Patents

Literature

229results about How to "Reduce acid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

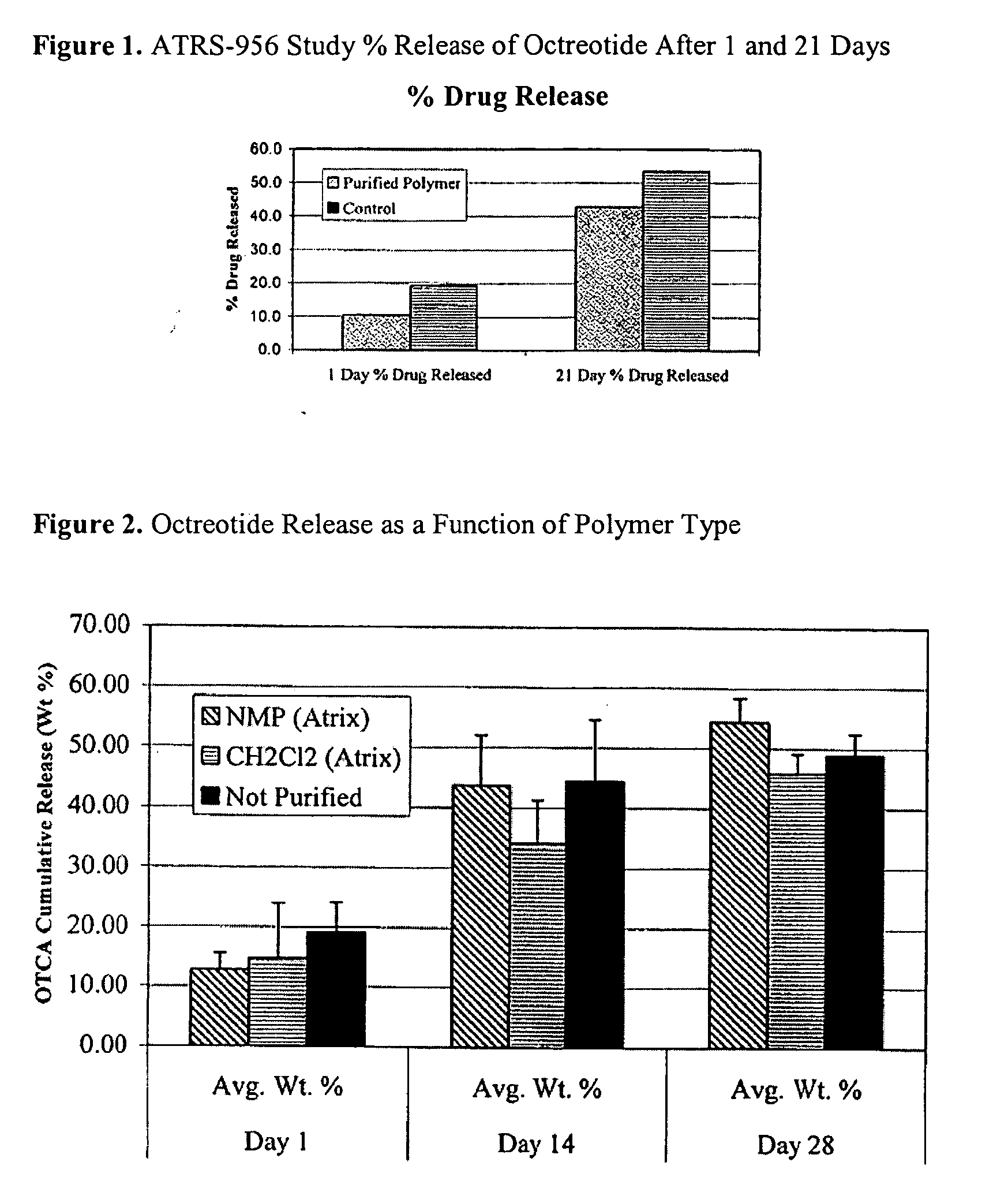

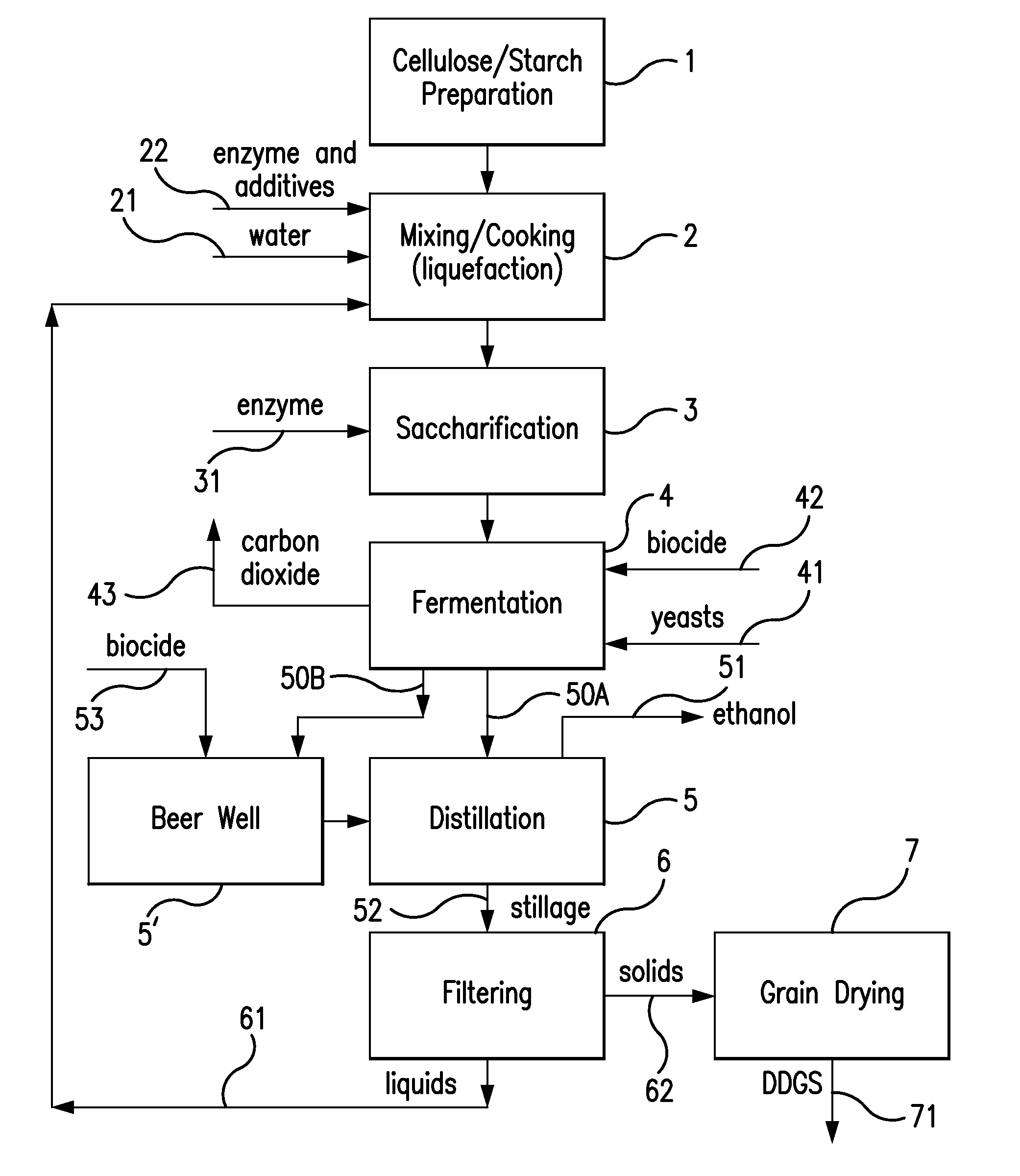

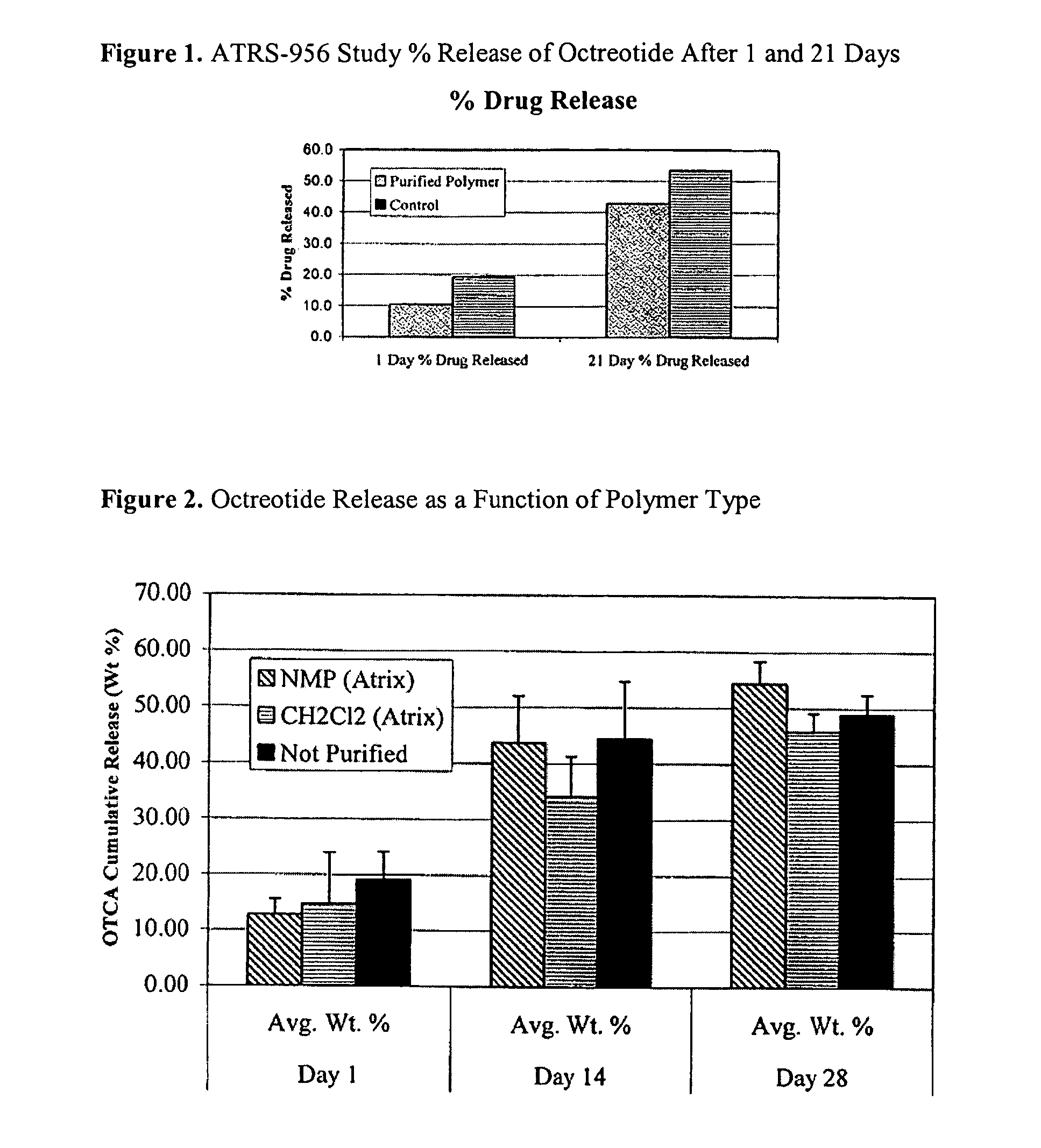

Low burst polymers and methods to produce polymer

ActiveUS20100292195A1Increase release rateReduced initial burstAntibacterial agentsBiocideDrug biological activityCopolymer

A PLG copolymer material, termed a PLG(p) copolymer material, adapted for use in a controlled release formulation for a bioactive material is provided, wherein the formulation exhibits a reduced “initial burst” effect when introduced into the tissue of a patient in need thereof. A method of preparation of the PLG copolymer material is also provided, as are methods of use.

Owner:TOLMAR INC

Dehydrogenation catalyst and preparation method and application thereof

ActiveCN103769156AReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsManganeseDehydrogenation

The invention discloses a dehydrogenation catalyst and a preparation method and application thereof. The dehydrogenation catalyst uses ammonia processed alumina as a carrier, chrome as an active component, and one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc as an additive, the additive is loaded onto the carrier by a co-impregnation method, and taking oxide weight content in the final catalyst as a reference, the catalyst comprises 2%-6% of chromium oxide, and 0.1-5% of the additive. The preparation method of the hydrocarbon dehydrogenation catalyst comprises the following processes: using ammonia to preprocess an alumina carrier, using the co-impregnation method to load one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc, and loading the active component chrome. The dehydrogenation catalyst can be used in dehydrogenation of propane for preparation of propylene. The low carbon alkane dehydrogenation catalyst prepared by the preparation method has the advantages of low active component chromium oxide content, good propylene selectivity, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

