Patents

Literature

89 results about "Ammonium perrhenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium perrhenate (APR) is the ammonium salt of perrhenic acid, NH₄ReO₄. It is the most common form in which rhenium is traded. It is a white, water-soluble salt. It was first described soon after the discovery of rhenium.

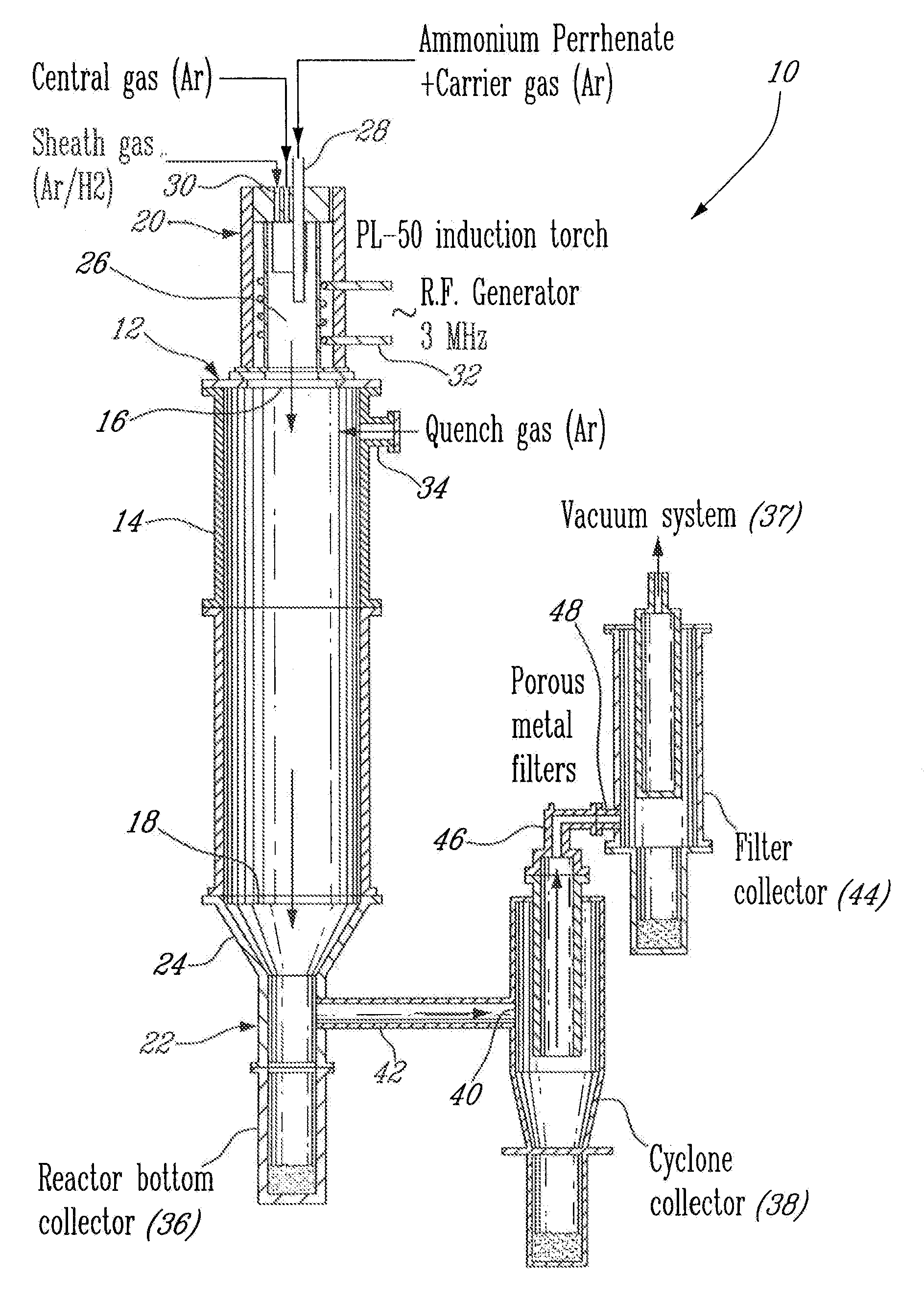

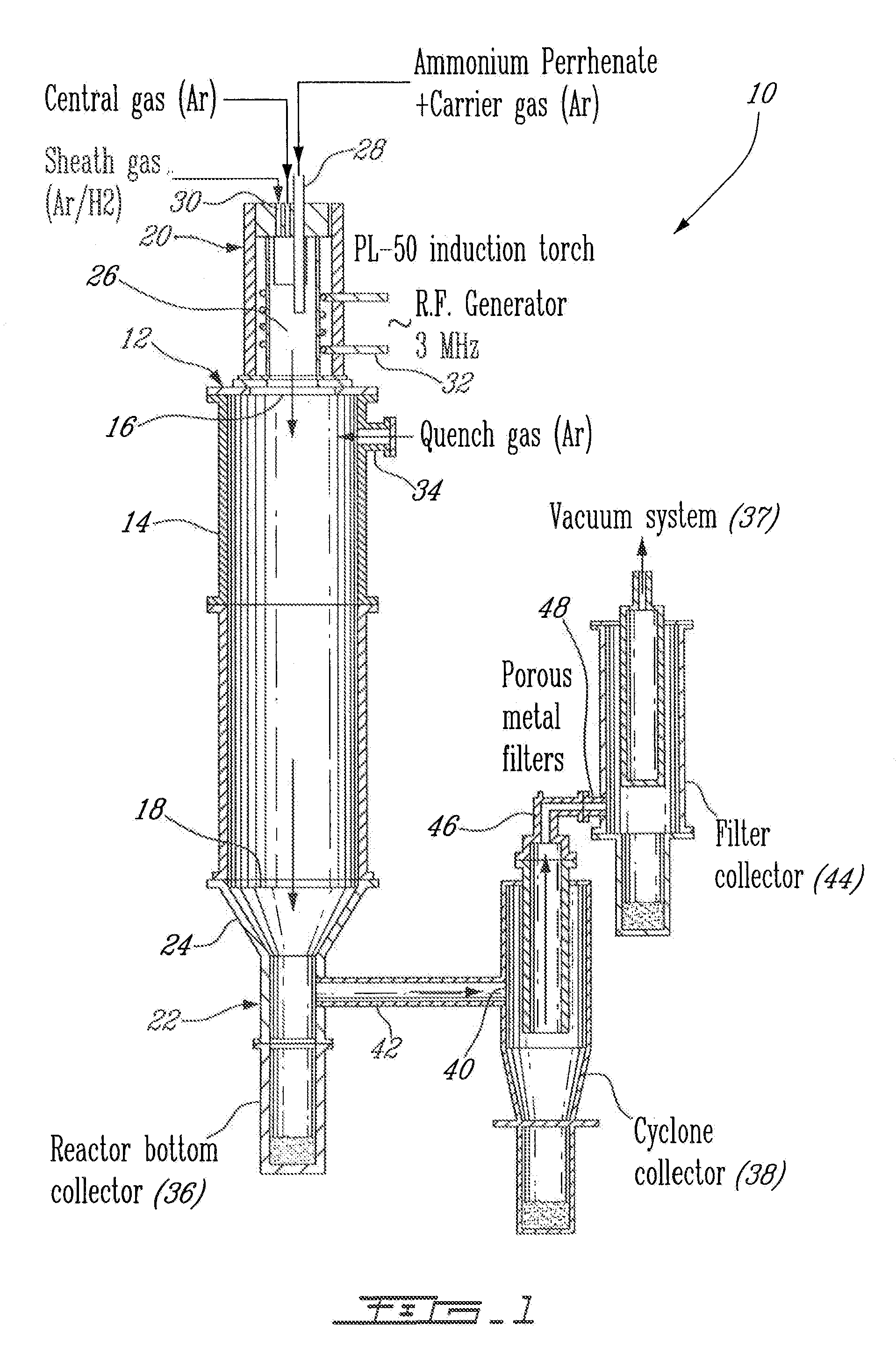

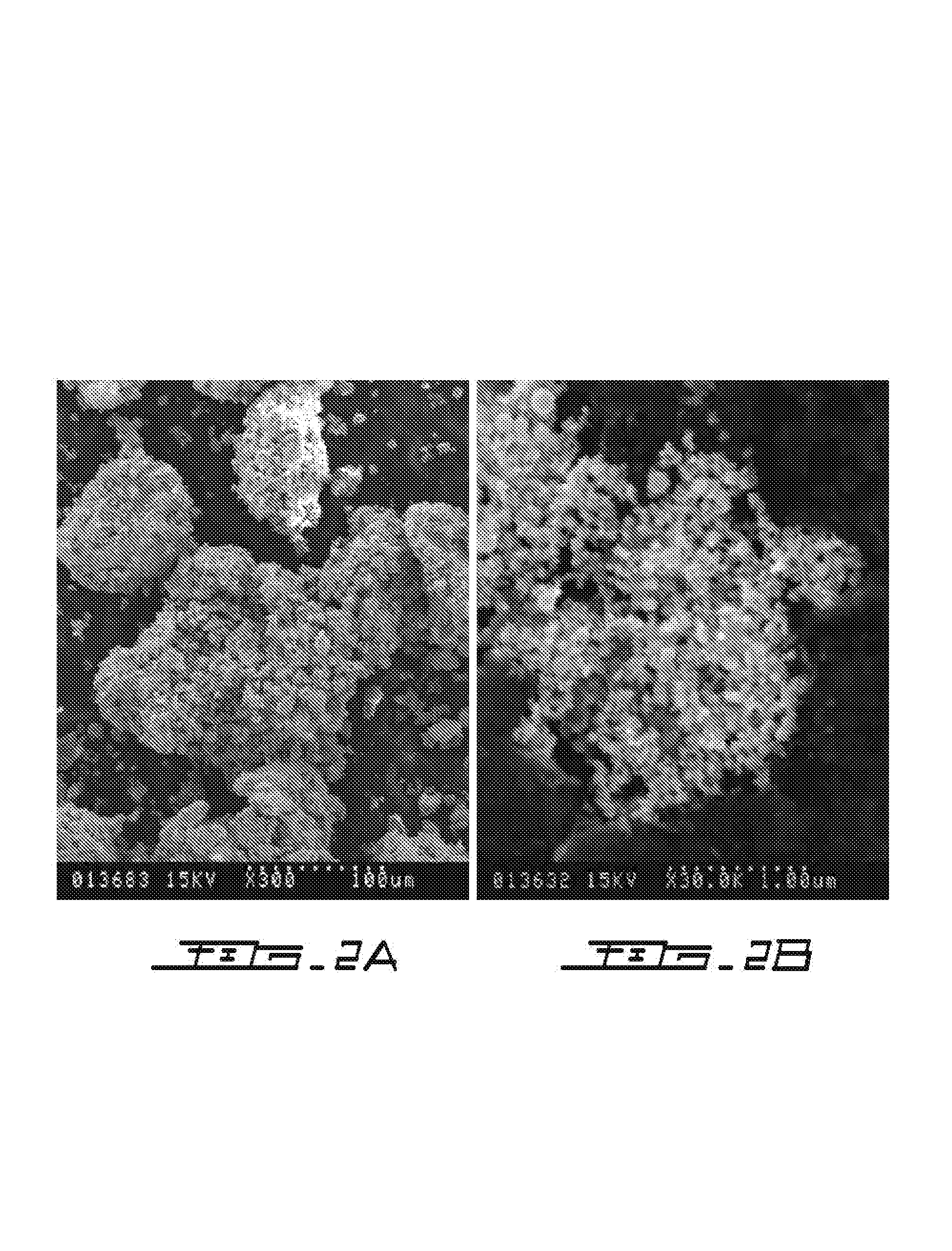

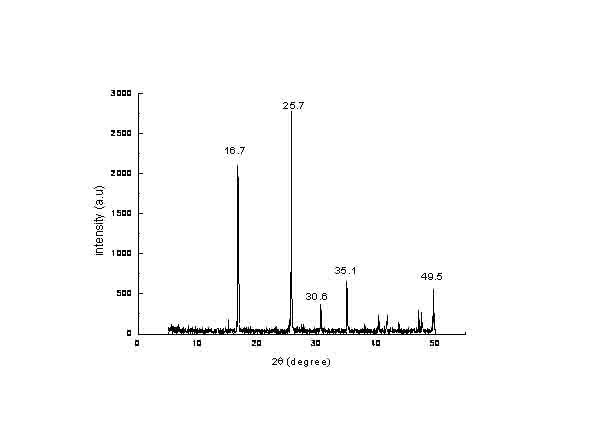

Process for plasma synthesis of rhenium nano and micro powders, and for coatings and near net shape deposits thereof and apparatus therefor

Owner:TEKNA PLASMA SYST INC

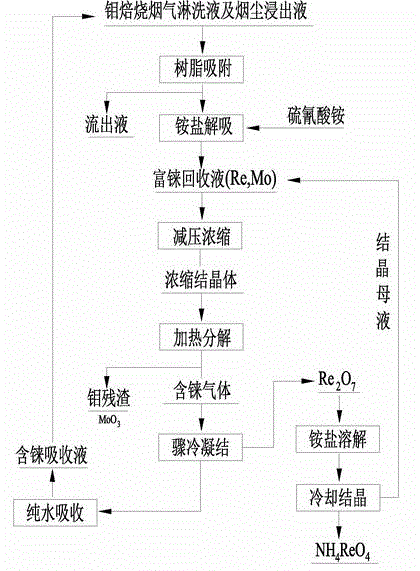

Method for extracting rhenium from eluate of flue ash generated by baking enriched ore of molybdenum

This invention relates to a method for extracting Re from flue dust and tail gas rinsing solution of Mo concentrate calcination. The method comprises: (1) adding water to flue dust, leaching out Re in the flue dust to obtain Re-containing leaching solution; (2) adjusting the pH value of the Re-containing leaching solution and tail gas rinsing solution to 5 with ammonium bicarbonate so that Mo, Fe, Cu and Zn ions are converted into hydroxides, separated from Re and precipitated, and filtering to obtain Re-containing solution for extraction; (3) extracting with extractant so that Re enters into the extractant, which is named enriched oil; (4) back-extracting the enriched oil with 3 N ammonia solution so that Re enters into the back extraction solution; (5) adding the back extraction solution into an ion exchange system so that Re is adsorbed onto the resin; (6) preparing 5-10% ammonium thiocyanate solution, adding ammonia solution to adjust the pH value to 8-9, and desorbing Re adsorbed onto the resin to obtain Re-containing desorption solution; (7) evaporating the desorption solution, concentrating, and crystallizing to obtain ammonium perrhenate product.

Owner:锦州沈宏实业集团有限公司

Method for preparing ammonium perrhenate from waste liquid containing molybdenum and rhenium

ActiveCN102173457APromote enrichmentSave resourcesRhenium compoundsCalcium hydroxideAmmonium perrhenate

The invention relates to a method for preparing ammonium perrhenate from waste liquid containing molybdenum and rhenium. In the technical scheme of the invention, the method comprises the following steps of: adding hydrogen peroxide into the waste liquid containing molybdenum and rhenium until the solution turns to yellow, then adding a mixed agent until the pH of the solution is 6 to 7, separating by filter pressing, collecting the filtrate, absorbing the filtrate by a resin exchange column, stopping adsorption until the concentration of rhenium in effluent is constant, eluting with NH3.H2O,collecting the eluate, heating to concentrate the eluate at 98-100 DEG C, cooling, and crystallizing to obtain ammonium perrhenate. The mixed agent is a mixture of calcium hydroxide and calcium oxidein a weight ratio of 5:1. According to the invention, the waste liquid containing molybdenum and rhenium, particularly the absorption liquid of the flue gas during molybdenum roasting, is used as theraw material; the enrichment of rhenium is increased by about 20 times; ammonia water is determined as the eluent of rhenium; the elution rate of rhenium is higher than 98%; the recovery rate of rhenium is higher than 93%, the purity of the ammonium perrhenate product is higher than 99.5%, and the economic, social and environmental benefits are significantly improved.

Owner:爱瑞克(大连)安全技术集团有限公司

Alkyl imidazoles perrhenate ion liquid and preparation method thereof

ActiveCN101386597ASimple processShort reaction timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeIon-exchange resin

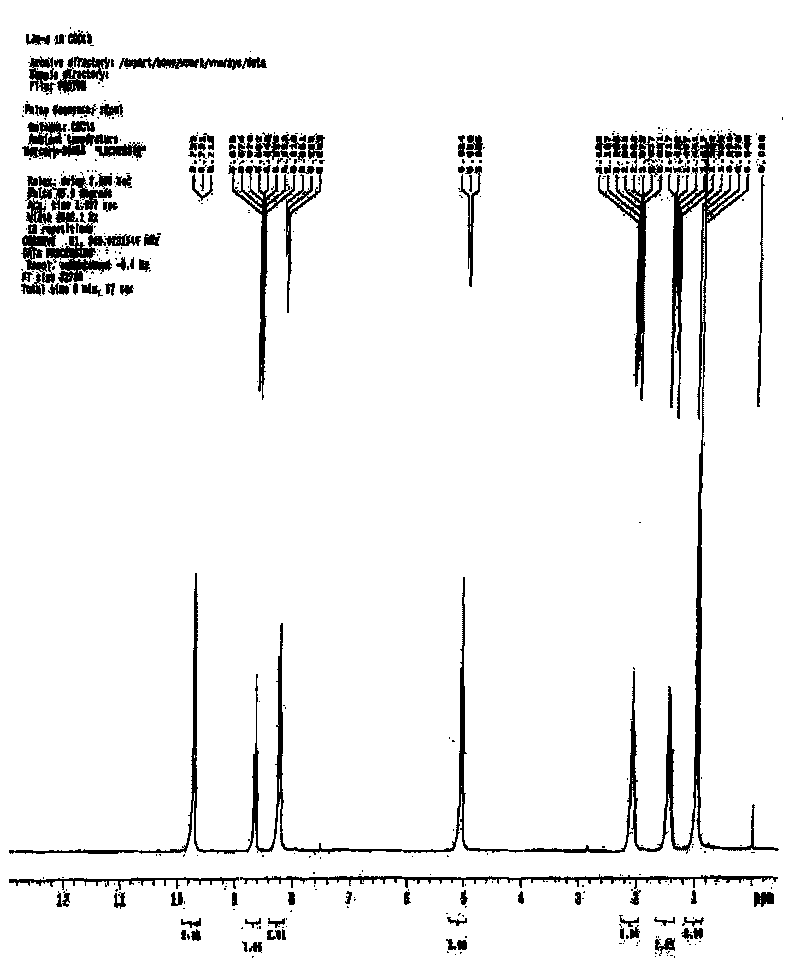

The invention relates to alkyl imidazole perrhenate ionic liquid and a method for preparing the same. The adopted technical proposal is follows: the preparation method comprises the following steps: taking certain volume of alkyl imidazole chloride compounds or alky imidazole bromide compounds, adding deionized water the volume of which is 2 to 4 times of that of the alkyl imidazole chloride compounds or the alky imidazole bromide compounds to dissolve the alkyl imidazole chloride compounds or the alky imidazole bromide compounds, adding the mixture to OH-type anion exchange resin to perform ion exchange, and collecting outflow solution which is alkyl imidazole hydroxide; then adding the alkyl imidazole hydroxide to ammonium perrhenate aqueous solution, wherein the molar ratio of the alkyl imidazole hydroxide to the high ammonium perrhenate is between 1 to 1 and 1 to 2, then stirring the mixture for 3 to 5 hours at a temperature of between 70 and 90 DEG C, reducing the pressure and distilling the mixture to remove water, adding the mixed solution of anhydrous methanol and acetonitrile to the mixture after cooling the mixture, sealing and stirring the mixture intensely, keeping stand the mixture for 10 to 15 hours at a temperature of between 30 DEG C below zero and 40 DEG C below zero, reducing the pressure and distilling the mixture to remove the methanol and the acetonitrile, and performing vacuum drying on the treated mixture. The ionic liquid prepared by the method has the advantages of high yield and high stabilities of air and water.

