Patents

Literature

127 results about "Planned maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planned Preventive Maintenance or more usual just simple Planned Maintenance or Scheduled Maintenance is any variety of scheduled maintenance to an object or item of equipment. Specifically, Planned Maintenance is a scheduled service visit carried out by a competent and suitable agent, to ensure that an item of equipment is operating correctly and to therefore avoid any unscheduled breakdown and downtime. Together with Condition Based Maintenance, Planned maintenance comprises preventive maintenance, in which the maintenance event is preplanned, and all future maintenance is preprogrammed. Planned maintenance is created for every item separately according to manufacturers recommendation or legislation. Plan can be based on equipment running hours, date based, or for vehicles distance travelled. A good example of a planned maintenance program is car maintenance, where time and distance determine fluid change requirements. A good example of Condition Based Maintenance is the oil pressure warning light that provides notification that you should stop the vehicle because failure will occur because engine lubrication has stopped.

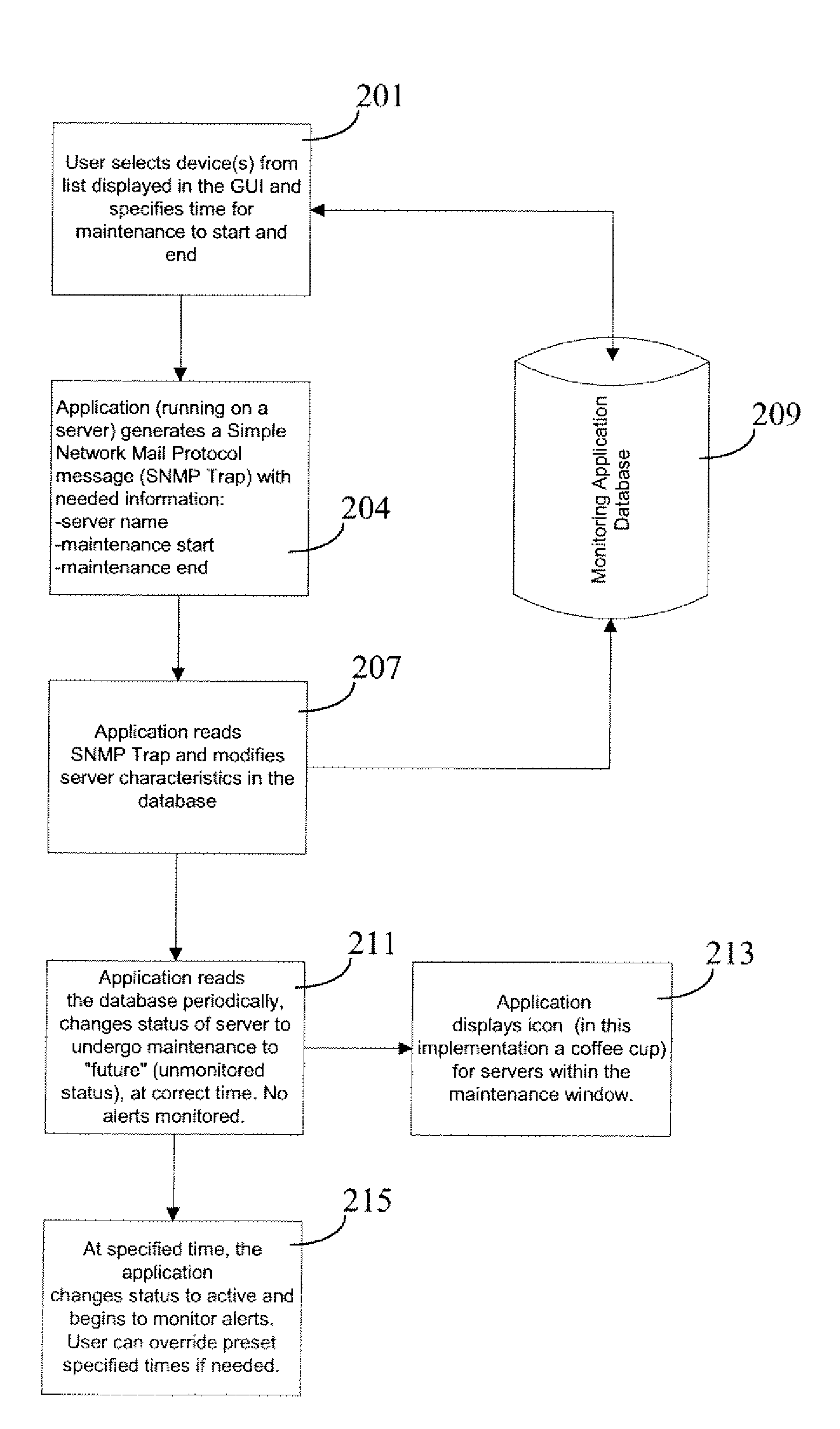

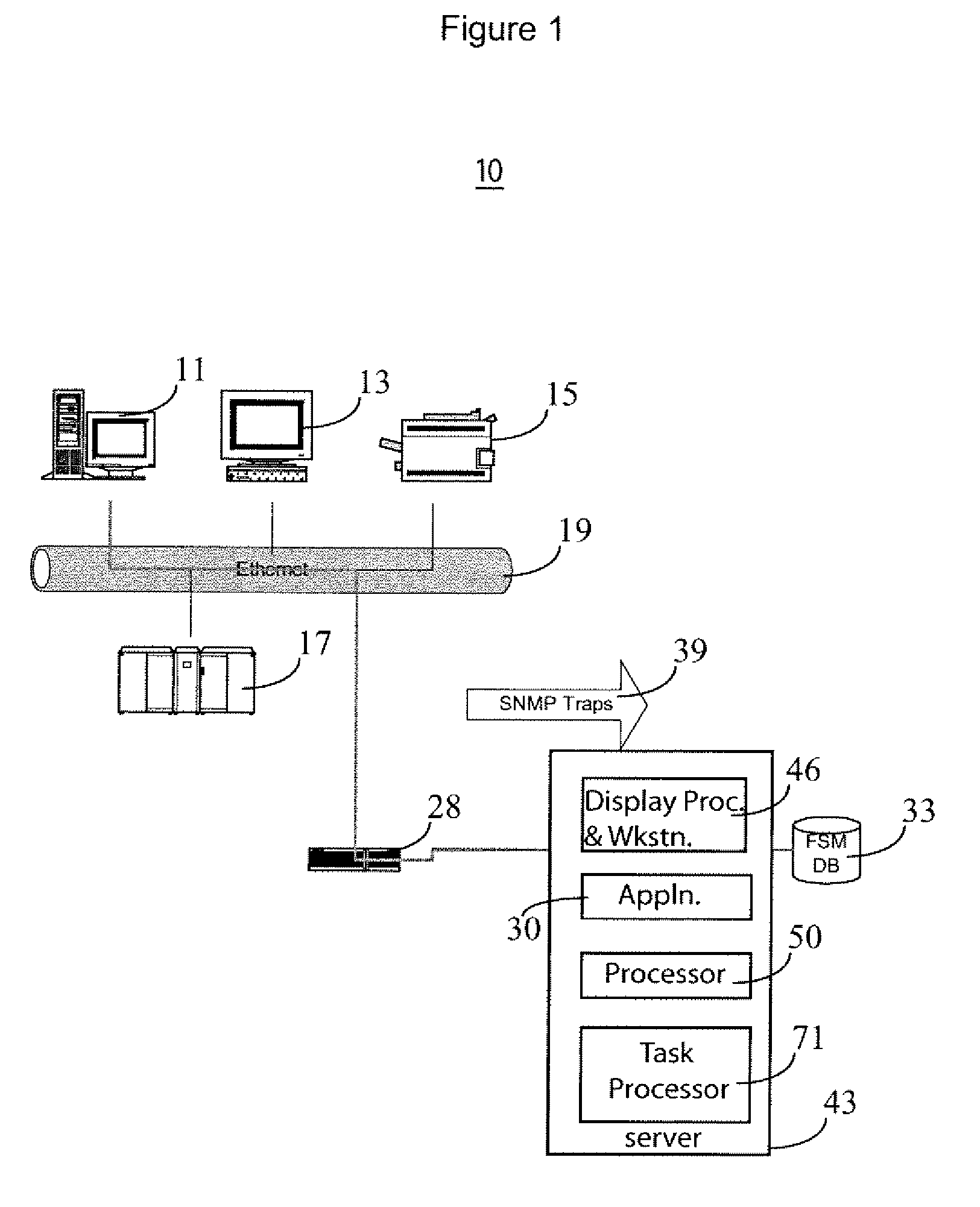

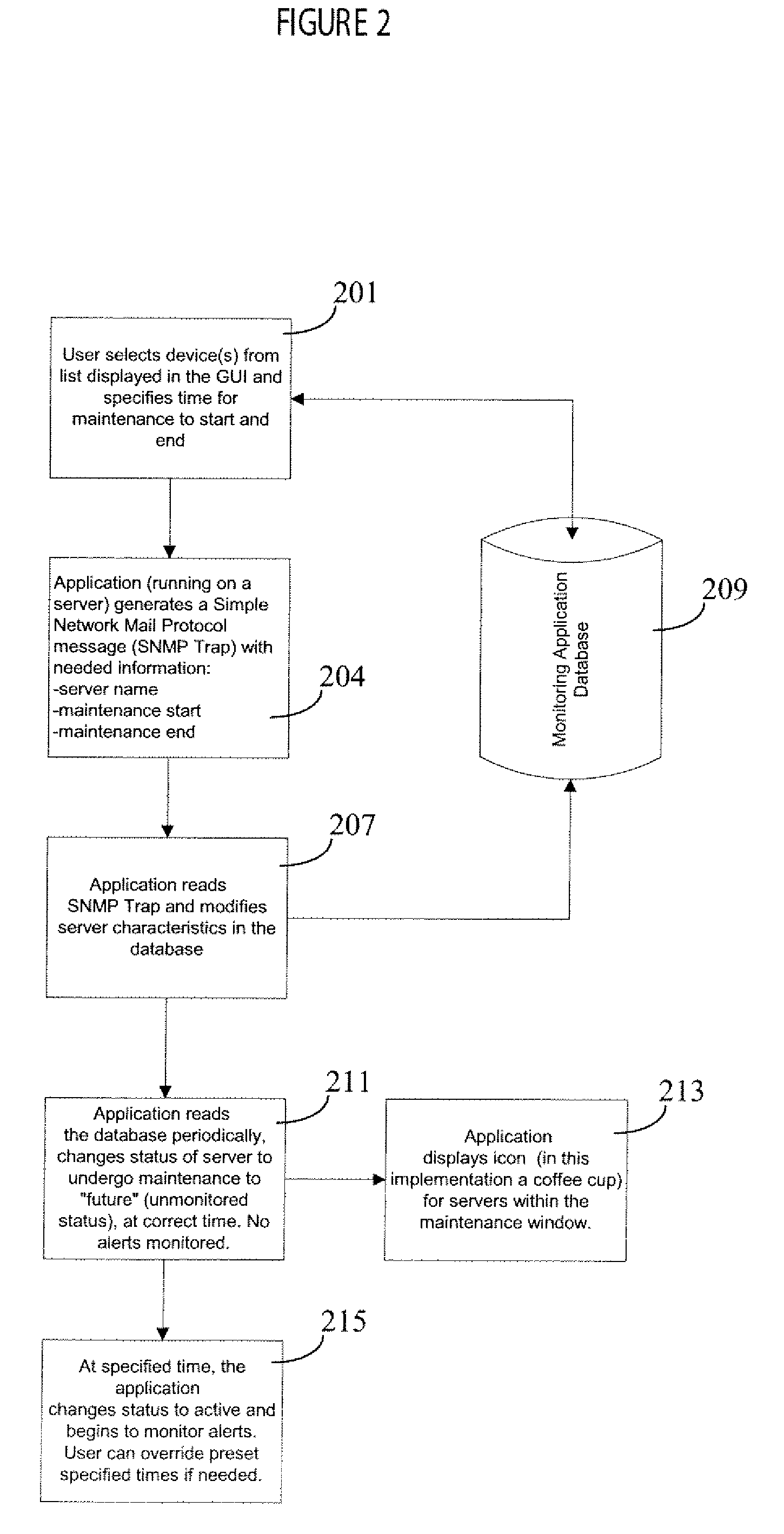

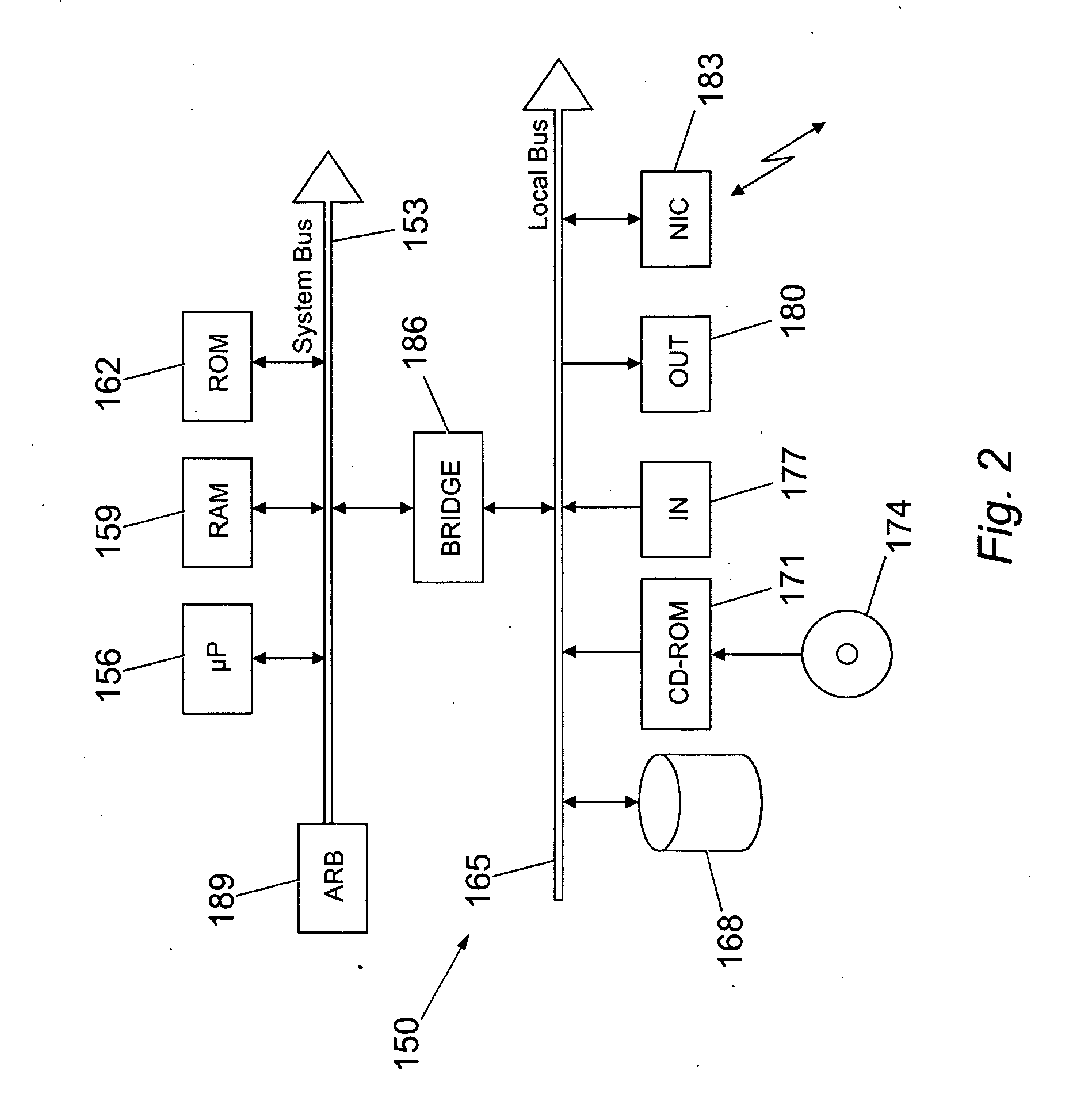

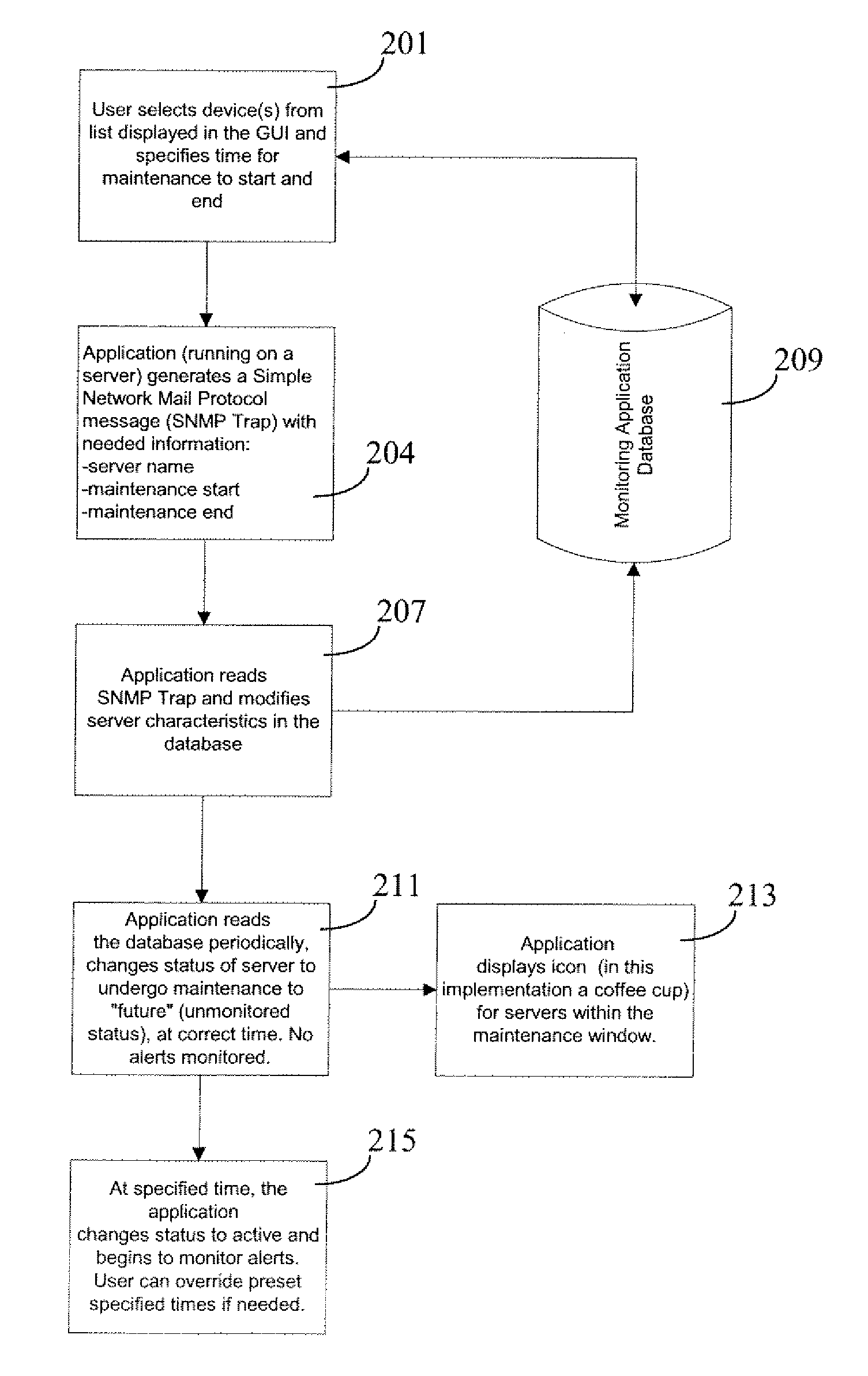

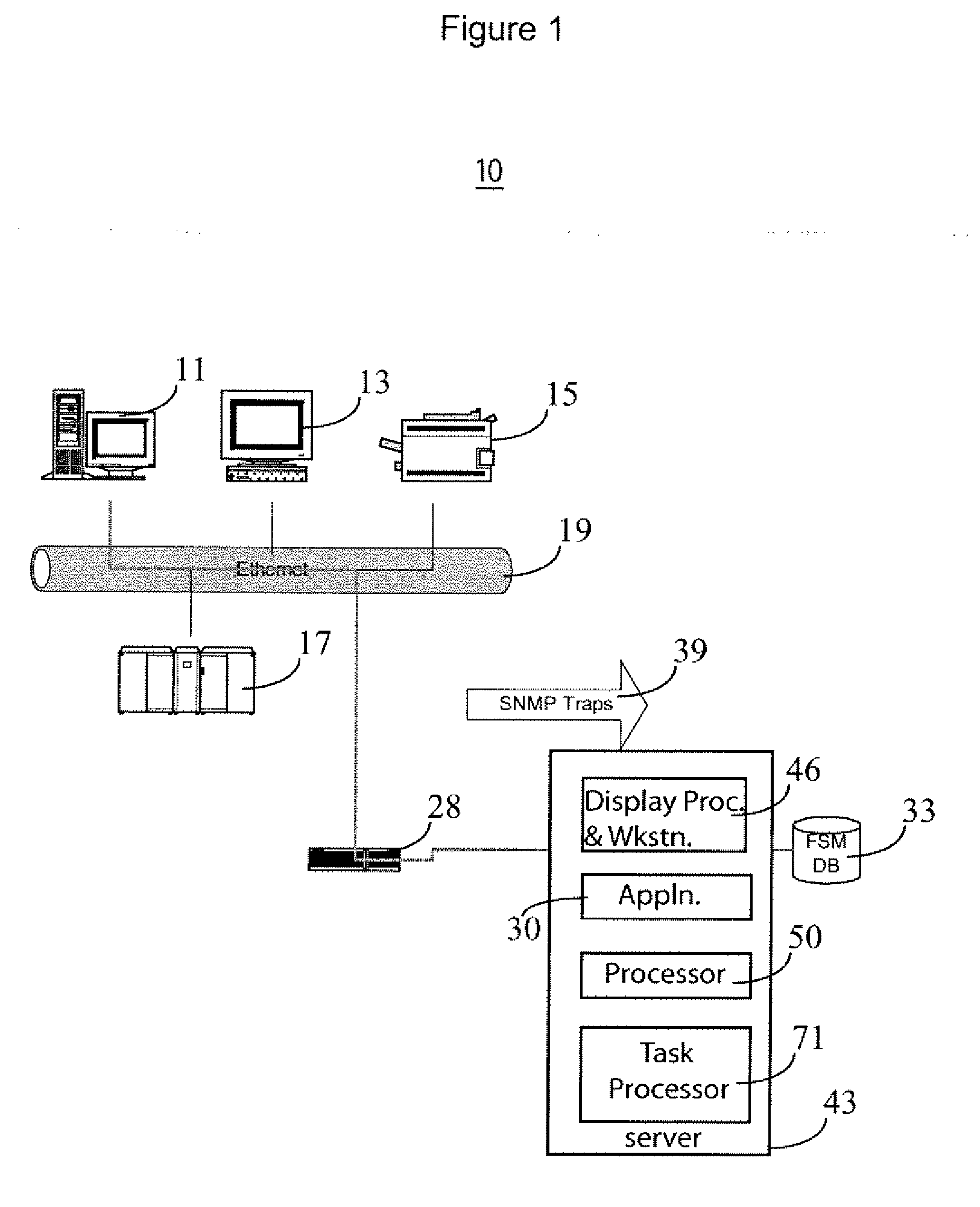

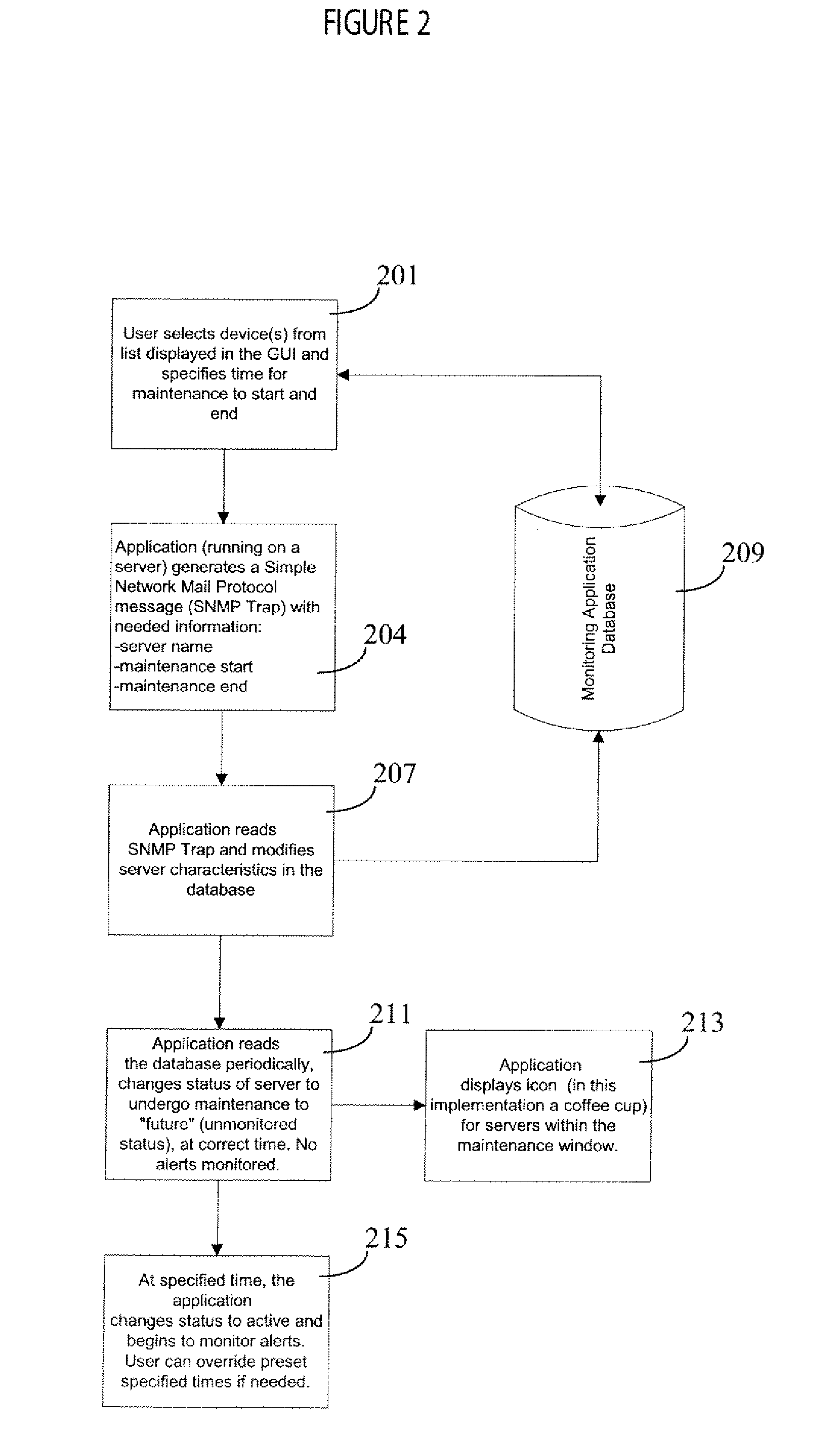

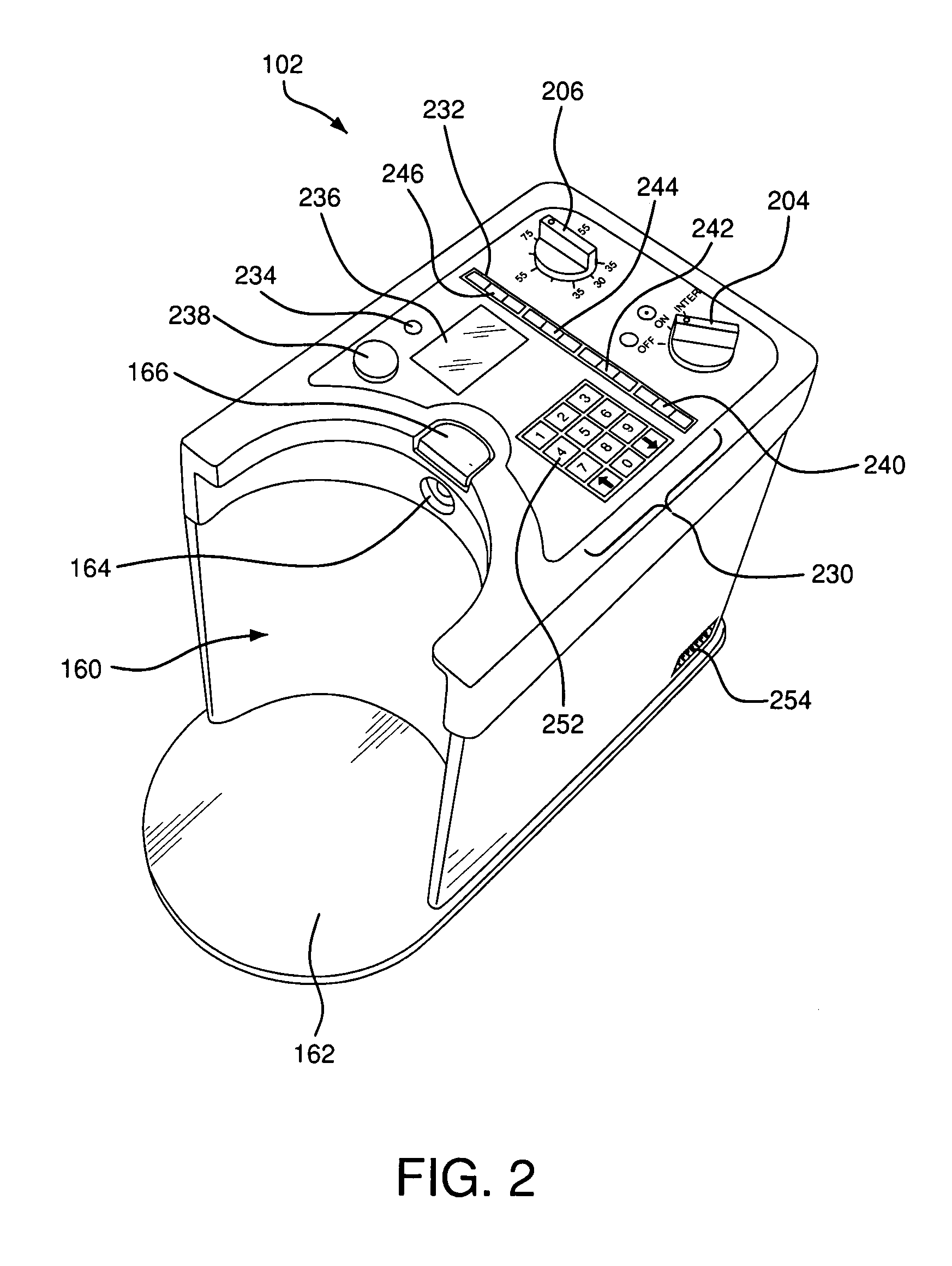

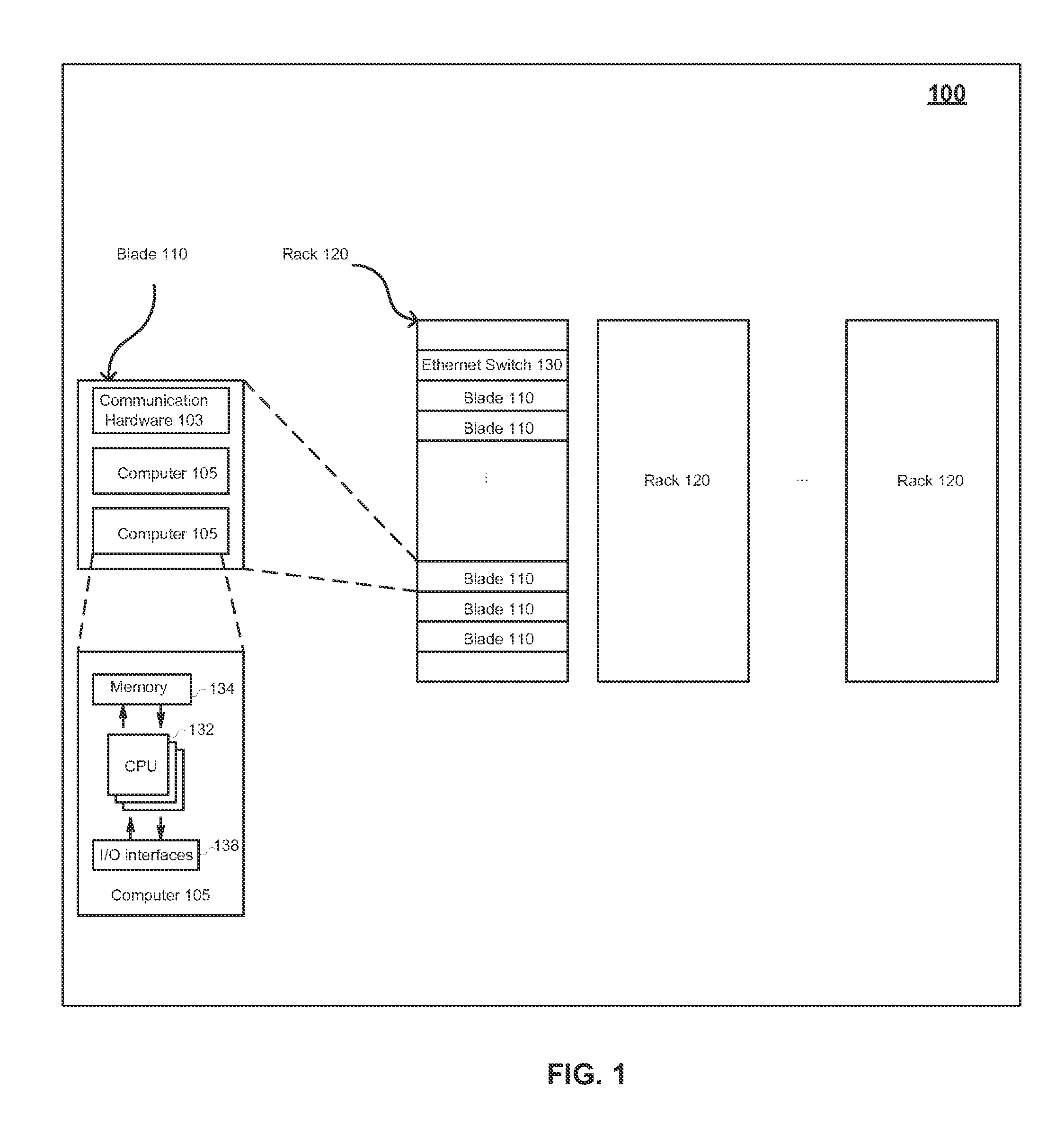

Processor operational status management system

InactiveUS7430692B2Error detection/correctionMultiprogramming arrangementsSystem maintenanceComputer science

A system inhibits alert monitoring during a predefined time period such as system maintenance by suppressing automatic communication of false alert messages to systems, on call personnel and availability reports and enables future scheduling of planned maintenance events, as well as real-time suppression of alerting during a chosen period. A system supports maintenance of one or more processing devices. The system includes a display processor for initiating generation of data representing at least one display image enabling a user to, select a processing device from multiple different processing devices intermittently receiving maintenance and schedule a time period for suppression of communication of alert messages indicating a failure condition of the selected processing device.