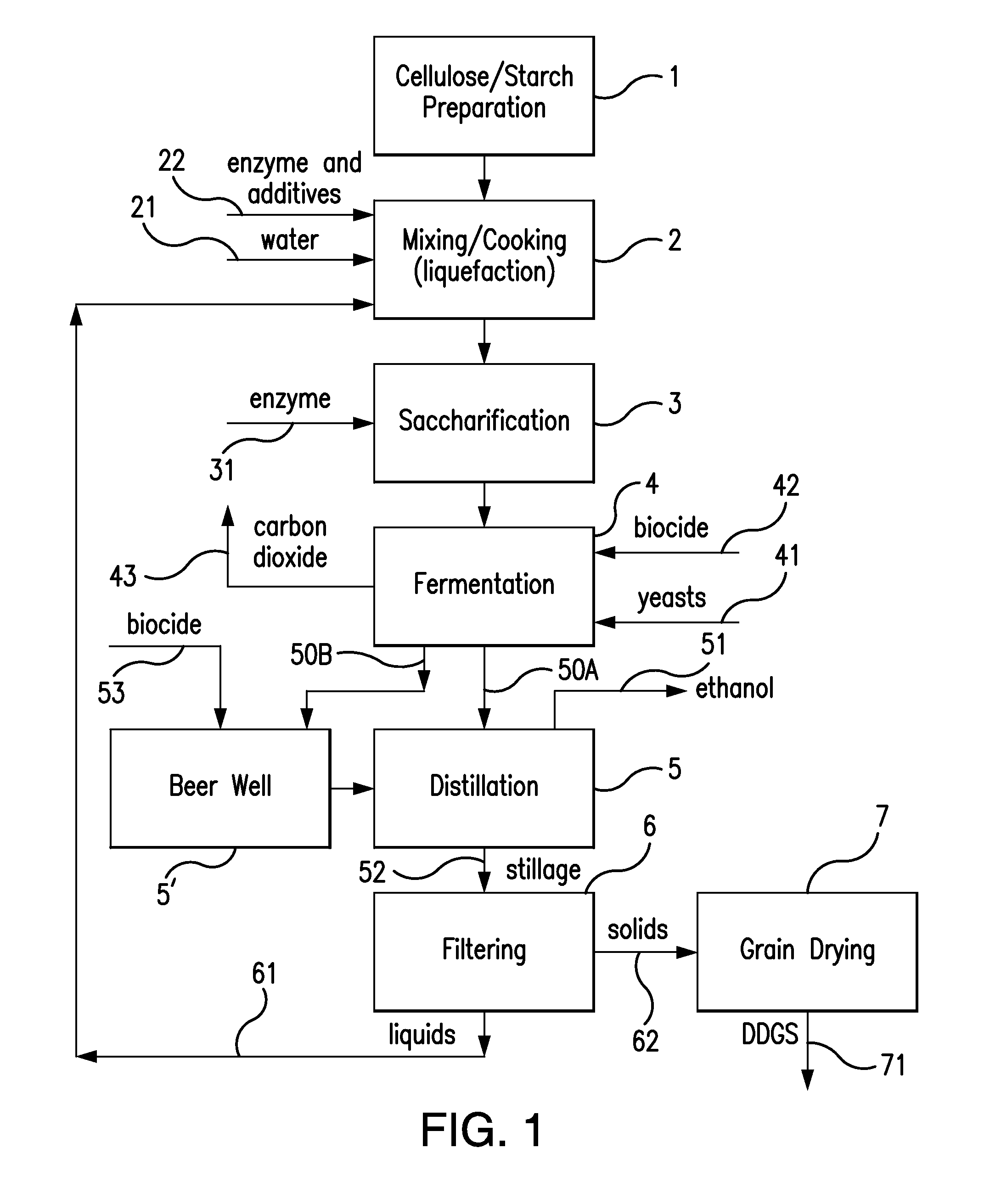

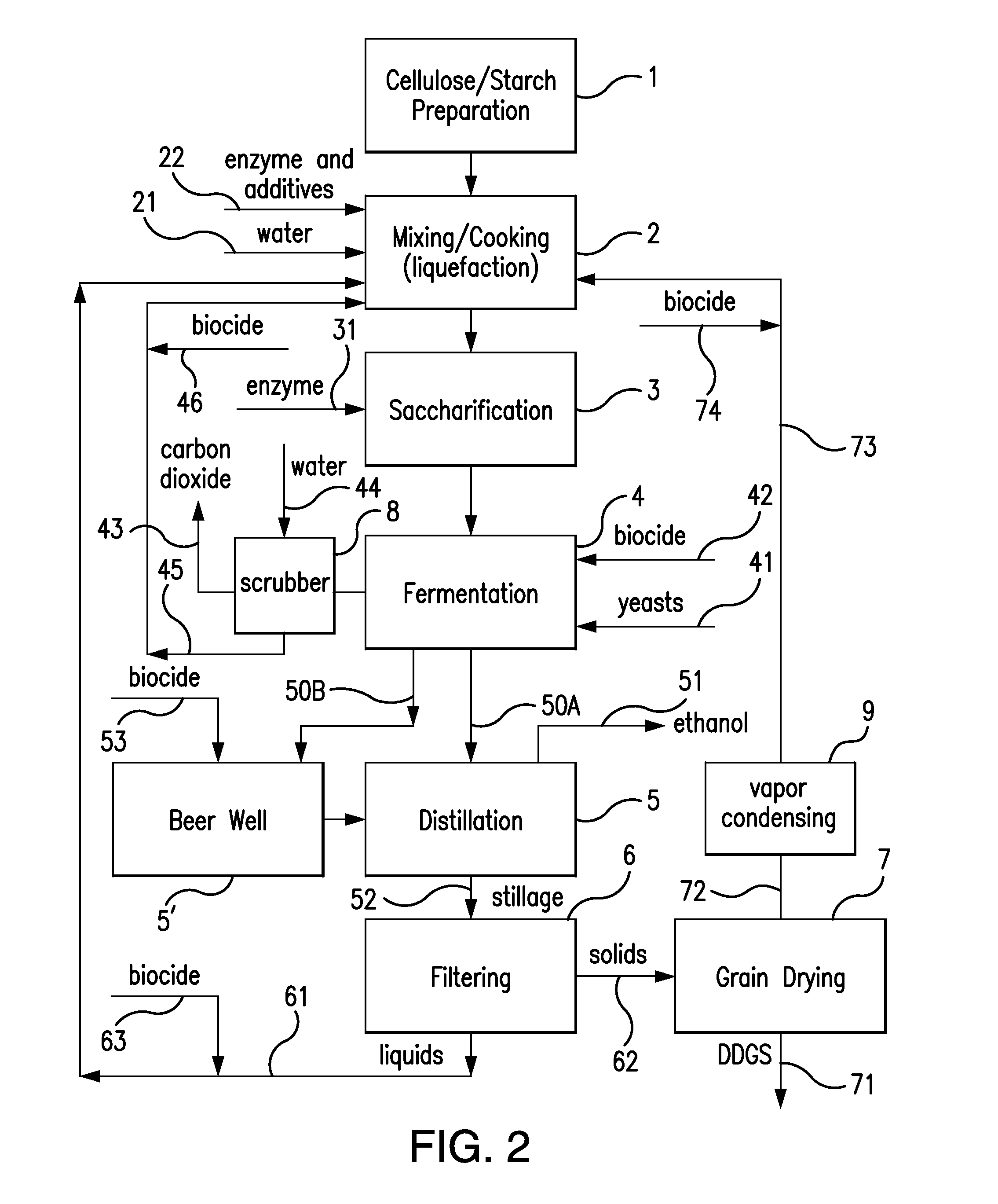

Processes Using Antibiotic Alternatives In Bioethanol Production

ActiveUS20110230394A1Increase productionLow and no adverse environmental impactAntibacterial agentsBiocideEthanol yieldAntibacterial peptide

Methods for controlling the growth of bacteria in ethanol fermentation systems with antibiotic alternatives, which can be nonoxidizing biocides, stabilized oxidizers, or any combinations thereof, are described. As an option, a process or composition of the present invention can include one or more polycyclic antibacterial peptides. The methods can provide improvements, such as increased ethanol yields with minimal carryover of biocide into co-products of the processes.

Owner:BUCKMAN LAB INT INC

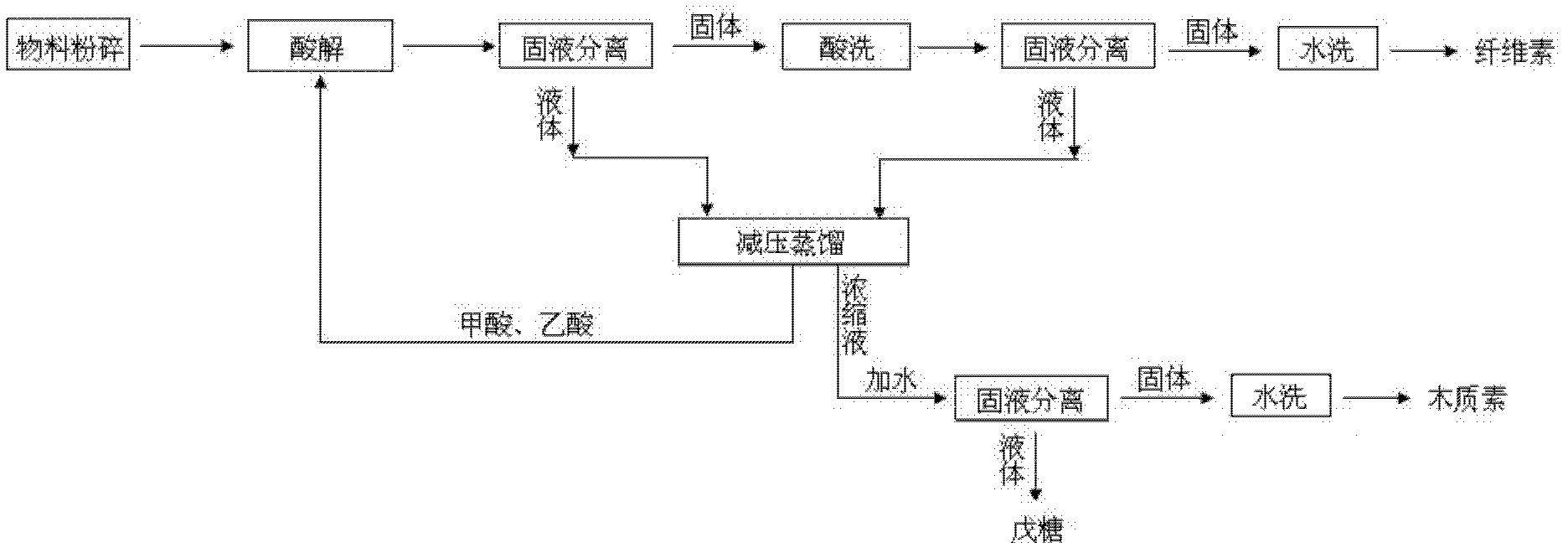

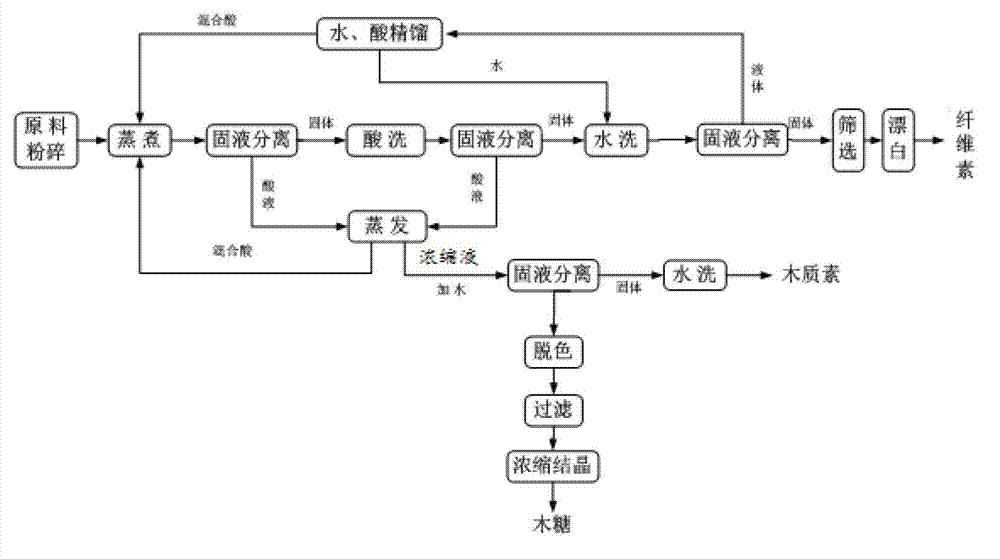

Comprehensive utilization process of lignocellulose biomass

ActiveCN103131018AHigh acid hydrolysis efficiencyImprove extraction efficiencySugar derivativesSugar derivatives preparationAcetic acidOrganic acid

The invention relates to a comprehensive utilization method of lignocellulose biomass, and particularly relates to a comprehensive utilization method of cellulose, hemicellulose and lignin in lignocellulose biomass. The method of the invention respectively extracts cellulose, lignin, and hemicellulose by performing acidolysis of lignocellulose biomass with a mixed organic acid of formic acid and acetic acid; the comprehensive extraction rates of all the three substances are high; the cellulose extraction rate is 75%-100%; the lignin extraction rate is 55%-90%; the pentose extraction rate is 85%-95%; the method of the invention not only facilitates the comprehensive and stable operation of the three routes, but also ensures the extraction rates of the three products to the maximum extent.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

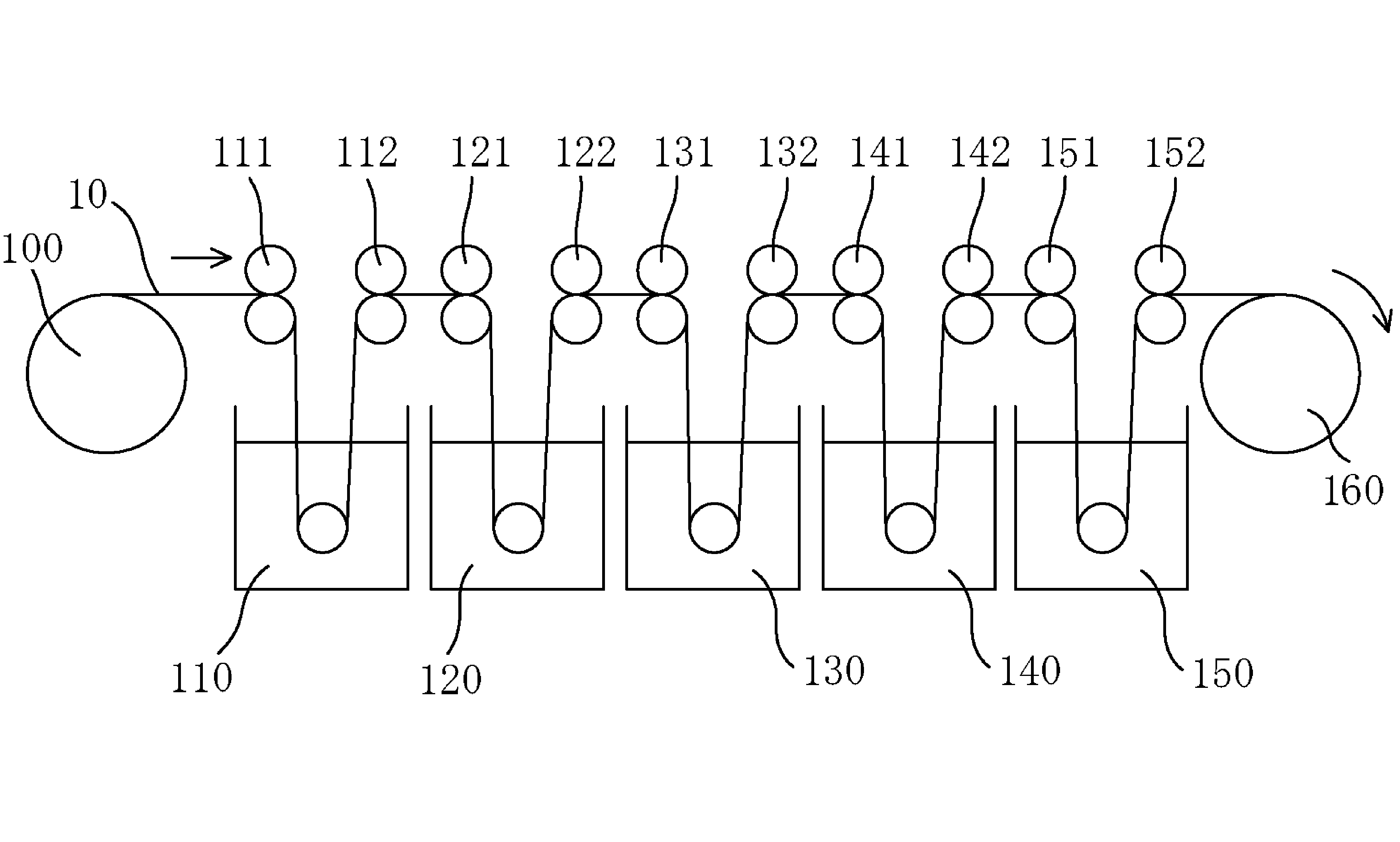

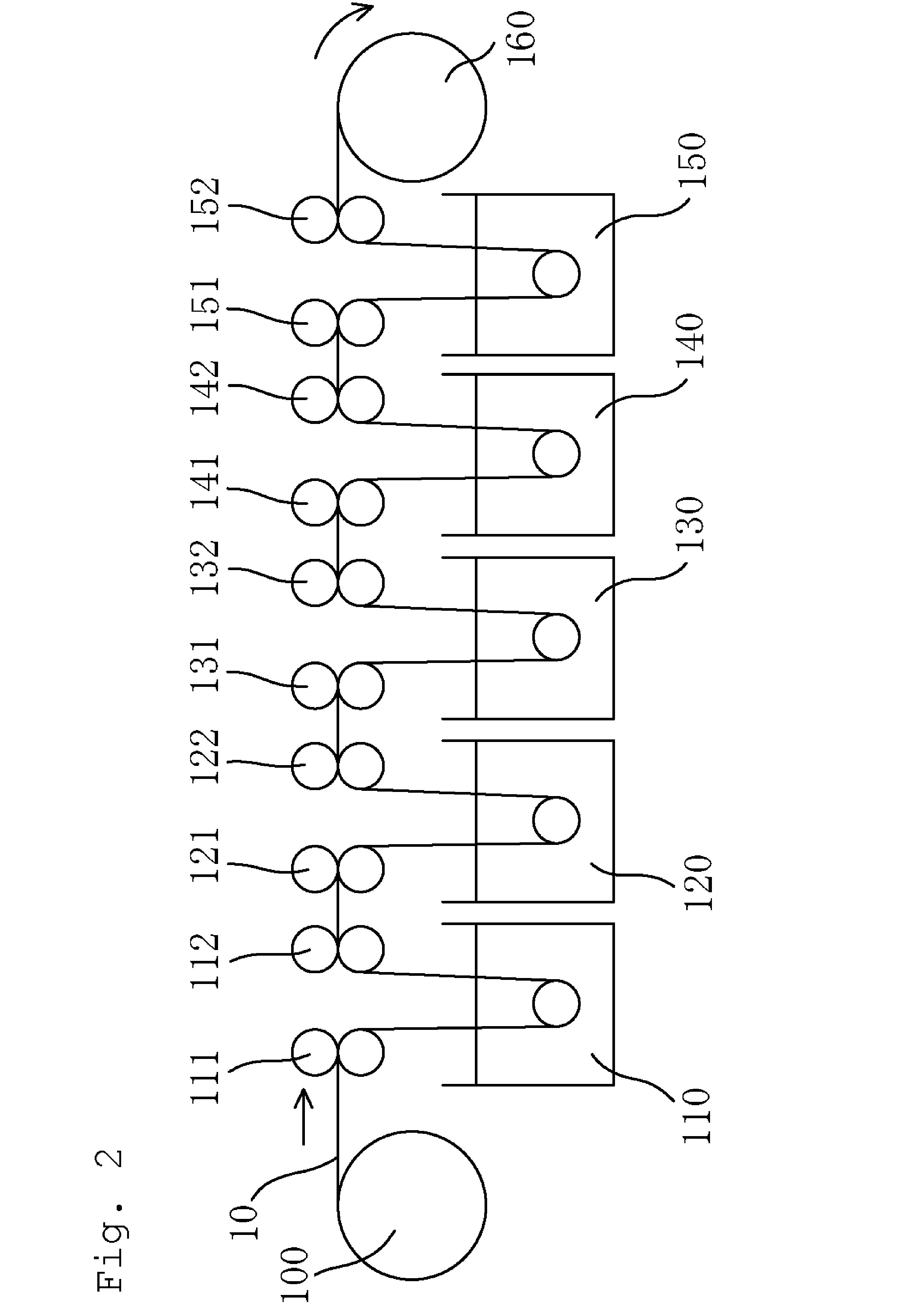

Thin polarizing film, optical laminate with thin polarizing film, and production method for thin polarizing film

ActiveUS20130128357A1Raise the ratioGood mannersOptical articlesPolarising elementsIon chromatographySquare Millimeter

The present invention provides a thin polarizing film which has only a small environmental load and has excellent optical characteristics.The thin polarizing film is produced by forming a polyvinyl alcohol-based resin layer on a thermoplastic resin substrate. The thin polarizing film has a thickness of 10 μm or less, a single axis transmittance of 42.0% or more, a polarization degree of 99.95% or more, and an iodine content of 17.6 grams per 400×700 square millimeters or less, which is measured by an ion chromatography method.

