Rhenium tungsten based cathode material and preparation method thereof

A cathode material, tungsten-based technology, applied in the cathode material and preparation, rhenium-tungsten-based cathode and its preparation field, can solve the problems of complex preparation process, short cathode life, poor controllability and repeatability, etc., and achieve simple preparation process, distributed Uniform, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

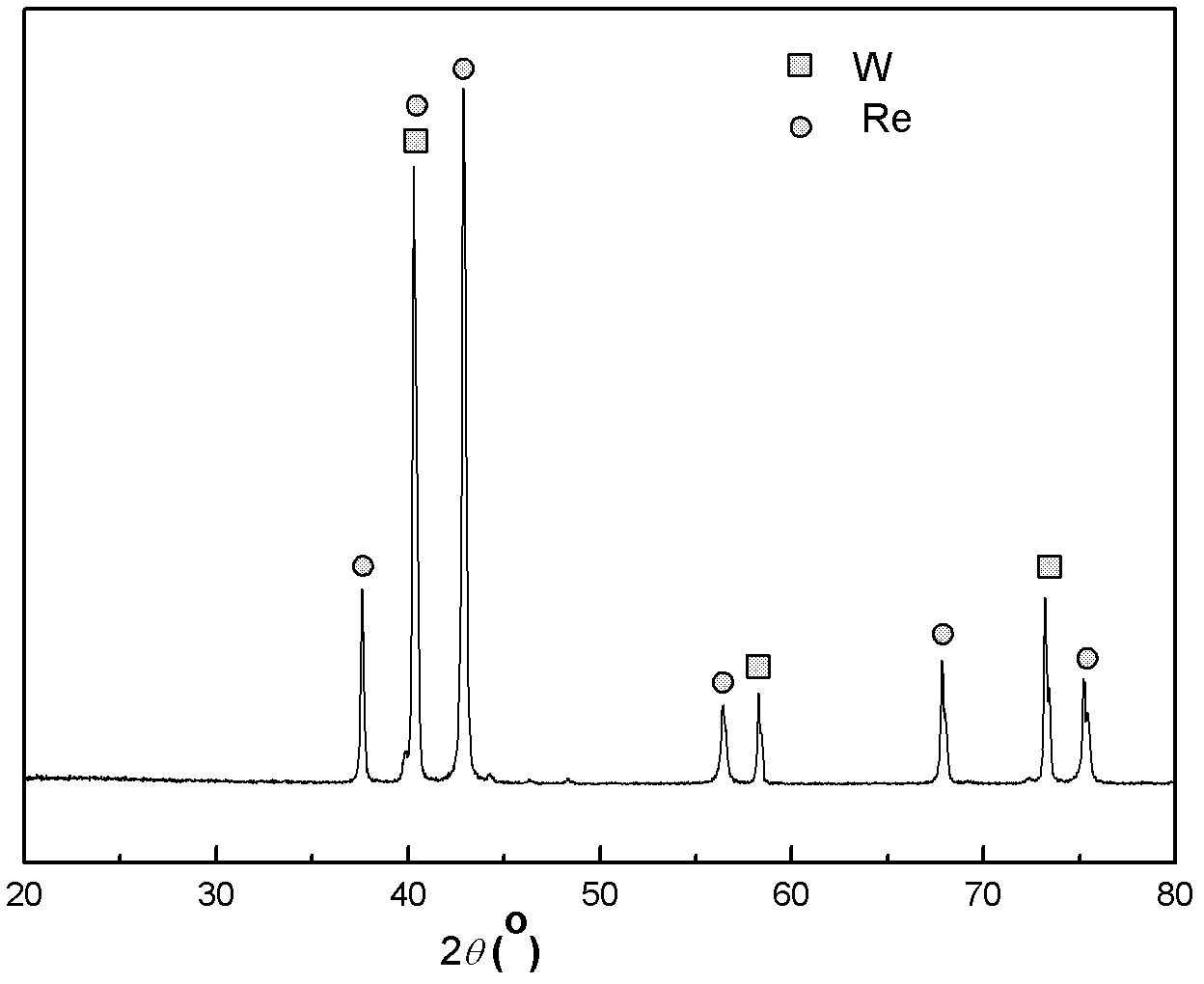

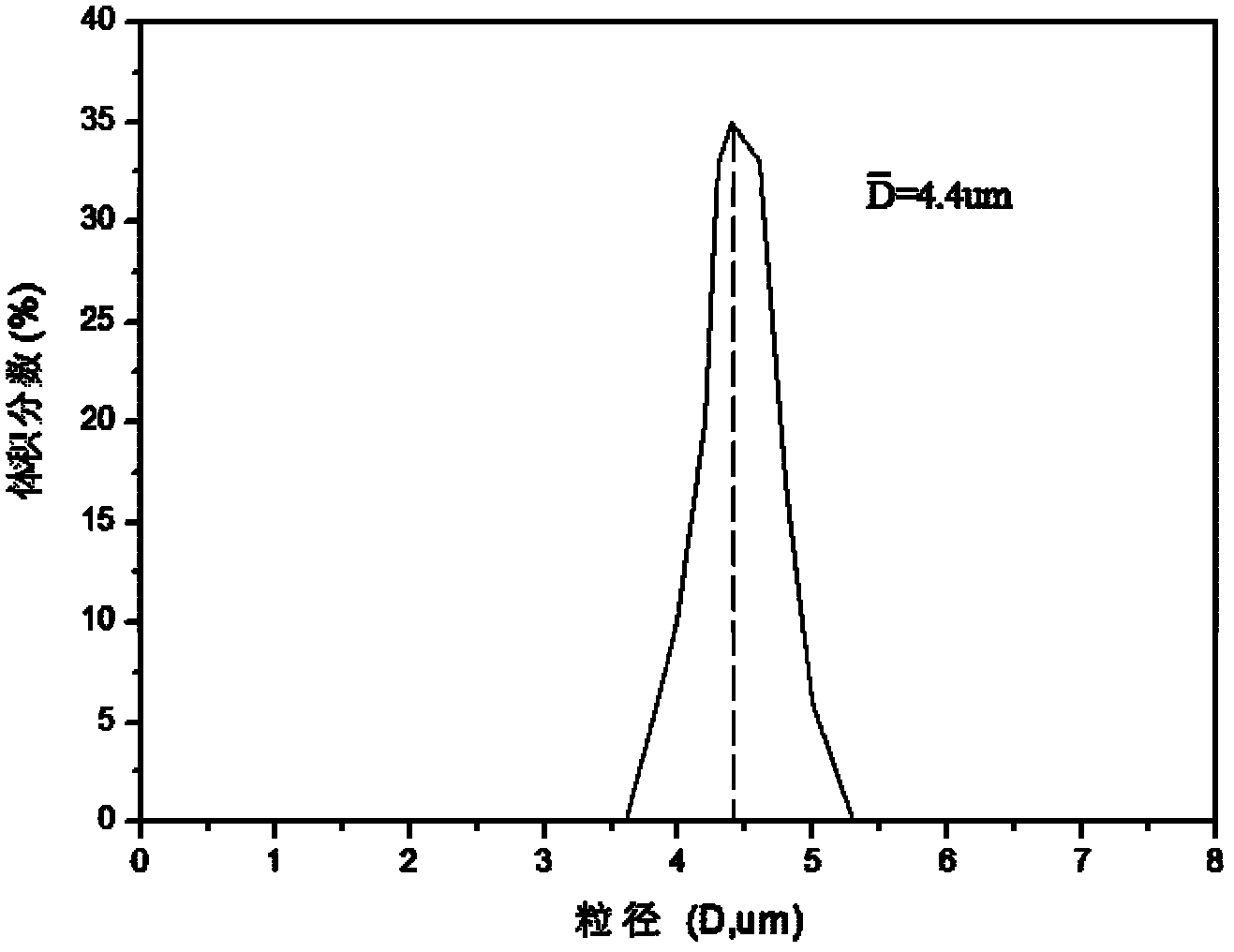

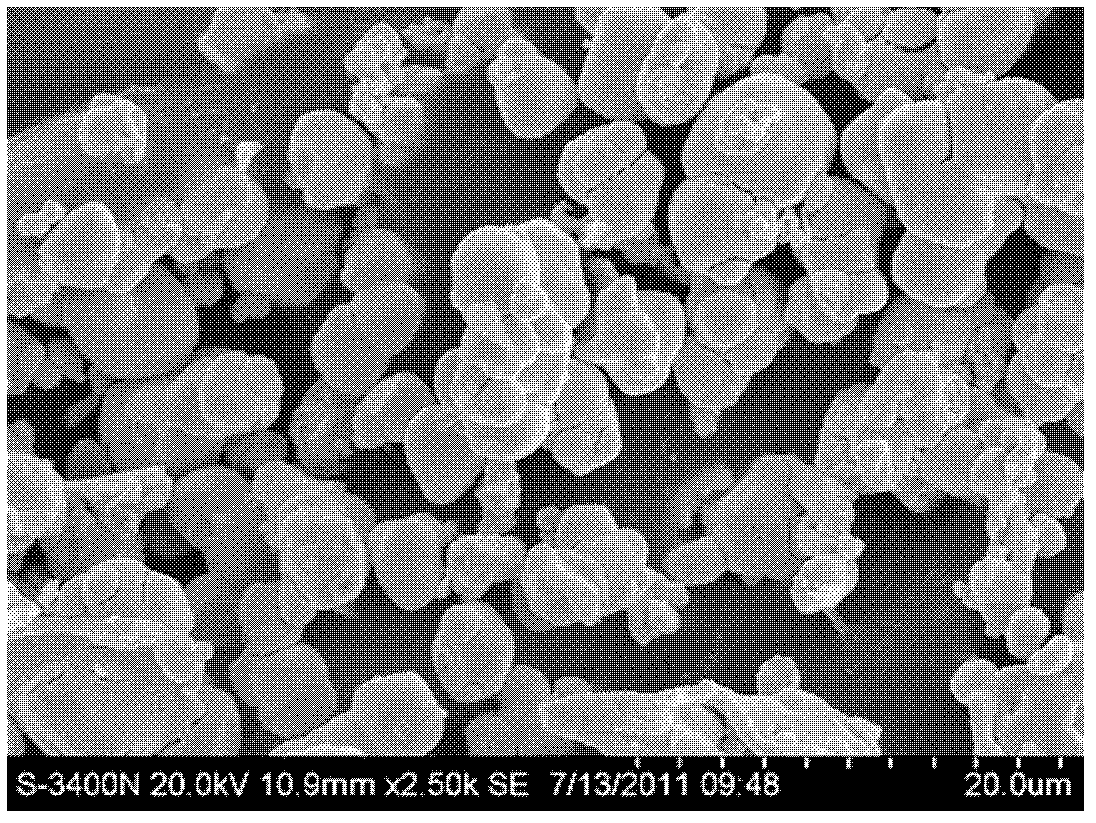

[0015] Example 1: Dissolve 10.824g of ammonium perrhenate in water to form a solution, add 2.5g of tungsten powder into the ammonium perrhenate solution and stir to form a solid-liquid mixture, then heat the solid-liquid mixture in a water bath at 90°C, and the water evaporates completely The mixed powder is then dried. Put the dried mixed powder in a hydrogen tube furnace for reduction. The first reduction temperature is 400°C, and the holding time is 1h; the second reduction temperature is 900°C, and the holding time is 2h, and then lowered to room temperature Obtain tungsten-rhenium powder containing 