Method for improving catalyst activity and selectivity based on atomic layer deposition directional regulation

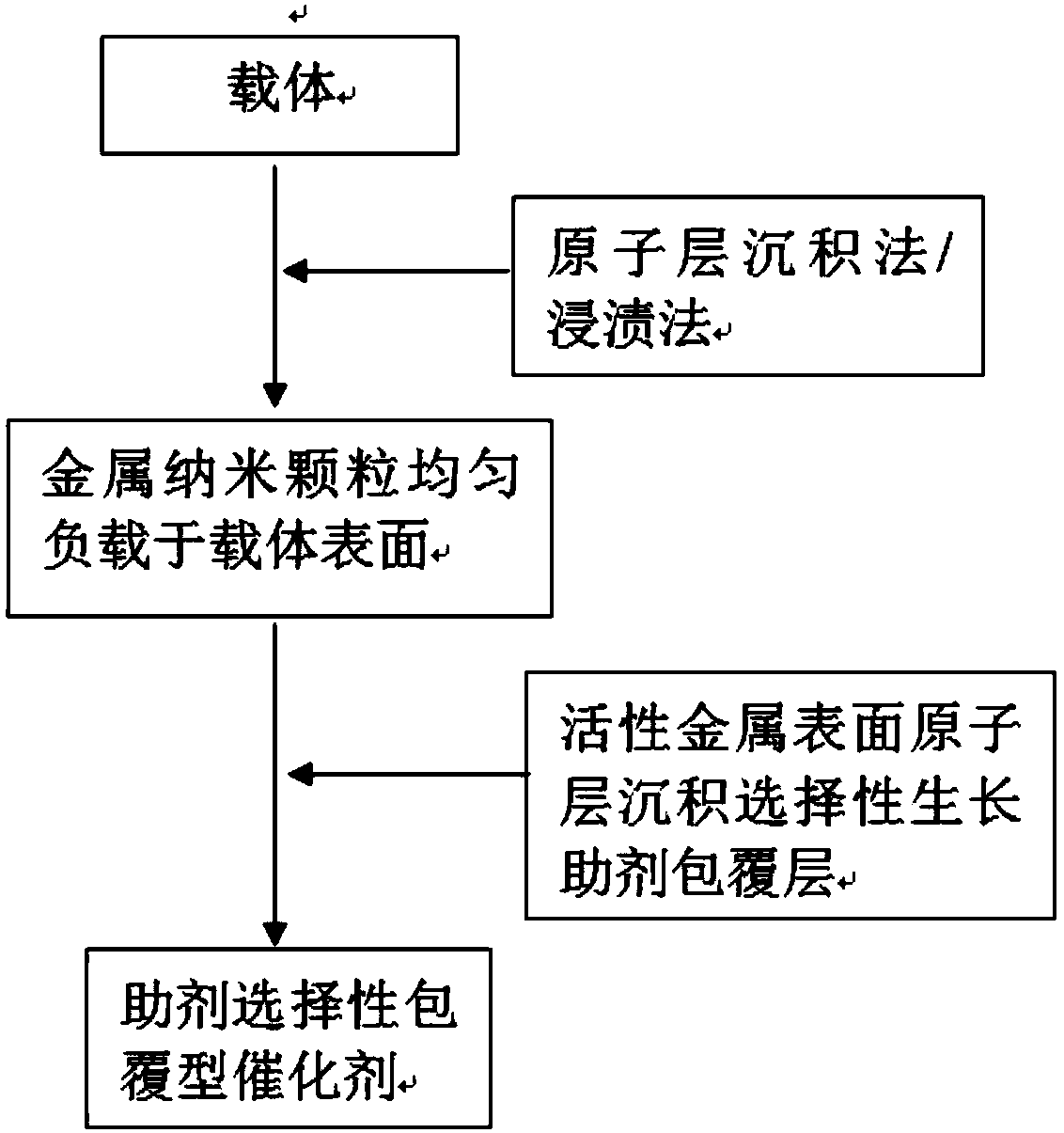

A technique of atomic layer deposition and catalyst, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor controllability, cumbersome operation, and inability to achieve non-continuous specific packaging, etc., to achieve Effect of improving activity and selectivity and enlarging interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 0.2g SiO 2 , baked in a muffle furnace at 600°C for 2h, put it into an atomic layer deposition device, and deposited 10 cycles of Rh nanoparticles on its surface, using rhodium acetylacetonate and oxygen as precursors. The reaction temperature of atomic layer deposition is 200°C, the carrier gas is nitrogen, the precursor pulse time is 30s, and the nitrogen purge time is 60s. Finally, highly dispersed RhO was obtained on the surface of the carrier x nanoparticles.

