Heating film for low-temperature lithium ion battery and preparation method and application of heating film

A technology of lithium ion battery and heating film, applied in the field of lithium ion battery, can solve the problems of easy damage of battery heating, low temperature performance of lithium ion battery can not be performed normally, etc., achieves good heating effect, avoids capacity decay, and protects the effect of battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

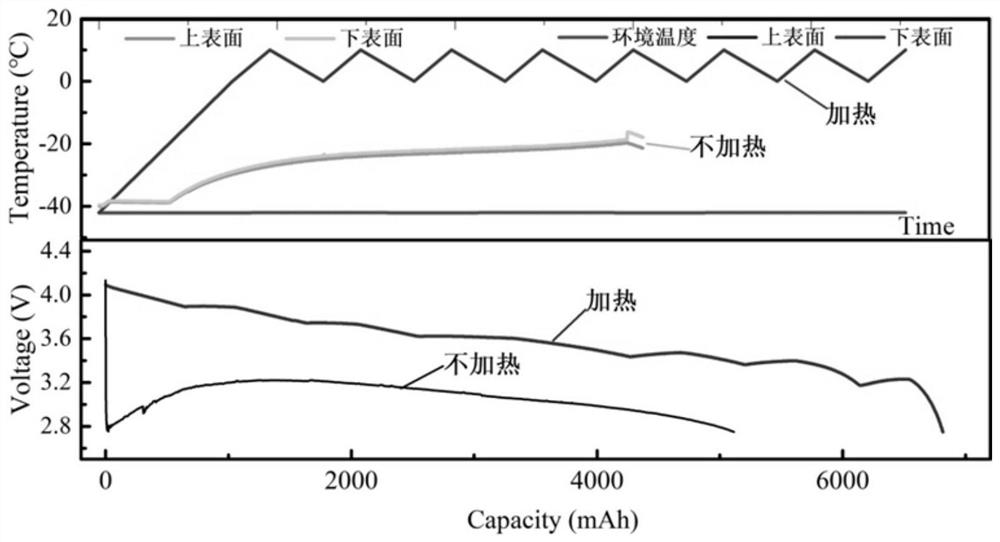

[0028] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

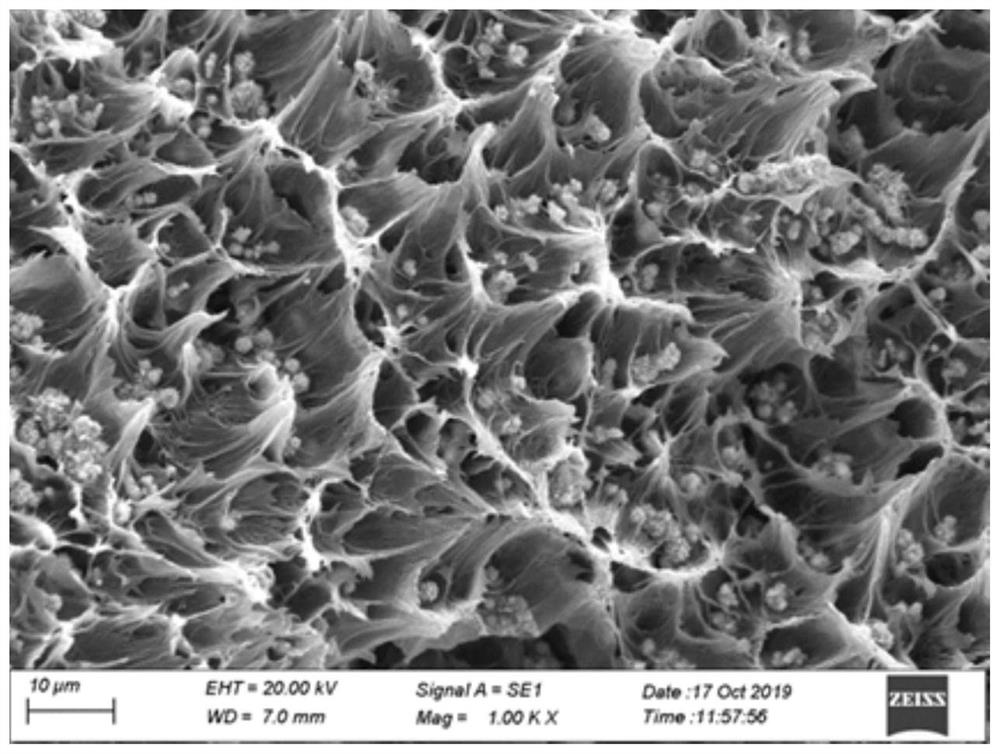

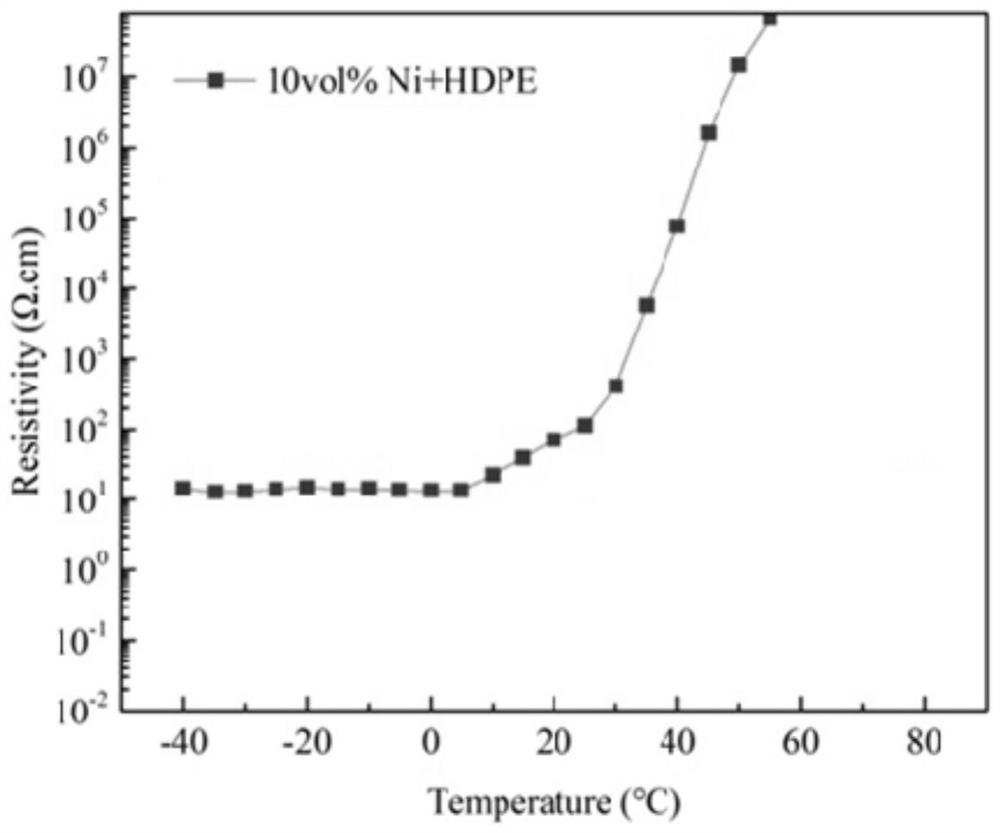

[0029] (1) Add nano-nickel powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and low-density polyethylene to obtain mixture 2, and then heat mixture 2 to a molten state at 180°C and stir , to obtain a melt; titanate coupling agent volume accounts for 1% of the nano-nickel powder volume, and the nano-nickel powder volume accounts for 10% of the mixture two volumes (i.e. low density polyethylene and nano-nickel powder volume ratio is 90:10);

[0030] (2) Press the melt obtained in step (1) into a film with a thickness of 1 mm in a hot press molding machine or a hot roll molding machine under the conditions of 150 ° C and 0.6 MPa. Before molding, it is necessary to apply a layer of mold release in the molding mold agent, heat treatment at 120°C for 30 minutes, and cool at room temperature to obtain a heating film for low-t...

Embodiment 2

[0033] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

