Patents

Literature

351 results about "Ammonium thiocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium thiocyanate is an inorganic compound with the formula NH₄SCN. It is the salt of the ammonium cation and the thiocyanate anion.

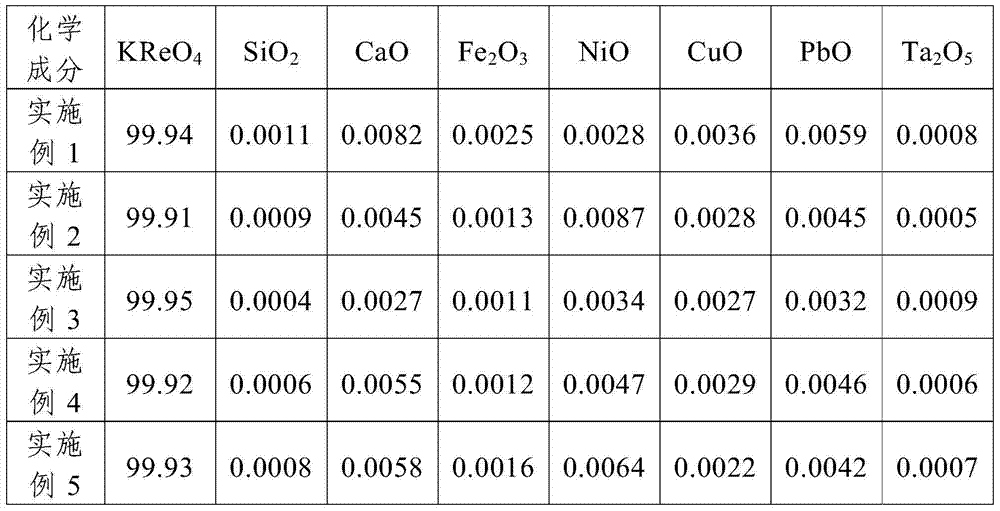

Method for extracting rhenium from eluate of flue ash generated by baking enriched ore of molybdenum

This invention relates to a method for extracting Re from flue dust and tail gas rinsing solution of Mo concentrate calcination. The method comprises: (1) adding water to flue dust, leaching out Re in the flue dust to obtain Re-containing leaching solution; (2) adjusting the pH value of the Re-containing leaching solution and tail gas rinsing solution to 5 with ammonium bicarbonate so that Mo, Fe, Cu and Zn ions are converted into hydroxides, separated from Re and precipitated, and filtering to obtain Re-containing solution for extraction; (3) extracting with extractant so that Re enters into the extractant, which is named enriched oil; (4) back-extracting the enriched oil with 3 N ammonia solution so that Re enters into the back extraction solution; (5) adding the back extraction solution into an ion exchange system so that Re is adsorbed onto the resin; (6) preparing 5-10% ammonium thiocyanate solution, adding ammonia solution to adjust the pH value to 8-9, and desorbing Re adsorbed onto the resin to obtain Re-containing desorption solution; (7) evaporating the desorption solution, concentrating, and crystallizing to obtain ammonium perrhenate product.

Owner:锦州沈宏实业集团有限公司

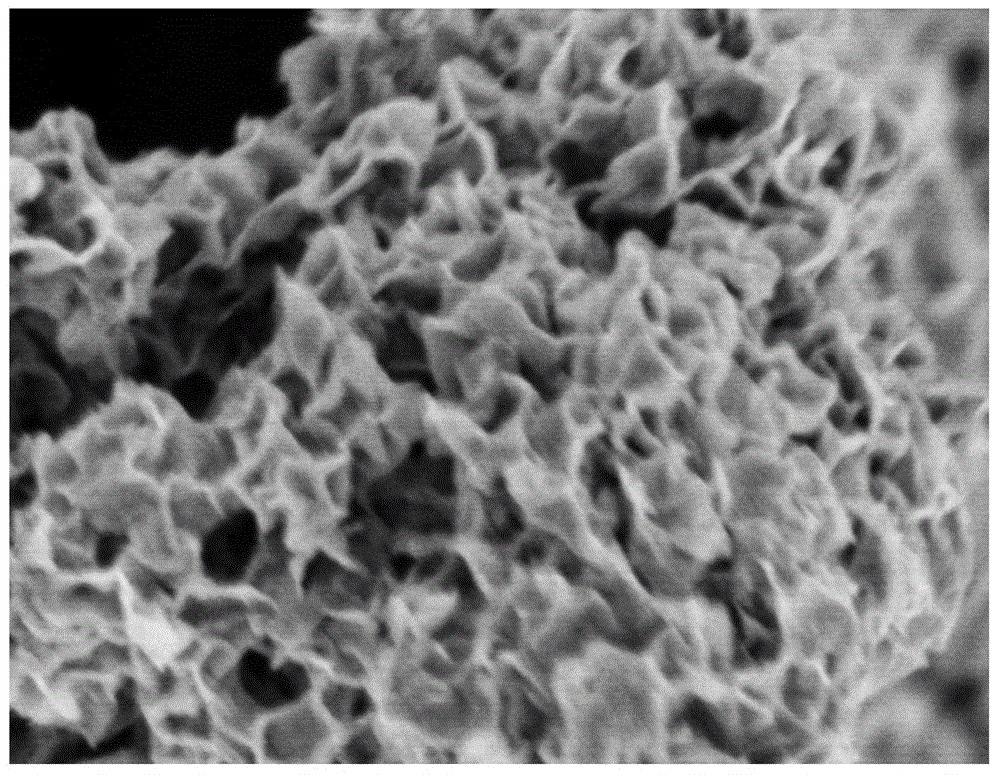

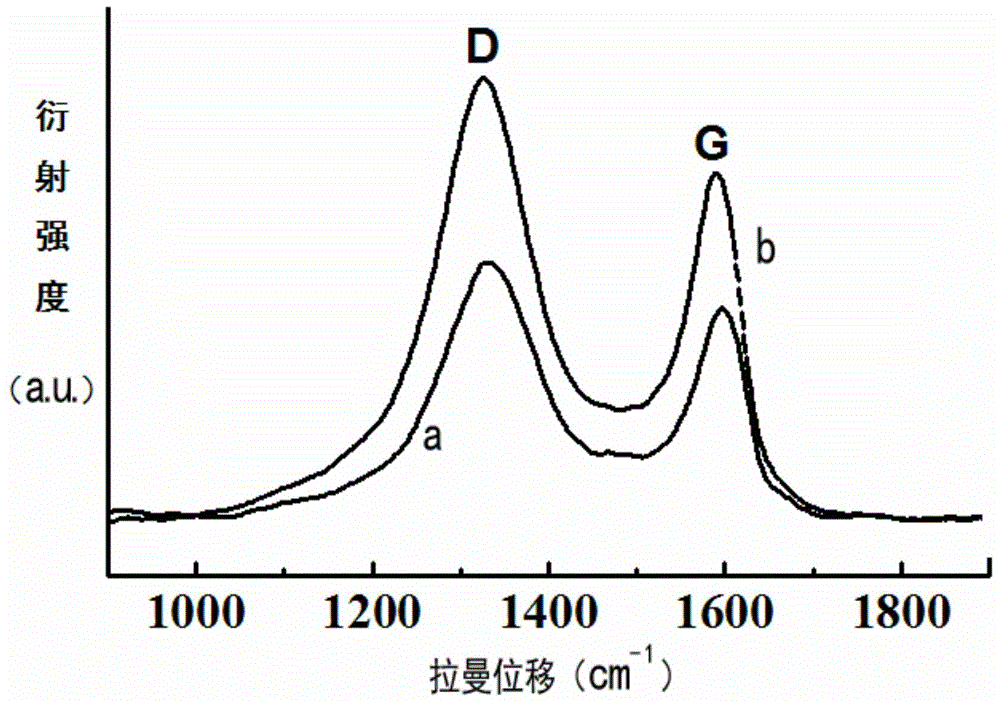

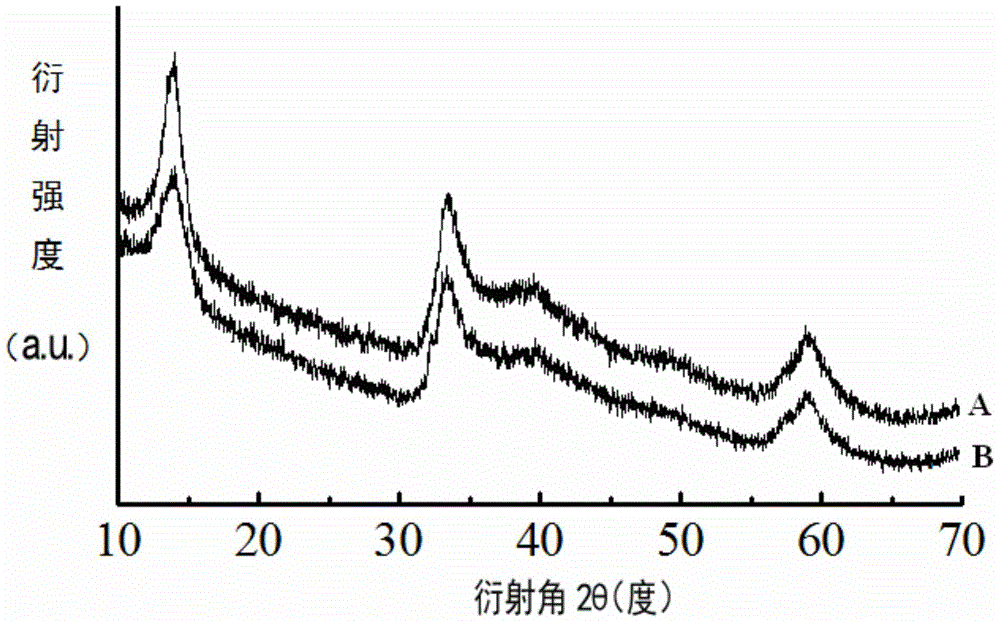

Method for preparing three-dimensional flower-shaped graphene/molybdenum disulfide composite loaded fibrous counter electrode

InactiveCN104319102ASimple processMild reaction conditionsLight-sensitive devicesFinal product manufactureFiberCarbon fibers

The invention discloses a method for preparing a three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode uses a one-step hydrothermal reduction method, to be specific, adding molybdic acid or the water solution of molybdenum oxide, ammonium thiocyanate and graphene oxide in a hydrothermal reactor, vertically immersing carbon fiber in the reaction liquid, carrying out hydrothermal reduction reaction for 12 to 36 hours under 160 to 200 degrees centigrade, taking out the carbon fiber after ending reacting, using deionized water and absolute ethyl alcohol to wash, and drying. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode has advantages of simple technique, moderate reaction condition, high yield, good reproducibility, easiness in scale production and the like; the photoelectric conversion rate of a dye-sensitized solar cell composed of the prepared fibrous counter electrode is obviously higher than that of a dye-sensitized solar cell composed of an MoS2 or platinum loaded fibrous counter electrode, and the method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode is important for promoting the commercial application of the dye-sensitized solar cell.