Owner:NITTO DENKO CORP

Composition and method for controlling precipitation when acidizing wells

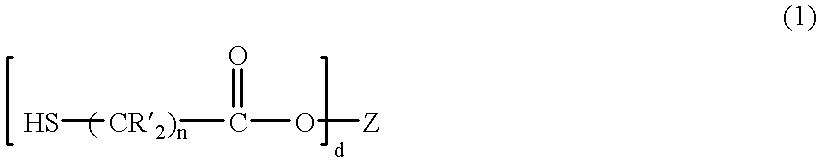

InactiveUS6225261B1Prevent precipitationEasy to cleanOther chemical processesCleaning apparatusDiketoneKetone

A composition and method for acidizing a formation in the presence of ferric ion, free sulfur and / or sulfides is disclosed. The composition employs a ferric ion reducing agent and a sulfide reactant separately or in combination. The ferric ion reducing agent is a thioalkyl acid. The sulfide reactant compounds include alpha-diketones and saturated and alpha-unsaturated cyclic ketones. In another aspect, the reducing activity of the thioalkyl acid is accelerated by the presence of a catalytic quantity of a compound or mixture of compounds which yield in acid solution cuprous ion, cupric ion or combinations thereof with iodide ion.

Owner:HALLIBURTON CO

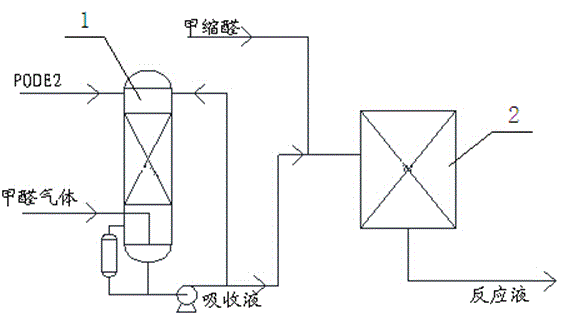

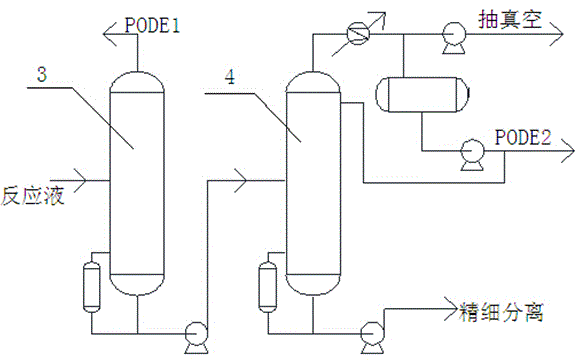

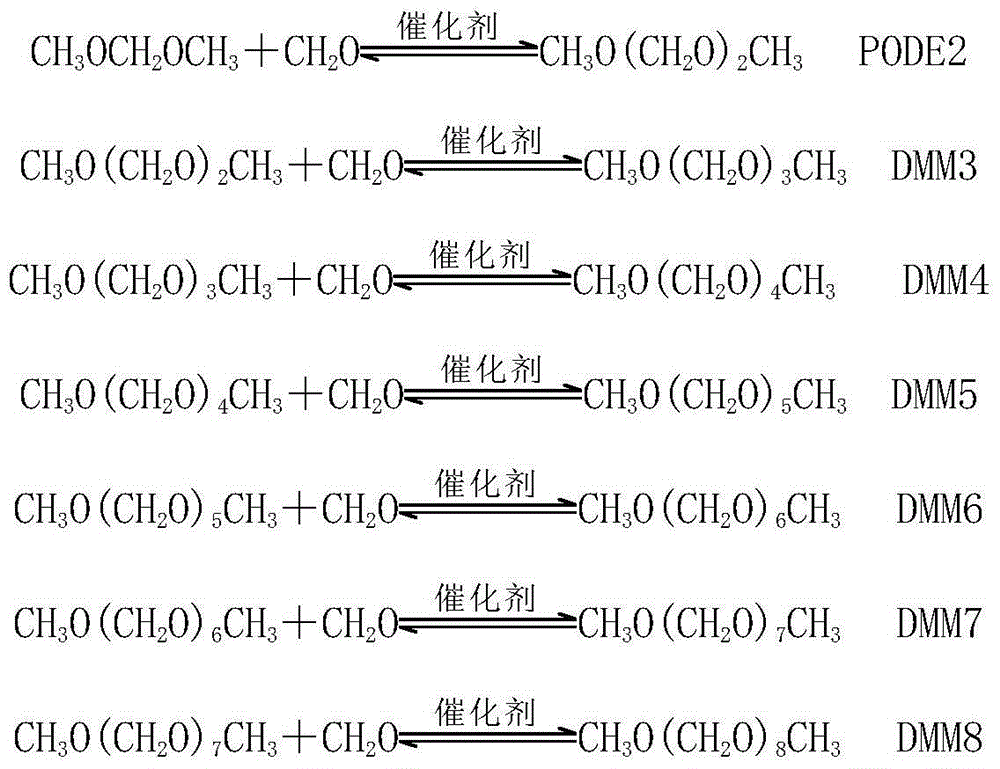

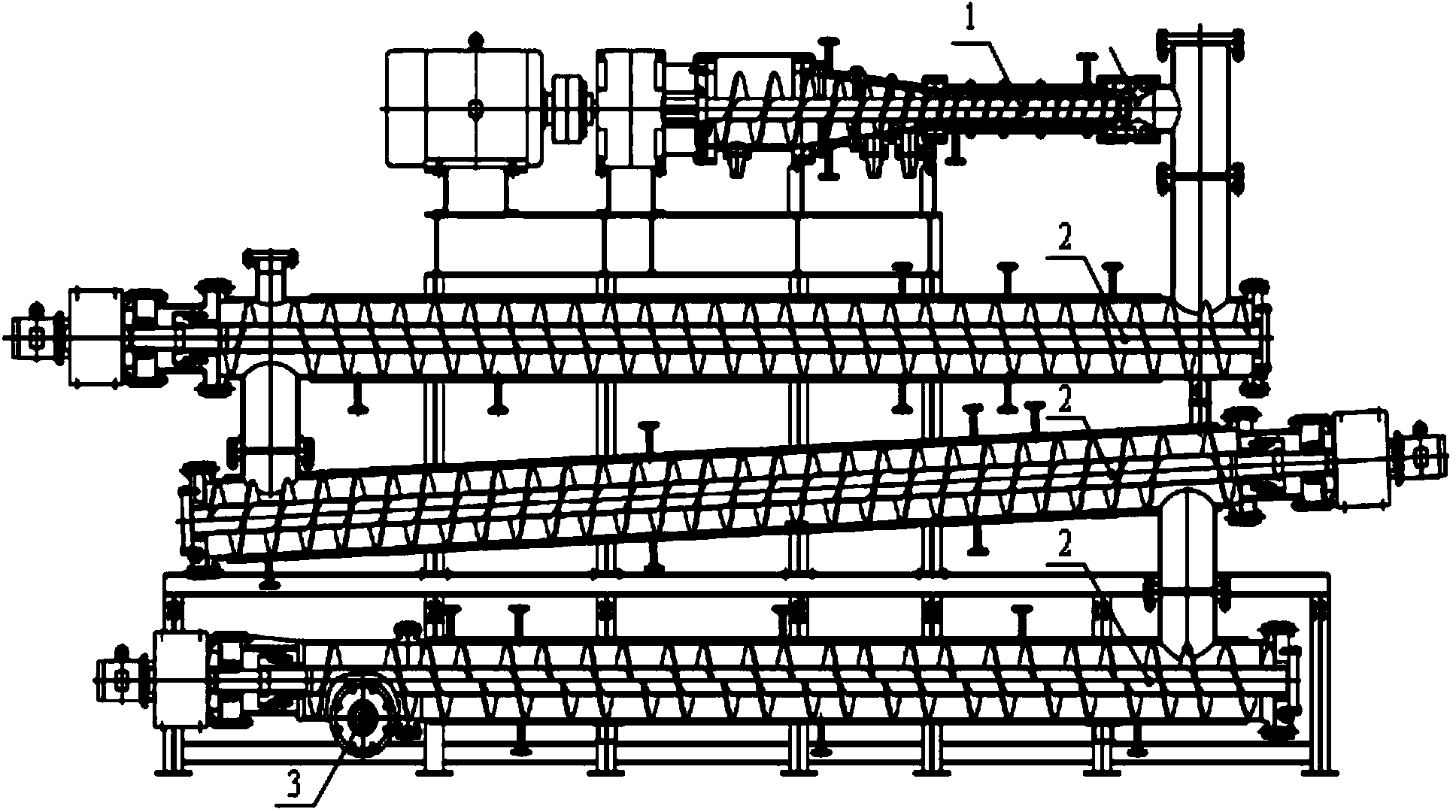

Process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis

ActiveCN104817440APrevent self-aggregationAvoid reactionOrganic chemistryOrganic compound preparationBoiling pointDimethoxymethane

The invention discloses a process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis. According to the process, higher-boiling-point intermediate component dimer PODE2 of polymethoxy dimethyl ether is adopted, the formaldehyde dissolved amount is much higher than the methylal dissolved amount, and a PODE2 solution of formaldehyde is obtained, so that the operating pressure and temperature for the subsequent reaction are on the lower level, thereby avoiding the self-polymerization and disproportionation reaction of the formaldehyde, further avoiding the pipeline blockage, lowering the acid content in the polymethoxy dimethyl ether product, and finally enhancing the product yield.

