Patents

Literature

41results about How to "Large crystal particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

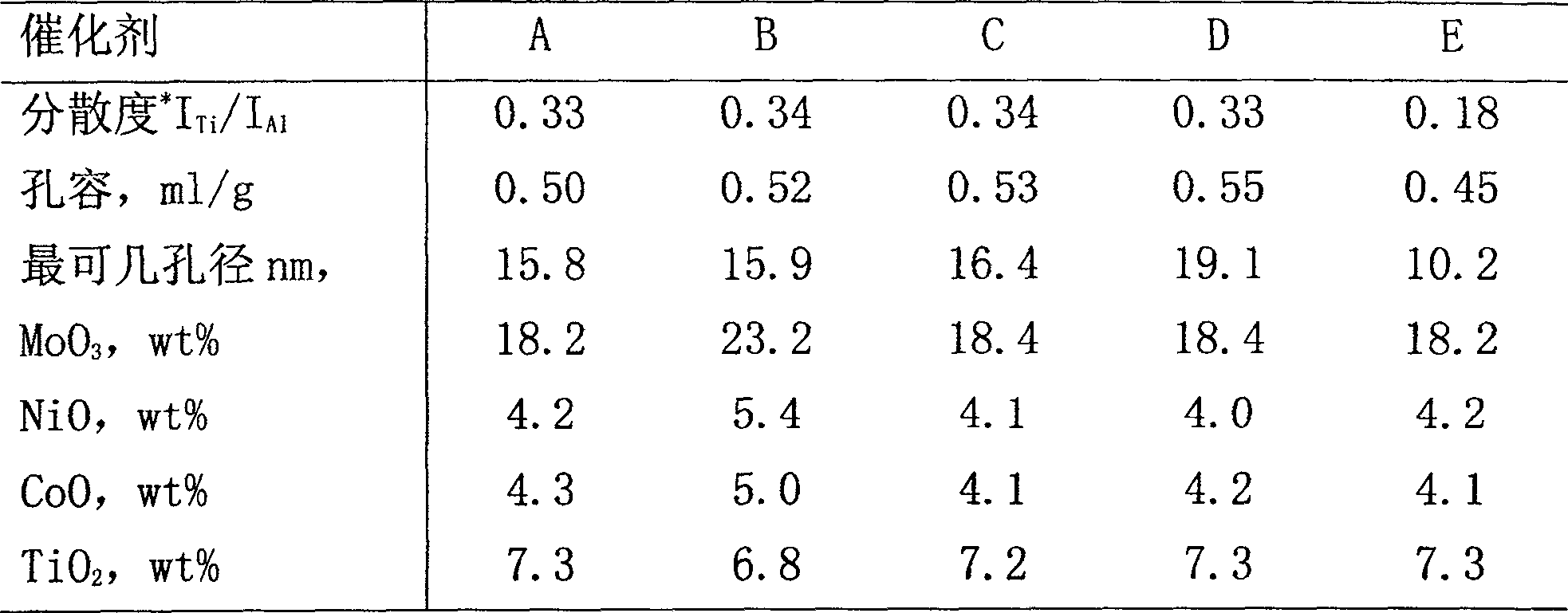

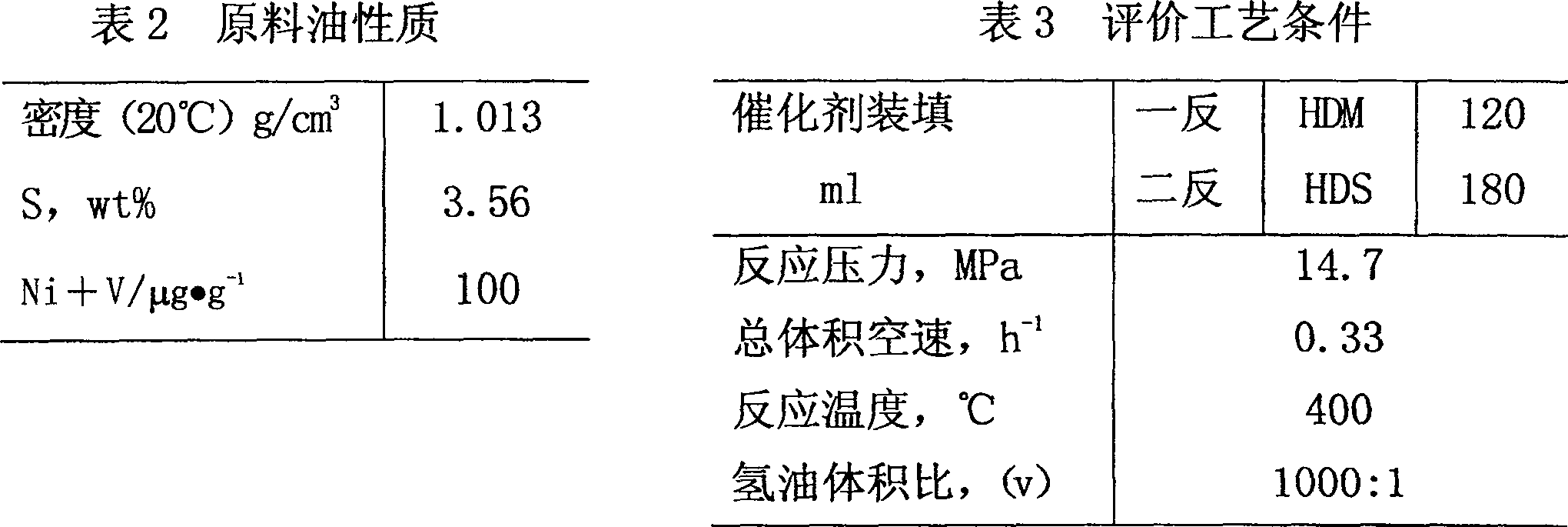

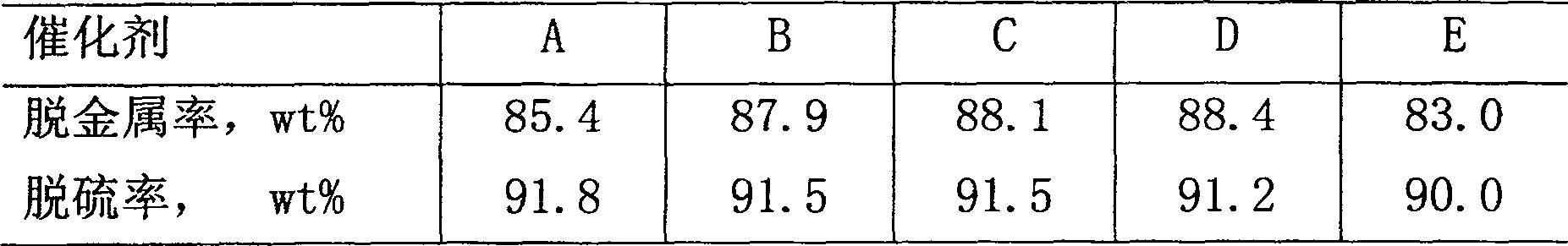

Prepn process of hydroprocessing catalyst

ActiveCN101088610AHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsPlastic materialsActive component

The present invention relates to preparation process of hydrocarbon hydroprocessing catalyst, which has gamma-Al2O3 as carrier, VIB and VIII metal as the active component, and Ti, etc as the active assistant, with the assistant Ti being introduced in the pH swinging carbonization process for producing aluminum hydroxide. The process of preparing the catalyst is one complete mixing and kneading process including the steps of introducing Ti to aluminum hydroxide powder via adding Ti salt solution, adding Mo and / or W containing alkaline solution, mixing and kneading until the aluminum hydroxide powder is wetted completely by the alkaline solution, adding Co and / or Ni containing acid solution, mixing and kneading to obtain plastic material, extruding, drying, and roasting to obtain the catalyst. The catalyst has homogeneously distributed Ti component and obviously raised performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

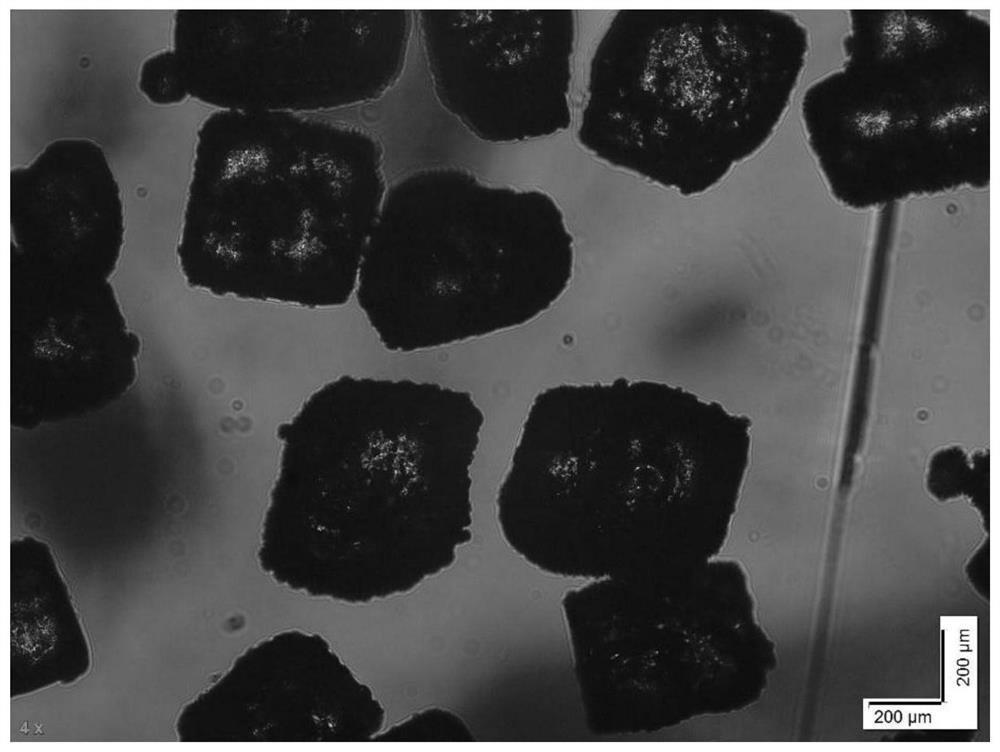

Preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate

The invention belongs to the field of the chemical industry, and relates to a preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate. The preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate comprises the following steps that 2-hydroxy-4-(methylthio)butyric acid, a calcium compound and a crystallizing agent are arranged in an aqueous medium, the pH is adjusted to be 5-7, the temperature is 60-80DEG C, stirring and full reactions are carried out, cooling crystallization is carried out to obtain calcium 2-hydroxy-4-(methylthio)butyrate crystals, separation is carried out to obtain crystals and coarse product mother liquid, and the crystals serve as calcium 2-hydroxy-4-(methylthio)butyrate coarse products. The calcium compound is one or more of calcium salt, calcium oxide and calcium hydroxide, and the use amount of the crystallizing agent is 50ppm-3000ppm of the mass of the 2-hydroxy-4-(methylthio)butyric acid. Materials produced through the preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate are high in purity, dehydration is easy, drying is rapid, crystal particles obtained after drying are large, good in mobility and large in bulk density, the amount of dust is low, glossiness is high, and the materials are more applicable to fodder.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Preparation method of high-content aglycon soybean isoflavone

InactiveCN102167688ADo not leaveLow equipment requirementsOrganic chemistryAcid hydrolysisIsoflavones

The invention discloses a process method for preparing aglycon soybean isoflavone by performing acid hydrolysis with primary proportion soybean isoflavone as a raw material. The method comprises the following steps of: scattering the primary proportion soybean isoflavone into a low-concentration ethanol aqueous solution of which the weight is 10-30 times that of the primary proportion soybean isoflavone; keeping return flow agitation at a temperature of 70-90 DEG C; after the temperature keeps stable, adding inorganic acid in an amount of 0.2-2 percent of the mass of the solution; preserving heat and stirring for 3-10 hours; after a reaction stops, evaporating ethanol out of the solution; cooling to less than 0-10 DEG C; filtering and crystallizing; and washing with water to a neutral state so as to obtain the aglycon soybean isoflavone. The process is easy, convenient and practical, and has high transformation ratio, low cost, mechanical application of acid liquors and small environmental pollution.