Owner:辽宁中科航远科技有限公司

Method for preparing metallic rhenium

The invention relates to the technical field of rhenium recycling and use, in particular to a method for preparing metallic rhenium. According to the method provided by the invention, the high-purity metallic rhenium is prepared by taking ammonium perrhenate as a raw material through two steps; in the first step, high-purity ultrafine ammonium perrhenate is first prepared; in the second step, the ammonium perrhenate is reduced into high-purity metallic rhenium powder through a reducing method; ultrasonic auxiliary crystallization and vacuum drying are adopted; in the process of ultrasonic crystallization, an ultrasonic crystallizer with an opened kettle body and a detachable ultrasonic transducer are adopted. Due to the adoption of an ultrasonic crystallization-hydrogen reduction combined process, the ammonium perrhenate serving as the raw material is used for preparing the high-purity metallic rhenium, so that the flow is simplified, the reaction time is shortened, the energy is saved, and the consumption is reduced; the raw material is high in adaptability, so that the requirement on the raw material is lowered; ultrasonic waves directly act on the ammonium perrhenate material, and the utilization rate is high; the detachable structure is easy to check and replace, and favorable for industrialization.

Owner:洛阳双罗铼材料科技有限公司

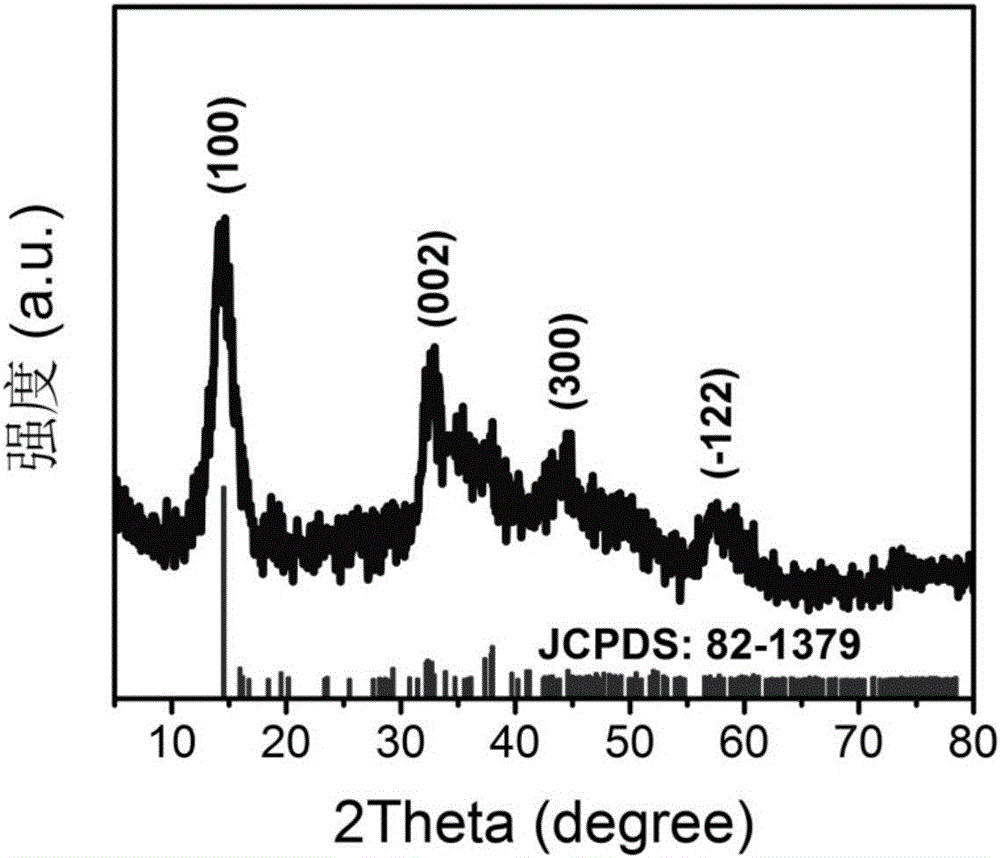

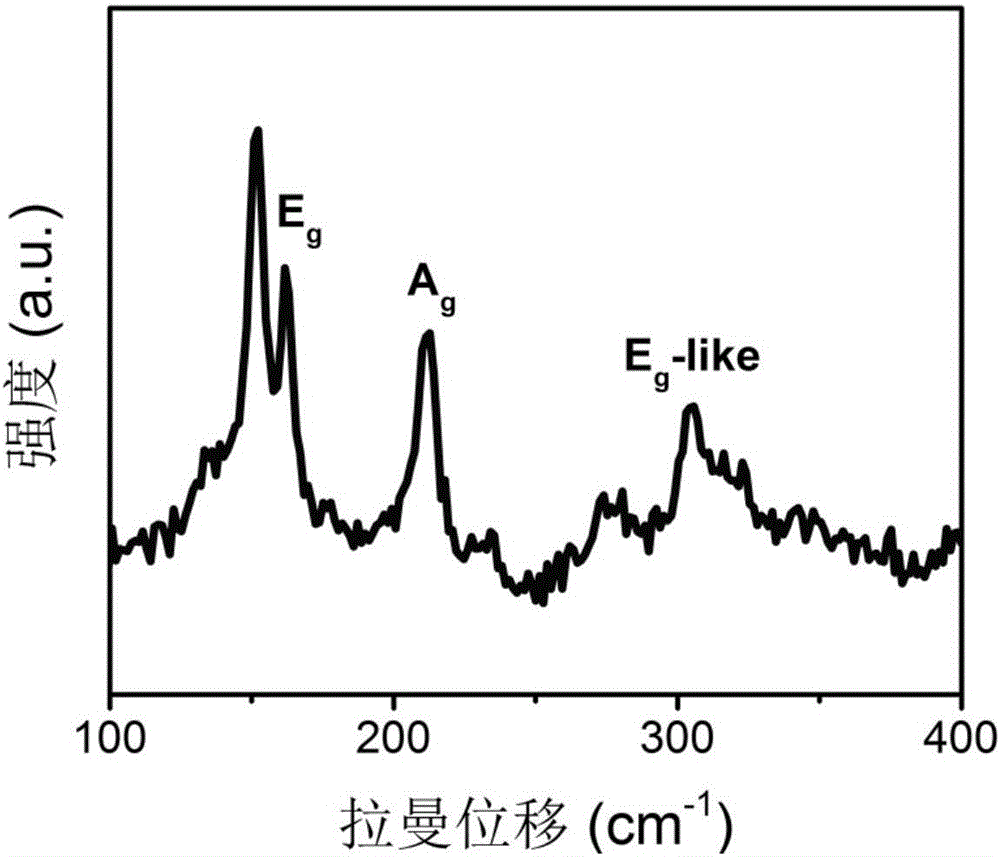

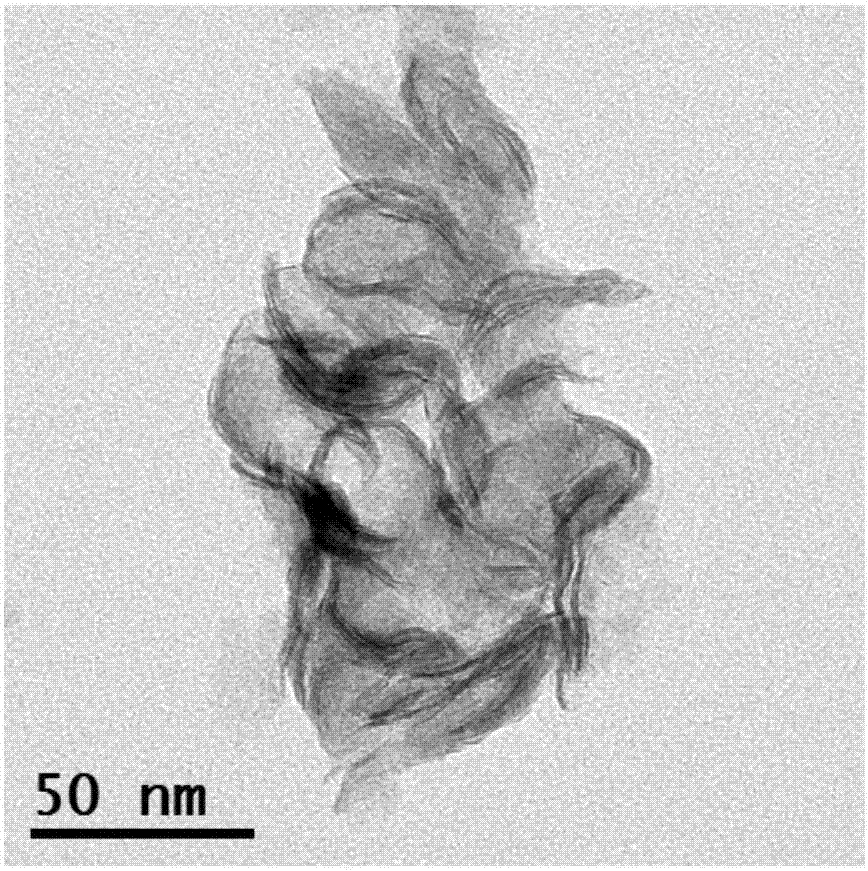

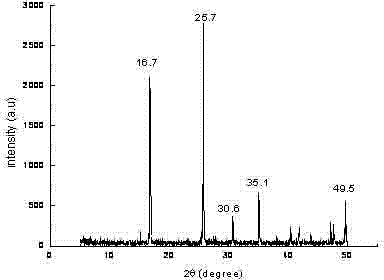

Method for preparing rhenium disulfide nanosheets

InactiveCN106277064AQuality improvementReliable preparation methodRhenium compoundsChemical reactionThiourea

The invention discloses a method for preparing rhenium disulfide nanosheets, and belongs to the field of preparation of novel two-dimensional nanomaterials. The method includes the steps that ammonium perrhenate serves as a rhenium source, thiourea serves as a sulfur source, hydroxylamine hydrochloride serves as a reducing agent, the three reactants are dissolved in solvent water, and a chemical reaction is carried out by regulating the reaction temperature and reaction time; then, a product is cleaned and dried; finally, rhenium disulfide nanosheets are synthesized. The method is simple in operation process, high in efficiency, good in repeatability and low in cost, and high-quality rhenium disulfide nanosheets can be papered in a large batch; meanwhile, the method provides a reliable sample preparation method for application of rhenium disulfide nanosheets in electrics and optics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

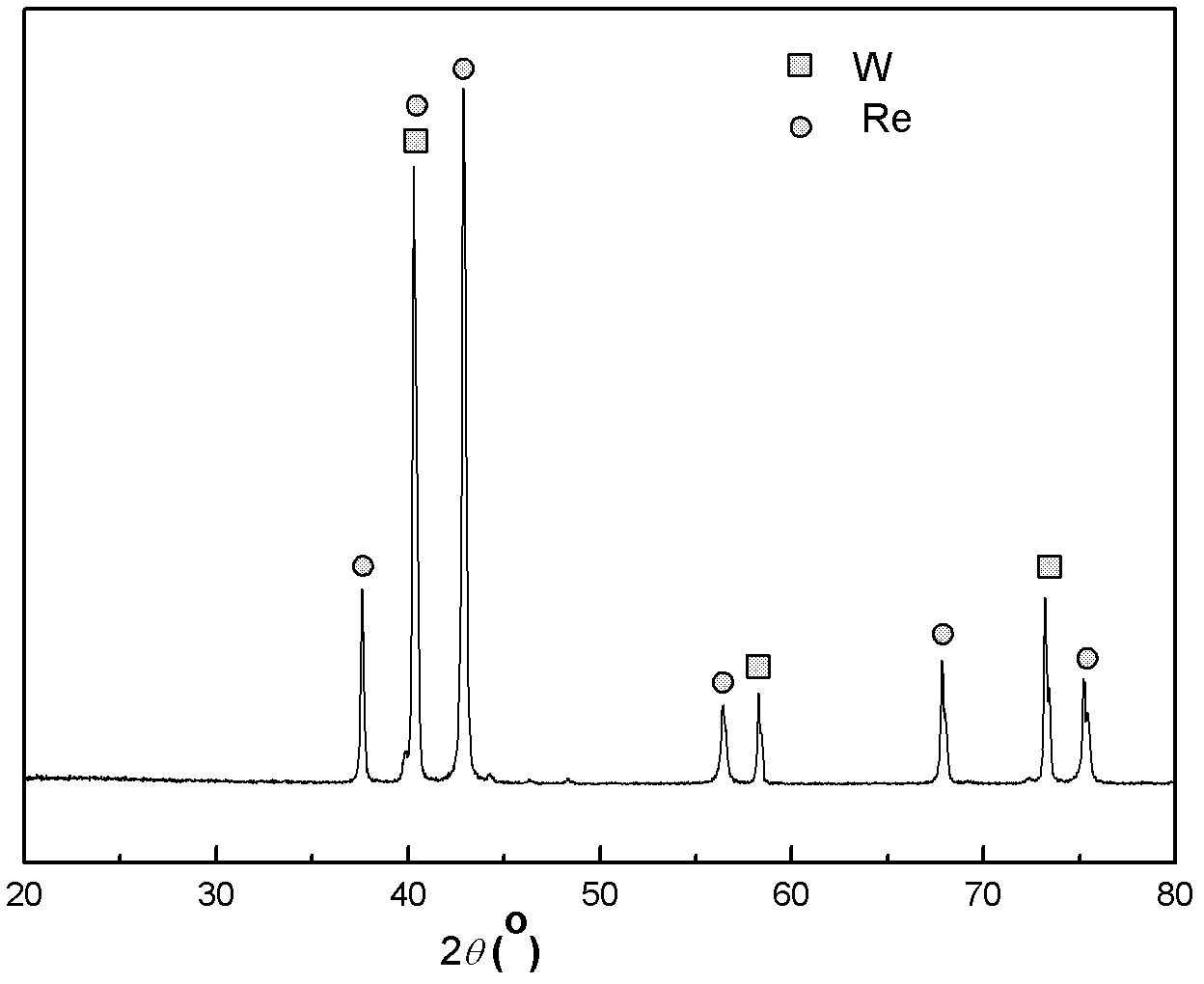

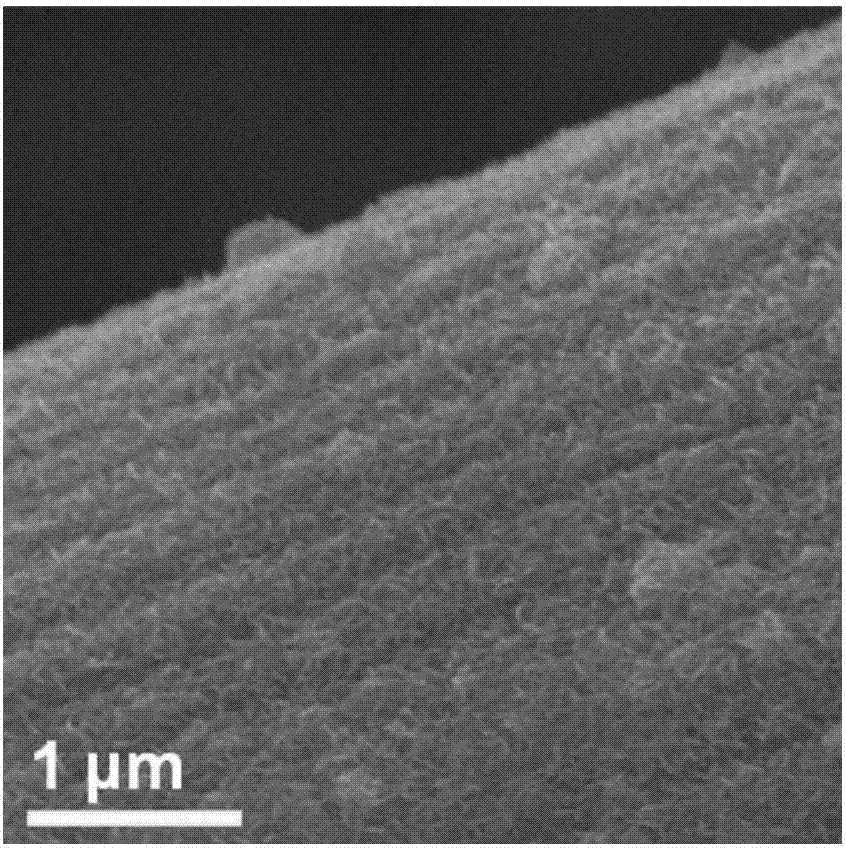

Rhenium tungsten based cathode material and preparation method thereof

The invention relates to a rhenium tungsten based cathode material and a preparation method thereof and belongs to the technical field of a refractory metal thermal cathode material. BaO, CaO and Al2O3 are loaded in pores of a porous rhenium tungsten base; the rhenium tungsten base is formed by coating tungsten grains by rhenium. The preparation method comprises the following steps: dissolving ammonium perrhenate in water, thereby preparing into a solution; adding tungsten powder into the ammonium perrhenate solution and stirring; drying; resolving and reducing in two steps under the hydrogen atmosphere, thereby obtaining rhenium tungsten powder; and pressing and sintering the rhenium tungsten powder under the hydrogen atmosphere, thereby obtaining a rhenium tungsten base and steeping into a molten barium aluminate calcium salt. The preparation method provided by the invention has the advantages that the preparation process is simple, the introduction of impurity element during the preparation process is avoided, the repeatability is strong, the prepared cathode material is excellent in emitting property, and the ion bombardment resistance of a traditional barium tungsten cathode is enhanced.

