Patents

Literature

66results about How to "Dense surface structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealing agent for aluminum and aluminum alloy anode oxide films and preparation method for sealing agent

InactiveCN102650068AGood sealingImprove closureSurface reaction electrolytic coatingRare earthBond strength

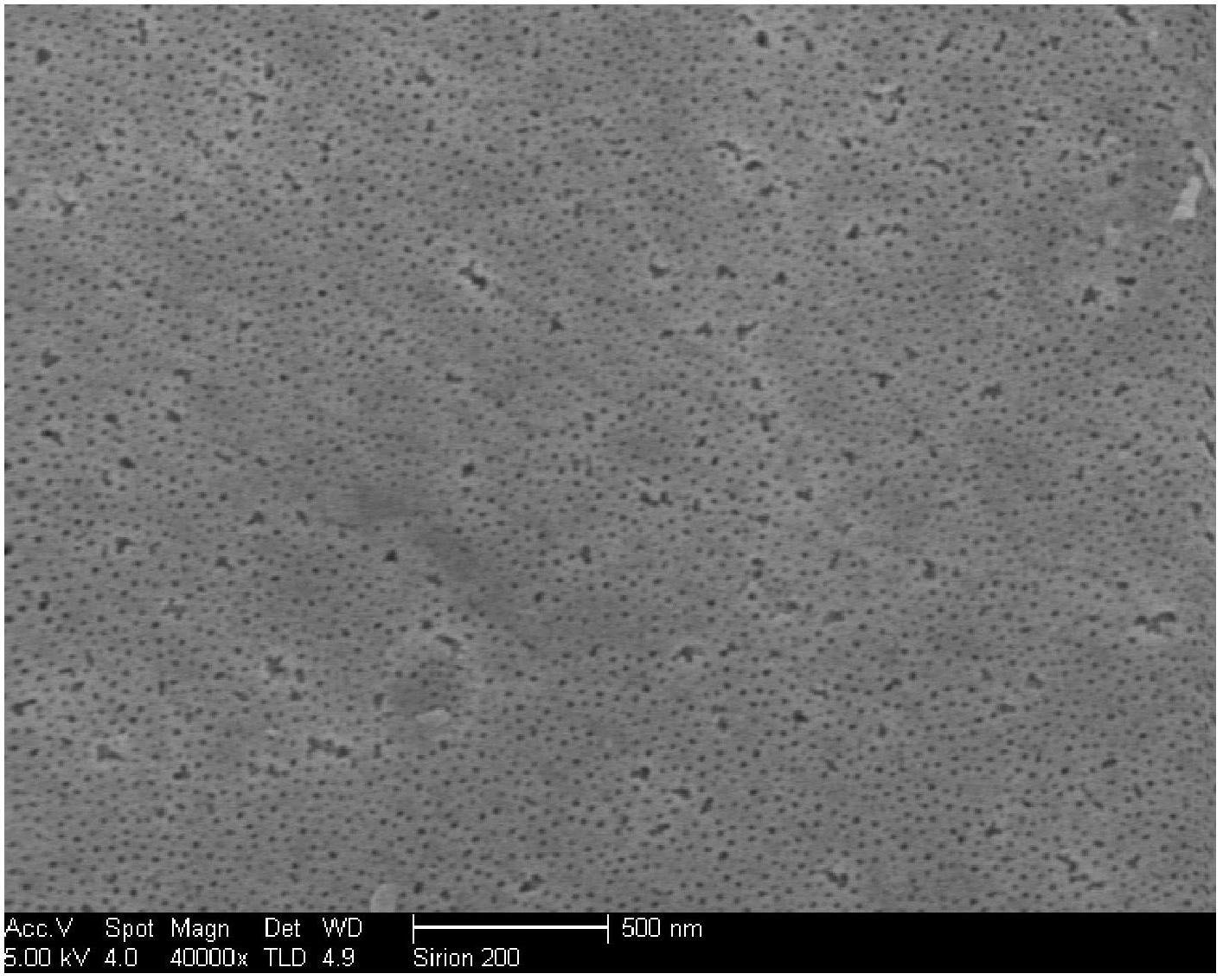

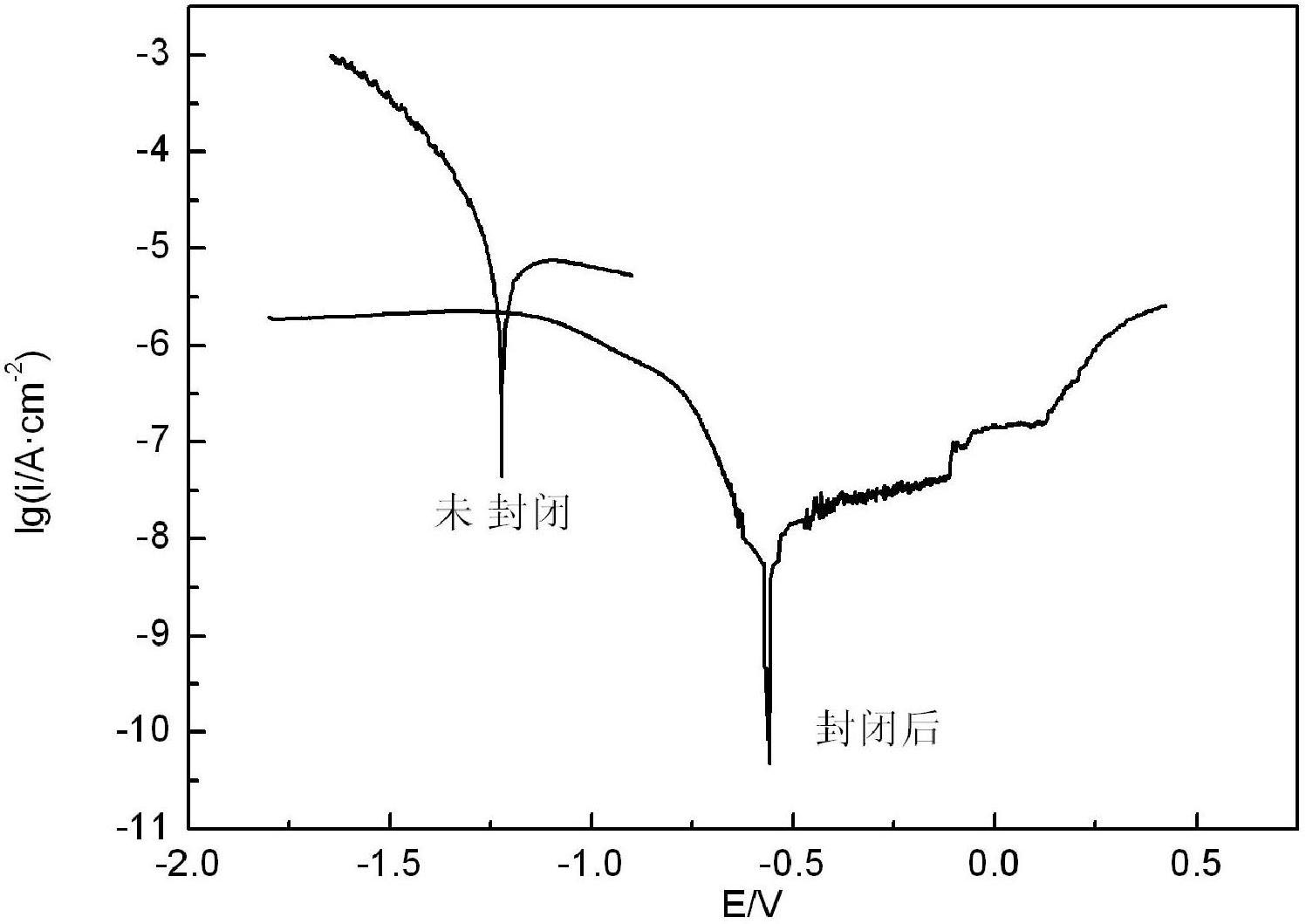

The invention discloses a sealing agent for aluminum and aluminum alloy anode oxide films and a preparation method for the sealing agent. The sealing agent comprises the following raw materials by lL: 15-20g of lanthanide nitrate, 0.6-0.8g of oxidizing agent, 0.25-0.3g of stabilizing agent and deionized water, wherein the additive amount of the deionized water is the amount of adding the deionized water until the volume is constant at 1L after the rest raw materials are mixed. According to the sealing agent disclosed by the invention, by utilizing the combined action of rare-earth metal and the oxidizing agent, porous layers of the anode oxide films can be effectively sealed, and the corrosion resistance of the anode oxide films is obviously improved. Meanwhile, the sealing agent disclosed by the invention does not contain chromium, nickel or fluorine, therefore, the human body cannot be harmed, and the environment cannot be polluted. The sealing agent is a green environmental-protection sealing agent. Moreover, the aluminum and aluminum alloy anode oxide films can be sealed at normal temperature, therefore, not only is the energy consumption reduced but also the operation convenient is improved. After being treated by the sealing agent disclosed by the invention, the aluminum and aluminum alloy anode oxide films are compact in surface structure, is in uniform golden yellow and is higher in bonding strength.

