Patents

Literature

193results about How to "Increase interface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

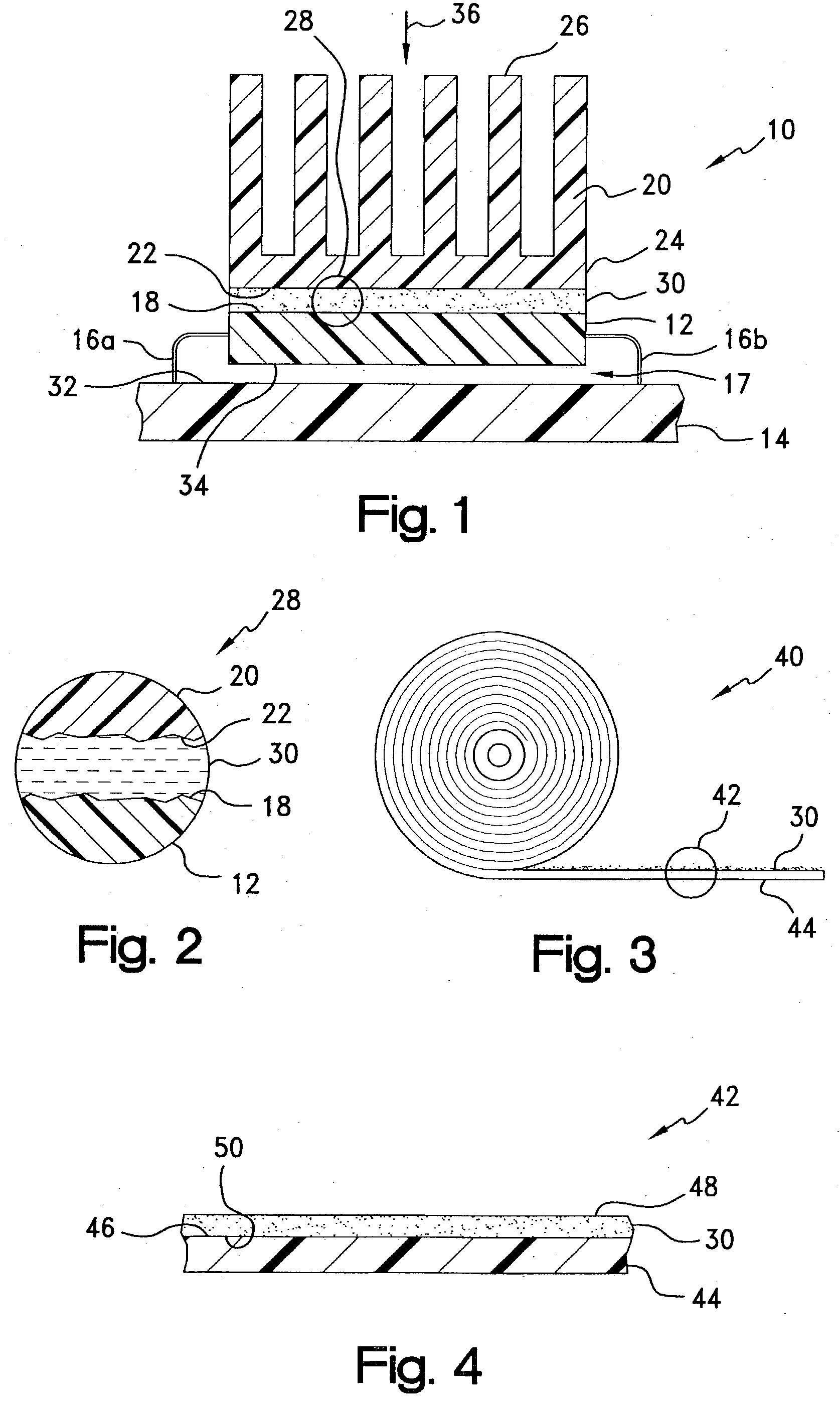

Conformal thermal interface material for electronic components

InactiveUS6054198AOptimize allocationReadily apparentSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureConductive materials

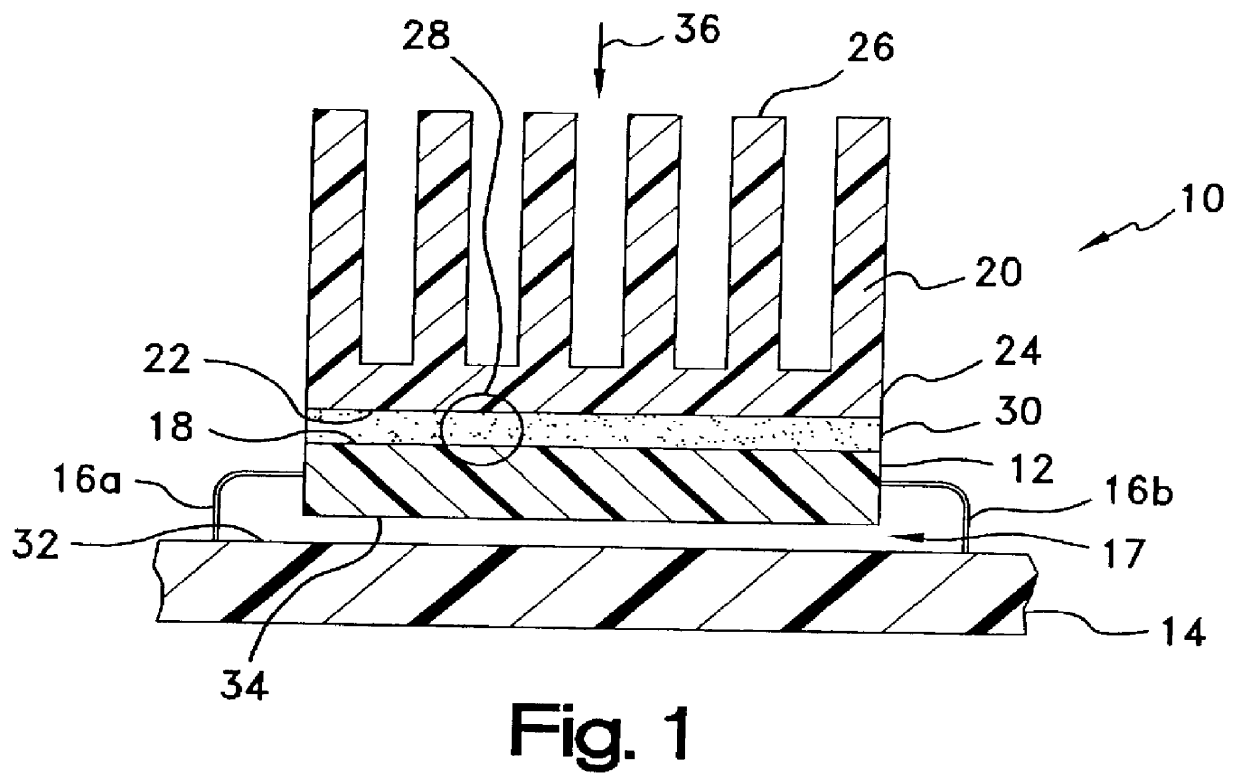

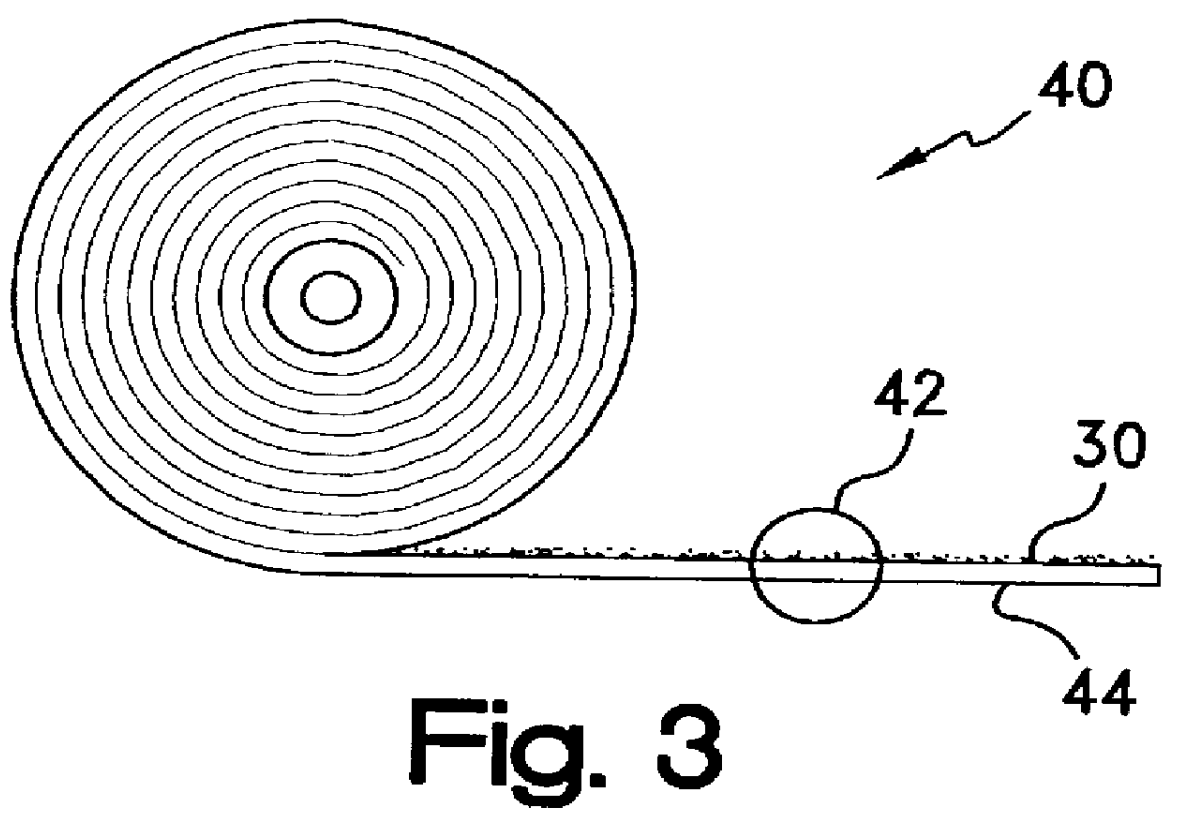

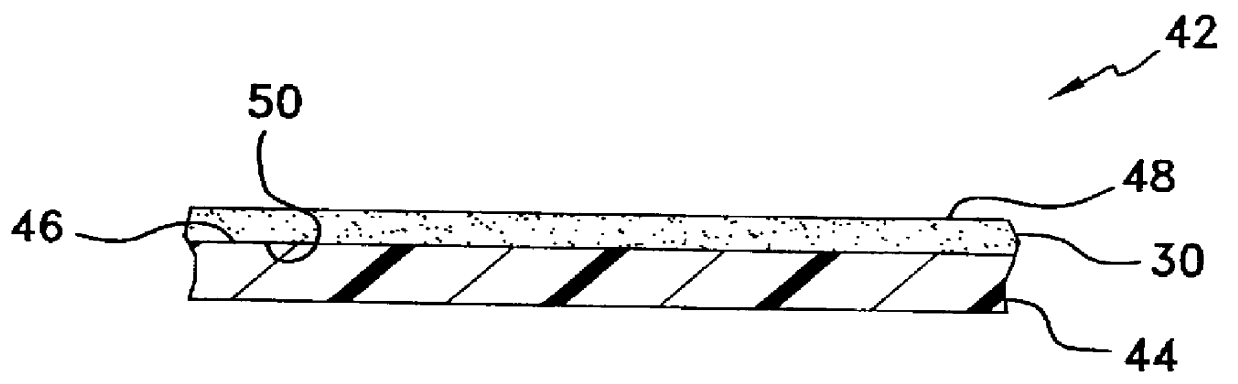

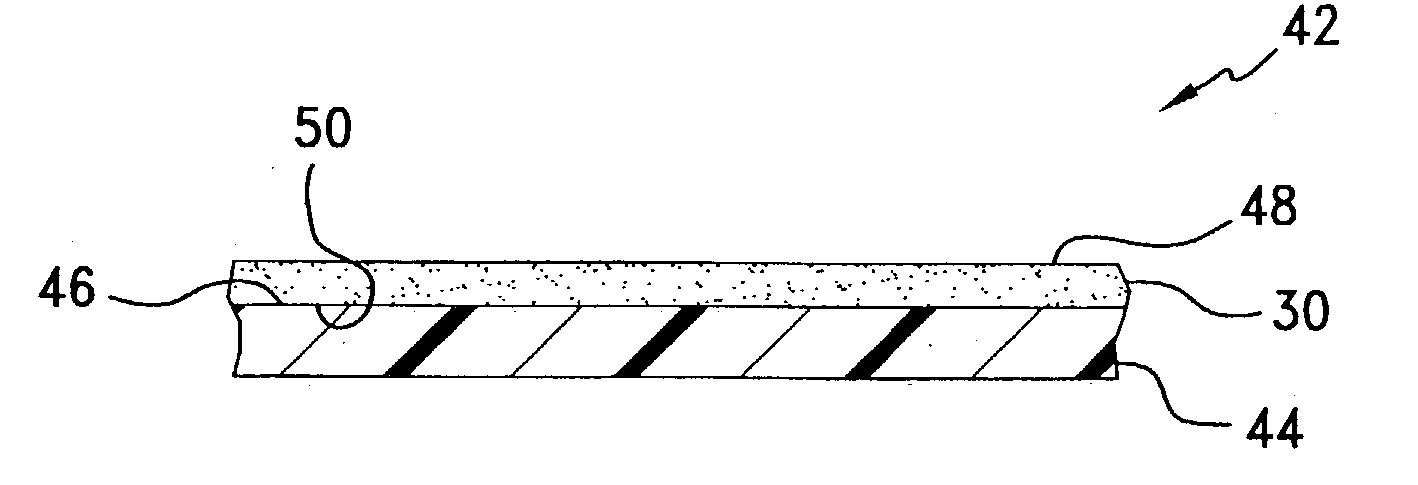

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:PARKER INTANGIBLES LLC

Conformal thermal interface material for electronic components

InactiveUS20030207064A1Readily apparentIncrease interface areaLamination ancillary operationsSemiconductor/solid-state device detailsRoom temperatureConductive materials

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:BUNYAN MICHAEL H +1

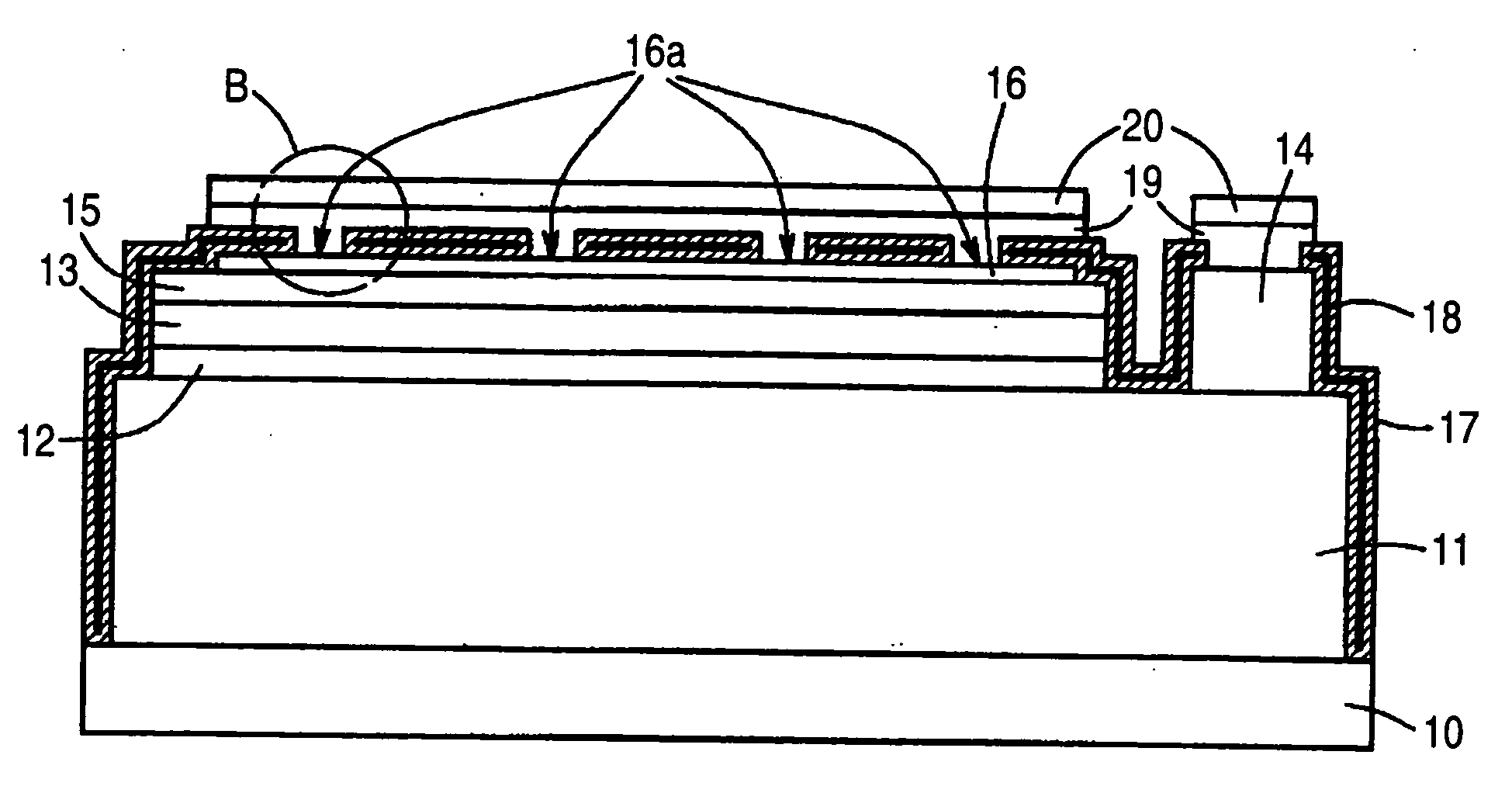

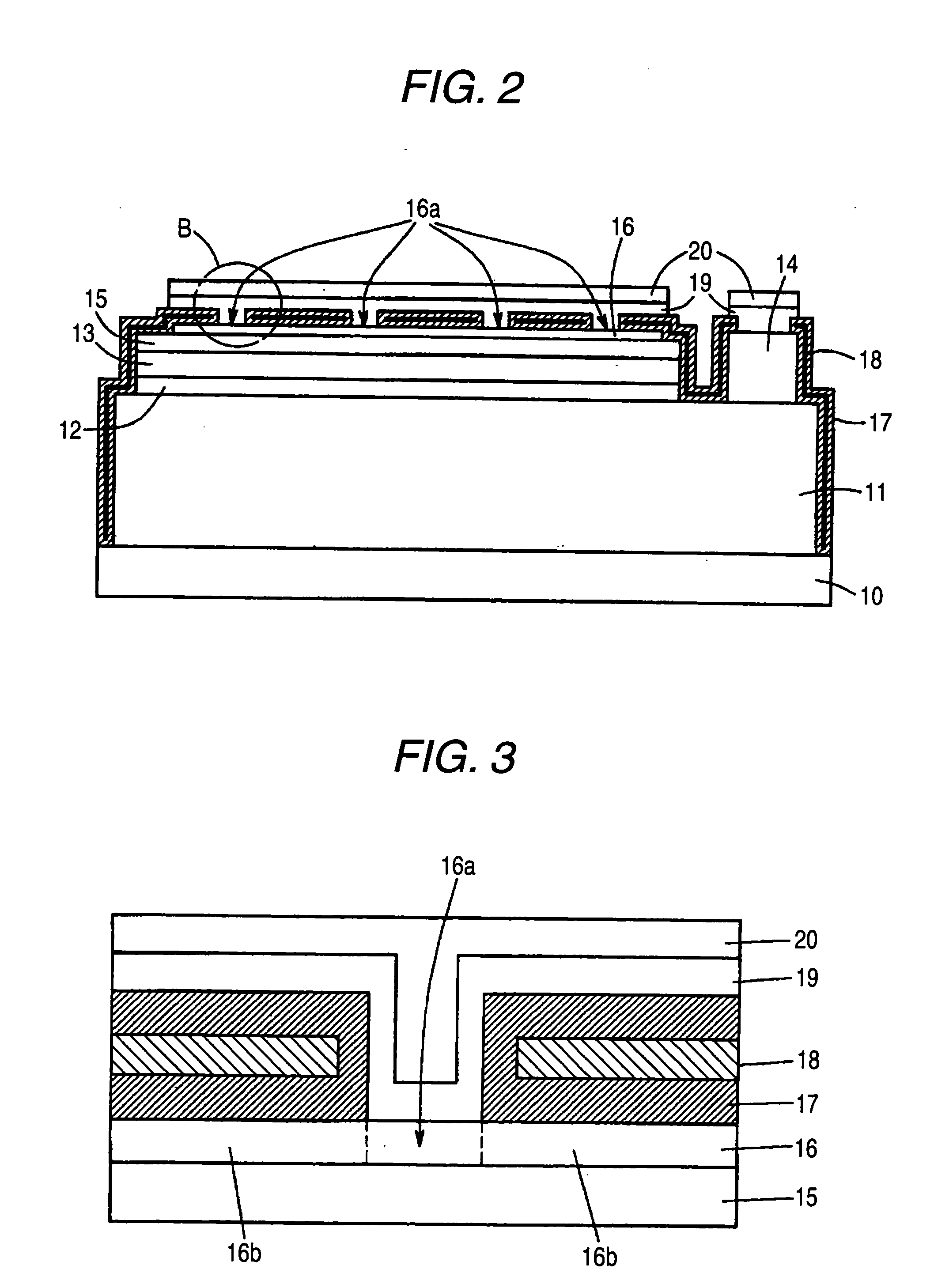

Flip chip type light-emitting element

ActiveUS20090039374A1Inhibit deteriorationIncrease interface areaSolid-state devicesSemiconductor devicesContact electrodeLight transmission

In a flip chip type light-emitting element of the present invention, an n type contact electrode 14 is formed on an n layer 11 exposed in a comb-tooth shape, a light transmission electrode 15 made of an ITO is formed over the entire surface of an upper surface of a p layer 13 and twenty pad electrodes 16 are formed at prescribed intervals on the light transmission electrode 15. The plane form of the pad electrode 16 has four branches 16b protruding in the form of a cross from a circular central part 16a and the adjacent pad electrodes 16 connected to each other by the branches 16b.