Owner:BEIJING UNIV OF TECH

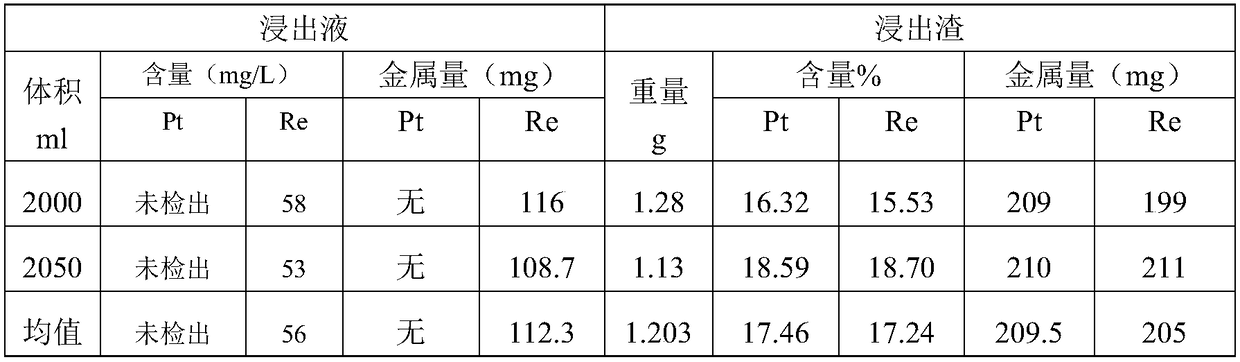

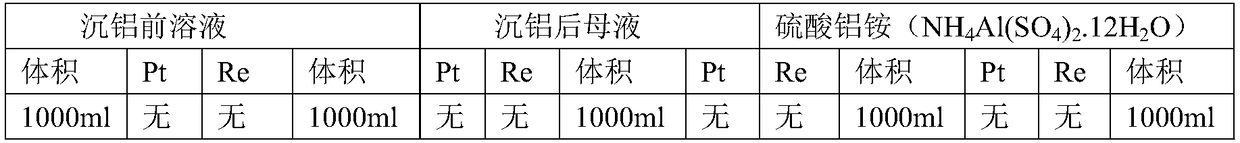

Process of recycling platinum-rhenium aluminum from platinum-rhenium waste catalyst of alumina carrier

ActiveCN109097584AShort processHigh recovery rateProcess efficiency improvementPlatinumAmmonium perrhenate

The invention discloses a process of recycling platinum-rhenium aluminum from platinum-rhenium waste catalyst of an alumina carrier. The process includes the steps that (1) the platinum-rhenium catalyst of the alumina carrier is conducted to roasting; (2) the carrier alumina is leached; (3) R410 negative ion exchange resin is used by leaching agent to adsorb rhenium, resin containing the rhenium is obtained and effluent goes to the next step; (4) the effluent from the last step is added with ammonia liquor to react, solid ammonium aluminum sulfate is produced; (5) leaching residue in step (2)is added with lime to conducted to roast; (6) roasting material of (5) is leaching by water; (7) residue containing platinum in step (6) is leaching, spongy platinum is produced by nitre; and (8) 001*7 positive ion exchange resin is used for exchanging, the effluent is neutralized, concentrated, froze through the ammonium hydroxide to produce ammonium perrhenate. The process has the characteristics of short circulation, high recovery rate and simple operation. The alumina carriers are all recycled, no waste water, waste residue is produced of all-wet technology. Platinum recovery rate is greater than 99.0%, rhenium recovery rate is greater than 97.0% and alumina recovery rate is greater than 98.0%.

Owner:ZHEJIANG TELI RECYCLING RESOURCES

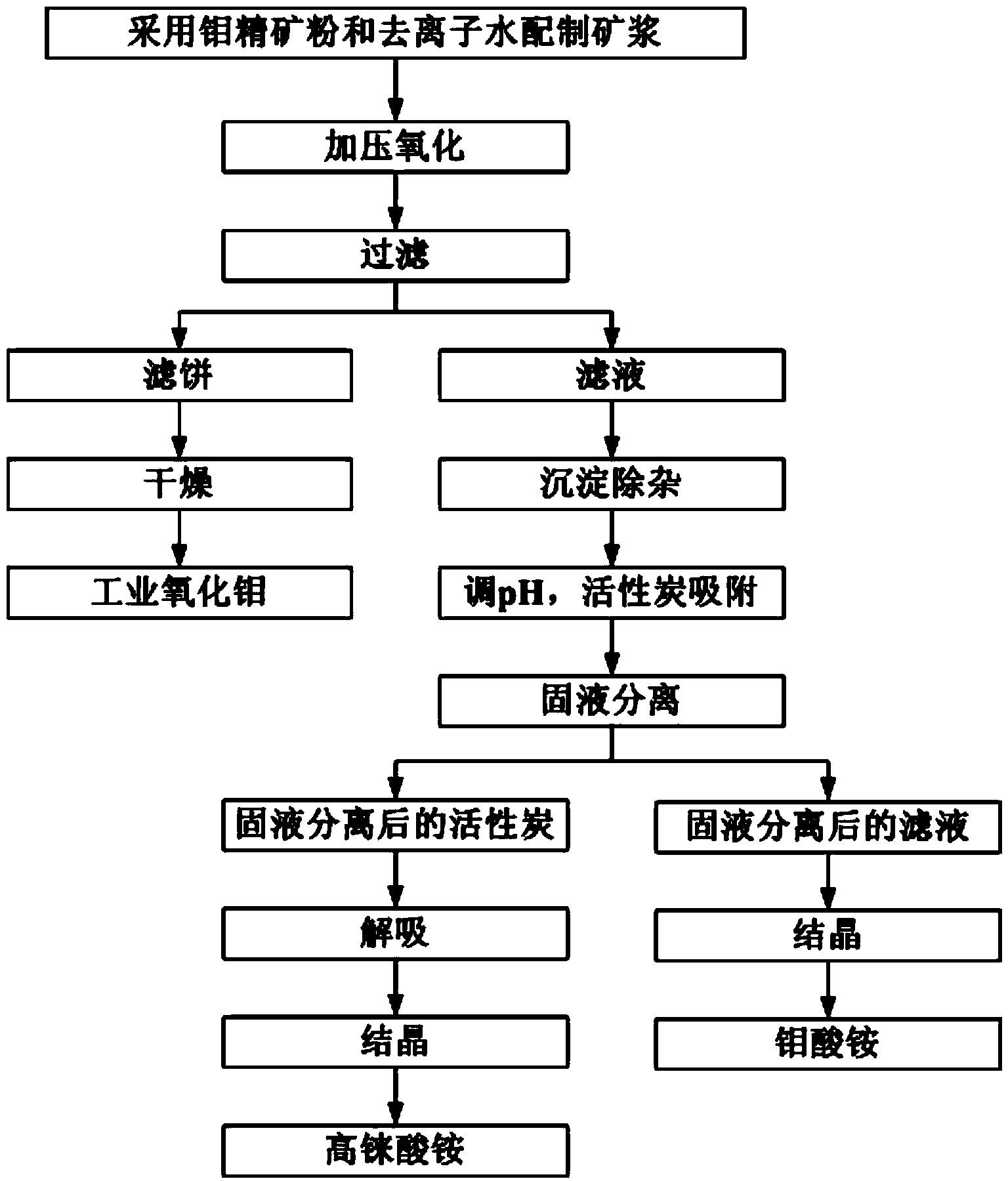

Method of recycling molybdenum and rhenium from molybdenum concentrate by hydrometallurgy

InactiveCN103866142AImprove leaching rateHigh molybdenum trioxide contentProcess efficiency improvementActivated carbonAmmonium perrhenate

The invention provides a method of recycling molybdenum and rhenium from molybdenum concentrate by hydrometallurgy. The method comprises the following steps: I, mixing molybdenum concentrate powder with deionized water to prepare ore pulp; II, carrying out pressurizing oxidization treatment onto the ore pulp; III, filtering to obtain a filter cake and filtrate; and IV, respectively treating the filter cake and the filtrate: drying the filter cake to obtain industrial molybdenum oxide; carrying out precipitation and impurity removal, active carbon adsorption and solid-liquid separation treatment onto the filtrate in sequence, crystallizing the filtrate treated by solid-liquid separation to obtain ammonium molybdate, and desorbing and crystallizing rhenium on the active carbon treated by the solid-liquid separation to obtain ammonium perrhenate. The method disclosed by the invention is simple in process, strong in repeatability, high in recovery rate of the molybdenum and the rhenium and suitable for large-scale industrial production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

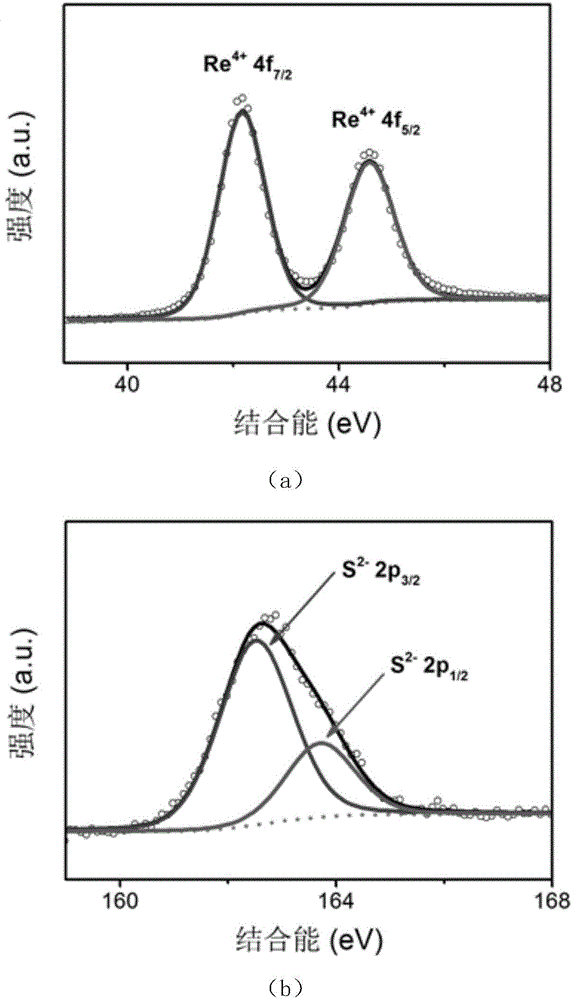

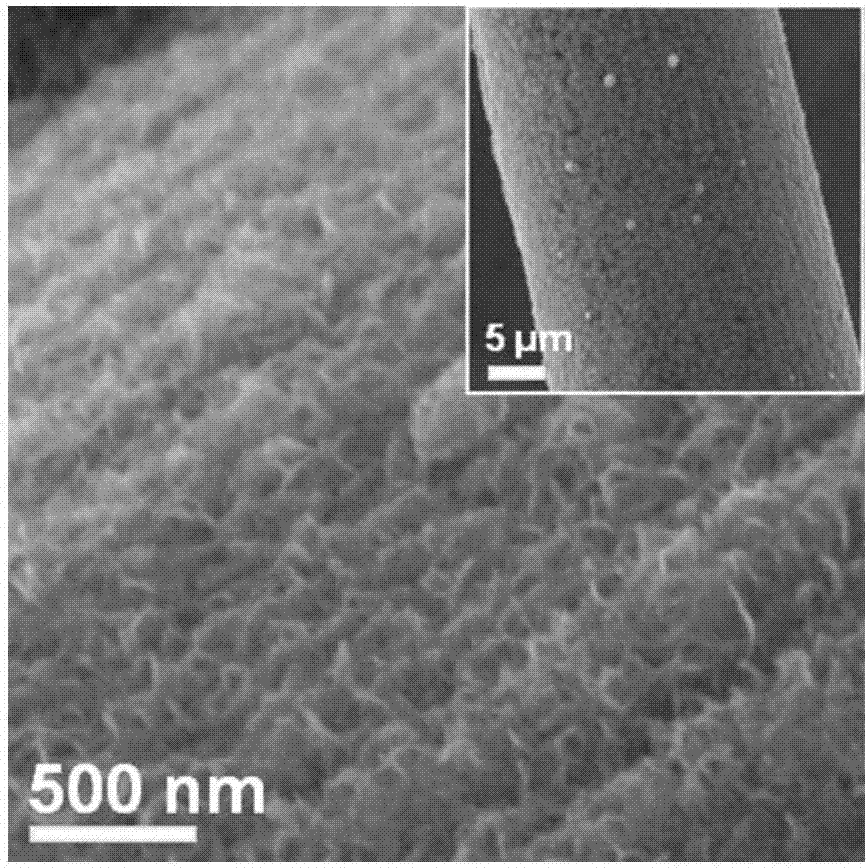

Selenium rhenium sulfide composite two-dimensional material and preparation method and application thereof

ActiveCN107362812ATune electronic structureReduce the free energy of hydrogen absorptionCatalyst activation/preparationElectrodesThioureaSe element

The invention relates to a selenium rhenium sulfide composite two-dimensional material and a preparation method and application thereof; the preparation method comprises the steps of (a) dissolving ammonium perrhenate and thiourea in an organic solvent to form a first solution; (b) dissolving selenium powder in hydrazine hydrate to obtain a second solution; (c) mixing the first solution and the second solution, and pouring the mixture in a reactor with a substrate to carry out hydrothermal reaction; after the hydrothermal reaction, cooling, and taking out the substrate. By controlling minor doping of sulfur, a selenium rhenium sulfide nanosheet with high coverage, good distribution uniformity and small size is obtained on the substrate, the size of the nanosheet reaches 50-100 nm; the nanosheet with high coverage and vertical growth can provide larger specific surface area, and greater current density is provided in electric catalysis. By adjusting doping quantity of sulfur, the electronic structure of the material is adjusted, hydrogen absorption free energy of the material is lowered, conductivity of the material is improved, more defects and active sites are created, and the electrocatalytic performance of the material is improved.

Owner:SUZHOU UNIV

Recovery method of molybdenum concentrates

InactiveCN101956070AResolve recovery rateSolve environmental pollutionMolybdeum compoundsProcess efficiency improvementRecovery methodSlag

The invention discloses a recovery method of molybdenum concentrates. The method comprises the following steps of: carrying out a hot pressing natural reaction of materials to be processed under an alkaline condition; enriching molybdenite through flotation from natural oxide slag after natural leaching, returning for hot pressing oxidation and floating tailing slag to recover copper; producing high-purity ammonium molybdate and ammonium perrhenate from leached liquid after the natural leaching through the process of extraction, purification, acid precipitation, ammonia dissolution, concentration and crystallization; and removing sodium sulfate by evaporating or freezing and crystallizing raffinate to produce a sodium sulfate product. According to the invention, the recovery rate of the molybdenum concentrates is improved.

Owner:ZIJIN MINING GROUP

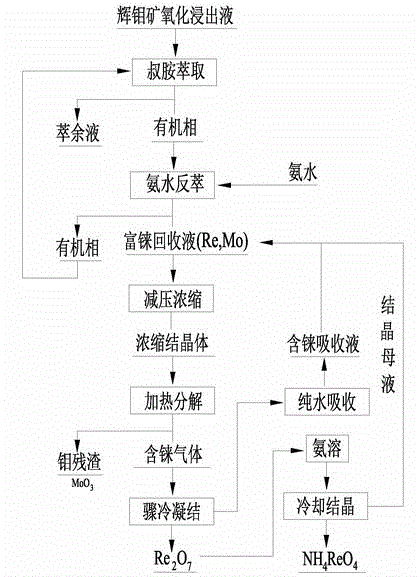

Method for preparing ammonium perrhenate

ActiveCN104630509AEfficient separationRaise the gradeProcess efficiency improvementAmmonium perrhenateRhenium(VII) oxide

The invention relates to the technical field of rhenium recycling and in particular relates to a method for preparing ammonium perrhenate. The ammonium perrhenate is prepared by purifying rhenium-enriched recovery liquid obtained by enrichment of poor-rhenium stock solution, and the rhenium-enriched recovery liquid is subjected to vacuum concentration, heating decomposition and dissolution-crystallization so as to prepare ammonium perrhenate. The method comprises the following steps: step 1, performing vacuum concentration to prepare a concentrated crystal; step 2, performing heating decomposition to collect rhenium heptoxide solids; step 3, performing dissolution-crystallization to prepare ammonium perrhenate; and step 4, recycling molybdenum and rhenium. According to the method disclosed by the invention, molybdenum and rhenium can be effectively separated from each other, and high-grade ammonium perrhenate can be prepared; and moreover, the poor-rhenium stock solution serves as a raw material, the raw materials are wide and readily available, and integrated resource recycling is realized.

