Patents

Literature

40results about How to "Improve job success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

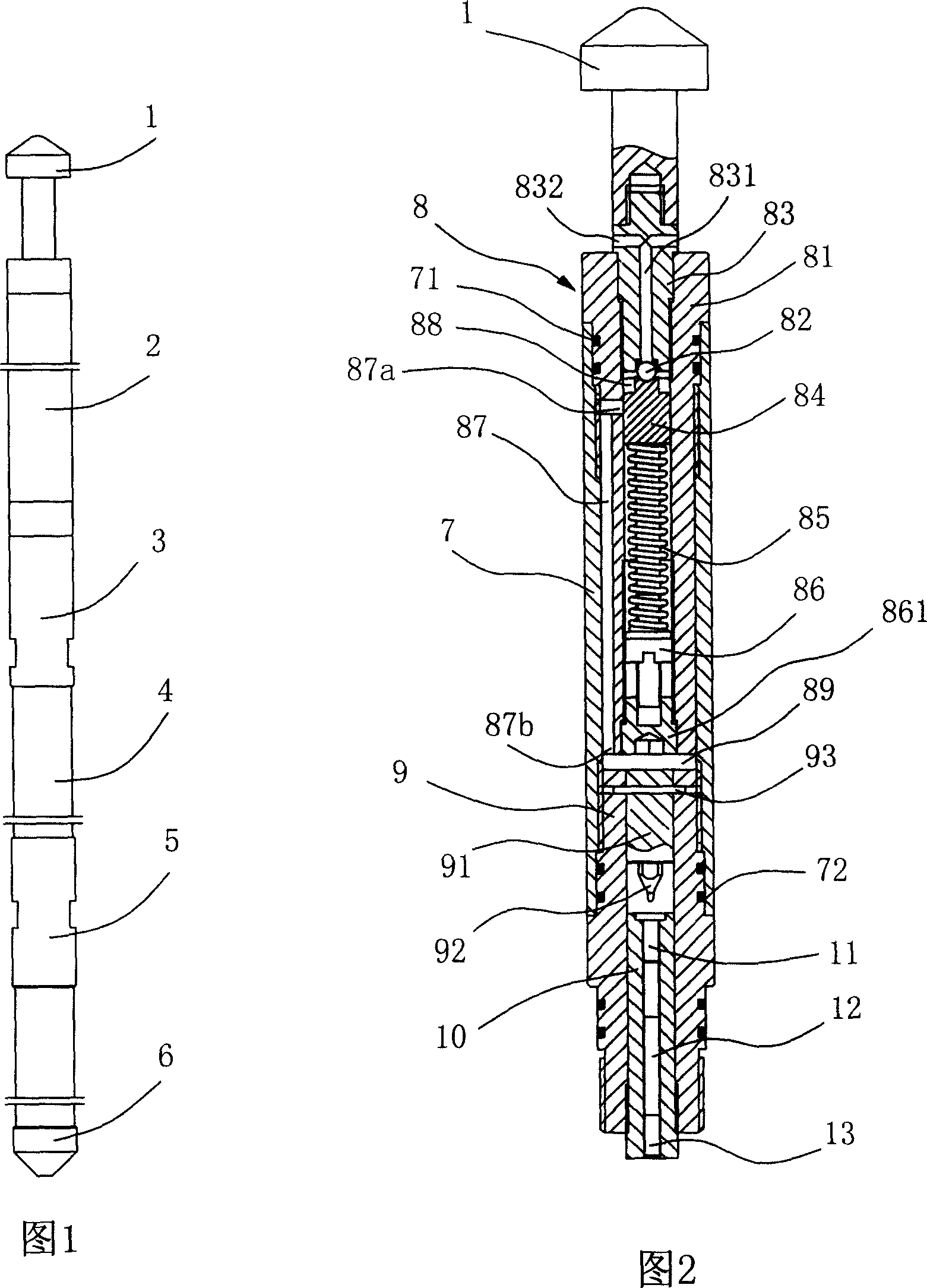

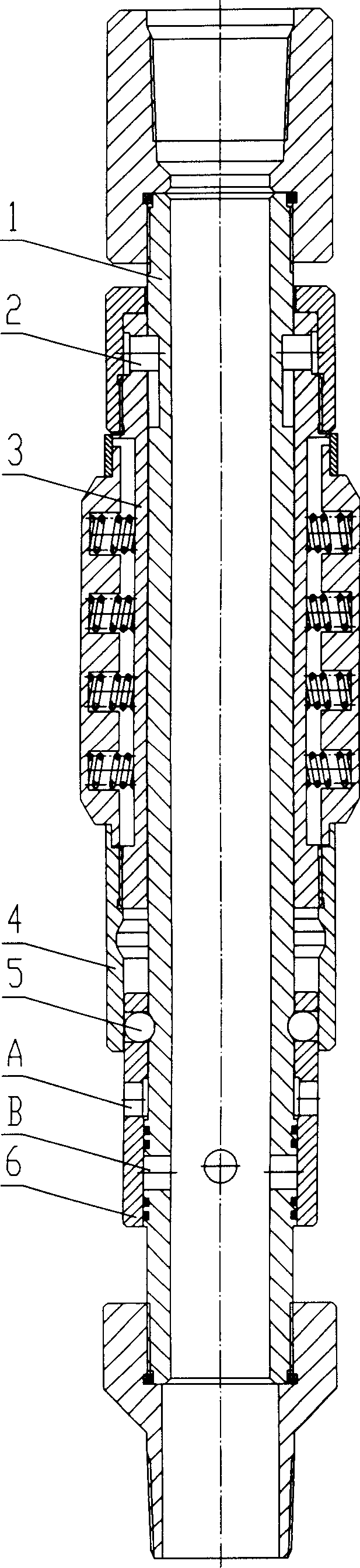

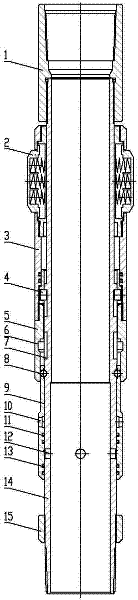

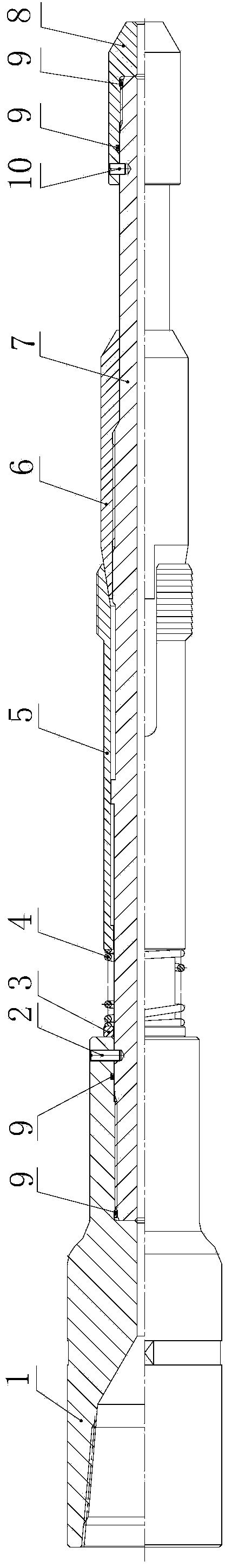

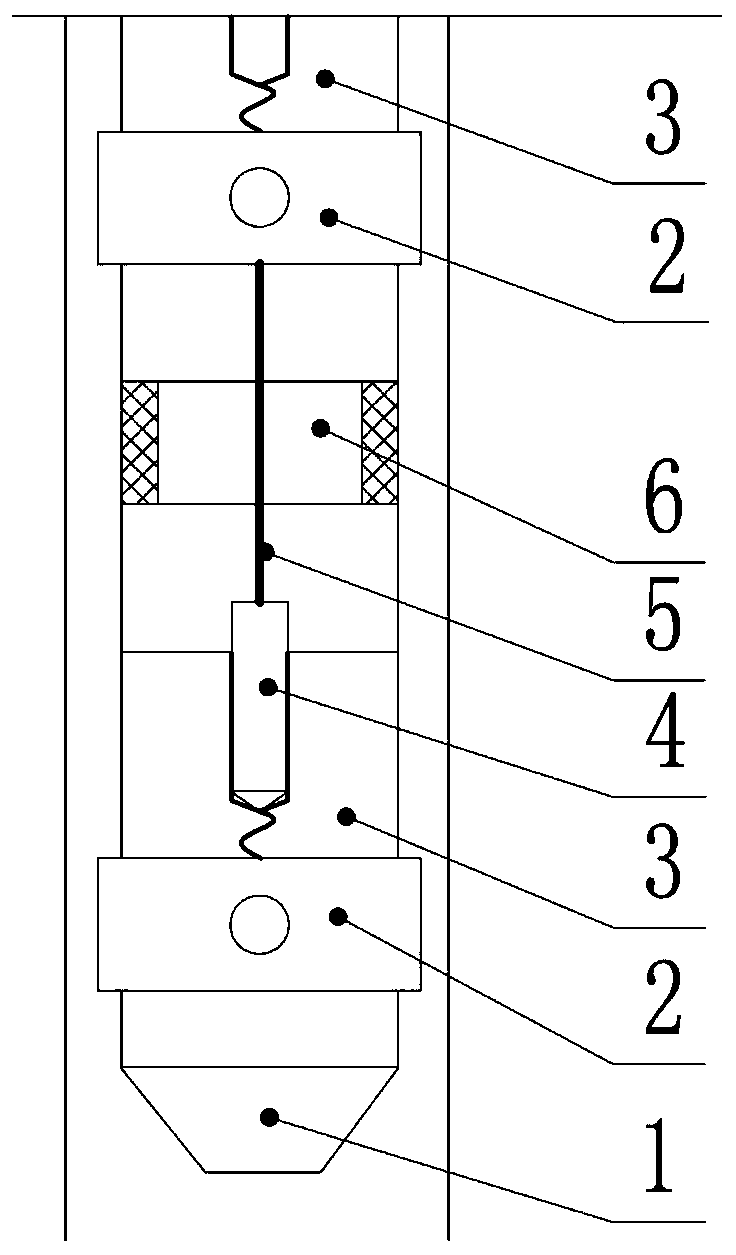

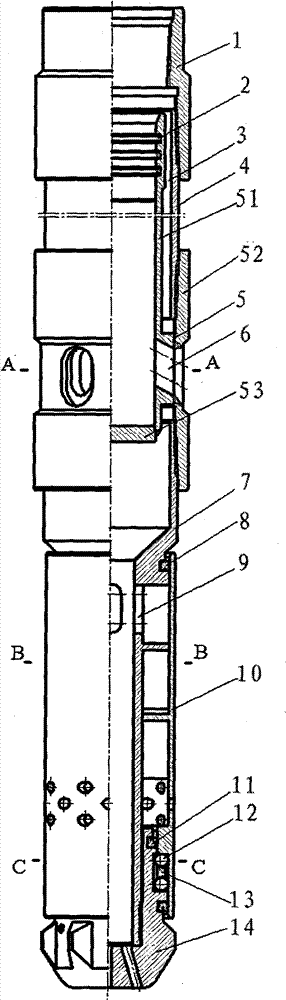

Throwing type high energy gas fracturing device

The invention relates to an expendable fracturing machine with high-energy air, belonging to increasing technology for oil and gas well, comprising ignition device, fracturing bomb connected with the ignition device. The ignition device comprises piston for firing pin in the cylinder and exciting device. The piston for firing pin is connected with the cylinder by radial fixed pin. The detonator or artillery primer of fracturing bomb is set at the bottom of cylinder and is corresponding to firing pin. The special feature of invention is that said exciting device for firing pin comprises pilot valve controlled by spring to open; the inlet of pilot valve is connected with outside, the first port of connecting pipe is located at the position of outlet of pilot valve and the second port of connecting pipe is connected with sealing hollow cavity at the tail of the piston for firing pin. Because the spring is used to control the open of pilot valve so as to guide the fluid in well to the piston for firing pin, it is provided with quick respond, high control accuracy, reliably running and high success rate of work.

Owner:XIAN TONGYUAN PETROTECH

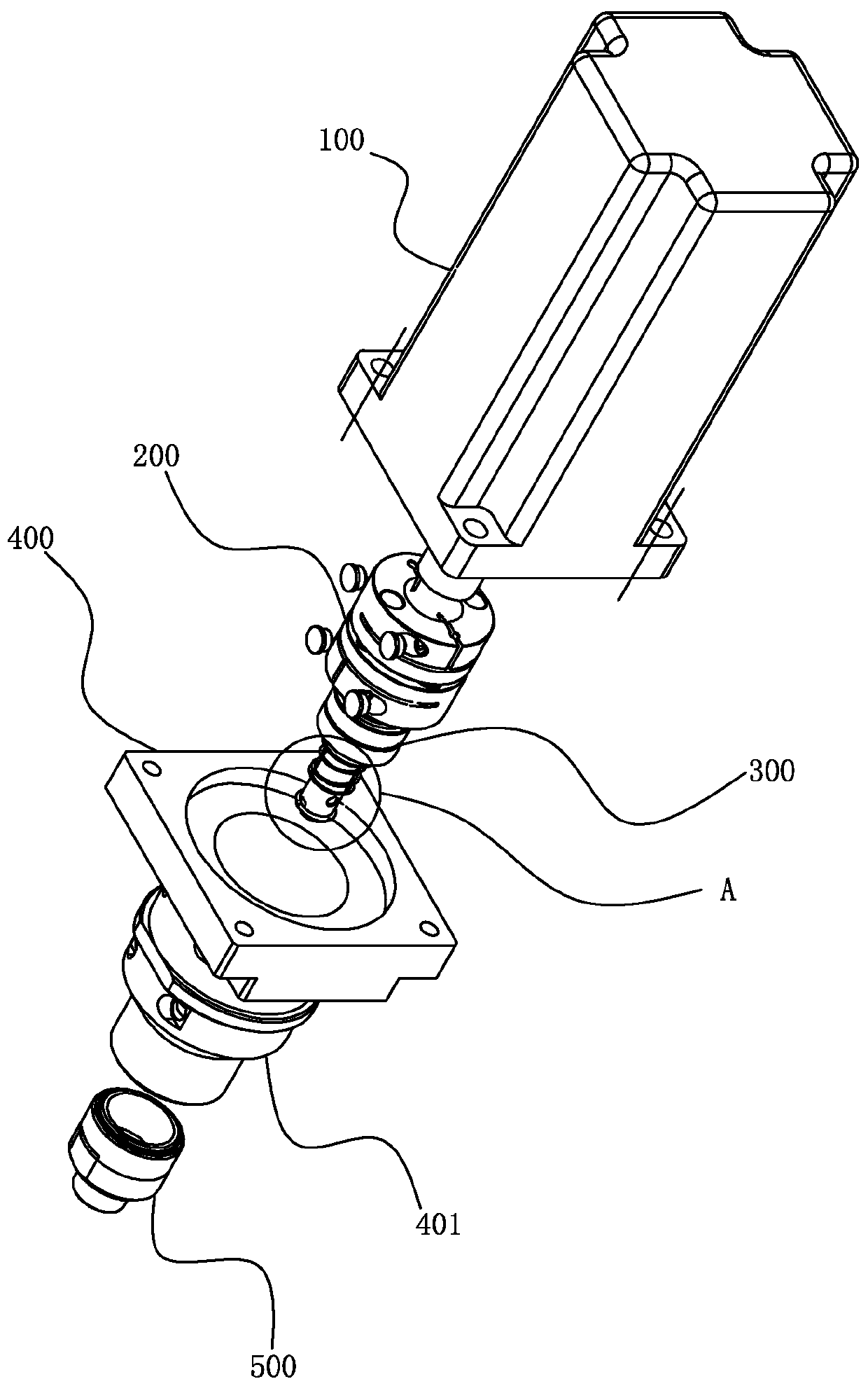

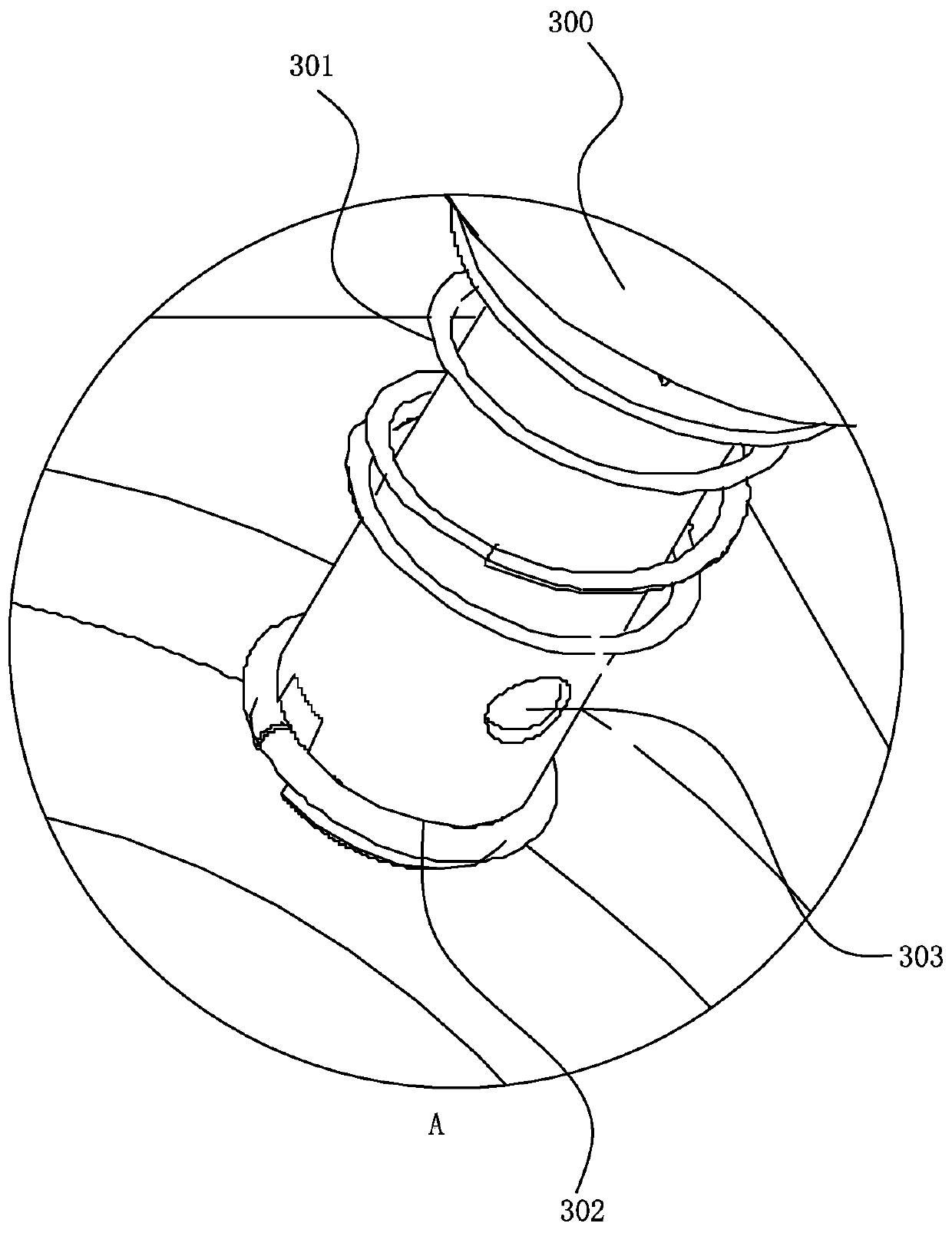

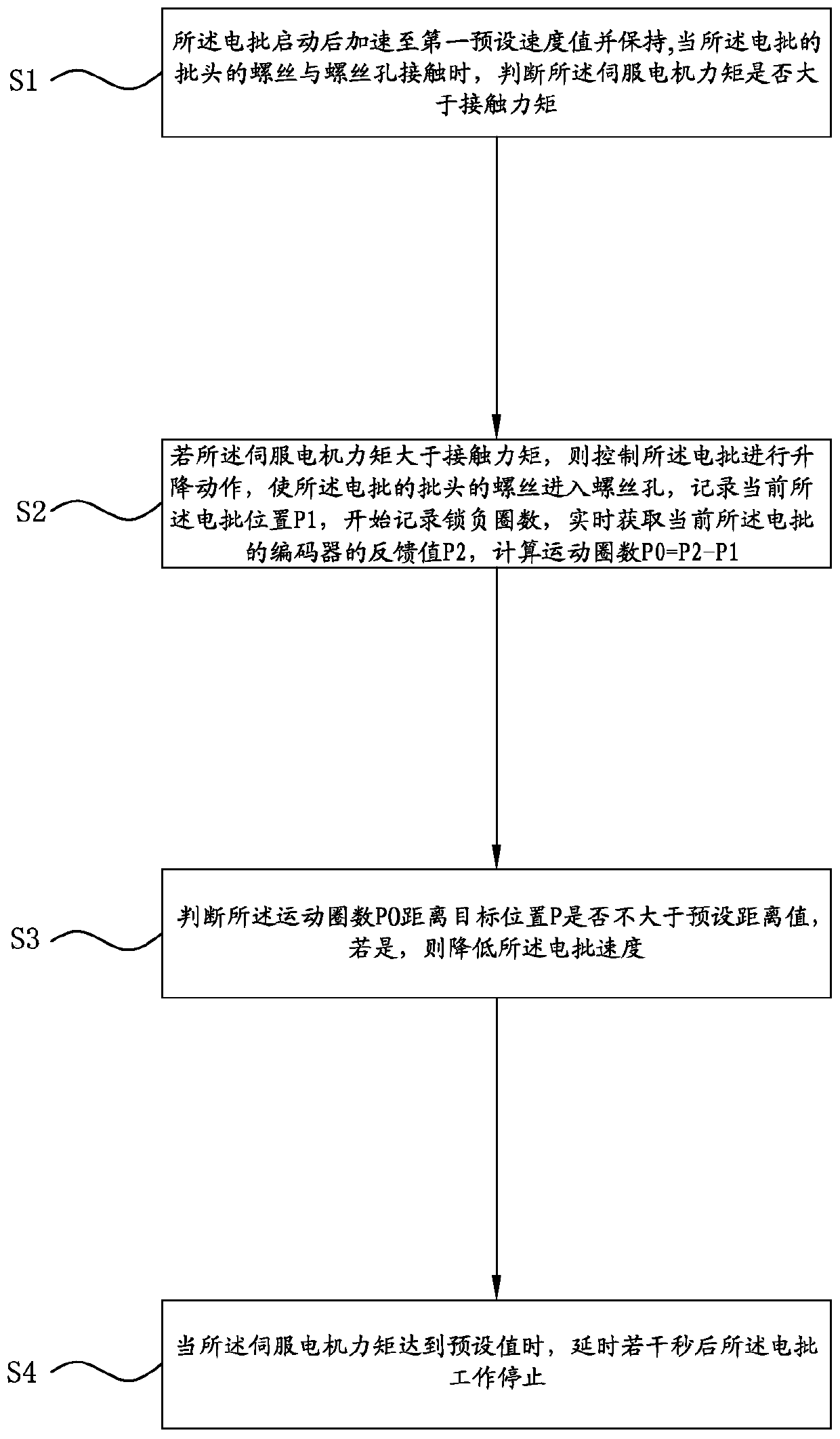

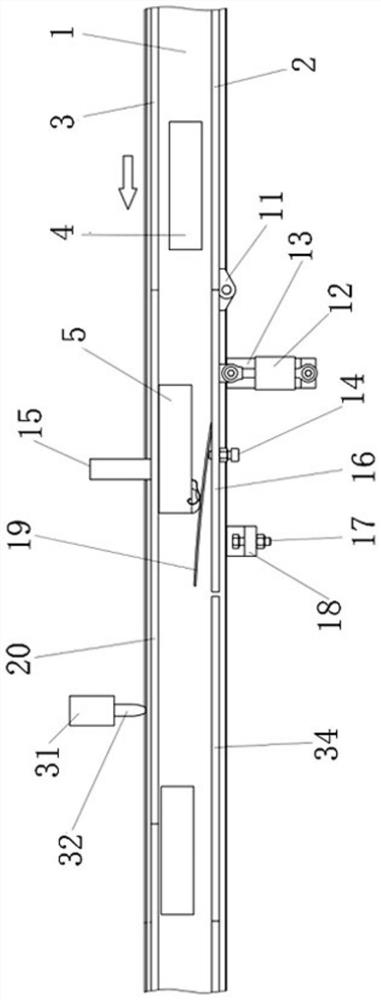

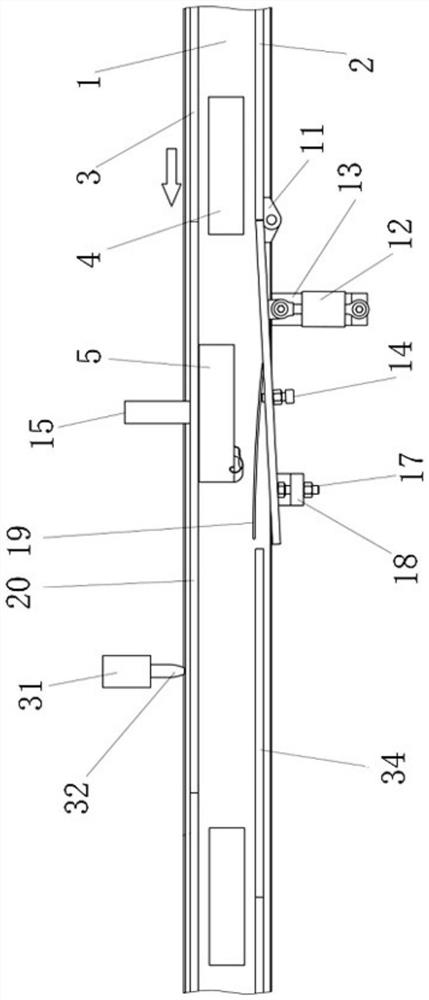

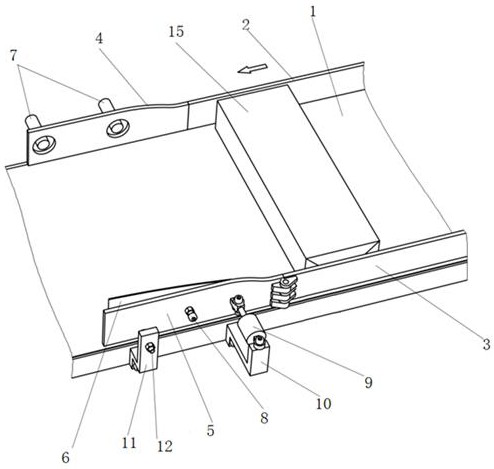

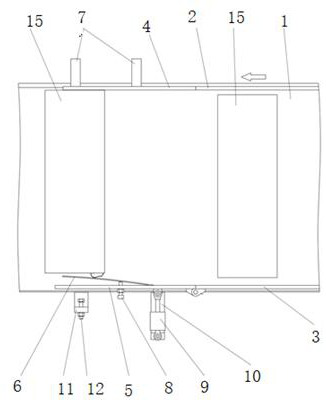

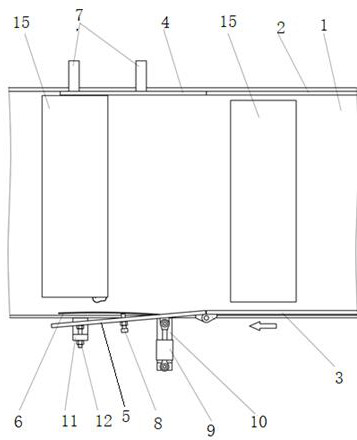

Intelligent servo electric screwdriver and use method thereof

PendingCN110834194AImprove job success rateEnsure consistencyMetal working apparatusScrew looseningServo

The invention discloses an intelligent servo electric screwdriver and a use method thereof. The electric screwdriver comprises a servo motor used for providing torque, a connector connected with an output shaft of the servo motor, a screwdriver bit sleeve fixed to the lower end of the connector, a flange structure fixedly connected with the servo motor and used for supporting protecting, and a screwdriver bit connected with the screwdriver bit sleeve. The screwdriver bit sleeve is sleeved with a spring, the position, on the upper end of the spring, of the screwdriver bit sleeve is provided with a limiting ring, a mounting hole is formed in the position, between the spring and the limiting ring, of the screwdriver bit sleeve, the flange structure is connected with a connecting base, the screwdriver bit sleeve penetrates through the connecting base to be connected with the screwdriver bit, and the screwdriver bit and the screwdriver bit sleeve are detachably connected. According to the intelligent servo electric screwdriver, the work success rate is greatly improved compared with that that of a common electric screwdriver, a micro fine screw can be locked, consistency of fastening and connecting torque each time can be ensured, and the problems of floating, screw loosening, idling, clamping, and damage of a locked object during production can be reduced.

