A kind of loaded perrhenate ionic liquid and preparation method thereof

A perrhenate, ionic liquid technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of high cost of ionic liquids, large amount of catalysts, and difficult separation of products. and other problems, to achieve the effect of promoting the reaction process, reducing the dosage, reducing the dosage of catalyst and the cost of catalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 supported perrhenate ionic liquid

[0018] In a 100mL reactor, add 25mL toluene, add MCM-41 (2g), chloropropyltriethoxysilane (1g), stir at 60°C for 12h under nitrogen protection, filter with suction, and wash with ethanol (5mL) 3 times, vacuum drying at 50°C for 10 h to obtain Intermediate A.

[0019] Using toluene (25mL) as solvent, add intermediate A (2g) and N-methylimidazole (1g), stir at 60°C for 12h under nitrogen atmosphere, filter with suction, wash with methanol (5mL) three times, and dry in vacuum at 50°C Intermediate B was obtained in 10h.

[0020] Using toluene (25mL) as solvent, add intermediate B (2g) and ammonium perrhenate (0.5g), react at room temperature for 24h, filter with suction, wash with water (10mL) three times, dry in a constant temperature oven at 110°C for 12h , to obtain the target product-loaded perrhenate ionic liquid, the structural formula of which is shown in I. Calculate its load to be about 8%.