Owner:洛阳双罗铼材料科技有限公司

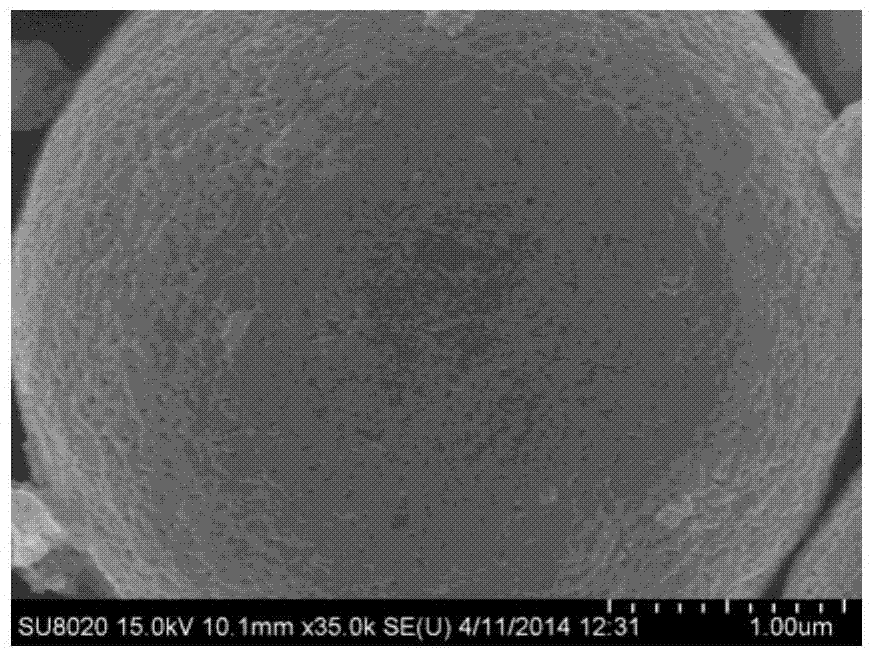

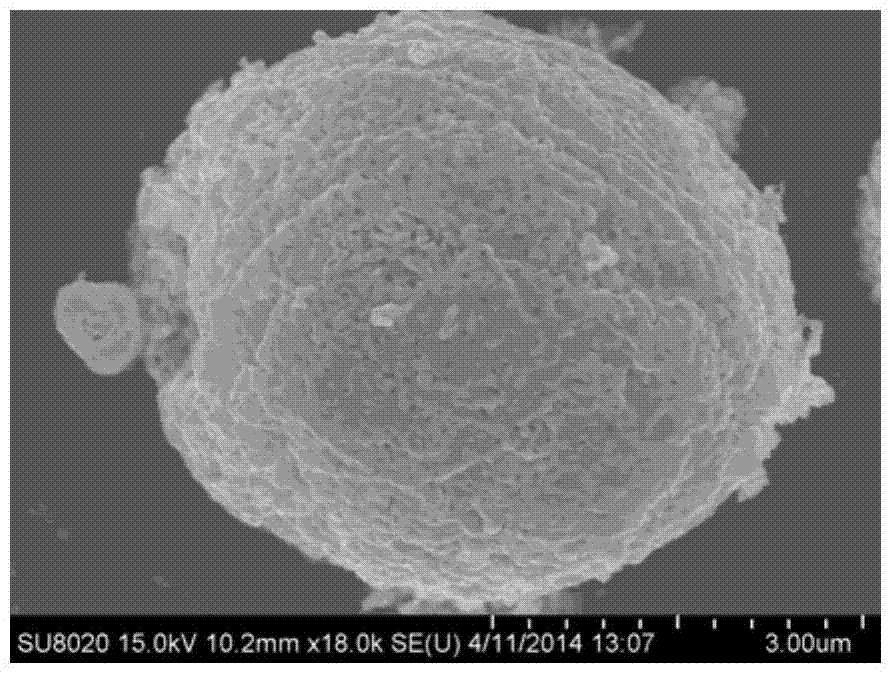

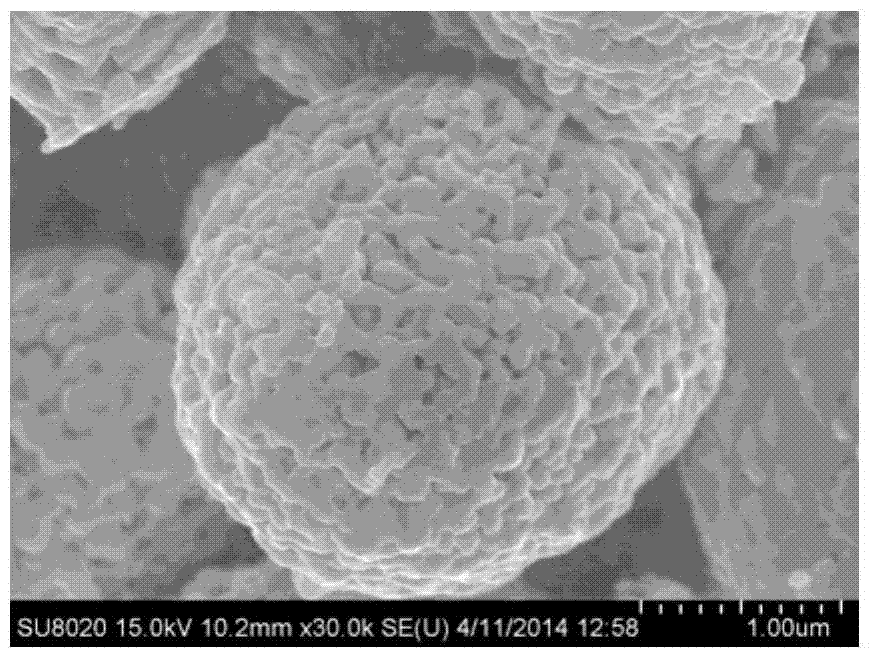

Porous spherical tungsten rhenium alloy powder and preparation method thereof

The invention relates to a porous spherical tungsten rhenium alloy powder and a preparation method thereof, and belongs to the technical field of alloy powder. The mixture of tungsten and rhenium is in the atomic level, the content of the tungsten in proportion by weight ranges from 25% to 90%, and the content of the rhenium in proportion by weight ranges from 10% to 75%. The method includes adopting ammonium perrhenate and ammonium metatungstate as raw materials, configuring into solution, and preparing precursor powder by the spray drying method; depositing and reducing in the atmosphere of hydrogen gas in two steps, namely in the first step,allowing the temperature to be 450 to 550 DEG C and insulating heat for 1 to 2 hours, in the second step, allowing the reducing temperature to be 850 to 950 DEG C, and insulating heat for 2 to 3 hours; and obtaining the porous spherical tungsten rhenium alloy powder. According to the method, process is simple, repeatability and operability are high, the introduction of impurity elements in the preparation process is avoided, the purity of prepared samples is high, and appearance control of a porous spherical tungsten rhenium alloy ball can be implemented by controlling the content of the tungsten, the reducing temperature and heat insulating time.

Owner:韶关元泰资源科技有限公司

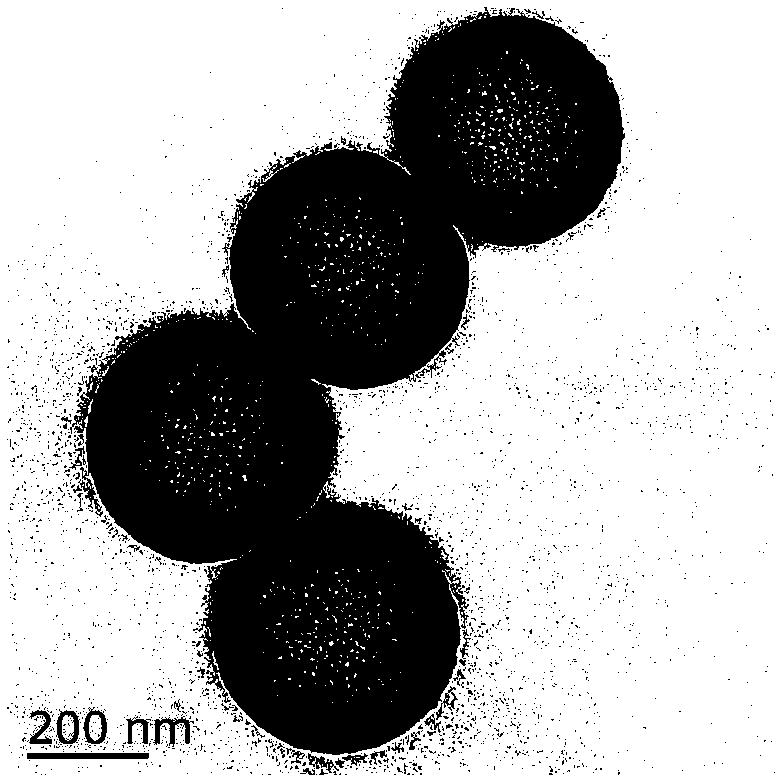

Less-layer rhenium disulfide nanosheet/hollow carbon spheres for sodium-ion battery negative electrode material and preparation method thereof

InactiveCN108807957APolyintercalated active siteImprove conductivityCell electrodesSecondary cellsSodium-ion batteryStructural stability

The invention discloses less-layer rhenium disulfide nanosheet / hollow carbon spheres for a sodium-ion battery negative electrode material and a preparation method thereof. The negative electrode material is formed by attaching rhenium disulfide nanosheets to carbon shells inside and outside the porous hollow carbon spheres. The preparation method of the negative electrode material comprises the following steps: taking ammonium perrhenate as a precursor, taking thioacetamide as a sulfur source, taking hydrazine hydrate as a reducing agent, and taking the porous hollow carbon spheres as a rhenium disulfide growth framework, thereby obtaining the negative electrode material. According to the negative electrode material prepared in the invention, the porous hollow carbon spheres of uniform particle size are taken as the framework, and the rhenium disulfide sheet structures are uniformly dispersed on the carbon shells. According to use of the porous hollow carbon spheres, the number of growth layers of the rhenium disulfide nanosheets is limited as 2-7. The less-layer rhenium disulfide nanosheet / hollow carbon sphere nanocomposite material has many sodium-embedded active sites and high conductivity, the volume effect can be buffered by the inner cavity, the sheet layers are prevented from dropping to maintain the structural stability, and the rhenium disulfide nanosheets do not haveany obvious agglomeration phenomenon.

Owner:YANGZHOU UNIV

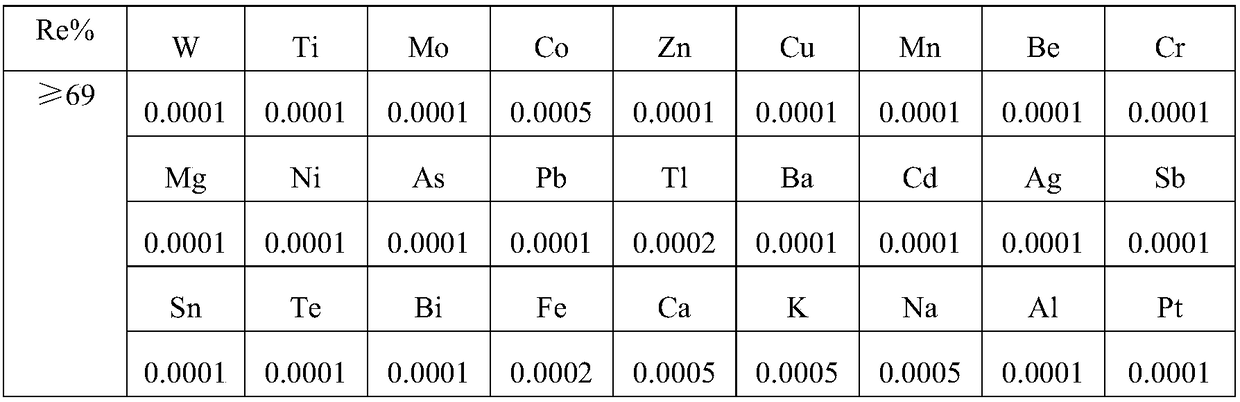

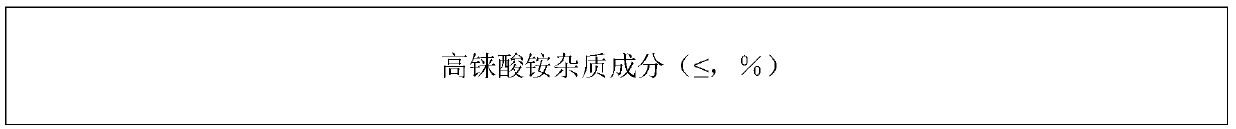

Method for purifying ammonium perrhenate

The invention discloses a method for purifying ammonium perrhenate. The method specifically comprises the steps: firstly, adding crude ammonium perrhenate into ultrapure water, dissolving, then sequentially filtering through three stage of screens to obtain a crude ammonium perrhenate solution, then adding hydrogen peroxide and ammonia water, stirring, then adsorbing through two cation exchange resins connected in series, evaporating, concentrating, freezing, crystallizing, filtering and drying to obtain ammonium perrhenate. The purity of the ammonium perrhenate prepared by the method disclosed by the invention is 99.99% or above, the loss of the ammonium perrhenate subjected to multiple evaporative crystallization can be effectively reduced, and the recovery rate of the ammonium perrhenate is 95% or above.

Owner:JINDUICHENG MOLYBDENUM CO LTD

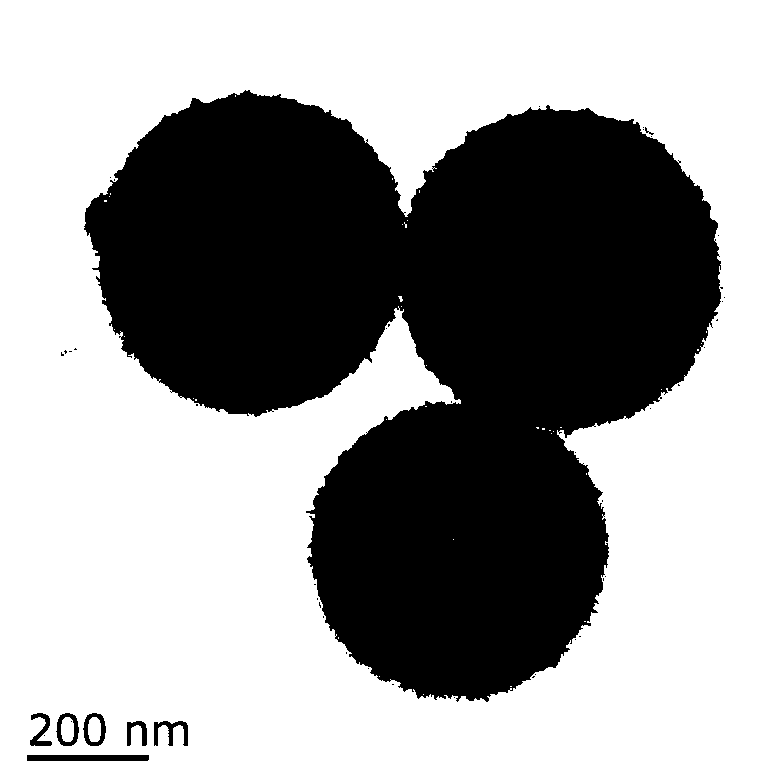

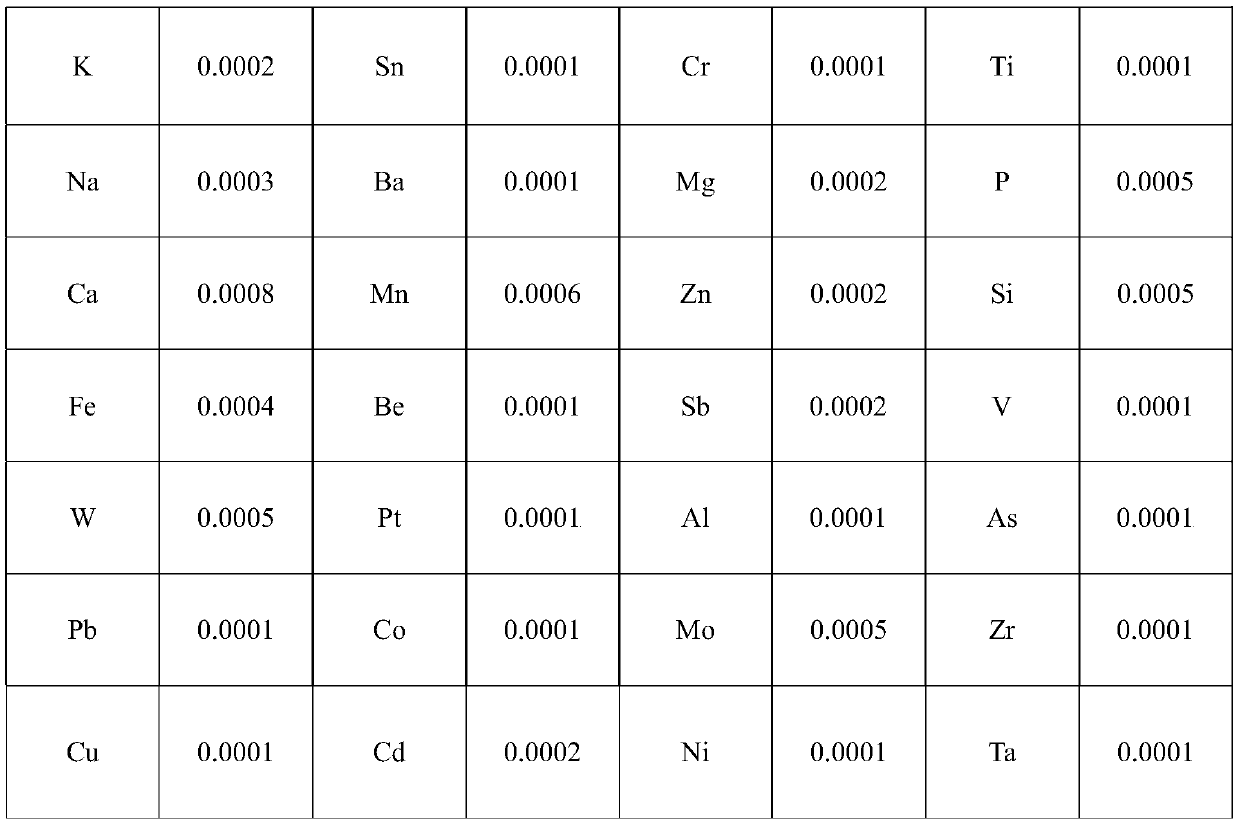

ReS2/CdS photocatalyst and preparation method and application thereof

InactiveCN108855141AEasy control of hydrothermal reaction conditionsConditions that control the hydrothermal reactionPhysical/chemical process catalystsHydrogen productionAmmonium perrhenateCharge carrier

The invention discloses a ReS2 / CdS photocatalyst and a preparation method and application thereof. The preparation method of the ReS2 / CdS photocatalyst comprises the following steps that 1, ammonium perrhenate, thioacetamide, hexamine and cadmium sulfide are weighed and dissolved in distilled water to obtain a mixed solution B; 2, the mixed solution B obtained in the step 1 is placed in a hydrothermal reactor for hydrothermal reaction; 3, after the reaction is completed, when the hydrothermal reactor is cooled to a room temperature, dark green ReS2 / CdS in the hydrothermal reactor is subjectedto ethanol washing, washing and drying for use. According to the preparation method of the ReS2 / CdS photocatalyst, the obtained ReS2 / CdS photocatalyst greatly improves the performance of CdS semiconductor photocatalysis hydrogen production, a flexible ReS2 load is used as a promoter on the CdS surface, not only are the problems of the scarcity and high cost of Pt solved, but also CdS semiconductorphotocatalytic material electron transferring is accelerated, the carrier compound probability of a CdS semiconductor photocatalytic material is reduced, and a brand new way is provided for a CdS photocatalysis hydrogen production technology.