Owner:天津市尖峰天然产物研究开发有限公司

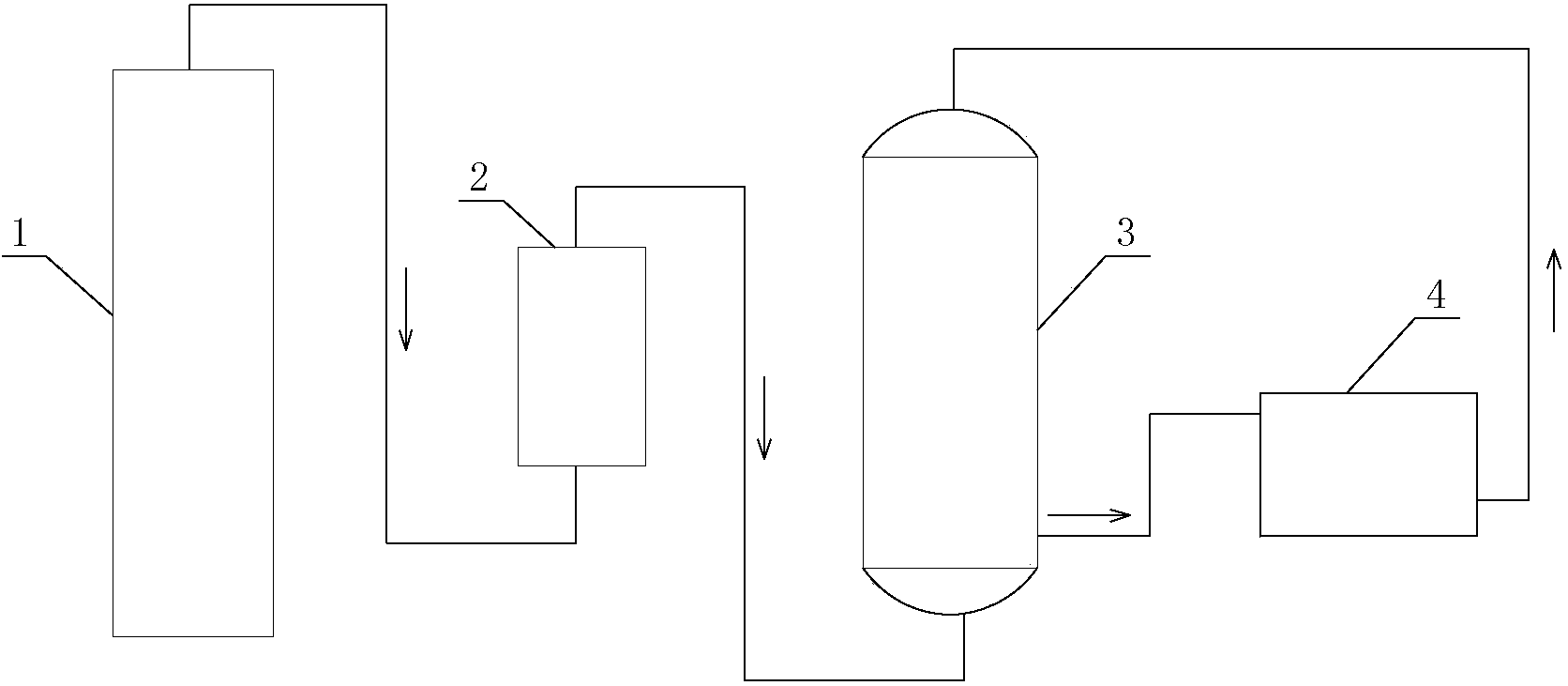

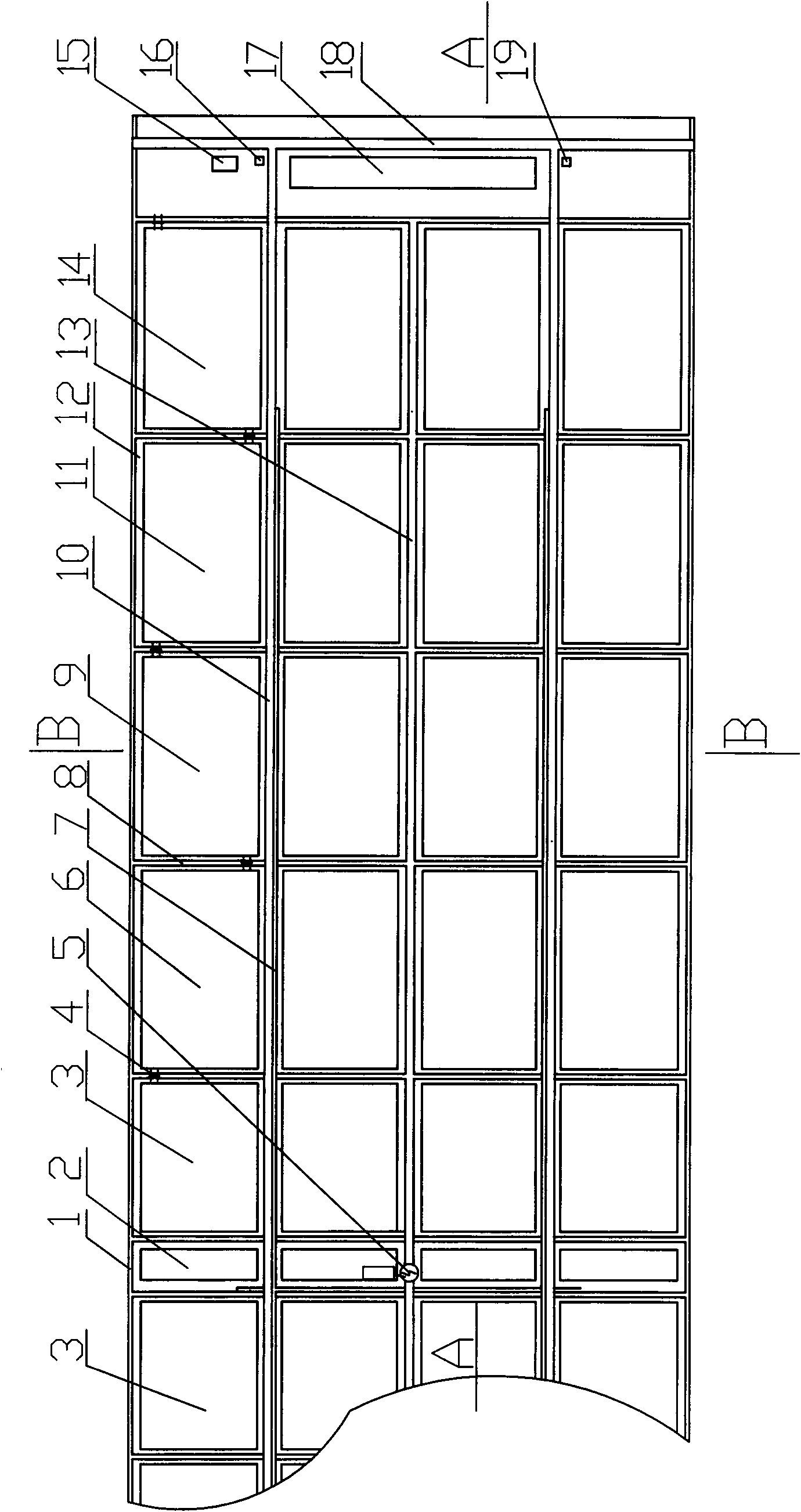

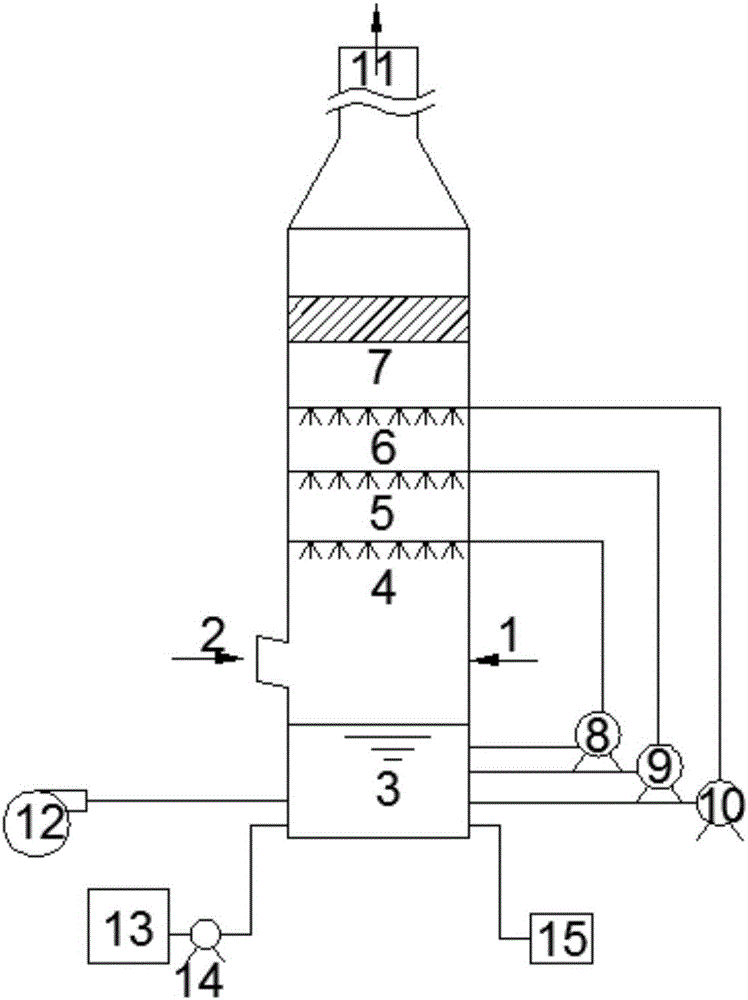

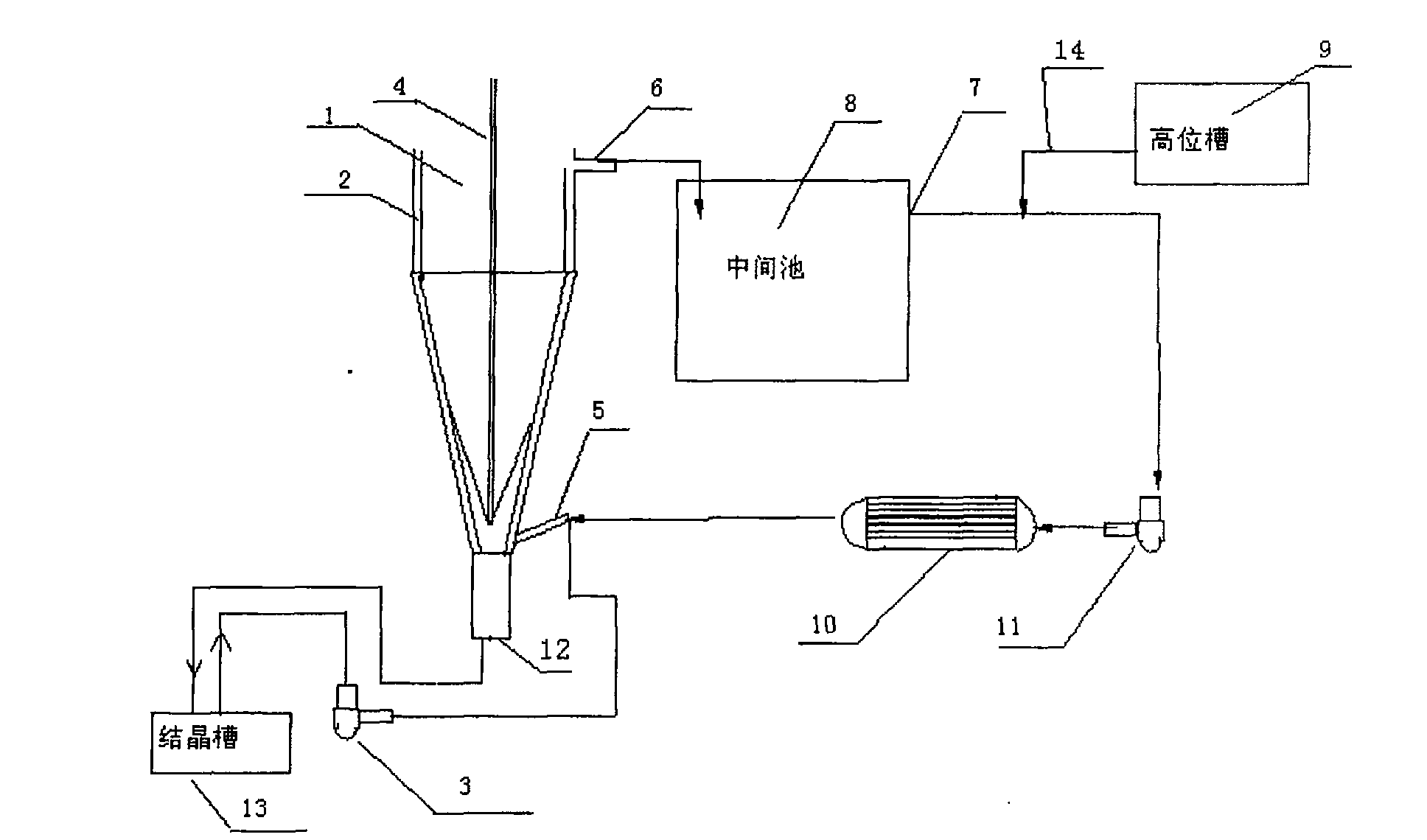

Circulation-type crystallizer

InactiveCN101143269AImprove efficiencyReduce energy consumptionSolution crystallizationEngineeringCirculating pump

The invention relates to a circulating typed mould. The invention contains a crystallization container and a cooling interlayer which is arranged around the crystallization container. A stirring rod is arranged inside the crystallization container. A liquid inlet and a liquid outlet are arranged on the crystallization container. A circulating pipeline is arranged between the liquid inlet and the liquid outlet. Middle pools of the water overflow port are arranged in turn on the circulating pipeline, which are used for storing high-level tank and condenser of crystal initial solution. A circulating pump is also arranged on the circulating pipeline. A crystal liquid outlet is arranged on the lower part of the crystallization container. The crystal liquid outlet is communicated with a crystal groove. The crystal groove has a mother liquor back-in-tank pipeline which is communicated with the crystallization container. A vacuum pump is arranged on the mother liquor back-in-tank pipeline. The mother liquid of the circulating typed mould circulates back into the crystallization container, which makes the invention has high efficiency and low energy consumption.

Owner:HANGZHOU LINAN JINLONG CHEM

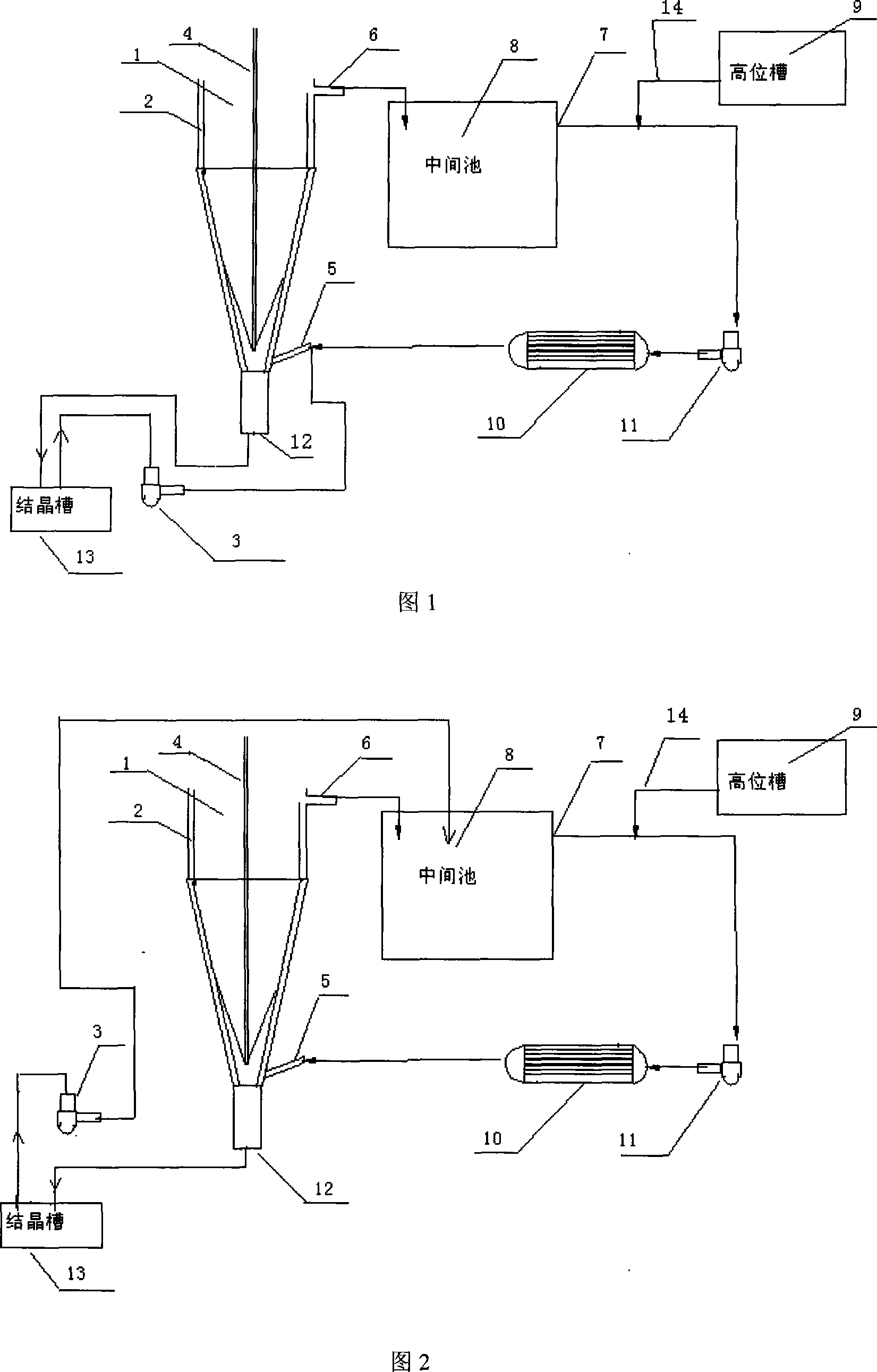

Production method of ore brine crystal salt

InactiveCN102205977AReduce energy consumptionLarge crystal particlesAlkali metal chloridesAlkali metal sulfites/sulfatesImpurity ionsSea salt

The invention provides a production method of an ore brine crystal salt. In the method, ore brine is used as raw brine, wind and sunlight are used as energy sources, and a shoal pool is used as a crystallization pool. The production method is characterized by comprising the following steps: after exploiting the ore brine, firstly passing the exploited ore brine through a pipeline and then weighing with a pump station, respectively storing the weighed ore brine crystallization salt in a brine hoarding table, pouring to a crystallization pool from the brine hoarding table, and evaporating and crystallizing through the wind and sunlight in the crystallization pool; and controlling the concentration and depth of the brine, properly adding or replacing novel brine, mastering the depth and market demand of the crystal salt, discharging the brine and recovering the salt timely, and recycling the old brine. According to the invention, energy consumption is low, 0.18 ton of coal and 50-60kw.h of electricity are consumed for producing every ton of ore salt, and the electricity consumption of every ton of salt is about 5kw.h in the invention; large land area is saved and accounts for 1 / 20 of that of sea salt; the method is environmentally-friendly, and zero emission is basically achieved; and the produced ore brine crystal salt has high quality, meets a GB / T5 462-2003 prior industrial salt standard, has extremely less impurity ions and large crystalline particles, and is especially suitable for a chlor-alkali industry.

