Patents

Literature

119 results about "Screw loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screws may become loose due to vibration or insufficient friction in the mating surface or both. If a screw is subjected to vibration constantly it is likely to work itself loose over time. If a screw is inserted into a substance that cannot provide sufficient friction, it will be loose.

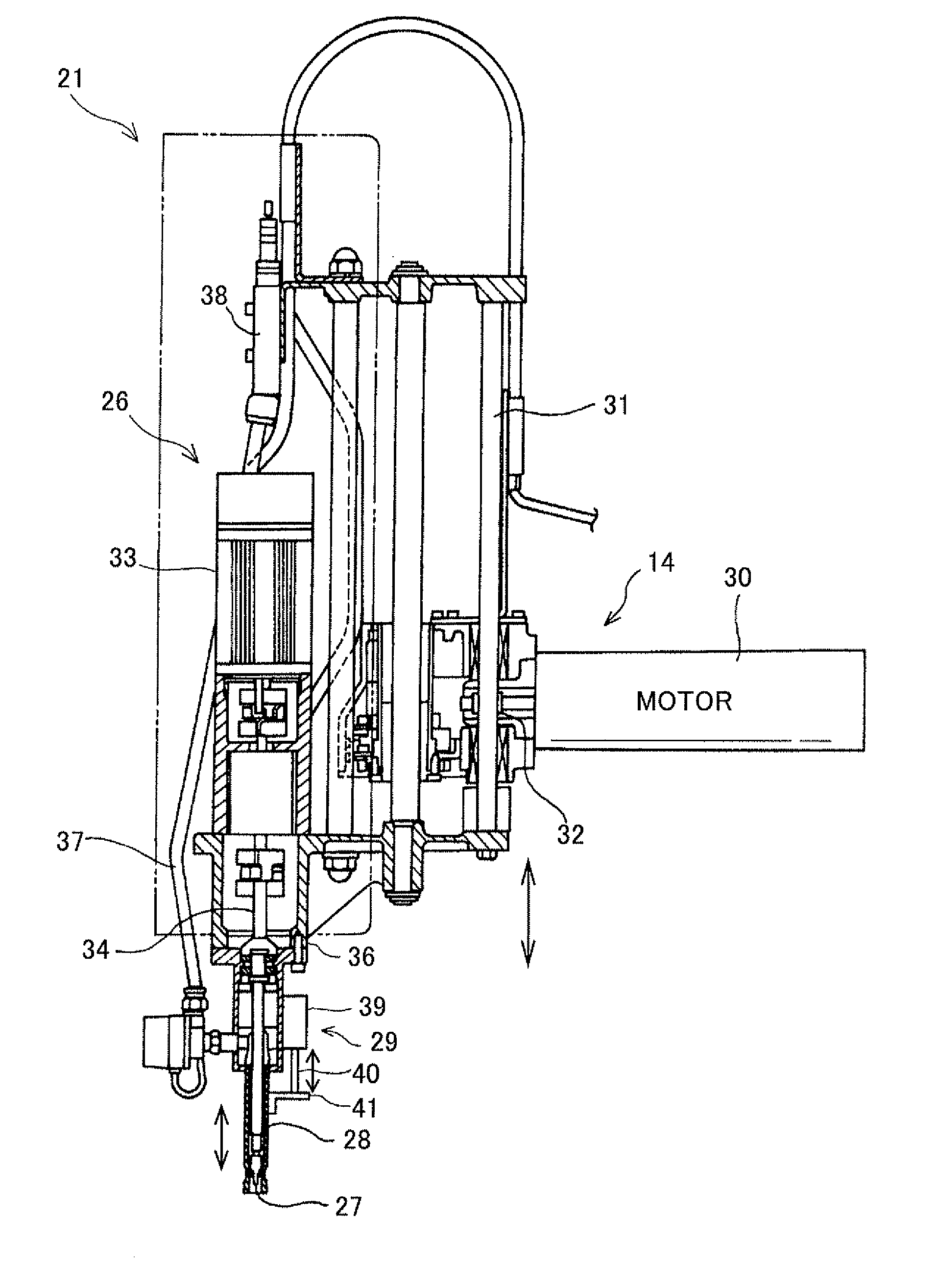

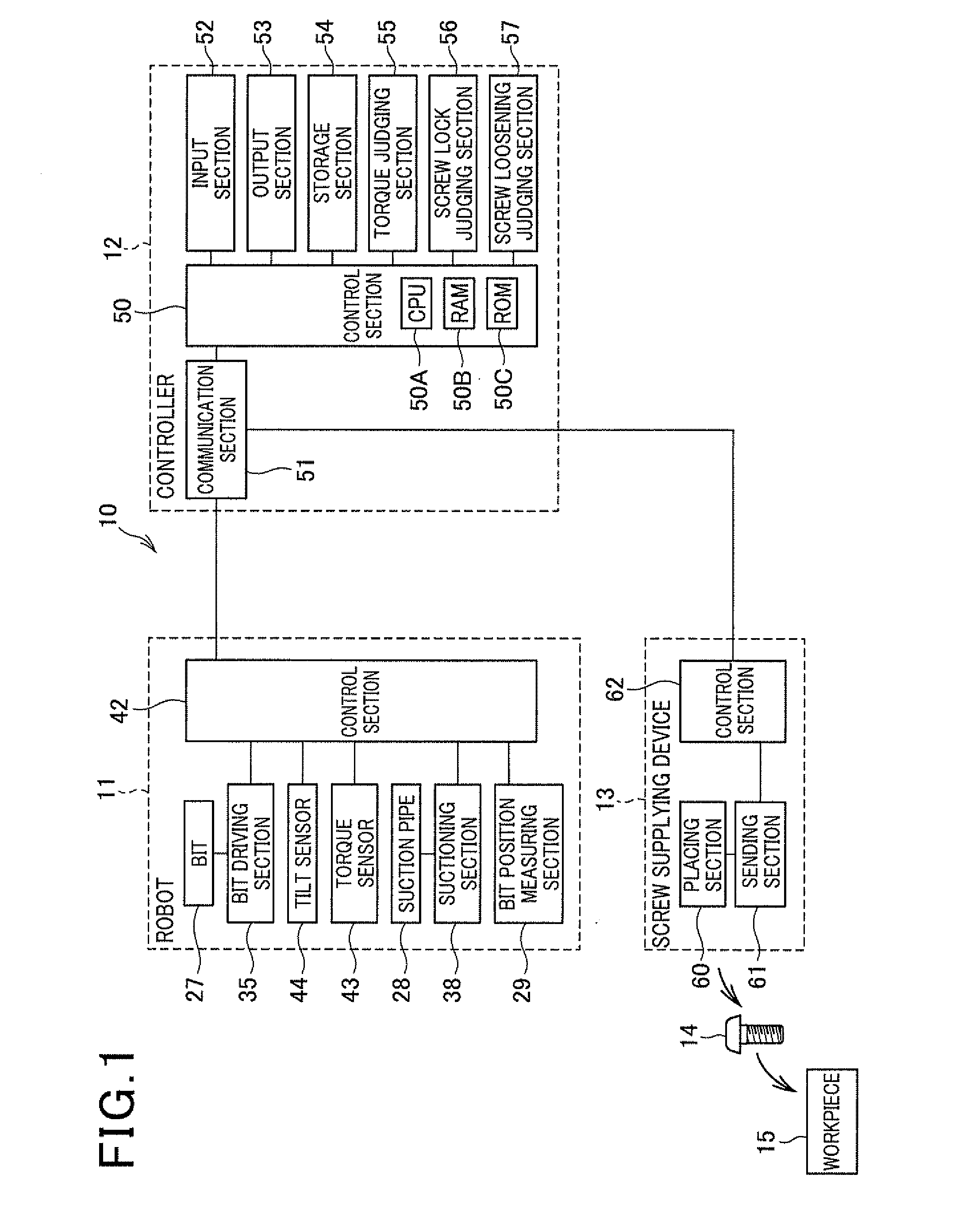

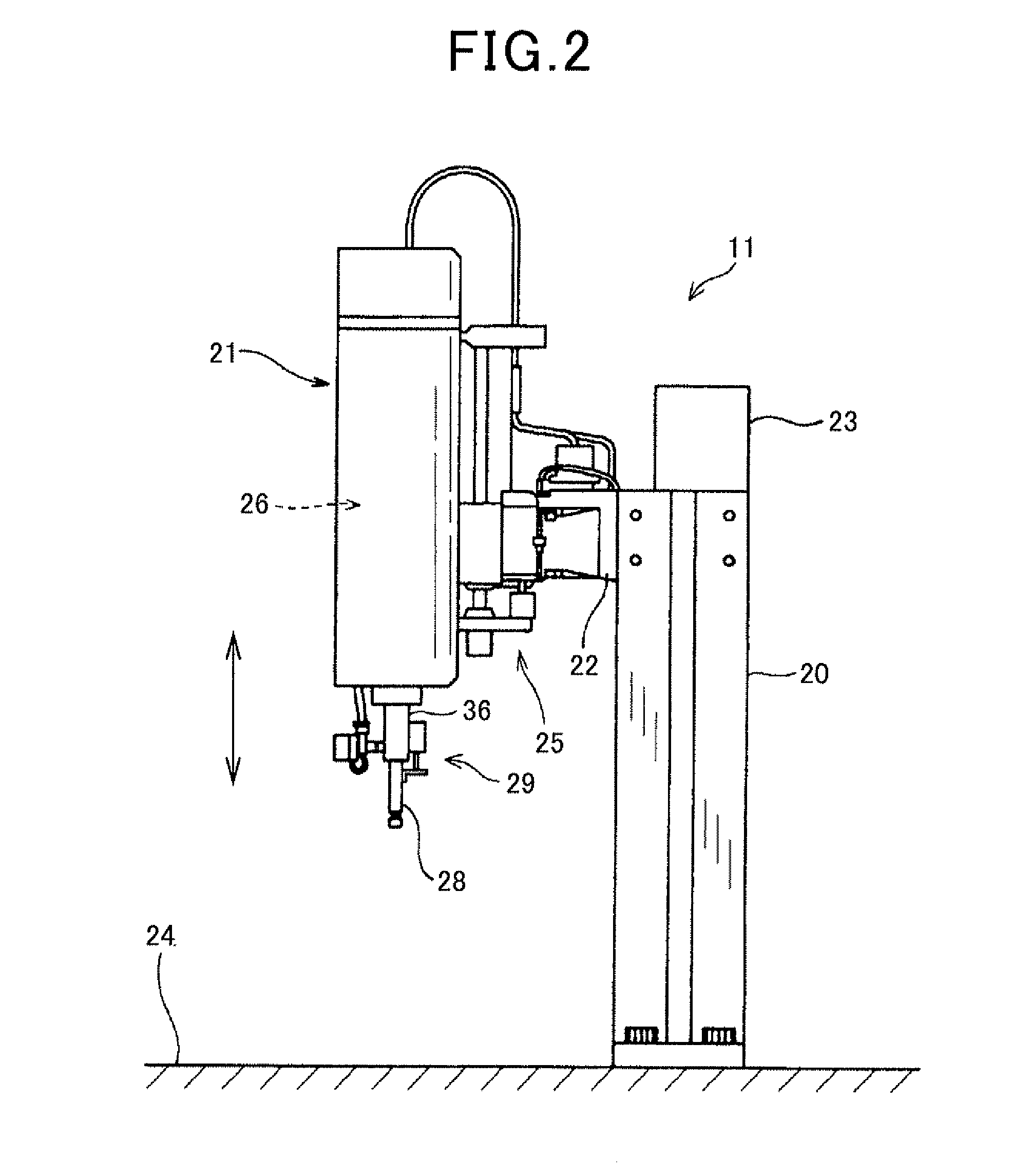

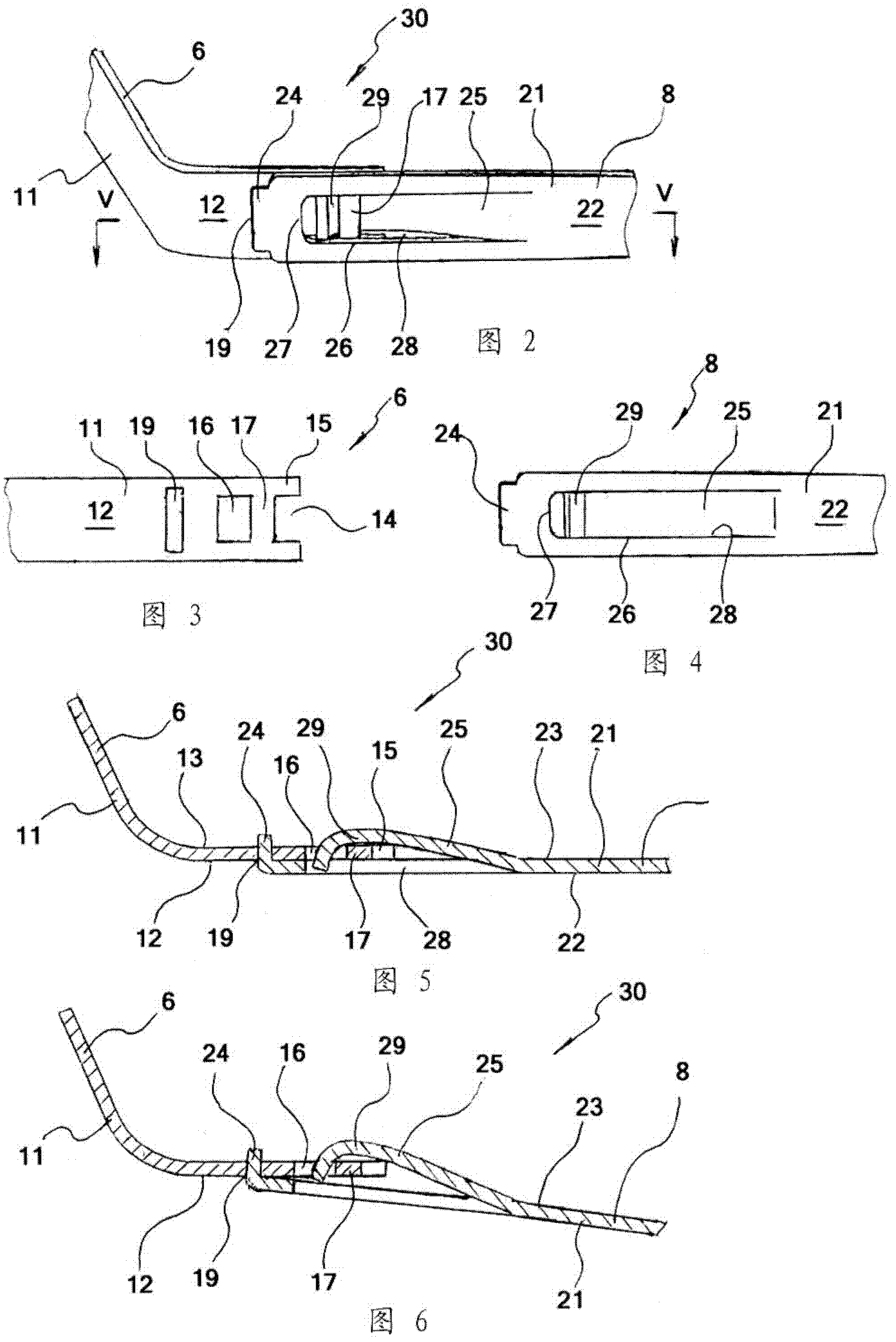

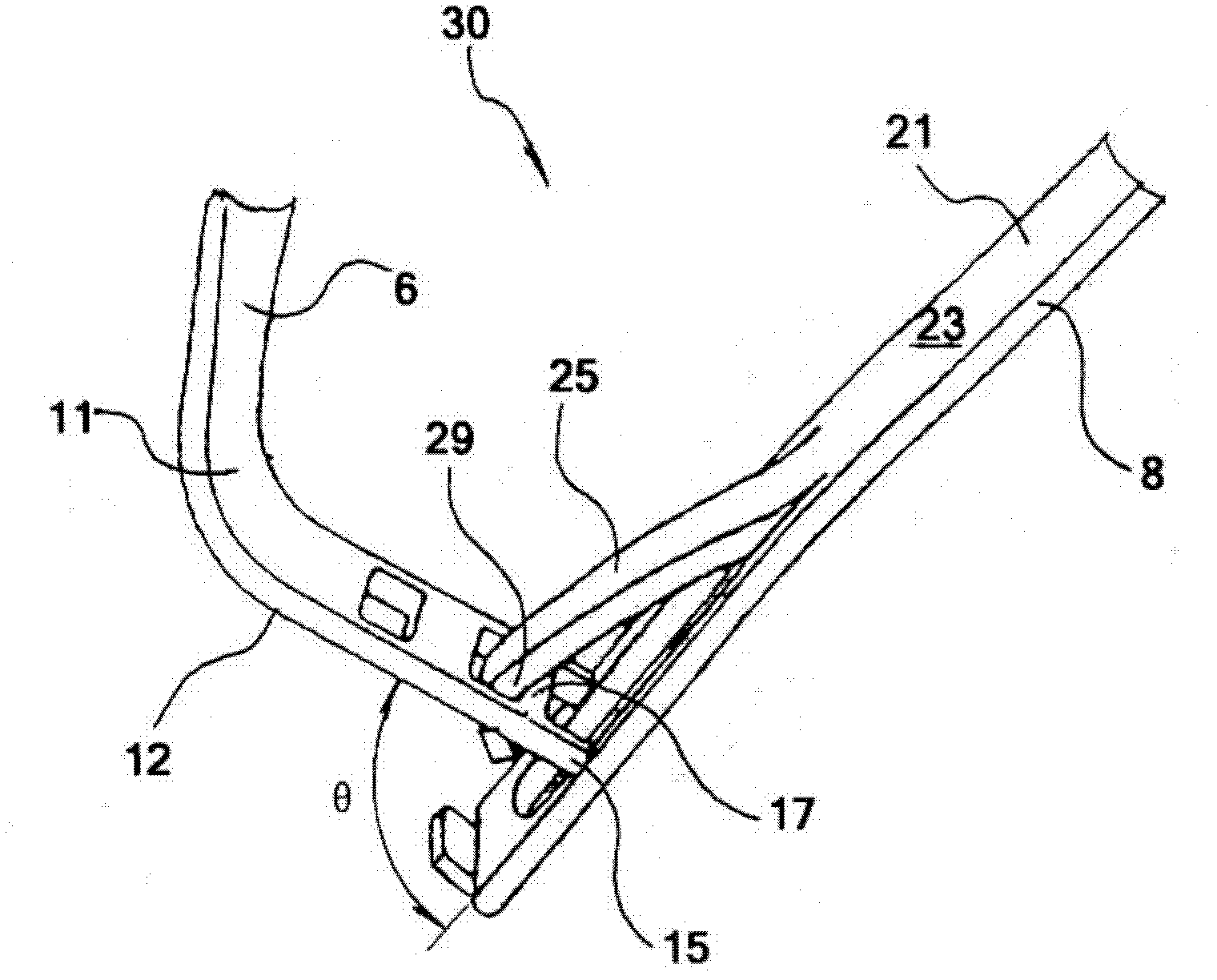

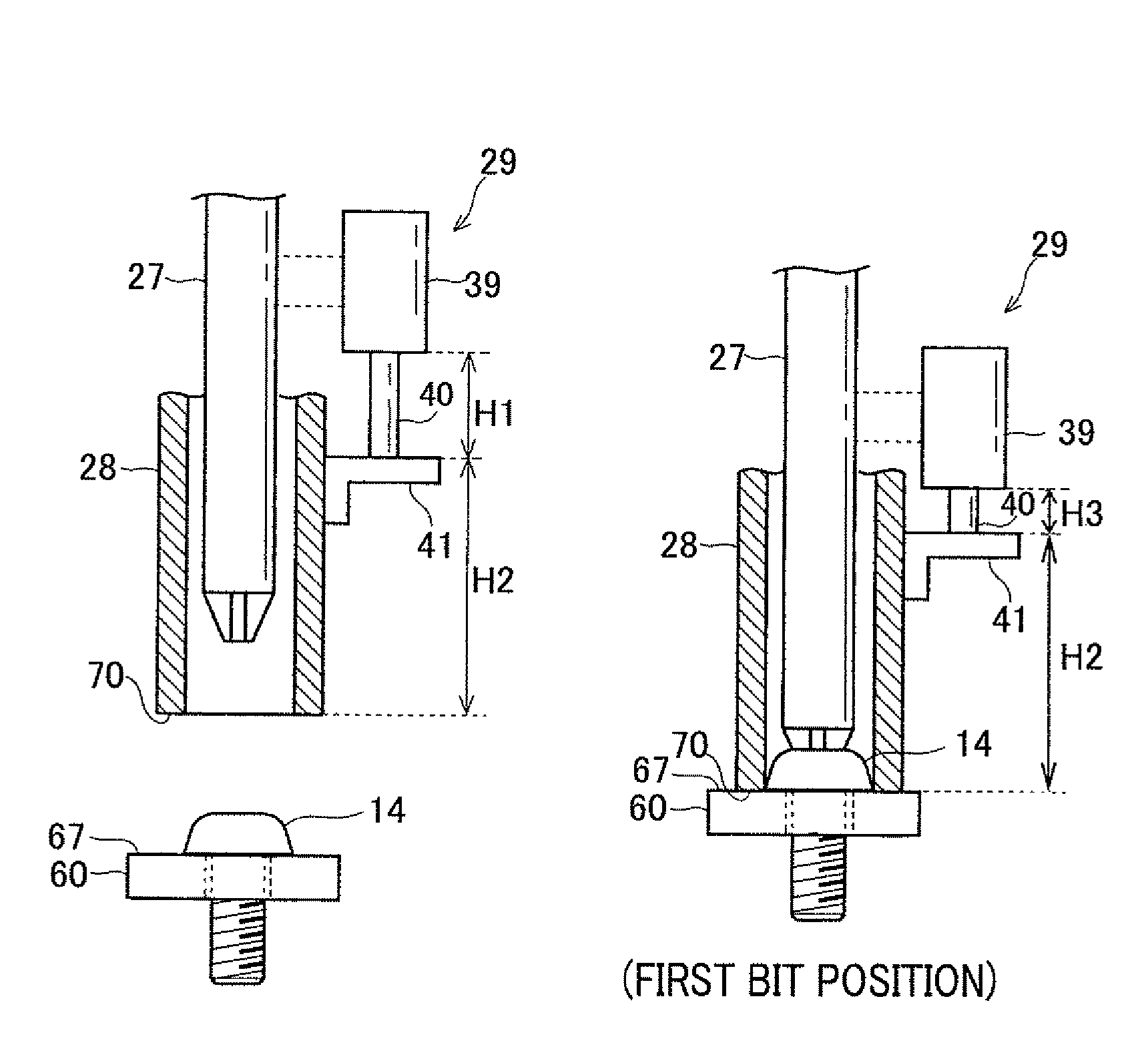

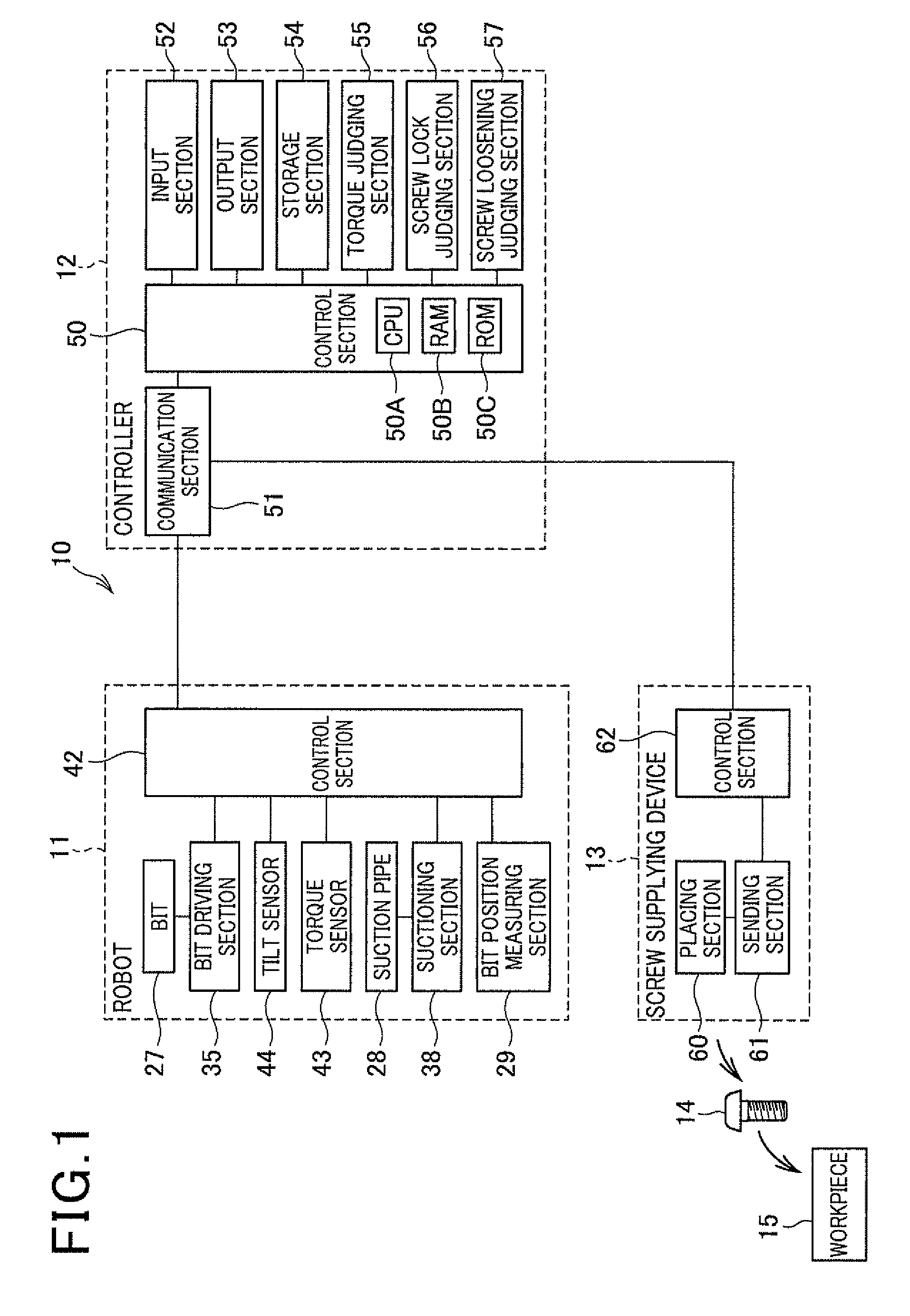

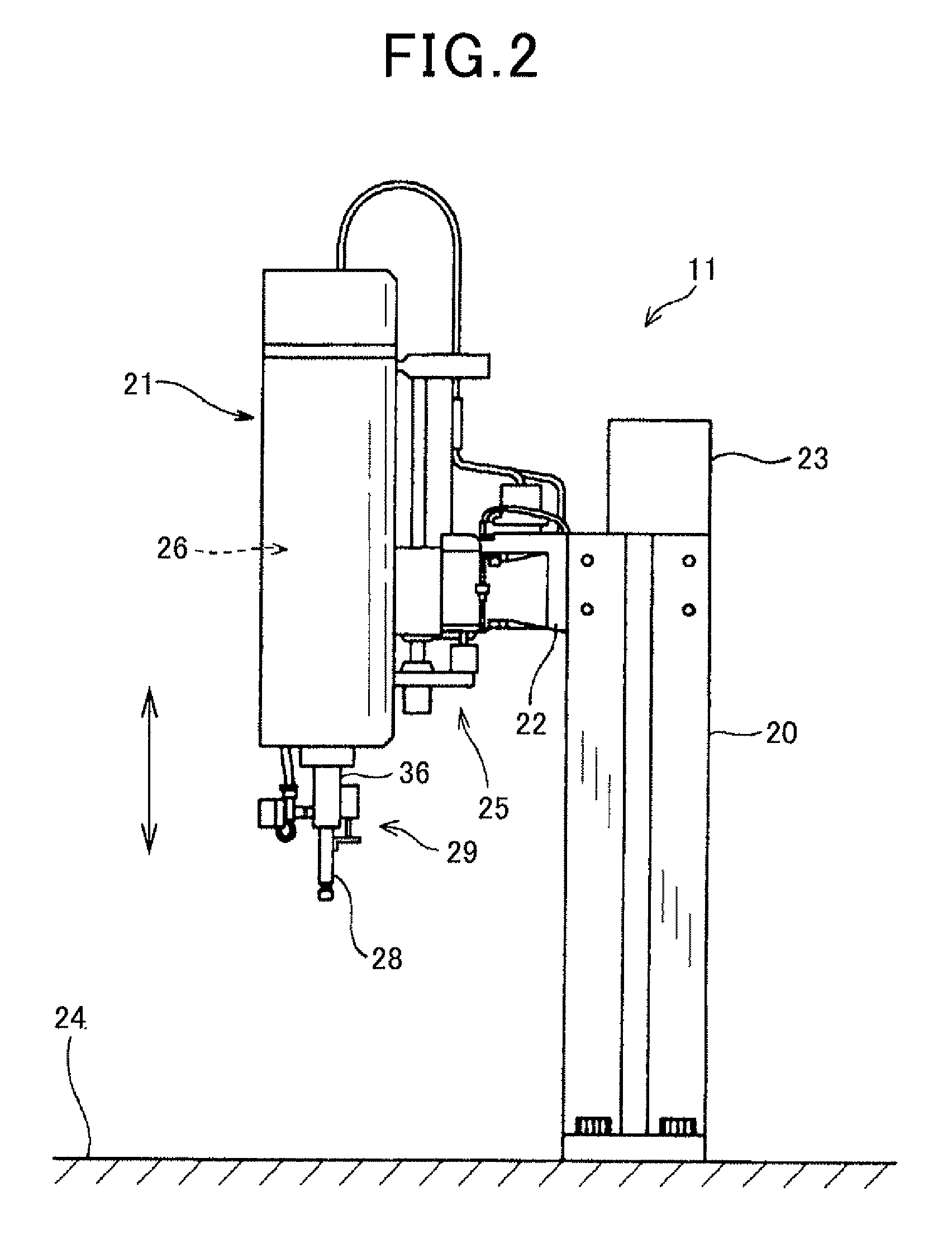

Device for fastening screw onto workpiece and method of judging loosening of screw

ActiveUS20130067711A1Increase ratingsIncrease in load timeProgramme controlProgramme-controlled manipulatorEngineeringScrew loosening

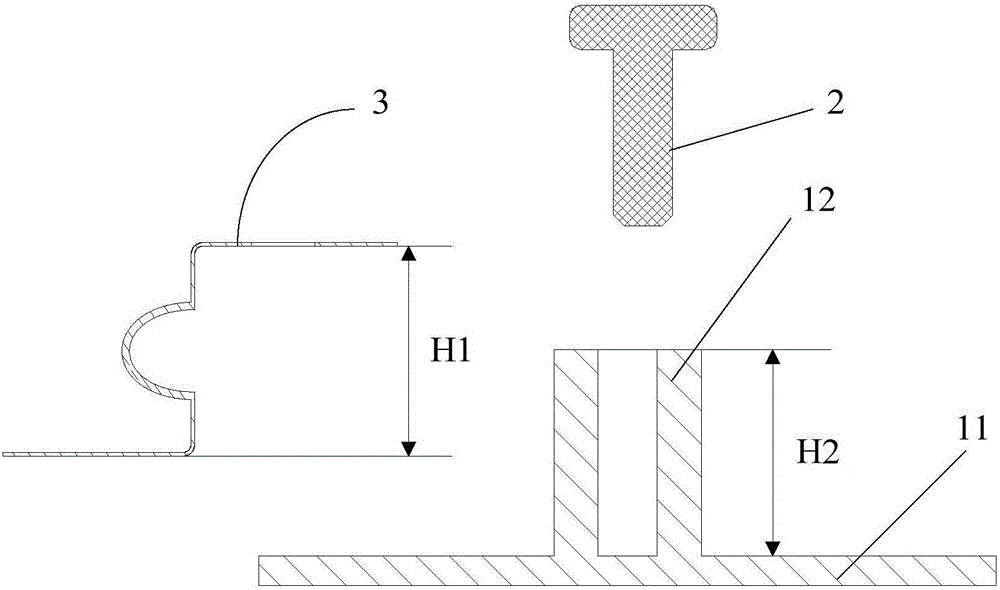

In judging loosening of a crew, a measuring section measures a position of a bit as a relative position in relation to a placement surface of a screw supplying device when the screw is acquired from the screw supplying device. The measuring section also measures the position of the bit as a relative position in relation to a workpiece surface when fastening of the screw onto a workpiece has been completed. A judging section judges that screw loosening has not occurred when, based on the first and second bit positions, a difference between the first and second bit positions falls within an allowable range. The judging section judges that screw loosening has occurred when the difference does not fall within the allowable range.

