Patents

Literature

253 results about "Early prediction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

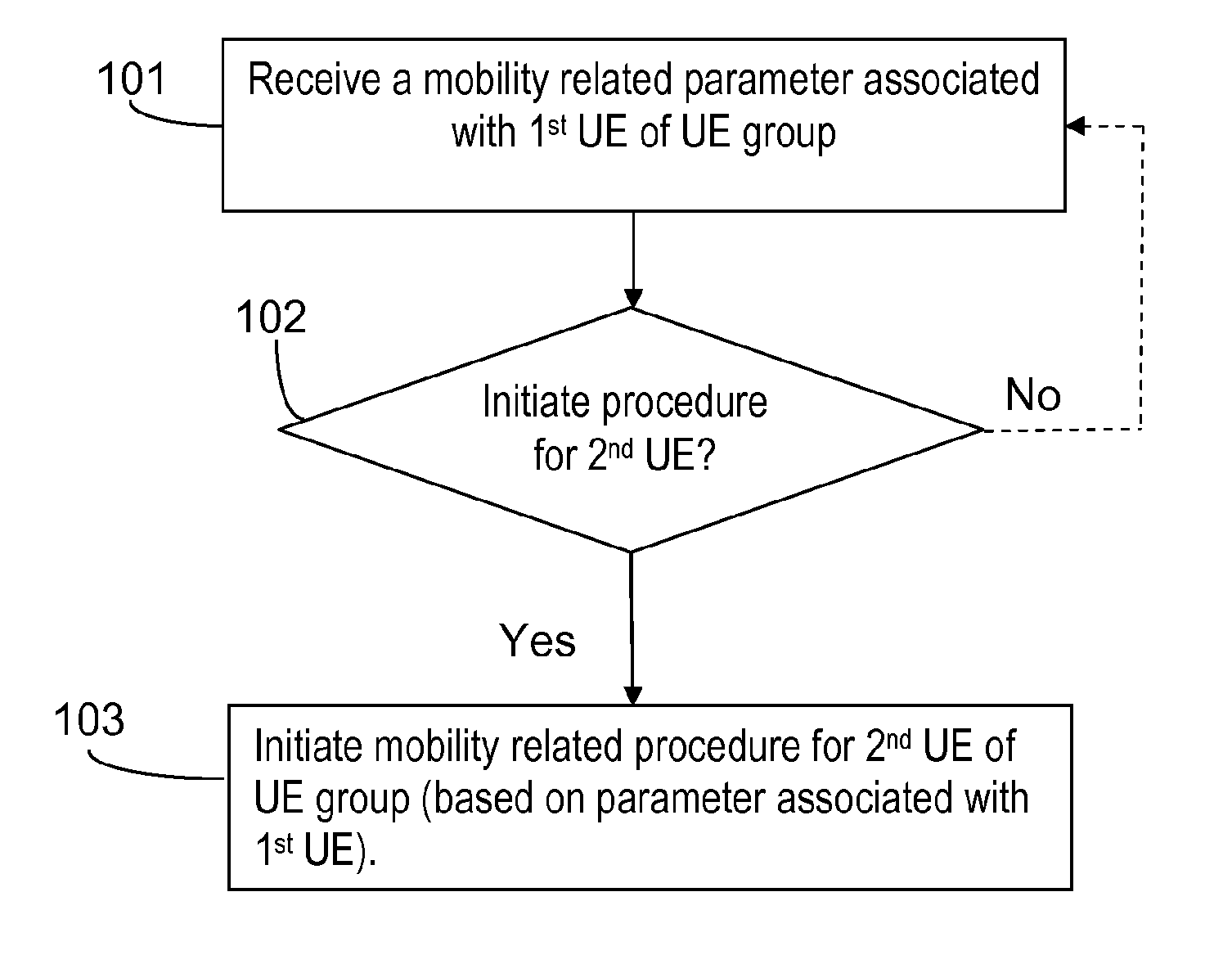

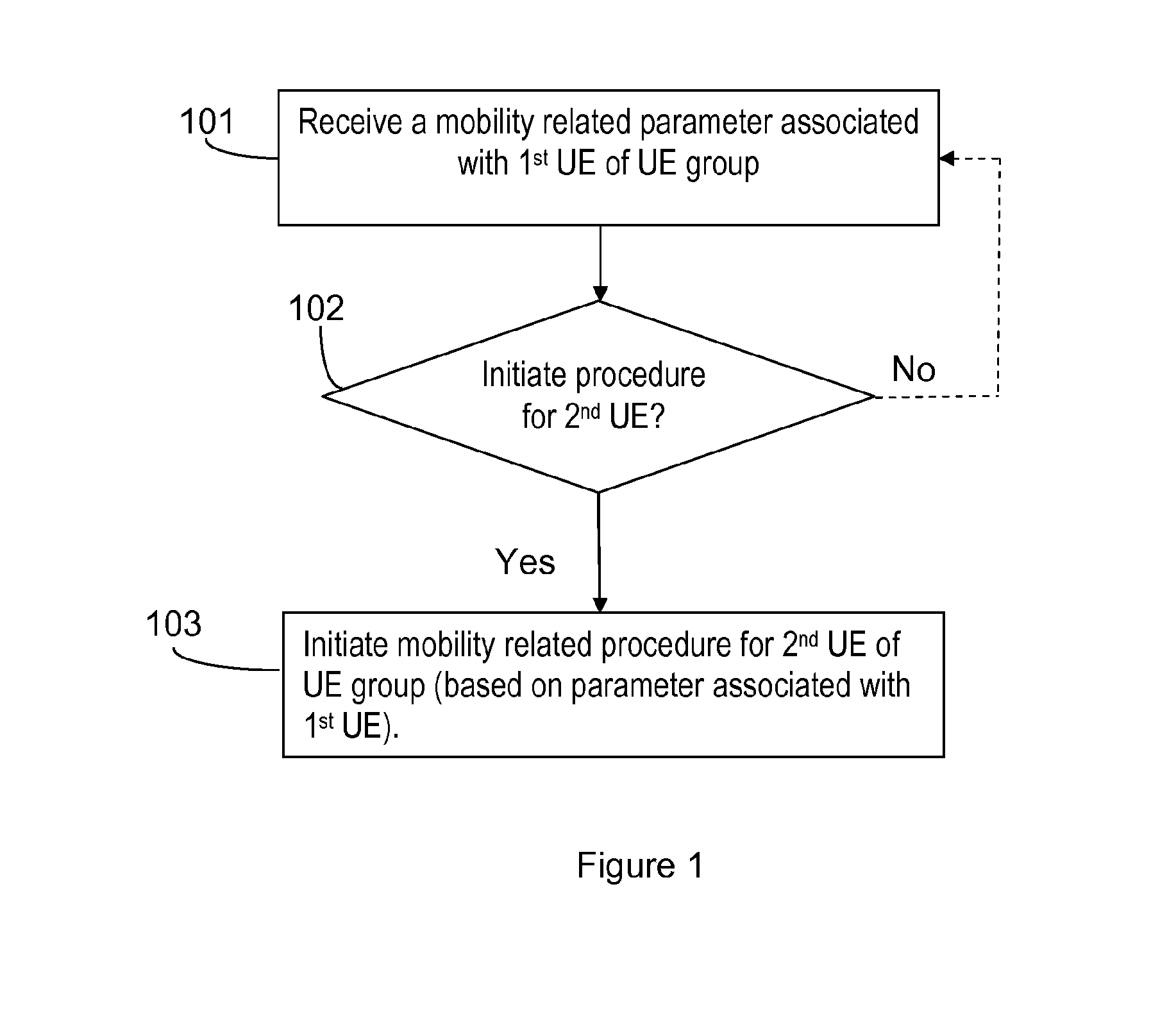

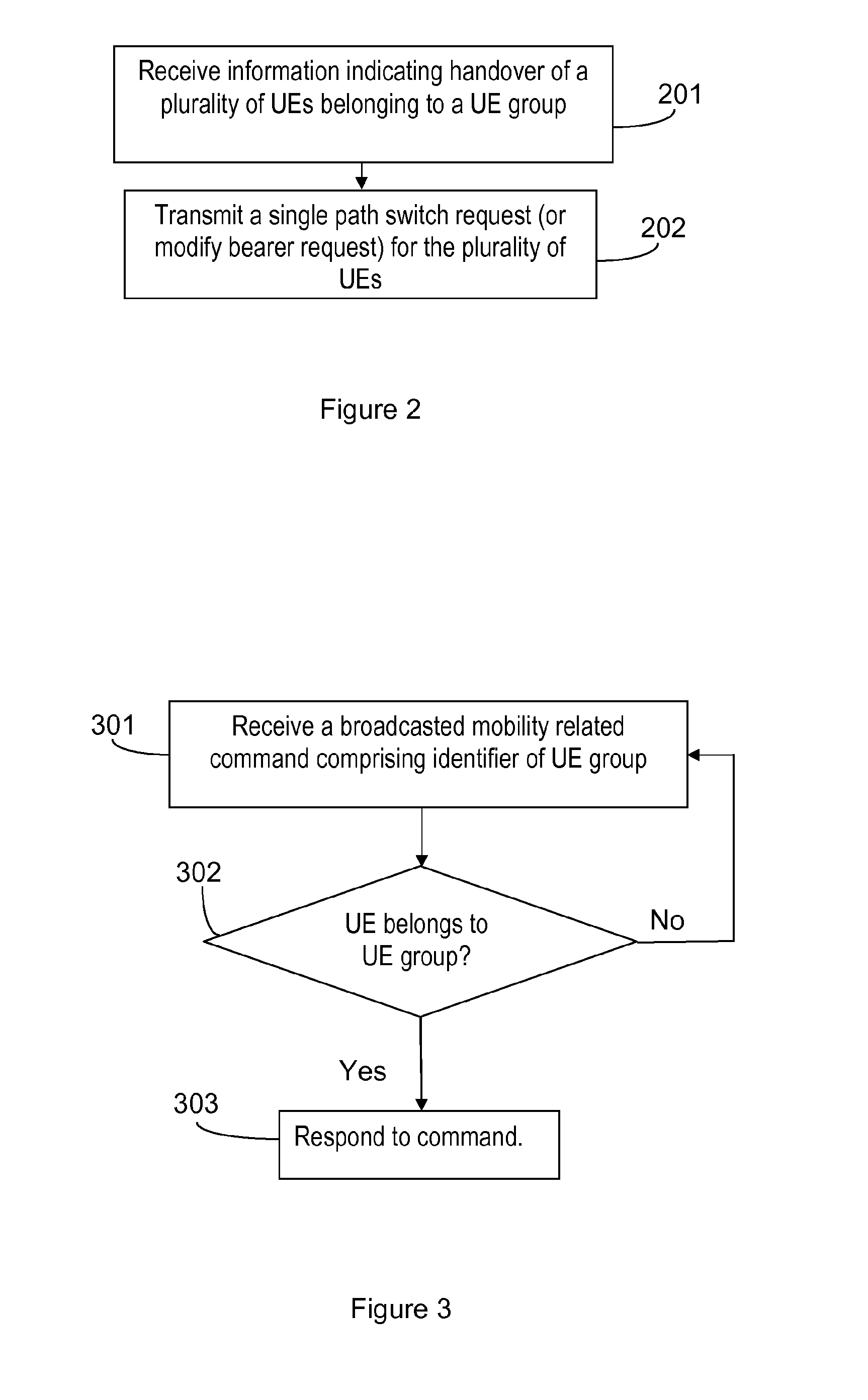

Method and Arrangement for Mobility Procedures

ActiveUS20150181481A1Good switching effectRobust procedureWireless communicationEarly predictionCommunications system

Cooperating nodes, and methods therein, for mobility procedures in a wireless communication system supporting UE groups. One of the cooperating nodes is a base station being associated with a UE group comprising UEs having correlated mobility related parameters. The method in the base station comprises receiving, from a first UE in the UE group, a mobility related parameter associated with the first UE. The method further comprises determining whether to initiate a mobility related procedure for a second UE in the UE group based on the received mobility related parameter; and further comprises initiating the mobility related procedure for the second UE when it is determined that the mobility related procedure is to be performed. Thereby, prediction and decisions related to mobility events, e.g. handover events, for the second UE or for the whole group may be performed e.g. before or without receiving any mobility information related to the second UE, thereby enabling early prediction and better preparation, which can lead to more robust mobility procedures.

Owner:TELEFON AB LM ERICSSON (PUBL)

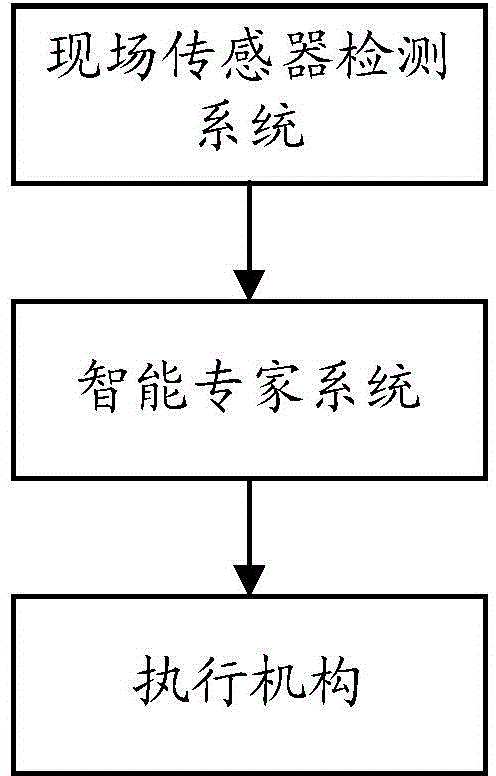

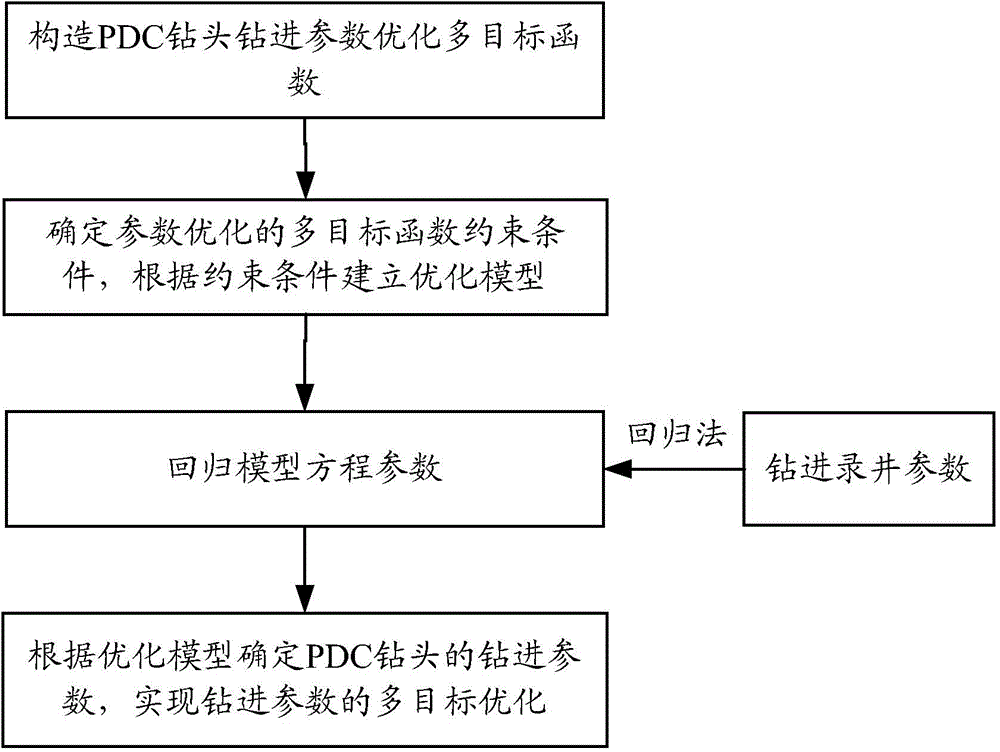

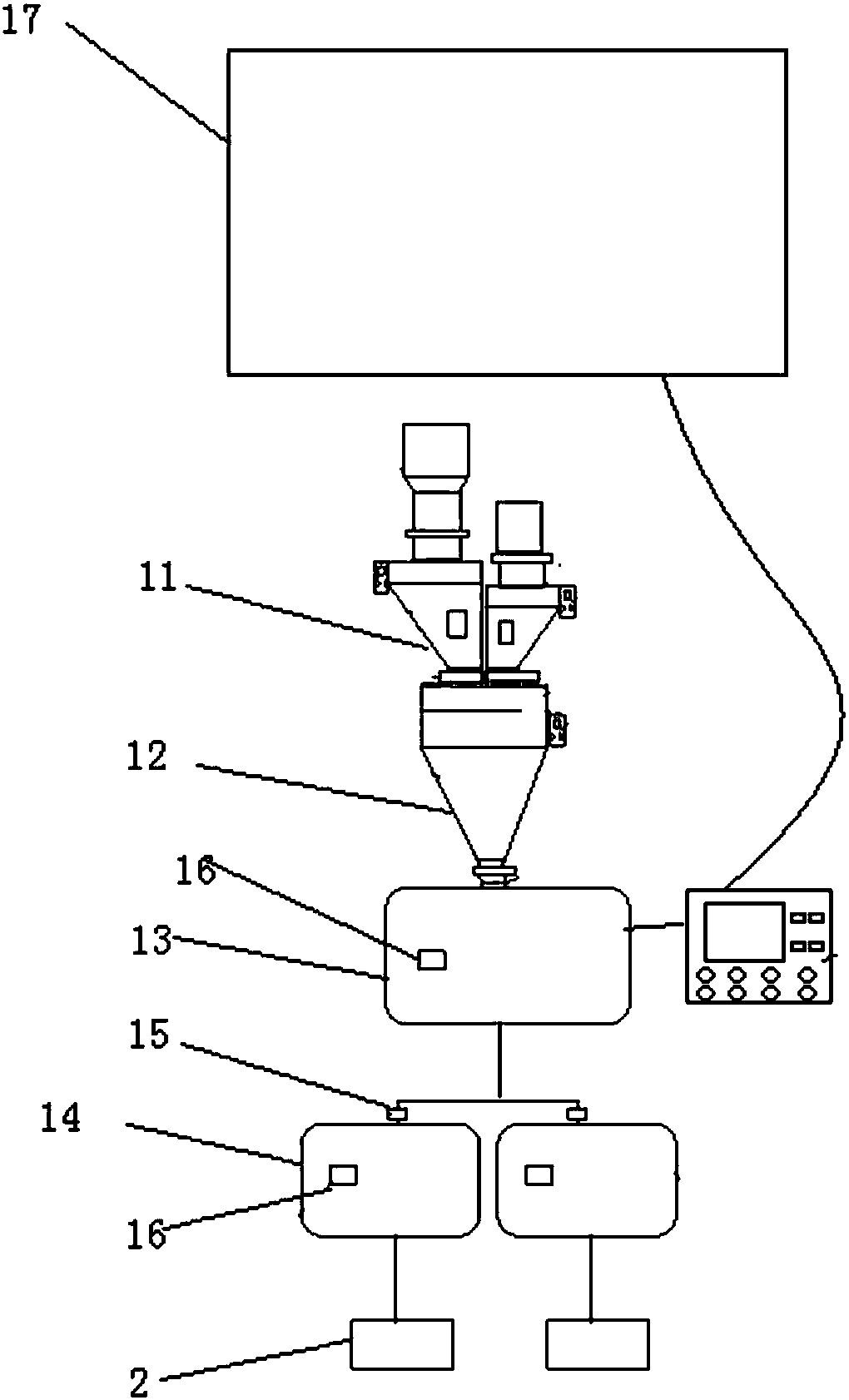

Intelligent drilling expert system

ActiveCN104806226AAccurate discoveryReal-timeAutomatic control for drillingEarly predictionAutomatic control

The invention provides an intelligent drilling expert system. The intelligent drilling expert system comprises a field sensor detection system, an intelligent expert system and an execution mechanism. An automatic closed-loop drilling regulation and control system is formed. Data in a whole drilling process are acquired through a field sensor; then, the acquired data are transmitted into a computer for processing, monitoring, prediction, analysis, explanation, control and the like. Most importantly, through the researched cross-specialty and cross-industry intelligent expert control models for drilling hydraulic control, well wall stability control, friction resistance and torque control, drilling speed and cost control, drilling complexity and accident control and the like, instantaneity, early discovery, early prediction, interpretation while drilling and an automatic control function can be realized, and accurate information is provided for drilling engineering; moreover, the intelligent drilling expert system has the advantages of reducing the drilling cost, increasing the drilling speed, avoiding sudden accidents and discovering oil and gas accurately.

Owner:北京四利通控制技术股份有限公司

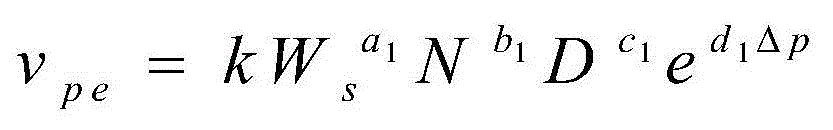

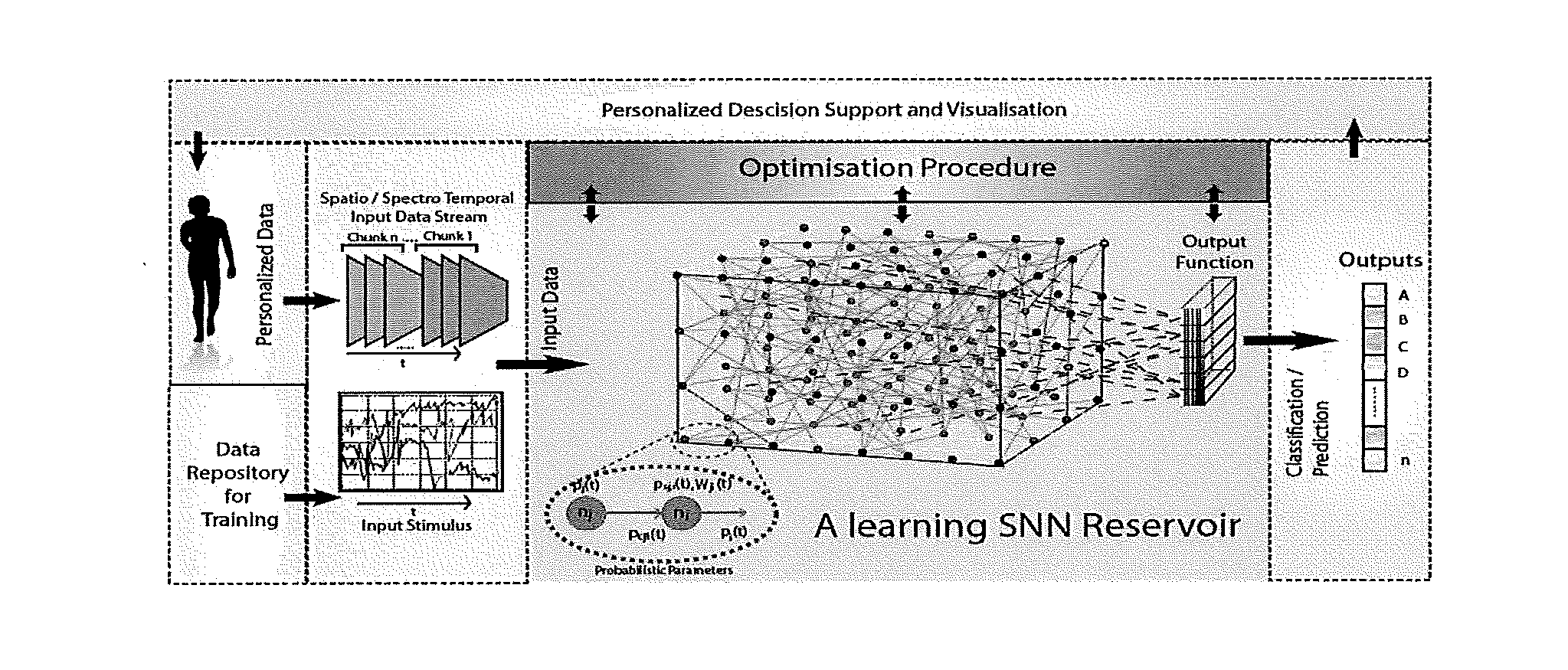

Improved Method And System For Predicting Outcomes Based On Spatio/Spectro-Temporal Data

ActiveUS20160210552A1Improve accuracyShorten the timeDigital computer detailsDigital dataSpike trainSpatiotemporal pattern

This invention involves use of temporal or spatio / spector-temporal data (SSTD) for early classification of outputs that are results of spatio-temporal patterns of data. Classification models are based on spiking neural networks (SNN) suitable to learn and classify SSTD. The invention may predict early events in many applications, i.e. engineering, bioinformatics, neuroinformatics, predicting response to treatment of neurological and brain disease, ecology, environment, medicine, and economics, among others. The invention involves a method and system for personalized modelling of SSTD and early prediction of events based on evolving spiking neural network reservoir architecture (eSNNr). The system includes a spike-time encoding module to encode continuous value input information into spike trains, a recurrent 3D SNNr and an eSSN as an output classification module.