Owner:江苏省东泰盐业投资管理有限公司

Preparation method of 2-hydroxy-4-methylthio butyric acid metal chelate

ActiveCN103497131AShorten production timeIncrease productivitySulfide preparationMetal chelateButyric acid

The invention relates to a preparation method of a 2-hydroxy-4-methylthio butyric acid metal chelate. The method comprises the following steps: performing a full reaction on hydrocyanic acid mixed gas prepared from an Andrussow method and methylthio propionaldehyde under the catalytic action of an alkali so as to obtain a 2-hydroxy-4-methylthio butyronitrile reaction system; performing a hydrolytic action on the 2-hydroxy-4-methylthio butyronitrile reaction system and sulfuric acid so as to obtain 2-hydroxy-4-methylthio butyric acid; adding an aqueous medium, a metallic compound and a crystallizing agent into the 2-hydroxy-4-methylthio butyric acid; regulating a pH value to reach 5 to 7 by using the alkali; heating to reach 60 DEG C to 90 DEG C; and performing cooling crystallization, thereby obtaining a 2-hydroxy-4-methylthio butyric acid metal chelate crystal. The method is low in production cost, wherein the obtained 2-hydroxy-4-methylthio butyric acid is easy to separate and purify, so that the 2-hydroxy-4-methylthio butyric acid with the high purity and the high yield can be obtained. Thus, the 2-hydroxy-4-methylthio butyric acid metal chelate which is further prepared from the 2-hydroxy-4-methylthio butyric acid has large crystalline particles.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Titanium-containing aluminium hydroxide preparation method

ActiveCN1951818AHigh crystal purityIncrease contentCatalyst activation/preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideTitanium

The invention discloses a making method of titanium aluminium hydroxide, which is characterized by the following: introducing adjuvant titanium in the gelling course of aluminium hydroxide through shaking pH value reciprocally; dispersing titanium evenly on the surface of aluminium hydroxide; enlarging the most probable aperture of titanium aluminium hydroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

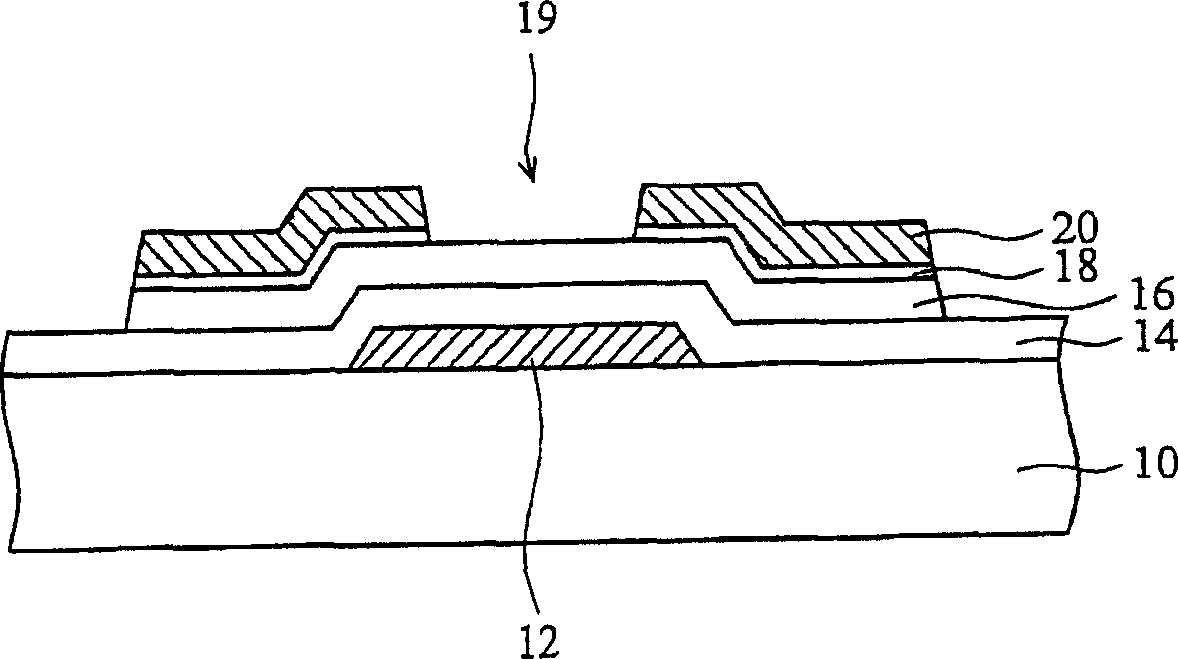

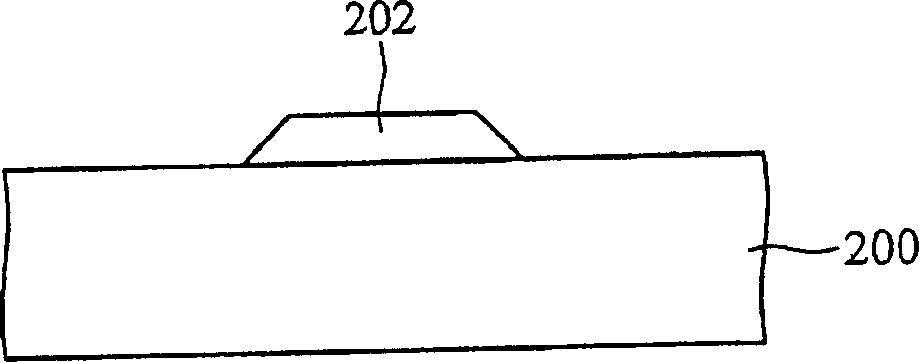

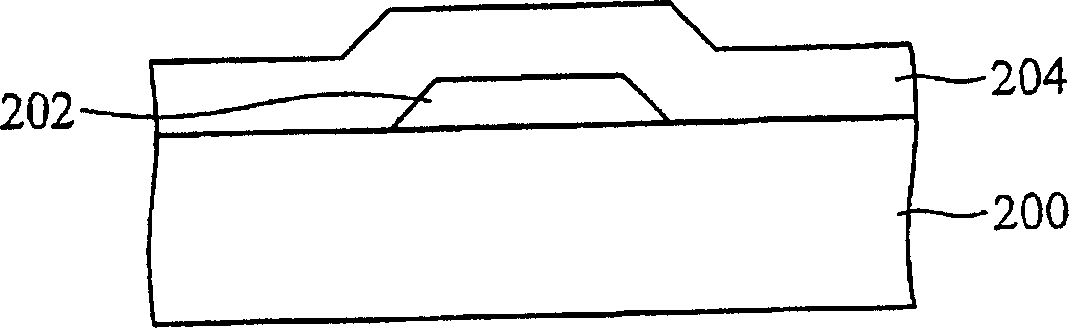

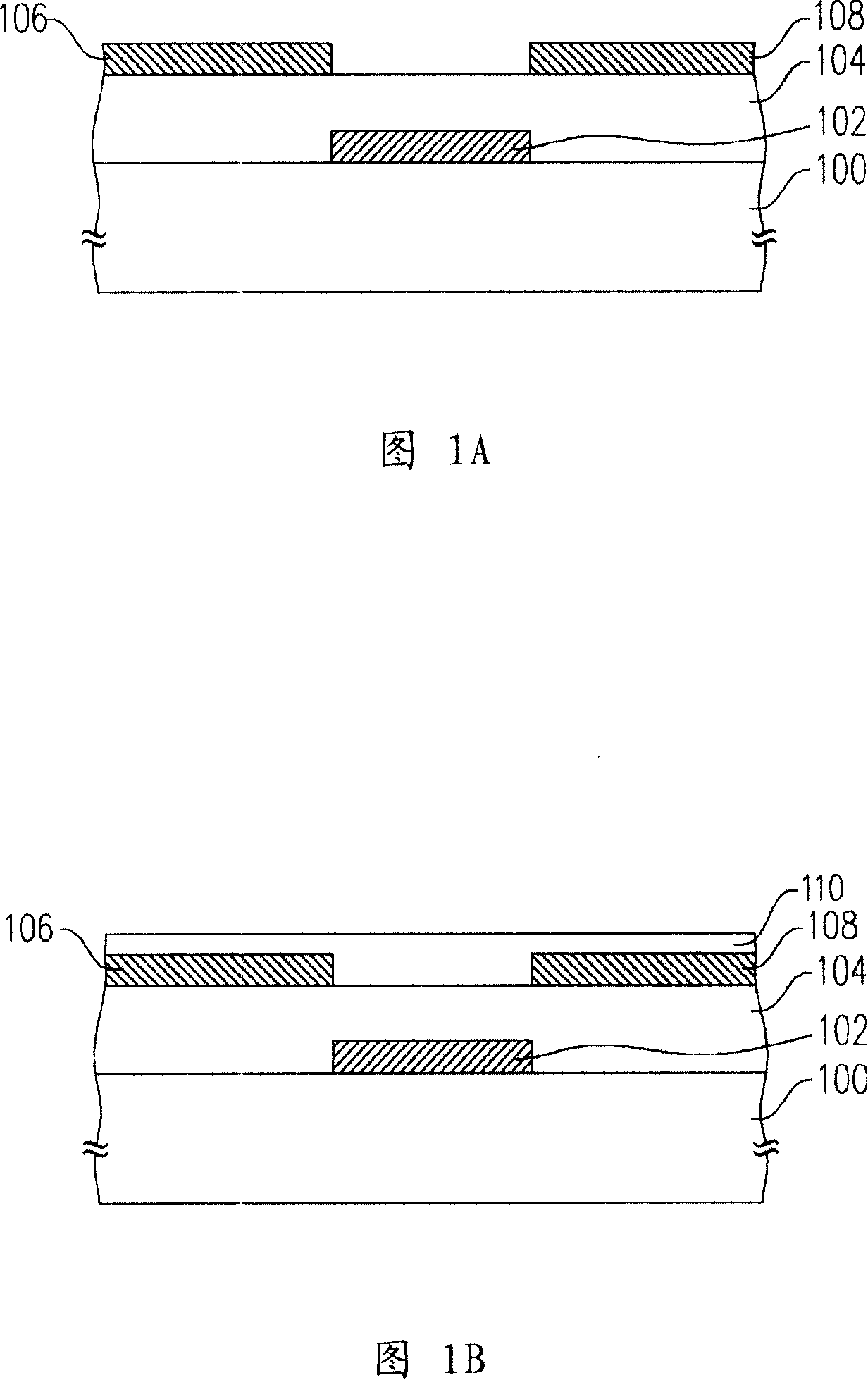

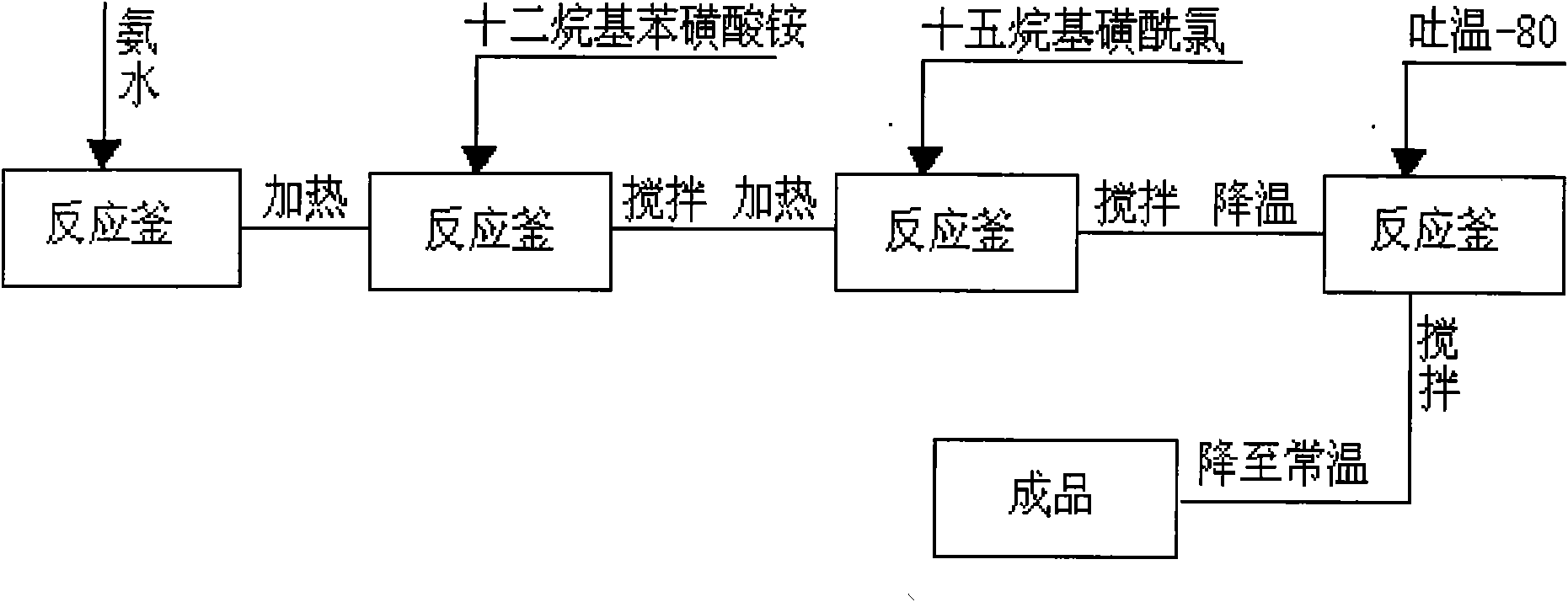

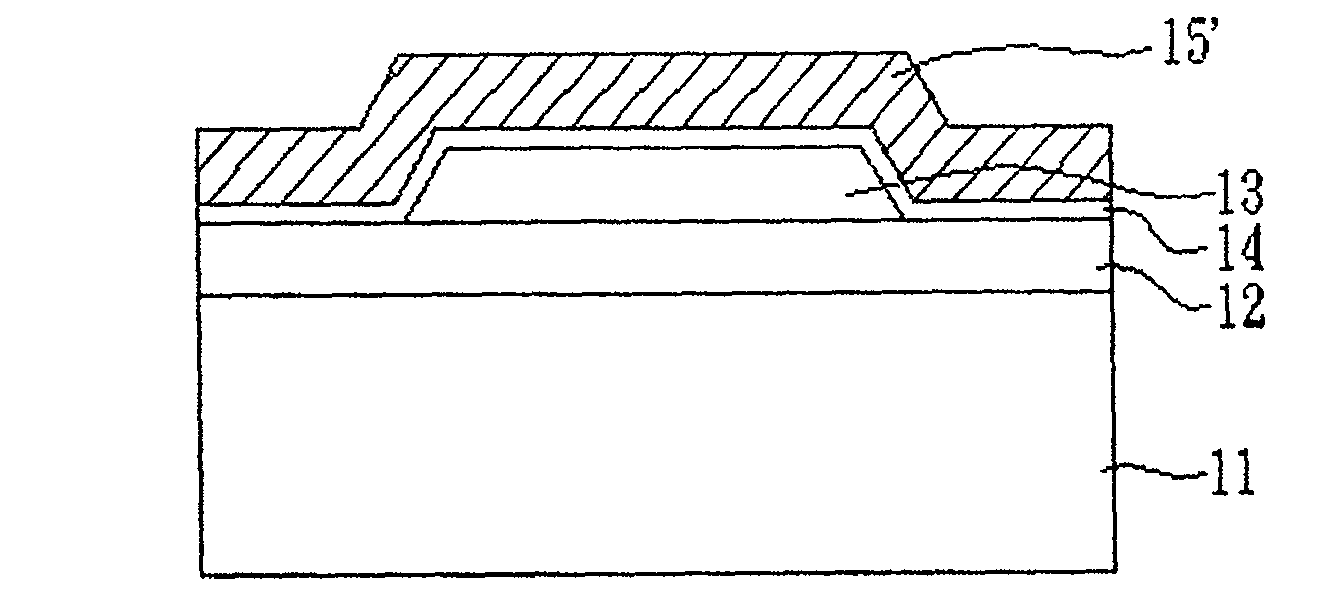

Structure and making method of thin film transistor

ActiveCN1560908AImprove performanceIncrease movement speedTransistorSemiconductor/solid-state device manufacturingGratingElectrical conductor

The invention discloses a structure of a film transistor and a manufacturing method. The method includes at providing a base board, a grating electrode is formed on the base board, and a grating electrode dielectric layer covers the grating electrode and the base board; the, carries on ion injection step to the grating electrode dielectric layer; and forms a semi-conductor on the grating electrode dielectric layer after the injection.