Owner:TOYODA GOSEI CO LTD

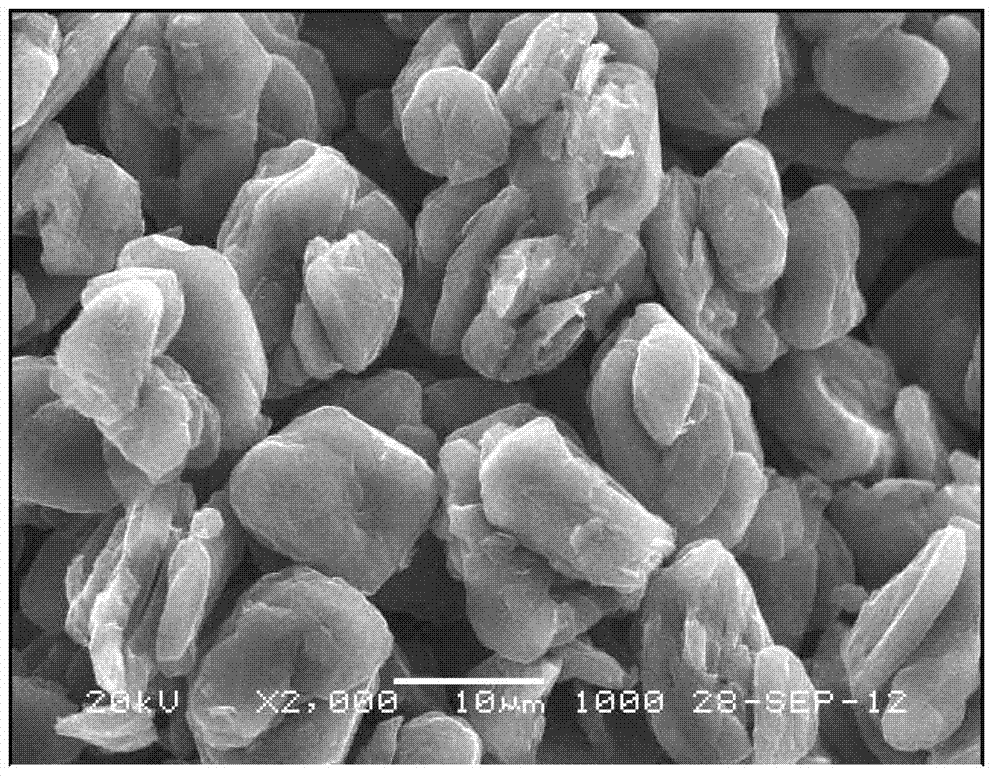

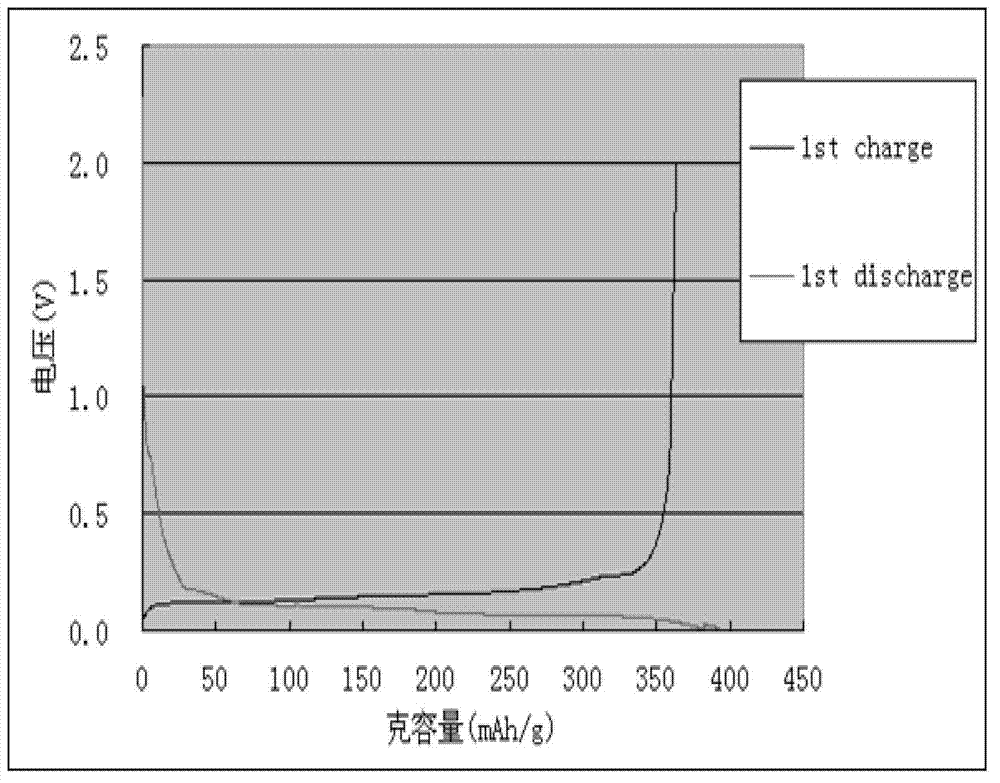

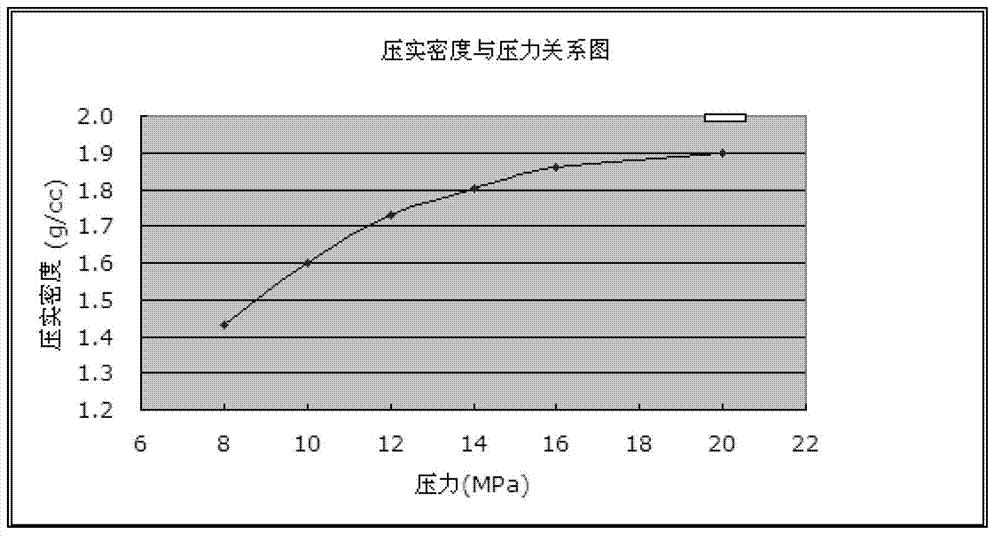

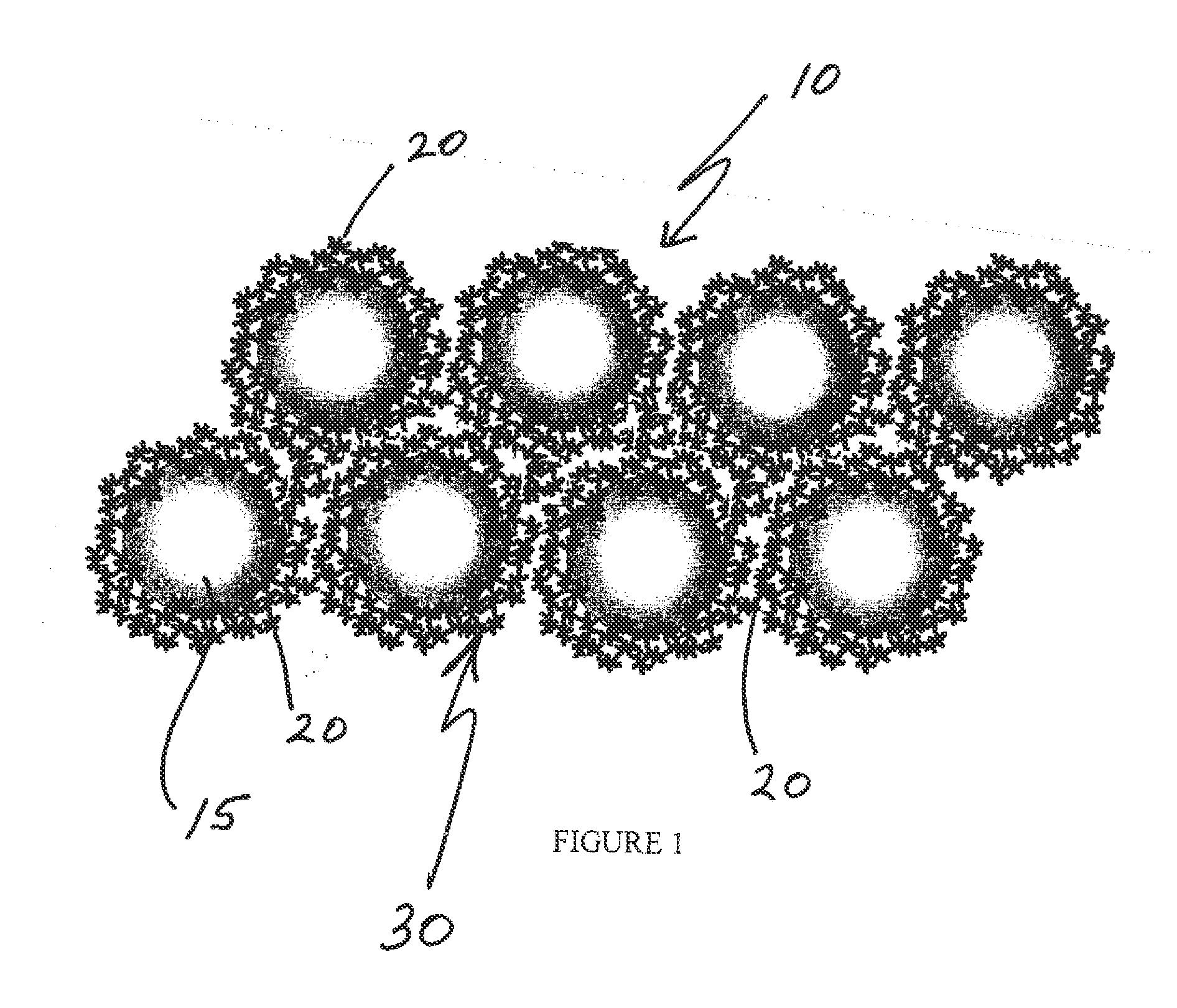

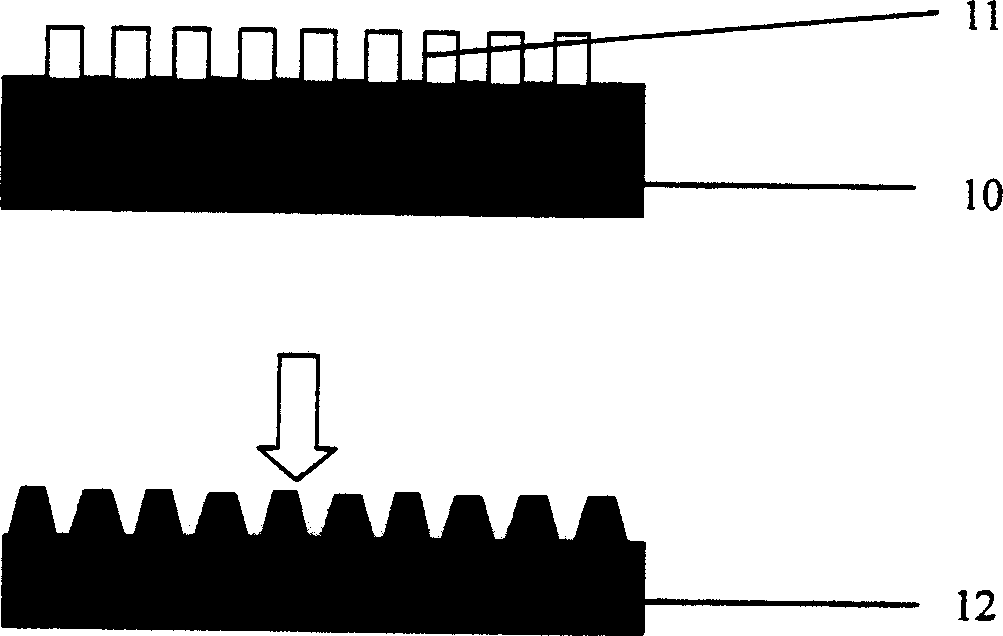

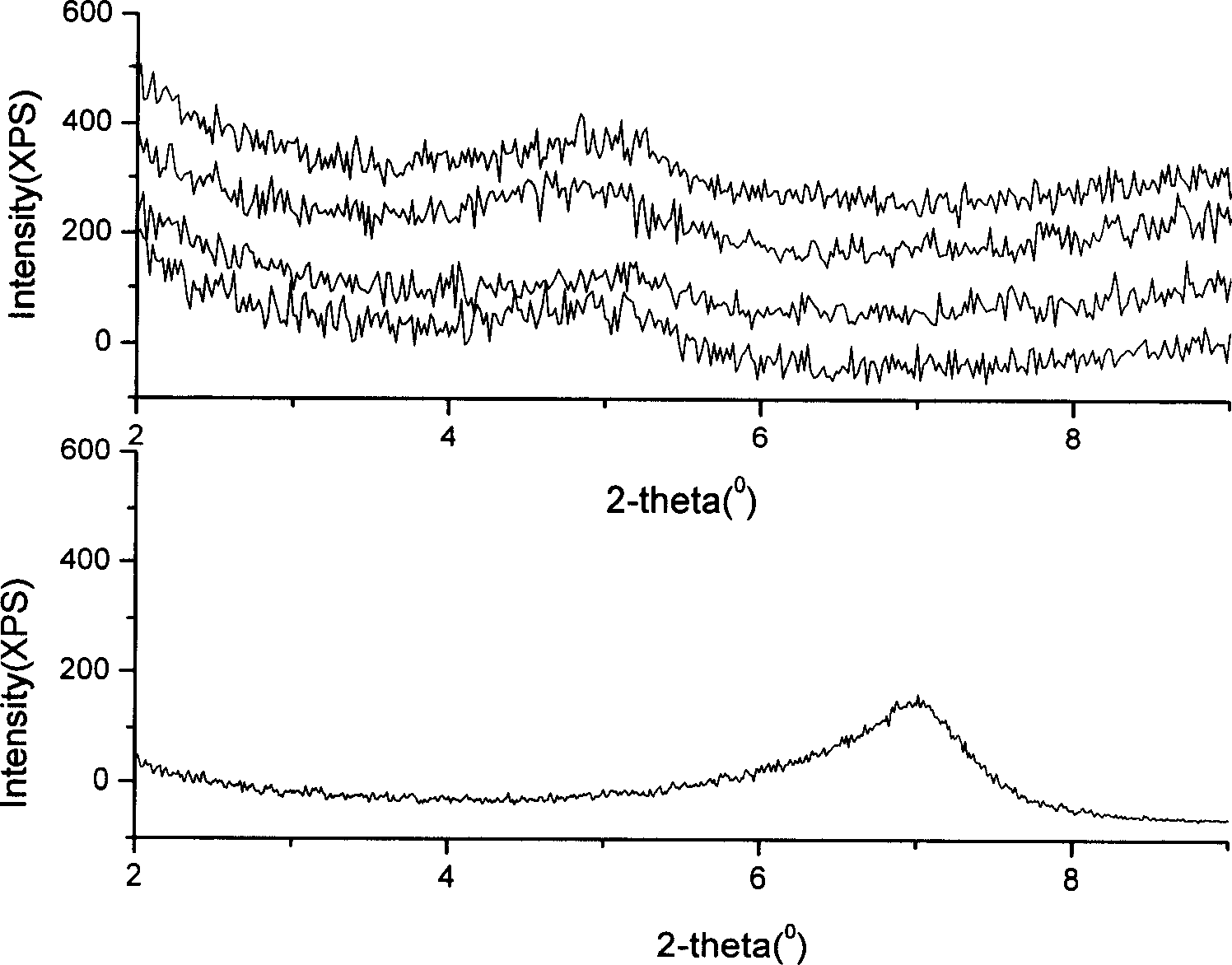

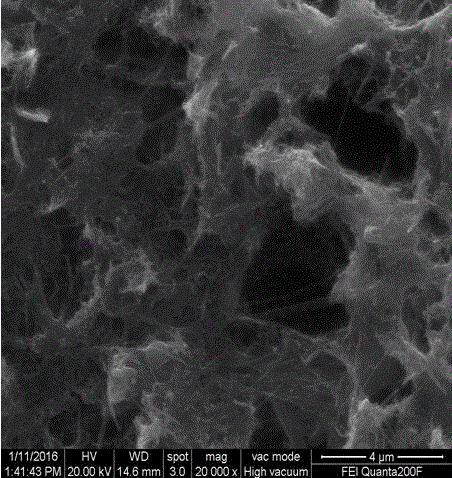

Preparation method of compound graphite material for lithium ion secondary battery

ActiveCN103241731AHigher than the surfaceHigh magnificationGraphiteCell electrodesLarge capacityLithium

The invention discloses a preparation method of a compound graphite material for a lithium ion secondary battery. The preparation method comprises the following steps of: firstly pouring natural graphite, a binding agent and a graphite catalyst which are taken as raw materials into a roller furnace, wherein the roller furnace rotates all the time in a raw material pouring process; then progressively heating the raw materials, namely heating the raw materials in the roller furnace by adopting a progressive heating mode while the roller furnace rotates in a heating process, and then carrying out natural cooling to normal temperature after the raw materials in the roller furnace are heated; and finally carrying out graphitizing treatment on the raw materials, thus the binding agent forms artificial graphite, and the artificial graphite forms a coating on natural graphite particles, so as to form a shell-core structure, and compound particles of the shell-core structure are further spliced to form compound graphite particles with the required grain diameter. The compound graphite material prepared by the invention is of the shell-core structure with the natural graphite as an inner core and an artificial graphite layer as a coating, and the compound graphite has good isotropy, high capacity, high compactness, excellent multiplying, low temperature and cyclic performances and low electrode expansion. The preparation method of the compound graphite material for the lithium ion secondary battery adopts a method that coating and splicing are carried out at the same time, the preparation method is simple and practicable, and the cost is low.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Gel Technology Suitable for Use in Cosmetic Compositions

InactiveUS20100266649A1Optimize optical diffusion effectIncrease interfacial areaBiocideHeavy metal active ingredientsWrinkleFine grain

A gel system comprising a fractal network of nanoparticles and macroscopic particles is disclosed. The gel system is capable of forming an “optical gel” effective to blurrfine lines and wrinkles as a consequence of the size domain differences between the fractal particles and the macroscopic particles. Cosmetic compositions comprising such gels and methods for their use are also disclosed.

Owner:AVON PROD INC

High-luminance chip of luminescent tube in GaN base, and preparation method

InactiveCN1874012AImprove thermal characteristicsImprovement and conductivityLaser detailsSolid-state devicesPhotonic crystal structureLead structure

The technical scheme discloses high brightness LED structure with graphic surface and microstructure. Using Nano pressing technique prepares each graphic film from organic material on luminous surface of LED so as to form microstructure on LED surface in favor of transgression of emitting light from active region, for example micrographics with structure or coarsening, and photon crystal structure. Introducing the said micrographics on surface makes interfacial area of light emergence medium increase. The increased surface presents great lot small areas unordered arranged. Emergence of light from active region and interface of medium is at random in a certain extent. The invention improves directions of emergence light, increases probability of emergence so as to raise light extraction efficiency and external quantum efficiency of LED.

Owner:PEKING UNIV

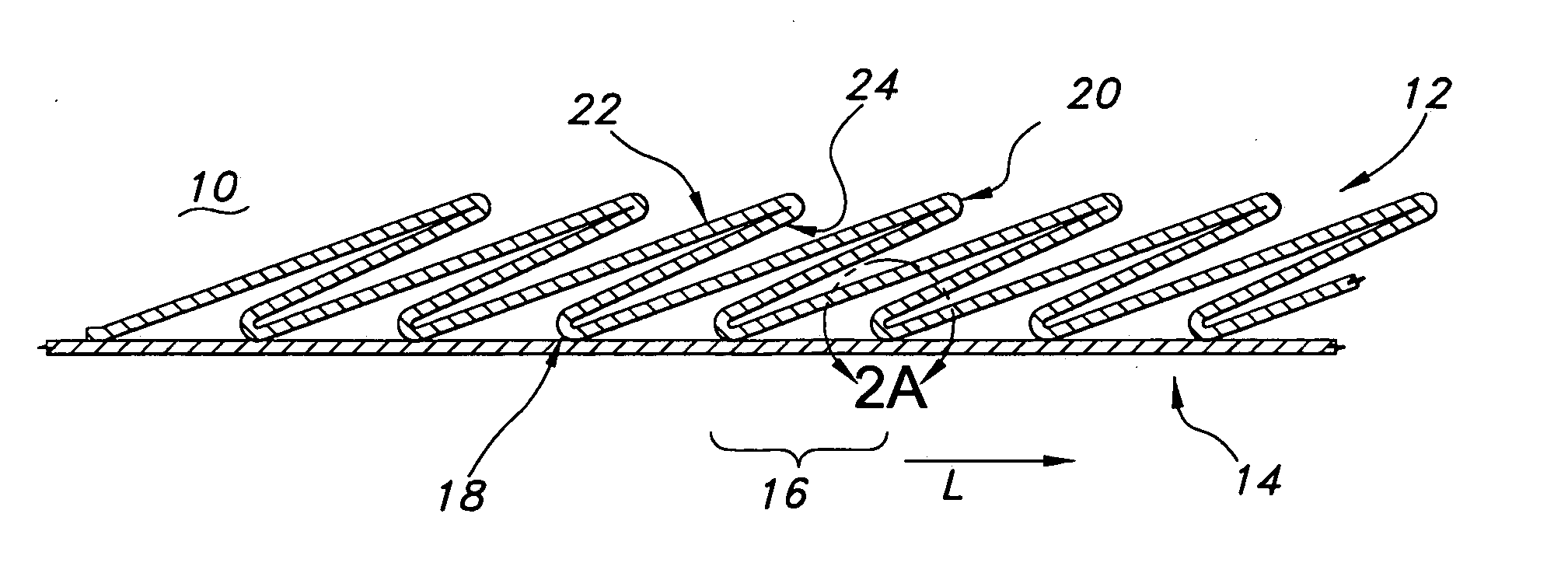

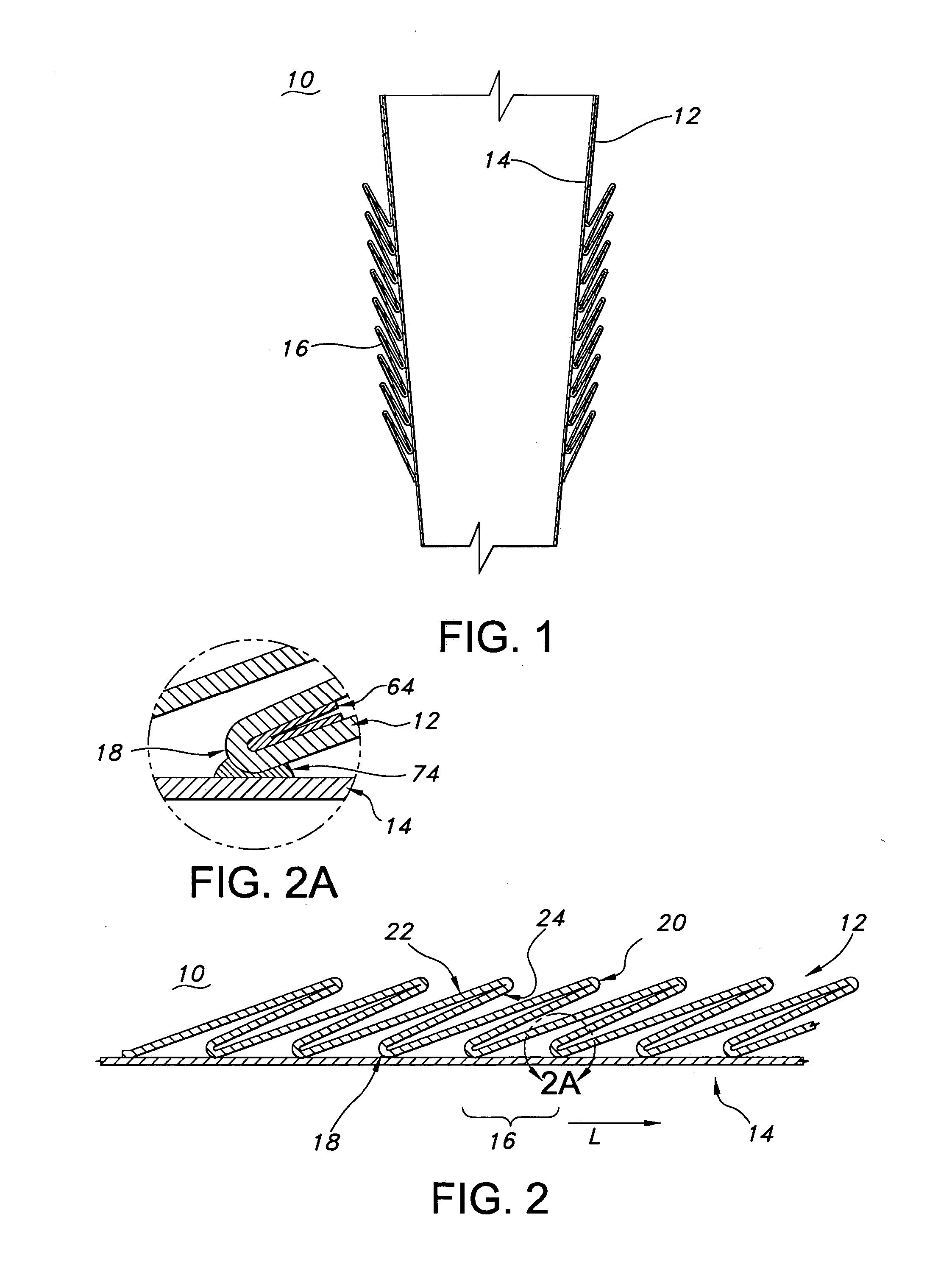

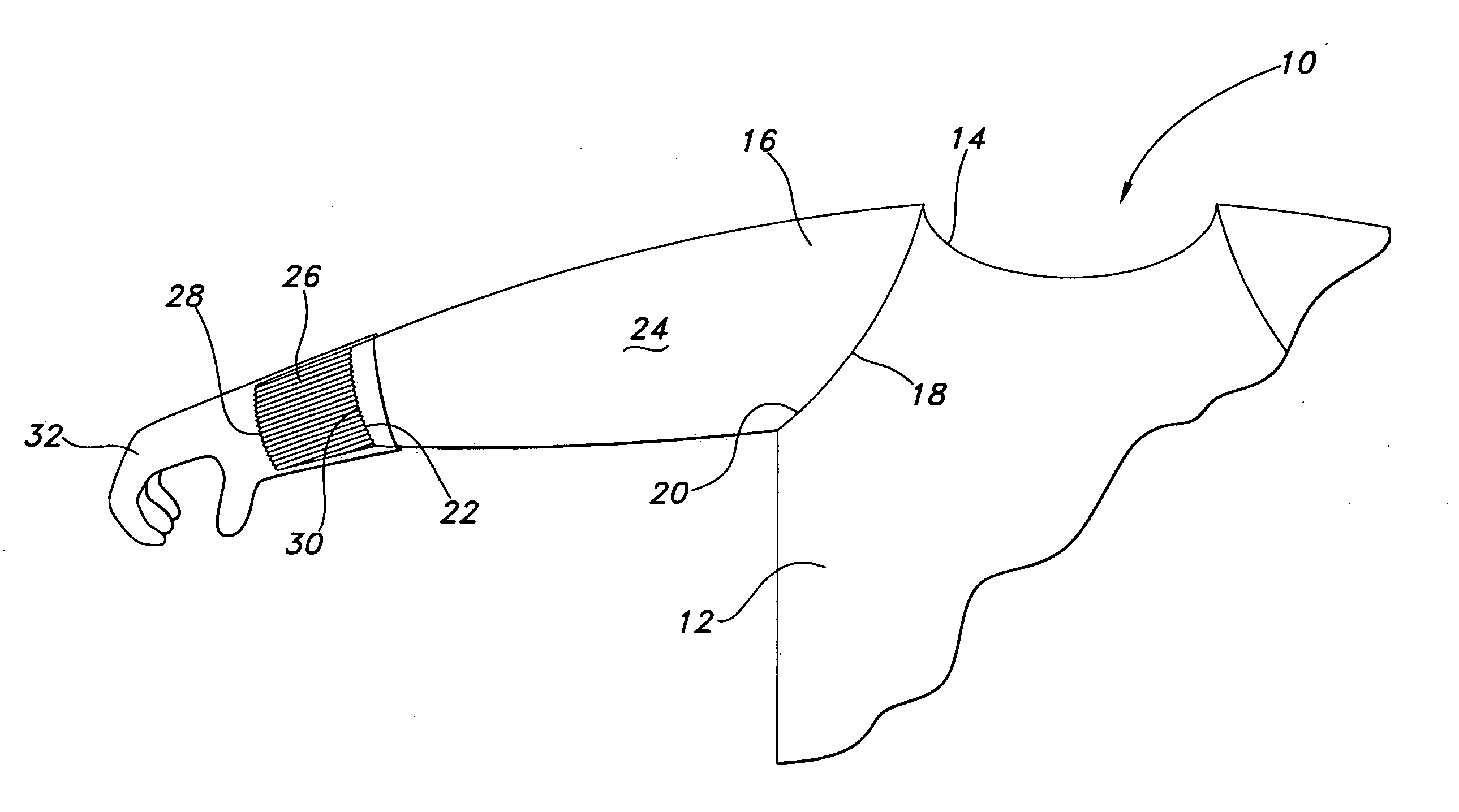

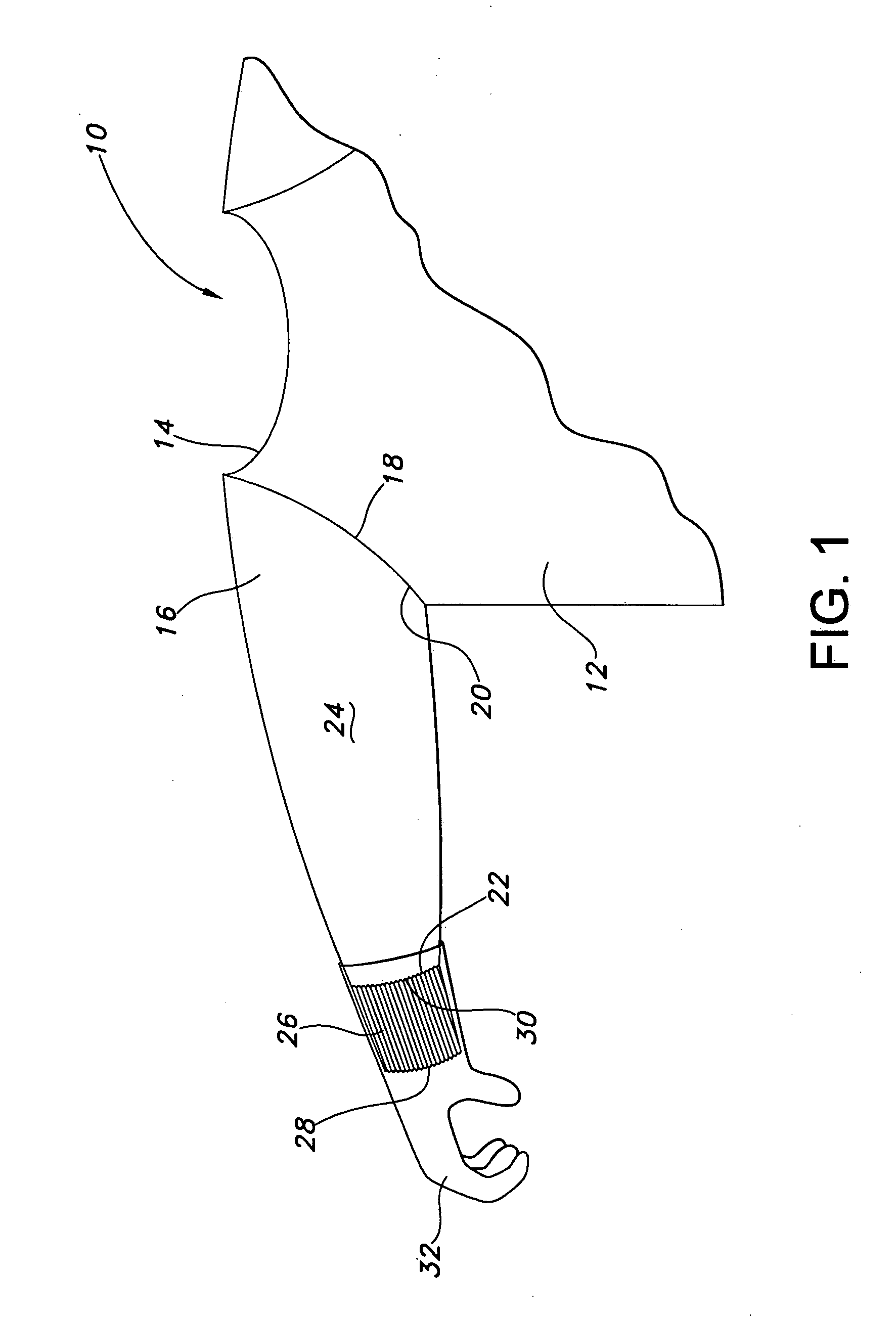

Apparel with telescoping sleeves

InactiveUS20060107437A1Prevent movementEffective and economical mechanismConvertible garmentGlovesEngineeringBiomedical engineering

An extensible sleeve having a first sleeve portion and a second sleeve portion is provided. The extensible sleeve is adapted to be used in a protective garment. A plurality of creases are disposed along one of the sleeve portions forming pleats. The other sleeve portion is placed internal and coincident to the first and the pleats are affixed to an outer surface of this internal sleeve portion. Pulling upon the sleeve portion would cause a partial to a total unfolding of at least one pleat resulting in a lengthening of the sleeve. The pleats may also prove useful in retaining a glove upon the sleeve.

