Patents

Literature

36 results about "Perrhenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The perrhenate ion is the anion with the formula ReO⁻₄, or a compound containing this ion. The perrhenate anion is tetrahedral, being similar in size and shape to perchlorate and the valence isoelectronic permanganate. The perrhenate anion is stable over a broad pH range and can be precipitated from solutions with the use of organic cations. At normal pH, perrhenate exists as metaperrhenate (ReO⁻₄), but at high pH mesoperrhenate (ReO³⁻₅) forms. Perrhenate, like its conjugate acid perrhenic acid, features rhenium in the oxidation state of +7 with a d⁰ configuration. Solid perrhenate salts takes on the color of the cation.

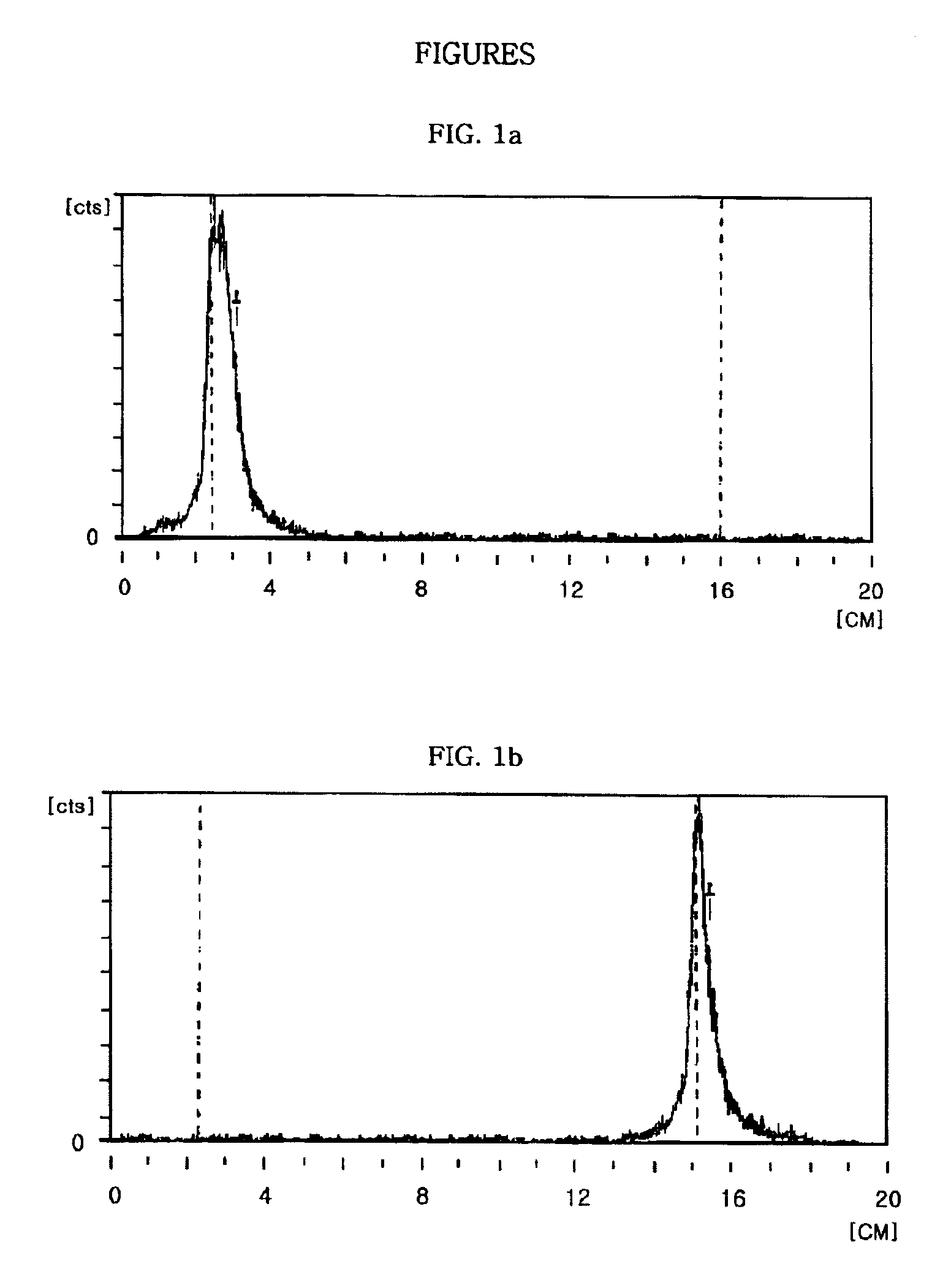

Method of preparing rhenium-tricarbonyl complex and its precursor

InactiveUS20070140959A1High yieldInhibit productionIn-vivo radioactive preparationsRhenium compounds preparationScavengerPhosphate