Owner:SHANGHAI UNIV OF ENG SCI

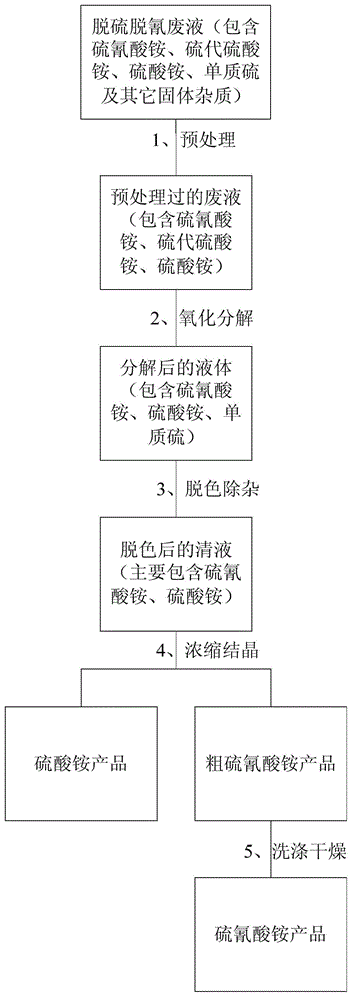

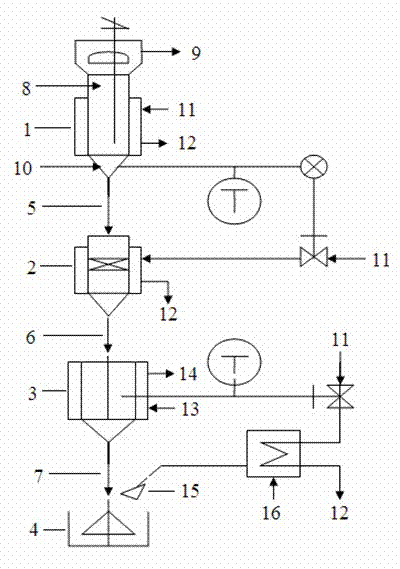

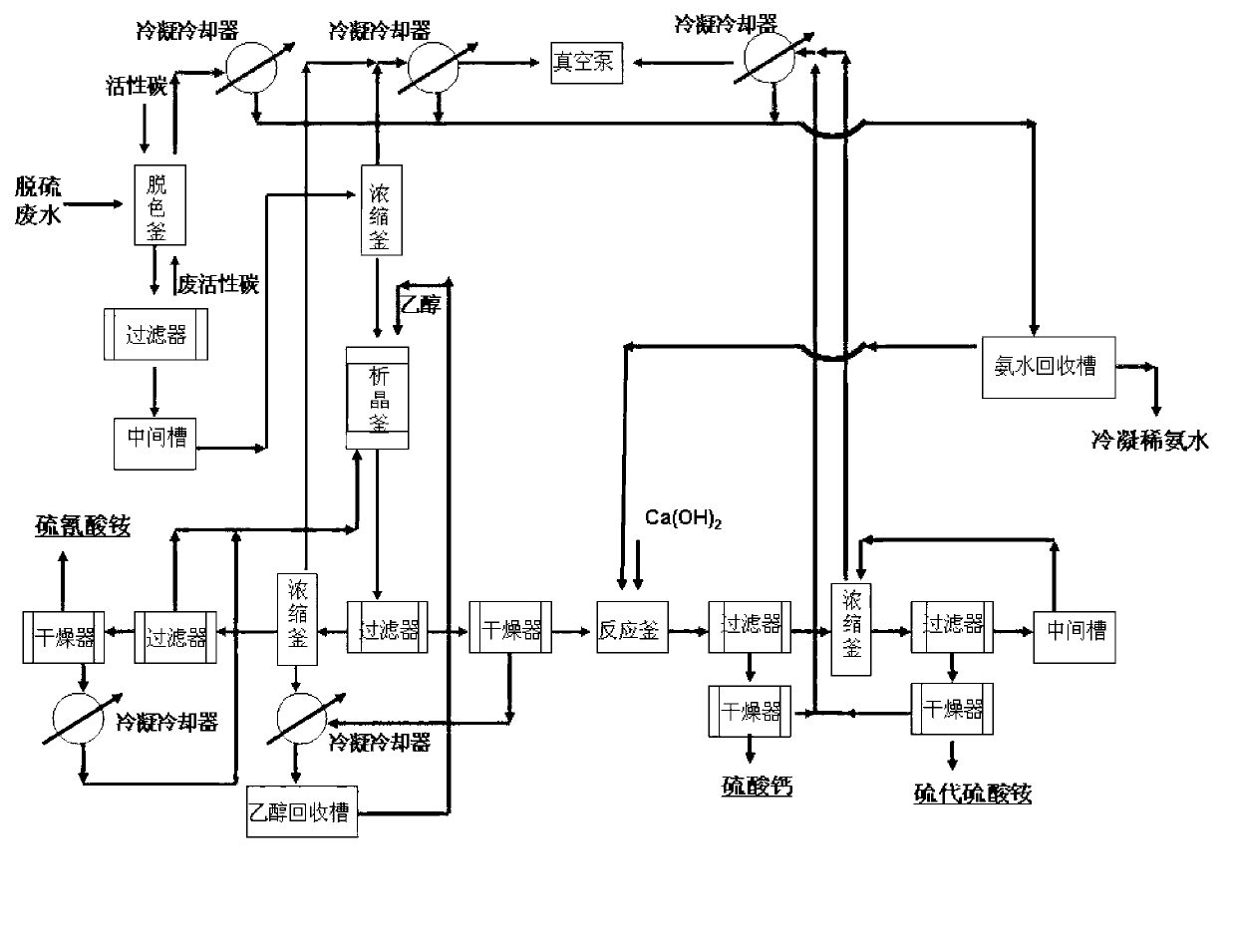

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

InactiveCN102976361AEfficient decompositionHigh purityThiocyanic acidAmmonium sulfatesPollutionAmmonium sulfate

The invention provides a method for recycling ammonium salt from chemical waste liquor generated in the desulfurization / decyanation process of coke oven gas, and particularly, the invention provides a method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization / decyanation waste liquor. The purities of ammonium thiocyanate and ammonium sulphate produced by using the method disclosed by the invention are greatly improved in comparison with those of products produced by contrasted embodiments. According to the method disclosed by the invention, high-purity products can be prepared under the condition of only carrying out one-time step-by-step concentration, so that the wastewater discharge amount is reduced and the environment pollution of coking plants is alleviated; and high-purity and high-added-value chemical raw materials are recycled, thereby increasing the economic benefits of enterprises.

Owner:BEIJING RISUN TECH CO LTD

Method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater

ActiveCN102424401AMeet the requirements of green circular economyEasy to handleThiocyanic acidPersulfateThiocyanate

The invention discloses a method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater. The method comprises the steps of: adding persulfate or sulfuric acid to polyamine salt wastewater for reacting with ammonium thiosulfate so as to generate ammonium sulfate and ammonium sulfite, and further oxidizing into ammonium sulfate and sulfur, thus the wastewater is changed into a two-component mixed liquid which contains ammonium thiocyanate and ammonium sulfate and is easy to separate by crystallization from a three-component mixed liquid, and high-efficiency separation is realized. The purity of the obtained ammonium thiocyanate crystal can reach 99%.

Owner:江苏燎原环保科技股份有限公司

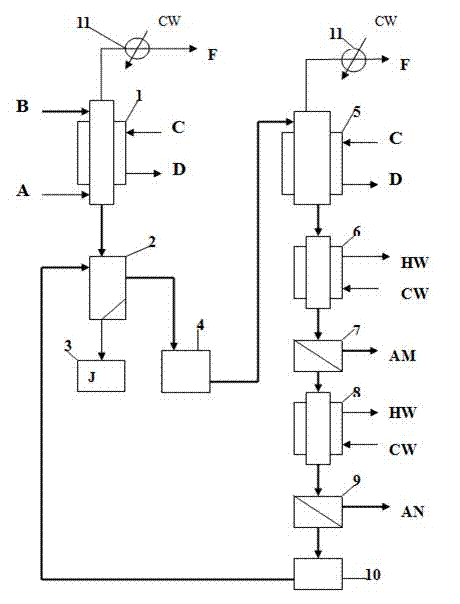

Method for extracting salt from coking desulphurization waste solution and special device thereof

InactiveCN102161541AEffective interceptionAvoid diversionThiocyanic acidWater/sewage treatment bu osmosis/dialysisFiltrationDecomposition

The invention discloses a method for extracting salt from coking desulphurization waste solution and a special device thereof. The method comprises the following steps of: heating raw material waste solution for decomposition, adsorbing and decolorizing, then heating, evaporating and concentrating to obtain concentrated solution, performing heat filtration at constant temperature to remove fine sulfur particles, cooling and crystallizing in a crystallizer, filtering at constant temperature, separating filtrate to obtain crystals, washing the crystals to obtain high-purity ammonium thiocyanate, dissolving mixed salt crystals in ammonium sulfate mother liquor, regulating the acidity to be below 20 percent, preheating to ensure that the temperature is between 90 and 110 DEG C, blowing air oroxygen, performing oxidative transformation for 1min to obtain ammonium sulfate transformation liquid, and adding ammonium sulfate production mother liquor to obtain an ammonium sulfate product. By the method, a high-purity product can be extracted from the waste solution through one-time operation, so that processing and treatment times are reduced; solid-phase impurities are effectively intercepted and prevented from transferring to the crystals at constant temperature; and the mixed salt is subjected to oxidative transformation treatment, all ammonium thiosulfate is transformed into the ammonium sulfate product with high nitrogen content, the process is simple, operation cost is low, and product marketing is broad.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

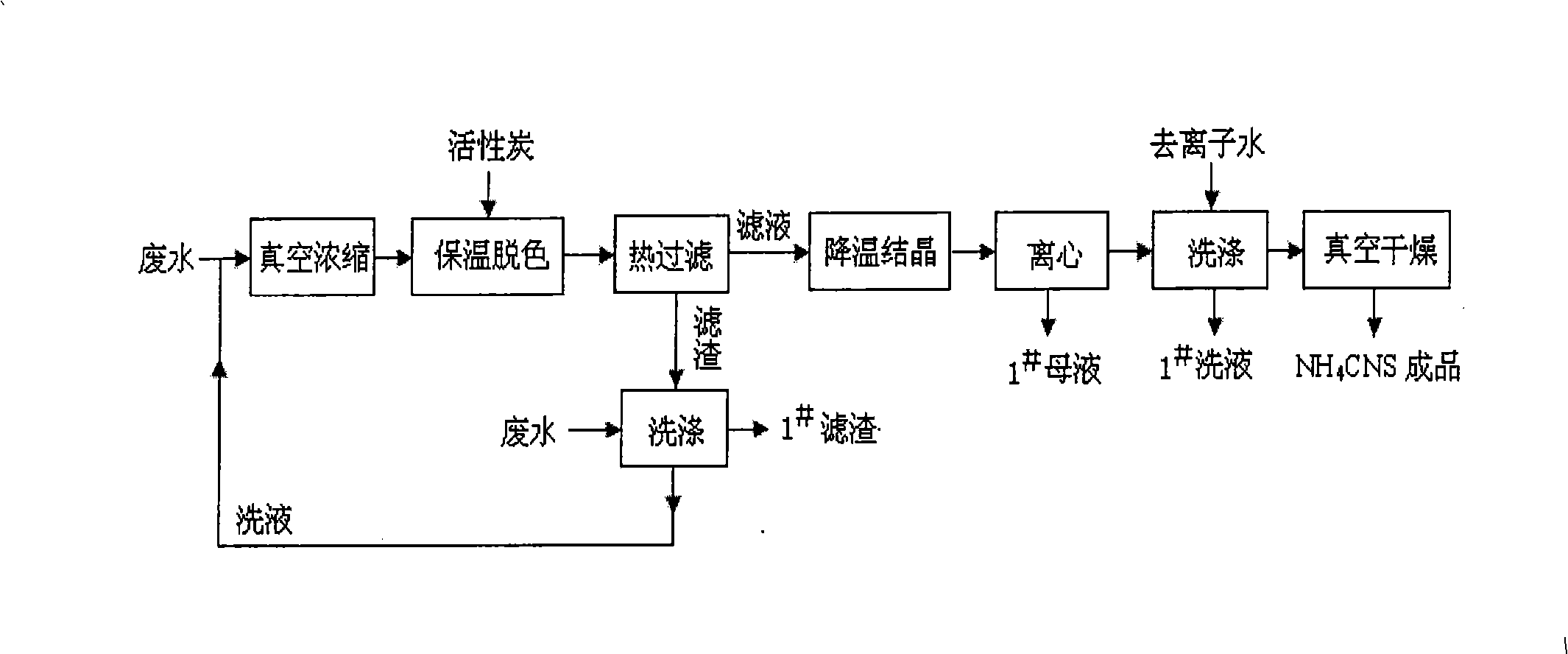

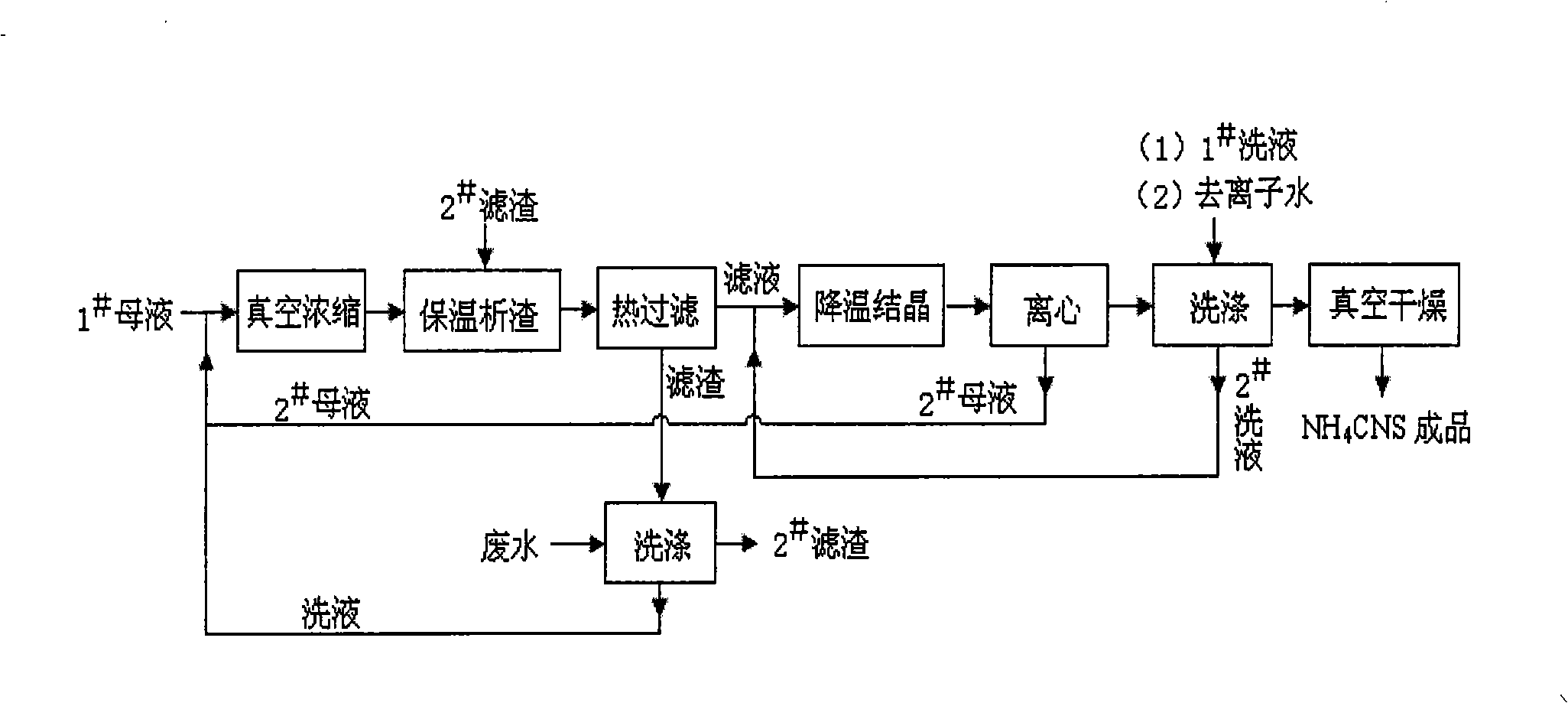

Method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor

ActiveCN102674398AImprove desulfurization efficiencyEconomicalThiocyanic acidAmmonium sulfatesPhthalocyanineCobalt

The invention relates to a method for recycling chemical wastewater, in particular to a method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor. By the method, inorganic salt in the desulfuration waste liquor generated by a phthalocyanine cobalt sulfonate (PDS) method in a coking plant is extracted by a two-stage concentration and fractional crystallization separation method. The method is easy to operate and control, the purity of the ammonium thiocyanate which is finally recovered reaches more than 98 percent, and the yield reaches more than 80 percent. By the method, the circulation volume of desulfuration liquor in a desulfuration working section and the total salt content in the desulfuration liquor are reduced, and the desulfuration efficiency of the desulfuration working section is improved; environmental problems generated by wastewater discharge pollution of coking plants are solved; and useful chemical raw materials are recovered from the desulfuration waste liquor, so that social, environmental and economic benefits for enterprises are increased.