Owner:AUT VENTURES LTD

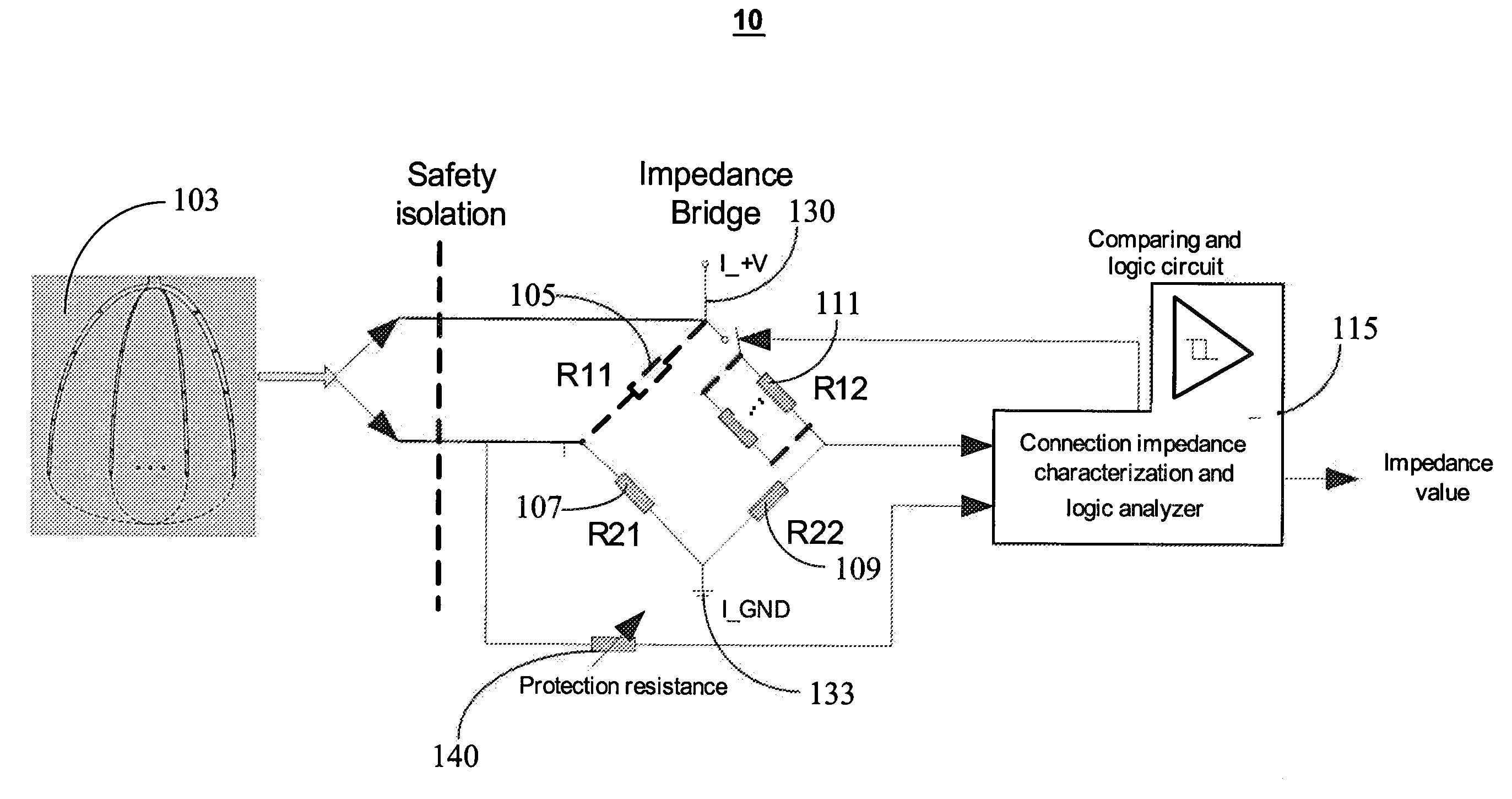

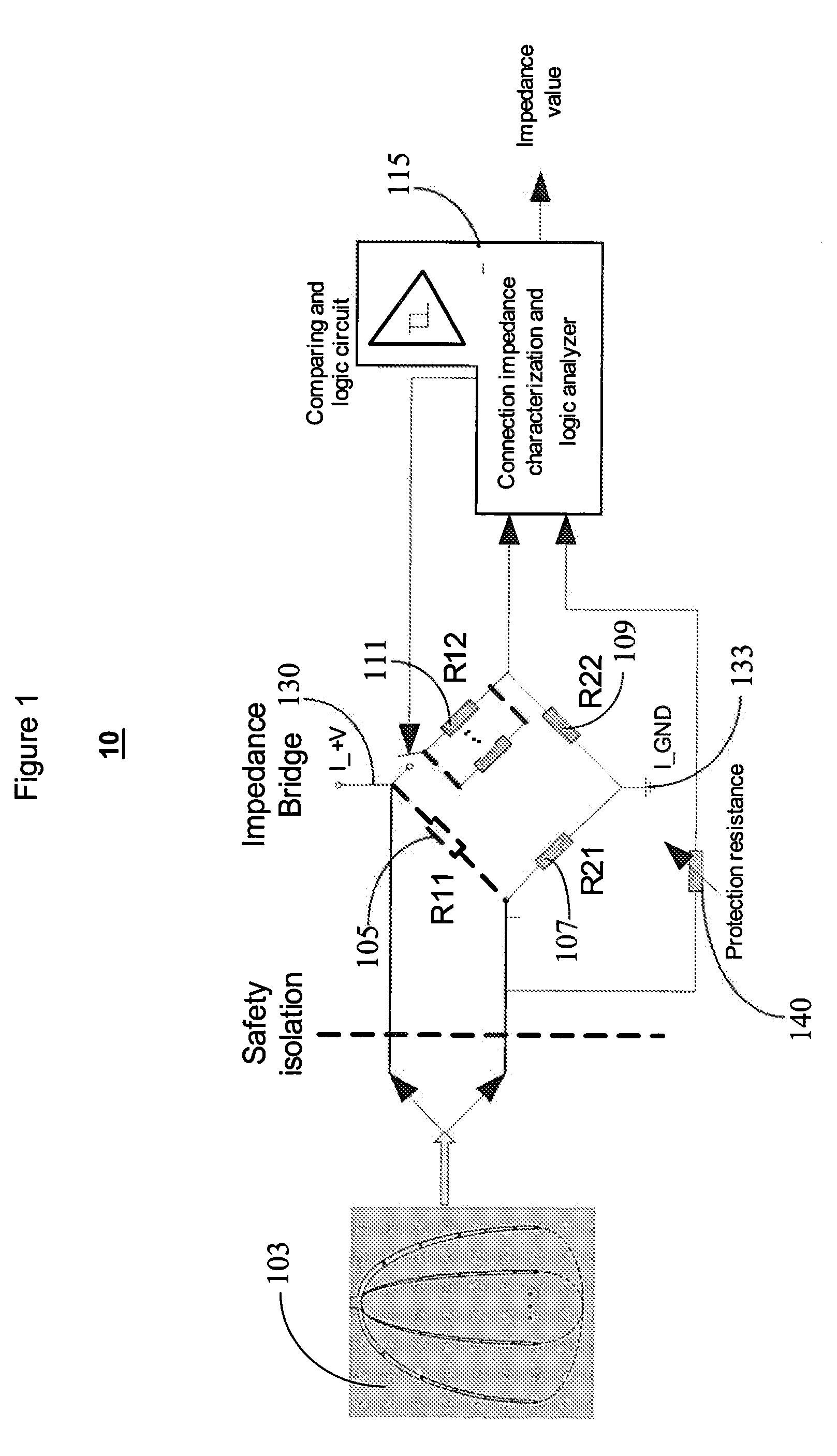

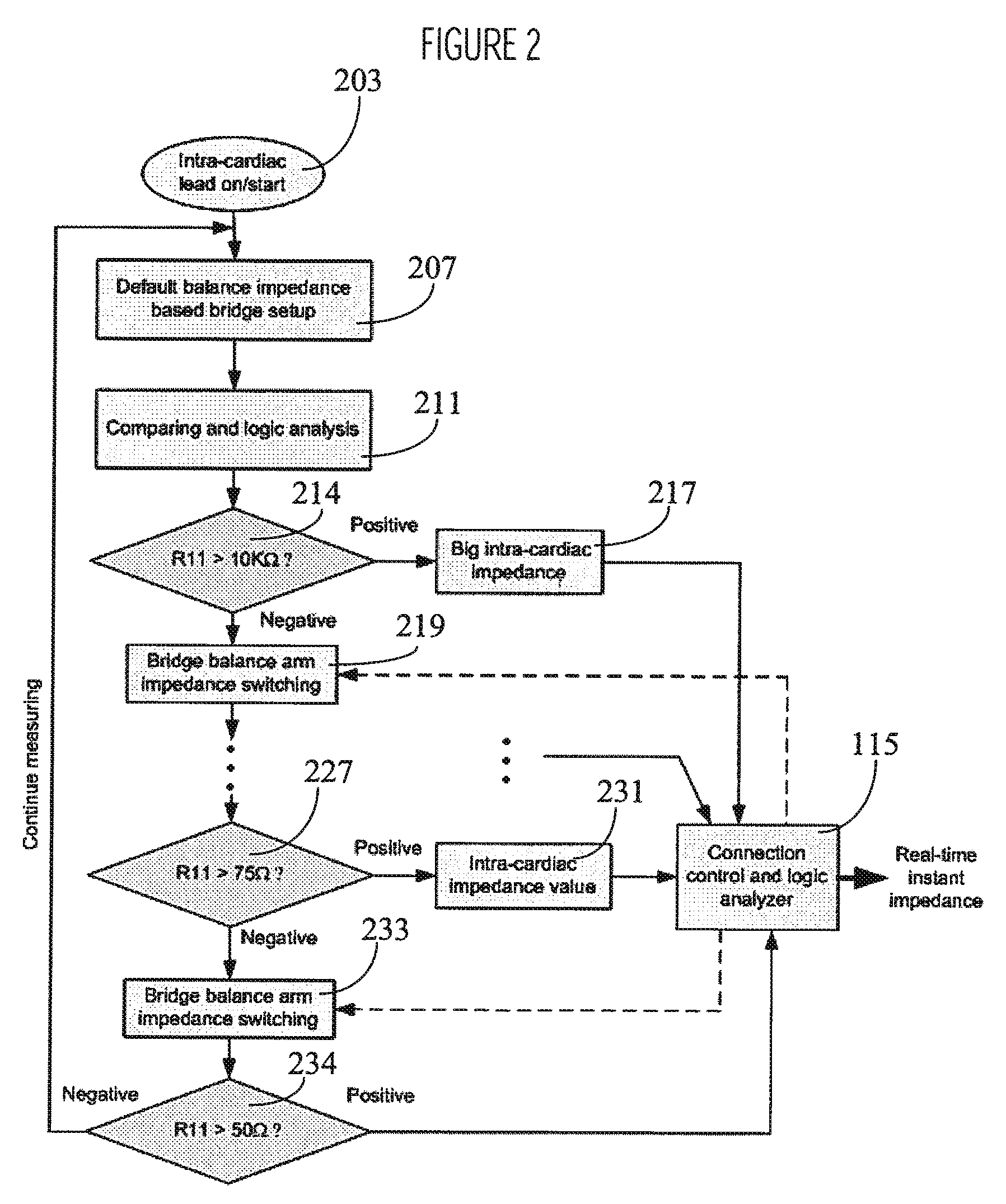

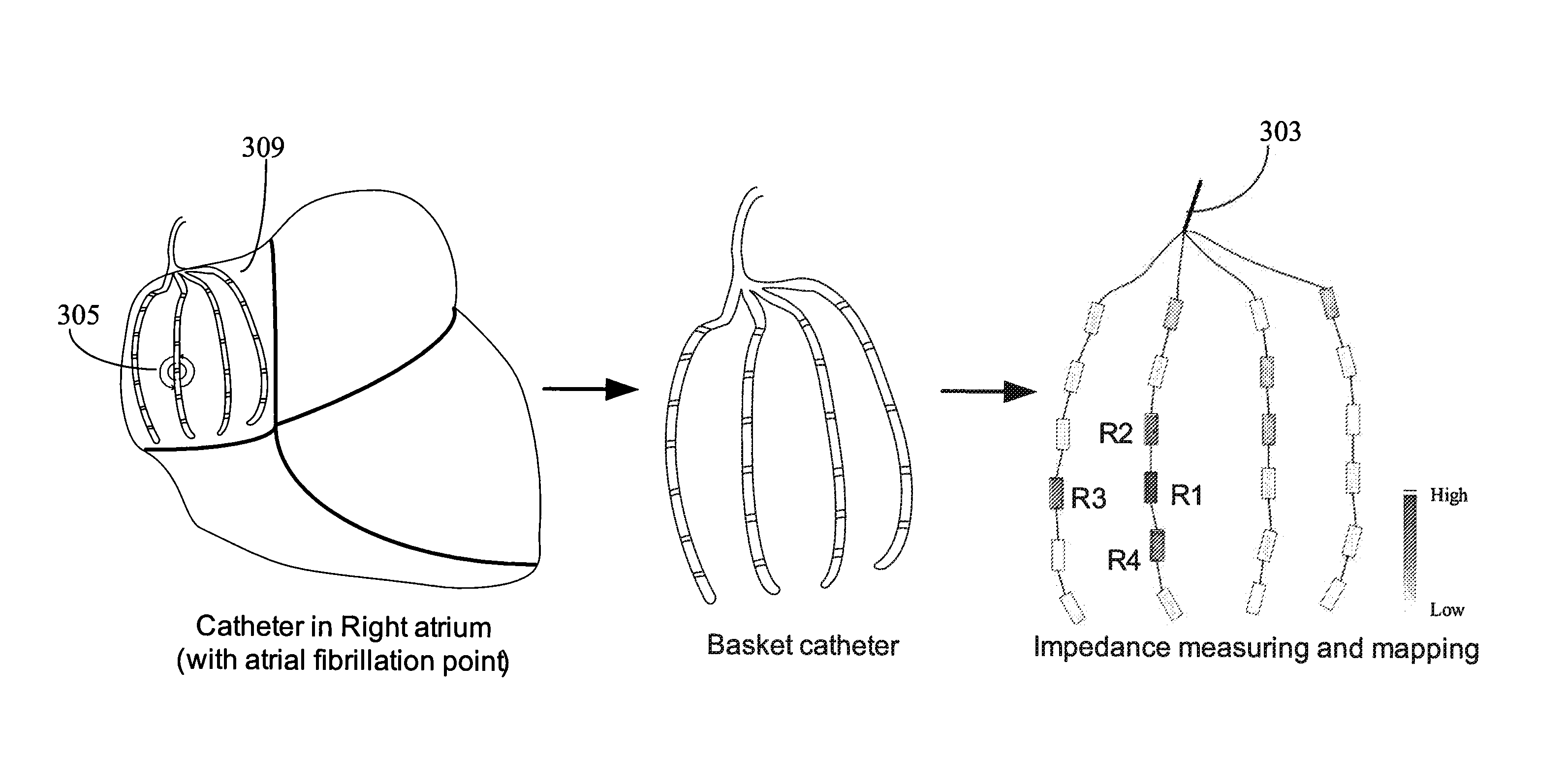

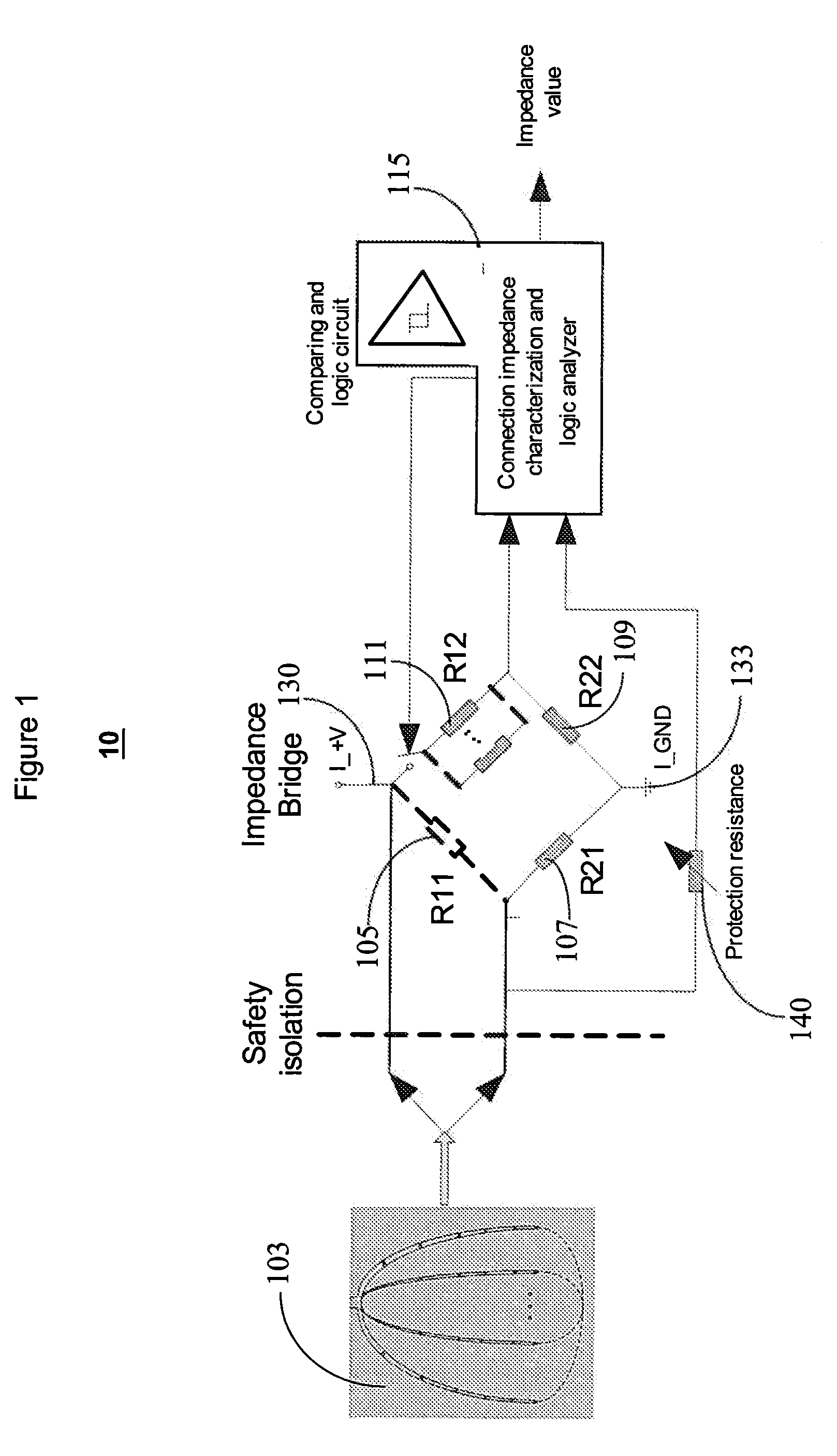

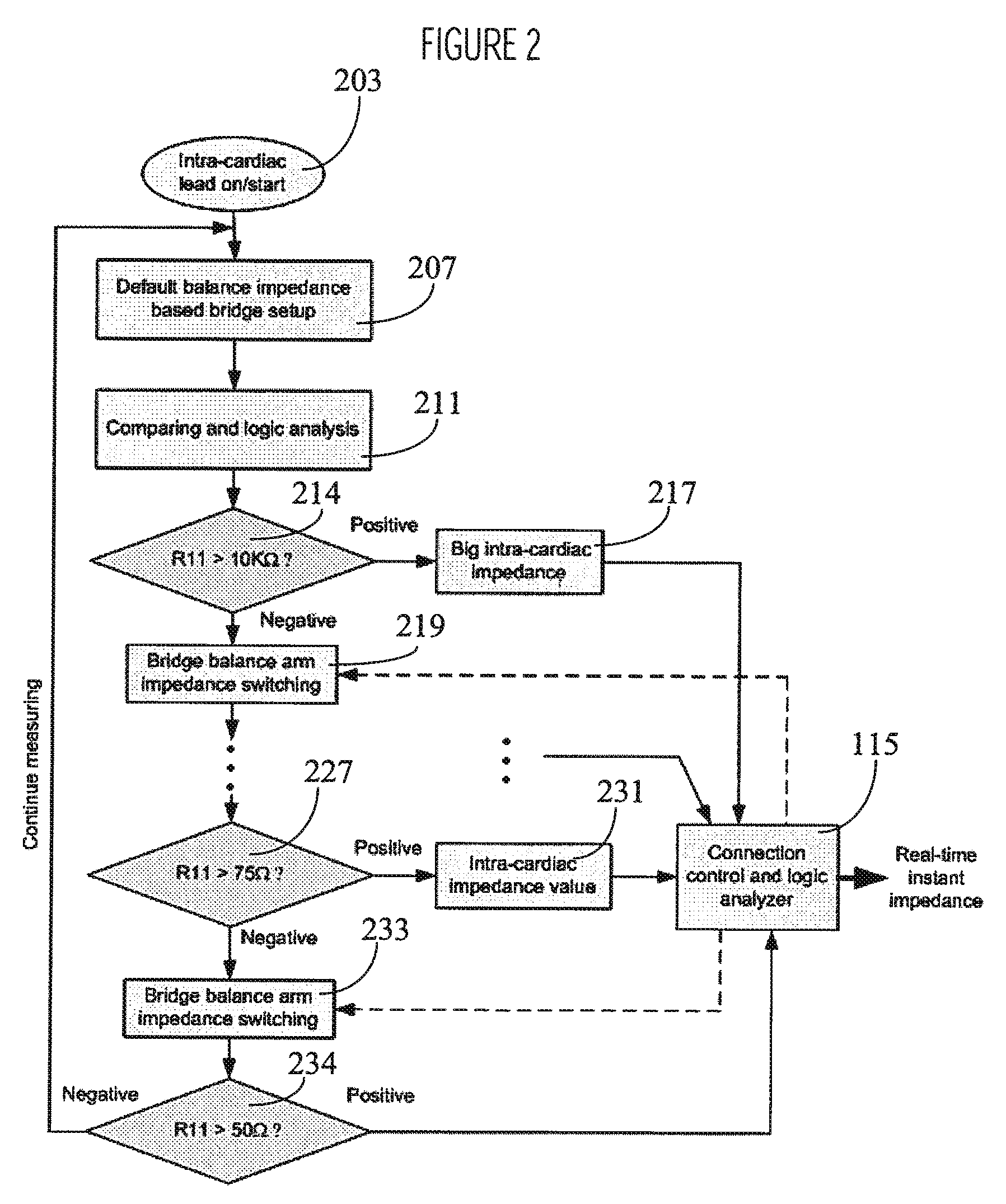

System for Characterizing Patient Tissue Impedance for Monitoring and Treatment

ActiveUS20090198300A1Precise positioningElectrocardiographyHeart defibrillatorsEarly predictionPathology diagnosis

A system provides early prediction of heart tissue malfunction and electrophysiological pathology by determining anatomical tissue impedance characteristics for use in medical patient monitoring and treatment decision making. At least one repository of data indicates multiple predetermined expected impedance value ranges for corresponding multiple impedance measurements taken at multiple particular different sites of at least one anatomical organ. An impedance measurement processor automatically determines whether multiple measured impedance values taken at multiple particular different sites of an anatomical organ using an invasive catheter are within corresponding multiple predetermined expected impedance value ranges derived from the at least one repository. An output processor automatically communicates data comprising at least one message to a destination. The at least one message includes data indicating whether the multiple measured impedance values taken at the multiple particular different sites of the anatomical organ are within the corresponding multiple predetermined expected impedance value ranges.

