Preparation method and application of plasma activated chitosan micropheres

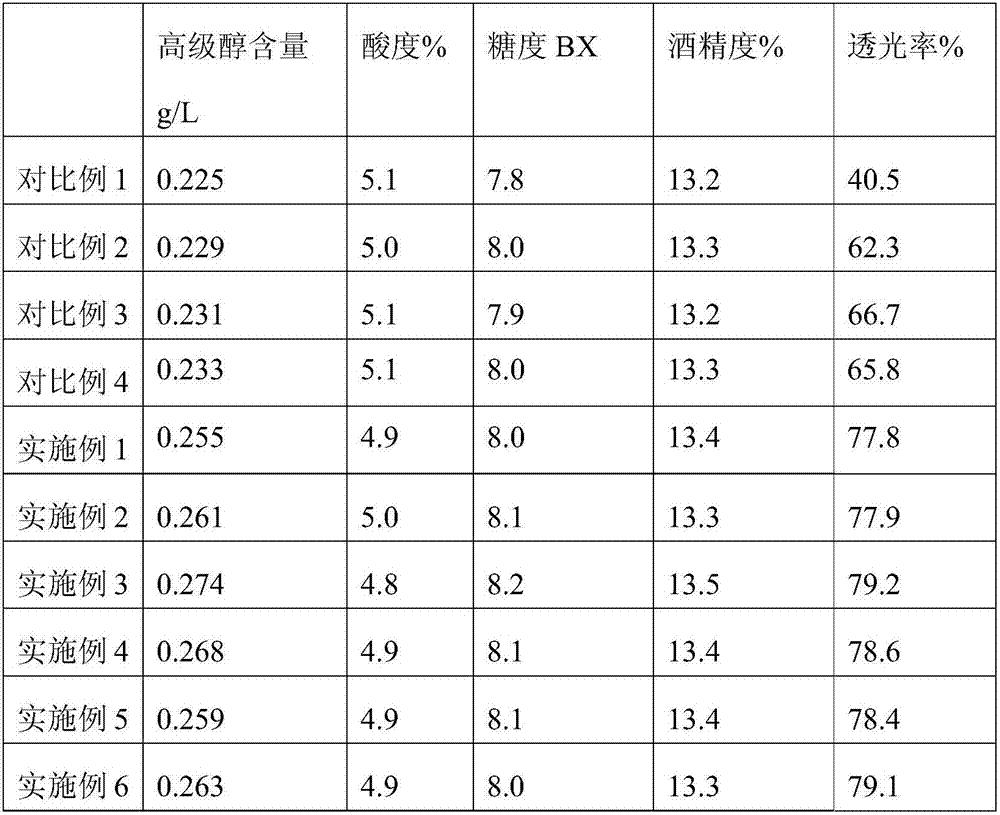

A technology of chitosan microspheres and plasma activation, which is applied in the preparation of alcoholic beverages, chemical instruments and methods, inorganic chemistry, etc., can solve the problems that the effect of organic acids and solid substances is not obvious, and achieve a significant adsorption effect and improve Light transmittance, the effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preliminary preparation:

[0035]Preparation of active bentonite: in parts by weight, mix 20 parts of bentonite, 2 parts of medium calcium hydroxide and 50 parts of ammonium chloride solution with a mass fraction of 5%, and after infrared treatment, filter and wash the filter residue for 2 times , adding 100 parts of deionized water, freezing at -17°C for 12h, then thawing, drying, and finally roasting in a muffle furnace at 160°C for 2h to obtain activated bentonite.

[0036] The substance prepared above was used in the following preparation method.

[0037] 2. a preparation method of plasma-activated chitosan microspheres, comprising the following steps:

[0038] (1) Preparation of inner core material: in parts by weight, 100 parts of activated bentonite, 5 parts of 2% acetic acid solution, 15 parts of sodium carbonate, 2 parts of polyethylene glycol 200 and 200 parts of deionized water are put into the reactor In the process, raise the temperature to 75°C, stir ...

Embodiment 2

[0042] 1. Preliminary preparation:

[0043] Preparation of active bentonite: in parts by weight, mix 25 parts of bentonite, 2.5 parts of medium magnesium hydroxide and 52 parts of ammonium chloride solution with a mass fraction of 7%, and filter and wash the filter residue twice after infrared treatment , adding 100 parts of deionized water, freezing at -17°C for 15 hours, then thawing, drying, and finally roasting in a muffle furnace at 185°C for 2.5 hours to obtain activated bentonite.

[0044] The substance prepared above was used in the following preparation method.

[0045] 2. a preparation method of plasma-activated chitosan microspheres, comprising the following steps:

[0046] (1) Preparation of inner core material: in parts by weight, 100 parts of activated bentonite, 10 parts of 2.5% acetic acid solution, 16 parts of sodium carbonate, 2 parts of polyacrylamide and 220 parts of deionized water are put into the reactor, Raise the temperature to 76°C, stir for 17min a...

Embodiment 3

[0050] 1. Preliminary preparation:

[0051] The preparation of activated bentonite: in parts by weight, 29 parts of bentonite, 3 parts of calcium hydroxide and 54 parts of ammonium chloride solution with a mass fraction of 10% were mixed uniformly, after infrared treatment, filtered, and after washing the filter residue for 2 times, Add 100 parts of deionized water, freeze at -17°C for 17 hours, thaw and dry, and finally roast in a muffle furnace at 200°C for 3 hours to obtain activated bentonite.

[0052] The substance prepared above was used in the following preparation method.

[0053] 2. a preparation method of plasma-activated chitosan microspheres, comprising the following steps:

[0054] (1) Preparation of inner core material: in parts by weight, 100 parts of active bentonite, 9 parts of 4% acetic acid solution, 18 parts of sodium carbonate, 2 parts of sodium lauryl sulfate and 215 parts of deionized water are put into reaction In the container, raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com