Owner:KIMBERLY-CLARK WORLDWIDE INC

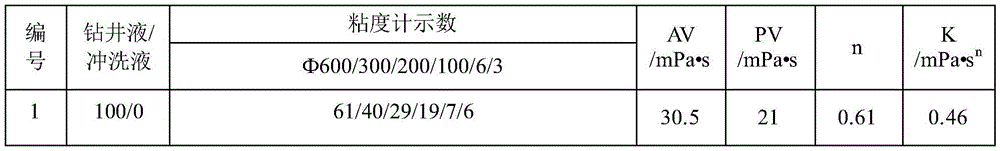

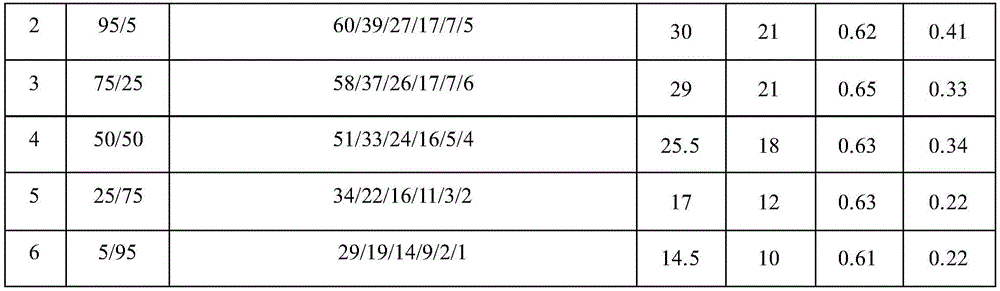

Well cementation flushing liquid system suitable for oil-based drilling fluid and preparation method thereof

InactiveCN105419758AReduce interfacial tensionImprove flushing effectDrilling compositionEngineeringVolumetric Mass Density

A well cementation flushing liquid system suitable for an oil-based drilling fluid and a preparation method thereof. The invention mainly solves the defects of low flushing efficiency, poor wetting conversion capability and poor interface cementing quality in the flushing liquids in the prior art. The flushing liquid system comprises the following components, by weight: 100 parts of clear water, 0.8-1.2 parts of an anionic surfactant, 0.6-0.8 parts of a nonionic surfactant, 0.7-1.0 part of a cosurfactant, 6.0-10.0 parts of an oil phase, 8.0-12.0 parts of a salt water phase, 0.15-5.0 parts of a polymer, 0.0-150 parts of a weighting agent and 1.0-2.5 parts of salt. The flushing liquid system is adjustable in density within 1.01-1.90 g / cm<3> and is 20-130 DEG C in available temperature range. The flushing liquid system can quickly remove residual oil-based drilling fluid, is strong in wetting conversion capability, ensures cementation between cement rings and an annular space, and is wide in application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

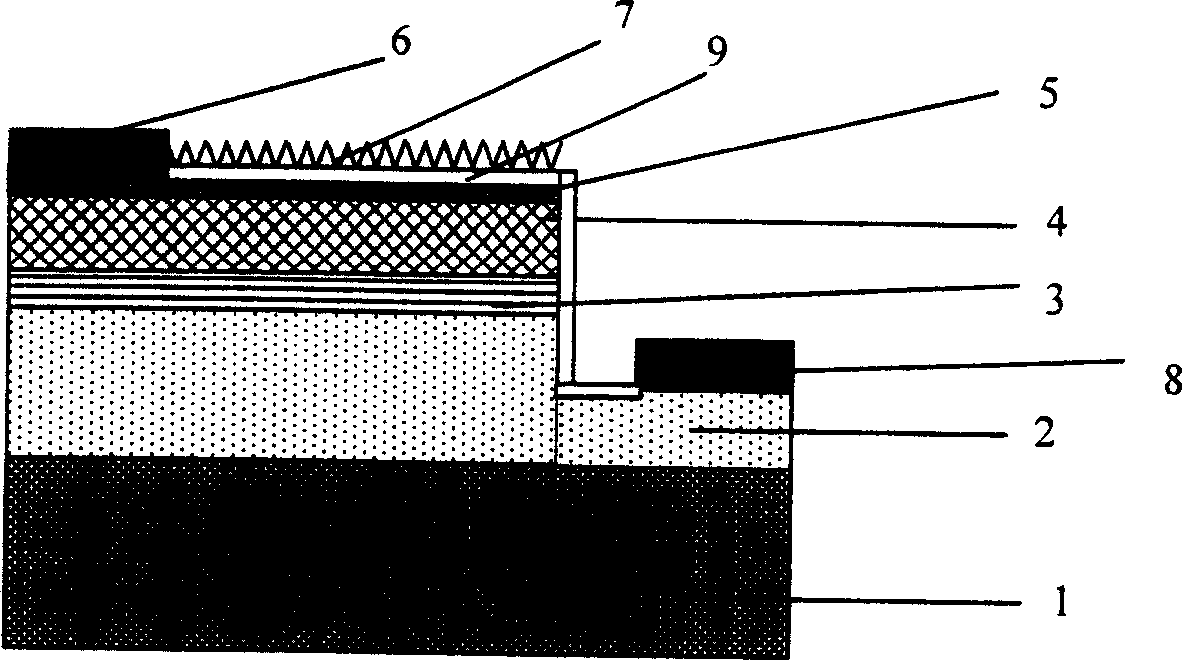

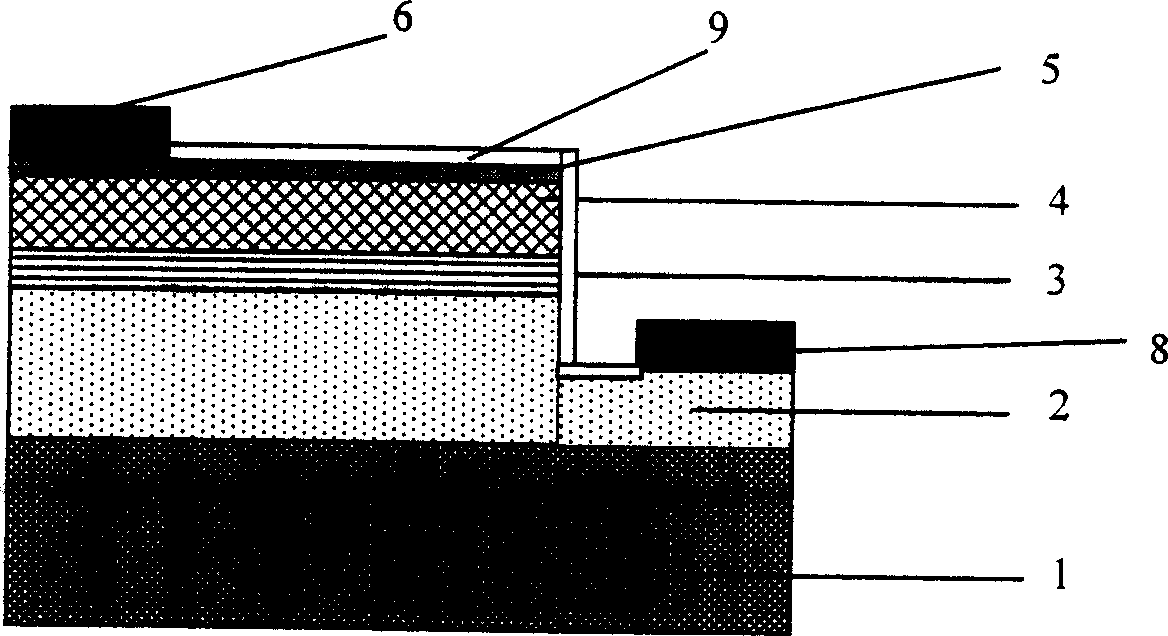

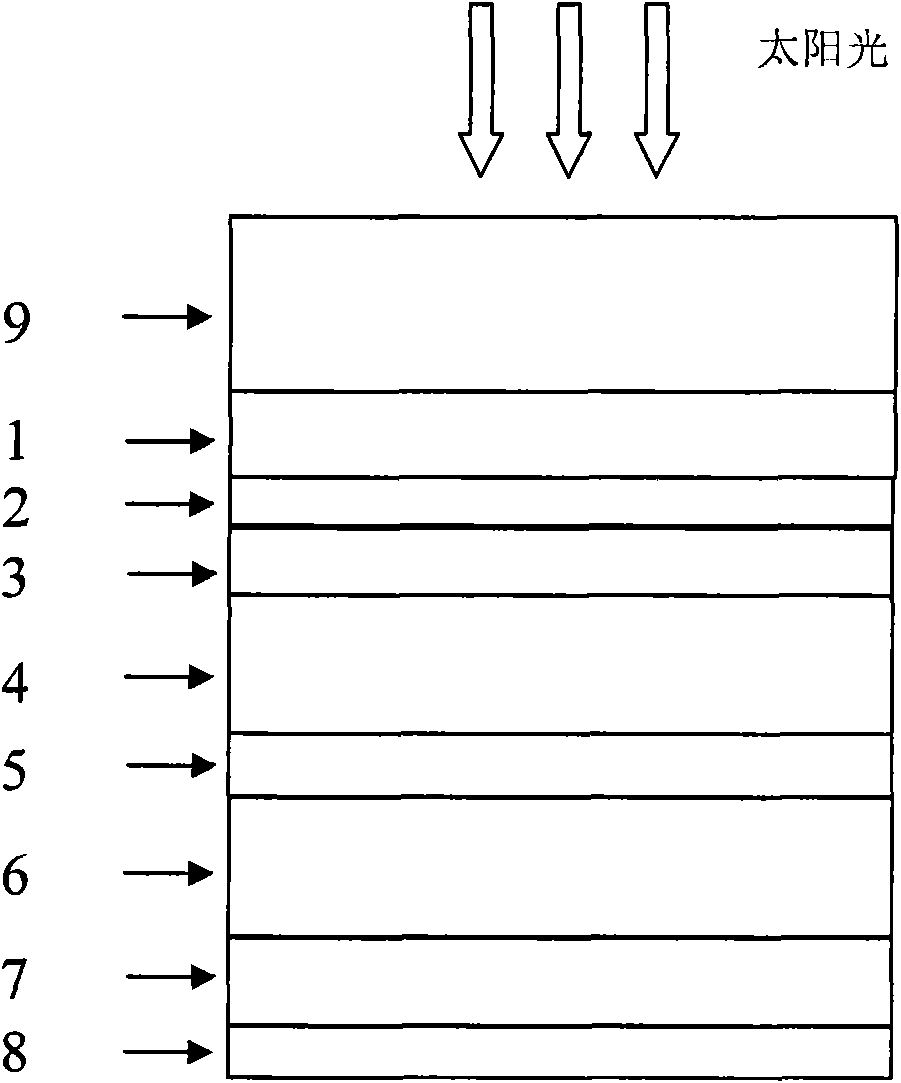

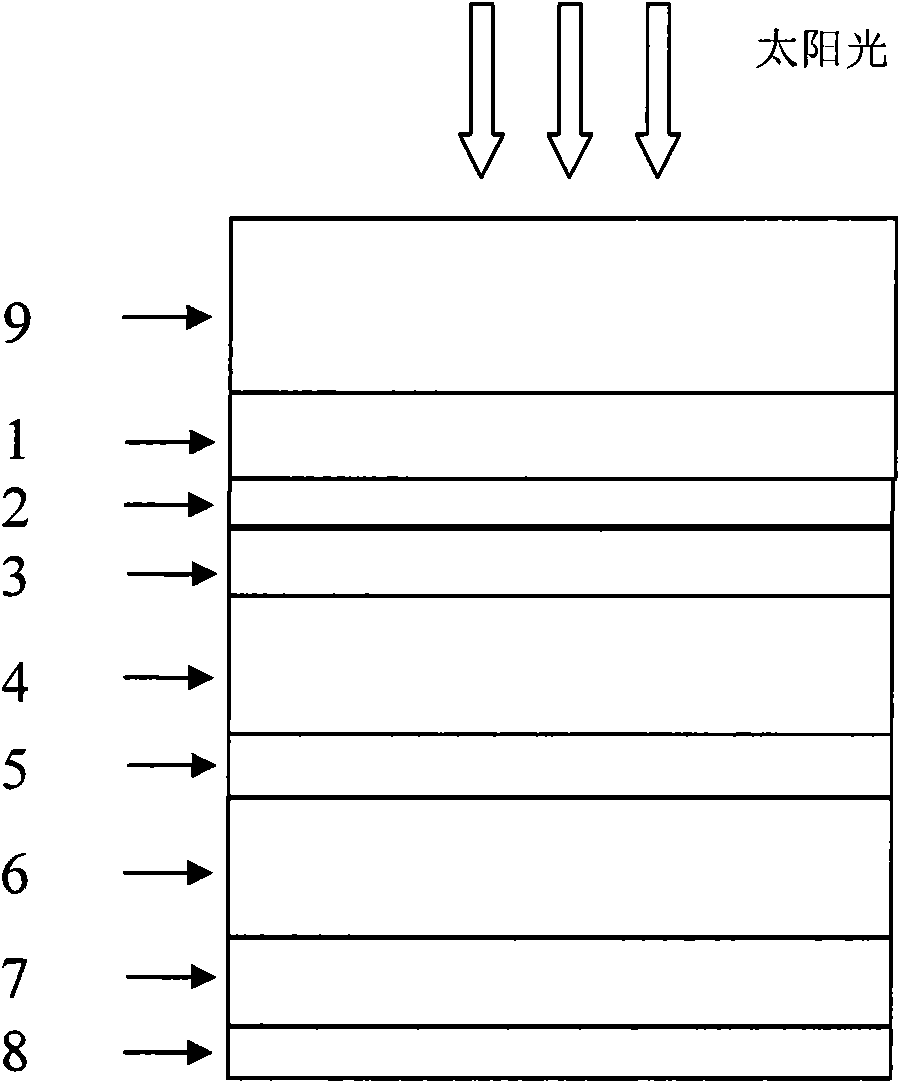

Solar cell with small organic molecule mixture heterojunction and preparation method of solar cell

InactiveCN102148331AImprove light utilizationIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionSolar cell

The invention relates to a solar cell with a small organic molecule mixture heterojunction, which comprises a transparent insulating layer, wherein a transparent electrode layer, a first buffer layer, a first photosensitive layer, a second photosensitive layer, a third photosensitive layer, a second buffer layer and a high-reflectivity electrode layer are sequentially laminated at one side of the transparent insulating layer; and a lower transition layer is formed at the other side of the transparent insulating layer. The mixture heterojunction and the lower transition layer are combined together, so that the solar spectrum utilization ratio of the organic solar cell and exciton dissociation efficiency can be improved; meanwhile, the high-reflectivity electrode is reasonable utilized, the optical field distribution in the device can be adjusted, therefore, the solar cell can work at an optimum state. The invention also relates to a preparation method of the solar cell.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

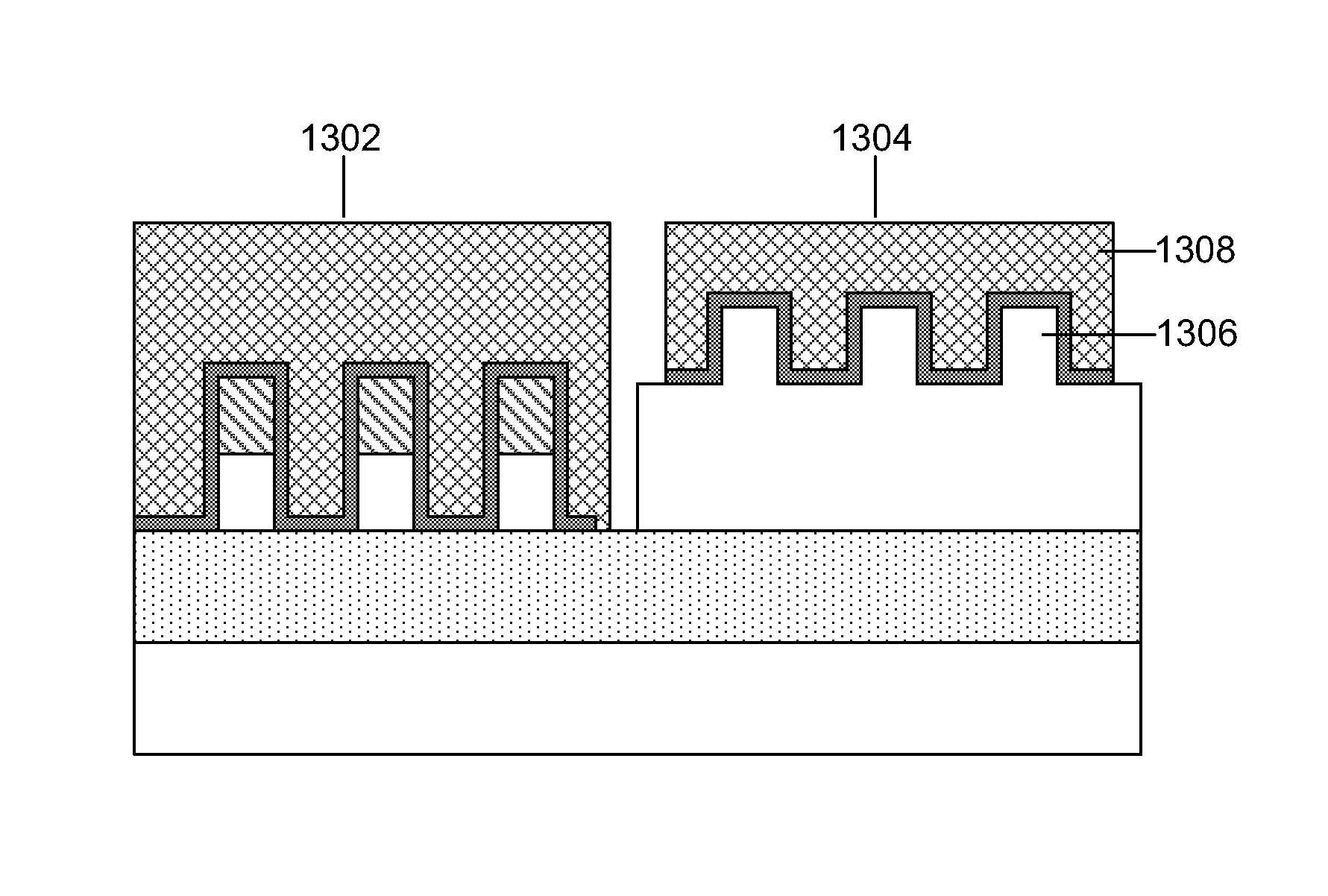

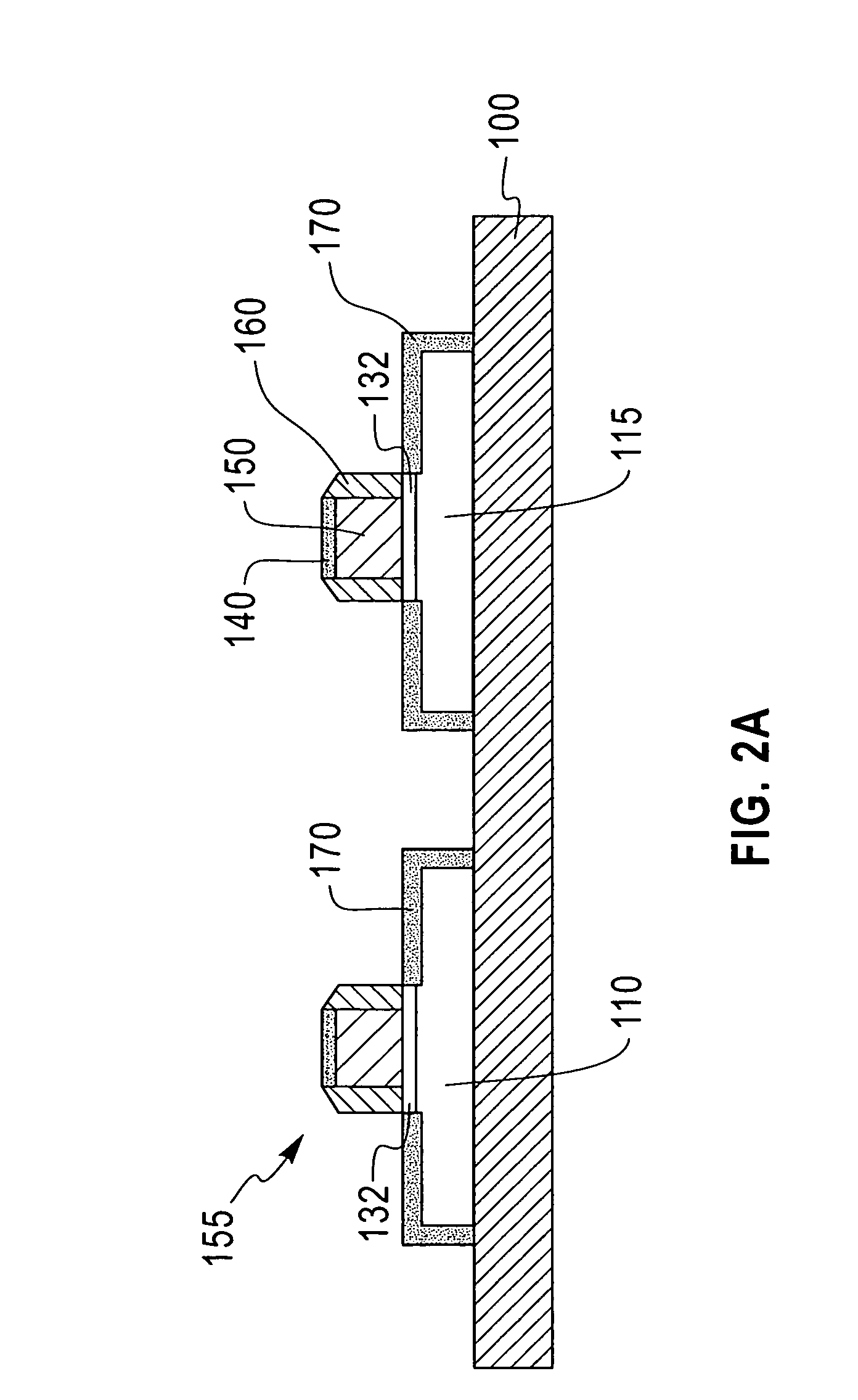

MOS capacitors with a finfet process

Capacitors include a first electrical terminal that has fins formed from doped semiconductor on a top layer of doped semiconductor on a semiconductor-on-insulator substrate; a second electrical terminal that has an undoped material having bottom surface shape that is complementary to the first electrical terminal, such that an interface area between the first electrical terminal and the second electrical terminal is larger than a capacitor footprint; and a dielectric layer separating the first and second electrical terminals.