Owner:SIEMENS HEALTHCARE GMBH

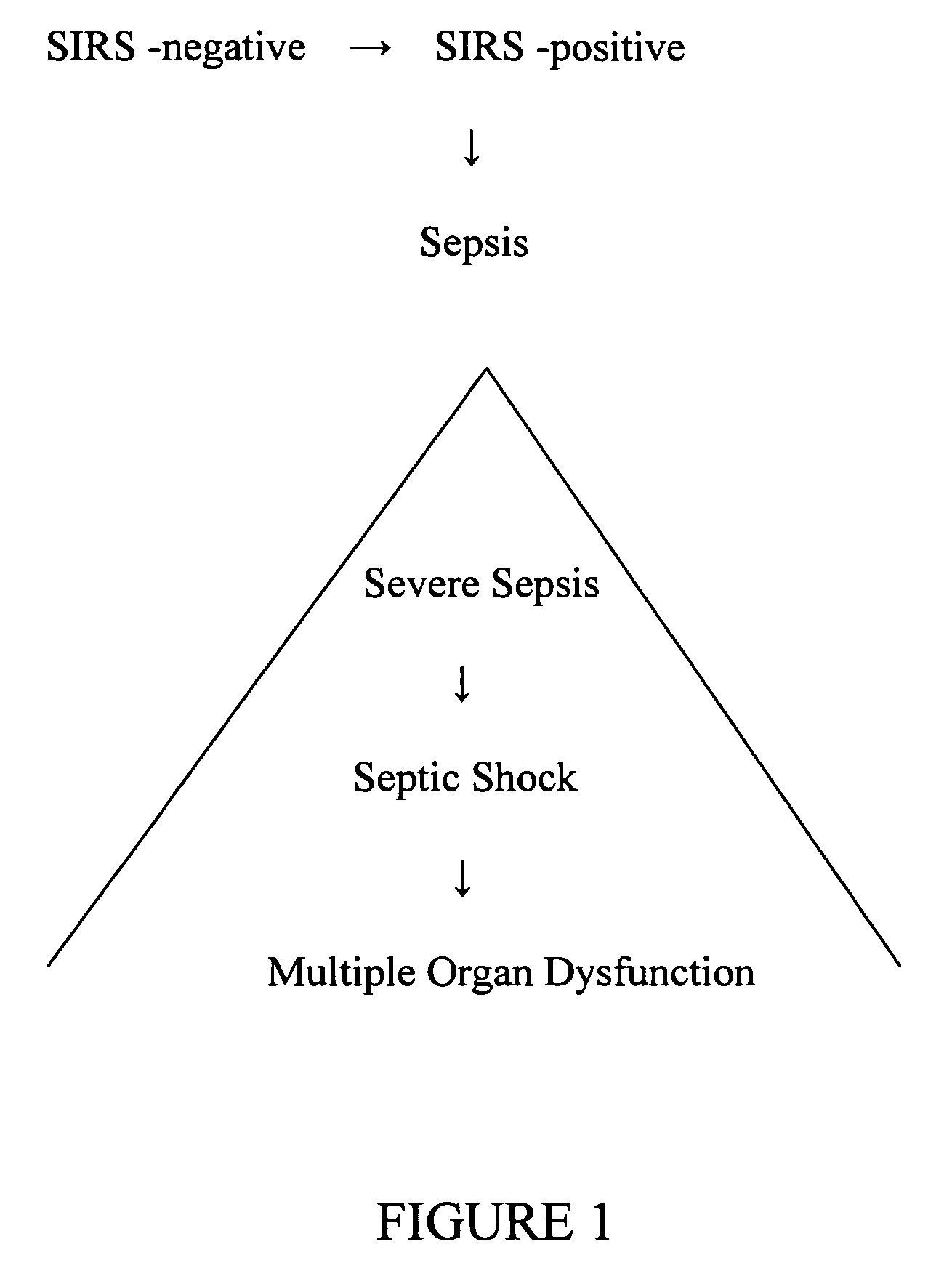

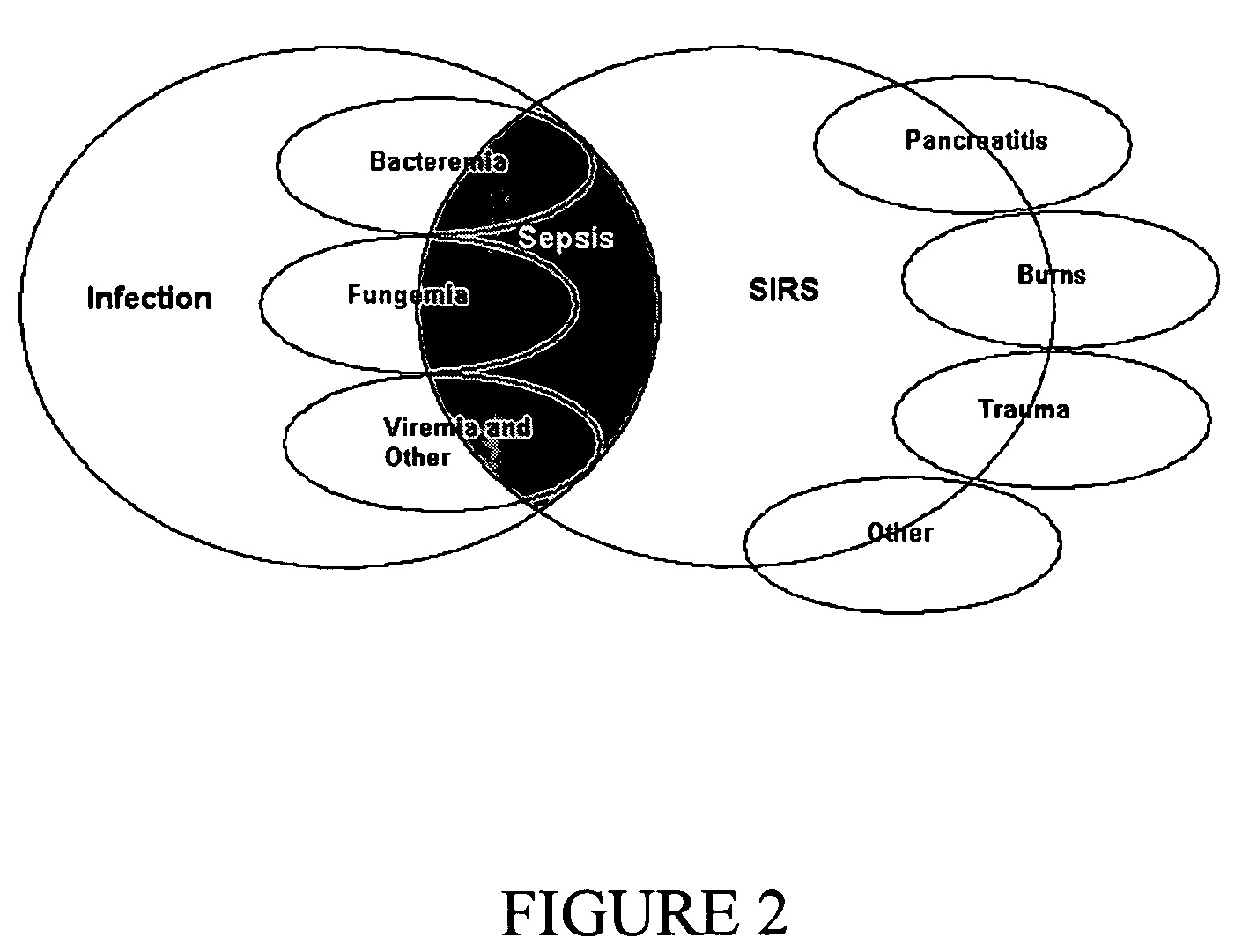

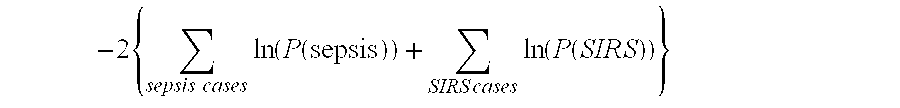

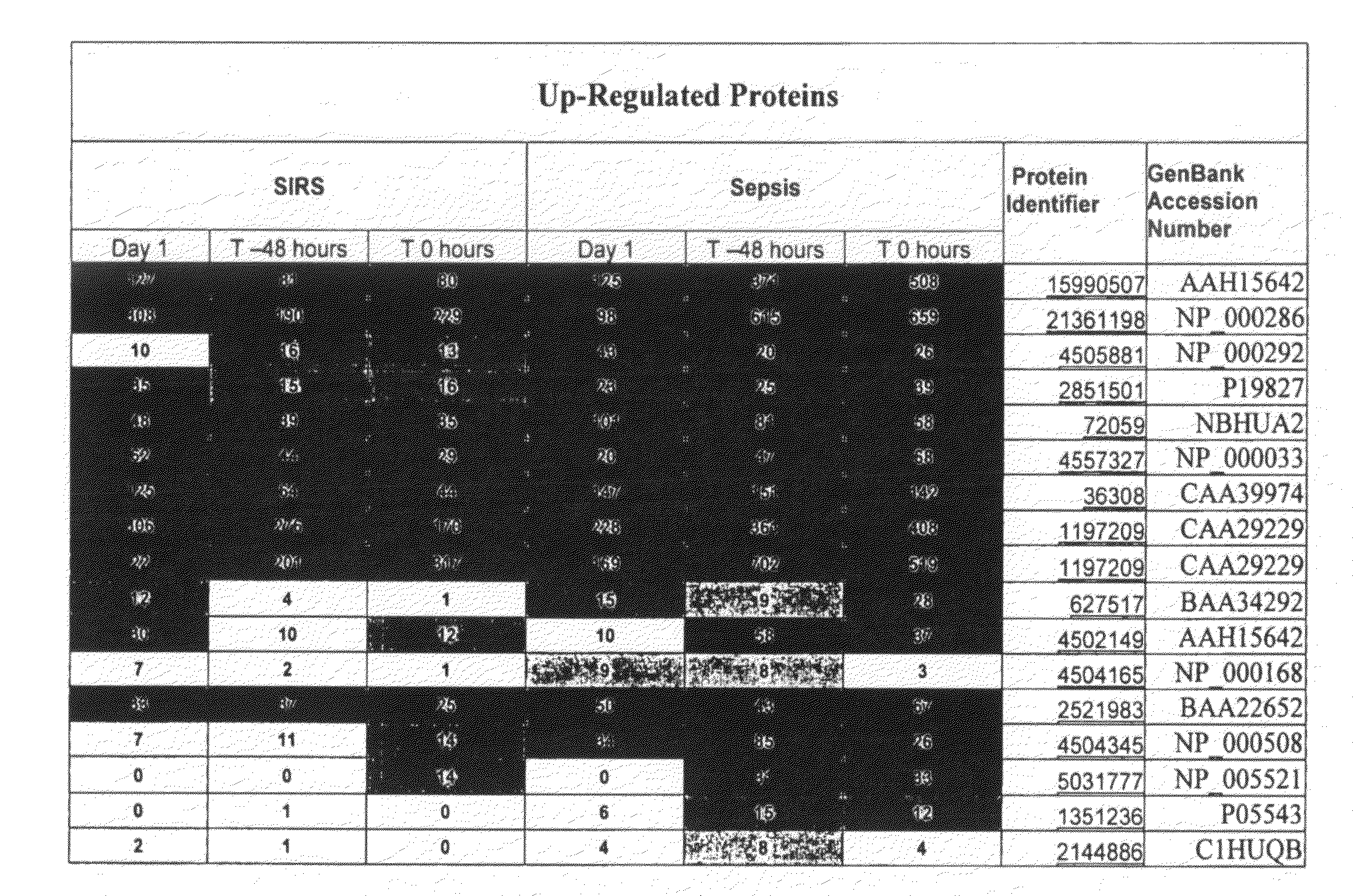

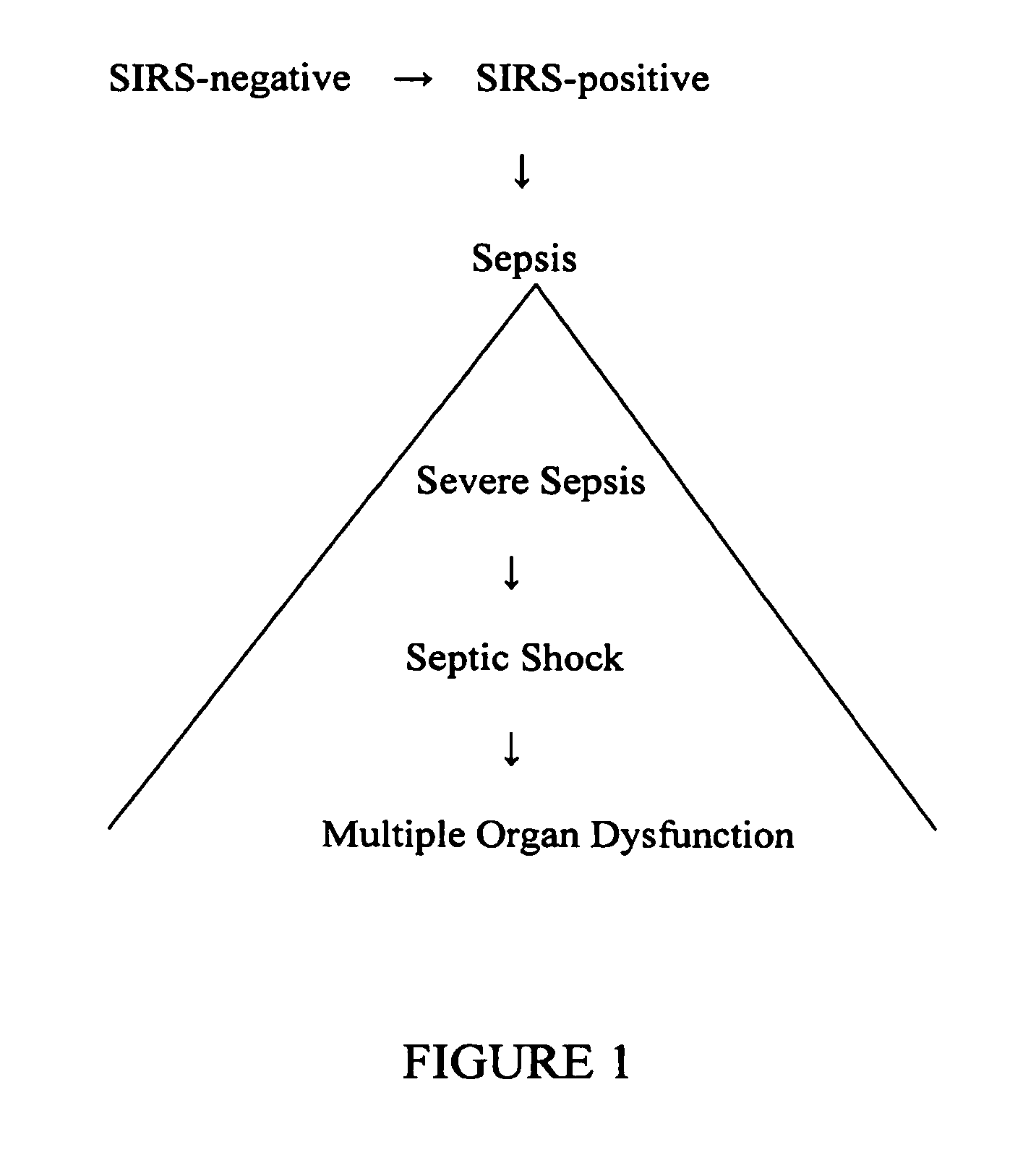

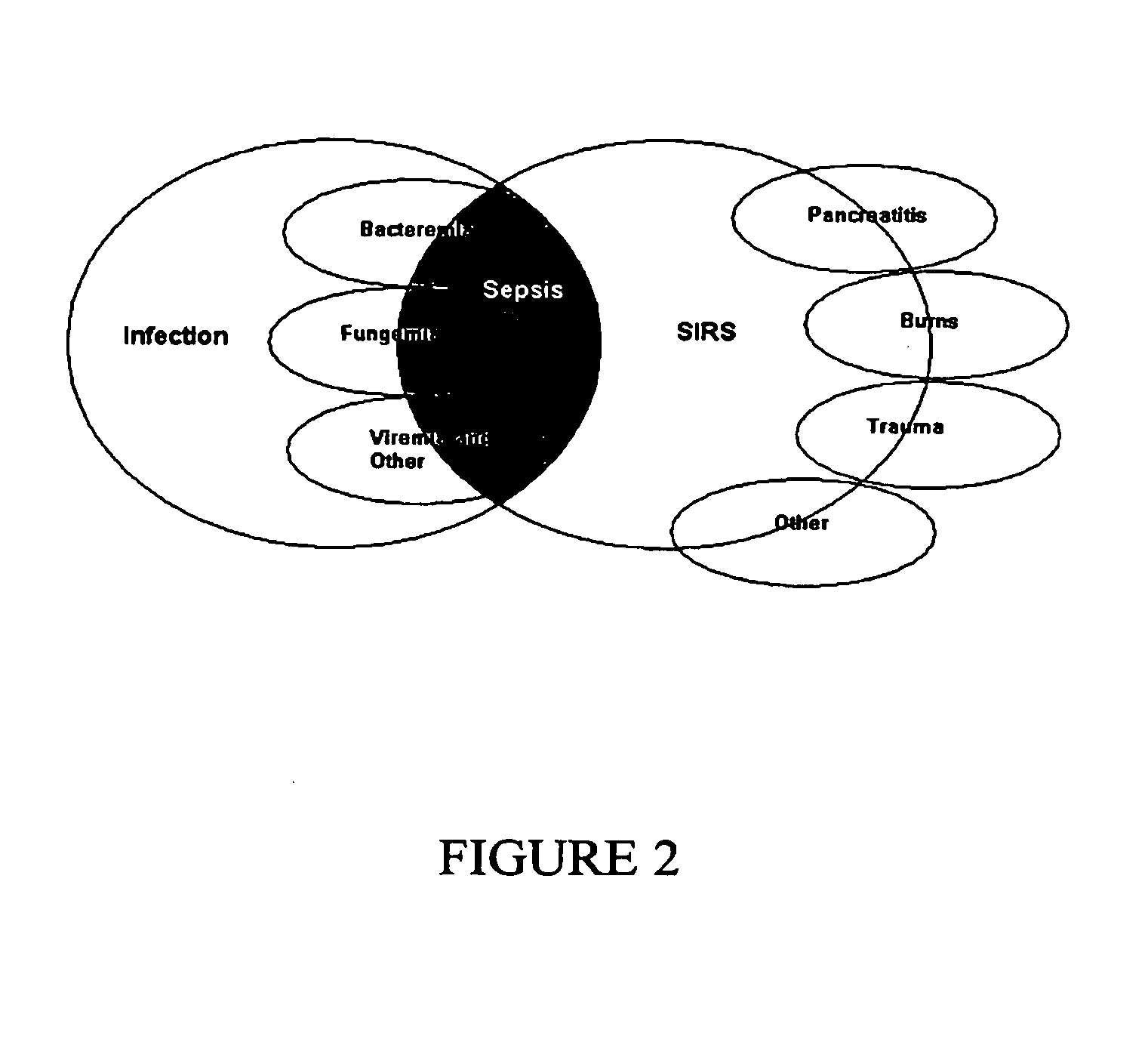

Diagnosis of sepsis or SIRS using biomarker profiles

ActiveUS7645573B2Accurate and rapid and sensitive prediction and diagnosisMicrobiological testing/measurementDisease diagnosisDiseaseEarly prediction

The early prediction or diagnosis of sepsis advantageously allows for clinical intervention before the disease rapidly progresses beyond initial stages to the more severe stages, such as severe sepsis or septic shock, which are associated with high mortality. Early prediction or diagnosis is accomplished using a molecular diagnostics approach, involving comparing an individual's profile of biomarker expression to profiles obtained from one or more control, or reference, populations, which may include a population who develops sepsis. Recognition of features in the individual's biomarker profile that are characteristic of the onset of sepsis allows a clinician to diagnose the onset of sepsis from a bodily fluid isolated at the individual at a single point in time. The necessity of monitoring the patient over a period of time is, therefore, avoided, advantageously allowing clinical intervention before the onset of serious symptoms. Further, because the biomarker expression is assayed for its profile, identification of the particular biomarkers is unnecessary. The comparison of an individual's biomarker profile to biomarker profiles of appropriate reference populations likewise can be used to diagnose SIRS in the individual.

Owner:BECTON DICKINSON & CO

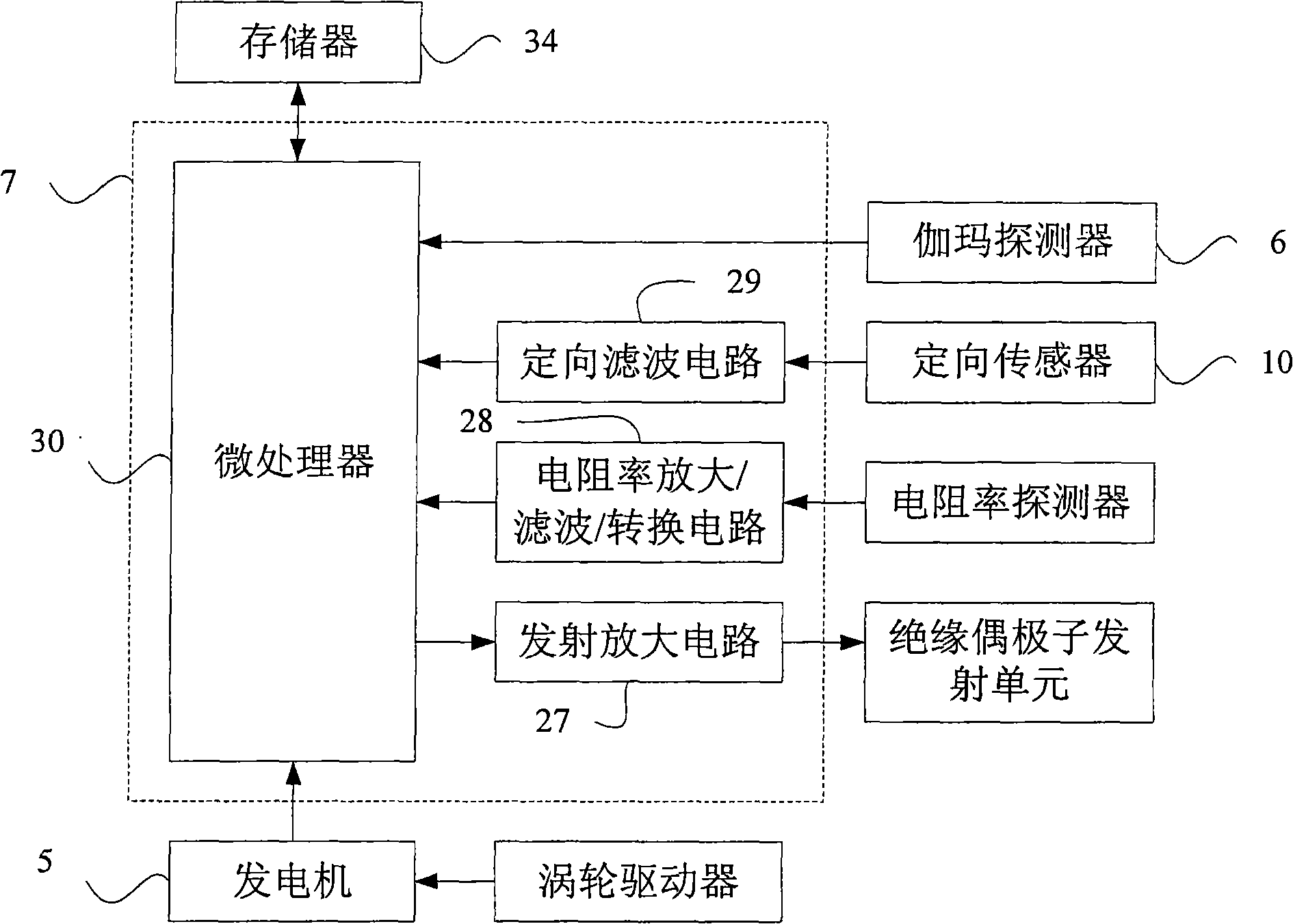

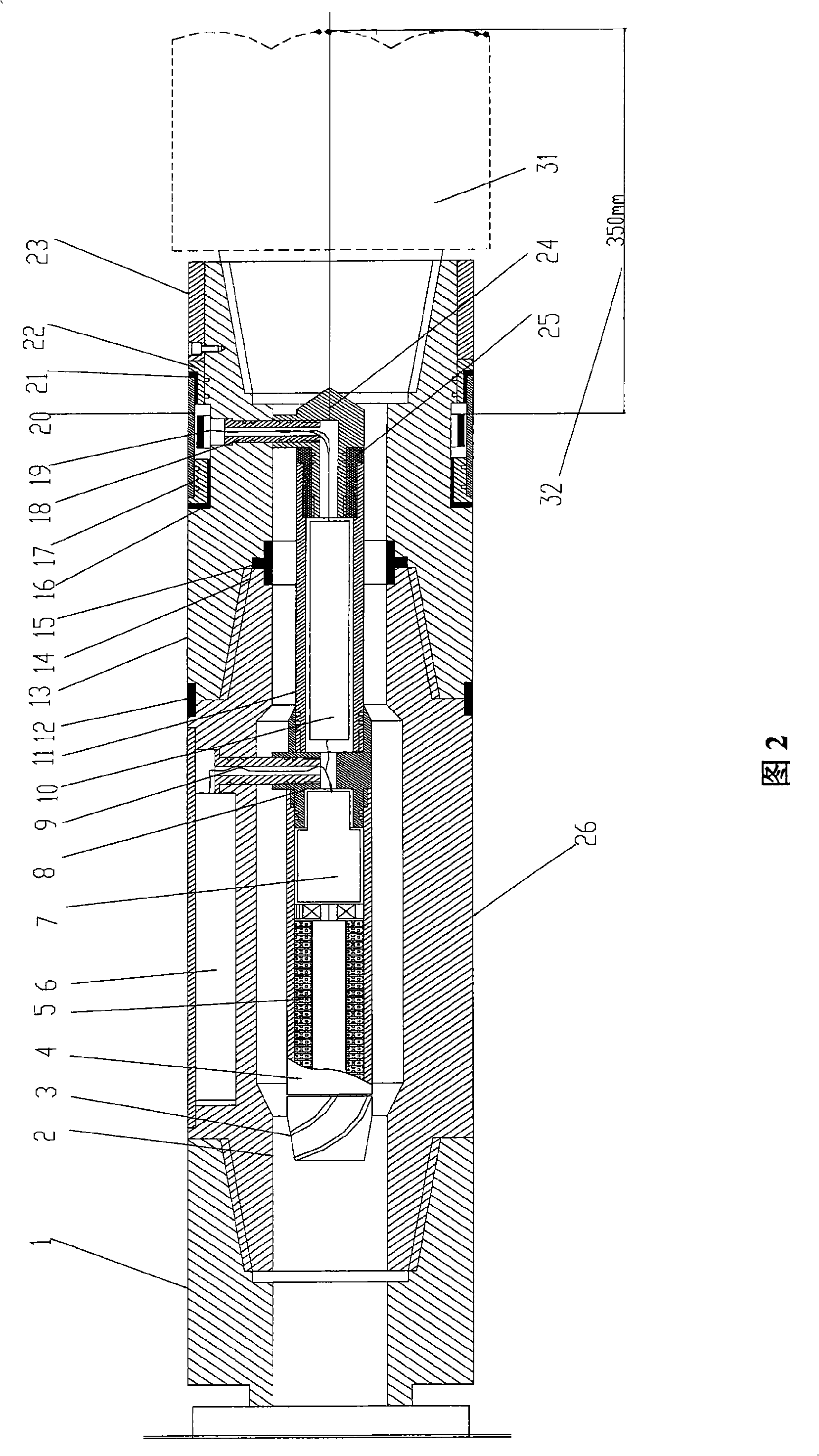

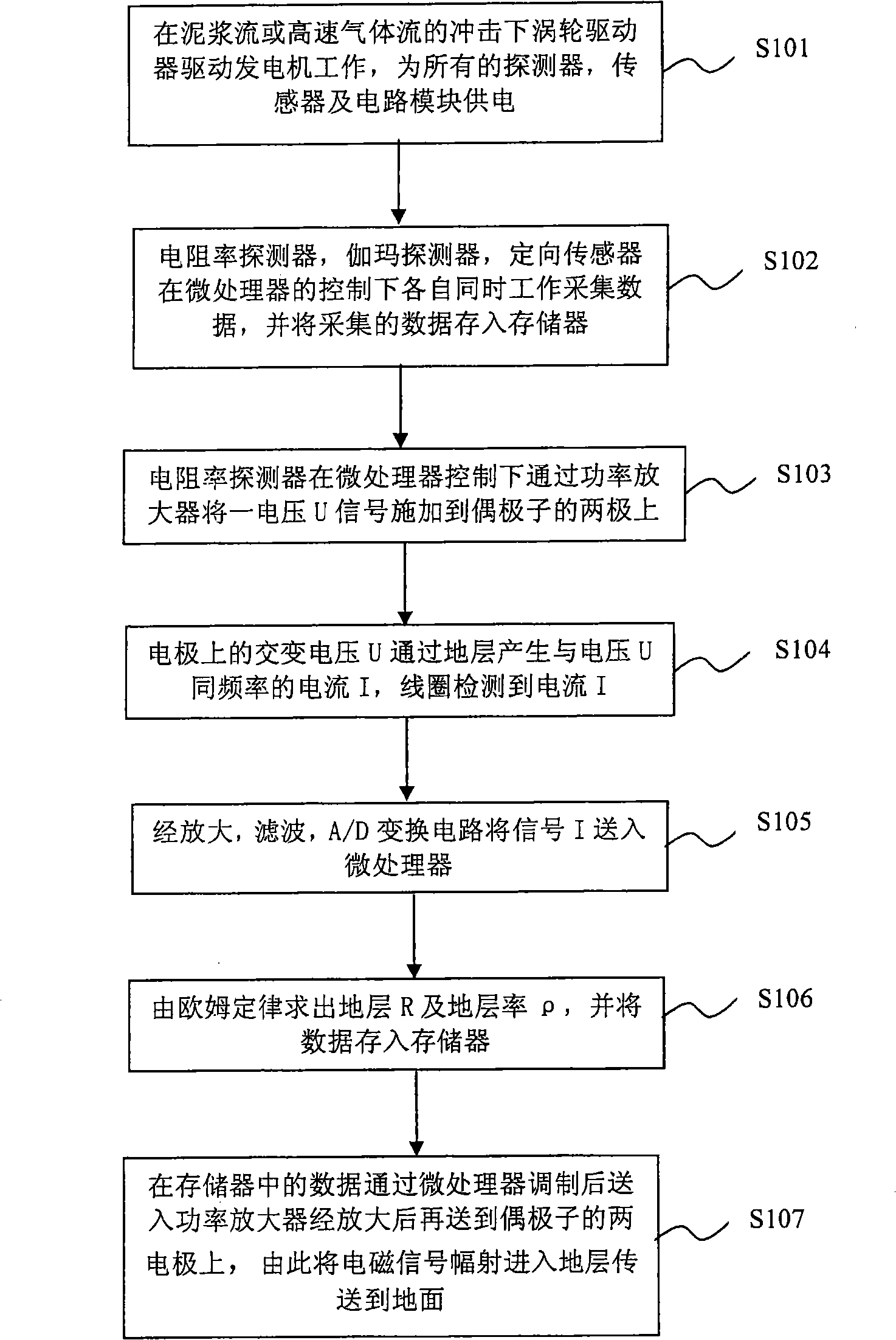

Near-bit geological guiding probe system

InactiveCN101289935AAchieve forecastTimely decisionSurveyConstructionsElectrical resistance and conductanceEarly prediction

The invention provides a near-bit geology guide detecting system, comprising an electricalresistivity detecting unit, a gamma detecting unit, a position sensing unit and an insulating dipole transmitting unit, wherein the electricresistivity detecting unit is used for measuring the electricresistivity a near-bit stratum to generate electricresistivity data; the gamma detecting unit is used for measuring near-bit gamma rays to generate gamma ray data; the position sensing unit is used for measuring near-bit inclination and an implemental surface to generate position data; and the insulating dipole transmitting unit is used for transmitting the electricresistivity data, the gamma ray data and the position data to the ground through a wireless electromagnetic signal channel. A sensor is close to the near bit as much as possible, so when a drill drills into the sensor, the sensor makes an early prediction to information of the front part of the drill and information of the periphery stratum of the drill, thereby the aim of geology guide is achieved during drilling process.

Owner:CNPC DRILLING RES INST

System for characterizing patient tissue impedance for monitoring and treatment

Owner:SIEMENS HEALTHCARE GMBH

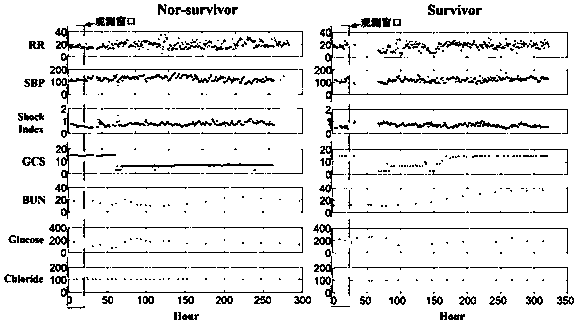

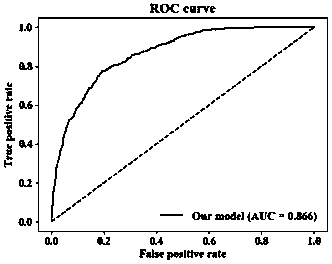

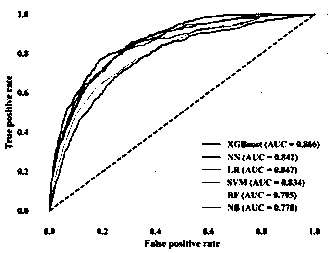

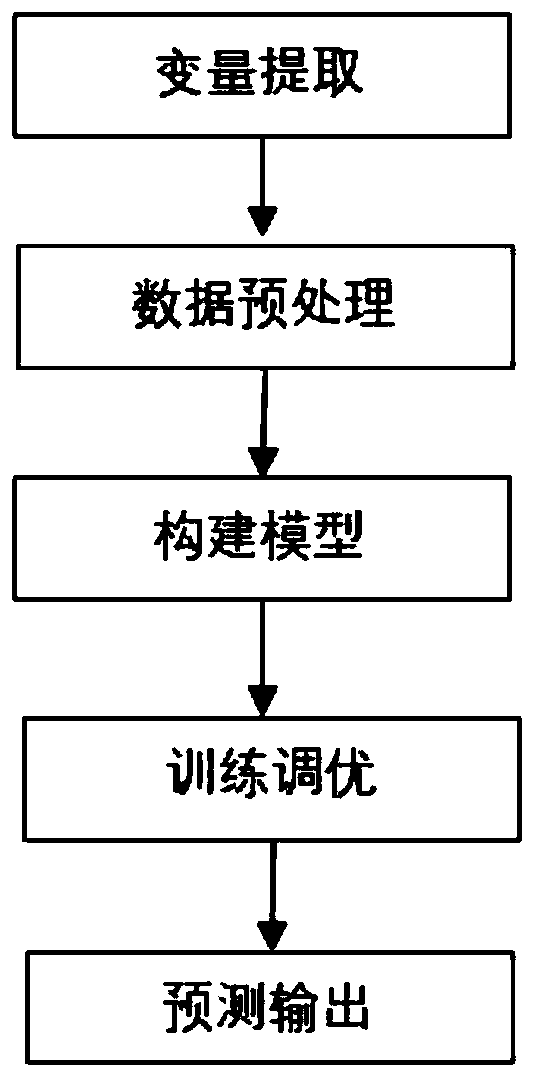

Early death risk assessment model establishing method and device based on ensemble learning

InactiveCN110827993AEarly interventionEarly treatmentMedical data miningEnsemble learningMedical intensive care unitEmergency medicine

The invention provides an early death risk assessment model establishing method and device based on ensemble learning. The method and device are used for assessing the death risk of an old multi-organfailure patient during hospitalization based on diagnosis and treatment data of the first day when the old multi-organ failure patient enters an intensive care unit. The method comprises the steps ofdata set construction, data processing and model construction and evaluation. The method comprises the following steps: acquiring three pieces of demographic information, five pieces of vital sign information, five laboratory examination indexes and two clinical indexes of a patient on the first day during living in an intensive care unit; inputting the data into a risk assessment device, and carrying out internal data preprocessing, feature calculation and model operation. Finally, the risk of adverse outcomes in the hospital of the patient can be predicted early, and doctors are helped to treat the patient as soon as possible.

