Aircraft structure checking task planning method based on risk and cost analysis

A technology for aircraft structure and cost analysis, applied in data processing applications, predictions, calculations, etc., can solve problems such as rising false alarm events, increasing maintenance costs and operating costs, shutdown inspection activities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

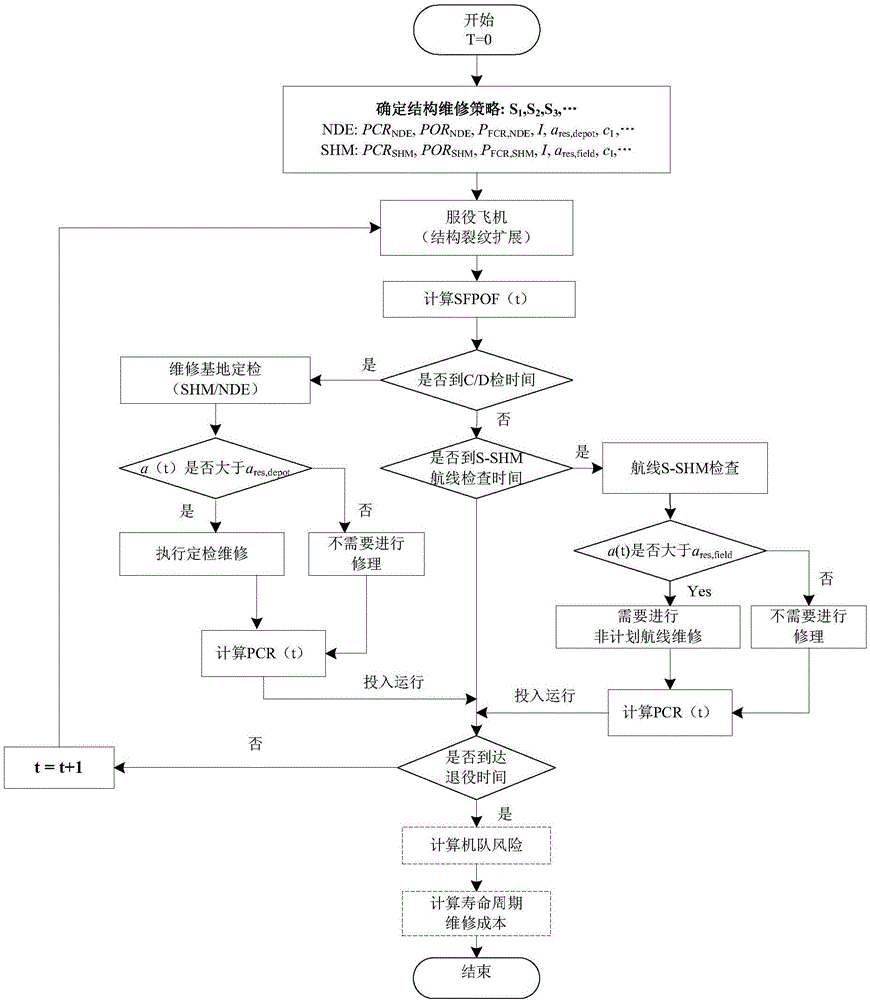

Method used

Image

Examples

Embodiment

[0057] The embodiments described here are only used to explain and illustrate the present invention, not to limit the present invention.