Owner:深圳市山龙智控有限公司

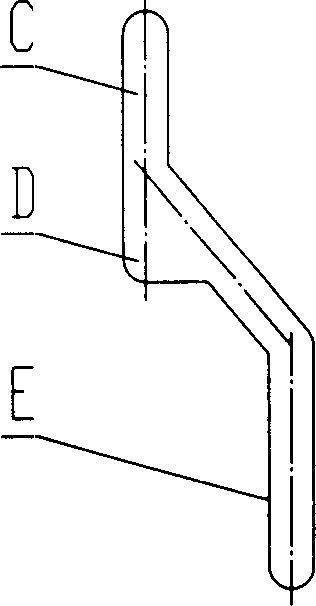

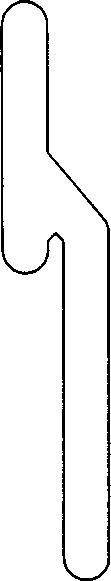

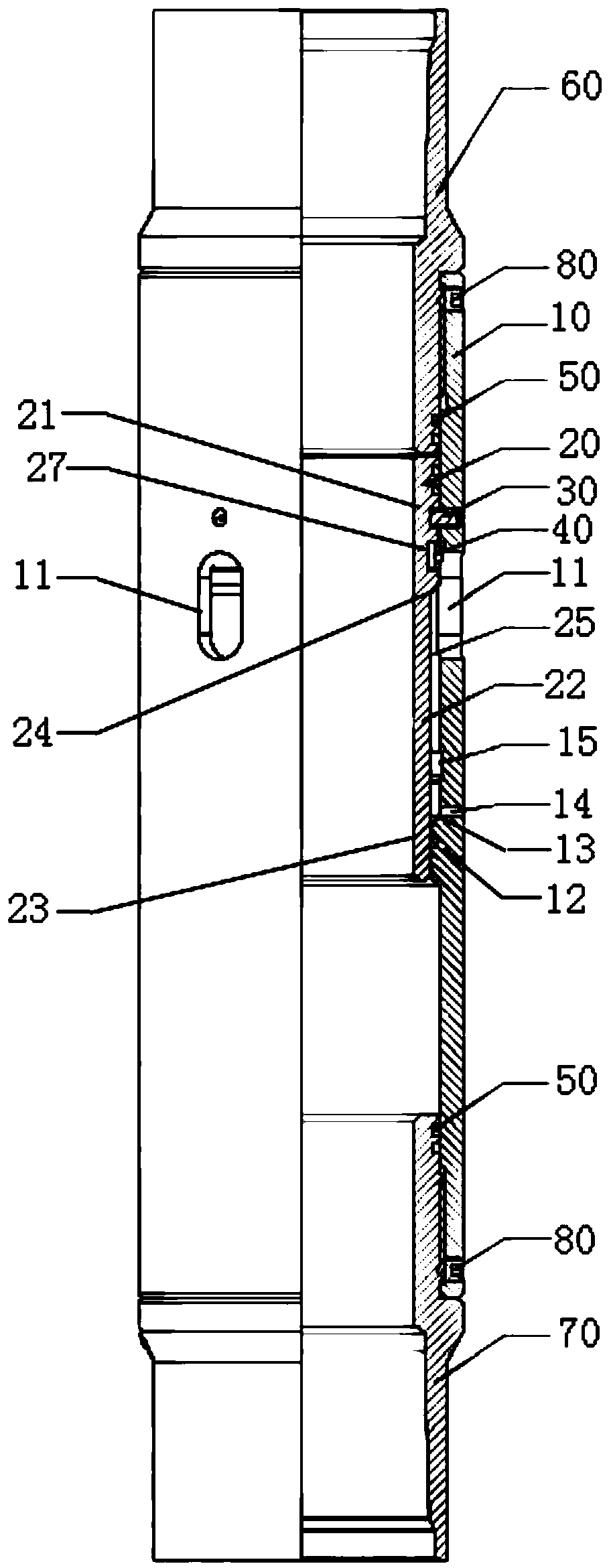

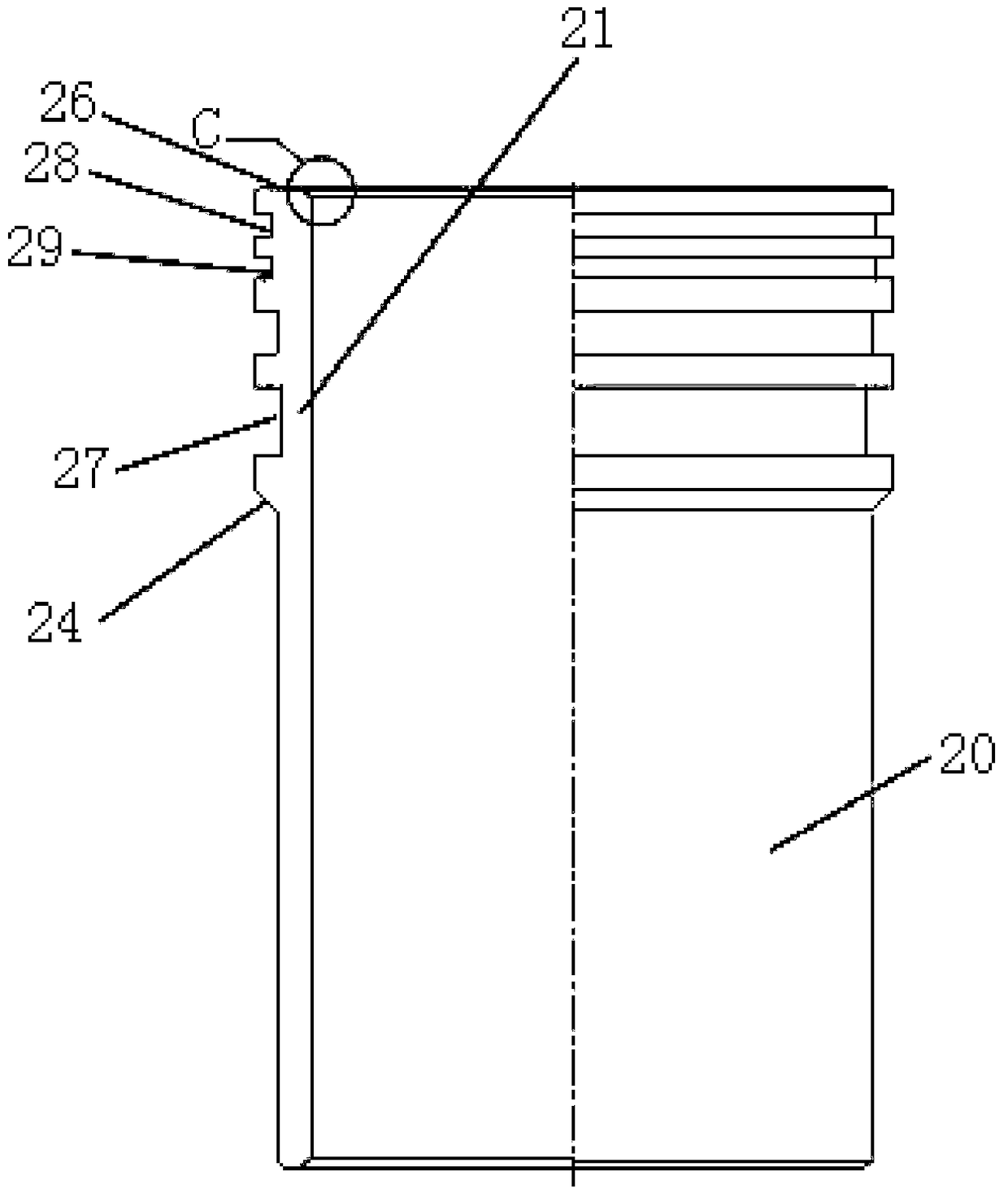

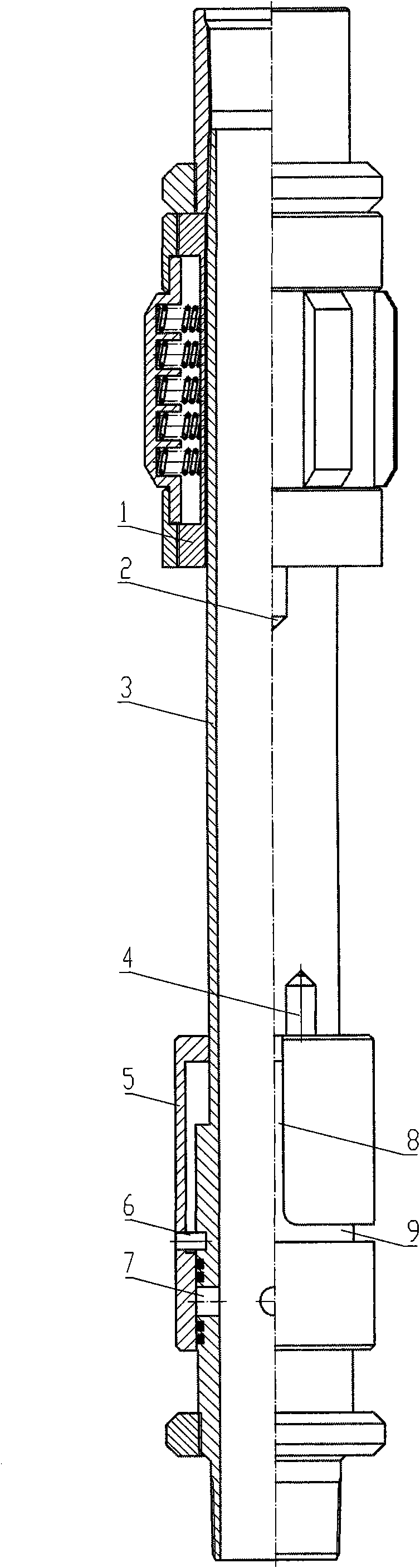

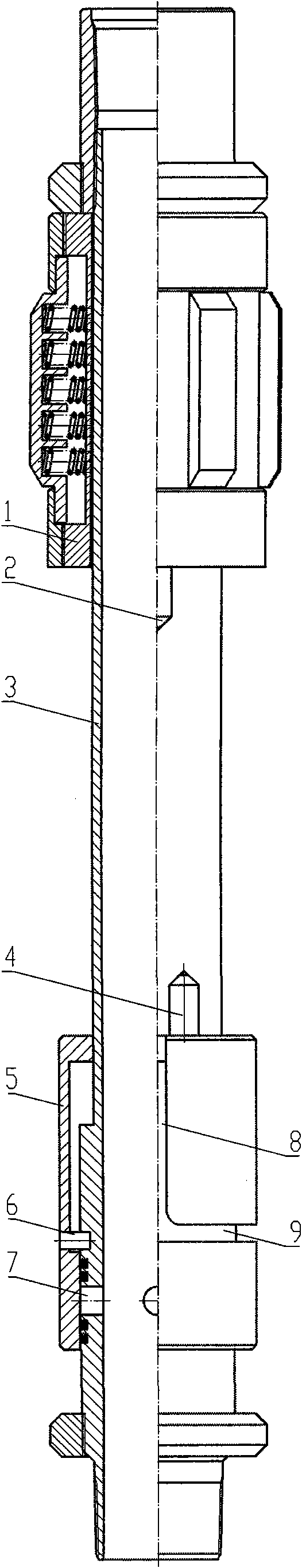

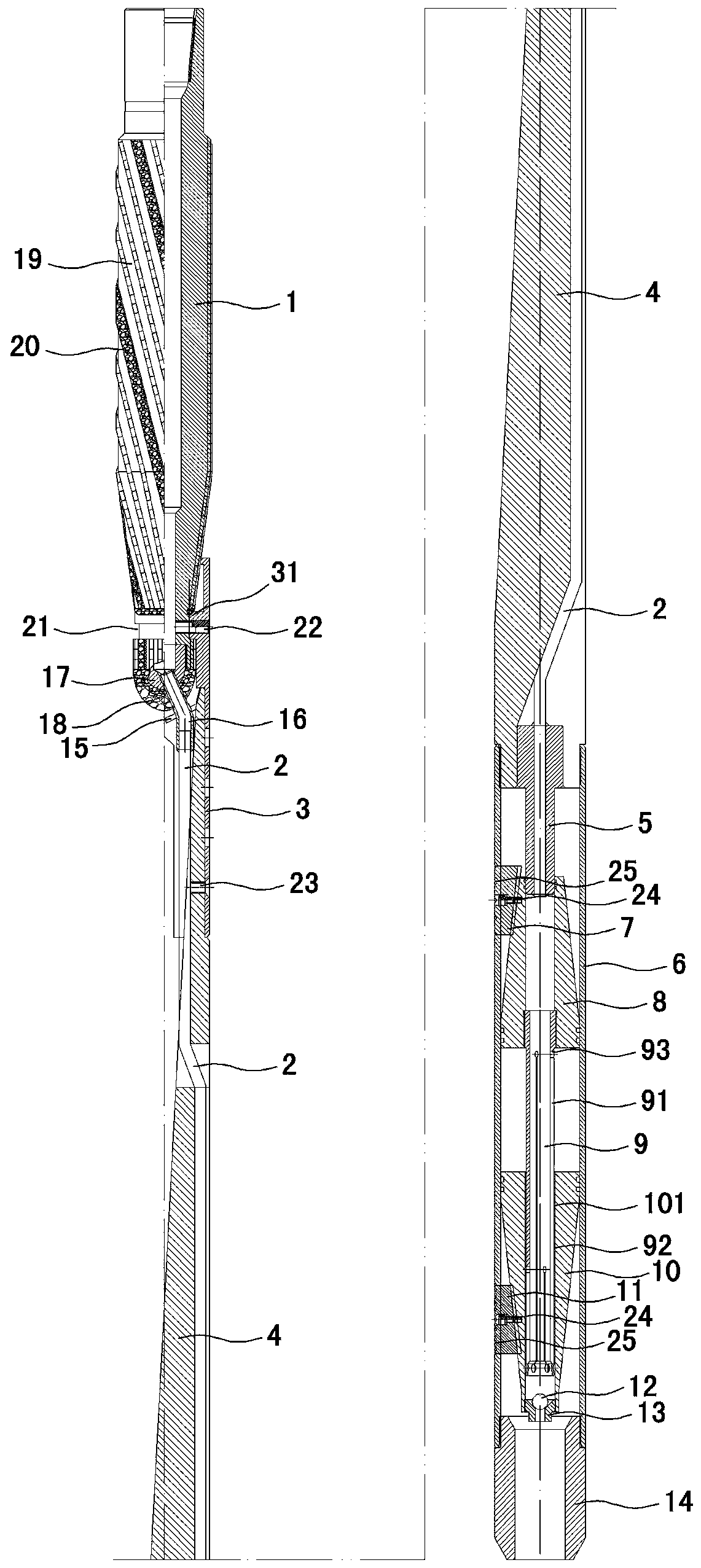

Oil riser bleeder

InactiveCN1702291AWork reliablyImprove job success rateWell/borehole valve arrangementsSealing/packingEngineeringElectrical and Electronics engineering

This invention relates to an oil drainer, which comprises inner tube, track pin, frictional mechanism, discharging cover, lock ball and sealing sleeve, wherein the frictional mechanism covers on the inner tube connecting through the track pin; the discharging cover is on the lower of the frictional mechanism, and the sealing sleeve is arranged on the lower of the inner tube connecting through lock ball; the discharging cover is outside the sealing sleeve, and its end face is below the lock ball. When draining oil, pulling upwards the drainer, rotating oil pipe, then pulling upwards the drainer again; it can control when draining freely and dose not need instruments and pumping rod. The device will not cause oil leaking.

Owner:孙贵艳

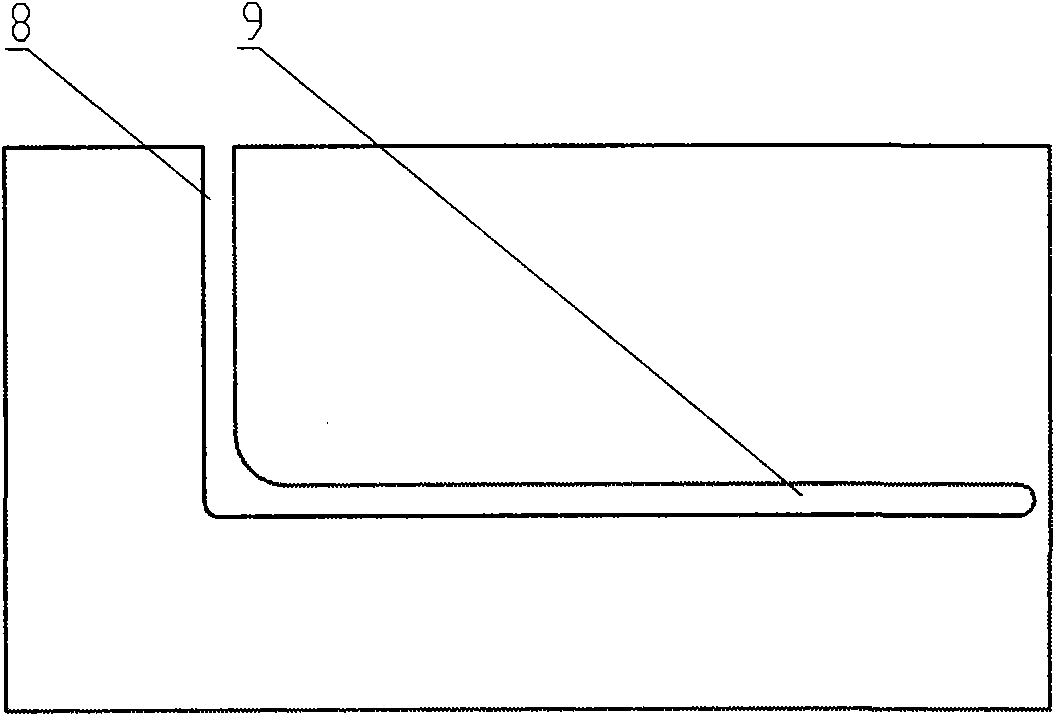

Rotary oil draining device

InactiveCN102337863AWork reliablyImprove job success rateWell/borehole valve arrangementsSealing/packingSucker rod

The invention relates to a rotary draining device. In the rotary draining device, an inner pipe is provided with a track; the front end of a track pin is inserted into the track on the inner pipe; a sealing sleeve is sleeved on the inner pipe; the sealing sleeve covers an oil draining hole; an upper sealing ring and a lower sealing ring are arranged between the inner pipe and the sealing sleeve; the sealing sleeve is hung on the inner pipe through a lock ball; the lower part of a lock sleeve covers the lock ball; a releasing slot is formed in the lock sleeve; the lower part of a friction mechanism is connected with the upper part of a connecting sleeve; the lower part of the connecting sleeve is connected with the lock sleeve; the connecting sleeve covers the track pin; the sealing sleeve is provided with a through hole; and the track pin can move from an upper track slot to a lower track slot. When the rotary oil draining device drains oil, an oil pipe is laid down, rotated and lifted to drain oil; the time when the oil is drained can be manually controlled voluntarily, tools and sucker rods for starting the oil draining device are not required to be invested, and the rotary oil draining device is not influenced by the separation of the sucker rods; the drift diameter of the inner pipe is same as that of the oil pipe on a pump, and various matched tools can be laid down, so that the rotary oil draining device has a wide application range, can be repeatedly operated, and works reliably and is high in an operation success rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