Owner:NANYANG NORMAL UNIV

Method for recycling rhenium and bismuth from acidic waste solution

ActiveCN105714121AEfficient separation and recoveryAvoid hydrolysisProcess efficiency improvementSlagDesorption

The invention provides a method for recycling rhenium and bismuth from an acidic waste solution. The method comprises the following steps that firstly, ion exchange adsorption treatment is conducted on the acidic waste solution through ion exchange resin, and the rhenium and the bismuth in the acidic waste solution are adsorbed to the ion exchange resin; secondly, a mixed solution of sodium hydroxide and tartaric acid is utilized for desorbing the bismuth adsorbed to the ion exchange resin to a liquid phase, bismuth-containing desorption liquid is obtained, the rhenium adsorbed to the ion exchange resin is desorbed to the liquid phase through an ammonium thiocyanate solution, and rhenium-containing desorption liquid is obtained; and thirdly, concentrated hydrochloric acid is dripped into the bismuth-containing desorption liquid to enable the bismuth to be subjected to the precipitation reaction, bismuth enrichment slag is obtained, after heating and concentrating are conducted on the rhenium-containing desorption liquid, crystallization treatment is conducted, and ammonium perrhenate is obtained. According to the method, the rhenium and the bismuth in the acidic waste solution can be efficiently separated and recycled, the separation effect is obvious, the technology is simple and feasible, the equipment investment is small, and industrial application is facilitated.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

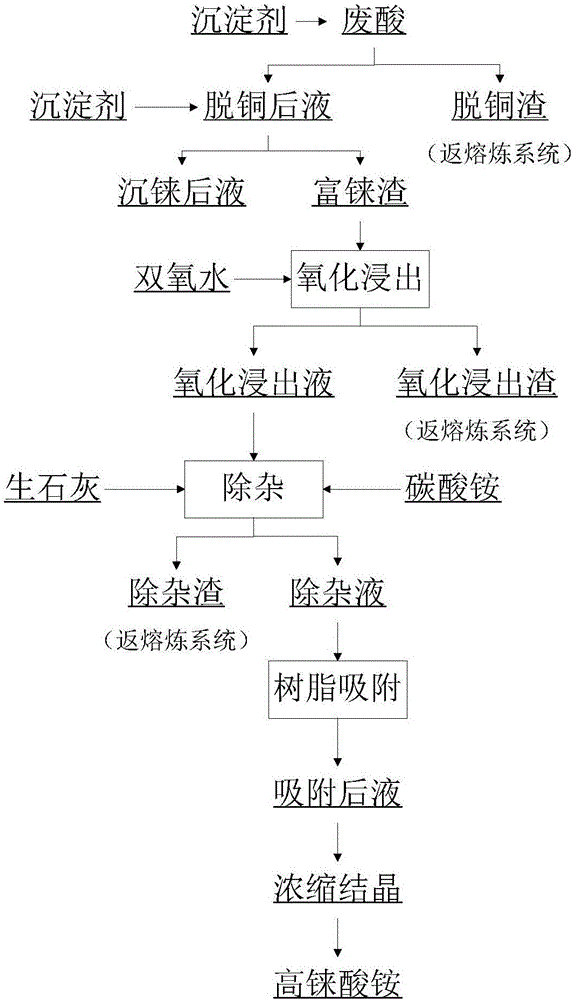

Method for producing ammonium perrhenate from rhenium-enriched residues

ActiveCN106315682AImprove recycling efficiencyShort processRhenium compoundsAmmonium perrhenateHydrometallurgy

The invention provides a method for producing ammonium perrhenate from rhenium-enriched residues. The method comprises the following steps: S1) mixing the rhenium-enriched residues and an oxidant solution for oxidizing leaching to obtain an oxidizing leaching solution; S2) adding an alkali compound into the oxidizing leaching solution to remove impurities so as to obtain an impurity removal solution; and S3) allowing the impurity removal solution to pass through a cation exchange resin to obtain the ammonium perrhenate. Compared with the prior art, the method disclosed by the invention has the advantages that the rhenium-enriched residues are subjected to oxidizing leaching and impurity removal by virtue of the alkali compound and adsorbed to further remove the impurities by virtue of the cation exchange resin, and then ammonium perrhenate can be obtained. The process flow is short, the treatment quantity is great, the equipment and raw material input is cheap, and the method can be operated at normal pressure. Moreover, the whole process is an all wet process metallurgy method, the problem of environmental pollution is solved, and the recovery efficiency is high.

Owner:YANGGU XIANGGUANG COPPER

Method for preparing ammonium perrhenate from waste liquid containing molybdenum and rhenium

ActiveCN102173457BReduce coprecipitation lossImprove adsorption capacityRhenium compoundsCalcium hydroxideAmmonium perrhenate

The invention relates to a method for preparing ammonium perrhenate from waste liquid containing molybdenum and rhenium. In the technical scheme of the invention, the method comprises the following steps of: adding hydrogen peroxide into the waste liquid containing molybdenum and rhenium until the solution turns to yellow, then adding a mixed agent until the pH of the solution is 6 to 7, separating by filter pressing, collecting the filtrate, absorbing the filtrate by a resin exchange column, stopping adsorption until the concentration of rhenium in effluent is constant, eluting with NH3.H2O,collecting the eluate, heating to concentrate the eluate at 98-100 DEG C, cooling, and crystallizing to obtain ammonium perrhenate. The mixed agent is a mixture of calcium hydroxide and calcium oxidein a weight ratio of 5:1. According to the invention, the waste liquid containing molybdenum and rhenium, particularly the absorption liquid of the flue gas during molybdenum roasting, is used as theraw material; the enrichment of rhenium is increased by about 20 times; ammonia water is determined as the eluent of rhenium; the elution rate of rhenium is higher than 98%; the recovery rate of rhenium is higher than 93%, the purity of the ammonium perrhenate product is higher than 99.5%, and the economic, social and environmental benefits are significantly improved.

Owner:爱瑞克(大连)安全技术集团有限公司

Supported perrhenate ionic liquid as well as preparation method thereof

ActiveCN103464200AReduce dosageEfficient separationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPerrhenic acidIonic liquid

The invention relates to a supported perrhenate ionic liquid as well as a preparation method thereof. The technical scheme adopted is as follows: the preparation method comprises the following steps: selecting MCM-41 (Mobil Composition of Matters) as a carrier material; firstly, carrying out a reaction on chloropropyl triethoxysilane and the MCM-41; grafting a chloropropyl silicon structure to the surface of the MCM-41, and removing the byproduct ethanol; then, adding N-methyl imidazole so as to quaternize to obtain MCM-41 supported alkyl imidazole chlorine salt; and further adding ammonium perrhenate, and converting the chlorine salt into perrhenate through double-decompose reaction to obtain the MCM-41 supported alkyl imidazole perrhenate ionic liquid. The molar ratio of the reaction materials chloropropyl triethoxysilane, N-methyl imidazole, the MCM-41 and perrhenate is 1:(4-1):(3-1):(10-0.1). The method is applicable to support of various different types of alkyl imidazole perrhenate ionic liquids.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

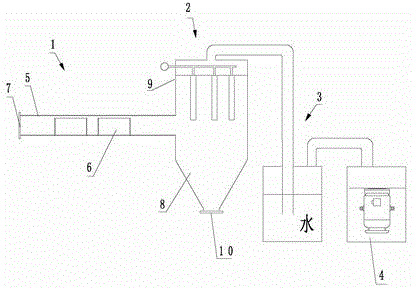

Method for preparing ammonium perrhenate

ActiveCN104176784AAchieve recyclingImprove economyRhenium compoundsPerrhenic acidAmmonium perrhenate