Owner:HEFEI UNIV OF TECH

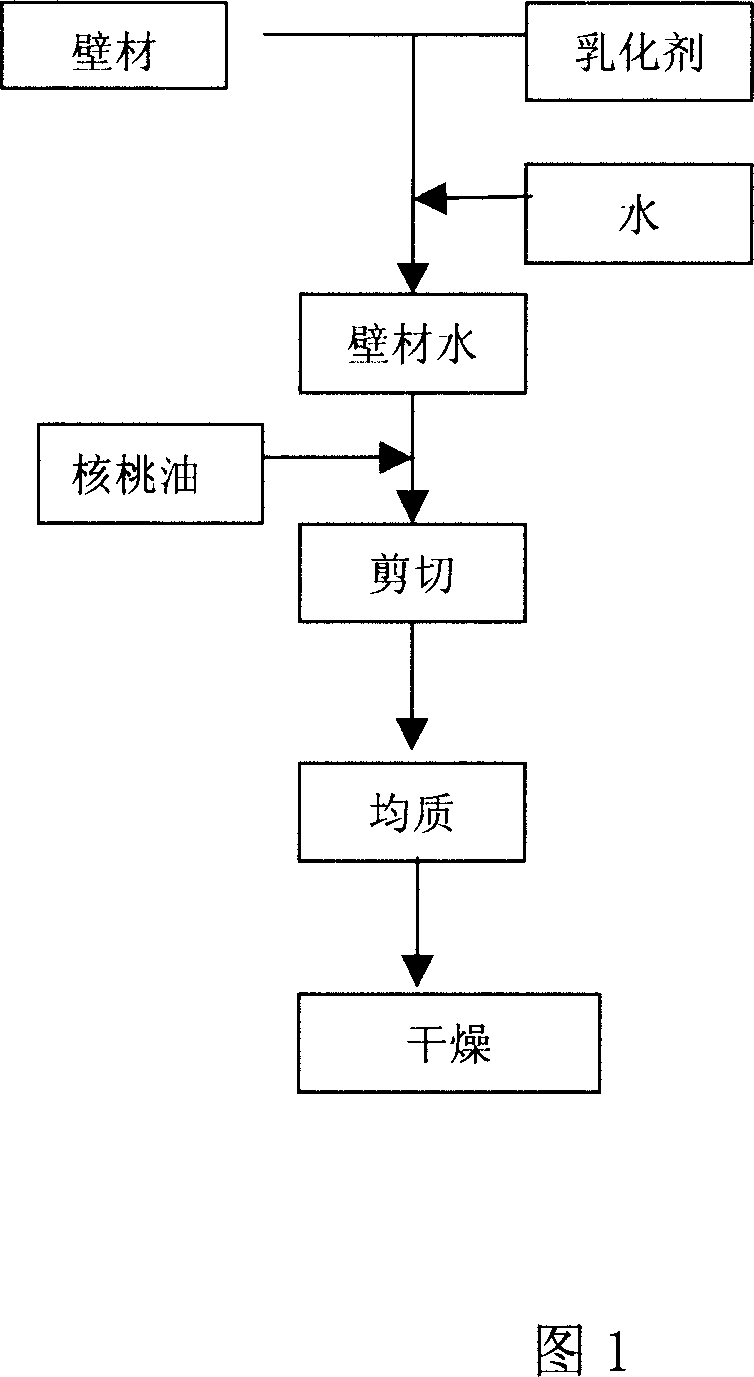

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

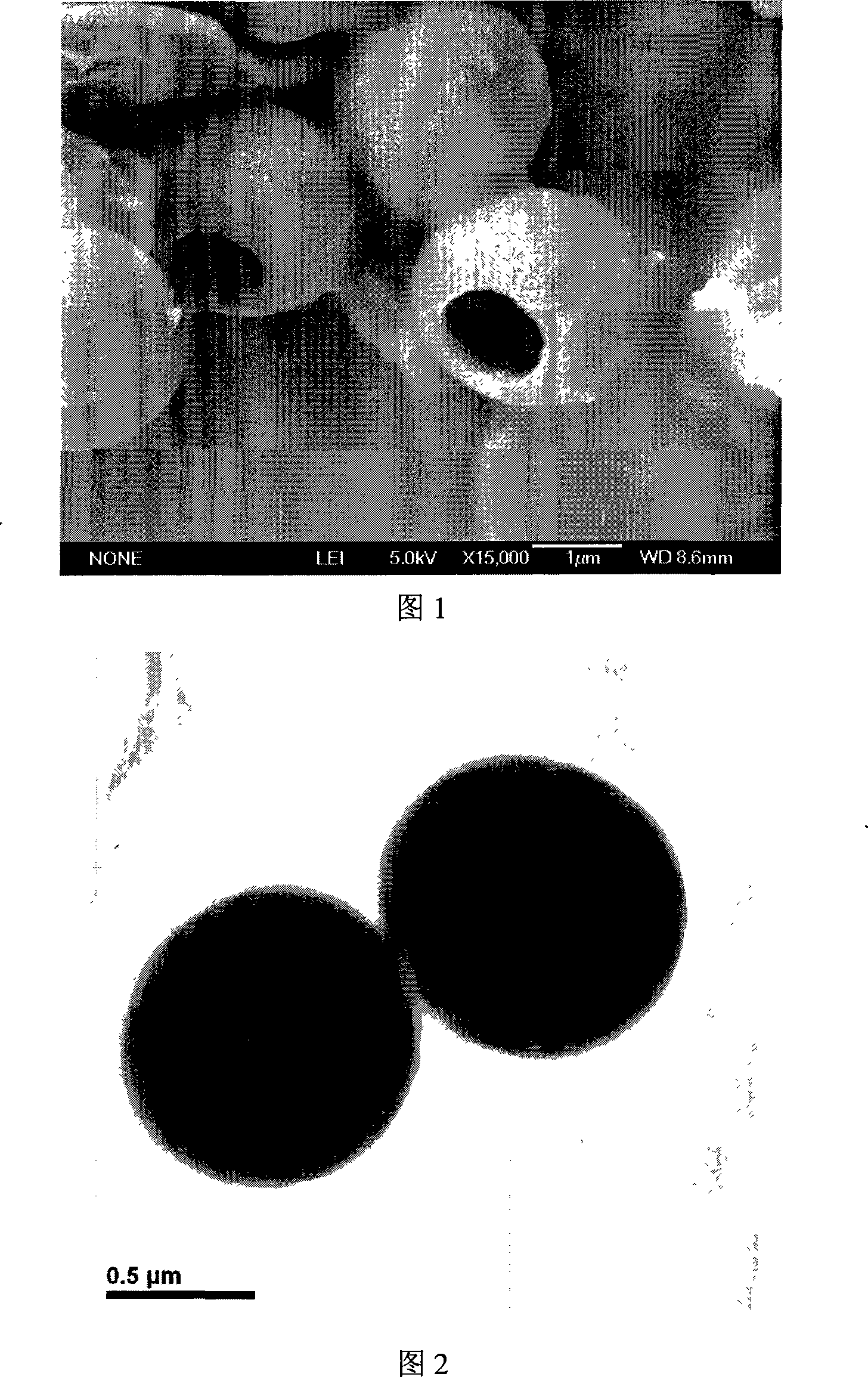

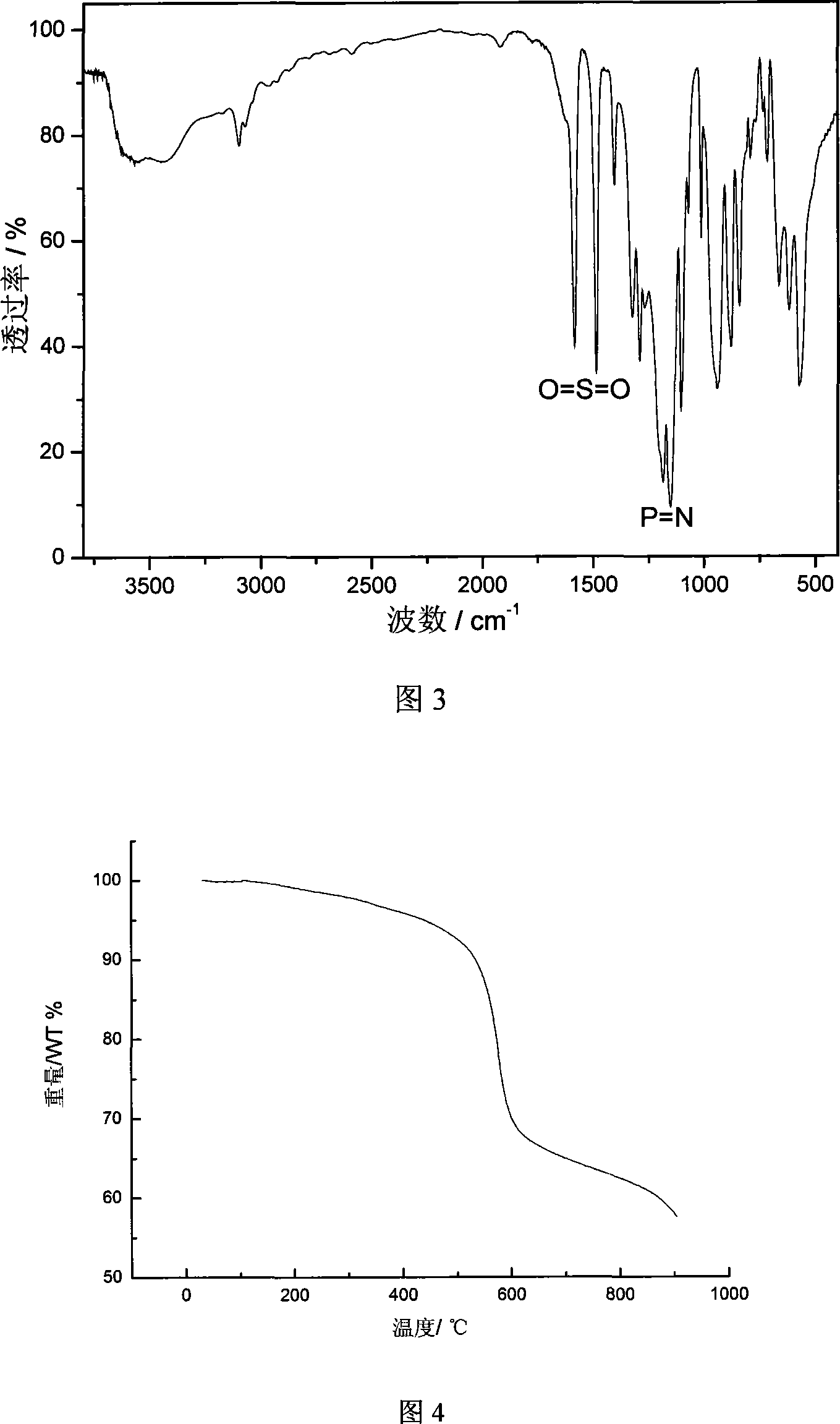

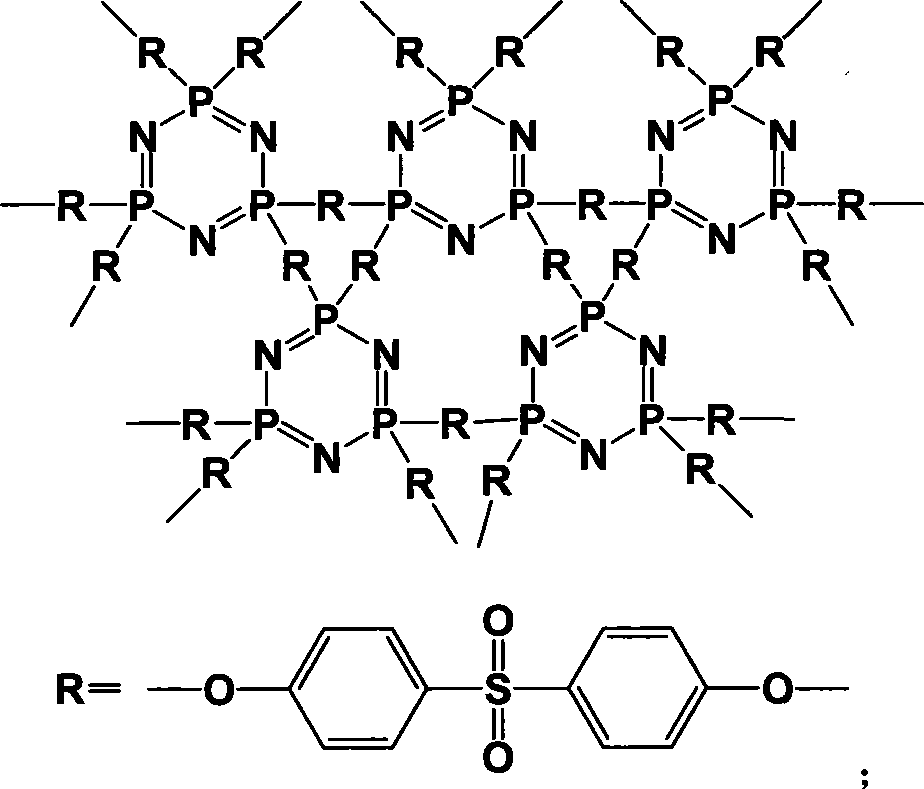

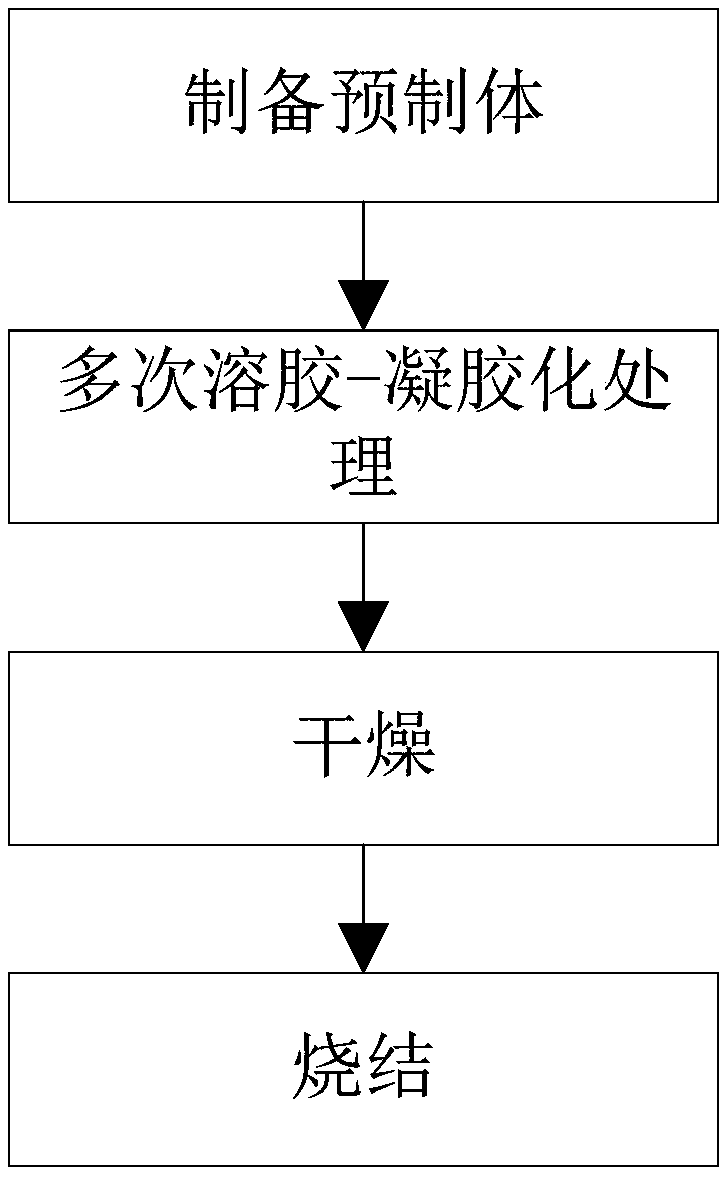

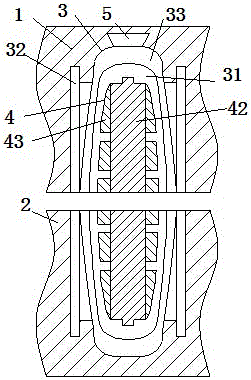

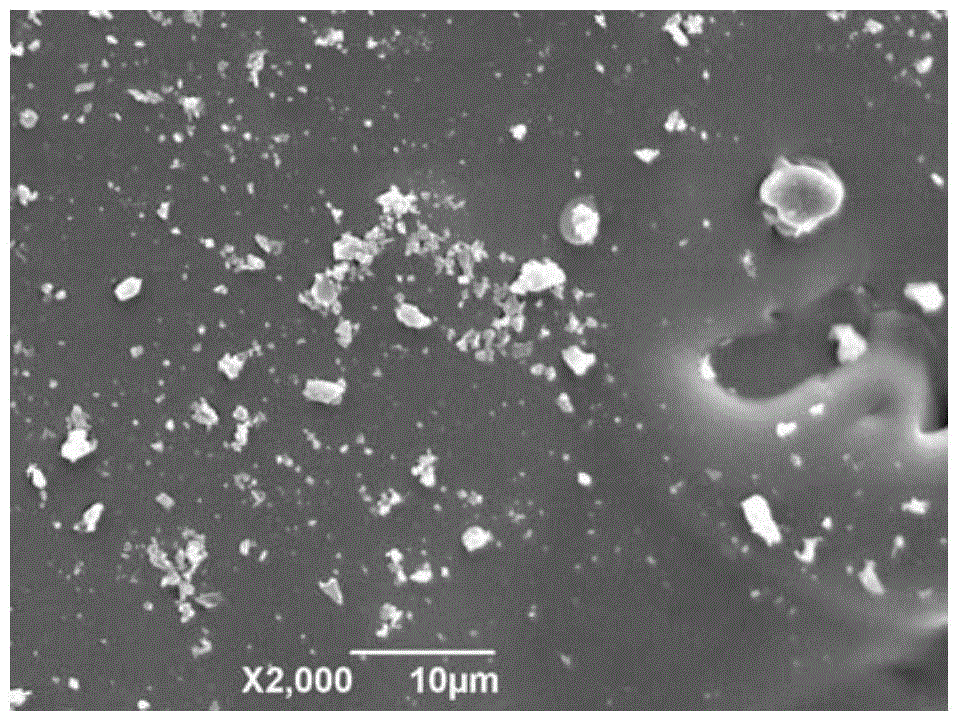

Hollow micro-ball containing phosphazene and preparing method

InactiveCN101070389ALoose internal structureDense surface structurePharmaceutical non-active ingredientsPolymer sciencePtru catalyst

The present invention discloses a kind of phosphazenes-containing hollow microsphere as shown in the following figure, and its preparation method; specifically, the diameter of the hollow microsphere is 0.3-2.0mu m, and the internal hollow diameter of the hollow microsphere is 100-800 nm. The phosphazenes-containing hollow microsphere which has a body-type crosslinking structure, can be produced by crosslinking condensation reaction under the function of acid binding agent, and controllable hydrolysis, in sequence, between hexachlorocyclotriphosphazene and 4, 4'-dihydroxy diphenyl sulfone; the preparation method is novel, simple and feasible, which can be large scale prepared in industrial applications.The phosphazenes-containing hollow microsphere can be used in controlling drug release, efficient catalyst carriers, new photoelectric material, flame retardant materials, etc.

Owner:SHANGHAI JIAO TONG UNIV

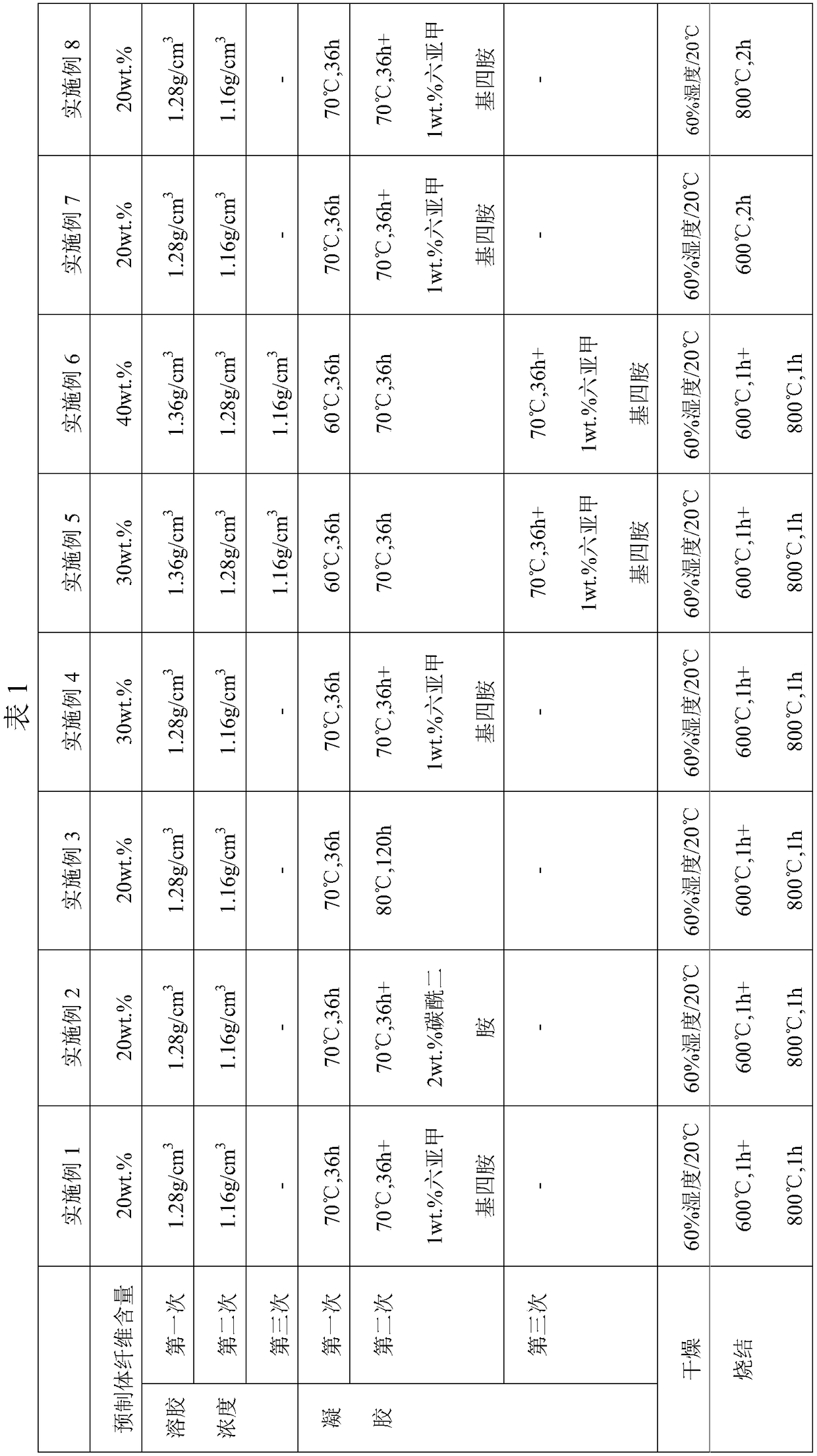

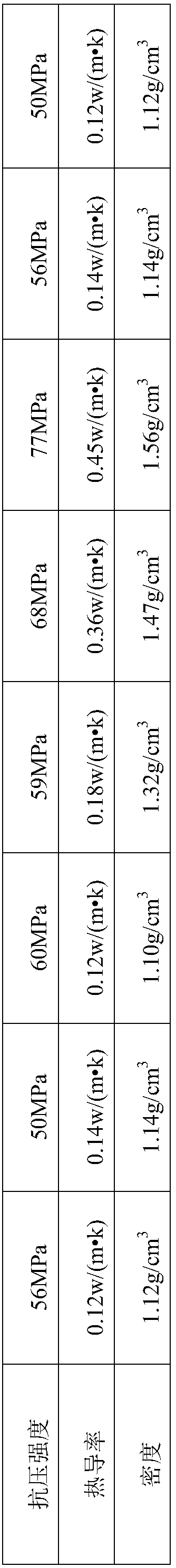

Fiber-reinforced silicon dioxide heat-insulating ceramic material and preparation method and application thereof