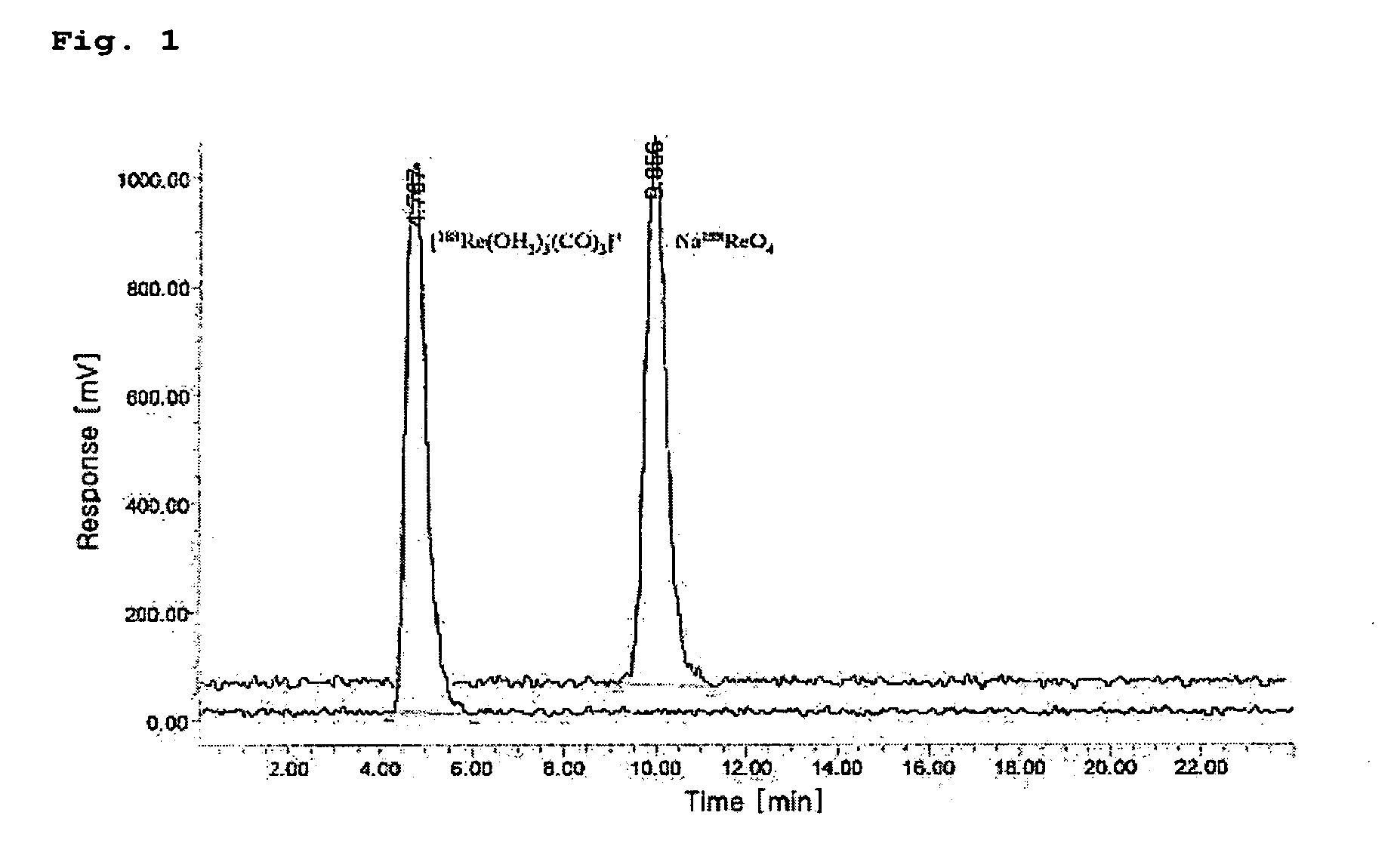

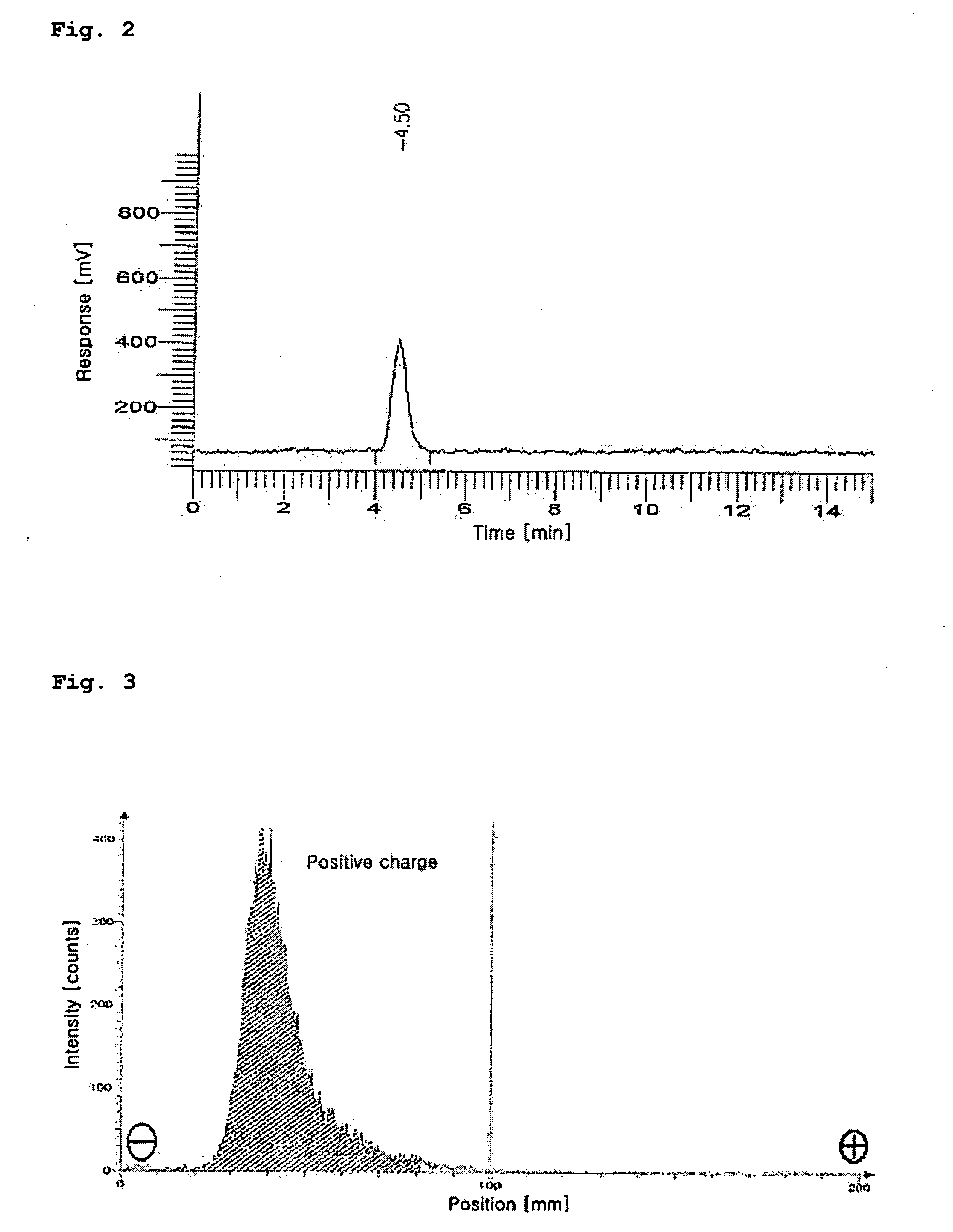

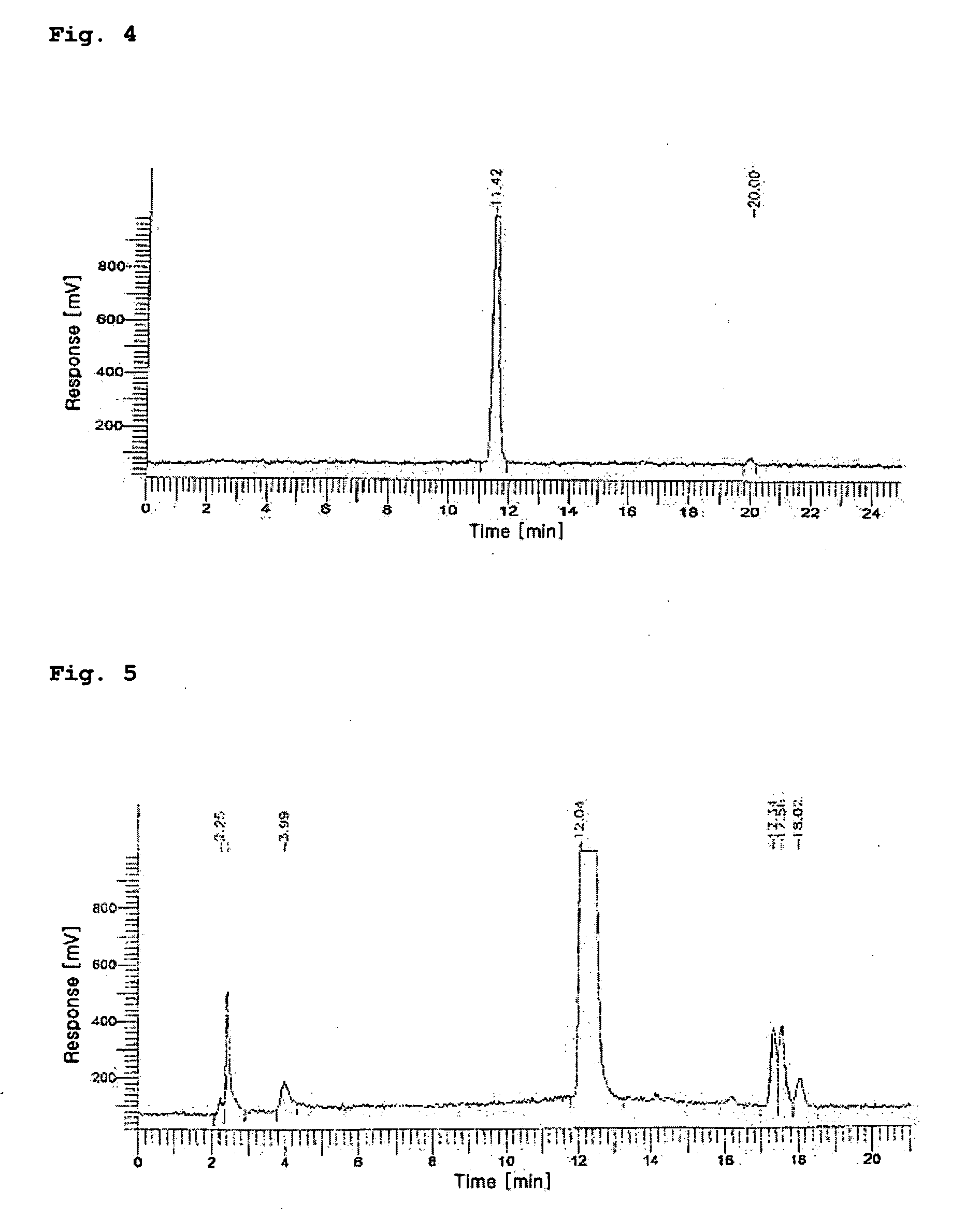

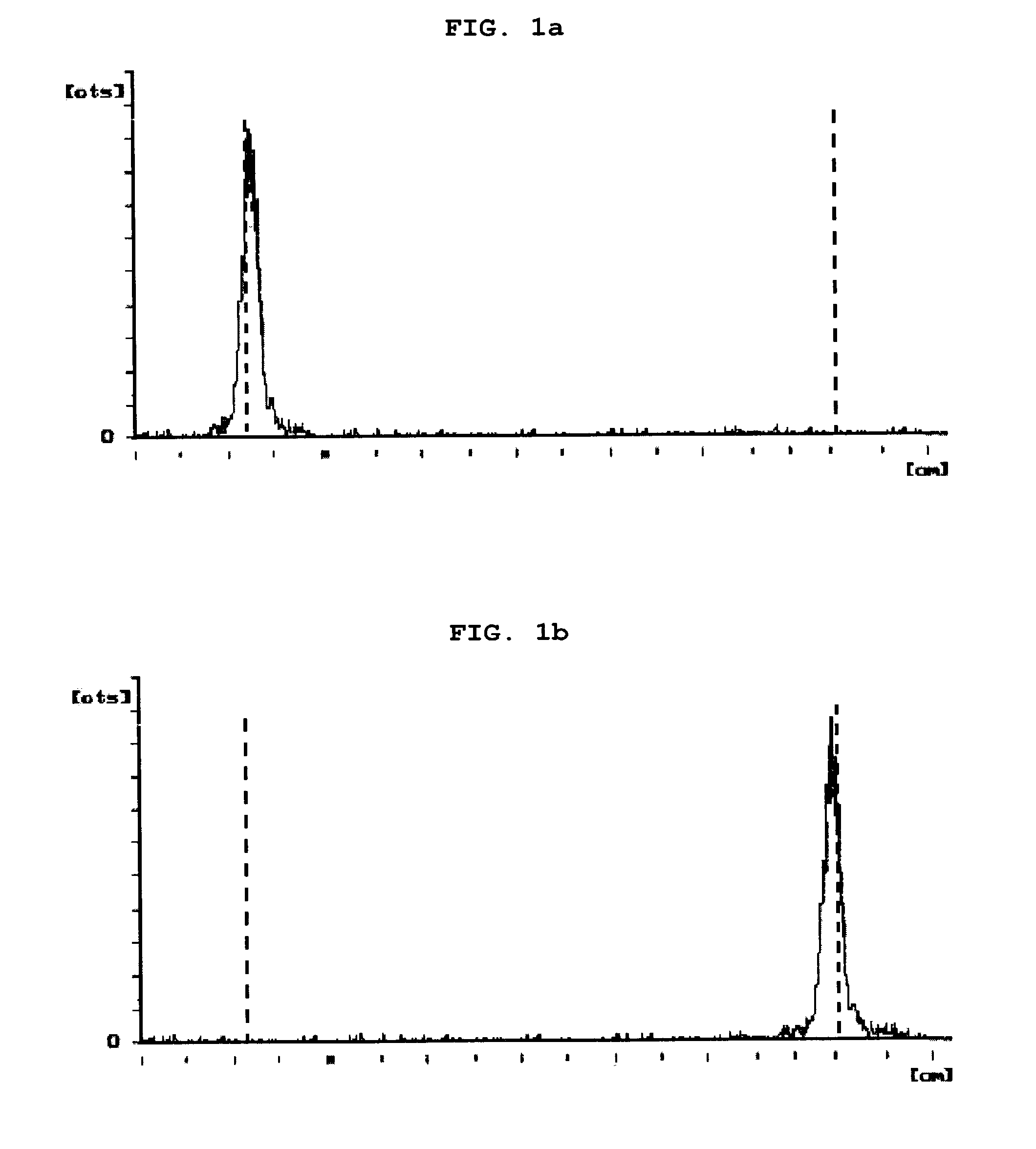

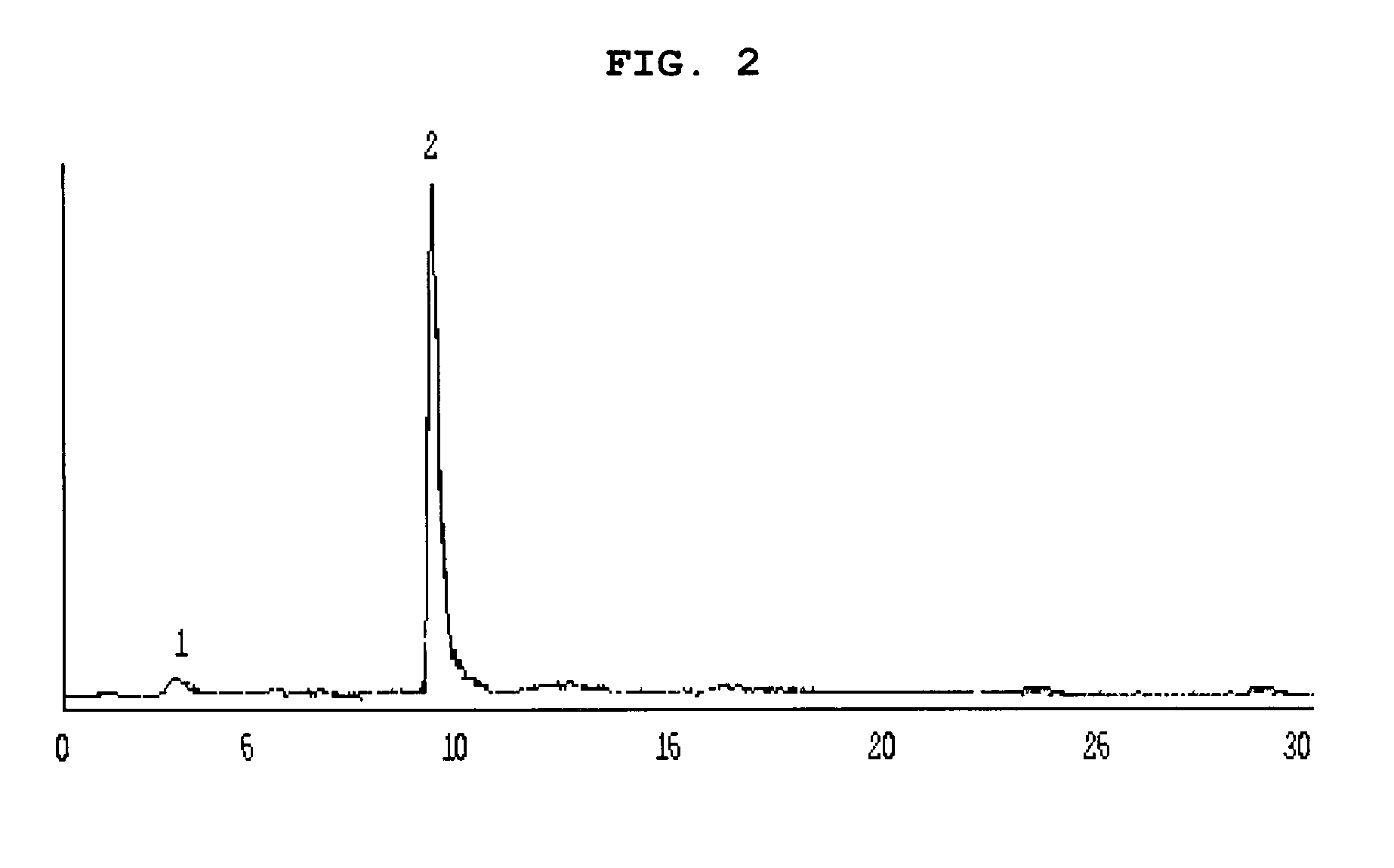

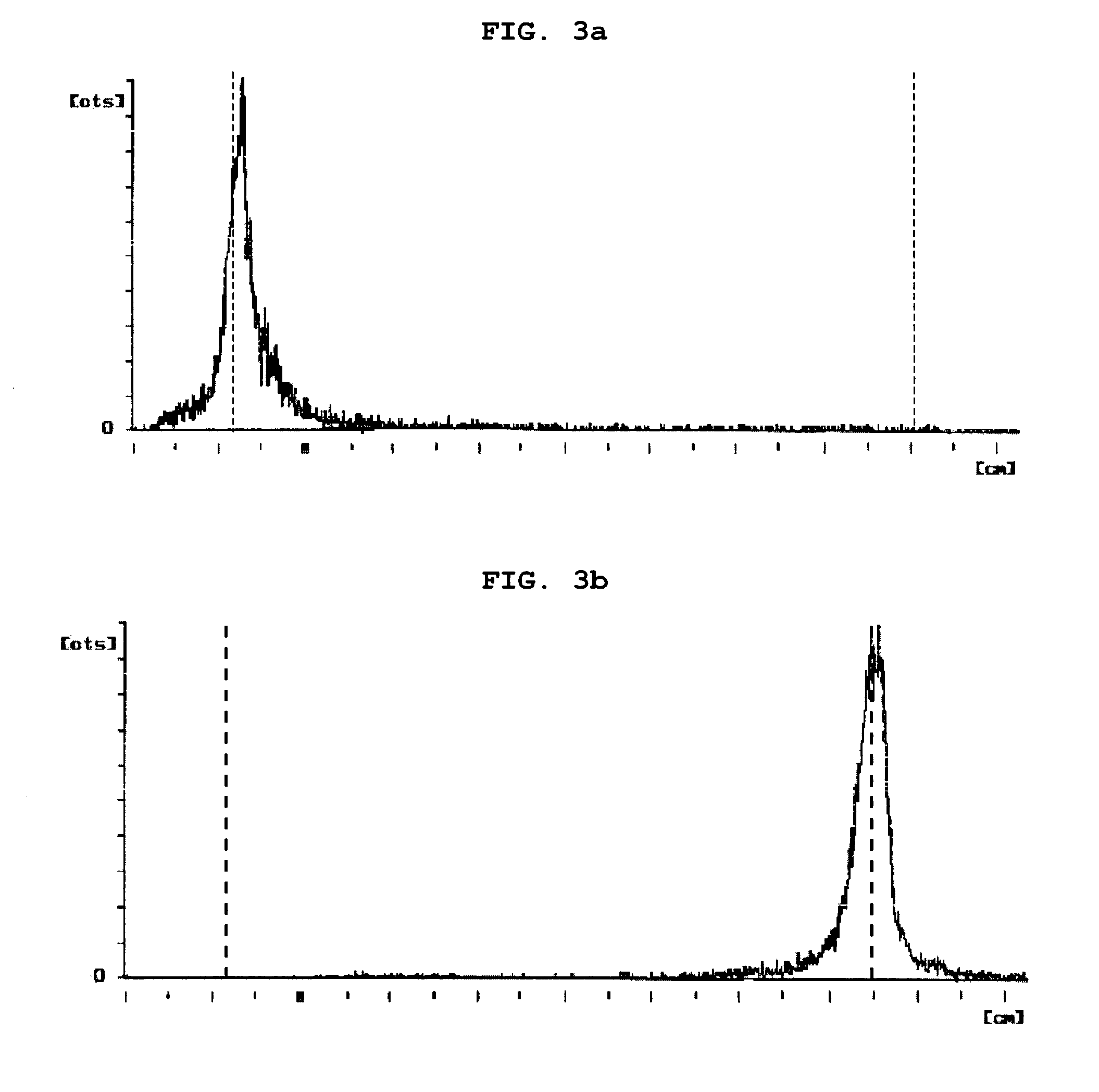

Disclosed herein is a method of preparing a 188Re-tricarbonyl complex for radiopharmaceutical use and of preparing a precursor thereof, and a contrast agent using the same. Particularly, this invention provides a method of preparing a 188Re-tricarbonyl precursor by reacting perrhenate with borane-ammonia (BH3.NH3), potassium boranocarbonate (K2[H3BCO2]) and phosphate in the presence of borohydride exchange resin as a reducing agent, and a method of preparing a 188Re-tricarbonyl complex by reacting the 188Re-tricarbonyl precursor with a ligand. According to the method of this invention, the borohydride exchange resin is used as a reducing agent and as an anion scavenger, thereby obtaining the 188Re-tricarbonyl precursor and complex having high radiolabeling yield and high purity. In addition, the 188Re-tricarbonyl complex can be used as a contrast agent having excellent plasma stability.

Owner:KOREA ATOMIC ENERGY RES INST

Alkyl imidazoles perrhenate ion liquid and preparation method thereof

ActiveCN101386597ASimple processShort reaction timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeIon-exchange resin

The invention relates to alkyl imidazole perrhenate ionic liquid and a method for preparing the same. The adopted technical proposal is follows: the preparation method comprises the following steps: taking certain volume of alkyl imidazole chloride compounds or alky imidazole bromide compounds, adding deionized water the volume of which is 2 to 4 times of that of the alkyl imidazole chloride compounds or the alky imidazole bromide compounds to dissolve the alkyl imidazole chloride compounds or the alky imidazole bromide compounds, adding the mixture to OH-type anion exchange resin to perform ion exchange, and collecting outflow solution which is alkyl imidazole hydroxide; then adding the alkyl imidazole hydroxide to ammonium perrhenate aqueous solution, wherein the molar ratio of the alkyl imidazole hydroxide to the high ammonium perrhenate is between 1 to 1 and 1 to 2, then stirring the mixture for 3 to 5 hours at a temperature of between 70 and 90 DEG C, reducing the pressure and distilling the mixture to remove water, adding the mixed solution of anhydrous methanol and acetonitrile to the mixture after cooling the mixture, sealing and stirring the mixture intensely, keeping stand the mixture for 10 to 15 hours at a temperature of between 30 DEG C below zero and 40 DEG C below zero, reducing the pressure and distilling the mixture to remove the methanol and the acetonitrile, and performing vacuum drying on the treated mixture. The ionic liquid prepared by the method has the advantages of high yield and high stabilities of air and water.

Owner:辽宁中科航远科技有限公司

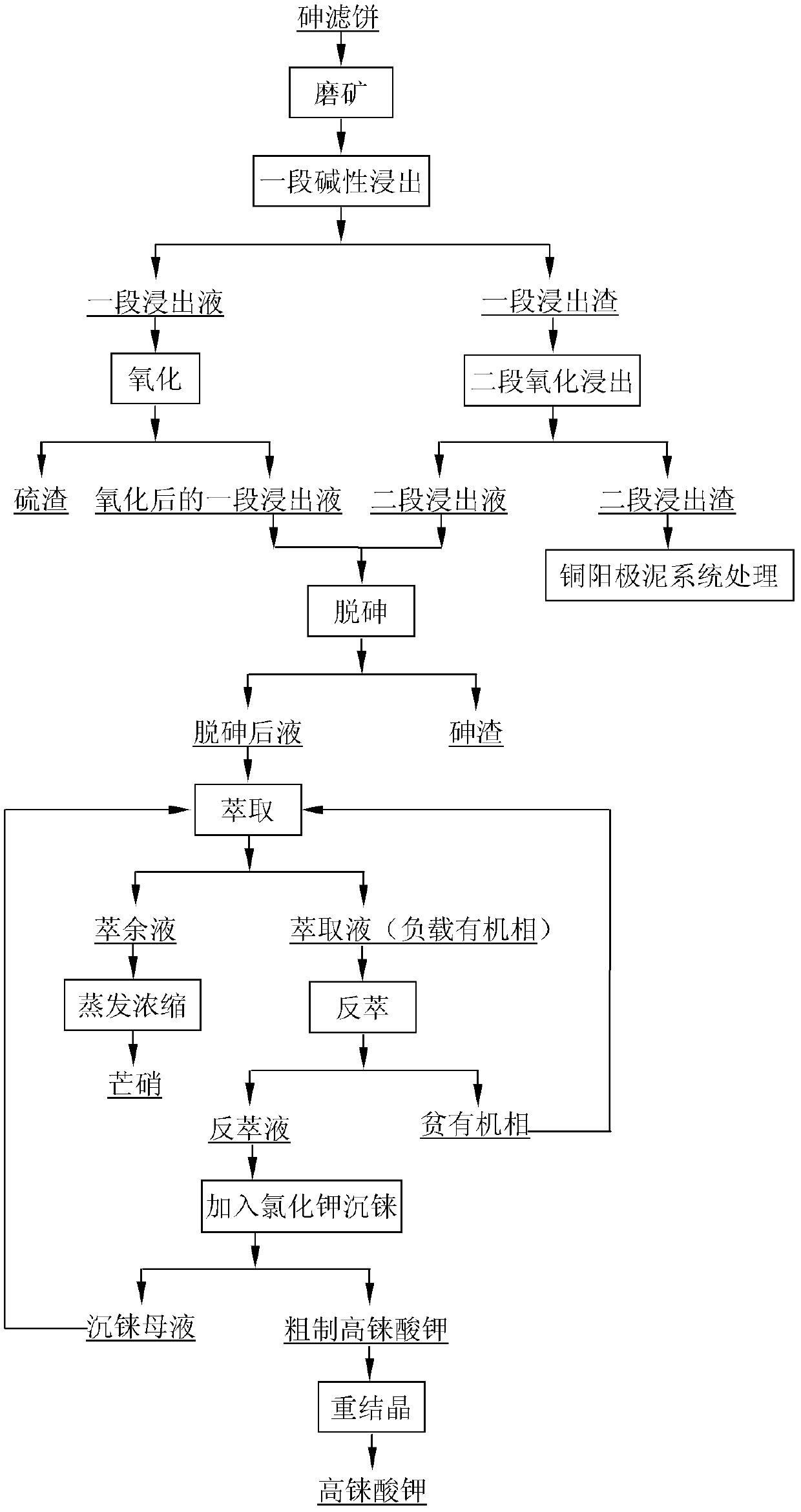

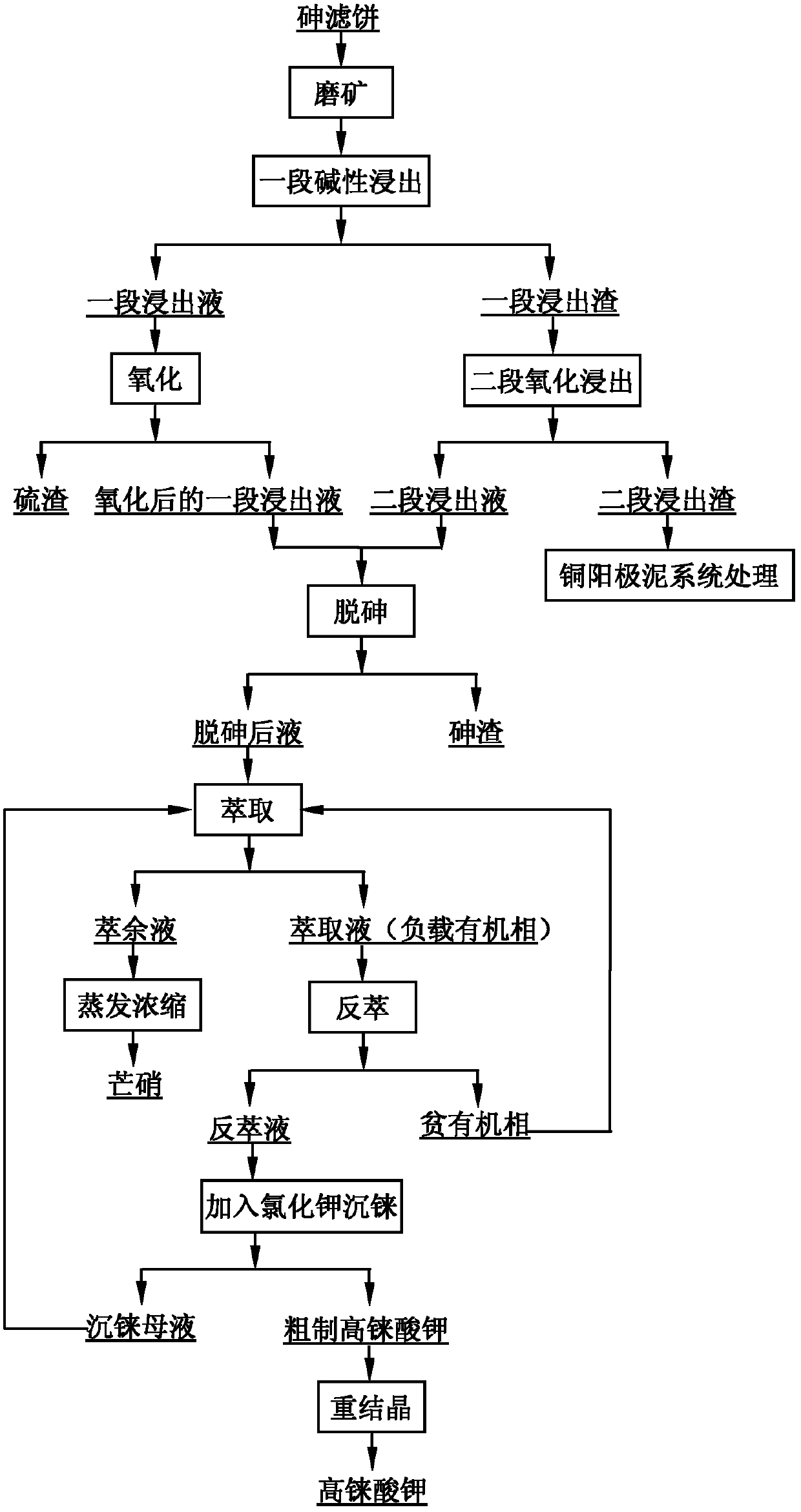

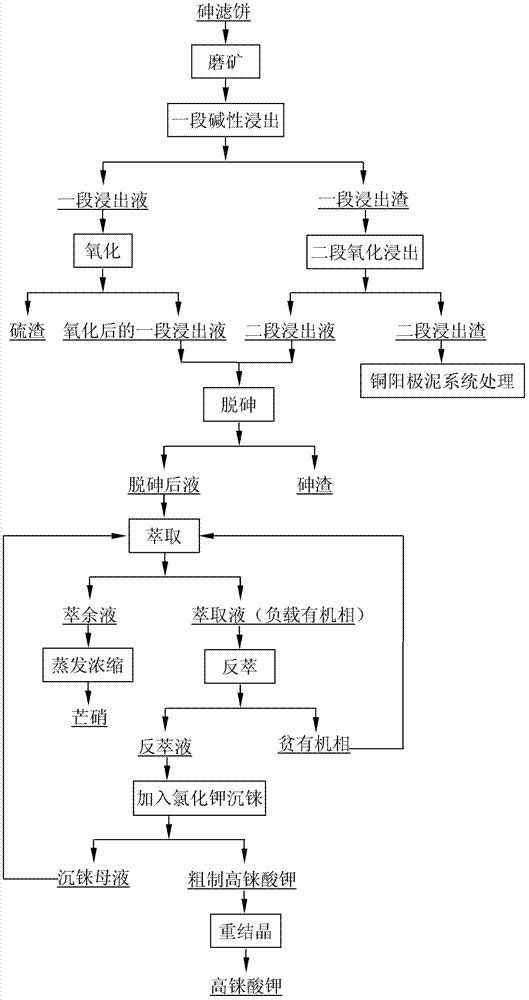

Method for recovering rhenium from arsenic filter cake

The invention provides a method for recovering rhenium from an arsenic filter cake. The method comprises the following steps: entering rhenium, arsenic and sulfur into a solution by adopting one-section alkali leaching and second-section oxidization and leaching, and simultaneously enriching lead, bismuth, copper and selenium in leaching slag; in the one-section leachate, converting rhenium into perrhenate in a form of sodium thioperrhenate by adopting an oxidization method, converting sodium thioarsenate into sodium arsenate, and separating out sulfur in a form of simple substance sulfur; removing arsenic from the solution obtained by oxidization conversion by using a sulfur dioxide reduction method or lime method; carrying out rhenium enrichment on the solution obtained after arsenic isremoved; treating a rhenium reextraction liquid by using a potassium chloride precipitation method to obtain crude potassium perrhenate; and refining crude potassium perrhenate to obtain potassium perrhenate. The method has short process flow, high rhenium recovery rate and low treatment cost; and by using the method, the comprehensive utilization of valuable metals in the arsenic filter cake canbe realized.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

Method for recovering rhenium from high-temperature alloy pickle liquor

InactiveCN103789552AOmit hydrolysisSave the processProcess efficiency improvementSal ammoniacDesorption

The invention provides a method for recovering rhenium from a high-temperature alloy pickle liquor. The method comprises the following steps: 1, adjusting the pH value of the high-temperature alloy pickle liquor to 1-2, and then adsorbing rhenium and molybdenum in the high-temperature alloy pickle liquor by adopting ion exchange resin; 2, desorbing molybdenum by adopting a mixed solution of ammonia water and ammonium chloride, and then desorbing the rhenium by using an ammonium thiocyanate solution, so as to obtain stripping liquid containing rhenium; 3, adding water soluble potassium to the stripping liquid containing rhenium according to the ratio, and then orderly heating, concentrating, crystallizing, washing and recrystallizing, so as to obtain potassium perrhenate. The ion exchange resin adsorption and step-by-step desorption are organically combined, the rhenium loss can be effectively avoided, the technological process is shortened, the process is simple and feasible, and the production cost is greatly reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Rhenium recovery

ActiveUS20120058029A1Avoid disadvantagesProcess efficiency improvementRhenium compoundsAlloyHydrometallurgy

There is provided a hydrometallurgical process of recovering rhenium values from mixtures thereof with other metal values in which the rhenium values constitute a minority amount, for example super-alloys, which comprises subjecting the mixture to strongly oxidizing acid conditions, preferably an aqueous mixture of hydrochloric acid and nitric acid, so as to form perrhenate species of at least the major proportion of the rhenium values in the mixture, dissolving the perrhenate species and other soluble metal species in aqueous solution, removing insoluble metal species from the aqueous solution, and isolating the rhenium species from the solution.