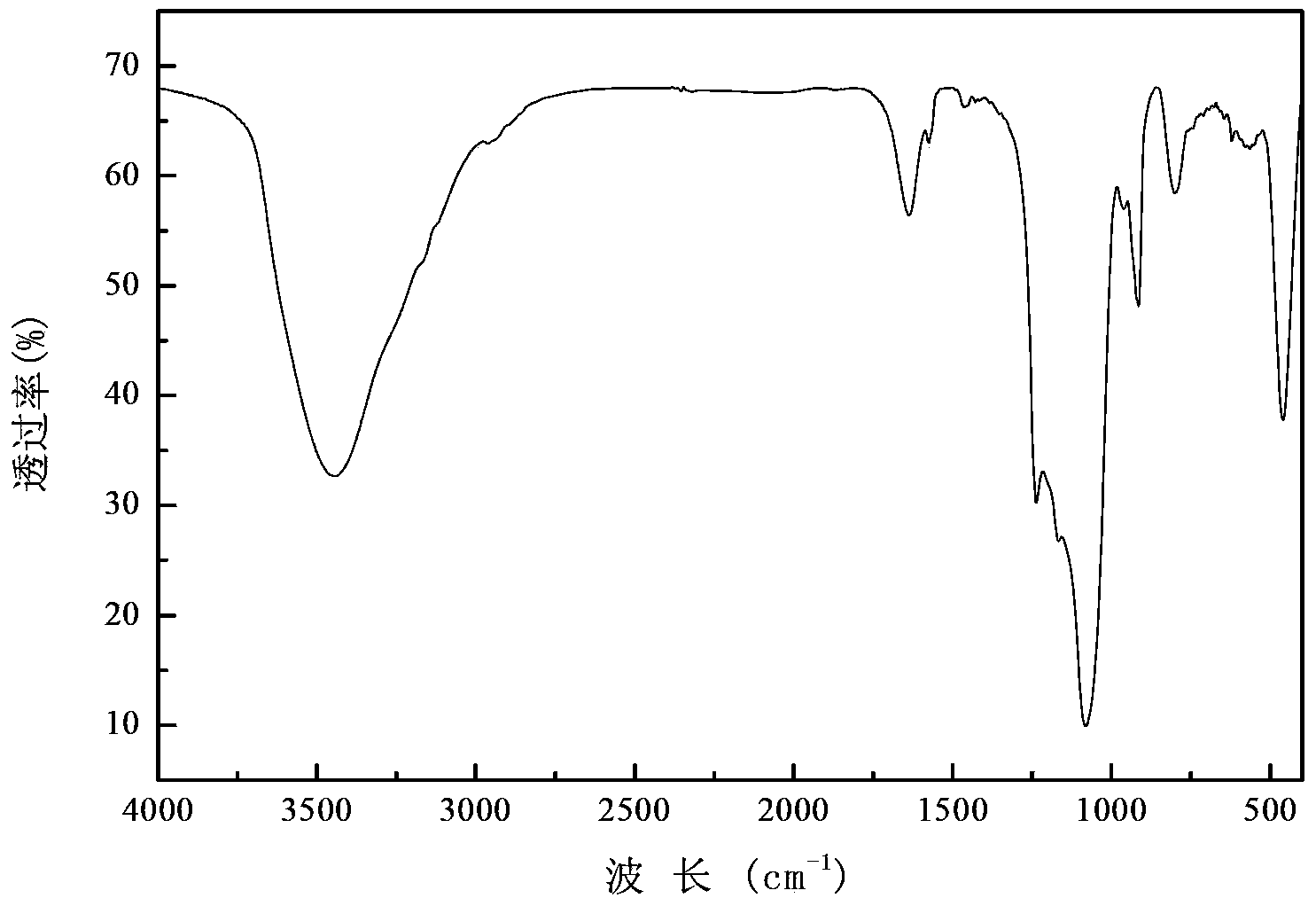

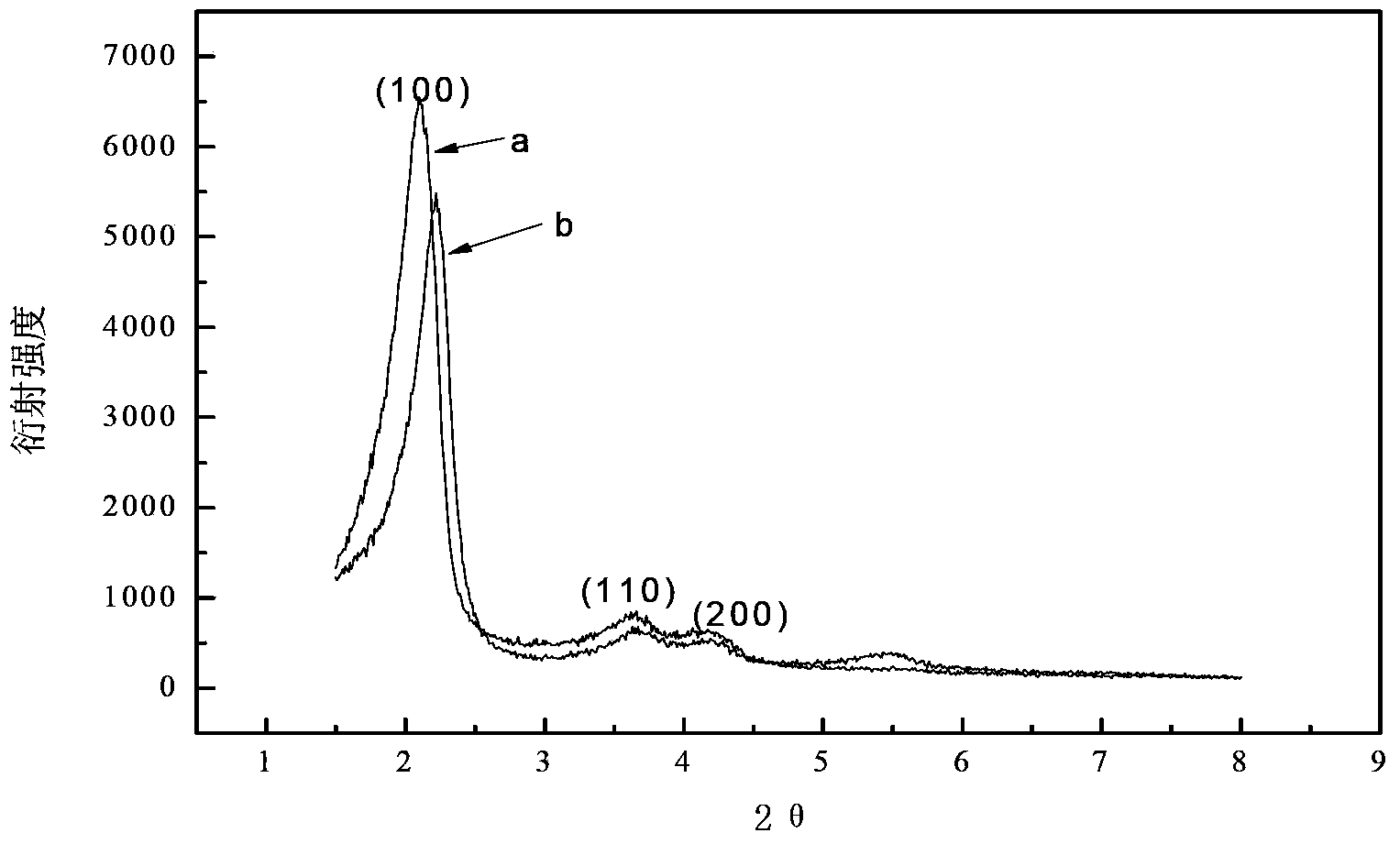

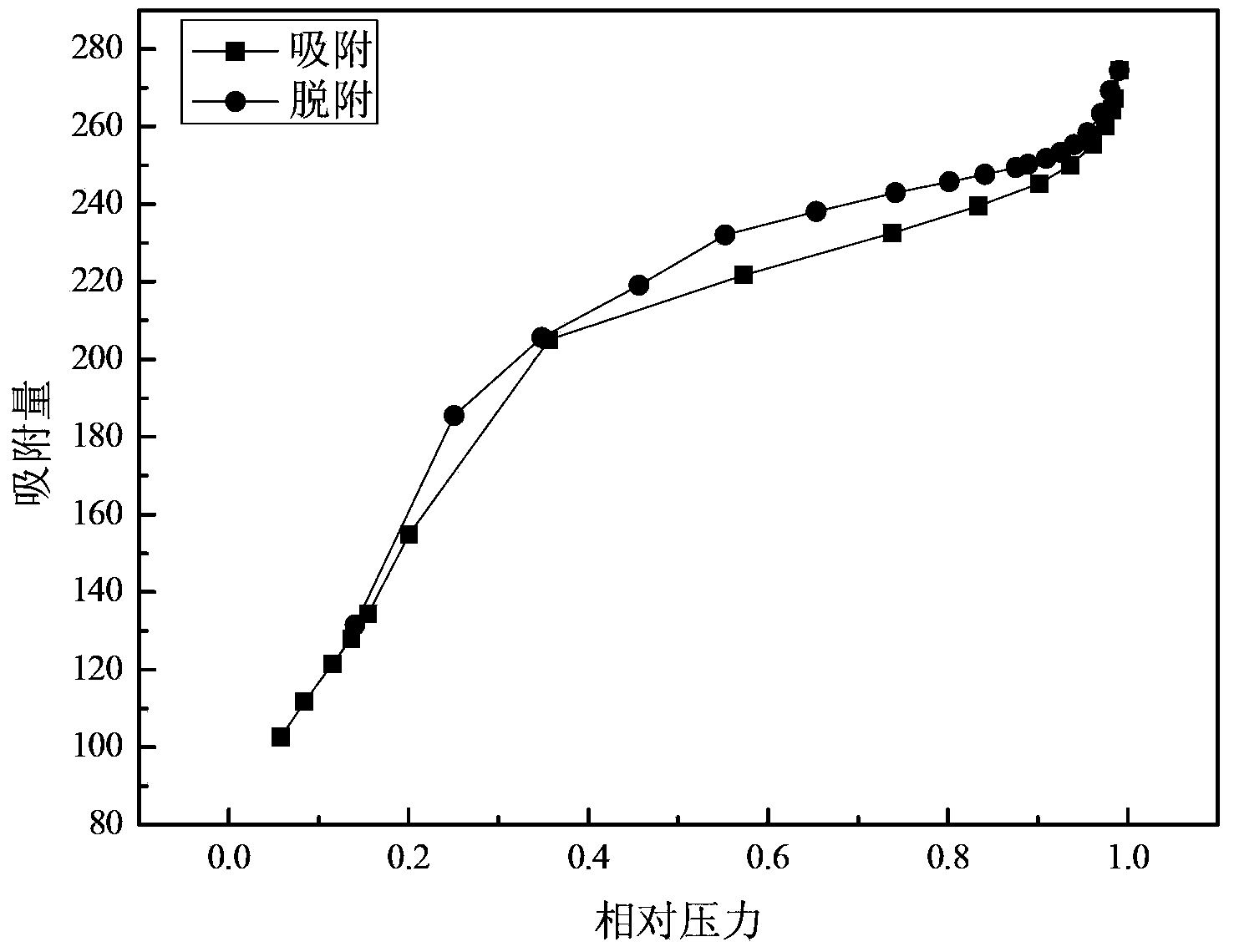

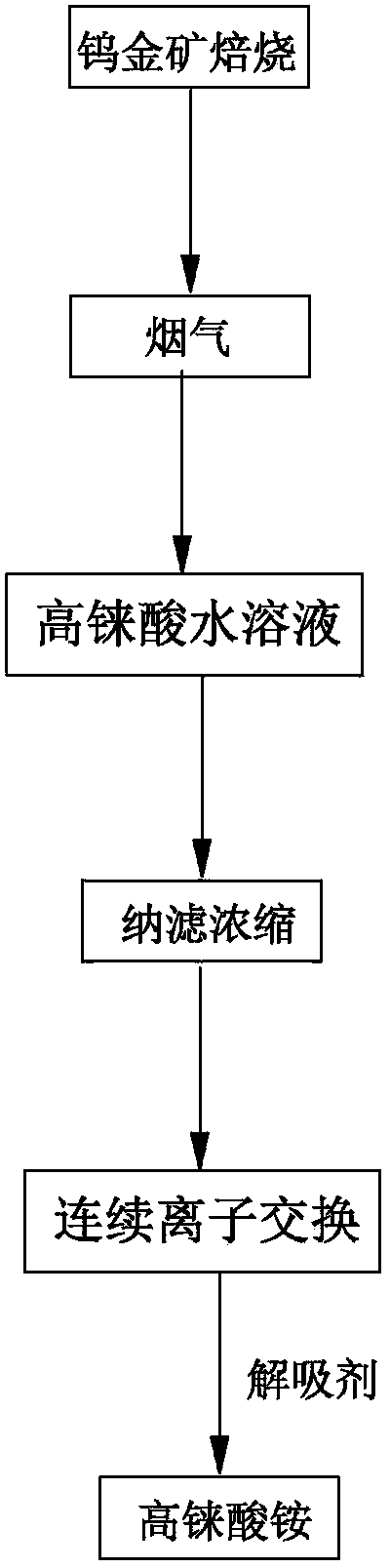

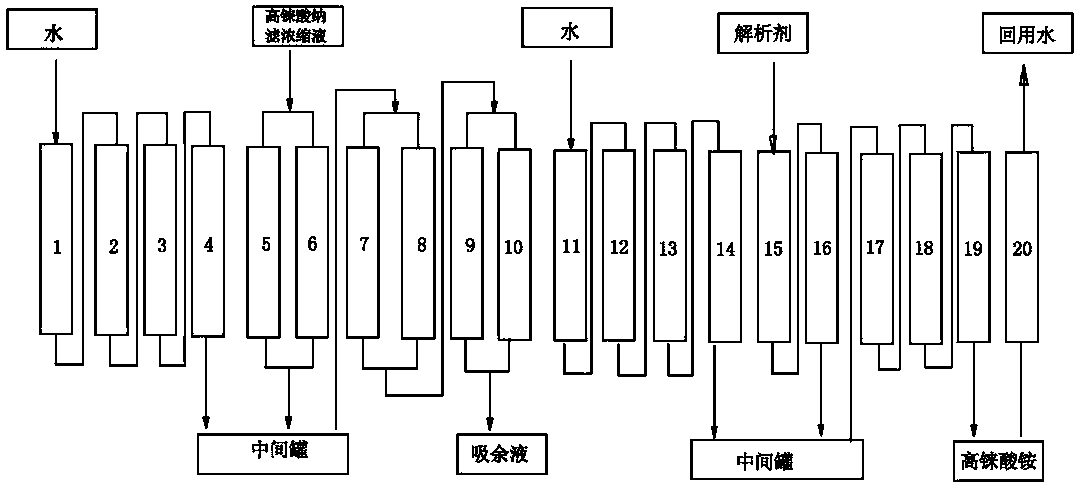

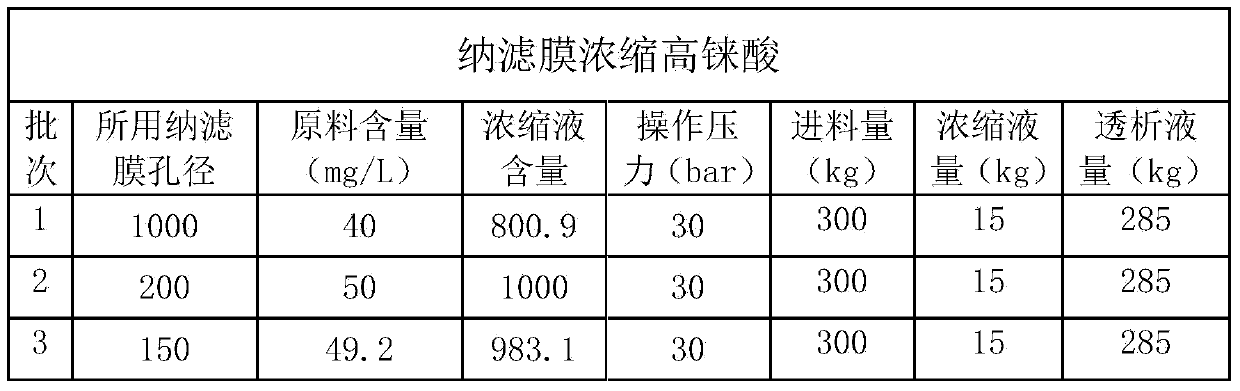

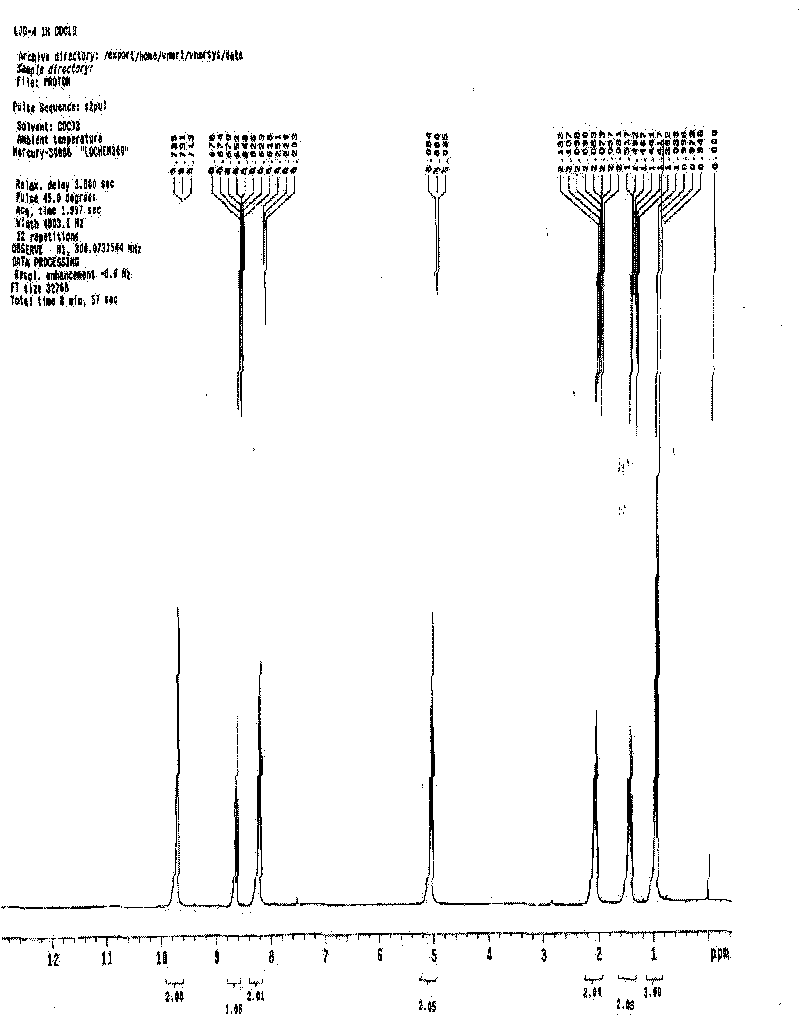

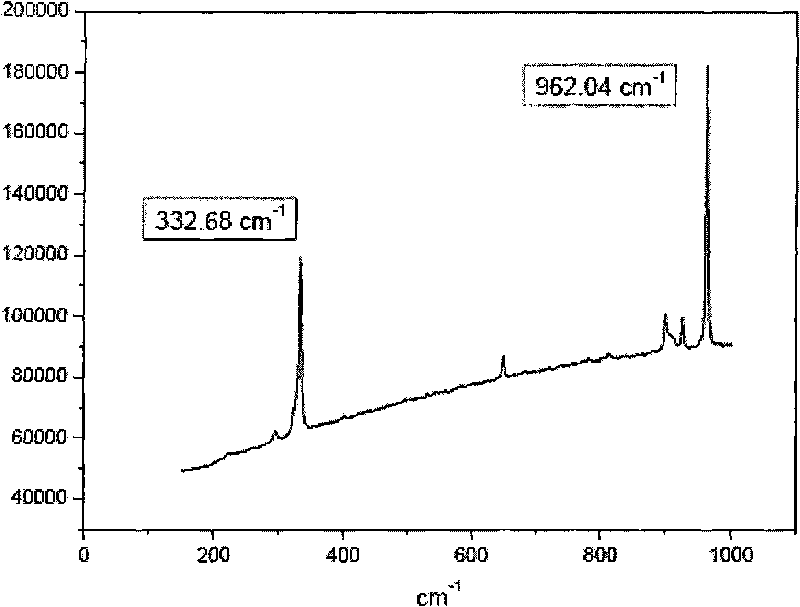

The invention discloses a method for preparing ammonium perrhenate, which is characterized by comprising the following steps: 1. washing and cooling flue gas generated by tungsten gold ore roasting through an eluting tower, so that perrhenic acid contained in the flue gas is dissolved in water, and the water solution containing the perrhenic acid is used for circularly eluting the roasting flue gas to increase the concentration; 2. collecting the perrhenic acid water solution, carrying out rough filtration, and carrying out nanofiltration concentration on the filtrate with nanofiltration membrane equipment to obtain a perrhenic acid nanofiltration concentrated solution; and 3. passing the perrhenic acid nanofiltration concentrated solution through continuous ion exchange equipment, eluting rhenium with a resolving agent, heating to concentrate the collected eluate at 100 DEG C, cooling, and crystallizing to obtain the ammonium perrhenate. By using the flue gas generated by tungsten gold ore roasting as the raw material, the nanofiltration membrane equipment and continuous ion exchange equipment are utilized to recover the ammonium perrhenate, thereby achieving the goals of resource recovery and environment protection; and thus, the method has favorable economic value and environmental benefit.

Owner:XIAMEN STARMEM TECH

Method for preparing dissipated metal rhenium ionic liquid

InactiveCN101735138ASimple processHomogeneous catalysisOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeDissolution

The invention relates to a method for preparing dissipated metal rhenium ionic liquid. The adopted technical scheme is as follows: the preparation method comprises the following steps: taking a certain amount of alkyl bromide pyridine compound, adding 2-4 times of deionized water for dissolution, adding into OH type anion exchange resin for carrying out ion exchange, and collecting effluent solution which is hydroxyalkyl pyridine; adding the hydroxyalkyl pyridine into ammonium perrhenate water solution, leading the molar ratio of the hydroxyalkyl pyridine to the ammonium perrhenate to be 1:1-1:2, stirring for 3-5 hours at the temperature of 70-90 DEG C, carrying out vacuum distillation for removing water, cooling, then adding mixed solution of anhydrous methanol and acetonitrile, sealing, churning, placing at the temperature of minus 30-minus 40 DEG C for 10-15 hours, carrying out the vacuum distillation, removing the methanol and the acetonitrile and carrying out vacuum drying. The ionic liquid has high yield and is stable to air and water.

Owner:LIAONING UNIVERSITY

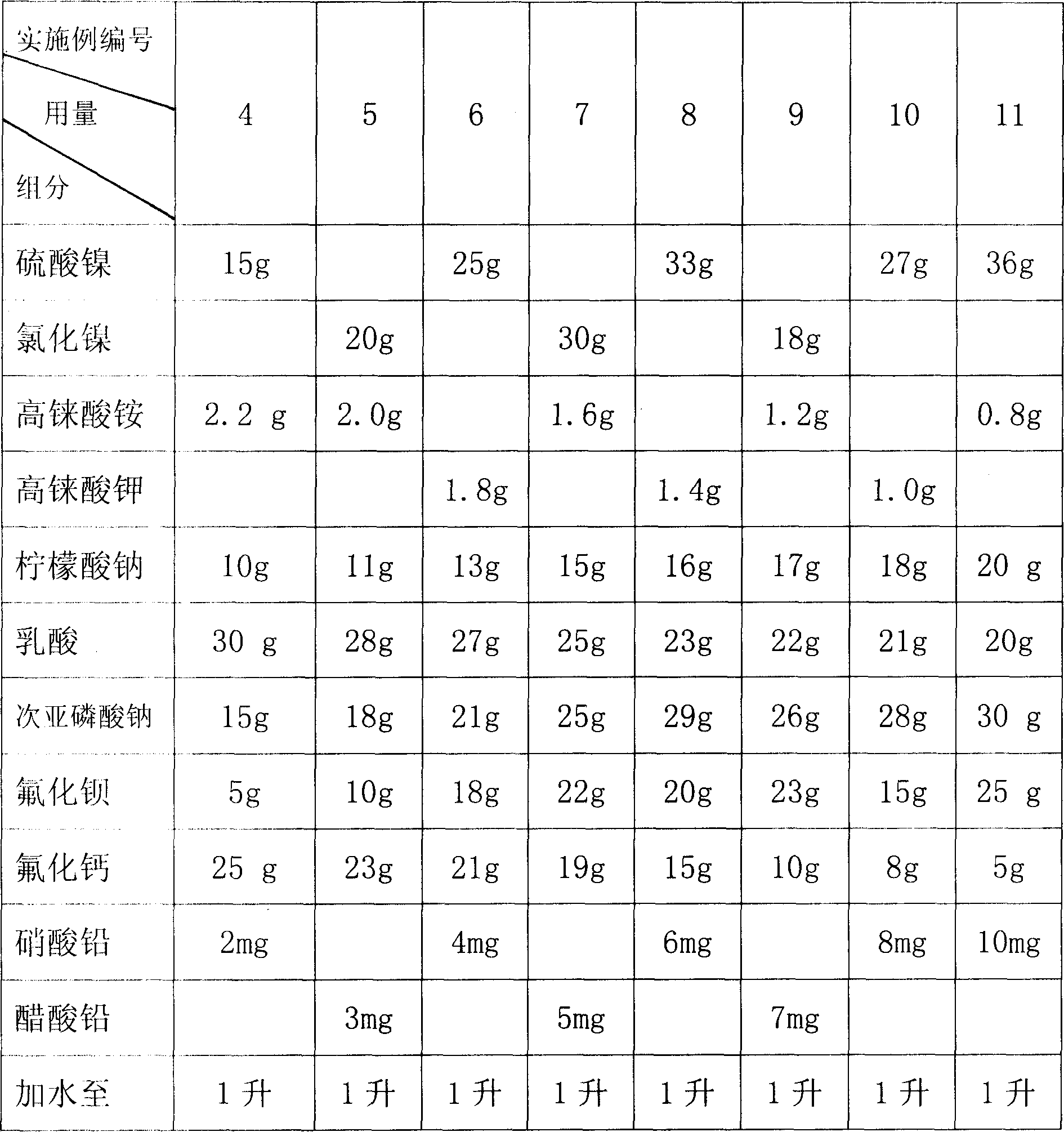

Chemical plating liquid for preparing high temperature self lubricating composite coating and chemical plating method

InactiveCN1858300AImprove surface friction and wear resistanceOvercome the shortcoming of short working lifeLiquid/solution decomposition chemical coatingChemical platingLead nitrate

The chemical plating liquid for preparing high temperature self lubricating composite coating consists of nickel sulfate 15-36 g / L, ammonium perrhenate 0.8-2.2 g / L, sodium citrate 10-20 g / L, lactic acid 20-30 g / L, sodium hypophosphorate 15-30 g / L, barium fluoride 5-25 g / L, calcium fluoride 5-25 g / L and lead nitrate 2-10 mg / L. The chemical plating process includes cleaning and activating the surface of the workpiece, immersion plating the workpiece inside the chemical plating liquid of pH 5-7 at 85-95 for 10-60 min. The present invention can form composite Ni-Re-P / barium fluoride + calcium fluoride coating on the surface of mechanical parts to raise the surface friction reducing and wear resisting performance at very high temperature work condition and to increase the service life. The present invention is especially suitable for turbine blade, jet engine, etc.

