Technology for extracting ammonium thiosulfate and ammonium thiocyanate by desulphurization waste liquid

A technology of ammonium thiosulfate and ammonium thiocyanate, applied in the field of desulfurization, can solve the problems of unutilized latent heat of water vapor, large heating steam consumption, large equipment investment, etc., and achieves easy separation, small equipment investment, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

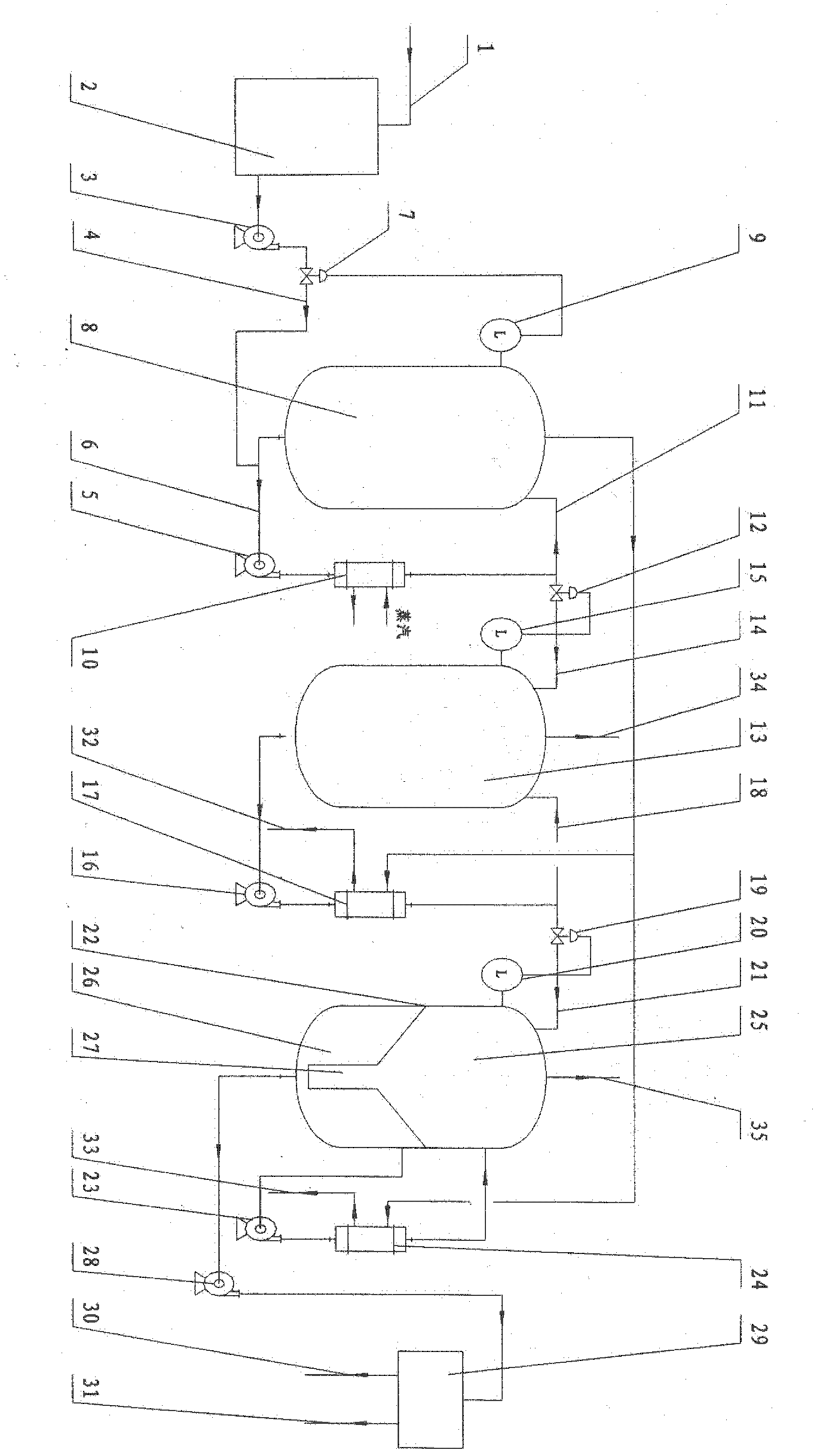

[0021] Combine below figure 1 The present invention is further described by examples.

[0022] like figure 1 As shown, a process for extracting ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquid, the process is as follows: the desulfurization liquid containing ammonium thiosulfate and ammonium thiocyanate filtered by activated carbon from the desulfurization system is passed through the pipeline. 1 is sent to the desulfurization liquid tank 2 after decolorization, and is sent to the inlet pipe 6 of the first evaporator circulating pump 5 by the pump 3 through the pipeline 4. 9. The detected liquid level adjusts the valve opening. After the material in the first evaporator 8 is pumped out by the circulating pump 5 and indirectly heated by the external first evaporator heater 10, part of the material is returned to the first evaporator 8 through the pipeline 11 to provide the first evaporator 8 with the heat required for evaporation. Part of it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com