Owner:邢台旭阳科技有限公司

Method for quickly leaching gold and silver by using mixed leaching agent

The invention discloses a method for quickly leaching gold and silver by using a mixed leaching agent, which comprises the following steps of: crushing gold-containing pyrite smelting slag, a sulfide-containing visible gold ore or / and a gold-containing oxidized ore serving as raw materials, conditioning the raw materials with water to form slurry, adding ammonium thiocyanate, thiocarbamide, urea and an oxidant, namely manganese dioxide or ferric chloride, into the ore slurry and stirring and leaching the mixed slurry to leach the gold and silver out. The method has the advantage that: the mixed leaching agent formed by adding the urea into the ammonium thiocyanate can quickly leach the gold and the silver out of the sulphur and arsen-containing gold ore by adding the urea with a low cost, particularly the gold and the silver which are contained in pyrolusite can be leached out with a lower cost. At the same time, beneficial elements in the ores can be comprehensively used.

Owner:梁伟基 +1

Deplating liquid for NiCuNi plating on surface of sintered NdFeB and deplating process thereof

InactiveCN102787321AFast stripping speedImprove deplating efficiencySodium sulfocyanatePotassium thiocyanate

The invention discloses a deplating liquid for a NiCuNi plating on the surface of sintered NdFeB and a deplating process thereof. The deplating liquid for the NiCuNi plating on the surface of sintered NdFeB adopts deionized water or clean tap water as the liquid solvent, and all components and component contents are as follows: 60-90g / L reserve salt S, 120-150ml / L ethylene diamine, 20-40g / L anti-corrosion complexing agent and 50-100ml / L mineral acid. The solute further comprises a surface active agent of 0.5-1g / L. The anti-corrosion complexing agent is sodium citrate or triammonium citrate; the mineral acid is nitric acid or ammonium nitrate; and the surface active agent is potassium thiocyanate, or sodium sulfocyanate or ammonium thiocyanate. The deplating process comprises the following steps: preparing a deplating bath; disposing a deplating liquid; executing the deplating; and removing the deplating liquid on a product. The deplating liquid has the advantages of stable property, good deplating effect and low cost; and the deplating operation is simple and convenient, pollution is prevented, body harm of operators is relieved, waste is changed into valuable and the benefits are remarkable.

Owner:牛凯

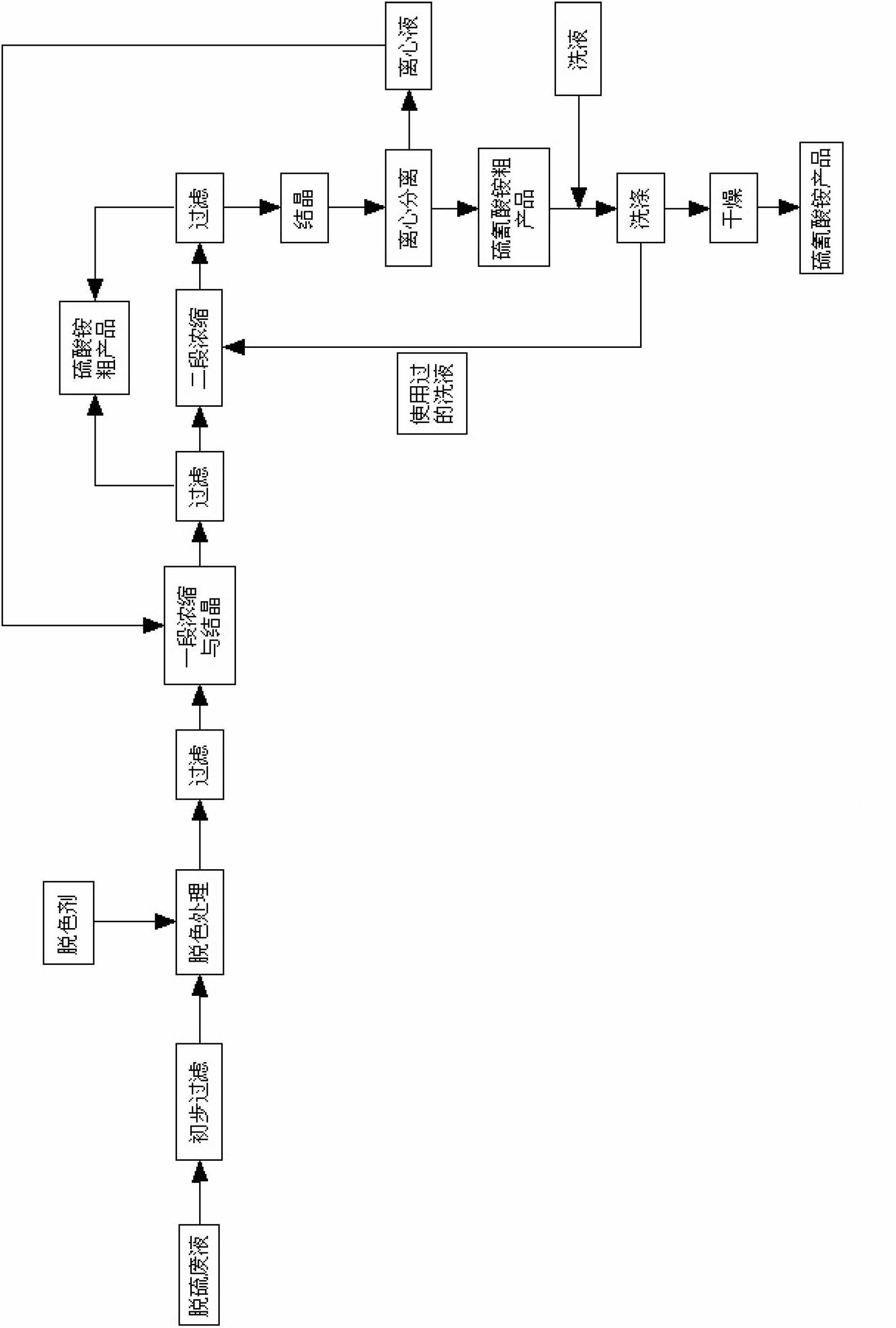

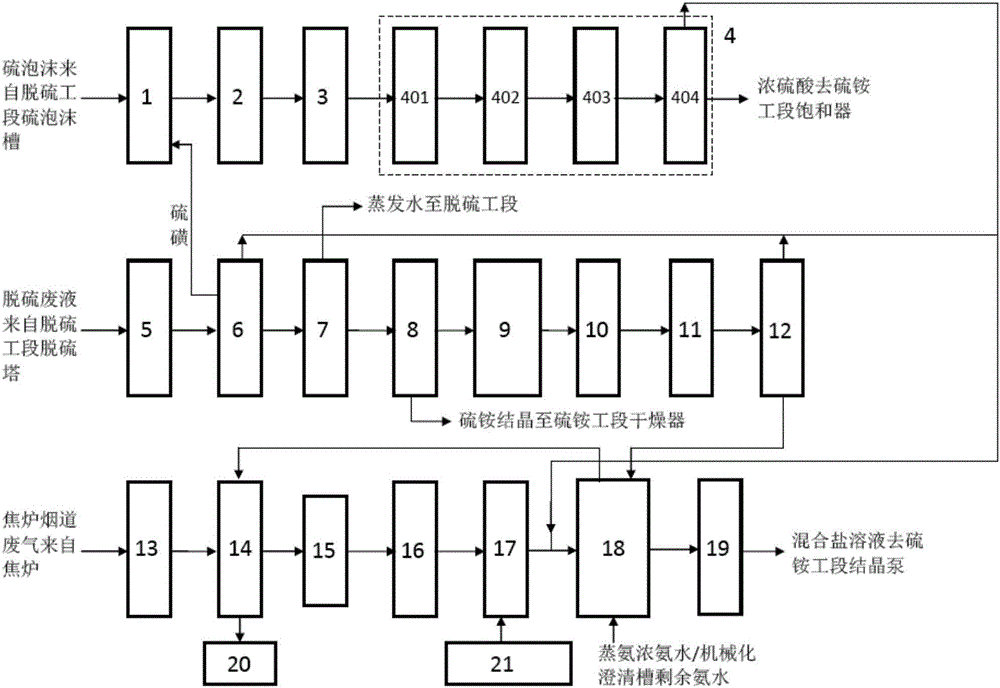

Distributed recycling system and method for sulfur in coking industry

ActiveCN106276973AImprove qualityImprove productivityAmmonium nitratesEnergy inputSelf purificationAmmonium nitrate

The invention relates to a distributed recycling system and method for sulfur in coking industry. Based on coking flow system resource balance, the self-purification function of coking flows are brought into full play, the system considers coupling treatment of sulfur foams, sulfur-containing waste gas and sulfur-containing waste liquid, waste materials are recycled, and the resource process value is increased. According to the technical scheme, sulfur foams are purified, then, pure sulfur is obtained, incineration is performed to produce acid, and obtained concentrated sulfuric acid absorbs ammonia in coke oven gas to produce ammonium sulfate; the desulfurization waste liquid is subjected to decoloration and then subjected to sulfo-oxidation, sulfur is separated out for incineration to produce acid, after solution crystallization and separation, ammonium sulfate and ammonium thiocyanate mother liquor are obtained, the ammonium thiocyanate mother liquor is incinerated to produce SO2, ammonium hydroxide is used for absorbing the produced ammonium sulfite, the ammonium sulfite is oxidized to produce ammonium sulfate or ammonium sulfite to be adopted as a denitrification agent for flue gas denitrification; waste heat of coke oven flue gas is recycled, the coke oven flue gas is mixed with ozone, some or all NO in the flue gas is oxidized, then, the flue gas and the recycling process tail gas are subjected to desulfurization and denitrification, and finally ammonium sulfate and ammonium nitrate are produced.

Owner:TSINGHUA UNIV

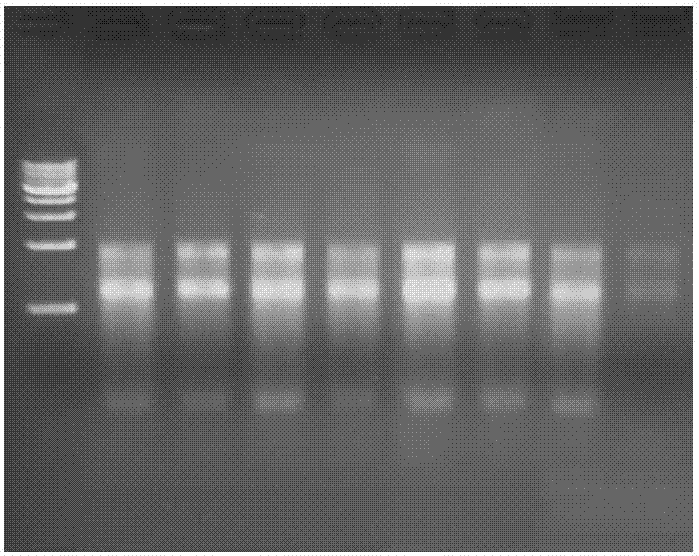

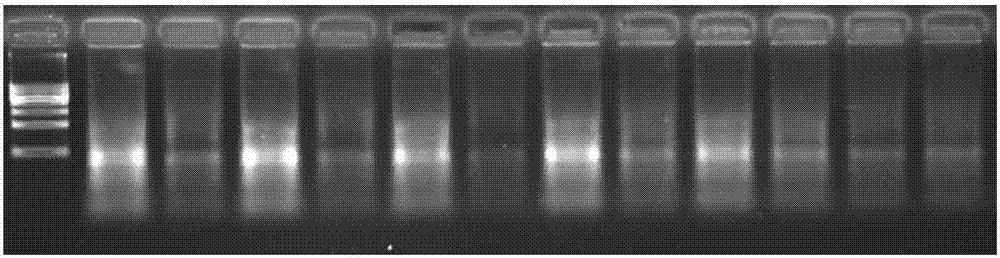

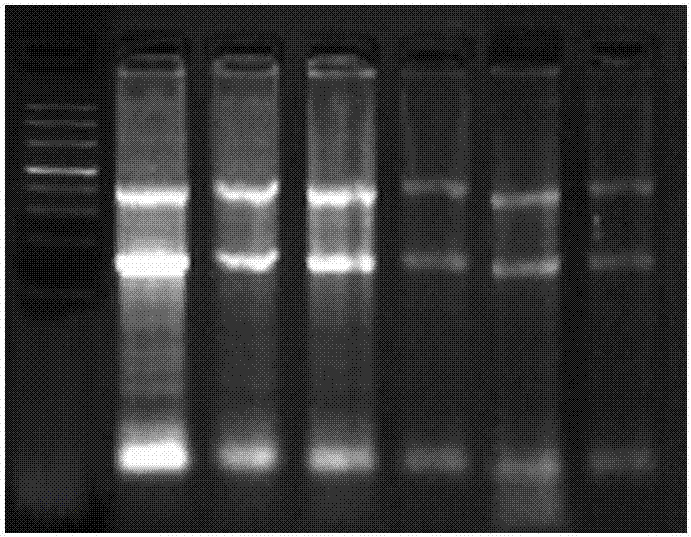

Lysis solution and application thereof in tissue or cell preservation and RNA (Ribonucleic Acid) extraction

ActiveCN107475251AAvoid Fragmentation IncompleteAvoid interferenceMicrobiological testing/measurementDead animal preservationSodium acetateIsothiocyanic acid

The invention discloses a lysis solution and an application thereof in tissue or cell preservation and RNA (Ribonucleic Acid) extraction. The lysis solution comprises a lysis solution A and a lysis solution B, wherein the lysis solution A comprises 2-4mol / L guanidinium isothiocyanate, 5-10mmol / L sodium chloride, 10-15mmol / L potassium chloride, the lysis solution B comprises 2-4mol / L guanidinium isothiocyanate, 1-5mmol / L spermidine, 30-40vt% of water saturated phenol, 0.4-0.5mol / L ammonium thiocyanate, 7-8vt% of glycerinum, 0.1-0.5mol / L sodium acetate and 0.2-0.5wt% of SDS (Sodium Dodecyl Sulfonate). When RNA is extracted by using the lysis solution A and the lysis solution B, tissue or cells do not need to be washed, and thus the extraction efficiency is remarkably improved; and due to synergistic effects of the components, the extracted RNA is high in purity and high in yield, and the purpose that animal RNA is extracted in laboratories rapidly with low cost and high quality in a large scale can be realized.