Owner:CERNER INNOVATION

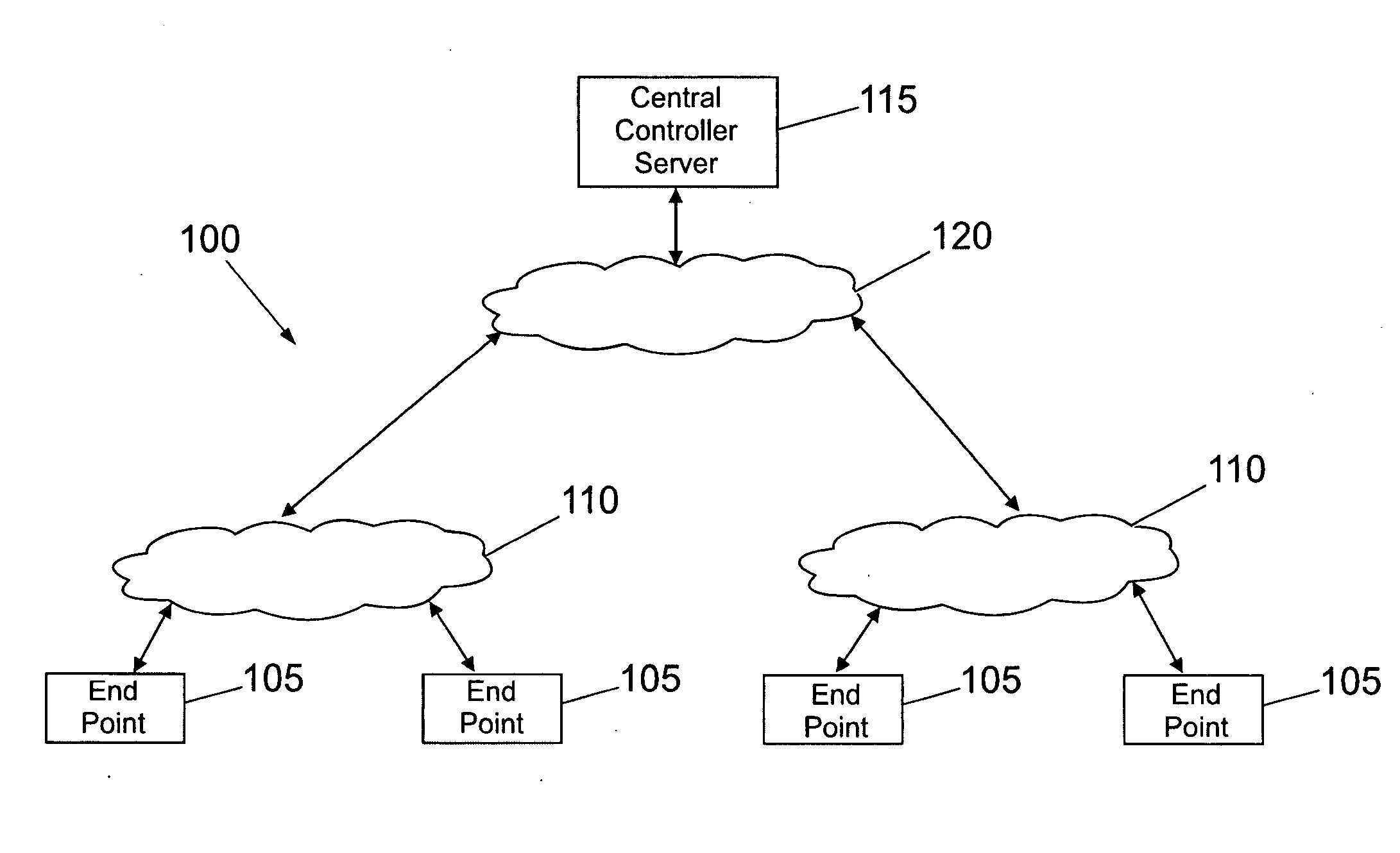

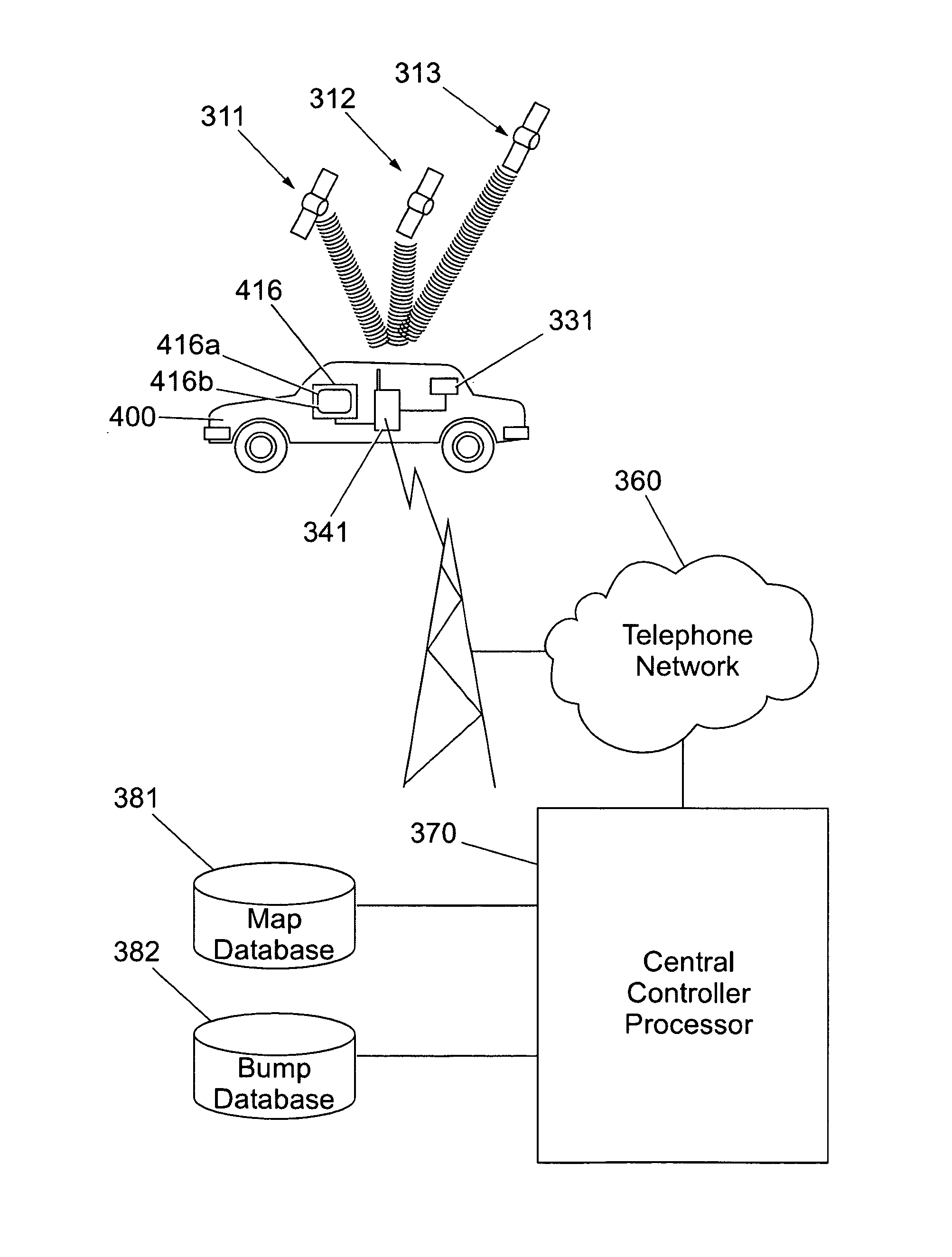

Method and System for Monitoring Road Surface Conditions

InactiveUS20090160675A1Analogue computers for vehiclesArrangements for variable traffic instructionsJourney planningRoad networks

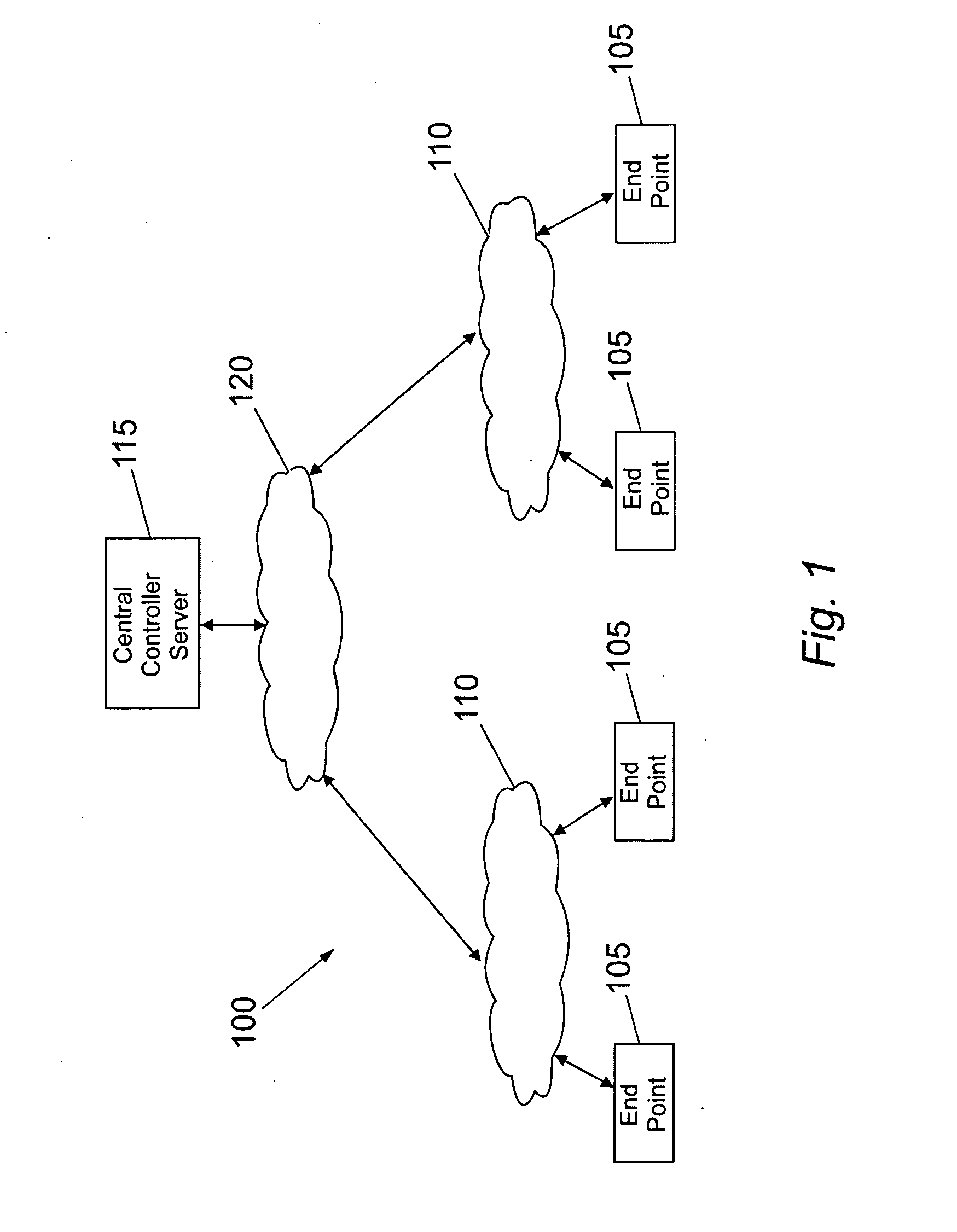

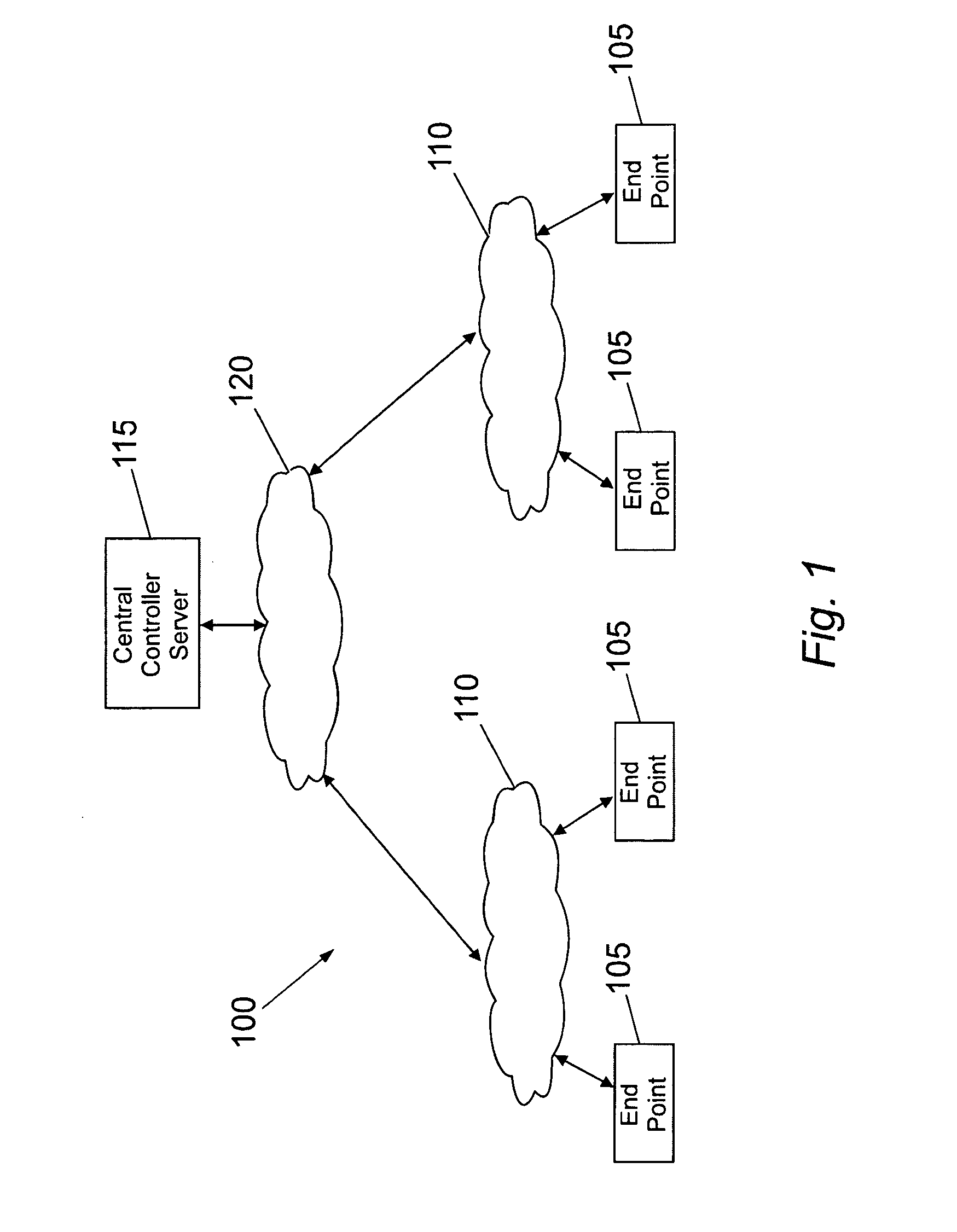

Monitoring road surface conditions using a mobile computer unit carried by a vehicle operating on a road network and adapted to detect information about the road surface conditions. The detection may be done by means of bump sensors which may also provide information on the size and the depth of the bump according to a detected shock with respect to the vehicle speed. Such information may then be transmitted to a central controller server. The central server may use the collected information for several purposes, such as help in planning maintenance of the road network; forwarded to users and vehicles for journey planning purposes; and to deviate traffic in case of extreme surface damage.

Owner:IBM CORP

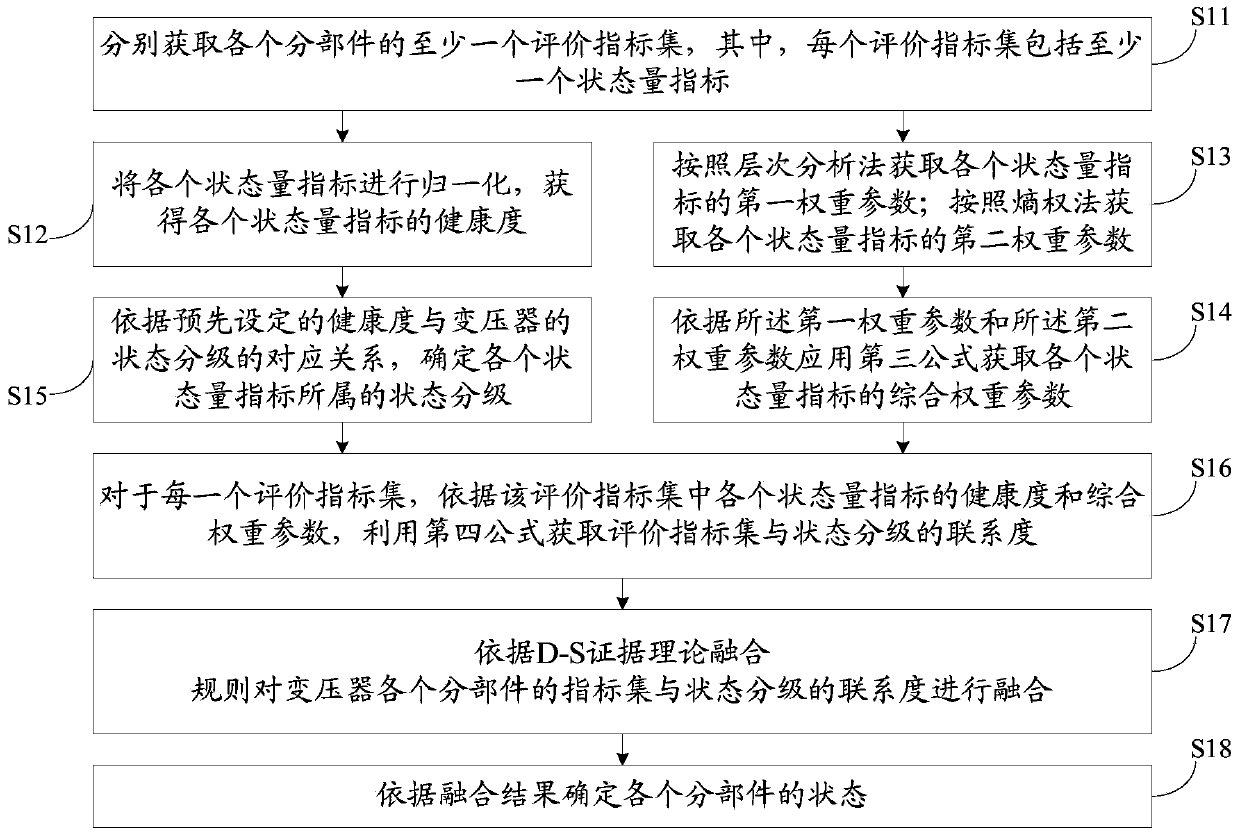

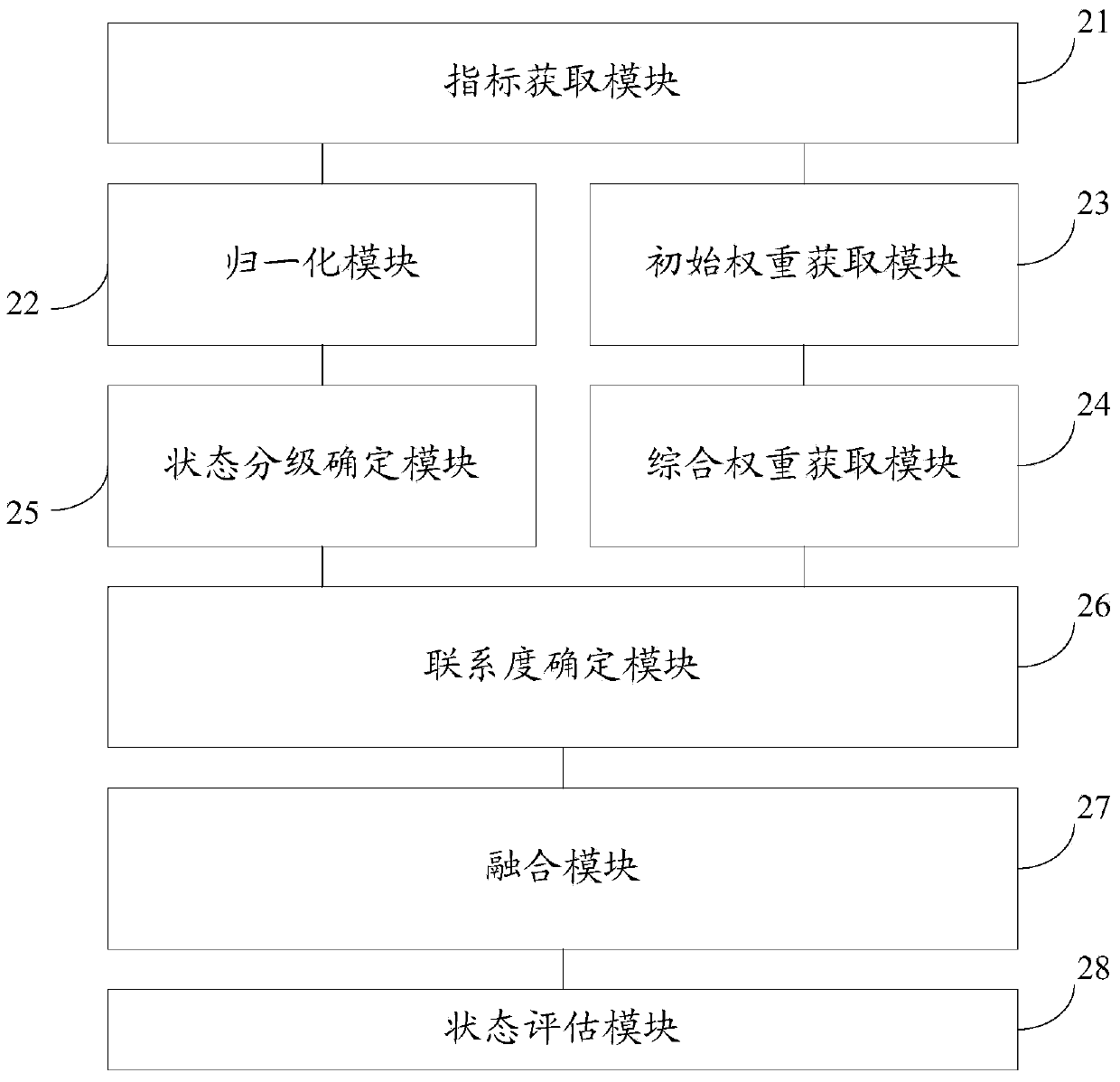

Transformer state evaluation method and system

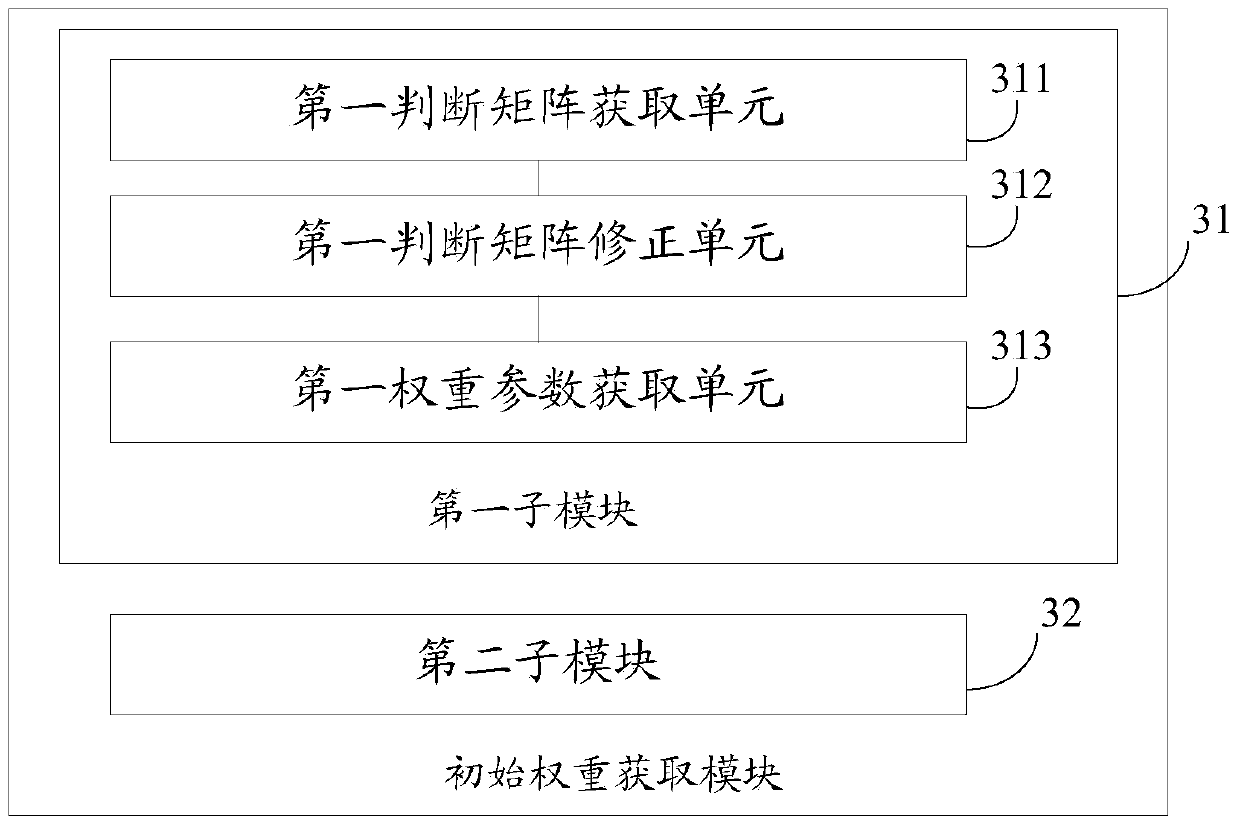

An embodiment of the invention discloses a transformer state evaluation method and system. State quantity indexes are normalized to obtain the health degree of the state quantity indexes, the subjective weight of each state quantity index is determined by an analytic hierarchy process in a fuzzy comprehensive evaluation theory, an objective weight corresponding to each state quantity is obtained by an entropy weight method and used for correcting the subjective weight to obtain comprehensive weight parameters of each state quantity index, the connection degree of each state quantity index and state classification is obtained by the aid of connection degree in a set pair analysis theory, and finally, data of evaluation results of a hierarchical index set of each unit are integrated by the aid of D-S evidence theory fusion rules to obtain state evaluation results of each sub-unit. Whether a transformer needs maintenance or not can be determined according to the state evaluation results, so that blindness of planned maintenance is avoided, and human and material resources needed by maintenance for the transformer are reduced.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

