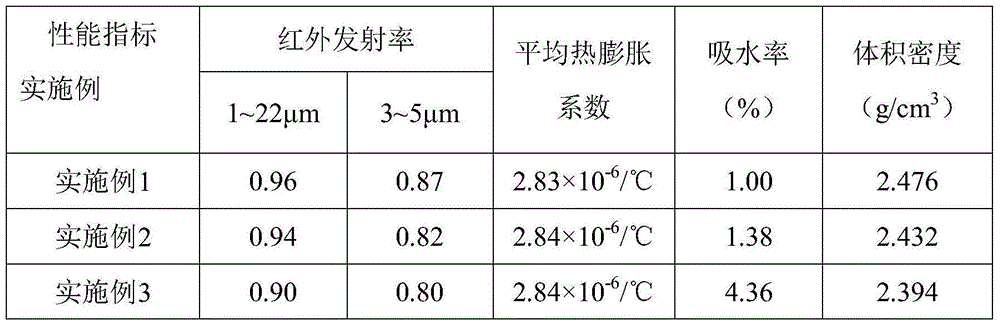

InactiveCN109095911AImprove infrared radiation performanceQuality improvementThermal expansionCordierite

The invention relates to a preparation method of cordierite infrared radiation multiphase ceramic. The preparation method comprises the following steps: (1) weighing 35% of Fe2O3, 45% of MnO2, 10% ofCo2O3 and 10% of CuO in percentage by weight and preparing ferrite through a gel method; (2) weighing 10% of ferrite, 87% of cordierite and 3% of calcined kaolin calculated in percentage by weight, grinding and uniformly mixing the raw materials with an agate mortar to obtain powder for later use; (3) adding a binder solution which accounts for 3% of the total weight of the powder to granulate andaging for 24 to 36 hours, (4) pressing the powder into a shape and drying to obtain a ceramic blank; (5) firing the ceramic blank to obtain the cordierite infrared radiation multiphase ceramic. The preparation method of the cordierite infrared radiation multiphase ceramic disclosed by the invention adopts ferrite composite cordierite with high radiation performances and the calcined kaolin, so that the prepared infrared radiation ceramic is lower in thermal expansion coefficient, good in thermal shock resistance and higher in infrared radiation properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

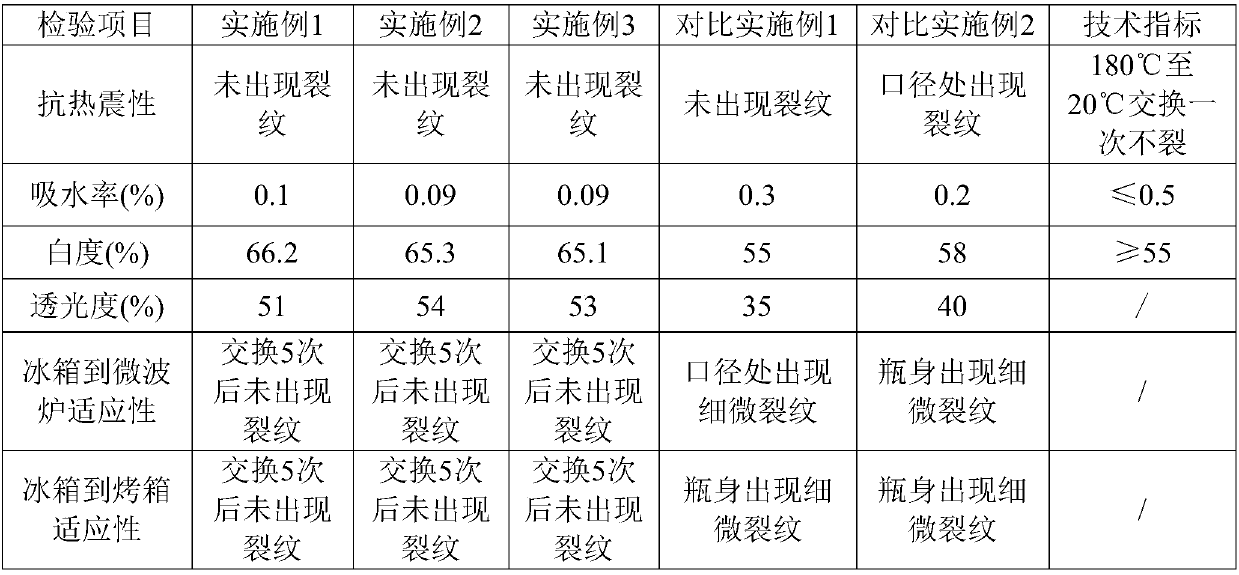

Far infrared self-generated enamel bone china prepared by highly utilizing desert material, and preparation process of far infrared self-generated enamel bone china

The invention relates to far infrared self-generated enamel bone china prepared by highly utilizing a desert material, and a preparation process of the far infrared self-generated enamel bone china. The far infrared self-generated enamel bone china is prepared from the following raw materials in percent by weight: 50%-60% of sand from a desert, 10%-20% of pyrophyllite, 8%-15% of knar clay, 10%-18%of coal gangue, 2%-4% of magnesium-based bentonite, 4%-8% of potassium feldspar, 4%-8% of albite, 2%-5% of spodumene, 3%-5% of zirconium silicate and 4%-6% of wollastonite. The preparation process ofthe bone china comprises the following steps: blending according to a formula, performing ball milling, sieving, removing iron, performing filter pressing, performing primary pugging, performing secondary pugging, shaping and firing. The self-generated enamel bone china prepared by the invention is better in toughness, higher in strength and good in thermal stability, is suitable for splat cooling and heating environments, and has better radiation rate and wide spectrum at the same time.