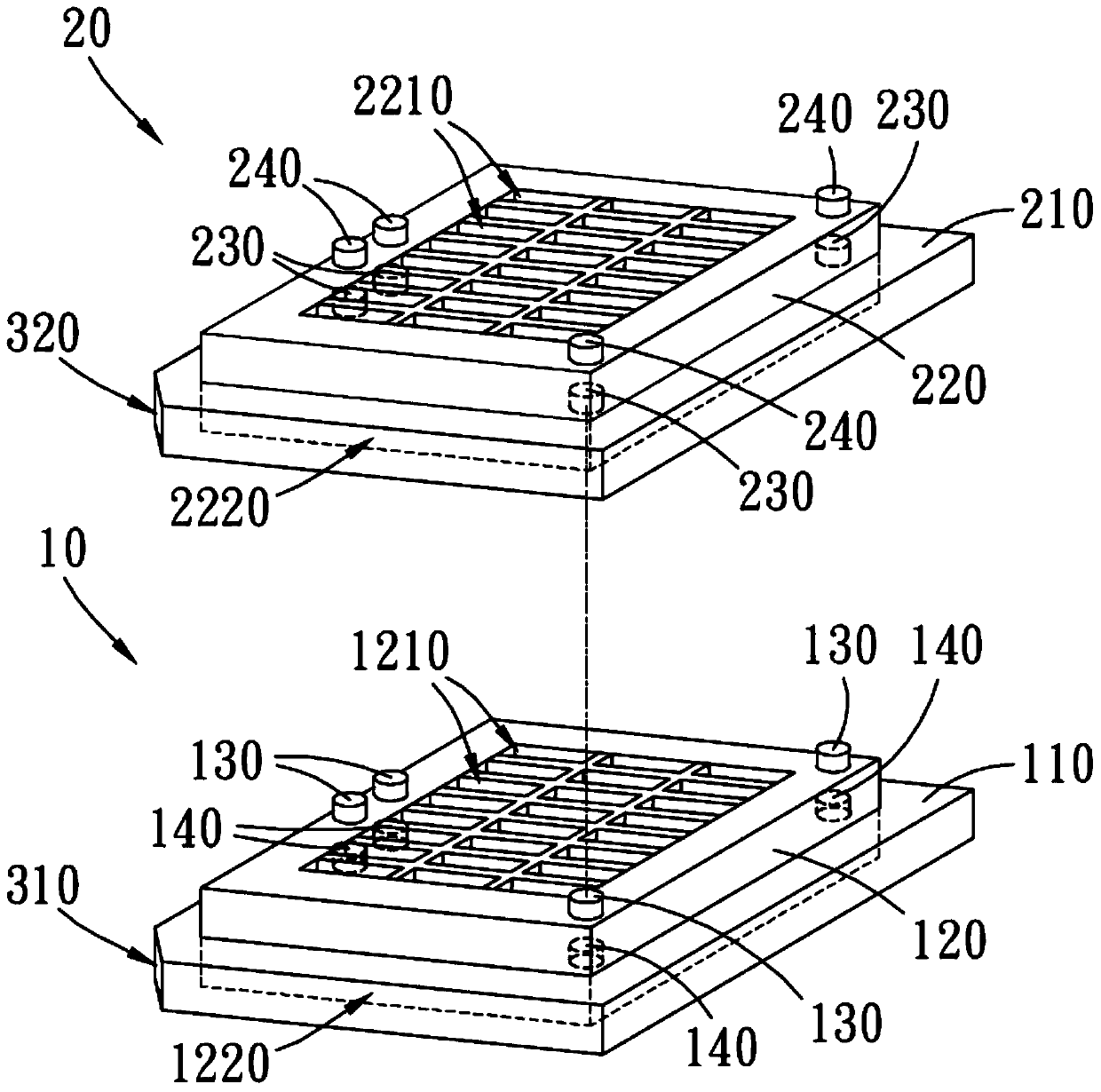

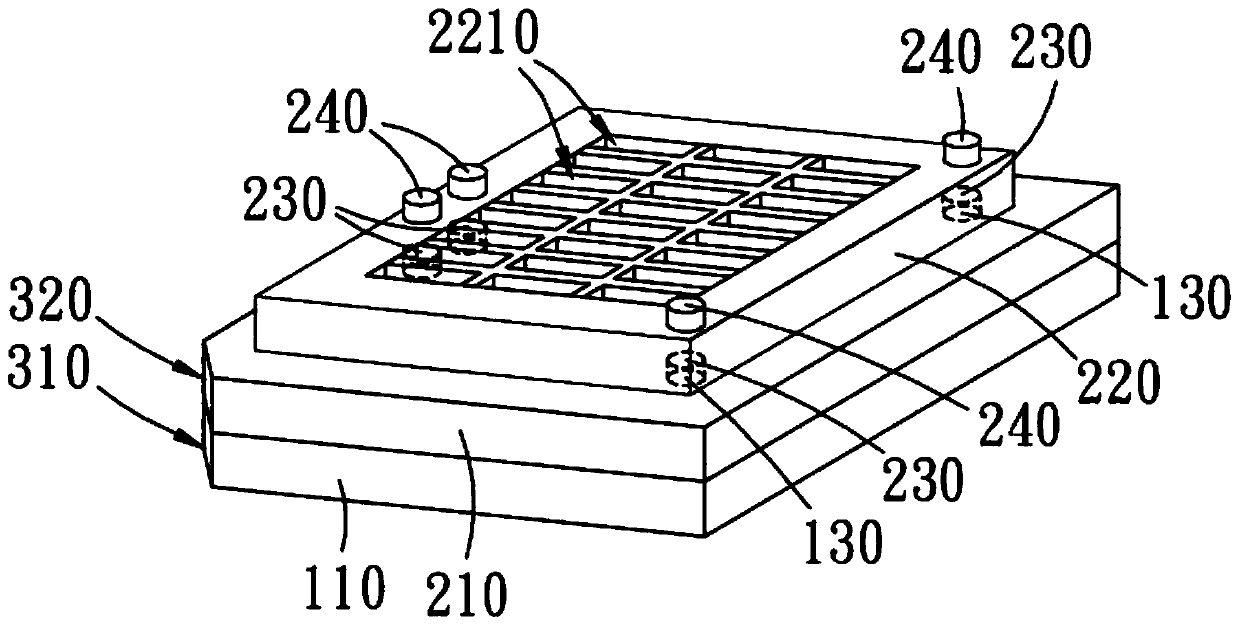

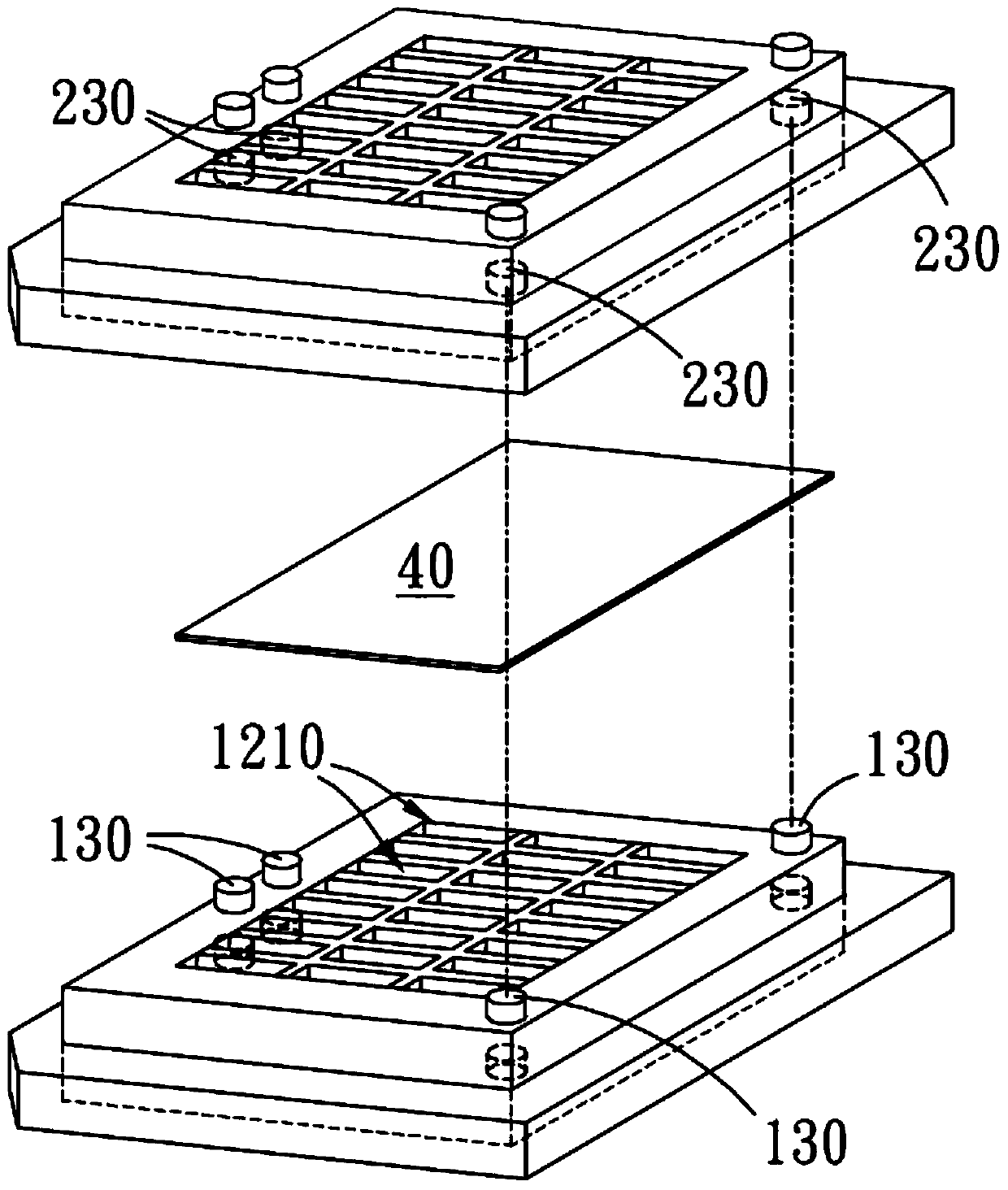

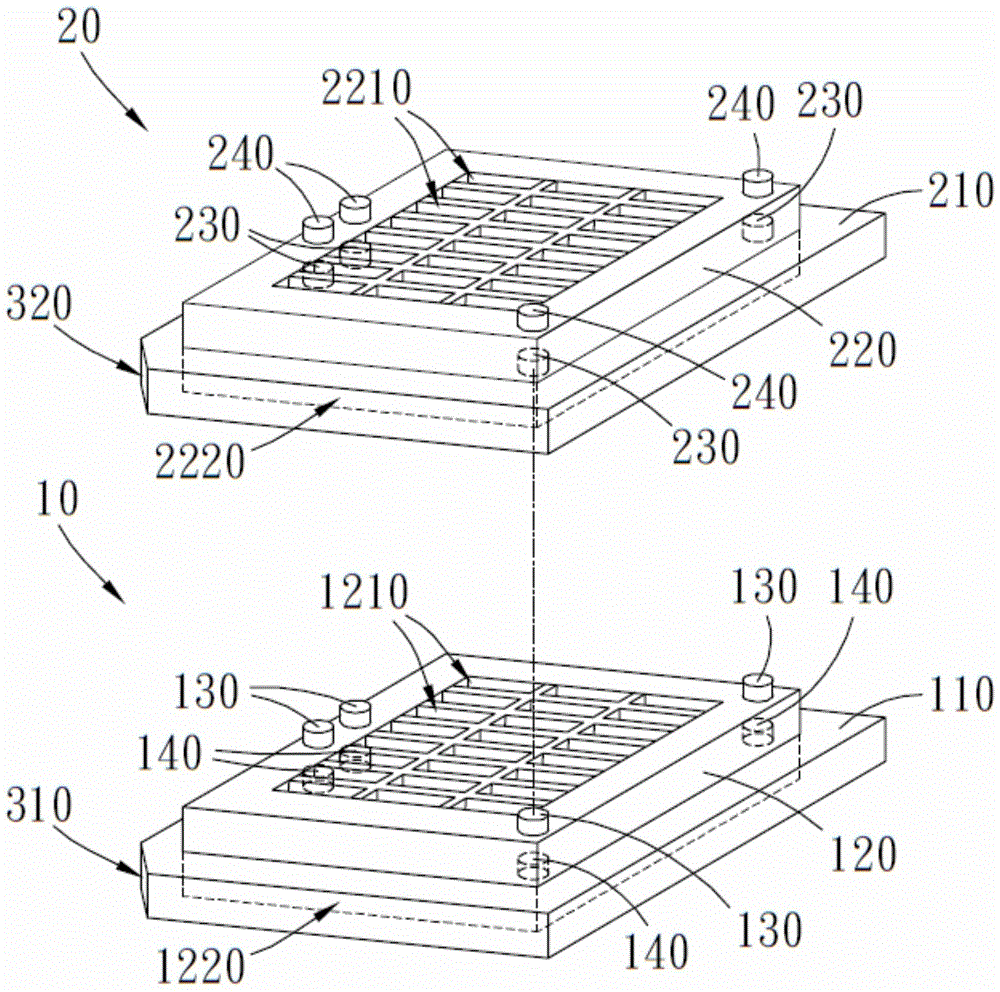

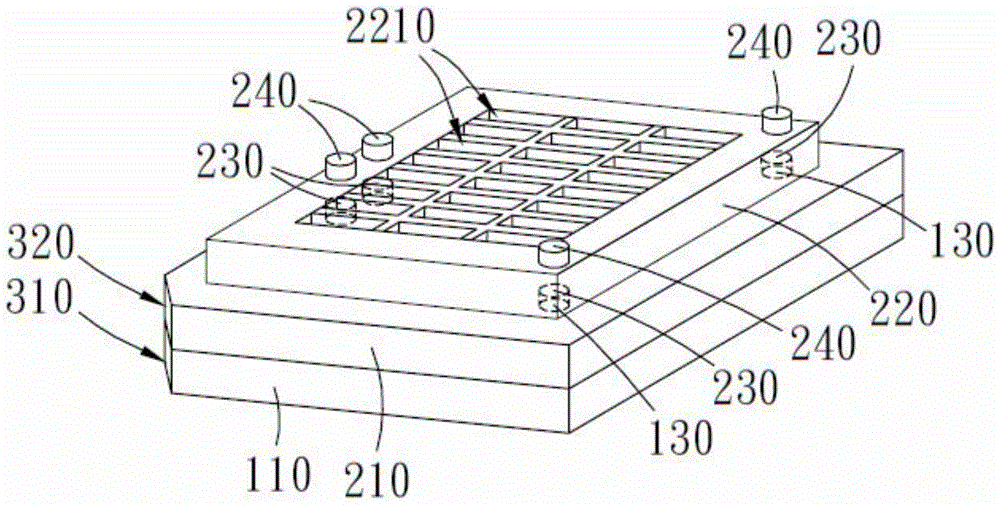

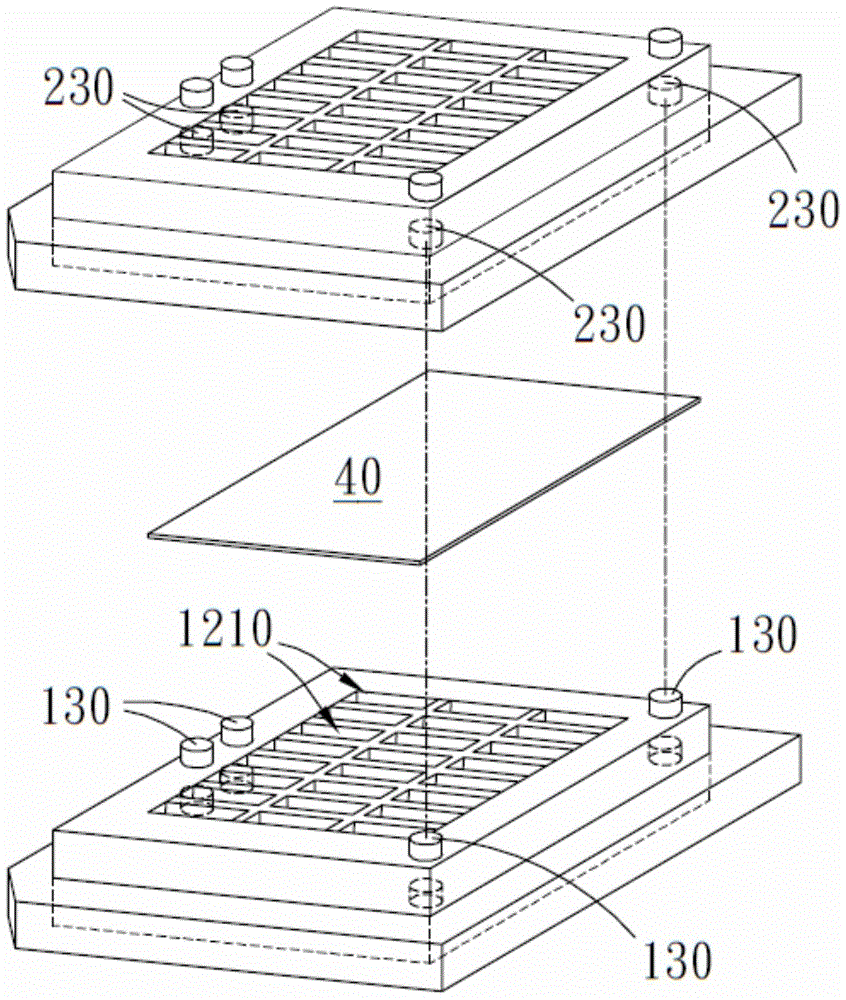

Structure of chip bearing discs

ActiveCN103996646AEasy flipSave labor costsSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

The invention provides a structure of chip bearing discs. The structure is used for containing a plurality of chips. The chip bearing discs are provided with a plurality of inversed alignment pieces, the inversed alignment pieces of the chip bearing disc containing the multiple chips are matched with the inversed alignment pieces of the chip bearing disc without the chips, and the chip bearing disc containing the multiple chips can be overturned to be inversely arranged on the other chip bearing disc so that the chips can be overturned to be really inversely arranged into the other chip bearing disc; in addition, the chip bearing discs are further provided with a plurality of stacking alignment pieces, the stacking alignment pieces are arranged on the chip bearing discs in an asymmetric mode to assist in stacked alignment of the multiple bearing discs, and the stacking direction of the stacked bearing discs is limited.

Owner:SITRONIX TECH CORP

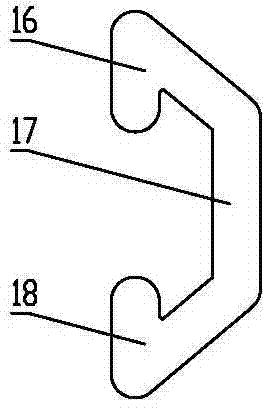

Anti-jarring reversing fishing spear

InactiveCN103470205ACooperate wellEasy to get rid ofBorehole/well accessoriesEngineeringFunctional type

The invention relates to an anti-jarring reversing fishing spear. The anti-jarring reversing fishing spear comprises a top connector, a spear rod threadedly connected with the top connector, and a spear tile arranged on the spear rod in a sleeve mode. The anti-jarring reversing fishing spear is characterized in that the spear rod and the top connector are fastened through an anti-twist pin, an auxiliary spring which is arranged on the spear rod in a sleeve mode is arranged between one end of the top connector and the spear tile, and a fishing spear base and a guide cone are arranged on the spear rod in a sleeve mode through threads. The anti-jarring reversing fishing spear has the advantages that the release mode between the fishing spear and the a falling drill string is changed to increase the operation functions of the fishing spear and to achieve the effect of long-time jarring and convenient reversing and releasing, so that resources are saved and the success rate of operation is improved. The anti-jarring reversing fishing spear can be widely applied to operation of drilling, well completion and well maintenance, solves the problems of resource backlogging due to fishing spears of different functional types, difficulties of tool selection of complex situations and large influences of subjective factors in an operation process, and can be preferably used for solving problems particularly in situation that the sticking reasons and sticking points of the underground falling drill string are not clear.

Owner:CHINA NAT OFFSHORE OIL CORP +1

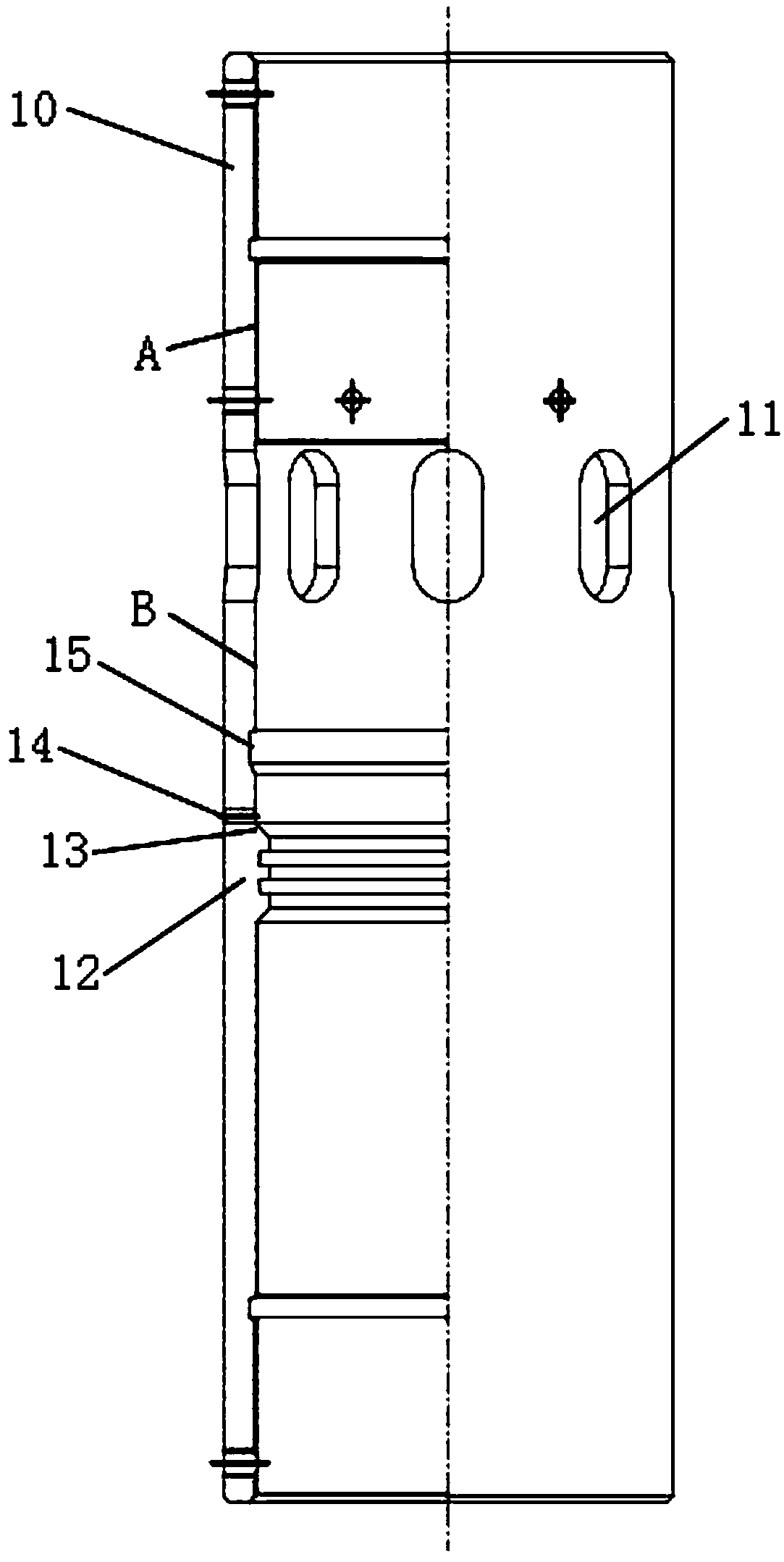

Open-hole segmental fracturing differential pressure sliding sleeve

PendingCN109138916AOpen success rate is highEasy to openConstructionsFluid removalSegmental fractureDifferential pressure

The present invention provides an open-hole segmental fracturing differential pressure sliding sleeve, and belongs to devices used in the horizontal open-hole completion segmental fracturing process.The open-hole segmental fracturing differential pressure sliding sleeve comprises an outer cylinder and an inner sliding sleeve. The outer cylinder and the inner sliding sleeve are vertically arrangedand are cylinder-shaped bodies communicating up and down. The outer cylinder is arranged on the exterior of the inner sliding sleeve in a sleeving mode and fixedly connected with the inner sliding sleeve through a shear pin. The inner sliding sleeve comprises a first connecting part, a sliding part and a second connecting part which are sequentially arranged from top to bottom, the first connecting part and the second connecting part are in sealing fit with the inner wall of the outer cylinder, the height of the sliding part is greater than that of the first connecting part, the outer diameter of the sliding part is less than the outer diameter of the first connecting part, and a first step is formed at the bottom end of the first connecting part. An annular sliding cavity is formed by enclosing the sliding part and the inner wall of the outer cylinder, fracturing holes communicating with the sliding cavity are formed in the outer wall of the outer cylinder, and the end face of the top end of the inner sliding sleeve is arranged downward gradually in a inclination mode from outside to inside in the radial direction of the inner sliding sleeve. According to the open-hole segmentalfracturing differential pressure sliding sleeve, the opening success rate of existing differential pressure sliding sleeves can be effectively improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

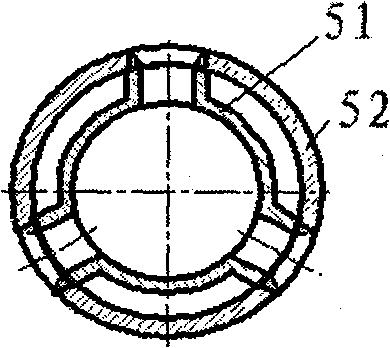

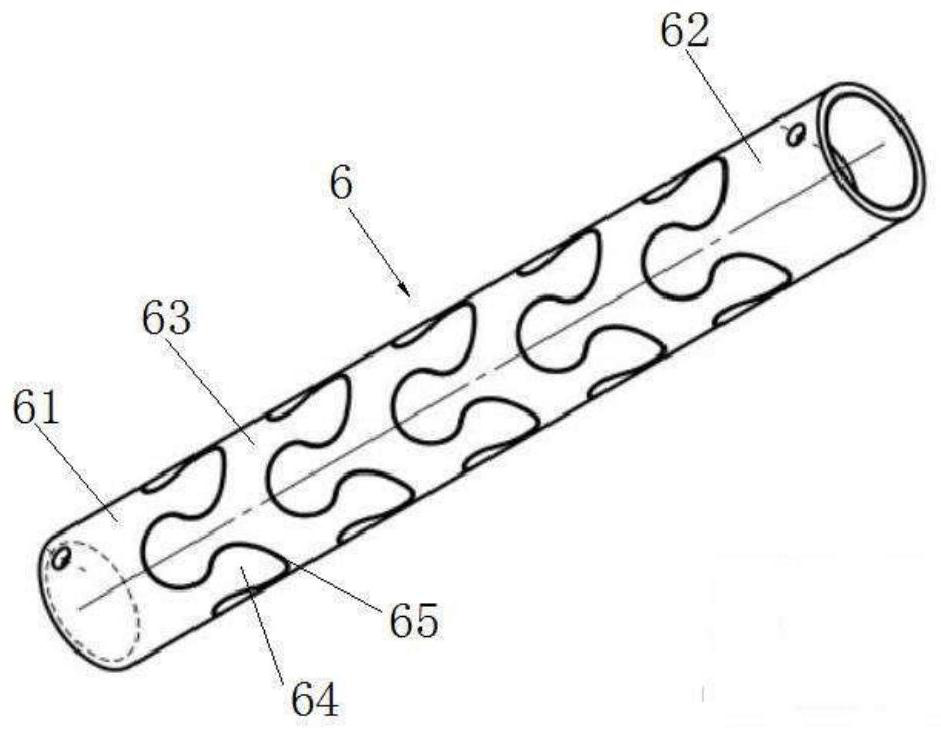

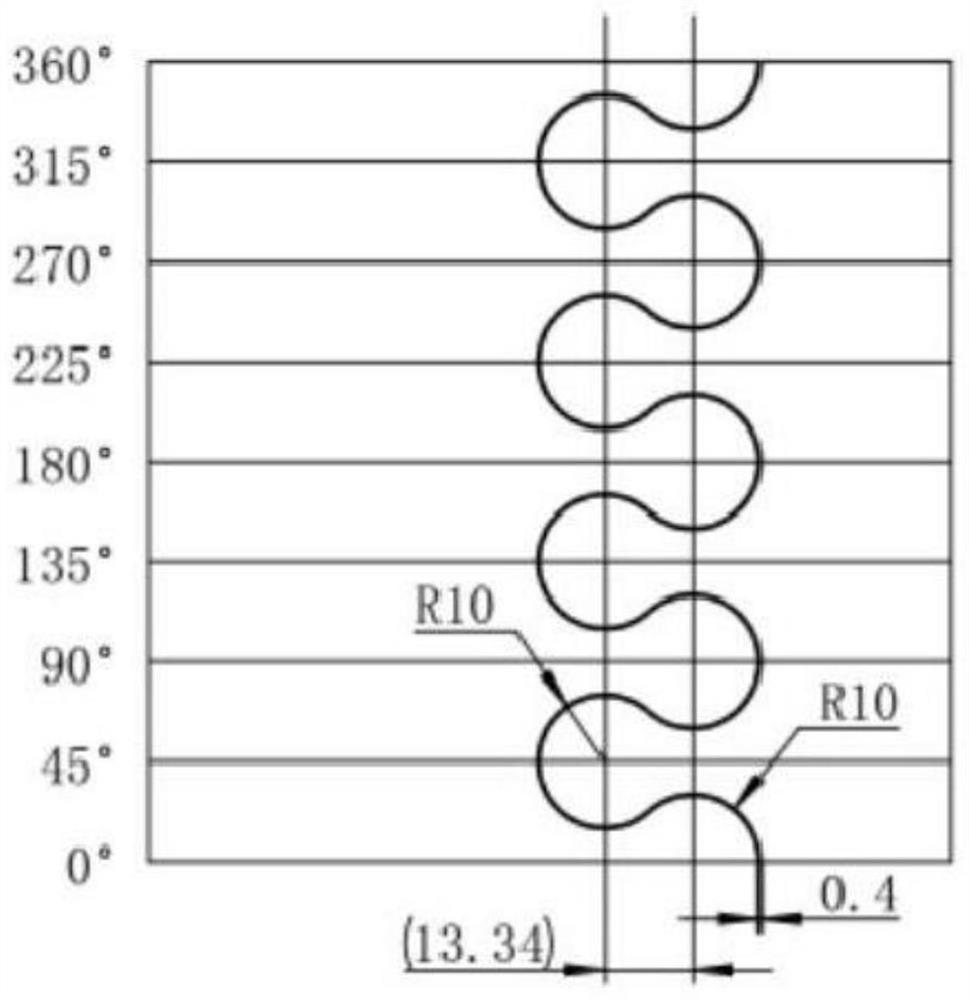

Double-filtering layer meander circular seam self-cleaning sieve tube

The invention discloses a double filtering-layer meandering circumferential weld self-cleaning sieve tube which is composed of a filter element and a basal tube; the filter element is embedded in a stepped hole at the side wall of the basal tube and is composed of a central cap, a plurality of filtering rings, a fixed ring and a protective cover. The size of the inner diameter of the filtering rings are increased one by one and the inner wall of each filtering ring is a double-stair shape, the outer wall of each filtering ring is an inverted double-stair shape. The outer wall of the central cap is an inverted double-stair shape and the central cap are sheathed in the filtering ring with the smallest inner diameter; all the filtering rings are axially sheathed together according to the size order of the inner diameter. The inner wall of the fixed ring is a double-stair shape and the filtering ring with the largest inner diameter is sheathed in the fixed ring; the outer wall of the fixed ring is an inverted double-stair shape and the upper part of the fixed ring is a conical surface and the lower part thereof is a cylindrical surface. The protective cover is covered on the conical surface of the outer wall of the fixed ring, a plurality of air vent windows are opened on the top surface of the protective cover. The double filtering-layer meandering circumferential weld self-cleaning sieve tube can filter the thin-fine sand, the permeability is high, the filter precision is high, and the filtering seam has extremely strong damage-resistance capacity and is not easily to block.

