Patents

Literature

48results about How to "Avoid early damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

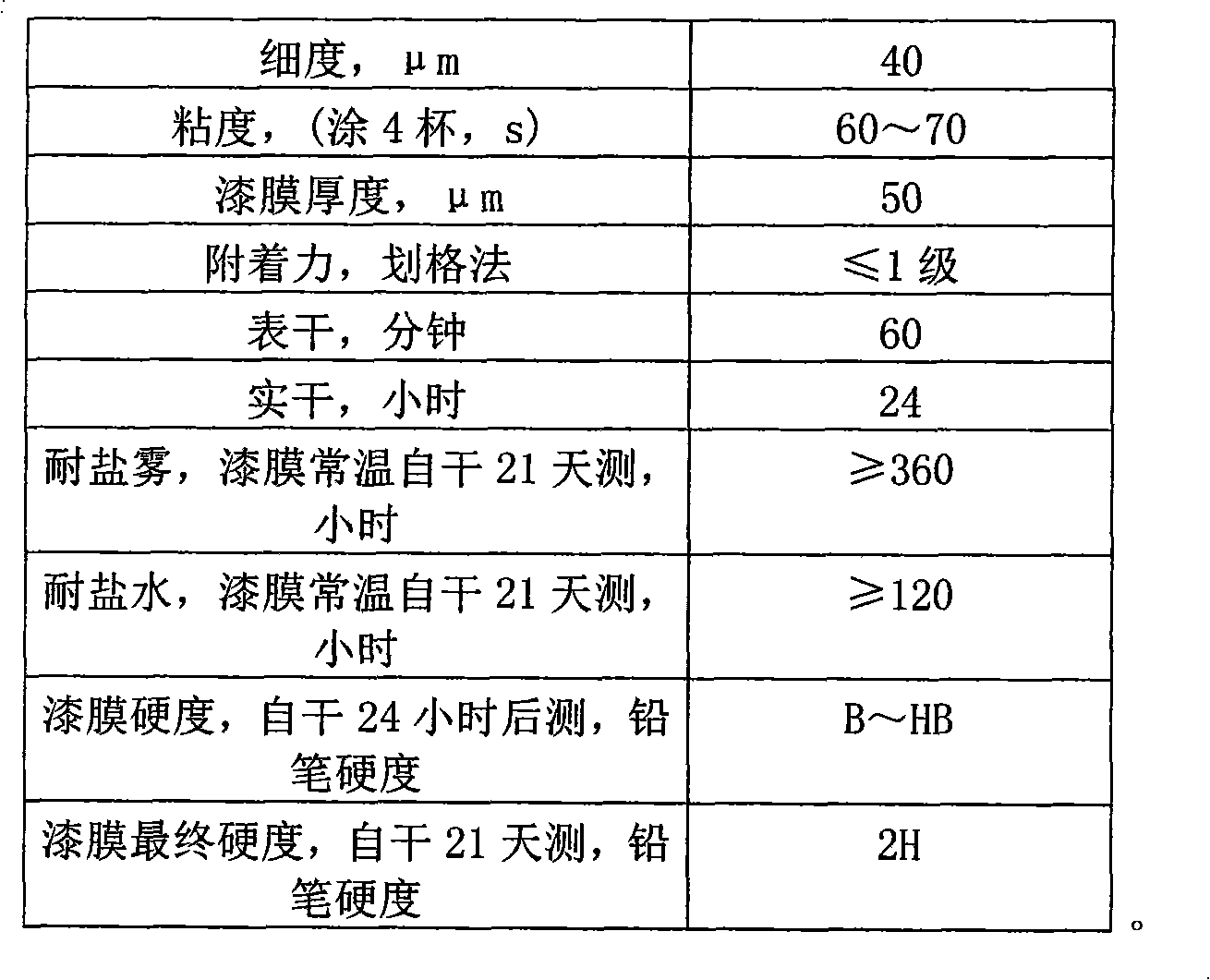

Waterborne epoxy ester resin composition and preparation method thereof and water-based paint prepared from same

ActiveCN101851396AExcellent corrosion resistance and water resistanceImprove drynessEpoxy resin coatingsEpoxyChemical industry

The invention belongs to the field of water-based paints in chemical industry and provides a waterborne epoxy ester resin composition and a preparation method thereof and a water-based paint prepared from the same. The waterborne epoxy ester resin composition is prepared by the following methods: (1) preparing a carboxyl-containing vinyl polymer (a) by polymerizing vinyl monomer free radicals; (2) performing ring-opening reaction on excessive epoxy group, fatty acid and an epoxy resin to prepare a fatty acid epoxy ester resin (b); (3) adding the (a) into the (b) to make the carboxyl in the (a) react with the epoxy group in the (b) so as to prepare a vinyl modified epoxy ester resin (A); and (4) neutralizing the (A), adding water, and dispersing to obtain the waterborne epoxy ester resin composition. The waterborne epoxy ester resin composition can overcome the defects that the conventional epoxy ester resin has poor corrosion and water resistance, and the speed that the film has intensity is low. The obtained resin composition film has excellent corrosion and water resistance, and both the resin and the paint have excellent storage stability; the resin film has good dryness, and the speed that the film has the intensity is high; and the paint can be widely applied to the field of metal corrosion resistance.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Cold-regenerated emulsified asphalt mixture and method of cold-regenerated emulsified asphalt mixture for road surface reconstruction

ActiveCN101748677AThe damage is correct and reasonableCorrect and reasonable damageRoads maintainenceSpecial data processing applicationsRoad surfaceMaterials science

The invention provides a cold-regenerated emulsified asphalt mixture and a method of the cold-regenerated emulsified asphalt mixture for road surface reconstruction. In the method, the damage condition of a structural layer below a surface layer is measured on the spot, and then quantitative evaluation is carried out on the bearing capacity so as to obtain actual mechanics and structural parameters; the production of the regenerated asphalt mixture is carried out in a cold mixing factory after milling materials on the asphalt surface layer of an old road, cement, emulsified asphalt and water mixed together; the regenerated asphalt mixture passes the forming test piece detection; the mixture obtained by the above steps is used for a to-be-reconstructed road surface structure, including the laying of a roadbed, a base layer and the surface layer. Moreover, the cold-regenerated asphalt mixture used for the above method has the following characteristics: mineral materials which are mainly composed of the milling materials of the asphalt surface layer of the old road, asphalt cementing materials and residual gaps form a multi-phase disperse system structure with a space network structure; the material property is granular; and the mechanics strength is reached by the cohesive force and the inner frictional resistance of the asphalt mixture.

Owner:JIANGXI GANYUE EXPRESSWAY

Device and method for separating objects from silo

InactiveCN101734491AExclude human involvementAvoid manual errorsDe-stacking articlesLoading/unloadingSeparation processEngineering

The invention relates to a device and a method for separating objects from a silo, the device comprises the silo, a material table, a pushing device and a material supporting part, wherein when the material support part is set to be a pushing board of the pushing device and positioned in the pushing-out position relative to the pushing direction, a material supporting fork of the material supporting part moves between the position allowing the object to be separated to fall and the position blocking the object to be separated from falling; when the pushing board is positioned in the returning position relative to the pushing direction, the material support fork is positioned in the position blocking the object to be separated from falling. The separation method can realize the object separation by carrying out single-object pushing from the object positioned at the bottom of the silo, the separation process comprises the control step of blocking the object to be separated from falling, and the position of the material supporting part is changed according to the position change of the pushing board relative to the pushing direction. The adoption of the device and the method can eliminate the artificial participation, avoid errors of manual operation, save labor resources, further improve product quality and avoid early damage of operation equipment.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

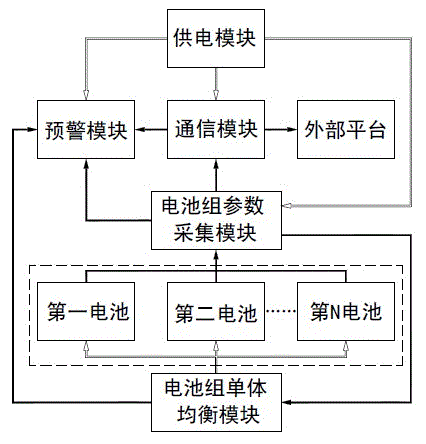

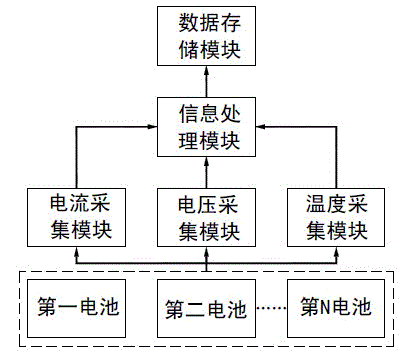

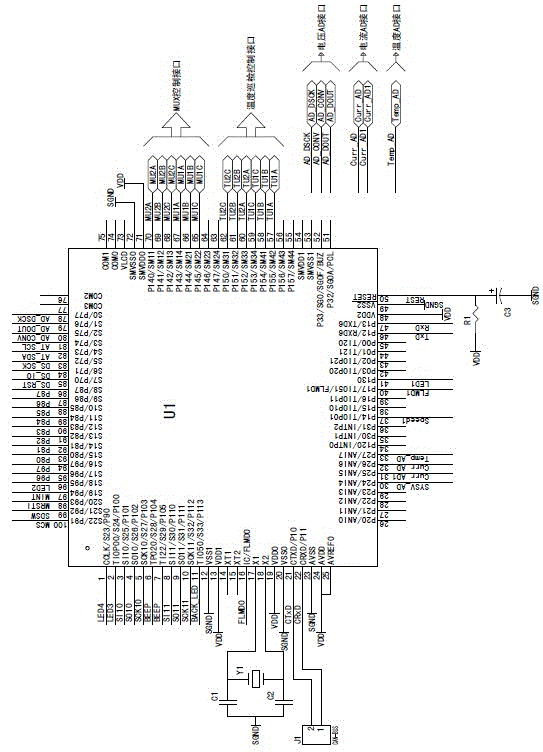

Battery charging and discharging management system

InactiveCN104617627AImprove cycle lifeAvoid excessive dischargeCharge equalisation circuitElectric powerBattery chargeEngineering

The invention discloses a battery charging and discharging management system and belongs to the technical field of storage battery charging and discharging. The battery charging and discharging management system comprises a plurality of batteries inside a battery pack and is characterized by comprising a power supply module, a battery pack parameter collection module and a battery pack single balancing module; the power supply module which is connected with the battery pack parameter collection module and provides power for the battery pack parameter collection module; the battery pack single balancing module is simultaneously connected with the batteries inside the battery pack; the battery pack parameter collection module is connected with the battery pack single balancing module. According to the battery charging and discharging management system, parameters of the battery pack can be collected in real time, balanced charging and discharging of the single battery inside the battery pack is achieved, and the service life of the batteries is effectively prolonged, deep discharging, over discharge of the single batteries, high temperature during the charging process and unbalanced charging are avoided, working states of the batteries can be interrupted in time during abnormal accidents, and personal safety can be guaranteed.

Owner:石狮领顺能源科技有限公司

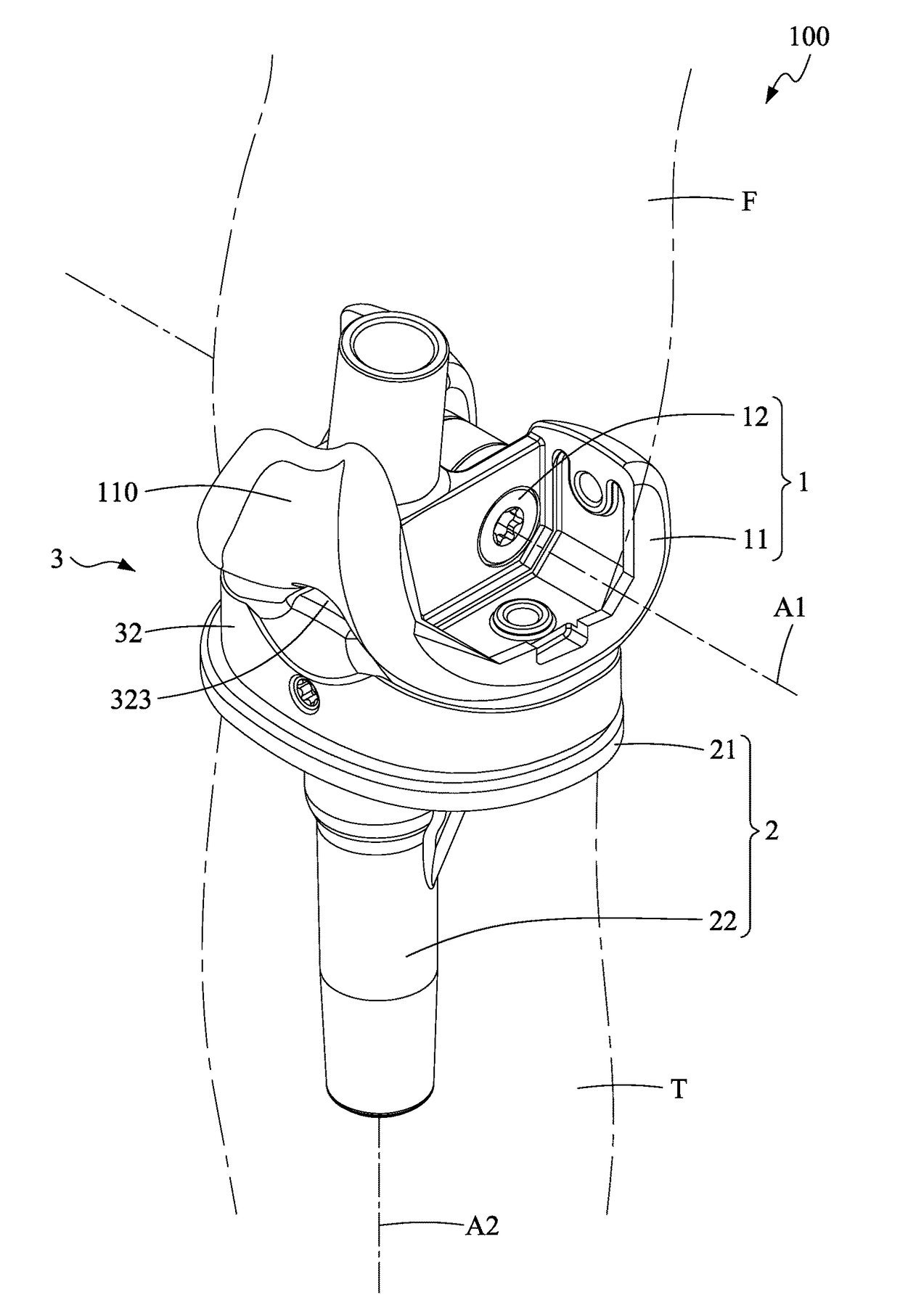

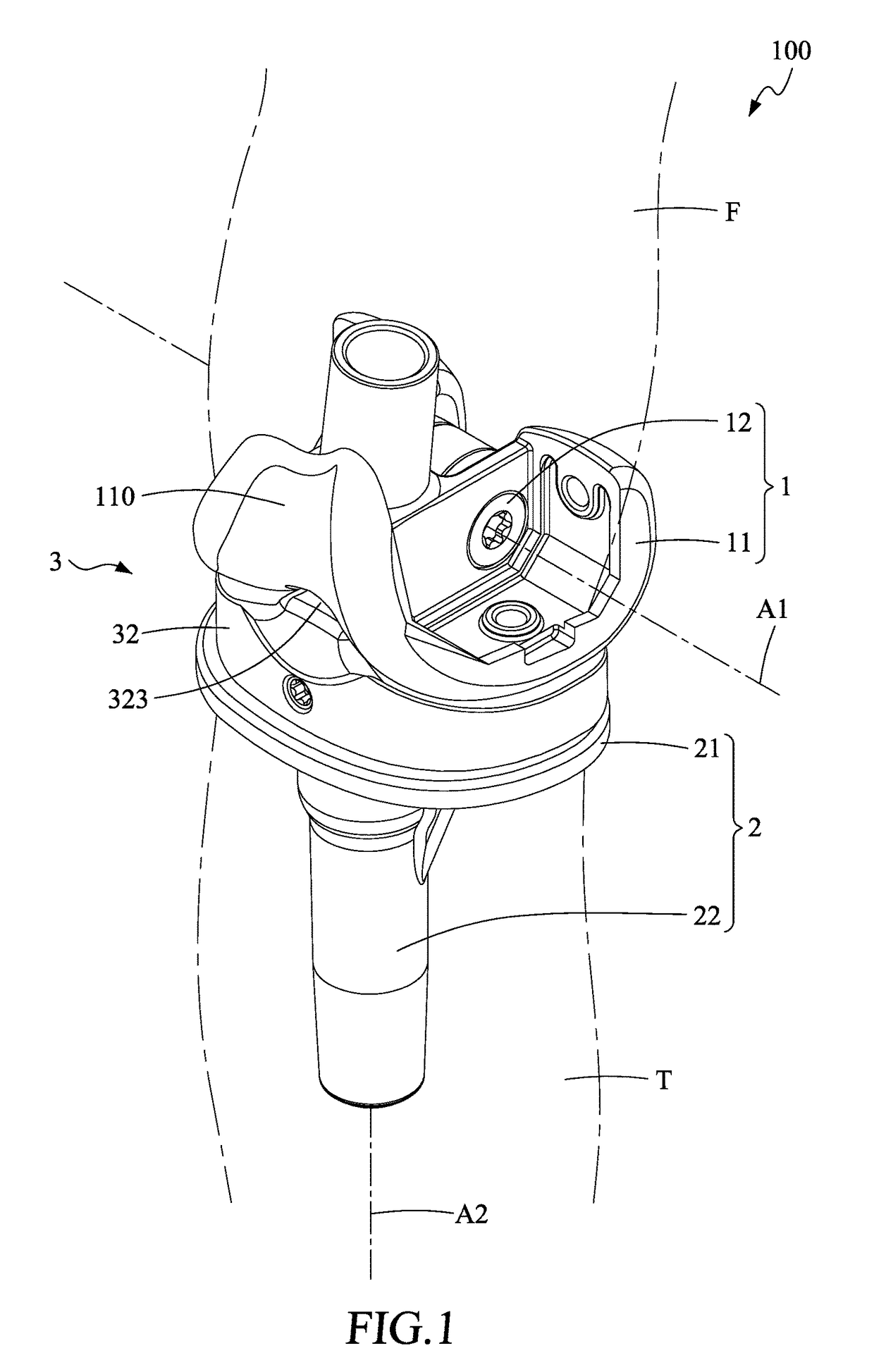

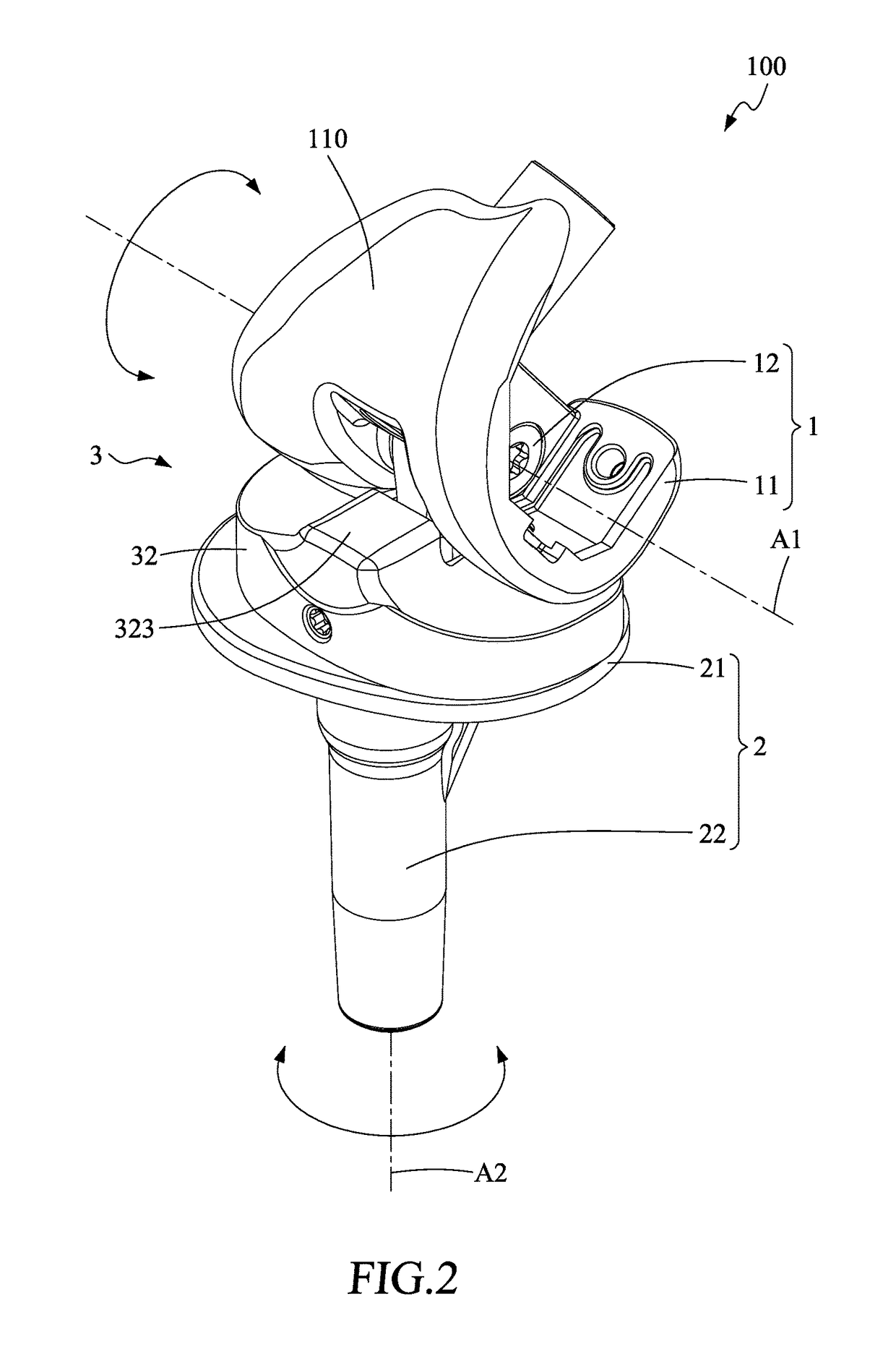

Artificial joint

ActiveUS20170231773A1Prevent reversalIneffectiveness of the artificial jointJoint implantsKnee jointsArtificial jointsSacroiliac joint

The present invention provides an artificial joint, including a femur connecting member, a tibia connecting member, and a receiving member, wherein the femur connecting member is connected and fixed with the receiving member and the tibia connecting member via a fixing member unparallel to a joint-twisting axis, and wherein cushion member receives the femur connecting member via a pivot-receiving surface and receives the tibia connecting member via a twist-receiving surface, thereby providing an durable and reliable artificial joint.

