Patents

Literature

74results about How to "Excellent electric heating performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room temperature-curing environment-friendly anticorrosive coating for circuit board and preparation method thereof

InactiveCN103305106ASmall smellFast curingAnti-corrosive paintsPolyurea/polyurethane coatingsAromatic solventZircon

The invention discloses a room temperature-curing environment-friendly anticorrosive coating for a circuit board and a preparation method thereof. The anticorrosive coating is prepared through complex formulation of the following raw materials by mass: 50 to 90 parts of a polyurethane modified alkyd resin, 20 to 80 parts of an environment-friendly solvent, 0.01 to 2.0 parts of a main drier, i.e., cobalt naphthenate, 0.01 to 3.0 parts of a secondary drier A which is one or two selected from the group consisting of zinc isocaprylate and zinc naphthenate, 0.01 to 6.0 parts of a secondary drier B which is one or two selected from the group consisting of zircon isocaprylate and zirconium naphthenate, 0.1 to 3.0 parts of a fluorescent agent and 0.01 to 2 parts of a stabilizing agent. The tri-proof coating for the circuit board provided by the invention uses a plant extract as a resin source and is prepared through complex formulation of the resin, the environment-friendly solvent, corresponding metal driers and other auxiliary agents. The prepared coating does not contain aromatic solvents like xylene and ethylbenzene and has the advantages of little smell, a fast curing speed, good adhesion and excellent electrothermal performance.

Owner:DONGGUAN BAOHAN LIGHT IND TECH

Anti-icing coating for surface of ultra-high voltage transmission line

The invention discloses anti-icing coating for the surface of an ultra-high voltage transmission line. The anti-icing coating for the surface of the ultra-high voltage transmission line is prepared from the following raw materials in parts by weight: 45-60 parts of fluorosilicon resin, 5-10 parts of functional nano ions, 5-8 parts of TiO2, 8-12 parts of nano SiO2, 0.5-1 part of an emulsifying agent, 0.5-1 part of a defoaming agent, 0.3-1 part of a flatting agent, 1-2 parts of a silane coupling agent and 20-30 parts of a solvent. The prepared anti-icing coating for the surface of the ultra-high voltage transmission line has the advantages that a contact angle with water is 128-168 degrees; compared with the condition that no anti-icing coating is coated, vertical adhesive force between a coating coated with the anti-icing coating and ice is reduced by 76-91.5%; and the anti-icing coating for the surface of the ultra-high voltage transmission line has good electric heating effect, average temperature rise is 10.8-16.5 DEG C, and the anti-icing coating for the surface of the ultra-high voltage transmission line also has good acid resistance, alkali resistance and insulating properties.

Owner:STATE GRID CORP OF CHINA +1

Composite electric heating carbon film and preparation method

A composite electric heating carbon membrane contains heat resisting substrate, electric carbon membrane ,oxidation resisting protective coating, conductive electrode, wherein the electric carbon membrane consisting of scale graphite, carbon fiber, steel fiber, zinc stearate, phenolic resin, pioloform and acetone, oxidation resisting protective coating consisting of boron carbide, silicon carbide, silica fume, mini-aluminium phosphate and water. The preparation method contains painting, hot pressing, oxygen isolation charring and solidifying after spraying. The surface heating temperature can be high than 2000 deg.C.

Owner:涂川俊

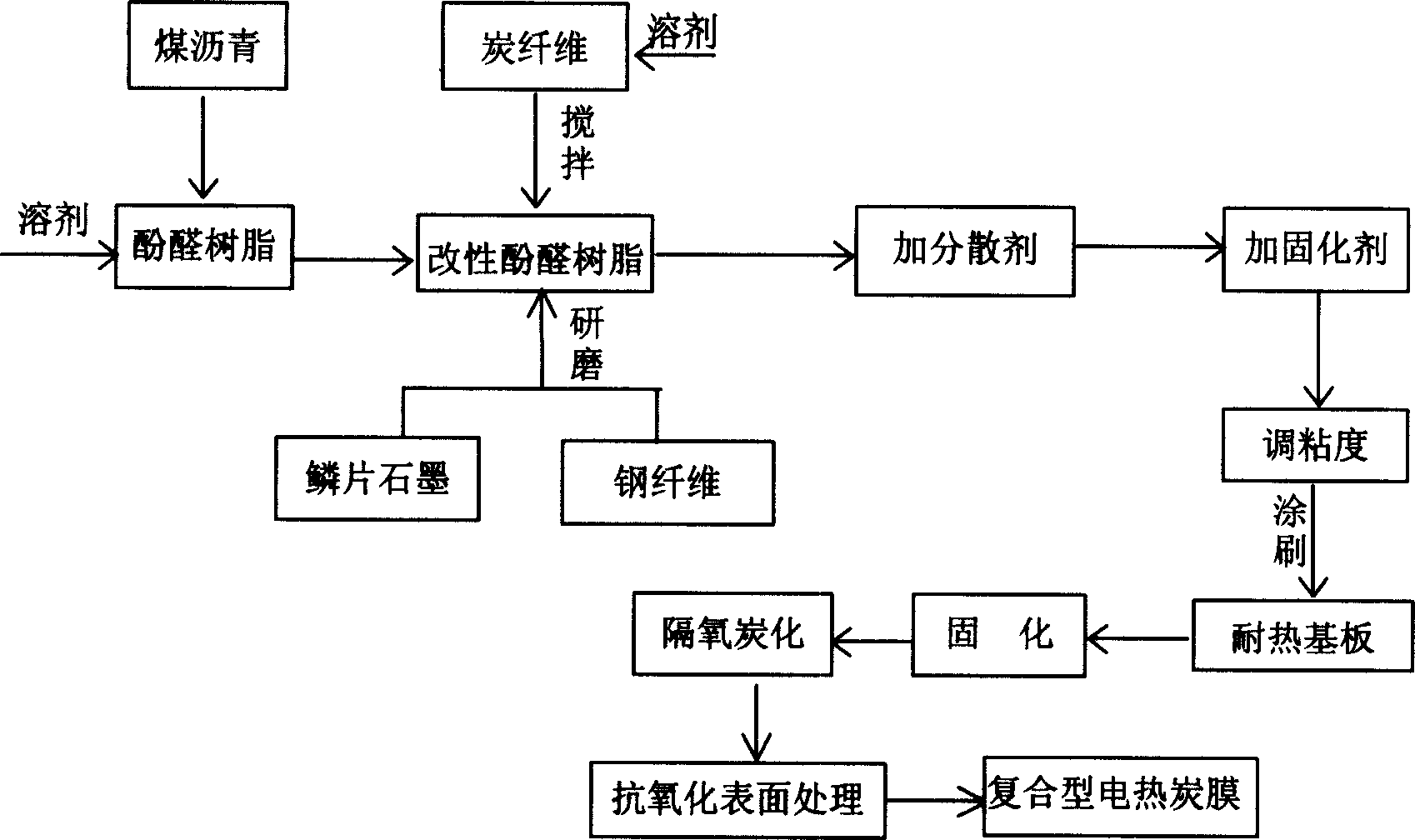

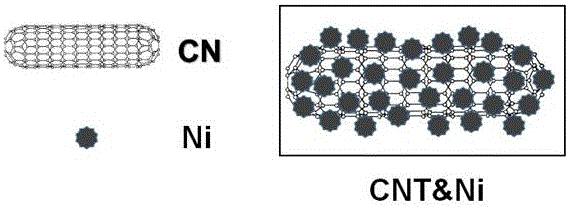

Water-based electrothermal coating and preparation method thereof

InactiveCN105778678AExcellent electric heating performanceImprove utilization efficiencyCoatingsWater basedLow voltage

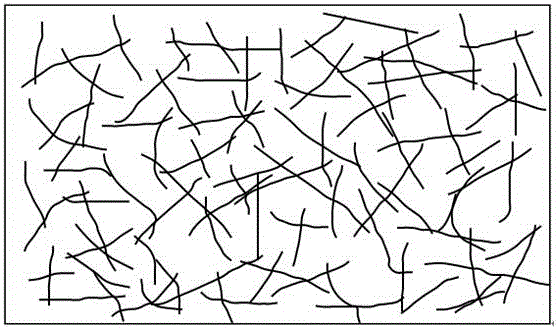

The invention discloses a water-based electrothermal coating and a preparation method of the water-based electrothermal coating. The coating comprises a water-based dispersion containing a matrix resin, nickel coated carbon nanotube composite powder and auxiliary materials which can be selectively added, wherein the composite powder comprises a carbon nanotube and nickel coated on the carbon nanotube. The preparation method of the water-based electrothermal coating comprises the following steps: the surface of a carboxylated carbon nanotube is subjected to the adsorption of nickel ions, and the nickel ions are reduced to a nickel elementary substance to be served as a nucleation core, chemical nickel-plating is carried out to form the nickel coated carbon nanotube composite powder, and then the composite powder is mixed with the water-based dispersion containing the matrix resin and ground to obtain a composite dispersion paste, and the composite dispersion paste is further compounded with the other auxiliaries to prepare the electrothermal coating. According to the invention, the contact resistance of the original carbon nanotube network can be greatly reduced, so that the coating has the advantages of being low in resistance, high in electrothermal conversion efficiency and the like, is suitable for being used as various electrothermal coatings driven by low voltage, and further has convenience in construction, safety and environmental protection and wide application prospects.

Owner:江苏联科纳米科技有限公司

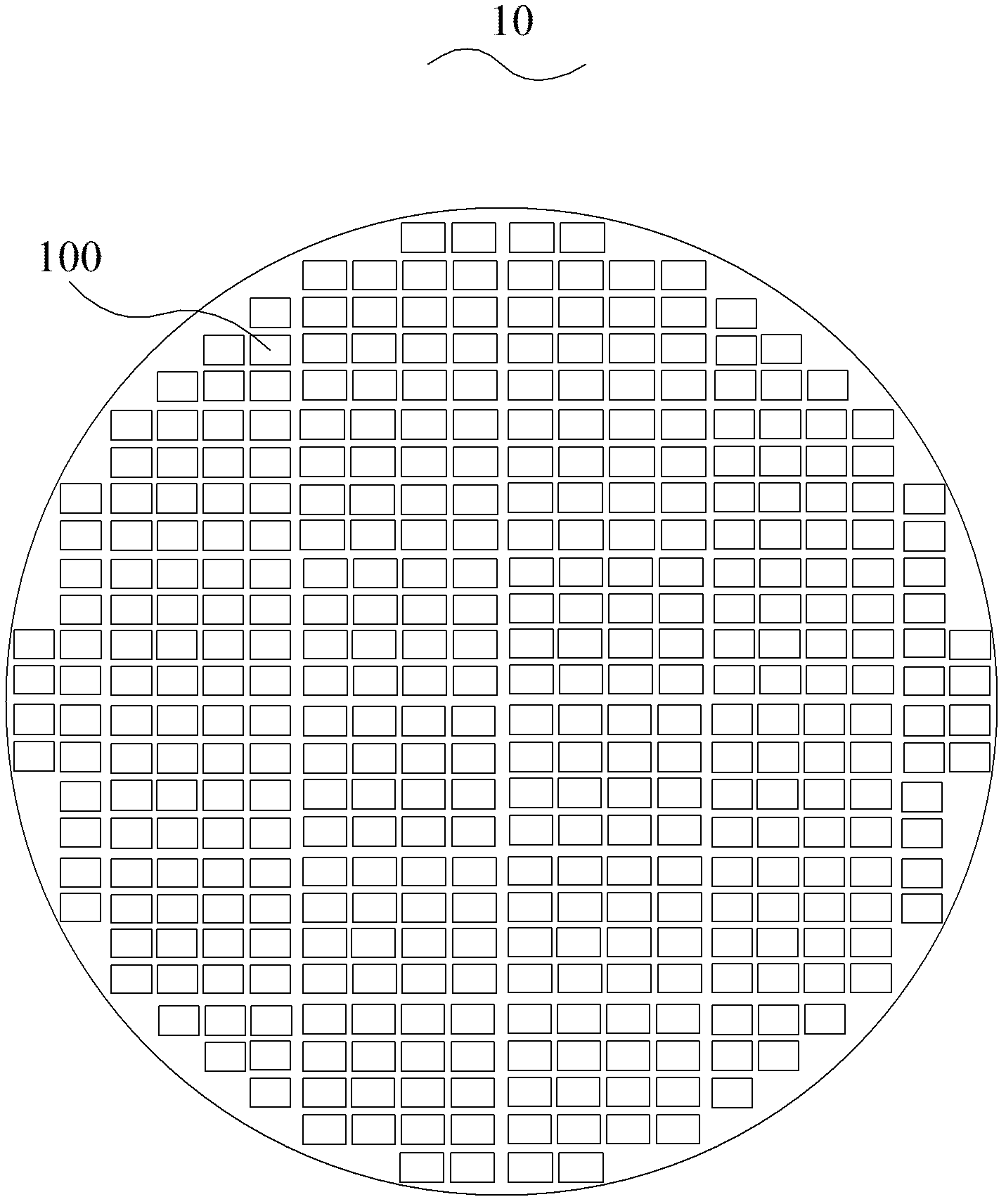

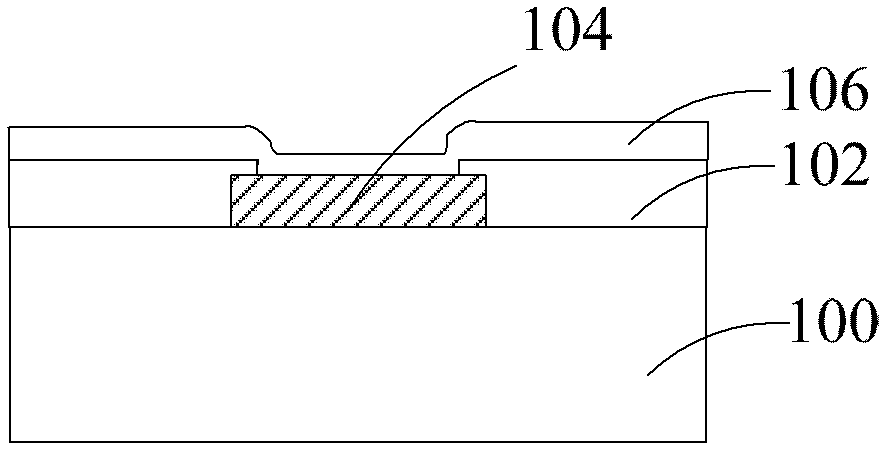

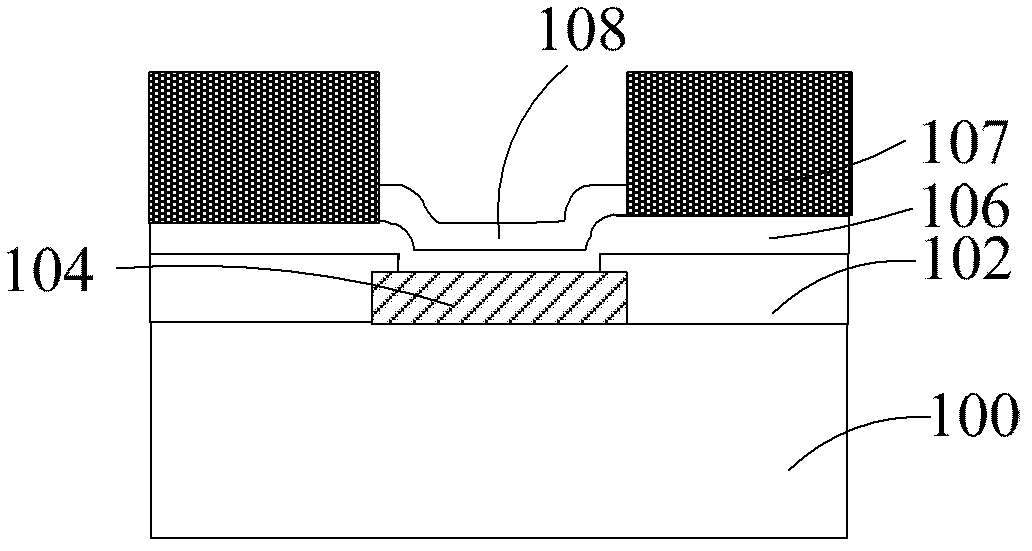

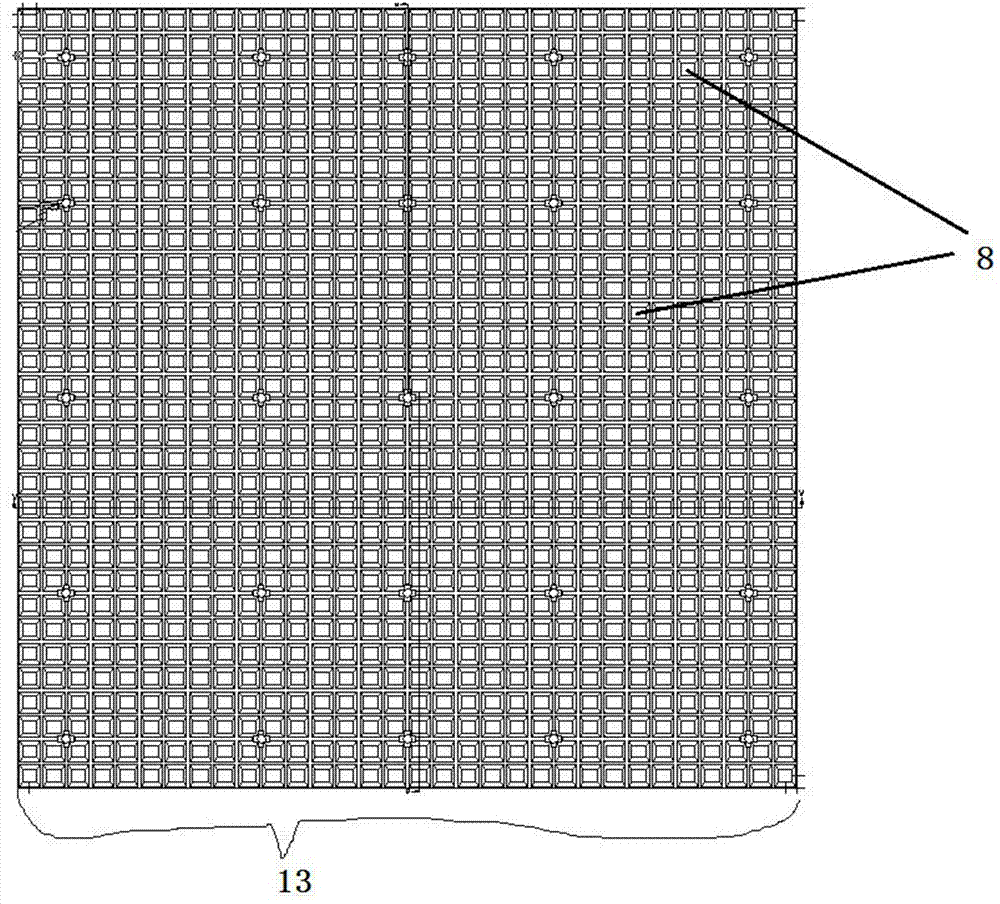

Optimizing process of wafer-level packaging

InactiveCN102543781AShort processEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveMetal

The invention relates to an optimizing process of wafer-level packaging. The optimizing process comprises the following steps of: forming a bonded metal convex block on a bonding pad of a chip, wherein the bonded metal convex block is higher than the surface of a passivation layer; forming a protective adhesive on the chip, wherein the protective adhesive is used for covering the passivation layer and the bonded metal convex block; grinding a protective adhesive layer for exposing the surface of the bonded metal convex block; and forming a solder bump on the exposed surface of the bonded metal convex block and refluxing. The process disclosed by the invention has the advantages of short flow process, easiness in management and control, low cost and high performances.