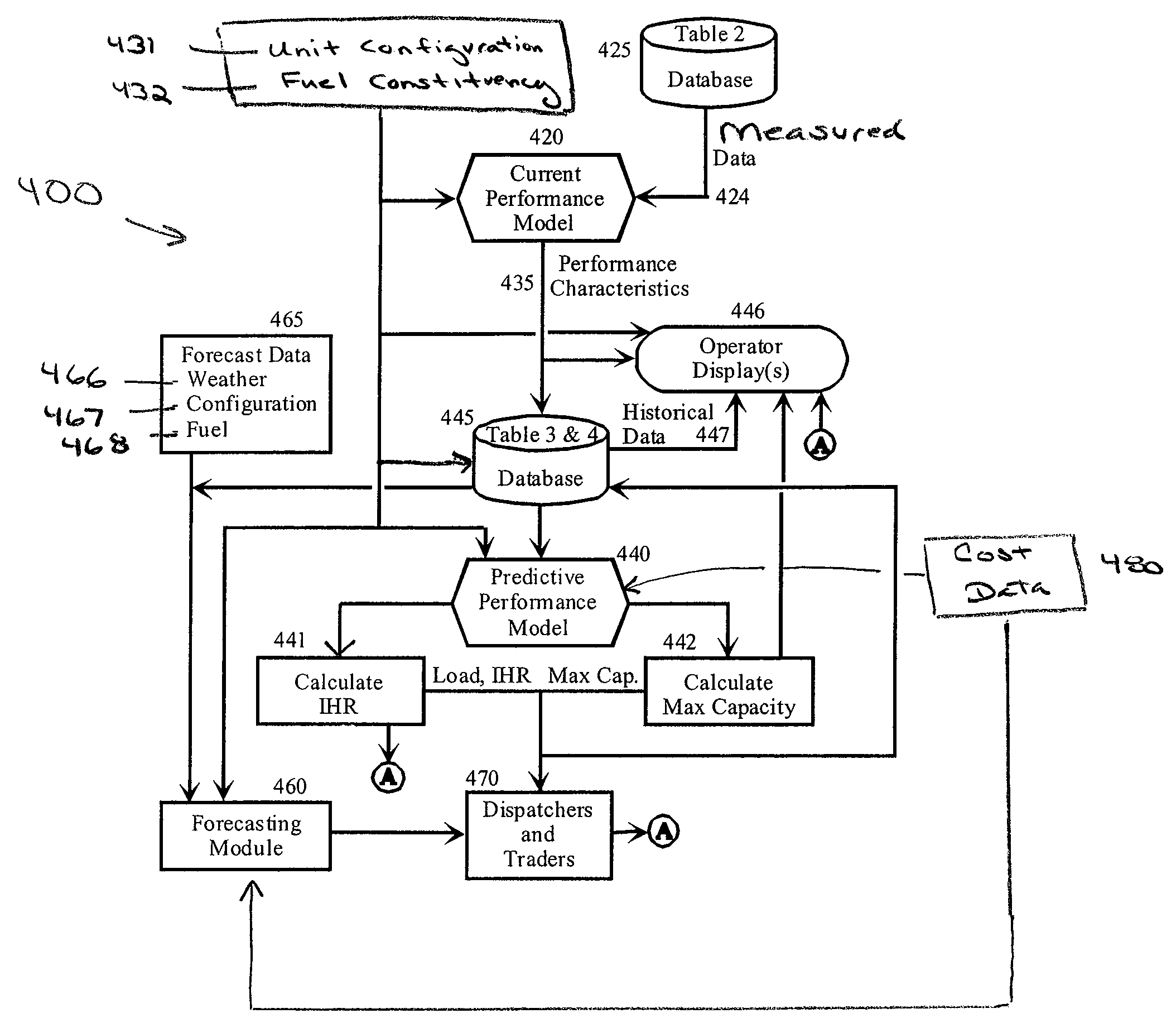

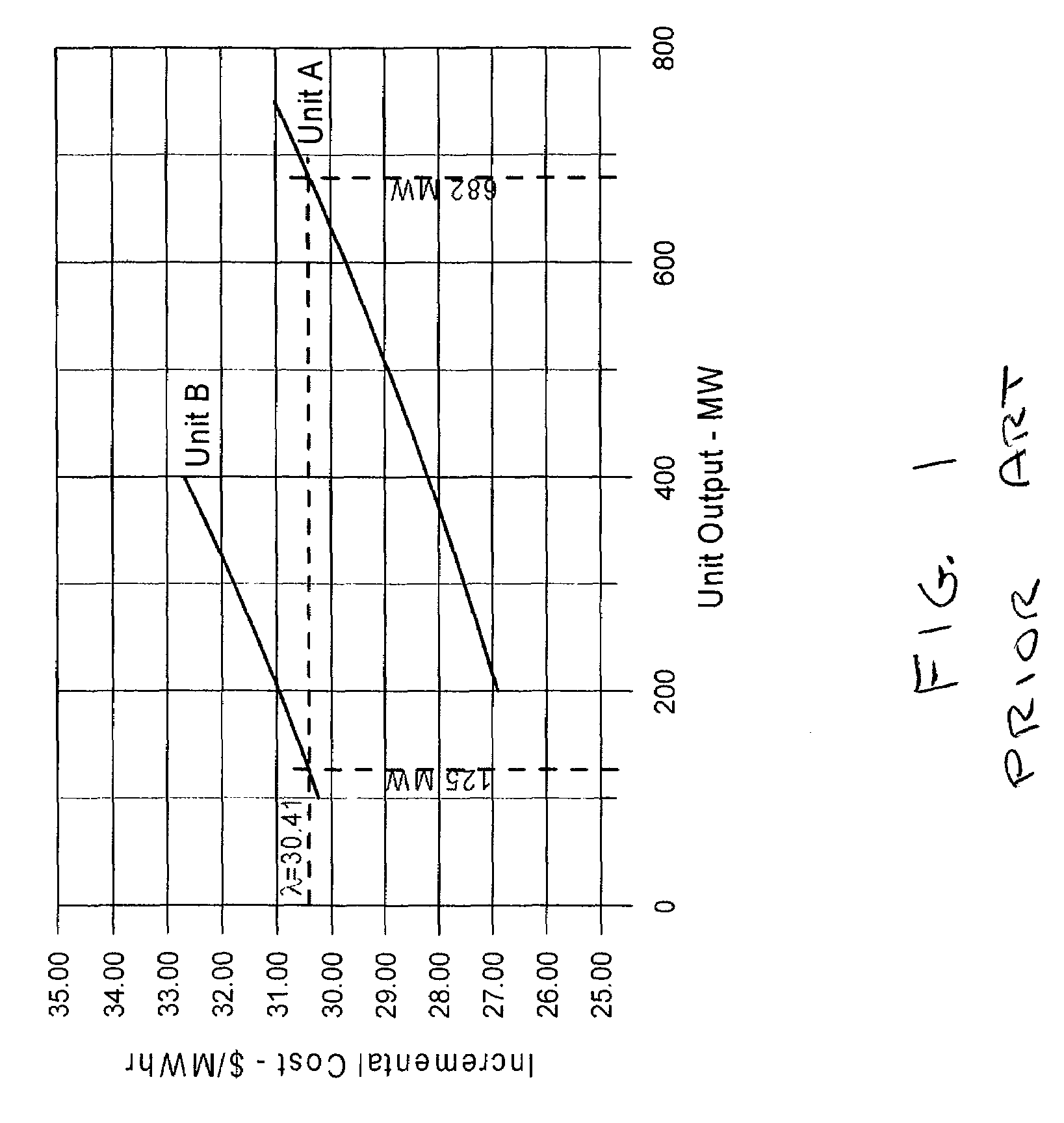

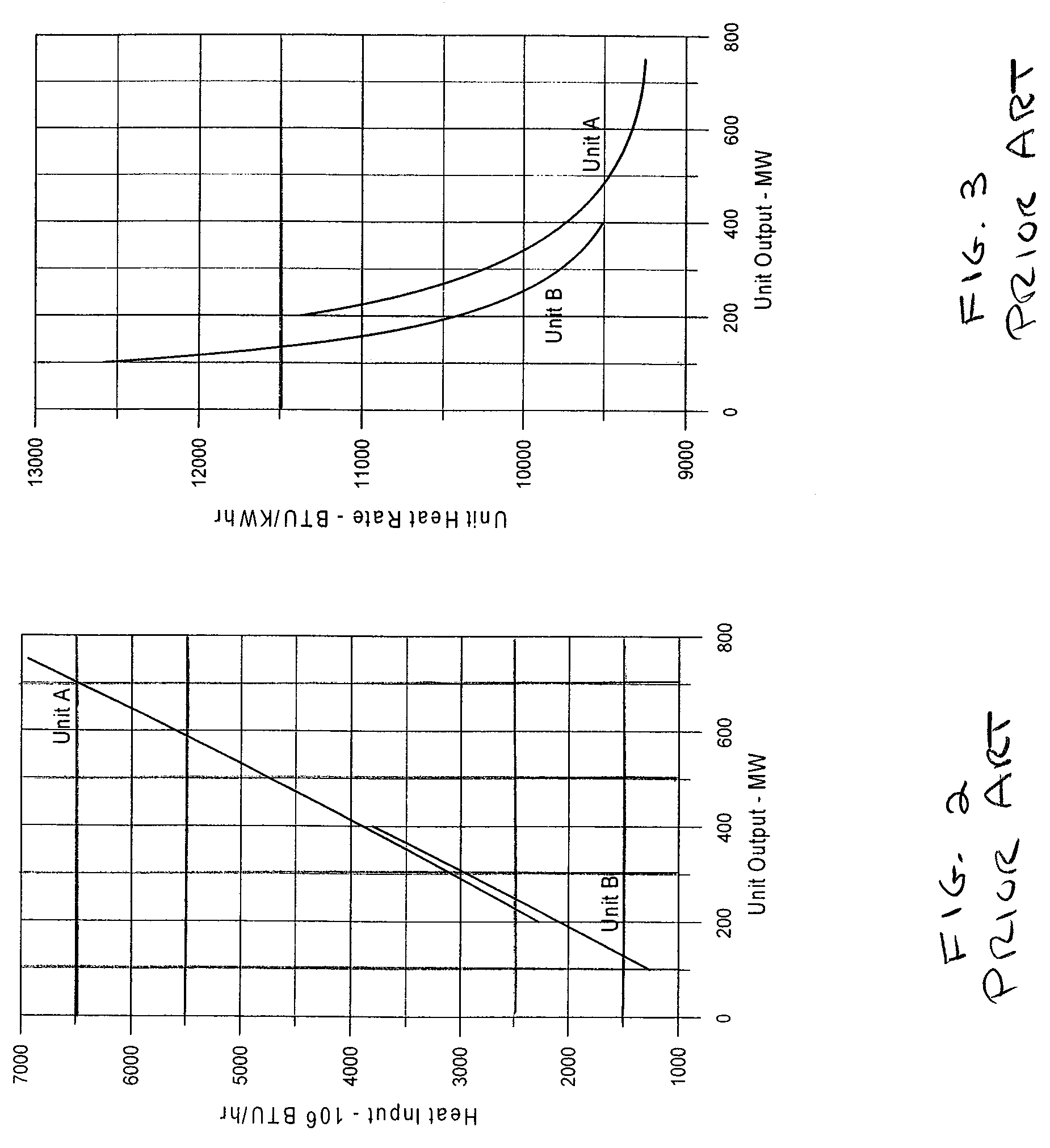

Systems and methods for calculating and predicting near term production cost, incremental heat rate, capacity and emissions of electric generation power plants based on current operating and, optionally, atmospheric conditions

Systems and methods for calculating and predicting performance characteristics, incremental heat rate, capacity, incremental costs, production cost and emissions, for electric power generation plants, and in particular, those that use steam and gas-turbine prime movers. The system includes models and modules for calculating current unit performance and predicting unit performance, including the incremental heat rate and maximum capacity, using unit operating parameters, unit configuration data, and fuel constituency data. The system further includes a module for forecasting or predicting unit performance and cost information, by allowing the user to alter unit configuration and fuel constituency data to model planned maintenance and projected fuel changes, and to account for anticipated atmospheric conditions.

Owner:FEHR STEPHEN L +1

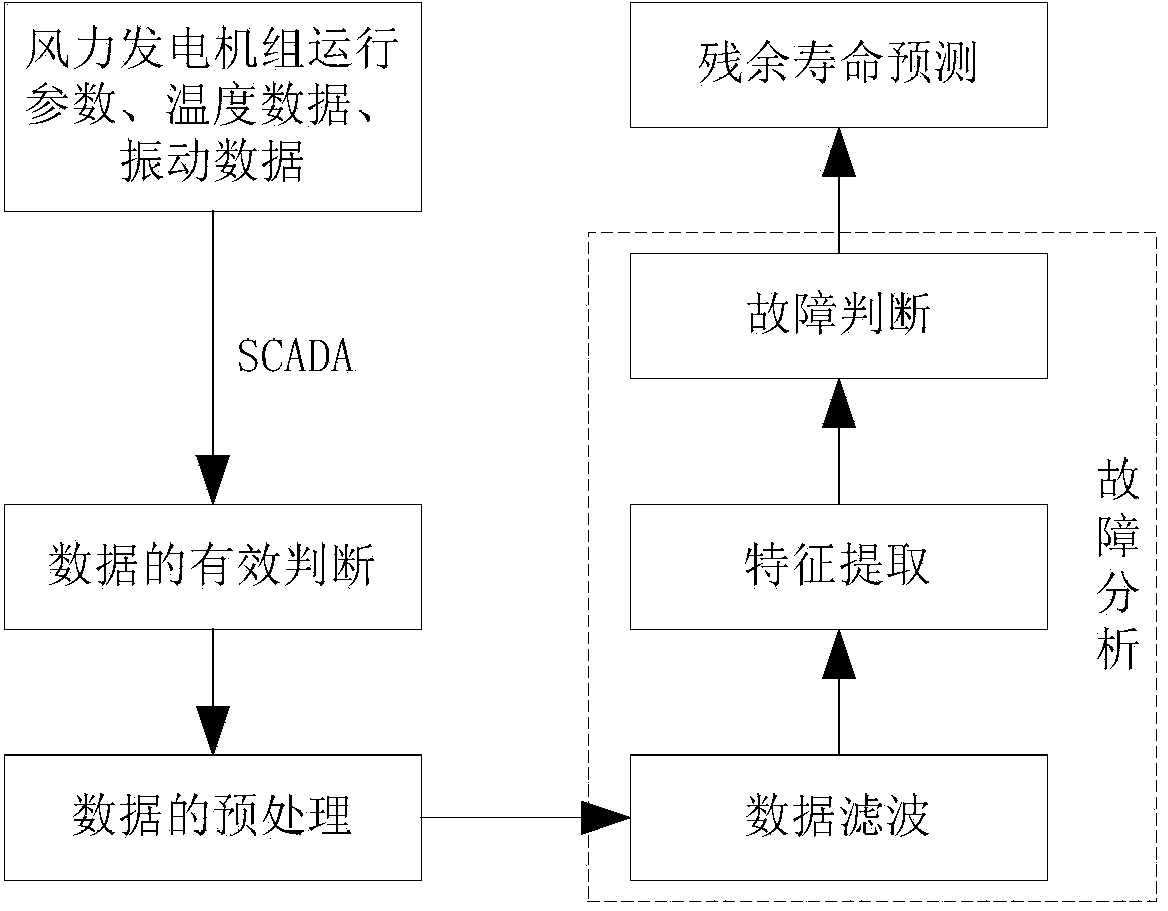

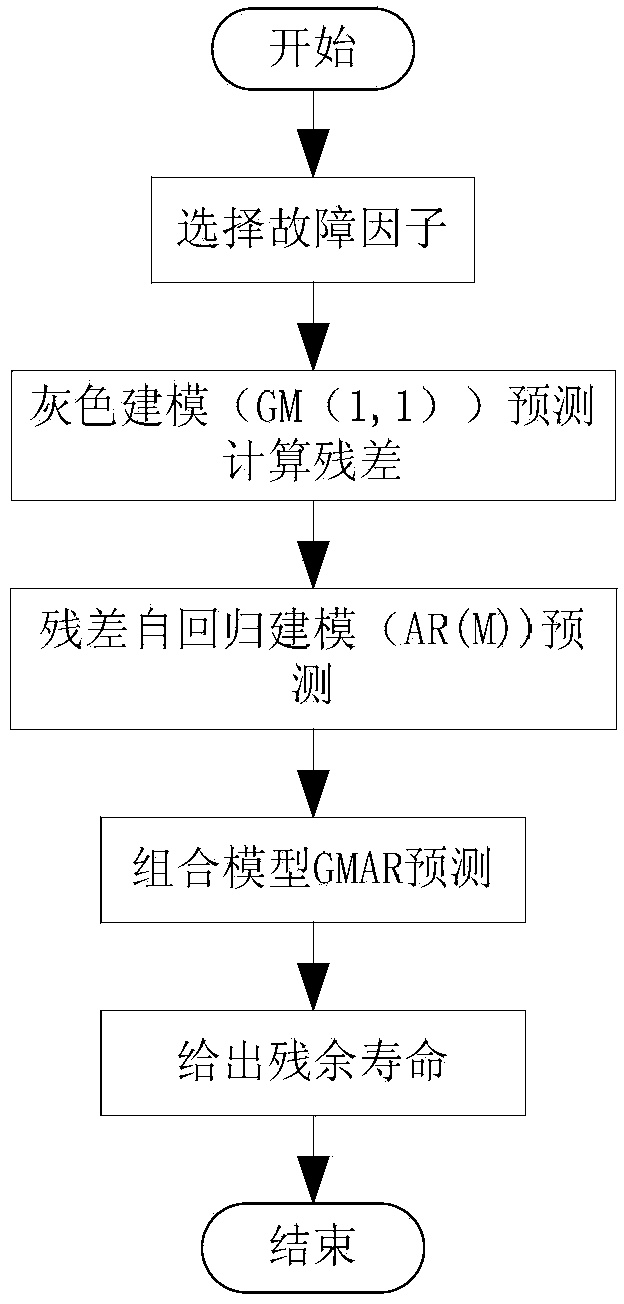

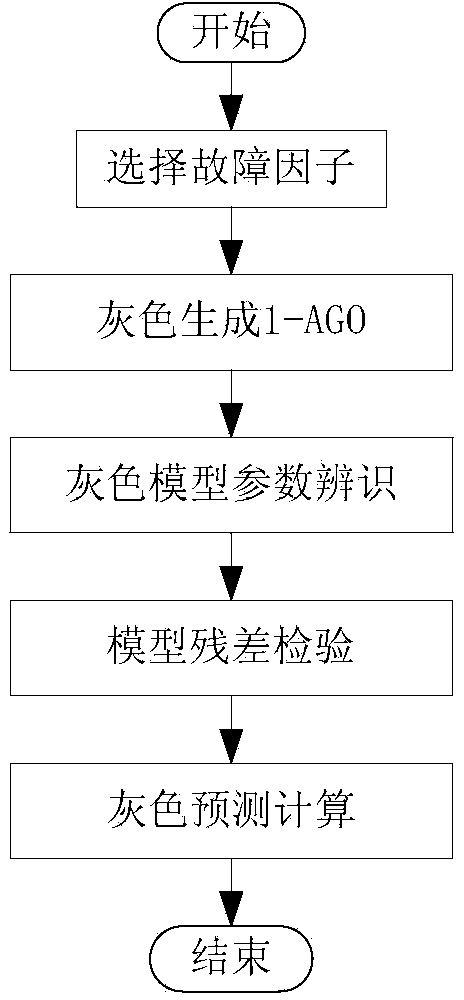

Wind turbine set gearbox remote online state monitoring and life assessment method

InactiveCN103645052AEnable real-time estimationImprove reliabilityMachine gearing/transmission testingElectricityTime domain

The invention provides a wind turbine set gearbox remote online state monitoring and life assessment method. The method comprises the following steps: (1) a remote center computer collects a real-time operation parameter, temperature data and vibration data of each wind turbine through SCADA; (2) through analyzing the characteristic values of signal time domain and frequency domain, whether a vibration sensor has a fault or not is diagnosed; (3) the data is subjected to normalization process, a difference between data is reduced, and the diagnosis precision is raised; (4) when the fault of a wind generator set gearbox is diagnosed, different filtering modes are employed for different algorithms to extract the corresponding characteristic; (5) the collected data is subjected to characteristic extraction; (6) the fault diagnosis is carried out to provide the fact that whether the fault exists or not and the degree of the fault; (7) the residual life of the failed gearbox is estimated through a gray theory model, and an autoregression model is established for the residual error of the predication result to raise the predication precision. According to the method, the real-time estimation of the residual life is realized, and a basis is provided for the planned maintenance of the wind turbine set.

Owner:BEIHANG UNIV +1

Monitoring road surface conditions

InactiveUS8451140B2Analogue computers for vehiclesArrangements for variable traffic instructionsJourney planningRoad networks

Monitoring road surface conditions using a mobile computer unit carried by a vehicle operating on a road network and adapted to detect information about the road surface conditions. The detection may be done by means of bump sensors which may also provide information on the size and the depth of the bump according to a detected shock with respect to the vehicle speed. Such information may then be transmitted to a central controller server. The central server may use the collected information for several purposes, such as help in planning maintenance of the road network; forwarded to users and vehicles for journey planning purposes; and to deviate traffic in case of extreme surface damage.

Owner:INT BUSINESS MASCH CORP

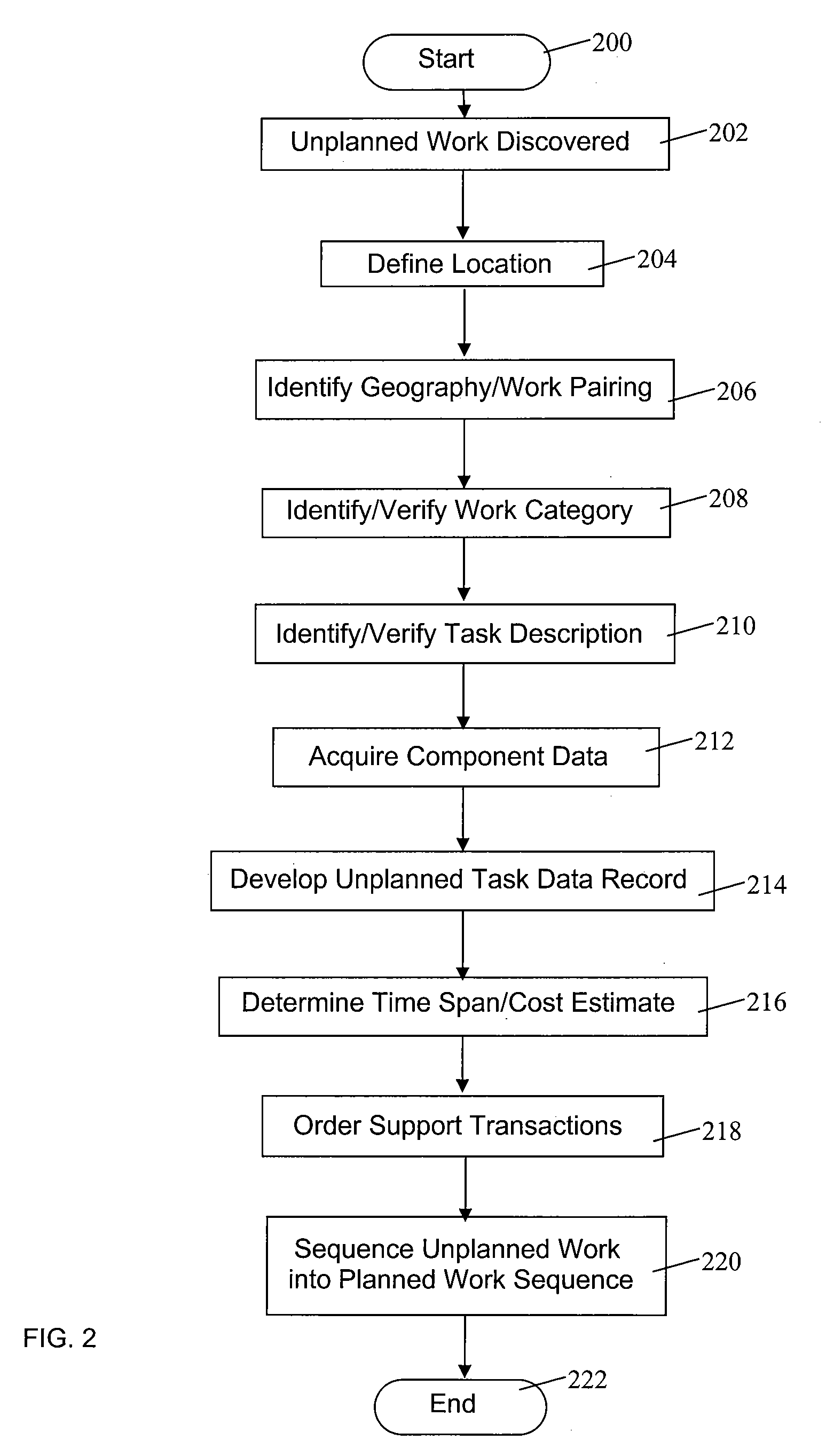

Identification, categorization, and integration of unplanned maintenance, repair and overhaul work on mechanical equipment

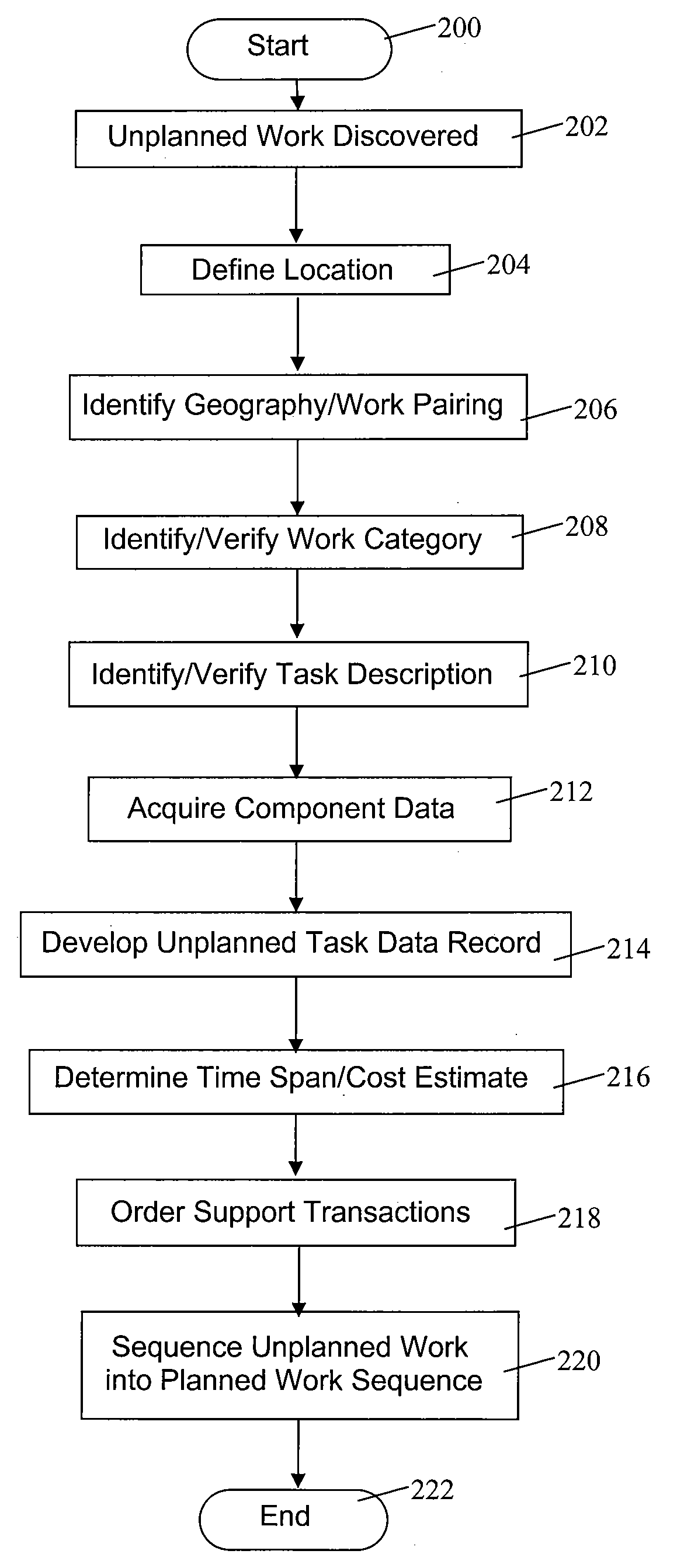

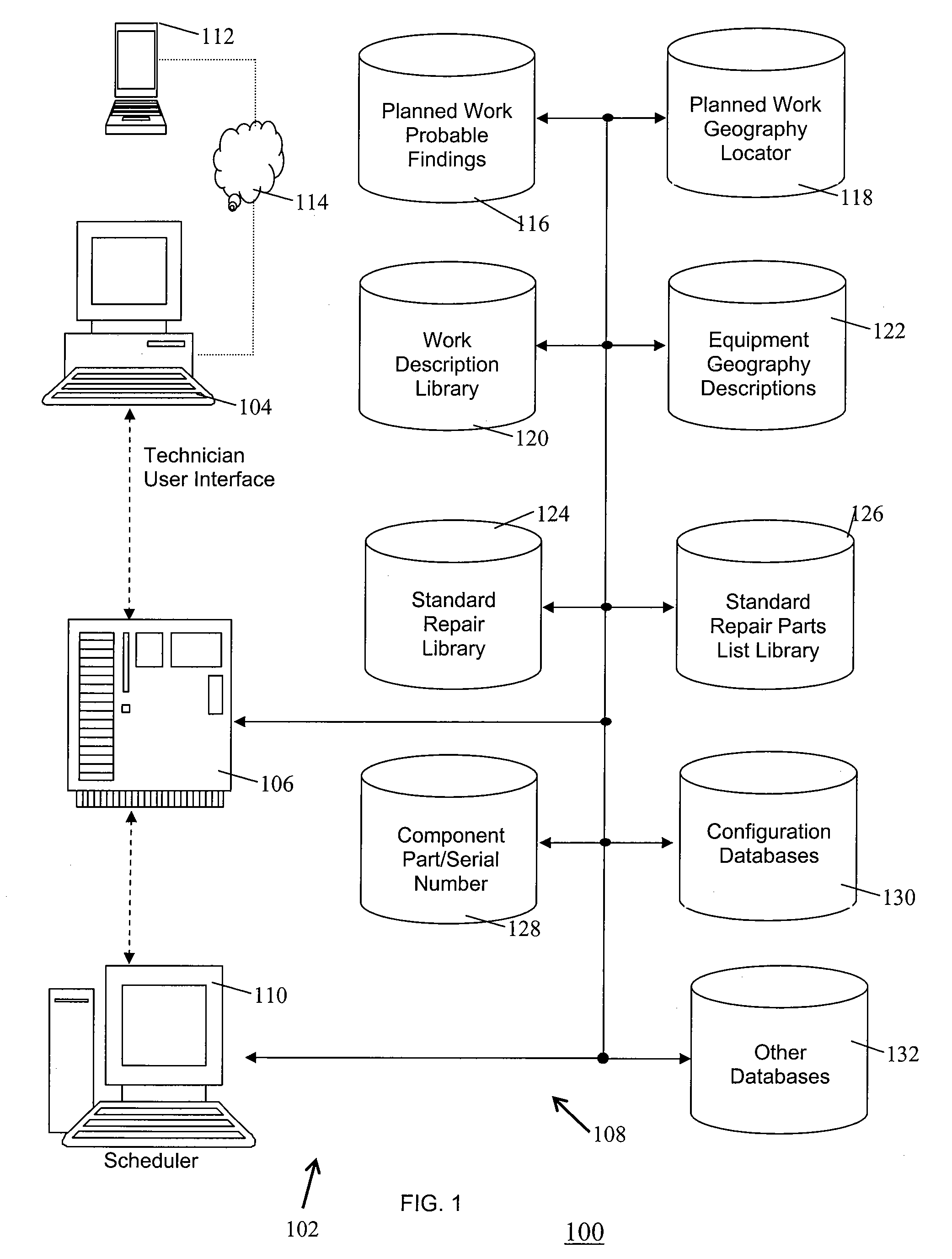

An automated interactive method dynamically identifies an unplanned maintenance task during execution of a planned maintenance task on equipment. A user device displays a maintenance menu system for data entry and access and provides an input relating to unplanned maintenance task discovered on the equipment. The unplanned maintenance task is associated with the planned maintenance task at least with respect to a location. The automated interactive method sequentially processes unplanned maintenance task information based on the input from the user device. The automated interactive method establishes and stores an unplanned maintenance task data record including a selected geographical location, a selected item, a selected work category, a selected task type, a selected task description, and selected component data of the unplanned maintenance task.