Owner:UNITED ORTHOPEDIC CORP

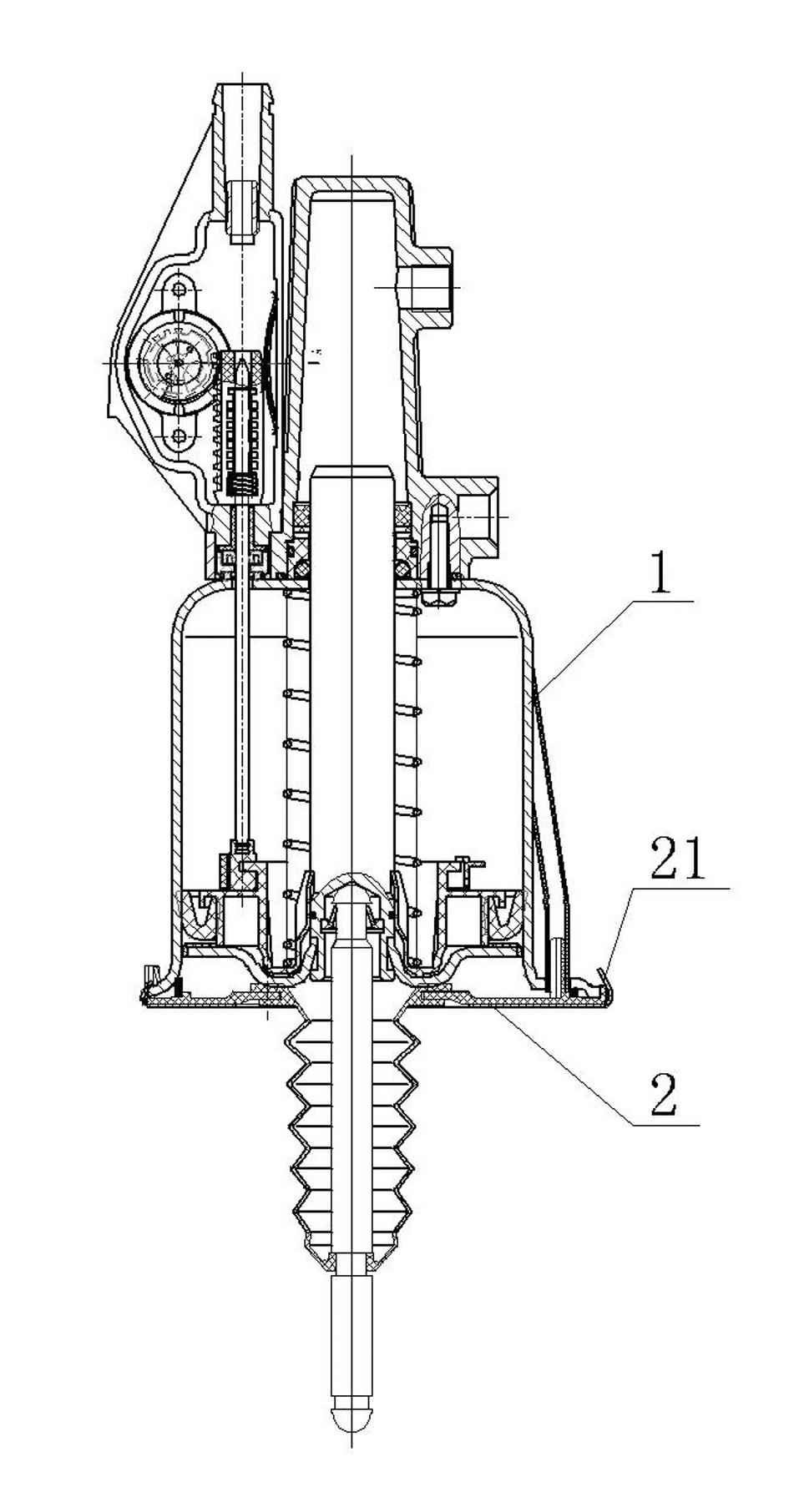

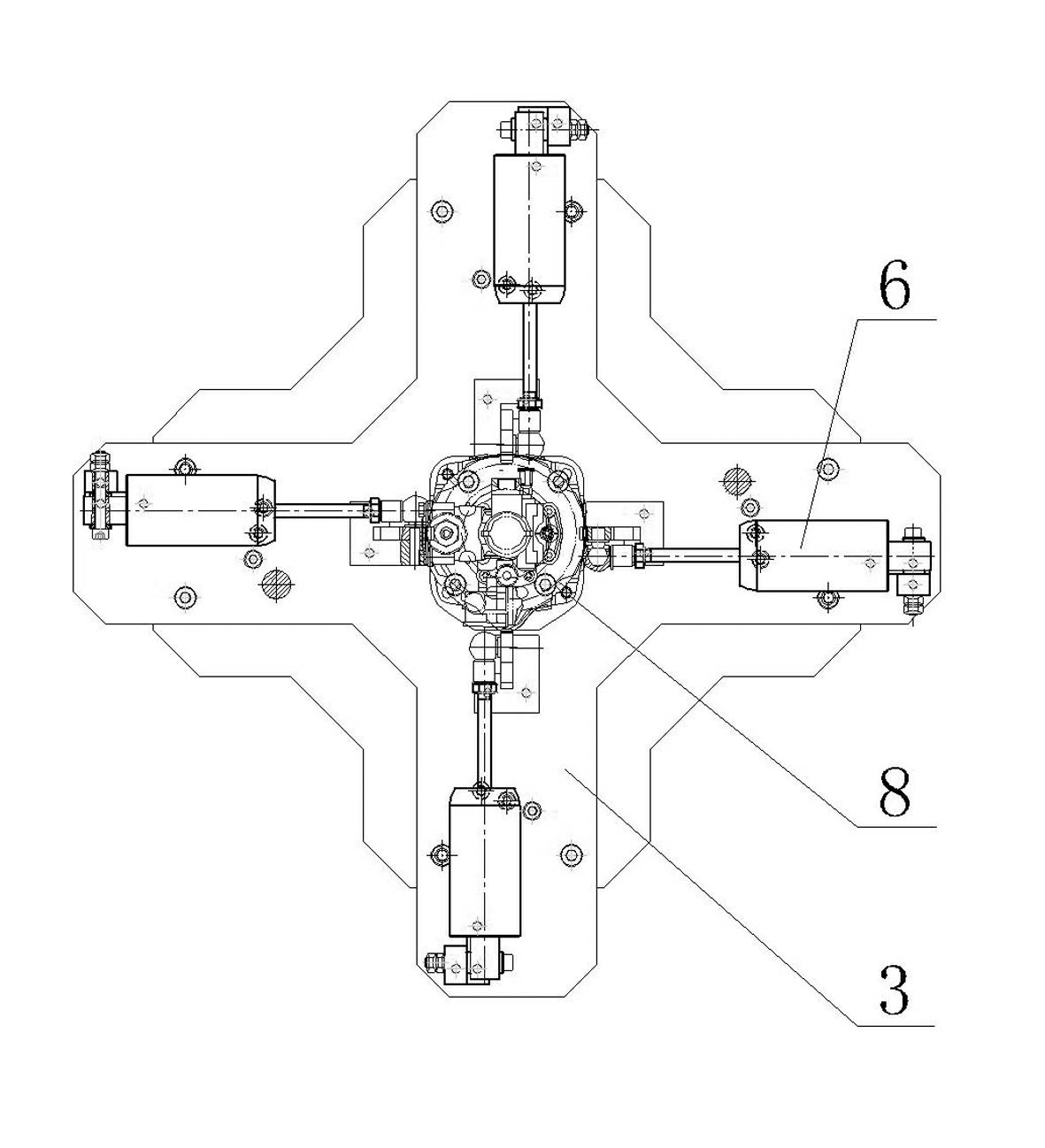

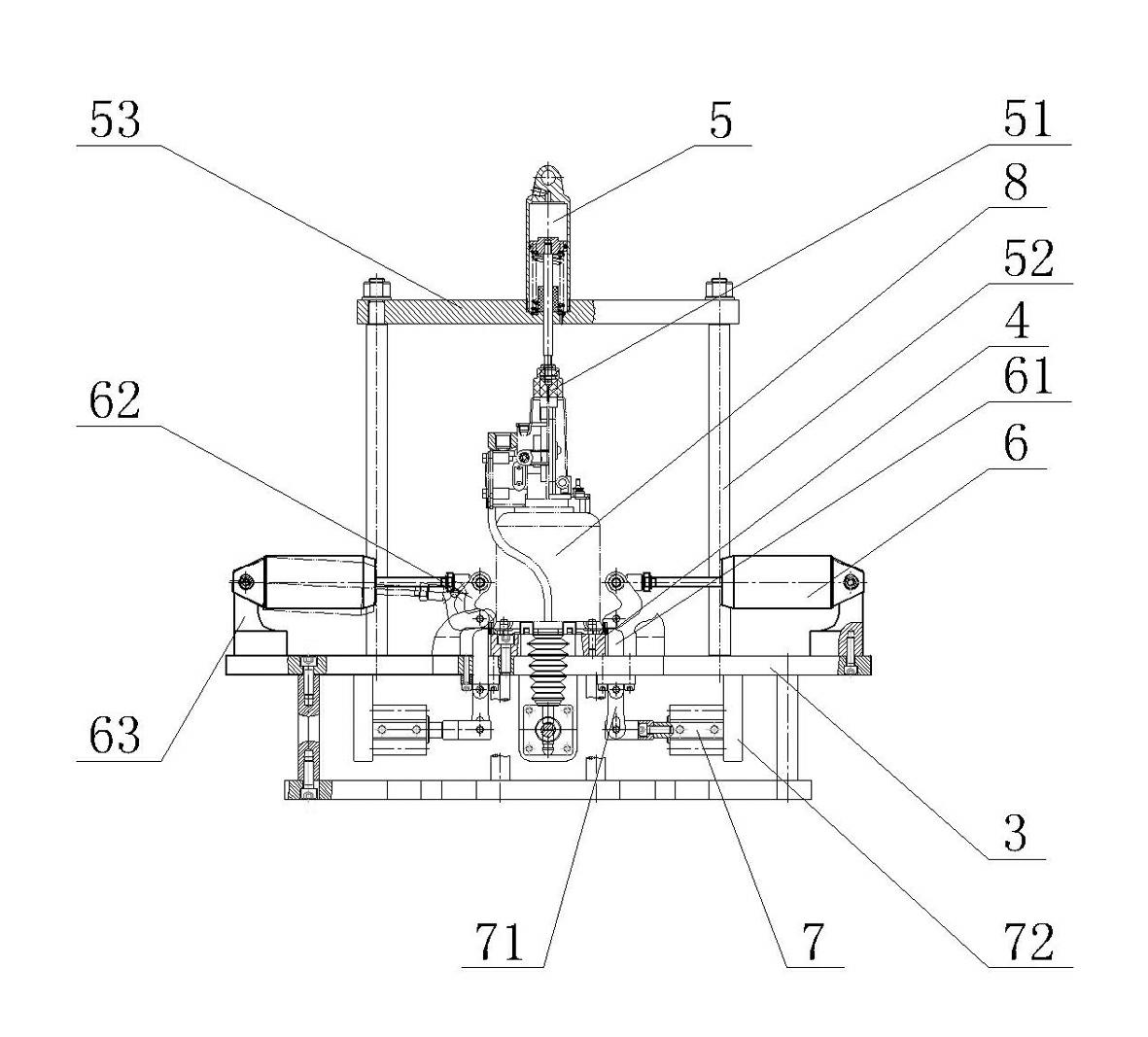

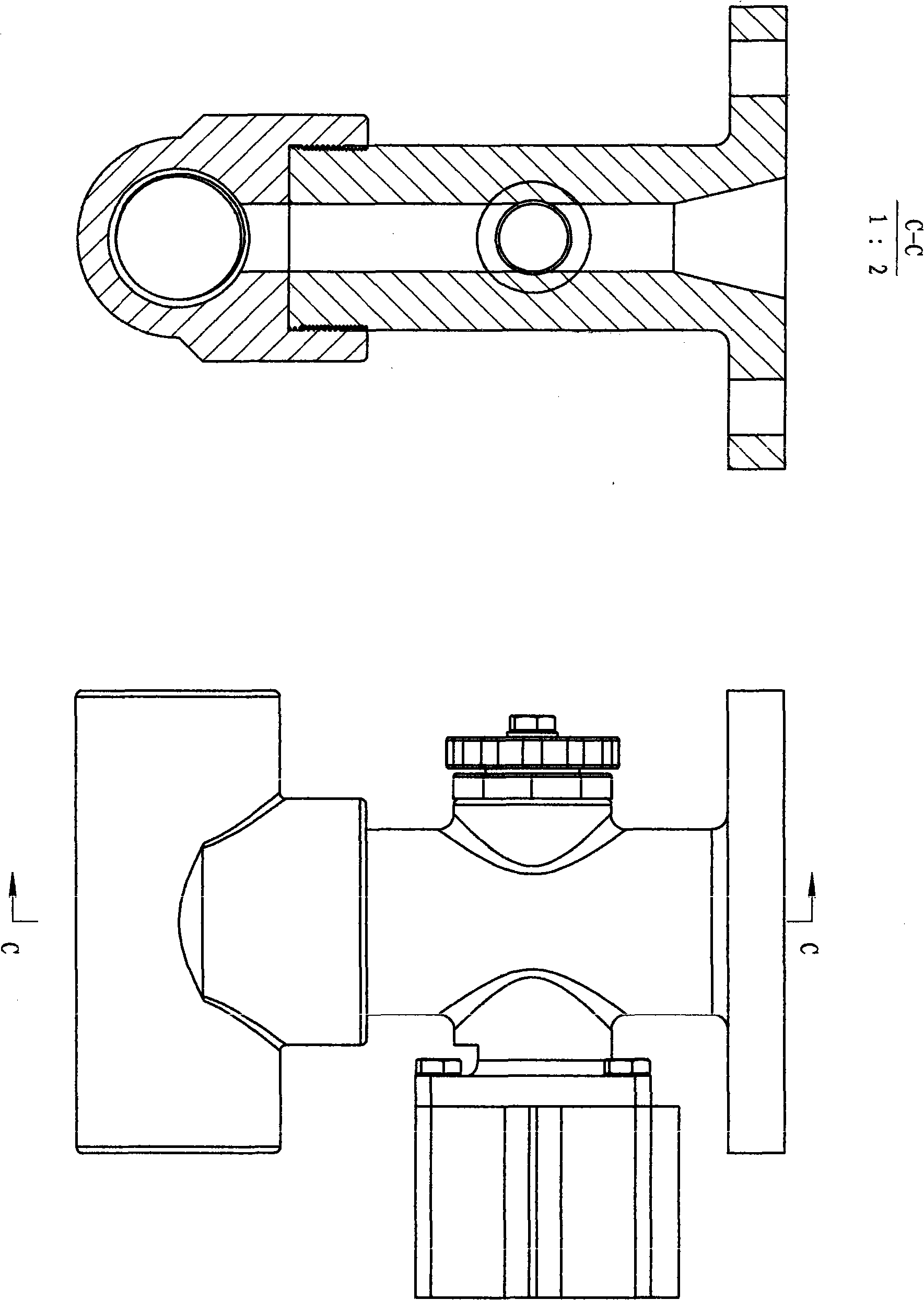

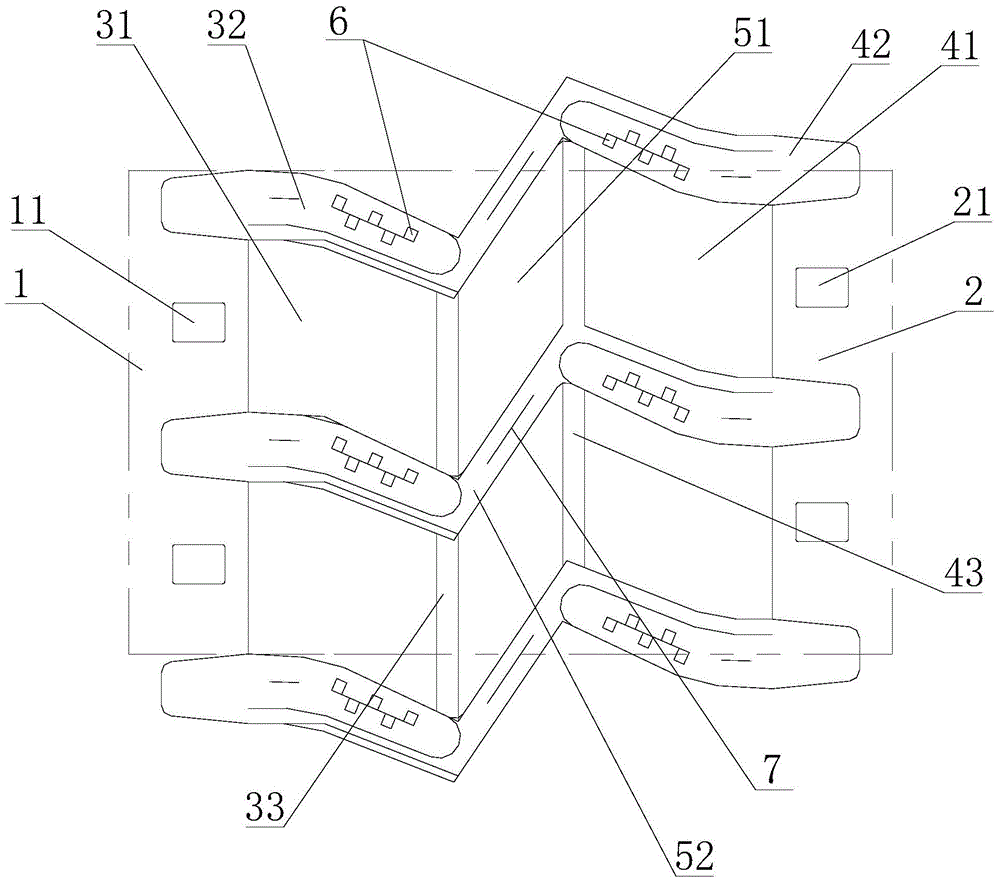

Riveting pressing forming device for cover plate of automobile clutch booster

The invention discloses a riveting pressing forming device for a cover plate of an automobile clutch booster. The riveting pressing forming device for the cover plate of the automobile clutch booster comprises a base plate, wherein a positioning base is arranged on the base plate; a positioning cylinder is arranged rightly opposite to the positioning base; a pressing block is arranged on the positioning cylinder; a riveting cylinder is arranged on the base plate; the output end of the riveting cylinder is connected with the riveting assembly; a pressing cylinder is arranged below the base plate of the corresponding riveting cylinder; the output end of the pressing cylinder is connected with the pressing assembly; the riveting assembly comprises an installing base and a hinging pressing head; the installing base is fixedly installed on the base plate; the hinging pressing head are hinged with the installing base and the output end of the riveting cylinder; an installing plate is fixedly arranged on the base plate; the end part of the riveting cylinder is hinged with the installing plate; the pressing assembly comprises a pressing plate; the pressing plate is fixedly connected with the output end of the pressing cylinder vertically; and the pressing cylinder is fixed below the base plate through a fixing plate. The riveting pressing forming device for the cover plate of the automobile clutch booster has good riveting quality; in the riveting process, the damage to an electrophoretic paint layer at a cover plate forming position is avoided; the consistency of products is good; and the production efficiency is high.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

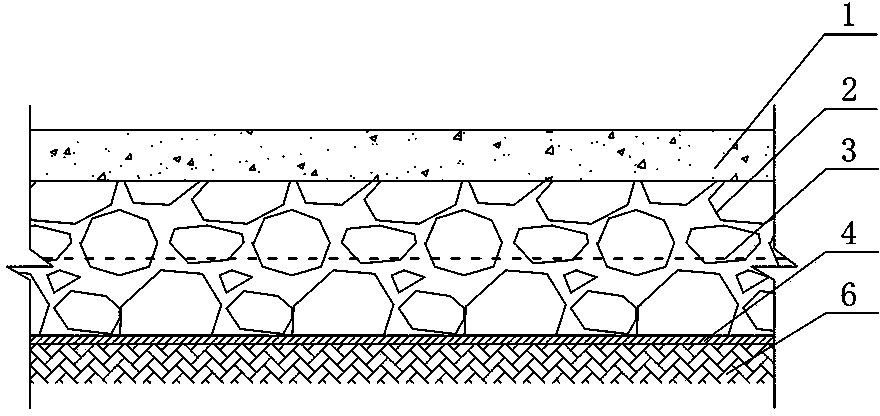

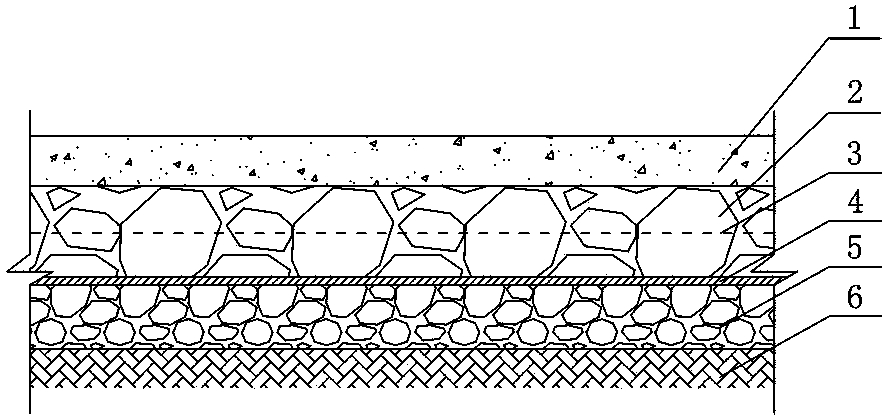

Low-dose cement modified graded broken stone base pavement

The invention discloses a low-dose cement modified graded broken stone base pavement comprising an asphalt concrete pavement layer, an anti-seepage bonding layer and a soil foundation, wherein the anti-seepage bonding layer is paved above the soil foundation; the asphalt concrete pavement layer is paved above the anti-seepage bonding layer; a low-dose cement modified graded broken stone base is paved between the asphalt concrete pavement layer and the anti-seepage bonding layer. The low-dose cement modified graded broken stone base pavement has the advantages that structure is simple, construction is convenient and early destruction phenomenon can be avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

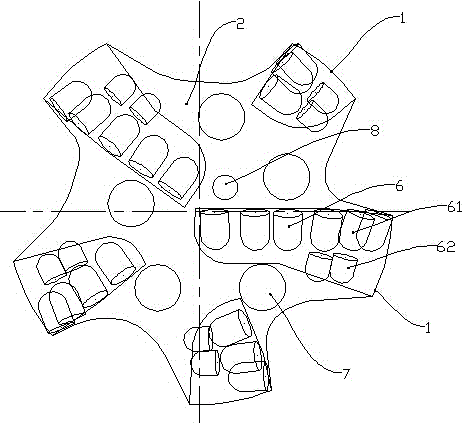

PDC (Polycrystalline Diamond Compact) drill bit suitable for shale gas well shale stratum drilling

InactiveCN104358522AEven by forceNegative cutting angle is suitableDrill bitsConstructionsShale gasPolycrystalline diamond

The invention relates to drilling equipment of shale gas, in particular to a PDC (Polycrystalline Diamond Compact) drill bit suitable for shale gas well shale stratum drilling. The drill bit comprises a crown portion with a plurality of tool wings, wherein the revolution contour line of the crown portion consists of three sections, namely an inner cone section extending outwards along an inner cone from the concave center of the crown portion of the drill bit, a circular arc section extending from the edge of the inner cone to a gauge section on the outer side and a gauge section with a straight line contour, the circular arc section is formed by combining a plurality of sections of circular arcs with different radii, and the radii of the circular arcs are gradually increased from inside to outside; cutting teeth are distributed on the three sections of counters. The PDC drill bit can be suitable for drilling operation of shale stratums, and is high in drilling efficiency and long in service life.