Owner:CHENGDU DAOSHENG BIOTECH CO LTD

Method of separating multi-ammonium compound salt

InactiveCN101012065ANon-flammableNon-explosiveThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium compoundsWastewater

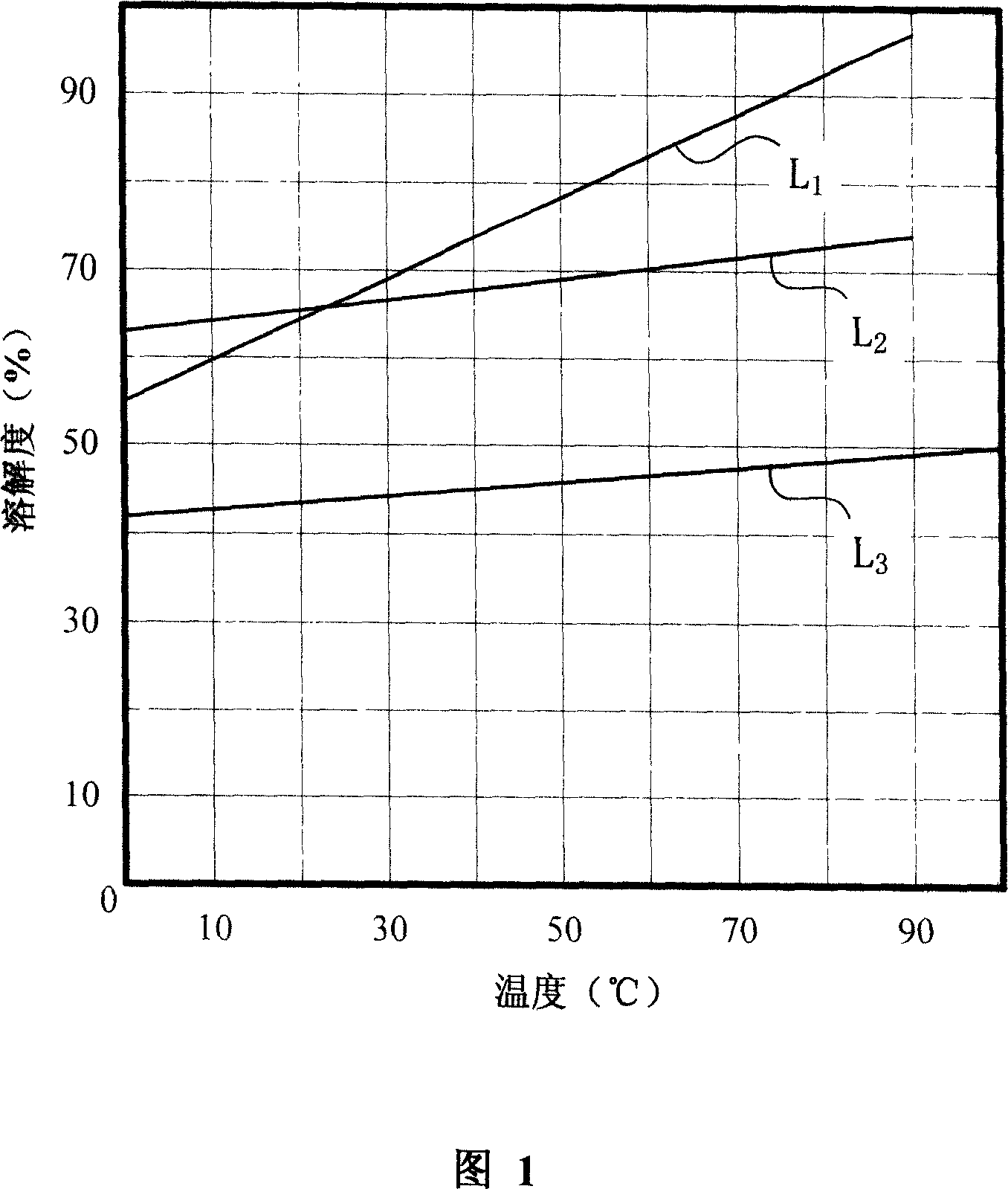

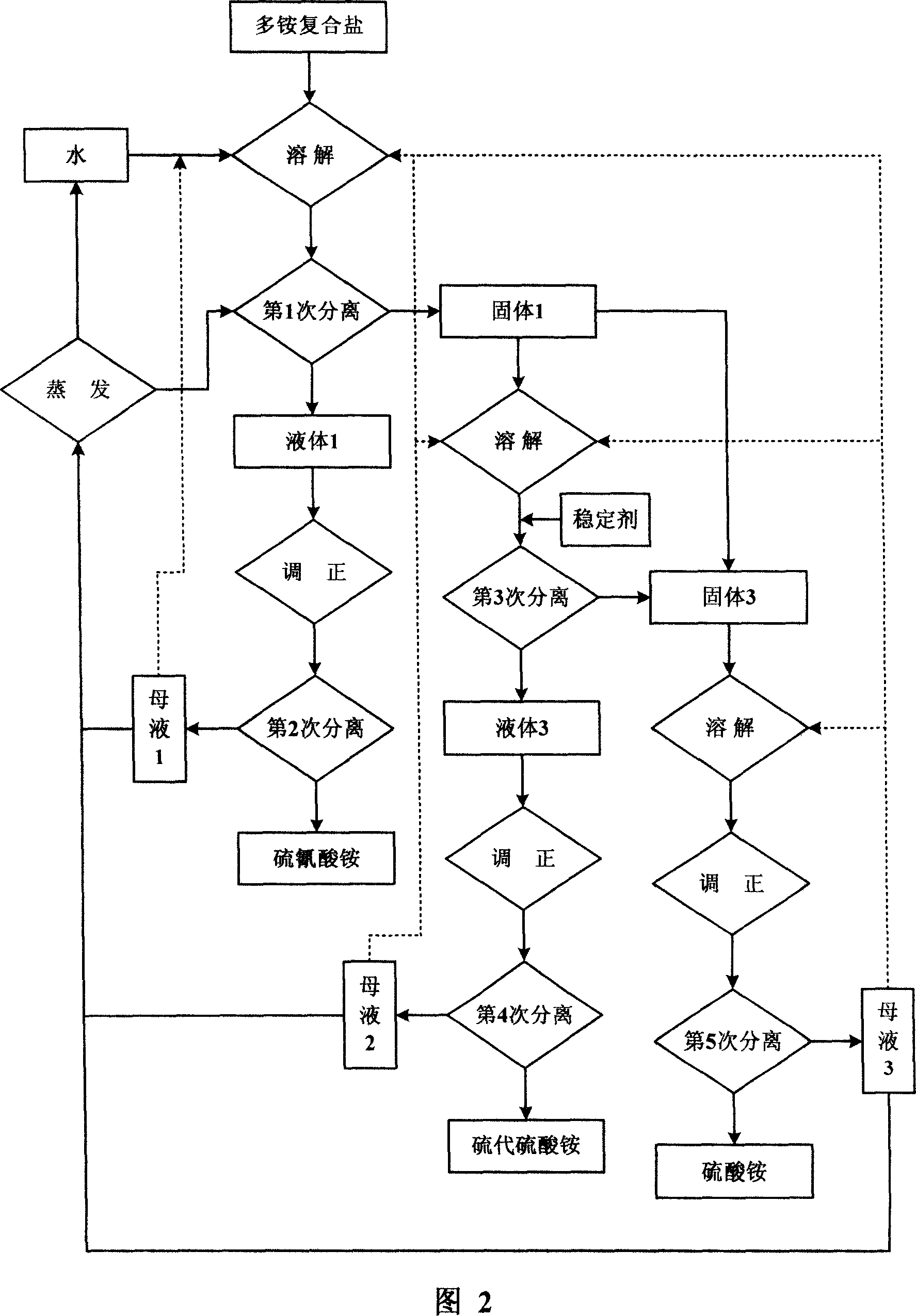

The invention discloses a separating method of multi-ammonia composite salt, which comprises the following steps: separating ammonia thiocyanate under low temperature (0-25 deg.c); enriching ammonium thiosulfate and ammonium sulfate under middle temperature (40-65 deg.c); separating ammonium sulfate under high temperature (80-90 deg.c); separating enriched ammonium thiosulfate at 20-40 deg.c; dissolving, crystallizing and separating solid from liquid for several times under different temperature to separate ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate one by one.

Owner:苏州久王环保科技股份有限公司

Method for absorbing hydrogen sulfide gas by using ionic liquid

InactiveCN101961598ALow priceReduce pollutionDispersed particle separationHigh absorptionGreen chemistry

The invention provides a method for absorbing hydrogen sulfide gas by using ionic liquid. The method comprises the following steps of: uniformly mixing one of alkyl ammonium halide, ammonium thiocyanate, ammonium chloride, ammonium bromide or acetylcholine and caprolactam according to a molar ratio of 1:1-10; reacting at the temperature of between 25 and 120 DEG C for 1 to 10 hours; drying the liquid in vacuum at the temperature of between 20 and 80 DEG C for 1 to 10 hours to obtain the ionic liquid; and introducing the hydrogen sulfide gas into the ionic liquid at the temperature of between 20 and 150 DEG C. The method has the characteristics of simple process, small investment, high absorption ratio, no pollution, and low energy consumption, is suitable for industrial production and meets the requirement of development of environmentally-friendly chemistry at present.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

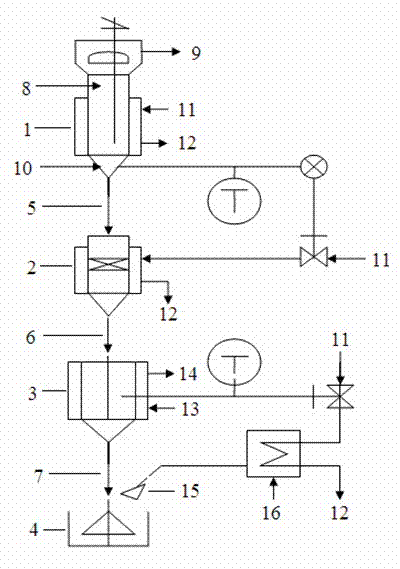

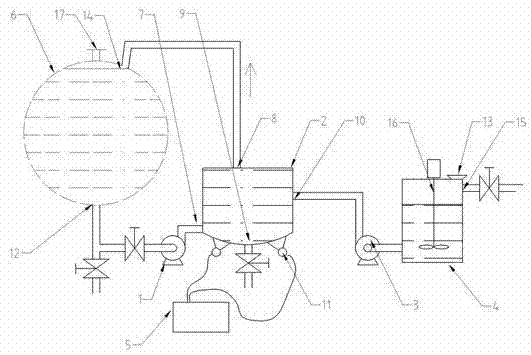

Chemical for cleaning boiler, using method and cleaning device thereof

InactiveCN102418104ALow cleaning temperatureShorten the timeMetallic material coating processesCetyldimethylbenzylammonium chlorideHydrazine compound

The invention relates to a chemical for cleaning a boiler, a using method and a cleaning device thereof, and belongs to the technical field of the chemical cleaning of equipment. A corrosion-inhibiting acid-washing agent comprises acid liquor, 1,3,5,7-tetraaza-adamantane, hydrazine hydrate, silicic acid, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate and the like; a bleaching agent is citric acid solution; and a passivant consists of hydrogen peroxide and other additives. The cleaning device consists of a cleaning circulating pump, a cleaning fluid processing tank, a water injection pump and a water replenishing tank; and a plurality of ultrasonic energy converters are arranged on the outer surface of the cleaning fluid processing tank uniformly. The using method comprises the following steps of: establishing a cleaning pump station, testing under the pressure, cleaning scale deposits, bleaching the boiler and a system, passivating and performing water washing. The chemical has a simple process, is low in cost, energy-saving and environment-friendly, and avoids sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

Method for recovering rhenium from high-temperature alloy pickle liquor

InactiveCN103789552AOmit hydrolysisSave the processProcess efficiency improvementSal ammoniacDesorption

