Bone screw of three-dimensional through porous structure

A porous structure, bone screw technology, applied in the field of medical devices, can solve the problems of surrounding bone, nerve tissue damage, bone cement leakage, prone to fracture, etc., to promote the integration and growth of bone, increase the interface area, improve the bonding the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

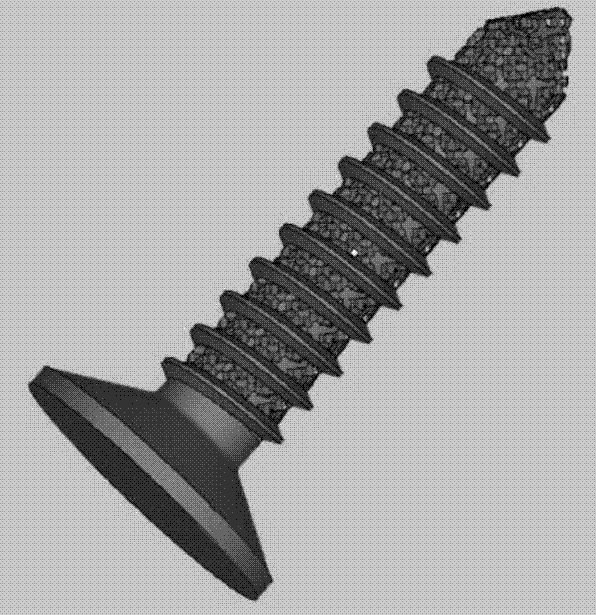

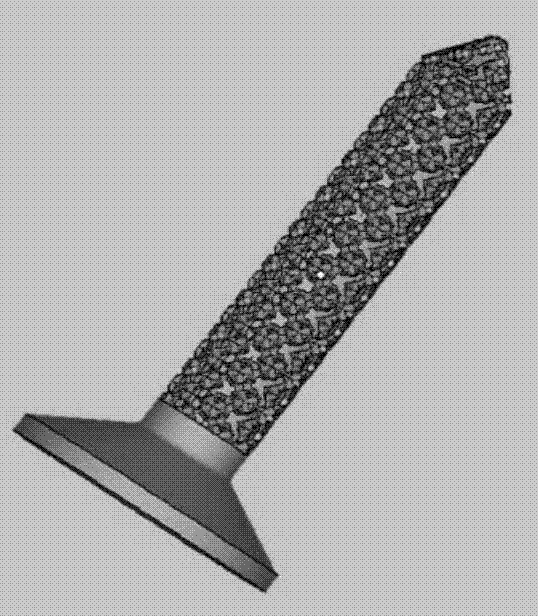

[0043] Example 1 A bone screw with a three-dimensional penetrating porous structure

[0044] A bone screw with a three-dimensional through-hole structure. The porous bone screw is composed of a nail head, a nail body, and a nail cap; the nail body is composed of a porous network formed by a three-dimensional through-hole structure; the pore size is 200 μm, and the porosity is 78%. The nail body diameter range is: 2mm. The cross-sectional shape of the nail body is various: circular, oval, triangular, square, polygonal, and the length range of the nail body is: 1cm. The nail cap is a solid structure with a variety of cross-sectional shapes: circular, oval, square, triangular, and polygonal. The raw materials for the preparation of the porous bone screw are medical metal materials, bioceramics, and medical polymer materials that can be implanted in the human body. Medical metal materials include but are not limited to titanium and titanium alloys.

Embodiment 2

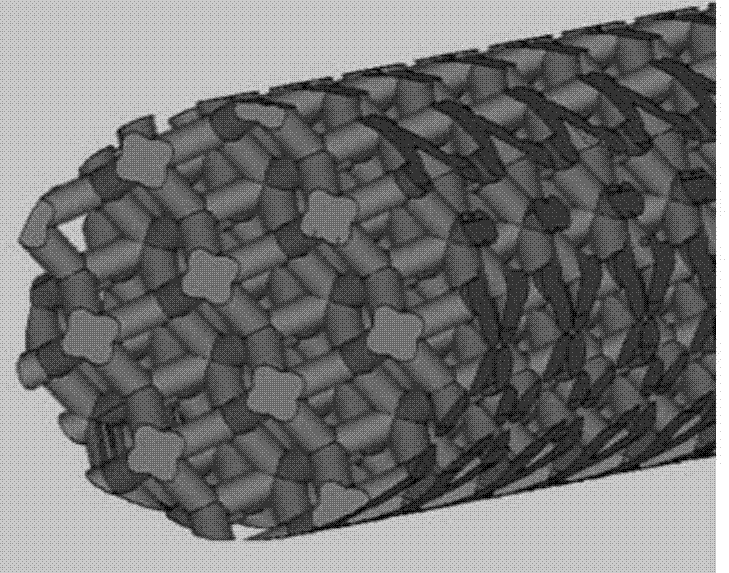

[0045] Example 2 A bone screw with a three-dimensional penetrating porous structure

[0046] A bone screw with a three-dimensional through-porous structure, the porous bone screw is composed of a nail head, a nail body, and a nail cap; the nail body is composed of a porous network formed by a three-dimensional through-hole structure and threads on the surface of the porous network; the pore size is 600 μm , the porosity is 80%, and the diameter of the nail body is 5mm. The cross-sectional shape of the nail body is various: circular, oval, triangular, square, polygonal, and the length of the nail body is 5 cm. The nail cap is a solid structure with a variety of cross-sectional shapes: circular, oval, square, triangular, and polygonal. The pore shape of the porous network is polyhedron, sphere or irregular shape. The raw materials for the preparation of the porous bone screw are medical metal materials, bioceramics, and medical polymer materials that can be implanted in the hu...

Embodiment 3

[0047] Example 3 A bone screw with a three-dimensional penetrating porous structure

[0048] A bone screw with a three-dimensional penetrating porous structure, the porous bone screw is composed of a nail head, a nail body, and a nail cap; the nail body is composed of a porous network formed by a central entity and a three-dimensional through-hole structure located outside the central entity; the porous network is independent On the surface of the central solid and around the central solid. The pore diameter of the three-dimensional through-hole structure is 900 μm, the porosity is 92%, and the diameter of the nail body is 8 mm. The cross-sectional shape of the nail body is various: circle, ellipse, triangle, square, polygon, and the range of the nail body length is 10cm. The nail cap is a solid structure with a variety of cross-sectional shapes: circular, oval, square, triangular, and polygonal. The pore shape of the porous network is polyhedron, sphere or irregular shape. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com