Owner:AU OPTRONICS CORP

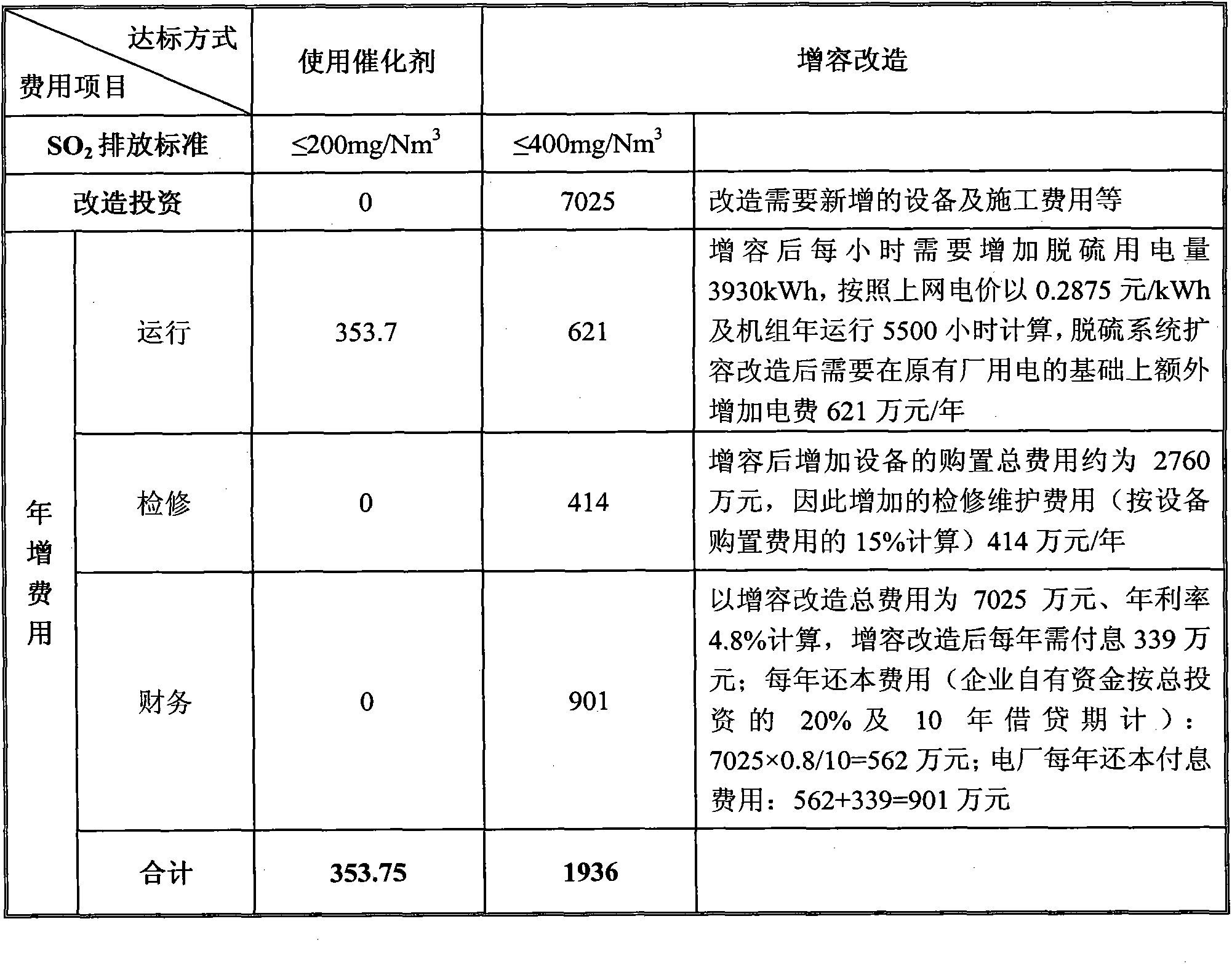

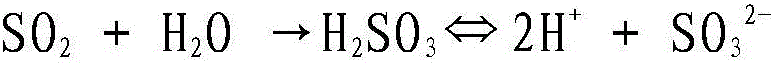

Desulfurization catalyst of limestone-gypsum wet coal-fired boiler flue gas desulfurization process

InactiveCN103433070AImprove surface activityReduce resistanceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEmission standardFatty alcohol

The present invention relates to a desulfurization catalyst of a limestone-gypsum wet coal-fired boiler flue gas desulfurization process. The desulfurization catalyst comprises the following raw materials, by weight: 78-85% of CH3COONH4, 12-20% of NH4C1, 0.3-1% of alcohol polyoxyethylene ether phosphoric monoester, 0.5-1.5% of alkyl alcohol ether carboxylate, and 0.3-1% of fatty alcohol ethyl oxide. The desulfurization catalyst has the following beneficial effects that: desulfurization efficiency of the limestone-gypsum wet coal-fired boiler flue gas desulfurization (FGD) process is economically and effectively improved, a SO2 pollutant emission concentration is reduced, a SO2 pollutant emission concentration of the coal-fired boiler achieves requirements of the newly revised emission standard of air pollutants for thermal power plants (GB13223-2011) (hereinafter short for new standard), and environment protection is achieved.

Owner:HUADIAN HIGH TECH GAOBEIDIAN ENVIRONMENTAL TECH

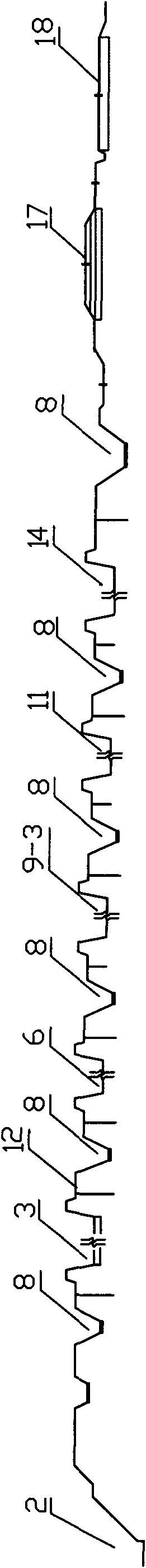

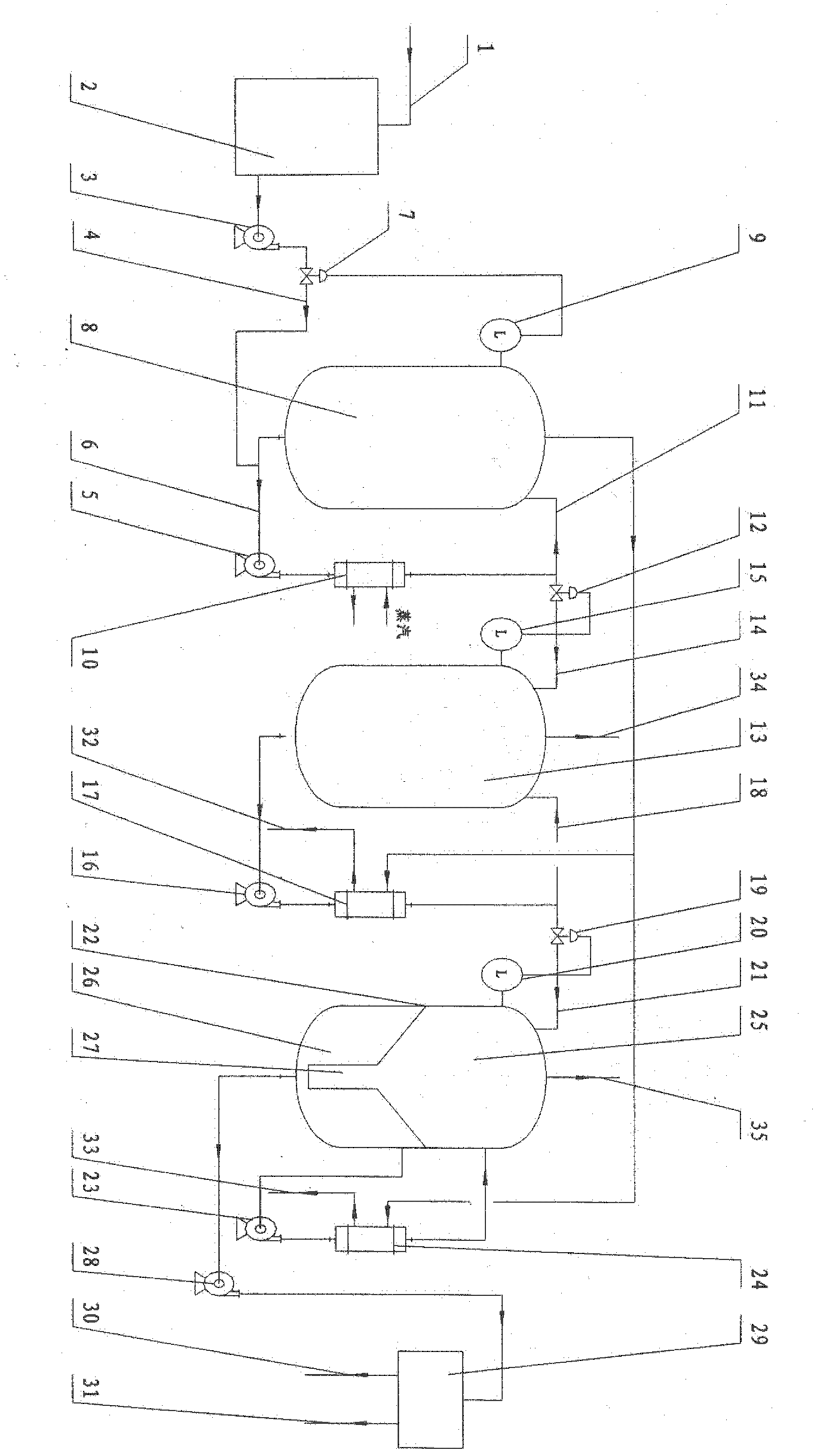

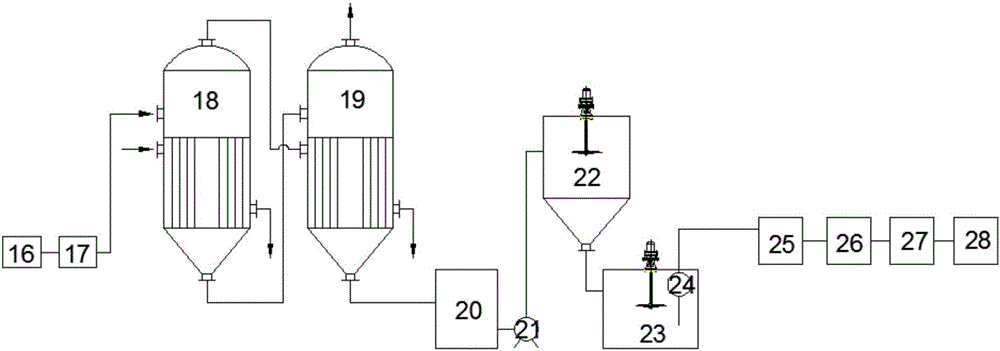

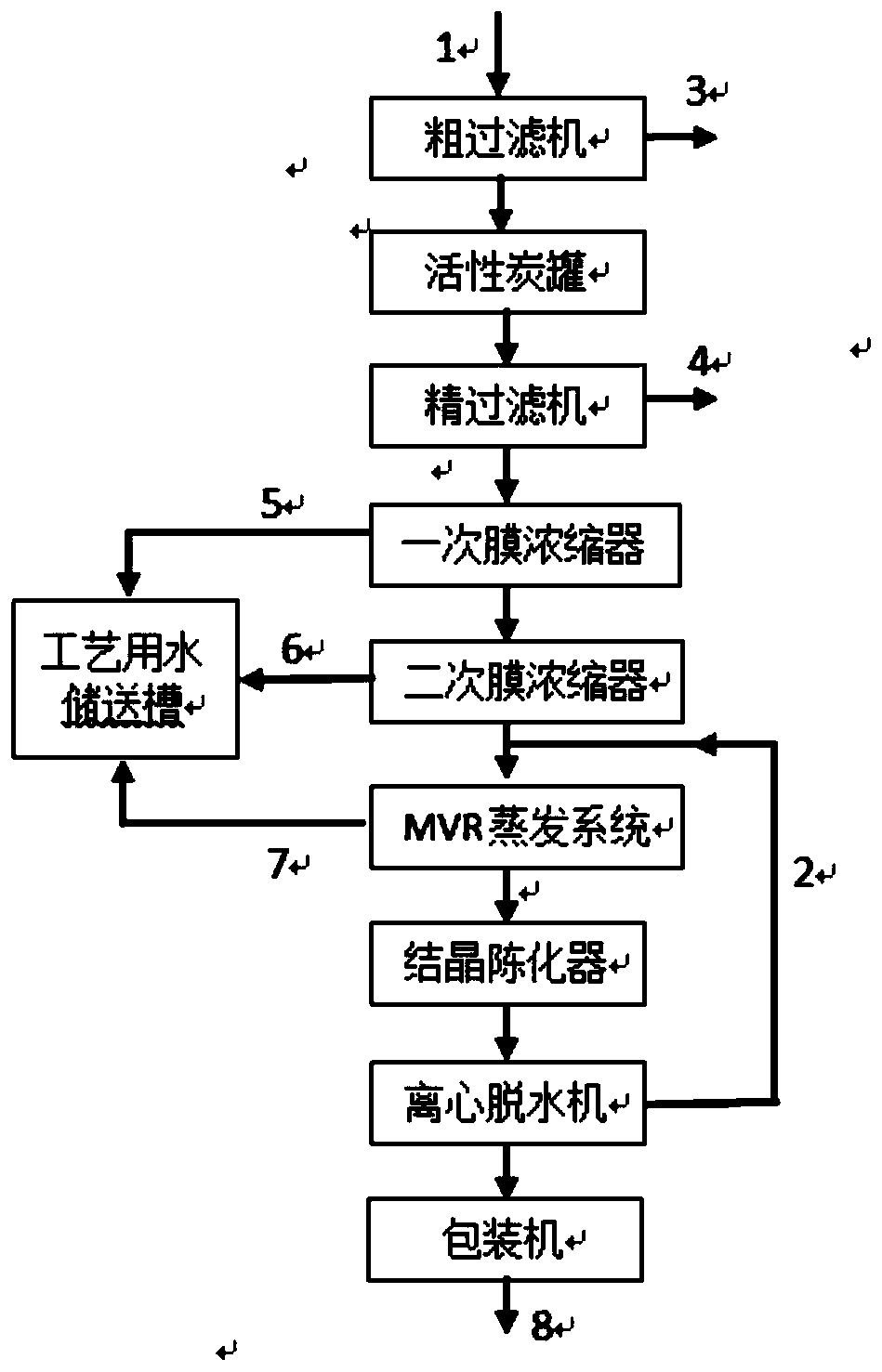

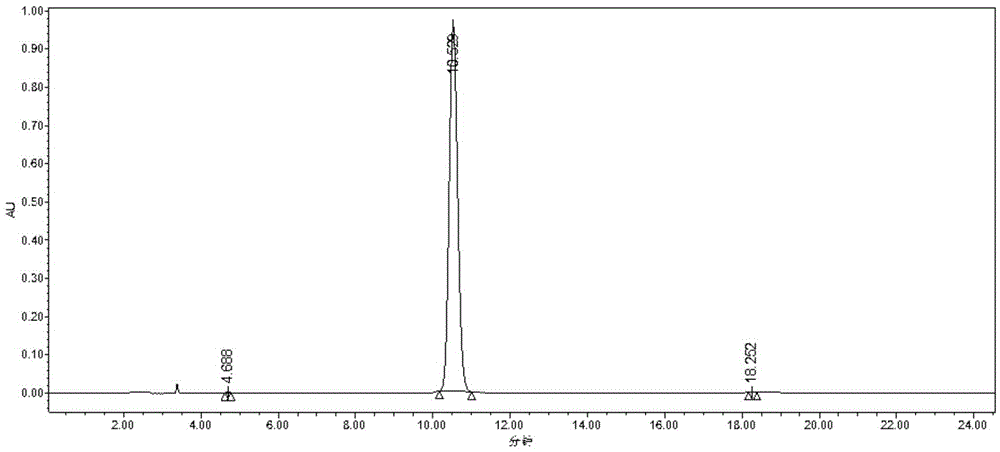

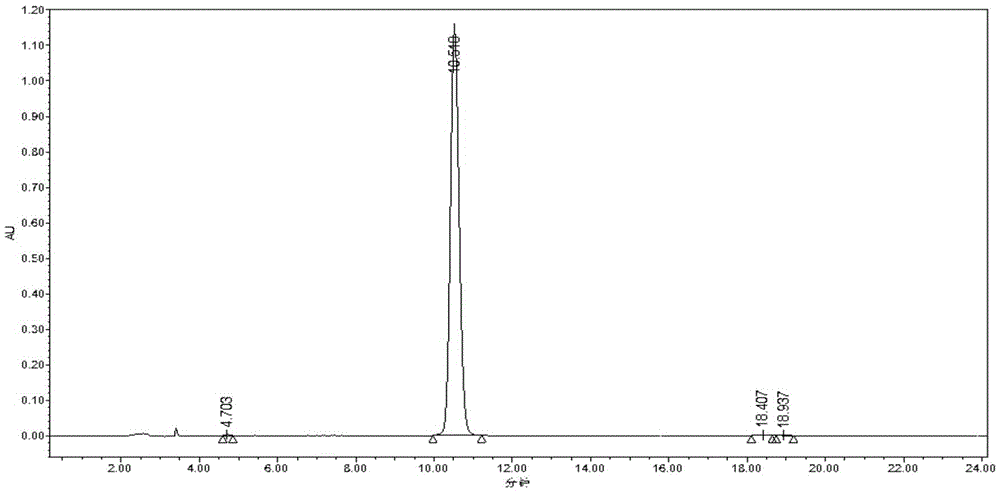

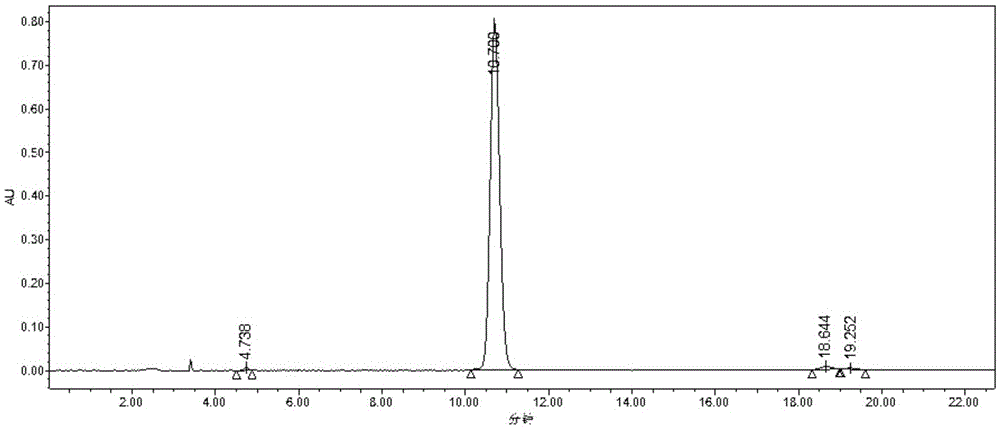

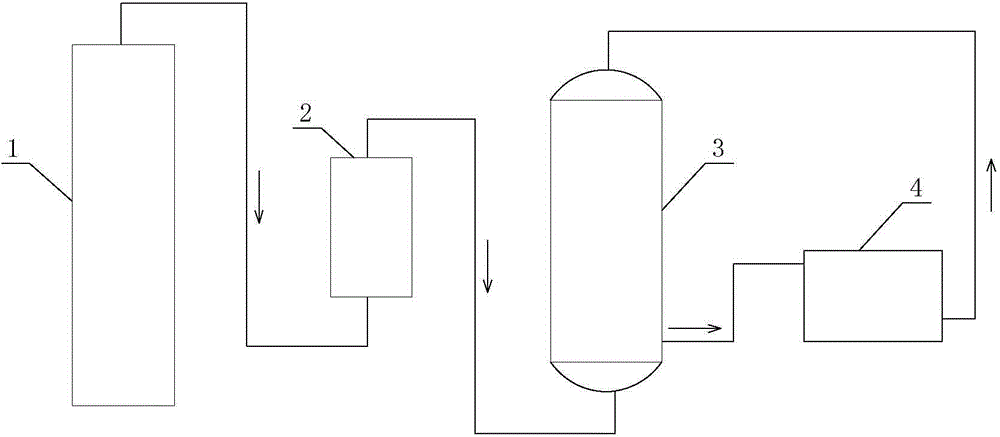

Technology for extracting ammonium thiosulfate and ammonium thiocyanate by desulphurization waste liquid

