Patents

Literature

72results about How to "Reduce strong interactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

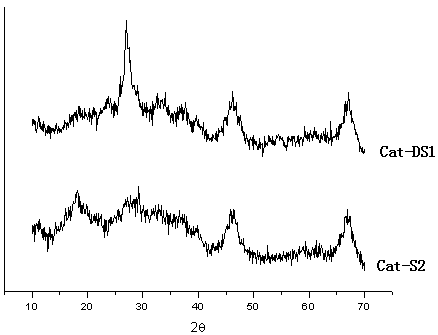

Low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application

ActiveCN103769078AGood dispersionIncrease loadHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideActive component

The invention discloses a low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application. The catalyst uses Al2O3 (alumina) as a carrier, chromium as an active component, and an alkali metal as an assistant catalyst component, taking to the final catalyst weight as the base, the chromium oxide content is 10.0%-30.0%, the alkali metal oxide content is 0.5%-3.0%, and the rest is the alumina. The active component chromium is stepwise impregnated onto the alumina carrier before and after impregnation of the alkali metal assistant catalyst component. The low carbon alkane dehydrogenation catalyst for alkene production is used in dehydrogenation of propane to produce propylene. The low carbon alkane dehydrogenation catalyst for alkene production has high activity stability and propylene selectivity, and the preparation method is simple, and is suitable for industrial applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydrogenation catalyst and preparation method and application thereof

ActiveCN103769156AReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsManganeseDehydrogenation

The invention discloses a dehydrogenation catalyst and a preparation method and application thereof. The dehydrogenation catalyst uses ammonia processed alumina as a carrier, chrome as an active component, and one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc as an additive, the additive is loaded onto the carrier by a co-impregnation method, and taking oxide weight content in the final catalyst as a reference, the catalyst comprises 2%-6% of chromium oxide, and 0.1-5% of the additive. The preparation method of the hydrocarbon dehydrogenation catalyst comprises the following processes: using ammonia to preprocess an alumina carrier, using the co-impregnation method to load one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc, and loading the active component chrome. The dehydrogenation catalyst can be used in dehydrogenation of propane for preparation of propylene. The low carbon alkane dehydrogenation catalyst prepared by the preparation method has the advantages of low active component chromium oxide content, good propylene selectivity, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

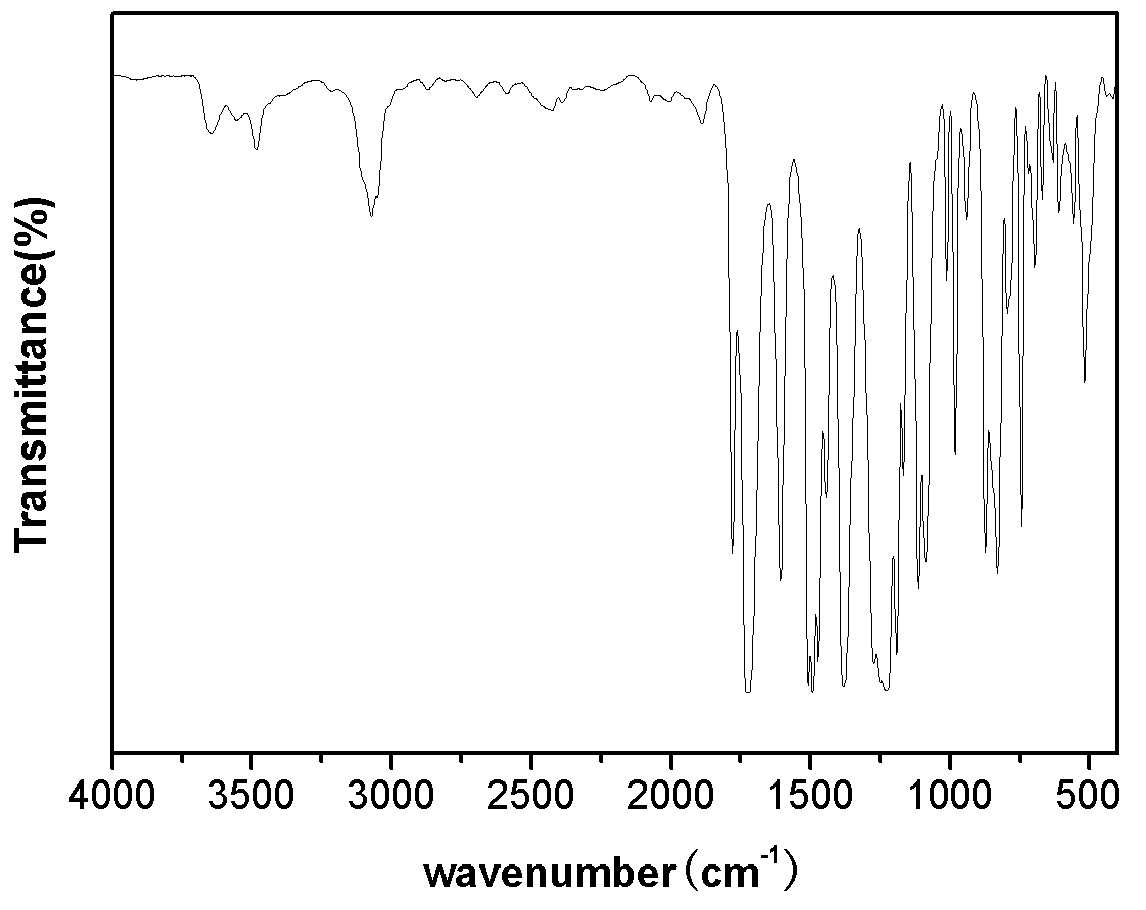

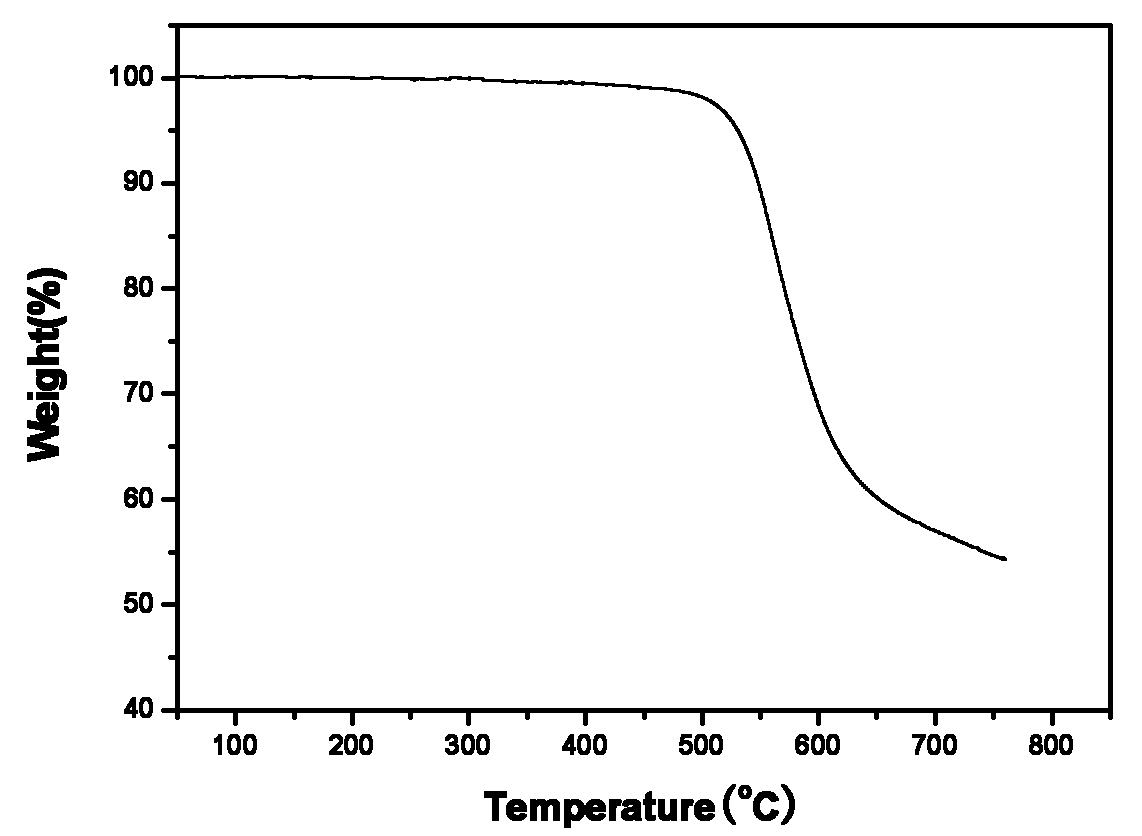

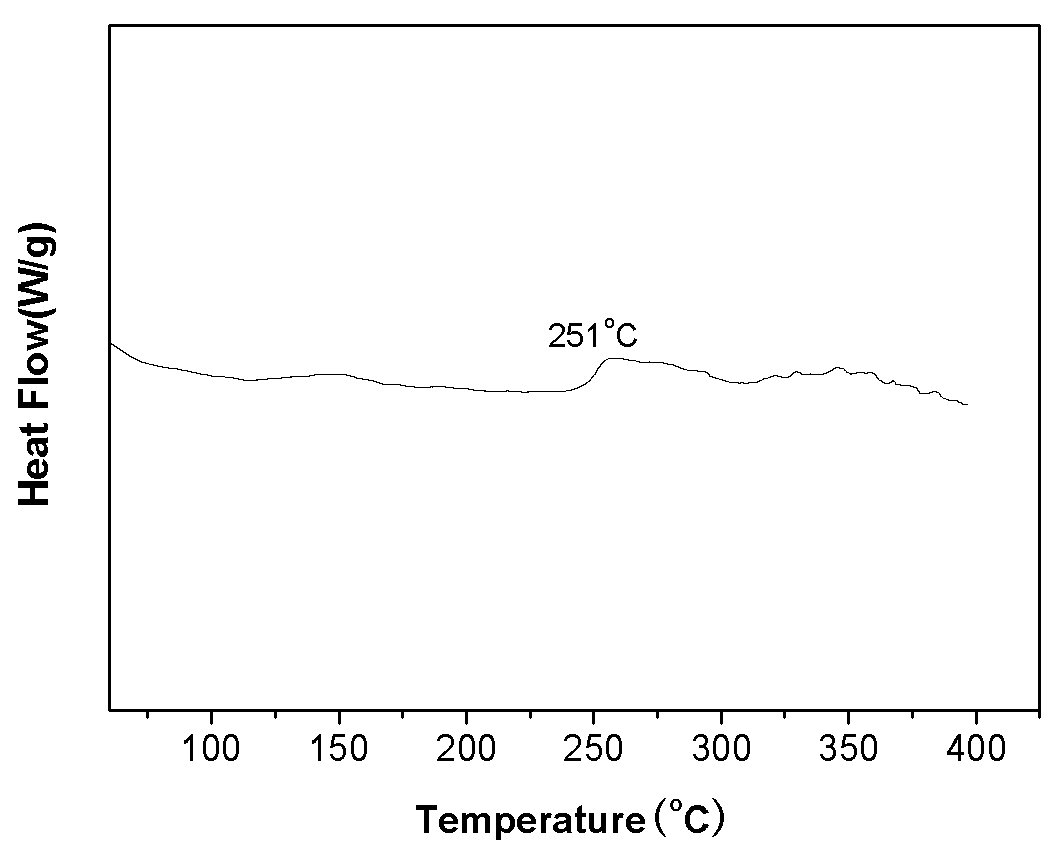

Polyimide film and preparation method and applications thereof

ActiveCN102167824AHigh transparencyReduced solar absorption and emission ratioDiphenyl etherOptical transparency

The invention discloses a polyimide film and a preparation method and applications thereof. The compound forming the polyimide film is the compound of which structural general formula is shown in the formula I. The preparation method of polyimide is as follows: aromatic dianhydride 2,3,3',4'-diphenyl ether tetracarboxylic acid dianhydride (aODPA) and a series of aromatic diamine monomers are used as raw materials to prepare polyimide resin through chemical imidization. The polyimide film prepared by the technology has good optical transparency, low solar absorptivity-emissivity ratio and good thermal stability, and can be used to prepare the thermal protection device of the spacecraft, the solar cell array substrate and the antenna reflector / collector or solar sail and have important application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