Owner:温克仁

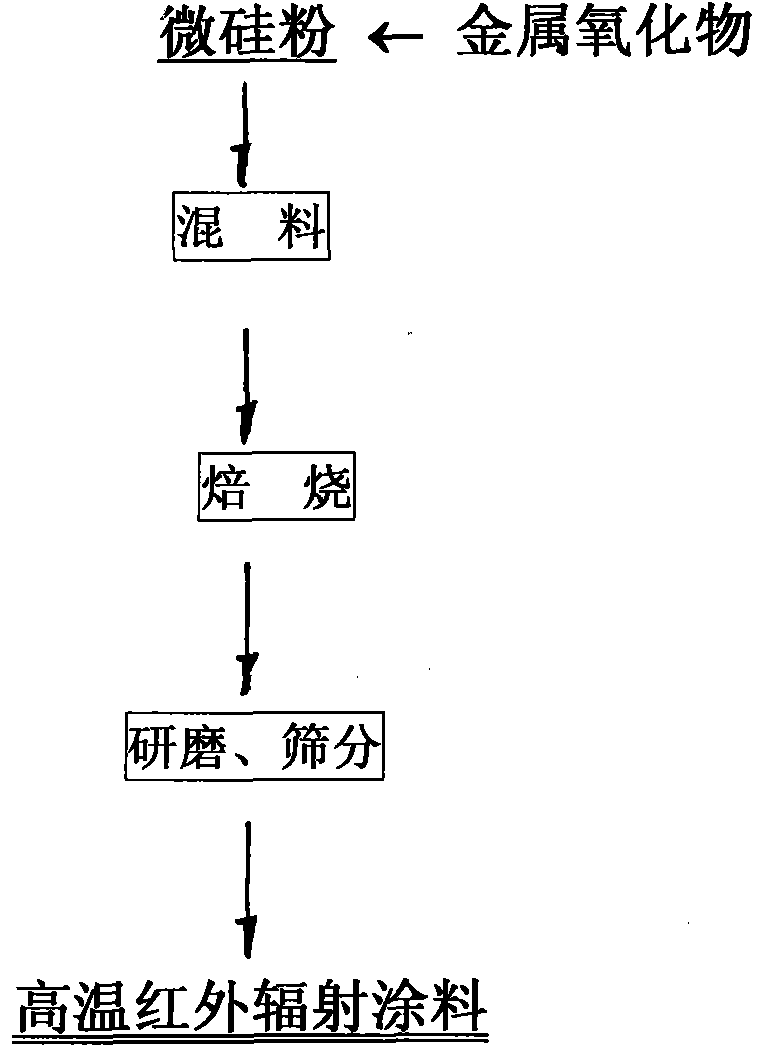

A kind of high temperature infrared radiation coating for industrial kiln and its preparation method

The invention discloses a high-temperature infrared radiant coating used for an industrial furnace and a preparation method thereof. The high-temperature infrared radiant coating is mainly prepared from an infrared radiant base material, a high-temperature thermal expansivity regulator and a binder by direct ball-milling and mixing, wherein the infrared radiant base material has a stable spinel structure; the high-temperature thermal expansivity regulator is selected from micro silicon dioxide powder; the binder is one or two selected from the group consisting of high-temperature sol and micro oxide powder; and the infrared radiant base material is prepared by high-temperature sintering of transition metal oxides prepared by proportioning and mixing of MnO2, industrial grade chrome green, Co2O3, Ni2O3, CuO, Fe2O3, TiO2 and ZrO2. According to the invention, infrared radiance of the coating can be improved; stability of the infrared radiance of the coating can be guaranteed; meanwhile, the service life is enhanced; the process is simple and has no pollution to products in a furnace; and strong bonding strength and thermal shock resistance are achieved.

Owner:ZHEJIANG UNIV

Infrared radiation paint

InactiveCN101153124AImprove heat resistanceImprove impact performanceAlkali metal silicate coatingsHigh rateHeat resistance

Coating of infrared radiation is made of 20 percent of radiator, 45 percent of additive and 35 percent of bonding material. The radiator consists of solid soluble zirconia and titania; the additive consists of silicon carbide, kaolin or particles; the bonding material consists of silicate solution; the silicate solution is 97 percent to 98 percent of the total weight of the bonding material. The radiator, additive and boning material is mixed well and then the product can be made. The present invention has the advantages of the good heat-resistance and heat-resistant impact resistance, high rate of infrared radiation, good process, strong adhesive capability, corrosion resistance and low cost.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Infrared radiation paint

InactiveCN101153129AImprove heat resistanceImprove impact performanceCoatingsHeat resistanceZirconium dioxide

Coating of infrared radiation is made of 15 percent of radiator, 40 percent of additive and 45 percent of bonding material. The radiator consists of solid soluble zirconia and titania; the additive consists of silicon carbide, kaolin or particles; the bonding material consists of silicate solution; the silicate solution is 97 percent to 98 percent of the total weight of the bonding material. The radiator of15 percent, additive of 40 percent and boning material of 45 percent are mixed well and then the product can be made. The present invention has the advantages of the good heat-resistance and heat-resistant impact resistance, high rate of infrared radiation, good process, strong adhesive capability, corrosion resistance and low cost.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Heat-isolating high-temperature-resistant protecting coating and preparation process thereof

InactiveCN109337577AEasy to processWillfulFireproof paintsAnti-corrosive paintsPolyvinyl alcoholHot Temperature

The invention discloses a heat-isolating high-temperature-resistant protecting coating which is prepared from the following components: polysiloxane, resin, pigments and filler, a dispersant, a flatting agent, a defoamer, a pH regulator, a curing agent and polyvinyl alcohol. The invention also designs a preparation process of the heat-isolating high-temperature-resistant protecting coating. The preparation process is simple and feasible. The prepared heat-isolating high-temperature-resistant protecting coating has a good heat-isolating property, has relatively high high-tempreature resistance,and can play a very good protecting role, so that the service life of the coating is prolonged, and the cost is lowered.