The invention relates to a fiber-reinforced silicon dioxide heat-insulating ceramic material and a preparation method and application thereof. The preparation method comprises the following steps: (1), preparing a preform; (2), performing multiple sol-gelation treatment: impregnating the preform with silica sol, then gelating to complete once sol-gelation treatment, repeating the sol-gelation treatment for multiple times, and sequentially reducing the density of the silica sol for impregnation to form gradient impregnation; (3), drying a material treated in the step (2) to obtain a blank; (4),sintering the blank to obtain the fiber-reinforced silicon dioxide heat-insulating ceramic material. By the preparation method, the heat-insulating ceramic material with high compressive strength andlow heat conductivity can be prepared; the heat-insulating ceramic material can be applied to an aircraft heat insulating system.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

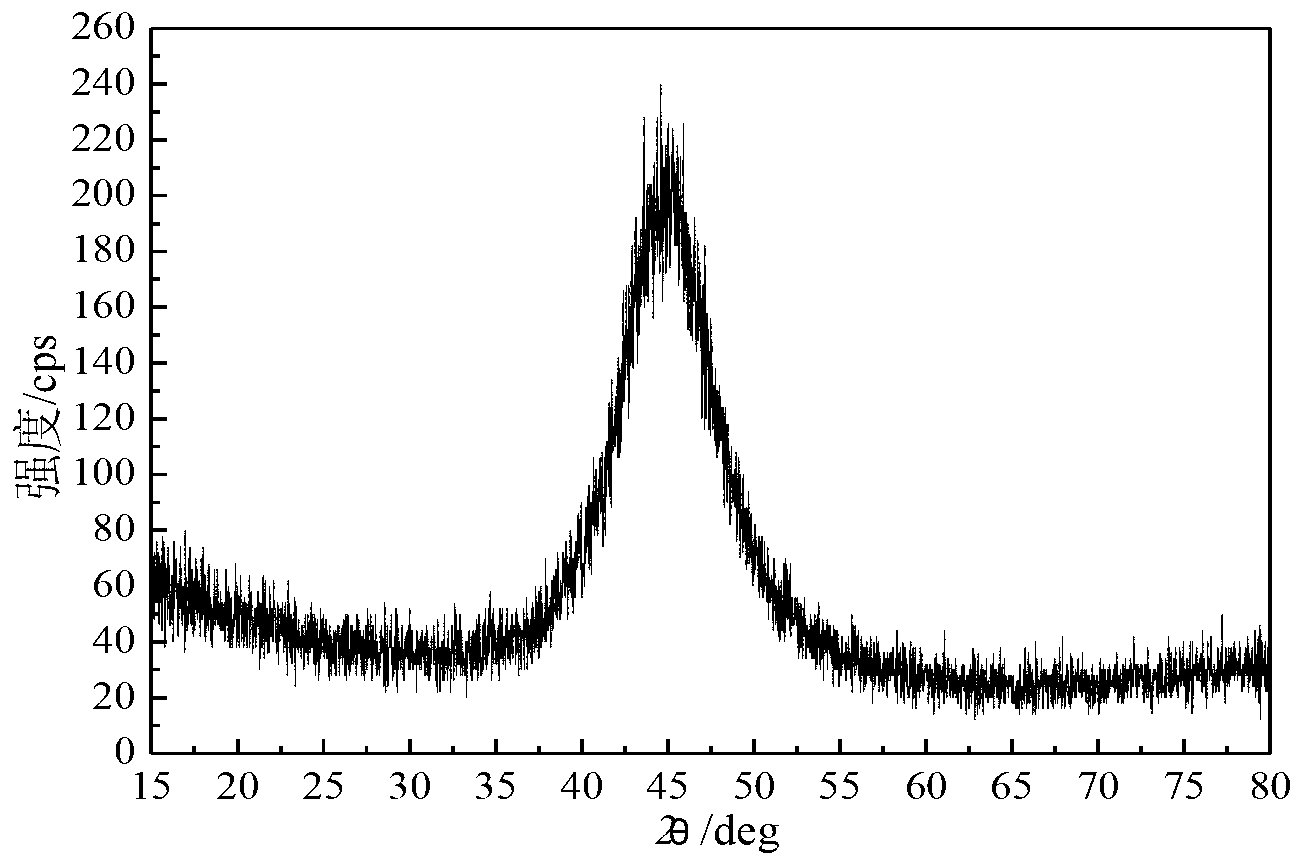

Plating solution for plating nickel and phosphorus on surface of magnesium lithium alloy and low-temperature plating method

ActiveCN103266312AImprove the decorative effectAvoid corrosionLiquid/solution decomposition chemical coatingThioureaAcid washing

The invention relates to a plating solution for plating nickel and phosphorus on a surface of magnesium lithium alloy. 1 L of the plating solution consists the following components: 25-35 g of main salt nickel sulfate, 25-35 g of reducing agent sodium hypophosphite, 5-10 g of complexing agent citric acid, 10-15 g of corrosion inhibitor ammonium hydrogen fluoride, 10-15 mL of accelerator hydrofluoric acid, 0-2 mg of stabilizer thiourea and 0.5-5 mg of brightener lauryl sodium sulfate. A low-temperature plating method comprises the following steps of: performing surface grinding on a magnesium lithium alloy workpiece; degreasing; performing alkali washing; performing acid washing; activating; and finally placing the magnesium lithium alloy workpiece into the plating solution for plating nickel and phosphorus on the surface of the magnesium lithium alloy, and plating. According to the plating solution, the nickel sulfate serves as the main salt, and the corrosion inhibitor and the brightener are added, so the matrix can be prevented from being corroded in the chemical nickel phosphorus plating process of the magnesium lithium alloy, the obtained plating layer is uniform, compact and bright, the nickel phosphorus plating layer has a good binding force and good corrosion resistance, the surface of the magnesium lithium alloy is effectively protected, and a good decorative effect is achieved.

Owner:镁高镁诺奖(铜川)新材料有限公司

Preliminary dip material for vacuum forming massive article

The invention relates to a high polymer material field, in particular to a prepreg compound used in a vacuum forming massive article, which comprises reinforcing fiber, matrix resin and fiber base-material and is characterized in that the reinforcing fiber is retted by the matrix resin to form the reinforcing fiber at one side which is completely soaked by the matrix resin and the prepreg compound at the other side which is not completely soaked by the matrix resin; wherein for one side of the reinforcing fiber which is not completely by the matrix resin, the soakage rate of the matrix resin is more than or equal to 20% and is less than or equal to 95%.

Owner:WEIHAI GUANGWEI COMPOSITES

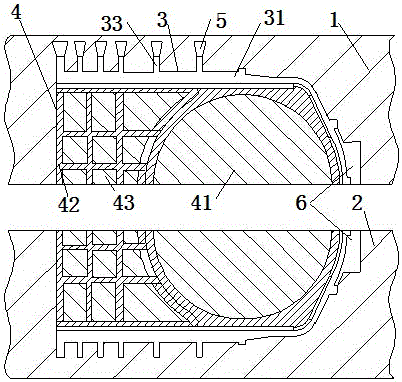

High-performance gate valve casting

ActiveCN106513592ACompact structureThere will be no problems such as damage and crackingFoundry mouldsFoundry coresSurface structureMaterials science

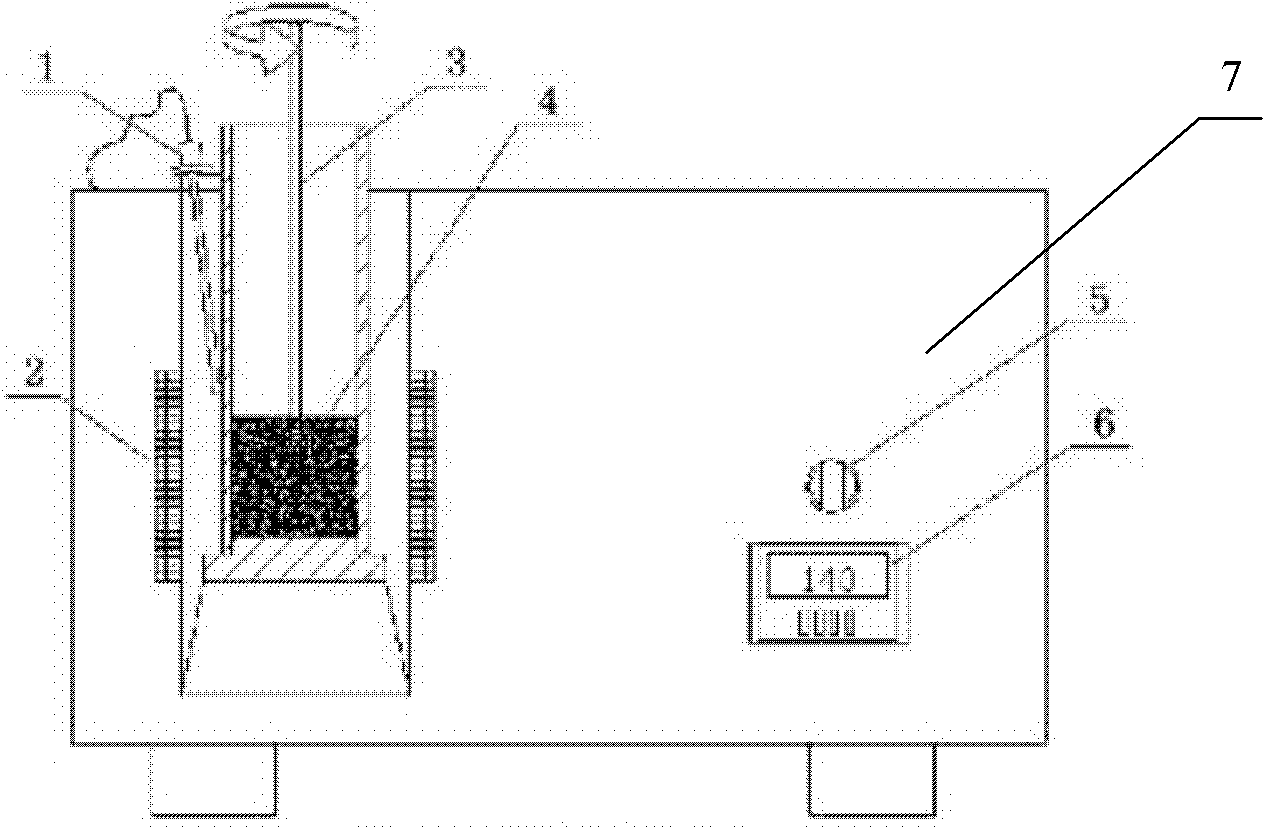

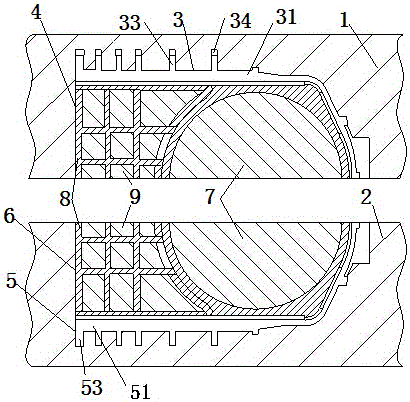

The invention discloses a high-performance gate valve casting. The high-performance gate valve casting comprises an upper sand box (1) and a lower sand box (2); molding cavities (3) are symmetrically arranged in the upper sand box (1) and the lower sand box (2); molding cores (4) are arranged in the molding cavities (3); the molding cavities (3) include gate plate groove molding cavities (31); pipe port molding cavities (32) are formed in one ends of the gate plate groove molding cavities (31); rib molding cavities (33) are formed in the gate plate groove molding cavities (31); the molding cores (4) include pipe port molding cores (41) with semicylindrical structures, and gate plate groove molding cores (42) arranged in the gate plate groove molding cavities (31); groove molding cores (43) with square section structures are respectively arranged on the front and back two sides of the gate plate groove molding cores (42); and riser feed molding cavities (5) are formed in the upper ends of the rib molding cavities (33) arranged in the upper sand box (1). The high-performance gate valve casting has the characteristics of compact surface structures of gate valve finished products, improvement of the yield of the gate valve finished products, reduction of the production cost and improvement of the production efficiency.

Owner:ZHEJIANG OUYEDA MACHINE MFG

Heavy metal waste slag treatment method and sulfur building material prepared thereby

ActiveCN101885600AAvoid toxicityAchieve harmless treatmentSolid waste managementSlagMetallic sulfide

The invention discloses a heavy metal waste slag treatment method and a sulfur building material prepared thereby. The method comprises: soaking heavy metal waste slag in solution of sodium sulfide to pre-vulcanize excessive heavy metal ions in the waste slag into metal sulfides; drying the metal sulfides, grinding the metal sulfides and sieving the ground metal sulfides with a 100 mesh sieve; mixing the powder with sulfur uniformly, adding gypsum slag into the powder and the sulfur to obtain a mixture; filling the mixture in a mold, and placing the mold in a heating furnace to heat the mold at 140 to 150 DEG C with constant stirring till the sulfur melts and the heavy metal waste slag turns viscous; and taking the mold out 20 to 40 minutes later, compacting the mixture in the mold, cooling the mold and removing the mold to obtain the sulfur building material. The method can prevent the damages of freely discharged industrial waste slag with high heavy metal content to the environment by covering the heavy metal slag with sulfur to make the sulfur building material; and thus, the harmless treatment of industrial heavy metal waste slag is realized, the heavy metal waste slag is recycled and the utilization rate of the heavy metal waste slag is improved. The extraction procedure toxicity of the prepared sulfur building material is in complete accordance with the standards of Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity (GB 5085.3-2007). The method can be used for high, medium and low content heavy metal waste slag.