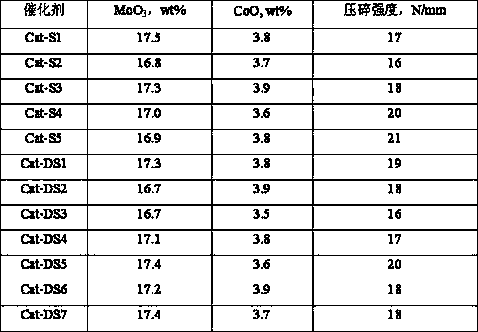

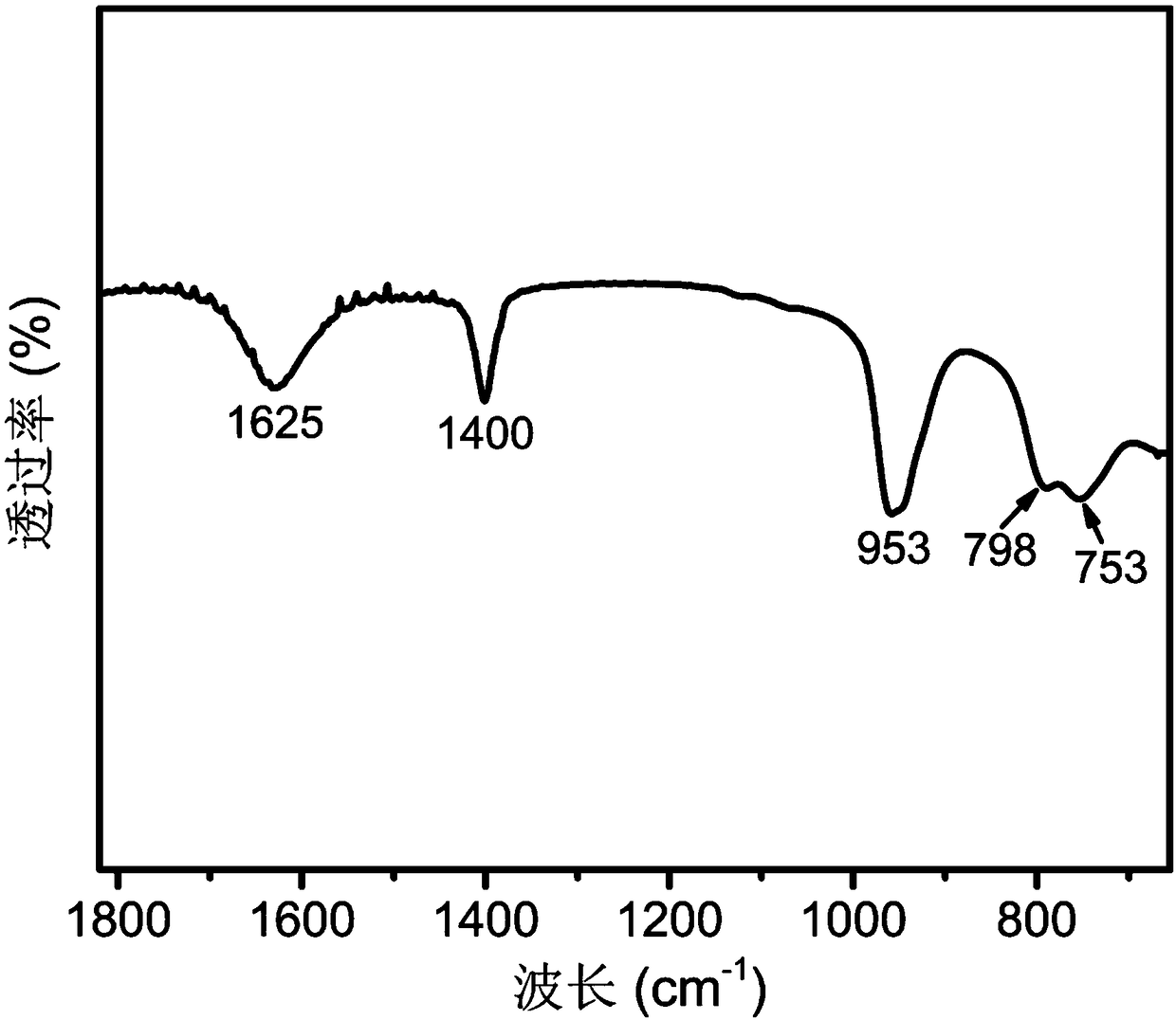

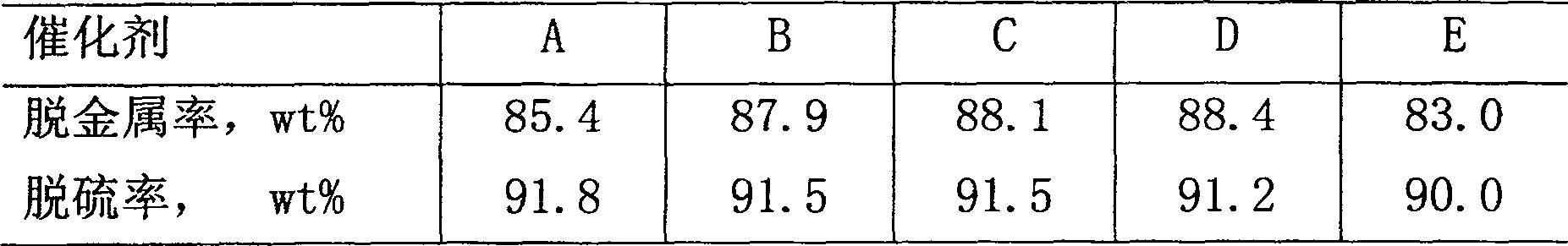

Multi-metal non-supported hydrofining catalyst, preparation method and applications thereof

ActiveCN111215094AEasy to synthesizeEasy to operateHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystHydrogen pressure

The invention relates to a multi-metal non-supported hydrofining catalyst and a preparation method thereof. The hydrofining catalyst is composed of at least one +3 valent metal oxide, at least one VIII group metal oxide, at least one IVB group metal oxide and two VIB group metal oxides, wherein based on metal oxide, the catalyst contains 10-50 wt% of VIII group metal, 1-30 wt% of IVB group metal,1-50 wt% of + 3 valent metal and 5-80 wt% of two VIB group metals. According to the invention, the catalyst can remove sulfur and nitrogen in model diesel oil to less than 10 ppm under the conditionsthat the temperature is 280-440 DEG C, the hydrogen pressure is 1-20 MPa, the volume ratio of hydrogen to diesel oil fraction is 50-1000 V / V, and the volume space velocity of the diesel oil fraction is 0.1-10 h<-1>.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

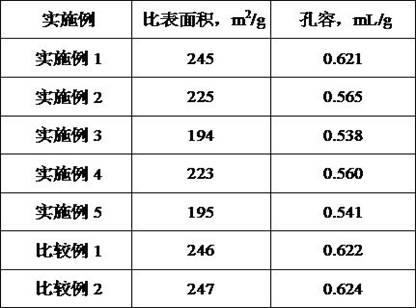

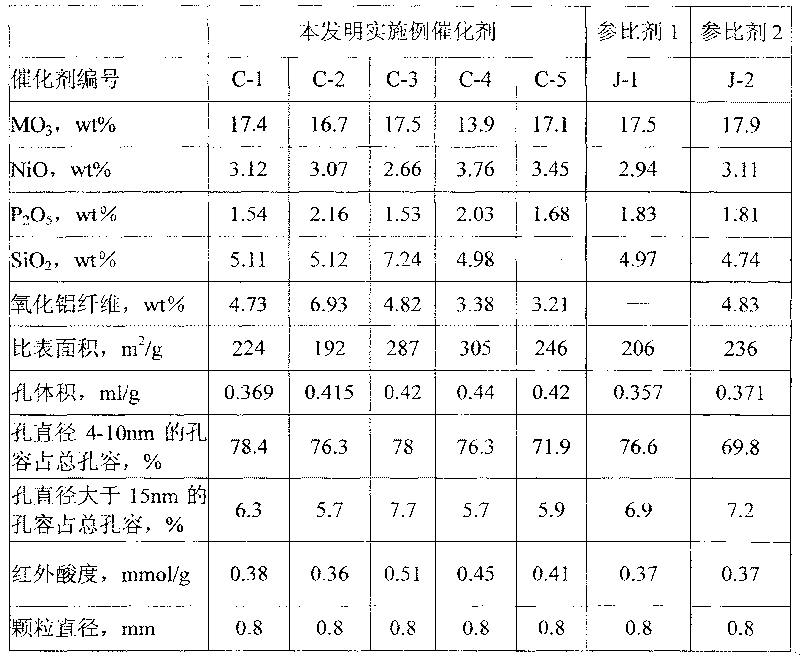

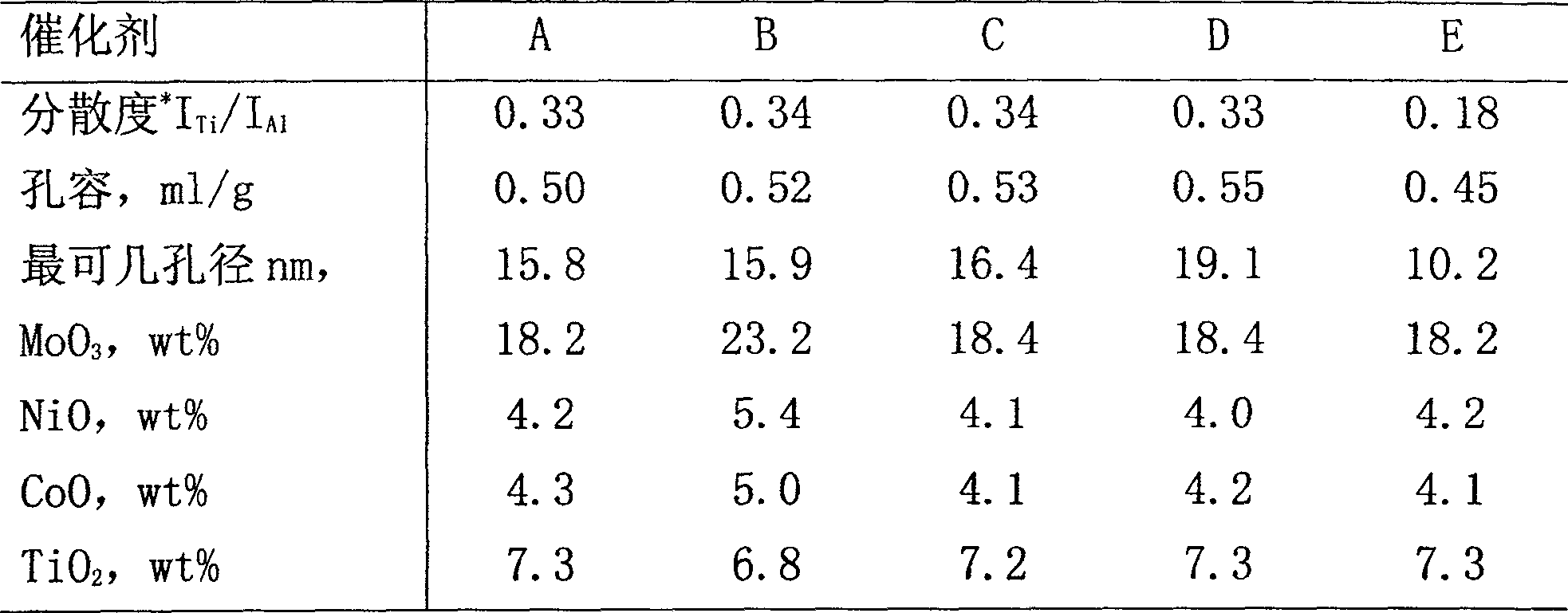

Prepn process of hydroprocessing catalyst

ActiveCN101088610AHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsPlastic materialsActive component

The present invention relates to preparation process of hydrocarbon hydroprocessing catalyst, which has gamma-Al2O3 as carrier, VIB and VIII metal as the active component, and Ti, etc as the active assistant, with the assistant Ti being introduced in the pH swinging carbonization process for producing aluminum hydroxide. The process of preparing the catalyst is one complete mixing and kneading process including the steps of introducing Ti to aluminum hydroxide powder via adding Ti salt solution, adding Mo and / or W containing alkaline solution, mixing and kneading until the aluminum hydroxide powder is wetted completely by the alkaline solution, adding Co and / or Ni containing acid solution, mixing and kneading to obtain plastic material, extruding, drying, and roasting to obtain the catalyst. The catalyst has homogeneously distributed Ti component and obviously raised performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst

ActiveCN105521791AGood dispersionImprove catalytic activity of hydrodesulfurizationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationSulfur

The invention provides a method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst. A main content of the method is characterized in that hydrogenation active metal elements of the gasoline selective hydro-desulfurization catalyst are combination of Co and Mo, the hydrogenation active metal element Co is introduced and is calcinated, the hydrogenation active metal element Mo is introduced by employing an impregnation method and then is dried, the dried catalyst is directly and rapidly procured in short time without calcination, preferably, surface sulfur polymer reduction operation can be carried out. The catalyst has obvious usage performance by the method, and the method has the advantages of simple precuring step, short on-stream time of the catalyst, low heat energy consumption, less amount of a toxic vulcanizing agent which has easy corrosion performance, and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

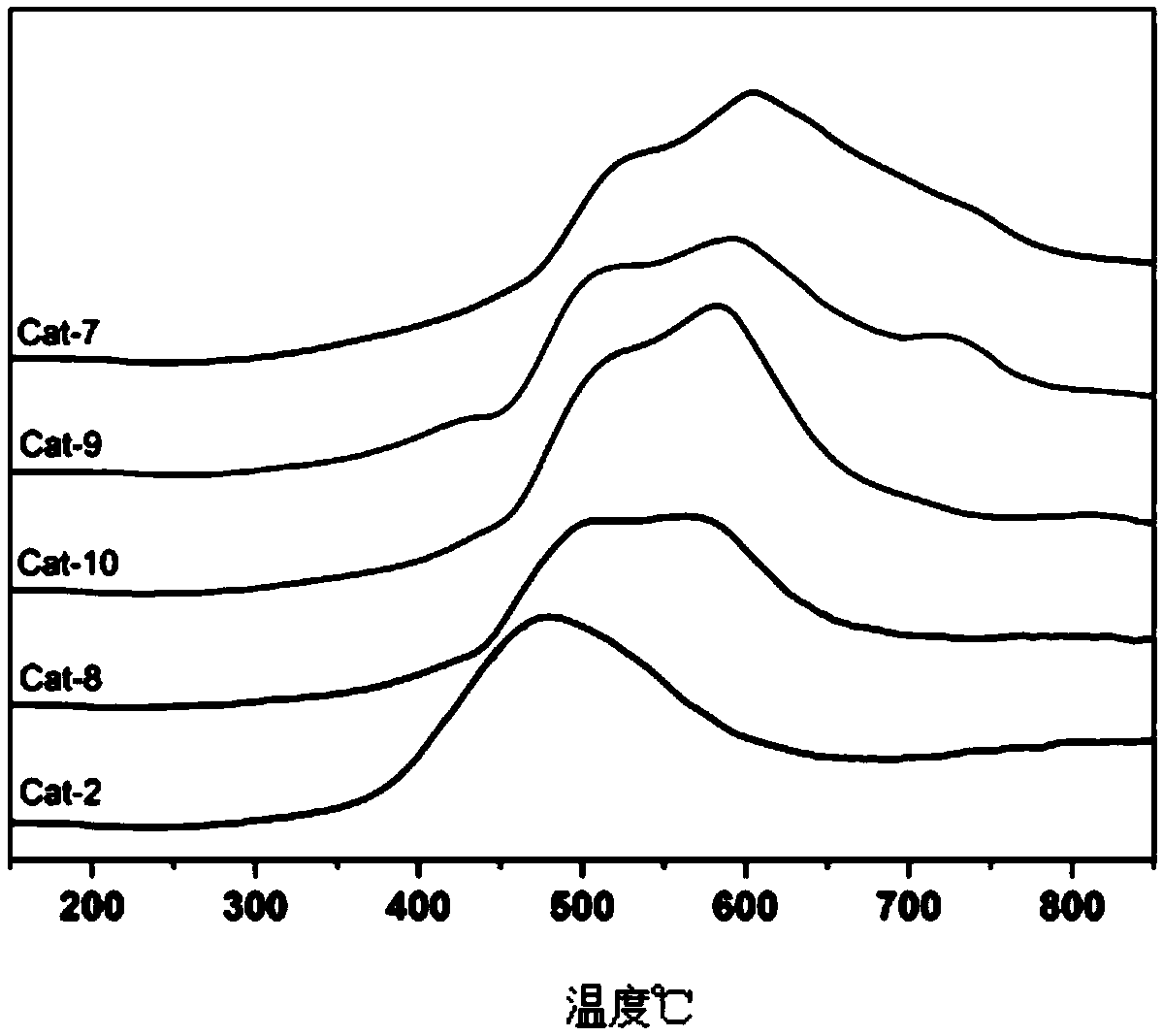

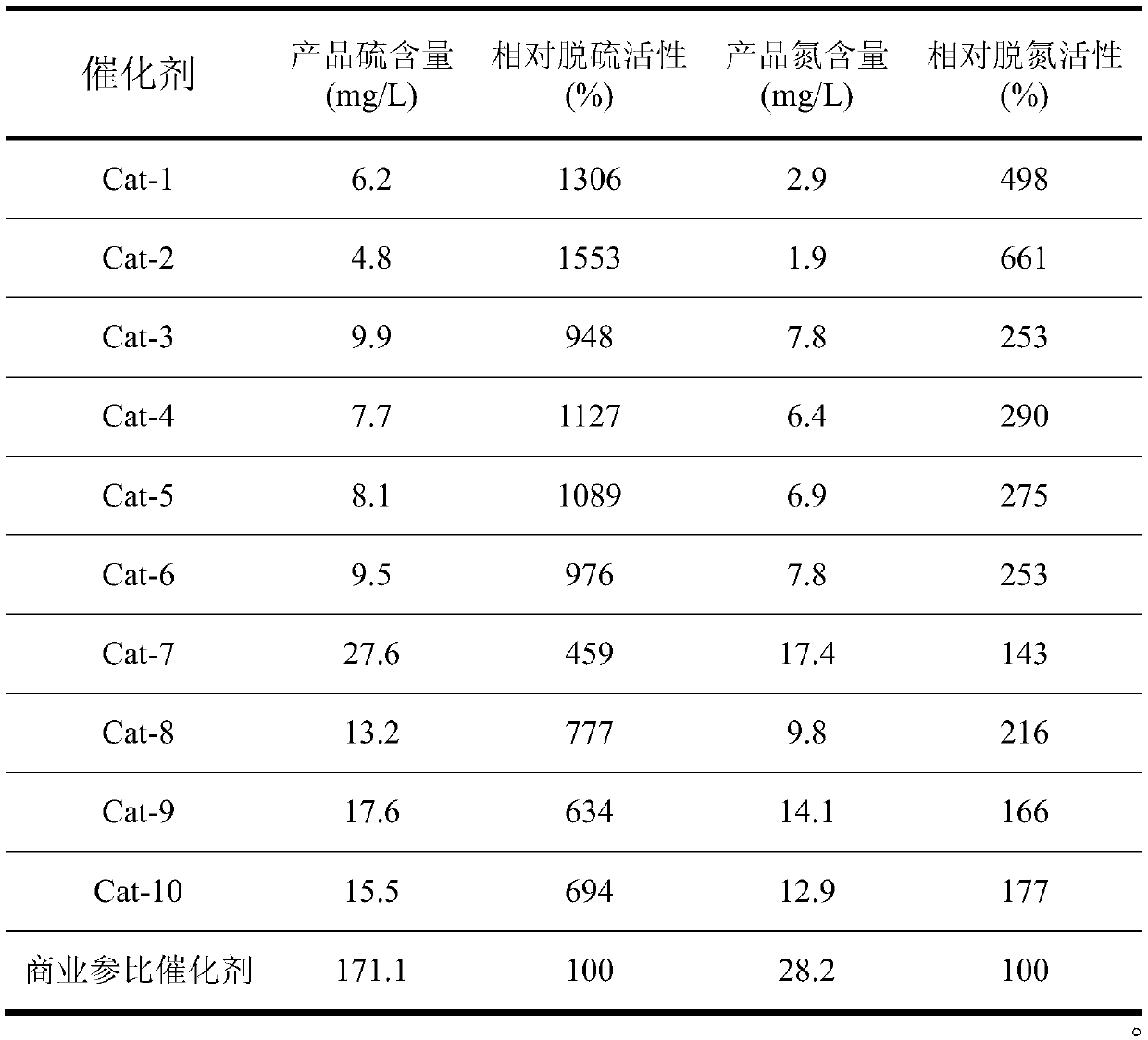

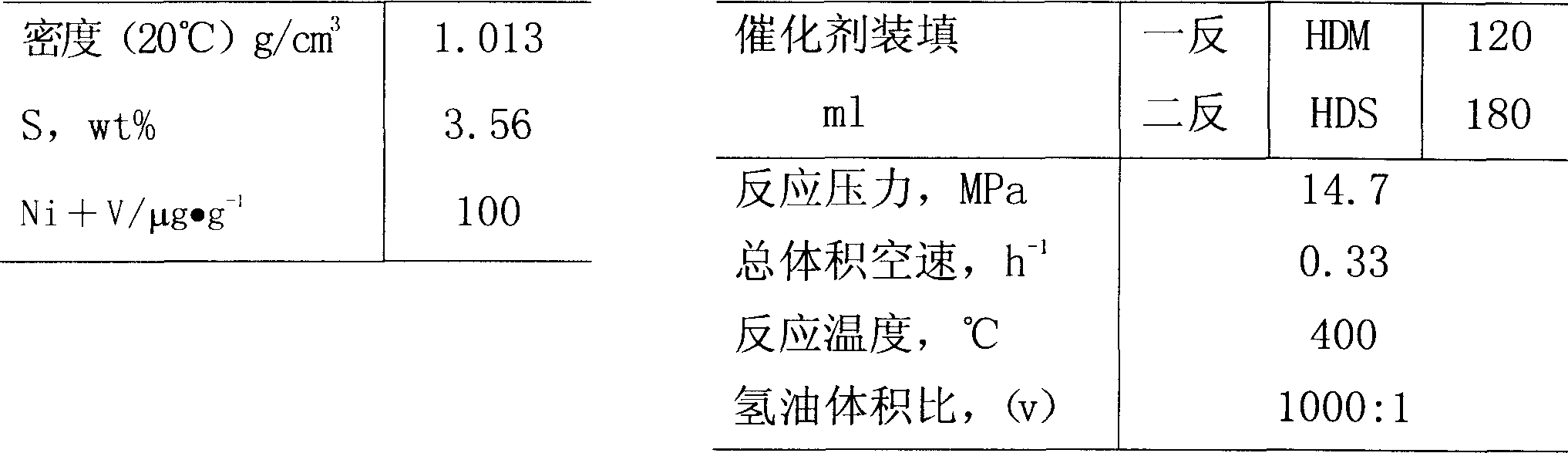

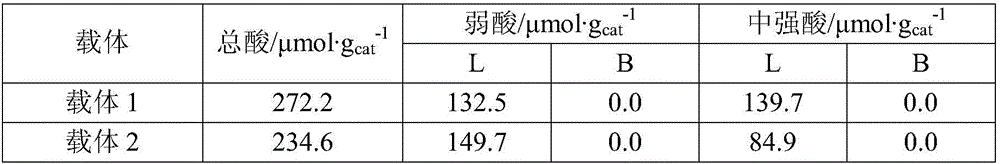

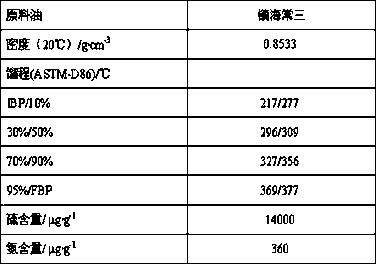

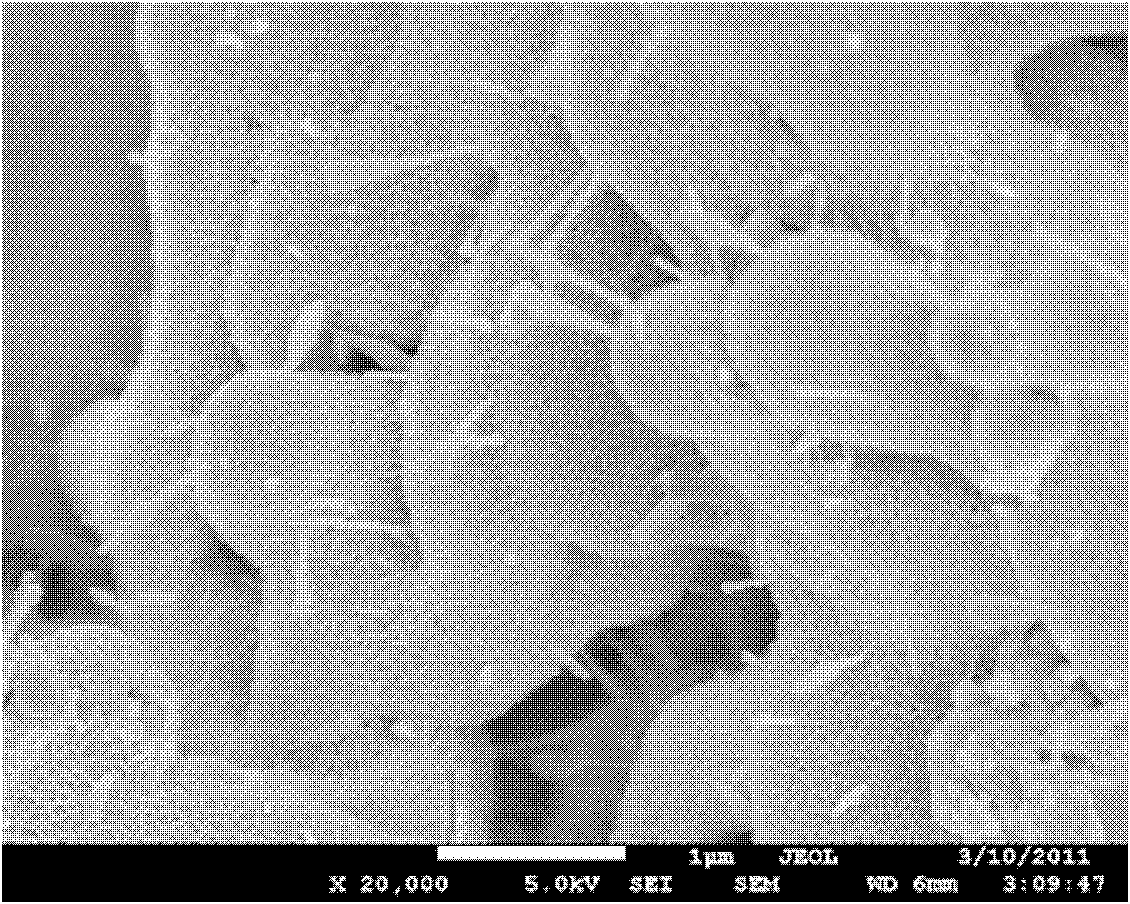

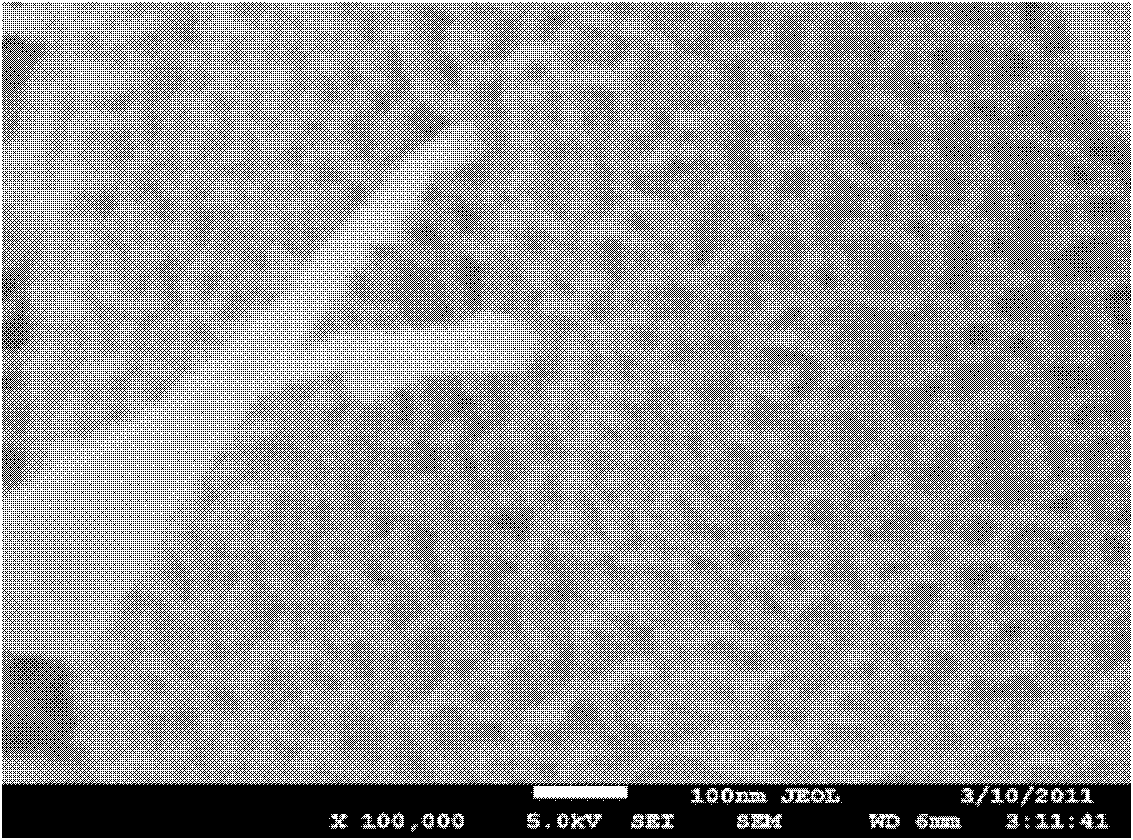

Hydrotreating catalyst and preparation method and application thereof

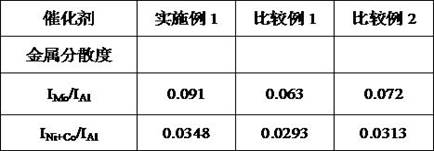

ActiveCN105833879AImprove the problem of high proportion of L acid on the surfaceReduce strong interactionsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen treatment

The invention provides a hydrotreating catalyst and a preparation method and application thereof .The preparation method of the hydrotreating catalyst comprises the steps that firstly, an aluminum oxide carrier is prepared by adopting a complexing agent roasting-drying combined mode; secondly, complexing agent surface imprednation is conducted on the aluminum oxide carrier, and the aluminum oxide carrier is roasted and modified in inert gas to obtain a modified aluminum oxide carrier; lastly, metal active components are supported through isovolumetric stepped impregnation and directly dried without needing roasting, and then the hydrotreating catalyst is finally prepared .According to the preparation method of the hydrotreating catalyst, the problem that the ratio of L acid on the surface of