Owner:DENSO WAVE INC

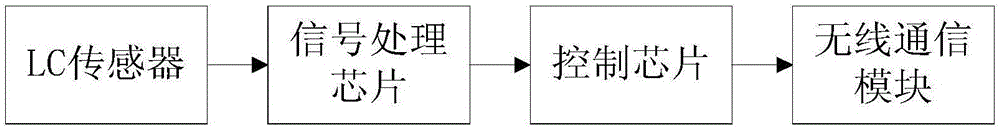

Screw loosening monitoring device and system

InactiveCN106054263AImprove work efficiencySimple structureElectric/magnetic detectionAcoustic wave reradiationComputer moduleEngineering

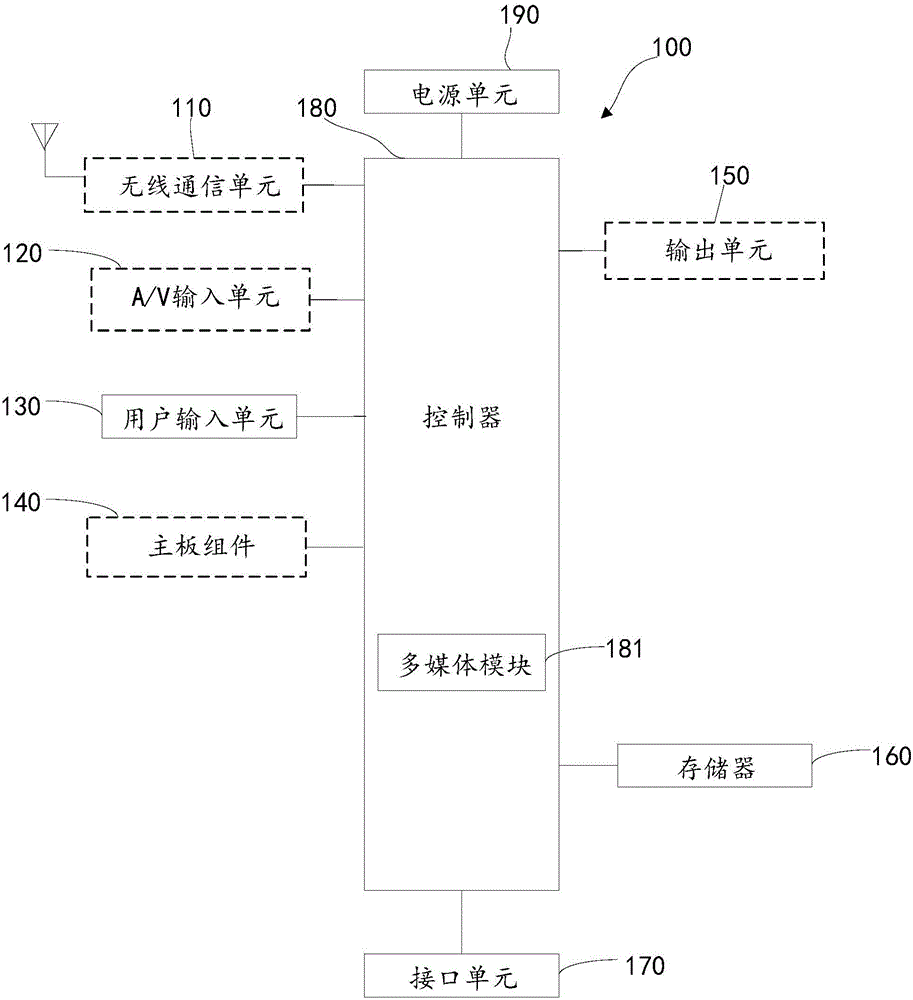

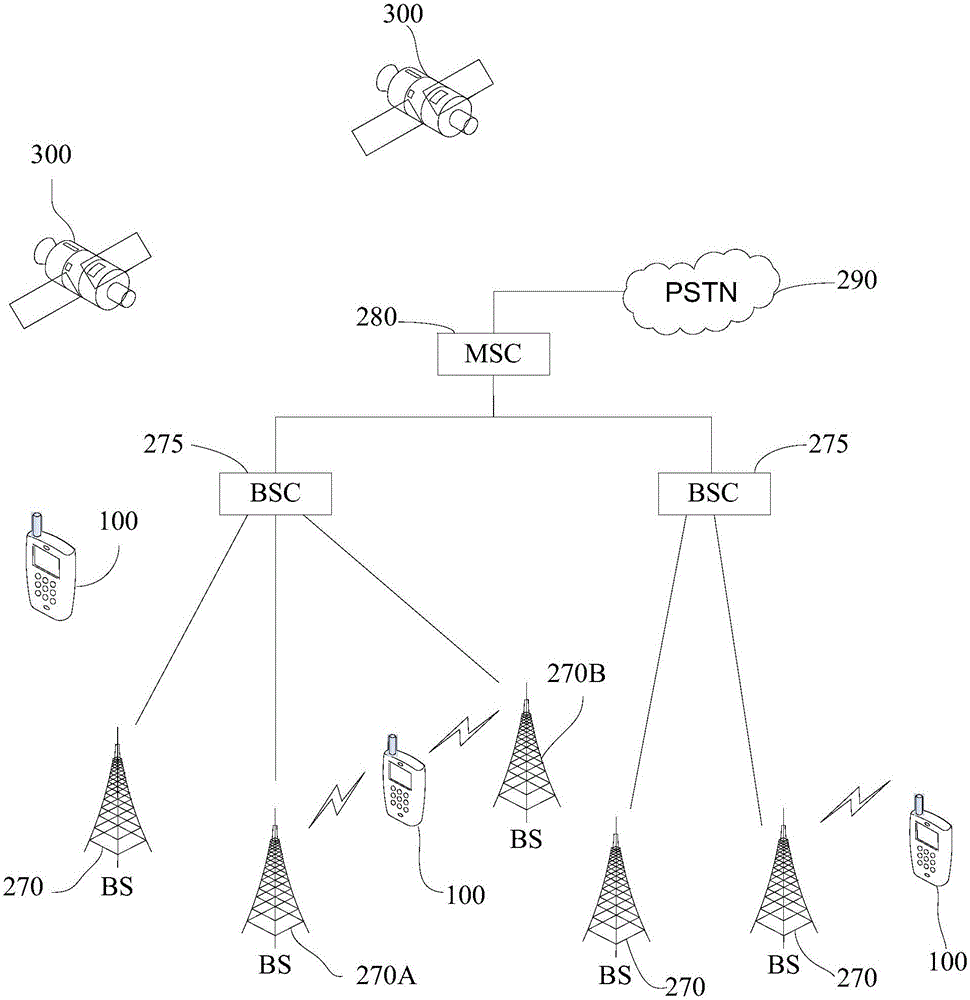

The invention discloses a screw loosening monitoring device and system. The device comprises an LC sensor, a signal processing chip, a control chip and a wireless communication module which are electrically connected in sequence. The LC sensor is a coil. The LC sensor is used for measuring an inductance signal between the LC sensor and detected metal. The signal processing chip is used for converting the received inductance signal into a position signal. The control chip converts the received position signal into distance data. The wireless communication module is used for transmitting the received distance data to a background computer. Compared with an existing screw loosening monitoring device in the market, the device provided by the invention is simple in structure, convenient to install, low in cost, high in monitoring precision and wide in utilization range; in addition, regular inspection by maintenance personnel is not needed, online detection is practically realized, the manpower is substantially saved, the working efficiency of bolt monitoring is improved, and the working efficiency of the equipment is improved.

Owner:杨志强

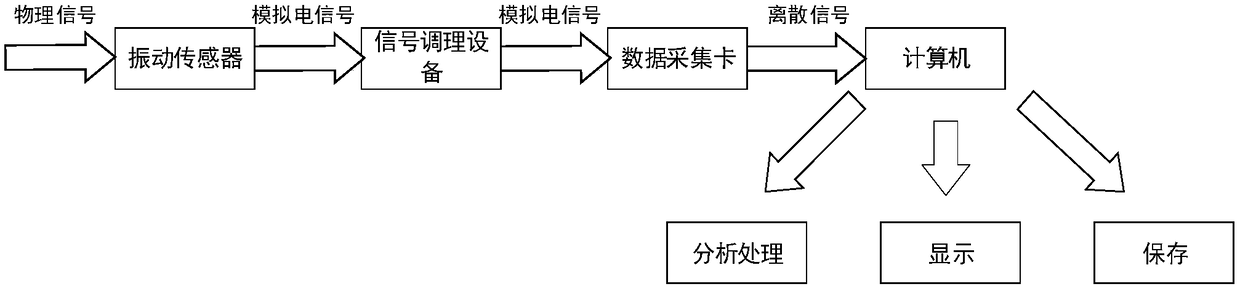

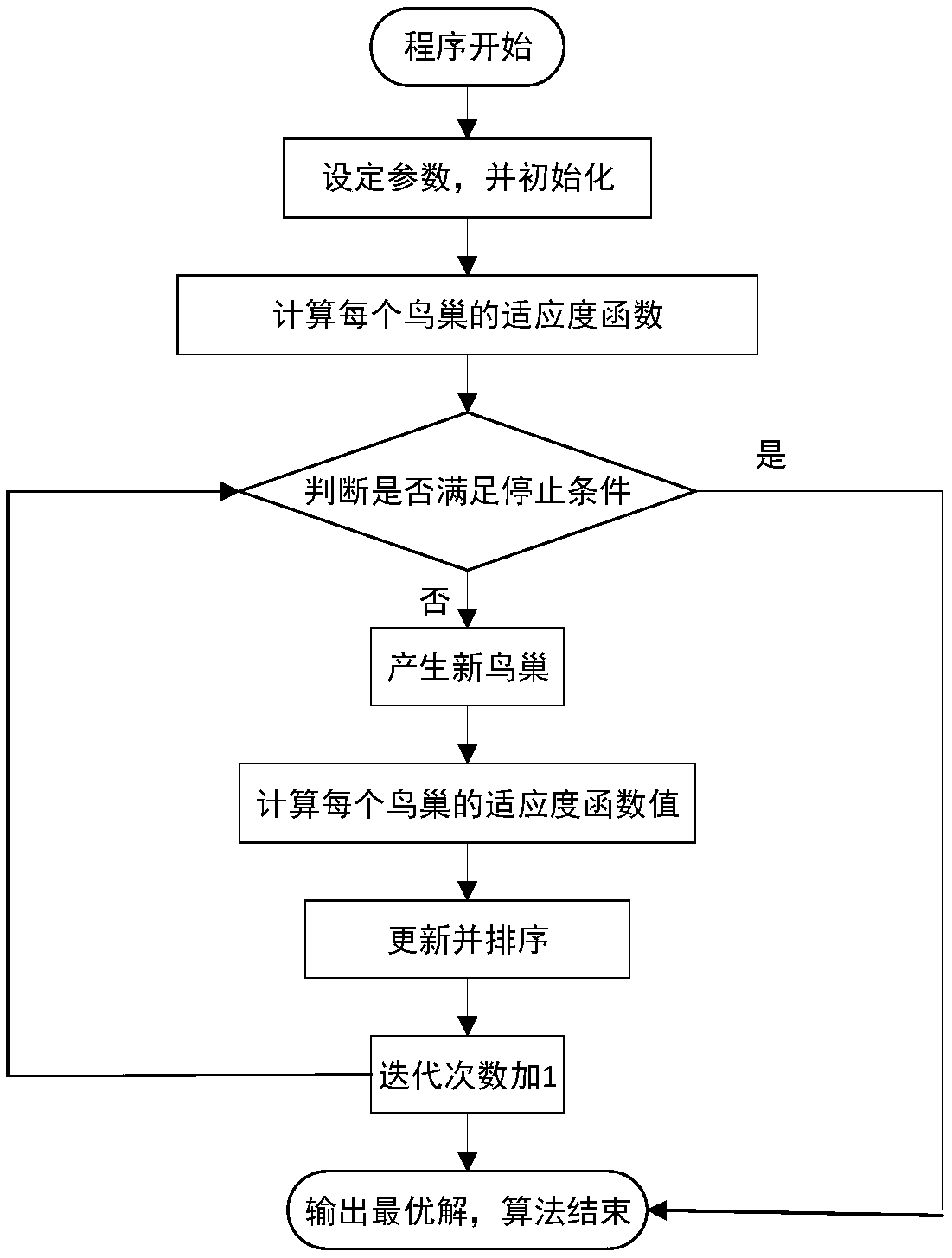

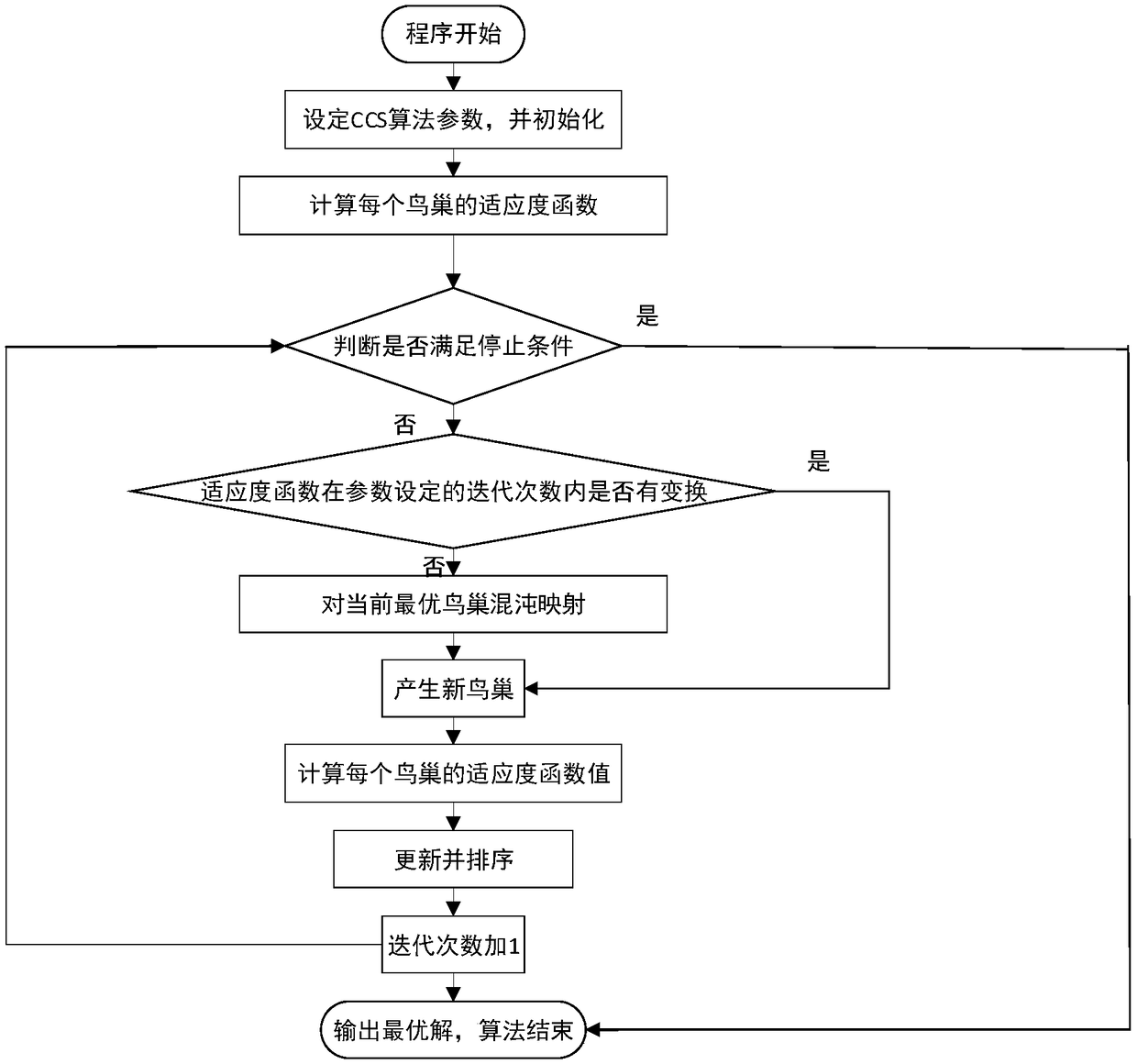

GIS mechanical fault diagnosis method and system based on chaotic cuckoo algorithm

InactiveCN108663202AAvoid mechanical failureIncrease signal decomposition rateMachine part testingFeature vectorDiagnosis methods

The invention discloses a GIS mechanical fault diagnosis method and system based on the chaotic cuckoo algorithm. For two common GIS mechanical faults of screw loosening and metal particle vibration,a VMD parameter is optimized with the chaotic cuckoo algorithm; GIS normal vibration signals and fault signals are subjected to VMD decomposition, and feature vectors with different fault type signalsare extracted; feature vector sets of training samples are clustered with the K-means clustering algorithm optimized through linearly decreasing weight PSO, and different clustering centers are obtained; feature vector sets of test samples are identified through the minimum euclidean distance rule, and diagnosis of GIS mechanical faults is achieved.

Owner:STATE GRID CORP OF CHINA +1

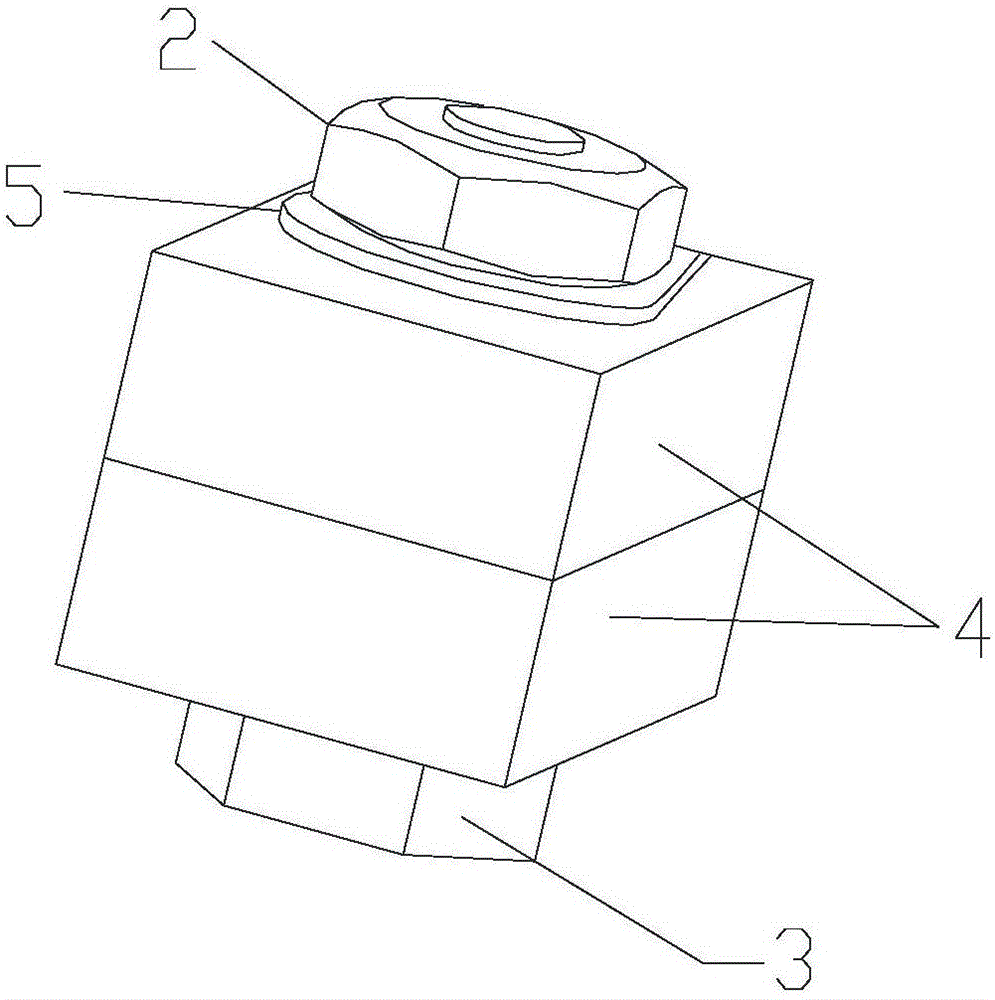

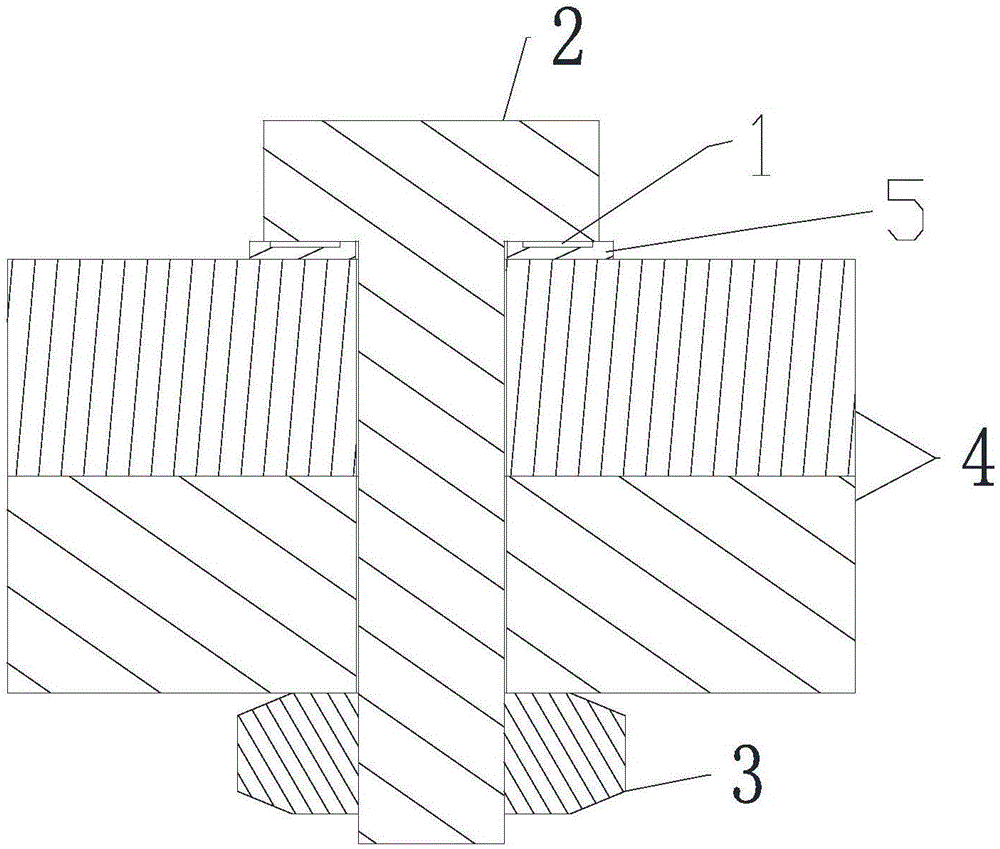

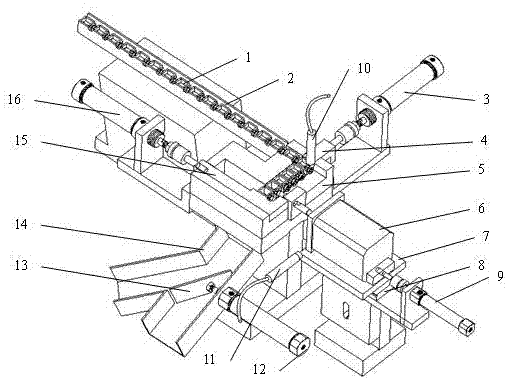

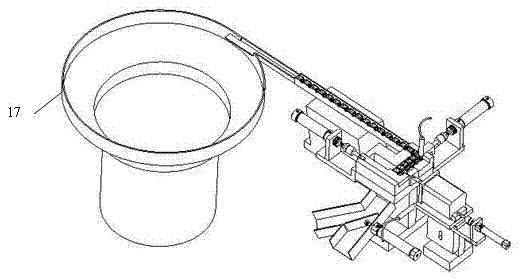

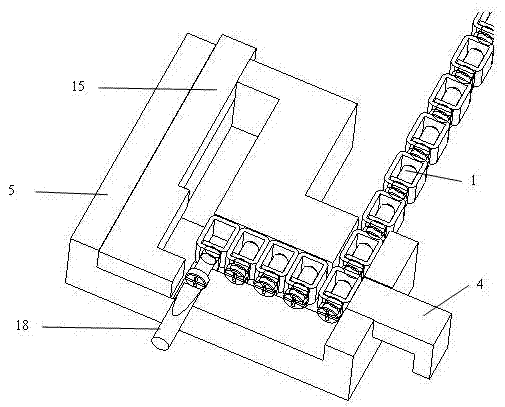

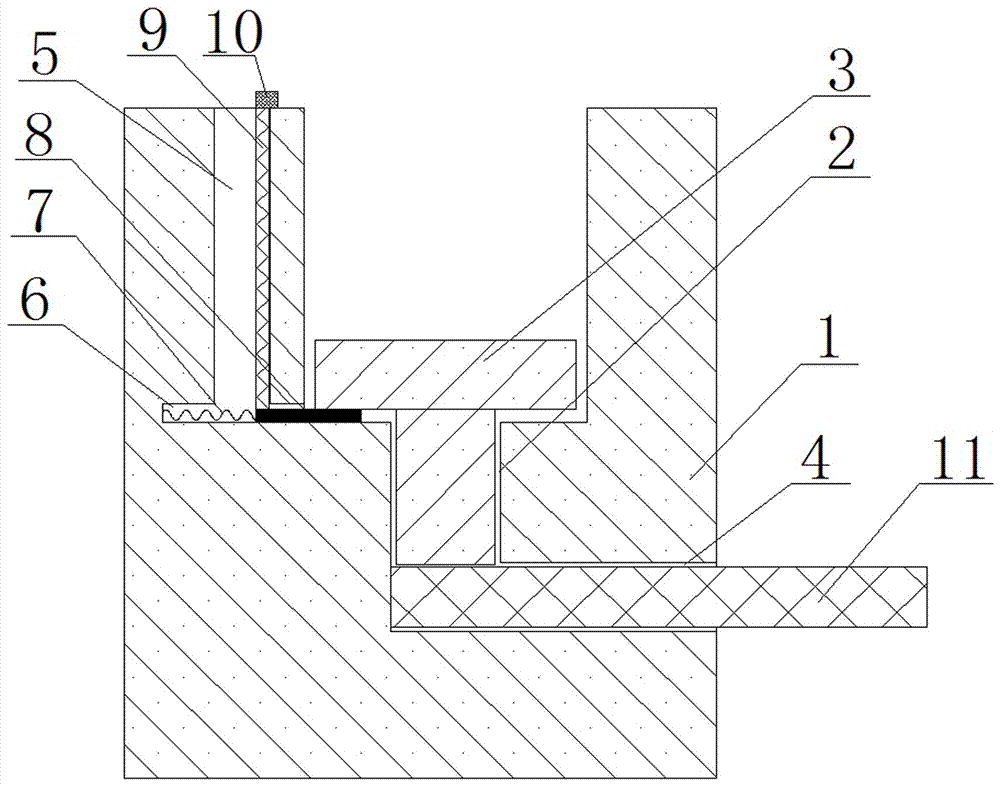

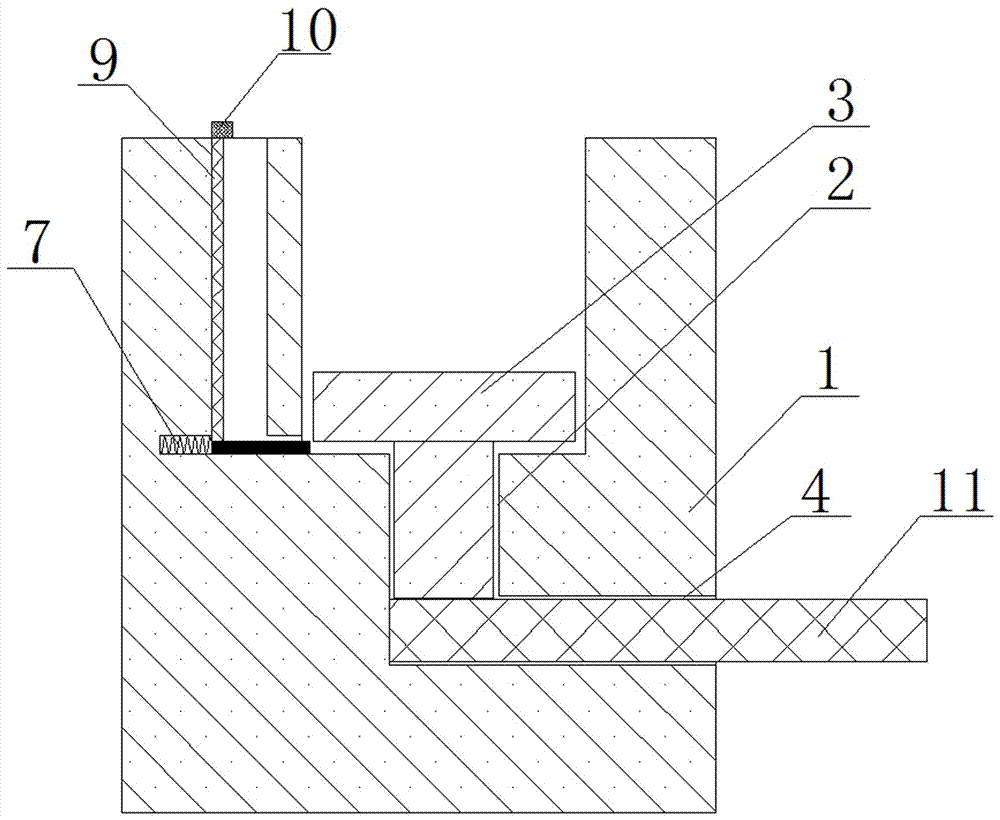

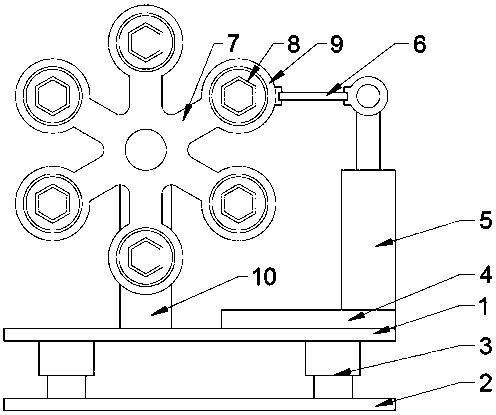

Circuit breaker terminal screw loosening device

ActiveCN102284857AReasonable structureSolving inefficienciesMetal working apparatusEngineeringUltimate tensile strength

The invention discloses equipment for unscrewing a terminal bolt of a circuit breaker. The equipment is characterized by comprising a flat vibration feeder (2), wherein a discharge hole of the flat vibration feeder (2) is connected to a corresponding notch on a fixture main plate (5); the fixture main plate (5) is provided with a feeding push block (4) and a discharging push block (15); the feeding push block (4) is driven by a feeding cylinder (3); the discharging push block (15) is driven by a discharging cylinder (16); one side of the fixture main plate (5) is provided with a motor (6); the rear part of the motor (6) is connected with a piston rod of a motor feeding cylinder (9); and an output shaft of the motor (6) is provided with a screwdriver head (18). The equipment has a reasonable structure, solves the problem of low efficiency of the conventional manual production mode, can automatically feed a workpiece and unscrew the bolt through the screwdriver head to reach specified length, and can analyze the unscrewing condition of the bolt to identify whether the bolt is a qualified product or a defective product, so that production efficiency is improved, and labor intensity is reduced.