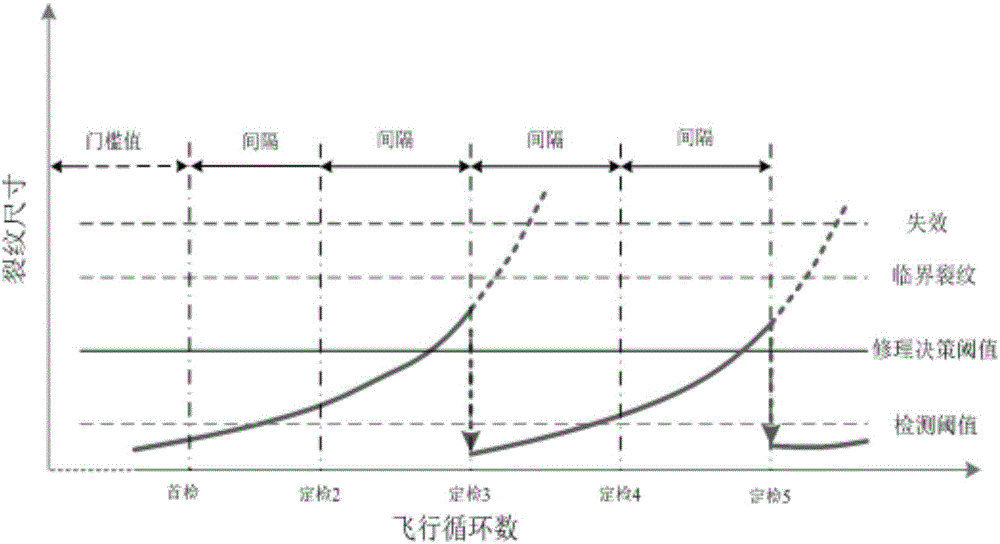

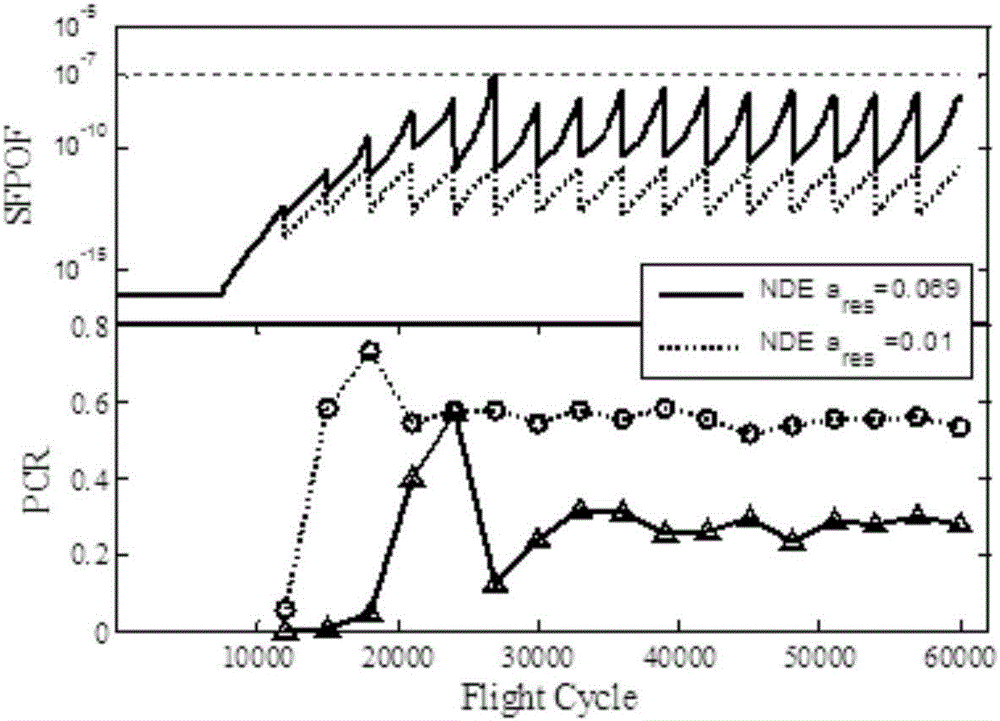

[0058] This embodiment takes typical modern civil aircraft structural planning and maintenance task planning as an example, figure 1 It represents a typical contemporary civil aircraft structure maintenance plan, in which the first inspection time is set at 12000FC, and the repeated inspection interval is 3000FC. In the analysis of the embodiment, it is assumed that there is a fleet of 1,000 aircraft, and the design service life of the aircraft structure is 60,000 cycles. Assume that the cost of an NDE inspection of structural parts in base maintenance is $1000, the cost of inspection using the online SHM system is $50, the cost of structural repairs in base regular inspections is $2000, and the cost of unplanned repairs on the route is $10000.

[0059] image 3 It represents the single-flight failure risk (SFPOF) and each The change cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com