the aluminum oxide carrier is high can be effectively solved, and meanwhile the strong interaction between active metal and the aluminum oxide carrier can be effectively weakened; the prepared hydrotreating catalyst is suitable for the hydrodesulfurization and hydrodenitrification process of coker gas oil with the high sulfur and nitrogen content and not only has the good hydrodenitrification activity but also has the good hydrodesulfurization activity.

Owner:PETROCHINA CO LTD +1

Preparation method of hydrocarbon hydrotreatment catalyst

The invention relates to a preparation method for a catalyst to hydrotreat hydrocarbons, which comprises gama- Al2O3 as carrier, metal from VIB group and VIII group as active constituents, and Ti as active adjuvant. The prepraration method comprises: adding titanate solution to bring said Ti during the gelatinization for preparing aluminum hydroxide; adding basic solution contained Mo or W into the dried aluminum hydroxide powder, mixing till the powder wet fully by solution; adding acid solution contained Co or Ni, mixing till plastic, extruding to form, drying, baking, and obtaining the catalyst. This invention improves the catalyst property obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

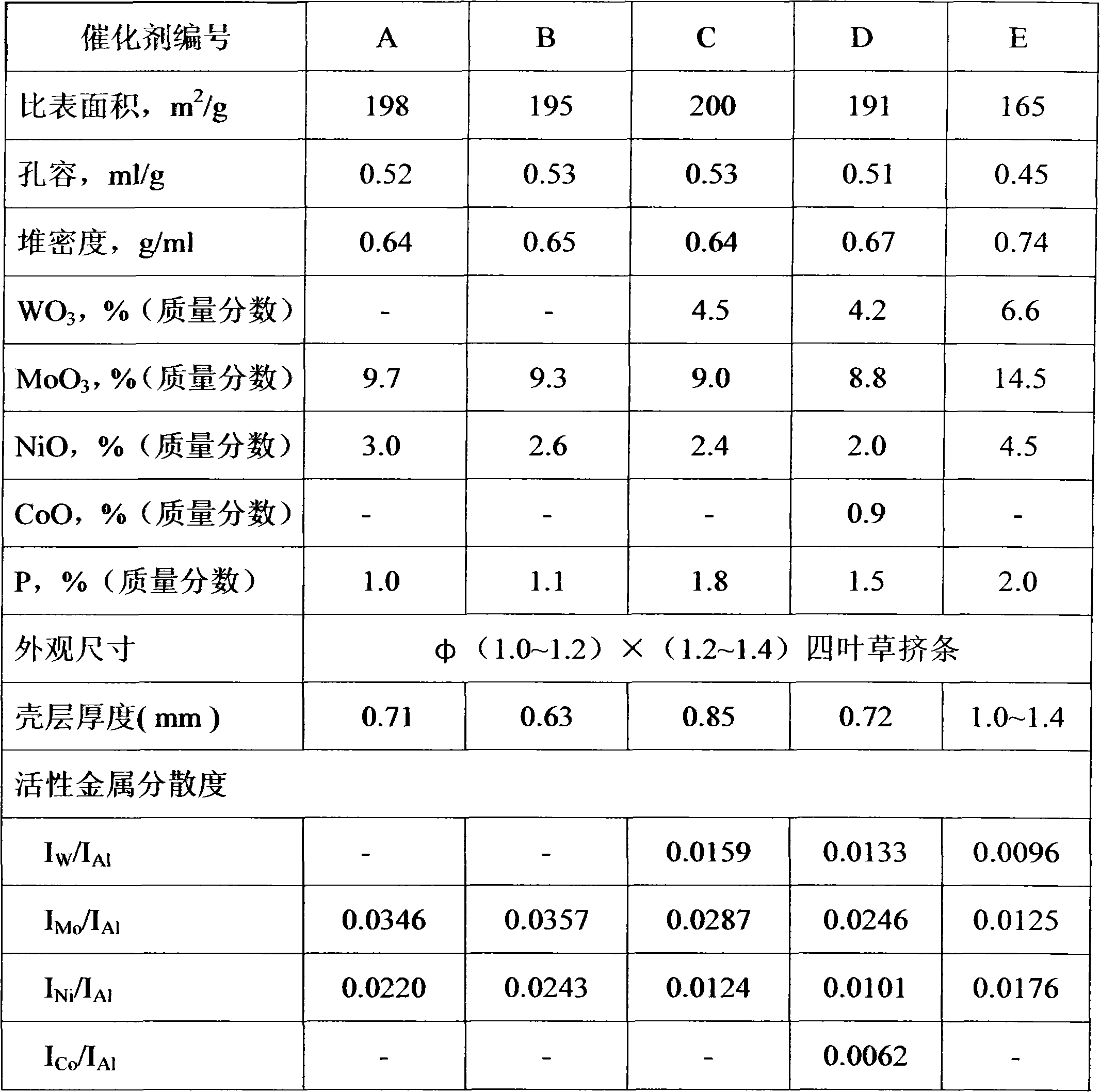

Preparation method of eggshell hydrogenation catalyst

ActiveCN103100391APH controlLow viscosityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystMetallurgy

The invention discloses a preparation method of an eggshell hydrogenation catalyst. The method consists of: mixing an alumina precursor with a gemini surfactant and an adhesive uniformly, conducting mixing and kneading to obtain a catalyst carrier, then dipping the carrier in a dipping solution containing a thickening agent under the condition of introducing air to undergo bubbling, and then performing drying and roasting, thus obtaining the eggshell hydrogenation catalyst. The method provided in the invention can effectively regulate the surface active metal shell thickness and active metal dispersity of the eggshell hydrogenation catalyst, also can stabilize the active metal components on the hydrogenation catalyst, reduce loss of the active metal components, as well as reduce the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of eggshell-type hydrogenation catalyst

ActiveCN102451722BLarge hole volumeIncrease the areaPhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityCalcination

The invention discloses a preparation method of an eggshell-type hydrogenation catalyst. The preparation method is characterized in that conventional carriers are dipped in an active metal dipping solution containing one or more thickening agents and one or more active metal dispersants under the condition of air bubbling and then are subjected to drying and calcination so that the eggshell-type hydrogenation catalyst is obtained. The preparation method can effectively adjust the thickness of a surface active metal shell layer of the eggshell-type hydrogenation catalyst and the dispersity of active metals, stabilize the active metals of the eggshell-type hydrogenation catalyst, reduce the loss of the active metals, and reduce an eggshell-type hydrogenation catalyst product cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultra-deep desulfurization catalyst, preparation method thereof and application of catalyst

ActiveCN109364957ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides an ultra-deep desulfurization catalyst, a preparation method thereof and an application of the catalyst. The preparation method of the desulfurization catalyst includes the steps: weighing ammonium paramolybdate and nickel acetate tetrahydrate, dissolving the ammonium paramolybdate and the nickel acetate tetrahydrate in glacial acetic acid and water mixed solution in a stirring manner; adding hydrazine sulfate and dissolving the hydrazine sulfate in a stirring manner; performing stirring reaction in a thermostatic water bath to obtain polyoxometallate after reaction; dispersing the polyoxometallate in water and performing ultrasonic treatment; adding aluminum oxide, uniformly stirring the materials and performing hydro-thermal decentralization loading in an autoclaveto obtain the desulfurization catalyst after reaction. The prepared desulfurization catalyst is good in dispersing performance and high in activity, ultra-deep desulfurization can be achieved, and desulfurization rate reaches up to 93.8%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

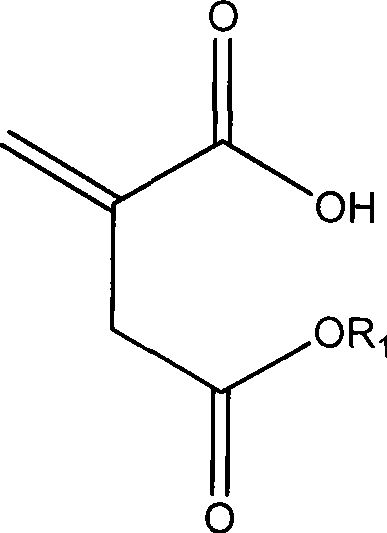

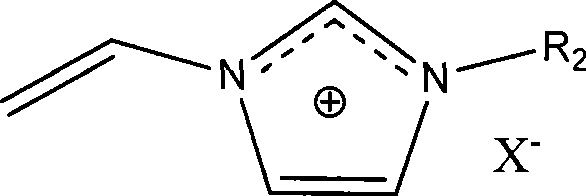

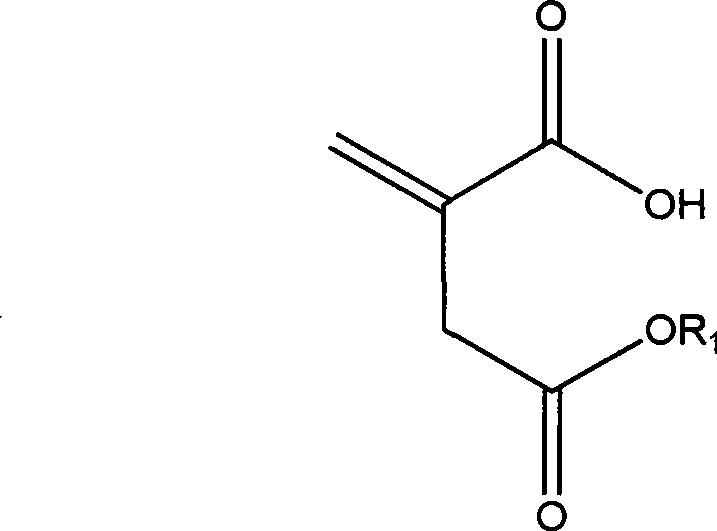

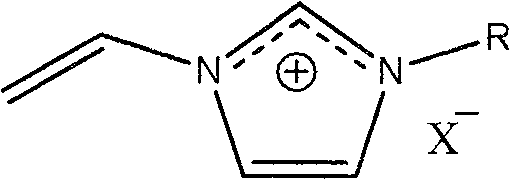

Acrylonitrile terpolymer spinning fluid containing hydrophilic group and preparation thereof

InactiveCN101413152AHigh molecular weightImprove spinnabilityMonocomponent synthetic polymer artificial filamentChain structureAcrylonitrile

The invention relates to an acrylonitrile terpolymer spinning solution containing hydrophilic groups and a preparation method. The preparation method comprises the following steps: in dimethyl sulfoxide solution, using azo-bis-iso-heptonitrile to initiate acrylonitrile, itaconate beta-monoester and vinyl imidazole salt to carry out copolymerization reaction, using small amount of chain transfer agent to adjust molecular weight of the copolymer, and synthesizing the acrylonitrile terpolymer at a temperature of between 25 and 45 DEG C, wherein the molecular weight of the acrylonitrile terpolymer is controllable to between 100, 000 and 500, 000, and distribution index of the molecular weight is lower than 2.3. The acrylonitrile terpolymer spinning solution has the characteristics of controllable molecular weight, even chain structure, narrower molecular weight distribution, and excellent hydrophilicity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for recycling hydrogenation catalyst waste

ActiveCN108067242AEfficient recyclingReduce strong interactionsCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidAluminium oxide

The invention discloses a method for recycling hydrogenation catalyst waste. The method comprises the following steps: (1) alumina support waste and / or the hydrogenation catalyst waste are / is smashedand sieved, powder obtained after sieving is pulped, slurry with solid content being 15wt%-55wt% is obtained, a nitric acid-phosphoric acid-organic acid mixed solution is added with stirring, the obtained solution is heated to 65-100 DEG C, kept at the temperature for 30-90 min and cooled to room temperature, then organic amine is added, the solution is mixed uniformly, and sol slurry of the wasteis obtained; (2) the sol slurry of the waste in step (1), alumina powder and an extrusion aid are mixed uniformly, then mixed kneading, forming, drying and roasting are performed, and an alumina support is obtained; (3) an active component is supported on the alumina support, and a hydrogenation catalyst is obtained. With adoption of the method, the hydrogenation catalyst waste can be recycled effectively, wastewater and waste residues are not produced, pollution to the environment is avoided, and the catalyst prepared with the method has higher catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

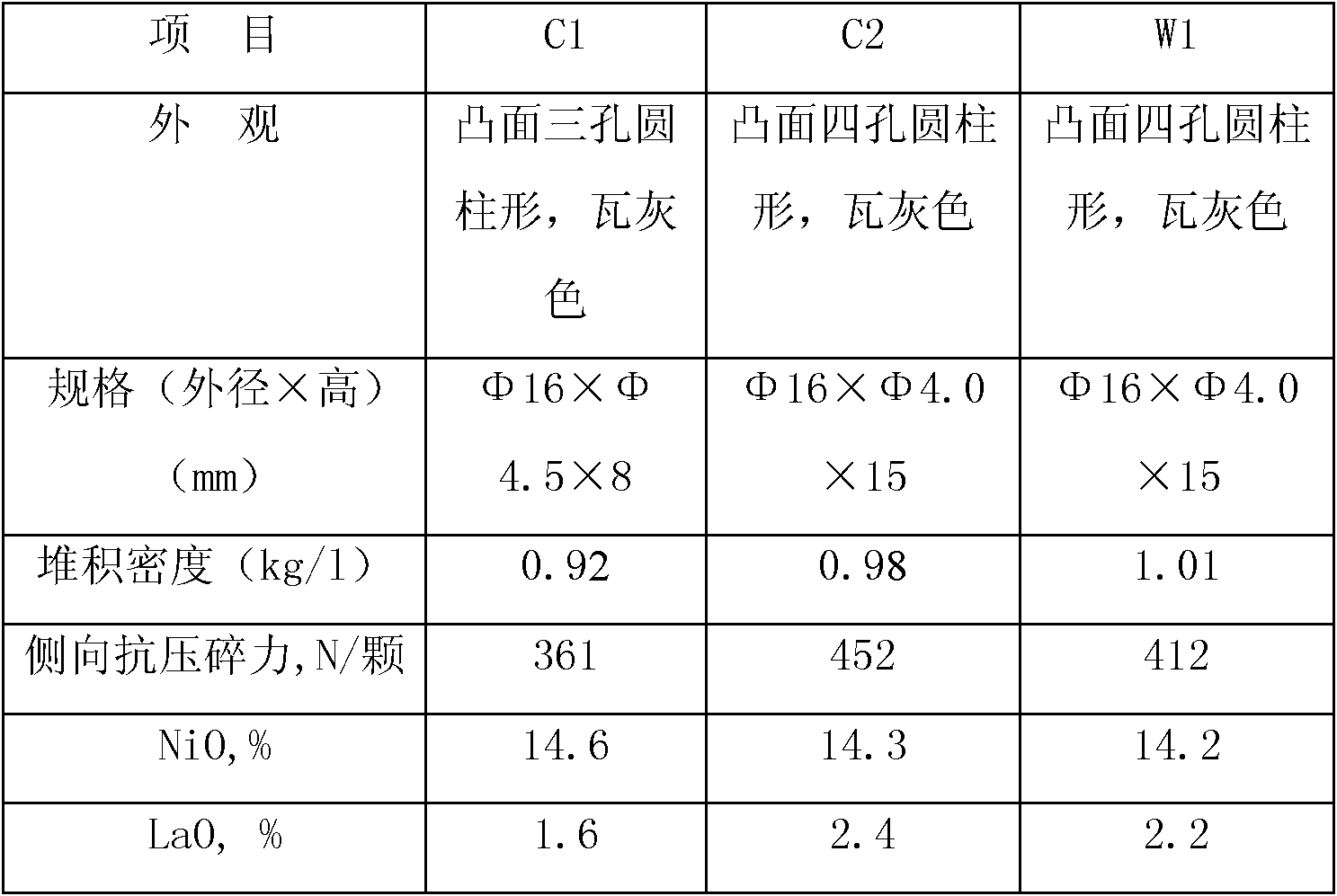

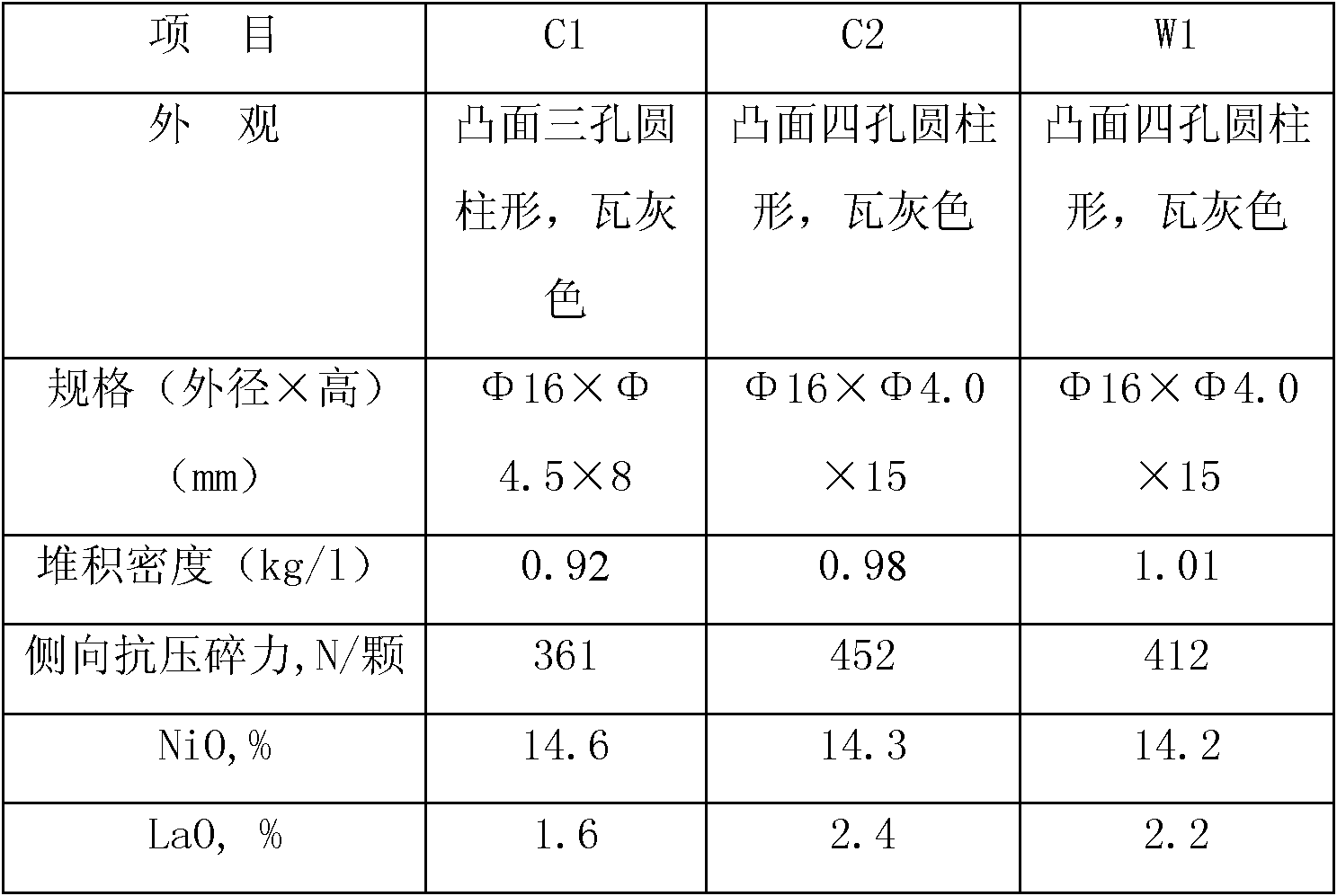

Preparation method for catalyst for hydrogen production by hydrocarbon reforming

ActiveCN102836721AHigh activityImprove anti-coking performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingRoom temperature