Owner:SOUTHWEAT UNIV OF SCI & TECH

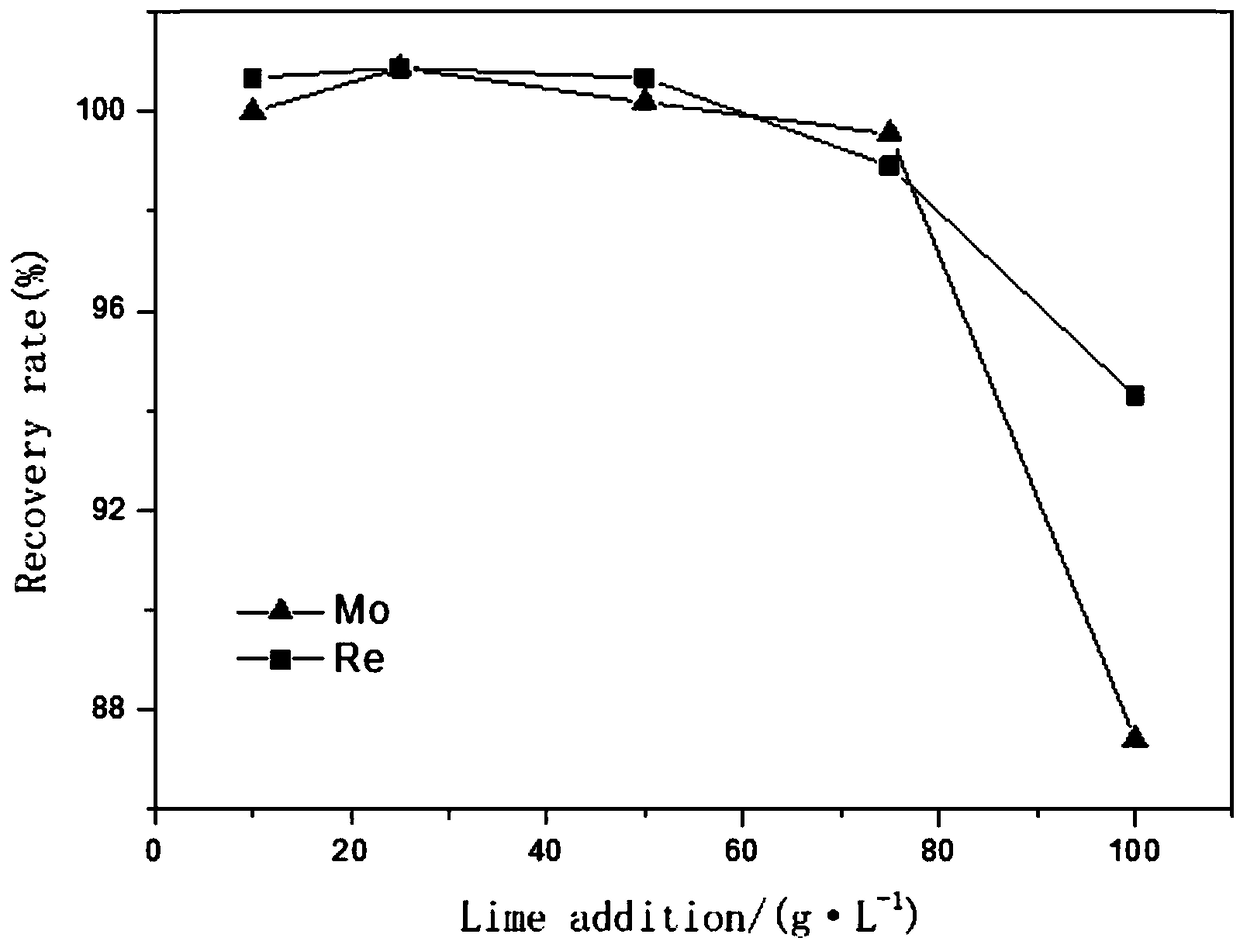

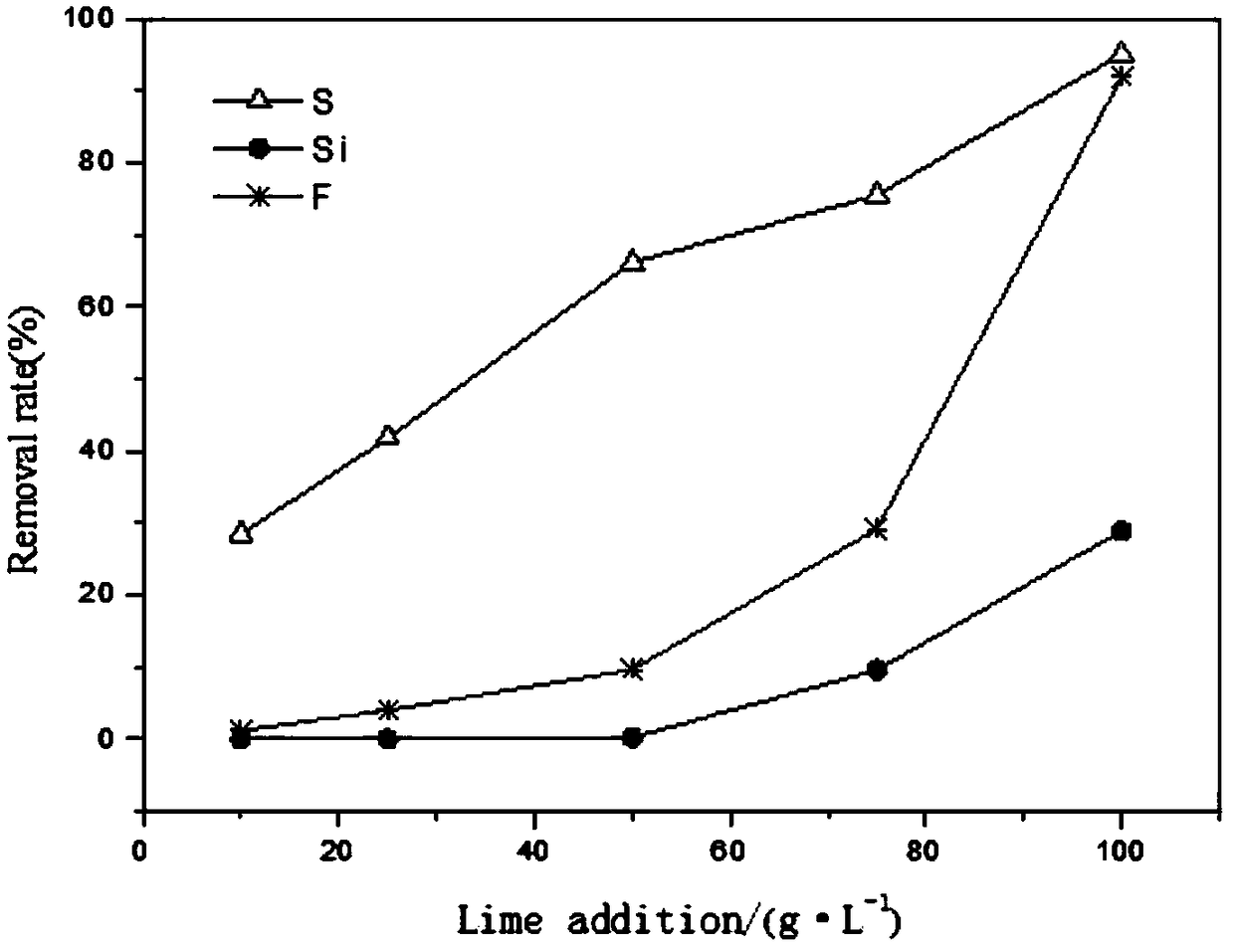

Method for synergistic recovery of molybdenum and rhenium from molybdenum concentrate roasting eluent

ActiveCN109179506AImprove adsorption speedImprove adsorption capacityRhenium compounds preparationMolybdeum compounds preparationLoss rateDesorption

The invention discloses a method for synergistic recovery of molybdenum and rhenium from a molybdenum concentrate roasting eluent, which belongs to the technical field of comprehensive recycling of metal rhenium and molybdenum. The method comprises the following steps: mixing the molybdenum smelting waste acid and a pretreatment agent, stirring a mixture, and then performing solid-liquid separation; introducing a filtrate to an exchange column containing weakly basic anion exchange resin A to adsorb rhenium, and introducing the adsorbed liquid in an exchange column filled with the weakly basicanion exchange resin B to adsorb molybdenum; performing desorption with the adsorbed saturated A column, collecting a desorption solution, and performing evaporation crystallization to obtain an ammonium perrhenate product; performing desorption with the adsorbed saturated B column, collecting the desorption solution, and performing evaporation crystallization to obtain an ammonium molybdate product. In a pretreatment step in the process, no rhenium loss is generated, the molybdenum loss rate is less than 8%, after treatment, the liquid is introduced into ion exchange, compared with the direct adsorption process, the method can increase the adsorption capacity of the resin A to the rhenium, and by changing the acidity of the solution and the impurity ion content, the high-efficiency adsorption of the resin B to the molybdenum is achieved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

