Horizontal well deflecting section trajectory optimization method based on stratum thickness change

A technology of thickness change and trajectory optimization, applied in design optimization/simulation, directional drilling, earthwork drilling and production, etc., can solve problems such as difficult to provide accurate data, difficult to solve, and difficult to control the trajectory, so as to improve the success rate of operations, Reduce operational risks and achieve safe operation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] For the horizontal well Deng 2 in the target layer of a certain well, the build-up section is the Sinian Deng 4 + Deng 3 + the top of Deng 2, and the stratum thickness change section is Deng 3. The well trajectory optimization method includes the following steps:

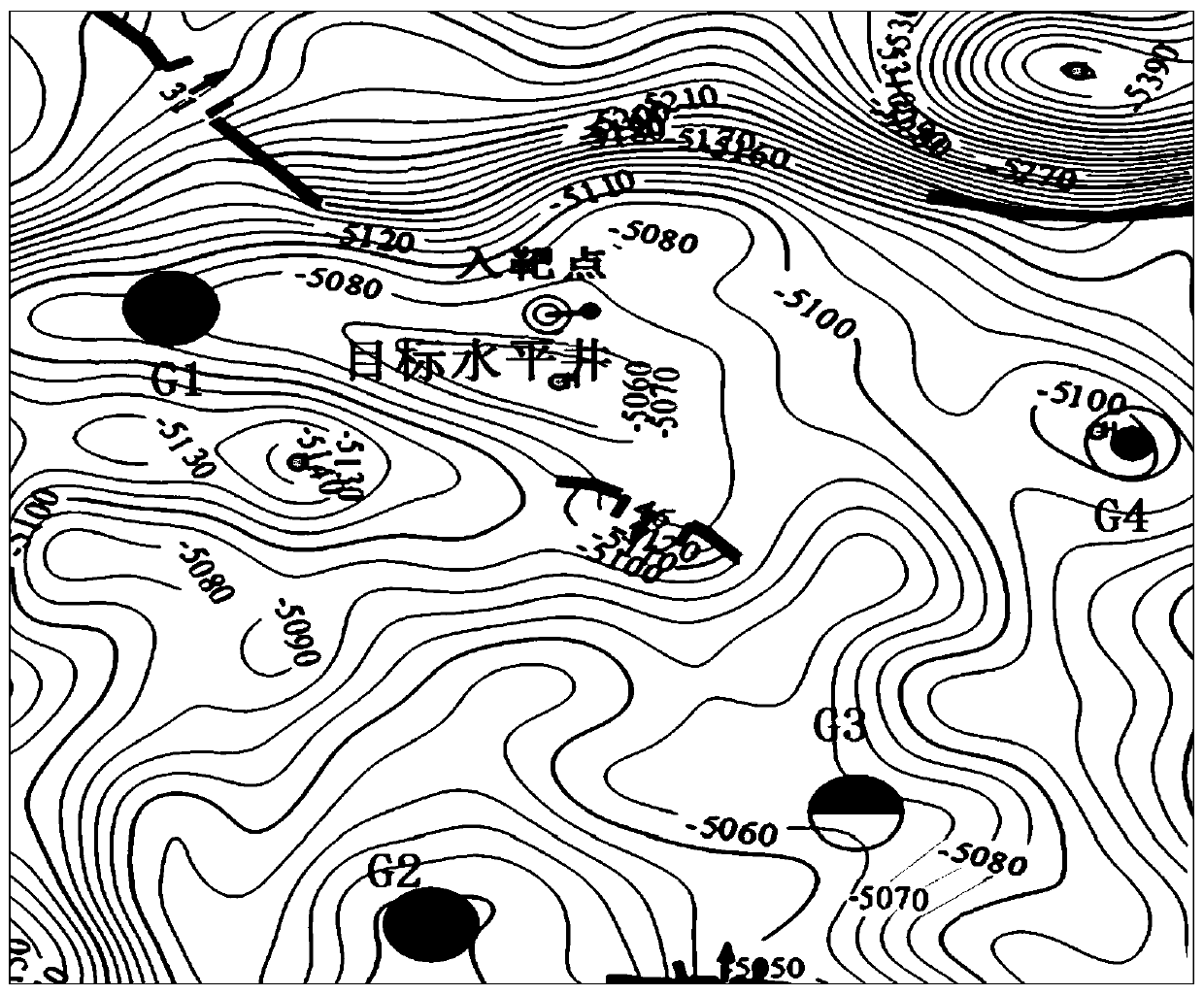