Owner:NANTONG FUJITSU MICROELECTRONICS

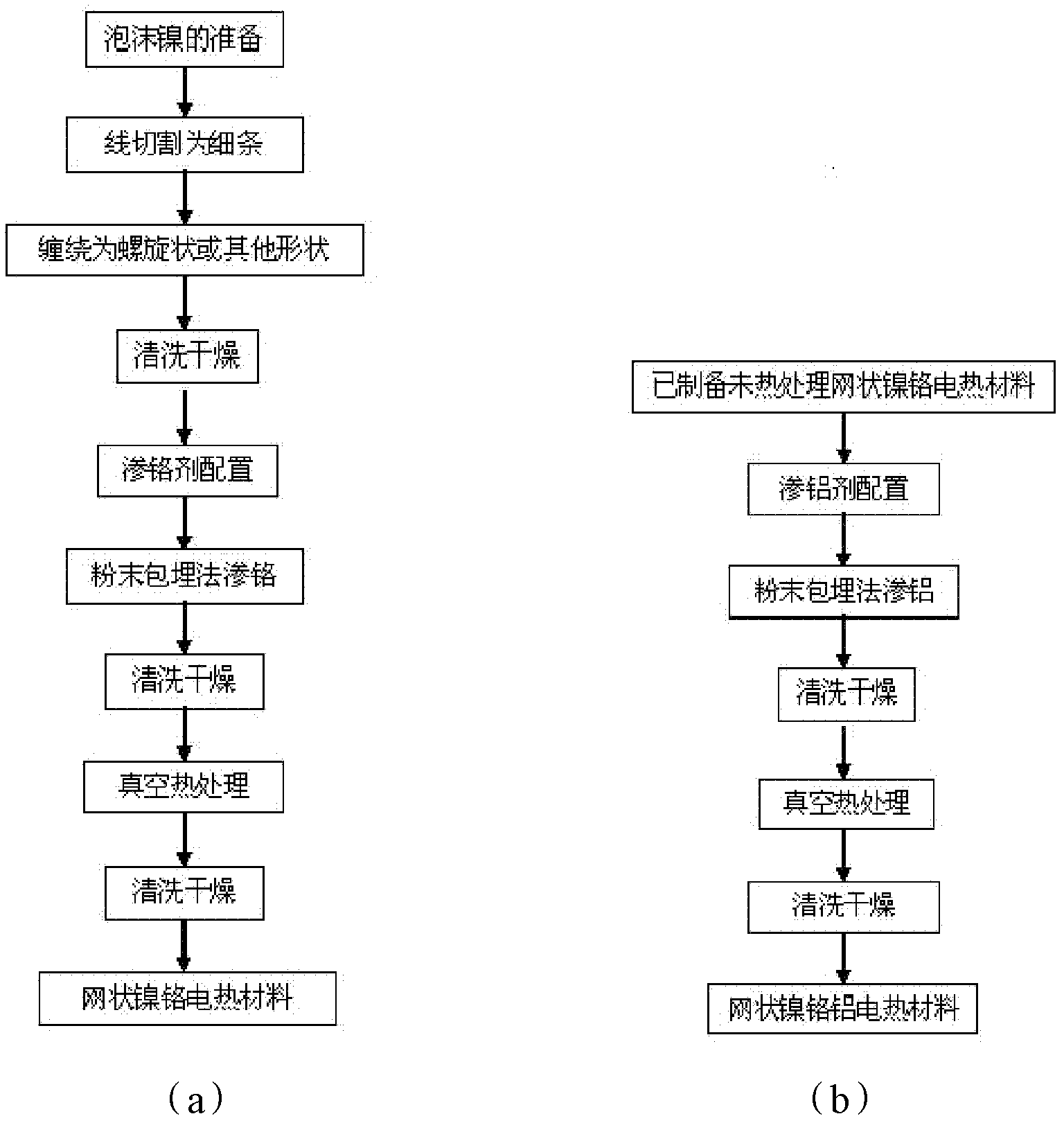

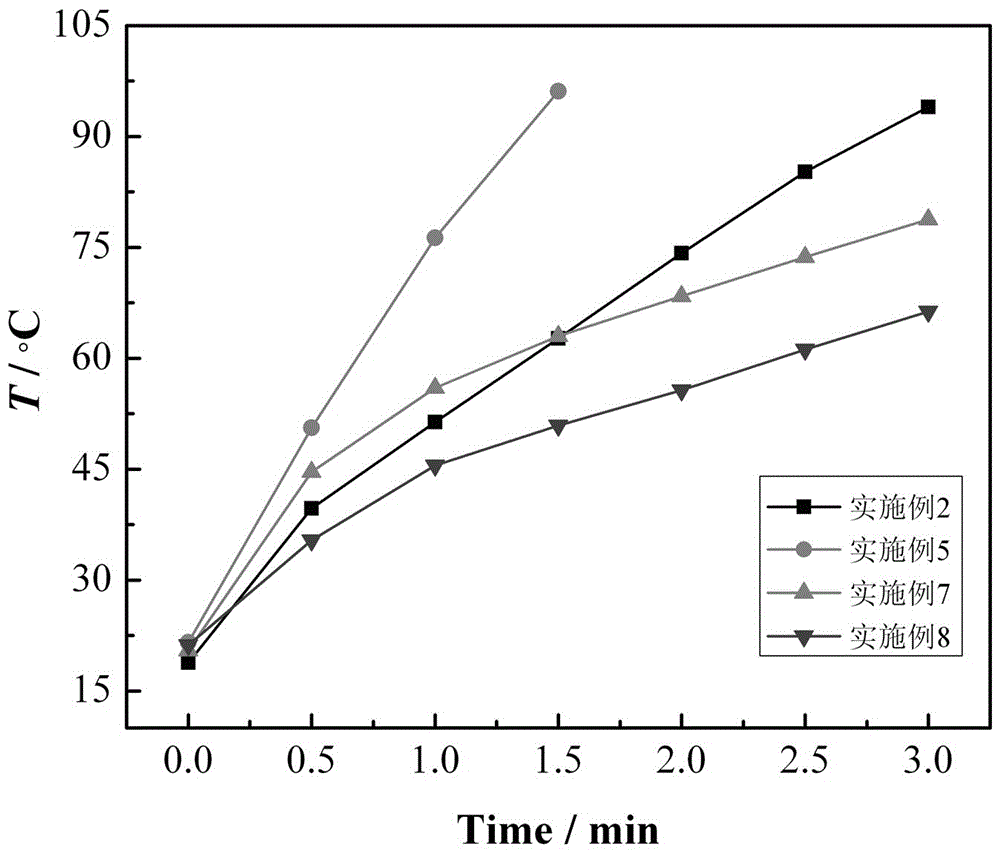

Meshed porous electric heating material for built-in porous heater and manufacturing method thereof

InactiveCN103002606AHigh porosityLarge specific surface areaSolid state diffusion coatingHeating element materialsPorosityMetal

The invention discloses a meshed porous electric heating material for a built-in porous heater and a manufacturing method thereof. The manufacturing method includes: processing a nickel foam plate into bar-type helical nickel foam, chromizing the bar-type helical nickel foam via solid phase chromizing method, and subjecting the chromized bar-type helical nickel foam to vacuum heat treatment to obtain the meshed porous electric heating material, or subjecting the bar-type helical nickel foam to vacuum heat treatment after the nickel foam is chromized and aluminized to obtain the meshed porous electric heating material. The manufactured electric heating material is a three-dimensional meshed porous structure formed by mutually communicated hollow thin-wall metal edges, is high in porosity, uniform in aperture size and distribution and large in specific surface area, the pores are mutually communicated and good in air permeability , thickness of the thin-wall metal is controllable, and a higher electrical resistivity can be obtained. The meshed porous electric heating material can be used for manufacturing the integrated heating core of the built-in porous heater.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite electric heating paint for flexible base material as well as preparation method and use thereof

ActiveCN105754462AExcellent electric heating performanceImprove oxidation resistancePolyurea/polyurethane coatingsEpoxy resin coatingsDaily livingMaterials science

The invention provides composite electric heating paint for a flexible base material as well as a preparation method and a use thereof. Organic or inorganic resin is used as a binder, and the composite material is added into various auxiliaries as conductive filler. The composite electric heating paint consists of the following components in parts by weight: 1-100 parts of composite conductive filler, 1-200 parts of a high molecular resin binder, 1-50 parts of auxiliaries and 100-300 parts of a solvent. The composite electric heating material can be quickly heated within 3-5 minutes, namely the heating rate is higher than the heating rate of the existing similar electric heating paint; the electric heating paint is suitable for being applied in a low-temperature heating field within 0-100 DEG C, is especially suitable for being applied to agricultural, military and industrial production as well as heating, warming and the like in daily life, and can be used for biological breeding, hatching electric-heating insulating chamber and the like in agriculture.

Owner:SHENYANG AEROSPACE XINGUANG GRP

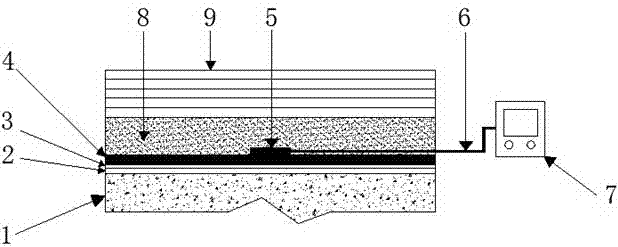

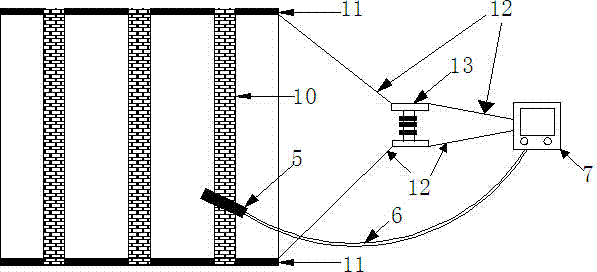

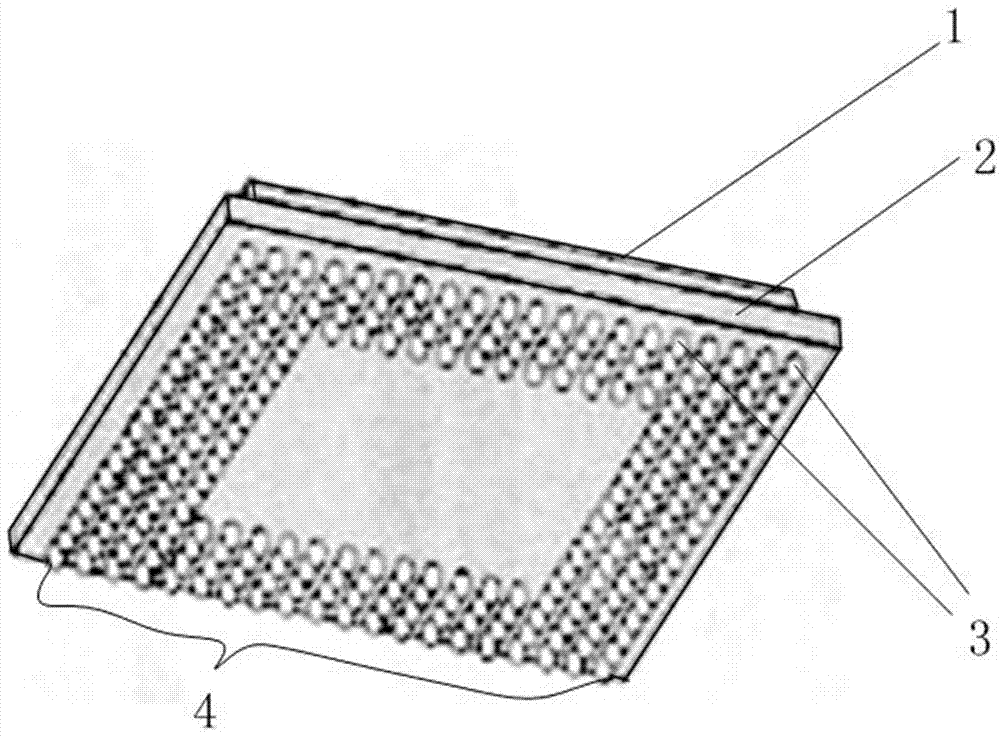

Carbon fiber floor heating device

InactiveCN104748200AStable chemical propertiesHigh tensile strengthLighting and heating apparatusElectric heating systemFiberTemperature control

The invention discloses a carbon fiber floor heating device. The device comprises an insulation reflecting layer arranged on a floor surface slab, wherein the insulation reflecting layer consists of a floor heating reflecting film and an insulation layer; a carbon fiber floor heating film is arranged at the upper part of an insulation layer of the insulation reflecting layer; a temperature sensor probe is arranged in the middle of the upper part of the carbon fiber floor heating film and communicates with a temperature control instrument through a temperature sensor conductor; the carbon fiber floor heating film is provided with a copper coil tape; the conductor externally connected to the copper foil tape is connected with one output voltage end of a transformer; the input voltage at the other end of the transformer is connected with a temperature control instrument inserting hole; a temperature control instrument socket is arranged at an external power supply. According to the device adopting the structure above, a carbon fiber cloth strip can be applied to an indoor floor heating device; good heating effect can be achieved; the operation is convenient and quick; the green and cleanness are achieved; the features of high energy consumption and low efficiency of the traditional heating manner can be overcome; in addition, indoor temperature can be preset under the control of the temperature control instrument; therefore, a user can use comfortable, and meanwhile, the energy waste can be reduced, and as a result, the energy consumption is reduced.

Owner:山东天意高科技有限公司

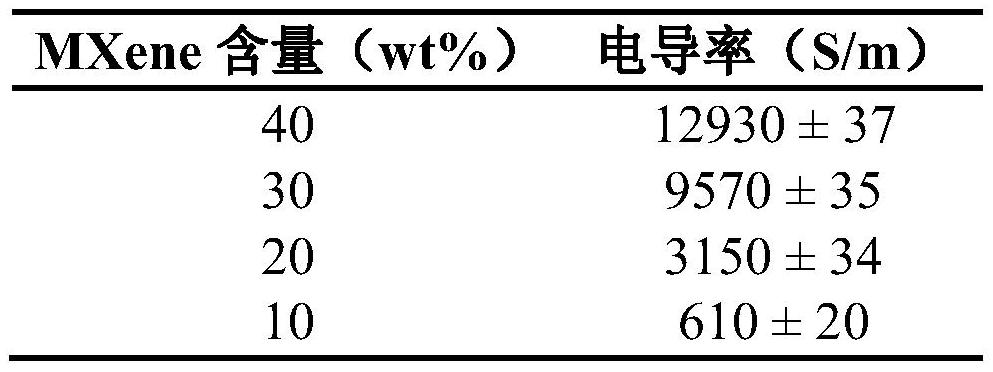

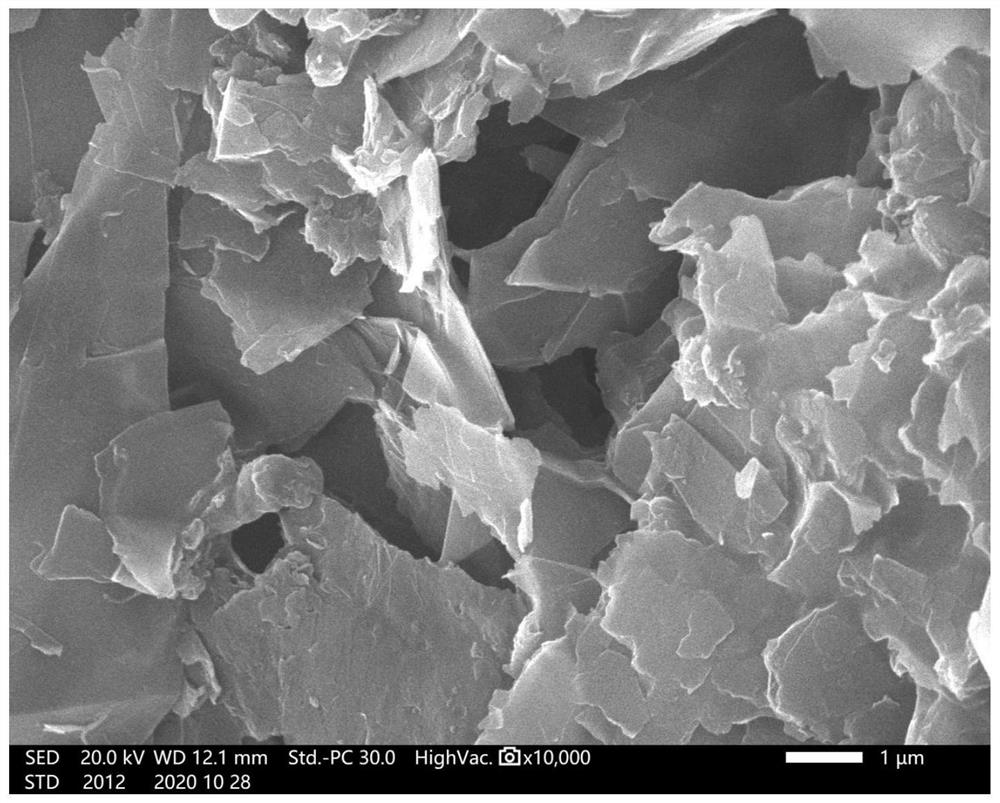

MXene-based water-based nano electric heating composite coating and preparation method thereof

PendingCN112920638AExcellent electric heating performanceImprove the heating effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention relates to an MXene-based water-based nano electric heating composite coating and a preparation method thereof, and the MXene-based water-based nano electric heating composite coating is prepared by the following steps: by using a water-dispersible MXene nanosheet as a conductive filler, respectively using water-based polyurethane, water-based polyacrylate or water-based epoxy resin and MXene to prepare water dispersion liquids with certain mass fractions, adding the MXene dispersion liquid into the water-based resin according to a preset mass ratio of the water-based resin to the MXene under the stirring action, and continuously conducting stirring to enable water-based resin macromolecules to be fully and uniformly adsorbed on MXene nanosheets, so as to obtain the water-based resin ester-MXene nano electric heating composite coating. The prepared coating can be constructed through spraying, dip-coating, roller coating or dispensing and other methods, has excellent electric heating performance and heating regulation performance, is high in adhesive force and good in flexibility, has the resistivity capable of being regulated as required, is low in required voltage and high in temperature rise rate, is not limited by the surface appearance of a base material in use, and is wide in application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing functional carbon fiber composite electrothermal paper

ActiveCN103103870AHigh functional efficiencyEffective and long-lastingSynthetic cellulose/non-cellulose material pulp/paperActivated carbonFiber

The invention relates to a method for preparing functional carbon fiber composite electrothermal paper. The method comprises the following steps of: (1) preparing functional carbon fibers; (2) preparing papermaking slurry; (3) making paper; and (4) performing post-treatment. The functional carbon fibers are prepared by carrying a functional body on the surface of an activated carbon fiber; wet papermaking is executed, so that functionalization of the functional carbon fiber composite electrothermal paper is realized; compared with the conventional functionalization method for the carbon fiber composite electrothermal paper, the method has the advantages that the problems of large using amount of functional powder bodies and high waste during preparation are solved; during preparation, the problems of large using amount of wet papermaking technological auxiliaries and severe water pollution are solved; the method is environment-friendly and energy-saving; and the prepared functional carbon fiber composite electrothermal paper has the advantages of high functionalization efficiency, obvious effect, durability and stability.