Owner:浙江省星炬科技有限公司

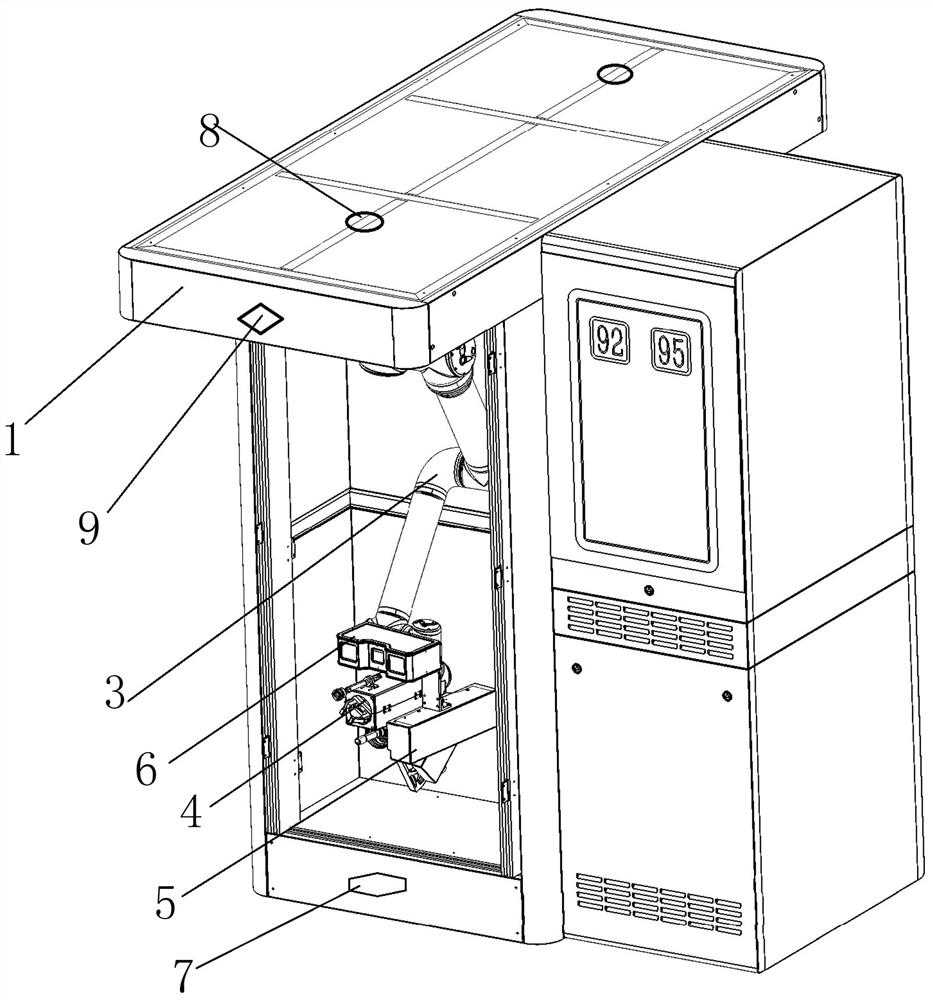

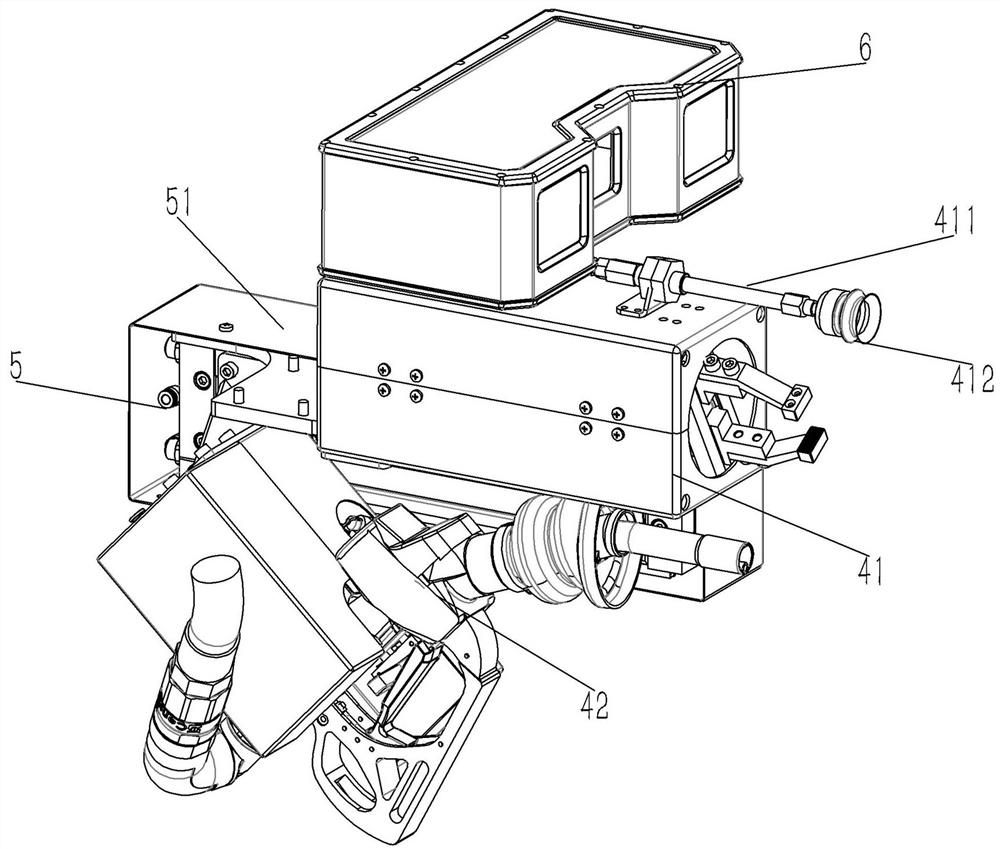

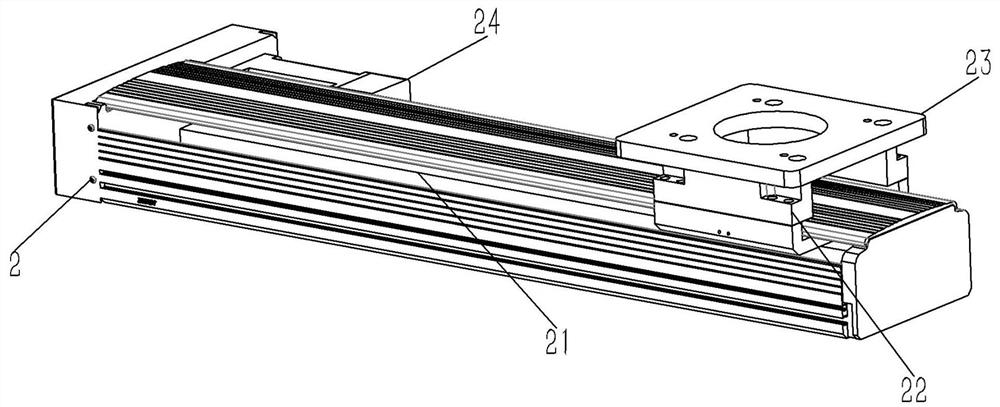

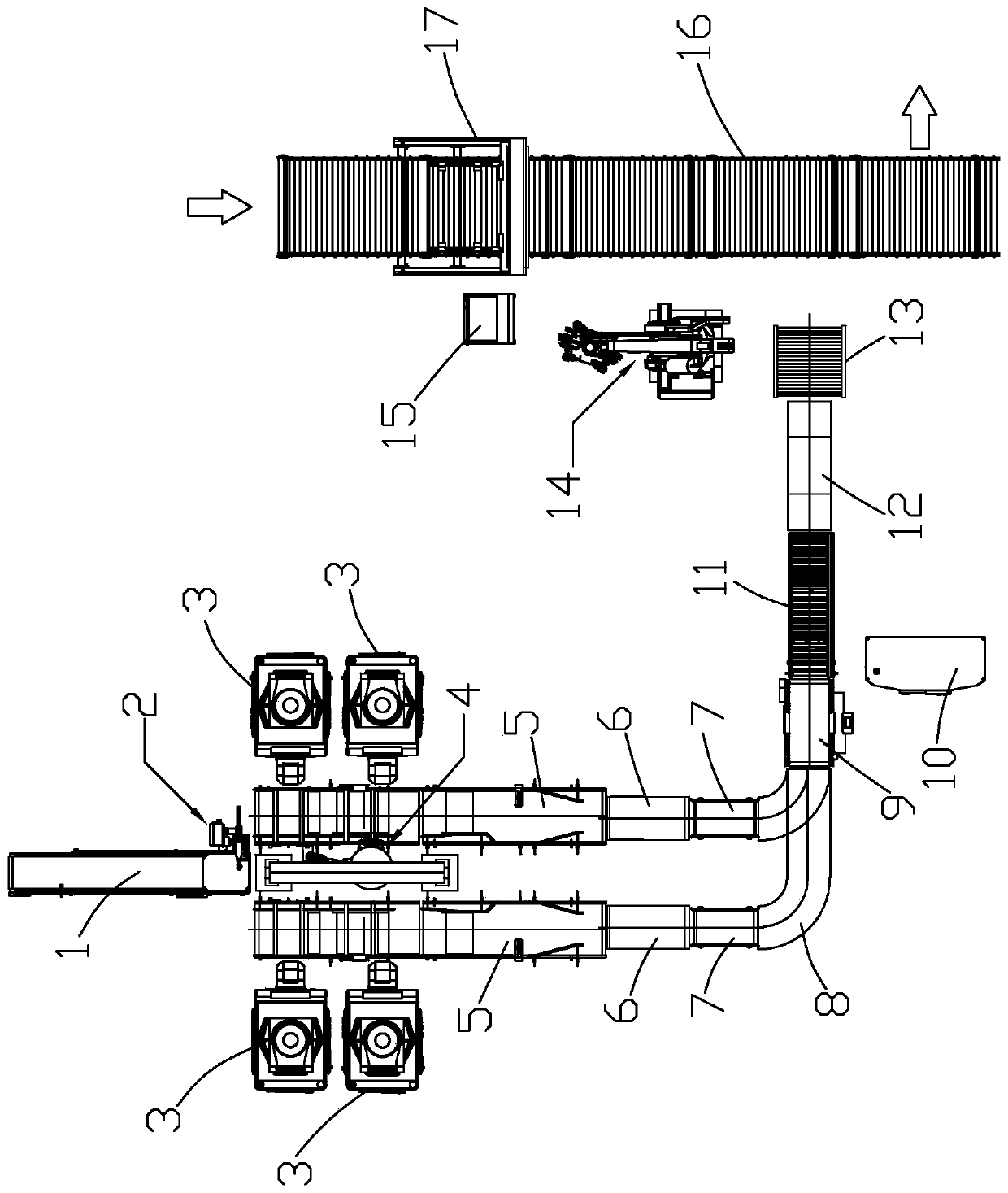

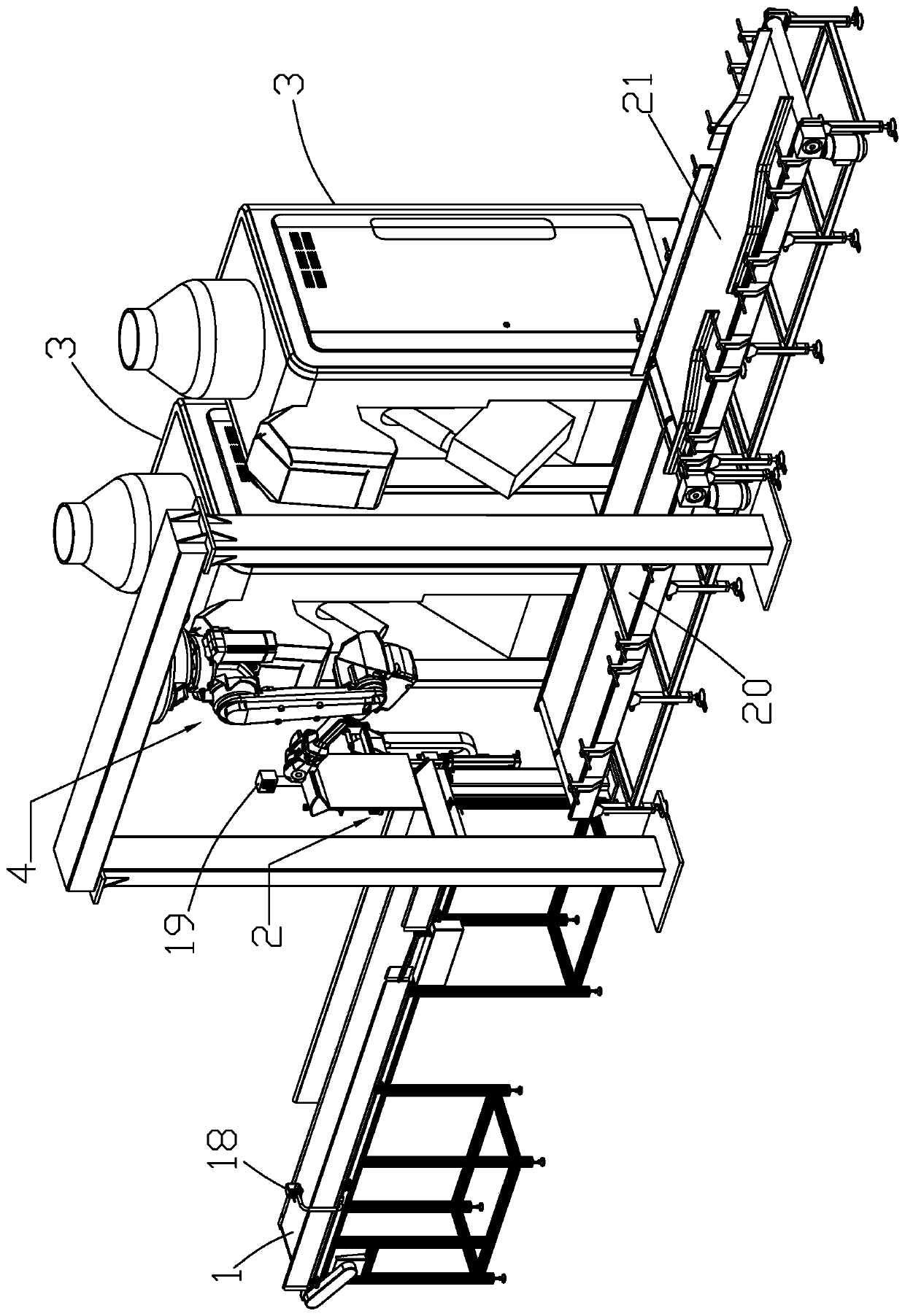

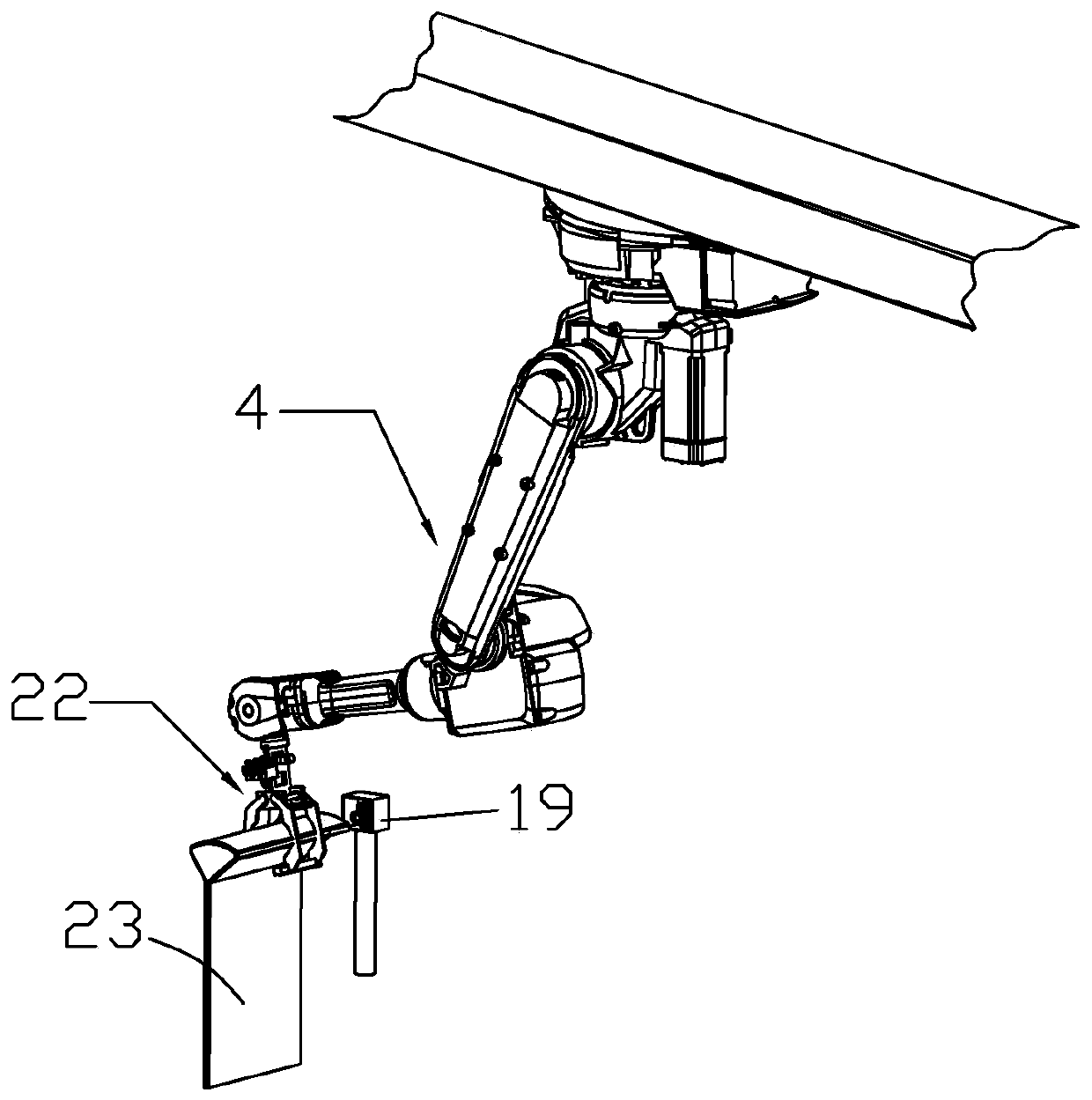

Automatic robot refueling device and refueling method

PendingCN114195083AImprove transmission flexibilityImprove filling efficiencyLiquid transferring devicesNuclear energy generationRobot handControl theory

The invention discloses an automatic robot refueling device and method. The automatic robot refueling device comprises a mounting cabinet body, and the mounting cabinet body internally comprises a movable base, a mechanical arm and a refueling mechanism; the refueling mechanism comprises an oil tank cover opening and closing assembly and a refueling assembly which are close to each other and can work independently. The oil tank cover opening and closing assembly comprises a clamping jaw rotating device arranged at the end of the mechanical arm, a buffering piece connected with the clamping jaw rotating device and a clamping jaw driving device connected with the buffering piece. The clamping jaw driving device is provided with clamping jaws capable of relatively clamping or loosening, and the clamping jaws are used for opening and closing the oil tank inner cover; the oil filling assembly comprises an oil filling support, an oil filling gun arranged on the oil filling support and a shifting rod driving device arranged on the oil filling gun and connected with an oil filling gun shifting rod. The technical problems that an existing robot refueling device is complex in structure, can only achieve single-side refueling and is small in operation radius, consequently, the requirement for controlling the parking precision range of a refueling automobile is high, and the refueling efficiency is low due to the fact that the matching precision of a refueling gun and a fuel tank opening is not high in the refueling process are solved.

Owner:正星科技股份有限公司

Full-automatic valve bag packaging and stacking production line

PendingCN111003284AImprove stability and reliabilityVersatileSolid materialStacking articlesOpen mouthManufacturing engineering

The invention discloses a full-automatic valve bag packaging and stacking production line, which comprises a valve bag conveying line, a main control cabinet and a bagging robot, and further comprisesa bag opening machine, a valve bag packaging machine and a falling bag conveying line, wherein the bag opening machine is located on one side close to the tail end of the valve bag conveying line, abag opening contour detection device is arranged on the same side as the bag opening machine on the valve bag conveying line, the bag opening machine comprises a bag opening mouth opening device, thebag opening mouth opening device comprises an opening mouth opening and closing mechanism, a valve bag is opened through the opening mouth opening and closing mechanism, the valve bag is grabbed by the bagging robot to be arranged on the valve bag packaging machine in a sleeving mode for material filling, and the filled valve bag is conveyed in a staggered steering mode through the falling bag conveying line. According to the invention, the production line is diversified in function, the program modification is easy and convenient, the technical requirement and the using effect of intelligentmanufacturing can be achieved, mechanical faults, mechanical abrasion fatigue and other factors are reduced at the same time, and the operation success rate is increased.