Owner:GLOBALFOUNDRIES US INC

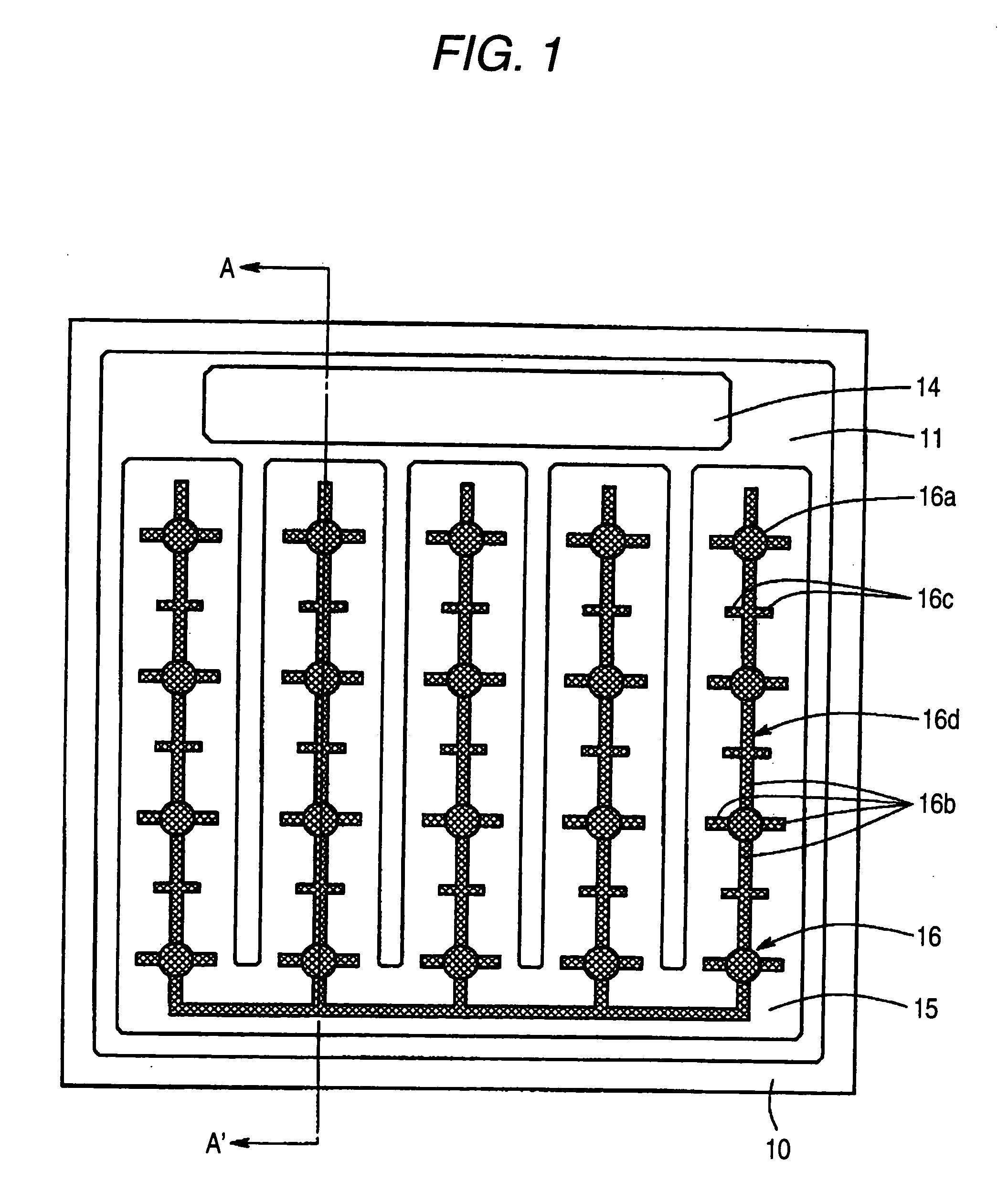

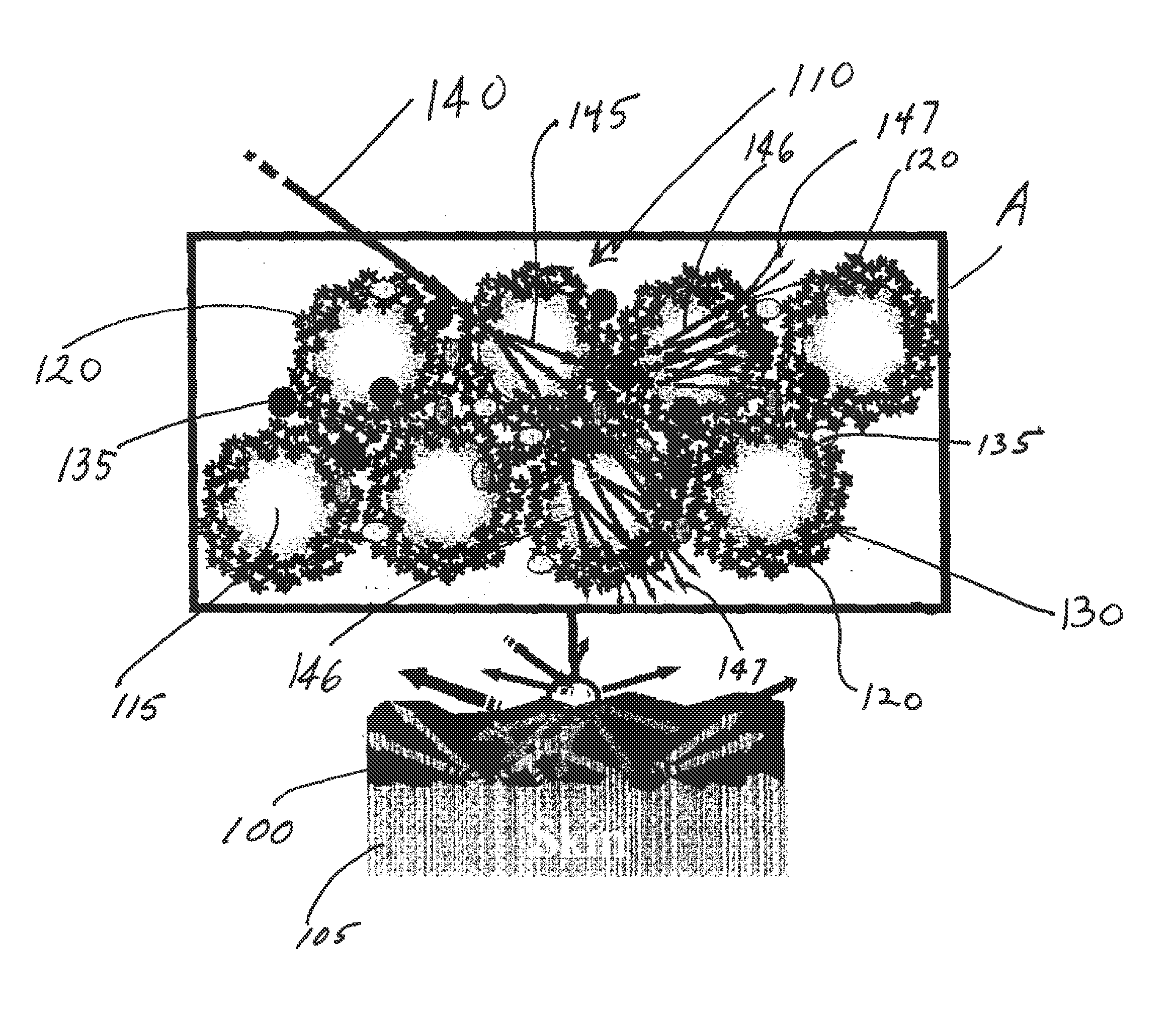

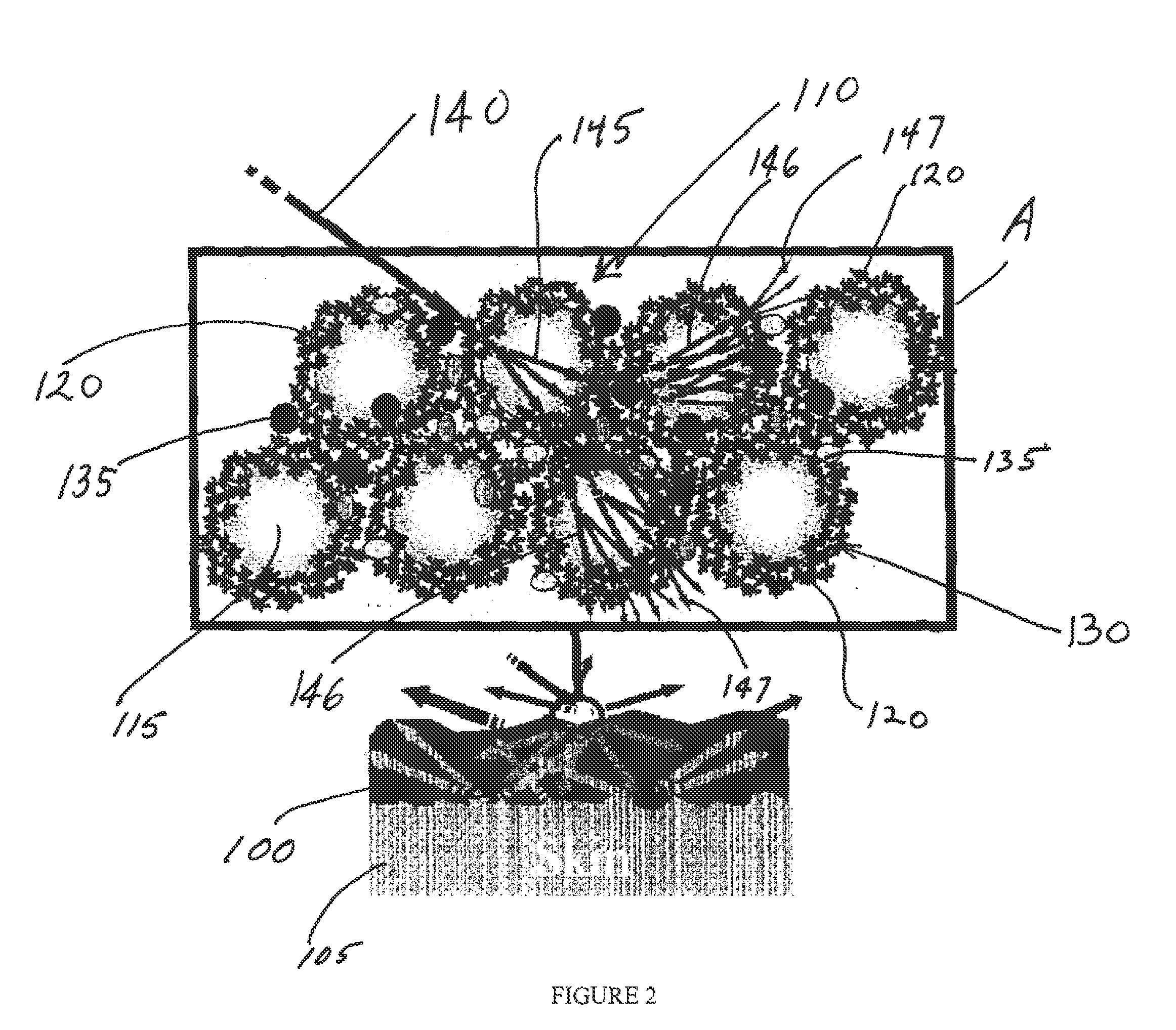

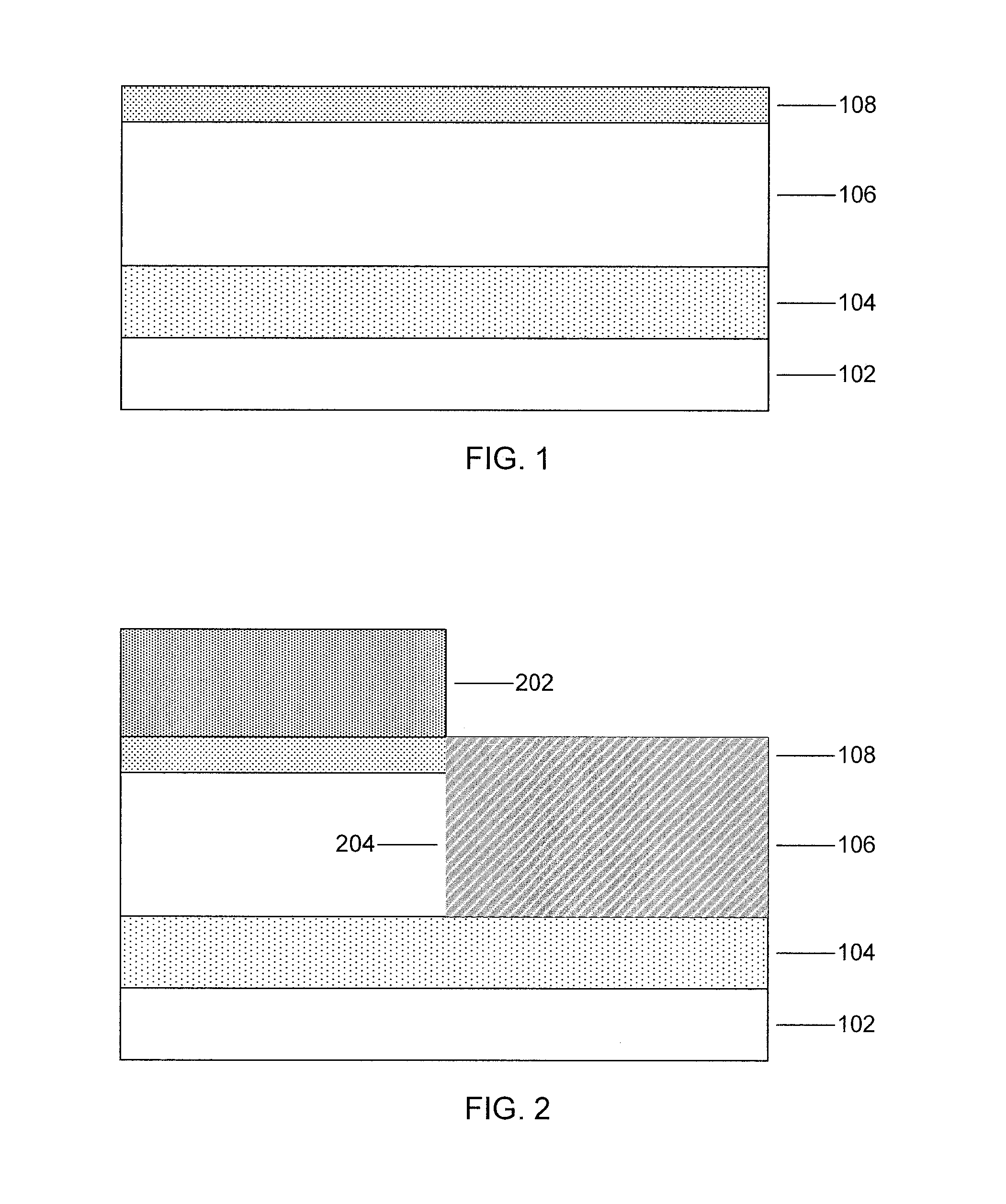

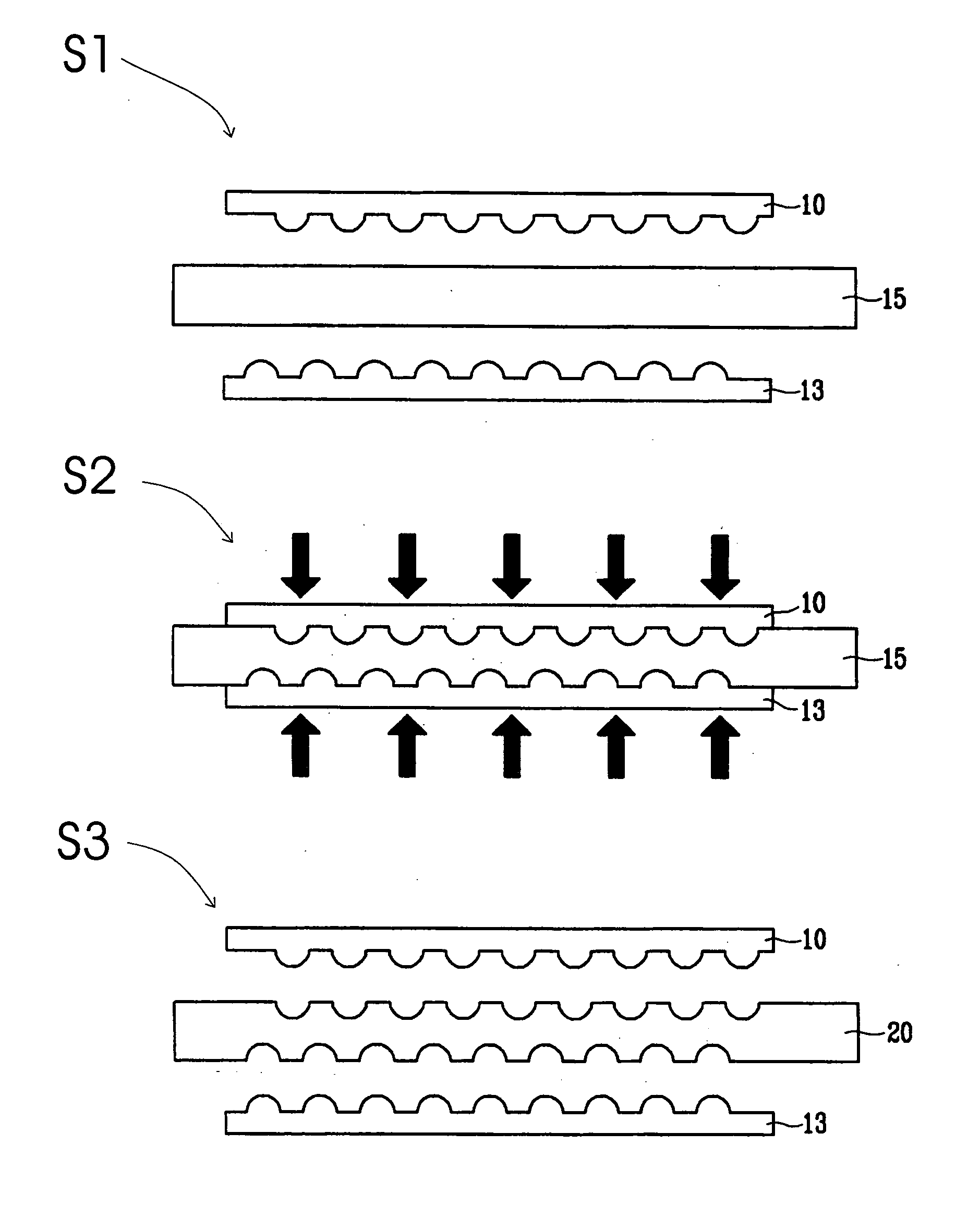

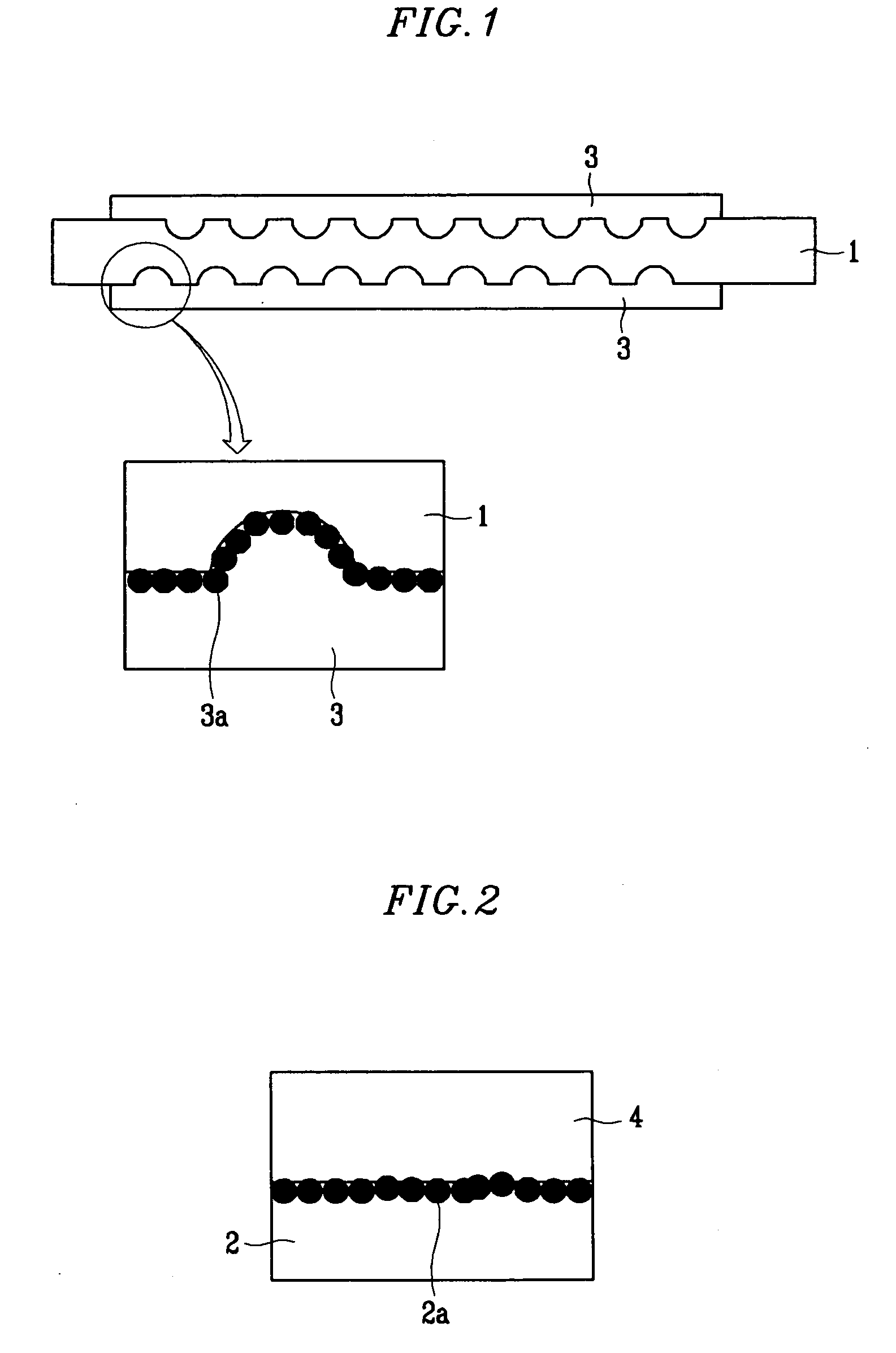

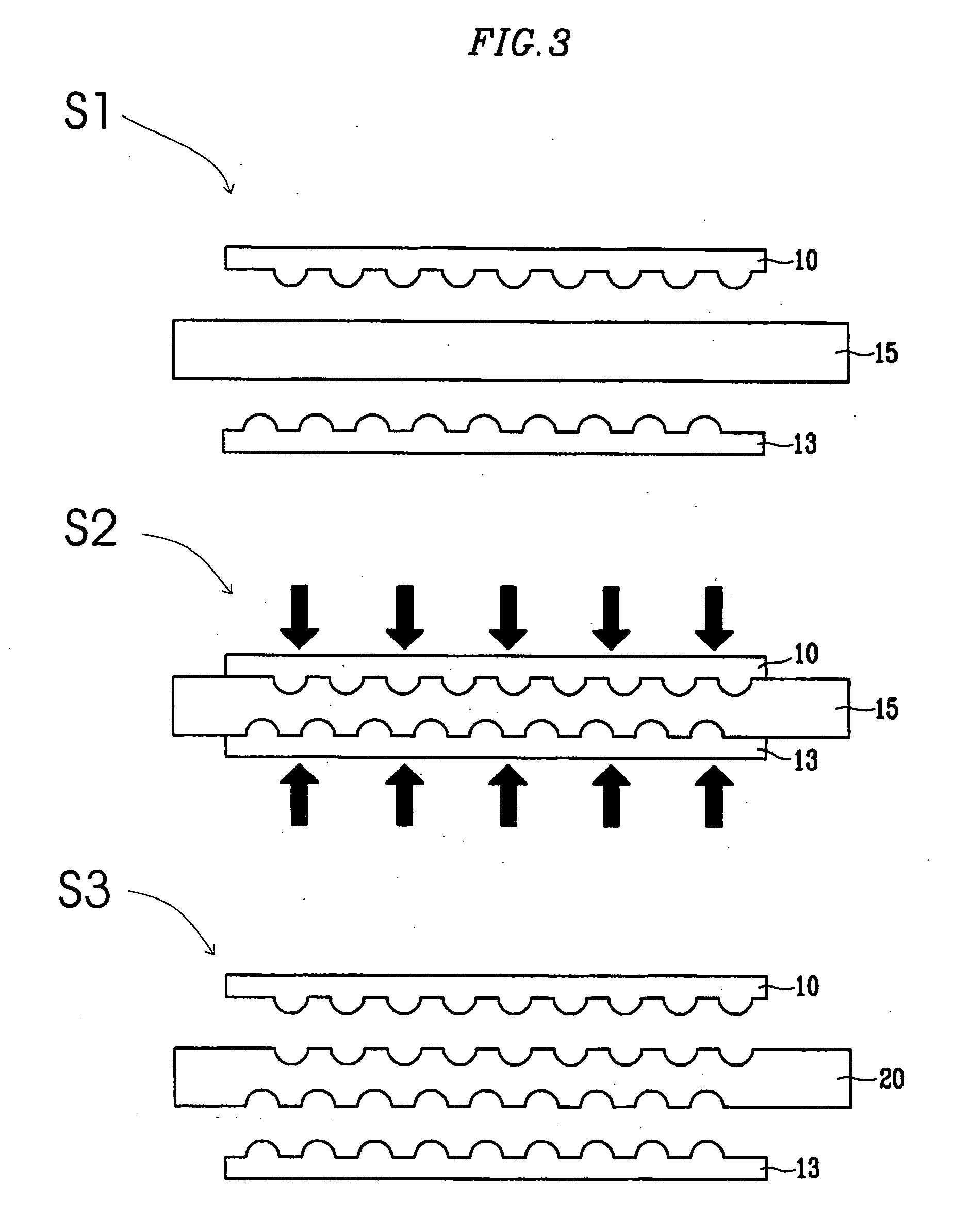

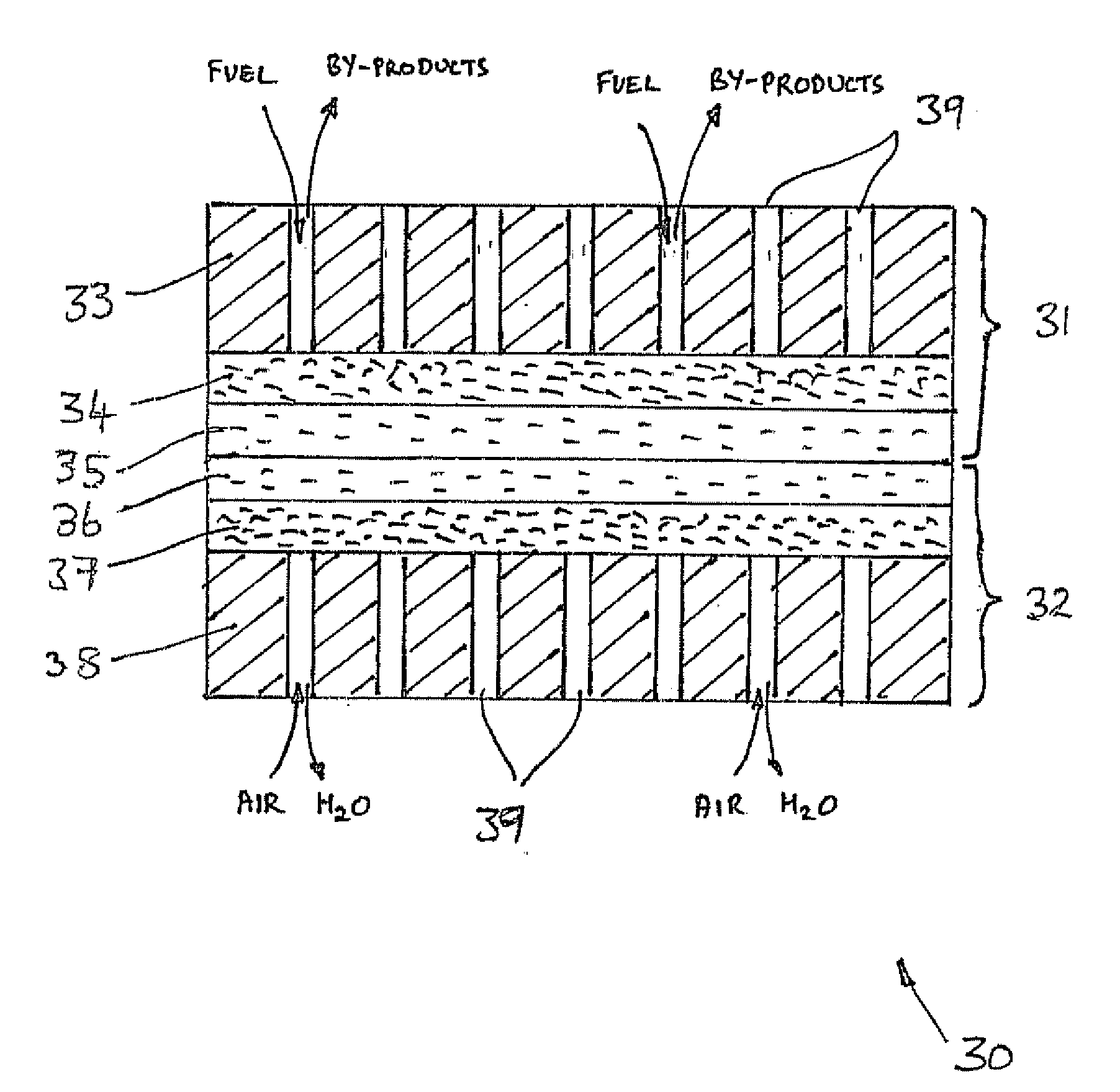

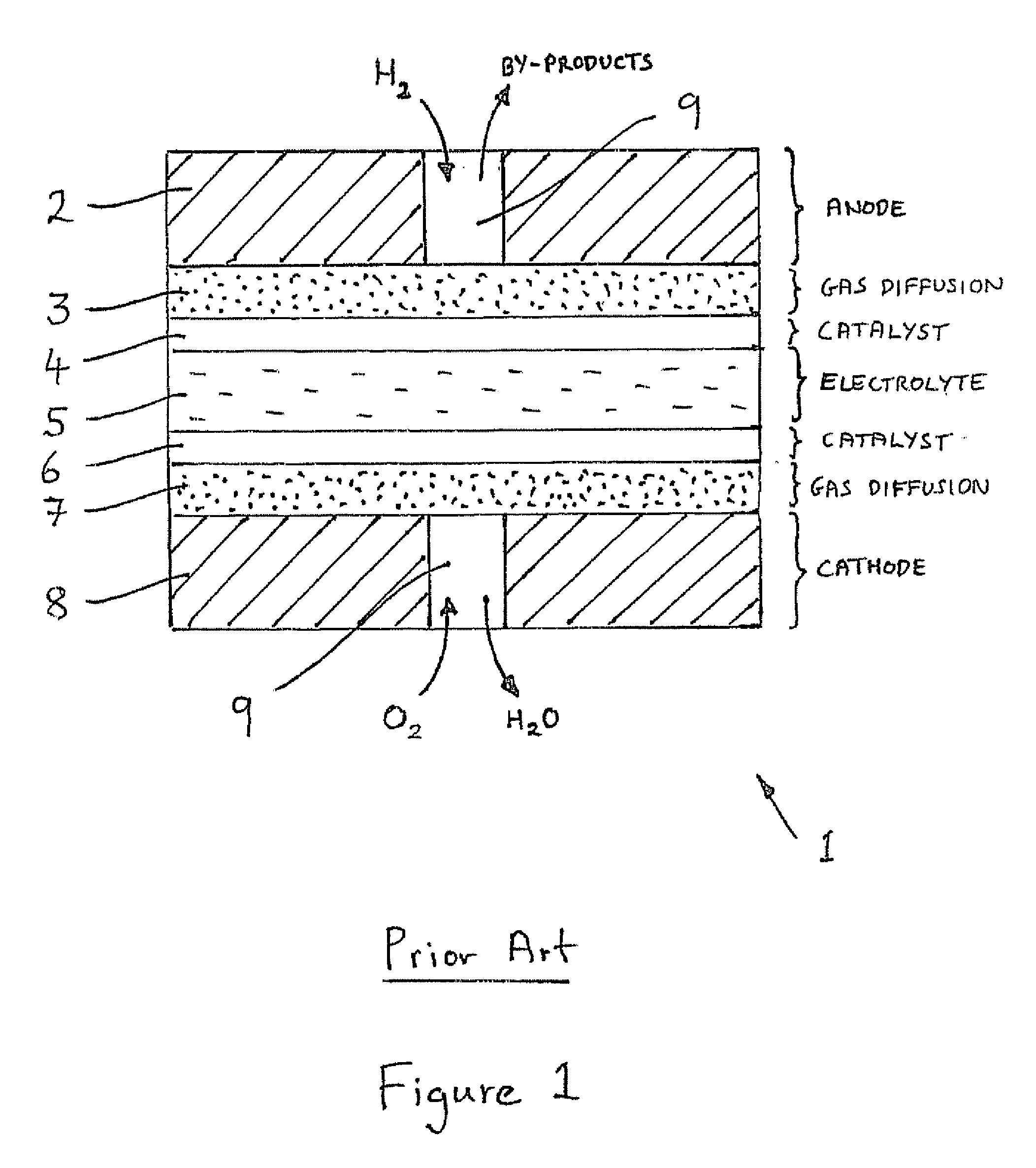

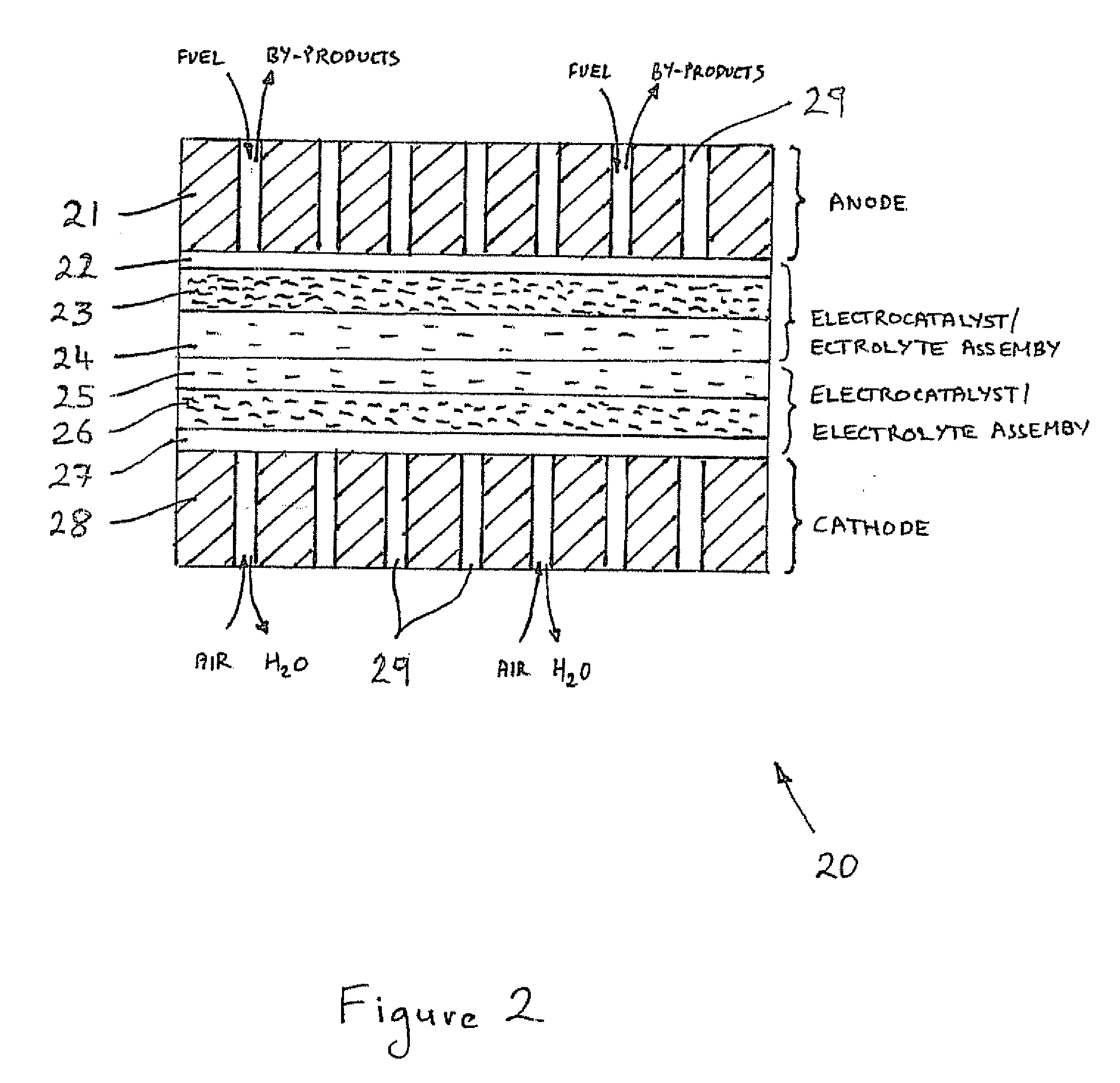

Membrane-electrode assembly for fuel cell and fuel cell system comprising the same

InactiveUS20070026291A1Improve performanceIncrease interface areaSolid electrolytesFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a membrane-electrode assembly and a fuel cell system including the membrane-electrode assembly. The membrane-electrode assembly includes a corrugated polymer electrolyte membrane and an anode and a cathode respectively disposed at each side of the polymer electrolyte membrane. The corrugated polymer electrolyte membrane has a pattern on its surface, and the corrugated surface of the polymer electrolyte membrane increase an area of an interface between the polymer electrolyte membrane and a catalyst layer. The present invention provides a fuel cell system with high power and high performance by adapting the corrugated polymer electrolyte membrane to a membrane-electrode assembly of a fuel cell.

Owner:SAMSUNG SDI CO LTD

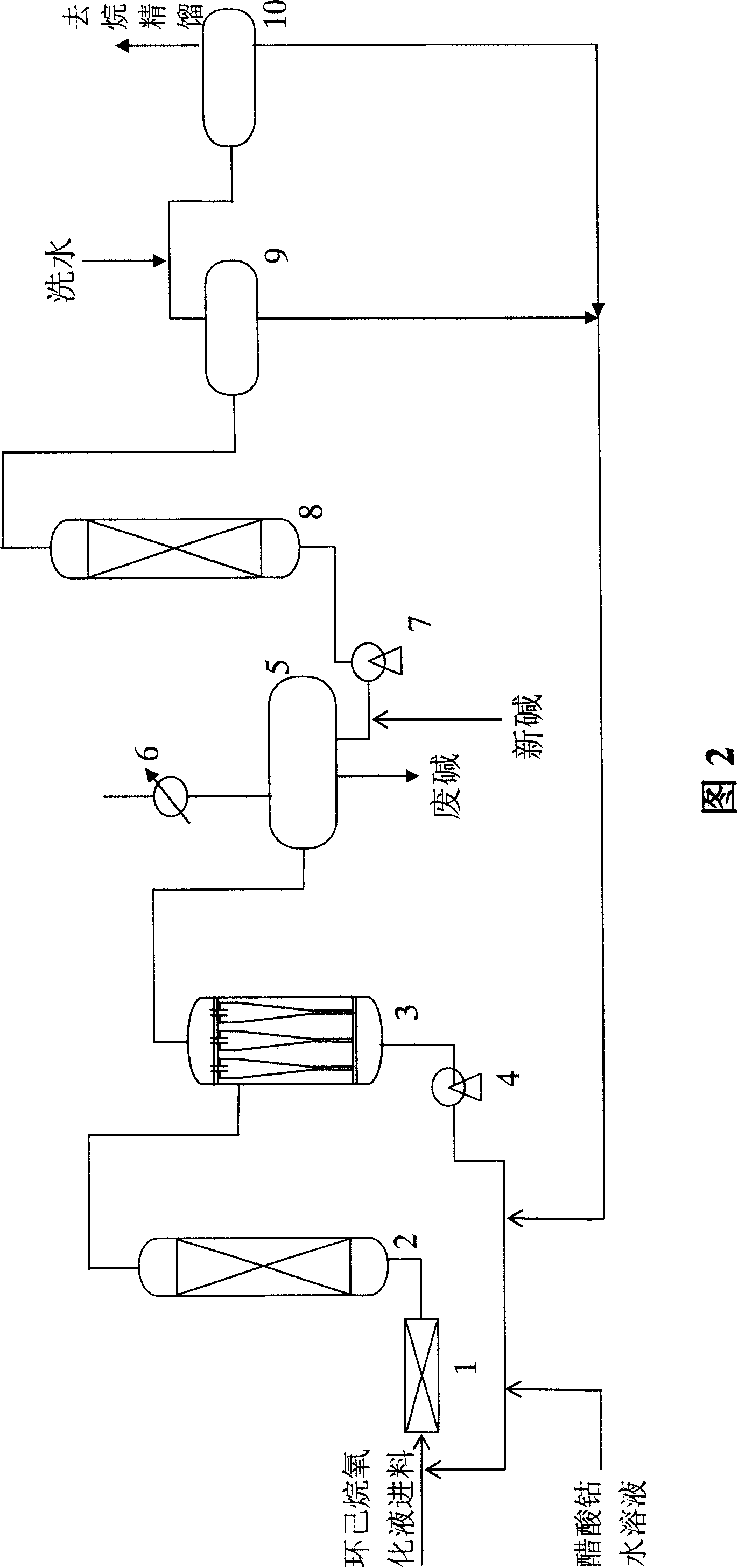

Improved process for producing cyclohexanol and pimelinketone

InactiveCN101172931AGood dispersionIncrease interface areaOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneHydrogen peroxide breakdown

The invention discloses an improved method for preparing cyclohexanol and cyclohexanone. The invention is characterized in that the decomposition reaction of cyclohexyl peroxide is accomplished with two steps; during the first decomposition reaction, the flow of circulated alkaline is equal to or larger than that of cyclohexane oxydic liquid, thereby ensuring the alkaline water phase to become a continuous phase of the material in the first decomposition reaction; the cyclohexane phase is dispersed; the decomposition reaction is accomplished under an emulsification state, or is called even phase decomposition; the compound from the decomposition reaction is rough separated through a hydrocyclone separator; a large amount of alkaline liquid is separated from the lower outlet of the hydrocyclone separator to be recycled; the material of cyclohexane from the upper outlet of the hydrocyclone separator is changed to the continuous phase, while little alkaline liquid is changed into the dispersing phase; the waste alkaline liquid is separated by lifting a separation groove through gravity; the second decomposition reaction is then accomplished to ensure a full decomposition reaction. With the technical improvement, the total mol yield of the oxidation of cyclohexane prepared cyclohexanol and the cyclohexanone device is increased by 5 percent.