Owner:JIANGSU KAIMAO PETROCHEM TECH

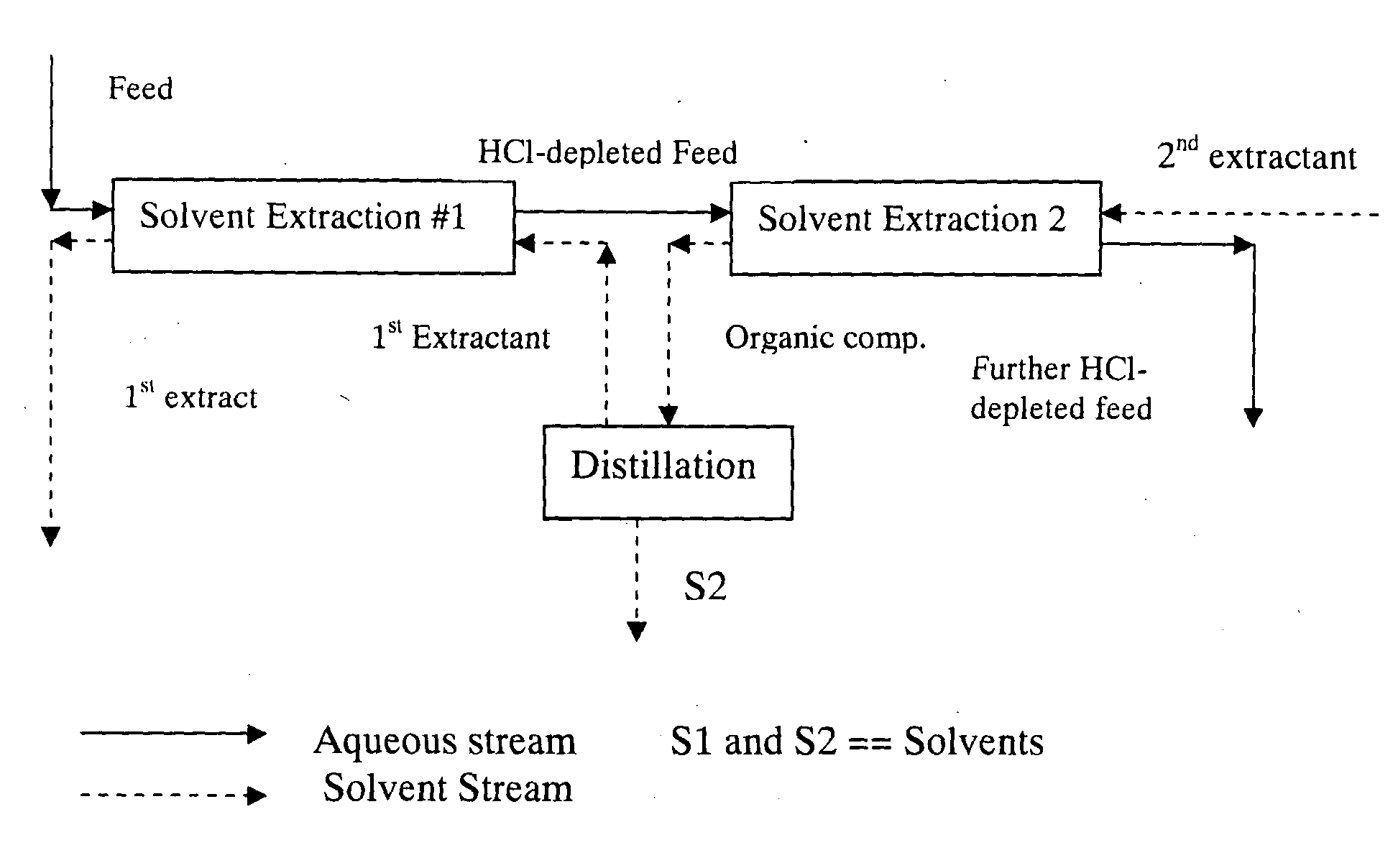

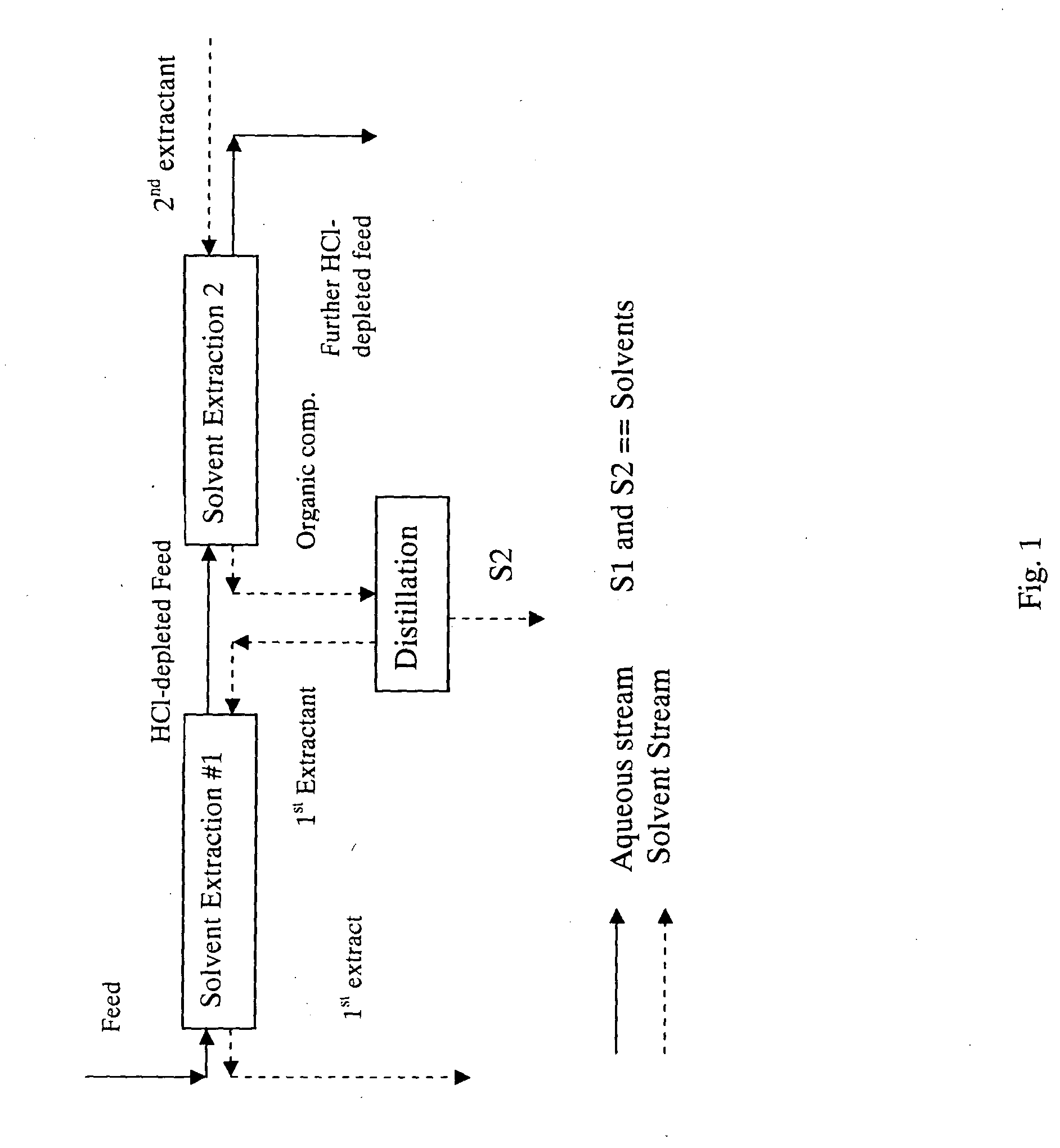

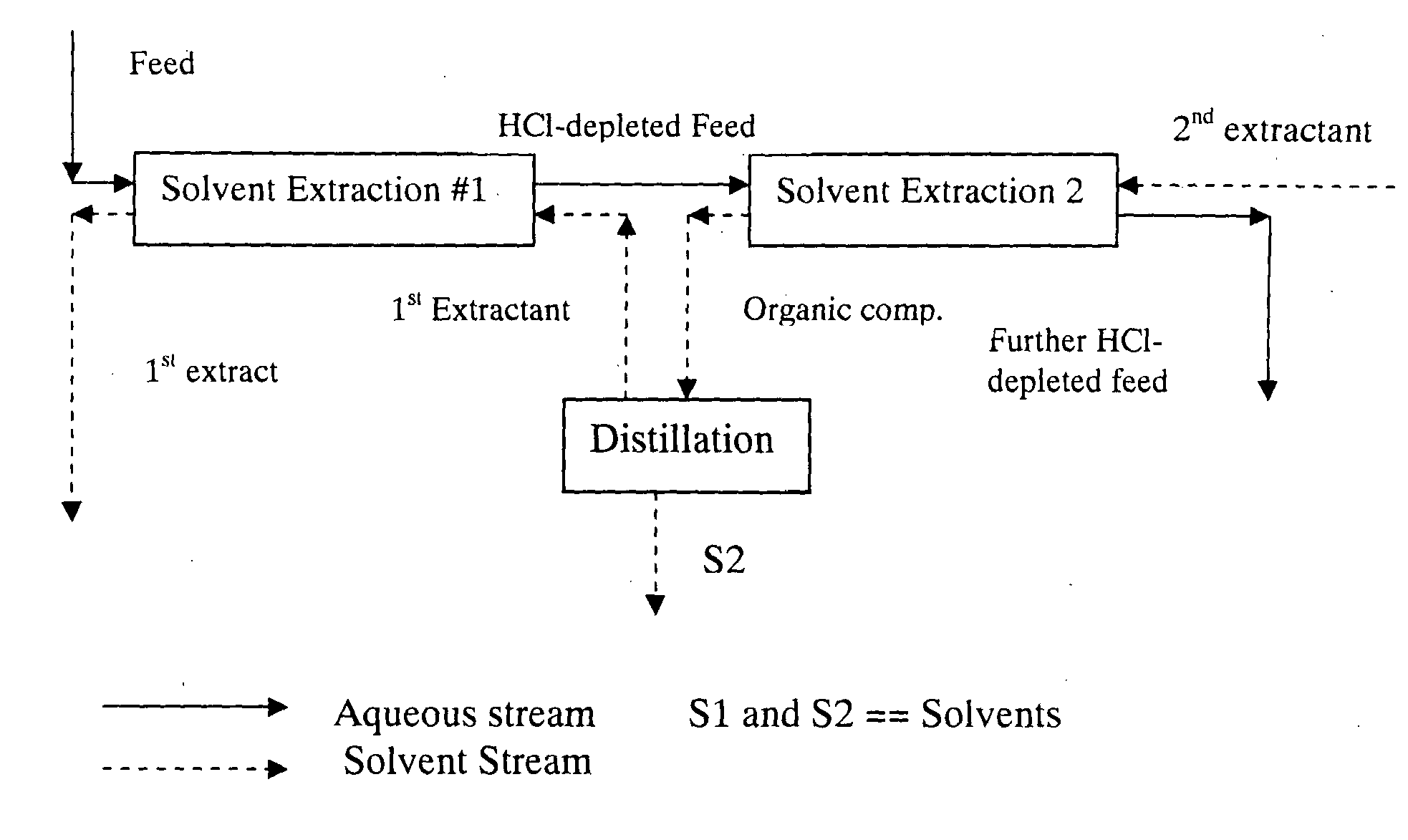

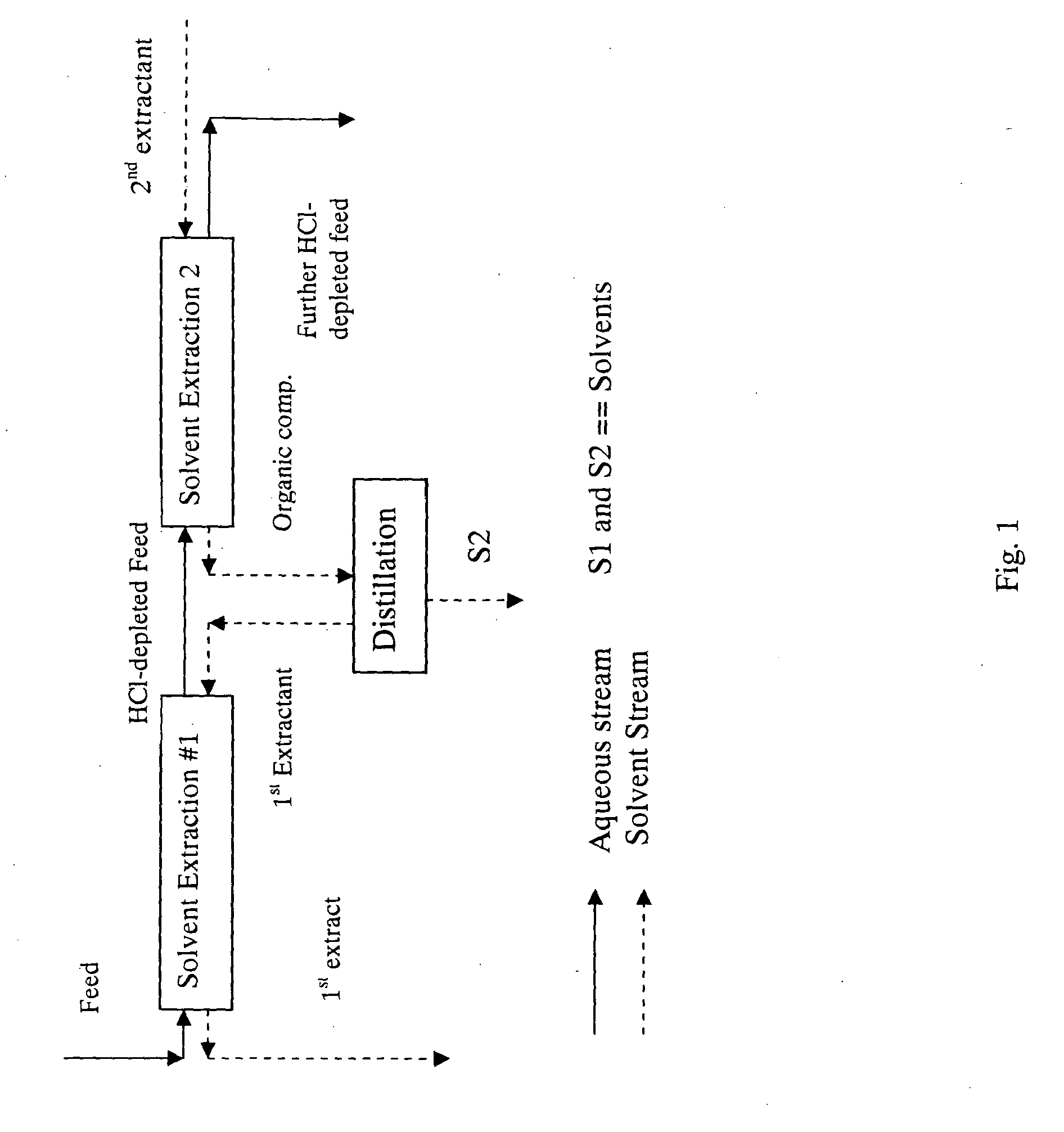

Methods for the separation of hcl from a carbohydrate and compositions produced thereby

InactiveUS20130028832A1Low costLow-cost rapid growing biomassChlorine/hydrogen-chloride purificationOther chemical processesSolventSolubility

The present invention provides an organic phase composition comprising:(a) a first solvent (S1) characterized by a water solubility of less than 10% and by at least one of (a1) having a polarity related component of Hoy's cohesion parameter (delta-P) between 5 and 10 MPa1 / 2 and (b1) having a Hydrogen bonding related component of Hoy's cohesion parameter (delta-H) between 5 and 20 MPa1 / 2;(b) a second solvent (S2) characterized by a water solubility of at least 30% and by at least one of (a2) having a delta-P greater than 8 MPa1 / 2 and (b2) having a delta-H greater than 12 MPa1 / 2;(c) water;(d) HCl; and(e) a carbohydrate.

Owner:VIRIDA

Method for preparing a hydrolyzate

InactiveUS20130028833A1Low costLow-cost rapid growing biomassChlorine/hydrogen-chloride purificationOther chemical processesSolubilityHydrogen

The present invention provides an organic phase composition comprising(f) a first solvent (S1) characterized by water solubility of less than 10% and by at least one of (a1) having a polarity related component of Hoy's cohesion parameter (delta-P) between 5 and 10 mPa1 / 2 and (b1) having a Hydrogen bonding related component of Hoy's cohesion parameter (delta-H) between 5 and 20 MPa1 / 2;(g) a second solvent (S2) characterized by water solubility of at least 30% and by at least one of (a2) having a delta-P greater than 8 MPa1 / 2 and (b2) having a delta-H greater than 12 MPa1 / 2;(h) water(i) HCl, and(j) a chloride salt.

Owner:VIRDIA

Conductive macromolecular solution, preparation thereof, conductive polymer coated film and solid electrolyte capacitor

InactiveCN101486836AImprove conductivityHigh light transmittanceCapacitor electrolytes/absorbentsOrganic conductorsElectrolysisPolymer science

An electroconductive polymer solution contains electroconductive high molecules and polyanion. Under 25 DEG C, the oxygen content in the electroconductive polymer solution is below 8 weight ppm. An electroconductive coating film using the solution has high transmittance and low resistance. Applied to a solid electrolytic capacitor, the electroconductive polymer solution can improve the conductivity of solid electrolysis and filling behavior, therefore, a solid electrolytic capacitor with low ESR and other excellent properties is obtained.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