Owner:MARITIME HOUSE METALS

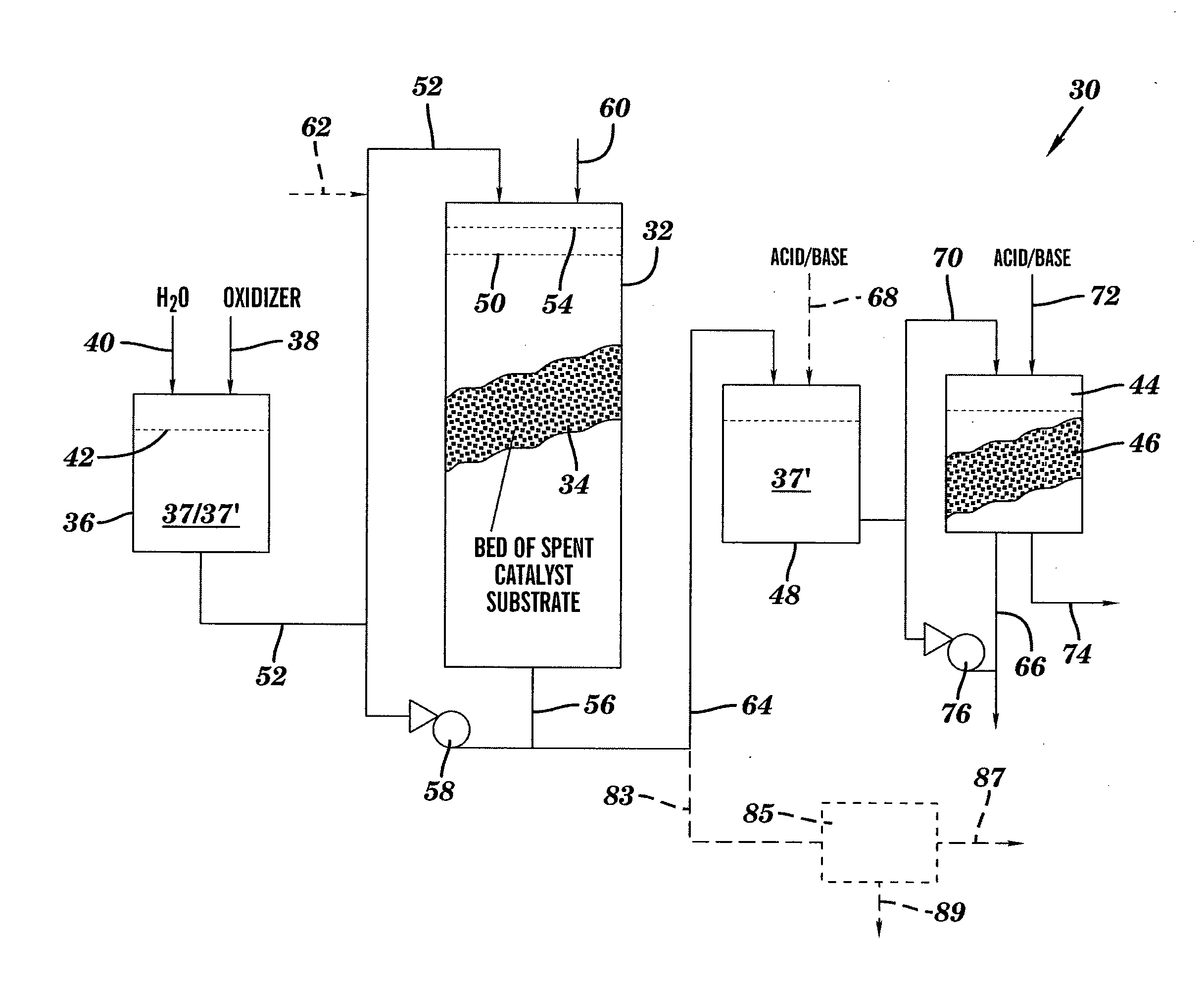

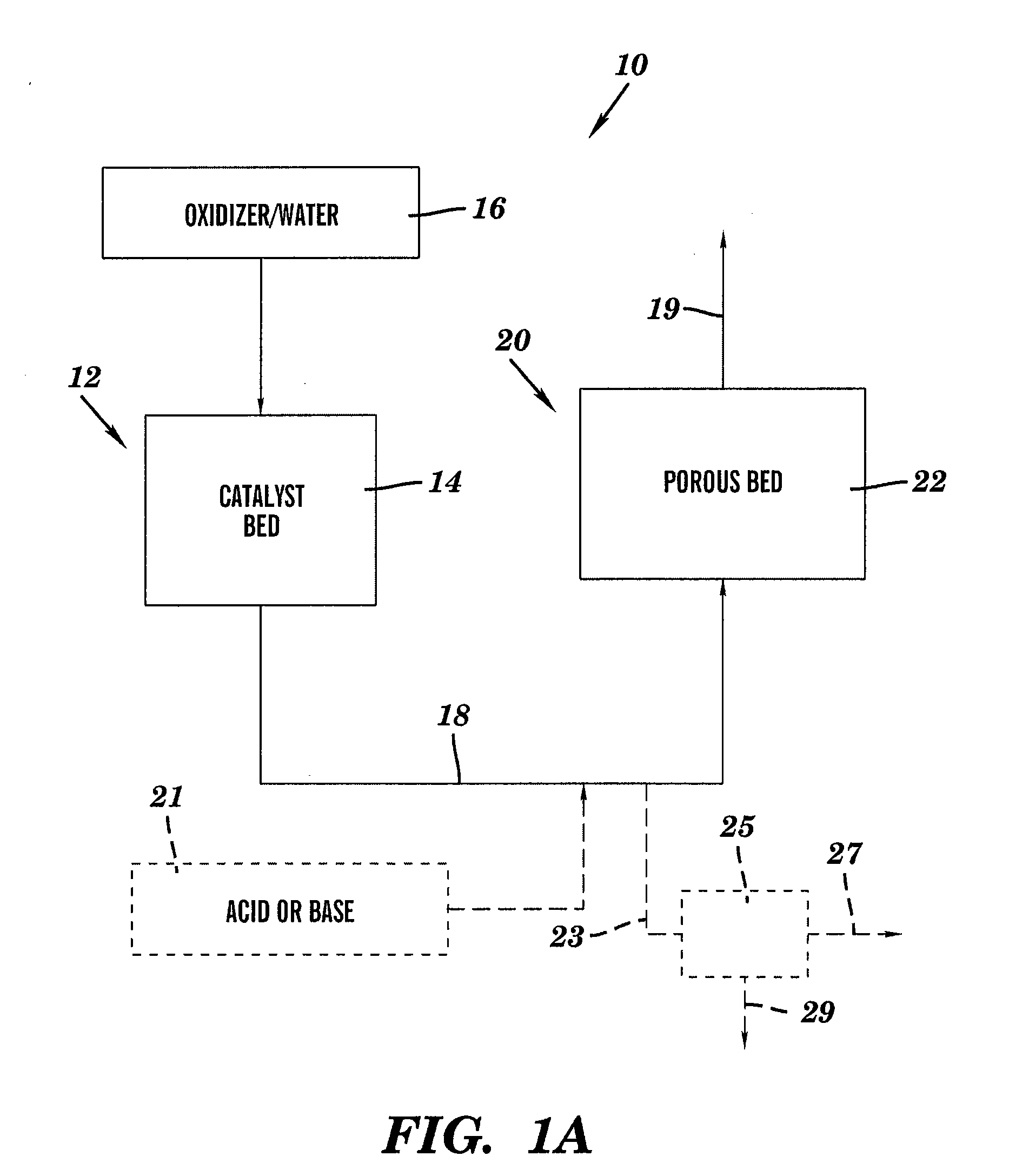

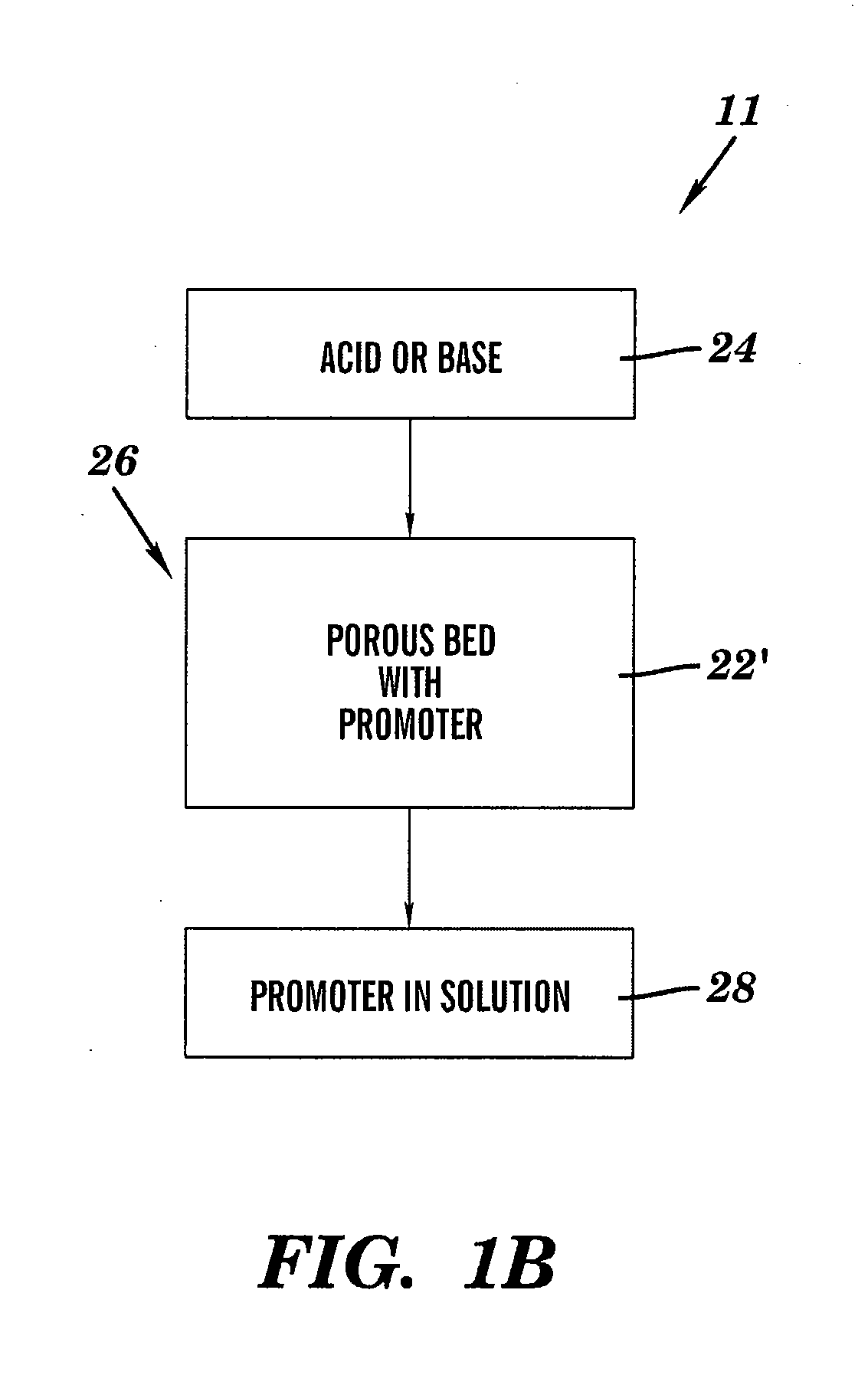

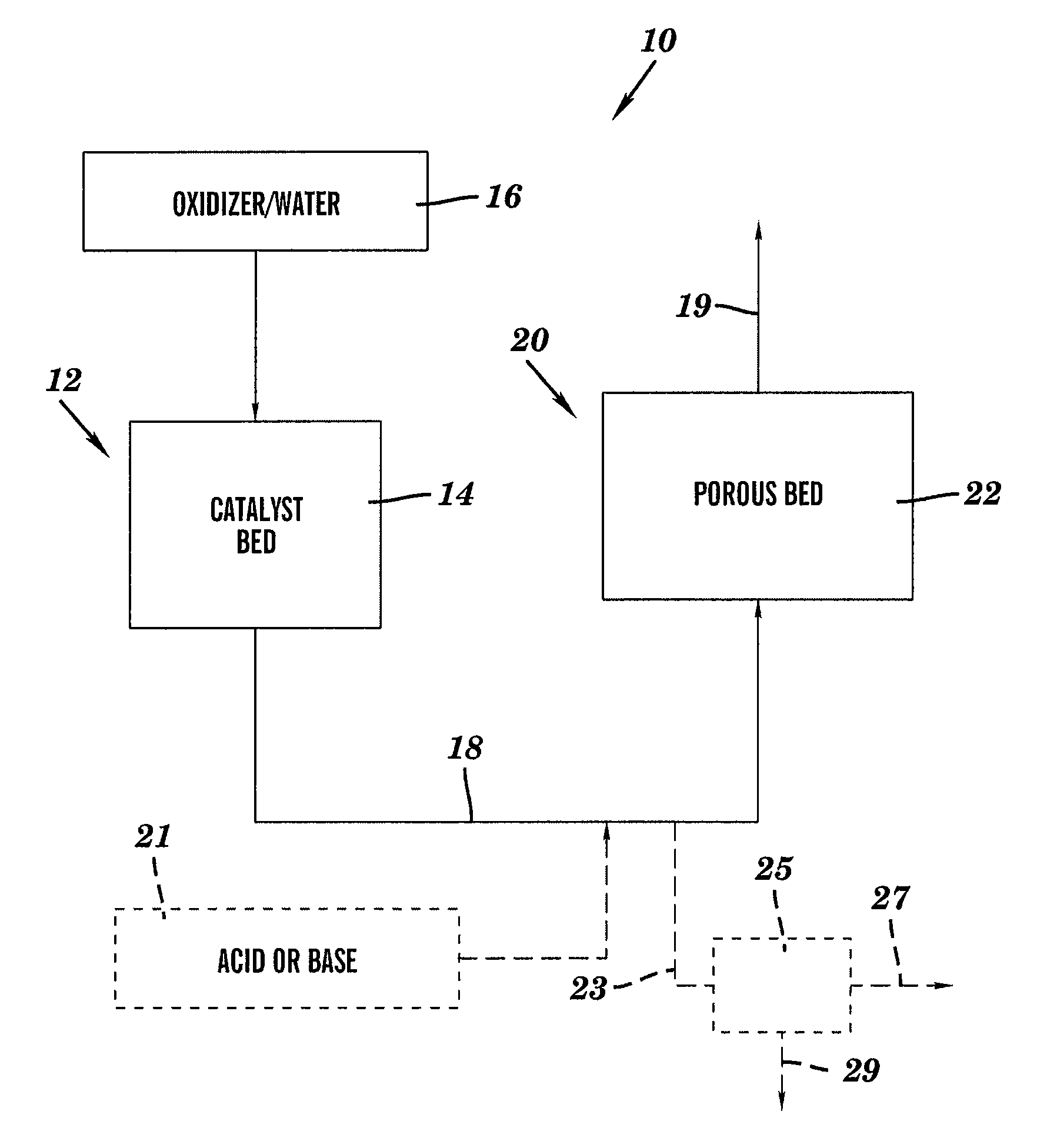

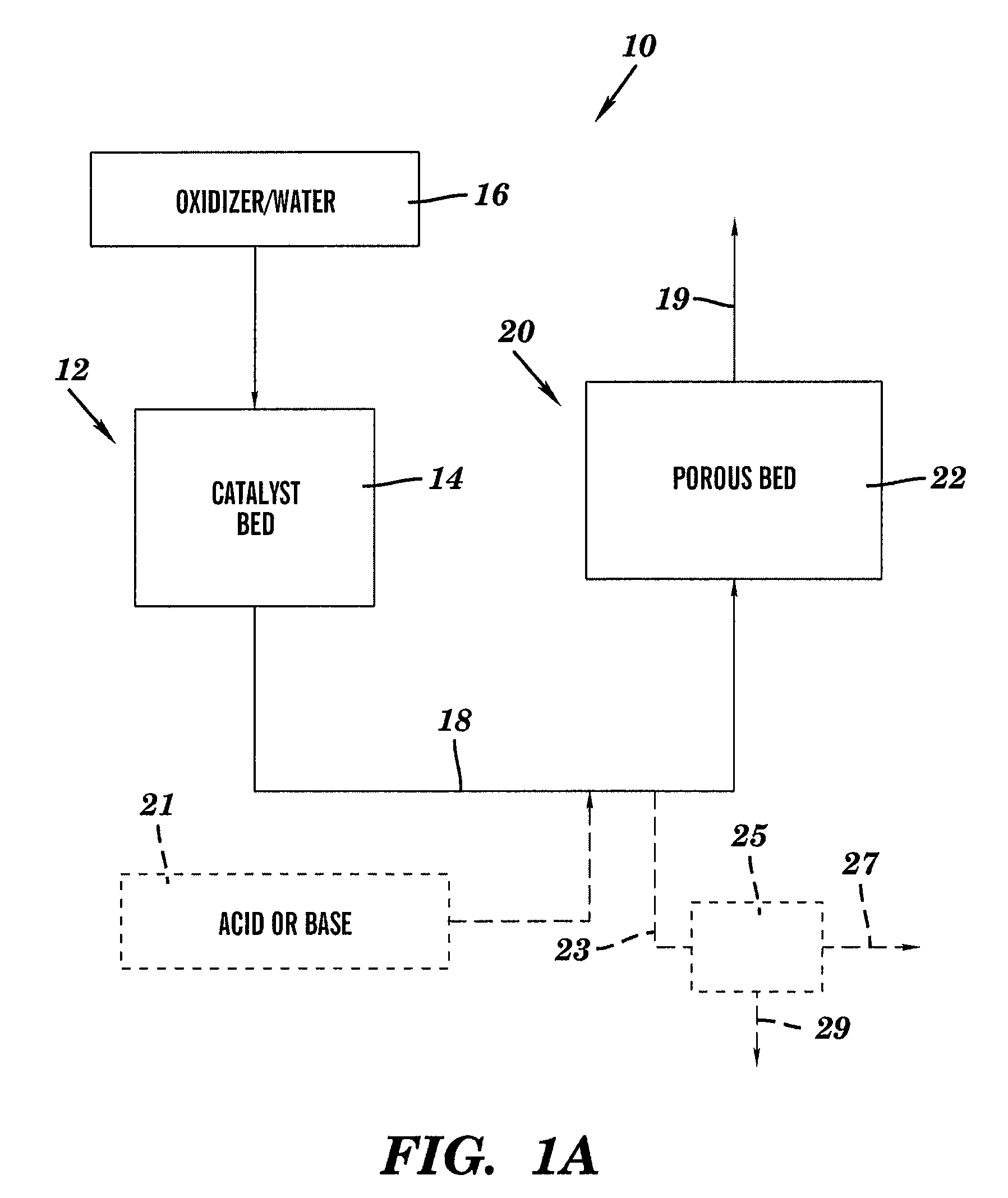

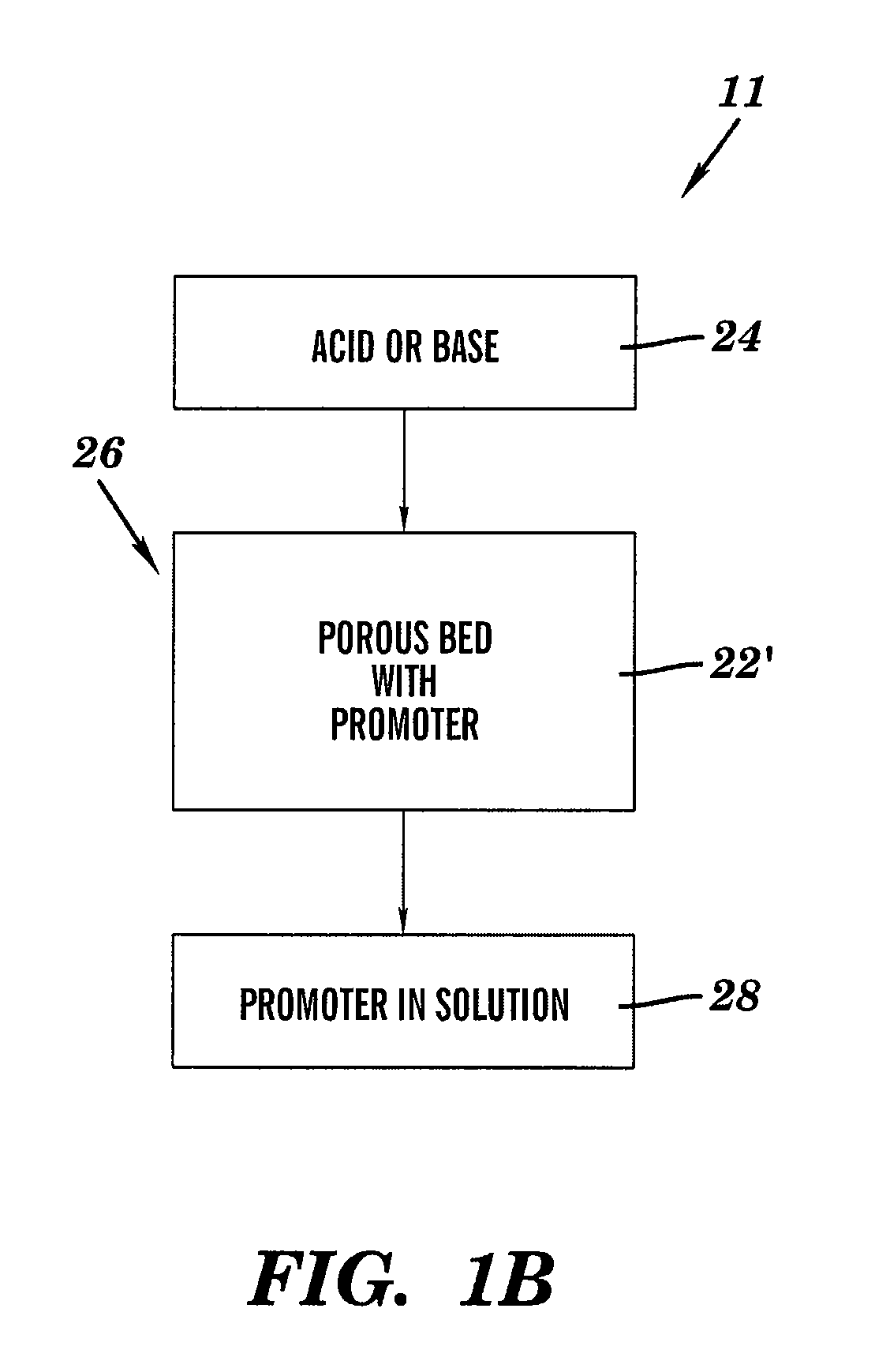

Processes and systems for recovering catalyst promoter from catalyst substrates

Processes and systems for recovering promoter-containing compounds, for example, perrhenates, from promoter-containing catalyst substrates, for example, substrates containing precious metals, such as silver, are disclosed. The processes include contacting the substrates with a first solution adapted to remove at least some of the catalyst promoter from the substrates, for example, an oxidizing agent, to produce a second solution containing catalyst promoter, passing the second solution through a porous medium adapted to capture at least some of the catalyst promoter, for example, a ion exchange resin; and passing a third solution, for example, a base solution, through the porous medium to remove at least some of the catalyst promoter from the porous medium and produce a fourth solution containing compounds having a catalyst promoter. Systems adapted to practice these processes are also disclosed.

Owner:AMES GOLDSMITH

Preparation method of nano-grade rhenium sulfide colloid particle

The invention discloses a preparing method of nanometer grade rhenium sulfide colloid particle, which comprises the following steps: mixing tall-rhenate with hyposulfite evenly in multi-alcohol solvent; adding into perchloric acid or alcaine; reacting under normal temperature; preparing rhenium sulfide colloid; adjusting acidity of colloid; getting nanometer grade small size rhenium sulfide colloid particle with stable particle. This invention does not need add into protective agent and heat, which can be used to diagnose and cure tumor in medical domain.

Owner:BEIJING UNIV OF CHEM TECH

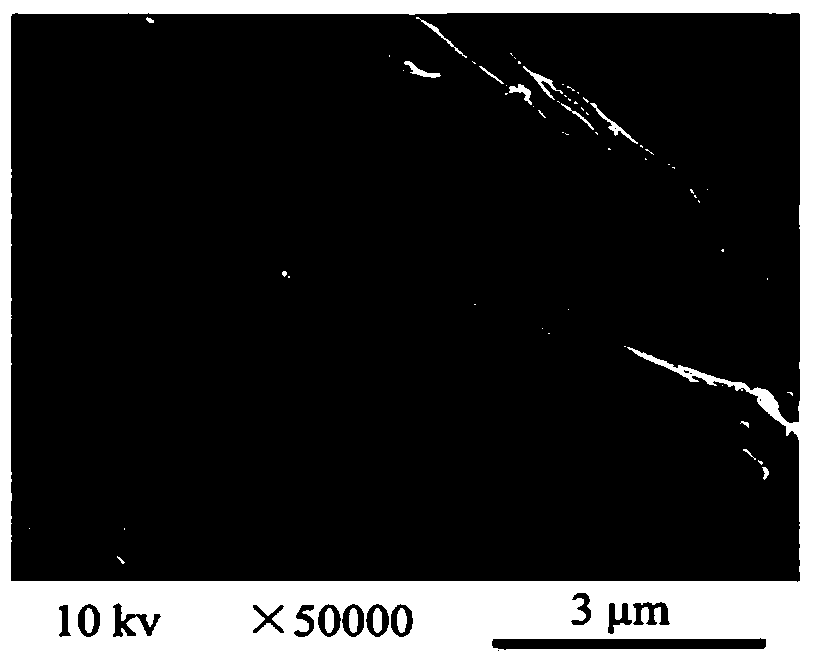

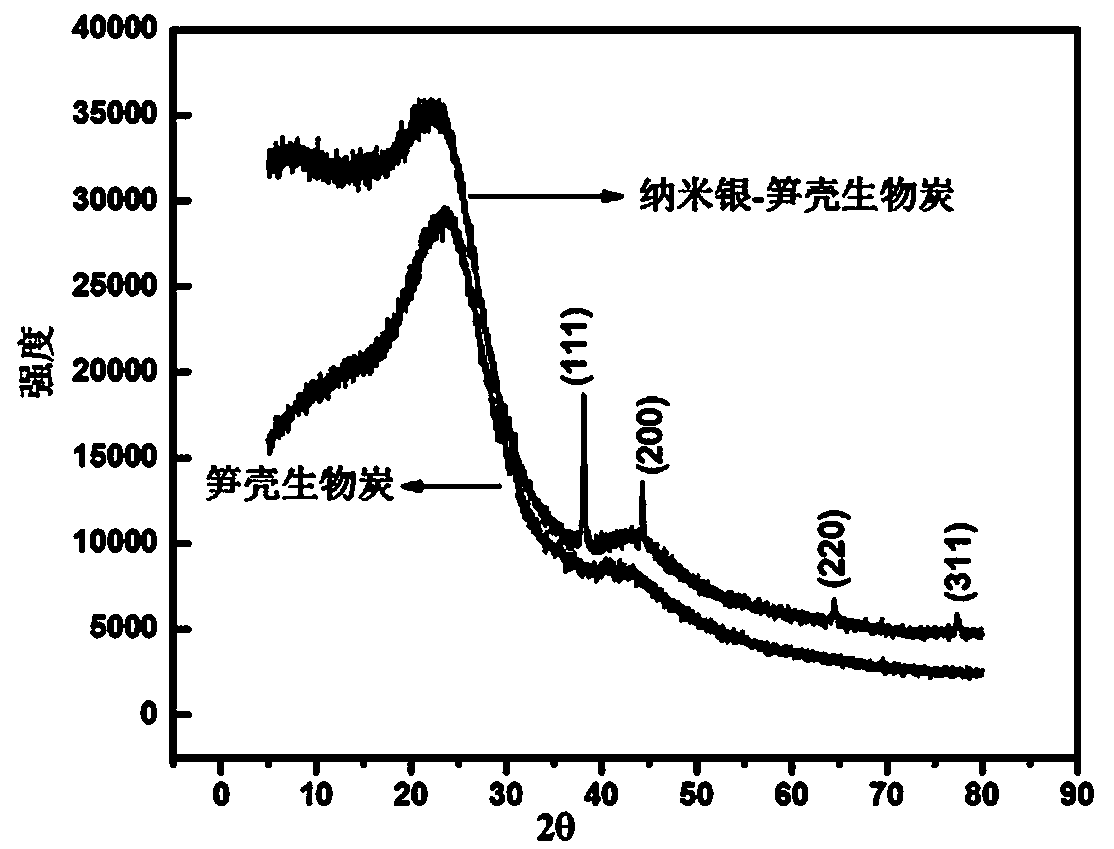

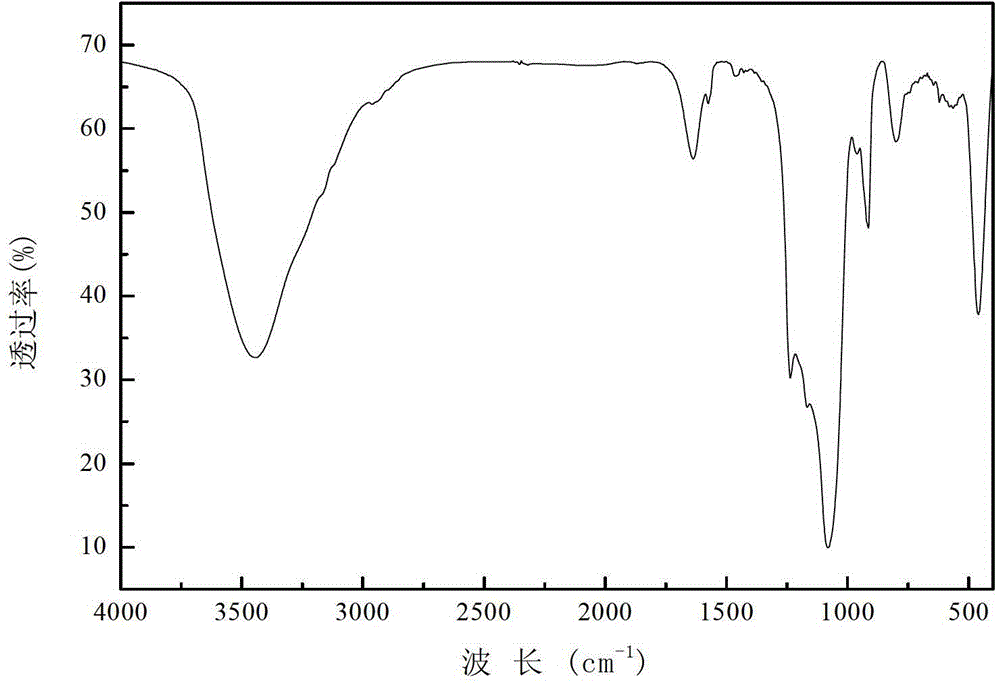

Preparation method and application of nano silver-bamboo shoot shell biochar composite material

ActiveCN110280215AReduce pollutionLow costOther chemical processesSolid sorbent liquid separationWater bathsAgricultural residue

The invention discloses a preparation method and application of a nano silver-bamboo shoot shell biochar composite material. The preparation method comprises the following steps: 1) granulation: pulverizing washed and dried bamboo shoot shells, and sieving; 2) carbonization: carbonizing the bamboo shoot shells at a certain temperature under an inert atmosphere and cooling to room temperature, taking out, washing with deionized water to neutral, and drying to prepare bamboo shoot shell biochar; 3) silver loading: mixing the bamboo shoot shell biochar and a silver nitrate-citric acid solution, dropwise adding an ascorbic acid solution, placing in a water