Owner:ACCENTURE GLOBAL SERVICES LTD

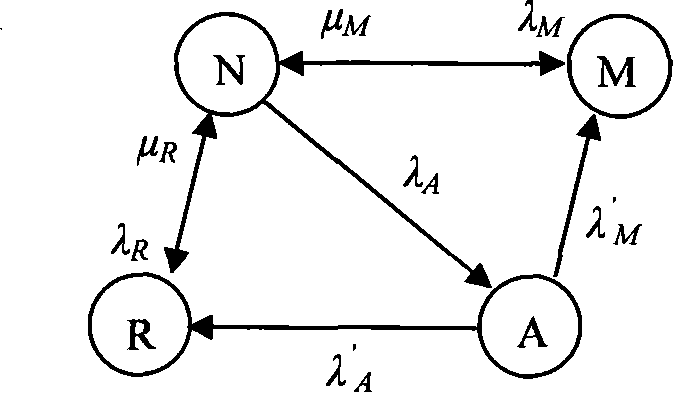

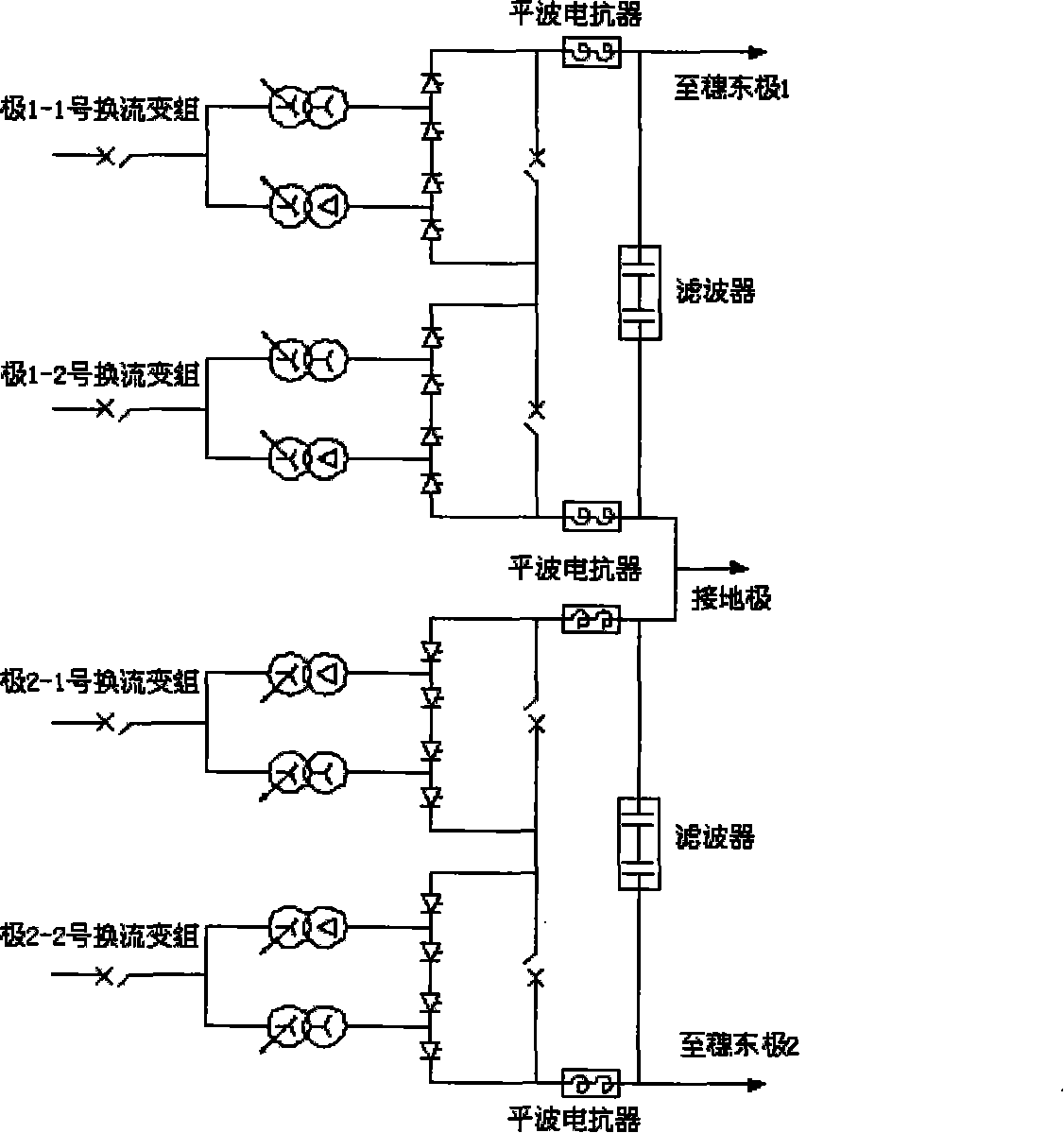

Method for evaluating reliability of +/- 800kV current exchanging station main wire connection

InactiveCN101251835AReliability responseData processing applicationsEmergency protective circuit arrangementsState modelDependability

The invention provides a method for a reliability evaluation of a main wiring of a +-800kV convertor station, which is characterized in: establishing improved models of four states of elements; reliability models of relay protection and a secondary device in a process of evaluating the reliability of the main wiring; simplifying the prior complicated main wiring of the +-800kV convertor station by using partition of the elements; applying the improved models of the four states of the elements in each simplified partition; redefining abnormal states and maintenance states of the elements; combining and classifying a state maintenance state and a planned maintenance state of the elements into the maintenance state of the elements; determining conversion relationships between the states and acquiring parameters; simplifying a minimal path matrix searching method by a matrix multiplication to perform a minimal path searching to a directed network; enumerating states of various failures of the directed network by using an analysis method; and calculating reliable data of the network.

Owner:KUNMING UNIV OF SCI & TECH

Medical equipment predictive maintenance method and apparatus

InactiveUS6912481B2Radiation diagnosis data transmissionAmplifier modifications to reduce noise influenceMedical imagingPredictive maintenance

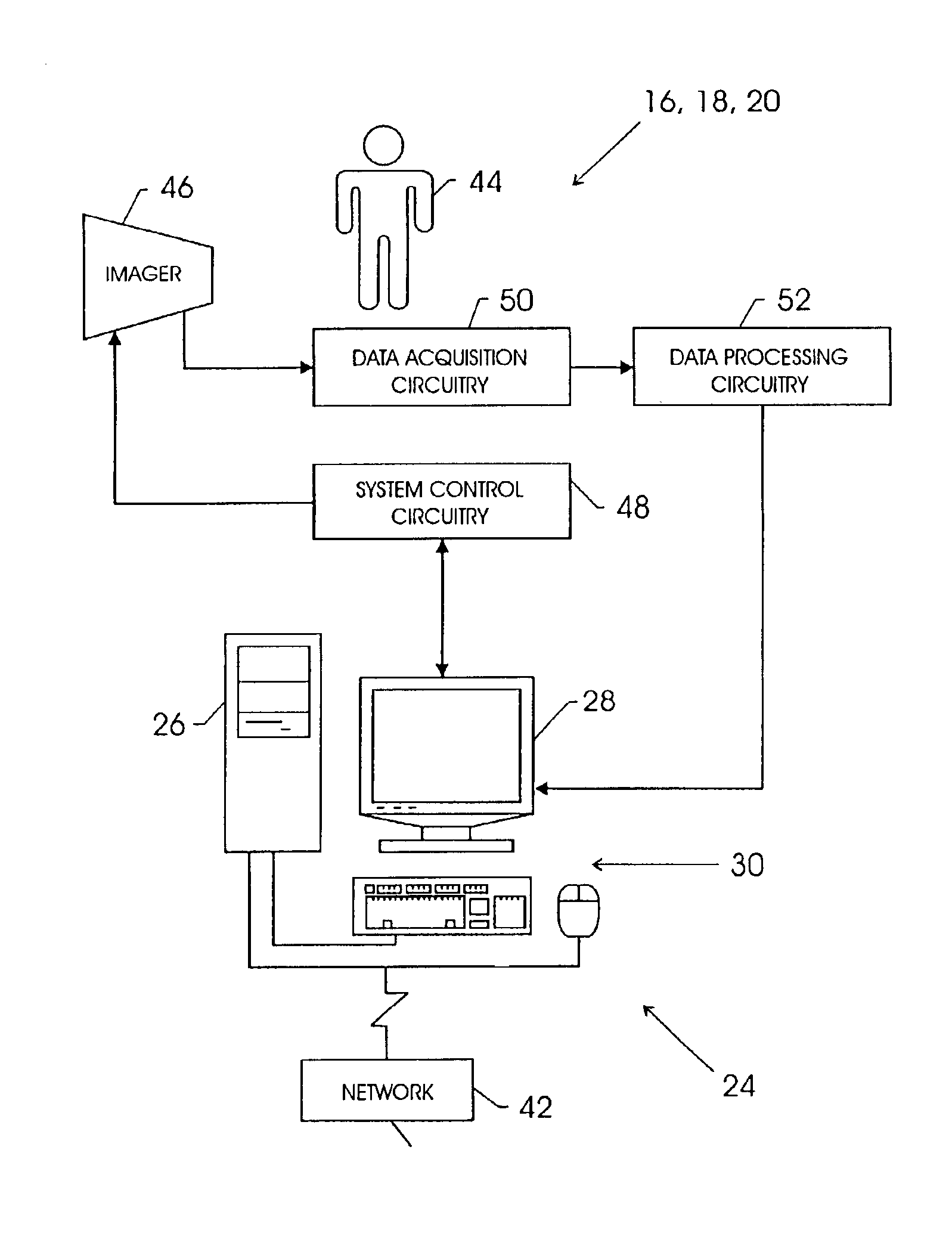

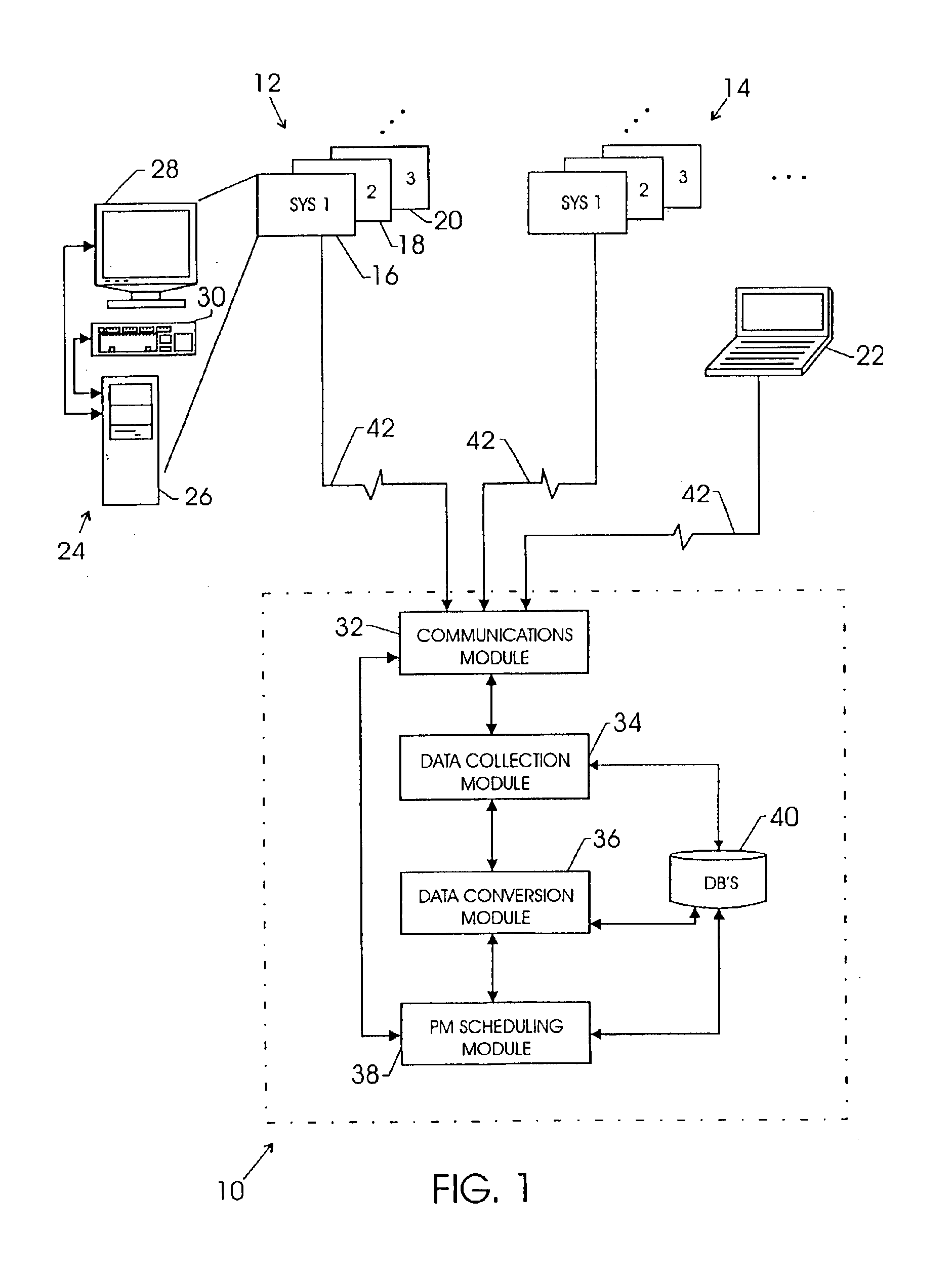

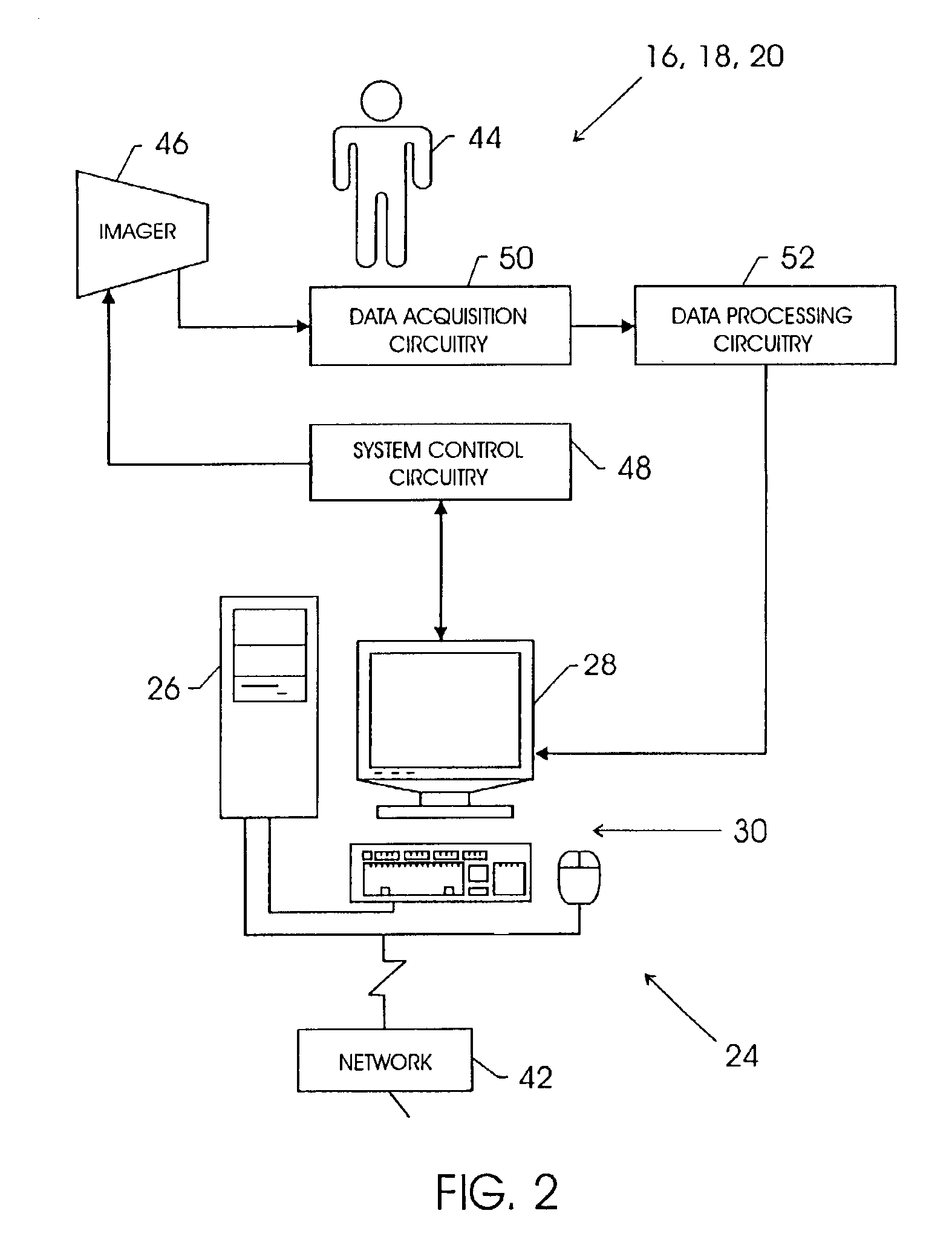

A technique for scheduling planned maintenance of equipment, such as medical imaging systems, permits selection of time-based or usage-based scheduling. If usage-based scheduling is selected, operational data collected from the systems serves as the basis for computing a maintenance schedule along with reference usage values for parameters indicative of use. Reference may be made to norms for similar equipment, and the schedule may be adapted accordingly. Trends in usage, increasing or decreasing, may be accommodated by comparison of the usage determinations over time, and schedules may be adjusted accordingly.

Owner:GE MEDICAL TECH SERVICES

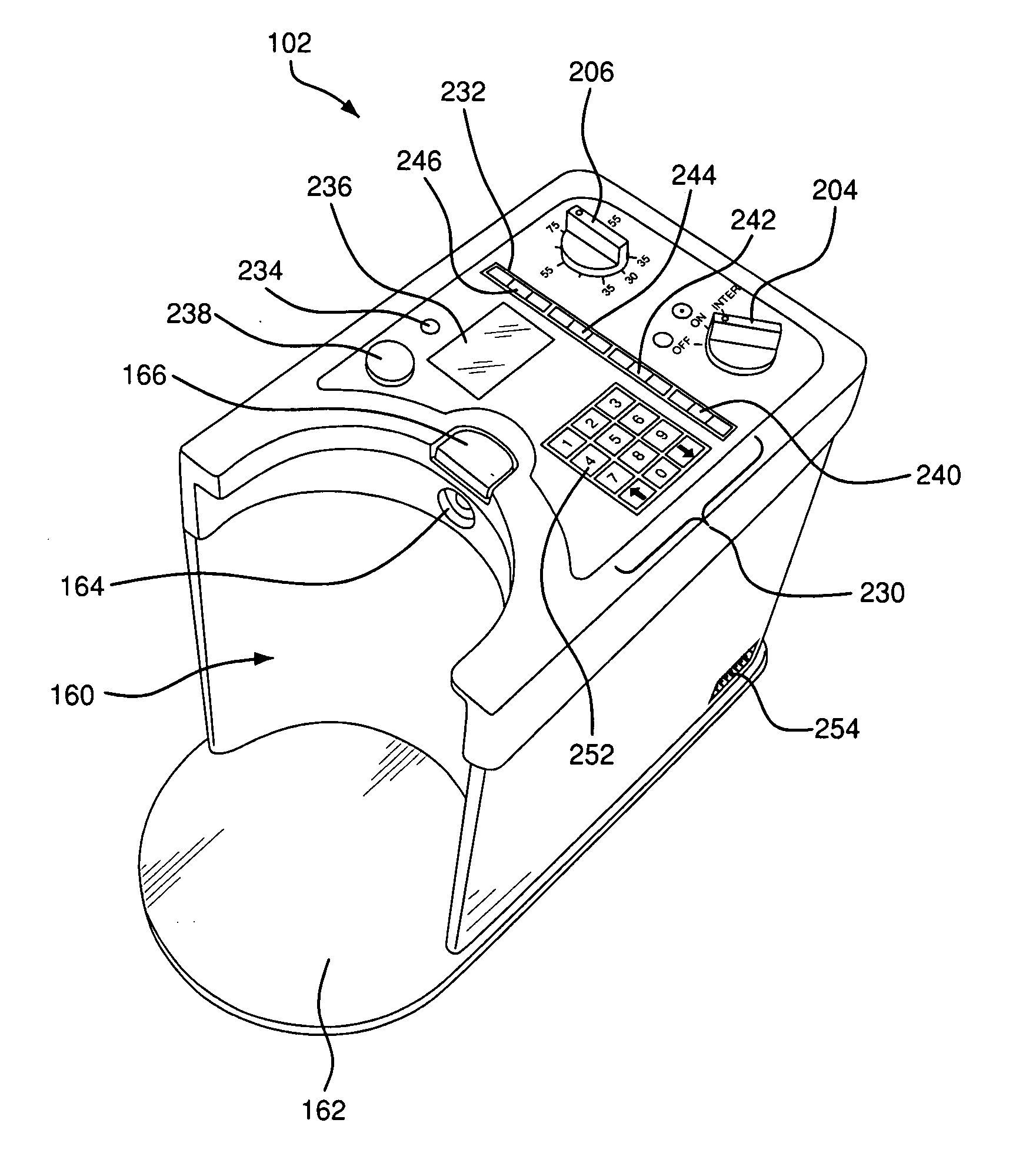

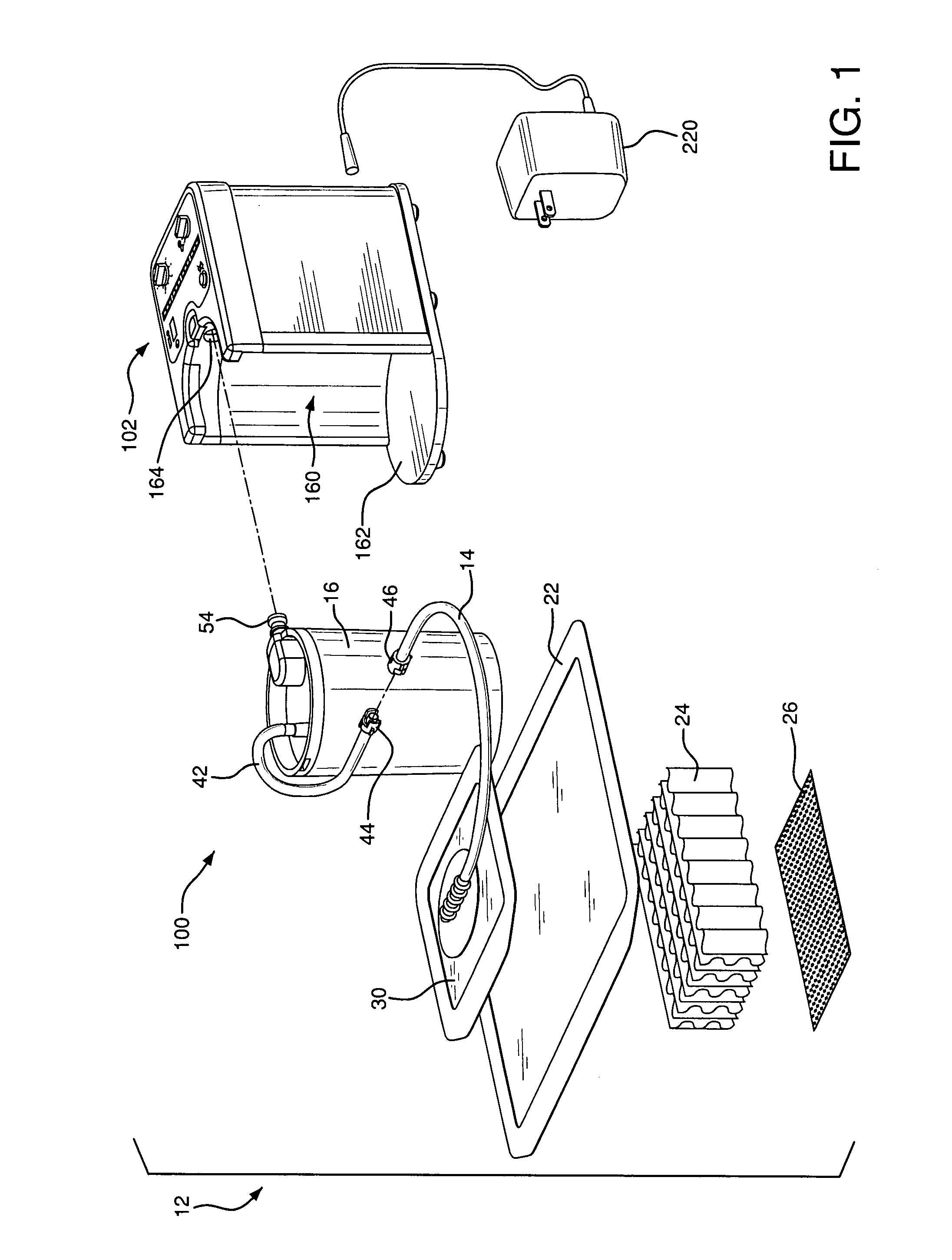

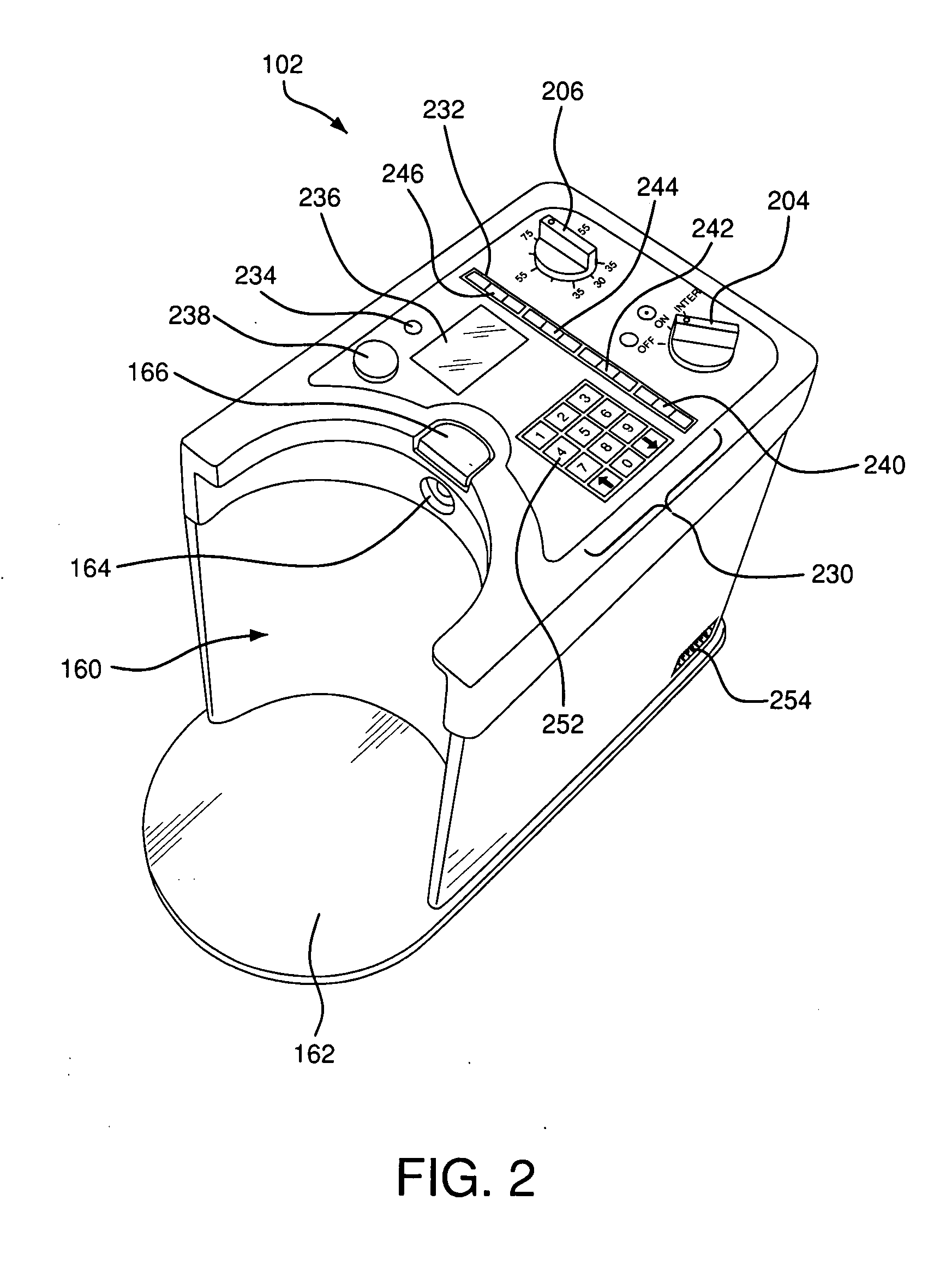

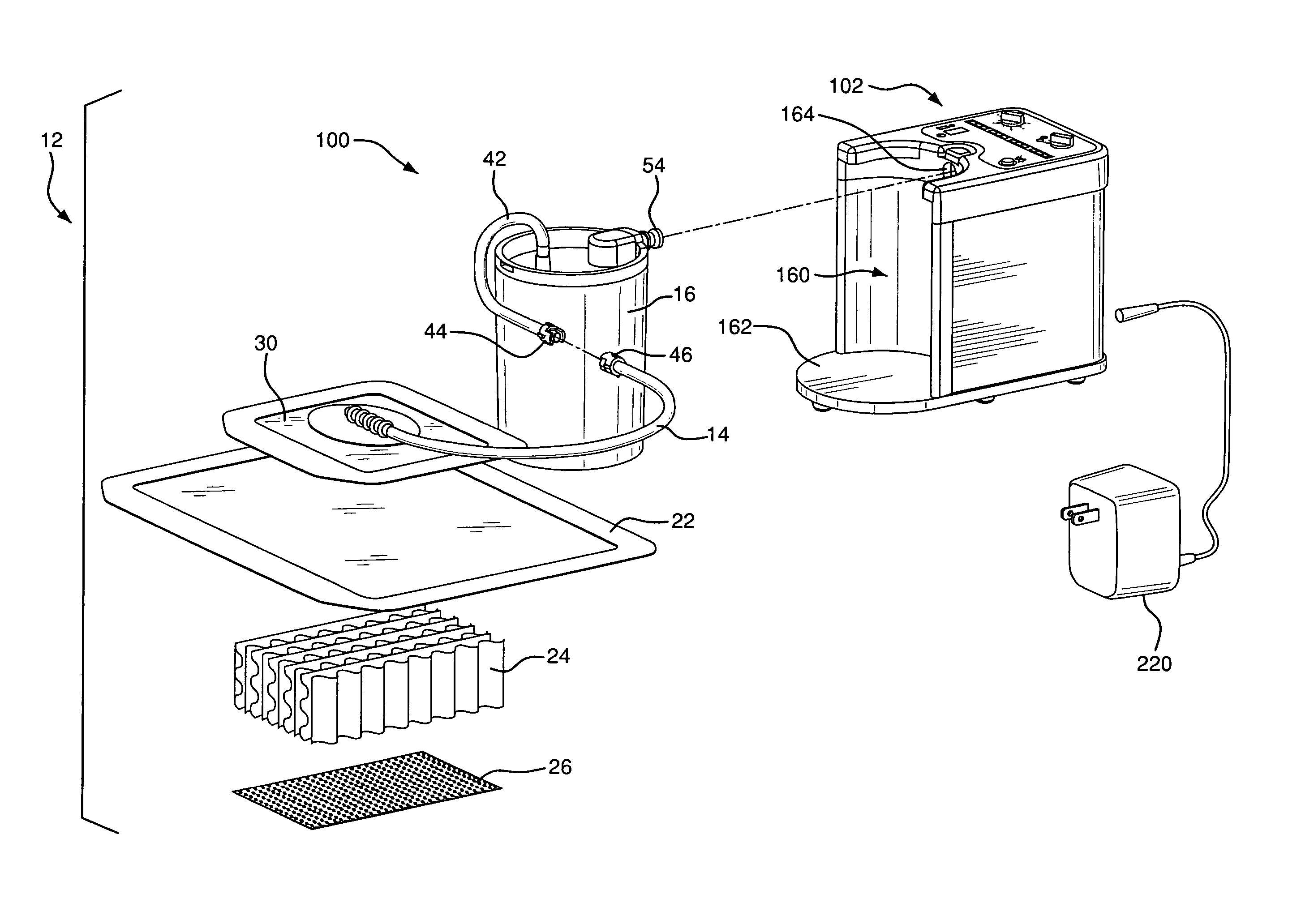

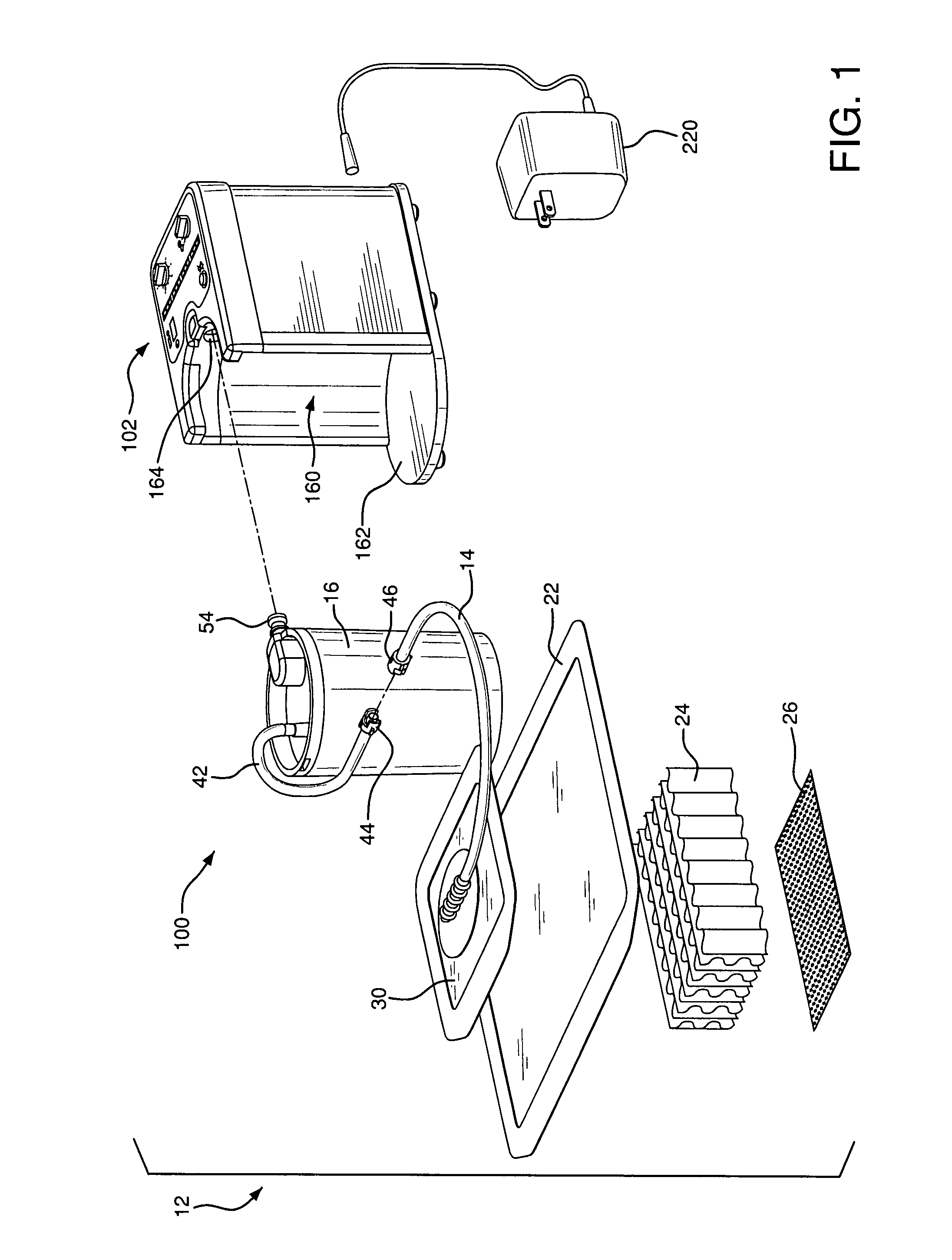

Billing method for pump usage

InactiveUS20080005000A1Mechanical/radiation/invasive therapiesMedical devicesPayment scheduleUnit of time

Disclosed are methods of leasing or billing for the usage of a portable suction pump adapted for use in a suction-assisted would treatment system. The pump has means for recording time units corresponding to periods of time when the pump is operating and for providing reports of usage time. The pump further has means for detecting that the wound treatment system is operating normally so as to be compliant with standards for suction wound treatment, and for recording and reporting time of normal operation or compliant usage. The methods include leasing the pump at a payment schedule that is based upon the amount of actual usage time or the amount of compliant usage time. The lease payment may include an amount of pre-paid time units such that unused time units can be credited to a new or renewed lease for a replacement pump. The billing methods can also be based in whole or in part on a planned maintenance schedule for the pump.

