Hollow micro-ball containing phosphazene and preparing method

A hollow microsphere and phosphazene technology, which is applied in the field of polymer microspheres and their preparation, can solve the problems of complicated preparation method of hollow microspheres and limited research, and is easy to realize and good biologically possible to meet the requirements of experimental equipment and experimental conditions. The effect of degradability and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

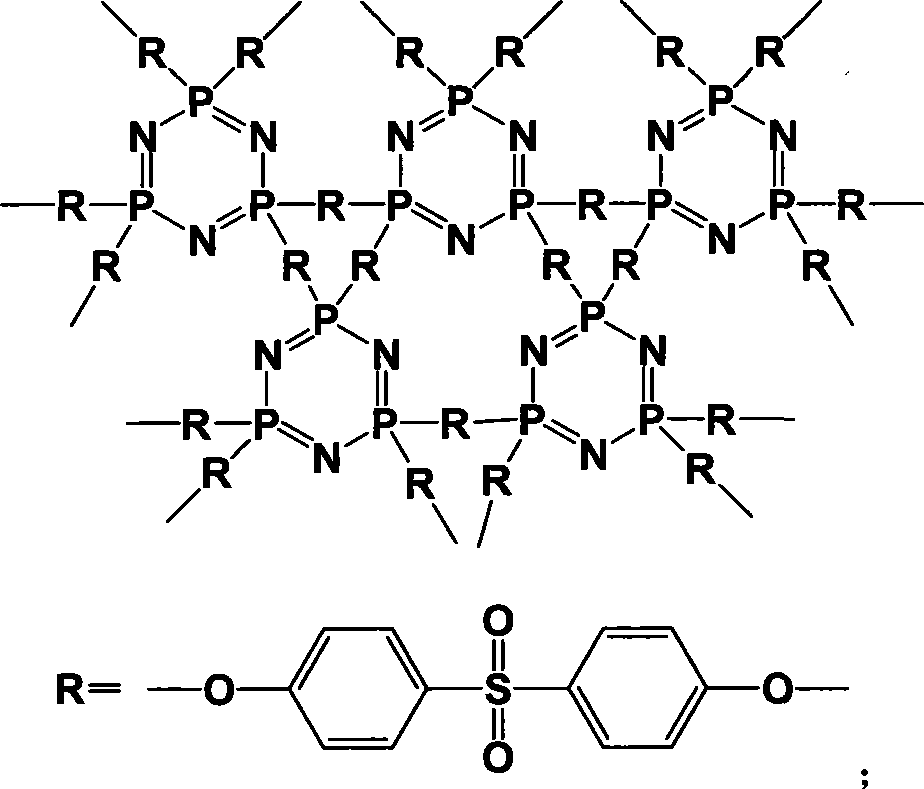

[0022] In a 500 ml flask, 0.5 g (1.44 mmol) of hexachlorocyclotriphosphazene and 1.08 g (4.32 mmol) of 4,4'-dihydroxydiphenyl sulfone were dissolved in 250 ml of acetone, and then 0.87 g ( 8.64 mmol) acid-binding agent triethylamine was added to the above reaction system; under the action of 100w ultrasound, reacted at room temperature for 2 hours. After the reaction, the white powder was obtained by centrifugation; washed three times with acetone and three times with deionized water, then placed in an aqueous solution with a pH value of 7.0, stirred for 72 hours at 80°C for controlled hydrolysis, and then centrifuged After separation and drying, 0.82 g of hollow microspheres containing phosphazene were obtained.