bath and stirring, impregnating, filtering, washing, and drying; 4) activation: taking an appropriate amount of a product obtained in step 3), activating under an inert atmosphere for a certain period of time, then cooling to room temperature, washing to neutral, and drying to obtain the nano silver-bamboo shoot shell biochar composite material. The nano silver-bamboo shoot shell biochar composite material is prepared by the invention through utilizing the bamboo shoot shells of forestry and agricultural residue as a raw material; the raw material is rich, the preparation is simple, and the adsorption effect on perrhenate in a smelting waste acid solution is remarkable.

Owner:FUZHOU UNIV

Rhenium recovery

There is provided a hydrometallurgical process of recovering rhenium values from mixtures thereof with other metal values in which the rhenium values constitute a minority amount, for example super-alloys, which comprises subjecting the mixture to strongly oxidizing acid conditions, preferably an aqueous mixture of hydrochloric acid and nitric acid, so as to form perrhenate species of at least the major proportion of the rhenium values in the mixture, dissolving the perrhenate species and other soluble metal species in aqueous solution, removing insoluble metal species from the aqueous solution, and isolating the rhenium species from the solution.

Owner:MARITIME HOUSE METALS

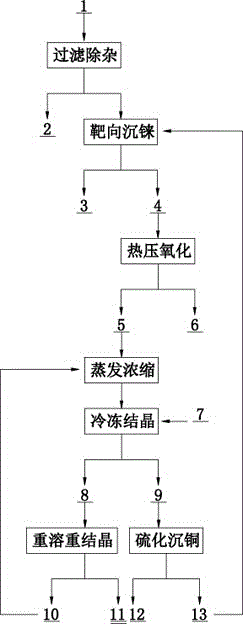

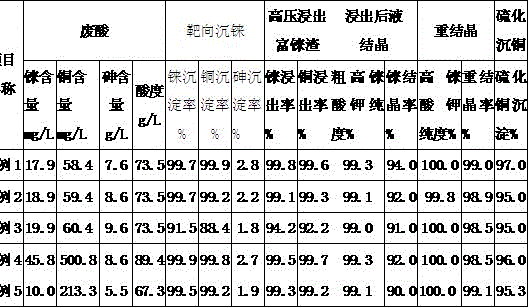

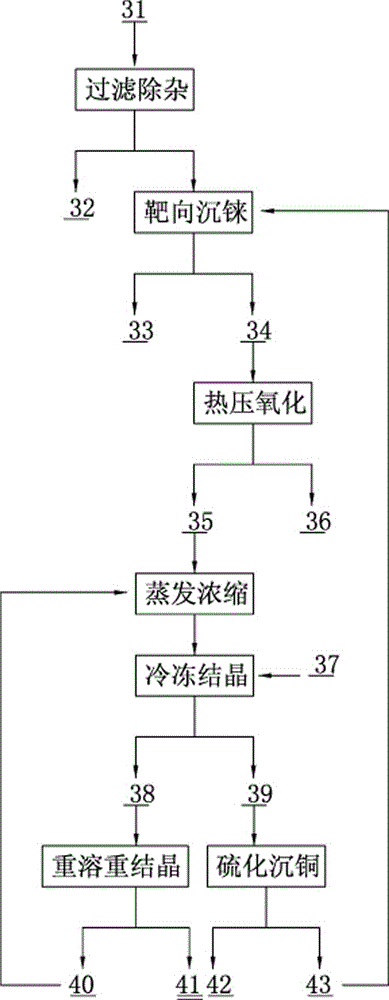

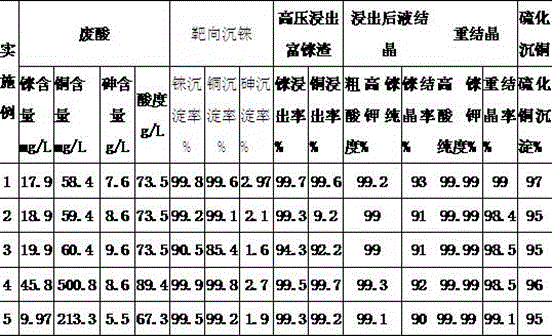

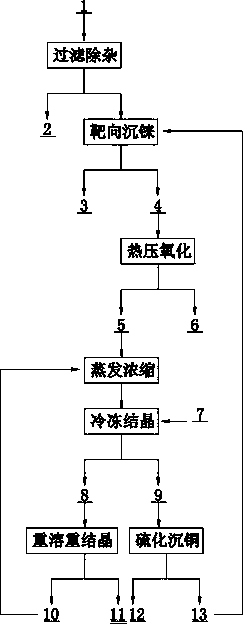

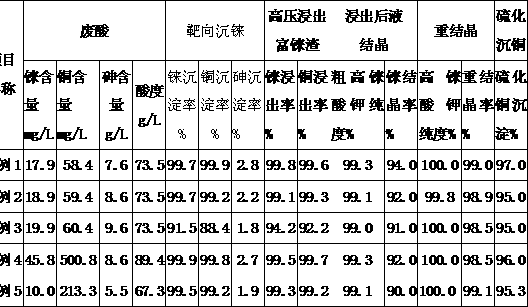

A method of comprehensively recovering rhenium and copper from copper smelting waste acid

ActiveCN105969985AIncrease sedimentation rateReduce dosageProcess efficiency improvementSlagPotassium

A method of comprehensively recovering rhenium and copper from copper smelting waste acid is disclosed. The method includes subjecting the copper smelting waste acid after being filtered to remove lead to targeted rhenium settling to obtain rhenium-rich slag, subjecting the rhenium-rich slag to hot-press oxidation leaching to obtain a rhenium-rich leachate, evaporating and concentrating to make the rhenium concentration 10-20 g / L, performing rhenium settling with KCl, and recrystallizing to obtain potassium perrhenate, and subjecting the liquid after rhenium settling to sulfuration copper settling. The objective of the method is to overcome complex processes, long treatment time, low recovery rates, and other disadvantages of processes recovering rhenium and copper from copper smelting waste acid through leaching at present, and to form a process which is low in investment, simple in operation, high in recovery rate, low in cost, low in pollution and convenient for industrial popularization and application, thus achieving high-value utilization of the rhenium resource in the copper smelting waste acid.