Owner:浙江美联智能科技有限公司

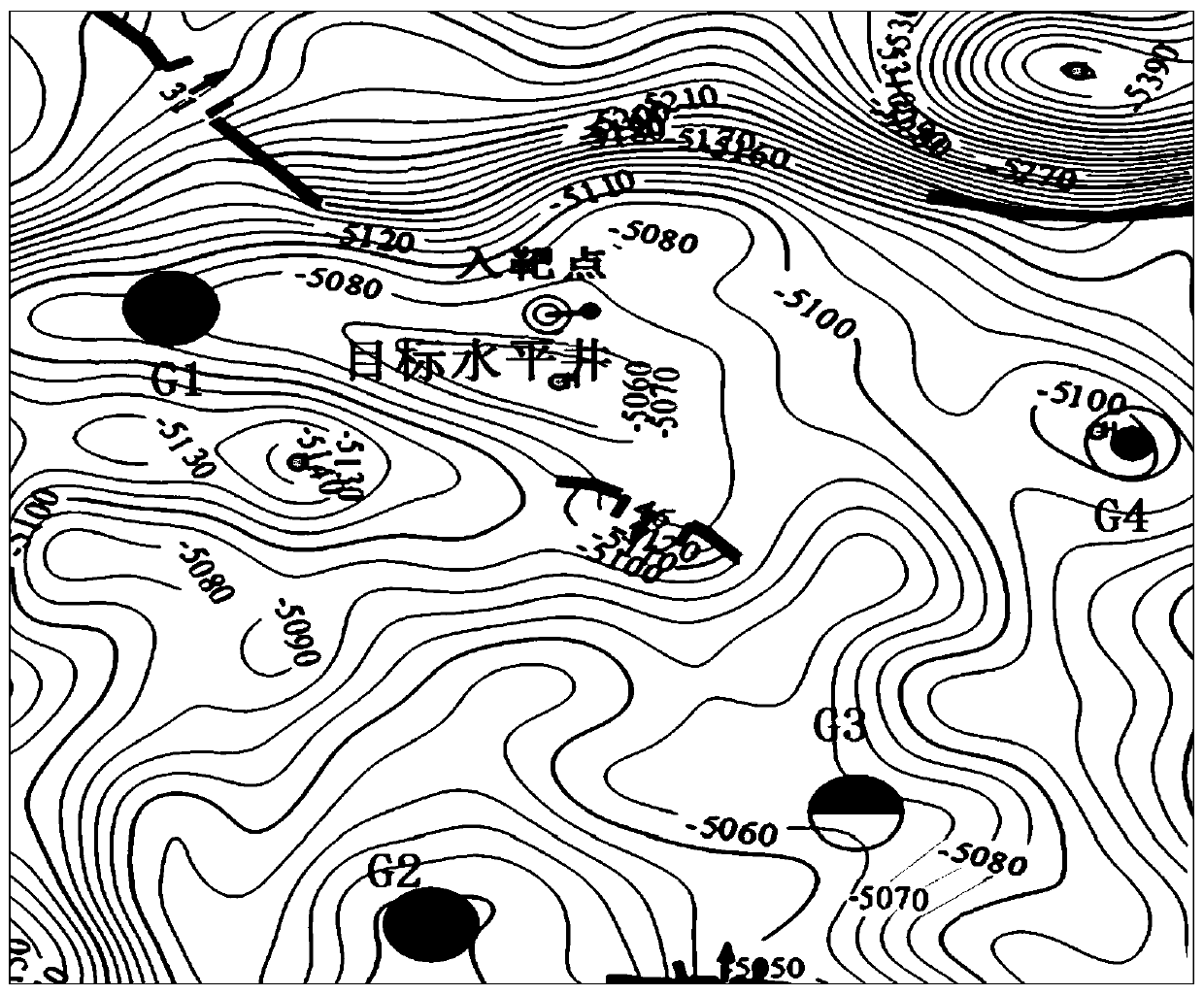

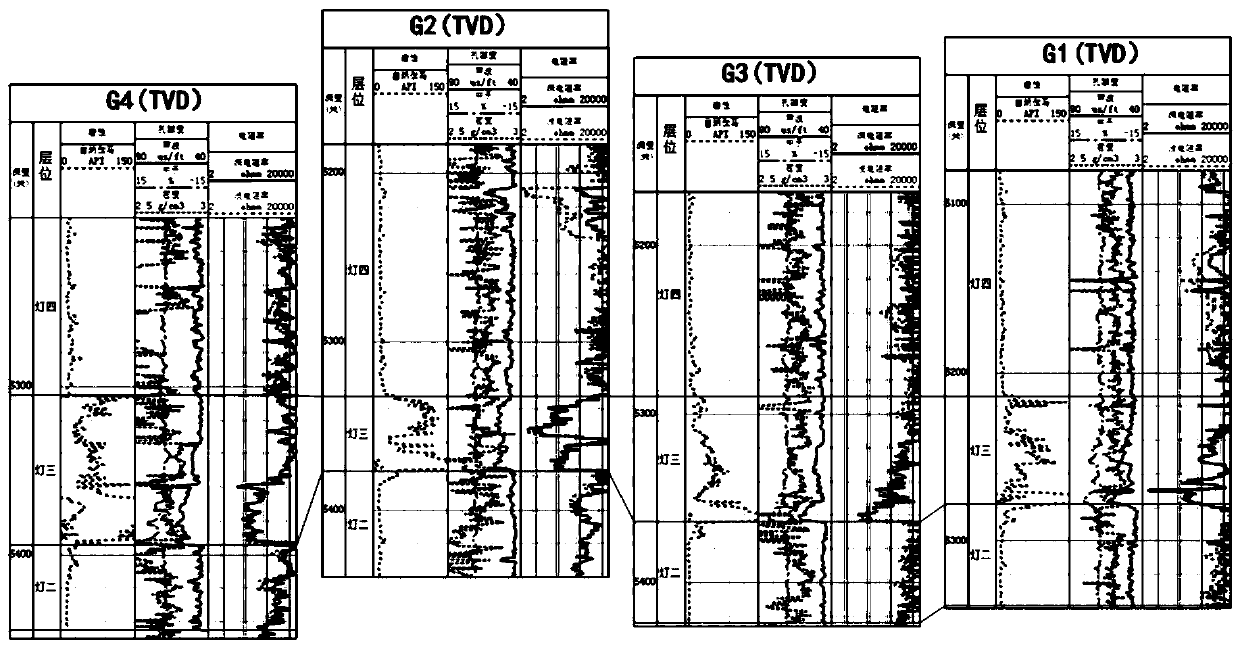

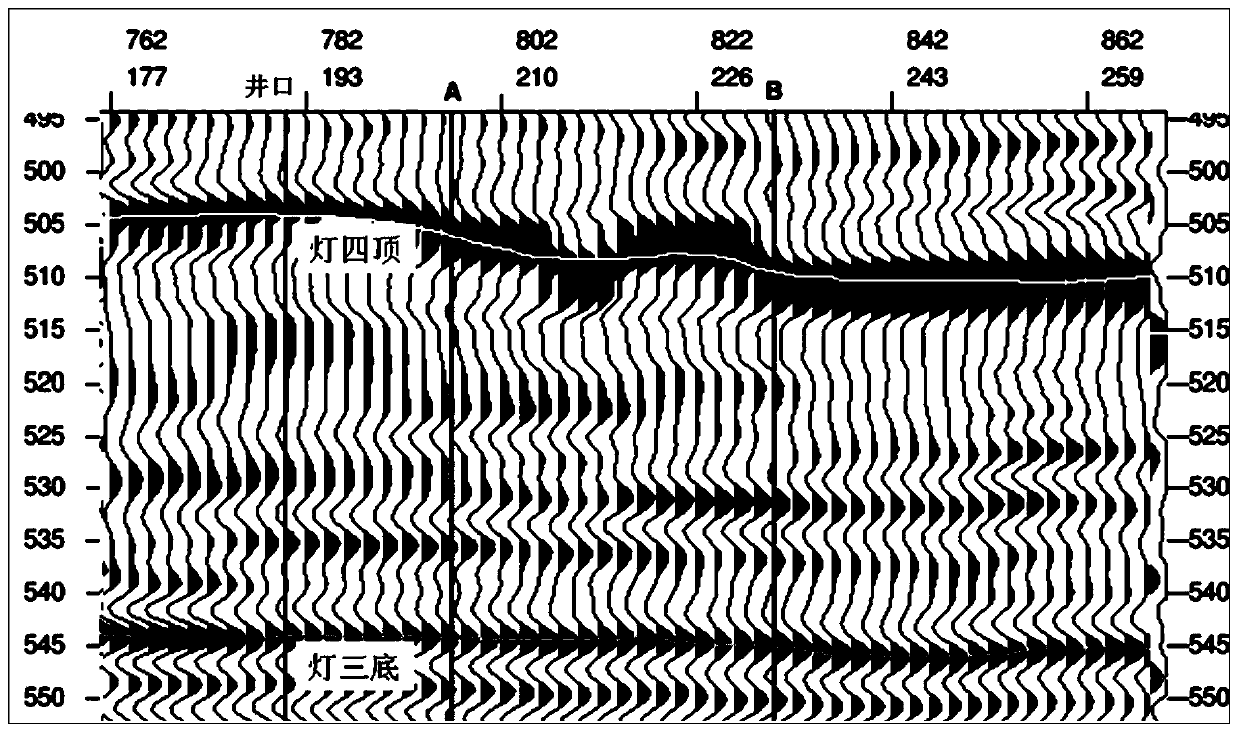

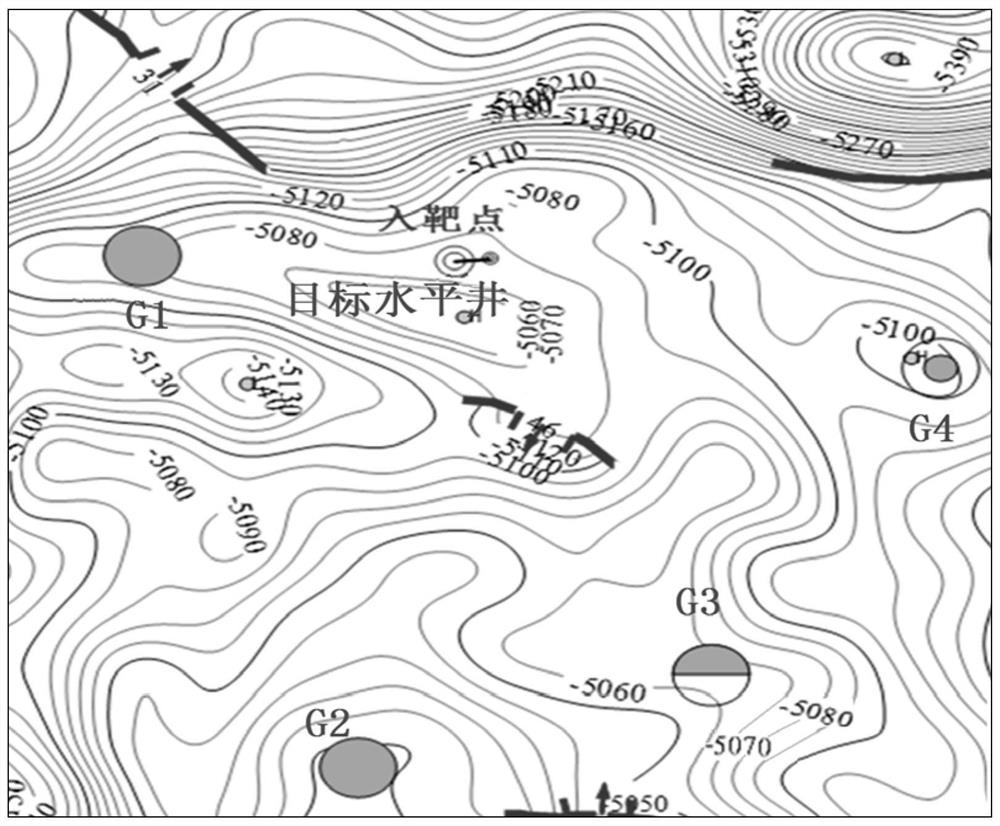

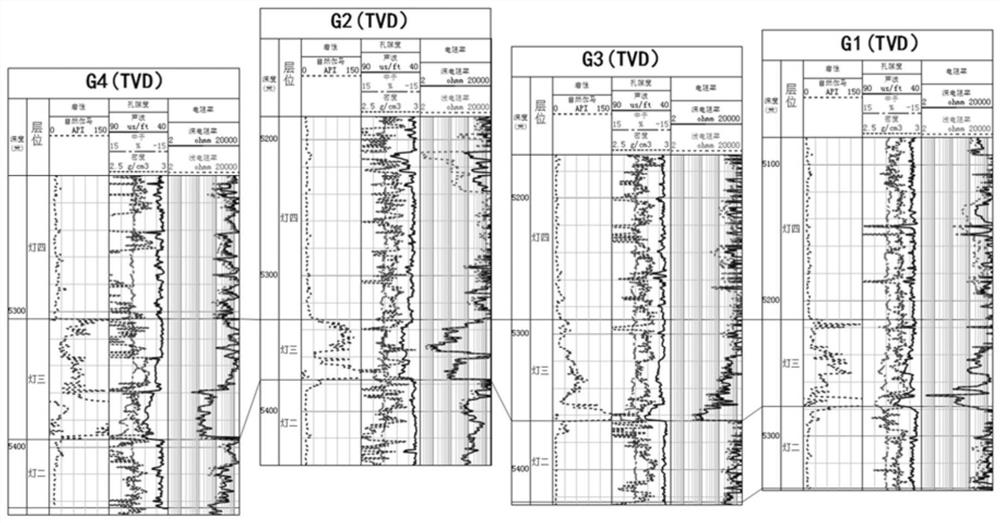

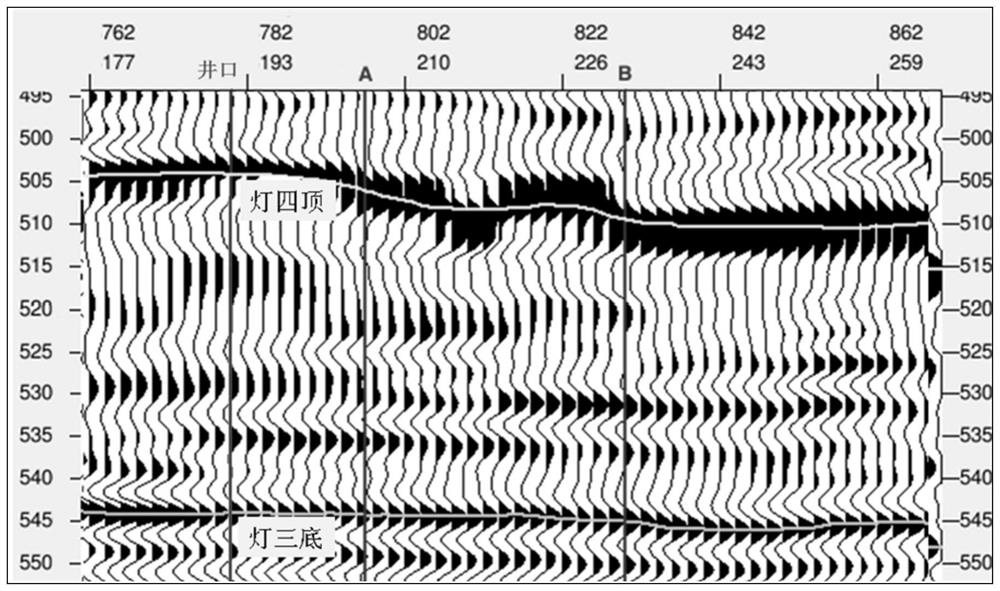

Horizontal well deflecting section trajectory optimization method based on stratum thickness change

ActiveCN111550186AImplementing Optimal Design MethodsRealize safe operationDirectional drillingDesign optimisation/simulationWell loggingWell drilling

The invention discloses a horizontal well deflecting section well trajectory optimization method based on stratum thickness change. The method comprises the following steps that 1, multi-well logginginformation is finely compared, lithofacies and stratum thickness change characteristic parameters are analyzed; 2, the stratum calibration is carried out on the seismic data according to the analysisresult of the multi-well logging information in the step 1, then the seismic data are finely processed, and the thickness and structure change rule of a target stratum series is found out; 3, well logging and seismic data results are combined, a thickness abnormal layer in the deflecting section is found out, and the stratum thickness variation and the burial depth variation range of the thickness abnormal layer are determined; 4, small-layer subdivision is carried out on the interior, the upper layer and the lower layer of the thickness abnormal layer in the deflecting section according to the electrical identification marks, and the electrical identification marks are arranged; and 5, risk well trajectory design is carried out, and an optimized drilling scheme is proposed. According tothe method for optimizing the well trajectory under the condition that the stratum thickness of the deflecting section of the horizontal well changes, a design thought and an operation method are provided, and a practical favorable tool is provided for high-quality landing of a horizontal well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

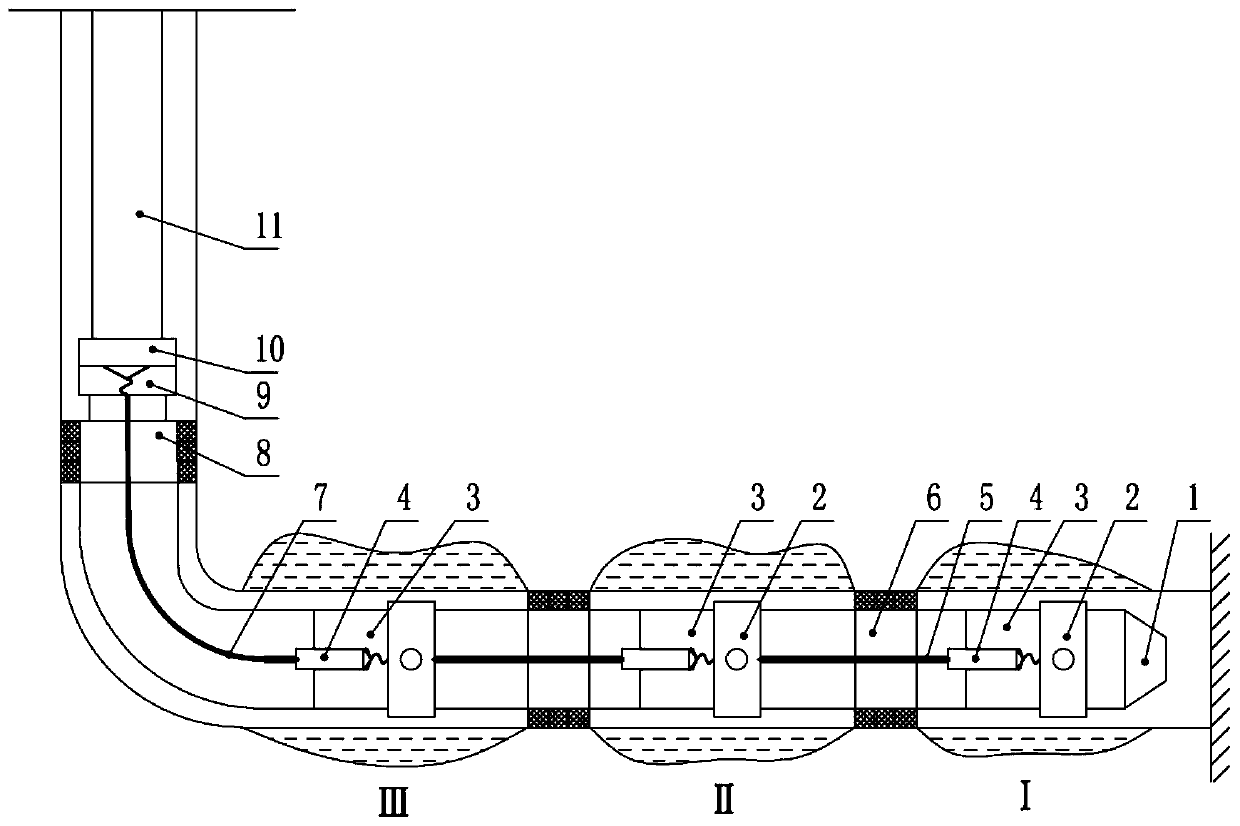

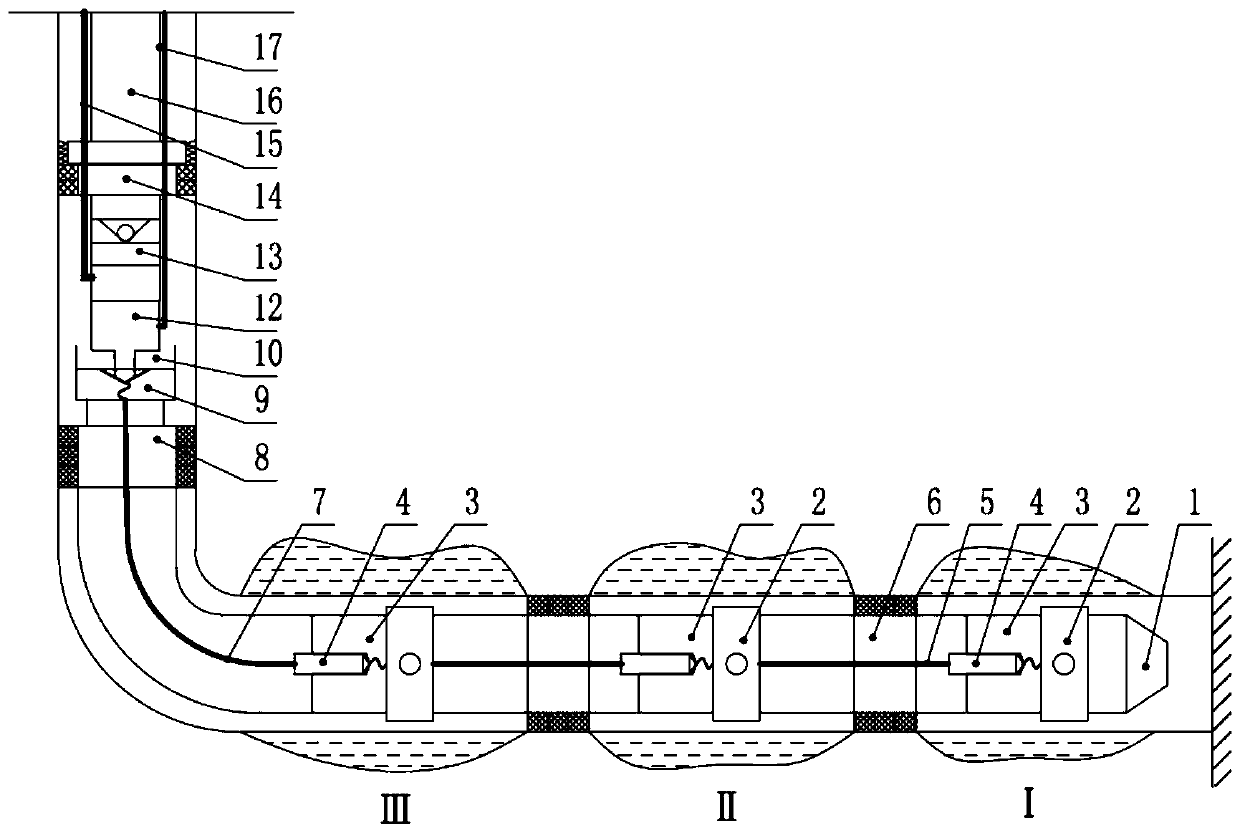

In-pipe butt joint type cable control separate mining process

ActiveCN109779579AQuick docking and downloadingImprove the efficiency of separate mining operationsFluid removalButt jointData transmission

The invention belongs to the technical field of oil well cable control intelligent mining, and discloses an in-pipe butt joint type cable control separate mining process. The process is achieved through two pipe columns and comprises the steps of: firstly, a lower layer pipe column is put down to separate oil layers; after releasing is conducted, the lower layer pipe column is put down to an upperproduction pipe column to conduct circuit butt joint; and meanwhile production is regulated and controlled. According to the invention, rapid tripping-in and butt joint of a signal cable in a pipe column can be realized; the cable joint is prevented from being made after the cable is cut off for multiple times in the pipe column tripping-in process; and the separated mining operation efficiency is improved; and the signal cable is arranged in the pipe column to descend the well, so that the risks of extrusion, collision and the like of the cable and the well wall in the descending process ofthe pipe column are avoided, and the operation success rate and the cable data transmission service life of the oil well cable control intelligent well technology are effectively improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

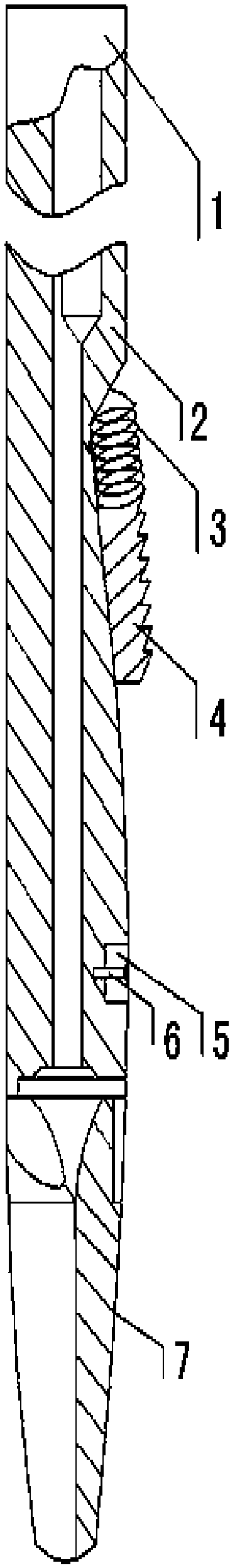

Tubing drain

InactiveCN101984215AEasy to drainWork reliablyWell/borehole valve arrangementsSealing/packingPumpjackFriction force

The invention provides a tubing drain. The tubing drain consists of a friction mechanism, an inner tube and a gland cover, wherein the friction mechanism and the gland cover are sleeved outside the inner tube; the friction mechanism is arranged on the gland cover; an oil drain hole is arranged on the lower part of the inner tube; a thread is arranged on the drain hole, and is coupled with the inner thread on the upper part of the gland cover; and the lower part of the gland cover covers the drain hole on the lower part of the inner tube. When the tubing drain is connected to a defueling pump, and an oil extraction tube is required to drain oil in next operation, the oil extraction tube is assembled to ensure that two raised keys are buckled together, the inner tube is rotated, and the friction mechanism and the gland cover stand still under the friction force action between the friction mechanism and a sleeve; and under the action of turning moment, the coupled threads of the inner tube and the gland cover are released, and the gland cover moves upwards, coverage of the oil drain hole is lost to ensure that the inside and outside of the drain hole on the inner tube are communicated to drain oil. Oil drainage is performed by rotating the oil tube after the oil tube is lifted upwards in oil draining, the time for draining oil can be manually controlled at will, so the tubing drain is convenient in oil drainage, reliable in operation, high in operation success rate, simple in structure and convenient in processing and use.

Owner:白霞

Oil field downhole junk salvage device

InactiveCN109113628ANot easy to damageExtended service lifeBorehole/well accessoriesOil fieldEngineering

The invention discloses an oil field downhole junk salvage device which comprises a joint, a spear rod, a spring, a round slip, a locking block, a screw and a guiding shoe. The spear rod is fixed to the joint; the round slip is fixed to the spear rod through the locking block; the locking block can adjust floating of the round slip and is fixed through the screw; the tail end of the spear rod is connected with the guiding shoe; the spring is arranged between the spear rod and the round slip; and the middle of the spear rod is of a retractable structure. The oil field downhole junk salvage device is simple in structure, flexible and reliable in action, convenient and easy to operate, high in working success rate, not prone to damaging the fish roof, large in contact area with fishes, thus high in tensile load, large in impact-resisting load, and capable of being recycled.

Owner:西安瑞杰实业股份有限公司

Ultra-wide cigarette packet detecting and removing device

InactiveCN112224857AAvoid enteringImprove restraintSortingConveyor partsEmbedded systemElectrical and Electronics engineering

The invention relates to the technical field of tobacco electrical automation detection, and provides an ultra-wide cigarette packet detecting and removing device. The ultra-wide cigarette packet detecting and removing device comprises a conveying belt, a first blocking plate, a movable blocking plate assembly, a blocking sensor, a removing mechanism and a controller. An ultra-wide blocking channel is defined by the conveying belt, the first blocking plate and the movable blocking plate assembly together. The removing mechanism is arranged at the downstream position of the ultra-wide blockingchannel. A probe of the blocking sensor points to the ultra-wide blocking channel. The controller is electrically connected with the blocking sensor. The controller is further connected with and controls the movable blocking plate assembly, the conveying belt and the removing mechanism. Compared with the prior art, the ultra-wide cigarette packet detecting and removing device has the advantages that the device can detect and remove ultra-wide cigarette packets and can prevent the ultra-wide cigarette packets from entering a conveying channel and downstream equipment, and therefore displacement, deformation and even breakage damage of a downstream packaging machine mechanism can be avoided. The automation degree of the detecting and removing process is high.

Owner:HONGTA TOBACCO GRP

Vortex sand washing device

The invention discloses a vortex sand washing device which comprises an upper connector, a tubing pup joint, a conversion body, a sand washing core tube, a revolving body and a sand washing head, wherein the upper connector is connected with the tubing pup joint, the conversion body, the sand washing core tube, the revolving body and the sand washing head in sequence; an annulus is formed betweenthe upper part of the inner pup joint of the conversion body and the cavity of the tubing pup joint; the lower end of the inner pup joint of the conversion body is provided with a stopper; a flow channel is arranged axially between the inner pup joint and the outer pup joint of the conversion body; the revolving body is arranged outside the sand washing core pipe and the sand washing head; and a bearing hoop is arranged between the lower cavity of the revolving body and the sand washing head. The vortex sand washing device adopts a double-tube structure, thus providing different channels for washing and upward-returning of sand washing fluid, and is characterized by high adaptability, high sand washing efficiency, high sand washing and well cleaning speed, good effect, high operation success rate and the like, thus being adapted to sand washing operation of common oil gas wells, especially to sand washing operation of highly-deviated wells and horizontal wells.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

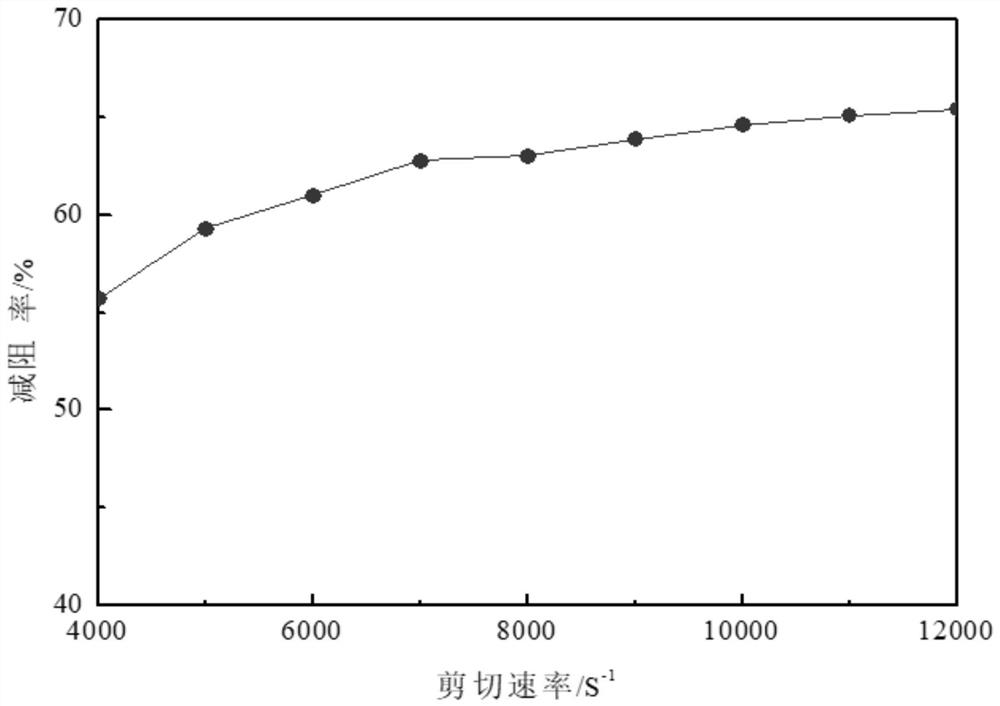

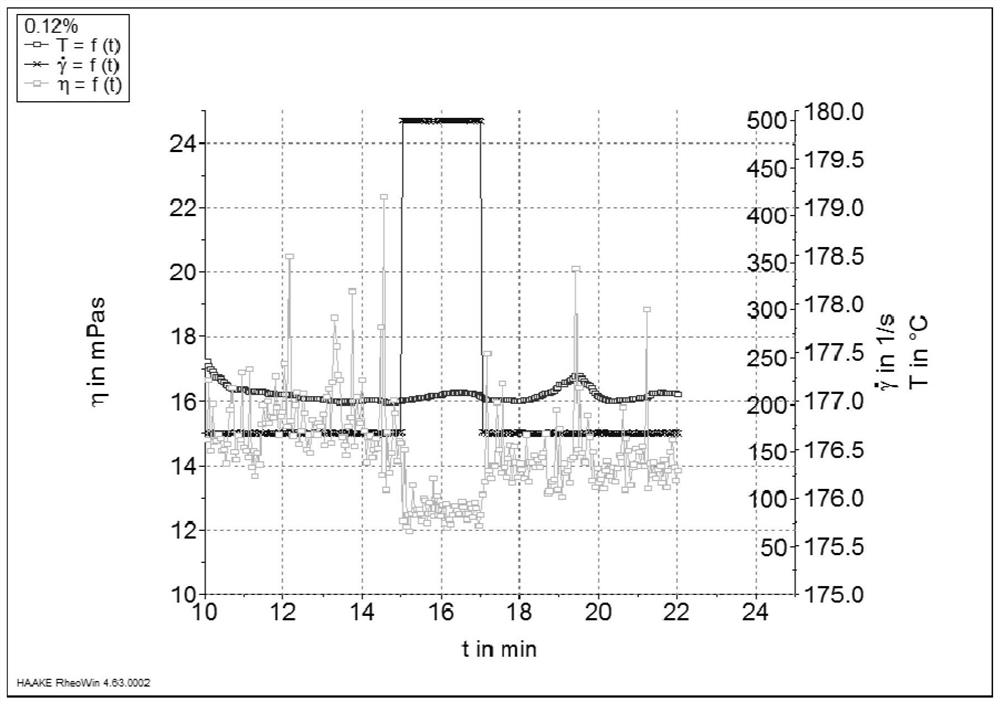

Sand washing drilling and grinding fluid system for high-temperature sulfur-containing deep well

PendingCN113913169ARelieve pressureProtection securityDrilling compositionBorehole/well accessoriesPhysical chemistrySulfur containing

The invention relates to a sand washing drilling and grinding fluid system for a high-temperature sulfur-containing deep well, which comprises the following components in percentage by mass: 0.01-0.3% of a temperature-resistant drag reducer, 0.1-0.3% of a discharge aiding agent, 0.1-0.3% of a clay stabilizer, 0.03-0.2% of a sulfur removal agent, 0.001-1.0% of a pH regulator and the balance of water. The system is suitable for underground sand washing, drilling and grinding and well washing operation of oil and gas reservoirs with the temperature of 180 DEG C or below, pump injection friction resistance can be effectively reduced, hydrogen sulfide returned along with operation liquid can be efficiently removed under the high-temperature condition, damage of hydrogen sulfide to ground personnel, equipment, underground tools and drilling tools is avoided, and therefore high-temperature sulfur-containing deep well sand washing, drilling and grinding operation is smoothly achieved.

