Apparel with telescoping sleeves

a technology of telescopic sleeves and sleeves, which is applied in the direction of protective clothing, pyjamas, nightdresses, etc., can solve the problems of linen gowns not being able to prevent “strikethrough”, unsatisfactory openings or seams in garments, and high cost, and achieve the effect of inhibiting the movement of gloves on sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference will now be made in detail to one or more examples of the invention depicted in the figures. Each example is provided by way of explanation of the invention, and not meant as a limitation of the invention. For example, features illustrated or described as part of one embodiment may be used with another embodiment to yield still a different embodiment. Other modifications and variations to the described embodiments are also contemplated within the scope and spirit of the invention.

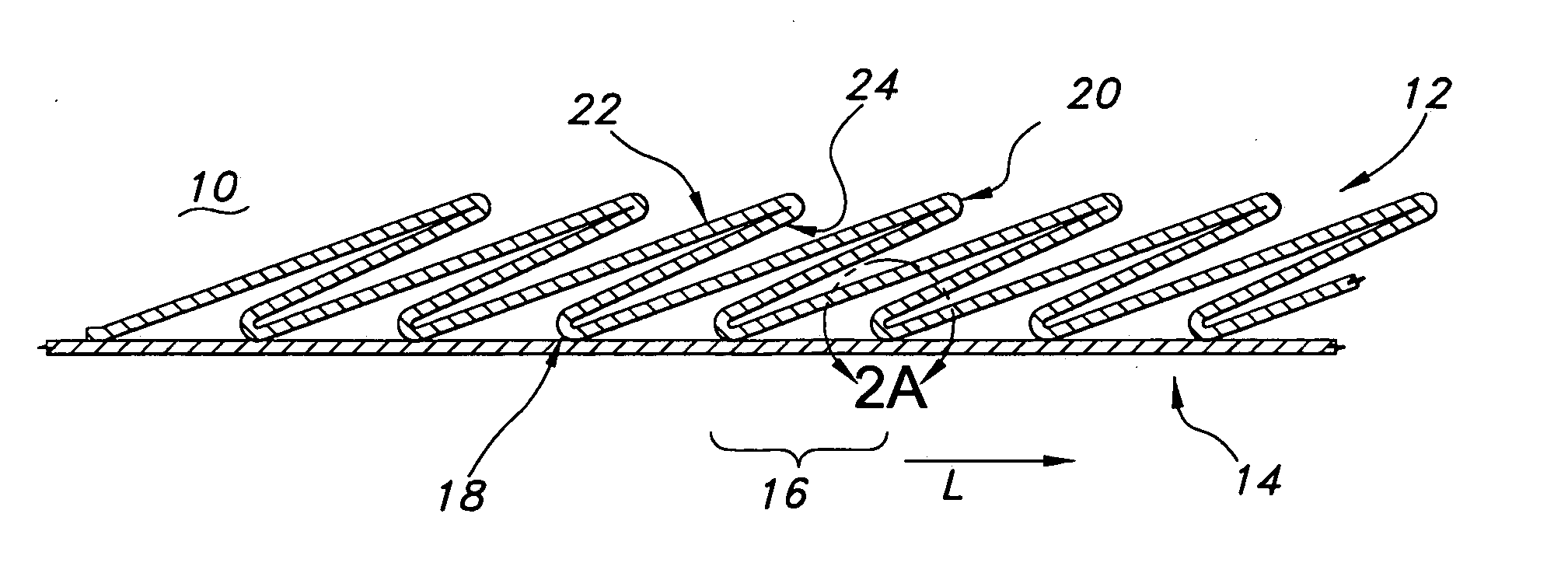

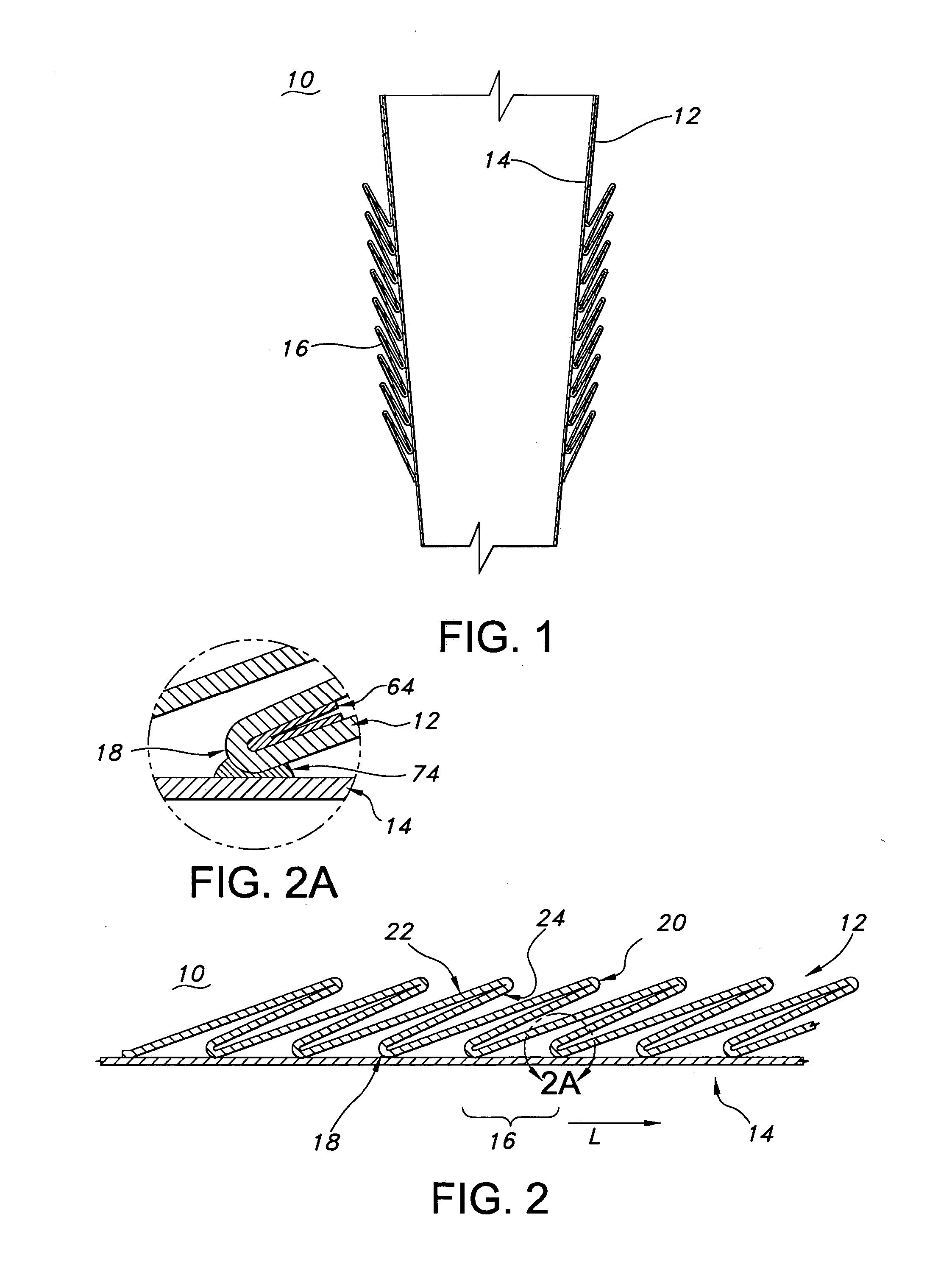

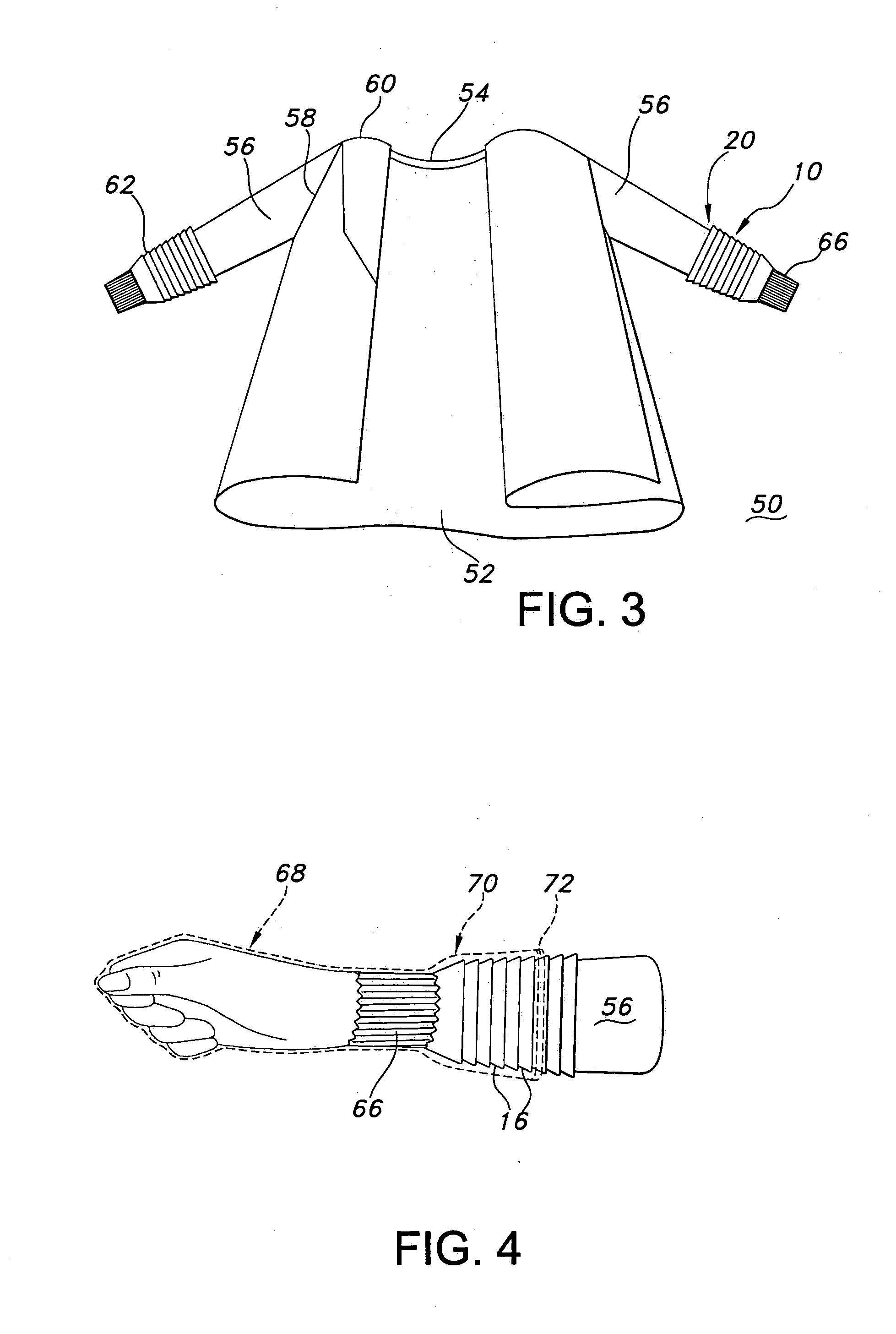

[0026]FIG. 1 illustrates a radially telescoping sleeve section 10 having a first sleeve portion 12 and a second sleeve portion 14. Each of the portions 12 and 14 are provided in the form of a generally tubular arrangement, casing, or sleeve made up of at least a single layer of sheet material. Each of the sleeve portions 12 and 14 may be manufactured from the sheet materials during or subsequent to the manufacturing process through the use of any mechanical, chemical, or thermal process in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com