Owner:江苏天泽教育咨询有限公司

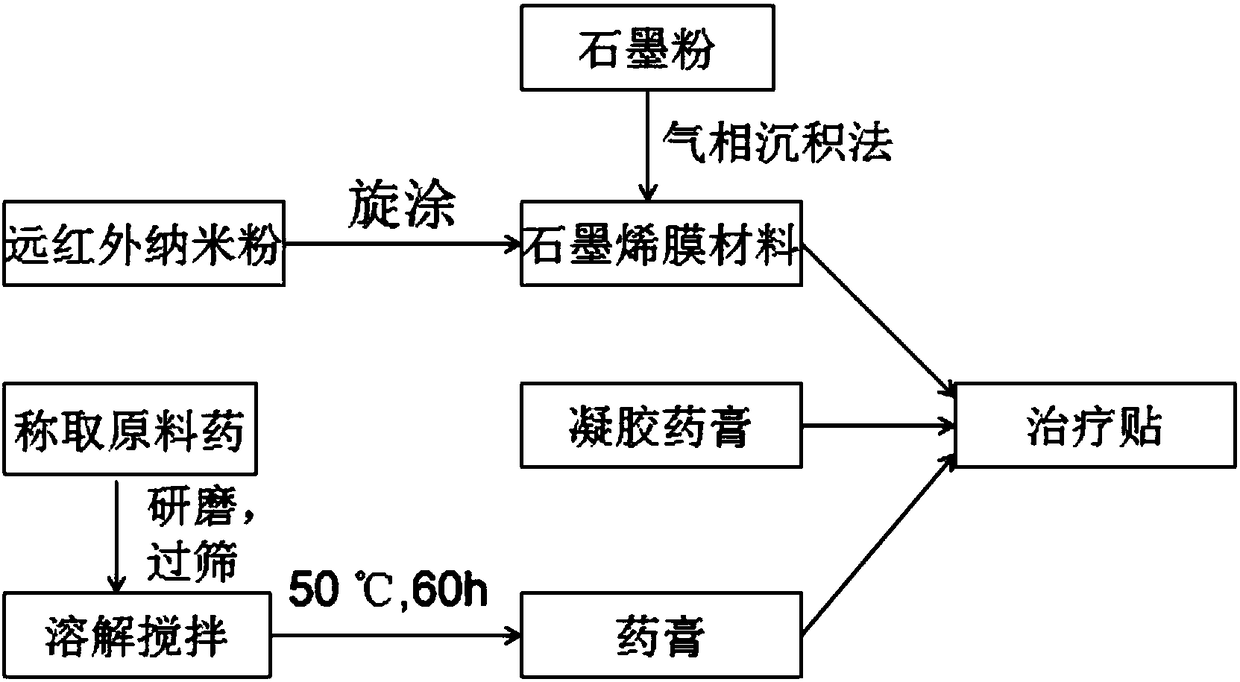

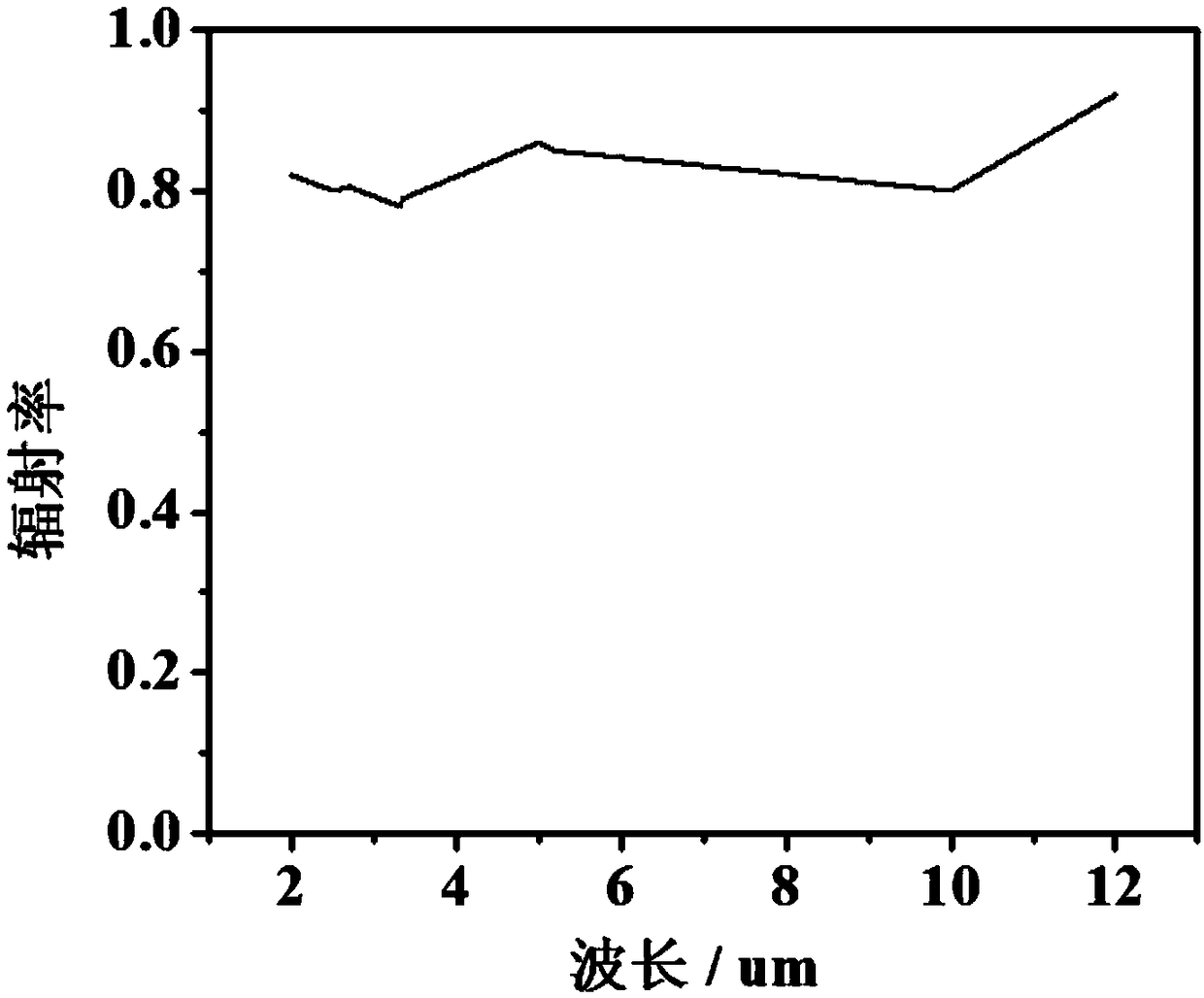