Owner:肖藻生

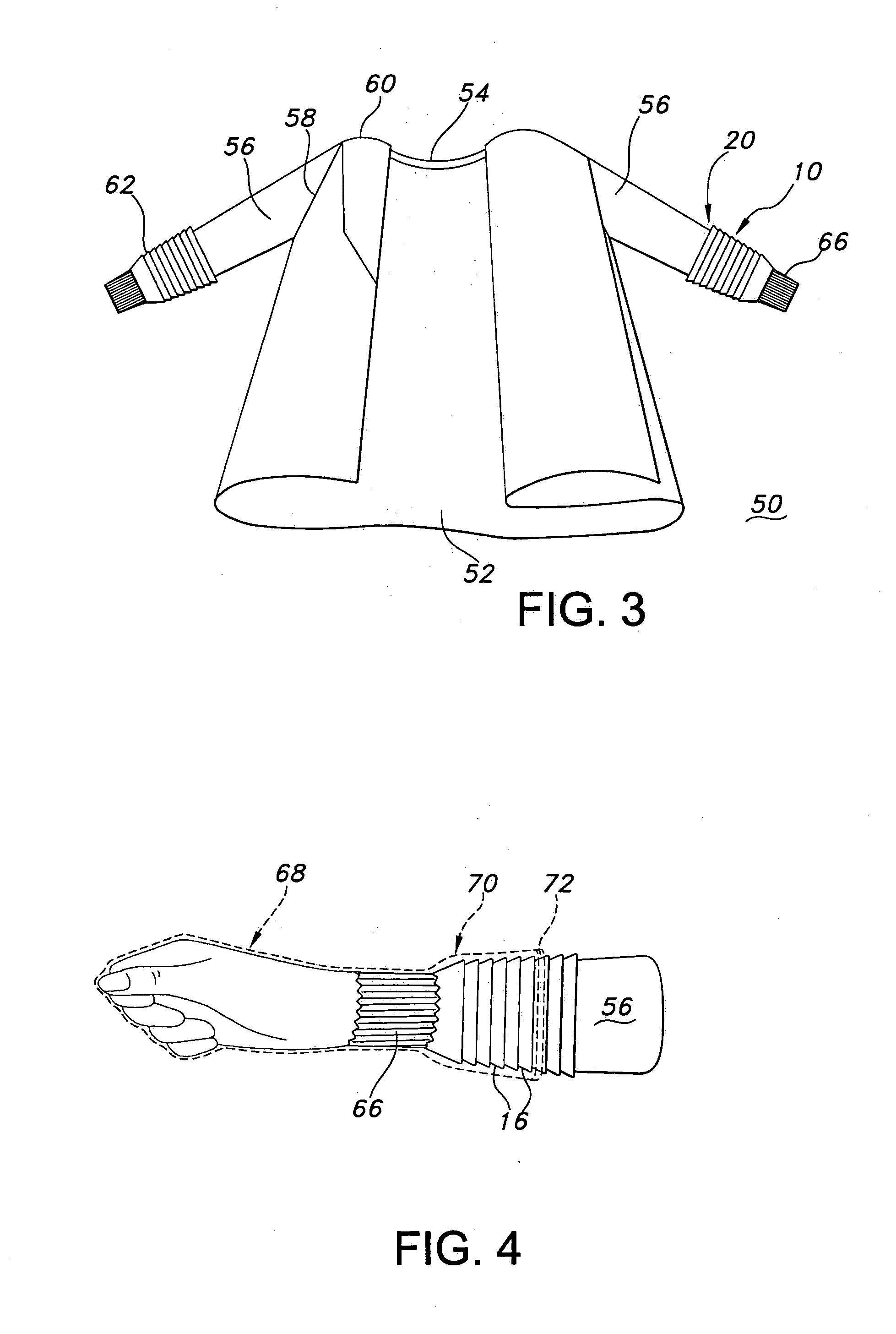

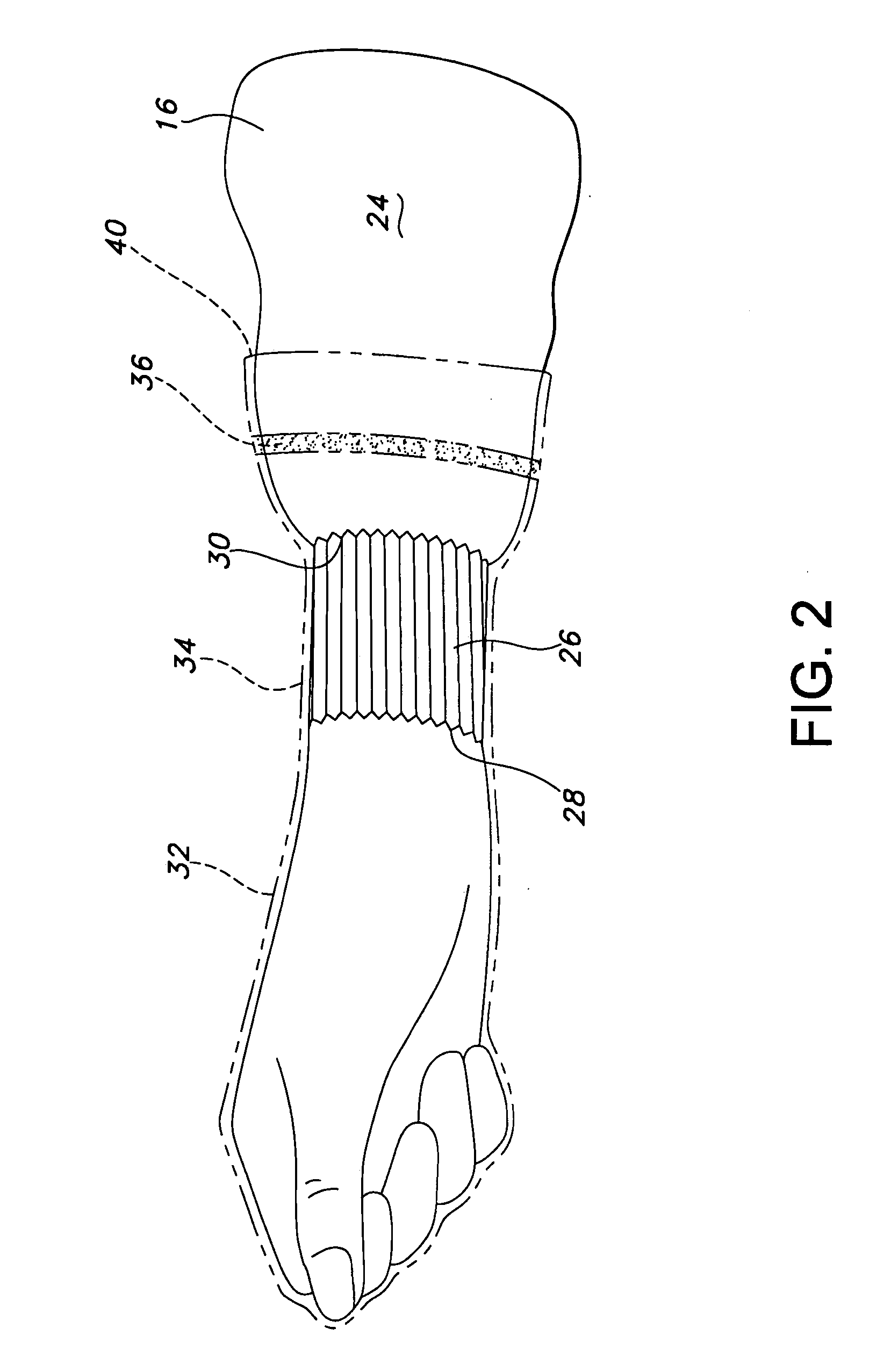

Gloves attached but removable from garments

InactiveUS20050223471A1Solve the lack of adhesionHigh strengthGlovesProtective garmentEngineeringUltimate tensile strength

A protective garment is provided consisting of a garment body having at least one sleeve, a glove associated with the sleeve, and an adhesive disposed upon a surface of the glove, the sleeve, or both. The adhesive forms an interface between the two surfaces. The adhesive has sufficient adhesion to remain affixed substantially to the surface to which it is applied while having sufficient strength to enable donning of the garment without damaging the interface. The glove is removable from the garment body by breaking the interface, without causing damage to the surfaces of the glove or garment body, and without migration of the adhesive from the surface to which it was applied.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fuel tank made from Nano composite material of nylon / clay, and preparation method

InactiveCN1796456AGood mechanical propertiesThe mechanical properties will not affectUnderstructuresFuel tanksNylon materialIn situ polymerization

This invention discloses a process for preparing a nylon / clay nanocomposite fuel tank. In the process, in situ polymerization is employed for the insertion into the interlayers of the nanocomposite so that clay can be dispersed to the degree of nanoscale in the nylon matrix, which results in a very large interfacial area. The ideal adhesion between the dispersed inorganic phase and the polymer matrix can eliminate the problem of thermal expansion coefficient mismatch between the inorganic phase and the polymer matrix, and sufficiently exploit the intrinsic good mechanical properties and heat durability of the inorganic phase. The composite fuel tank prepared by this invention exhibits improved heat-resisting property while has little influence on the mechanical properties of the matrix material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

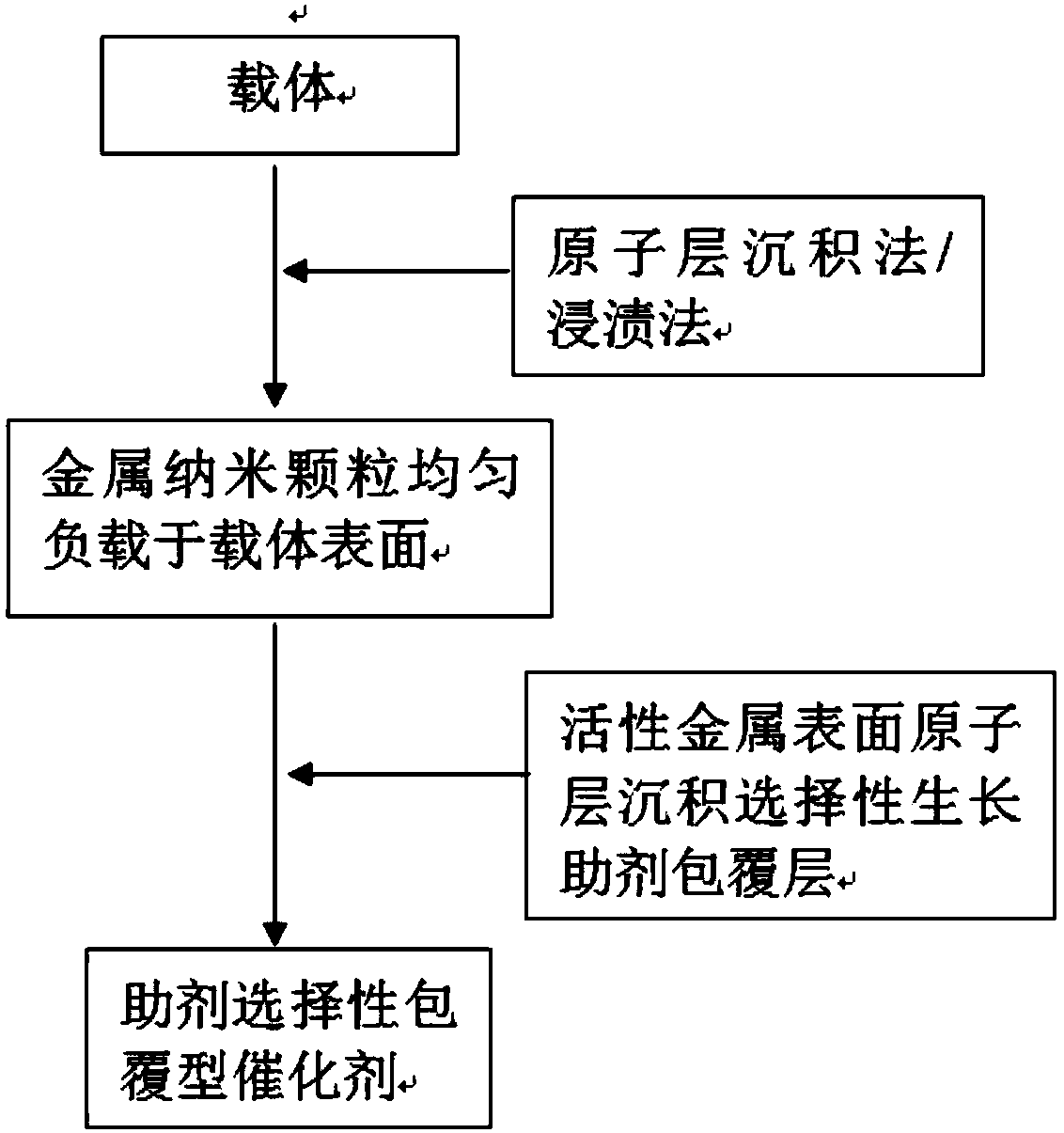

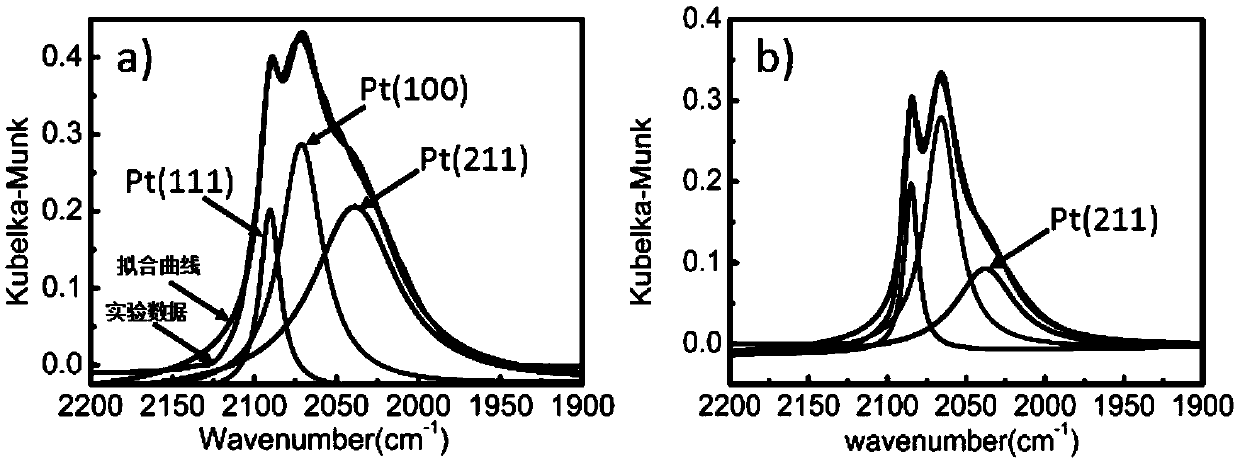

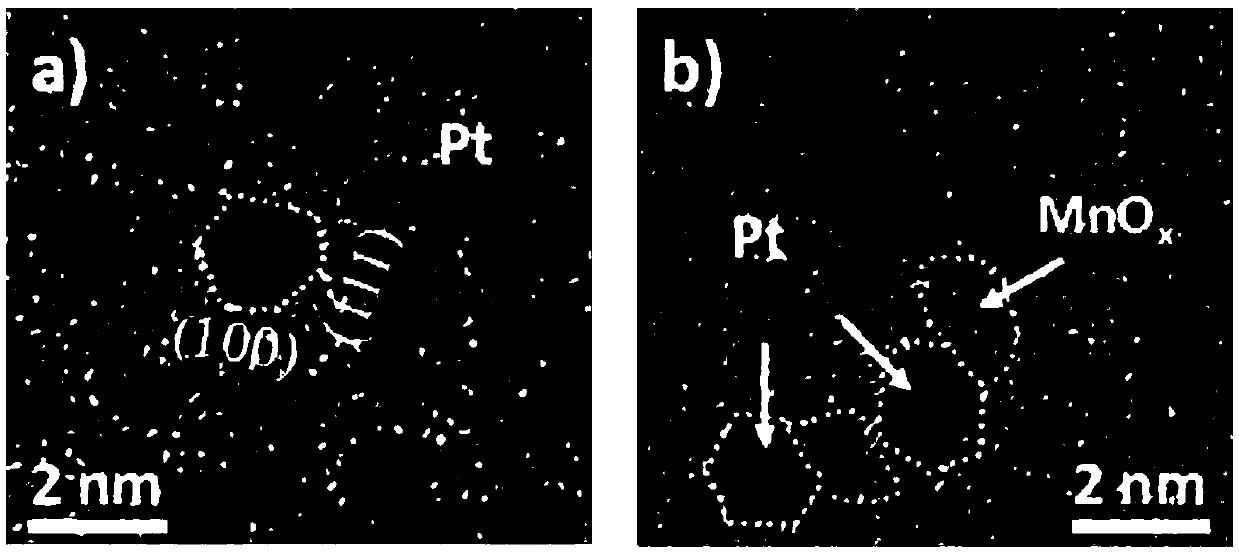

Method for improving catalyst activity and selectivity based on atomic layer deposition directional regulation