Owner:BEIHANG UNIV +1

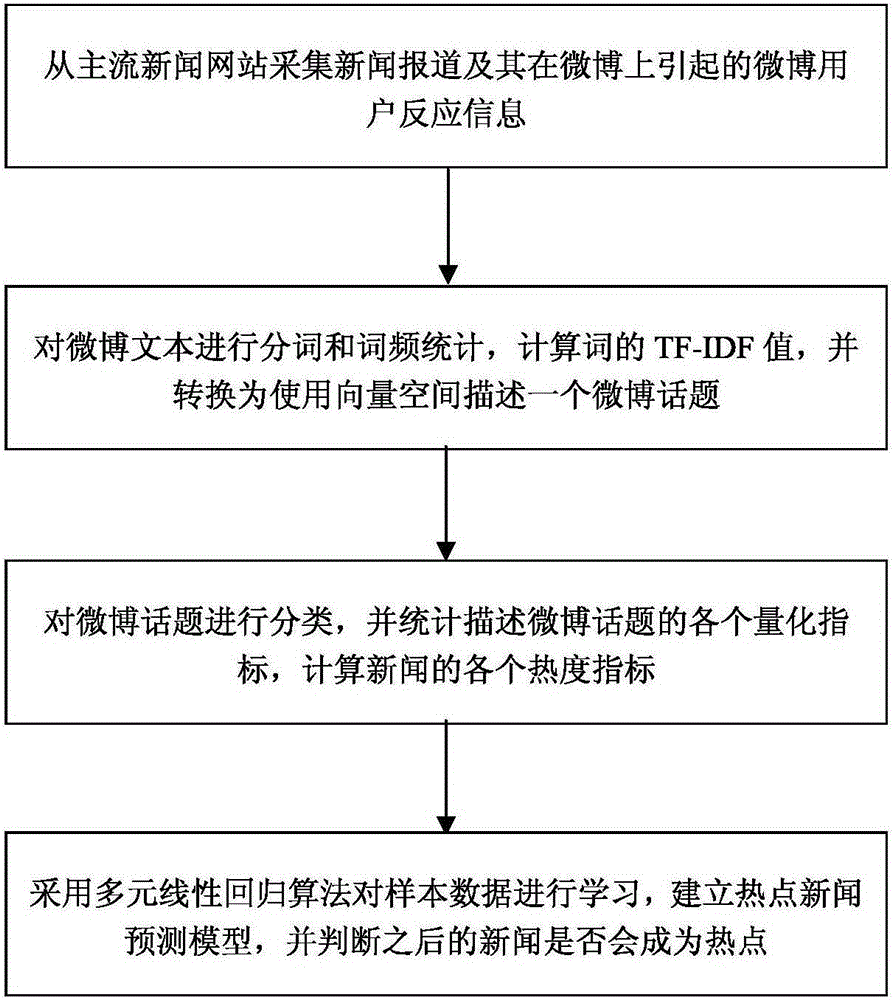

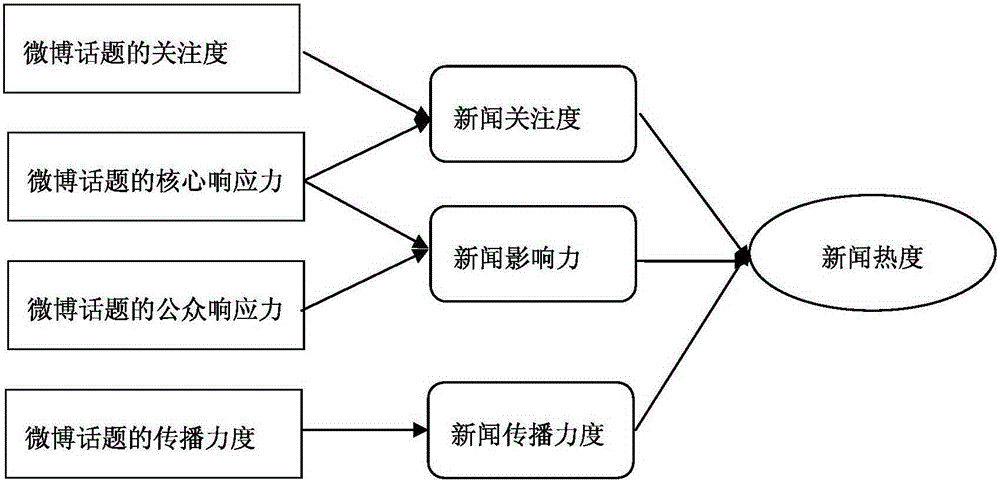

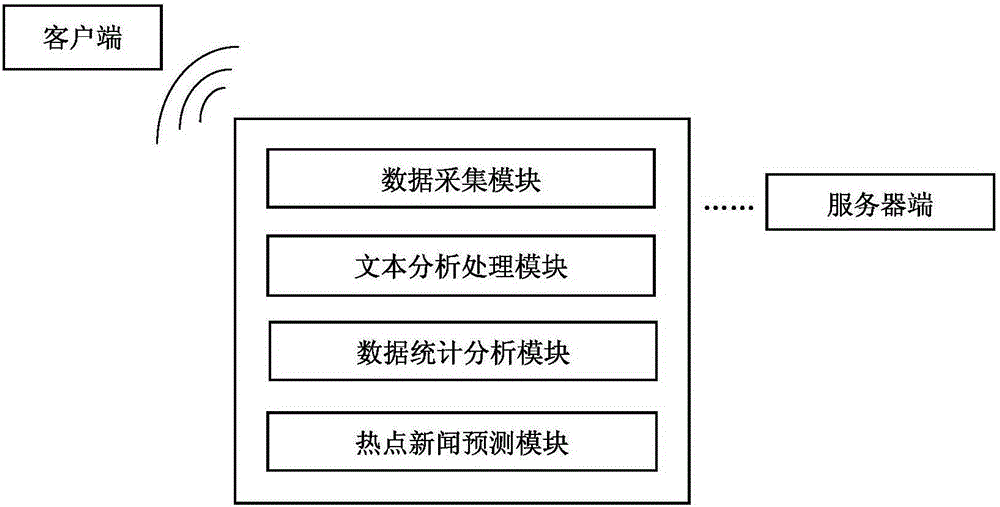

Microblog data analysis based hot news prediction method and system

ActiveCN105224608ASolve the problem of early predictionImprove practical abilityWeb data indexingSpecial data processing applicationsEarly predictionStatistical analysis

The present invention discloses a microblog data analysis based hot news prediction method and system. The method comprises: acquiring news reports from mainstream news sites and microblog user response information caused by the news reports on the microblog; carrying out word segmentation and word frequency statistics to a microblog text, calculating a TF-IDF value of a word, and converting the value into a microblog topic described by using a vector space; classifying the microblog topics, counting each quantitative index for describing the microblog topics, and calculating each hot index of news; and using a multivariate linear regression algorithm to learn sample data, establishing a hot news prediction model, and determining whether the latter news can become a hot news or not. The system comprises a data acquisition module, a text analysis processing module, a data statistical analysis module and a hot news prediction module. According to the method and system disclosed by the present invention, the trend of news reported by media in microblog topics is comprehensively analyzed to predict whether the news can become a hot news or not in public sentiments, so that the problem of early prediction of hot news can be well solved.

Owner:SOUTH CHINA UNIV OF TECH

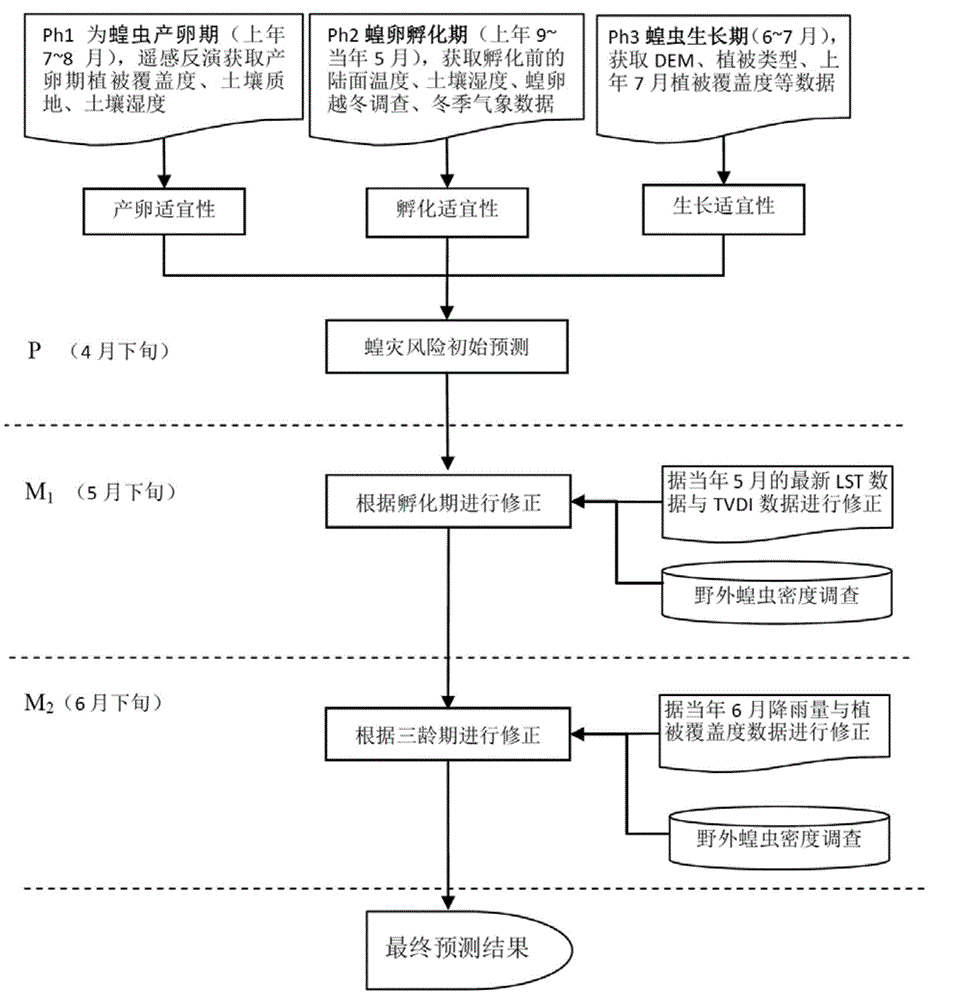

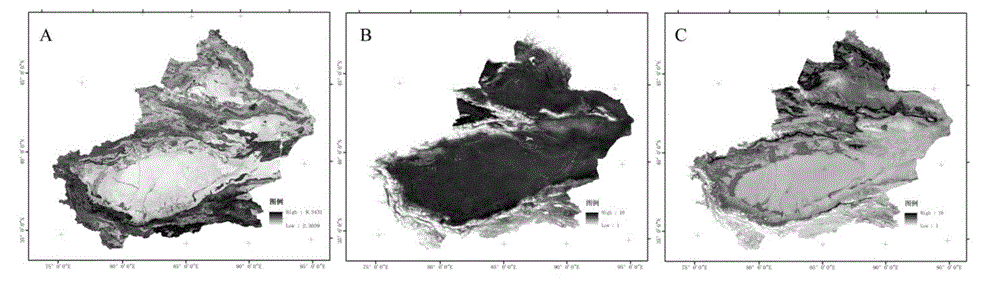

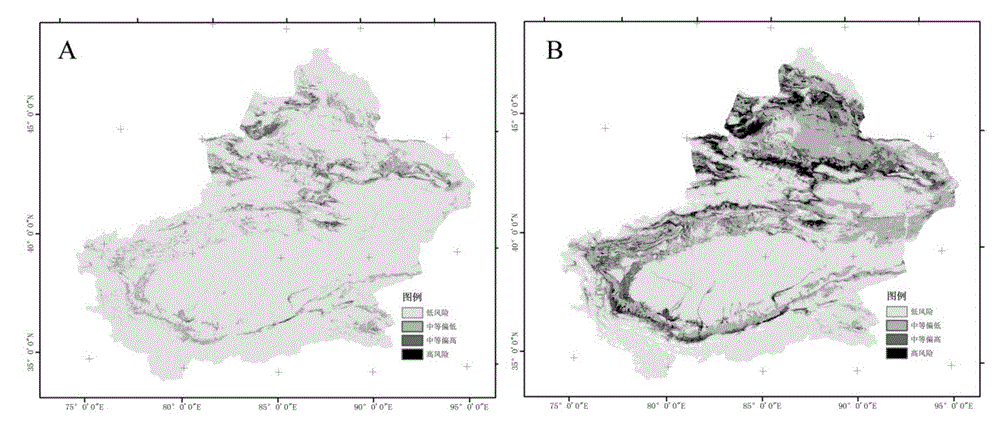

Remote sensing technology-based grassland locust plague progressive prediction method

ActiveCN103955606AHigh accuracy of resultsHigh precisionSpecial data processing applicationsVegetationSensing data

The invention discloses a remote sensing technology-based grassland locust plague progressive prediction method. According to the method, the distribution of key habitat elements which influencing the development of a grassland locust population is obtained by the means of quantitative remote sensing inversion, meteorological station observation and the like, wherein the key habitat elements subjected to remote sensing inversion comprises land surface temperature, vegetation coverage and soil moisture; the spawning suitability, the incubation suitability and the growth suitability of locusts are analyzed quantitatively by establishing an evaluation model, and a locust plague risk early prediction model is established; a locust plague risk level prediction result is corrected by utilizing the remote sensing observation of an incubation period and a third period and the locust density data measured in the field according to the incubation and development time axes of the locusts, and the situations of a grassland locust plague are predicted progressively. According to the technical scheme provided by the invention, the progressive update of sensitive habitat elements is obtained by performing quantitative inversion on remote sensing data with higher time resolution, so that the prediction precision of a locust plague monitoring and prediction model is improved.

Owner:PEKING UNIV

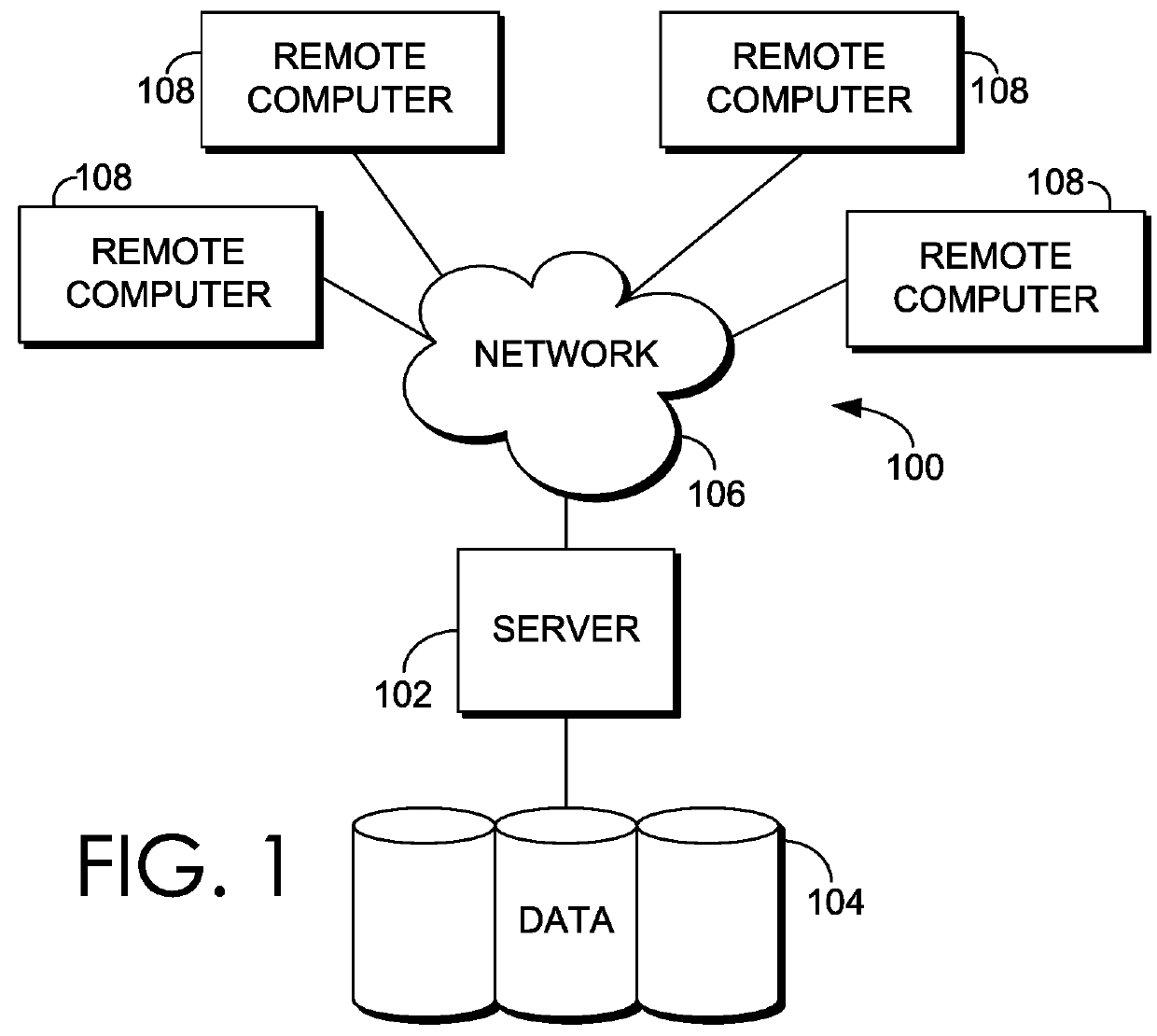

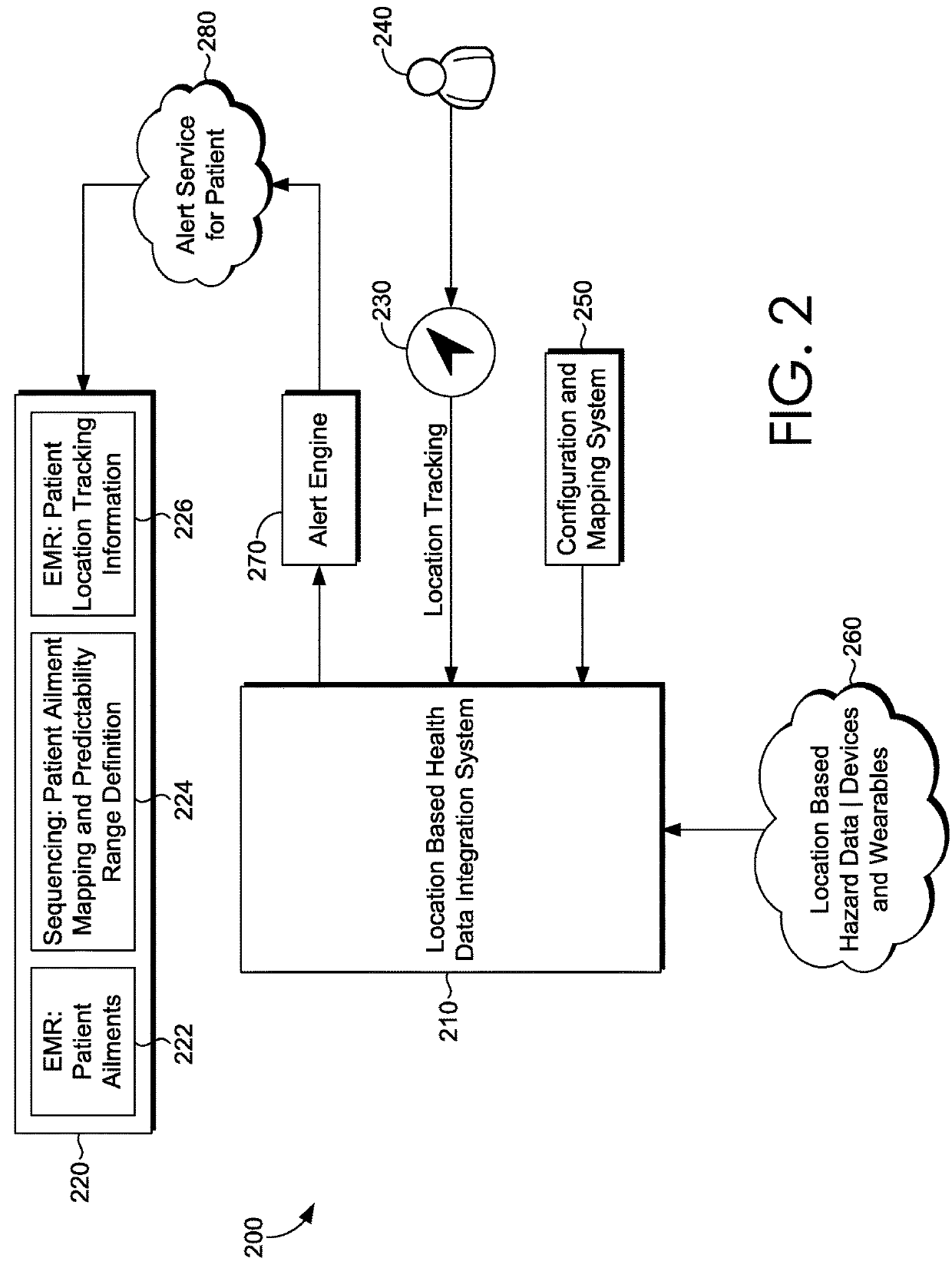

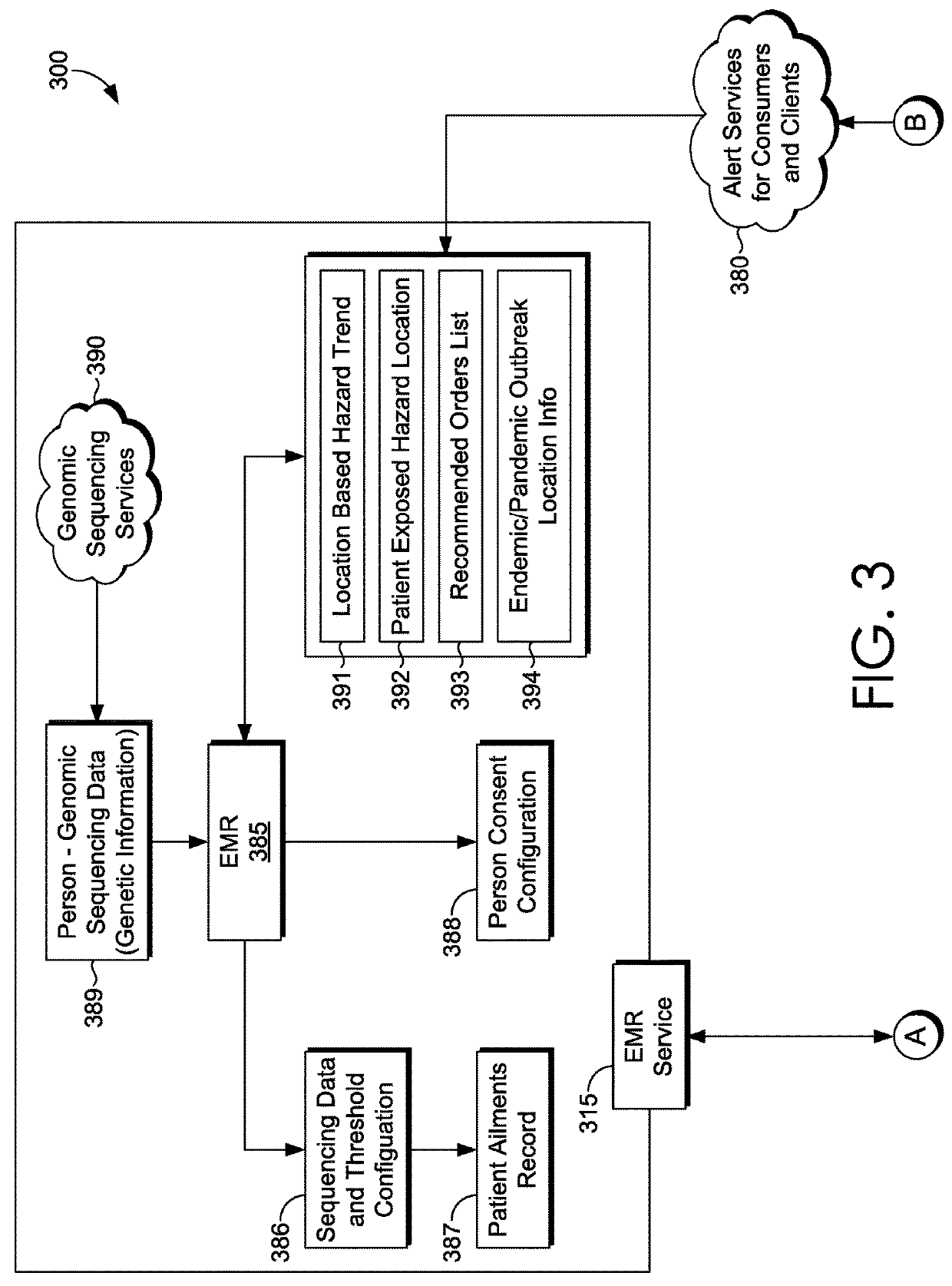

Healthcare System Based on Devices and Wearables

ActiveUS20180181714A1Digital data information retrievalHealth-index calculationMedical recordMedical risk

A computerized method is presented for improving medical records of an individual based on received information from a device or wearable, the method comprising: retrieving from a record-keeping database medical-related information associated with the individual; retrieving from a device associated with the individual a measurable factor; determining, based at least partly on the medical-related information, that the measurable factor poses a medical risk to the individual; and communicating instructions to the record-keeping database to store, in association with the individual, information related to the medical risk. Other methods may associate a location with a medical risk. Other methods may aggregate medical information received from devices or wearables and associate it with a location. Mapping this information with regard to locations may allow early prediction of an epidemic.