Owner:JIANGSU SUZHONG CONSTR GROUP +1

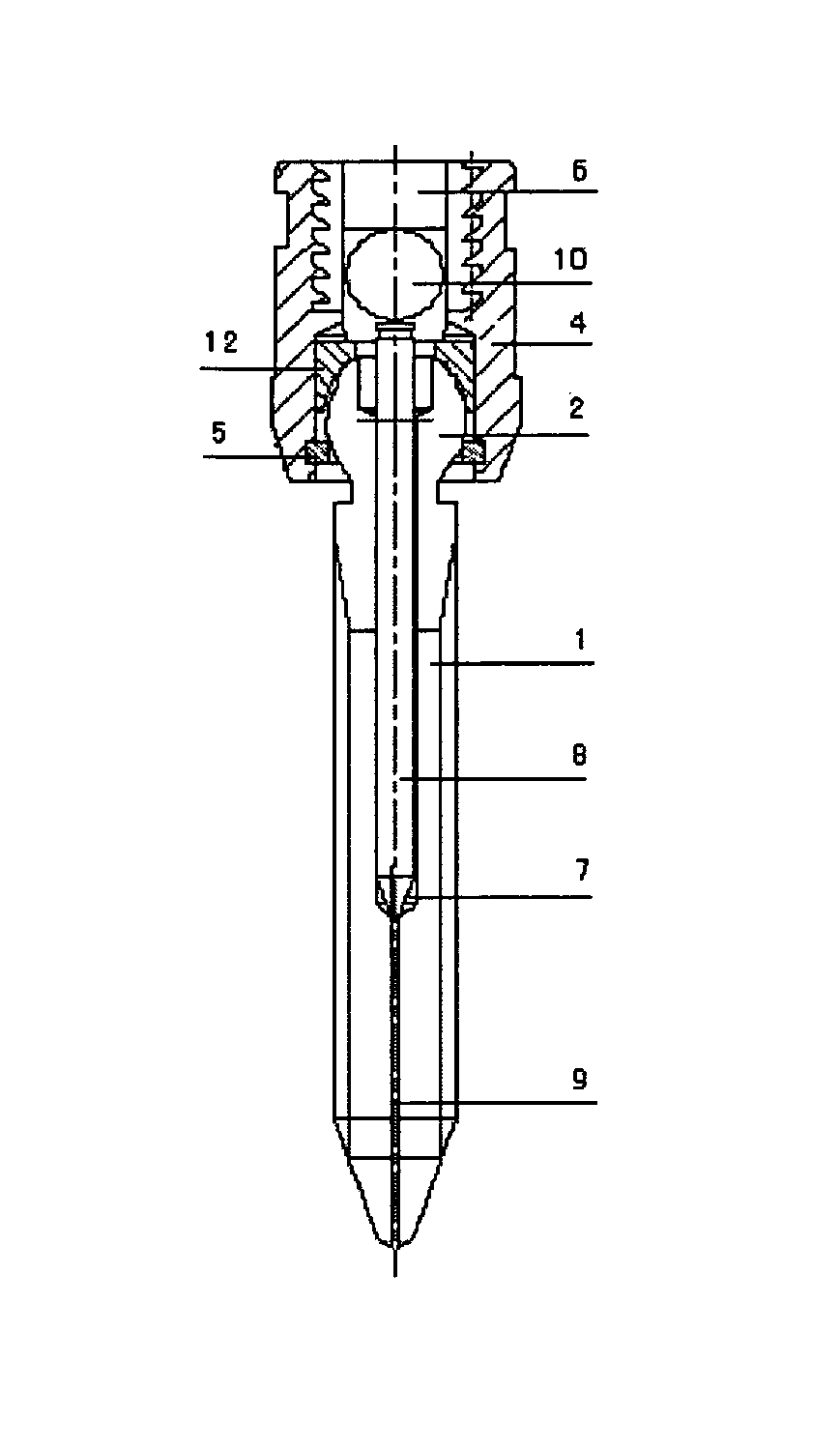

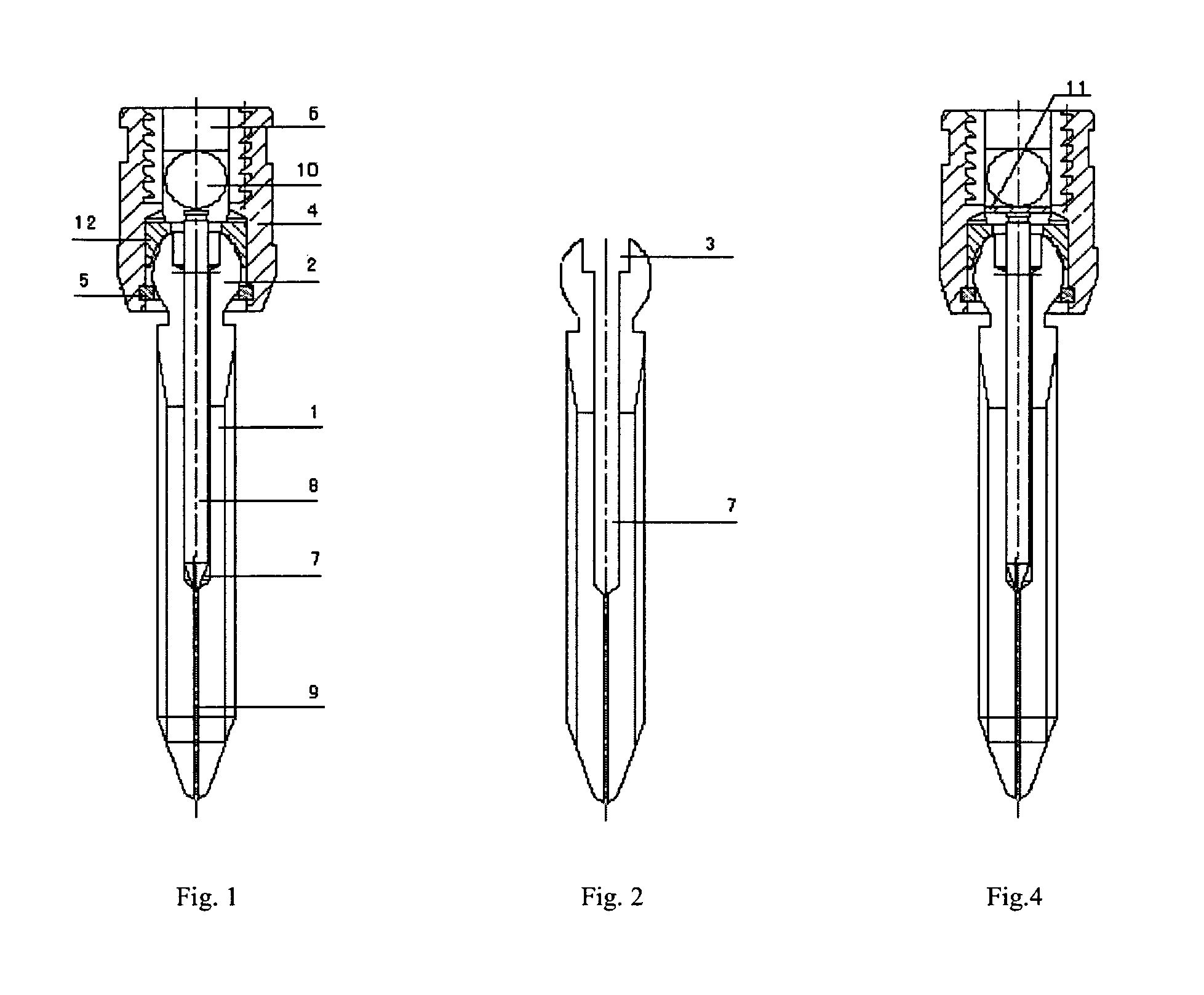

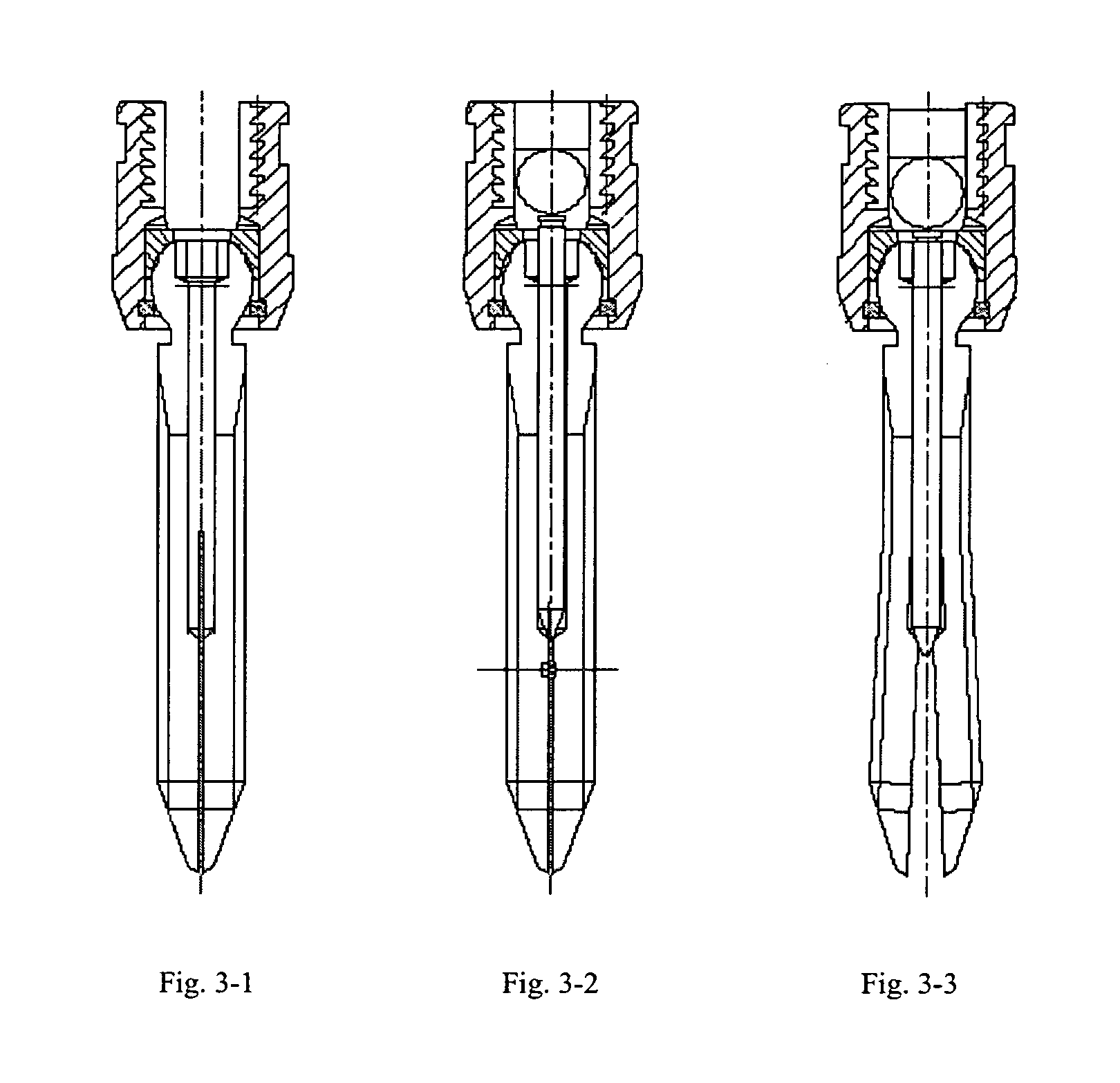

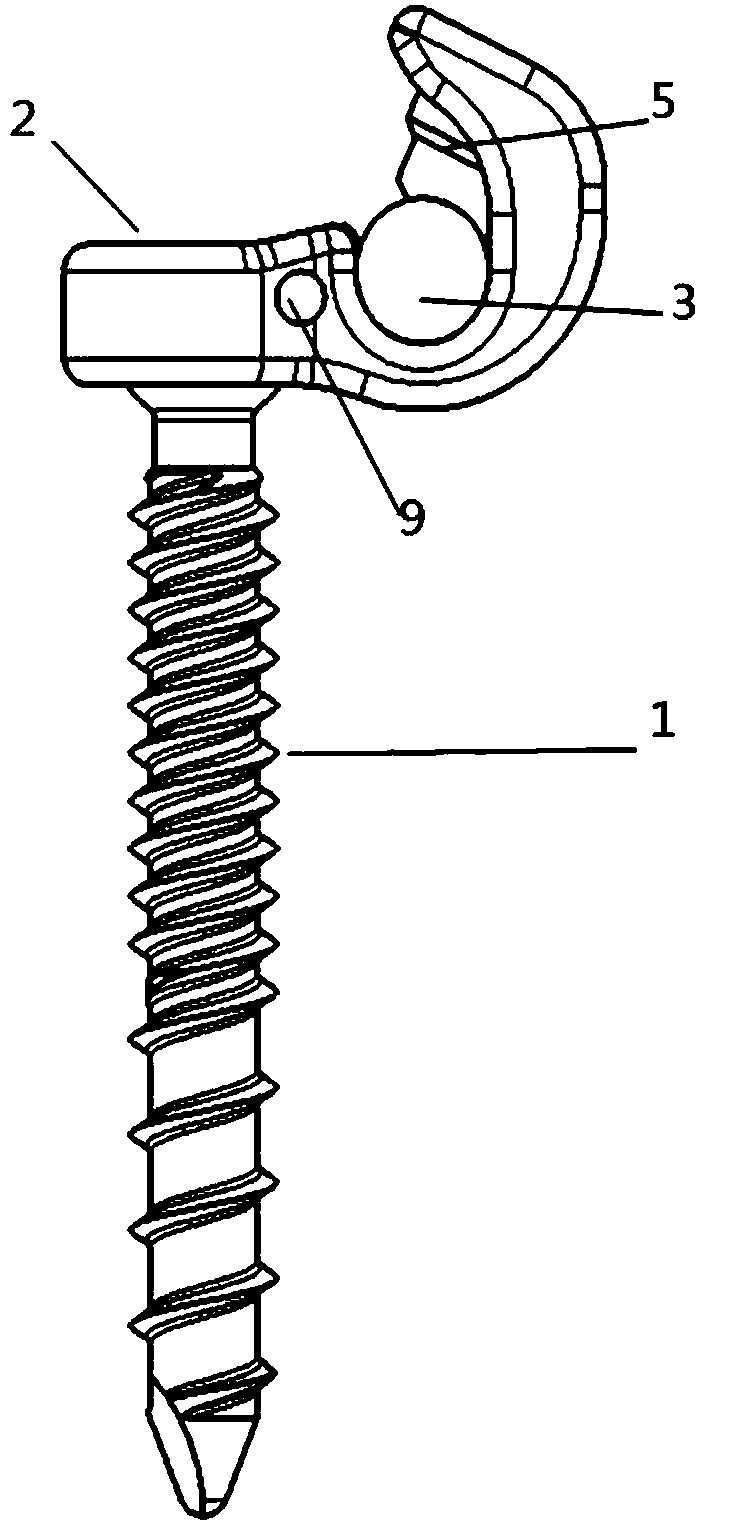

Multi-axial expandable pedicle screw and an expansion method thereof

ActiveUS8911484B2Reduce probabilityEasy to controlSuture equipmentsInternal osteosythesisFailure rateUniversal joint

Owner:LEI WEI +1

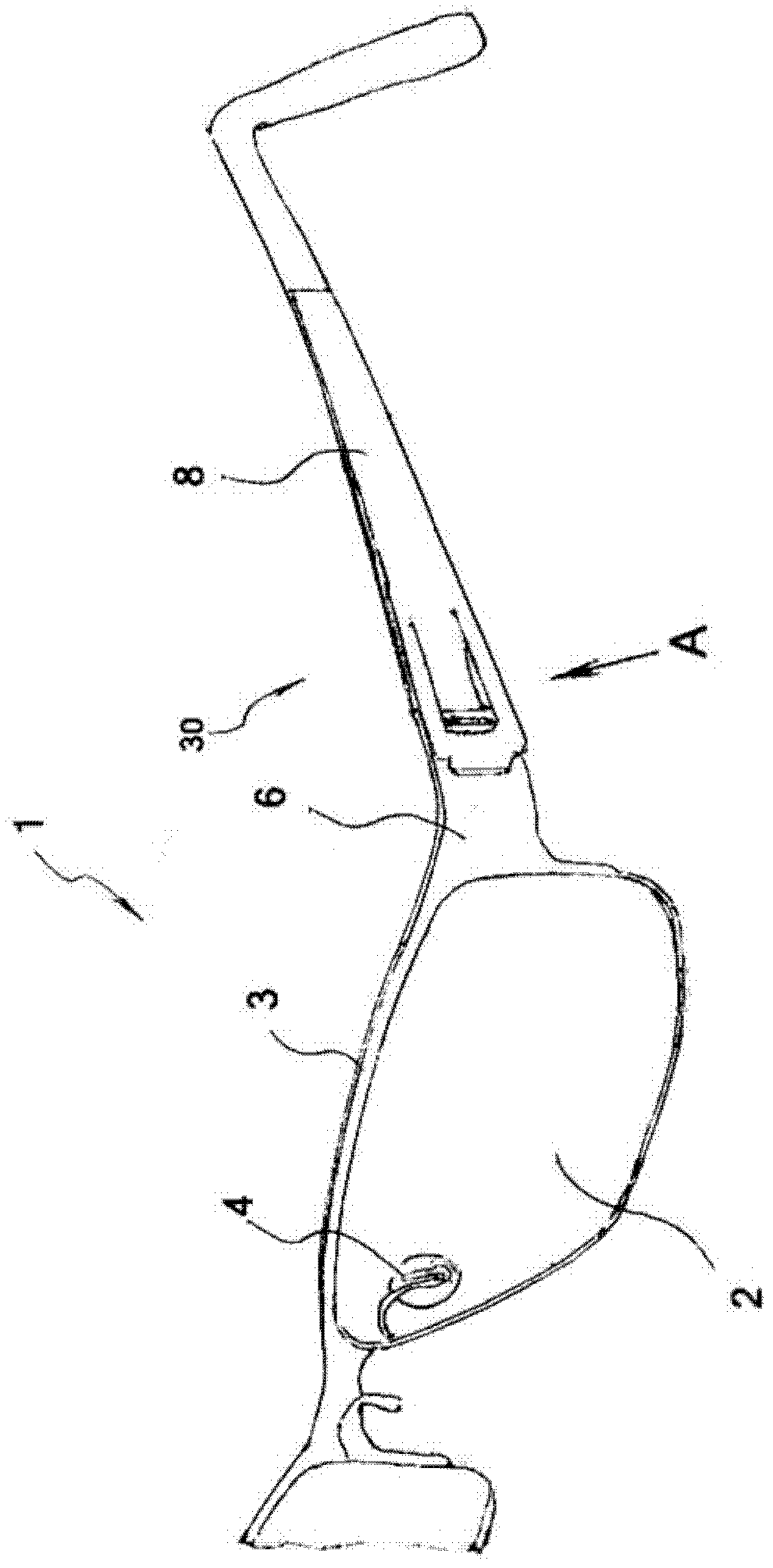

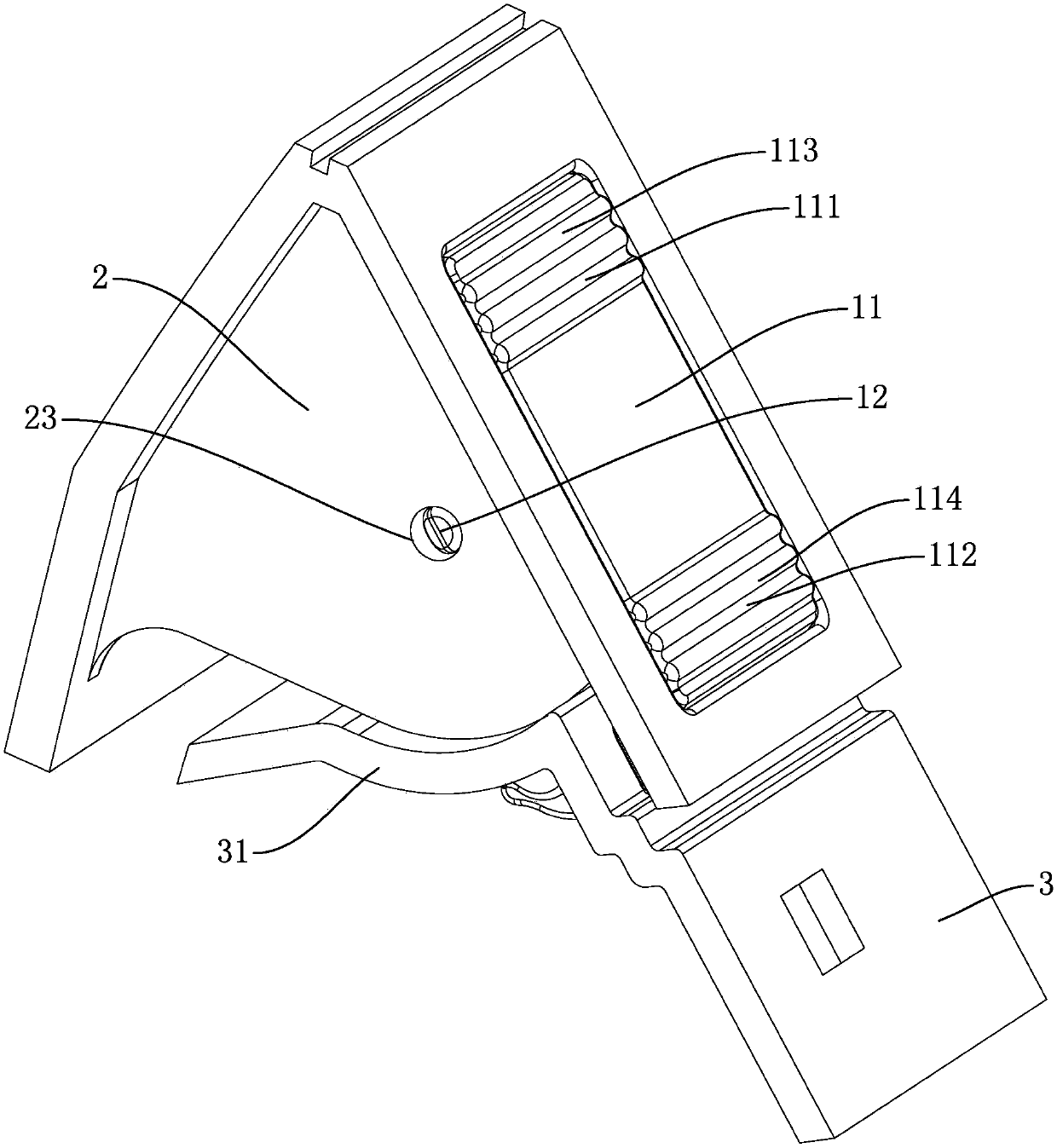

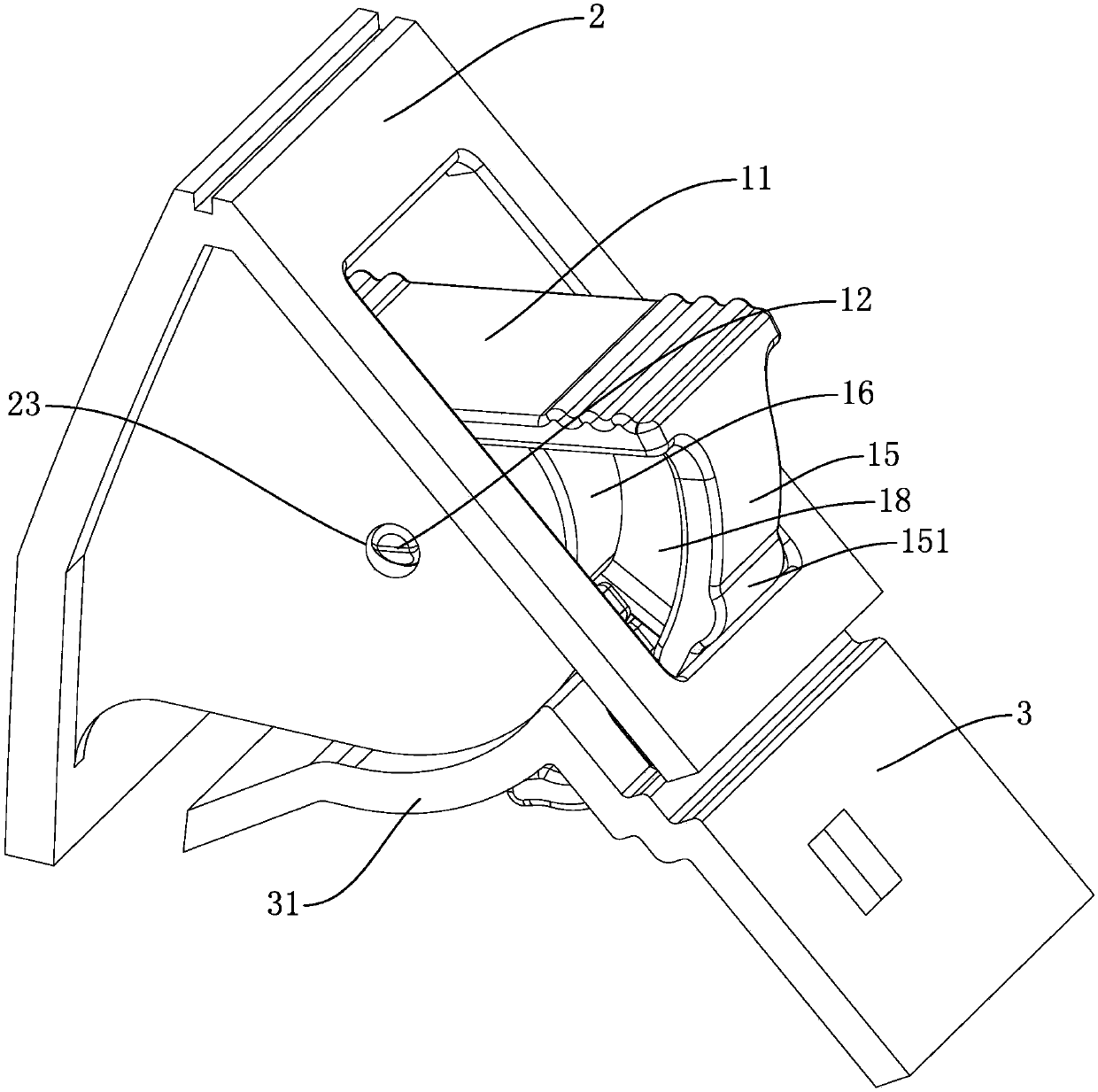

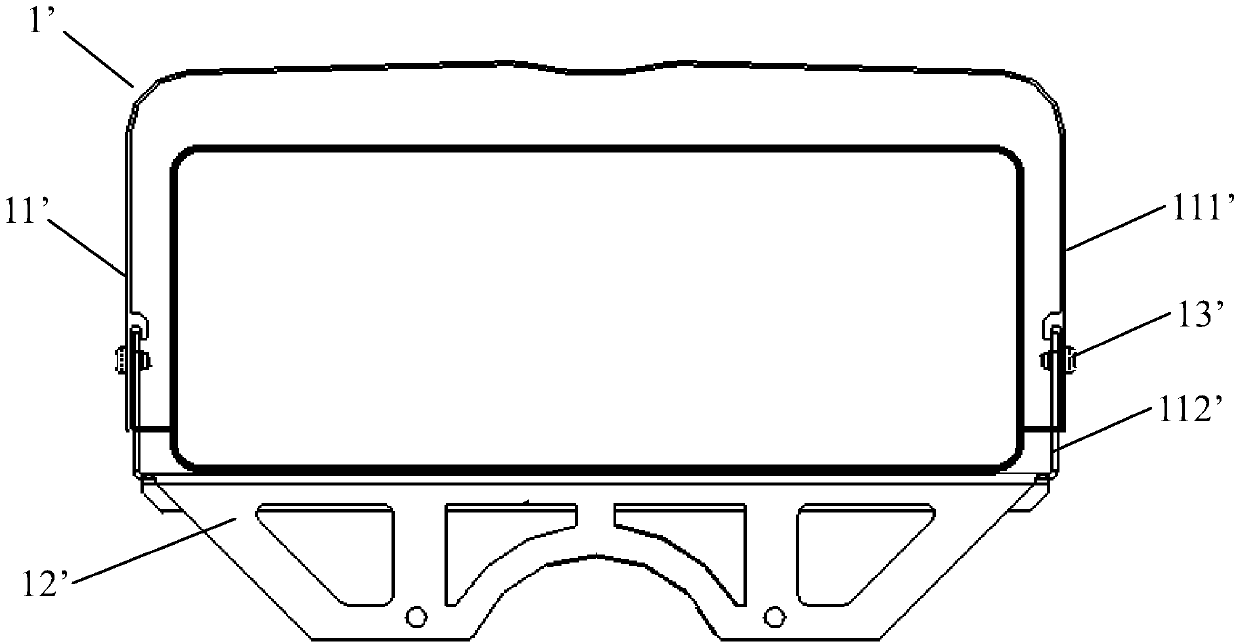

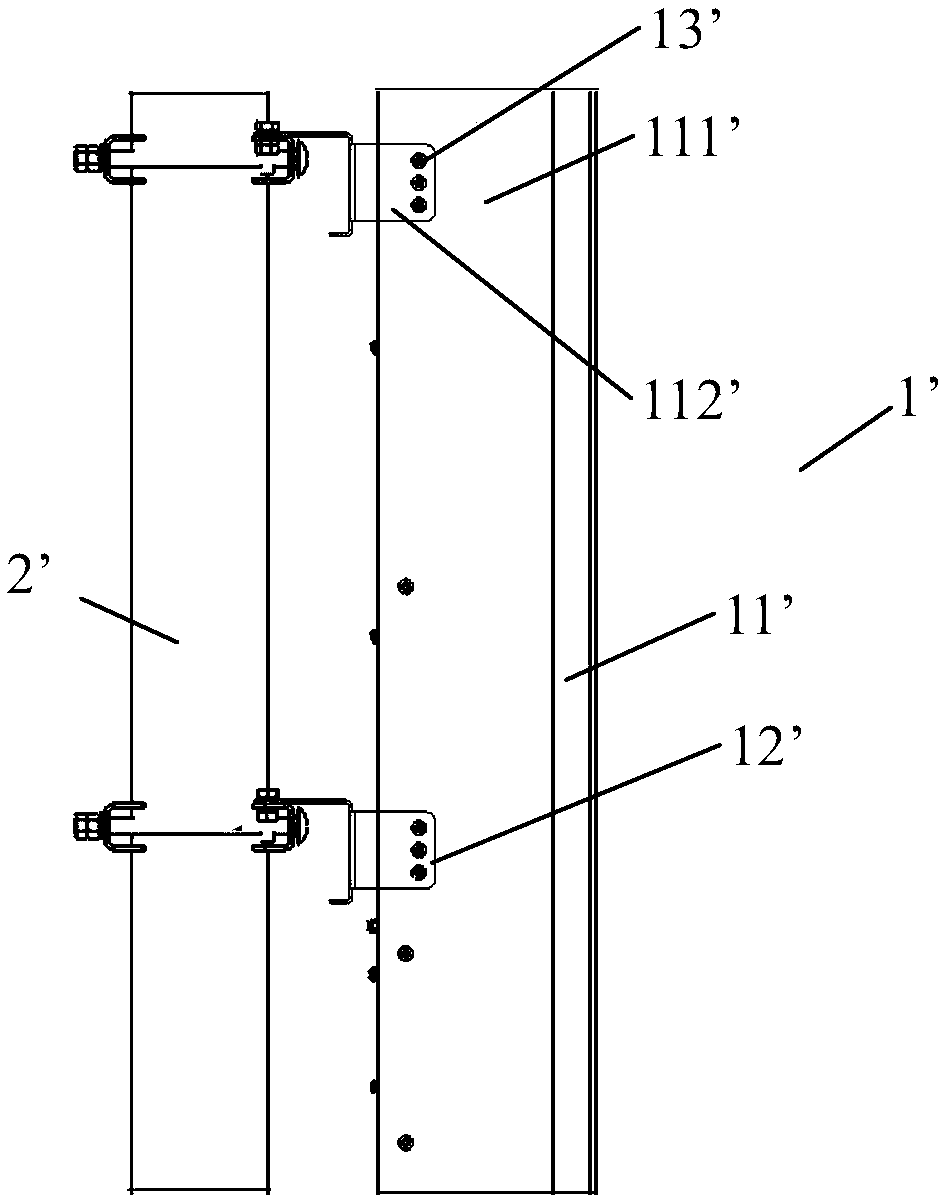

Pivot connection device of glasses earpiece and endpiece

InactiveCN103135247ALoose noRisk of lossSpectales/gogglesNon-optical partsEyewearMechanical engineering

The invention discloses a pivot connection device of a glasses earpiece and an endpiece; the endpiece is disposed outside a glasses frame; the glasses earpiece is connected with the endpiece, and can rotate around a pivot relative to the endpiece between an unfolding position and a folding position. A long sheet body is disposed at the connection end position of the endpiece and the earpiece; a pivot body is formed between a back groove and a front through hole; a clamping hole is disposed in front of the through hole. A long sheet body is disposed at the connection end position of the earpiece and the endpiece; a bend is disposed at the front end; a long elastic sheet is disposed at a center position behind the bend and extends forwards along a longitudinal direction; an arc end part bending outwards is disposed at the front end of the elastic sheet. The earpiece is mounted at the outer side of the endpiece; the elastic sheet arc end part extends out from the inner surface of the endpiece, passes through the through hole, and elastically presses the pivot body, and the bend is clamped in the clamping hole. The pivot connection device of the glasses earpiece and the endpiece of the invention needs no weld point or screw device, and thus has no problems of screw loosening or loss; the structure is simple; the manufacturing cost is low; the installation is convenient; and the service life is long.

