Multi-parameter correction turbo generator unit remote vibration fault diagnosis method and system

A technology of turbo-generator set and generator set, which is applied in the test of machine gear/transmission mechanism, the test of engine, the test of mechanical parts, etc., can solve the difficulty of vibration fault diagnosis, the intervention and adjustment of vibration fault of turbo-generator set , failure to guide power plants in a timely manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

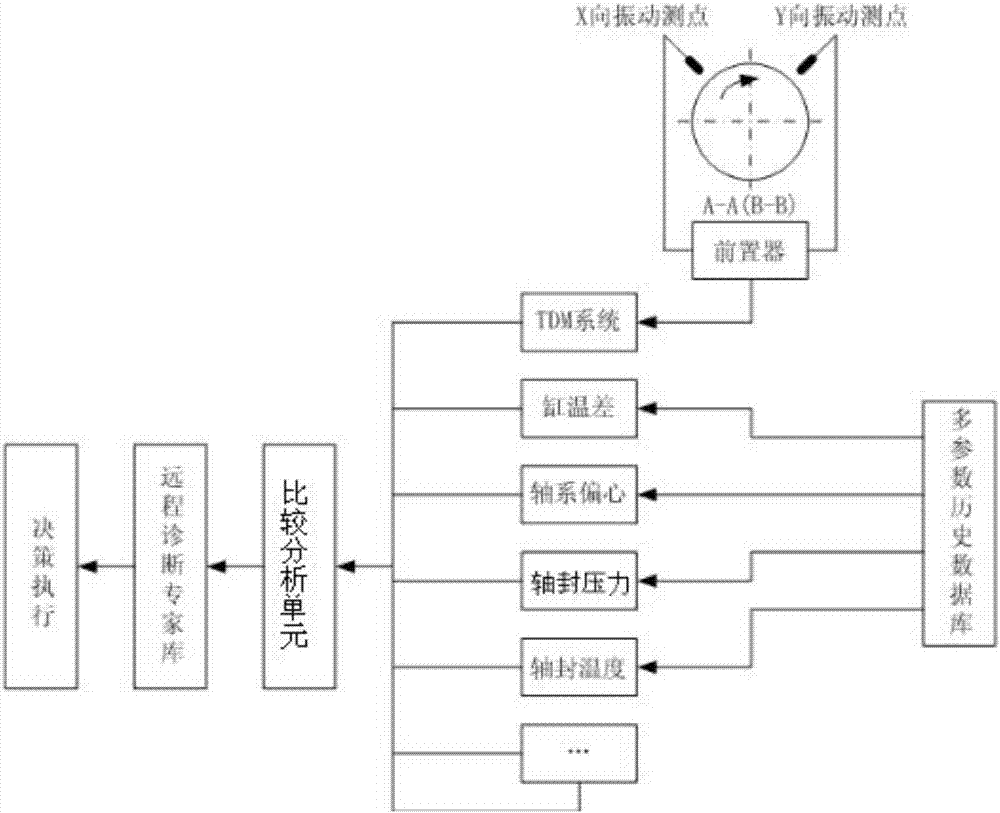

[0045] The multi-parameter corrected remote vibration fault diagnosis method for turbo-generator sets in this embodiment includes: the establishment of a multi-parameter historical database and the diagnosis of vibration faults; wherein,

[0046] The establishment of the multi-parameter historical database: establish the standard numerical intervals corresponding to the corresponding parameters that affect the shafting vibration of the generator set when the rotor vibration data is normal;

[0047] Diagnosis of the vibration fault described:

[0048] Collect the real-time vibration data of each rotor of the shaft system of the steam turbine generator set, and simultaneously collect the real-time values of multiple parameters that affect the vibration of the shaft system of the generator set corresponding to the vibration vibration data;

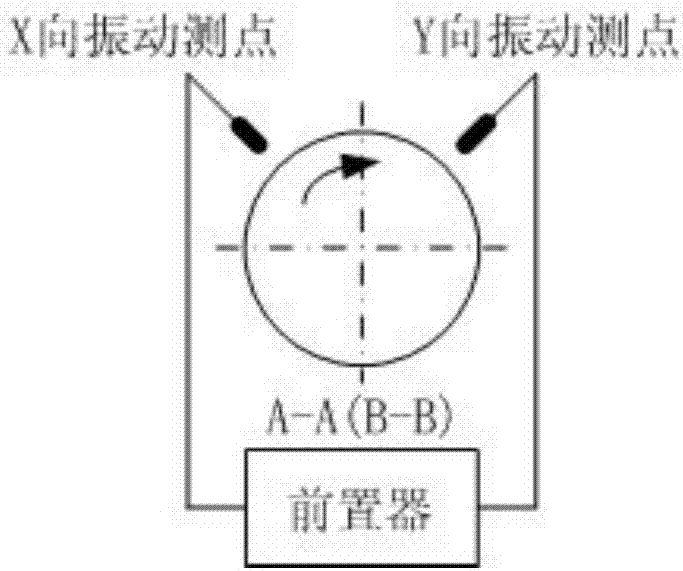

[0049] output the acquired vibration data of each rotor to the front-end device, and the front-end device performs analog / digital conversi...

Embodiment 2

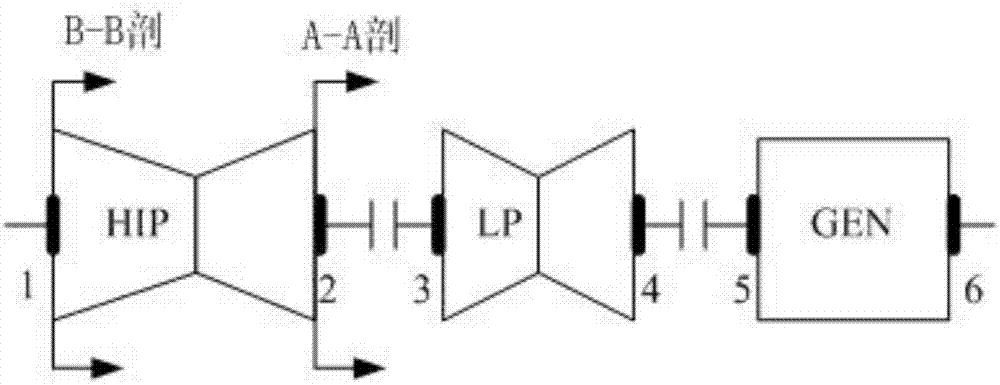

[0064] Such as Figures 1 to 3 As shown, the multi-parameter corrected remote vibration fault diagnosis system for turbogenerator sets in this embodiment includes:

[0065] The series-connected steam turbine high and medium pressure rotor HIP, steam turbine low pressure LP, steam turbine generator set generator rotor GEN, and the steam turbine high and medium pressure rotor front bearing respectively supporting the steam turbine high and medium pressure rotor HIP, steam turbine low pressure LP, and steam turbine generator set generator rotor GEN 1. Rear bearing of steam turbine high and medium pressure rotor 2; Front bearing of steam turbine low pressure rotor 3; Rear bearing of steam turbine medium pressure rotor 4; Front bearing of steam turbine generator generator rotor 5;

[0066] The multi-parameter historical database is used to store the standard value intervals of multiple parameters that affect the vibration of the shafting of the generator set corresponding to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com