The invention relates to a preparation method for a catalyst for hydrogen production by hydrocarbon reforming. The method is characterized by comprising the following steps of: adding La(NP3)2 into deionized water to prepare a solution; placing an alumina-based carrier into the impregnating solution obtained above for isopyknic impregnation; drying after the impregnation; roasting the catalyst obtained above for 2-6 hours, and cooling to room temperature; preparing a Ni(NO3)2 solution by using Ni(NO3)2, deionized water and a surfactant; placing the catalyst prepared above into the Ni(NO3)2 solution for isopyknic impregnation; drying the sample obtained above, and then roasting; placing the sample obtained above into the Ni(NO3)2 solution again for another isopyknic impregnation the, and then drying and roasting again to obtain a product. The prepared catalyst for hydrogen production by hydrocarbon reforming has stabilized high activity; and when using hydrocarbon gas containing a large amount of C2-C4 hydrocarbons as a raw material, catalytic cracking and steam reforming of the C2-C4 hydrocarbons can be realized quickly by the prepared catalyst, preventing the C2-C4 hydrocarbons from moving down to a high temperature bed for carbon deposition.

Owner:SHANDONG GONGQUAN CHEM

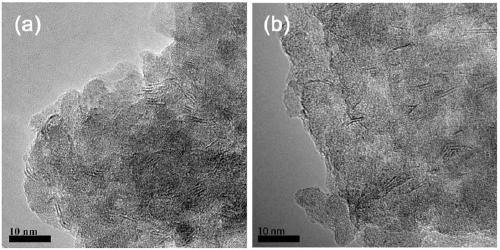

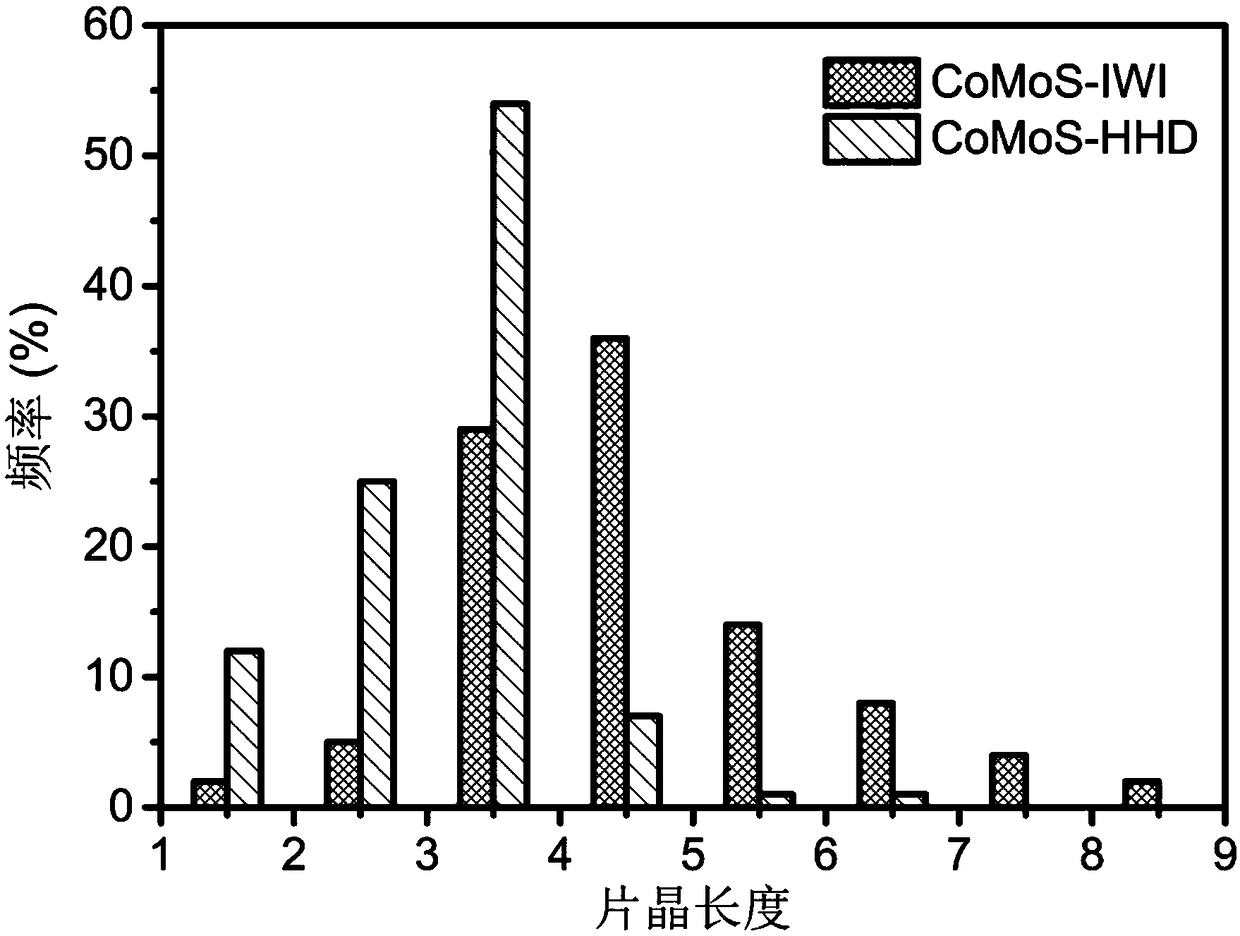

Deep desulfurization catalyst and preparation method and application thereof

ActiveCN109289876ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides a deep desulfurization catalyst and a preparation method and application thereof. The preparation method of the deep desulfurization catalyst includes: weighing ammonium paramolybdate and cobalt acetate tetrahydrate, dissolving into glacial acetic acid and water mixed solution, stirring to dissolve, adding hydrazine sulfate, stirring to dissolve, performing stirring reactionin a constant-temperature water bath to obtain a cobalt-molybdenum heteropoly compound after reaction is finished; dispersing the cobalt-molybdenum heteropoly compound into water, ultrasonically treating, adding aluminum oxide, well stirring, and performing hydrothermal load dispersion in an autoclave to obtain the desulfurization catalyst after reaction is finished. The desulfurization catalystis high in dispersion performance and activity, deep desulfurization can be realized, and the desulfurization rate is up to 94.1%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

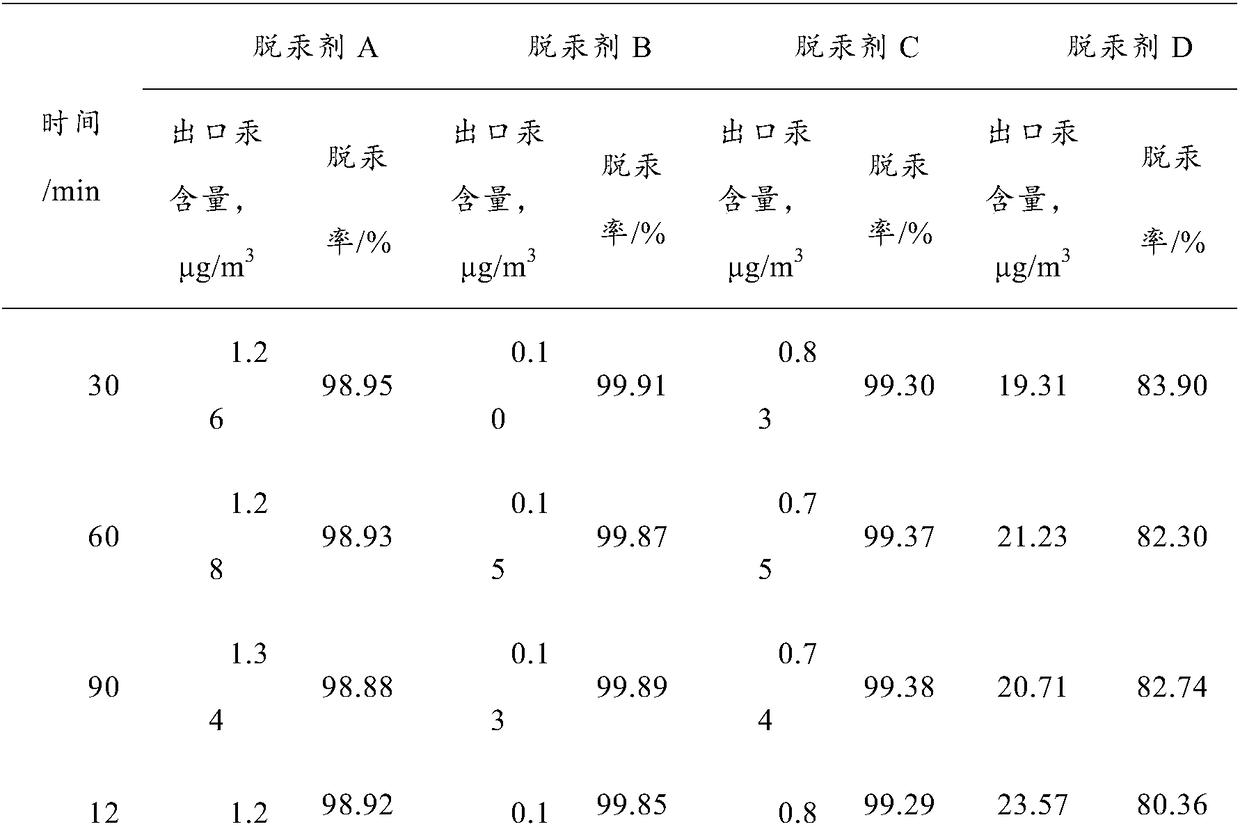

Mercury removal agent for moisture mercury removal and preparation method of mercury removal agent

InactiveCN108456574AImprove mercury removal performanceGood mercury removal effectOther chemical processesGaseous fuelsActivated carbonVulcanization

The invention provides a mercury removal agent for moisture mercury removal. The mercury removal agent comprises an active substance, carrier particles and an auxiliary component, wherein the active substance is metal sulfide, wherein copper sulfide accounts for 80% or more by mass; the carrier particles include active aluminum oxide, coconut shell activated carbon and an adhesion promoter; the auxiliary component is silver sulfide; the active substance and the auxiliary component are loaded on the carrier particles. The invention also provides a preparation method of the mercury removal agent. The preparation method comprises the following steps: mixing the active aluminum oxide, the coconut shell activated carbon and the adhesion promoter, performing extrusion forming, and drying to obtain the carrier particles; impregnating the carrier particles in a solution containing Cu<2+> and Ag<+>; after complete impregnation, calcining at 500-800 DEG C to obtain a mercury removal agent precursor; impregnating the mercury removal agent precursor in a sulfide solution for 2-4h; after vulcanization, calcining at 500-800 DEG C to obtain the mercury removal agent, wherein the mercury removal agent has better mercury removal performance when the loading quantity of copper sulfide is the same.