Owner:CERNER INNOVATION

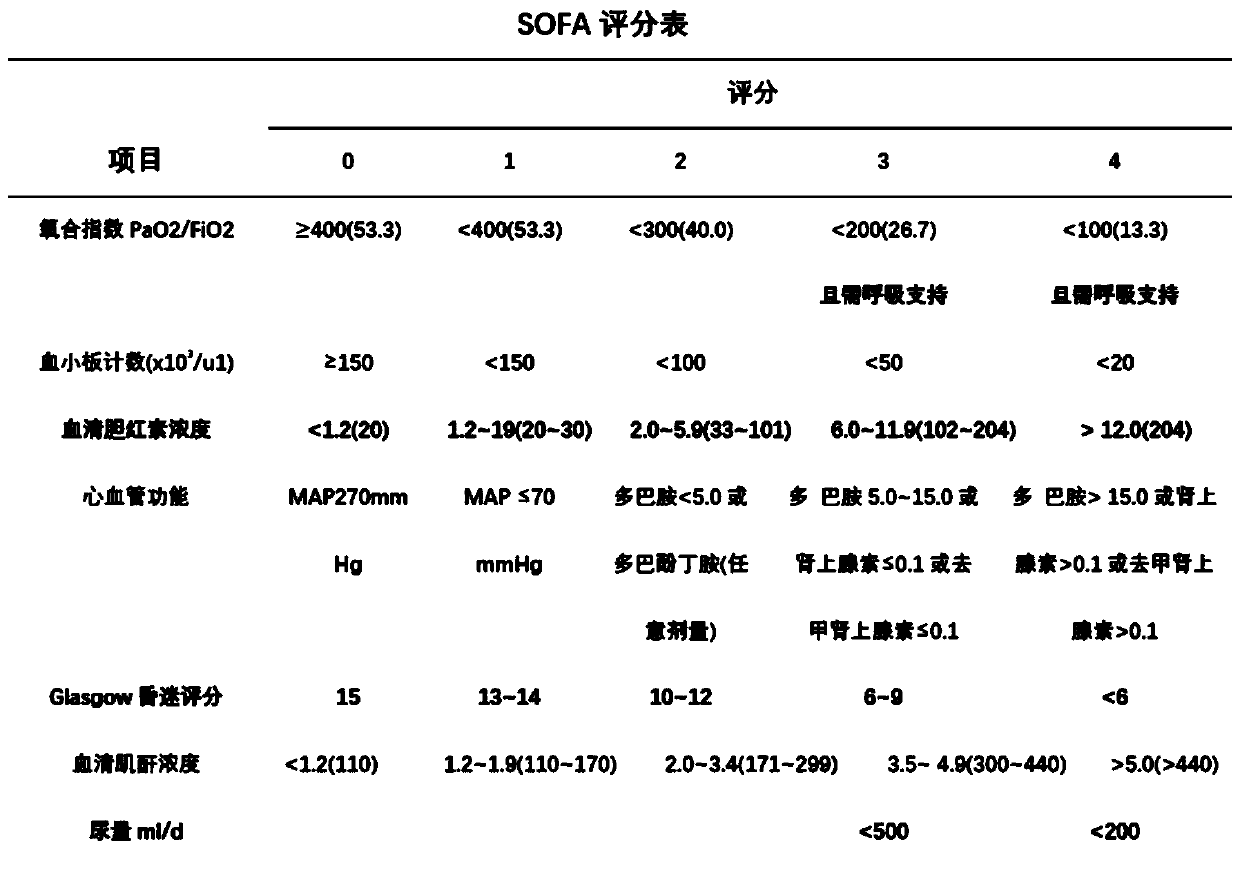

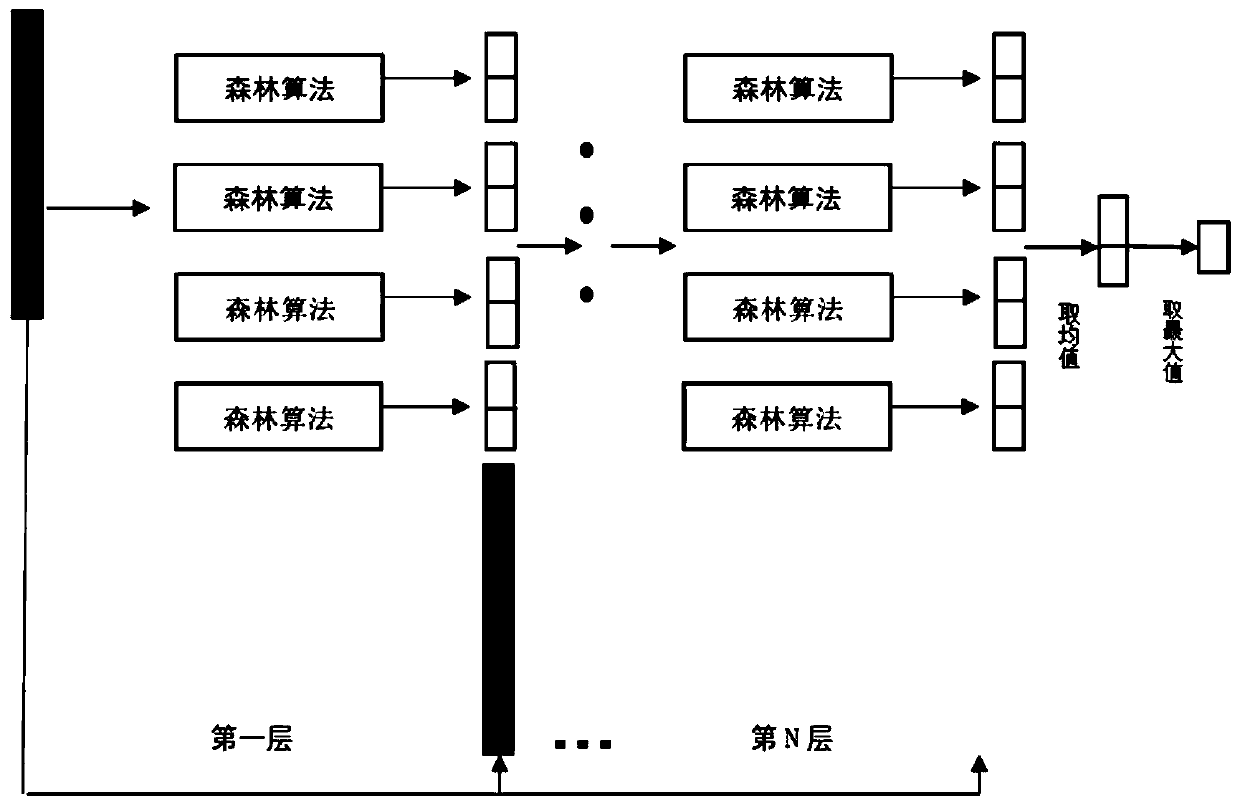

Sepsis early prediction method based on machine learning

PendingCN111261282AHigh predictive classification accuracyTimely treatmentCharacter and pattern recognitionMedical automated diagnosisMedical recordPatient need

The invention discloses a sepsis early prediction method based on machine learning. The method comprises the following steps: firstly, extracting clinical data, including demographic statistics (suchas age and gender), vital sign variables (such as heart rate and systolic pressure) and laboratory measurement indexes (such as creatinine and platelet count), of a patient within 24 hours after a patient enters an ICU by utilizing an electronic medical record, preprocessing the data, inputting the preprocessed data into an improved deep forest algorithm model for training, and outputting the disease probability of the patient after training optimization. And meanwhile, the algorithm model can also sort characteristic variables and output an early warning factor which has great influence on early prediction of sepsis. Finally, corresponding variables of the patient needing to be predicted are input into the trained model, so that early prediction of sepsis can be carried out on the patient. According to the invention, early prediction is carried out on sepsis based on a machine learning method, doctors can be assisted in making clinical decisions, and the prediction accuracy is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

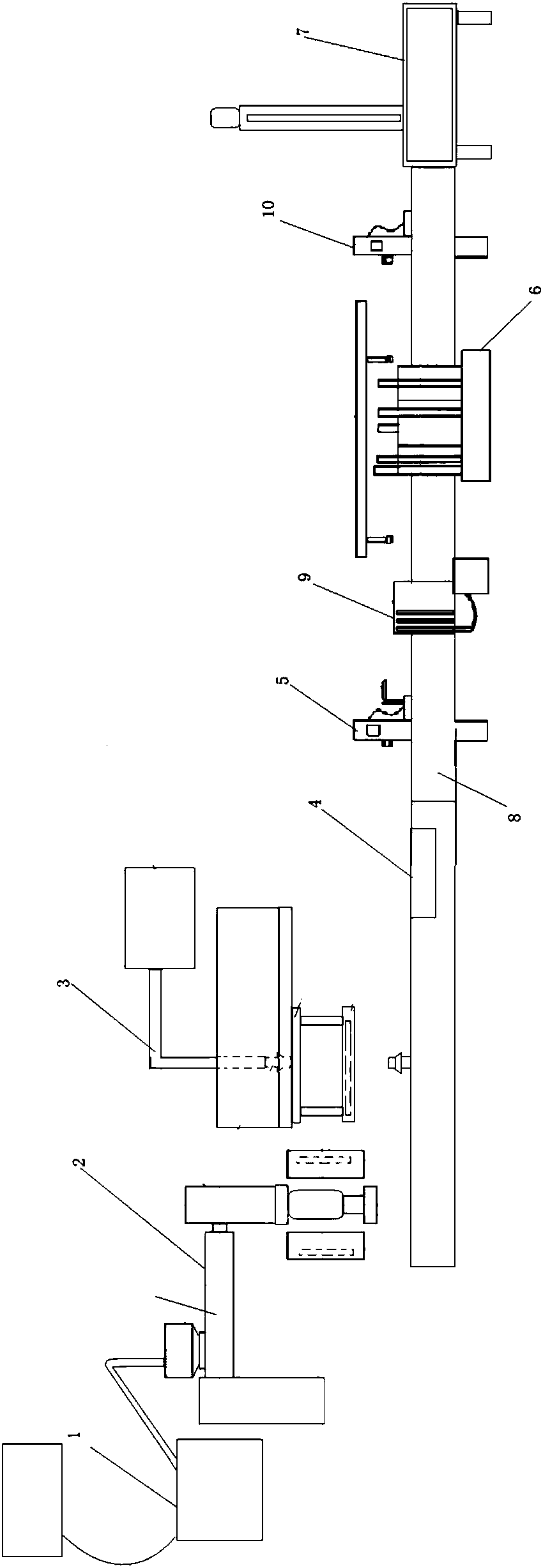

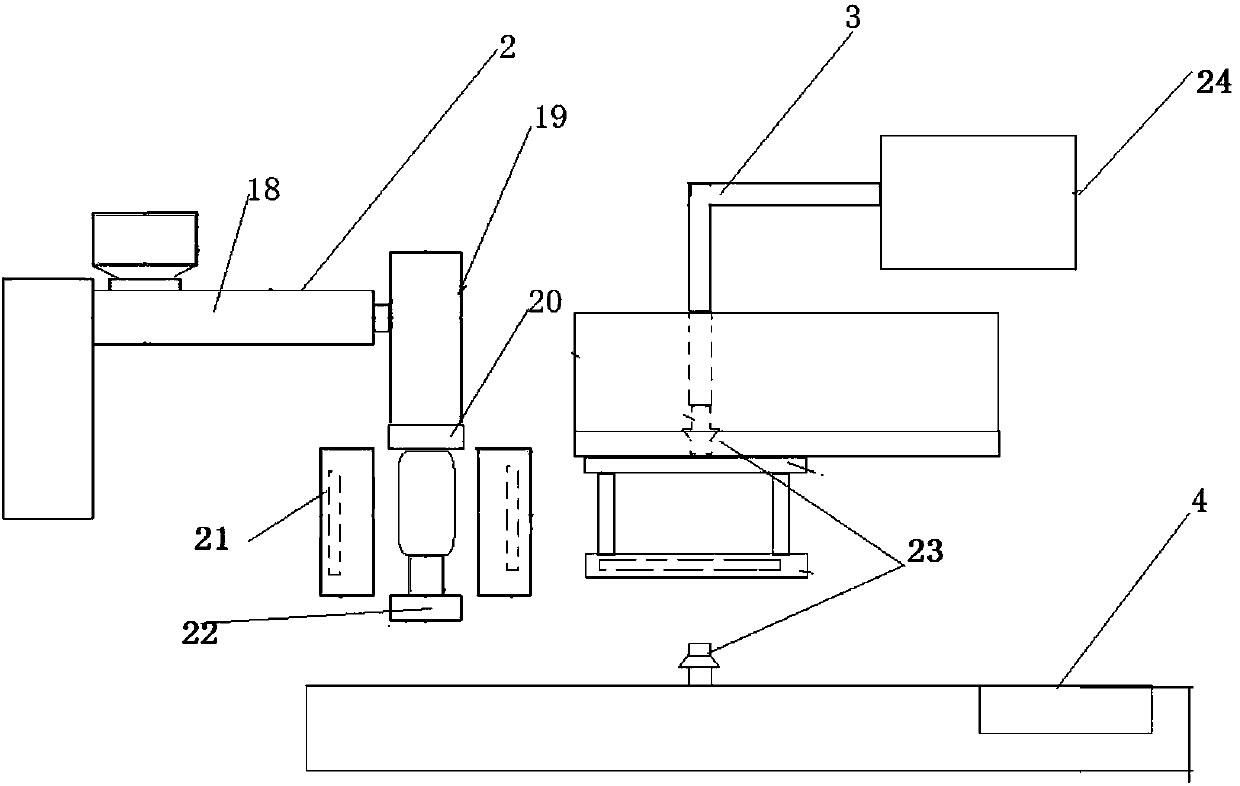

Human-computer interaction intelligent closed-loop control method of full-automatic blow-molding production line and process thereof

InactiveCN107775946ASolving Dispersion ProblemsSolve the problem of energy consumptionClosed loop feedbackClosed loop

The invention belongs to the field of blow-molding production and particularly relates to a human-computer interaction intelligent closed-loop control method of a full-automatic blow-molding production line and a process thereof. The method successively comprises the following steps: scanning and inputting a 3D bottle shape or a 3D drawing; selecting a suitable flow glue head and determining a flow glue curve; automatically mixing materials, checking and feeding color difference on line and automatically adjusting a color masterbatch ratio; carrying out electromagnetic induction heating, flexibly adjusting the thickness of the radial wall and the axial wall of an extrusion blank, monitoring and feeding the wall thickness of the blank, and enabling the wall thickness of the products to be more uniformly distributed; carrying out a blow molding process by checking and feeding the appearance and the cutting quality on line; automatically removing burrs, measuring the size of bottle openings and bottle bodies on line, testing leakage on line, labeling on line, shooting video on line and finally automatically stacking and packing through a packing machine. The method has the beneficialeffects that the operation is based on lasting and automatic process adjustment; the manual intervention is not needed; hollow container raw materials are accurately distributed; the products are monitored in real time and are measured and fed back; the process is automatically adjusted; the products are in dynamic and continuous adjustment state and continuously tend to be standard samples; the quality of hollow containers is improved; the production of waste products is reduced or avoided; the passive situation of established fact caused by post detection can be completely changed; the method is capable of achieving online detection and closed-loop feedback and adjusting at first time; the ideal state with early prediction, process control and high-quality production can be really achieved.

Owner:岱纳包装(天津)有限公司

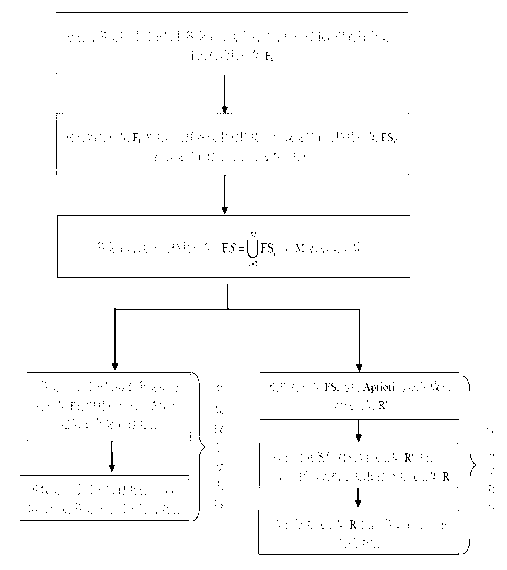

Classification method based on kernel feature extraction early prediction multivariate time series category

InactiveCN103020643AReduce redundant featuresImprove stabilityCharacter and pattern recognitionExperimental validationEarly prediction

The invention provides a classification method based on a kernel feature extraction early prediction multivariate time series category according to early prediction multivariate time series classification. To extract the essential features of variable time series, first the variable time series undergo feature extraction respectively, and a clustering method is adopted to reduce redundancy features, remove noise and improve classification stability; then, to improve classification efficiency, precision and early degree, a method for comprehensively evaluating feature performances is provided on the basis of accuracy rate, recall rate and the early degree and the like, and the optimal feature in each cluster is selected to serve as a kernel feature of a variable; and finally, two simple effective classifier construction methods are provided on the basis of a kernel feature set of each variable. Correctness and effectiveness of the method and an algorithm are proven through experiments, and experiment results prove that a classifier can have high accuracy rate and good early degree.

Owner:WUHAN UNIV

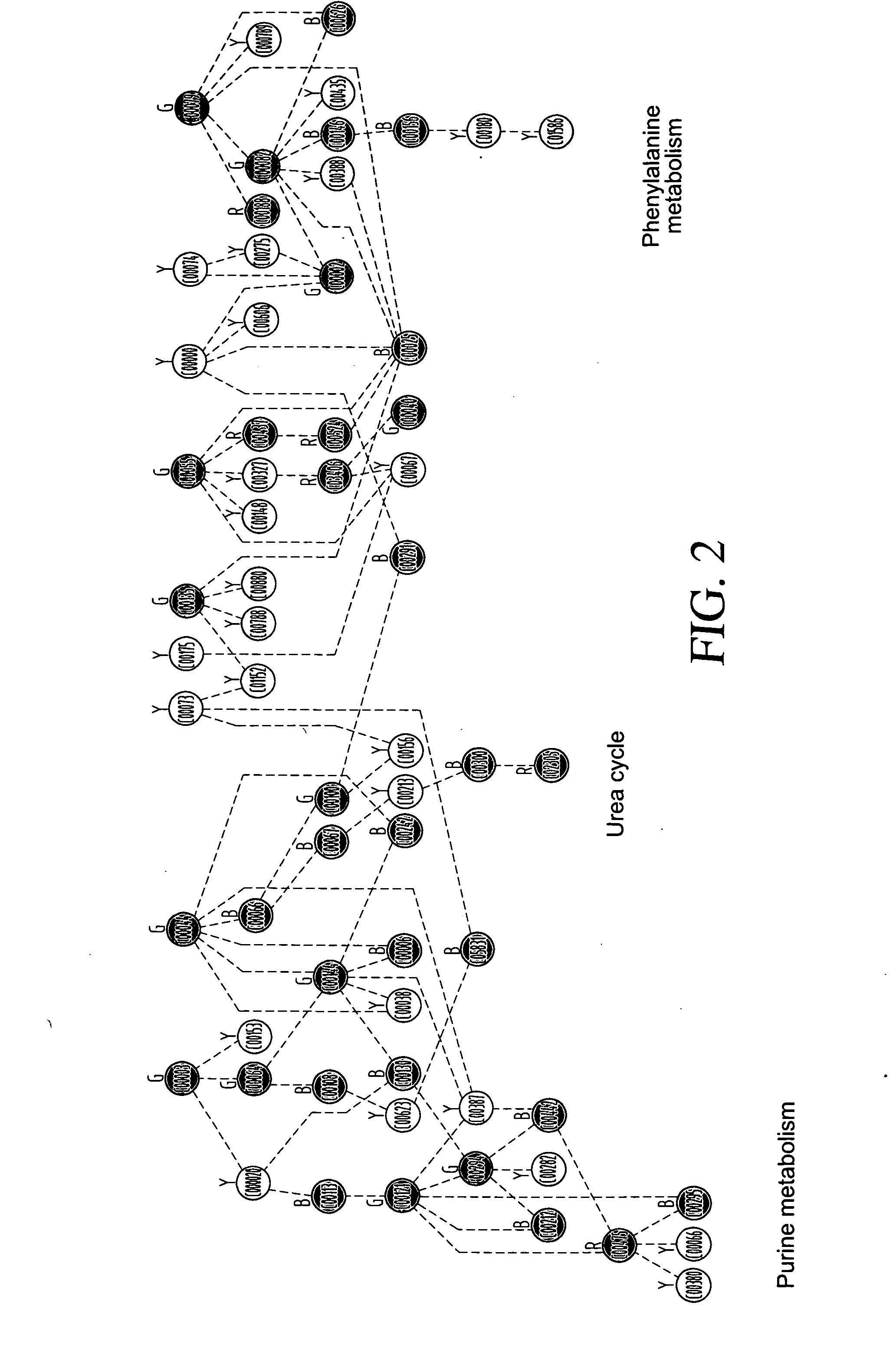

Diagnosis of sepsis or SIRS using biomarker profiles

InactiveUS20080138832A1Accurate and rapid and sensitive prediction and diagnosisMicrobiological testing/measurementDisease diagnosisDiseaseEarly prediction

The early prediction or diagnosis of sepsis advantageously allows for clinical intervention before the disease rapidly progresses beyond initial stages to the more severe stages, such as severe sepsis or septic shock, which are associated with high mortality. Early prediction or diagnosis is accomplished by comparing an individual's profile of biomarker expression to profiles obtained from one or more control, or reference, populations, which may include a population that develops sepsis. Recognition of features in the individual's biomarker profile that are characteristic of the onset of sepsis allows a clinician to diagnose the onset of sepsis from a bodily fluid isolated from the individual at a single point in time. The necessity of monitoring the patient over a period of time is, therefore, avoided, advantageously allowing clinical intervention before the onset of serious symptoms of sepsis. Further, because the biomarker expression is assayed for its profile, identification of the particular biomarkers is unnecessary. The comparison of an individual's biomarker profile to biomarker profiles of appropriate reference populations likewise can be used to diagnose SIRS in the individual.

Owner:BECTON DICKINSON & CO

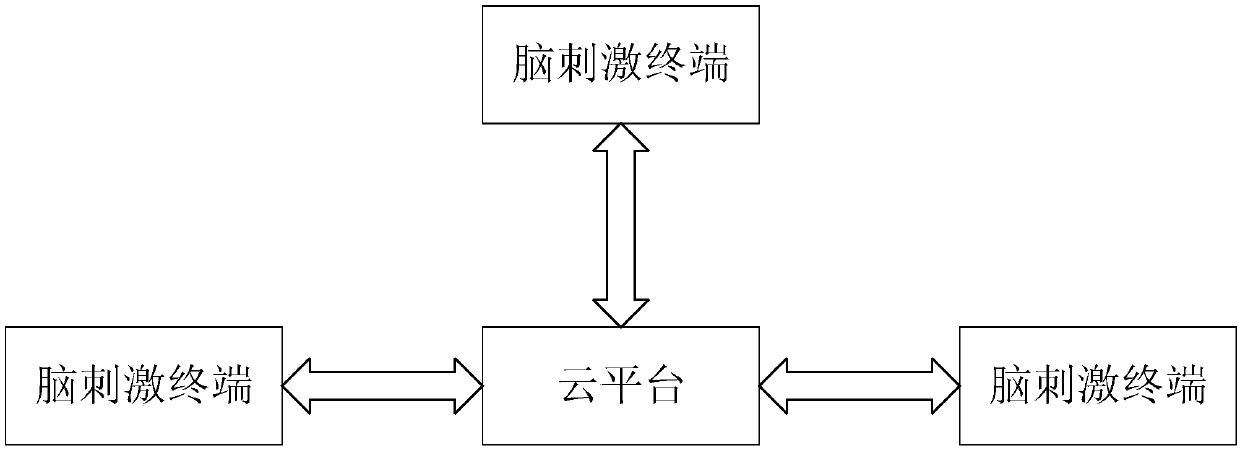

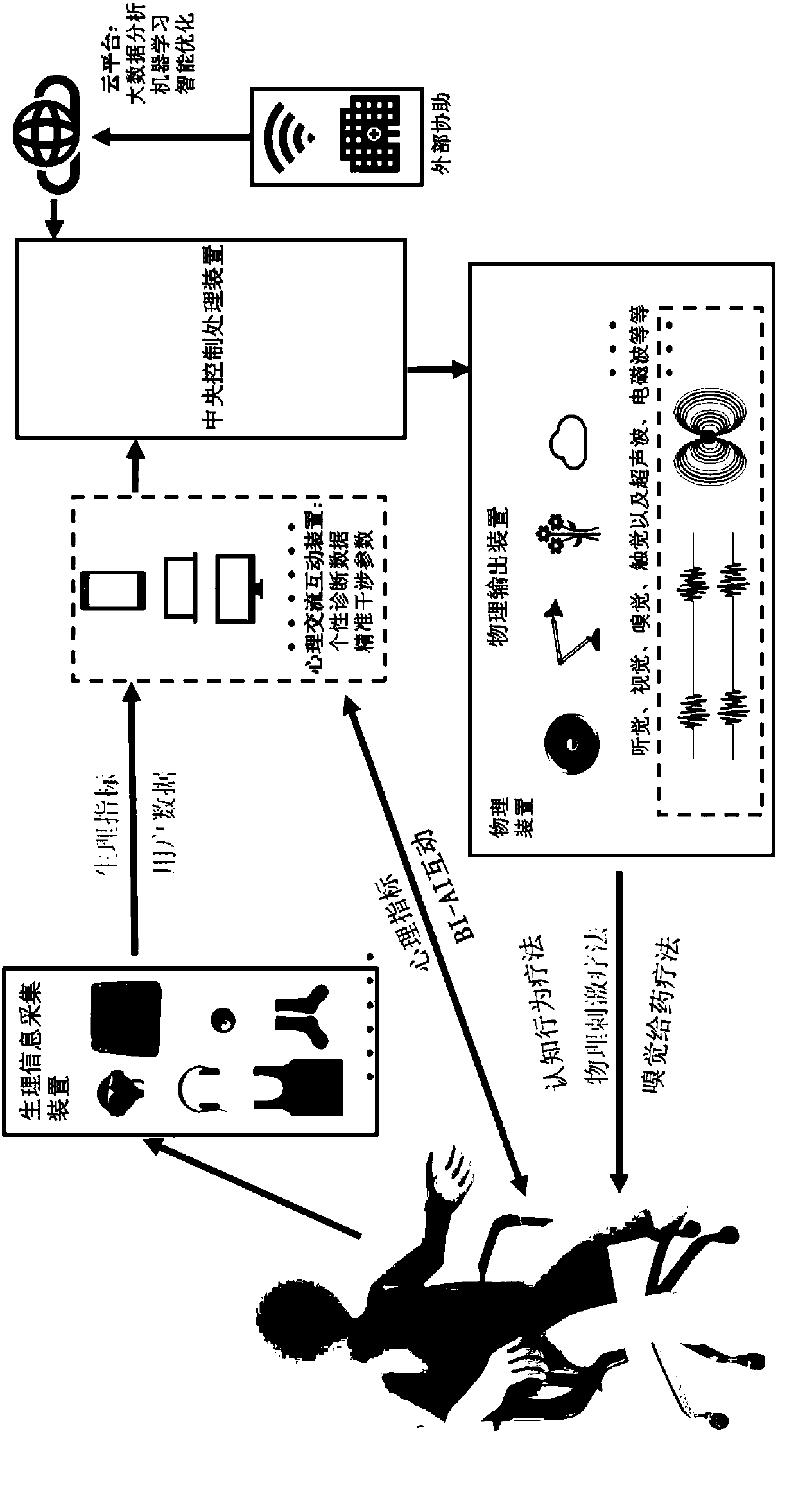

Brain stimulation system and method based on artificial intelligence, equipment and storage medium

ActiveCN110522983AEarly preventionEarly interventionMedical devicesMental therapiesDiseaseObject based

The embodiments of the invention disclose a brain stimulation system and method based on artificial intelligence, equipment and a storage medium. The system comprises a plurality of brain stimulationterminals and a cloud platform; the cloud platform is used for adopting an artificial intelligence technology to generate multidirectional psychological big data by learning physiological data and psychological state evaluation parameters from the multiple brain stimulation terminals and combining a preset diagnosis treatment model for various diseases; and the brain stimulation terminals are usedfor adopting the artificial intelligence technology to analyze the collected physiological data and psychological state evaluation parameters of a target object based on the multidirectional psychological big data, the mental state of the target object is determined, brain stimulation parameters required for the target object are obtained according to the mental state, and corresponding noninvasive bran stimulation is generated to the target object according to the brain stimulation parameters. The brain stimulation system and method based on the artificial intelligence, the equipment and thestorage medium are suitable for maintaining mental health of ordinary people and regulating unhealthy emotions of ordinary people and at least have the effects of early prediction, professional prevention and timely interference on certain serious mental diseases.