Owner:CHINA PETROCHEMICAL CORP +3

Detection device for blocking type super-long cigarette bar

PendingCN114162375AAvoid enteringImprove restraintPackaging cigarettePackaging automatic controlStructural engineeringMechanical engineering

The invention discloses a blocking type ultra-long cigarette carton detection device, and belongs to the technical field of tobacco equipment. The blocking type ultra-long cigarette carton detection device comprises a conveying belt, a guide plate I, a guide plate II, a blocking plate I, a blocking plate II, a blocking piece and a blocking sensor. The device can be used for detecting the ultra-long cigarette strips, the ultra-long cigarette strips are prevented from entering the next working procedure, the product quality is improved, and the ultra-long cigarette strips are prevented from entering downstream equipment to be blocked or even broken to damage the downstream equipment; the width of the downstream equipment operation point can be reduced to the maximum allowable length of the cigarette bar, and the restraining effect on the cigarette bar is improved, so that the operation precision is improved, and the operation success rate is increased. Meanwhile, the blockage removing unit is arranged, so that the cigarette strips cannot be blocked for a long time, the cigarette strips can smoothly pass through, and blockage or connection of the cigarette strips cannot be caused. In addition, the width of the blocking channel can be adjusted, and it is guaranteed that the operation point of the blocking channel has good restraining performance on the cigarette strips in the cigarette strip conveying process.

Owner:HONGTA TOBACCO GRP

Double-filtering layer meander circular seam self-cleaning sieve tube

The invention discloses a double filtering-layer meandering circumferential weld self-cleaning sieve tube which is composed of a filter element and a basal tube; the filter element is embedded in a stepped hole at the side wall of the basal tube and is composed of a central cap, a plurality of filtering rings, a fixed ring and a protective cover. The size of the inner diameter of the filtering rings are increased one by one and the inner wall of each filtering ring is a double-stair shape, the outer wall of each filtering ring is an inverted double-stair shape. The outer wall of the central cap is an inverted double-stair shape and the central cap are sheathed in the filtering ring with the smallest inner diameter; all the filtering rings are axially sheathed together according to the size order of the inner diameter. The inner wall of the fixed ring is a double-stair shape and the filtering ring with the largest inner diameter is sheathed in the fixed ring; the outer wall of the fixed ring is an inverted double-stair shape and the upper part of the fixed ring is a conical surface and the lower part thereof is a cylindrical surface. The protective cover is covered on the conical surface of the outer wall of the fixed ring, a plurality of air vent windows are opened on the top surface of the protective cover. The double filtering-layer meandering circumferential weld self-cleaning sieve tube can filter the thin-fine sand, the permeability is high, the filter precision is high, and the filtering seam has extremely strong damage-resistance capacity and is not easily to block.

Owner:浙江省星炬科技有限公司

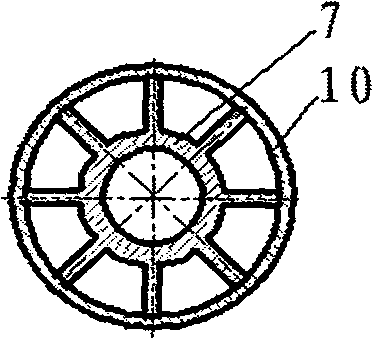

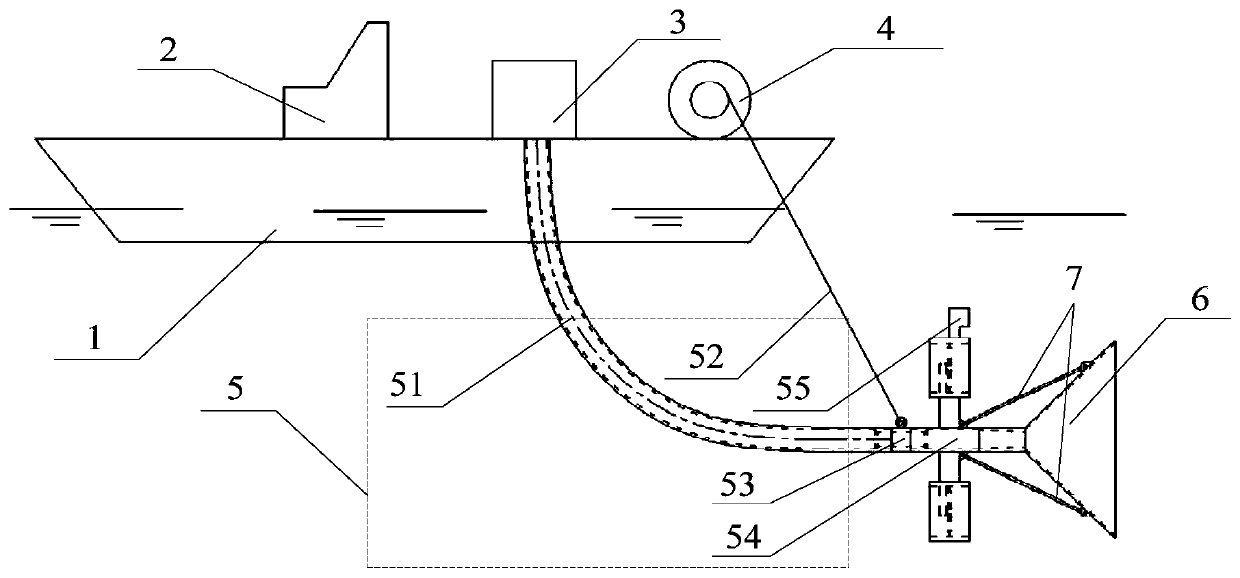

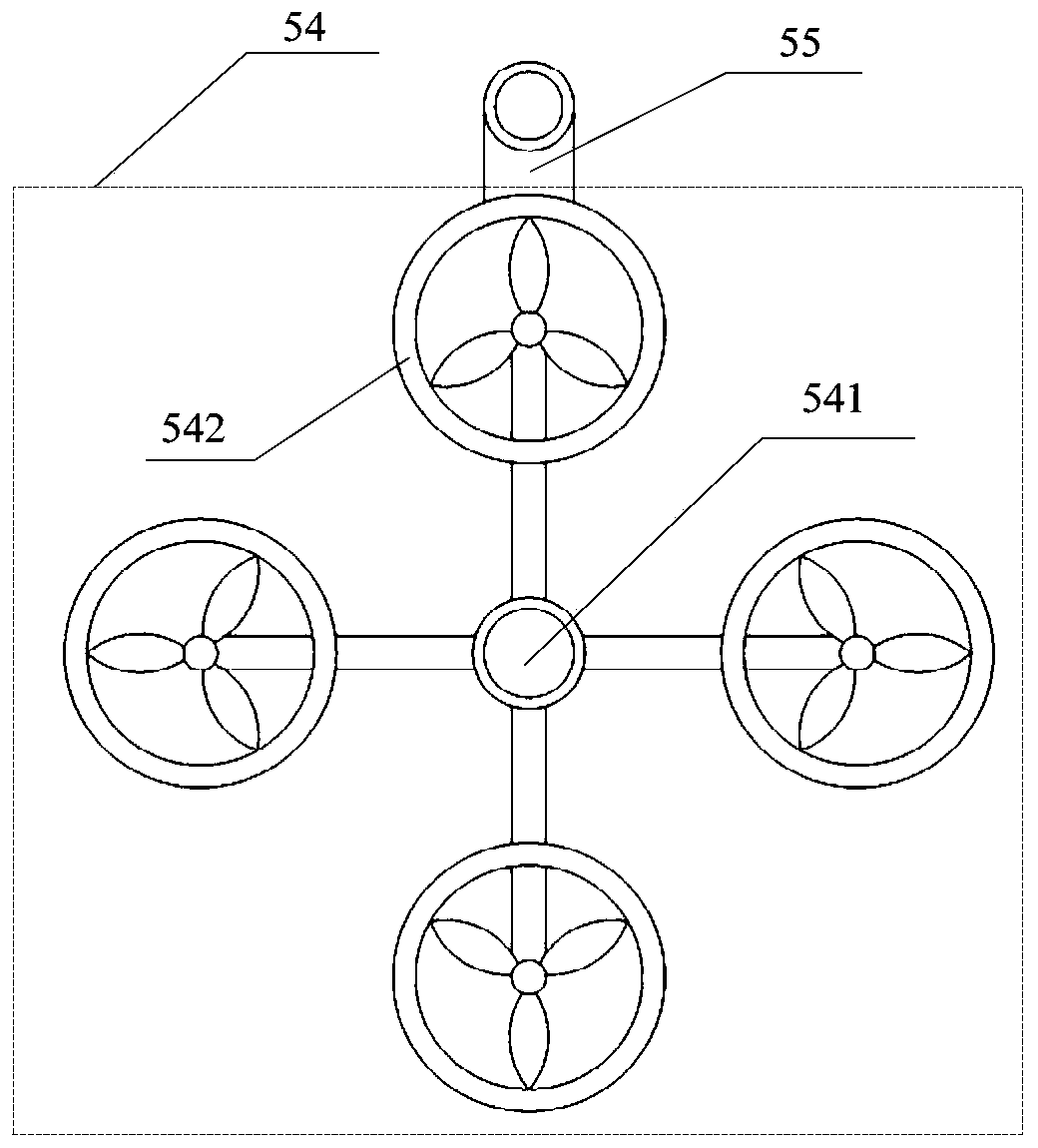

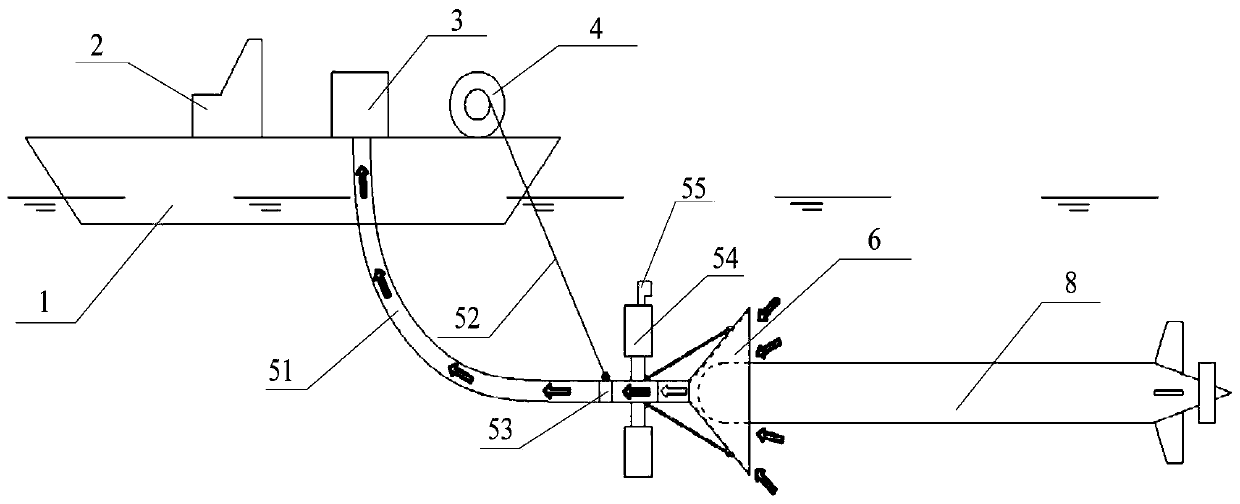

A kind of auv underwater recovery system

ActiveCN109334897BUnderwater Recycling SafetyReliable underwater recoveryVessel salvagingUnderwaterMarine engineering

The invention discloses an AUV underwater retracting system, and relates to the technical field of AUV. The AUV underwater retracting system pulls a capturing taper sleeve through a pulling mechanism,the negative pressure suction formed in an inner cavity of the capturing taper sleeve is converted into a dragging force applied on the AUV to be retracted by using pumping of a pump, and thus safe,reliable, rapid and hidden underwater retracting of the AUV is realized.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

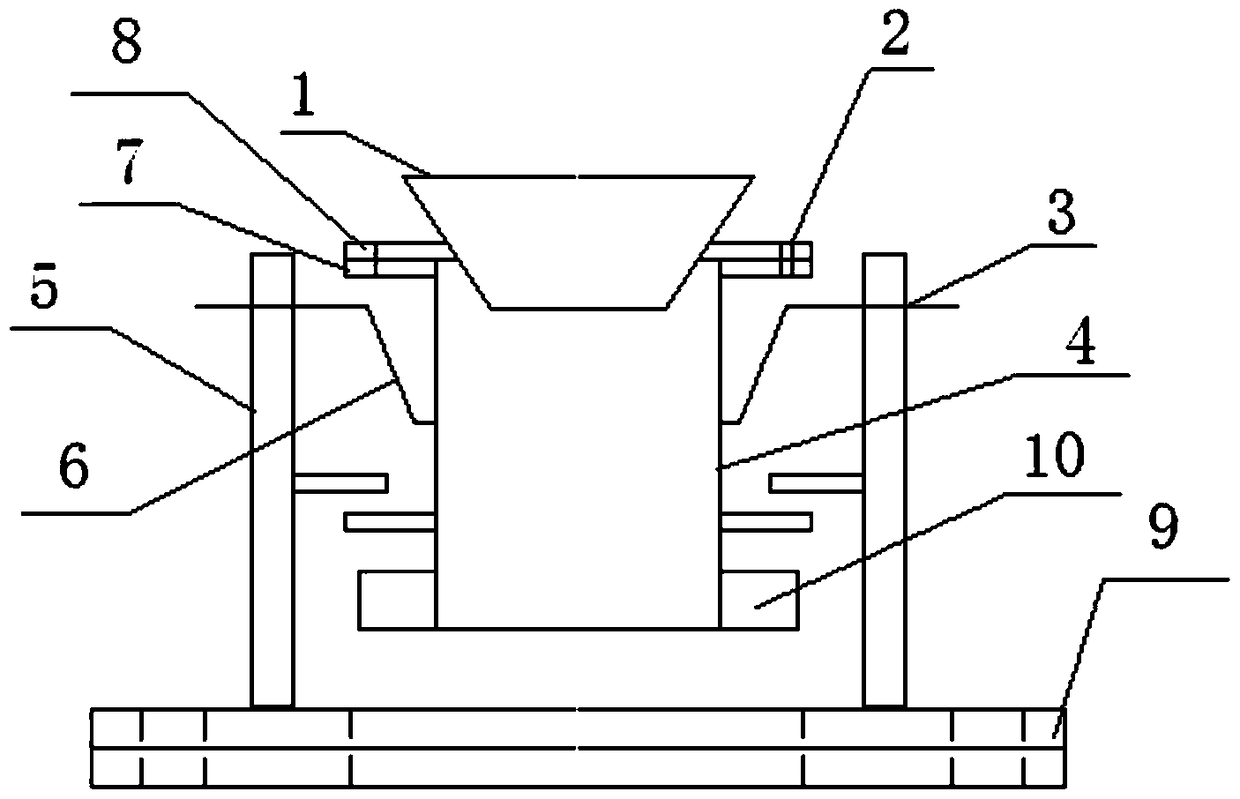

A converter sub-lance centering device and centering method

The invention provides a converter sublance centering device. The converter sublance centering device comprises a conical centering cylinder, supporting frames, hoisting steel ropes, centering adjusting bolts A, centering adjusting bolts B, a fixing frame, a fine adjustment frame, a balancing weight and a base. One end of each hoisting steel rope is connected with a balancing weight cylinder, and the other end of each hoisting steel rope is connected with the corresponding centering adjusting bolt B. The centering adjusting bolts B are in screw joint with the supporting frames. The balancing weight is fixedly arranged at the lower end of the balancing weight cylinder, the fixing frame is fixedly arranged at the upper end of the balancing weight cylinder, and the fine adjustment frame is fixedly arranged on the periphery of the conical centering cylinder. Bolt holes are formed in the fixing frame, long bolt holes are formed in the fine adjustment frame, the fine adjustment frame is in lap joint to the fixing frame, and the fine adjustment frame and the fixing frame are connected through the centering adjusting bolts A. The base is arranged above the position where a probe is inserted into a mechanical hand, and the supporting frames are fixedly arranged on the base. The converter sublance centering device is simple in technical scheme and easy to implement, adjust and control, can guarantee the construction quality of sublance centering adjustment, can also improve the production efficiency, saves the production cost and guarantees stable operation of production.

Owner:ANGANG STEEL CO LTD

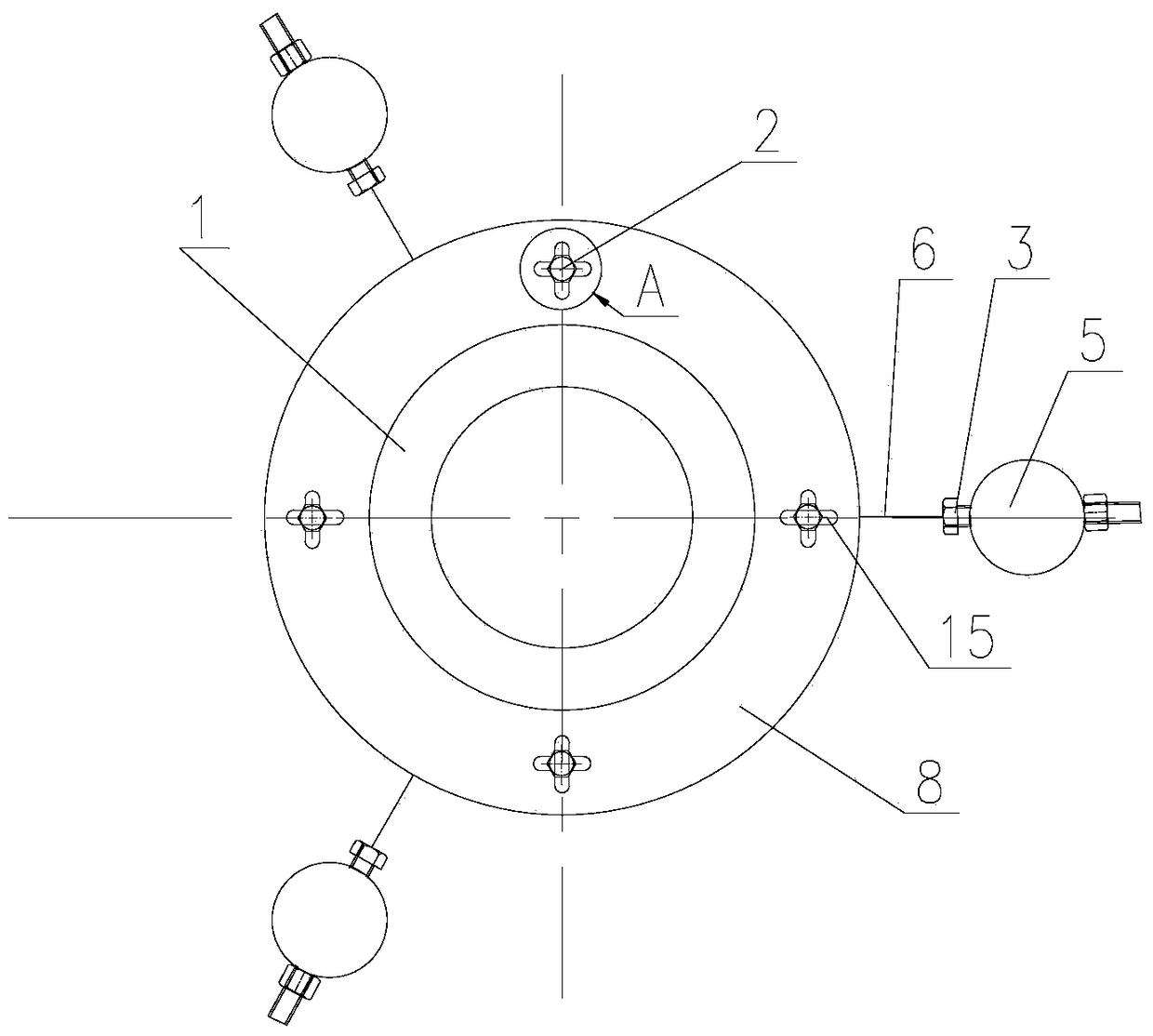

A Hard Rod Capturing and Connecting Device with Cables for Underwater Robots

ActiveCN112591042BAchieve connectionExpand the capture rangeVessel salvagingUnderwater equipmentRoboticsAlgorithm

The invention provides a hard rod with cable capture and connection device for underwater robots, which belongs to the field of underwater operation robot devices, and realizes the capture of the target hard rod with cables on the upper part of the water twice in a row, and realizes A device attached to a hard rod on the target. The device includes a linkage rotary mechanism, a locking docking mechanism, a differential mechanism, and auxiliary mechanisms such as brackets, limit cylinders, and stepping motors. The linkage rotation mechanism includes guide arms, pressing arms, and cam push rods. The device can guide and capture the target hard rod in a large range through the linkage slewing mechanism, realize the connection of the target hard rod through the locking and docking mechanism, and realize the sequential movement of the linkage slewing mechanism under a single driving source through the differential mechanism. The device can effectively capture the underwater target hard rod within the opening angle range of 112° in front of the robot, and complete the locking and connecting actions of the target hard rod. The device has the advantages of simple structure, large capture range, wide adaptability to environment, high reliability and the like.

Owner:HARBIN ENG UNIV

Trajectory optimization method of horizontal well build-up section based on variation of formation thickness

ActiveCN111550186BImplementing Optimal Design MethodsRealize safe operationDirectional drillingDesign optimisation/simulationWell drillingWell logging

The invention discloses a method for optimizing the well trajectory of the deflection section of a horizontal well based on the change of the formation thickness, comprising the following steps: 1. Finely comparing the logging data of multiple wells, analyzing the characteristic parameters of lithofacies and formation thickness changes; 2. Calibrating according to the well logging , finely process the seismic data, and find out the stratum thickness and structure change law of the target stratum; 3. Combine the logging and seismic data results to find out the abnormal thickness layer in the deflection section, and determine the stratum thickness variation and buried depth of the abnormal thickness layer. 4. Carry out subdivision of sublayers in the abnormal thickness layer and the upper and lower layers in the build-up section according to the electrical identification marks, and set the electrical identification marks; 5. Design the trajectory of the risky well and propose an optimized drilling plan. The method for optimizing the trajectory of the well under the condition of the stratum thickness variation in the kickoff section of the horizontal well disclosed by the invention provides a design idea and an operation method, and provides a practical and advantageous tool for high-quality landing of the horizontal well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

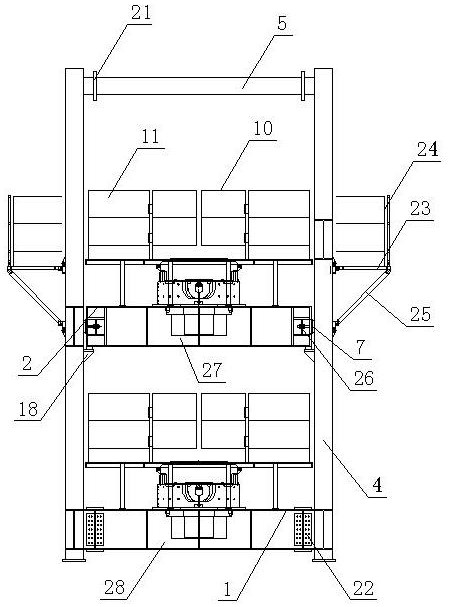

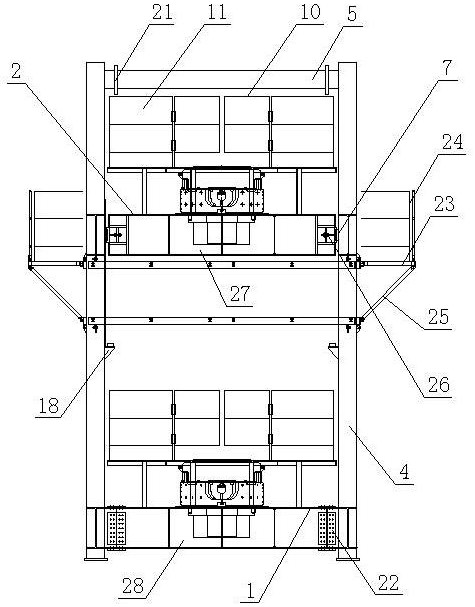

A double-platform hydraulic lifting casing device

ActiveCN112174025BSmall footprintSuitable for offshore working environmentLifting framesHydraulic cylinderStructural engineering

The invention discloses a dual-platform hydraulic lifting casing device, which belongs to the technical field of operation equipment and includes a base platform, an upper lifting platform, a lifting hydraulic system, and a lifting cylinder arranged between the base platform and the upper lifting platform , an upstanding main frame column is fixed above the base platform, and a fixed beam is connected to the top of the adjacent main frame column; a lifting cylinder is connected and fixed on the base platform and inside the main frame column, and the lifting cylinder The hydraulic cylinder push rod is connected to the bottom of the upper lifting platform, and the double wellhead platform is adopted, which occupies a small space and is suitable for offshore operation environment; the hydraulic system is used to drive the hydraulic cylinder to lift the top platform instead of the driving system of the drilling and repairing machine, and the equipment setting is convenient and effective. The construction procedure is simplified, the operation success rate is improved, the deficiencies of the existing technology are effectively made up, and the needs of the actual situation are met.