ActiveCN103213953AReduce dosageLarge crystal particlesThiosulfates/dithionites/polythionitesThiocyanic acidActivated carbon filtrationWater vapor

The invention provides a technology for extracting ammonium thiosulfate and ammonium thiocyanate by a desulphurization waste liquid. The technology comprises the following steps: a desulphurization liquid filtered by active carbon in a desulphurization system is sent to a first evaporator by a transfer pump, a material in the first evaporator is heated by an external heater, a part of material is returned to the evaporator, and a part of the material is sent to a second evaporator; the material in the second evaporator is heated by the external heater, and then a part of the material is returned to the second evaporator, and a part of the material is sent to a third evaporator; and the material in the third evaporator is directly heated by the external heater and then is returned to the third evaporator, the second evaporator and the third evaporator take water vapor generated by the first evaporator through evaporation as a heat source for heating. The bottom material of the third evaporator is sent to a crystallizer through a crystallization pump, a crystallization liquid is separated, the separated solid is the product containing ammonium thiosulfate, and a centrifugate is collected and then crystallized to obtain the product containing ammonium thiocyanate. The technology has the characteristics of continuous production of salt extraction operation by the desulphurization liquid, low energy consumption, low engineering construction and the like.

Owner:鞍钢集团工程技术有限公司

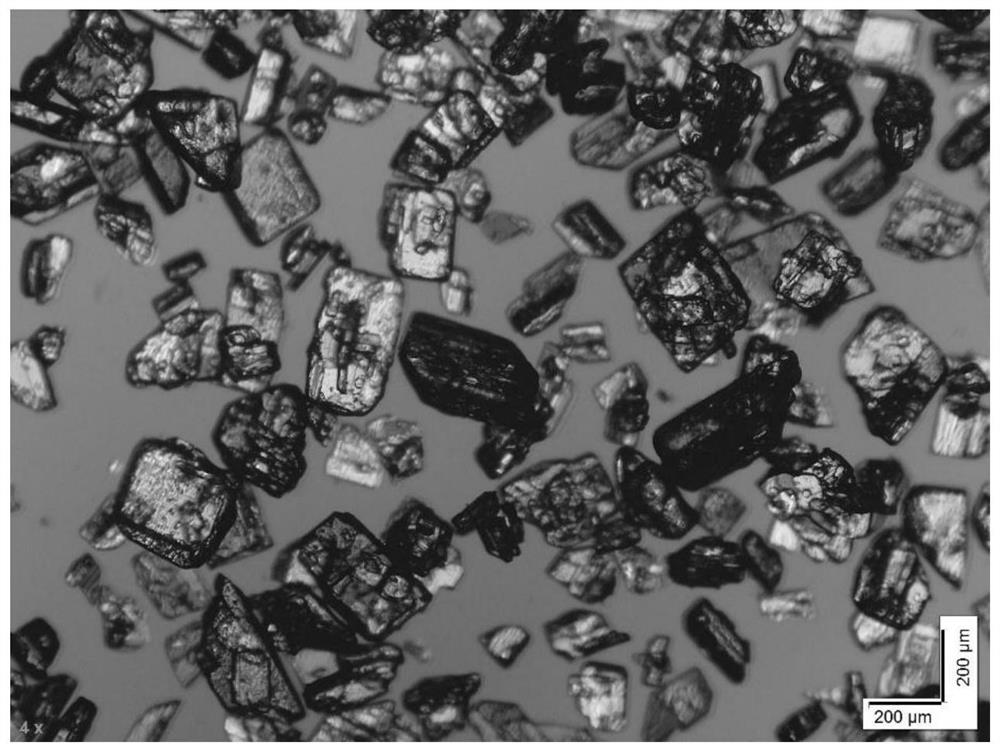

Preparation method of ammonium persulfate crystal

PendingCN112551490AUniform particle sizeLarge crystal particlesPeroxyhydrates/peroxyacidsPhysical chemistryCrystalline particle

The invention discloses a preparation method of an ammonium persulfate crystal, and the method comprises the following steps of: using an ammonium persulfate-ammonium sulfate mixed solution as a mother solution, adding a seed crystal and carrying out staged cooling and crystal growing treatment to obtain an ammonium persulfate crystal with uniform particle size distribution, wherein the staged cooling and crystal growing treatment refers to staged cooling, heat preservation and crystal growing of the mother solution, and the staged cooling, heat preservation and crystal growing are carried outin five stages, and the five stages include: first time of cooling and crystal growing, second time of cooling and crystal growing, third time of cooling and crystal growing, fourth time of cooling and crystal growing, and fifth time of cooling and crystal growing; the step of adding the seed crystal is carried out after the first time of cooling, and the first crystal growing treatment is carried out after the seed crystal is added. Through staged cooling and crystal growing treatment, the crystal growing time is prolonged; the seed crystal is added in the crystallization process, and the stirring size is increased by using a stirring paddle with a large diameter, so that the prepared ammonium persulfate finished product is uniform in particle size distribution and relatively large in crystalline particles, and is not easy to cake.

Owner:河北冀衡集团有限公司

Preparation method of dihydroxy oxethyl fluorene

InactiveCN103058833AIncrease production capacityEasy to useEther separation/purificationOrganic compound preparationEthylene glycol monophenyl etherChemical synthesis

The invention belongs to the field of chemical synthesis, and relates to a preparation method of dihydroxy oxethyl fluorine. The method comprises the following steps of: executing condensation reaction of ethylene glycol monophenyl ether and 9-fluorenone in the presence of catalyst mercaptoethanol, extracting and purifying the reaction liquid by water-organic solvent, and then, obtaining the target product after recrystallization. With the preparation method provided by the invention, the reaction time is reduced, the yield is improved, the crystal form and the liquidity of products are improved, the solvent of a single type is more beneficial for recycling, and the technical operation is simplified, so that the preparation method is suitable for industrial production.

Owner:常州市正锋光电新材料有限公司

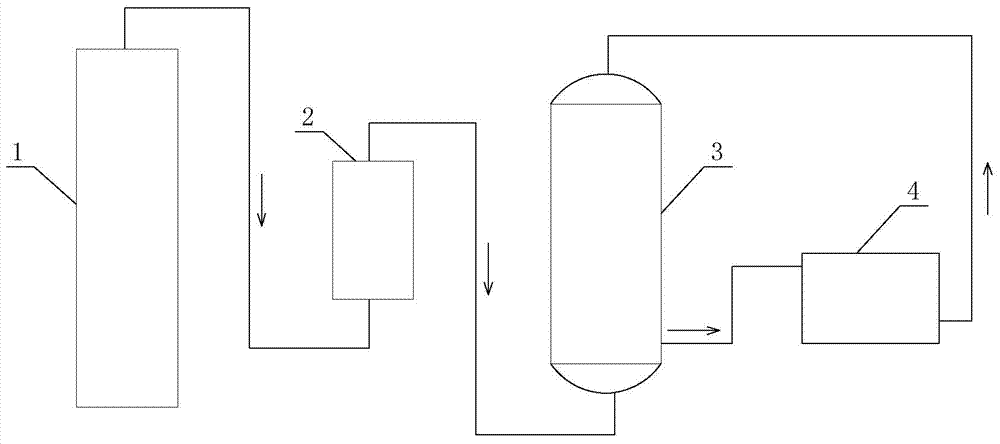

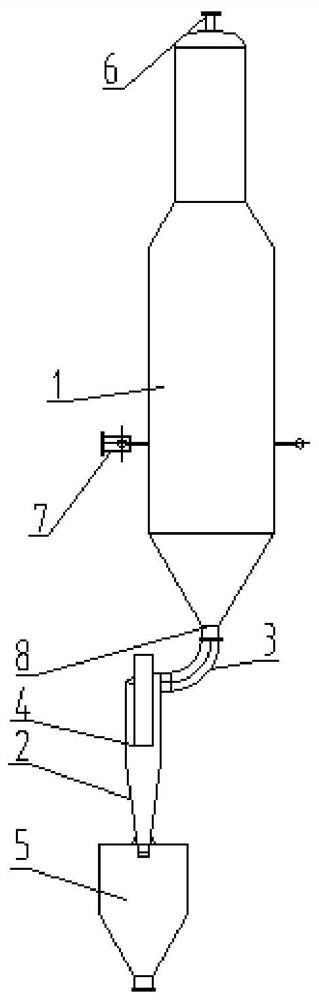

System for desulfurization and magnesium sulfate heptahydrate co-production by using magnesium oxide

PendingCN106731634AReduce loadLarge particlesGas treatmentDispersed particle separationFlue gasSlurry

The invention relates to a system and a method for desulfurization and magnesium sulfate heptahydrate co-production by using magnesium oxide. The system comprises an absorption tower, a slurry preparation device used for preparing magnesium hydroxide slurry, an oxidization device, a filter-press device used for filtering the slurry obtained after a reaction is finished, and a by-product preparation device, wherein a flue gas outlet is formed in the top of the absorption tower, an absorption tower flue gas inlet is formed in one side of the lower part of the absorption tower, and an absorbed slurry outlet is formed in the bottom of the absorption tower; a tower top chimney, an absorption tower demisting area, an absorption tower spray reaction area and an absorption tower slurry area are sequentially arranged in the absorption tower from top to bottom; the absorption tower demisting area is provided with a demister, and the absorption tower spray reaction area is provided with a spray head; the slurry preparation device is communicated with the absorption tower slurry area by a pipeline; the oxidization device is communicated with the absorption tower; the filter-press device is communicated with the absorbed slurry outlet; an inlet of the by-product preparation device is communicated with the filter-press device. A cooling crystallizer is adopted by the by-product preparation device, so that the system has the advantages of being large in particles of a prepared product, easy in separation of the product, high in product quality, low in load of separation and drying unit equipment, easy to operate, and the like.

Owner:北京金投清蓝环境科技有限公司

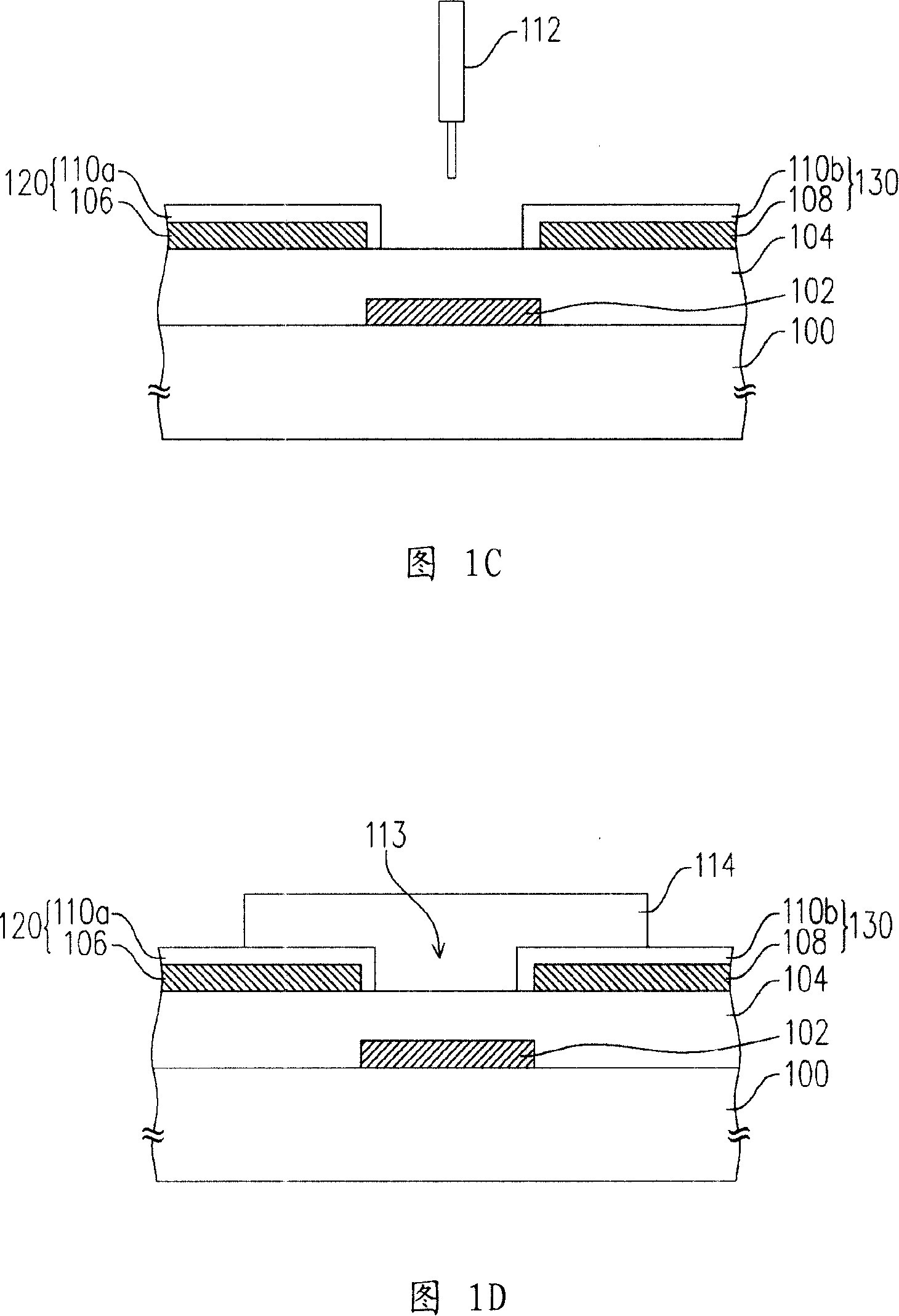

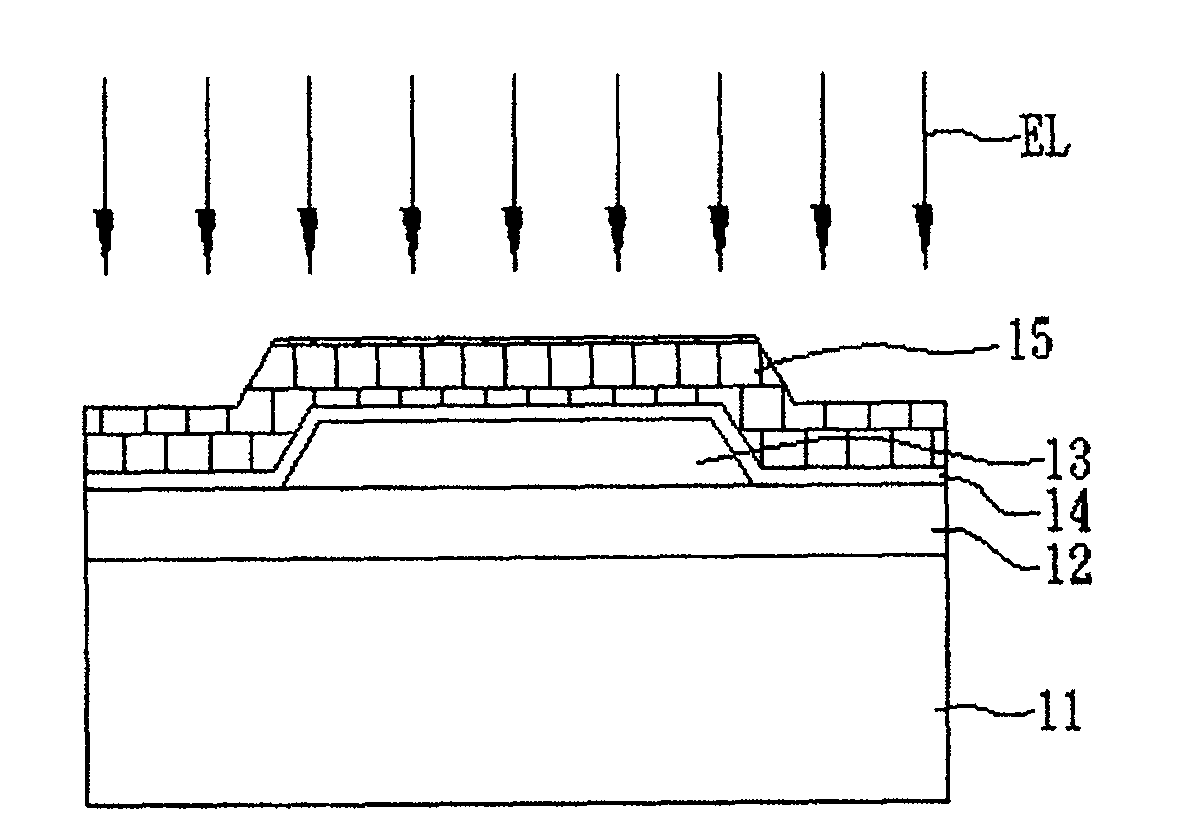

Organic semiconductor elements and manufacturing method therefor

InactiveCN101136454AIncrease movement speedLarge crystal particlesSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorOrganic semiconductor

This invention relates to a manufacturing method for semiconductor elements, which forms a grid conduction layer and grid dielectric layers on a base orderly, then forms patternized metal layers on the grid dielectric layers at both sides of the conduction layer and forms electrode reformed layer on the top of the metal layers and adjacent side walls to constitute a source and a drain with the covered patternized metal layers and then forms an organic semiconductor layer as an active layer between the source and the drain and above them.