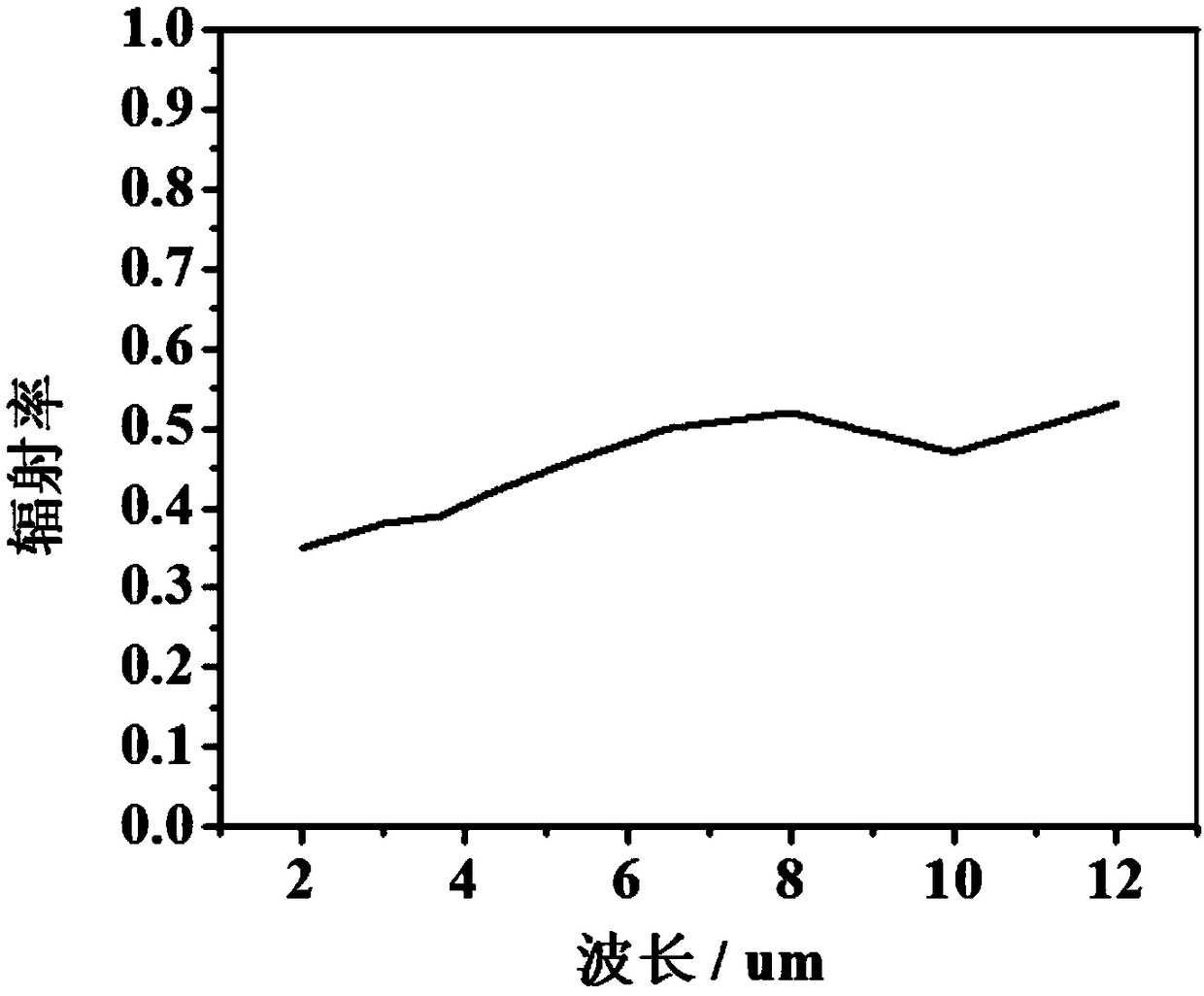

Graphene patch for treating hyperplasia of mammary glands and preparation method thereof