The invention provides a method for recovering rhenium from a high-temperature alloy pickle liquor. The method comprises the following steps: 1, adjusting the pH value of the high-temperature alloy pickle liquor to 1-2, and then adsorbing rhenium and molybdenum in the high-temperature alloy pickle liquor by adopting ion exchange resin; 2, desorbing molybdenum by adopting a mixed solution of ammonia water and ammonium chloride, and then desorbing the rhenium by using an ammonium thiocyanate solution, so as to obtain stripping liquid containing rhenium; 3, adding water soluble potassium to the stripping liquid containing rhenium according to the ratio, and then orderly heating, concentrating, crystallizing, washing and recrystallizing, so as to obtain potassium perrhenate. The ion exchange resin adsorption and step-by-step desorption are organically combined, the rhenium loss can be effectively avoided, the technological process is shortened, the process is simple and feasible, and the production cost is greatly reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for treating ammonia desulfurization waste liquid by oxidation method

InactiveCN103030207AEasy to separateSimple processDispersed particle separationThiocyanic acidThio-Catalytic oxidation

The invention provides a method for treating ammonia desulfurization waste liquid by an oxidation method, and belongs to the technical field of desulfurization waste liquid treatment. According to the method, oxidation reaction is conducted by blowing air or oxygen into the ammonia desulfurization waste liquid; ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate in the oxidation reaction process; ammonium thiocyanate is not oxidized, but continues to be reserved in the desulfurization waste liquid; and then ammonium thiocyanate is extracted through evaporation and secondary crystallization. The method is suitable for treating desulfurization waste liquid generated in a gas desulfurization and decyanation technological process by a catalytic oxidation method, and suitable for waste liquid treatment in the desulfurization technology field of hydrogen sulfide such as coke oven gas, natural gas, coalbed methane and refinery gas. With the adoption of the method, ammonium thiosulfate salt in the waste liquid can be converted to ammonium sulfate salt, ammonium thiocyanate salt can be protected, and ammonium sulfate salt and ammonium thiocyanate salt can be separated and purified from the waste liquid into a product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for extracting sodium thiocyanate from coking desulfurization waste liquid

The invention relates to a method for extracting sodium thiocyanate from desulfurization waste liquid in a coking plant, which is characterized by comprising the following steps of: adding 2 to 6 weight percent of activated carbon into the desulfurization waste liquid, heating to the temperature of between 70 and 90 DEG C, and keeping stirring for 1 to 2 hours; filtering, adding sulfuric acid into filtrate in a closed container until pH is 3.5 to 4.5, heating to the temperature of between 60 and 80 DEG C, and keeping stirring for 1 to 2 hours; leading escaping sulfur dioxide gas out by using a guide pipe and absorbing by using dilute ammonia water; filtering after reaction is finished, adding sodium hydroxide with the same mol as ammonium thiocyanate in filtrate and calcium hydroxide with the same mol as ammonium sulfate in the filtrate into the filtrate in the closed container, heating to the temperature of between 50 and 70 DEG C, and keeping stirring for 1 to 2 hours; and leading escaping ammonia gas out by using the guide pipe and absorbing by using water to obtain the dilute ammonia water, filtering after reaction is finished, and performing evaporation crystallization on filtrate to obtain a sodium thiocyanate product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

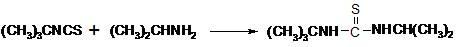

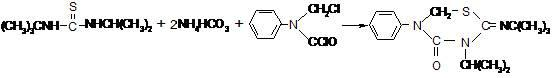

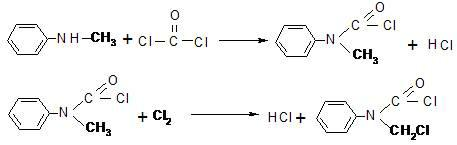

Preparation method of buprofezin

The invention discloses a preparation method of buprofezin, which is characterized in that chlorobenzene is uniformly used as a solvent in all reaction steps requiring the solvent. The preparation method specifically comprises the steps of preparation of isosulfocyanic acid butyl ester, preparation of a 1-isopropyl-3-tert-butyl thiourea solution, preparation of an N-chloromethyl-N-phenyl carbamyl chloride solution and preparation of raw buprofezin powder. In the invention, the chlorobenzene is uniformly used as the solvent in all steps requiring the solvent for preparing the buprofezin so that dangers are reduced in a production process in a production department, the purpose of environmental-friendliness is achieved, and product quality reaches an international standard. The preparation method in the invention is simple, convenient, environmental-friendly and more reasonable, has low cost and high quality, and is more suitable for industrialized production. The total reaction yield of the method can reach more than 68.5% if taking ammonium thiocyanate as reference.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD

Method for extracting ammonium sulfate from ammonia desulphurization wastewater by oxidation process

The invention provides a method for extracting ammonium sulfate from ammonia desulphurization wastewater by an oxidation process, and belongs to the technical field of treatment of desulphurization waste solutions. The method comprises the steps of: carrying out oxidation reaction in a manner of blowing air or oxygen into the ammonia desulphurization wastewater, wherein in the oxidization reaction, ammonium thiosulfate in the desulphurization wastewater is oxidized into ammonium sulfate, ammonium thiocyanate is not oxidized and further maintained in the desulphurization wastewater; and then extracting ammonium sulfate in an evaporation or crystallization manner. The method disclosed by the invention is suitable for treatment of the desulphurization wastewater produced in the air desulfurization and cyanide-removal processes by a catalytic oxidation method. The method is suitable for treatment of waste liquor in the field of the desulfurization process of hydrogen sulfide containing gases such as coke even gas, natural gas, coal bed gas and refinery gas. By using the method disclosed by the invention, ammonium thiosulfate salt in the wastewater can be transformed into ammonia sulfate salt, ammonium thiocyanate is protected, and the ammonium thiosulfate salt and the ammonium thiocyanate can be separated from the wastewater and purified to obtain the products.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

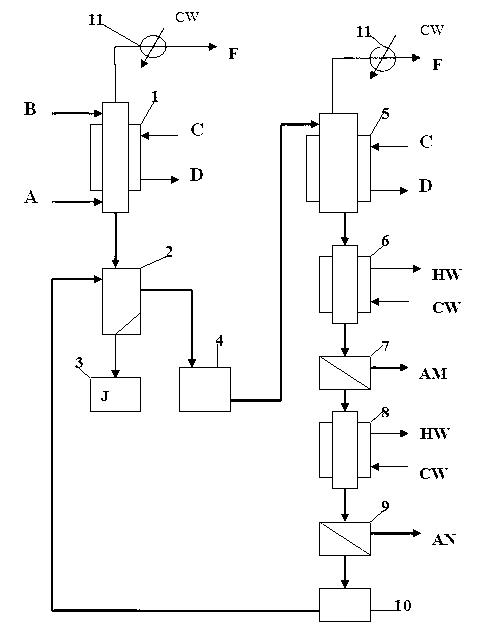

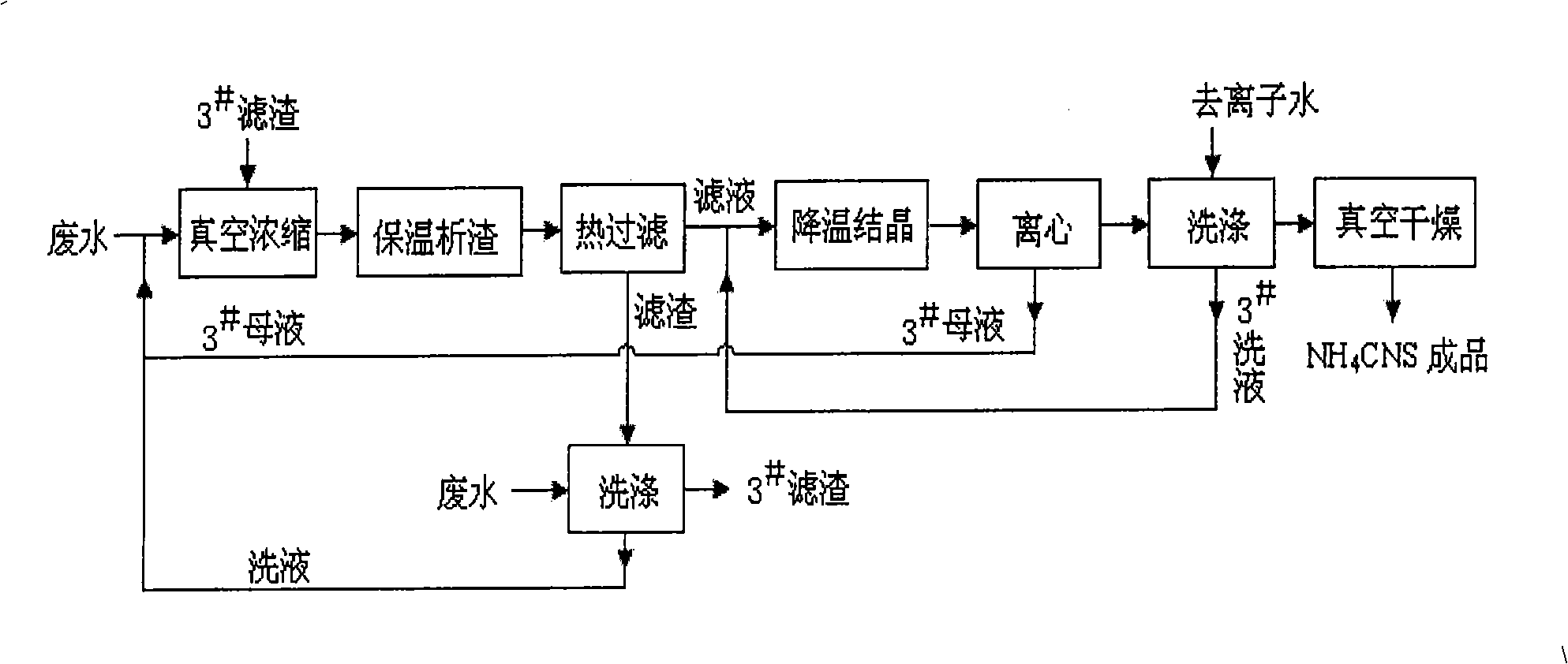

Process for recycling inorganic salt from wastewater for desulfurization and decyanation of coke oven gas

ActiveCN101402461AHigh recovery rateEasy to operateThiosulfates/dithionites/polythionitesThiocyanic acidCatalytic oxidationNo production

The invention provides a process for reclaiming inorganic salt from wastewater in the desulphurization and decyanation of coal gas of a coke furnace. The process aims at reclaiming ammonium thiocyanate (NH4CNS), ammonium thiosulfate ((NH4)2S2O3) and ammonium sulphate ((NH4)2SO4) from wastewater produced by a liquid-phase catalytic oxidation, desulphurization and decyanation process taking ammonia as an alkaline resource. In particular, the process comprises that the wastewater and a mother solution with the ratio of NH4CNS to (NH4)2S2O3 more than or equal to 1.0 (wt) and the ratio of NH4CNS to (NH4)2S2O3 less than 1.0 (wt) are separated to obtain finished products of NH4CNS, (NH4)2S2O3 and (NH4)2SO4 through a targeted process. The process is easy to operate and control parameter, has high salt reclaiming rate and high product quality, reaches the aim that the wastewater can be fully treated and has no production of three wastes, and has good economic and social benefits.

Owner:JINNENG SCI & TECH

Method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by oxidation process

InactiveCN103011201AEasy to separateSimple processThiocyanic acidMultistage water/sewage treatmentLiquid wasteEvaporation

The invention discloses a method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by an oxidation process, and belongs to the technical field of treatment of the desulfurization waste liquid. According to the method, an oxidation reaction is implemented by a way of blowing air or oxygen into ammonia-process desulfurization waste liquid; by the oxidation reaction, ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate, but ammonium thiocyanate is not oxidized and is still reserved in the desulfurization waste liquid; and the ammonium thiocyanate is extracted by ways of evaporation and secondary crystallization. The method disclosed by the invention is applicable to the treatment of the desulfurization waste liquid which is generated from the process of desulfurization and decyanation of the gas by a catalytic oxidation process, and is suitable for the waste liquid treatment in the field of desulfurization process of hydrogen sulfide-containing gases such as coke oven gas, natural gas, coal-bed methane and refinery gas. By the method, the ammonium thiosulfate salt in the waste liquid is converted into the ammonium sulfate salt and the ammonium thiocyanate salt is protected, and the ammonium thiosulfate salt and the ammonium thiocyanate salt are separated from the waste liquid and purified into products.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

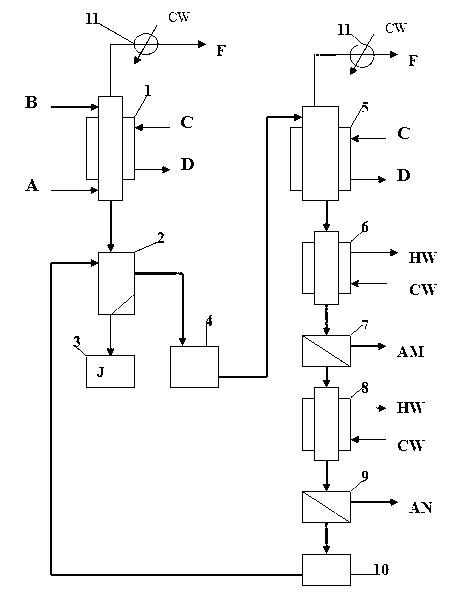

Production technique for extracting ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

InactiveCN101850952ASolving Recycling ProblemsEmission reductionThiosulfates/dithionites/polythionitesThiocyanic acidOrganic solventEconomic benefits

The invention discloses a production technique for extracting ammonium thiosulfate and ammonium thiocyanate from a desulfurization waste liquor, which comprises the following steps: settling, filtering, decoloring, concentrating, crystallizing, separating, drying a sulfur-containing waste liquor generated in a desulfurization production process of HPF in a coke-oven plant, and finally, recovering ammonium thiocyanate and ammonium thiosulfate by using a mixed organic solvent. The invention is a production technique for comprehensively treating waste water generated in the prior HPF desulfurization technique, and the mixed organic solvent is used for separating ammonium thiocyanate and ammonium thiosulfate. The invention effectively solves the problem of waste water recovery in the desulfurization process, reduces discharge and environmental pollution of waste water, recovers important chemical raw materials (ammonium thiocyanate and ammonium thiosulfate), and can increase the economic benefit.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