75% rhenium; put the cathode powder at 2t / cm 2 Under pressure, it is pressed into a cathode substrate with a diameter of 3 mm, and sintered at 1500 ° C by powder metallurgy; then impregnated with barium aluminate calcium salt (BaO, CaO and Al 2 o 3 The molar ratio is 6:1:2), the impregnation amount is 10%, and the emission of the cathode is tested at different temperatures, s...

Embodiment 2

[0016] Example 2: Dissolve 3.608g of ammonium perrhenate in water to make a solution, add 7.5g of tungsten powder into the ammonium perrhenate solution and stir to form a solid-liquid mixture, then stir and heat the solid-liquid mixture in a water bath at 70°C, and the water evaporates completely The mixed powder is then dried. Put the dried mixed powder in a hydrogen tube furnace for reduction. The first reduction temperature is 400°C, and the holding time is 1h; the second reduction temperature is 900°C, and the holding time is 2h, and then lowered to room temperature Obtain the tungsten-rhenium powder containing rhenium 25wt%; 2 A cathode substrate with a diameter of 3mm was pressed under pressure and sintered at 1700°C; then impregnated with barium aluminate calcium salts (BaO, CaO and Al 2 o 3 The molar ratio is 6:1:2), the impregnation amount is 10%, and the emission of the cathode is tested at different temperatures, see Table 1.

Embodiment 3

[0017] Example 3: Dissolve 7.216g of ammonium perrhenate in water to make a solution, add 5g of tungsten powder into the ammonium perrhenate solution and stir to form a solid-liquid mixture, then heat the solid-liquid mixture in a water bath at 80°C, and after the water is completely evaporated The mixed powder is dried. Put the dried mixed powder in a hydrogen tube furnace for reduction. The first reduction temperature is 400°C, and the holding time is 1h; the second reduction temperature is 900°C, and the holding time is 2h, and then lowered to room temperature Obtain the tungsten-rhenium powder containing rhenium 50wt%; 2 Under pressure, it is pressed into a cathode substrate with a diameter of 3 mm, and is sintered at 1900 ° C by powder metallurgy; then impregnated with barium aluminate calcium salt (BaO, CaO and Al 2 o 3 The molar ratio is 6:1:2), the impregnation amount is 10%, and the emission of the cathode is tested at different temperatures, see Table 1.

[0018] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com