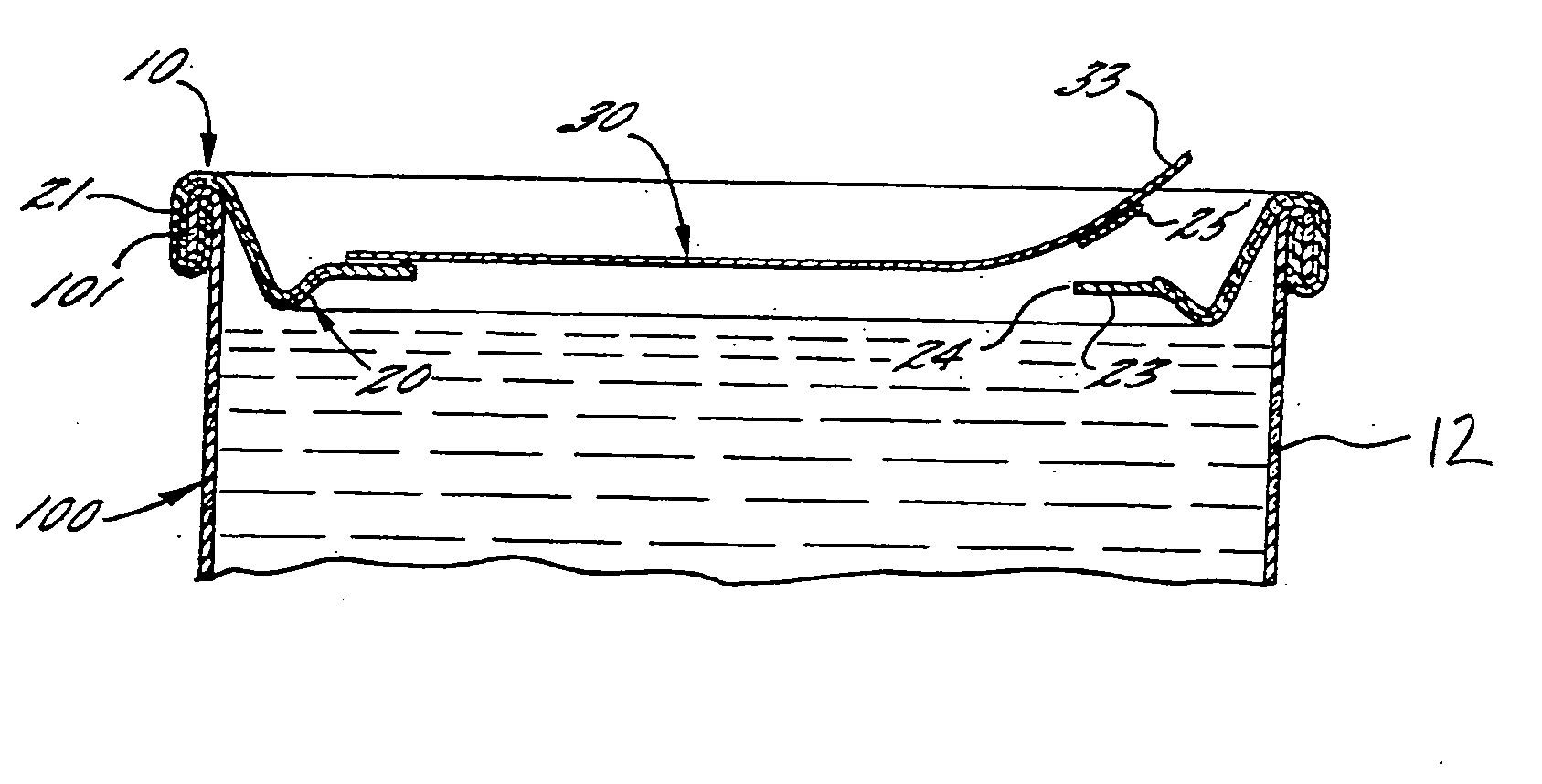

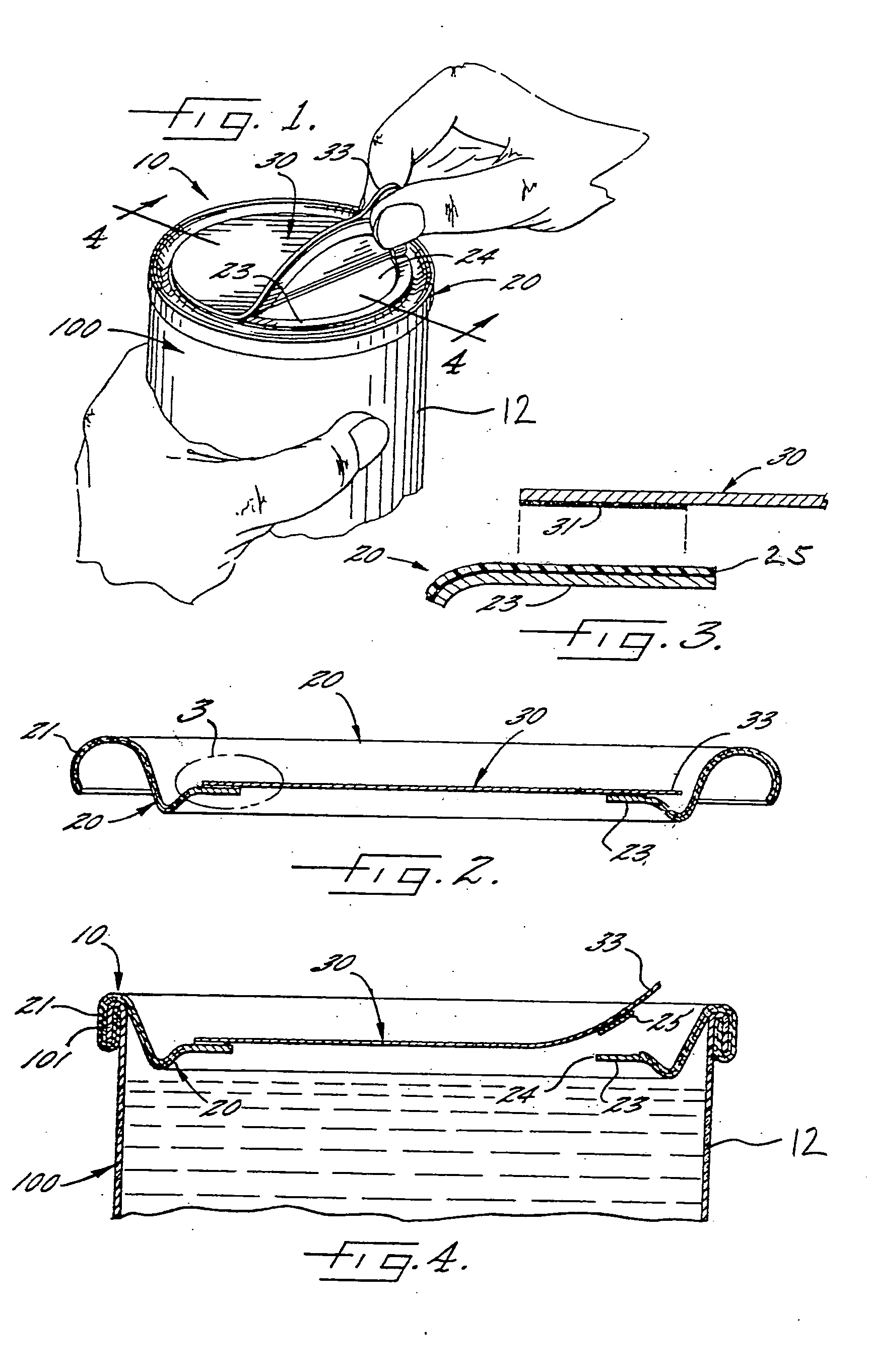

Easy-open container and closure assembly therefor

A container comprises a container body defining a top opening, a sealing surface being defined on the container body encircling the top opening, and a closure sealed to the sealing surface by a heat-seal material comprising a blend of two different acidic ionomers having respectively higher and lower acid content such that the heat-seal material has an acid content intermediate between that of the two different ionomers, whereby the resulting heat seal strikes a balance between oil-resistance and age-up.

Owner:SONOCO DEV INC

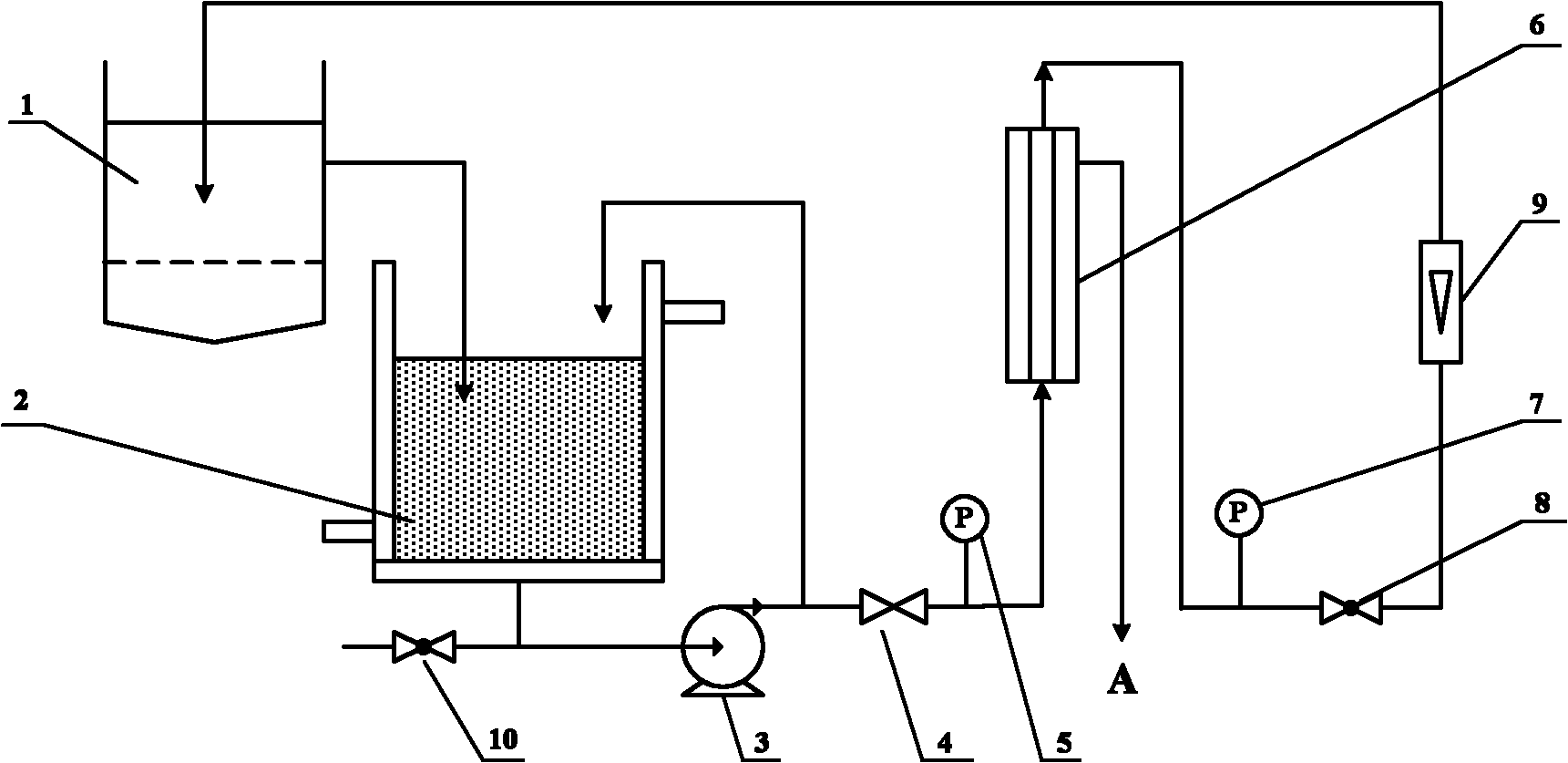

Method for deacidification of alkylation reaction product

ActiveCN102021016AReduce dosageReduce productionRefining by dialysisCross-flow filtrationElectrostatic precipitation

The invention relates to a method for deacidification of an alkylation reaction product. In the method, after being subject to gravity settling, mixed emulsified liquid of the alkylation reaction product (hydrocarbon oil) and sulfuric acid passes through a component with hydrophobic modified ceramic membrane at a membrane surface speed of 0.01-5m / s for separation, and the deacidification of oil is achieved in a cross current filtration mode under the operation pressure of 0.01-0.3MPa and at the operation temperature of 0-40 DEG C. Under the push of pressure, the oil passes through the ceramic membrane, acid in the oil is trapped, and the acid content in the obtained oil is lower than 100ppm, thereby greatly reducing alkaline usage and waste water generation amount in an acid-base refine system of an alkylation technology and reducing the use of electrostatic precipitation; and the ceramic membrane surface is subject to hydrophobic modification, thus the contact angle of water droplet on the membrane surface is 70 degrees-16 degrees. The method is suitable for removal of polar liquid in various oils, has the advantages of simple process, low energy consumption, high separation precision, no environment pollution and high economic and practical value, and is easy to achieve industrial application.

Owner:NANJING UNIV OF TECH

Method for preparing hawthorn fruit vinegar

InactiveCN101649286AImprove stabilityGreat tasteMicroorganism based processesVinegar preparationFiberFruit juice

The invention relates to a method for preparing hawthorn fruit vinegar, which comprises the following steps: extracting hawthorn juice containing rich biological effective constituent flavone by an enzymatic method extracting process; deacidifying the hawthorn juice by weakly basic anion exchange resin; adding wine active dried yeast into the deacidified hawthorn juice to ferment at low temperature so as to brew hawthorn wine; and further brewing the hawthorn wine into the hawthorn fruit vinegar by an acetic acid bacterium deep liquid fermentation method. Ecipients, such as malt-dextrin, lactose, and the like are added into a by-product after hawthorn processing to be mixed, stirred, granulated, dried, tabletted, classified and packaged to be capable of obtaining a hawthorn fiber sheet. The invention adopts a full juice low-temperature second deep liquid fermentation method, improves a comprehensive development industrial chain of the hawthorn, realizes no pollution production, and provides an effective path for enriching the deep processing and the comprehensive utilization of high-quality hawthorn resources, not only can enrich the variety of juice beverage and meet the market requirement but also can directly protect and simulate the development of forest fruit and improve an additional value of a product.

Owner:TIANJIN UNIV OF SCI & TECH

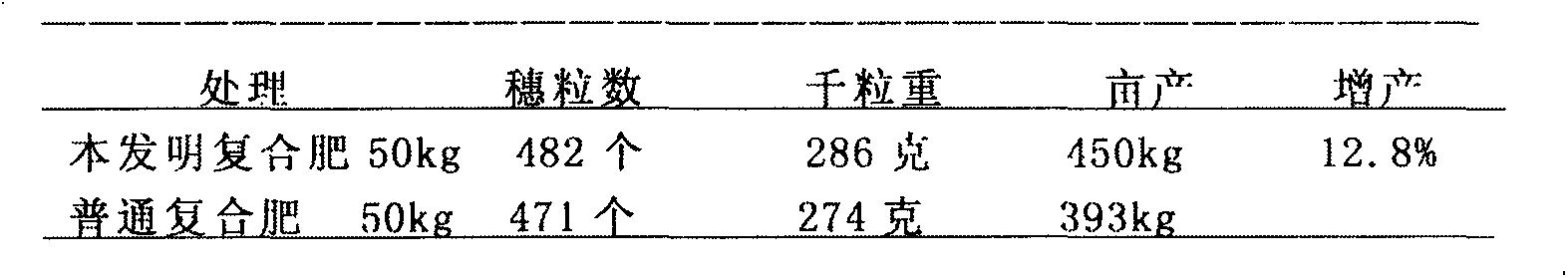

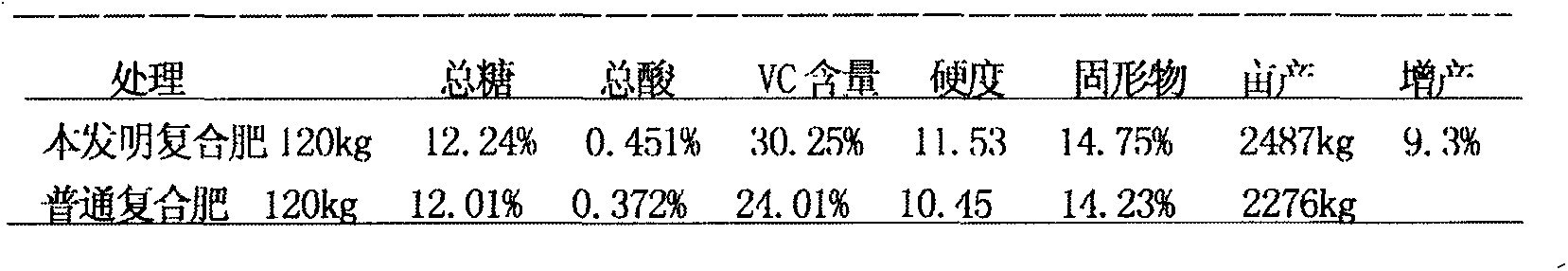

Organic and inorganic biological compound fertilizer and preparation method

InactiveCN103304319AImprove physical and chemical propertiesIncrease profitFertilizer mixturesMicroorganismSorbent

The invention discloses an organic and inorganic biological compound fertilizer and a preparation method. The organic and inorganic biological compound fertilizer consists of a nitrogen fertilizer, a phosphatic fertilizer, a potassic fertilizer, chicken manure and vinasse fermented fertilizer, an adsorbent, an enveloping agent and a bioremediating inoculant. Organic matters, inorganic nutrition and functional microorganisms are processed and mixed according to own different functional effects through specific equipment and a technology; after being applied, the three fertilizers jointly generate action and cannot influence the effect; the synergism and the effect improving effect of the biological fertilizer, the stable and long-time effect of the inorganic fertilizer and the quick-acting effect of the inorganic fertilizer are combined with one another; and the organic and inorganic biological compound fertilizer has the characteristics of urgent and delayed supplementation, advantage complementation, comprehensive nutrition, durable balance, high efficiency and the like. The same-fertilizer-price comprehensive experiment result shows that the yield of food crops is increased by 9-14 percent when being compared with the common compound fertilizer; the yield of economical crops is increased by 12-30 percent.

Owner:SINO AGRI SHUNTIAN ECOLOGICAL FERTILIZER CO LTD

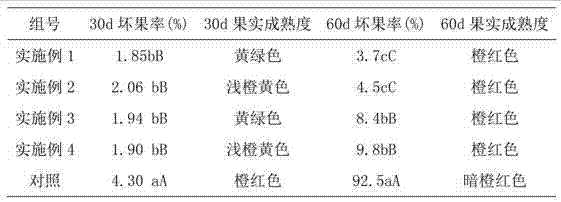

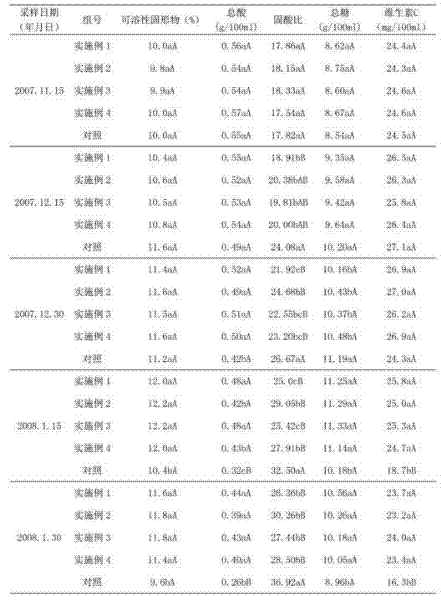

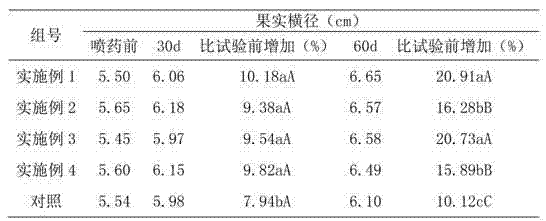

On-tree refreshing method of citrus gonggan

InactiveCN102210250ADelayed total acid content andAnti agingCultivating equipmentsHorticulture methodsDisinfectantFruit maturation

The invention discloses an on-tree refreshing method of citrus gonggan, and the method comprises the following steps: spraying and applying a preservation solution once in the first third of November; and spraying and applying a disinfectant once every 15-30 days. By adopting the processing method, the reduction in the content of total acid in citrus gonggan fruits and the content of vitamin C in fruit juice can be effectively stayed, and the occurrence time of enabling the content of soluble solids and the content of total sugar to achieve the highest values can be delayed, thereby being conductive to on-tree refreshing of the citrus gonggan fruits, delaying aging of the citrus gonggan fruits, prolonging the fruit maturation period and improving the fruit quality.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Process for reducing the naphthenic acidity of petroleum oils or their fractions

InactiveUS20060201855A1Reduce acid contentReducing naphthenic acidityLiquid separation by electricityRefining by electric/magnetic meansWater in oilChemistry