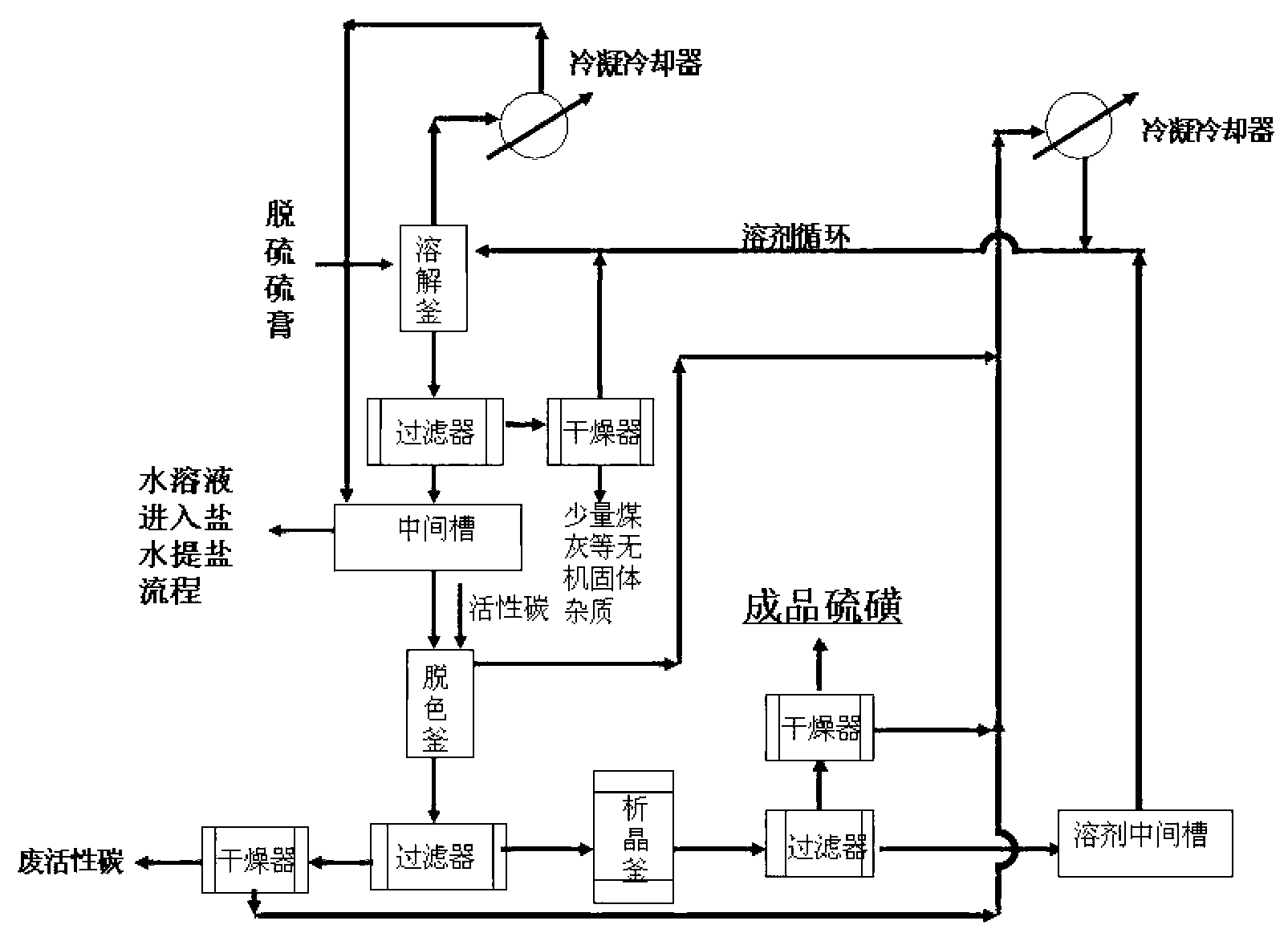

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

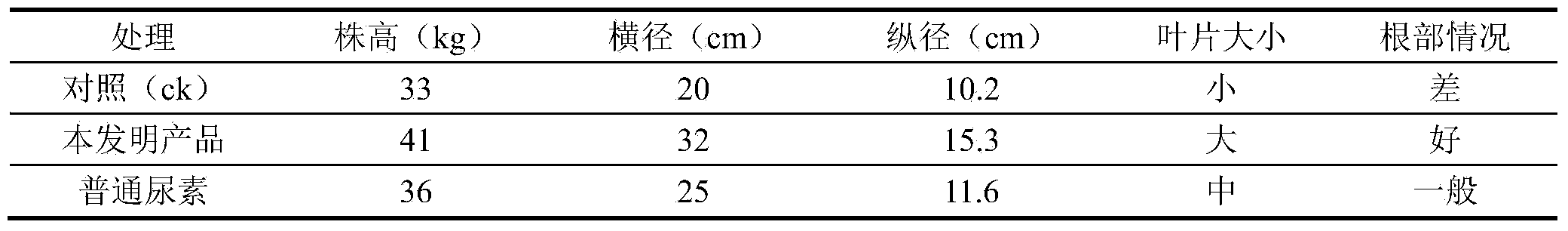

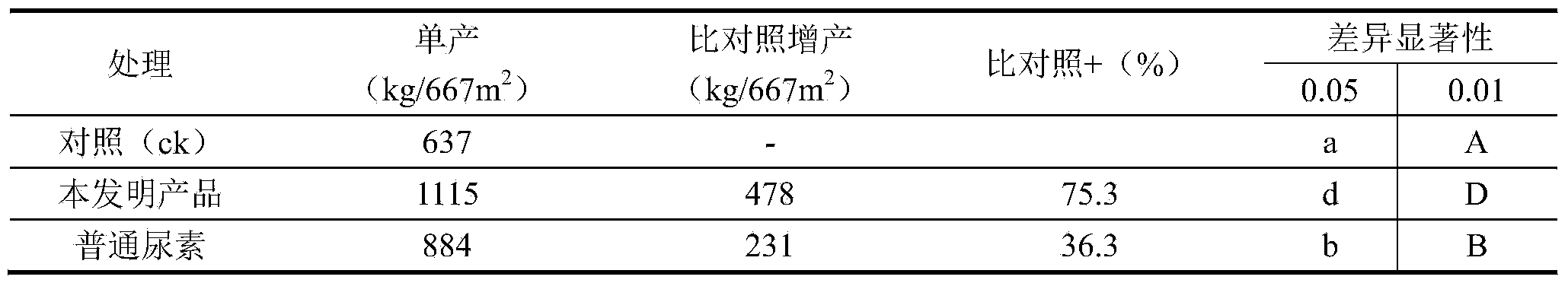

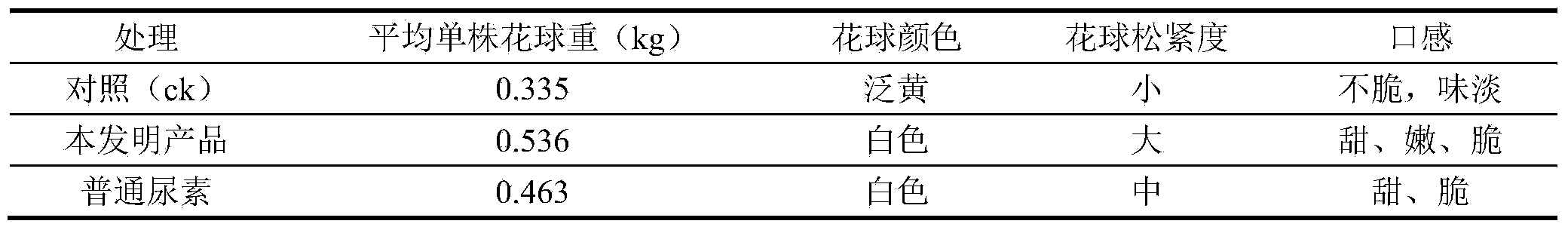

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

Microelement-rich liquid urea ammonium nitrate solution fertilizer and preparation method thereof

ActiveCN104262064AImprove securityAvoid corrosionMagnesium fertilisersAmmonium nitrate fertilisersPolyethylene glycolManganese

The invention discloses a microelement-rich liquid urea ammonium nitrate solution fertilizer, which comprises 20-25 parts of urea, 20-30 parts of ammonium nitrate, 0.1-2 parts of liquid ammonia, 0.01-0.1 part of magnesium nitrate, 1-3 parts of sodium polyaspartate, 0.01-0.1 part of any one or a mixture of any more than two of ammonium carbonate, ammonium thiocyanate and ammonium bicarbonate, 0.02-0.08 part of an urease inhibitor, 1-2 parts of edta-2nacu tetrahydrate, 1-3 parts of ferric-sodium edentate, 1-3 parts of magnesium-disodium edetate, 1-3 parts of manganese-disodium edetate, 1-3 parts of zinc-disodium edentate, 1-3 parts of disodium octaborate tetrahydrate, 0.01-0.1 part of ammonium heptamolybdate, 1-3 parts of citric acid, 1-3 parts of an antifreezing agent PX-60 or polyethylene glycol PEG-200, and 16.5-41 parts of water. A product disclosed by the invention is high in safety, and pH value is 6-7; and due to the addition of an anticorrosive antiscale agent, the corrosion of products on production, storage, transportation and application facilities is effectively prevented.

Owner:中化(临沂)作物营养有限公司

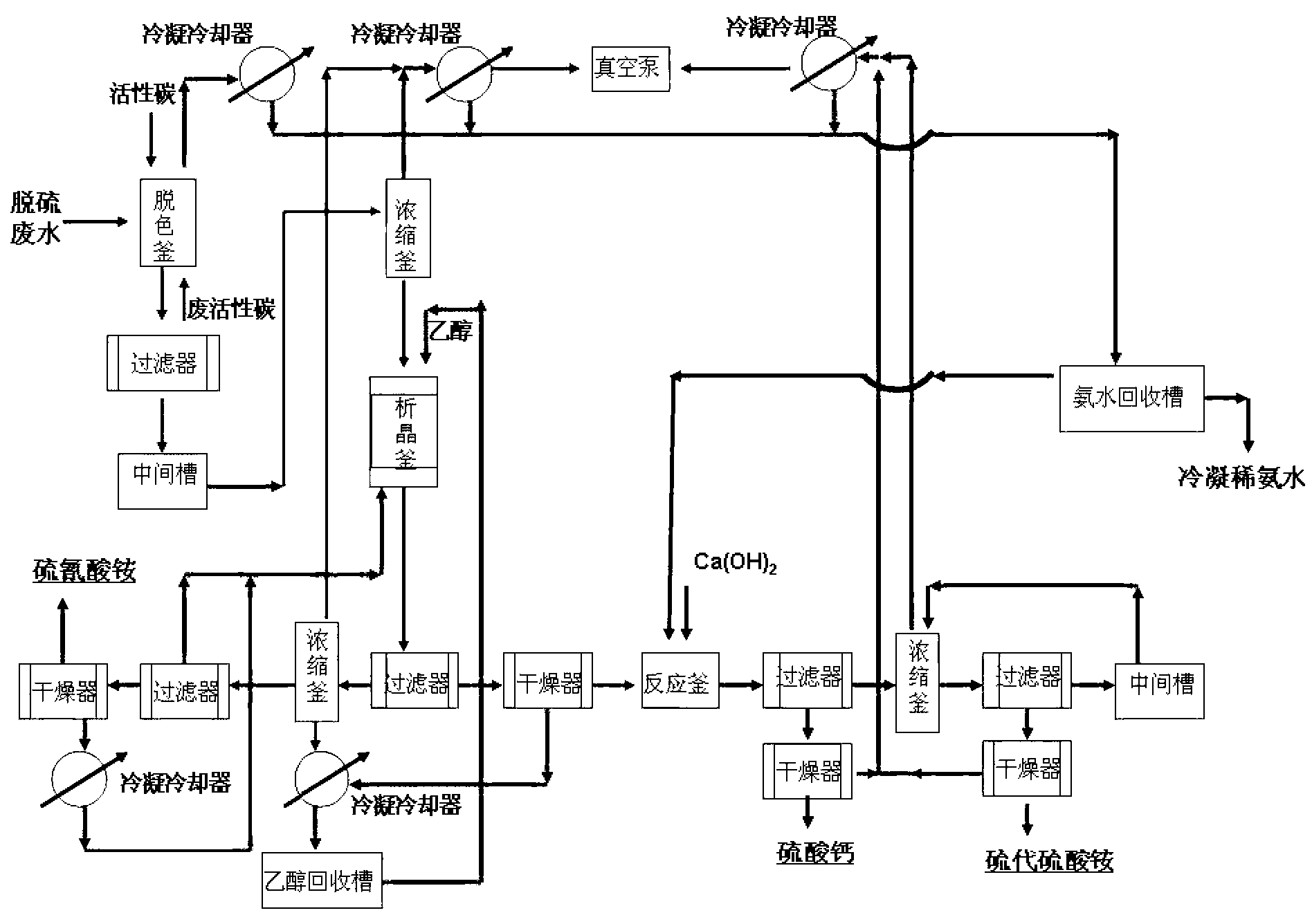

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

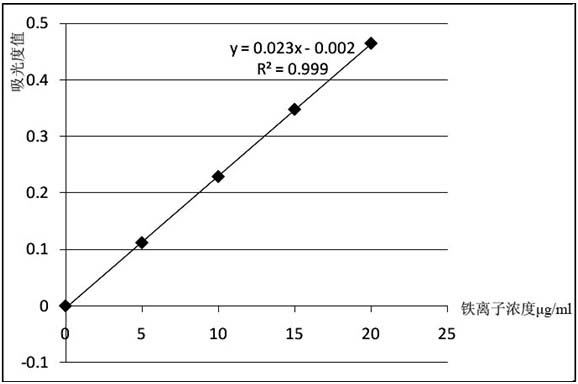

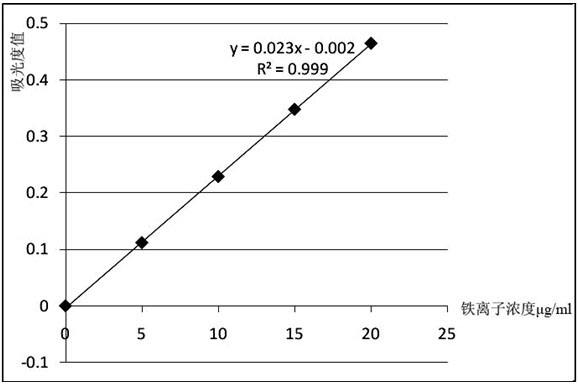

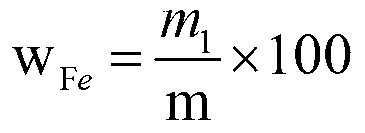

Method for detecting trace iron in copper sulfate

InactiveCN102323257AThe measurement result is accurateEliminate errors from light absorptionMaterial analysis by observing effect on chemical indicatorCu2 ionsDissolution