Owner:DONGHUA UNIV

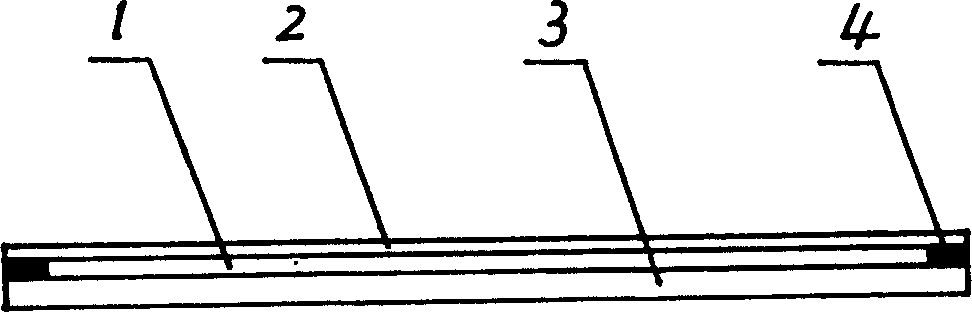

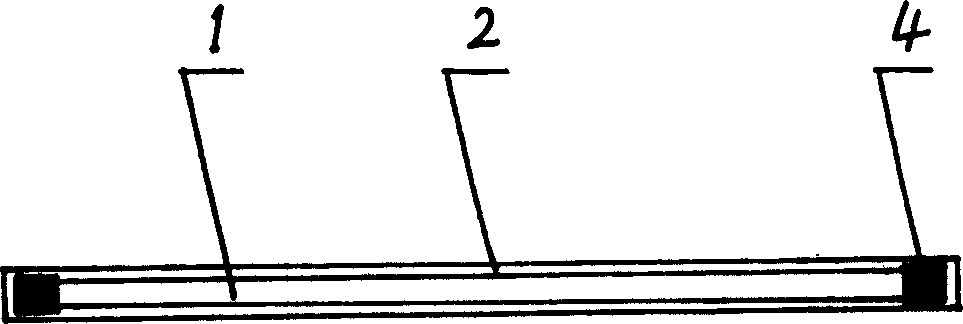

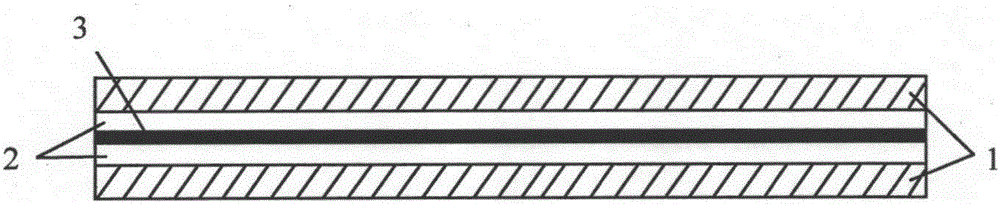

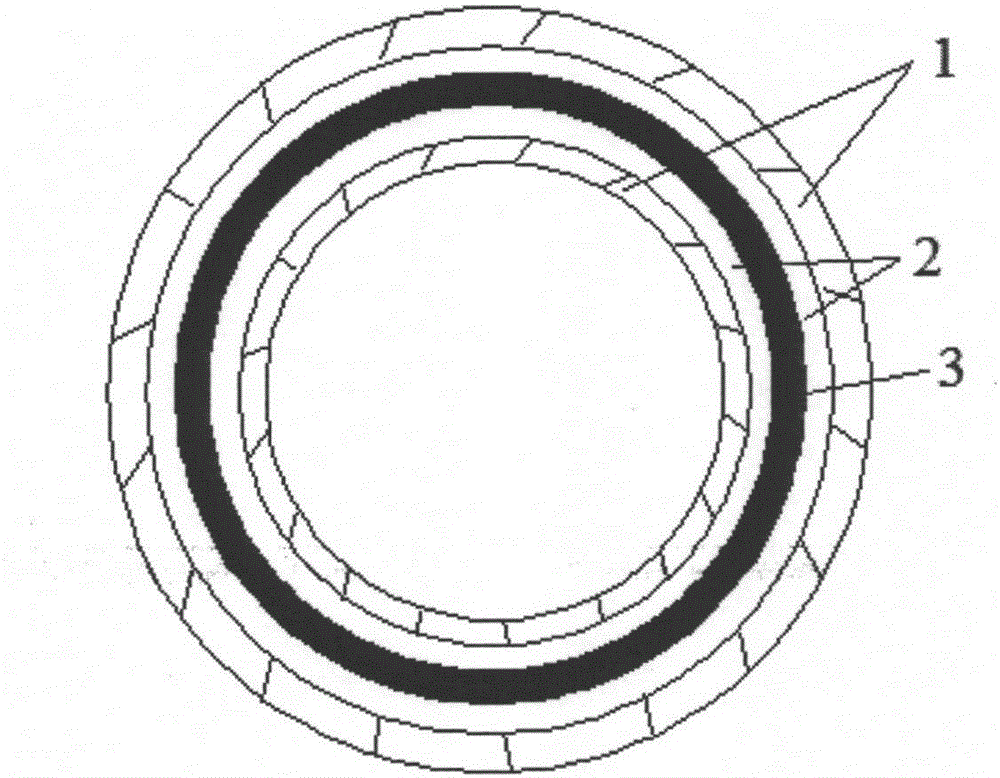

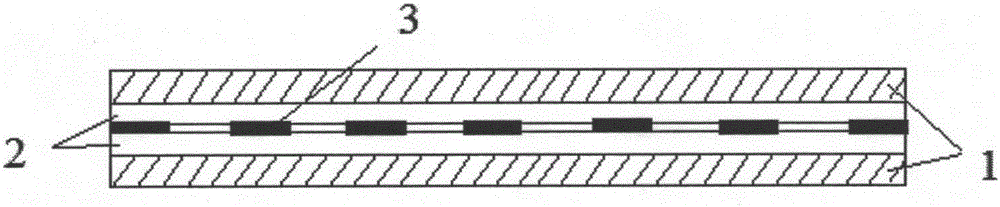

Large power carbon fiber electric heating tube for industrial use

InactiveCN101389163AUniform temperatureUniform working temperatureHeating element shapesFiberCarbon fibers

The invention provides a large power carbon fiber electric heating tube for industrial use, which comprises an outer electrode, electrode packing heads, electric heater bodies, an electrode wire, internal racks, a tubular case, and an exhaust hole. Two or more electric heating bodies are connected in series in the tubular case, an internal rack is disposed between the electric heating body and the tubular case, an internal sleeved tube runs through the electric heating body having electric wire penetrating therein, an internal rack is disposed between the internal sleeved tube and the electric heating body, sleeve shaped electrodes are disposed on both ends of the electric heating body, which are connected with the electrode wire through connection wires. Electrode packing heads equipped with outer electrodes are disposed on both ends of the tubular case, and the electrode wire is connected with the outer electrode through high temperature tolerant metal connection plates. Comparing with technique in prior art, the electric heating tube has uniform working temperature, stable electric heating performance, long life, and heating efficiency reaches over 98%, consequently has great propagation and application value.

Owner:黄溯

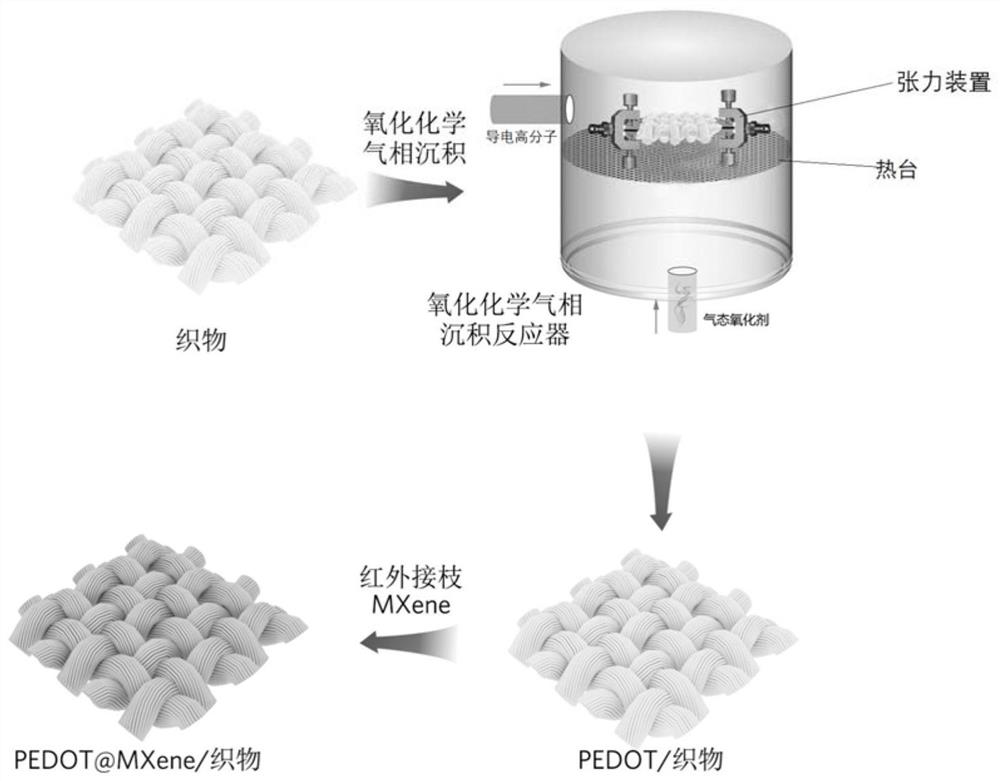

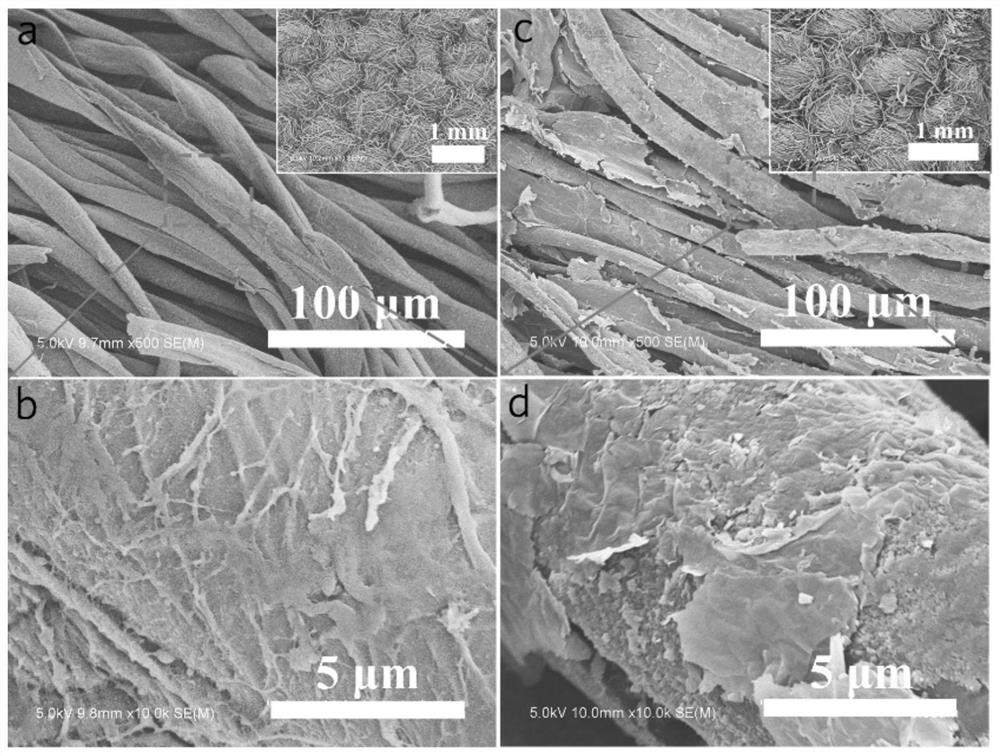

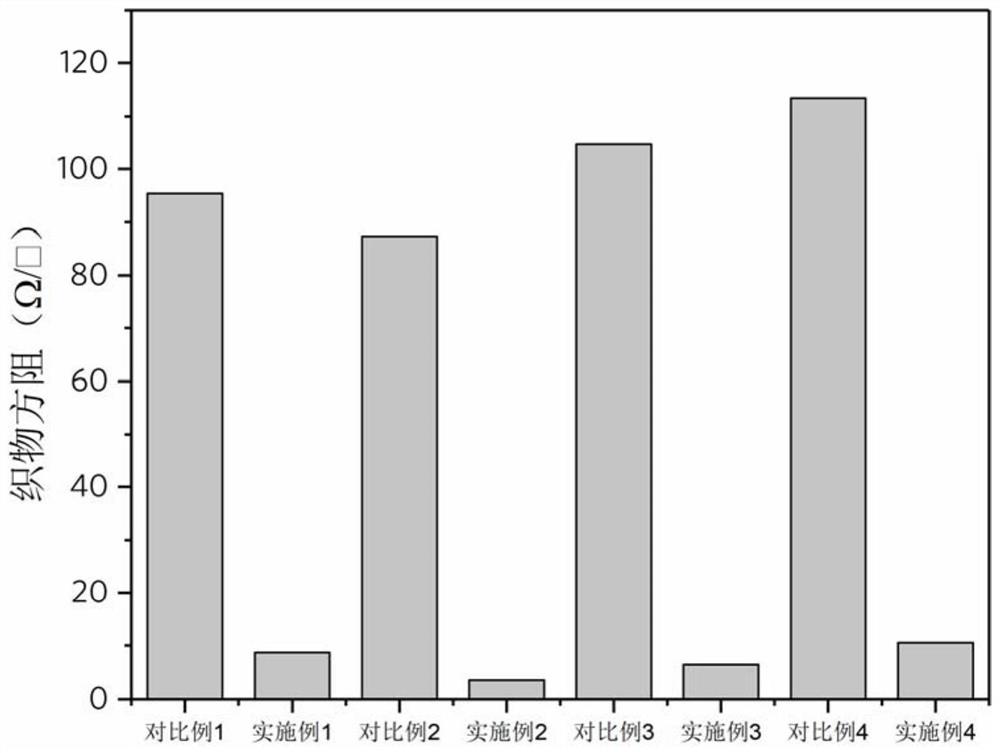

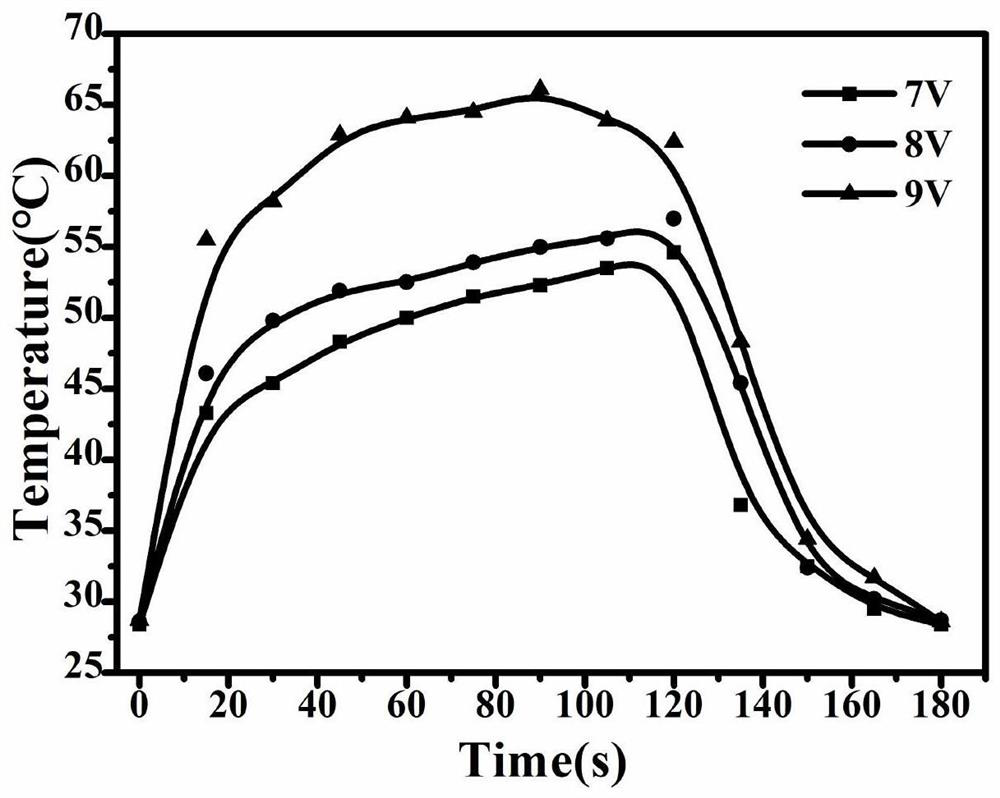

Multi-functional fabric and preparation method and application thereof

PendingCN112323498ALarge chip rateLarge diameterLiquid surface applicatorsPhysical treatmentFiberPolymer science

The invention provides multi-functional fabric and a preparation method and application thereof. A conductive polymer film is deposited on the surface of the fabric through an oxidative chemical vapordeposition method, and a conductive polymer / MXene composite film is constructed on the fiber surface in the fabric through MXene surface modification to form a continuous conductive network, so thatthe fabric is endowed with excellent conductivity, electric heating performance, sensing performance and electrochemical performance. Besides, the MXene can generate active oxygen, so that lipid peroxidation of bacterial cell membranes and damage to proteins or genes in cells are caused, and the finally prepared conductive polymer / MXene modified fabric has excellent antibacterial performance.