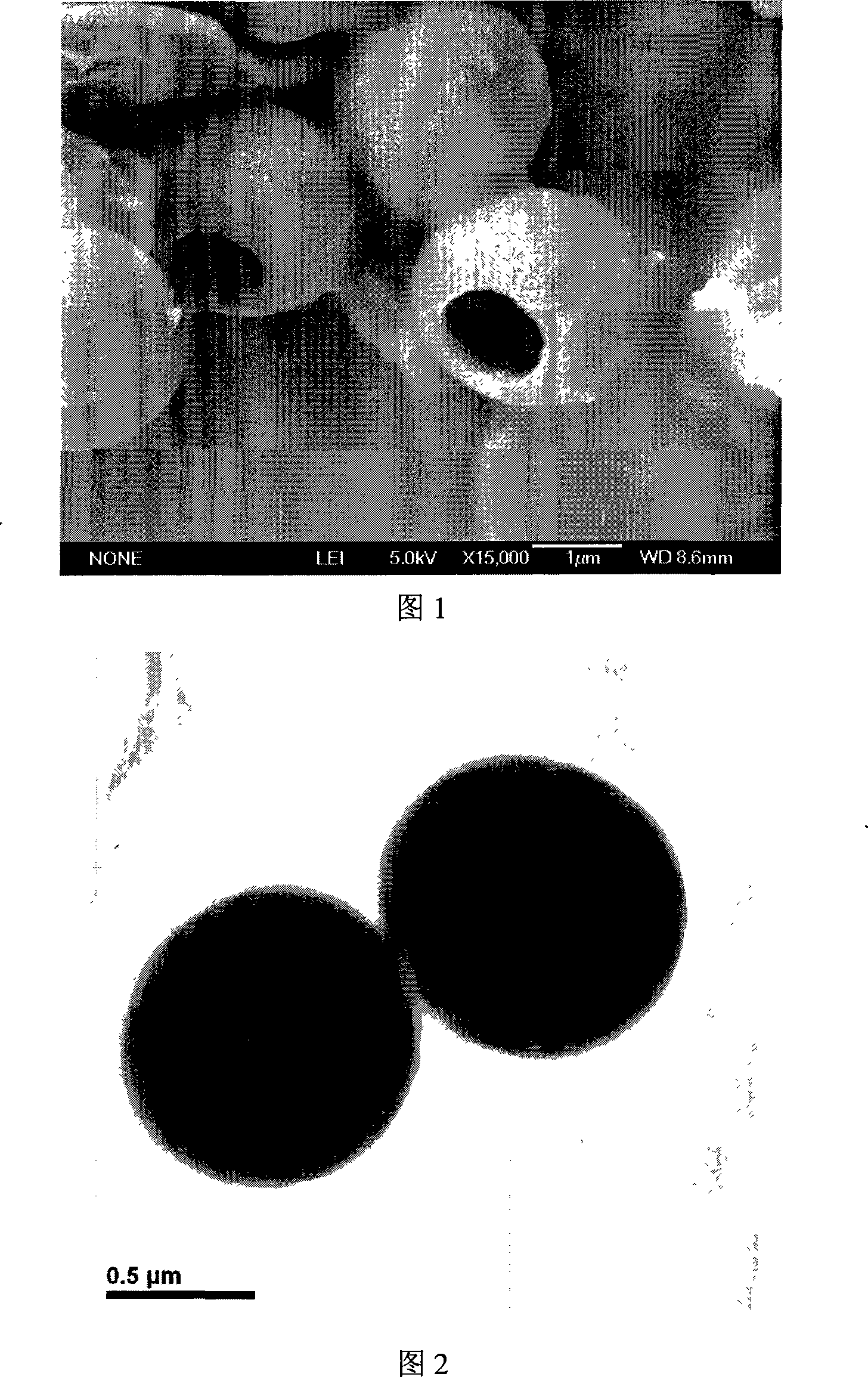

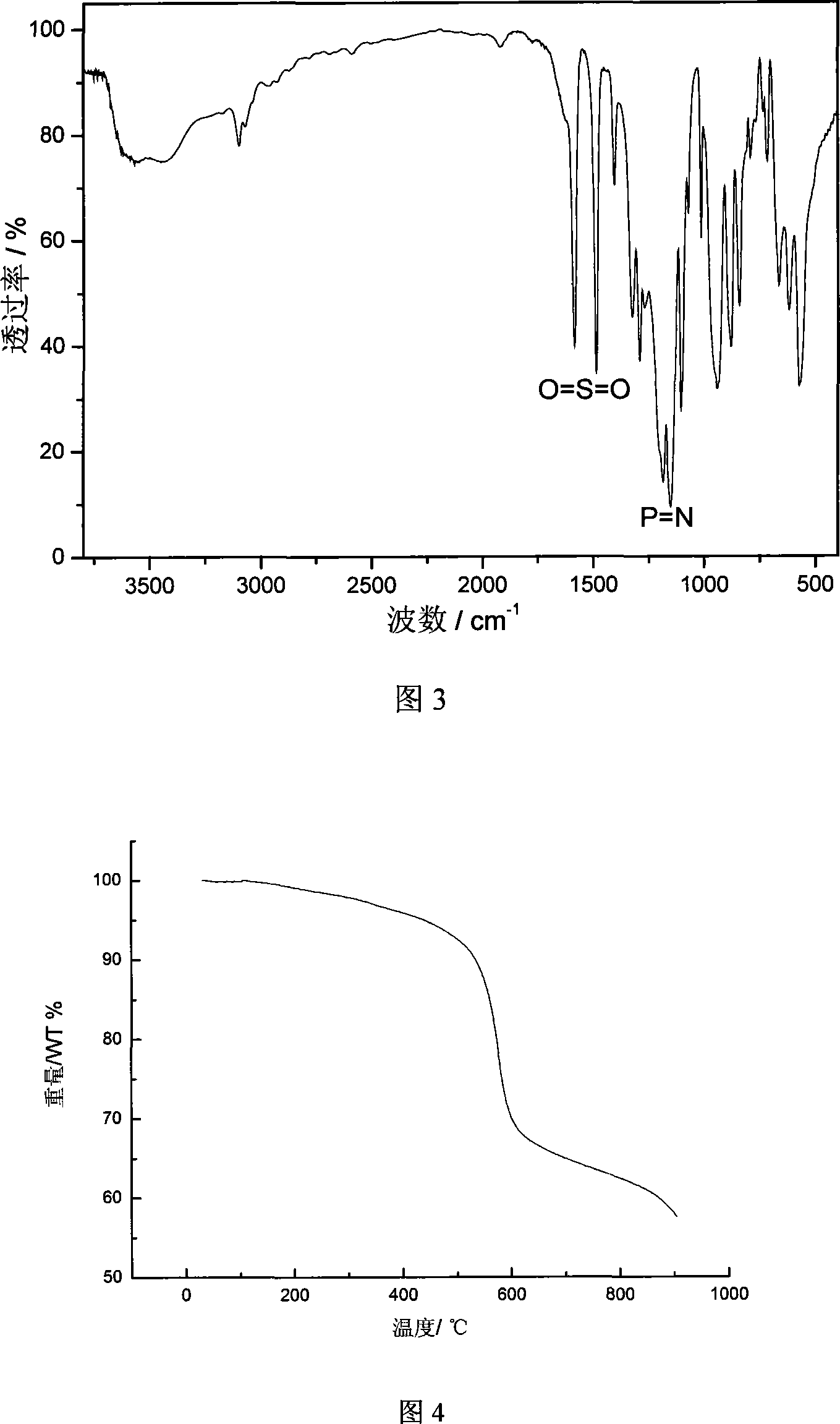

[0023] Fig. 1 is the field emission scanning electron micrograph of the phosphazene-containing hollow microspheres obtained in Example 1, and Fig. 2 is the transmission electron micrograph of the phosphazene-containing hollow microspheres obtained in Example 1, and ...

Embodiment 2

[0027] In a 500 ml flask, 0.5 g (1.44 mmol) of hexachlorocyclotriphosphazene and 1.08 g (4.32 mmol) of 4,4'-dihydroxydiphenyl sulfone were dissolved in 250 ml of acetone, and then 0.87 g ( 8.64 mmol) acid-binding agent triethylamine was added to the above reaction system; under the action of magnetic stirring, the reaction was carried out at room temperature for 5 hours. After the reaction, the white powder was obtained by centrifugation; washed three times with acetone and three times with deionized water, then placed in an aqueous solution with a pH value of 7.0, stirred for 72 hours at 80°C for controlled hydrolysis, and then centrifuged After separation and drying, 0.86 g of hollow microspheres containing phosphazene can be obtained by centrifugation. Electron micrographs show that the diameter of the microsphere is 1.0-1.2 microns, and the diameter of the inner hollow is 250-350 nanometers. Spectrum analysis shows that its structure is the cross-linked condensation struc...

Embodiment 3

[0029] The equipment and preparation process described in Example 1 were adopted, except that the reaction temperature was carried out at the reflux temperature of acetone to obtain 0.85 g of hollow microspheres. The analysis of the experimental results shows that the diameter of the microsphere is 1.3-1.5 microns, and the inner hollow diameter is 400-450 nanometers. The spectrum analysis shows that its structure is a cross-linking of hexachlorocyclotriphosphazene and 4,4'-dihydroxydiphenylsulfone condensation structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com