Owner:ZIJIN MINING GROUP

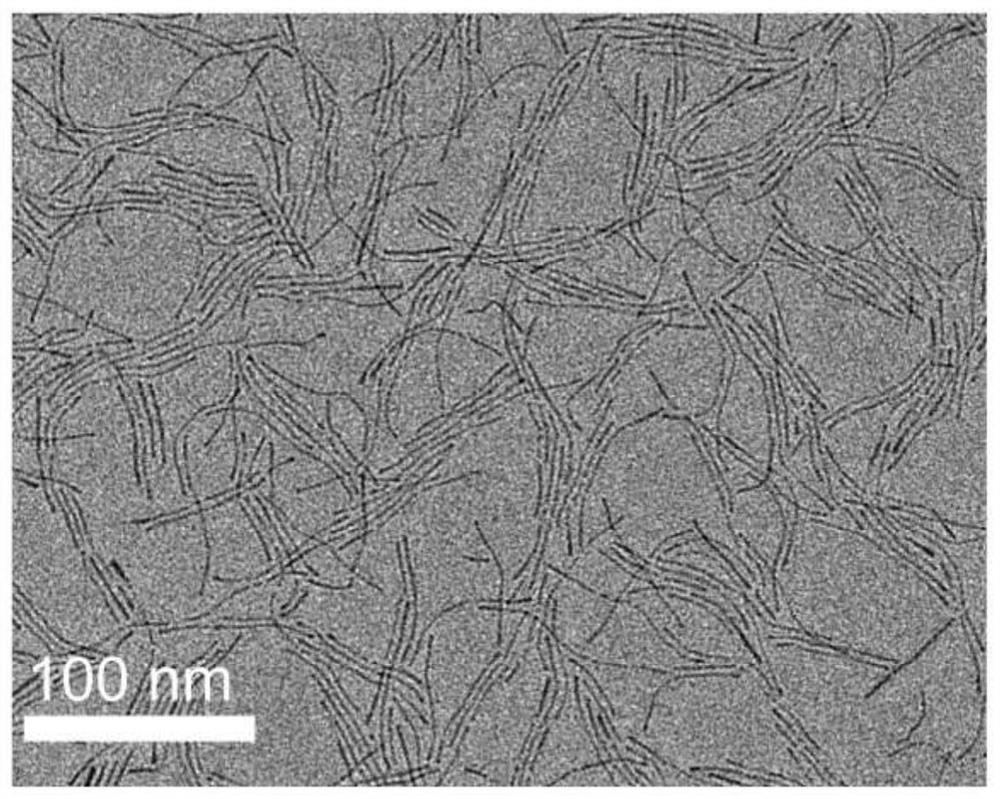

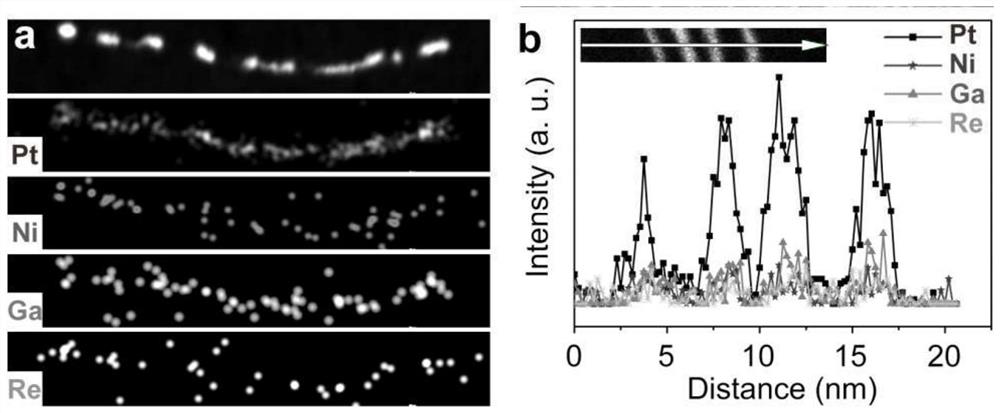

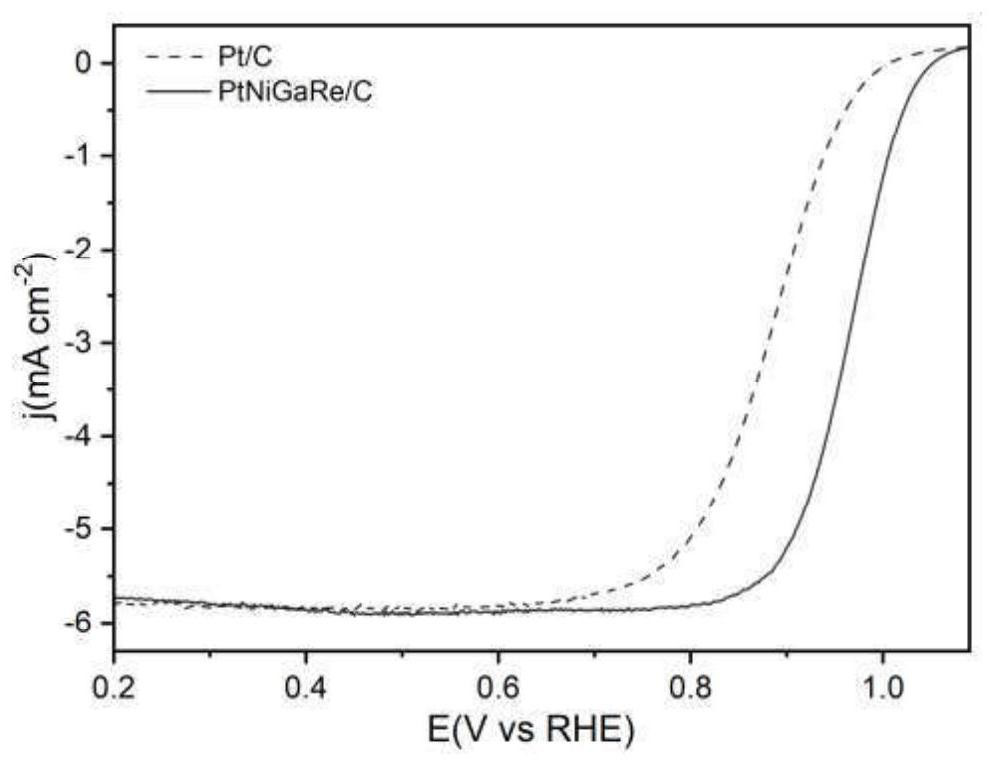

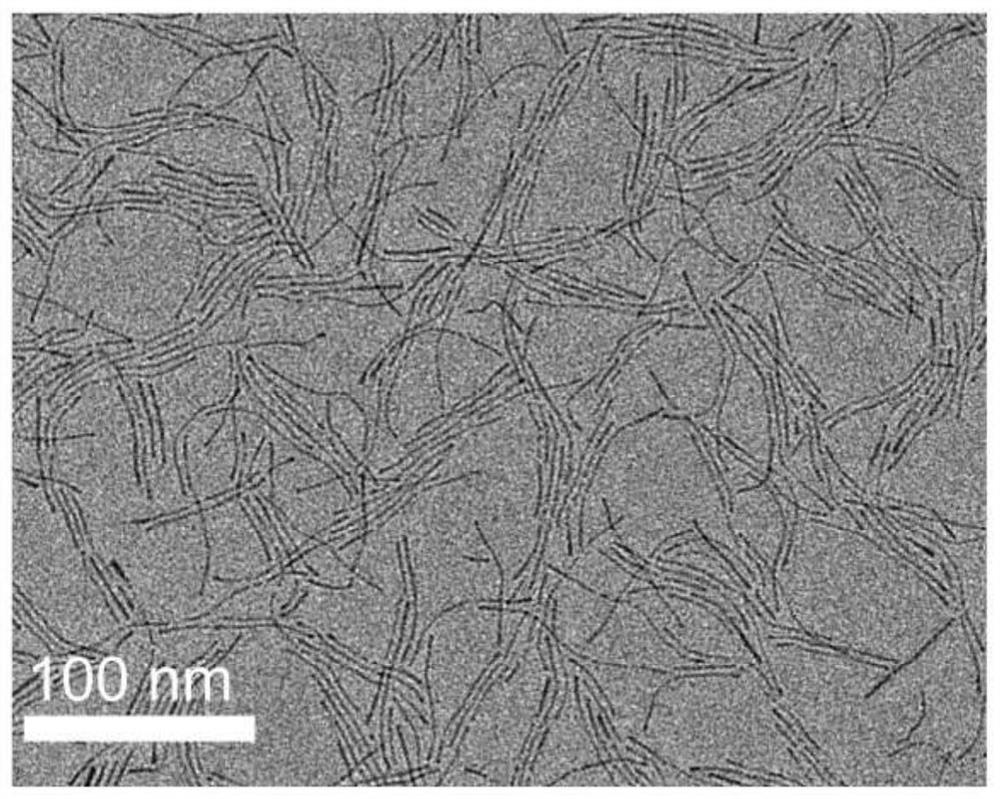

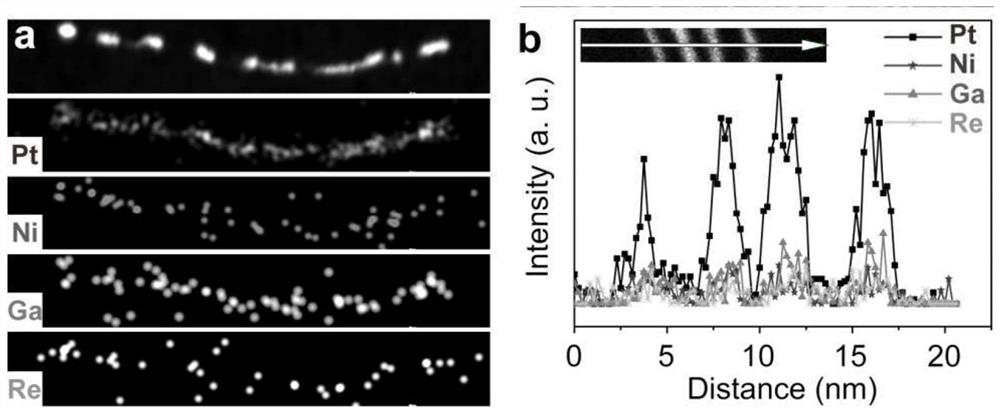

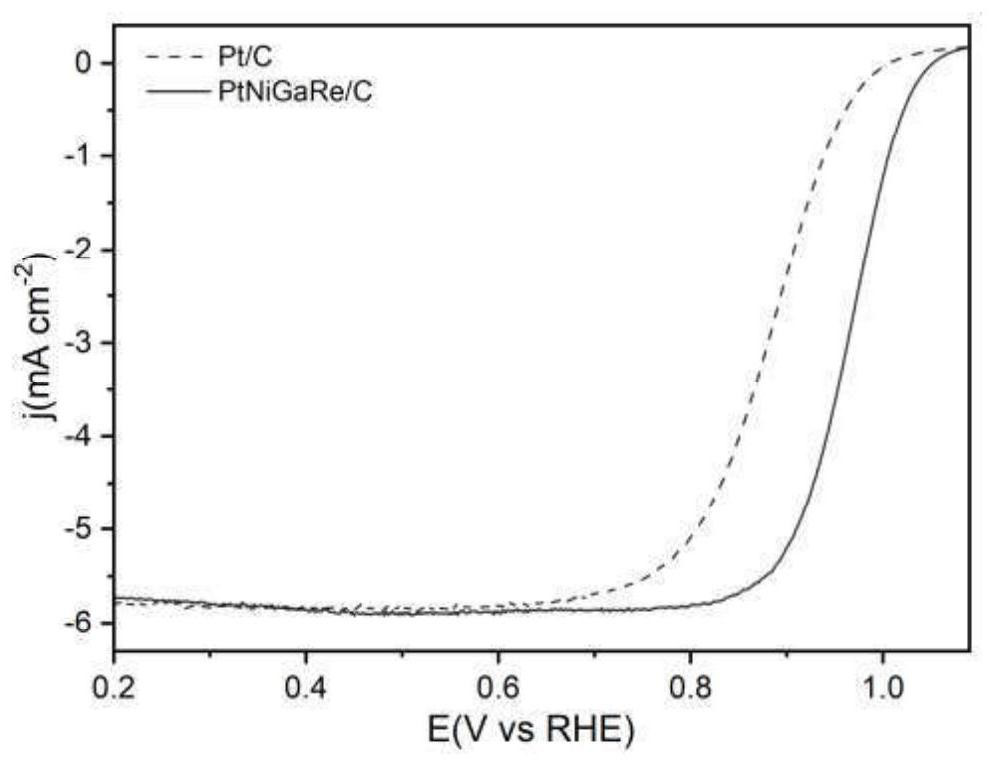

Cathode catalyst active material for hydrogen fuel cell, preparation method and catalyst

ActiveCN112054219AImprove performanceInhibit sheddingMaterial nanotechnologyCell electrodesNanowirePtru catalyst

The invention provides a cathode catalyst active material for a hydrogen fuel cell. The cathode catalyst active material is a one-dimensional PtNiGaRe quaternary alloy nanowire formed by Pt, Ni, Ga and Re metal elements, the invention also provides a cathode catalyst for the hydrogen fuel cell, and the cathode catalyst for the hydrogen fuel cell can be obtained by loading the one-dimensional PtNiGaRe quaternary alloy nanowire on carbon. The invention also provides a preparation method of the quaternary alloy nanowire. The method comprises the following steps: dispersing Pt-containing salt, Ni-containing salt, Ga-containing salt, perrhenate and hexadecyl trimethyl molecular chain-containing quaternary ammonium salt in oleylamine, carrying out ultrasonic treatment to form a uniform system, adding W(CO) 6 into the uniform system, reacting at certain temperature for certain time, and carrying out centrifugal separation and cleaning to obtain the one-dimensional superfine PtNiGaRe nanowire.The quaternary one-dimensional alloy nanowire material is a brand-new quaternary alloy catalytic system, the utilization rate of platinum atoms on the surface is increased, and the activity and stability of a catalyst are improved. According to the invention, the four-metal alloy nanowires are synthesized in one step by adopting a wet chemical method for the first time, so that the operation is simple, the reaction conditions are mild, and the use of Pt can be greatly reduced.

Owner:HUNAN UNIV

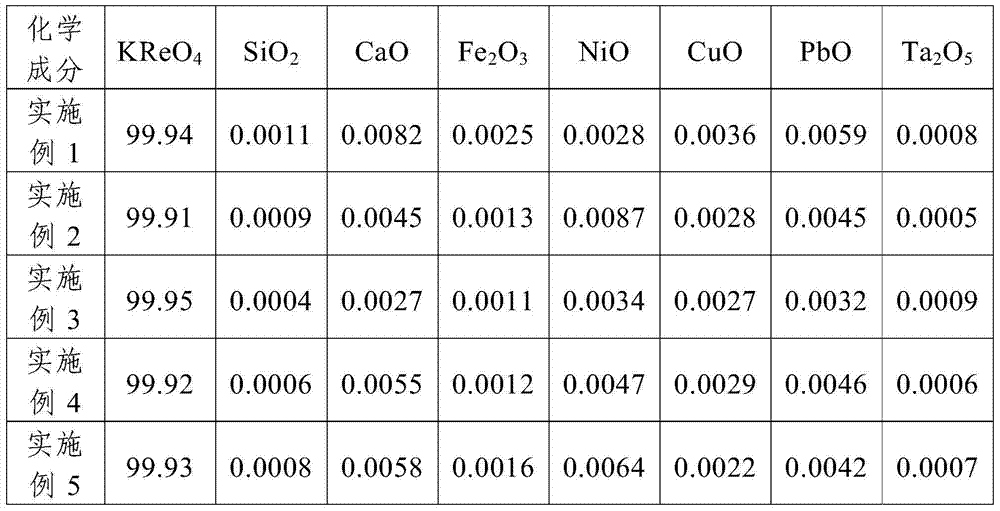

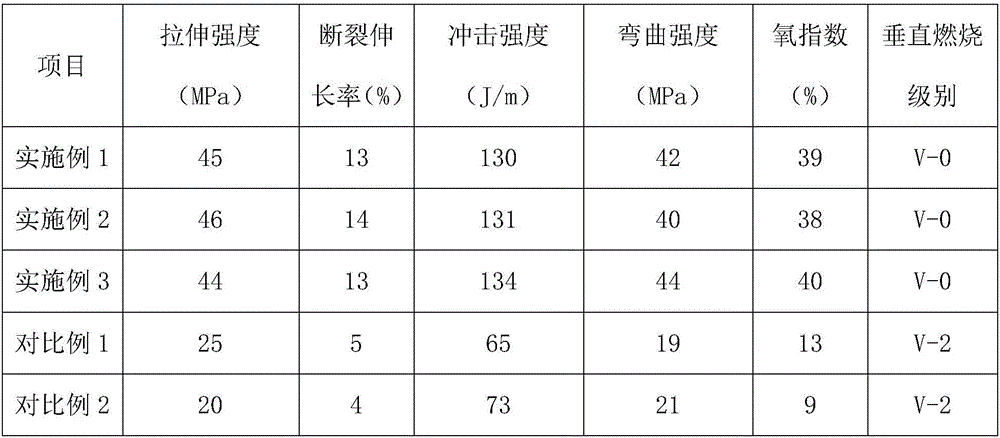

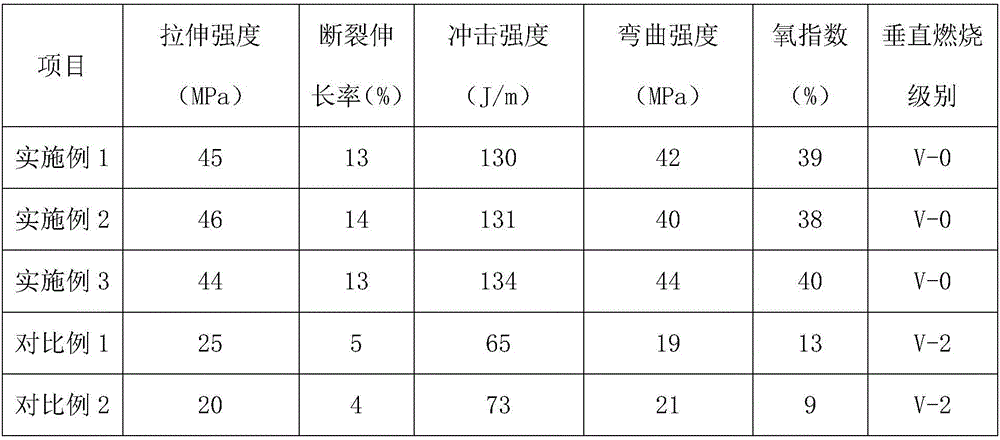

ABS flame retardant plastic and preparation method thereof

InactiveCN106519553AImprove heat resistanceImprove flame retardant performanceFiberFlexural strength