Owner:WUHU FUCHUN DYEING & WEAVING

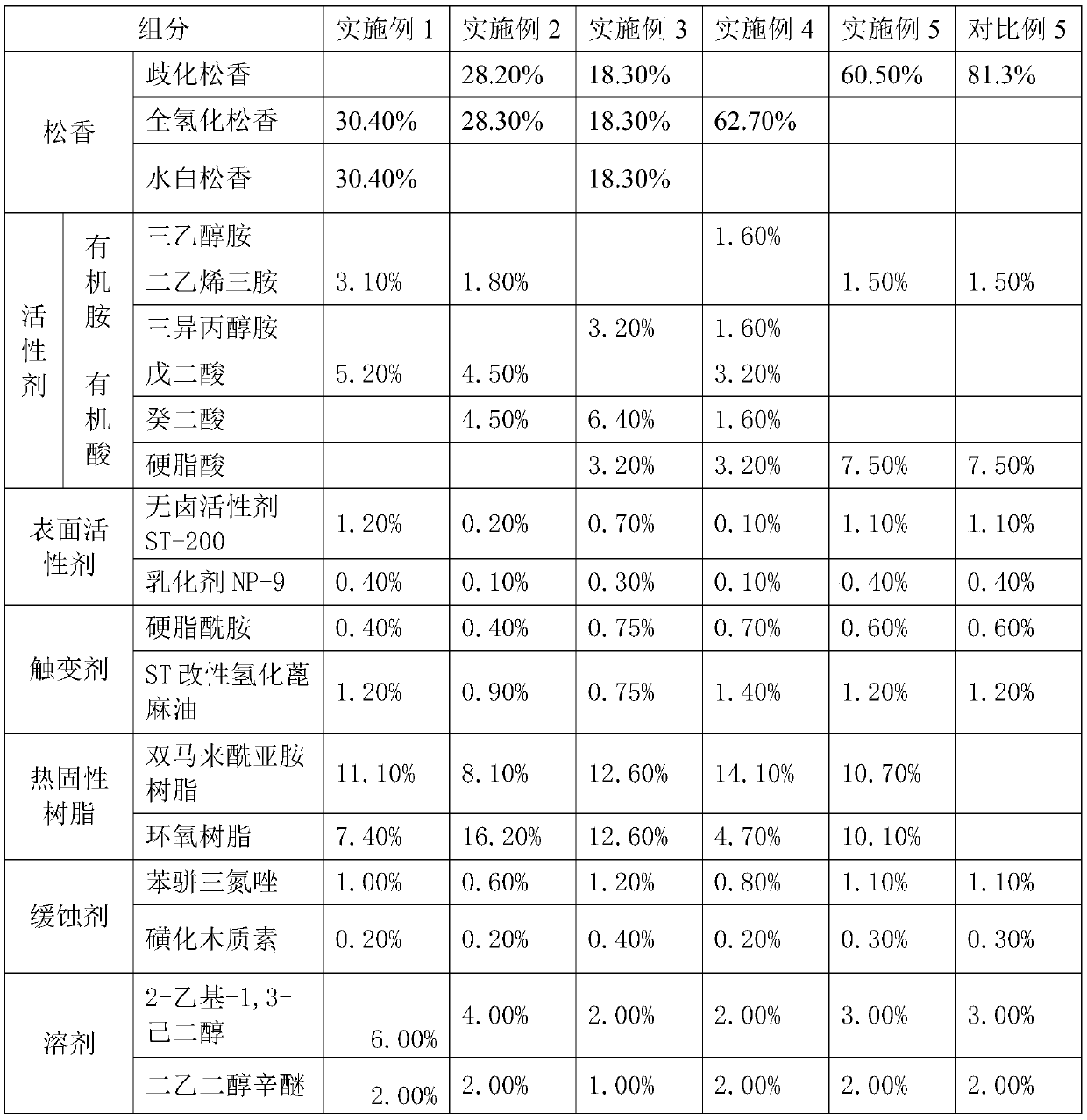

High-weldability environment-friendly superfine solder wire for intelligent manipulator welding and preparation method thereof

ActiveCN111590233AAvoid wastingHigh yieldWelding/cutting media/materialsSoldering mediaLutetiumCerium

The invention discloses a high-weldability environment-friendly superfine solder wire for intelligent manipulator welding and a preparation method thereof. The superfine solder wire comprises 96.9 wt%-98.1 wt% of solder alloy and 1.9 wt%-3.1 wt% of scaling powder, wherein the solder alloy comprises the components of tin, silver, copper, molybdenum, cerium, tellurium and lutetium, by adding the cerium, the structure of the solder can be changed, so that crystal grains are refined, solder joint bridges are reduced, the surface wettability of the solder alloy is changed, and the creep property and the tensile property are improved; the addition of tellurium can improve the corrosion resistance, the wear resistance and the strength of the material, the tensile strength of the solder can be improved, the generation of tin whiskers can be prevented; lutetium has good electrical conductivity and ductility and extremely high activity, and is excellent in effect of improving electric heating performance and oxidation resistance in soldering tin alloy powder, so that tensile strength and toughness of the solder are improved, the wettability of solder wires is good, the tensile strength is excellent, and lead-free and environment-friendly effects are achieved. The superfine solder wire has the advantages of being high in weldability and not prone to core breakage, and high weldability andlead-free environment-friendly development of products are achieved when the superfine solder wire is applied to the high-end application field of intelligent manipulator welding and the like.

Owner:中山翰华锡业有限公司

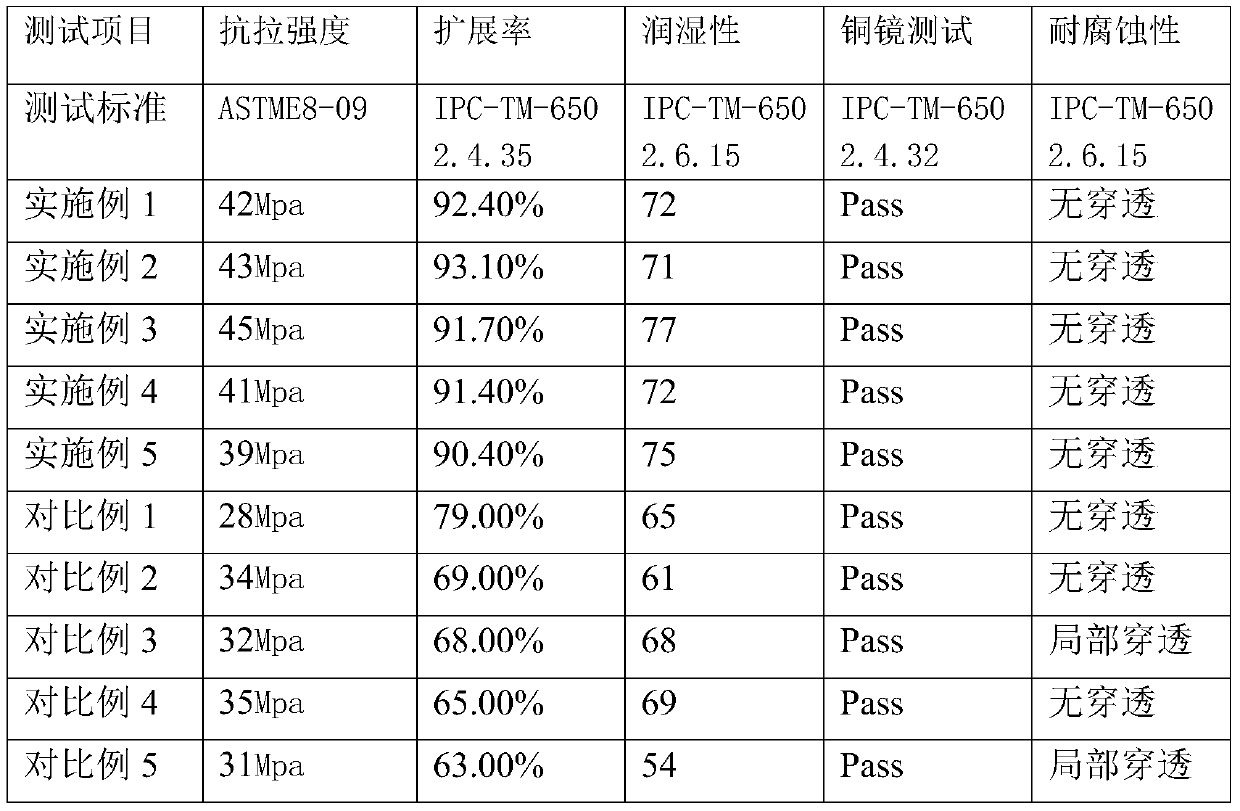

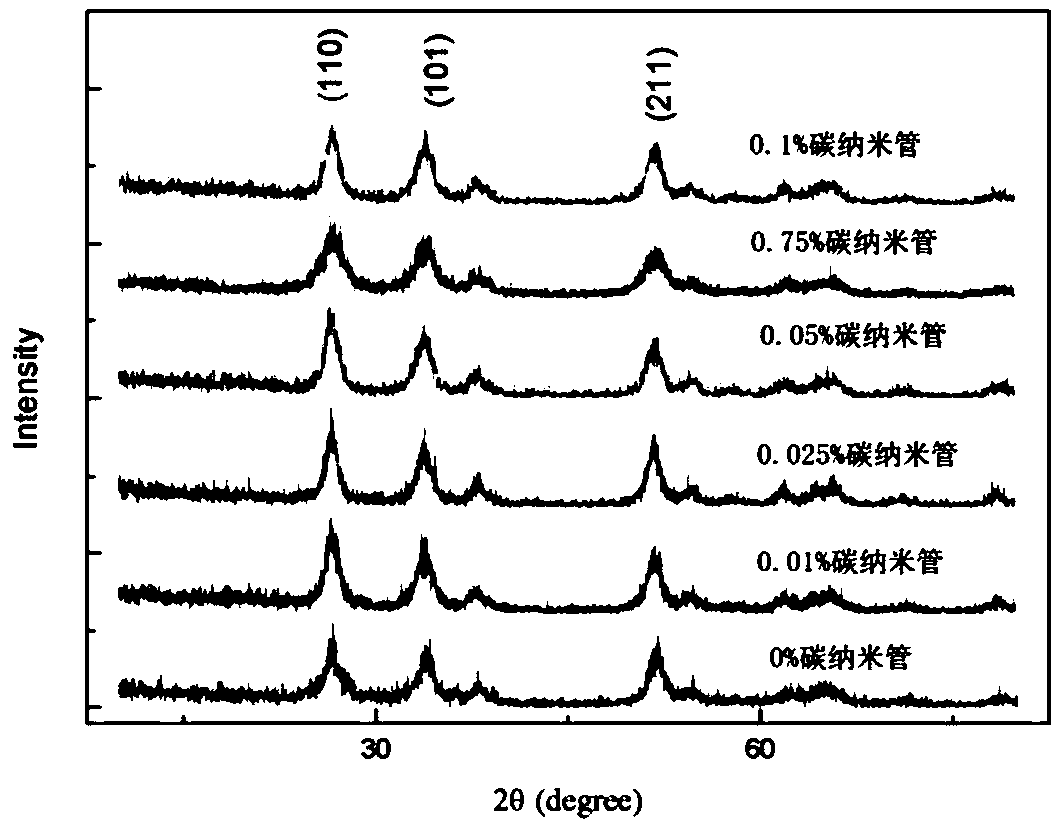

A SnO2 composite carbon nanotube electrothermal film and a preparation method thereof

InactiveCN109068418ALower resistanceGood thermal efficiencyHeating element materialsMass ratioModified carbon

The invention discloses a SnO2 composite carbon nanotube electric heating film and a preparation method thereof. The electric heating film is a tetragonal rutile structure and comprises a carbon nanotube and SnO2 with a mass ratio of 0.0002 to 0.002 : 1; A manufacture method comprises adde tin salt and modifier into a solvent to prepare a mixed solution, SnO2 composite carbon nanotube electrothermal film was prepared by adding modified carbon nanotube and stirring evenly to obtain electrothermal film precursor solution, spraying the electrothermal film precursor solution onto the coated substrate, and then annealing the coated substrate at 470 - 570 DEG C for 10 - 20 min to obtain SnO2 composite carbon nanotube electrothermal film. The electric heating film of the invention has small resistance, high emissivity, excellent thermal efficiency and strong chemical stability, and can replace the existing heating element with poor thermal efficiency and heat resistance, and is energy-savingand environmentally friendly. At that same time, the manufacture method is simple, energy-saving and environment-friendly, and can be industrialized.

Owner:YANCHENG INST OF TECH

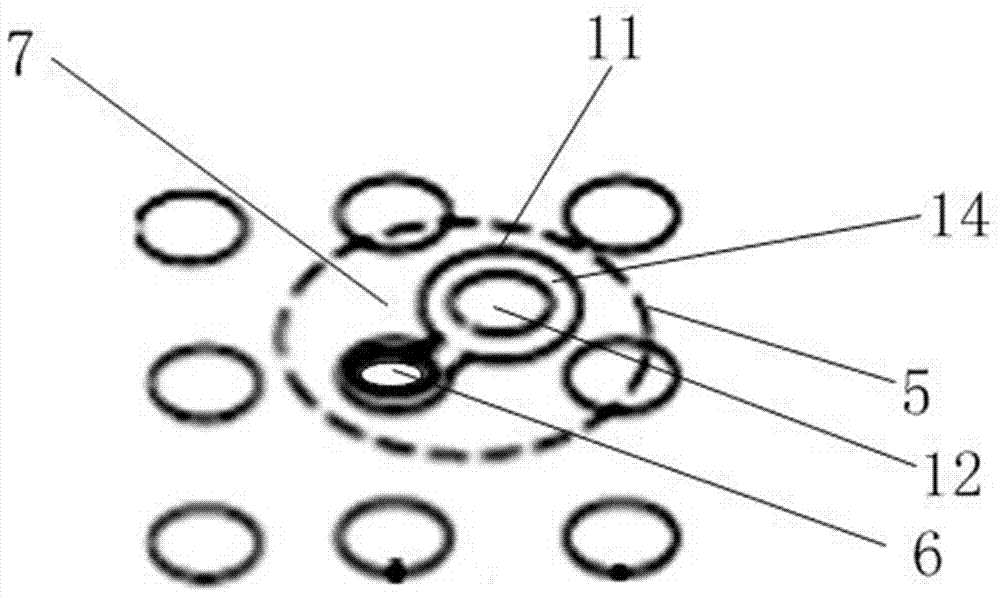

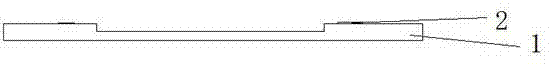

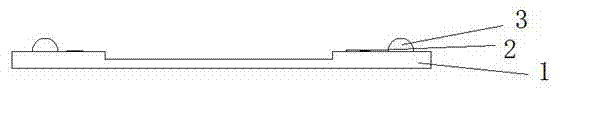

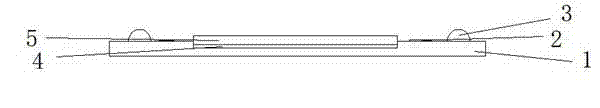

BGA package fixing structure of LED module

ActiveCN106898602AImprove electrical performanceIncreased pin countSolid-state devicesSemiconductor devicesSalient pointWelding process

The invention provides the BGA package fixing structure of an LED module, which comprises an LED module, a PCB and a BGA surface-mount welding jig. The LED module is a light source device of a BGA package. The welding spots of a salient point array are positioned on the back surface of a BGA package substrate. An LSI chip is located on the front surface of the BGA package substrate. An LED light-emitting tube and a matching circuit, which are packaged and fixed by the mold or filled resin material, are arranged Inside the LSI chip. The LSI chip is electrically connected with the salient point array. The PCB is provided with a BGA light-source bonding pad. The BGA surface-mount welding jig is a positioning plate. The positioning plate is provided with more than one light source fixing hole. During the surface-mounting or welding process of the LED module, the positioning plate is detachably fixed on the PCB. The LED module is subjected to surface-mounting positioning or welding positioning on the PCB through the light source fixing hole. When the LED module is welded and fixed on the PCB, the positioning plate is taken down. According to the technical scheme of the invention, high-availability LED light sources can be manufactured through the BGA package.

Owner:FUJIAN XIANGYUN PHOTOELECTRIC TECH

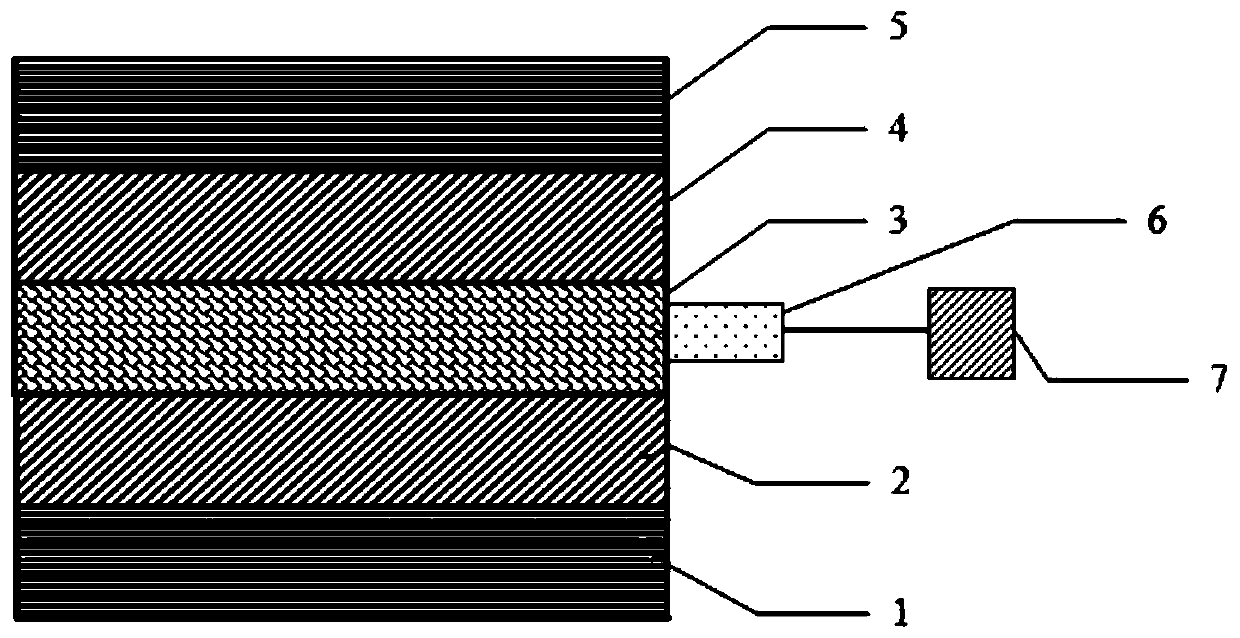

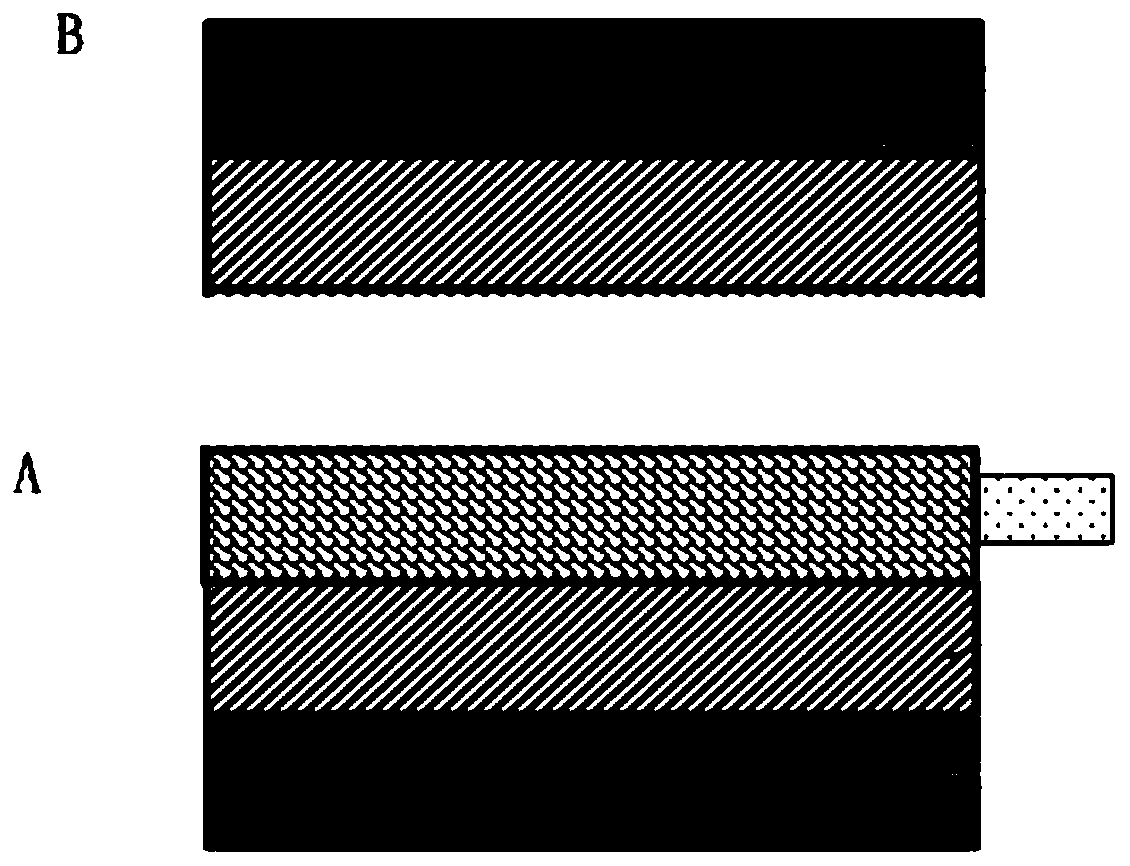

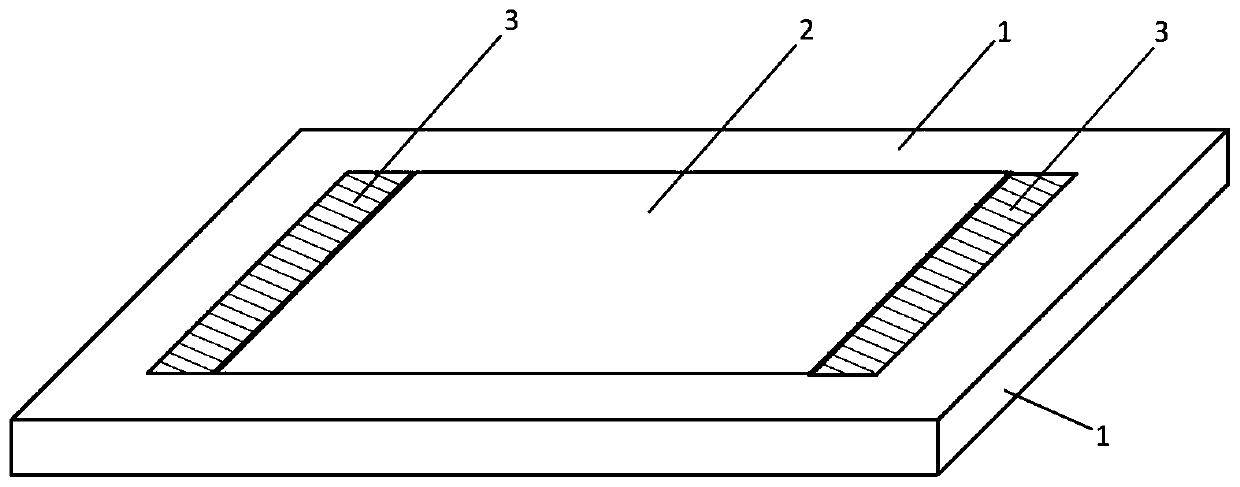

Packaging piece based on substrate and adopting slotting technology and manufacturing process of packaging piece