Owner:IND TECH RES INST

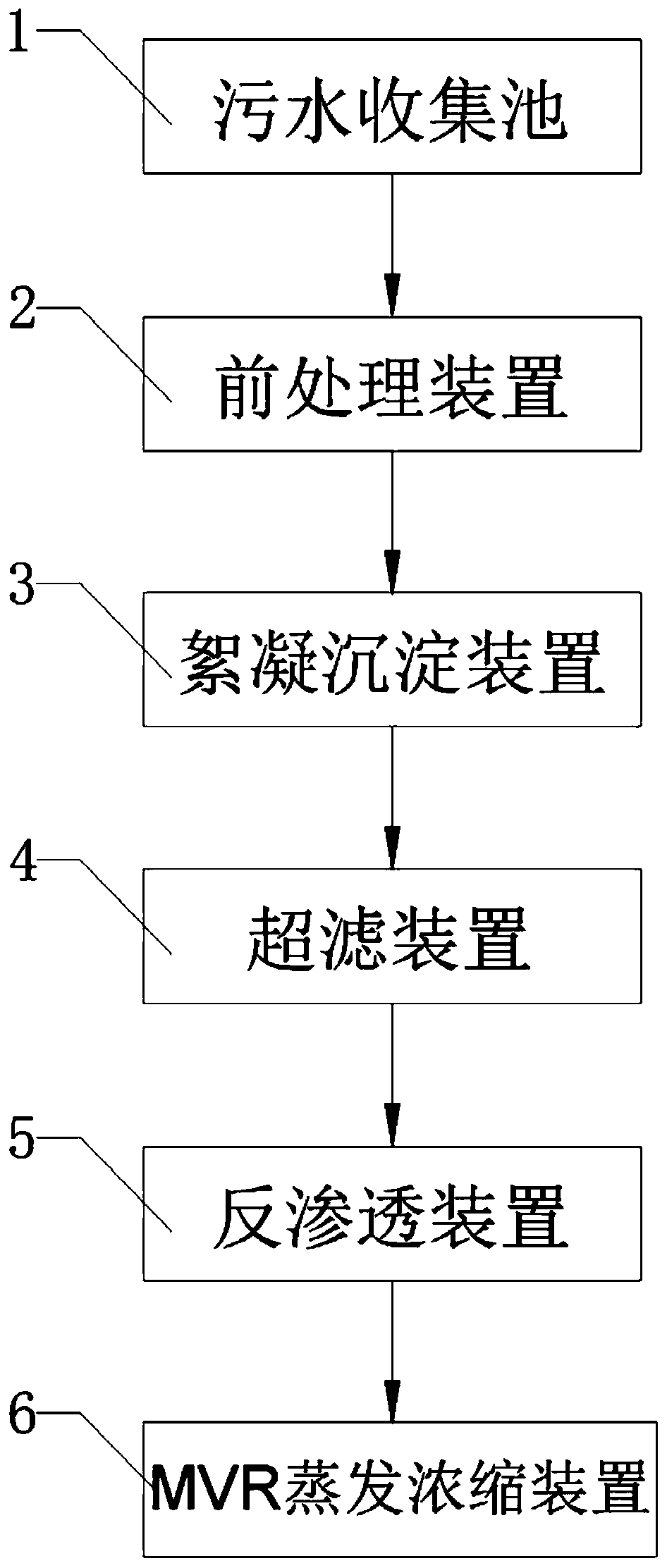

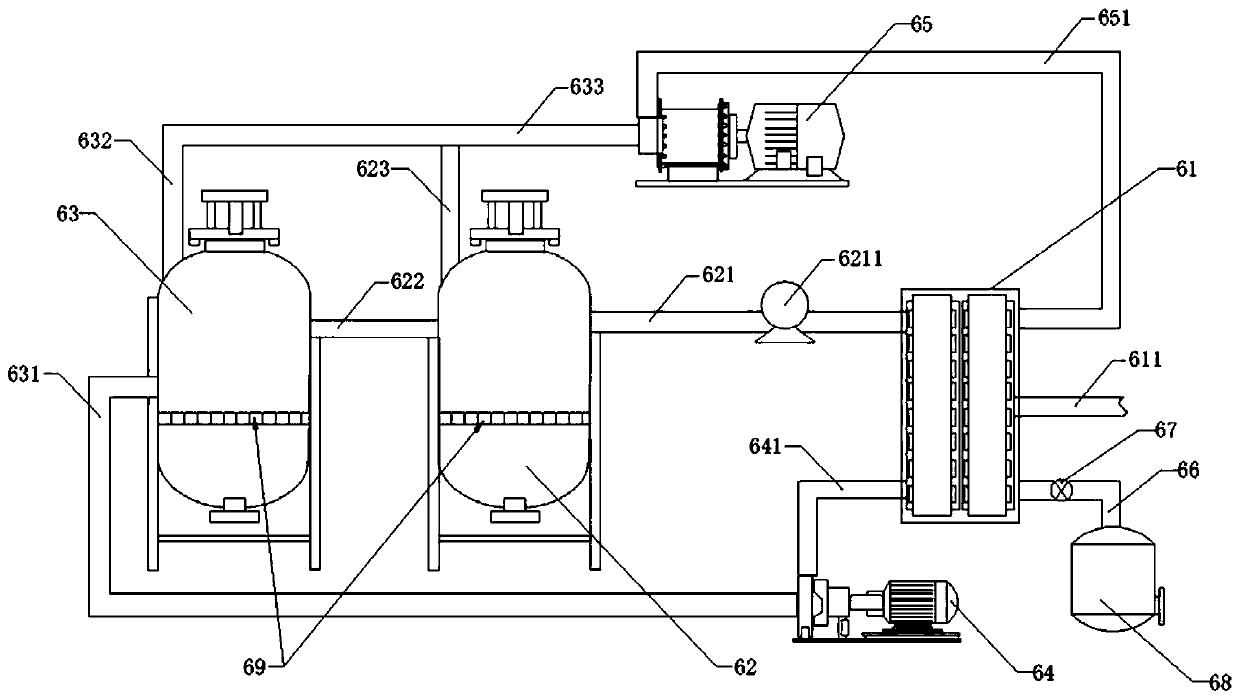

System and technology for concentration and crystallization treatment of high-salinity water

ActiveCN110723857AReduce energy consumptionAchieve recyclingWater treatment parameter controlFatty/oily/floating substances removal devicesSaline waterPlate heat exchanger

The invention relates to the technical field of sewage discharge, and concretely relates to a system and a technology for concentration and crystallization treatment of high-salinity water. The treatment system sequentially comprises a sewage collection tank, a pretreatment device, a flocculent precipitation device, an ultrafiltration device, a reverse osmosis device and an MVR evaporation concentration device according to the treatment use sequence, the MVR evaporation concentration device sequentially comprises a plate heat exchanger, a first precipitation and crystallization tank, a secondprecipitation and crystallization tank and a feed liquid circulating pump according to the treatment use sequence, and the steam outlet end of the first precipitation and crystallization tank and thesteam outlet end of the second precipitation and crystallization tank are communicated with the plate heat exchanger through a steam compressor; and the plate heat exchanger is provided with a feedingend, and the feeding end of the plate heat exchanger is communicated with the output end of the reverse osmosis device through a feeding pipeline. The system for concentration and crystallization treatment of high-salinity water has the advantages of novel structure, simplicity in operation, and ensuring of the integrity of crystals by precipitation, crystallization and growth of crystals of high-salinity water at the bottoms of the tank bodies of the first precipitation and crystallization tank and the second precipitation and crystallization tank.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

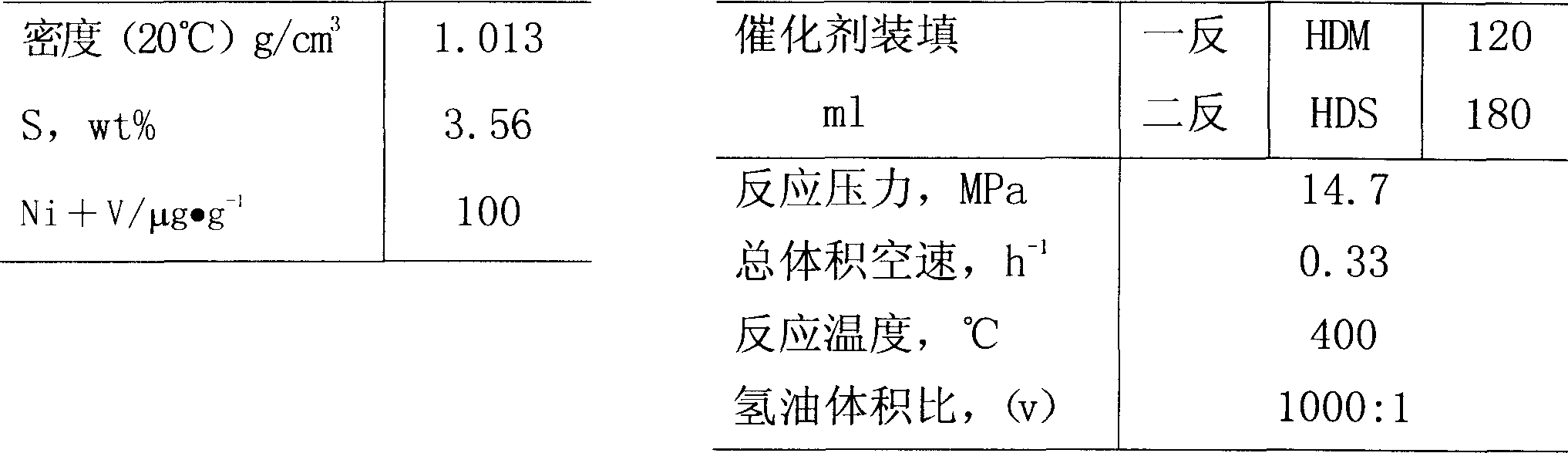

Preparation process of hydroprocessing catalyst

ActiveCN100537028CHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsActive componentAluminium hydroxide