Owner:CENT SOUTH UNIV

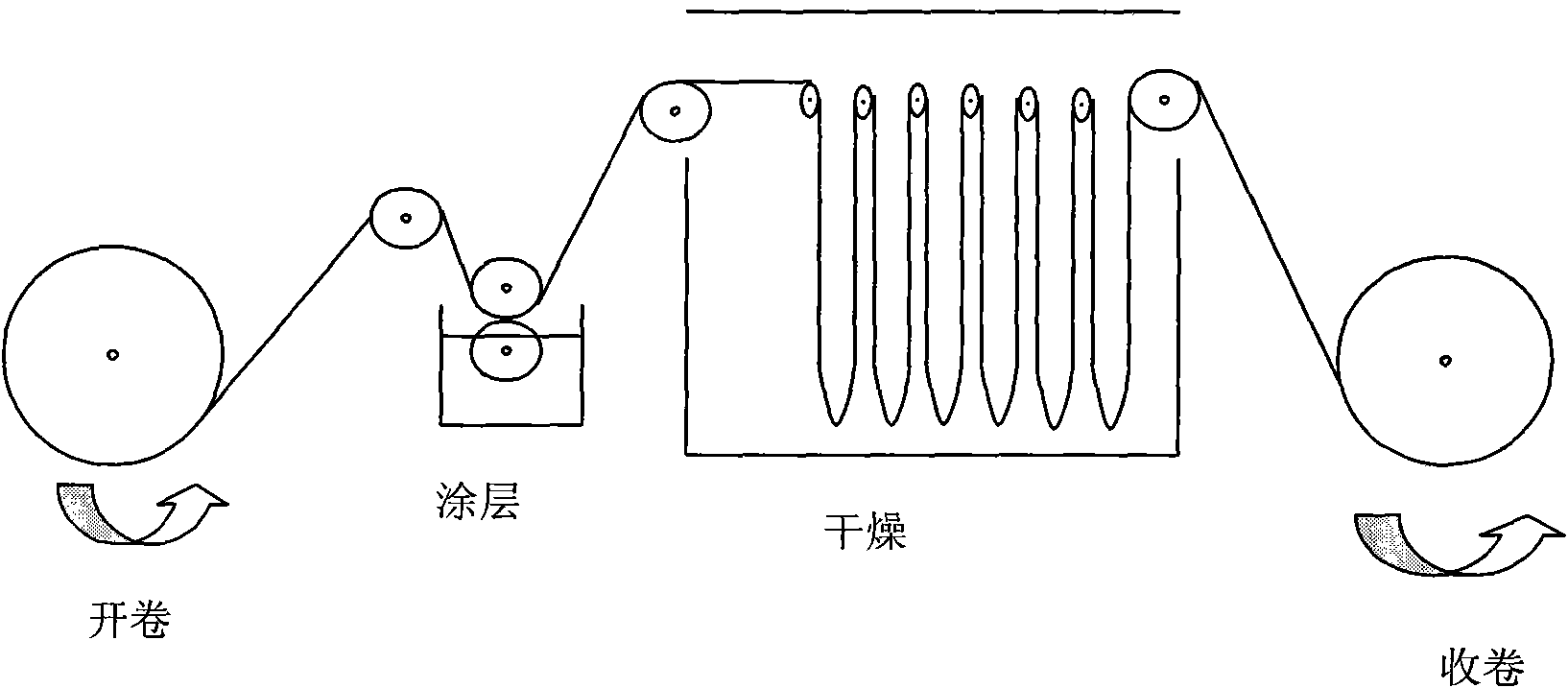

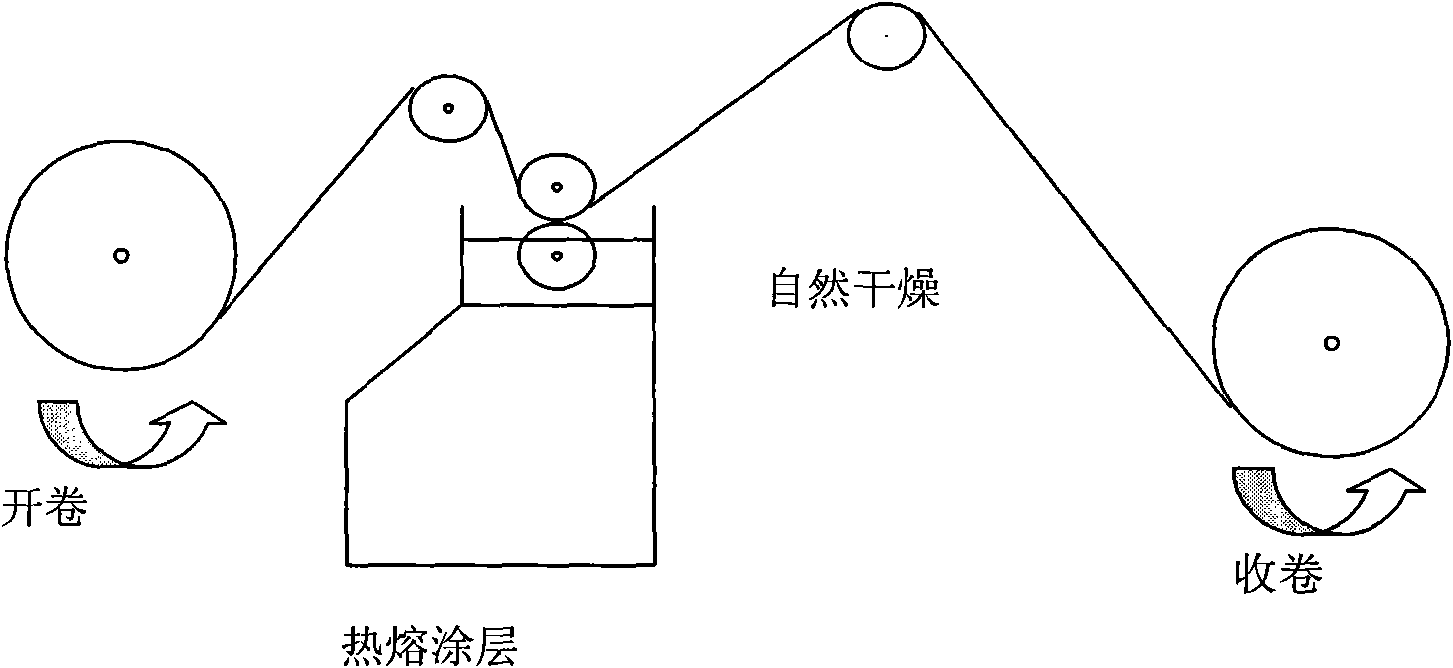

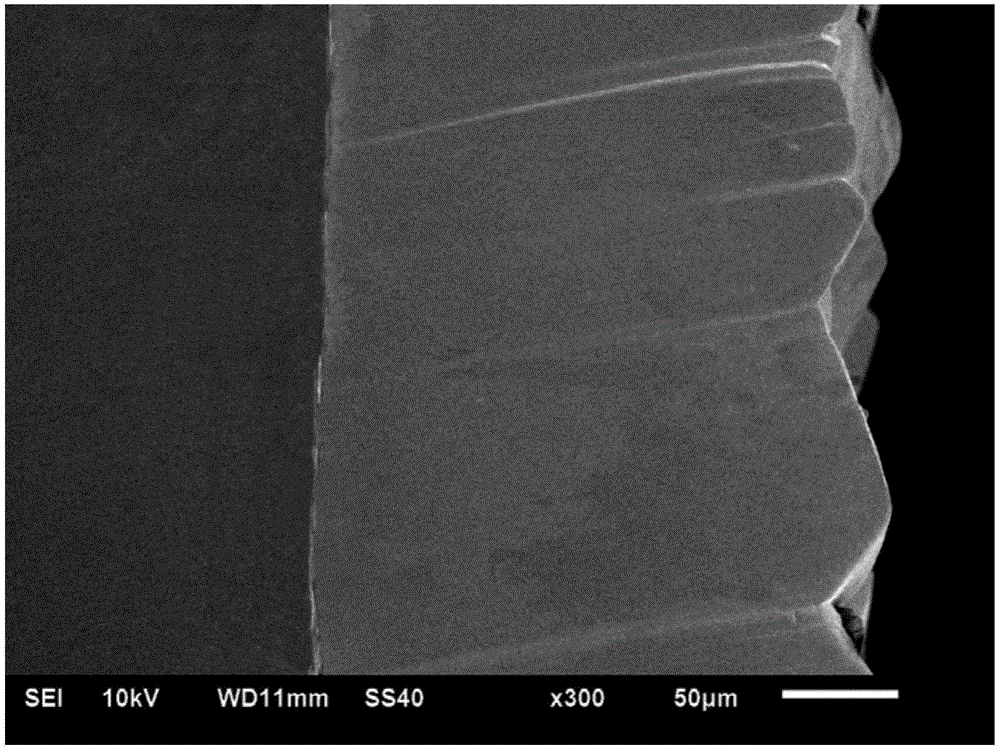

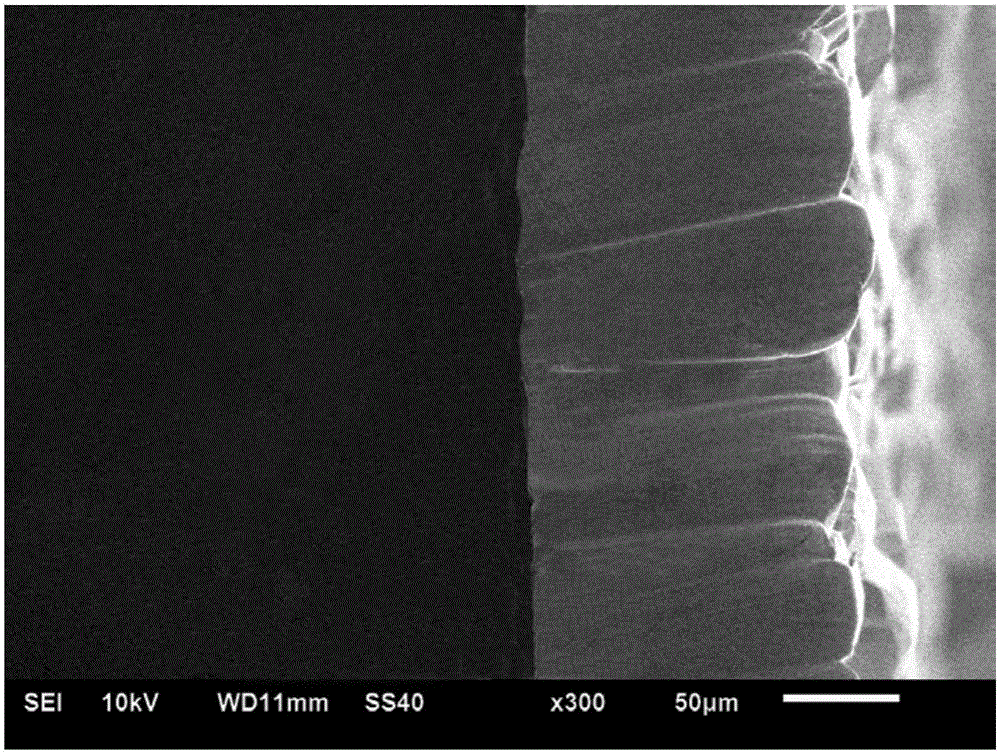

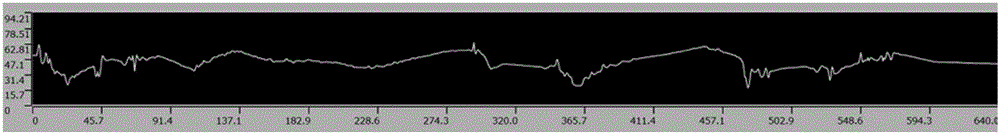

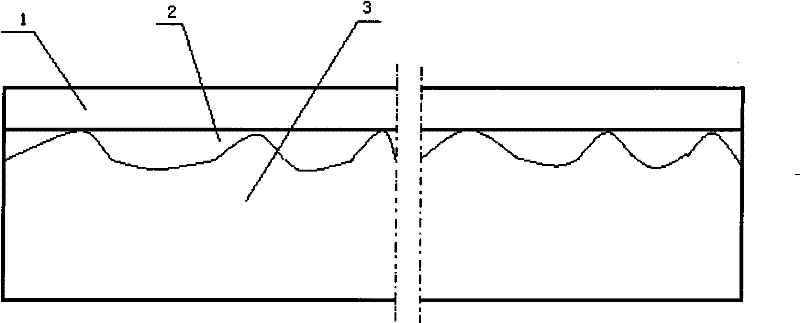

Method for forming hot melt super coating on coated abrasive tool

InactiveCN102009038ADense surface structureLow costLiquid surface applicatorsAbrasion apparatusHot melt coatingStearate

The invention discloses a method for forming a hot melt super coating on a coated abrasive tool, which is to heat and melt a material and coat the molten material by a roller coating equipment onto the surface of the coated abrasive tool, and is characterized in that: the material is stearate, or a mixture of stearate and paraffin wax or a mixture of stearate, paraffin wax and antioxidant or mixture of stearate, paraffin wax, antioxidant and EVA resin or PP resin and is heated and melted at the temperature of 110 to 160 DEG C; the molten stearate or mixtures of the stearate is coated on the surface of abrasive paper or abrasive cloth by hot melt coating equipment; and naturally cooling, drying and obtaining hot melt coating products. The hot melt coating has the advantages of no toxicity, no solvent, low cost, short production route and the like compared with water soluble or solvent coating, and the obtained abrasive tool has a more compact surface structure and has the advantages of blockage prevention, burn prevention and the like in use.

Owner:ZIBO RIKEN MT COATED ABRASIVES

Resin with low surface energy and preparation method thereof

The invention discloses resin with low surface energy and a preparation method thereof. The resin with low surface energy is prepared from the following raw materials in parts by weight: 100-120 parts of organic silicon resin, 5-10 parts of epoxy resin, 0.5-1.0 part of coupler KH560, 0.5-1.0 part of catalyst, 10-20 parts of cyclohexanone and 20-40 parts of toluol. The preparation method comprises the following three steps of: dissolving the epoxy resin and the catalyst, carrying out a heating reaction and dewatering under reduced pressure to finally obtain the resin with low surface energy. Under the action of the coupler and the catalyst, the invention effectively grafts the epoxy resin onto the silicon resin to form composite resin. Detected according to a GB 1720-79 (89) paint film adhesion force measuring method and a sessile drop method contact angle measuring method, the resin solidified by gamma-aminopropyl triethoxysilane and ethyl orthosilicate reaches the second level of the adhesion force and a contact angle of 112 degrees while corresponding pure silicon resin reaches the fourth level of the adhesion force and a contact angle of 96 degrees.

Owner:SHANGHAI HUILI PAINT

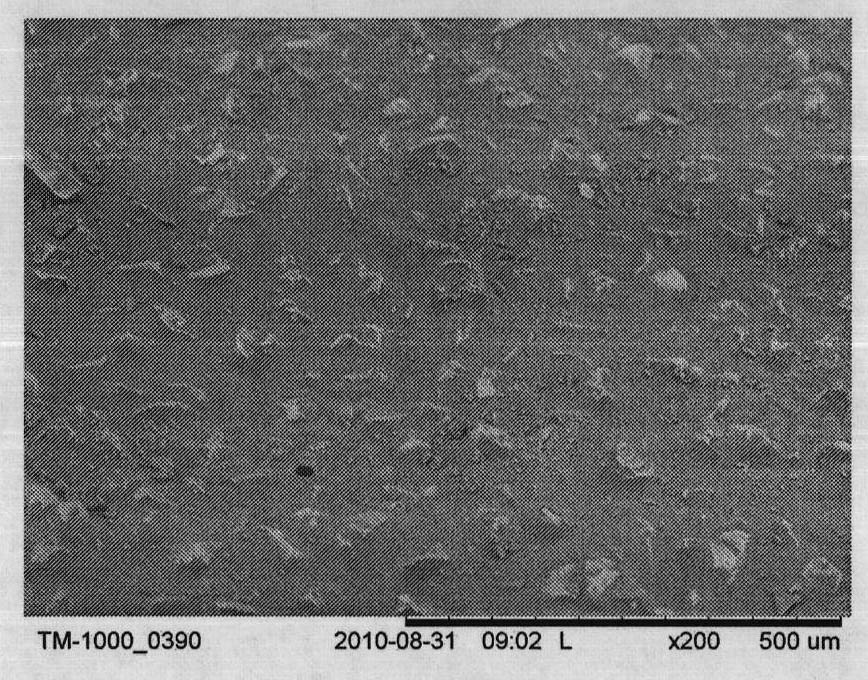

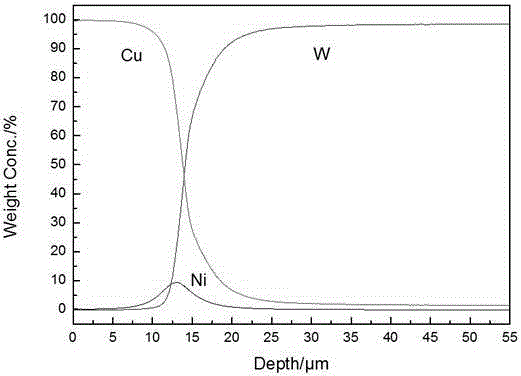

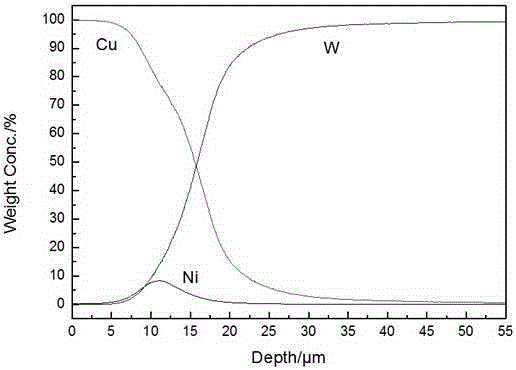

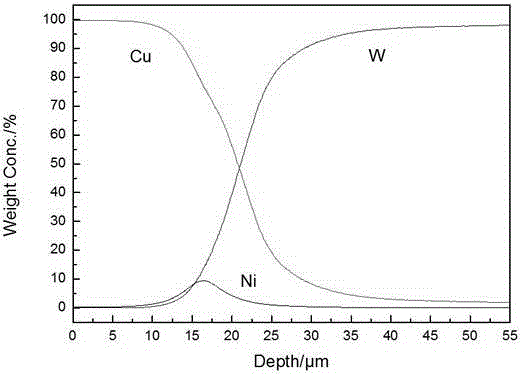

W-Ni-Cu gradient material and preparation method thereof

InactiveCN105177633AImprove impact performanceImprove heat resistanceCopper platingGradient material

The invention discloses a W-Ni-Cu gradient material and a preparation method thereof. The method comprises the following steps: taking a molten salt system of NaCl-KCl-NaF-NiO as an Ni leakage source and taking a copper-plating aqueous solution as a Cu leakage source; electrically depositing and leaking nickel on a pure W plate through molten salt, electrically depositing and leaking Cu through an aqueous solution; and finally diffusing and annealing to obtain the W-Ni-Cu gradient material. The material is high in thermal shock resistance and thermal fatigue resistance; all the components of the material are combined closely; the material surface structure is compact and smooth; the material has high electrical conductivity, high thermal conductivity and high mechanical performance. The method is capable of simultaneously carrying out mutual diffusion between W and Ni and carrying out mutual diffusion between Ni and Cu under the action of an electric field and a temperature field by using an electric deposition method according to the basic diffusion theory (the electric field can accelerate the diffusion of solid metals, and the diffusion speed of the opposite party can also be mutually improved when carrying out multi-element diffusion in the solid diffusion); the thickening of gradient layers can be accelerated; the W-Ni-Cu gradient material has the characteristics of rapid forming speed of the gradient layers, short preparation time, randomly controllable thickness of the gradient layers, compact surface structure of the material, high thermal conductivity and simple process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Weaving wicker modifying treatment method

InactiveCN109049219AImprove uniformityHigh specific surface areaRadiation/waves wood treatmentWood treatment detailsCorrosion preventionPre treatment

The invention discloses a weaving wicker modifying treatment method, and belongs to the technical field of wicker treatment. The method comprises the following steps of wicker pretreatment, socking treatment, irradiation treatment and ultraviolet curing treatment. Wicker treated by the modifying treatment method has good overall performance and is more compact in surface structure, the acid and alkali resistance, corrosion prevention and aging resistance properties are improved, toughness is improved, wicker produces can be prepared more easily, and the economic benefits and the market popularization value are quite good.