InactiveCN103325757AImprove cooling effectExcellent electric heating performanceSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingAdhesive

The invention discloses a packaging piece based on a substrate and adopting a slotting technology and a manufacturing process of the packaging piece. The packaging piece is mainly composed of a lead frame, a PAD, a solder ball, conducting adhesive, a chip, a bonding wire and a plastic package body. The PAD and the solder ball are arranged on the lead frame, and a notch is formed in the lead frame. The chip is connected into the notch of the lead frame through the conducting adhesive, and welding spots on the chip are connected with the PAD on the lead frame through the bonding wire. The chip, the bonding wire, the solder ball and the lead frame form a power and signal channel of a circuit. The plastic package body wraps the lead frame, the PAD, the solder ball, the chip and the bonding wire. The procedures of the manufacturing process are wafer thinning, scribing, substrate slotting and ball replacing, chip installing, installed chip baking, bonding, plasma cleaning, post curing, plastic packaging and product finishing. According to the packaging piece based on the substrate and adopting the slotting technology and the manufacturing process of the packaging piece, electric heating performance of the chip is improved, and the performance of the whole packaging piece is improved greatly.

Owner:HUATIAN TECH XIAN

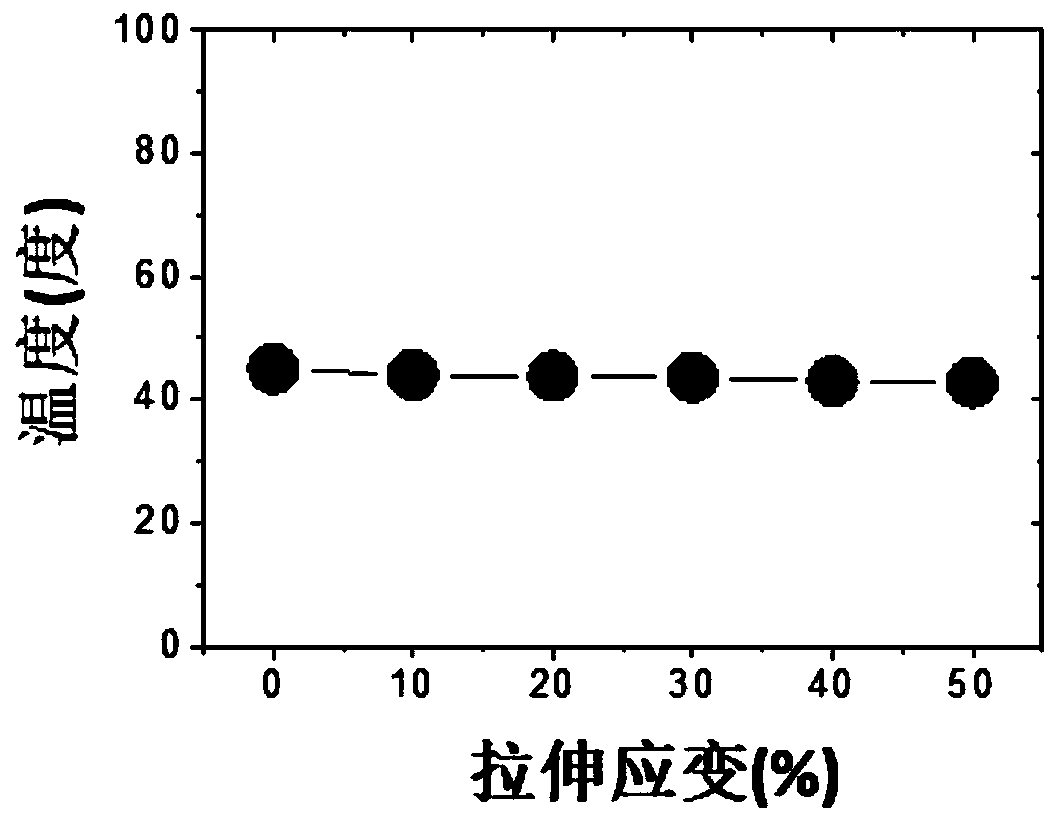

High-elastic electric-induced-heating compound film and preparation method thereof

InactiveCN106003889AIncrease elasticityImprove tensile propertiesLamination ancillary operationsSynthetic resin layered productsCarbon nanotubeRoom temperature

The invention provides a high-elastic electric-induced-heating compound film and a preparation method thereof. The preparation method for the high-elastic electric-induced-heating compound film is characterized by comprising the following steps: 1) soaking a carbon nano tube film into a graphene suspension liquid for a period of time, and then taking out and naturally airing under room temperature, thereby obtaining a flexible nanometer conductive film; 2) taking an elastic film as an elastic adhering substrate, applying a certain tensile force to the two ends thereof, stretching for a certain elongation and then fixing, and coating the upper surface of the elastic adhering substrate with a layer of liquid elastic adhesive; 3) pressing and soaking the flexible nanometer conductive film on the liquid elastic adhesive and curing the adhesive under a certain condition; 4) releasing the tensile force applied to the elastic adhering substrate and driving the flexible nanometer conductive film to retract, thereby obtaining the electric-induced-heating compound film. The electric-induced-heating compound film acquired according to the preparation method has the advantages of light weight, high flexibility and high elasticity as well as excellent anti-ageing property, safety and long service life.

Owner:DONGHUA UNIV

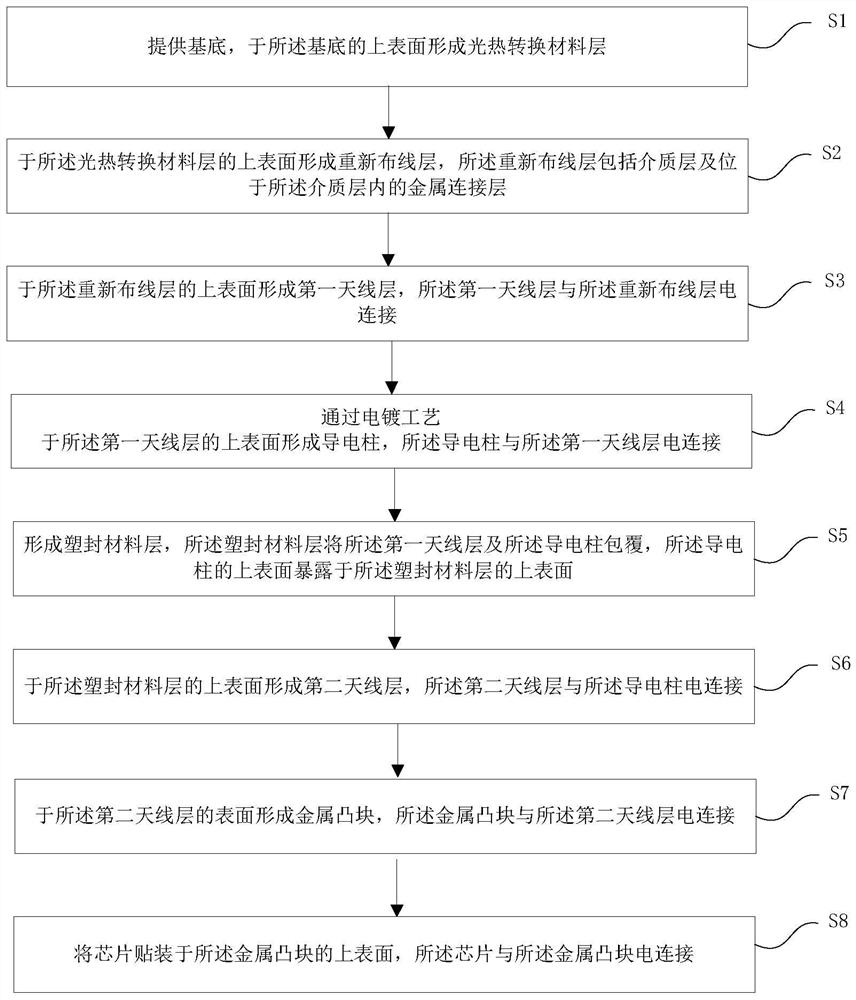

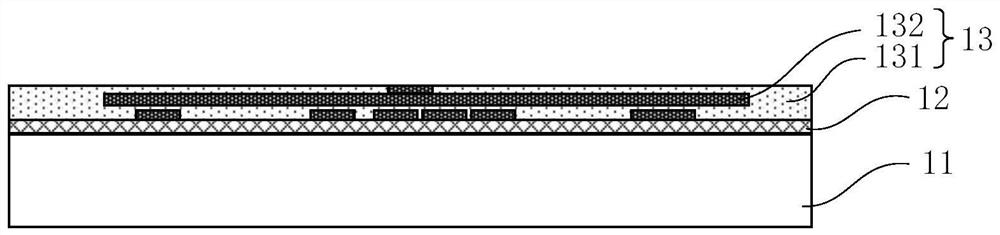

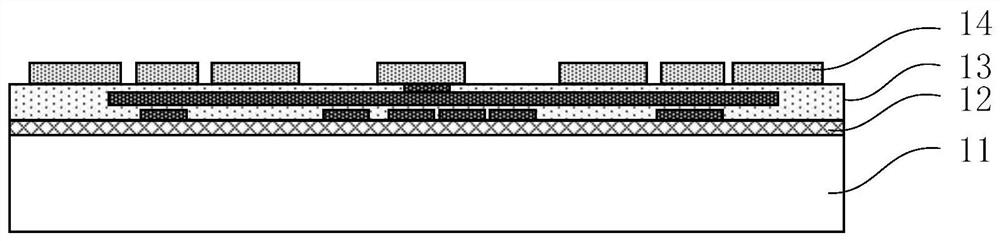

Semiconductor packaging structure and preparation method thereof

PendingCN113497008AExcellent electric heating performanceHigh-efficiency antenna with good performanceAntenna supports/mountingsSemiconductor/solid-state device detailsPhotothermal conversionSemiconductor package

The invention provides a semiconductor packaging structure and a preparation method thereof. The structure comprises a substrate, a photothermal conversion material layer, a rewiring layer, a first antenna layer, a conductive column, a plastic package material layer, a second antenna layer, a metal bump and a chip, the photothermal conversion material layer is located on the upper surface of the substrate; the rewiring layer is located on the upper surface of the photothermal conversion material layer; the first antenna layer is located on the upper surface of the rewiring layer; the conductive columns are located on the upper surface of the first antenna layer; the plastic package material layer wraps the first antenna layer and the conductive column, and the upper surface of the conductive column is exposed on the upper surface of the plastic package material layer; the second antenna layer is located on the upper surface of the plastic package material layer; the metal bump is located on the upper surface of the second antenna layer; and the chip is located on the upper surface of the metal bump. According to the invention, interconnection of the chip and the plurality of antenna layers in the vertical direction can be realized to ensure good conduction of the upper layer and the lower layer, the size of the packaging structure can be reduced, the integration level and the performance of the device can be improved, and the production cost can be reduced.

Owner:SJ SEMICON JIANGYIN CORP

Textile material with flexible electric heating function, preparation method and application of textile material

PendingCN110351906ARealize electric heating functionComfortable to wearLayered productsOhmic-resistance heatingLiquid stateLiquid metal

The invention provides a textile material with a flexible electric heating function and a preparation method of the textile material. The textile material is of a stack structure; the textile materialcomprises a first textile material layer, a first flexible insulation layer, a flexible heating layer, a second flexible insulation layer and a second textile material layer which are distributed sequentially from bottom to top; the flexible heating layer material is liquid metal and is electrically connected with one end of an electrode; and the other end of the electrode is connected with a power source. The liquid metal is heated under an electrified condition, so that the electric heating function of the textile material is realized. The textile material is comfortable to wear. The stability of the electric heating can be kept when the textile material is deformed. Therefore, the textile material has a bright application prospect in the field of clothes and other environments needingheating.

Owner:NINGBO ELASTECH CO LTD

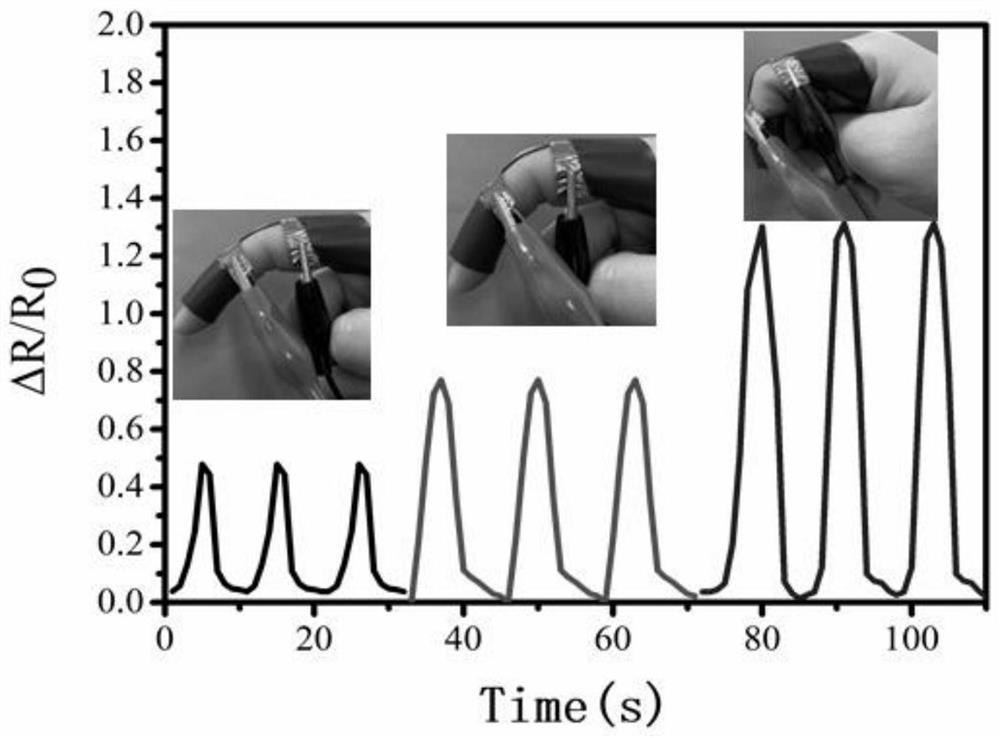

Elastic electrically-driven thermochromic sensing fiber with skin-core structure and preparation method of elastic electrically-driven thermochromic sensing fiber

ActiveCN112522809AImprove adhesionImprove mechanical propertiesElectroconductive/antistatic filament manufactureFibre typesFiberCellulose

The invention belongs to the technical field of functional electrically-driven thermochromic yarns, and particularly relates to an elastic electrically-driven thermochromic sensing fiber with a skin-core structure and a preparation method of the elastic electrically-driven thermochromic sensing fiber. The preparation method comprises the following steps that firstly, the adhesive force of the surface of the fiber is improved through pretreatment, and then a polyurethane fiber substrate is orderly coated with graphene after cellulose nanocrystal stripping through simple ultrasonic soaking, so as to prepare a flexible stretchable sensitive conductive fiber; and then, the polyurethane nanofibers containing different thermochromic inks are electrospun onto the surfaces of elastic fibers to prepare the elastic electrically-driven thermochromic sensing fiber with the skin-core structure. The novel skin-core composite structure fiber has excellent mechanical property and electric heating property, thermochromism is enhanced by utilizing force-electricity cooperation, and the elastic electrically-driven thermochromic sensing fiber is durable.