Owner:SEE KIANG OPTICAL MANUFACTORY

Device for fastening screw onto workpiece and method of judging loosening of screw

ActiveUS9370848B2Accurate ratingIncrease in loadProgramme controlProgramme-controlled manipulatorEngineeringMechanical engineering

In judging loosening of a crew, a measuring section measures a position of a bit as a relative position in relation to a placement surface of a screw supplying device when the screw is acquired from the screw supplying device. The measuring section also measures the position of the bit as a relative position in relation to a workpiece surface when fastening of the screw onto a workpiece has been completed. A judging section judges that screw loosening has not occurred when, based on the first and second bit positions, a difference between the first and second bit positions falls within an allowable range. The judging section judges that screw loosening has occurred when the difference does not fall within the allowable range.

Owner:DENSO WAVE INC

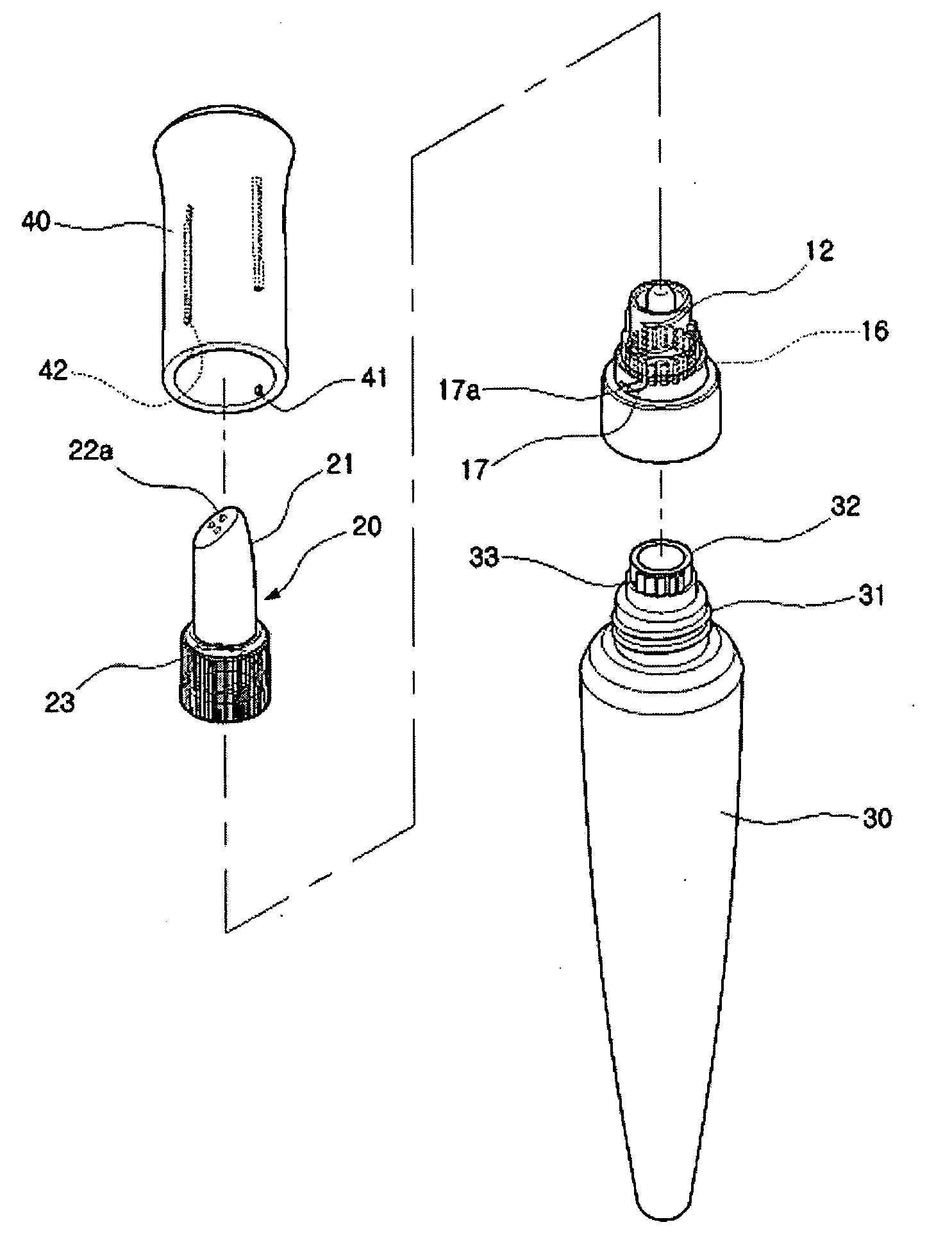

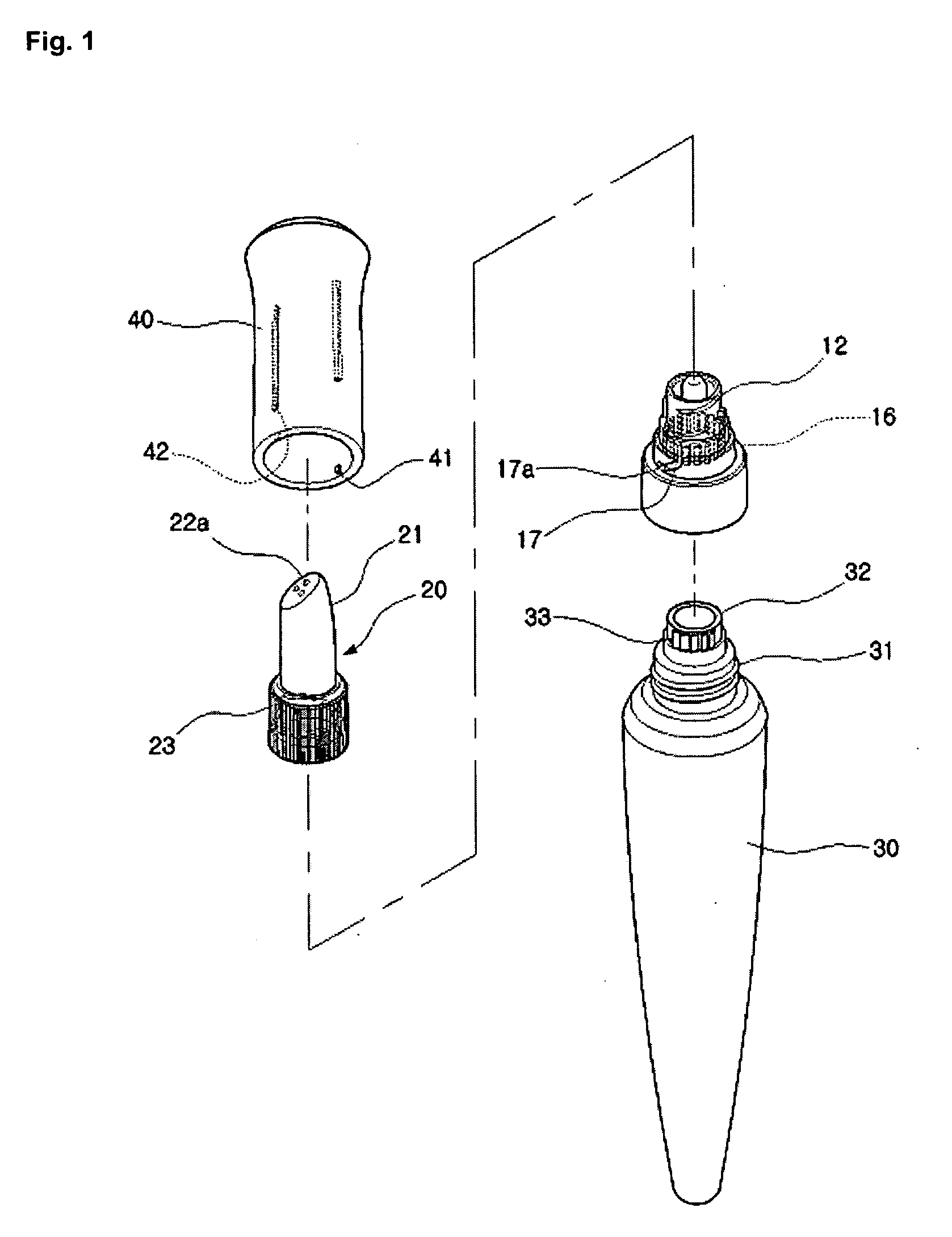

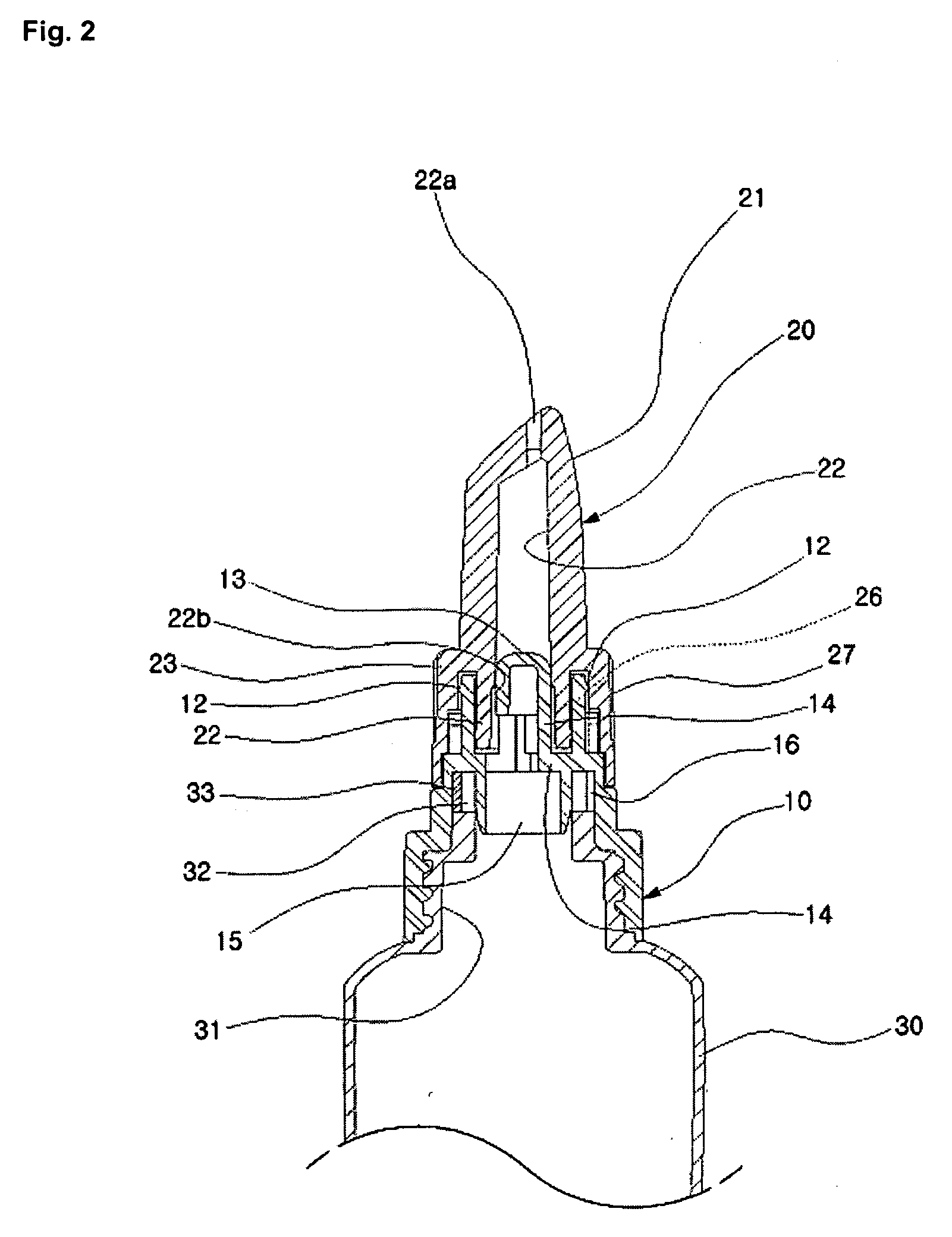

Cosmetic case capable of blocking nozzle tip air tightly

InactiveUS20080138145A1Increase credibilityImprove productivityLiquid surface applicatorsWriting connectorsScrew looseningCosmetics

A cosmetic case capable of solving the problem that the oily or watery tint-care cosmetic is unnecessarily leaked out and hardened when it is carried or maintained is provided. An elastic ratchet projection 16, which is provided on a connecting part 23 of a nozzle tip 20, is engaged with ratchet projection 33, which is provided on a opening portion 31 of a container 30, so that loosening cannot happens even though rotating force in the screw-loosening direction at the installed nozzle tip 20 is occurred.

Owner:KWON HYUKTARK

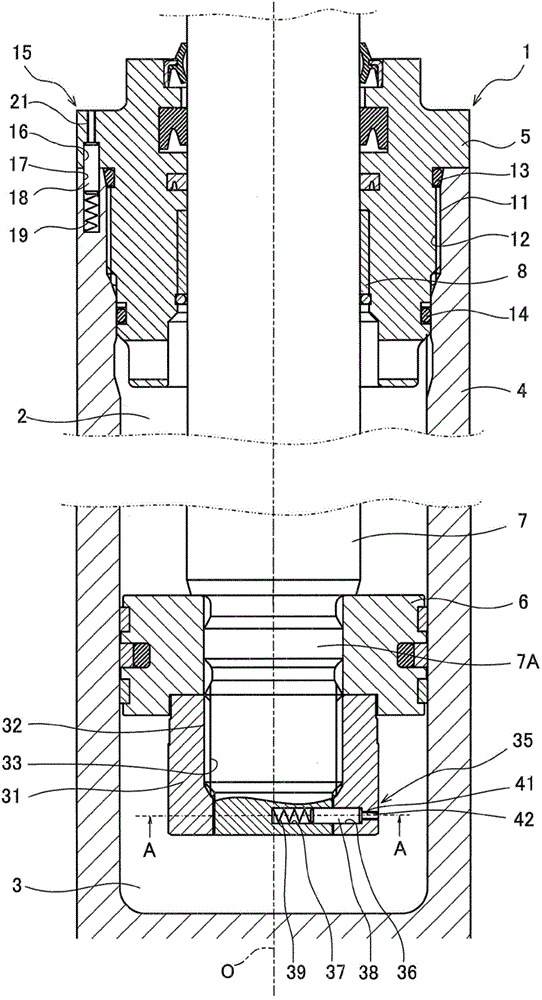

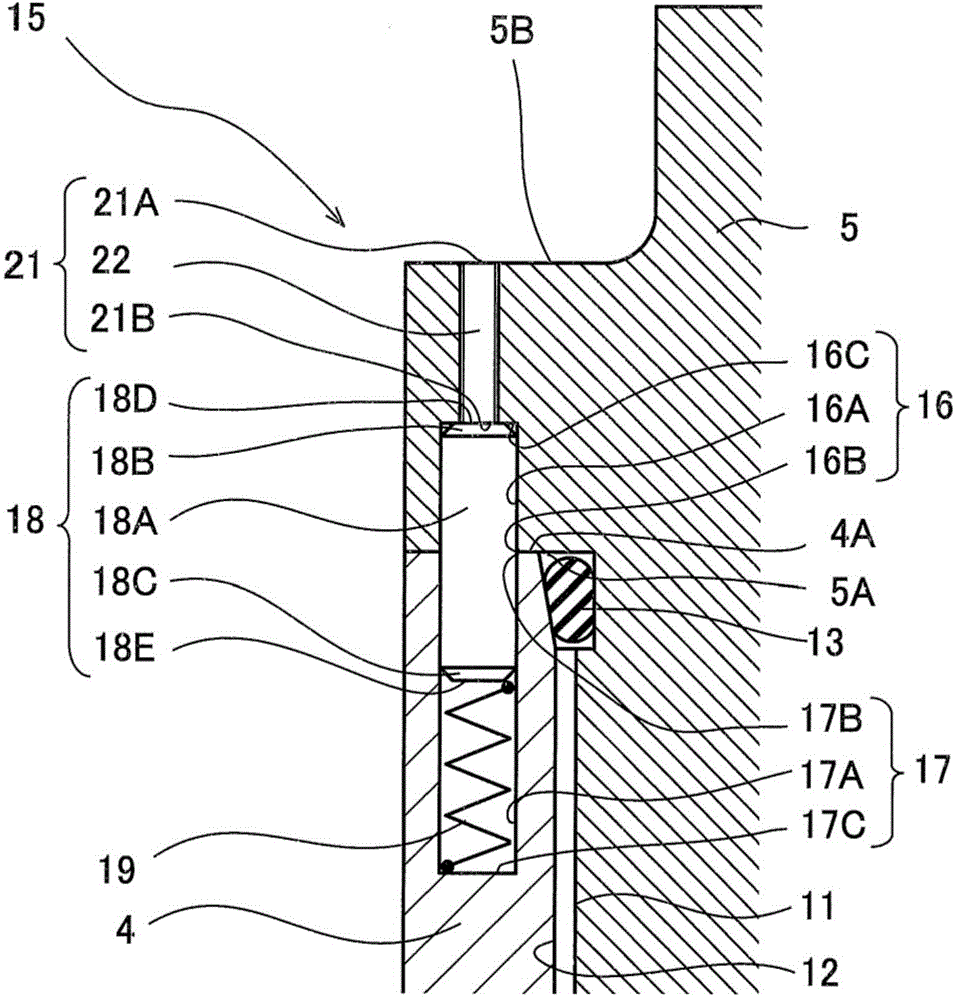

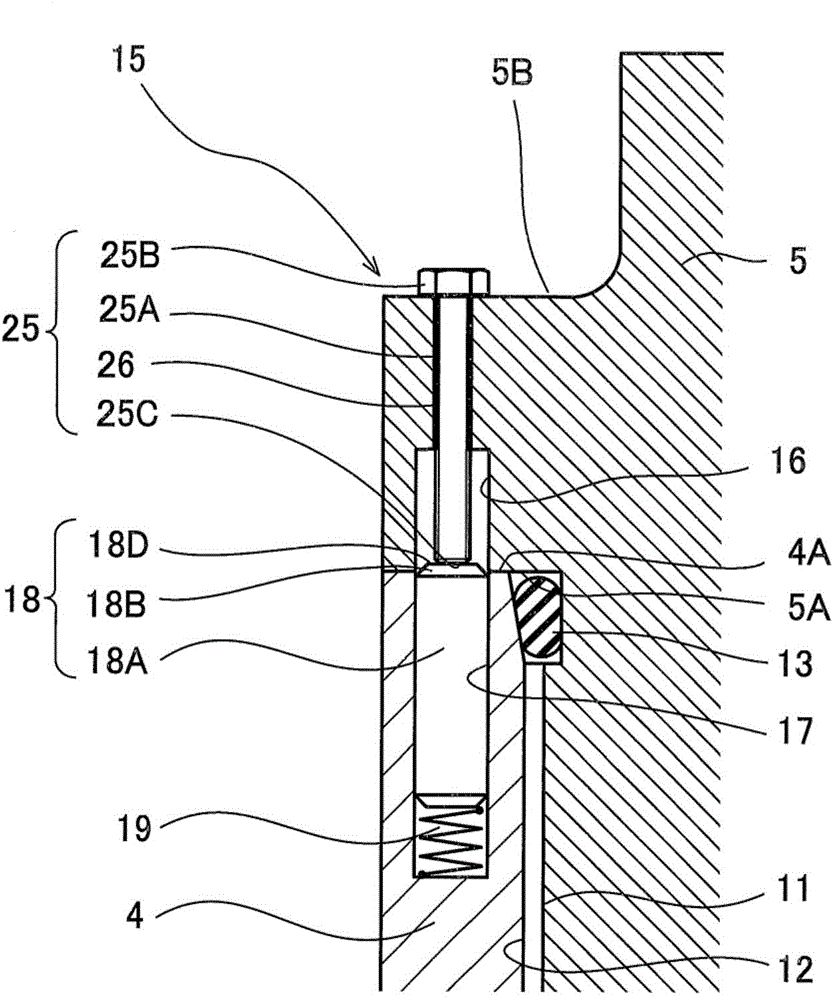

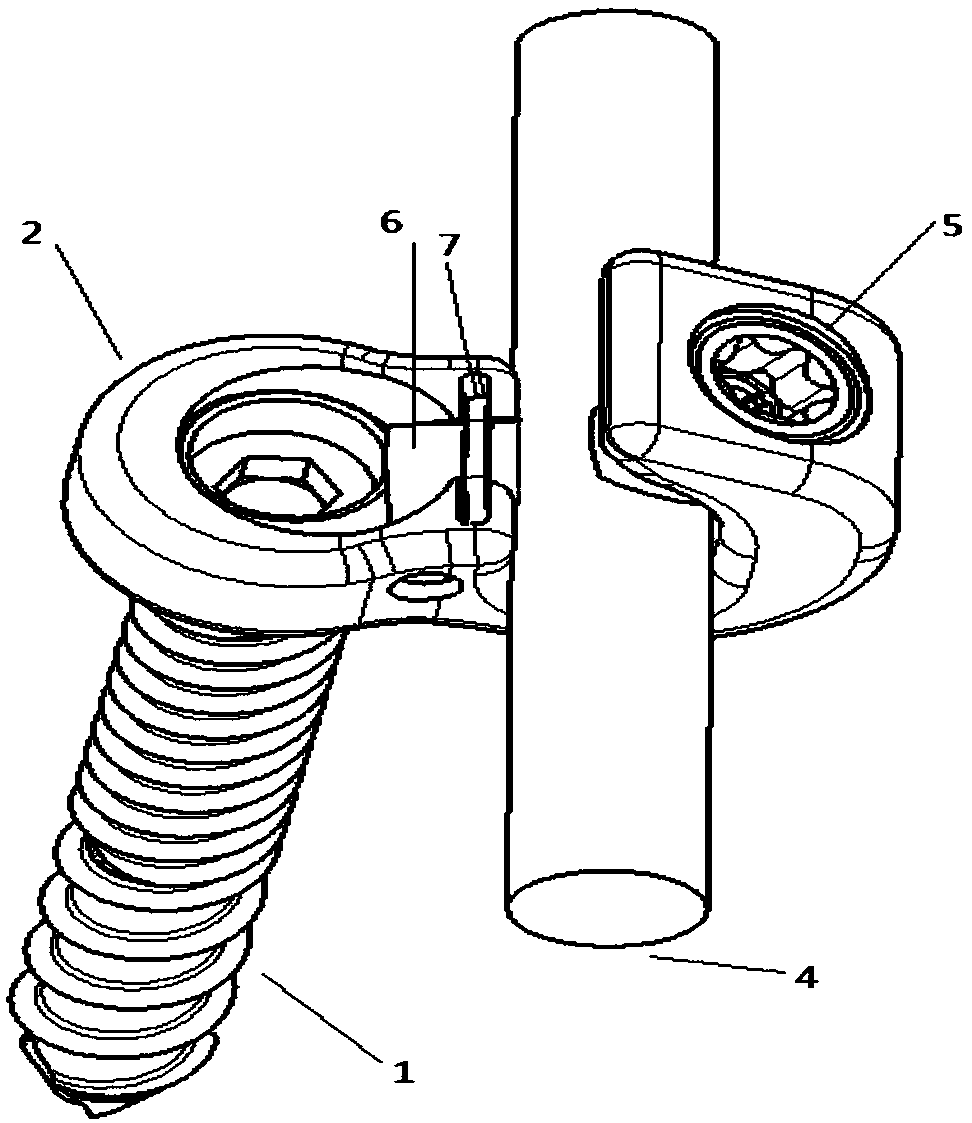

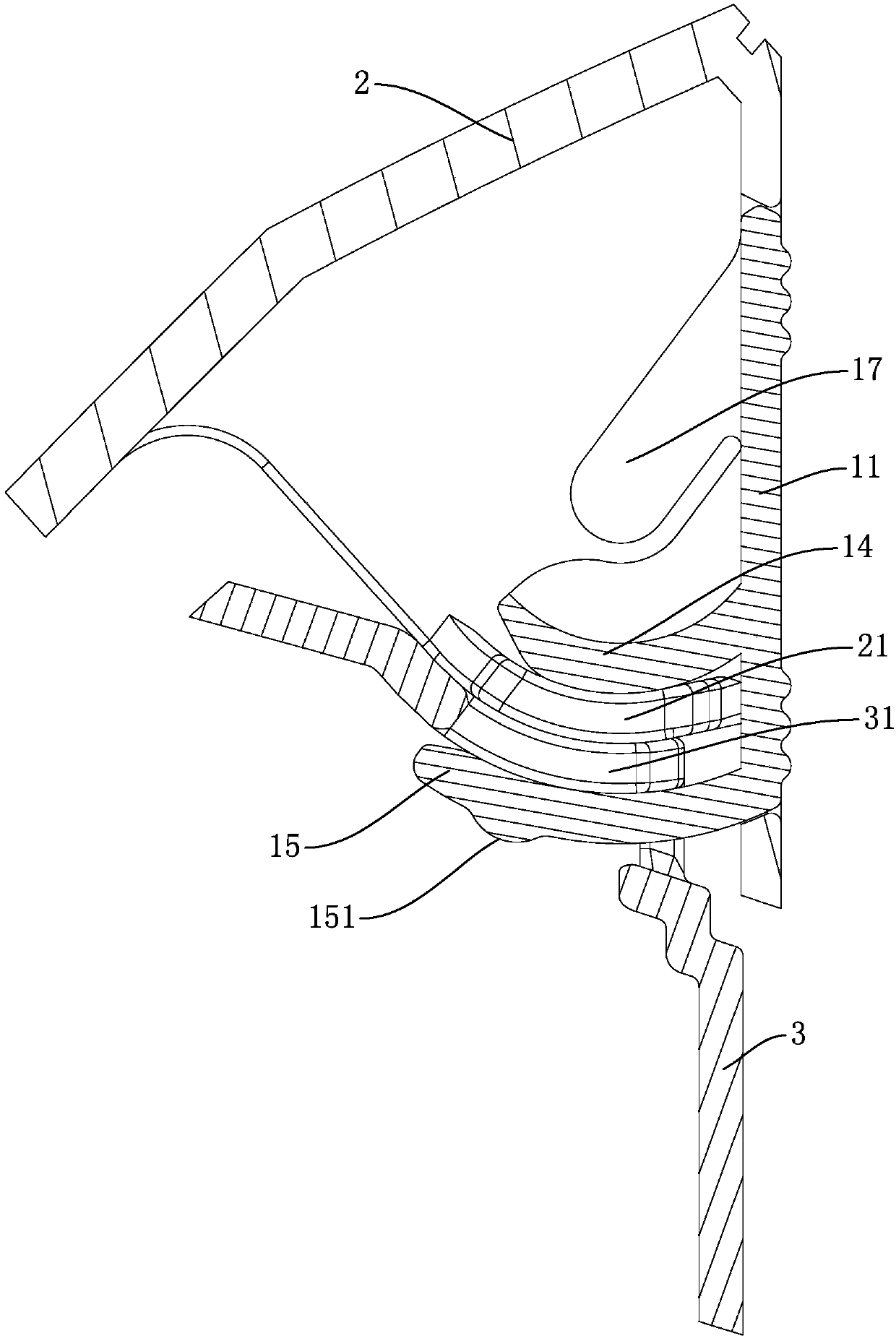

Screw loosening prevention structure

A screw loosening prevention structure (15), that restrains the opposing rotation of a cylinder head (5) (first member) and a cylinder tube (4) (second member) that are coupled together by the screwing action of screws (11, 12), is provided with a first hole (16) that is formed in the cylinder head (5), a second hole (17) that is formed in the cylinder tube (4), a pin (18) that is inserted into the second hole (17), and an energizing member (spring (19)) that is inserted into the second hole (17) and applies energy to the pin (18) in the direction of pushing the pin out of the second hole (17). In a state where the cylinder head (5) and the cylinder tube (4) are engaged, the pin (18) is inserted through the first hole (16) and the second hole (17).