[0032] Prepared RhO x / SiO 2 Catalyst in 10% H 2 / N 2 Under the atmosphere, it was reduced in a muffle furnace at 400°C for 2 hours to obtain Rh / SiO 2 Catalyst; put into atomic layer deposition equipment, deposit 2 / 4 / 6 cycles of oxide promoter on its surface, using tris(2,2,6,6-tetramethyl-3,5-heptanedionic acid ) manganese and ozone as precursors. The reaction temperature of atomic layer deposition is 150°C, the carrier gas is nitrogen, the precursor pulse time is 60s, and the nitrogen purge ti...

Embodiment 2

[0035] Dissolve rhodium nitrate in deionized water, add rhodium nitrate solution to silicon oxide by equal volume impregnation method, dry at room temperature for 12 hours, dry at 120°C for 12 hours, roast at 350°C in air for 4 hours, and finally in 10% hydrogen atmosphere at 400°C Reducing for 2h, Rh / SiO can be obtained 2 catalyst.

[0036] The prepared Rh / SiO 2 The catalyst is placed in an atomic layer deposition device, and 2 / 4 / 6 cycles of oxide promoters are deposited on its surface, using tris(2,2,6,6-tetramethyl-3,5-heptanedionic acid) Manganese and ozone are precursors. The reaction temperature of atomic layer deposition is 150°C, the carrier gas is nitrogen, the precursor pulse time is 60s, and the nitrogen purge time is 60s. Finally, manganese oxide nanolayers are selectively grown on the surface of active metal Rh nanoparticles to obtain Rh-Mn / SiO 2 catalyst.

Embodiment 3

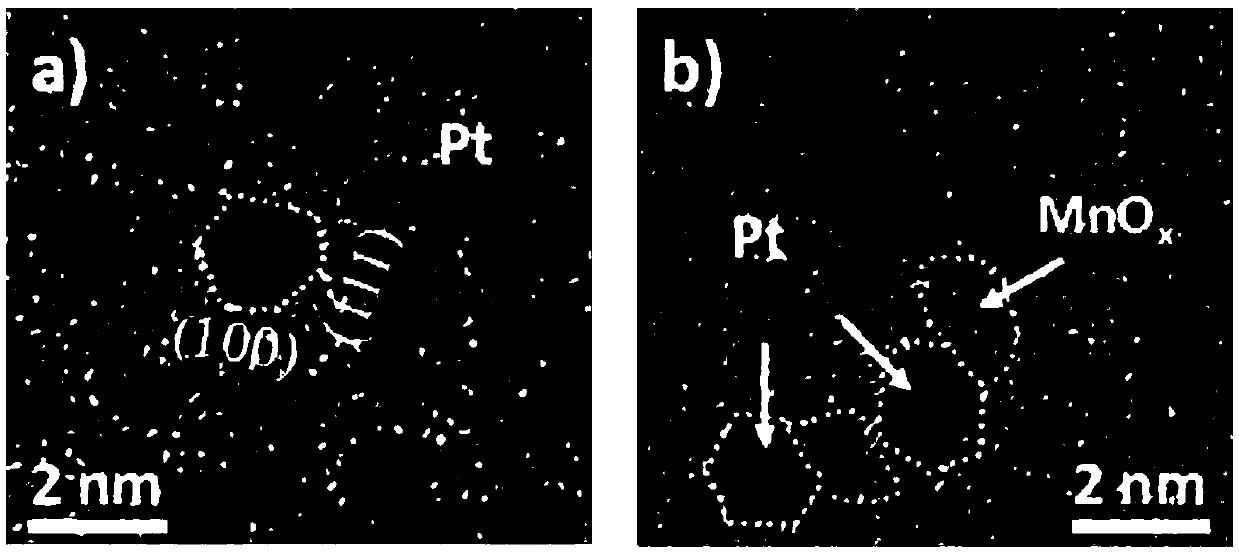

[0038] Take 0.2g Al 2 o 3 , baked in a muffle furnace at 650 ° C for 5 h, put it into an atomic layer deposition device, and deposited two cycles of Pt nanoparticles on its surface, using trimethyl (methylcyclopentadienyl) platinum (IV) and ozone for the precursor. The reaction temperature of atomic layer deposition is 150°C, the carrier gas is nitrogen, the precursor pulse time is 60s, and the nitrogen purge time is 60s. Finally, highly dispersed Pt nanoparticles were obtained on the surface of the carrier.

[0039] Prepared Pt / Al 2 o 3 The catalyst is placed in atomic layer deposition equipment, and 2 / 5 / 8 cycles of oxide additives are deposited on its surface, using bis(acetylacetonate)cobalt as the cobalt source, and another precursor is ozone. The reaction temperature of atomic layer deposition is 150°C, the carrier gas is nitrogen, the precursor pulse time is 60s, and the nitrogen purge time is 60s. Finally, cobalt oxide nanolayers are selectively grown on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com