Graphene constant-temperature electrothermal film and preparation method thereof

A graphene, electric heating film technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve problems such as unsatisfactory physical and chemical properties, potential safety hazards, troubles, etc., and achieve excellent electric heating performance and far-infrared radiation effect, electrical and thermal conductivity. The effect of excellent performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] I) Immerse the washed copper sheet in a mixture of 200mL sodium hydroxide solution (10mol / L) and 100mL ammonia water (25%), let it stand for 12h, and then wash it several times with deionized water and absolute ethanol. Dry in the air to get Cu / Cu(OH) 2 The nanorod array is then calcined at 550°C for 2h in an argon atmosphere to obtain the Cu / CuO nanorod array;

[0056] II) Mix 8g of sodium hydroxide and 8g of glucose in 80mL of water, add the composite material obtained in step I) to it, microwave hydrothermal reaction at 160℃ for 1h, after cooling to room temperature, take out the solid with deionized water and Washing with water and ethanol for several times, and drying at 60°C to obtain a Cu sheet supported Cu nanorod array;

[0057] III) Put the material obtained in step II) into a CVD tube furnace. Under a mixed atmosphere of hydrogen (flow rate of 20sccm) and argon (flow rate of 800sccm), the tube furnace is heated to 1000°C at a rate of 5°C / min Then, adjust the hydr...

Embodiment 2

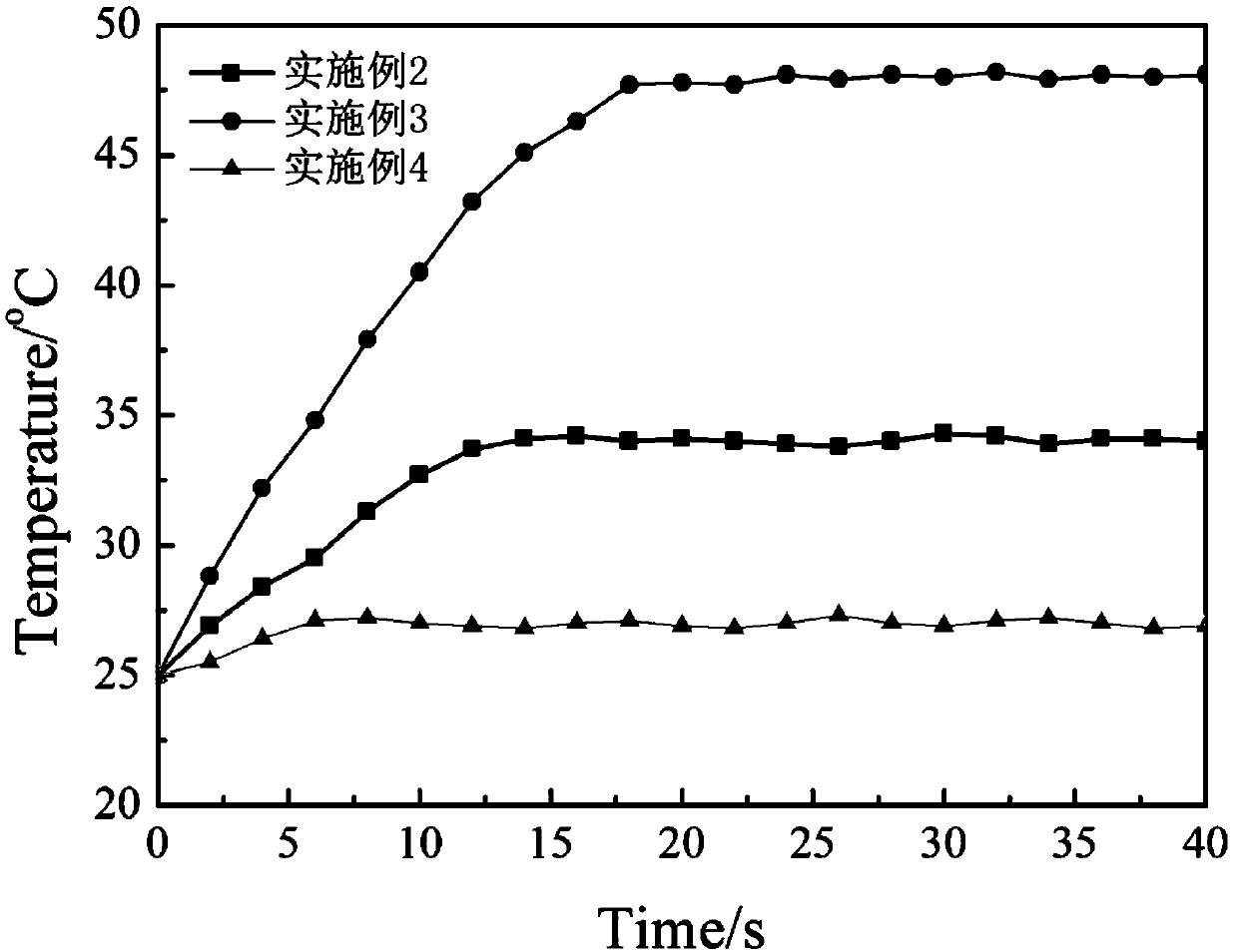

[0060] Accurately weigh 1g of graphene prepared in Example 1, 30g of n-eicosane, 10g of polyurethane resin, 56g of DMF, 1g of HT-5027, 1g of SN-612, 1g of T-7511, mix them and vigorously stir for 2h to fully dissolve the solids Or disperse to obtain a mixed slurry, apply the slurry to the surface of the PVC film by a coating process, set the coating thickness to 120μm, and dry it at 120°C to obtain a conductive composite film with a thickness of about 30μm. Two conductive copper tapes are attached in parallel on both ends of the film as electrodes, and then a layer of polyurethane film is attached to the surface, the PVC film on the other side is removed, and a layer of polyurethane film is also attached to the surface to obtain self-temperature graphene Electric heating film.

Embodiment 3

[0062] Accurately weigh 0.5g graphene prepared in Example 1, 40g n-tetracosane, 5g epoxy resin, 51.5g triethylamine, 1gHT-5027, 1g SN-612, 1g T-7511, mix them and vigorously Stir for 2 hours to fully dissolve or disperse the solids to obtain a mixed slurry. Use the coating process to coat the slurry on the surface of the PTFE film. The coating thickness is set to 160μm, and dried at 130°C to obtain a thickness of about 40μm conductive composite film, two conductive copper tapes are attached in parallel on both ends of the film as electrodes, and then a layer of polyurethane film is attached to the surface, the PVC film on the other side is removed, and a layer of polyurethane film is also attached to the surface , Which is obtained from the constant temperature graphene electric heating film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com