The invention discloses ABS flame retardant plastic and a preparation method thereof. The ABS flame retardant plastic is composed of the following raw materials in parts by weight: 150-200 parts of ABS resin, 25-30 parts of melamine, 10-15 parts of sodium silicate, 2-8 parts of bis(triphenylphosphine)palladium chloride, 2-5 parts of aluminum oxide, 2-5 parts of talcum powder, 2-8 parts of triallyl isocyanurate, 3-5 parts of potassium perrhenate, 1-3 parts of kaolin, 0.5-2 parts of tantalum pentoxide, 0.1-1 part of lanthanum hexaboride and 2-10 parts of flame retardant fibers. The ABS flame retardant plastic is excellent in heat resistance and flame retardance and high in tensile strength, breaking elongation rate, impact strength, bending strength and oxygen index; a preparation process is simple; the product cost is low; the product comprehensive performance is excellent; and a halogen flame retardant is not adopted, so that halogen hydride is not emitted in the combustion process, the human health is protected, and the popularization value is good.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

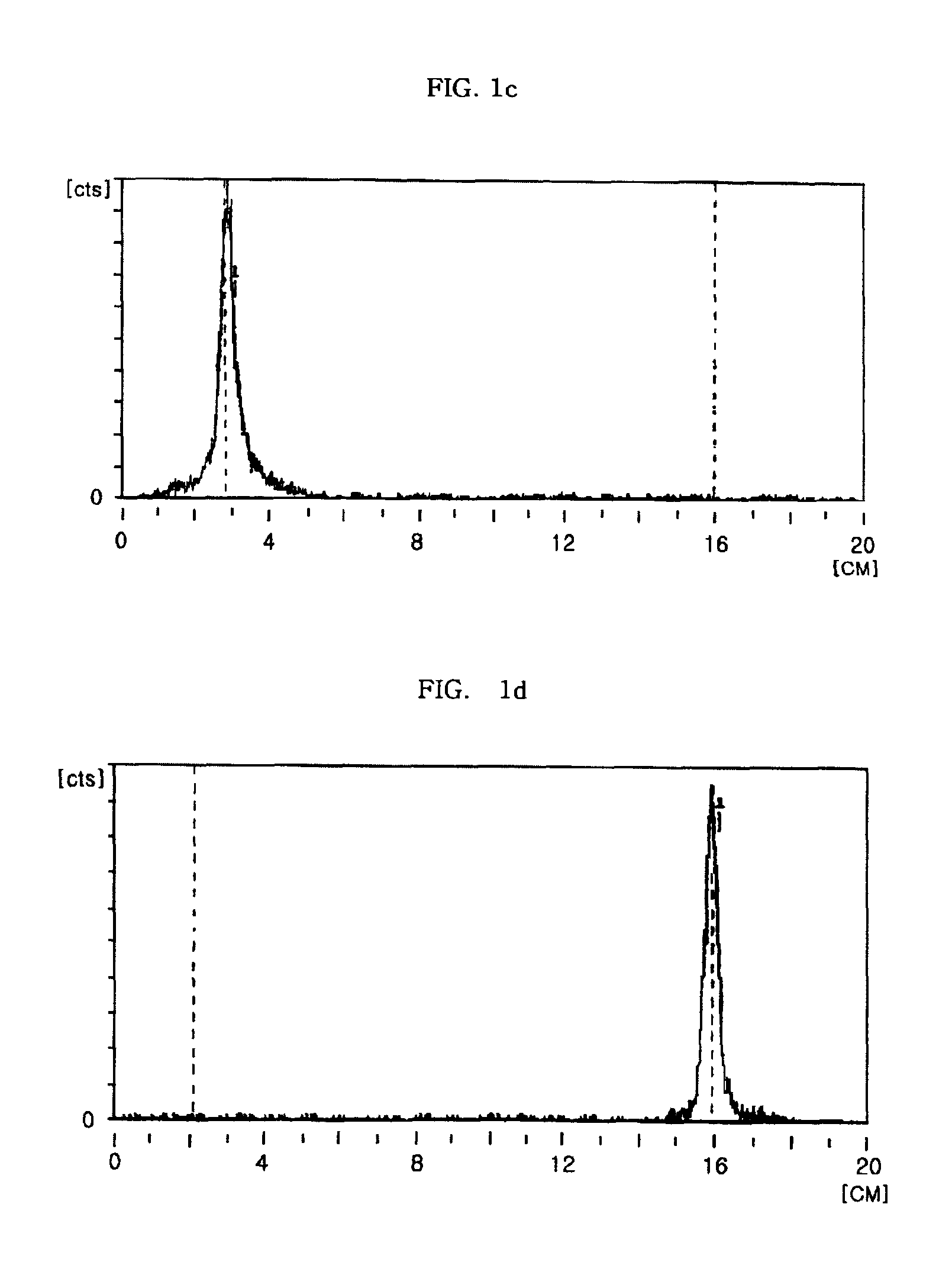

Method for the preparation of technetium or rhenium complex for radiopharmaceuticals

The present invention relates to a method of preparing technetium or rhenium complex for radiopharmaceuticals, through reaction of pertechnetate or perrhenate with a ligand in the presence of a reducing agent, wherein the reducing agent is a borohydride exchange resin (BER). The borohydride exchange resin of the present invention has advantages of being stable in a wide range of Ph, including acidic or alkaline condition(Ph 2˜14) and thus being applicable to biological materials as well as being easily removable through filtration when being administrated. Also since the radiolabelled complex is produced under conditions milder than those required for the conventional reducing agents as well as has high radiochemical purity and high labeling efficiency, the conventional reducing agents can be replaced by the BER of the present invention.

Owner:KOREA ATOMIC ENERGY RES INST

POM flame retardant plastic and preparation method thereof

The invention discloses a POM flame retardant plastic and a preparation method thereof, and the POM flame retardant plastic is prepared from the following materials in parts by weight: 150 to 200 parts of POM resin, 25 to 30 parts of melamine, 10 to 15 parts of sodium silicate, 2 to 8 parts of palladium dichloride (triphenylphosphine), 2 to 5 parts of aluminium hydroxide, 2 to 5 parts of talcum powder, 2 to 8 parts of triallyl isocyanurate, 3 to 5 parts of potassium perrhenate, 1 to 3 parts of kaolin, 0.5 to 2 parts of tantalum pentoxide, 0.1 to 1 part of lanthanum hexaboride and 2 to 10 parts of fire resistant fibre. The POM flame retardant plastic provided by the invention has excellent heat resistance and flame resistance and higher tensile strength, breaking elongation, impact strength, bending strength and oxygen index; the preparation process is simple, the cost of a product is low, the comprehensive performance of the product is excellent, a halogen-flame retardant is not adopted, hydrogen halide is not emitted in a burning process, the human health is protected and the promotion value is good.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Radiopharmaceutical products suitable for the selective labeling of lymphocytes, and their preparation

The invention concerns radiopharmaceutical products suitable for the selective labeling of lymphomas containing a metal complex with the formula:in which M is chosen from among 99mTc, 186Re and 188Re, and R1 represents an alkyl, cycloalkyl, aralkyl or aryl group, optionally substituted, obtained by reaction of a pertechnetate or a perrhenate with a reducing agent such as SnCl2ZP2O in the presence of a dithiocarboxylate having the formula: (R1CS2)-Z2+.

Owner:CIS BIO INT

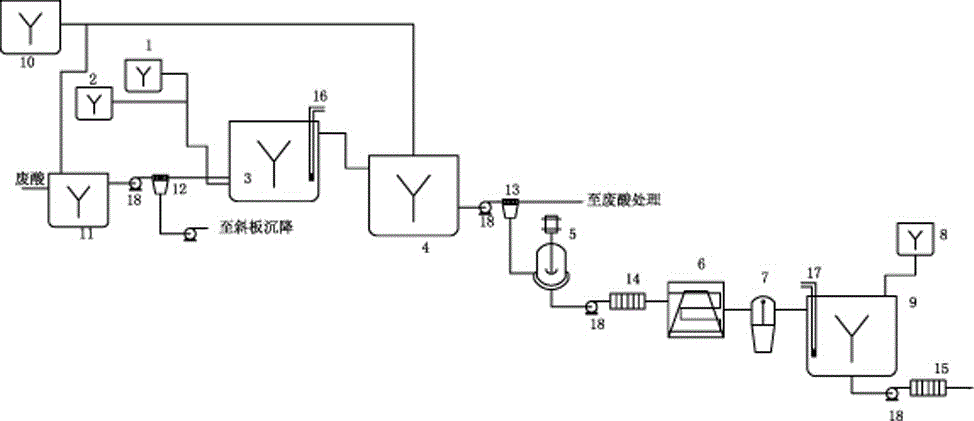

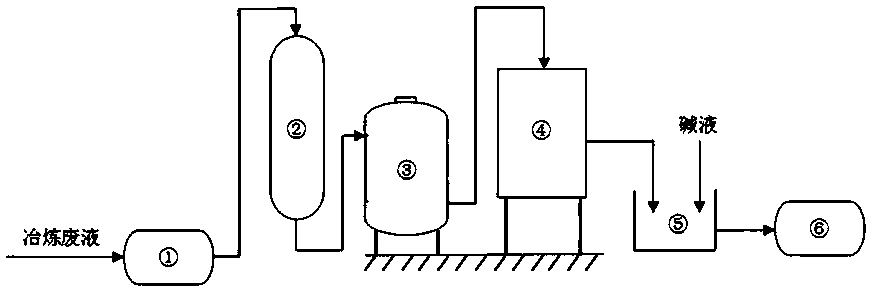

Method for rapidly recovering rhenium, copper and lead from copper smelting waste acid and device for implementing method

ActiveCN105543491AReduce processingImprove protectionProcess efficiency improvementEnvironmental resistanceAnti-gravity

The invention discloses a method for rapidly recovering rhenium, copper and lead from copper smelting waste acid and a device for implementing the method. According to the method, the copper smelting waste acid is subjected to lead removing through filtering, lead residues with the lead content higher than 55% are obtained and taken as lead extraction raw materials, the lead extraction raw materials are subjected to targeted rhenium precipitation, rhenium-rich residues are obtained and are subjected to hot-pressing oxidizing leaching, a rhenium-rich leaching agent is obtained, the rhenium-rich leaching agent after evaporation and concentration is subjected to KCl rhenium precipitation and recrystallization, potassium perrhenate is prepared, and a liquid obtained after rhenium precipitation is vulcanized for copper deposition. The device comprises a rhenium and copper precipitant storage tank, a precipitation tank, a flocculating agent storage tank, a flocculation reaction tank, a reaction kettle, an evaporation-crystallization device, a centrifugal separator, a waste acid anti-gravity-osmosis filter, a rhenium-rich copper residue anti-gravity-osmosis filter, a filter press, a rhenium and copper precipitation tank steam heating system, a copper precipitation tank steam heating system and a slurry pump. The method and the device have the characteristics of low investment, rapid and short procedures, simple and efficient operation, and high recovery rate, and are clean and environment-friendly.

Owner:ZIJIN MINING GROUP

Processes and systems for recovering catalyst promoter from catalyst substrates

Processes and systems for recovering promoter-containing compounds, for example, perrhenates, from promoter-containing catalyst substrates, for example, substrates containing precious metals, such as silver, are disclosed. The processes include contacting the substrates with a first solution adapted to remove at least some of the catalyst promoter from the substrates, for example, an oxidizing agent, to produce a second solution containing catalyst promoter, passing the second solution through a porous medium adapted to capture at least some of the catalyst promoter, for example, a ion exchange resin; and passing a third solution, for example, a base solution, through the porous medium to remove at least some of the catalyst promoter from the porous medium and produce a fourth solution containing compounds having a catalyst promoter. Systems adapted to practice these processes are also disclosed.

Owner:AMES GOLDSMITH

Formula of acid plating solution for rhenium iridium alloy coating on surface of glass die and preparation method thereof

The invention discloses a formula of an acid plating solution for a rhenium iridium alloy coating on surface of a glass die and a preparation method thereof. The formula of the acid plating solution is characterized by comprising of 0.001-0.5mol / L of perrhenate, 0.001-0.45mol / L of sodium hexabromoiridate, 0.001-0.25mol / L of chloriridium acid hydrate, 0.001-0.95mol / L of oxalic acid treated as a complex or (and) 0.001-0.95mol / L of citric acid treated as the complex, and additives, wherein the additives include one or a plurality of 0.001-0.035mol / L of sulfuric acid, 0.001-0.045mol / L of nitrous acid, 0.001-0.020mol / L of hydrofluoric acid, and 0.001-0.015mol / L of hydrogen bromide. The preparation method comprises the steps of dissolving all the above-mentioned components in deionized water; adding 1.0-3.0mol / L of sodium hydroxide or 1.0-3.0mol / L of ammonium hydroxide solution to regulate the pH of electrolyze to be 1.5-6.5; and then electrolytically depositing a rhenium iridium alloy coating on the surface of a conductive die workpiece electrode through constant current or pulse, wherein the rhenium iridium alloy coating contains 1-85at% of iridium, the thickness of the coating is 1nm-100 microns, and the current efficiency is up to 50-90%, so that the amorphous or (and) nanocrystalline rhenium iridium alloy coating is obtained. The amorphous or (and) nanocrystalline rhenium iridium alloy coating is uniform in component distribution, high in combination intensity, outstanding in corrosion resistance, high in hardness, high in oxidation resistance, high in mechanical stability,resistant to abrasion, resistant to high temperature and releasability. Therefore, the service life of the glass die can be effectively prolonged.

Owner:CHANGZHOU UNIV

Method for comprehensive recovery of rhenium and copper from waste acid of copper smelting

ActiveCN105969985BIncrease sedimentation rateReduce dosageProcess efficiency improvementSlagPotassium

A method of comprehensively recovering rhenium and copper from copper smelting waste acid is disclosed. The method includes subjecting the copper smelting waste acid after being filtered to remove lead to targeted rhenium settling to obtain rhenium-rich slag, subjecting the rhenium-rich slag to hot-press oxidation leaching to obtain a rhenium-rich leachate, evaporating and concentrating to make the rhenium concentration 10-20 g / L, performing rhenium settling with KCl, and recrystallizing to obtain potassium perrhenate, and subjecting the liquid after rhenium settling to sulfuration copper settling. The objective of the method is to overcome complex processes, long treatment time, low recovery rates, and other disadvantages of processes recovering rhenium and copper from copper smelting waste acid through leaching at present, and to form a process which is low in investment, simple in operation, high in recovery rate, low in cost, low in pollution and convenient for industrial popularization and application, thus achieving high-value utilization of the rhenium resource in the copper smelting waste acid.