InactiveCN108671918AHigh activityHigh selectivityOrganic compound preparationHydroxy compound preparationSyngasNanoparticle

Belonging to the technical field related to preparation of metal oxide catalysts, the invention discloses a method for improving the catalyst activity and selectivity based on atomic layer depositiondirectional regulation. The method includes: growing and distributing noble metal nanoparticles uniformly on the surface of a reaction carrier to obtain a noble metal loaded catalyst sample; and depositing a metal oxide assistant on the surface of the noble metal loaded catalyst sample by atomic layer deposition reaction method to obtain a needed catalyst product, and making targeted design to thespecific process parameters of the atomic layer deposition reaction at the same time. The method provided by the invention can enable the oxide assistant to carry out selective deposition on a plurality of crystal planes of the active metal surface, realizes incontinuous coating at special position, at the same time effectively improves the activity and selectivity of the catalyst, and consequently is especially suitable for the application occasion of preparing a catalyst for preparation of a C<2+> oxygenated compound from synthesis gas.

Owner:HUAZHONG UNIV OF SCI & TECH

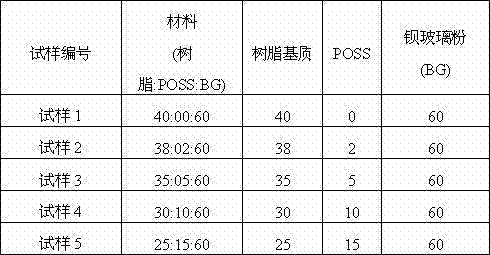

Organic-inorganic nano composite resin and preparation method thereof

ActiveCN102643500AImprove mechanical propertiesGood micro-leakageImpression capsDentistry preparationsResin matrixBiocompatibility Testing

The invention relates to organic-inorganic nano composite resin and a preparation method thereof, belonging to the technical field of biomedical high-molecular materials. The organic-inorganic nano composite resin is characterized in that polyfunctional reactive nano monomer, i.e. polyhedral oligosilsesquioxane (POSS) is added on the basis of organic matrixes and inorganic fillers. The preparation method comprises the steps of adding the POSS into the resin matrixes, placing in a constant-temperature oven, fully dissolving the POSS in the resin matrixes and even agitating; adding an initiator system and evenly agitating; adding the inorganic fillers which are subject to surface silanization treatment, fully and evenly agitating in a vacuum agitator and removing air bubbles to obtain nano composite resin paste. By adding the POSS into dental composite resin, polymerization shrinkage can be obviously reduced, the mechanical property of the composite resin is comprehensively improved, the micro-leakage performance and the biocompatibility are good and the application prospect in the field of oral rehabilitation is wide. Besides, the preparation process is simple, the cost is lower and the popularization value and the application value are great.

Owner:HARBIN INST OF TECH

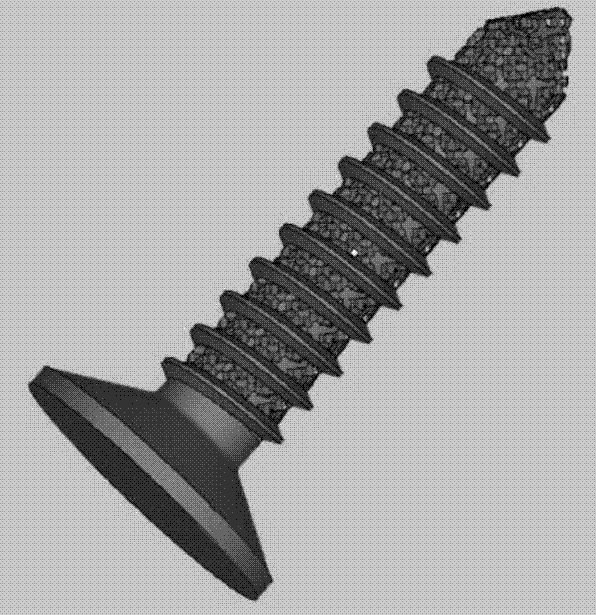

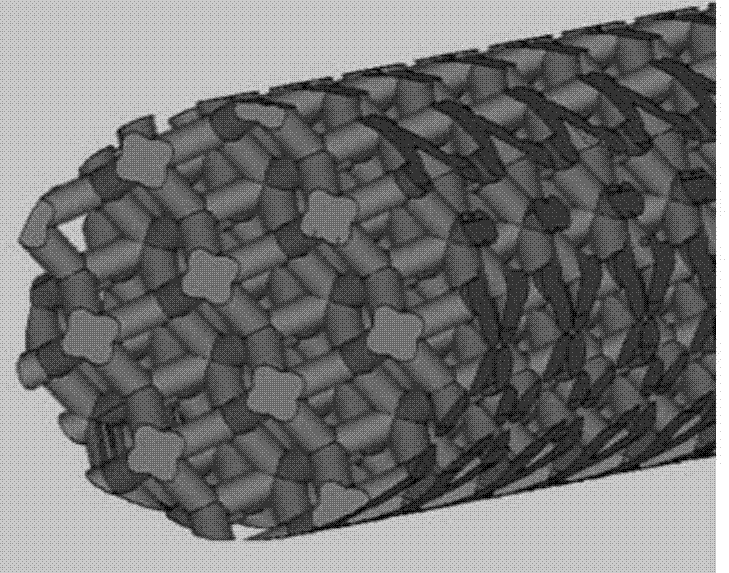

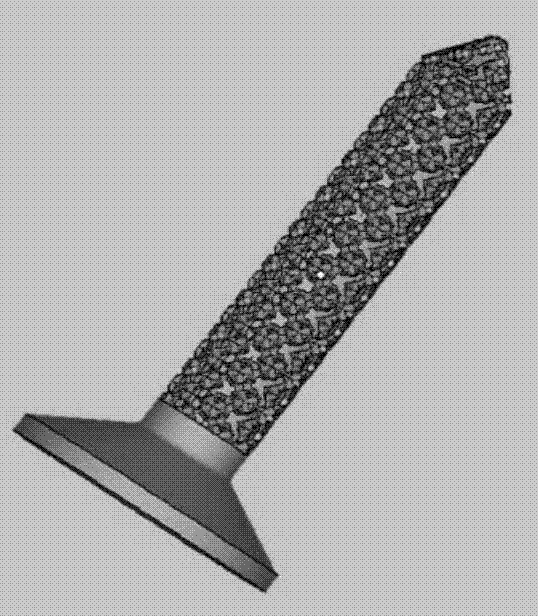

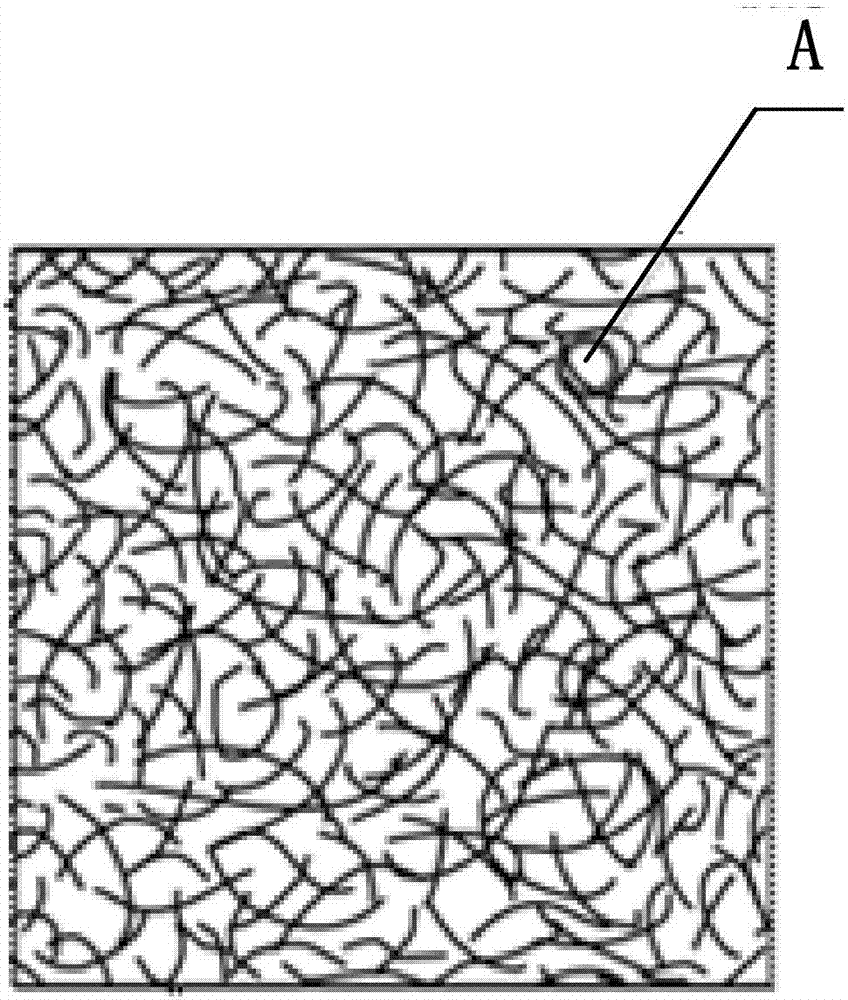

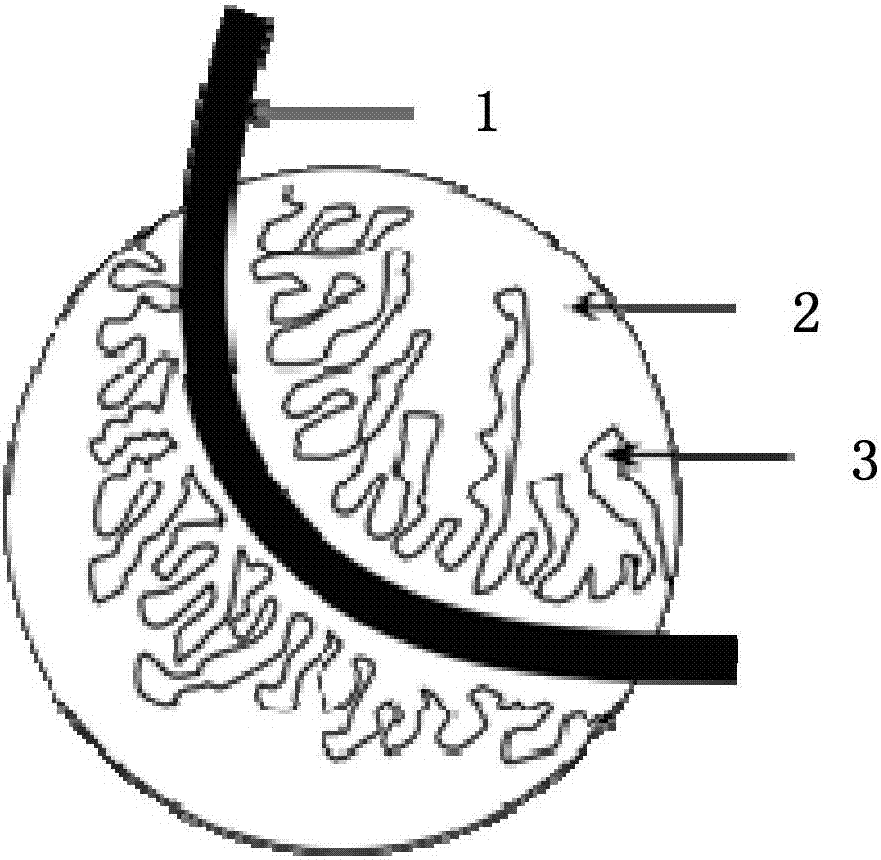

Bone screw of three-dimensional through porous structure

InactiveCN104758042AGood biocompatibilityEquivalent mechanical propertiesPharmaceutical delivery mechanismCoatingsBone tissueBone screws

The invention discloses a bone screw of a three-dimensional through porous structure. The porous bone screw comprises a screw head, a screw body and a screw cap. The screw body comprises a porous network composed of the three-dimensional through porous structure. The porous bone screw is made of medical materials which can be implanted into a human body, the three-dimensional through porous structure of the porous bone screw provides more space for the growth of bone cells, the combination between the implanted screw and the bone tissues of the human body is promoted, and the anchoring can be firm.

Owner:吴志宏

Preparation method of high-strength high-conductivity copper-niobium multi-core composite wire

ActiveCN105869778AShorten the processing cycleLow costCable/conductor manufactureNiobiumAcid washing

The invention provides a preparation method of a high-strength high-conductivity copper-niobium multi-core composite wire. The preparation method comprises the following steps that 1, oxygen-free copper foil and niobium foil are stacked in order and wound around an oxygen-free copper bar to obtain a copper-niobium winding body, then, the copper-niobium winding body is installed in a first oxygen-free copper tube, and a copper-niobium composite sleeve is obtained after seal welding; 2, isostatic cool pressing forming is carried out, and a copper-niobium pressed formed part is obtained; 3, hot extrusion machining is carried out to obtain a copper-niobium extrusion bar billet; 4, multi-pass drawing machining is carried out to obtain a copper-niobium single-core wire; 5, sizing, shearing, straightening and acid pickling treatment are carried out in sequence; 6, bundling assembling is carried out to prepare a copper-niobium bundle sleeve, the steps 2-5 are repeatedly executed, and the high-strength high-conductivity copper-niobium multi-core composite wire is obtained. The initial machining size of a niobium core wire can be lowered, the machining hardness of materials is reduced, the machining period is shortened, and the preparation method is the novel method for preparing the high-strength high-conductivity copper-niobium multi-core composite wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Nano composite of unsaturation poly-ester/active rubber/montmorllonite and preparation process thereof

The invention is a unsaturated polyester / active rubber / montmorillonite composite and its preparing method, adding modified montmorillonite and reactive active rubber in the unsaturated polyester, then making solidifying reaction at room temperature, forming a whole network structure by copolymerizing and cross-linking reaction, and forming intercalated nano compound with the montmorillonite, thus achieving the cooperative effect of reinforcing, flexibilizing and improving thermal stability, and implementing high performance of the unsaturated polyester and its composite. The invention can be widely applied to the industries, such as automobiles, building materials, electronics, home appliances, machinery, packaging, etc as well as high-new technique fields such as electronic information, bio-technique, aviation and spaceflight.

Owner:SOUTH CHINA UNIV OF TECH

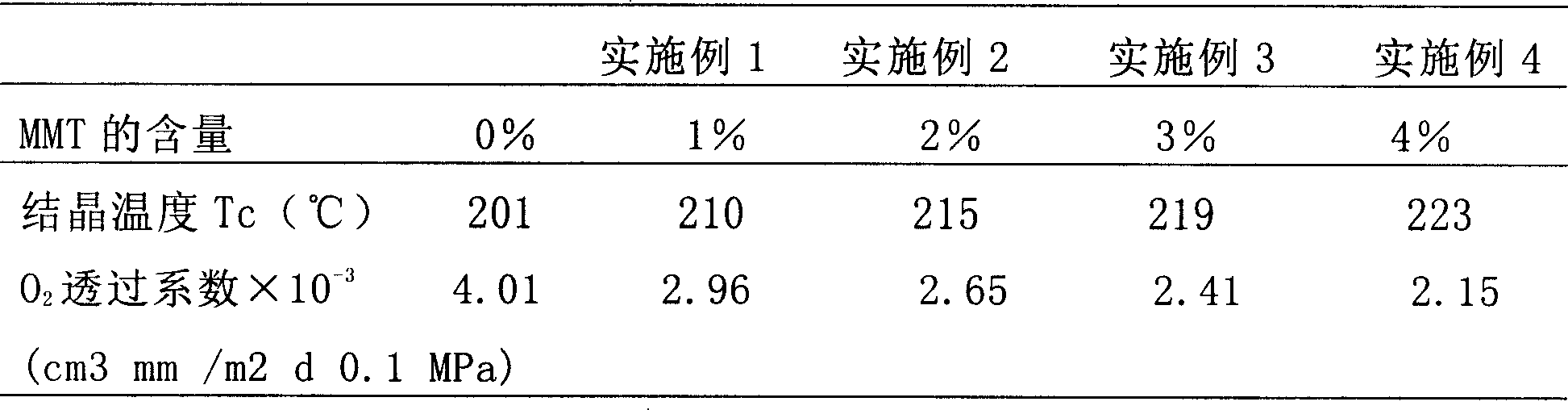

Montmorillonite modified polyester and preparation method thereof

InactiveCN101200575AIncrease interface areaHigh molecular weightDimethyl terephthalateMontmorillonite

The present invention provides a preparation method of imvite modified polyester, including the following steps: (a) aqueous mixture of 1 to 4wtg. imvite original soil, 50 to 80wtg. glycol and 50 to 500wtg. water is provided; (b) the aqueous mixture in step (a) is mixed with 40 to 50wtg. terephthalic acid dimethyl ester; (c) the mixture in step (b) is polymerized under the temperature of 160 to 290 DEG C so as to obtain the imvite modified polyester. The present invention also provides composite material prepared by the method. The polyester composite material has excellent air barrier property and crystallization property.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

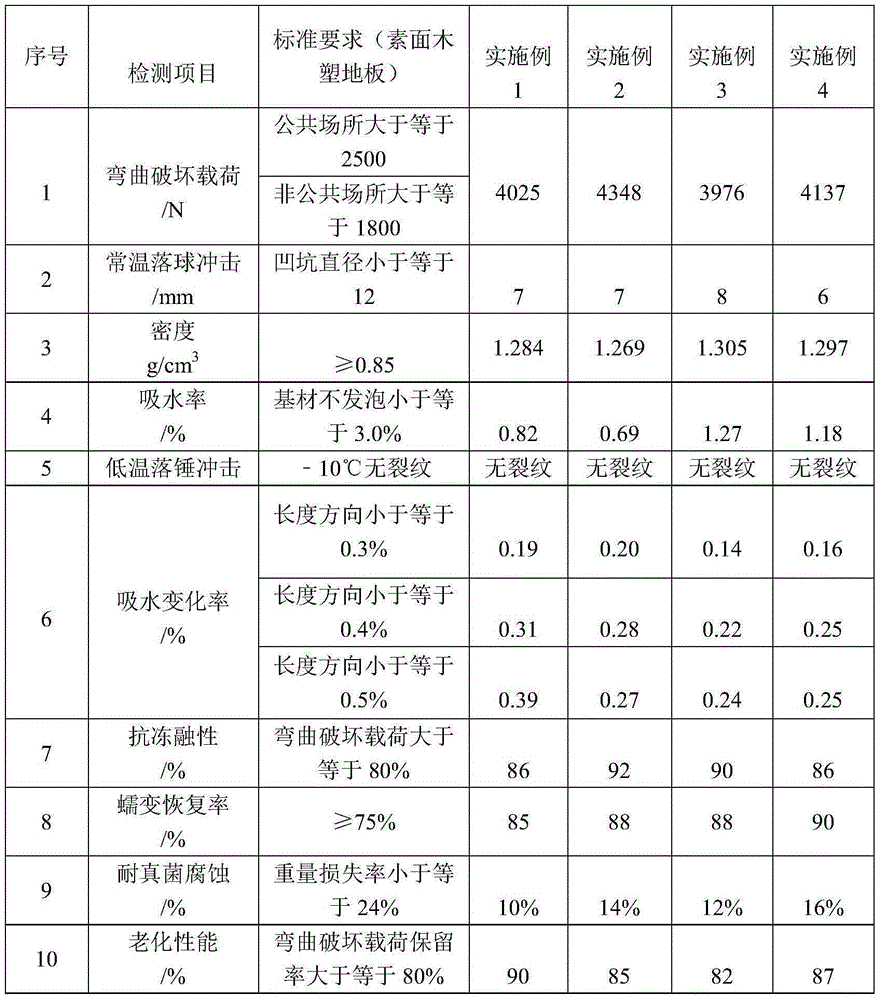

Chinese medicine residue reinforced reprocessed plastic composite material, and preparation method thereof

InactiveCN105400052AImprove physical performanceImprove mechanical propertiesWeather resistanceNational standard

The invention relates to a Chinese medicine residue reinforced reprocessed plastic composite material, and a preparation method thereof, and belongs to the field of composite material. The Chinese medicine residue reinforced reprocessed plastic composite material comprises, by mass, 50 to 70% of Chinese medicine residue, 20 to 40% of modified reprocessed plastic, 2 to 10% of a mineral filling material, 2 to 5% of a compatilizer, 1 to 5% of a lubricant, 1 to 3% of a colouring agent, 1 to 3% of an anti-oxidant, and 1 to 3% of a light stabilizer. The preparation method comprises following steps: Chinese medicine residue pretreatment; reprocessed plastic modification; material mixing; pelletizing; extrusion moulding, and surface post-processing. The physical properties, mechanical properties, and weathering resistance of the Chinese medicine residue reinforced reprocessed plastic composite material are equal to or better than that disclosed in national standard GB / T 24508-2009 <wood-plastic flooring>; and the Chinese medicine residue reinforced reprocessed plastic composite material is capable of satisfying market requirements, and possesses insect expelling effect and mould resistance.