Owner:BOEHRINGER TECH

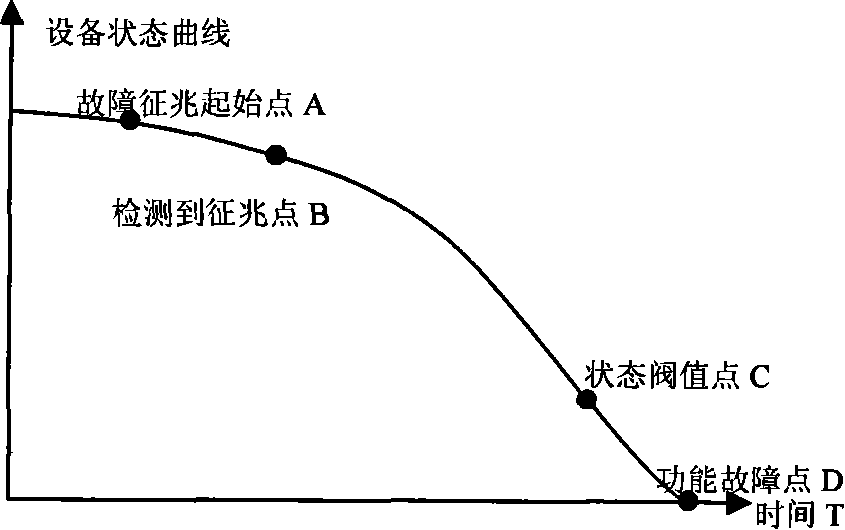

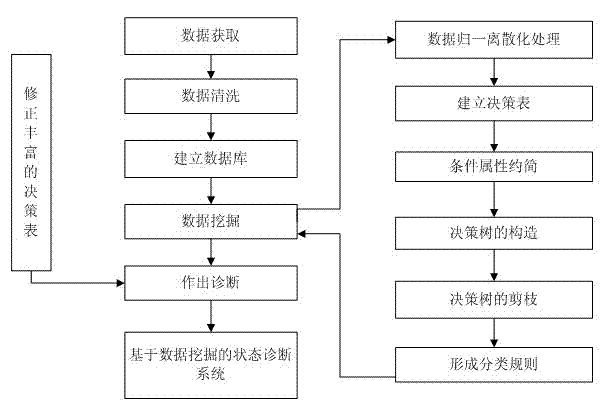

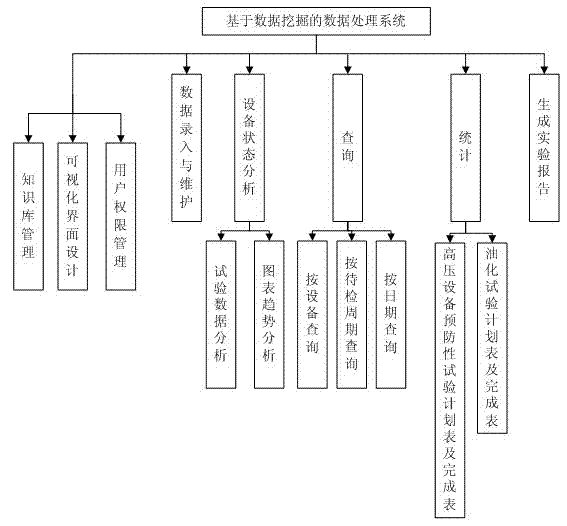

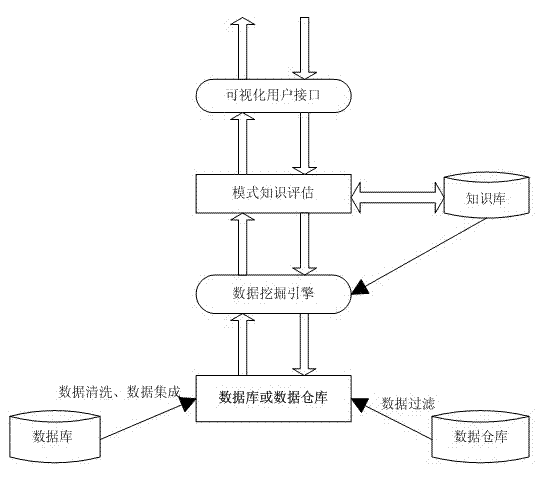

Electrification detection data processing method based on data mining technology

InactiveCN103902816AAchieve loose couplingImprove execution efficiencySpecial data processing applicationsAnalytic modelTransformer

The invention belongs to the technical field of data mining in information technologies, and relates to an electrification detection data processing method based on a data mining technology, in particular to a state analysis technology and method for a transformer, a breaker, an arrester and others in electrical equipment. The processing method includes the steps that according to maintenance lag existing in traditional state maintenance of the electrical equipment and redundant work of overmuch planned maintenance, and a data mining state analyzing model with a rough set and a decision-making tree combined is built and combined with an existing electrical equipment state maintenance system to build the electrification detection data processing system based on the data mining technology. The rough set and the decision-making tree fusion technology is applied to state data analysis of the electric equipment, according to existing state judgment standards, state data of an over 35 KV transformer, an SF6 breaker and other electric equipment are preprocessed, Gini coefficient indexing, attribute reduction, threshold value selection and other steps are performed on attributes, state analysis is performed on the basis, meanwhile a work state table is formed, and a corresponding processing scheme is given.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

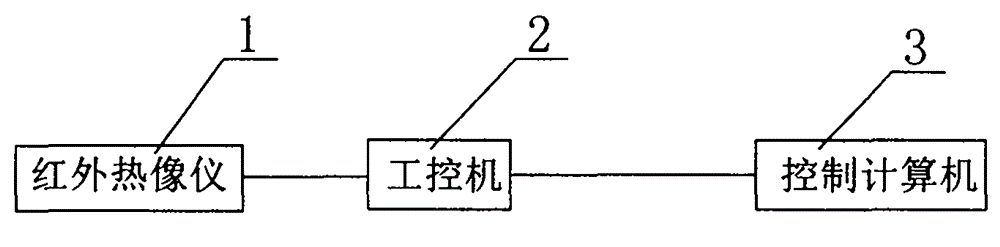

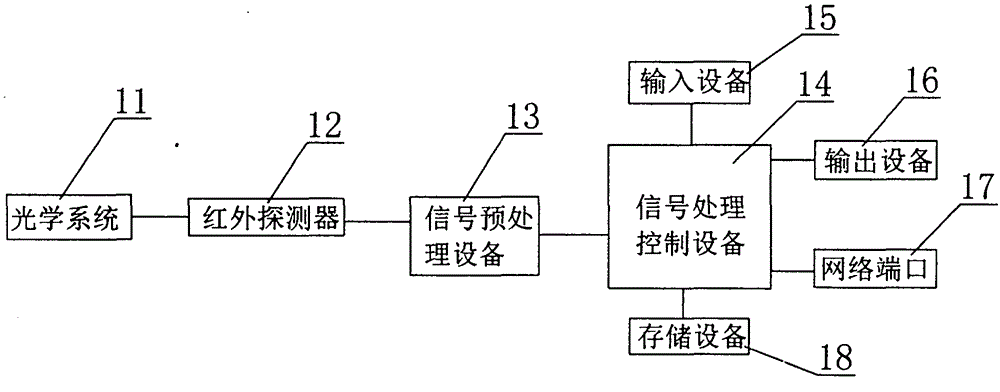

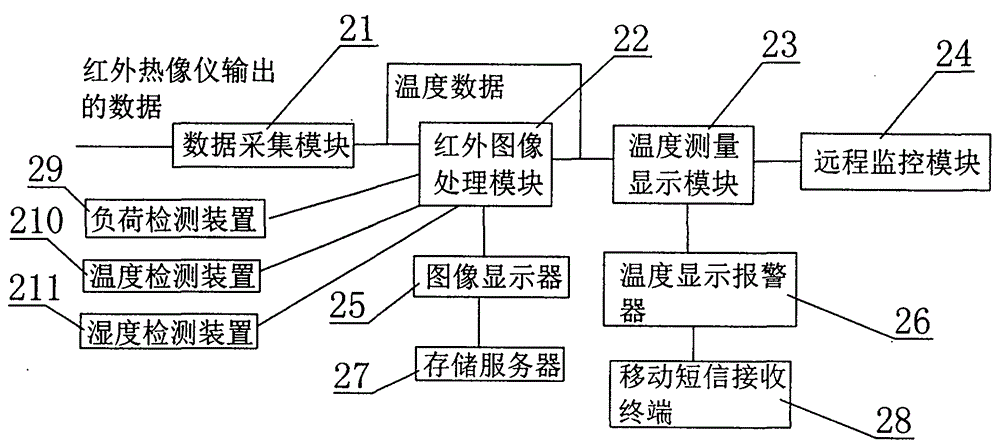

Substation power transformer overheating fault monitoring system based on thermal infrared imager

InactiveCN104165698ARealize online timing automatic temperature monitoringRealize intelligent over-temperature fault alarmRadiation pyrometryCircuit arrangementsData informationTransformer

The invention relates to a substation power transformer overheating fault monitoring system based on a thermal infrared imager. A data acquisition module receives data output by the thermal infrared imager. The data acquisition module acquires infrared images obtained by the thermal infrared imager into a computer monitoring software system, and the infrared images are processed by an infrared image processing module. The data acquisition module transmits obtained temperature data information to a temperature measurement and display module. After format conversion is conducted on the infrared images acquired by the infrared image processing module, the infrared images are transmitted to an image displayer. The output end of the temperature measurement and display module is connected with a temperature displaying and alarming device. According to the substation power transformer overheating fault monitoring system based on the thermal infrared imager, online timed full-automatic temperature monitoring and intelligent fault alarming can be conducted on a transformer through the online monitoring software system, remote temperature monitoring of the unattended substation power transformer is achieved, manpower and material resources are saved greatly, and traditional planned maintenance of power equipment is converted into cognition-based maintenance of power equipment.

Owner:STATE GRID CORP OF CHINA +1

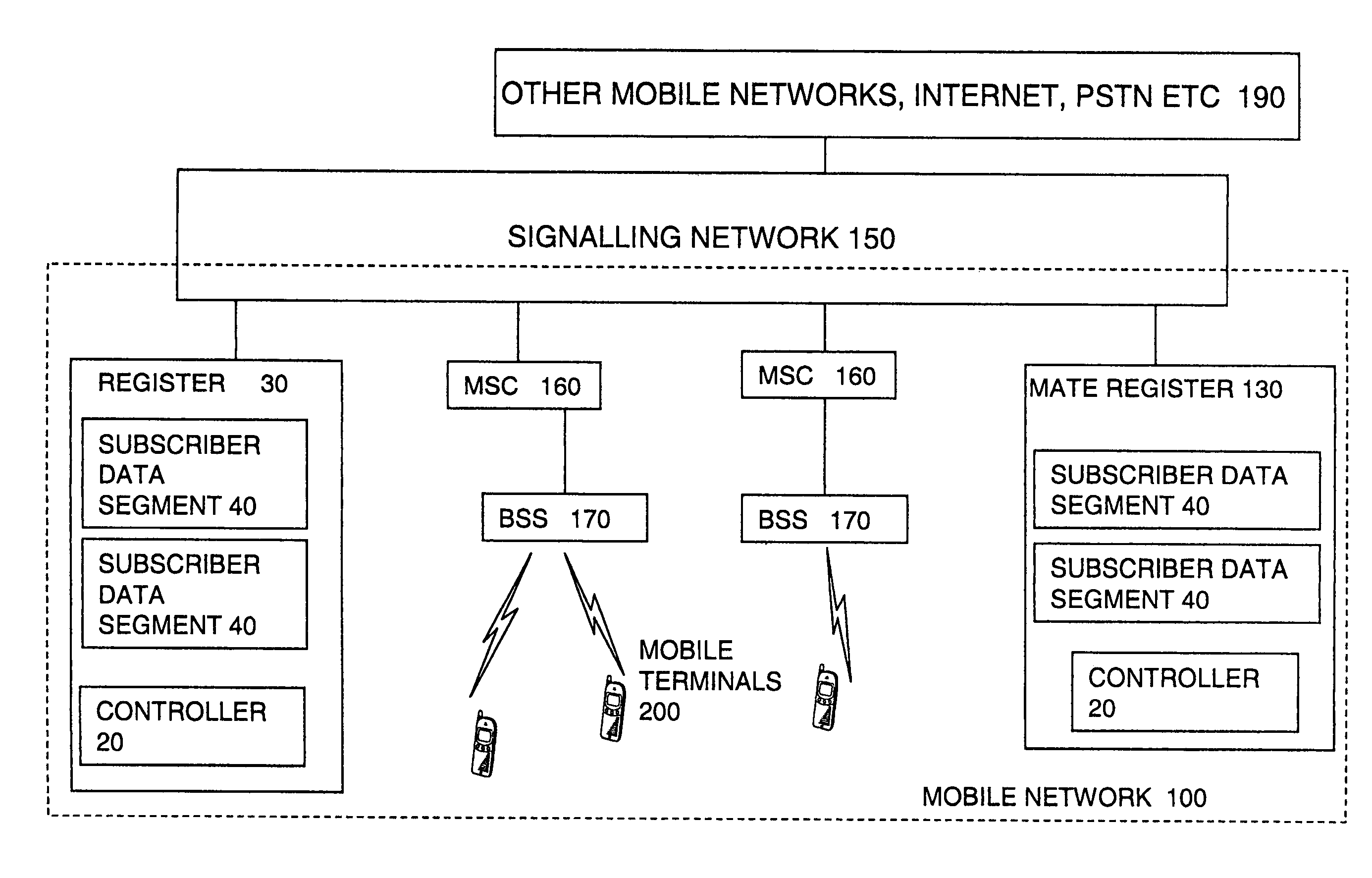

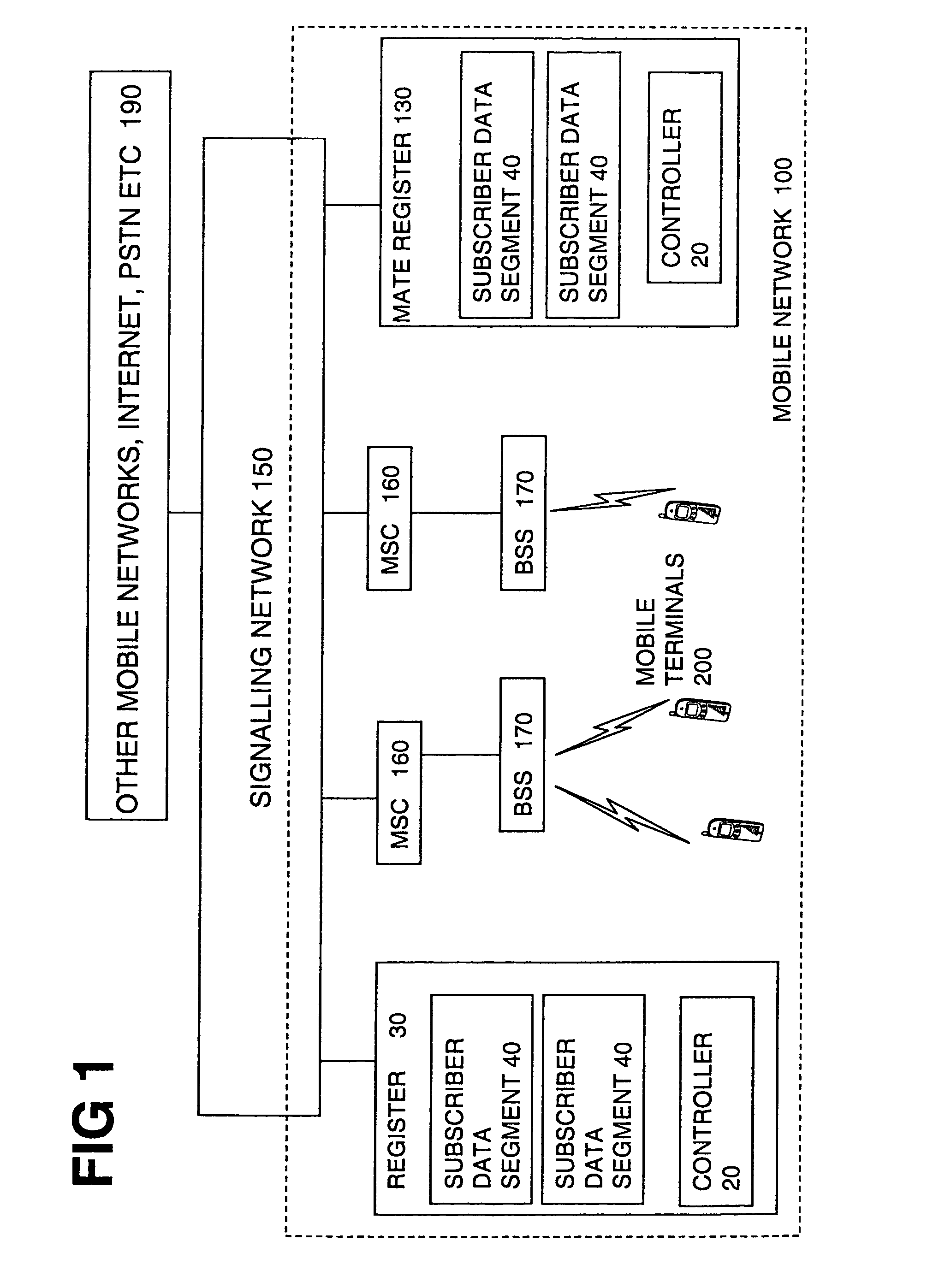

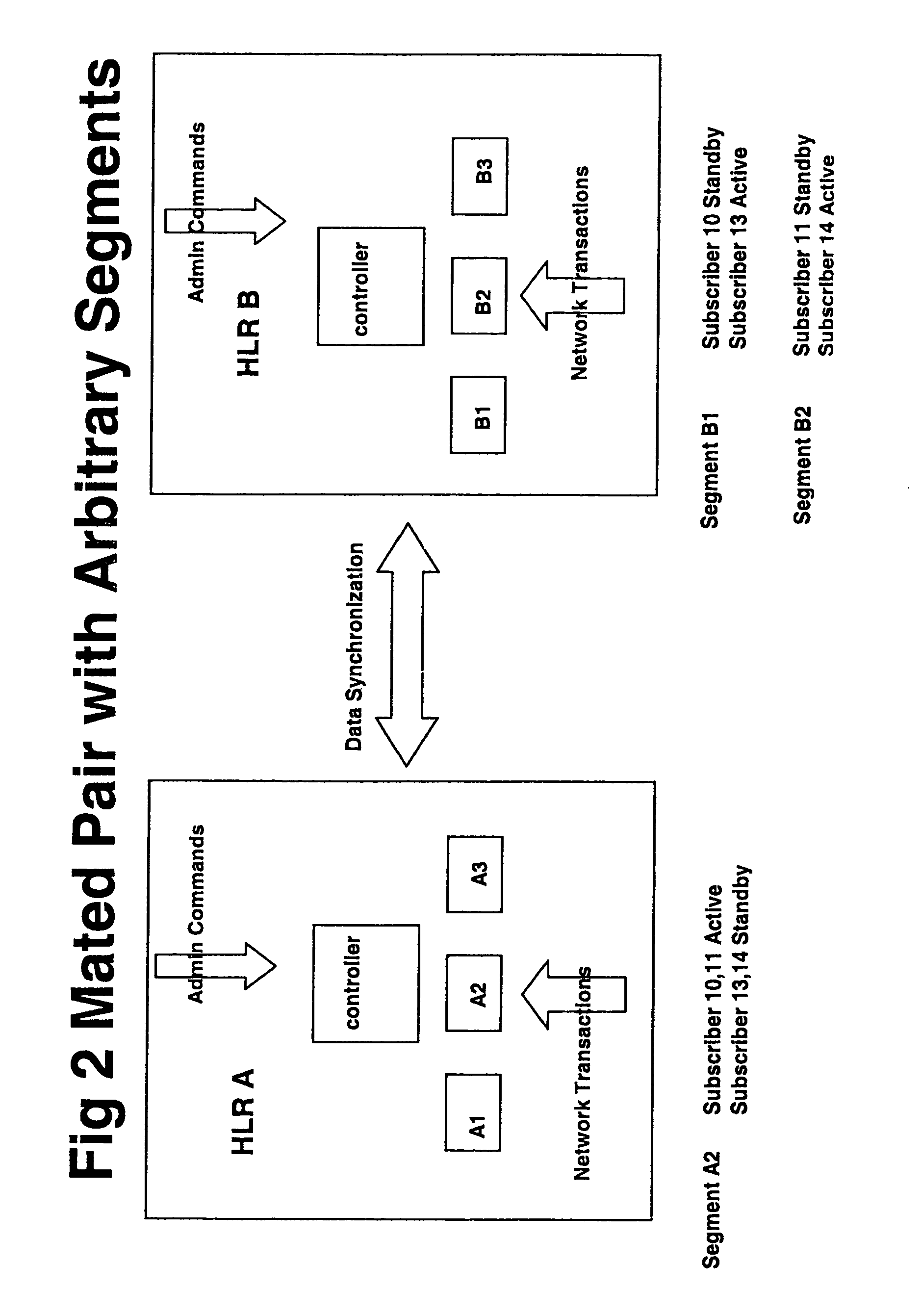

Disaster recovery for very large GSM/UMTS HLR databases

ActiveUS7039402B1Reduce riskThe process is simple and fastCommmunication supplementary servicesRadio/inductive link selection arrangementsProcessor registerData loss

An HLR register for maintaining data relating to mobile users of a network for use by the network, the register being arranged to be coupled to a mate register at a remote location for back up of the data, the register being divided into segments and arranged to carry out a partial handover to the mate register by handing over maintenance of data of one or some of the segments to the mate register temporarily. By allowing a partial handover rather than requiring a complete handover, the handover can be simpler and quicker. This can reduce the risk of loss of data or reduce an amount of down time and consequential losses of revenue. This is particularly important for larger registers. The handover can be triggered by a fault in the segment or for the purpose of planned maintenance for example. It can be triggered manually or automatically.