Owner:CHINA PETROLEUM & CHEM CORP

Self-adjusting preload steel wire rope rigging

Owner:山东鲁班机械科技有限公司

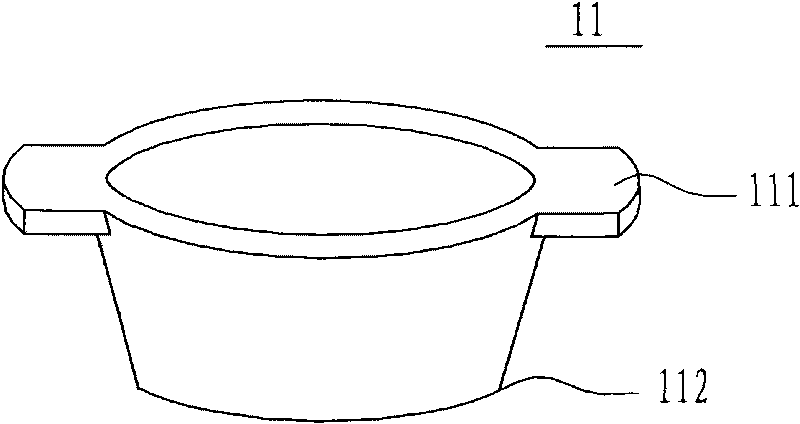

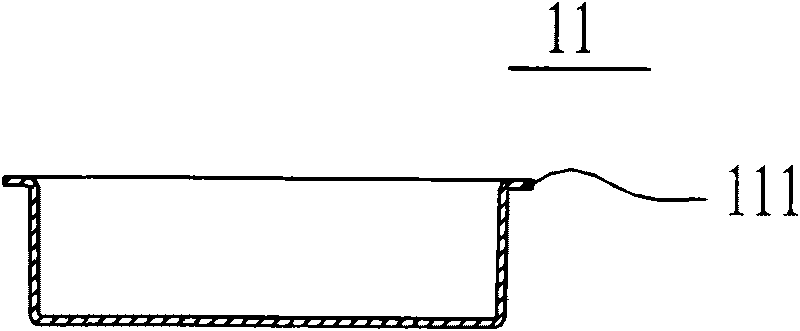

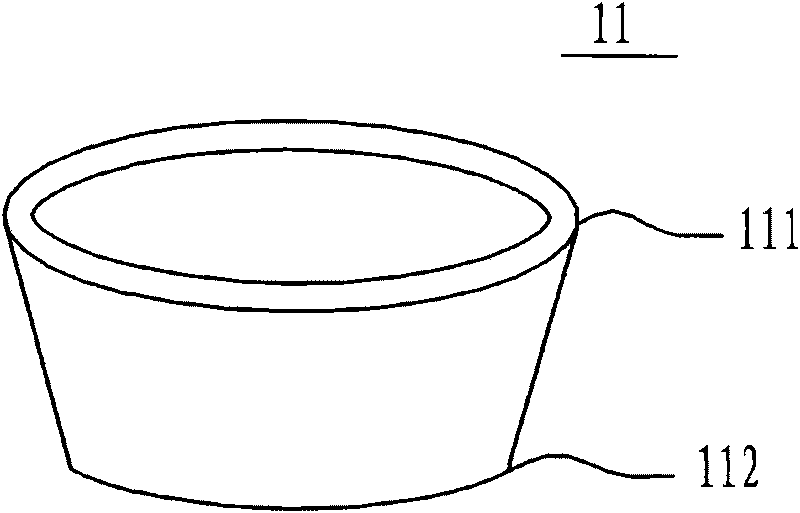

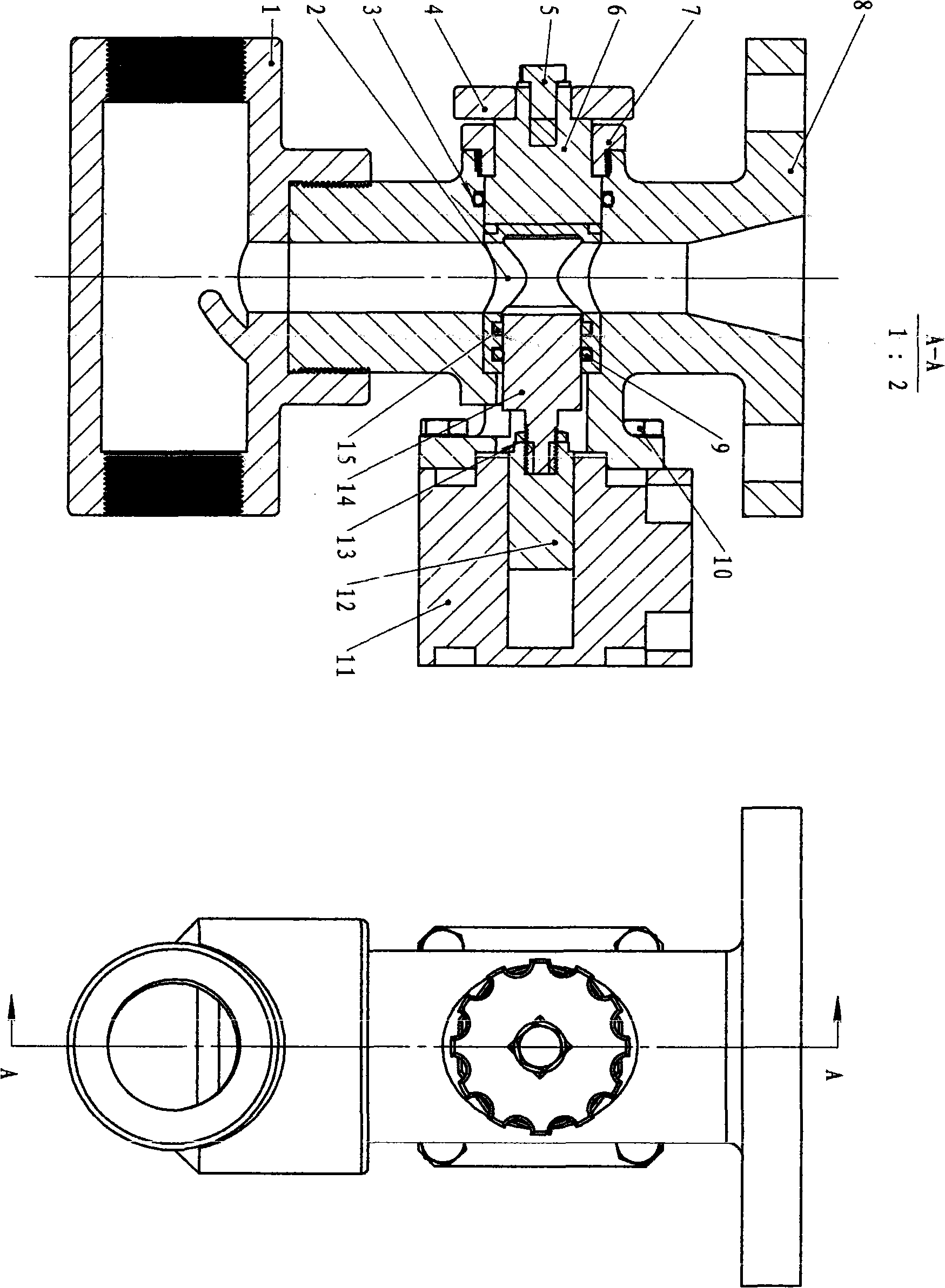

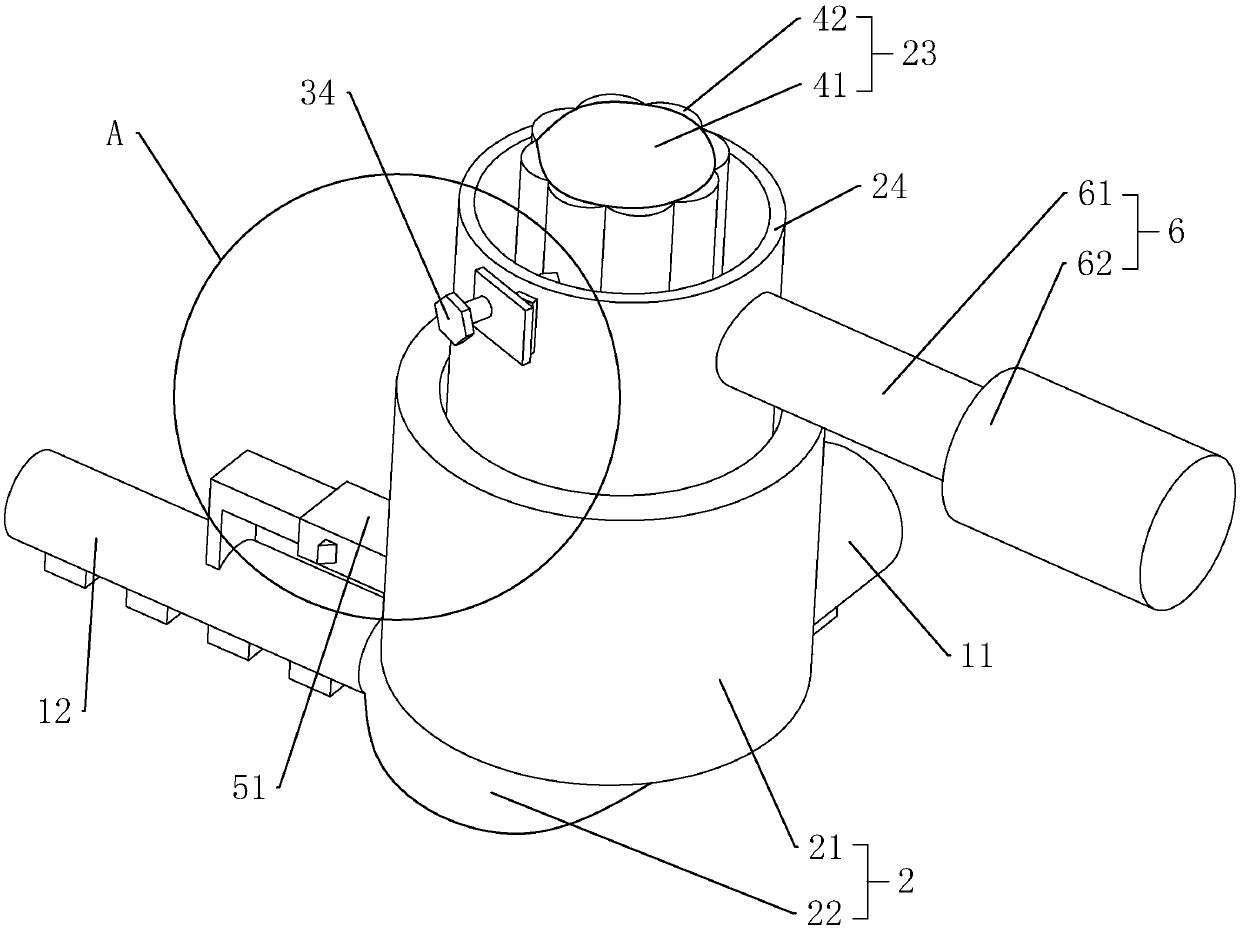

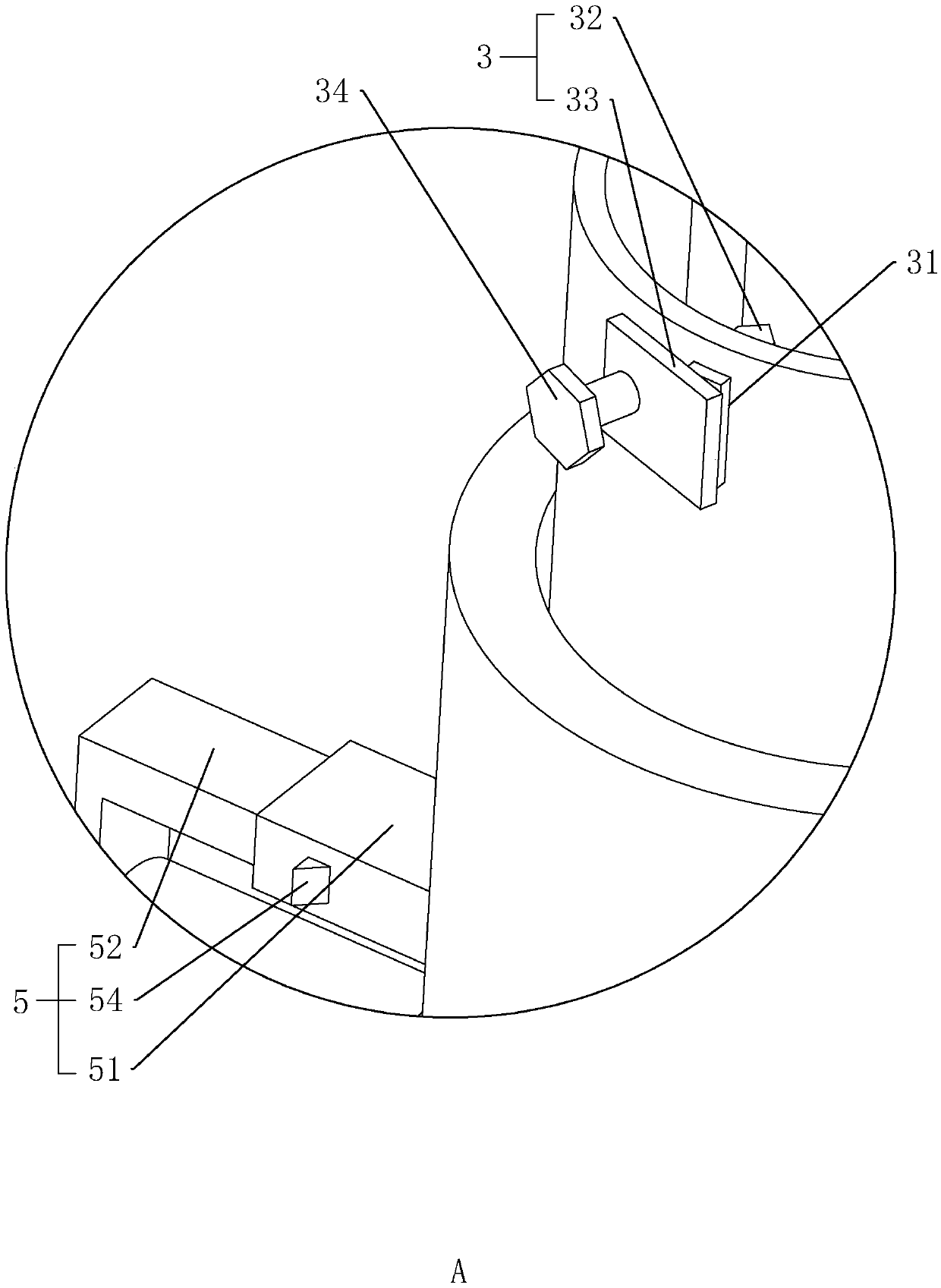

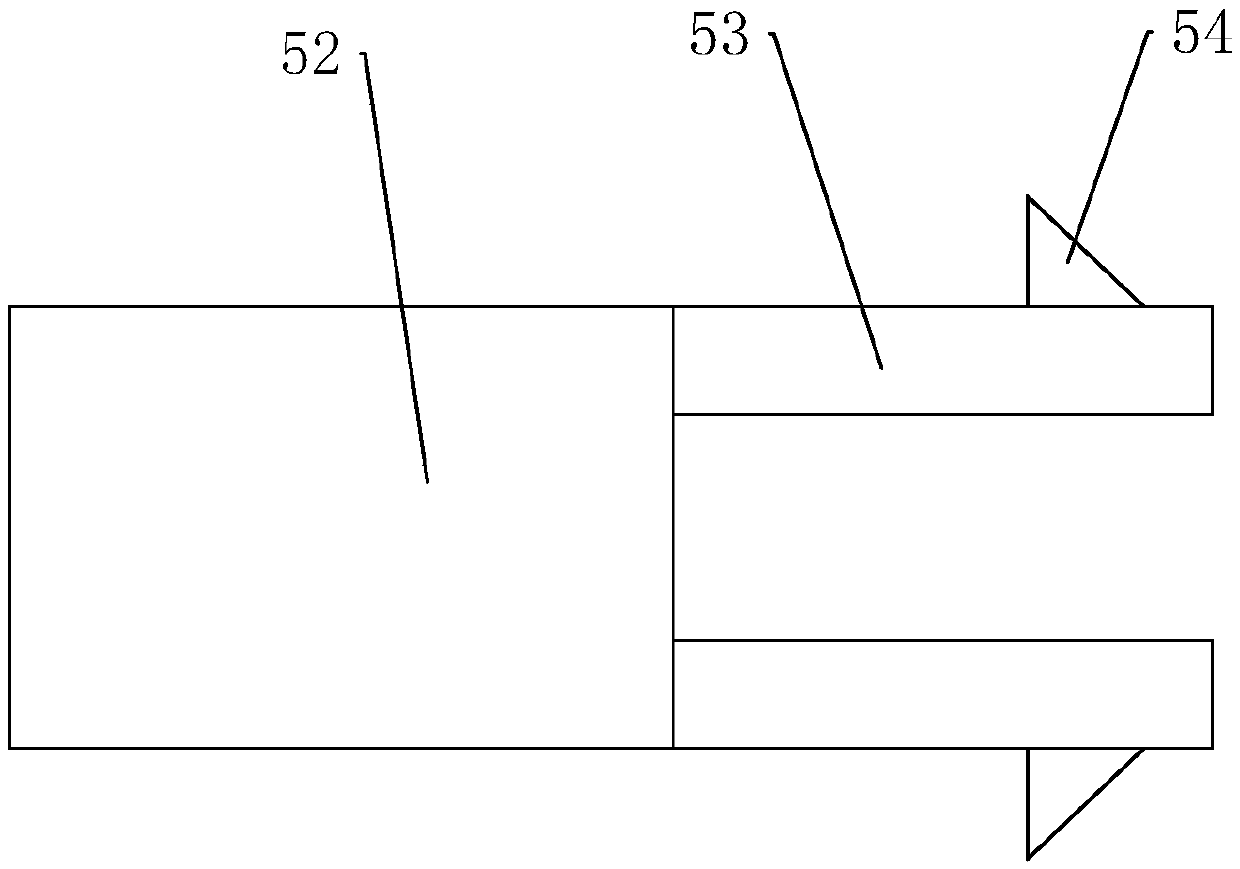

Arc runner stirring tank

InactiveCN103753706AAvoid under-deposit corrosionAvoid early damageCement mixing apparatusEngineeringStructural engineering