Owner:SHENZHEN INST OF ADVANCED TECH

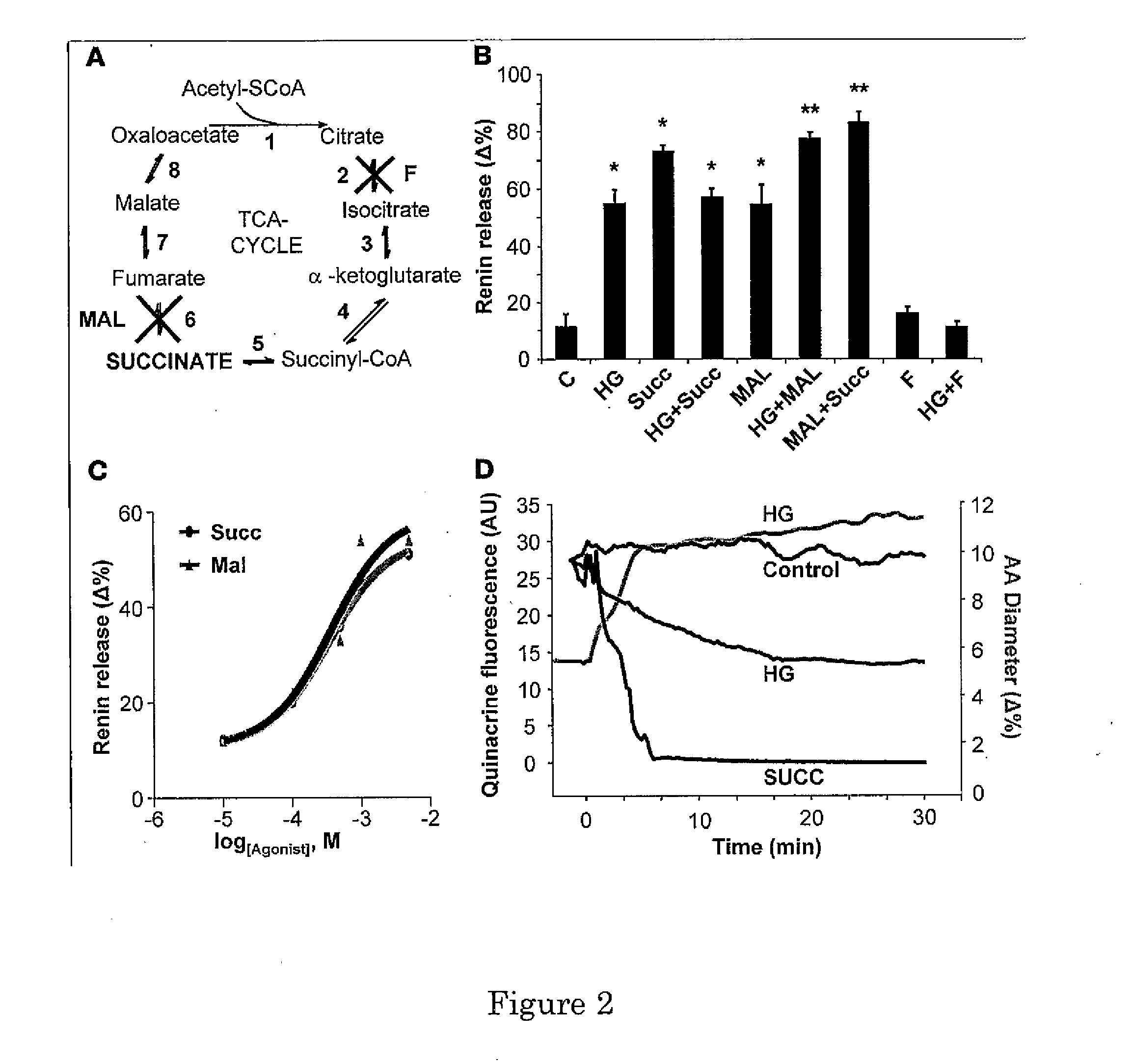

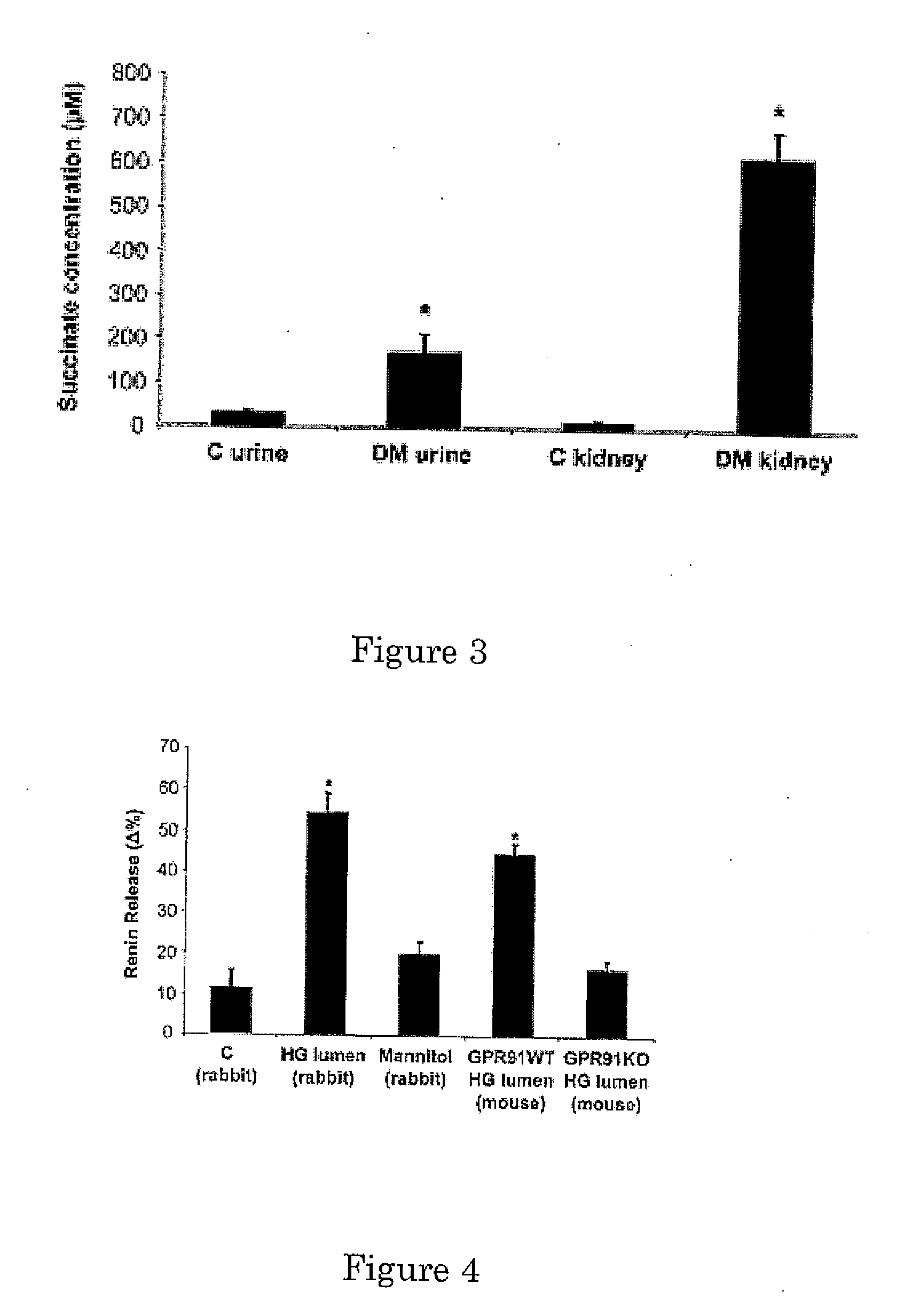

Measurement of a dicarboxylate in urine samples as a novel biomarker of kidney damage

The present invention relates in general to the discovery of urinary succinate as a novel biomarker of kidney disease. More specifically, the invention provides for the measurement of succinate in urine samples that has great potential for the easy and early diagnosis of kidney damage and would allow early prediction of kidney disease and therapeutic intervention.

Owner:UNIV OF SOUTHERN CALIFORNIA

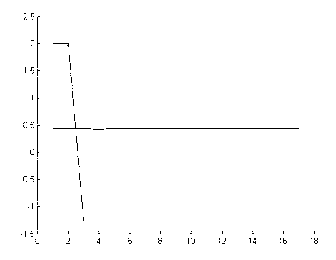

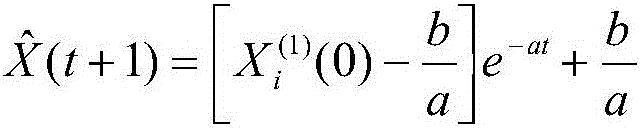

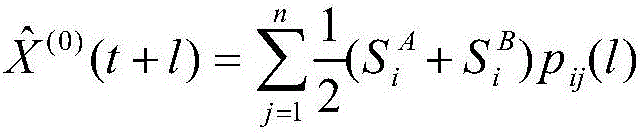

Effective parking space prediction method

ActiveCN106548254ASmall error volatilityReduce random volatilityForecastingEarly predictionPredictive methods

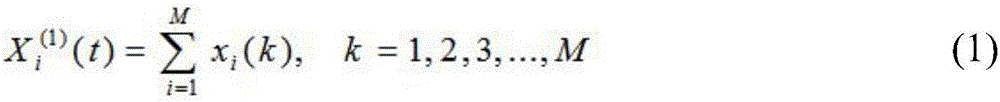

The invention relates to an effective parking space prediction method which is used for predicting the number of effective parking spaces of small and medium-sized parking lots. The effective parking space prediction method is characterized by comprising the following steps: step one, a time sequence of initial effective parking spaces is acquired; step two, initial prediction is performed by applying a GM(1, 1) prediction model according to the time sequence of the effective parking spaces so as to acquire an initial prediction time sequence; step three, a Markov prediction model is built to perform modification prediction so as to acquire a modification prediction time sequence; step four, an early prediction time period and a late prediction time period are set; step five, early prediction is performed on the early prediction time period by applying a wavelet neural network according to the modification prediction time sequence so as to acquire an early prediction value and an early prediction time sequence; step six, prediction is performed on the late prediction time period by applying a Lyapunov exponent method according to the early prediction time sequence so as to acquire a late prediction value; and step seven, performing combination calculation on the early prediction value and the late prediction value so as to acquire a predicted value of the parking spaces.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

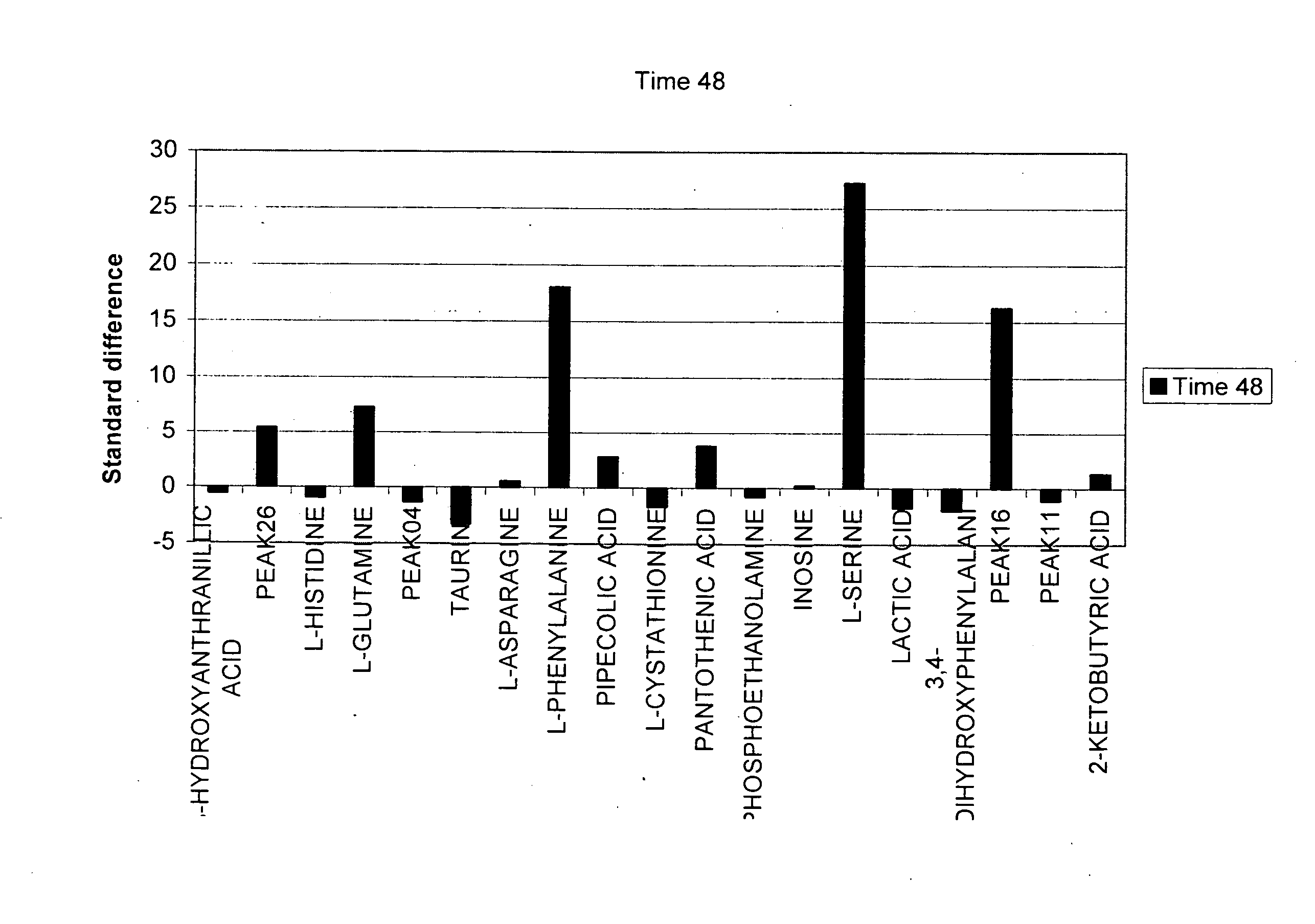

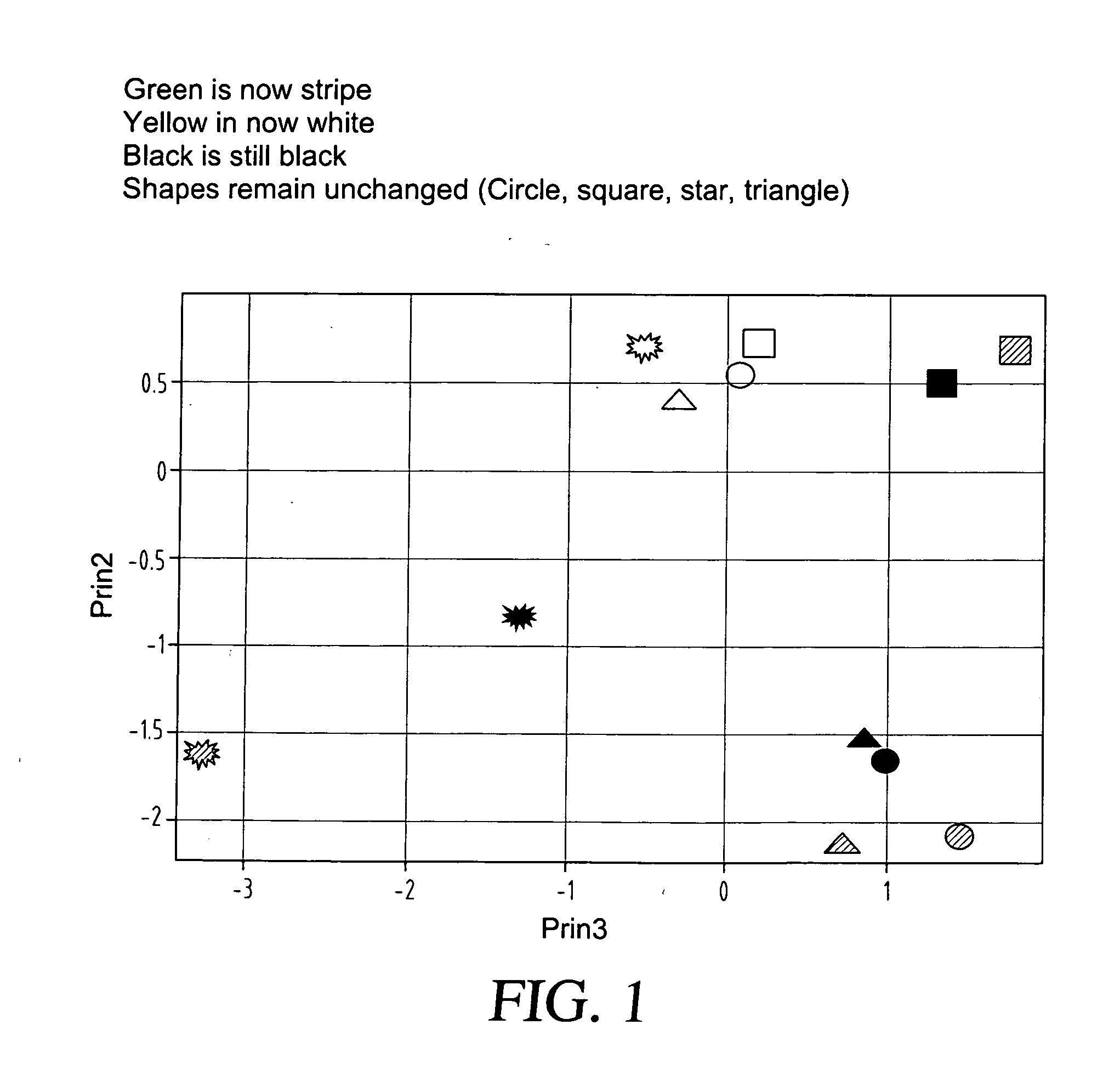

Identification and use of biomarkers for non-invasive and early detection of liver injury

InactiveUS20080213768A1Increase the number ofMicrobiological testing/measurementEarly predictionEfficacy

The present invention provides methods for identifying and evaluating suites of biochemical and / or gene entities useful as biomarkers for early prediction of disease and / or toxicity, disease staging, target identification / validation, and monitoring of drug efficacy / toxicity. The present invention further provides suites of small molecule entities as biomarkers for non-invasive and early prediction of hepatic injury.

Owner:METABOLON

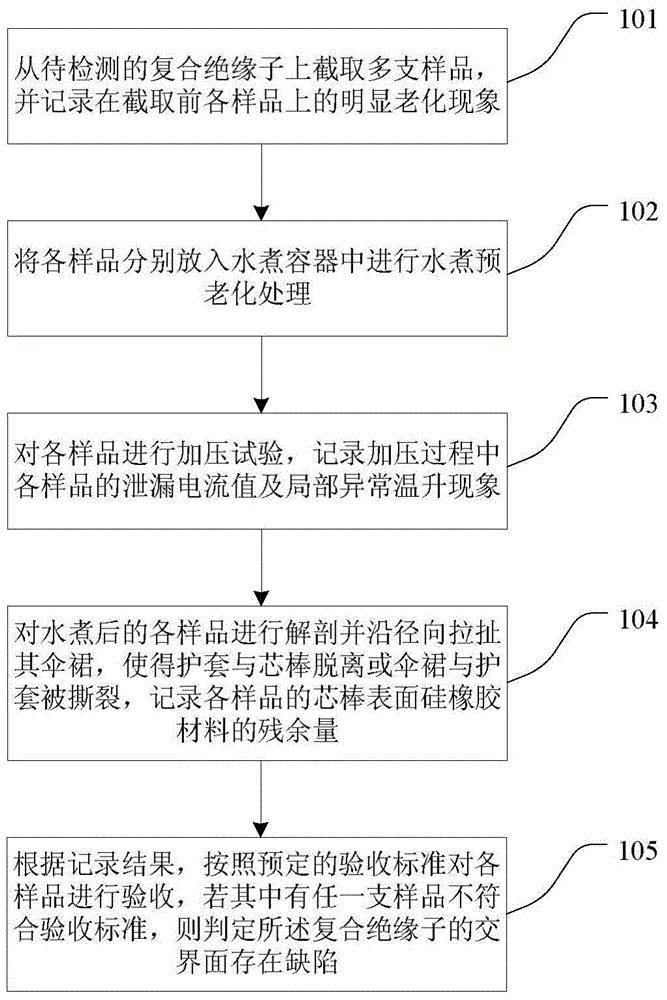

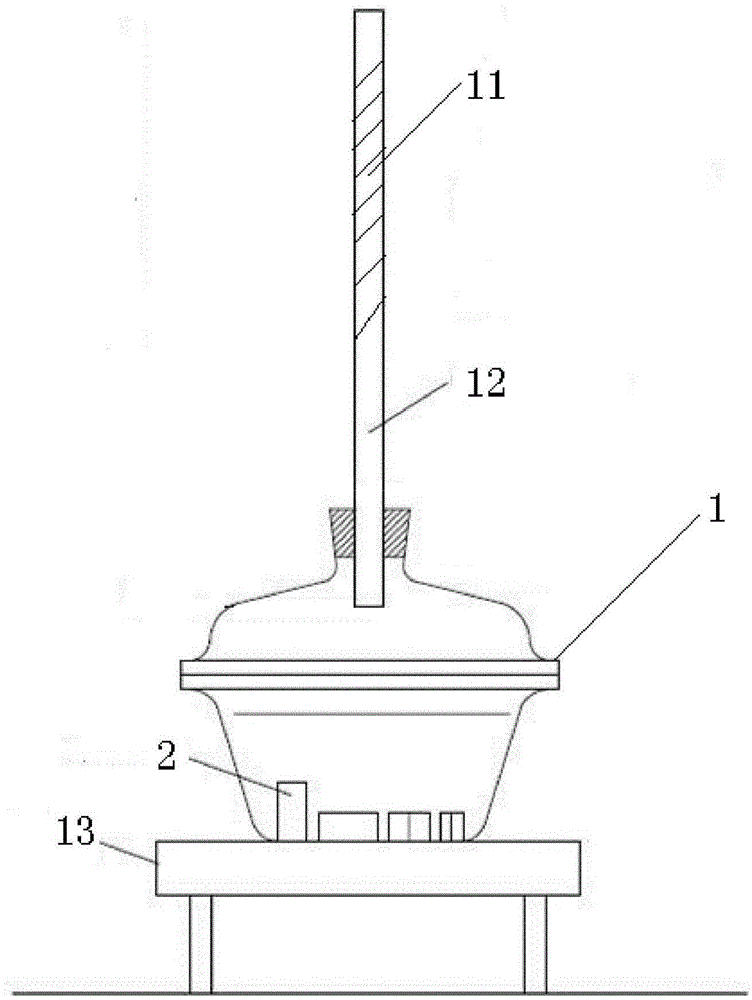

Composite insulator interface flaw detection method based on water diffusion and dissection method

InactiveCN104459029AAccelerated agingReduce missed detection rateMaterial analysisEarly predictionComposite insulators

The invention provides a composite insulator interface flaw detection method based on a water diffusion and dissection method. The method comprises the steps: (1) intercepting a plurality of samples, and recording obvious aging phenomenon on each sample before the samples are intercepted; (2) pre-aging each sample in a boiling way; (3) carrying out a pressure test on each sample, recording a leak current value and local abnormal temperature rising phenomenon; (4) dissecting each sample, pulling an umbrella skirt of each sample along the radial direction, and recording the residual amount of a silicone rubber material on the surface of a core bar of each sample; and (5) checking and accepting each sample according to an acceptance criterion according to the recorded result. By boiling the insulator with a jacket, the aging of the composite insulator interface is accelerated, so that early prediction on the insulator having the interface potential danger can be realized, the missing rate of the detection on the flaw of the interface can be greatly reduced, and the interface flaw of the composite insulator can be effectively detected. The method has advantages of being high in accuracy, easy to realize, low in cost and the like.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