Owner:ZIJIN MINING GROUP

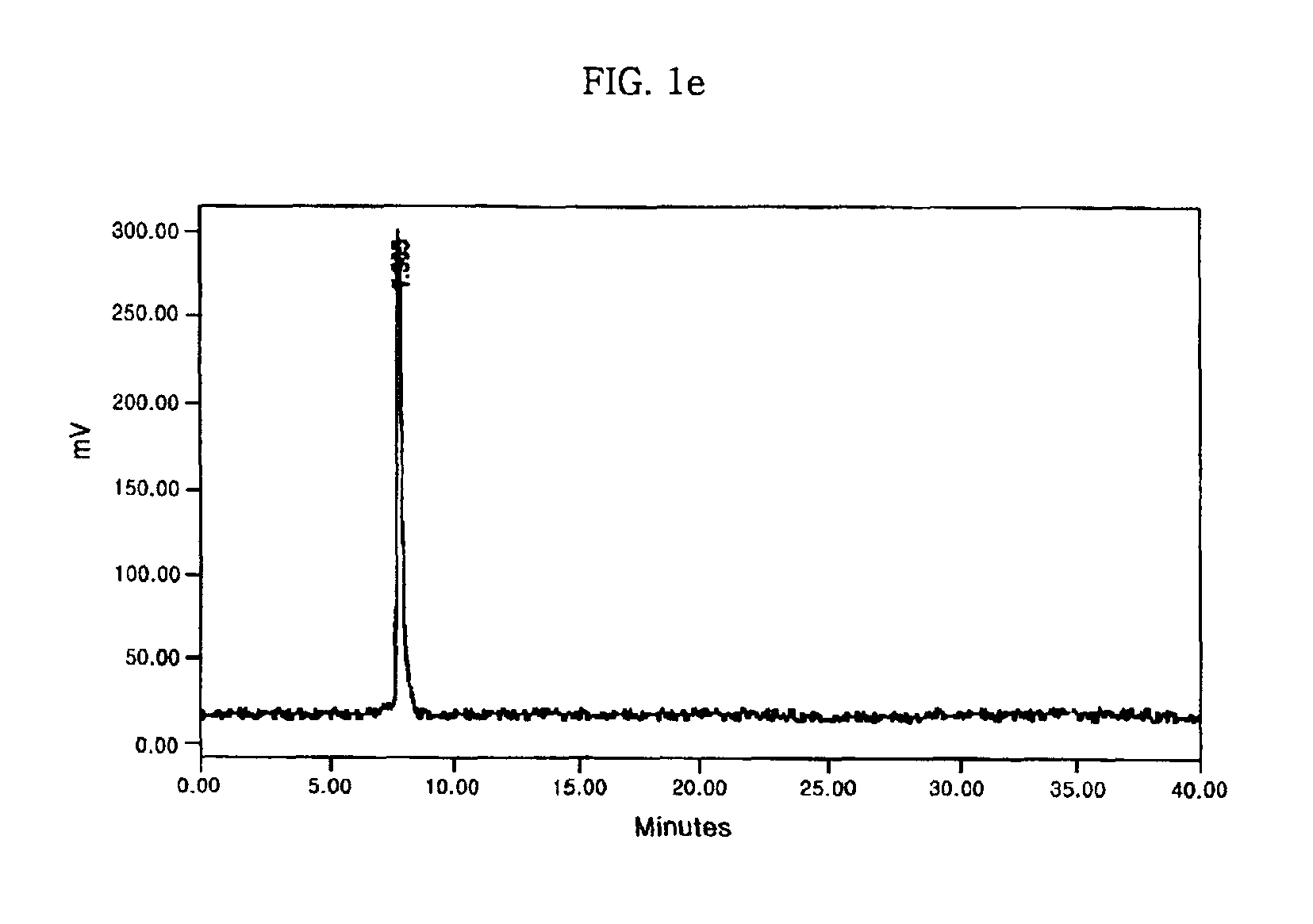

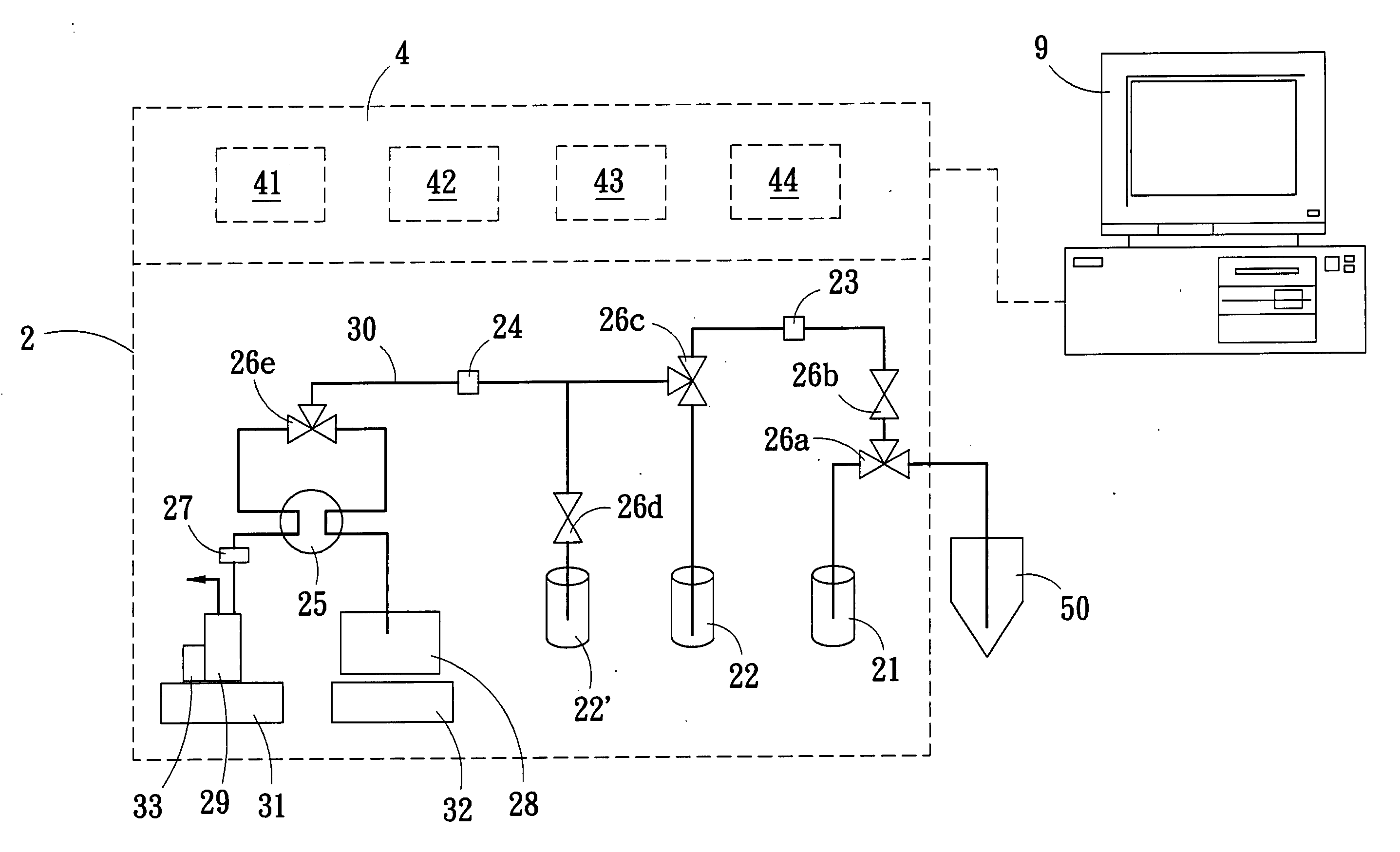

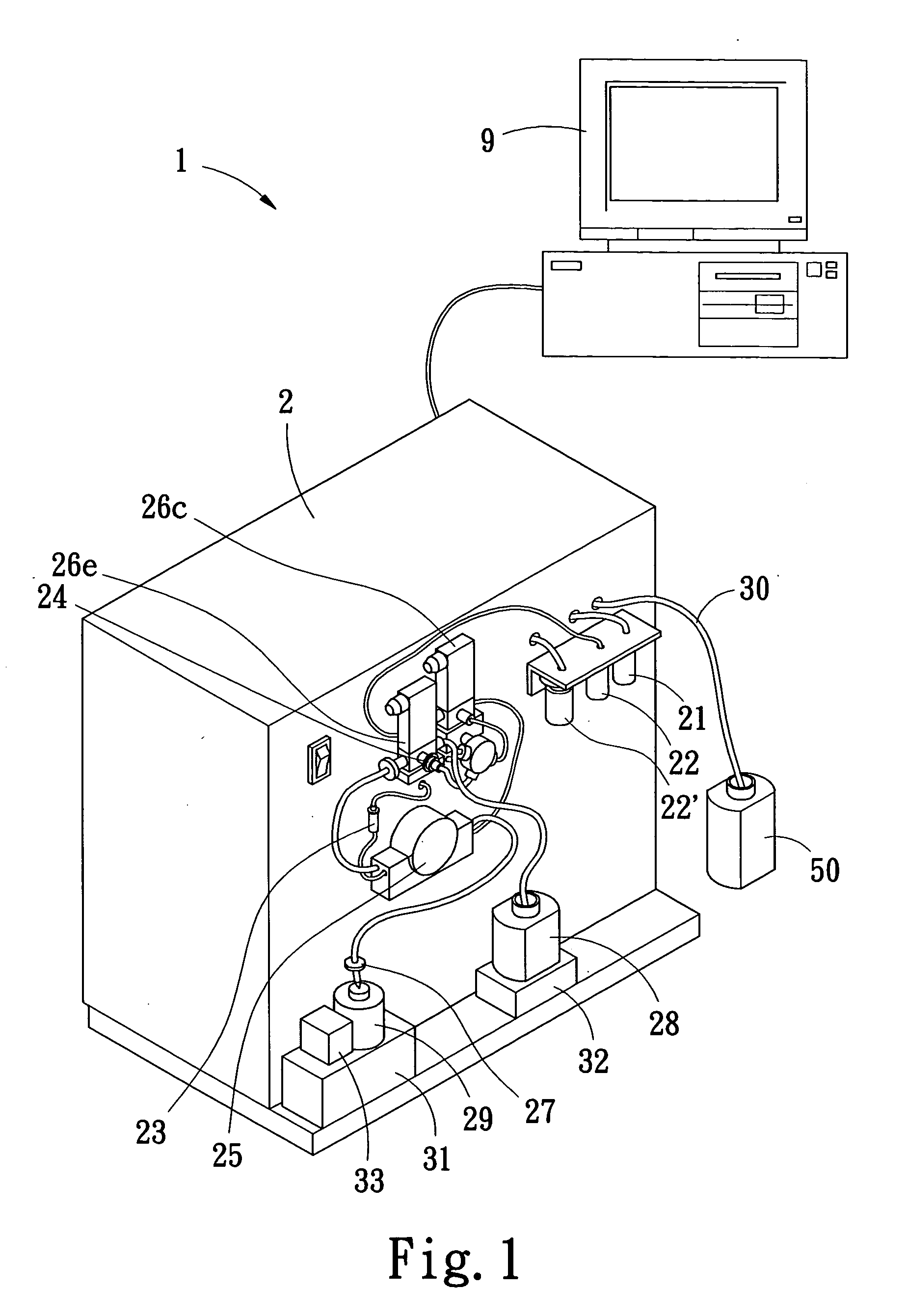

Apparatus and method for automatic preparation of 188 Re-perrhenate solution

InactiveUS20050255010A1Improve efficiencyQuality improvementLayered productsContainmentFiltrationEngineering

An apparatus includes: a fully automated concentrator for 188Re-Perrhenate solution, a control box, and a control computer. The concentrator is controlled by the control box which obtains the signals from the computer. The operator can control it from far away, and monitor the processes such as liquid transfer, washing, filtration, collection etc. from a monitor for the computer. The apparatus can measure the radioactive activities of the collected concentrated 188Re-perrhenate solution and waste during operation; and can also measure the weights of the collecting bottle and solution. Hence the product quality and working efficiency can be increased, and radiation absorbed dose of an operator can be reduced.

Owner:INST OF NUCLEAR ENERGY ATOMIG ENERGY COUNCIL

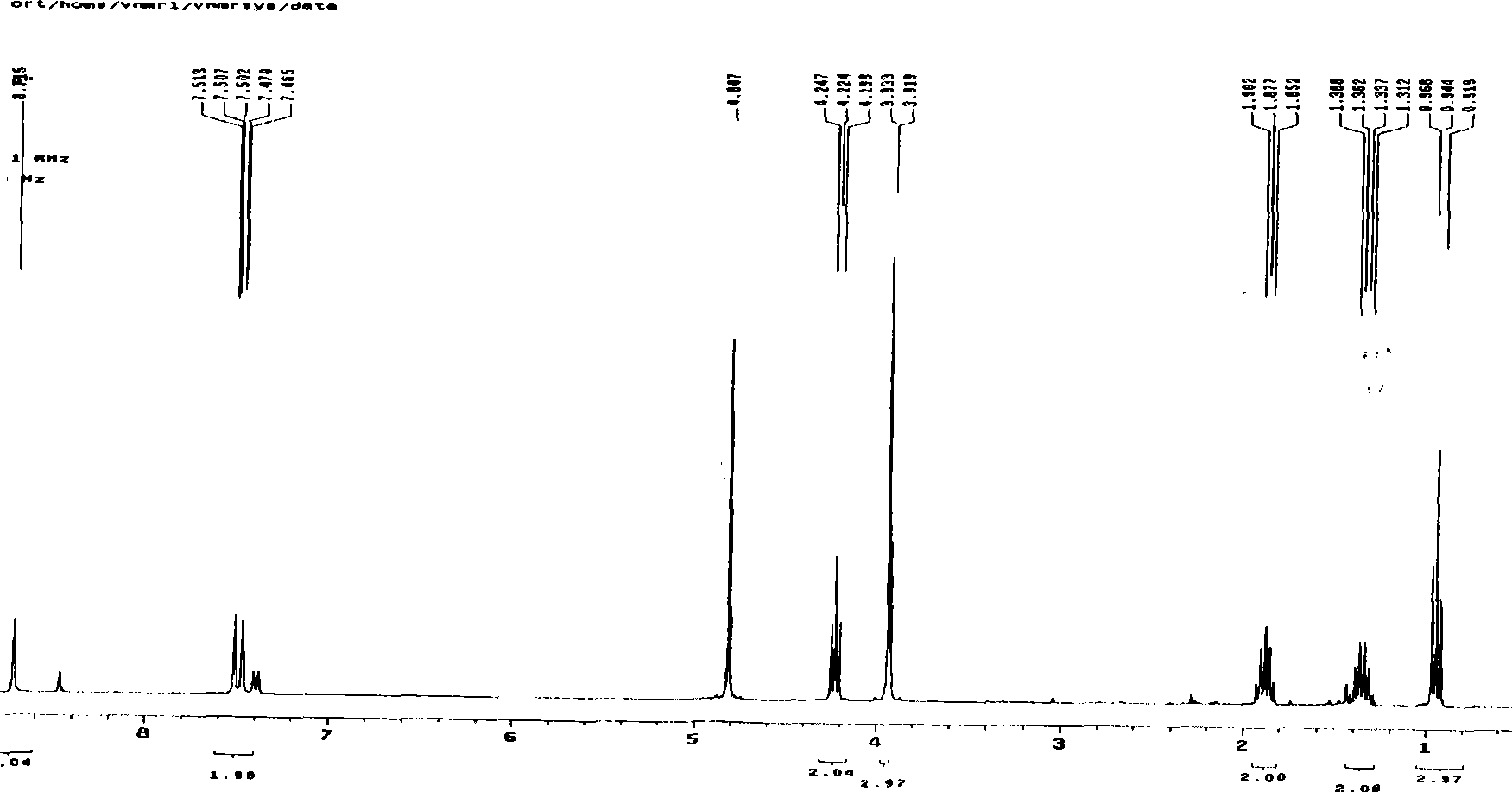

Formulation of Tc and Re carbonyl complexes using stannous ion as the reductant for pertechnetate and perrhenate

The invention relates to novel aminocarboxylate ligands that are suitable for complexing with a radionuclide, and are useful as therapeutic agents and as imaging agents for diagnostic purposes. In accordance with the present invention, a method of preparing a compound of formula fac-[M(CO)3(OH2)3]+ (I) where M is MN, 99mTc, 186Re or 188Re, involves reacting a metal in permetallate form with carbon monoxide and stannous ion. The compound of formula (I) can be reacted with a ligand Lx to form a compound of the formula fac-[M(CO)3Lx]n (II) wherein M is as defined above, Lx is a monodentate or multidentate ligand or a mixture of these ligands, and n is a charge of the ligand Lx increased with one+charge. The invention also is directed to novel compounds, and kits for carrying out the disclosed methods.

Owner:MALLINCKRODT INC

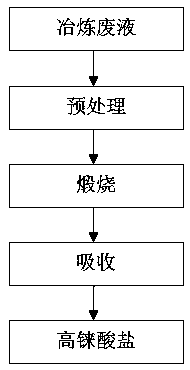

Method for recovering rhenium from metallurgical waste liquid

InactiveCN107746958AWide variety of sourcesEfficient separationProcess efficiency improvementLiquid wasteCarbon adsorption

The invention relates to a method for recovering rhenium from metallurgical waste liquid. A precipitant is added into the rhenium-containing metallurgical waste liquid till the pH of the liquid is 8-12, filter pressing is conducted for separation, filter liquid is collected, and the pH of the filter liquid is adjusted to be 5-7; the filter liquid is pre-treated through a biological carbon adsorption tower, and thus coexisting ions are further removed; then the filter liquid enters a stirring reactor, and biological carbon is added to adsorb rhenium; after adsorption is conducted till saturation is achieved, stirring is stopped, filter pressing is conducted for separation, and a filter cake is taken to be sent into a calcinatory to be calcined; and calcined gas is absorbed through alkalineliquid to obtain a perrhenate product. According to the method for recovering rhenium from the metallurgical waste liquid, a novel technique is adopted to recover rhenium in the metallurgical waste liquid, and the method has the remarkable advantages that the technique is simple, the practicability is high, the investment is few, the operation cost is low, and the recovery rate is high.

Owner:FUZHOU UNIV

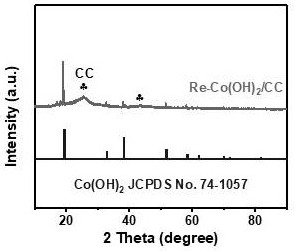

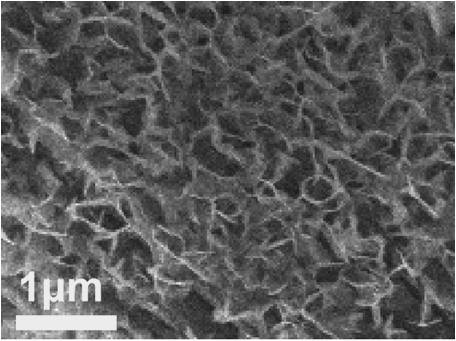

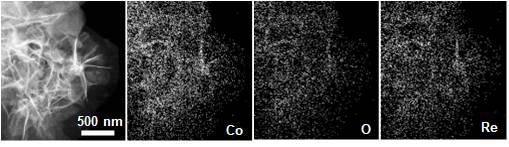

Catalyst for producing furoic acid through electro-catalytic oxidation of furfural and preparation method and use method of catalyst

ActiveCN114438524ASimple processImprove stabilityElectrolytic organic productionElectrodesPtru catalystCatalytic oxidation

The invention belongs to the technical field of biomass conversion, and discloses a catalyst for producing furoic acid through electro-catalysis furfural oxidation and a preparation method and a use method of the catalyst. The catalyst takes carbon cloth as a substrate, and rhenium-doped cobalt hydroxide nanosheets grow on the substrate in situ. The preparation method comprises the following steps: cutting commercial carbon cloth, pickling and drying for later use; the preparation method comprises the following steps: uniformly stirring perrhenate, cobalt salt, an acid solution, urea and an alcohol solution together, transferring the mixed solution into a hydrothermal kettle, and transferring the mixed solution into the hydrothermal kettle; and putting the carbon cloth into a hydrothermal kettle, screwing a kettle cover, reacting the hydrothermal kettle at 80-260 DEG C for 400-1200 minutes, cooling to room temperature, taking out the carbon cloth, and drying to obtain the catalyst. An H-type electrolytic tank is adopted, a catalyst, silver chloride and a carbon rod serve as a working electrode, a reference electrode and a counter electrode respectively, the voltage range is set to be 0.6-1.0 V, and the time is 30-240 min. The catalyst prepared by the invention shows excellent activity of electro-catalysis of furfural oxidation.

Owner:ZHENGZHOU UNIV +1

A method of cellulose degradation based on loaded perrhenate ionic liquid

ActiveCN107267687BHigh activityPromote degradationOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePtru catalyst

The invention relates to a load type perrhenate ionic liquid based cellulose degradation method. According to the technical scheme, the method is characterized in that cellulose is dissolved in an ionic liquid solvent, and load type perrhenate ionic liquid in which ReO4<-> is used as negative ion is used as a catalyst for degrading; the degrading reaction is carried out for 10-60min at the temperature of 120-170 DEG C; and water is added to dilute reaction liquid after the reaction is finished, and then the dilute is filtered and separated. The method is simple; the catalyst is green, environment-friendly and easily recovered; the cellulose degrading effect is good.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for recovering rhenium from arsenic filter cake

The invention provides a method for recovering rhenium from an arsenic filter cake. The method comprises the following steps: entering rhenium, arsenic and sulfur into a solution by adopting one-section alkali leaching and second-section oxidization and leaching, and simultaneously enriching lead, bismuth, copper and selenium in leaching slag; in the one-section leachate, converting rhenium into perrhenate in a form of sodium thioperrhenate by adopting an oxidization method, converting sodium thioarsenate into sodium arsenate, and separating out sulfur in a form of simple substance sulfur; removing arsenic from the solution obtained by oxidization conversion by using a sulfur dioxide reduction method or lime method; carrying out rhenium enrichment on the solution obtained after arsenic isremoved; treating a rhenium reextraction liquid by using a potassium chloride precipitation method to obtain crude potassium perrhenate; and refining crude potassium perrhenate to obtain potassium perrhenate. The method has short process flow, high rhenium recovery rate and low treatment cost; and by using the method, the comprehensive utilization of valuable metals in the arsenic filter cake canbe realized.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

Cathode catalyst active material for hydrogen fuel cell, preparation method and catalyst

ActiveCN112054219BInhibit sheddingIncrease profitMaterial nanotechnologyCell electrodesNanowirePtru catalyst

The invention provides a cathode catalyst active material for a hydrogen fuel cell, a one-dimensional PtNiGaRe quaternary alloy nanowire formed by Pt, Ni, Ga and Re metal elements; and a one-dimensional PtNiGaRe quaternary alloy nanowire loaded on carbon A cathode catalyst for a hydrogen fuel cell can be obtained. Also provided is a preparation method of a quaternary alloy nanowire, which comprises dispersing Pt-containing salt, Ni-containing salt, Ga-containing salt, perrhenate and quaternary ammonium salt containing hexadecyltrimethyl molecular chain In oleylamine, ultrasonication forms a homogeneous system, and then adds W(CO) 6 Adding it into the above system at a certain temperature, reacting for a certain period of time, and then centrifuging and cleaning to obtain one-dimensional ultrafine PtNiGaRe nanowires. The quaternary one-dimensional alloy nanowire material of the present invention is a brand-new quaternary alloy catalytic system, which not only increases the utilization rate of platinum atoms on the surface, but also improves the activity and stability of the catalyst. The invention adopts the wet chemical method for the first time to synthesize the alloy nanowires of four metals in one step, not only the operation is simple, but also the reaction conditions are relatively mild, and the use of Pt can be greatly reduced.