InactiveCN108310155ARelieve pain and discomfortRelieve redness and other problemsAlgae medical ingredientsLight therapyLicorice rootsFar infrared

The invention discloses a graphene patch for treating hyperplasia of mammary glands and a preparation method thereof. The graphene patch comprises a back lining layer, a medicine layer and an anti-sticking layer, wherein the medicine layer is arranged above the back lining layer; the anti-sticking layer is arranged under the back lining layer; raw medicines for treating hyperplasia of mammary glands are arranged at the middle position of the medicine layer and comprise lychee seeds, semen cuscutae, buddhas lamp twig and leaf, seaweed, fructus corni, honey-fried licorice root and ginger processed rhizoma pinelliae which are capable of promoting blood circulation to remove blood stasis and softening hardness to dissipate stagnation; a graphene film layer is arranged under the raw medicines;the thickness of the graphene film layer is 0.1-0.3mm; the graphene film layer is uniformly coated with far infrared nanopowder. The graphene patch has high normal-temperature radiation rate; the macromolecular activity in the living organisms can be activated; the graphene patch for treating hyperplasia of mammary glands is prepared by an infrared microwave physiotherapy method with combination of a traditional Chinese medicine administration technology, effectively penetrates the body by means of the far infrared physiotherapy effect of graphene, initiates the heat effect, accelerates bloodcirculation, is high in infrared radiation rate and excellent in medicine delivery, and has a good curative effect.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