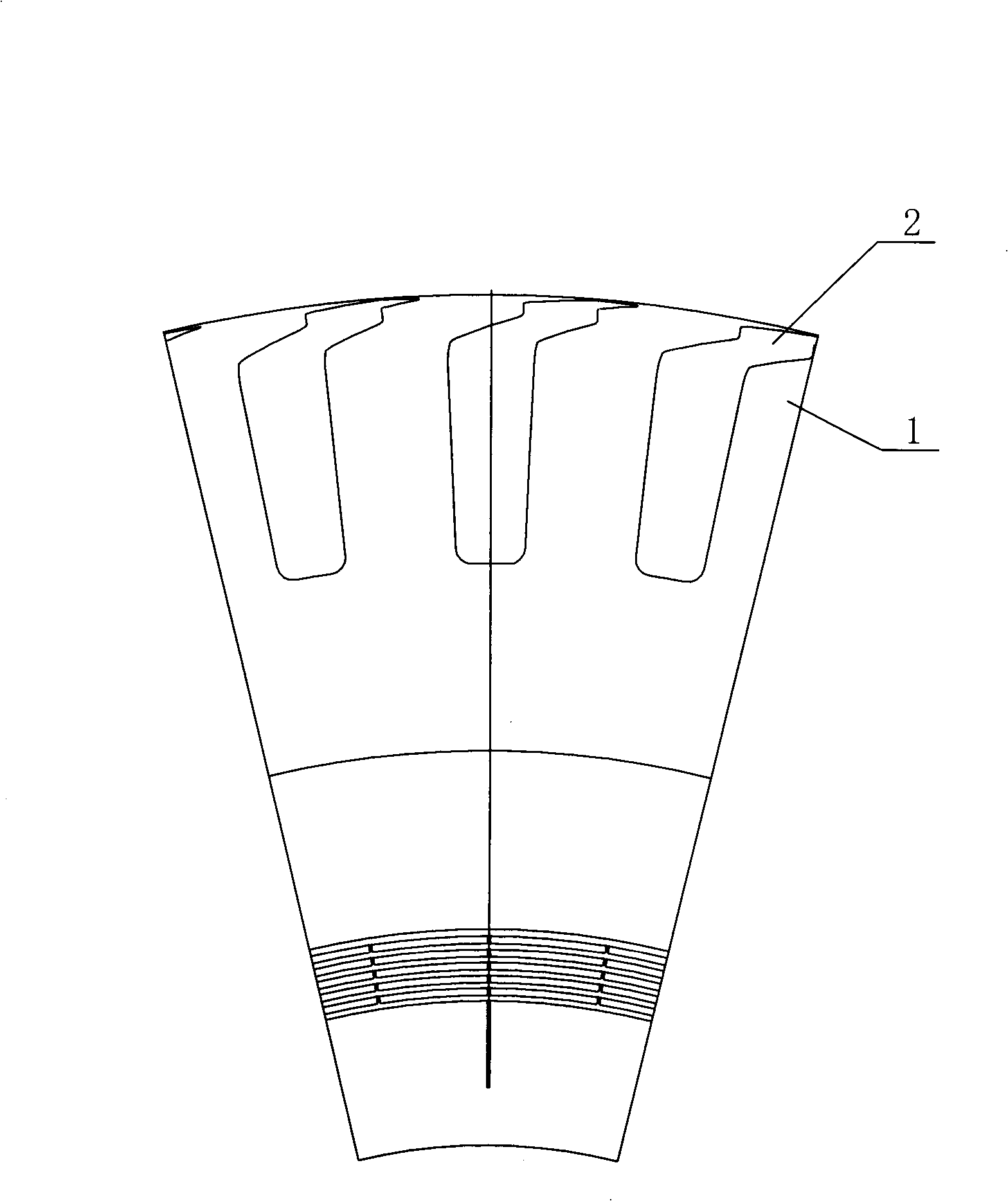

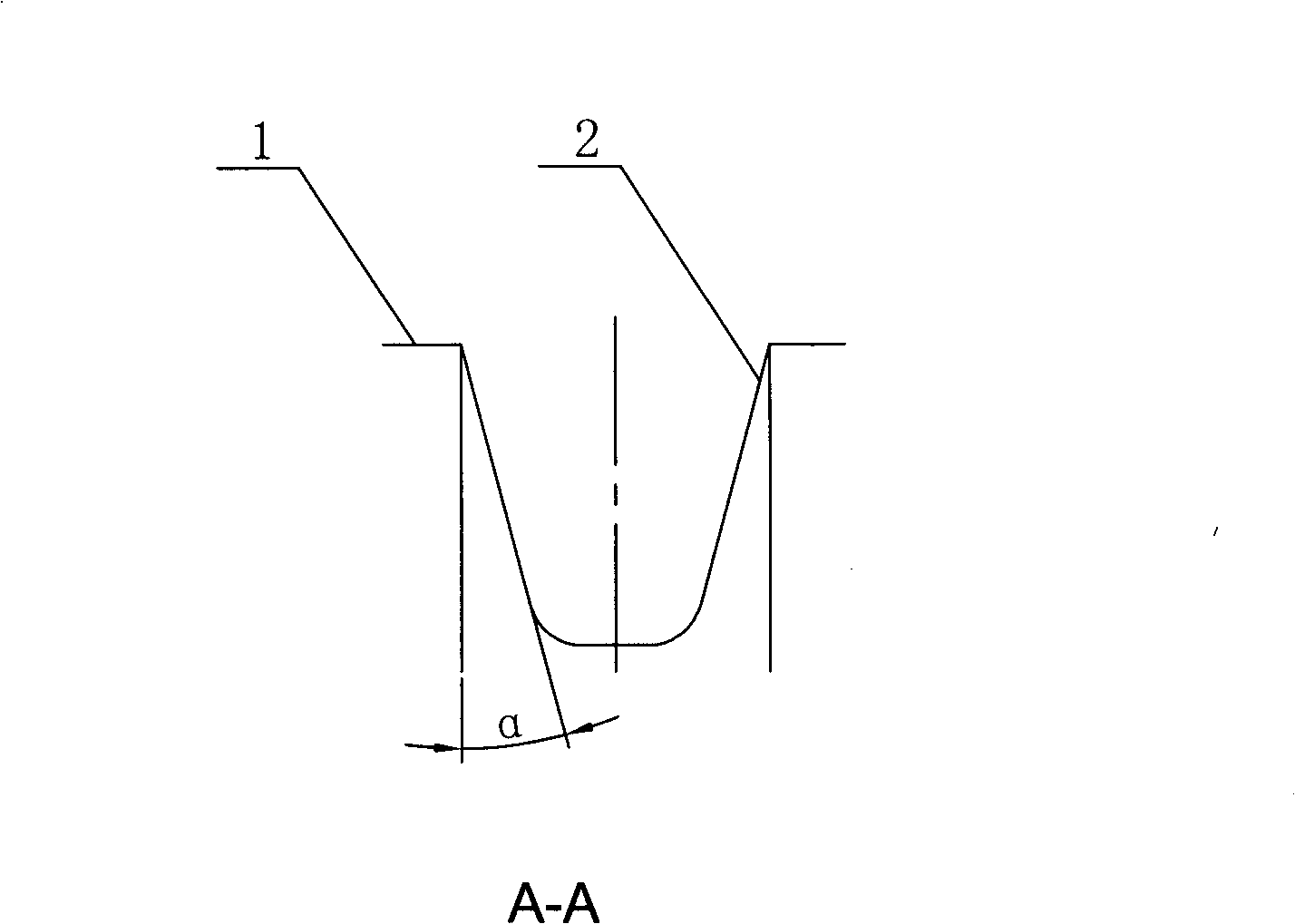

The invention relates to the technical field of concrete tanks and relates to an arc runner stirring tank. The arc runner stirring tank comprises a drive flange and a tank body with an opening facing rightward, wherein the drive flange capable of driving the tank body to rotate is fixedly installed at the left end of the tank body, at least three spiral stirring diversion trenches from left to right are distributed adjacently along the circumference and inside the tank body, the cross section of each stirring diversion trench is U-shaped, and the overall trench surface is in smooth round corner transition. The arc runner stirring tank is reasonable and compact in structure, the stirring diversion trenches with the U-shaped cross sections are arranged in the tank body, so that the dead angle is effectively avoided, adhesions to the residual concrete are reduced, clearing to the residual concrete is avoided, and then the under-deposit corrosion damage of the tank is avoided, meanwhile, the flow resistance in the processes of stirring and unloading the concrete is also reduced, and the energy consumption is lowered; due to the arrangement of a circulating pipe or a jacket or an insulating layer, the tank body and the concrete in the tank body are heated or refrigerated or thermally insulated and controlled on temperature, so that the quality of the conveyed concrete is guaranteed.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

Composite surface treatment piston and preparation method thereof

InactiveCN105909418AReduce frictionImprove corrosion resistanceMachines/enginesLiquid/solution decomposition chemical coatingFailure ratePiston ring

The invention belongs to the field of piston processing and relates to piston surface processing, in particular to a composite surface treatment piston and a preparation method thereof. The preparation method comprises two links namely printing an antifriction coating on the piston skirt and tinning the overall piston surface, the composite surface treatment method of printing the antifriction coating on the piston skirt and tinning the overall piston surface is adopted; printing a graphitic layer or a MoS2 layer on the piston skirt effectively prevents piston skirt friction, and tinning the overall piston surface effectively prevents friction between a piston ring groove and a piston ring and friction between a piston land and an air cylinder, so that the corrosion resistance and the anti-attrition lubricity of the piston are enhanced, the anti-seizure property of the air cylinder and the piston is greatly improved, early damage is prevented, the cylinder scoring phenomenon is avoided, a complete machine operates steadily, the failure rate is reduced, and the service life of the complete machine is prolonged.

Owner:QUFU JINHUANG PISTON

Radially regulating sandblasting valve with long life

InactiveCN101913118AExtend working lifeAvoid early damageGrinding/polishing apparatusSand blastingEngineering