Owner:HUNAN UNIV

A kind of acid plating solution of rhenium-iridium alloy coating on glass mold surface and preparation method thereof

The invention discloses a formula of an acid plating solution for a rhenium iridium alloy coating on surface of a glass die and a preparation method thereof. The formula of the acid plating solution is characterized by comprising of 0.001-0.5mol / L of perrhenate, 0.001-0.45mol / L of sodium hexabromoiridate, 0.001-0.25mol / L of chloriridium acid hydrate, 0.001-0.95mol / L of oxalic acid treated as a complex or (and) 0.001-0.95mol / L of citric acid treated as the complex, and additives, wherein the additives include one or a plurality of 0.001-0.035mol / L of sulfuric acid, 0.001-0.045mol / L of nitrous acid, 0.001-0.020mol / L of hydrofluoric acid, and 0.001-0.015mol / L of hydrogen bromide. The preparation method comprises the steps of dissolving all the above-mentioned components in deionized water; adding 1.0-3.0mol / L of sodium hydroxide or 1.0-3.0mol / L of ammonium hydroxide solution to regulate the pH of electrolyze to be 1.5-6.5; and then electrolytically depositing a rhenium iridium alloy coating on the surface of a conductive die workpiece electrode through constant current or pulse, wherein the rhenium iridium alloy coating contains 1-85at% of iridium, the thickness of the coating is 1nm-100 microns, and the current efficiency is up to 50-90%, so that the amorphous or (and) nanocrystalline rhenium iridium alloy coating is obtained. The amorphous or (and) nanocrystalline rhenium iridium alloy coating is uniform in component distribution, high in combination intensity, outstanding in corrosion resistance, high in hardness, high in oxidation resistance, high in mechanical stability,resistant to abrasion, resistant to high temperature and releasability. Therefore, the service life of the glass die can be effectively prolonged.

Owner:CHANGZHOU UNIV

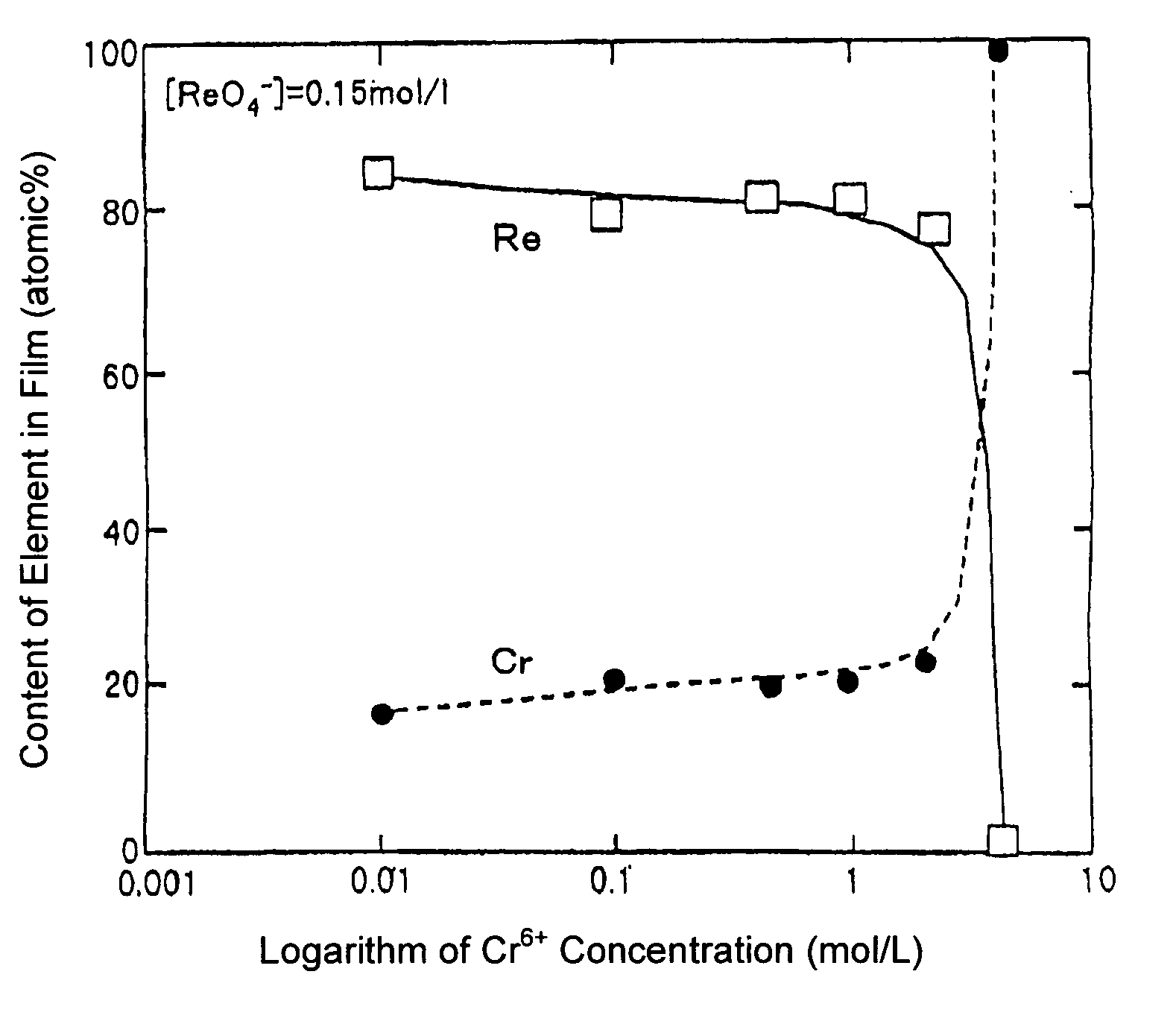

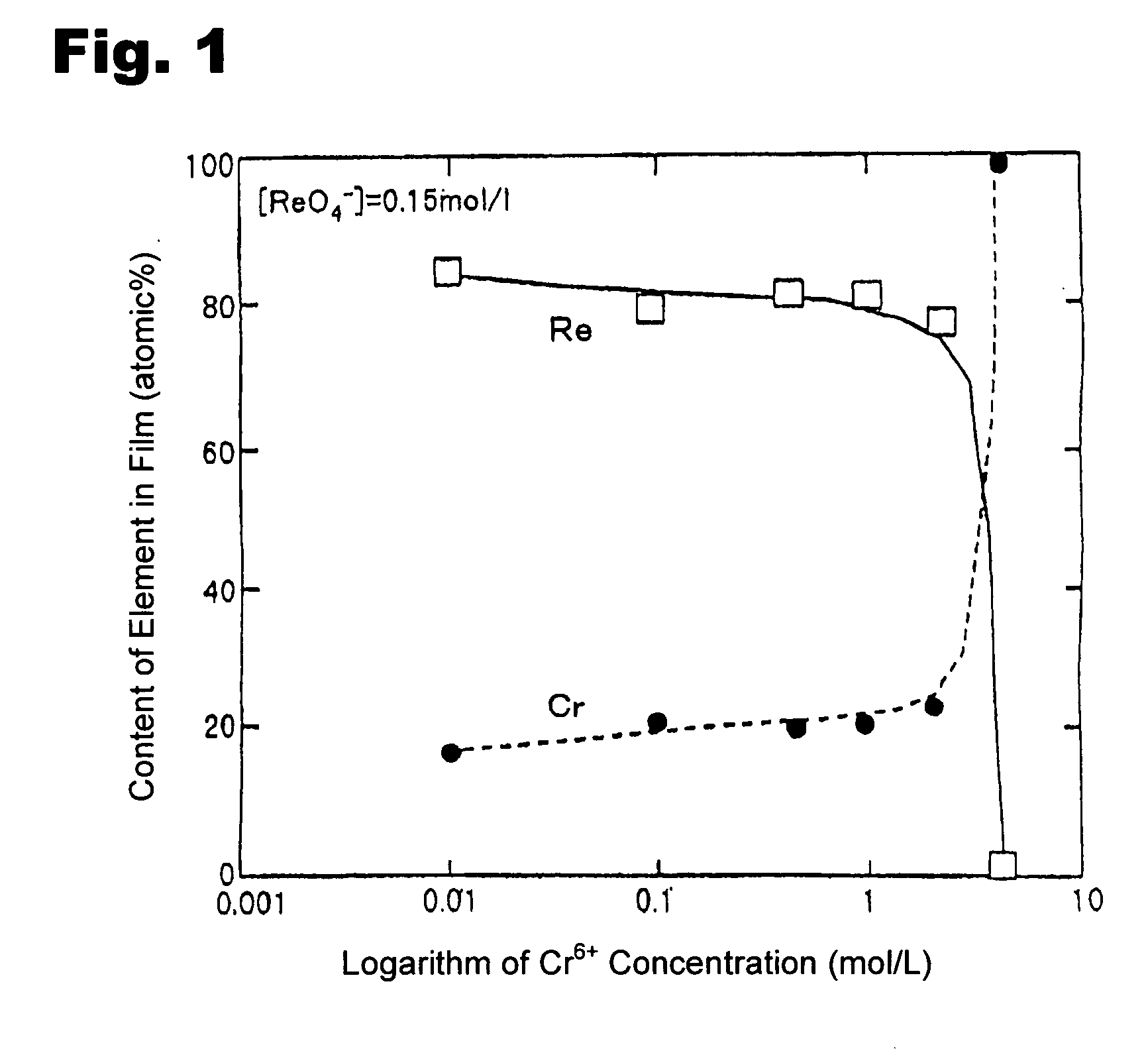

Method for forming Re-Cr alloy film through electroplating process using bath containing Cr(VI)

InactiveUS20050167282A1Improve plating efficiencyEduce occurrenceCorrosion resistant alloyAqueous solution

Disclosed is a method for forming a Re—Cr alloy film consisting of Re in the range of 60 to 90% by atomic composition. The method comprises performing an electroplating process using an electroplating bath containing an aqueous solution which includes a perrhenate ion and a chromium (IV) ion. The present invention allows a Re—Cr alloy film usable as a corrosion-resistant alloy coating for a high-temperature component or the like to be formed through an electroplating process using an aqueous solution, so as to provide heat / corrosion resistances to the component, even if it has a complicated shape, in a simplified manner at a low cost.

Owner:JAPAN SCI & TECH CORP +2

Method for labelling technetium or rhenium using borohydride exchange resin

A method for labelling a sulfide compound with technetium or rhenium, comprising the reaction of a disulfide compound with pertechnetate or perrhenate in the presence of borohydride exchange resin to obtain a complex of technetium or rhenium with the sulfide compound. The method can directly label disulfide compounds with technetium or rhenium, can skip the synthetic step of thiol-protected S-precursor, and is useful for high value-added radiopharmaceuticals.

Owner:KOREA ATOMIC ENERGY RES INST

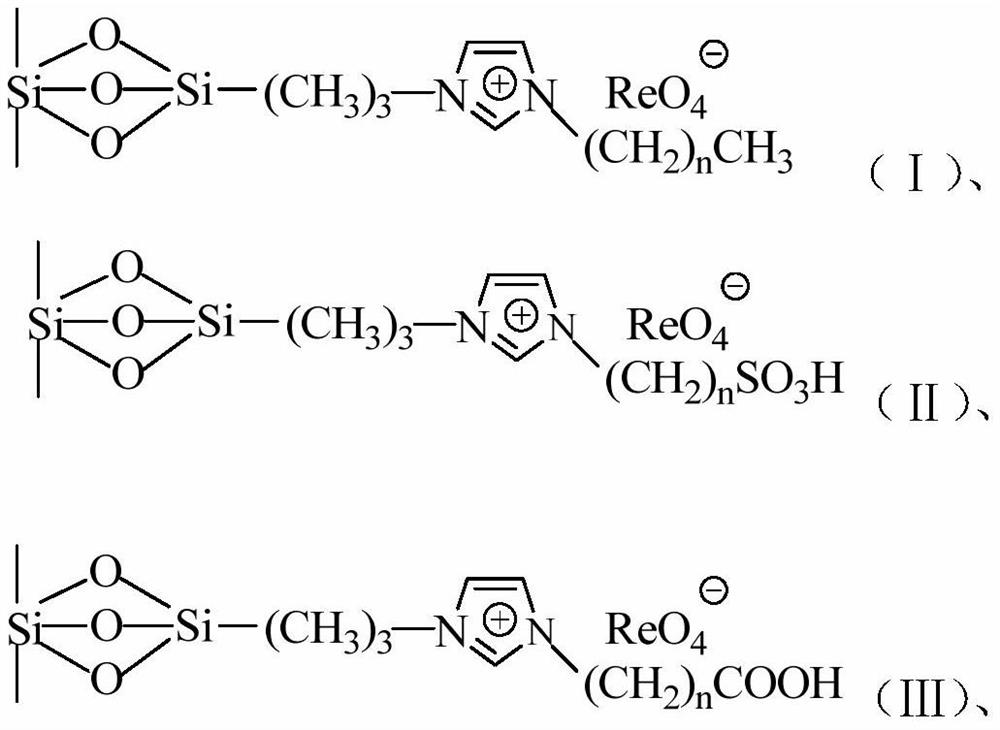

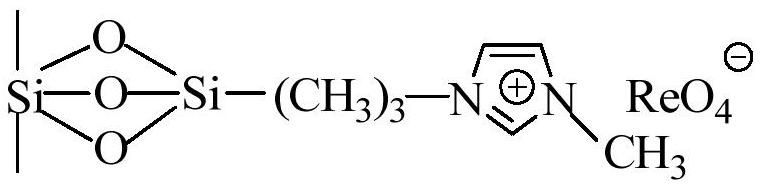

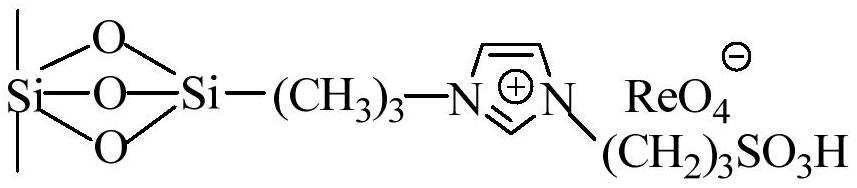

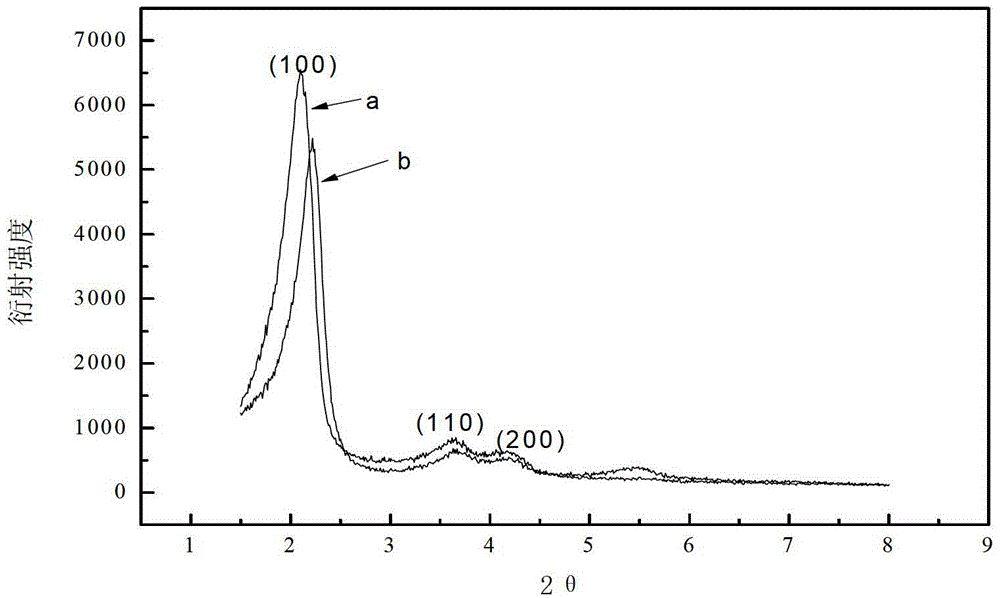

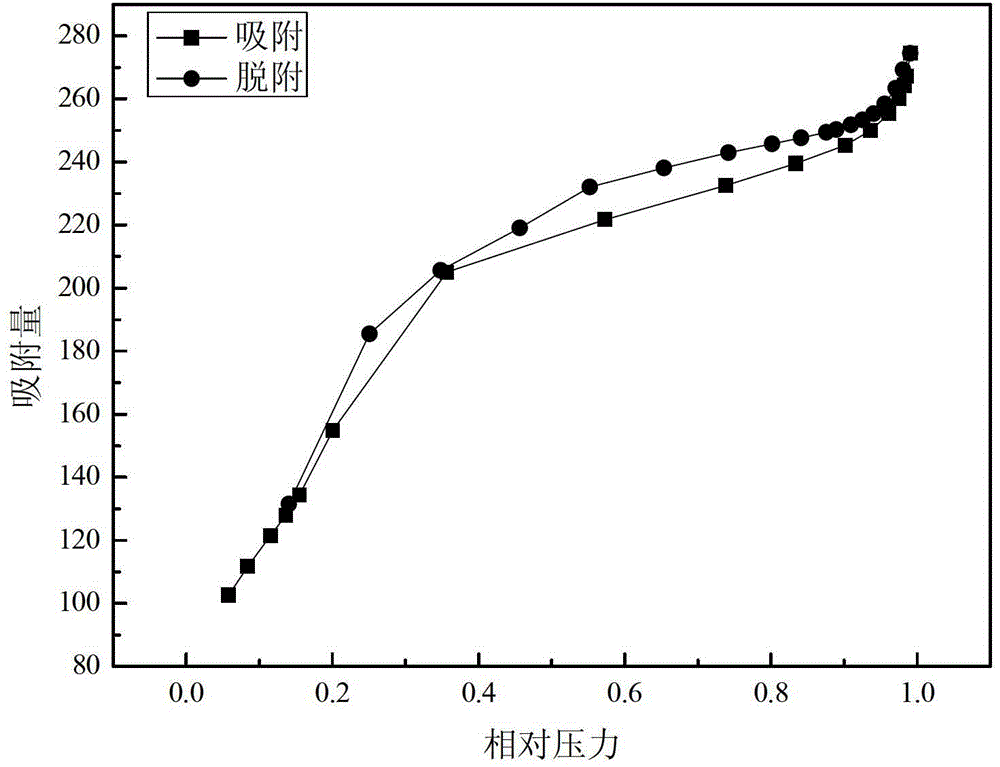

A kind of loaded perrhenate ionic liquid and preparation method thereof

ActiveCN103464200BReduce dosageEfficient separationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIonic liquidPerrhenate

The invention relates to a supported perrhenate ionic liquid as well as a preparation method thereof. The technical scheme adopted is as follows: the preparation method comprises the following steps: selecting MCM-41 (Mobil Composition of Matters) as a carrier material; firstly, carrying out a reaction on chloropropyl triethoxysilane and the MCM-41; grafting a chloropropyl silicon structure to the surface of the MCM-41, and removing the byproduct ethanol; then, adding N-methyl imidazole so as to quaternize to obtain MCM-41 supported alkyl imidazole chlorine salt; and further adding ammonium perrhenate, and converting the chlorine salt into perrhenate through double-decompose reaction to obtain the MCM-41 supported alkyl imidazole perrhenate ionic liquid. The molar ratio of the reaction materials chloropropyl triethoxysilane, N-methyl imidazole, the MCM-41 and perrhenate is 1:(4-1):(3-1):(10-0.1). The method is applicable to support of various different types of alkyl imidazole perrhenate ionic liquids.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com