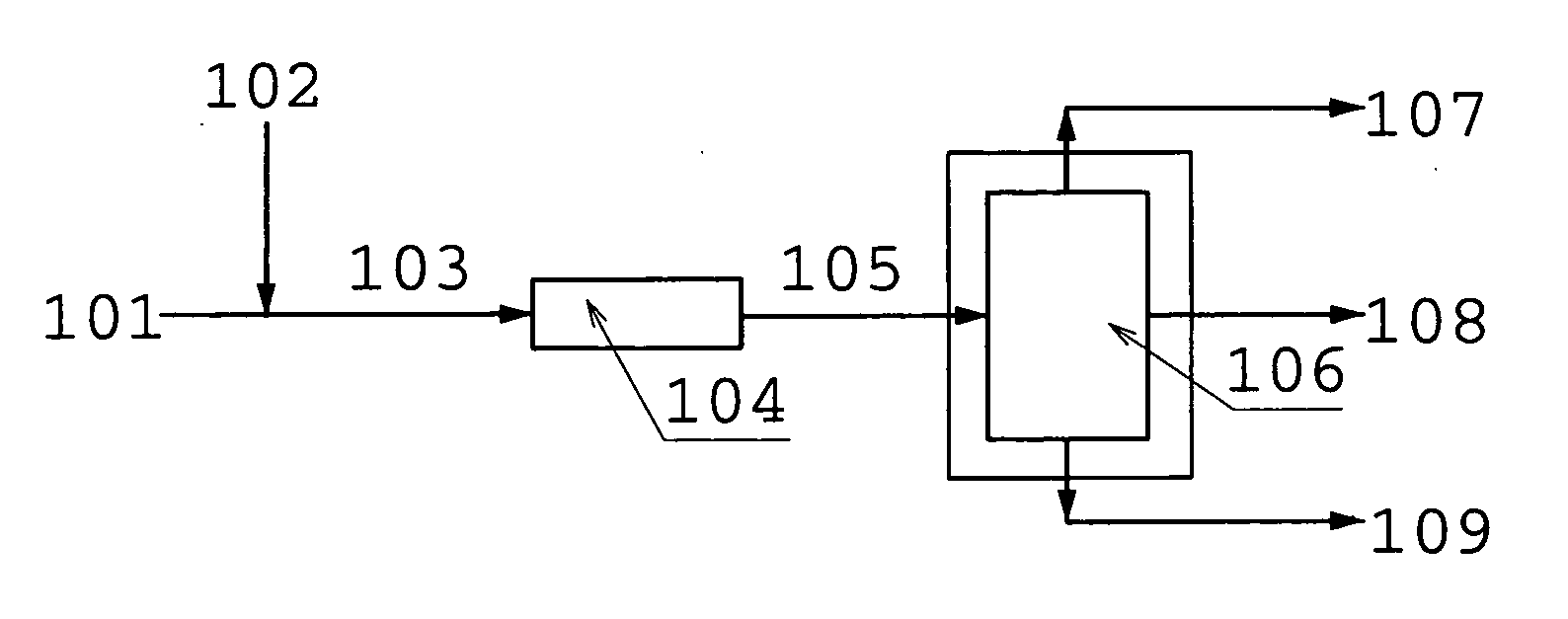

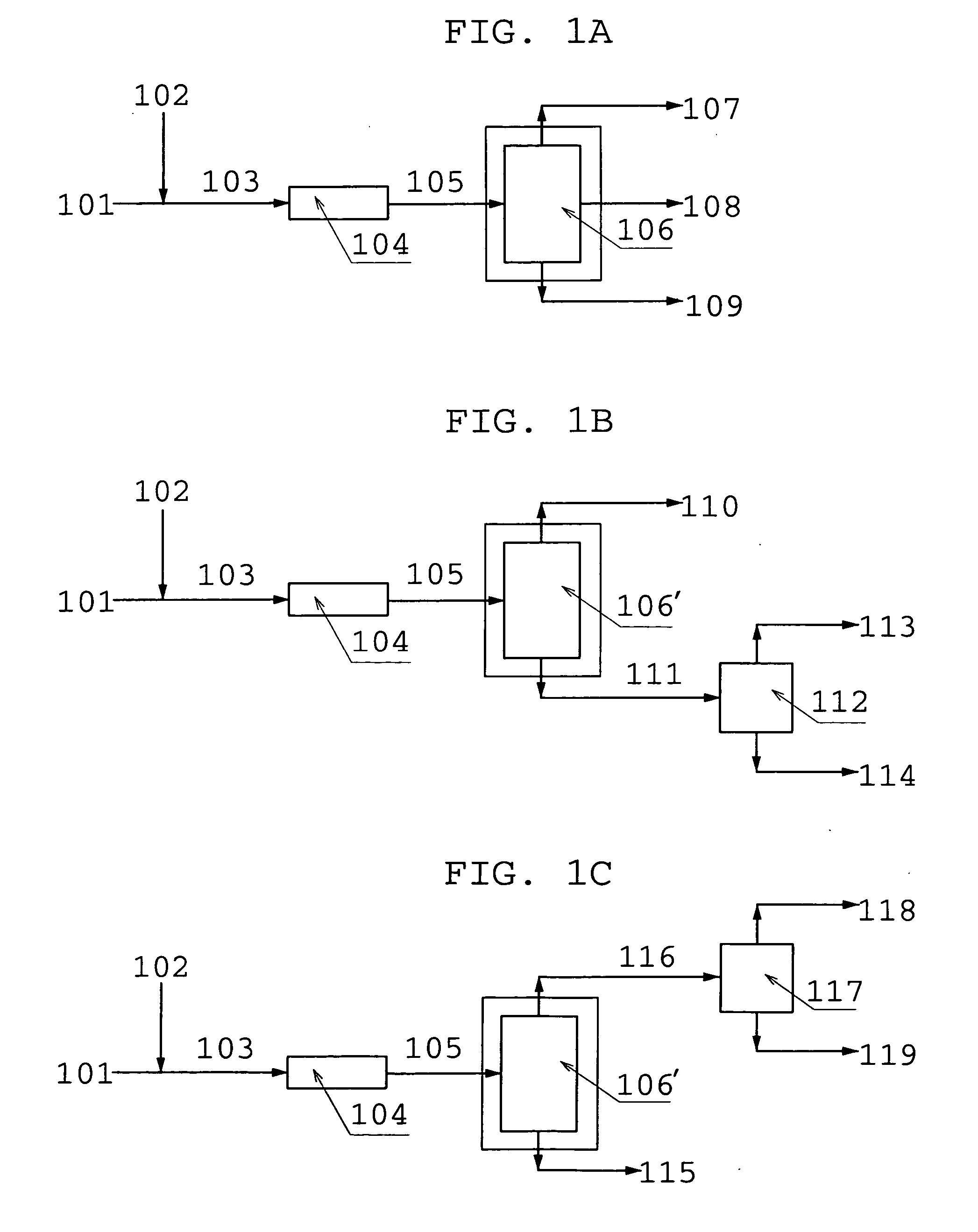

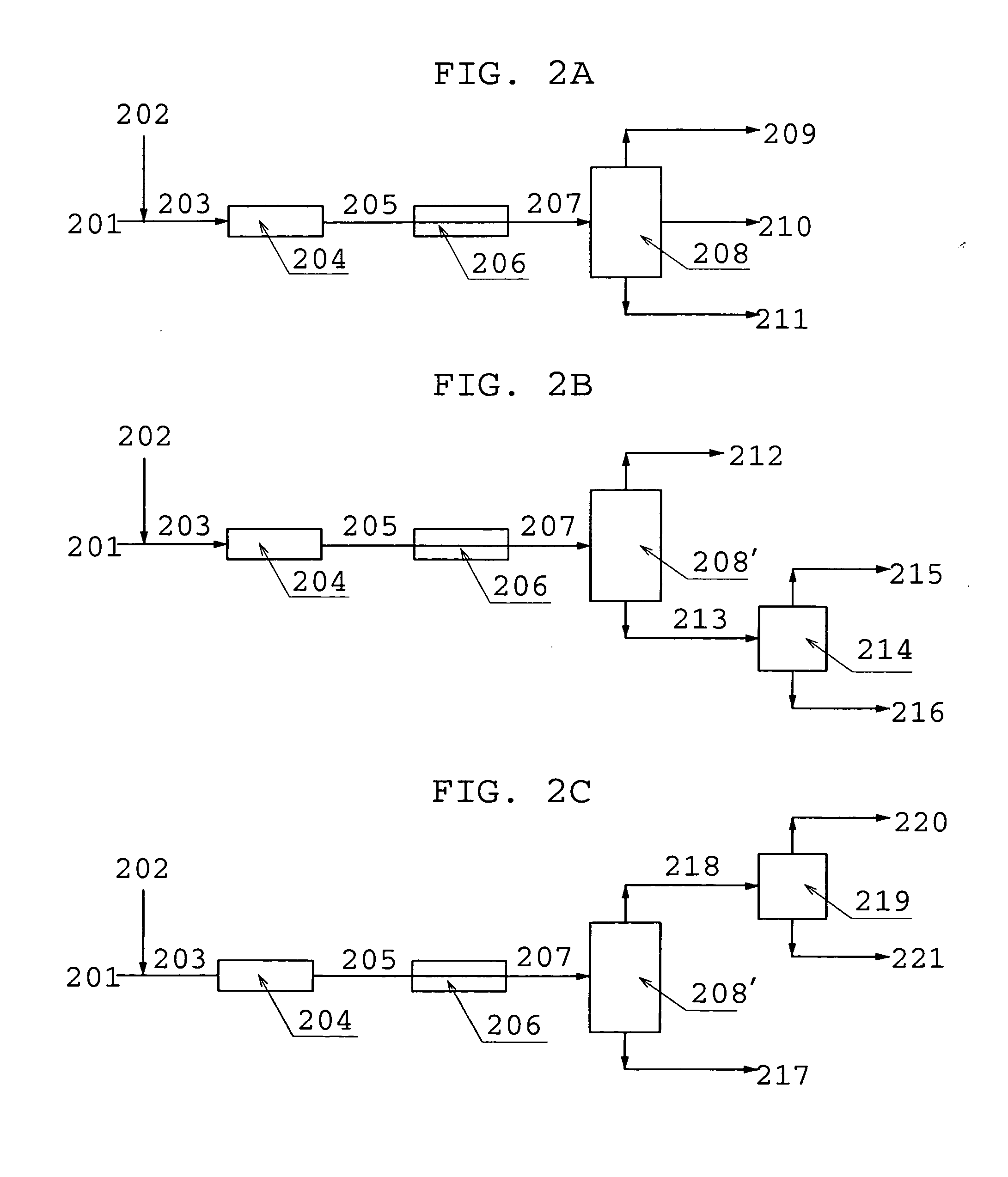

A process for reducing the naphthenic acidity of petroleum oils or their fractions is described, said process comprising providing a hydrocarbon feed 103 / 203 / 303 having between 0.1 and 99 wt % of emulsified / dispersed water in oil, said feed containing salts and a content of naphthenic acids measured as TAN between 0.1 and 10 mg KOH / g oil; directing the said petroleum oil feed and emulsified / dispersed water towards an energy emitter device in the microwave range and submitting said feed 103 / 203 / 303 in liquid phase, under pressure between 0.7 and 4.5 MPa at temperatures between 50° C. and 350° C. to the microwave radiation, applied in the range of 1 mm to 30 cm to said feed so that the presence of salts, the applied temperature and the high dielectric constant of the water droplets make that the heat is absorbed on the spot by the water and heat said water preferentially to the oil, while the naphthenic compounds at the interface between the droplets and the oil catch said heat; effecting the decomposition of the carboxylic acids responsible for the naphthenic acidity in the petroleum feed at temperatures around 320° C. and generating CO2; separating with the aid of any known device 106 / 106′ / 112 / 117 / 208 / 208′ / 214 / 219 / 310 / 310′ / 316 / 321 any gas phase generated, water and oil; and recovering the hydrocarbon oil stream 108 / 113 / 119 / 210 / 215 / 221 / 312 / 317 / 323 having a reduced content in naphthenic acids. The process is designed to be applied to the reduction of naphthenic acids in feeds of petroleum oils and their fractions in the oil production step, in refineries or any industrial installation.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

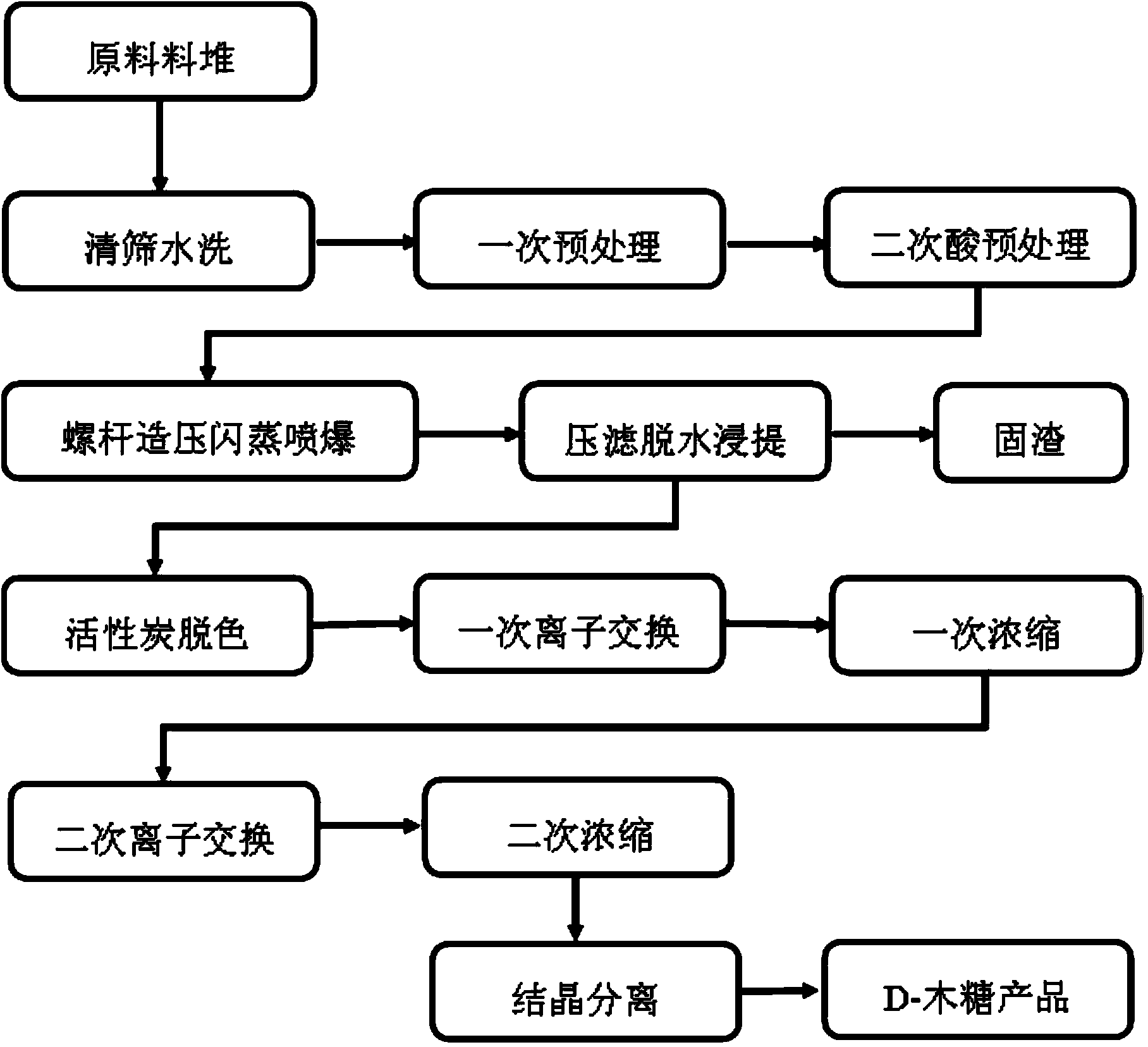

Clean technology for producing D-xylose with screw pressure producing flashing spray explosion method

ActiveCN103467532AIncrease concentrationQuality improvementSugar derivativesSugar derivatives preparationHigh concentrationFiber

The invention belongs to the field of biochemical engineering and relates to a clean technology for producing D-xylose with a screw pressure producing flashing spray explosion method. According to the clean technology, pretreatment is performed on wood fiber raw materials at first, then, a traditional sulfuric acid hydrolysis technology is replaced by the screw pressure producing flashing spray explosion technology to produce spray explosion materials rich in the D-xylose, feed liquid of the D-xylose is extracted through filter-press dehydration in a high concentration mode, therefore, subsequent decoloration, ion exchange, concentration, crystal separation technological processes are improved according to the characteristics of the feed liquid, and D-xylose products are obtained finally. Compared with a traditional sulfuric acid hydrolysis technology, the clean technology has the advantages of being capable of achieving continuous production, small in acid-base dosage, small in waste water discharge amount and low in energy consumption and cost. The obtained feed liquid is high in concentration of the D-xylose and extremely low in acid content, the complicated neutralization process of the technology can be removed, meanwhile, the decoloration, concentration and ion exchange technological processes are simplified, and the burdens in later-stage purification processing are greatly reduced. The clean technology for producing the D-xylose with the screw pressure producing flashing spray explosion method is simple, simple in industrial production, and capable of greatly improving the quality and the yield of D-xylose products.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting nickel sulfate from waste solution of copper electrolysis

This invention relates to a method for extracting nickel sulfate from waste copper electrolyte. The method comprises: (1) removing copper from waste copper electrolyte discharged from the electrobath so that the Cu2+ content is less than or equal to 0.1 g / L; (2) adding the waste electrolyte into a reaction tank (70-80 vol.% of the tank), stirring at 20-25 rpm, introducing 0.1-0.3 MPa steam, and vacuumizing to 0.01-0.05 MPa; (3) ending heating and vacuumizing when the negative pressure in the tank reaches 0.05 MPa and the temperature reaches 120 deg.C, cooling to 60 deg.C and discharging the waste electrolyte; (4) standing, cooling to 30 deg.C, performing solid-liquid separation, discharging the upper layer, and dehydrating the sediment to obtain nickel sulfate crystal. The method has such advantages as safe operation, little pollution, high efficiency, high nickel sulfate recovery rate (98%), and stable product quality.