Owner:SOUTHWEST PETROLEUM UNIV +1

Preparation method of hydrogenation catalyst of hydrocarbon

ActiveCN1952056AHigh pore volumeHigh surface areaHydrocarbon oil crackingRefining to eliminate hetero atomsAluminium chlorideAlkane

The invention relates to the preparing method of an alkanes hydrogenating catalyst. The carrier of the catalyst is gamma-Al2O3 and the active ingredient is VIB group and VIII group metals. The invention adopts the complete mix-and-pinch method to prepare the catalyst. It uses the method of alkalinizing- evaporating-sedimentating of aluminum hydroxid solution to prepare the dry aluminium hydroxide gel. During the sedimentating process, the material is treated by ultrasonic of certain energy. The prepared aluminium hydroxide has larger bore volume, larger specific surface area and more concentrated bore distribution; besides, it has omitted the aging, filtering and washing procedures in the regular method, so it has shortened the preparing cycle and it does no harm to the environment at all. Ammonium oxalate serves as reaming agent in the invention and it can enlarge the bore very well. The catalyst can be used in the hydrogenating process of different kinds of distillate, especially the hydrogenation process of the heavy magnesium carbonate distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrogenation catalyst of hydrocarbon

ActiveCN1952055AHigh pore volumeIncrease the areaRefining to eliminate hetero atomsAlkaneAluminium hydroxide

The invention relates to the preparing method of an alkanes hydrogenating catalyst. The carrier of the catalyst is gamma-Al2O3, the active ingredient is VIB group and VIII group metals and the active accessory ingredient is Ti. Ti is led in the aluminum hydroxide gel. It adopts second-aging in the stage of gel-forming so it can ensure the uniform disperse of Ti on the aluminum hydroxide surface and larger bore volume, larger specific surface area and larger aperture. The invention adopts complete mix-and-pinch method to prepare the catalyst. The processing procedure comprises the following steps: adding alkaline solution that contains Mo and / or W to the second-aging aluminum hydroxide dry gel powder which contains Ti; mixing and pinching fully until the aluminium hydrate powder is totally sodden by alkaline solution; adding acid solution that contains Co and / or Ni, mixing and pinching until the material is able to be molded; squeezing the materials to be strips; drying and calcinating. Ti spreads more uniformly on the catalyst made in the invention; the function of the catalyst also improves substantially.

Owner:CHINA PETROLEUM & CHEM CORP +1

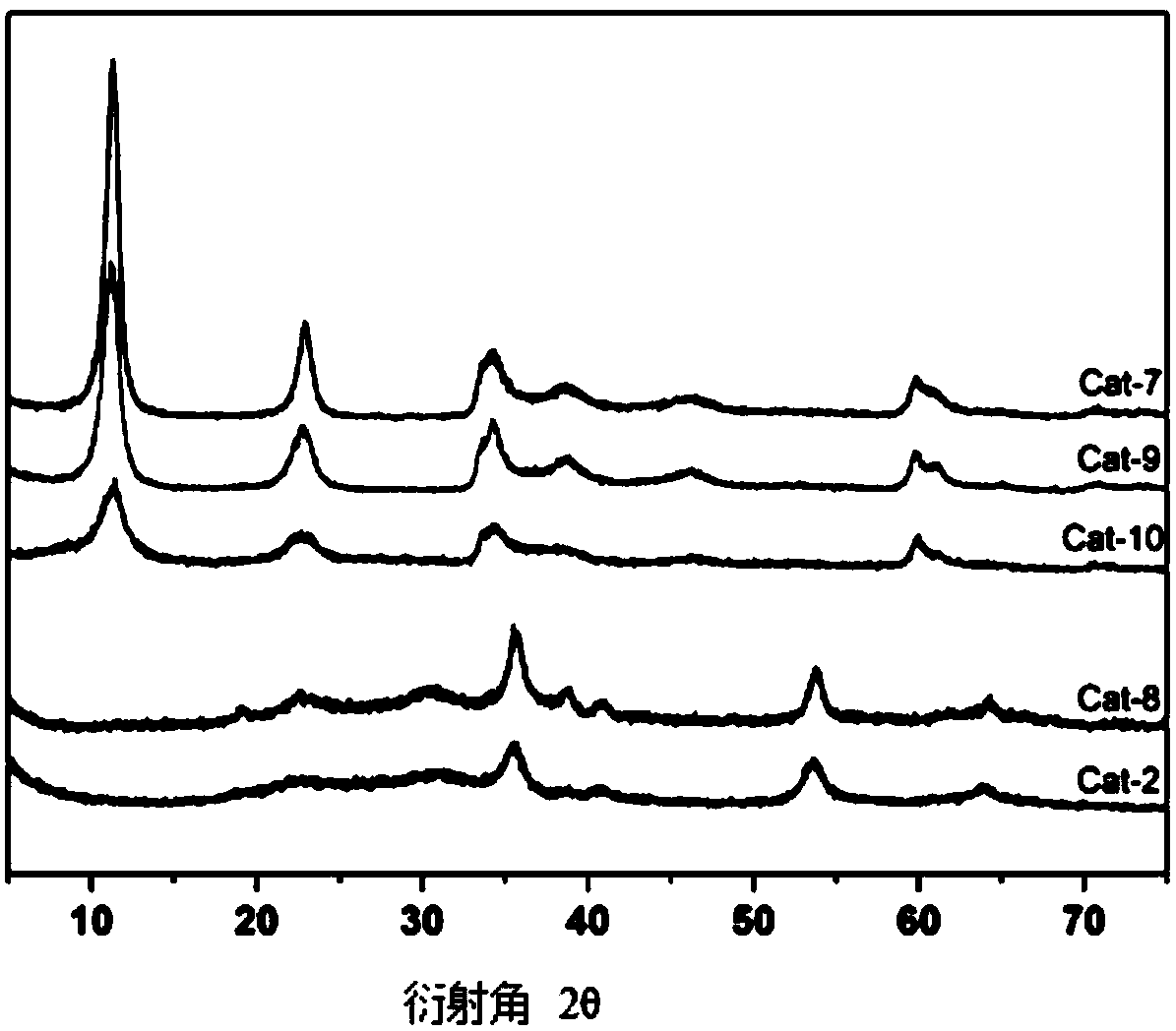

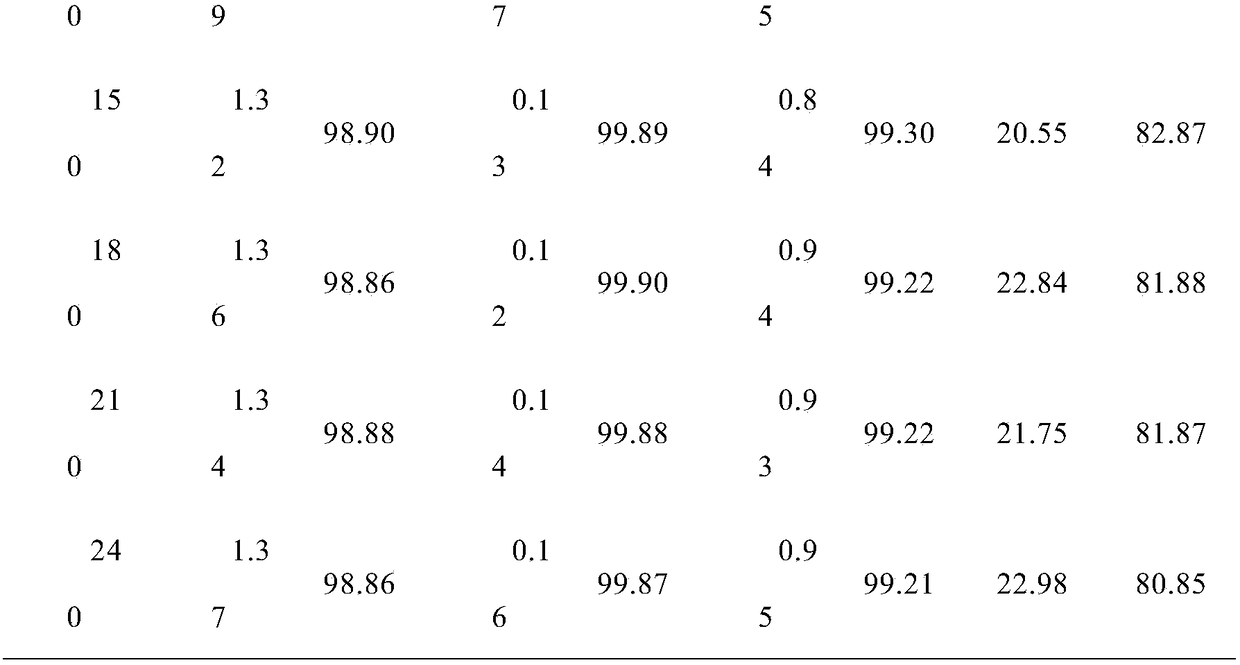

Quaternary platinum-based catalyst for propane dehydrogenation to propylene, preparation method and application thereof

ActiveCN104148069BReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The invention discloses a quaternary platinum-based catalyst used for production of propylene through propane dehydrogenation, and a preparation method and an application thereof. The catalyst treats alumina processed by an alkaline gas as a carrier, precious metal Pt and metal Sn as active components, and M1 and M2 as assistants, M1 is one selected from Na, K, Rb, Mg, Ca and Sr, and M2 is one selected from La, Ce, Pm, Sm, Ti, Ga, In, Zn and Fe. The finally obtained catalyst comprises 0.2-0.3wt% of Pt, 0.1-2wt% of Sn, 0.5-2wt% of M1 and 0.5-2wt% of M2. The preparation method of the catalyst comprises the following steps: preprocessing the alumina carrier by the alkaline gas, and loading Pt, Sn, M1 and M2 through an impregnation process. The catalyst prepared through the method has the advantages of low price, simple operation, high reaction activity, good propylene selectivity, long single-use life and the like when the catalyst is used to catalyze a production reaction of propylene through propane dehydrogenation.

Owner:HUALU ENG & TECH

A kind of preparation method of palladium adsorbent used for deep desulfurization of benzene

ActiveCN109499534BGood dispersionReduce strong interactionsOther chemical processesAdsorption purification/separationBenzeneEngineering