Owner:KYB CORP

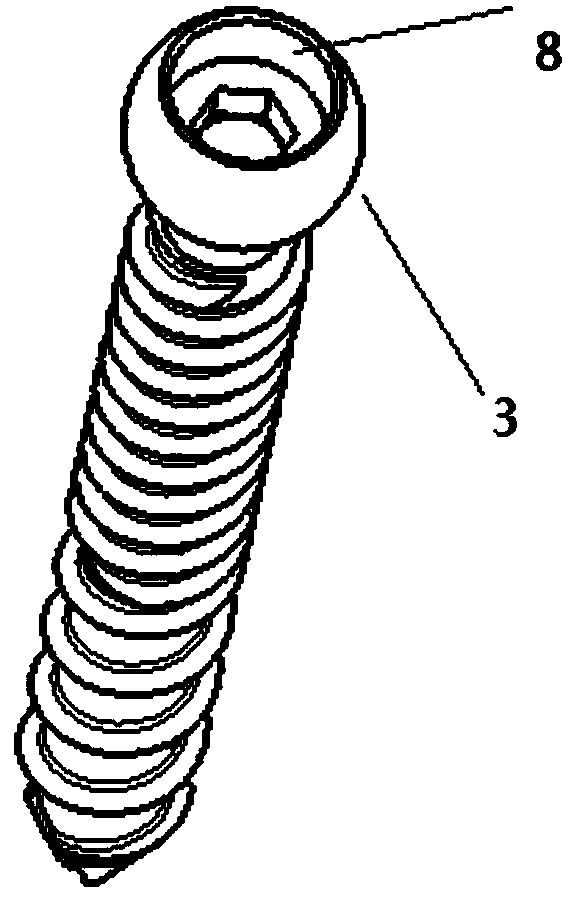

Low-profile easily-locked universal pedicle screw

InactiveCN108186092ALimited rotationEasy to installInternal osteosythesisFastenersEngineeringIliac screw

The invention relates to a low-profile easily-locked universal pedicle screw for fixation and correction use in posterior spinal instrumentation and belongs to the field of medical instruments. The low-profile easily-locked universal pedicle screw is composed of a screw body and a cap which are split; the top of the screw body is provided with a spherical head and is inserted into the cap; the side of the cap at the spherical head is provided with a U-shaped groove for mounting a connection rod and a lock screw for fixing the connection rod; a side fixing presser is arranged between the connection rod and the spherical head and is fixed to the cap through a clamp spring. The low-profile easily-locked universal pedicle screw has good locking convenience, great activity and good anti-pull strength, enables screw fixation to be less difficult and fixation effect to be enhanced, can prevent screw loosening, and has simplified operating steps, shorter operating time and improved fixing effect, with fewer complications occurred.

Owner:武汉光谷北宸医疗器械有限公司

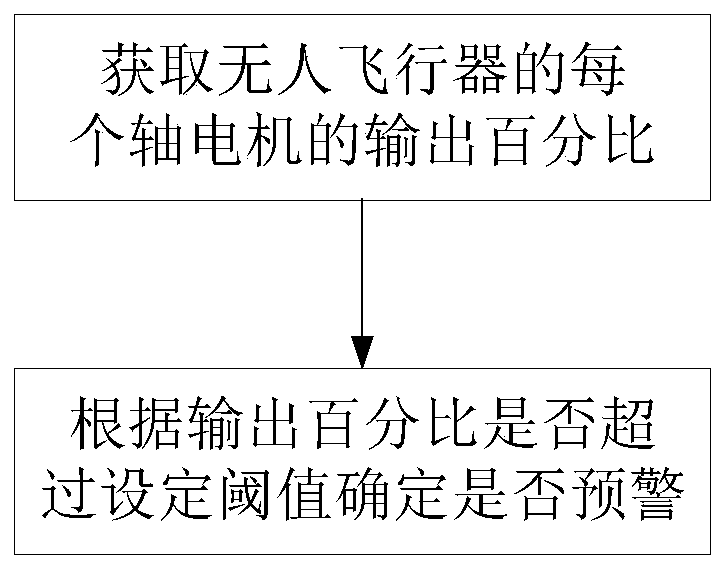

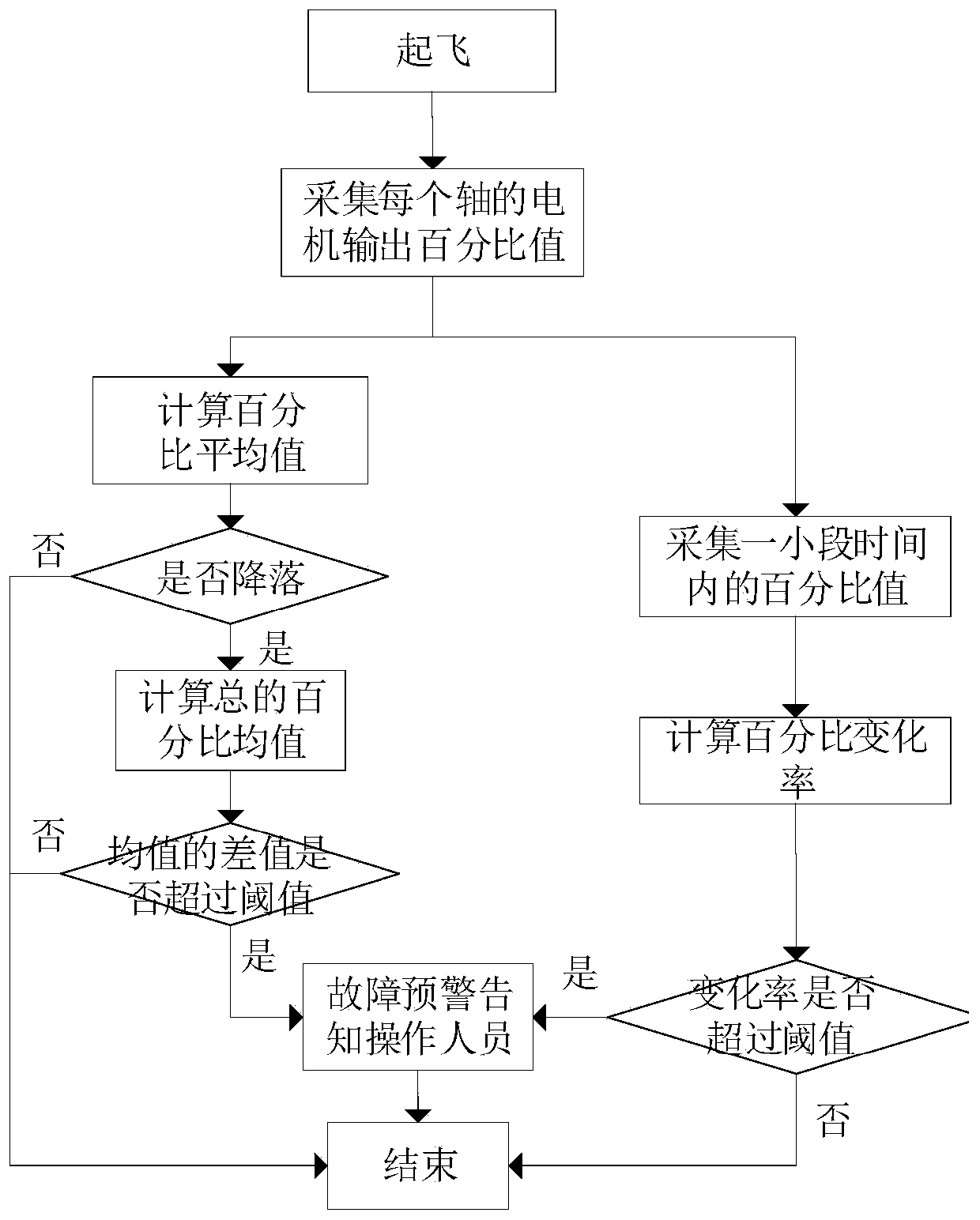

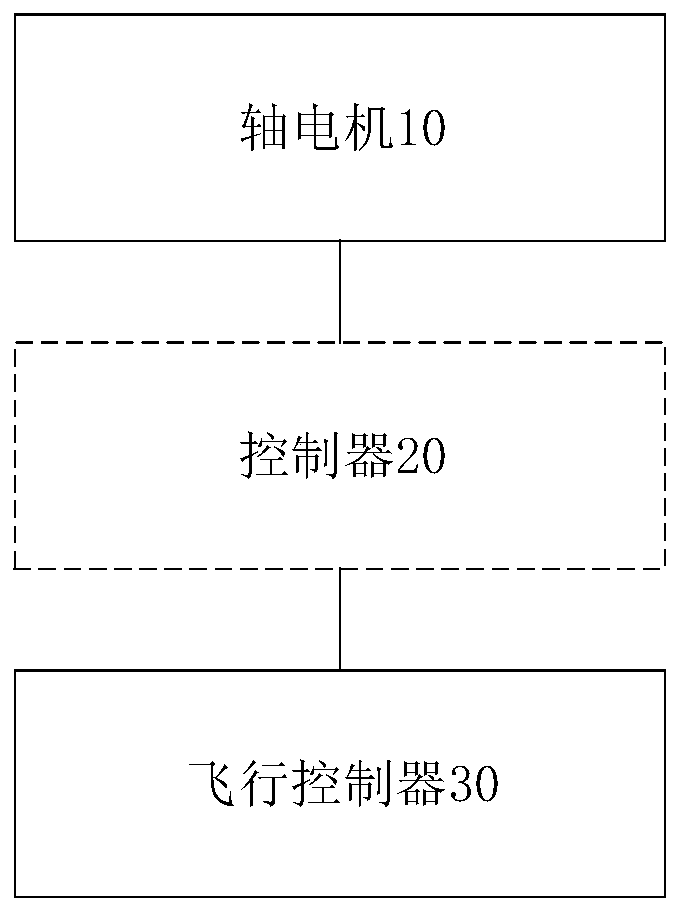

A fault monitoring and early warning method of an unmanned aerial vehicle and the unmanned aerial vehicle

ActiveCN109878715ATimely discovery of potential safety hazardsImprove flight safetyAircraft componentsRotocraftComputer scienceUnmanned spacecraft

The embodiments of the invention provide a fault monitoring and early warning method of an unmanned aerial vehicle, the unmanned aerial vehicle and a storage medium, and belongs to the field of unmanned aerial vehicles. The method includes the following steps: obtaining power output percentages of shaft motors of the unmanned aerial vehicle; and determining whether an early warning is generated ornot according to whether the power output percentages exceed a set threshold. The invention also provides the unmanned aerial vehicle using the fault monitoring and early warning method. The fault monitoring and early warning method finds out safety hazards such as screw loosening, machine arm loosening and motor bearing damage in time by monitoring the abnormality of the power output percentagesof the shaft motors of the unmanned aerial vehicle, thereby improving the flight safety of the unmanned aerial vehicle.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

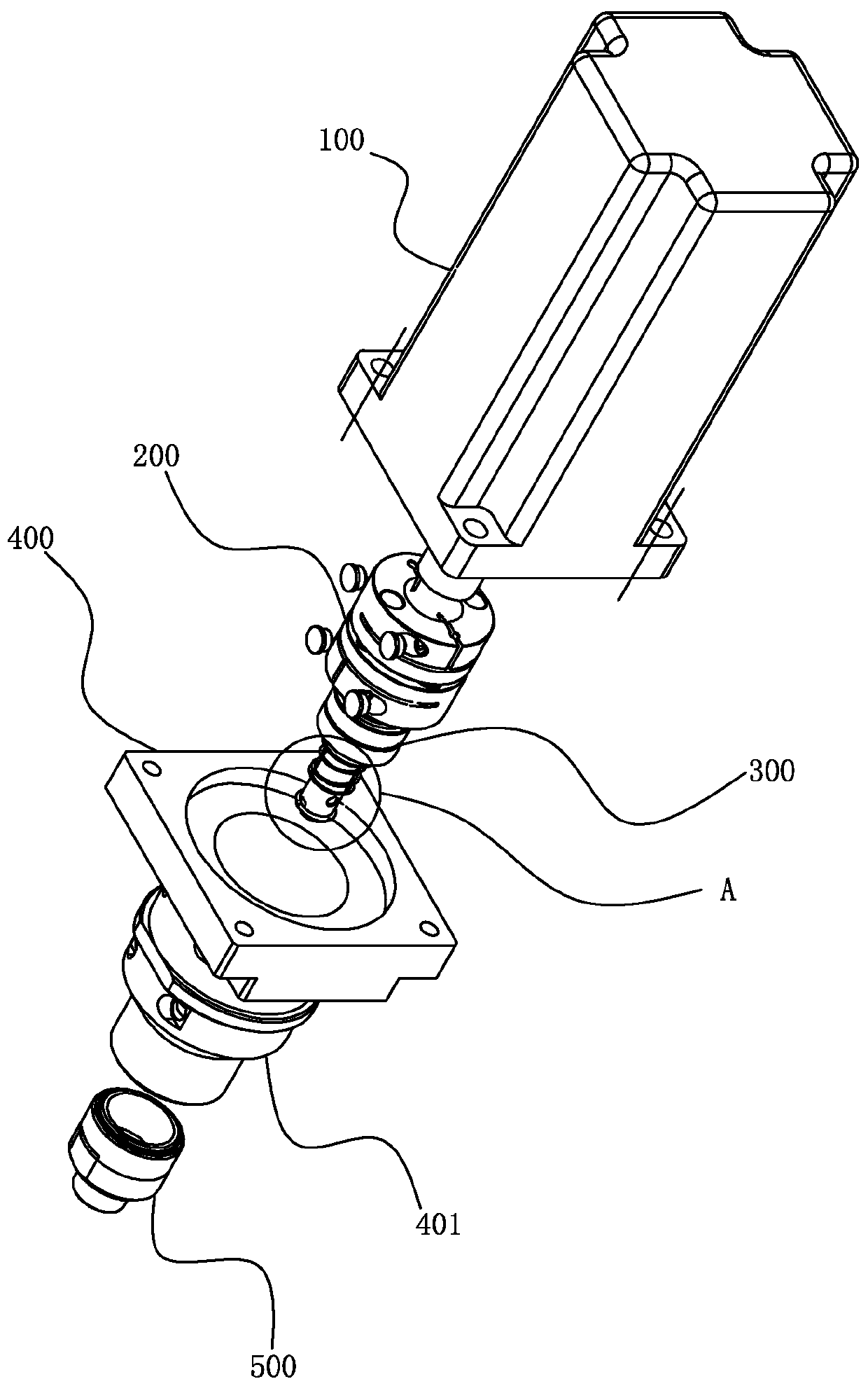

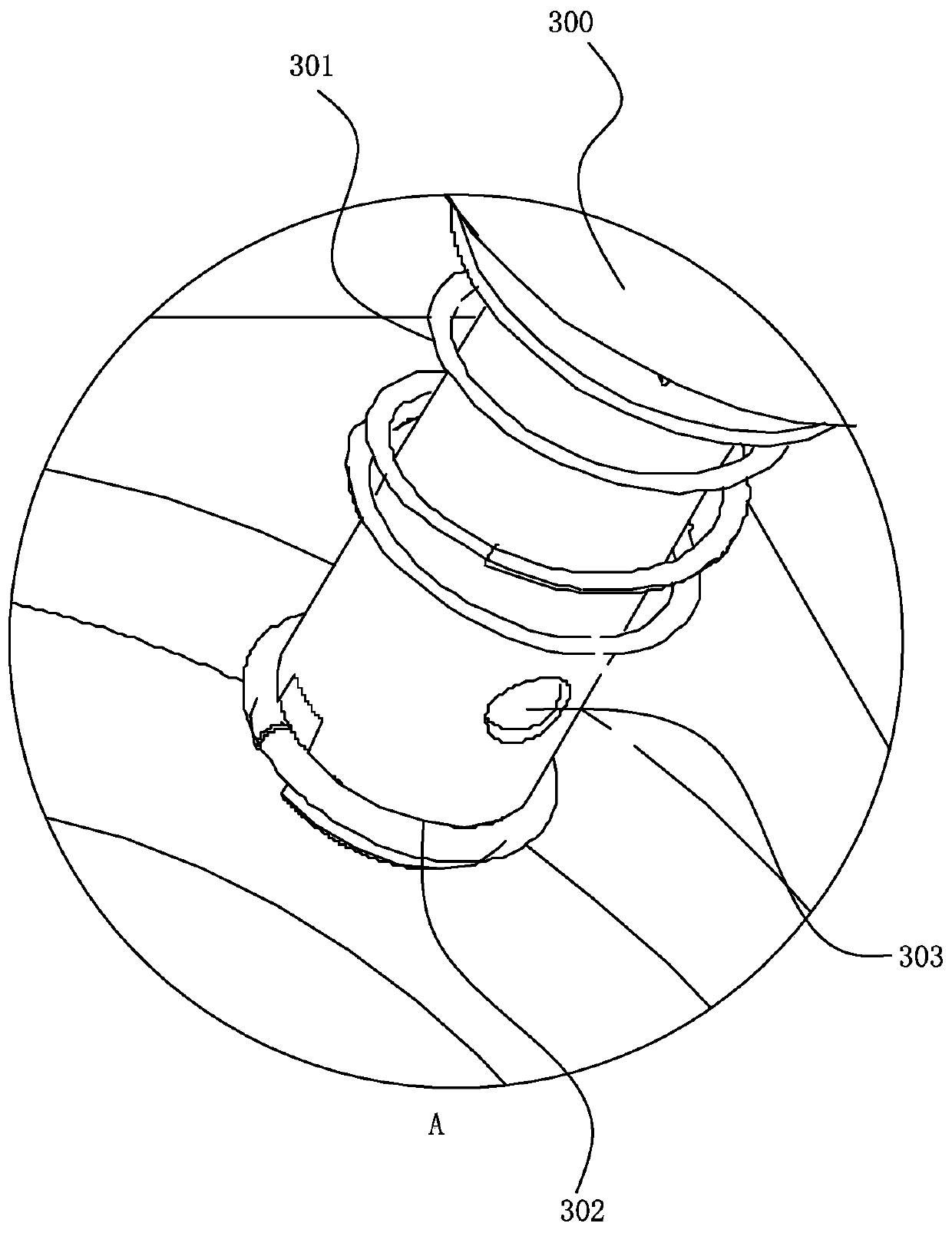

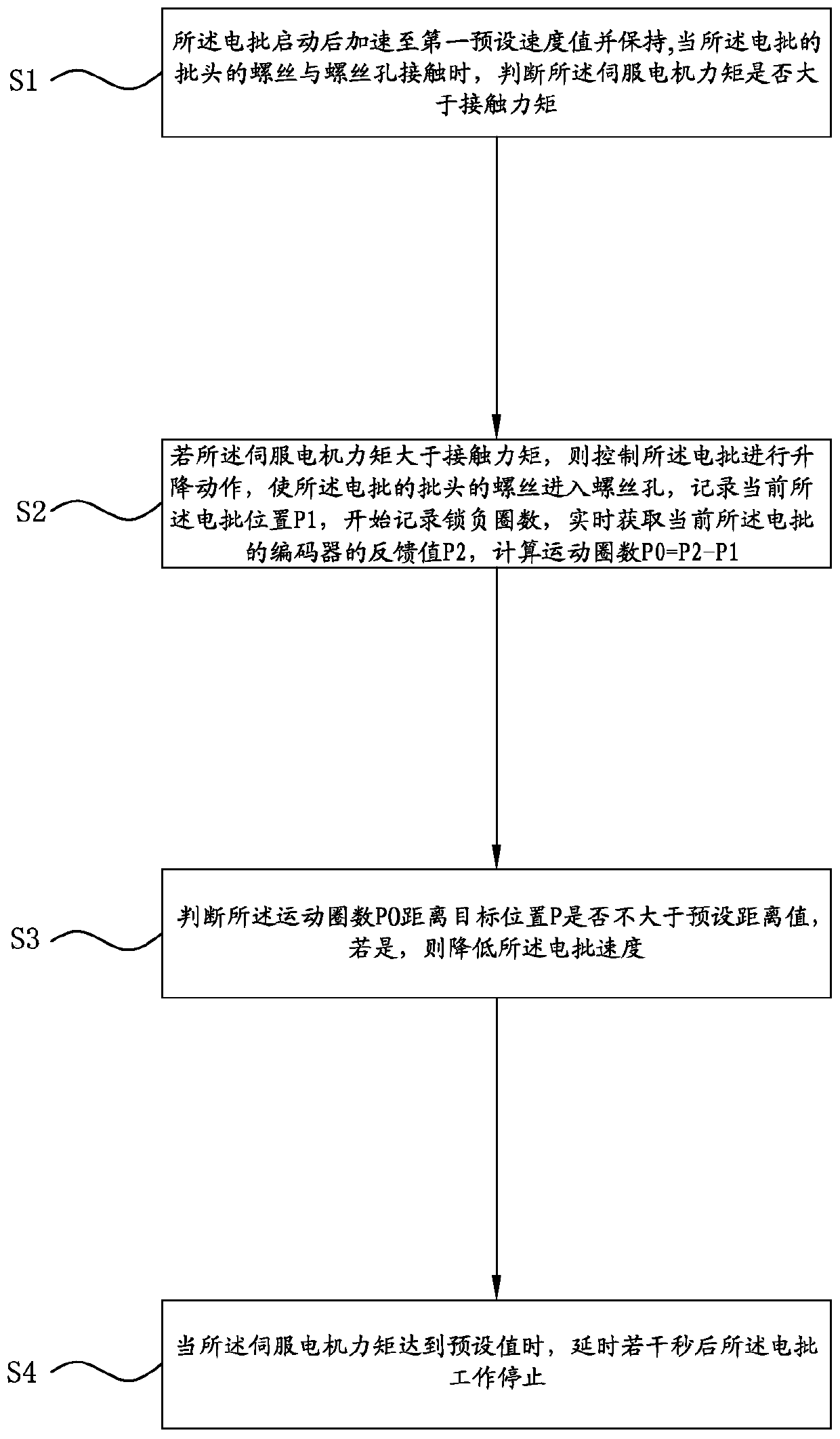

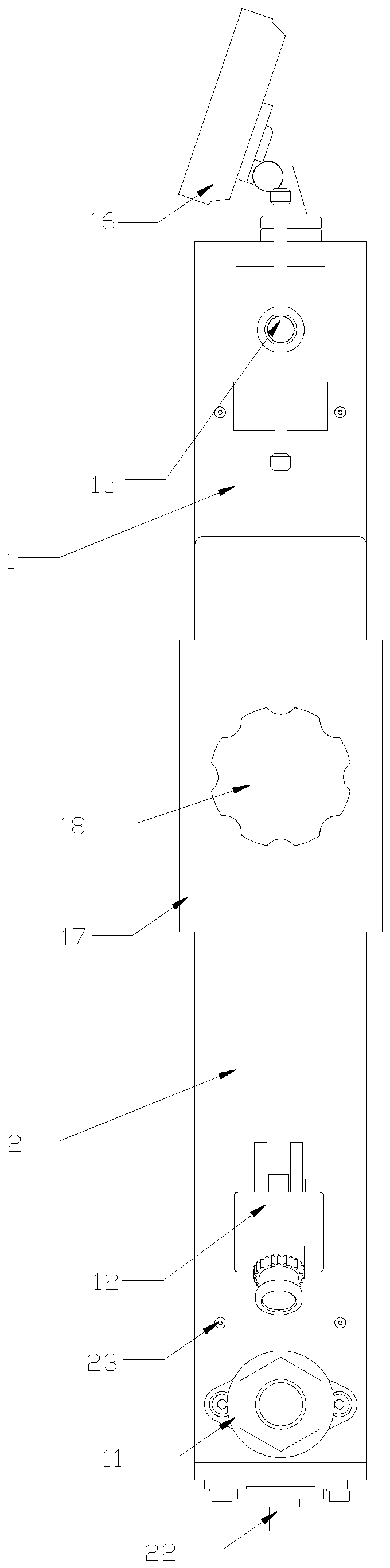

Intelligent servo electric screwdriver and use method thereof

PendingCN110834194AImprove job success rateEnsure consistencyMetal working apparatusScrew looseningServo

The invention discloses an intelligent servo electric screwdriver and a use method thereof. The electric screwdriver comprises a servo motor used for providing torque, a connector connected with an output shaft of the servo motor, a screwdriver bit sleeve fixed to the lower end of the connector, a flange structure fixedly connected with the servo motor and used for supporting protecting, and a screwdriver bit connected with the screwdriver bit sleeve. The screwdriver bit sleeve is sleeved with a spring, the position, on the upper end of the spring, of the screwdriver bit sleeve is provided with a limiting ring, a mounting hole is formed in the position, between the spring and the limiting ring, of the screwdriver bit sleeve, the flange structure is connected with a connecting base, the screwdriver bit sleeve penetrates through the connecting base to be connected with the screwdriver bit, and the screwdriver bit and the screwdriver bit sleeve are detachably connected. According to the intelligent servo electric screwdriver, the work success rate is greatly improved compared with that that of a common electric screwdriver, a micro fine screw can be locked, consistency of fastening and connecting torque each time can be ensured, and the problems of floating, screw loosening, idling, clamping, and damage of a locked object during production can be reduced.

Owner:深圳市山龙智控有限公司

Screw loosening agent and preparing method thereof

The invention discloses a screw loosening agent and a preparing method thereof. According to the technical scheme, the screw loosening agent is mainly prepared by weight by the raw materials which are 70-90 parts of solvent, 5-20 parts of antirust agents, 1-10 parts of corrosion-resistant agents and 1-10 parts of penetrants. The invention further discloses the preparing method of the screw loosening agent. The screw loosening agent has the functions of rust loosening, rust removing, penetrating, lubricating, corrosion resistance and the like, using is convenient, price is reasonable, the problem that traditional disassembling is high in difficulty and bad in effect is solved, manpower and material resources are saved, cost is saved, and great convenience is brought to production and life.

Owner:HENAN NORMAL UNIV

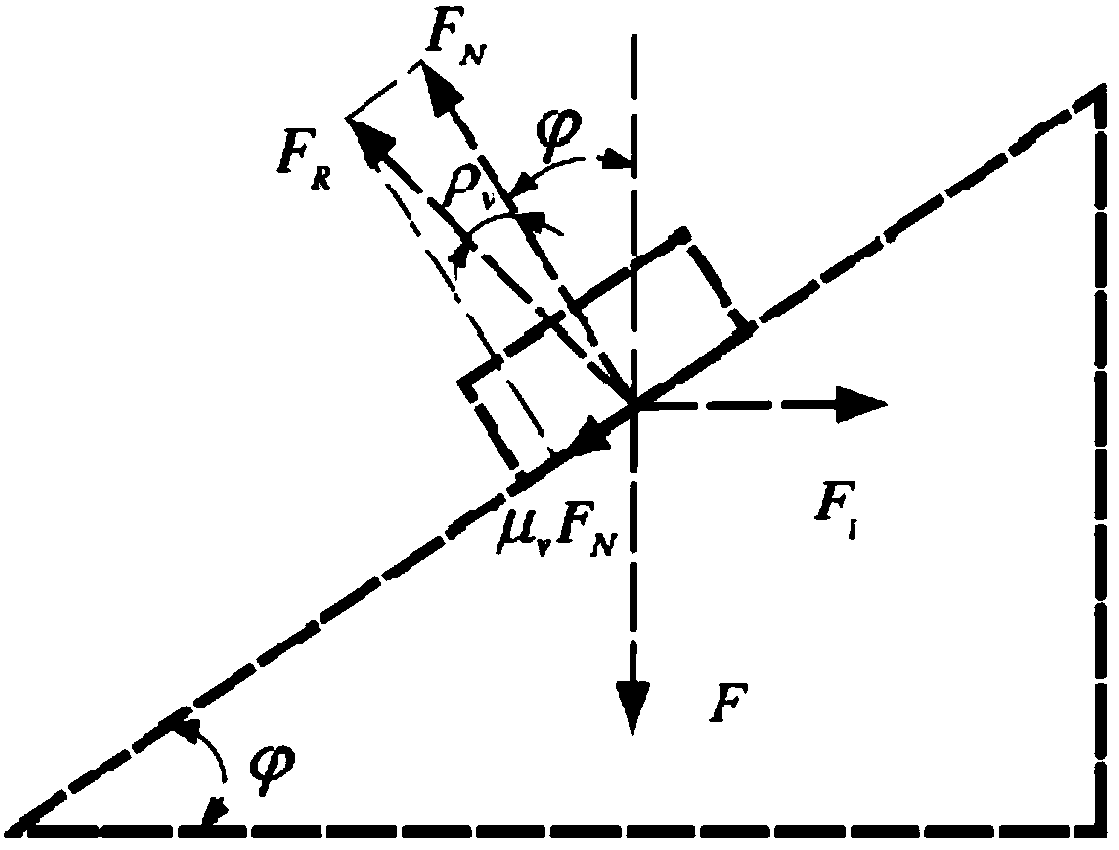

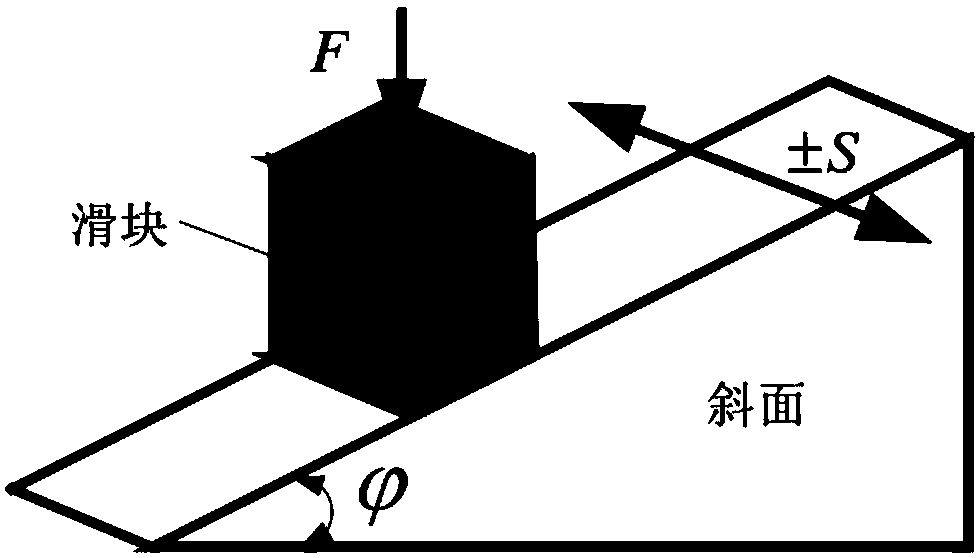

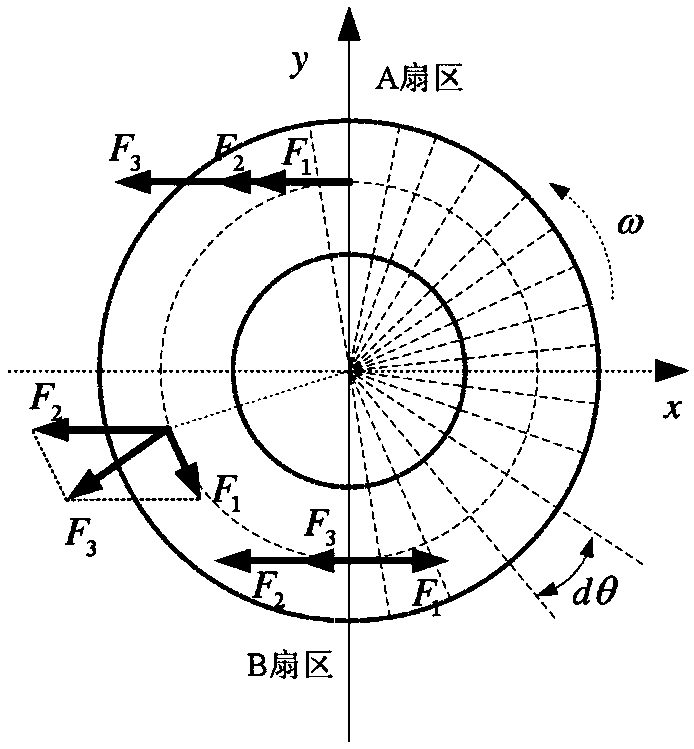

A thread loosening analysis method based on fretting friction theory

ActiveCN109241598ALoose state is clearGeometric CADDesign optimisation/simulationStress distributionFretting

The invention belongs to the technical field of thread loosening. A thread loosening analysis method based on fretting friction theory is provided, which includes the analysis of stress and looseningof thread model, the analysis of fretting slip state, the establishment of fretting slip model, the establishment of simulation model, the analysis of fretting slip state based on grain dissipation energy, and the analysis of fretting slip state using fretting diagram. On the basis of fully considering the influence of fretting friction on thread loosening, a thread loosening analysis method basedon fretting friction theory is presented, A mathematical model of that contact surface is established, theoretical formulas of stress distribution and pressure distribution at the screw loosening interface are established, and the interface stress and pressure are simulated to analyze the loosening phenomenon, and the loosening state is clearer by introducing the theory of screw dissipation energy and fretting diagram, which provides a reference for the future research on this kind of screw loosening. For the above reasons, the present invention can be widely popularized in the field of thread loosening.