Owner:广东金雁工业集团有限公司

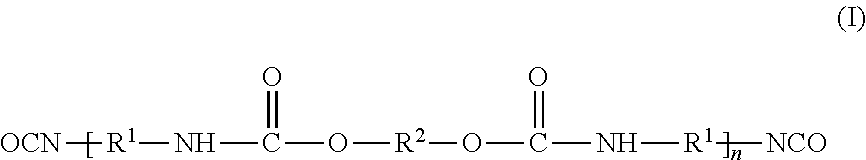

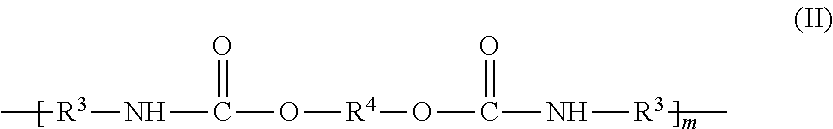

Aqueous ink-jet inks containing alternating polyurethanes as binders

The present disclosure provides novel aqueous ink-jet inks containing an aqueous vehicle, a pigment and an alternating polyurethane as a binder.

Owner:DUPONT ELECTRONICS INC

Low burst polymers and methods to produce polymer

ActiveUS9187593B2Increase release rateReduced initial burstAntibacterial agentsOrganic active ingredientsPolymer chemistryControlled-Release Formulations

Owner:TOLMAR INC

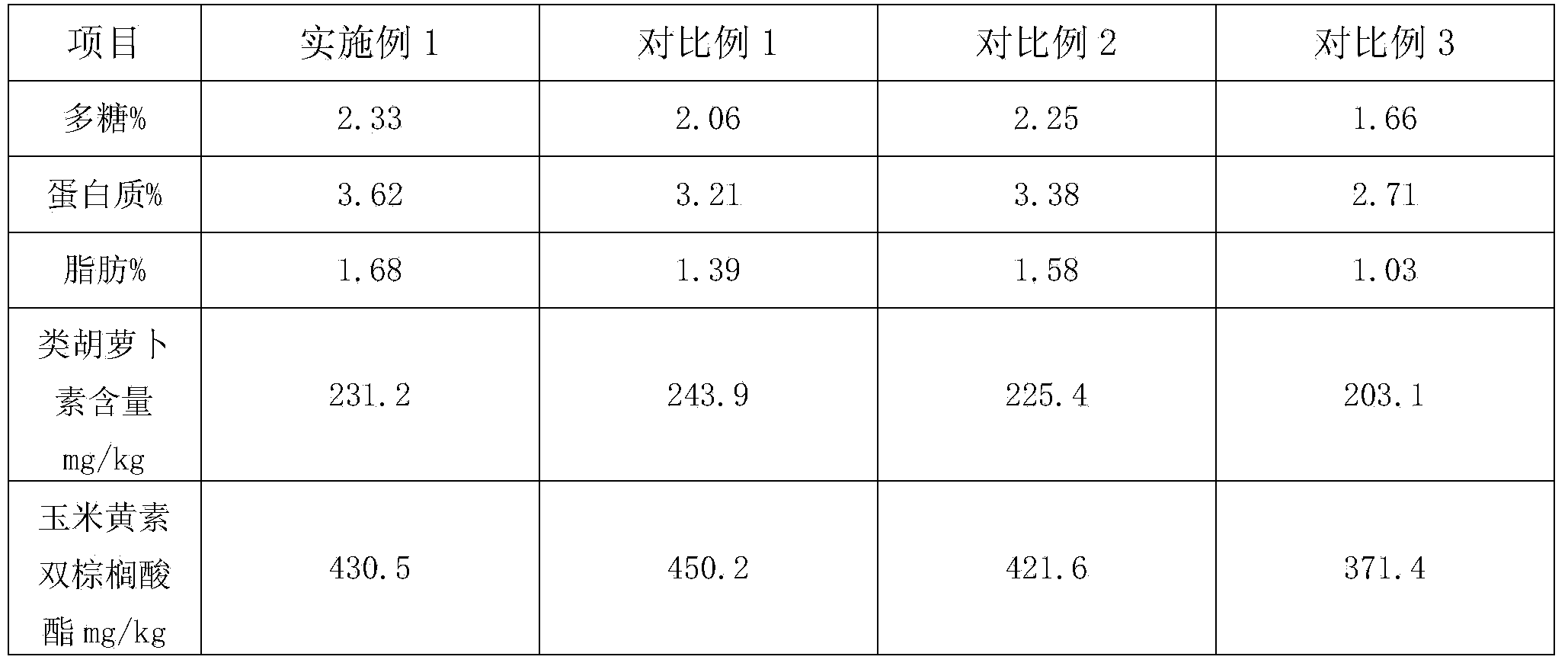

Active protein feed and its preparing method

InactiveCN1899080ALoose texturePromote digestion and absorptionFood processingAnimal feeding stuffActive proteinBiotin

The present invention discloses a kind of active protein feed and its preparation process. The active protein feed is prepared with the materials comprising fresh solid fermented distiller's grains 96-98 wt%, urea 0.5-1 wt%, ammonium sulfate 1-3 wt% and koji tray strain 0.1-0.6 wt%, and the preparation process is simple, low in labor strength and low in cost. The said process can eliminate the pollution caused by distiller's grains while producing loose feed with special fragrance, rich protein, vitamins, amino acid, biotin mineral and nutritious elements essential for animal growth.

Owner:李同军

Comprehensive utilization process of biomass raw material

ActiveCN103074790AImprove cooking efficiencyImprove extraction efficiencyPulp bleachingPulping with organic solventsAcetic acidOrganic acid

The invention relates to a method for comprehensive utilization of a biomass raw material, in particular to a method for comprehensive utilization of cellulose, hemicellulose and lignose in a biomass raw material. The method provided by the invention is that under the catalytic action of hydrogen peroxide, the biomass raw material is digested through the organic acid mixture of formic acid and acetic acid, so that cellulose, lignose and hemicellulose are respectively extracted to obtain cellulose, lignose and xylose, wherein the cellulose can be used in the textile industry.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparing method of acidophilus milk lump

The invention discloses a preparation method for yogurt lump. The method comprises the steps of fermenting, acidization, curdling, whey discharging, water washing, storing, forming, sealing, after-ripening and packaging by adopting special lactic acid bacteria to inoculate milk or goat milk which is standardized and pasteurized. The invention can not only lead the traditional yogurt lump product to be safer and more sanitary with stable quality, subtle taste and modest hardness. And since the step of the after-ripening is controlled appropriately, the prepared yogurt lump is of fuller flavor with little cream precipitated, high yielding rate and can meet popular taste and be used for producing yogurt lump with different water content, tastes and textural quality, which has more market competitiveness and can greatly enrich the processing technology and flavor of traditional yogurt lump.

Owner:SOUTH CHINA AGRI UNIV +1

Preparation method of wolfberry pulp

InactiveCN103859512AReduce browningPrevent browningFood ingredientsFood preparationVitamin CMacromolecular Substances

The invention relates to a preparation method of wolfberry pulp. The preparation method comprises the following steps: firstly, screening fresh wolfberries, cleaning and draining off to obtain clean wolfberries; secondly, mixing the clean wolfberries with vitamin C and citric acid, and pulping and grinding under a low-oxygen condition to obtain raw wolfberry pulp; thirdly, heating the raw wolfberry pulp, and separating the pulp and seeds to obtain primary wolfberry pulp; and fourthly, carrying out ultrafine grinding on the primary wolfberry pulp, degassing and sterilizing to obtain the wolfberry pulp. The wolfberry pulp is ultrafine-ground in a high-speed shearing mode, so that the sizes of ground wolfberry pulp can be reduced; the wolfberry pulp is heated before grinding to facilitate the dissolving of pectin in wolfberry pulp and improve the viscosity of the wolfberry pulp particles; besides, the serious layering phenomenon of the wolfberry pulp containing macromolecular substances polysaccharide, protein and the like can be avoided by operations of reducing the sizes of the ground wolfberry pulp and increasing the viscosity.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

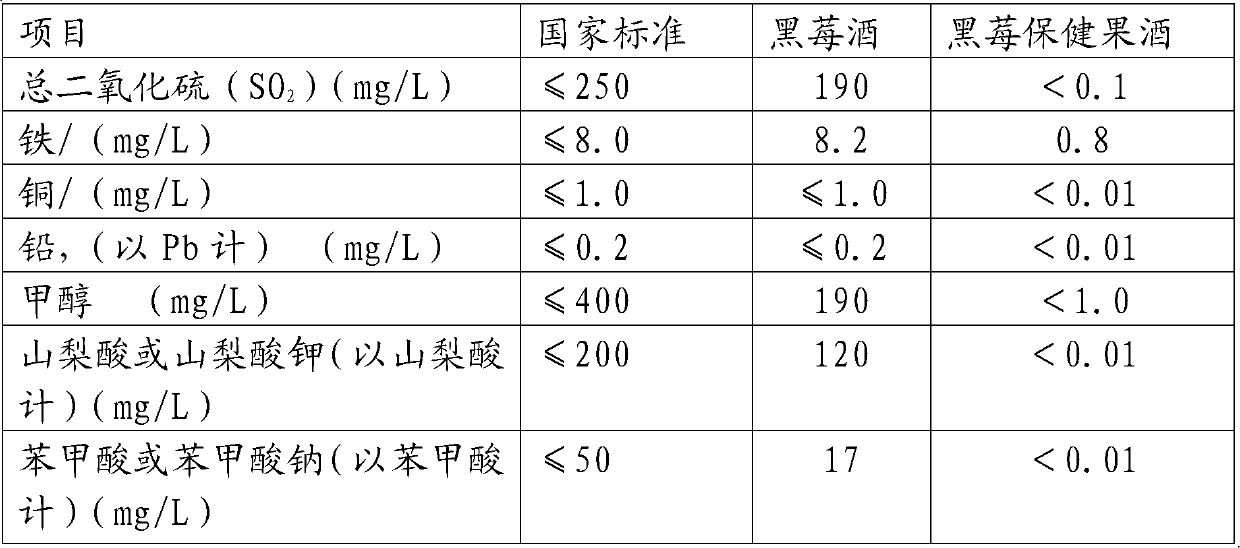

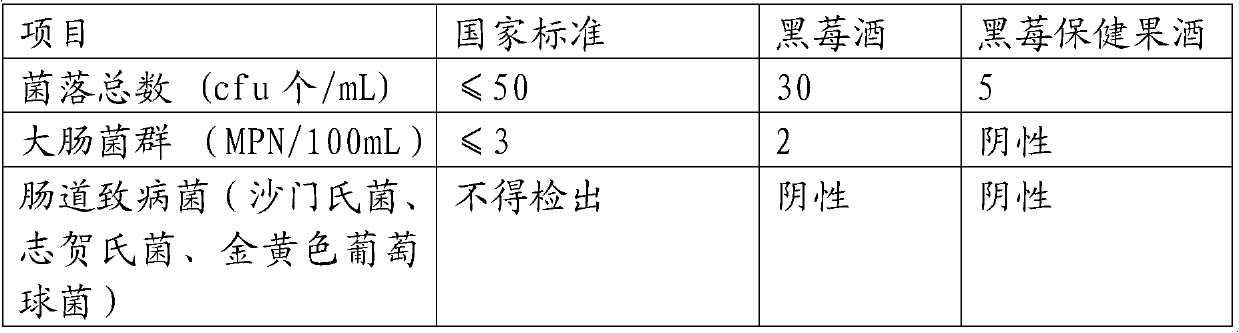

Method for brewing health blackberry fruit wine

InactiveCN102604776AMake up for the deficiency of trace elementsHigh in sugarAlcoholic beverage preparationMicroorganism based processesFruit winePreservative

The invention discloses a method for brewing health blackberry fruit wine. The method comprises the following steps of: compounding blackberries, red dates and fructus lycii according to a proportion, performing fermentation, clarification treatment and refrigeration treatment, and performing ageing in an oak barrel to prepare the health blackberry fruit wine. The red dates and the fructus lycii are high in sugar content and low in acid content, so that the problem of peracid of pure blackberry wine can be solved, the shortcoming of deficiency of certain trace elements in the blackberries canalso be overcome, and a finished product is fully fruity and elegant in bouquet; due to the addition of a compound clarifier in the brewing of the fruit wine, the key problem about the precipitation of the fruit wine is solved; and moreover, the addition of sulfur dioxide, preservatives and pigments in the brewing is avoided, so that the health blackberry fruit wine can be safer to drink.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

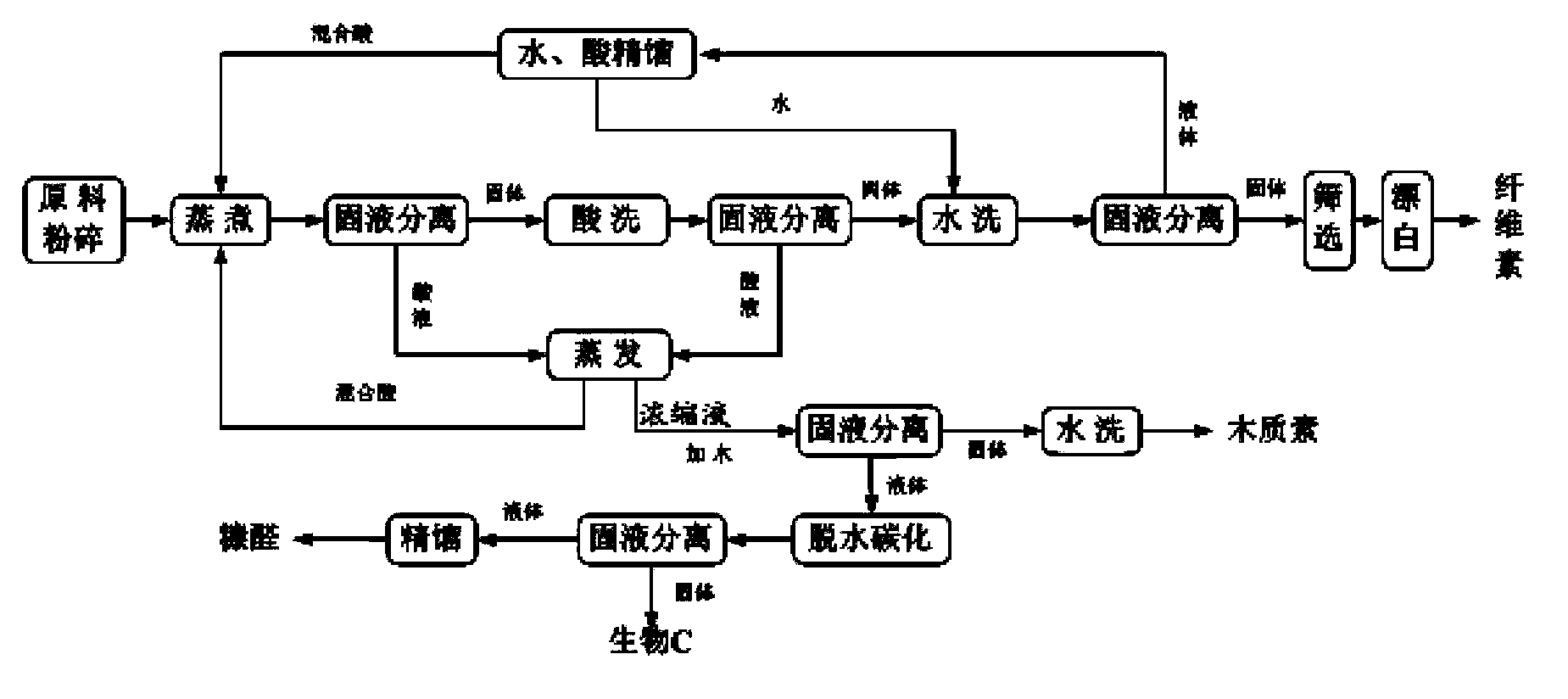

Comprehensive utilization method of biomass raw material

ActiveCN103898787AImprove extraction efficiencyShorten cooking timePulp bleachingCarbon preparation/purificationOrganic acidFormic acid

The invention relates to a comprehensive utilization method of a biomass raw material, and concretely relates to a method for comprehensively utilizing celluloses, hemicelluloses and lignin in the biomass raw material. The method is characterized in that the celluloses, lignin and the hemicelluloses can be respectively extracted by boiling the biomass raw material through a formic acid and acetic acid mixed organic acid under the catalysis action of hydrogen peroxide in order to obtain highly pure celluloses and lignin, the combined production of furfural and biochar is realized by utilizing a residual sugar solution, and the highly pure celluloses can be used in the textile industry.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Purification technology of artificial diamond synthesis material

The present invention relates to an artificial diamond synthetic material purification process, belonging to the field of diamond synthesis technology. It is characterized by using potassium chlorate and small quantity of hydrochloric acid to remove graphite and metal from after-refined material of shaker simultaneously.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Method for producing starting materials for obtaining conjugated linoleic acid

InactiveUS20030181522A1Attractive colorReduce acid contentBiocideFatty acid esterificationAlcoholTransesterification

Processes for preparing linoleic acid raw materials are described wherein the processes comprise: (a) transesterifying a triglyceride component with an alcohol having from 1 to 4 carbon atoms, at a temperature of from 80 to 120° C., to form a transesterification mixture comprising linoleic acid esters and one or more by-products selected from the group consisting of glycerides, free glycerol, and soaps, wherein the triglyceride component is comprised of at least 60% by weight linoleic acid; and (b) removing the one or more by-products from the transesterification mixture.

