All steel radial tire

A technology of radial tires and steel wires, applied to tire parts, tire edges, transportation and packaging, etc., can solve problems such as unsatisfactory effects, and achieve the effects of simple structure, easy implementation, and obvious use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

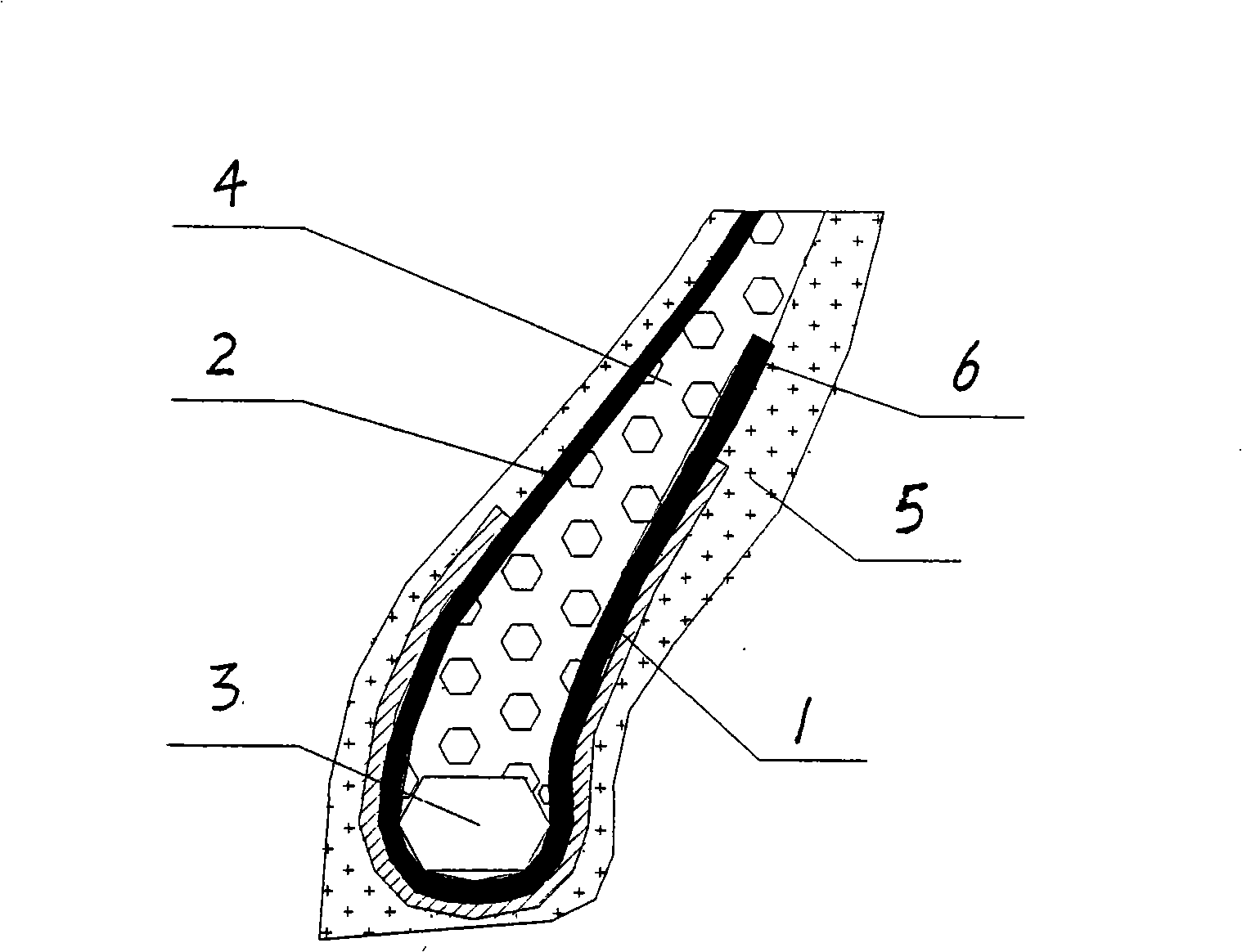

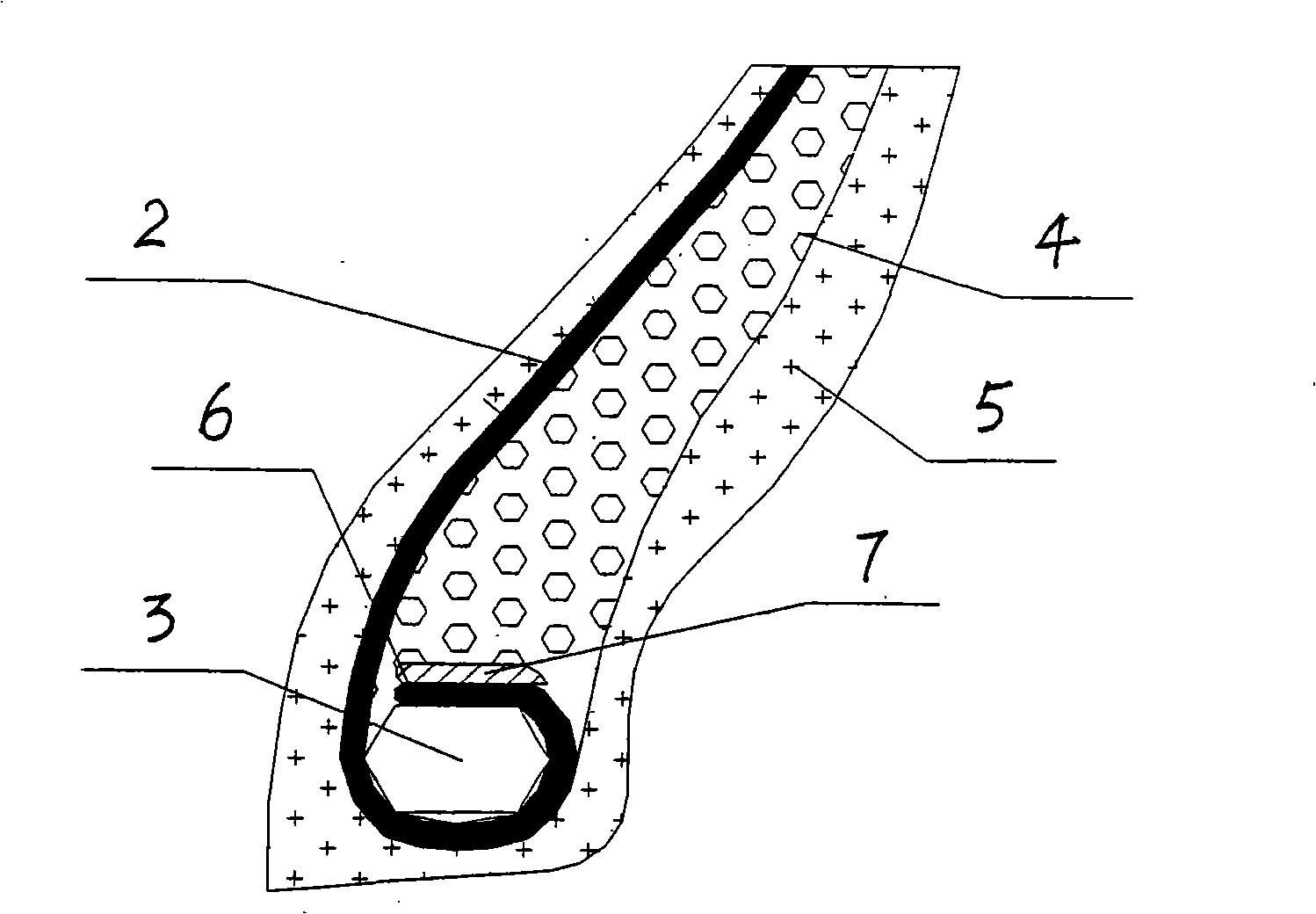

[0009] Such as figure 2 As shown, an all-steel radial tire, its bead portion includes a rubber part 5, a carcass ply 2 located in the rubber part 5, a steel traveler 3 and a bead filler 4 arranged close to the carcass ply 2, The carcass ply 2 is turned up over the bead ring 3, which is characterized in that the turn-up end 6 of the carcass ply 2 is fixed on the top of the bead ring 3, and the turn-up end 6 of the carcass ply 2 passes through a hoop 7 hoop Press and fix on the top of the traveler 3.

[0010] The early damage to the bead of the tire is caused by the emptying of the end of the carcass cord turnup. In the present invention, the turned-up end of the carcass cord is moved out of the bending deformation area in use of the tire, and a hoop is used to press and fix the turned-up end of the carcass cord on the top of the steel ring, thus avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com