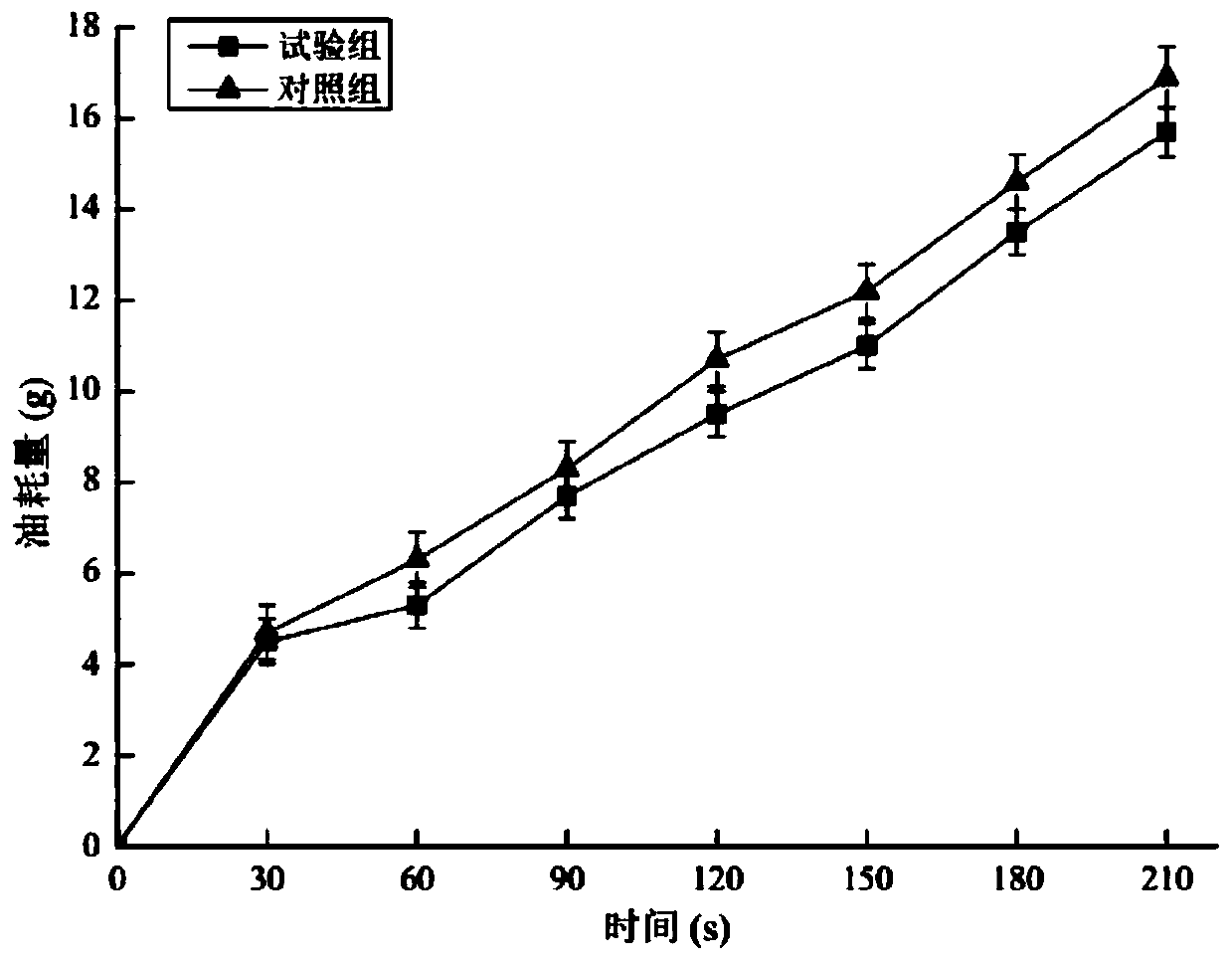

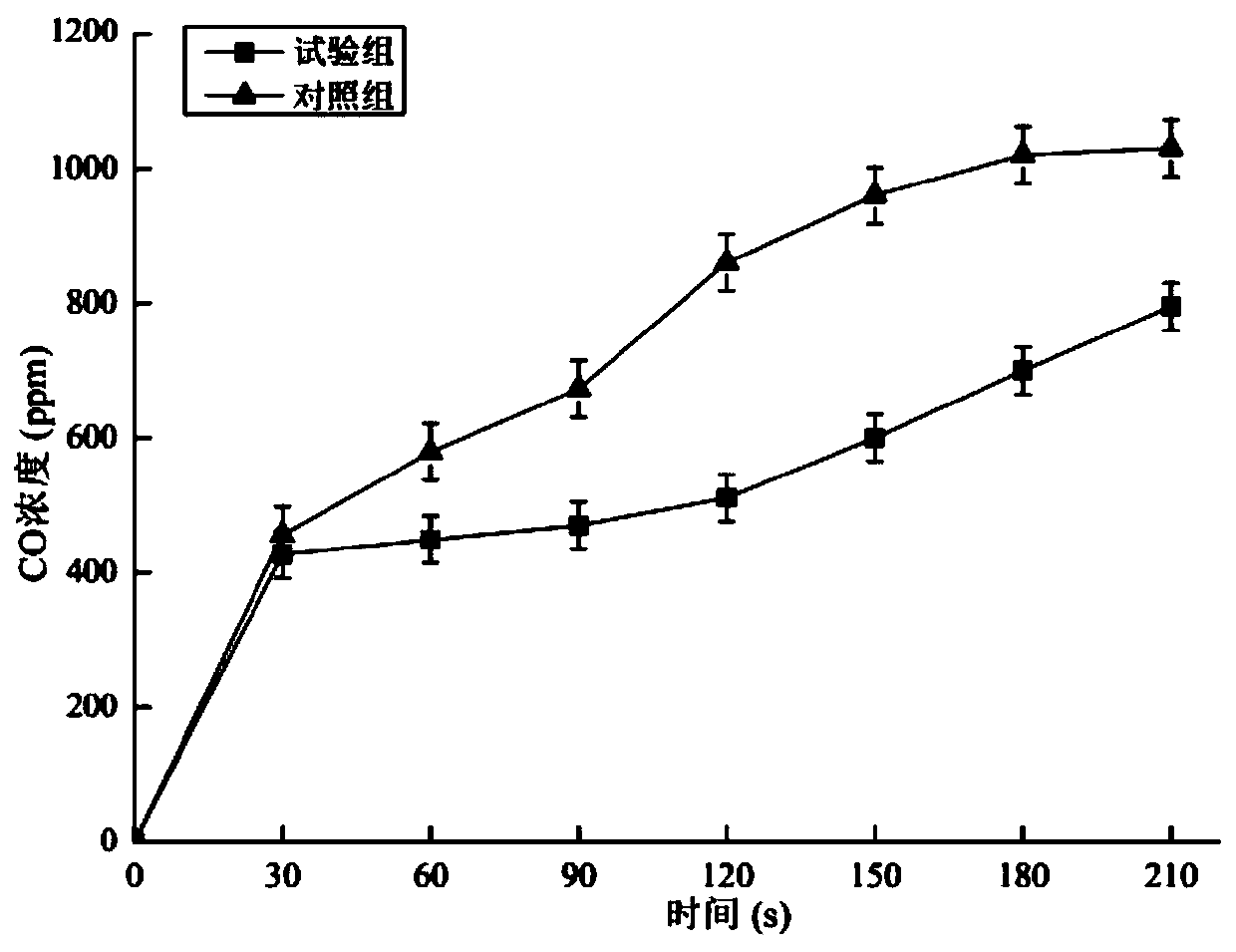

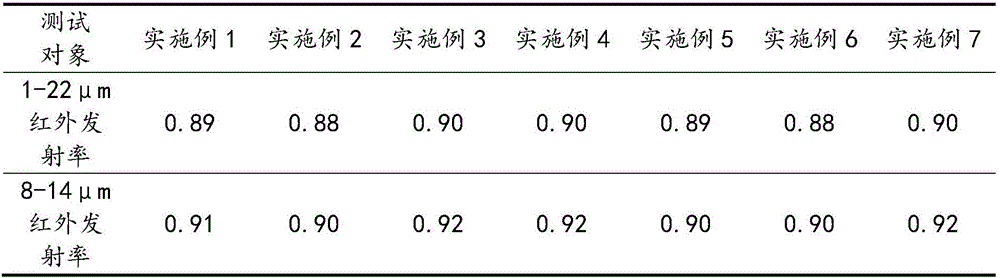

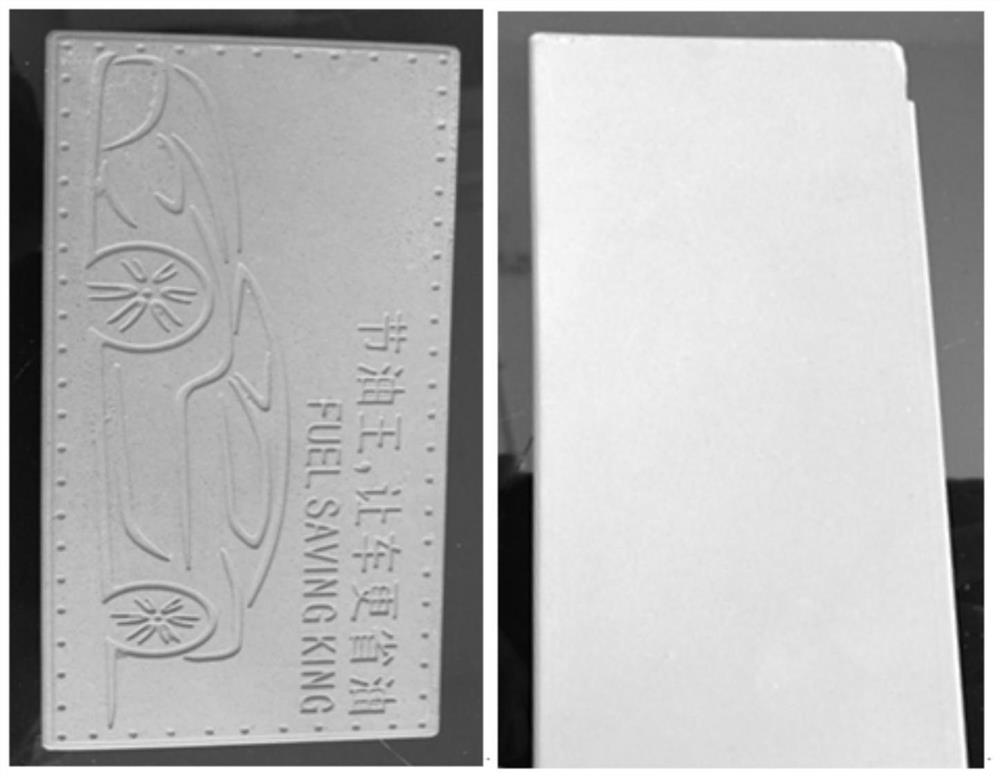

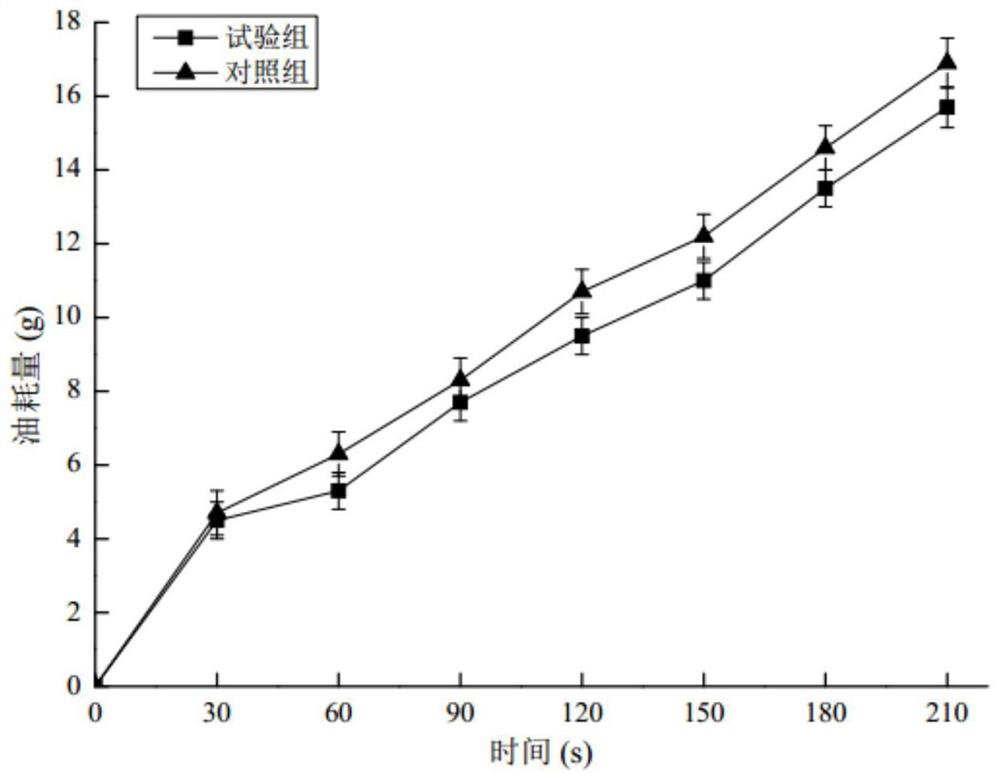

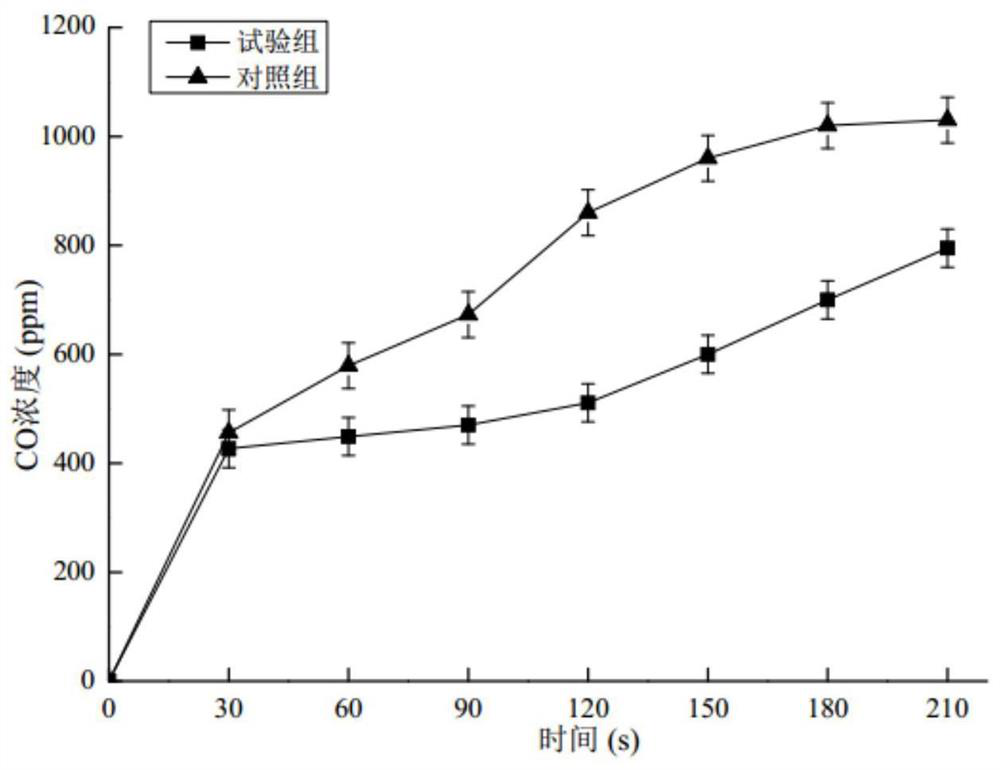

Oil-saving vehicle-protecting graphene composite material and preparation method thereof

ActiveCN110527566AQuality improvementImprove combustion efficiencyLiquid carbonaceous fuelsFuel additivesMaterials scienceEnergy conservation

The invention provides an oil-saving vehicle-protecting graphene composite material, and belongs to the technical field of energy conservation. The composite material comprises a matrix and a graphenematerial which is dispersed in the matrix, wherein the matrix is mineral powder, the graphene material is loaded with negative ion bodies, and the graphene composite material is of a block-shaped porous structure with a pore diameter of less than 10 microns. The preparation method of the graphene composite material comprises the steps: mixing at least one binder with at least one additive, graphene powder and the mineral powder, then performing compression molding, and performing fixed dispersion on the graphene material in the matrix of the mineral powder. Through the graphene composite material, negative ions can be provided so as to improve the fuel combustion efficiency and power output, the fuel consumption amount per 100 kilometers is reduced after use, deposited carbon in automobile parts is