Owner:WUHAN TEXTILE UNIV

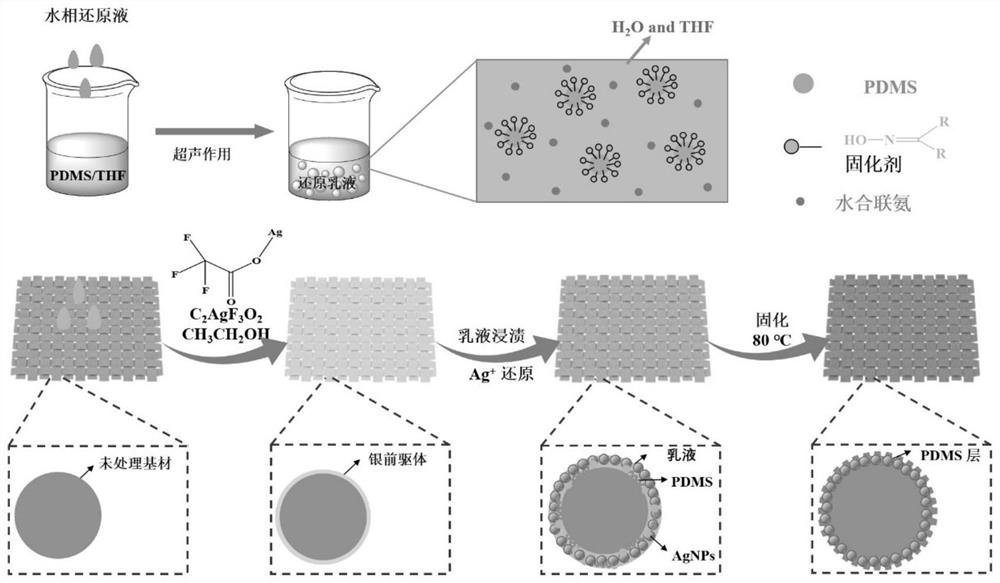

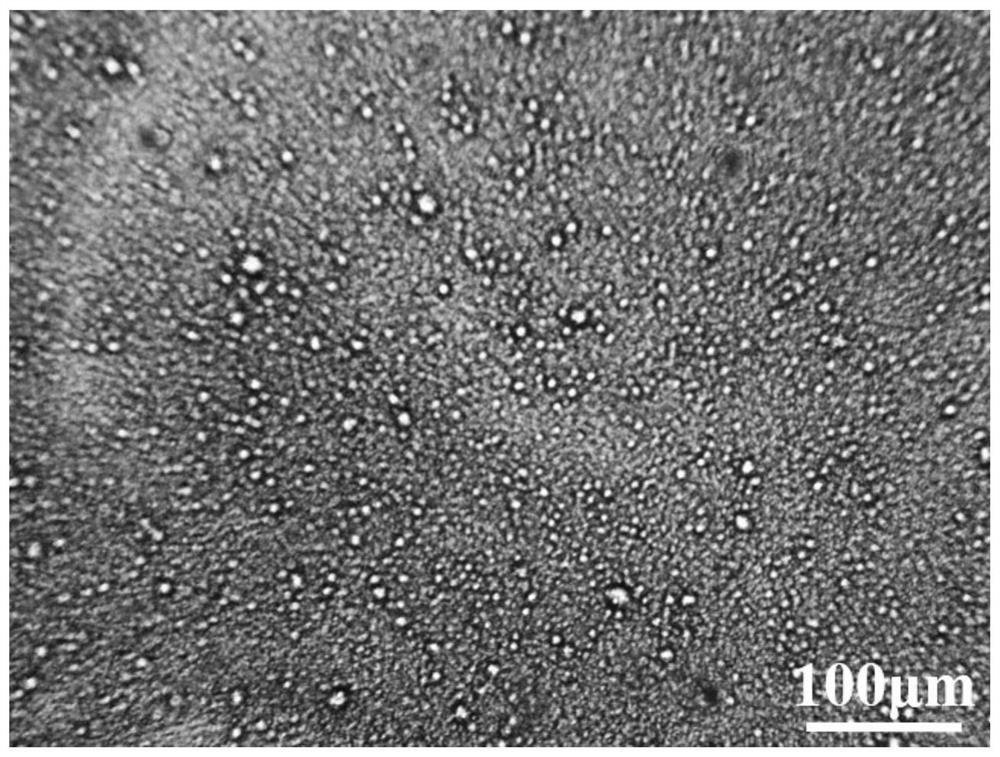

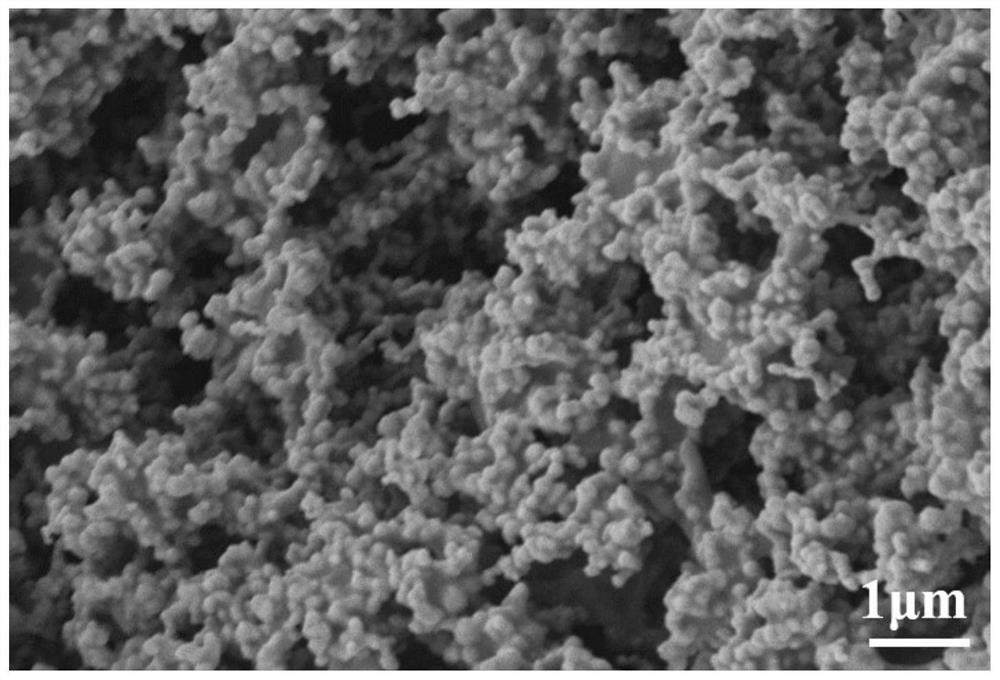

Preparation method of multifunctional super-hydrophobic composite material

ActiveCN112210992ASimple preparation processReduce energy consumptionFibre typesElectrical/magnetic solid deformation measurementMoisture resistanceConductive composites

The invention discloses a multifunctional super-hydrophobic conductive composite material and a preparation method thereof. Pre-coating with a silver precursor solution is carried out on a flexible base material, then the pretreated base material is fully dipped in an oil-in-water emulsion system with reducing capacity at 60 DEG C for 0.5 h, and finally a reduced sample is cured at 80 DEG C to obtain the composite material. The composite material prepared by the preparation method has excellent moisture resistance, electric heating performance and excellent use stability, and has a considerable application prospect in the field of flexible wearable electronic equipment.

Owner:YANGZHOU UNIV

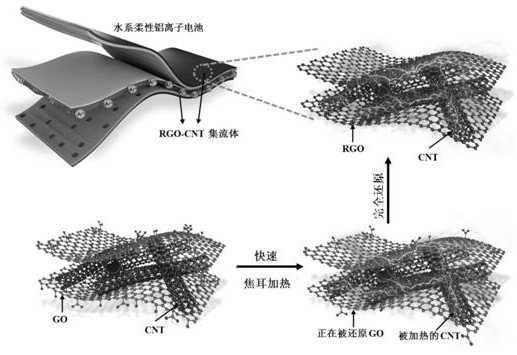

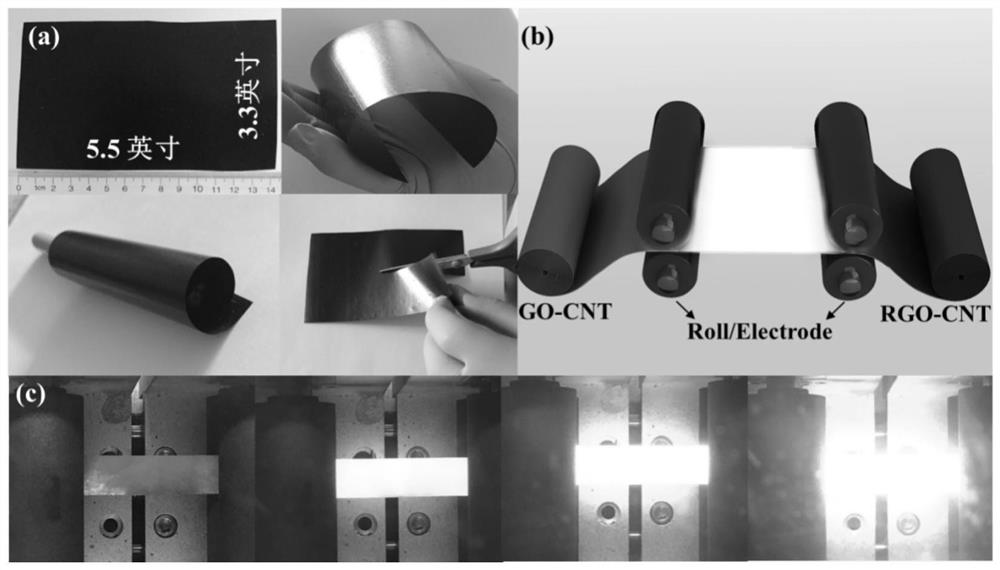

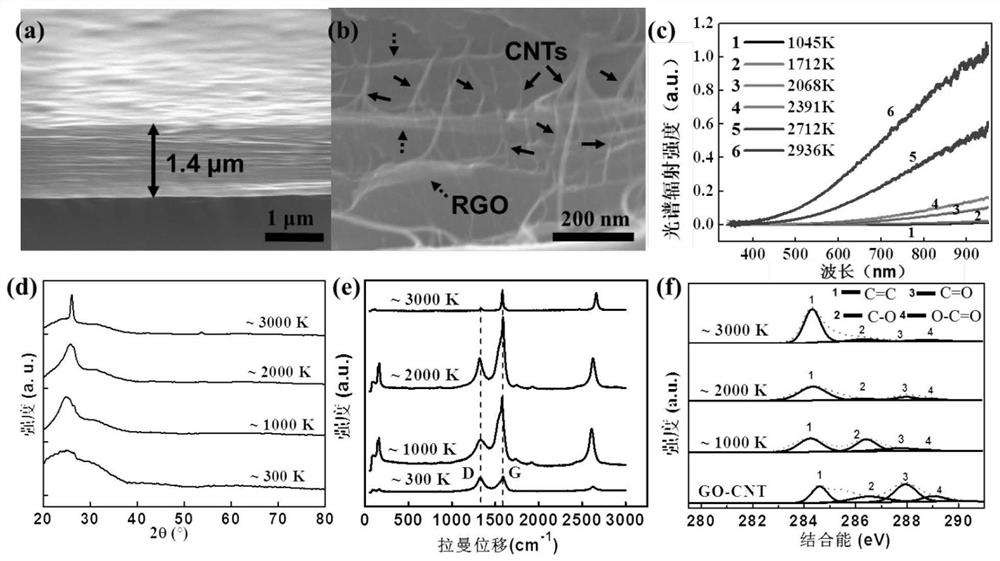

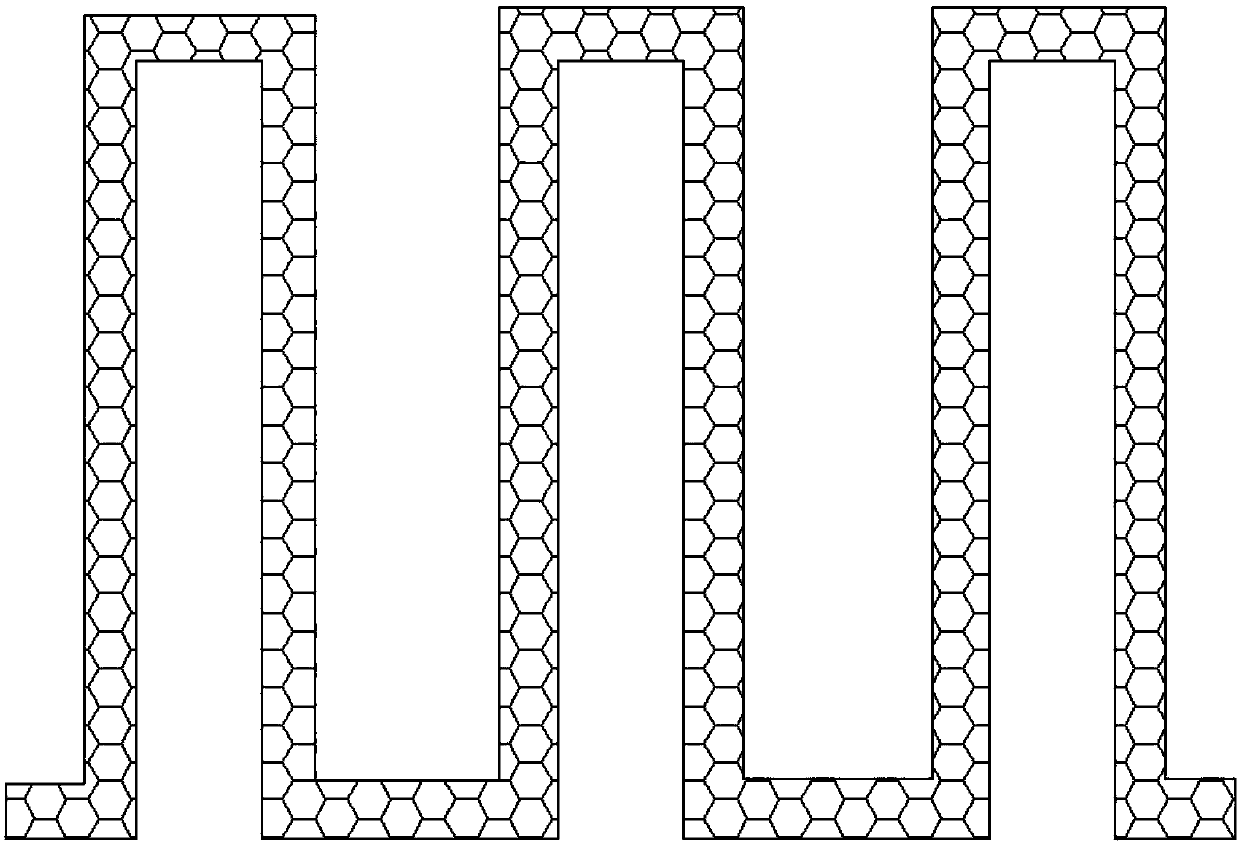

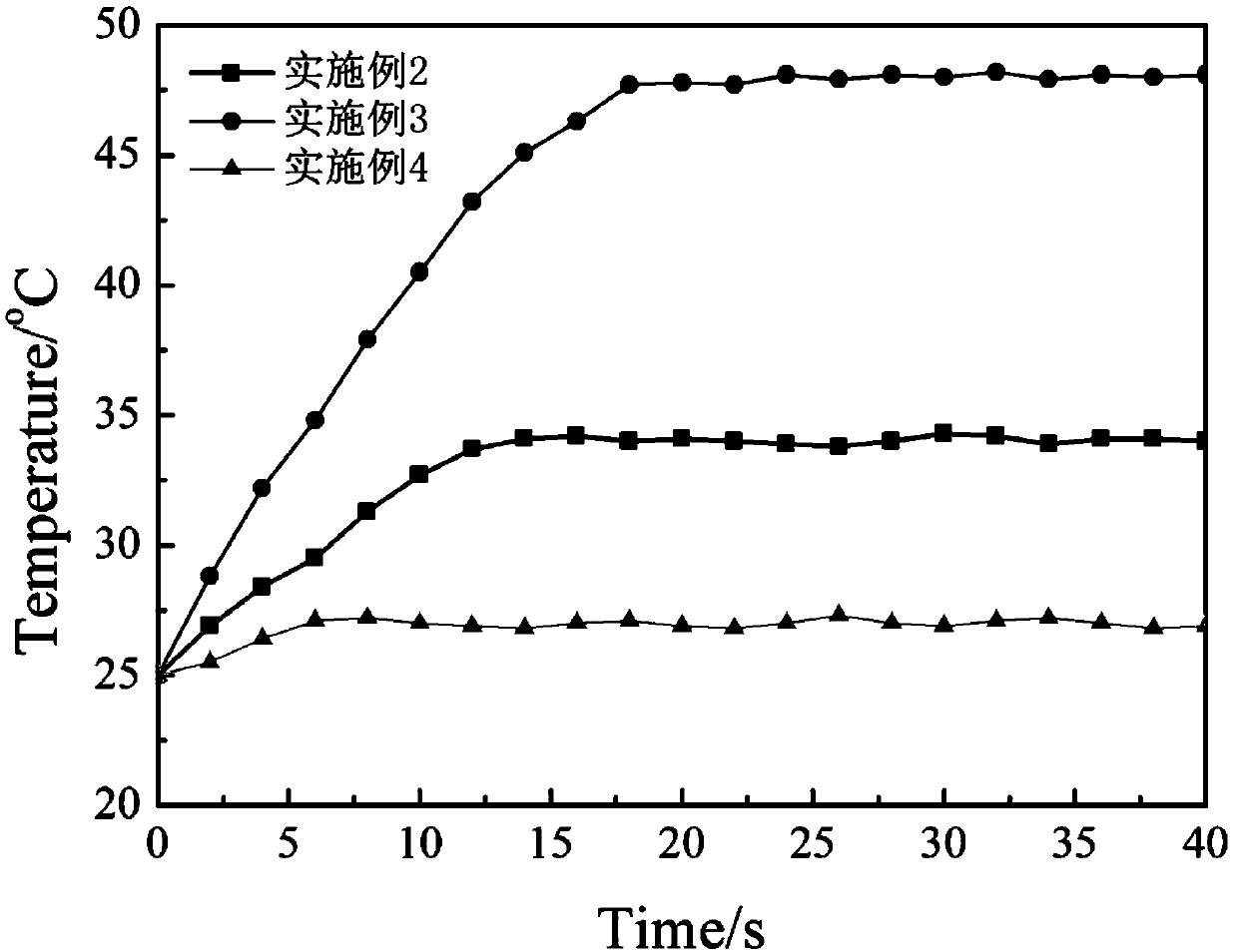

Graphene-carbon nanotube composite film material and preparation method and application thereof

InactiveCN113270588AImprove conductivityImprove toleranceElectrode carriers/collectorsSecondary cellsAluminum IonComposite film

The invention provides a graphene-carbon nanotube composite film material and a preparation method and application thereof. The method comprises the following steps: mixing graphene oxide ink with prepared carbon nano tube ink, performing ultrasonic treatment to obtain a graphene-carbon nano tube mixed solution, uniformly dripping the mixed solution onto a Teflon plate, and performing natural drying at room temperature (20-25 DEG C) to obtain the graphene oxide-carbon nano tube composite film material; adding the graphene oxide-carbon nano tube composite film material into a reaction kettle, stirring to obtain the graphene oxide-carbon nano tube composite film material, placing the graphene oxide-carbon nano tube composite film material on two graphite rollers which are oppositely arranged, connecting the graphene oxide-carbon nano tube composite film material with the two graphite rollers, and moving the graphene oxide-carbon nano tube composite film material at a speed of 0.1-0.3 m / min to obtain the graphene-carbon nano tube composite film material. After Joule heating, the conductivity of the graphene-carbon nanotube composite film material is sharply increased to 2750 S cm<-1>, and in a flexible aqueous aluminum ion battery, the graphene-carbon nanotube composite film material as a current collector has good cycle stability and higher rate capability.

Owner:TIANJIN UNIV

Graphene constant-temperature electrothermal film and preparation method thereof

ActiveCN109640411AWith room temperature PTC effectLow powerHeating element materialsTemperature controlOrganic solvent

The invention provides a graphene constant-temperature electrothermal film and a preparation method thereof. The preparation method comprises the following steps: fully stirring graphene, an alkane substance, resin, an organic solvent and an auxiliary agent at room temperature to prepare mixed slurry, coating the surface of a base film with the slurry, performing drying, arranging conductive electrodes at two ends of the film, removing the base film, and covering the film with an insulating film to obtain the graphene constant-temperature electric heating film. According to the invention, theprepared graphene constant-temperature electric heating film is better in electric conduction and heat conduction performances than that in the prior art due to the adding of a graphene material of aspecial structure, and the self constant temperature (normal-temperature PTC thermal control effect) in a low-temperature range can be realized on the premise of not introducing other temperature control devices. Based on the excellent electric heating performance and the far infrared radiation effect, the far infrared electric heating film has good application prospects in the field of warm-keeping and health-care products.