Owner:CHINA PETROLEUM & CHEM CORP +1

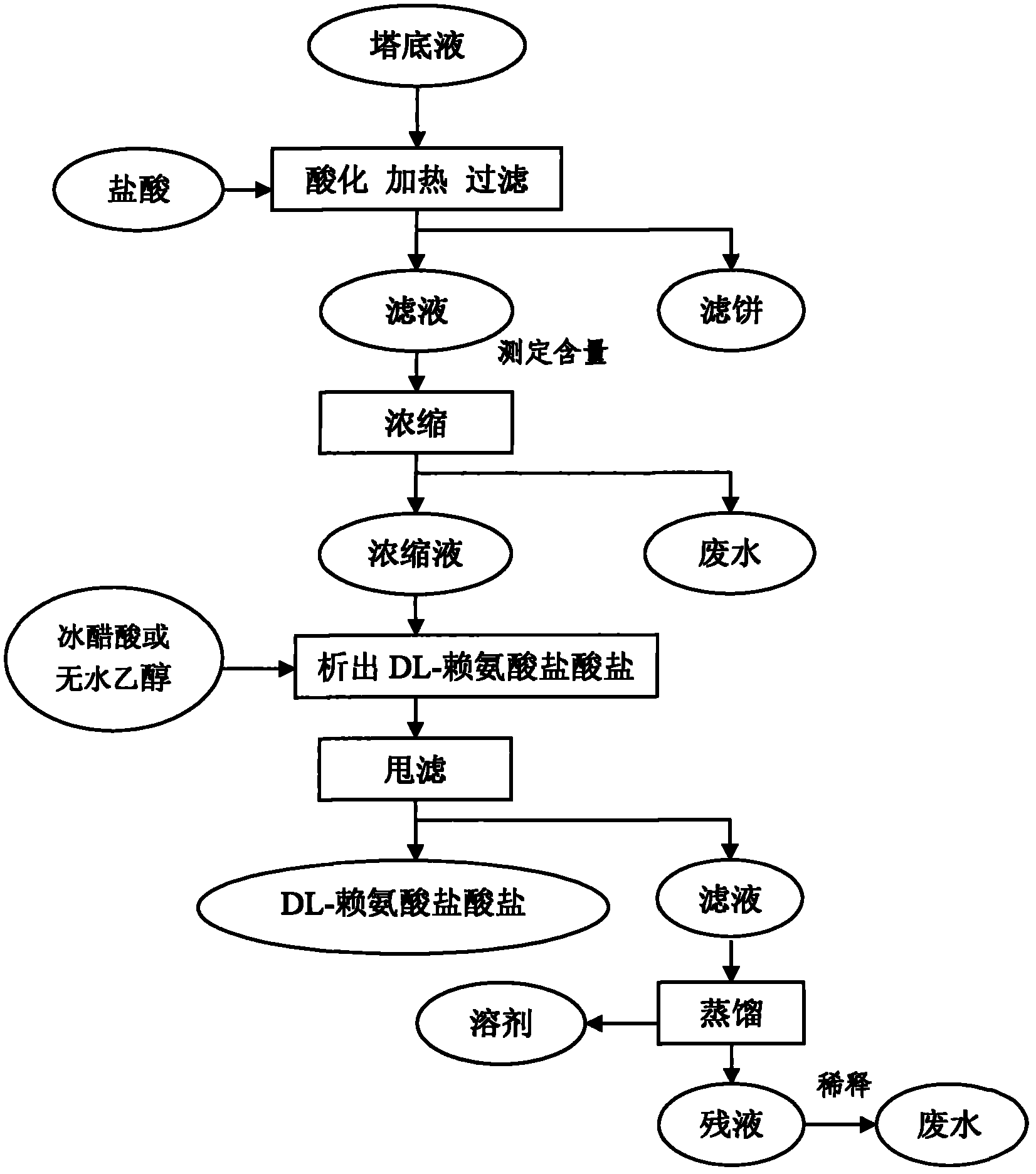

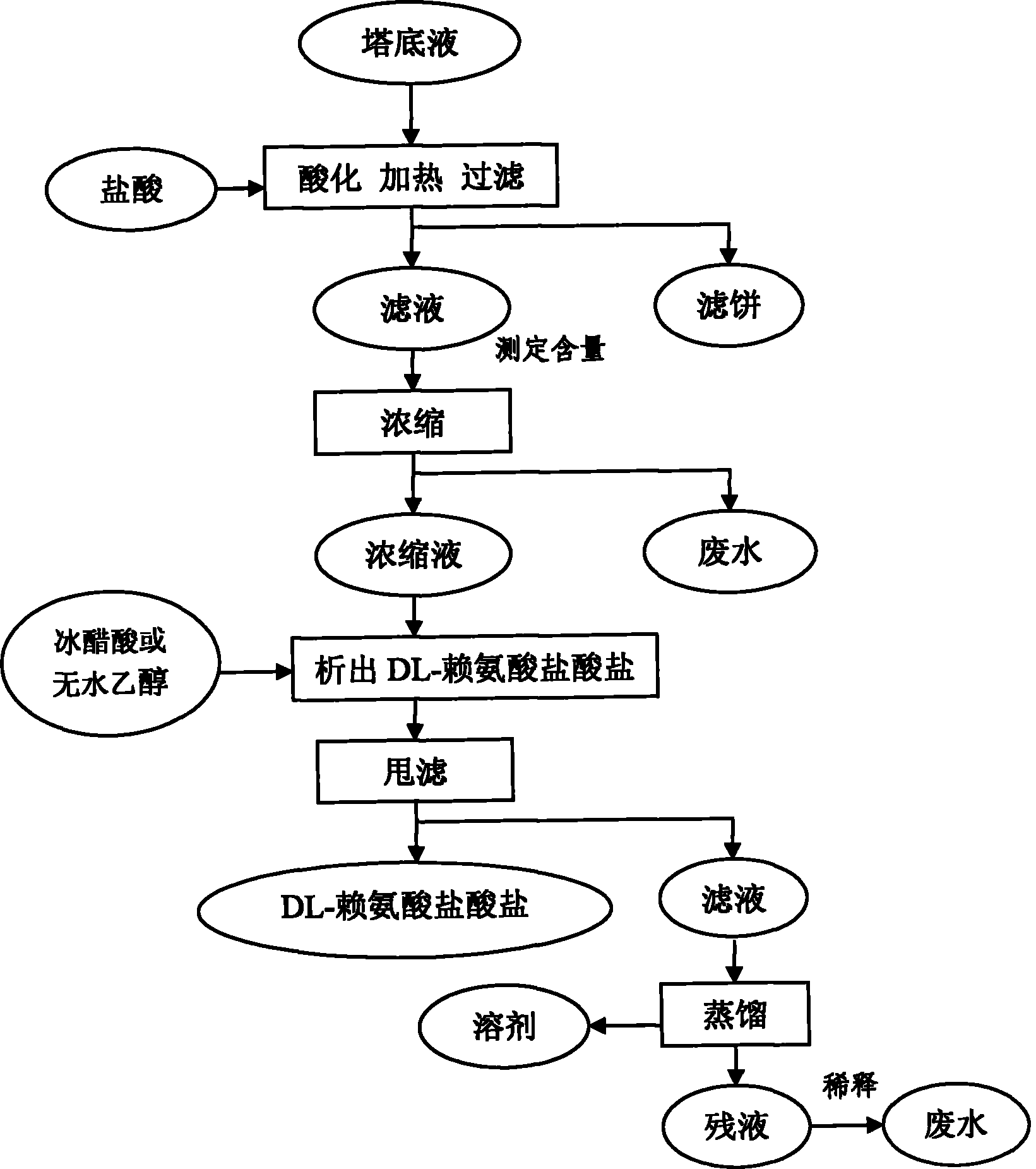

Method for recycling DL-lysine hydrochloride from aspirin-DL-lysine mother liquor

ActiveCN102060724ASave energySave costsOrganic compound preparationAmino-carboxyl compound preparationAspirin DL-LysineSocial benefits

The invention relates to a method for recycling DL-lysine hydrochloride from aspirin-DL-lysine mother liquor, comprising the steps of: evaporating out ethanol, adding hydrochloric acid for separation and precipitation, concentrating filtrate and separating out crystals. The method disclosed by the invention has the advantages of simplicity and high product purity, and the recycled DL-lysine hydrochloride can be used as an intermediate for further synthesis of aspirin-DL-lysine, therefore, the production cost is greatly saved and reduced, the difficulty in waste water treatment and environmental pollution are simultaneously reduced, and the economic and social benefits are improved.

Owner:蚌埠丰原涂山制药有限公司

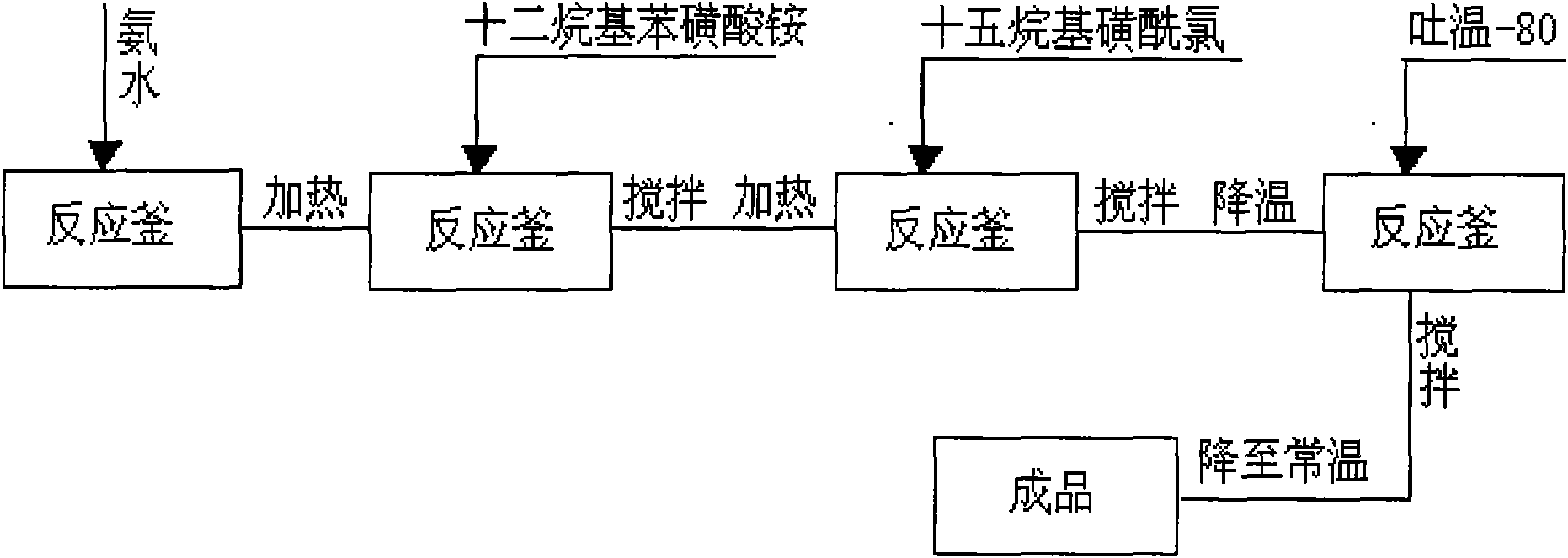

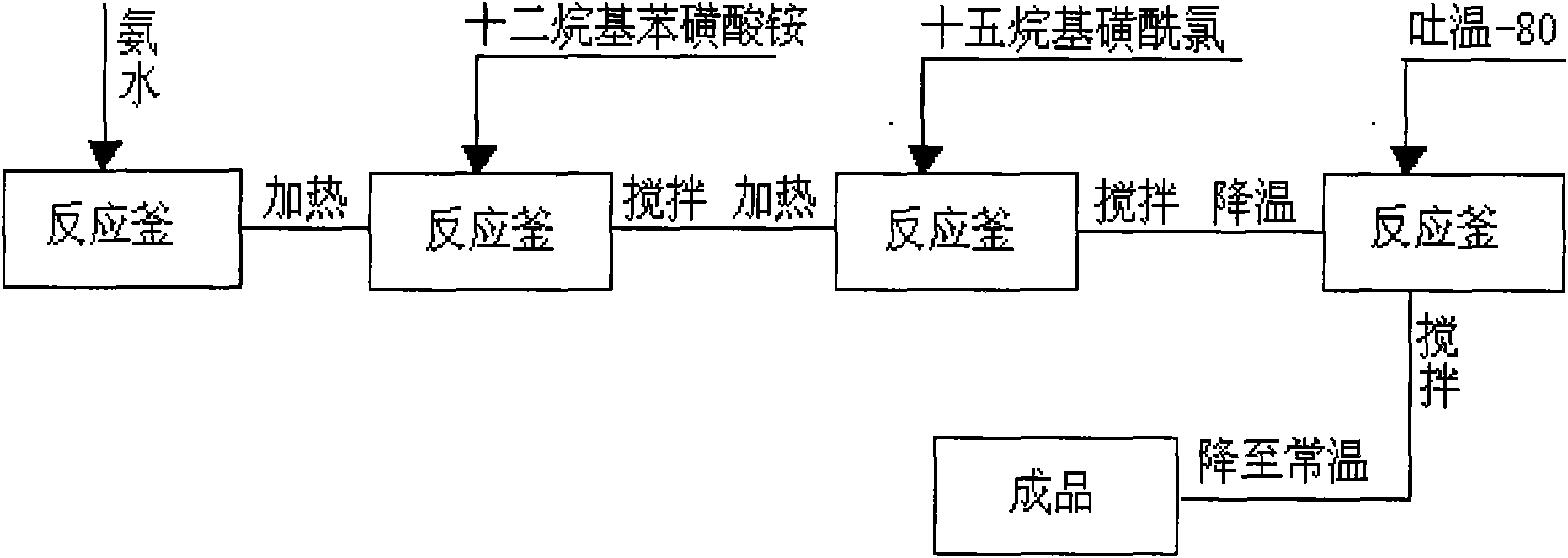

Compound ammonium bicarbonate additive and production method thereof

InactiveCN101591027AEasy to useReduce moisture contentAmmonium carbonates/bicarbonatesSodium bicarbonateDecomposition

The invention provides a compound ammonium bicarbonate additive and a production method thereof. The ammonium bicarbonate additive is compounded with the following materials: ammonia with mass concentration of 4 to 8 percent, ammonium dodecylbenzenesulfonate, 1-pentadecanesulfonyl chloride and Tween 80. The weight portion ratio of the compounded materials is 45-55:13-15:28-32:3-6. The compounding method comprises the following steps: preparing materials according to the weight portion ratio; adding the ammonia into a reaction kettle, and adding the ammonium dodecylbenzenesulfonate when the ammonia temperature in the kettle is between 58 and 62 DEG C; stirring the mixture of the two, adding the 1-pentadecanesulfonyl chloride when the temperature in the kettle is between 70 and 78 DEG C, stirring for 60 minutes, and slowly reducing temperature; and adding the Tween 80 when the temperature in the kettle is between 58 and 62 DEG C, evenly stirring, cooling to normal temperature, and obtaining a finished product. The ammonium bicarbonate additive prepared by the invention reduces the moisture content of the ammonium bicarbonate finished product to below 3 percent, improves the nitrogen content to over 17 percent, increases crystalline particles, reduces decomposition loss, is not easy to cake, facilitates the storage and transportation of ammonium bicarbonate, and reduces the production cost of the ammonium bicarbonate.

Owner:JIANGSU HEYOU CHEM

Circulation-type crystallizer

InactiveCN100544804CImprove efficiencyReduce energy consumptionSolution crystallizationEngineeringVacuum pump

A circulating crystallizer, comprising a crystallization tank, a cooling interlayer arranged around the crystallization tank, a stirring bar is arranged in the crystallization tank, a liquid inlet and a liquid outlet are arranged on the crystallization tank, and the liquid outlet and the A circulation pipeline is arranged between the liquid inlets, and an intermediate pool with an overflow is arranged in sequence on the circulation pipeline, a high-level tank and a condenser for storing the initial solution of crystallization, and the circulation pipeline is also equipped with a circulation Mercury, the crystallization tank is also provided with a crystallization liquid outlet below the crystallization tank, and the crystallization liquid outlet is connected with the crystallization tank. vacuum pump. The circulating crystallizer mother liquid is circulated back to the crystallization tank, which has high efficiency and low energy consumption.

Owner:HANGZHOU LINAN JINLONG CHEM

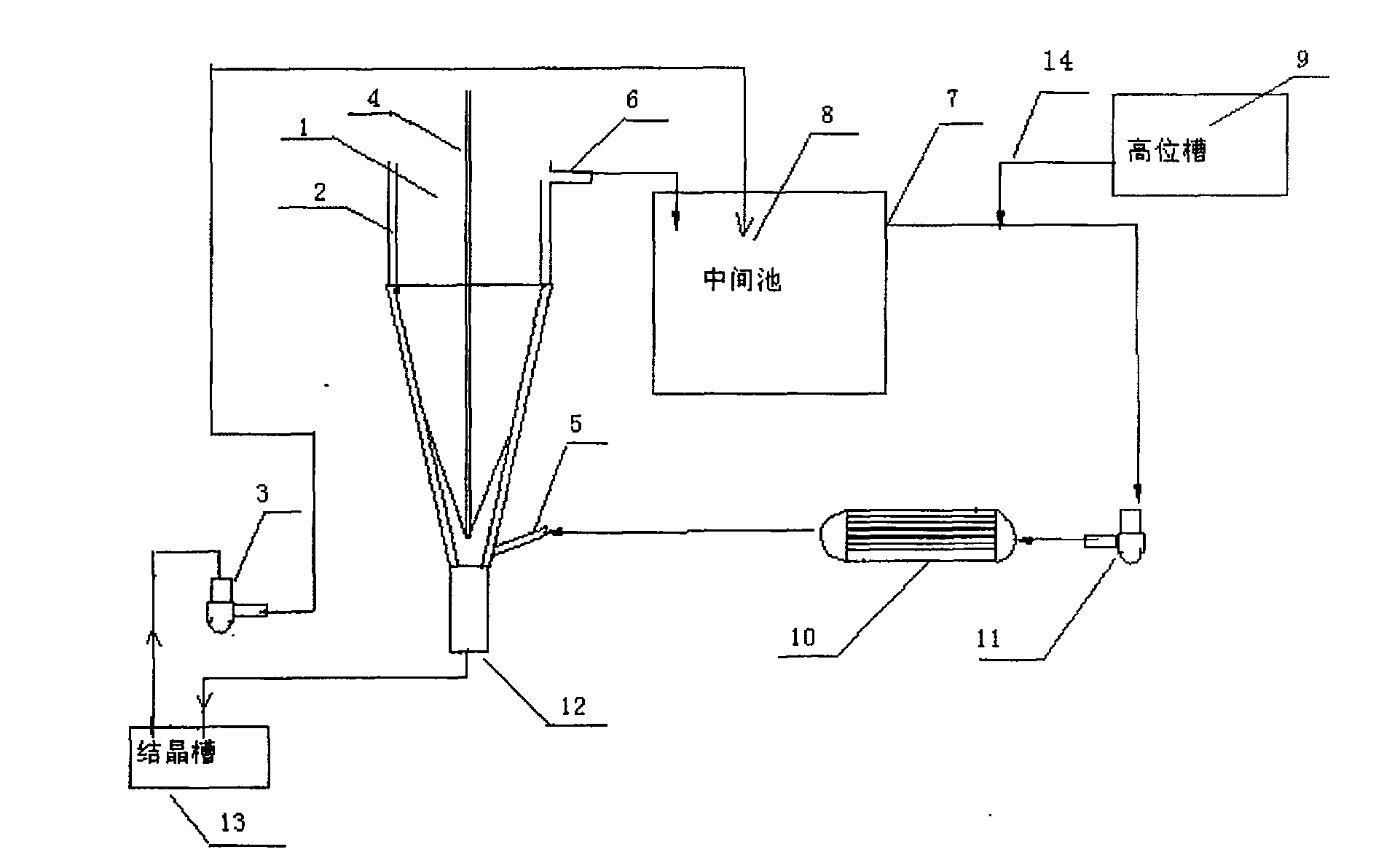

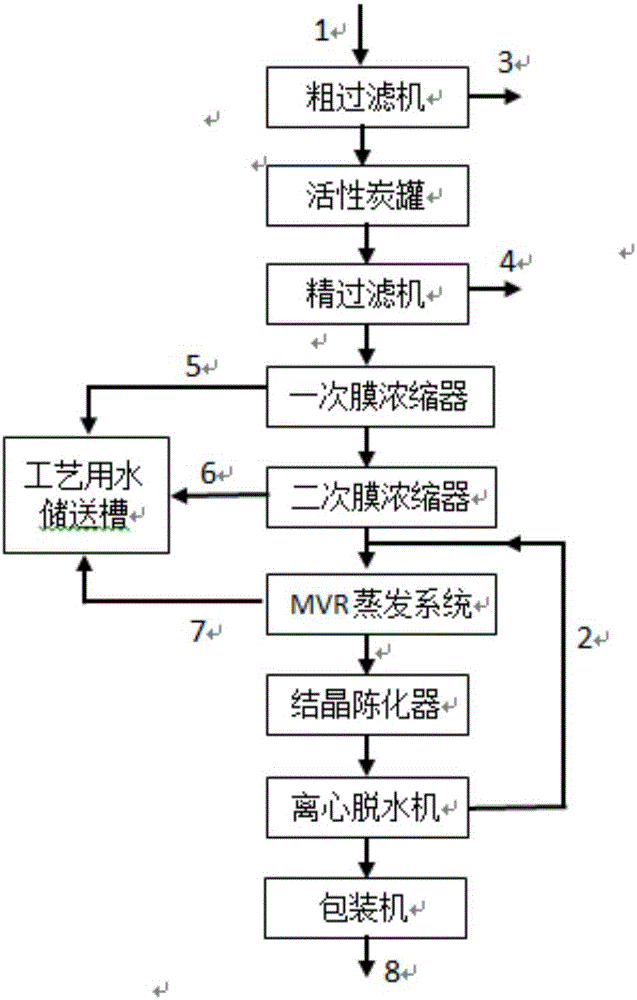

A method for recycling washing water and by-product magnesium ammonium fertilizer in the production process of carbonization magnesia

ActiveCN106277520BGuaranteed uptimeSave waterMultistage water/sewage treatmentNature of treatment waterFiltrationEvaporation

The invention relates to a method for recycling washing water and coproducing a magnesium ammonium fertilizer during carbonization-process magnesium oxide production. The method comprises the following steps: hydrocyclone separation, activated carbon adsorption, plate and frame filter and other liquid-solid separation processes are utilized to remove solid matters in the washing water; two-stage reverse osmosis membrane filtration is utilized to concentrate the washing water; a mechanical compression heat pump evaporation technique is adopted to perform further evaporative concentration; purified water with very low total salt content obtained in the concentration process is recycled to the production system as process water; and the concentrated solution generates a large-granule ammonium sulfate magnesium fertilizer in a crystallization aging device, and the large-granule ammonium sulfate magnesium fertilizer is subjected to centrifugal separation, packaging and the like to obtain the ammonium sulfate magnesium fertilizer byproduct. In the washing water recycling process, the ammonium magnesium fertilizer byproduct is obtained, thereby being beneficial to implementing wastewater zero discharge in the medical magnesium oxide production process, and achieving the goal of changing wastes into valuable substances.