Owner:COGNIS DEUT GMBH & CO KG

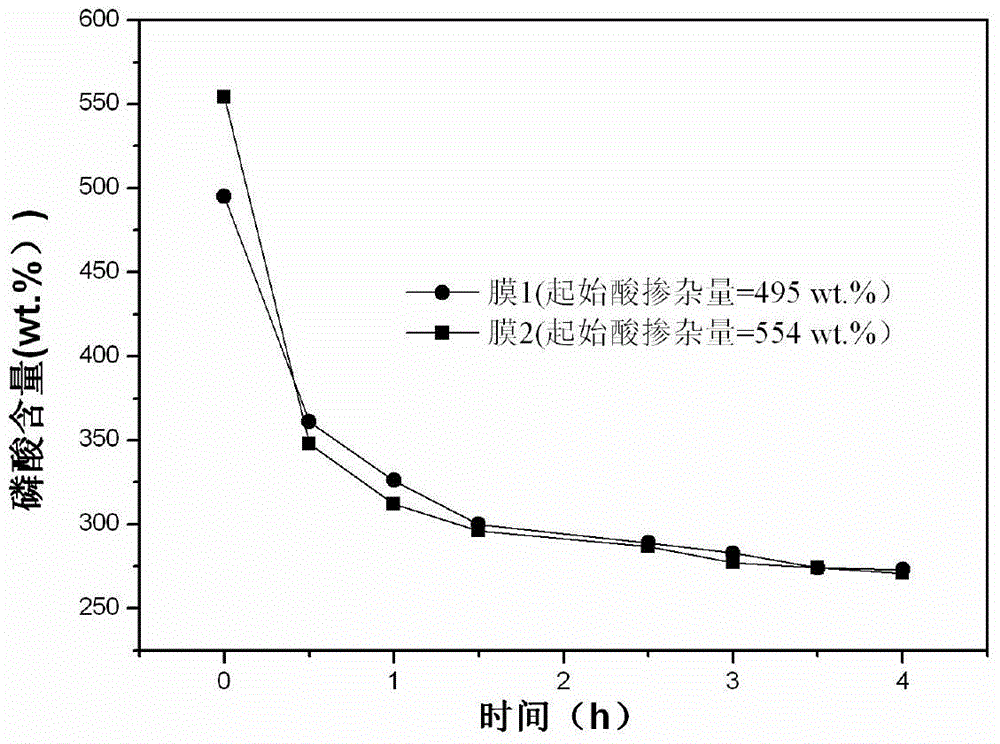

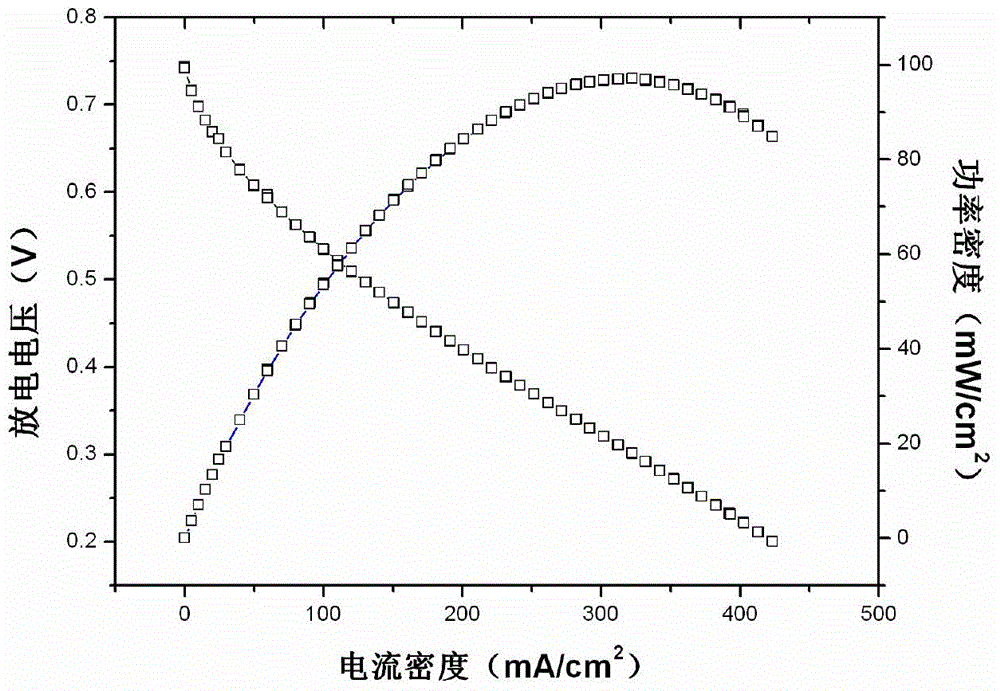

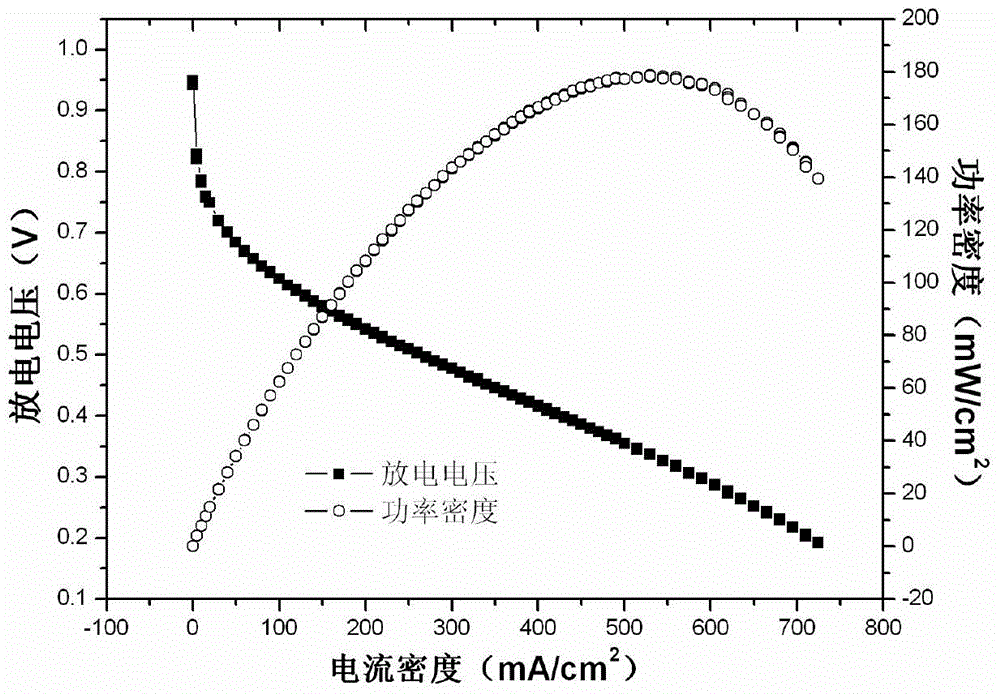

High-temperature proton exchange membrane fuel cell membrane electrode and preparation method thereof

ActiveCN105742649AReduce acid contentGuaranteed certaintyCell electrodesFuel cell detailsProtonSolvent

The invention provides a high-temperature proton exchange membrane fuel cell membrane electrode, which an acid-doped high-temperature proton exchange membrane and acid-doped gas diffusion electrodes, wherein the acid-doped gas diffusion electrodes are arranged at two sides of the acid-doped high-temperature proton exchange membrane; the mass percentage of the acid doping amount in the high-temperature proton exchange membrane is 150-200wt.%; the acid doping amount of the unit electrode area in the gas diffusion electrodes is 1-10mg / cm<2>; and the preparation method of the high-temperature proton exchange membrane fuel cell membrane electrode comprises the following steps: carrying out acid soaking treatment and aftertreatment of the membrane to constant weight; uniformly arranging the acid-doped solution on the surface of each gas diffusion electrode and removing a solvent through vacuum drying; and carrying out hot-pressing and cooling on the acid-treated gas diffusion electrodes and the acid-doped membrane and then obtaining the high-temperature proton exchange membrane fuel cell membrane electrode. According to the method, the problem of the uncertainty of the effective acid doping amount in the proton exchange membrane can be effectively solved; and the membrane electrode preparation consistency is ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

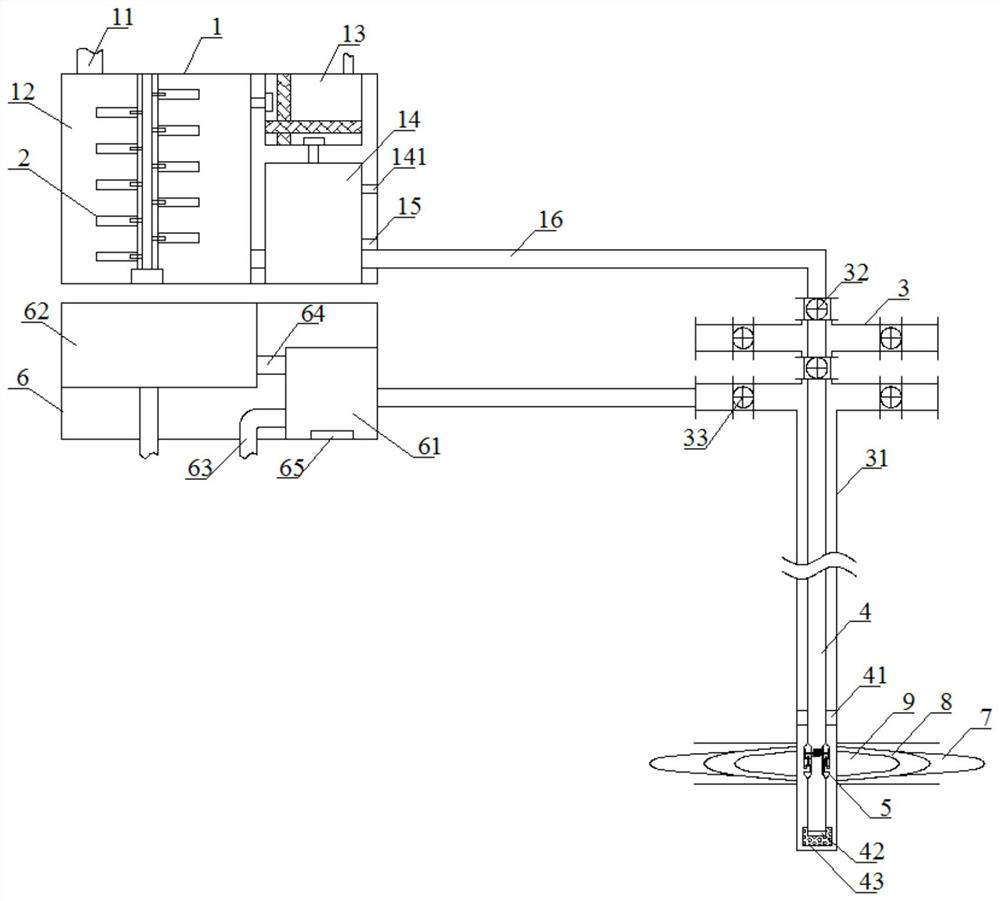

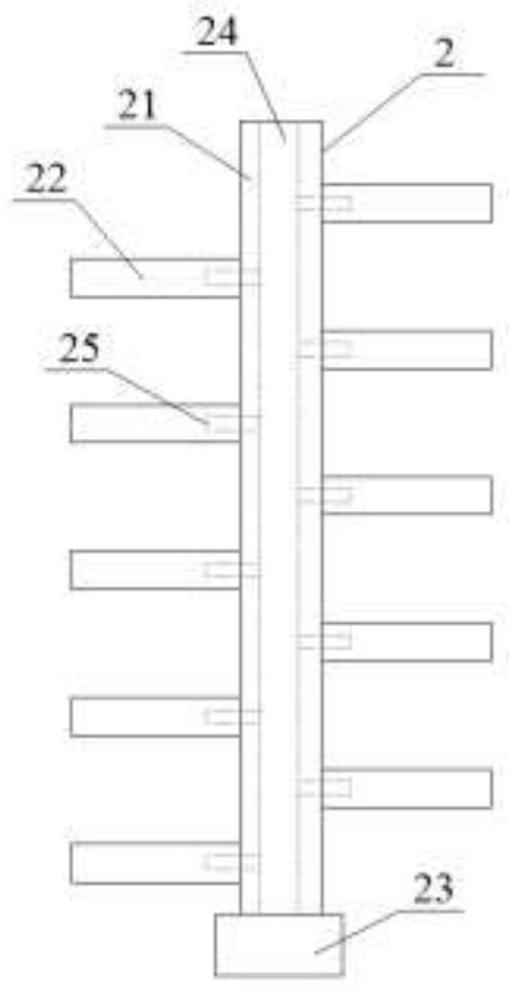

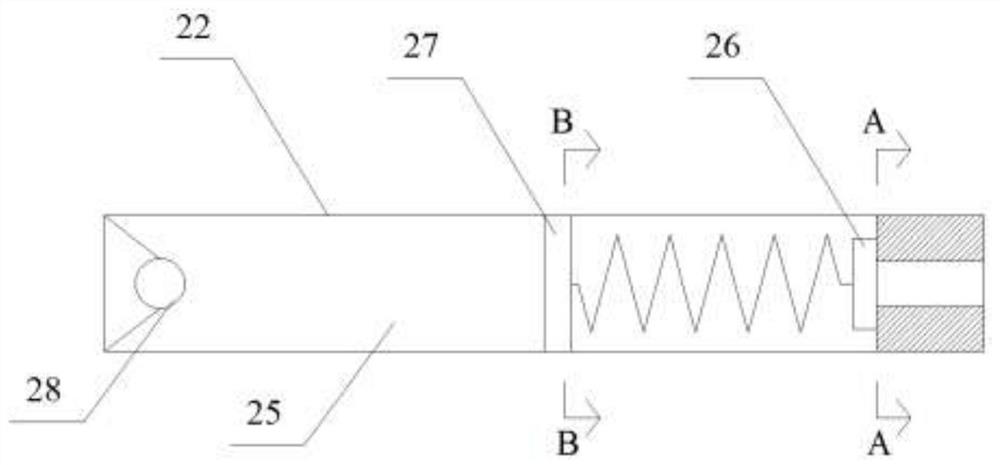

Oil well acidification process and device for increasing oil-gas well yield

ActiveCN112523737AReduce acid contentAvoid cloggingFluid removalDrilling compositionLiquid tankPre treatment

The invention discloses an oil well acidification process and device for increasing oil-gas well yield. The oil well acidification device comprises an acid liquid tank and a waste liquid tank, whereina stirring tank is arranged in the acid liquid tank, a stirring device is arranged in the stirring tank, an acidification pipe column penetrates through a wellhead device and then extends into the bottom of a casing pipe, a nozzle is arranged at the bottom of the acidification pipe column, and pulse supercharging devices are arranged on the two sides of the acidification pipe column above the nozzle; and the waste liquid tank is connected with a liquid outlet of the wellhead device. The acidification process comprises the following steps that S1, acidification pretreatment is conducted; S2, preposed acid liquid is injected; S3, reaction acid liquid is injected; and S4, a neutralizer is injected in a pulse pressurization mode, so that the acid liquid enters an oil layer in a fluctuation mode, the swept area is enlarged, the injection effect of the acid liquid is effectively enhanced, residual acid liquid is neutralized in sections at the bottom of a well, the content of the acid liquidin flowback fluid is reduced, components of preposed acid liquid, reaction acid liquid and the neutralizer are optimized, the problem of oil layer blockage can be effectively solved, and the purposeof increasing the yield is achieved.

Owner:西安石油大油气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com