Prepn process of hydroprocessing catalyst

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the structural damage of alumina and affect the particle size of aluminum hydroxide , titanium distribution and other issues, to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

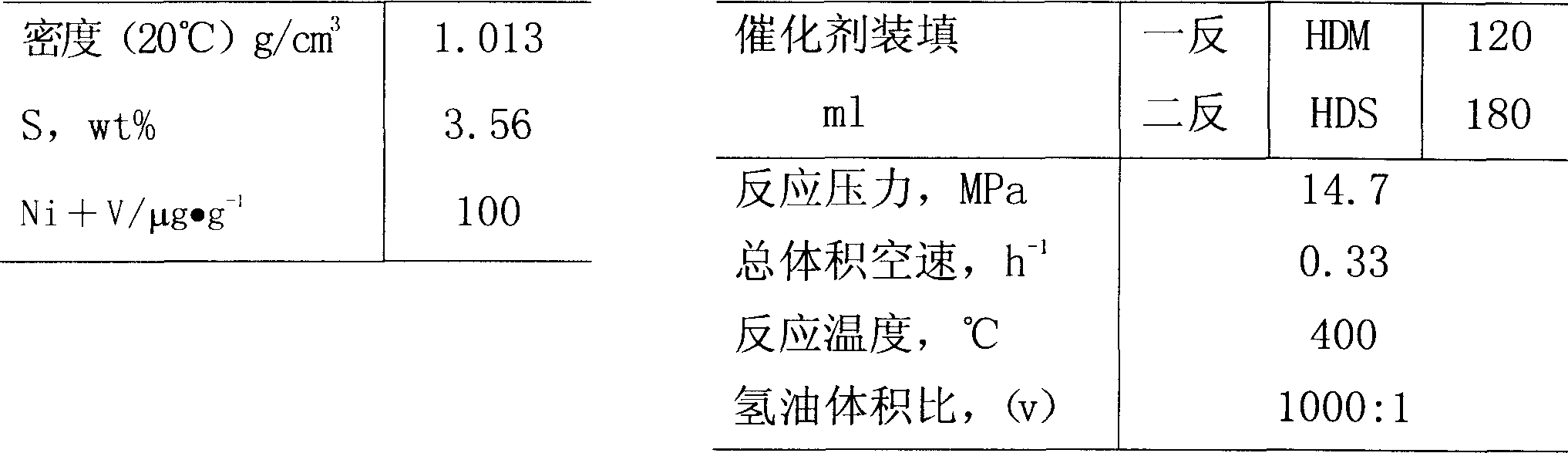

Method used

Image

Examples

Embodiment 1

[0025] The preparation concentration is 30gAl 2 O 3 / l, sodium meta aluminate solution with Na to Al atomic ratio of 1.4. Take a certain amount of sodium metaaluminate solution and place it in the gel forming kettle, adjust the pH to 14, the temperature at 25°C, and start to pass in carbon dioxide gas with a concentration of 40v%. While the carbon dioxide is passed through, add the pH value under stirring. For the titanium trichloride solution of 2, when the pH value becomes 6.5, add sodium metaaluminate solution to make the pH value 10.5 and stir for 5-10 minutes; repeat the above steps once, and then the slurry pH value is 10.5 Stop the carbon dioxide gas at the time. The slurry was aged for 1.0 hour. Filter and wash with deionized water until the aluminum hydroxide contains Na + When the weight is less than 0.05wt%, dry (120°C) for 4 hours, and then crush to 180 mesh. Weigh 50g of the titanium-containing aluminum hydroxide dry rubber powder, add 35g of ammonium molybdate solutio...

Embodiment 2

[0027] Compared with Example 1, the atomic ratio of Na to Al in the sodium metaaluminate solution is changed to 1.6, and the amount of other materials and operating conditions are the same as in Example 1, that is, the product B of the example is cost.

Embodiment 3

[0029] Compared with Example 1, the process of changing the pH value of the sodium metaaluminate solution from 14 to 6.5 and then to 10.5 was repeated three times. The amount of other materials and operating conditions were the same as in Example 1, that is, the cost example product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com