Owner:LENOVO INNOVATIONS LTD HONG KONG

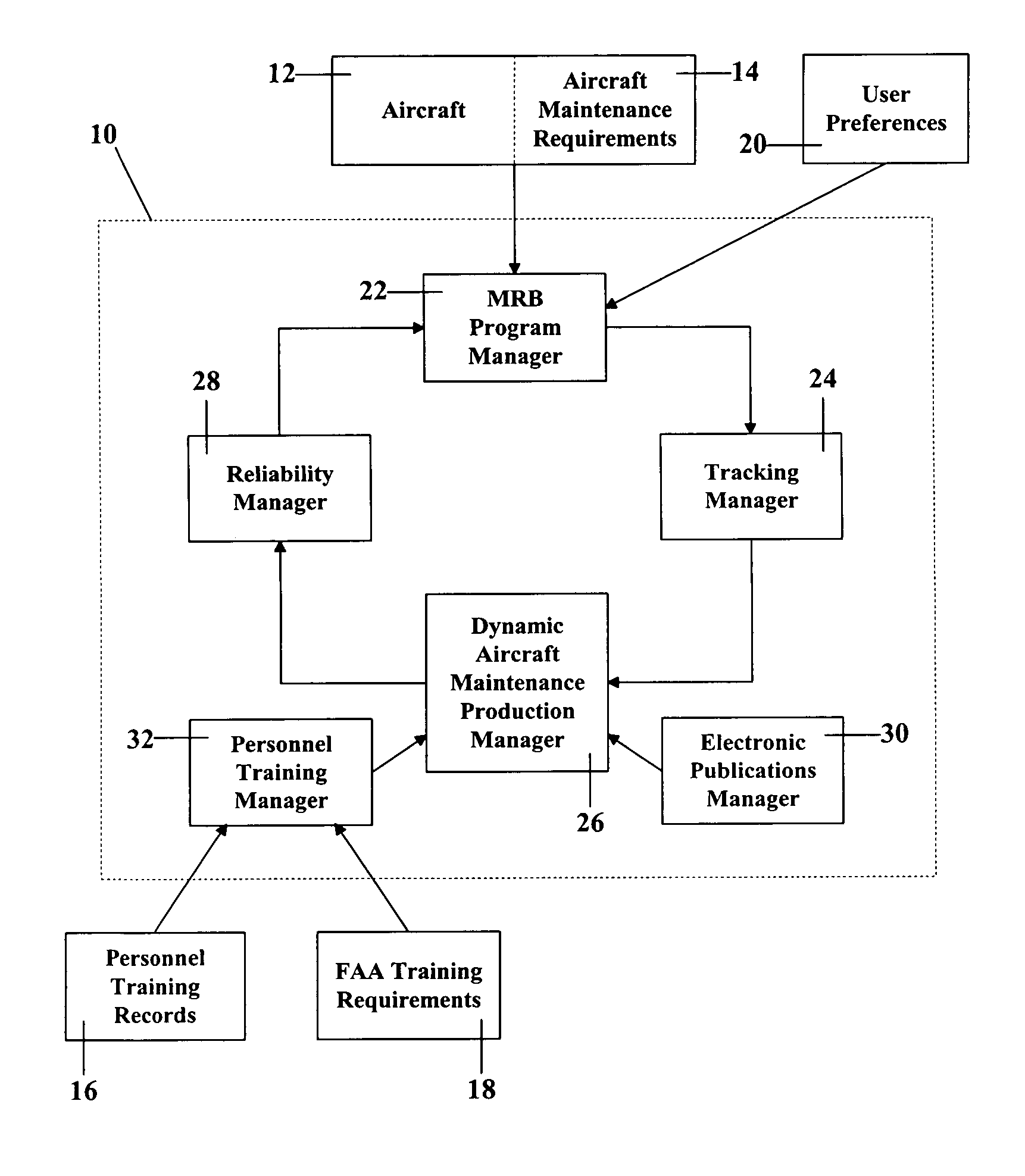

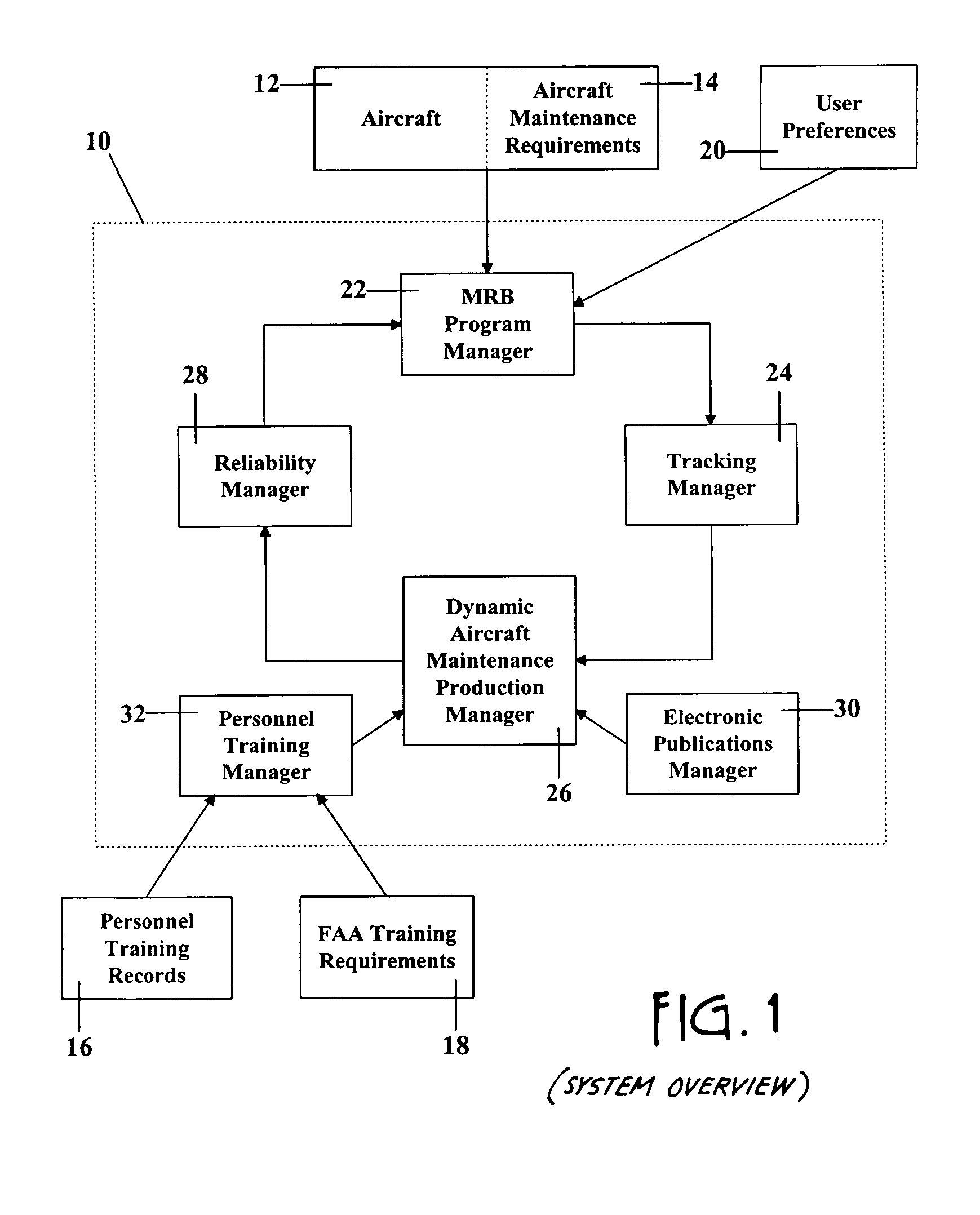

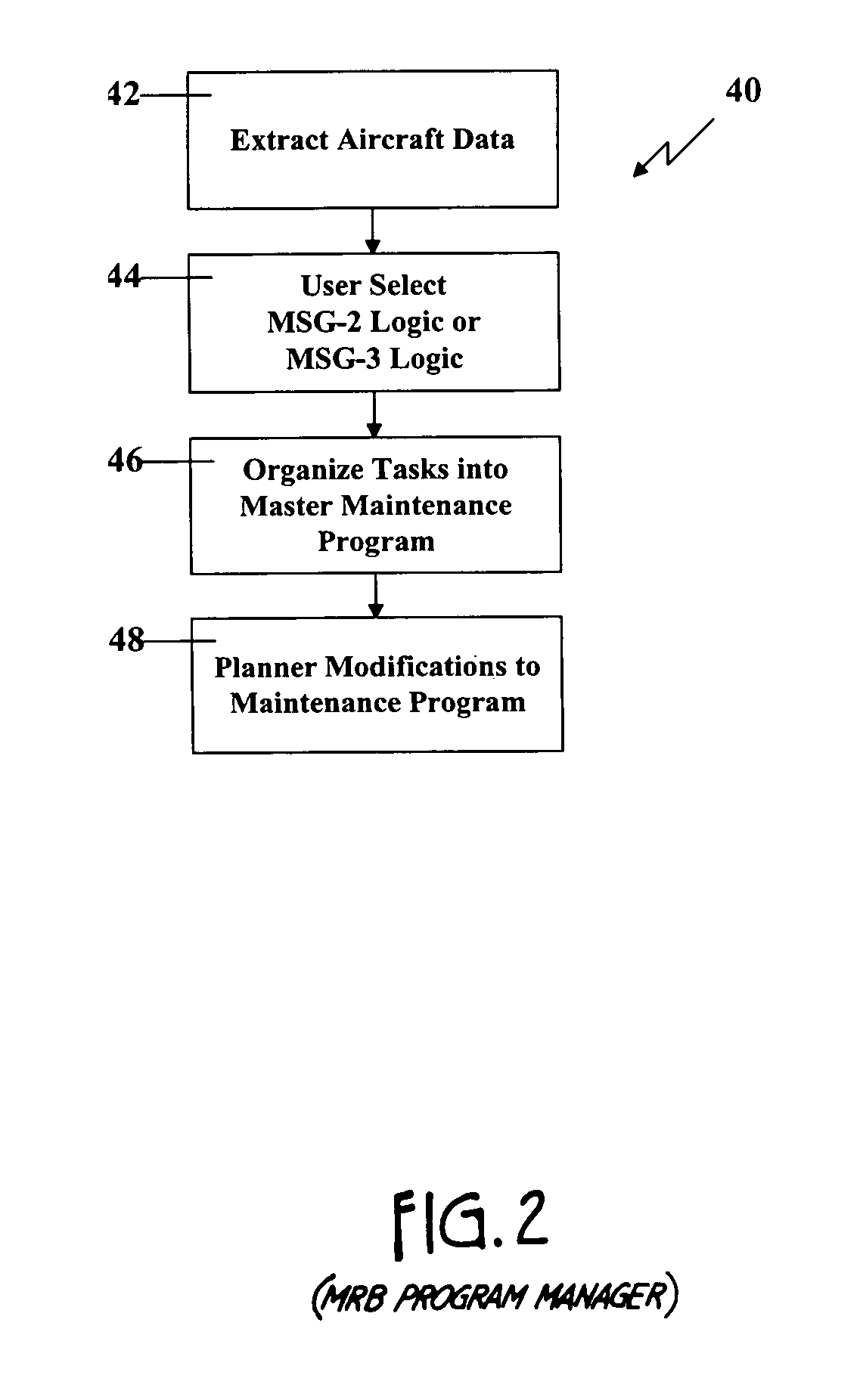

Dynamic management of aircraft part reliability data

InactiveUS7167786B2Vehicle testingRegistering/indicating working of vehiclesDynamic planningDynamic management

A system for recording and analyzing reliability data for an aircraft during a dynamically-planned maintenance check of the aircraft includes means for obtaining and logging warranty-based reliability data from maintenance records generated during the performance of any routine or non-routine tasks that may exist, and which pertain to rotable parts of the aircraft; means for obtaining and logging maintenance program-based reliability data from maintenance records generated during the performance of any non-routine tasks that may exist; means for identifying for each non-routine task, a routine task whose performance resulted in the generation of the non-routine task; means for obtaining and logging maintenance program-based reliability data from maintenance records generated during the performance of any identified routine tasks that may exist; and means for analyzing and reporting the warranty-based reliability data and the maintenance program-based reliability data.

Owner:FLEETMX AVIATION SOLUTIONS INC

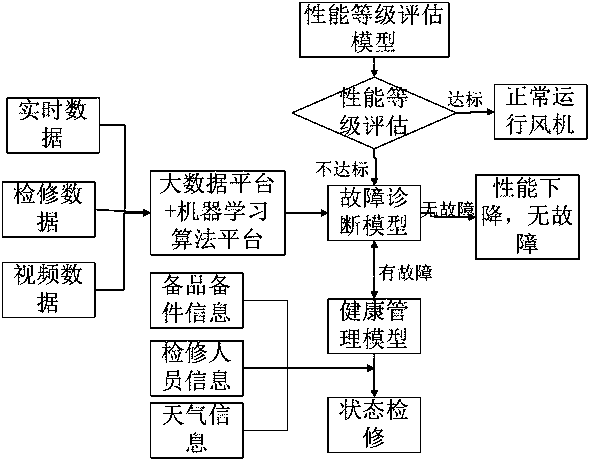

Wind turbine generator health management method based on machine learning algorithm platform

PendingCN109492777AAccurate Health Assessment ReportAccurate device health analysisCharacter and pattern recognitionResourcesEngineeringPerformance grade

The invention provides a wind turbine generator health management method based on machine learning algorithm platform. The health management method includes: theoretical power generation balance analysis, performance grade evaluation, fault diagnosis model and health management model design, health evaluation and health analysis, health management is the realization of condition-based maintenance.According to the deep application of the theoretical electric quantity balance analysis method, Combining Big Data Technology, through the combination of machine learning and artificial intelligence,to realize the prediction and evaluation of the health status of the fan and its accessories and main equipment, finally, the maintenance mode of wind turbine generator system is transited from planned maintenance and fixed maintenance to condition-based maintenance, so as to reduce the power loss of planned maintenance, unplanned maintenance and performance loss of wind turbine generator system,so as to achieve the goal of increasing the power generation of wind farm station and improving the economic benefit of wind farm station.

Owner:国电电力宁夏新能源开发有限公司

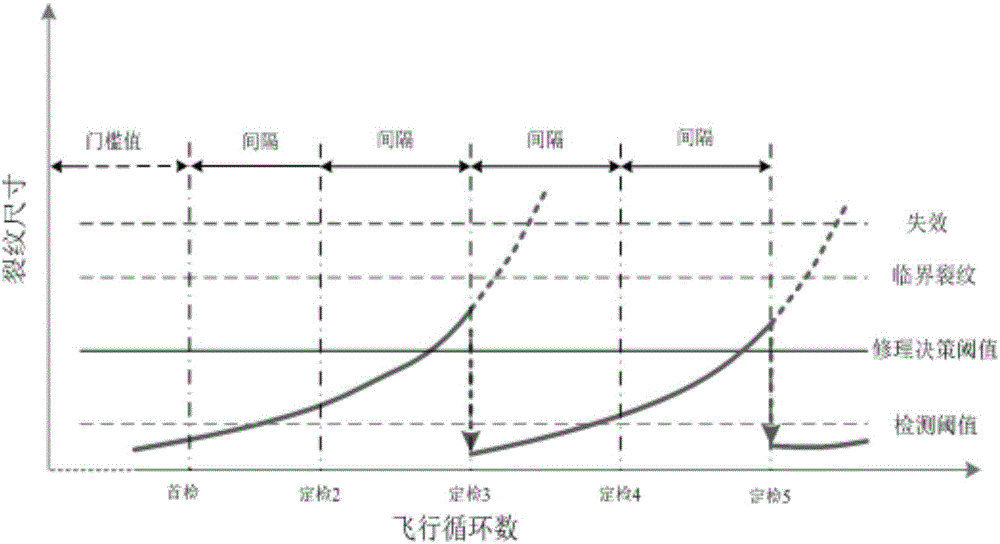

Aircraft structure checking task planning method based on risk and cost analysis

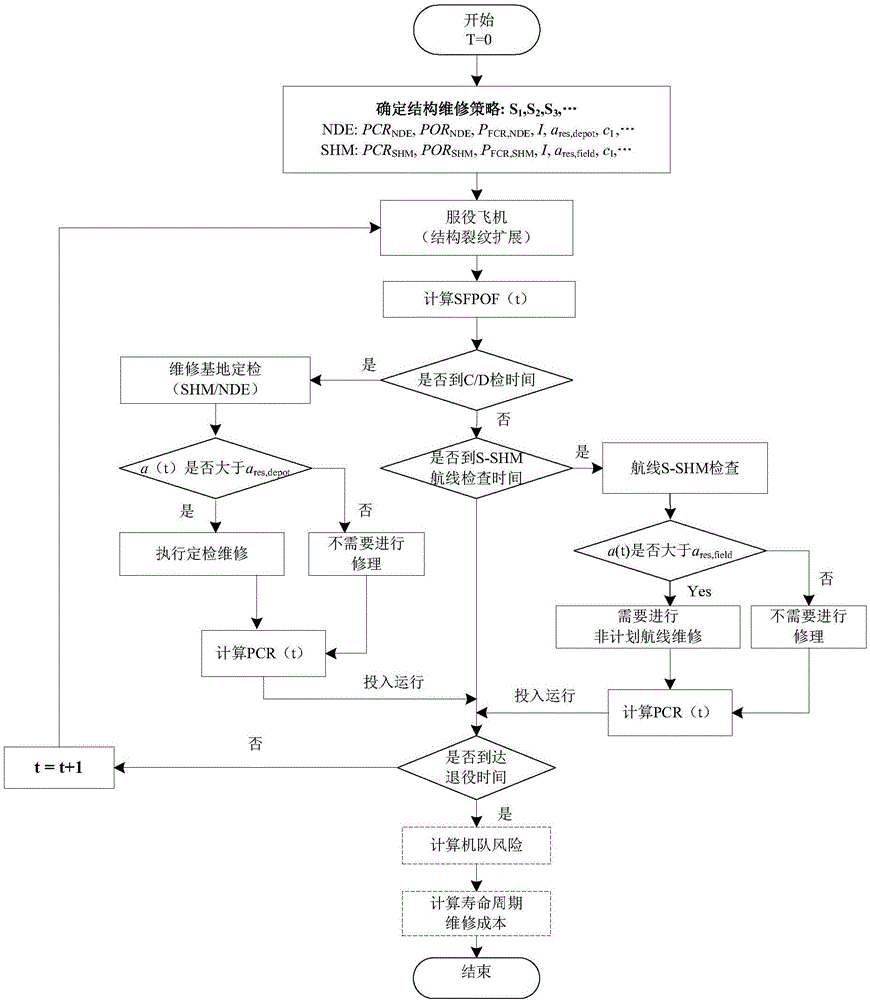

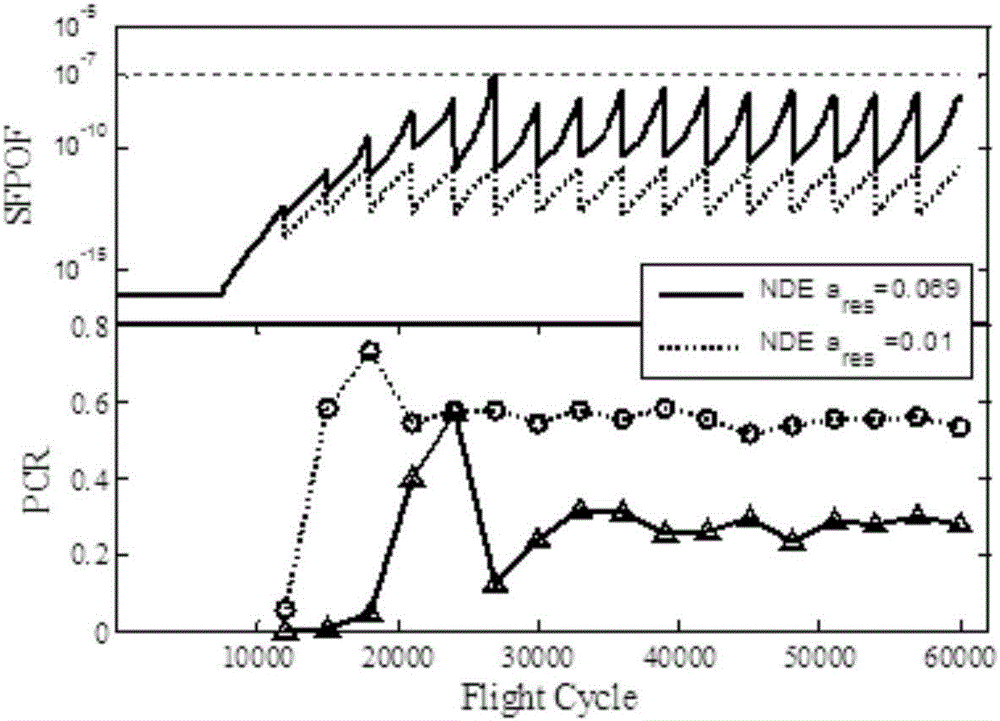

InactiveCN106295897AMeet minimum security requirementsEfficient integrationForecastingCumulative riskFailure risk

The invention discloses an aircraft structure checking task planning method based on risk and cost analysis. The checking mode comprises traditional structure non-destructive detection and structure health monitoring. The method comprises the steps that based on the principle of probability damage tolerance analysis, the calculation model of single flight failure probability of an aircraft structure element is established; based on the model, a cumulative risk calculation model of a fleet in a certain period of time is established; in the existing aircraft structure plan maintenance mode, the maintenance cost calculation model of the aircraft structure element in the service life cycle is established, wherein the calculation model comprises structure checking cost, repair cost and false alarm cost; the single flight failure risk and fleet cumulative risk are used as the risk assessment indicators of a structure maintenance policy; under the premise that a safety risk requirement is satisfied, the optimal structure checking policy can be determined according to the analysis of the structure whole service life cycle maintenance cost. The optimal structure checking interval and repair threshold can be determined based on the tradeoff between the structure failure risk and the service life cycle maintenance cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

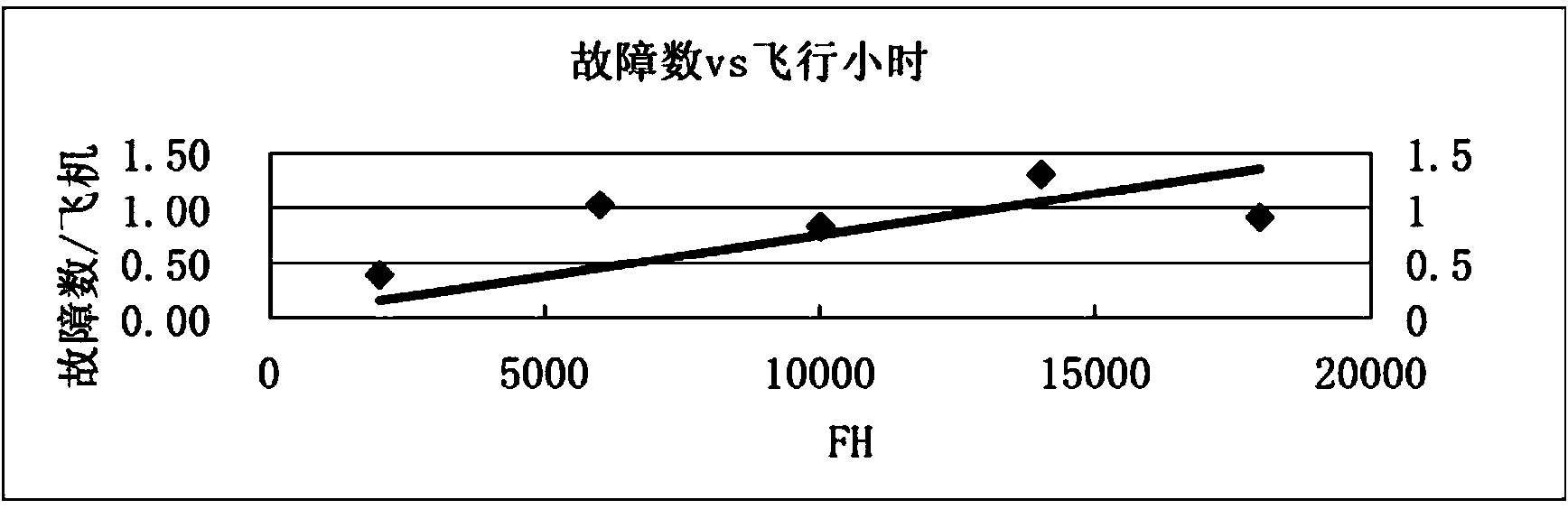

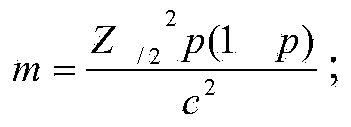

Method for optimizing product planned maintenance interval by civil airplane manufacturer

The invention relates to the technical field of aviation, in particular to a method for optimizing a product planned maintenance interval by a civil airplane manufacturer. The method comprises the steps that an operator is selected, a number of samples are extracted, selected data are verified and classified, a main fault data table is established with relevant and important data, linear regression is conducted through the least square method with the number of flight hours serving as the abscissa and the number of faults serving as the ordinate, the relationship between time adjustment of the maintenance interval and the relevant and important data is established, and the growth rate of the number of relevant and important faults is calculated; hypothesis testing is conducted, whether the ratio of the number of the faults existing after the maintenance interval is adjusted belongs to a rejection region is judged, and whether the requirement for the confidence coefficient is met or not is judged; when the ratio of the number of the faults existing after the maintenance interval is adjusted belongs to the rejection region and the requirement for the confidence coefficient regulated by the industry is met, an existing maintenance time interval is prolonged to a new maintenance interval. According to the method for optimizing the product planned maintenance interval by the civil airplane manufacturer, on the premise that safety and reliability are guaranteed, on the basis of analysis of service data, planned maintenance tasks are optimized, a maintenance program is more effective and more economical, and the maintenance cost of the aviation operators is continuously reduced.

Owner:AVIC SAC COMML AIRCRAFT

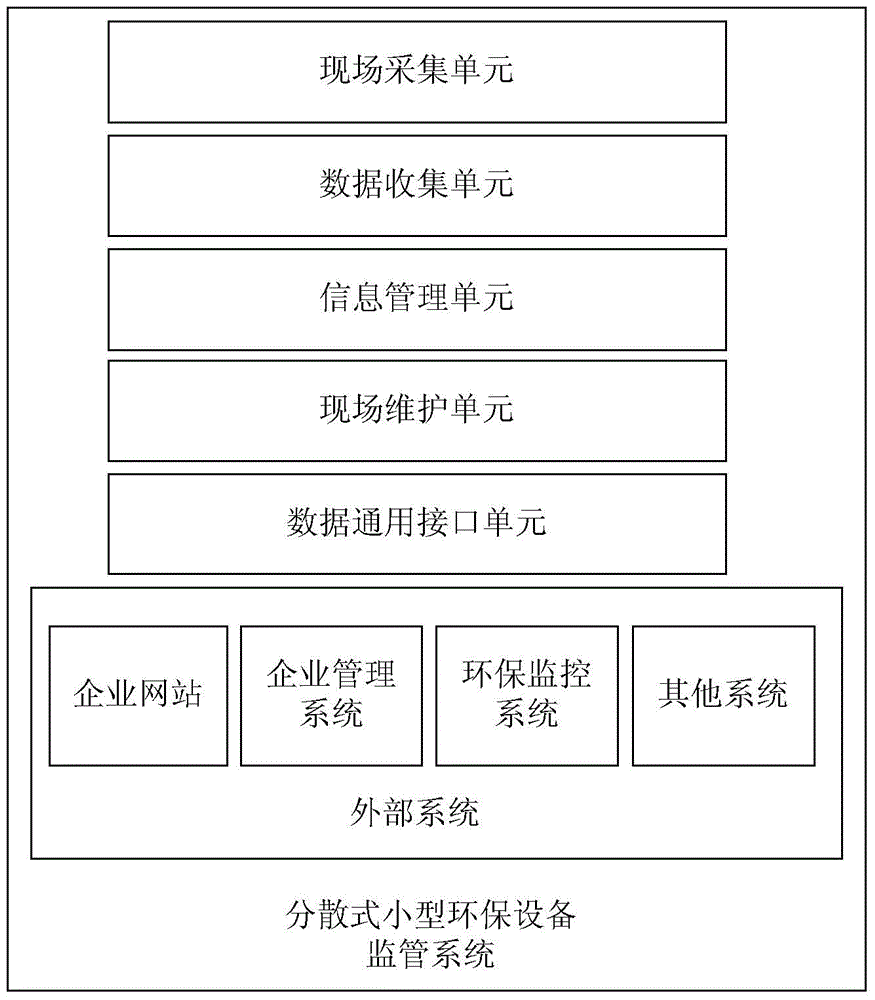

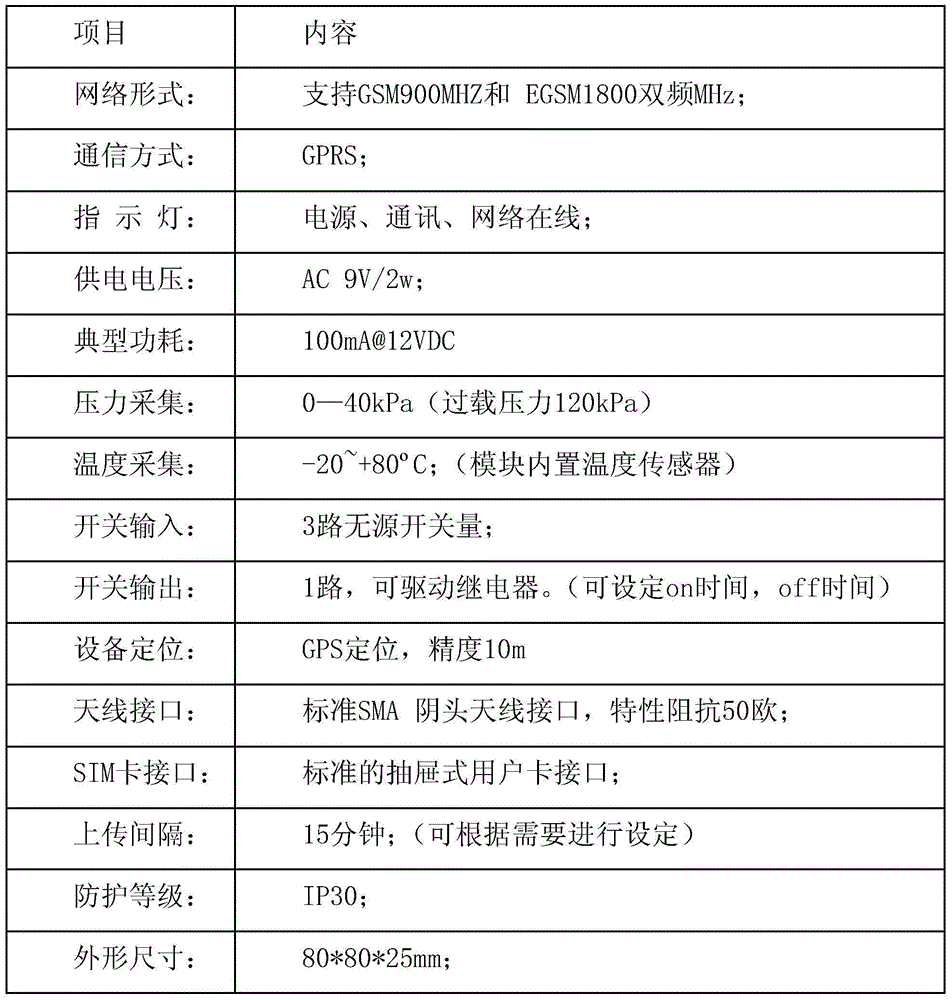

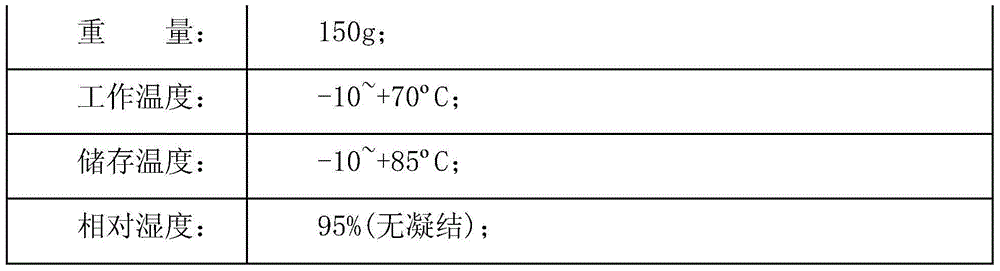

Remote monitoring system for small distributed environment-friendly equipment

ActiveCN104483949ARealize managementEasy to manageTotal factory controlProgramme total factory controlMonitoring systemWater quality

An embodiment of the invention discloses a remote monitoring system for a piece of small distributed environment-friendly equipment, and relates to the technical field of monitoring. The system comprises a field collection unit, an information management unit, a data acquisition unit, a field maintenance unit and a data universal interface unit. Through the technical scheme provided by the embodiment of the invention, the application effect of the small distributed environment-friendly equipment can be improved, the operation state of the environment-friendly equipment is monitored in real time, the utilization rate of the equipment and water quality are ensured, and sewage treatment effect and emission reduction effect are maximized; moreover, the pertinence and timeliness for maintenance of such equipment as a purification tank are improved; warning maintenance and planned maintenance are combined; daily round check is eliminated, and the maintenance cost is reduced greatly.

Owner:DALIAN JIUPENG ELECTRONICS SYST ENG

Processor Operational Status Management System

InactiveUS20070300228A1Multiprogramming arrangementsData switching networksSystem maintenanceState management

A system inhibits alert monitoring during a predefined time period such as system maintenance by suppressing automatic communication of false alert messages to systems, on call personnel and availability reports and enables future scheduling of planned maintenance events, as well as realtime suppression of alerting during a chosen period. A system supports maintenance of one or more processing devices. The system includes a display processor for initiating generation of data representing at least one display image enabling a user to, select a processing device from multiple different processing devices intermittently receiving maintenance and schedule a time period for suppression of communication of alert messages indicating a failure condition of the selected processing device.