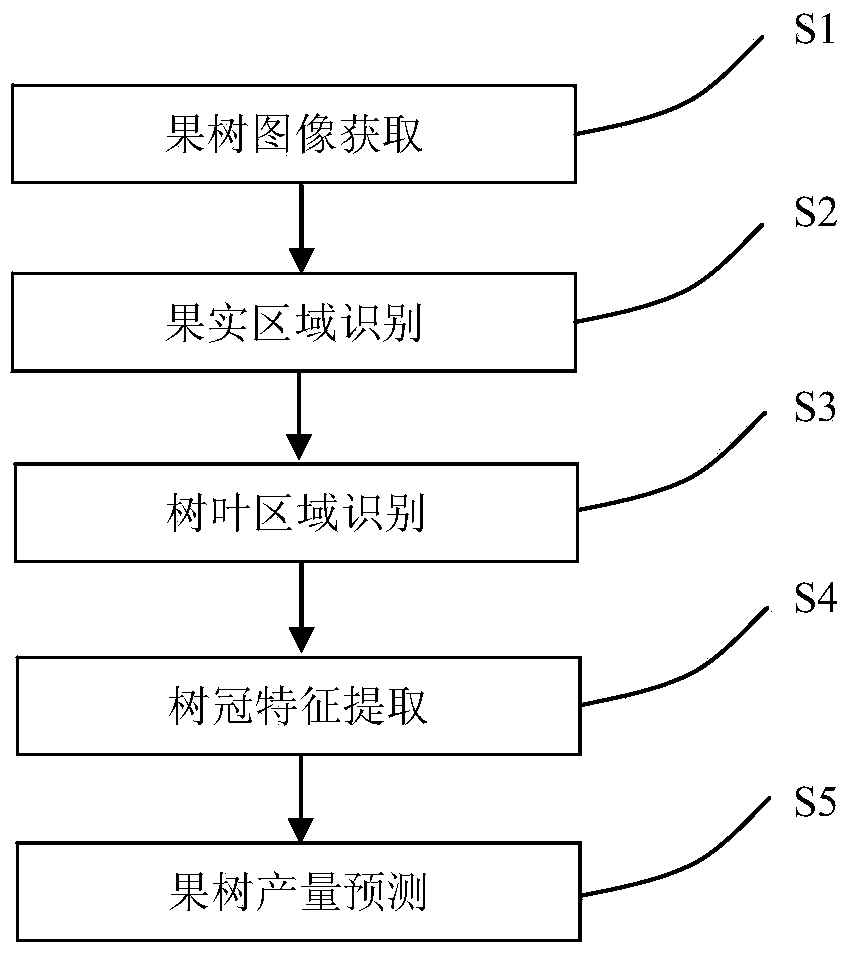

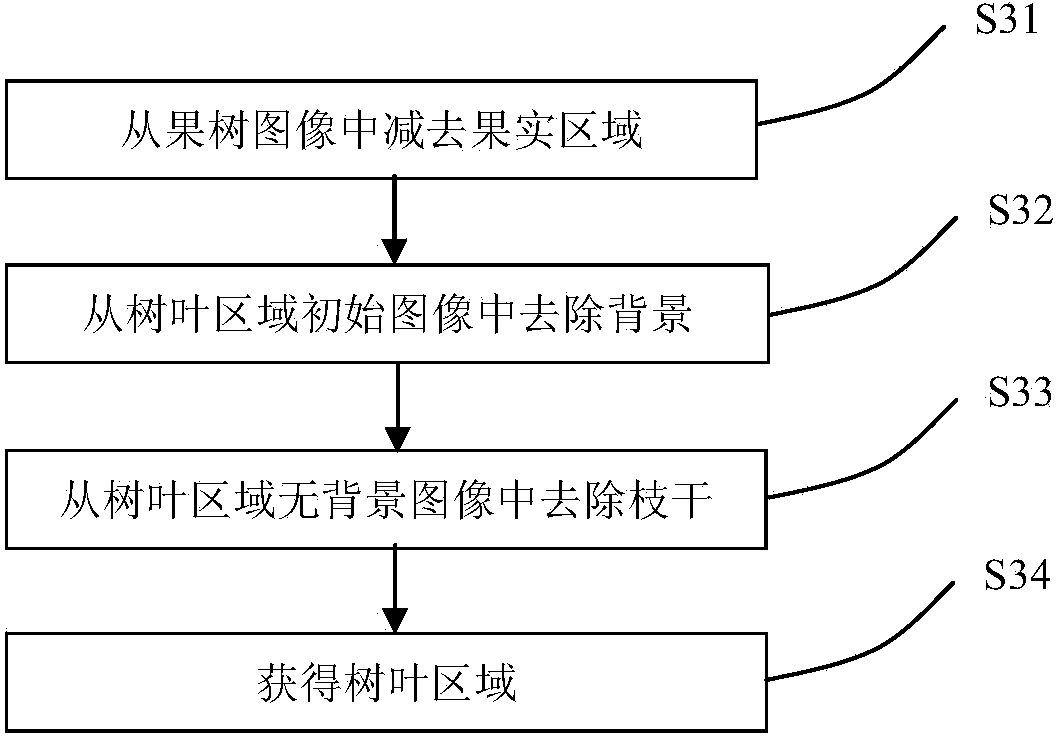

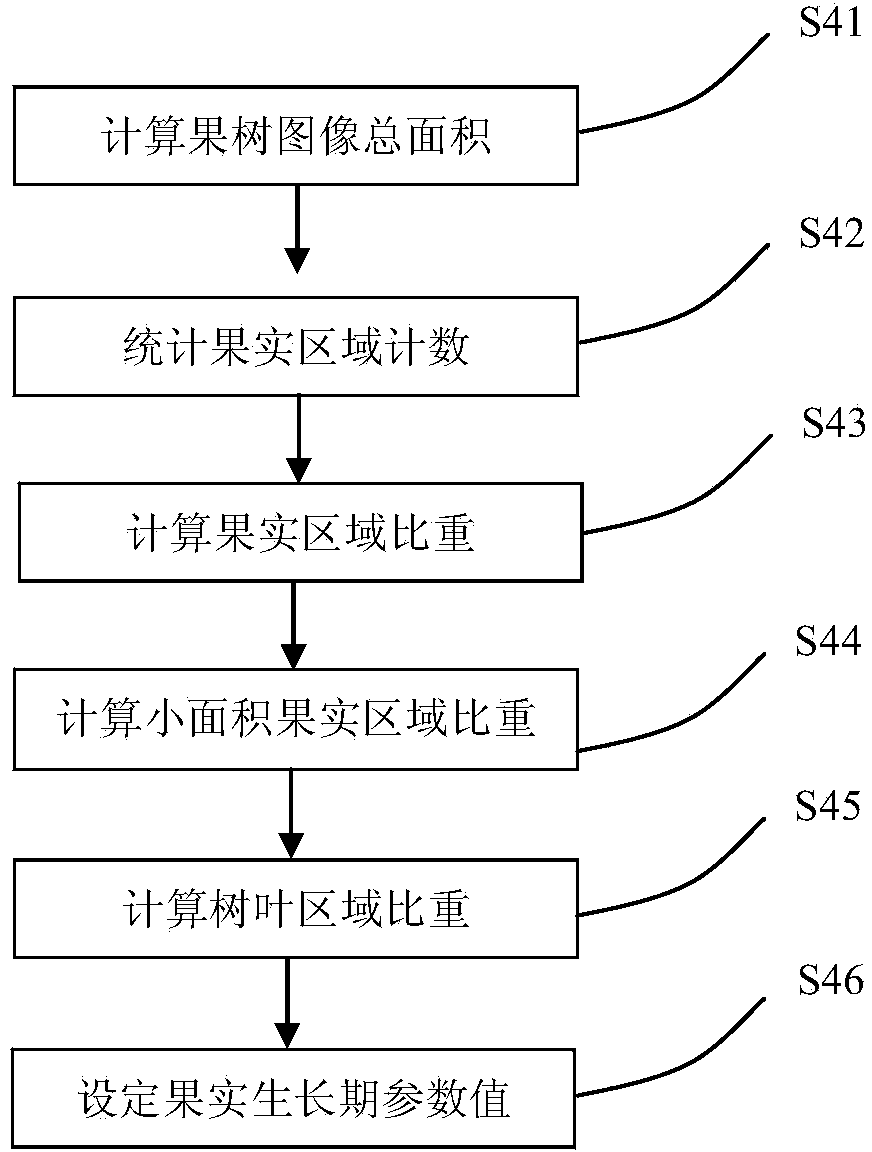

Method for early-prediction of fruit tree yield

InactiveCN103793686AAccurate predictionCharacter and pattern recognitionPattern recognitionFruit tree

The invention provides a method for early-prediction of the fruit tree yield. The method comprises the steps that S1, according to the requirement for fruit ranch management, the image obtaining time is determined and images of a fruit tree which is ready to be predicated in yield are collected by a portable image collecting device in a certain time under a certain image collecting condition; S2, fruit zone identification is conducted according to image characteristics; S3, leaf zone identification is conducted according to the image characteristics; S4, characteristics of a fruit zone and a leaf zone are extracted to serve as fruit tree crown characteristics; S5, the fruit tree crown characteristics are input into an artificial neural network yield measuring model for predicting the yield of the fruit tree. According to the method, the image processing and identification technology is effectively combined with the artificial intelligence technology, the defect that only the image processing and identification technology is used for prediction is overcome, and therefore prediction can be accurately conducted on apples in the fruit ranch in an early period.

Owner:CHINA AGRI UNIV

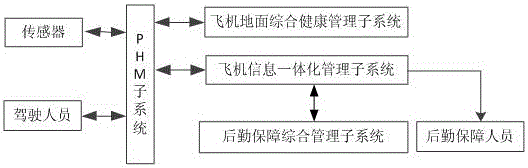

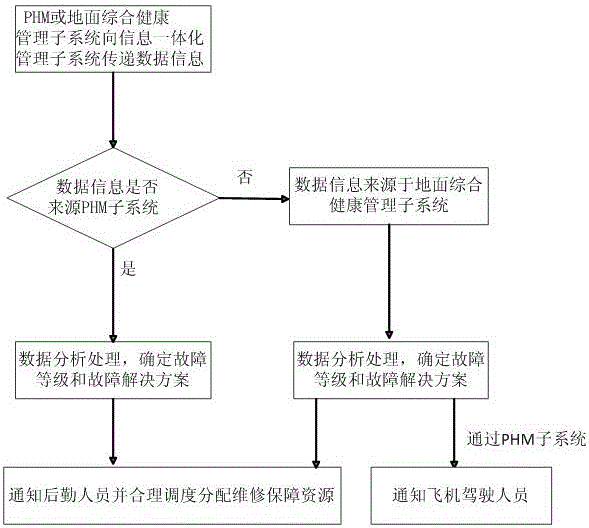

Airplane autonomous guarantee system and method based on internet of things

InactiveCN106741988ATimely and effective maintenance guaranteeEnsure flight safetyAircraft health monitoring devicesJet aeroplaneEarly prediction

The invention discloses an airplane autonomous guarantee system and method based on the internet of things. The system comprises a PHM subsystem, an airplane information integrated management subsystem and an airplane ground comprehensive health management subsystem. The method includes the following steps that 1, by means of information interaction of the PHM subsystem and the airplane information integrated management subsystem, airplane parameters and fault diagnosis results are transmitted; 2, the airplane ground comprehensive health management subsystem conducts performance degradation trend analysis on key equipment of an airplane, and early prediction and diagnosis of potential faults are achieved; 3, the airplane information integrated management subsystem analyzes transmission data information, a fault grade and a fault solution are determined, corresponding army maintenance staff, other guarantee staff and maintenance equipment are reasonably scheduled and allocated, and maintenance conditions of the airplane are monitored in the whole process. Conversion from planned maintenance to condition maintenance in airplane maintenance guarantee is achieved, and the system and method play an important role in guaranteeing safe flight of the airplane, improving maintainability, increasing the task success rate, improving use efficiency and the like.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

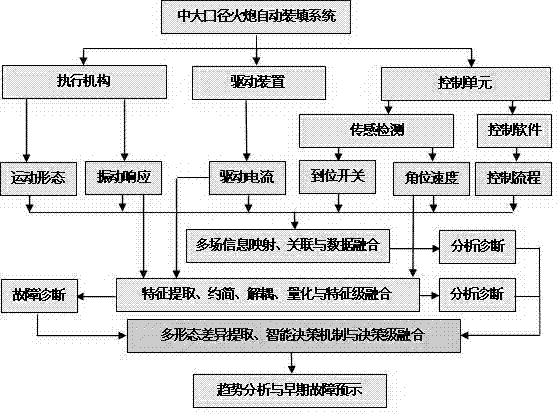

Self-loading system early failure predicting method based on multi-field information fusion

The invention relates to a self-loading system early failure predicting method based on multi-field information fusion and belongs to the technical field of failure prediction analysis of self-loading systems of artillery. The self-loading system early failure predicting method based on multi-field information fusion is used for fusing data through information of various kinds of physical fields and is high in anti-interference capacity, recognition accuracy and reliability. According to the technical scheme, the method includes the steps that original data information of various physical fields is obtained, and the acceleration and the angle parameter of a self-loading system, an analog signal output by a current sensor, and in-place signals, angles, rates and digital signals of time characteristics of all proximity switches are acquired in real time; the acquired information is mapped, correlated, weighed and subjected to dimensionality reduction optimization, a model based on D-S evidence and the fuzzy set theory is built, and thus multi-field information fusion and failure prediction are carried out. The self-loading system early failure predicting method based on multi-field information fusion is high in accuracy and can be widely used for early prediction analysis of failure of the self-loading systems of artillery.

Owner:ZHONGBEI UNIV

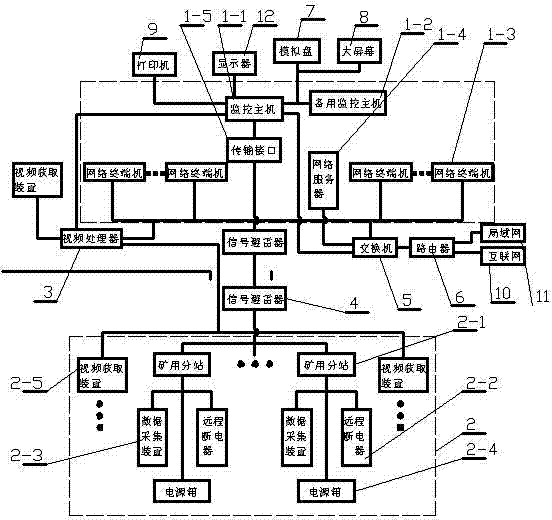

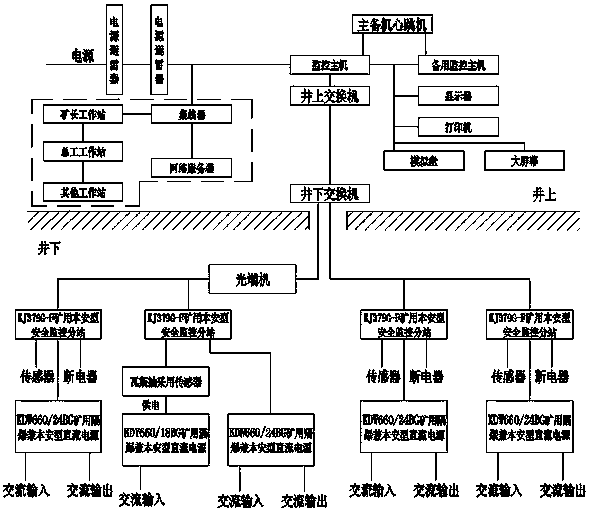

Safety monitoring system for mine

InactiveCN103573292AAccurate downhole environmental parametersEffective command of productionMining devicesNetwork terminationEarly prediction

The invention relates to a safety monitoring system for a mine. The safety monitoring system comprises a monitoring system and a monitor executing system, wherein the monitoring system is placed on the ground, and comprises a monitoring mainframe, a network server and a network terminal; the monitoring mainframe is connected with a transmission interface; the monitoring mainframe, the network terminal and the network server are all connected to an exchanger; the exchanger is connected with a router; the monitor executing system comprises a video obtaining device, a substation for the mine, a data acquiring device and a remote breaker; the data acquiring device and the remote breaker are both connected with the substation for the mine; the video obtaining device is connected with a video processor; the video processor is respectively connected with the monitoring mainframe and the network terminal; the substation for the mine is connected with the monitoring mainframe by cables and transmission interfaces; the cables, arranged on the ground and well mouths, are all provided with signal arresters. The system can realize the monitoring to the underground environment to obtain accurate underground environmental parameters, and monitors and controls each device to achieve early prediction and processing for accidents.

Owner:XUZHOU JIANGMEI TECH +1

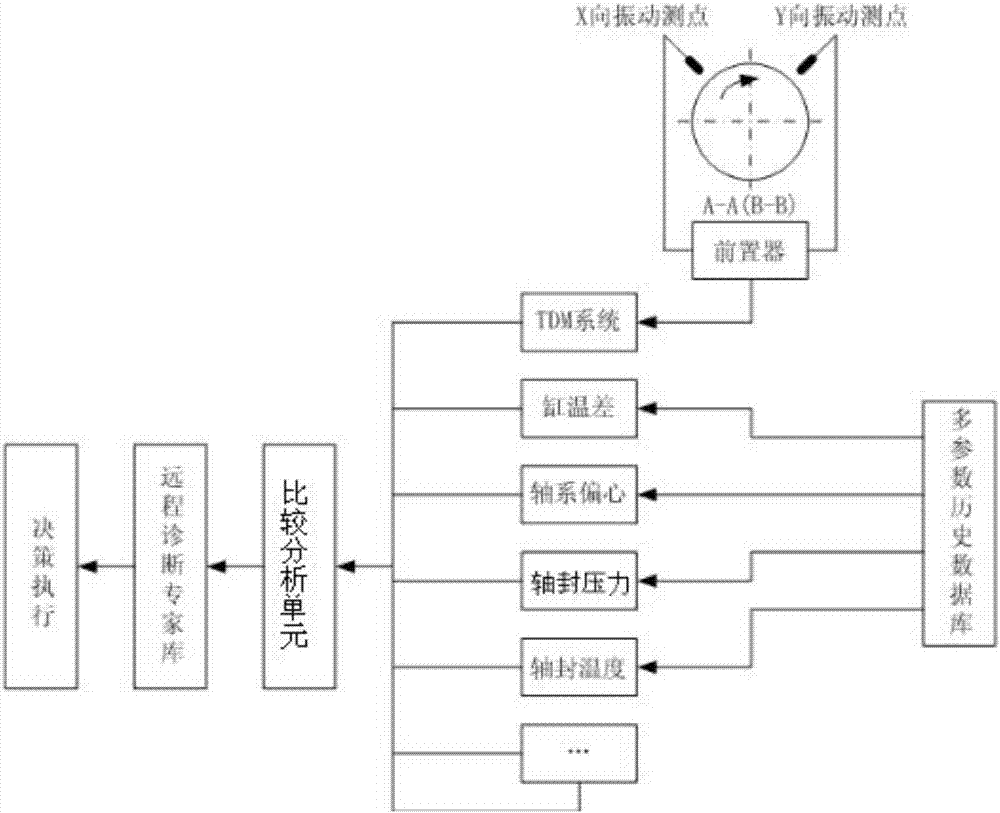

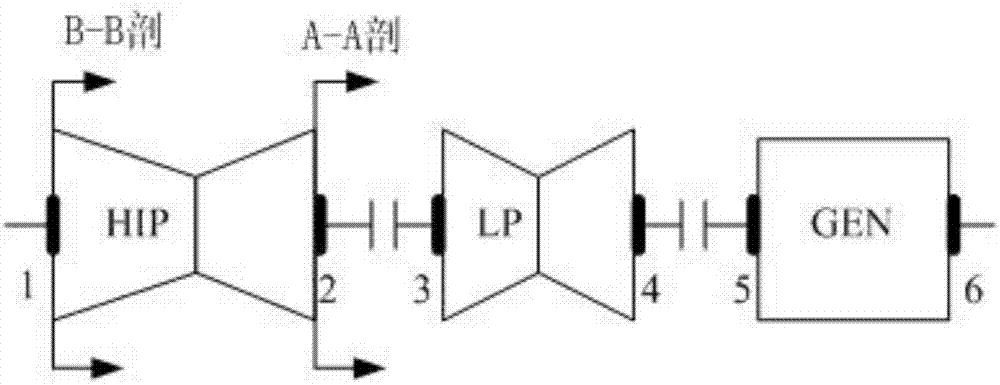

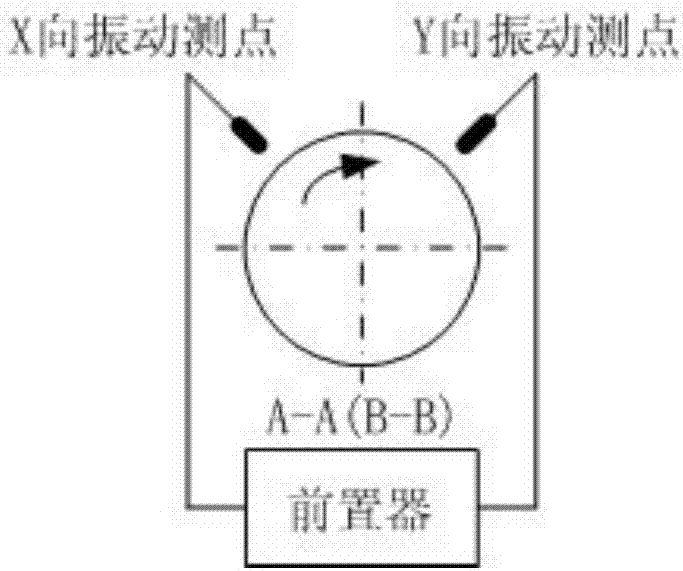

Multi-parameter correction turbo generator unit remote vibration fault diagnosis method and system

The present invention relates to a multi-parameter correction turbo generator unit remote vibration fault diagnosis method and system. Two eddy-current sensors which form an 90-degree angle with each other and a proximitor are installed at two support bearings of each rotor of a turbine-generator shaft system to perform real-time online collection of vibration data of the turbine-generator shaft system, and the vibration data is taken as the basis of remote diagnosis of the turbo generator unit; operation parameters closely related to the turbine-generator shaft system such as temperature differences of upper cylinders and lower cylinders of a high pressure cylinder and an intermediate pressure cylinder and set condenser vacuum are subjected to real-time online collection through each related sensor; and the measured vibration data of the turbo generator shaft system and the current parameters are fed into an optimally operating vibration database, and through comparison analysis, a result is transmitted to a vibration engineer in a remote mode for performing diagnosis and early prediction of vibration faults.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

Coal mine safety monitoring system

InactiveCN107939448ALess investmentAdvanced technologyMining devicesSafety equipmentsEarly predictionMonitoring system

The invention discloses a coal mine safety monitoring system, which comprises an upper part and an underground part. The upper part includes a power surge arrester sequentially connected to a power supply, a monitoring host and a standby monitoring host. The heartbeat machine is connected, the monitoring host is also connected with the uphole switch and the downhole switch in turn, and the monitoring host is also connected with the display, printer, large screen, and analog disk respectively; the downhole part includes At least one safety monitoring substation, the safety monitoring substation is respectively connected with the sensor, the breaker and the DC power supply. The invention can not only accurately and timely reflect downhole environmental parameters to achieve early prediction of disasters and necessary treatment of accidents, but also provide timely operation status of various equipment for production scheduling, thereby effectively directing production.

Owner:XUZHOU JIANGMEI TECH

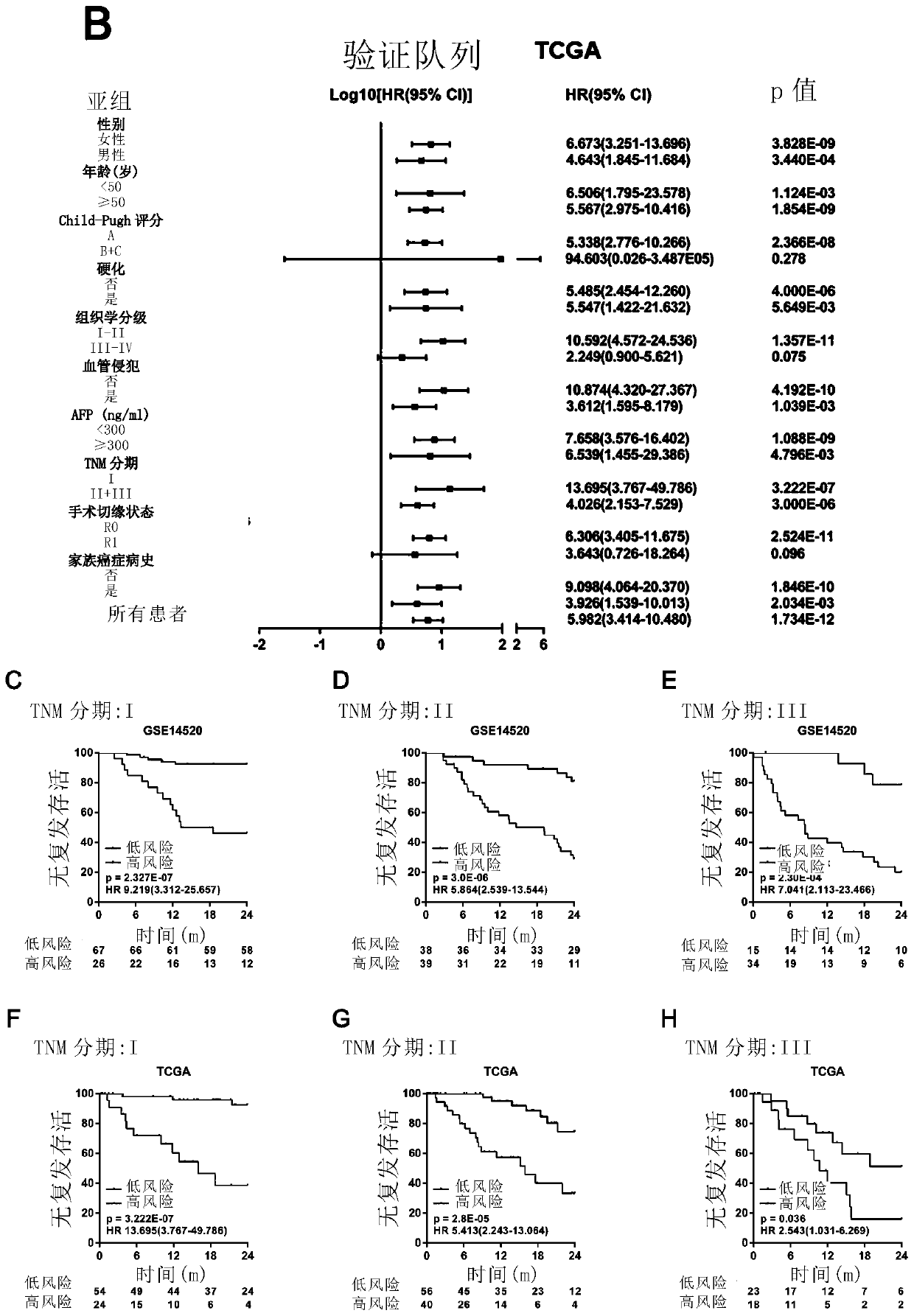

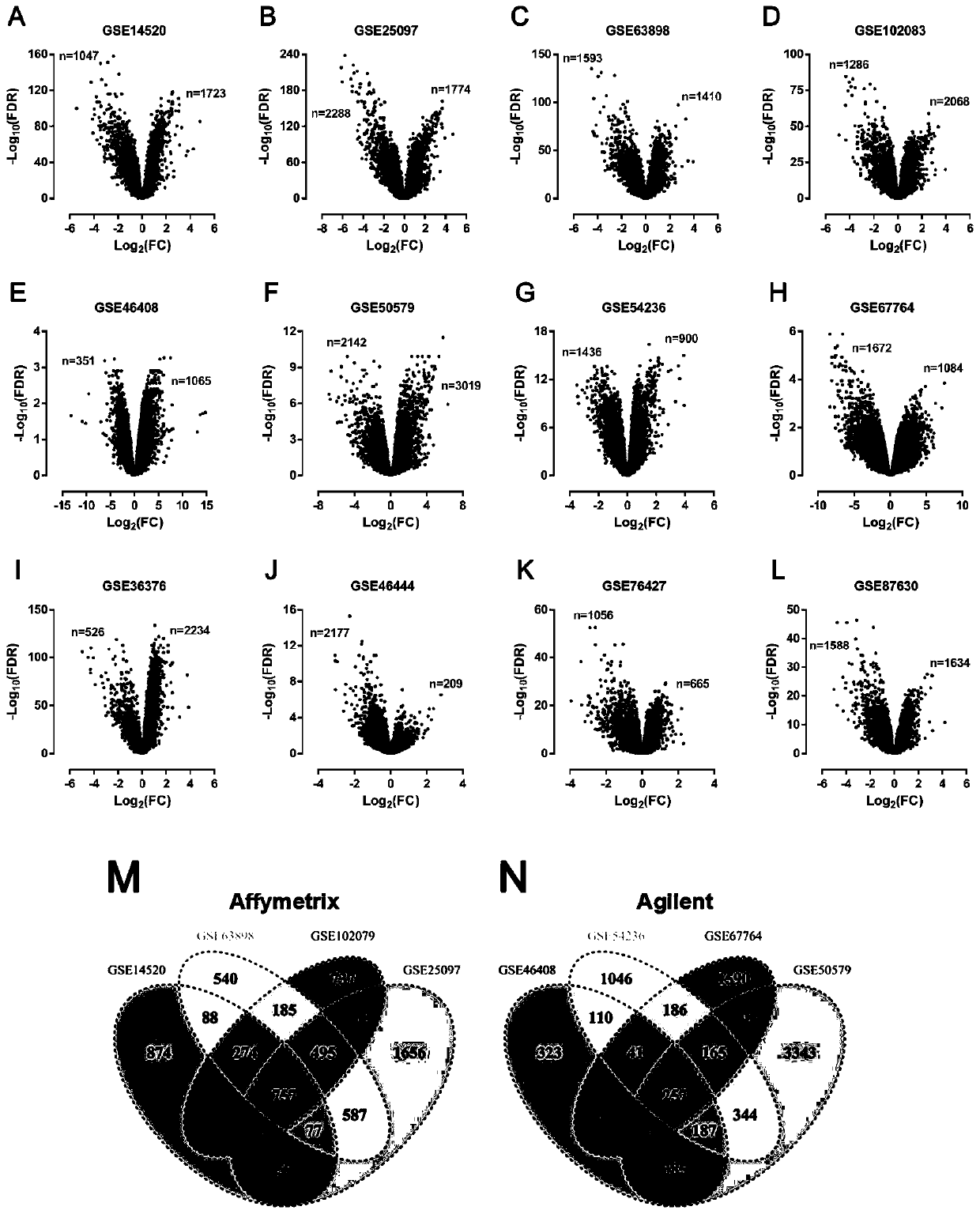

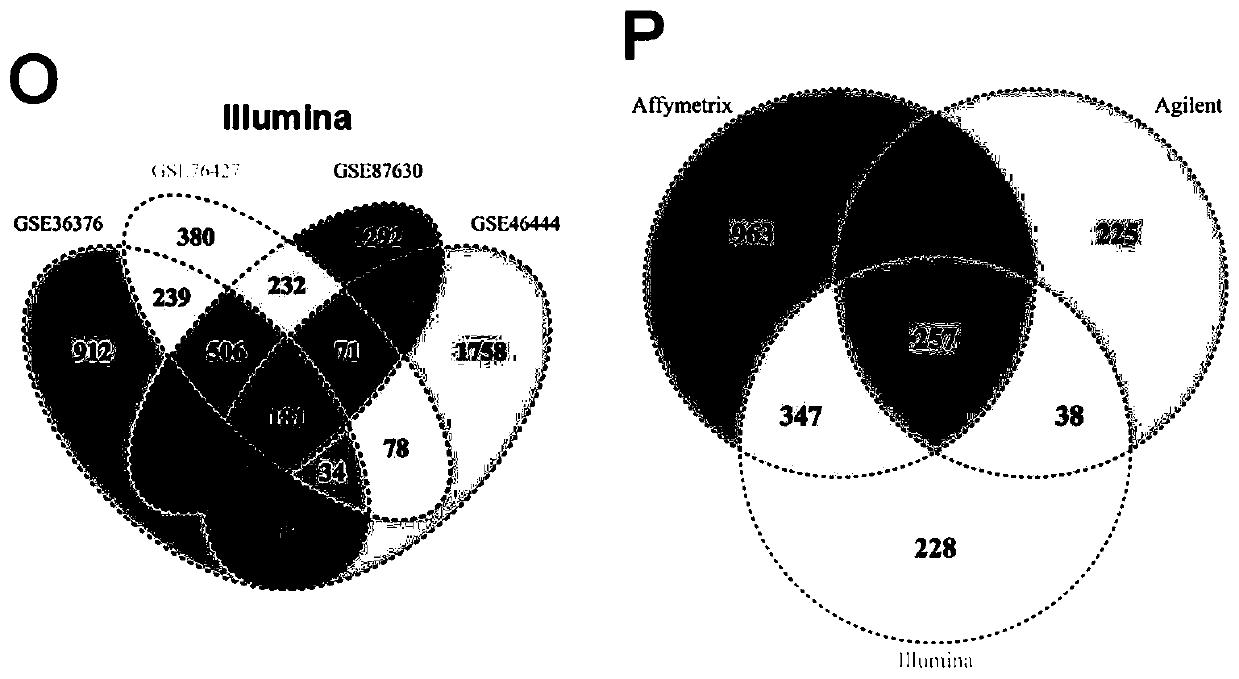

Construction and application evaluation of molecular model for predicting postoperative early recurrence risk of liver cancer

PendingCN110577998AMicrobiological testing/measurementDNA/RNA fragmentationPrediction algorithmsEarly prediction

The invention relates to construction and application evaluation of a molecular model for predicting postoperative early recurrence risk of liver cancer. Specifically, the invention found a biomarkerset which comprises various biomarkers for early postoperative recurrence of liver cancer, can be used for evaluating the risk of postoperative early recurrence of liver cancer patients, has the advantages of high sensitivity, high specificity and high accuracy, and has important application value. The invention further develops a risk prediction algorithm model and a device for postoperative early recurrence of liver cancer for the first time. The model can assist in clinically carrying out early prediction and early diagnosis on postoperative early recurrence of liver cancer. By implementingcloser postoperative follow-up visit and further adjuvant therapy, postoperative prognosis of liver cancer patients will be greatly improved.