Owner:DALIAN UNIV OF TECH

Locking member, locking structure and air conditioner

ActiveCN107606759AAchieve lockingImprove fixation efficiencyLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention discloses a locking member, a locking structure and an air conditioner. The locking member comprises a plate body part; a rotary shaft is arranged at one end of the plate body part; a clamping-connection part is arranged at the other end of the plate body part, thus, locking of the two parts can be achieved, and compared with the traditional mode that the two parts are fixed throughscrews, the fixing efficiency between the two parts is improved; and meanwhile, the screw loosening phenomenon caused by repeated screw turning can be avoided, and thus damage of a fixed structure canbe effectively avoided.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

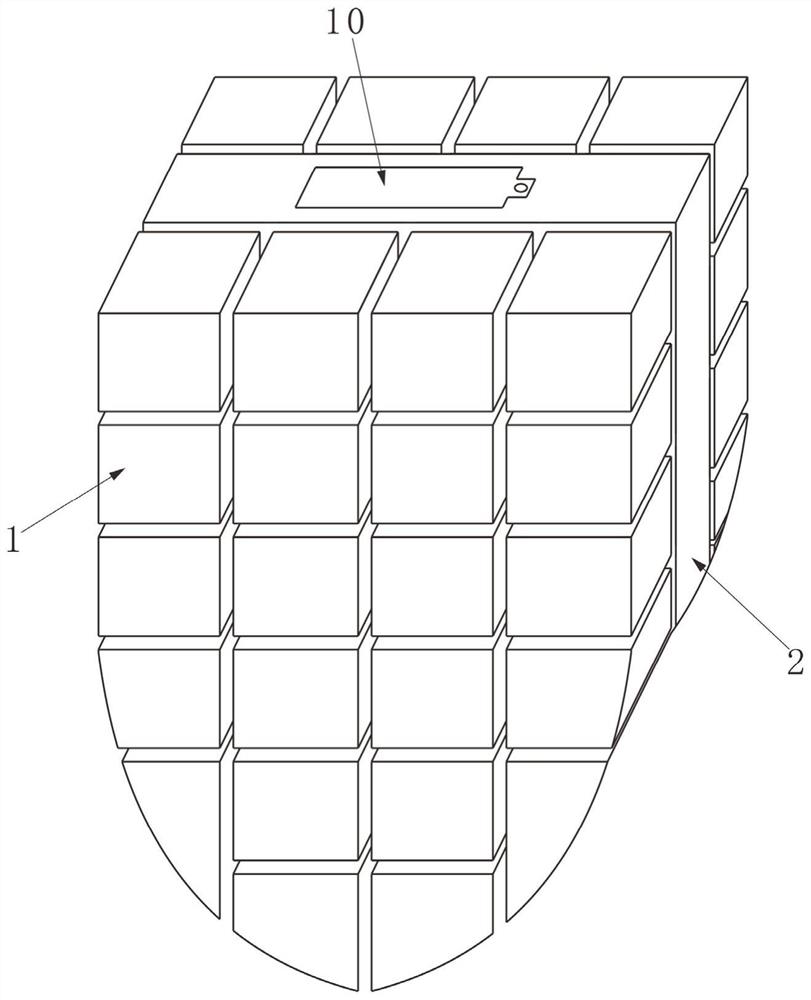

Multi-unit adjustable intelligent interbody fusion cage

ActiveCN112274302AIntuitive and real-time guidanceGuaranteed tightnessSpinal implantsSpinal cageEngineering

The invention discloses a multi-unit adjustable intelligent interbody fusion cage which comprises a fixing plate, the upper end of the fixing plate is of a square structure, the lower end of the fixing plate is of an arc-shaped structure, a plurality of adjusting units are evenly arranged on the fixing plate, each adjusting unit comprises two adjusting blocks, and the two adjusting blocks are arranged on the two sides of the fixing plate respectively. The adjusting blocks are connected with the fixing plate through the linear moving modules, and the edge formed by the multiple adjusting blocksis attached to the edges of the two sides of the fixing plate to form a whole. The multiple adjustable units are innovatively designed, the adjustable units are perfectly attached to the upper end plate and the lower end plate by adjusting the different telescopic heights of the adjustable units, the curvature of the cervical vertebra operation segment can be better adjusted, the contact area ofthe implant and the end plate is increased, the gap between the implant and the end plate is reduced, and therefore stress concentration is avoided; and complications such as screw loosening, bone resorption around the implant and fusion cage sinking are reduced.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Wiring terminal with screw loosening alarming function

ActiveCN107579364AImpact of compression forceDoes not affect normal operationCoupling device detailsElectric connection basesTransverse grooveEngineering

Owner:国网河南省电力公司内乡县供电公司

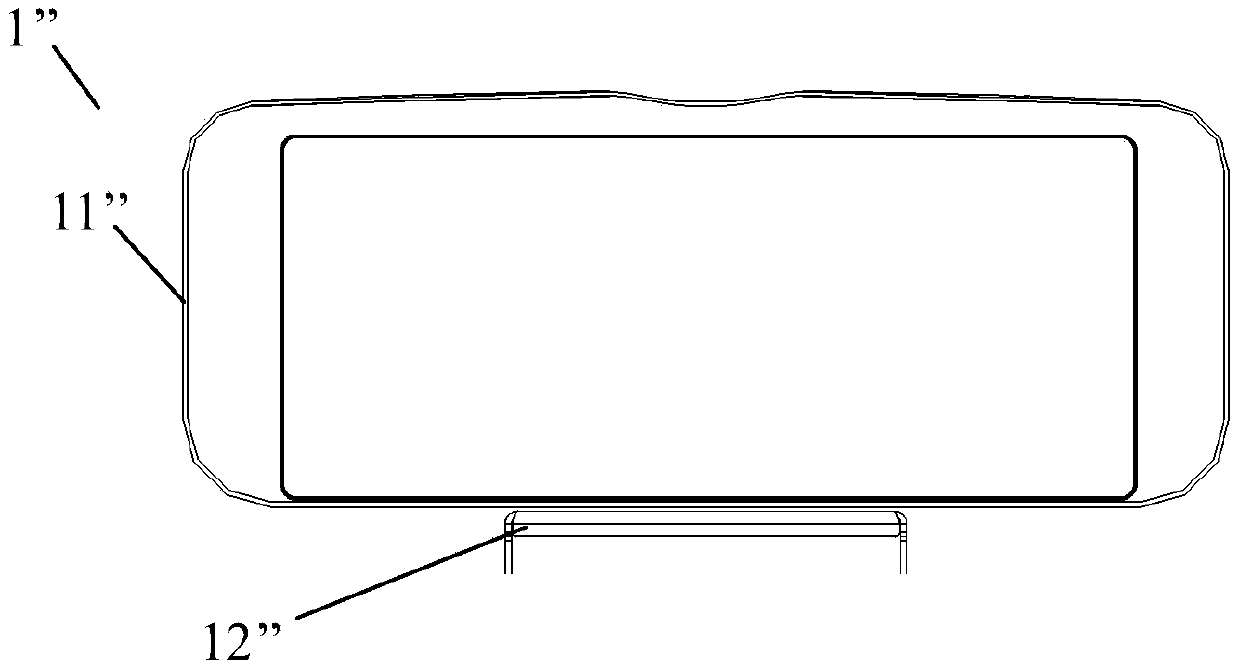

Clamping holding structure and mobile terminal

ActiveCN105979030AIncrease preloadPrevent looseningFriction grip releasable fasteningsTelephone set constructionsElastic componentEngineering

The invention discloses a clamping holding structure and a mobile terminal. The clamping holding structure comprises a pedestal, a screw hole column, a bolt and an elastic component. The screw hole column is arranged on the pedestal. The bolt is movably connected to the screw hole column. One end of the elastic component is connected to the pedestal, and the other end of the elastic component, which is relative to the pedestal, is connected to the bolt. A height of the elastic component is greater than or less than a height of the screw hole column. The pedestal, the screw hole column, the bolt and the elastic component are conductive components. In the invention, a pretightening force of a screw is increased so that the screw is guaranteed to be fully intersected with a screw thread in the screw hole column and screw loosening is prevented; reliability of assembling contact among the elastic component, the screw hole column and the pedestal is guaranteed; and a condition that poor contact among the elastic component, the screw hole column and the pedestal influences grounding performance of a metal shell and a metal frame is avoided.

Owner:NUBIA TECHNOLOGY CO LTD

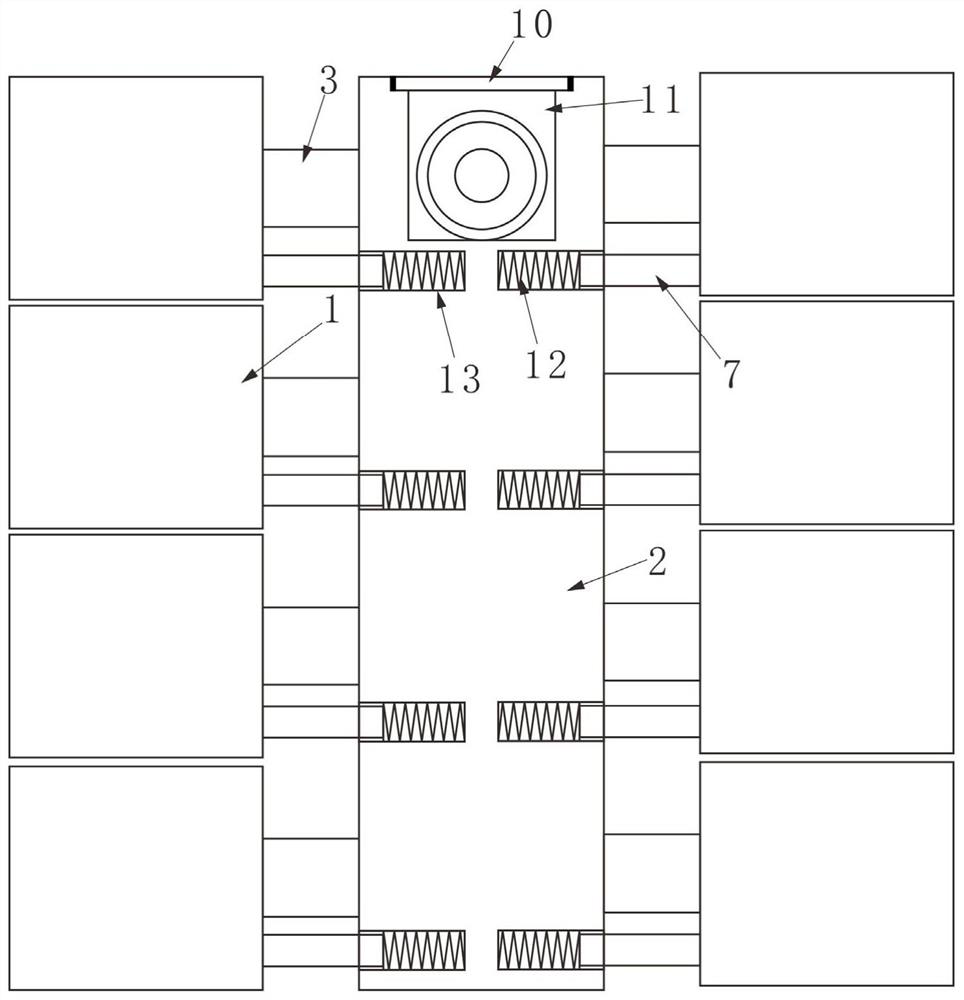

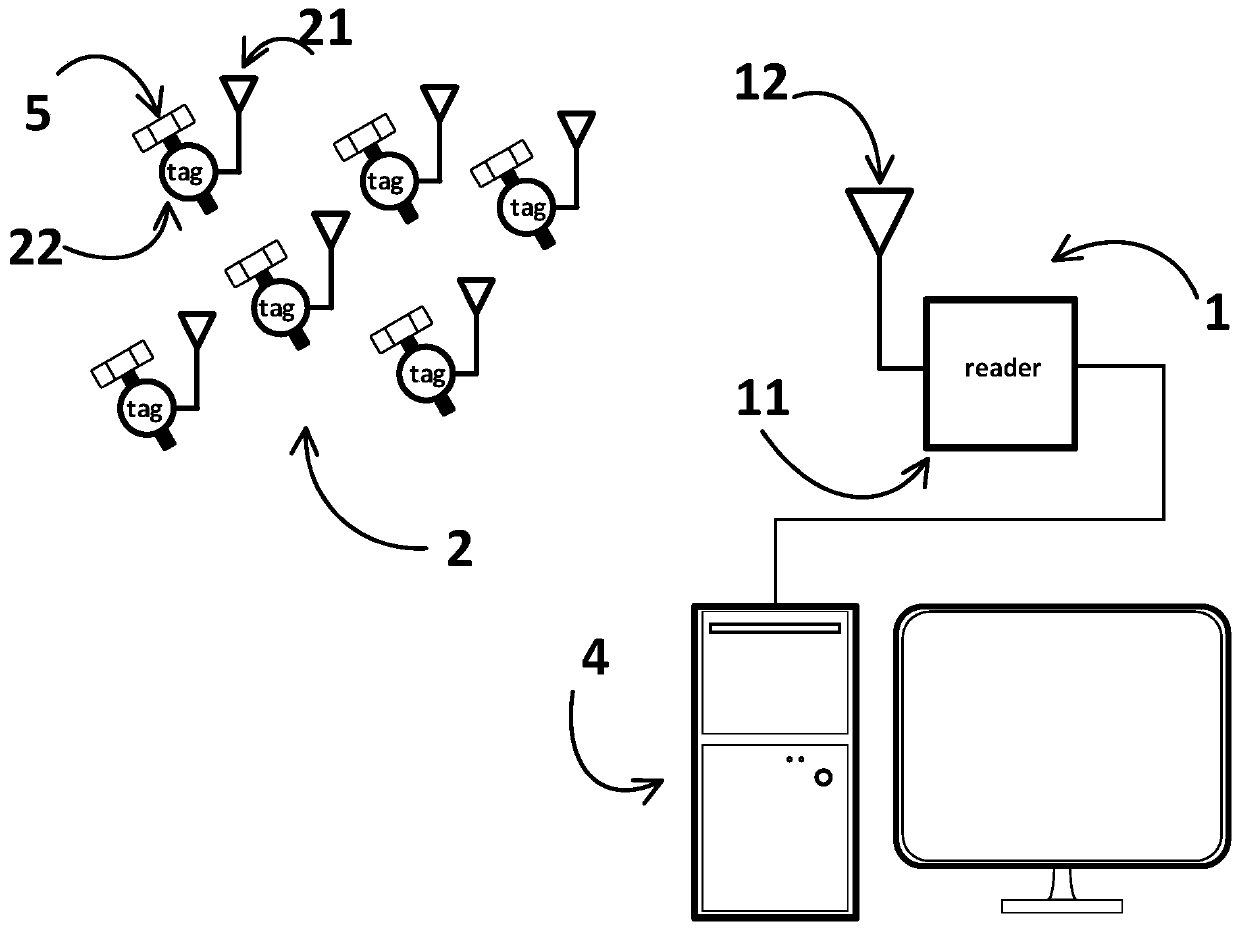

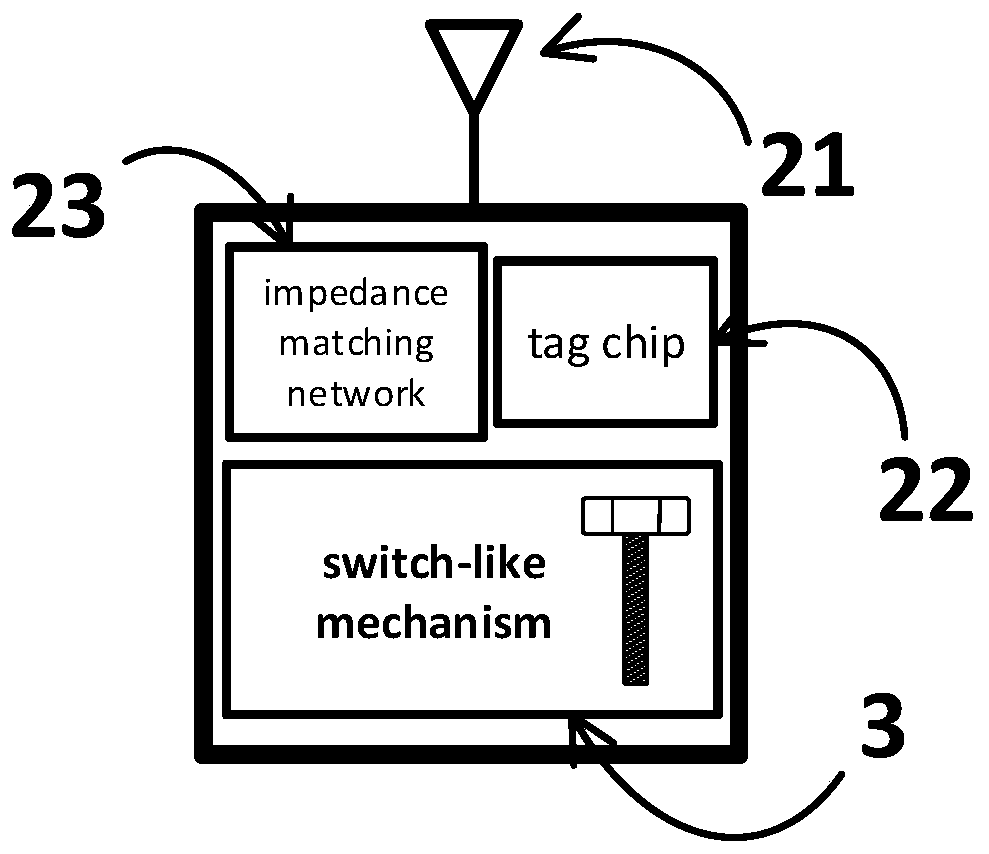

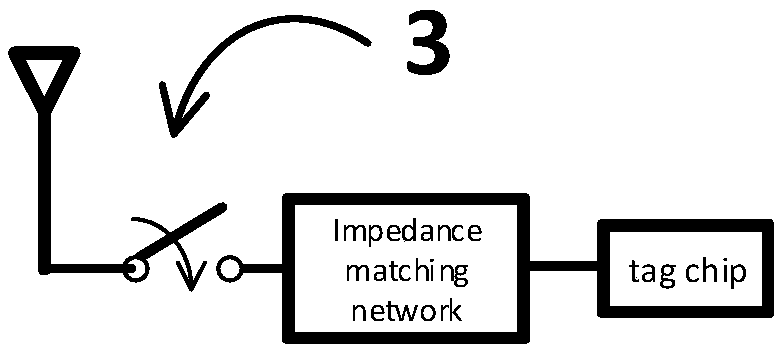

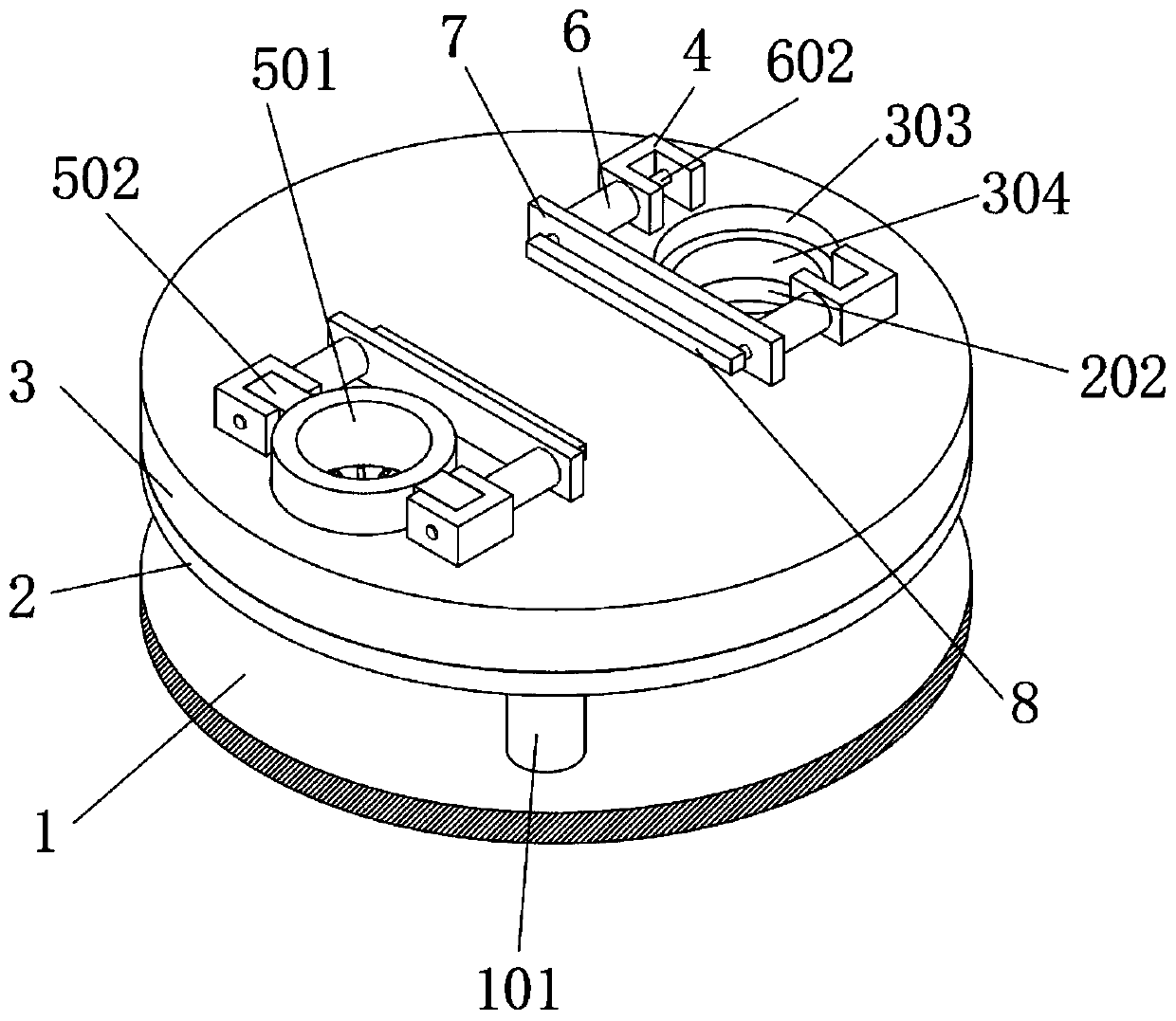

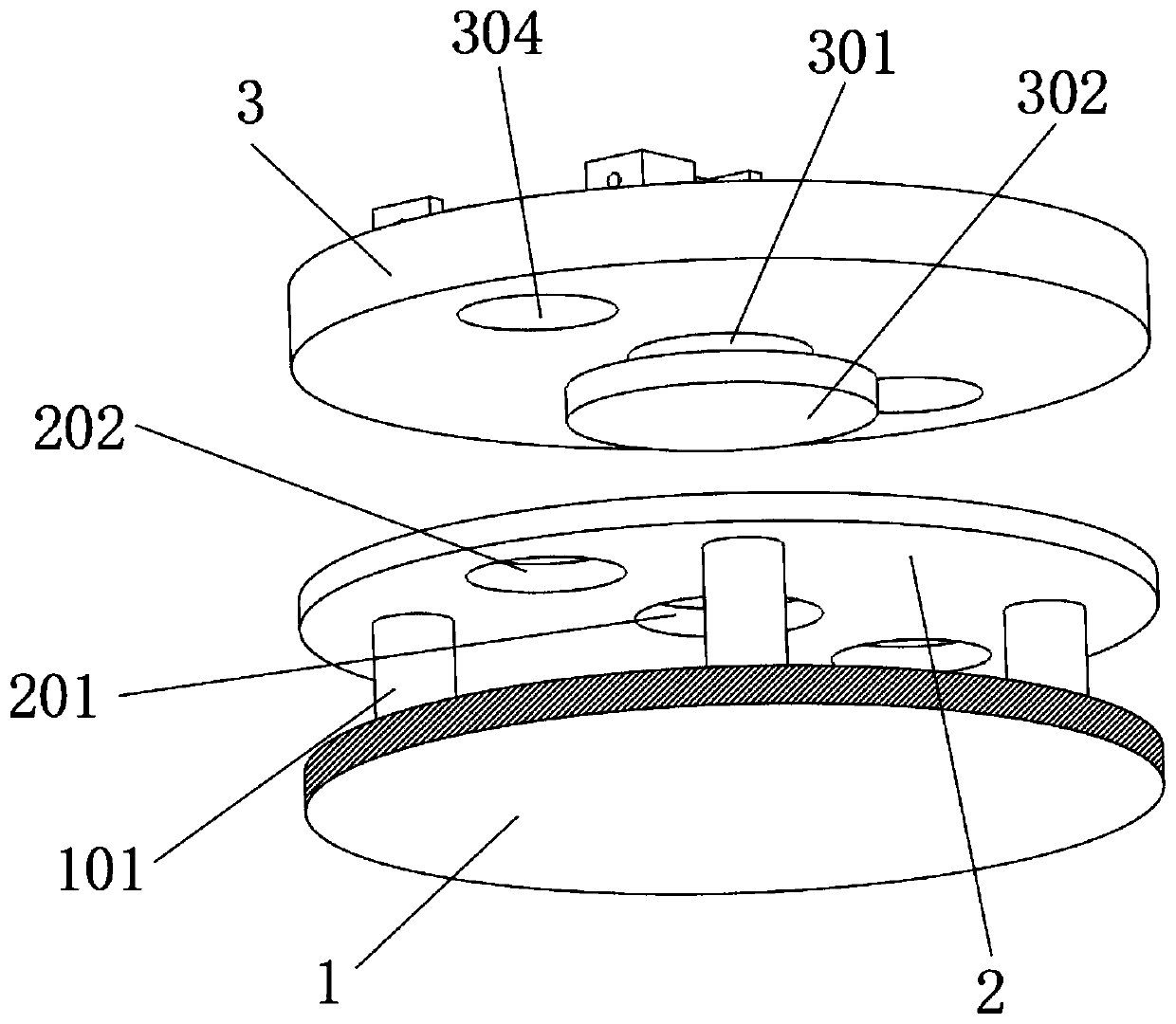

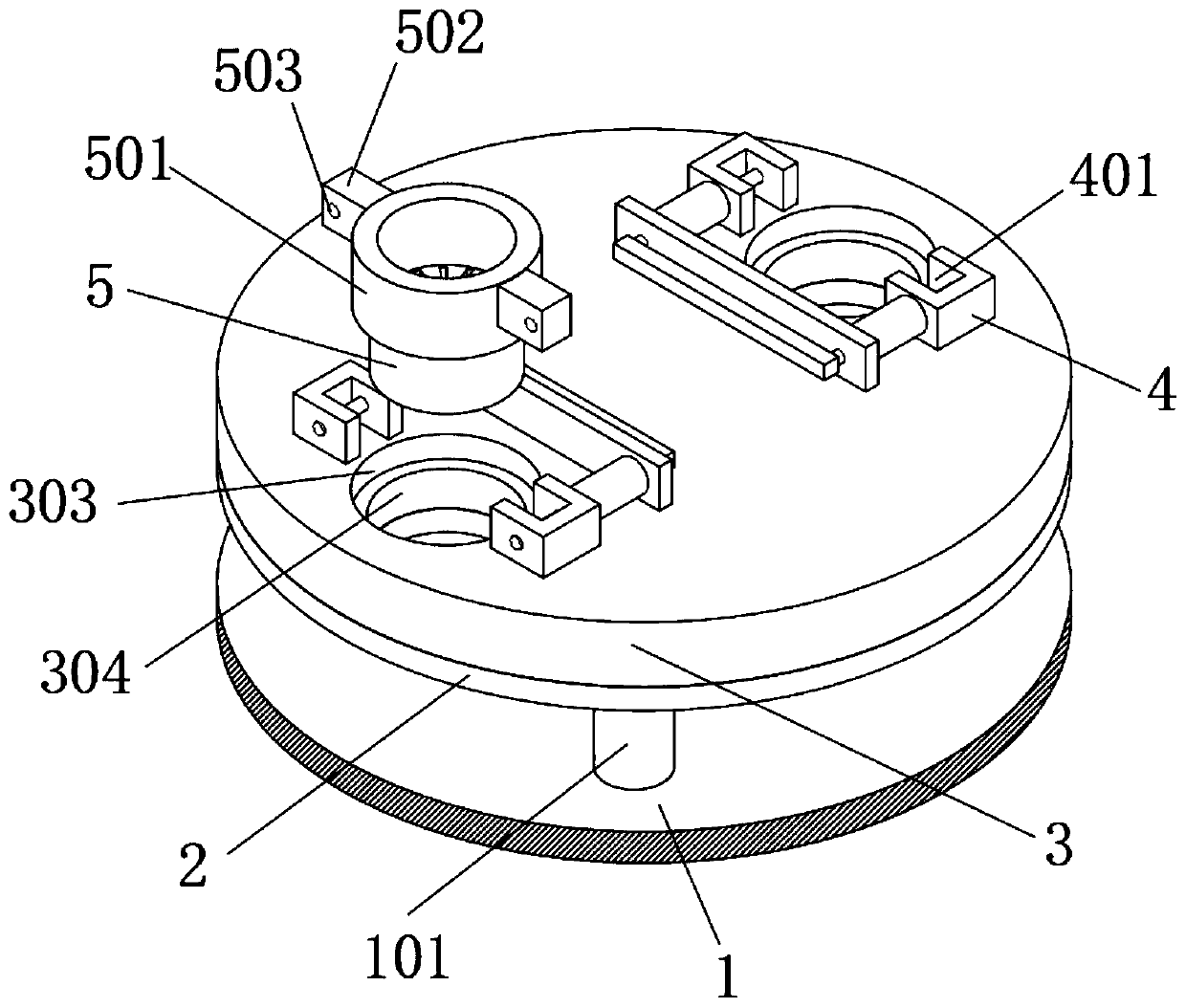

RFID (radio frequency identification) tag and screw loosening state monitoring system based on same