The invention discloses a method for detecting trace iron in copper sulfate. In the method, an ammonium thiocyanate spectrophotometry is adopted; a background is removed by guarantee reagent copper sulfate which does not contain iron; and the iron content is measured by using ammonium thiocyanate as a color development reagent. In the detection method, iron ions in copper sulfate are oxidized into ferric iron and when solution is regulated into acidity, ammonium thiocyanate is used as a color development reagent, so that Fe3+ can be completely complexed with ammonium thiocyanate and a measurement result is more accurate; and the color of copper ions of the background is removed to carry out measurement by using the same amount of guarantee reagent copper sulfate as a sample, so that an error which is caused by the blue color of copper sulfate and influences light absorption of the sample solution is eliminated and the detection accuracy is improved. Moreover, in the detection method, steps of sedimentation, filtering separation, dissolution measurement and the like do not need to be carried out, so that errors caused by fussy steps are greatly reduced and the measurement result is more reliable.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

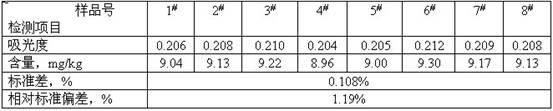

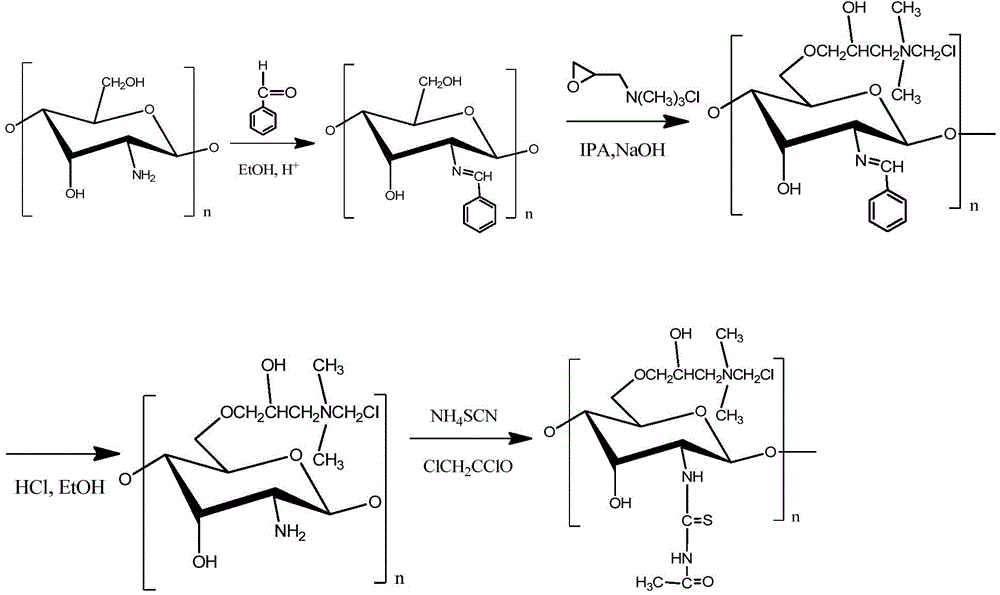

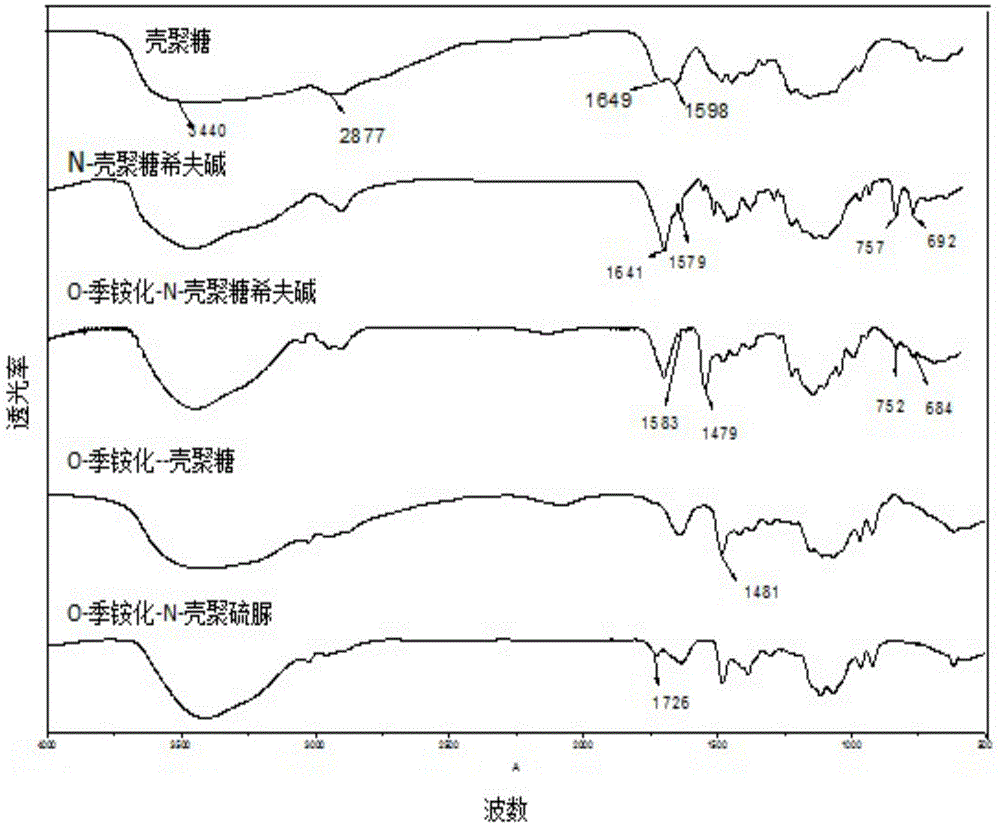

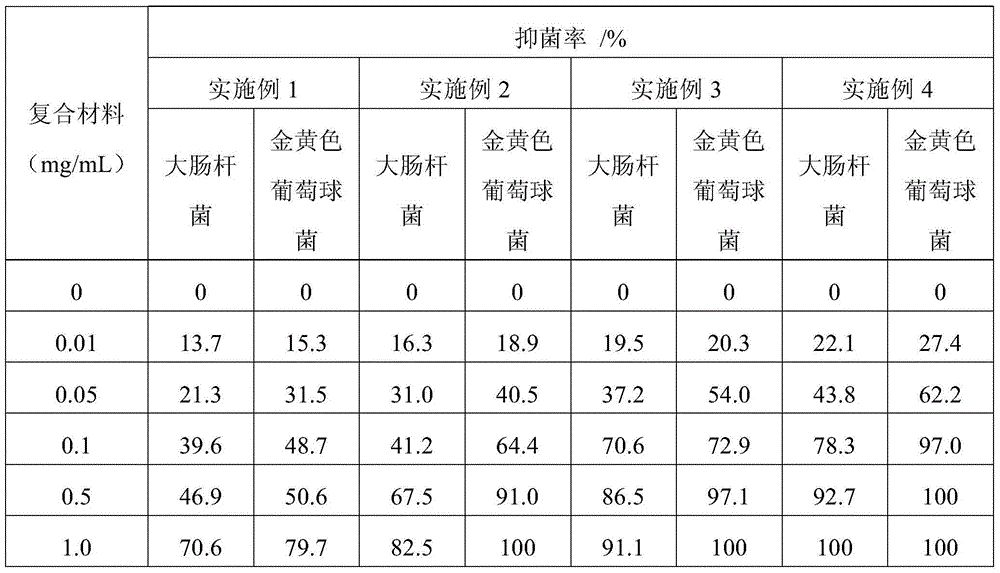

O-quaternary-N-thiourea chitosan, preparation method and application thereof

InactiveCN103980385AGood water solubilityGood antibacterial effectBiocideDisinfectantsBenzaldehydeThiourea

The present invention belongs to the field of polymer compound material. The invention discloses an O-quaternary-N-thiourea chitosan, a preparation method and application thereof, and the chitosan is a chemical modified functional derivative of chitosan. The preparation method of the O-quaternary-N-thiourea chitosan comprises the following steps: adopting chitosan as a raw material and carrying out reaction with benzaldehyde to obtain chitosan Schiff base, then carrying out reaction with 2,3-glycidyl trimethyl ammonium chloride to obtain O-quaternary-N-chitosan Schiff base; carrying out deprotection of an amino group positioned on the second carbon atom (C2) of the O-quaternary-N-chitosan Schiff base through a methanol-hydrochloric acid solution to obtain O-quaternary chitosan, adding the O-quaternary chitosan to the mixture of ammonium thiocyanate and chloroacetyl chloride to carry out reaction, and then obtaining the O-quaternary-N-thiourea chitosan. The O-quaternary-N-thiourea chitosan provided in the invention achieves a substantial increase in antibacterial property compared with chitosan. The invention can be used in a plurality of application fields of antibacterial material, daily chemical products, industrial wastewater treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

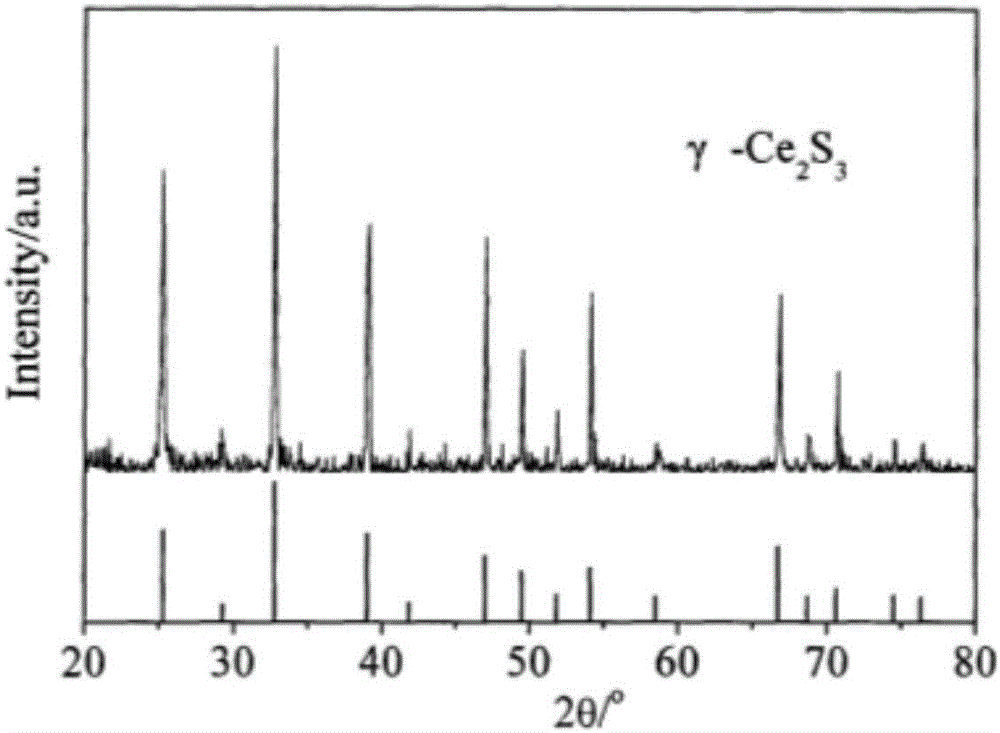

Method for preparing nano cerium sulfide by adopting liquid phase method

The invention relates to a method for preparing nano cerium sulfide by adopting a liquid phase method. The method comprises the following steps that a water-soluble trivalent cerium salt and a water-soluble sulfide reacts in a base solution to generate sol, and then filtration and drying are performed, wherein the base solution is prepared from mica powder and water; the obtained product and ammonium thiocyanate are uniformly mixed, and calcination is performed at the temperature of 800-1000 DEG C; then fluoridation treatment is performed by using an affiliative fluorinating agent. The prepared nano cerium sulfide (gamma-Ce2S3) product is bright in color and strong in tinting strength, the tinting strength can be up to 85% of the tinting strength of a cadmium red pigment and is greatly better than iron oxide red, molybdate red, manganese red and other inorganic red pigment. The covering power can be up to the level of the cadmium-based red pigment, the particle size is uniform, the dispersibility is good, and temperature resistance and corrosion resistance are good.