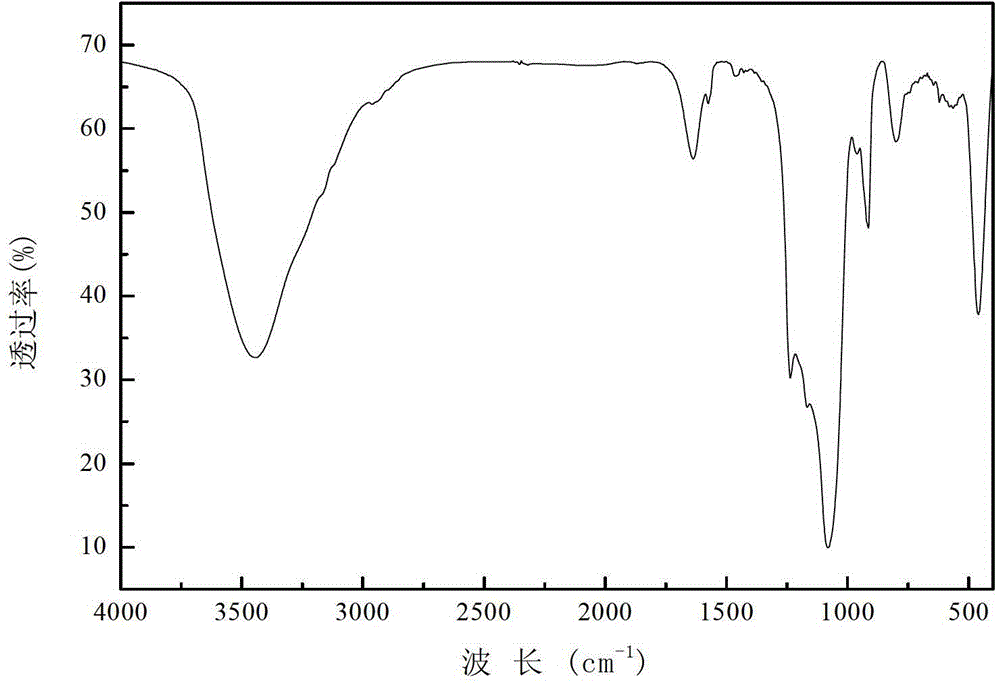

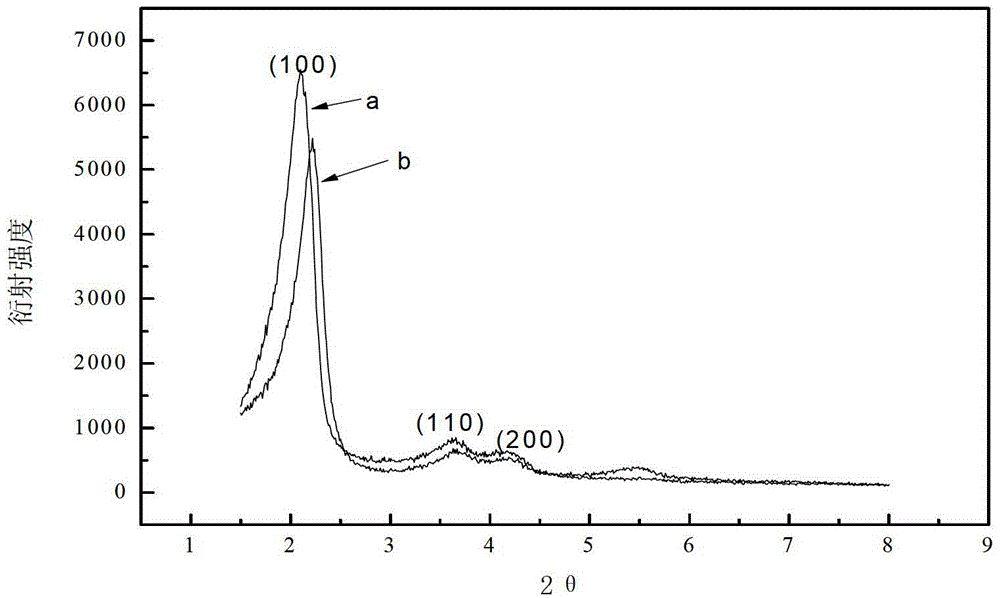

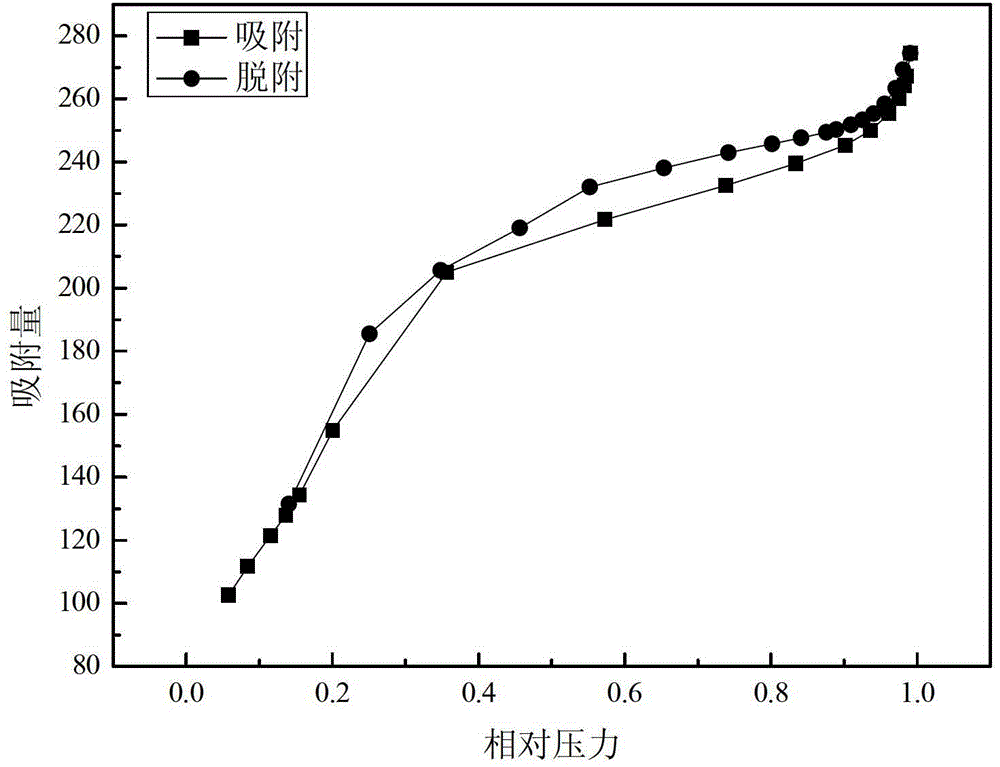

[0021] The product w...

Embodiment 2

[0025] Embodiment 2 supported perrhenate ionic liquid

[0026] In a 100mL reactor, add 25mL of dichloromethane, add MCM-41 (2g), chloropropyltriethoxysilane (1g), stir at 95°C for 10h under a nitrogen atmosphere, filter with suction, ethanol (5mL ) was washed three times, and dried in vacuum at 50°C for 10 h to obtain Intermediate A.

[0027] Using dichloromethane (25mL) as solvent, add intermediate A (2g), nitrogen methyl imidazole (1g) to react under nitrogen atmosphere, stir at 95°C for 15h, filter with suction, wash with methanol (5mL) three times, at 50 °C and vacuum-dried for 10 h to obtain the product intermediate B.

[0028] Using dichloromethane (25mL) as solvent, add intermediate B (2g) and ammonium perrhenate (0.5g), react at room temperature for 24h, filter with suction, wash with water (10mL) three times, and dry at 110°C After 12 hours in the box, the target product-loaded perrhenate ionic liquid was obtained, and its structural formula was shown in I. Calcula...

Embodiment 3

[0030] Embodiment 3 supported perrhenate ionic liquid

[0031] In a 100mL reactor, add 25mL ethanol, add MCM-41 (2g), chloropropyltriethoxysilane (1g), under nitrogen protection environment, stir at 180°C for 9h, suction filter, wash with ethanol (5mL) Three times, vacuum drying at 50 ° C for 10 h to obtain Intermediate A.

[0032] Using ethanol (25mL) as solvent, add intermediate A (2g), nitrogen methyl imidazole (1g) to react under nitrogen atmosphere, stir at 180°C for 8h, filter with suction, wash with methanol (5mL) three times, vacuum at 50°C After drying for 10 h, Intermediate B was obtained.

[0033] Using ethanol (25mL) as solvent, add intermediate B (2g) and ammonium perrhenate (0.5g), react at room temperature for 24h, filter with suction, wash with water (10mL) three times, dry in a constant temperature oven at 110°C for 12h , to obtain the target product-loaded perrhenate ionic liquid, the structural formula of which is shown in I. Calculate its load to be abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com