Owner:CHINA TIANCHEN ENG +1

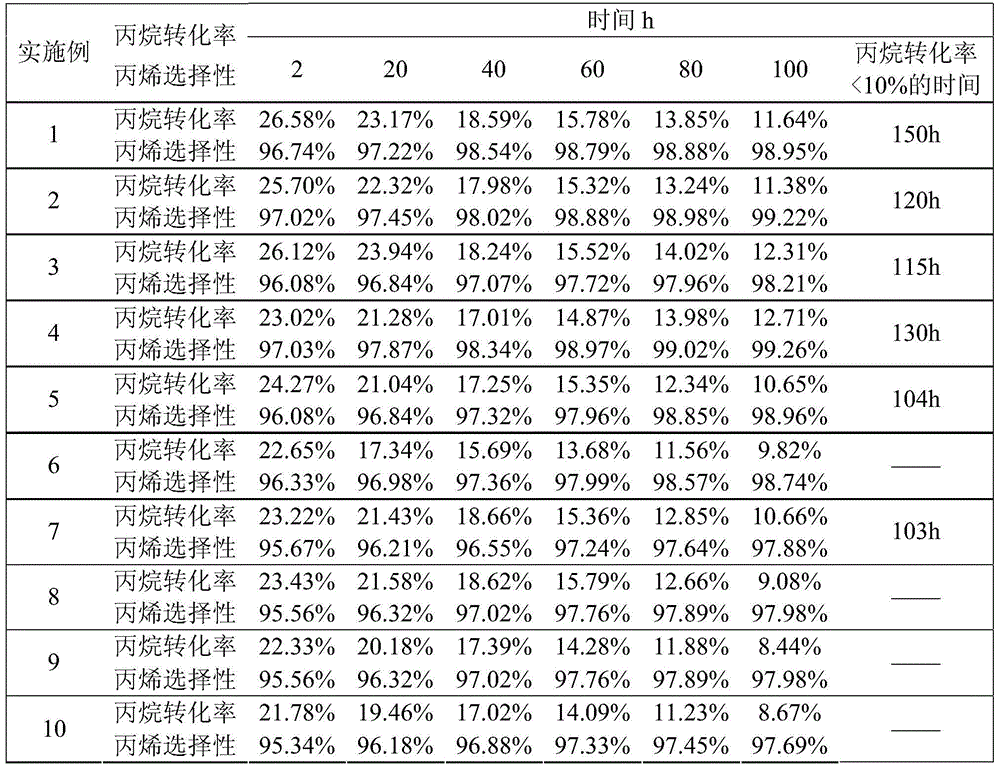

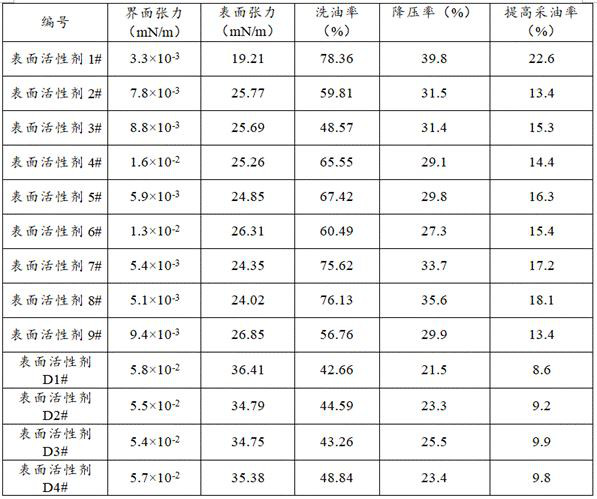

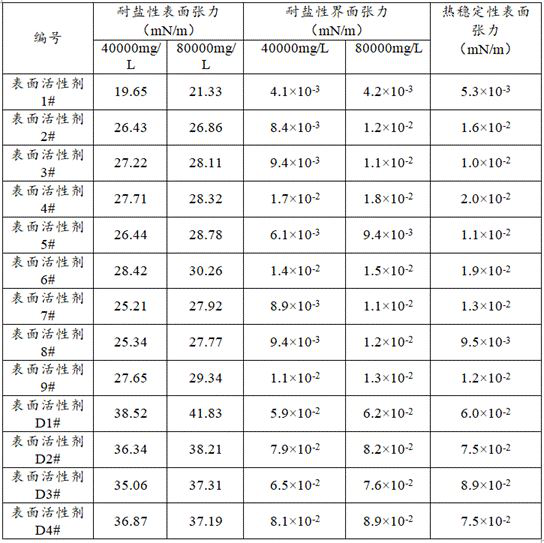

Surfactant for improving water injection efficiency of low-permeability oil reservoir as well as preparation method and application

ActiveCN113897190AReduce water injection pressureReduce interfacial tensionFluid removalDrilling compositionCapillary pressureActive agent

The invention discloses a surfactant for improving the water injection efficiency of a low-permeability reservoir as well as a preparation method and application of the surfactant, and belongs to the technical field of surfactants for oil and gas field exploitation. The surfactant is prepared from the following components in parts by weight: 1 to 5 parts of a nonionic surfactant and 25 to 50 parts of a cationic surfactant. The surfactant can effectively reduce the water injection pressure of a water injection well, avoid water injection pressure rise caused by a large amount of emulsification of crude oil, improve the water injection capacity of the water injection well, change rock wettability, reduce capillary pressure and inhibit damage of precipitation of carbonates such as calcium carbonate to stratums; and meanwhile, the oil-water interfacial tension can be effectively reduced, excellent surface performance is achieved, and improvement of the crude oil recovery rate is facilitated.

Owner:SHANDONG DESHI CHEM IND CO LTD +1

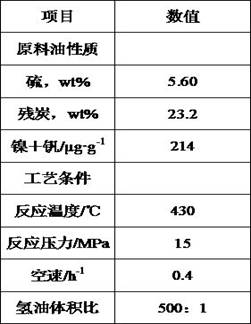

Heavy oil hydrogenation catalyst with high desulfurization activity and preparation method thereof

ActiveCN112742430AIncreased dispersionWeaken the strong interactionPhysical/chemical process catalystsBulk chemical productionOrganic acidSulfidation

The invention discloses a heavy oil hydrogenation catalyst with high desulfurization activity and a preparation method thereof, and the preparation method comprises the following steps: adding an alumina carrier into an organic acid solution for soaking treatment, further performing extraction treatment, then performing low-temperature heat treatment to obtain a carrier, then loading active metal, and finally drying and roasting to obtain the catalyst. The preparation method of the catalyst provided by the invention can effectively weaken the interaction between the active metal and the alumina carrier, improves the uniform dispersion of the active metal on the carrier to a certain extent, and the obtained catalyst is easier to sulfurize, thereby greatly improving the hydrodesulfurization activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-hydrophilicity spinning fluid for high-performance polyacrylonitrile base carbon fiber and preparation method thereof

InactiveCN100545181CGood water solubilityIncrease in sizeFibre chemical featuresPolymer scienceCarbon fibers

A hydrophilic spinning solution of polyacrylonitrile-based carbon fibers constitutes a dimethyl sulfoxide solution of acrylonitrile as the main monomer and a comonomer copolymer; comonomer 1 is vinyl imidazolium salt, and comonomer 2 is Itaconic acid, acrylic acid, methacrylic acid or their mixtures; the main monomer is 90-99.5% of the total weight of monomers, and the total weight of comonomers is 0.5-10% of the total weight of monomers; where comonomer 1 accounts for 10-90% of the total weight of the comonomer, comonomer 2 accounts for 90-10% of the total weight of the comonomer, and the weight percentage of the total monomer concentration is 15-25%. Add solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer 1 and comonomer 2, free radical initiator azobisisobutyronitrile into the reactor with condenser tube and mechanical stirring device according to the proportion Stir and mix at room temperature. After bubbling nitrogen for 20 minutes, under nitrogen protection, react at a constant temperature of 50-70°C for 6-36 hours, and then remove residual monomers and air bubbles to obtain a hydrophilic carbon fiber spinning liquid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Synthetic gas conversion catalyst, and preparation method and applications thereof

ActiveCN103769109AReduce hydroxyl concentrationReduce strong interactionsLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSyngasSurface modification

The invention discloses a synthetic gas conversion catalyst. According to the synthetic gas conversion catalyst, modified silica gel is taken as a carrier; cobalt is taken as an active component, and accounts for 5 to 35wt% of the synthetic gas conversion catalyst; and the modified silica gel is modified with a zinc-containing aqueous solution with a pH value of 3 to 4.5 via excessive immersion treatment. The invention also discloses a preparation method of the synthetic gas conversion catalyst. The preparation method comprises following steps: silica gel is taken as the carrier, and is subjected to surface modification, wherein excessive immersion treatment with the zinc-containing aqueous solution with a pH value of 3 to 4.5 is used for surface modification of the silica gel carrier; and loading of the active component Co is carried out via immersion method. The invention also discloses applications of the synthetic gas conversion catalyst in Fischer-Tropsch synthetic reaction. The preparation method is simple; and the synthetic gas conversion catalyst is high in activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocarbon hydrotreatment catalyst

The invention relates to a preparation method for a catalyst to hydrotreat hydrocarbons, which comprises gama- Al2O3 as carrier, metal from VIB group and VIII group as active constituents, and Ti as active adjuvant. The prepraration method comprises: adding titanate solution to bring said Ti during the gelatinization for preparing aluminum hydroxide; adding basic solution contained Mo or W into the dried aluminum hydroxide powder, mixing till the powder wet fully by solution; adding acid solution contained Co or Ni, mixing till plastic, extruding to form, drying, baking, and obtaining the catalyst. This invention improves the catalyst property obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

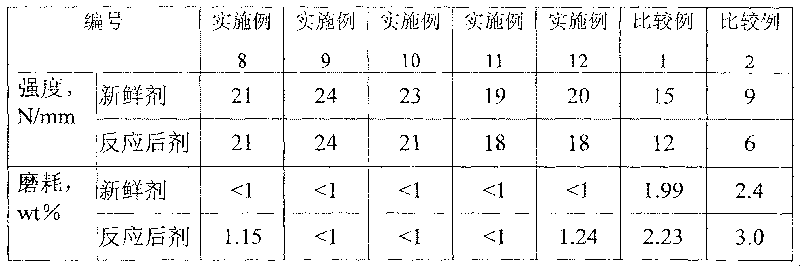

Method for producing hydrogenation catalyst with fluidized bed

ActiveCN101173187BEvenly dispersedHigh mechanical strengthTreatment with moving solid particlesFiberAdhesive

The invention discloses a preparation method for fluidized bed hydrotreating catalysts, which is characterized in that alumina fiber is also added with the content of 3wt% to 10wt% in the catalyst besides the conventional hydrogenated catalyst component in the catalyst. The invention has the advantages that alumina fiber is added to increase mechanical strength of the catalyst; service life of thecatalyst is prolonged, and production cost is reduced; the complete mixing kneading method is adopted in the preparation method, wherein the hydrogenated active metallic ions are added into the catalyst in the mode of solution ions rather than granular metal salts, thus the metallic ions are dispersed more evenly, and mechanical strength of the catalyst is enhanced; and the acidic adhesive in themethod is added after the mixture of refractory porous inorganic oxide and alumina fiber is wetted by the active metallic solution, thus strong interaction of acid and refractory porous inorganic oxide as well as alumina fiber is greatly mitigated, and loss of pore volume and specific surface area is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of hydroprocessing catalyst

ActiveCN100537028CHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsActive componentAluminium hydroxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy, residual oil hydrogenating catalyst and its preparation

InactiveCN1227332CIncrease the areaLarge hole volumeRefining to eliminate hetero atomsHydrodesulfurizationActive component

The invention relates to a catalyst of hydrodesulfurization of heavy oil and residual oil and its preparing method. The catalyst takes gama-Al2O3 as its carrier, with VIB family and VIII family metals as active components, and with Ti etc. as active assistants. The catalyst assistants Ti of the invention is drawn into by ultrasonic wave in aluminum hydrate gelatinization. The catalyst is prepared by complete mixed kneading method, i.e., adding alkaline solution containing Mo and / or W into aluminum hydrate dry gel powder of Ti drawn by ultrasonic wave to intensively mix until aluminum hydrate powder is wetted by alkaline solution completely, re-adding acid solution containing Co and / or Ni to be mixed until materials become plastic body, extrusion molding, drying, and roasting to get catalyst. Distribution of the catalyst assistants Ti prepared by the method is of more uniform, having pore capacity and specific area improved apparently with excellent performance in use.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrocarbon hydroprocessing catalyst

ActiveCN1951560AEvenly distributedHigh pore volumeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive agentActive component

The invention relates to a method for preparing hydrocarbon hydrogenation catalyst. Wherein, said catalyst uses gamma-Al2O3 as carrier, uses VIB group and VIII group metal as active components; uses Ti as active agent. The invention adds organic Ti salt into the agglutination process that prepares aluminum hydroxide with carbonization method. And the catalyst preparation uses complete mixing method that adding alkali solution with Mo and / or W into the aluminum hydroxide dry powder, mixing until the aluminum hydroxide powder is wetted by alkali solution; adding the acid solution of Co and / or Ni; mixing and shaping into bars, drying, baking to obtain the catalyst. In said catalyst, the catalyst agent Ti has uniform distribution, and the property of catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for catalyst for hydrogen production by hydrocarbon reforming

ActiveCN102836721BHigh activityImprove anti-coking performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingRoom temperature

The invention relates to a preparation method for a catalyst for hydrogen production by hydrocarbon reforming. The method is characterized by comprising the following steps of: adding La(NP3)2 into deionized water to prepare a solution; placing an alumina-based carrier into the impregnating solution obtained above for isopyknic impregnation; drying after the impregnation; roasting the catalyst obtained above for 2-6 hours, and cooling to room temperature; preparing a Ni(NO3)2 solution by using Ni(NO3)2, deionized water and a surfactant; placing the catalyst prepared above into the Ni(NO3)2 solution for isopyknic impregnation; drying the sample obtained above, and then roasting; placing the sample obtained above into the Ni(NO3)2 solution again for another isopyknic impregnation the, and then drying and roasting again to obtain a product. The prepared catalyst for hydrogen production by hydrocarbon reforming has stabilized high activity; and when using hydrocarbon gas containing a large amount of C2-C4 hydrocarbons as a raw material, catalytic cracking and steam reforming of the C2-C4 hydrocarbons can be realized quickly by the prepared catalyst, preventing the C2-C4 hydrocarbons from moving down to a high temperature bed for carbon deposition.

Owner:SHANDONG GONGQUAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com