[0034] (1) Add nano-silver powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and low-density polyethylene to obtain mixture 2, then heat mixture 2 to a molten state at 170° C. and stir, Obtain molten body; Titanate coupling agent volume accounts for 1% of nano-silver powder volume, and nano-silver powder volume accounts for 15% of mixture two volumes (that is low density polyethylene and nano-silver powder volume ratio are 85:15);

[0035] (2) Press the melt obtained in step (1) into a film with a thickness of 1.1mm in a hot press molding machine or a hot roll molding machine under the conditions of 130°C and 0.5MPa. The molding agent is then heat-treated at 110° C. for 25 minutes, and cooled at room temperature to obtain a heating film for a low-temperature lithium-ion battery.

Embodiment 3

[0037] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

[0038] (1) Add nano-carbon powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and polypropylene to obtain mixture 2, and then heat mixture 2 to a molten state at 200°C and stir to obtain Melt body; the volume of titanate coupling agent accounts for 3% of the volume of nano-carbon powder, and the volume of nano-carbon powder accounts for 12% of the volume of the mixture (that is, the volume ratio of polypropylene and nano-carbon powder is 88:12);

[0039] (2) Press the melt obtained in step (1) into a film with a thickness of 0.8mm in a thermocompression molding machine or a hot roll molding machine under the conditions of 160°C and 0.7MPa. The molding agent is then heat-treated at 100° C. for 40 minutes, and cooled at room temperature to obtain a heating film for a low-temperature lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com