Owner:南京聚锋新材料有限公司 +1

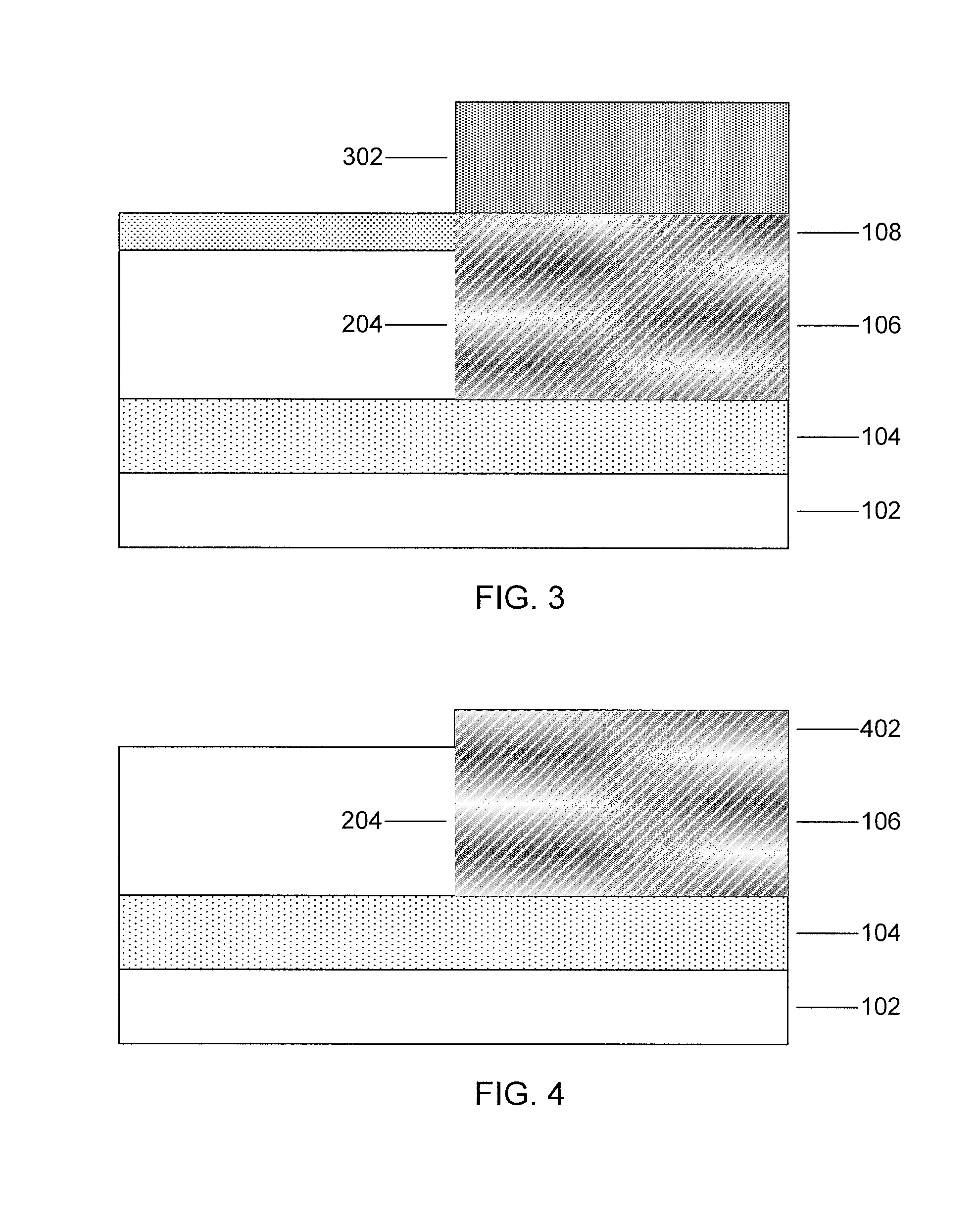

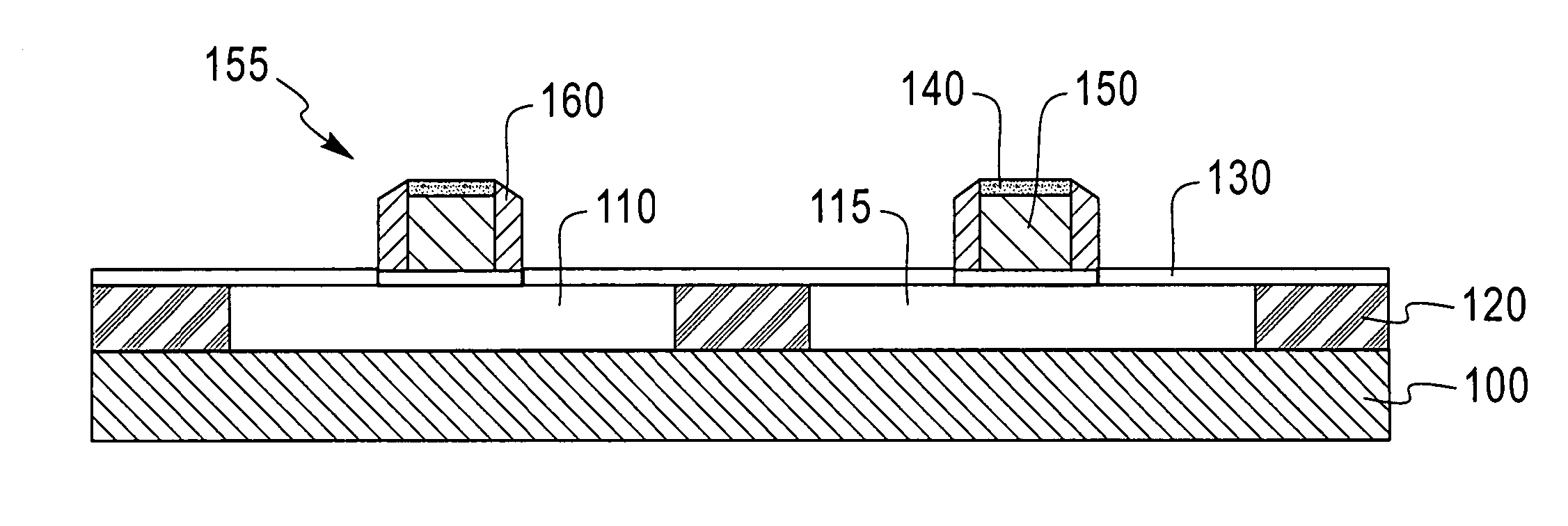

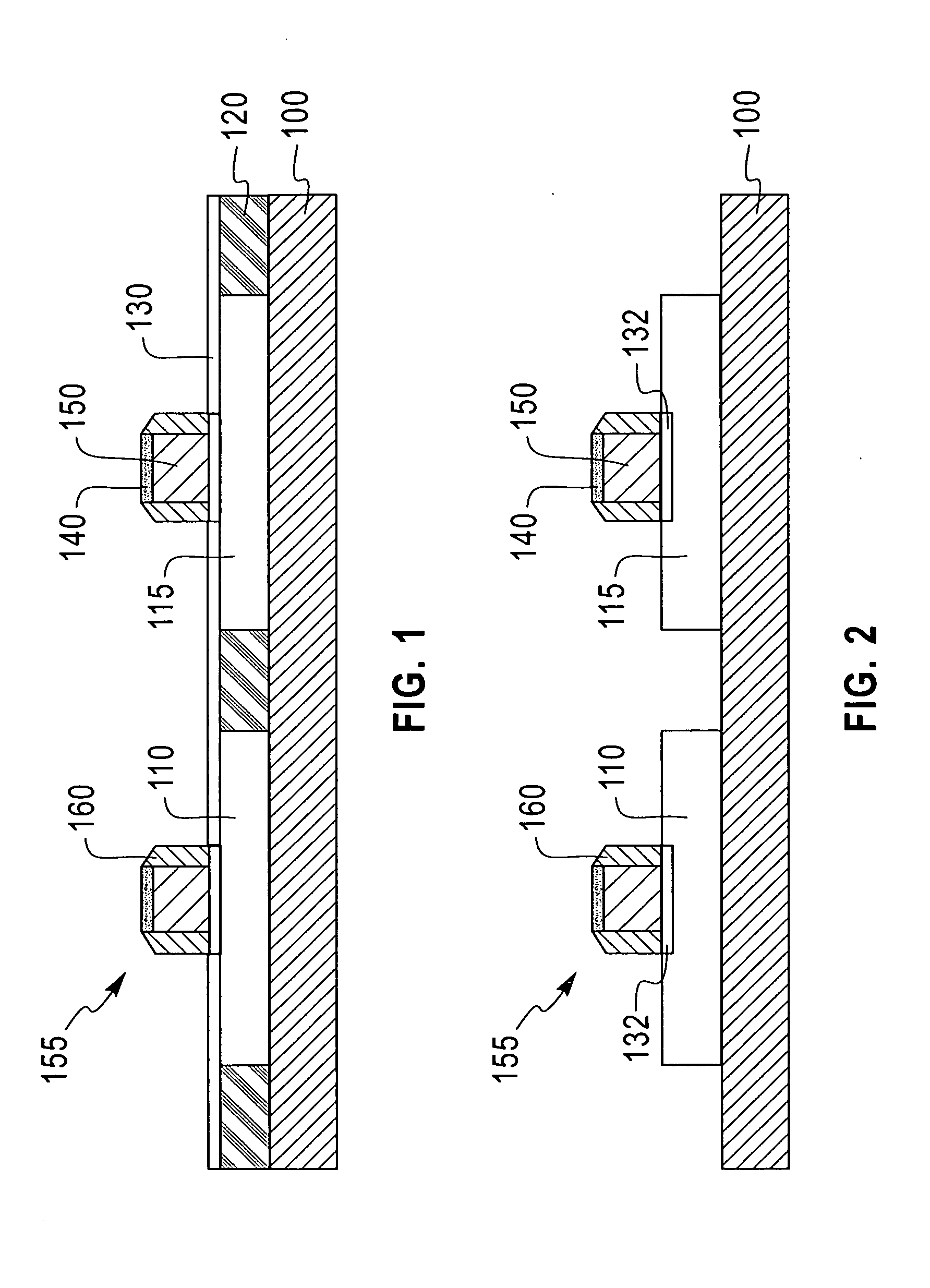

Method and structure to reduce contact resistance on thin silicon-on-insulator device

InactiveUS20070254464A1Avoiding silcidationReduced series resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringContact resistance

A method (and system) of reducing contact resistance on a silicon-on-insulator device, including controlling a silicide depth in a source-drain region of the device.

Owner:GLOBALFOUNDRIES INC

Process for the production of oryzanol enriched fraction from rice bran oil soapstock

InactiveUS20040192948A1Easy to handleIncrease temperatureFatty oils/acids recovery from wasteBiocideRice Bran ExtractRice bran oil

The present invention relates to an improved process for the production of oryzanol enriched fraction from rice bran oil soapstock; the present invention particularly relates to saponification, dehydration and leaching of rice bran oil soapstock for production of oryzanol enriched fraction.

Owner:COUNCIL OF SCI & IND RES

Method for preparing lithium-sulfur battery by taking graphitized carbon nanotube flexible film as current collector of lithium-sulfur battery

InactiveCN106374113AImprove conductivityFacilitate depositionElectrode carriers/collectorsElectrochemical responseLithium–sulfur battery

A method for preparing a lithium-sulfur battery by taking a graphitized carbon nanotube flexible film as a current collector of the lithium-sulfur battery comprises the following steps of (1) taking sulfur as an active material, adding a conductive agent and a binding agent, taking N-methylpyrrolidone or deionized water as a solvent, and mixing paste; (2) coating the active material subjected to paste mixing already on the graphitized carbon nanotube flexible film, performing drying after coating, cutting the graphitized carbon nanotube flexible film to a product with the same size as a negative pole plate, and performing vacuum drying to obtain a positive pole plate; and (3) taking a lithium sheet as the negative pole plate, adding an electrolyte in a vacuum glove box, and assembling the battery according to a sequence of a negative electrode shell, the negative pole plate, a separator, the positive pole plate, foamed nickel and a positive electrode shell. The nanotube flexible film has a large amount of micropores with different sizes, the sulfur are very favorably deposited and absorbed into the micropores, thus, sulfur loading quantity in the positive pole plate and electrochemical reaction interface area are effectively increased, electron and ion conduction are enhanced, and the charge / discharge performance of the lithium-sulfur battery can be substantially improved.

Owner:NANCHANG UNIV

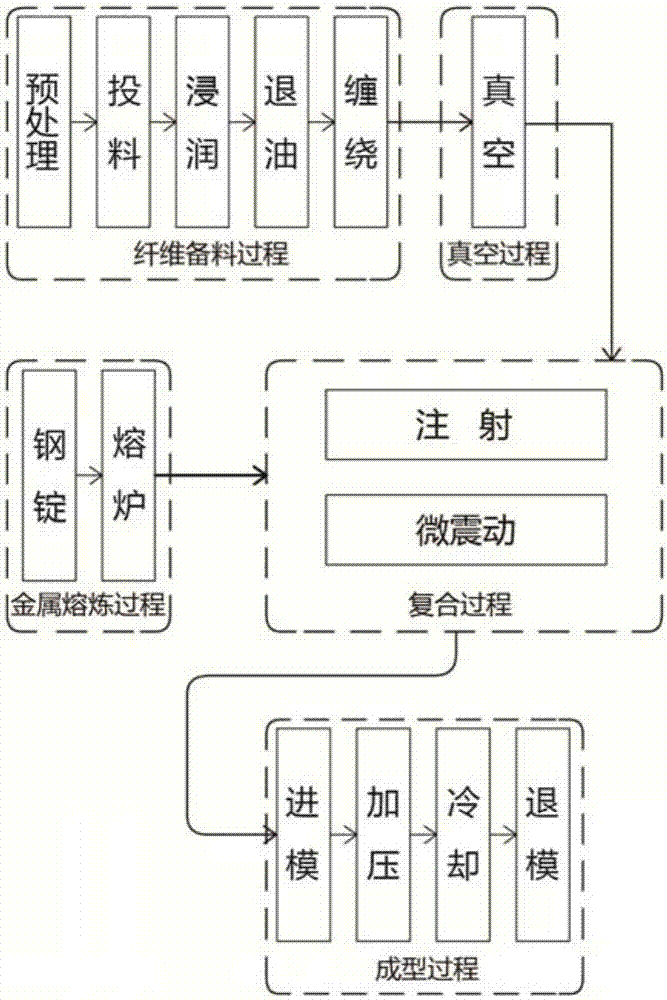

Steel-based carbon fibre composite material and preparation method thereof

ActiveCN107022724AEasy to prepareThe preparation method is reasonableAdhesiveUltimate tensile strength

The invention relates to a steel-based carbon fibre composite material and a preparation method thereof. The steel-based carbon fibre composite material comprises a plurality of bent carbon fibres which intertwine one another, a steel-based material and an adhesive which is adhered to the surface of the carbon fibres, wherein the carbon fibres, the adhesive and the steel-based material are formed by connecting through chemical bonds; a coral-like interface is formed between the adhesive which is adhered to the surfaces of the carbon fibres and the steel-based material through the chemical bonds; the preparation method for the steel-based carbon fibre composite material comprises the following steps: infiltrating the carbon fibres by utilizing the liquid adhesive; intertwining the carbon fibres after excessive adhesive is extruded away so that three-dimensional structural sponge-shaped carbon fibres which are adhered with the adhesive are formed; compounding the carbon fibres with the steel-base material after vacuumizing treatment is performed; finally, placing the composite material into a mould, pressurizing, cooling and moulding to obtain the steel-based carbon fibre composite material which is connected through the chemical bonds. The composite material prepared by the preparation method is far beyond the upper modulus limit of various types of conventional steel substrate materials; the rigidity, the tensile strength, the breaking power and the shearing strength are greatly improved.

Owner:靳普

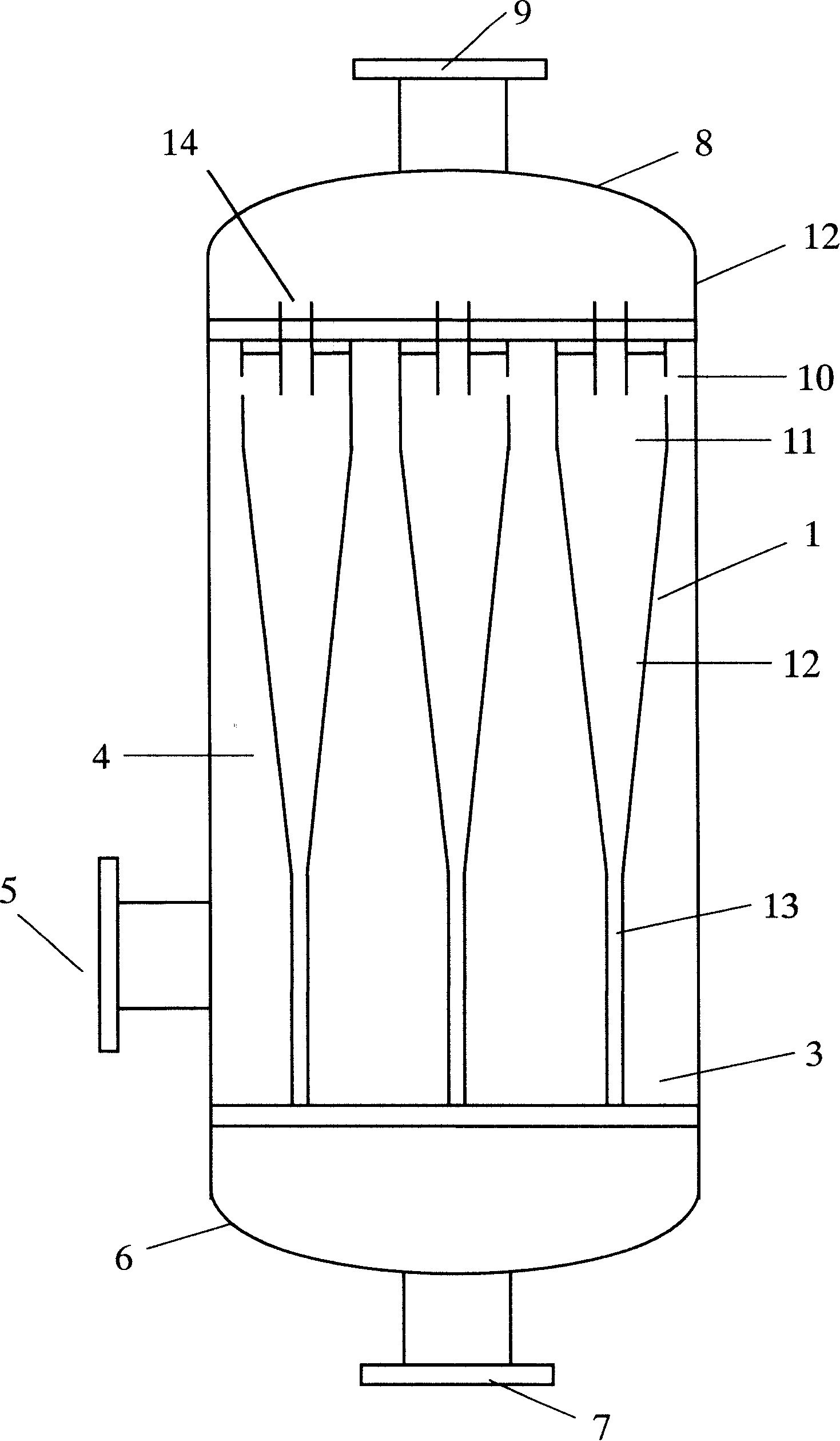

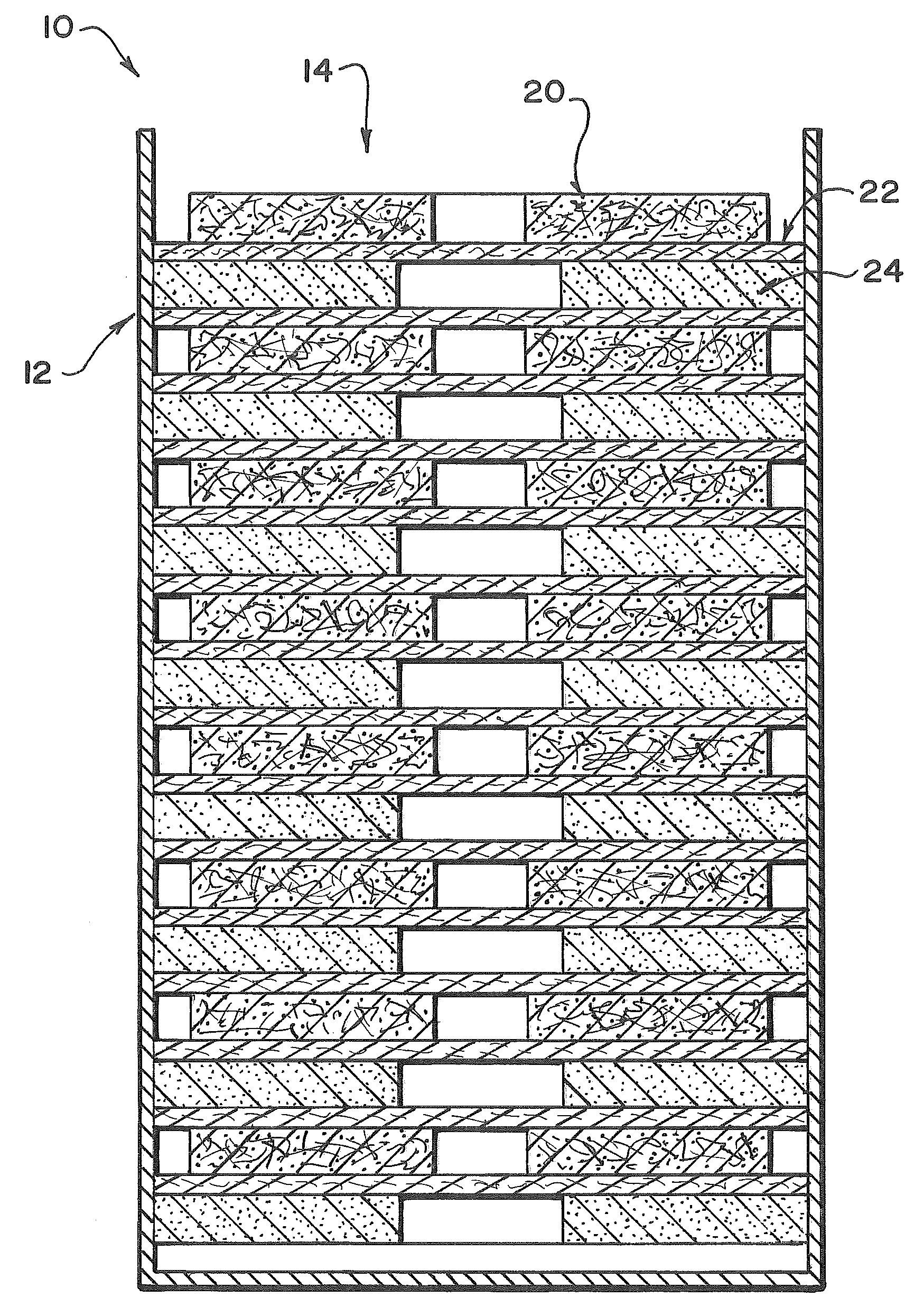

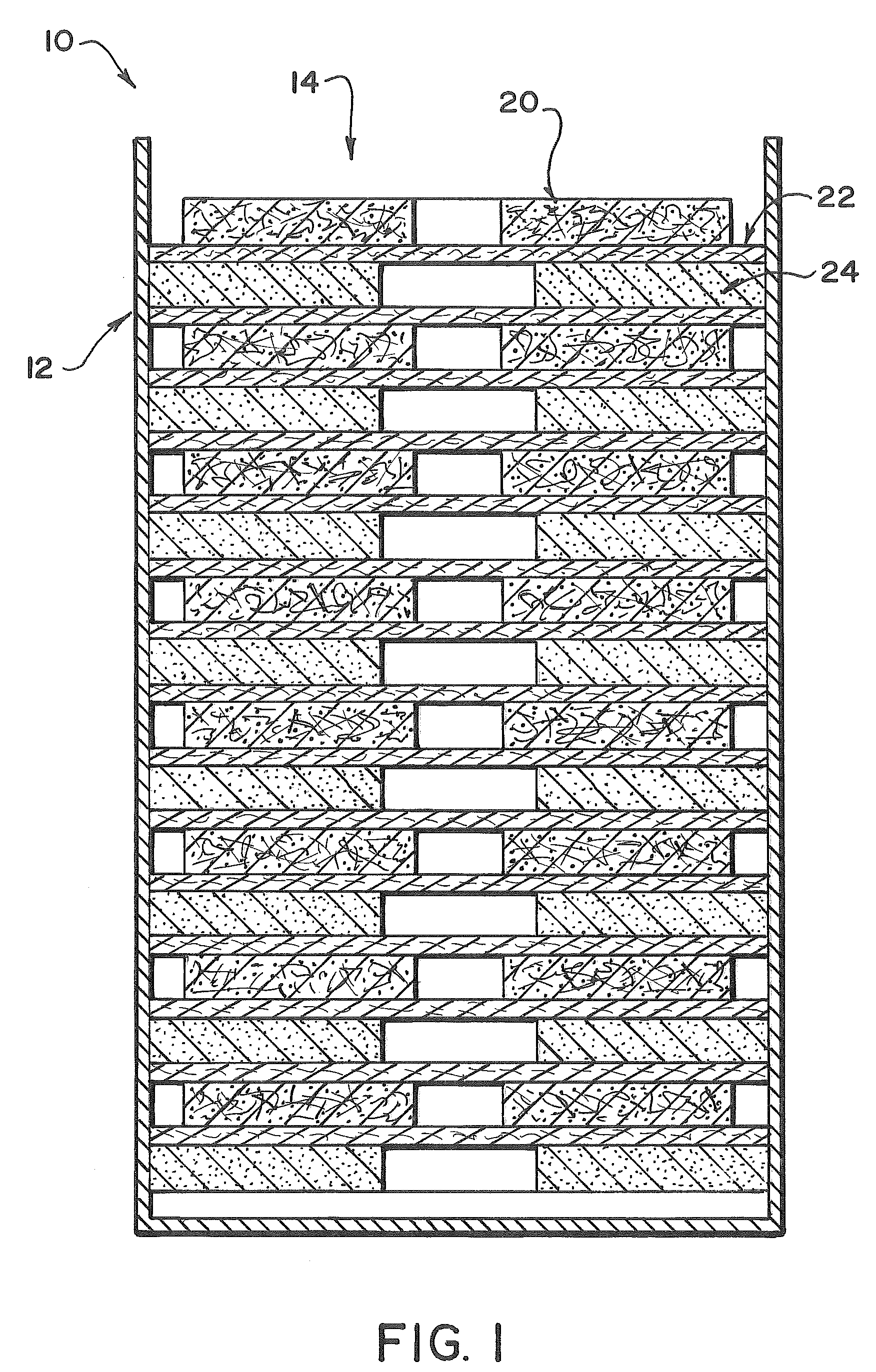

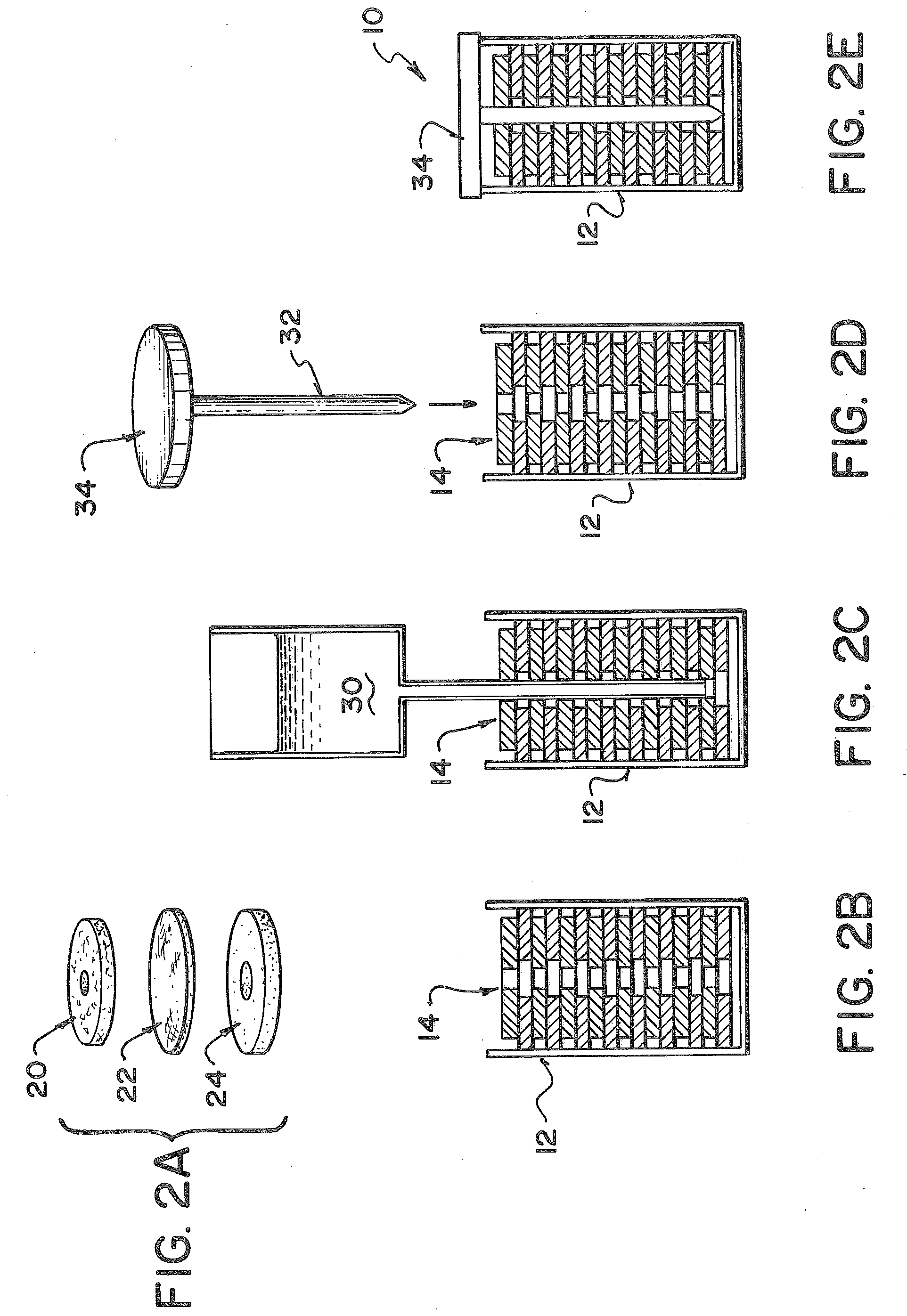

High power batteries and electrochemical cells and methods of making same

InactiveUS20080268341A1Improve material utilizationEasily fabricated into controlledElectrode carriers/collectorsAlkaline accumulator electrodesEngineeringElectrochemical cell