Owner:深蓝(天津)智能制造有限责任公司

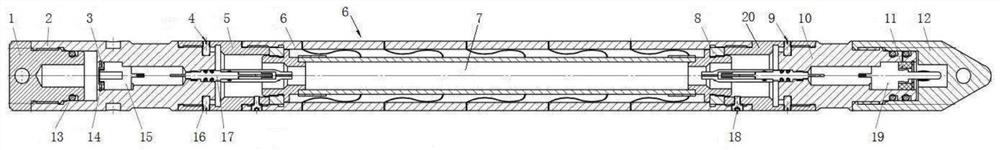

Flexible universal connecting short section for high-inclination and horizontal wells

PendingCN113073944AImprove pass rateArrive successfullySurveyDrilling rodsUpper jointHorizontal wells

The invention discloses a flexible universal connecting short section for high-inclination and horizontal wells. The flexible universal connecting short section comprises a bendable flexible section, wherein a first flexible section joint is fixed at one end of the flexible section; an upper joint is fixed at the other end of the first flexible section joint; an upper plug is fixed at the other end of the upper joint; a first single-core rubber socket is arranged in the upper joint along the axis direction; silicone grease is filled in the flexible section along the axis direction; a second flexible section joint is fixed at the other end of the flexible section; a lower joint is fixed at the other end of the second flexible section joint; a lower protective cap is fixed at the other end of the lower joint; a second single-core rubber socket is arranged in the lower joint along the axis direction; and an insulating pad B is arranged at the end part of the second single-core rubber socket. The flexible universal connecting short section has the beneficial effects that the passing rate of the high-inclination and horizontal wells can be effectively increased, the operation time is shortened, a test instrument can smoothly reach a test layer, and the operation success rate is further increased.

Owner:高庆伟 +1

High-sealing flux-cored soluble ball

InactiveCN112443294AGuaranteed starting pressureGuaranteed under pressureWell/borehole valve arrangementsSealing/packingPressure risePhysical chemistry

The invention relates to the technical field of oil and gas well resource exploitation, and particularly discloses a high-sealing flux-cored soluble ball. The high-sealing flux-cored soluble ball comprises an outer surface coating layer, a soluble metal layer is arranged in the outer surface coating layer, and a dissolution assisting material is arranged in the soluble metal layer; and the outer surface coating layer is made of a soluble elastic material. The high-sealing flux-cored soluble ball can be tightly attached to a bridge plug ball seat in a sealed mode, pressure rising and bearing ofa bridge plug are guaranteed, and fracturing operation is smoothly completed; and the dissolving speed of the soluble bridge plug can be increased, one-time ball throwing, one-time fracturing, rapiddissolving and automatic drifting are achieved, the operation time of operators is shortened, the operation period is shortened, and the production economic benefits are improved.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