Owner:CERNER INNOVATION

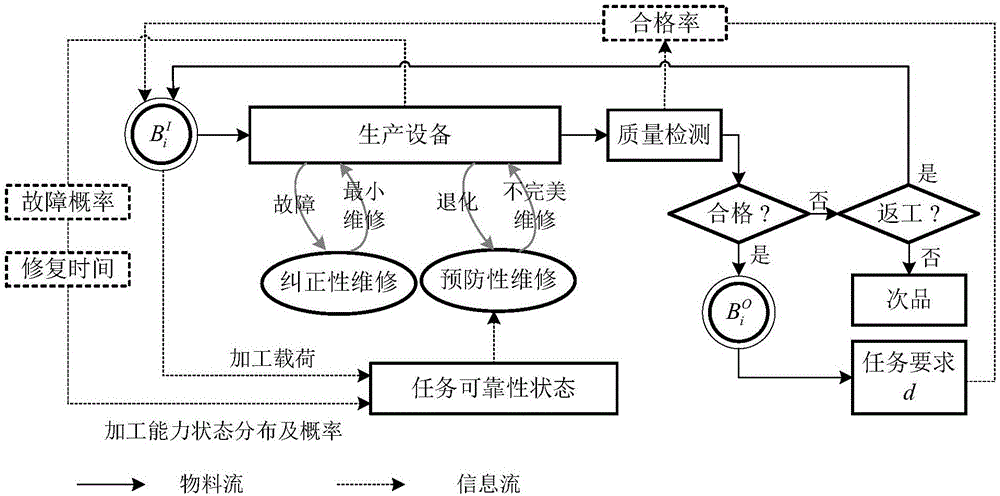

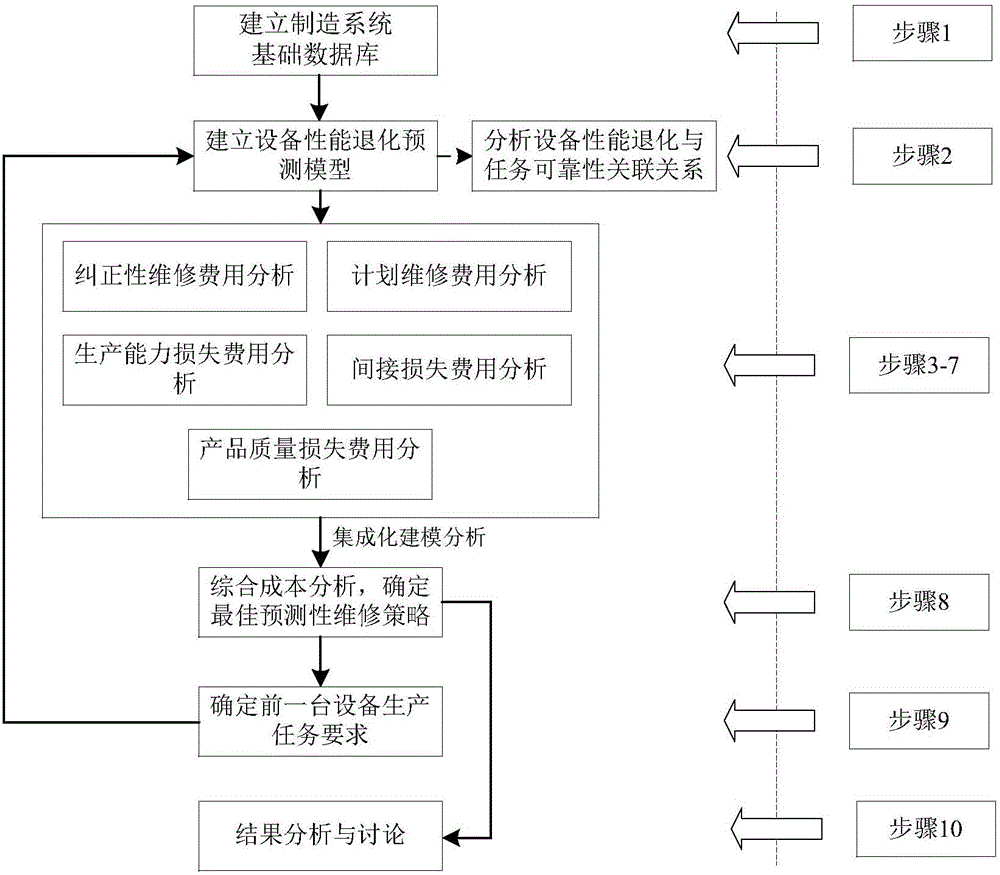

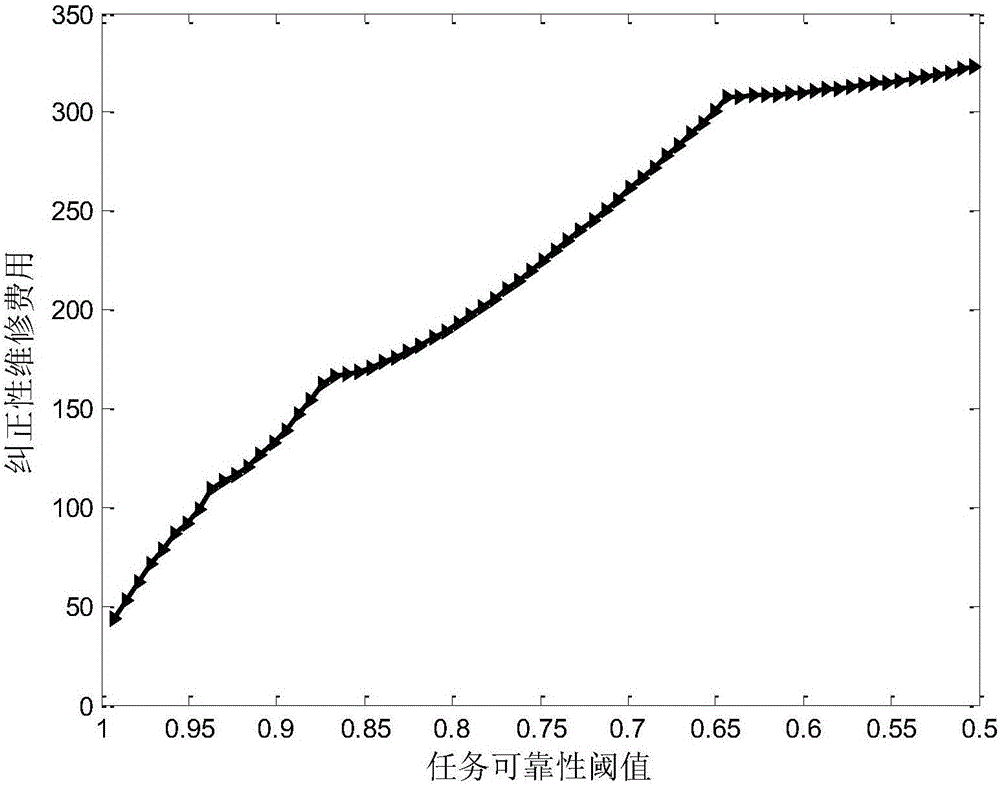

Task reliability state-based manufacturing system predictive maintenance method

InactiveCN106127358AImprove targetingImprove scienceForecastingManufacturing computing systemsTask demandPredictive maintenance

A task reliability state-based manufacturing system predictive maintenance method is disclosed and comprises the following steps: in a first step, a manufacturing system underlying database is built; in a second step, device performance variation trends and all relevant parameters are analyzed via use of underlying data; in a third step, corrective maintenance cost of a device is predicted; in a fourth step, planned maintenance cost of the device is predicted; in a fifth step, processing capability loss cost of the device is predicted; in a sixth step, indirect loss cost of the device is predicted; in a seventh step, product quality loss cost of the device is predicted; in an eighth step, comprehensive cost is predicted, a task reliability threshold value of the device is determined, and an optimal predictive maintenance strategy is further determined; in a ninth step, task demand of the last device is determined according to a result of the eighth step, and the second step to the eighth step are repeated till a predictive maintenance strategy of a whole manufacturing system is made; in a tenth step, via the above steps, an aim of combining device performance conditions with production tasks is attained, and problems of conventional neglect of production states and blind periodic maintenance can be solved.

Owner:BEIHANG UNIV

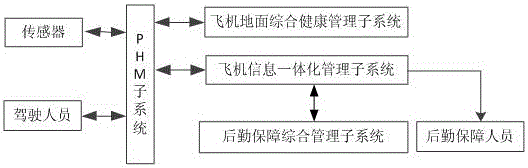

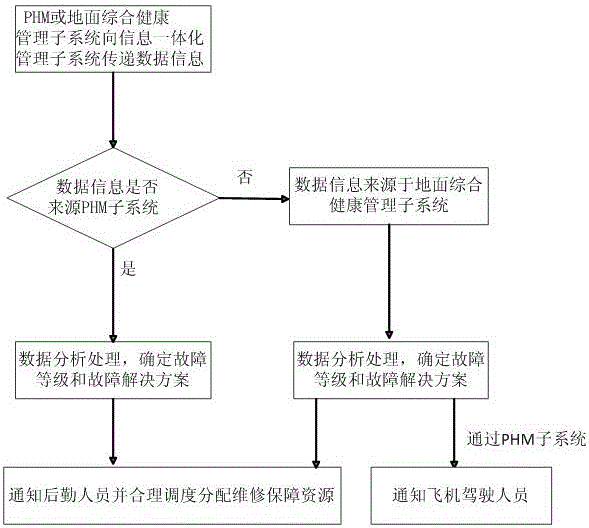

Airplane autonomous guarantee system and method based on internet of things

InactiveCN106741988ATimely and effective maintenance guaranteeEnsure flight safetyAircraft health monitoring devicesJet aeroplaneEarly prediction

The invention discloses an airplane autonomous guarantee system and method based on the internet of things. The system comprises a PHM subsystem, an airplane information integrated management subsystem and an airplane ground comprehensive health management subsystem. The method includes the following steps that 1, by means of information interaction of the PHM subsystem and the airplane information integrated management subsystem, airplane parameters and fault diagnosis results are transmitted; 2, the airplane ground comprehensive health management subsystem conducts performance degradation trend analysis on key equipment of an airplane, and early prediction and diagnosis of potential faults are achieved; 3, the airplane information integrated management subsystem analyzes transmission data information, a fault grade and a fault solution are determined, corresponding army maintenance staff, other guarantee staff and maintenance equipment are reasonably scheduled and allocated, and maintenance conditions of the airplane are monitored in the whole process. Conversion from planned maintenance to condition maintenance in airplane maintenance guarantee is achieved, and the system and method play an important role in guaranteeing safe flight of the airplane, improving maintainability, increasing the task success rate, improving use efficiency and the like.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

Billing method for pump usage

InactiveUS7933817B2Mechanical/radiation/invasive therapiesMedical devicesPayment scheduleRunning time

Disclosed are methods of leasing or billing for the usage of a portable suction pump adapted for use in a suction-assisted would treatment system. The pump has means for recording time units corresponding to periods of time when the pump is operating and for providing reports of usage time. The pump further has means for detecting that the wound treatment system is operating normally so as to be compliant with standards for suction wound treatment, and for recording and reporting time of normal operation or compliant usage. The methods include leasing the pump at a payment schedule that is based upon the amount of actual usage time or the amount of compliant usage time. The lease payment may include an amount of pre-paid time units such that unused time units can be credited to a new or renewed lease for a replacement pump. The billing methods can also be based in whole or in part on a planned maintenance schedule for the pump.

Owner:BOEHRINGER TECH

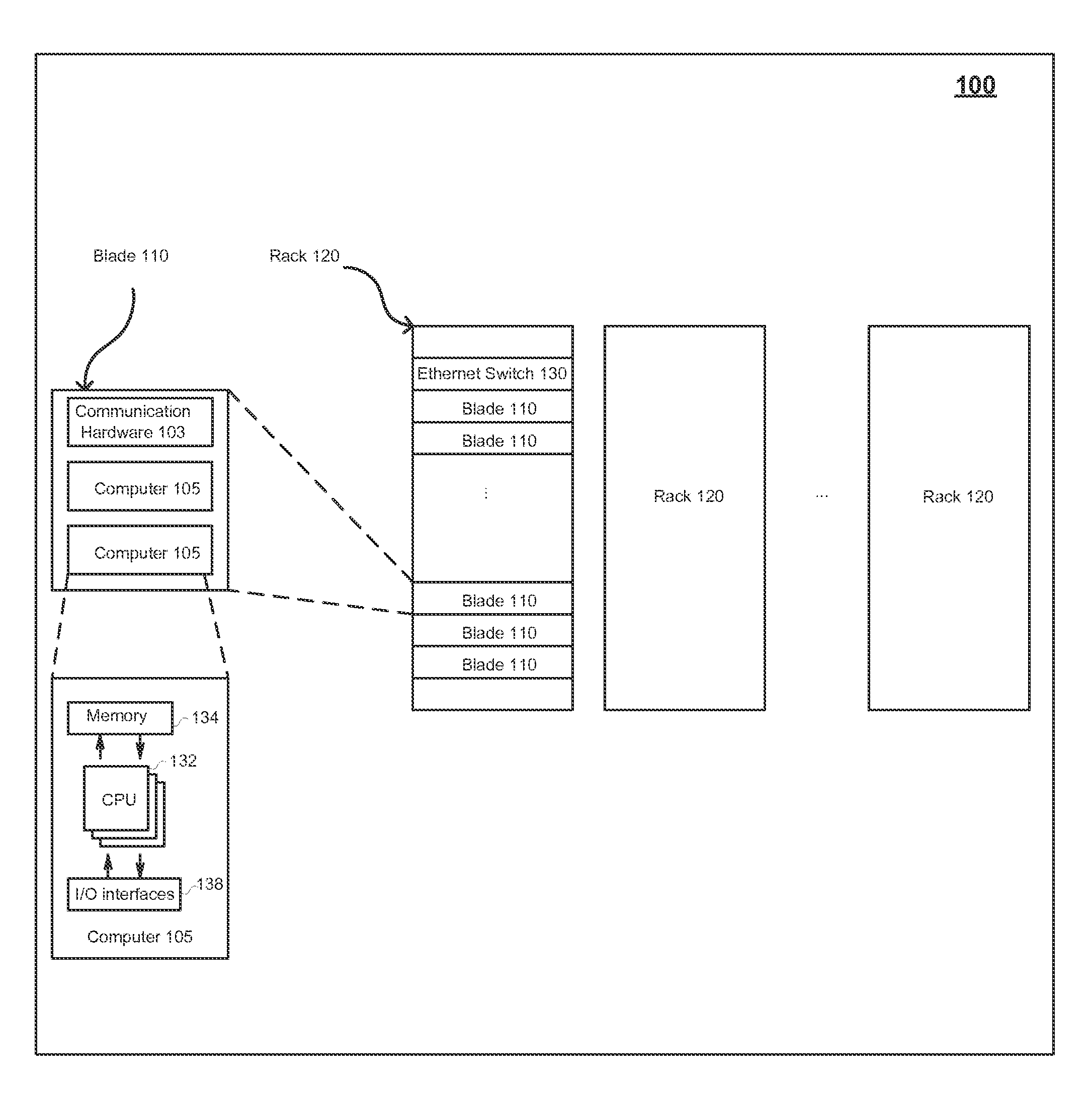

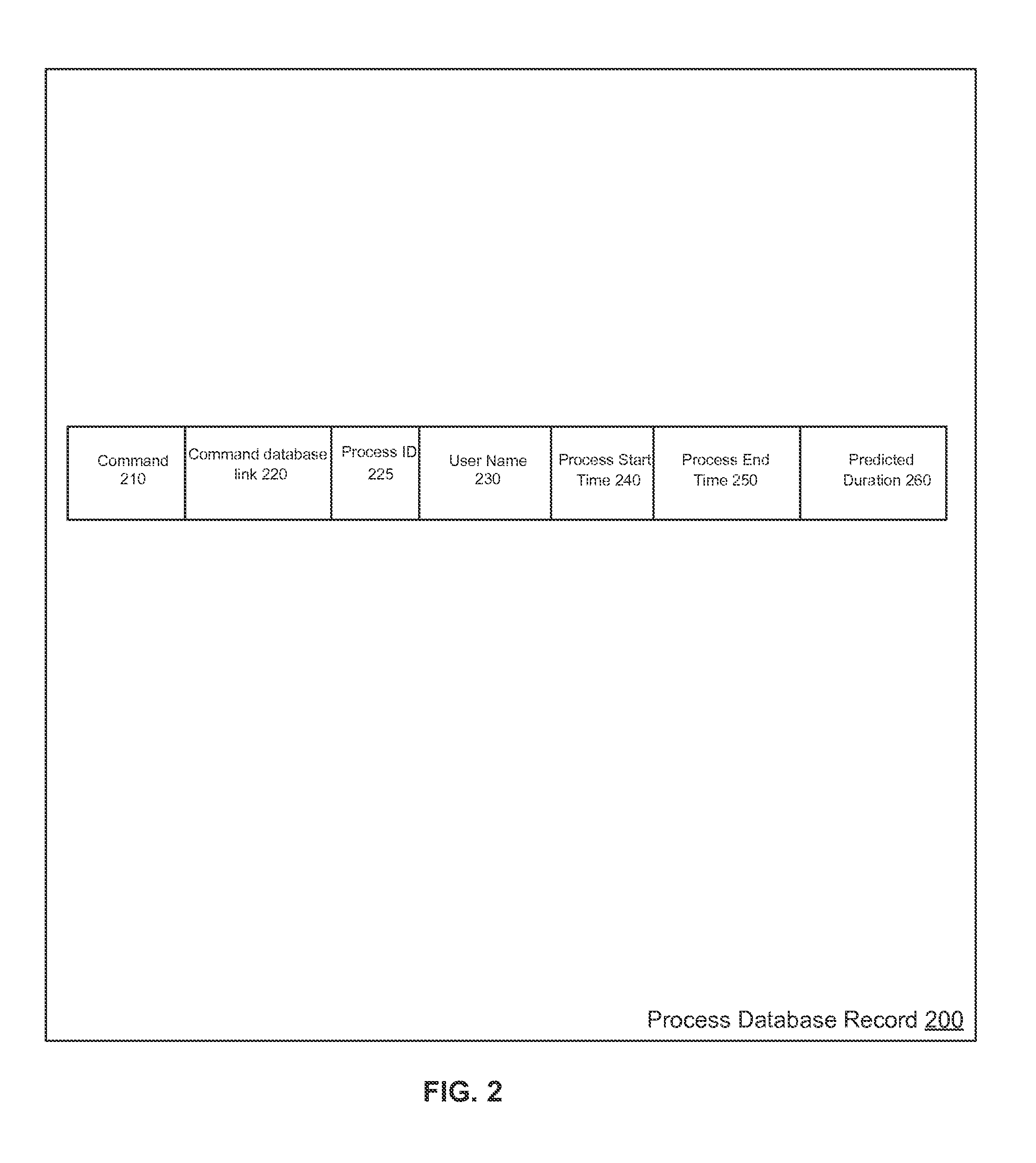

System and method for process run-time prediction

Various embodiments provide process run-time prediction for processes running on server computers. In one embodiment, process run-time of a process is determined by building a database with a history of users, command lines and runtime associated with each command line, and comparing the process with stored records of completed processes in the database. In some embodiments, in response to a determination that the time interval of a process is likely to intersect a planned maintenance period on a server computer, a maintenance notification can be sent to a user of the process and therefore allow the affected process to be migrated to unaffected server computer(s).

Owner:CISCO TECH INC

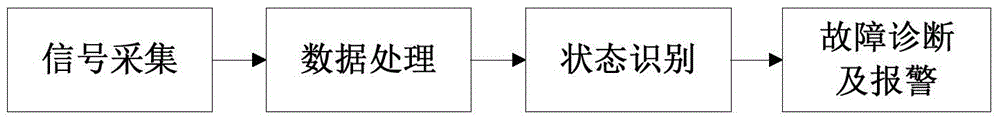

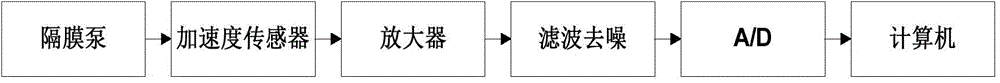

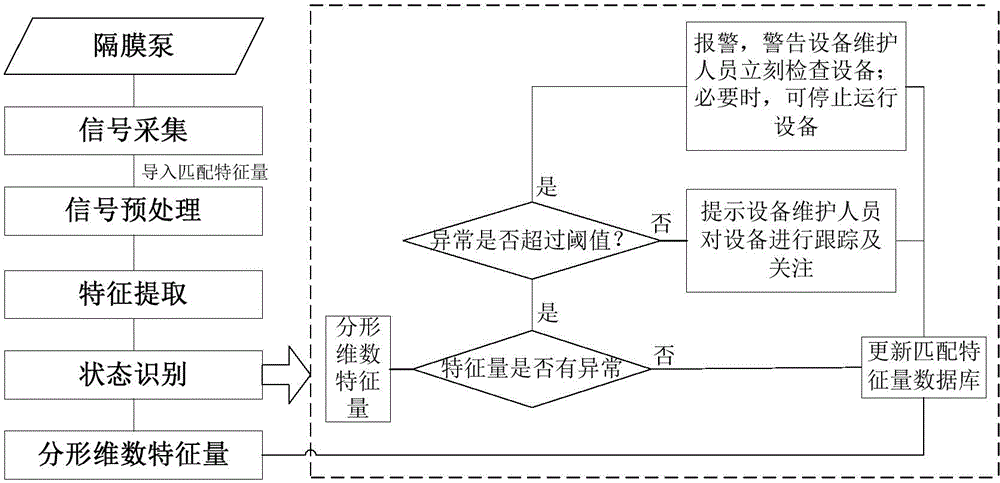

Diaphragm pump fault diagnosis method and device based on fractal theory

ActiveCN104863842ARealize real-time status monitoringIntuitive reflectionPump testingPositive-displacement liquid enginesFeature extractionDiagnosis methods

The invention relates to a diaphragm pump fault diagnosis method and device based on a fractal theory and belongs to the technical field of machine fault diagnosis. The diaphragm pump fault diagnosis device comprises a signal collecting module used for detecting vibrating signals of a diaphragm pump through an acceleration sensor, a signal preprocessing module used for preprocessing the collected vibrating signals of the diaphragm pump, a feature extracting module used for extracting fractal fault features from the denoised vibrating signals, a state recognition module used for conducting fault matching and recognizing on the extracted fractal fault features and all initially-imported fault fractal feature quantity obtained through historical training, a fault diagnosis and alarm module used for reminding device maintenance personnel to correspondingly process the device. According to the diaphragm pump fault diagnosis method and device, the running state of the device can be rapidly and visually reflected, the reliable running information of the device can be provided for the device maintenance personnel in time, running of the device is effectively ensured, and therefore the downtime, the planned maintenance time and the unplanned maintenance time of the device are shortened.

Owner:KUNMING UNIV OF SCI & TECH

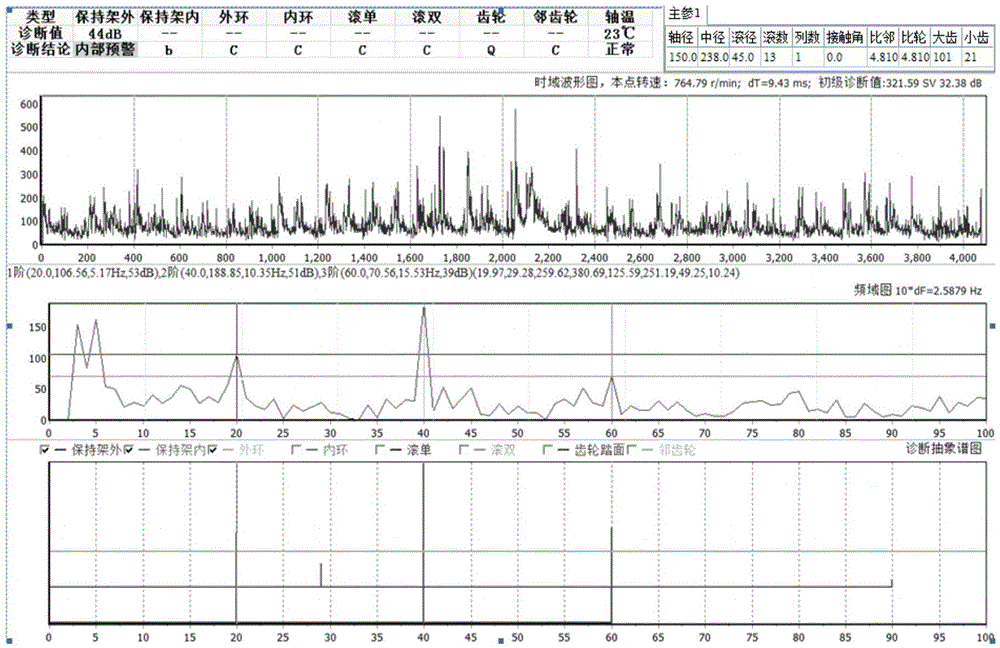

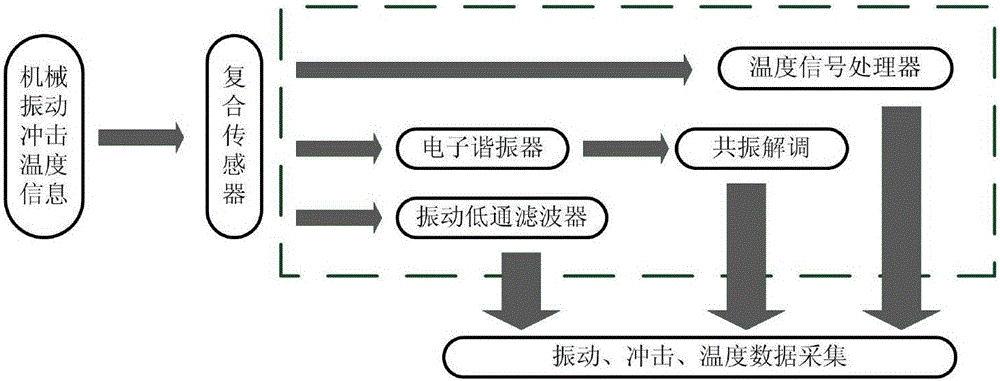

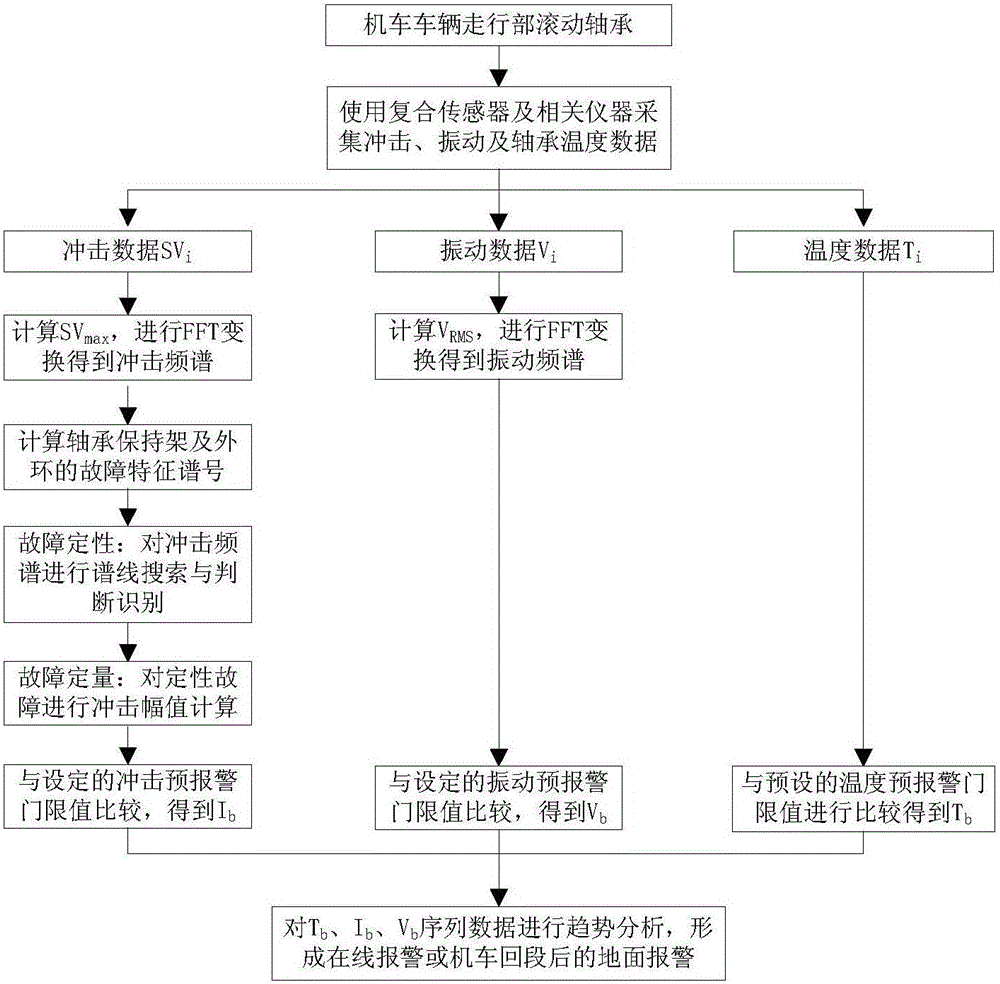

Locomotive vehicle running gear bearing holder fault pre-alarm method

ActiveCN105806604AImprove diagnostic accuracyImprove accuracyMachine part testingTime domainFast Fourier transform

The invention provides a locomotive vehicle running gear bearing holder fault pre-alarm method.According to the method, a composite sensor and a detection instrument are installed on a locomotive vehicle running gear bearing seat for online data acquisition and preprocessing, time domain impact SVi data, time domain vibration Vi data and temperature data Ti are generated, the time domain impact characteristic value SVmax and the time domain vibration characteristic value VRMS are calculated, fast Fourier transform is conducted, a corresponding shock frequency spectrum and a vibration frequency spectrum are obtained, an impact fault characteristic mark Ib and a vibration fault characteristic mark Vb are obtained through processing, a temperature pre-alarm mark Tb is obtained through calculation with temperature data, trend analysis is conducted on the Ib, the Vb and the Tb sequence data, and an alarm or pre-alarm is given according to the trend analysis result.The locomotive vehicle running gear bearing holder fault pre-alarm method is high in diagnosis accuracy, easy to master, high in operability and wide in application range; scientific operation or maintenance guidance opinion is provided, planned maintenance is converted to state maintenance, safety of the locomotive vehicle is greatly improved, maintenance cost is saved, and operation economic benefits are raised.