Owner:王安伟 +1

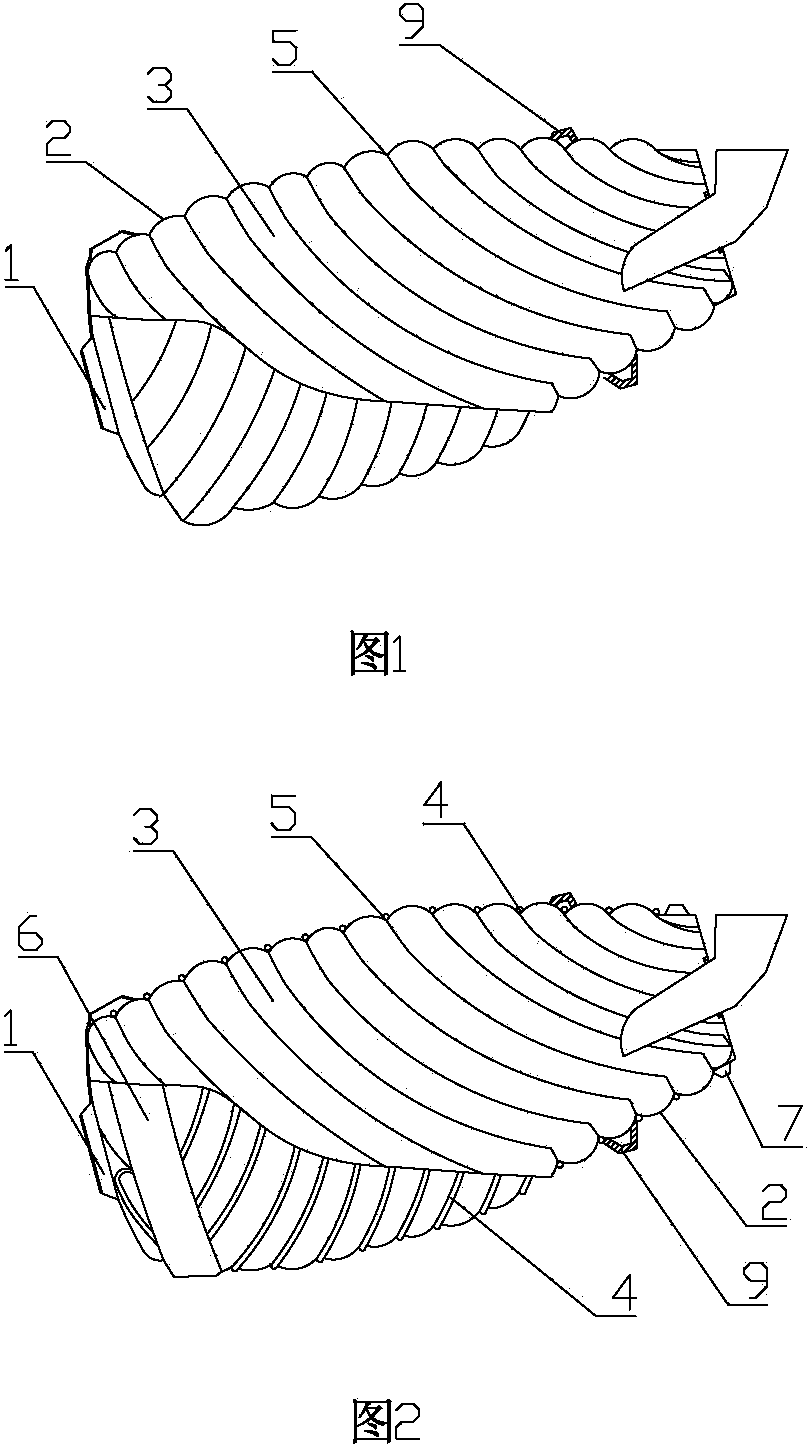

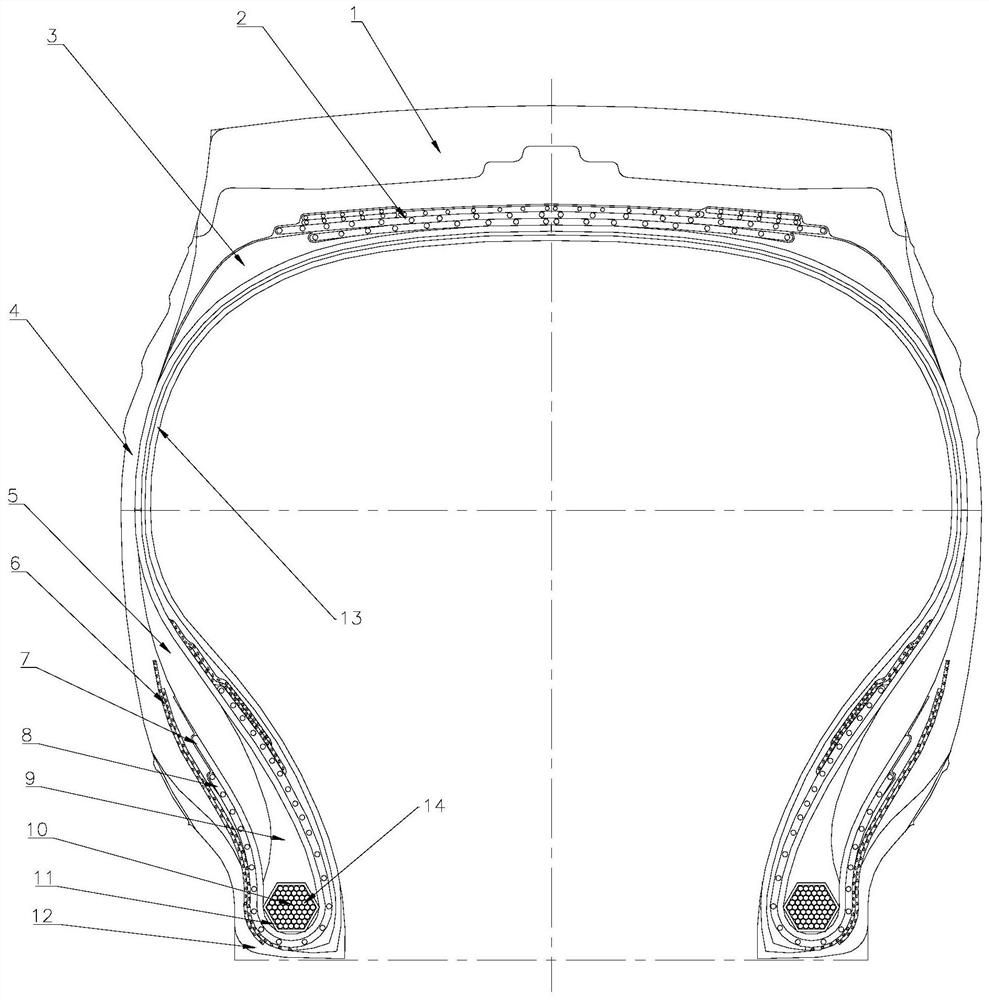

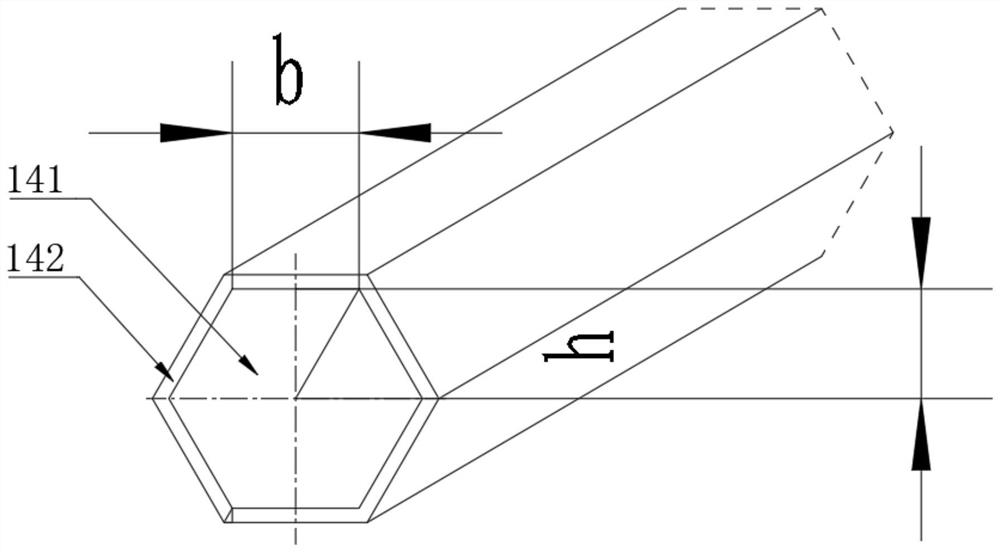

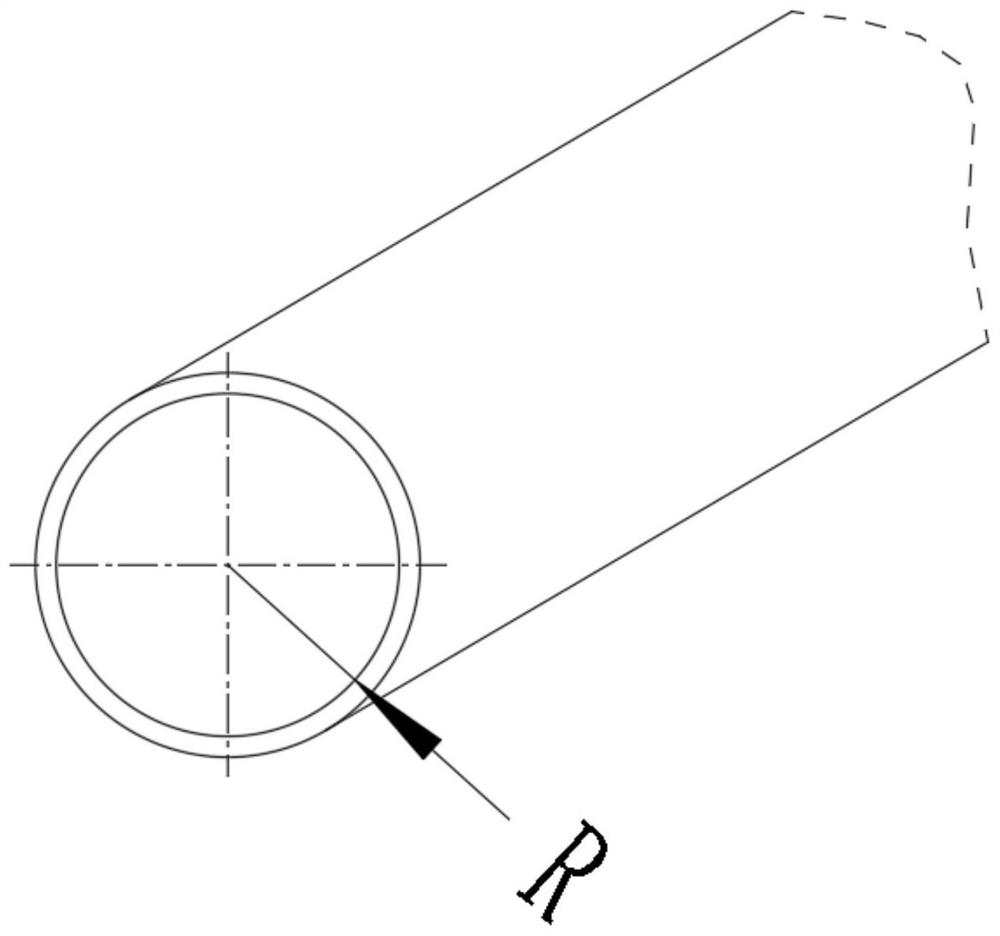

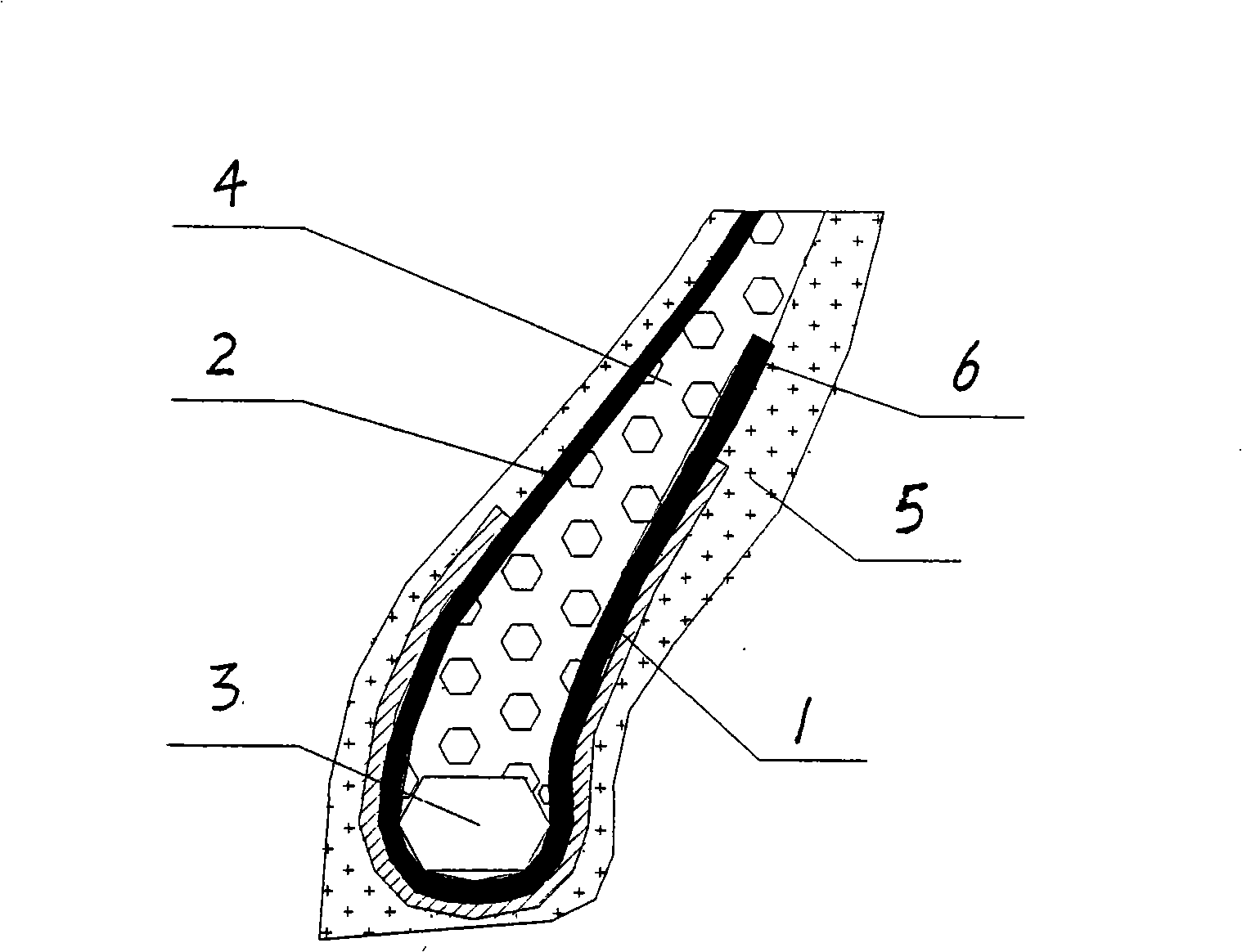

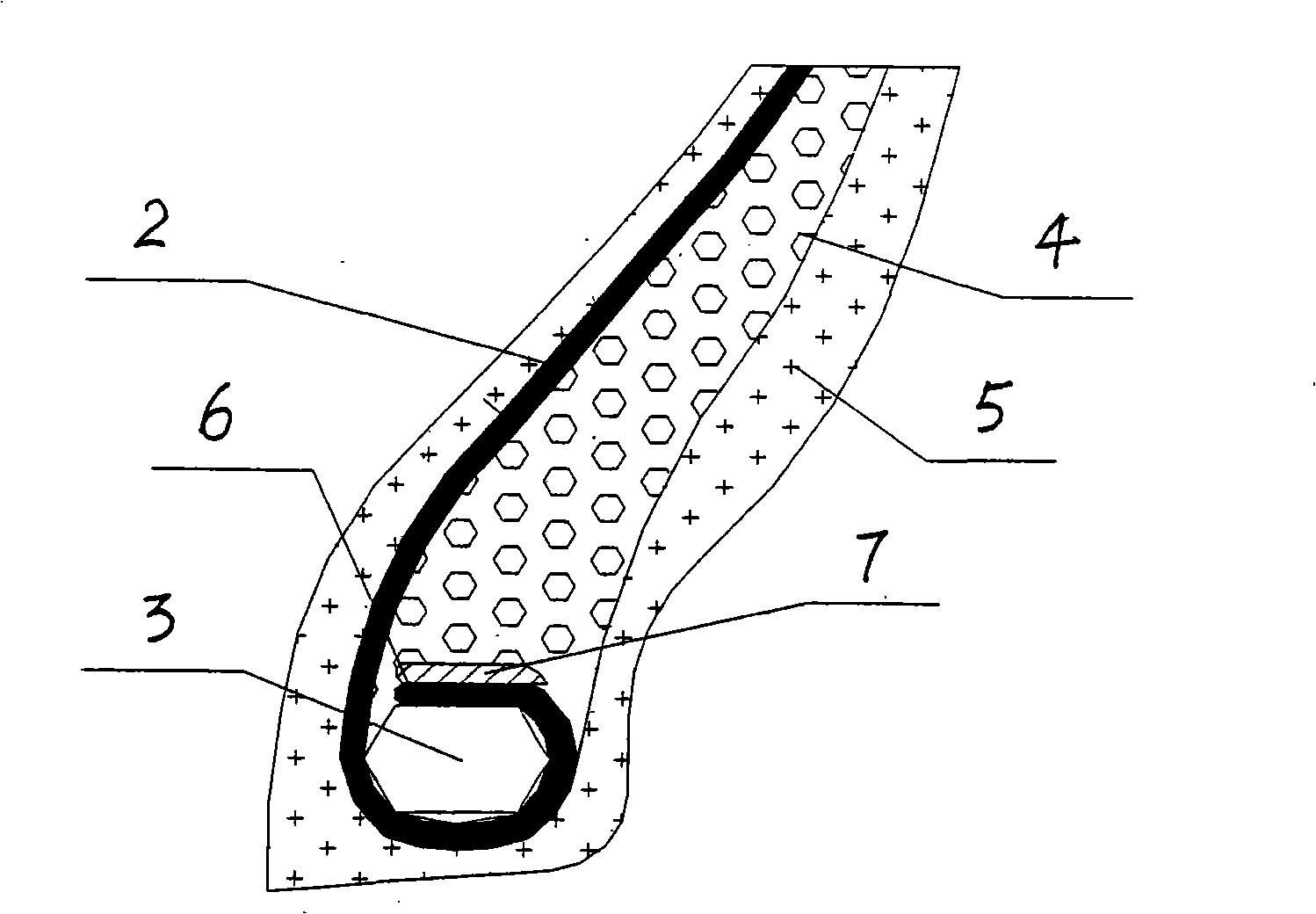

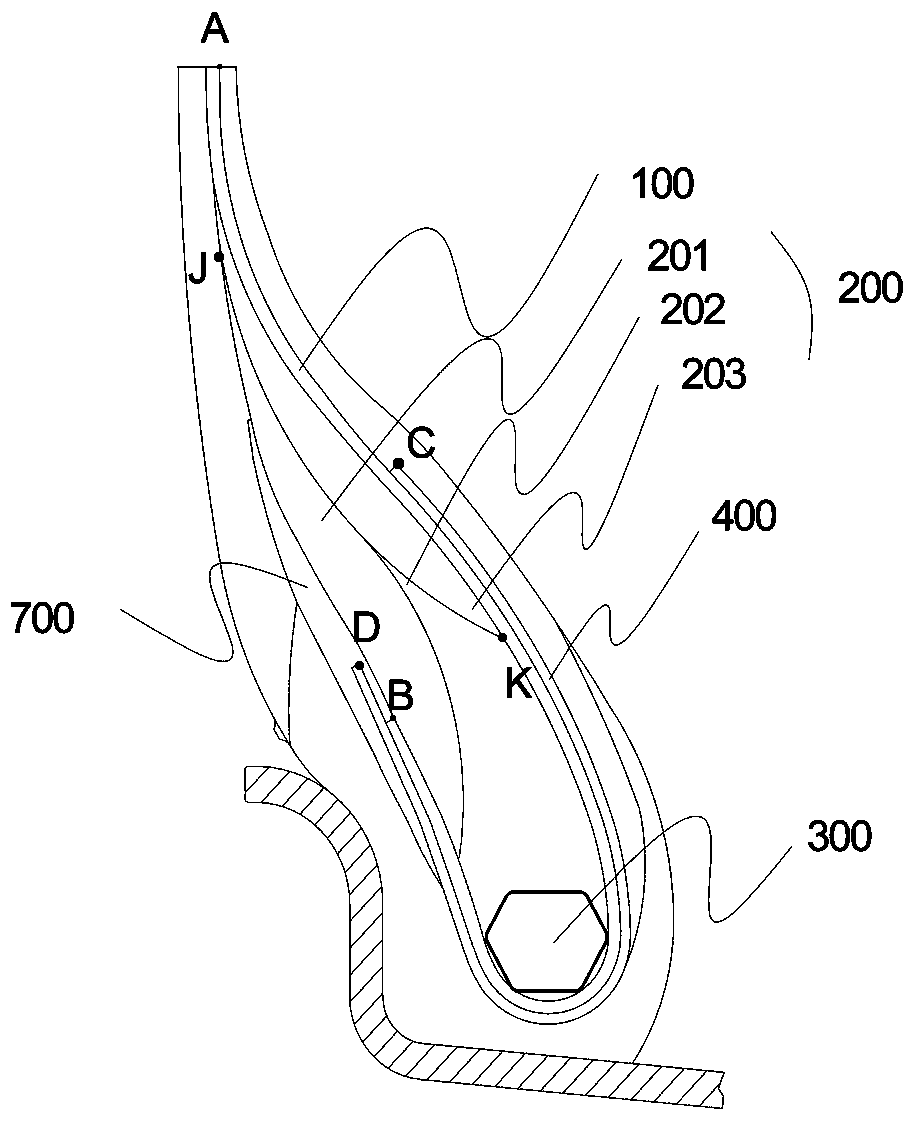

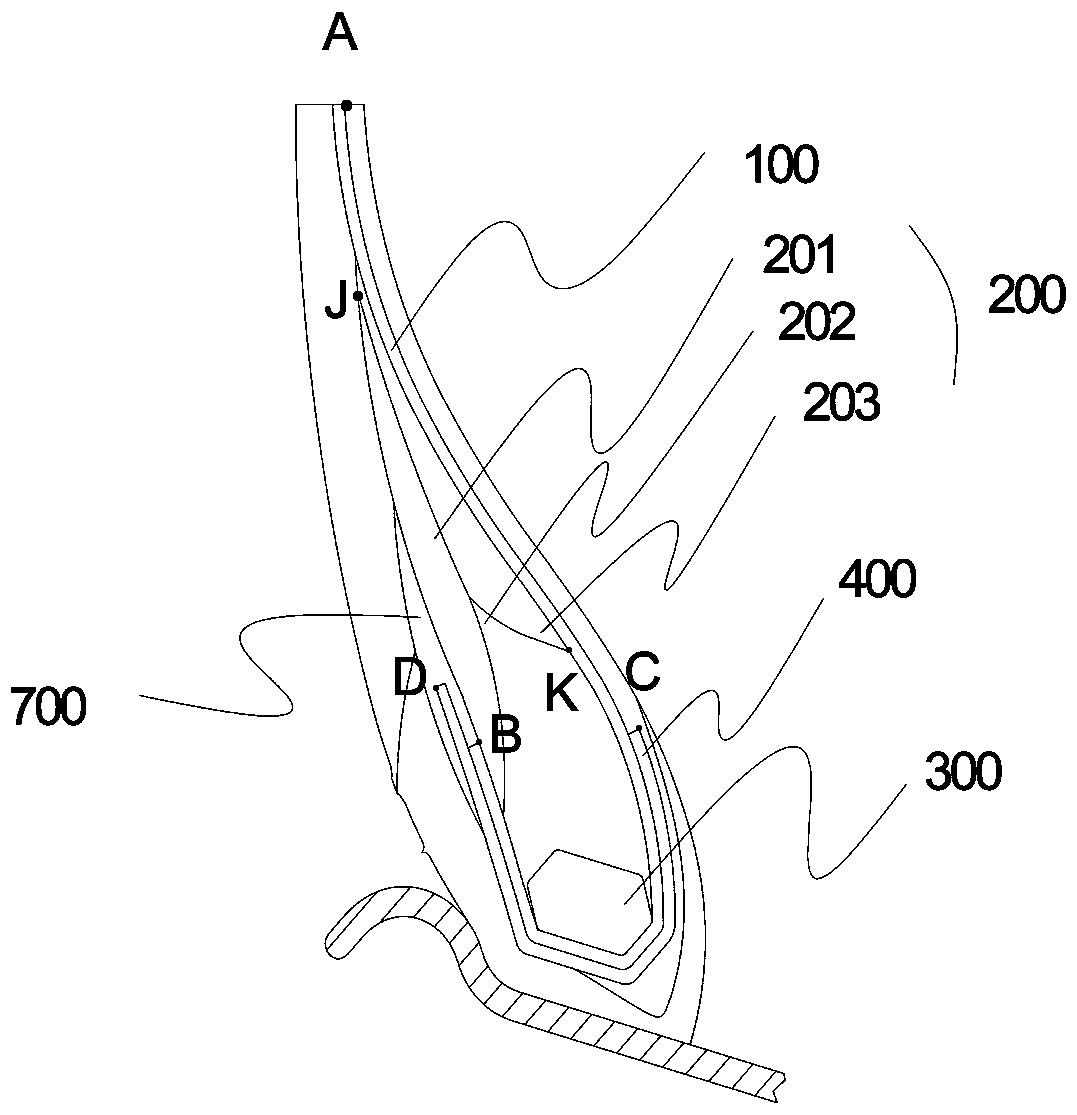

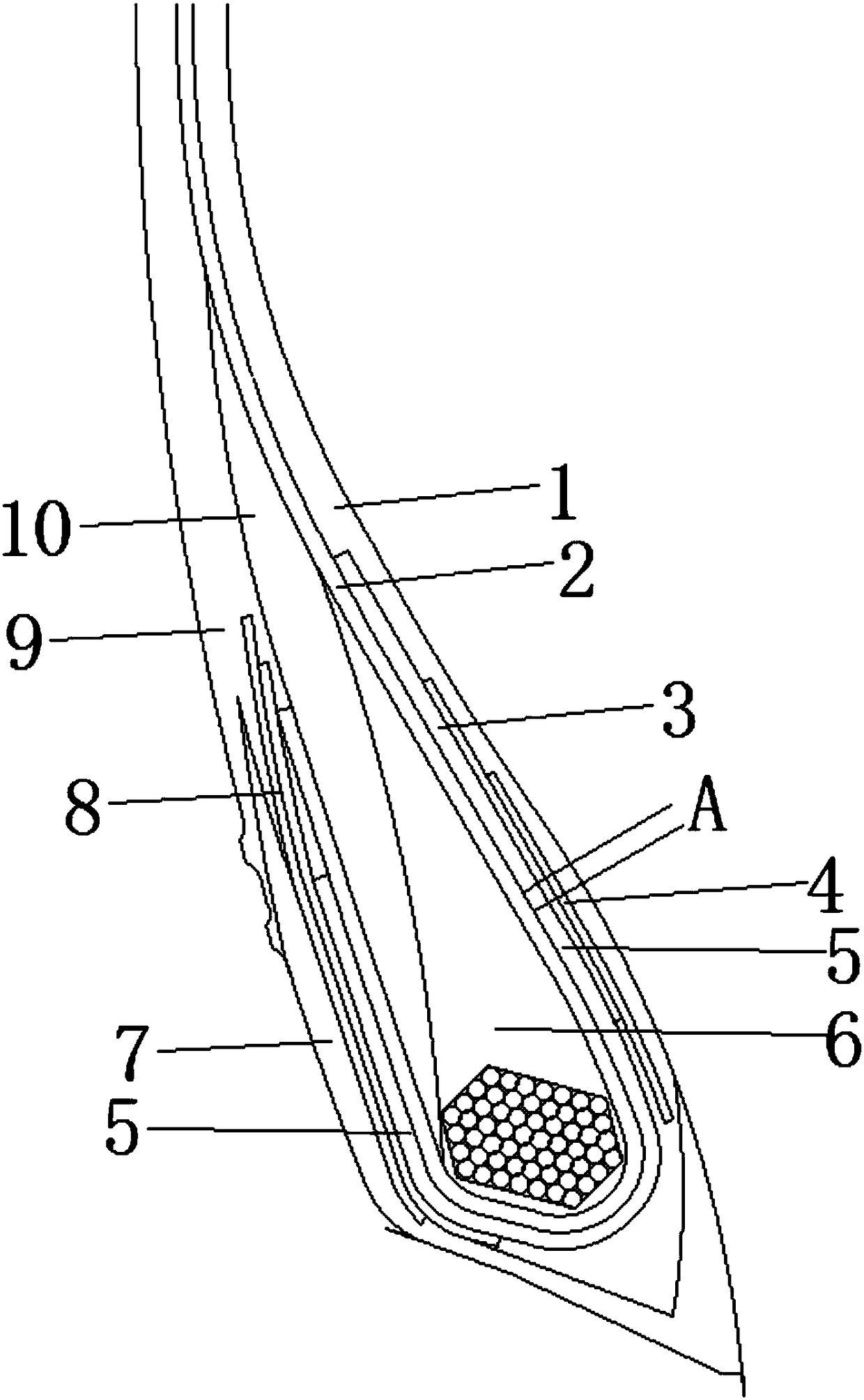

Truck radial tire with full-contact steel wire ring and winding disc of truck radial tire

The invention discloses a truck radial tire with a full-contact steel wire ring. The truck radial tire comprises a tread, a belted layer, tire shoulder pad rubber, a sidewall, upper apex, nylon wrapping cloth, a tire body, steel wire wrapping cloth, lower apex, seam allowance wear-resistant rubber, a lining layer and the steel wire ring. The invention further provides a winding disc of the truck radial tire with the full-contact type steel wire ring. According to the steel wire ring composed of the regular hexagonal tire bead steel wires, the left face and the right face of each regular hexagonal tire bead steel wire are automatically vertical faces through the triangular sawtooth faces of the corresponding winding discs of the steel wire ring, and therefore it is guaranteed that the six faces of the regular hexagonal tire bead steel wires are attached to one another to form a face contact stable structure with a self-locking function; no gap exists between the steel wires, it is guaranteed that no residual air exists in the wound steel wire ring, the early-stage damage problems such as ring empty, three-wire cracks, seam allowance burning and wire drawing explosion caused by too high heat generation of the tire bead under the heavy load condition of a vehicle are avoided, and powerful guarantee is provided for long-term durability and safe driving of the tire.

Owner:HUBEI AULICE TIRE

All steel radial tire

The invention relates to an all steel cord truck radial tire which is characterized in that the reverse encapsulation end of a tire body curtain layer is fixed at the top part of a steel wire ring; the reverse encapsulation end of the tire body curtain layer is pressed and fixed at the top part of the steel wire ring by an annular hoop. In the invention, the reverse encapsulation end of the tire body curtain layer is pressed and fixed at the top part of the steel wire ring by the annular hoop; as the top part of the steel wire ring during the using process of the tire belongs to a non-circumnutating deformation area, the disengaging of the reverse encapsulation end is avoided, thus completely solving the early damage of the ring part of the tire caused by the disengaging of the reverse encapsulation end of the tire body curtain layer. The all steel cord truck radial tire has the advantages of simple structure, easy production and remarkable use effect.