Owner:阜南县环宇柳木工艺制品有限公司

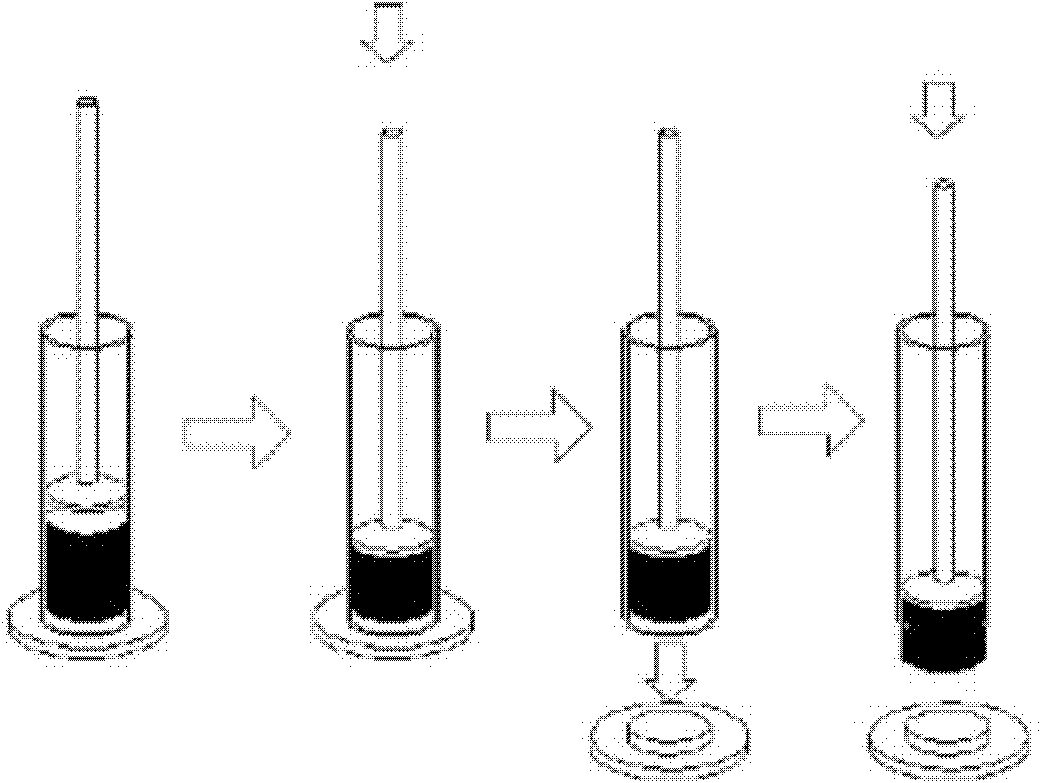

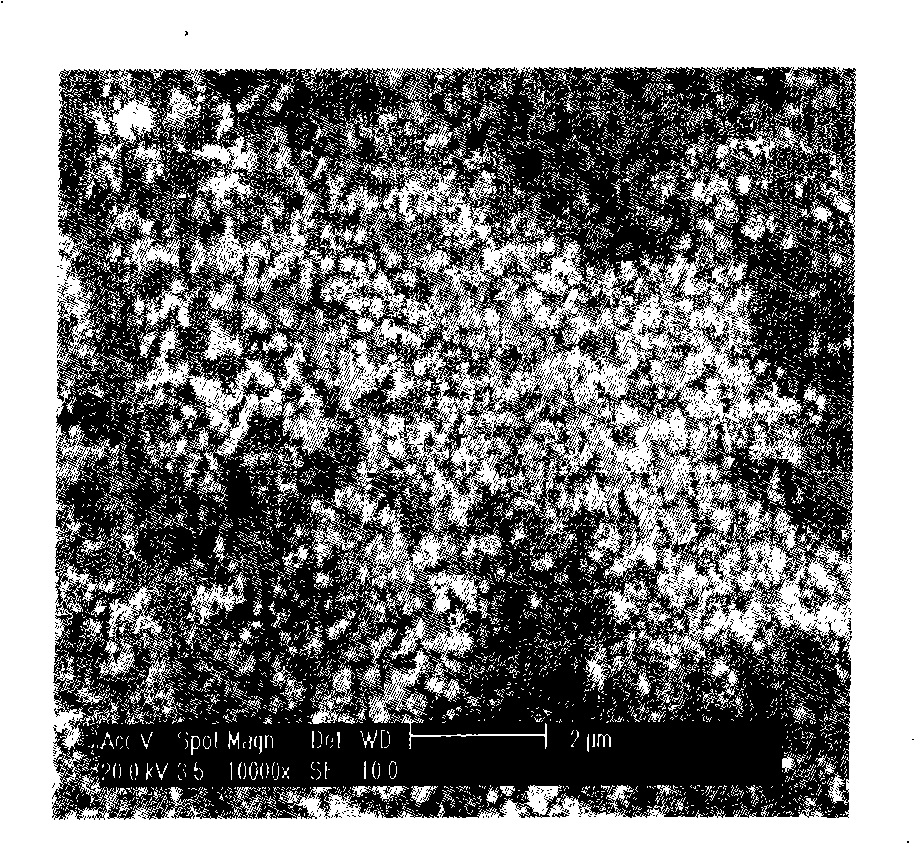

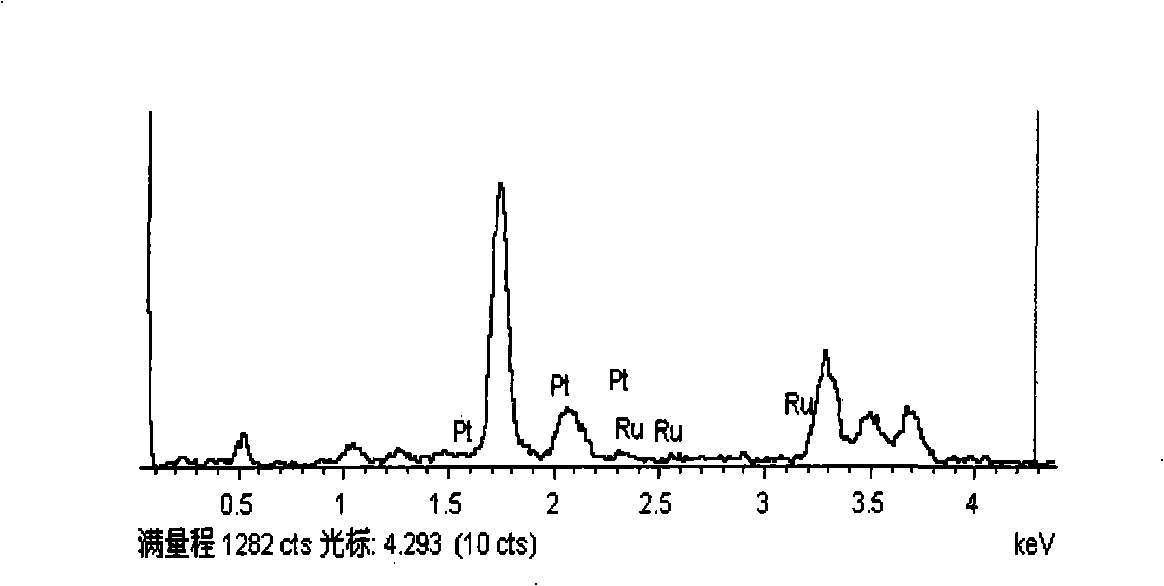

Platinum alloy electrode and method for producing the same

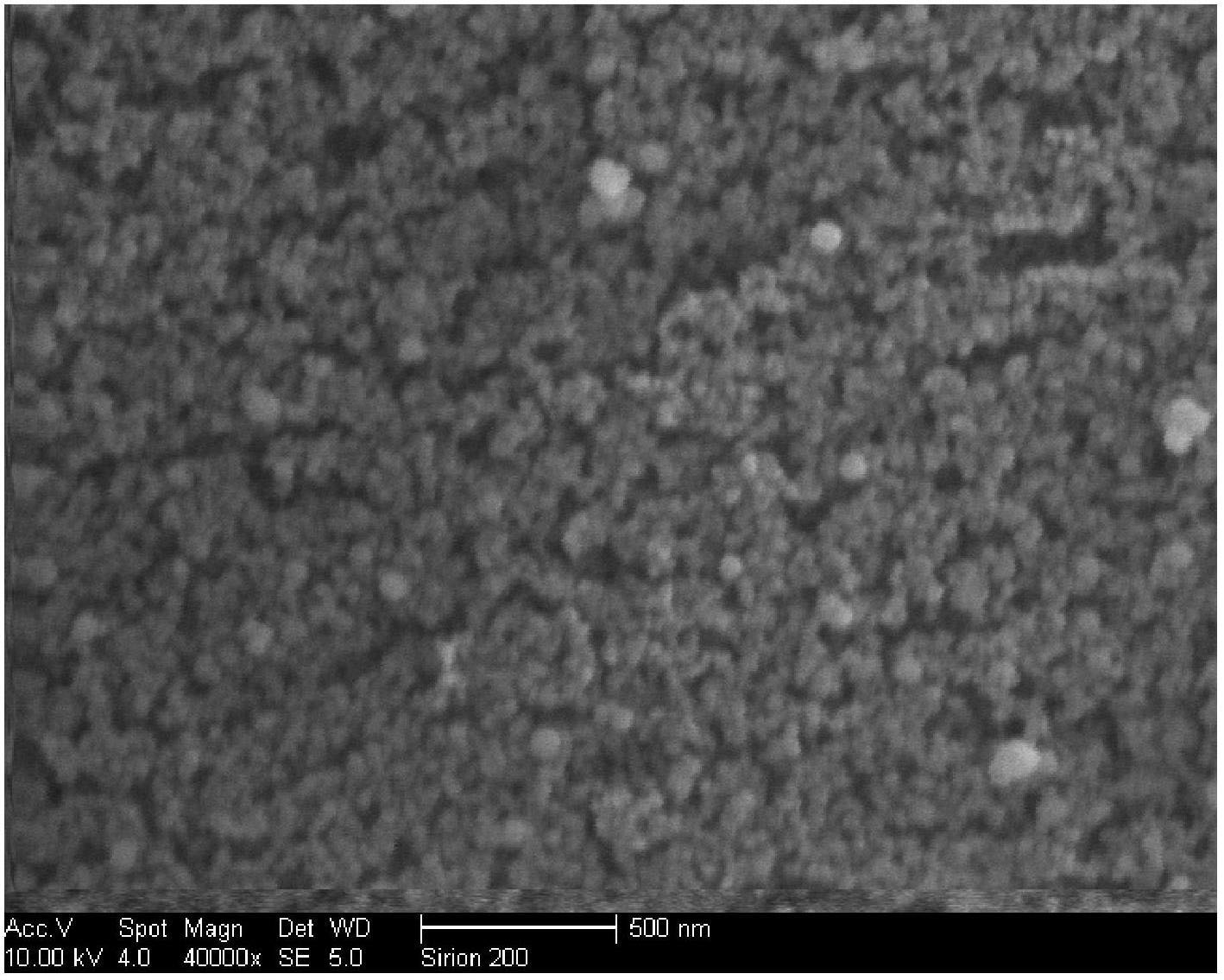

InactiveCN101271775ADense surface structureEvenly distributedLight-sensitive devicesCell electrodesDeoxidizationMetal

The invention relates to a platinum alloy electrode and a preparation method of the platinum alloy. Mixed water solution of H2PtCl6 and RuCl3 is prepared and is added with (NH4)2HPO4 and Na2HPO4; the mixed solution is heated to a nearly boiling state when smell of ammonia gradually disappears and the color of solution is changed from yellow into colorless, and 5% of NaOH or Na2CO3 saturated water solution is added and the pH value of the solution is adjusted to 7-8; electrodeposit is carried out by taking ITO conductive glass as a cathode, and the current density is 10-30mAcm<-2>, the electrodeposit time is 1-2 minutes, and the electrolyte temperature is 70-80 DEG C; a deposited Pt-Ru / ITO electrode is cleanly washed by distilled water, dried and kept in a dry environment with normal temperature before the battery is assembled. The dimension of iron particle of the Pt-Ru / ITO of the invention is nano-class, with compact surface structure and uniform distribution; the Pt-Ru / ITO of the invention has good electro-catalytic activity on the electro-chemical deoxidization of I3<->, has more stability performance in DSSC electrolyte compared with a Pt electrode. The platinum alloy electrode of the invention is used as an optical cathode in the dye sensitized solar battery, and the preparation method of the electrode can be applied to the field of fuel battery.