Owner:河北镁神科技股份有限公司

Method and device for crystallizing and separating dicyandiamide

PendingCN113620844ANo generationNo pollution in the processOrganic chemistryOrganic compound preparationCold airGas solid

The invention discloses a method and device for crystallizing and separating dicyandiamide, belonging to the technical field of dicyandiamide production. The method comprises the following steps: S1, introducing hot gas of a dicyandiamide process into a crystallizer; S2, introducing cold air of a process into the crystallizer, and mixing the cold air of the process with the hot air of the dicyandiamide process to form a gas-solid mixture; and S3, discharging the gas-solid mixture out of the crystallizer, and introducing the gas-solid mixture into a gas-solid separator to obtain a dicyandiamide solid. The whole flow process is free of pollution, the technological process is free of decalcification reaction and process waste residues, a unique gas-phase cooling crystallization process is adopted, and no process waste water is generated.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Preparation method for high-purity baicalin

ActiveCN105566416ALow viscosityEasy to follow upSugar derivativesSugar derivatives preparationAlcoholBoiling point

The invention discloses a preparation method for high-purity baicalin and belongs to the technical field of natural product chemistry. The preparation method includes the following steps that 1, a baicalin crude product is taken and added into mixed solvent of dimethyl sulfoxide and lower alcohol, and the mixture is stirred and heated to 30 DEG C-70 DEG C to be dissolved to obtain a baicalin solution, wherein the mass ratio of the baicalin crude product to dimethyl sulfoxide to lower alcohol is 1:(0.8-3):(0-2) according to the addition amount; 2, filtering is performed to remove insoluble impurities and collect filtrate; 3, lower alcohol is added into the filtrate in the step2, the mass ratio of lower alcohol to the baicalin crude product is (3-10):1 according to the addition amount of lower alcohol, the mixture is constantly stirred and heated to 50 DEG C-90 DEG C to generate yellow sediment, and temperature is kept for 0.5-3 hours; 4, cooling, filtering, lower alcohol washing and lower alcohol drying are performed to obtain yellow powder which is high-purity baicalin. Operation conditions are mild; because no high-boiling-point second-class solvent is used, follow-up treatment of residual solvent is facilitated; the preparation method is suitable for large-scale production.

Owner:SHANDONG ANALYSIS & TEST CENT

Method for recycling washing water and coproducing magnesium ammonium fertilizer during carbonization-process magnesium oxide production

ActiveCN106277520AGuaranteed uptimeSave waterMultistage water/sewage treatmentNature of treatment waterFiltrationReverse osmosis

The invention relates to a method for recycling washing water and coproducing a magnesium ammonium fertilizer during carbonization-process magnesium oxide production. The method comprises the following steps: hydrocyclone separation, activated carbon adsorption, plate and frame filter and other liquid-solid separation processes are utilized to remove solid matters in the washing water; two-stage reverse osmosis membrane filtration is utilized to concentrate the washing water; a mechanical compression heat pump evaporation technique is adopted to perform further evaporative concentration; purified water with very low total salt content obtained in the concentration process is recycled to the production system as process water; and the concentrated solution generates a large-granule ammonium sulfate magnesium fertilizer in a crystallization aging device, and the large-granule ammonium sulfate magnesium fertilizer is subjected to centrifugal separation, packaging and the like to obtain the ammonium sulfate magnesium fertilizer byproduct. In the washing water recycling process, the ammonium magnesium fertilizer byproduct is obtained, thereby being beneficial to implementing wastewater zero discharge in the medical magnesium oxide production process, and achieving the goal of changing wastes into valuable substances.

Owner:河北镁神科技股份有限公司

Compound ammonium bicarbonate additive and production method thereof

InactiveCN101591027BReduce moisture contentNot easy to storeAmmonium carbonates/bicarbonatesSodium bicarbonateDecomposition

The invention provides a compound ammonium bicarbonate additive and a production method thereof. The ammonium bicarbonate additive is compounded with the following materials: ammonia with mass concentration of 4 to 8 percent, ammonium dodecylbenzenesulfonate, 1-pentadecanesulfonyl chloride and Tween 80. The weight portion ratio of the compounded materials is 45-55:13-15:28-32:3-6. The compoundingmethod comprises the following steps: preparing materials according to the weight portion ratio; adding the ammonia into a reaction kettle, and adding the ammonium dodecylbenzenesulfonate when the ammonia temperature in the kettle is between 58 and 62 DEG C; stirring the mixture of the two, adding the 1-pentadecanesulfonyl chloride when the temperature in the kettle is between 70 and 78 DEG C, stirring for 60 minutes, and slowly reducing temperature; and adding the Tween 80 when the temperature in the kettle is between 58 and 62 DEG C, evenly stirring, cooling to normal temperature, and obtaining a finished product. The ammonium bicarbonate additive prepared by the invention reduces the moisture content of the ammonium bicarbonate finished product to below 3 percent, improves the nitrogencontent to over 17 percent, increases crystalline particles, reduces decomposition loss, is not easy to cake, facilitates the storage and transportation of ammonium bicarbonate, and reduces the production cost of the ammonium bicarbonate.

Owner:JIANGSU HEYOU CHEM

Titanium-containing aluminium hydroxide preparation method

ActiveCN100390063CHigh crystal purityIncrease contentCatalyst activation/preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideTitanium

The invention discloses a making method of titanium aluminium hydroxide, which is characterized by the following: introducing adjuvant titanium in the gelling course of aluminium hydroxide through shaking pH value reciprocally; dispersing titanium evenly on the surface of aluminium hydroxide; enlarging the most probable aperture of titanium aluminium hydroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

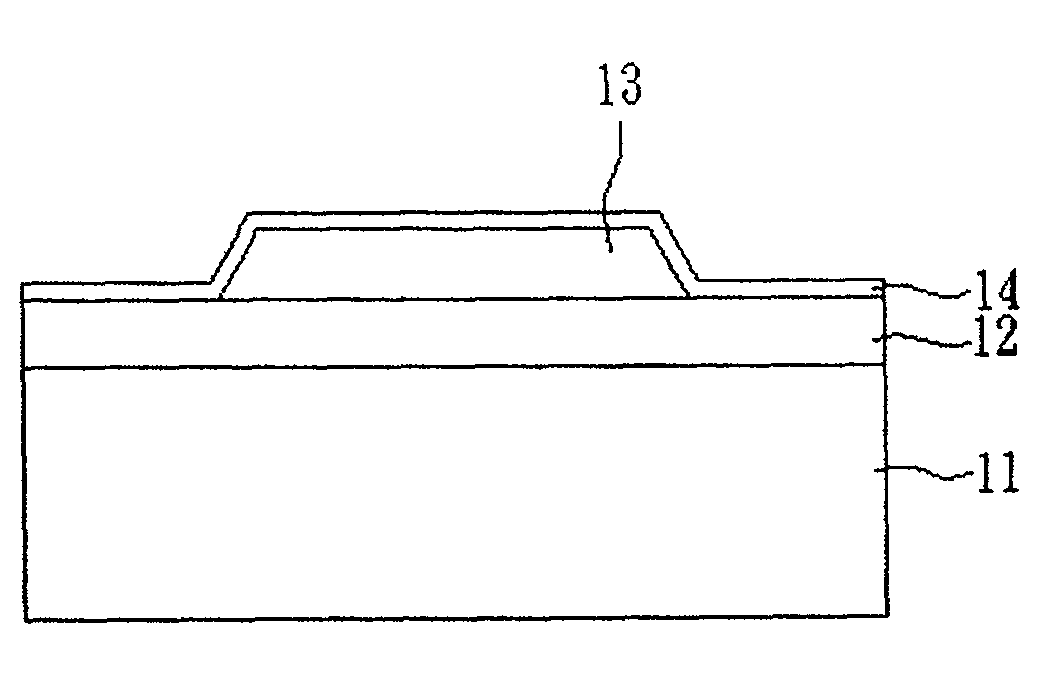

System for displaying image and method for laser annealing for cryogenic polycrystalline silicon

InactiveCN100547733CIncrease usageHigh electron mobilityTransistorSemiconductor/solid-state device manufacturingRoom temperatureLength wave

The invention relates to a system for displaying images and a laser annealing method for low-temperature polysilicon. The low-temperature polysilicon annealing method is used for a glass substrate on which a first metal layer and a silicon film layer are formed. The annealing method includes the following steps: irradiating a laser beam with a wavelength greater than 400 nanometers on the silicon film layer, and the silicon film layer is formed on the glass substrate. The film layer absorbs a part of the laser beam and is heated and melted, and the other part of the laser beam penetrates the silicon film layer and reflects from the first metal layer to the silicon film layer, so that the silicon film layer absorbs the reflected laser beam and is reheated to crystallize ; and resting the silicon film layer after the laser beam irradiation, so that the temperature of the silicon film layer drops to room temperature. The system is used for displaying images, which includes a low-temperature polysilicon substrate with a glass substrate, a first metal layer and a polysilicon film layer. The invention can not only improve the utilization rate of the laser beam, but also save the use cost by using the solid-state laser beam, and further enhance the electron mobility of the thin film transistor.

Owner:TPO DISPLAY

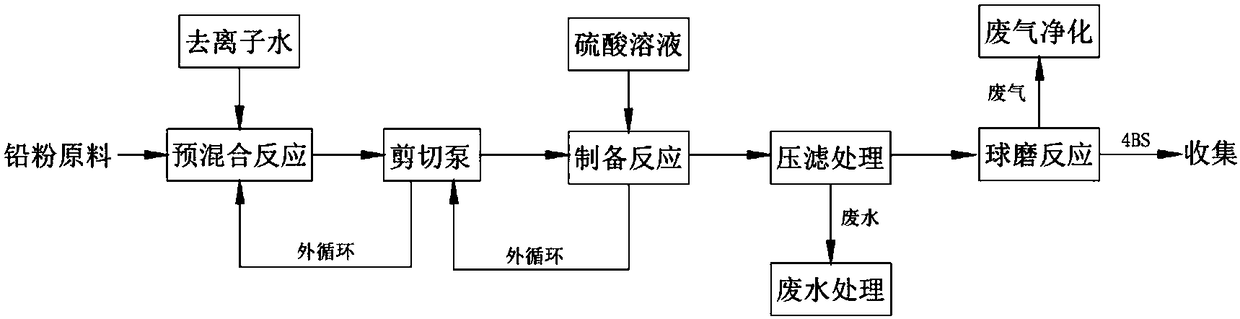

A method for preparing tetrabasic lead sulfate

ActiveCN106564941BShorten mixing timeShorten heating timeFinal product manufactureLead sulfatesSulfateReaction temperature

The invention relates to a method for preparing tetrabasic lead sulfate, which comprises the following steps: A. Prepare the reaction, send the pre-mixed lead material into the reaction kettle, and carry out internal circulation stirring while adding sulfuric acid solution into the reaction kettle After uniformity, feed compressed air into the reaction kettle to cool the lead slime; B. Ball milling reaction, transport the lead slime in step A to a drying ball milling device, and perform drying and ball milling simultaneously to obtain a tetrabasic lead sulfate product. The present invention adopts the method of directly reacting the premixed lead material with sulfuric acid, makes full use of the heat generated by the exothermic reaction of concentrated sulfuric acid to rapidly heat up the reactor, thereby shortening the preparation reaction time, and the reaction product is rapidly cooled by compressed air, further Effectively inhibit the 4BS crystal particles from becoming larger, and the formed 4BS has a small and uniform particle size, which effectively solves the problem in the prior art that the reaction product crystal particles are large and uneven due to the high reaction temperature and long reaction time for the preparation of tetrabasic lead sulfate. technical problem.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

Preparation method of large particle crystal form high bulk density 2-hydroxy-4-methylthiobutyrate calcium

The invention belongs to the field of the chemical industry, and relates to a preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate. The preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate comprises the following steps that 2-hydroxy-4-(methylthio)butyric acid, a calcium compound and a crystallizing agent are arranged in an aqueous medium, the pH is adjusted to be 5-7, the temperature is 60-80DEG C, stirring and full reactions are carried out, cooling crystallization is carried out to obtain calcium 2-hydroxy-4-(methylthio)butyrate crystals, separation is carried out to obtain crystals and coarse product mother liquid, and the crystals serve as calcium 2-hydroxy-4-(methylthio)butyrate coarse products. The calcium compound is one or more of calcium salt, calcium oxide and calcium hydroxide, and the use amount of the crystallizing agent is 50ppm-3000ppm of the mass of the 2-hydroxy-4-(methylthio)butyric acid. Materials produced through the preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate are high in purity, dehydration is easy, drying is rapid, crystal particles obtained after drying are large, good in mobility and large in bulk density, the amount of dust is low, glossiness is high, and the materials are more applicable to fodder.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

A kind of cigs-based thin film solar cell and preparation method thereof

ActiveCN105244394BSimple interfaceLarge crystal particlesFinal product manufacturePhotovoltaic energy generationManufacturing cost reductionAbsorption layer

The invention provides a CIGS-based film solar cell and preparation method thereof. The CIGS-based film solar cell comprises a substrate, a back electrode layer formed on the substrate, an alloy film layer formed on the back electrode layer, a p-type light absorption layer formed on the alloy film layer, a buffer layer formed on the p-type light absorption layer, and a transparent conductive layer formed on the buffer layer. The alloy film layer is formed by antimony and at least one selected from silver, platinum, chromium and gallium. The alloy film layer formed on the back electrode layer can be used to increase the size of crystalline particles of the p-type light absorption layer, increase the short-circuit current, and prevents the back electrode layer from corrosion of sulfur group elements; and thus, performance of the film solar cell is improved, and the manufacture cost is reduced.

Owner:厦门神科太阳能有限公司

A kind of preparation method of high-purity baicalin

ActiveCN105566416BLow viscosityEasy to follow upSugar derivativesSugar derivatives preparationAlcoholBoiling point

The invention discloses a preparation method for high-purity baicalin and belongs to the technical field of natural product chemistry. The preparation method includes the following steps that 1, a baicalin crude product is taken and added into mixed solvent of dimethyl sulfoxide and lower alcohol, and the mixture is stirred and heated to 30 DEG C-70 DEG C to be dissolved to obtain a baicalin solution, wherein the mass ratio of the baicalin crude product to dimethyl sulfoxide to lower alcohol is 1:(0.8-3):(0-2) according to the addition amount; 2, filtering is performed to remove insoluble impurities and collect filtrate; 3, lower alcohol is added into the filtrate in the step2, the mass ratio of lower alcohol to the baicalin crude product is (3-10):1 according to the addition amount of lower alcohol, the mixture is constantly stirred and heated to 50 DEG C-90 DEG C to generate yellow sediment, and temperature is kept for 0.5-3 hours; 4, cooling, filtering, lower alcohol washing and lower alcohol drying are performed to obtain yellow powder which is high-purity baicalin. Operation conditions are mild; because no high-boiling-point second-class solvent is used, follow-up treatment of residual solvent is facilitated; the preparation method is suitable for large-scale production.

Owner:SHANDONG ANALYSIS & TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com