Owner:SHANGHAI TIRE & RUBBER TIRE RES INST

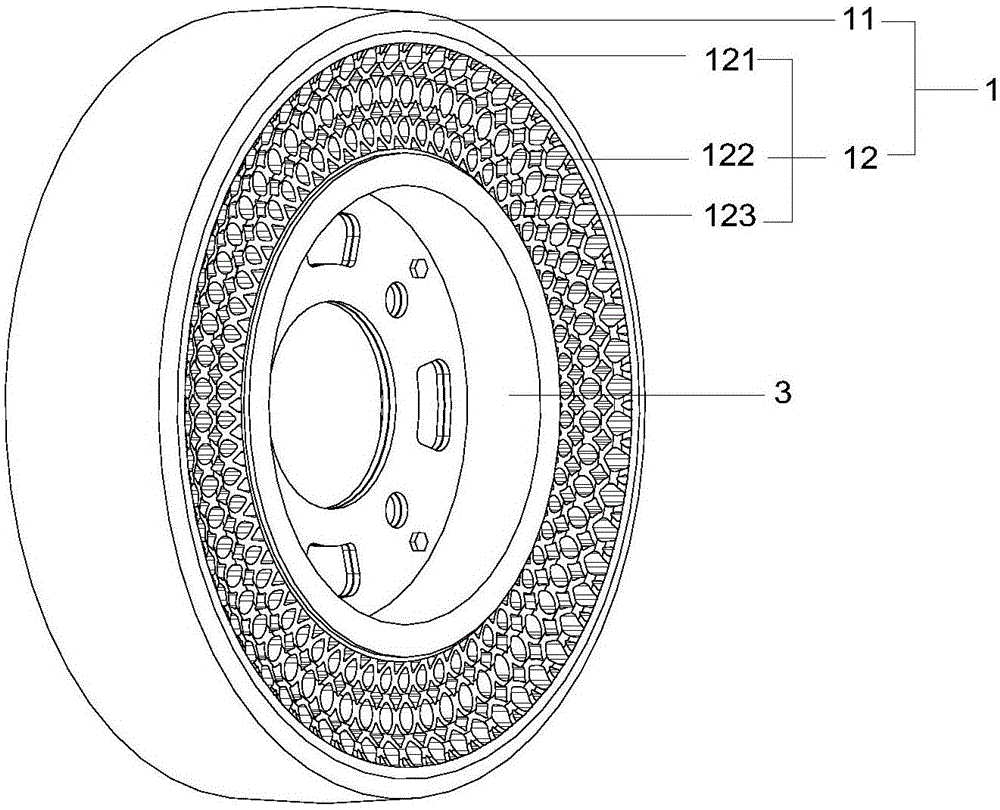

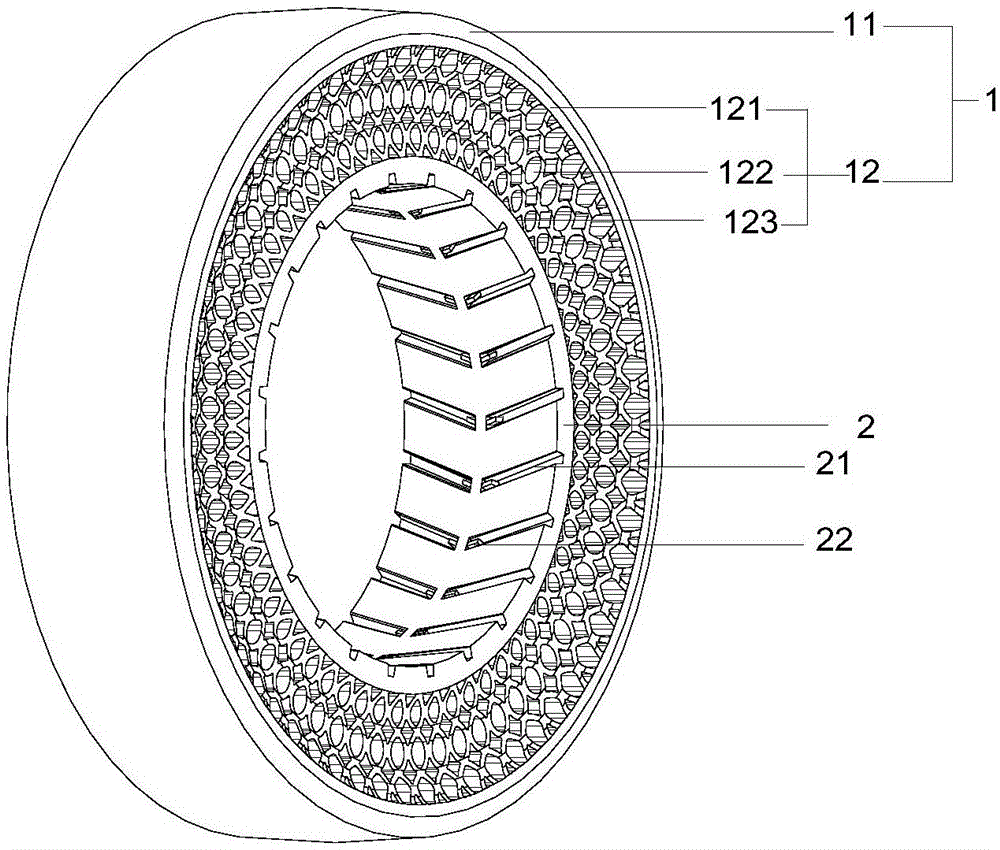

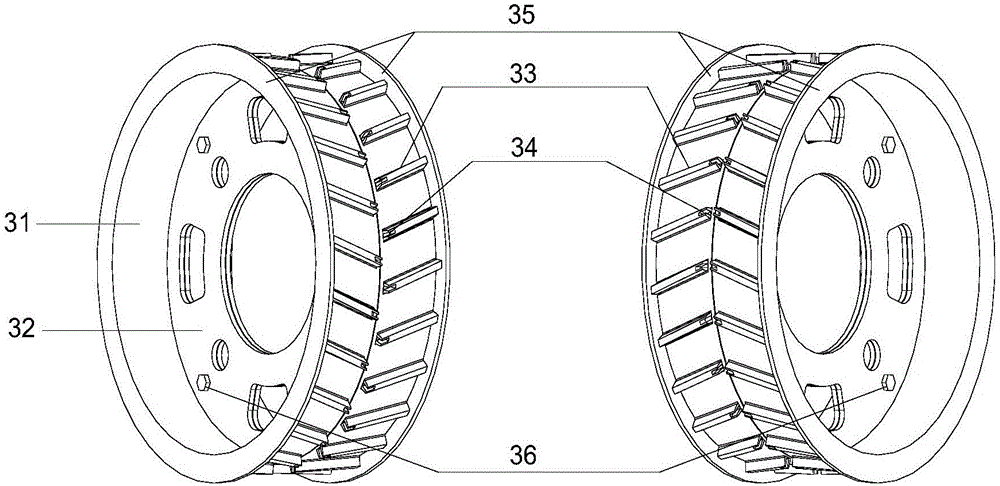

Two-piece type wheel hub used for non-pneumatic tire

ActiveCN106739766AImprove insulation performanceAvoid early damageRimsDisc wheelsThermal insulationEngineering

The invention provides a two-piece type wheel hub used for a non-pneumatic tire. The wheel hub includes a first wheel ring and a second wheel ring which are coaxially and relatively arranged, the second wheel ring and the first wheel ring both includes a wheel disk part and a wheel rim part, and each wheel disk part and the corresponding wheel rim part are formed into an integral structure; the non-pneumatic tire includes a supporting body, the contact surface of the wheel hub and the supporting body is provided with a thermal insulation strip, the radial outer side of the thermal insulation strip is connected with the supporting body, and the radial inner side of the wheel rim part is connected with the wheel rim part in a sleeving mode; the surface, making contact with the thermal insulation strip, of the wheel rim part is uniformly provided with helical teeth, an included angle is formed between each helical tooth and the axial line, and the surface, making contact with the wheel rim part, of the thermal insulation strip is provided with grooves cooperated with the helical teeth. According to the two-piece type wheel hub used for the non-pneumatic tire, the problems that the wheel hub installation of the non-pneumatic tire is difficult, the non-pneumatic tire is easily separated from the wheel hub due to local overheating and aging in the high speed running or emergency brake condition and the thickness of the non-pneumatic wheel hub part is large are solved, and the safety of tire is improved.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Road surface base maintenance technology

The invention relates to a road surface base maintenance technology. The road surface base maintenance technology is characterized by comprising the following steps: step 1: closing the traffic; step2: connecting a water outlet pipe of a sprinkling truck through a rotary positioning mechanism; step 3: opening a plurality of water outlets on the water outlet pipe and the extending pipe, wherein each water outlet is provided with an atomization device; step 4: driving the sprinkling truck along a road; step 5: dredging the traffic to realize the aim of reducing damages to a base.

Owner:苏州交通工程集团有限公司

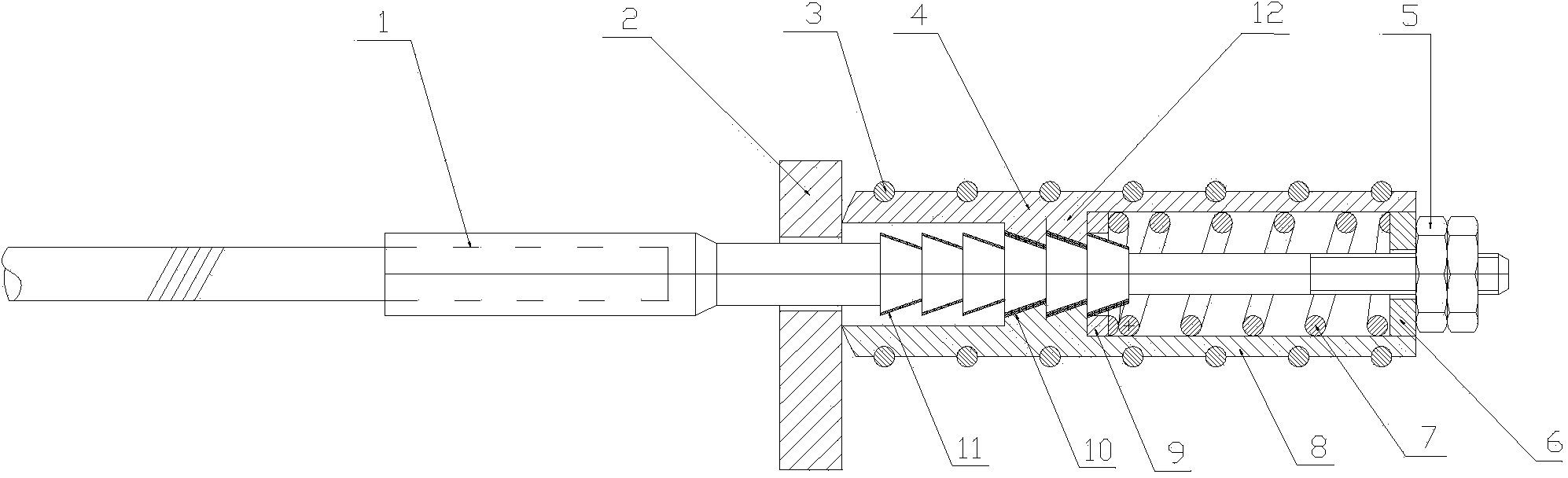

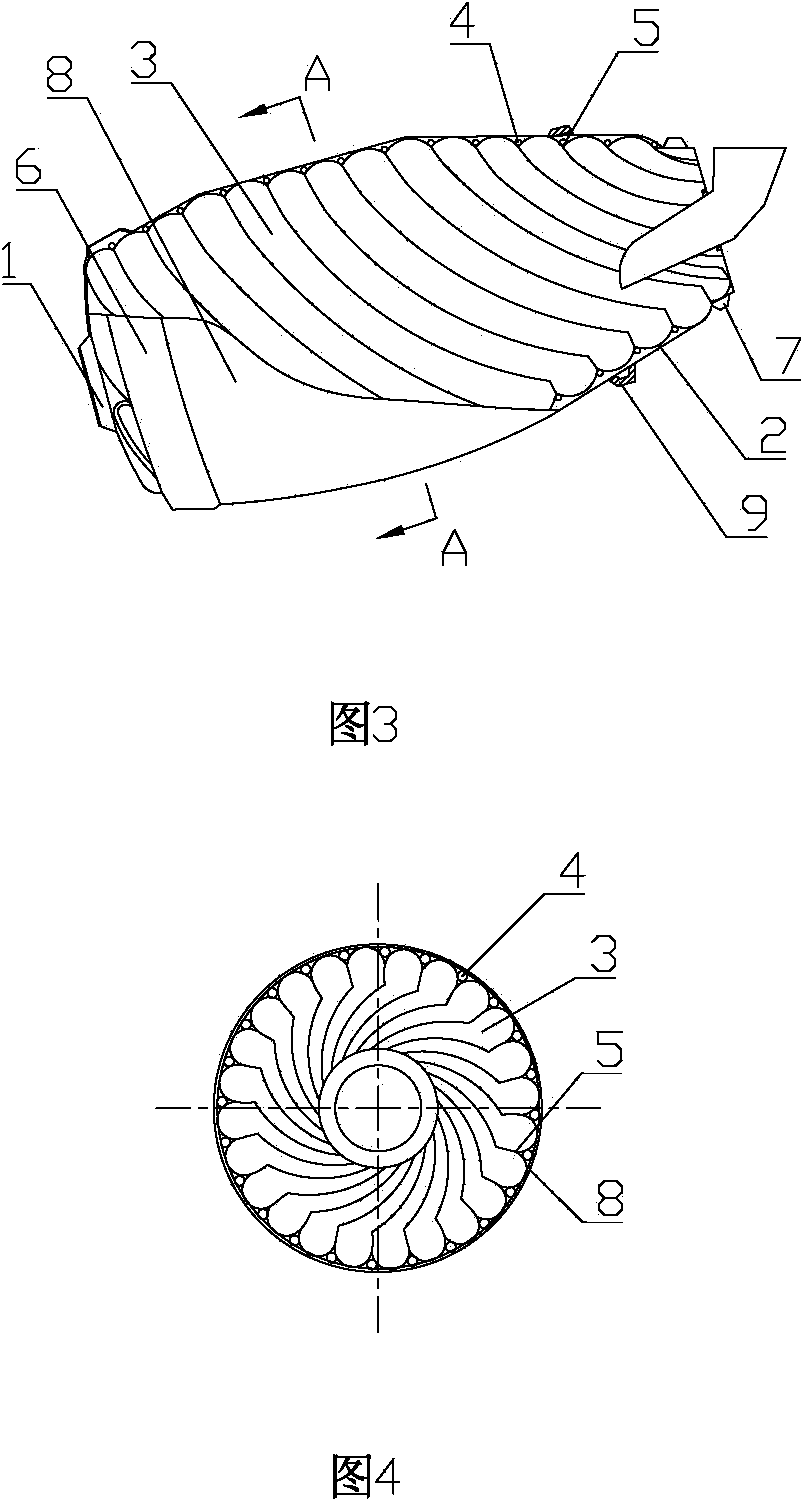

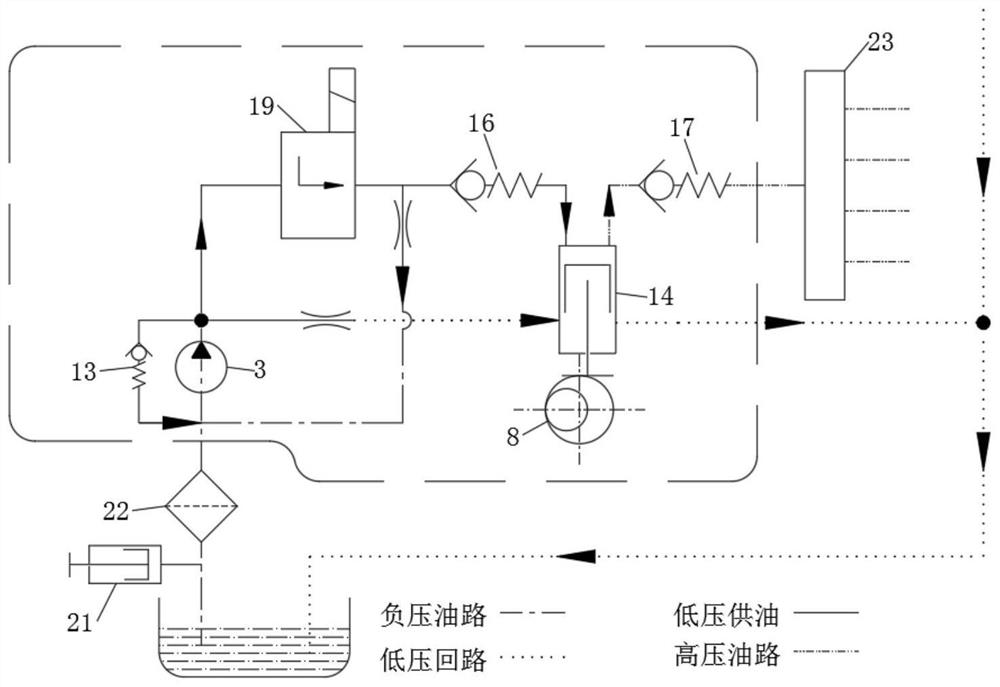

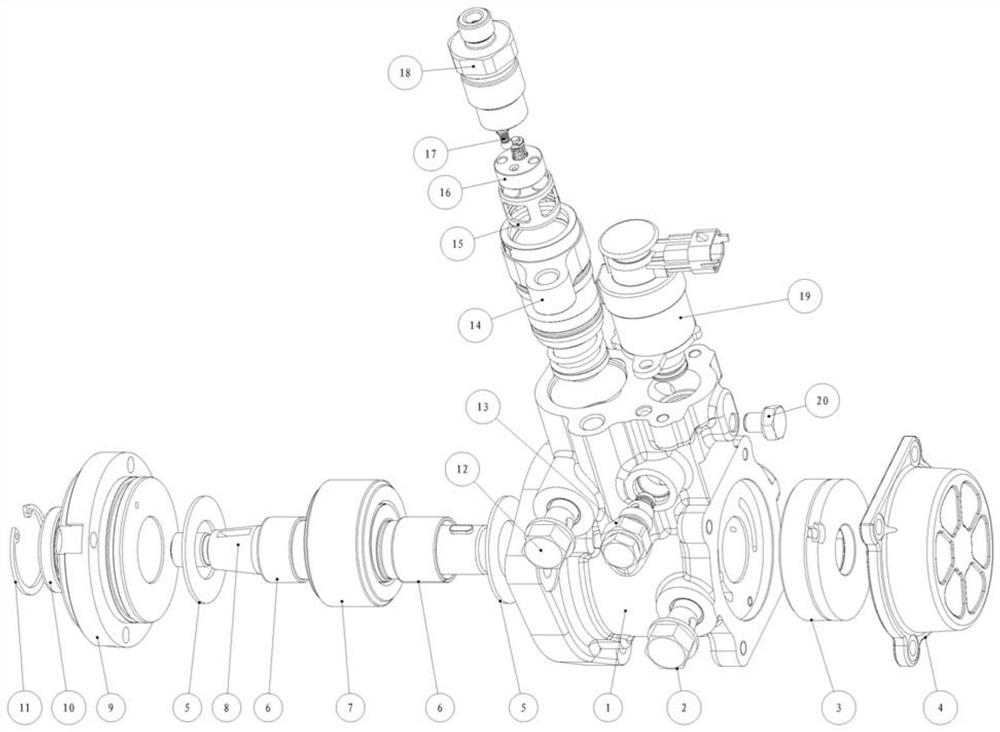

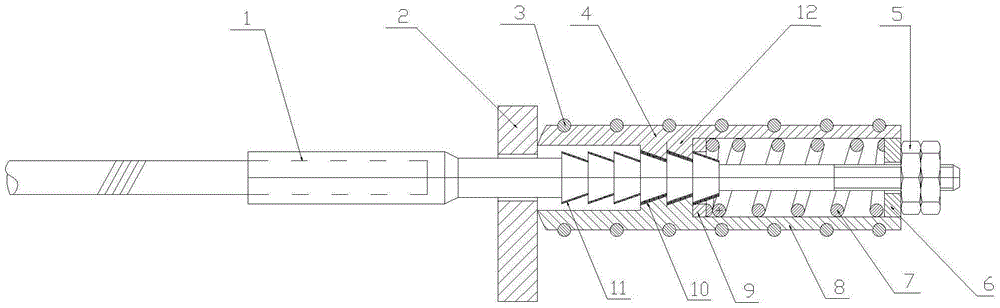

High-pressure in-line plunger pump and high-pressure common-rail fuel injection system

PendingCN112780468AReduce processing difficultyGuaranteed reliabilityPositive displacement pump componentsFuel injecting pumpsMarine engineeringReciprocating motion

The invention discloses a high-pressure in-line plunger pump. The high-pressure in-line plunger pump comprises a pump body component, and further comprises an oil delivery pump, an eccentric driving mechanism, a plunger and barrel assembly, an oil valve component, an oil outlet valve, an oil control valve tightening cap and an oil inlet metering valve which are mounted on the pump body component, wherein the eccentric driving mechanism drives the plunger and barrel assembly to do reciprocating motion in the pump body component, high-pressure oil output by the oil delivery pump passes through the oil inlet metering valve and then enters a high-pressure cavity formed by the oil valve component and the plunger and barrel assembly, and through the reciprocating motion of the plunger and barrel assembly, high-pressure oil flows out of the oil outlet valve and the oil control valve tightening cap in sequence. The invention further discloses a high-pressure common-rail fuel injection system which comprises the high-pressure in-line plunger pump.