Owner:TIANJIN UNIV

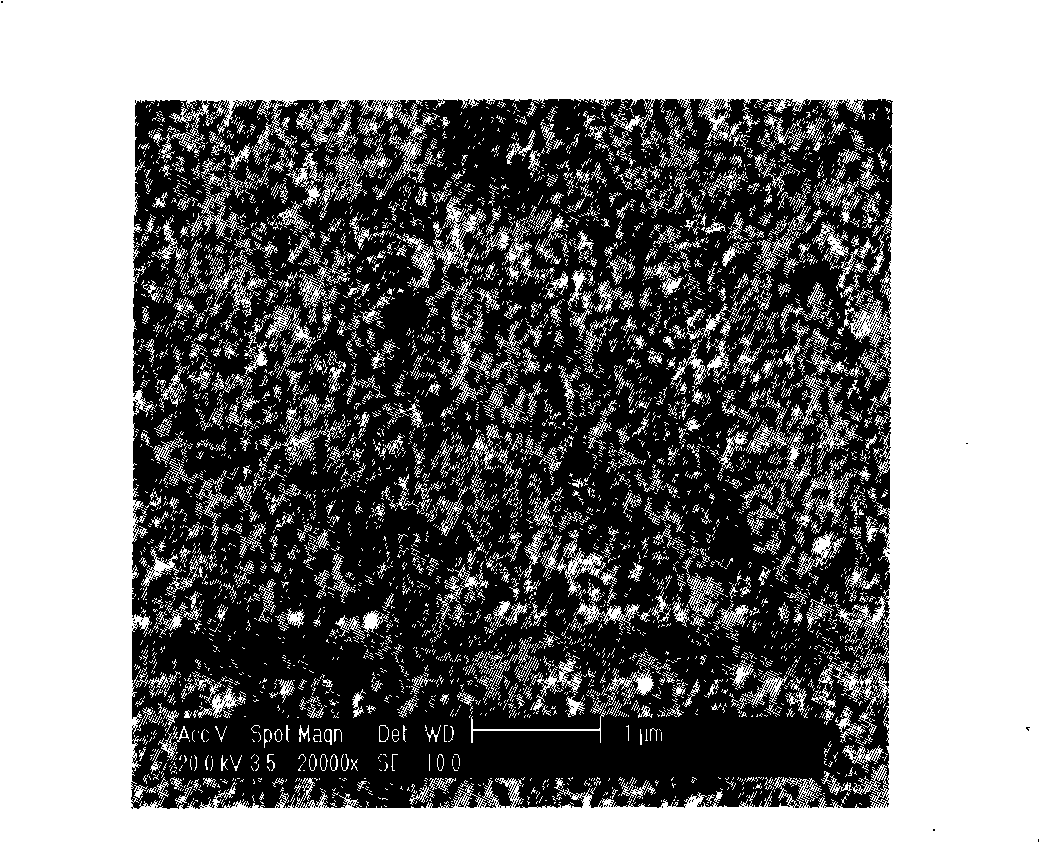

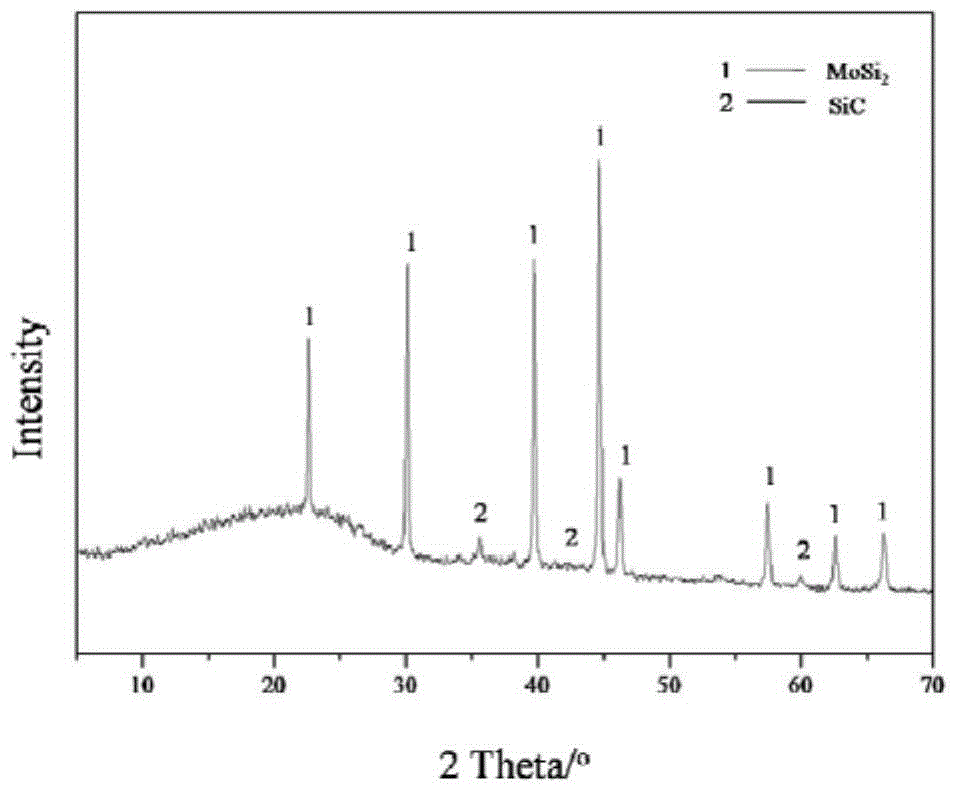

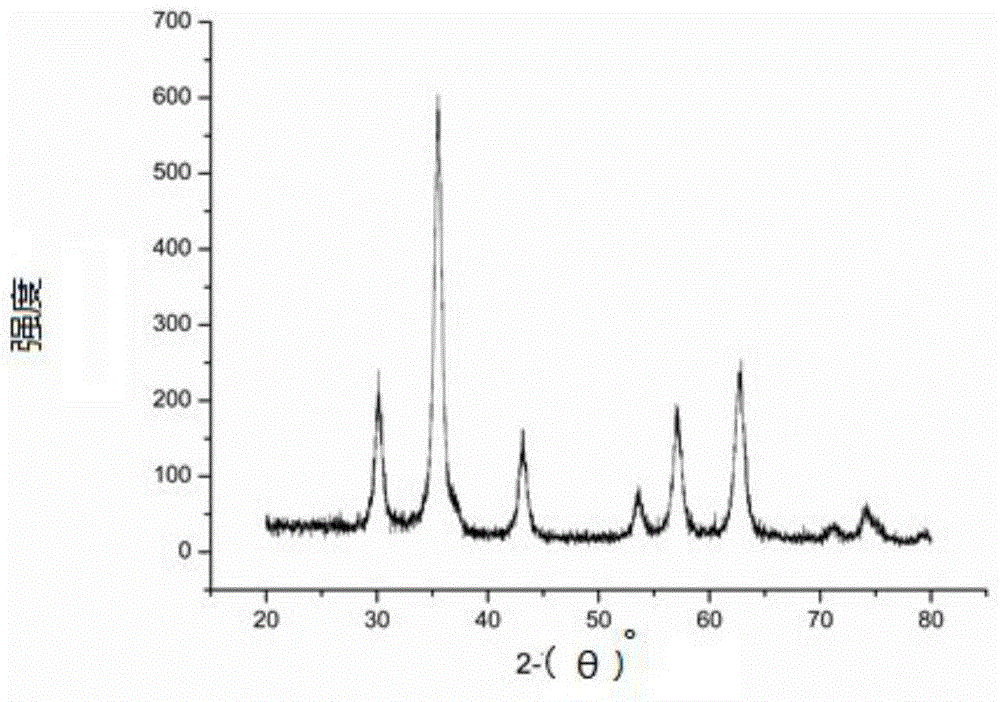

Preparation method of carbon fiber reinforced MoSi2-SiC ceramic matrix composite

ActiveCN105669231AImprove the bonding strength of the interfaceEliminate negative effects on mechanical propertiesCarbon compositesCarbon fibers

A preparation method of a carbon fiber reinforced MoSi2-SiC ceramic matrix composite comprises steps as follows: evenly mixing molybdenum disilicide powder, Si-Mo powder and Al2O3 powder to obtain mixed powder; cutting a porous C / C composite with the density of 0.4-0.8 g / cm<3> into round slices; placing the round slices into a graphite crucible, covering the round slices with the mixed powder, placing the round slices into a glucose aqueous solution for hydrothermal treatment after heat treatment, repeating hydrothermal treatment until the density reaches 1.2-1.5 g / cm<3>, and finally performing carbonization treatment to obtain the carbon fiber reinforced MoSi2-SiC ceramic matrix composite. The prepared C / C-MoSi2-SiC ceramic matrix composite has medium density, compact surface structure and good interface bonding, and the composite with high strength and good high-temperature oxidation and ablation resistance can be obtained at the low temperature.

Silicon low surface energy self-cleaning nano-coating for photovoltaic panel

InactiveCN109370423AImprove stabilityImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesPhotovoltaic solar energyDiluent

A silicon low surface energy self-cleaning nano-coating for a photovoltaic panel comprises 20-30 parts of nano-photocatalysts, 50-80 parts of first solvents, 0.5-1 part of polyvinylidene fluoride, 50-80 parts of second solvents, diluents, 100-120 parts of low surface energy resin and 20-30 parts of carbon powder. According to the method, firstly, the nano-photocatalysts and the first solvents aremixed, and then the polyvinylidene fluoride is added, so that the stability of nano-particles and the polyvinylidene fluoride is improved. Roughness is reduced, so that the antenna of silicon resin isimproved, so that the low surface energy of the silicon resin is further reduced. Finally, baking is performed, the stability of the coating can be further improved, and the corrosion resistance andthe mechanical damage resistance of the coating are improved. A photovoltaic solar super-hydrophobic self-cleaning coating prepared by the method has an outstanding self-cleaning function, has high stability, can resist pollution, mechanical damage and the like, and has high durability.

Owner:普施耐(苏州)工业技术有限公司

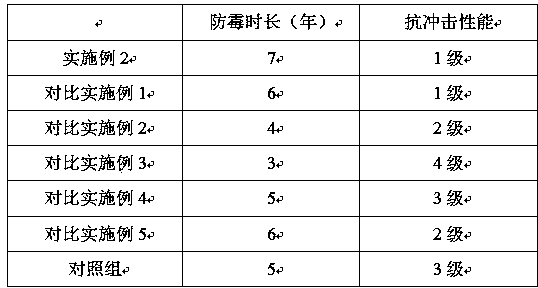

Method for preparing micro-capsule type natural preservatives

InactiveCN105724552ADense surface structureNot volatileClimate change adaptationNatural extract food ingredientsCarboxymethyl celluloseEugenol

The invention discloses a method for preparing micro-capsule type natural preservatives, and belongs to the field of preservatives. The method includes coating eugenol and litsea cubeba oil in micro-capsules by the aid of re-coagulation reaction on chitosan and sodium carboxymethyl celluloses; solidifying, filtering, drying and smashing the micro-capsules to obtain the micro-capsule type natural preservatives. The method has the advantages that micro-capsule wall materials are compact in surface structure, the eugenol and the litsea cubeba oil are non-volatile during heating, and accordingly the oxidation resistance and the stability can be improved; the micro-capsule type natural preservatives are high in activity, convenient to use and long in preservative effect duration, and raw materials for preparing the micro-capsule type natural preservatives are environmentally friendly and safe.

Owner:张静

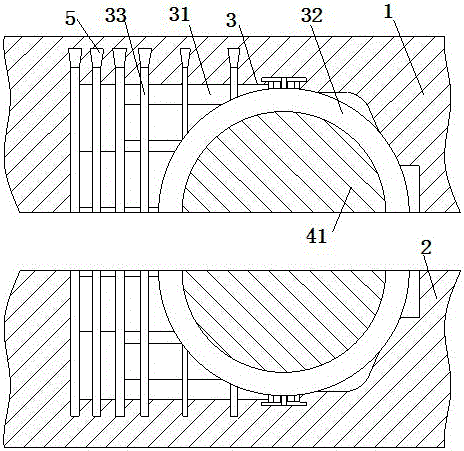

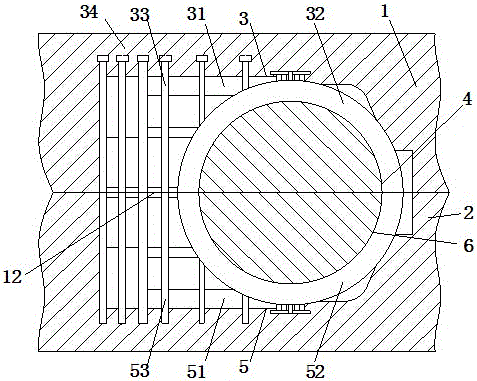

Low-cost and dead-head-free gate valve casting

ActiveCN106493308AThere will be no problem of damage and crackingDense surface structureFoundry mouldsFoundry coresSurface structureMaterials science

The invention discloses a low-cost and dead-head-free gate valve casting. The low-cost and dead-head-free gate valve casting comprises an upper sand box (1) and a lower sand box (2), wherein an upper gate valve mold cavity (3) is arranged in the upper sand box (1), and an upper mold core (4) is arranged in the upper gate valve mold cavity (3); a lower gate valve mold cavity (5) is arranged in the lower sand box (2), and a lower mold core (6) is arranged in the lower gate valve mold cavity (5); the upper gate valve mold cavity (3) comprises an upper gate board groove mold cavity (31) of which one end is provided with an upper pipe port mold cavity (32); an upper rib mold cavity (33) is arranged on the upper gate board groove mold cavity (31); an air exhausting sheet (34) is arranged on the upper rib mold cavity (33). The low-cost and dead-head-free gate valve casting has the characteristics that the surface structure of a gate valve product is compact, the qualification rate of the gate valve product is improved, the production cost is reduced, and the production efficiency is improved.

Owner:ZHEJIANG OUYEDA MACHINE MFG

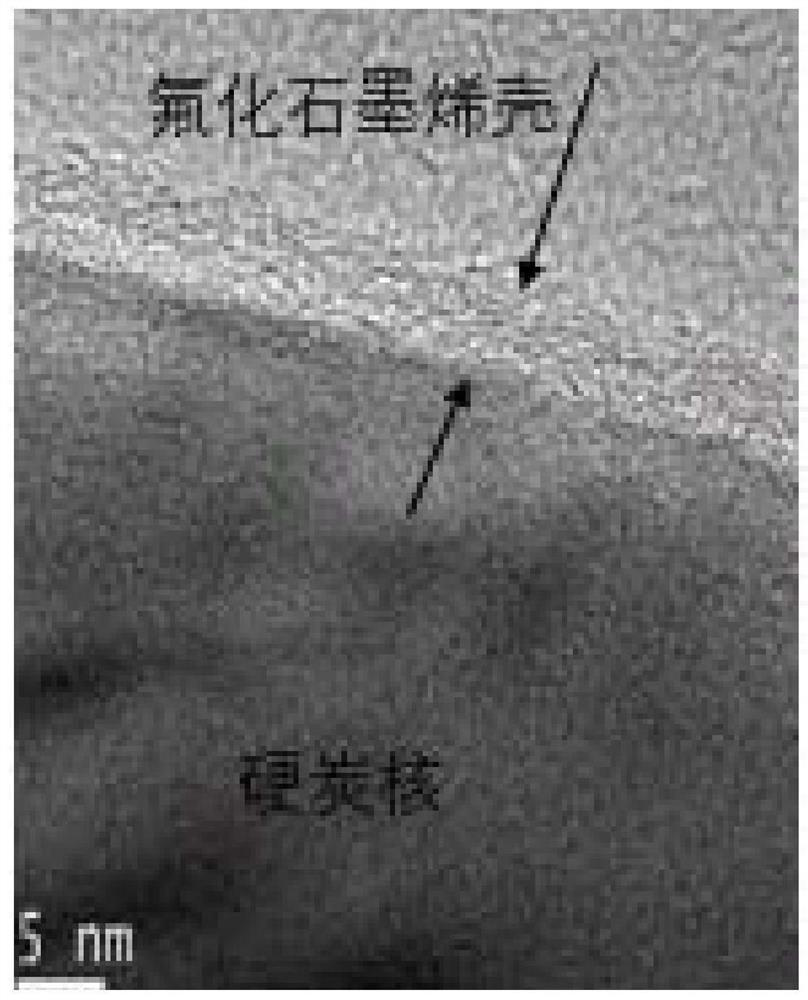

Negative electrode material for high-specific-power lithium ion battery as well as preparation and application thereof

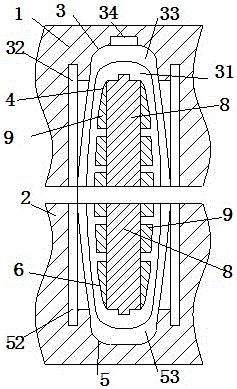

ActiveCN112993218AImproved magnification performanceIncrease spacingSecondary cellsNegative electrodesInterface impedanceInterfacial impedance

The invention provides a negative electrode material for a high-specific-power lithium ion battery as well as a preparation method and application of the negative electrode material. The negative electrode material for the battery is of a core-shell structure; the internal core has a hard carbon structure characteristic, and the external shell has a fluorinated graphene structure characteristic; the battery negative electrode material is a micron-scale particle formed by tightly combining the inner part and the outer part. A hard carbon structure is arranged inside, and a fluorinated graphene structure is arranged on the surface; and the internal interlayer spacing is large and the surface interlayer spacing is small. The rapid charge-discharge inside the electrode can be met, the compact solid electrolyte interface film outside the negative electrode can be achieved; and the solid electrolyte interface film formed by the participation of the fluorine atoms in the fluorinated graphene has the lithium ion transmission low interface impedance so as to achieve the high rate performance of the negative electrode material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