This invention relates to novel designs of high power batteries, electrochemical cells, energy storage materials and electrode materials, and processes for manufacturing same. A battery comprising: (a) an alternating stack of one or more anodes and one or more cathodes; (b) one or more non-conducting separators separating the one or more anodes and cathodes; (c) an electrolyte; (d) a current collector extending through the stack; and (e) a casing holding the one or more anodes, the one or more cathodes, the one or more non-conducting separators, the electrolyte and the current collector

Owner:TECK METALS

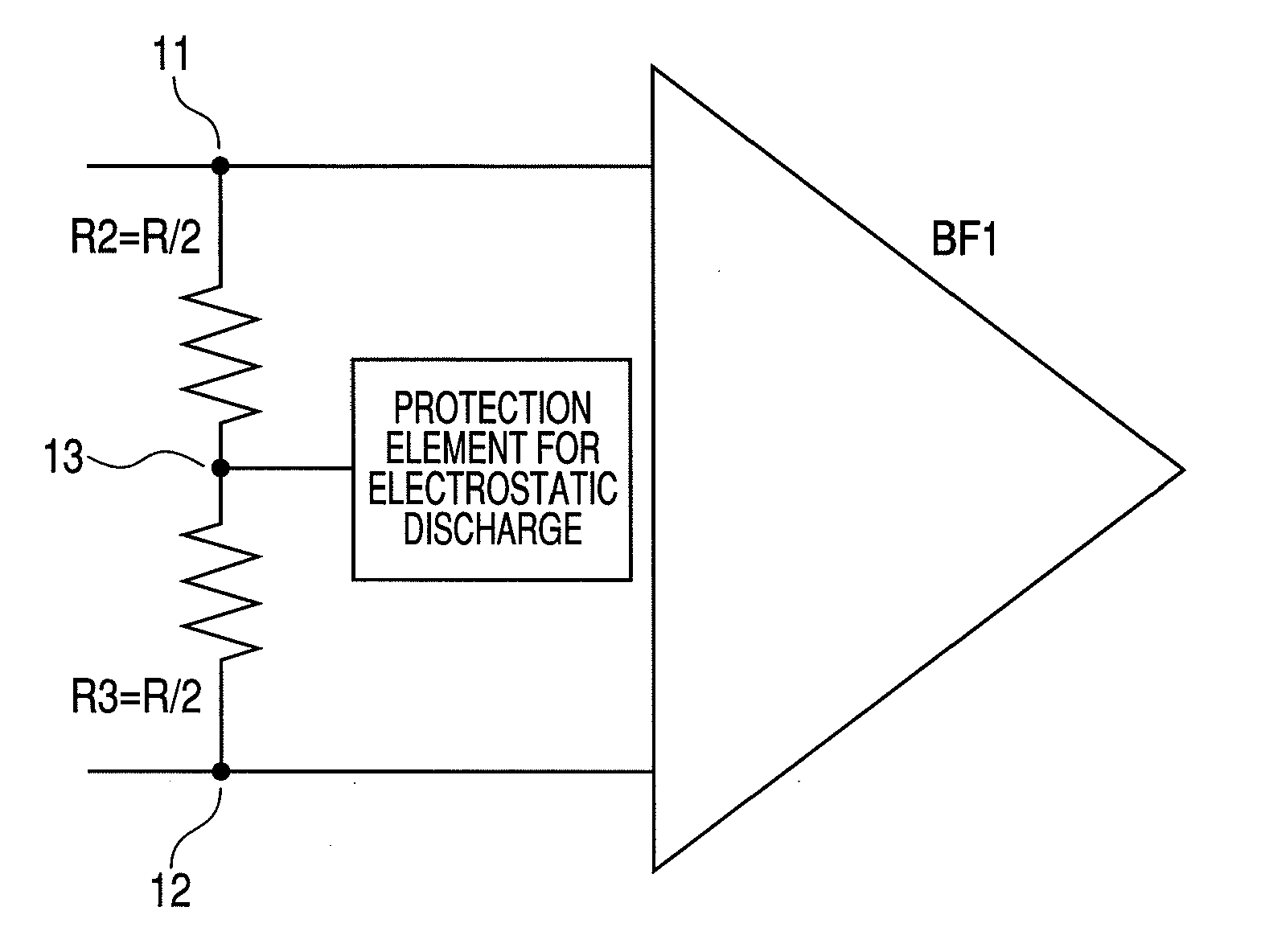

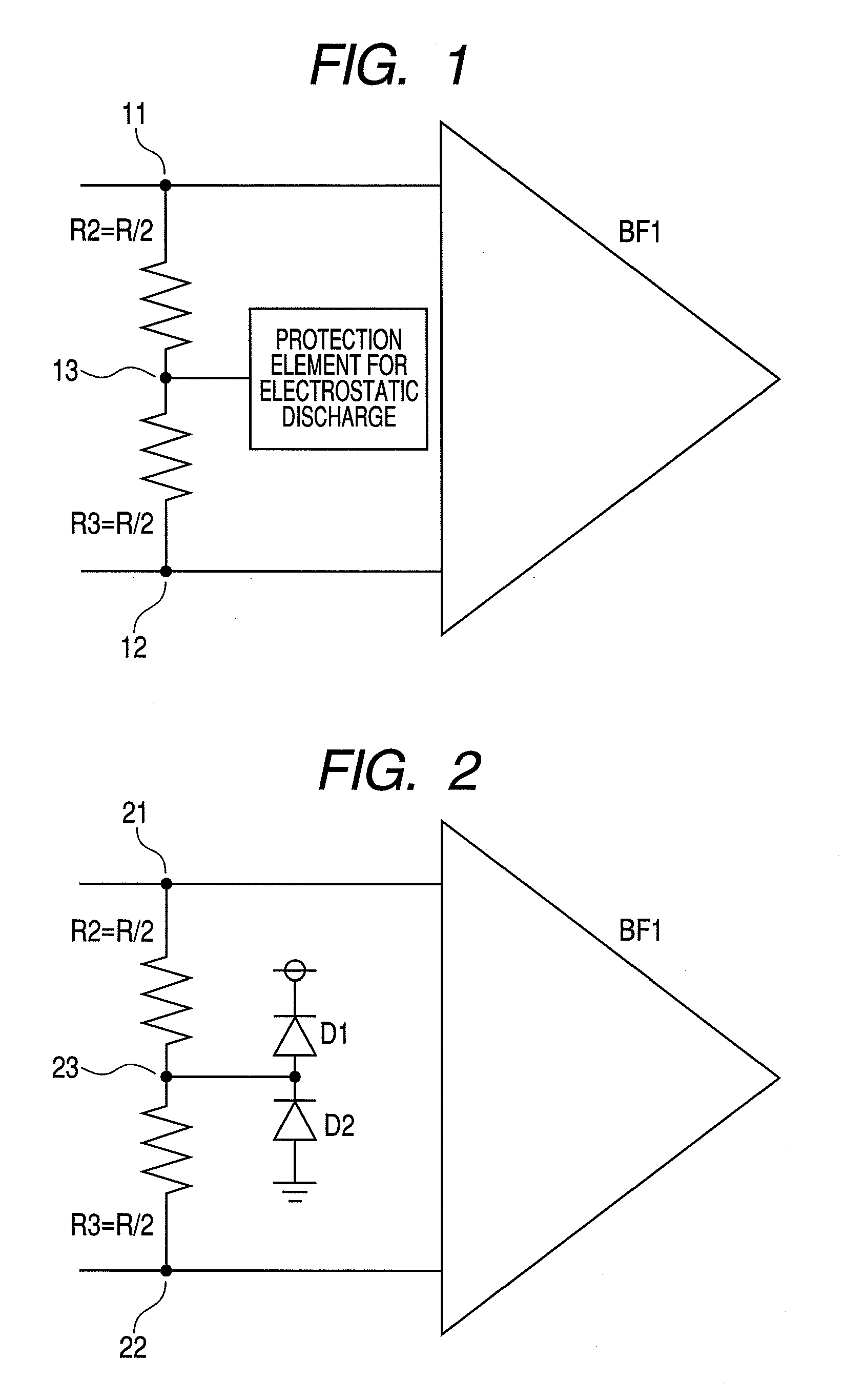

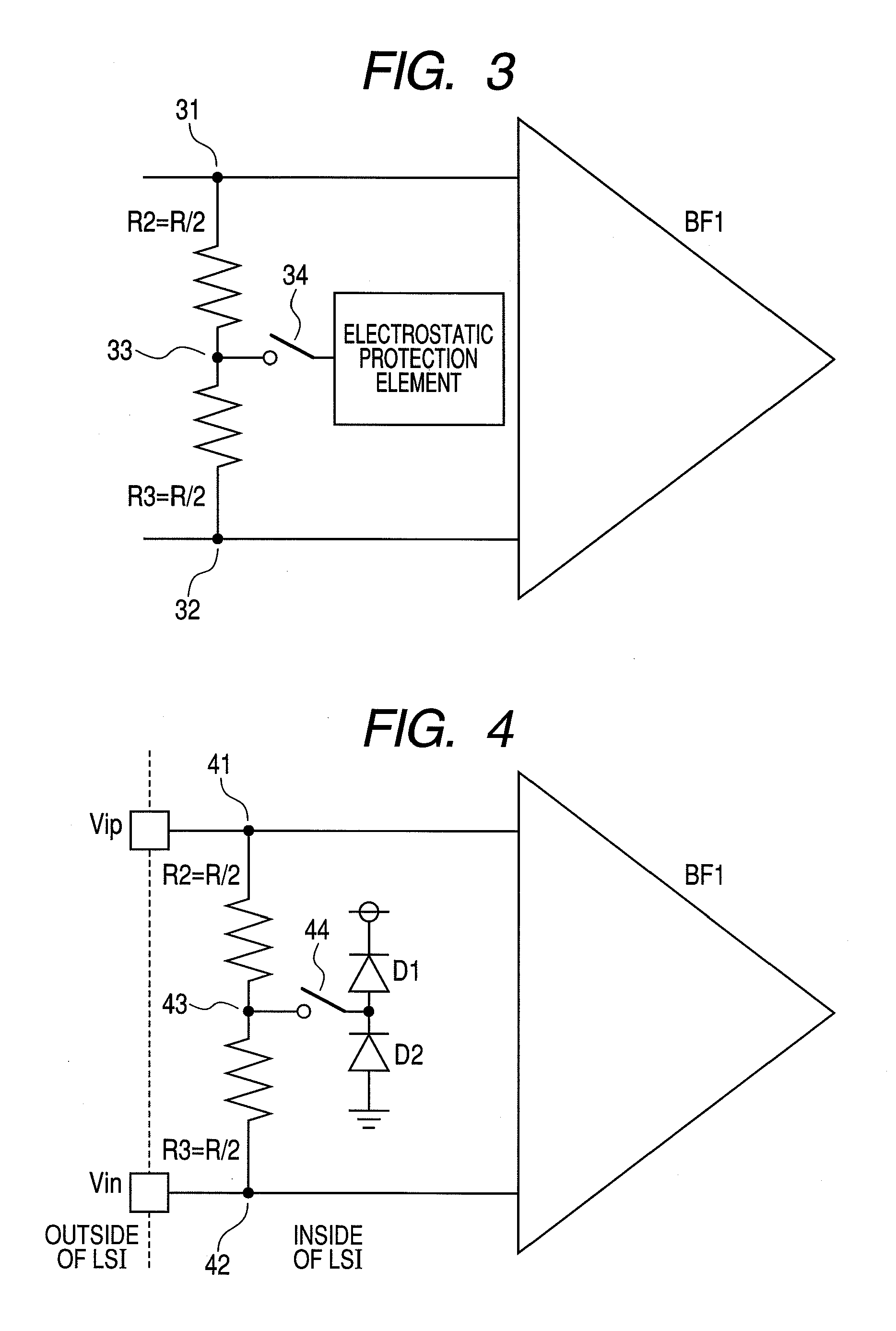

Semiconductor integrated circuit device

InactiveUS20100246078A1Reduce loadIncrease interface areaAmplifier with semiconductor-devices/discharge-tubesDiodeWave shapeEngineering

A semiconductor integrated circuit device supports maintenance of a signal transfer frequency and waveform quality and electrostatic protection, and also suppresses expansion of a chip area. In order to maintain the signal transfer frequency and the waveform quality as well as to keep an effect of the electrostatic protection, and simultaneously to protect a differential input pair by a single electrostatic protection element and to attain area superiority, the electrostatic protection element that is arbitrarily separable is disposed at a middle point of a terminator.

Owner:HITACHI LTD

Solid electrolyte fuel cell

InactiveUS20090148740A1Catalytic activity can be maximizedReduce carbon monoxide poisoningSolid electrolytesActive material electrodesCarbon fibersGas phase

A membrane electrode assembly for a solid electrolyte fuel cell comprises: an electrode having a layer of nano-structured material on one of its faces, an electrocatalyst deposited on the nano-structured material and an electrolyte deposited on the electrocatalyst / nano-structured material. The nano-structured material can comprise carbon, silicon, graphite, boron, titanium and be in the form of multi-walled nano-tubes (MWNTs), single-walled nano-tubes (SWNTs), nano-fibers, nano-rods or a combination thereof. The nano-structured material can be grown or deposited on one face of an electrode of the cell or on a substrate such as a flexible sheet material of carbon fibers using chemical vapor deposition. The electrocatalyst and electrolyte can be incorporated in the nano structured material using physical vapor deposition (PVD), ion beam sputtering or molecular beam epitaxy (MBE).

Owner:INTEMATIX

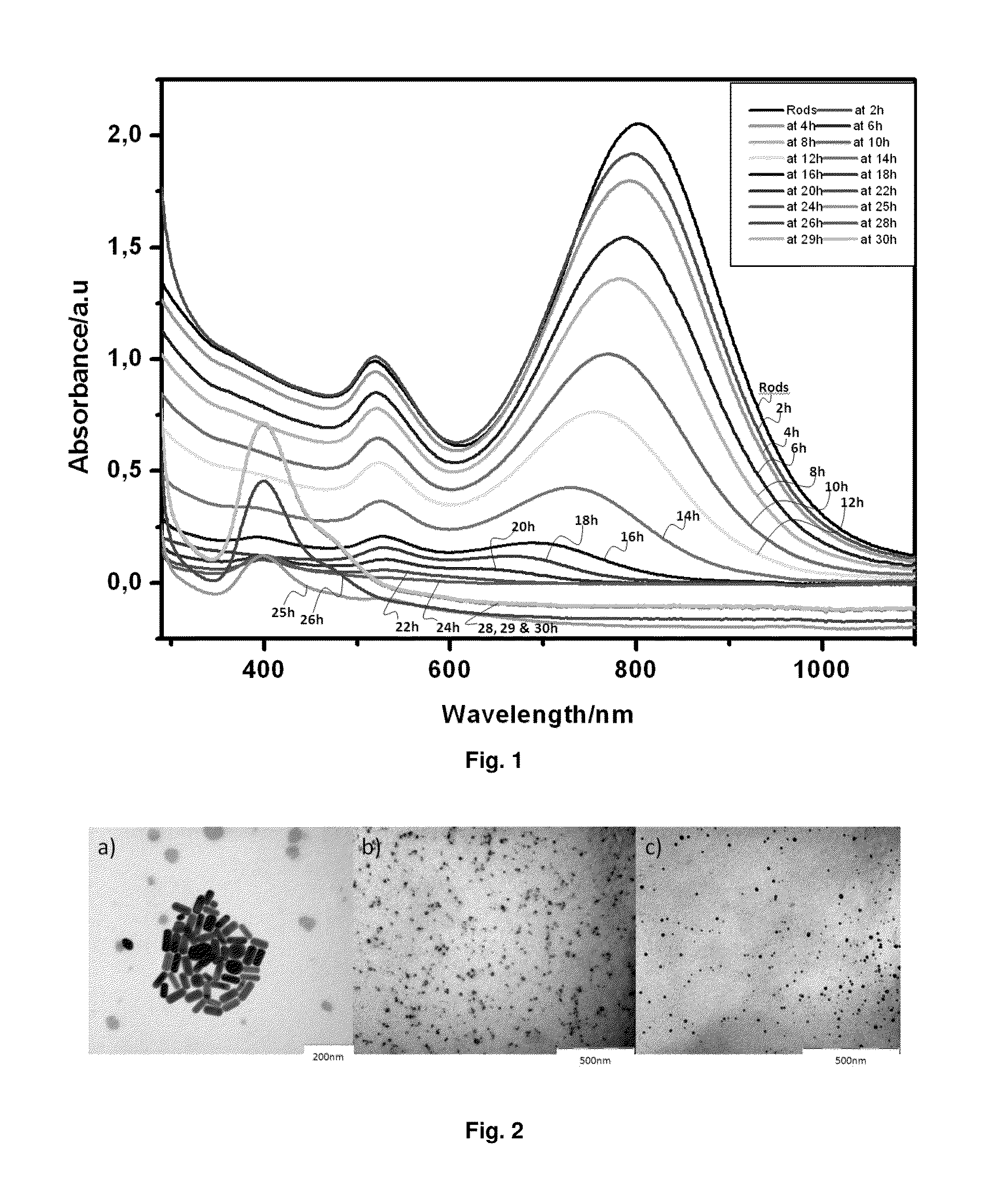

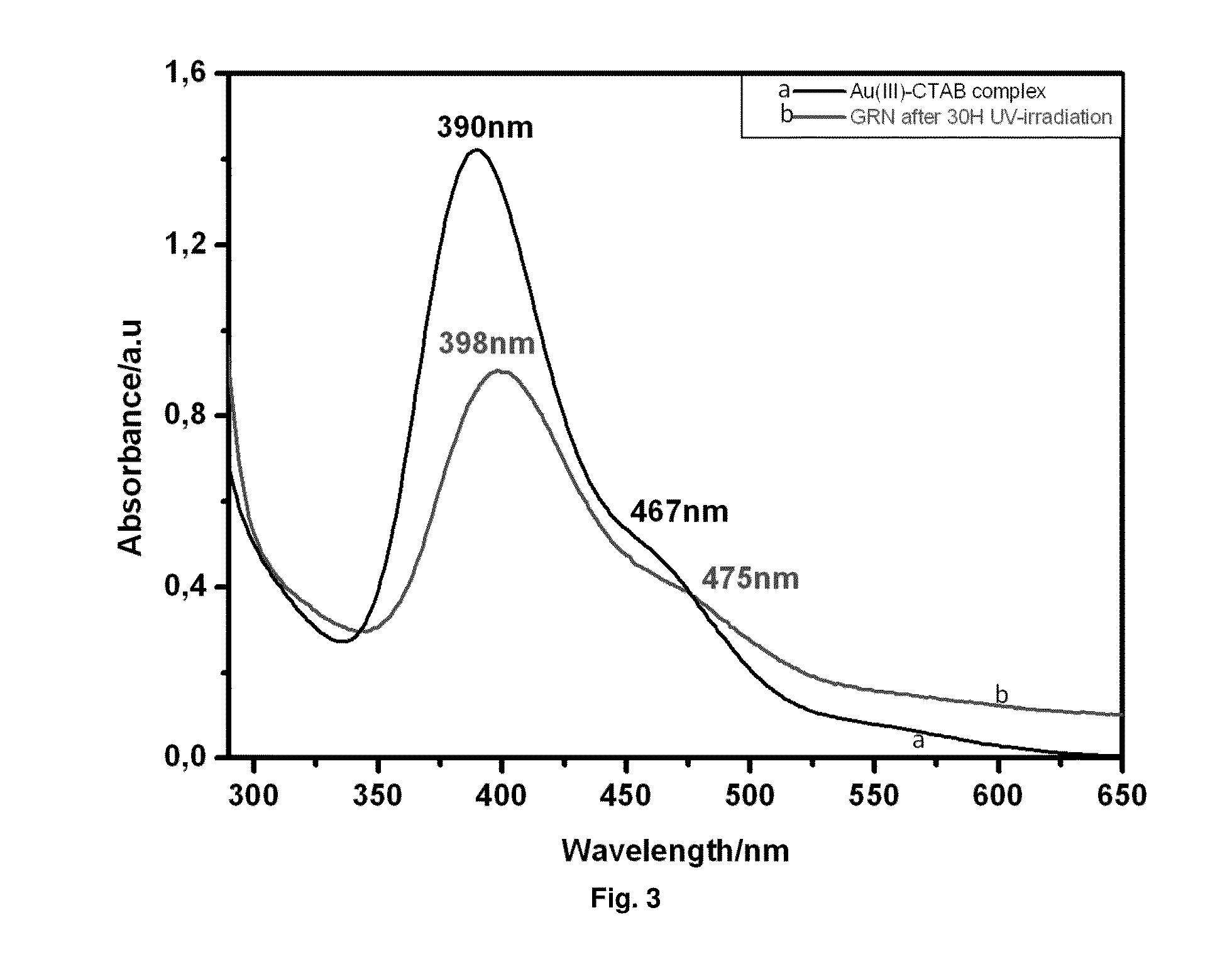

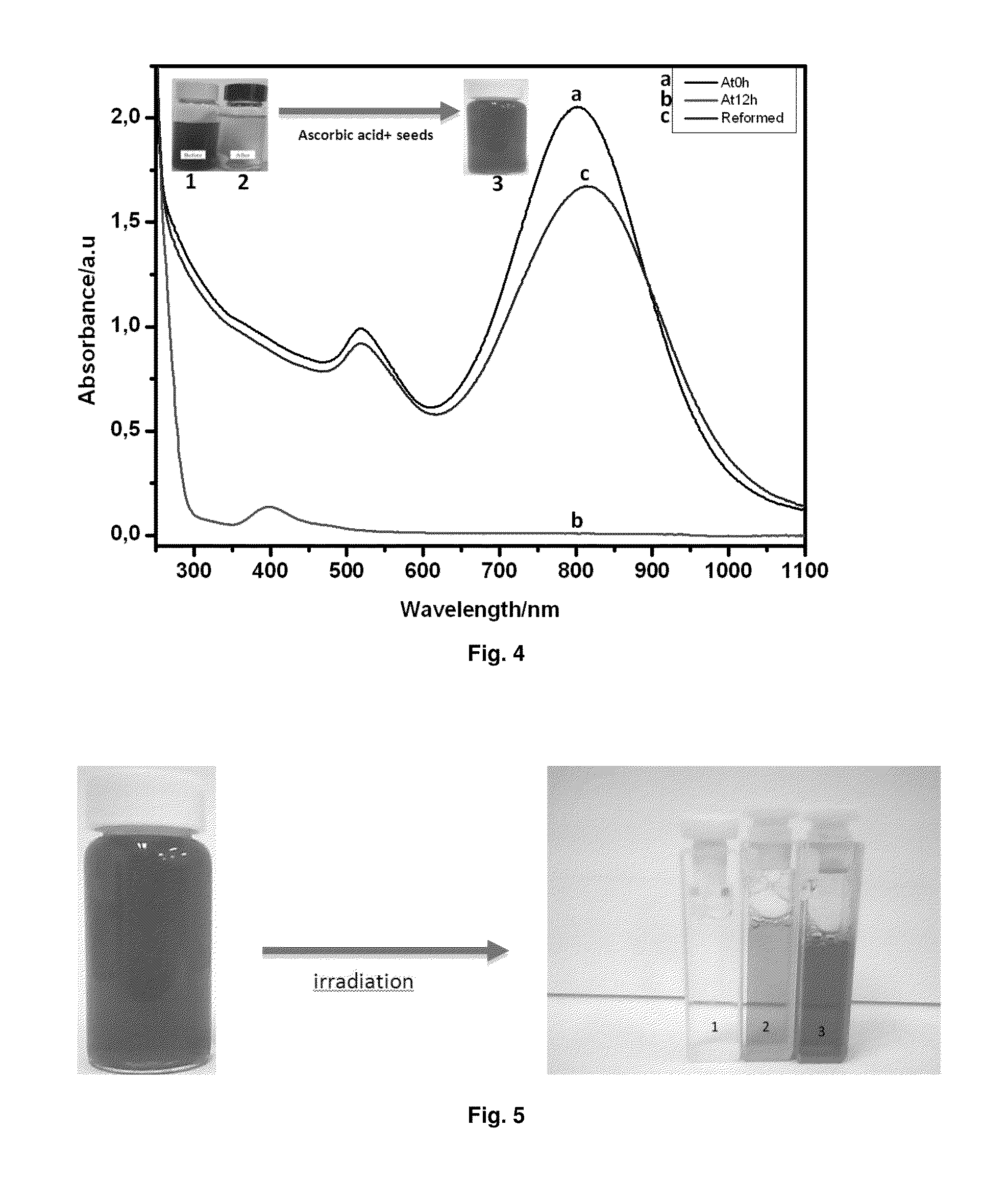

Photoconversion of light using metal supported atomic quantum clusters

ActiveUS20140318980A1Easy to separateIncrease interface areaMaterial nanotechnologyLight-sensitive devicesTransition metal atomsNanometre

The present invention discloses the use of a metal nanoparticle which comprises at least one semiconductor attached to it, wherein the at least one semiconductor is an atomic quantum cluster (AQC) consisting of between 2 and 55 zero-valent transition metal atoms, as photocatalysts in photocatalytic processes and applications thereof.

Owner:UNIVERSITY OF SANTIAGO DE COMPOSTELA

Organic-inorganic hybrid solar cell

ActiveCN106233482AIncrease charge mobilityHigh current density increasesElectrolytic capacitorsPalladium organic compoundsHybrid solar cellSilicon

In the present specification, an organic-inorganic hybrid solar cell is provided, which comprises: a first electrode; a second electrode provided opposite the first electrode; a light active layer provided between the first electrode and the second electrode; and a silicon material layer provided between the light active layer and the first electrode. The light active layer includes a perovskite structure compound.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com