Owner:钧风电控科技泰州有限责任公司

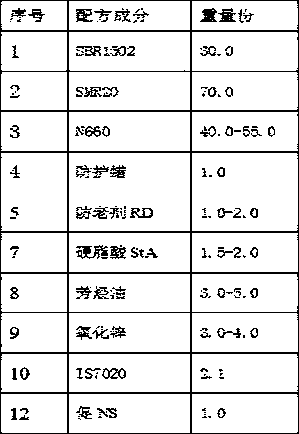

Fatigue-resistant chloroprene rubber air spring air bag and preparation method thereof

InactiveCN111434489AImprove air tightnessImprove adhesionSpringsSynthetic resin layered productsRubber materialAir spring

The invention discloses a fatigue-resistant chloroprene rubber air spring air bag and a preparation method thereof. The preparation method comprises proportioning, mixing and extruding steps, takes pure chloroprene rubber as a main body rubber material to inner and outer layer rubber and cord fabric rubber of an air spring air bag for an automobile. The air bag of the air spring has better flexural fatigue resistance, the service life of the air spring is prolonged, and meanwhile various comprehensive properties of the air spring are better. Test results prove that the fatigue durability and the comprehensive performance of the air spring adopting the air bag are effectively improved.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

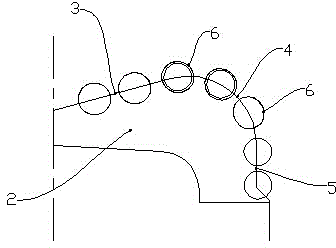

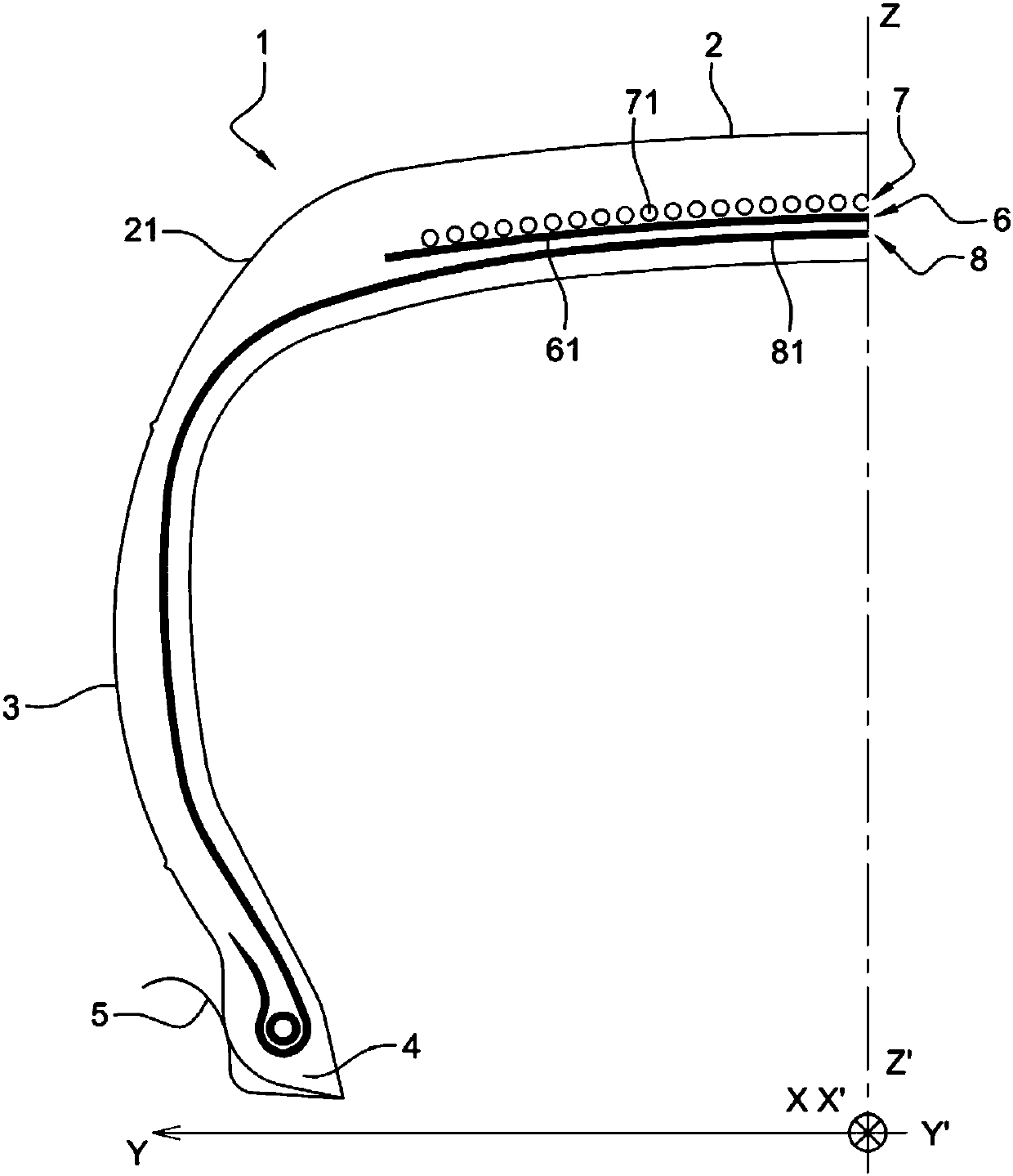

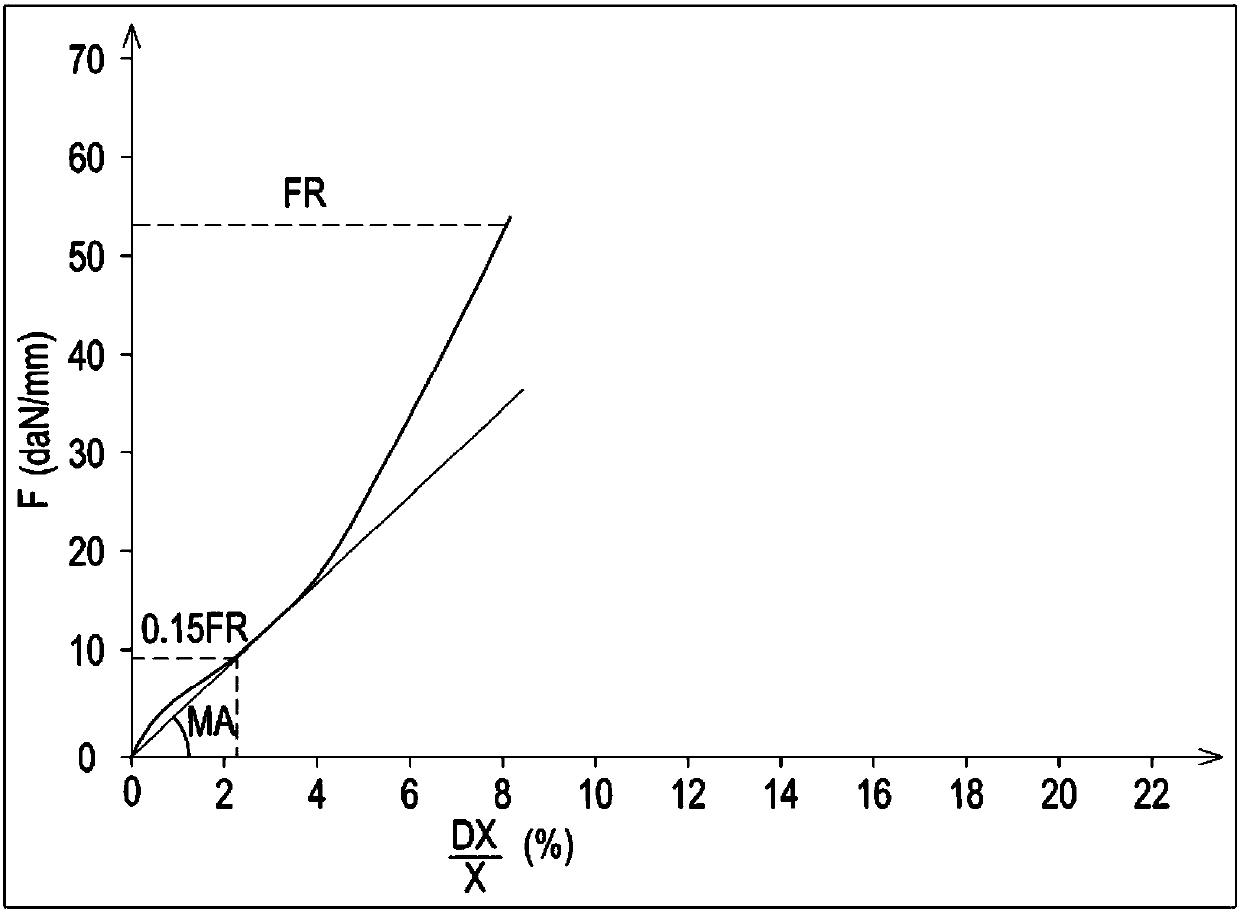

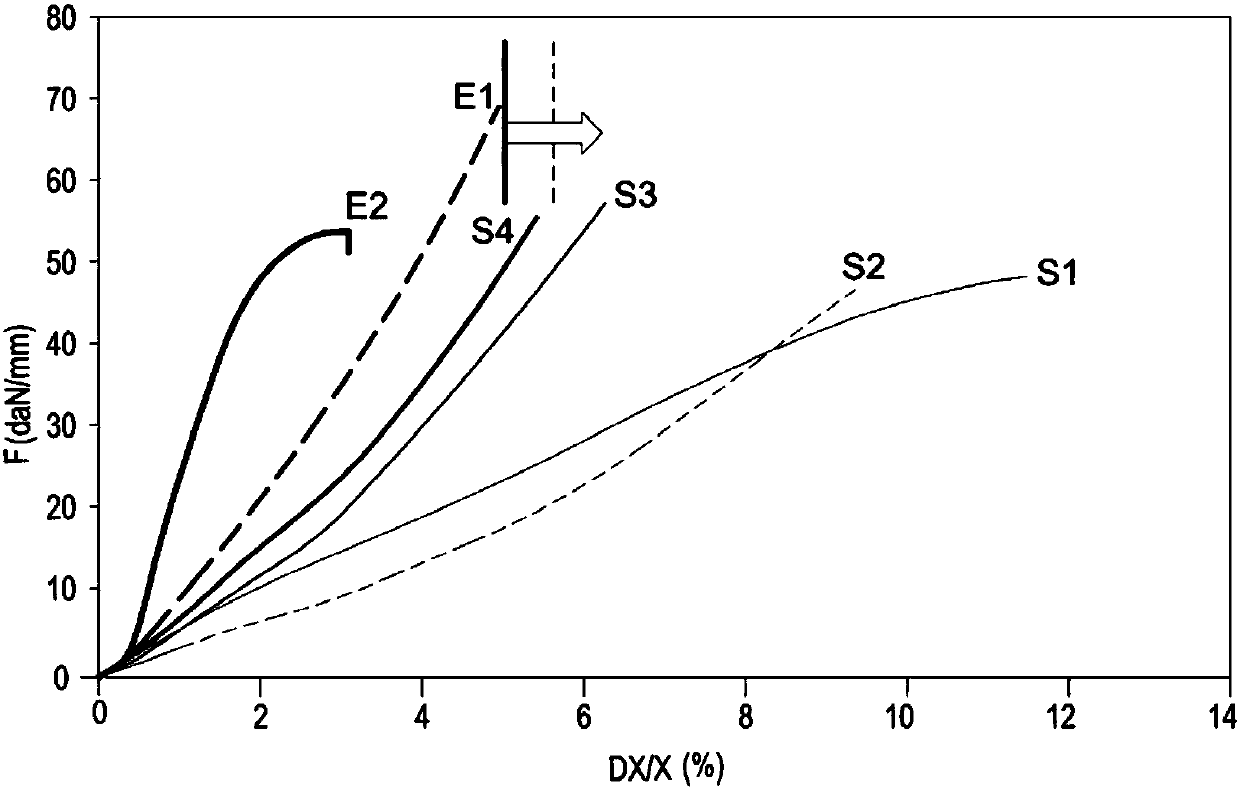

Tyre reinforcement

ActiveCN107592841AReduce variationControl Deformation ProfilePneumatic tyre reinforcementsBreaking strengthHooping

The invention relates to the reinforcement that reinforces a passenger vehicle tyre. It targets good resistance to penetration and perforation of its crown by foreign objects, with a reinforcing architecture that is simple and lightweight. According to the invention, the hooping layer (71) has a breaking strength per mm of axial width of the hooping layer FR at least equal to 35 daN / mm, an elongation at break AR at least equal to 5% and a secant extension modulus MA at least equal to 250 daN / mm, for an applied force F equal to 15% of the rupture strength FR of the said hooping layer (71). Theworking reinforcement (6) comprises a single working layer (61) of which the working reinforcements form, with the circumferential direction (YY'), an angle AT at least equal to 30 degrees and at mostequal to 50 degrees. The carcass reinforcements of the at least one carcass layer (81) form, with the circumferential direction (YY') and in the equatorial plane (XZ), an angle Ac2 at least equal to55 degrees and at most equal to 80 degrees and having an orientation that is the opposite of that of the angle AT of the working reinforcers, so that the carcass reinforcers and the working reinforcers constitute a triangulation system.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

High-performance rubber sizing material and preparation method thereof

The invention discloses a high-performance rubber sizing material. The high-performance rubber sizing material is prepared from the following components in parts by weight: 100 parts of composite synthetic rubber, 20 to 30 parts of thermoplastic elastomer SBS (styrene butadiene styrene), 2 to 5 parts of alumina nano-fibers, 3 to 7 parts of flaky nano-silicon, 10 to 15 parts of waste tire rubber powder, 20 to 30 parts of clay and 2 to 3 parts of coupling agent. A preparation method of the high-performance rubber compound comprises the following steps: feeding the composite synthetic rubber, thethermoplastic elastomer SBS, the waste tire rubber powder and the coupling agent into an internal mixer according to proportions and mixing for 2 to 4 minutes; then adding the alumina nano-fibers andthe clay and continuously mixing for 3 to 5 minutes; finally, adding the flaky nano-silicon and mixing again for 3 to 5 minutes, and discharging materials to a cutting machine for tabletting to obtain the rubber sizing material. The high-performance rubber sizing material has the advantages of more obvious wear resistance, higher strength, better elasticity, more excellent high and low temperature resistance, better anti-ultraviolet aging performance and weather fastness.

Owner:深圳市峰源化工新材料股份有限公司

Intelligent cycle switching control method of electronic capacitor

InactiveCN107979097AAdequate restAvoid early damageReactive power adjustment/elimination/compensationReactive power compensationCompensation effectEngineering

The invention discloses an intelligent cycle switching control method of an electronic capacitor. Under the condition that the number of electronic capacitors switched is maintained unchanged, a control device controls to circularly switch the electronic capacitors in a passive dynamic compensation or passive intelligent compensation mode, so that each electronic capacitor can get full rest, and the condition of employing circular switching is in a way that the capacitor of each electronic capacitor is same. The output of each capacitor group in each phase is same, meanwhile, each capacitor group can get full rest, and thus, the electronic capacitor is prevented from being early damaged and is long in service lifetime and good in compensation effect.

Owner:李莉

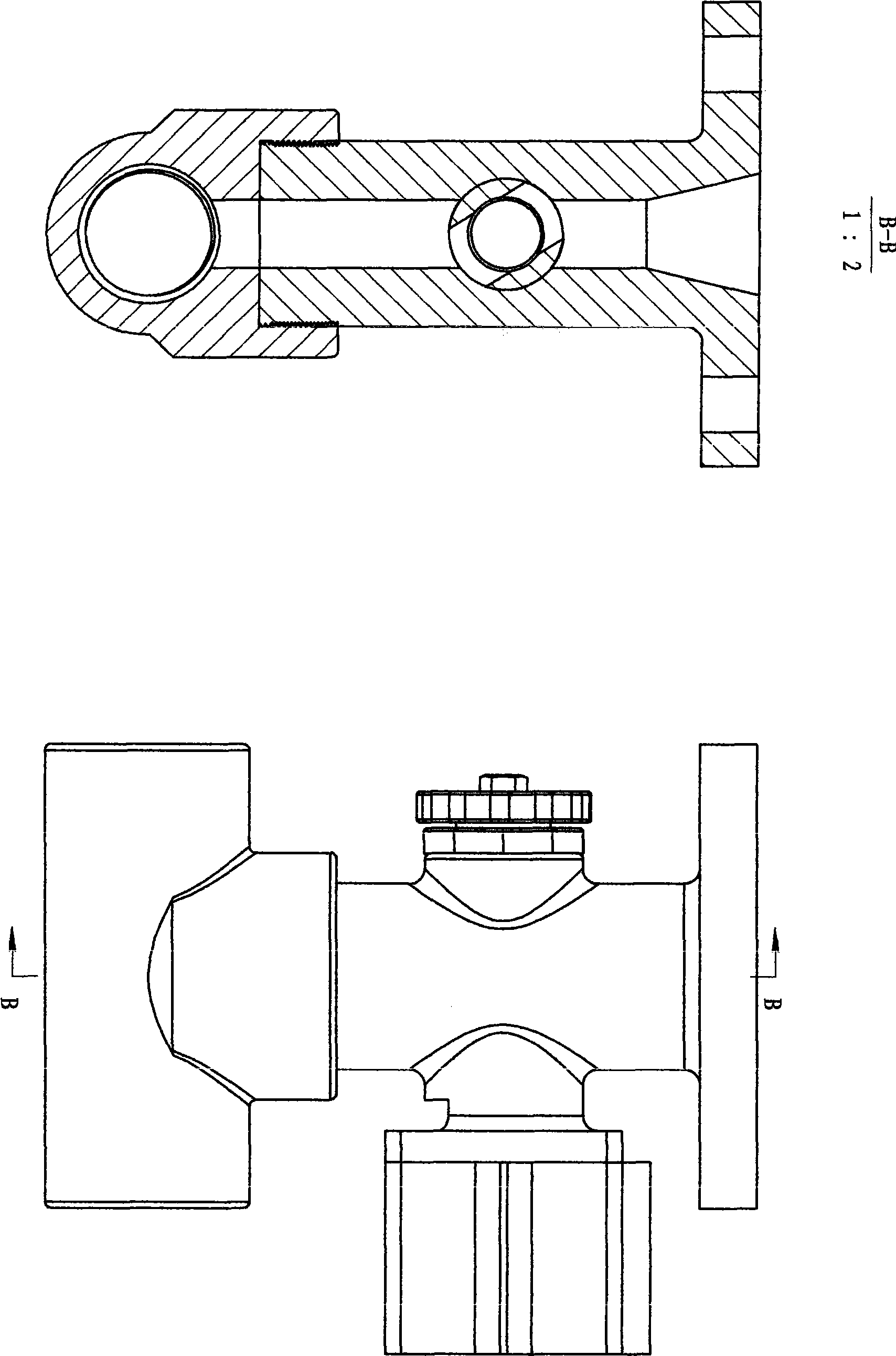

A self-adjusting pretension steel wire rope sling

ActiveCN103818839BAvoid early damageNo pollution in the processWinding mechanismsCoil springArchitectural engineering

The invention relates to a self-adjusting preload steel wire rope rigging. The self-adjusting preload steel wire rope rigging comprises a rigging body, wherein the middle part of the rigging body is provided with a plurality of outer coniform trapezoidal bulges, an upper semicircular body and a lower semicircular body which are buckled together are arranged at the outside of the outer coniform trapezoidal bulges; one end of each of the upper semicircular body and the lower semicircular body is provided with a fixing plate, and each of the other ends of the upper semicircular body and the lower semicircular body is provided with an external spring support; the rigging body penetrates through the fixing plate and the external spring support and then is fixed by a locking nut; the middle parts of the inner sides of the upper semicircular body and the lower semicircular body are provided with projected blocks; a cavity is formed between the projected blocks and the spring support; the rigging body is sleeved with a spiral spring; the upper semicircular body and the lower semicircular body are compressed on the fixing plate under the function of the preload of the spiral spring. The self-adjusting preload steel wire rope rigging provided by the invention automatically adjusts through the spiral spring, which is timely and reliable; and the cumbersome labor is saved, and the performance reduction due as a telescopic boom is not in place due to the untimely adjusting as well as the not smooth operation and the early damage of the parts due to the impact can be avoided; electrostatic spray is performed on the surfaces of the outer coniform trapezoidal bulges and the inner coniform trapezoidal bulges, so that the friction resistance of the automatic adjustment can be reduced.

Owner:山东鲁班机械科技有限公司

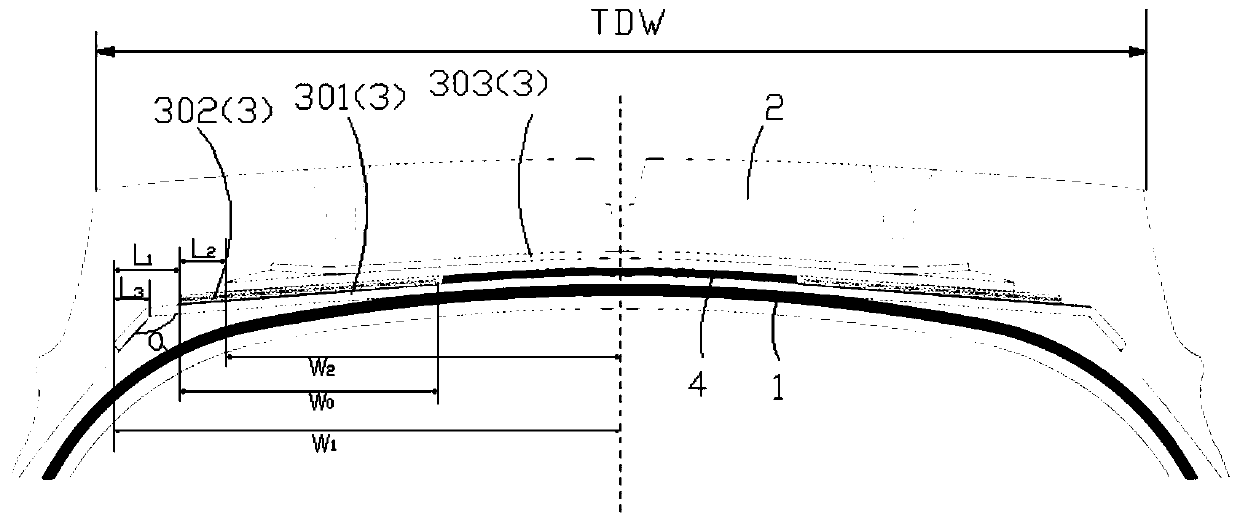

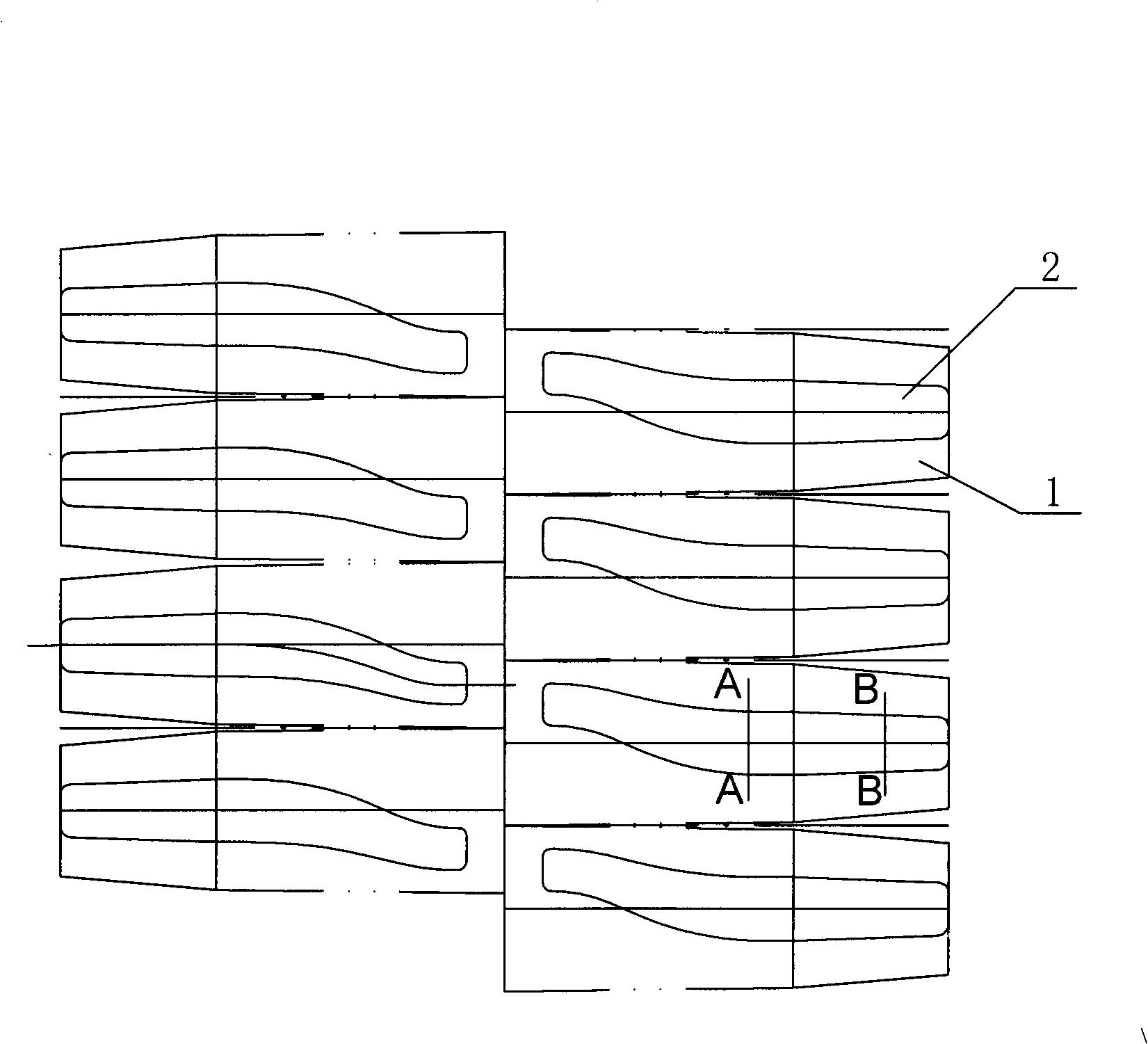

All-steel truck radical tire structure

ActiveCN110978893AImprove high-speed performanceExtend your lifePneumatic tyre reinforcementsRubber materialStructural engineering