Owner:湖南科莱新材料有限公司

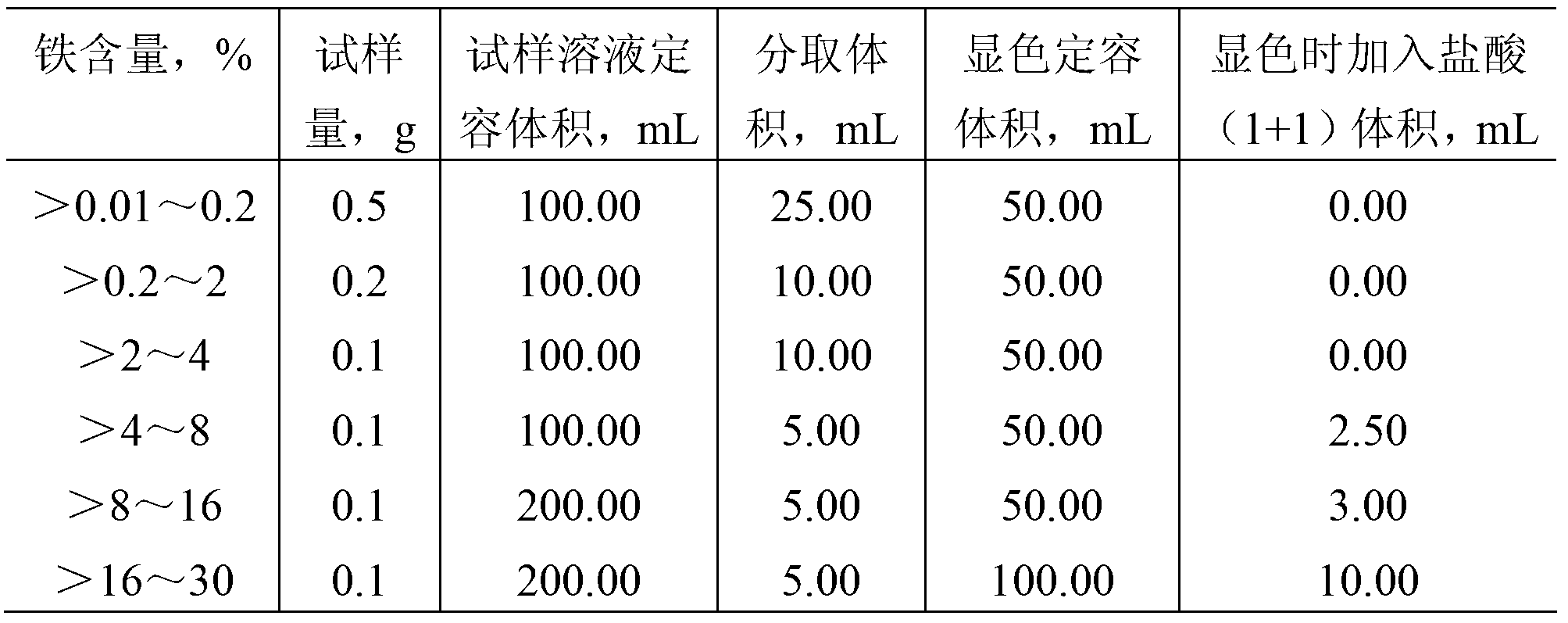

Thiocyanate spectrophotometry method for detecting iron content of high-temperature alloy

ActiveCN103323412AResolve interferenceImprove stabilityColor/spectral properties measurementsSuperalloyCobalt

The invention provides a thiocyanate spectrophotometry method for detecting iron content of a high-temperature alloy. The thiocyanate spectrophotometry method comprises the following steps of 1, dissolving a sample by an acid to obtain a sample solution, 2, taking two equal sample solution parts, and adjusting the sample solution parts to color development acidity, 3, adding an ammonium persulfate solution into one of the two equal sample solution parts, carrying out mixing, adding an ammonium thiocyanate solution into the mixture, and diluting the mixed solution to a volume indicated by a scale line so that a color development solution is obtained, 4, diluting the other one of the sample solution parts by water to a volume indicated by a scale line so that a reference solution is obtained, 5, through the reference solution as a reference substance, measuring absorbancy of the color development solution by a spectrophotometer and calculating iron content wFe by a standard curve drawn according to an iron standard solution, and 6, calculating iron content wFe' of a high-temperature alloy according to a formula of w'Fe=wFe+0.0084wCu+0.00244wCo+0.0011wV, wherein wCu, wCo and wV respectively represent mass percentages of Cu, Co and V in the high-temperature alloy. The thiocyanate spectrophotometry method for detecting iron content of a high-temperature alloy has simple processes, high sensitivity, good selectivity and good reappearance, has a wide detection scope and is not interfered by nickel, cobalt, copper and vanadium.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

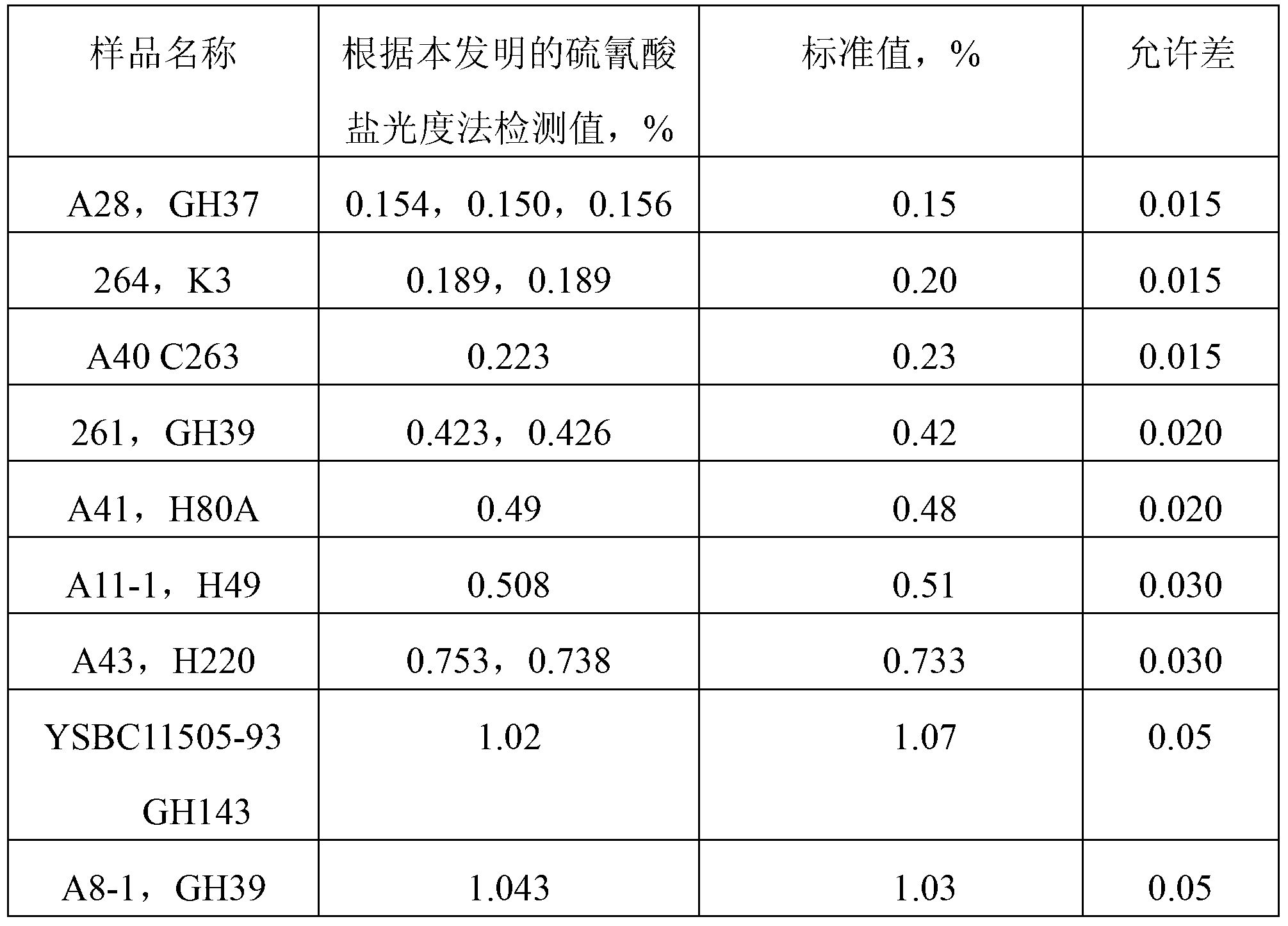

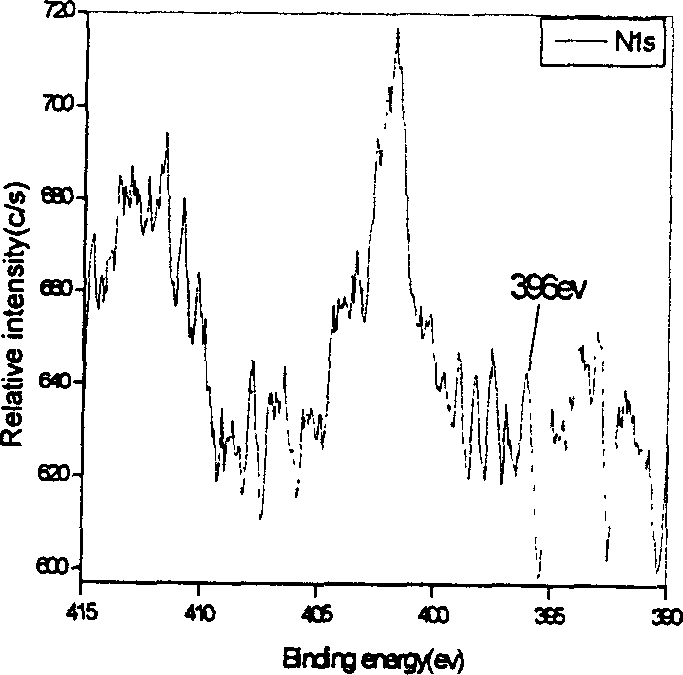

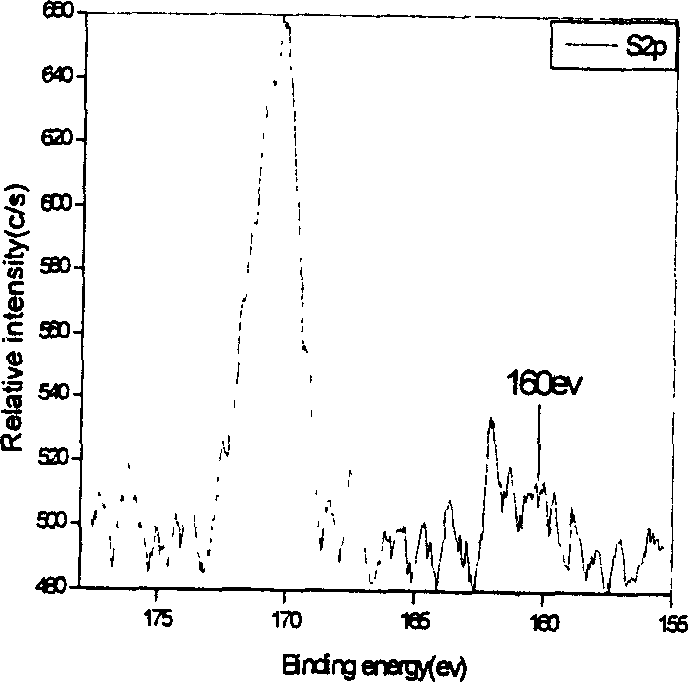

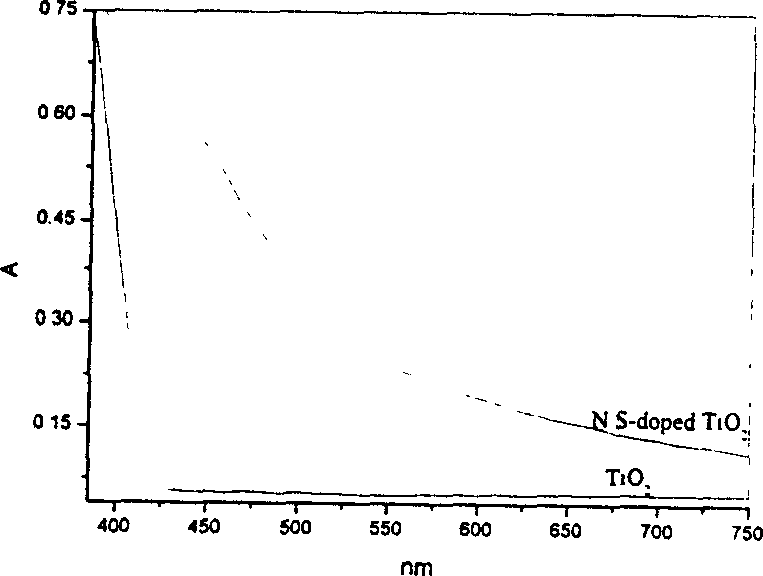

Nitrogen and sulfur two-component doped nano titanium dioxide with long-wave absorbing function and its preparing method

The invention is an N-S doped nano TiO2 with long wave absorbing function, characterized in that N content is 0.65%-1.62%, S content is 0.6%-1.12%, and TiO2 the rest, where in its XPS pattern, characteristic peak of bond energy of 2p electrons of S in Ti-S bond is 160eV and that of 1S electron of N in Ti-N bond is 396eV; UV / visible absorption pattern shows that its absorption side range is 550nm-650nm, and its preparing method: adding N- and S- containing compound into alcohol-hydrochloric acid mixed solution in the molar ratio of 1 to 1; dropping in alchol solution of butyl titanate; after hydrolyzation completely ends, evaporate to dryness at 80-150 deg.C to make it. And the N-containing compound is selected from urea, ammonium chloride, and ammonium nitrate; and the S-containing compound is selected from thiourea and ammonium thiocyanate.

Owner:NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com