Montmorillonite modified polyester and preparation method thereof

A technology of montmorillonite and polyester, applied in the field of montmorillonite/PET nanocomposite and its in-situ preparation, can solve the problems of high cost, unsatisfactory results and high temperature of processing molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

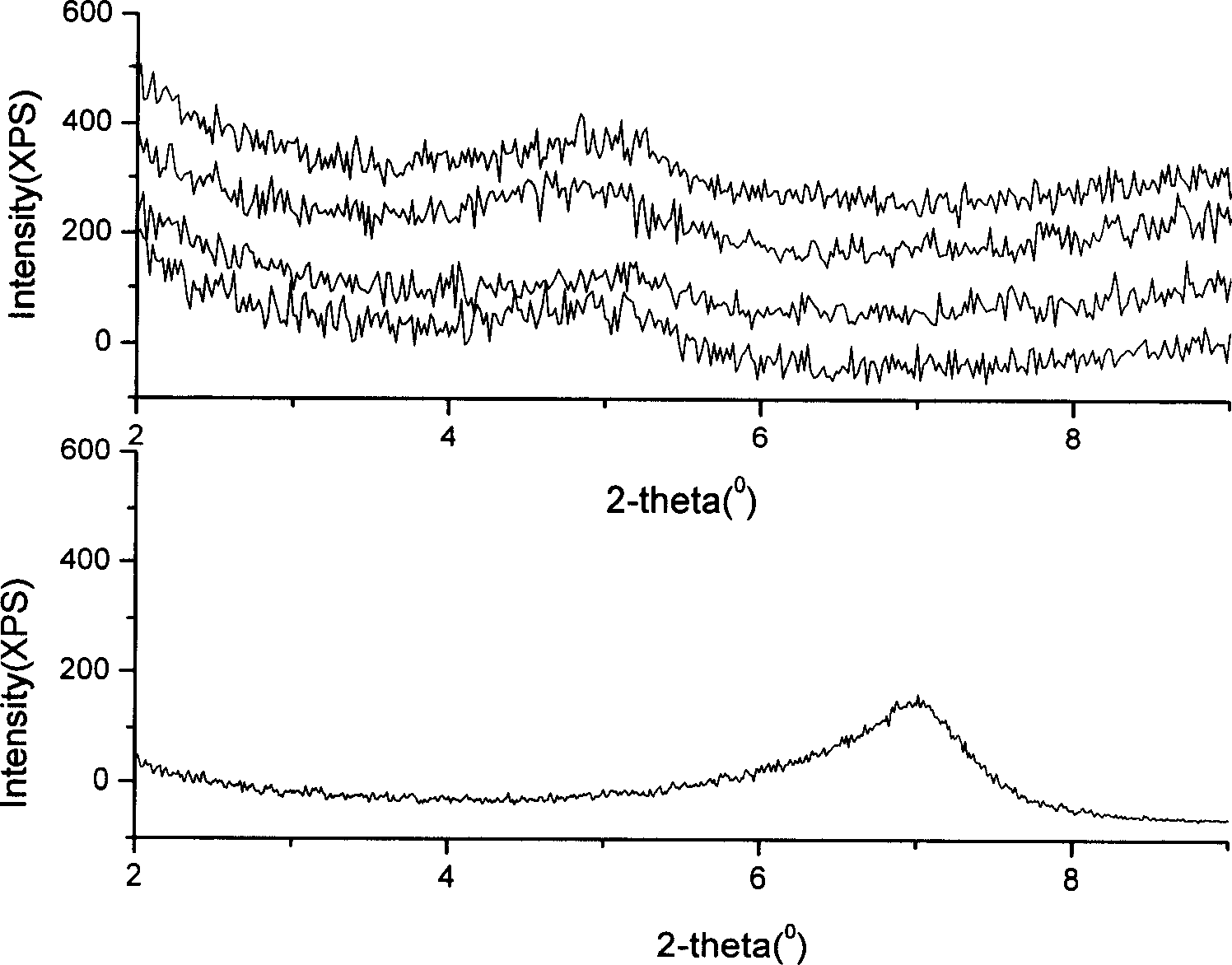

Image

Examples

preparation example Construction

[0034] The preparation method of the present invention is described in detail below:

[0035] Preparation

[0036] The preparation method of montmorillonite modified polyester of the present invention comprises the steps:

[0037] (a) providing an aqueous mixture of 1 to 4 parts by weight of montmorillonite raw soil, 50 to 80 parts by weight of ethylene glycol in 50 to 500 parts by weight of water;

[0038] (b) mixing the aqueous mixture obtained in step (a) with 40 to 80 parts by weight of dimethyl terephthalate to obtain a mixture;

[0039] (c) The mixture obtained in step (b) is polymerized at 160-290° C. to obtain the montmorillonite-modified polyester.

[0040] In order to make the dispersion more uniform, preferably, the aqueous mixture of step (a) is obtained through the following steps: providing an aqueous dispersion of 1 to 4 parts by weight of montmorillonite in 50 to 500 parts by weight of water, and adding the dispersion to 50-80 parts by weight of ethylene gly...

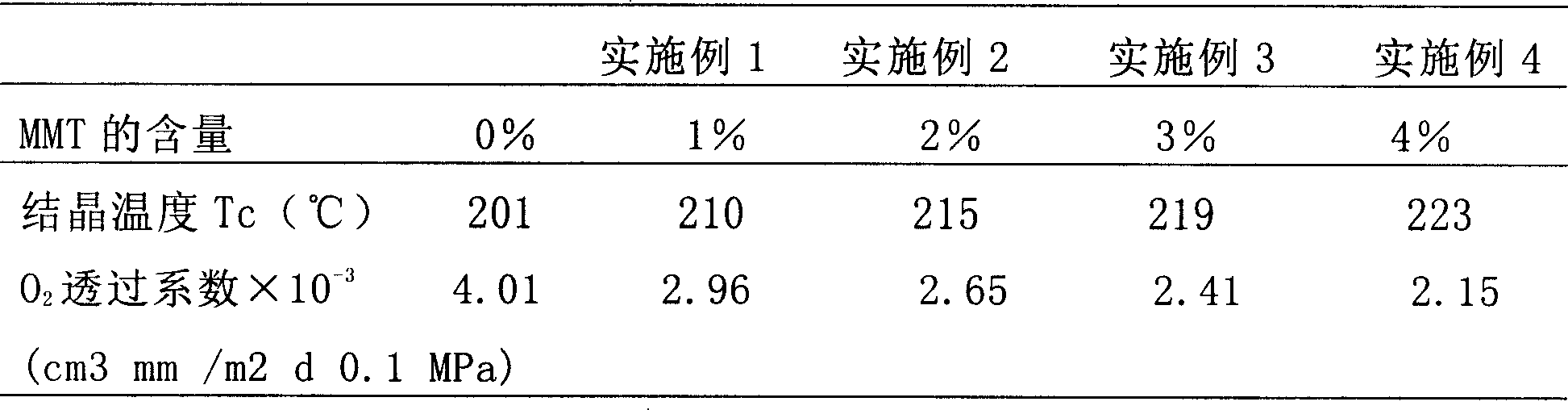

Embodiment 1

[0071] Disperse 1 part of montmorillonite in 100 parts of boiling water, stir for 2 hours, then add 0.2 parts of PEG with a molecular weight of 1000, add 80 parts of EG after ultrasonic dispersion for 3 hours, remove the water after dispersion, and then add to the reactor In; 80 parts of DMT, 0.03 parts of antimony trioxide and 0.12 parts of calcium acetate were added to the reactor. Under the protection of nitrogen, the temperature was raised to 180°C for 2 hours, the vacuum degree was kept below 60Pa, the temperature was raised to 280°C for 3 hours, the reaction was stopped, and the product was taken out.

Embodiment 2

[0073] With embodiment 1, only change the content of MMT to be 2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com