Heat dissipation hydrophilic coating and preparation method thereof

A coating and hydrophilic technology, applied in coatings, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of difficult control of coating film formation, difficulty in obtaining uniform compounding with high volume content, poor compatibility, etc., to achieve The effect of superior dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

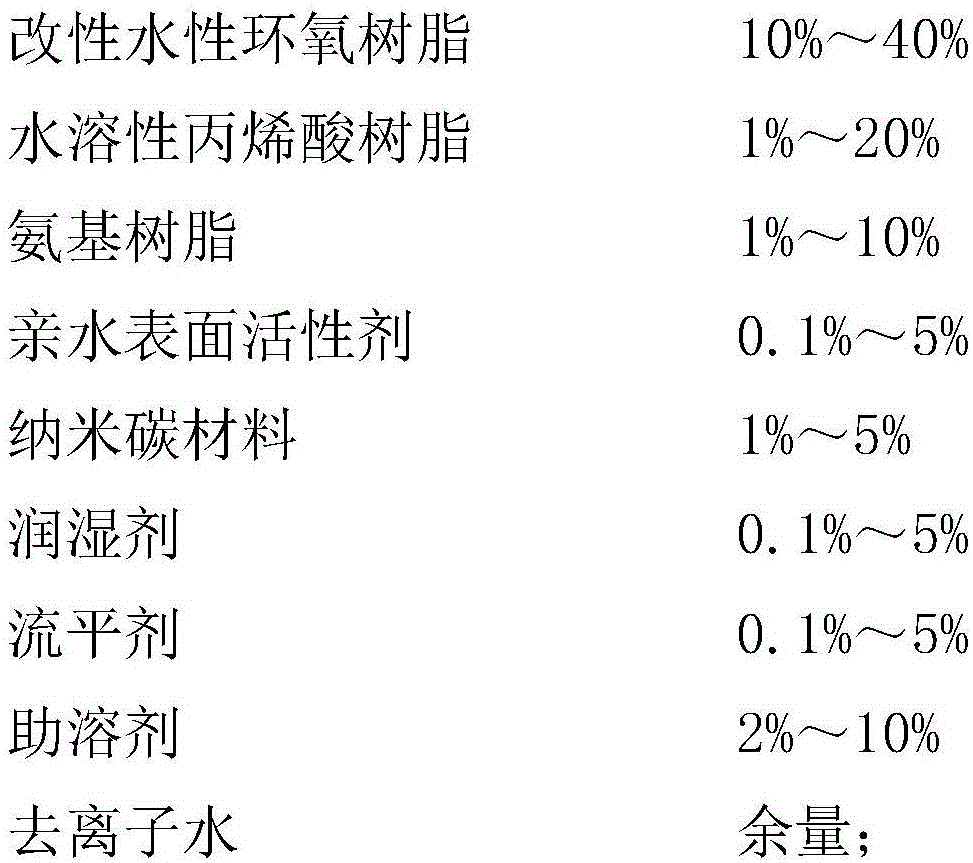

[0034] A heat-dissipating hydrophilic coating, its basic composition and weight percentage are:

[0035]

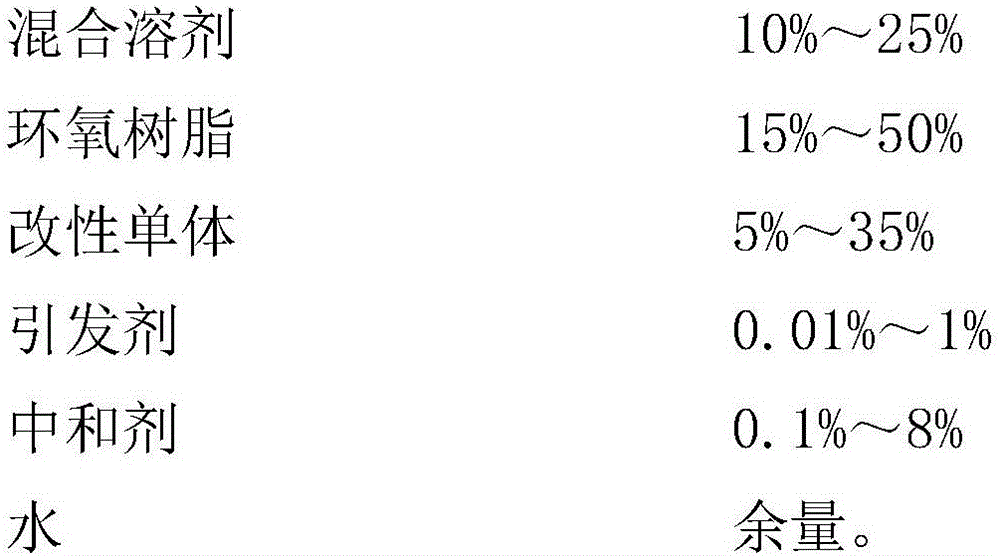

[0036] Wherein, the modified water-based epoxy resin is a water-based acrylic modified epoxy resin, which is a water-based resin formed by graft polymerization of the following components:

[0037]

[0038] Wherein, mixed solvent is made with the ratio of 2:3 for n-butanol and ethylene glycol butyl ether;

[0039] Described epoxy resin is epoxy resin E44;

[0040] The modified monomer is made by mixing styrene: methacrylic acid: methyl methacrylate: hydroxypropyl acrylate, and the styrene: methacrylic acid: methyl methacrylate: hydroxypropyl acrylate=3: 2:3:2;

[0041] Described initiator is benzoyl peroxide;

[0042] Described neutralizing agent is ethanolamine;

[0043] The water is deionized water.