The invention provides an all-steel truck radical tire structure. The all-steel radial tire structure comprises a tire body, a tire tread coating the radial outermost periphery of the tire body, and abelt ply arranged between the tire body and the tire tread, the belt ply comprises a first belt ply, a 0-degree winding belt ply and a second belt ply which are sequentially distributed from the tirebody to the tire tread, and the first belt ply, the second belt ply and the 0-degree winding belt ply are arranged in a trapezoid shape, wherein the length 2W1 of the first belt ply in the tire widthdirection and the length 2W2 of the second belt ply in the tire width direction meets a relationship that W1>W2, and the length 2W1 of the first belt ply in the tire width direction and the horizontal width TDW of a crown meets a relationship that 0.81 <= 2W1 / TDW <= 0.96. The paving mode of the 0-degree winding belt ply, the first belt ply and the second belt ply is optimally designed, so the problem that the end parts of the belt plies cannot be fully bonded with rubber materials is solved, thereby cracks at the end parts of the belt plies are reduced, the high-speed performance of the tireis improved, and the mileage service life of the tire is prolonged.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

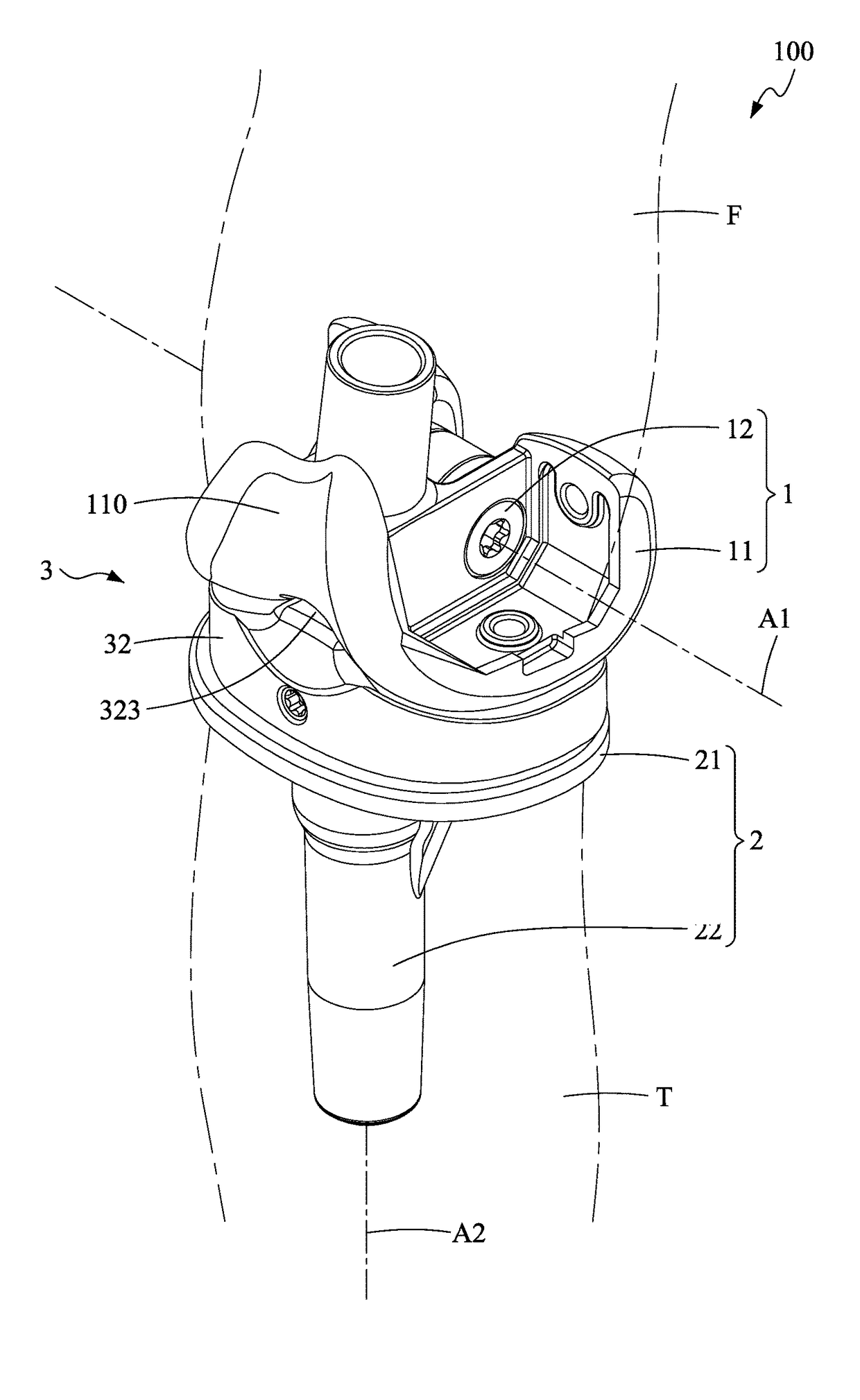

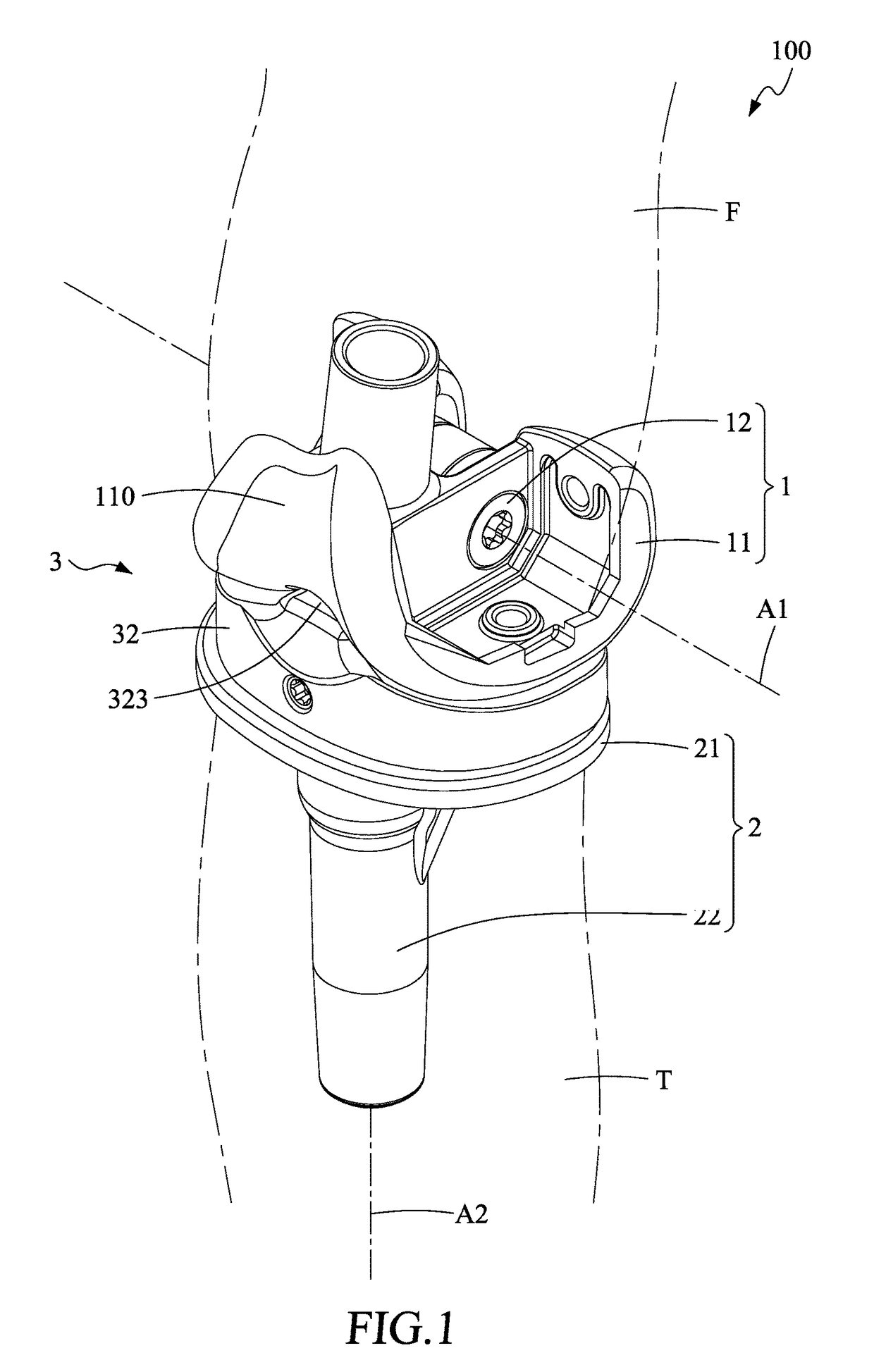

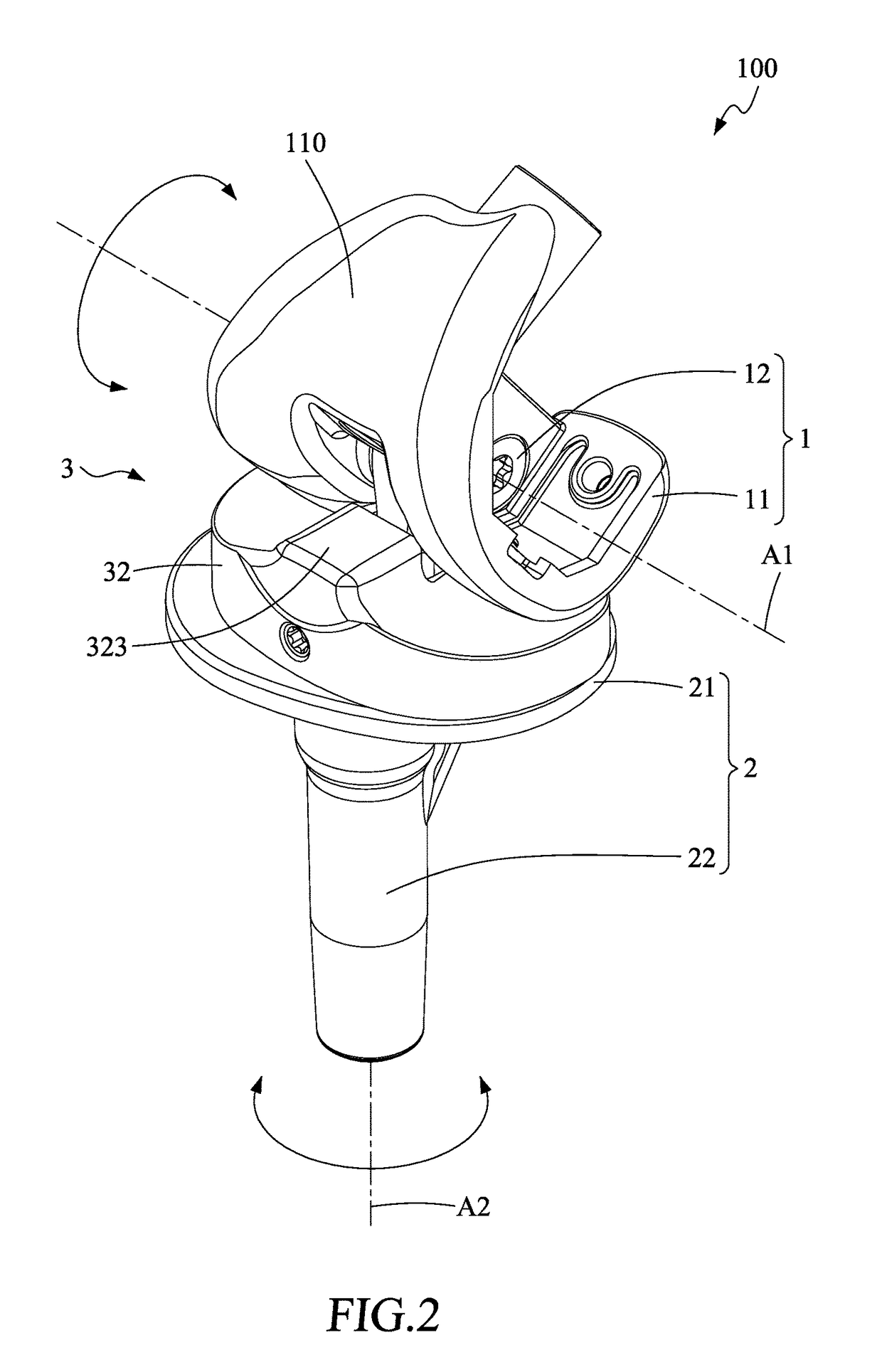

Artificial knee joint

ActiveUS10064732B2Prevent reversalIneffectiveness of the artificial jointJoint implantsKnee jointsTibiaArtificial joints

The present invention provides an artificial joint, including a femur connecting device, a tibia connecting device, and a receiving device, wherein the femur connecting device is connected and fixed with the receiving device and the tibia connecting device via a fixing member unparallel to a joint-twisting axis, and wherein cushion member receives the femur connecting device via a pivot-receiving surface and receives the tibia connecting device via a twist-receiving surface, thereby providing an durable and reliable artificial joint.

Owner:UNITED ORTHOPEDIC CORP

Modified mineral aggregate for bituminous pavement and method for producing same

The invention discloses a modified ore material and preparing method of asphalt pavement, which is characterized by the following: heating up the ore material in hot cylinder and adding in 0.5-5kg coupler per 1000kg aggregates; putting the above materials in mixture vat to mix for 10-25 minutes; modifying the surface modification. Using coupler to modify the surface modification of main composite materialore material (aggregate, brasque) of asphalt mixture improves the combination property of asphalt mixture. Making the adhesion to change for cementation on the surface between ore material and asphalt improves the binding power and constancy between ore material and asphalt. The invention improves the affinity of ore material and asphalt, which improves the intensity, constancy and durability of asphalt pavement.

Owner:关长禄

Waterborne epoxy ester resin composition and preparation method thereof and water-based paint prepared from same

ActiveCN101851396BExcellent corrosion resistance and water resistanceImprove drynessEpoxy resin coatingsChemical industryWater based

The invention belongs to the field of water-based paints in chemical industry and provides a waterborne epoxy ester resin composition and a preparation method thereof and a water-based paint prepared from the same. The waterborne epoxy ester resin composition is prepared by the following methods: (1) preparing a carboxyl-containing vinyl polymer (a) by polymerizing vinyl monomer free radicals; (2) performing ring-opening reaction on excessive epoxy group, fatty acid and an epoxy resin to prepare a fatty acid epoxy ester resin (b); (3) adding the (a) into the (b) to make the carboxyl in the (a) react with the epoxy group in the (b) so as to prepare a vinyl modified epoxy ester resin (A); and (4) neutralizing the (A), adding water, and dispersing to obtain the waterborne epoxy ester resin composition. The waterborne epoxy ester resin composition can overcome the defects that the conventional epoxy ester resin has poor corrosion and water resistance, and the speed that the film has intensity is low. The obtained resin composition film has excellent corrosion and water resistance, and both the resin and the paint have excellent storage stability; the resin film has good dryness, and the speed that the film has the intensity is high; and the paint can be widely applied to the field of metal corrosion resistance.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

All-steel pattern tyre for mining

The invention relates to a vehicular tyre, and in particular relates to an all-steel pattern tyre for mining. The all-steel pattern tyre for mining disclosed by the invention has the advantages that by means of design of unique large pattern blocks and transverse deep trenches, the road grabbing capability of the tyre can be increased; the tyre is more steady to use; the driving property is more obvious; by means of design that the transverse deep trenches extend to a tyre shoulder in a stepped manner, damage of base rubber at the bottom of pattern transverse trenches by sharp stones in mining can be effectively reduced; the all-steel pattern tyre for mining has the characteristics of preventing horse stone and trench bottom cracking; by means of design of a groove on the tyre shoulder, heat at the tyre shoulder can be sufficiently volatilized; by means of an unique steel disc in a proper position, heat caused by self characteristics of patterns in the use process can be effectively reduced; early damage of the tyre is prevented; and the service life of the tyre is prolonged.

Owner:SHANDONG KAIXUAN RUBBER

Tire bead structure of tires

The invention belongs to the tire technology field, and particularly relates to a tire bead structure of tires. The tire bead structure of the tires comprises a tire body, a tire bead core and a tire sidewall, wherein the tire body bypasses the bottom of the tire bead core and is reversely wrapped around the outer side of the tire bead core. The tire bead structure of the tires further comprises a first steel wire reinforcement layer and transition type glue. The tire bear core further comprises a steel wire ring and an apex strip. The first steel wire reinforcement layer bypasses the bottom of the steel wire ring and is wrapped around the outer side of the tire body, and the transition type glue is located above the outer endpoint of the tire body and between the apex strip and the tire sidewall. The tire bead structure of the tires has the advantages that compared with the prior art, stress-strain transition among adjacent materials is balanced, physical property matching among the materials is reasonable, and simultaneously the transition type glue is added, stress-strain equilibrium distribution on the endpoint of a steel wire is achieved, stress-strain concentration is avoided, heat generation amount of the tire bead structure is reduced, and therefore carrying capacity of the tires is improved, and use life of the tires is prolonged.

Owner:HEFEI WANLI TIRE CO LTD

Off-the-road tyre tread pattern

InactiveCN101352998AImprove self-cleaning abilityAvoid early damageTyre tread bands/patternsEngineeringWear resistance

The invention discloses tread patterns of construction machinery rubber tires and the patterns comprise transverse tread blocks and tread grooves; wherein, the transverse tread blocks and tread grooves dislocate in the circumferential direction and take a center line of the tread as the reference to be antisymmetric; the transverse tread grooves are stripy tread grooves which are arranged from the place close to the center line to a tire shoulder and extend to the tire side, and each tread block is repeatedly allocated into the form of equal interval, and upper groove edges and lower groove edges of the tread grooves are both of the shape of S and the curvature of the upper groove edges is smaller than that of the lower groove edges; the upper groove edges at groove heads of the tread grooves are convex outside a groove and the upper grooves edges of the rest part on a tire tip are concave inside the groove; the lower groove edges which are in the corresponding projection length of the upper groove edges which are convex outside the groove are concave inside the groove and the lower groove edges in the corresponding projection length of the upper groove edges which are concave inside the groove are convex outside the groove; the upper groove edges and lower groove edges of the tread grooves at the tire side are two straight lines which are approximately parallel. The tread patterns of construction machinery rubber tires are high in self-cleanness and good in wear resistance and piercing resisting performance and are particularly suitable for skew tires used in engineering vehicles such as dump trucks, bulldozers or wheel loaders.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Full steel radial brand-new tire with heavy duty tire bead structure

PendingCN108215671AEffectively disperse stressAvoid early damagePneumatic tyre reinforcementsTyre beadsTire beadHeavy duty

The invention discloses a full steel radial brand-new tire with a heavy duty tire bead structure. The tire comprises a tire bead structure, which comprises a triangular rubber core. A carcass cord layer is wrapped on the rubber core. The external part, which is arranged on the end face direction of the tire bead structure, of the carcass cord is wrapped by an external opening reinforcing cord. Thesurface of the part, which is arranged on the inner side of the tire bead structure, is provided with an internal opening reinforcing cord. The internal side direction of the tire bead structure is also provided with an internal fibrous cord covered on the external opening reinforcing cord and the internal opening reinforcing cord, and the external side direction of the tire bead structure is also provided with an external fibrous cord covered on the external opening reinforcing cord. The structure has the advantages that through the application of internal and external one layer or multilayer fibrous cords and internal and external two opening reinforcing cords, the end points of tire beads are arranged between the external opening reinforcing cord and the internal opening reinforcing cord, the stress on the tire bead ends is effectively dispersed, and the damage of the carcass ends in the early stage is avoided.

Owner:SHANDONG LINGLONG TIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com