InactiveCN110261082AImprove reliabilityMachine part testingCo-operative working arrangementsTag antennaMonitoring system

The invention discloses an RFID (radio frequency identification) tag and a screw loosening state monitoring system based on the same and belongs to the field of screw state monitoring. The invention aims to solve the problems of leakage detection and false detection in the prior art. The structure of the RFID tag is mainly composed of an antenna and a tag chip; when the chip and the antenna are connected with each other, the tag can be accessed through a reader-writer; and a metal screw body serves as a switch-like mechanical structure and determines the switching of the disconnection state and connection state of the tag chip and the tag antenna, that is, the tag can be read and communicate with the reader-writer when the screw is firmly fixed; and the chip is disconnected from the tag antenna when the screw is loosened, and as a result, communication between the tag and the reader-writer is interrupted. The switch-like mechanical structure can be integrated in the tag antenna or an impedance matching network separately so as to form an integrated body with the tag, and therefore, the reliability of screw state detection is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

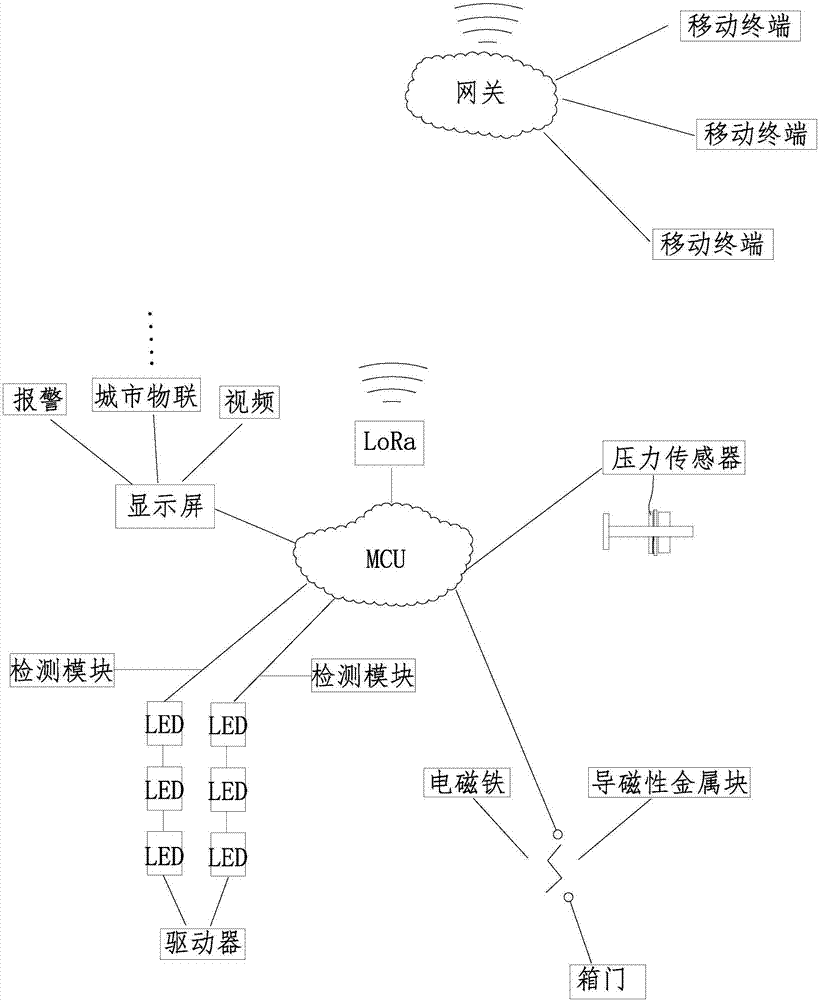

Light source carrier with Internet of Things man-machine interaction and self inspection functions, and interactive method

PendingCN107493634AEasy maintenanceElectrical apparatusElectroluminescent light sourcesComputer moduleCritical position

The invention provides a light source carrier with Internet of Things man-machine interaction and self inspection functions, and an interactive method. The light source carrier comprises an outer shell, multiple detection modules, a processing module and a mobile terminal, wherein a display screen and LED back light sources connected in parallel are arranged in the outer shell; each LED back light source is driven by a driver; the multiple detection modules are distributed on the connecting circuits of the LED back light sources, and the detection modules are connected with the processing module; the processing module is used for performing information collection and processing, and integrating wireless signal transmitting and wireless signal receiving; the mobile terminal integrates wireless signal transmitting and wireless signal receiving and is connected with the processing module in a signal feedback manner; and the processing module feeds back the processed information to the mobile terminal in real time. A processor is mainly connected with an LED back light source detection module, a box door airtightness detection module, a screw loosening detection module and an urban Internet of Things module, and transmits the problem of an advertisement lamp box to the mobile terminal, so as to feedback the problem to a maintenance staff in time, so that the maintenance staff can find the problem and the key position of the problem immediately in order to perform maintenance conveniently.

Owner:浙江灵奇光电科技有限公司

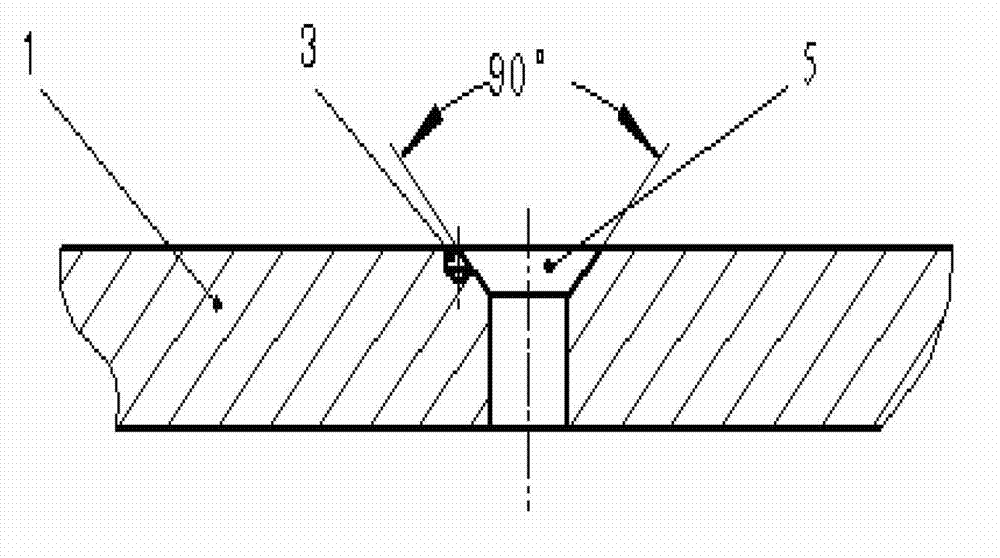

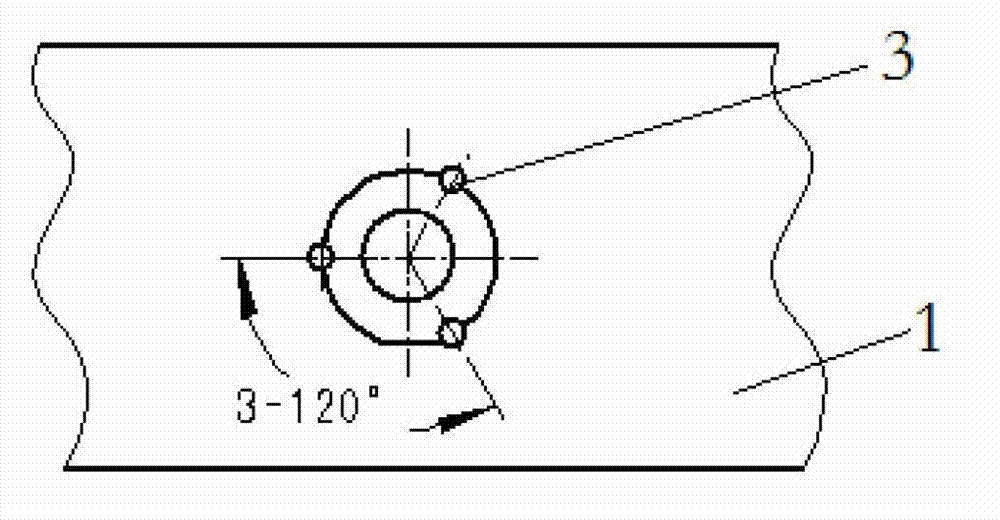

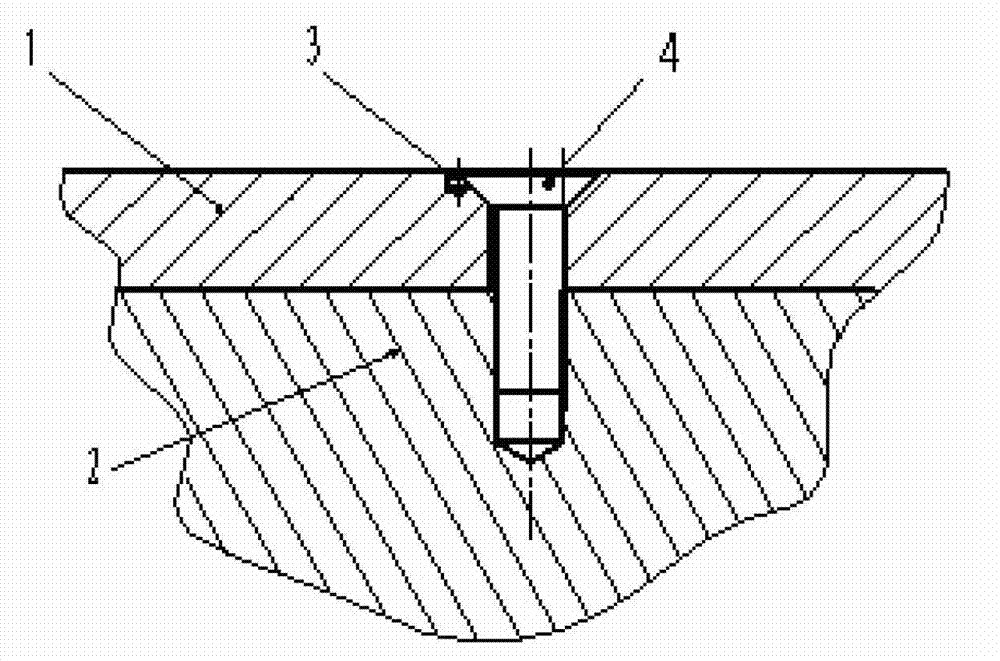

Punched point anti-loosening method for sunk screw connection

InactiveCN102767556AOvercome the problem of poor anti-loosening effect of connection punching pointReliable and anti-looseNutsBoltsPunchingEngineering

Provided is a punched point anti-loosening method for sunk screw connection. 2-4 punched point grooves or punched point holes are formed on the circumferential edge of the opening of a sunk screw hole by mechanical processing, the width or diameter of the opening of the punched point groove or punched point hole is 1.2mm-2.5mm, the punched point grooves or punched point holes are evenly distributed on the circumferential edge of the opening of the sunk screw hole, and the central line of the punched point groove or punched point hole is perpendicular to the central line of the sunk screw hole. In connection, a punch is abutted against the part of the screw head of the sunk screw opposite to the punched point groove or punched point hole prefabricated on the edge of a sunk screw hole in a to-be-connected member, and a punching tool is hit, so that the screw head of the sunk screw deforms to get squeezed into the punched point groove or punched point hole prefabricated on the edge of the sunk screw hole in the to-be-connected member, therefore achieving the purpose of mechanical motion stop and loosening prevention for screw. The inventive method has the characteristics of simple and easy operation, reliable screw loosening prevention, and wide application. The punched point groove or punched point hole is round, V-shaped or conical.

Owner:XIAN AVIATION BRAKE TECH

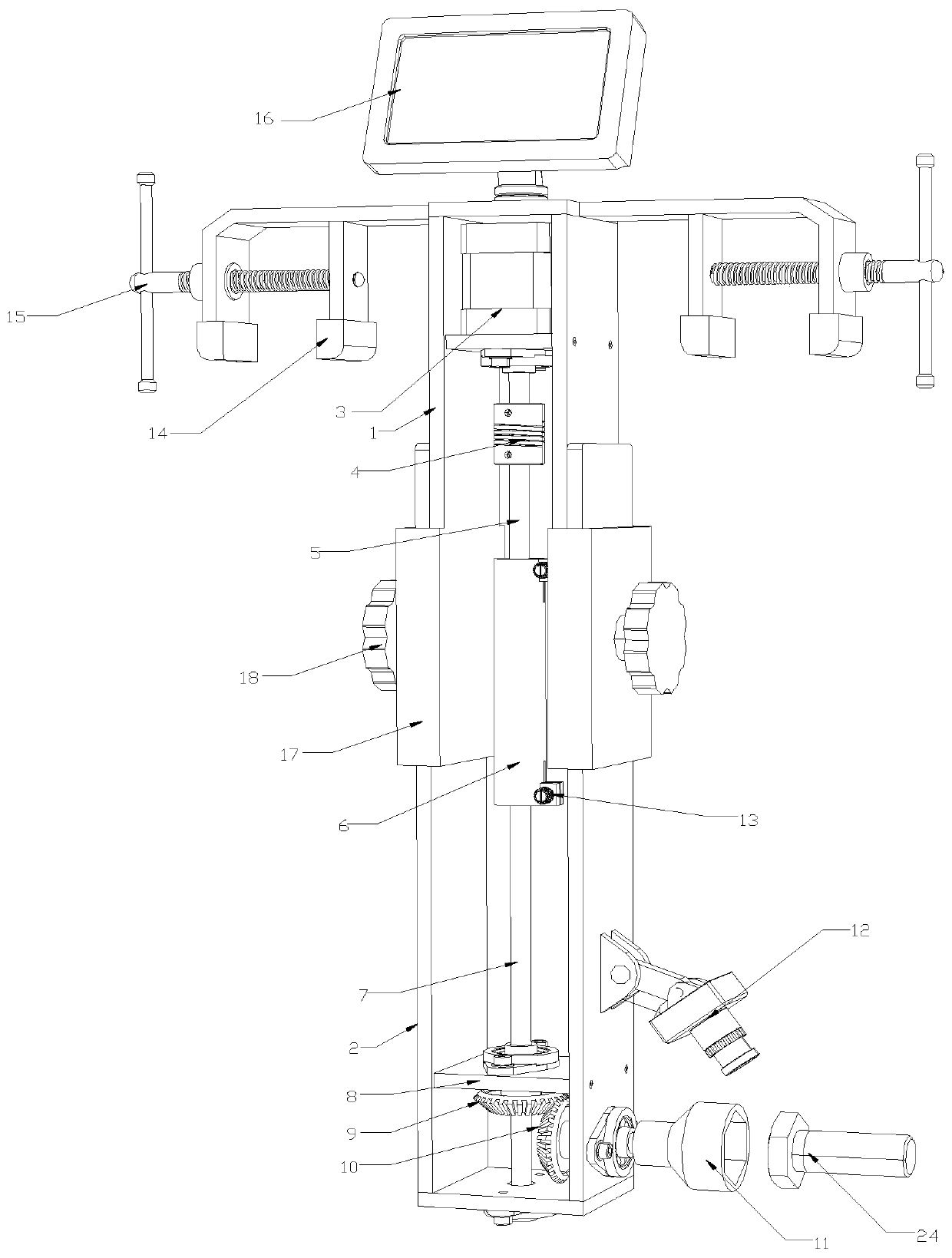

Special visual fast wrench in limited space

ActiveCN110039475AAvoid problems that reduce screw tightening efficiencyQuick elasticSpannersWrenchesSpatial structureEngineering

The invention provides a special visual fast wrench in a limited space. The special visual fast wrench comprises a driving mechanism and a transmission mechanism. A fixing mechanism is arranged out ofthe transmission mechanism, a reversing mechanism is arranged at the end, far away from the driving mechanism, of the transmission mechanism, a fastening head is arranged at the end, far away from the transmission mechanism, of the reversing mechanism, a display screen is arranged on the upper part of the fixing mechanism, a camera is arranged next to the fastening head, and the camera is electrically connected to the display screen. The special visual fast wrench can loosen and tighten a screw in the limited space quickly, so that the problem that the screw loosening and tightening efficiency is reduced as a twisting handle is affected by two side walls in a twisting direction when a common ratchet wrench is used is solved. The special visual fast wrench can fit space structures with different wall widths and depths. For places which cannot be reached by a human eye vision, the camera is arranged to feed the places back to the display screen, so that an operator can find the positionof the screw. The special visual fast wrench is convenient to carry and quite convenient to mount and use, and has wide adaptability in the field of industrial assembly and production and life.

Owner:SECOND INST OF OCEANOGRAPHY MNR

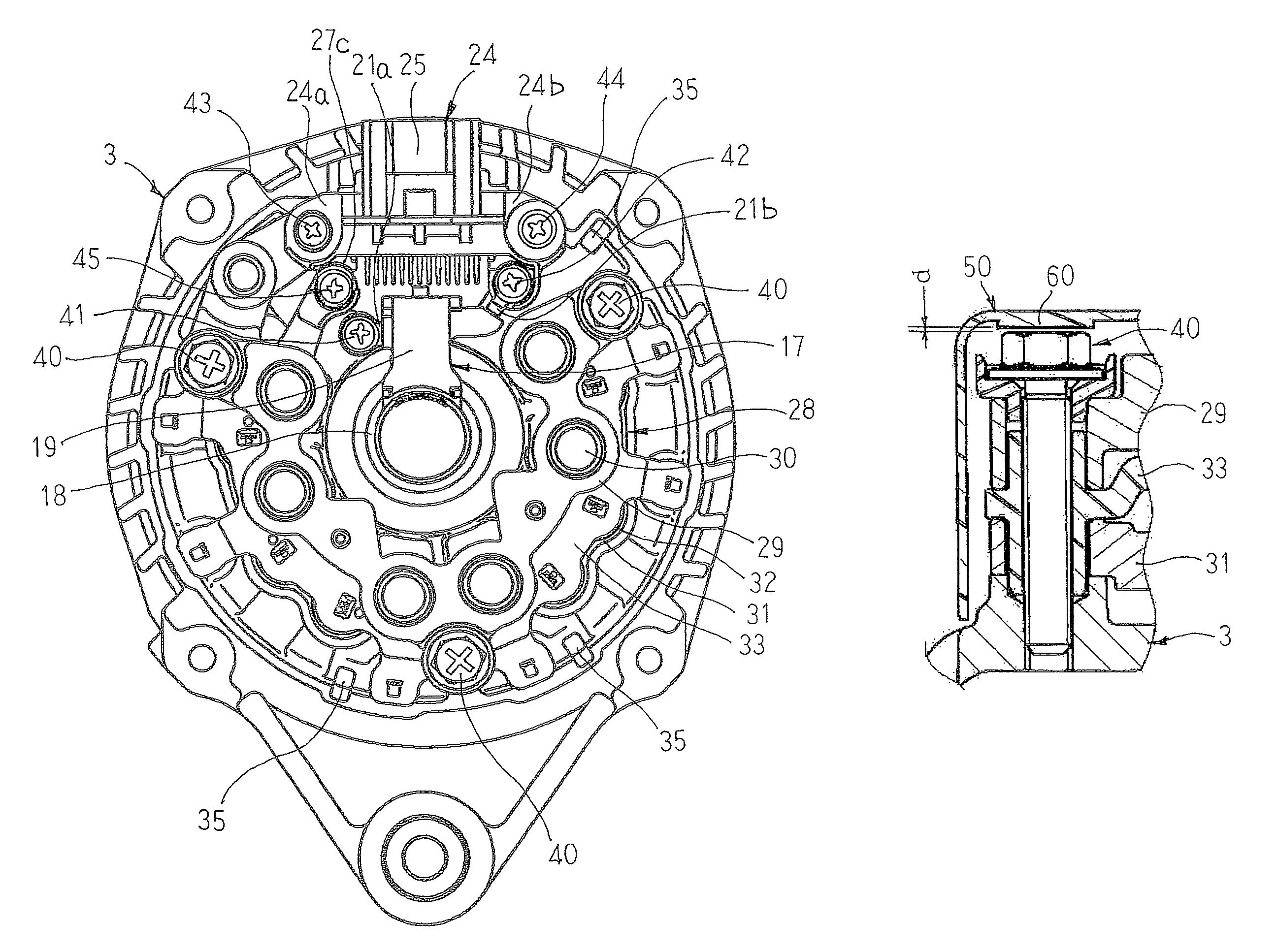

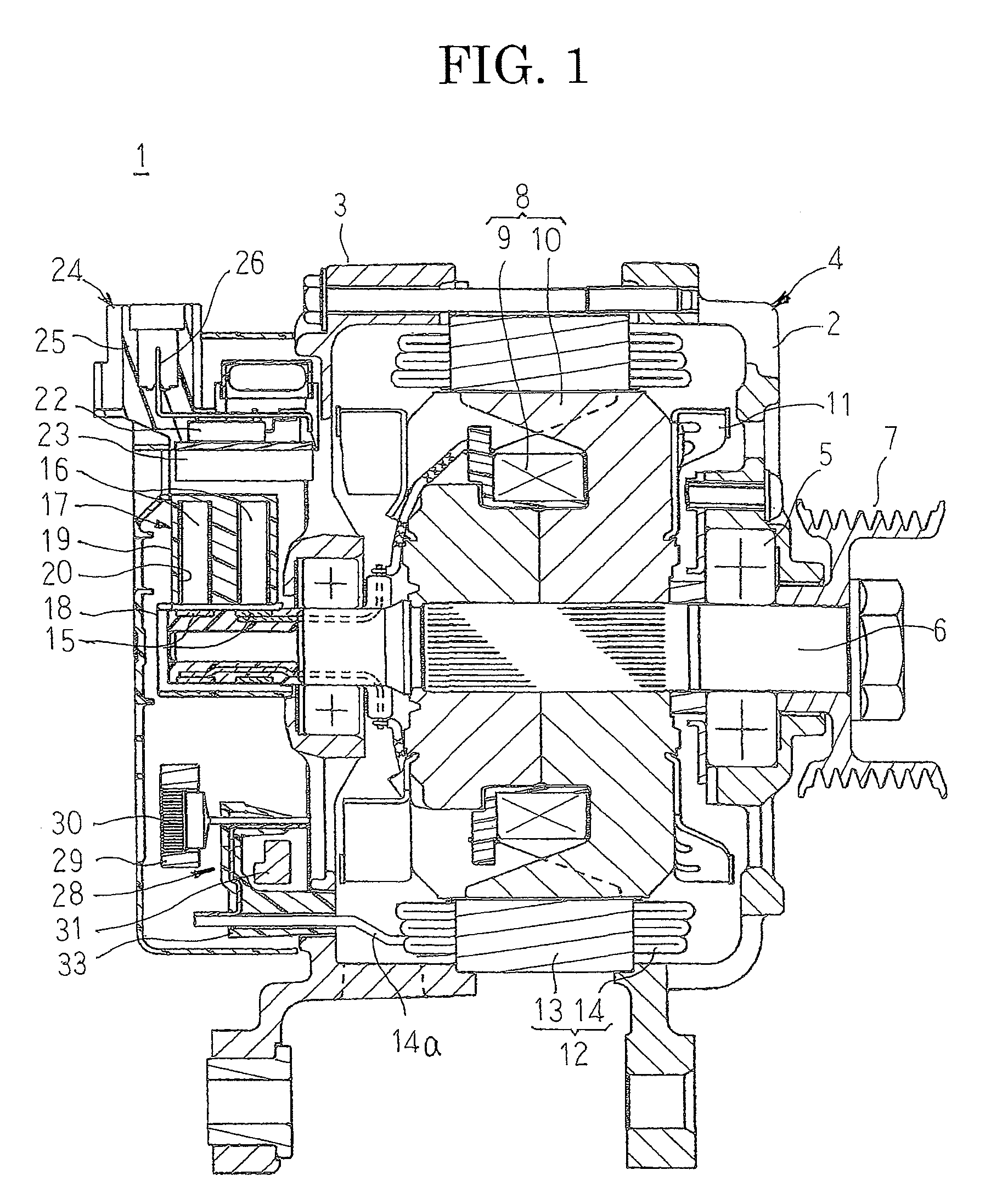

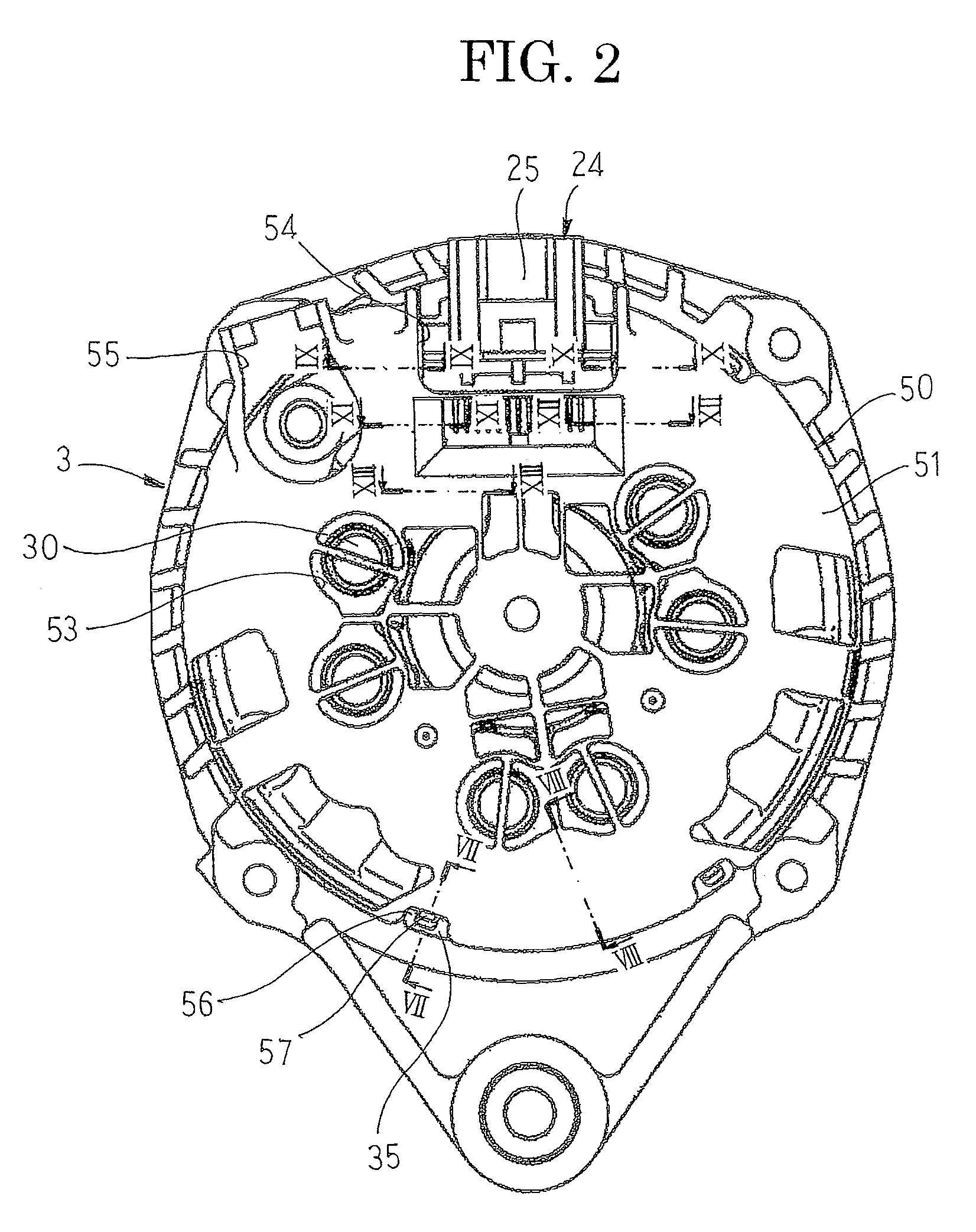

Automotive rotary electric machine

ActiveUS8350426B2InhibitionPrevent rotationSynchronous generatorsMagnetic circuit characterised by insulating materialsElectricityElectric machine

Owner:MITSUBISHI ELECTRIC CORP

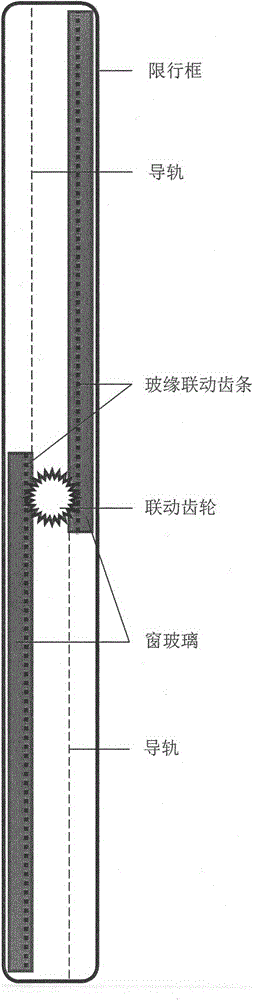

Safe overlapped window

The invention relates to a safe overlapped window, and relates to a housing construction supporting device, namely, an overlapped window of which the upper and lower parts are separated and which can slide in a staggered way. Window glass slides up and down by gear and rack linkage or counterweight traction until the window is opened in an overlapped way (ventilation), and reversely operates until the overlapped parts are separated to close the window (windproof, rainproof, warming and keeping quiet). From the structure, the existing window mainly comprises a flat opening (sash) type window and a smooth sliding (overlapped) type window. In the use process, on the one hand, the window falling event is caused by derailing or pivot breaking, pivotal screw loosening and falling and the like due to aging or improper maintenance or use; on the other hand, cleaning is difficultly thorough, and dusty corners are often left. According to the invention, the window falling risk is eliminated to the utmost extent; meanwhile, the joint of the two adjacent window glass of such window is provided with a sealing plate equipped with a glass wiper, so that the window has a self-cleaning function in the opening and closing process and can eliminate and avoid the dusty corners.

