Method for preparing lithium-sulfur battery by taking graphitized carbon nanotube flexible film as current collector of lithium-sulfur battery

A lithium-sulfur battery, graphitized carbon technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as poor conductivity, shedding, and impact on battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

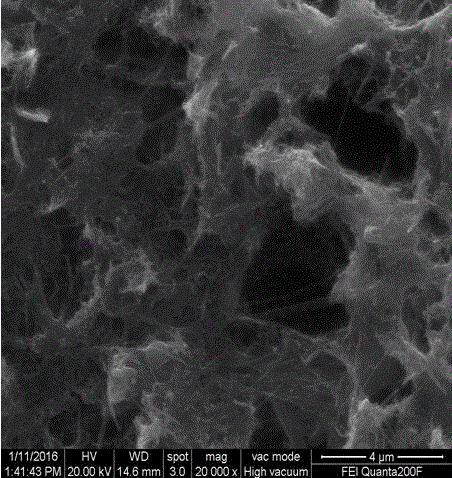

Image

Examples

Embodiment 1

[0022] (1) Take 100g of carbon nanotubes, heat it in the graphitization furnace at 2300°C for 20h, and take it out.

[0023] (2) The carbon nanotubes are ball milled at 300r / min for 3h to a fine and compact powder.

[0024] (3) Using NMP as the solvent and carbon nanotubes (CNTs) as the basic material, the mass ratio of CNTs:PVDF:SDS is 91:5:4, the solid content is adjusted to 4%, the high-speed shearing is 2h, and the pulp is made.

[0025] (4) Choose aluminum foil as the base material, take 10ml of slurry, and coat it into 5x8cm 2 The area is dried at 50℃ to form a film.

[0026] (5) Soak the aluminum foil module in the hydrochloric acid solution for 24 hours to completely corrode the substrate, and take it out carefully to dry.

[0027] (6) Carbonize the prepared CNTs film at 900°C, graphitize it at 2300°C, and take it out for rolling. And after carbonization and graphitization, the impurity content is low, and the crystallinity of CNTs is improved.

[0028] (7) The mass ratio is sul...

Embodiment 2

[0031] (1) Take 100g of carbon nanotubes, keep them in a graphitization furnace at 3000°C for 16h, and take them out.

[0032] (2) The carbon nanotubes are ball milled at 200r / min for 6h to a fine and compact powder.

[0033] (3) Using ethanol as the solvent and carbon nanotubes (CNTs) as the basic material, the mass ratio of CNTs:PVDF:SDBS is 96:2:2, the solid content is adjusted to 2%, the high-speed shear is 1h, and the pulp is made.

[0034] (4) Choose copper foil as the base material, take 10ml of slurry, and coat it into 5x8cm 2 The area is dried at 50℃ to form a film.

[0035] (5) Soak the copper foil module in a concentrated nitric acid solution for 10 hours to completely corrode the substrate, and take it out carefully to dry.

[0036] (6) The prepared CNTs film is carbonized at 1000°C, graphitized at 3000°C, and taken out and compacted. And after carbonization and graphitization, the impurity content is low, and the crystallinity of CNTs is improved.

[0037] (7) The mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com