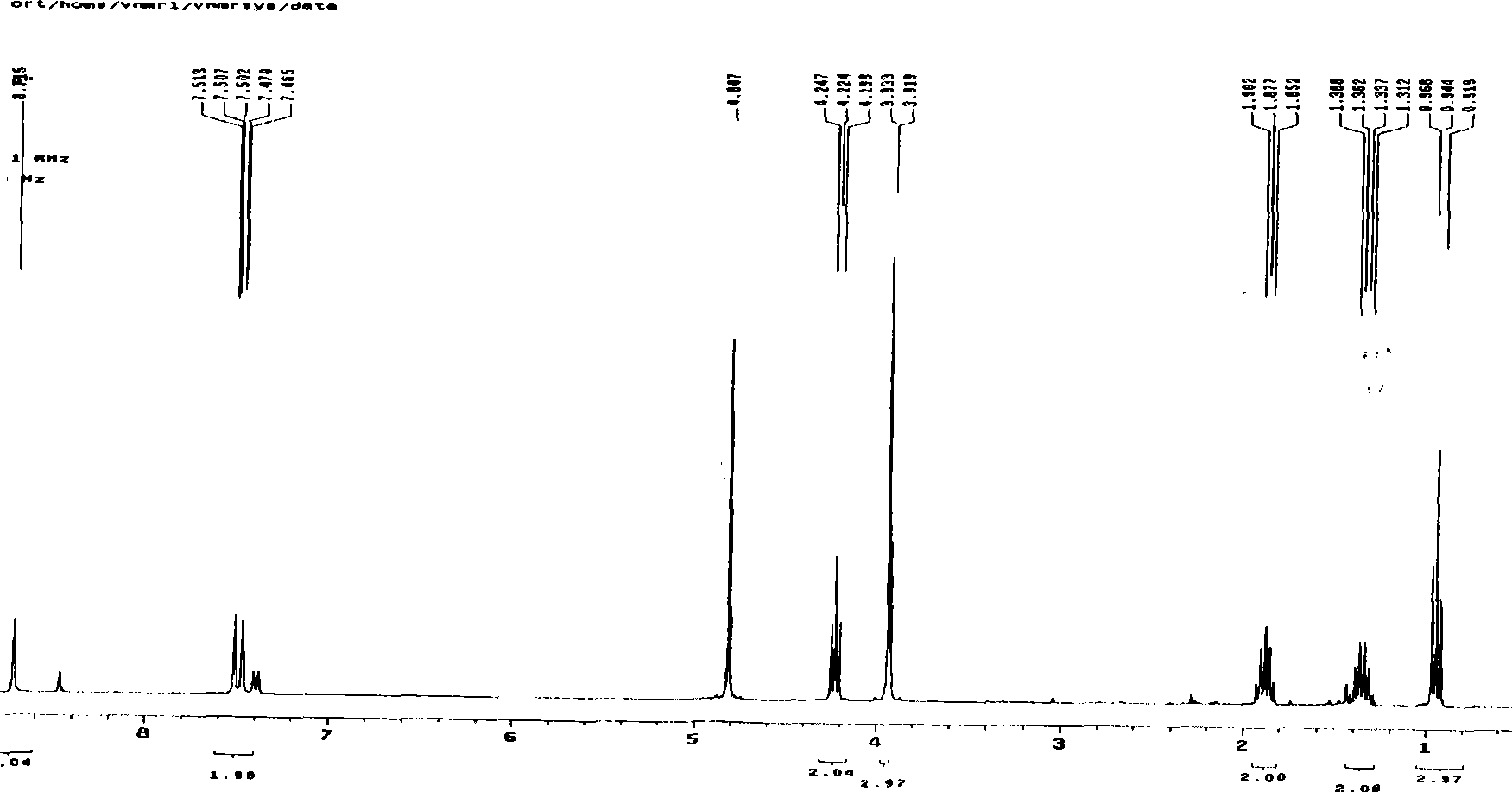

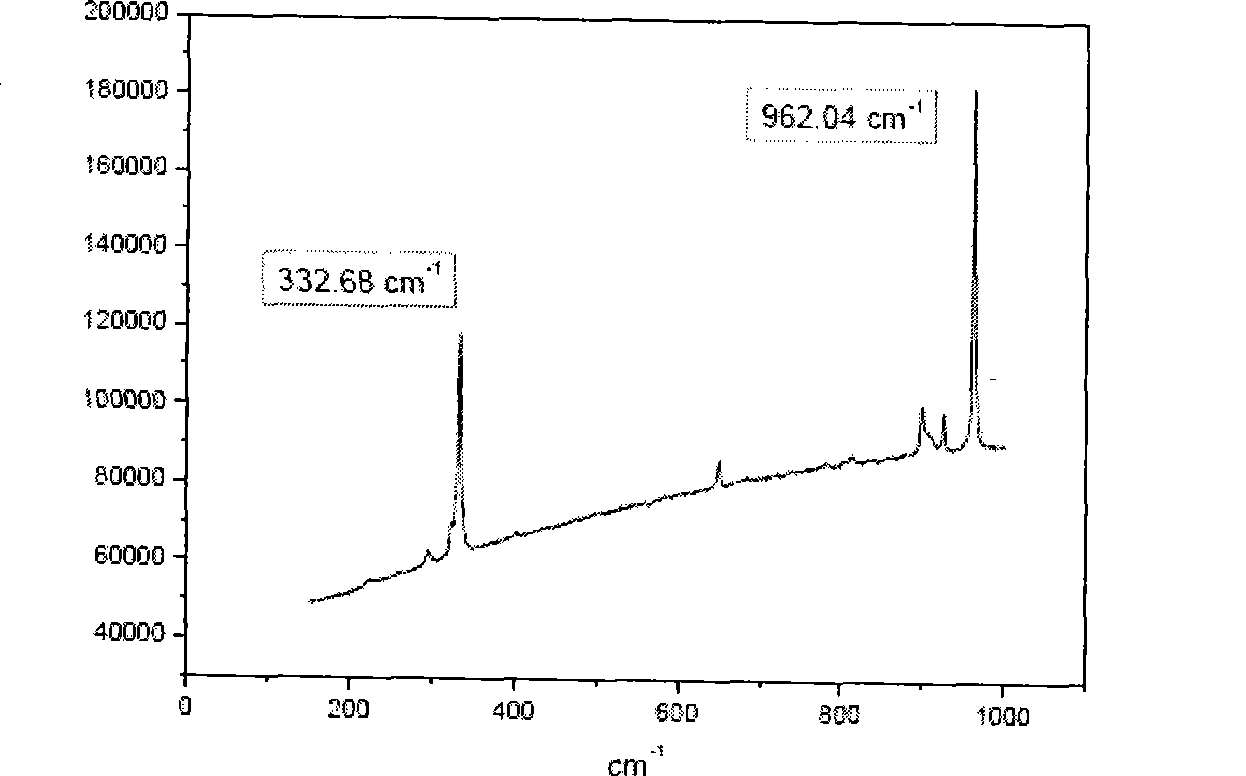

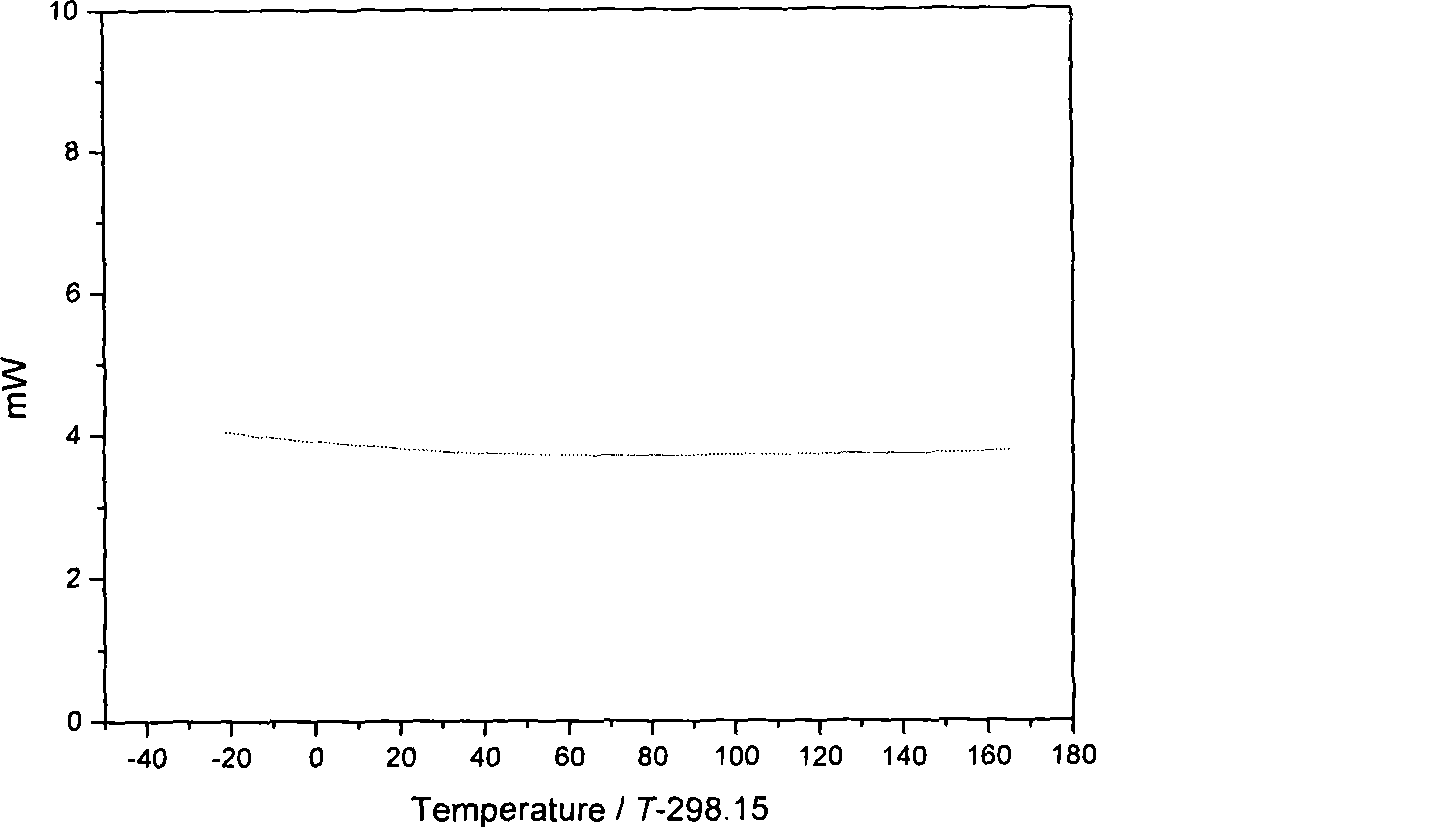

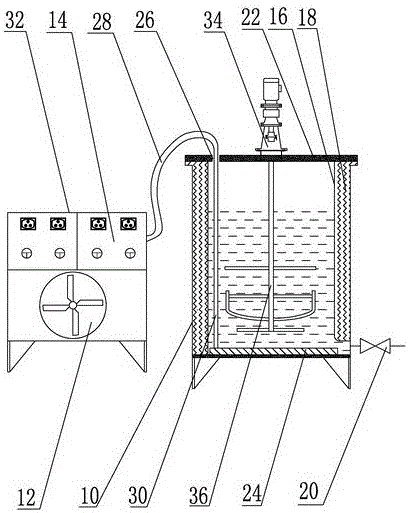

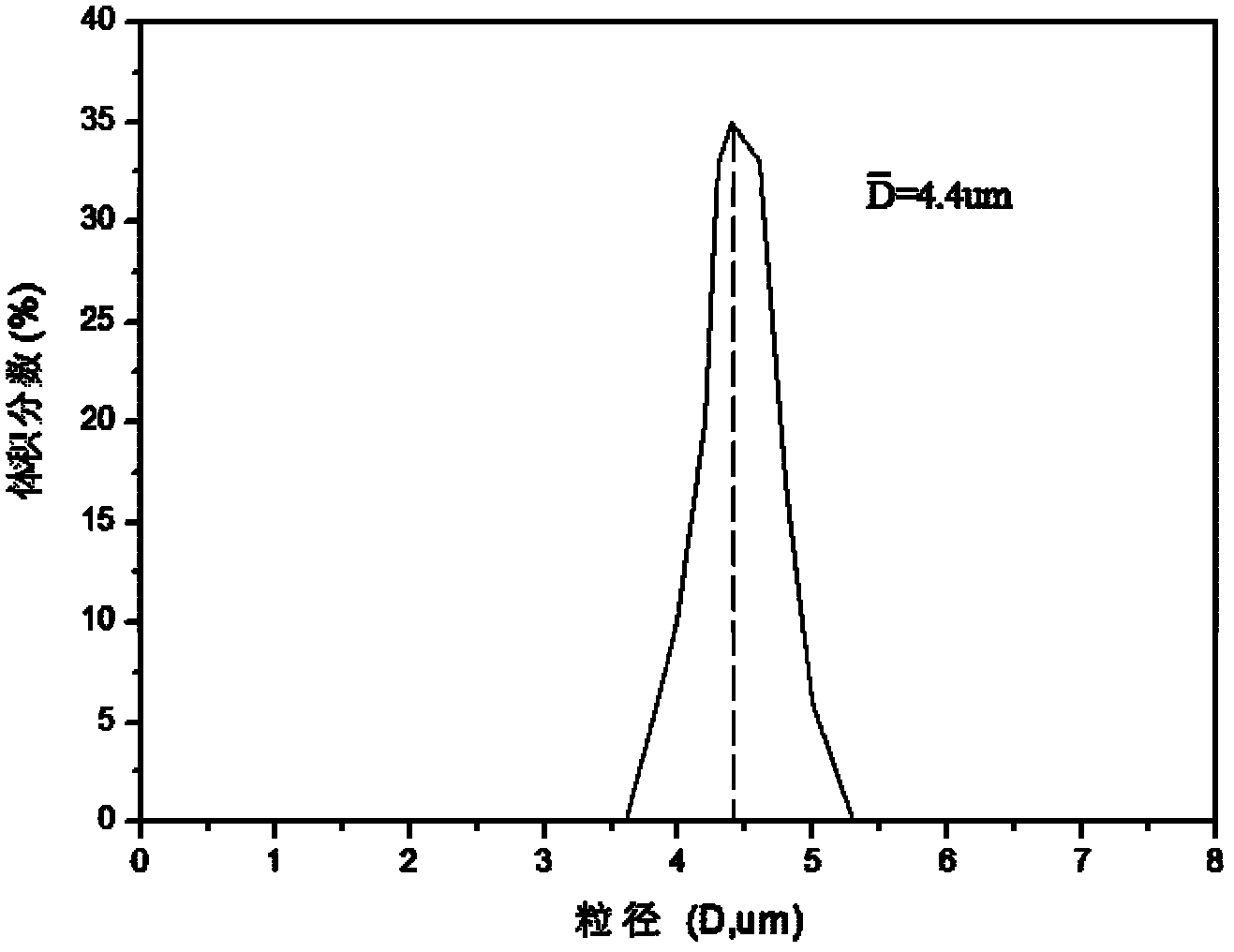

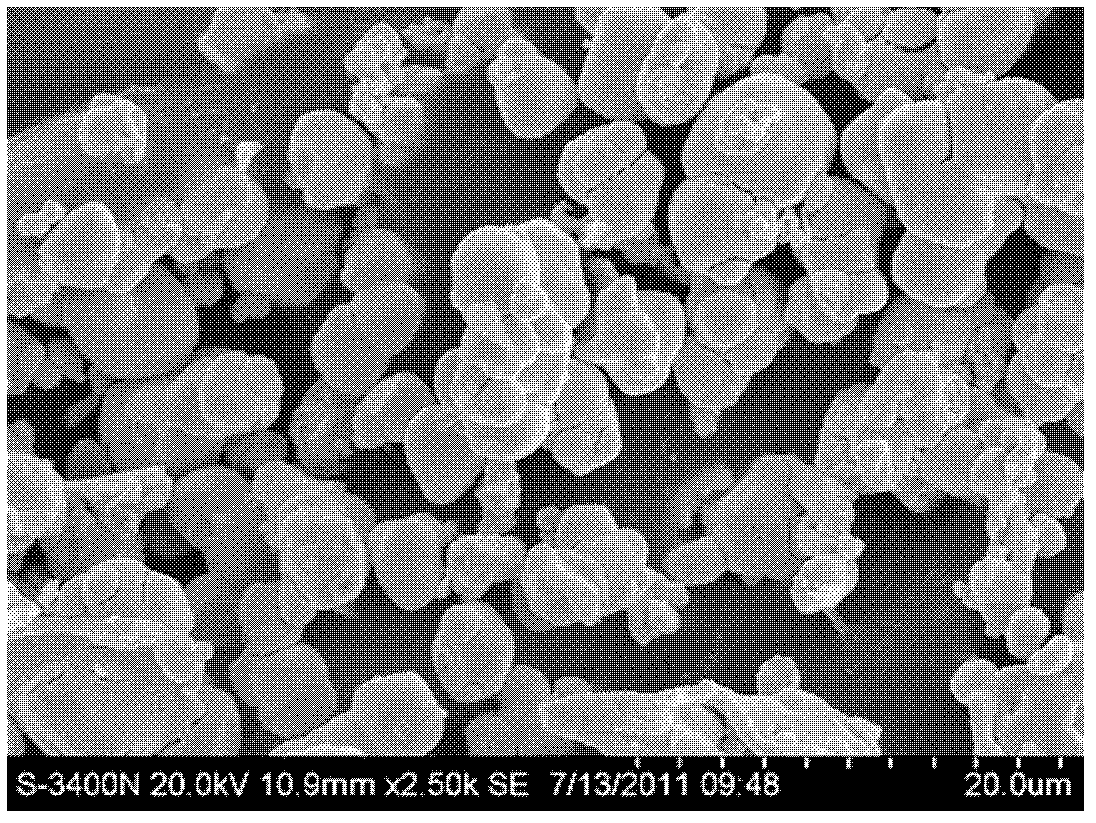

Ammonium rhenate with uniform granularity and preparation method thereof

InactiveCN110606511AUniform particle sizeNarrow particle size distributionRhenium compoundsRotary evaporatorFiltration

The invention discloses ammonium rhenate with uniform granularity and a preparation method thereof, and belongs to the technical field of ammonium rhenate purification. The method includes: with industrial crude ammonium rhenate crystals as raw materials, adding distilled water, and heating the solution until the distilled water is completely dissolved, evaporating the distilled water by using a rotary evaporator to form a supersaturated ammonium rhenate solution, adding the solution into a homogeneous crystallization reaction kettle to perform cooling and stirring crystallization, carrying out suction filtration on the recrystallized ammonium perrhenate, and naturally air-drying the product to obtain ammonium perrhenate crystal powder with uniform particle size distribution and high purity. The method has the advantages that compared with a traditional recrystallization method, the recrystallization process of ammonium rhenate can be effectively controlled, and the granularity and purity of ammonium rhenate particles are uniformly refined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Method for recovering rhenium, copper, selenium and sulfur in rhenium concentrates

ActiveCN107299222AAchieve recyclingHigh recovery rateCopper oxides/halidesProcess efficiency improvementAmmonium perrhenateSulfidation

The invention provides a method for recovering rhenium, copper, selenium and sulfur in rhenium concentrates. The method comprises the following steps: A) washing the rhenium concentrates, and filtering the rhenium concentrates to obtain a filtrate A and filter residues A; B) oxidatively leaching the filter residues A, and filtering the leached filter residues A to obtain a filtrate B and filter residues B; C) neutralizing the filtrate B for copper sedimentation to obtain copper hydroxide and a crude ammonium perrhenate solution, carrying out ion exchange on the crude ammonium perrhenate solution, carrying out thickening crystallization on the obtained solution to obtain ammonium perrhenate, carrying out sulfidation reaction on the filter residues B, and filtering the treated filter residues B to obtain a filtrate C and filter residues C. The method for recovering the rhenium, the copper, the selenium and the sulfur in the rhenium concentrates provided by the invention fully recovers and utilizes the copper, the selenium and the sulfur in the rhenium concentrates while treating the rhenium concentrates to recover the rhenium.

Owner:YANGGU XIANGGUANG COPPER

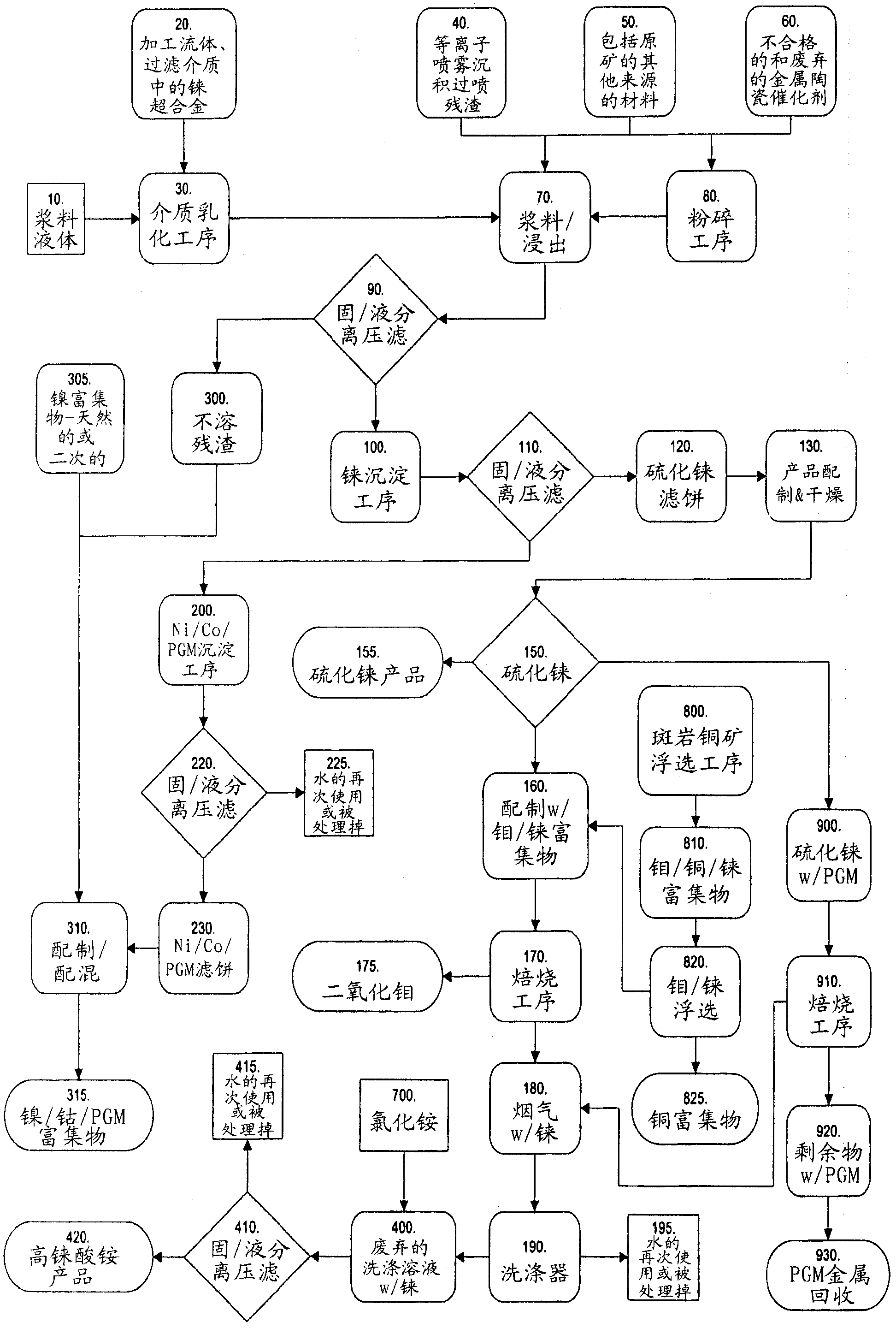

A method for recovering rhenium and other metals from rhenium-bearing materials

The present invention relates to a method of recovering rhenium (Re) and other metals from Re-bearing materials including, as an exemplary process, the steps: (i) adding Re-bearing materials into a leaching slurry; (ii) adjusting the pH of the slurry to obtain Re in soluble form in a metal salt solution and insoluble residues; (iii) filtering the metal salt solution to remove the insoluble residues; (iv) selectively precipitating Re from the metal salt solution; (v) filtering the Re precipitate from the metal salt solution to obtain a Re filtercake; (vi) formulating and drying the Re filtercake to obtain a Re sulfide product; (vii) combining the Re sulfide product with a Molybdenum (Mo) concentrate containing Re to obtain a Mo / Re concentrate; (viii) roasting the Mo / Re concentrate to obtain Mo oxide product and a flue gas containing Re; and (ix) treating the flue gas containing Re to obtain ammonium perrhennate.

Owner:WORLD RESOURCES CORP +1

A kind of preparation method of high-purity ammonium rhenate

The invention relates to a preparation method of high-purity ammonium rhenate. The preparation method comprises the steps of adding 5-20% of ammonia water into crude ammonium rhenate, and carrying out evaporation and concentration, wherein after the concentration is finished, the rhenium concentration is 15-25g / L; adding 0.5-5g of ammonium rhenate seed crystals into the concentrated solution, carrying out high-speed centrifugal treatment on the solution under the condition that the rotating speed is 500-2000rmp, putting the ammonium rhenate solution, subjected to the centrifugal treatment, into a crystallizer and adding 0.5-5m<2> of glass beads into the crystallizer at the same time, and standing for 20-30h at room temperature; carrying out solid-liquid separation on the solution to obtain an ammonium rhenate product; repeating the previous processes for 2-3 times to obtain the product. The preparation method of the high-purity ammonium rhenate can effectively control a crystallization process and reduce the entrainment of impurities, especially the entrainment of K ions, Na ions and the like, thus improving the purity of the ammonium rhenate; therefore, the high-purity ammonium rhenate with the purity of 99.99% can be prepared.

Owner:江苏杰之砂新材料有限公司

Method for producing temperature measuring tungsten-rhenium thermocouple wires in high-reliability manner through combined technology

Owner:无锡国涛钨铼合金科技有限公司

Method for detecting content of rhenium in rhenium containing test solution

InactiveCN105758853ASimple methodSimple and fast operationMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsWater bathsPotassium thiocyanate

The invention discloses a method for detecting the content of rhenium in a rhenium containing test solution.The to-be-tested test solution is transferred into a beaker, distilled water, EDTA and tartaric acid are added, the pH value is adjusted, a tetraphenylarsonium chloride hydrochloride solution is added, and the solution is transferred into a separating funnel; extraction is conducted with trichloromethane three times, organic phases on lower layers are combined, the organic phases are washed with a tetraphenylarsonium chloride hydrochloride washing solution two times, and the organic phases are completely transferred into the beaker; after a sodium chloride solution is added, water bath evaporation to dryness is conducted for about 20 min, hydrochloric acid is added after evaporation to dryness is conducted, and after water bath heating, the mixture is cooled to room temperature and transferred to a colorimetric tube; distilled water, potassium thiocyanate and stannous chloride are added, and the mixture is shaken up and developed; after ethyl acetate is transferred into the colorimetric tube for extraction, the organic phases are taken for ultraviolet measurement at the 426nm position.Compared with the prior art, the method is designed aiming at the rhenium containing test solution generated in the production process of ammonium perrhenate, the method is simple and easy and convenient to operate, mistakes are not easy to make, especially, the test result is accurate, and use and popularization value is achieved.

Owner:SHANGLUO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com