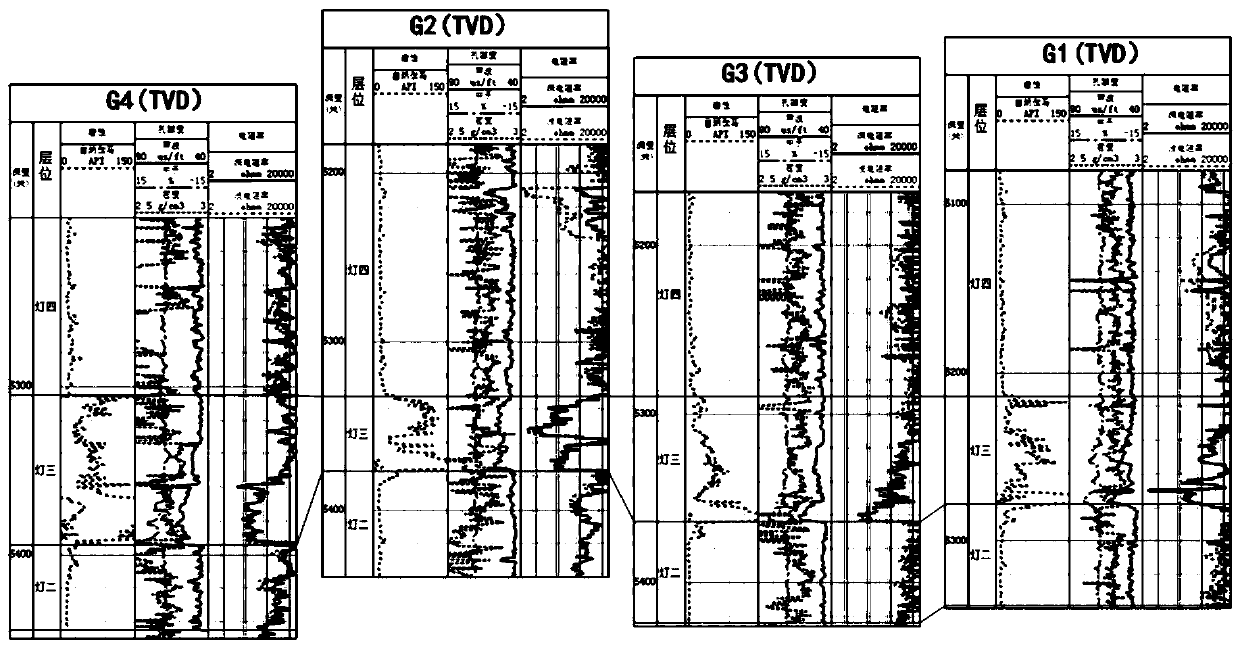

[0045] 1. Finely compare multi-well logging data, and analyze the characteristic parameters of lithofacies and formation thickness changes. Through the comparison of the thickness of the four vertical wells G1, G2, G3, and G4 around the target well, it is found that the thickness of Deng 3 varies greatly, ranging from 44m to 85m, and the thickness of the G1 well closest to the target well is 64 meters. This well will be used as the target well An important reference to ( figure 1 , figure 2 ,Table 1).

[0046] Table 1 Comparison table of four wells and three formation thicknesses

[0047]

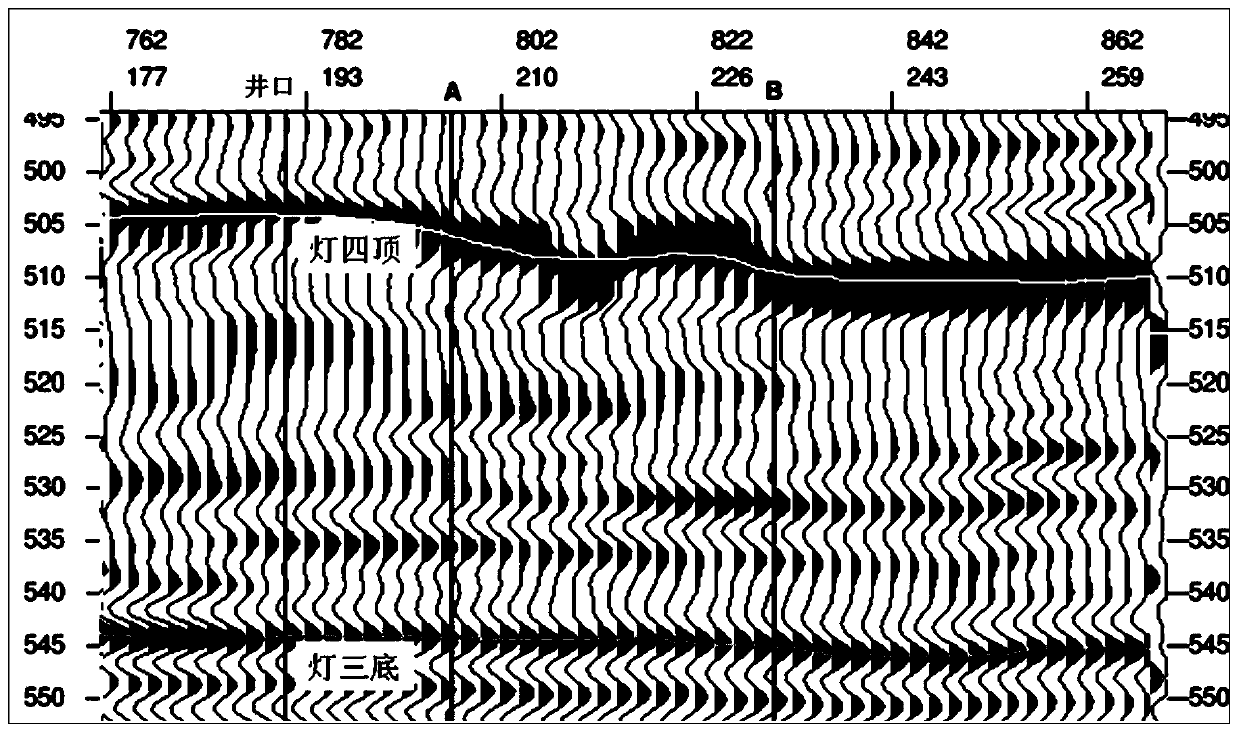

[0048] 2. According to logging calibration, finely process seismic data to find out the stratum thickness and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com