[0044] The water-soluble acrylic resin is Soluryl-20;

[0045] Described amino resin is melamine formaldehyde resin;

[0046] Described hydrophilic surfactant...

Embodiment 2

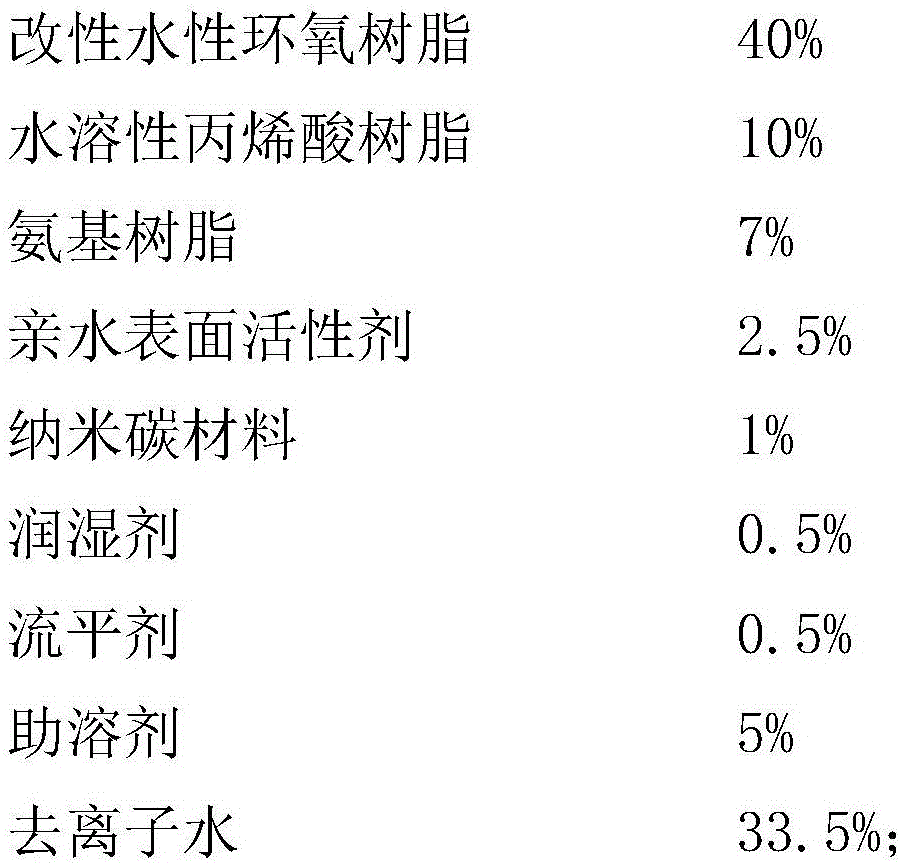

[0052]A heat-dissipating hydrophilic coating, its basic composition and weight percentage are:

[0053]

[0054] Wherein, the modified water-based epoxy resin is a water-based acrylic modified epoxy resin, which is a water-based resin formed by graft polymerization of the following components:

[0055]

[0056] Wherein, mixed solvent is made with the ratio of 2:3 for n-butanol and ethylene glycol butyl ether;

[0057] Described epoxy resin is epoxy resin E44;

[0058] The modified monomer is prepared by mixing styrene, methacrylic acid, methyl methacrylate, and isooctyl acrylate in a ratio of 3:2:3:2;

[0059] Described initiator is azobisisobutyronitrile;

[0060] Described neutralizing agent is N-methyl monoethanolamine;

[0061] The water is deionized water.

[0062] The water-soluble acrylic resin is Soluryl-90;

[0063] Described amino resin is urea-formaldehyde resin;

[0064] Described hydrophilic surfactant is sodium dodecylbenzenesulfonate;

[0065] The n...

Embodiment 3

[0070] A heat-dissipating hydrophilic coating, its basic composition and weight percentage are:

[0071]

[0072] Wherein, the modified water-based epoxy resin is a water-based acrylic modified epoxy resin, which is a water-based resin formed by graft polymerization of the following components:

[0073]

[0074] Wherein, mixed solvent is made with the ratio of 2:3 for n-butanol and ethylene glycol butyl ether;

[0075] Described epoxy resin is epoxy resin E44;

[0076] The modified monomer is prepared by mixing styrene, methacrylic acid, methyl methacrylate, and butyl methacrylate in a ratio of 3:2:3:2;

[0077] The initiator is methyl ethyl ketone peroxide;

[0078] Described neutralizing agent is NN-dimethylethanolamine;

[0079] The water is deionized water.

[0080] The water-soluble acrylic resin is Soluryl-120;

[0081] Described amino resin is hydrocarbyl melamine formaldehyde resin;

[0082] The hydrophilic surfactant is polyvinylpyrrolidone;

[0083] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com