Owner:北京唐智科技发展有限公司

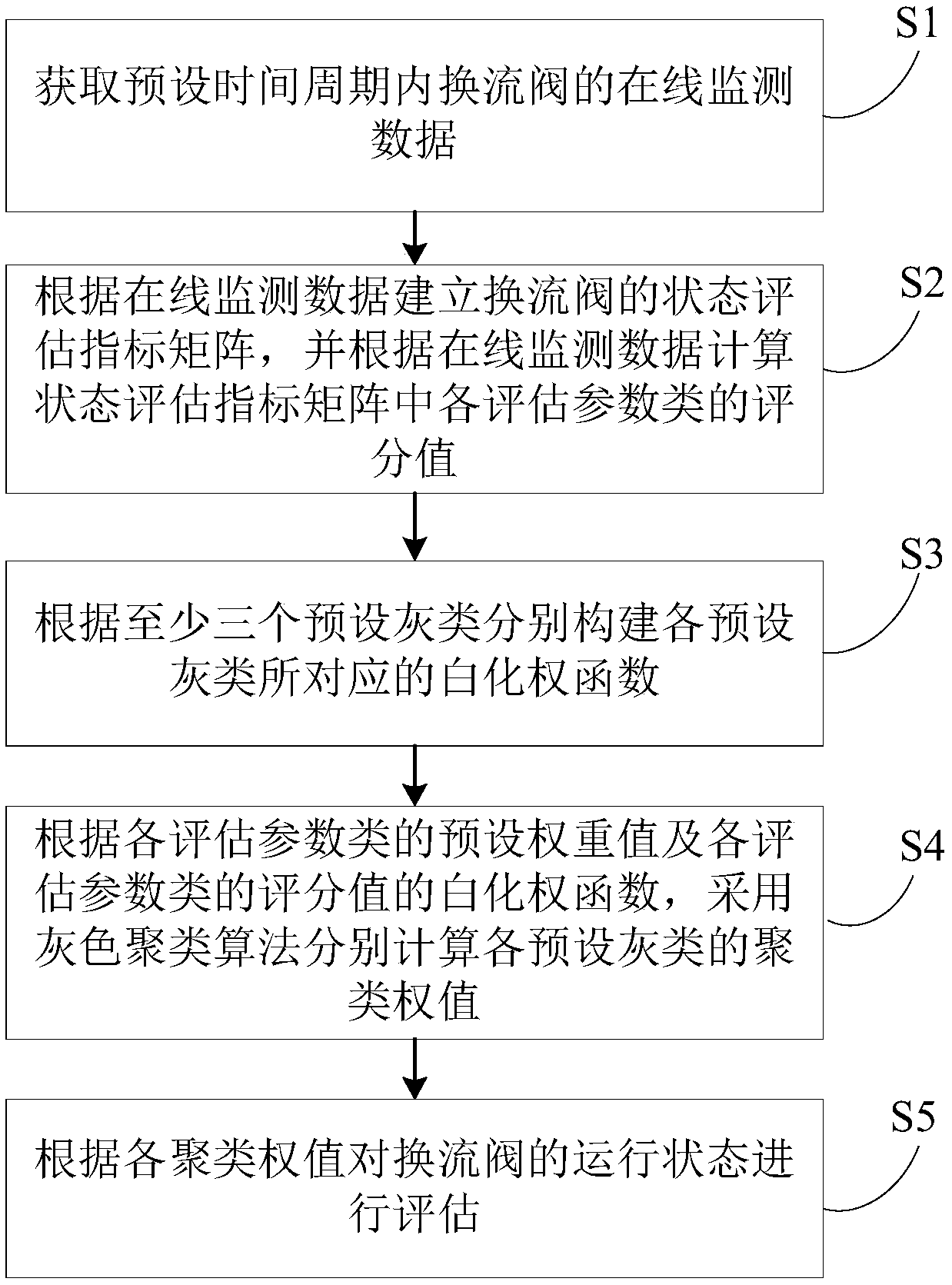

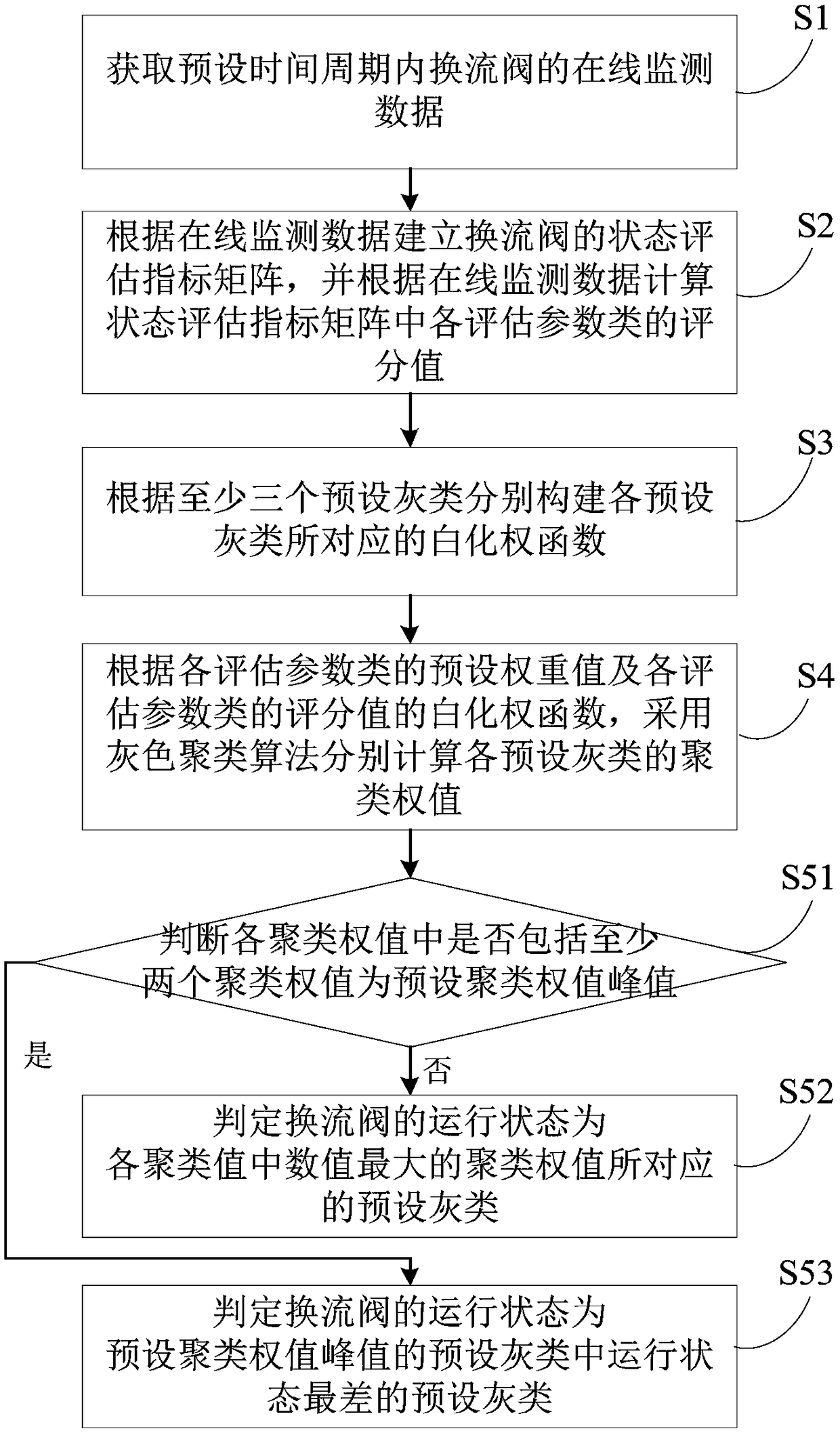

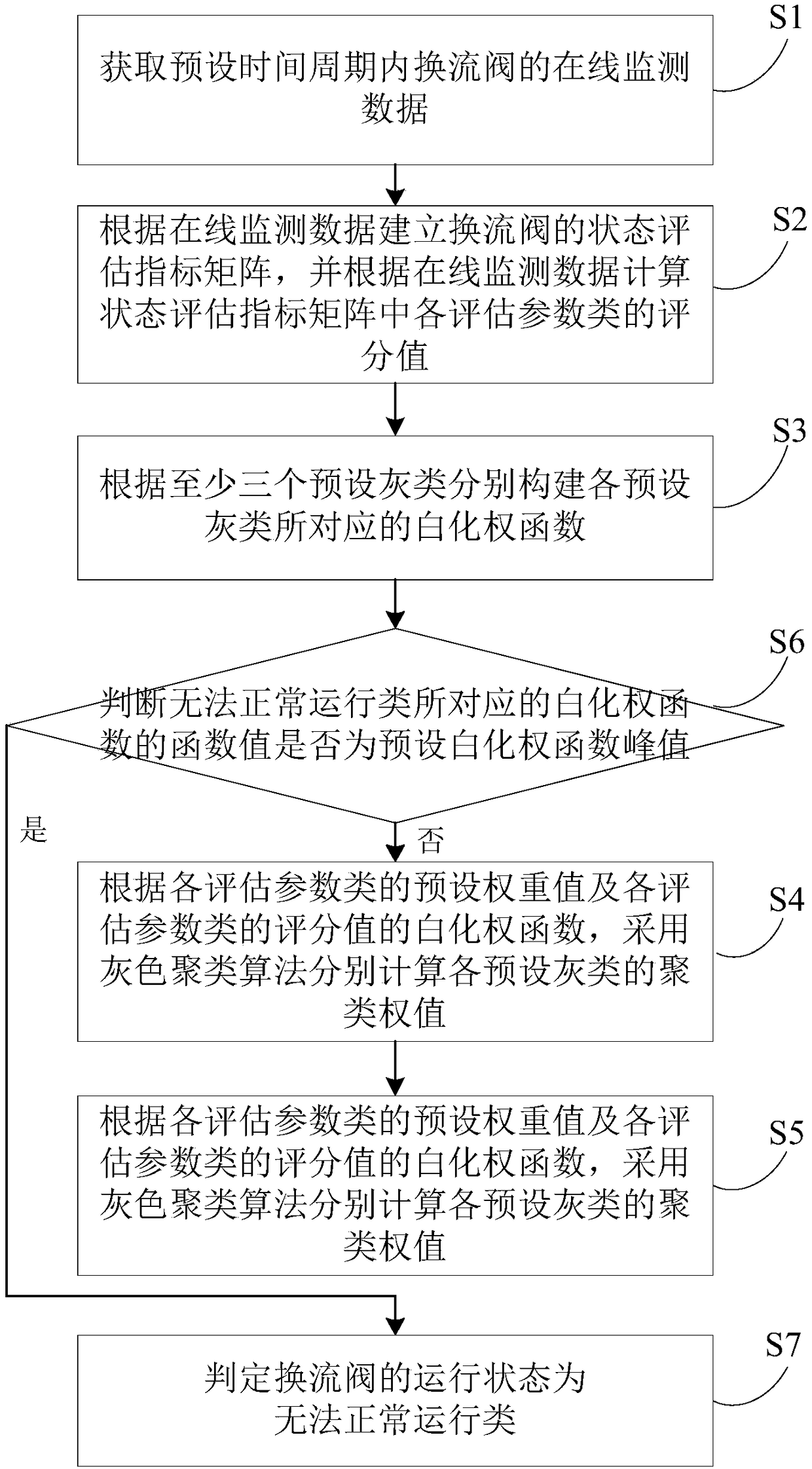

Method and device for online evaluation of converter valve state based on grey clustering

InactiveCN109387715AEnable real-time evaluationAchieving Potential Risk PredictionElectrical testingCharacter and pattern recognitionEvaluation resultCluster algorithm

The invention provides a method and a device for online evaluation of a converter valve state based on grey clustering. The method comprises: acquiring online monitoring data of a converter valve in apreset time period; establishing a state evaluation indicator matrix of the converter valve according to online monitoring data, and calculating a score value of each evaluation parameter class in the state evaluation indicator matrix according to the online monitoring data; respectively constructing a whitening weight function corresponding to each preset gray class according to at least three preset grey classes; according to a preset weight value of each evaluation parameter class and the whitening weight function of the score value of each evaluation parameter class, using a grey clustering algorithm to respectively calculate a clustering weight value of each preset grey class; and evaluating an operating state of the converter valve according to the each clustering weight value. By implementing the method, real-time evaluation of the operating state of the converter valve is realized without manual operation, accuracy of an evaluation result is improved, and potential risk prediction of the converter valve is realized, and provides good data basis for planned maintenance of the converter valve.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

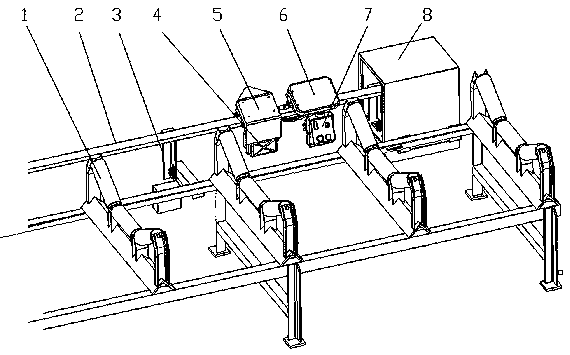

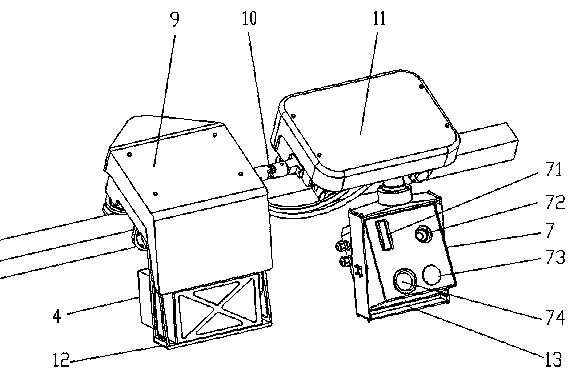

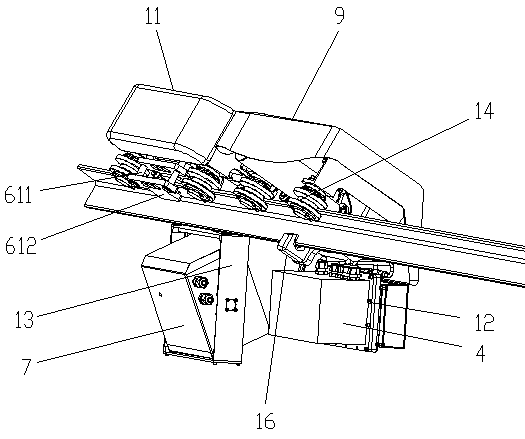

Monorail inspection robot system for belt conveyor in extreme environment

ActiveCN111217108AIncrease job securityReduce maintenance costsControl devices for conveyorsPackagingRobotic systemsMonorail

The invention discloses a monorail inspection robot system for a belt conveyor in extreme environment. The monorail inspection robot system comprises an angle steel track composed of an upper side surface and a lower side surface which are perpendicular to each other to form an angle shape, one or more tractors and one or more detection vehicles, the tractors and the detection vehicles are connected through connecting assemblies, the tractors and the detection vehicles are arranged on the angle steel track and can travel along the angle steel track, the tractors are connected with power supplydevices, the detection vehicles are connected with detection devices, and the power supply devices are further electrically connected with the detection devices. According to the monorail inspectionrobot system, instead of an original manual inspection, a robot is used for monitoring the phenomena of temperature, noise level, surface wear, deformation, micro crack and jamming of an idler of a conveyor belt to achieve the fault detection, early warning and remaining life prediction of the idler, the basis is provided for planned maintenance and timely replacement, thus the maintenance cost and production cost are lowered, and the work safety of the personnel is improved.

Owner:湖南中矿金禾机器人研究院有限公司

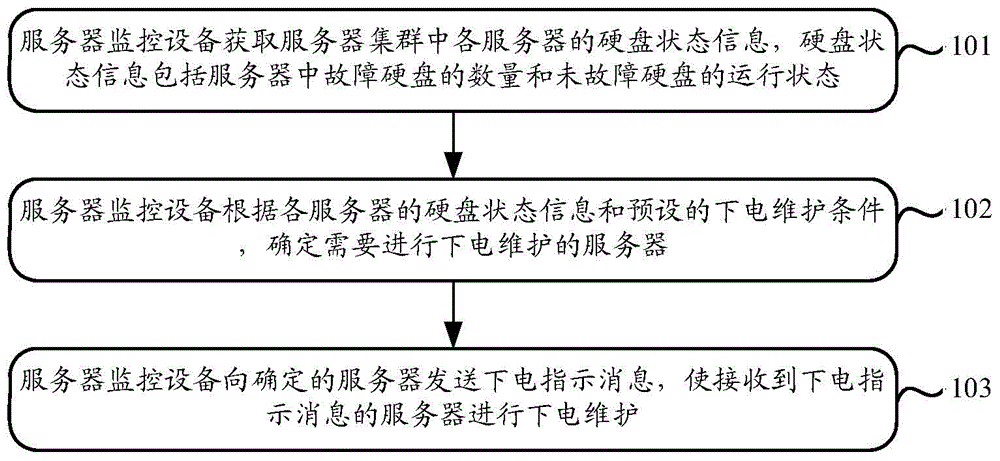

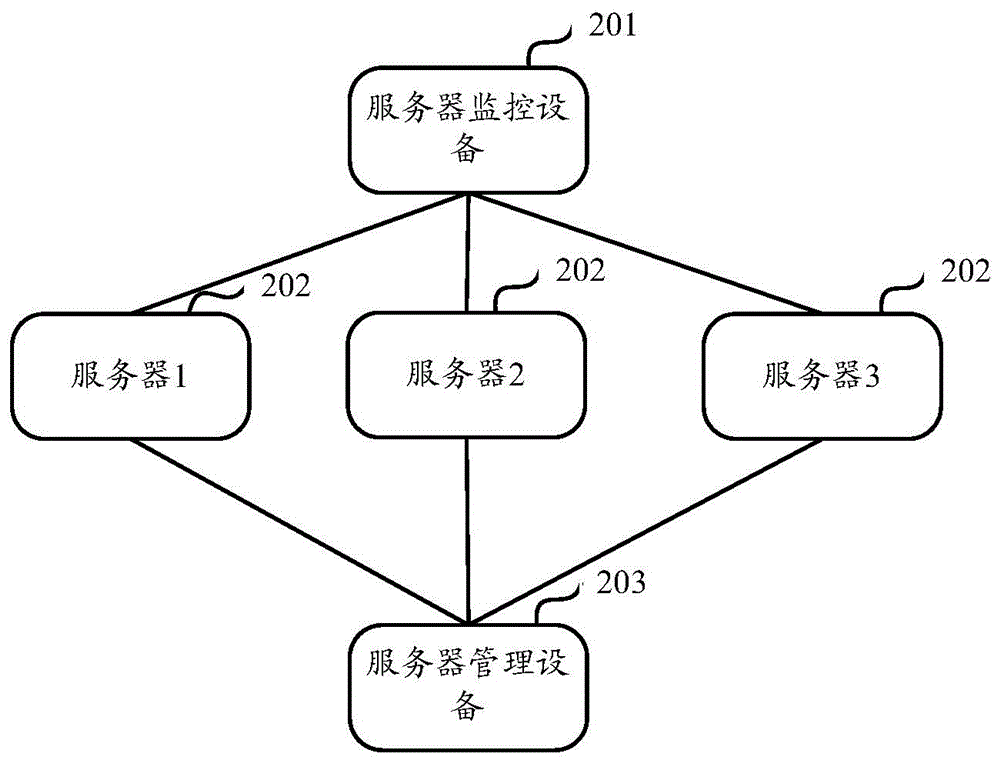

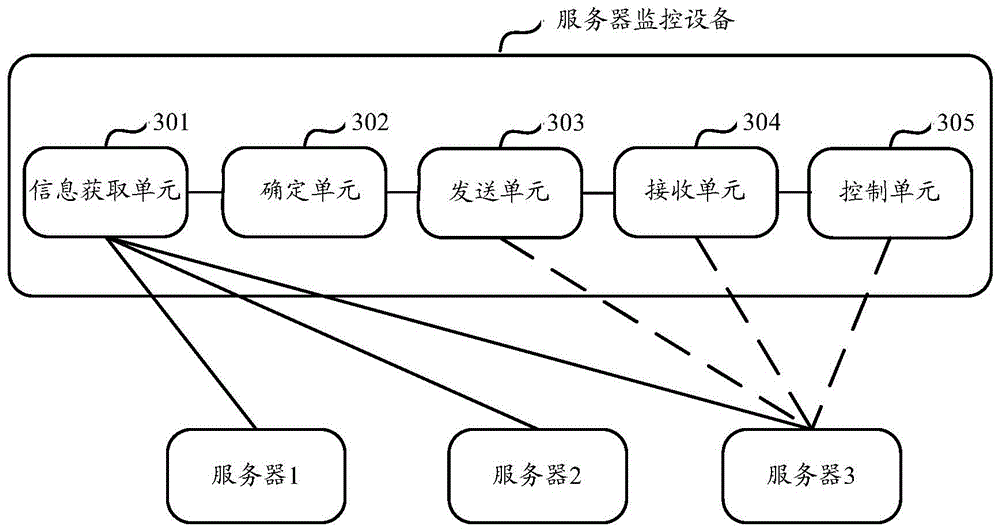

Server hard disk maintaining method, system and server monitoring equipment

InactiveCN104679623AAvoid capacity constraintsAvoid shockDetecting faulty computer hardwareMonitor equipmentData reconstruction

The invention discloses a server hard disk maintaining method, system and server monitoring equipment; the method mainly comprises the step of performing planned maintenance for the hard disks of the servers with respect to the usage states of the hard disks of each server in a server cluster, that is, acquiring the status information of the hard disks of each server in the server cluster and monitoring the states of the hard disks of the servers; whatever the whole states of the hard disks in the present server cluster are, when the hard disks of the servers have worse states, the hard disks of the servers can be maintained according to preset power-off maintenance conditions. Therefore, when a server has more failed hard disks and the quantity of the failed hard disks in the server cluster does not satisfy the batch replacement condition, the shortage of the capacitor of the server caused by the non-maintenance to the hard disks of the server is avoided; meanwhile, the maintenance process of the server becomes dispersed; compared with the batch replacement of the hard disks, the impact to the server cluster and the communication network caused by large-quantity data reconstruction is avoided and the stability of the server cluster and the communication network is facilitated.

Owner:CHINA MOBILE COMM GRP CO LTD

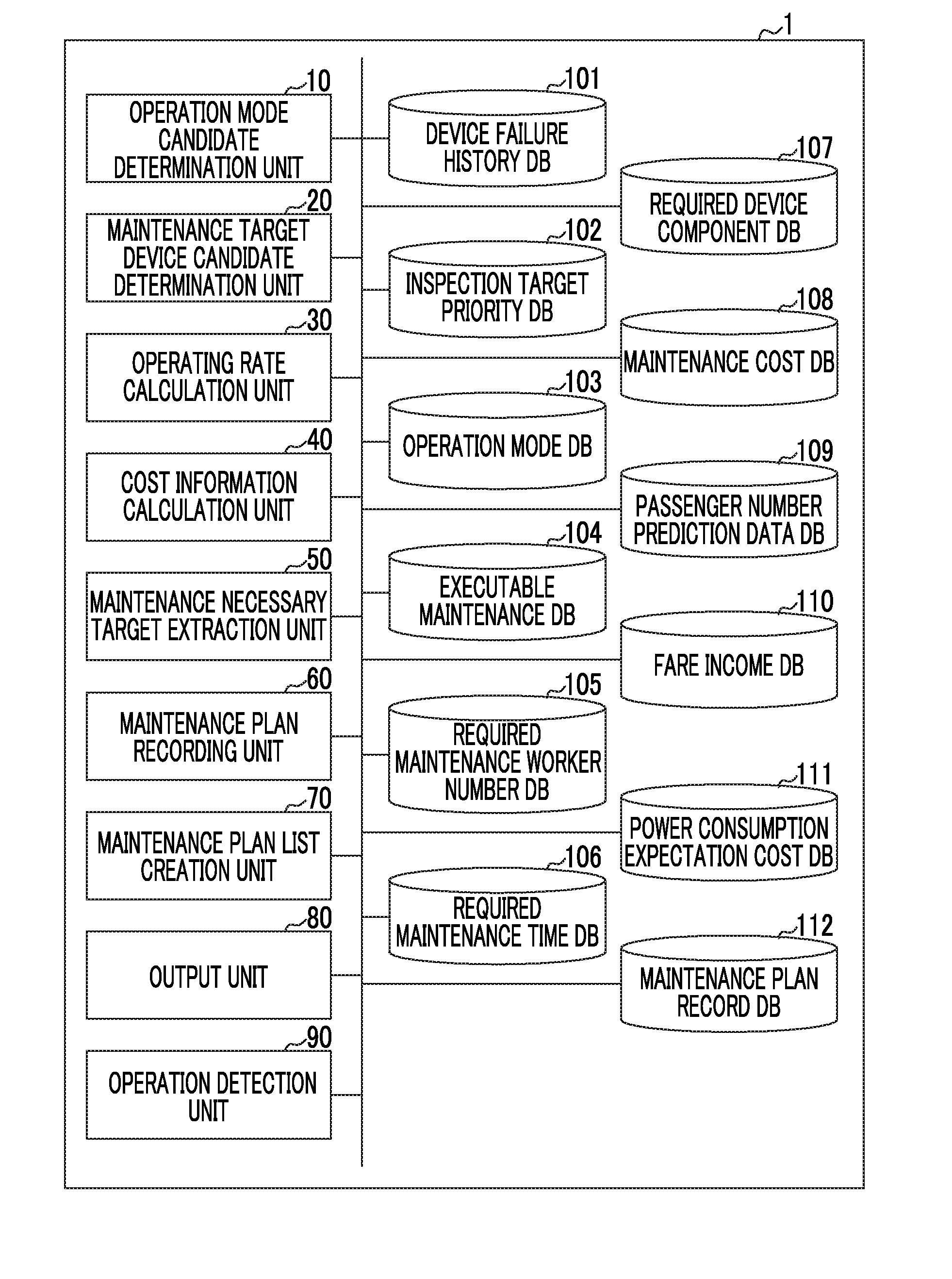

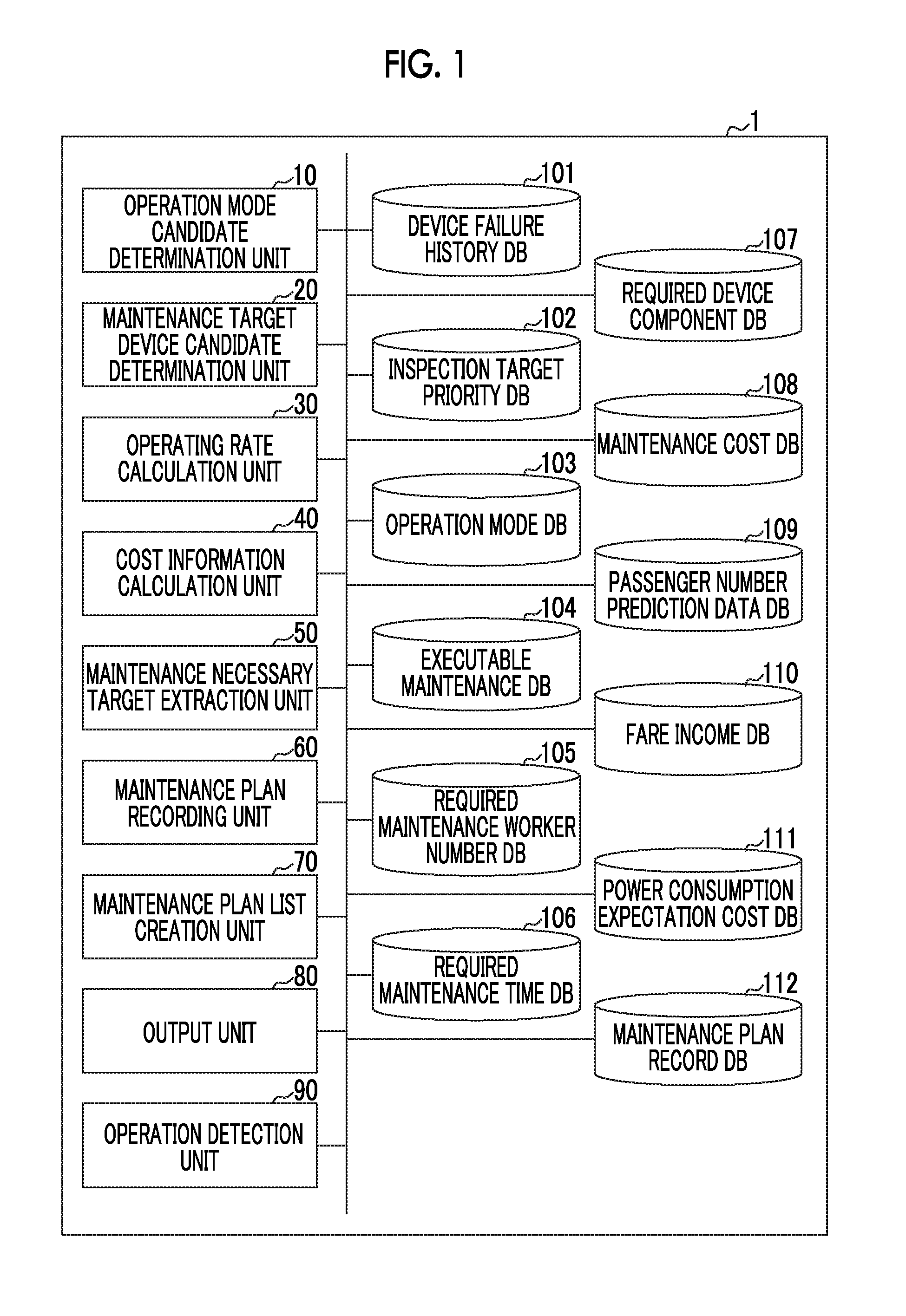

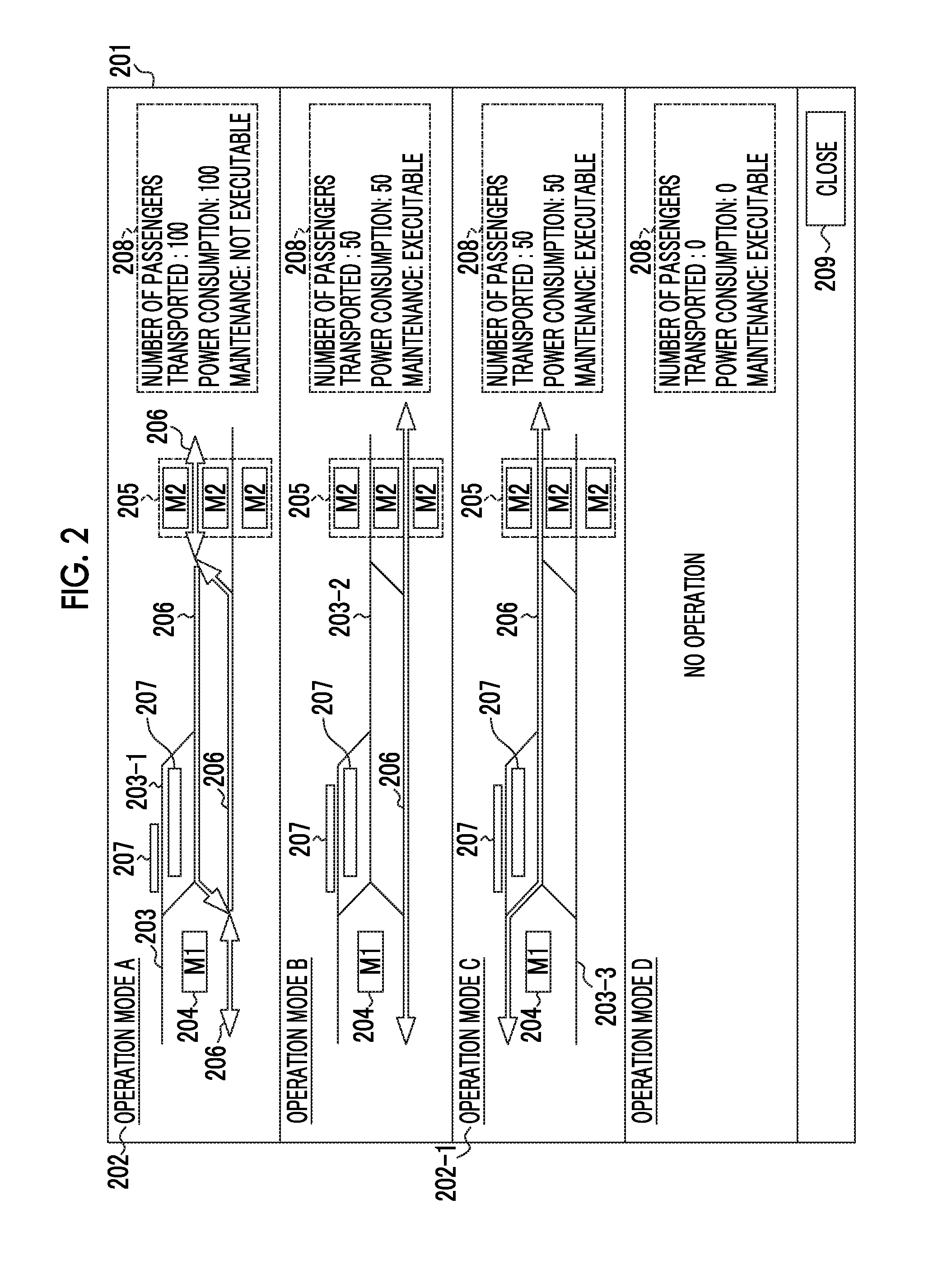

Maintenance management device, maintenance management method and program

InactiveUS20160292627A1Efficient executionRailway traffic control systemsLogisticsMaintenance managementEngineering

This maintenance management device is provided with a maintenance target device candidate determination unit which determines a maintenance target device candidate in a maintenance segment based on an operation mode determined for a track running vehicle system, and an output unit which outputs the determined maintenance target device candidate. Further, for each maintenance target device, the output unit outputs the time, number of worker, cost, etc., needed for maintenance operations, and supports the user in planning maintenance operations.

Owner:MITSUBISHI HEAVY IND LTD

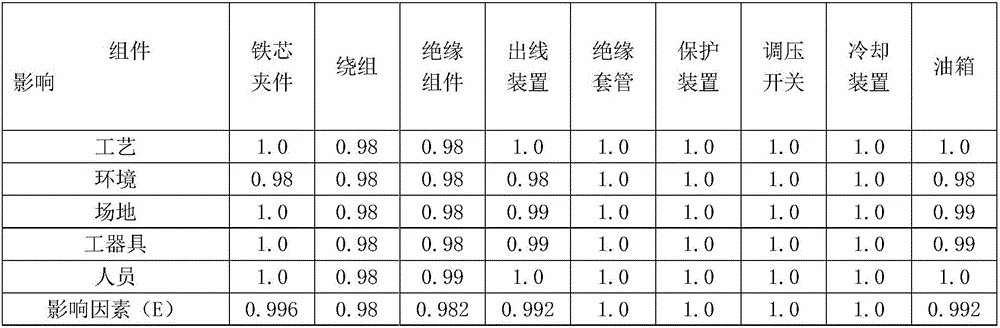

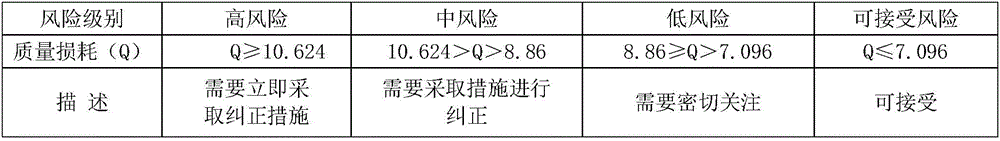

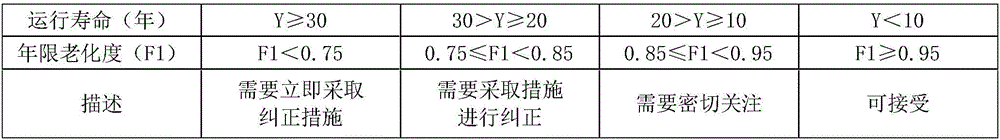

Method for evaluating quality state of transformer

ActiveCN106501641AImprove restoration qualityAvoid secondary disassembly and repairComponent separationElectrical testingRisk levelTransformer

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com