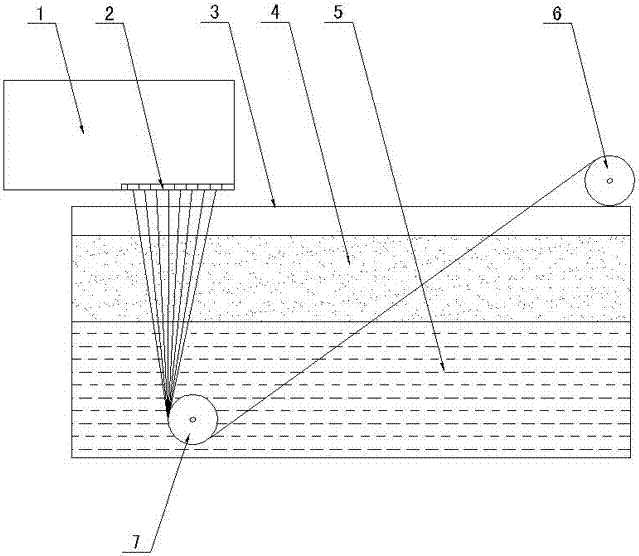

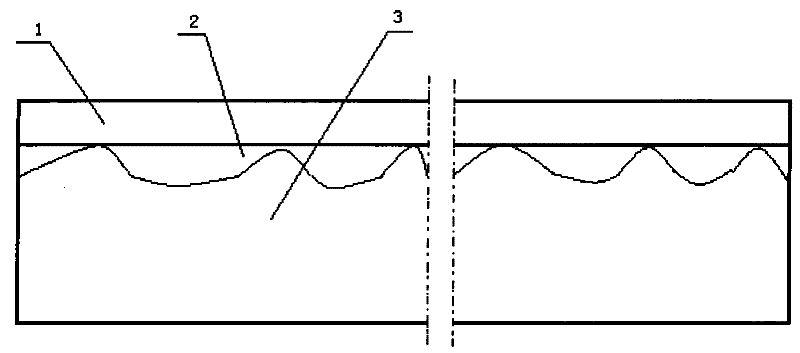

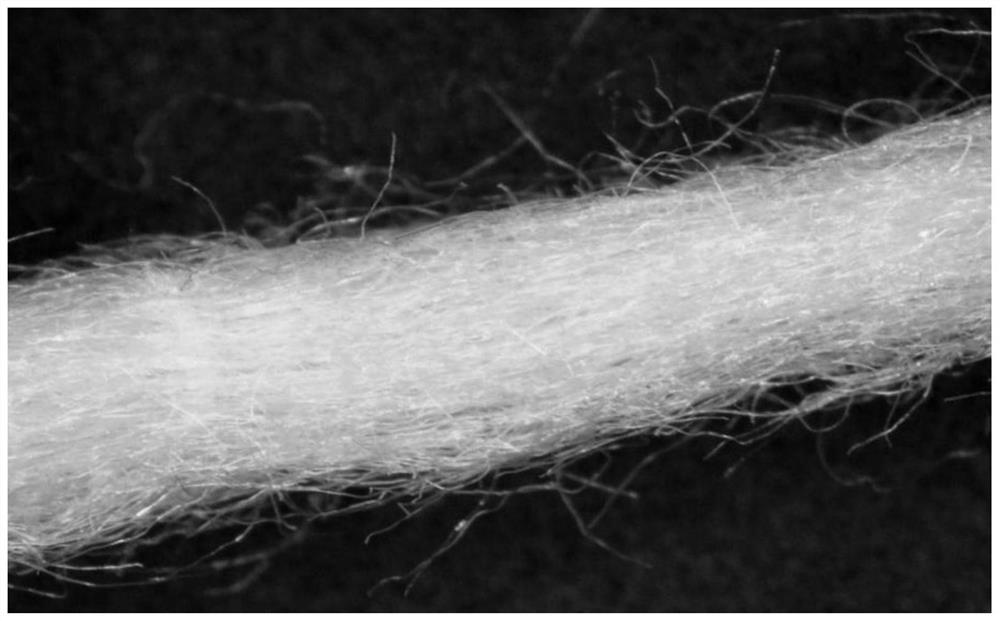

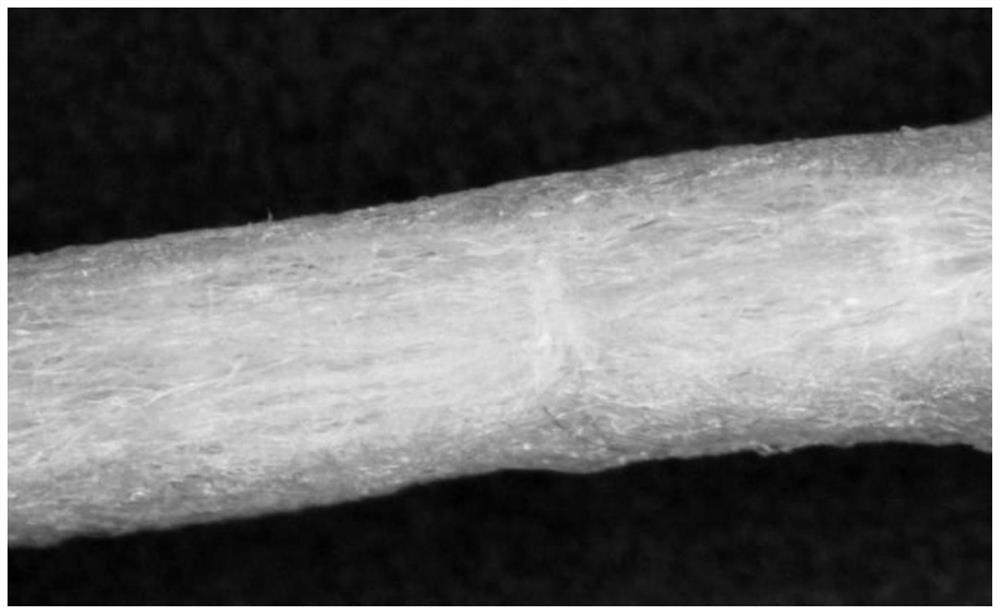

Method for solidifying and sizing gel-spun fibers in production process of ultra-high molecular weight polyethylene (UHMWPE) fibers

ActiveCN106978654AImprove performanceSimple processSynthetic polymer filament chemical after-treatmentParaffin oilsVolumetric Mass Density

The invention discloses a method for solidifying and sizing gel-spun fibers in a production process of ultra-high molecular weight polyethylene (UHMWPE) fibers. Cooling and sizing fluid in a cooling and sizing groove (3) is prepared from a lower phase separation accelerator (5) and an upper water seal (4), wherein the upper water seal (4) is used for cooling and sizing the gel-spun fibers; the lower phase separation accelerator (5) is used for accelerating phase separation so as to prompt paraffin oil on the surfaces of the gel-spun fibers to be separated out in an accelerating way, and forming porous and reticulated UHMWPE compact layers on the surfaces of the gel-spun fibers so as to increase the strength and initial modulus of the gel-spun fibers, enable the fineness consistency of finished products to be high and reduce strength fluctuation; the paraffin oil is separated out from the gel-spun fibers and is then dissolved in the phase separation accelerator so as to form lower mixed liquid, and the density of the lower mixed liquid is controlled to be greater than 1.1g / cm<3>; the gel-spun fibers are discharged out of the cooling and sizing groove (3), and the oil content of the gel-spun fibers is controlled to be within a range of 50-85%. After the structure is adopted, the method has the advantages of being simple in structure production process line, convenient in production and processing, high in strength and modulus, low in fineness dispersion, good in product performance consistency, and the like.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

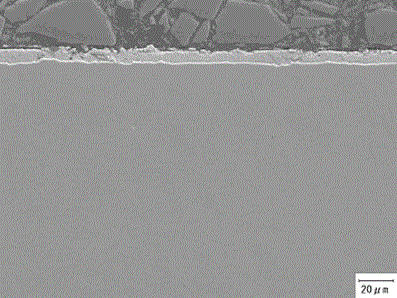

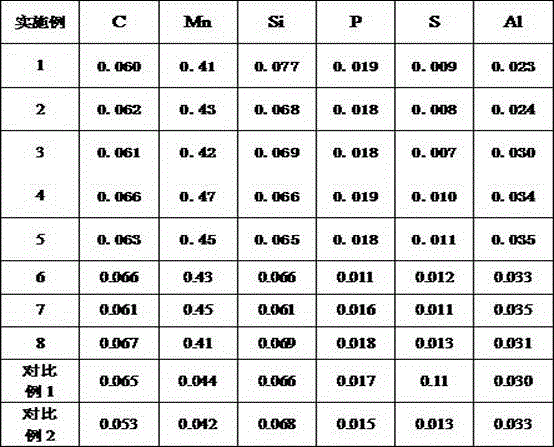

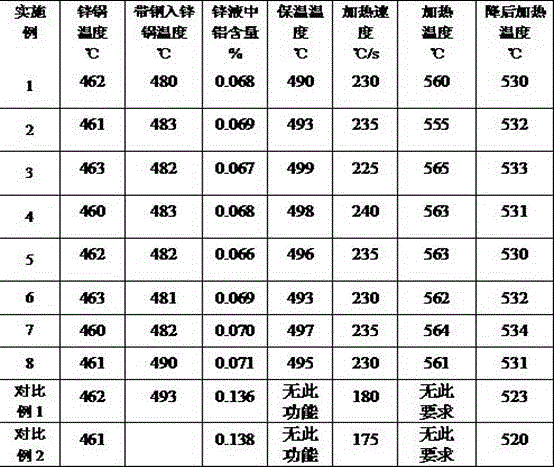

Iron-zinc plating layer steel plate with yield strength of 280 MPa grade and production method

ActiveCN106191663AGuaranteed use of mechanicsDense surface structureHot-dipping/immersion processesSheet steelRoom temperature

The invention discloses an iron-zinc plating layer steel plate with yield strength of 280 MPa grade. The iron-zinc plating layer steel plate comprises the following chemical components in percentage by weight (wt%): 0.06-0.07% of C, 0.065-0.08% of Si, 0.41-0.5% of Mn, P not more than 0.02%, S not more than 0.015%, and 0.015-0.05% of Als. A production method comprises the following production steps: the continuous hot zinc plating is performed for a cold-rolled steel plate; the steel plate is fed to a zinc-iron dispersion heating furnace under insulation measures; and the high-temperature zinc-iron dispersion treatment and the low-temperature zinc-iron dispersion treatment are performed for the zinc-plated steel plate in sequence. The steel plate is naturally cooled to the room temperature for future use. Under the precondition of guaranteeing the use mechanics of the steel plate, the surface of an alloying plating layer is compact in structure and free of obvious micro crack defects, the zinc-iron grains on the surface of the plating layer are fine and uniform in size distribution, the plating layer and a steel substrate are firm in bonding, and the plating layer is not easy to generate the pulverization and falling phenomenon in punch molding.

Owner:武汉钢铁有限公司

Method for pulse inversion electrodeposition of thick tungsten coating layer

ActiveCN105200471AUnaltered surface qualityNo change in surface roughnessCrazingConcentration polarization

The invention discloses a method for pulse inversion electrodeposition of a thick tungsten coating layer. The method comprises the steps of pretreatment, molten smelt preparation, pulse inversion electrodeposition and ultrasonic cleaning. The method improves the electrodeposition efficiency without changing the quality of the surface of the tungsten coating layer, and controls the roughness of the surface of the tungsten coating layer, so the surface of the produced thick tungsten coating layer has compact structure, good flatness and no cracks; and compared with a single phase pulse electrodeposition technology, a pulse inversion technology adopted in the invention allows the projecting part of the coating layer to be strong dissolved and leveled through highly-uneven anode current distribution caused by reverse current, so the cathode surface metal ion concentration rapidly rises, and the concentration polarization is reduced, thereby the surface of the tungsten coating layer produced in the invention is flattened, and the electrodeposition efficiency is increased. The thickness of the tungsten coating layer produced after pulse inversion electrodeposition for 10h reaches 220[mu]m, and the surface roughness is 6.673[mu]m; and the pulse inversion electrodeposition technology improves the electrodeposition rate without reducing the quality of the surface of the coating layer.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preliminary dip material for vacuum forming massive article

The invention relates to a high polymer material field, in particular to a prepreg compound used in a vacuum forming massive article, which comprises reinforcing fiber, matrix resin and fiber base-material and is characterized in that the reinforcing fiber is retted by the matrix resin to form the reinforcing fiber at one side which is completely soaked by the matrix resin and the prepreg compound at the other side which is not completely soaked by the matrix resin; wherein for one side of the reinforcing fiber which is not completely by the matrix resin, the soakage rate of the matrix resin is more than or equal to 20% and is less than or equal to 95%.

Owner:WEIHAI GUANGWEI COMPOSITES

Nano-column array heterojunction and preparation method thereof

ActiveCN109950138AReduce pollutionDense surface structureSemiconductor/solid-state device manufacturingHeterojunctionNanostructure

The present invention relates to the technical field of nanostructures and particularly relates to a nano-column array heterojunction and a preparation method thereof. The invention provides a preparation method of the nano-column array heterojunction, the method comprises the steps of opening a Bi2Te3 evaporation source to evaporate Bi2Te3 on a substrate, then turning off the Bi2Te3 evaporation source, opening a Sb2Te3 evaporation source to perform vacuum evaporation, and collecting a product on the substrate. The invention provides the nano-column array heterojunction and the preparation method thereof, the technical defect that the prior art lacks a one-dimensional nano-column array heterojunction and the vacuum thermal evaporation technology for preparing the nano-column array heterojunction is solved.

Owner:GUANGDONG UNIV OF TECH

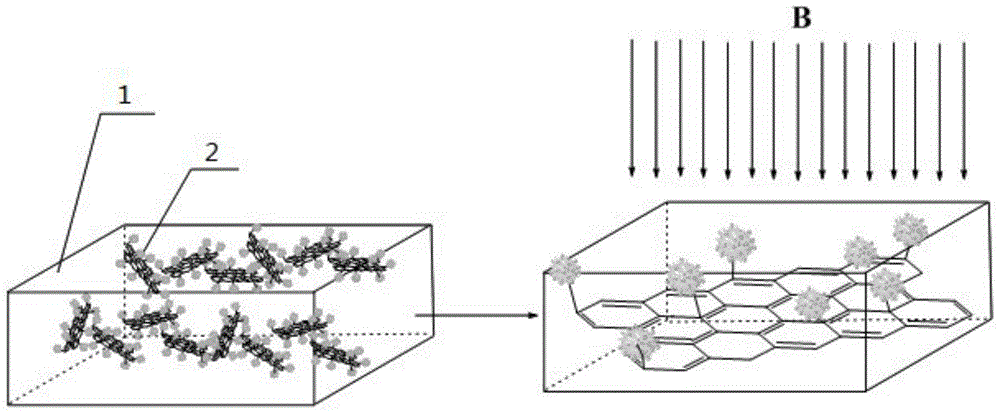

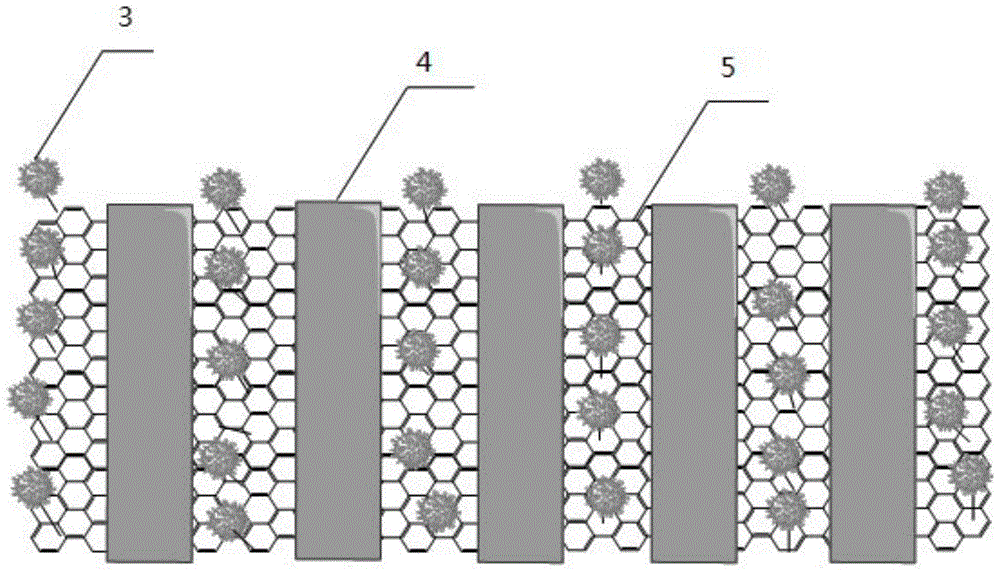

Polymers containing aligned magnetic graphene oxide sheets and methods for their preparation

The invention discloses a polymer containing oriented-arrangement magnetic graphene oxide sheets and a preparation method thereof. The invention is characterized in that the polymer containing oriented-arrangement magnetic graphene oxide sheets is composed of a polymer and oriented-arrangement graft magnetically-functionalized graphene oxide sheets in the polymer. The polymer is applicable to many fields, such as packaging film preparation, various bottle containers / can preparation and the like. The polymer greatly enhances the barrier property for gas, liquid and the like, solves the problem of poor barrier property of the polymer film or container in the prior art, has the high strength of the graphene oxide, can obtain high width / thickness ratio, high specific area and compact surface structure, and has the magnetism of nano Fe3O4 particles, thereby implementing functionalization.