Owner:长沙暖宇新材料科技有限公司

Iron-based amorphous alloy, preparing method of iron-based amorphous alloy and application of iron-based amorphous alloy to electrical heating material

ActiveCN108950436AEnhanced Amorphous Formation AbilityLow requirements for production conditionsElectric heatingCorrosion

The invention discloses an iron-based amorphous alloy, a preparing method of the iron-based amorphous alloy and application of the iron-based amorphous alloy to an electrical heating material. The iron-based amorphous alloy is composed of FeaTibNicBdPeCfMg, wherein a, b, c, d, e and f are all atom percents, a is larger than or equal to 45 and smaller than or equal to 70, b is larger than or equalto 10 and smaller than or equal to 25, c is larger than or equal to 3 and smaller than or equal to 20, d is larger than or equal to 5 and smaller than or equal to 15, e is larger than or equal to 1 and smaller than or equal to 6, f is larger than or equal to 0.5 and smaller than or equal to 3, g is larger than or equal to 1 and smaller than or equal to 5, and the sum of the a, the b, the c, the d,the e, the f and the g is 100; and the component M is at least one of Zr, Y, Ta and Hf. The iron-based amorphous alloy electrical heating material has the good electric heating performance, the low temperature coefficient of resistance is achieved, and the low coefficient of linear expansion is achieved. The iron-based amorphous alloy has the high abrasive resistance, the high corrosion resistance and the good toughness, can be widely applied to various electric heating devices, and has the important industrial application values.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing silicon carbide/molybdenum disilicide composite ceramic through reaction sintering

InactiveCN106116584ALower sintering temperatureSimple processTetramethylammonium hydroxideComposite ceramic

The invention discloses a method for preparing silicon carbide / molybdenum disilicide composite ceramics by reaction sintering. ~15% molybdenum, 15%~25% graphite; B. After mixing the main raw materials evenly, add polyvinyl alcohol as a binder and tetramethylammonium hydroxide as a dispersant, and prepare silicon carbide composite by mechanical ball milling powder; C, placing the granulated powder in a mold and forming it once by dry pressing to obtain a green body; D, placing the above-mentioned green body on a graphite plate, and then placing a metal silicon chip on the green body, and the green body The weight ratio to the metal silicon sheet is 1:2.5-3.5, and the silicon carbide / molybdenum disilicide composite ceramic is obtained by high-temperature silicon infiltrating sintering at 1500-1600°C for 3-6 hours.

Owner:浙江东新新材料科技有限公司

Preparation method and application of polyimide varnish

InactiveCN112608675AImprove mechanical propertiesExcellent electric heating performanceCoatingsSilicon-controlled rectifierPolymer science

The invention discloses a preparation method and the application of polyimide varnish. The method comprises the steps of dissolving the refined aromatic diamine and aliphatic diamine into the refined organic solvent, then adding the refined aromatic dianhydride in batches, and stirring and reacting for several hours under the protection of low-temperature inert gas to obtain polyimide varnish; after the varnish is filtered for multiple times, covering the surfaces of microelectronic devices with the varnish such as rectifiers, diodes, triodes, high-power silicon controlled rectifiers, high-voltage silicon stacks, thyristors and the like and large-scale integrated circuit patterns by adopting methods such as drop coating, roller coating, silk-screen printing and the like, and high-insulation, high-strength and then obtaining low-expansion electronic components through stepped heating and curing. The method has the advantages of accessible raw materials and simple operation, and is suitable for large-scale industrial production.

Owner:武汉市美克亚胺科技有限责任公司

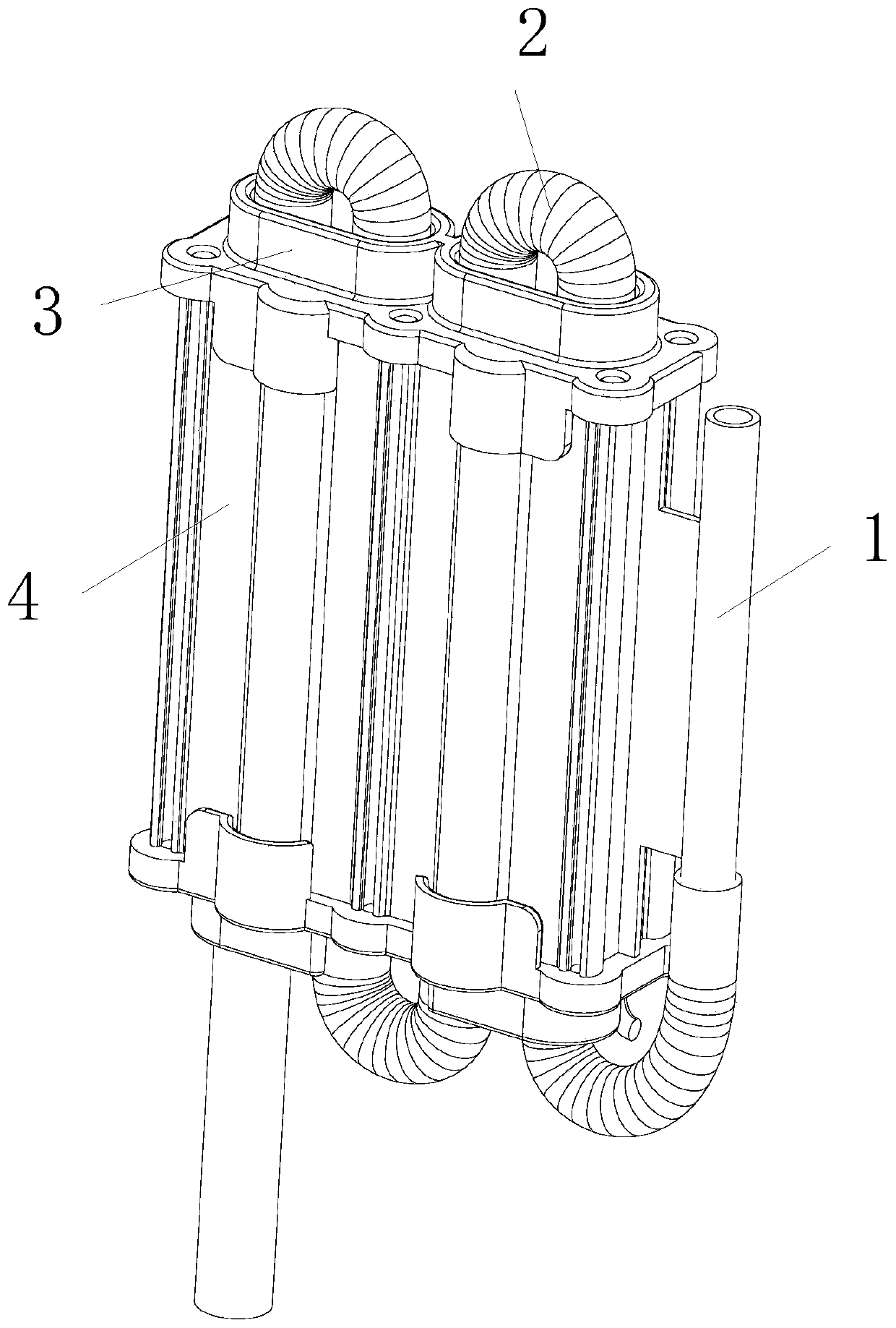

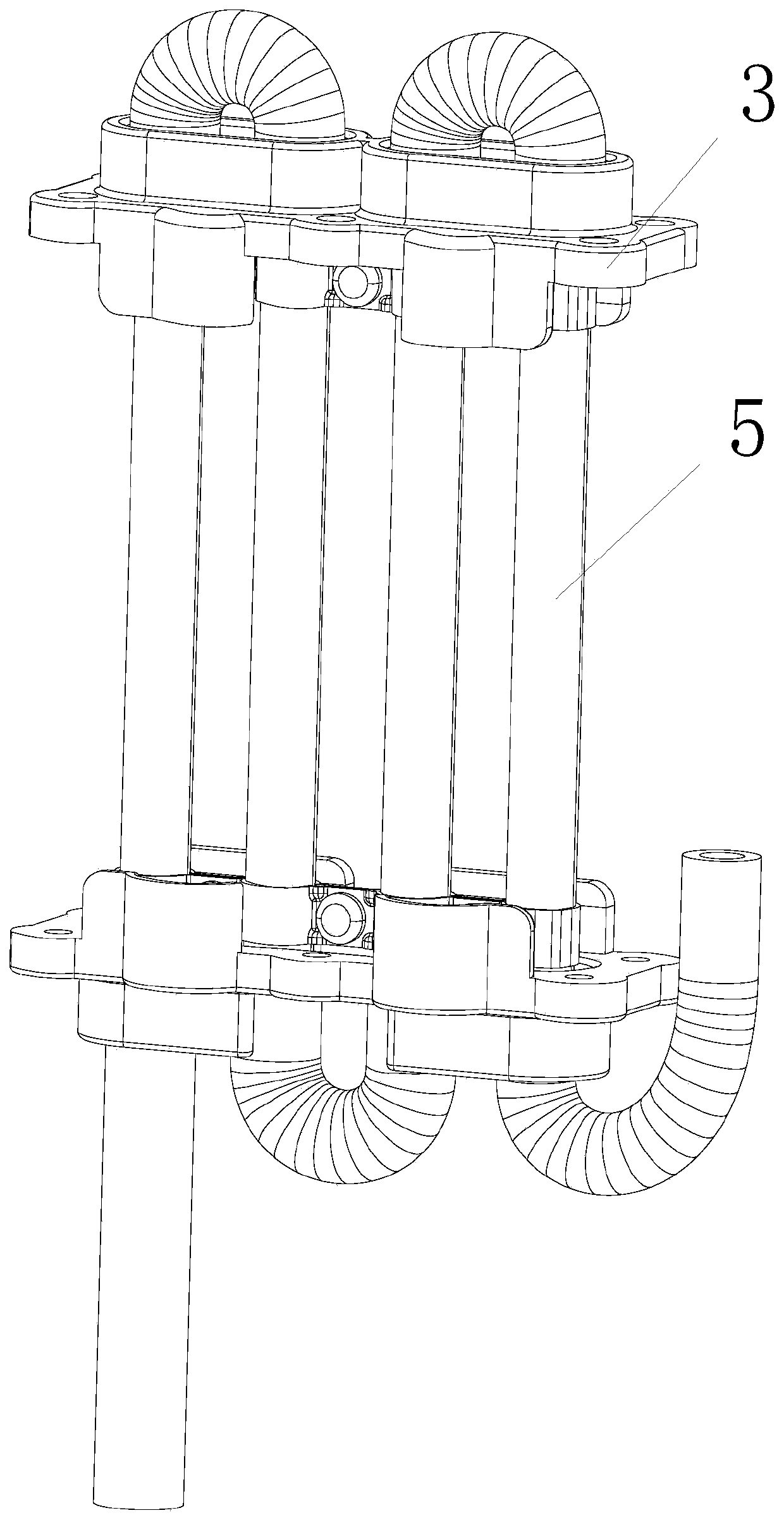

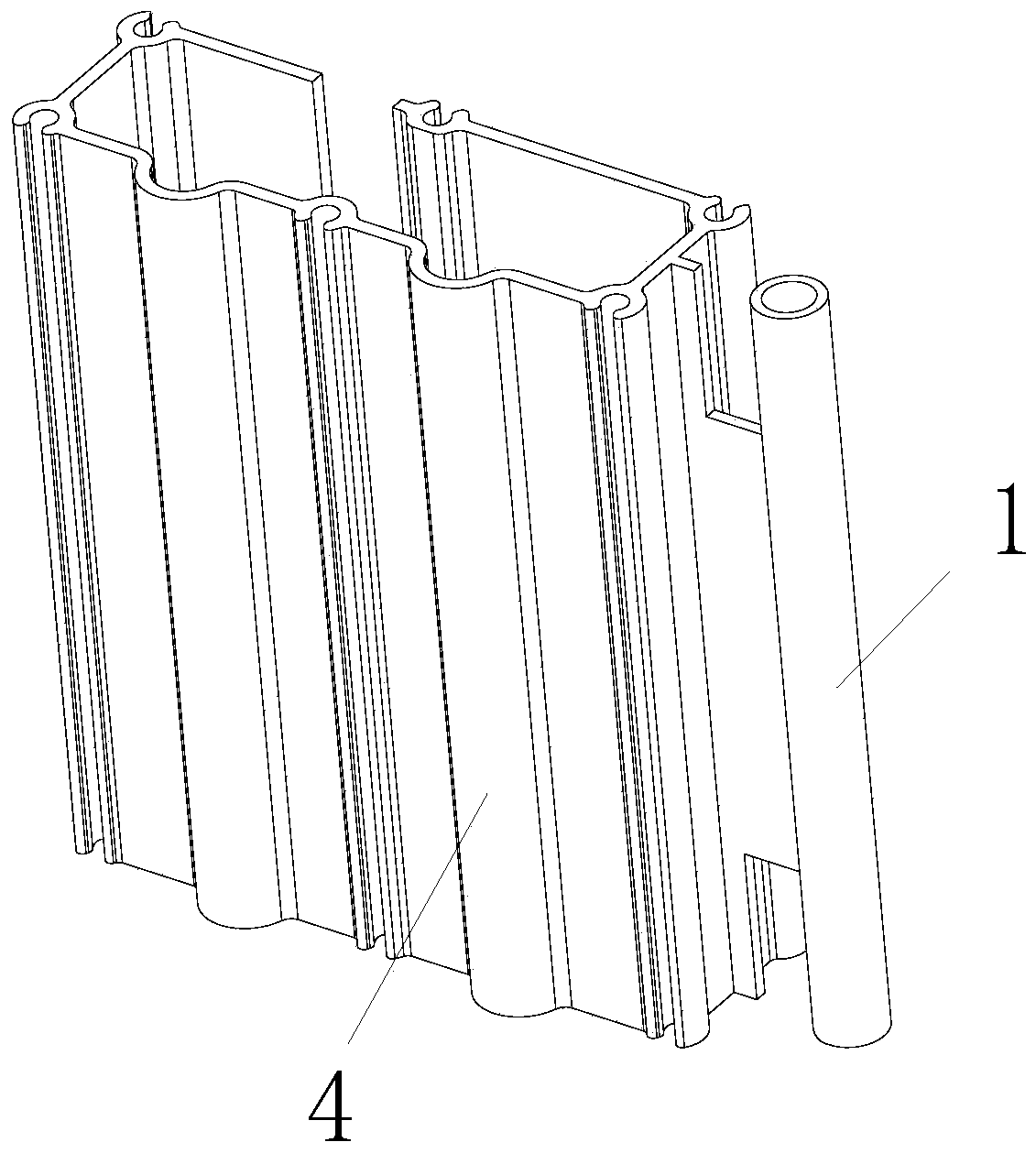

Small-size high-efficiency electric heating device with waste heat recovery function

PendingCN109974287ALittle influence of temperatureReduce volumeWater heatersElectricityWaste heat recovery unit

The invention relates to the technical field of liquid electric heating, in particular to a small-size high-efficiency electric heating device with a waste heat recovery function. The device comprisesa plurality of electric heating tubes, the plurality of electric heating tubes communicates with each other through connecting tubes to form a liquid electric heating channel, a heat conduction shellare arranged outside the electric heating tubes in a sleeved mode, the upper ends and the lower ends of the electric heating tubes are fixed together with the heat conduction shell through fixing pieces, the heat conduction shell is integrally formed with a water inlet tube, and the water inlet tube communicates with the water inlet end of the liquid electric heating channel. According to the device, a liquid electric heating assembly can effectively reduce the size of the assembly under the same power, the occupied volume of the space is reduced, meanwhile, heat can be recycled, so that theheat efficiency is improved, the energy is saved, the environment is protected, and meanwhile, the temperature of the outer sleeve shell is kept low and the outer sleeve shell is convenient to use ina narrow space.

Owner:WUHU ALDOC TECH CO LTD

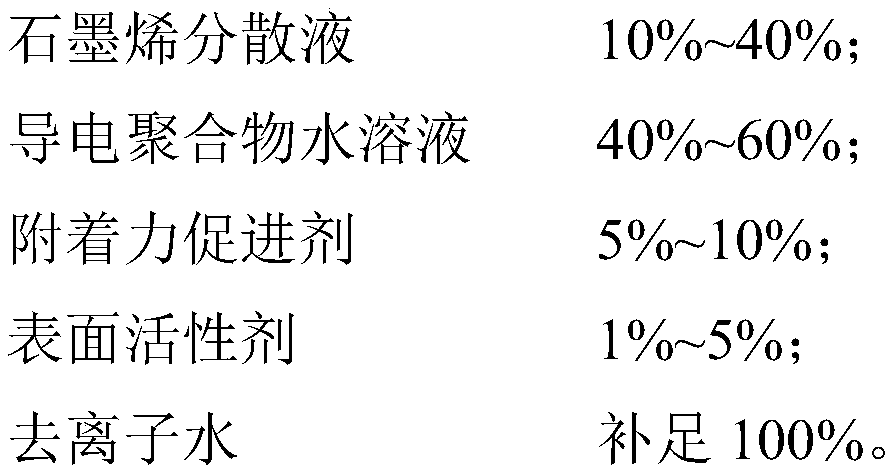

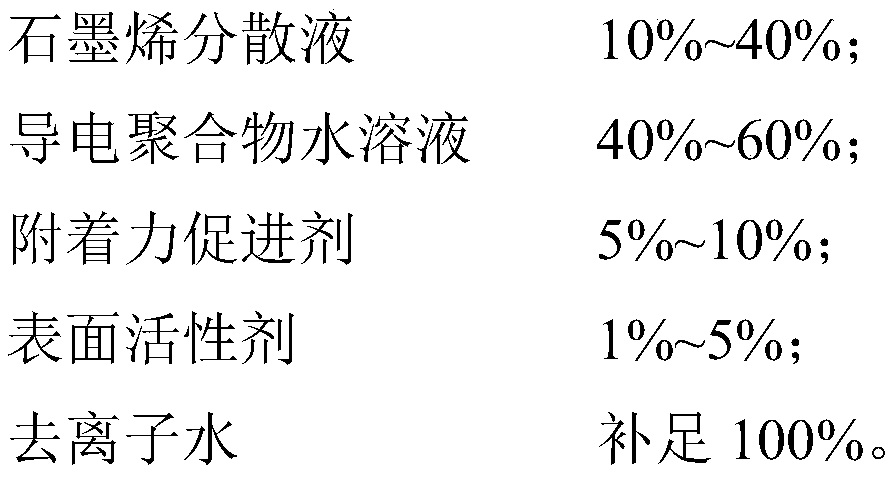

Transparent graphene ink and preparation method thereof, heating glass using transparent graphene ink and preparation method of heating glass

The invention mainly aims to provide transparent graphene ink and a preparation method thereof, heating glass using the transparent graphene ink and a preparation method of the heating glass. The transparent graphene ink is prepared from the components in percentage by mass: 10%-40% of a graphene dispersion solution, 40%-60% of a conductive polymer aqueous solution, 5%-10% of a adhesion promoter,1%-5% of a surfactant, and the balance of deionized water; the preparation method includes the steps that the deionized water, the graphene dispersion solution and the conductive polymer aqueous solution are mixed, and ultrasonic dispersion is conducted; the adhesion promoter and the surfactant are added to ultrasonic dispersion, and homogeneous dispersion is conducted to obtain the transparent graphene ink; and the transparent graphene ink is applied on the surface of the a glass substrate and dried; conductive materials are applied on both sides of a graphene ink layer and dried to obtain the heating glass. The transparent graphene ink is high in light transmittance, good in adhesion and low in sheet resistance, when the transparent graphene ink is applied to the glass, the glass can beheated at the low voltage, the anti-fog deicing and snow removal effects are achieved, and thus the transparent graphene ink is more practical.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