reduced, emission of exhaust gas is reduced, and odor of the exhaust gas is thinned; and through the preparation method, agglomeration of graphene can be avoided, high infrared emissivity can be maintained, the amount of released negative ions by the product can be increased, the time of a release reaction is shortened, the surface roughness and friction coefficient of the product can be reduced, the wear resistance of the product can be enhanced, and the production cost is reduced.

Owner:常州兴烯石墨烯科技有限公司

High-infrared-emissivity ceramic and preparation method thereof

The invention provides high-infrared-emissivity ceramic and a preparation method thereof, and belongs to the field of inorganic nonmetallic functional ceramic materials. The high-infrared-emissivity ceramic is prepared from the following raw materials in percentage by weight: 30 to 40 percent of high-magnesium metallurgical nickel residues, 30 to 35 percent of Al2O3, 25 to 32 percent of SiO2, 3 to 7 percent of Y2O3 and 2 to 5 percent of K2CO3. According to the high-infrared-emissivity ceramic and the preparation method thereof, the high-magnesium metallurgical nickel residues are adopted as a raw material, so that wastes are utilized, and in addition, the advantages of high infrared emissivity, relatively lighter color, strong bending strength and the like can be achieved under the condition of no additional transition metal oxides.

Owner:东兴市红石谷食品饮料有限公司

A kind of graphene composite material and preparation method thereof for fuel-saving ambulance

ActiveCN110527566BQuality improvementImprove combustion efficiencyCombustion-air/fuel-air treatmentLiquid carbonaceous fuelsCompression moldingExhaust gas emissions

The invention provides a graphene composite material used for fuel-saving ambulances, which belongs to the technical field of energy saving, and includes a matrix and a graphene material dispersed in the matrix, the matrix is mineral powder, and the graphene material is loaded with negative ions; the graphene The composite material is a massive porous structure with a pore size less than 10 microns. The preparation method comprises mixing at least one binder with at least one additive, graphene powder, and mineral powder, and then performing compression molding to immobilize and disperse the graphene material in the mineral powder matrix. The graphene composite material in the present invention can provide negative ions to improve fuel combustion efficiency and power output, reduce fuel consumption per 100 kilometers after use, reduce carbon deposits in auto parts, reduce waste gas emissions, and lighten tail gas odor; the preparation method can avoid graphene Agglomeration maintains high infrared radiation rate, increases product anion release, shortens release reaction time, reduces product surface roughness and friction coefficient, enhances product wear resistance, and has low production cost.

Owner:常州兴烯石墨烯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com