Owner:SHANGHAI UNIV OF ENG SCI

Superconducting graphite electrode nano antioxidant and preparation method thereof

ActiveCN111892833AReduce lossExtended service lifeElectric discharge heatingCoatingsPolyvinyl alcoholDiboride

The invention belongs to the technical field of graphite electrodes, and provides a superconducting graphite electrode nano antioxidant, which is prepared from the following components by weight: 80-100 parts of water, 20-40 parts of ceramic powder, 20-25 parts of graphene, 10-25 parts of polyethylene glycol, 6-12 parts of a stabilizer, 5-10 parts of an antioxidant aid and 10-15 parts of polyvinylalcohol. The antioxidant aid comprises calcium boride, vanadium diboride and sodium dihydrogen phosphate in a mass ratio of 2:(0.8-1.2):1. The preparation method includes: grinding the weighed ceramic powder to a particle size of 50-100nm, and adding polyethylene glycol to obtain ceramic powder slurry; adding the ceramic powder slurry and graphene into a solvent to obtain a premixed solution; andsequentially adding the antioxidant aid, the stabilizer and polyvinyl alcohol into the premixed solution, and performing mixing to obtain the superconducting graphite electrode nano antioxidant. By means of the technical scheme, the problem that in the prior art, the oxidation resistance of a graphite electrode nano antioxidant is not good enough is solved.

Owner:北京中科原创节能环保科技有限公司

Impact-resistant chemical adhesive wear-resistant coating with flame retardant function

InactiveCN109370387ACompact structureImprove stabilityFireproof paintsAnti-corrosive paintsSolventPolyvinylidene fluoride

An impact-resistant chemical adhesive wear-resistant coating with a flame retardant function consists of component A and curing agent component B. The component A includes 10-40 parts of nano-silica aerogel, 10-40 parts of nano-alumina solution, 5-10 parts of aramid pulp, 40-60 parts of bisphenol A epoxy resin, 300-400 parts of silicon carbide and 1-5 parts of a dispersant. The curing agent component B includes 5-15 parts of polyamine, 1-5 parts of polythiol, 0-5 parts of silane coupling agent and 0.5-5 parts of silica. During use, the ratio of the component A and the curing agent component Bis 10:1. The method includes firstly mixing a nano photocatalyst with a first solvent and then adding polyvinylidene fluoride to improve the stability of nanoparticles and polyvinylidene fluoride.

Owner:普施耐(苏州)工业技术有限公司

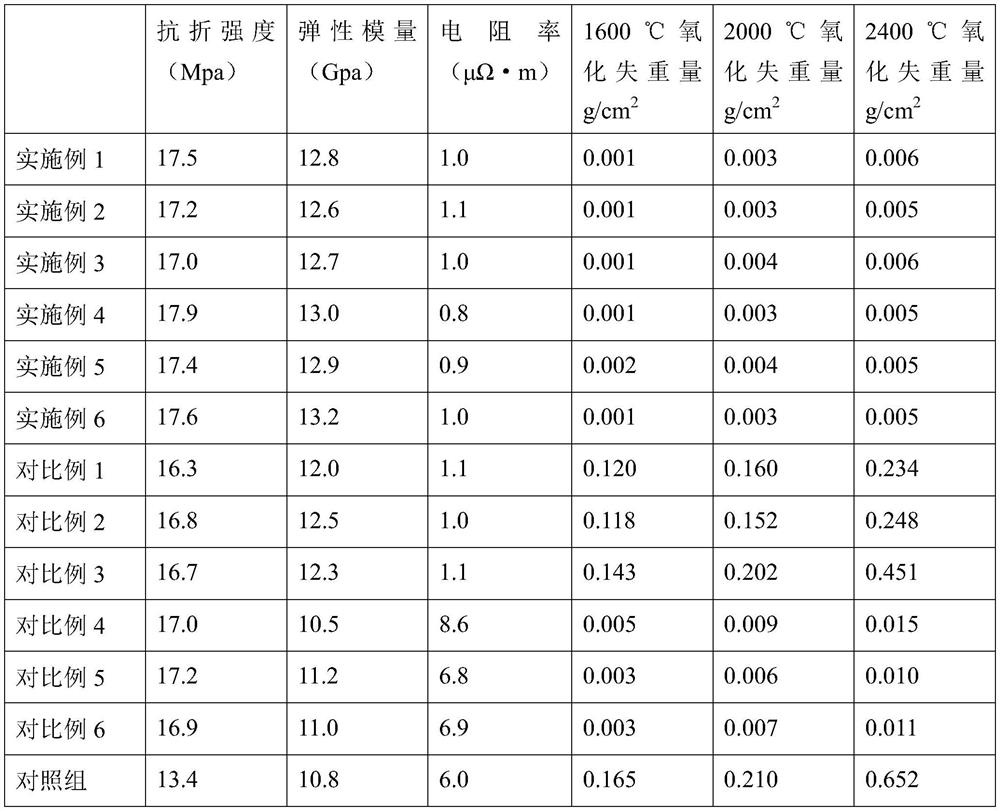

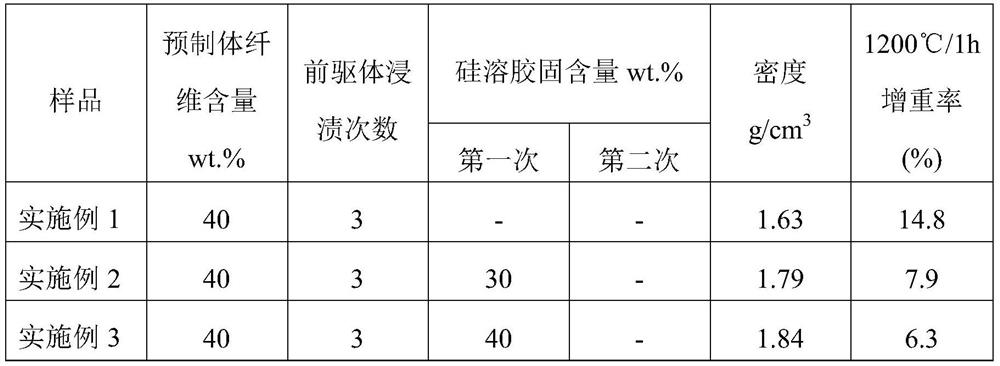

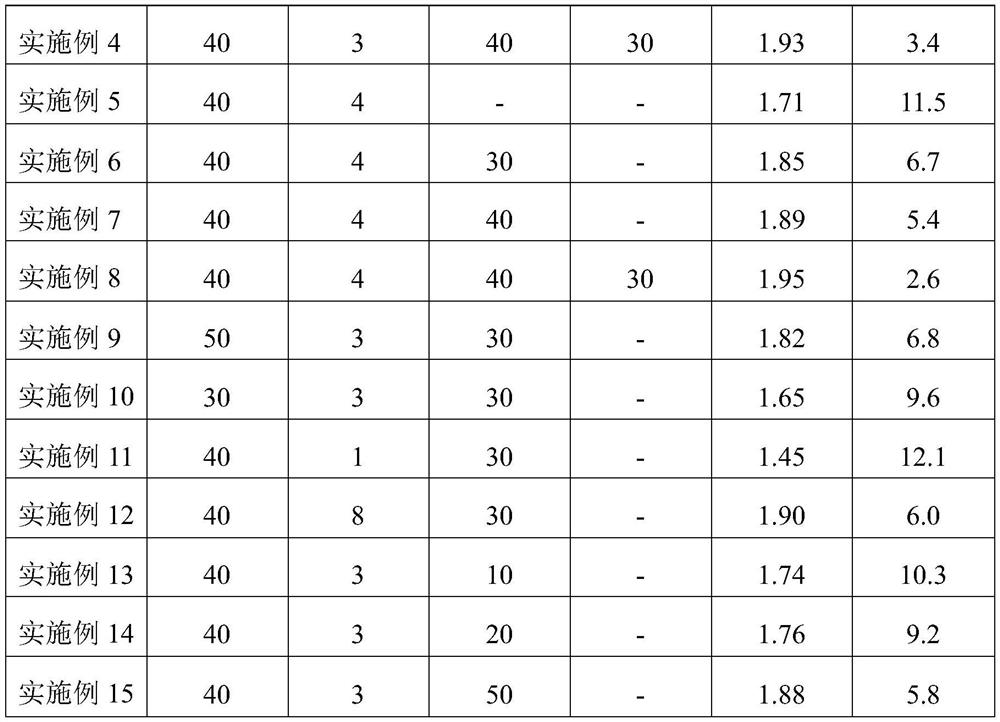

Antioxidant fiber-reinforced silicon-boron-nitrogen composite material and preparation method and application thereof

InactiveCN113831145AFully crosslinkedGood comprehensive effect of wave penetration/load bearing/heat insulationOxidation resistantHeat treated

The invention relates to the technical field of composite materials, in particular to an antioxidant fiber-reinforced silicon-boron-nitrogen composite material and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing a prefabricated body from silicon nitride fibers; (2) impregnating the preform obtained in the step (1) with a precursor, then carrying out a cross-linking curing reaction, and finally cracking; (3) repeating the step (2) for at least three times to obtain a green body; and (4) carrying out at least one silica sol dipping and gelation drying process on the green body obtained in the step (3), and further carrying out heat treatment to obtain the antioxidant fiber-reinforced silicon-boron-nitrogen composite material. The density of the prepared silicon-boron-nitrogen composite material is 1.79-1.95 g / cm < 3 >, the weight gain rate is 2.6-7.9% after oxidation treatment is carried out for 1 h in the air atmosphere at the temperature of 1200 DEG C, and the silicon-boron-nitrogen composite material has good compactness and high temperature resistance and oxidation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

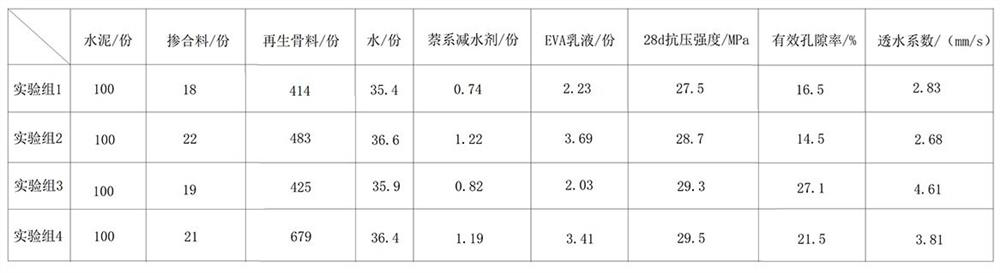

Method for preparing recycled aggregate pervious concrete by using aqueous capillary crystalline solution

The invention discloses a method for preparing recycled aggregate pervious concrete by using an aqueous capillary crystalline solution, which comprises the following steps: soaking 414-683 parts by mass of air-dried recycled aggregate in an aqueous capillary crystalline solution, conducting filtering, taking out the treated aggregate, and conducting drying; carrying out carbonization treatment on the dried recycled aggregate; and mixing and stirring the carbonized recycled aggregate with 35.4 to 36.6 parts by mass of water, 18 to 22 parts by mass of an admixture, 100 parts by mass of cement, 0.74 to 1.22 parts by mass of a water reducing agent and 2.23 to 3.69 parts by mass of an EVA (Ethylene Vinyl Acetate) emulsion, so as to obtain the recycled aggregate pervious concrete. The recycled aggregate pervious concrete has the advantages that the recycled aggregate pervious concrete subjected to double aggregate reinforcement and EVA modification is light in weight, green, environment-friendly and excellent in performance in all aspects.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

Preparation method of polyvinyl alcohol wrapping film

The invention discloses a preparation method of a polyvinyl alcohol wrapping film, and belongs to the field of packaging materials. The preparation method includes the steps: heating and melting rosinester, adding emulsifying agents, pouring mixture into water to stir the mixture, performing homogeneity on the mixture by a high-pressure homogeneous pump, and filtering the mixture to obtain filterliquid for standby application; mixing silane coupling agents, titanate coupling agents and acetone, adding titanium dioxide, and performing stirring, ultrasonic treatment, drying, grinding and sieving; grinding green tea leaves, placing the grinded green tea leaves into a polytetrafluoroethylene digestion tank, adding distilled water, placing the digestion tank into a microwave digestion instrument to perform extraction, mixing, soaking and filtering sieved objects and extraction liquid to obtain filter residue, and drying the filter residues to dried objects; uniformly stirring polyvinyl alcohol, distilled water, glutaraldehyde and sieved materials to obtain mixture; extruding the mixture by a double-screw extruder at high temperature, conveying the extruded mixture into a tape castingmachine to cast into a film, and packing the film to obtain the polyvinyl alcohol wrapping film.

Owner:上海十条实业有限公司

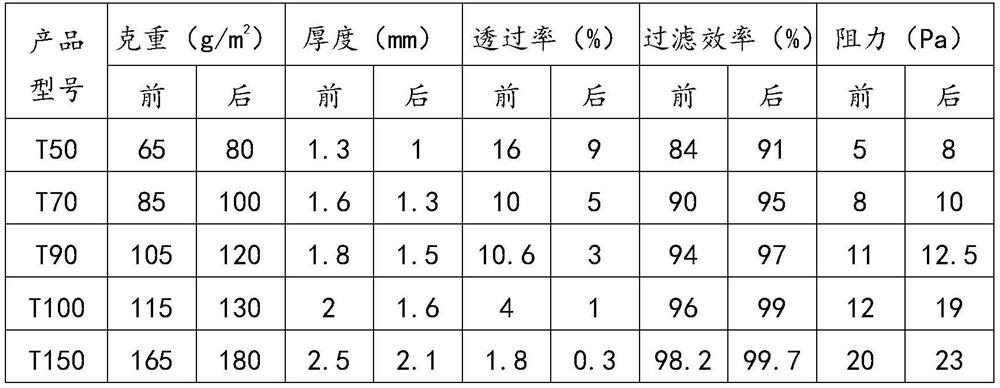

Electrostatic filter cotton with improved performance and preparation method and application thereof

ActiveCN112252047AImprove performanceDense surface structureDispersed particle filtrationTextiles and paperAir filterPhysical chemistry

The invention discloses electrostatic filter cotton with improved performance and a preparation method and application thereof, and belongs to the technical field of air filter materials of heating ventilation and air conditioning. The preparation method comprises the following steps: preparing unwound electrostatic filter cotton; preparing hot pressed electrostatic filter cotton; preparing the electrostatic filter cotton of which one side is coated with hot melt adhesive wires; preparing the electrostatic filter cotton coated with the hot melt adhesive wires on two sides or the electrostaticfilter cotton coated with multiple layers of hot melt adhesive wires on one side; and packaging finished products. The invention further discloses the electrostatic filter cotton with the improved performance and the application of the electrostatic filter cotton. The electrostatic filter cotton with the improved performance has the following advantages that the electrostatic filter cotton has a compact surface structure, large-particle dust can be effectively prevented from entering the filter cotton and quickly formed into a filter cake on the surface and thus is convenient to remove, the service life can be effectively prolonged; the filtering efficiency is effectively improved on the basis of approximate gram weight; and under the same filtering efficiency, the filter material has lower gram weight, and thus the material cost is greatly saved.

Owner:杨道光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com