Owner:杨屹

Screw loosening and foreign matter detection method and system for train bottom bogie

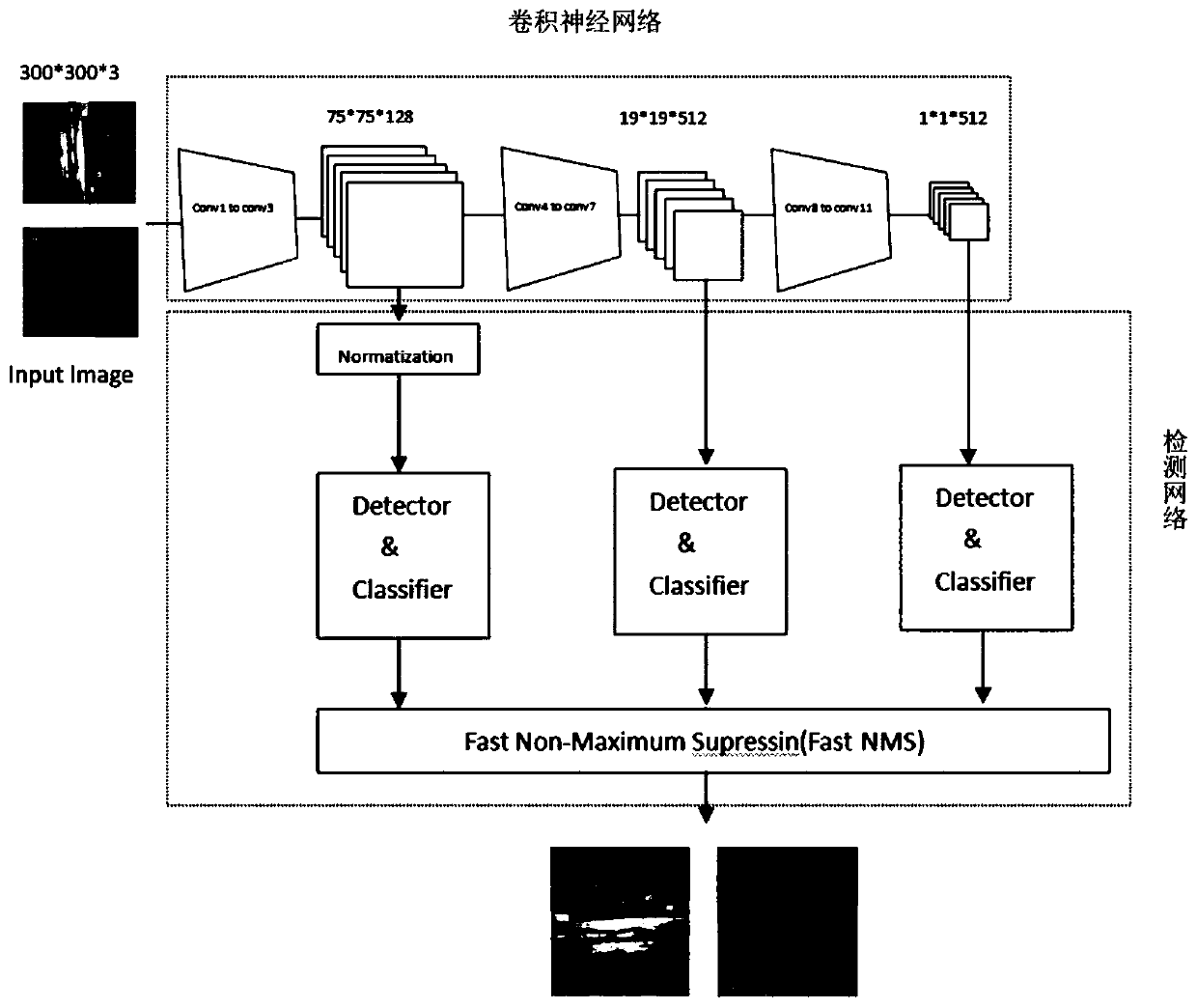

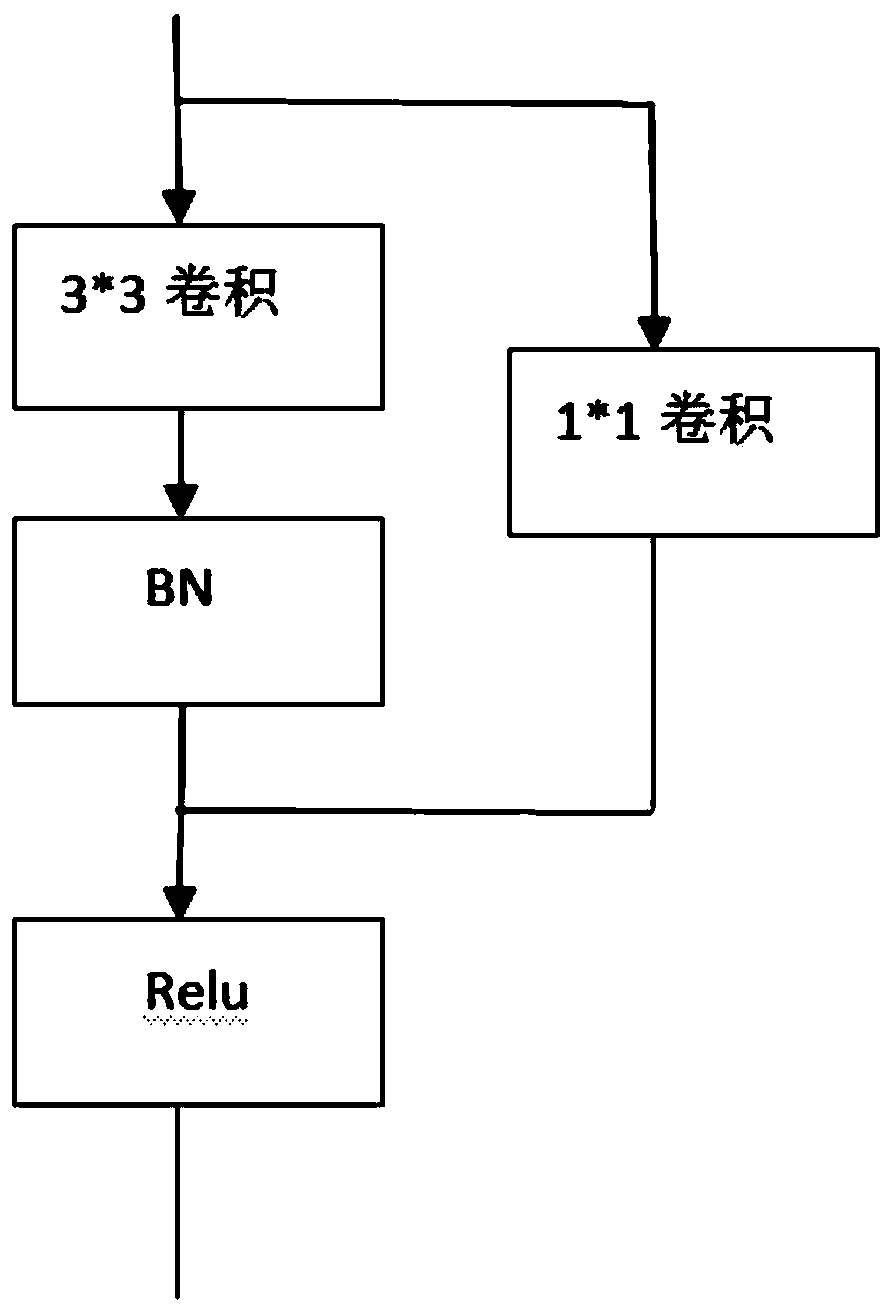

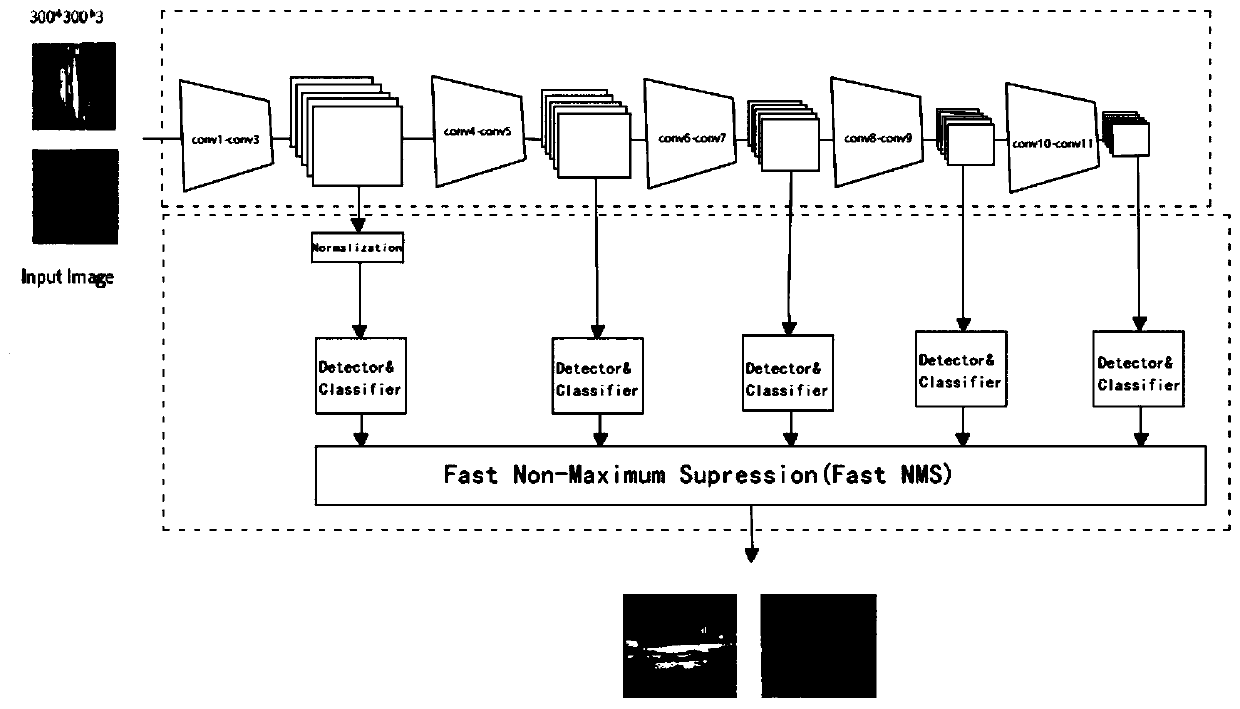

InactiveCN111582075AImprove detection accuracyHigh precisionCharacter and pattern recognitionRailway vehicle testingBogieForeign matter

The invention provides a screw loosening and foreign matter detection method and system for a train bottom bogie, and the method comprises the following steps: S1, collecting an image of the train bottom bogie, and obtaining a training data set which comprises the types and position information of a fault point and a foreign matter; S2, establishing a fault identification model according to the training data set; and S3, inputting a to-be-detected image to the fault identification model for detection, and if a fault is detected, outputting a fault type and a fault position and giving an alarm.When detection is needed, a to-be-detected image is input to the fault identification model, the fault identification model outputs positions and types of fault points and foreign matters and gives an alarm when detecting faults, the detection precision is high, the image is adopted for detection, contact type mechanical parameter acquisition is avoided, the safety is high, data acquisition is simple, accurate positioning is achieved, and the efficiency is high.

Owner:GUANGZHOU INST OF RAILWAY TECH +1

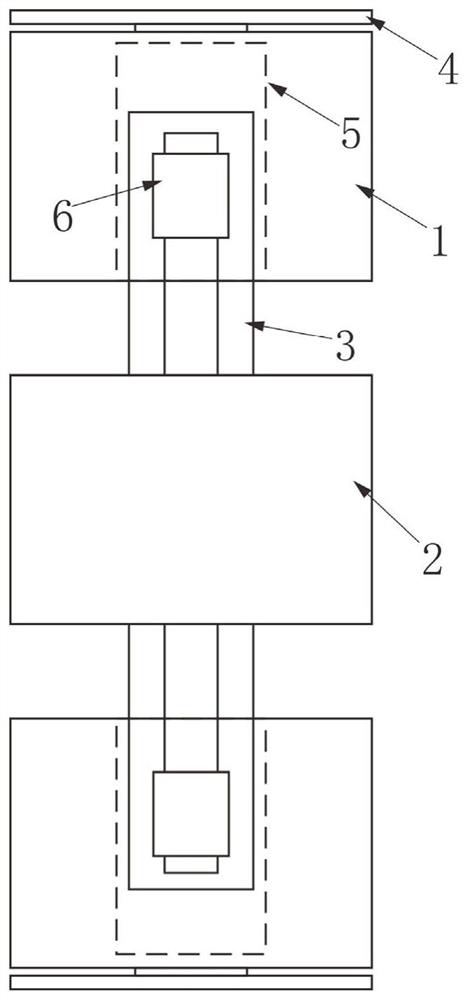

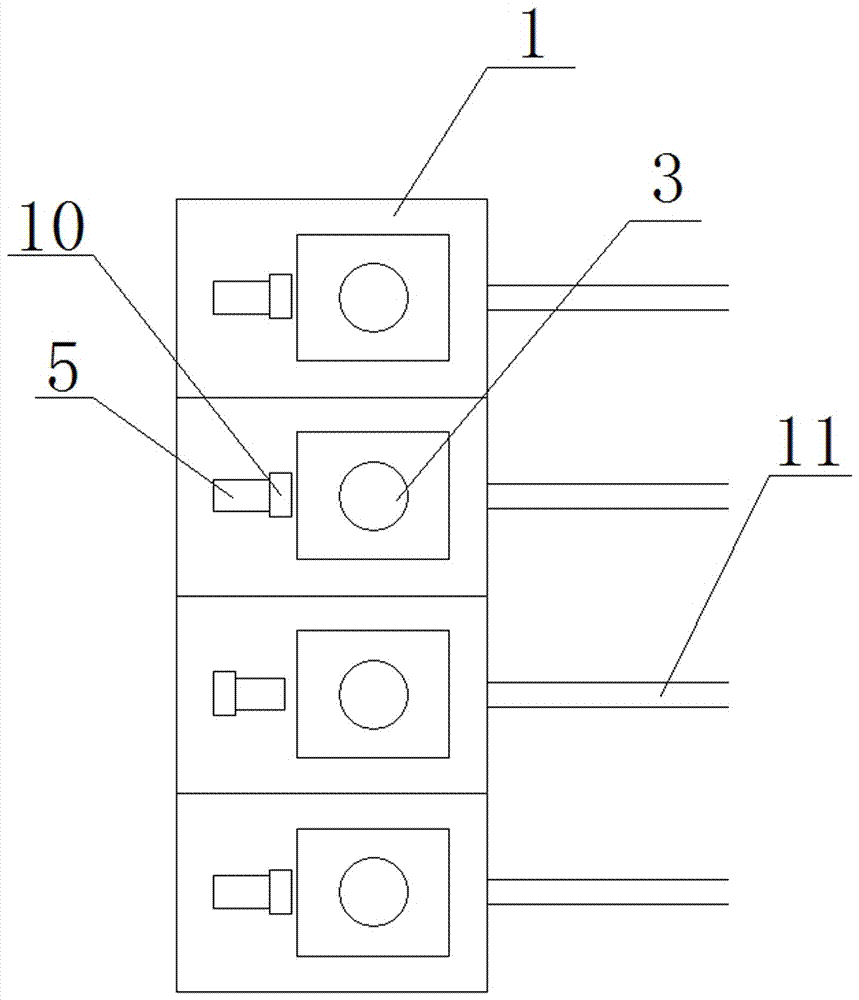

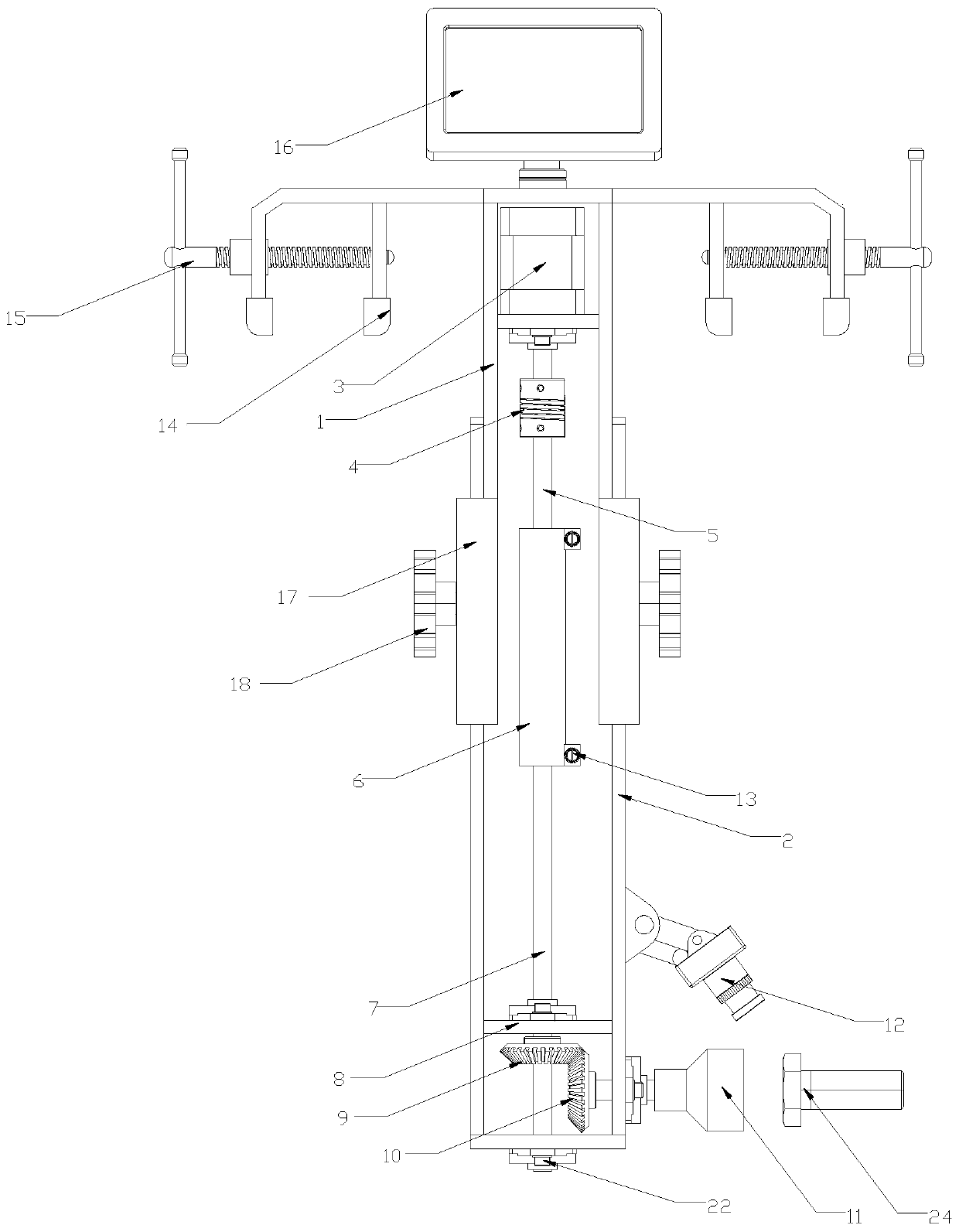

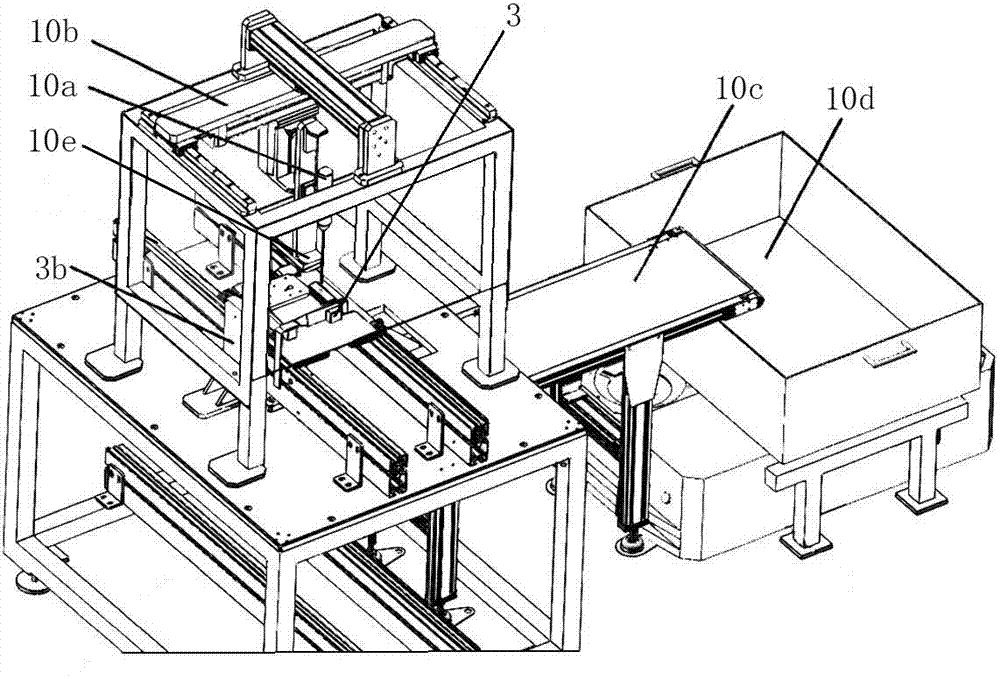

Automatic inner plate screw loosening system for waste electric energy meter

PendingCN107052778AFully automatedAutomate operationMetal working apparatusEngineeringElectricity meter

The invention discloses an automatic inner plate screw loosening system for a waste electric energy meter. The automatic inner plate screw loosening system comprises a screw loosening mechanism, a screw recycling system, a three-dimensional driving mechanism driving the screw loosening mechanism to advance, and a controllable screw suction mechanism synchronously advancing along with the screw loosening mechanism. The three-dimensional driving mechanism drives the screw loosening mechanism to advance to the position of an inner plate screw for screw loosening operation, the controllable screw suction mechanism sucks the screw which is screwed off, and the three-dimensional driving mechanism is used for conveying the screw to the screw recycling system to be recycled. By means of the automatic inner plate screw loosening system, automatic operation of screw loosening of an inner plate of the electric energy meter can be achieved, the work efficiency of electric energy meter recycling is obviously improved, and automation of electric energy meter recycling is better achieved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

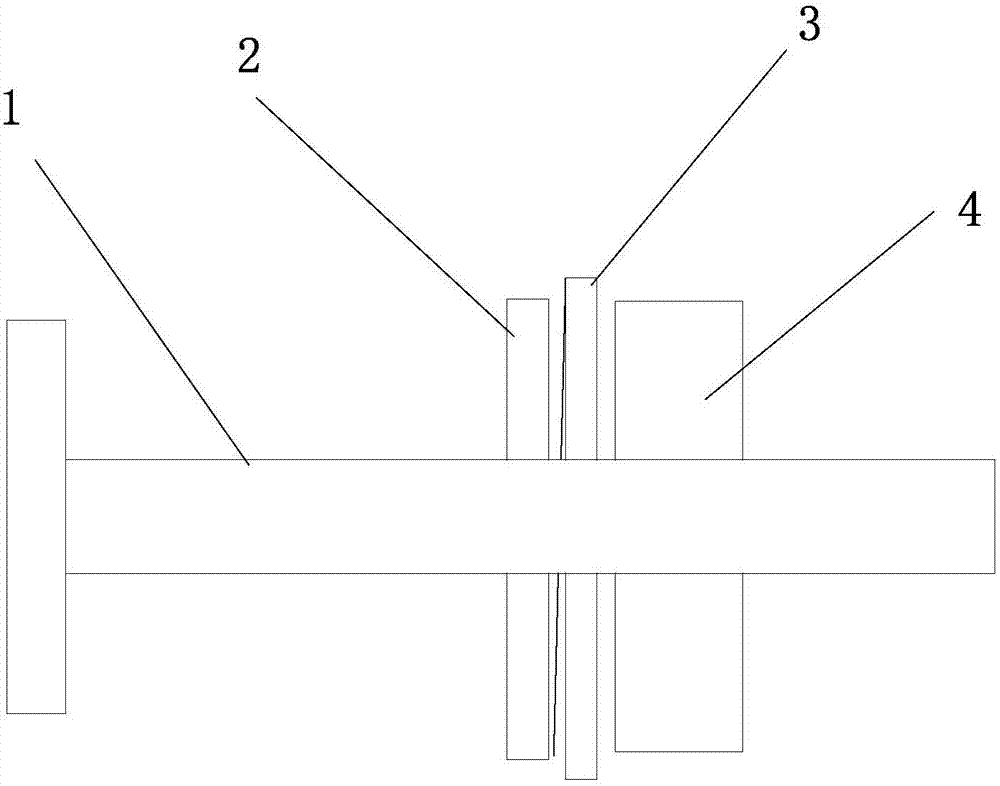

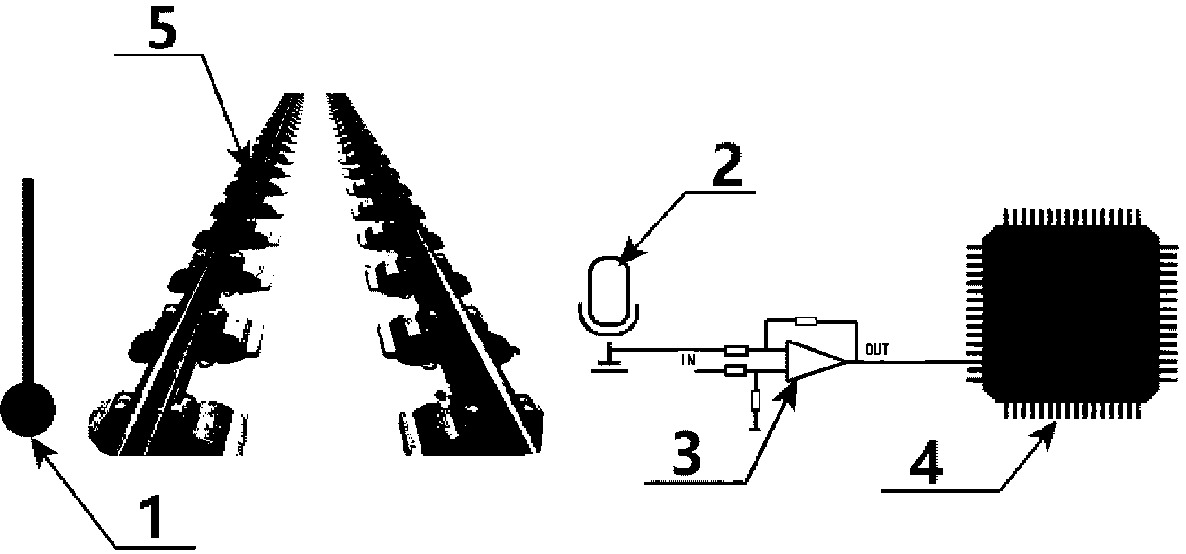

Rail traffic rail detection system based on acoustic waves

PendingCN109515472ARailway auxillary equipmentRailway profile gaugesAudio power amplifierFrequency spectrum

The invention belongs to the field of rail traffic rail detection and provides a rail traffic rail detection system based on acoustic waves. The rail traffic rail detection system based on acoustic waves comprises an impact hammer, a sound pick-up, a signal amplifier and a microprocessor; the impact hammer is a metal hammer; by using the impact hammer to strike a rail, the rail produces a sound; the sound pickup receives the sound produced by the rail; after amplifying a sound signal received by the sound pickup, the signal amplifier outputs the sound signal to the microprocessor; the microprocessor calculates the received signal by using a time domain-to-frequency domain algorithm to obtain frequency spectrum data of the received signal; the calculated frequency spectrum data are comparedwith hub frequency spectrum saved in the system; and therefore, rail cracks and screw loosening are detected.

Owner:北京天一高科科技有限公司

Aluminum material pressing mold

ActiveCN111545644AEliminate the effects ofEasy to replaceShaping toolsEngineeringMaterials processing

The invention discloses an aluminum material pressing mold and relates to the field of aluminum material processing. The aluminum material pressing mold comprises a bottom plate and a mold main body;the top of the bottom plate is fixedly connected with four groups of support columns; the tops of the support columns are fixedly connected with a support plate; the upper surface of the support plateis rotatably connected with a rotating plate; the mold main body is movably inserted into a mold hole and a clamping hole; an outer cylinder main body is movably inserted into an outer cylinder groove; and the side, close to the outer cylinder main body, of a clamping block is provided with a clamping slot; the sidewall of the clamping block is provided with a locking mechanism corresponding to the clamping block. The aluminum material pressing mold realizes that the mold at the bottom is convenient to replace in an aluminum material pressing process; therefore, when the mold is to be replaced, the operation is simple and convenient; time and efforts are saved; the locking mechanism achieves a good fixation effect on the mold main body; compared with a traditional bolt fixation method, the way of the aluminum material pressing mold prevents the occurrence of teeth slip caused by loosening of a screw; the locking mechanism can be repeatedly used for many times without being damaged; reliable work is also achieved; and the aluminum pressing effect is guaranteed.

Owner:佛山市南海驰腾模具有限公司

Auxiliary disassembling tool for screws of wheel

InactiveCN107738094AAchieve looseningEasy to fixWheel mounting apparatusMetal working apparatusLinear actuatorAnnular array

The invention relates to an auxiliary disassembling tool for screws of a wheel. The auxiliary disassembling tool comprises a lifting base, a fixing claw and a disassembling structure, wherein the fixing claw is rotationally connected to a connecting seat; the connecting seat is fixed on the lifting base; a plurality of sets of screw connectors are arranged on the fixing claw in an annular-arrayedmode, each screw connector comprises a fixed seat arranged on the fixing claw, the fixed seats are rotationally connected to screw sleeves, and driving rods are arranged at the tail ends of the screwsleeves; and the disassembling structure comprises a linear driver, the linear driver is fixed on the lifting base, a linear telescopic mechanism of the linear driver is provided with a telescopic connecting rod, a driving sleeve corresponding to the driving rods is arranged at the end of the telescopic connecting rod, and the driving sleeve is matched with the driving rods through a key groove. The auxiliary disassembling tool can be fixed stably relative to the wheel through the fixed claw, so that loosening is effectively prevented; in addition, the mechanism adopts pneumatic driving to replace manual driving, so that the loosening of the screws with larger pre-tightening force is realized, and the operation is simple.

Owner:朱毅

Shield of base station antenna

PendingCN111092298AAntenna supports/mountingsDisturbance protectionClassical mechanicsStructural engineering

The invention discloses a shield for a base station antenna. The shield comprises a shield body and a support, wherein the shield body stretches across a radiator of the base station antenna and comprises a front wall, a first side wall, a second side wall, a first rear flange and a second rear flange, wherein the first side wall and the second side wall extend backwards from the front wall, the first rear flange and the second rear flange extend inwards from the corresponding first side wall and second side wall, the support includes a body, and a first mounting flange and a second mounting flange extending forward from the body, the first mounting flange and the second mounting flange are matched with the corresponding first rear flange and the corresponding second rear flange of the cover body so as to connect the shield body to the support. The shield is advantaged in that appearance of the shield is attractive, and the possibility of screw loosening caused by lateral wind force isfurther reduced.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com