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

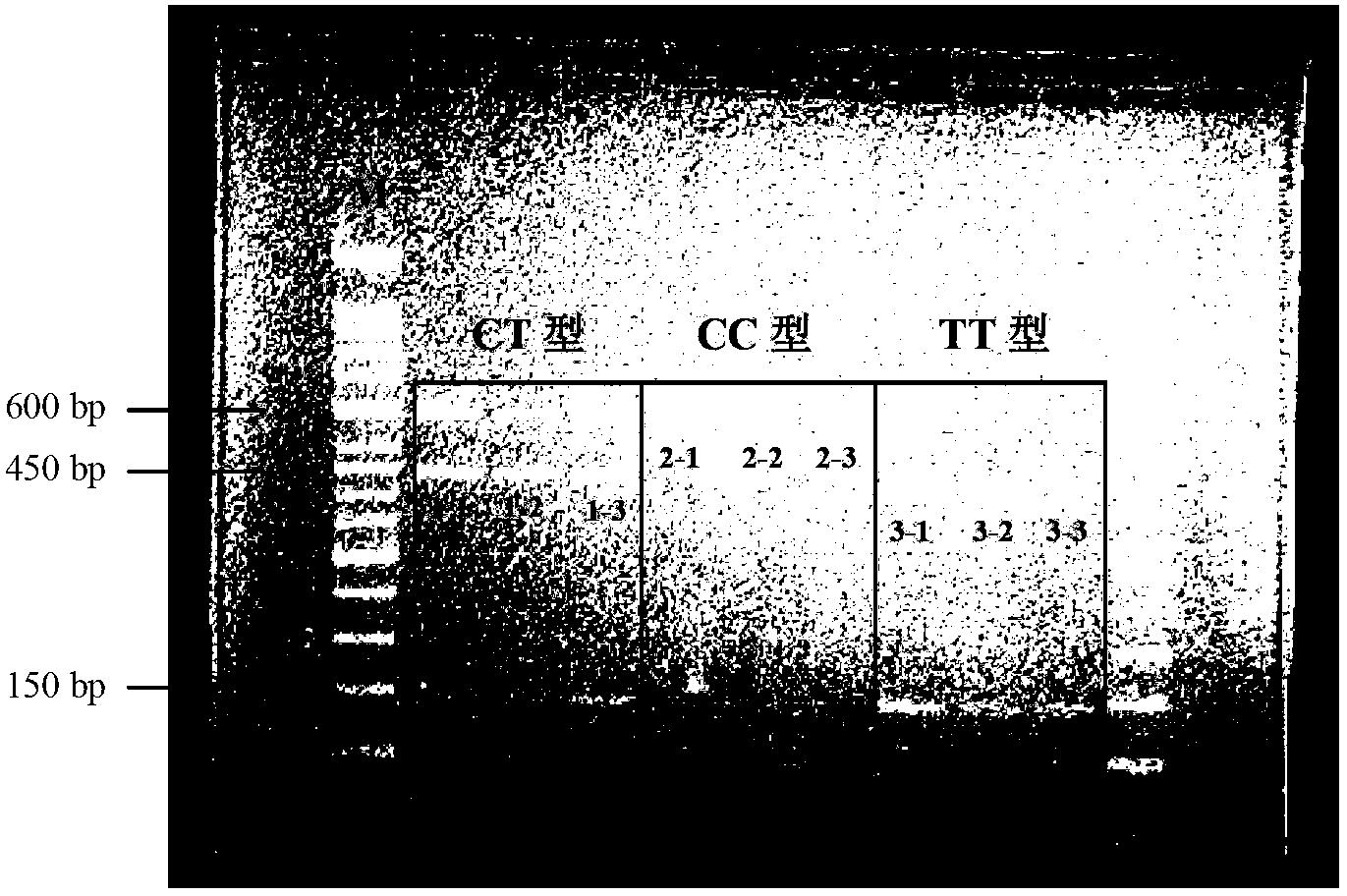

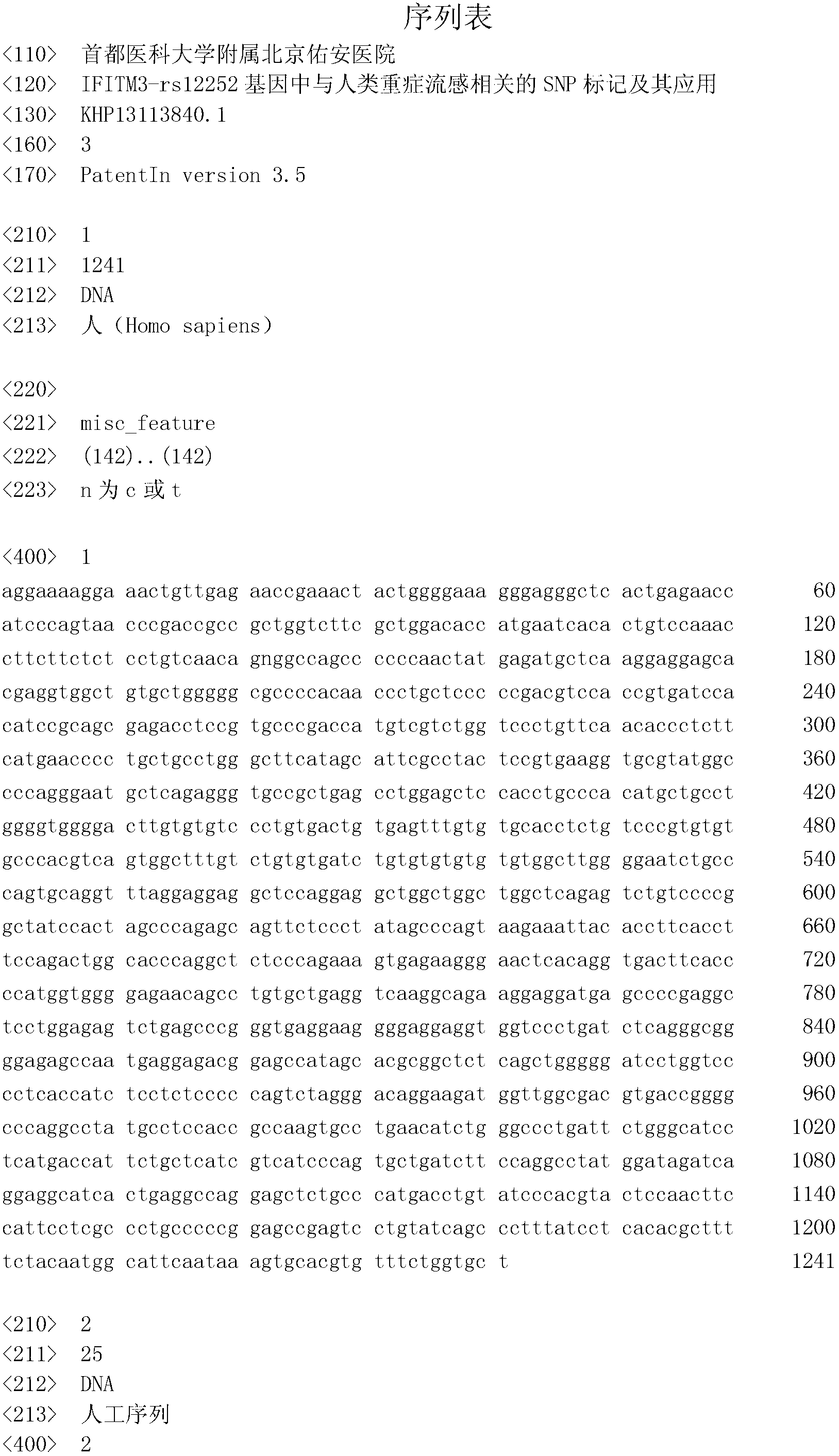

SNP (Single Nucleotide Polymorphism) marker related to human severe influenza in IFITM3-rs12252 gene and application thereof

InactiveCN103194446ALow costMicrobiological testing/measurementDNA/RNA fragmentationEarly predictionSevere influenza

The invention provides an SNP (Single Nucleotide Polymorphism) marker related to human severe influenza and an application thereof. The SNP marker related to human severe influenza is located at 142bp of the sequence of the IFITM3-rs12252 gene shown in SEQ ID NO. 1, and a basic group at 142bp is a C individual, which is at higher risk of suffering from severe influenza than the base group at 142bp, which is a T individual. Polymerase chain reaction (PCR) and sequencing technique are used for screening the SNP marker related to human severe influenza, a restricted fragment length polymorphism (RFLP) method is used for detecting the genotypes of a crowd to be tested, and the early prediction of severe influenza and the control on the generation of severe influenza are possible according to genotype judgment results. In addition, a genotype detecting method provided by the invention avoids the investment of expensive instrument, has the advantages of simpleness, rapidness, low cost and the like and is convenient for popularization and application at a basic level.

Owner:BEIJING YOUAN HOSPITAL CAPITAL MEDICAL UNIV

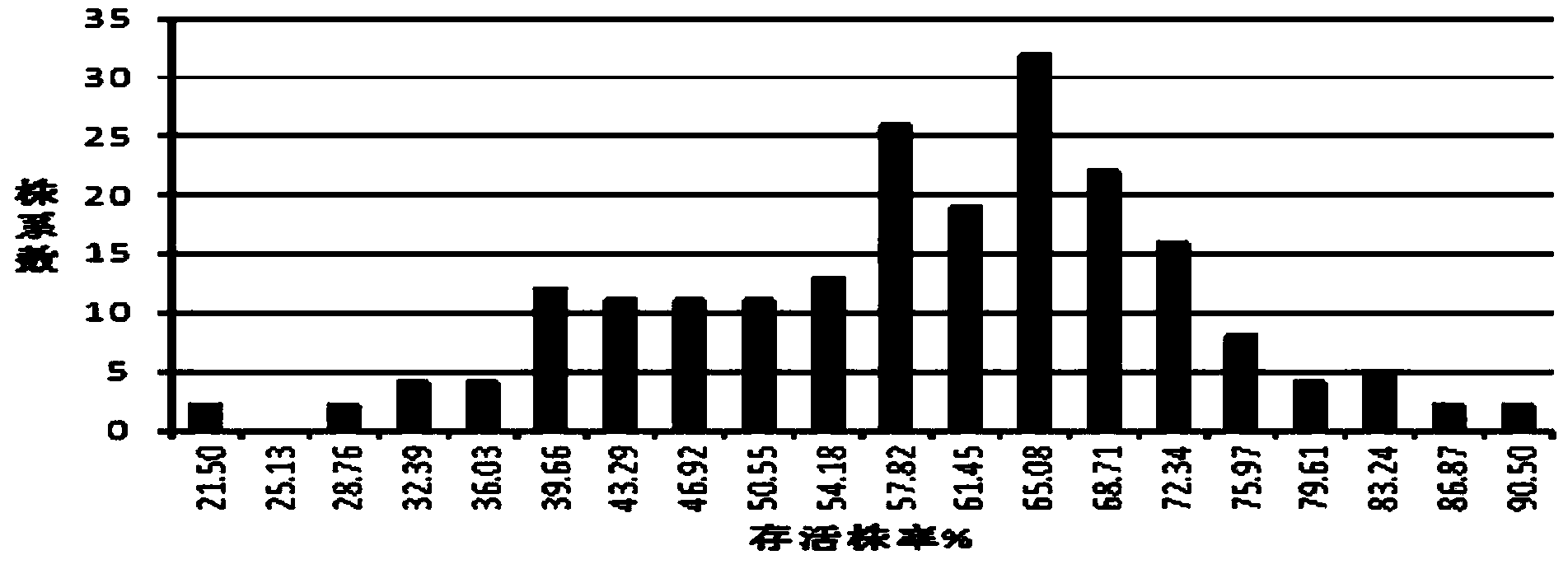

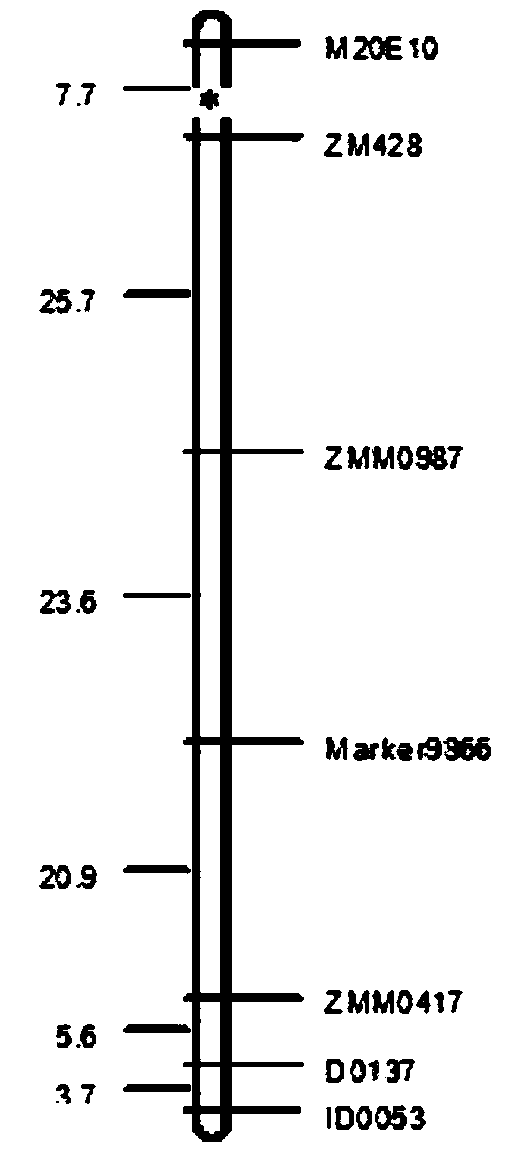

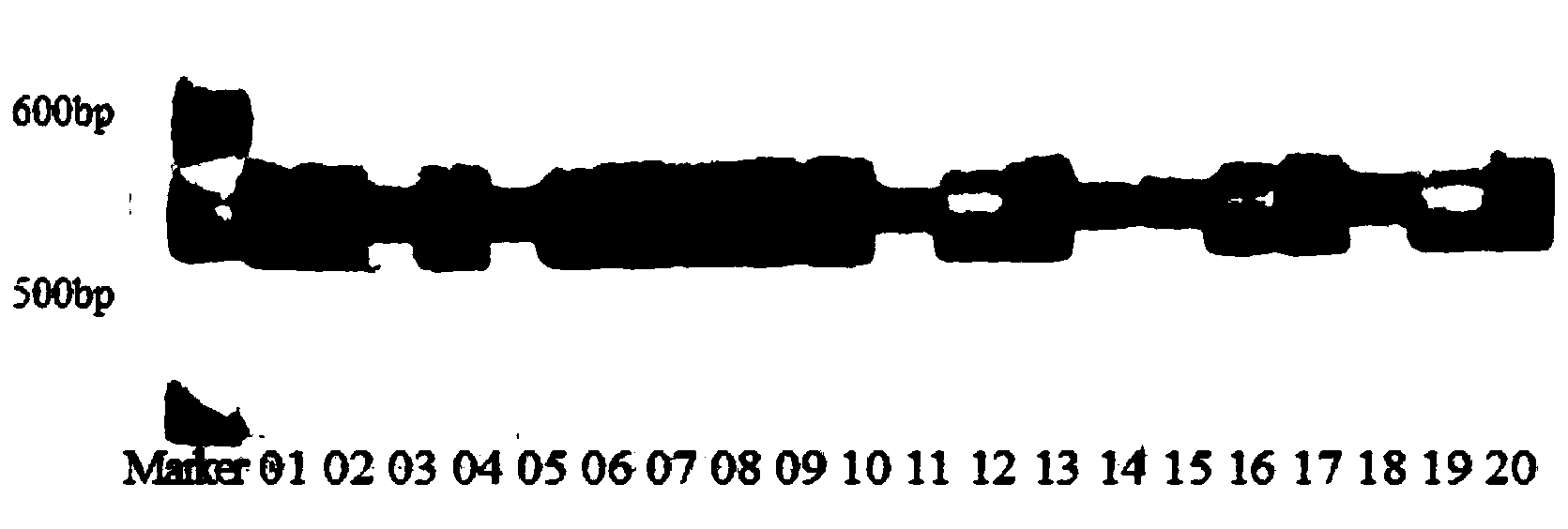

Molecular marker tightly linked with main effective genetic locus embodying sesame dampness resistance and application thereof

ActiveCN103525919AChoose a clear goalLow costMicrobiological testing/measurementPlant genotype modificationEarly predictionGermplasm

The invention relates to a molecular marker tightly linked with a main effective genetic locus embodying sesame dampness resistance and application thereof. The main effective genetic locus qWHCHL09 is located on the 9th linkage group, and the molecular marker tightly linked with the main effective genetic locus is ZM428 whose sequences are as follows: ZM428F: AGGATGATGATGTGATGAGAG (5'-3') and ZM428R: CTGCTACTCCTTTTGTCTCTG (5'-3'). The molecular marker is obtained by hybridizing sesame 13 in sesame dampness-resistant varieties and a sensitive germplasm Yiyangbai to obtain F6-generation segregation population, namely a recombinant inbred line (RIL) population, and performing molecular genetic linkage analysis on the F6-generation segregation population. The molecular marker tightly linked with the main effective genetic locus embodying the sesame dampness resistance is applied to breeding of the sesame dampness-resistant varieties and screening of dampness-resistant traits of the sesame germplasm as well as early prediction; the auxiliary dampness resistance choosing target is clear; and the cost is relatively low.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

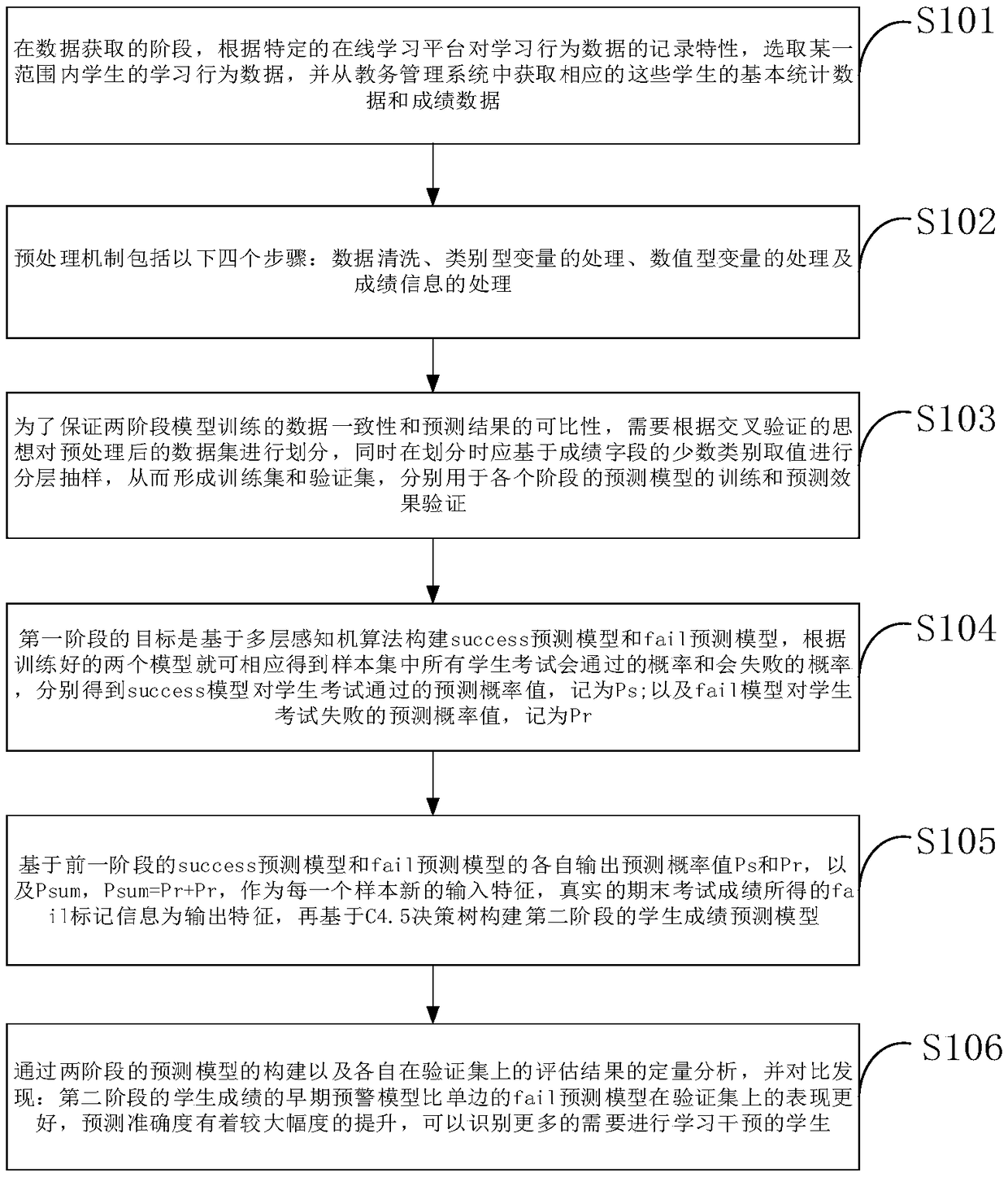

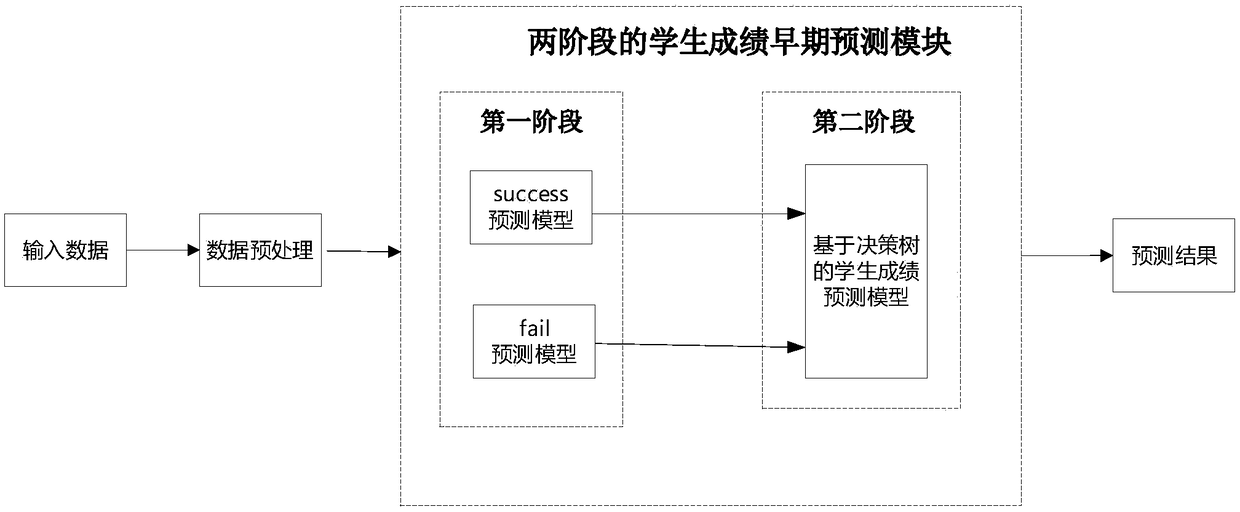

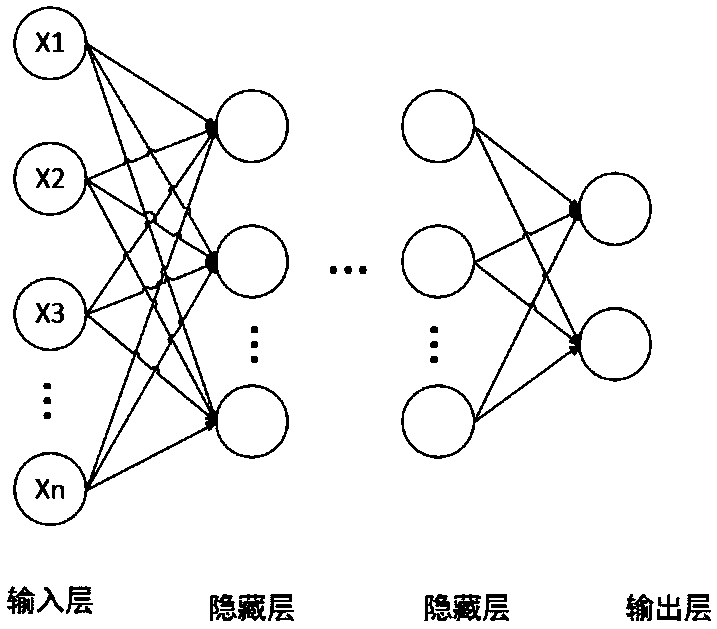

An early warning method and a system for students' achievement based on educational data mining

The invention belongs to the technical field of education and teaching, and discloses an early warning method and a system for students' achievement based on educational data mining. The method comprises: data obtaining; data preprocessing; partition of data sets; constructing of forecasting model of the first stage; constructing of the second stage prediction model;and forecasting of results. Theinvention obtains the learning behavior data of the students for a period of time, three prediction models in two stages are constructed to predict the students early and accurately, so that teacherscan teach students pertinently according to the predicted results. In the first stage, multi-layer perceptron algorithm is used to construct the success model to predict the students who pass the examination and the fail model to predict the students who fail the examination. The second stage is based on the two models of the first stage and their derivative variables, and then the decision treealgorithm to is used generate the final early warning of online students' performance, to early predict the learning results of students.

Owner:HUAZHONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com