Steel-based carbon fibre composite material and preparation method thereof

A steel-based carbon fiber and composite material technology is applied in the field of composite materials to achieve the effects of increasing the interface area, uniform stress distribution of materials, and enhancing fatigue resistance and creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the technical solution of the present application, the present invention will be further described in detail below in conjunction with the accompanying drawings.

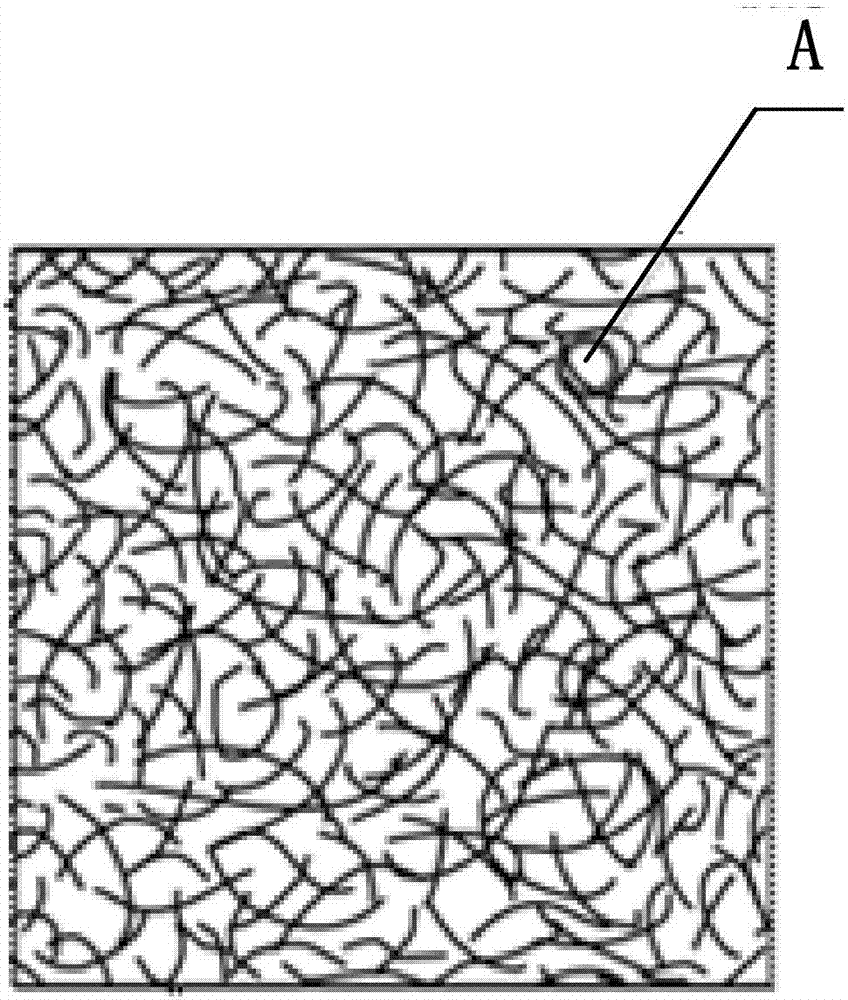

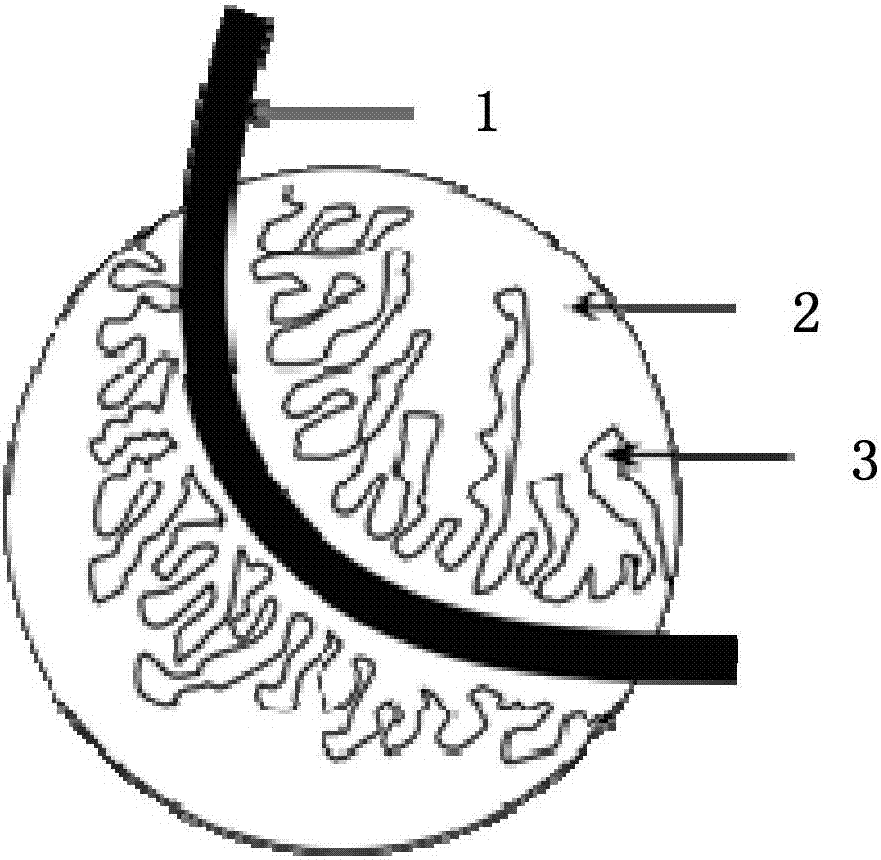

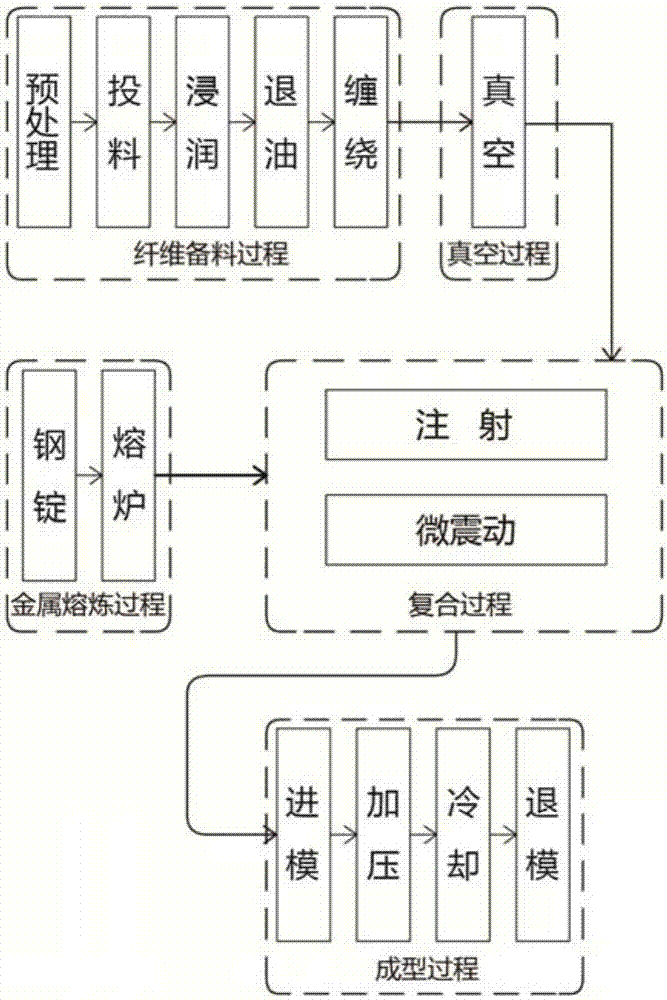

[0048] The invention provides a steel-based carbon fiber composite material, the structure of which is as follows figure 1 with figure 2 As shown, it is formed by chemical bonding of multiple intertwined bent carbon fibers, steel-based materials, and adhesives bonded to the surface of the carbon fibers. Among them, the adhesive bonded on the surface of the carbon fiber and the steel-based material form an extremely complex "coral-like" interface through chemical bonds.

[0049] Among the various components included in the above-mentioned steel-based carbon fiber composite material, by volume, carbon fiber accounts for 50-90%, preferably 70-85%, adhesive agent accounts for 5-20%, preferably 8-12%, and the rest is steel-based material . The ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com