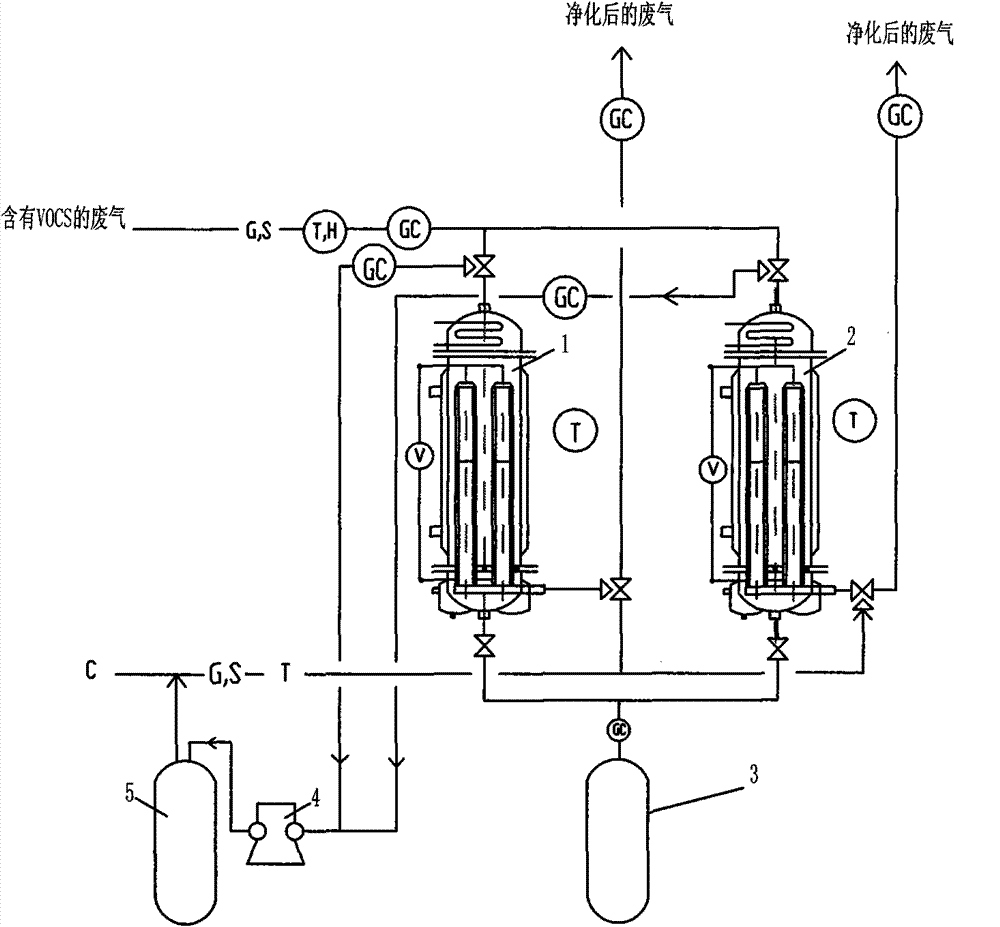

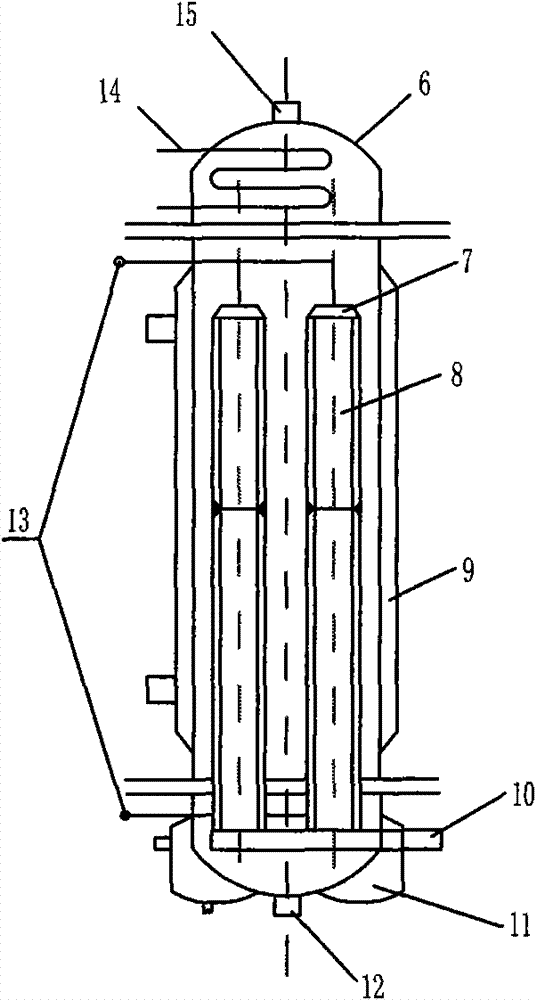

Method and device for recovering volatile organic compound through adsorption-electric heat desorption

ActiveCN101987275BRich in microporesLarge specific surface areaDispersed particle separationCombustible gas purificationDesorptionEngineering

The invention relates to a method and a device for recovering volatile organic compound through adsorption-electric heat desorption. The method comprises the following steps of: (1) inputting waste gas containing VOCS (Volatile Organic Chemicals) from the upper part of a shell of an adsorption-electric heat desorption device, wherein the waste gas absorbed and purified by a hollow cylinder containing VOCS is discharged from the lower part of the shell; (2) inputting inert gas into the VOCS-absorbed hollow cylinder, electrifying and heating to warm the hollow cylinder, continuously introducing inert gas which penetrates outward from a hollow passage in the hollow cylinder through the cylinder wall, desorbing the VOCS absorbed on the cylinder wall to obtain the VOCS-containing inert airflow; and (3) condensing the VOCS-containing inert airflow so that the inert airflow is liquefied and flows to a VOCS tank, and the inert gas is discharged from the upper part of the shell of the adsorption-electric heat desorption device for cycle use. The invention has the advantages that the method and device has the characteristics of high efficiency, energy saving, short operation period and capability of recycling the inert gas.

Owner:武汉旭日华环保科技股份有限公司 +2

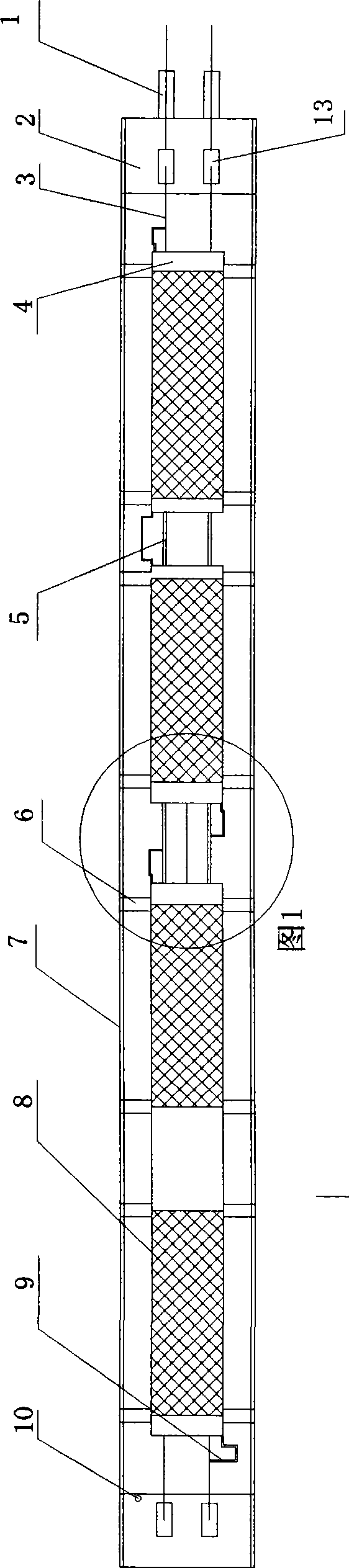

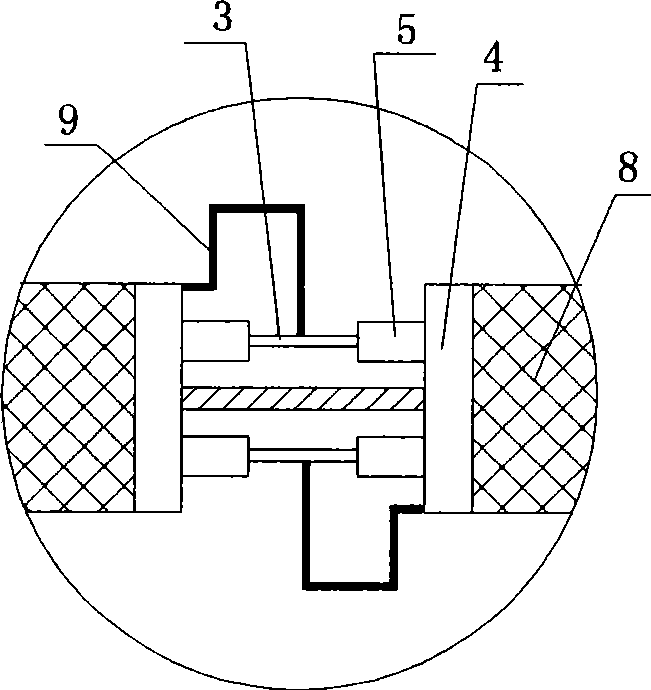

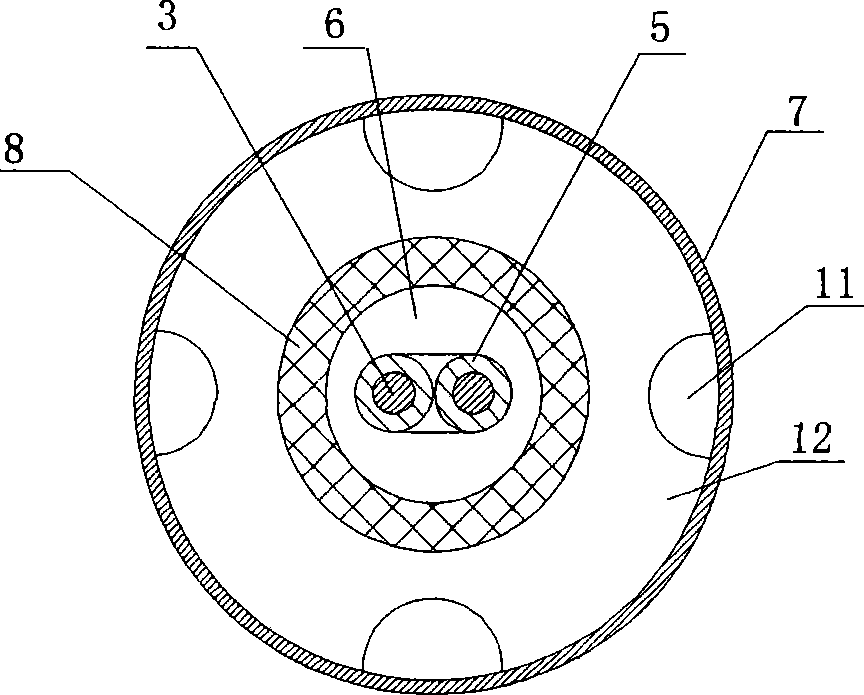

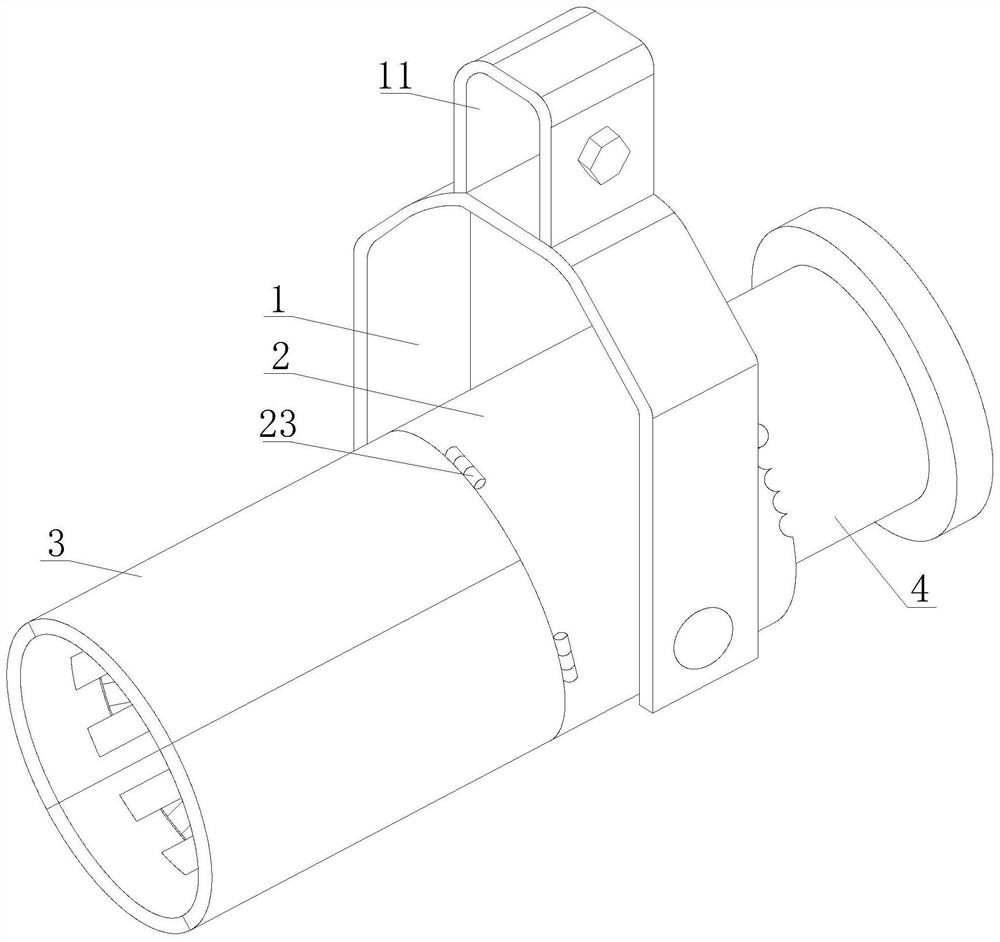

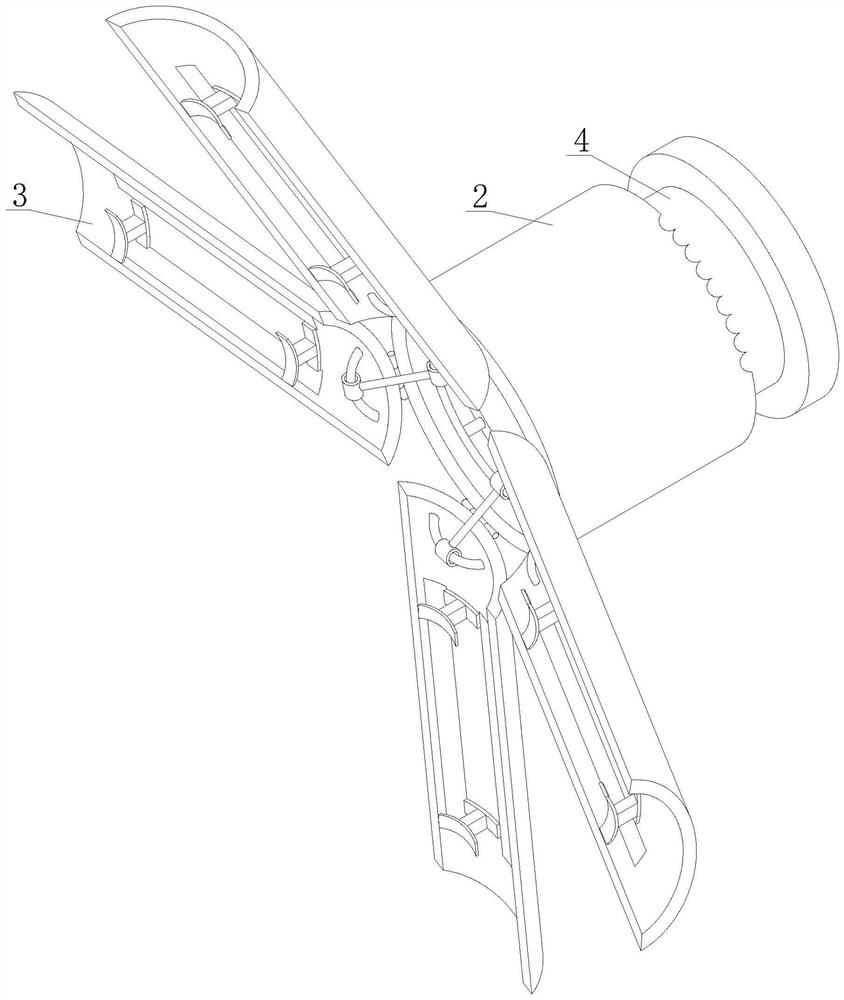

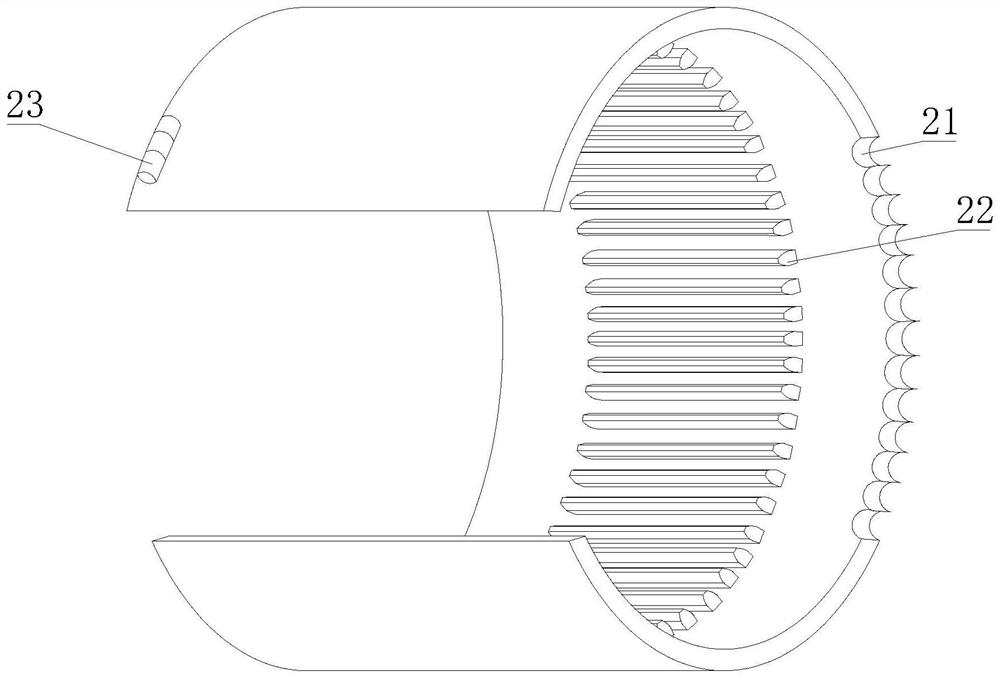

An electrothermal treatment device for aluminum cut pellets and its implementation method

ActiveCN112045108BUniform electric heat treatmentStrong penetrating powerOhmic-resistance heating detailsHeating element shapesHeat treatedPhysics

The invention discloses an electrothermal treatment device for aluminum cut pellets and an implementation method thereof, which comprises a mounting frame, a positioning cylinder and a preheating plate. The upper end of the mounting frame is fixedly connected with mounting ears, and the lower end of the mounting frame is equipped with a positioning cylinder. One end of the cylinder is connected with a preheating plate through a symmetrical hinge of the hinge, and a fixed heating cylinder is arranged inside the positioning cylinder, and the end of the positioning cylinder away from the preheating plate is symmetrically provided with an engaging groove, and the engaging groove is a continuous arc shaped groove. The invention proposes an electrothermal treatment device for cut aluminum shot and its implementation method, which performs electrothermal treatment on the processed aluminum wire before processing the cut aluminum shot, so as to ensure uniform electric heat treatment of the cut aluminum shot after cutting. The preheating plate is movably connected to the fixed heating cylinder, and the fixed heating cylinder can be pushed to turn over the positioning cylinder, rotate the positioning cylinder, realize the clamping rod to clamp the aluminum wire, and put the second heating plate close to the aluminum wire to heat it, electric heating The effect is good.

Owner:马鞍山市山峰金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com