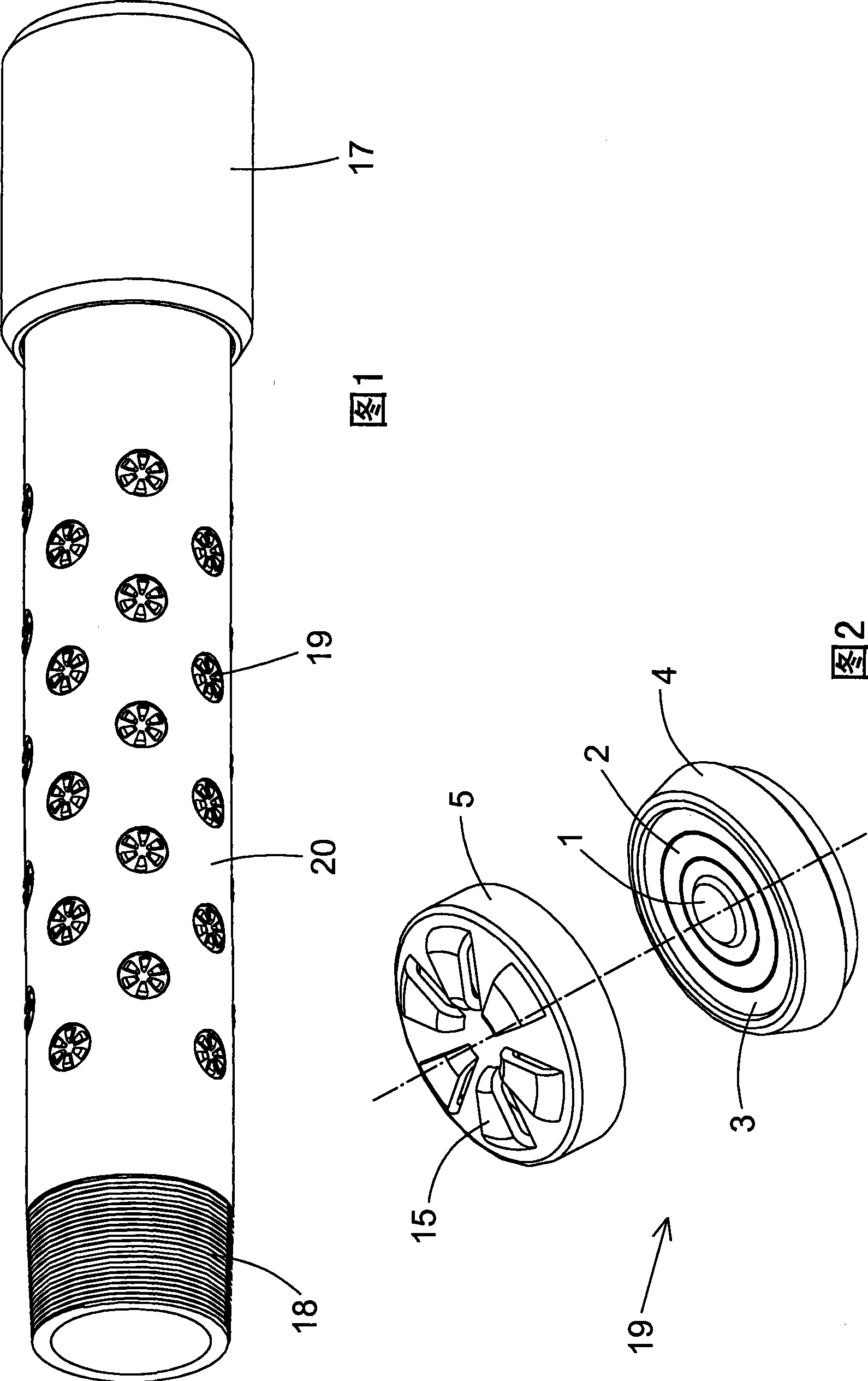

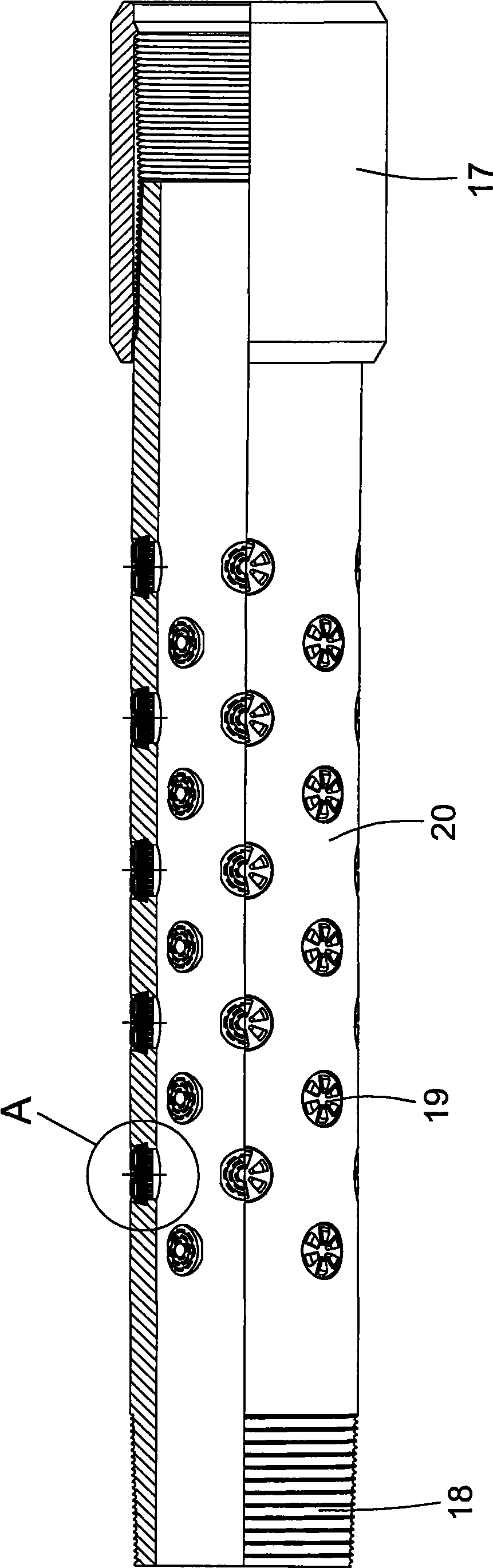

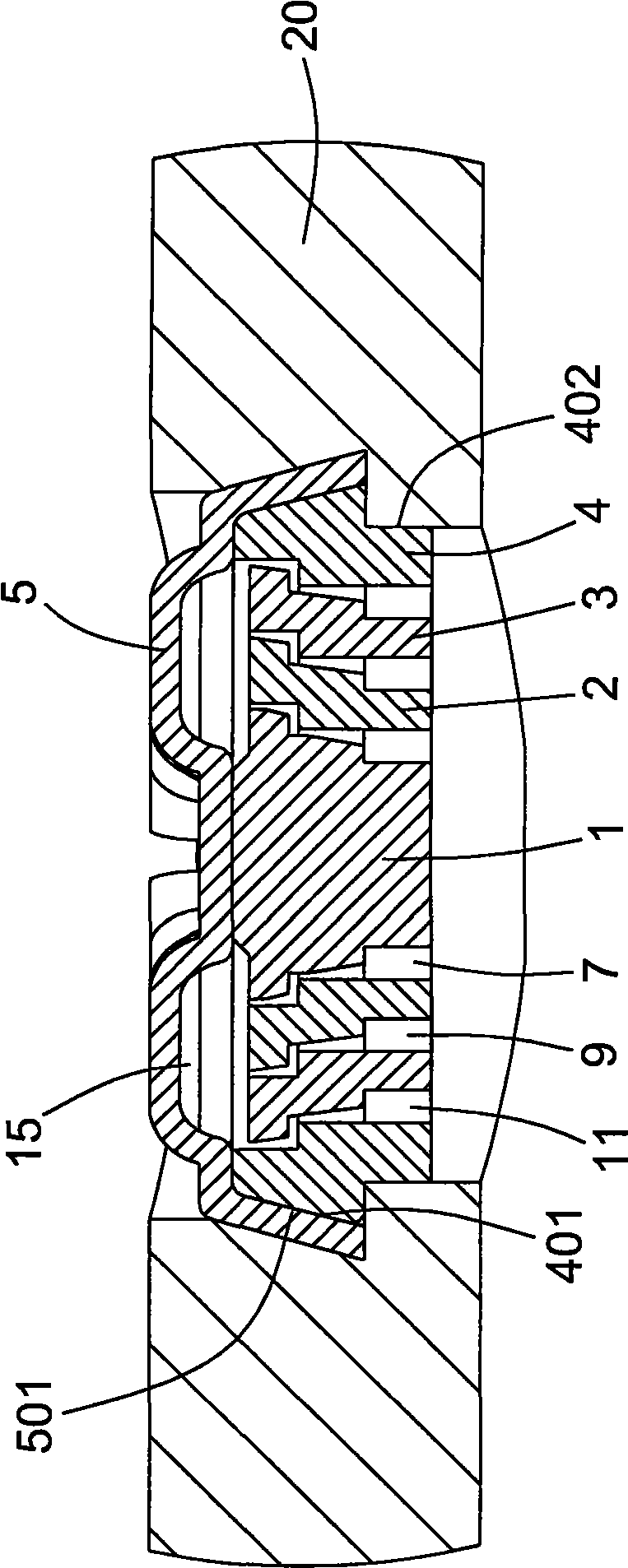

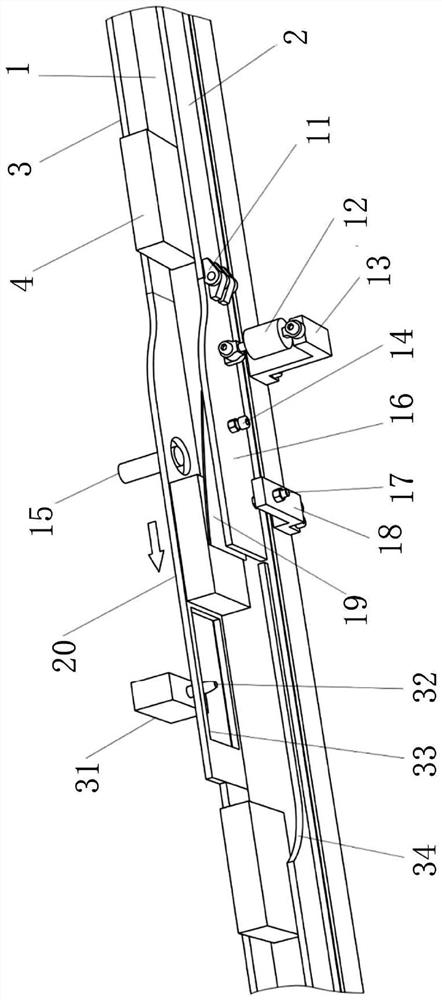

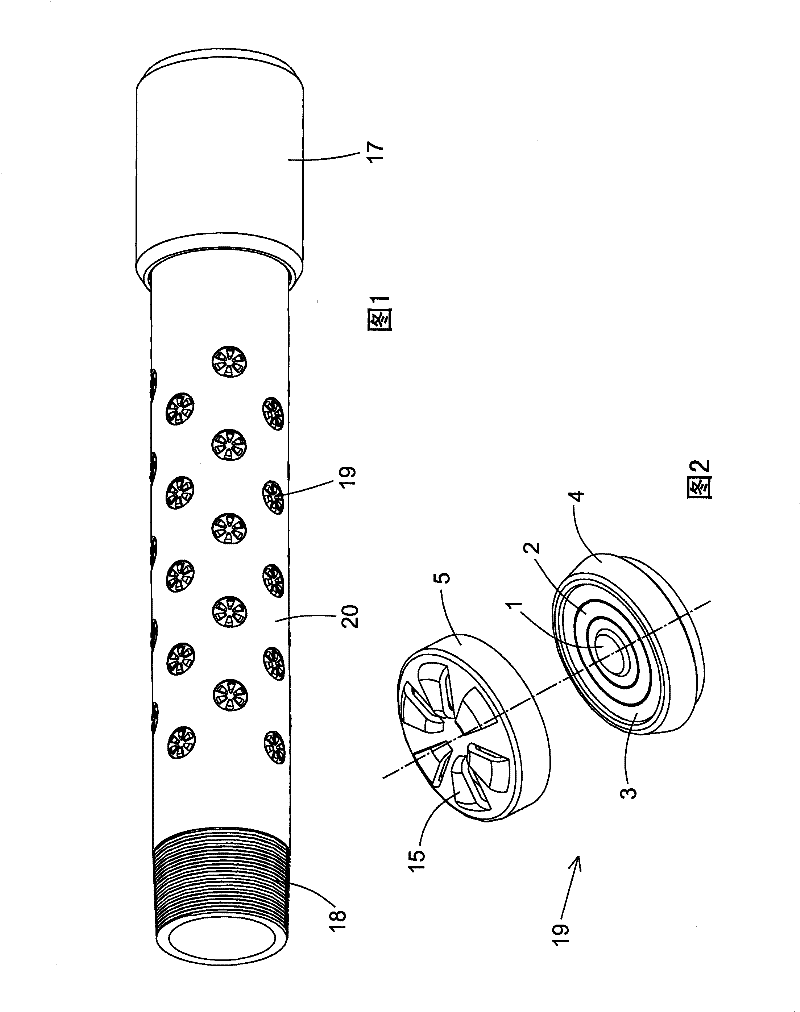

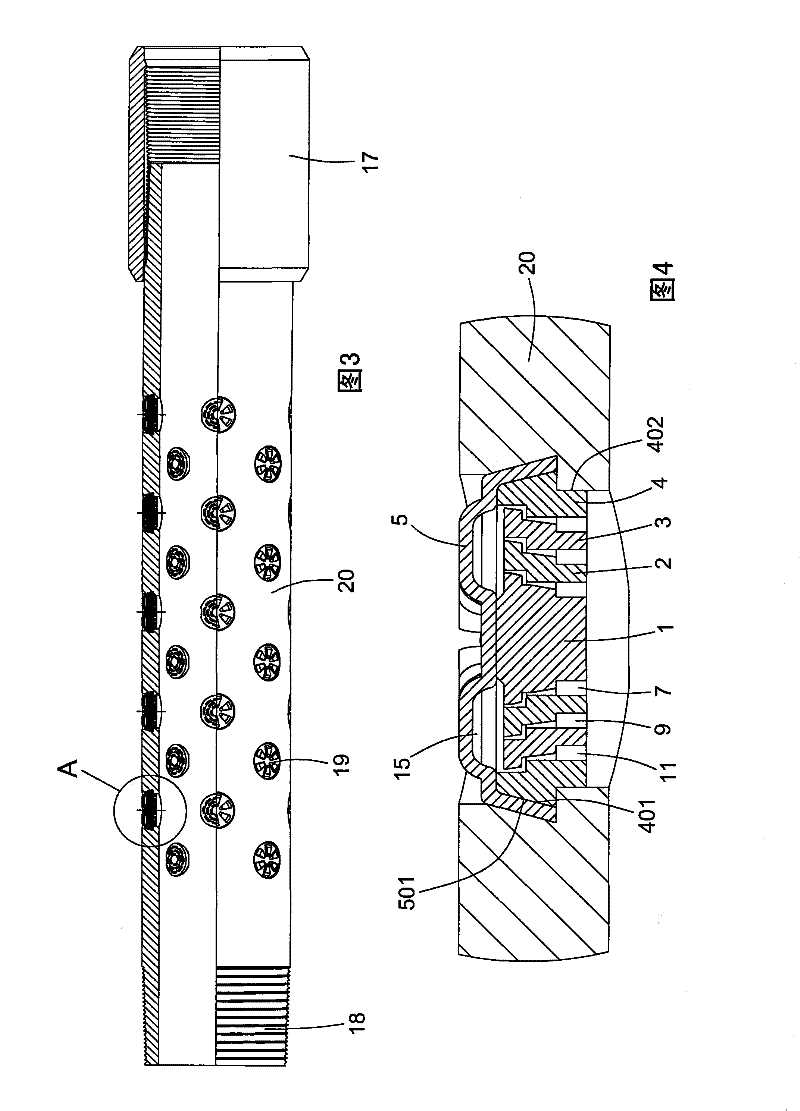

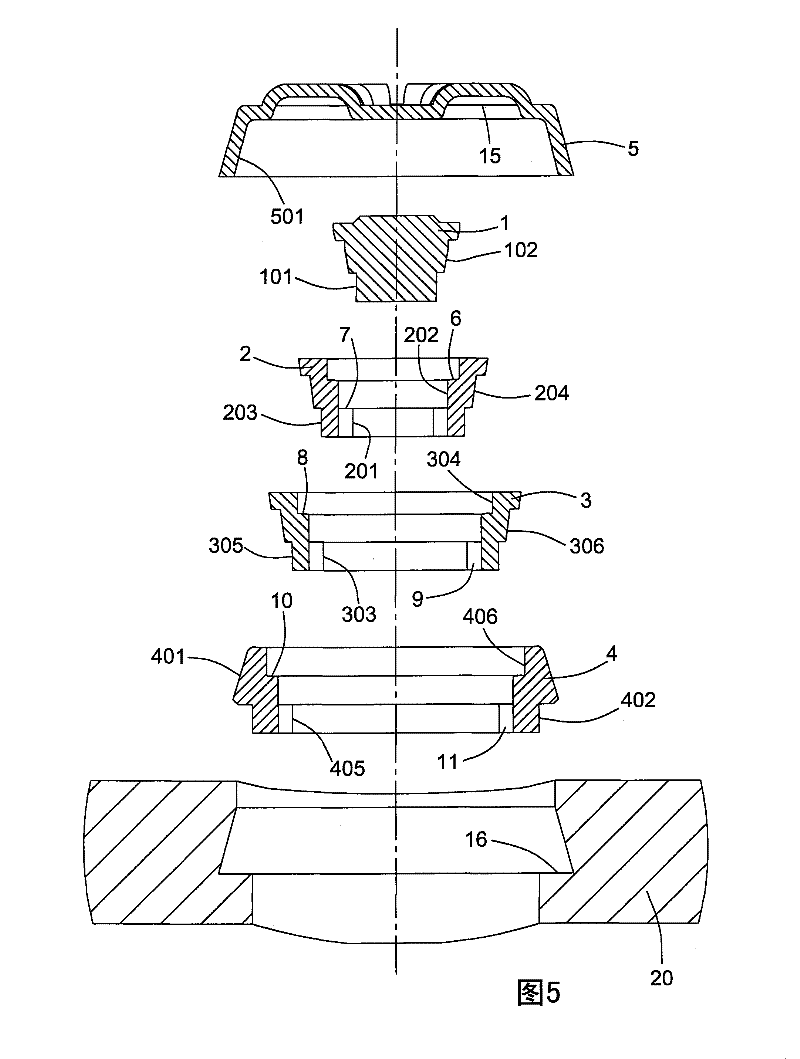

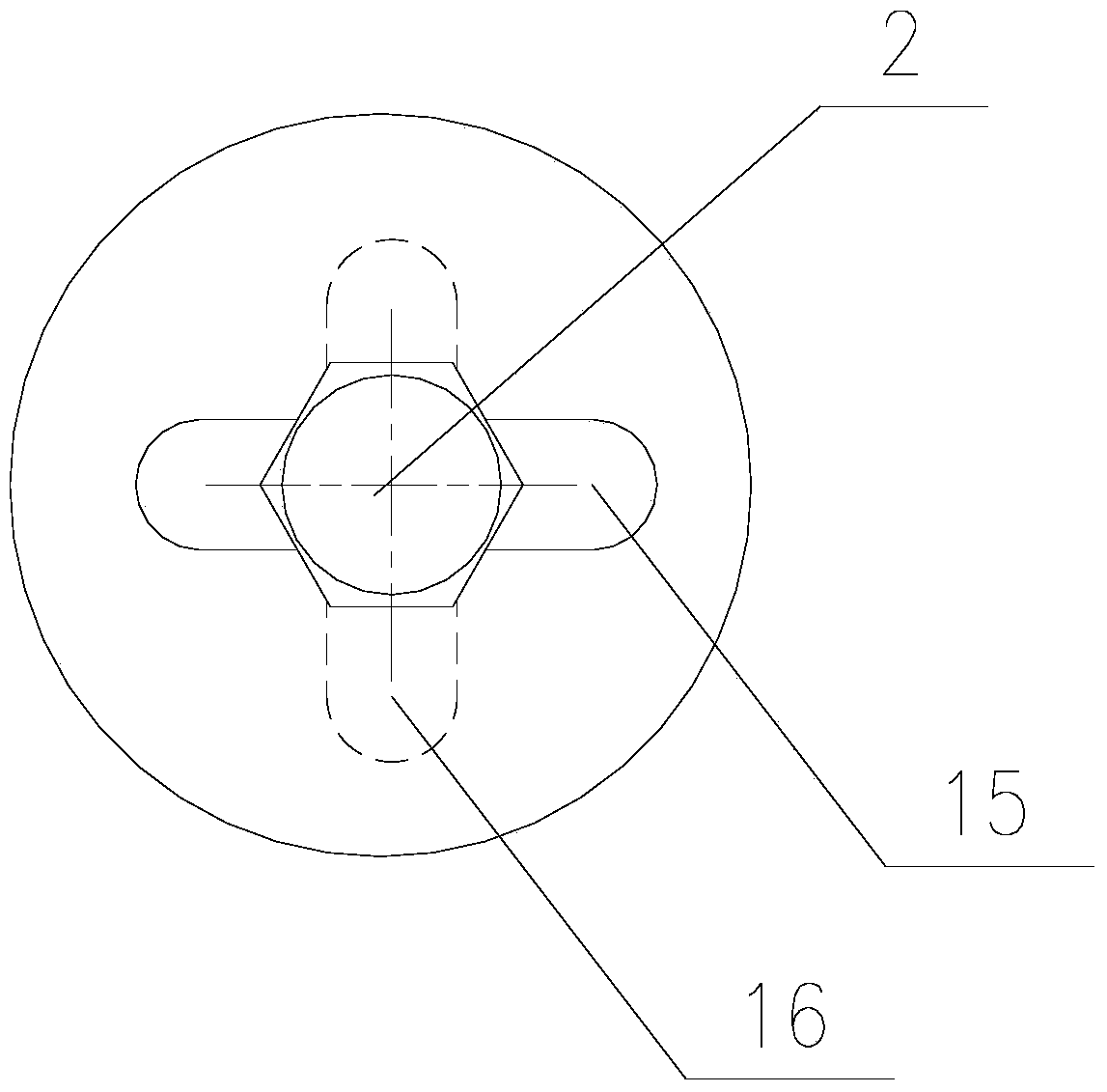

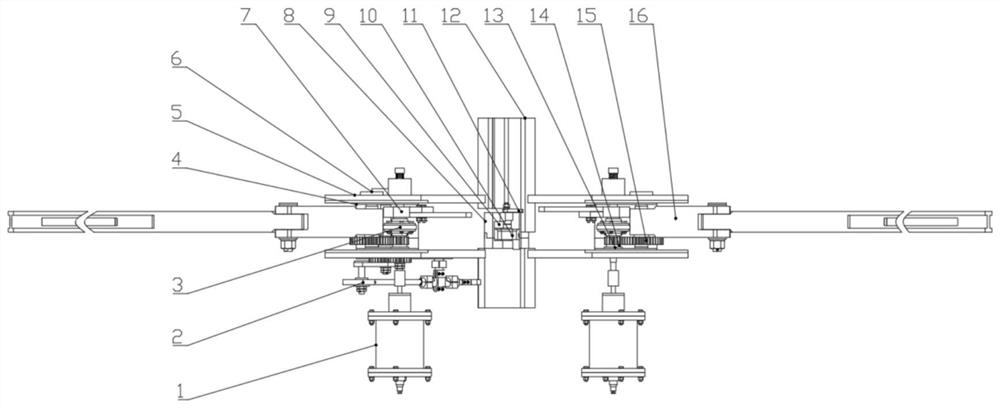

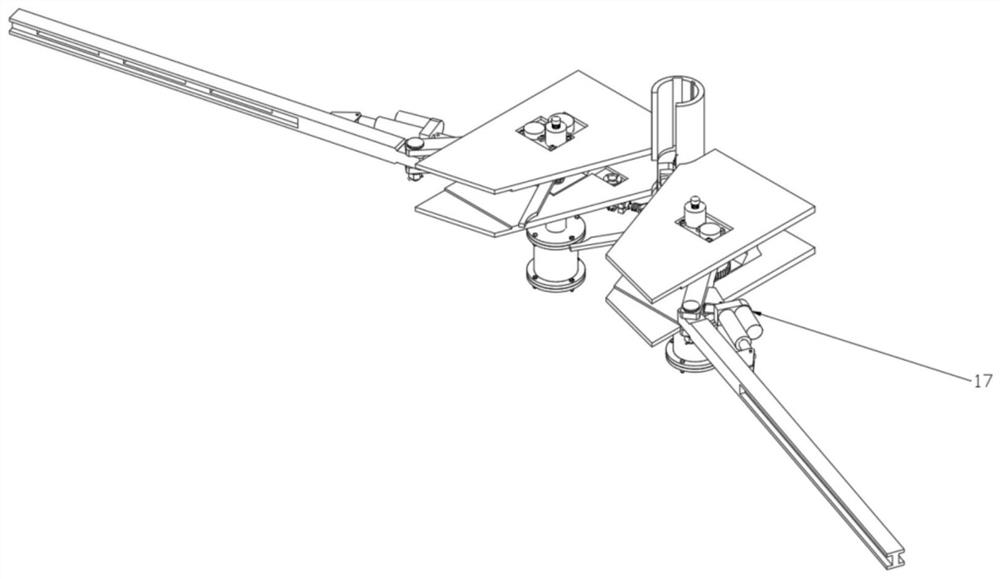

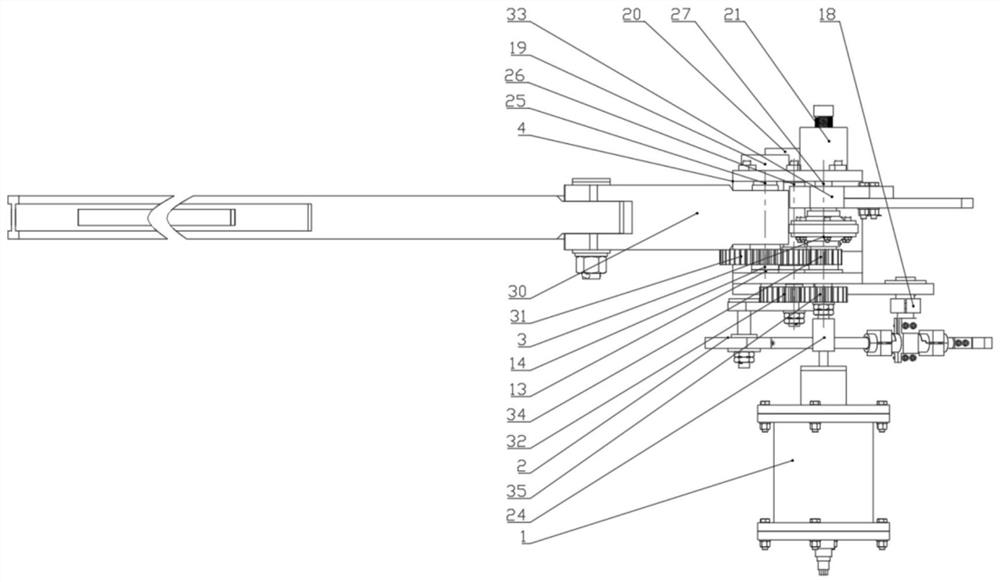

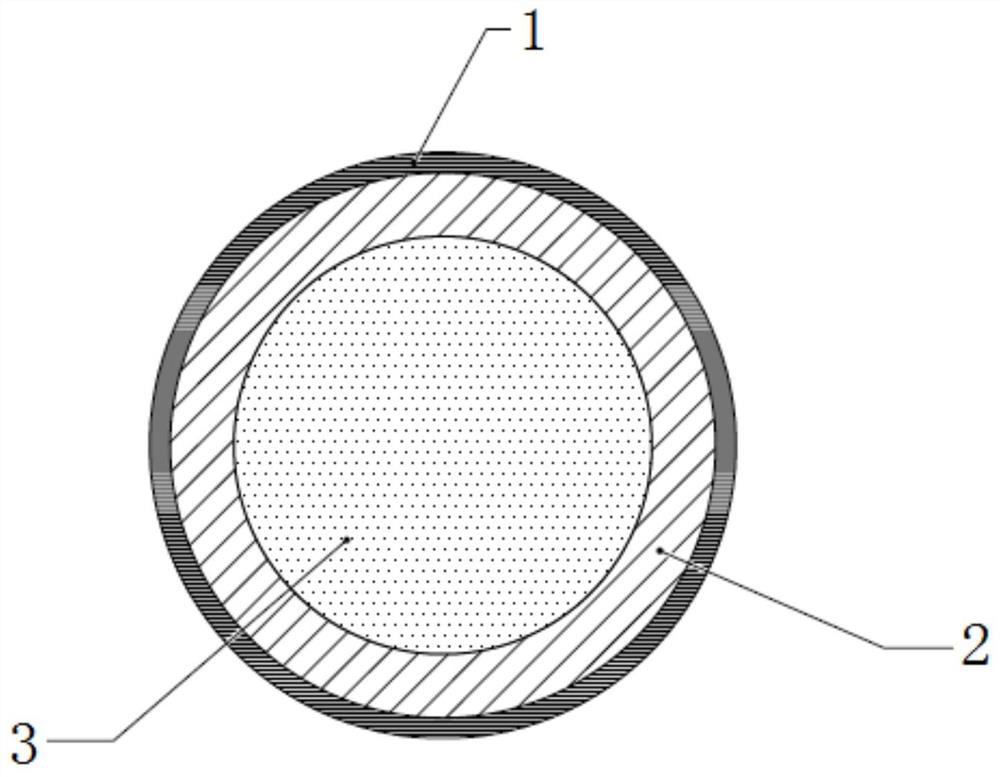

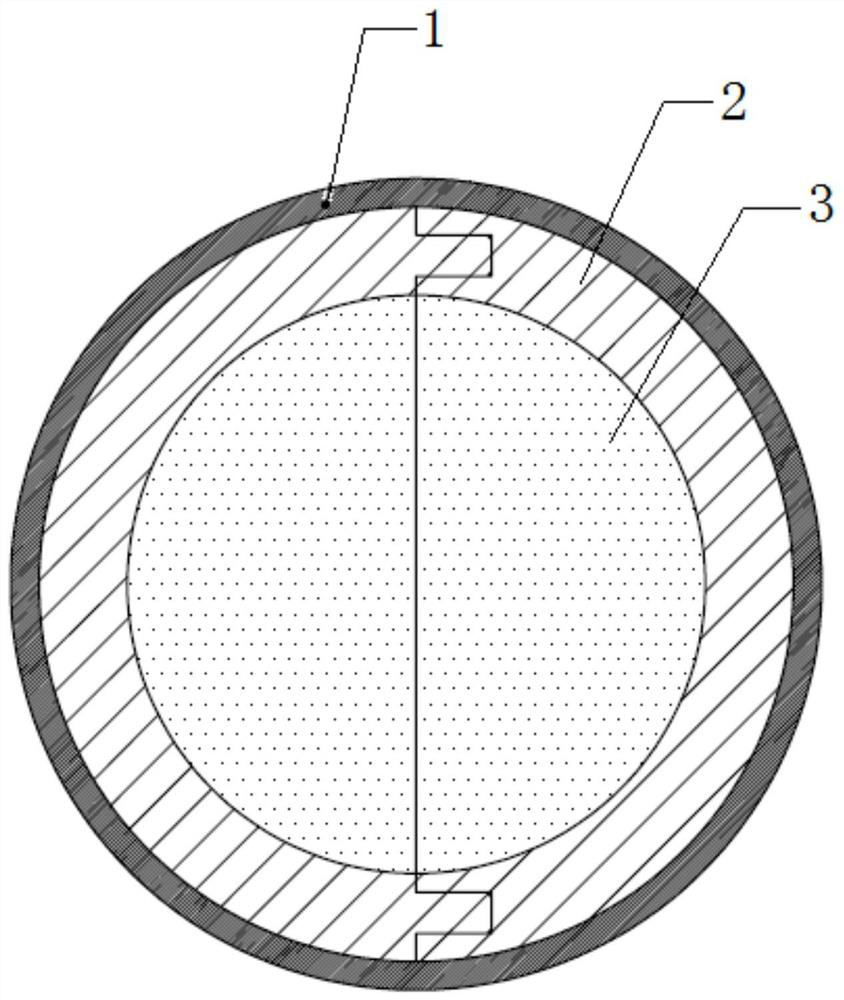

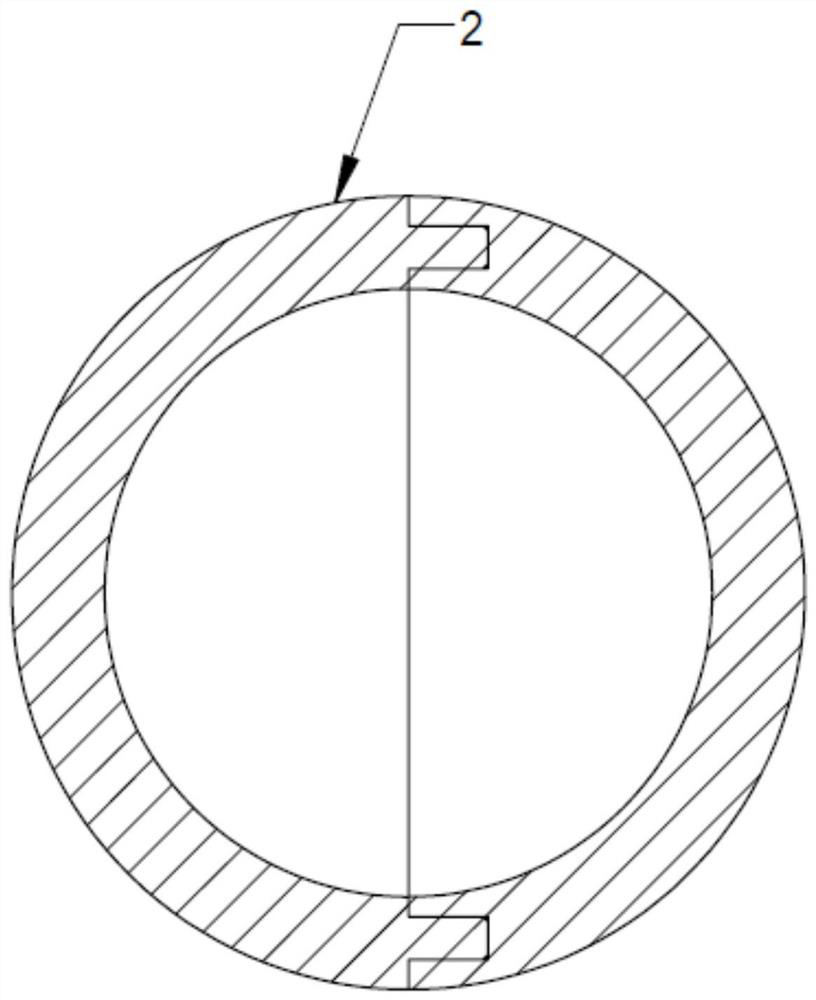

Integrated high-efficiency window sidetracking tool

ActiveCN108104753BThere will be no damage and fractureEasy to useBorehole/well accessoriesEngineeringHigh pressure

The invention relates to an integrated efficient windowing sidetrack drilling tool comprising a milling taper (1), a high-pressure pipe (2) and a protecting cylinder (3). A fixed plate (15) is arranged in the position, attached to the taper head of the milling taper (1), of the protecting cylinder (3); a high-pressure pipe nipple (16) is arranged between the upper end of the high-pressure pipe andthe milling taper, and the middle of the high-pressure pipe nipple (16) is welded to the fixed plate (15); a plurality of first backpitch grooves are formed in the outer wall of a crown part (17) atthe lower end of the milling taper, and a plurality of first cutting edges (18) are welded between the first backpitch grooves; and a plurality of second backpitch grooves (19) are formed in the positions, above the milling taper crown part (17), of the tapered face and the cylindrical face of the milling taper correspondingly, and a plurality of second cutting edges (20) are welded between the second backpitch grooves. The integrated efficient windowing sidetrack drilling tool is reliable in using performance, the operation success rate is high, and the phenomenon that tapered iron is damagedand fractured is avoided; the windowing speed is high, and the window shape is regular, so that a dead step is not formed, the windowing success rate is high, and the overall efficiency is high; andthe construction period can be shortened, and the drilling cost can be reduced.

Owner:海林新科石油耐磨工具有限责任公司

The structure of the chip carrier

ActiveCN103996646BEasy flipSave labor costsSemiconductor/solid-state device manufacturingEngineeringChip carrier

The invention provides a structure of chip bearing discs. The structure is used for containing a plurality of chips. The chip bearing discs are provided with a plurality of inversed alignment pieces, the inversed alignment pieces of the chip bearing disc containing the multiple chips are matched with the inversed alignment pieces of the chip bearing disc without the chips, and the chip bearing disc containing the multiple chips can be overturned to be inversely arranged on the other chip bearing disc so that the chips can be overturned to be really inversely arranged into the other chip bearing disc; in addition, the chip bearing discs are further provided with a plurality of stacking alignment pieces, the stacking alignment pieces are arranged on the chip bearing discs in an asymmetric mode to assist in stacked alignment of the multiple bearing discs, and the stacking direction of the stacked bearing discs is limited.

Owner:SITRONIX TECH CORP

Throwing type high energy gas fracturing device

The invention belongs to oil and gas well stimulation technology, and is a drop-in high-energy gas fracturing device. It includes an ignition device and a fracturing bomb connected to the ignition device. The ignition device includes a firing pin piston installed in the barrel and an excitation device for the firing pin. The firing pin piston is connected to the barrel through a radial fixing pin. The detonator of the fracturing bomb Or the primer is located at the bottom of the aforementioned barrel and corresponds to the firing pin; the special feature of the present invention is that the triggering device of the firing pin includes a pilot valve controlled by a spring, the inlet of the pilot valve communicates with the outside world, and a connection The first port of the pipe is located at the outlet of the pilot valve, and the second port of the connecting pipe communicates with the airtight cavity at the tail end of the striker piston. The invention uses a spring to control the opening of the pilot valve, and then leads the wellbore fluid to the striker piston, which not only has fast response, high control precision, but also reliable operation and high operation success rate.

Owner:XIAN TONGYUAN PETROTECH

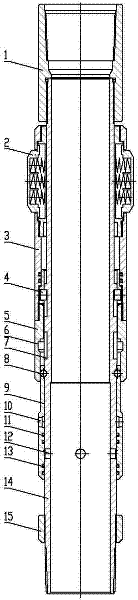

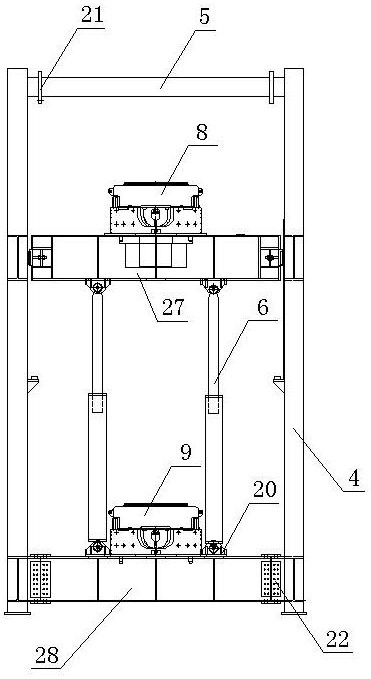

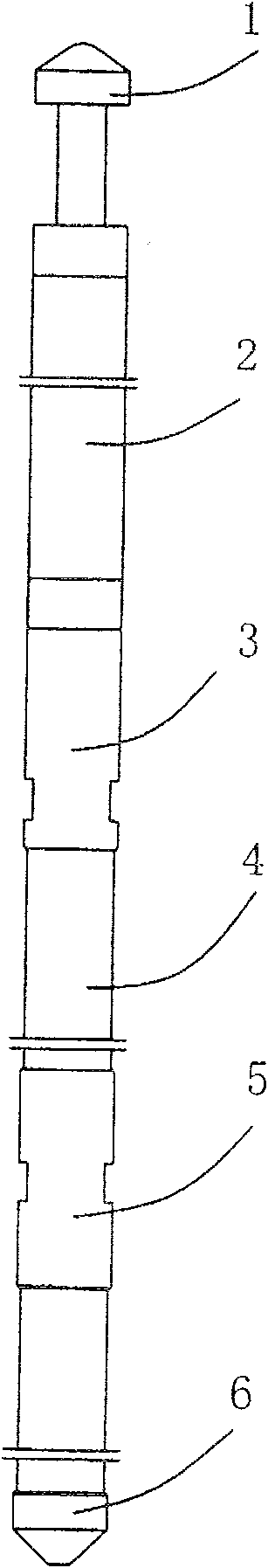

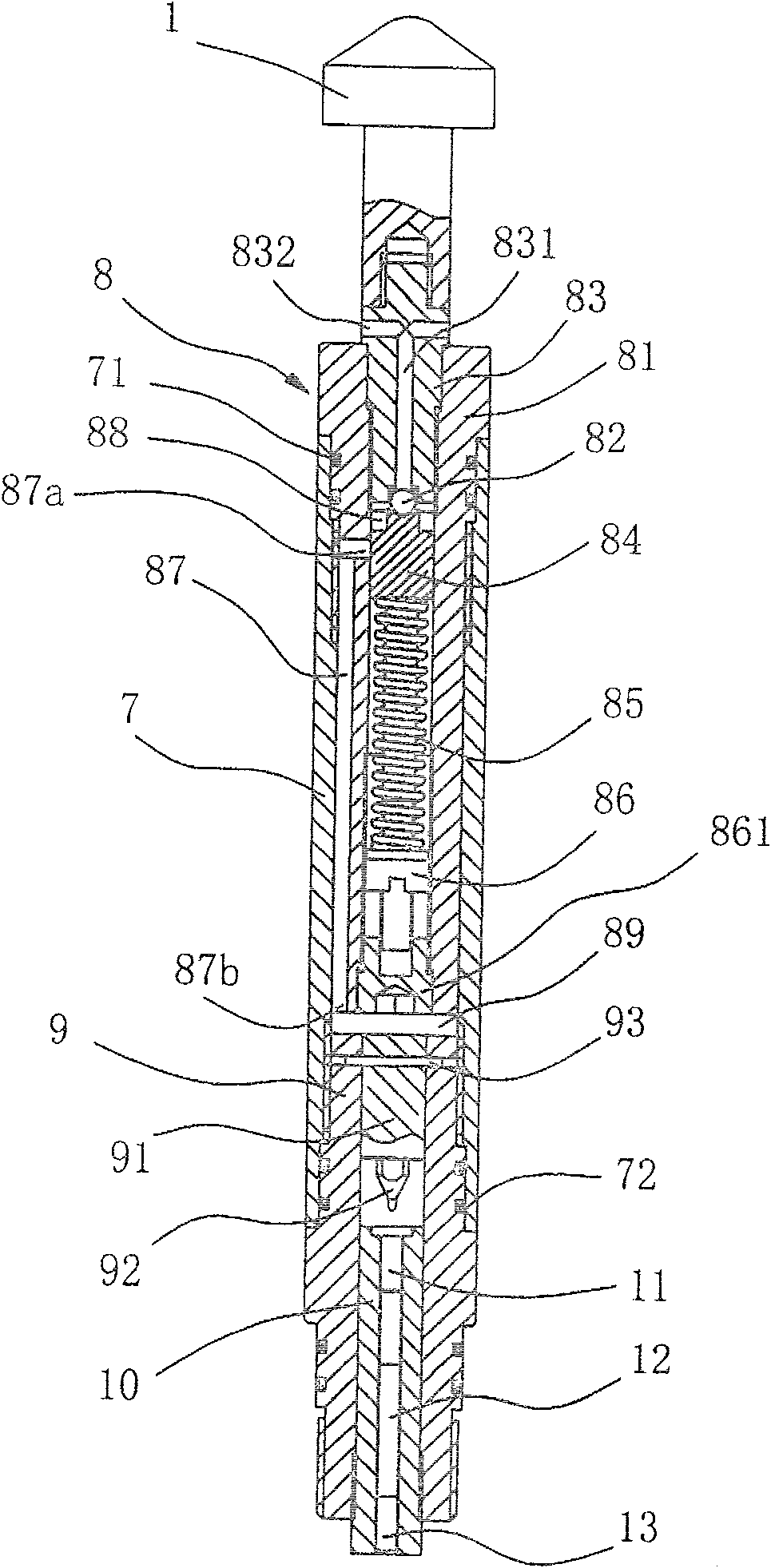

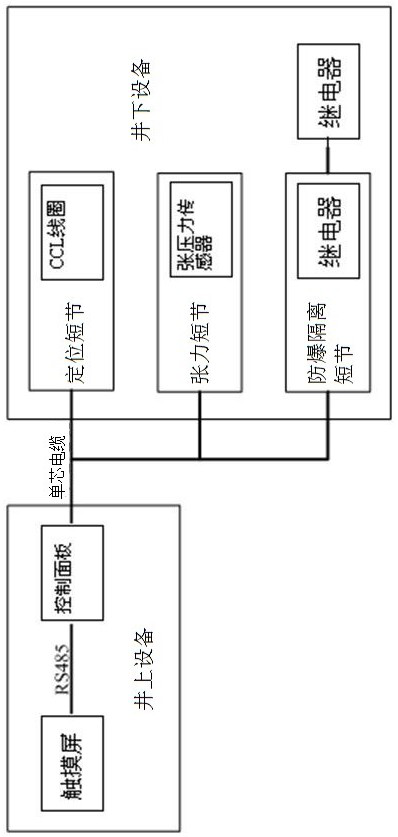

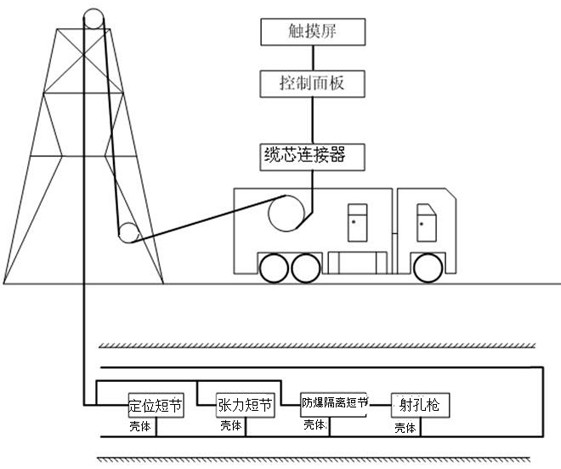

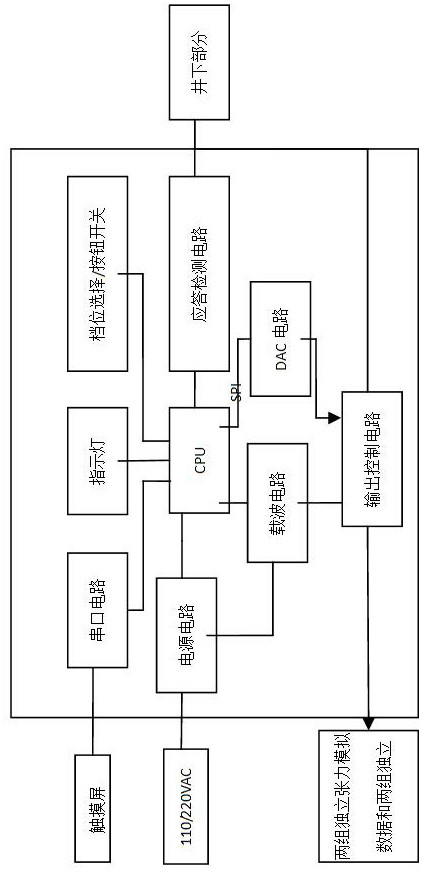

Real-time monitoring system and monitoring method for downhole tension of single-core cable for perforation

ActiveCN107727298BEasy to controlImprove reliabilitySurveyTension measurementHorizontal wellsMonitoring system

The invention discloses a real-time monitoring system of down-hole tension of a single-core cable used for perforating and a monitoring method thereof. The monitoring system comprises surface equipment and down-hole equipment, the surface portion comprises a display screen and a control panel, the display screen is connected with the control panel, the down-hole portion comprises a down-hole instrument string formed by sequentially connecting a locating sub, a tension sub and an explosion-proof isolation sub, the explosion-proof isolation sub is connected with a perforating gun, the control panel is connected with the locating sub, the tension sub and the explosion-proof isolation sub through the single-core cable separately, and control circuits of the locating sub, the tension sub and the explosion-proof isolation sub are connected with in parallel. By means of the system and the method, tension change of the down-hole cable is measured in real time, and tension signals are uploadedto the ground for display through the single-core cable, so that visual guidance is provided for cable tube column pumping operation of a horizontal well section, and a basis is provided for judging the stress state of a down-hole tube string.

Owner:CHUANNAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com